Patents

Literature

107results about How to "Play a synergistic flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

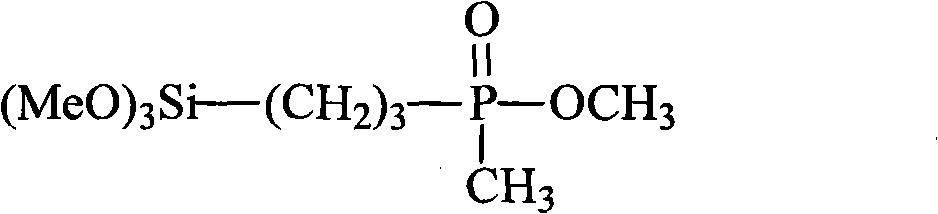

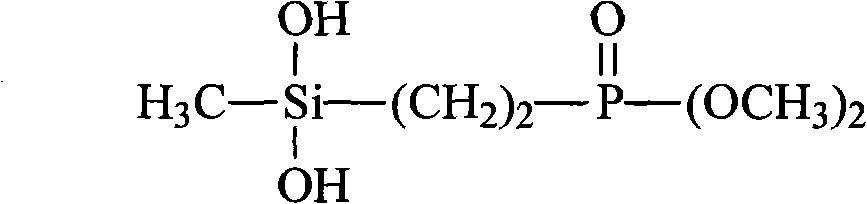

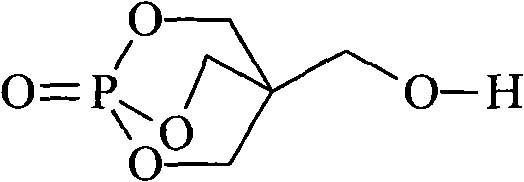

Caged bicyclic phosphate siloxane flame retardant and preparation method thereof

ActiveCN102153590AImprove thermal stabilityHigh molecular weightGroup 5/15 element organic compoundsCombustionSilanes

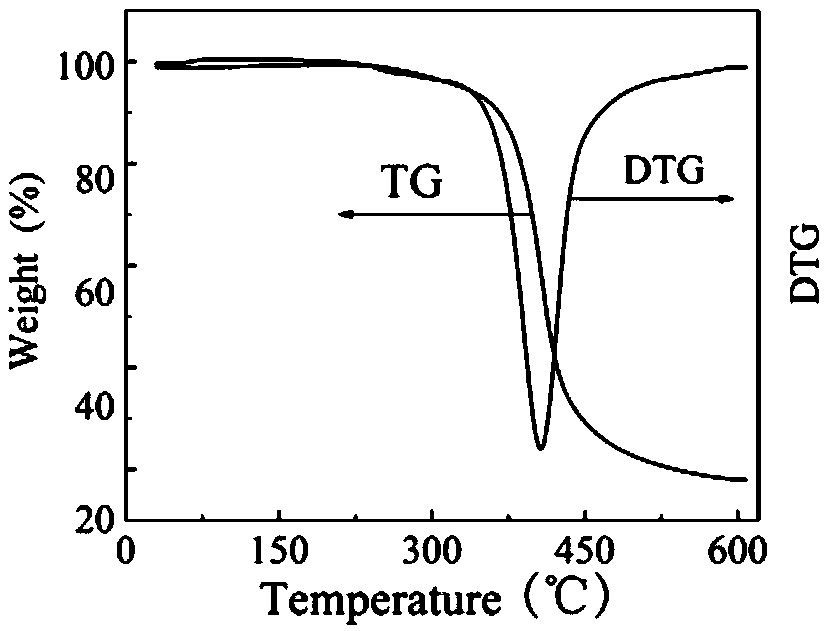

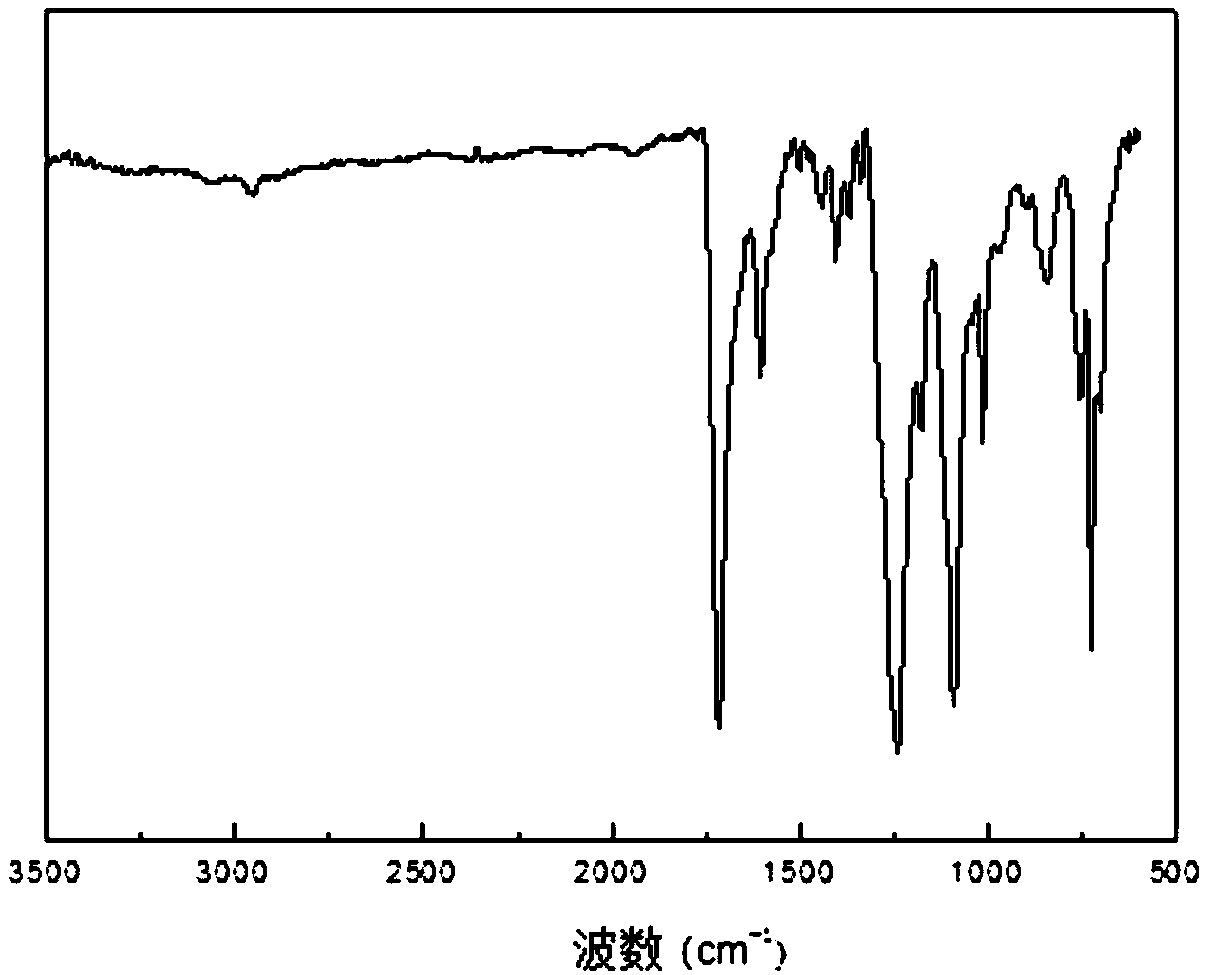

The invention discloses a caged bicyclic phosphate siloxane flame retardant and a preparation method thereof. A structural formula of the caged bicyclic phosphate siloxane flame retardant is shown in a general formula (I). During the preparation, the needed product can be obtained by reacting 1-oxophospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane and chlorosilane or alkoxy silane. A plurality of rigid caged bicyclic phosphate groups and silicon element which are contained in the compound play a role in synergistic flame retardancy; and the flame retardant has higher thermal stability and carbon-forming performance, and can effectively reduce the smoke produced in the combustion.

Owner:SOUTH CHINA UNIV OF TECH

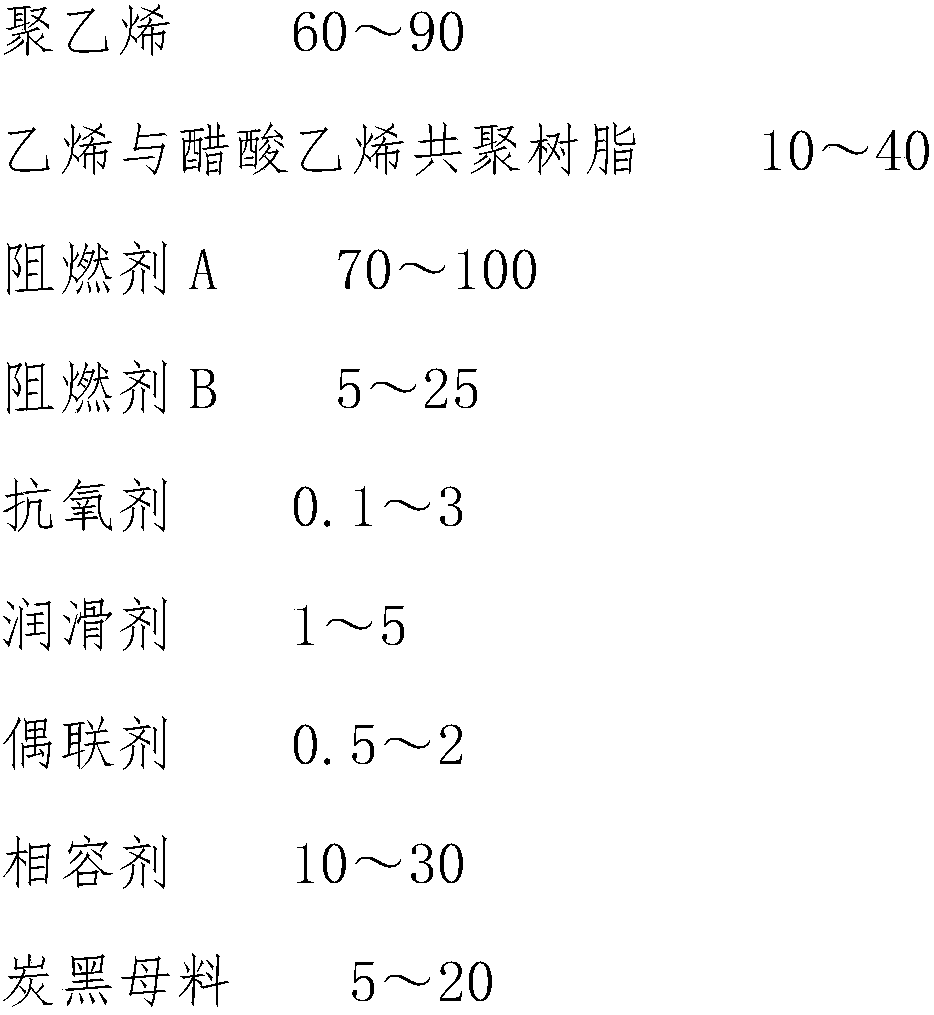

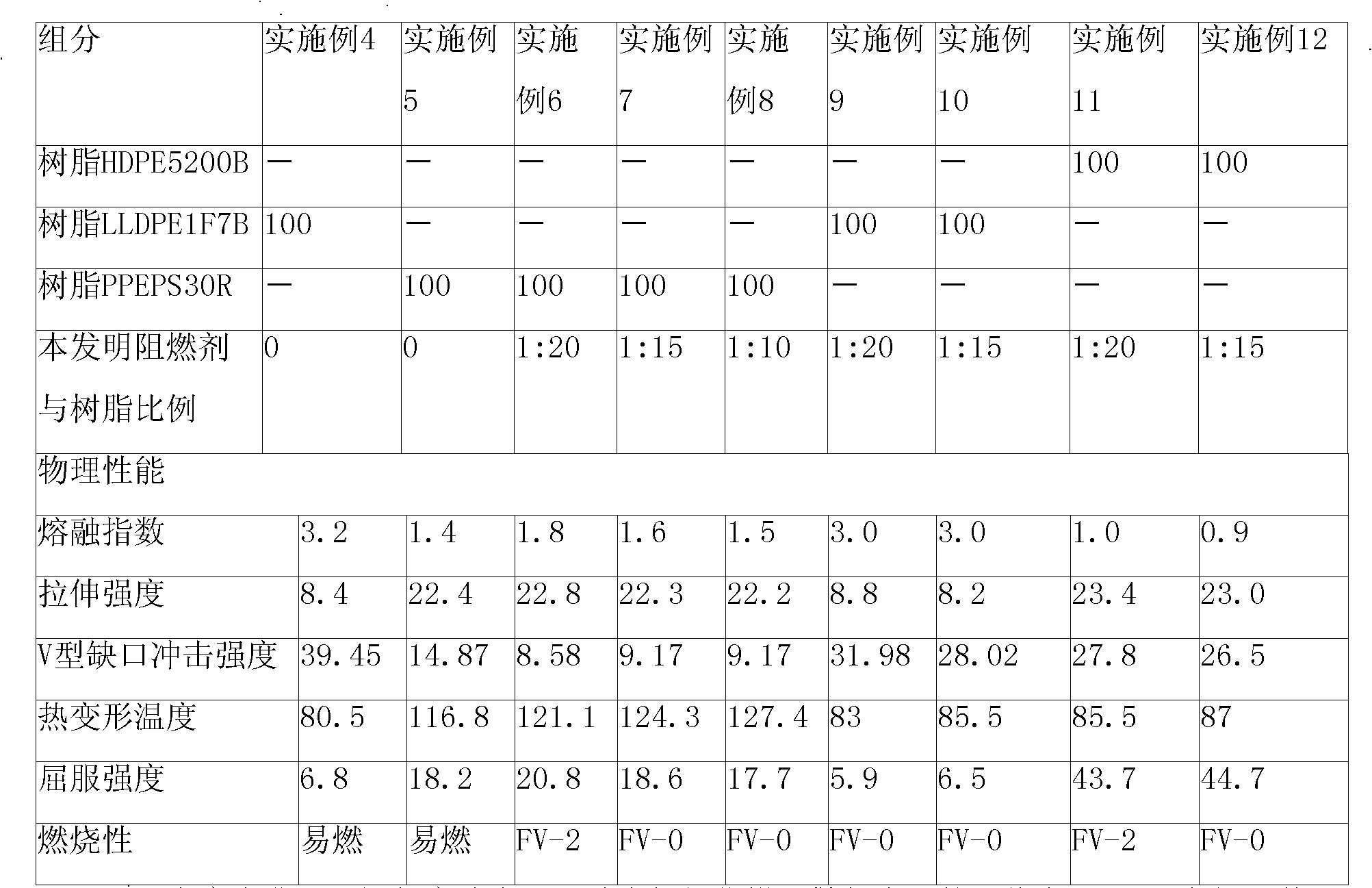

Flame-retardant polyethylene sheath material and preparation method thereof

ActiveCN108017826AImprove flame retardant performancePlay a synergistic flame retardant effectPlastic/resin/waxes insulatorsPolymer scienceAntioxidant

The invention discloses a flame-retardant polyethylene sheath material and a preparation method thereof. 60 to 100 parts of polyethylene, 10 to 40 parts of ethylene and vinyl acetate copolymer resin,70 to 100 parts of flame retardant A, 5 to 25 parts of flame retardant B, 0.1 to 3 parts of antioxidant, 1 to 5 parts of lubricant, 0.5 to 2 parts of coupling agent, 10 to 30 parts of compatibilizer,5 to 20 parts of carbon black masterbatch are added into a mixer successively during preparation, then mixing is conducted, when material temperature is 120 DEG C to 150 DEG C, discharged materials are sent into a cone feeding hopper, a twin screw extruder conducts extrusion granulation, and cold cutting is conducted to obtain products. The flame-retardant polyethylene sheath material has good flame retardancy, excellent mechanical properties and heat resistance. After the products are prepared into a wire and cable, the wire and cable can pass a high temperature pressure test.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

