Patents

Literature

266 results about "Vat dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vat dyes are a class of dyes that are classified as such because of the method by which they are applied. Vat dyeing is a process that refers to dyeing that takes place in a bucket or vat. Almost any dye, including fiber-reactive dyes, direct dyes, and acid dyes, can be used in a vat dye. Cotton, wool, leather and other fibers can be all dyed with vat dyes. The original vat dye is indigo, once obtained from plants but now produced synthetically.

Vat dye dyeing method using supercritical CO2 fluid

The invention is applicable to the field of dyeing technologies, and provides a vat dye dyeing method using a supercritical CO2 fluid. The vat dye before a reduction reaction is dissolved by a supercritical CO2 fluid; polyester fiber, cellulosic fiber, protein fiber and fabric thereof are dyed; meanwhile, a cosolvent is added to improve the solubility of the vat dye in the supercritical CO2 fluid, the dyeing depth and the like; moreover, a natural fiber swelling agent is added for the vat dye to enter the fiber for dyeing, thereby greatly saving the water resources and realizing a perfect dyeing effect.

Owner:CHENGDU TEXTILE COLLEGE

Process for making anti-infrared multifunctional camouflaged color cloth

InactiveCN101397708AShort production processHue once goodFibre treatmentSingeingFiberTextile printer

The invention relates to a textile printing and dyeing technique, in particular to a manufacturing technique of an infrared ray resistant multi-functional camouflage fabric. The technique flow is as follows: original cloth seaming, singeing, old rolling, 180 pre-treatment, shaping, mercerizing, ground dyeing, pattern printing, baking, aging, stentering of post treatment, examination and acceptance; wherein, the ground dyeing flow is as follows: padding liquor, two groups of infrared rays and drying; a formula adopted in the ground dyeing flow comprises 2g / l to 10g / l of dispersion dyes, 5g / l to 15g / l of vat dyes and 0.01g / l to 1.0g / l of infrared ray resistant regulators; the formula of pattern printing is as follows: 2kg to 15.7kg of dispersion material, 2. kg / l to 10.5kg / l of vat material and 0.01kg to 2.5kg of infrared ray resistant regulators; post treatment has the function compatibility of multiple functions which are water proofing, oil repellence, ventilation, crease resistance and static resistance. The technique has the advantages of having short production procedure, color phase with good uniformity, stable infrared reflectivity, low cost, multiple functions, mainly using environment friendly dyes and being suitable for infrared ray resistant camouflage fabric products with different fibers and different specifications.

Owner:XIANYANG JIHUA NEW 30 DYEING & PRINTING

Extract dyeing proces of fiber dyed fabric and fiberdyed yarn capable of being extract dyed

ActiveCN101021048AChange the situation that cannot be discharged and finishedImprove and enrich diversityDyeing processWoven fabricsYarnFiber

The present invention belongs to the field of discharge dyeing technology for fiber dyed fabric. The discharge dyeing process for fiber dyed fabric includes the following steps: 1. dyeing fiber with active dye or vat dye; 2. spinning with dyed fiber and primary color fiber; 3. weaving with the dyed fiber yarn; and 4. discharging the color of the fiber dyed fabric. The present invention provides novel diversified discharge dyed fiber dyed fabric.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Reducing agent for dyeing reduced dyes

The invention discloses a reducing agent for dyeing reduced dyes, belonging to the technical field of printing and dyeing technologies for textiles. The reducing agent consists of the following raw materials in percentage by mass: 5-10 percent of thiourea dioxide, 5-30 percent of sodium hydrosulfite 10-40 percent of reducing sugar type substances and 20-50 percent of salt. The reducing agent disclosed by the invention can effectively replace the sodium hydrosulfite to be used for dyeing of the reducer dyes and indigo dyes, the reduced dye leuco is long in existence time and slight in environment pollution, and the price of the dye leuco is superior to that of the sodium hydrosulfite. Moreover, the thiourea dioxide contained in the reducing agent for dyeing reduced dyes disclosed by the invention can be completely biodegraded, is high in reducing capacity, can effectively reduce the dyes into leuco, does not have a pungent smell and belongs to an environment-friendly substance; the reducing sugars refers to substances existing in the nature and have a certain reducing property, and the overall reducing capacity can be maintained and last for a long time; and moreover, according to salt substances, the stability of the components of the whole reducing agent can be enhanced.

Owner:濮阳圣恺环保新材料科技股份有限公司

High chlorine washing fastness dyeing process of blue series polyster cotton tooling fabric

InactiveCN101629390APromote reductionImprove chlorine wash fastnessDry-cleaning apparatus for textilesDyeing processAdditional valuesPulp and paper industry

The invention relates to a long vehicle continuous pad dyeing process in the processing of dyeing and finishing of fabrics, in particular to a high chlorine washing fastness dyeing process of blue series polyster cotton tooling fabric. The dyeing process in the invention strengthens the reduction clearing and soaping working procedures by screening and dispersing and reactive dyes, and improves chlorine washing fastness of the blue series polyster cotton tooling fabric by padding chlorine washing promoter; after the technology is improved, the invention solves the problem of low chlorine washing fastness of the blue series polyster cotton tooling fabric, avoids the defect of blackening and darkening of cloth cover caused by overoxidation and improves product grade and additional value.

Owner:HUAFANG

Double-faced two-tone printed and dyed fabric manufacturing method and its application for garment

InactiveCN1730811AEasy to prepareEasy to controlDyeing processLiquid/gas/vapor textile treatmentFiberPulp and paper industry

The present invention is double-sided and double-color printed and dyed cloth and its production process and application in making suits, and solves the technological problems of preventing uneven dyeing and cross color dyeing defects during preparing double-sided and double-color printed and dyed cloth and treating the suits of the cloth for comfort and unique visual effect. The production process of the double-sided and double-color printed and dyed cloth includes pre-treatment through cold rolling and stocking or continuous bleaching and boiling; dyeing background color with reducing dye or active dye; and blotch printing with pigment. The suits of the double-sided and double-color printed and dyed cloth is treated through ferment water washing and uniform decoloring.

