Patents

Literature

100results about How to "Improve printing and dyeing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

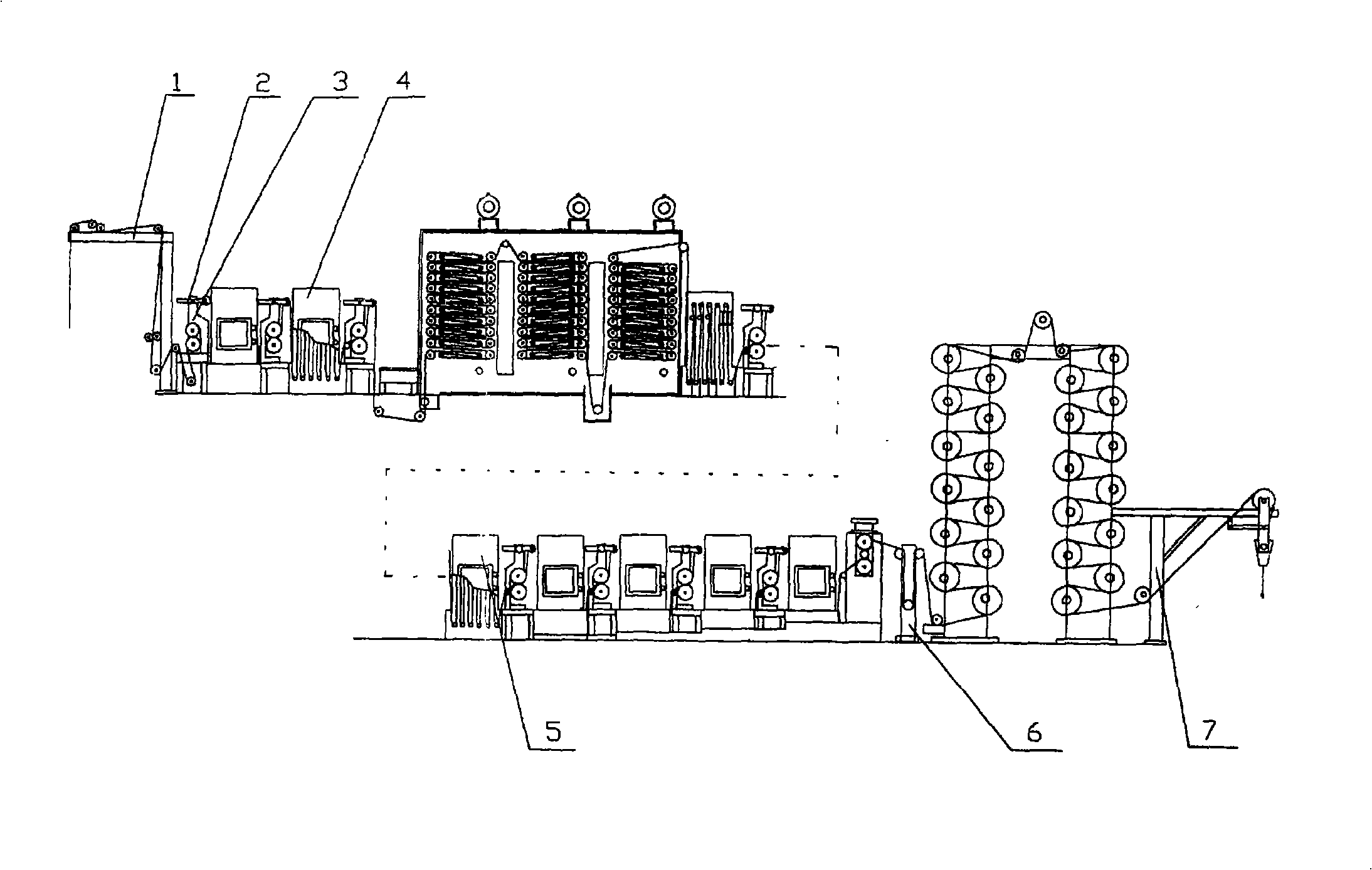

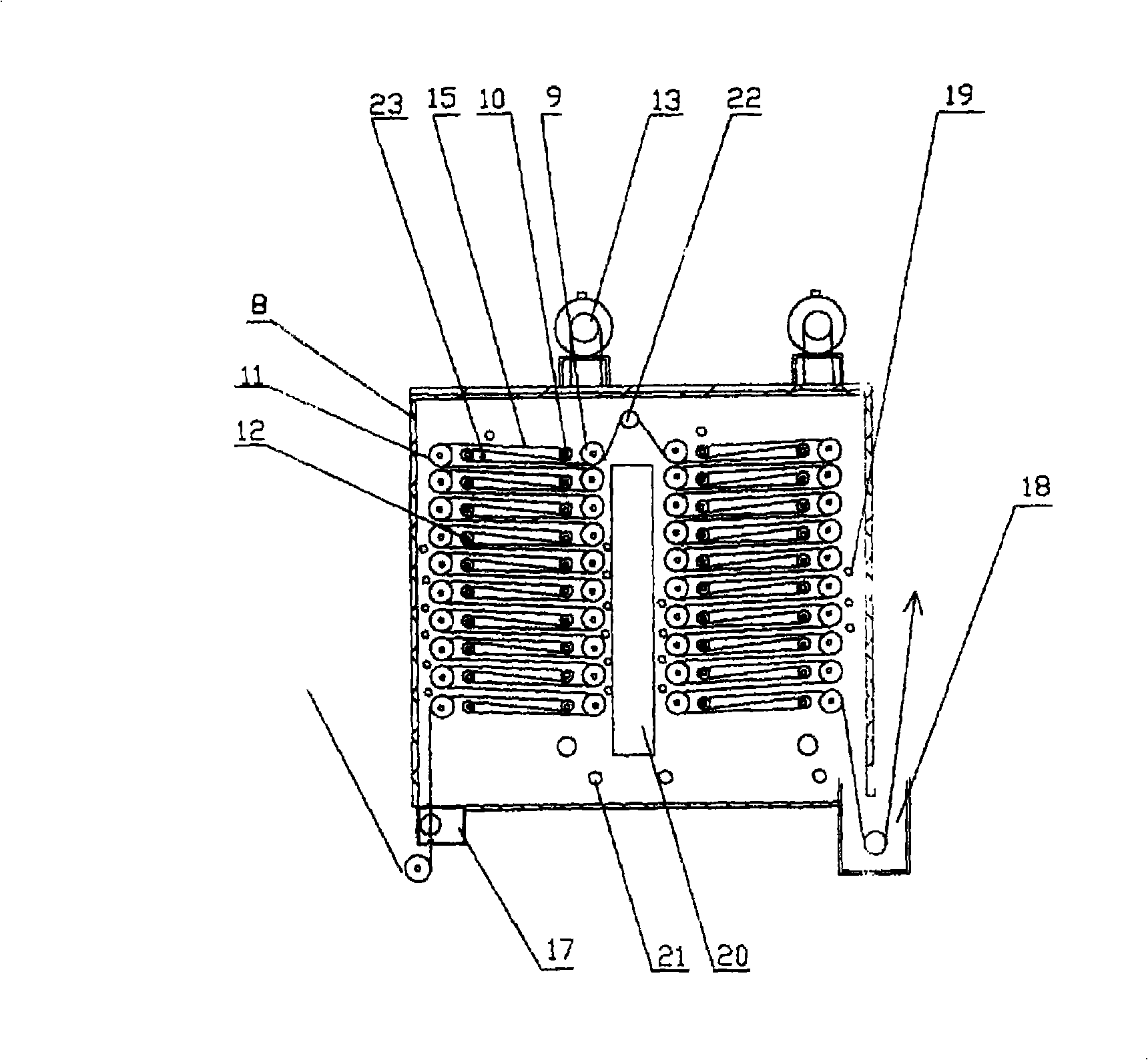

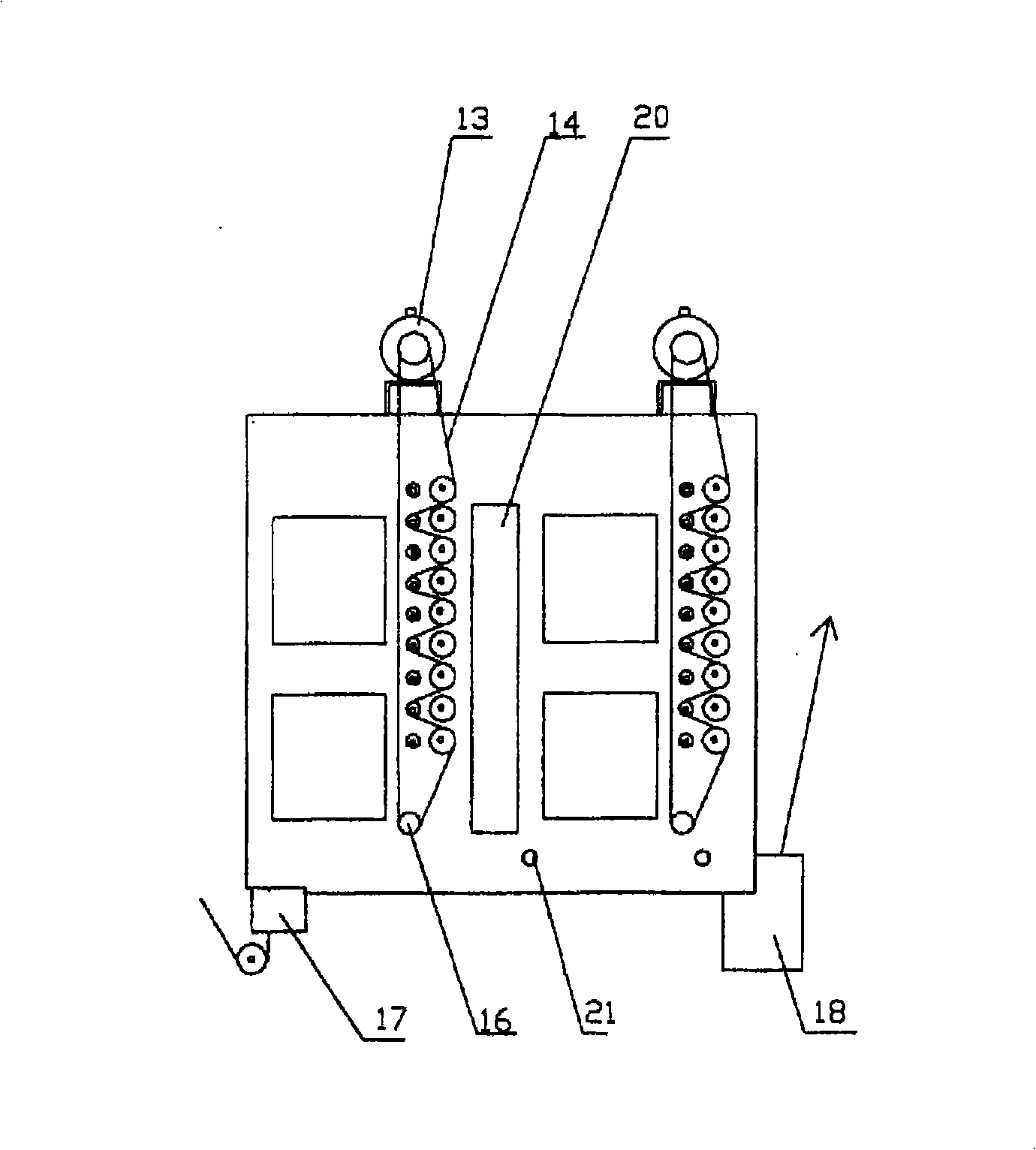

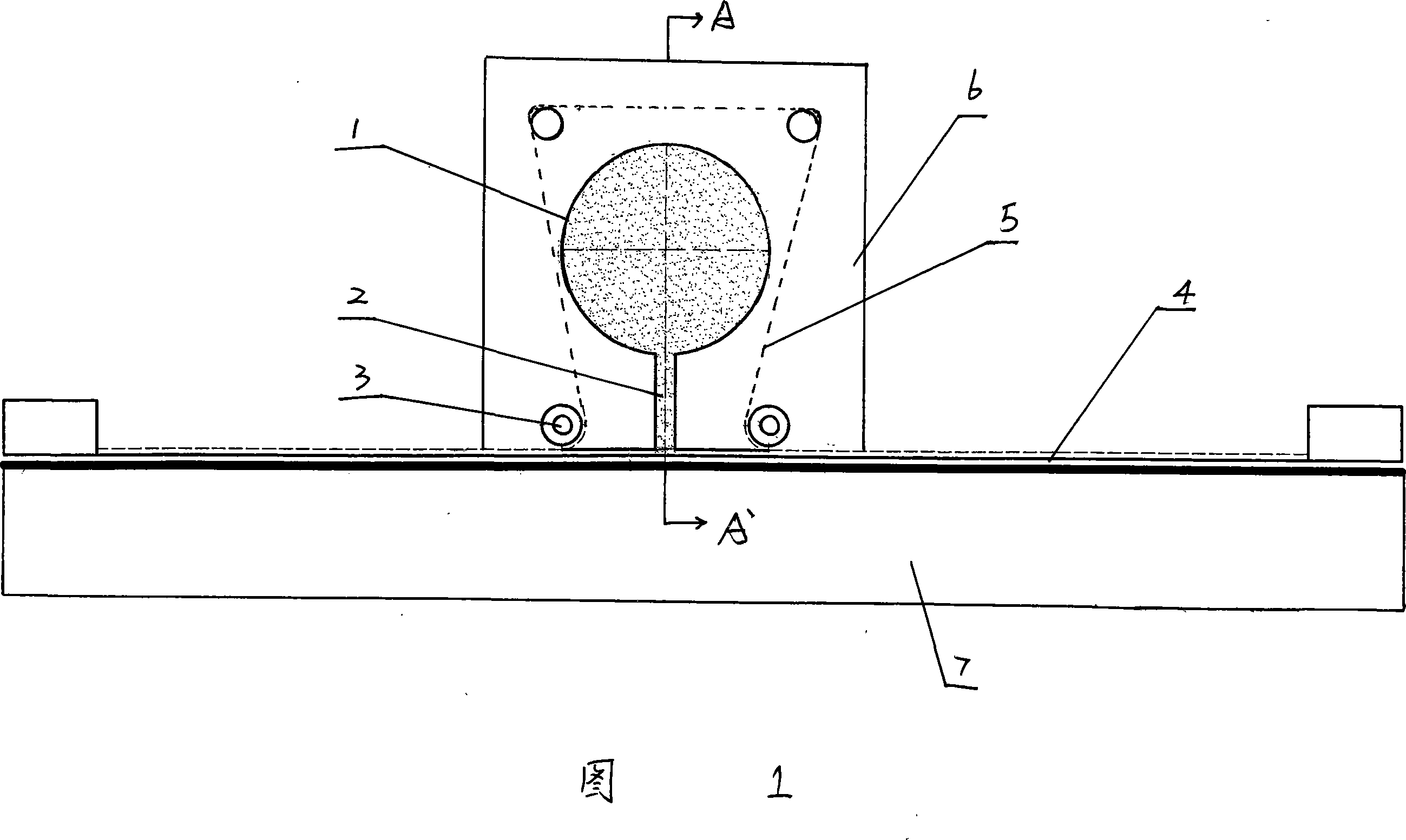

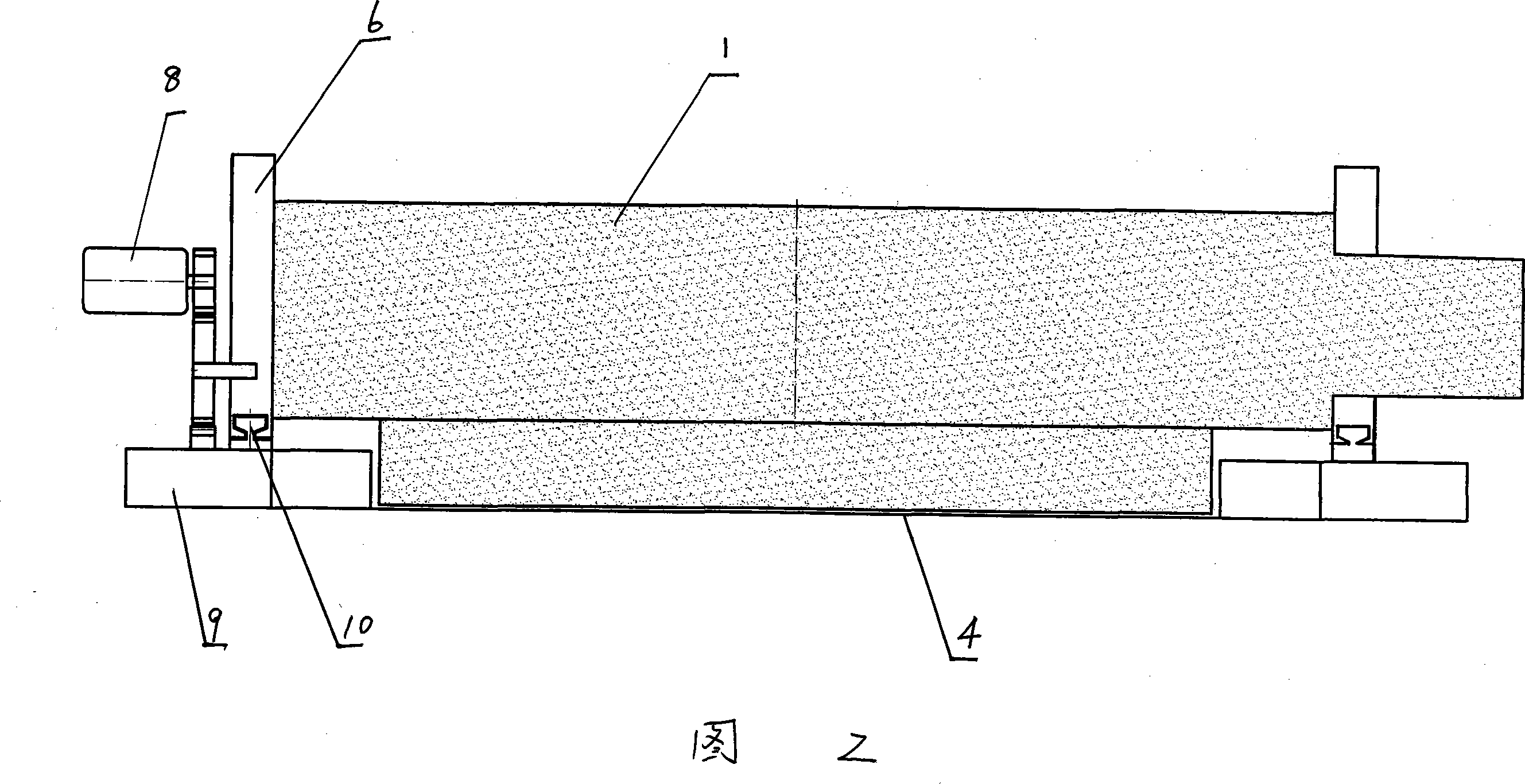

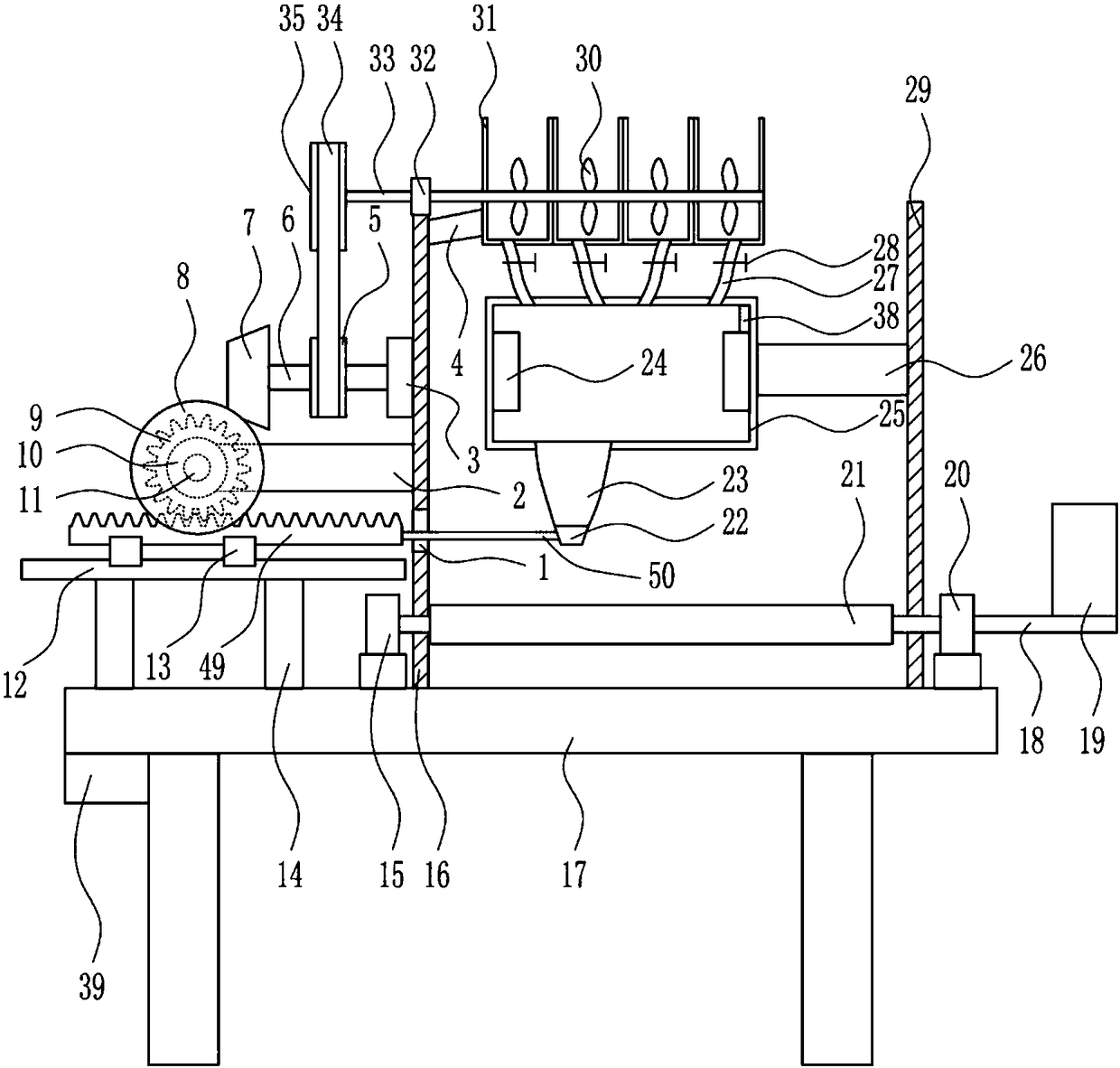

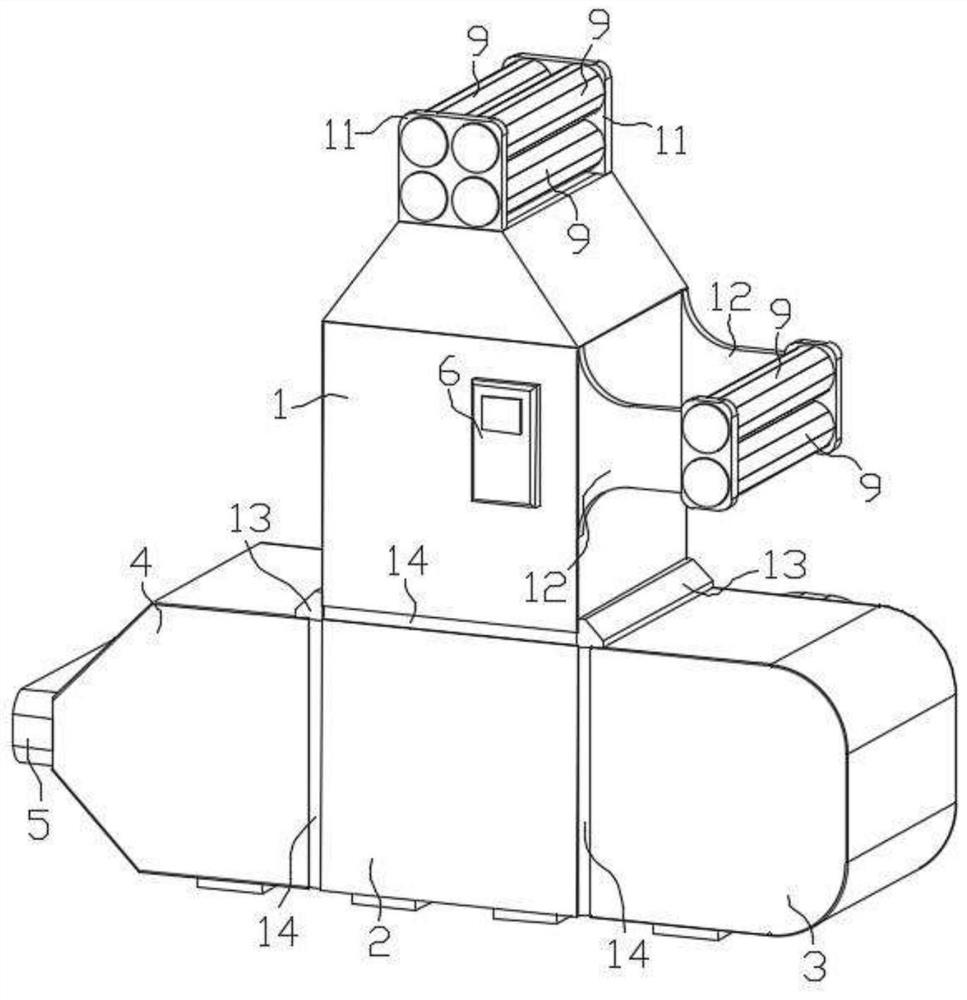

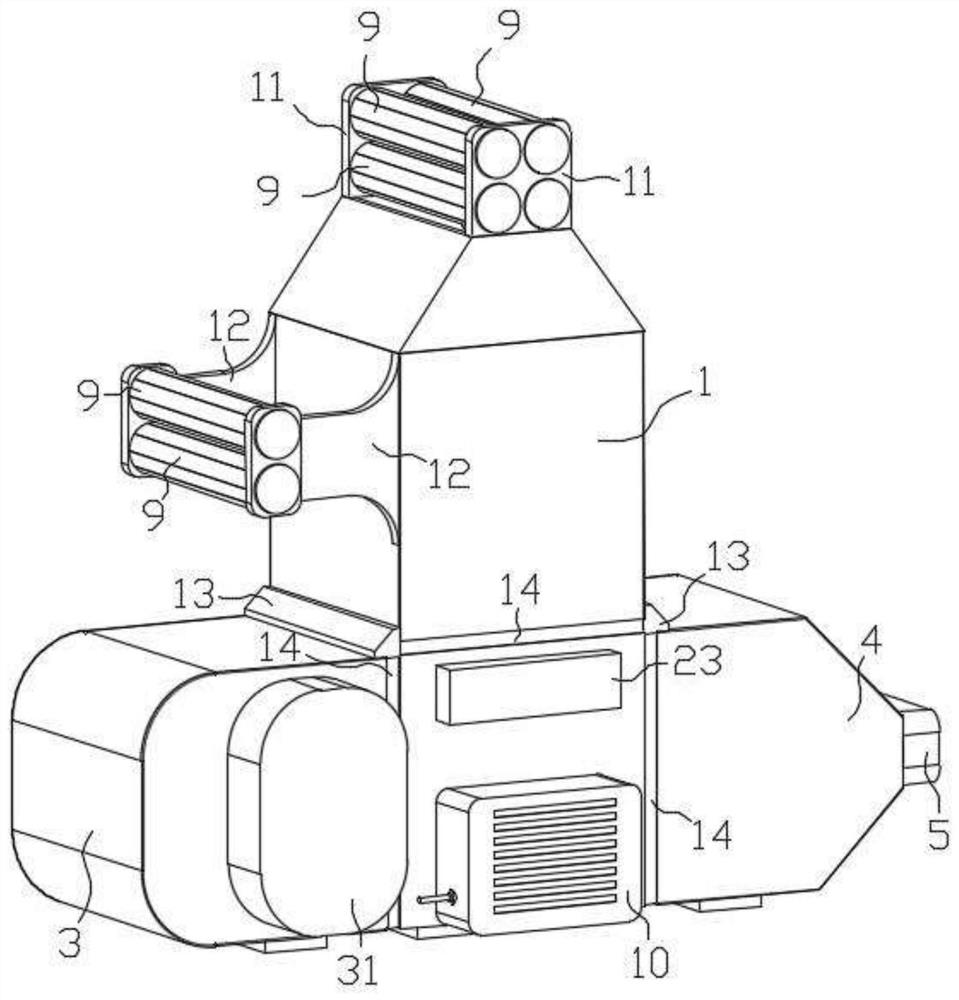

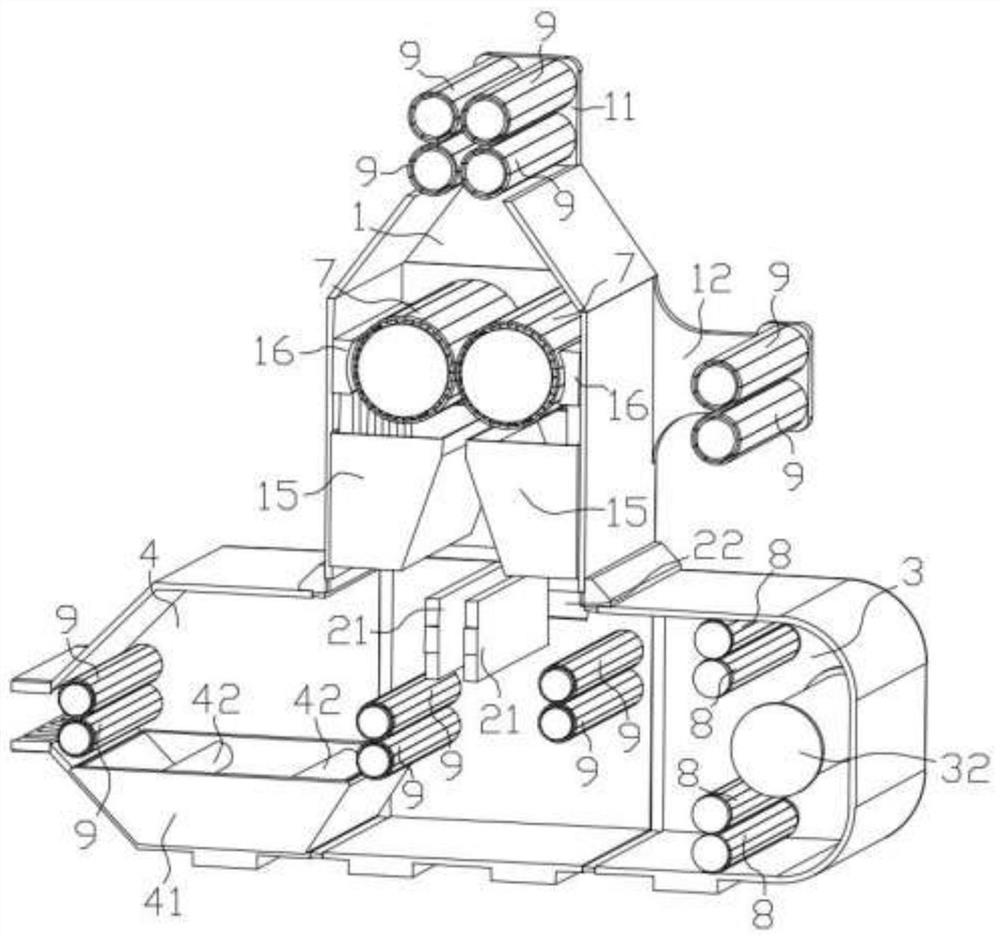

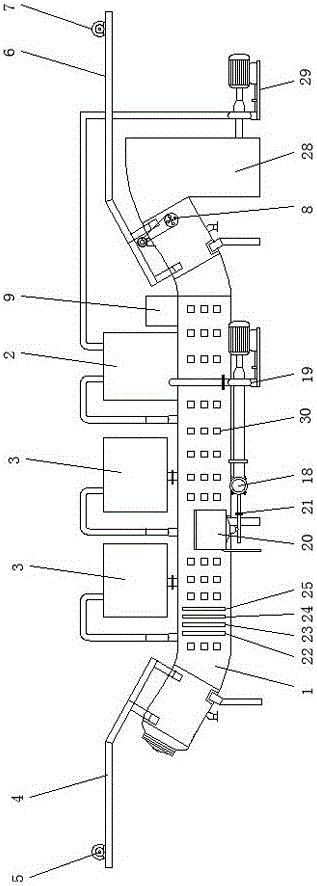

Kiering-bleaching dyeing-finishing equipment

InactiveCN101328651AImprove printing and dyeing efficiencyReduce printing and dyeing timeSucessive textile treatmentsTextile treatment machine partsComing outEngineering

The invention relates to smelting, bleaching, dyeing and finishing equipment. By adoption of a transverse guide roll reaction chamber and a jet cleaner in the smelting and bleaching equipment, the dyeing efficiency is improved and the dyeing time is reduced; due to a transverse guide roll which makes dyed piece goods circulate transversely in the transverse guide roll reaction chamber, dye and the piece goods have enough reaction time in the reaction chamber with enough temperature; and a colored cloth coming out of the transverse guide roll reaction chamber subsequently enters into the jet cleaner, and the optimum smelting and bleaching effect is achieved through jet cleaning.

Owner:石建明

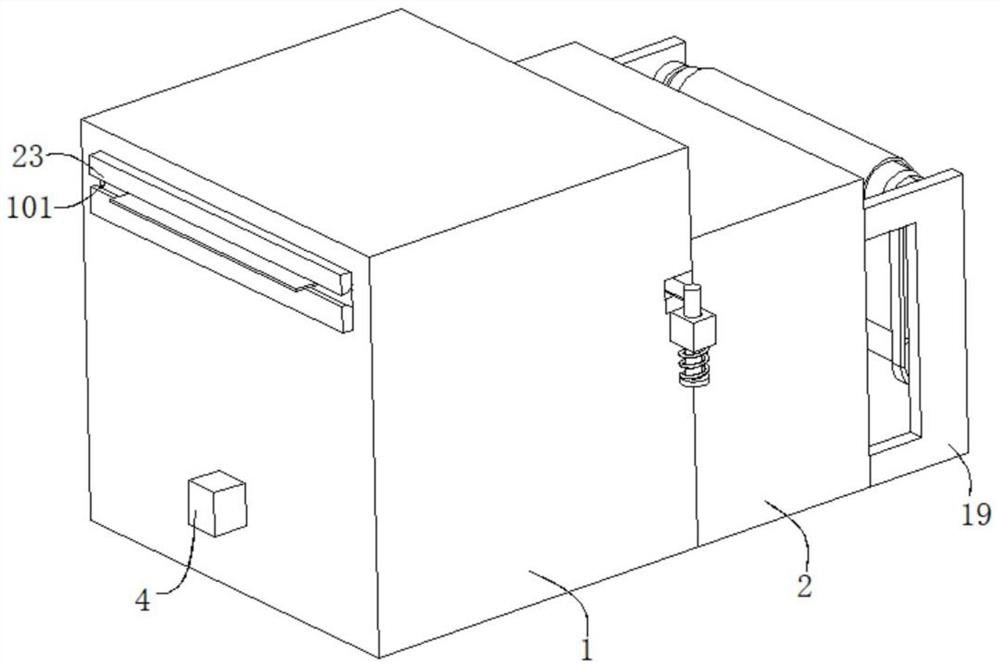

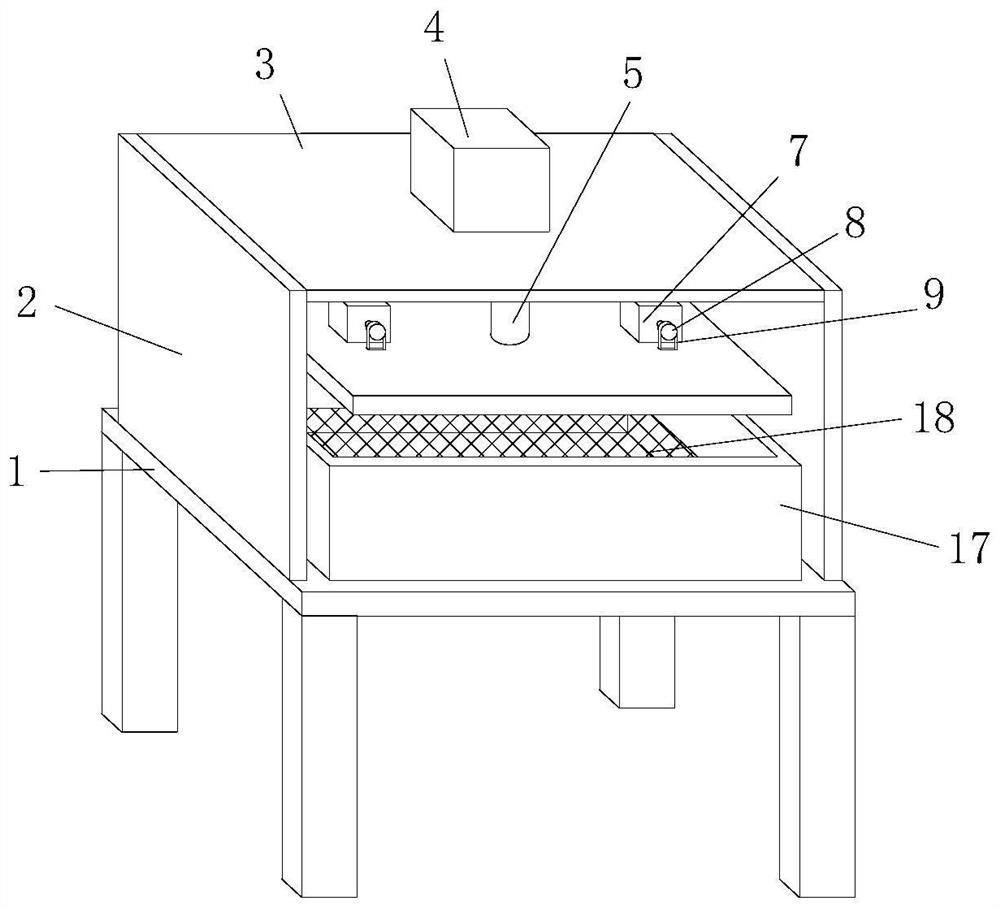

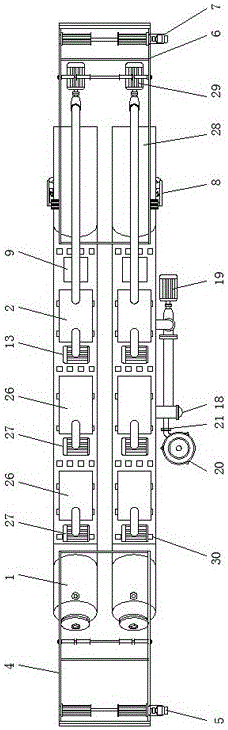

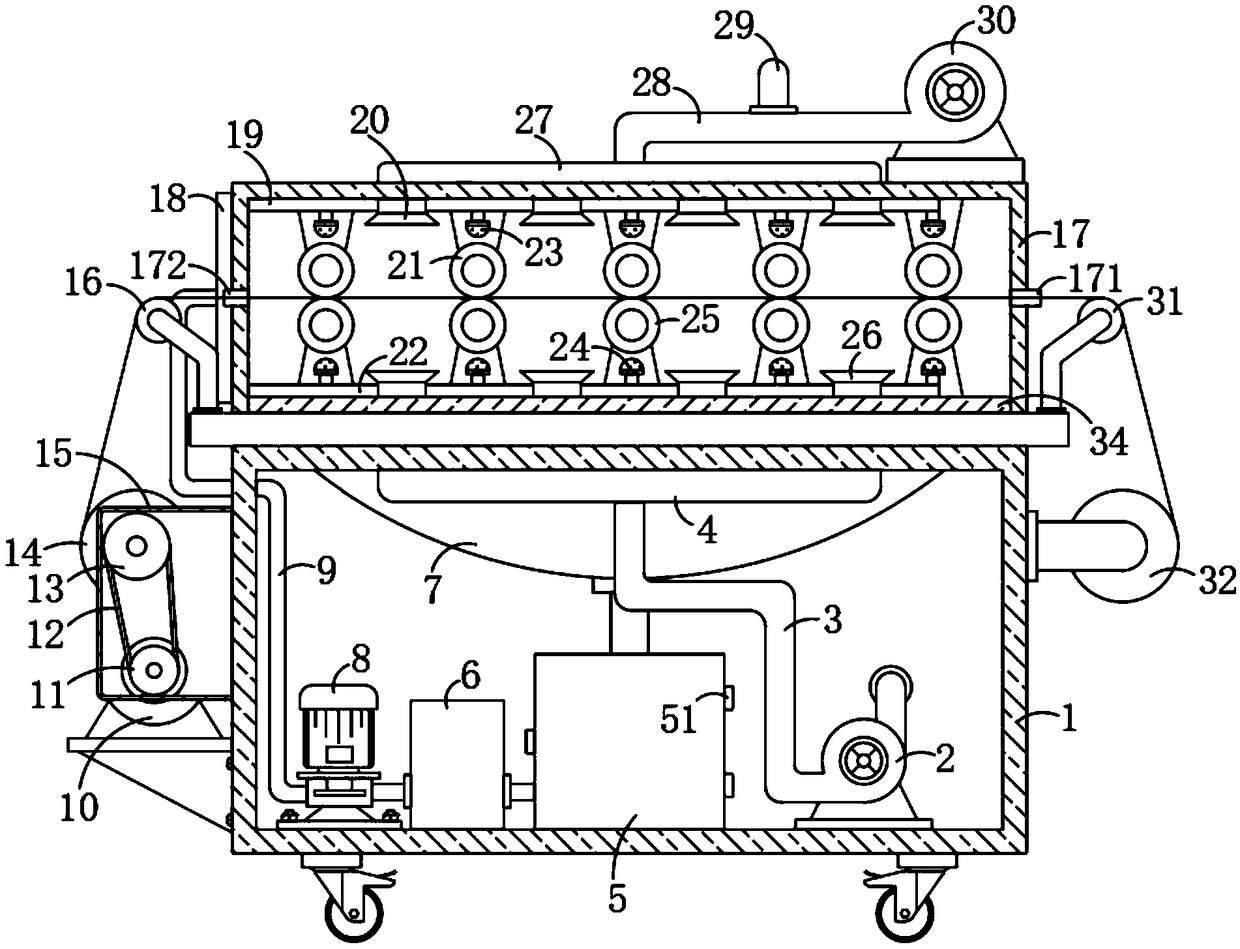

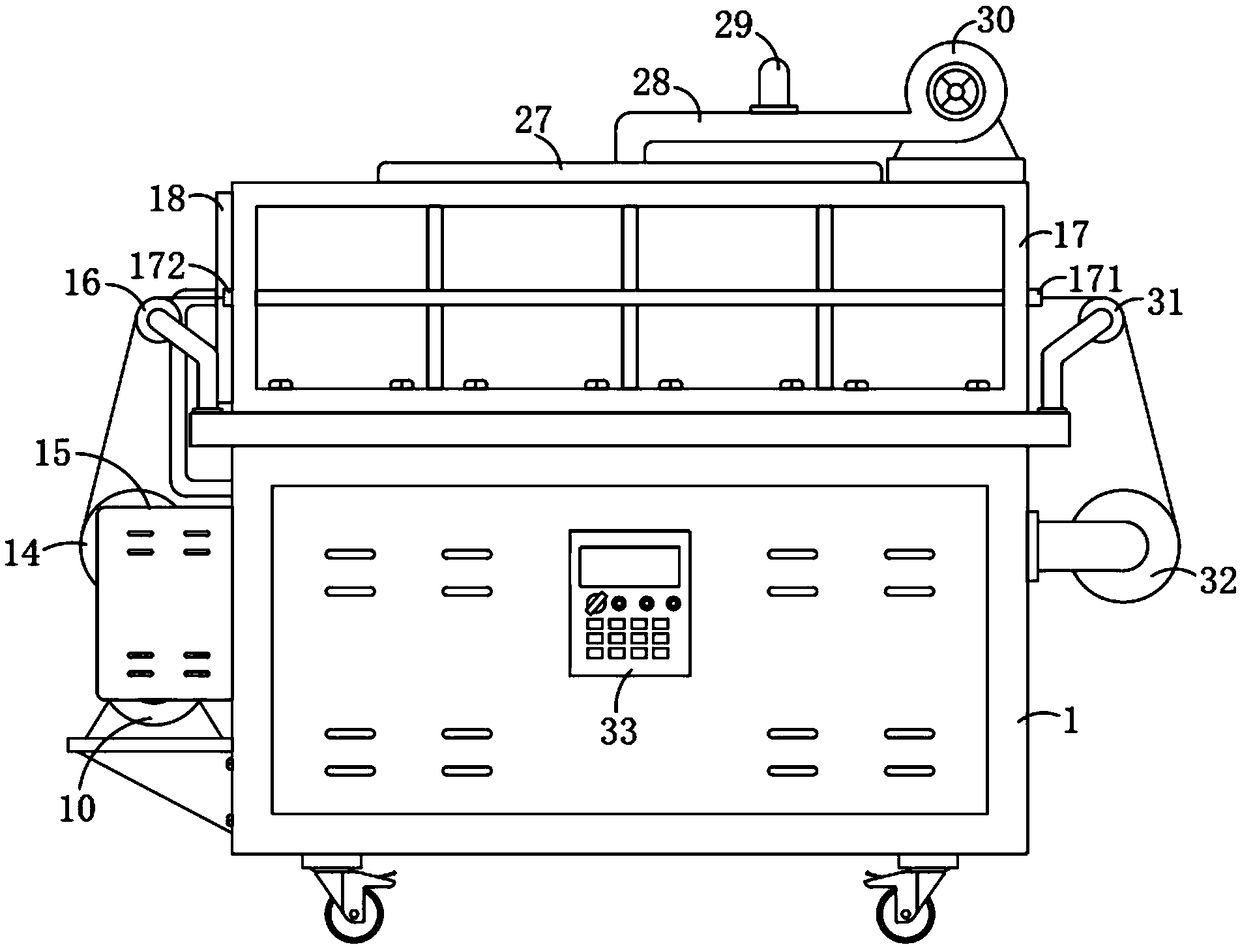

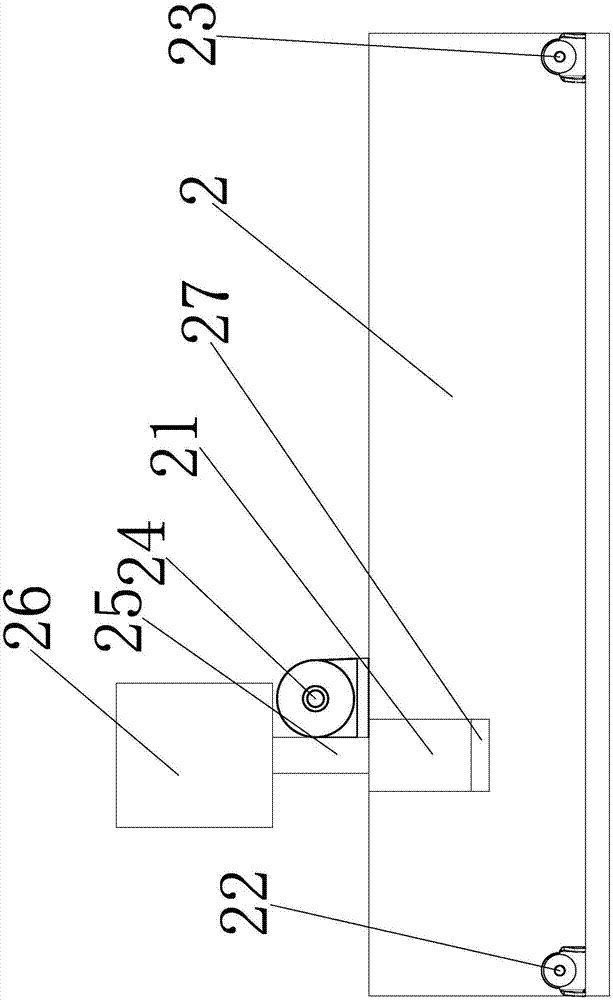

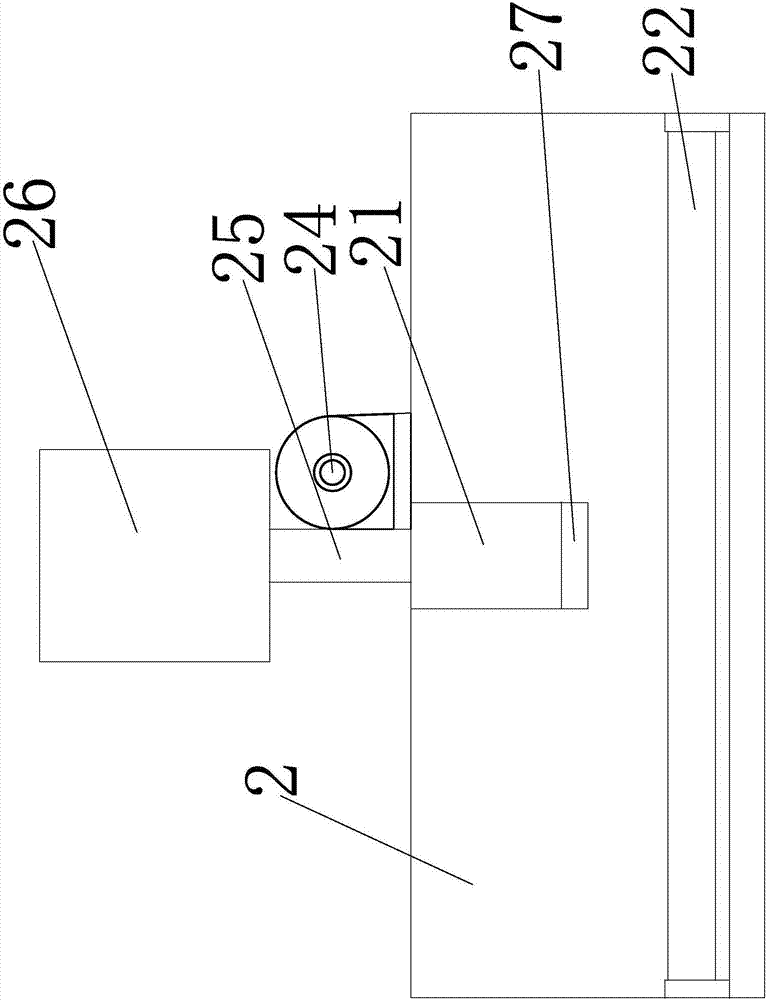