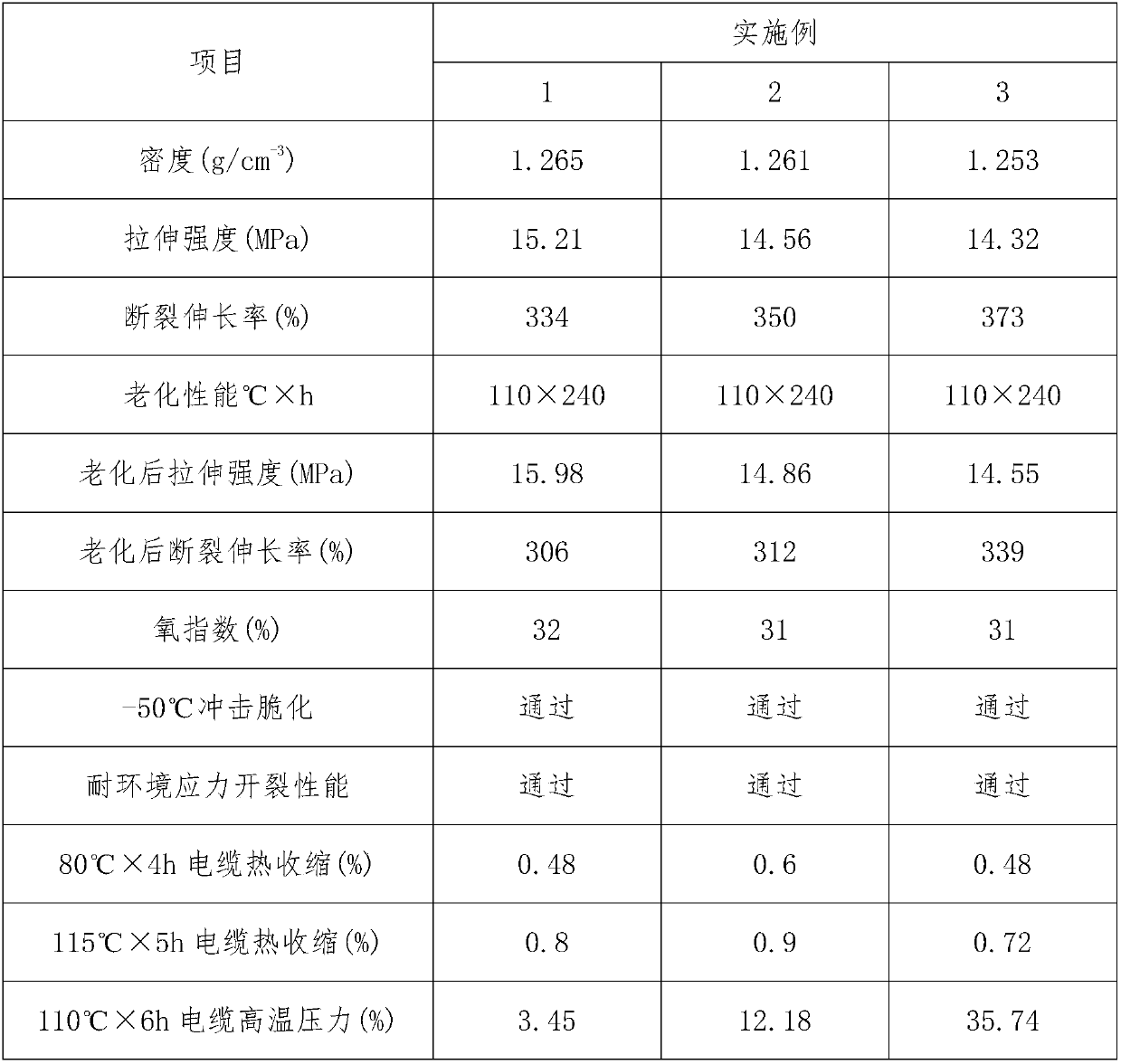

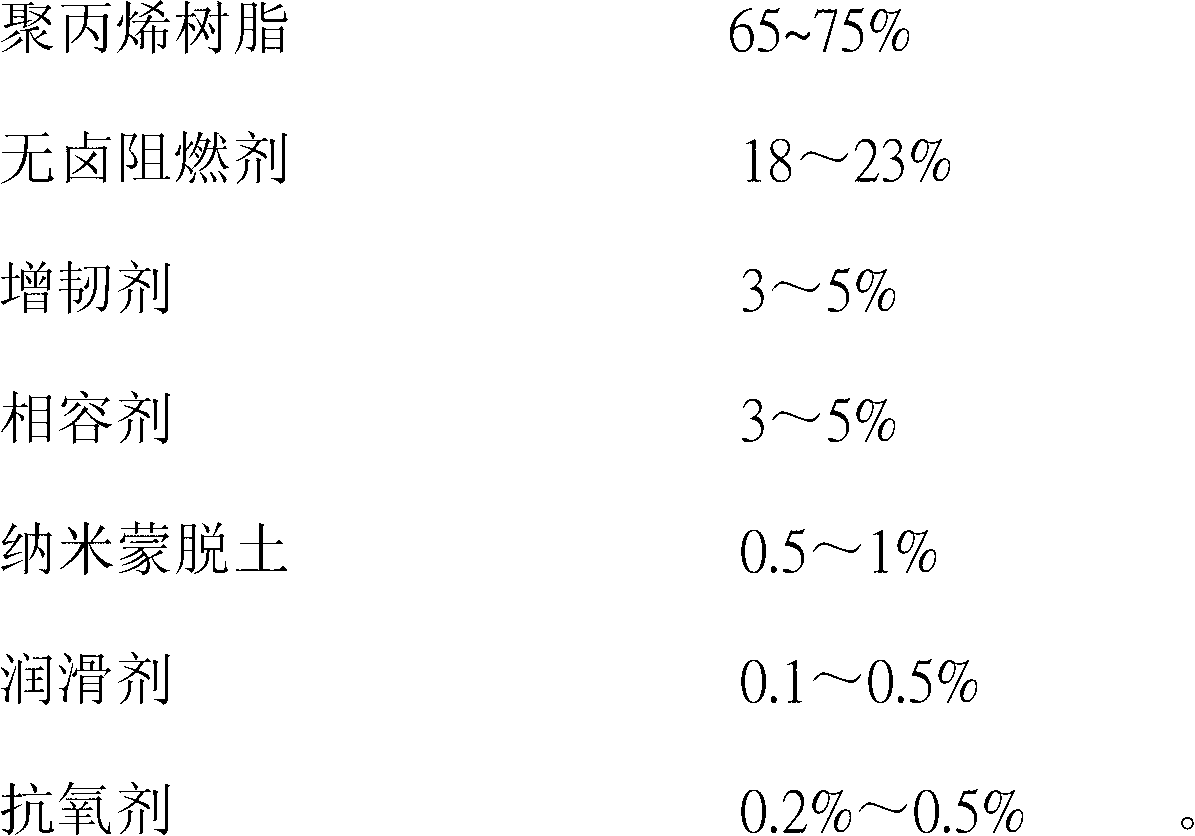

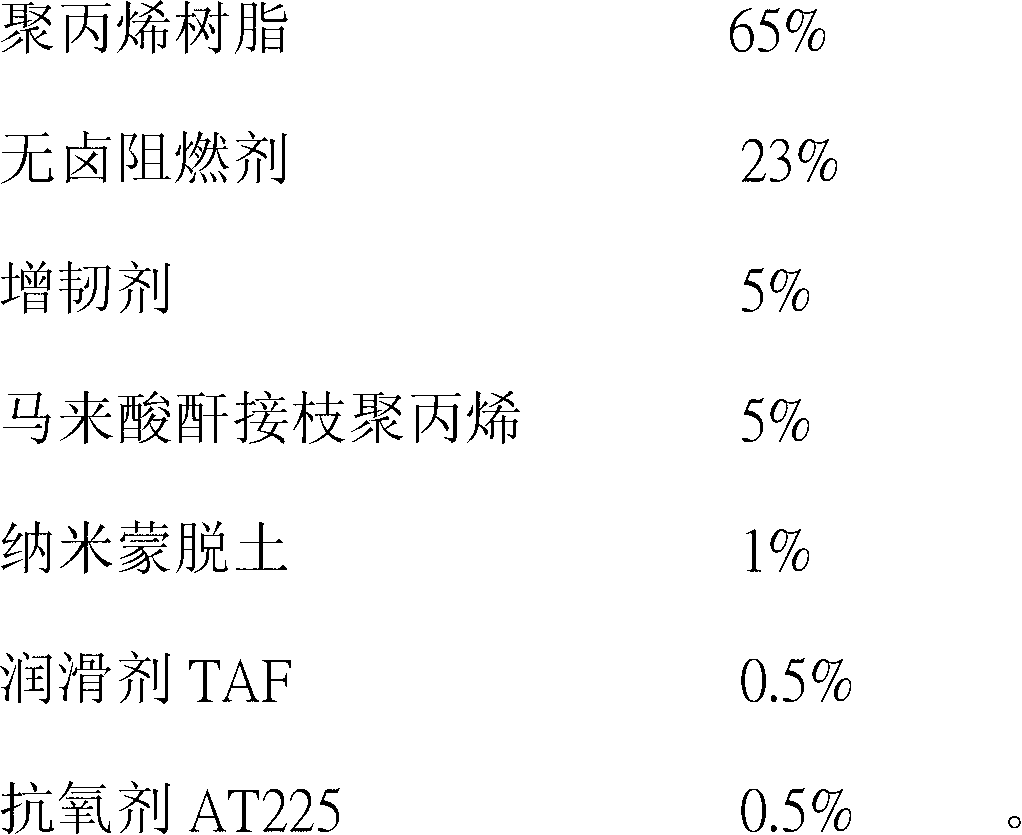

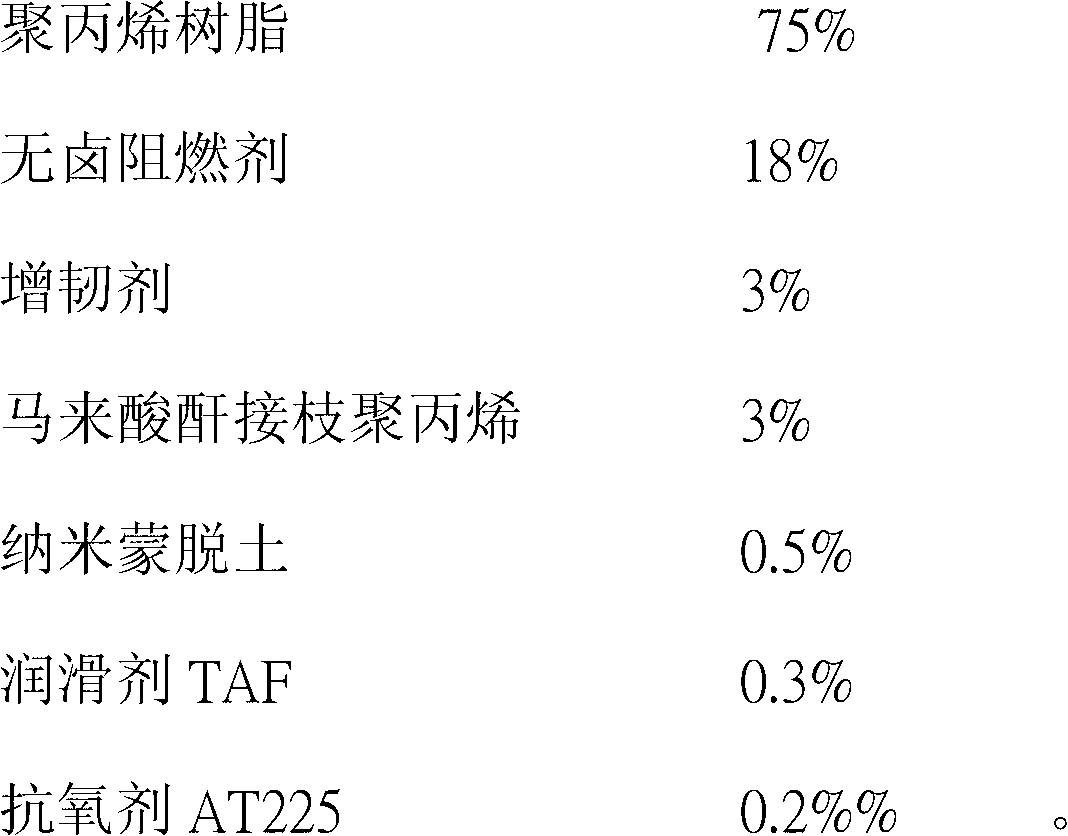

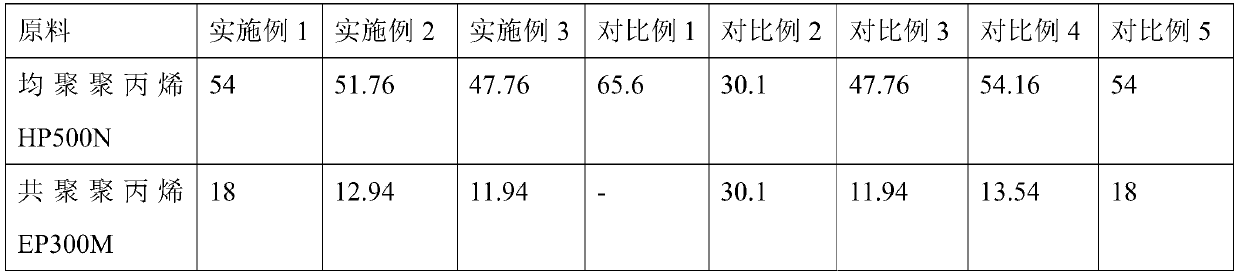

Expansion type flame-retardant polypropylene composite

ActiveCN102796319AReduce flame retardant contentImprove flame retardant stabilityPolypropylene compositesMontmorillonite

The invention discloses an expansion type flame-retardant polypropylene composite, which comprises the following components by weight percentages: 65-75% of polypropylene resin, 18-23% of halogen-free flame retardant, 3-5% of toughening agent, 3-5% of compatibilizing agent, 0.5-1% of nano-montmorillonite, 0.1-0.5% of lubricant and 0.2-0.5% of antioxidant. The expansion type flame-retardant polypropylene composite overcomes the disadvantage of current technology and provides the expansion type flame-retardant polypropylene composite with high toughness which is capable of reducing the content of the flame retardant and effectively preventing hydrolysis.

Owner:武汉顺威赛特工程塑料有限公司

Halogen-free flame-resistant glass fiber reinforced polyformaldehyde composite material and preparation method thereof

The invention discloses a halogen-free flame-resistant glass fiber reinforced polyformaldehyde composite material and a preparation method thereof. The preparation method is characterized by comprising the following steps of: firstly and proportionally mixing tripolycyanamide, ammonium polyphosphate, a polymer carbon-forming agent, polysiloxane, an imide compound and a polyformaldehyde heat stabilizer in a high-speed mixer for 2-4 minutes, then adding polyformaldehyde and a flexibilizer to the mixture and continuously mixing for 3-6 minutes; and adding the mixture to a double-screw extruder for melt extrusion at the temperature of 165-200 DEG C, simultaneously adding glass fiber from a side feeding port of the extruder, and then drying a granulated extrudate. The preparation method provided by the invention has the advantages of simple process, lower cost and easiness enforcement; raw materials are easy to obtain; and the prepared halogen-free flame-resistant glass fiber reinforced polyformaldehyde composite material has the advantages of excellent flame resistance and physical property, environmental friendliness, no halogen and wide application prospect.

Owner:SICHUAN UNIV

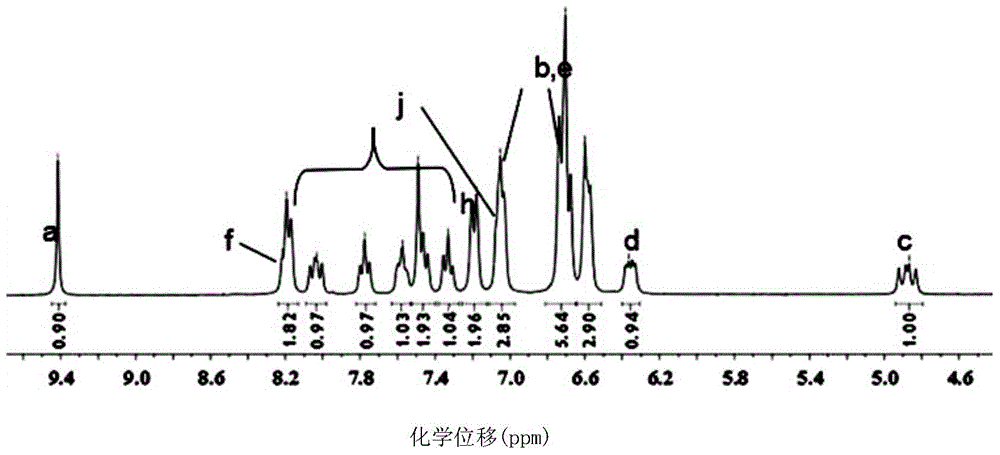

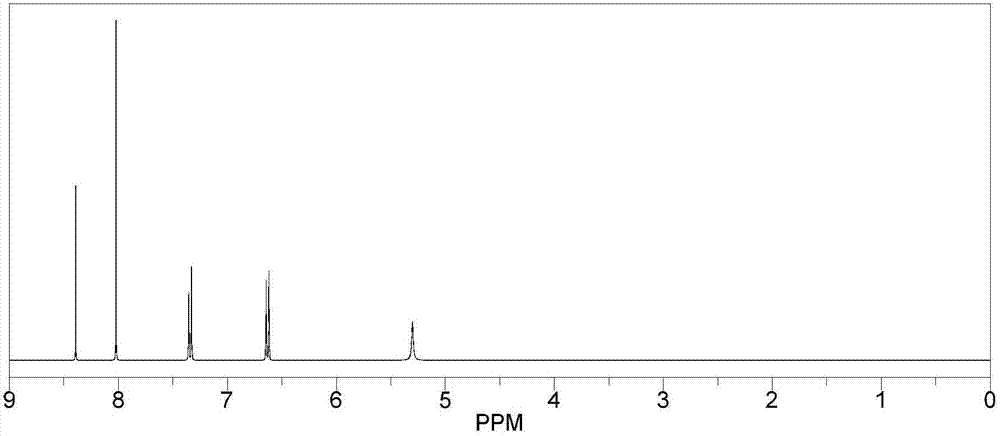

Self-inflaming-retarding epoxy resin curing agent containing phosphorus-nitrogen and preparation method thereof

InactiveCN104693421AGood compatibilityEasy to prepareGroup 5/15 element organic compoundsEpoxyBenzaldehyde

The invention discloses a self-inflaming-retarding epoxy resin curing agent containing phosphorus-nitrogen and a preparation method thereof and relates to epoxy resin curing agents. The method comprises the steps that N-phenyl-1, 4-phenylenediamine and 4-hydroxy benzaldehyde are added into a container provided with a condensation pipe and a stirrer for reacting with first solvent, the reaction system is filtered, and solids obtained after the filtering are washed and dried, so that an intermediate body is obtained; the intermediate body, DOPO and second solvent are added into a container provided with a condensation pipe and a stirrer for reacting, the reaction system is filtered, and solids obtained after the filtering are washed and dried, so that the self-inflaming-retarding epoxy resin curing agent containing the phosphorus-nitrogen is obtained; or alternatively, the N-phenyl-1, the 4-phenylenediamine, the 4-hydroxy benzaldehyde and the DOPO are added into a container provided with a condensation pipe and a stirrer sequentially for reacting with solvent, the reaction system is filtered, and articles obtained after the filtering are washed and dried, so that the self-inflaming-retarding epoxy resin curing agent containing the phosphorus-nitrogen is obtained. The curing agent contains two active imino groups, one active hydroxyl group and P and N synergistic flame retardant elements simultaneously and can be used for epoxy resin curing and inflaming retardation.

