Patents

Literature

58results about How to "High bromine content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

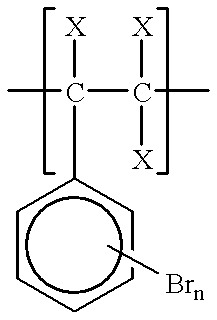

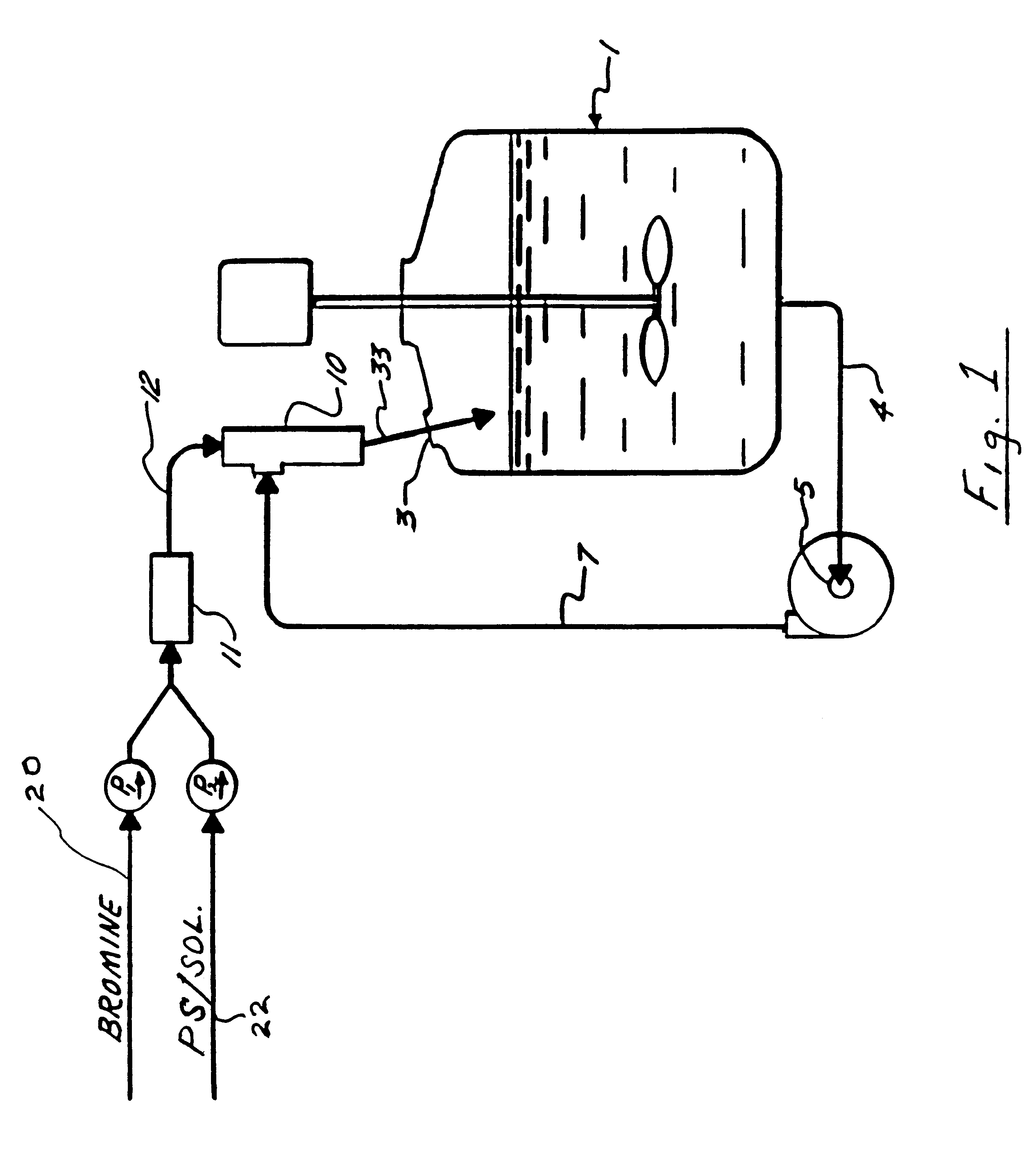

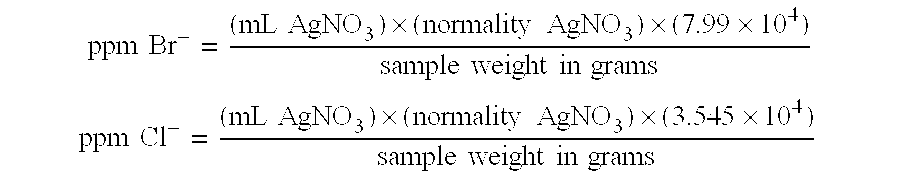

Process for brominating polystyrenic resins

This invention relates to a thermally stable brominated polystyrene having less than 100 ppm total Cl-, above about 68 wt % bromine and less than about 6,000 ppm hydrolyzable halide. The brominated polystyrene exhibits little or no polymer cross-linking or chain cleavage relative to the starting polystyrene.

Owner:ALBEMARLE CORP

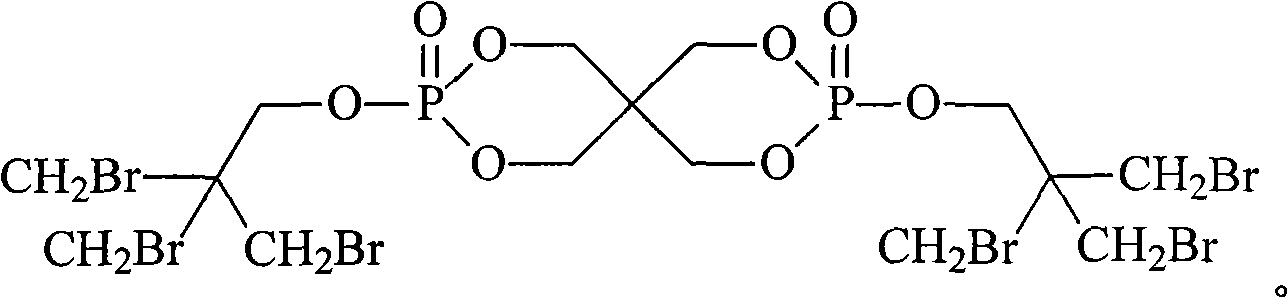

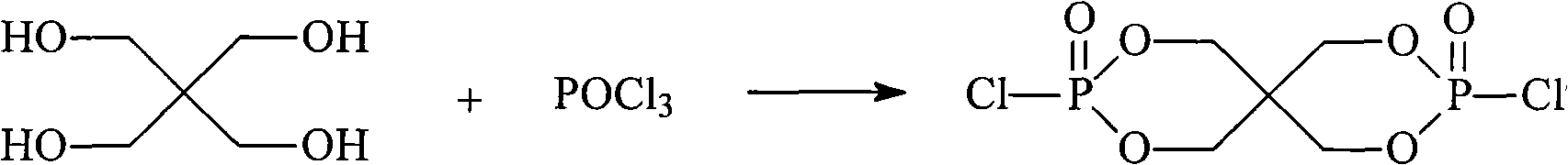

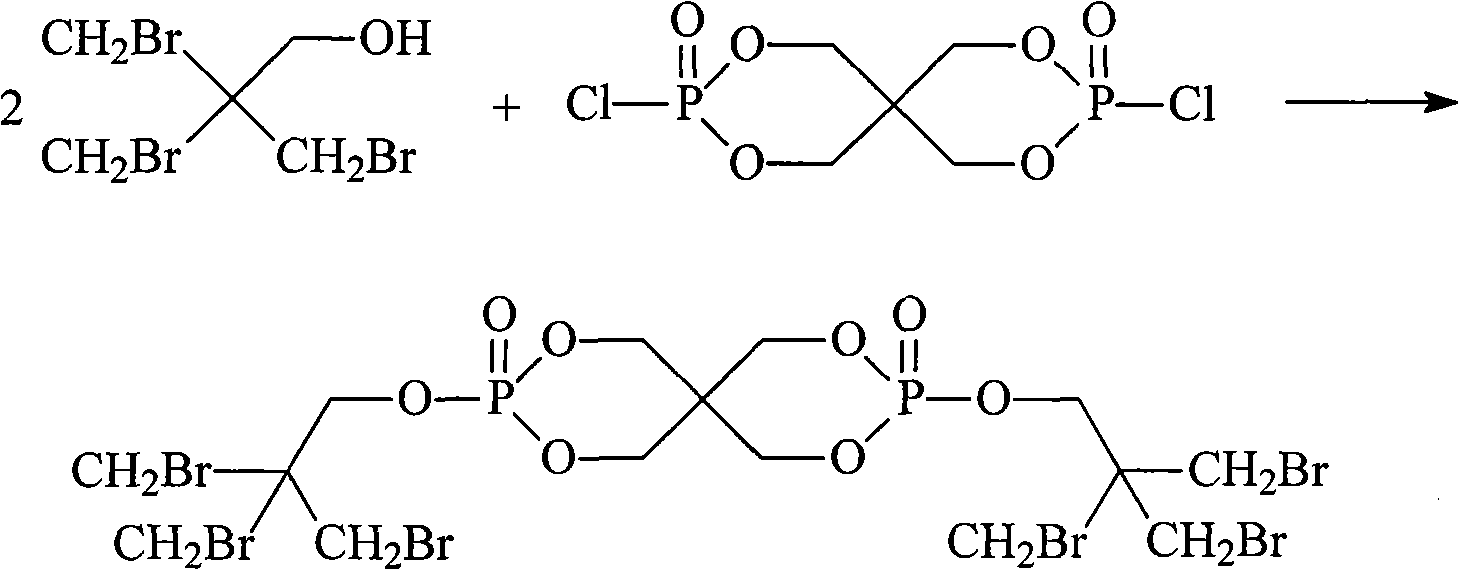

Bromine-containing pentaerythritol phosphoester retardant and preparation method thereof

InactiveCN101921407AToxicBring health risksGroup 5/15 element organic compoundsBulk chemical productionTribromoneopentyl alcoholQuaternary ammonium cation

The invention relates to a bromine-containing pentaerythritol phosphoester fire retardant and a preparation method thereof. The bromine-containing pentaerythritol phosphoester fire retardant is pentaerythritol double-spiro phosphoryl double-tribromo neopentyl alcohol ester. The preparation method of the novel bromine-containing pentaerythritol phosphoester comprises the following steps of: 1, reacting pentaerythritol with phosphorus oxychloride to generate an intermediate pentaerythritol double-spiro double-phosphorus oxychloride; and 2, reacting the pentaerythritol double-spiro phosphorus oxychloride with tribromo neopentyl alcohol to generate the pentaerythritol double-spiro phosphoryl double-tribromo neopentyl alcohol ester, wherein in the reaction, quaternary ammonium salt cation ionic liquid serves as a solvent and a catalyst. The invention discloses a new synthesis method of the bromine-containing pentaerythritol phosphoester fire retardant. The ionic liquid serves as the solvent, so the synthesis yield is improved; and a phosphorus-bromine synergistic flame retardant technique is adopted in the design of a molecular structure, so the anti-flaming efficiency of the flame retardant for high molecular materials is improved.

Owner:DONGHUA UNIV

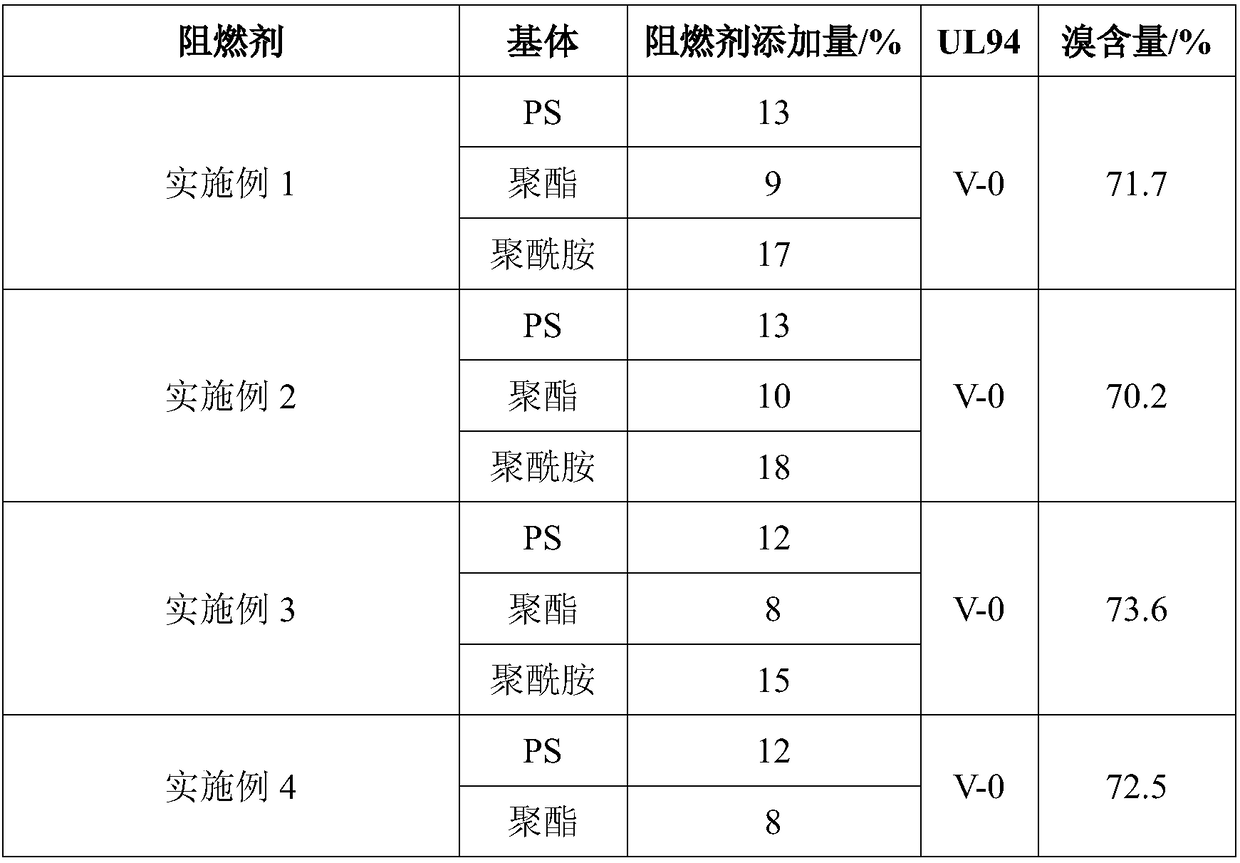

Method for preparing flame retardant brominated polystyrene by using composite catalyst

The invention relates to a method to prepare polystyrene bromide with compound catalyst system. Use polystyrene as the raw material, alkyl halide as solvent, with the existence of catalyst and dehydrating agent, the polystyrene bromide is made by bromination of brominating agent. Its characteristics include: the catalyst is composed of ó° family metal, ó�B family metal, tin or stibium and lewis acid, and the polystyrene bromide has large content of bromine (the largest-one can be 60%), high melt point (30-50% higher) and productivity (larger than 95%). It can be applied for antiflaming of resin such as PET, PBT and nyloen nylon.