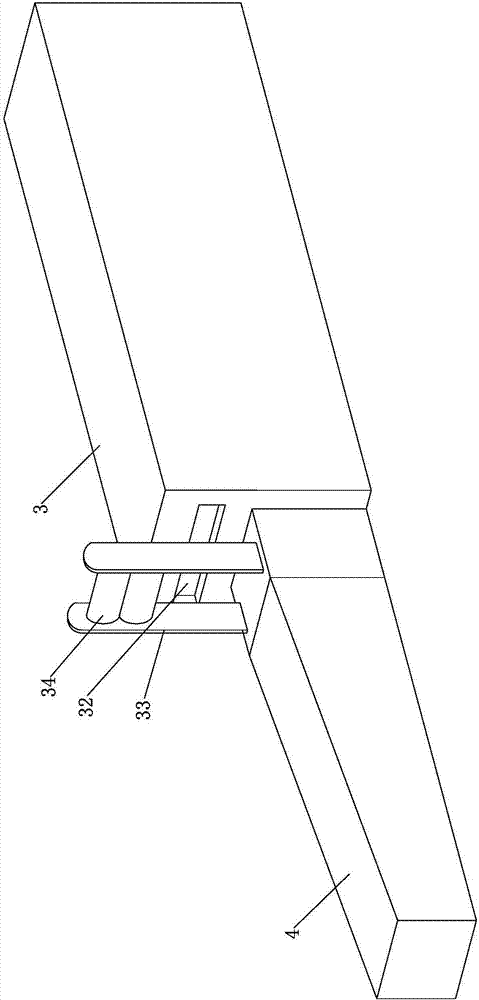

Cloth soaking, printing and dyeing device and using method thereof

InactiveCN111826854AFast realization of printing and dyeingAvoid uneven printing and dyeingMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsMechanical engineeringDyeing

The invention discloses a cloth soaking, printing and dyeing device and a using method of the cloth soaking, printing and dyeing device, and belongs to the technical field of printing and dyeing. Thecloth soaking, printing and dyeing device comprises a dye box and a drying box, a through hole is connected between the dye box and the drying box, the dye box communicates with the drying box, a feeding hole is formed in the outer wall of the dye box, a discharge hole is formed in the outer wall of the drying box, the outer wall of the dye box is connected with a motor, the output end of the motor is connected with a first rotating shaft, the first rotating shaft is rotationally connected to the inner wall of the dye box, a second rotating shaft is rotationally connected to the inner wall ofthe dye box through a bearing, stirring blades are connected to the outer walls of the first rotating shaft and the second rotating shaft, cams are connected to the ends, away from the inner wall of the dye box, of the first rotating shaft and the second rotating shaft, and a connecting piece is fixedly connected between the two cams. With the technical scheme, the dye immersion into cloth can beaccelerated, so that the printing and dyeing efficiency is improved, meanwhile, the cloth can be rapidly dried, thus the situation that printing and dyeing are uneven after the cloth is rolled up is avoided, and the printing and dyeing effect of the cloth can be guaranteed.