Owner:XIAMEN UNIV

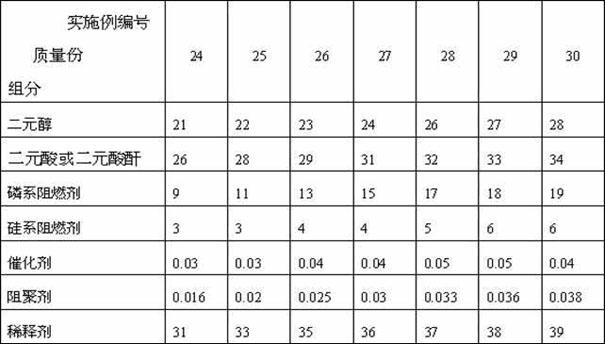

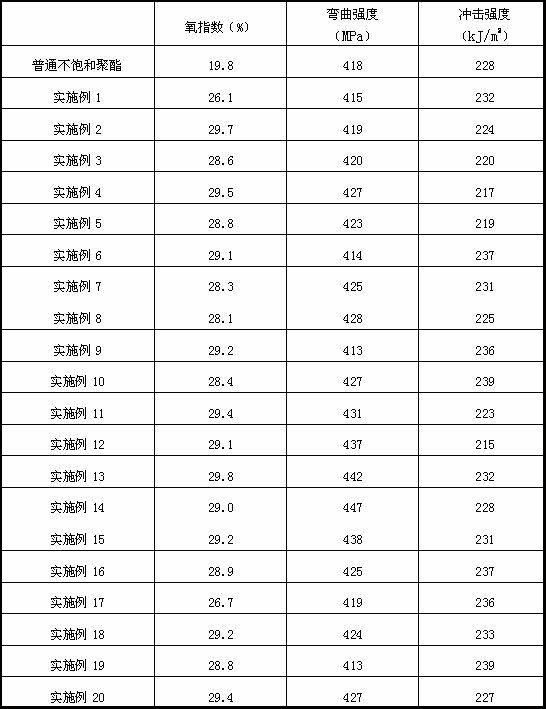

Method for synthesizing reactive halogen-free flame-retardant unsaturated polyester resin

The invention discloses a method for synthesizing reactive halogen-free flame-retardant unsaturated polyester resin. The method is characterized by taking dihydric alcohol, dibasic acid or dibasic acid anhydride, reactive phosphorus flame retardants such as 2- carboxyethyl (phenyl) phosphinic acid and phenyl hydroxymethyl phosphinic acid, and reactive silicon flame retardants such as dihydroxy diphenyl silane and dihydroxy dimethyl silane as basic materials, conducting esterification and polycondensation under the conditions of catalysts such as dibutyltin oxide and sodium acetate, and then adding diluent, thus preparing the halogen-free flame-retardant unsaturated polyester resin. The resin prepared by the method is especially applicable to the production of unsaturated polyester resin moulding compounds, glass fiber reinforced plastics and electrical plastic products, can meet the requirements of products on flame retarding and lightweight and has good properties.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

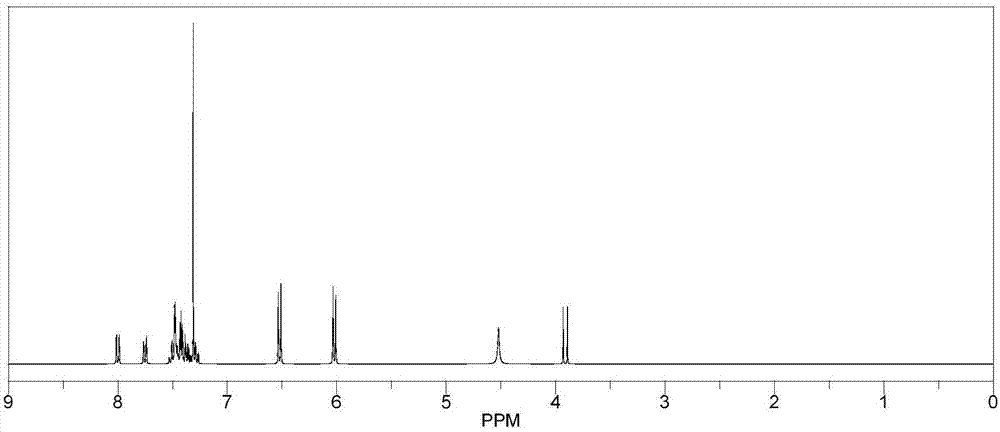

Reactive type flame-retardant epoxy resin curing agent and preparation method thereof

InactiveCN107400197APlay a synergistic flame retardant effectPlay a role in cross-linking and curingGroup 5/15 element organic compoundsChemistryP-Phenylenediamine

The invention discloses a reactive type flame-retardant epoxy resin curing agent and a preparation method thereof. The curing agent is prepared by enabling p-phenylenediamine and terephthalaldehyde to react to generate an intermediate product and by further enabling the intermediate product to react with DOPO. The curing agent has two active amino groups and two imino groups, can be used for curing epoxy resins, has flame-retardant elements P and N, and has a function of synergic flame retardancy. The curing agent has the advantages that raw materials are easy to obtain, a preparation process is simple, separation and purification are easily implemented and the like, and is convenient in large-scale popularization and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Biomass graphene-modified fire retardant and master batch and preparation method

The invention provides a biomass graphene-modified fire retardant and master batch and a preparation method thereof. The biomass graphene-modified fire retardant is mainly prepared from biomass graphene, a fire retardant and a coupling agent. The fire retardant is used as a disperse medium for the biomass graphene. By simple physical mixing, bond joint of the biomass graphene with the fire retardant and uniform dispersion of the biomass graphene are realized, thus finally playing a synergistic flame retardant effect in a polymer matrix. By the adoption of the Biomass graphene-modified fire retardant for preparation of high-molecular polymer master batch, the dispersion problem of biomass graphene is solved, and it is possible to effectively raise fire resistance under the condition of low addition amount of the fire retardant. For practical application fields of different fire-resistant high-molecular polymer materials, anti-dripping, enhancing, ultraviolet-resistant and coloring functions can be obtained simultaneously by the adoption of the master batch product.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

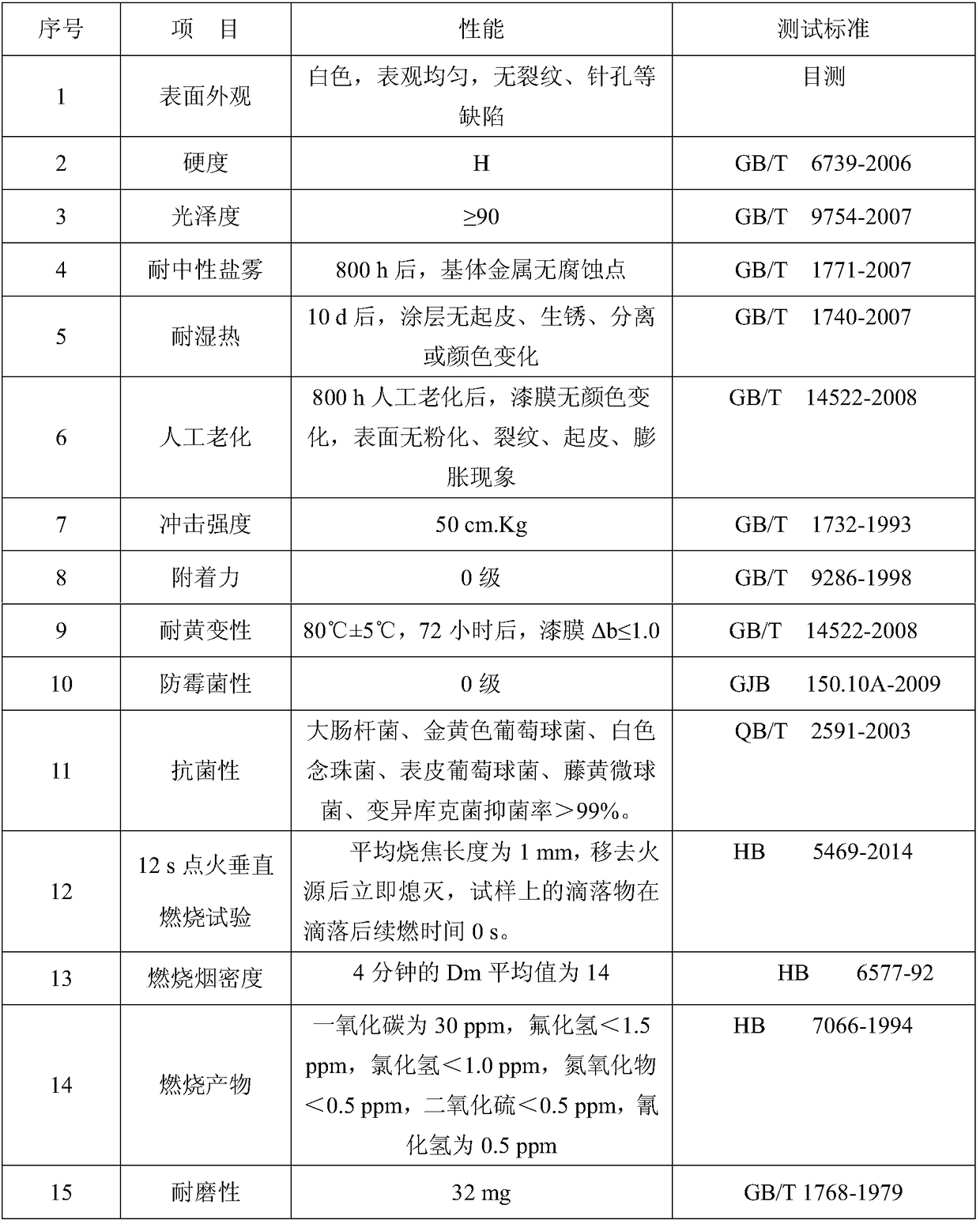

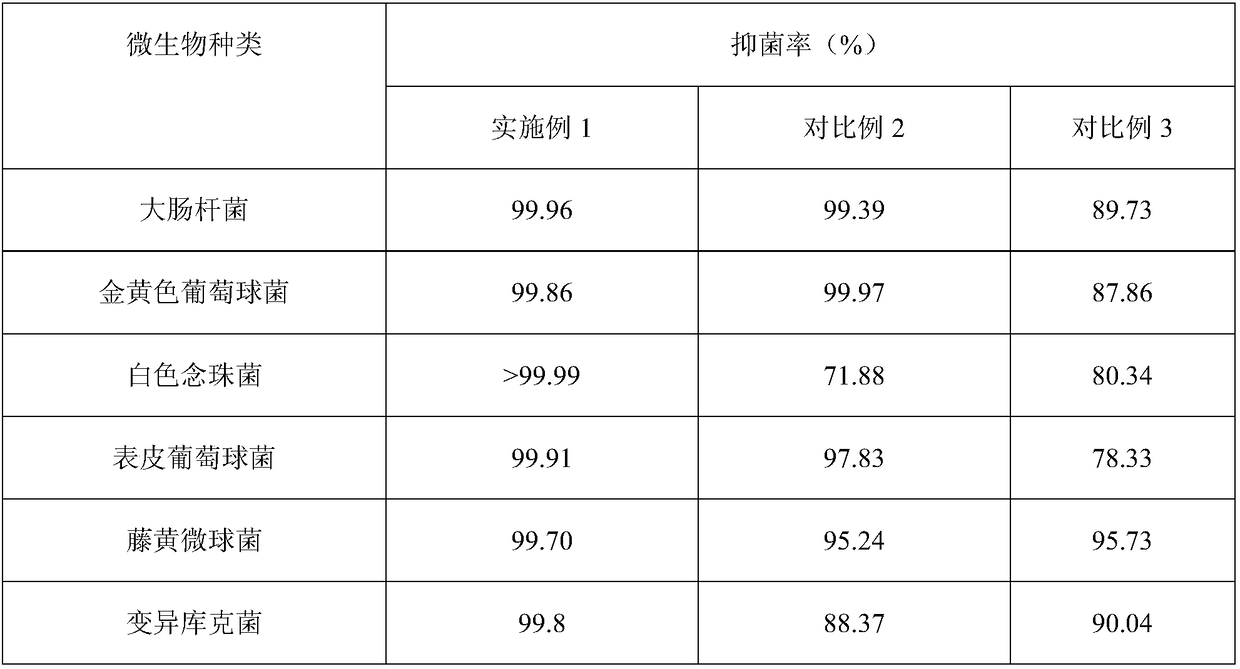

Antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint, and preparation method and applications thereof

InactiveCN108912945AImprove flame retardant performanceImprove corrosion resistanceFireproof paintsAntifouling/underwater paintsWear resistantAntiseptic solutions

The invention discloses an antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint, and preparation method and applications thereof. The antibacterialmildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint is mainly composed of a corrosion-resistant flame-resistant epoxy priming paint and an antibacterial mildew-resistant wear-resistant polyurethane finish paint. According to the preparation method, an intumescent flame retardant and graphene are added into the epoxy priming paint as flame retardation auxiliary agents; the paint flame resistance is improved greatly through the cooperative effect of the nanometer material and the intumescent flame retardant; nanometer silver antiseptic and hyperbranched polyethylene imide quaternary ammonium salt nanometer particles are added into the polyurethane finish paint as antibacterial auxiliary agents, and the paint antibacterial mildew-resistant performance isimproved through the cooperative effect of the nanometer silver antiseptic and the hyperbranched polyethylene imide quaternary ammonium salt nanometer particles. The reasonable combination of the priming paint with the finish paint is capable of improving the paint corrosion resistance further. The antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functionalpaint possesses the antibacterial performance, the mildew resistance, the flame resistance, the corrosion resistance, and the wear resistance, is wide in application range, is simple in preparation method, is convenient in operation, and is convenient for large scale applications.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Waterborne polyurethane coating and preparation process

InactiveCN106634530AImprove flame retardant performanceHarm reductionFireproof paintsAntifouling/underwater paintsFire retardantPolyurethane coating

The invention discloses waterborne polyurethane coating and a preparation process thereof. The waterborne polyurethane coating is prepared from modified waterborne polyurethane, an expansive fire-retardant system, a flame retardant synergist, water, filler, a dispersing agent, an antifoaming agent, a thickening agent, a curing agent, a mildew-proof bactericide, a coalescing agent and a penetrating agent. The preparation process is simple, feasible and low in preparation cost, and the coating prepared according to the method is great in flame retardation effect, nontoxic and free of environment pollution.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Halogen-free environment-friendly inflaming retarding HIPS (High Impact Polystyrene) material as well as preparation method and application thereof

The invention belongs to the technical field of HIPS (High Impact Polystyrene) materials and discloses a halogen-free environment-friendly inflaming retarding HIPS material as well as a preparation method and an application thereof. The material comprises the following components in percentage by mass: 45-65% of HIPS resin, 10-25% of hypophosphite, 2-13% of an auxiliary fire retardant, 1-10% of a toughening agent, 0.1-2% of a silane coupling agent and 1-5% of fillers. According to the halogen-free environment-friendly inflaming retarding HIPS material, the hypophosphite is added into the auxiliary fire retardant; polyol and a nitrogen-containing compound are used as a gas source and an acid source to have the synergic inflaming retarding effect and have small influences on mechanical properties; the silane coupling agent is used for carrying out surface treatment on the hypophosphite so that the hypophosphite and polymer resin have very good compatibility; other resin does not need to be added and the stable inflaming retarding can be realized; V-0-grade inflaming retarding can be realized. The halogen-free environment-friendly inflaming retarding HIPS material has good rigidity and impact resistance, good processability and good appearance, and can be widely applied to a thin-wall part.