Owner:EAST CHINA UNIV OF SCI & TECH

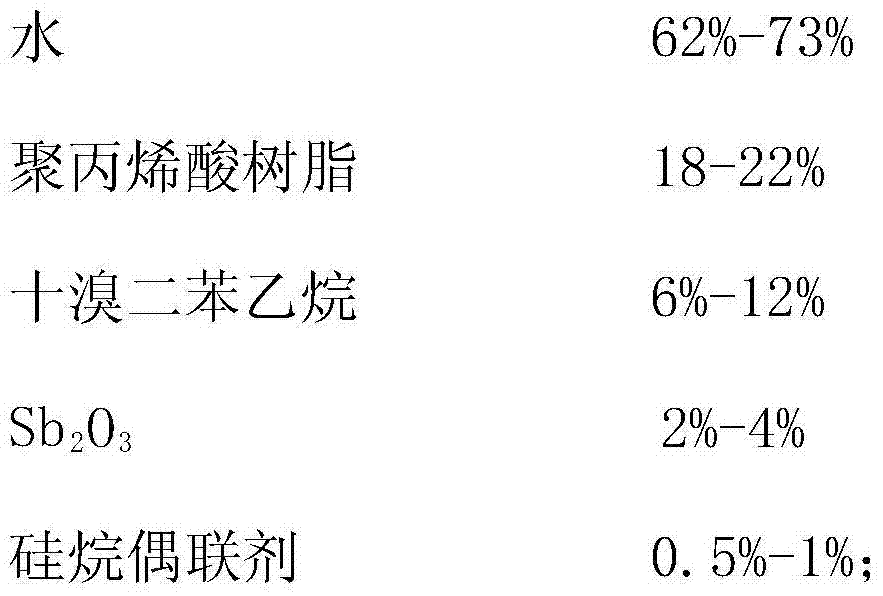

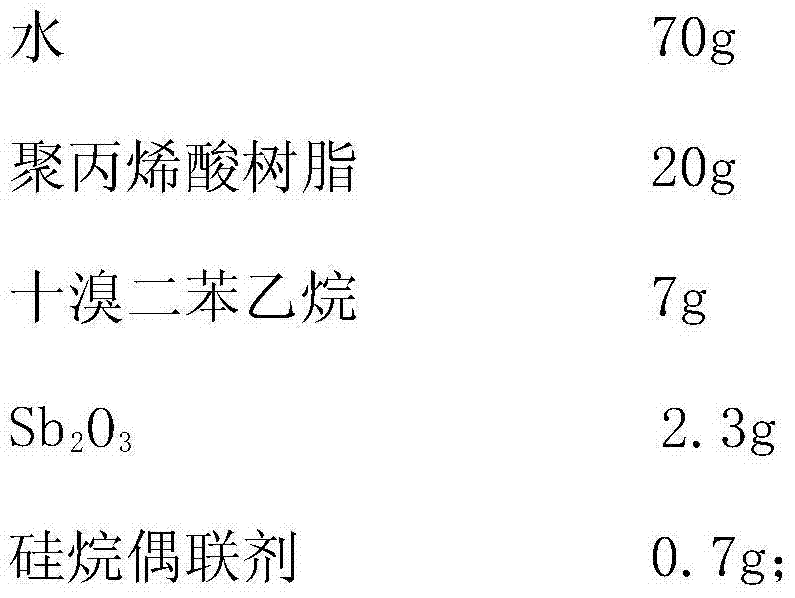

Preparation method of flame retardant PP (polypropylene) non-woven fabric

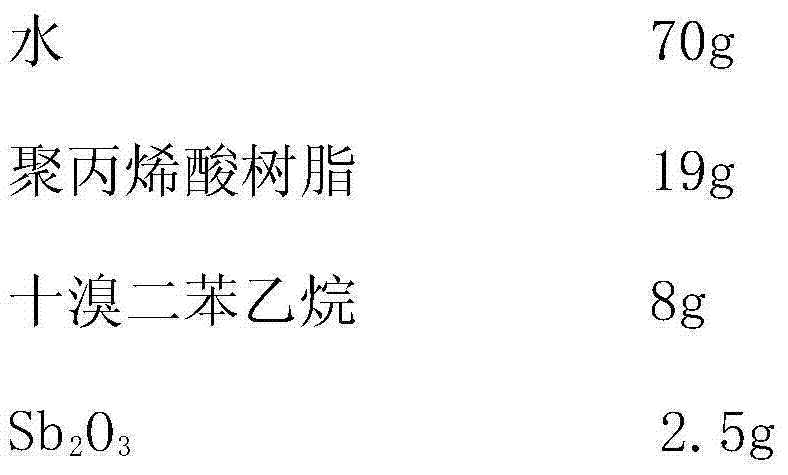

The invention relates to a preparation method of flame retardant PP (polypropylene) non-woven fabric. The non-woven base fabric obtained by a melt blowing method is subjected to flame retardant finishing. The preparation method comprises the following steps: preparing flame retardant slurry from the following components in percentage by mass: 62 to 73 percent of water, 18 to 22 percent of polyacrylic acid, 6 to 12 percent of decabromodiphenylethane, 2 to 4 percent of Sb2O3 and 0.5 to 1 percent of a silane coupling agent; pouring the flame retardant slurry into a slurry barrel with a stirring device, making the non-woven base fabric pass through a pressure roller and a slurry feeding roller, and transferring the slurry in a slurry groove to the base fabric through a screen frame by using the slurry feeding roller; placing the base fabric which is coated with the slurry between two rubber pressure rollers of a roller press for extruding to remove excessive slurry; finally, drying the base fabric to obtain the flame retardant non-woven fabric. The preparation method is simple in process, convenient to operate, and environmental friendly; the selected decabromodiphenylethane is a high-efficiency brominated flame retardant, and has the characteristics of high bromine content, high thermal stability, low toxicity and the like; meanwhile, the decabromodiphenylethane and the added Sb2O3 have a synergistic flame retardant effect, so that the prepared non-woven fabric has a good flame retardant effect.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

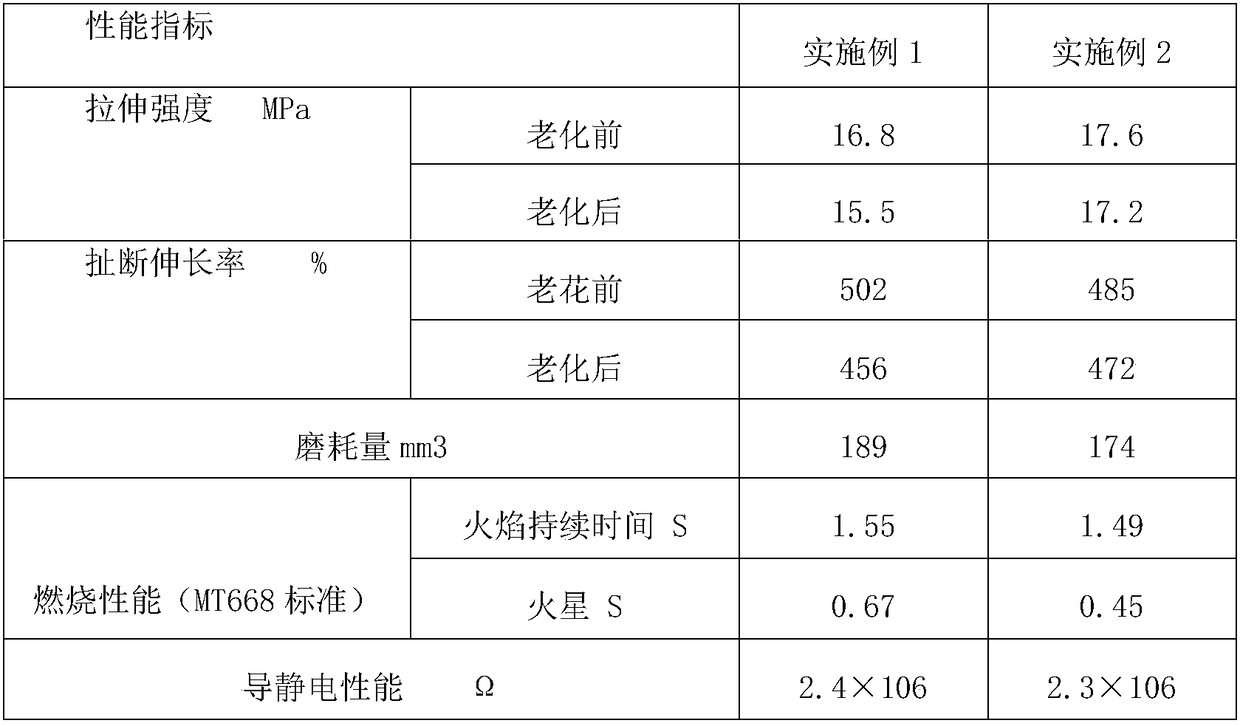

Low-smoke low-halogen flame-retardant conveyor belt covering glue for coal mine and preparation process thereof

InactiveCN108659285AHigh bromine contentImprove thermal stabilityConveyorsComposite ceramicEngineering

The invention discloses low-smoke low-halogen flame-retardant conveyor belt covering glue for a coal mine, and relates to the technical field of conveyor belt covering glue. The covering glue comprises the following chemical components: natural standard rubber, styrene-butadiene rubber SBR1502, cis-butyl BR9000 rubber, polyisobutylene PB1300, an anti-aging agent, zinc oxide, magnesium oxide, stearic acid, a flow release agent, N234 carbon black, nano-aluminum hydroxide, antimony trioxide, decabromodiphenylethane, composite ceramic powder, expanded halogen-free flame-retardant IFR, a multi-purpose synergistic halogen-free flame retardant PNA220, molybdenum salt used as a smoke suppressant, an accelerator and sulfur. The low-smoke low-halogen flame-retardant conveyor belt covering glue disclosed by the invention is used under a coal mine well to meet flame-retardant performance of the conveyor belt, has excellent wear resistance and flame retardancy, and is low in smoke amount and smoketoxicity.

Owner:江苏凯嘉橡胶科技股份有限公司

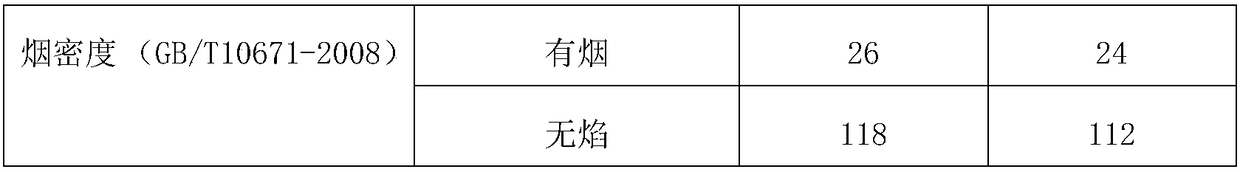

Efficient seawater desalination and comprehensive utilization method

ActiveCN110734166AEfficient removalHigh bromine contentGeneral water supply conservationCalcium/strontium/barium chloridesSeawaterUltrafiltration

The invention discloses an efficient seawater desalination and comprehensive utilization method. The efficient seawater desalination and comprehensive utilization method comprise following steps: carrying out pretreatment on raw seawater, filtering using a microfiltration and / or ultrafiltration device to obtain pretreated seawater; adding a scale inhibitor into the pretreated seawater; pressurizing and conveying the pretreated seawater into a primary nanofiltration device; adjusting the pH value of obtained primary nanofiltration produced water to 3-7, pressurizing and feeding into a secondarynanofiltration device; mixing obtained primary nanofiltration concentrated water with obtained secondary nanofiltration concentrated water; adding a precipitant to react with SO4<2-> in an obtained concentrated water mixed solution to generate calcium sulfate precipitate; continuously adding lime emulsion into an obtained reacted mother liquor to react with Mg<2+> in the mother liquor to generatemagnesium hydroxide precipitate, adjusting the pH value of the residual mother liquor to 7-8, producing sodium chloride and calcium chloride through multi-effect evaporation, adjusting the pH value of obtained secondary nanofiltration produced water to 6.5-7.8, and pressurizing and introducing the secondary nanofiltration produced water into a reverse osmosis seawater desalination device. According to the efficient seawater desalination and comprehensive utilization method, seawater grading pretreatment process is adopted, the component difference of various concentrated water is fully utilized, seawater desalination and the chemical technology are combined, and the fresh water yield and the seawater utilization rate are increased.

