Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Short heat treatment time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

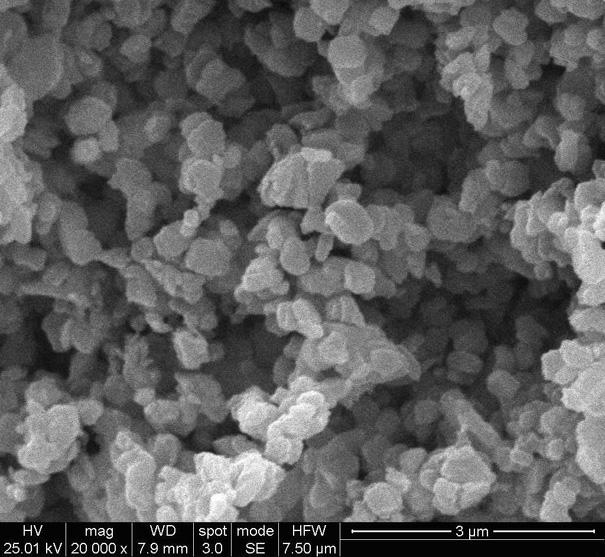

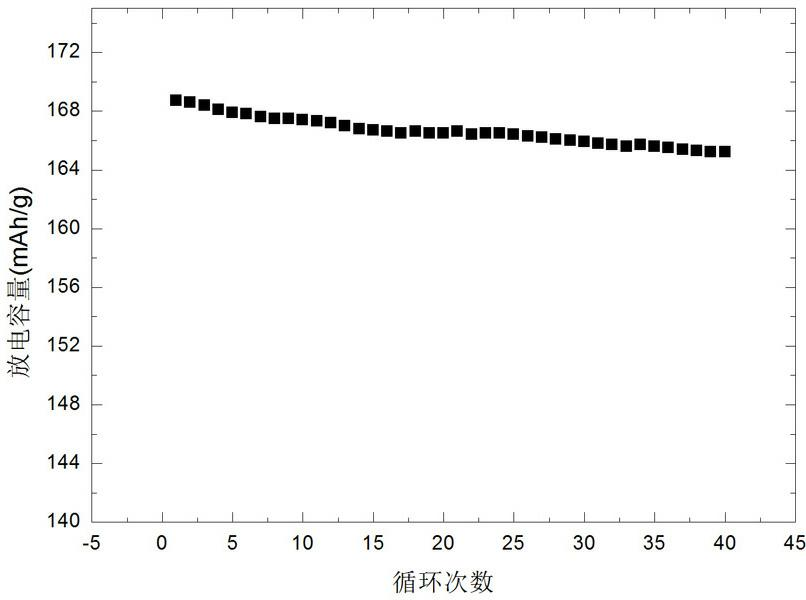

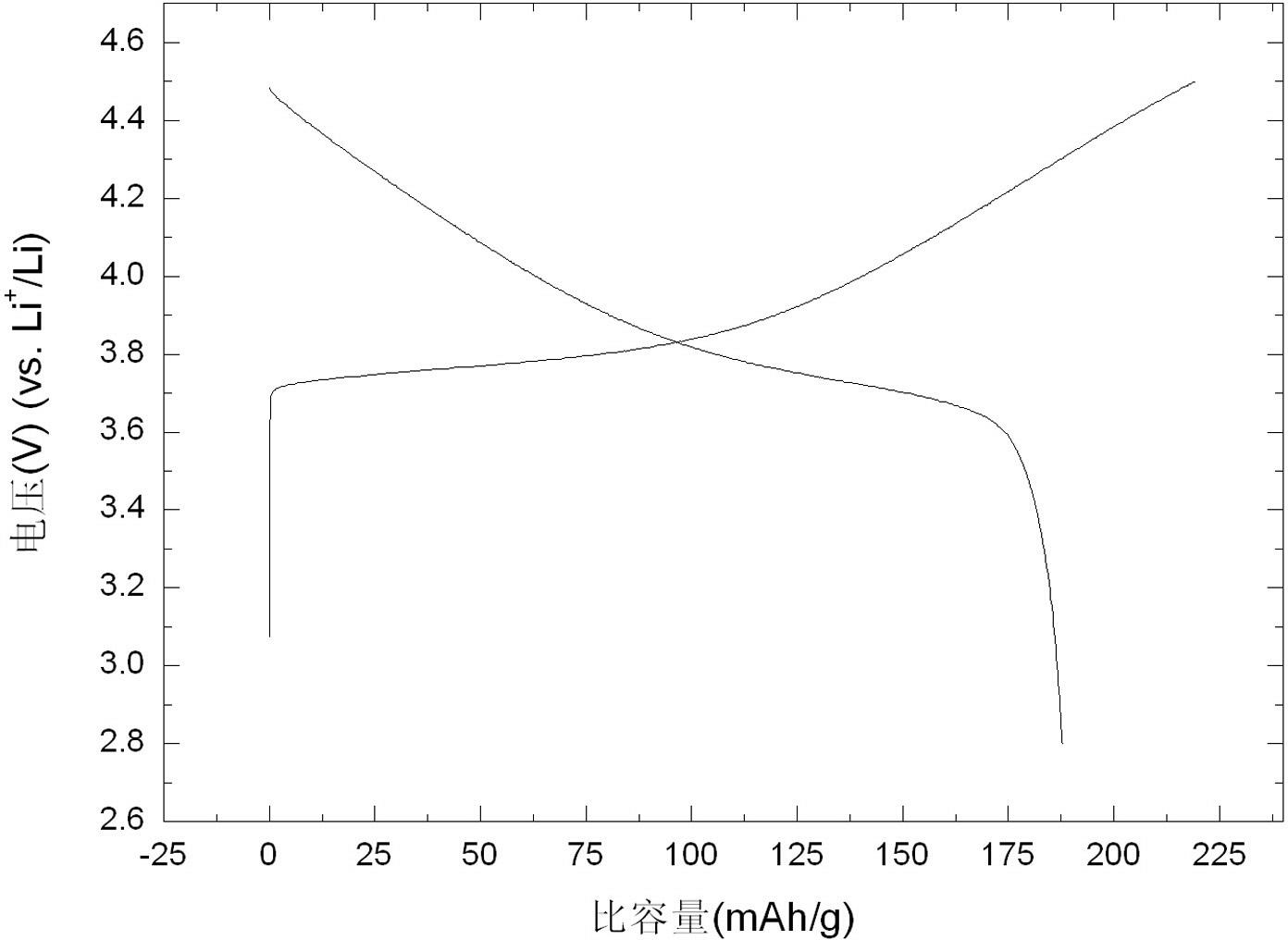

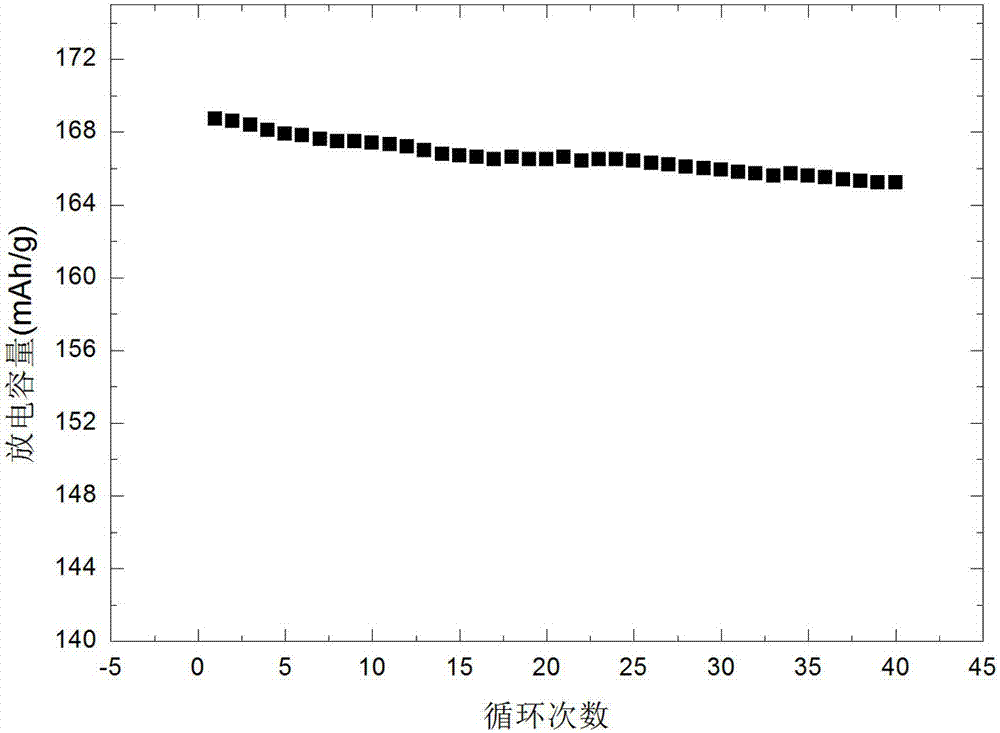

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