Owner:KINGFA SCI & TECH CO LTD

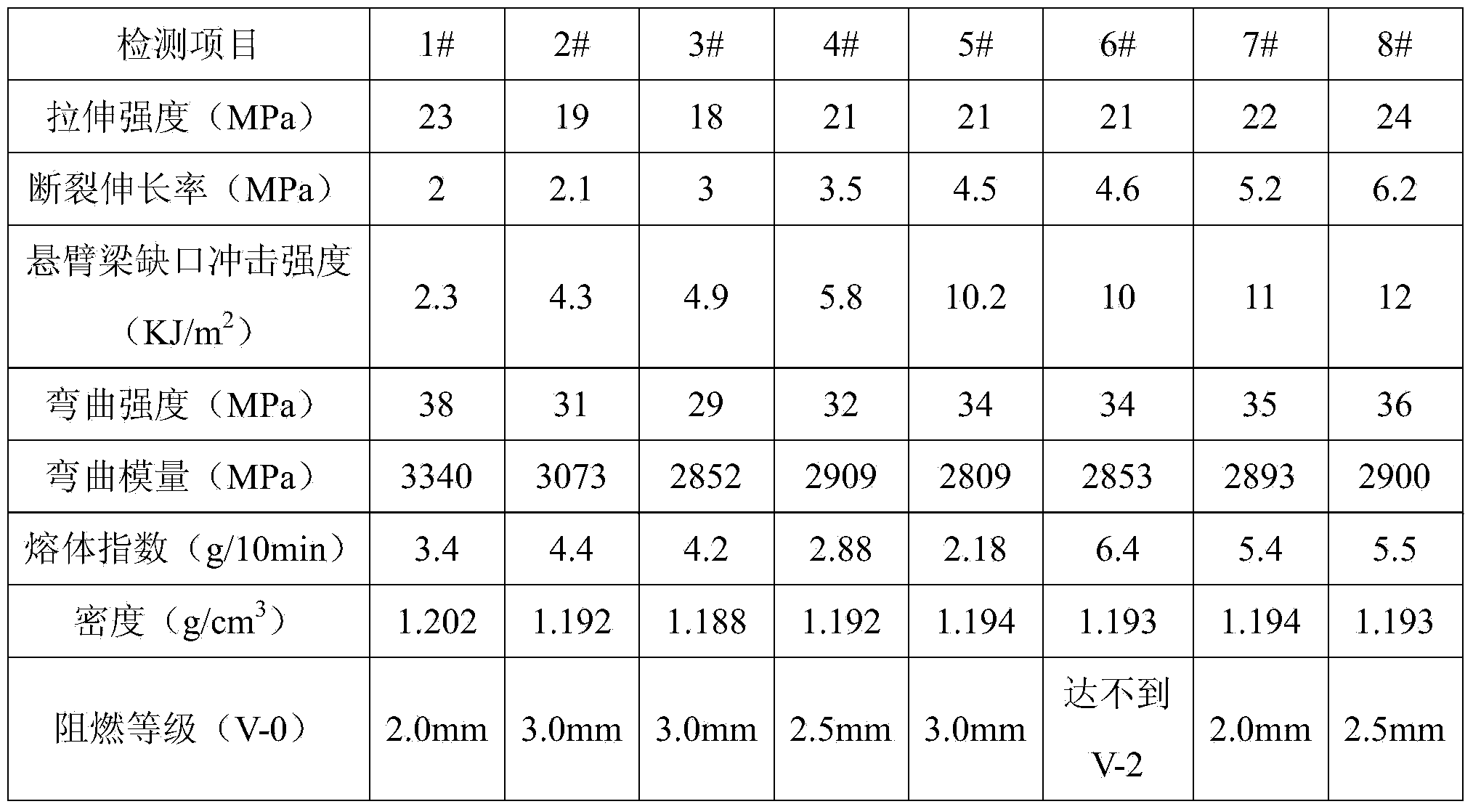

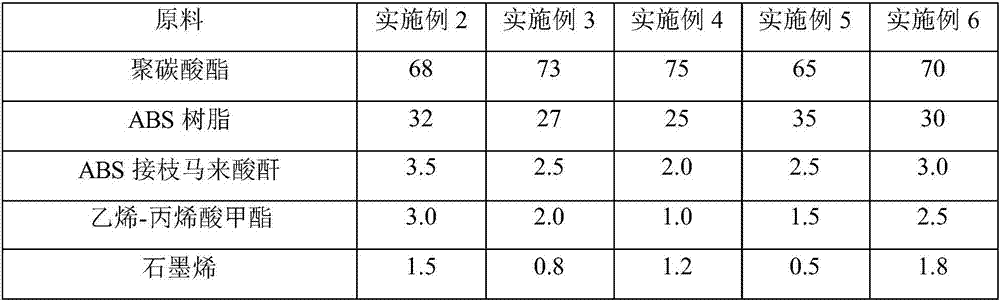

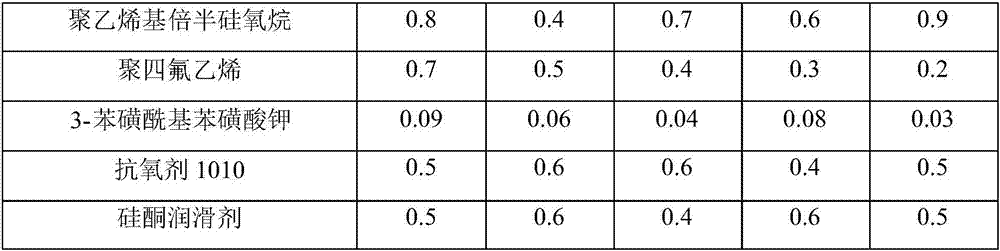

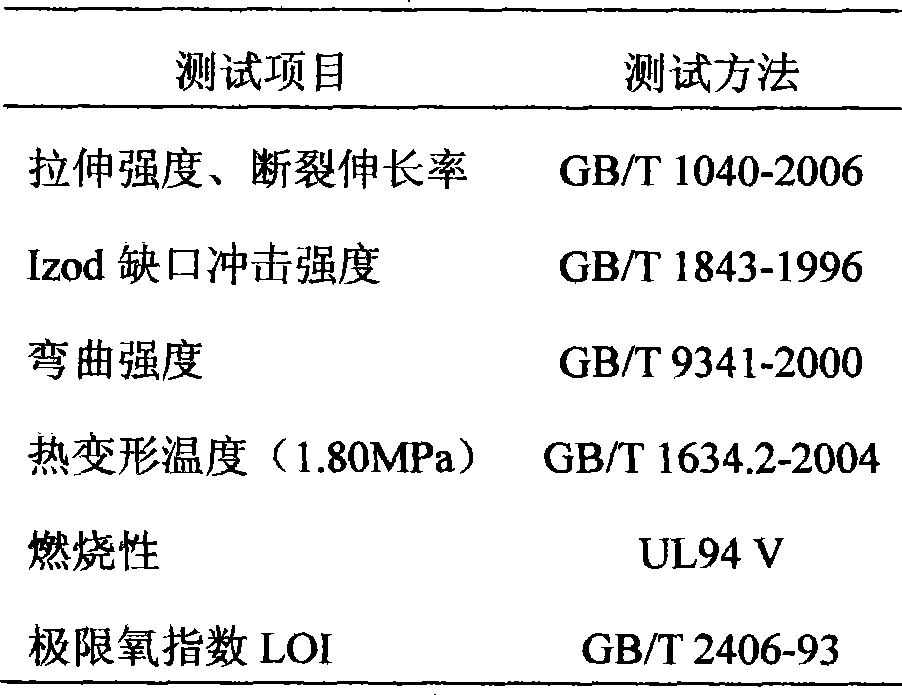

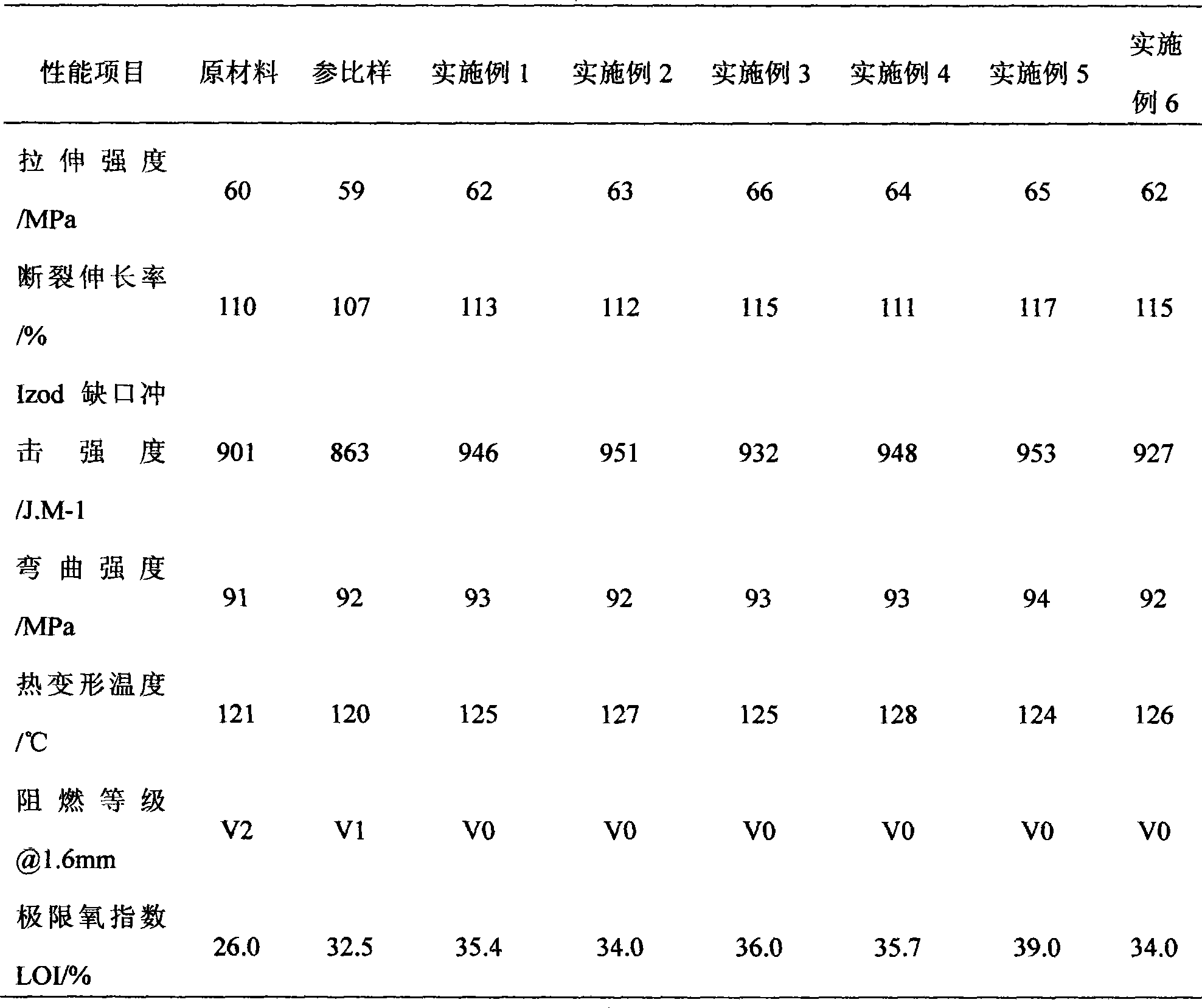

Halogen-free anti-flaming PC/ABS plastic alloy and preparation method thereof

The invention relates to a halogen-free anti-flaming PC / ABS plastic alloy and a preparation method thereof. The halogen-free anti-flaming PC / ABS plastic alloy is prepared by the following raw materials by weight: 65-75 parts of polycarbonate, 25-35 parts of an acrylonitrile-butadiene-styrol copolymer, 2-4 parts of a compatilizer, 1-3 parts of a flexibilizer, 0.5-2.0 parts of graphene, 0.4-1.0 part of polyvinyl silsesquioxane, 0.2-0.8 parts of polytetrafluoroethylene, and 0.02-0.10 parts of 3-potassium phenylsulphonyl benzene sulfonate. The PC / ABS plastic alloy uses four substances of the graphene, polyvinyl silsesquioxane, the polytetrafluoroethylene and 3-potassium phenylsulphonyl benzene sulfonate to retard the flaming synergistically. The total additive amount of an anti-flaming agent is reduced, the limited oxygen index is more than 30 vol% on the basis of guaranteeing the mechanical property of the plastic alloy, the vertical combustion level is up to UL 94 V-0, and the PC / ABS plastic alloy has the remarkable anti-flaming effect.

Owner:汕头市忠诚行塑料环保科技有限公司

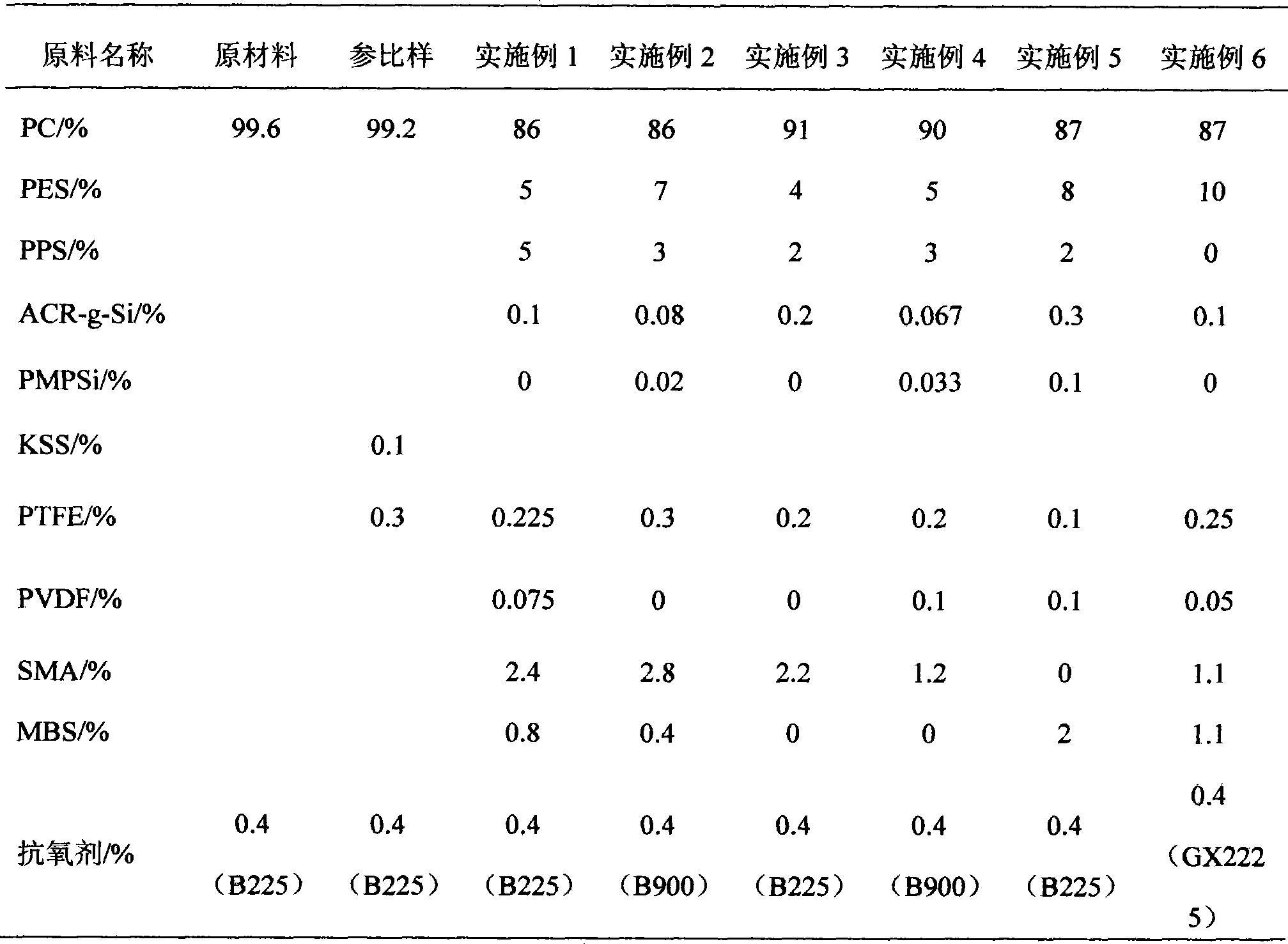

Non-halogen flame-retarding high performance polycarbonate engineering plastics and preparation method thereof

The invention relates to a halogen-free inflaming retarding high-performance polycarbonate engineering plastic and a preparation method thereof. Counted in weight percentage, the components of the engineering plastic include as follows: 78 to 92 percent of PC resin, 5 to 10 percent of sulfur-bearing super engineering plastics, 0.1 to 3 percent of flame retardant containing silicon, 0.1 to 1 percent of anti-dropping agent, 1 to 5 percent of compatilizers and 0.1 to 1 percent of chemical inhibitors; wherein, the sulfur-bearing engineering resin is polyethersulfone or the composition of the polyethersulfone and polyphenyl thioether; the flame retardant containing silicon is acrylic ester graft modification polysiloxane or the composition of the acrylic ester graft modification polysiloxane and poly methyl phenyl siloxane. The preparation method includes as follows: the materials of the prescription are fully mixed in a high speed mixer; then is fed into a co-rotating meshed double-screw extruder to melt, blend and extrude. In the invention, the sulfur-bearing super engineering plastics and the flame retardant containing silicon are matched and used, thus endowing the polycarbonate with excellent flame retardation and higher heat resistance as well as excellent compatibility, improving the mechanical property of the composite material and overcoming the defects of being easily separated out and absorbing moisture of a micromolecule flame retardant containing silicon.