Owner:CHINA NAT OFFSHORE OIL CORP +3

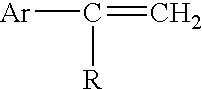

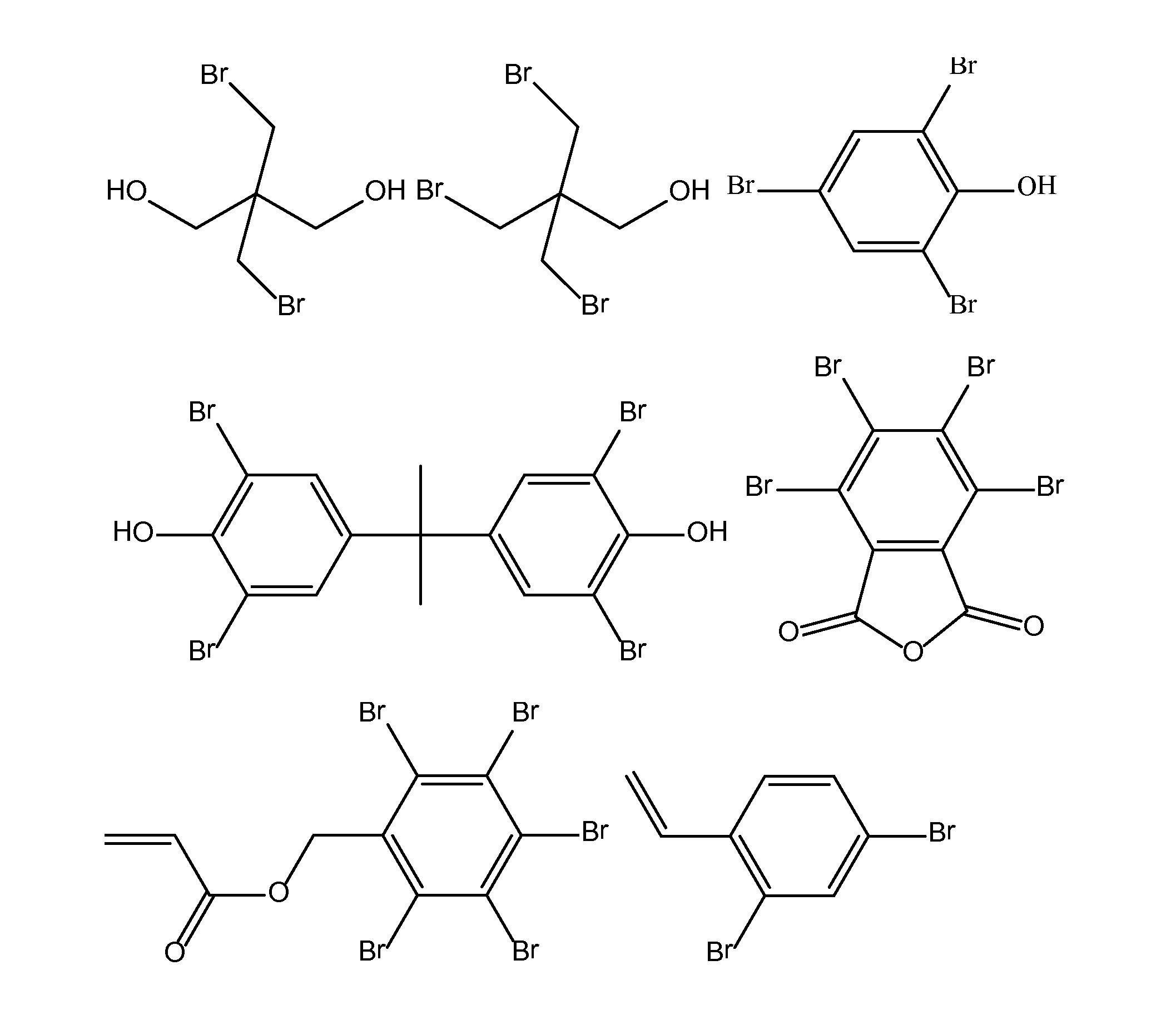

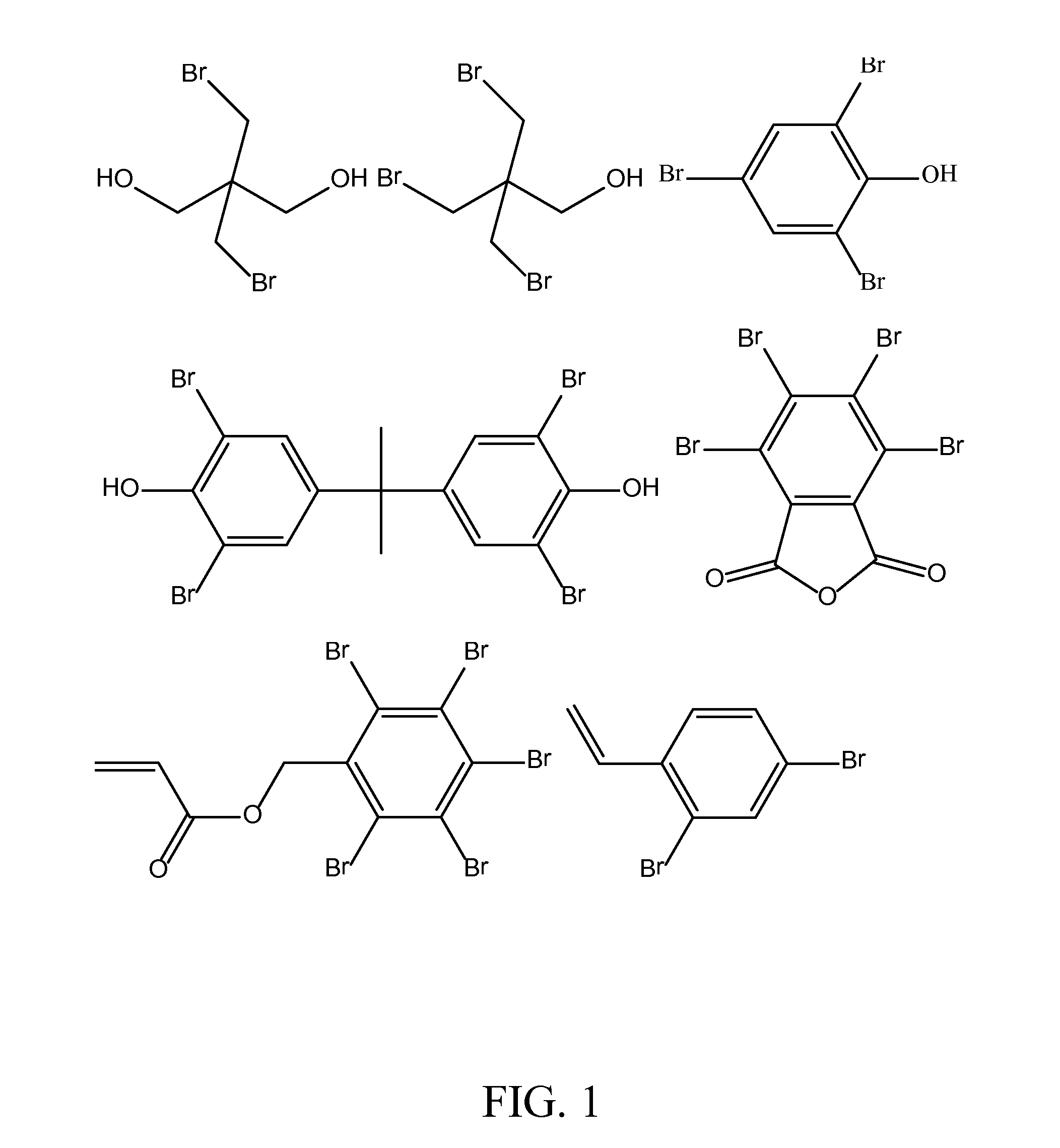

Flame Retarded Styrenic Foams and Foam Precursors

Styrenic polymer foams, especially expanded and / or extruded styrenic polymer foams, are flame retarded by use of one or more flame retardant additives. These additives are i) a diether of tetrabromobisphenol-S, which ether groups do not contain bromine and wherein at least one of the ether groups is an allyl group; ii) a diether of tetrabromobisphenol-S, wherein at least one of the ether groups contains bromine; iii) a substituted benzene having a total of 6 substituents on the ring and wherein at least 3 of the substituents are bromine atoms and at least two of the substituents are C1-4 alkyl groups; iv) tribromoneopentyl alcohol; v) a tris(dibromoalkyl) benzenetricarboxylate in which each dibromoalkyl group contains, independently, 3 to 8 carbon atoms; vi) a brominated polybutadiene which is partially hydrogenated and / or aryl-terminated; vii) at least one brominated allyl ether of a novolac; viii) a brominated poly(1,3-cycloalkadiene); ix) a brominated poly(4-vinylphenol allyl ether); x) a brominated N,TSP-phenylenebismaleimide; xi) a brominated N,N′-(4,4′-methylenediphenyl)bismaleimide; xii) a brominated N,N′-ethylenebis-maleimide; xiii) ethylenebis(dibromonorbornane-dicarboxrmide); xiv) tetrabromobisphenol-A; or xv) a combination of any two or more of i) through xiv).

Owner:ALBEMARLE CORP

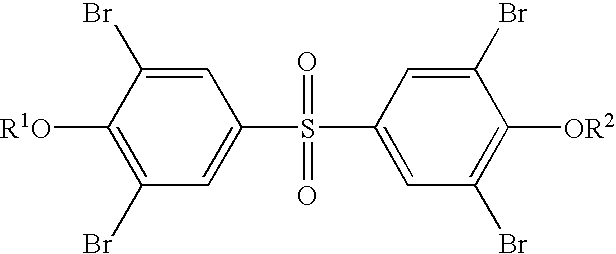

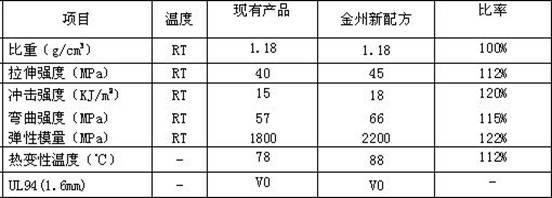

Environment-friendly inflaming-retarding acrylonitrile-butadiene-styrene (ABS) material

An environment-friendly inflaming-retarding acrylonitrile-butadiene-styrene (ABS) material belongs to the technical field of high polymer materials, which comprises the following components, by weight: 50-90 parts of ABS, 10-50 parts of flame retardants, 5-20 parts of flame retardant association effect agents, 0-2 parts of antioxidants and 0-2 parts of processing agents. The ABS material is friendly to the environment and has high inflaming-retarding performance and an excellent mechanics effect.

Owner:杭州金州高分子科技有限公司

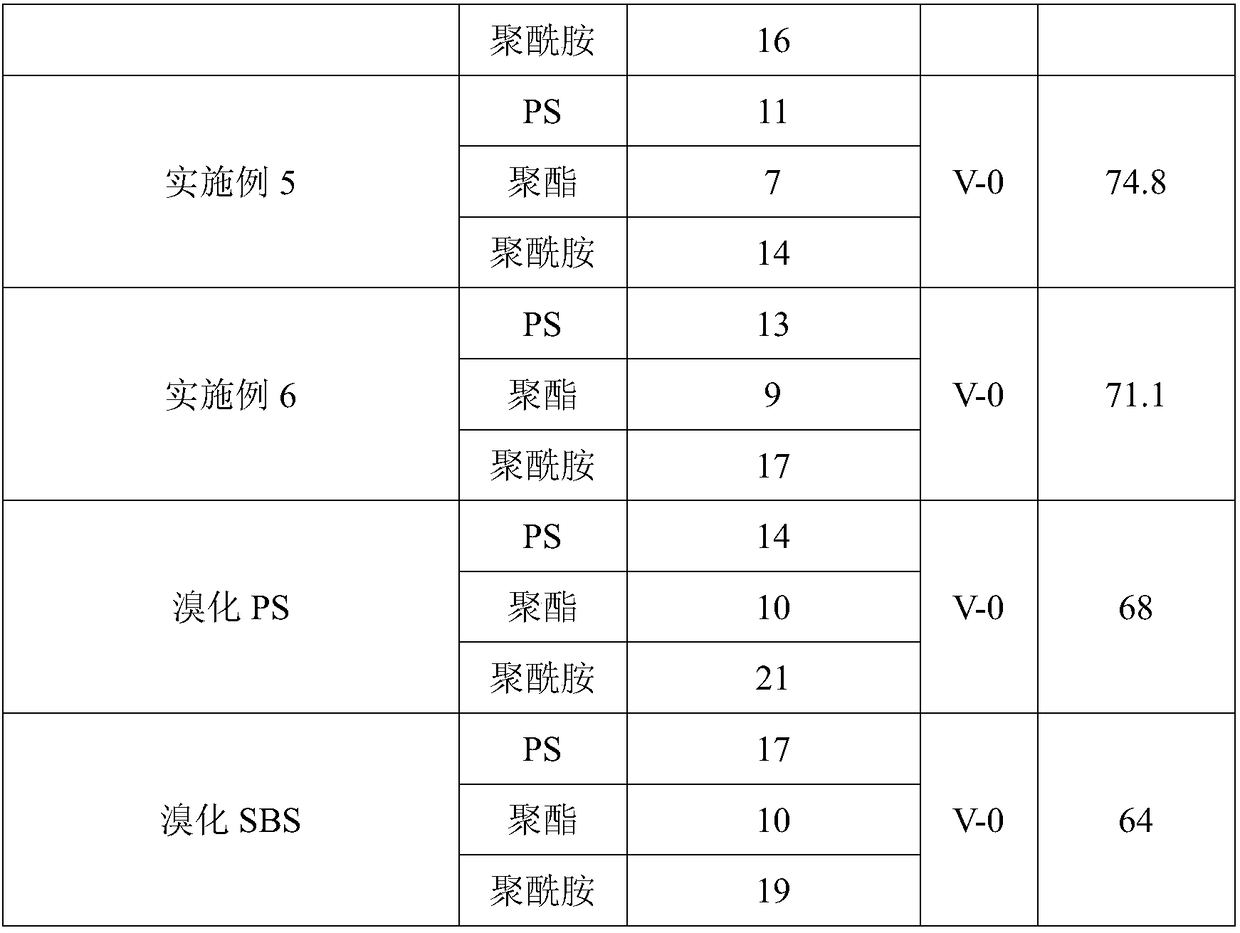

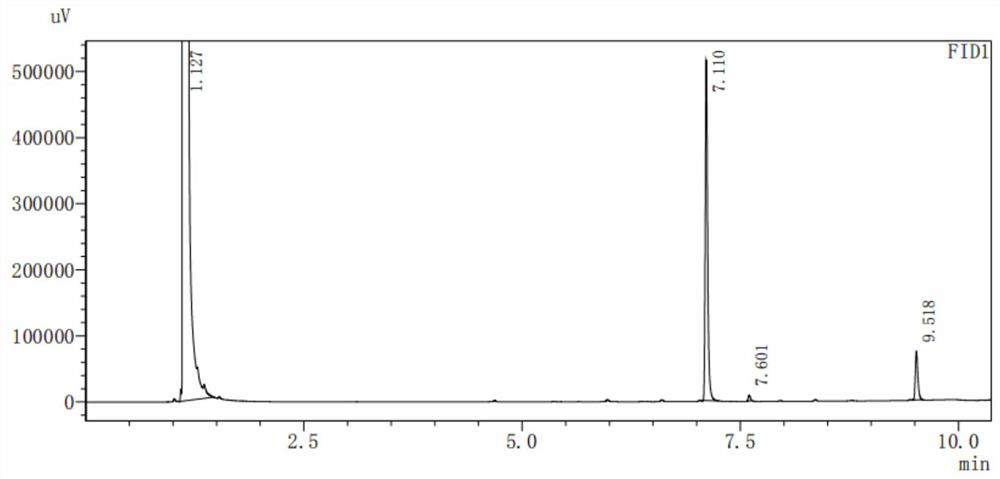

Method for synthesizing brominated polystyrene

The invention relates to a method for synthesizing brominated polystyrene. The method comprises the following steps: under the protection of nitrogen, uniformly mixing a dichloroethane solution of polystyrene with a certain amount of a catalyst and a free radical inhibitor, dropwise adding bromine, controlling the dropwise adding time and the temperature after dropwise adding, carrying out a heatpreservation reaction, carrying out post-treatment after the heat preservation reaction is finished to obtain a crude product, and drying the crude product to constant weight to obtain the brominatedpolystyrene product. The method for synthesizing the brominated polystyrene is simple in process and easy to control, and the synthesized brominated polystyrene is high in stability, high in bromine content, low in chromaticity and narrow in molecular weight distribution.

Owner:TAIZHOU BAILLY CHEM CO LTD

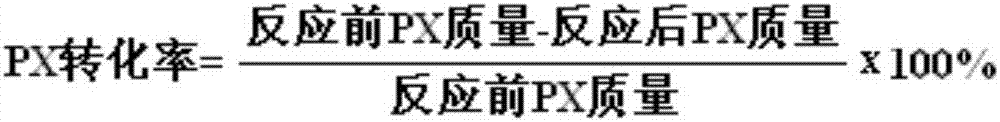

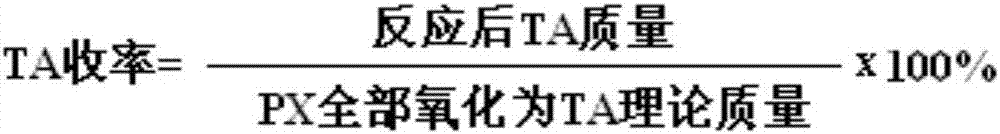

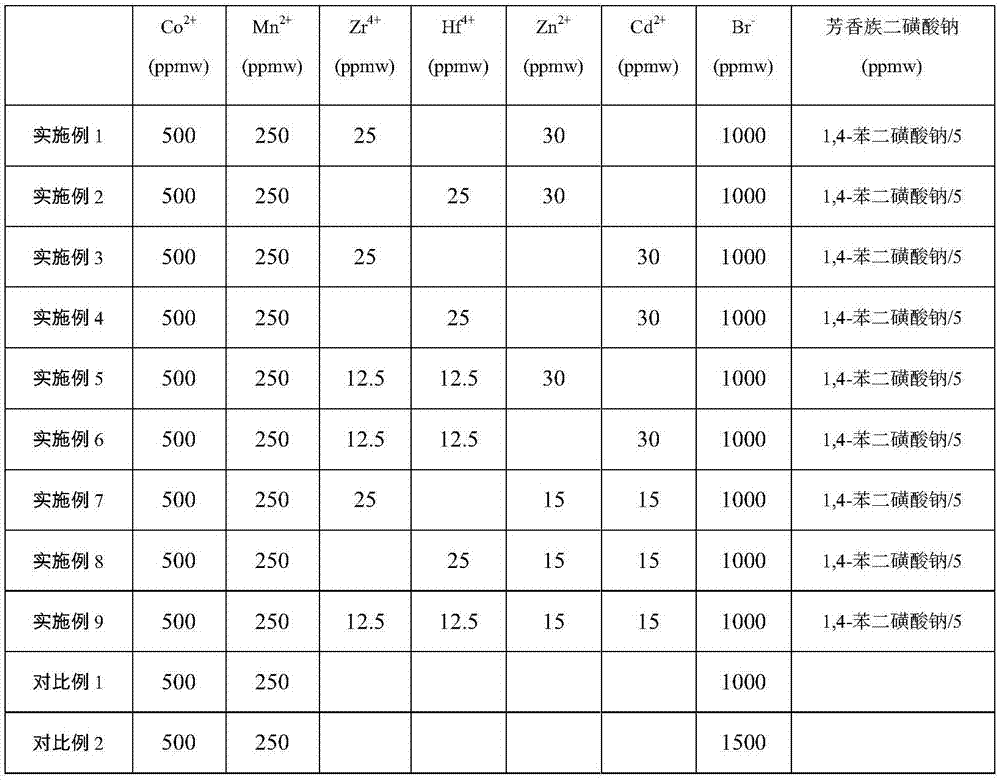

Catalyst for preparing aromatic polycarboxylic acid

ActiveCN107282103AHigh bromine contentLow in bromineOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBromineCarboxylic acid

