Kiering-bleaching dyeing-finishing equipment

A technology for refining, bleaching and dyeing equipment, applied in the field of printing and dyeing equipment, which can solve the problems of huge equipment, long production cycle, and large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

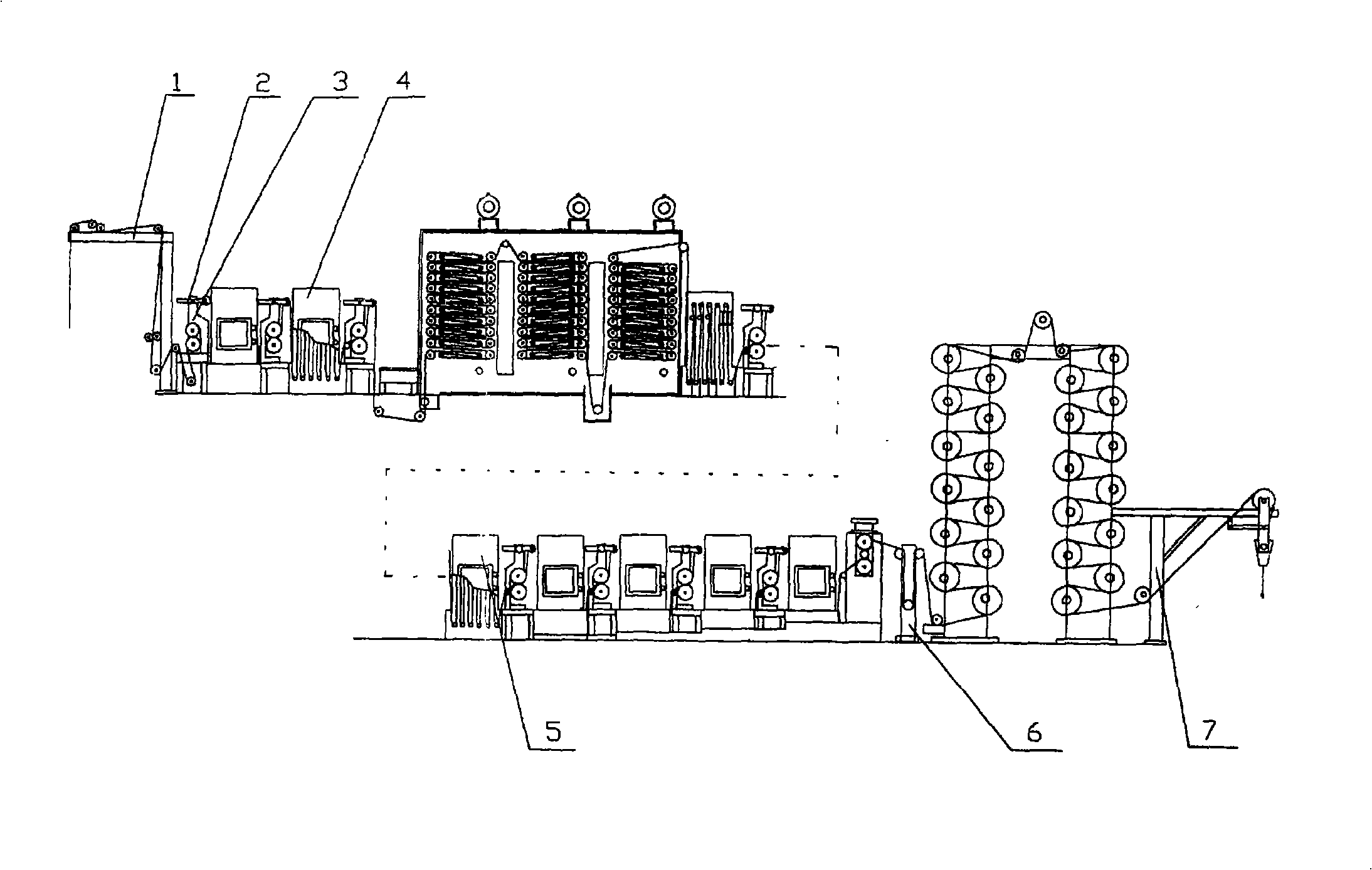

[0010] The refining, bleaching, dyeing and finishing equipment of the present invention is composed of a cloth feeding device 1, a middle padding car 3 with a direct connection sensor 2, a dipping tank 4, a horizontal guide roller reaction box, a jet flat washing machine, a high-efficiency cooking box 5, The three-roll padding car 6 and the cloth outlet machine 7 are composed of a horizontal guide roller reaction box and a jet-type flat washing box connected in series to the cloth feeding device 1, the middle-supported padding car 3 with a direct sensor 2, the dipping tank 4, and the high-efficiency cooking tank 5. Between the three-roll padding car 6 and the cloth outlet machine 7.