Owner:SOUTH CHINA UNIV OF TECH

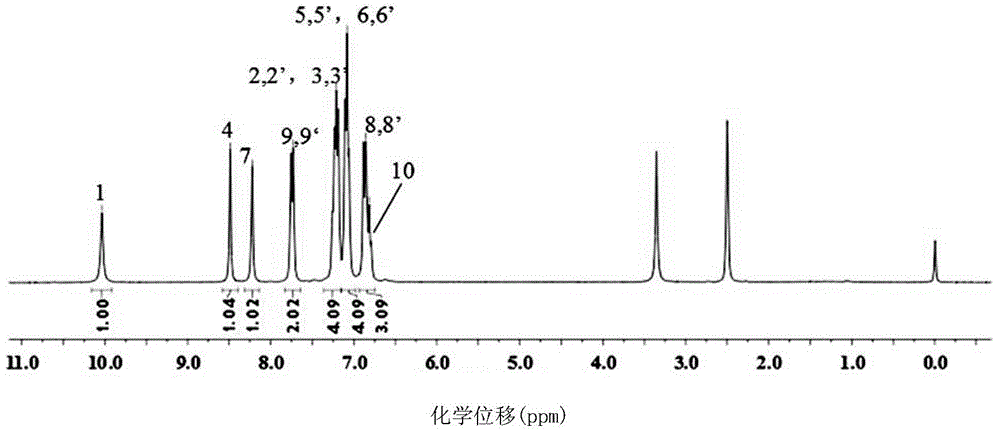

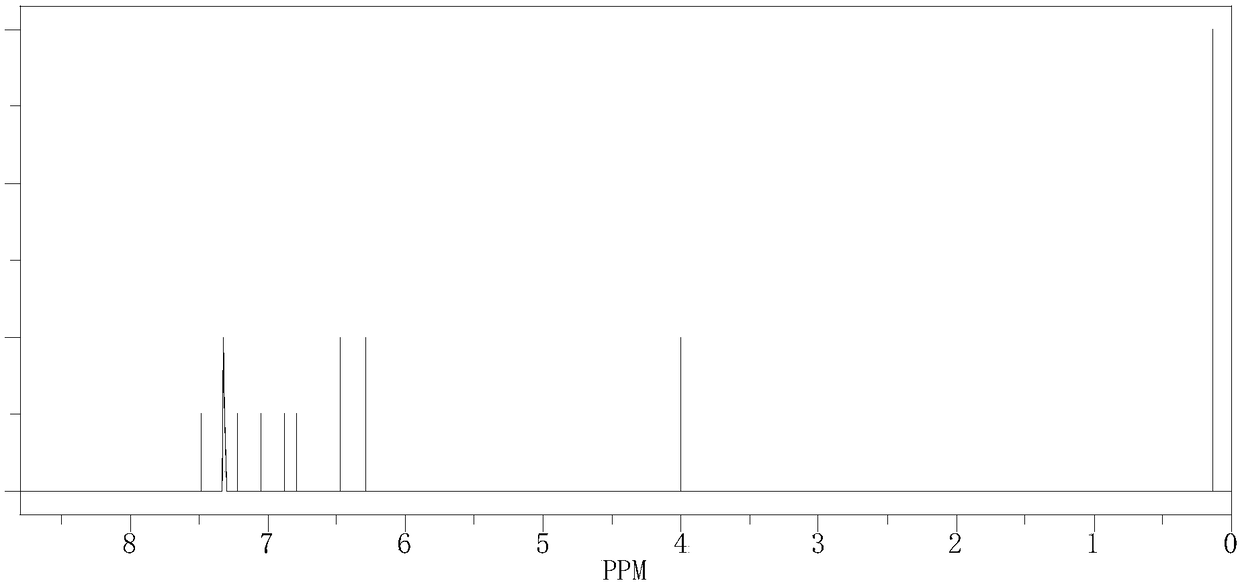

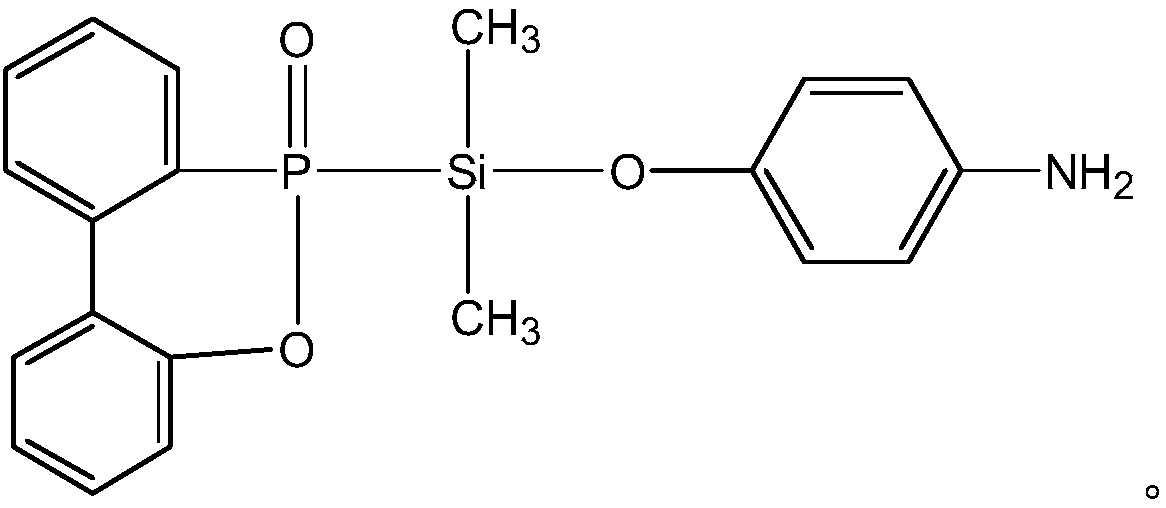

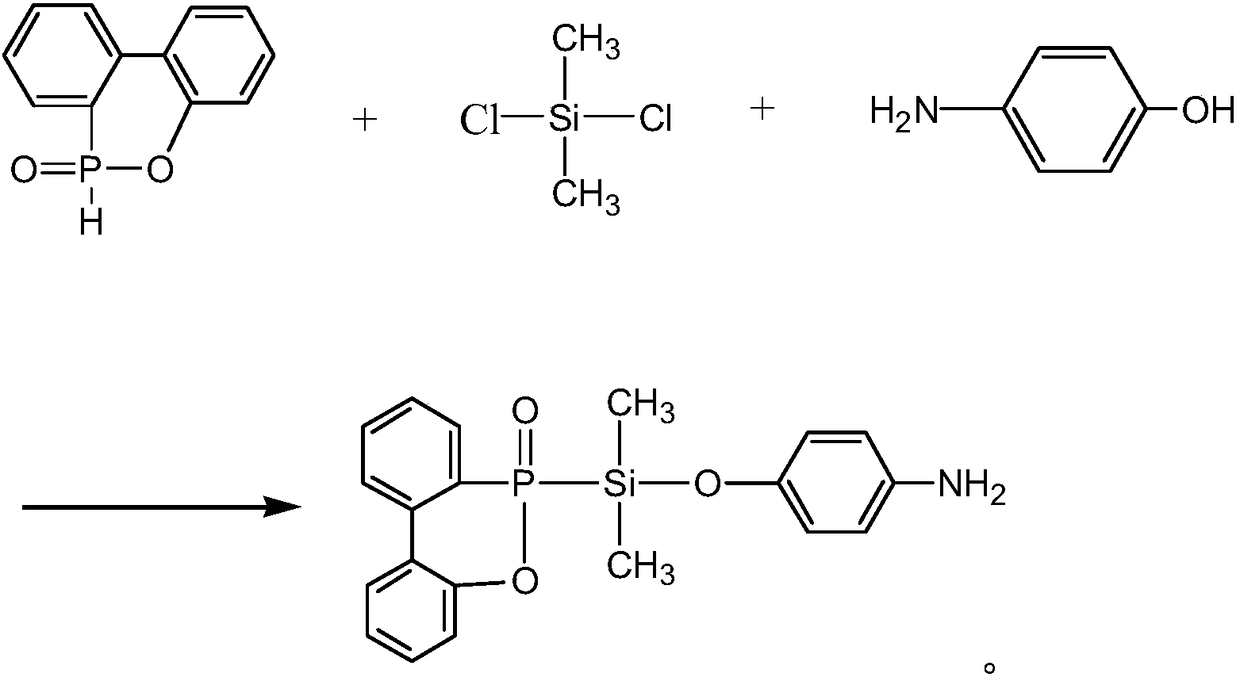

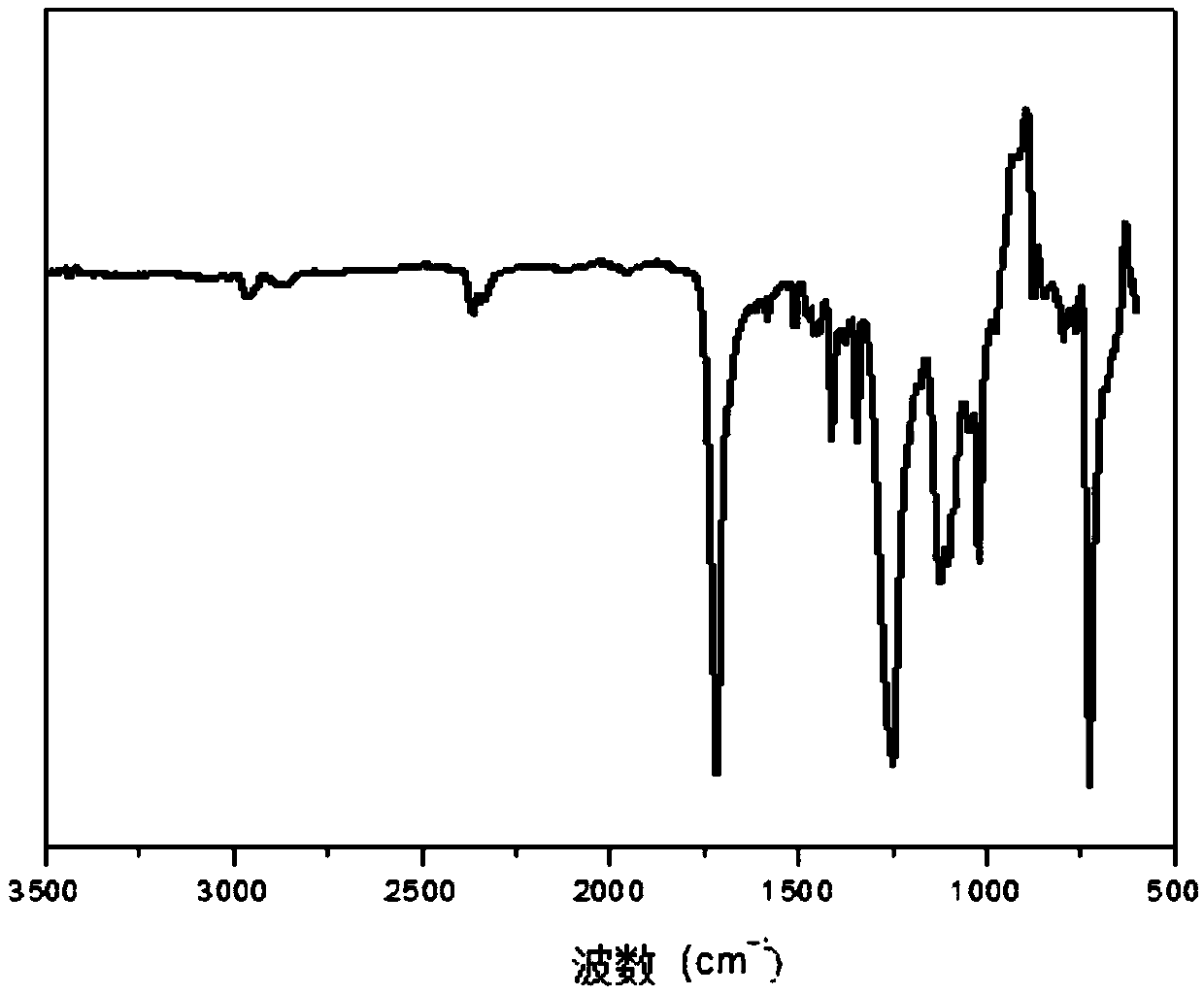

Novel P-N-Si synergistic flame retardant epoxy resin curing agent and preparation method thereof

ActiveCN109096471APlay a role in cross-linking and curingPlay a synergistic flame retardant effectGroup 5/15 element organic compoundsEpoxyP-Aminophenol

The invention discloses a novel P-N-Si synergistic flame retardant epoxy resin curing agent with a molecular structure in the description below. The novel P-N-Si synergistic flame retardant epoxy resin curing agent includes 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), dichlorodimethylsilane and p-aminophenol. The preparation process of a flame retardant is divided into two steps, first an intermediate product is obtained by reacting dichlorodimethylsilane with p-aminophenol, and then the intermediate product and the DOPO react to obtain a final product. The molecular structure contains three elements, P, N and Si, which greatly improves the flame retardant properties of an epoxy resin after curing.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

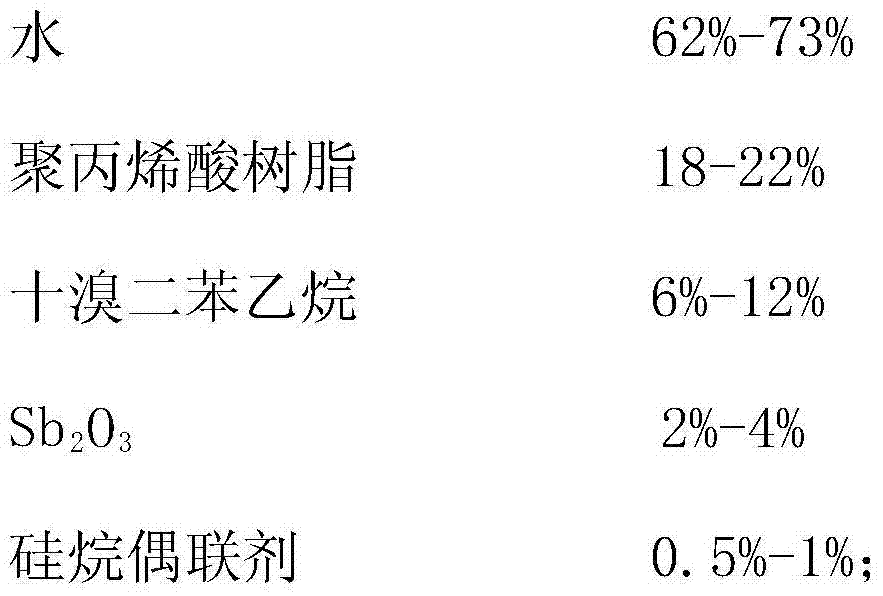

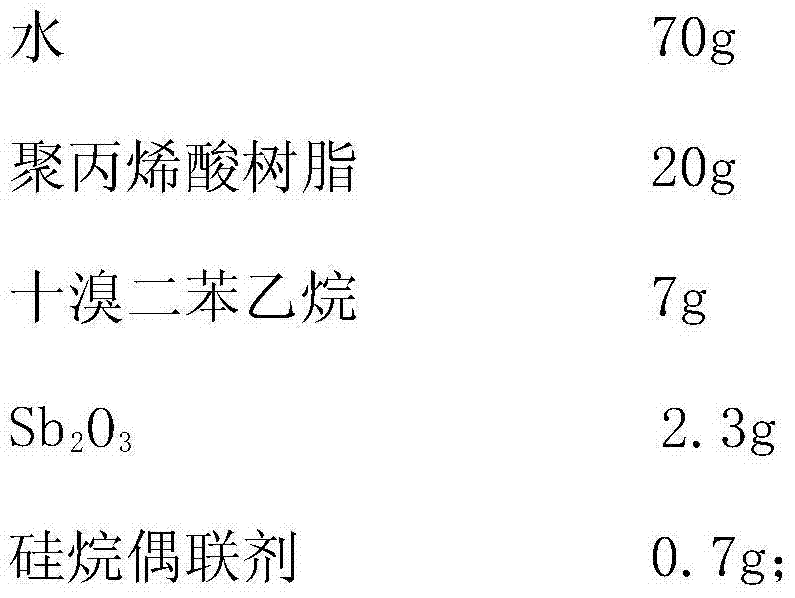

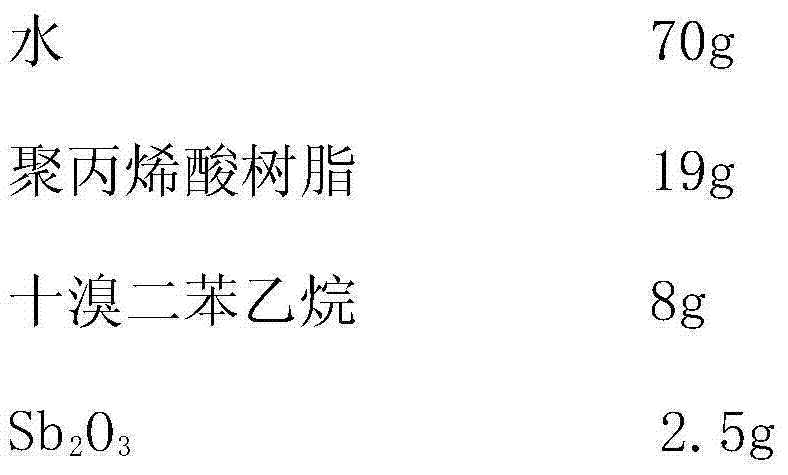

Preparation method of flame retardant PP (polypropylene) non-woven fabric

The invention relates to a preparation method of flame retardant PP (polypropylene) non-woven fabric. The non-woven base fabric obtained by a melt blowing method is subjected to flame retardant finishing. The preparation method comprises the following steps: preparing flame retardant slurry from the following components in percentage by mass: 62 to 73 percent of water, 18 to 22 percent of polyacrylic acid, 6 to 12 percent of decabromodiphenylethane, 2 to 4 percent of Sb2O3 and 0.5 to 1 percent of a silane coupling agent; pouring the flame retardant slurry into a slurry barrel with a stirring device, making the non-woven base fabric pass through a pressure roller and a slurry feeding roller, and transferring the slurry in a slurry groove to the base fabric through a screen frame by using the slurry feeding roller; placing the base fabric which is coated with the slurry between two rubber pressure rollers of a roller press for extruding to remove excessive slurry; finally, drying the base fabric to obtain the flame retardant non-woven fabric. The preparation method is simple in process, convenient to operate, and environmental friendly; the selected decabromodiphenylethane is a high-efficiency brominated flame retardant, and has the characteristics of high bromine content, high thermal stability, low toxicity and the like; meanwhile, the decabromodiphenylethane and the added Sb2O3 have a synergistic flame retardant effect, so that the prepared non-woven fabric has a good flame retardant effect.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

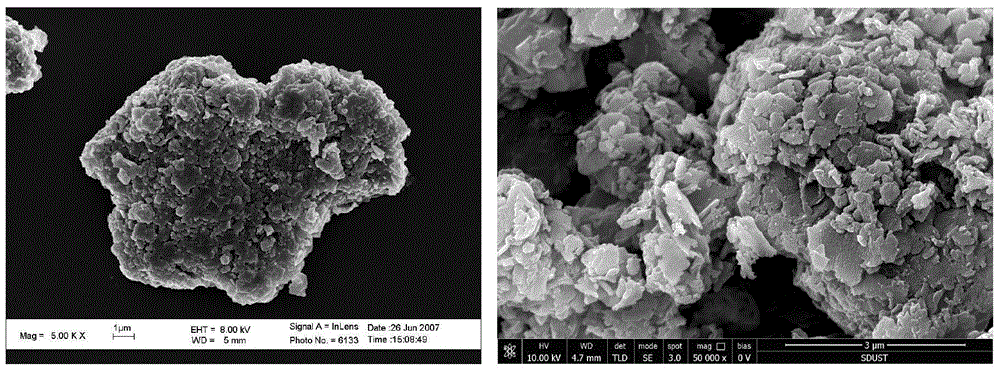

Montmorillonite/polyaniline nano flame-retardant polystyrene composite material

The invention relates to a montmorillonite / polyaniline nano flame-retardant polystyrene composite material. The preparation method comprises: adding montmorillonite to a modifying agent, reacting under stirring, adding an aniline monomer, stirring, ultrasonically dispersing uniformly, adding an oxidation agent, and reacting at room temperature under stirring to obtain a montmorillonite / polyaniline nano complex; and mixing the material with polystyrene resin in a torque rheometer, and extruding and granulating with a double screw extruder to obtain the montmorillonite / polyaniline nano flame-retardant polystyrene composite material. The montmorillonite / polyaniline nano complex is prepared by adopting an in-situ polymerization method, and the flame retardance of the material is effectively improved by synergistic action between one-dimensional polyaniline and two-dimensional nano montmorillonite lamellae.