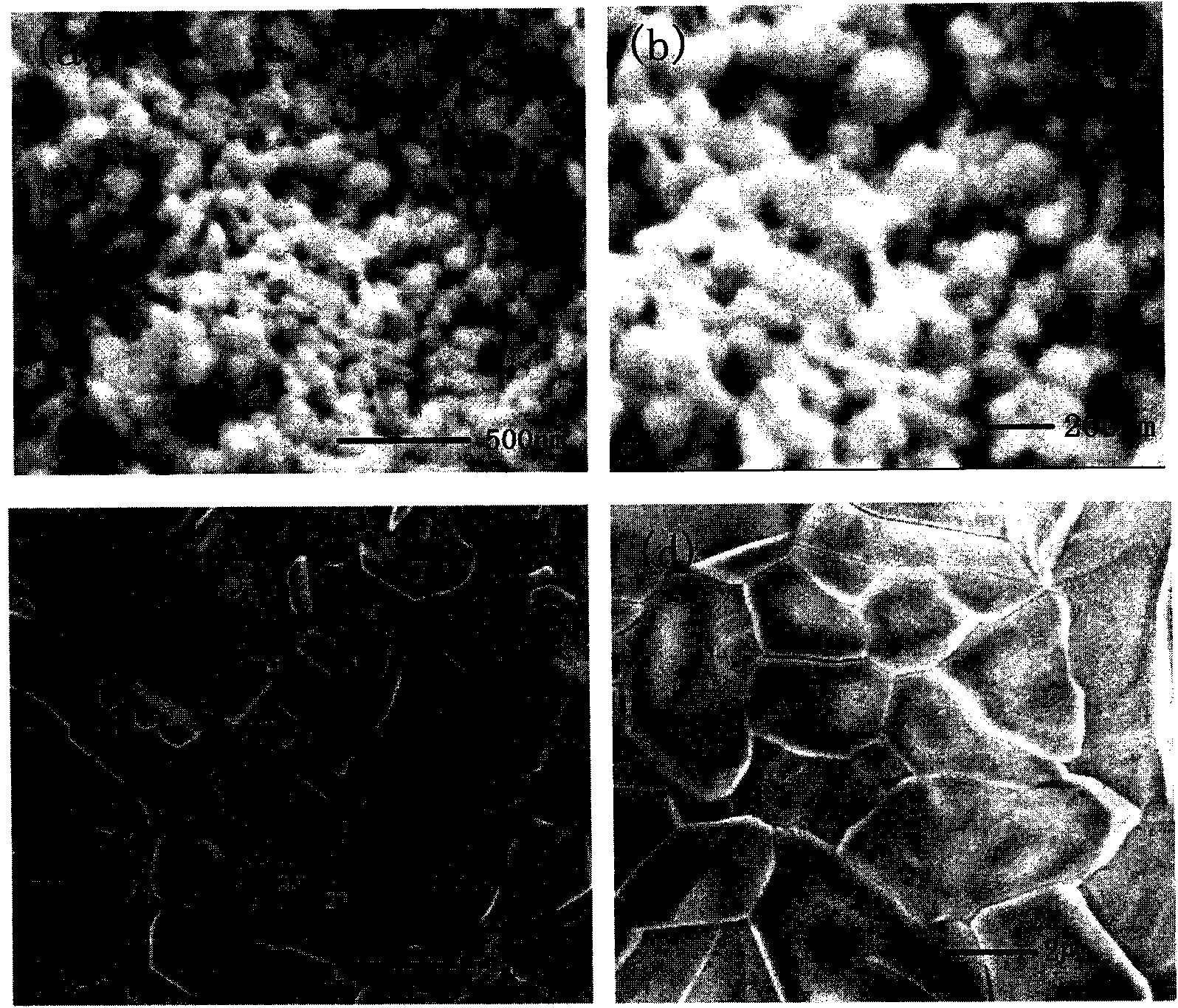

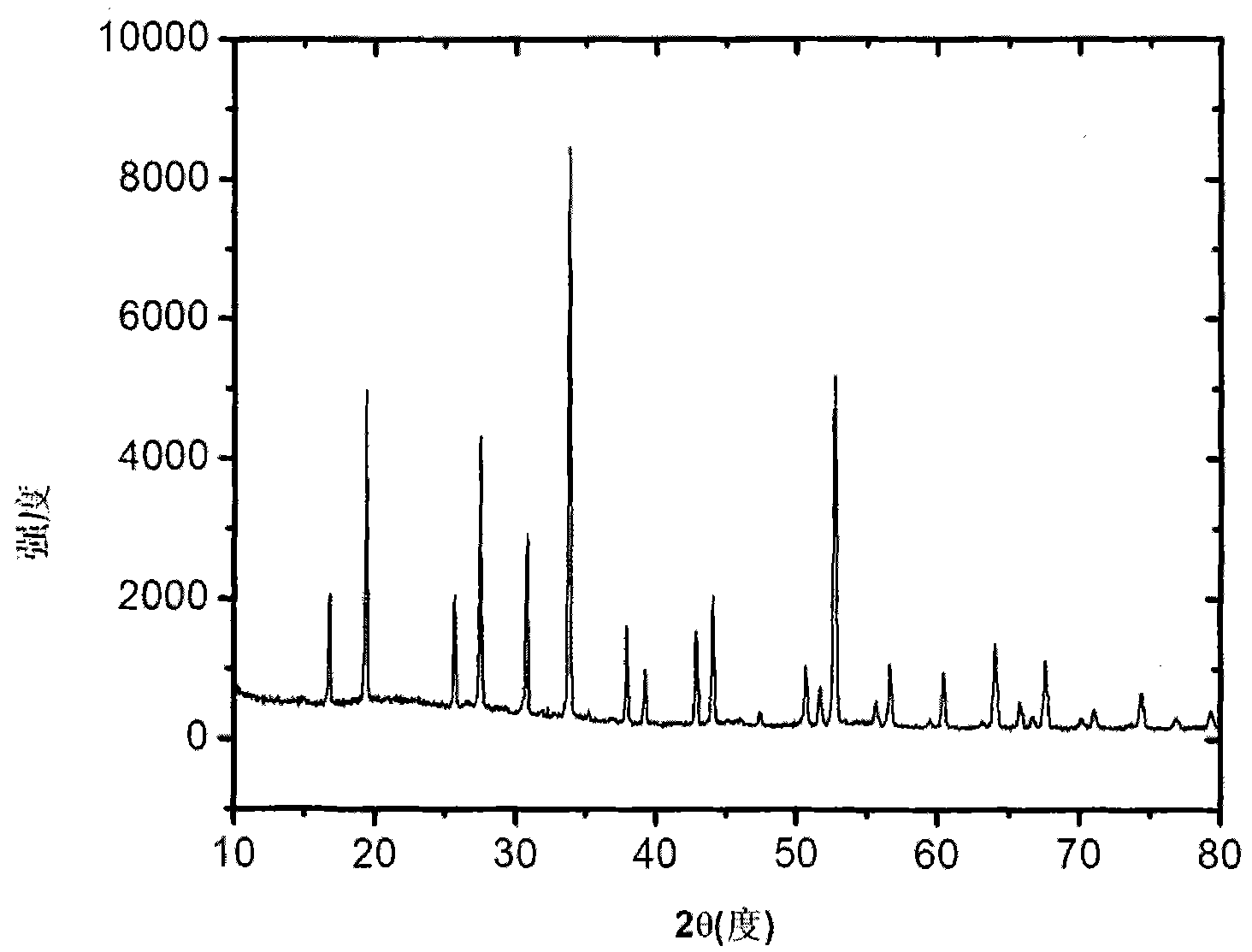

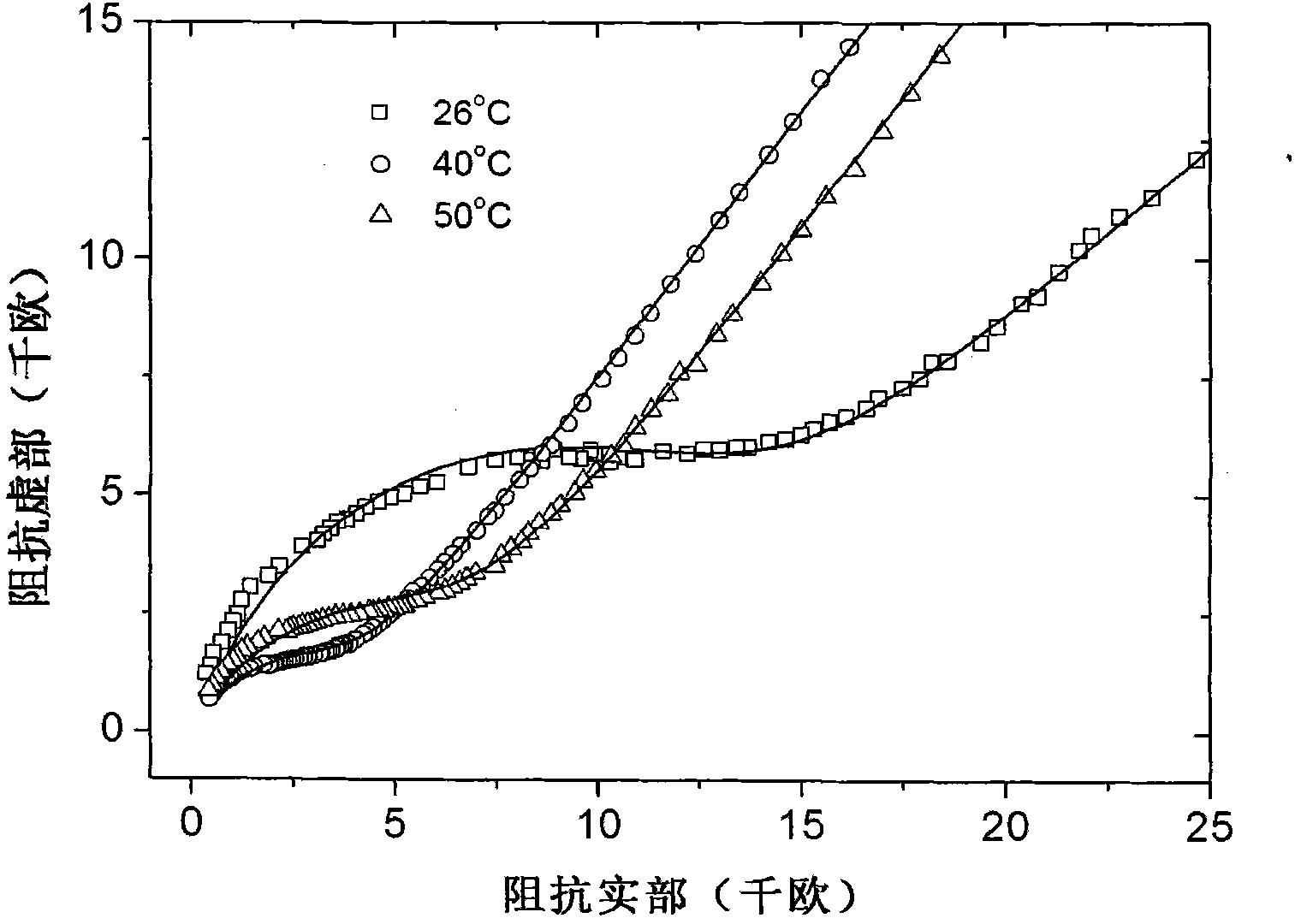

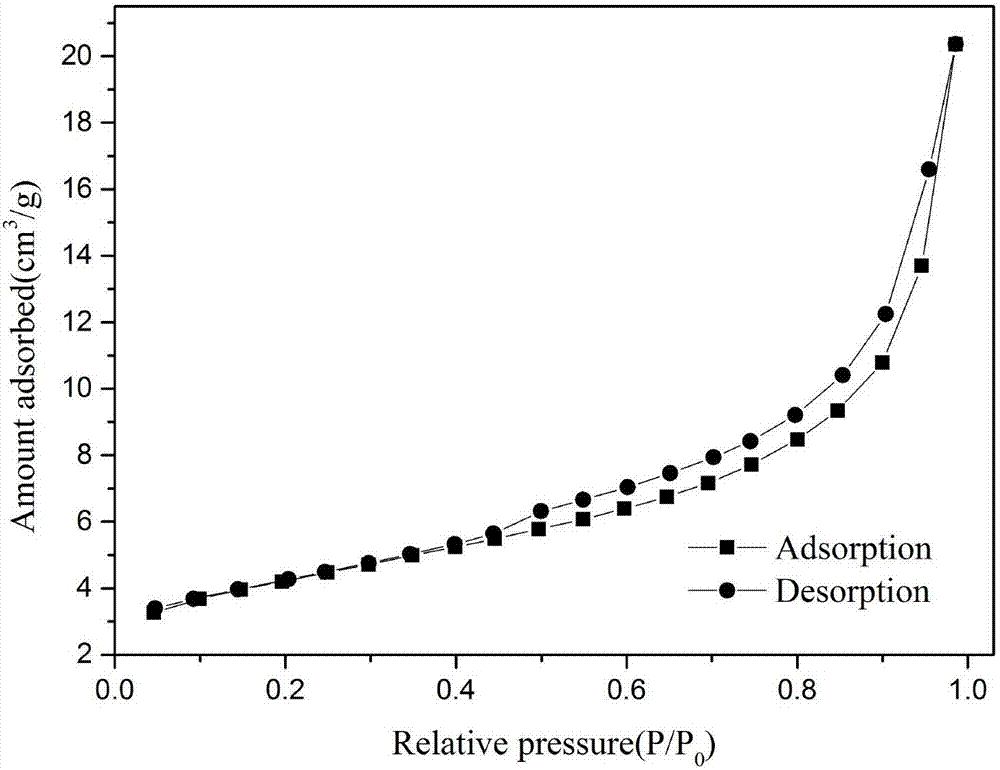

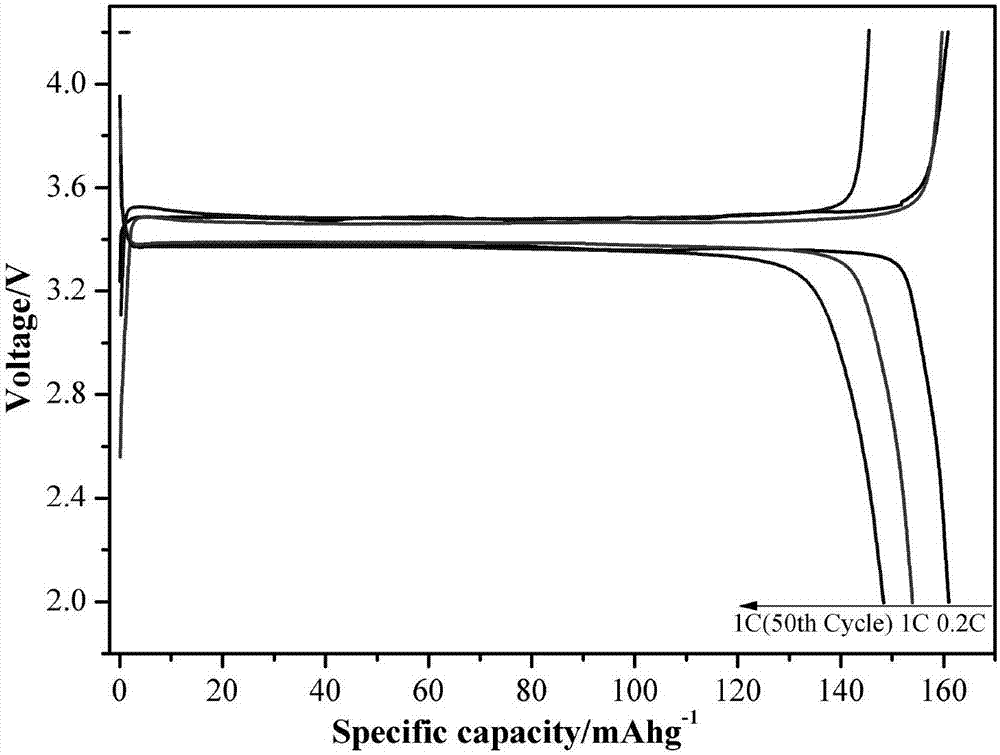

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

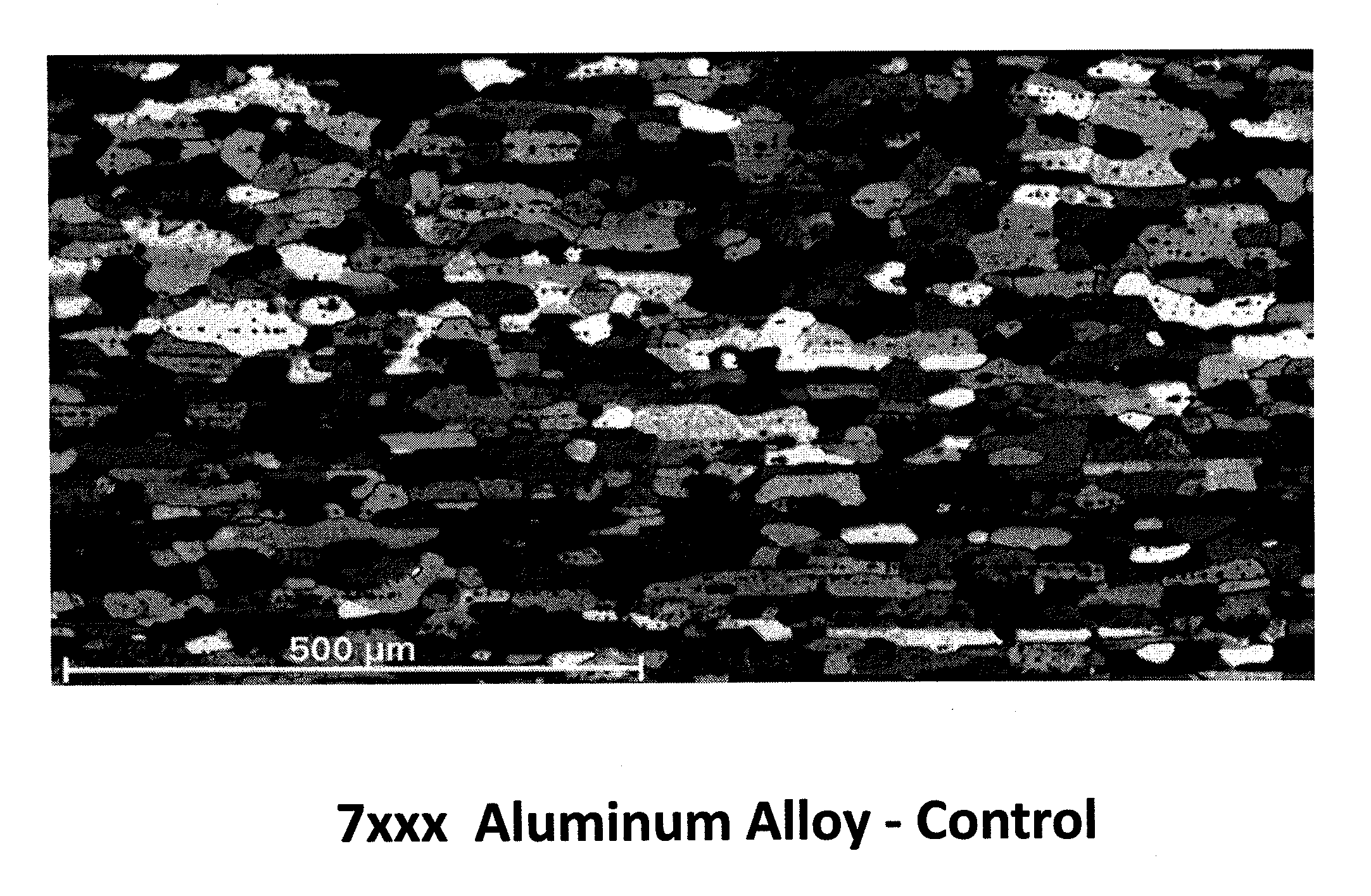