Owner:浙江七色彩虹科技有限公司

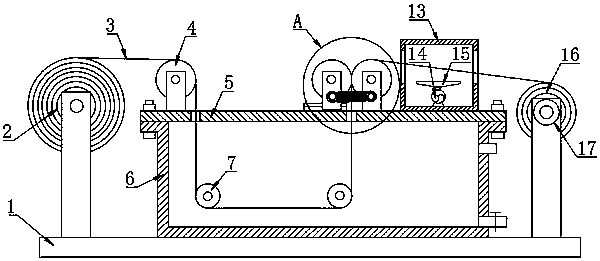

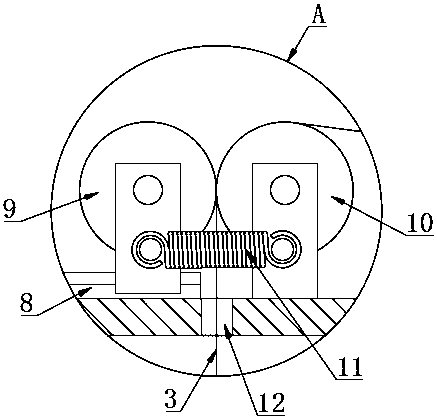

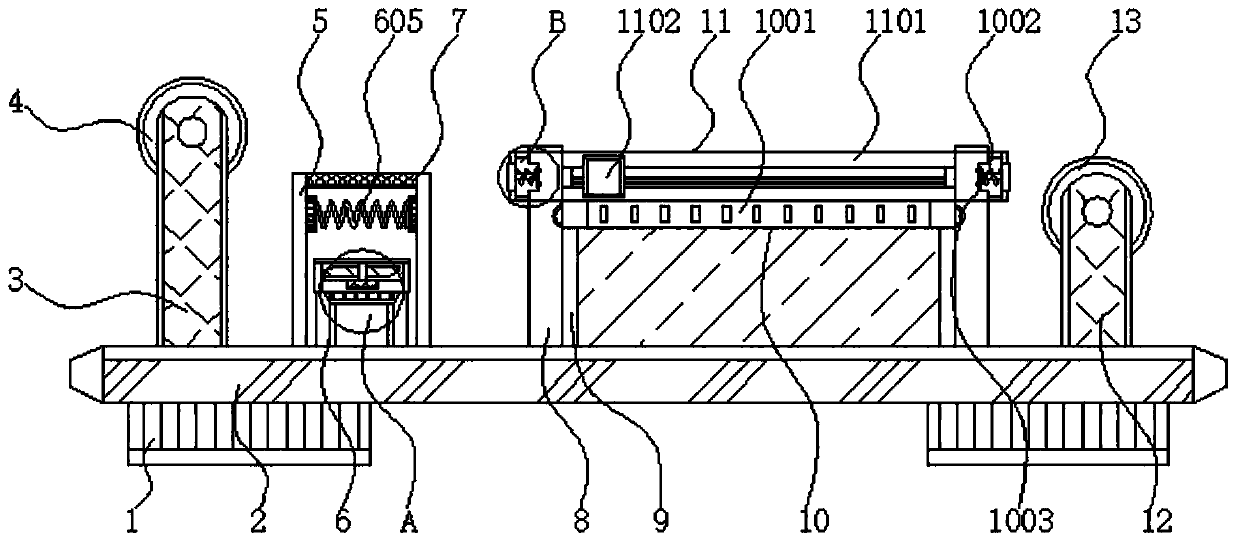

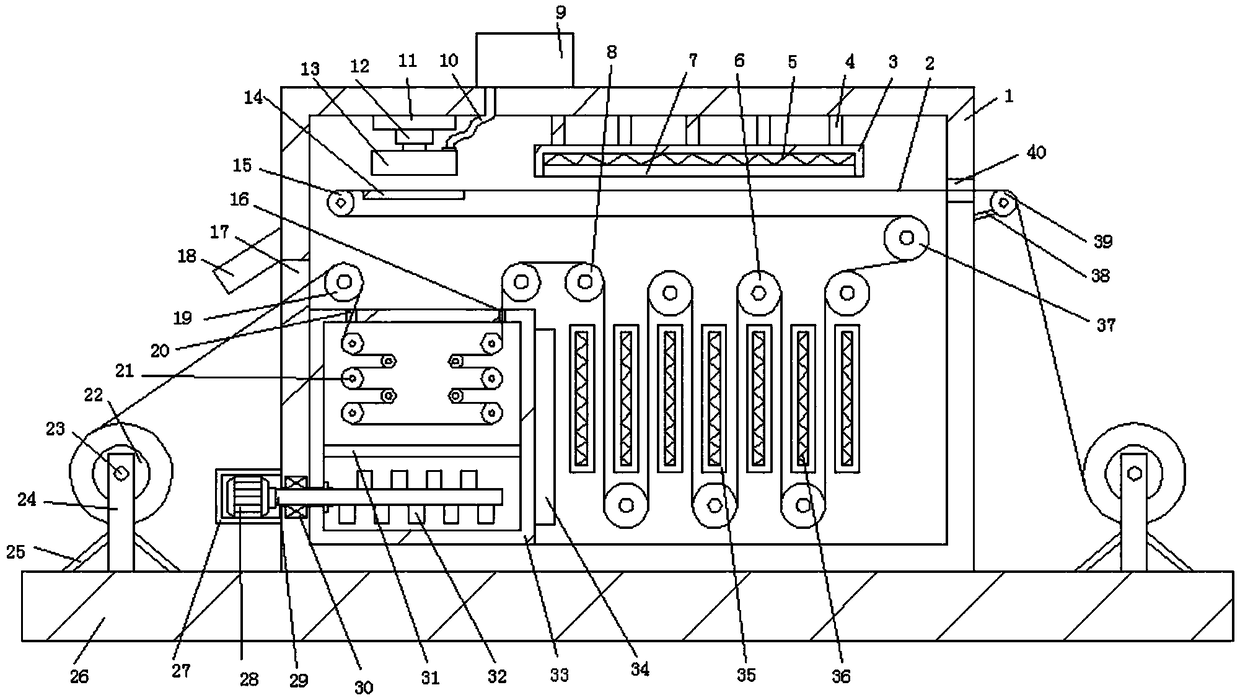

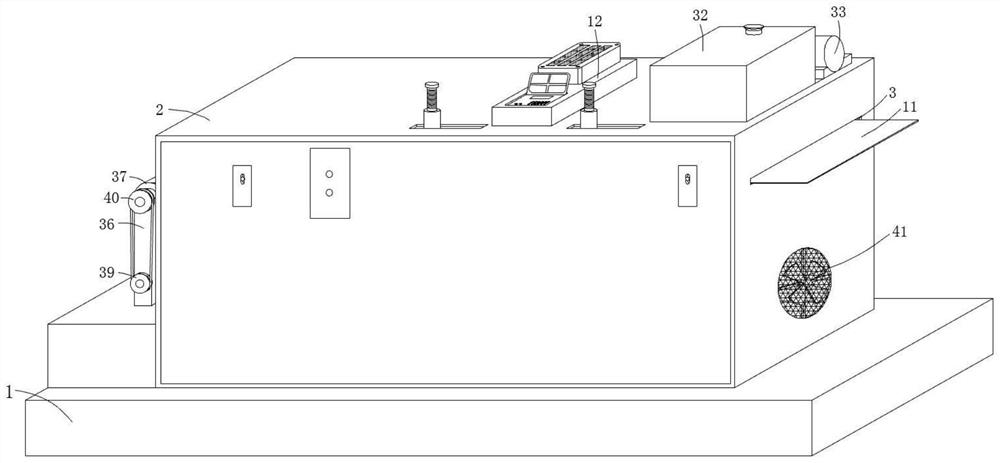

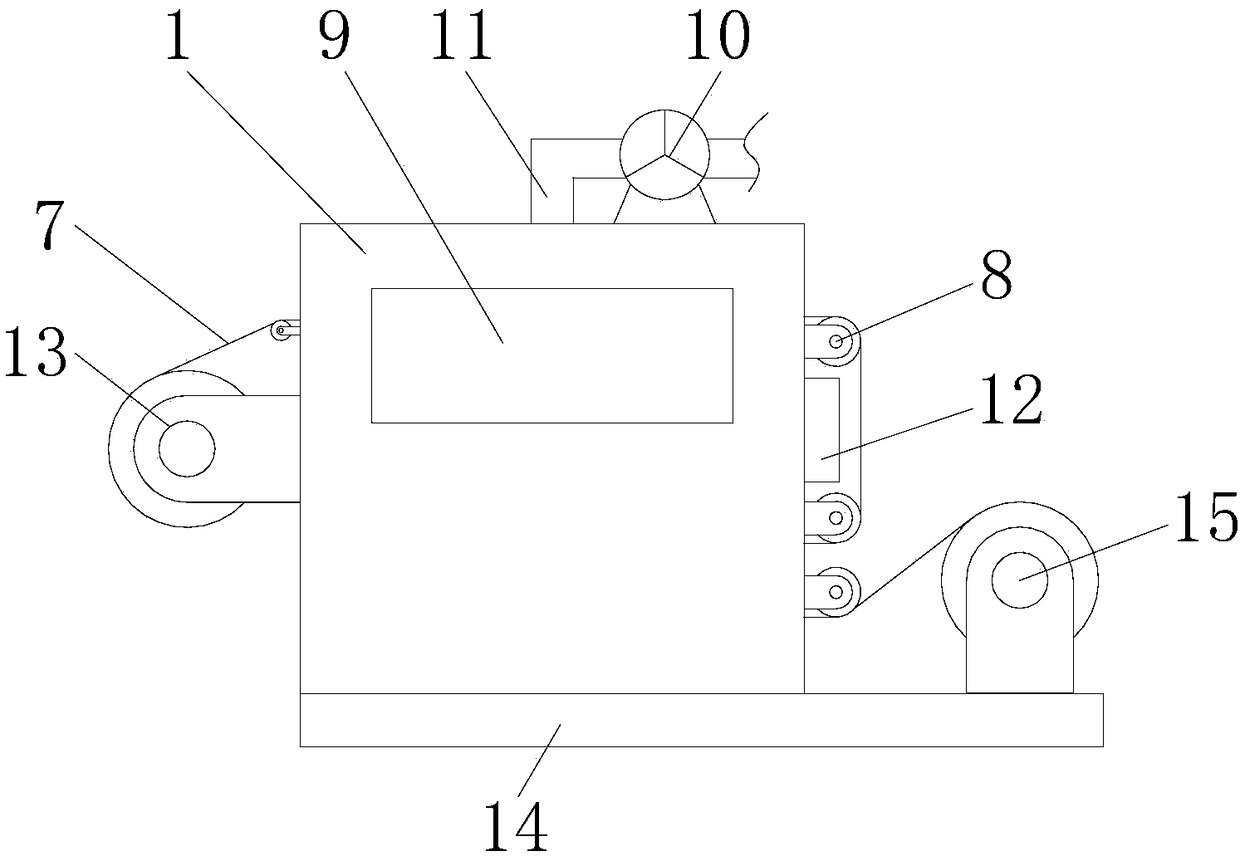

Cloth printing, dyeing and drying device for textile

InactiveCN108486807AImprove flatnessShorten drying timeLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsEngineeringMechanical engineering

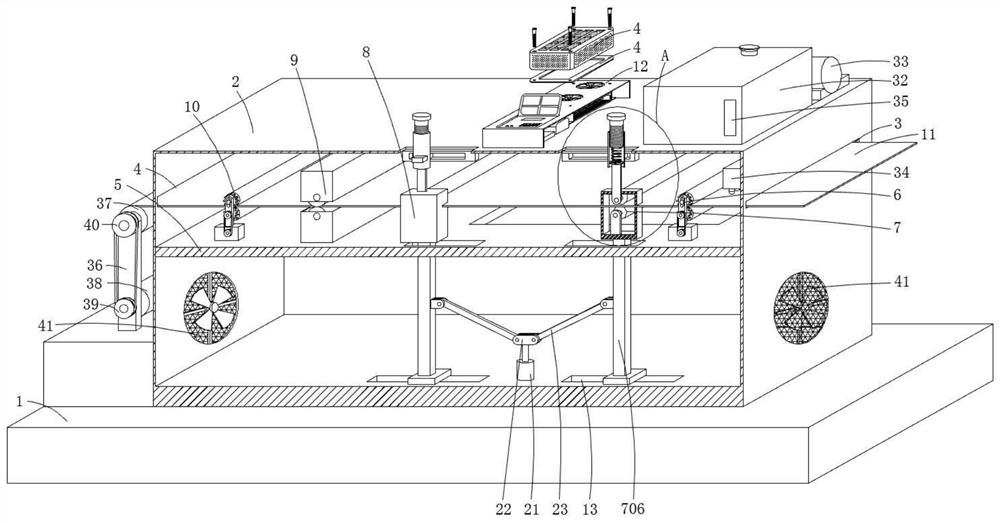

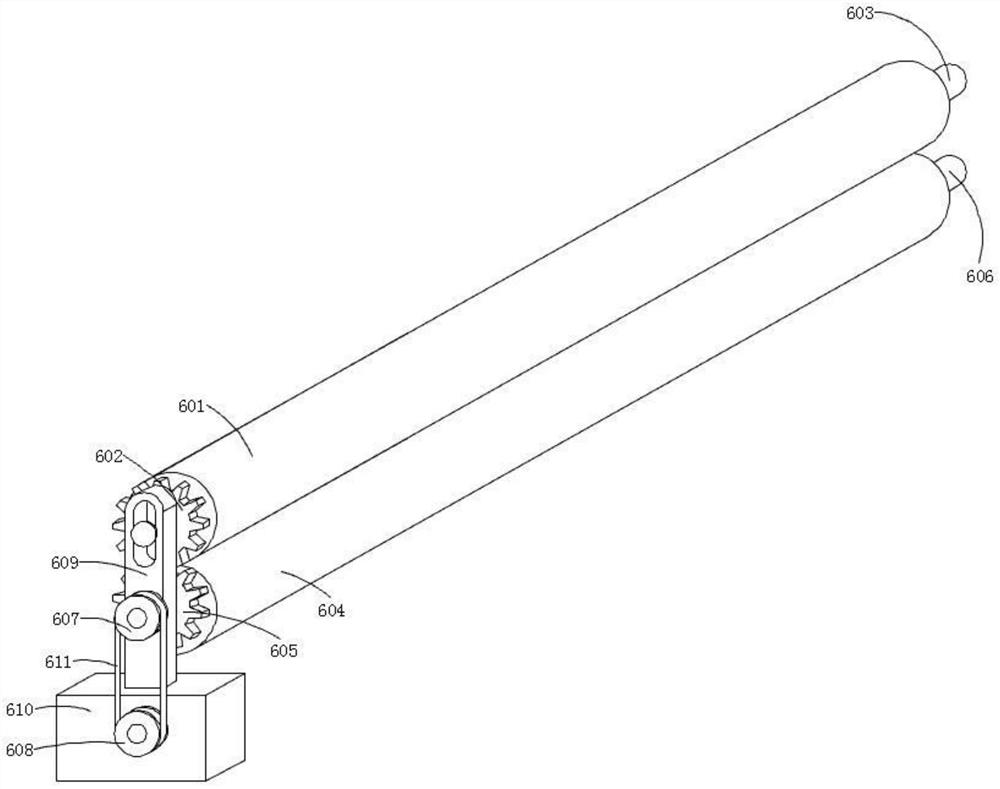

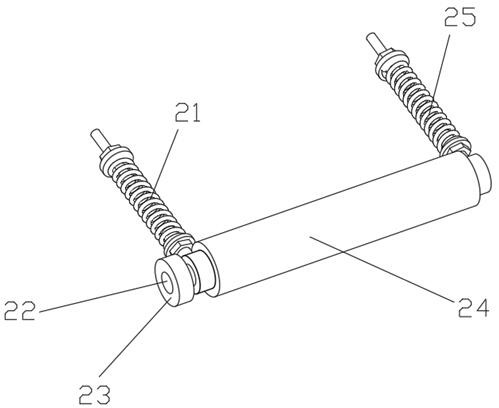

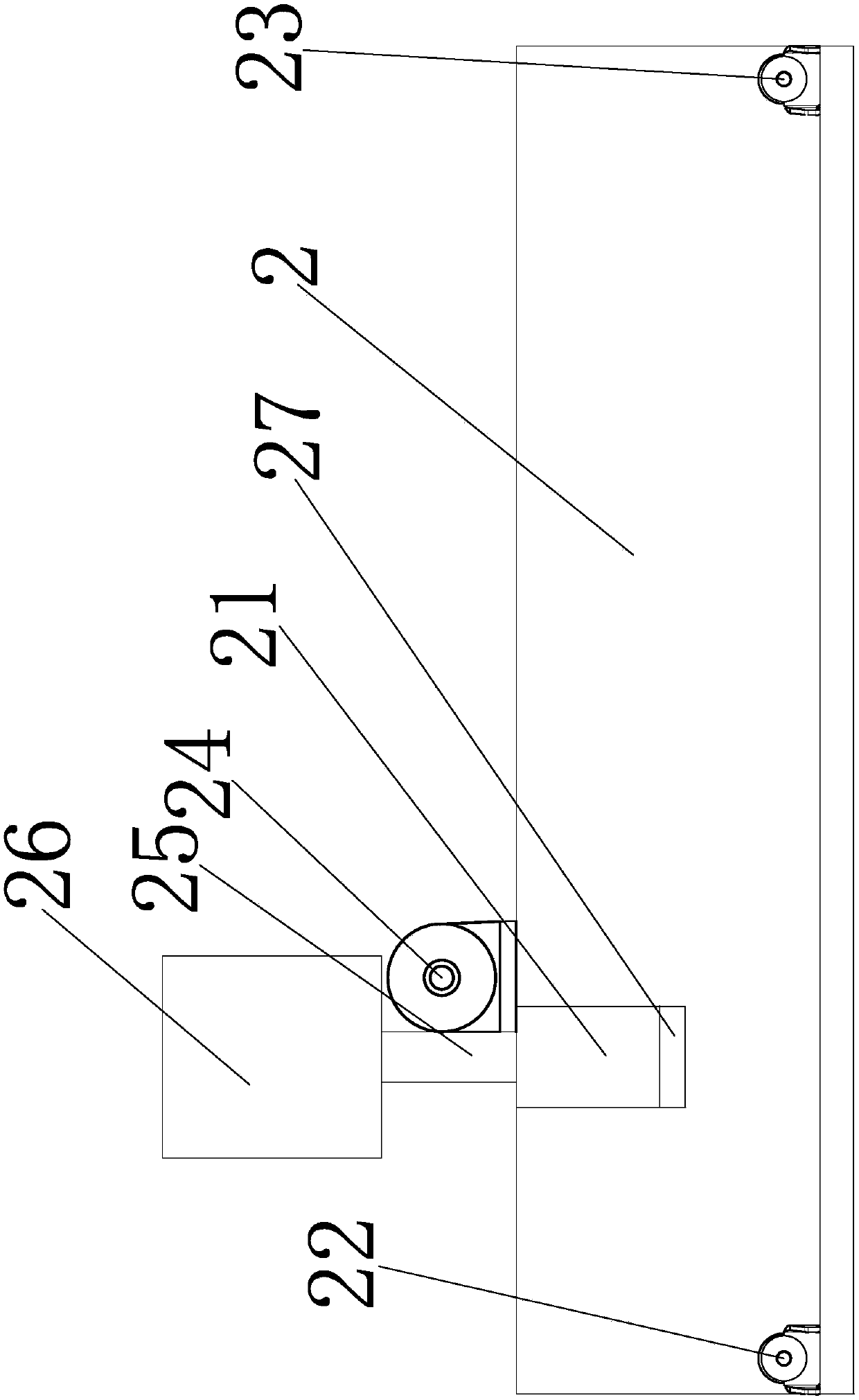

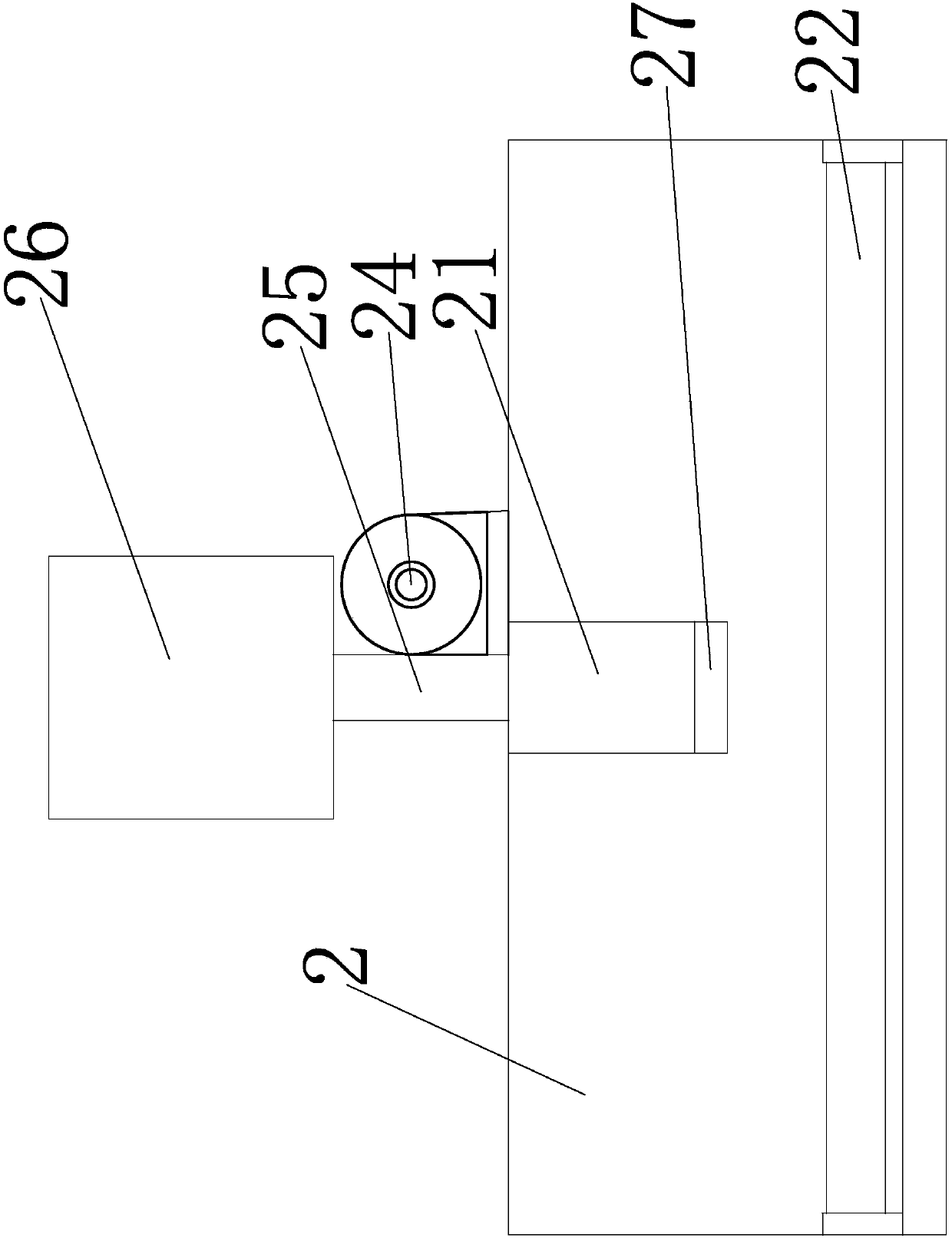

The invention discloses a cloth printing, dyeing and drying device for textile. The cloth printing, dyeing and drying device for textile comprises a base and cloth, wherein a cloth outlet roll and a cloth feeding roll are rotatably arranged on the left side and the right side of the top of the base through supports separately; the cloth feeding roll is driven by a gear motor which is positioned onthe front side of the cloth feeding roll; a printing and dyeing box is further fixedly arranged on the top of the base and is positioned between the cloth outlet roll and the cloth feeding roll; a cover plate is fixedly arranged on the top of the printing and dyeing box through bolts and nuts; a first guiding roll is rotatably arranged on the left side of the top of the cover plate through a support; a third guiding roll is further rotatably arranged on the top of the cover plate through a support; a left second guiding roll and a right second guiding roll are rotatably arranged in the printing and dyeing box in the front-back direction; two ends of the cloth are separately wound on the cloth outlet roll and the cloth feeding roll; the cloth is wound through the first guiding roll, the second guiding roll and the third guiding roll separately; and a cloth opening for cloth to penetrate through is formed in the cover plate. In a printing and dyeing process, cloth cannot be messy; afterprinting and dyeing, the cloth is reeled directly; and the smoothness of the cloth is good.

Owner:PINGHU YIFANJIA LUGGAGE CO LTD

Fabric dyeing and printing device

InactiveCN101245537AImprove printing and dyeing effectUniform and beautiful colorTextile treatment by spraying/projectingTextile treatment carriersEngineeringControllability

The invention relates to a fabric printing and dyeing device which includes a machine frame, a power system and a transmission system. The device is characterized in that: a fabric supporting piece is arranged on the machine frame or the transmission system. The fabric supporting piece is made by ventilating materials or is provided with a ventilating hole. The upward side and the downward side of the fabric supporting piece are respectively provided with a vacuum absorption cavity and an atomizing system. The vacuum absorption cavity is connected with a vacuum pipeline. A vacuum pump is arranged on the vacuum pipeline. The atomizing system includes an atomizer and a dye channel. A pattern templet is fixedly on the machine frame below the outlet of the dye channel. The atomizing system moves opposite to the pattern templet under the drive of the power system and the transmission system. The device of the invention utilizes vacuum subpressure absorption to print and dye atomized dyes on the fabric and has the advantages of simple and reasonable structure, low dyeing cost, high controllability on operation and high dyeing efficiency, being beneficial to improving the dyeing effect of the fabric. The color of the fabric after printing and dyeing is uniform and beautiful.