Owner:SHANDONG UNIV OF SCI & TECH

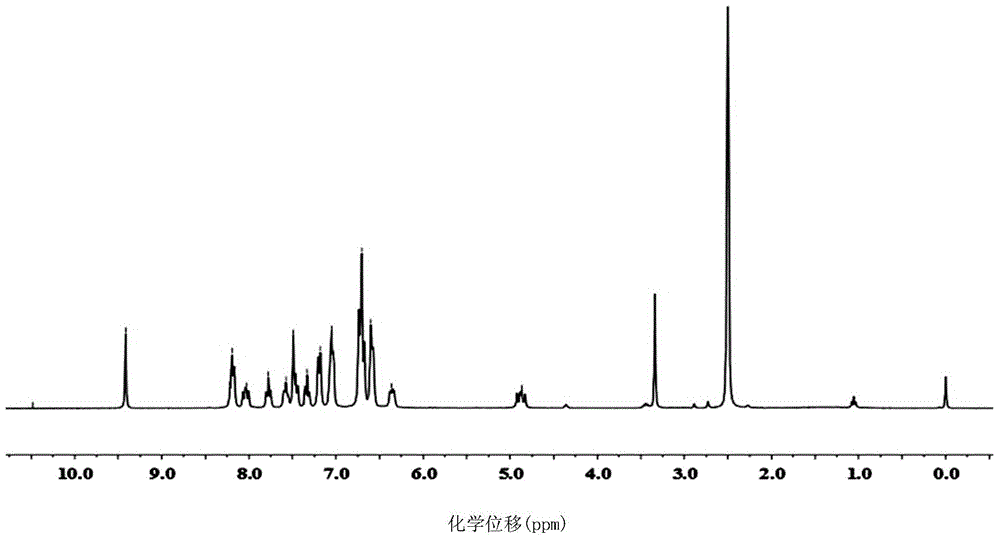

P/N/Si-multi-element-containing poly-phosphorus-silazane fire retardant for epoxy resin and preparing method thereof

The invention discloses a P / N / Si-multi-element-containing poly-phosphorus-silazane fire retardant for epoxy resin and a preparing method thereof. The fire retardant is obtained after a C=C key in a PVSZ structure and a P-H key in a DOPO structure are subjected to an addition reaction. The preparing method includes the following steps that under protection of inert gas, an AIBN serves as an initiating agent, and through the addition reaction between the PVSZ and the DOPO, the P / N / Si-multi-element-containing poly-phosphorus-silazane fire retardant for the epoxy resin is prepared with the one-step method, wherein the molar ratio of the PVSZ to DOPO is 1:(1-3). The method has the advantages that the raw materials are easy to obtain, the technology is simple, the method is fast, simple and convenient, and large-scale production is easy to achieve; the main chain of the fire retardant prepared with the method is a Si-NH repetition structure unit, and can be subjected to a cross-linking reaction with the epoxy resin, and the good heat stability and the high quality retention rate are provided for the fire retardant; a phosphaphenanthrene structure of a side chain can generate phosphoric-acid substances in the combustion process, fast dehydration and carbonization of the surface of a polymer are promoted, and a carbonized layer or a non-combustible layer is formed to cover a base material; meanwhile, P / N / Si multi-elements in the structure can also have the synergistic flame retardant effect, and the flame retardant effect is further improved.

Owner:库贝化学(上海)有限公司

Phosphorus series non-halogen composite flame retardant for polyolefin, preparation method thereof and flame retardant polyolefin

The invention discloses a phosphorus halogen-free compound flame retardant used in polyolefin, a preparatin method thereof and a flame retardant polyolefin thereof. The flame retardant is prepared through modified red phosphorus, nano-hydroxides dispersant, copolymer emulsion containing carbonyl and unsaturated double bond, comonomer containing carbonyl and unsaturated double bond, and free radical initiator under the high-speed shear force. The flame retardant polyolefin is prepared by the flame retardant of the invention and polyolefin polymers. In improving the dispersivity of red phosphorus, the nano-hydroxides of the invention has synergistic flame retardant effect of red phosphorus and hydroxides, and has the advantages of halogen-free low smoke, the combustion does not produce toxic gases, a little amount of flame retardant is added, and the impact on the mechanical properties of the materials is low. And even an amount of the flame retardant of the invention added in polyolefin is reduced by at least 20 to 50 percent, and the flame retardant level of the polyolefin is capable of achieving FV level.

Owner:贵州省复合改性聚合物材料工程技术研究中心

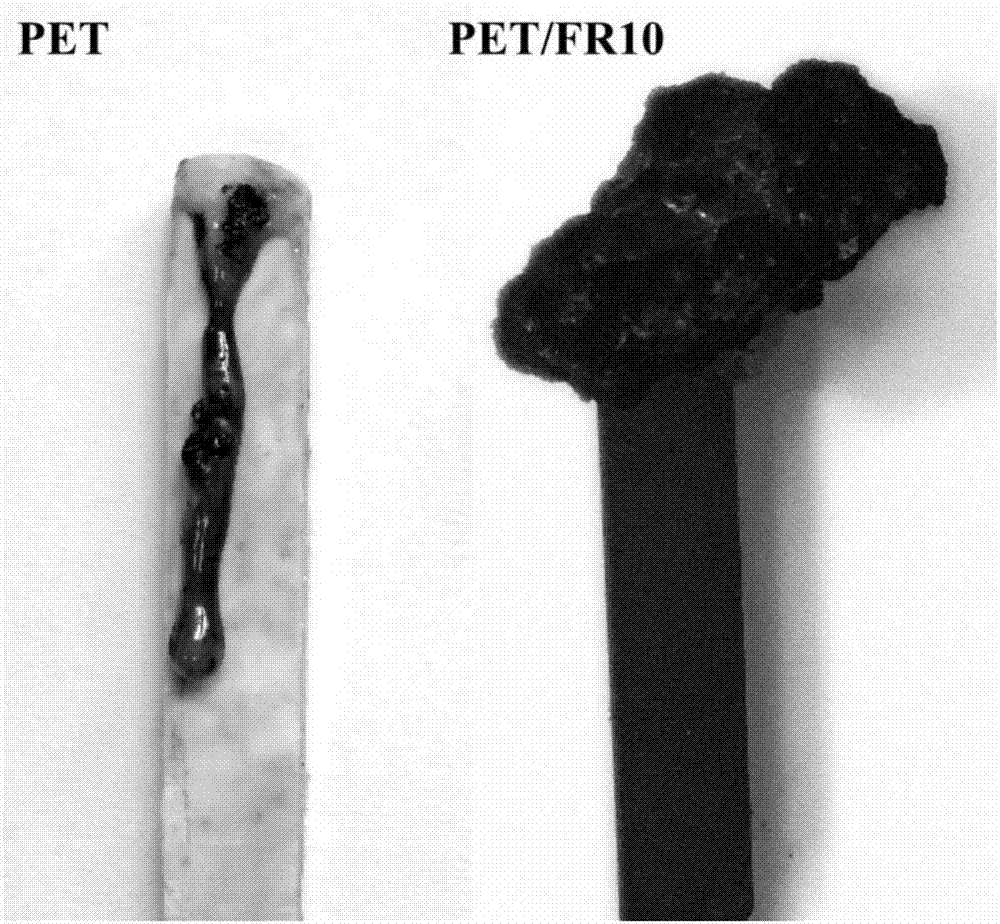

Uses of fluorine-containing sulfonate salt as flame retardant in polyester PET, and flame retardant composition comprising same

PendingCN111138648APlay a synergistic flame retardant effectExcellent resistance to drippingFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterSulfonate

The invention provides applications of fluorine-containing sulfonate as a flame retardant in polyester PET, and a flame-retardant composition containing the fluorine-containing sulfonate. According tothe invention, a compound containing fluorine and sulfur (preferably perfluorosulfonate) and a DOPO flame retardant take a synergistic effect on fire retardation of PET; and the flame-retardant composition comprises a compound containing fluorine and sulfur and a DOPO flame retardant, can be used as a PET flame retardant, and enables flame-retardant PET to have excellent molten drop resistance and excellent flame retardance under the condition of maintaining good spinning capability.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Halogen-free flame-retardant polypropylene composite cable material and preparation method thereof

ActiveCN103554657AImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesElastomerPolypropylene composites

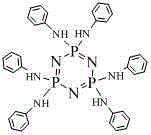

The invention relates to a halogen-free flame-retardant polypropylene composite cable material and a preparation method thereof. The cable material is prepared from the following raw materials in 100 parts of polypropylene by weight: 1-10 parts of hexa-aniline cyclotriphosphazene, 10-100 parts of magnesium hydroxide, 5-20 parts of elastomer, 5-30 parts of compatilizer, and 0.1-1 part of antioxidant. By adopting the halogen-free flame-retardant, the potential hazard of a traditional flame-retardant polypropylene cable material to the environment and human bodies can be solved, the halogen-free flame-retardant polypropylene composite cable material is excellent in flame retardant performance and excellent in mechanical performance; the method for preparing the halogen-free flame-retardant polypropylene composite cable material does not produce toxic or corrosive gases in the preparation process, and accords with the environment-friendly requirement.

Owner:IND RES INST ZHIJIANG COLLEGE OF ZHEJIANG UNIV OF TECH

A light-weight bacteriostatic building thermal-insulation material and a preparing method thereof

A light-weight bacteriostatic building thermal-insulation material is disclosed. The thermal-insulation material is prepared from, by weight, a proper amount of polyvinylpyrrolidone, 100-120 parts of an aqueous silver nitrate solution having a concentration of 3-5%, 27-30 parts of ethyl orthosilicate, 3-4 parts of sericin, 2-3 parts of tributyltetradecylphosphonium chloride, 1-2 parts of pentaerythritol, a proper amount of ammonia water, 0.4-1 part of divinyl benzene, 0.2-0.3 part of Span 80, 3-5 parts of 1,3,5-triglycidyl isocyanurate, 180-200 parts of styrene, 0.1-0.2 part of hexadecyldimethylamine, 7-10 parts of ammonium persulfate, 5-6 parts of stannous octoate, 16-20 parts of a pentane foaming agent, a proper amount of glycol and a proper amount of dimethylformamide. The thermal-insulation material has good flame retardance, thermal insulation performance, bacteriostatic performance, and a light weight, and is convenient to mount and transport.

Owner:赵阳

Production process of emery cloth

InactiveCN107199520AGood lookingImprove stabilityPolyureas/polyurethane adhesivesAbrasion apparatusWater basedEpoxy

The invention discloses a production process of emery cloth. The production process of the emery cloth includes the working procedures of base cloth processing, base glue feeding, abrasive grain dispensing, repeating glue feeding and finishing. An adhesive used for base cloth processing is formed by latex and resin, and is prepared according to the following steps that firstly, water-based epoxy resin is added into the latex, and uniform stirring is performed under the temperature of 25-40 DEG C; and secondly, a proper amount of thickening agent is added into a glue solution obtained in the first step, stirring is performed for 25-45 min, various technical indicators are detected, and filtering is performed for use after detection is qualified. The grinding gravel is composed of, by mass percentage, 60%-70% of brazing pre-alloyed powder and 30%-40% of a diamond / cubic boron nitride mixture; and according to a preparation method of the grinding gravel, after material mixing of the brazing pre-alloyed powder, the brazing pre-alloyed powder is mixed with diamond / cubic boron nitride, cold pressing is performed to form thin sheets, then the cold-pressed thin sheets are contained in a high-temperature-resistant ceramic combustion boat to be fed into a vacuum brazing heating device to be heated and sintered, and after heat preservation is performed for 30 min, natural cooling with the furnace is performed.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

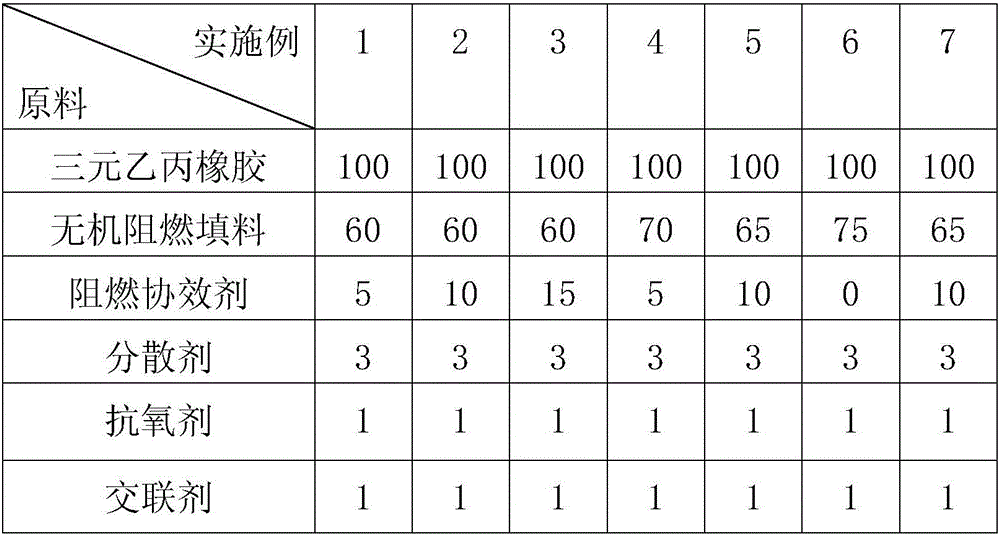

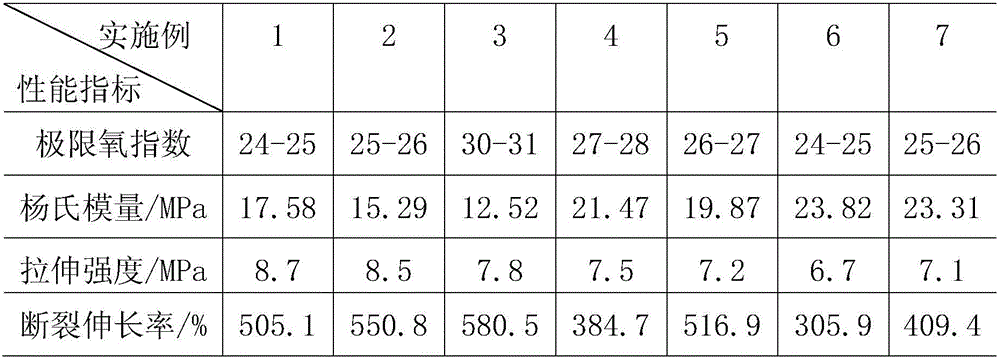

Halogen-free flame retardant irradiation-crosslinked cable material and preparation method thereof

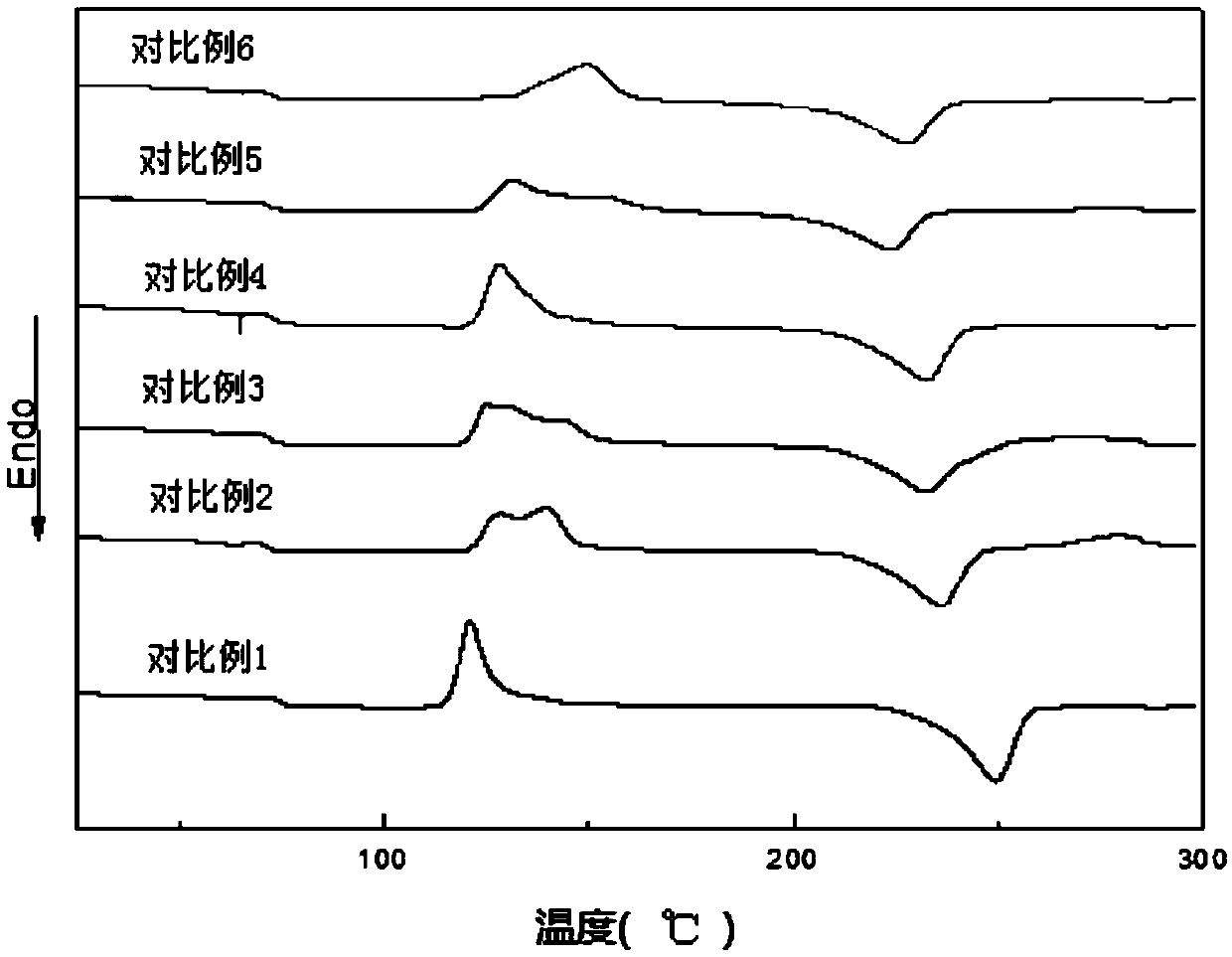

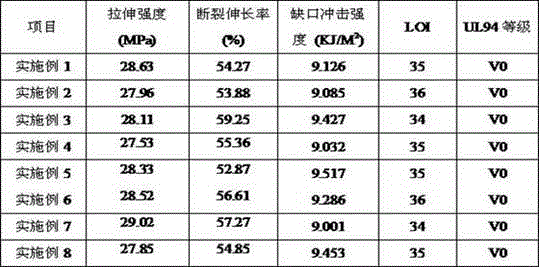

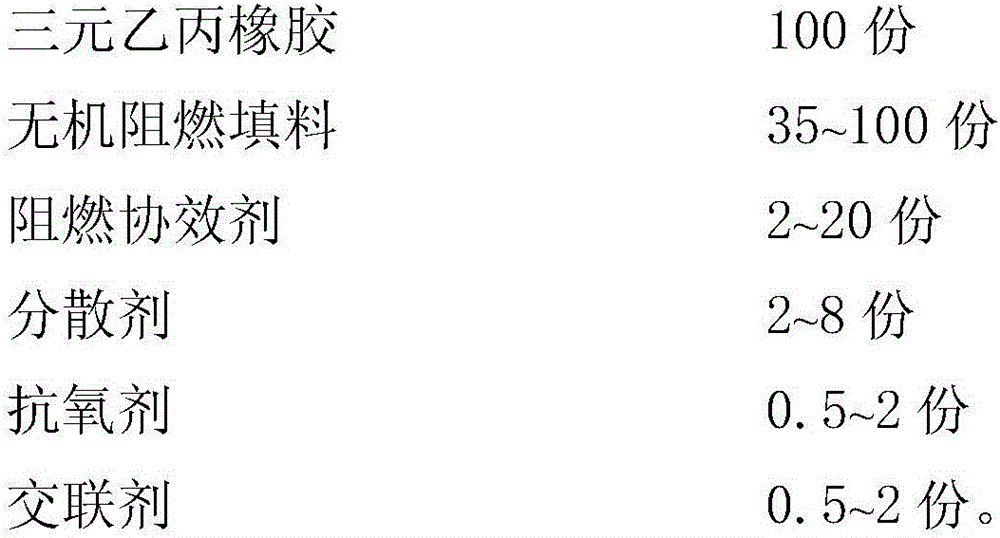

InactiveCN106554574AReduce usageImprove performanceRubber insulatorsPolyolefinEthylene-propylene-diene-monomer