The invention relates to a catalyst for preparing aromatic polycarboxiylic acid and mainly solves the problem that the using amount of bromine of a catalyst for preparing the aromatic polycarboxylic acid by substituting aromatic hydrocarbons by multiple alkyl groups through liquid-phase oxidation in the prior art is too high. By adopting the technical scheme, the catalyst for preparing the aromatic polycarboxylic acid is prepared from Co salt, Mn salt, IVB group metal salt, IIB group metal salt, a bromine-containing compound and an aromatic sulfonic acid compound, wherein the aromatic sulfonic acid compound is selected from at least one of aromatic disulfonic acid or aromatic disulfonate, the technical problem is well solved, and the catalyst can be used for production of preparing the aromatic polycarboxylic acid by substituting the aromatic hydrocarbons by the multiple alkyl groups through the liquid-phase oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process of brominated SBS

The invention discloses a production process of brominated SBS, and belongs to the technical field of flame retardant production, and the production process comprises the following steps: adding SBS and isobutanol into a reaction kettle, heating to 20-40 DEG C, stirring, and keeping the temperature until the materials are completely dissolved; adding sodium bromide, introducing oxidizing agent chlorine, filling lime milk at the tail end of the reaction kettle to absorb unreacted chlorine in the reaction kettle, and heating to 60-75 DEG C and then stopping heating; cooling to 20 DEG C, adding acatalyst, and continuously heating to 75 DEG C to react for 1 hour, wherein the catalyst being tin tetrachloride and ferric trichloride; and cooling to room temperature, adding peroxide and alkali metal alkoxide into the material liquid after the reaction is finished, heating to 30-40 DEG C, keeping the temperature for 2 hours, filtering, washing, removing impurities, and drying to obtain the target product brominated SBS, wherein the peroxide is hydrogen peroxide, and the alkali metal alkoxide is sodium methoxide. The preparation of the brominated SBS is realized by adopting a direct bromination method, the reaction is mild, the bromine content, the yield and the thermal stability of the brominated SBS are improved, and the use requirements are met.