Owner:佛山南方印染服饰有限公司 +1

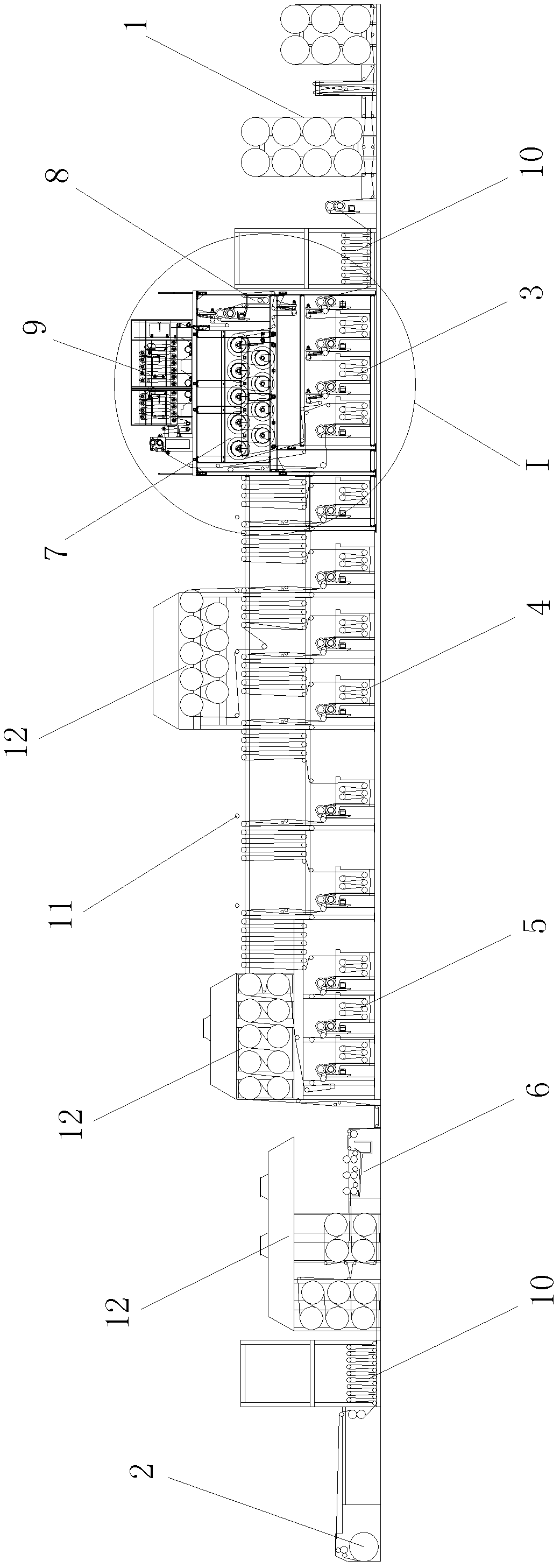

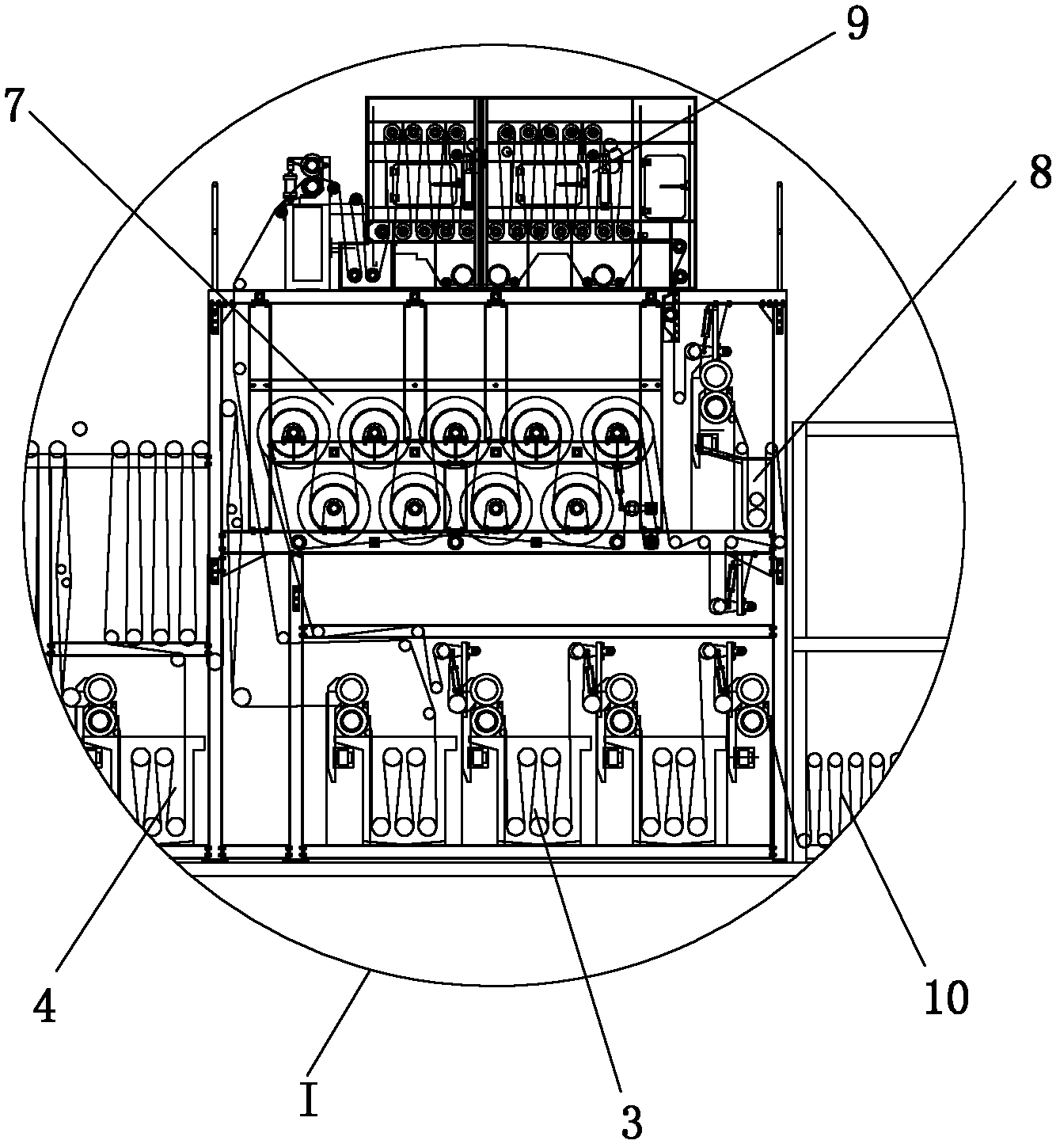

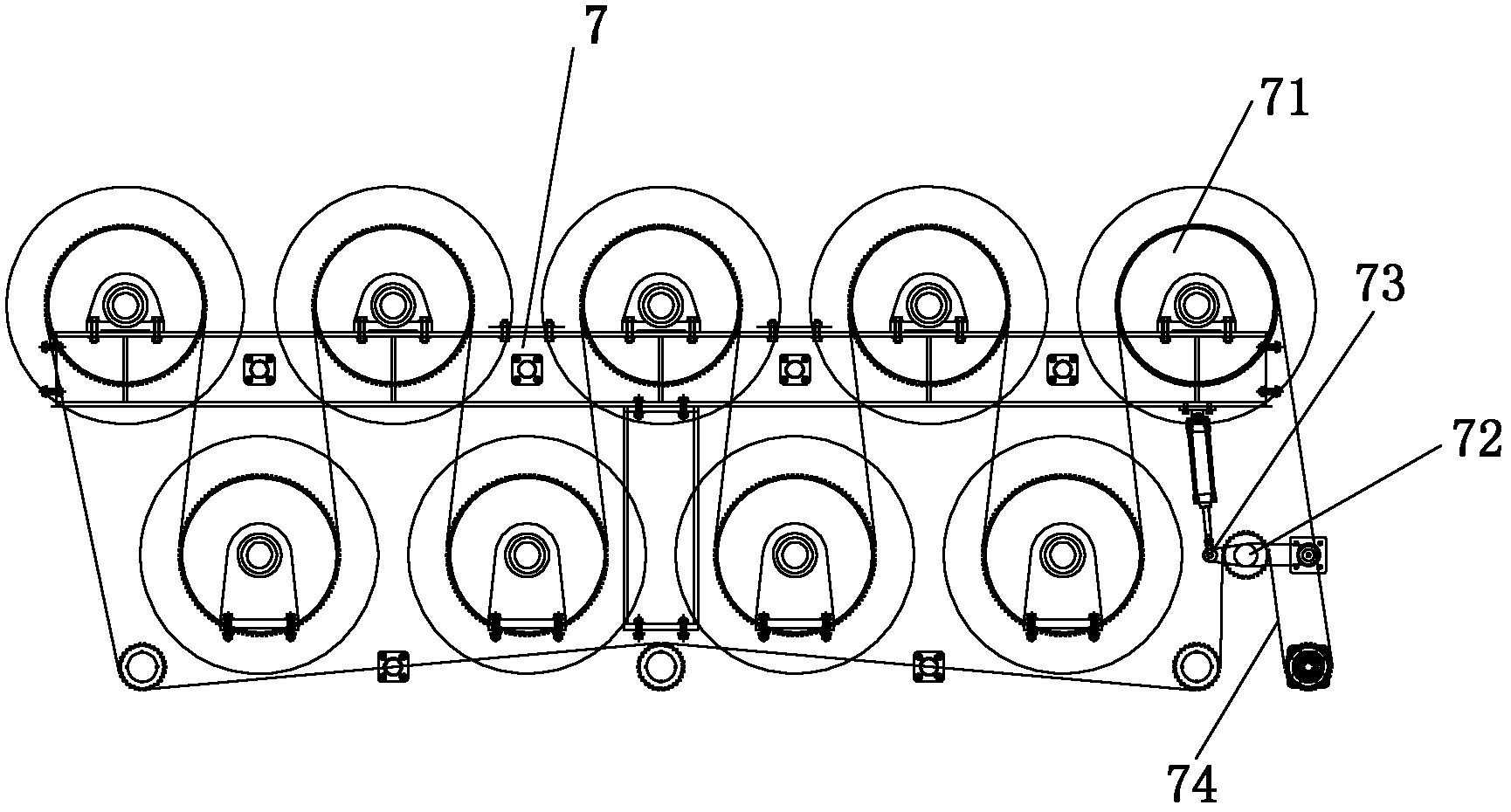

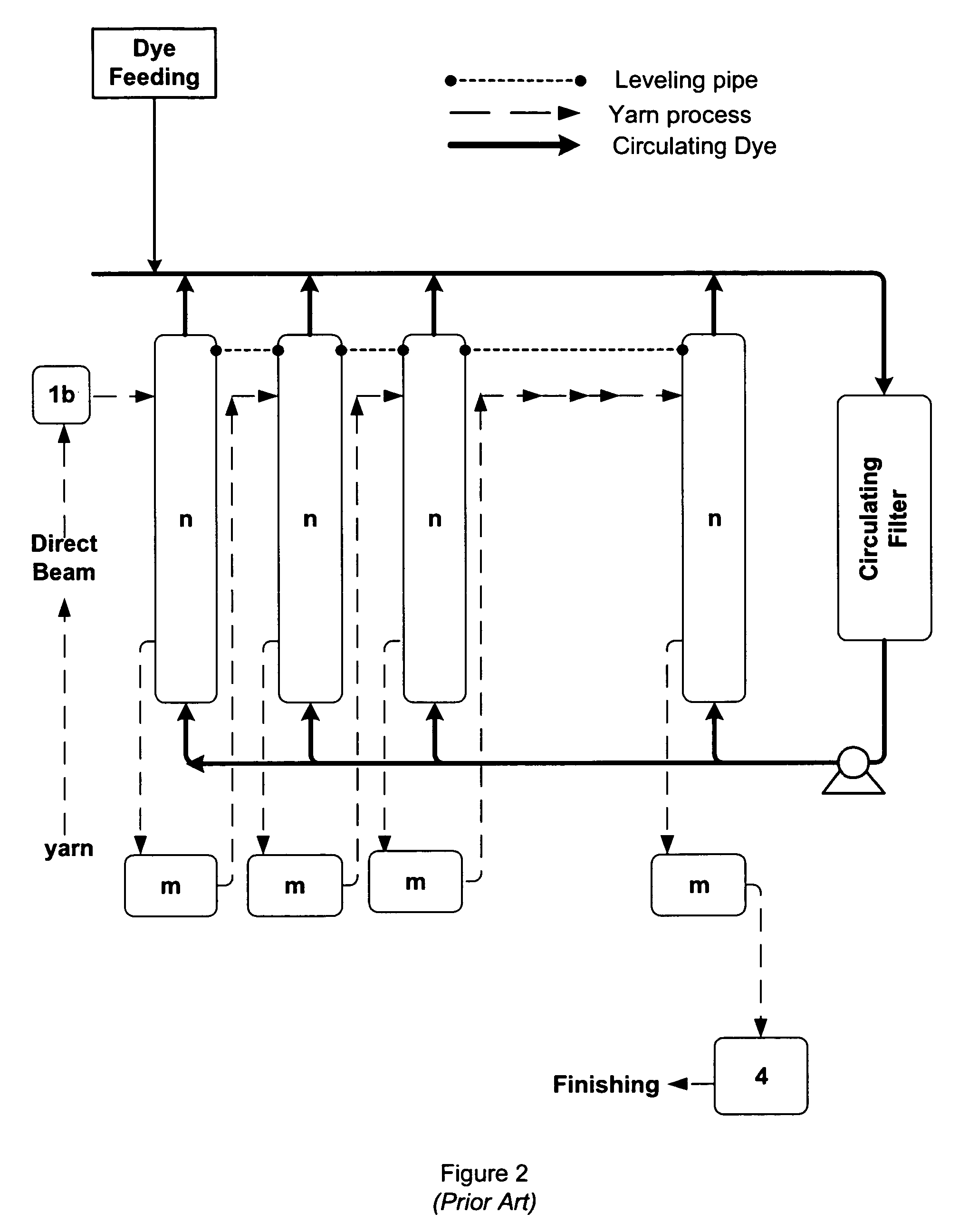

Multifunctional denim warp dyeing machine

InactiveCN102605582ARealize compound dyeingImprove dyeing effectSucessive textile treatmentsLiquid/gas/vapor removalPulp and paper industryPre treatment

The invention provides a multifunctional denim warp dyeing machine, which comprises a to-be-dyed warp rack and a dyed warp reel. A warp pretreatment tank, a warp dyeing groove, a washing tank and a slashing tank are successively arranged between the to-be-dyed warp rack and the dyed warp reel, wherein the warp pretreatment tank is used for removing impurities of warps and washing the warps, the warp dyeing tank is used for dyeing the warps by indigo dyes or sulfur dyes, the washing tank is used for washing the dyed warps, a combined drying barrel, a small colorful dyeing tank and a steaming box are successively disposed between the warp pretreatment tank and the warp dyeing tank, the combined drying barrel is used for colorfully dyeing the warps, and the small colorful dyeing tank dyes the warps by reduced dyes. The problems that when warps are dyed, a color selection range is narrow, color fastness is poor, and the warps cannot be dyed by bright-colored dyes are resolved; after the dyed warps are woven into denim, the characteristics that the warps of the denim are colorful while wefts of the denim are white can be kept; composite dyeing by the aid of the indigo dyes or the sulfur dyes can be realized, and a dyeing effect is good.

Owner:HAINING DENIM WEAVING CO LTD

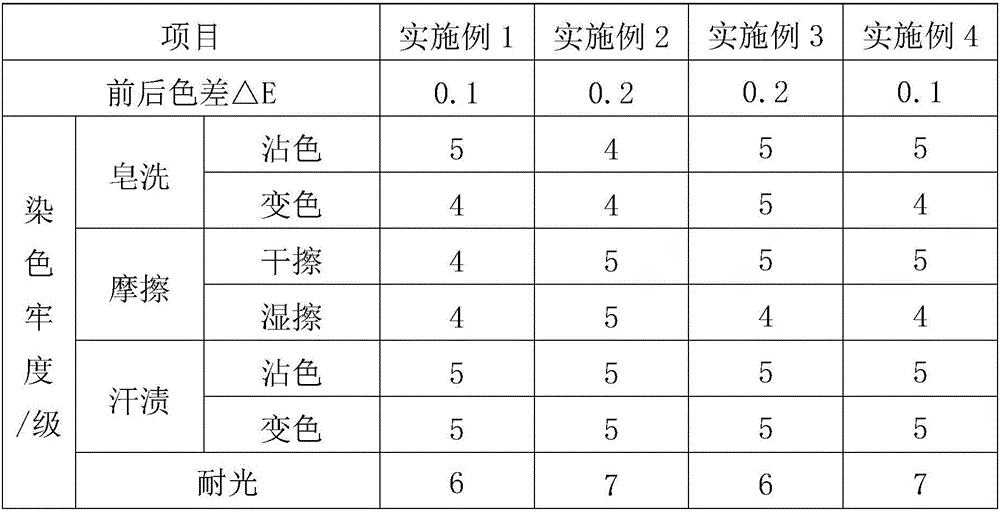

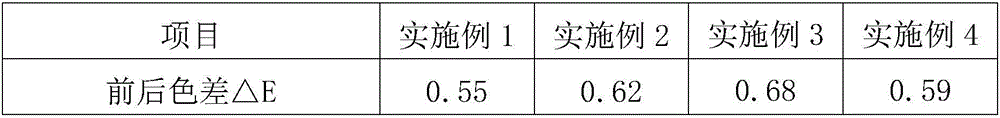

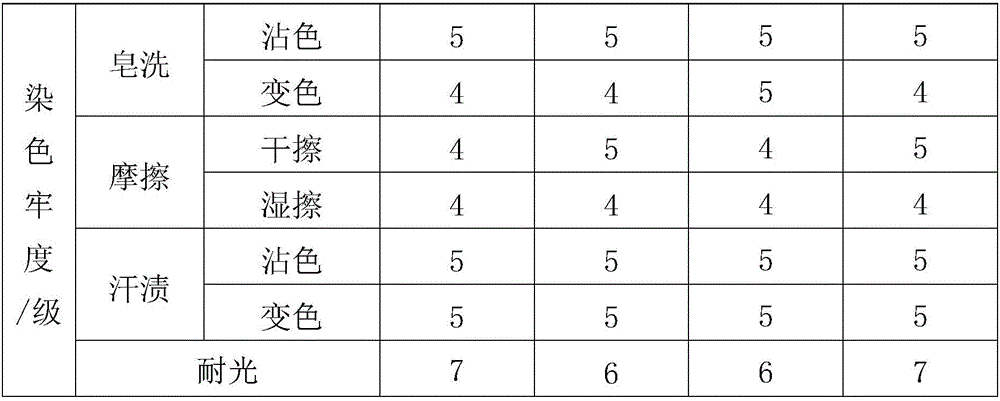

Dispersion-reduction dyeing process for cotton-polyester blended fabric

ActiveCN106087463AImprove reducibilityImprove dyeing effectSucessive textile treatmentsDyeing processDisperse dyeVat dye

The invention discloses a dispersion-reduction dyeing process for a cotton-polyester blended fabric. The dispersion-reduction dyeing process comprises a disperse dyestuff treating procedure and a vat dye treating procedure which are successively carried out. The disperse dyestuff treating procedure comprises dyeing, reduction cleaning, washing and pickling; the vat dye treating procedure comprises dip padding with a vat dye suspension, dip padding with a reducing solution, steaming, oxidation, soaping, hot washing and drying; in the disperse dyestuff treating procedure, a disperse dyestuff microcapsule method is used for dyeing; and in the vat dyestuff treating procedure, vat dye wet rapid-steaming pad dyeing process is employed. The dispersion-reduction dyeing process for the cotton-polyester blended fabric has the advantages of good level dyeing effect, small chromatic aberration and high color fastness, and is simple in process.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Single-face dyeing method for woven fabric

InactiveCN101200858AReduce dosageEasy emissionsSingeingHeating/cooling textile fabricsTextile printerEngineering

A single-side dyeing method of woven fabrics belongs to the novel technical field of textile printing and dyeing. The single-side dyeing method of woven fabrics includes three steps; firstly, pure cotton, tencel and an elastic woven fabric are preprocessed, including the turnover sewing of greige cloth, singeing, desizing, boiling-off, bleaching, mercerization, etc., secondly, the full-width single-side dying of the woven fabric is to coat color sizing A on the woven fabric by a coating machine, and then high-temperature hot-air stentering, oxygenation, soaping, water washing, drying and cropping are carried out; finally, color sizing B is coated on the woven fabric by the coating machine, and high-temperature hot-air stentering and cropping are carried out. The technology realizes the fashion of the fabrics of jeans, leisure clothes and children dresses and has obvious ecological function; the technology also resolves the technical problem that a coating-shaping combination machine can carry out the single-side dyeing of fabrics by using sulfide colours, paints, etc., meanwhile, compared with the conventional techniques of vat dye, reactive dye, etc., the technology saves water, gas and electricity and reduces the discharge of a great deal of dyeing sewage. The side of the single-side dyed fabric, which touches the skin of the body, does not contain dyestuff and auxiliaries, thus having the characteristics of ecological and environmental protection.

