Patents

Literature

110results about How to "Fully dyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

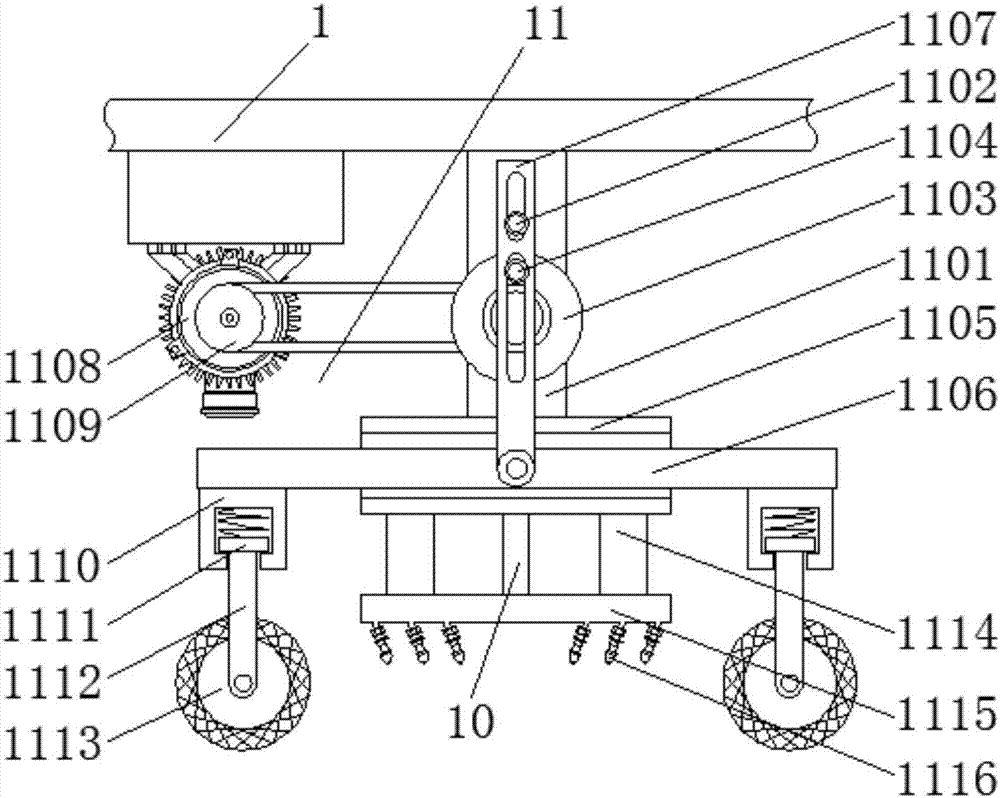

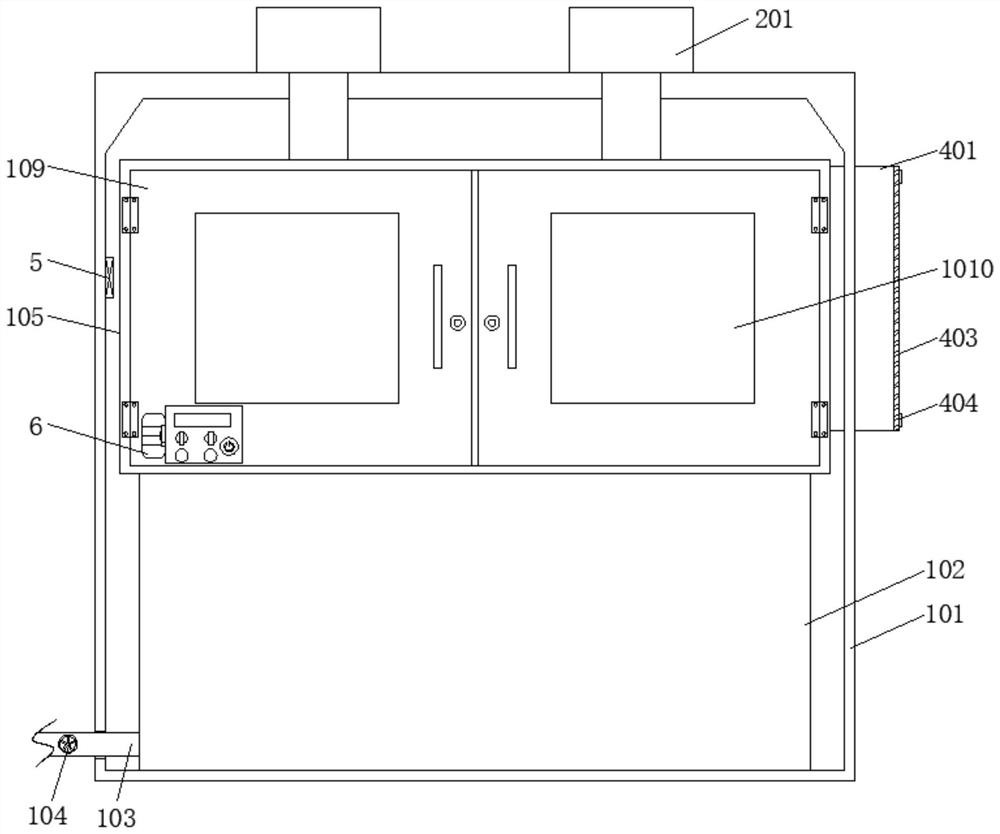

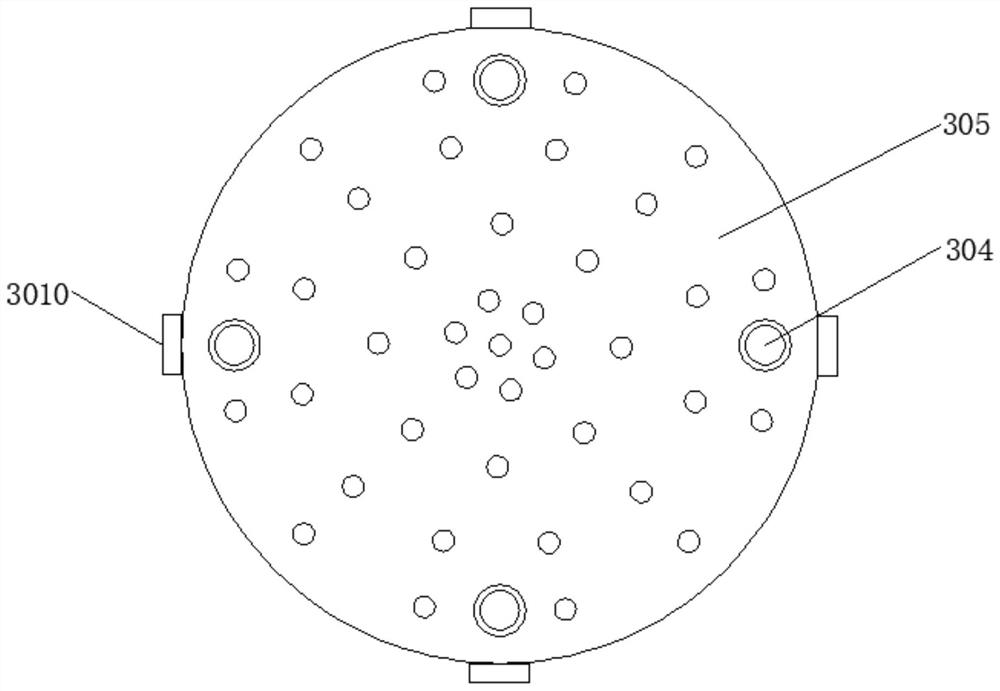

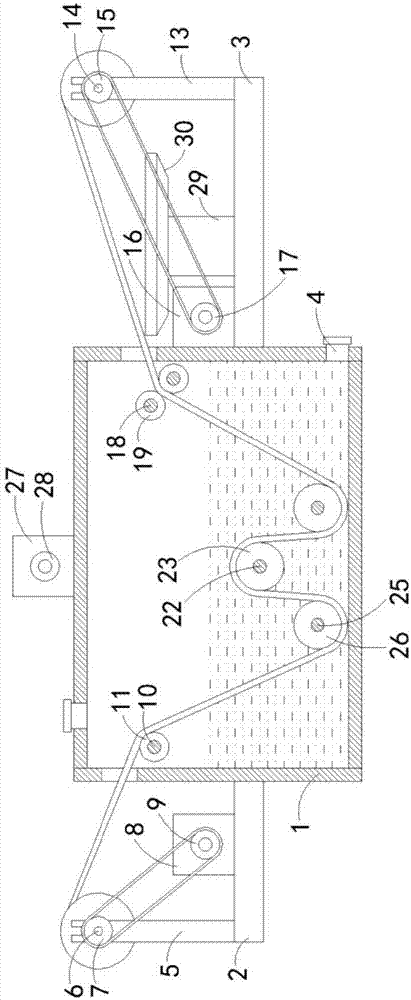

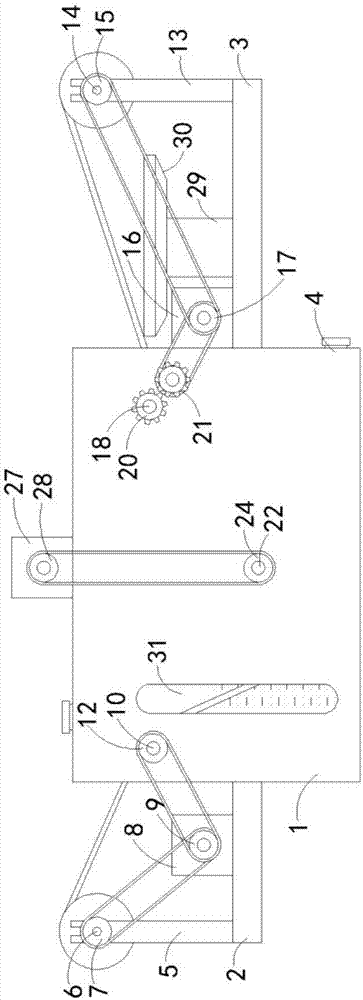

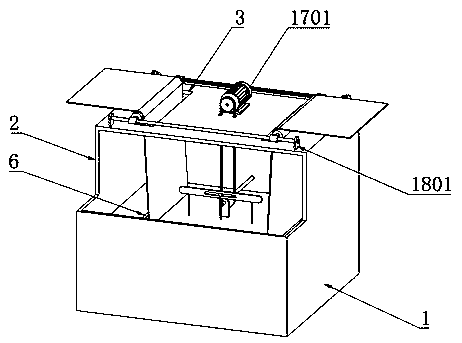

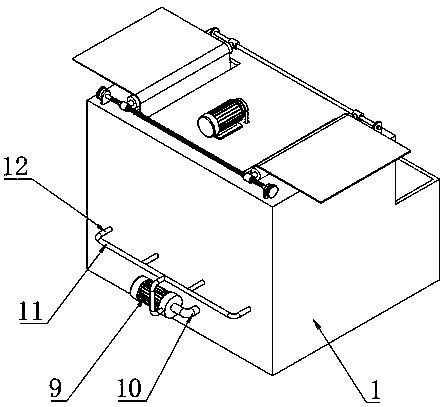

Environment-friendly spray printing and dyeing device for textile fabric

InactiveCN107447389AStir fully and evenlyImprove utilization efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringUltimate tensile strength

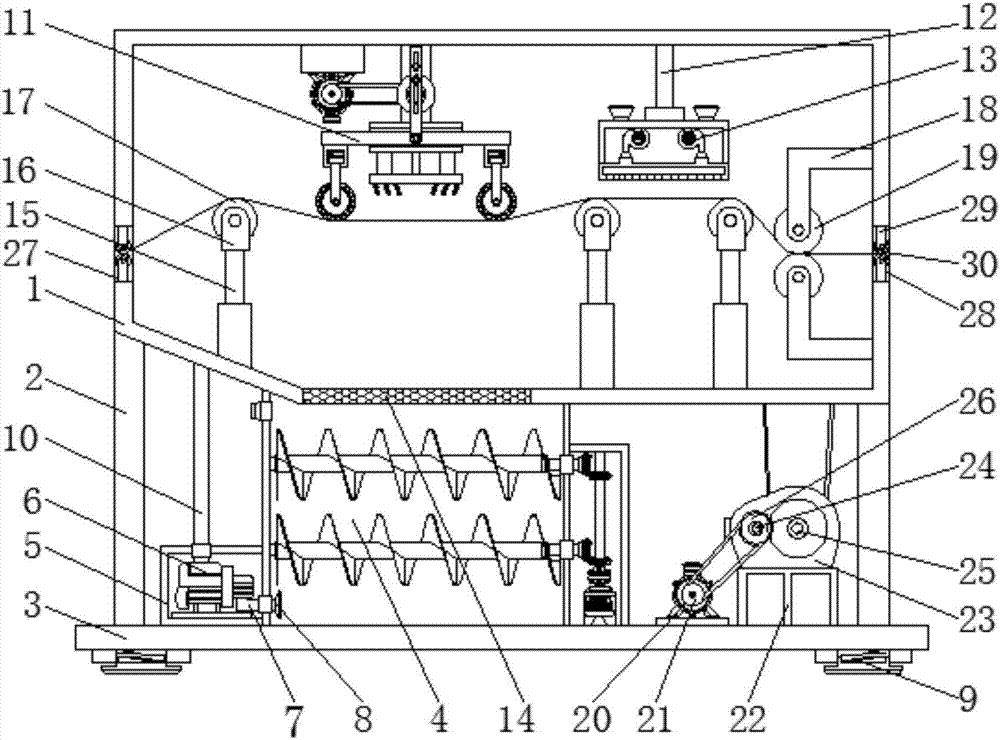

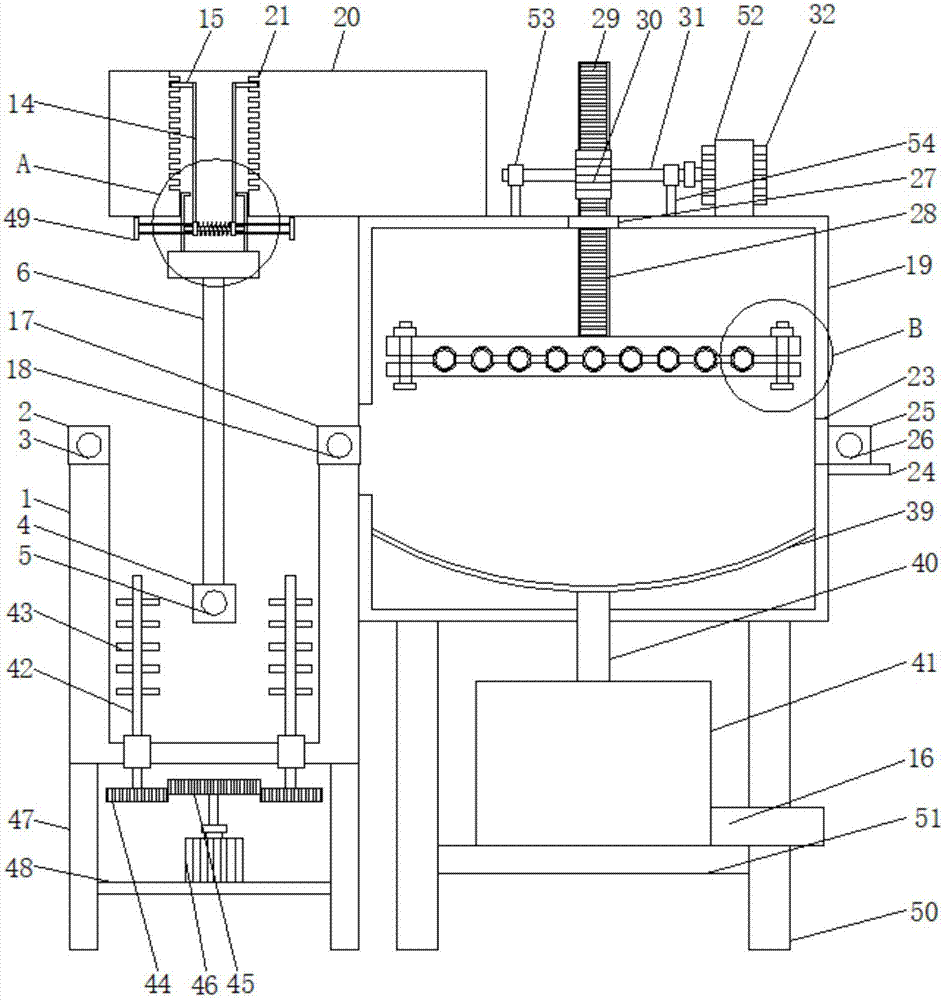

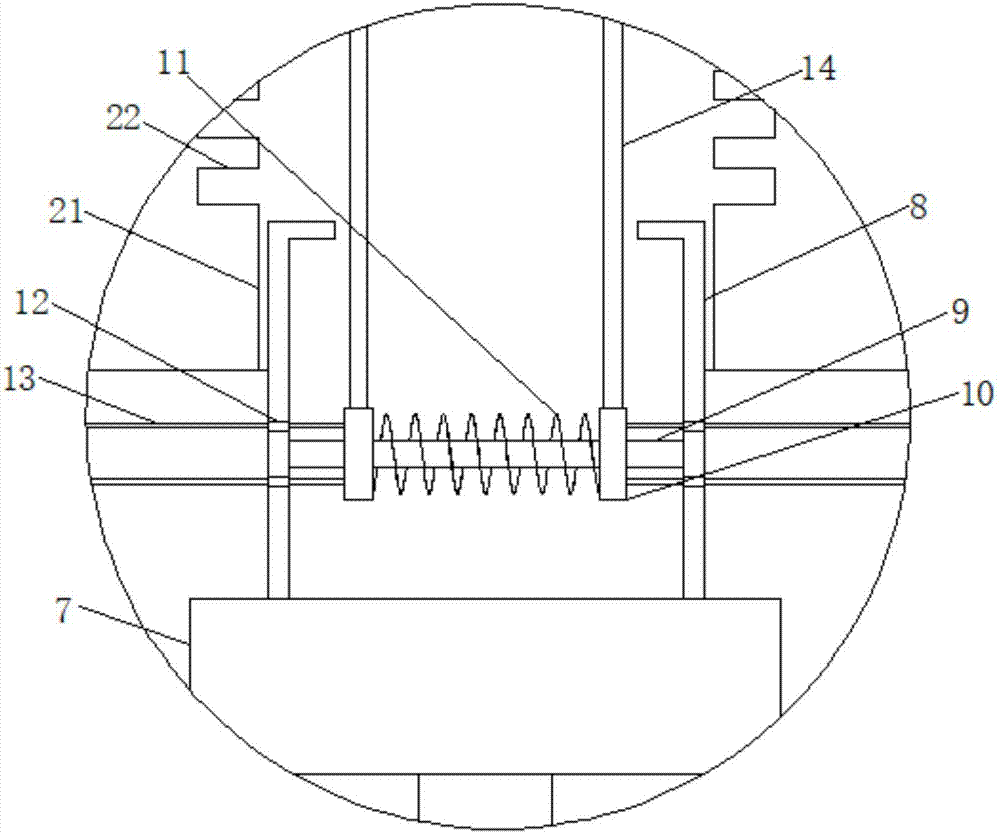

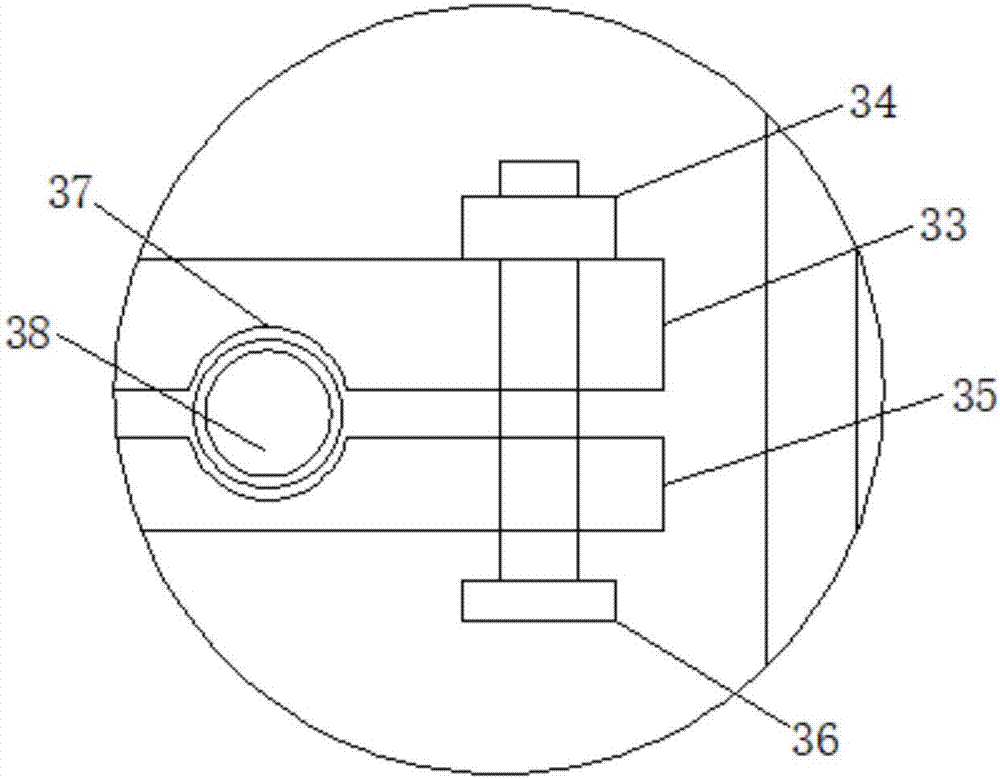

The invention discloses an environment-friendly spray printing and dyeing device for a textile fabric, and relates to the technical field of textile machinery equipment. The environment-friendly spray printing and dyeing device comprises a box, two sides of the bottom of the box are fixedly connected with mutually symmetric supporting vertical plates, the bottoms of the two supporting vertical plates are fixedly connected with bottom supporting plates, two sides of the bottoms of the bottom supporting plates are fixedly connected with mutually symmetric damping anti-slip mats, the centers of the tops of the bottom supporting plates are fixedly connected with dye stirring devices, through holes are formed in the bottom of the inner wall of the box and positioned above the dye stirring devices, and an impurity filter screen is arranged on the inner walls of the through holes. The environment-friendly spray printing and dyeing device for the textile fabric solves the problems of high dyeing cost, environmental pollution, low use ratio and poor fabric dyeing effect of existing textile fabric dyeing equipment. The use efficiency of dyes is effectively improved, the device is safe and environmentally friendly, environmental pollution is reduced, manual operation of workers is omitted, the labor intensity of staff is reduced, and production efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