The invention discloses a halogen-free flame retardant irradiation-crosslinked cable material. The halogen-free flame retardant irradiation-crosslinked cable material comprises, by weight, 100 parts of an ethylene propylene diene monomer, 35 to 100 parts of an inorganic flame retardant filler, 2 to 20 parts of a flame retardant synergist, 2 to 8 parts of a dispersant, 0.5 to 2 parts of an antioxidant and 0.5 to 2 parts of a crosslinking agent. Through use of the flame retardant synergist, the inorganic flame retardant filler and the crosslinking agent in a polyolefin cable material, mechanical properties are improved. The flame retardant synergist can produce intumescent flame retardancy in cable material burning and the flame retardant synergist and the inorganic flame retardant filler form an obstruction layer so that combustion-supporting gas obstruction is realized and the use amount of the inorganic flame retardant filler is reduced. Through the electron beam irradiation to the ethylene propylene diene monomer, an ethylene propylene diene monomer molecular chain is crosslinked so that the overall performances and flame retardant effects of the cable material are improved.

Owner:ANHUI SIAIT CABLE GROUP

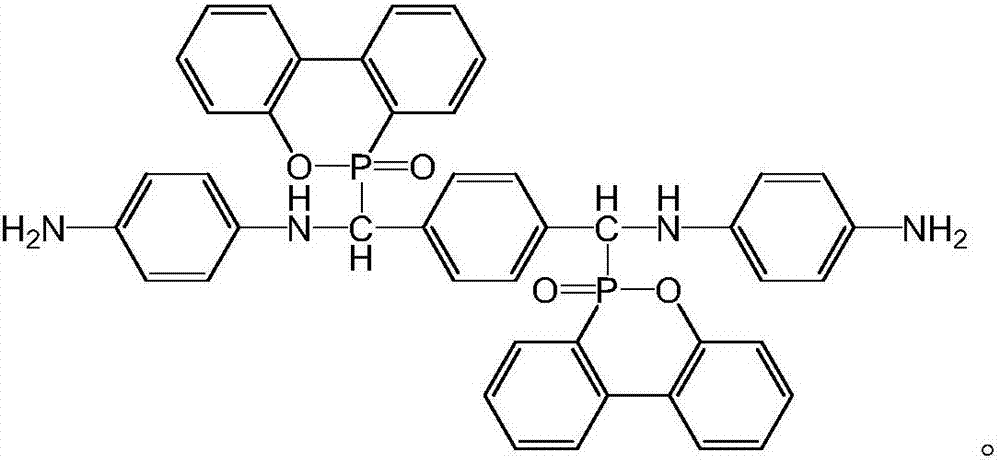

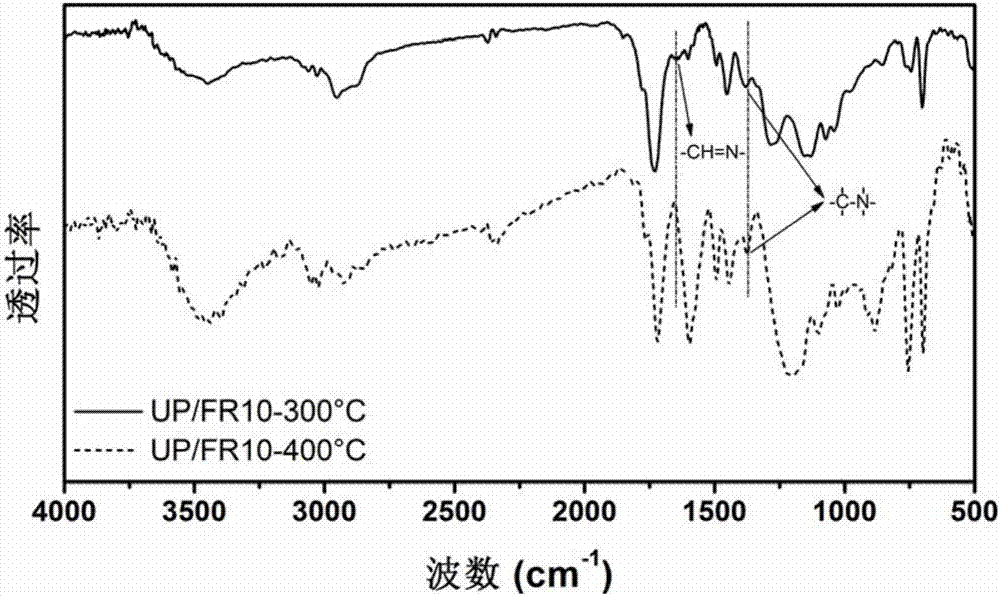

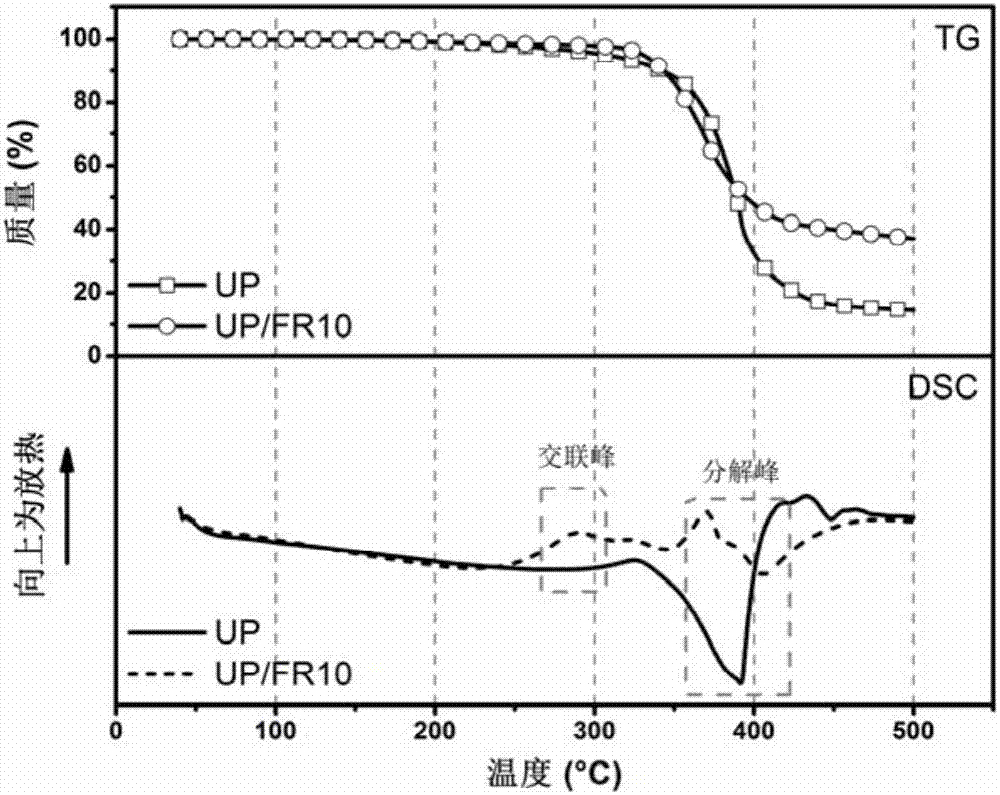

High temperature crosslinked flame retardant with Schiff base and phosphoryl (phosphonyl) structure, preparation method and application thereof

The invention discloses a high temperature crosslinked anti-dripping flame retardant with Schiff base and phosphoryl (phosphonyl) structure. The flame retardant has the following repeating structure unit shown as the specification. The flame retardant is obtained by subjecting a monomer I with a Schiff base structure and a monomer II with a phosphoryl (phosphonyl) structure to melting reaction or solution reaction under nitrogen protection. The flame retardant disclosed by the invention simultaneously introduces the Schiff base high temperature chemical crosslinking structure and the phosphoryl (phosphonyl) high efficiency flame retardant group, not only can produce a synergistic flame retardant effect of phosphorus and nitrogen, endows the polymer with excellent flame retardant and anti-dripping effects, but also can significantly reduce the heat release rate and total heat release of the material, and can be used for flame retardation of unsaturated polyester resin, epoxy resin, polyester, polyolefin and other materials. The preparation method provided by the invention is simple and easy for control, and is suitable for industrial production.

Owner:SICHUAN UNIV

Flame-retardant, high-transmittance and weather-proof polycarbonate composite used for LED lampshade and preparation method

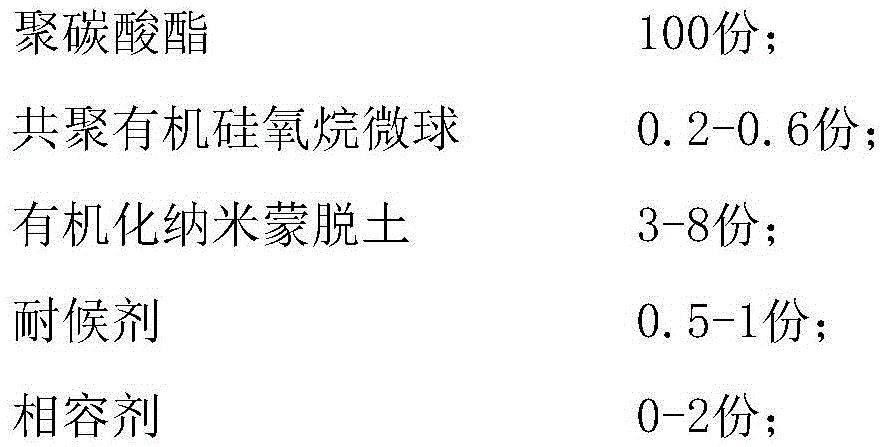

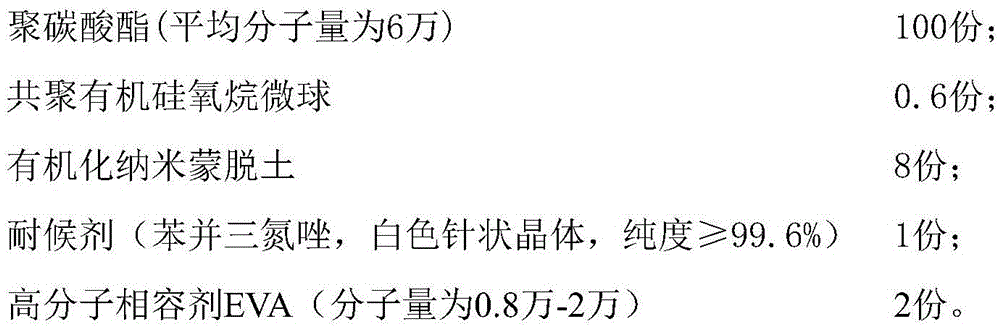

The invention belongs to the technical field of polycarbonate composites, and particularly discloses a flame-retardant, high-transmittance and weather-proof polycarbonate composite used for an LED lampshade and a preparation method. The polycarbonate composite is prepared from raw materials including, by weight, 100 parts of polycarbonate, 0.2-0.6 part of copolymerized organic siloxane microspheres, 3-8 parts of organic nano-montmorillonite, 0.5-1 part of weather-proof agent, compatilizer and 0-2 parts of other auxiliaries. The prepared flame-retardant, high-transmittance and weather-proof polycarbonate composite has excellent chemical performance and processing performance, has the advantages of high transmittance, high flame retardance, excellent weather resistance and the like, can meet requirements of LED illumination lampshades, and is simple in process and beneficial to wide application and popularization.

Owner:HUBEI ENG UNIV

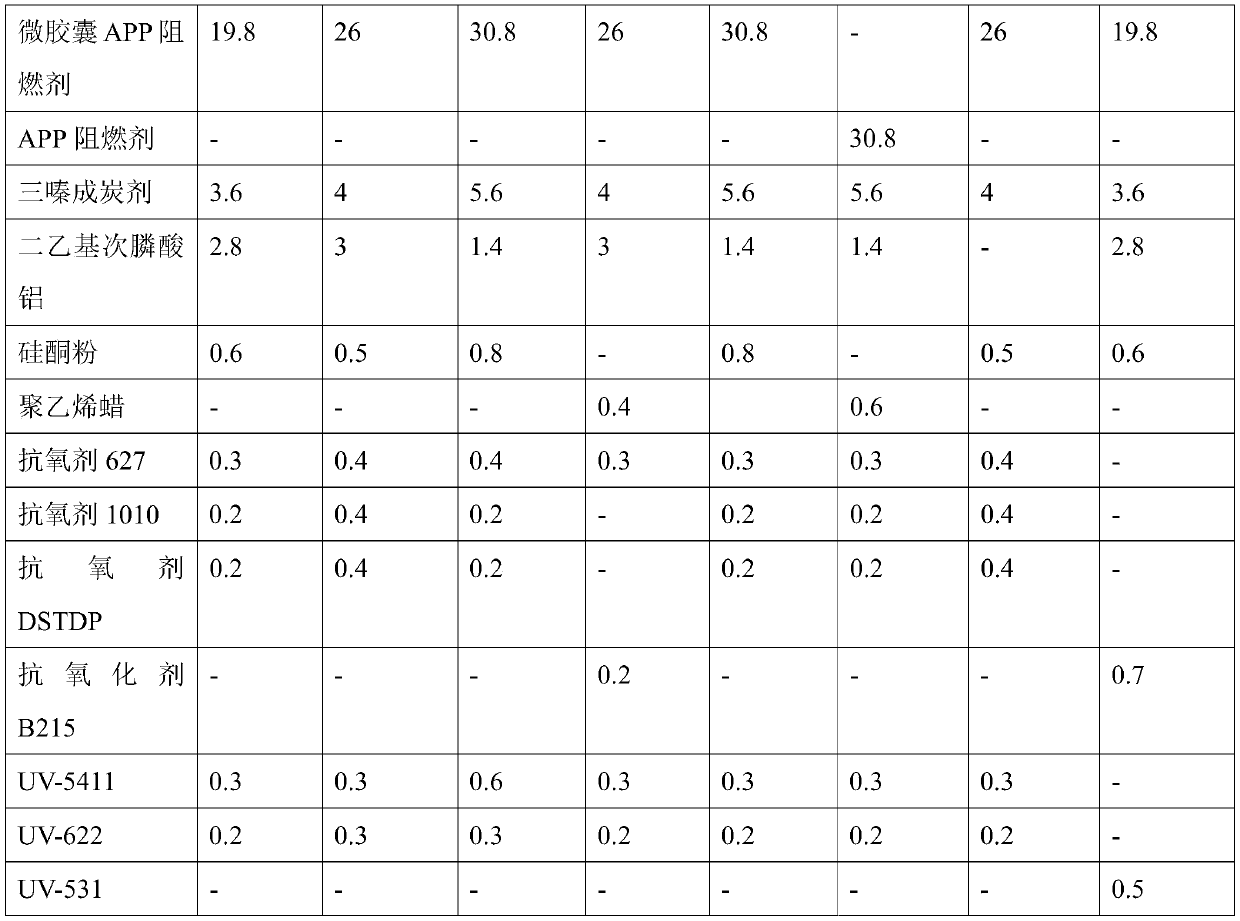

Weather-resistant halogen-free flame-retardant polypropylene material as well as preparation method and application thereof

PendingCN111548559AImprove flame retardant performanceImprove water resistancePolymer sciencePolypropylene

The invention provides a weather-resistant halogen-free flame-retardant polypropylene material as well as a preparation method and application thereof. The weather-resistant halogen-free flame-retardant polypropylene material is prepared from the following raw materials in parts by mass: 55-75 parts of polypropylene resin, 20-38 parts of halogen-free flame retardant, 1-3 parts of a flame-retardantsynergist, 0.5-0.8 part of a lubricant, 0.5-1.2 parts of an antioxidant and 0.3-1 part of a light stabilizer; wherein the halogen-free flame retardant comprises microcapsule ammonium polyphosphate and a charring agent. The weather-resistant halogen-free combustion-supporting polypropylene material has a high flame retardant performance (UL94 V-0 and UL1694 SC-0 with a thickness of 0.75 mm), and after being soaked in water at 70 DEG C for 7 days, at least 90% of mechanical properties are still maintained. After the material is irradiated by a xenon lamp for 1000 hours, at least 90% of mechanical properties are maintained. In addition, the preparation method is simple and easy to control. The material is applied to a soft core of decorative lighting.