Owner:SHANXI CAIJIA PRINTING & DYEING

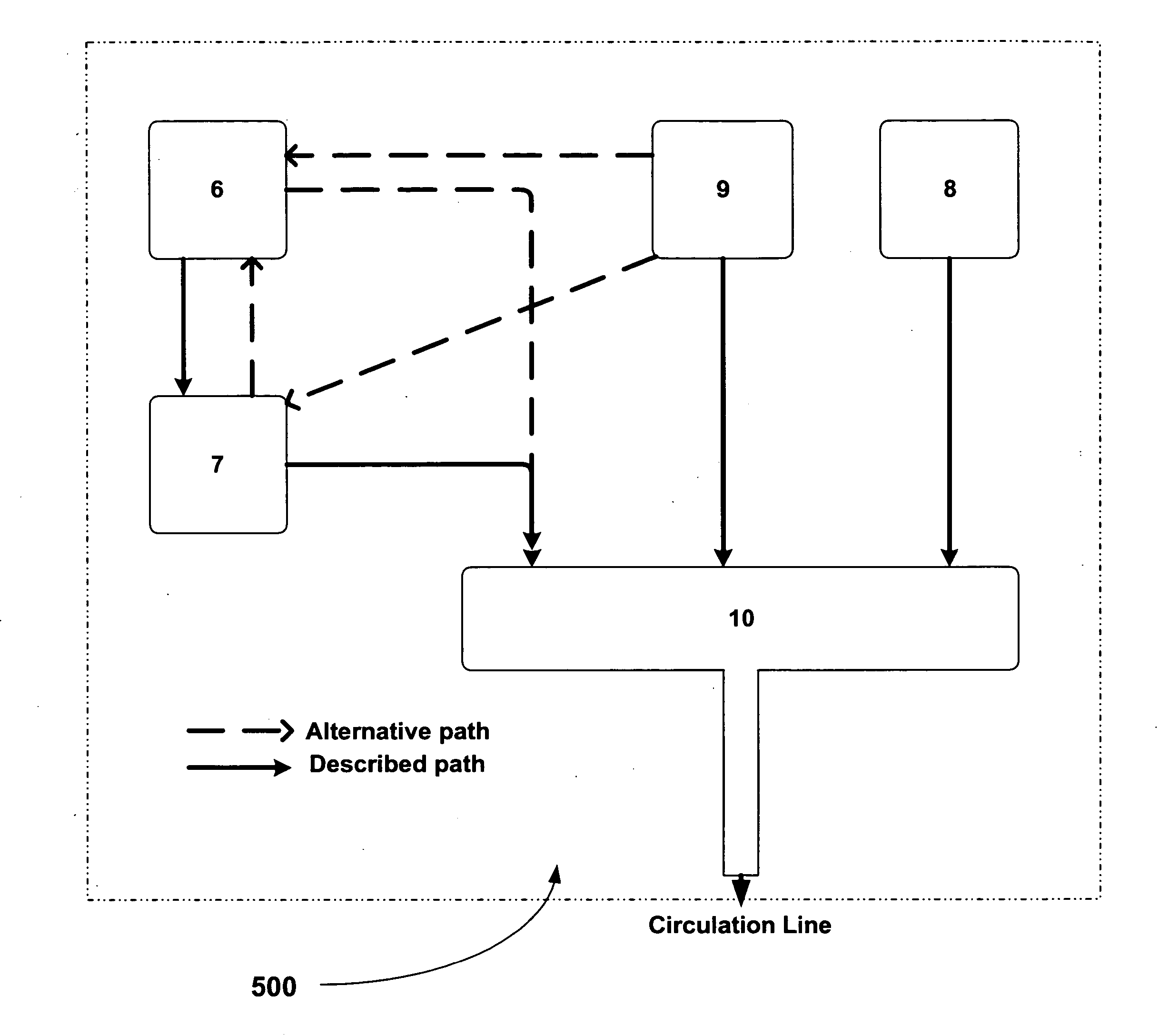

Process for introducing vat dyes and chemicals into textiles

ActiveUS20070033748A1Efficient reductionDye is reduced efficientlyTextile treatment machine partsDyeing processYarnVat dye

