Heat-resistant polylactic acid composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of polylactic acid material and its preparation, heat-resistant polylactic acid composite material and its preparation, can solve the problems of high cost, poor mechanical properties, etc., achieve low price, strong processing performance, heat The effect of short treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

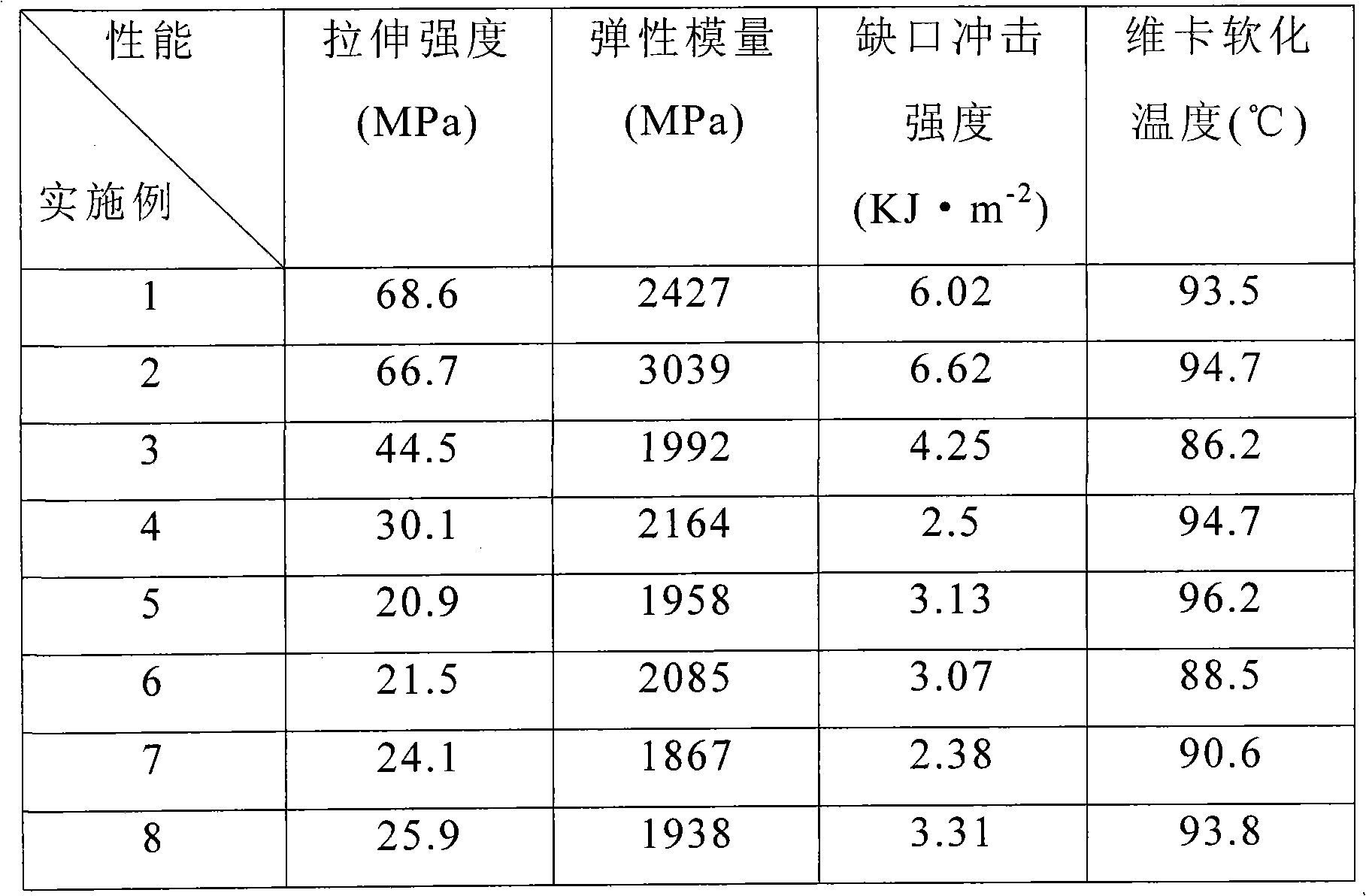

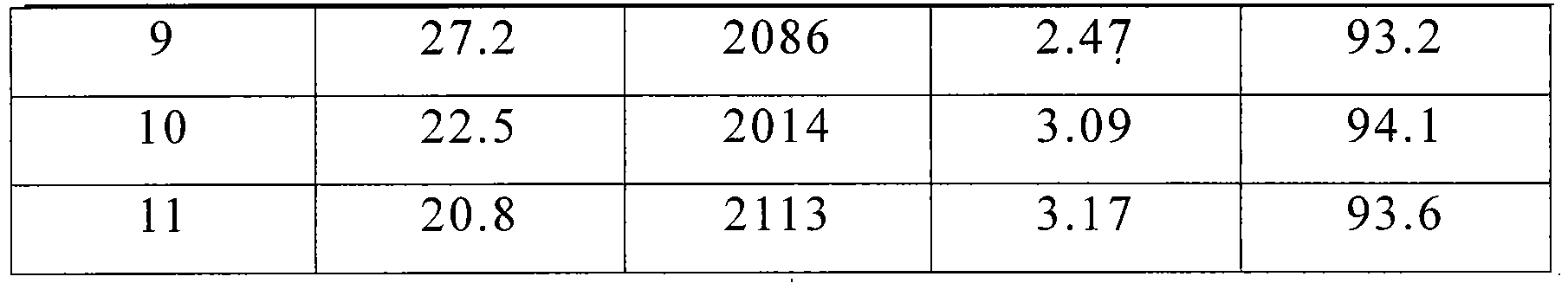

[0029] 99 parts of poly-L-lactic acid with low D (poly-D-lactic acid) content in vacuum drying, 1 part of nucleating agent zinc phenyl phosphite, 20 parts of inorganic filler talc powder with particle size of 1250 mesh-12500 mesh, and 10 parts of starch acetate , 20 parts of wood fiber, 0.1 part of silane coupling agent γ-(2,3-glycidoxy)propyltrimethoxysilane, 1 part of toughening modifier polycaprolactone, lubricant aluminum stearate 0.3 part The parts are melted and blended in a twin-screw extruder evenly and then extruded and pelletized. The temperature settings of each section of the screw are: 190°C, 200°C, 210°C, 220°C, 210°C, and the rotation speed is: 50rpm. After granulation, injection molding is carried out in an injection molding machine. The injection temperature is 210° C., the injection pressure is 100 MPa, and the residence time is about 40 seconds. The samples obtained by injection molding were heat-treated at a constant temperature of 80°C in an oven for 180 m...

Embodiment 2