Owner:山东东信新材料科技股份有限公司

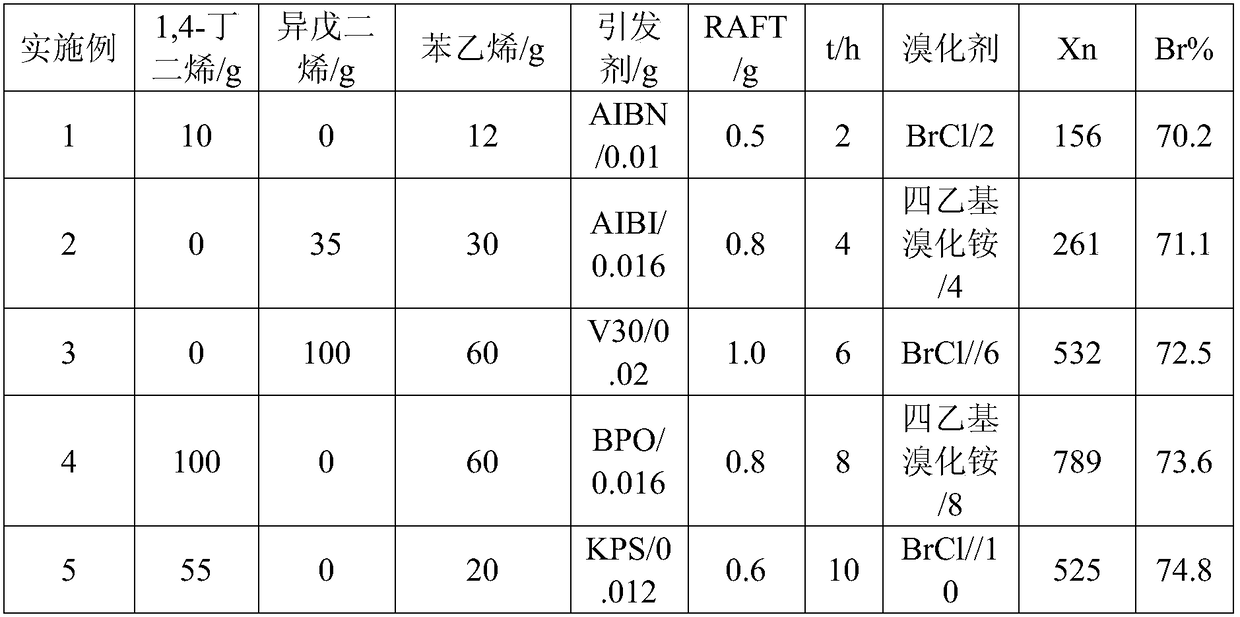

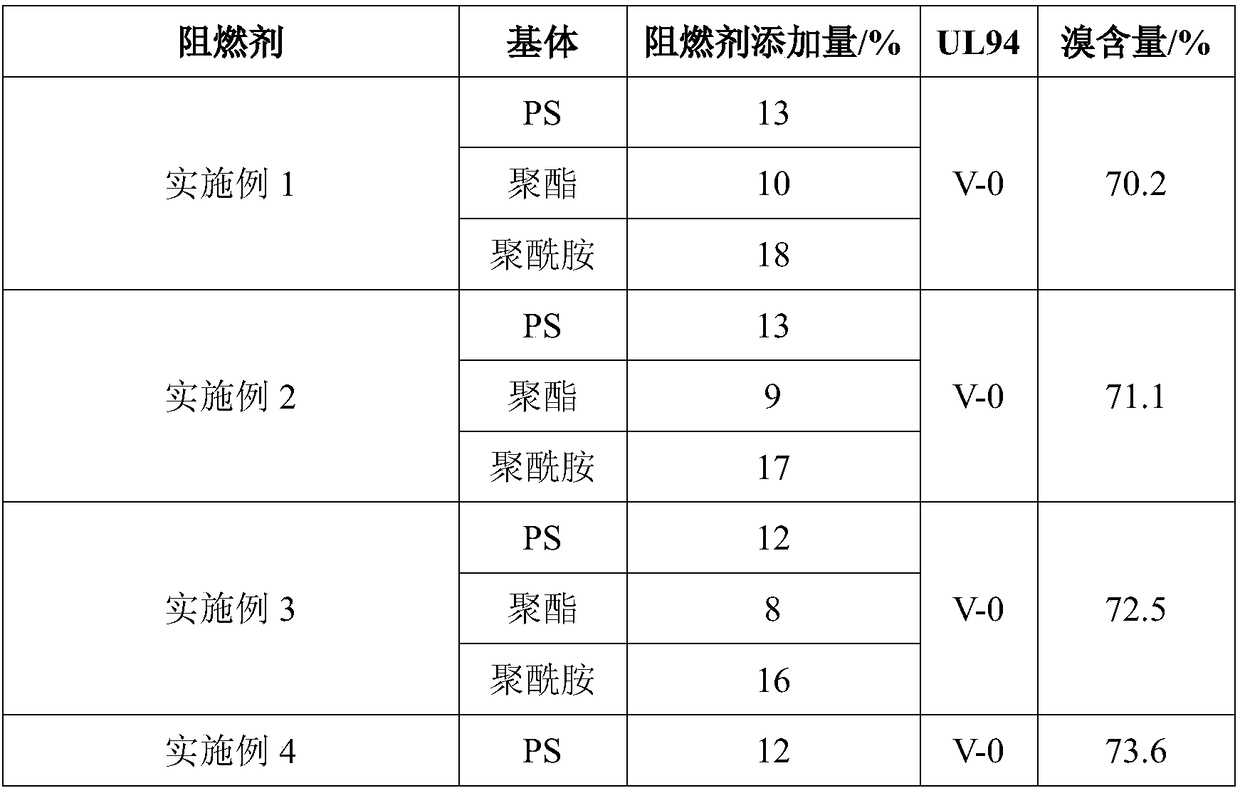

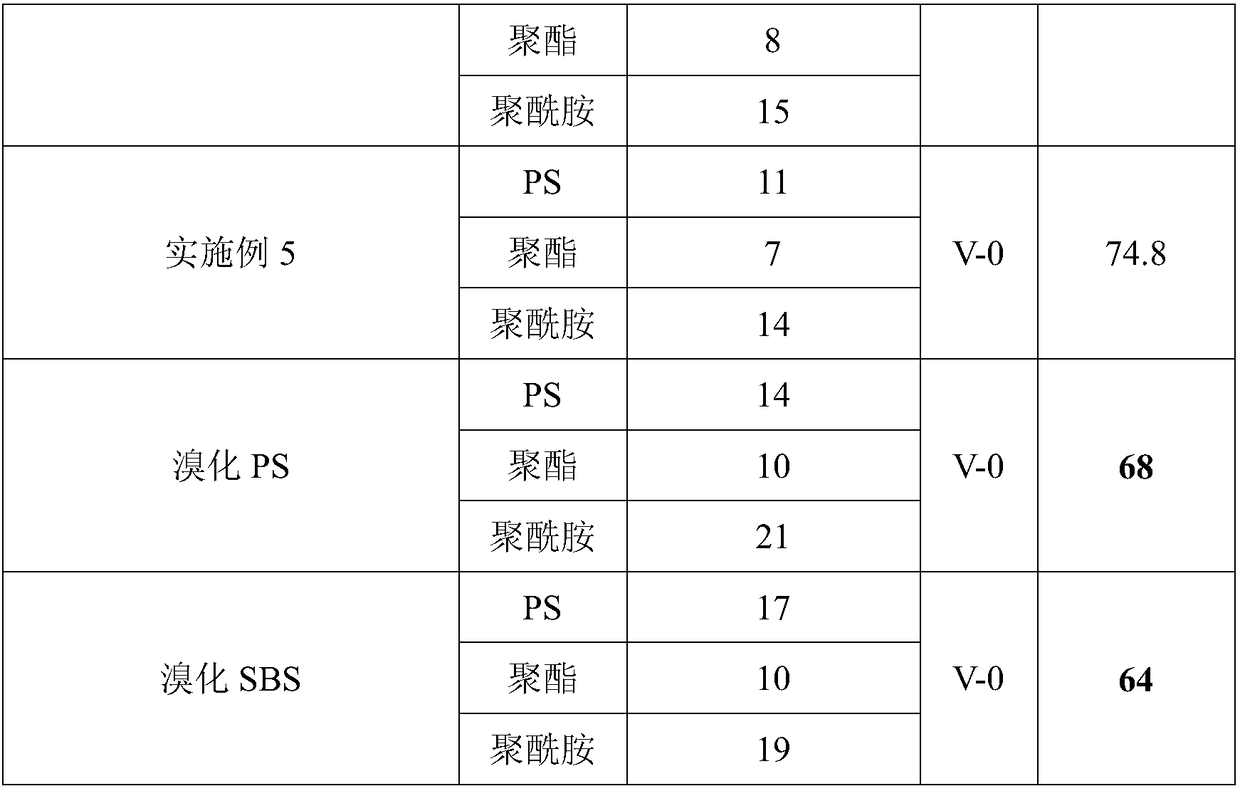

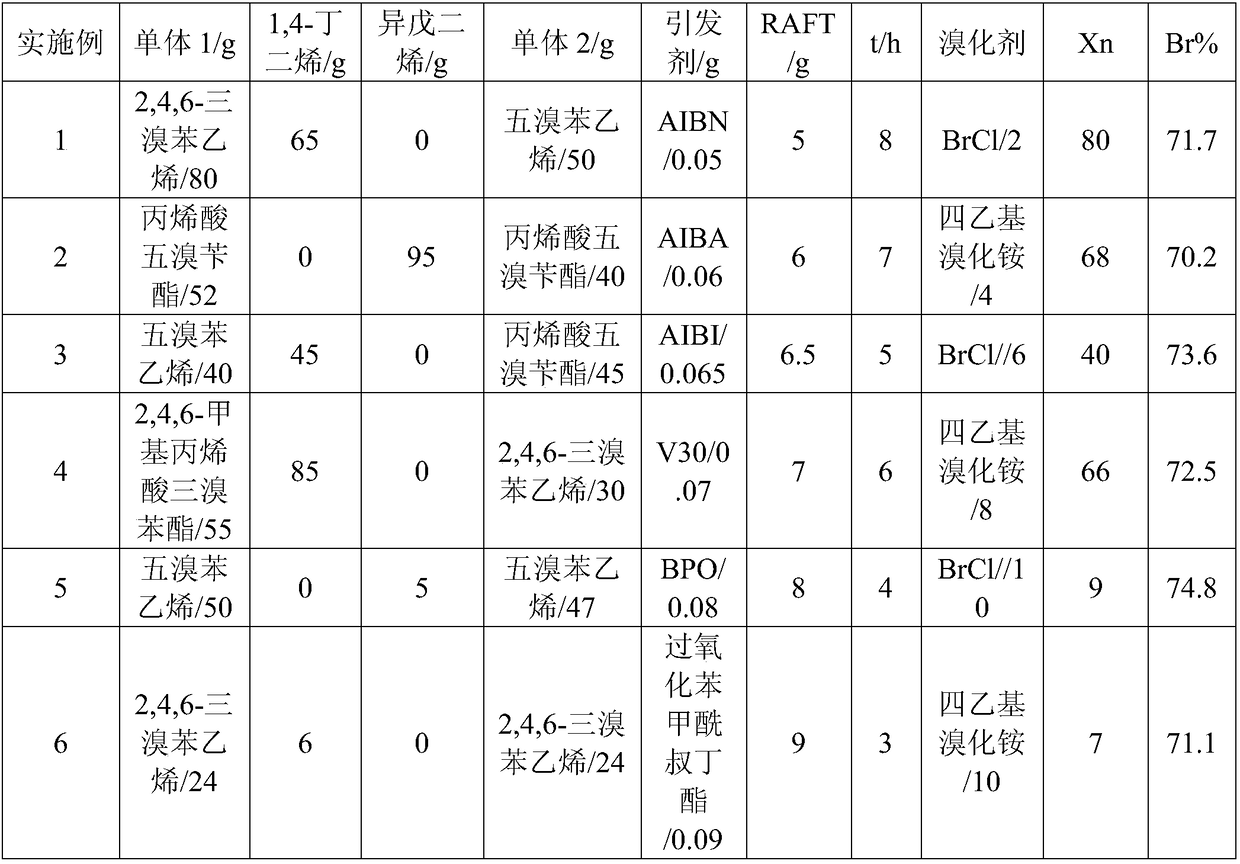

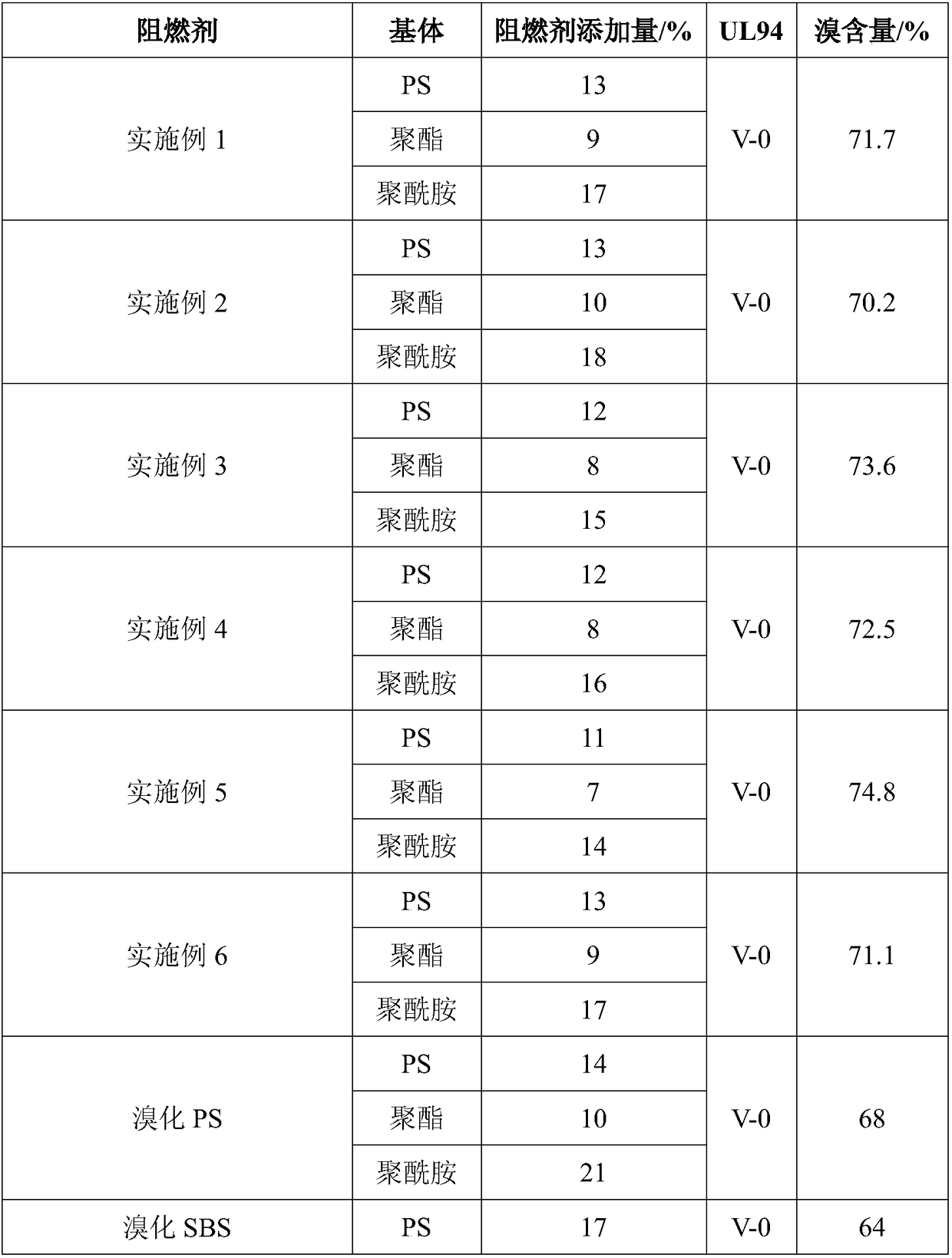

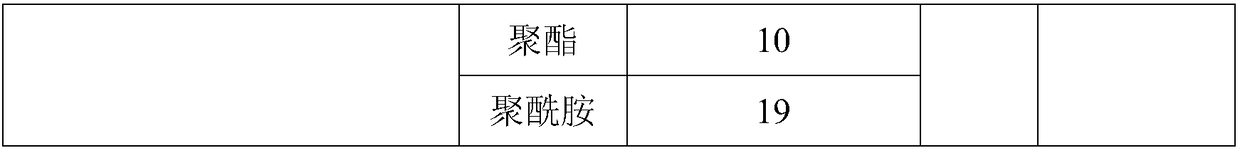

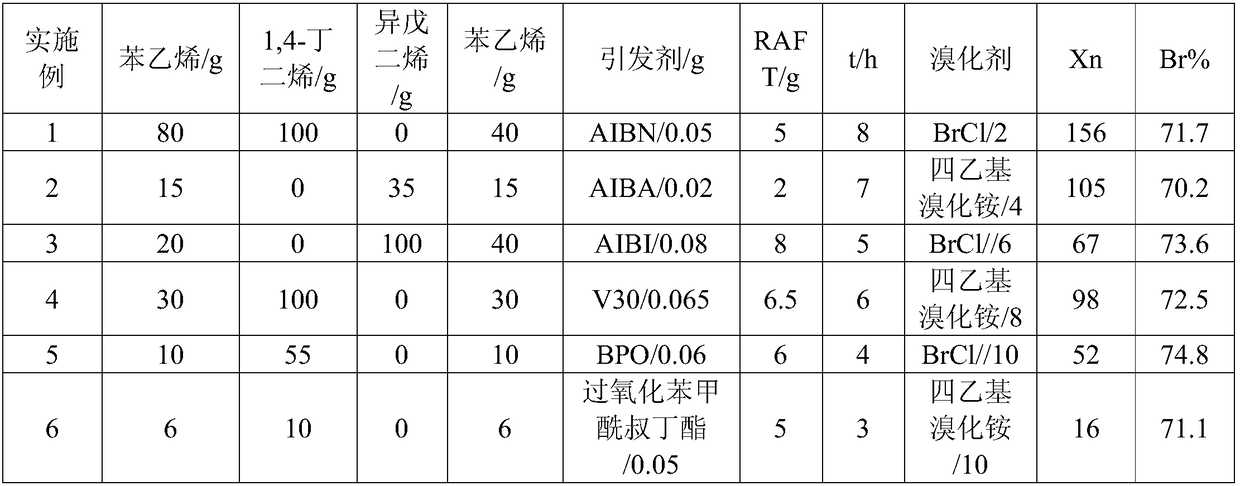

Brominated multi-block copolymer flame retardant with medium molecular weight and two-step preparation method for emulsion thereof

The invention discloses a two-step preparation method for an emulsion of a brominated multi-block copolymer flame retardant with medium molecular weight (a polymerization degree of 150 to 790). According to the invention, a reversible addition-fragmentation chain transfer (RAFT) polymerization method is adopted for preparation, and a styrene-diolefin-styrene triblock copolymer with medium molecular weight is obtained by polymerization through a two-step method with styrene and diolefin as polymerization monomers, an azo compound or an organic peroxide as an initiator and a trithioester derivative as a chain transfer agent; and after the copolymer is brominated with a brominating agent, the brominated multi-block copolymer flame retardant with medium molecular weight is obtained, i.e., a brominated styrene-diolefin-styrene triblock copolymer bromine-based flame retardant with medium molecular weight is obtained. The flame retardant provided by the invention has high bromine content andgood flame retardation effect.

Owner:ZHEJIANG UNIV

Middle-low molecular weight brominated multi-block copolymer flame retardant and solution three-step preparation method thereof

The invention discloses a solution three-step preparation method of a middle-low molecular weight brominated multi-block copolymer flame retardant. The preparation method comprises that brominated styrene and / or brominated acrylate and diolefin as polymerization monomers, an azo-compound or organic peroxide as an initiator and a dithioester derivative as a chain transfer agent undergo a polymerization reaction in a solvent to produce a middle-low molecular weight brominated styrene / acrylate-diolefin-styrene / acrylate triblock copolymer through a three step method, and the copolymer is brominated through a brominating agent to produce the middle-low molecular weight brominated multi-block copolymer flame retardant which is a middle-low molecular weight brominated styrene / acrylate-diolefin-styrene / acrylate triblock copolymer. The flame retardant has the characteristics of medium and low molecular weight, high bromine content and multi-block structure.

Owner:ZHEJIANG UNIV

EPE mat with high density, high elasticity and high strength

InactiveCN108641157AExcellent formabilityHigh surface glossLow-density polyethyleneVolumetric Mass Density

The invention relates to the technical field of EPE mats, and particularly relates to an EPE mat with high density, high elasticity and high strength. The mat comprises the following components in parts by weight: 30-80 parts of low-density polyethylene, 10-40 parts of modified polypropylene, 3-10 parts of a silane coupling agent, 0.5-3 parts of a butane foaming agent, 2-4 parts of monostearin, 1-3 parts of stearic acid, 1-5 parts of a flame retardant, and 1-5 parts of talcum powder. 10-30% of MPP Vistamaxx is added to the mats in the prior art which have the functions of ventilating, shock absorbing and cushioning, in order to enable the mats to have better strength, higher density, better elasticity, higher comfort degree during use, wear resistance, and other characteristics.

Owner:广东富利时实业有限公司

Method for preparing flame retardant brominated polystyrene by using composite catalyst

The invention relates to a method to prepare polystyrene bromide with compound catalyst system. Use polystyrene as the raw material, alkyl halide as solvent, with the existence of catalyst and dehydrating agent, the polystyrene bromide is made by bromination of brominating agent. Its characteristics include: the catalyst is composed of VIII family metal, IIB family metal, tin or stibium and lewis acid, and the polystyrene bromide has large content of bromine (the largest-one can be 60%), high melt point (30-50% higher) and productivity (larger than 95%). It can be applied for antiflaming of resin such as PET, PBT and nyloen nylon.

Owner:EAST CHINA UNIV OF SCI & TECH

Novel synthetic process of bromized polyphenyl ether

ActiveCN106243345AImprove mechanical propertiesImprove flame retardant performanceDecabromodiphenyl etherFiltration

The invention discloses a novel synthetic process of bromized polyphenyl ether. The novel synthetic process comprises the following steps of (1) polymerization: putting solid tribromophenol and solid sodium methylate with the molar ratio of 1 to (0.5 to 2) into methanol, adding a catalyst, rising the temperature to 65 DEG C, carrying out backflow reaction for 4 hours, cooling for suction filtration, leaching with the methanol, and drying to obtain a POBP crude product; (2) recrystallization: weighing the POBP crude product prepared in the step (1), dissolving into tetrahydrofuran with the weight three times of that of the POBP crude product, stirring at normal temperature till the POBP crude product is completely dissolved, starting electromagnetic stirring, quickly dripping into the methanol with the weight equal to that of the tetrahydrofuran, then continuously stirring for 1 hour, carrying out suction filtration and drying for spare use; (3) bromization: taking and dissolving POBP in dichloroethane with the weight three times of that of the POBP, dripping excessive bromine at the temperature of 20-30 DEG C, rising the temperature to 75 DEG C, reacting for 4 hours, cooling to 30 DEG C, adjusting PH, carrying out suction filtration, leaching, secondary suction filtration and drying to obtain the product. The novel synthetic process disclosed by the invention has the advantages that after bromized polyphenyl ether is used, the flame retardance and the mechanical property of a resin product can be obviously enhanced, and all detection indexes of the resin product are obviously more excellent, so that the bromized polyphenyl ether can be used as a great substitute product of decabromodiphenyl ether.

Owner:WEIFANG XINYANG CHEM CO LTD

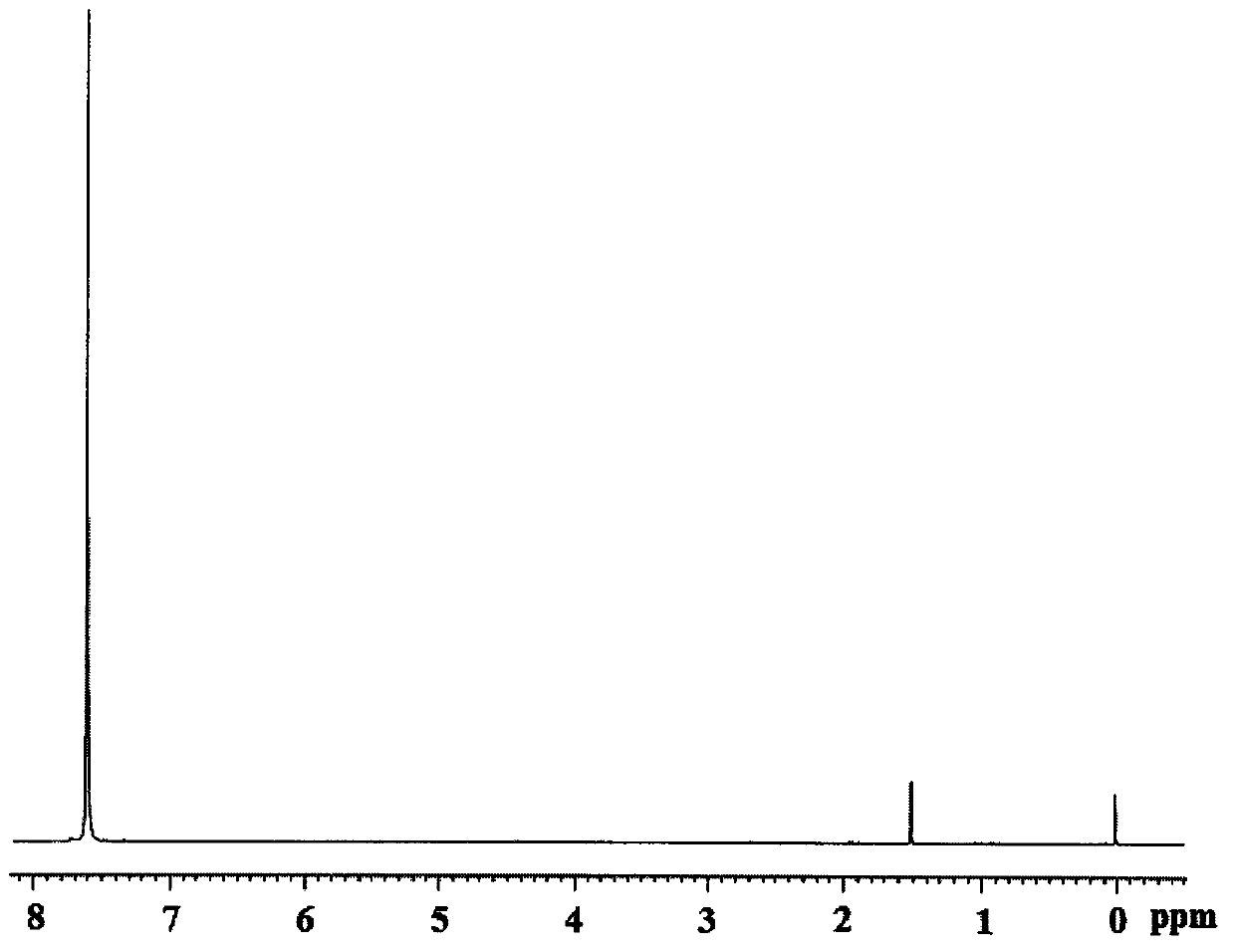

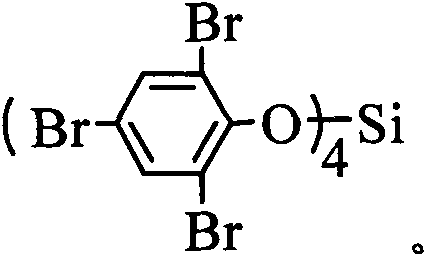

Flame retardant tetra(tribromophenyl) silicate esterification compound and preparation method thereof