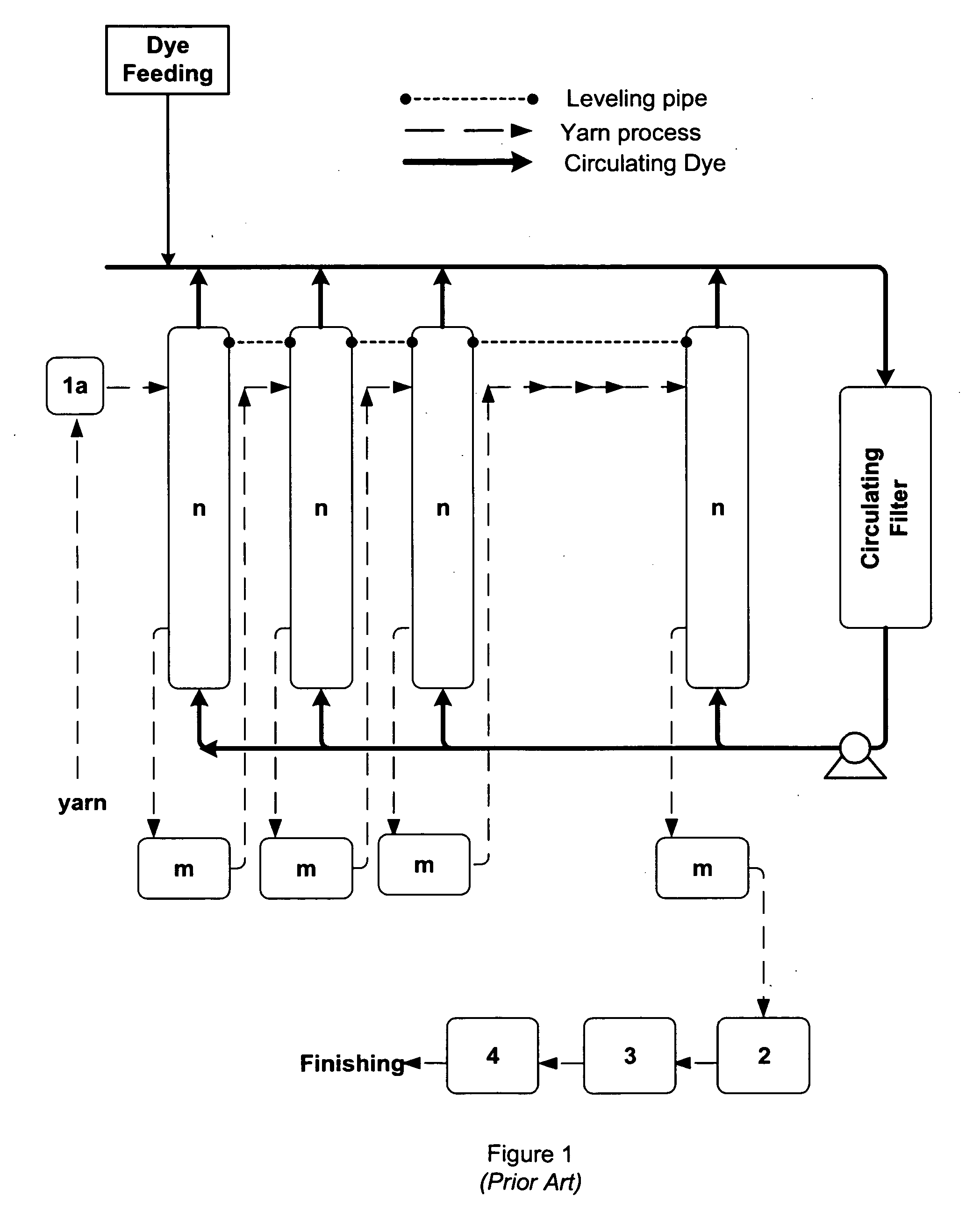

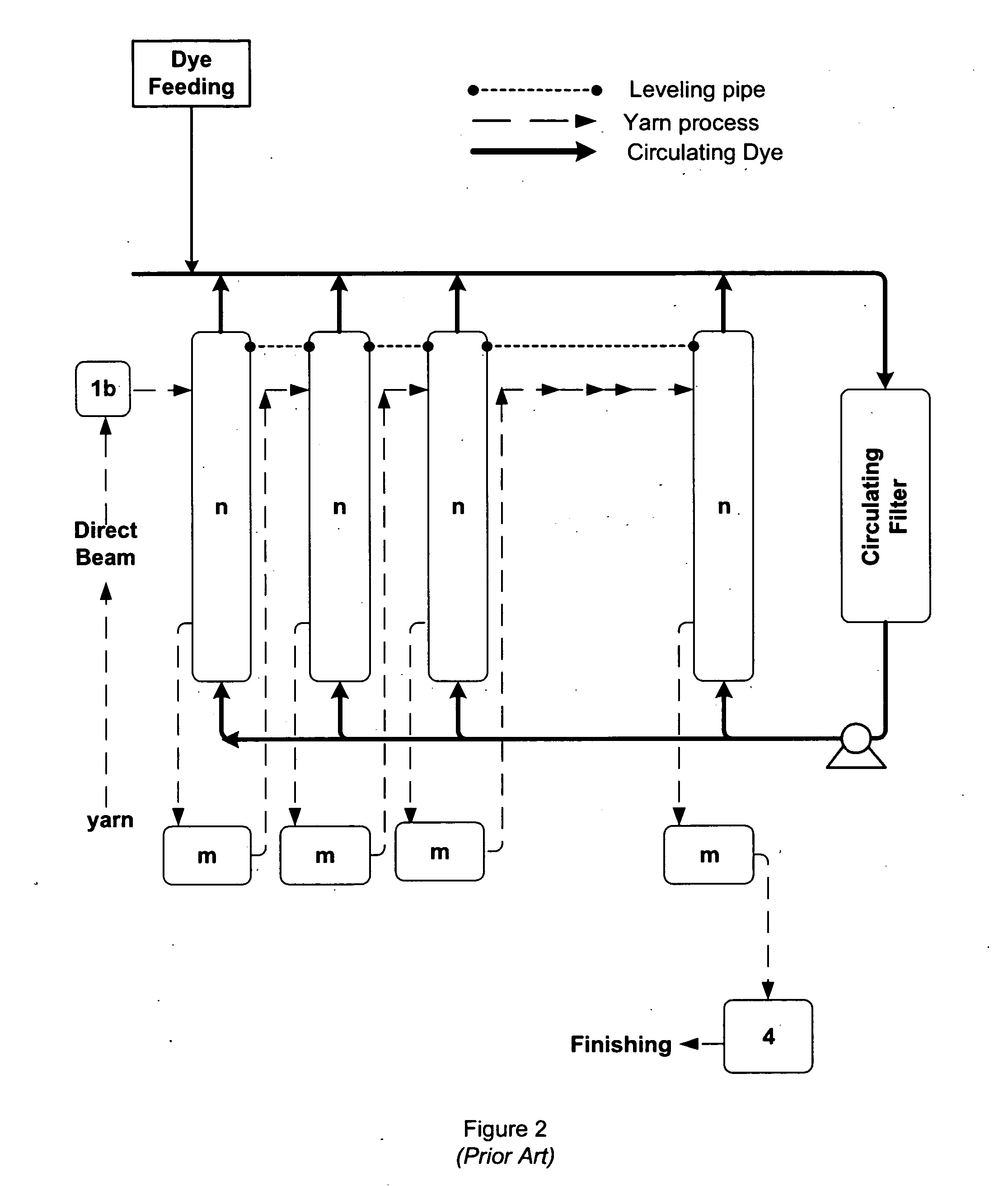

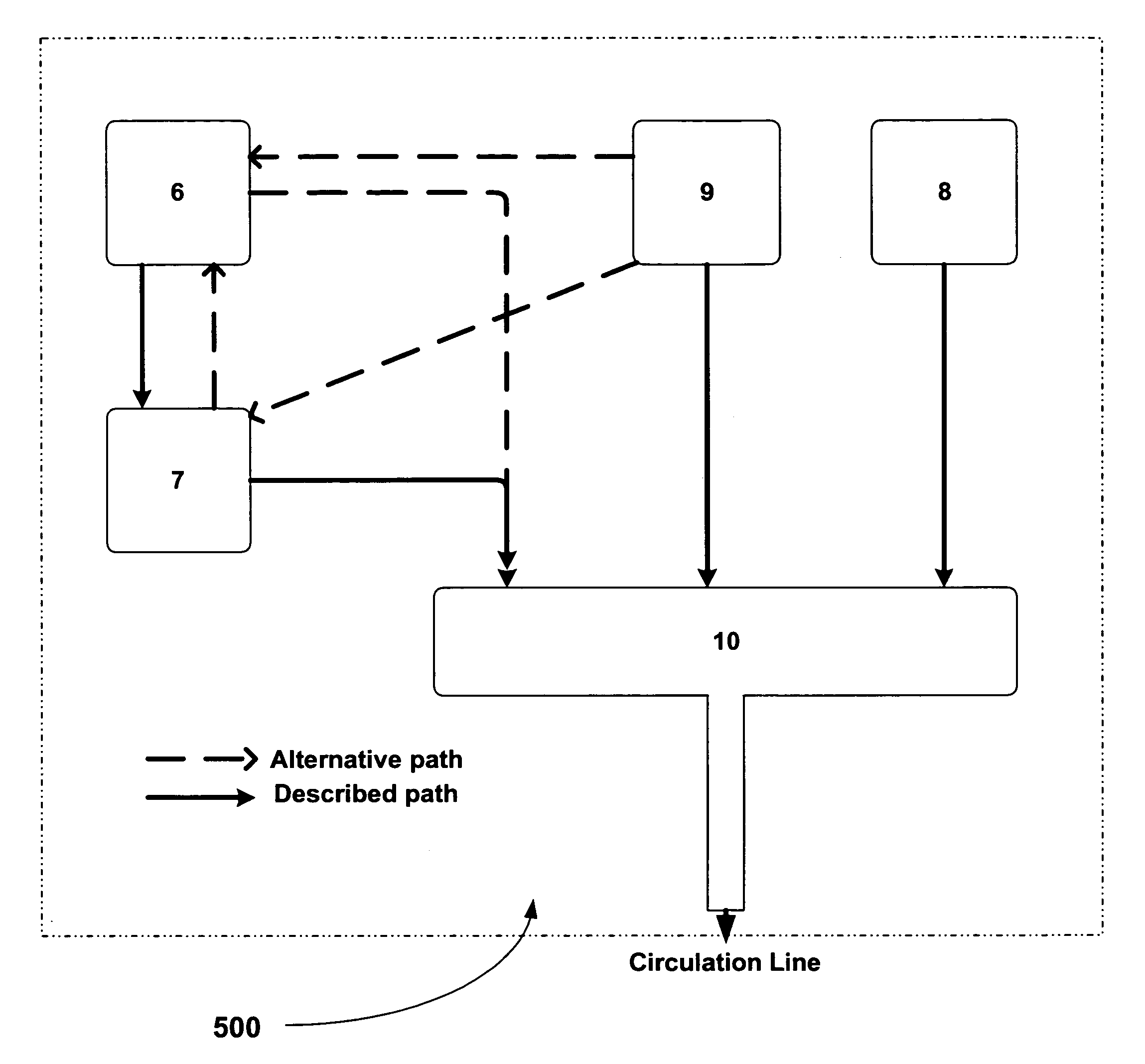

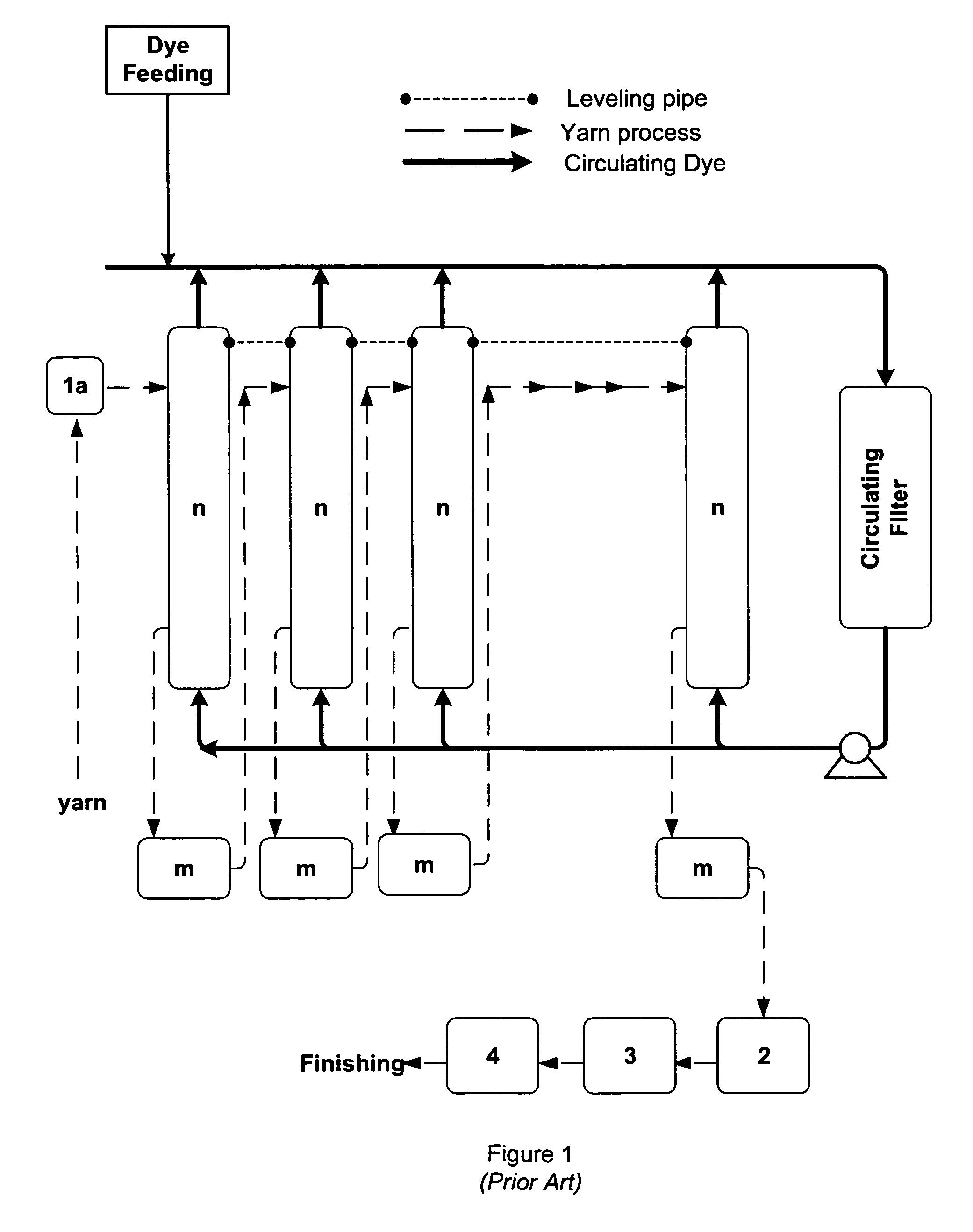

A process for using reduced vat dyes in a continuous dyeing process for production of dyed yarns and fabrics of different colors. In the process, dye composition is introduced to a treatment unit for reduction to desired dye composition. The dye concentration in the treatment unit is lower than feeding dye concentration so that dye precipitation does not occur, but significantly higher than the circulating dye concentration so that the dye is reduced efficiently. Although the preferred location for the treatment unit is before the circulation line, it may be at any location before the dip-dye tank.

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

Dyeing and finishing process for polyester blended fiber fabric

ActiveCN106223003ASoft touchImprove water absorptionHeating/cooling textile fabricsHeat resistant fibresDisperse dyeAfter treatment

The invention discloses a dyeing and finishing process for a polyester blended fiber fabric. The process comprises the following steps of 1, pretreatment, wherein the polyester blended fiber fabric is sequentially subjected to scouring, bleaching and enzyme washing; 2, mercerizing and sizing, wherein the fabric is subjected to padding of alkali liquor under the room temperature for pre-sizing; 3, dyeing, wherein the fabric is soaked into dye liquor formed by disperse dyes, dyeing is performed under the temperature of 30-40 DEG C, temperature is increased to 90-110 DEG C at the heating rate being 0.8-1 DEG C / min, washing is performed through warm water, infrared ray pre-heating is performed, and then hot-blast air drying is performed; padding is performed again under the room temperature to reduce the suspended solid dye liquor formed by dyes, a reduction solution is subjected to padding, steam reduction and oxidation are performed, washing is performed through warm water, soaping is performed, and then washing and drying are performed; 4, after-treatment, wherein soft and flame-proof treatment is performed in sequence. According to the dyeing and finishing process for the polyester blended fiber fabric, the touch feeling, elasticity and other properties of the fabric are improved remarkably, dyeing is uniform, the color fastness is high, and the color is full.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Dyeing method for suspension cotton yarn by reduced dye

InactiveCN107476094AAdaptableModerate reduction rateDyeing processVegetal fibresYarnSodium dithionite

The invention discloses a dyeing method for suspension cotton yarn by reduced dye. The dyeing method comprises the following steps: slacking, pretreatment, and dyeing. The bath ratio in the pretreatment step is 1:(6 to 10), and the bath ratio in the dyeing step is 1:(6 to 10). The dyeing method comprises the following specific steps: adding a reefing agent for operating, then adding alkali for operating, raising the temperature, adding hydrogen peroxide for operating, and carrying out acid pickling and water washing; operating for a period of time, then sequentially adding a dye leveler, sodium hydroxide and sodium dithionite, and then raising the temperature for operating; draining, adding water again, and then adding the hydrogen peroxide for operating; adding a soaping agent, and finally draining liquid to obtain dyed cone yarns. The method has the advantages of simple steps, simple dyeing operation, high production efficiency and good dyeing effect.

Owner:XINJIANG RUYI TEXTILE GARMENT CO LTD +2

Production method of color fabric imitating cowboy style

ActiveCN105780554AReduce strong damageDegree of reductionDyeing processTextile shapingHigh colorPulp and paper industry

The invention discloses a production method of a color fabric imitating cowboy style and relates to the technical field of production of woven fabrics. The production method comprises the techniques of slashing, weaving, dyeing gray fabrics, washing and desizing, finishing and the like. Warp and weft yarn components prepared from different materials are selected for weaving and the dyeing difference of the warp and weft yarn components is utilized, so that the whitening effect of dyed fabrics can be realized; a color separating agent with dye-retarding capability is added into a sizing agent for slashing, and is mixed and sized, so that the color separating agent can be uniformly distributed on the surfaces of warp yarns; when the woven fabrics are dyed by adopting active, indigo blue or reducing dye, the dyeing of dye is stopped by a covering area of the woven fabric, and stripe-shaped color spots with different depths in the direction of warp yarns can be obtained after amylase is adopted at later stage for performing desizing treatment, so that the grey effect of traditional yarn dyed denims is realized. The color imitated denim produced by using the production method has the advantages of vivid style, abundant colors, simple process, high production efficiency, high color fastness and the like.

Owner:JIANGSU LIANFA TEXTILE

Dyeing method of cotton product reduced dye with low bath ratio

The invention discloses a dyeing method of cotton product reduced dye with low bath ratio and belongs to the textile dyeing and finishing processing technical field. The dyeing method aims to solve problems of large consumption of dyestuffs during dyeing of conventional cotton product reduced dyes and difficult control of surface color uniformity of dyed objects. The dyeing method employs nitrogen as protective gas. Based on elimination of air in a dyeing device, uniform adsorption and diffusion of reduced dye leuco compound sodium salt on cotton fiber are achieved. Combined with water washing, oxidation and soaping, dyeing of cotton product reduced dye with low bath ratio is finished. The concrete technological process comprises steps: reduction and dissolution of a dye, elimination of air in a dyeing device, dyeing of the reduced dye, oxidation, soaping and drying. When the dyeing method is compared to conventional dyeing technologies, the dyeing uniformity of cotton product dyed objects is improved; the dyeing depth and the dyeing fastness are increased; the consumption of dyestuffs is decreased under condition of the same surface color depth of dyed objects; the discharge of dyeing waste water is reduced; the production energy consumption is lowered.

Owner:浙江环发纺织印染有限公司

Process for dyeing yarns with vat dye

The invention discloses a process for dyeing yarns with a vat dye. The process flow comprises dye preparation, suspension cold dyeing, alkaline circulation, sodium hydrosulfite circulation, heating reduced dyeing, heat preservation standing, cooling absorption, washing oxidation, soaping and softening. When dyeing starts by using the process, the dye in a dye bath is in a non-reduced state at room temperature and is not in direct contact with fibers, and the dye and chemicals are uniformly distributed on the fibers by low-temperature circulation. As the temperature rises, the dye is gradually reduced into direct leuco sodium salt, and the fibers on which the dye is uniformly distributed are uniformly dyed.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Pure cotton fabric reduced dye dyeing method

InactiveCN104047186AImprove reducibilityMaintain resilienceBleaching apparatusDyeing processPolymer scienceDioxyethylene Ether

The invention relates to a pure cotton fabric reduced dye dyeing method which comprises the following steps: (1) textile preparation; (2) textile pretreatment; (3) preparation of reduced dye leuco body solution; (4) dip dyeing of reduced dye; (5) soap boiling and (6) after-finishing. The reduced dye leuco body solution is prepared by the following raw materials: 1-10g / L thiourea dioxide, 2-5g / L of iso-tridecanol polyoxyethylene ether, 1-2g / L of glucose, 2-5g / L of sodium silicate, and 1-2g / L of sodium sulfide. The K / S value of the dyed textile is obviously improved.