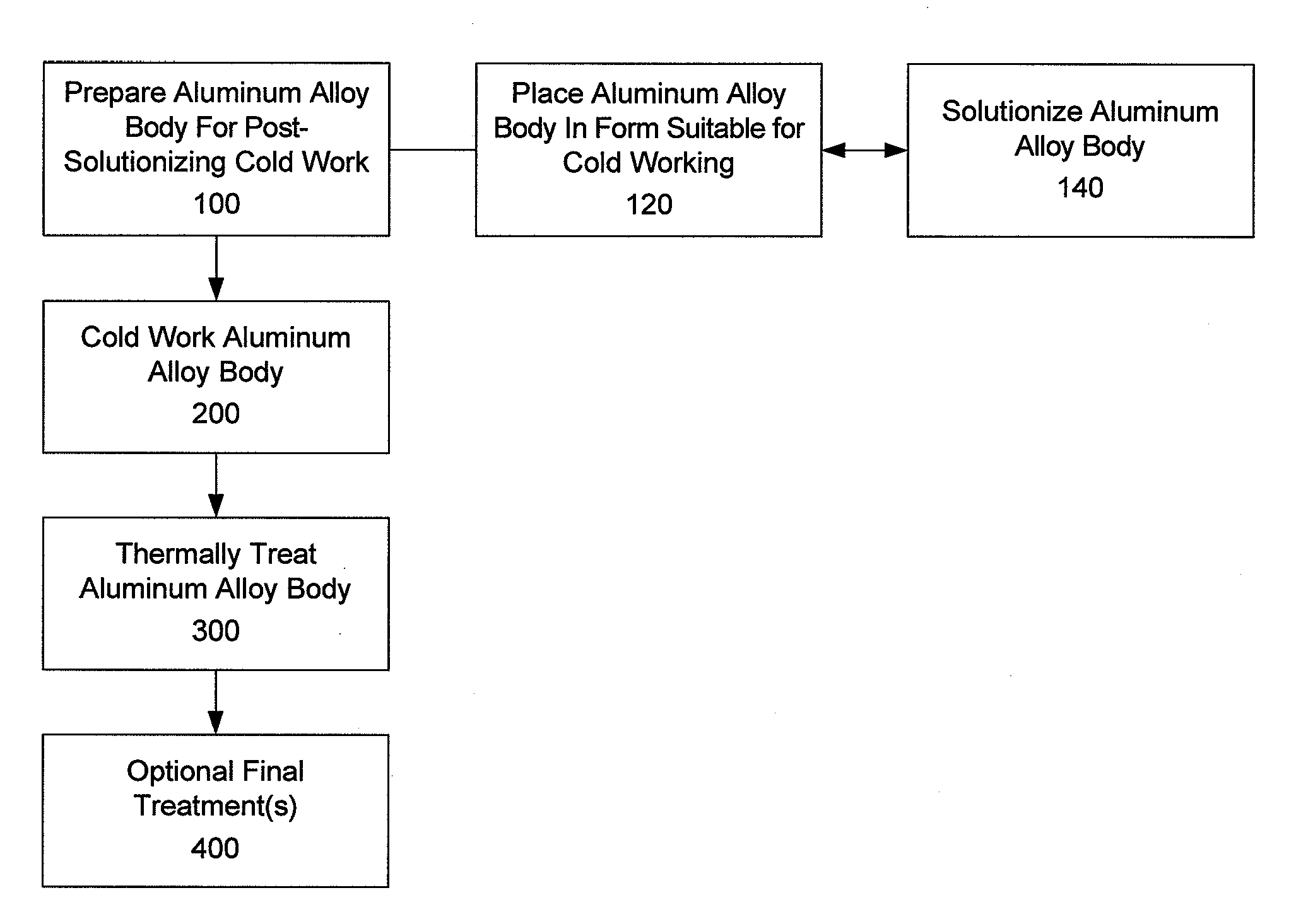

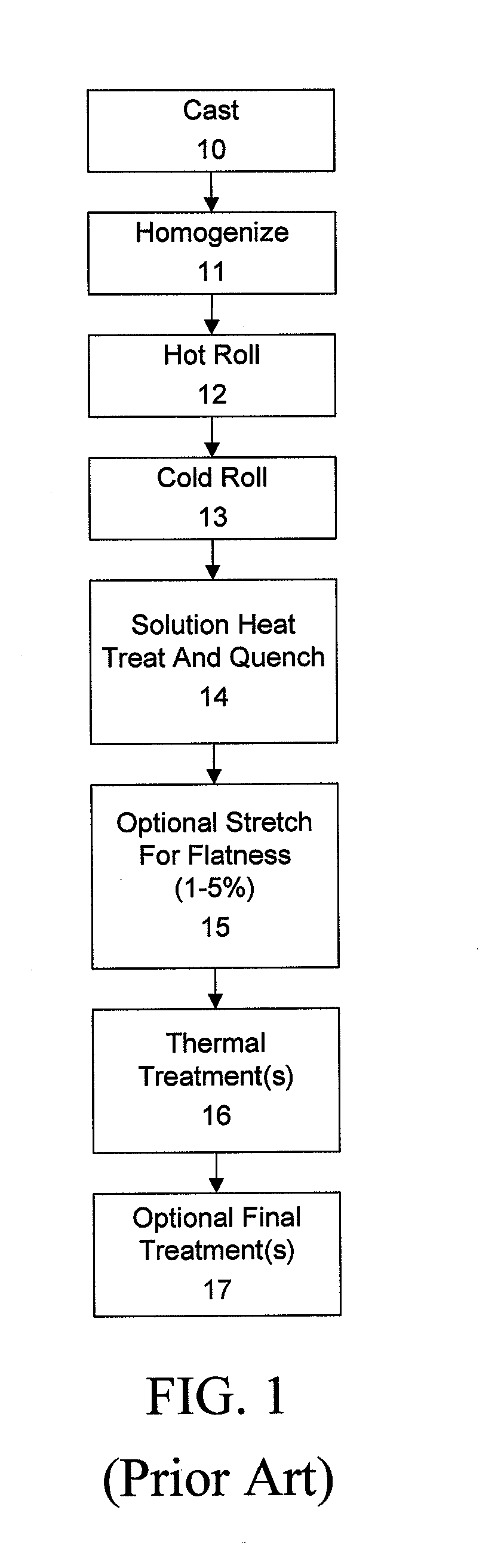

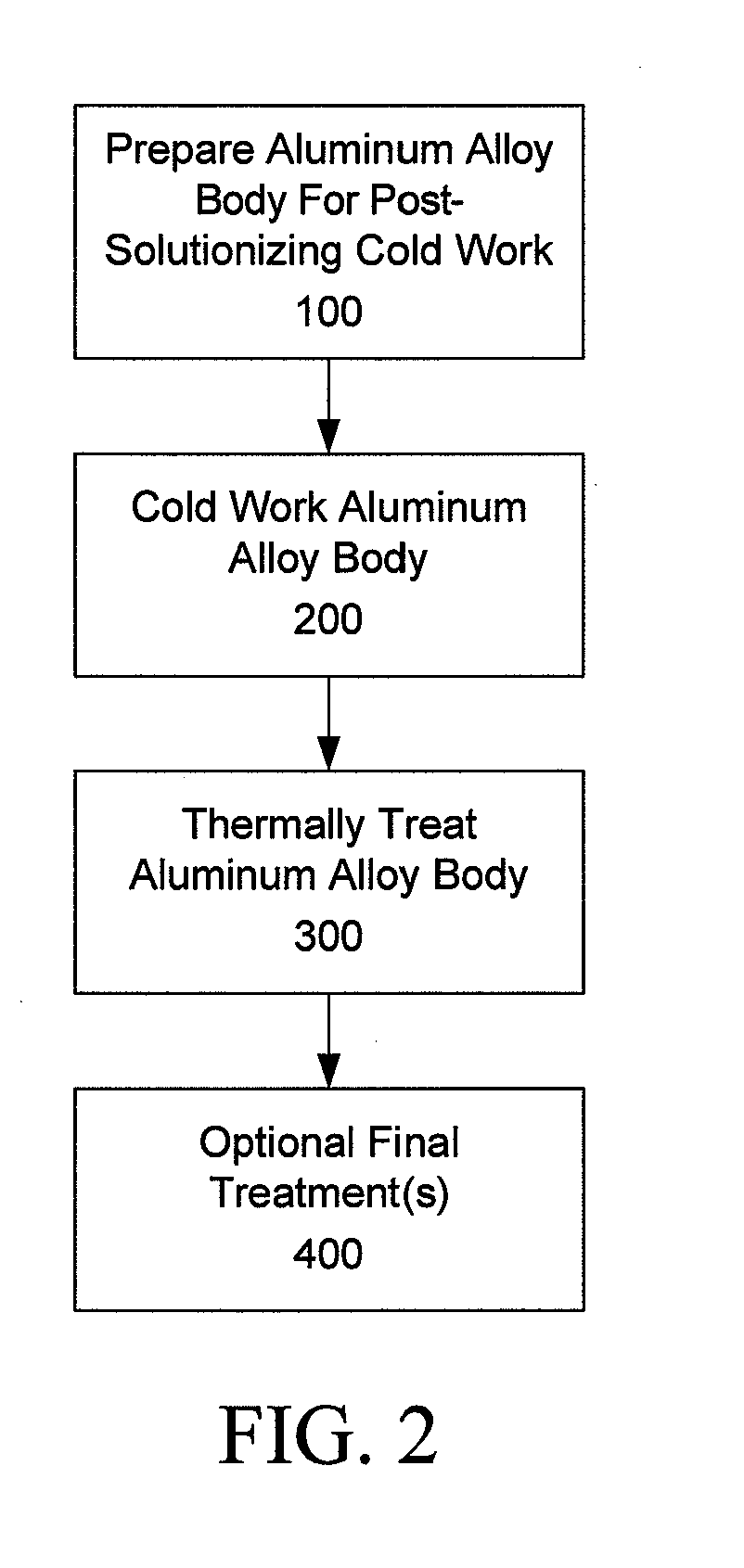

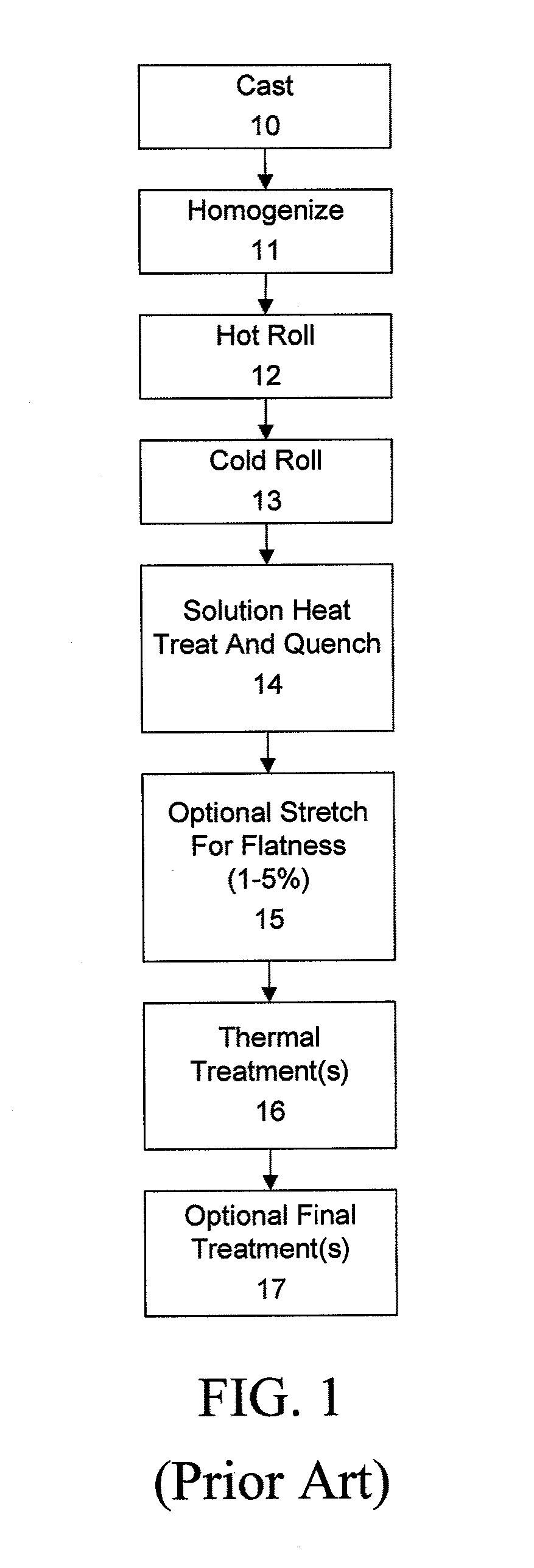

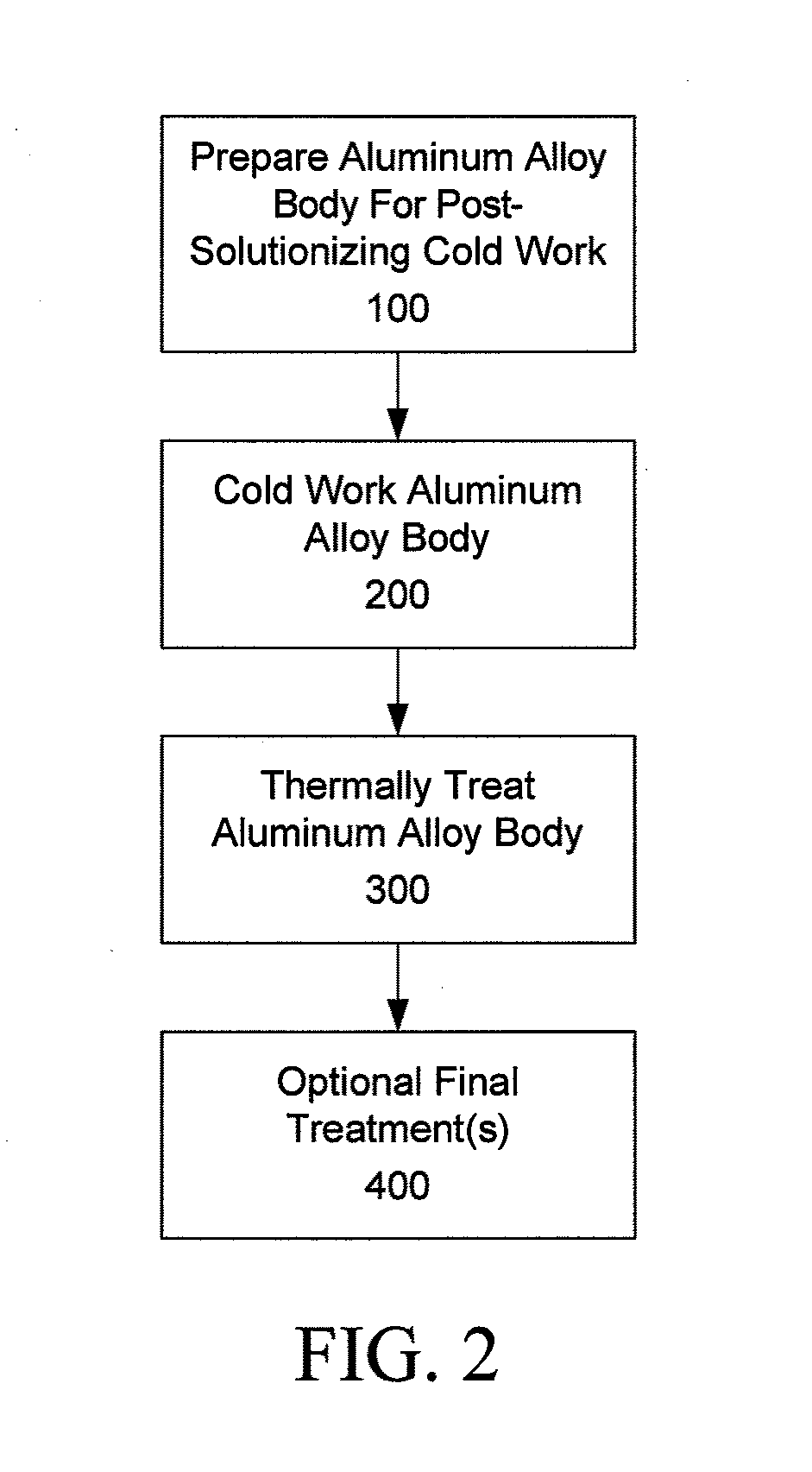

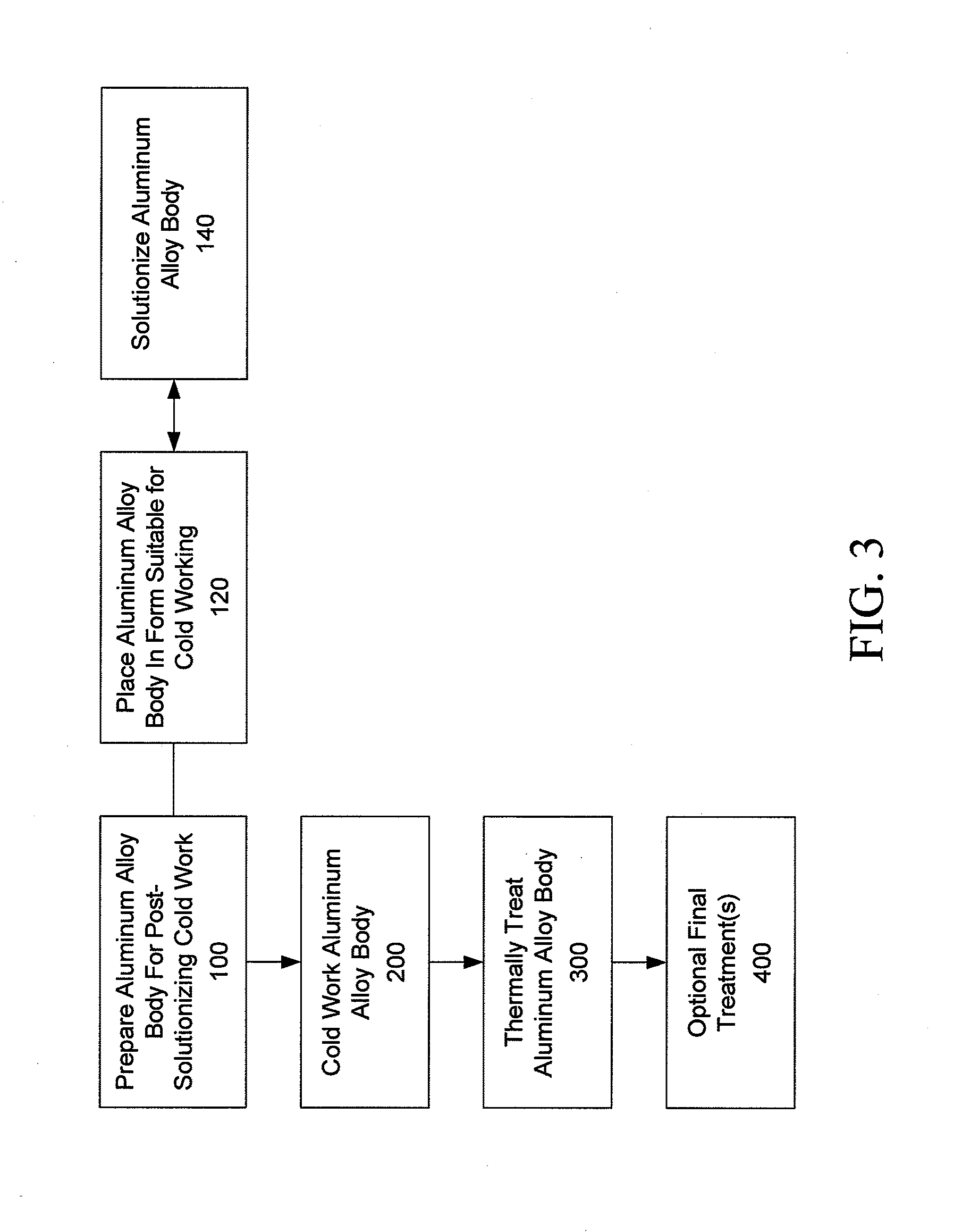

7xxx aluminum alloys, and methods for producing the same

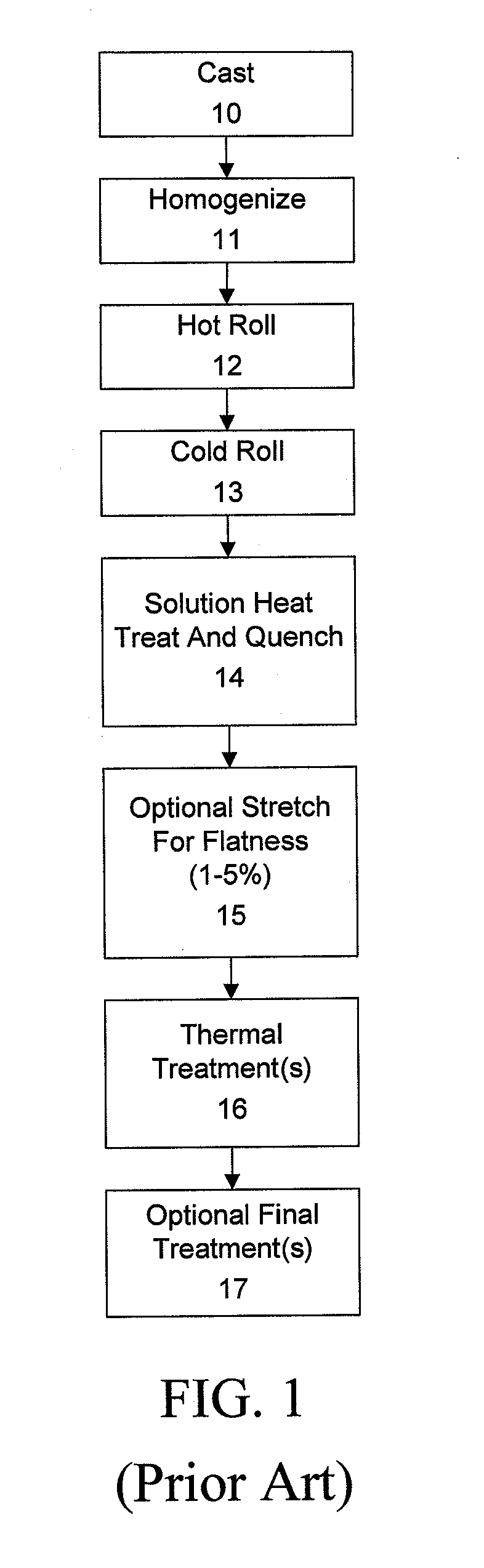