Owner:浙江宝通环保印染设备科技有限公司

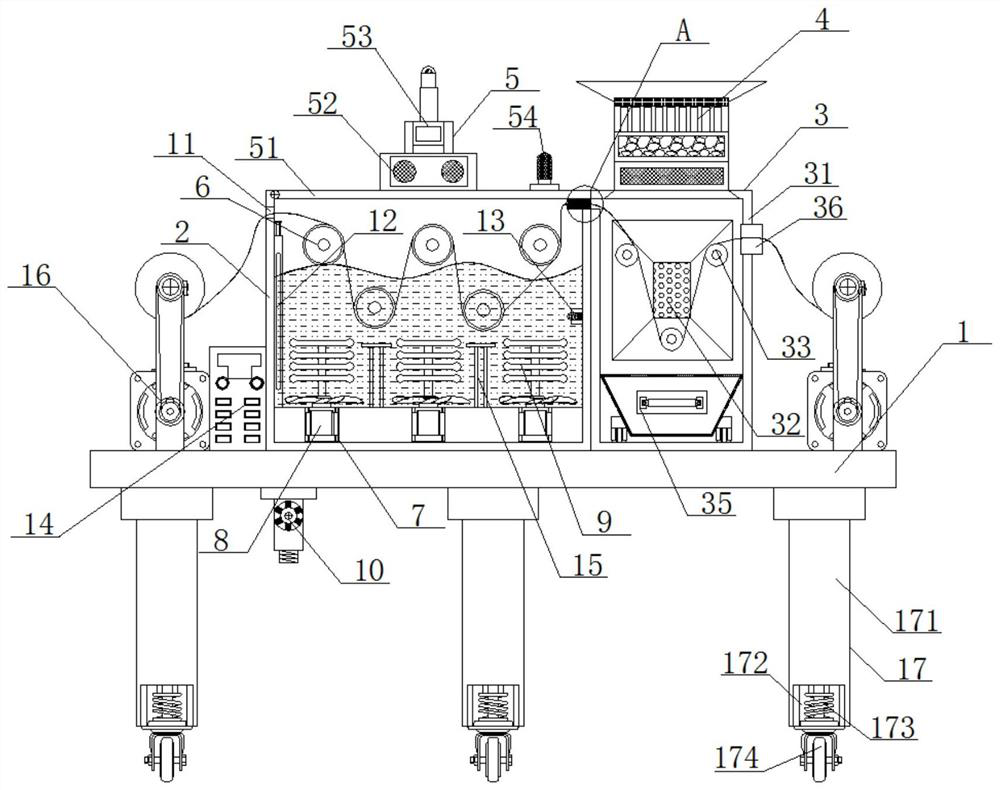

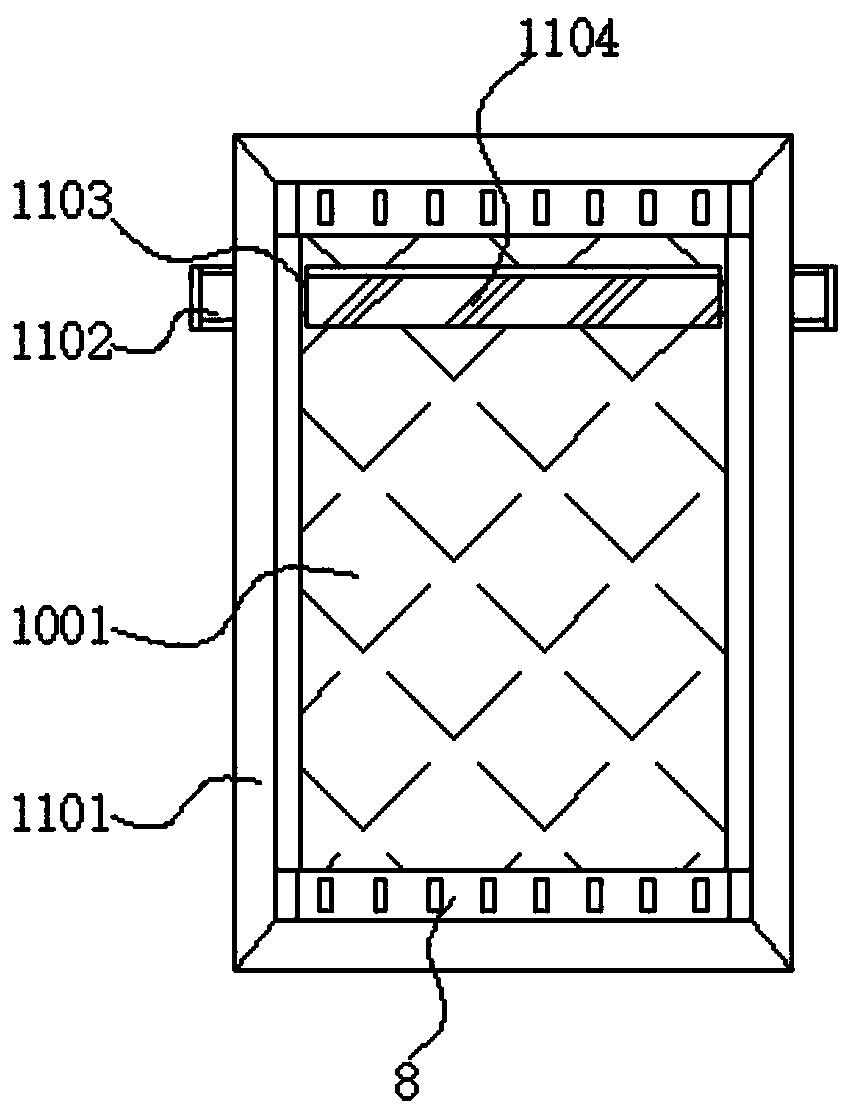

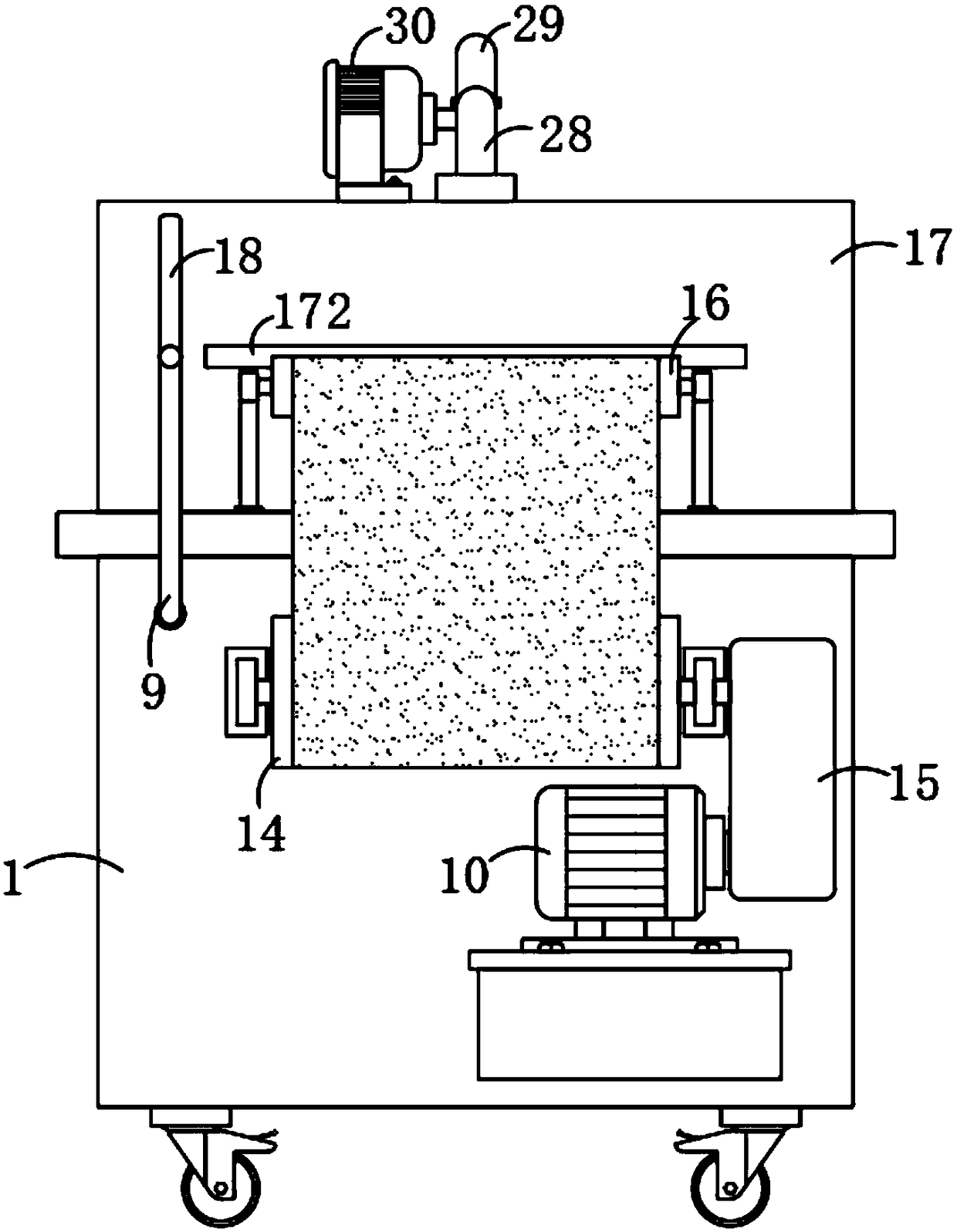

Dyeing equipment for textile fabric production

InactiveCN112430942AEfficient mixingThoroughly tumble up and down to mixTextile treatment containersTextile treatment machine arrangementsAir cleaningElectric machinery

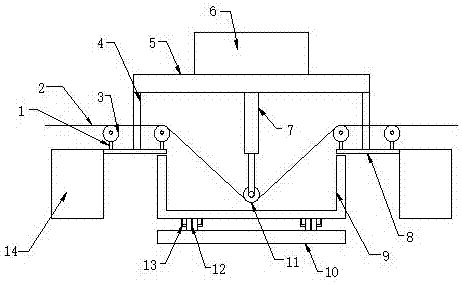

The invention discloses dyeing equipment for textile fabric production. The drying equipment comprises an operation table, wherein the middle of the top of the operation table is fixedly connected toa printing and dyeing box; the right side of the printing and dyeing box is fixedly equipped with a drying device; the top of the drying device is fixedly equipped with an air purifying device; the top of the printing and dyeing box is fixedly equipped with a box cover assembly; five groups of printing and dyeing rollers are alternatively and rotatably connected on the middle in the printing and dyeing box at equal distance; three groups of grooves are formed in the bottom of the printing and dyeing box at equal distance; first drive motors are fixedly mounted inside the grooves; the output ends of the first drive motors are fixedly equipped with stirring frames; and a cloth inlet is formed in the left side of the printing and dyeing box. The dyeing equipment can perform efficient dyeing on the dyed textile fabric, is relatively uniform in dyeing, further can dry better, reduces emission of polluted air, is improved in practicability and environment friendliness, has a wide applicationprospect, and is worthy of being used.

Owner:绍兴宽裕机械股份有限公司

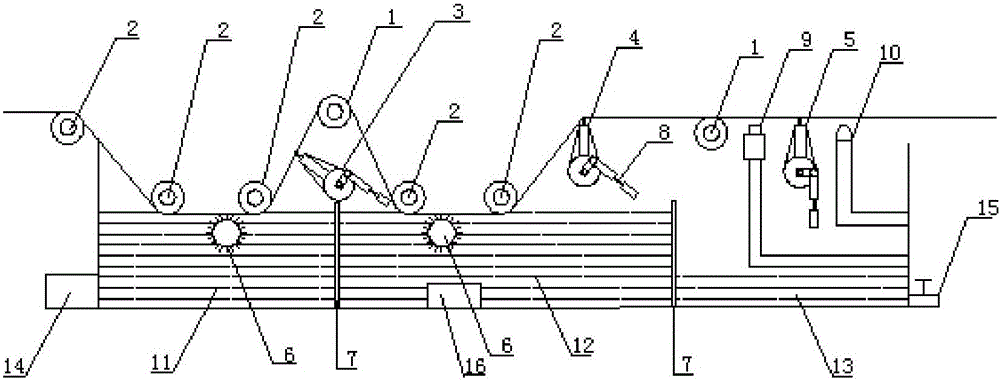

Conduction belt cleaning device of flat screen printing machine

InactiveCN106004039ASimple device structureEasy to usePrinting press partsEngineeringPower consumption

The invention provides a cleaning device for a guide belt of a flat screen printing machine. The third cleaning tank containing the cleaning residue. The guide belt cleaning device of the flat screen printing machine of the present invention uses a scraper and a cleaning tank to recover most of the slurry on the guide belt, and realizes the recovery of most of the slurry; On the premise of not affecting the cleaning effect of the guide belt, the water consumption in the cleaning process is reduced and the power consumption is reduced.

Owner:XINCHANG BENSHANG REFRIGERATING TECH CO LTD

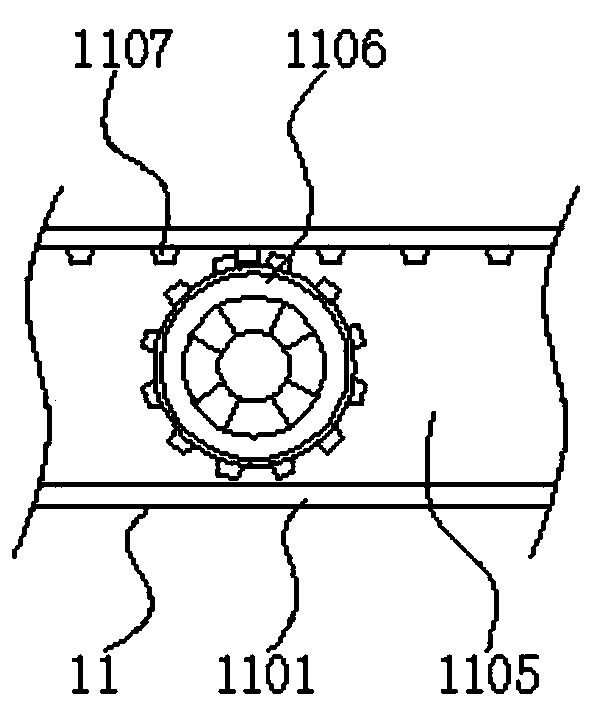

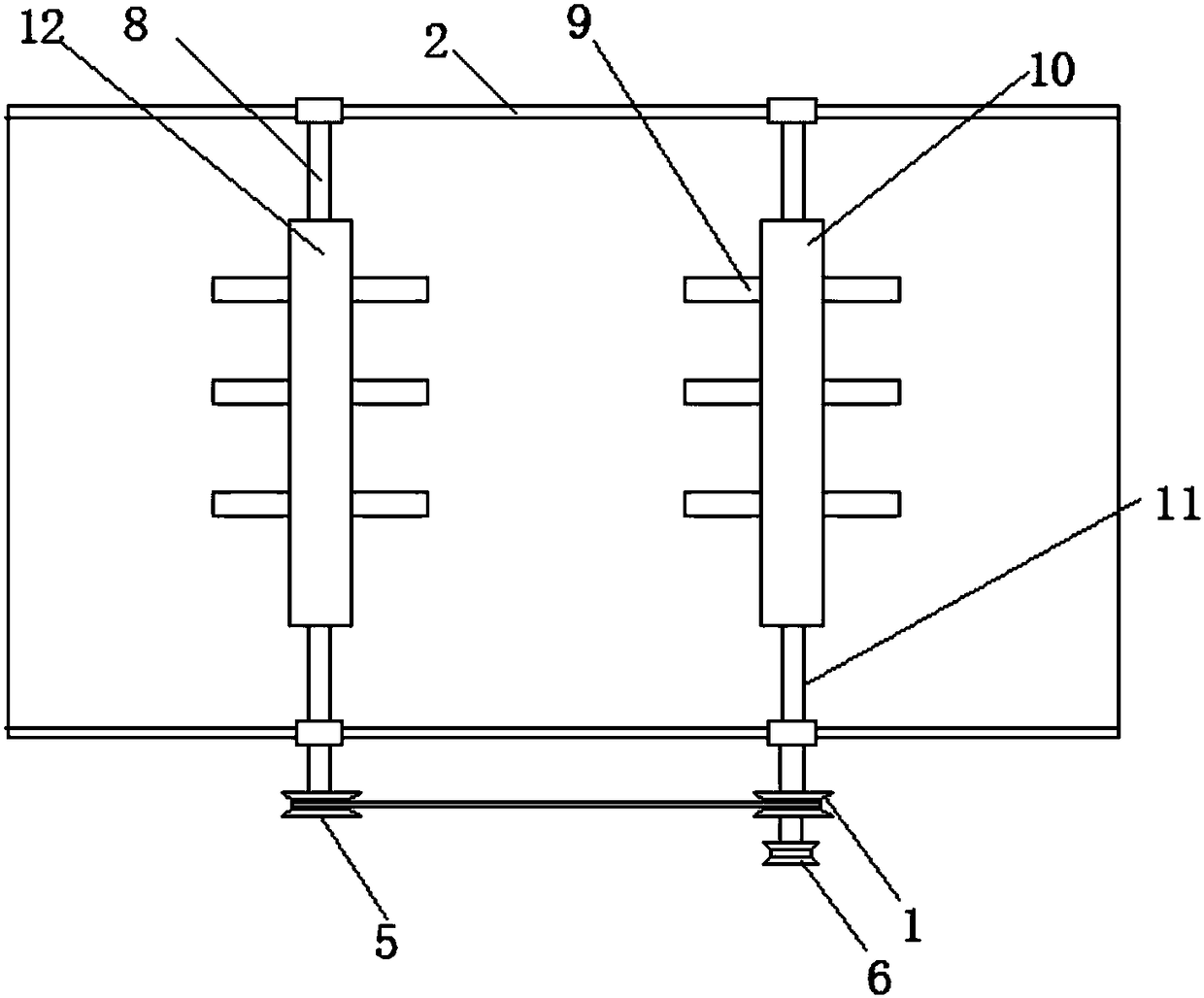

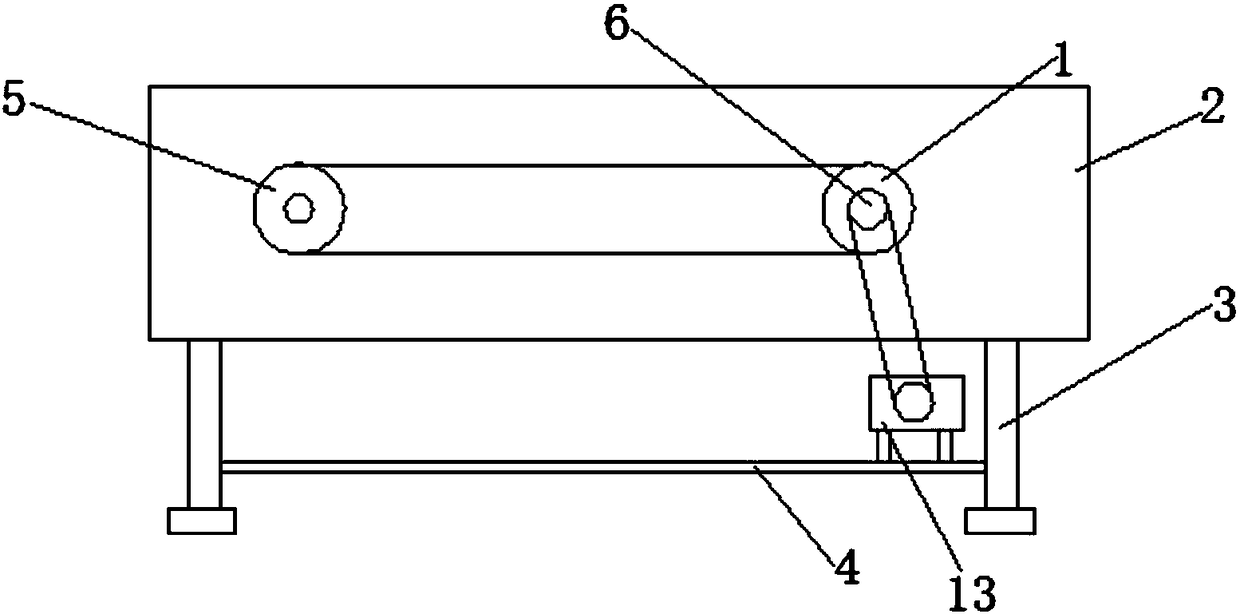

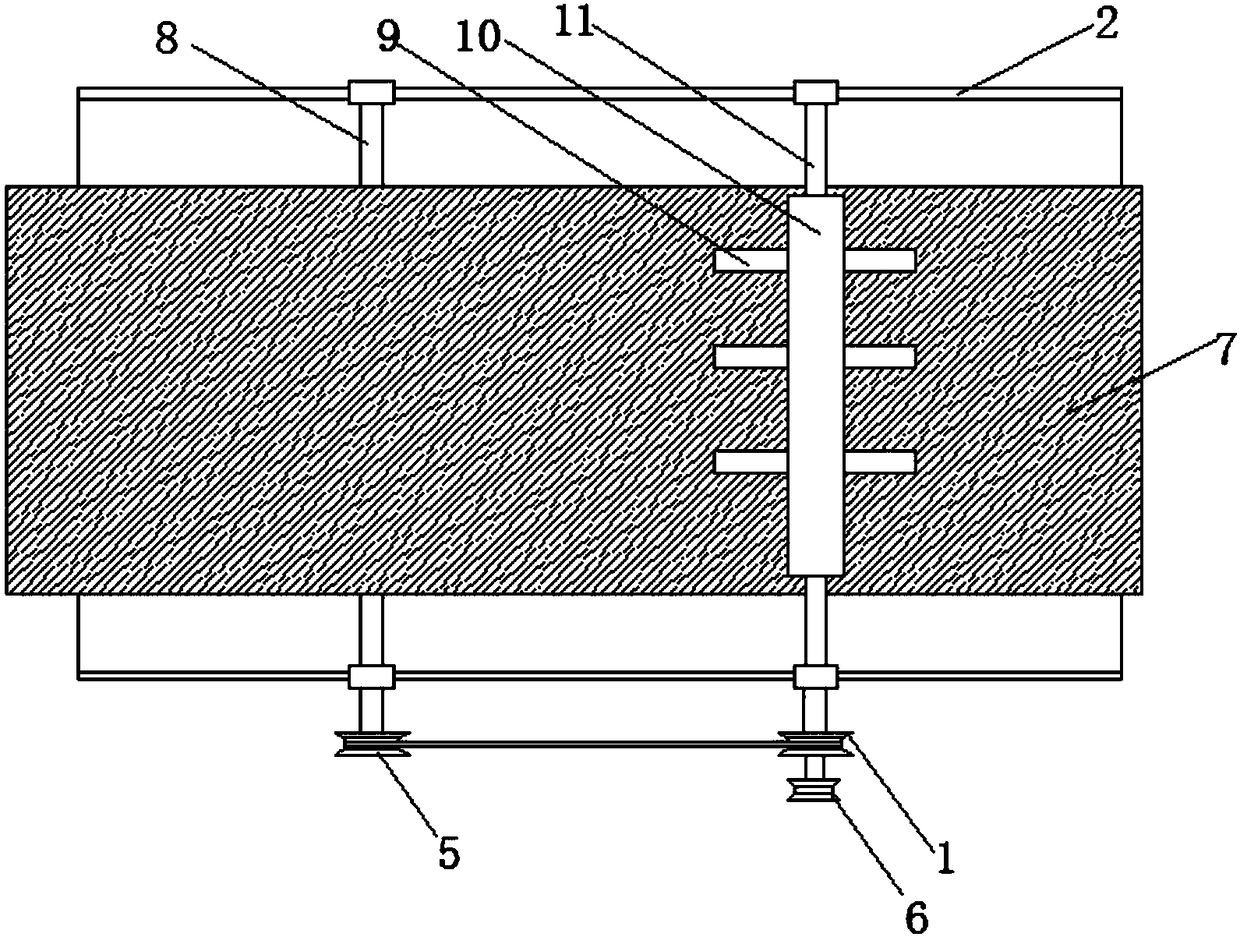

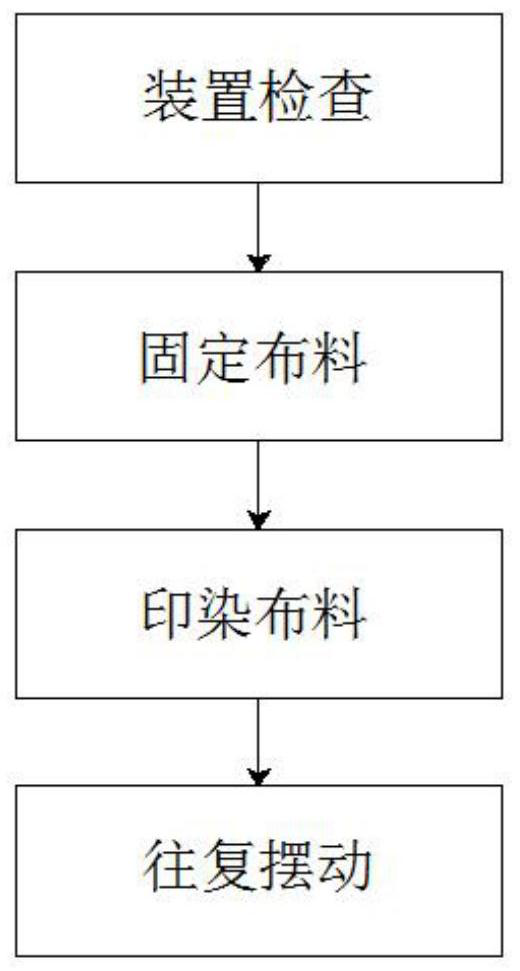

Printing equipment for textile fabric production

InactiveCN111764072AAvoid precipitationImprove printing and dyeing efficiencyTextile treatment machine arrangementsTextile treatment carriersTransmission beltElectric machinery

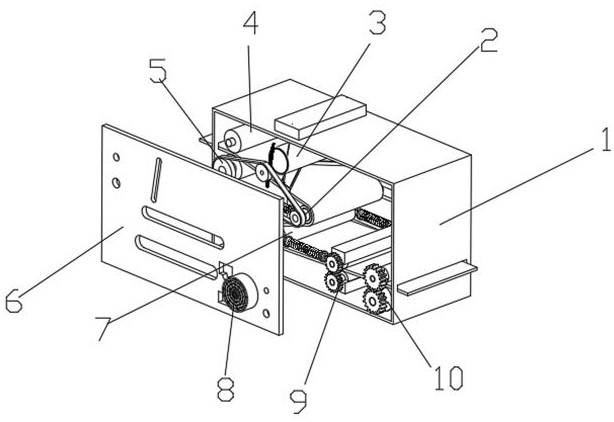

The invention discloses printing equipment for textile fabric production. The equipment comprises a control console, supporting plates, a top plate, a push rod box, an electric push rod, a drive plate, stepping motors, drive belt wheels, transmission belts, driven belt wheels, transmission shafts, supports, rotating rollers, fixing plates, open holes, positioning frames, limiting plates, metal rods, a fuel box, a limiting net, a rotating sealing bearing, a transmission column, stirring blades, a stirring motor, a machine frame, a drainage valve and a drainage pipe. The two stepping motors drive a fabric to reciprocate. After the fabric is soaked with dye, printing can be performed evenly, and the printing efficiency is improved. By arranging a drive motor, in the fabric printing process, the dye is stirred, dye precipitation can be avoided, and therefore the fabric printing effect is affected. Two ends of the fabric can be fixed through the positioning frame, the fabric can be prevented from being disengaged, and therefore the fabric dyeing work can be more completely performed.