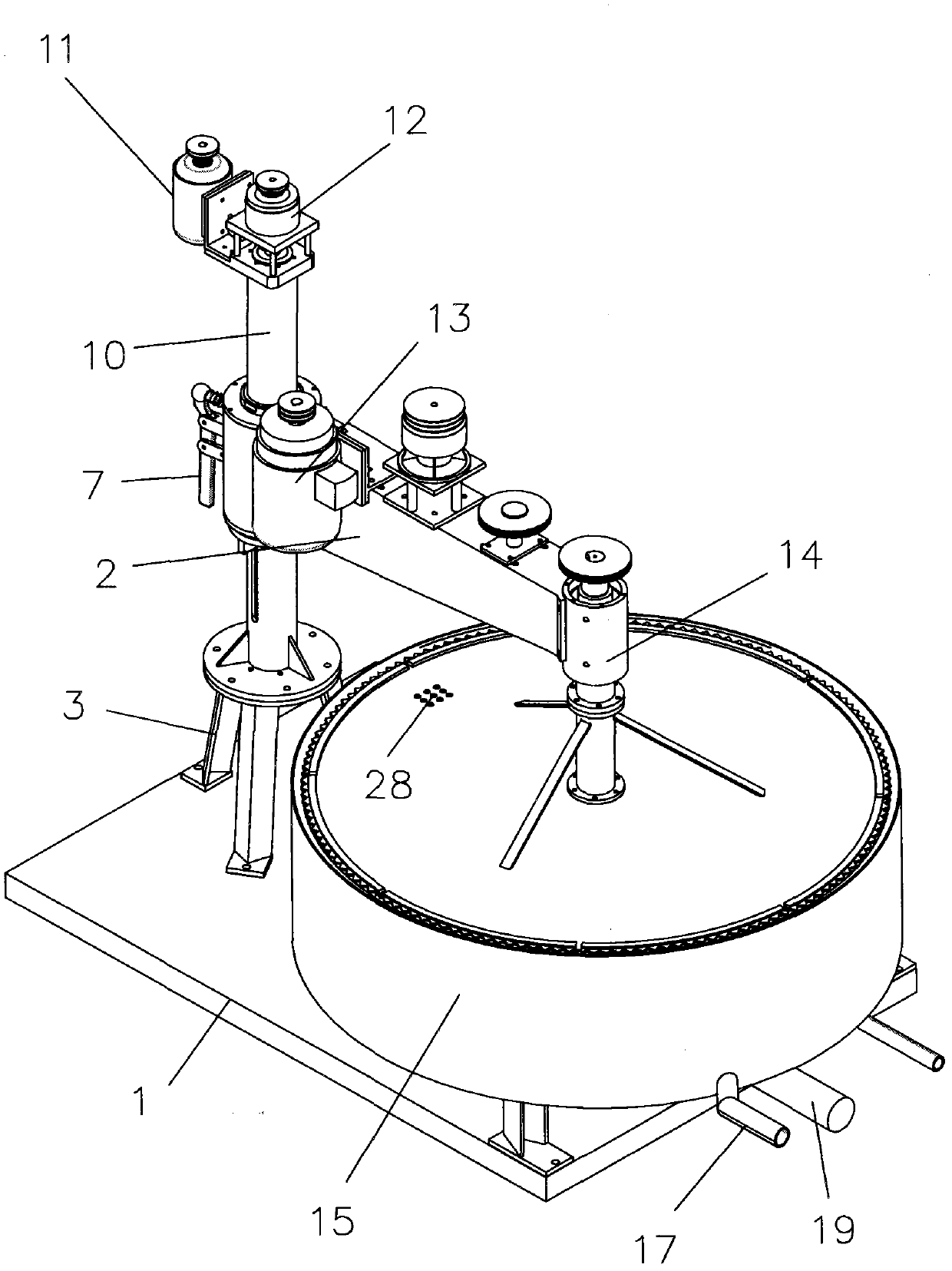

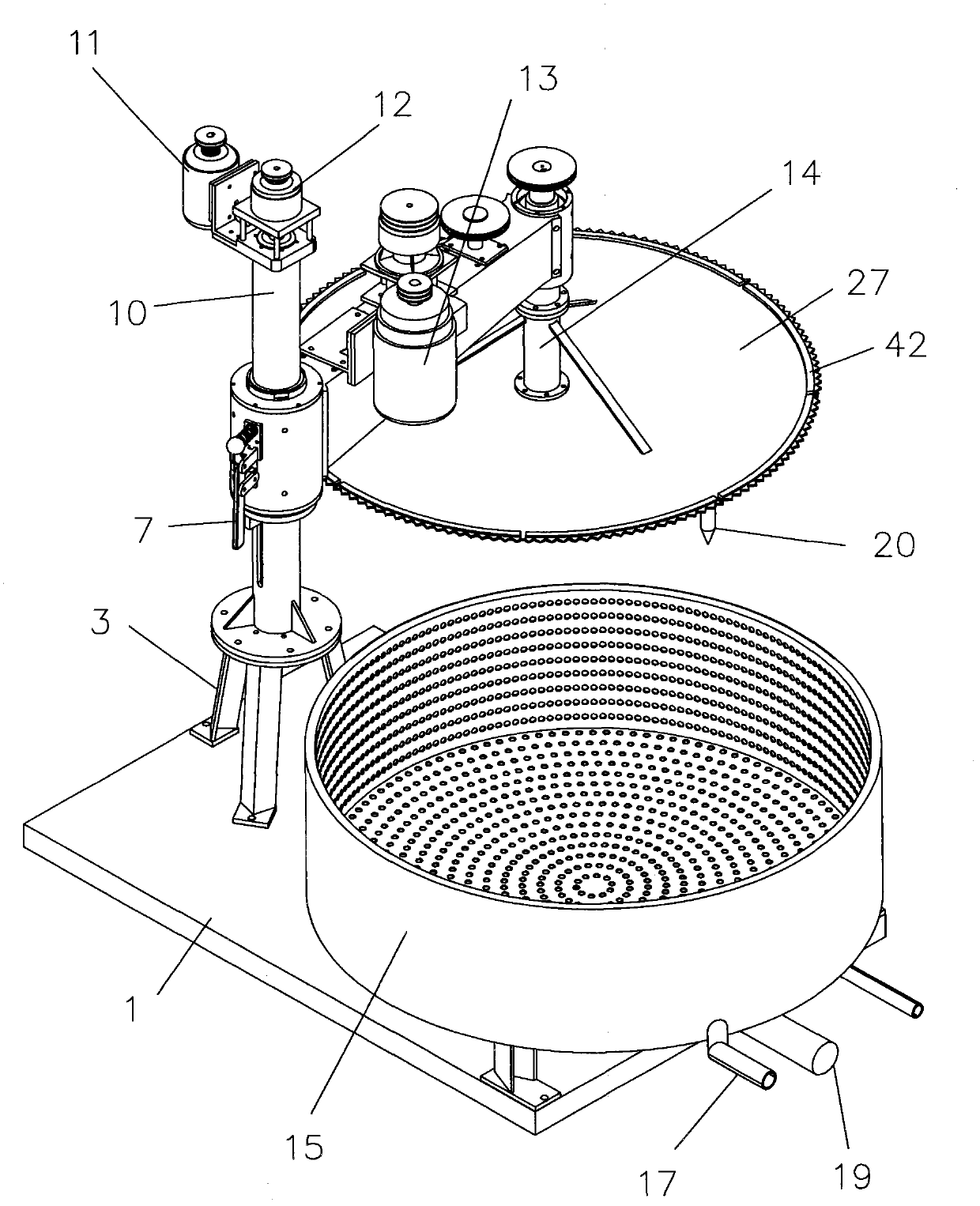

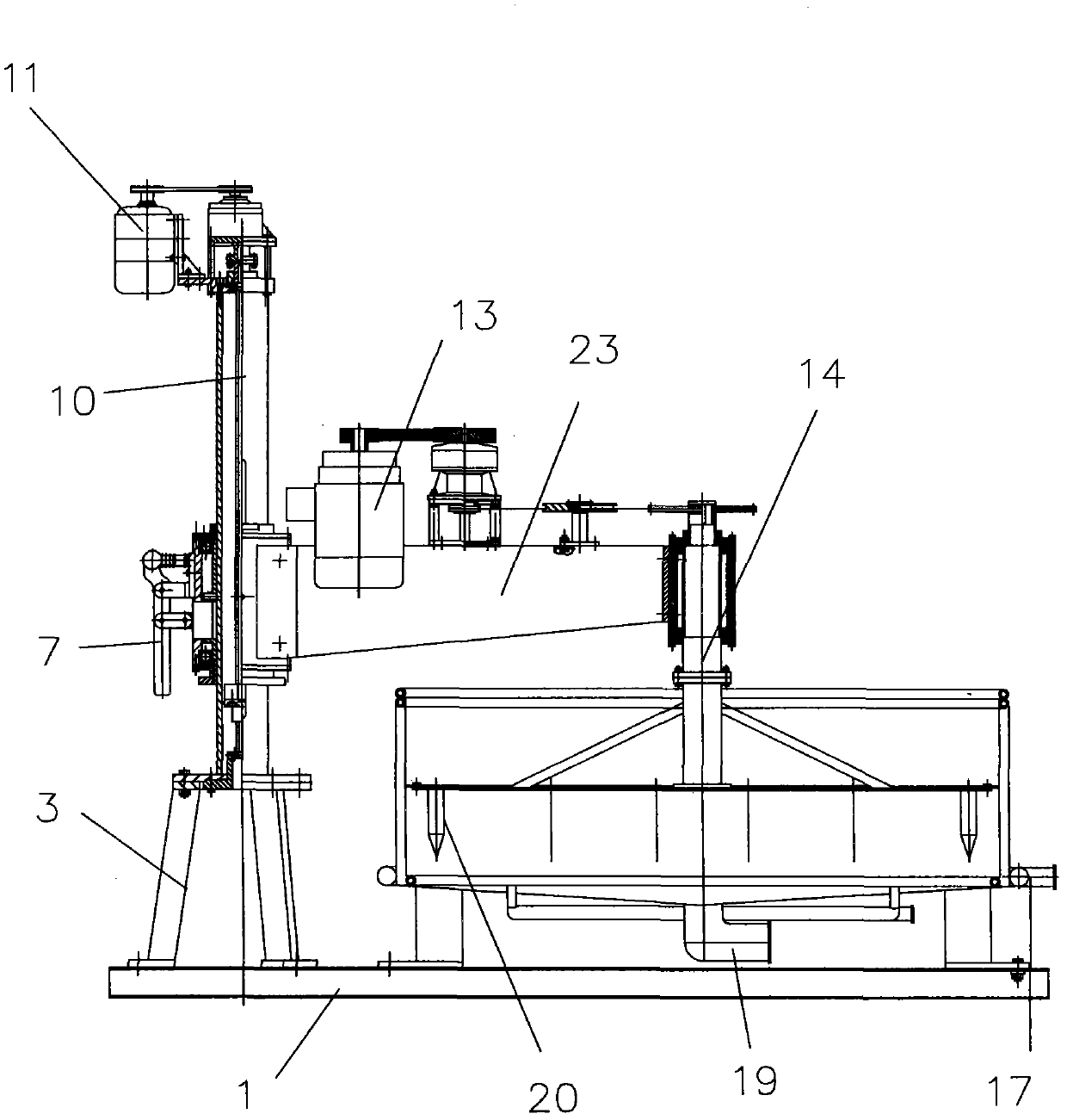

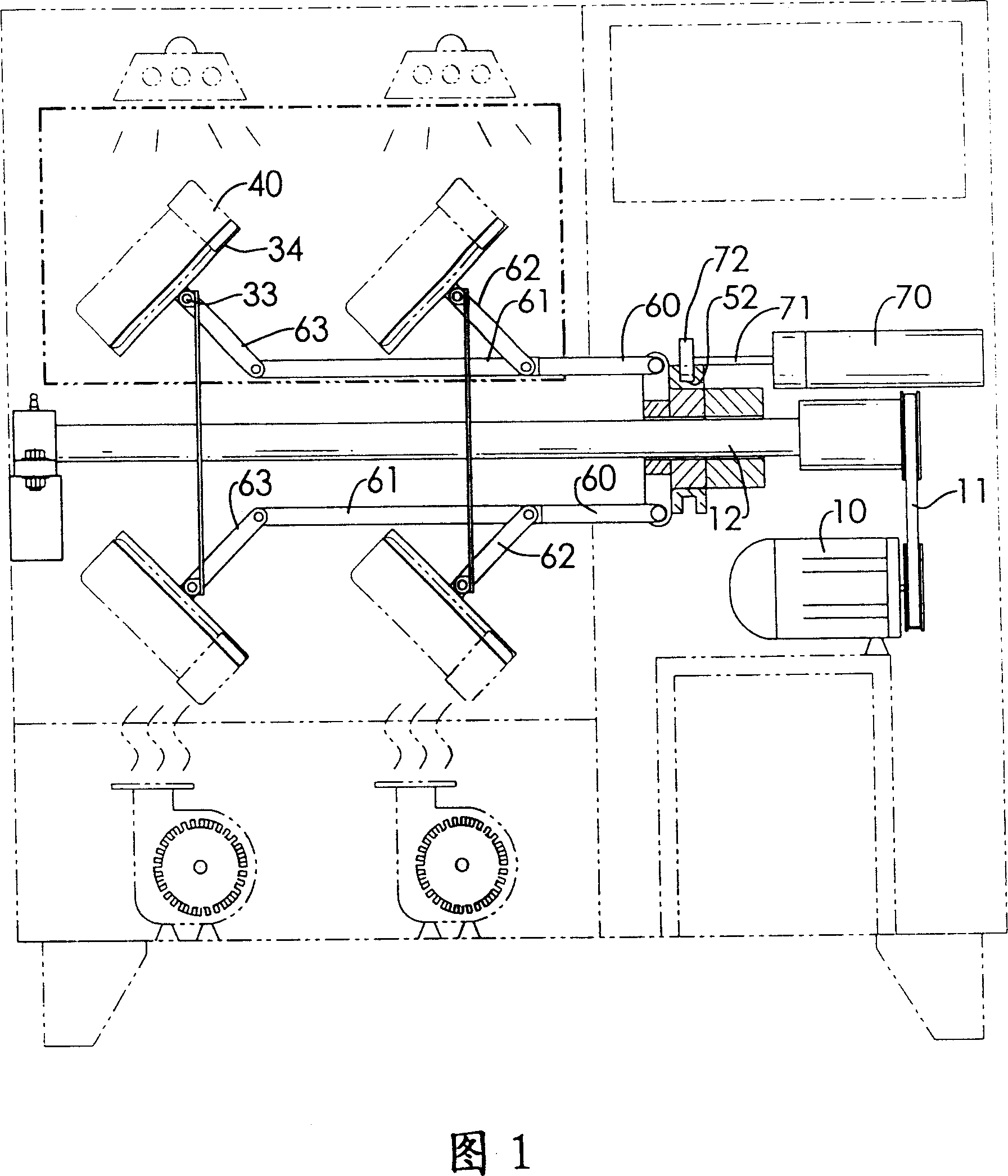

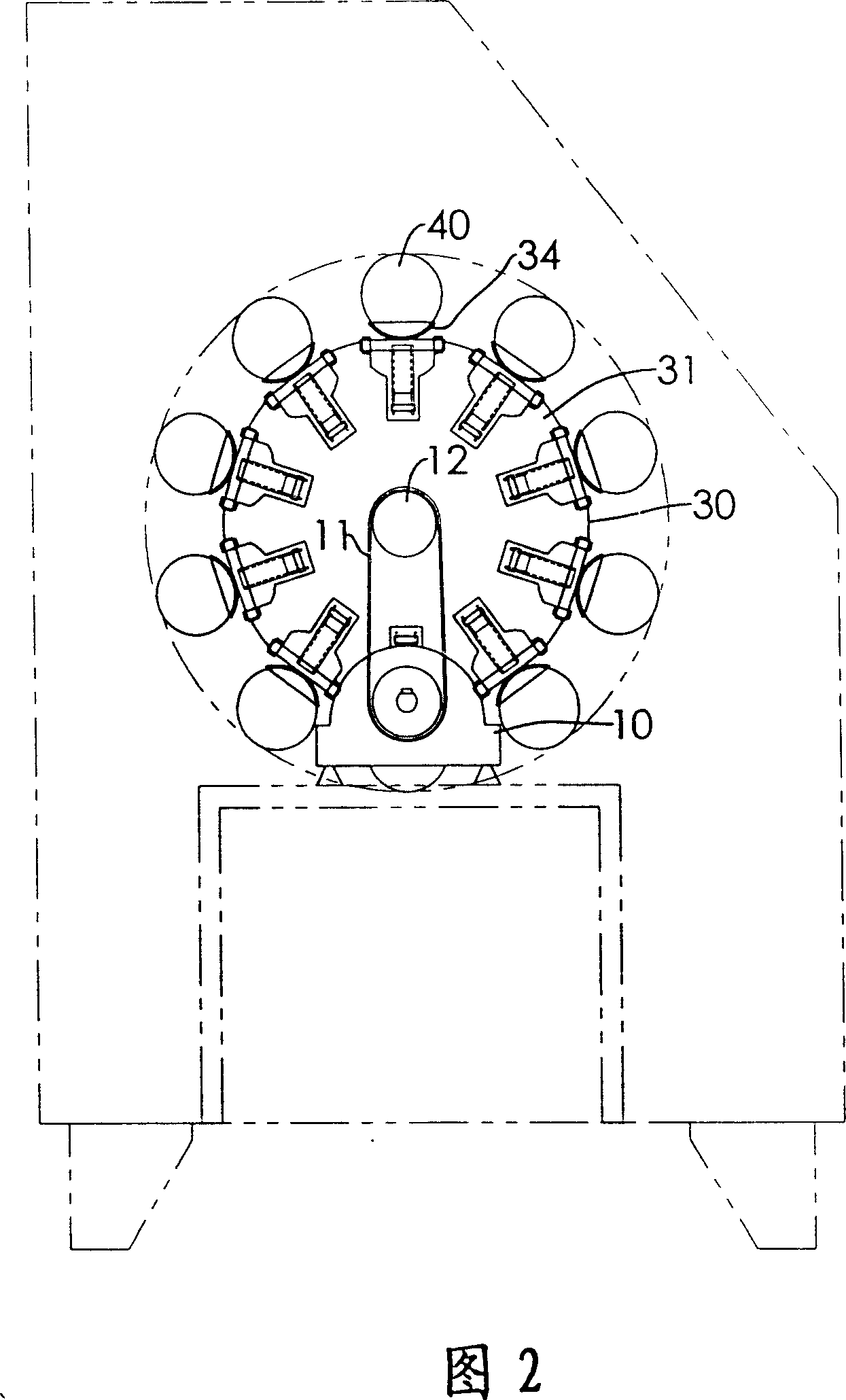

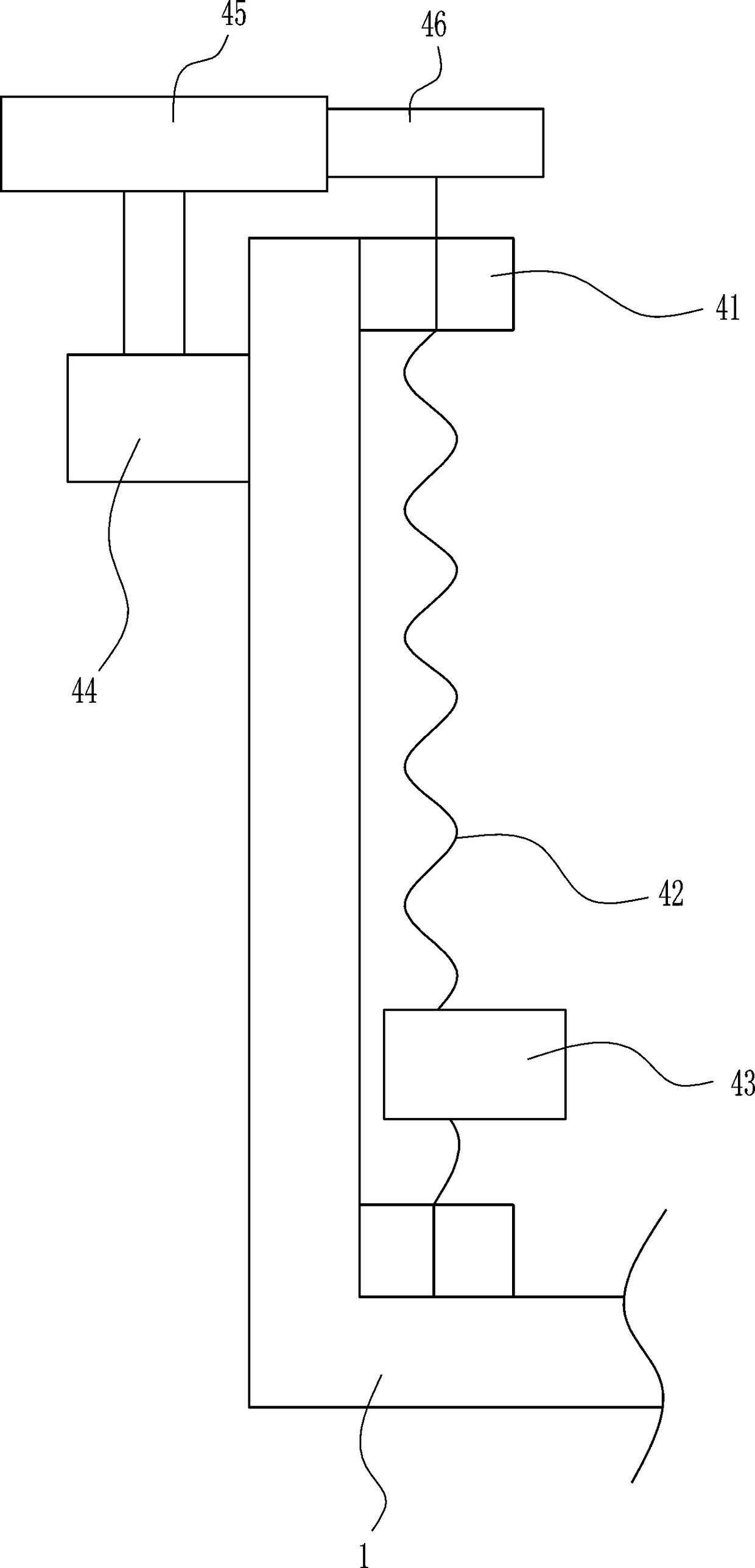

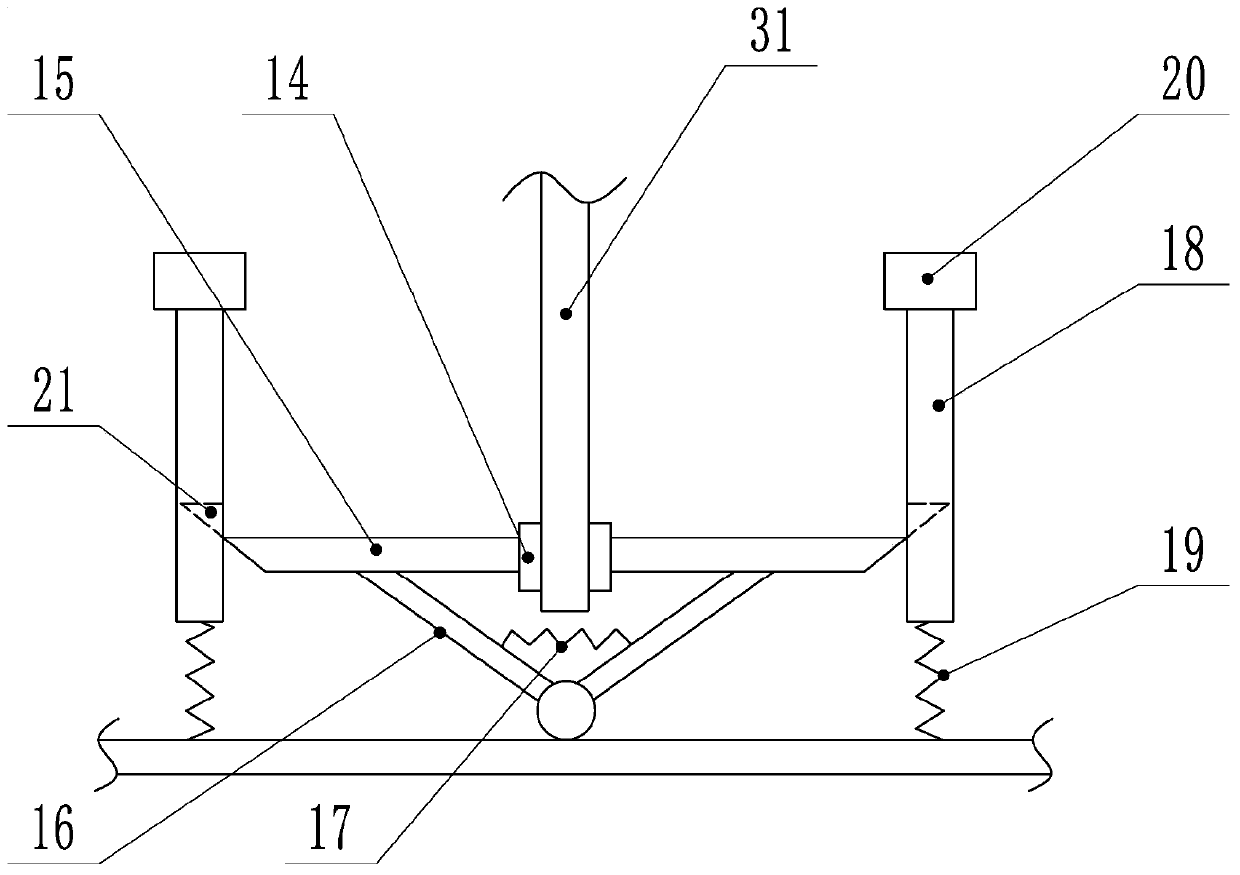

Automatic wig dyeing machine

The invention mainly discloses an automatic wig dyeing machine which comprises a base, a triangular frame, a barrel body, a lifting mechanism, a cantilever mechanism and a stirring mechanism, wherein the base is provided with the triangular frame for fixing the lifting mechanism; one end of the cantilever mechanism is mounted on the lifting mechanism, and the stirring mechanism is mounted at the other end of the cantilever mechanism; the cantilever mechanism moves vertically on the lifting mechanism and drives a stirrer to move up and down; the stirrer can be placed in the barrel body when moving downwards, and is at certain distance higher than the barrel body when moving upwards; the cantilever mechanism is provided with a handle controlling the cantilever mechanism to rotate or to be fixed in a horizontal plane; a main motor is mounted in the cantilever mechanism; the stirring mechanism is driven to rotate through a speed reducing mechanism; and a stirring rod of the stirring mechanism is inserted into the hair to be dyed in the barrel body and rotates along with the stirring mechanism. The automatic wig dyeing machine disclosed by the invention realizes sufficient dyeing, obviously improves the dyeing quality, effectively prevents the wig products from being twisted, and is an automatic dyeing machine which has low pollution, low labor cost, high dyeing quality and low price and is easy to operate.

Owner:ZHONGBEI UNIV

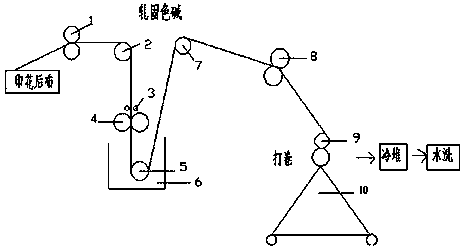

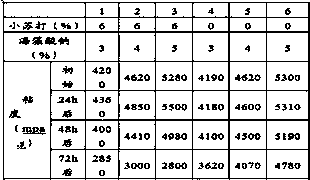

Disperse and reactive printing method for polyester-cotton fabric

InactiveCN103590265AColor paste stabilityViscosity changes greatlyDyeing processDisperse dyeTextile printer

The invention provides a disperse and reactive printing method for a polyester-cotton fabric. The method comprises the following steps: dissolved disperse dyes, dissolved reactive dyes, and a paste material are mixed to obtain a printing paste; the polyester-cotton fabric is printed through the printing paste and then dried; after being baked at high temperature, the dried polyester-cotton fabric is padded with a substitute fixation alkali liquor, and then stacked at the room temperature; the stacked polyester-cotton fabric is washed and dried to obtain disperse and reactive polyester-cotton printed fabric. According to the invention, during the disperse and reactive printing process, the printing paste contains no fixation alkaline agent, so that the stability of the printing paste is high, influences on the color development of the disperse dyes are small, the printed colors are dark, and the dye utilization rates are high. Through the alkali padding and indoor-temperature stacking of the printed and polyester-cotton baked fabric, the dyes react with the fibers under the alkaline condition and achieve adequate dyeing, so as to achieve the fixation effect; the fixation temperature is low in the fixation method, so as to improve the dye utilization rates and the dyeing depth and fastness, reduce the chromaticity of waste water and be beneficial to environmental protection.