Owner:福建金苑服饰有限公司

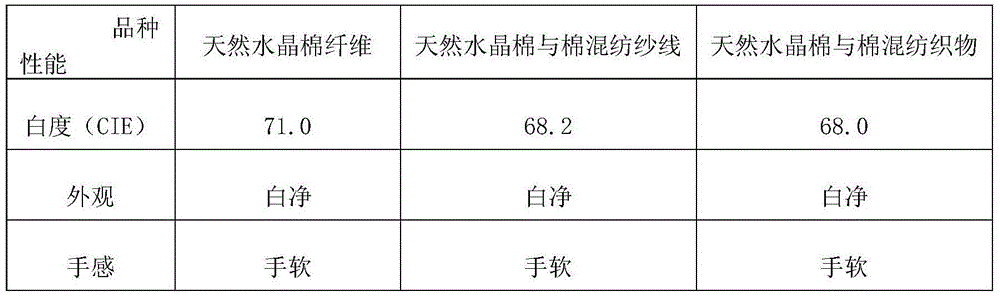

Pre-treatment and dyeing method for natural crystal fibers and blended or interwoven products of natural crystal fibers and other fibers

InactiveCN104878619AImprove use valueBeautiful appearanceSucessive textile treatmentsBleaching apparatusPolyesterFiber

The invention belongs to the technical field of a textile pre-treatment and dyeing machining technology and particularly discloses a pre-treatment and dyeing method for natural crystal fibers and blended or interwoven products of the natural crystal fibers and other fibers. The pre-treatment and dyeing method comprises the following steps: (1) pre-treatment: carrying out impurity removal and whitening treatment on a product by using a pre-treatment agent; (2) dyeing: dyeing by using an active dye, a reduction dye or a vulcanization dye, and dyeing polyester fibers in the blended or interwoven products containing polyester by adopting a dispersion dye; and (3) dyeing after-treatment: adopting a suitable dyeing after-treatment process according to different dyes and fiber systems, wherein the process comprises the steps of washing with water, washing with soap and drying. With the adoption of the treatment process provided by the invention, impurities on a product can be effectively removed, and the product has a good appearance and a good dye printing performance, so that the product has satisfied color and luster and good dyeing fastness. The blended product prepared by adopting the method has relatively good appearance and use performance and the application value of the product can be remarkably improved.

Owner:CHANGZHOU TEXTILE GARMENT INST

Preparation of coloured antibiotic viscose fiber

InactiveCN101302661AWill not polluteImprove the bactericidal effectMonocomponent cellulose artificial filamentArtifical filament manufactureSilver colloidAqueous solution

The invention relates to a preparation method for colored antibacterial viscose fiber, which consists of the following steps: (1) formulating the vat dyes of one or a plurality of colors into a paste respectively by alkaline solution according to the coloring requirements of fibers, and then adding hydrosulfite and stirring for reacting and generating vat dye leuco salt solution, mixing the vat dye leuco salt solution of a plurality of colors according to the color matching proportion; or formulating the vat dyes of a plurality of colors into a paste by alkaline solution after mixing according to the color matching proportion, then adding the hydrosulfite for generating vat dye leuco salt mixed solution, (2) fully mixing the nanometer silver powder having the particle size no more than 100 nm with the colloid mixture to formulate a nanometer silver colloid water solution containing 2-5 percent of nanometer silver and 4-10 percent of colloid protective agent, (3) mixing the two solutions prepared by step (1) and step (2) and adding the mixed solution into the raw material solution of viscose rayon in any phase of the aging process of the viscose to spin, refine and dry, thus preparing the colored antibacterial viscose fiber.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Cotton cloth reduced dye dyeing process

The invention discloses a cotton cloth reduced dye dyeing process. The cotton cloth reduced dye dyeing process includes the following steps of a, dye liquor preparation, wherein a wetting agent and reduced dye are added into deionized water in the environment of the 15 DEG C to 20 DEG C temperature, and the mixture circulates evenly; b, suspensoid cold dyeing, wherein cotton cloth is placed in dye liquor prepared in the step a, and cyclic dyeing is carried out; c, alkalifying circulation, wherein caustic soda is added into the dye liquor obtained in the step b, and circulation is carried out; d, adding of sodium hydrosulfite for circulation; e, heating reduction dye up-take, wherein the pH value of a dye bath is adjusted to range from 4 to 4.5 with acetic acid, the temperature is raised to 100 DEG C at the speed of 1.5 DEG C / min, heat preservation dyeing is carried out for 40-60 min, then the temperature is reduced to 60 DEG C from 100 DEG C at the speed of 1 DEG C / min, and heat preservation is carried out for 30 min; f, soaping, wherein a soap or a synthetic detergent is added into Na2CO3, washing is carried out till the material is neutral, and airing is carried out at room temperature. The cotton cloth reduced dye dyeing process has the advantages of being high in dyeing rate and good in migration property.

Owner:安徽融创化工科技股份有限公司

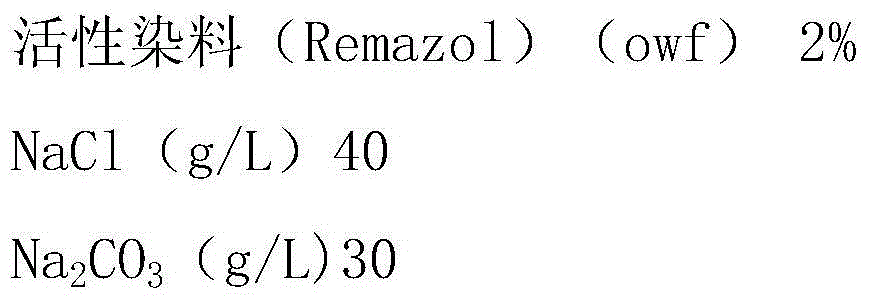

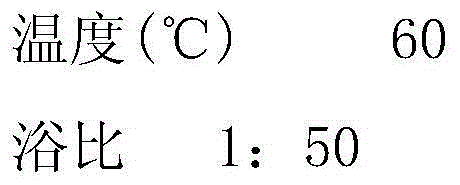

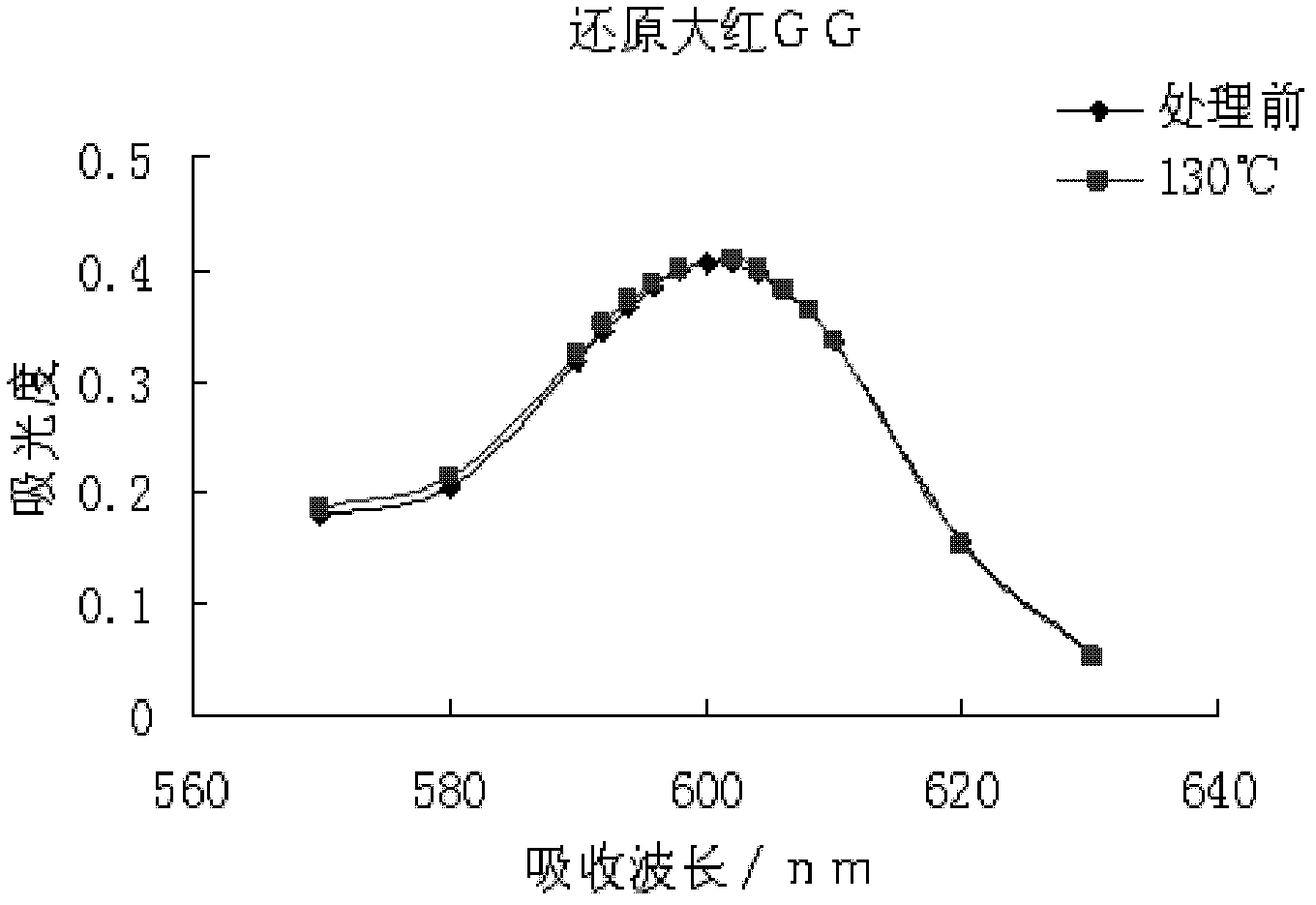

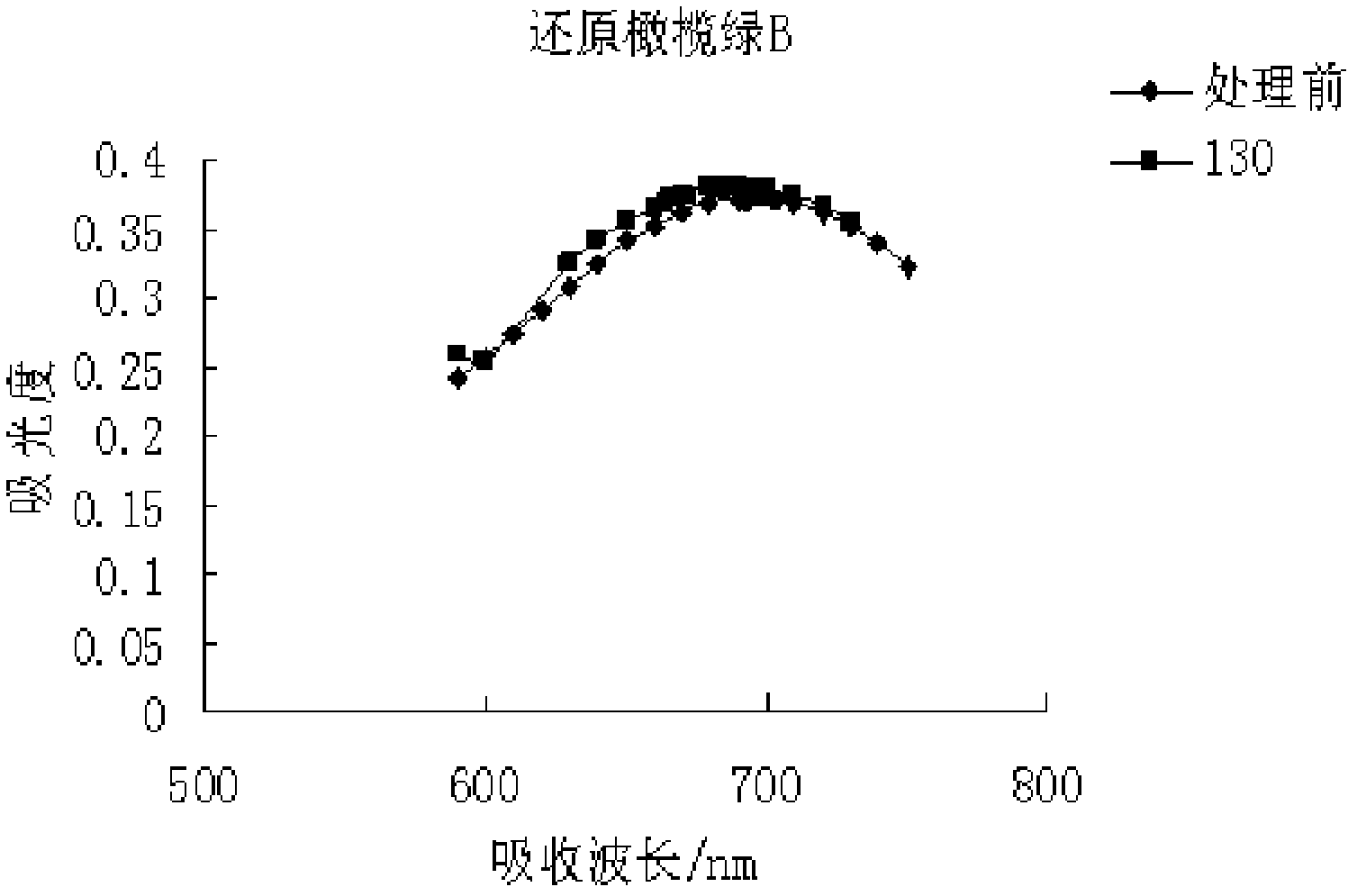

Method for dyeing linen fabric/fibres by reduced dye at high temperature

The invention relates to a method for dyeing linen fabric / fibres by a reduced dye at a high temperature. The method comprises the following steps of: (1) dye selection, namely, in the existence of reduced dyes, a reducer, NaOH and a dye high-temperature stabilizer, completely reducing the dyes into leuco bodies, and then determining the absorption curve of the completely-reduced-state dye solution before and after the treatments via temperature-rising, high-temperature and constant-temperature treatments, so as to find the reduced dye suitable for high-temperature drying; and (2) a dyeing process, namely, preparing the suspension of the reduced dye in a dye vat according to proper dyeing conditions including a bath ratio, a dye amount, the reducer, sodium hydroxide, and the high-temperature stabilizer, adequately reducing and then adding the linen fabric, heating, raising temperature and dying at 100-160 DEG C, then washing by cold water, developing via the complete oxidation of H2O2, performing soap-boiling in liquid soap, washing by hot water, drying and the like. The linen fabric dyed via the high-temperature dyeing process aforementioned is bright in colour, high in colour yield, and especially great in dye permeability.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Dyeing and finishing process for bleaching high-grade shirt fabrics after dyeing and knitting