Owner:GUANGDONG JUSHI CHEM CO LTD

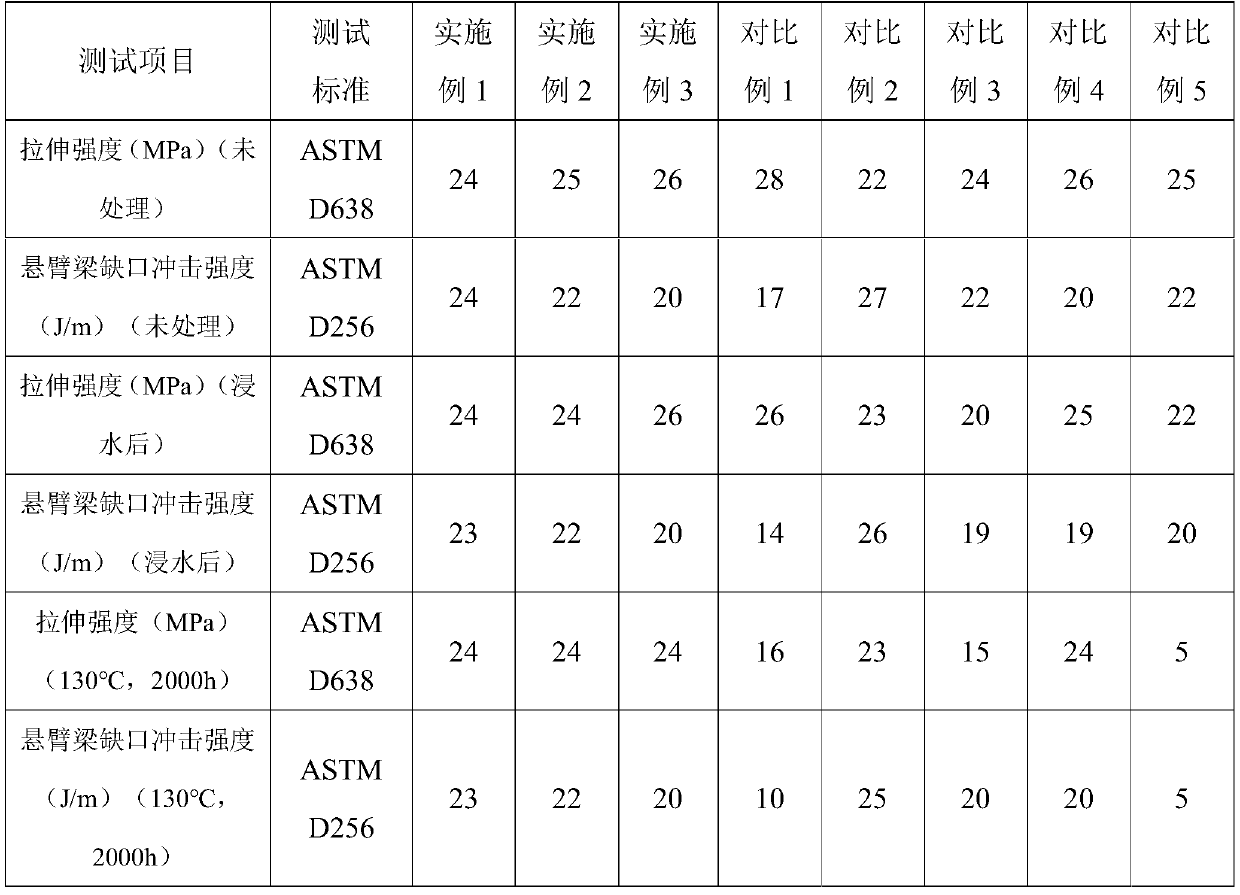

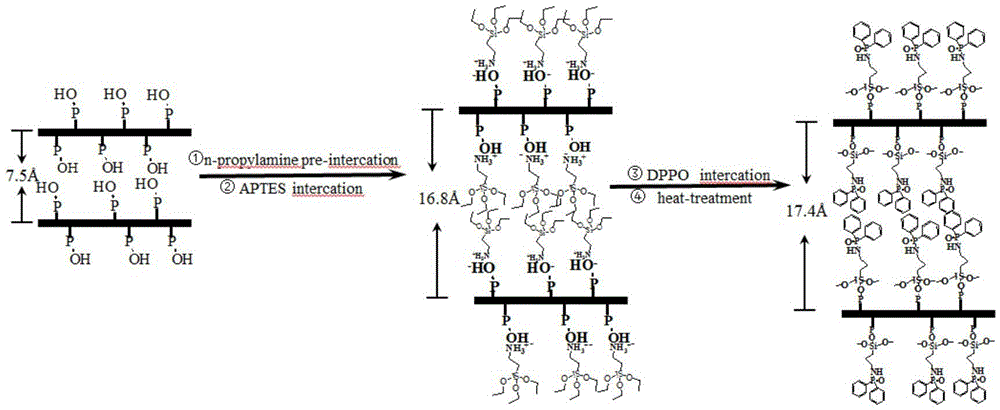

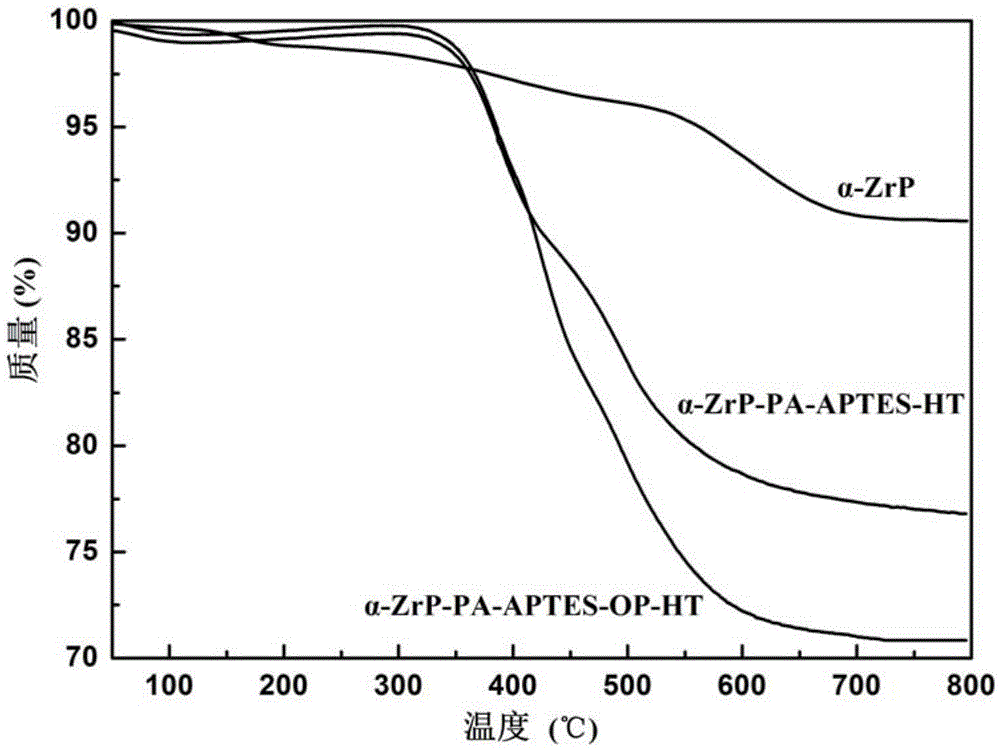

Organophosphorus hybrid alpha-ZrP flame-retardant material and preparation method thereof

InactiveCN105482498AImprove thermal stabilityOvercome the disadvantage of heat resistance temperature lower than 300℃Pigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsTO-18Polymer science

The present invention relates to an organophosphorus hybrid alpha-ZrP flame-retardant material and a preparation method thereof, alpha-ZrP is used as a substrate, a small molecule amine is used for supporting in advance to reduce alpha-ZrP inter-laminate force and increase interlayer spacing, then a silane coupling agent is inserted between layers, the small molecule amine for supporting in advance is removed by heat treatment, and the organophosphorus hybrid alpha-ZrP flame-retardant material can be prepared by the effect of formation of chemical bonding of a terminal group of the silane coupling agent and organophosphorus, wherein the initial decomposition temperature of the organophosphorus hybrid alpha-ZrP is 340-450 DEG C, the interlayer spacing is 1.60-2.50nm, the grafting ratio of the silane coupling agent is 6 to 18%, and the organophosphorus content is 1 to 15%. The organophosphorus hybrid alpha-ZrP flame-retardant material has high thermal stability, grafting ratio, interlayer spacing and organophosphorus content, has stronger nonpolar organic substance affinity, can be uniformly dispersed in a hydrophobic organic polymer material, may be added into most polymer materials (PET, PBT, PP, and the like) processed by melting for e preparation of flame-retardant materials, and has excellent flame retardant properties.

Owner:DONGHUA UNIV

Centerless grinding wheel for compressor piston machining and forming process thereof

InactiveCN109129216AHas acid and alkali resistanceWater resistantAbrasion apparatusGrinding devicesPolyvinyl alcoholGraphite particle

The invention discloses a centerless grinding wheel for compressor piston machining. The centerless grinding wheel comprises a base body and an abrasive layer, wherein the abrasive layer is arranged on the base body. The base body is aluminum alloy. The abrasive layer comprises an abrasive, a binder, resin powder, a pore forming agent, a binding agent and a wetting agent. The abrasive is a mixtureof diamond, black silicon carbide and monocrystalline corundum, and the mass ratio of the diamond to the black silicon carbide to the monocrystalline corundum is 1:3:1.5; the binder is a ceramic binder; the resin powder is imine resin powder; the wetting agent is a mixture of methylphenol and polyvinyl alcohol, and the volume ratio of the methylphenol to the polyvinyl alcohol is 1:2; the pore forming agent is a mixture of hollow alumina balls and graphite particles, and the mass ratio of the hollow alumina balls to the graphite particles is 3:1. The invention further discloses a forming process of the centerless grinding wheel for compressor piston machining. The forming process is simple and practicable, the formed centerless grinding wheel is resistant to high temperature, and a compressor piston with high precision can be machined.

Owner:扬中市飞宇磨具有限公司

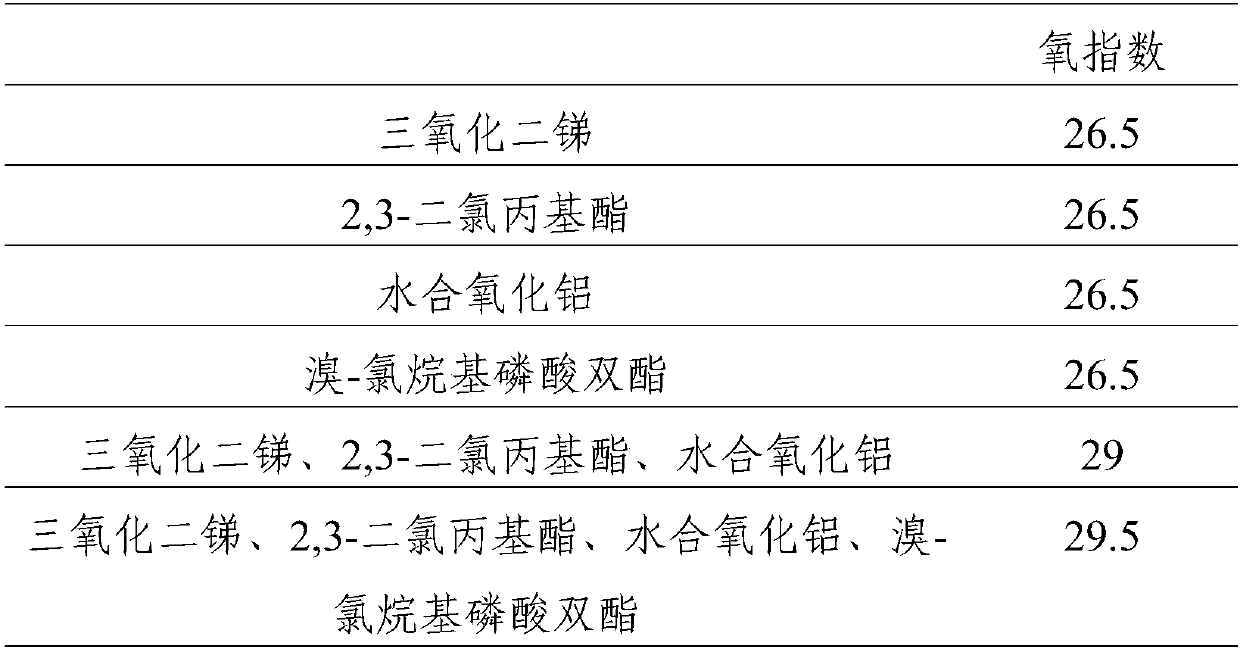

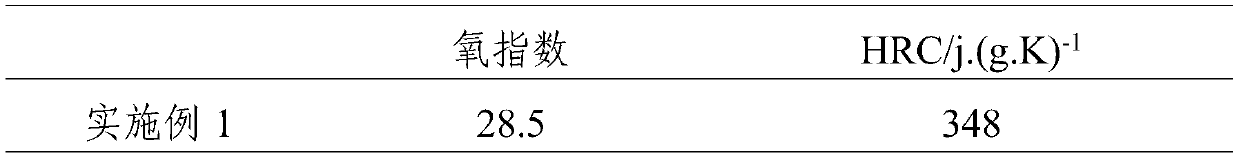

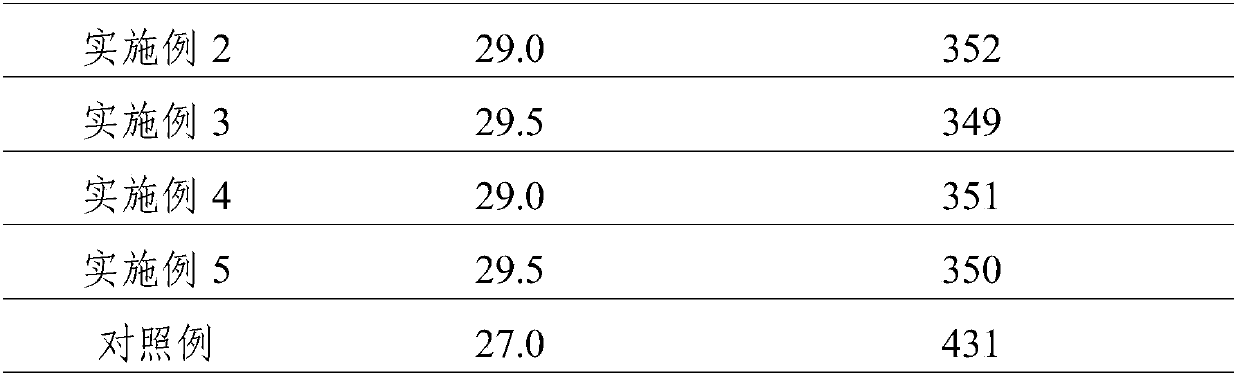

Flame-retarding and environment-friendly plastic material and preparation method thereof

ActiveCN107841117AImprove flame retardant performanceImprove densification performancePlastic materialsPhosphate

The invention relates to the technical field of flame-retarding materials and in particular relates to a flame-retarding and environment-friendly plastic material and a preparation method thereof. Theplastic material is prepared from the following raw materials in parts by weight: 10 to 15 parts of nano silicon dioxide, 3 to 7 parts of ammonium polyphosphate powder, 1 to 5 parts of aluminum hypophosphite, 4 to 9 parts of polylactic acid, 10 to 15 parts of antimony trioxide, 2 to 5 parts of 2,3-dichloropropyl ester, 3 to 7 parts of hydrated aluminum oxide, 6 to 10 parts of bromo-chloroalkyl phosphate diester, 1 to 4 parts of an ethylene-propylene-diene monomer and 0.5 to 2 parts of a dispersion lubricant. The flame-retarding and environment-friendly plastic material provided by the invention can be used for effectively overcoming the defects that a plastic material in the prior art has poor flame-retarding performance and the synergistic effect of the raw materials is poor.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Light-weight high-temperature-resistant flame-retardant polyethylene material for geogrids and manufacturing method thereof

The invention discloses a light-weight high-temperature-resistant flame-retardant polyethylene material for geogrids. The nano magnesium hydroxide is subjected to surface modification by siloxane to obtain a flame retardant, thereby improving the hydrophobicity of magnesium hydroxide to some extent, enhancing the compatibility of the magnesium hydroxide in the polymer, and achieving the effects of enhancing the mechanical properties and flame retardancy of the material. The red phosphorus is subjected to encapsulation modification to improve the problems of high moisture absorption tendency and poor safety in the red phosphorus; and the encapsulation-modified red phosphorus is heated to form phosphoric acid and metaphosphoric acid so as to form the strong dehydrating agent polymetaphosphoric acid, thereby accelerating the decomposition of the magnesium hydroxide and performing the synergic flame-retardant function. The inorganic filler citrus residue surface is subjected to chemical modification to enhance the compatibility in the polymer and improve the mechanical strength and wear resistance of the product; by compounding other effective aids, the prepared polyethylene material has favorable flame retardancy; and when the polyethylene material is used in the geogrid material, the prepared finished product has the advantages of light weight, high temperature resistance and wide application prospects.

Owner:ANHUI JIEAOMAKE SYNTHETIC MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com