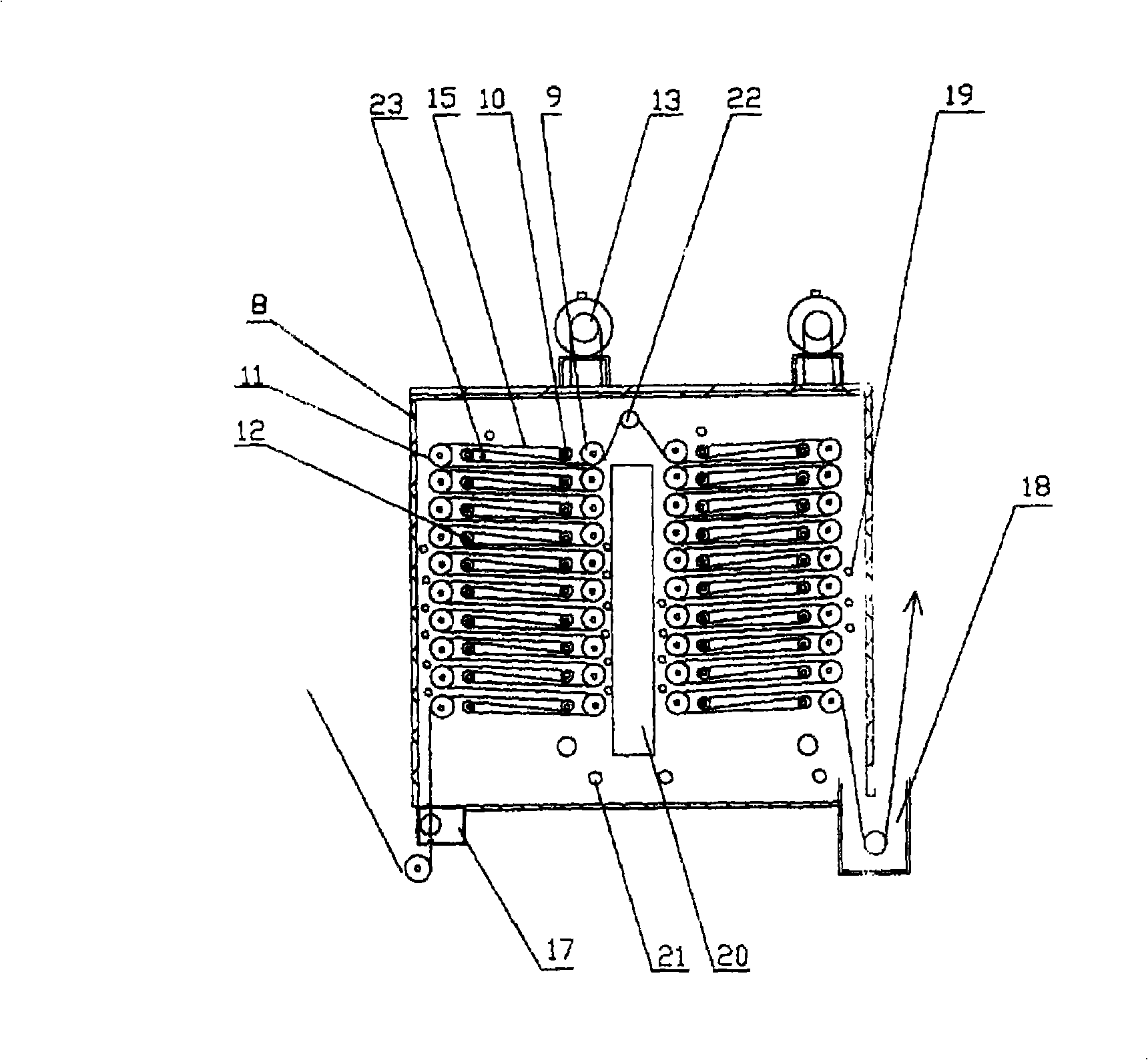

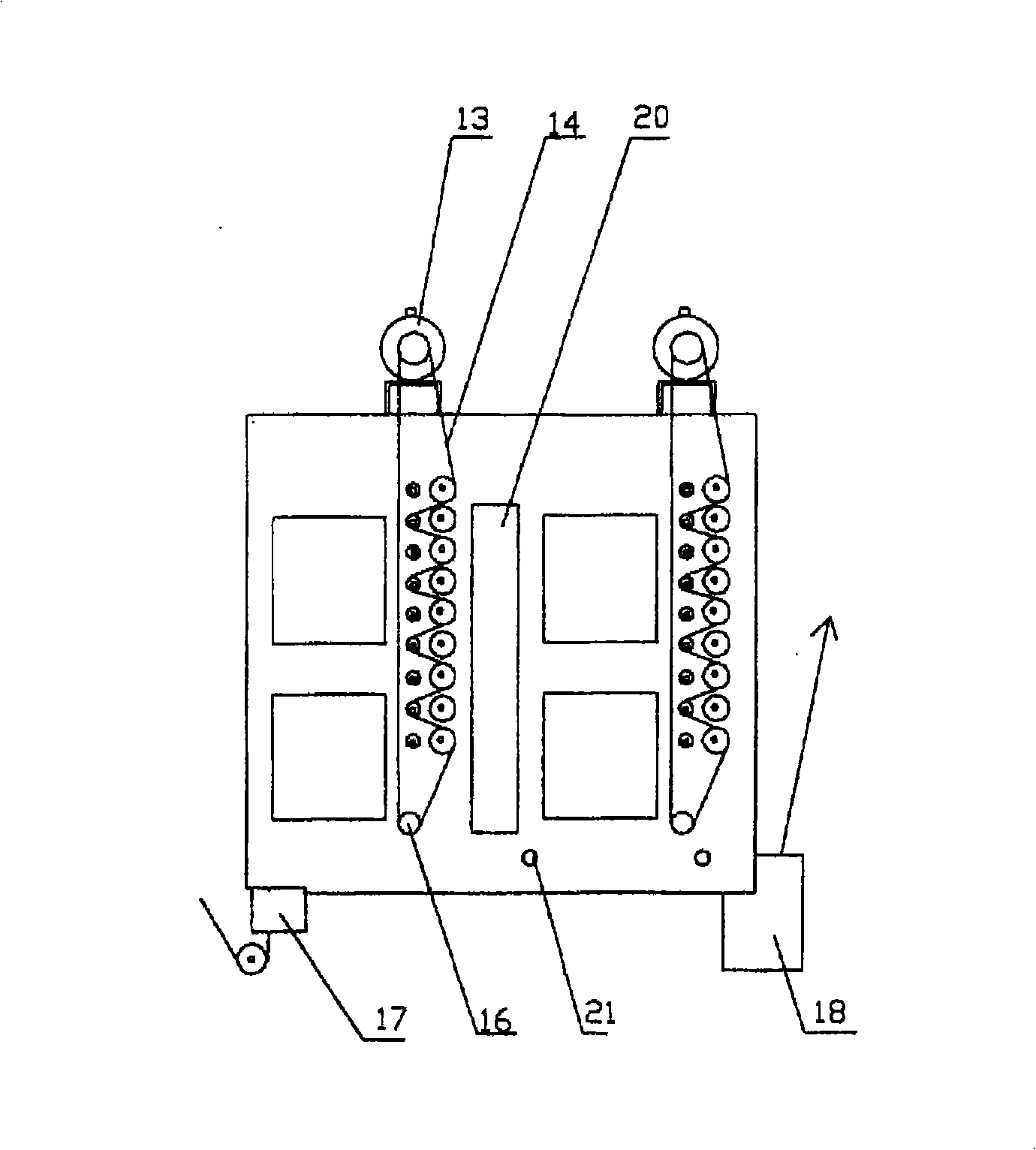

[0011] The horizontal guide roller reaction box is composed of an insulated box body 8, an active large horizontal guide roller 9, an active small horizontal guide roller 10, a driven large horizontal guide roller 11, a driven small horizontal guide roller 12, a motor 13, and a transmission belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com