Owner:YUYUE HOME TEXTILE

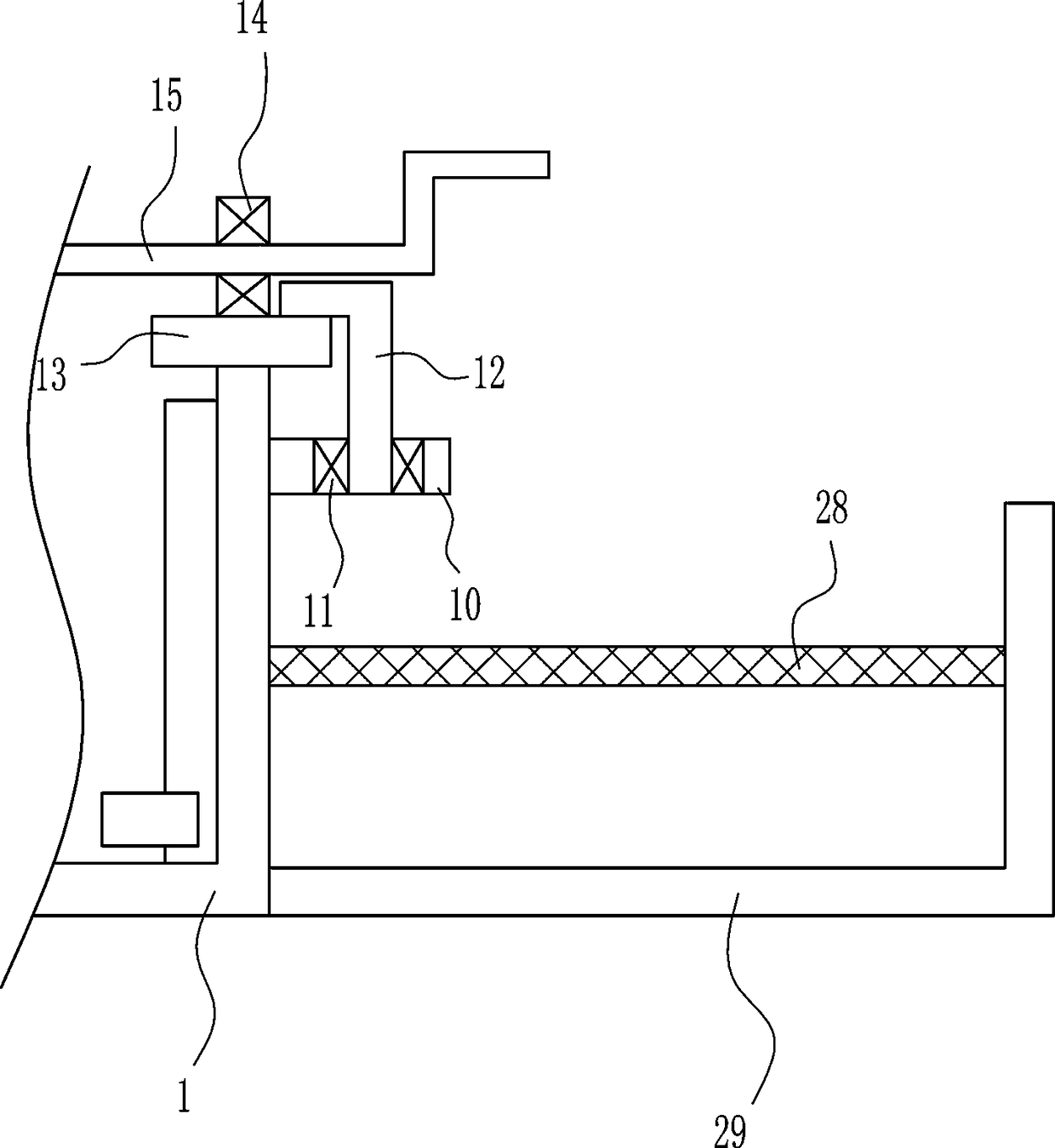

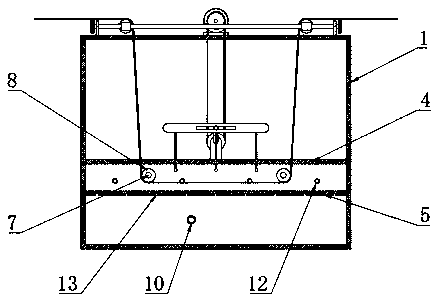

Dip dyeing device for textile fabric

InactiveCN107326578AFully dyedControl timeLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringThreaded rod

The invention discloses a dip-dyeing device for textile cloth, which comprises a paint bucket, a movable shaft is connected to the middle part inside the installation pipe, a compression spring is connected between two movable sleeves, and the top of the movable sleeve is connected to There is a clamping rod, the top of one side of the clamping rod is connected with a clamping block, the two sides of the inner wall of the installation groove are equidistantly provided with clamping slots, the inner side of the clamping slot is clamped with the clamping block, and the front of the adjustment plate It is connected with a rack, and the upper side of the front of the rack is meshed with a transmission gear, and the inside of the transmission gear is connected with a rotating shaft. The top of the threaded rod passes through the movable plate and is screwed with the nut. The two arcs Electric heating pipes are connected between the tanks. The invention has the advantages of being able to control the dyeing time of the cloth and the drying degree of the cloth after dyeing, and solves the problem that it is difficult to control the dyeing time of the cloth and the inconvenient control of the drying degree of the cloth will reduce the dyeing effect of the cloth.

Owner:范威

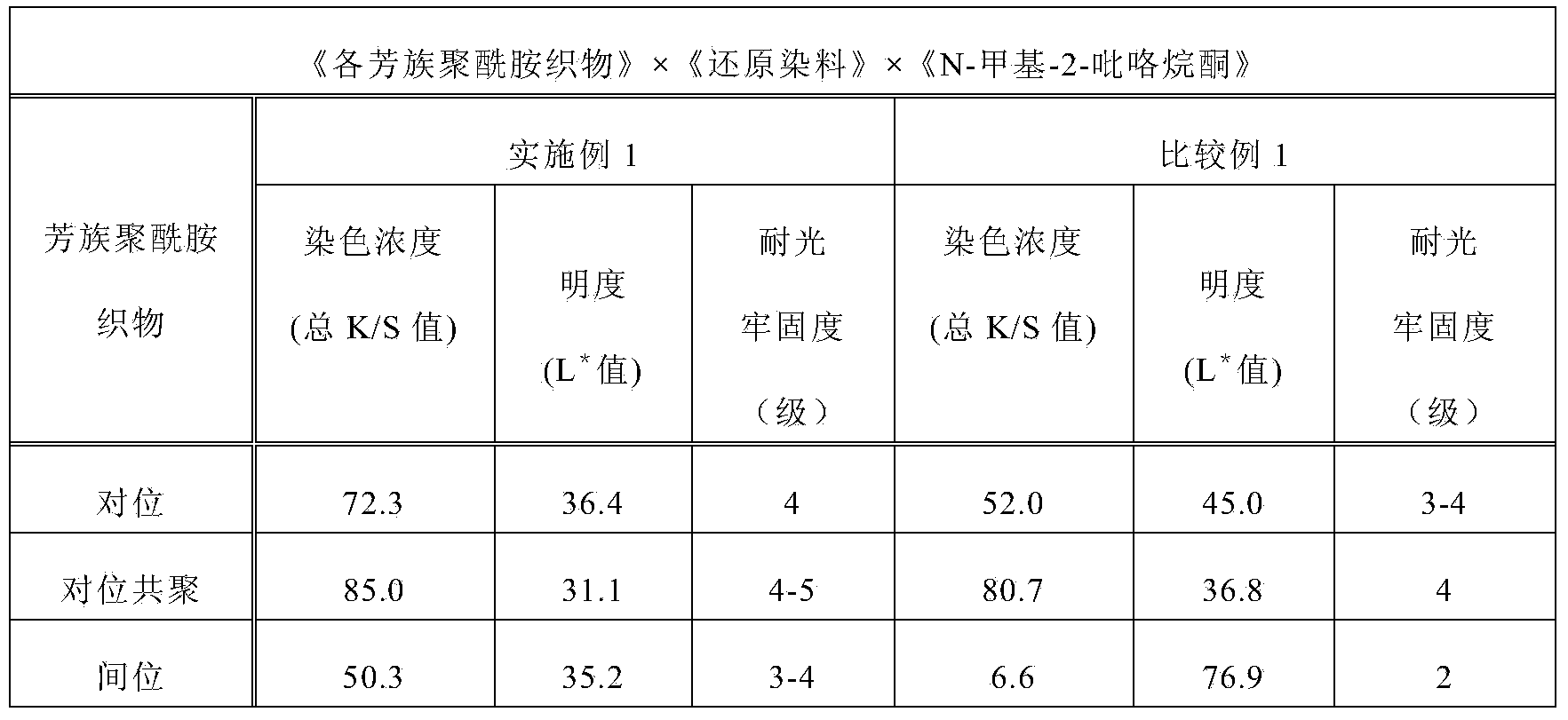

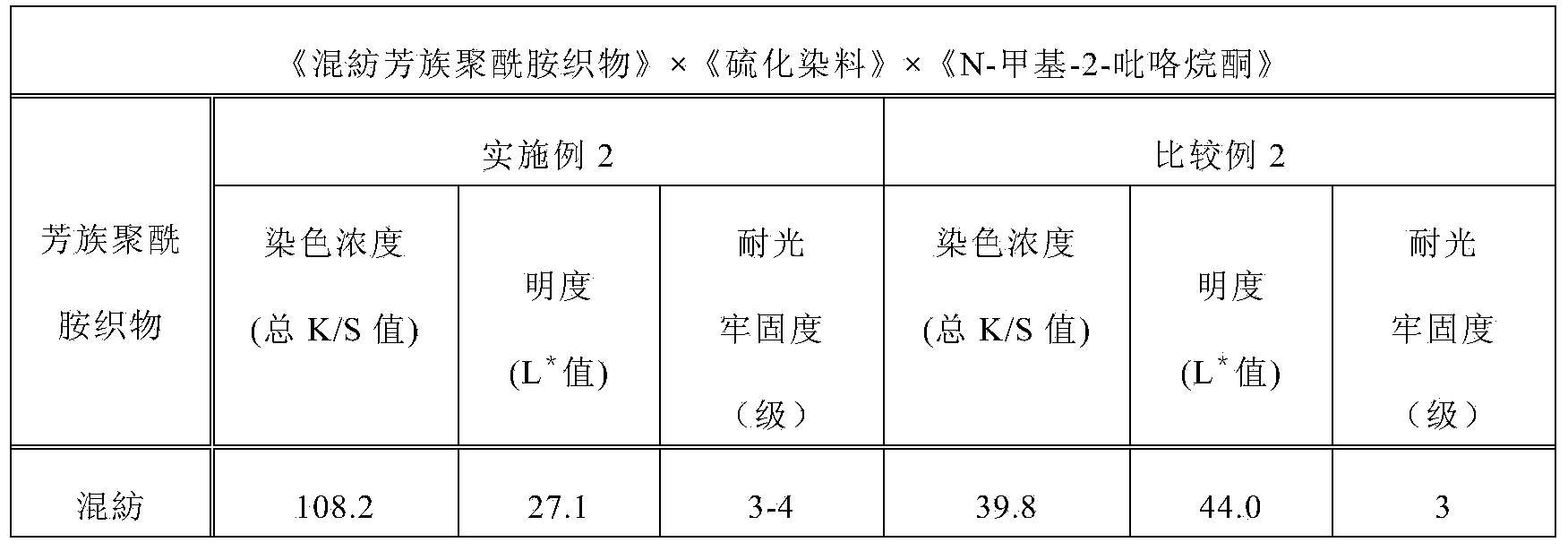

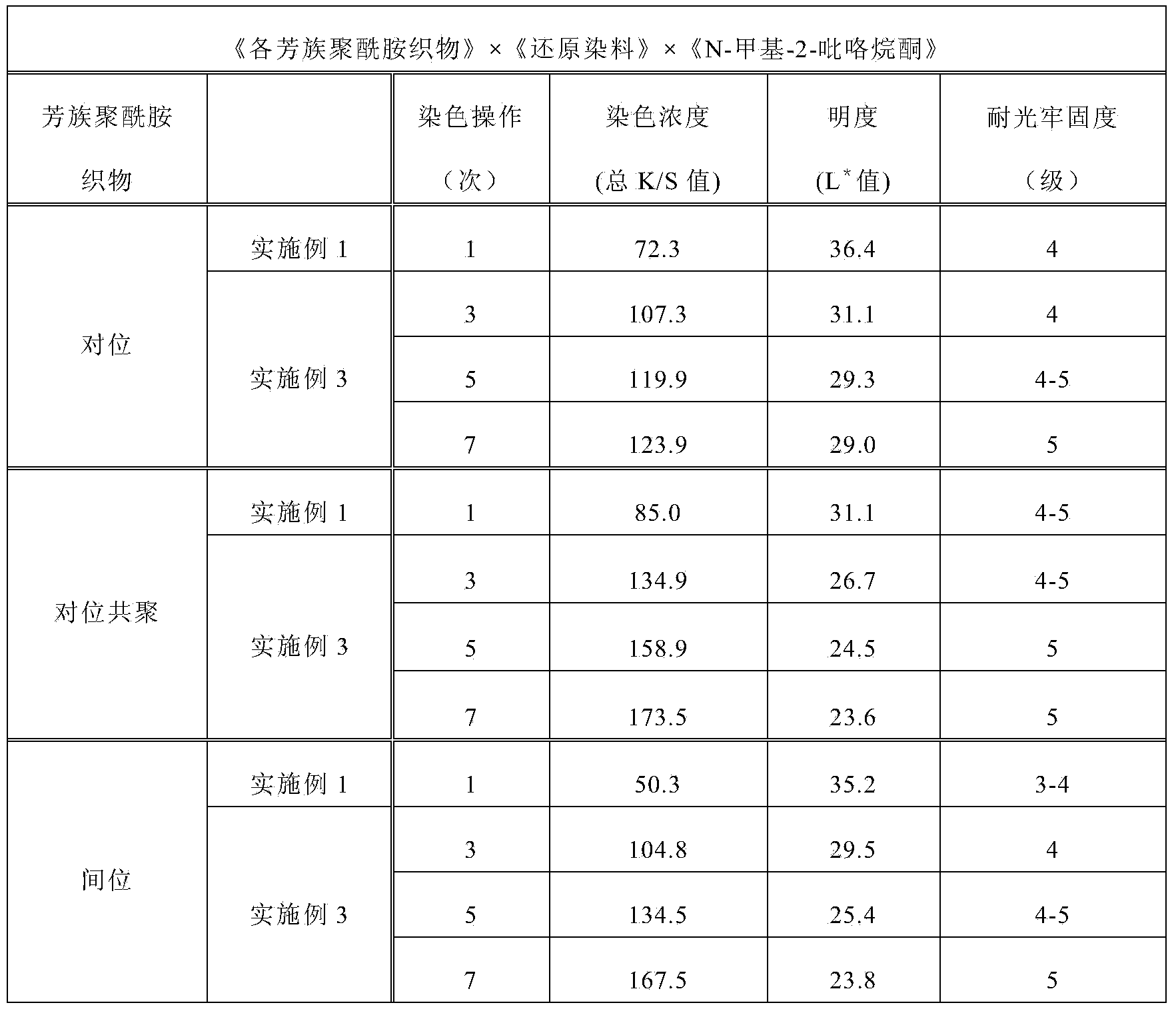

Method for dyeing aramid fibers and dyed aramid fibers

Provided are a method for dyeing aramid fibers and dyed aramid fibers. The method is applicable to any of para-aramid fibers, para-coaramid fibers, and meta-aramid fibers and by which aramid fibers are dyed in practical concentrations required for new applications of aramid fibers. The dyed aramid fibers have suffered neither considerable dyeing unevenness nor a considerable dimensional change nor a considerable decrease in material property. The dyed fibers further have satisfactory color fastness, in particular, light fastness. The dyeing method which comprises one or more dyeing operations each comprising a combination of the following steps: a dye application step in which a vat dye or a sulfur dye is applied to the aramid fibers; a solvent treatment step in which the aramid fibers are treated with a treating liquid comprising a polar solvent; and a heat treatment step in which after the solvent treatment step, the aramid fibers are heat-treated according to need.

