Multifunctional denim warp dyeing machine

A multi-functional, dyeing machine technology, applied in liquid/gas/steam yarn/filament processing, textile and paper making, removal of liquid/gas/steam, etc., can solve poor color fastness, narrow color selection surface, can not be dyed Problems such as bright colors, etc., to achieve good dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

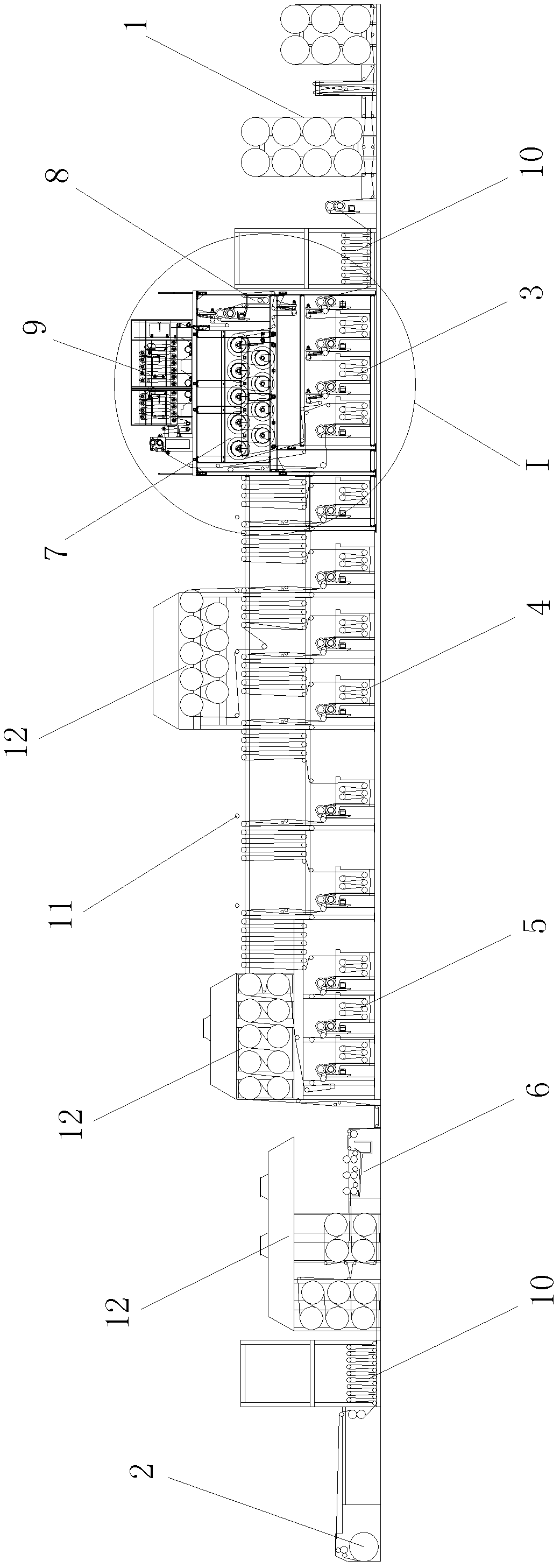

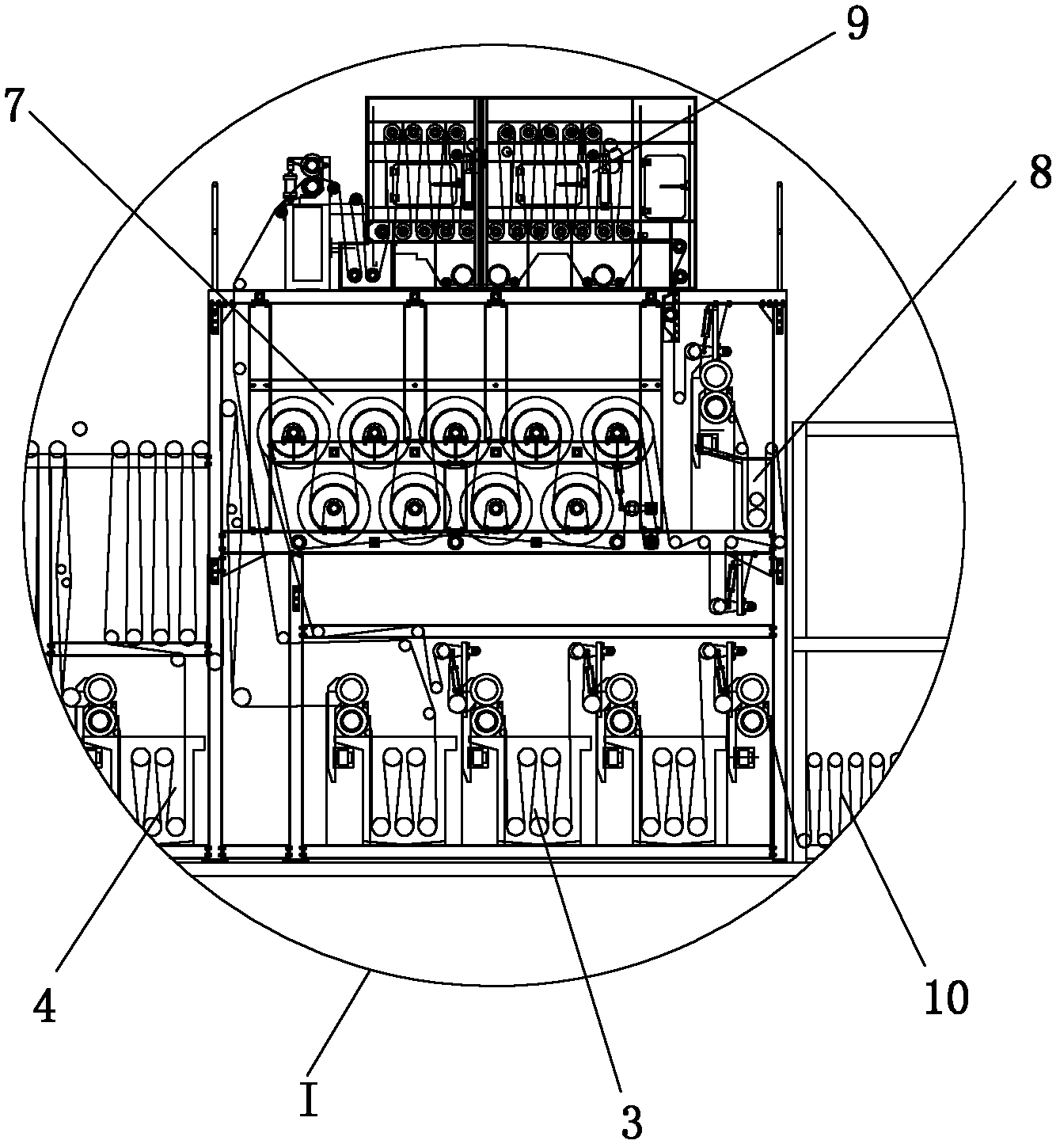

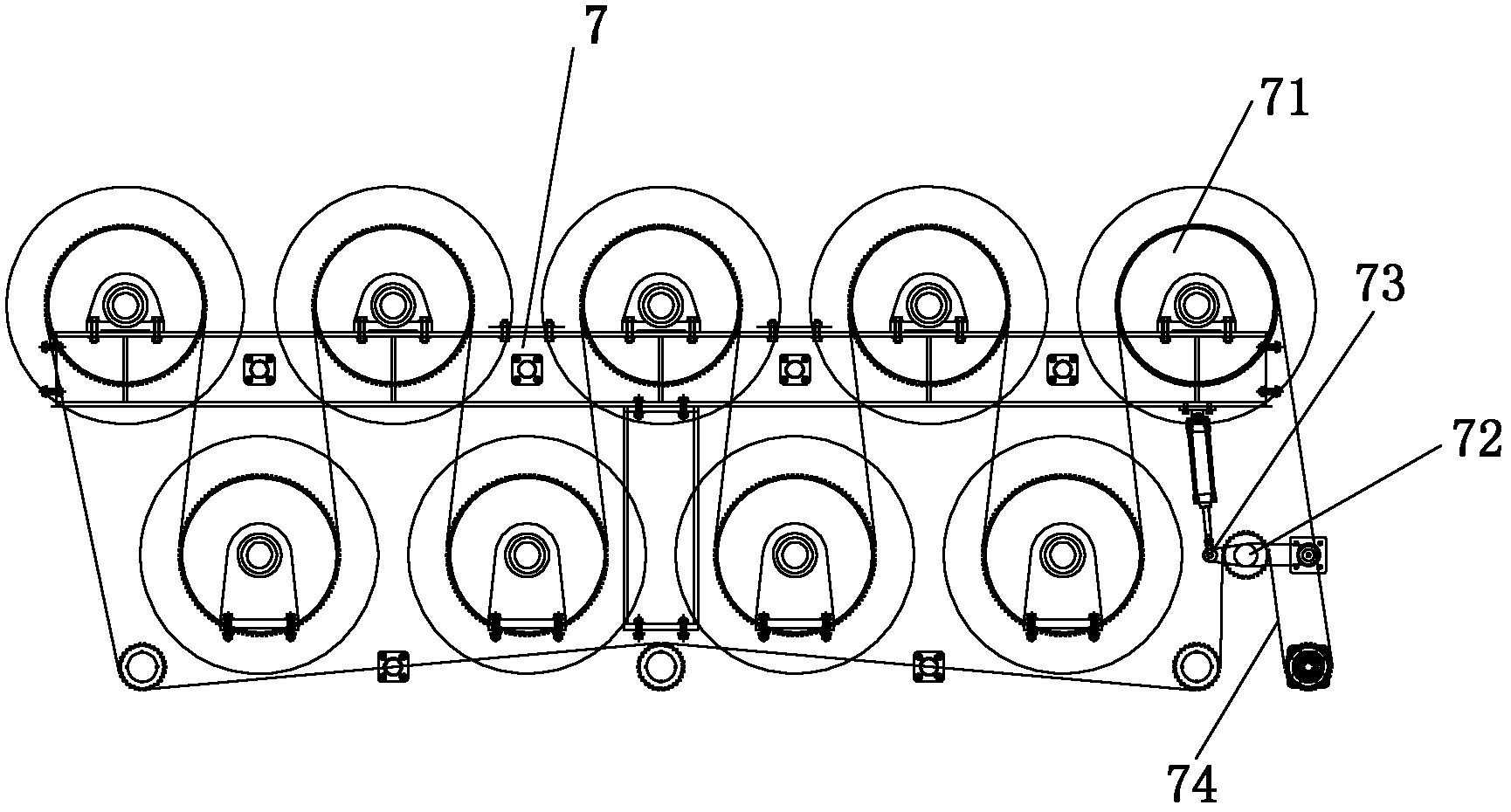

[0016] Such as Figure 1 to Figure 3 As shown, the multifunctional denim warp yarn dyeing machine includes a warp creel 1 to be dyed and a creel 2 for dyed warp yarns. Treated warp yarn pretreatment tank 3, warp yarn dyeing tank 4 that uses indigo dye or sulfur dye to dye warp yarn, washing tank 5 after warp yarn dyeing, sizing tank 6, between the warp yarn pretreatment tank 3 and warp yarn dyeing tank 4 A combined drying cylinder 7 for color dyeing treatment of warp yarns, a small color dye tank 8 for dyeing with vat dyes, and a steam box 9 are arranged in sequence. The combined drying cylinder 7 is provided with a plurality of parallel drying cylinders 71 , a driven wheel 72 driving the rotation of the drying cylinders 71 , and a driving wheel 73 driving the driven wheel 72 to rotate. The driven wheel 72 is driven by a transmission belt 74 and several parallel drying cylinders 71 . Said warp yarn enters the warp yarn pretreatment tank 3 to clean after being processed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com