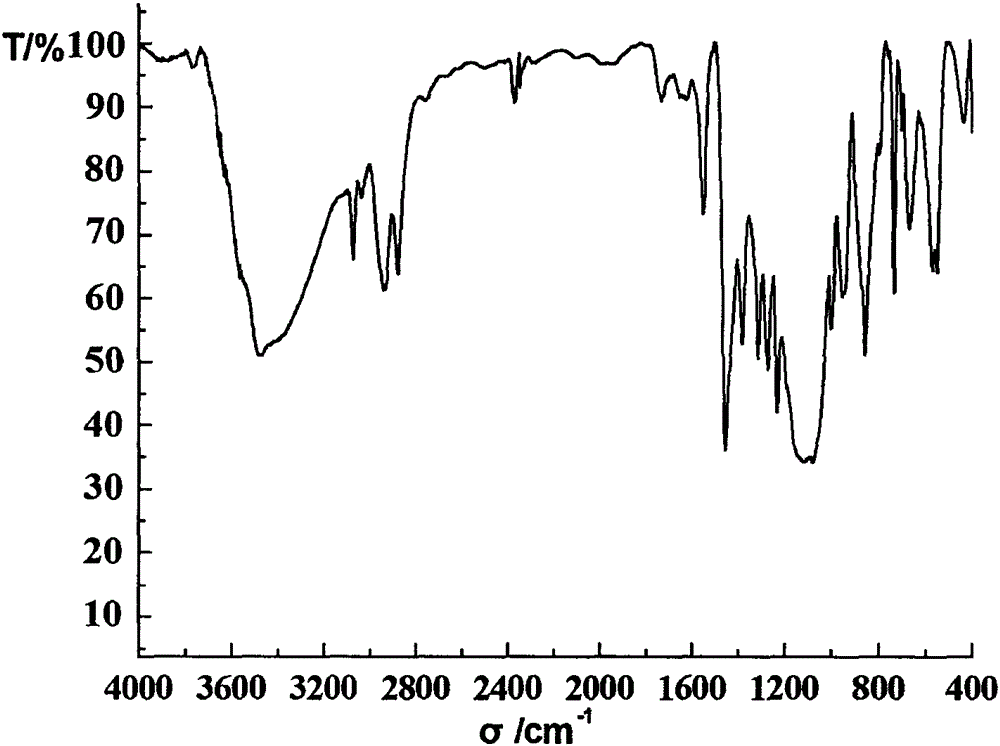

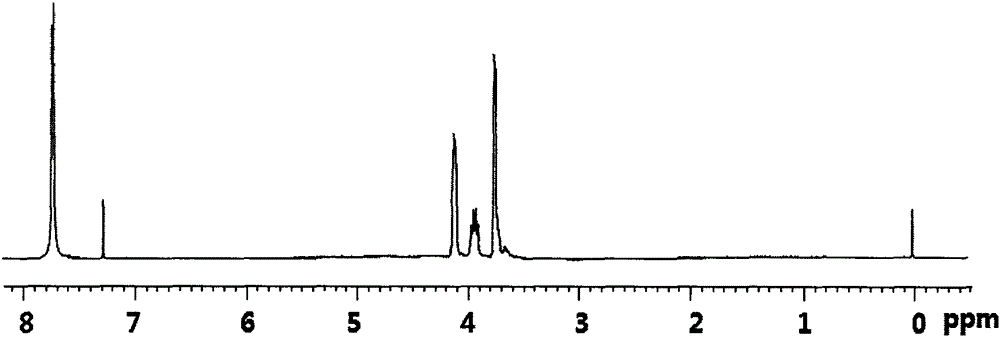

ActiveCN103342714APhysicochemically stableHigh decomposition temperatureSilicon organic compoundsEpoxySilicic acid

The invention relates to a flame retardant tetra(tribromophenyl) silicate esterification compound and a preparation method thereof. The structure of the compound is shown in the specification. The preparation method comprises the following steps of: adding tribromophenol of quadruple molar weight into an organic solution of silicon tetrachloride at 30 DEG C; heating to 45 DEG C in one hour, and performing a thermal-insulation reaction for one hour; heating to 100-120 DEG C, and performing a thermal-insulation reaction for 8-12 hours; and performing reduced-pressure distillation to remove the solvent to obtain the product tetra(tribromophenyl) silicate. The tetra(tribromophenyl) silicate provided by the invention is an excellent flame-retardant plasticizer with a charring anti-drop effect and good compatibility with a high-molecular material, and can be used as a flame retardant for the materials such as polyvinyl chloride, unsaturated polyester, polyurethane, epoxy resin and the like; and moreover, the flame retardant has the advantages of cheap and easily-available raw materials, low equipment investment and simple production technology, and is easy to produce in a large scale.

Owner:张家港市乐余科创园投资发展有限公司

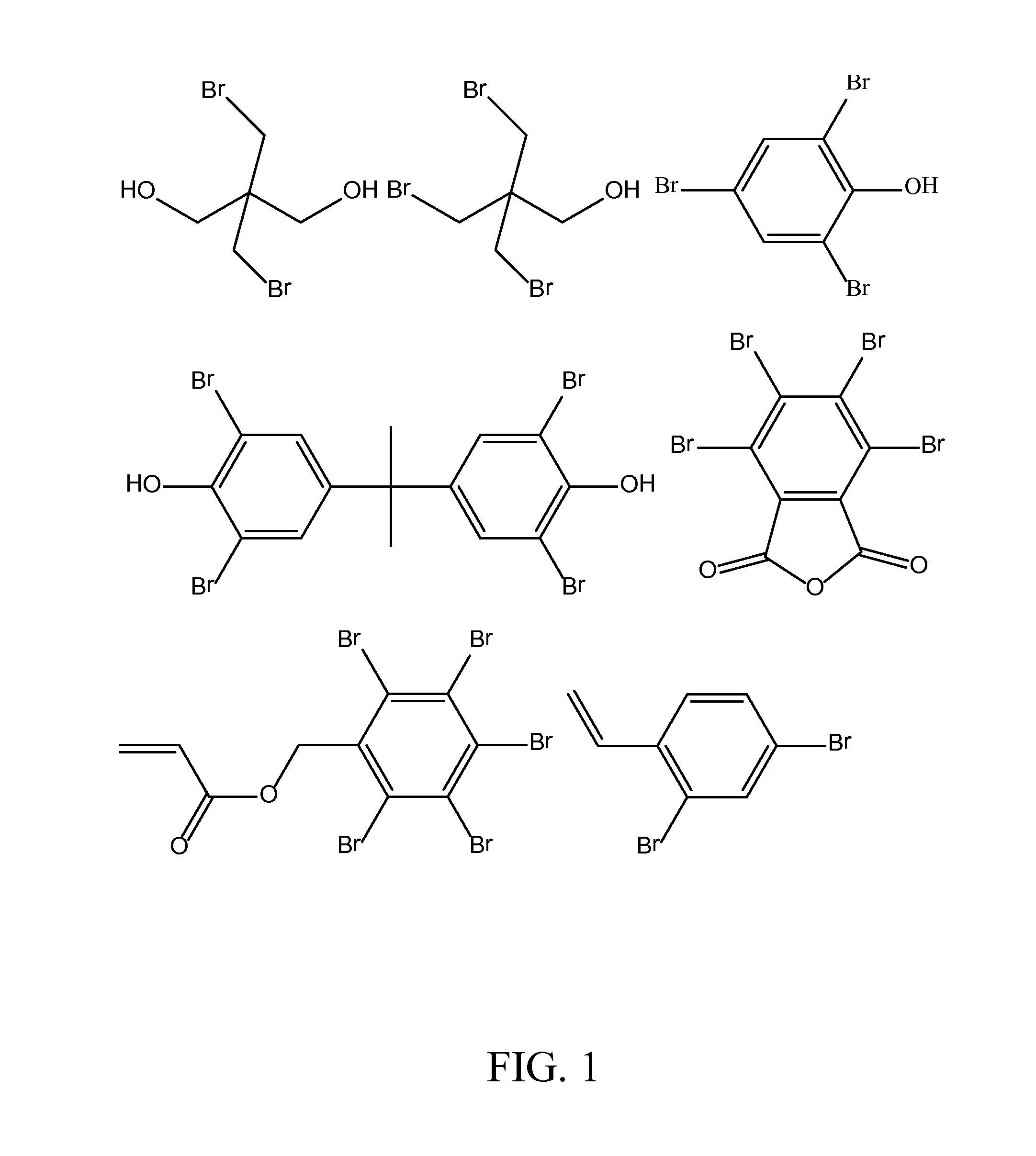

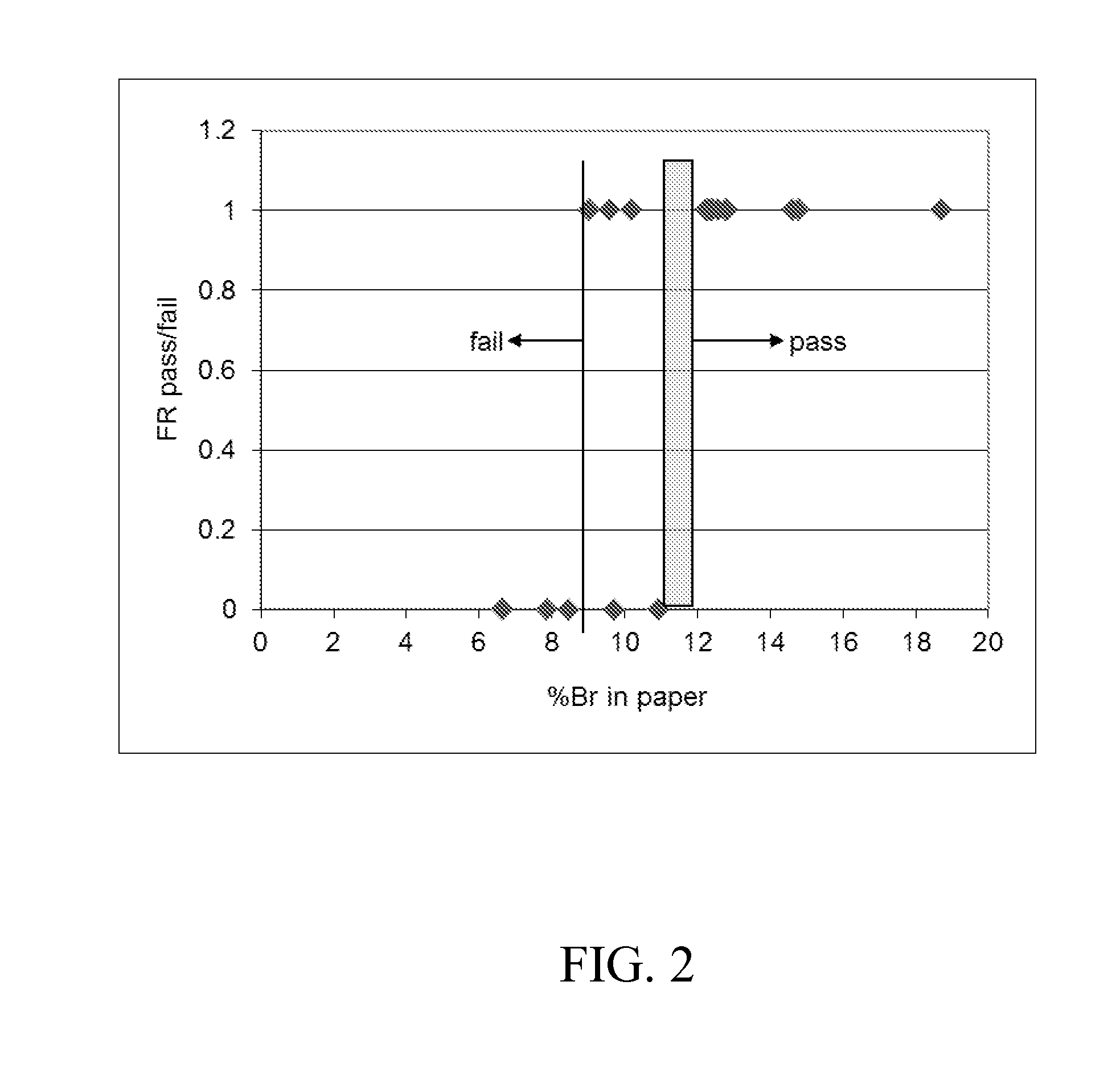

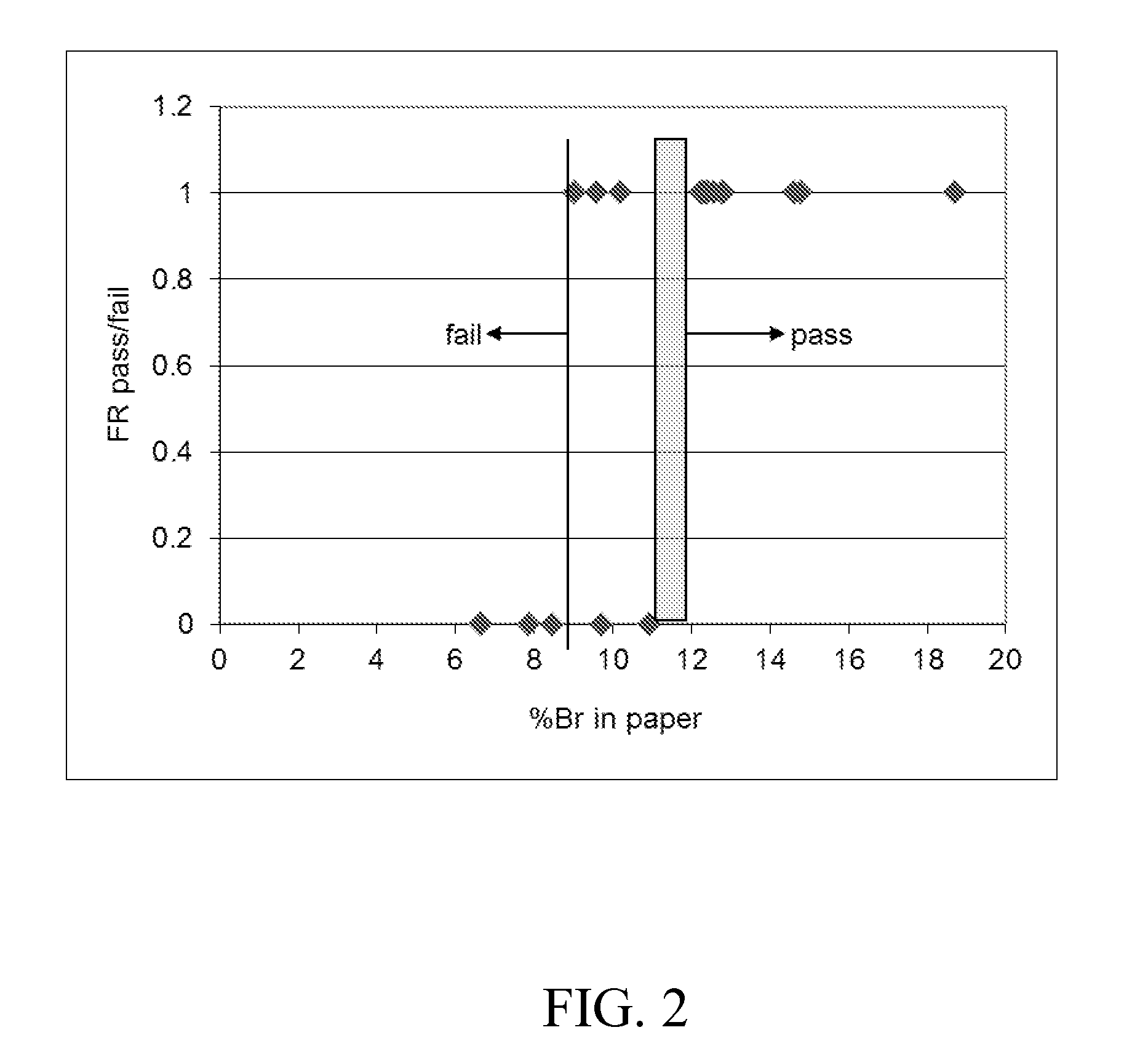

Flame-retarding oligomeric brominated urethane compositions

ActiveUS20130217286A1Improve flame retardant performanceHigh bromine contentSynthetic resin layered productsPaper/cardboard layered productsBrominePolymer