Owner:TOKAI SENKO KK +1

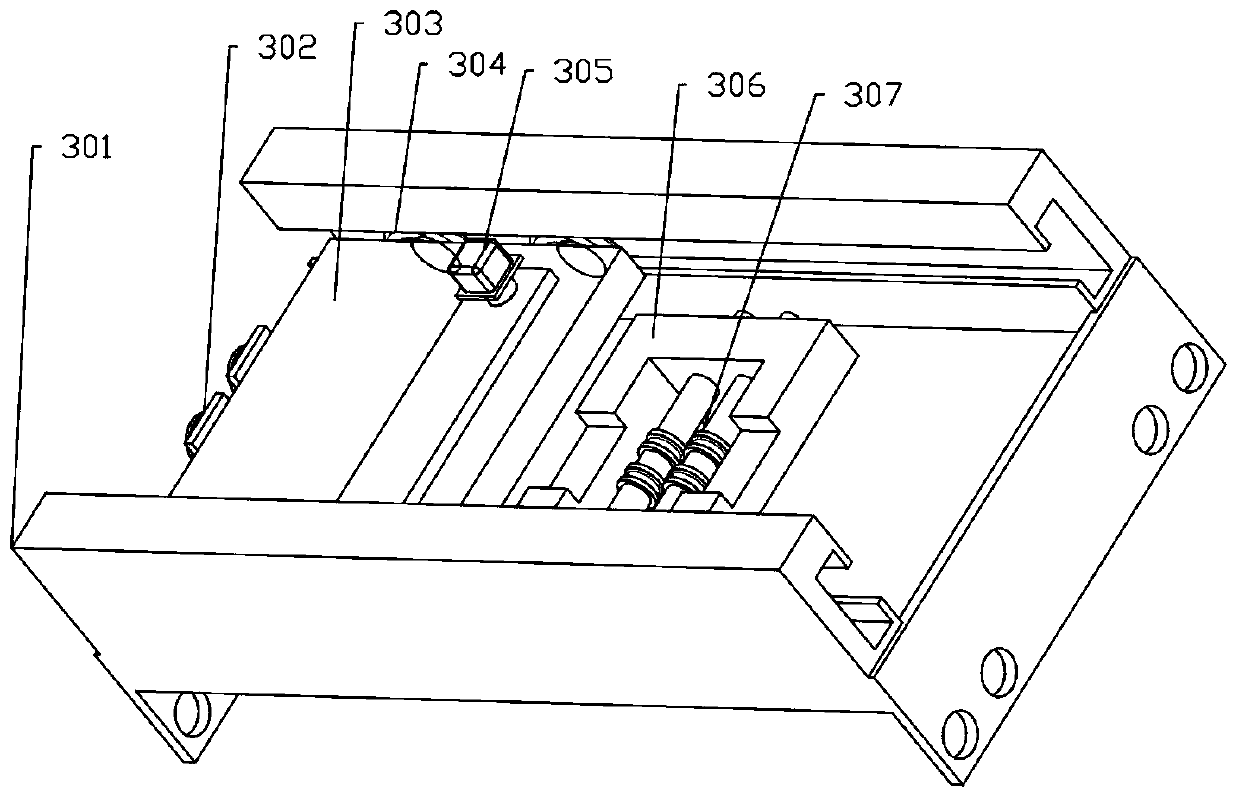

Sample staining device

PendingCN106706398AFully dyedSimple designPreparing sample for investigationFlat carrier supportsEngineeringSurface tension

The invention discloses a sample staining device which comprises a staining platform, a glass slide support structure and a glass slide driving mechanism, wherein the staining platform is provided with a staining solution and cleaning solution supply part; the glass slide support structure is located on the two sides of the staining platform and forms a certain clearance between a glass slide and the staining platform; and the glass slide driving mechanism allows the glass slide and the staining platform to move by keeping a certain clearance. When the device works, a staining solution is supplied to the staining platform; a convex liquid level is formed due to surface tension; when the glass slide moves to the convex liquid level of the staining solution, the staining solution performs infiltration and is diffused in the clearance between the staining platform and the glass slide to cover the glass slide to stain a sample; the staining time is determined by a movement stroke and speed of the glass slide in a staining solution area; and after the glass slide is stained, the cleaning solution is supplied to clean the residual staining solution to accomplish a staining process. The device is simple in structure; a glass slide conveying mechanism can allow multiple glass slides to pass through the staining platform for staining sequentially in a flowline manner; and the device has high working efficiency when the device is used for massive sample staining.

Owner:AVE SCI & TECH CO LTD

Device for testing color

The present invention relates to a color-testing machine. Said color-testing machine mainly includes the following several portions: rotating shaft, first rotary disk, second rotary disk, supporting frames, color-testing cups, pushing disk, pushing-pulling lever or pushing-pulling block, first connecting bar, second connecting bar, third connecting bar and fourth connecting bar. Said invention also provides the connection mode of all the above-mentioned portions. Said invention also provides the working principle of said color-testing machine and its concrete operation method.