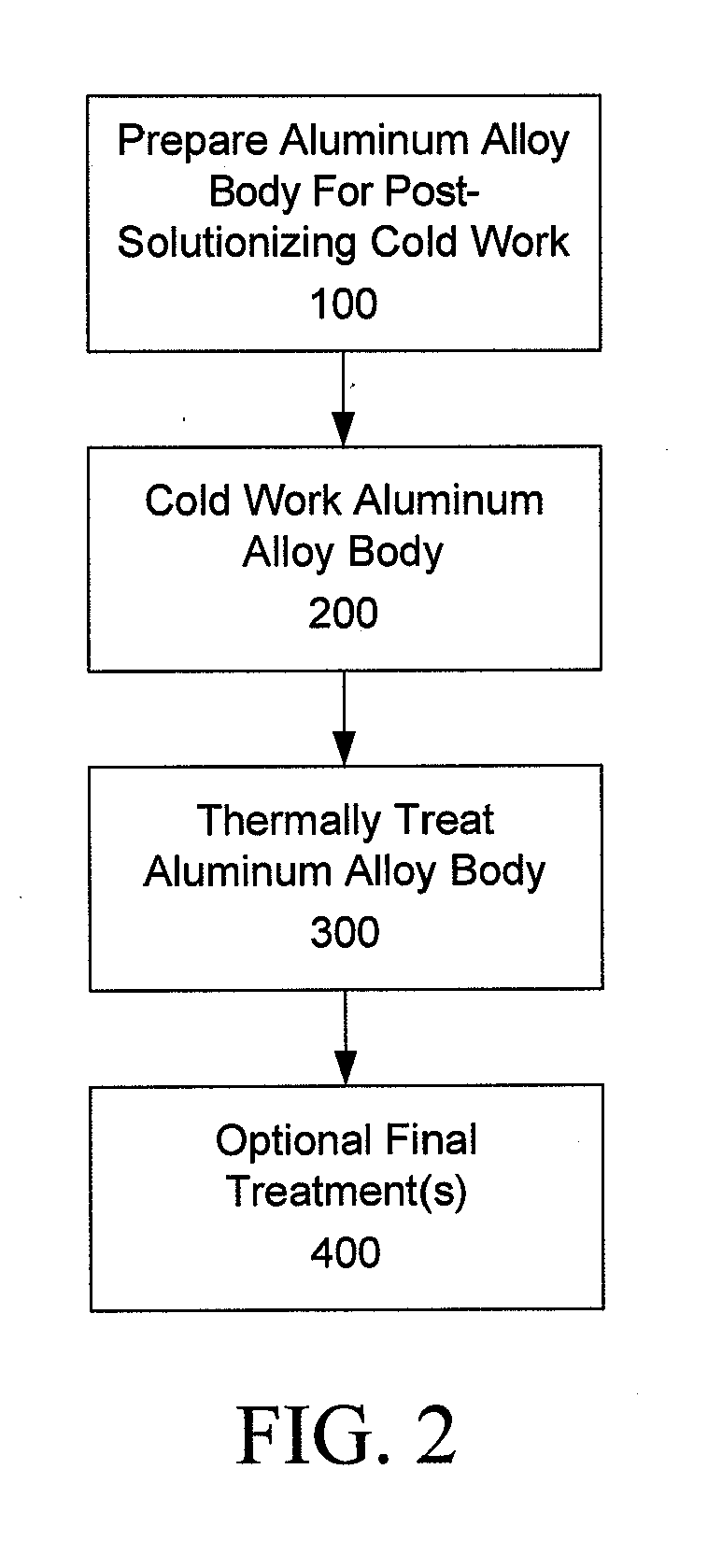

InactiveUS20120055588A1Improve ductilityShort heat treatment timeSolar heating energySolar heat devicesUltimate tensile strengthHeat treated

New 7xxx aluminum alloy bodies and methods of producing the same are disclosed. The new 7xxx aluminum alloy bodies may be produced by preparing the