Owner:LUBRIZOL ADVANCED MATERIALS INC

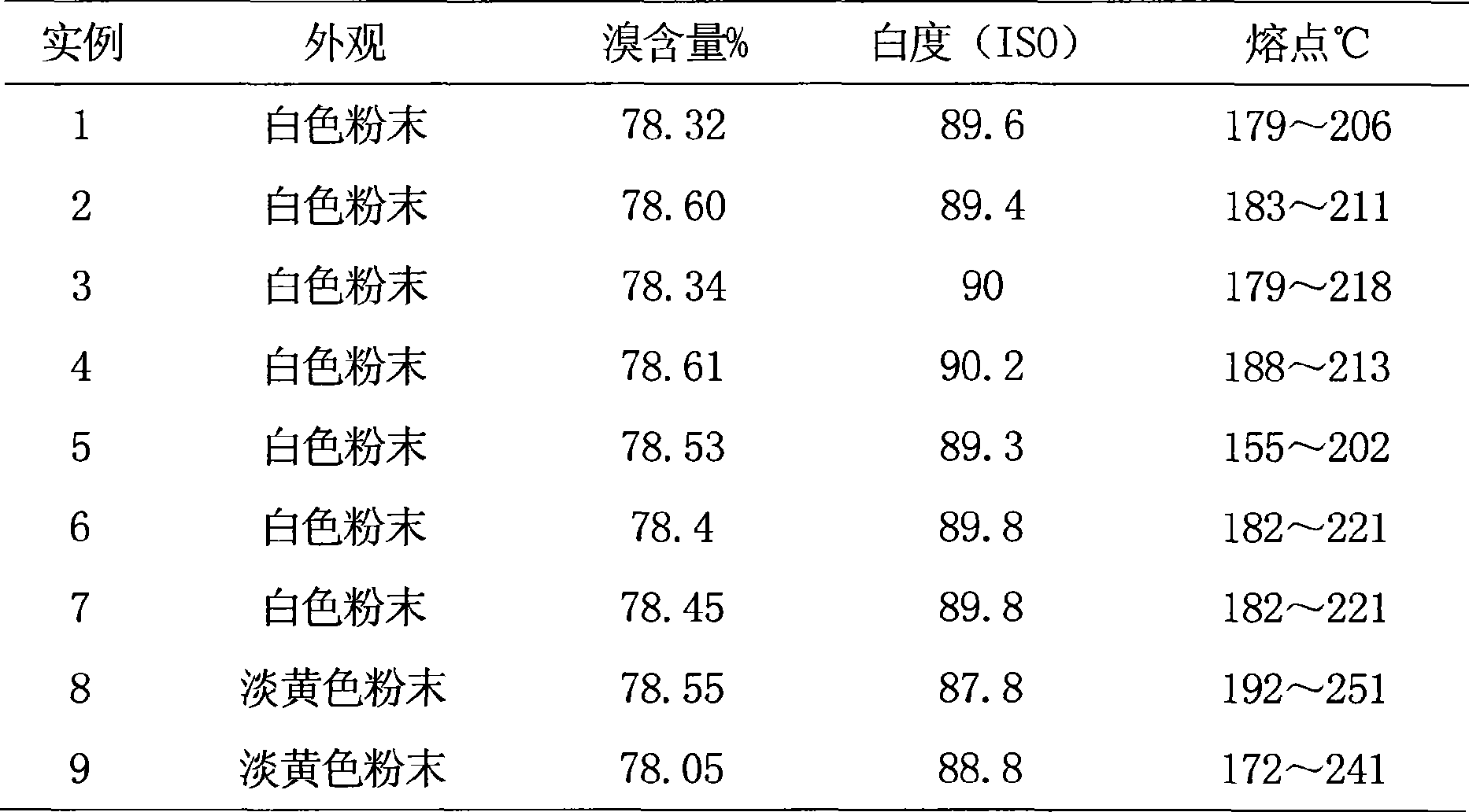

Process for producing octabromodiphenyl ethane

ActiveCN101429096ARaw materials are easy to getLess investmentHalogenated hydrocarbon preparationBromineDistillation

The invention discloses a method for preparing octabromo-diphenylethane. The method comprises the following steps: catalyst is added into liquid bromine and stirred for reaction, and a mixture A of the liquid bromine and the catalyst is obtained; diarylethane is dripped into the mixture A under the condition of stirring, and continuously stirred for reaction after the dripping process is over, and a mixture B is obtained; water and a metallic ion remover are added into the mixture B under the condition of stirring, and a mixture C is obtained; the mixture C is distilled for removal of superfluous liquid bromine and superfluous catalyst, and a product obtained after distillation is filtered to obtain a coarse octabromo-diphenylethane product; the octabromo-diphenylethane is added with water and a debrominating agent, crushed by the wet method, and subjected to solid-liquid separation after crushing to obtain a filter cake; and the filter cake is dried, and subjected to gas flow crushing to obtain white or primrose octabromo-diphenylethane solid powder. The method has easily obtained raw materials and small investment, and is simple in reaction control and easy in industrial production control. The bromine content of the product is high and can reach between 78 and 78.6.

Owner:SHANDONG TIANYI CHEM

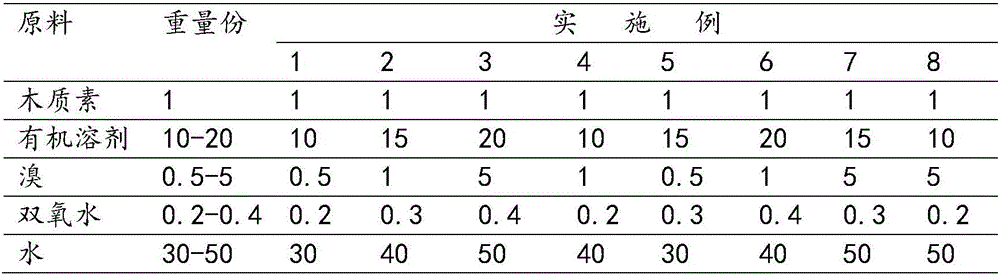

Production method of brominated lignin

The invention relates to a production method of brominated lignin. The production method comprises the following four steps: I, preparing a lignin raw material; II, dissolving lignin; III, brominating the lignin; and IV, preparing the brominated lignin. The brominated lignin prepared by the method is low in production cost, environmentally friendly and better in flame-retardant effect. Primary raw materials are regenerable and inexhaustible, and an organic solvent can be recycled, so that the brominated lignin is an ideal substitute product for a tetrabromo bisphenol A flame retardant.

Owner:ZHEJIANG FORESTRY UNIVERSITY

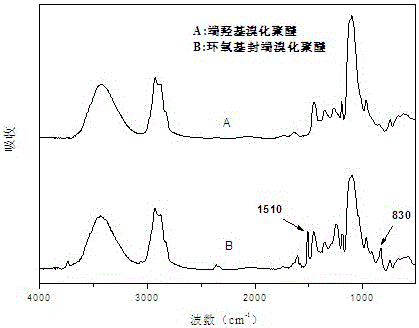

Preparation method and application of epoxy-terminated brominated polyether fabric flame-retardation finishing agent

InactiveCN105019243AHigh bromine contentPermanent and excellent flame retardant effectFibre treatmentFiberPolymer science

The invention discloses a preparation method and an application of an epoxy-terminated brominated polyether fabric flame-retardation finishing agent. A mass part ratio of epoxy-terminated brominated polyether to epoxy chloropropane to a catalyst to an initiator to a solvent is 20-30:10-20:0.1-5:0.1-10:45-60; or a mass part ratio of epoxy-terminated brominated polyether to epoxy chloropropane to the catalyst to a curing agent to the solvent is 15-25:10-15:0.1-5:20-50:38-50. The method is simple and convenient; the prepared flame-retardation finishing agent has a high content of bromine, and a permanent and excellent flame retardation effect; and a finished fabric does not contain free bromides, a polyether structure is firmly combined with the fabric, and an epoxy structure is firmly combined with a highly-polar fiber fabric, so the fabric is washable.

Owner:JIANGSU BAIHOO TEXTILES TECH CO LTD

Flame-retarding oligomeric brominated urethane compositions

ActiveUS9434884B2Improve flame retardant performanceHigh bromine contentSynthetic resin layered productsPaper/cardboard layered productsBrominePolymer

Owner:LUBRIZOL ADVANCED MATERIALS INC

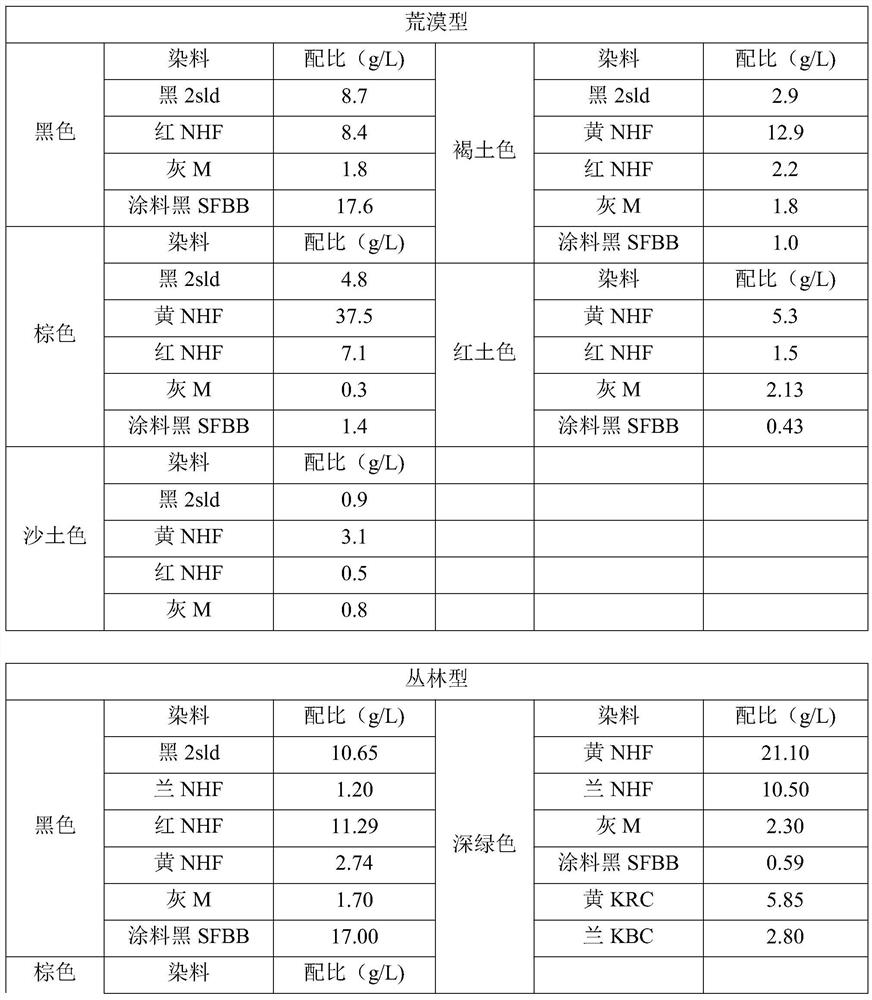

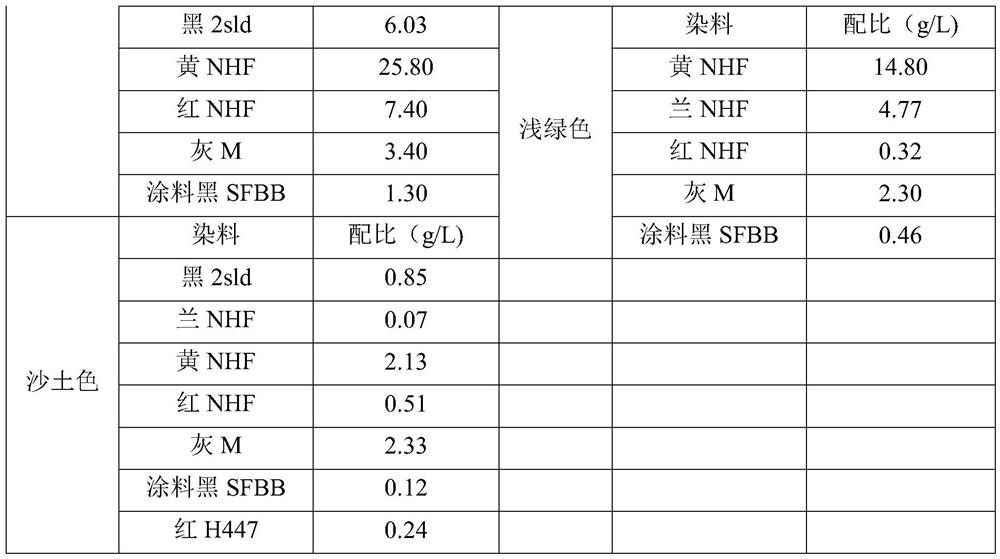

Polyamide pattern painting camouflage fabric printing process and fabric production and processing method

The invention relates to a polyamide pattern painting camouflage fabric printing process and a fabric production and processing method. The printing process is used for printing a pattern painting camouflage color, and vat grey M is added into color paste of the pattern painting camouflage color. The processing method comprises a coating finishing procedure, wherein coating finishing is performed on a waterproof set fabric printed with the pattern painting camouflage color, and a flame-retardant coating is completed according to a sequence of firstly performing bottom glue blade coating and calendaring, then performing middle glue blade coating and finally performing surface glue blade coating; during the bottom glue blade coating, the temperature of a drying oven is controlled to be close to the temperature of a cross-linking agent in a bottom glue formula, the vehicle speed is regulated and controlled, methylbenzene in polyurethane glue is completely volatilized, bottom glue is in a dried state, but part of the cross-linking agent does not completely react to form a net structure, more bottom glue is extruded into yarn gaps of a fabric during subsequent calendaring, and further the cross-linking agent reacts with the polyurethane glue and a curing process is finished. The color fastness of the fabric is stable, and the dark color migration phenomenon is reduced. The production and processing method meets the use requirements of novel equipment such as carrying tools and bulletproof vests.

Owner:北京邦维高科新材料科技股份有限公司

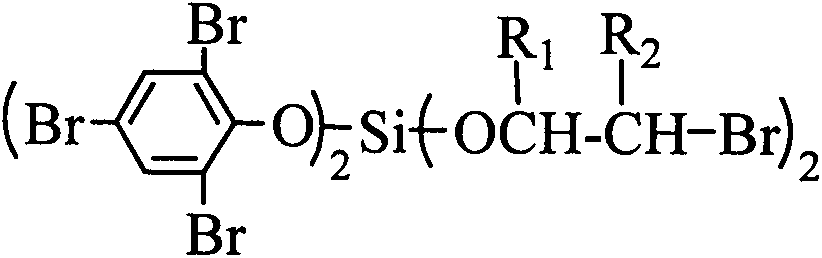

A kind of flame retardant bis(dibromopropoxy) bis(tribromophenoxy) silane compound and preparation method thereof

ActiveCN103319514BPhysicochemically stableHigh decomposition temperatureSilicon organic compoundsPolyesterEpoxy

The invention relates to a fire retardant di(dibromo propanolato)di(tribromophenoxy)silane compound and its preparation method. The structure of the compound is as shown in the formula in the specification, wherein R2=CH2Br when R1=H; and R2=H when R1=CH2Br. The preparation method comprises the following steps: dropwisely adding equimolar dibromopropyl alcohol into a silicon tetrachloride organic solution at 8 DEG C, keeping the temperature at 35 DEG C to react for 1h, adding two molar rations of tribromophenol, keeping the temperature at 60-90 DEG C to react for 4-6h, dropwisely adding equimolar dibromopropyl alcohol, keeping the temperature at 70-95 DEG C to react for 5-7h, and carrying out underpressure distillation to remove a solvent so as to obtain a product di(dibromo propanolato)di(tribromophenoxy)silane. The product is an excellent flame retardation plasticizer, has charcoal-forming and antidrip effects, and can be used as a fire retardant of materials such as polyvinyl chloride, nonsaturated polyester, polyurethane and epoxy resin, etc. Raw materials of the product are cheap and easily available. Production cost is low. Equipment investment is little. The production technology is simple. The preparation method is easy for large-scale production.

