Polyamide pattern painting camouflage fabric printing process and fabric production and processing method

A technology of printing process and processing method, applied in dyeing, textile and papermaking, etc., can solve the problems of poor wear resistance, hard hand feel, and poor coordination of soldiers' movements of polyester materials, and achieve the effect of precise formula control and stable spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Production and processing method of high-strength nylon camouflage flame retardant fabric:

[0065] 1, yarn empty change: select 600D nylon 66 high-strength industrial wire, and conduct air deformation of the yarn;

[0066] 2, gray fabric woven: Processing the empty yarn of step 1) into a gray fabric.

[0067] 3, the pre-sessile treatment: the gray fabric of step 2) is cold, washed, and the stipulations are cleared, and the printed white cloth before printing.

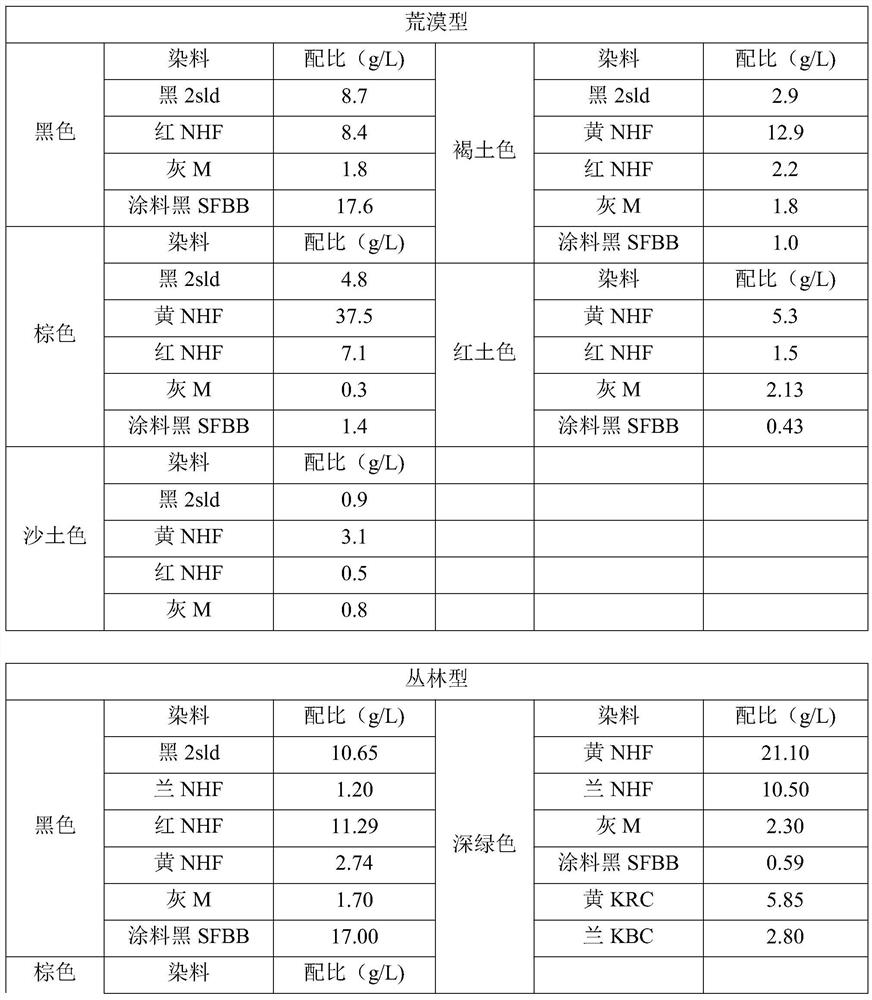

[0068] 4, print: Practice white cloth of step 3) to the round net printing machine to complete the printing process, the dye formulation is shown in Table 1, preparing desert or jungle type camouflage, and the substance in the table is in total volume 1L in each color slide. Content calculation;

[0069] 5, baked vaporization: The printing cloth of step 4) enters the baked machine, reacts the coating in the print formulation to the binder, crosslinking agent, operating temperature 150 ° C, bake 60s, and then enter a...

Embodiment 2

[0084] In this embodiment, high-strong nylon camouflage camouflage flame retardant fabric is prepared, and the arrangement of the fabric design is arranged in accordance with the empty variable yarns and the original wire 1: 1 ratio. After the filament is empty, the intensity of single yarn is reduced, and the present embodiment is introduced into the original filament Strengthen the role of the ribs, can effectively improve the tear power. The rest of the process is the same example 1.

[0085] Table 1 Printing Formulation

[0086]

[0087]

[0088] Table 2 Comparison of the performance of conventional materials

[0089]

Embodiment 3

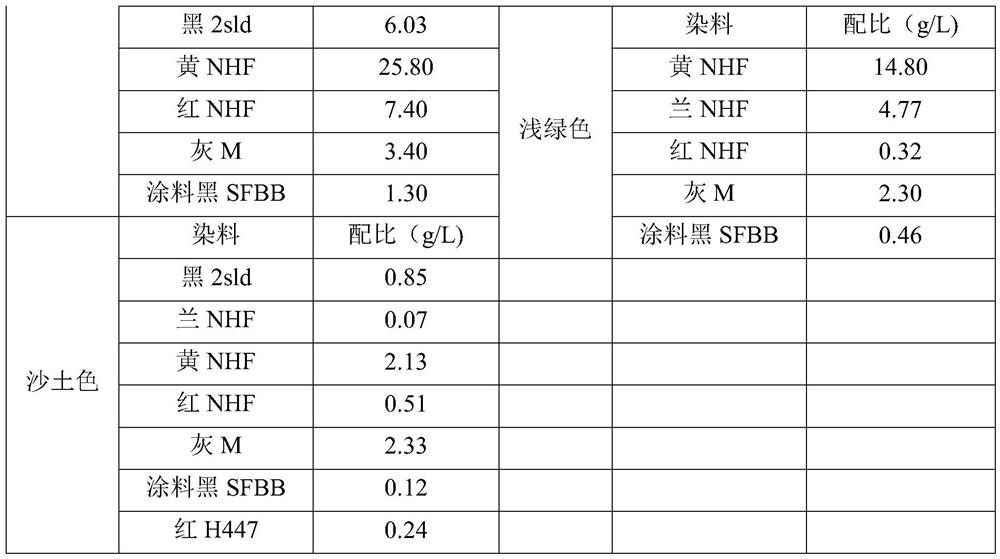

[0091]In this embodiment, high-strength nylon camouflage camouflage flame retardant fabric, changing the manufacturer of dyes and adjusting the process formulation, introducing the reduction gray M, follow the printing formulations in Table 3 - Table 4, will still achieve better camouflage camouflage effects.

[0092] Table 3 Desert printing formula

[0093]

[0094]

[0095] Table 4 Jungle type print formula

[0096]

[0097]

[0098] Other preparation processes are in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| Continue burning | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com