Owner:吴江舒宇纺织有限公司

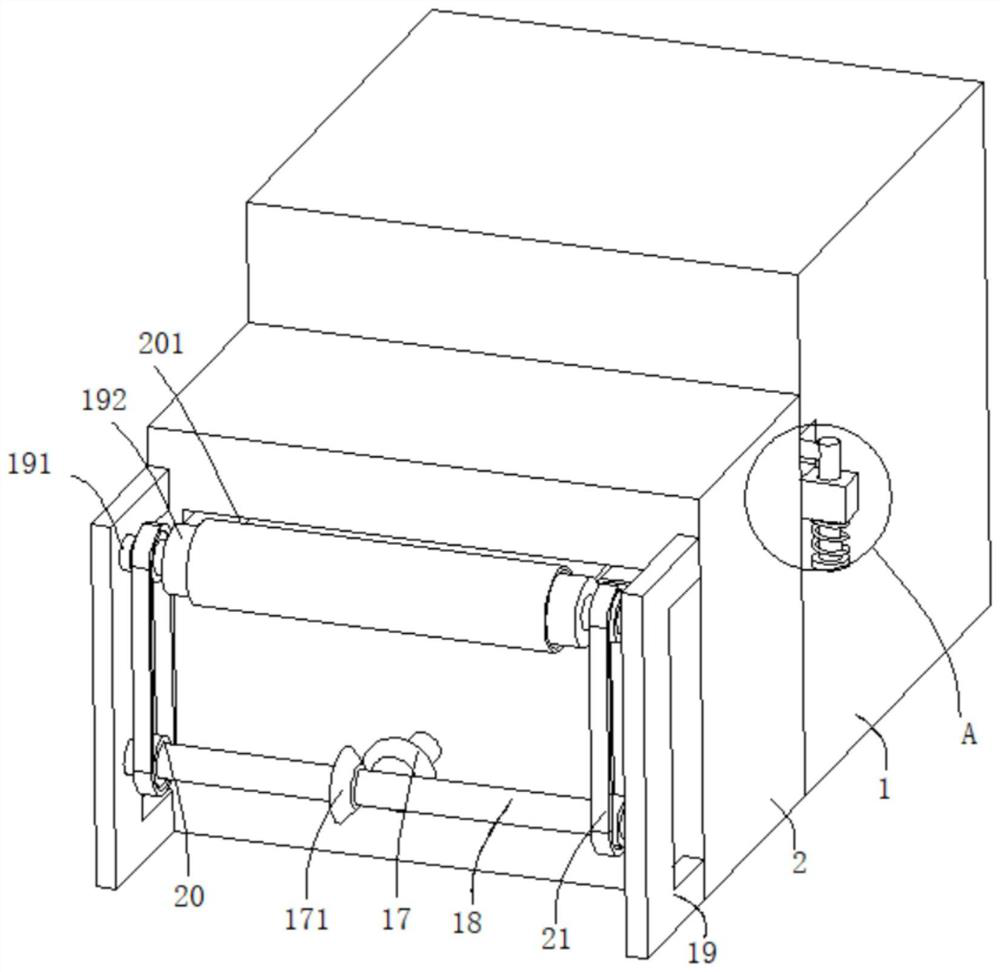

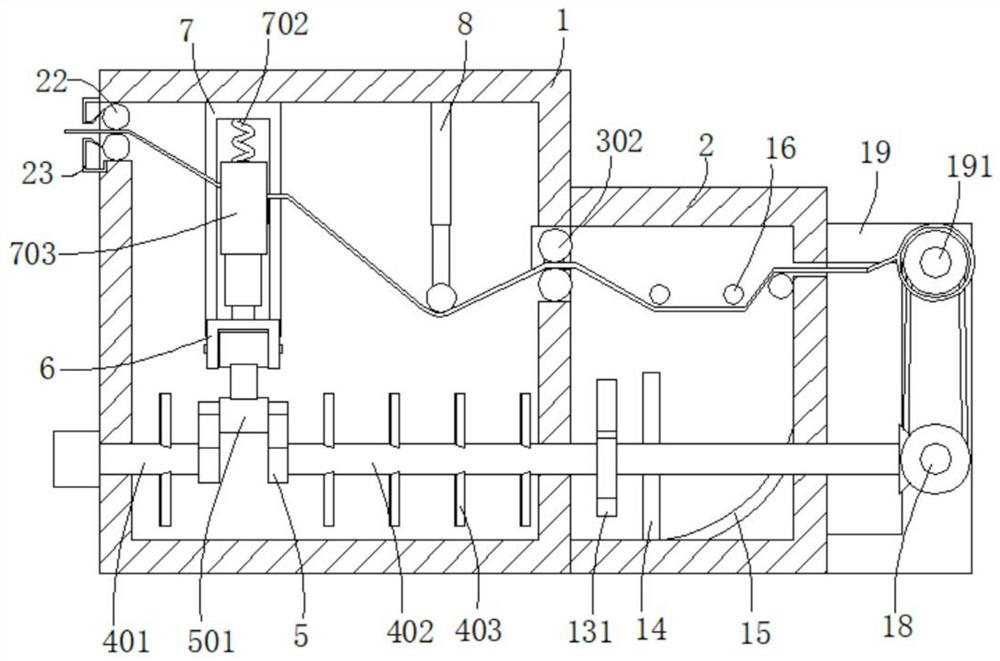

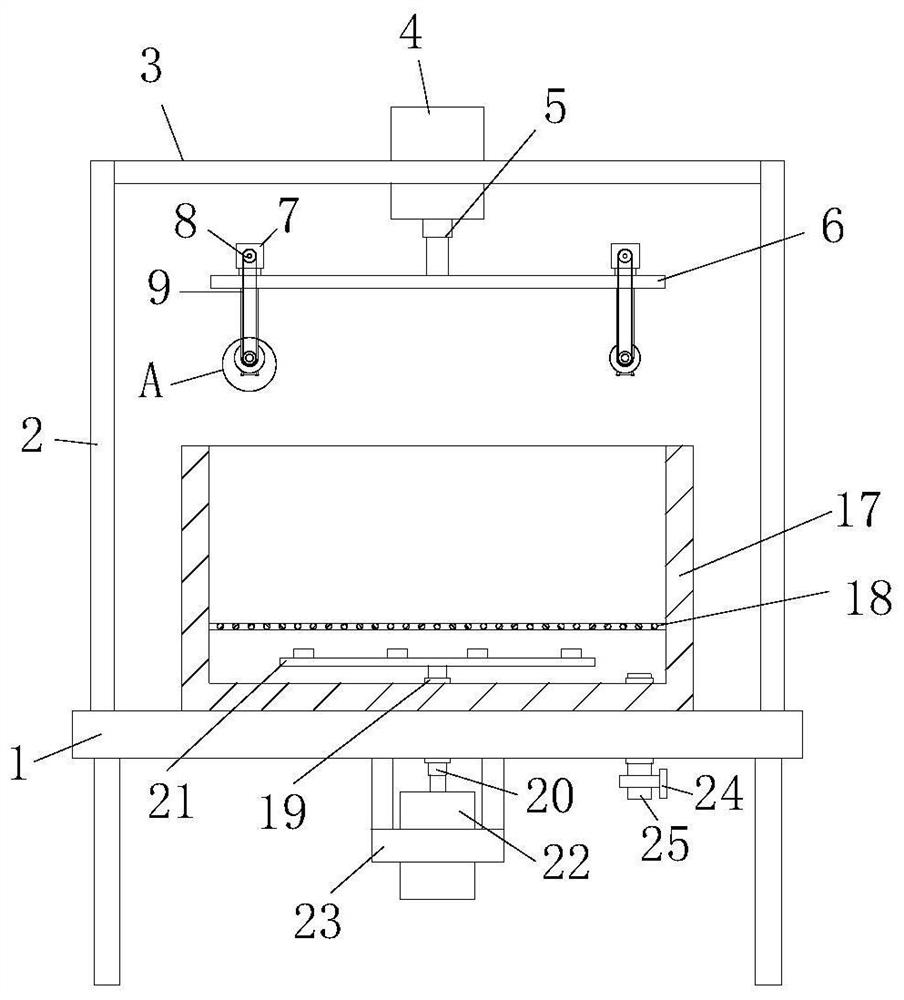

Textile fabric printing and dyeing equipment and printing and dyeing method

InactiveCN111455587AImprove uniformityImprove printing and dyeing efficiencyTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsManufacturing engineeringTextile printer

The invention discloses textile fabric printing and dyeing equipment and a printing and dyeing method, and belongs to the technical field of textile printing and dyeing equipment. The textile fabric printing and dyeing equipment comprises a box body and a base. A division plate is arranged on the inner side wall of the box body, and a preformed groove is formed in the division plate. The box bodyis divided into an upper drying chamber and a lower printing and dyeing chamber by the division plate, and a feeding hole and a discharging hole communicated with the upper drying chamber and the lower printing and dyeing chamber correspondingly are formed in one side of the box body in the vertical direction. Symmetrically distributed pre-traction mechanisms are arranged on the inner side wall ofthe box body, and two ends of the pre-traction mechanisms penetrate through the feeding hole, the preformed groove and the discharging hole correspondingly. A drying mechanism, a winding mechanism and a smoothing mechanism are arranged on the outer side wall of the box body in sequence in the vertical direction, and a cloth fixing part matched with the pre-traction mechanisms is detachably connected with the winding mechanism. According to the textile fabric printing and dyeing equipment and the printing and dyeing method, functions of the printing and dyeing and drying of textile fabrics areachieved, and the feeding is stable, so that the folds of the textile fabrics during the printing and dyeing process are effectively avoided, and the printing and dyeing uniformity is ensured.

Owner:绍兴柯桥三杰纺织品有限公司

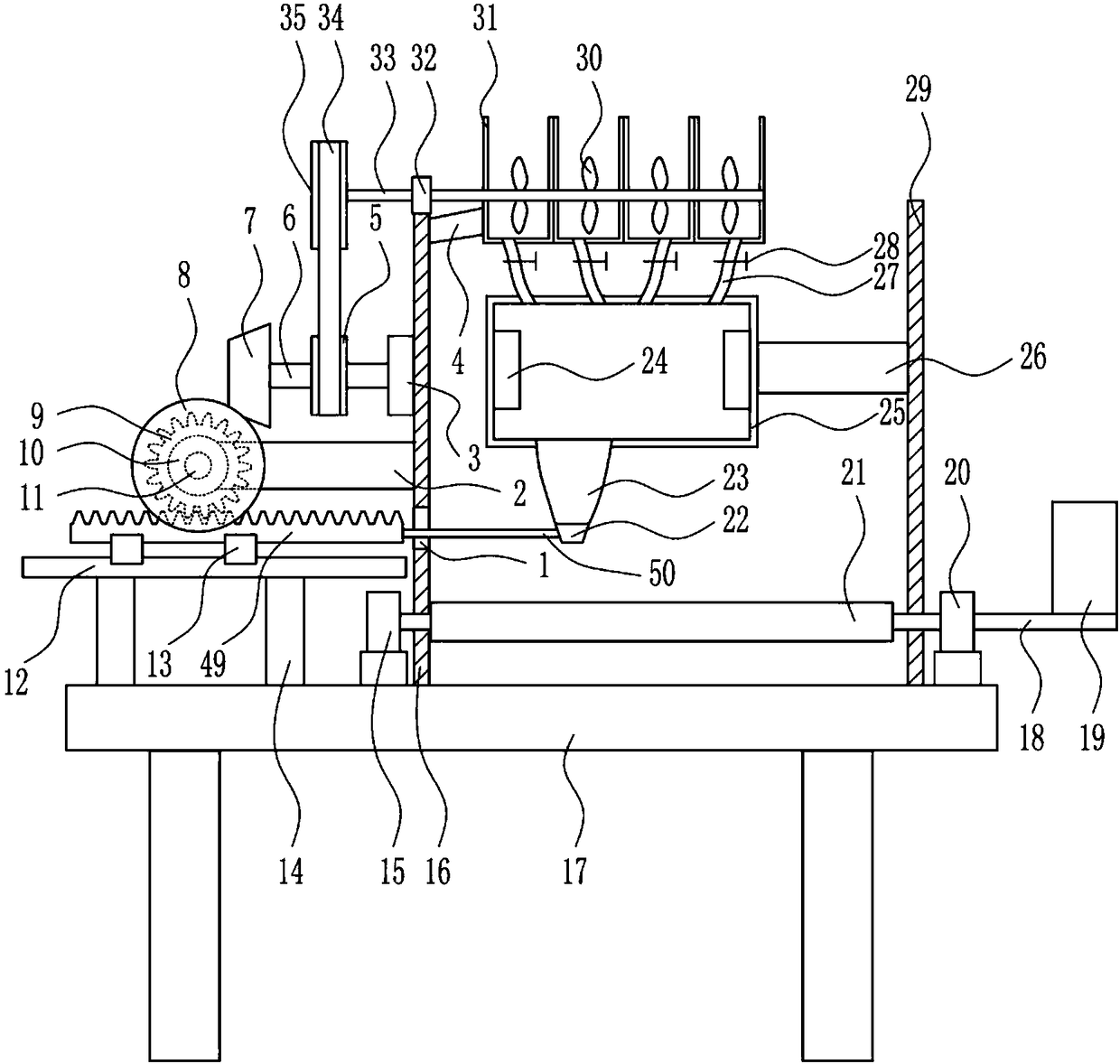

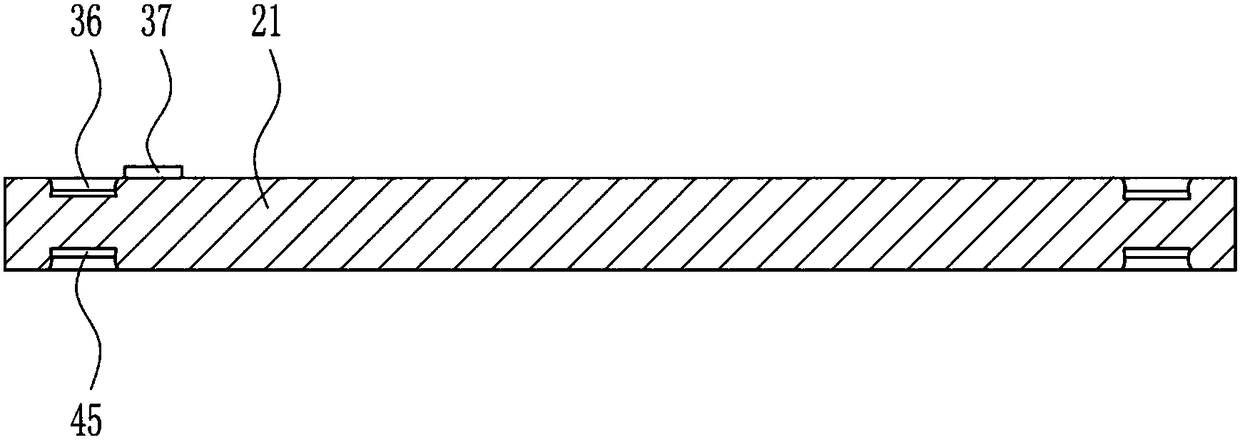

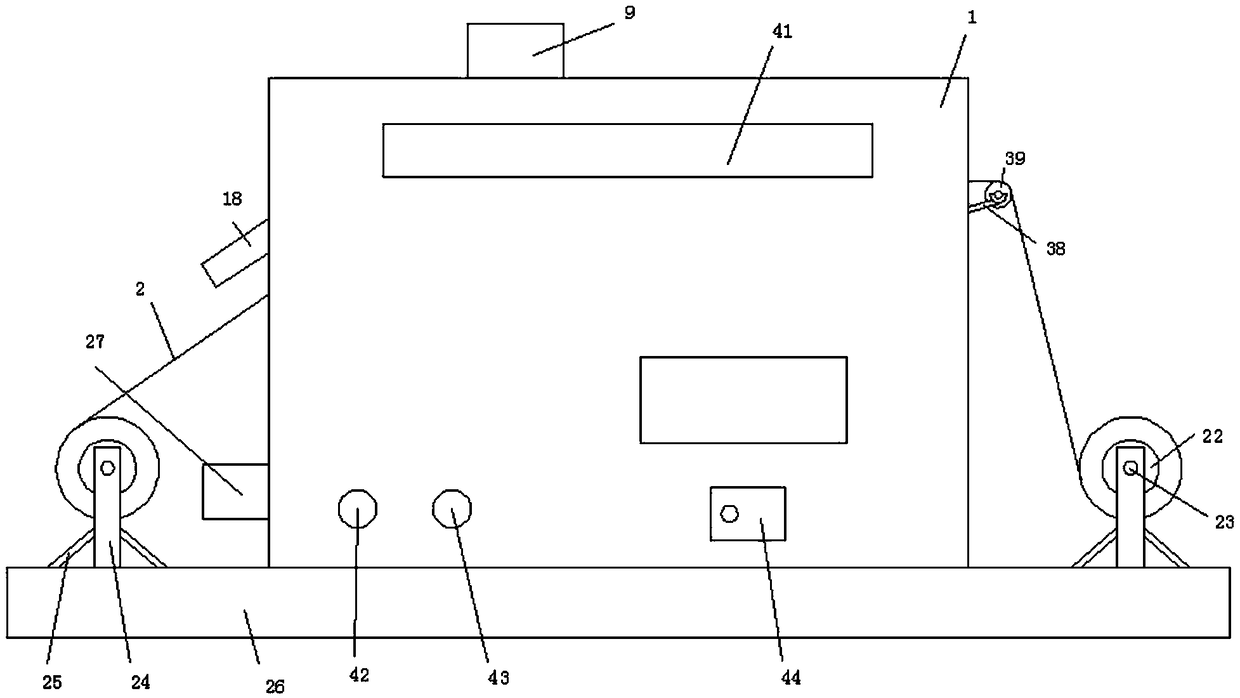

Printing and dyeing device with uniform dyeing effect and replaceable template for mechanical automated spinning

ActiveCN109722828AAdjustable positionRotation does not interfereSucessive textile treatmentsLiquid/gas/vapor removalEngineeringOverall efficiency

The invention discloses a printing and dyeing device with a uniform dyeing effect and a replaceable template for mechanical automated spinning and relates to the technical field of printing and dyeingof textiles. The printing and dyeing device with the uniform dyeing effect and the replaceable template for mechanical automated spinning comprises supporting feet, a drying chamber and a dyeing chamber, the drying chamber is formed above the supporting feet, and the dyeing chamber is formed in the right side of the drying chamber; a bottom plate is fixed to the top surfaces of the supporting feet, a discharging roller is connected to the rear portion of a first supporting rod, a drying mechanism is disposed in the drying chamber, and limiting blocks are fixed in the dyeing chamber. Accordingto the printing and dyeing device with the uniform dyeing effect and the replaceable template for mechanical automated spinning, the position of a spinning cloth can be automatically adjusted, thereis no need to require a lot of manpower when the device is used, the device is convenient to use, the spinning cloth after printing and dyeing are completed can be dried, the overall efficiency of processing the spinning cloth is improved, and printing and dyeing patterns can be replaced.