[0031] 89 parts of poly-L-lactic acid with low D (poly-D-lactic acid) content in vacuum drying, 1 part of nucleating agent zinc phenylphosphinate, 10 parts of inorganic filler talc powder with particle size of 1250 mesh-12500 mesh, starch laurate 20 parts, bamboo fiber 10 parts, silane coupling agent γ-aminopropyltriethoxysilane 1 part, toughening modifier polybutene-adipic acid-terephthalic acid 5 parts, lubricant stearic acid 0.5 part of calcium was melted and blended uniformly in a twin-screw extruder, and then extruded and pelletized. The temperature settings of each section of the screw were: 180°C, 190°C, 200°C, 210°C, 200°C, and the rotation speed was 30rpm. After granulation, injection molding is carried out in an injection molding machine. The injection temperature is 180° C., the injection pressure is 80 MPa, and the residence time is about 40 seconds. The injection-molded samples were kept in an oven at 80°C for 30 minutes. Its mechanical properties and heat resist...

Embodiment 3

[0033] 69 parts of poly-L-lactic acid with low D (poly-D-lactic acid) content in vacuum drying, 1 part of nucleating agent zinc phenyl phosphate, 40 parts of inorganic filler calcium carbonate with particle size of 1250 mesh-12500 mesh, 30 parts of starch, flax fiber 5 parts, silane coupling agent γ-(2,3-glycidoxy)propyltrimethoxysilane 0.1 part, toughening modifier polycaprolactone 1 part, lubricant aluminum stearate 0.8 part The screw extruder is melted and blended evenly and then extruded and pelletized. The temperature settings of each section of the screw are: 160°C, 170°C, 180°C, 190°C, 180°C, and the rotation speed is 50 rpm. After granulation, injection molding was performed in an injection molding machine. The injection temperature was 210° C., the injection pressure was 90 MPa, and the residence time was about 45 seconds. The injection-molded samples were kept in an oven at 90°C for 30 minutes. Its mechanical properties and heat resistance are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com