aluminum alloy body for post-solutionizing cold work, cold working by at least 25%, and then thermally treating. The new 7xxx aluminum alloy bodies may realize improved strength and other properties.

Owner:ARCONIC INC

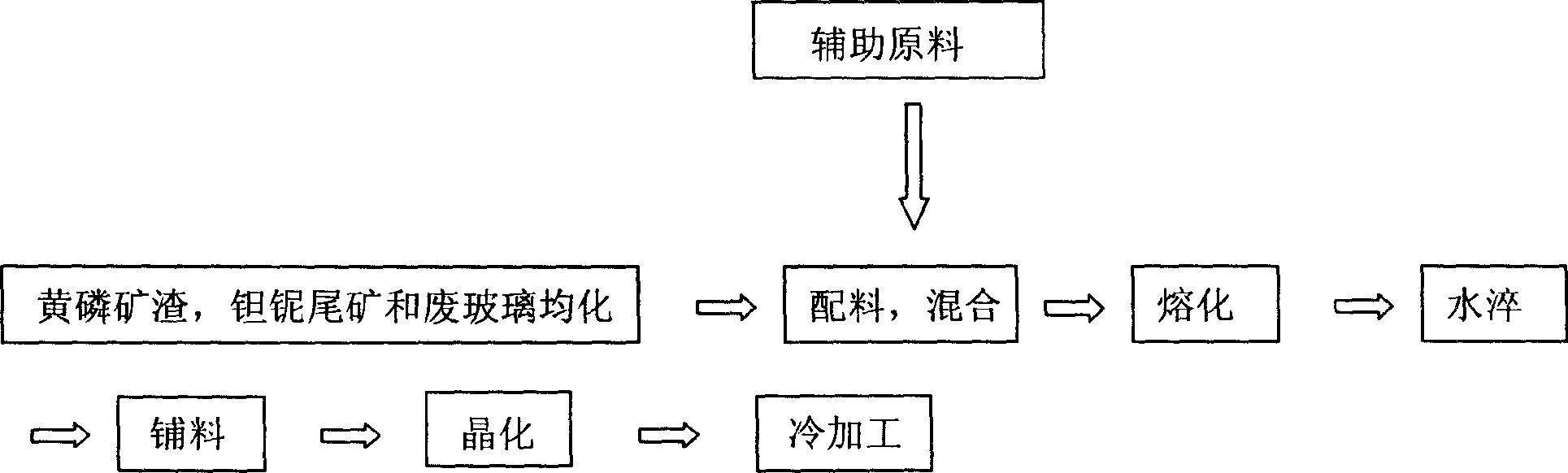

Waste residue microcrystal glass and its preparation method