Owner:温州市简弈科技有限公司

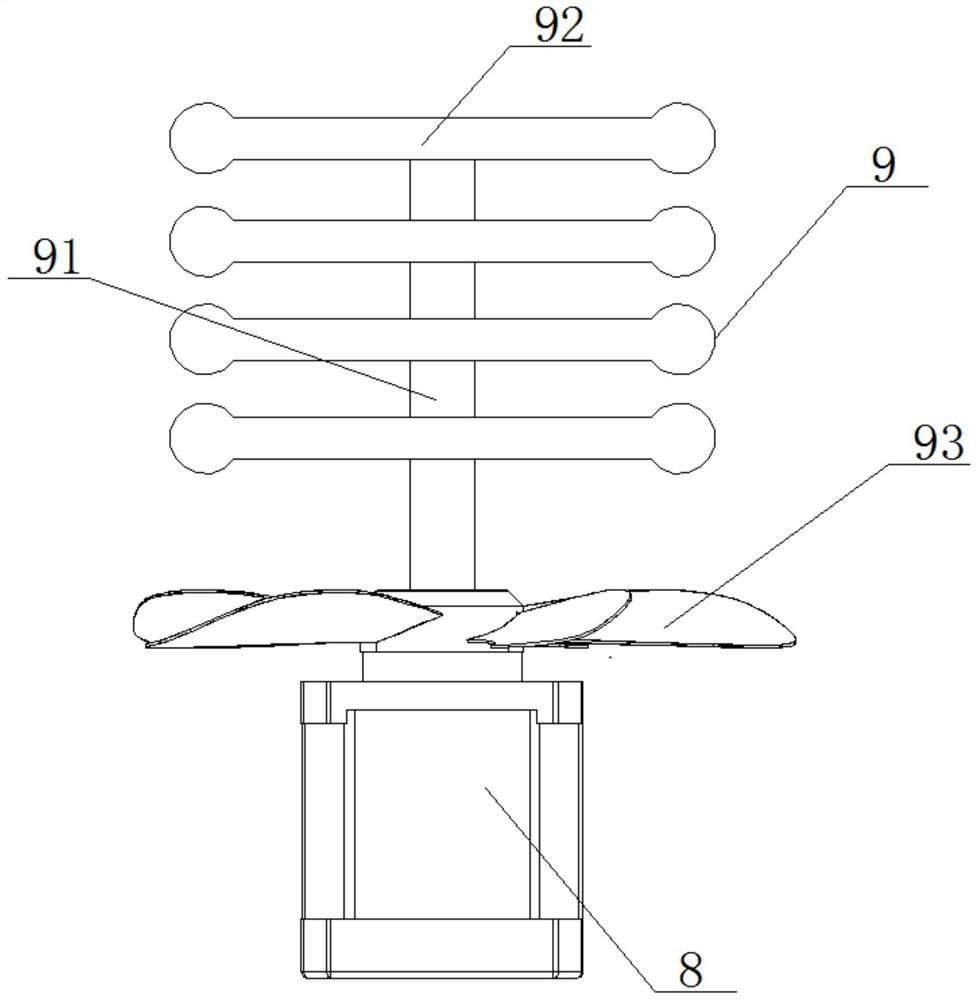

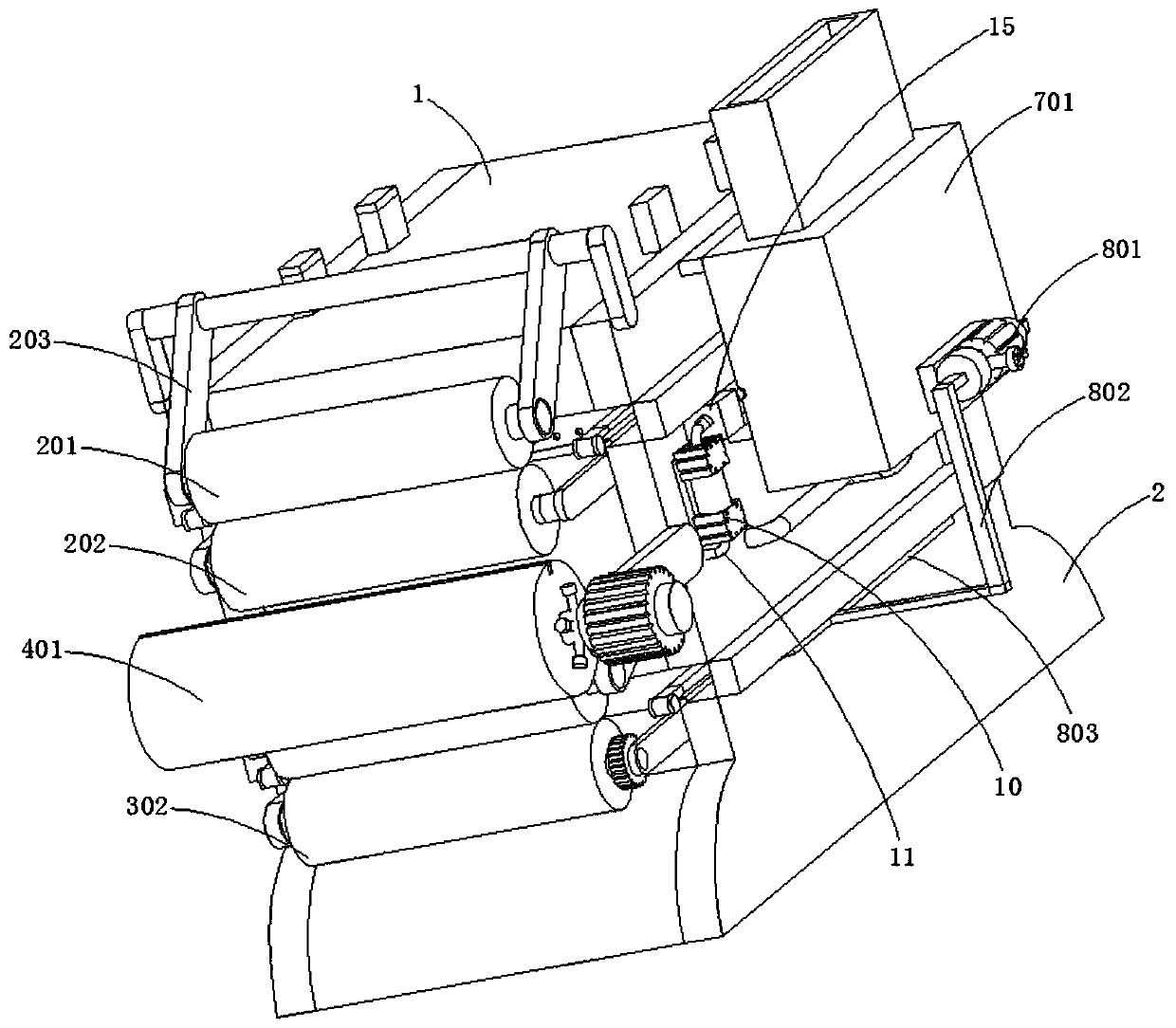

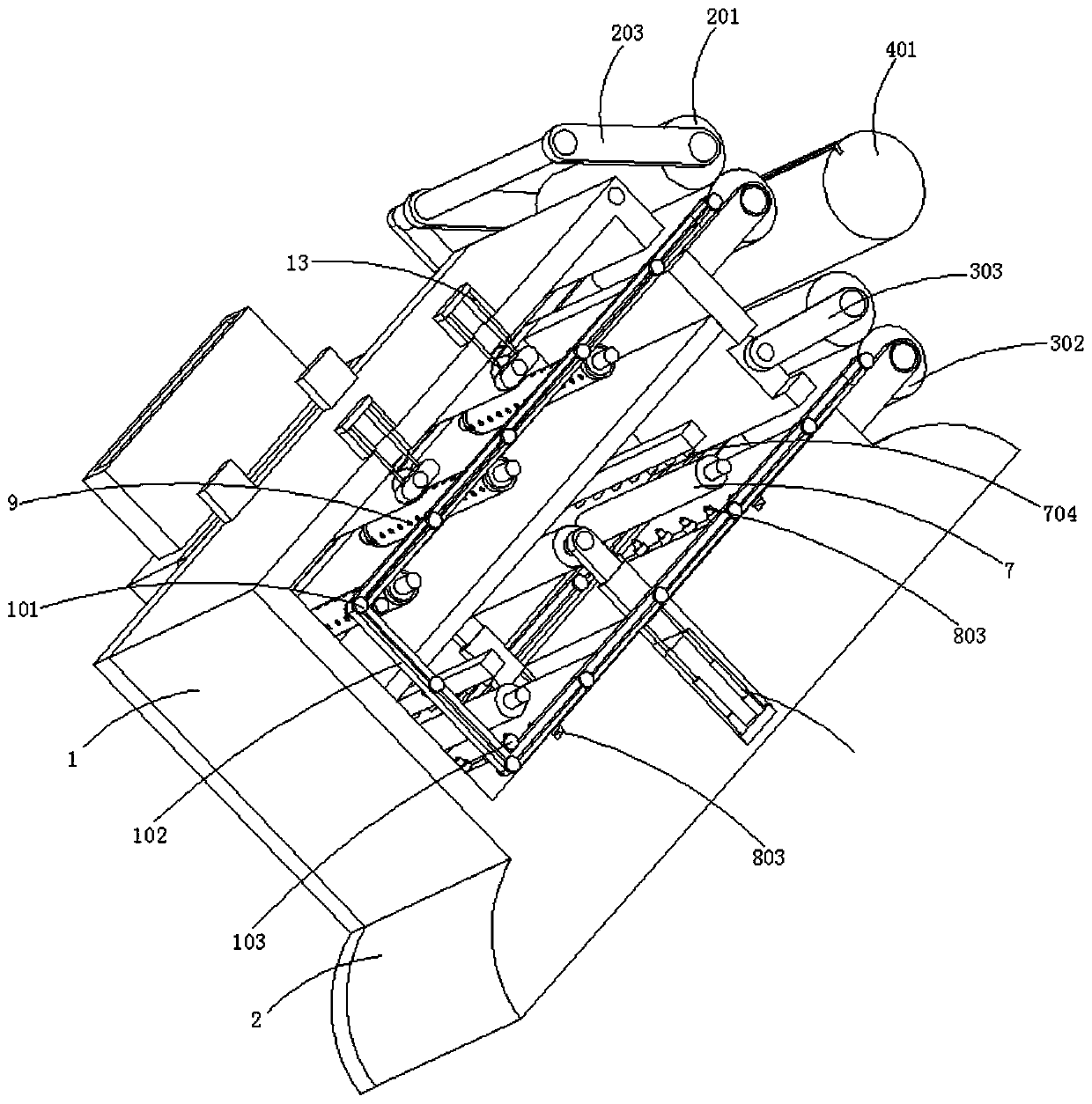

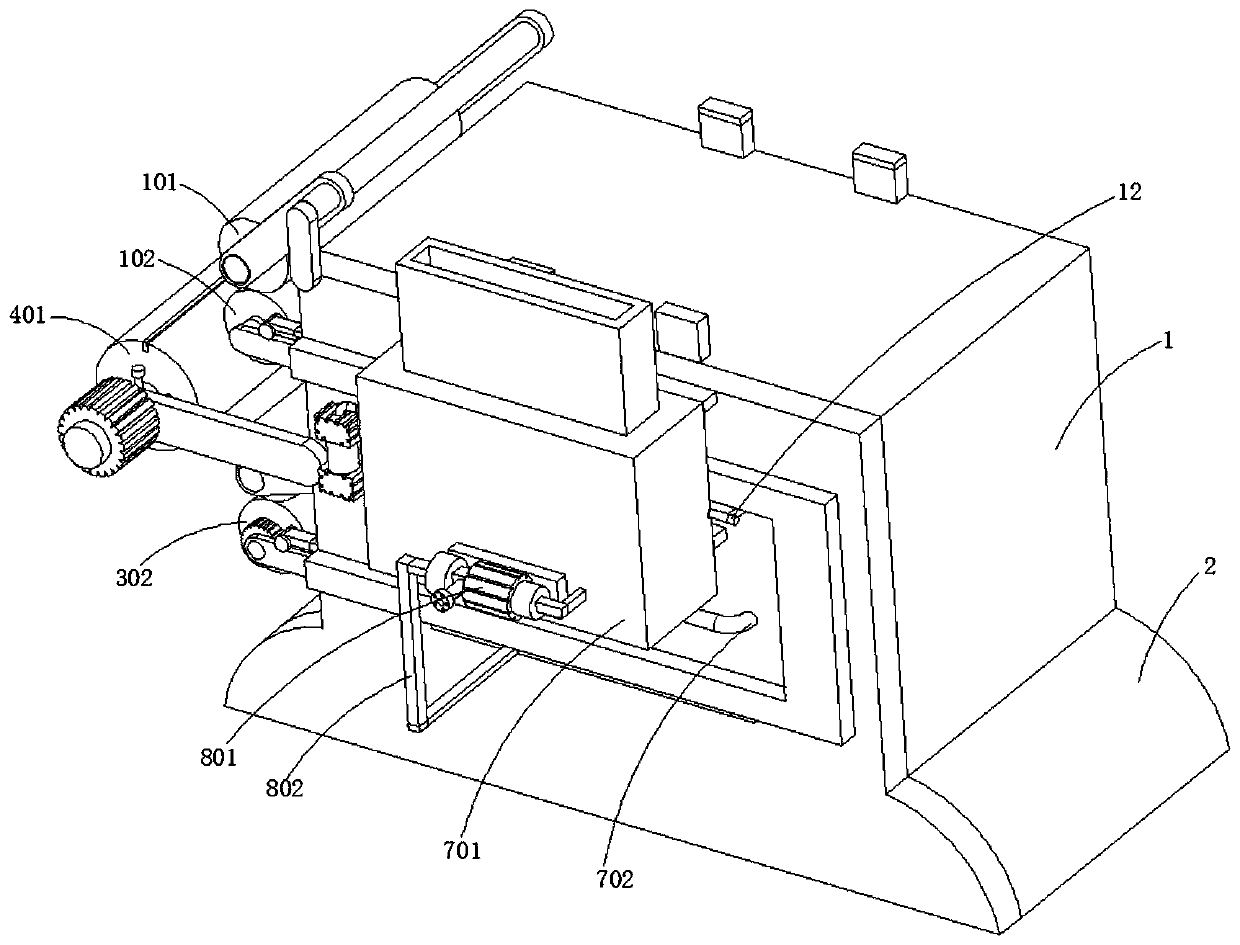

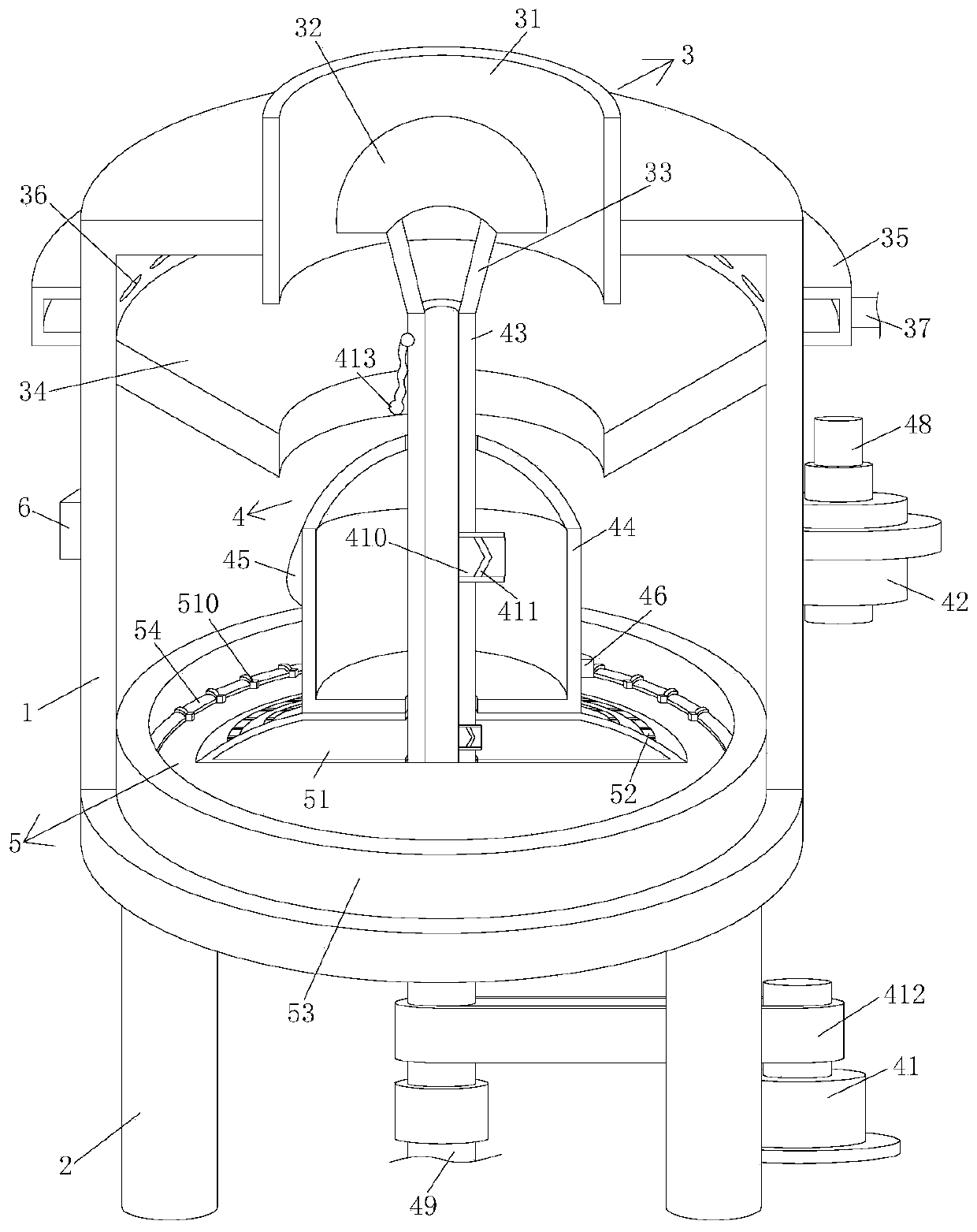

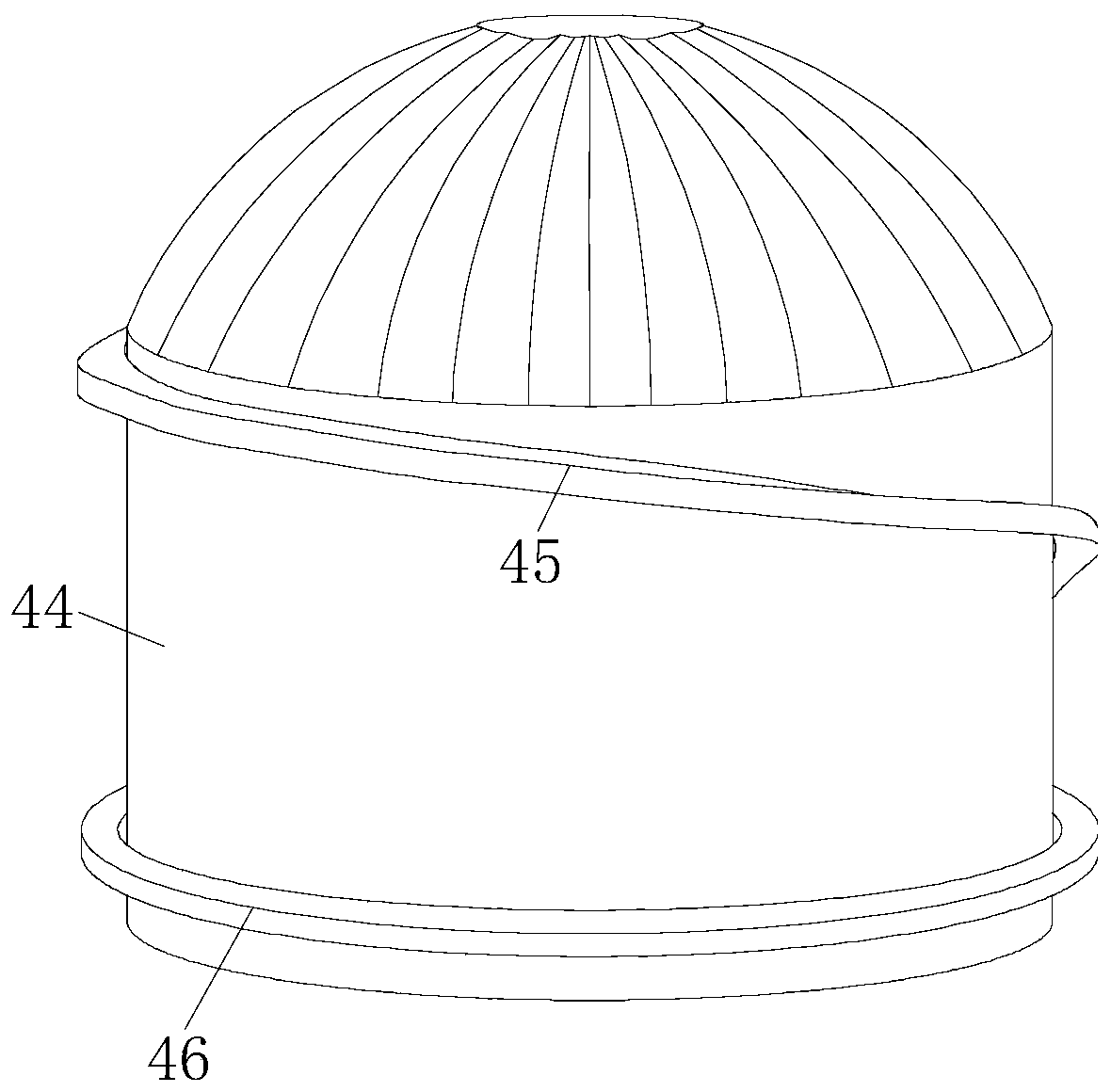

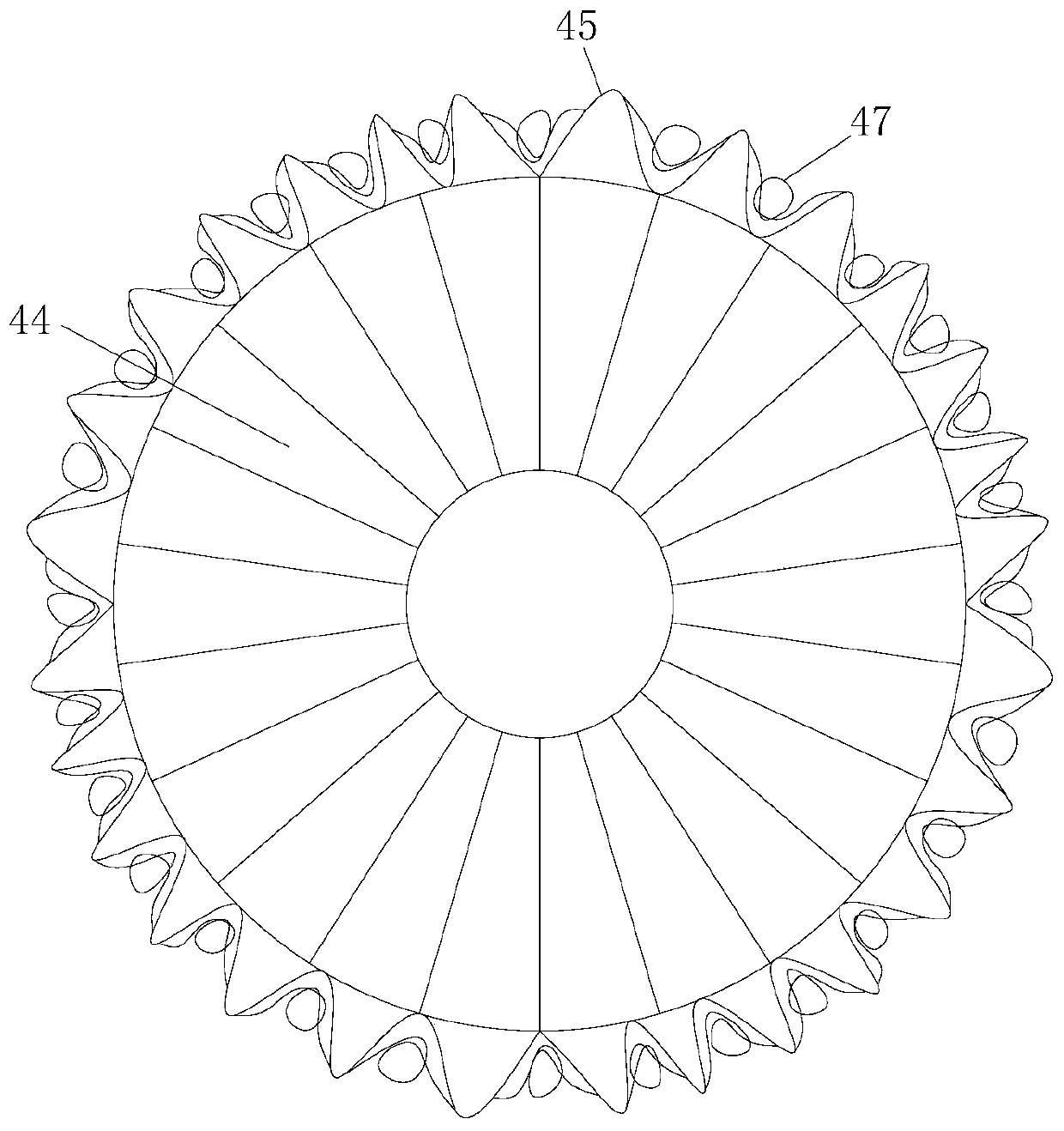

Tow printing and dyeing device based on textile processing

ActiveCN110306311AAvoid entanglementImprove printing and dyeing efficiencyTextile storage in superimposed formLiquid/gas/vapor treatment of definite length materialsPrinting inkDyeing

The invention provides a tow printing and dyeing device based on textile processing, and relates to the field of textile. The tow printing and dyeing device comprises a printing and dyeing box, supporting legs, a feeding mechanism, an offset centrifugal printing and dyeing mechanism and a storage mechanism, wherein the feeding mechanism is used for feeding tows in an umbrella scattered manner, theoffset centrifugal printing and dyeing mechanism is used for dividing the tows into different small tows and integrally spirally and rotationally printing and dyeing the tows, the storage mechanism is used for storing long printed and dyed tows, and the supporting legs are fixedly mounted at the bottom of the printing and dyeing box. According to the tow printing and dyeing device based on textile processing, the tows are scattered through a special structure by the aid of the flexibility of the tows, the tows are far away from a rotating shaft by different-level distance in the rotating process, winding can be avoided, printing and dyeing efficiency can be improved, and the device effectively solves the problems that tows are difficultly scattered by general tow printing and dyeing operation, parts of the tows cannot be sufficiently soaked in printing and dyeing liquor as the tows are stacked, winding of the tows is easily caused by swing operation, and working efficiency is affected.

Owner:曾婧

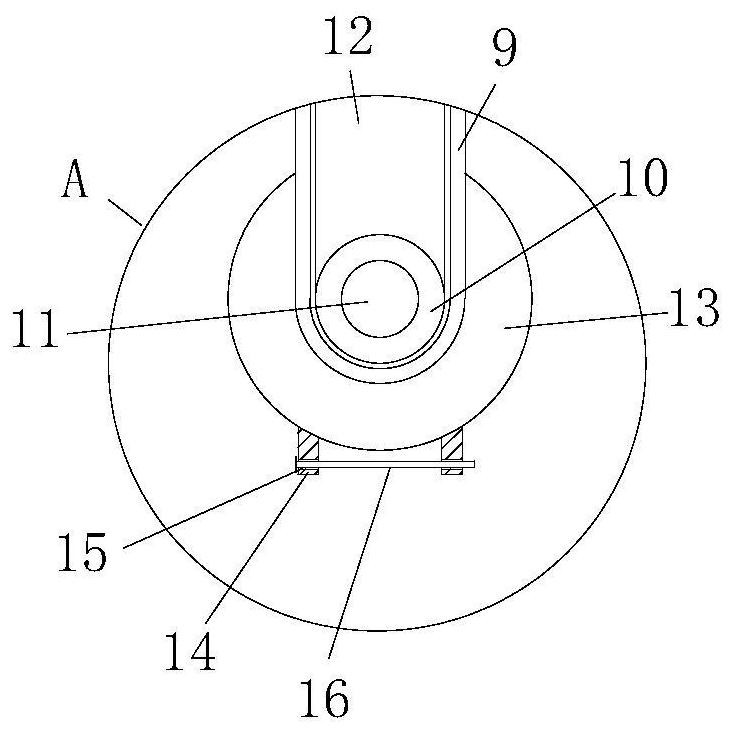

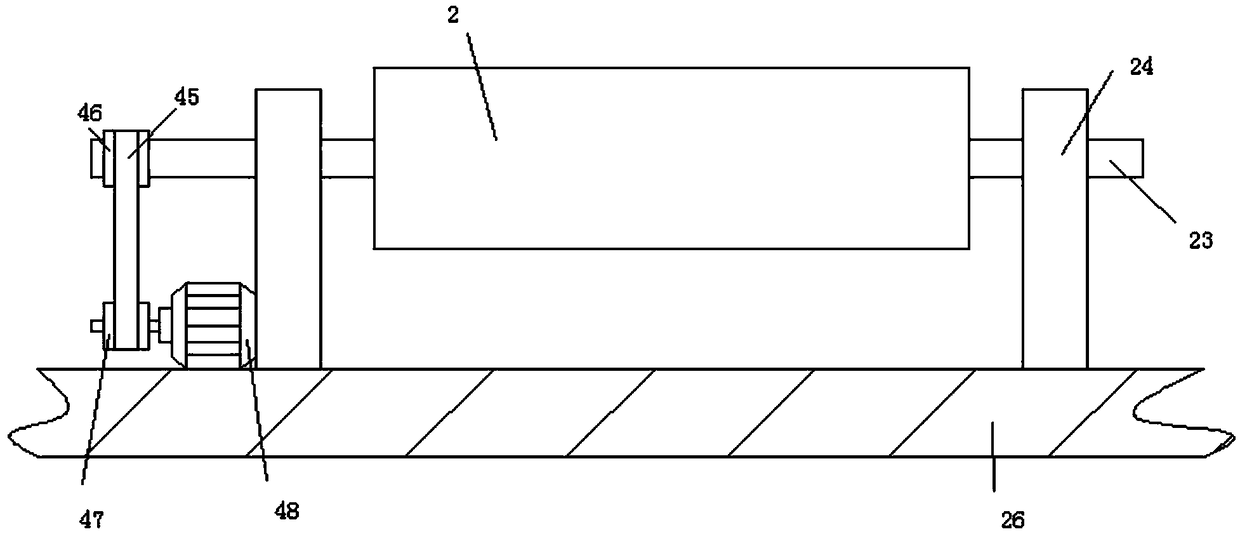

Household high energy-saving cloth dyeing machine

InactiveCN108796877APrecise temperature controlImprove printing and dyeing efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingHigh energyPulp and paper industry

The invention relates to a dyeing machine, in particular to a household high energy-saving cloth dyeing machine. The technical problem to be solved is provide a household high energy-saving cloth dyeing machine, wherein the range of printing and dyeing can be adjusted, and the dyestuff can be fully utilized. In order to solve the technical problem, the household high energy-saving cloth dyeing machine is provided, the machine comprises a first support rod, a first bearing seat, a second support rod, a first belt pulley, a first rotating shaft, a first bevel gear, a second bevel gear, a first gear, a motor and the like; the top of a mounting frame is connected with a sliding rail through bolts; the sliding rail is slidably connected with a sliding block; the sliding block is matched with the sliding rail; the top of the sliding block is connected with a rack through bolts; and a third rotating shaft is arranged between a third bearing seat and a fourth bearing seat. According to the dyeing machine, the range of printing and dyeing can be adjusted, the dyestuff can be fully utilized and the operation of the machine is simple.

Owner:许文华

Stable and highly-efficient cloth material printing and dyeing apparatus

ActiveCN108914449AWill not leakStir wellLiquid/gas/vapor removalTextile treatment machine arrangementsThermal insulationEngineering

The invention provides a stable and highly-efficient cloth material printing and dyeing apparatus. The stable and highly-efficient cloth material printing and dyeing apparatus comprises a base. The upper surface in the middle of the base is fixedly welded with a main frame body. Support racks are arranged on left and right sides of the main frame body. The outer surface at the right end of a dyeing drum is fixedly equipped with a thermal insulation board. The thermal insulation board is arranged leftwards below the interior of the main frame body. A turning wheel is arranged rightwards above drying wheel groups. Front and back ends of a printing wheel are rotatably installed on front and back walls leftwards above the interior of the main frame body. Cloth material is rotatably wounded around the outer surfaces of the turning wheel through the turning wheel. The right side is equipped with a bearing board. The right side of a printing board is equipped with a first installation frame.The right side of the first installation frame is equipped with a discharge opening. The left end of a support rod is fixedly welded on the right surface outside the main frame body. The stable and highly-efficient cloth material printing and dyeing apparatus is convenient in operation, high in stability, great in printing efficiency and high in practicality and suitable for all application conditions.

Owner:海宁鑫港源纺织品有限公司

Printing and dyeing production process and device for all-cotton antibacterial double-sided cloth

ActiveCN112342717AImprove efficiencyEasy to handleSucessive textile treatmentsTextile treatment machine arrangementsPolymer scienceColor printing

The invention discloses a printing and dyeing production process and device for all-cotton antibacterial double-sided cloth. The production process comprises the following steps that S1, dye color paste is prepared, and magnetization treatment is conducted on the dye color paste; S2, double-sided color printing is conducted on the all-cotton antibacterial double-sided cloth by using the productiondevice and the magnetized dye color paste obtained in the step S1, and then drying is conducted; and S3, steaming and color fixing are conducted on the treated all-cotton antibacterial double-sided fabric by using a prepared color fixing solution, and washing and shaping are conducted to obtain the all-cotton antibacterial double-sided printed and dyed fabric. The production device comprises a printing and dyeing bin, a drying bin, a color fixing bin and a washing bin. According to the double-sided printing and dyeing process and device, simultaneous double-sided printing and dyeing treatmentcan be conducted on the all-cotton antibacterial double-sided cloth, the printing and dyeing efficiency is effectively improved, the printing and dyeing effect can be effectively improved, and therefore the problems of printing and dyeing fading or insufficiency and the like can be avoided.

Owner:无锡迈克斯纺织品有限公司

Efficient short-process less-water textile printing and dyeing equipment and method

PendingCN114541050AEasy clampingEffective in anti-wrinkleRotary pressesDyeing processTextile printerEngineering

The equipment comprises a base, a box body is arranged on the base, a partition plate is arranged in the box body, and a cloth input mechanism, a first wrinkle removing mechanism, a second wrinkle removing mechanism, a printing and dyeing mechanism and a cloth output mechanism are arranged on the partition plate; the first wrinkle removing mechanism is arranged on the left side of the cloth input mechanism, and the second wrinkle removing mechanism is arranged on the left side of the first wrinkle removing mechanism; the printing and dyeing mechanism is arranged between the second wrinkle removing mechanism and the cloth output mechanism; an air drying mechanism is arranged between the first wrinkle removing mechanism and the second wrinkle removing mechanism and fixedly installed at the upper end of the box body. The two symmetrical wrinkle removing mechanisms are arranged, so that the first wrinkle removing mechanism and the second wrinkle removing mechanism tension the textile fabric, meanwhile, the smoothness of the textile fabric is improved, and wrinkles are avoided; and the textile fabric can be effectively steamed and ironed through the air drying mechanism, wrinkles of the textile fabric can be rapidly removed, and the printing and dyeing efficiency is improved.

Owner:宿迁市群英纺织印染科技有限公司

Efficient short-process less-water textile printing and dyeing method

InactiveCN111716889AAvoid wrinklesImprove flatnessRotary pressesPrinting press partsTextile printerProcess engineering

The invention discloses an efficient short-process less-water textile printing and dyeing method. Textile fabric is input in equipment through an input drive mechanism to sequentially penetrate through a wrinkle removing mechanism, a first tensioning mechanism, a second tensioning mechanism and a printing and dyeing mechanism and finally output by the equipment through an output mechanism; a transmission mechanism is started, the transmission mechanism drives the input drive mechanism, the first tensioning mechanism, the second tensioning mechanism, the printing and dyeing mechanism, an air-drying mechanism and the output mechanism to rotate; the input drive mechanism rotates, and the textile fabric is guided into the equipment; the wrinkle removing mechanism is heated to iron the textilefabric; the ironed textile fabric is tensioned through the first tensioning mechanism and the second tensioning mechanism, and the smoothness of the textile fabric is guaranteed; the smoothened textile fabric is printed and dyed through the printing and dyeing mechanism, and the printed and dyed textile fabric reaches the air-drying mechanism; and the air-drying mechanism rotates, thus, air suction is carried out, the printed and dyed textile fabric is rapidly dried, the dried textile fabric is guided out of the equipment through the output mechanism, and the textile fabric is printed and dyed.

