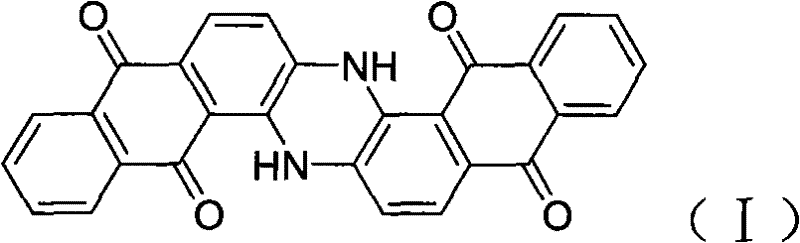

Preparation method of vat blue dye

A technology for dyes and raw materials, applied in the field of preparation of vat dyes, can solve problems such as difficulty in obtaining pigment-grade vat blue, and achieve the effects of good economic benefits, simplified synthesis procedures and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

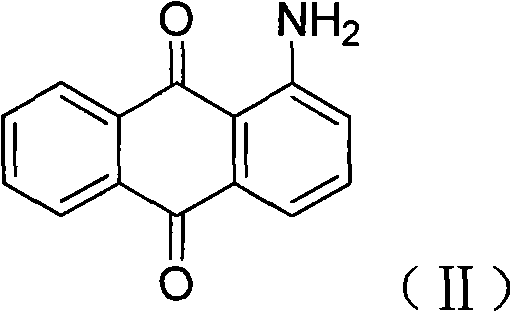

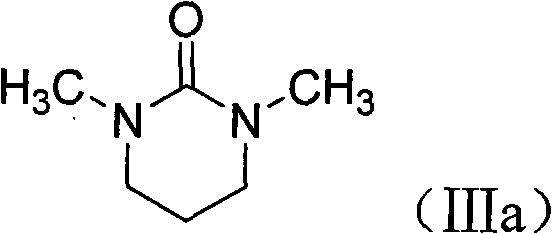

[0015] Example 1 In a 500mL four-necked flask, 120g of water was added into a 10% N,N'-dimethylcyclopropylene urea (IIIa), 0.1g catalyst, 50g of 99.0% purity in 1-aminoanthraquinone ( II), stir and heat up to 95°C, add 150mL 50% potassium hydroxide solution dropwise, oxidize with air, carry out condensation reaction at 100-125°C, add 100mL water to dilute the isolated material after 8 hours of heat preservation reaction, filter the material with suction, and collect the mother liquor , the filter cake was washed with hot water to neutrality, and dried to obtain vat blue 4 (I) 49.2g, yield 98.4%, without further refining and dyeing cotton cloth, bright red light blue can be obtained.

Embodiment 2

[0016] Example 2 In a 500mL four-necked flask, 120g of water was added into a 15% N,N'-dimethylcyclopropylene urea (IIIa), 0.1g catalyst, 50g of 99.0% purity in 1-aminoanthraquinone ( II), stir and heat up to 95°C, add 150mL 50% potassium hydroxide solution dropwise, oxidize with air, carry out condensation reaction at 100-125°C, add 100mL water to dilute the isolated material after 8 hours of heat preservation reaction, filter the material with suction, and collect the mother liquor , the filter cake was washed with hot water to neutrality, and dried to obtain Vat Blue 4 (I) 48.8g, with a yield of 97.6%, without further refining and dyeing cotton cloth to obtain bright red light blue.

Embodiment 3

[0017] Example 3 In a 500mL four-necked flask, 120g of water was added into a 20% N,N'-dimethylcyclopropylene urea (IIIa), 0.1g of catalyst, 50g of 99.0% purity in 1-aminoanthraquinone ( II), stir and heat up to 95°C, add 150mL 50% potassium hydroxide solution dropwise at 95-98°C, oxidize with air, carry out condensation reaction at 100-125°C, add 100mL water to dilute the isolated material after 8 hours of heat preservation reaction, and pump the material Filter, collect mother liquor, filter cake hot water washes to neutrality, dry to obtain vat blue 4 (I) 48.5g, yield 97.0%, can obtain bright red light blue without further refining and dyeing cotton cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com