Owner:陈昱仁 +1

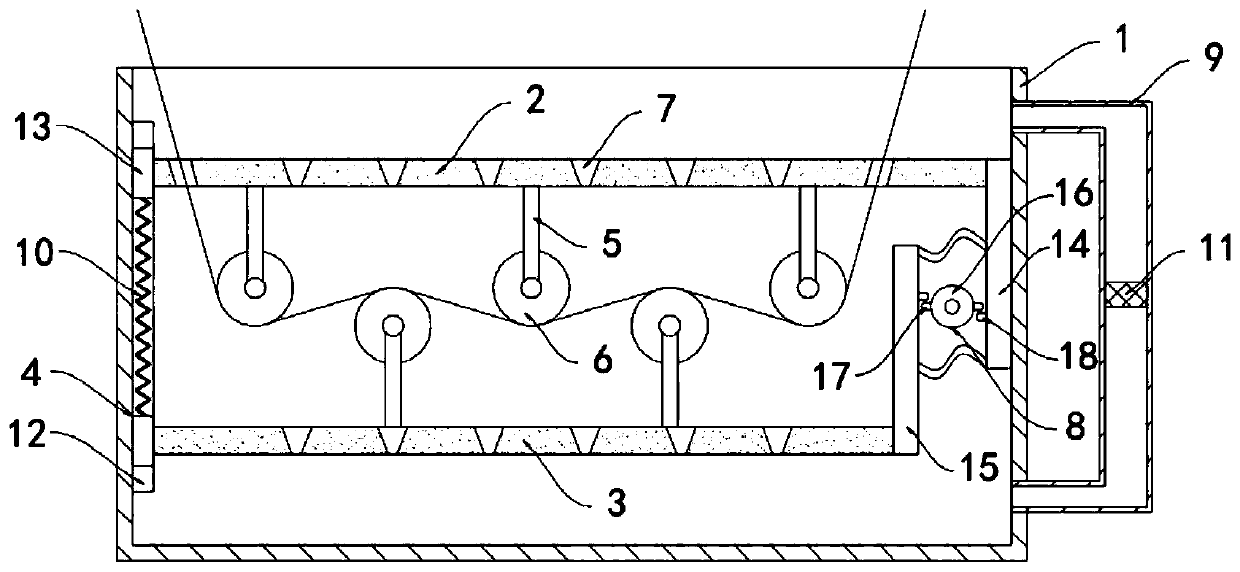

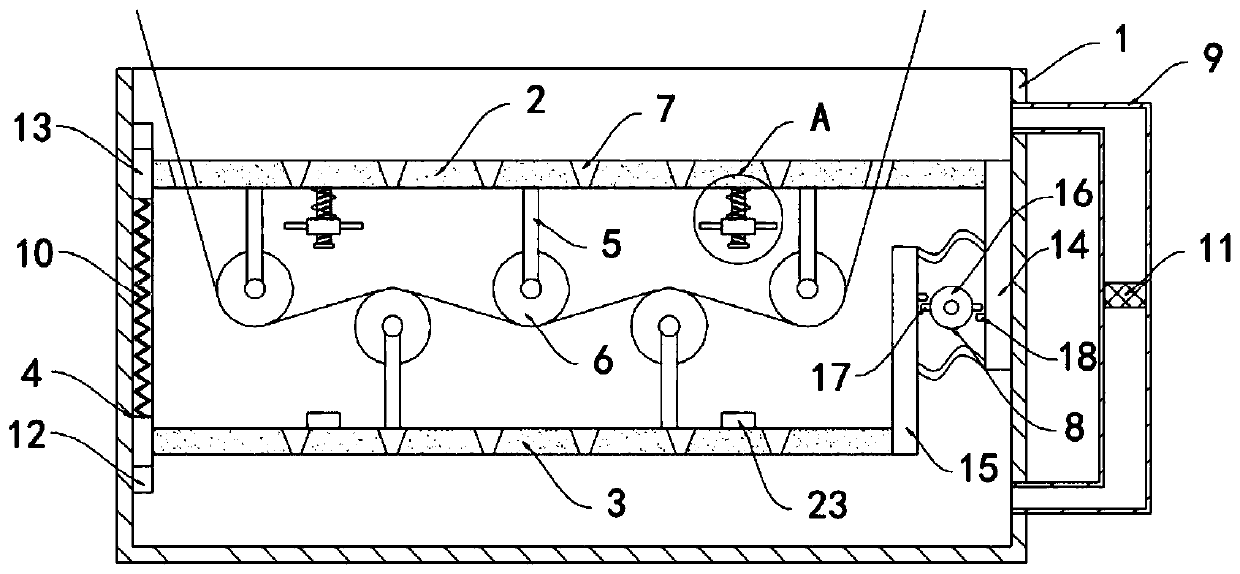

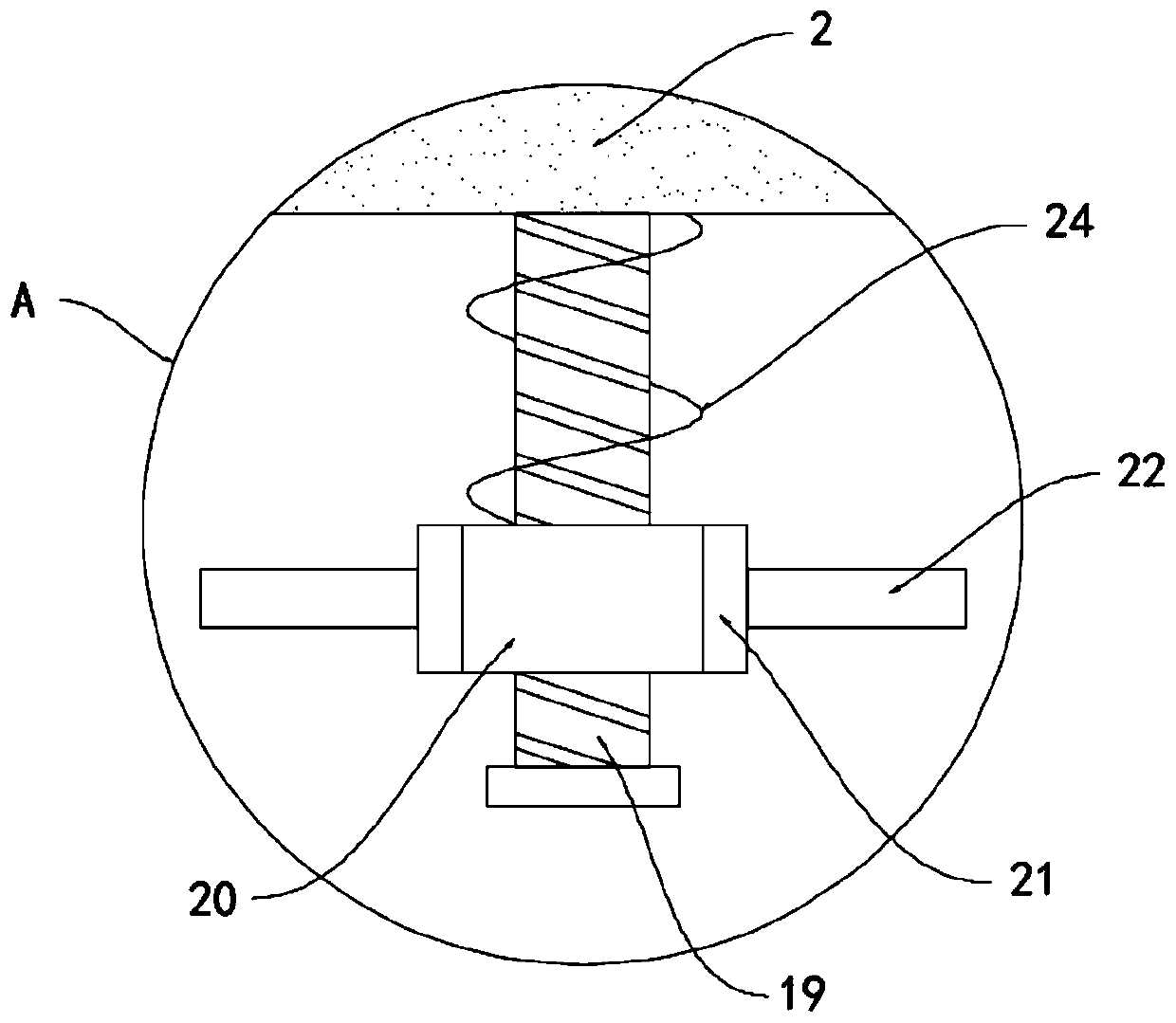

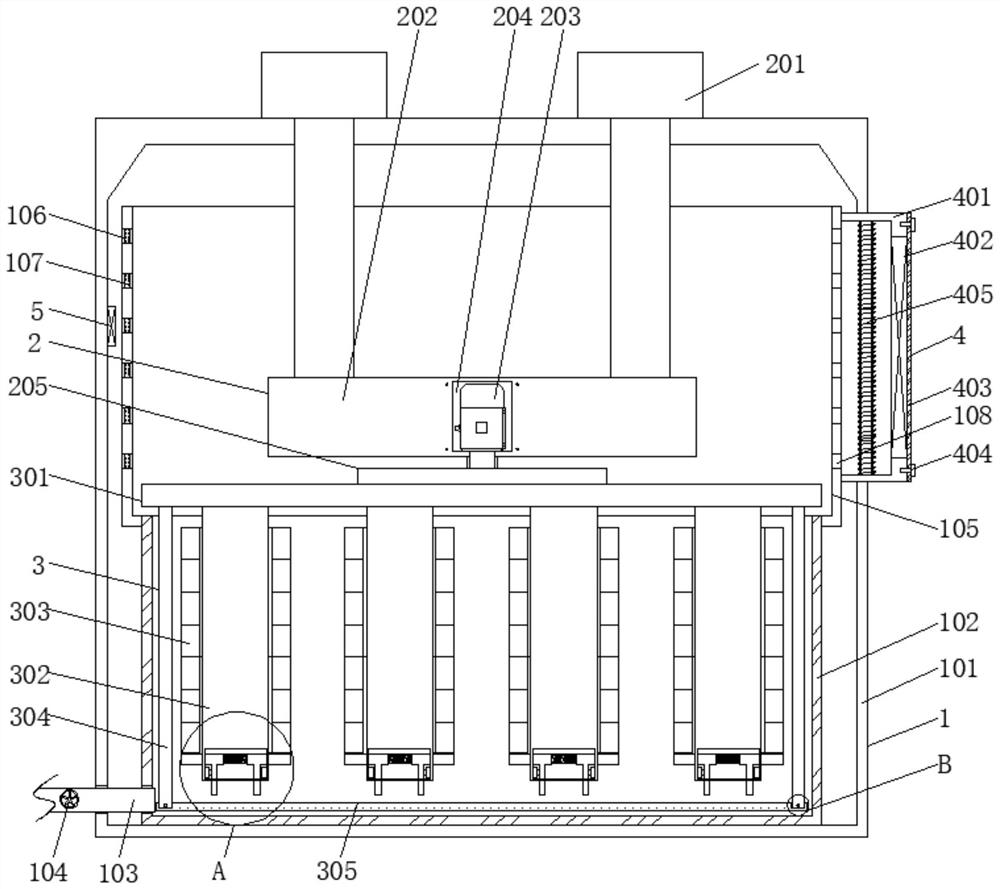

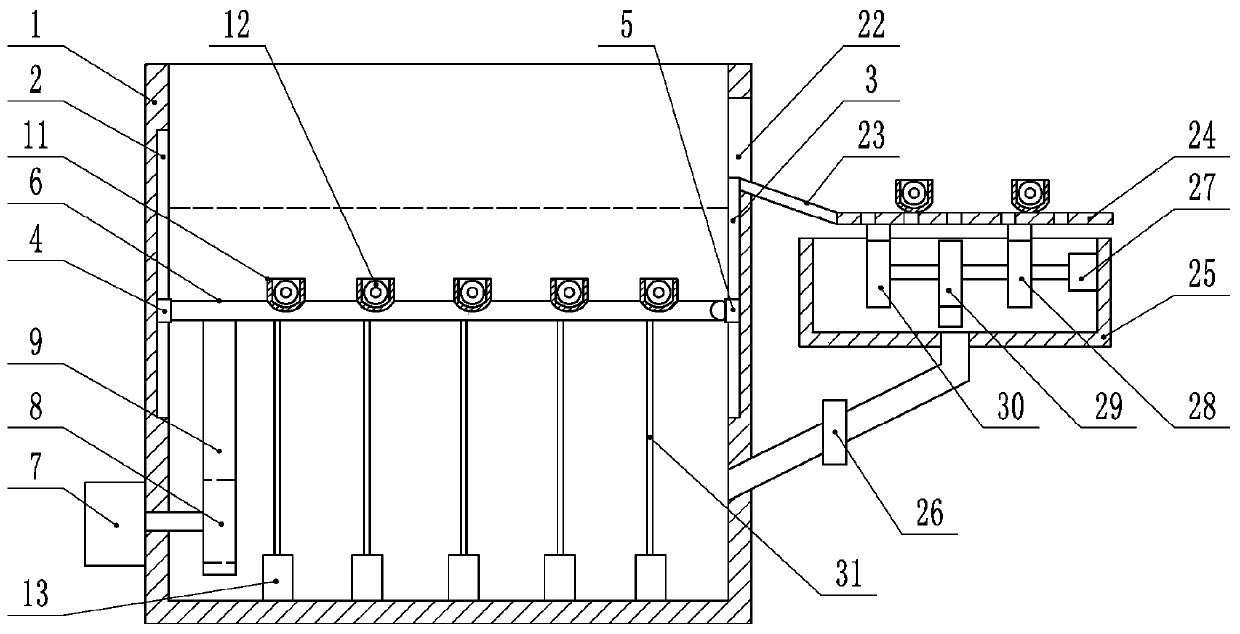

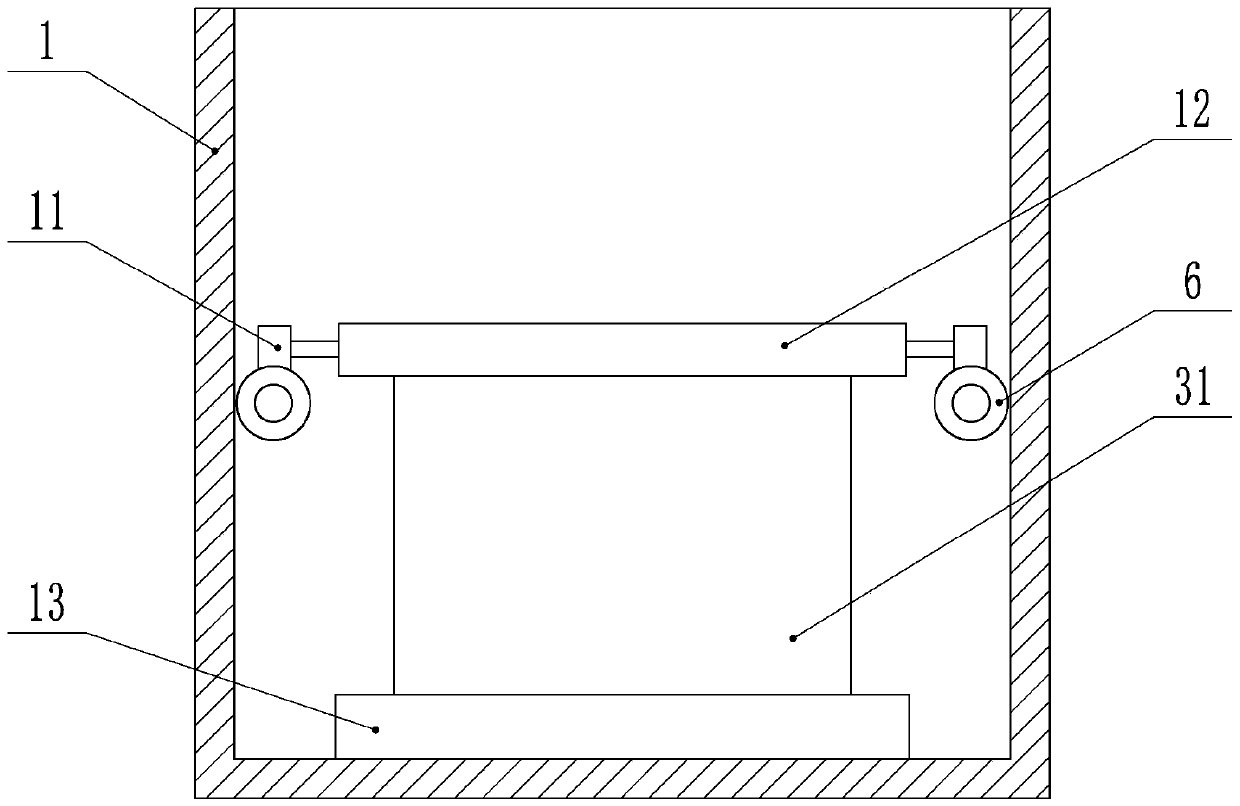

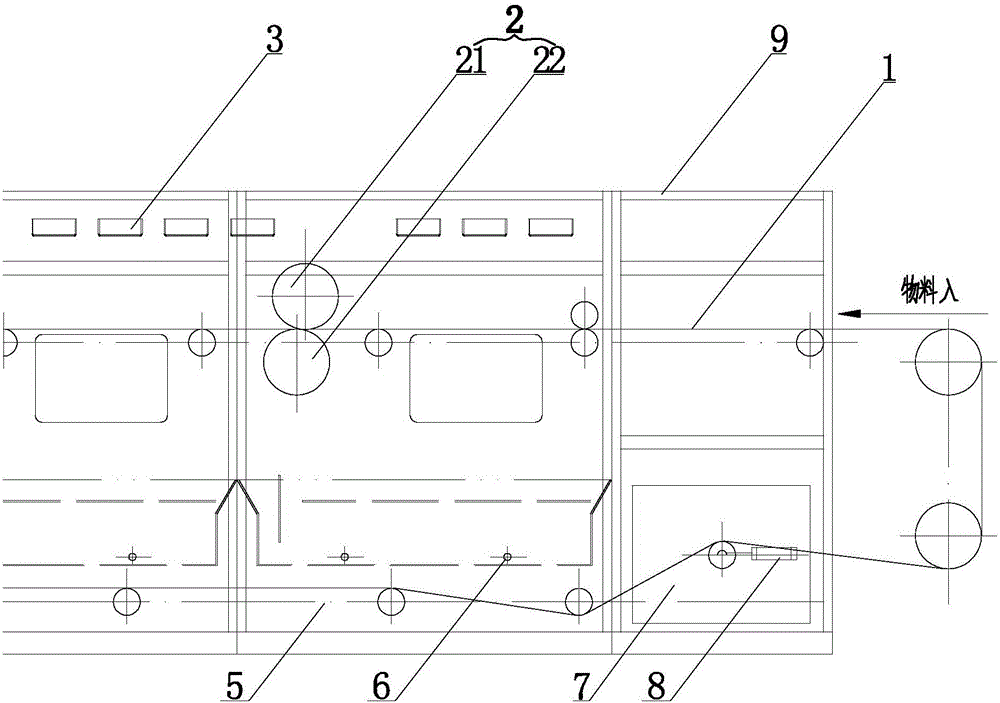

Efficient dyeing device for textile fabric production line

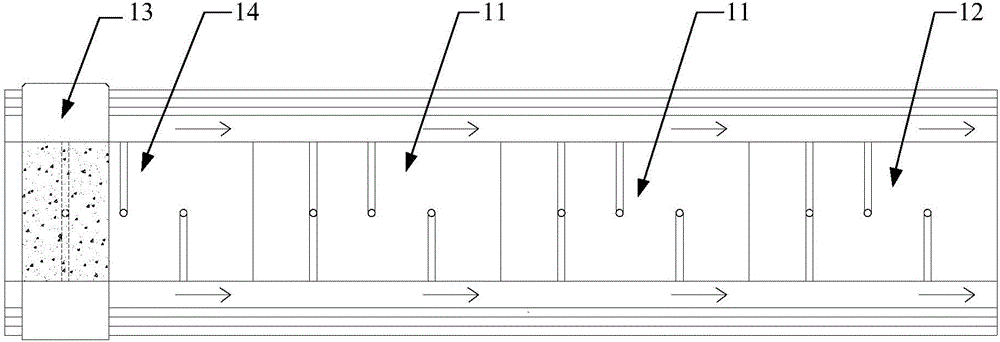

InactiveCN111485342AFully dyedUniform dyeingTextile treatment machine arrangementsTextile treatment carriersPolymer scienceMechanical engineering

The invention belongs to the technical field of textile equipment, and particularly relates to an efficient dyeing device for a textile fabric production line. The equipment comprises a dyeing tank, ahorizontally arranged upper sliding plate is arranged in the dyeing tank in a sliding manner, and a lower sliding plate parallel to the upper sliding plate is arranged below the upper sliding plate;the upper sliding plate and the lower sliding plate are both slidably connected with the inner side wall of the dyeing tank through sliding mechanisms, a plurality of supporting rods are fixedly mounted on the lower surface of the upper sliding plate and the upper surface of the lower sliding plate correspondingly, the supporting rods are distributed at equal intervals in a staggered mode, and guide rollers are mounted at the other ends of the supporting rods; through holes are formed in the upper sliding plate and the lower sliding plate in a penetrating mode, the diameter of an opening in the upper end of each through hole is larger than that of an opening in the lower end of each through hole, and a driving mechanism used for driving the upper sliding plate and the lower sliding plate to slide is arranged in the dyeing tank. Dye can be promoted to alternately flow in gaps between warps and wefts of the textile fabric from top to bottom, the permeation effect of the dye in the textile fabric is improved, and the dyeing effect is better.

Owner:韩兰珍

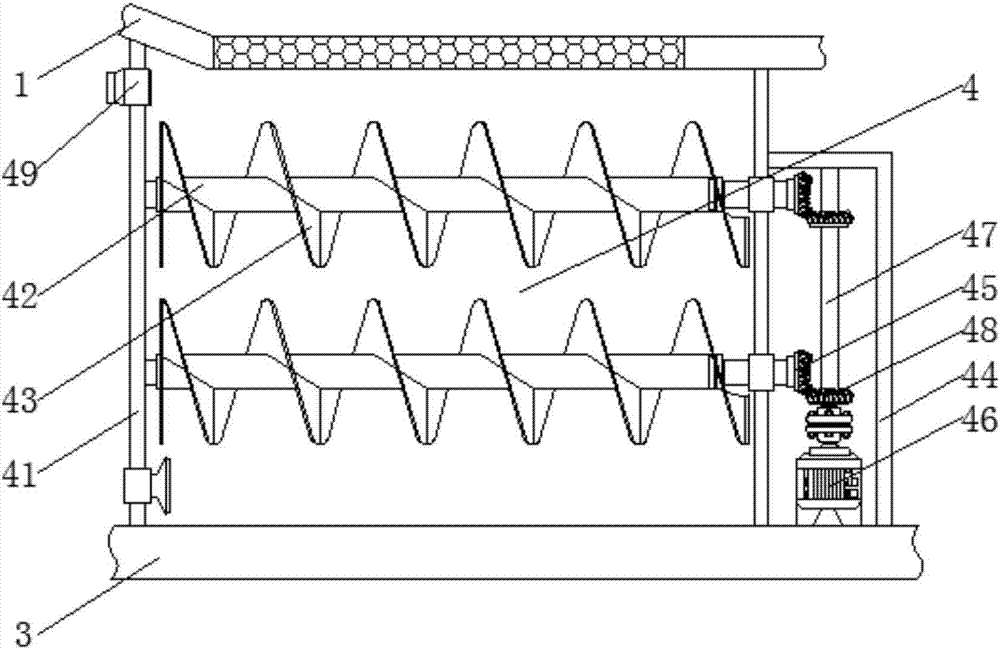

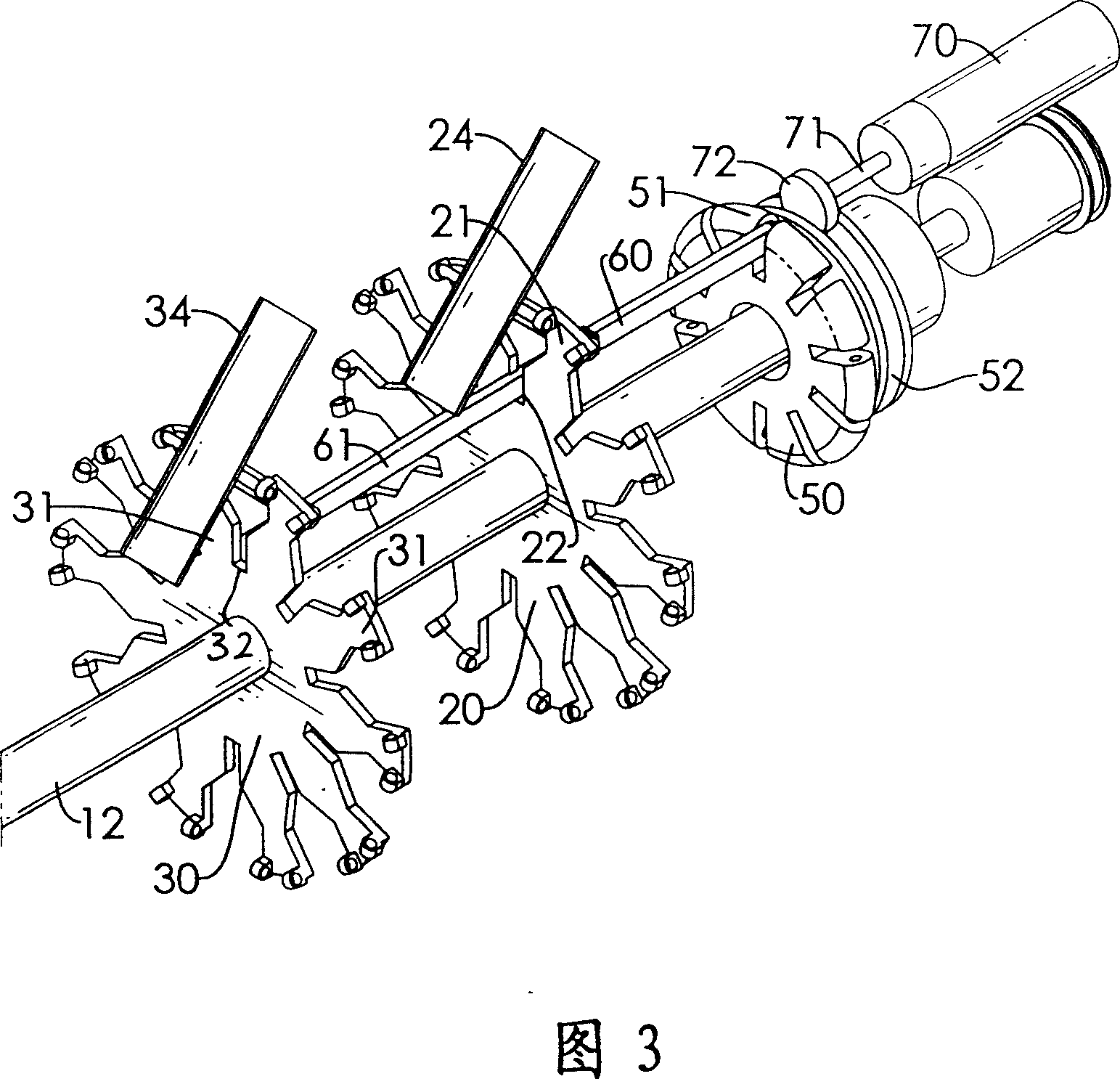

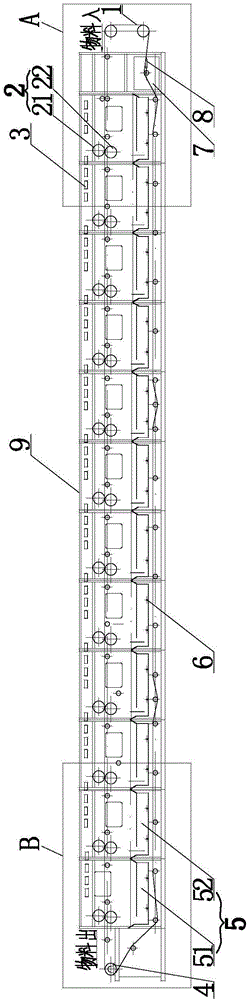

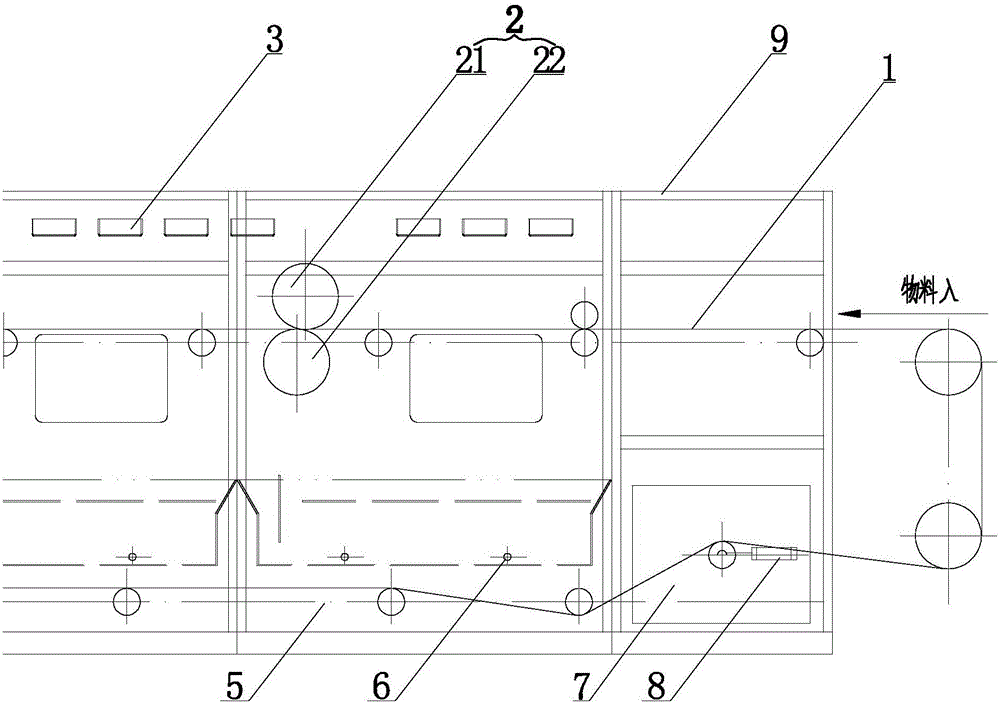

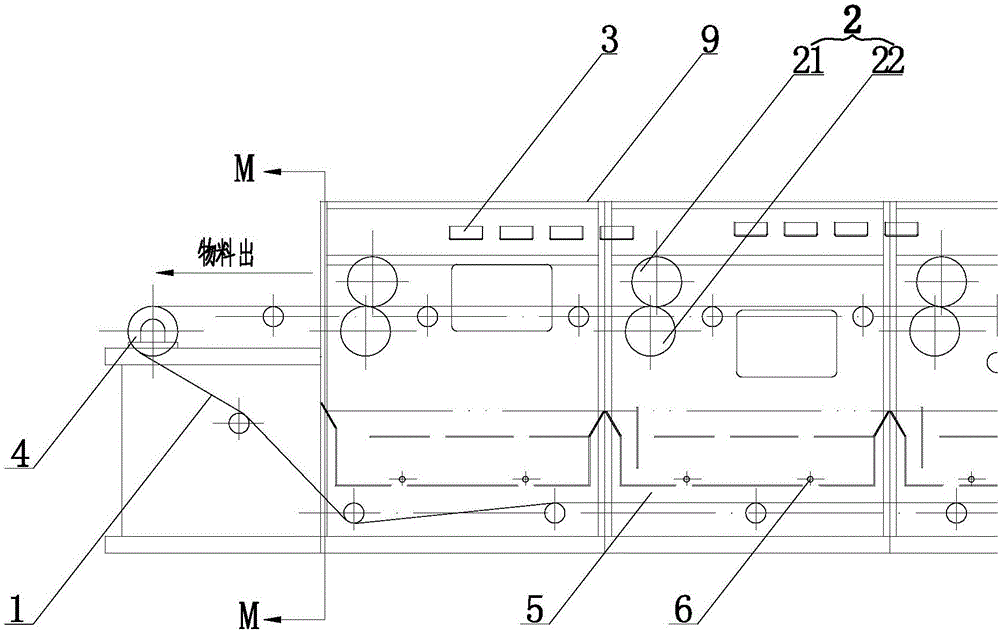

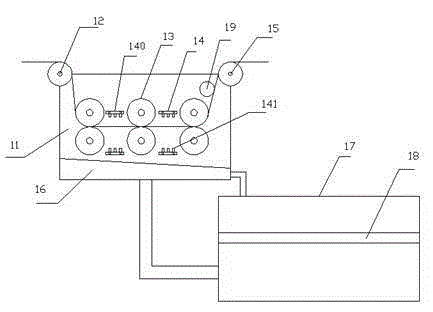

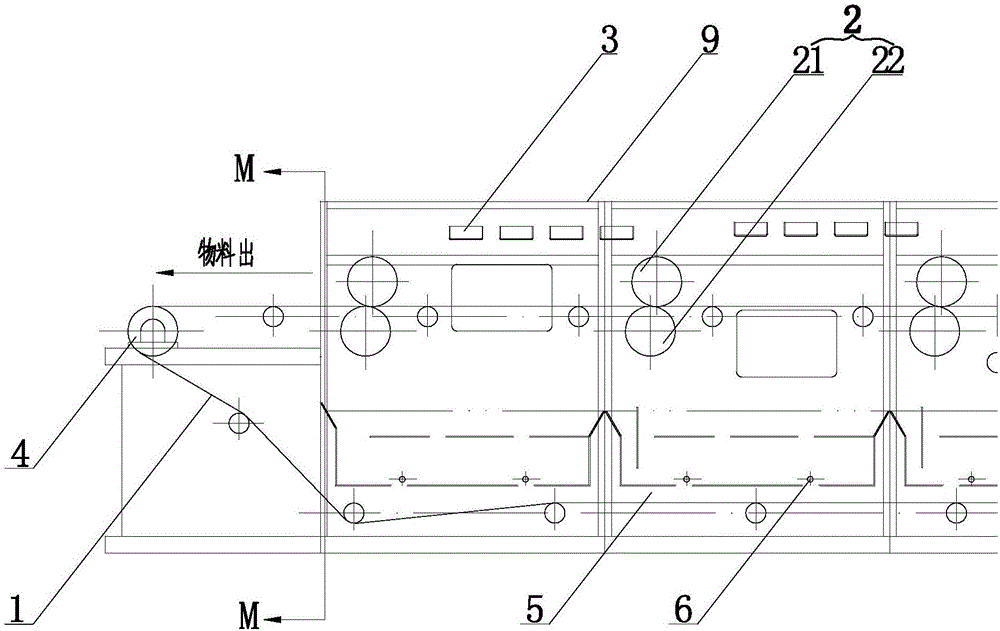

Spraying-type loose fiber treatment technology

ActiveCN106637754AGuaranteed treatment effectFully dyedTextile treatment containersTextile treatment machine arrangementsFiberTherapeutic effect

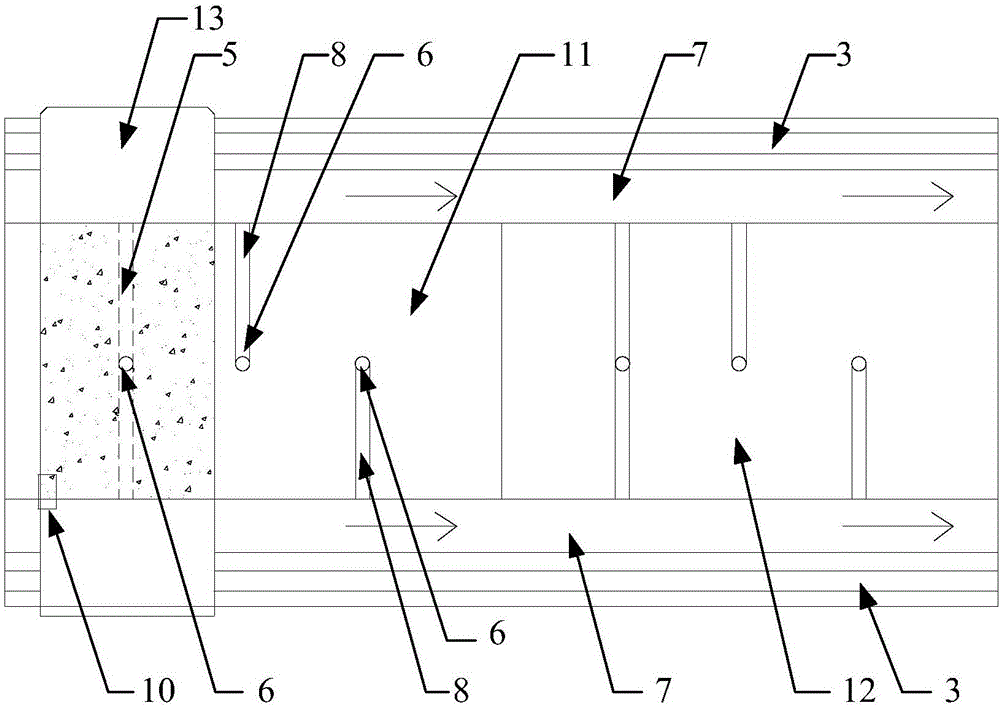

The invention relates to a spraying-type loose fiber treatment technology, and belongs to the technical field of loose fiber treatment. Loose fibers to be treated are placed on a treatment net, a plurality groups of rollers are arranged in the treatment net advancing direction, the rollers comprise the upper rollers and the lower rollers, the upper rollers and the lower rollers are arranged over and under the treatment net respectively, the central axes of the upper rollers and the central axes of the lower rollers are staggered, the central axes of the upper rollers penetrate through the lower rollers, the rotating direction of the upper rollers is opposite to that of the lower rollers, and then the loose fiber treatment net is dragged to advance; treatment liquid is sprayed downwards from the position over the upper rollers, and the loose fibers on the treatment net are delivered out after being treated. The spraying-type loose fiber treatment technology is applied to the processes of loose fiber dyeing, color fixing, cleaning, softening and the like and has the advantages of being low in energy consumption, large in treatment quantity, good in treatment effect and the like.

