Preparation method of flame retardant PP (polypropylene) non-woven fabric

A technology of flame retardant non-woven fabrics and non-woven fabrics, applied in textiles and papermaking, fiber processing, fiber types, etc., can solve the problems of white smoke and melt dripping, danger, etc., to achieve convenient operation, low toxicity, environmental protection friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The production process of PP non-woven base fabric: polypropylene polymer feeding---melt extrusion---fiber formation---fiber cooling---netting---reinforcement into cloth.

[0018] Take 100g / m 2 The PP non-woven base fabric is used for flame-retardant finishing, and the specific operation steps are as follows:

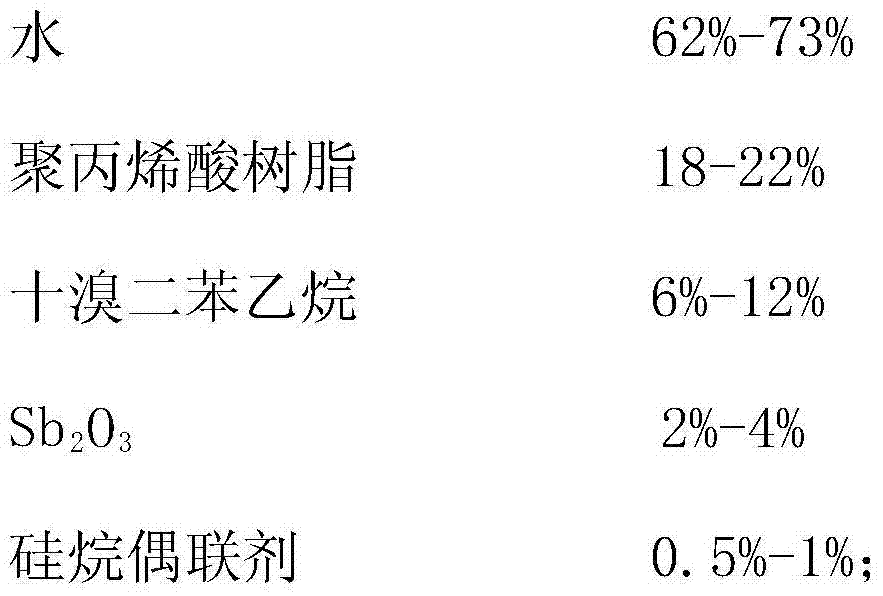

[0019] (1) Take the components according to the following quality, mix them evenly, and prepare them into flame-retardant slurry:

[0020]

[0021] (2) Pour the flame-retardant slurry into the slurry tank with a stirring device, so that the non-woven base fabric passes through the pressure roller and the sizing roller, and the sizing roller transfers the slurry in the size tank through the screen frame to the base. cloth;

[0022] (3) Arrange the sized non-woven fabric between the two rubber rollers of the roller press for extrusion. On the one hand, the slurry is pressed into the interior of the non-woven fabric to make it evenly distributed; Press to remo...

Embodiment 2

[0027] The production process of PP non-woven base fabric: polypropylene polymer feeding---melt extrusion---fiber formation---fiber cooling---netting---reinforcement into cloth.

[0028] Take 100g / m 2 The PP non-woven base fabric is used for flame-retardant finishing, and the specific operation steps are as follows:

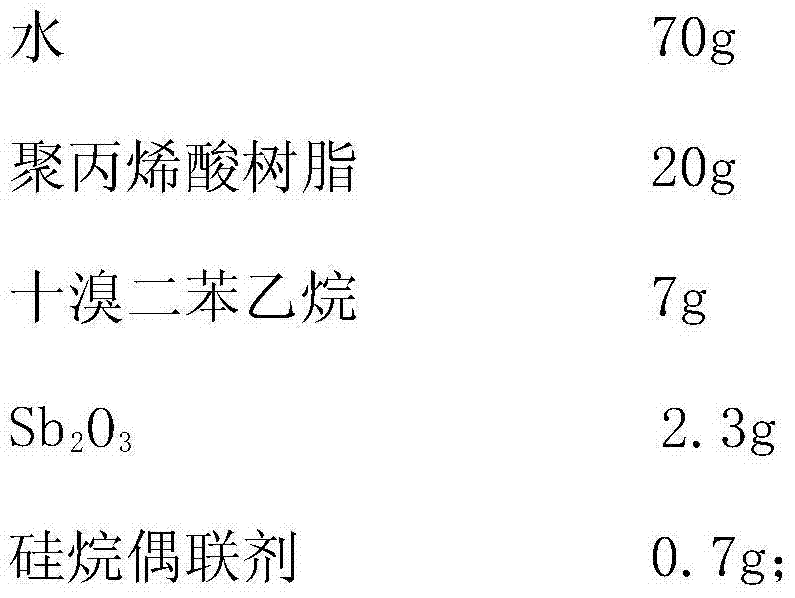

[0029] (1) Take each component according to the following quality, mix them evenly, and prepare a flame-retardant slurry:

[0030]

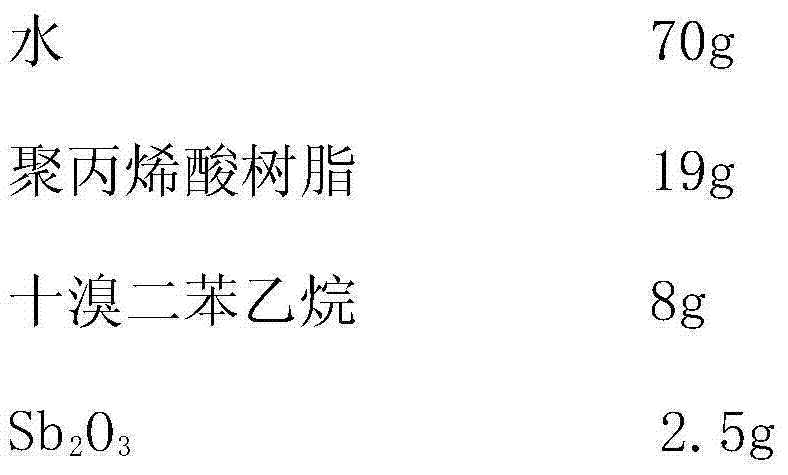

[0031]

[0032] (2) Pour the flame-retardant slurry into the slurry tank with a stirring device, so that the non-woven base fabric passes through the pressure roller and the sizing roller, and the sizing roller transfers the slurry in the size tank through the screen frame to the base. cloth;

[0033] (3) Arrange the sized non-woven fabric between the two rubber rollers of the roller press for extrusion. On the one hand, press the slurry into the interior of the non-woven fabric to make it evenly distributed; on the other ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com