Owner:杭州纯颐商贸有限公司

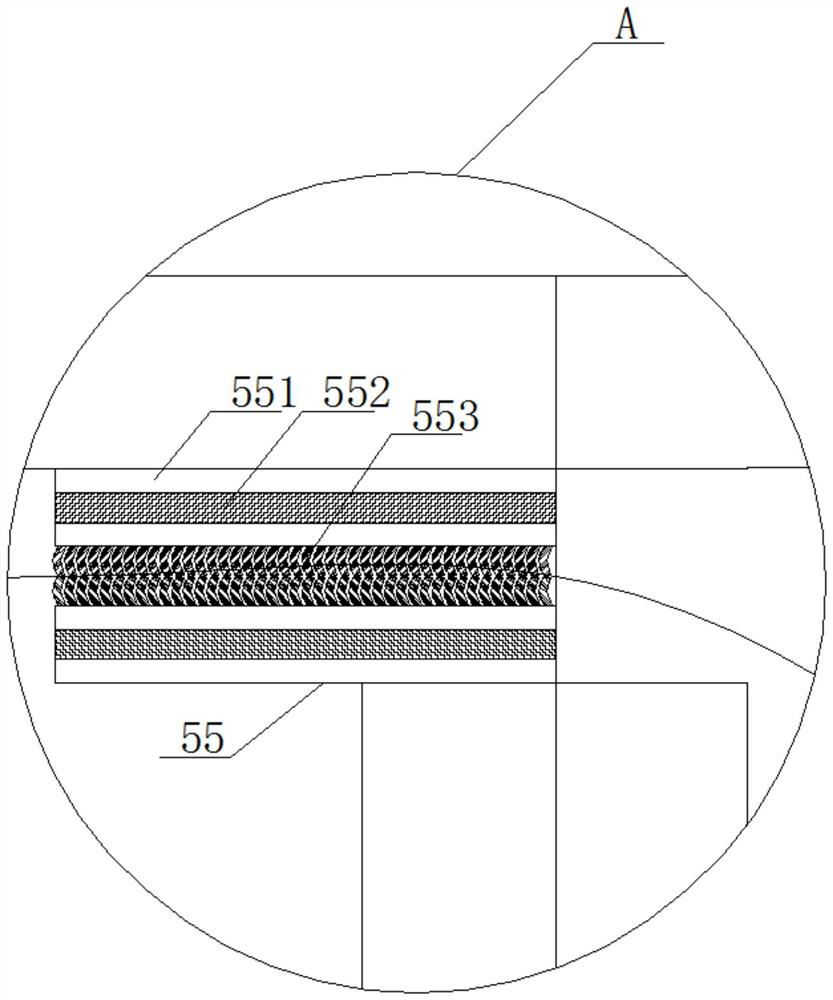

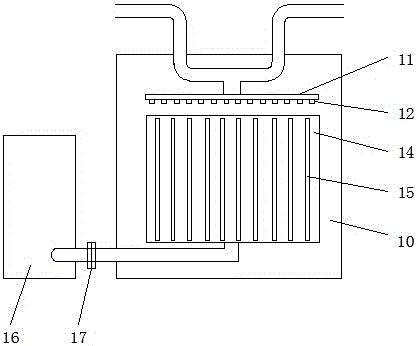

Dye stirring device of fabric dyeing equipment

ActiveCN105908429AHigh activityImprove printing and dyeing qualityTextile treatment containersTextile treatment machine arrangementsEngineeringDyeing

The invention provides a dye stirring device of fabric dyeing equipment and belongs to the technical field of machinery. The dye stirring device solves the problem that an existing clothes fabric dye spraying device is poor in dyeing quality. The dye stirring device of the fabric dyeing equipment comprises a stirring box. A liquid inlet is formed in the top of the stirring box, the stirring box is internally provided with stirring paddles, and a motor which can drive the stirring paddles to rotate is arranged on the outer side of the stirring box. The stirring box comprises a box body made of a heat preservation material. The top and the bottom of the box body are open. The box body is fixedly provided with a first sealing plate and a second sealing plate which seal the top opening and the bottom opening of the box body respectively. A groove is formed in the bottom of the second sealing plate, a first electric heating wire layer is fixed into the groove, a power source for supplying power to the electric heating wire layer is arranged outside the stirring box, and the box body is fixedly provided with a first switch and a first controller, wherein the first switch is used for controlling on-off of the power source and the first electric heating wire layer, and the first controller is used for controlling opening and closing of the first switch through a temperature sensor arranged in the box body. The stirring device has the advantage of being capable of improving the dyeing quality.

Owner:ZHEJIANG XIANYU FIBER WEAVING & DYEING GARMENT CO LTD

High-efficient comprehensive water recycling dyeing vat

ActiveCN106757919AImprove printing and dyeing efficiencySmooth dyeing processTextile treatment containersTextile treatment machine arrangementsControl systemFilter system

The invention relates to a high-efficient comprehensive water recycling dyeing vat comprising a vat body, a heating system, a filtering system, a feeding system, a detection system and a control system. The vat body has a cloth feeding end, a cloth discharging end and a main body; the cloth feeding end and the cloth discharging end are respectively provided with a cloth feeding device and a cloth discharging device; the main body is further connected with an oxidation device and a liquid storage device both controlled by the control system; the other end of the oxidation device is connected with the filtering system; and the heating system comprises a PTC semiconductor heating device and an air source heating device. Dye liquor can be oxidized and filtered when the dyeing vat normally works, so reducibility substance and solid particles in the dye liquor can be removed and the dye liquor is odourless; the dye liquor can be fed into the dye vat and reused; raw material can be greatly reduced and environment can be protected; with the cooperation of the liquid storage device, dye liquor recycling rate can be further improved; and zero emission can be reduced, and environment load can be reduced.

Owner:海宁萃智智能机器人有限公司

Textile drying device used for printing and dyeing processing

InactiveCN108330627AImprove printing and dyeing efficiencyEasy to addLiquid/gas/vapor removalTextile treatment machine arrangementsDyeingEngineering

The invention discloses a textile drying device used for printing and dyeing processing. The textile drying device comprises a box and a wheel roller, wherein two sides of the top of the inner cavityof the box are fixedly connected with a supporting plate respectively; a printing and dyeing groove is formed in the top of the supporting plate; and the right side of the bottom of the inner cavity of the box, positioned below the supporting plate, is fixedly connected with a first heating plate, a second heating plate and a third heating plate from top to bottom in sequence. Through the arrangement of the box, the supporting plate and the printing and dyeing groove, a printing and dyeing device capable of printing and dyeing the cloth is constructed together; through the arrangement of the first heating plate, the second heating plate, the third heating plate, the cloth and the wheel roller, a device capable of drying the printed and dyed cloth is constructed together; through the cooperation of the above structure, the purpose that the printing and dyeing operation and the drying operation of the cloth are integrally completed is met, and the problems of slow printing, dyeing and drying speed, low efficiency, high labor intensity, large occupied space and high production cost are solved.

Owner:叶青

Preparation method of rotary-screen plain-colored high-gram-weight single-layer raising blanket

InactiveCN109778416AFully ironedGuaranteed printing and dyeing effectWarp knittingHeating/cooling textile fabricsScreen printingGram

The invention relates to a preparation method of a rotary-screen plain-colored high-gram-weight single-layer raising blanket. Suitable raw materials are selected and woven to obtain a grey cloth, thenslitting and pre-shaping are conducted, and pre-treatment is conducted; in the pre-treatment process, after the grey cloth is subjected to pre-drying, brushing, luster finishing and hot shearing, printing and dyeing parameters are adjusted according to the fact that the net gram weight of the product is high, rotary screen printing and dyeing equipment is adopted, an empty rotary net is utilizedas a color paste adding net and a permeation net, a permeation device is additionally arranged for printing and dyeing, the printing and dyeing effect is ensured, a drying and steaming integrated machine is adopted for color fixation, the color fixation effect is ensured, and the efficiency is improved; then the front and reverse sides of a semi-finished single-layer blanket are sequentially subjected to brushing, luster finishing, hot shearing, reverse side raising, brushing, and hot shearing again, and then cloth cutting and edge covering are conducted to obtain the finished product. The preparation method is reasonable in process and high in efficiency, and has the good printing and dyeing effect and high production and application value.

Owner:SHANDONG XINSILU IND & TRADE

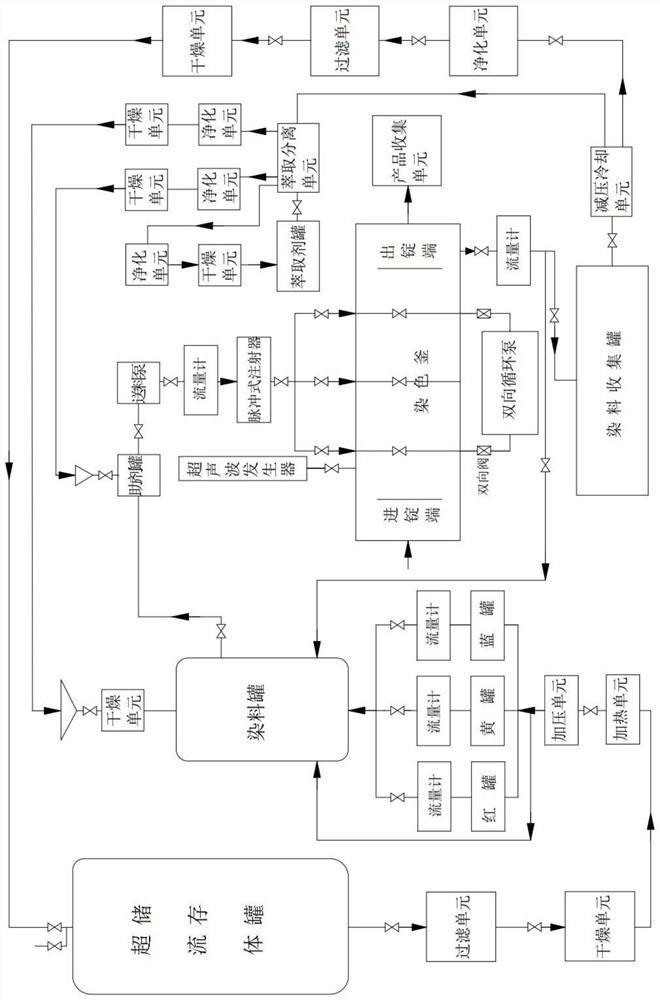

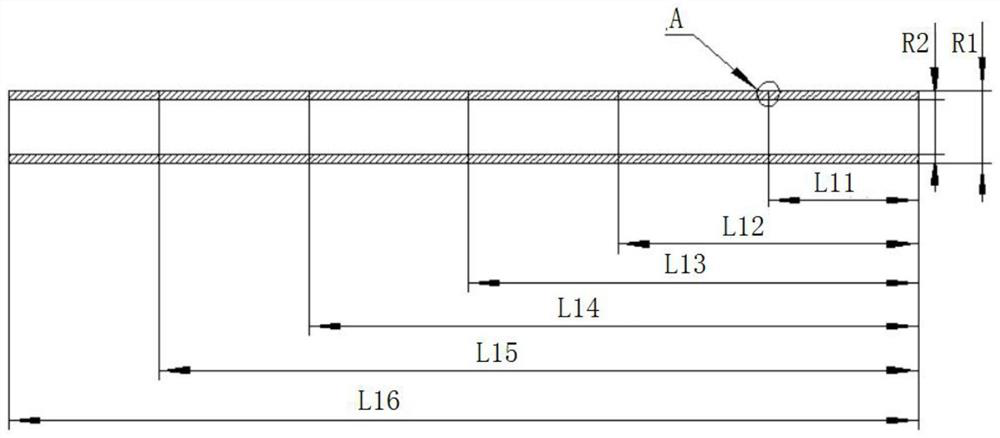

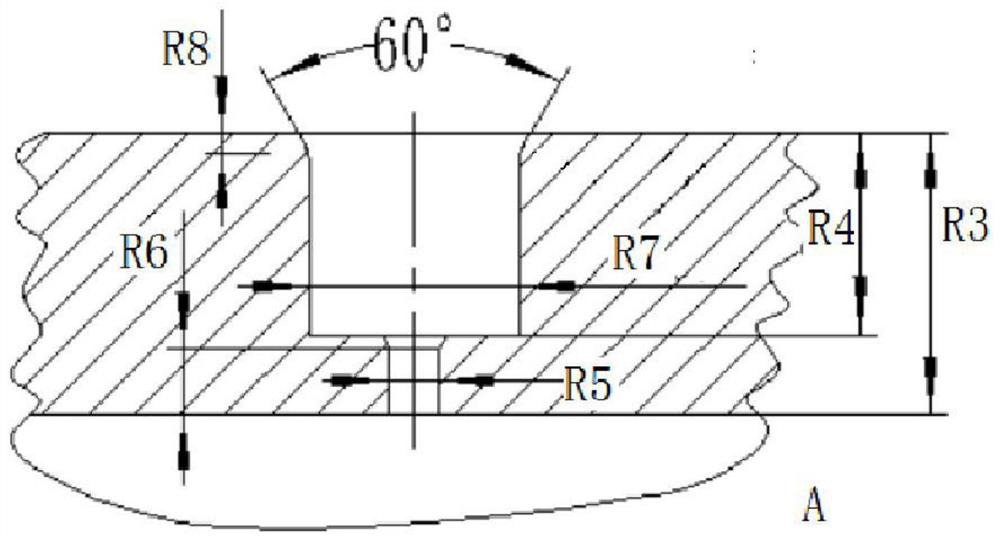

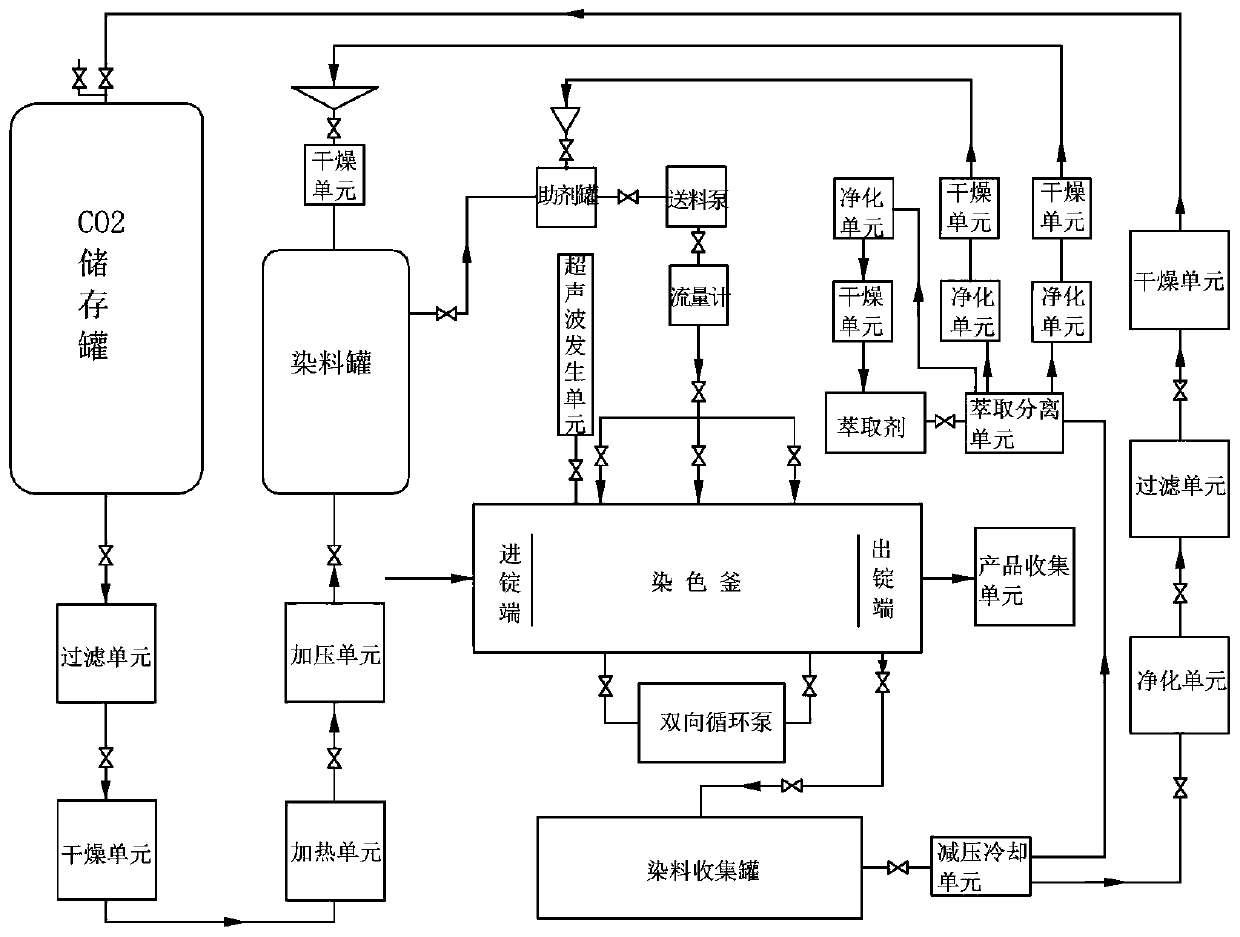

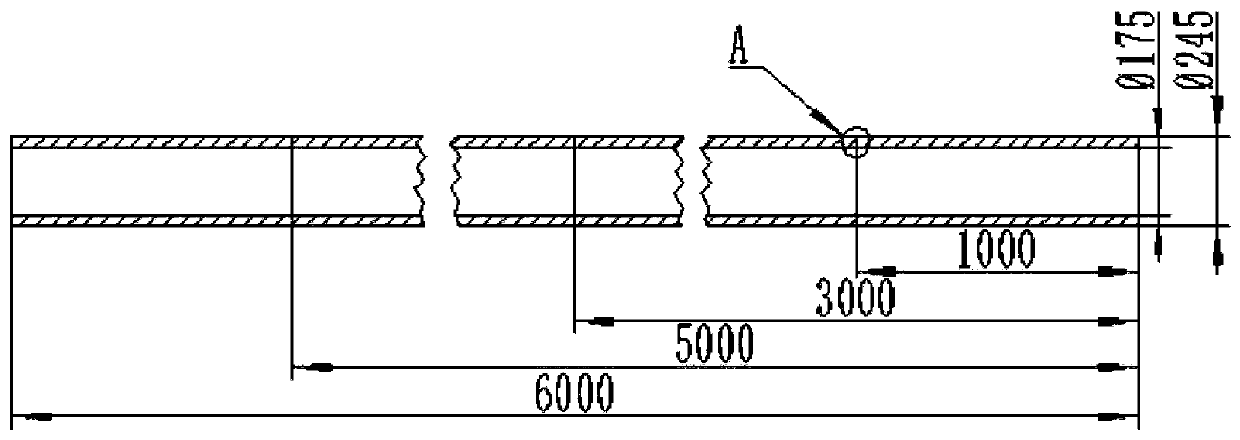

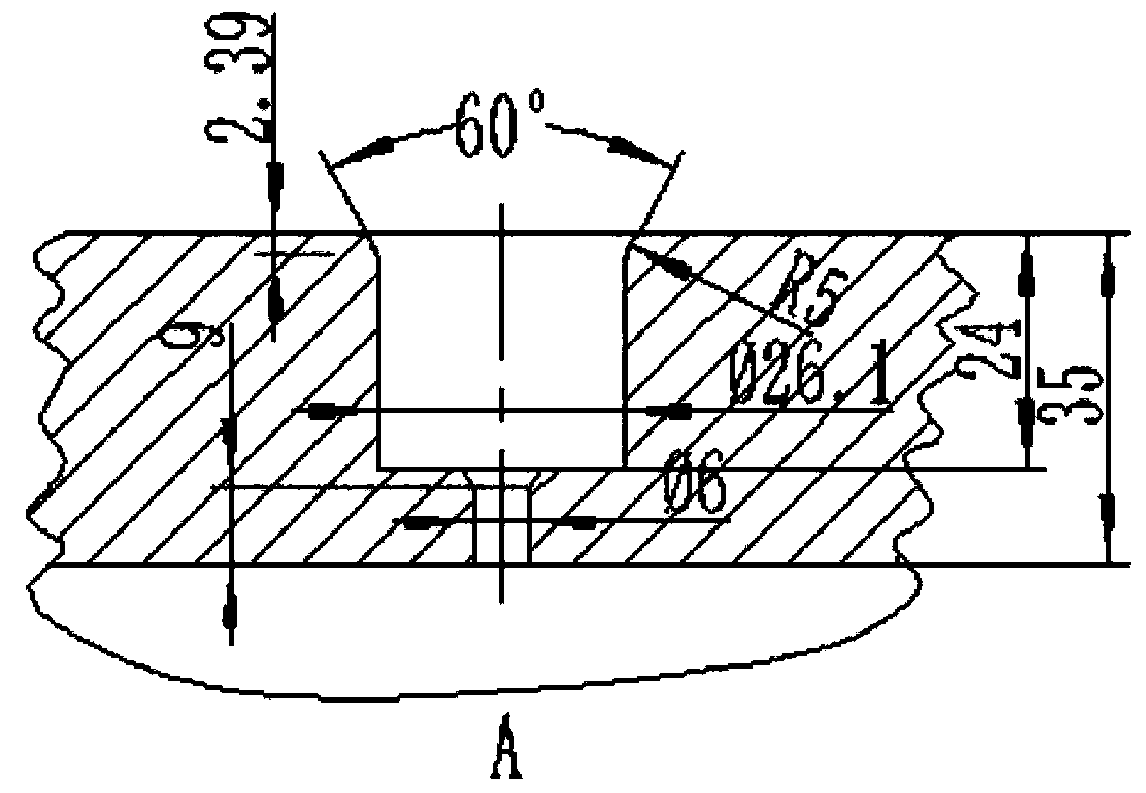

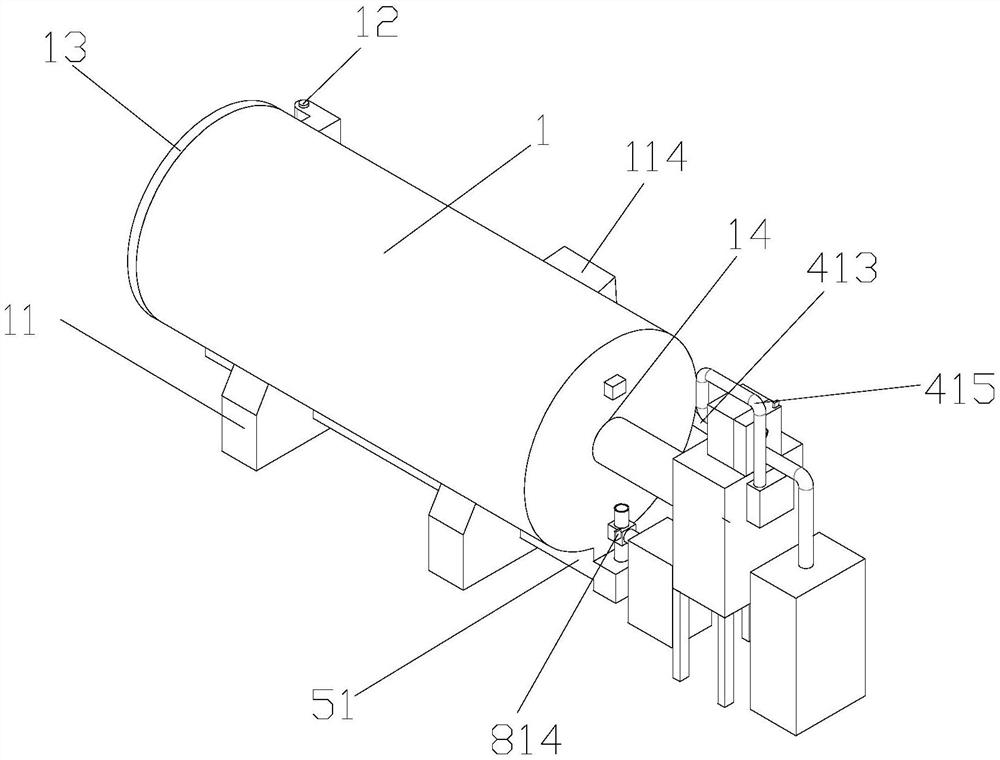

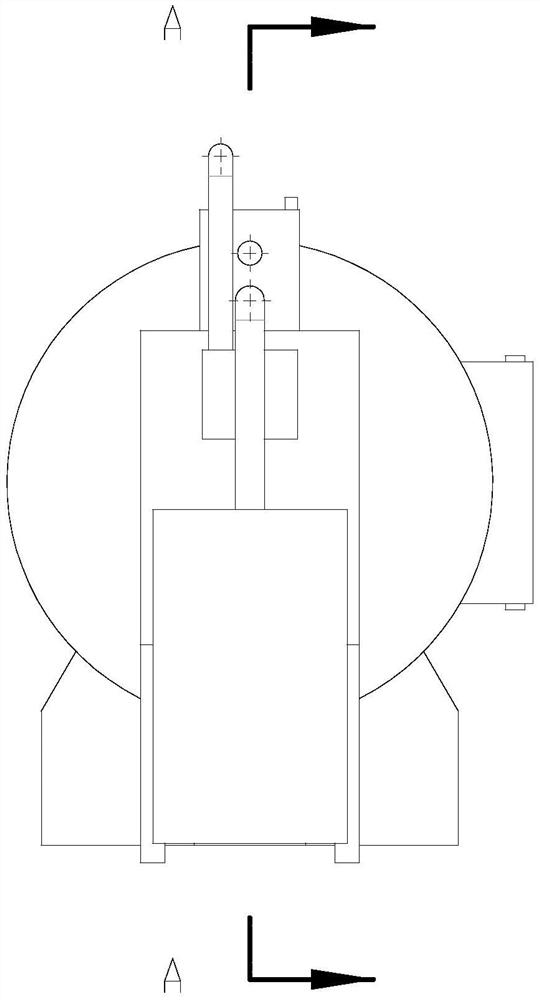

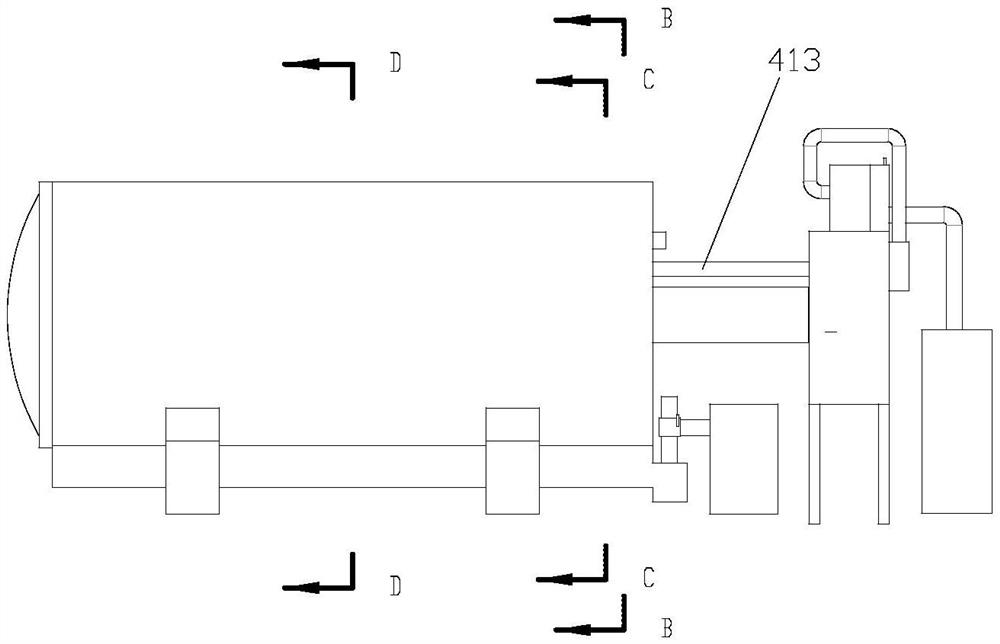

Pulse type supercritical fluid printing and dyeing process and device

InactiveCN111826846AHigh activityFacilitated DiffusionTextile treatment containersSolvent treatment with solvent recoveryLiquid stateProcess engineering

The invention discloses a pulse type supercritical fluid printing and dyeing process and device. The printing and dyeing process comprises the following steps: (1) converting liquid-state superfluid into supercritical fluid; (2) mixing the supercritical fluid with a three-primary-color dye to form dye liquor; (3) injecting the dye liquor into a dyeing kettle by adopting pulse type injectors, dyeing spindles from a spindle inlet end under the action of ultrasonic generators and bidirectional circulating pumps, and sending out the spindles from a spindle outlet end after the dyeing is mature; and (4) enabling the dye liquor discharged from the dyeing kettle to flow back to a dye tank for cyclic utilization, or separating and purifying the discharged dye liquor into liquid fluid and dye to berecycled or stored for later use. According to the pulse type supercritical fluid printing and dyeing process and device, the optimal dye liquor conveying condition can be realized through pulse typeconveying, and then the printing and dyeing uniformity and printing and dyeing efficiency are improved; and the printing and dyeing process is green and environmentally friendly, and is clean in production, good in economic benefit and remarkable in environmental benefit.