Owner:绍兴国周针织科技有限公司

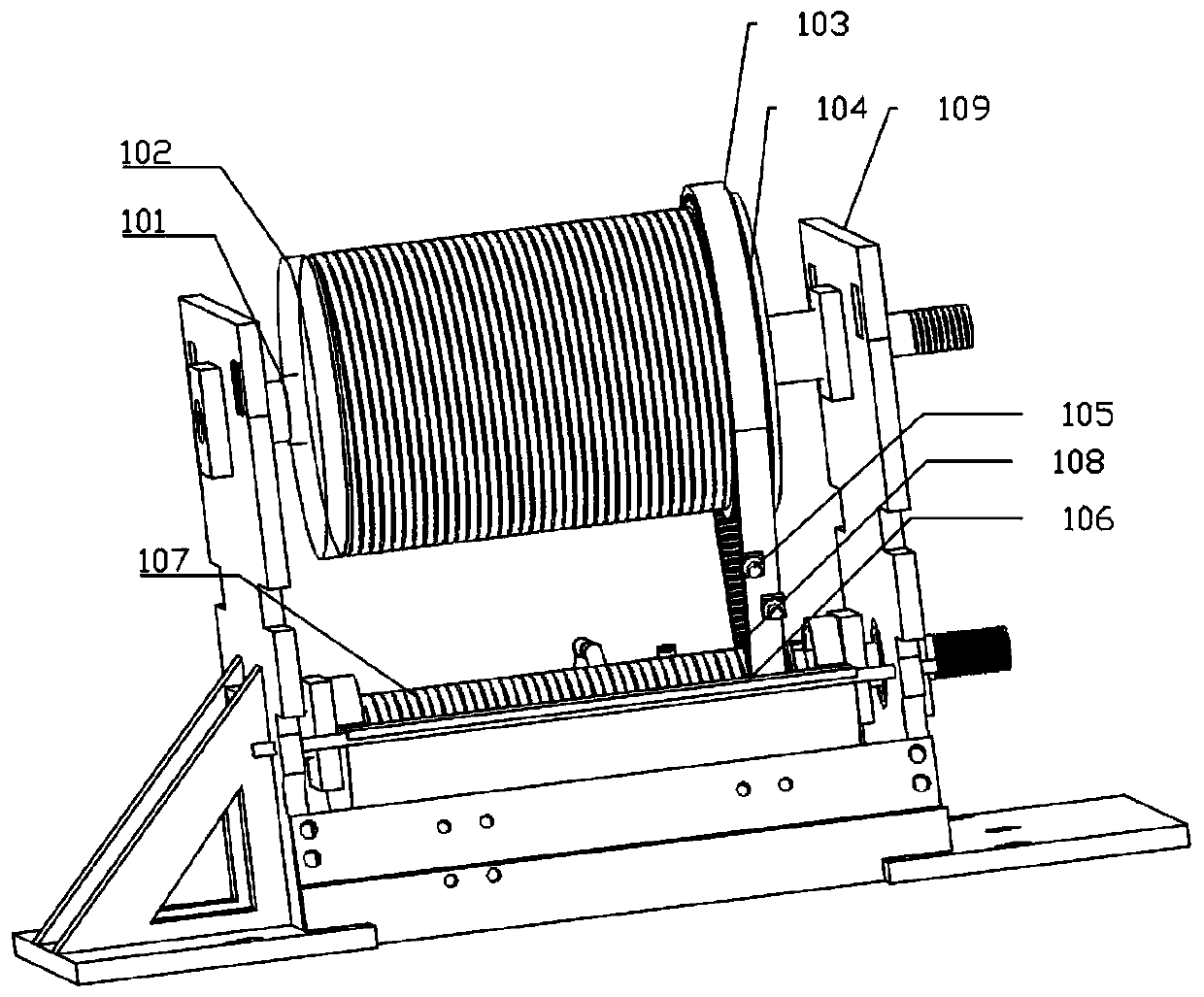

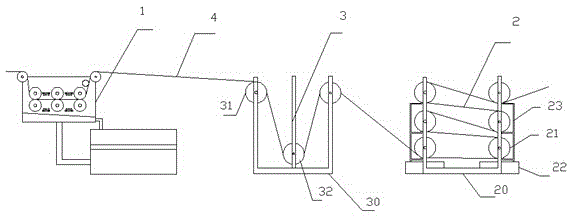

Intelligent equipment for dyeing and sizing plurality of single yarns or plied yarns

ActiveCN111519366AAchieve dyeingEasy to controlTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsProcess engineeringYarn tension

The invention discloses intelligent equipment for dyeing and sizing a plurality of single yarns or plied yarns. The intelligent equipment comprises a dye liquor distributing and heating cylinder, a yarn feeder, a yarn tension pretensioner, an automatic dyeing and yarn arranging mechanism, an automatic dye vat adjusting mechanism, an automatic sizing mechanism and an automatic drying and yarn arranging mechanism, the dye liquor distributing and heating cylinder is used for storing dye liquor and can be used for heating the dye liquor and detecting the concentration of the dye liquor; the yarn feeder is used for fixing the initial position of the yarn and guiding the yarn; the yarn tension pretensioner is used for tensioning and guiding yarns; the automatic dyeing and yarn arranging mechanism can be used for automatically arranging yarns; the automatic sizing mechanism is used for automatically sizing yarns; and the automatic drying and yarn arranging mechanism can be used for drying andarranging sized yarns. According to the intelligent equipment, the technical problem of size dyeing of a plurality of single yarns or plied yarns in a short process is solved, the size dyeing processrequirements of different yarns are met by adjusting the rotating speed of the automatic yarn arranging mechanism for yarn dyeing and the number of thread turns of the lead screw, and the problems ofhigh cost and serious waste in the sample making stage of yarn products are solved.

Owner:HUNAN INSTITUTE OF ENGINEERING

Preparation method of jujube flower paraffin slices

InactiveCN108333013AFully dyedClear organizational structurePreparing sample for investigationParaffin waxMegaspore

The invention provides a preparation method of jujube flower paraffin slices, and belongs to the technical field of paraffin slices. The preparation method comprises the following steps that (1) jujube flower buds are fixed; the jujube flower buds have one stem segment with the length being 0.3 to 0.5cm; (2) dehydration; (3) first transparency treatment; (4) second transparency treatment; (5) waxing; (6) embedding; (7) wax trimming; (8) slicing; (9) slice unfolding; (10) dewaxing; (11) rehydration; (12) secondary rehydration; (13) dyeing; (14) slice covering and slice sealing. The preparationmethod of the jujube flower paraffin slices provided by the invention has the advantages that the complete longitudinal section of the megaspore can be obtained; further, the jujube flower cellular morphology and the development change of the megaspore inside cell and tissue structures can be conveniently observed; meanwhile, the basic rule in the megaspore development structure change and reproduction process can be obtained through observing the jujube flower paraffin slices.

Owner:BEIJING FORESTRY UNIVERSITY

Device for conducting salt-free dyeing on cotton textiles without scouring and bleaching by adopting activated dye

InactiveCN109402907AEasy to dryPrevent precipitationTextile treatment containersLiquid/gas/vapor removal by squeezing rollersSalt freePulp and paper industry

The invention discloses a device for conducting salt-free dyeing on cotton textiles without scouring and bleaching by adopting activated dye. The device comprises a dip dyeing device, an extruding device and a drying device, the dip dyeing device, the extruding device and the drying device are successively arranged, and the dip dyeing device comprises a dyeing pond; a groove is formed in the dyeing pond, two fixed plates are fixedly and symmetrically connected to the side wall of the groove, and first guide rollers are rotatably connected to the ends, away from one end of the bottom side wallof the groove, of the two fixed plates. Through mutual effect of the first guide rollers and second guide rollers, a woven fabric passes through the inside of the dyeing pond to be subjected to dip dyeing, through extruding of two extruding rollers, excess water of the fabric after dip dyeing is extruded out, the woven fabric enters into a shell body through an inlet and is wound on a heating roller to be ironed, and therefore wrinkles generated from extruding of the fabric are ironed flat, and the fabric is more attractive; through a draught fan and a fan cover, the upper and lower sides of the fabric are blown by air, so that the fabric is dried.

Owner:宁建阳

A non-woven fabric dyeing device for garment production

InactiveCN106811887BEasy to addEasy to take outTextile treatment machine arrangementsTextile treatment carriersEngineeringNonwoven fabric

The invention relates to a non-woven fabric dyeing device, in particular to a non-woven fabric dyeing device for garment production. The technical problem to be solved by the invention is to provide a non-woven fabric which is convenient to take and dye and the non-woven fabric dyeing device for garment production which enables the woven-woven fabric to be dyed uniformly. In order to solve the problem, the non-woven fabric dyeing device for garment production provided by the invention comprises a dyeing box, a first sliding rail, a first sliding block, a lifting mechanism, first connecting rods and the like; the inner right wall of the dyeing box is connected with the first sliding rail, the first sliding rail is connected with the first sliding block; the inner left wall of the dyeing box is connected with the lifting mechanism, the lifting mechanism and the first sliding block are respectively connected with the first connecting rods, and each first connecting rod is connected with a first bearing seat. According to the non-woven fabric dyeing device for garment production designed in the invention, the device is provided with the lifting mechanism, so that a roller can move up and down, undyed non-woven fabric is conveniently to add and dyed non-woven fabric is convenient to take.

Owner:广州腾宏纺织服装有限公司

Dyeing and drying device for cotton yarn processing

ActiveCN112746411AImprove dyeing qualityOptimize internal structureTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsElectric machineryDyeing

The invention discloses a dyeing and drying device for cotton yarn processing. The dyeing and drying device comprises a supporting mechanism, an adjusting mechanism and a controller; the supporting mechanism comprises a shell, a dyeing barrel, a drainage pipe, a valve, a drying housing, air outlet holes, an activated carbon filter screen, an air inlet hole, a housing door and an observation window; the lower left part of the dyeing barrel is connected with the drainage pipe; a drying mechanism is connected to the right side of the drying housing; the housing door is rotatably connected to the front side of the drying housing; a fixing block is arranged in the drying housing; and a motor is arranged in a motor groove. According to the dyeing and drying device for cotton yarn processing, the motor is arranged, the motor can drive a yarn roll on a dyeing rod to rotate in the dyeing barrel, so that the yarn roll can be soaked and dyed more sufficiently, and the dyeing quality of the device is improved; and meanwhile, a supporting frame is arranged, and the top of the dyeing barrel can be covered with the supporting frame, therefore, random splashing of the dyeing liquid during rotation dyeing of the yarn roll is conveniently prevented, and the internal structure of the device is conveniently optimized.

Owner:宿迁至诚纺织品股份有限公司

Textile Dyeing Unit

ActiveCN108221230BPrevent extrusionSlide to achieveLiquid/gas/vapor removalTextile treatment machine arrangementsStructural engineeringTextile dyeing

The invention relates to the technical field of textile processing and discloses a textile dyeing device. The textile dyeing device comprises a dyeing box, wherein a first sliding chute and a second sliding chute are formed in the dyeing box, the first sliding chute is slidably connected with a first sliding block, the second sliding chute is slidably connected with a second sliding block, two material guiding rollers are slidably connected in the dyeing box, a limit slot is formed in each material guiding roller, an object carrying frame is arranged in each limit slot, a material rolling roller is rotatably connected in each object carrying frame, a fixing mechanism is arranged in the dyeing box, the fixing mechanism comprises two clamping plates, each clamping plate is fixedly connectedwith a wedge rod, each wedge rod is fixedly connected with a connecting rod, two connecting rods are hinged on the inner wall of the dyeing box, two sliding rods are slidably connected in the dyeing box, a first electromagnet is arranged on each sliding rod, and a second electromagnet is arranged on the inner wall of the dyeing box; a discharging hole is formed in the dyeing box, a touch switch isarranged at the discharging hole, the discharging hole is connected with a material guiding plate, the material guiding plate is connected with a hollow elastic filter screen, and a recycling tank isconnected below the elastic filter screen. The textile dyeing device disclosed by the invention can rapidly and uniformly carry out dyeing.

Owner:NINGBO WENZE TEXTILE CO LTD

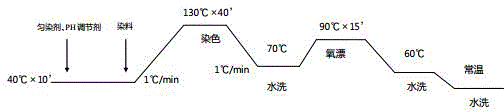

CVC knitted fabric dyeing and finishing method

InactiveCN104790225AUniform coloringFully dyedHeating/cooling textile fabricsDry-cleaning apparatus for textilesDyeingFiber

The invention belongs to the technical field of dyeing and finishing, and especially relates to a CVC knitted fabric dyeing and finishing method. The CVC knitted fabric dyeing and finishing method comprises following steps: dyeing, washing 1, oxygen bleaching, washing 2, washing 3, and setting; wherein in the step of dyeing, bath ratio ranges from 1:8 to 1:10, 0.5 to 1g of a leveling agent is added into each 1L of water, and 0.3 to 0.5g of a pH conditioning agent is added in each 1L of water. In the step of dyeing, a quantified dye is added at a uniform speed, temperature increasing speed is controlled to be 1 DEG C / min, and full level dyeing of two fibers is realized; at different stages, water at different temperature is used for washing, full washing is performed, so that cloth coloring uniformity is ensured; and setting temperature is determined to be 140 DEG C, and setting speed is determined to be 30m / min via repeated experiments, so that the best dyeing effect is obtained.

Owner:吴江新生针纺织有限责任公司

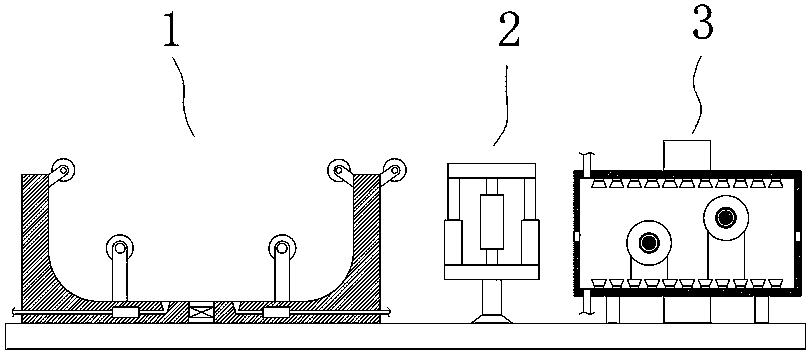

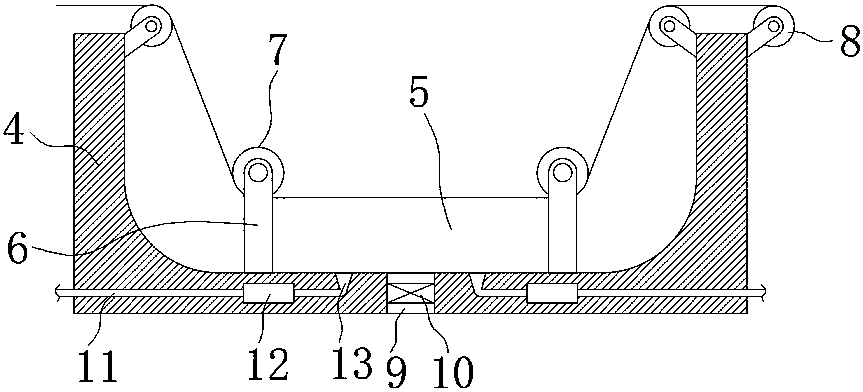

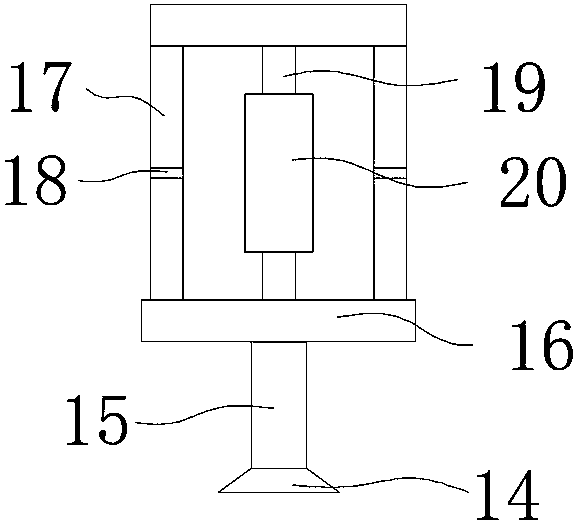

Cloth dyeing and shaping device

InactiveCN105133236AAvoid affecting the setting effectAvoid wastingHeating/cooling textile fabricsTextile treatment by spraying/projectingPulp and paper industryDyeing

The invention discloses a cloth dyeing and shaping device comprising a dyeing machine, a cloth storing machine and a shaping machine. The cloth storing machine includes a cloth storing machine rack, two cloth storing fixed rollers and a cloth storing movable roller which is arranged therebetween. The cloth storing movable roller is driven by a servo motor to move up-and-down on the cloth storing machine rack. The device ensures a whole dyeing and shaping process to be carried out continuously, thereby increasing work efficiency.

Owner:HUZHOU HESHENG DYEING & FINISHING

Dyeing device for cloth production

InactiveCN107988735AShorten drying timeAvoid wastingLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsEngineeringTextile dye

The invention belongs to the technical field of cloth production and particularly relates to a dyeing device for cloth production, comprising a box body. A first transverse plate and a second transverse plate are fixedly connected to the left and right walls of the box body respectively; the upper end of the first transverse plate is provided with a feed mechanism; a discharge mechanism and a drying mechanism are arranged at the upper end of the second transverse plate; the left and right walls of the box body are provided with a feed port and a discharge port respectively; the upper end of the box body is provided with a liquid inlet, the sidewall of the box body is provided with a liquid outlet, a seal plug is arranged in each of the liquid inlet and the liquid outlet, a guide mechanismis arranged in the box body, the guide mechanism is in transmission connection with the feed mechanism through a first transmission mechanism, an expansion mechanism and a compaction mechanism are arranged in the box body, and the compaction mechanism is in transmission connection with the discharge mechanism through a second transmission mechanism. The dyeing device for cloth production has the advantages that the expansion mechanism allows dyeing to be more thorough and comprehensive; the drying mechanism allows dyed cloth to be dried; the dyeing device is convenient to operate, low in timeand manpower consumption and lower in production cost.