InactiveCN1962995AStrong three-dimensional senseClear linesSucessive textile treatmentsBleaching apparatusYarnBobbin

The invention provides a dyeing and finishing art of high-grade shirt face fabric after colored woven and albefaction, the process includes bobbin winding, cheese pre-processing, dyeing, warping, weaving, burned retreat, mercerizing, stentering and pre-shrinking process, it characterized by : it adds cold rolling albefaction between burned retreat and mercerizing, adds whiting between mercerizing and stentering, the dyeing uses color streaks, so the whole process is bobbin winding, cheese pre-processing, dyeing, warping, weaving, burned retreat, cold rolling albefaction, mercerizing, whiting, stentering and pre-shrinking. The invention dyes the color streaks of check gingham before weaving, dyestuff is vat which can resistant oxidation and chlorine bleach, also can not migrate when in high temperature; the color streaks is weaved with greige yarn after dyeing, the white fundamental color is dealbated or whited in pad dyeing equipment, so the line of colored woven cloth is more intelligible after collating, the fabric style is fine and the whole cloth cover is more bright and clean, all the fastness can reach the 4 / 5 of GB, and it highlights the cubic effect of slivers and grids are more three-dimensional.

Owner:LUTAI TEXTILE

Process for introducing vat dyes and chemicals into textiles

ActiveUS8523957B2Dye is reduced efficientlyTextile treatment machine partsDyeing processYarnPhotochemistry

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

Reduced dye dyeing and finishing process for ramie fabric

ActiveCN106192458AFeel goodIncrease elasticityHeat resistant fibresDry-cleaning apparatus for textilesSodium Hypophosphite MonohydrateCarboxylic acid

The invention discloses a reduced dye dyeing and finishing process for a ramie fabric. The process comprises the following steps of S1, pre-treatment: after work liquid padding on the ramie fabric, performing stacking steaming, hot washing, cold washing and drying, and then performing pre-shaping; S2, finishing and modification: performing finishing liquid padding, wherein the finishing liquid is prepared from 5 to 10g / L of beta-cyclodextrin, 5 to 15g / L of polybasic carboxylic acid and 0.5 to 2g / L of sodium hypophosphite; performing pre-baking, baking, water washing and drying; S3, reduction and dyeing: padding the ramie fabrics into dye liquid formed by reduction dye; then, padding into reducing liquid; using saturated vapor for fast steaming; after the water washing, performing oxidization by hydrogen peroxide; performing soaping and hot washing, and then drying; S4, post-treatment: sequentially performing softening finishing and inflaming retarding finishing on the ramie fabric. According to the invention, the reduced dye dyeing and finishing process for the ramie fabric has the advantages that the properties such as hand feel and elasticity of the fabric are obviously improved; in addition, the dyeing is uniform; the color fastness is high; the color and luster are rich.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Dyeing process using reducing and bleeding

InactiveCN101768876ASatisfaction with faded distressed casual styleHeating/cooling textile fabricsDyeing processState of artEngineering

The invention discloses a dyeing processing using reducing and bleeding, which is realized by the following scheme: obtaining semi-finished product of plain white cloth, and working procedures of padding dye solution, steaming, washing, oxidizing, soaping, washing, drying, padding and softening, tentering, shrinking and obtaining a finished product. Another drying working procedure and the working procedure of padding reducing solution are sequentially added between the working procedures of padding dye solution and the steaming; and dye used by the working procedure of padding dye solution is a mixture of reducing dye the weight ratio of which is 2:3-3:2 and sulfur dye. By the invention, the reducing dye with excellent color fastness and sulfur dye which is easy to bleed are mixed and compounded according to a certain proportion to obtain new bleeding and reducing dye; and two kinds of dye can be simultaneously dyed on the cloth cover by adding a reducing agent suitable for the sulfur dye in a reducing solution prescription and using a one-step dyeing method. Compared with the prior art, clothes made of fabrics dyed by the process can obtain satisfied bleeding, traditional and leisure style after being subject to simple washing with enzyme; and in addition, the light fastness in the medium-light colors can reach 3-4 levels.

Owner:FUJIAN XIESHENG XIEFENG PRINTING & DYEING IND CO LTD

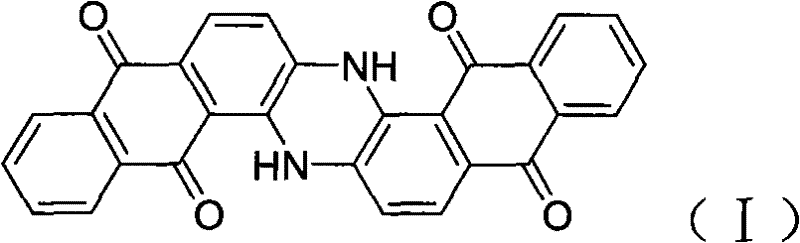

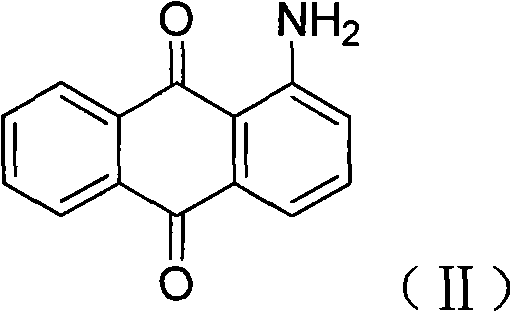

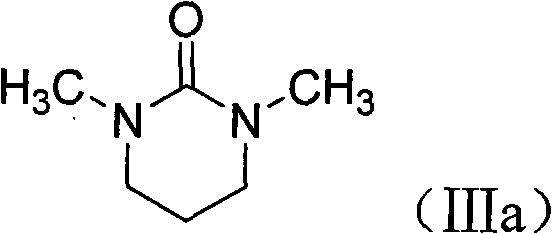

Preparation method of vat blue dye

The invention relates to a preparation method of a vat dye of a vat blue 4 (I) dye. 1- aminoanthraquinone (II) is used as a raw material, and a hydrous cyclic urea derivative, N, N'-dimethyl propyleneurea (IIIa), is used as a medium; in the presence of a strong base, potassium hydroxide, and a phase-transfer catalyst, condensation is performed using oxygen or air as an oxidant; when the reaction endpoint is reached, filtration, washing and drying are performed to obtain dianthraquinone-N, N'-dihydroazine, that is vat blue 4 (I), with high yield and high purity. After being further refined, the dye can be used as pigment-grade vat blue 4 (I).

Owner:JIANGSU HUAER CHEM

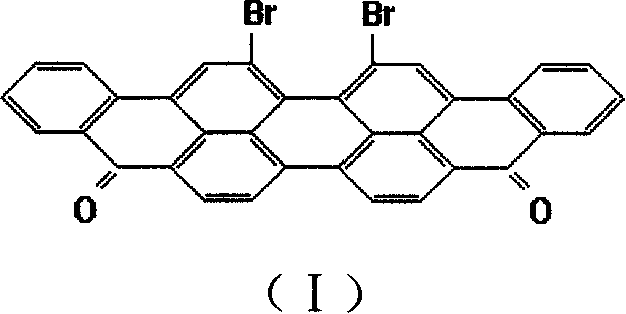

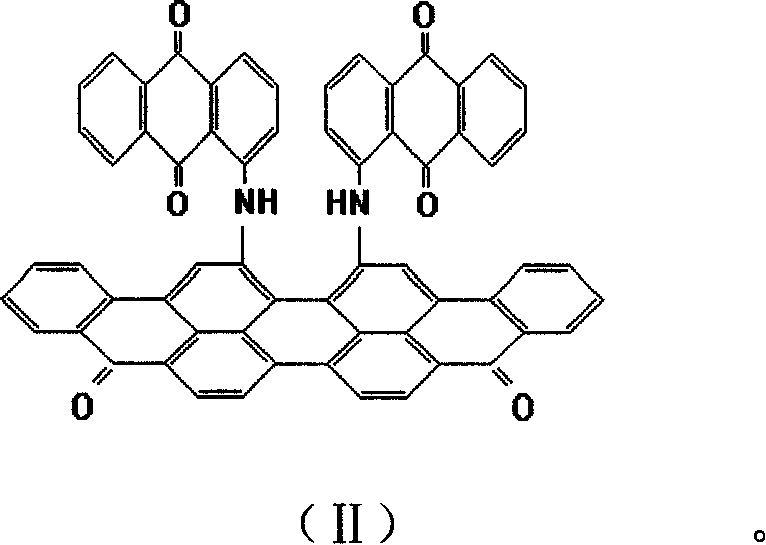

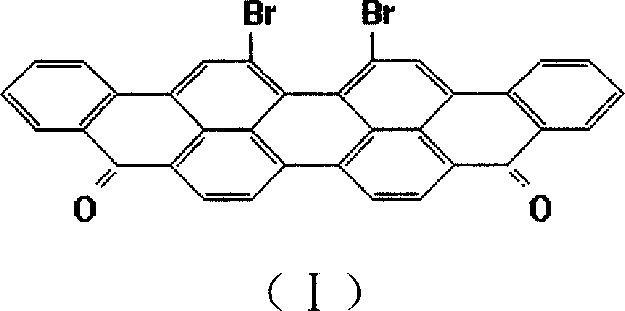

Anthraquinone vat dye 16,17- dibromviolanthrone and 16,17-di(1'-imdoanthraquinonyl) violanthrone and its preparation method

The invention discloses two dyes and making method, which is characterized by the following: the structure formula of reduced dye 16, 17-dianthrone dibromide is (I); the structure formula of reduced dye 16, 17-two (1'-imidogen anthraquinonyl) dianthrone is (II); the 16, 17-dianthrone dibromide (I) is made of brodianthrone, which condenses with 1-aminoanthraquinone to produce 16, 17-two (1'-imidogen anthraquinonyl) dianthrone is (II).