A microcrystalline glass with low cost and low smelting temp is proportionally prepared from the industrial slag (yellow phosphorus slag), Ta-Nb ore tailings, rejected glass and auxiliary. It contains SiO2 (55-71 Wt%), Al2O3 (3-10), CaO (16-30), ZnO (2-4), BaO (1-4), Na2O+K2O+Li2O (1-10), P2O5 (0-3) and B2O3 (0-3). Its preparing process is also disclosed.

Owner:WUHAN UNIV OF TECH

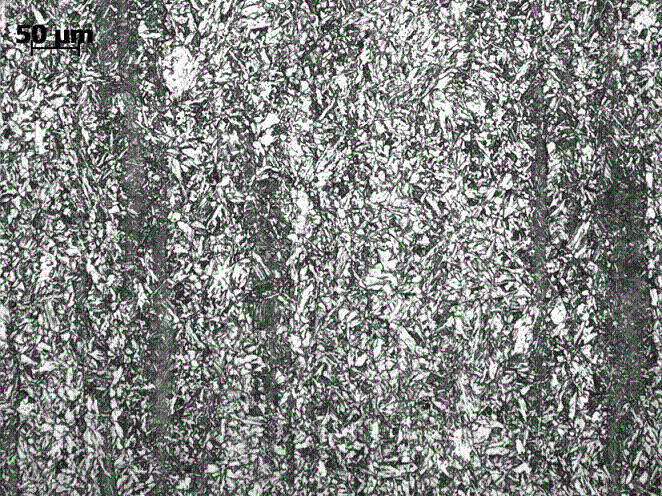

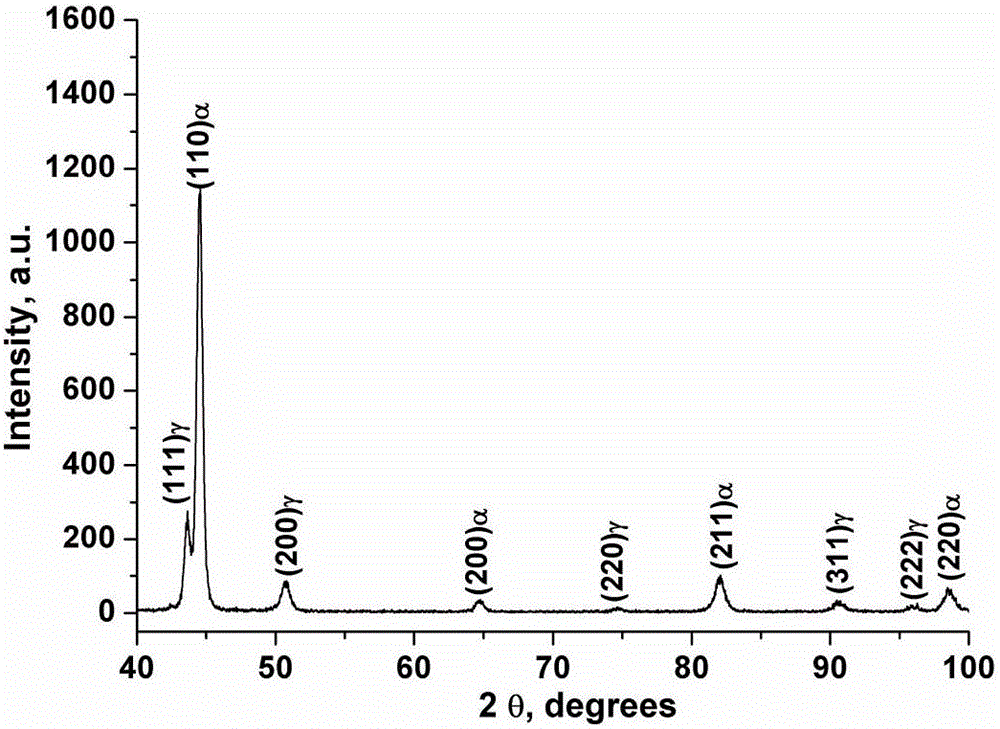

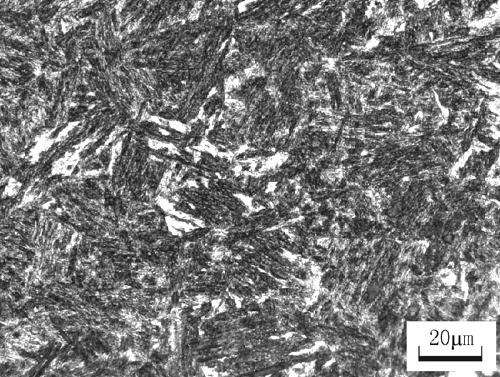

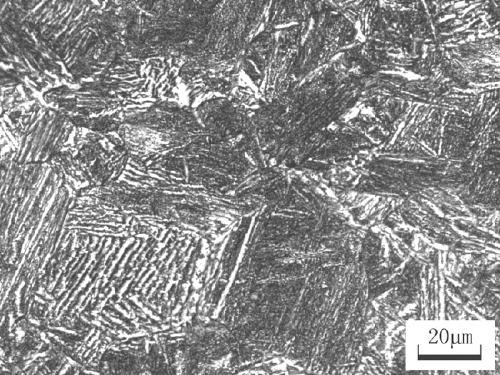

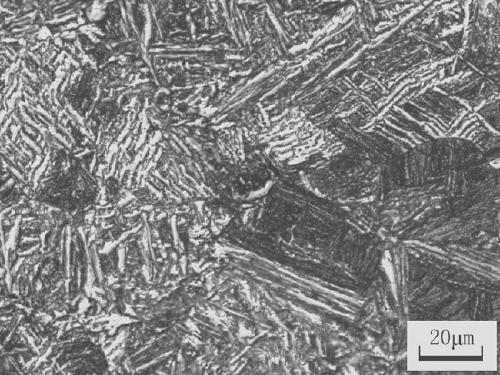

Low-compression ratio hot-rolled 9Ni steel thick plate and manufacturing method thereof