Owner:安徽省榛瑞塑胶制品有限公司

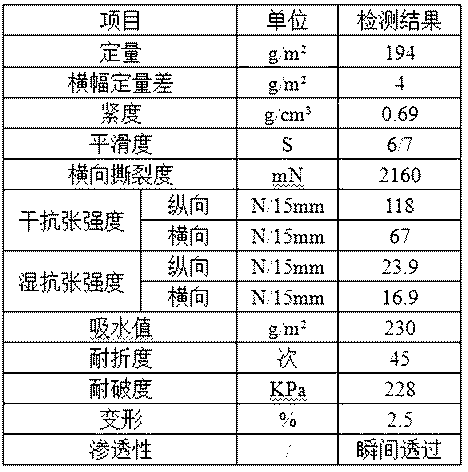

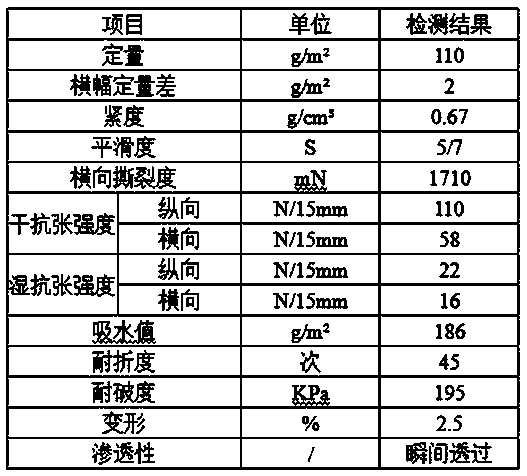

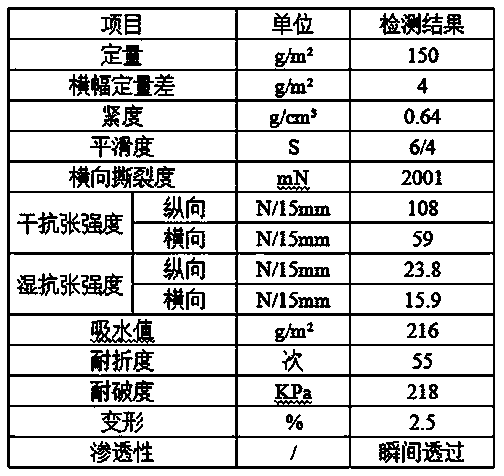

Impregnated white kraft paper and preparation technology thereof

The invention provides impregnated white kraft paper with the fixed quantity of 105-195 g / m<2>, the banner quantitative difference of less than or equal to 5g / m<2>, the tightness of 0.6-0.7 g / cm<3>, the smoothness of 6 / 8S, the transverse tearability of more than or equal to 1600mN, the longitudinal dry tensile strength of more than or equal to 90N / 15mm, the transverse dry tensile strength of more than or equal to 50N / 15mm, the longitudinal wet tensile strength of more than or equal to 20N / 15mm, the transverse wet tensile strength of more than or equal to 15N / 15mm and the water absorption value of more than or equal to 160g / m<2>. A preparation technology of the impregnated white kraft paper comprises the steps of pulping, mixing, carrying out papermaking, rewinding and packaging, wherein a wet strength agent and filler are fed in the papermaking step, so that the quality of the white kraft paper is further improved. The preparation technology of the impregnated white kraft paper is improved, so that the defect of incomplete impregnation is overcome, and the technology has the advantage of evenness in dyeing.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

Method for dyeing textile fabric

InactiveCN107700201AShorten dyeing timeIncrease profitSucessive textile treatmentsSingeingColour fastnessEngineering

The invention discloses a method for dyeing a textile fabric. The method comprises the following steps: soaking the prepared textile fabric in a desizing solution for 2 hours, airing the textile fabric subjected to desizing, tensioning the textile fabric to open width and enabling the fabric to rapidly pass through a singeing frame, cooling the textile fabric, immersing in bleaching liquid, allowing standing still for 2 hours, stirring, taking out the fabric and airing, immersing into a dye vat for dyeing, coloring with reactive dyes, and adding an alkaline agent for fixation. The method disclosed by the invention has the beneficial effects that the dyeing time is shortened, and the colorant utilization rate is improved, so that the textile fabric is fully dyed, and the color fastness is excellent.

Owner:JIANGSU MINGYUAN TEXTILE

Dyeing method for starch cation modified cotton fabric

The invention relates to a starch cationic modified cotton fabric dyeing method, which belongs to the technical field of fabric treatment. The fabric is modified by quaternary ammonium cationic starch, and after cationic modification is carried out by padding-baking, dyeing is carried out. The addition amount of the quaternary ammonium cationic starch is 1-3%owf, and the cationic modification temperature is 60- 100°C, modification time 10‑40 minutes. Applying the application to the treatment of cotton fabrics has the advantages of short process, high color fastness, good wrinkle resistance and the like.

Owner:SHAOXING UNIVERSITY

Preservation and treatment solution of in-vitro specimen for medical research

InactiveCN104798768ASatisfy preservation processing requirementsClear structureDead animal preservationOfficinalisGLYCYRRHIZA EXTRACT

The invention provides preservation and treatment solution of an in-vitro specimen for medical researches and relates to the technical field of treatment and preservation of specimens for medical researches. The preservation and treatment solution is prepared by using the following raw materials in parts by mass: 7 parts of boric acid, 13 parts of galangal, 10 parts of honeysuckle flower, 4 parts of common selfheal fruit-spike, 5 parts of red-rooted salvia root, 8 parts of wild chrysanthemum flower, 12 parts of corns officinalis, 15 parts of jujube and 15 parts of liquorice. According to actual use results, the preservation and treatment solution for histopathological tissue specimens can replace formalin for use. Tissue forms are kept well, the tissues are fully dyed, the microscopic cell structure is clear, the structure is complete and the requirements on thepreservation and treatment of the histopathological tissue specimens can be fully satisfied.

Owner:合肥金域医学检验实验室有限公司

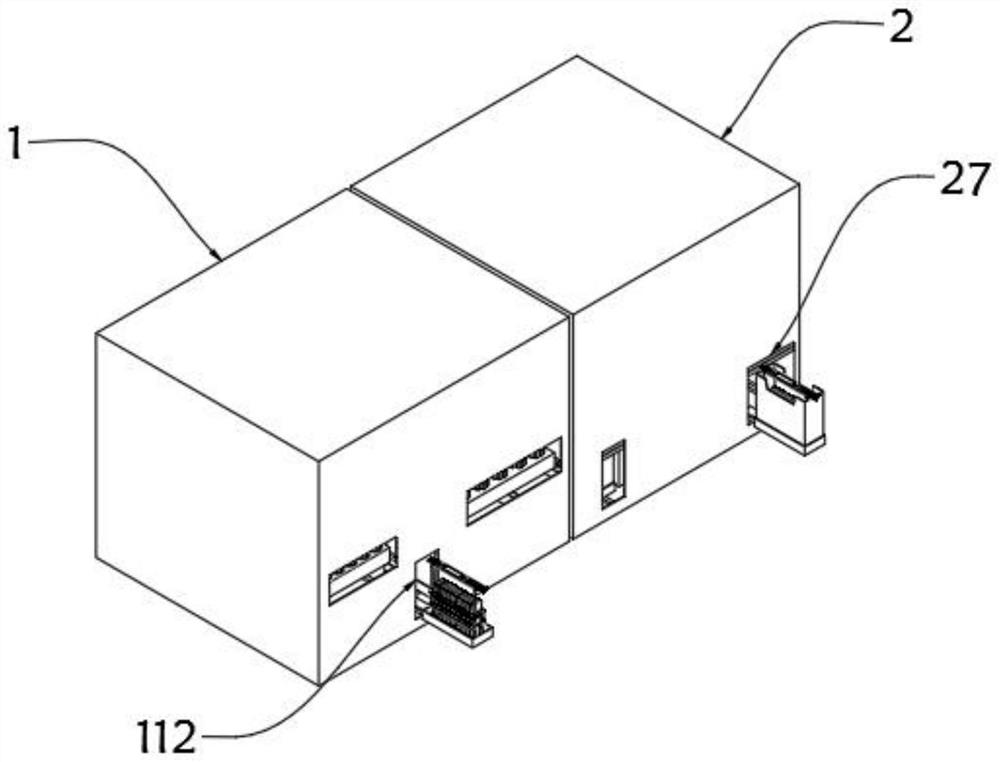

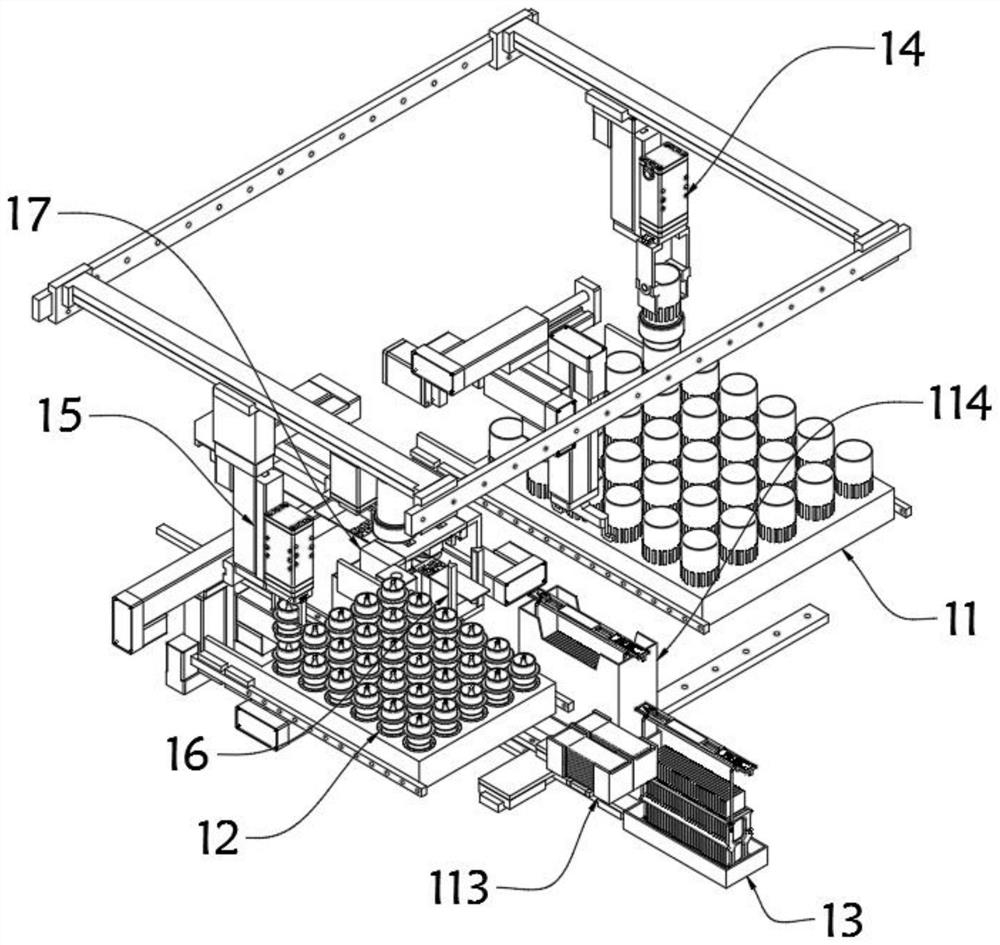

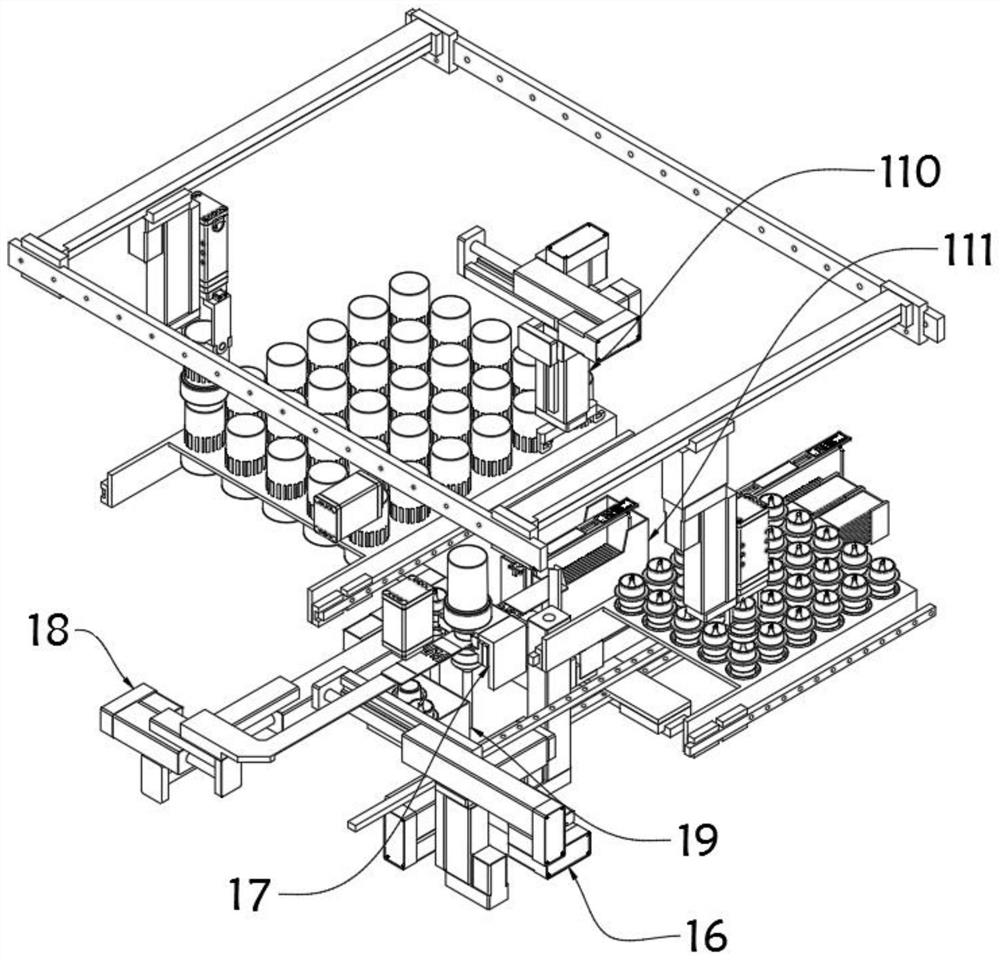

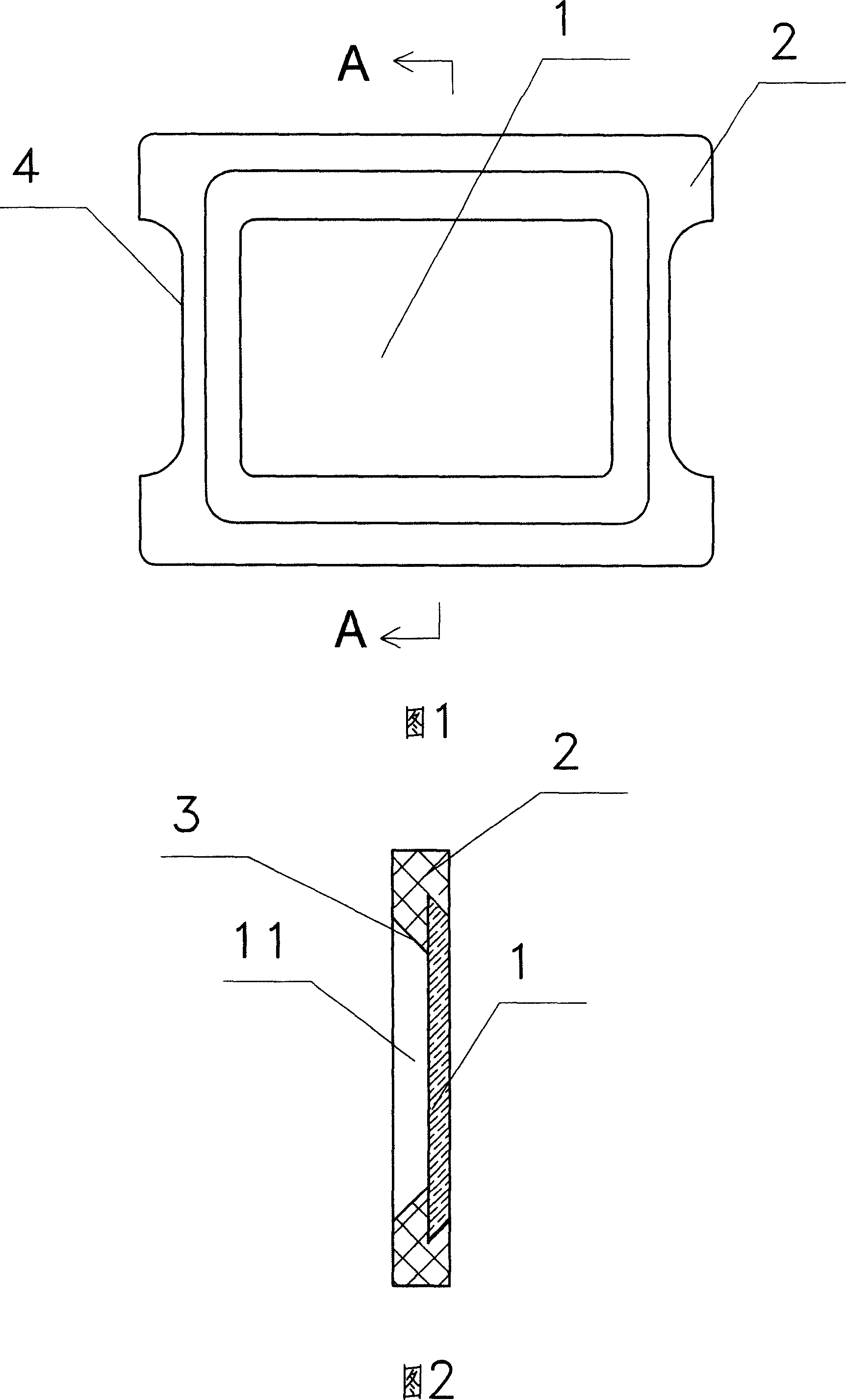

Full-automatic rapid slice-making dyeing machine

PendingCN113533006ANo human intervention requiredConsistent slide codingPreparing sample for investigationTransfer mechanismIndustrial engineering

The invention discloses a full-automatic rapid slide-making dyeing machine which comprises an automatic slide-making mechanism, a multi-dye-vat automatic dip dyeing mechanism and an automatic transfer mechanism, the automatic slide-making mechanism comprises a sample carrier drawer, a filter cup membrane cylinder carrier drawer, a slide rack carrier drawer and a slide carrier drawer, and a sample bottle operation module is arranged above the sample carrier drawer; and a filter cup and membrane cylinder operation module is arranged above the filter cup and membrane cylinder carrying lattice drawer, a clamping jaw assembly is arranged on one side of the slide rack carrying lattice drawer, and a slide making module is arranged on one side of the clamping jaw assembly. According to the full-automatic rapid slide-making dyeing machine, samples and slice-making consumables only need to be loaded on the machine at a time, the machine automatically achieves full-process treatment of recognition, code printing, code scanning, slice making, racking, transferring, dyeing and the like on batch samples, and the full-automatic rapid slice-making dyeing machine is provided with a slice sealing and transferring connector and can be in online operation with slice sealing equipment, and is used for transferring the dyed sample wafer into wafer sealing equipment for wafer sealing treatment. Manual intervention is not needed in the whole process.

Owner:HUBEI TAIKANG MEDICAL EQUIP

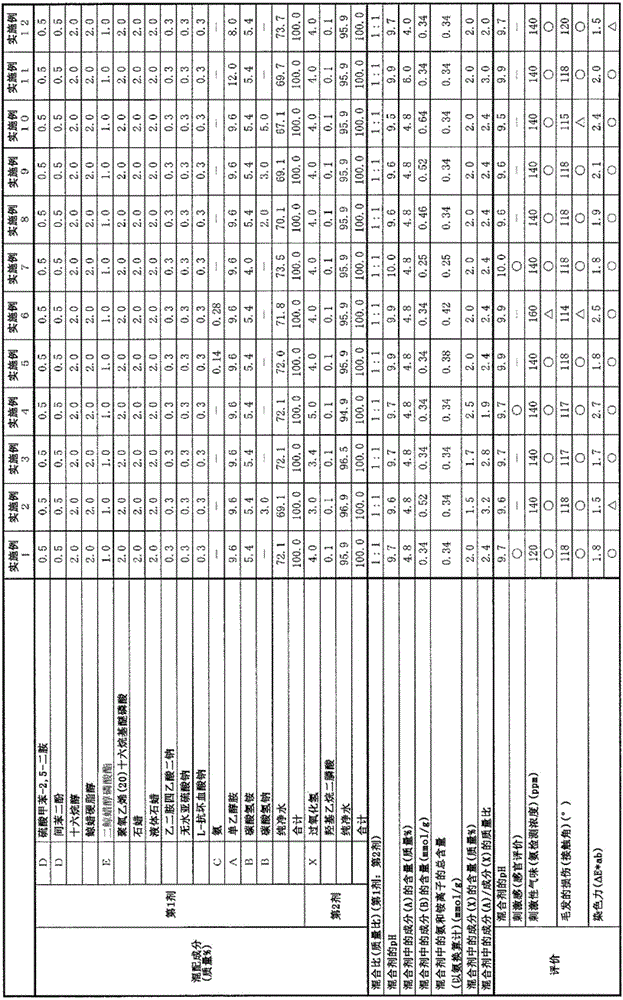

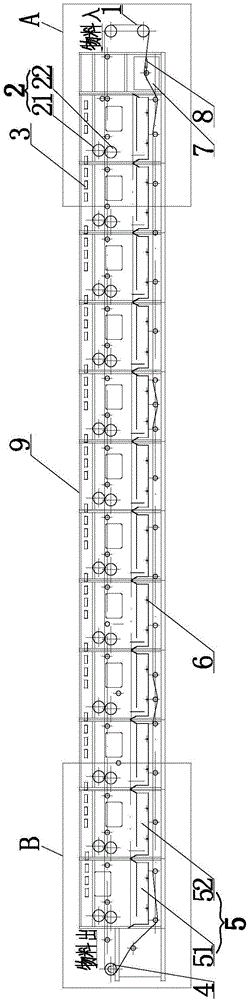

Oxidative hair dye, method for manufacturing mixture for oxidative hair dying, and oxidative hair dying method

ActiveCN106102701AAvoid damageLess irritatingCosmetic preparationsHair cosmeticsIrritationHair streams

Provided is an oxidative hair dye that causes minimal scalp irritation and can reduce irritating odors during use, reduce damage to the scalp and hair, and sufficiently dye hair. This oxidative hair dye contains: a first agent, which includes (A) monoethanolamine or the like, (B) carbonate or the like, (C) ammonia, and (D) an oxidative dye; and a second agent, which includes (X) hydrogen peroxide. In the mixture of the first agent and the second agent, the content of (A) is 4.0-7.0 mass%, the content of (B) is 0.20-0.70 mmol / g, the total content of the ammonia and ammonium ions, in terms of ammonia, is 0.20-0.45 mmol / g, and the content of (X) is at least 1.5 mass% and less than 2.7 mass%.