Owner:江苏嘉利精细化工有限公司

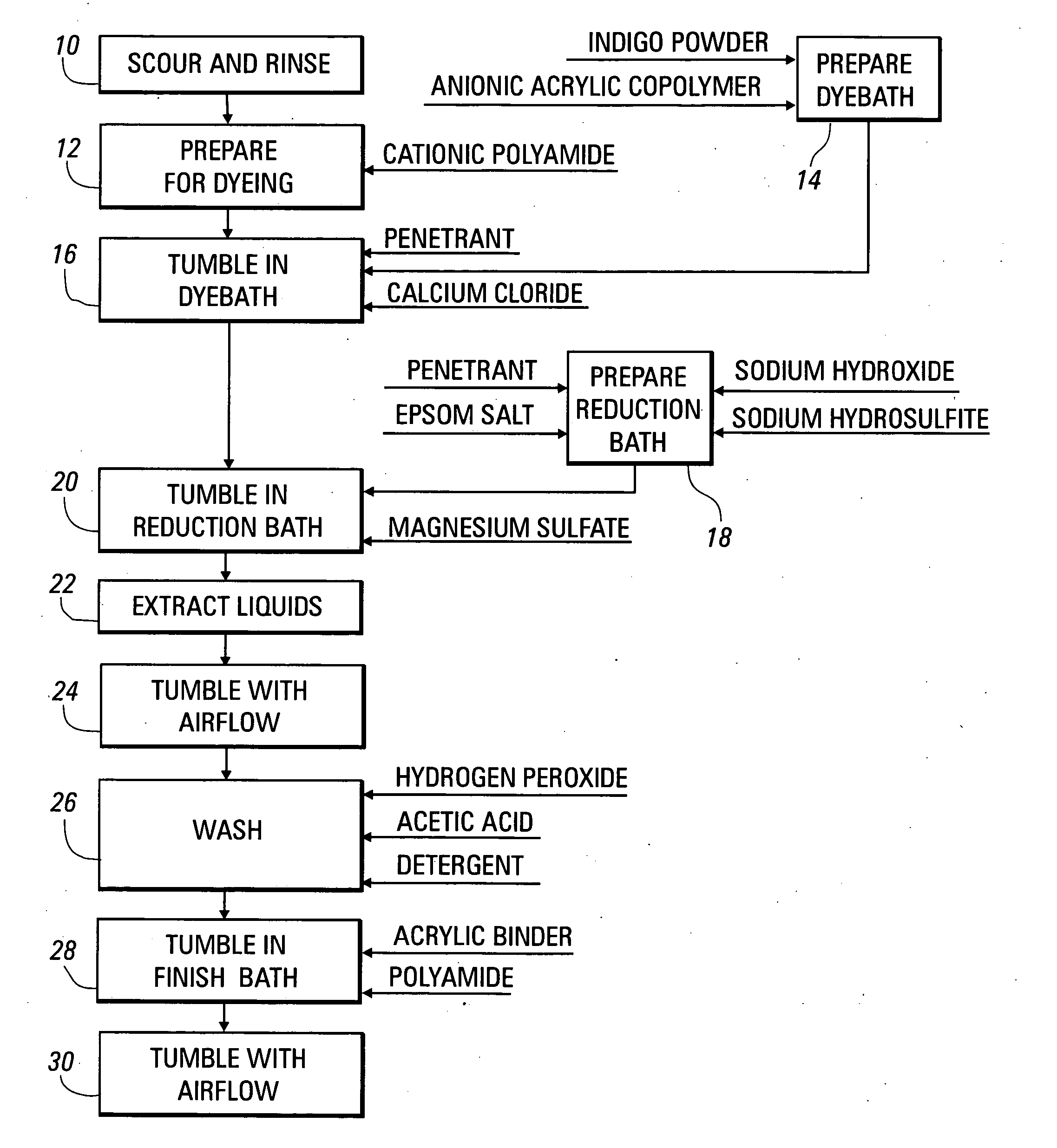

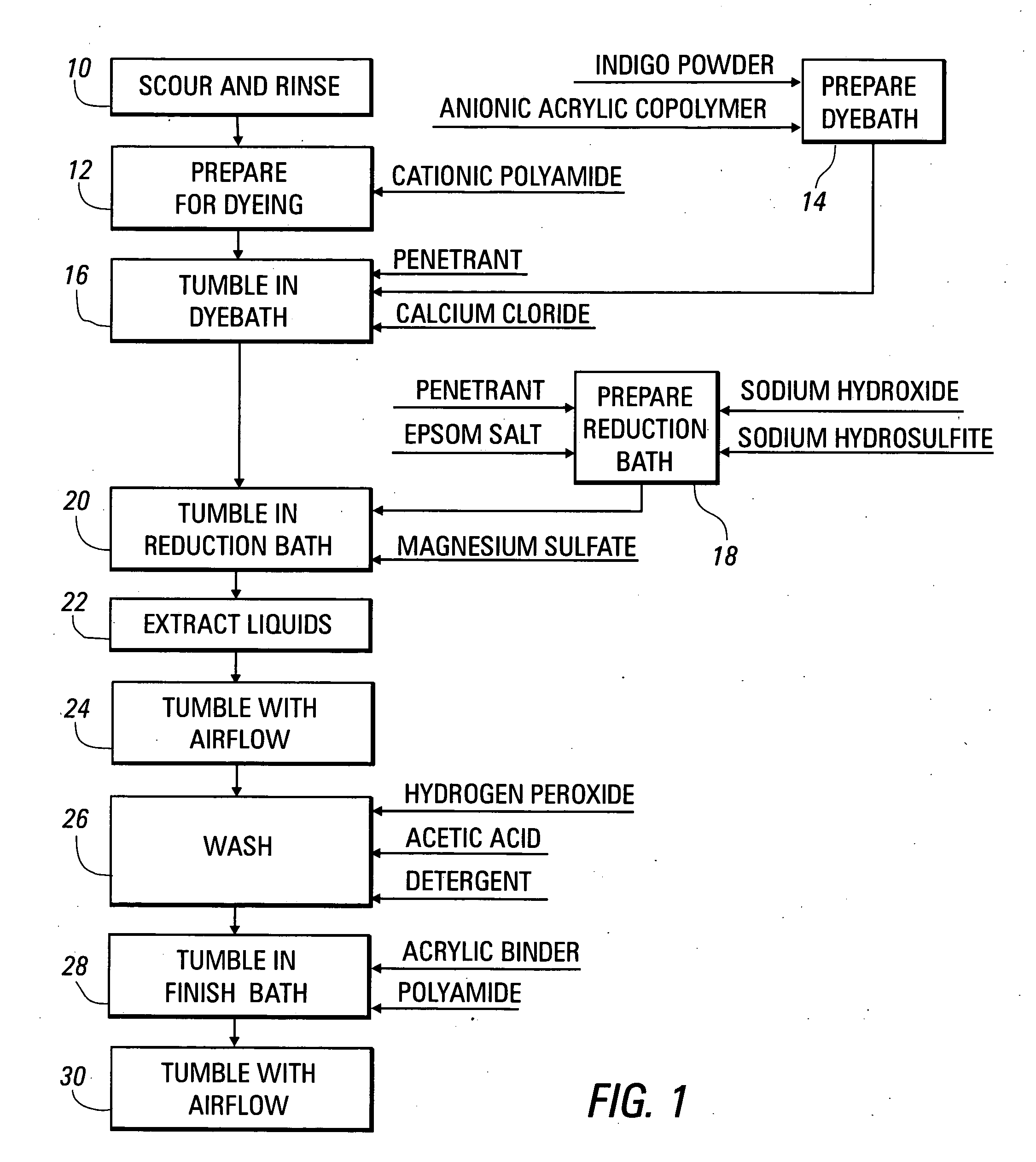

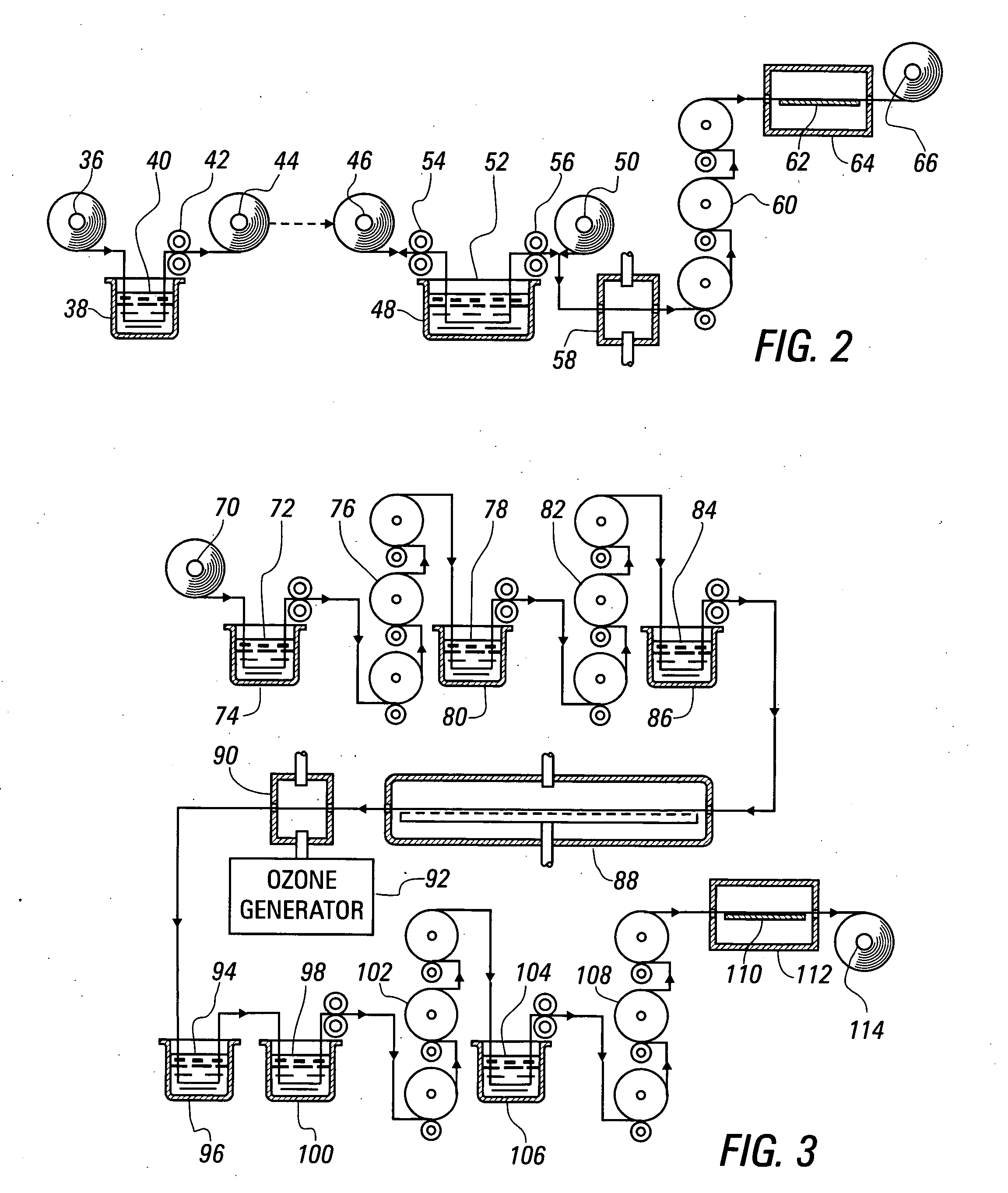

Method for dyeing fabric materials with indigo, other vat dyes, and sulfur dyes

A method for surface dyeing a range of textile materials, in the form of yarn, fabric, or garments, includes: a) preparing a dyebath including dye particles and an additive, such as an anionic acrylic copolymer, causing the particles to become charged; b) preparing the textile material by applying an additive, such as a cationic polyamide, forming a substrate with a charge attracting the particles, c) immersing the textile material in the dyebath; d) chemically reducing the dye particles retained on the textile material to a leuco form; and e) oxidizing the dye material.

Owner:ALPERT MELVIN

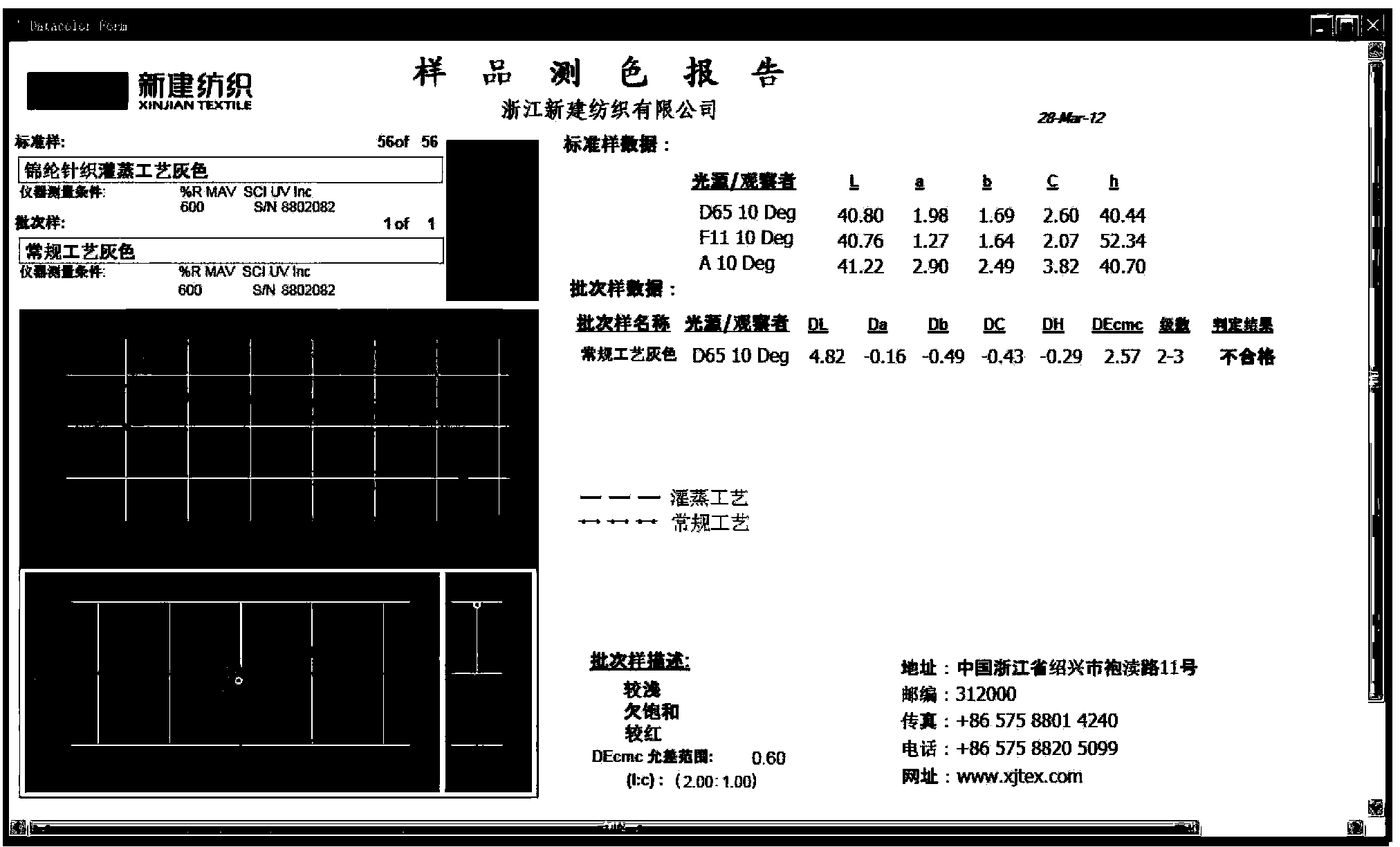

Chinlon or chinlon/cotton blended printed fabric and preparation method thereof

ActiveCN103572580AIncrease widthDoes not affect swathBleaching apparatusTextile treatment with treating outlet contectEngineeringVat dye