Owner:SHANGHAI FULUDI FLUID TECH CO LTD

Vest processing machine with printing and dyeing apparatus

InactiveCN108049142AAdd color styleIncrease valueMechanical cleaningPressure cleaningPulp and paper industryDyeing

The invention provides a vest processing machine with a printing and dyeing apparatus, and belongs to the technical field of tailoring equipment. The vest processing machine with a printing and dyeingapparatus solves the problem that a vest is single in color and style and is low in the processing efficiency. The vest processing machine with a printing and dyeing apparatus includes a frame, wherein the printing and dyeing apparatus is arranged on the frame; a dedusting device for dedusting printed and dyed fabrics, a cutting device for cutting the printed and dyed fabrics into a vest part, asewing device for sewing the vest part into a vest, and a collection device for collecting the processed vest are also arranged on the frame; the printing and dyeing apparatus, the dedusting device, the cutting device, the sewing device and the collection device are successively arranged along the frame; the printing and dyeing apparatus includes a vest printing and dyeing machine and a printing and dyeing table; a connecting pipe and a dye liquor tank are arranged at the top of the vest printing and dyeing machine; the dye liquor tank is connected with the vest printing and dyeing machine through the connecting pipe; a printing and dyeing plate is arranged at the bottom of the vest printing and dyeing machine; and the printing and dyeing apparatus also includes a drying chamber and a heating chamber. The vest processing machine with a printing and dyeing apparatus has the advantages of improving the color and the style of vests and the processing efficiency of the vests.

Owner:HAINING WENSHUO TECH CONSULTING CO LTD

High-efficient printing and dyeing machine for textiles

InactiveCN107988747AEasy to useReduce vibrationTextile treatment containersPulp and paper industryDrive motor

The invention discloses a high-efficient printing and dyeing machine for textiles. The machine comprises a main machine body, a telescopic motor is arranged on the top of the main machine body, a telescopic arm is arranged at the bottom of the telescopic motor, the telescopic motor is in transmission connection with the telescopic arm, a printing and dyeing roller is arranged at the bottom of thetelescopic arm, the printing and dyeing roller is rotatably connected with the telescopic arm, supporting frames are arranged on two sides of the main machine body, supporting columns are arranged atthe bottoms of the supporting frames, driving motors are arranged at one ends of the supporting columns, a pair of rotary rollers are arranged on the top of each supporting column, transmission rods are arranged between the supporting columns and the rotary rollers, the transmission rods are in transmission connection with the driving motors, a dye tank is arranged below the main machine body, a pair of rollers are arranged at the bottom of the dye tank, brake disks are arranged on the left and right sides of the rollers, a base is arranged at the bottoms of the rollers, and the base is shapedby high-carbon steel integrated pouring. The high-efficient printing and dyeing machine for the textiles has the advantages of being simple in structure and convenient to use, the dye tank can be replaced rapidly to greatly improve the printing and dyeing efficiency, and the high-efficient printing and dyeing machine for the textiles has market competitiveness to an extent.

Owner:苏州闽国纺织科技有限公司

Supercritical carbon dioxide printing and dyeing technology and system

PendingCN110565415AHigh activityFacilitated DiffusionSolvent treatment with solvent recoveryTextile treatment machine arrangementsWastewaterEconomic benefits

The invention discloses a supercritical carbon dioxide printing and dyeing technology and system. The supercritical carbon dioxide printing and dyeing technology comprises the steps that (1), liquid carbon dioxide is transformed into supercritical carbon dioxide; (2), the supercritical carbon dioxide is mixed with dye to form dye liquor; (3), the dye liquor is introduced into a dyeing kettle, andspindles from a spindle feeding end are dyed under the action of ultrasonic waves and bidirectional circulation; (4), the remaining dye liquor obtained after dyeing is collected, decompressed and separated, and the dye and the supercritical carbon dioxide which are obtained after separation are separately purified and dried to be recycled. The printing and dyeing technology and system have the advantages that no waste dyeing water or other wastes are generated, environment-friendly and clean production can be achieved, the economic benefits are high, and the environmental benefits are significant, and the aims of recycling, flowline production, improvement of the yield and reduction of industrial cost can be achieved.

Owner:SHANGHAI FULUDI FLUID TECH CO LTD

Waterless printing and dyeing process

InactiveCN112981804AEmission reductionGuaranteed working environmentTextile treatment containersSolvent-treatmentFiberPolymer science

The invention discloses a waterless printing and dyeing process which includes the following steps: preparing grey cloth to be printed and dyed, removing impurities and dust on the grey cloth, inspecting the grey cloth, turning the grey cloth, sewing the grey cloth, and then feeding the sewn grey cloth into a singeing machine for singeing, to remove rough selvedge and fuzz of the grey cloth; cleaning the cloth through cloth cleaning equipment, and removing fuzz on the cloth; winding the cloth obtained in the previous step; putting the rolled cloth into waterless printing and dyeing equipment for printing and dyeing, heating and pressurizing CO2 to be in a supercritical fluid state which is neither gas nor liquid so as to dissolve dye, and then dissolving the dye and sending the dissolved dye into fiber pores by taking supercritical CO2 as a dyeing medium so as to dye the fabric; depressurizing after dyeing; taking out the printed and dyed cloth; checking the cloth; and cutting or packaging for storage if the cloth is qualified. According to the process, sewage discharge is effectively reduced in a waterless printing and dyeing mode, and the environment is protected.

Owner:刘州豪

Pigment additive for sewage-free nano printing and dyeing, its preparation method and application

ActiveCN108004696BWon't happenSolve processing problemsDyeing processLiquid/gas/vapor textile treatmentAgricultural engineeringWastewater

The invention discloses a waste water-free nano printing and dyeing technology. The waste water-free nano printing and dyeing technology includes the following steps: (1) leading color paste to an evenness padder; (2) importing a gray fabric; (3) performing coloring; (4) importing an additive; and (5) performing shape forming, importing the color paste to the evenness padder, soaking the gray fabric in the color paste, and performing coloring at the temperature of 100-120 DEG C, wherein the color paste can quickly attach to and permeate into the gray fabric, and the dyed fabric has excellent color firmness. The shaping forming machine can perform shaping forming on the gray fabric, and the additive can improve the tenacity and the stiffness of the gray fabric; after the color paste permeates into the gray fabric and the dyeing is completed, there is no waste water in the evenness padder, and waste water can be avoided after dyeing.

Owner:常州安达环保科技有限公司

Printing and dyeing auxiliary for natural pigment dyeing

The invention discloses a printing and dyeing auxiliary for natural pigment dyeing. The printing and dyeing auxiliary is composed of the following components in parts by weight of 20 to 30 parts of coconut oil diethanolamide, 8 to 12 parts of octadecyl dimethyl benzyl amine chloride, 15 to 23 parts of sodium carboxymethylcellulose, 5 to 14 parts of sorbitan fatty acid ester, 5 to 9 parts of barium chloride, 6 to 8 parts of guar gum, 13 to 15 parts of polyethylene glycol laurate, 8 to 10 parts of polyalkyl acrylate, 8 to 10 parts of sodium dodecyl sulfate, 7 to 8 parts of polyalkyl acrylate, 6 to 7 parts of fatty alcohol, 5 to 7 parts of ethylene oxide, 2 to 3 parts of acetic acid and 9 to 24 parts of barium chloride. The printing and dyeing auxiliary for natural pigment dyeing has good effects of improving color fastness, protecting color and preventing fading through mutual combination of multiple components, can reduce the using amount of dye, is environment-friendly and non-toxic, effectively reduces the cost, can remarkably improve the color fastness of fabrics, and can be suitable for different types of fabrics.

Owner:JIANGSU SIXIN SURFACTANT TECH

Printing and dyeing equipment for chemical fabric

InactiveCN108691130AAchieve recyclingIncrease profitTextile treatment containersTextile treatment machine arrangementsDrive wheelSurface mounting

The invention discloses printing and dyeing equipment for chemical fabric. The printing and dyeing equipment comprises a machine box body. A printing and dyeing bin is installed on the upper surface of the machine box body, a collecting groove communicated with the printing and dyeing bin is formed in the top end in the machine box body, a cloth release roller is fixed to one side of the machine box body through a support, a cloth reeling roller is fixed to the side, opposite to the cloth release roller, of the machine box body through a support, a driven wheel is fixed to one side of the cloth reeling roller, a motor is fixed to the lower portion, close to the cloth reeling roller, of one side of the machine box body through a supporting frame, and one end of the motor is rotationally connected with a driving wheel through a rotary shaft. Through the arrangement of a filter box, a drawer type filter net and a guide plate, dyestuff liquid is recycled and filtered, the utilization rateof resources is increased, the device saves more energy, five upper printing and dyeing rollers, five lower printing and dyeing rollers, upper spray nozzles and lower spray nozzles are arranged, clothis evenly printed and dyed, the printing and dyeing efficiency of the cloth is improved, and production benefits of the equipment are increased.

Owner:黄林

Processing method of vest

InactiveCN107974772AAdd color styleIncrease valueMechanical cleaningPressure cleaningEngineeringDyeing

The invention provides a processing method of a vest, and belongs to the technical field of clothes processing. The processing method solves the problems that an existing vest is low in processing efficiency, wastes labor and is also monotonous in color and style. The processing method of the vest comprises the steps of dyeing, wherein before the vest is processed, vest fabric to be processed is dyed through a dyeing device; drying, wherein after the fabric is dyed, the fabric is dried through a drying chamber; dedusting, wherein after the fabric is dried, the fabric is dedusted through a dedusting device; tailoring, wherein the dedusted fabric is tailored into vest parts through a tailoring device; sewing, wherein the tailored vest parts are sewed through the sewing device to be processedinto a complete vest; collecting, wherein the manufactured vest is collected through a collecting device. The processing method has the advantages of improving the vest processing efficiency and thecolor and style.

Owner:HAINING WENSHUO TECH CONSULTING CO LTD

Dye vat for textile processing

InactiveCN108301155AEasy maintenanceFully dyedTextile treatment containersLiquid/gas/vapor fabric treatmentMechanical engineeringTextile processing

The invention discloses a dye vat for textile processing. The dye vat for textile processing includes a printing and dyeing vat; round holes for mounting bearing seats are formed in the two side wallsof the printing and dyeing vat, the bearing seats are installed in the round holes, and a first rotation shaft and a second rotation shaft are fixed to the bearing seats respectively, wherein a firstroller wheel is mounted on the first rotation shaft, a second roller wheel is mounted on the second rotation shaft, upright columns are welded to the outer side wall of the first roller wheel and theouter side wall of the second roller wheel, and a first belt wheel and a second belt wheel are mounted at the ends, outside the printing and dyeing vat, of the first and second rotation shafts respectively. The dye vat for textile processing is simple in structure, low in production cost and is extremely convenient to produce and maintain; the upright columns are arranged on the dye vat and can drag textiles to rotate in the dye vat, and therefore the textiles can be further fully printed and dyed and cannot tie; by the adoption of a rotation printing and dyeing mode, the printing and dyeingefficiency can be greatly improved, and the dye vat for textile processing is extremely easy to operate manually.

Owner:海宁德里法新材料有限公司

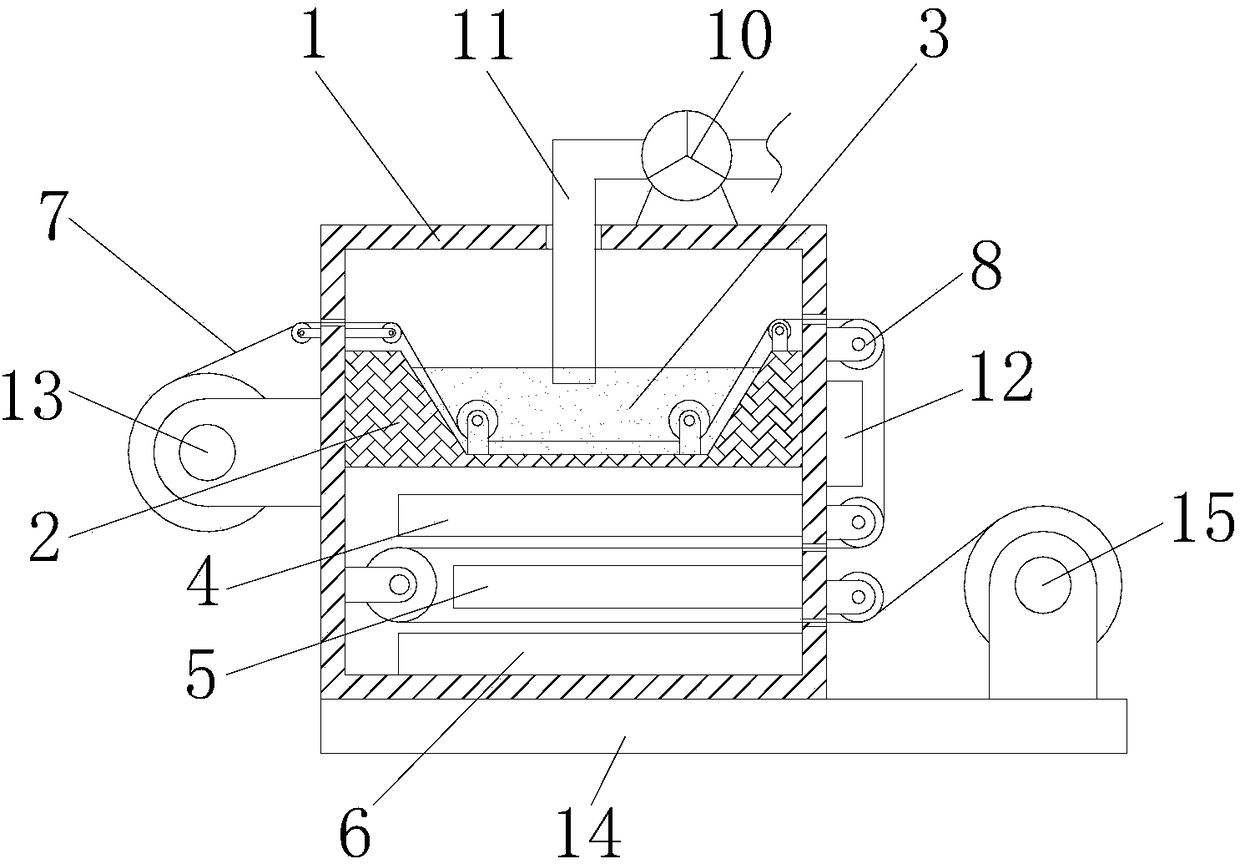

Blended fabric printing and dyeing process

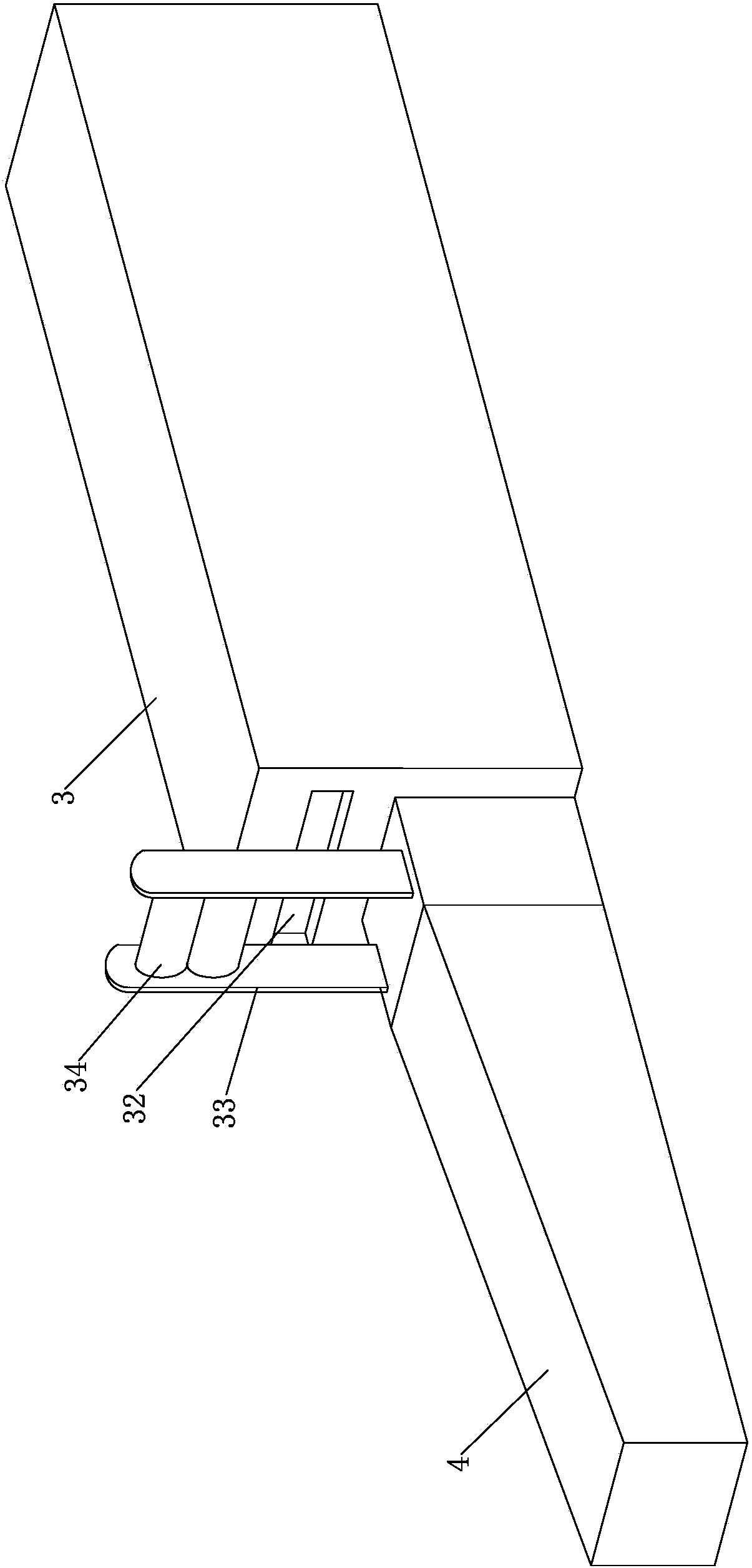

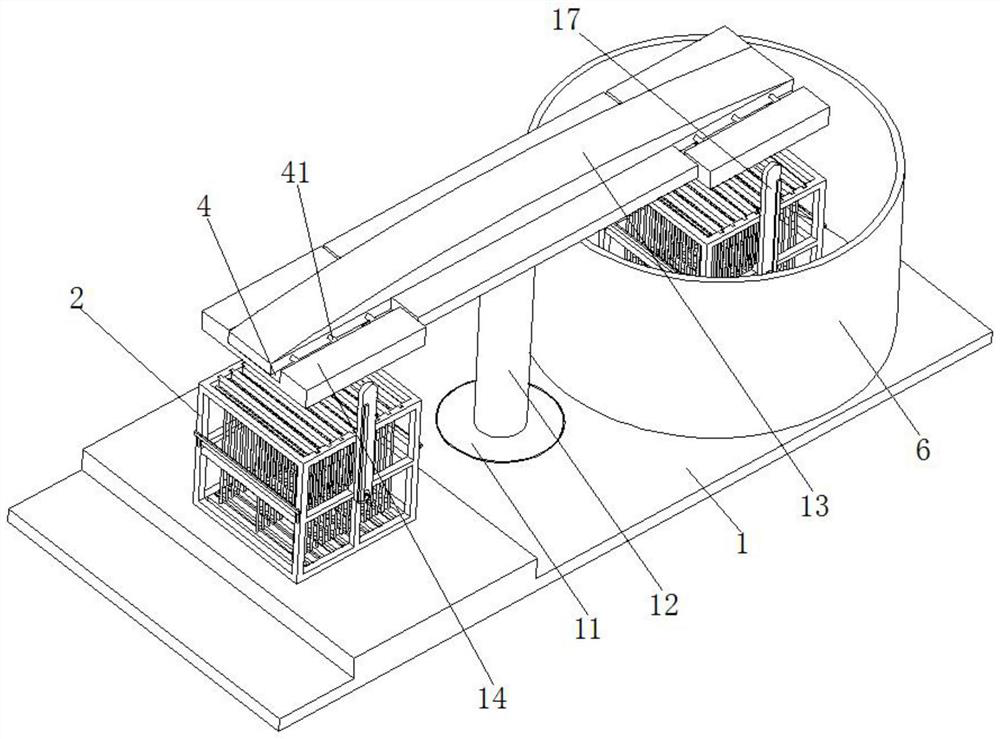

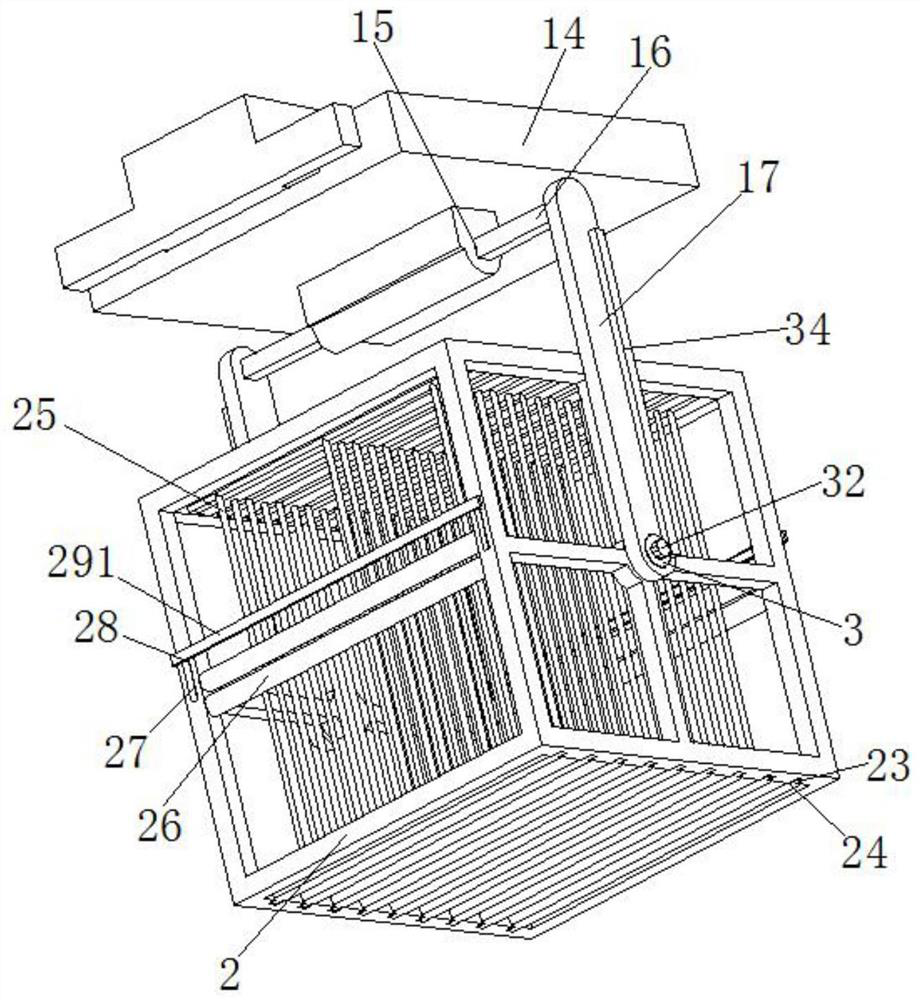

ActiveCN113106664AFast and efficient clamping and positioningImprove printing and dyeing efficiencyTextile treatment carriersLiquid/gas/vapor textile treatmentStructural engineeringMechanical engineering

The invention relates to the field of textile processing, in particular to a blended fabric printing and dyeing process. A blended fabric printing and dyeing device is used in the method. The blended fabric printing and dyeing device comprises a base seat and a fixed frame; a rotating base is arranged on the base seat; a first air cylinder is fixedly installed on the rotating base; a connecting frame is arranged at the output end of the first air cylinder; connecting plates are arranged at the two ends of the connecting frame; inserting grooves are symmetrically formed in the bottom of each connecting plate; inserting rods are arranged in the inserting grooves; one ends of the inserting rods penetrate through the inserting grooves respectively and are fixedly provided with supports; the supports on the same connecting plate correspond to one another; connecting grooves are formed in the ends, away from the inserting rods, of the supports; the two ends of each connecting groove penetrate through the supports; the fixed frame is of a rectangular hollow structure; rotating shafts are arranged on the two sides of the fixed frame; and the ends, away from the fixed frame, of the rotating shafts are inserted into the corresponding connecting grooves respectively. The device can quickly and efficiently clamp and position a blended fabric, and is suitable for popularization.

Owner:GUANGDONG JINGYING TEXTILE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com