Owner:MANDOM CORP

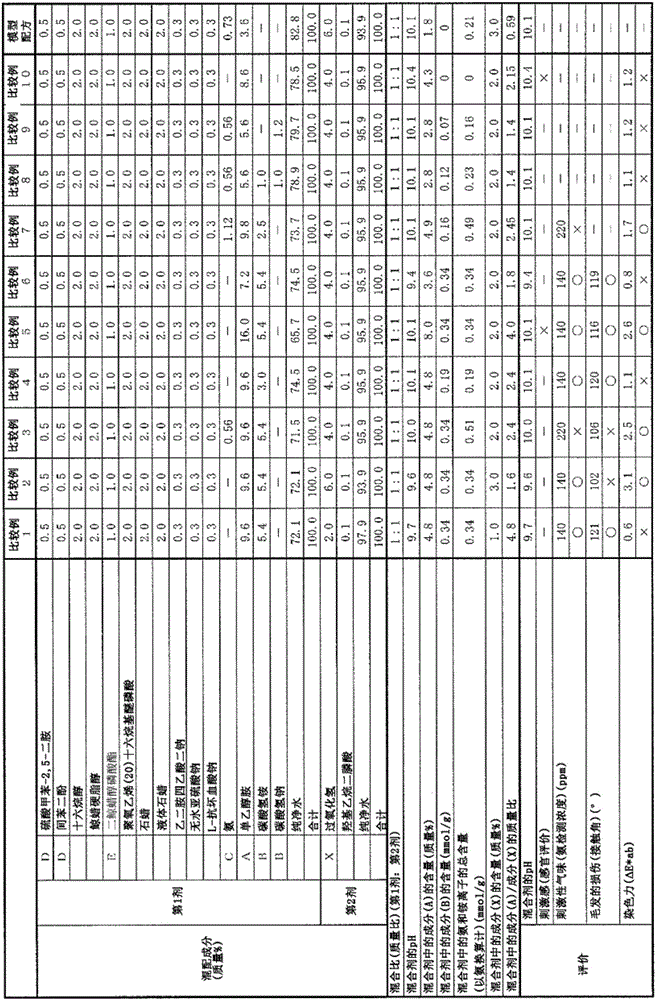

Microscope slide applied for direct microscopy milk somatic cell/bacteria automatic calculating instrument

InactiveCN101013194AImprove chemical reaction processing efficiencyPlay a protective effectMicroscopesBiological testingMicroscope slideDirect microscopy

The invention provides a carrier slide used for directly glass examining milk cells / bacteria automatic counter, which includes the glass, and the said carrier slide has the frame of the glass, the frame thickness greater than the glass thickness. The carrier slide of this invention can apply to the usage of automatic counter. During transmission, the frame has protective effect to the milk sample on the glass, preventing the spillage of the staining liquid during staining and making the milk sample fully staining, and meanwhile, the transmission device for transporting milk sample can use the structure with upper and lower synchronous belt, and making the carrier slide maintaining a correct posture in the transmission, to facilitate the automatic processing of the automatic counter to the carrier slide and milk sample, and the frame and the glass forming a shallow container, making milk sample fully staining, improving the chemical reaction efficiency of the automatic counter.

Owner:HANGZHOU ULTRASUN TECH

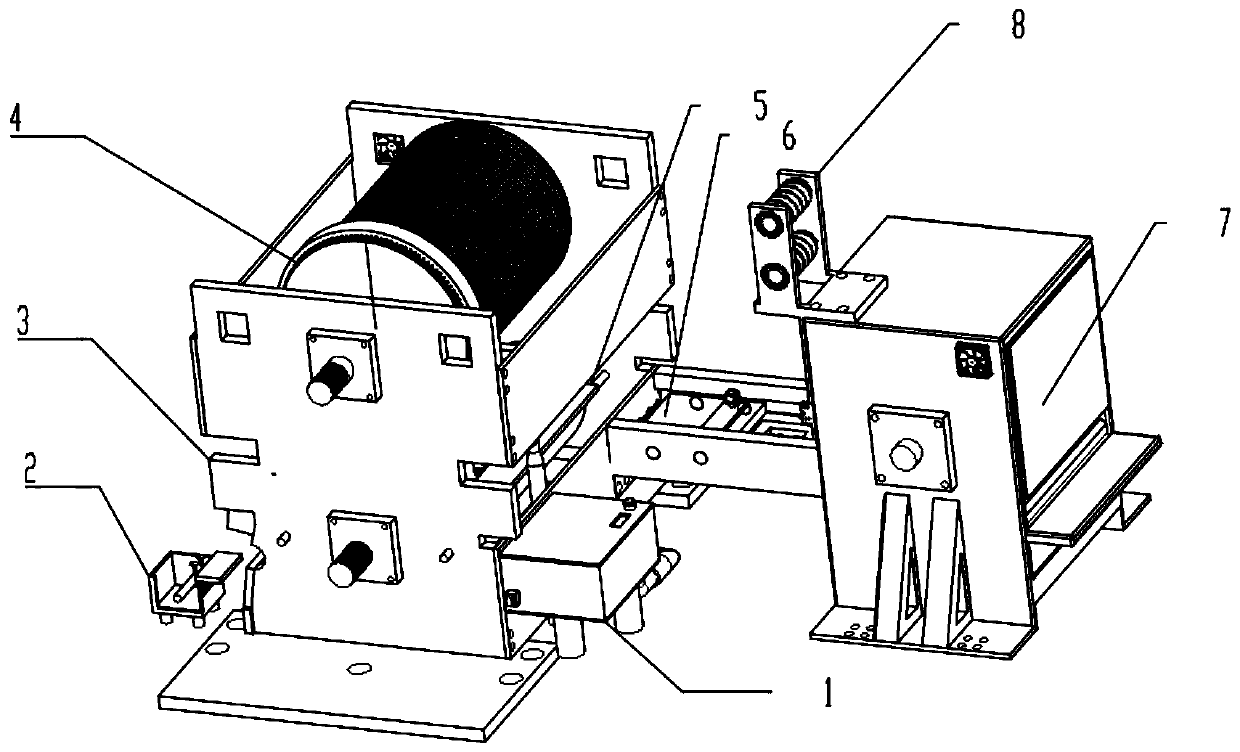

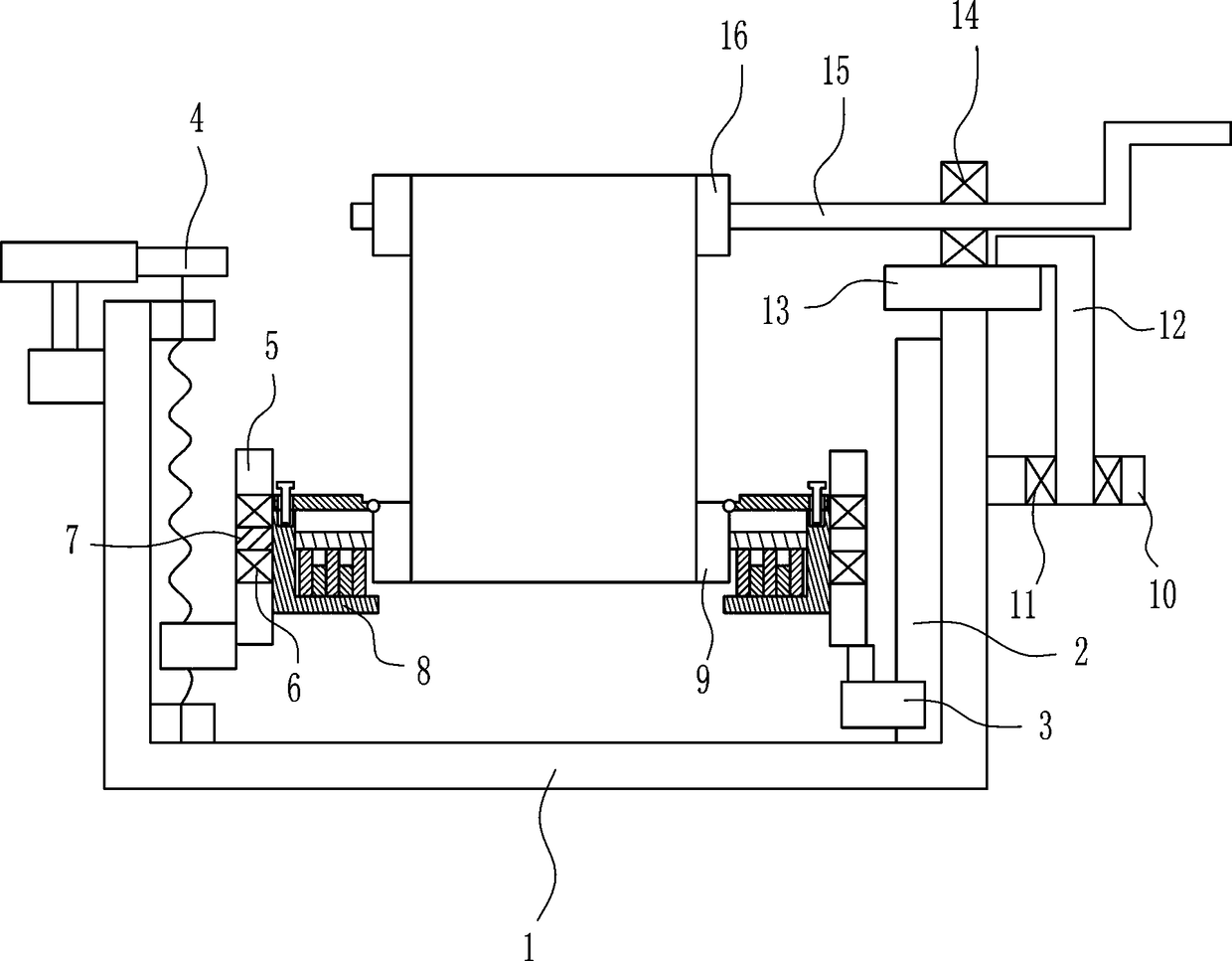

Spraying type loose fiber treatment device

ActiveCN106637755AGuaranteed treatment effectFully dyedTextile treatment containersTextile treatment machine arrangementsTherapeutic effectMechanical engineering

The invention relates to a spraying type loose fiber treatment device, belonging to the technical field of loose fiber treatment. The spraying type loose fiber treatment device comprises a box body, a treatment net, rollers and a spraying mechanism located in the box body, wherein four edges of the box body are sealed and an inlet and an outlet are formed in front and rear ends of the box body; the treatment net is driven by a driving roller and enters from the inlet and exits from the outlet; a plurality of groups of rollers are arranged along the movement direction of the treatment net; the rollers comprise upper rollers and lower rollers, and the upper rollers and the lower rollers are located above and below the treatment net respectively; the middle axis of each upper roller is staggered from the middle axis of each lower roller; the middle axis of each upper roller penetrates through the corresponding lower roller, and rotary directions of the upper rollers and the lower rollers are opposite; and a treatment solution in the spraying mechanism is sprayed downwards from the upper side of the treatment net. The spraying type loose fiber treatment device provided by the invention is applied to procedures of dyeing, color fixation, washing, softening and the like of loose fibers and has the advantages of low energy consumption, great treatment amount, good treatment effect and the like.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

Dyeing process of bamboo viscose fiber

InactiveCN106283461AGood moisture absorption and air permeabilityHigh removal rateTextile storage in superimposed formBiochemical fibre treatmentFiberSlurry

The invention discloses a dyeing process of bamboo viscose fiber, and relates to the technical field of bamboo fiber fabric production. The process comprises five process steps of singeing, pretreatment, dyeing, post treatment and pre-shrinkage. By optimizing the speed and the gasoline quantity, the singeing effect is good; in the pretreatment process, a mixed solution of caustic soda and hydrogen peroxide is used as a rinsing solution; the oxygen bleaching effect is improved; in addition, through the later stage puffing, swelling and fabric slurry and impurity degradation, cotton impurities are removed through steam steaming and water washing; the cotton impurity removal rate is high; the cloth damage is small; in the dyeing work procedure, the dyeing is sufficient; the effect is good; in addition, a cold batch dyeing process is used; the energy source consumption is reduced; the production efficiency is improved; the whole technical process is simple; the technical parameter controllability is good; the texture of the dyed fabric is soft; the moisture absorption and ventilation performance is good.

Owner:ANQING XUANZHU TECH

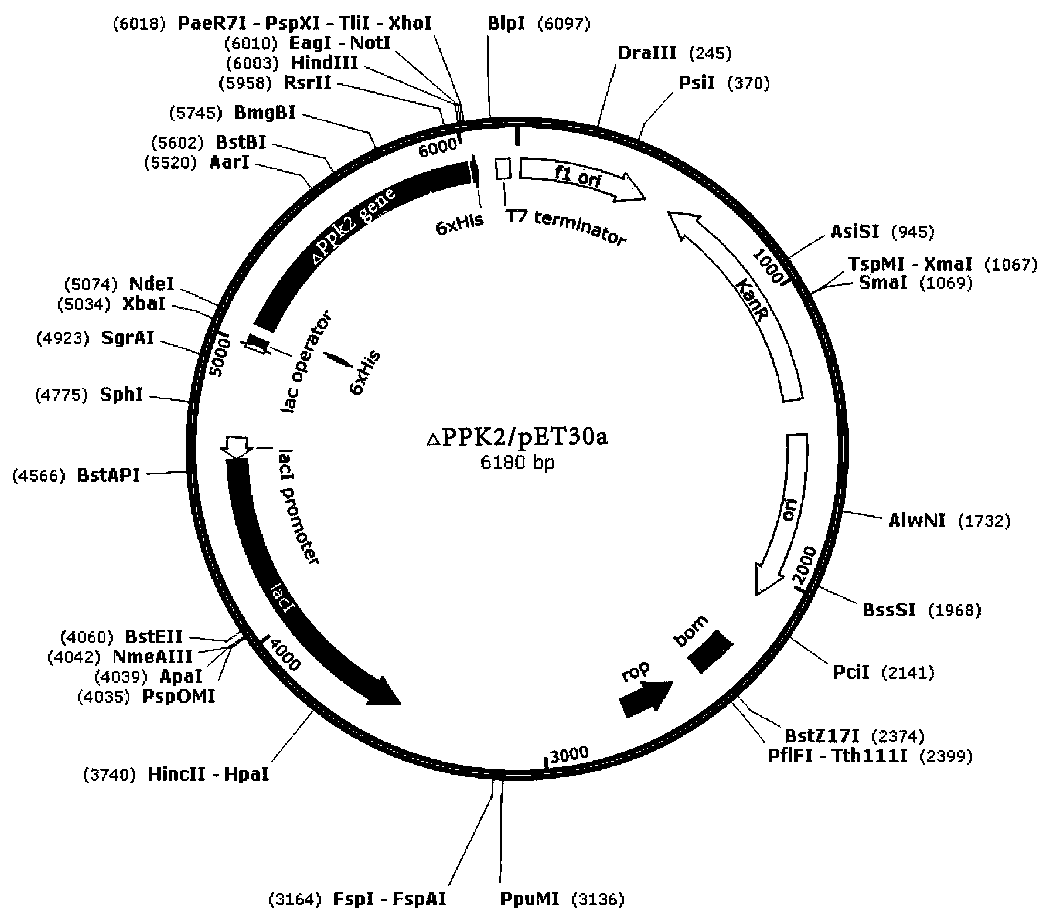

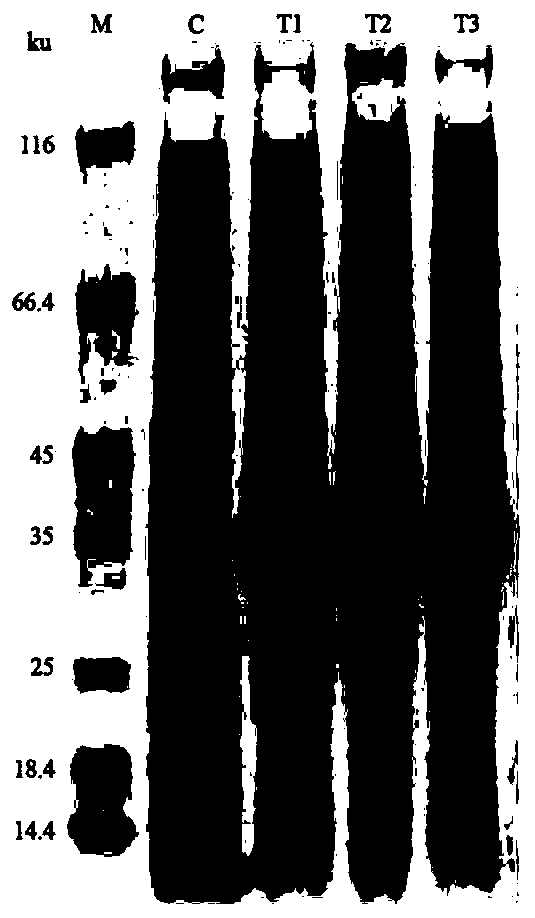

PPK2 protein, and application of PPK2 protein as polyacrylamide gel electrophoresis 35kd standard substance

The invention discloses a PPK2 protein, and an application of the PPK2 protein as a polyacrylamide gel electrophoresis 35kd standard substance. A ppk2 gene is inserted into a prokaryotic expression vector pET30a by using NdeI and Hind III, the obtained recombinant expression vector is transferred into an Escherichia coli BL21 (DE3) strain through a physical method, IPTG is used to induce trial expression of the target protein PPK2 at 37 DEG C, 25 DEG C and 16 DEG C, and the obtained expression product is identified and analyzed through SDS-PAGE electrophoresis and Western blotting; and finally, amplification culture is carried out by utilizing 3 L of an expression bacterial liquid, and the expression product is separated and purified through a Ni-IDA affinity chromatographic column, an anion exchange chromatographic column and a gel filtration chromatographic column in sequence. Results show that a large intestine prokaryotic expression system can be stably and efficiently expressed under the induction of the IPTG with the temperature of 16 DEG C and the final concentration of 0.2 mM.L<-1>, and the PPK2 protein has the advantages of specific charged property, existence in a monomerform in a solution, stable properties, non-degradability and long half-life period, and has an application prospect as the polyacrylamide gel electrophoresis 35 kd standard substance.

Owner:TIANJIN VOCATIONAL INST

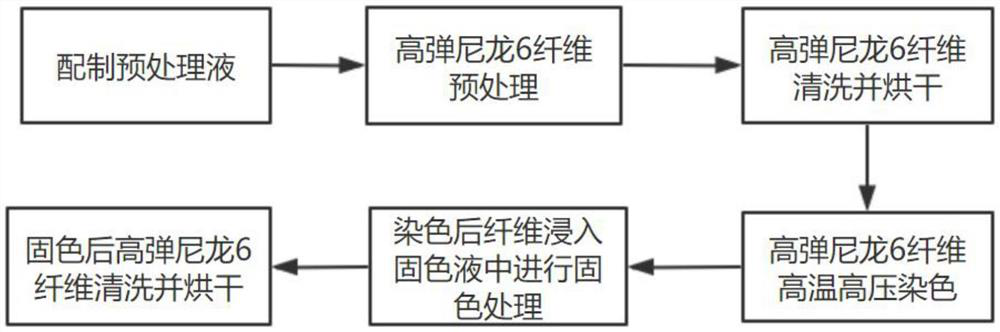

Dyeing method capable of improving dyeing performance of high-elastic nylon 6 fibers

PendingCN113073482AFully dyedImprove color fixationDyeing processColour fastnessEnvironmentally friendly

The invention discloses a dyeing method capable of improving the dyeing performance of high-elastic nylon 6 fibers. The method comprises the steps of dyeing pretreatment, a dyeing process and a color fixing process. According to the dyeing method, the dyeing performance of the high-elastic nylon 6 fibers can be effectively improved, the dyeing rate, the fixation rate, the K / S value and the level dyeing performance of the fibers are remarkably improved, and the washing color fastness, the rubbing color fastness and the light color fastness of fabric are improved. The process is simple and efficient, the usage amount of dye can be remarkably reduced, the method is environmentally friendly, the adopted reagent is efficient in dyeing, bright in color and not prone to fading, and the efficient and lasting dyeing effect can be achieved. On the basis that the dyeing performance of the high-elastic nylon 6 fibers is enhanced, the simplicity, high efficiency and environmental friendliness of the dyeing process are further improved, and wide application of the high-elastic nylon 6 fibers and fabric can be promoted.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

Anti-precipitation elastic jacquard screen fabric printing device and process

ActiveCN110117881AEasy to usePrevent precipitationFibre treatmentLiquid/gas/vapor removal by squeezing rollersEngineeringPrecipitation

The invention discloses an anti-precipitation elastic jacquard screen fabric printing device and process. The device comprises a dye vat, the top end of the dye vat is provided symmetrically in a penetrating mode with a first fabric feeding notch, the inner bottom of the dye vat is provided with a bottom separating plate corresponding to the bottom of a top separating plate, the top end of the topseparating plate is provided with a second fabric feeding notch formed in a penetrating mode and corresponding in position to the first fabric feeding notch, and the middle of each fixing shaft is rotatingly connected in a sleeve mode with a guide roller. The anti-precipitation elastic jacquard screen fabric printing device is scientific, reasonable, safe and convenient to use; dye liquor is pumped out from the bottom of the bottom separating plate by a suction pump and then flows via a liquor inlet branch pipe back to between the top separating plate and the bottom separating plate, jacquardscreen fabrics are driven by the two guide rollers and accordingly can be fully dyed between the two separating plates, and through circular flow of the dye liquor, precipitation between the top separating plate and the bottom separating plate can be avoided, and further insufficient dyeing or poor appearance of the jacquard screen fabrics due to precipitation can be avoided.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com