The invention discloses a chinlon or chinlon / cotton blended printed fabric and a preparation method thereof. The preparation method comprises the steps of (1) boiling and bleaching a gray fabric which is a chinlon fabric or chinlon / cotton blended printed fabric; (2) printing the gray fabric subjected to boiling and bleaching, wherein when the gray fabric is the chinlon fabric, a printing paste for printing is a neutral dye, and when the gray fabric is the chinlon / cotton blended printed fabric, the printing paste for printing is a mixture of the neutral dye and a reduced dye; (3) steaming and soaping the fabric obtained after printing treatment, and then drying to obtain a product. The printed fabric provided by the invention is full, rich and bright in color and high in color fastness, and has a clean cloth cover, clear pattern outlines and stable product quality.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

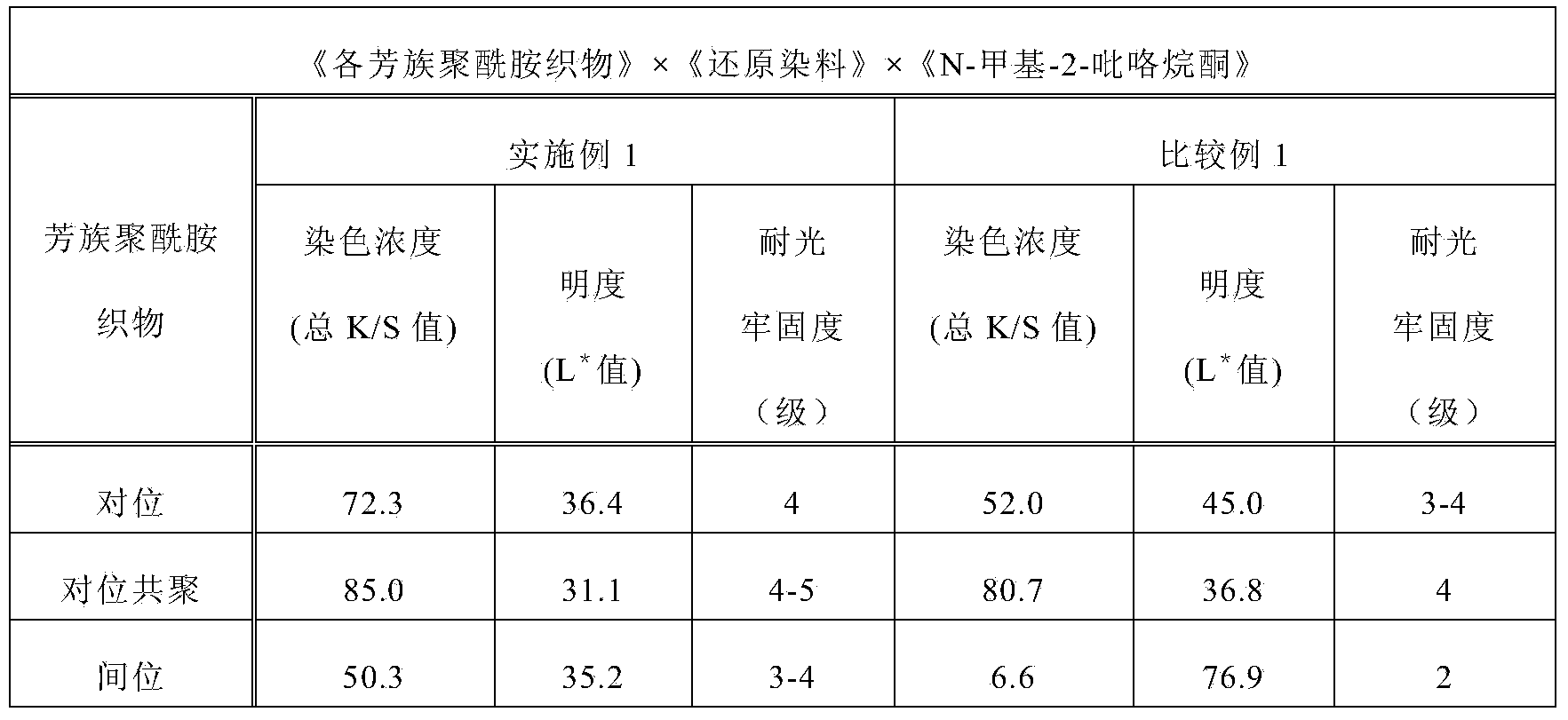

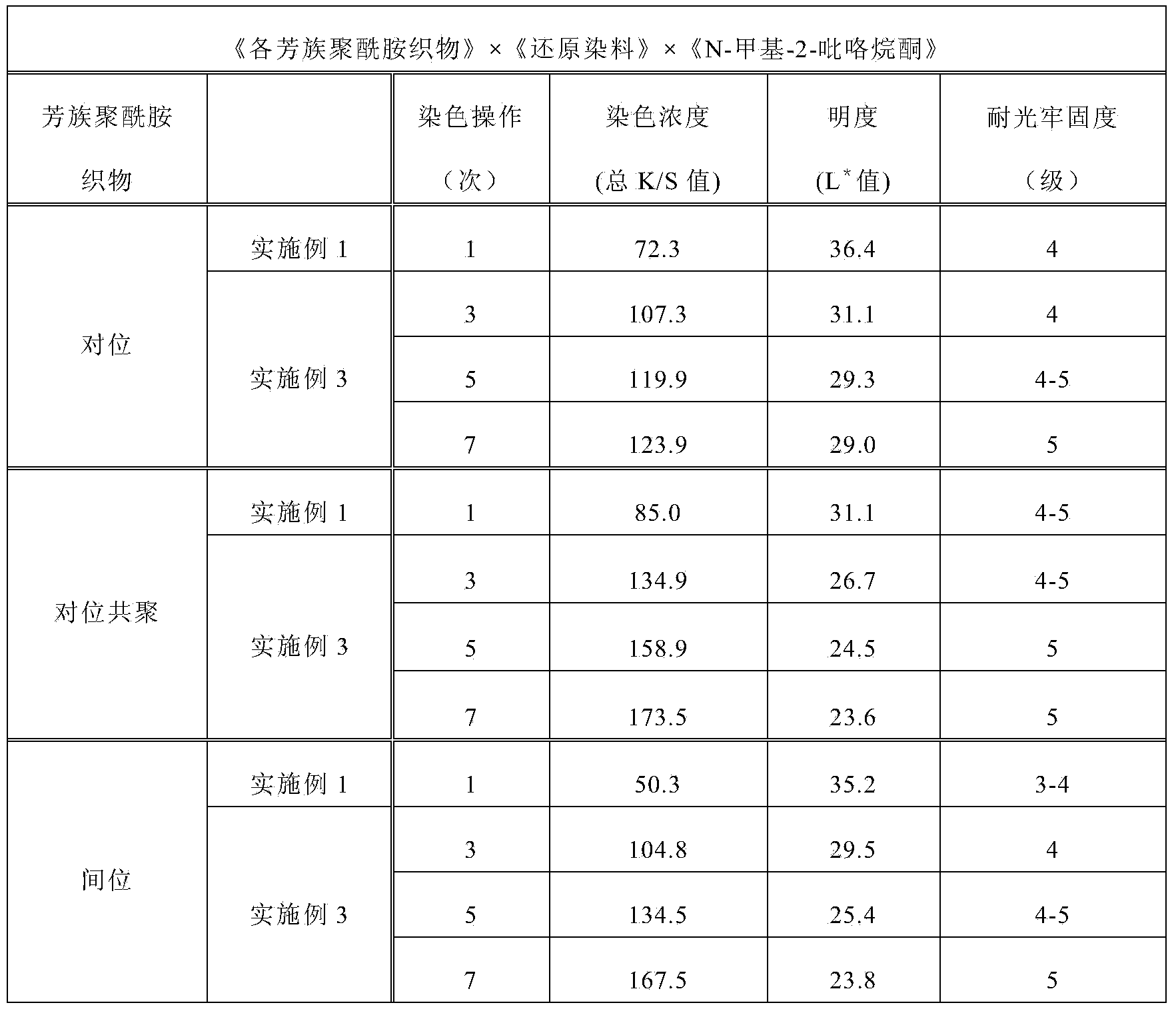

Method for dyeing aramid fibers and dyed aramid fibers

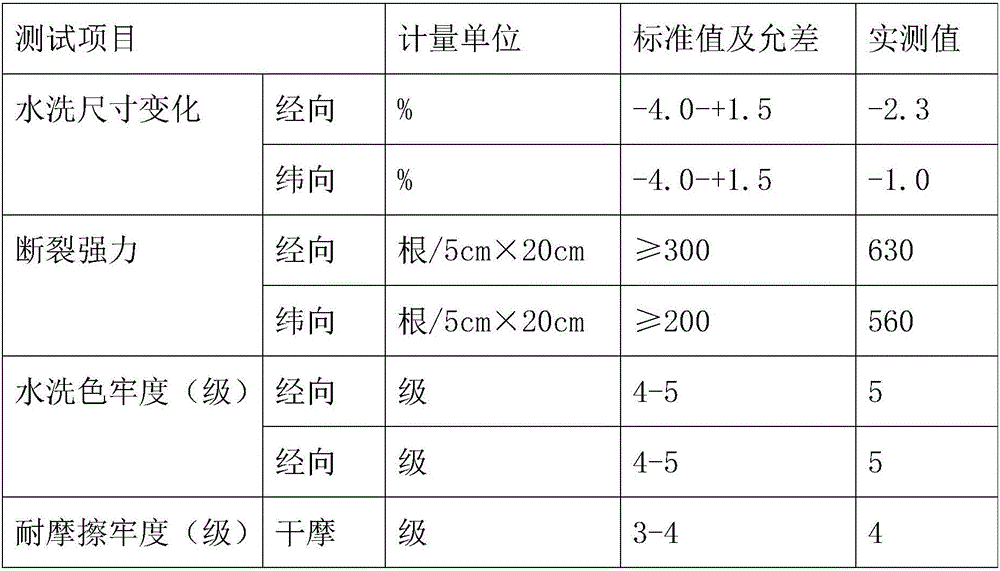

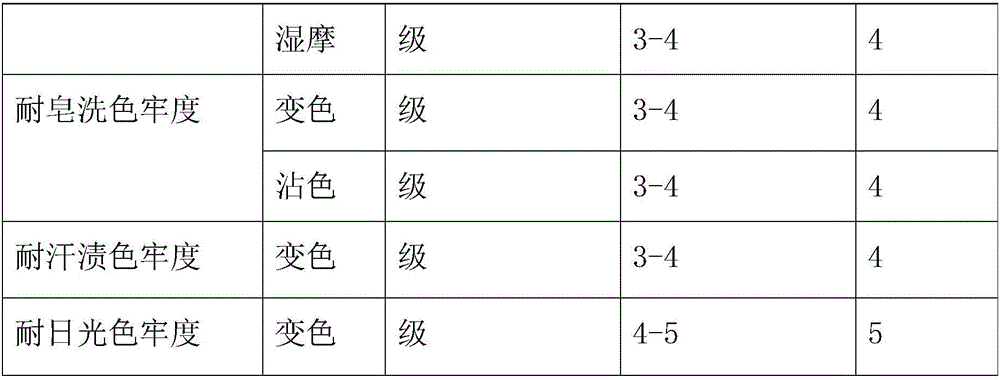

Provided are a method for dyeing aramid fibers and dyed aramid fibers. The method is applicable to any of para-aramid fibers, para-coaramid fibers, and meta-aramid fibers and by which aramid fibers are dyed in practical concentrations required for new applications of aramid fibers. The dyed aramid fibers have suffered neither considerable dyeing unevenness nor a considerable dimensional change nor a considerable decrease in material property. The dyed fibers further have satisfactory color fastness, in particular, light fastness. The dyeing method which comprises one or more dyeing operations each comprising a combination of the following steps: a dye application step in which a vat dye or a sulfur dye is applied to the aramid fibers; a solvent treatment step in which the aramid fibers are treated with a treating liquid comprising a polar solvent; and a heat treatment step in which after the solvent treatment step, the aramid fibers are heat-treated according to need.

Owner:TOKAI SENKO KK +1

Vat dye dyeing technology of full-cotton fabric

InactiveCN102965985AGuaranteed accuracyChlorine bleach fastnessFibre treatmentDyeing processBleachEngineering

The invention relates to the technical field of vat dye dyeing technology in the textile industry, and in particular relates to a vat dye dyeing technology of a full-cotton fabric. The vat dye dyeing technology comprises the steps of dyeing, adding auxiliaries, maintaining temperature, washing by water, oxidizing, soaping, pickling, and post-processing, wherein the water level is needed to be controlled during dyeing in order to ensure the accuracy of the degree in dyeing and the color and gloss; the amount of used auxiliaries is needed to be adjusted based on an auxiliary quantity form during adding the auxiliary, so as to ensure the quality of the full-cotton fabric in dyeing; and the soaping is needed to be carried out twice so as to ensure the color and gloss. The vat dye dyeing technology of the full-cotton fabric has the characteristics of being simple in technology, good in dyeing effect, resistant to high-temperature washing, and resistant and firm in chlorire bleach, and improves the quality of the full-cotton fabric.

Owner:江苏富邦纺织集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com