Owner:张家港市乐余科创园投资发展有限公司

Method for preparing brominated polypropylene

The invention discloses a method for preparing brominated polypropylene. The method comprises the following steps of: 1) mixing polypropylene, water and an excessive amount of bromine, and stirring uniformly, wherein the weight ratio of polypropylene to water is (1:9)-(3:7); 2) reacting with stirring under the condition of ultraviolet irritation and / or adding of an initiating agent at the temperature of between 30 and 60 DEG C for 60 to 360 minutes; 3) after reaction, separating brominated polypropylene out. According to the method, polypropylene and bromine react in water under irritation of light, reaction conditions are optimized, the irritation of ultraviolet of which the wavelength is 280 to 460nm is used for initiating, the reaction temperature of between 30 and 50 DEG C is used, and parameters such as a mixing ratio of polypropylene to water are adopted, so that polypropylene and bromine react smoothly to obtain brominated polypropylene, the bromine content of the brominated polypropylene is correspondingly increased along with the increasing of reaction time in the reaction time of 60 to 360 minutes, and the bromination progress of brominated polypropylene can be controlled.

Owner:HENAN UNIV OF SCI & TECH

Brominated multi-block copolymer flame retardant with medium-and-low molecular weight and three-step preparation method for solution thereof

The invention discloses a three-step preparation method for a solution of a brominated multi-block copolymer flame retardant with medium-and-low molecular weight. According to the invention, a reversible addition-tragmentation chain transfer (RAFT) polymerization method is adopted for preparation, and a styrene-butadiene / isoprene-styrene triblock copolymer with medium-and-low molecular weight is obtained by polymerization through a three-step method in a solvent with styrene and 1,4-butadiene / isoprene as polymerization monomers, an azo compound or an organic peroxide as an initiator and a dithioester derivative as a chain transfer agent; and after the copolymer is brominated with a brominating agent, the brominated multi-block copolymer flame retardant with medium-and-low molecular weight(a polymerization degree of 16 to 156) is obtained, i.e., a brominated styrene-butadiene / isoprene-styrene triblock copolymer bromine-based flame retardant with medium-and-low molecular weight is obtained. The triblock copolymer flame retardant provided by the invention has the characteristics of medium molecular weight, high bromine content and multi-block structure.

Owner:ZHEJIANG UNIV

A kind of synthetic method of brominated lignin

The invention relates to a synthesizing method for brominated lignin. According to the synthesizing method, technical problems like adoption of an organic solvent, high synthesis cost and poor transparency of synthetic brominated lignin in modified brominated lignin synthesis processes in the prior art are solved. The invention discloses a synthesizing method for brominated lignin, which comprisesthe following steps: adding lignin, water and an inorganic strong acid catalyst to a reaction vessel; heating to 40-50 Celsius system; adding excess bromine to react for 2 to 4 hours; heating continually to 60-70 Celsius system; reacting 5-8h; after the end of the reaction, removing the remaining bromine; adjusting the pH of the system to neutral with alkaline substances; adding peroxide; stirring, filtering, washing, drying, and obtaining a brominated lignin product. The invention is widely applied to the field of modification of natural polymer materials.

Owner:SHANDONG RUNKE CHEM +1

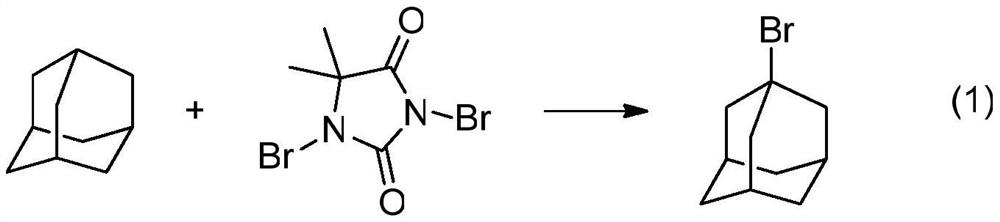

A kind of preparation method of 1-bromoadamantane

ActiveCN110304986BHigh reactivityImprove stabilityHalogenated hydrocarbon preparationBiochemical engineeringProcess engineering

The invention discloses a preparation method of 1-bromoadamantane, which is characterized in that: adamantane is used as a starting material, and 1,3-dibromo-5,5-dimethylhydantoin is a green brominated reagent. A mild bromination reaction was carried out in chloroform to obtain the target product with high purity. The synthesis process of the invention is environmentally friendly, easy to operate, low in price and easy to obtain, and suitable for large-scale industrial production.

Owner:KENTE CATALYSTS INC

ABS material for packaging and preparation method thereof

The invention discloses an ABS material for packaging and a preparation method thereof, and relates to the technical field of ABS materials. The material comprises the following components in parts byweight: 45-55 parts of an acrylonitrile-butadiene-styrene copolymer, 20-24 parts of vinyl acetate, 10-12 parts of ethylene, 3-5 parts of 1,2-bis(pentabromophenyl) ethane, 4-6 parts of glass fiber, 7-9 parts of magnesium hydroxide, 12-18 parts of tackifying resin, 6-10 parts of mullite powder, 5-7 parts of white carbon black, and 3-8 parts of a mixed solution. The ABS material of the scheme has excellent flame retardant properties and high-temperature resistance.

Owner:南京德荣包装制品有限公司

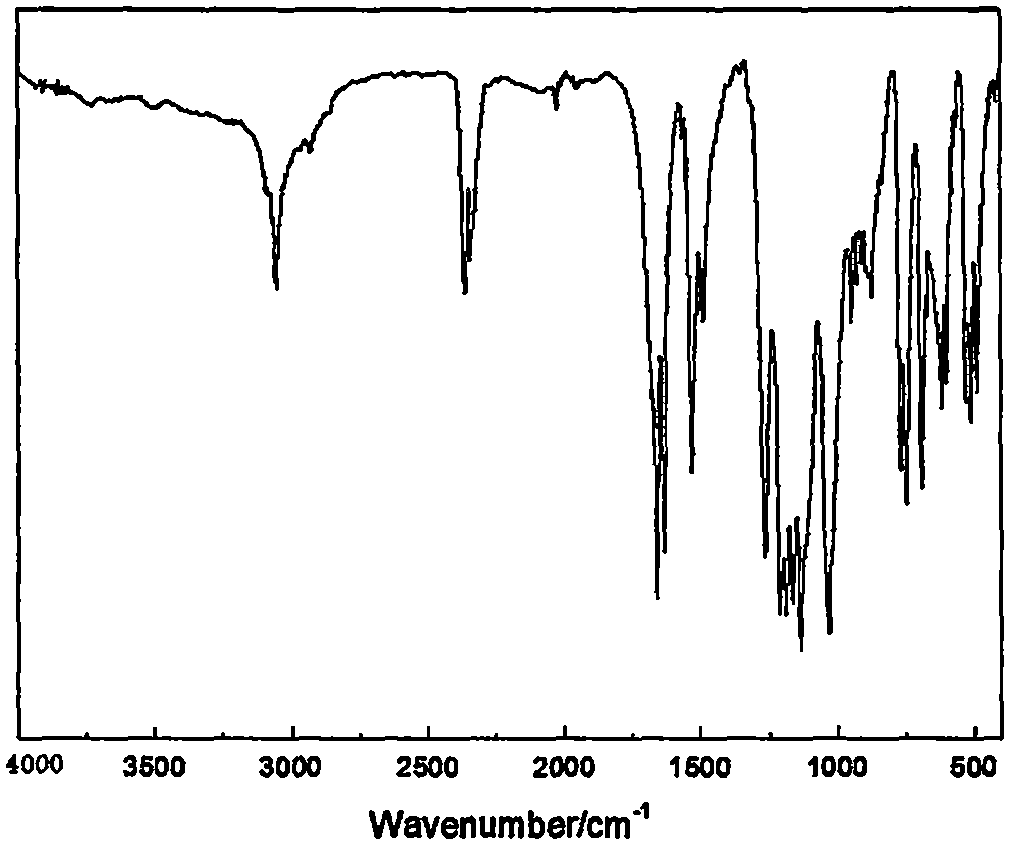

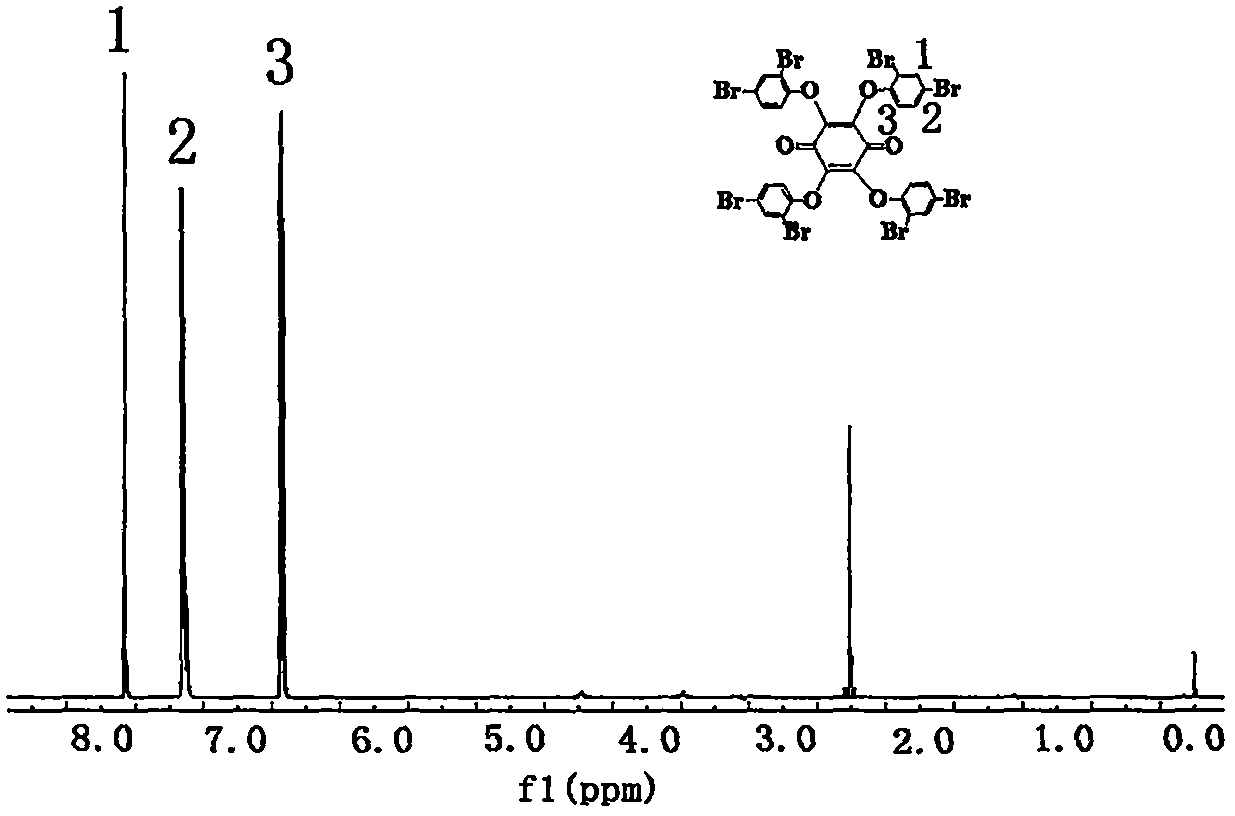

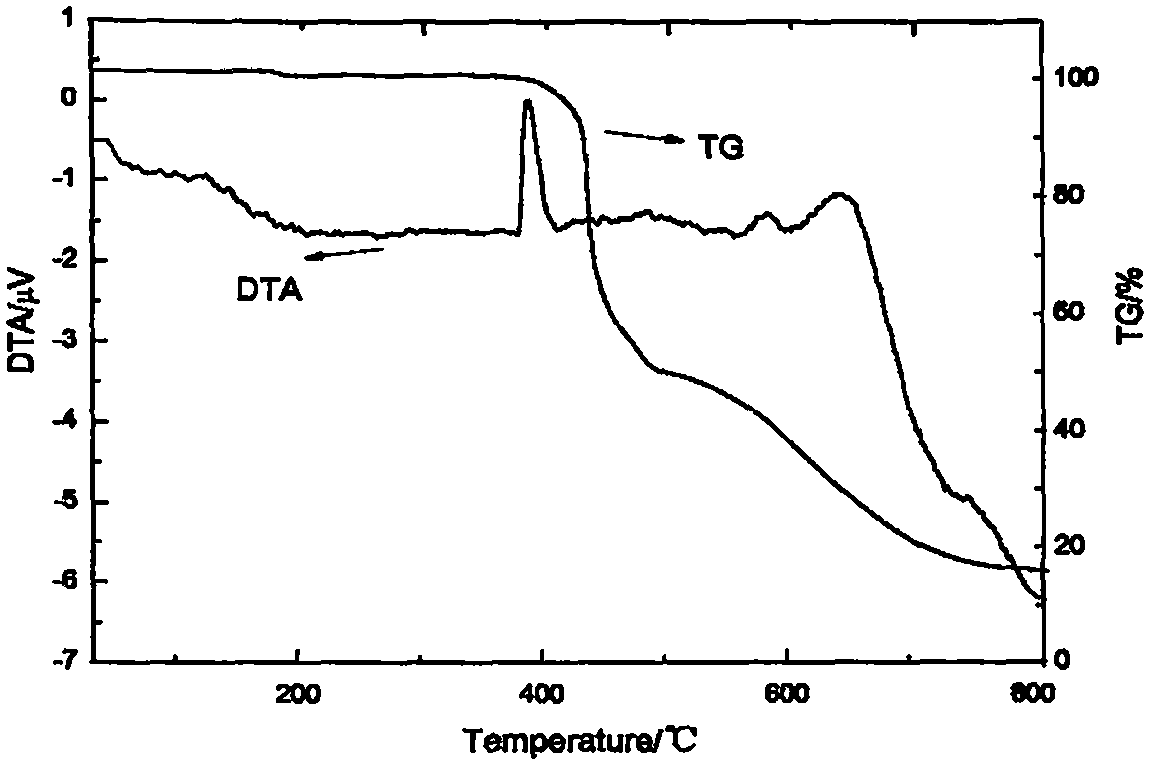

Colored flame retardant tetra(bromophenoxy)p-benzoquinone compound and preparation method thereof

ActiveCN109020798AStable physical and chemical propertiesHigh decomposition temperatureOrganic compound preparationQuinone preparationSolventPolyamide

The invention relates to a colored flame retardant tetra(bromophenoxy)p-benzoquinone compound and a preparation method thereof. The structure of the compound is shown as the following formula in the specification. The preparation method includes: subjecting tetrachloro-p-benzoquinone and sodium bromophenol to substitution reaction in an organic solvent, then conducting decompression to remove theorganic solvent, adding methanol for dissolving, filtering out insoluble substances, conducting distillation concentration on the filtrate, performing cooling crystallization, and conducting filteringand drying to obtain brown powder tetra(bromophenoxy)p-benzoquinone. The compound provided by the invention has excellent flame retardant performance, also has coloring effect, and is suitable for use as a flame retardant of polyester, polyamide, polyurethane, unsaturated resin, polyolefin, rubber and other materials. Also the preparation method has the characteristics of one-step reaction, simple process and low equipment investment, and is easy to realize industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com