Non-halogen flame-retarding high performance polycarbonate engineering plastics and preparation method thereof

A technology of polycarbonate and engineering plastics, applied in the field of halogen-free flame-retardant high-performance polycarbonate engineering plastics and its preparation, can solve the problems of high price, difficulty, and large investment, and achieve improved mechanical properties and good compatibility , the effect of high heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0025] The PC resin is L-1250Y from Japan TEIJIN Company.

[0026] The PES resin is E2010 from BASF.

[0027] The PPS resin is 0220A9 of Polyplastics.

[0028] Silicon-containing flame retardant (FRSi) adopts acrylate grafted modified siloxane (ACR-g-Si), and its preparation can be synthesized according to the method disclosed in application number 200710032309.9. Polymethylphenylsiloxane (PMPSi ).

[0029] The anti-dripping agent is selected from DAIKIN Company's fluorine-containing anti-dripping agent TS-AD001, and domestic PVDF.

[0030] The compatibilizer is domestic SMA and MBS.

[0031] The antioxidants are binary antioxidants B225, B900 or ternary antioxidant GX2225 from Ciba Special Chemical Company.

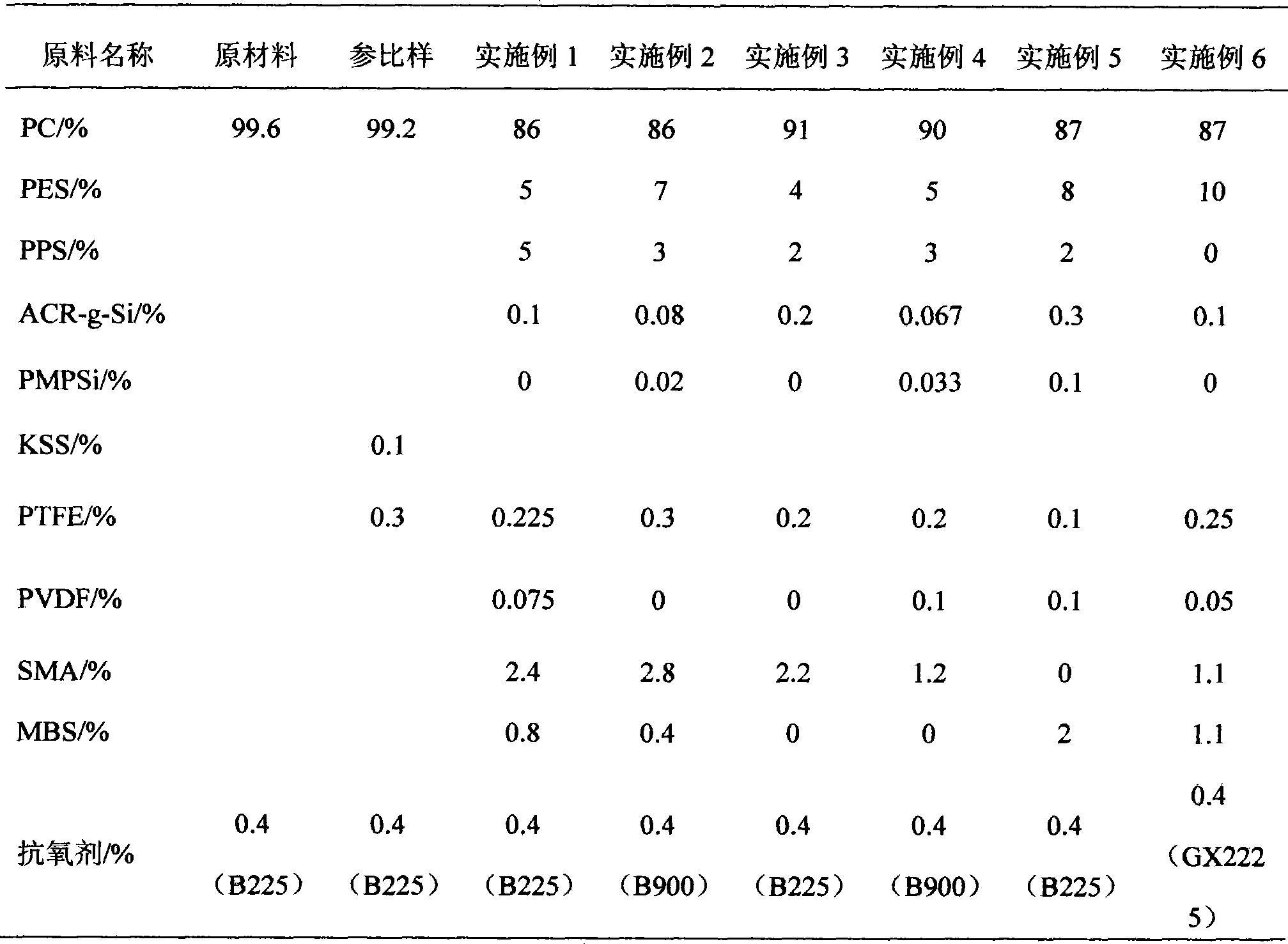

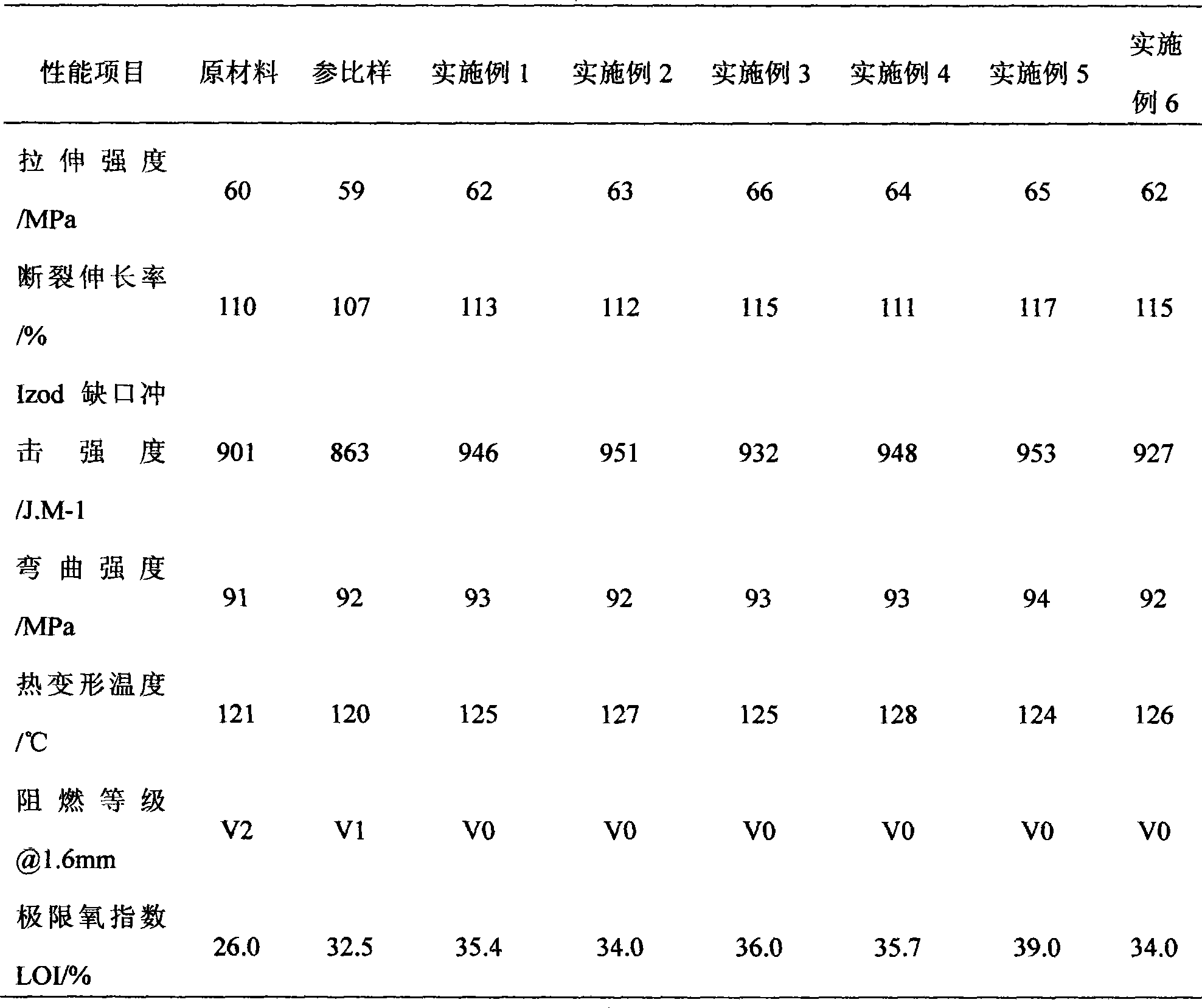

[0032] Examples and the reference formulation of the sulfonate-containing flame retardant KSS (product of Sloss Industries) are shown in Table 1.

[0033] When preparing, fully mix the dried PC resin with sulfur-containing special engineering resin, silicon-containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com