The invention discloses a low-compression ratio hot-rolled 9Ni steel thick plate and a manufacturing method thereof. The low-compression ratio hot-rolled 9Ni steel thick plate comprises, by mass, 0.035-0.075% of C, 0.15-0.25% of Si, 0.50-0.80% of Mn, less than or equal to 0.006% of S, less than or equal to 0.008% of P, 8.9-9.5% of Ni, 0.020-0.045% of Al and the balance Fe and impurities. The manufacturing method comprises the following steps of converter smelting, LF and RH refining, continuous casting of a thick plate blank having the thickness of 150mm, two-stage rolling, rolled workpiece laminar cooling, and heat treatment adopting an out-line quenching and tempering technology. The low-compression ratio hot-rolled 9Ni steel thick plate has simple alloy components and a low cost. Based on a low-compression ratio, the steel thick plate having the thickness above 35mm is rolled and has a good plate shape. After heat treatment, transverse impact energy at a temperature of -196 DEG C is greater than or equal to 160J. The low-compression ratio hot-rolled 9Ni steel thick plate has a good strength-toughness matching degree.

Owner:NANJING IRON & STEEL CO LTD +1

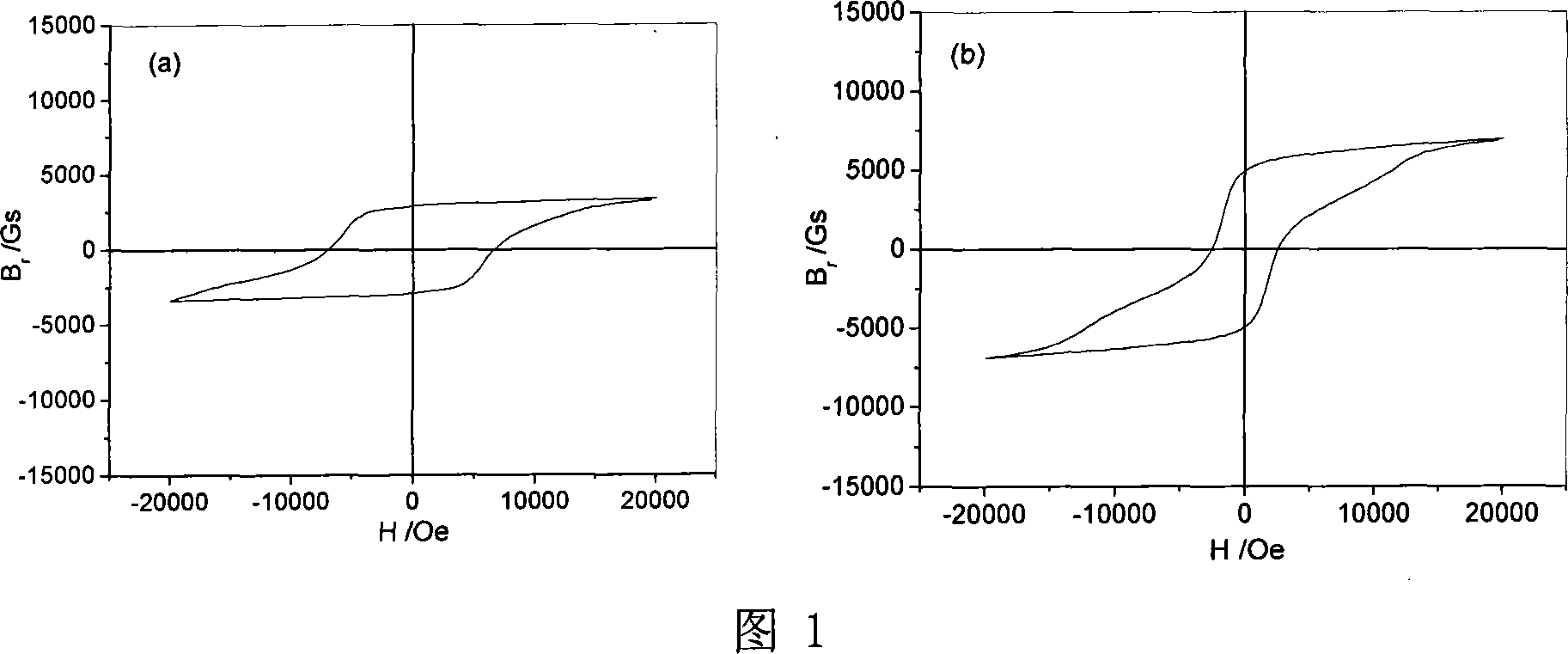

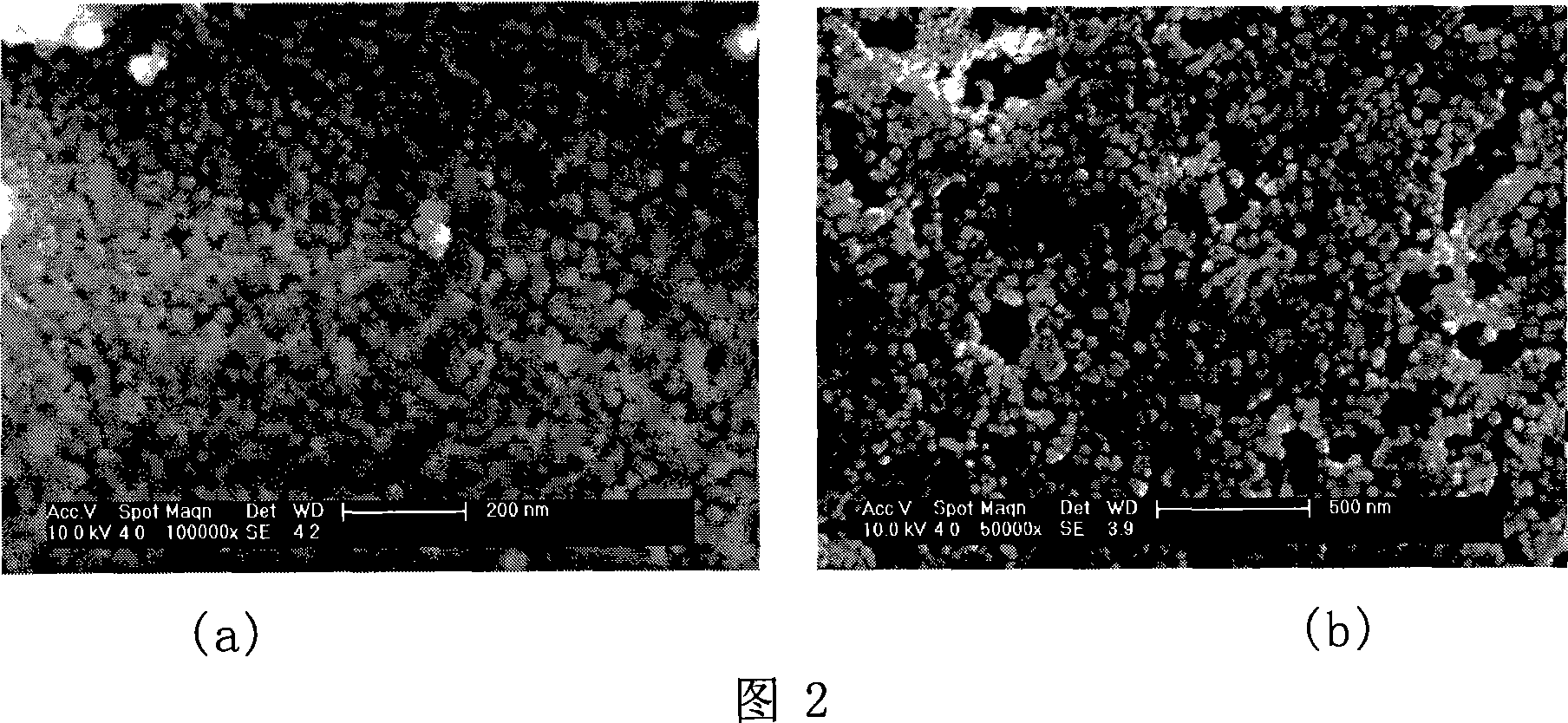

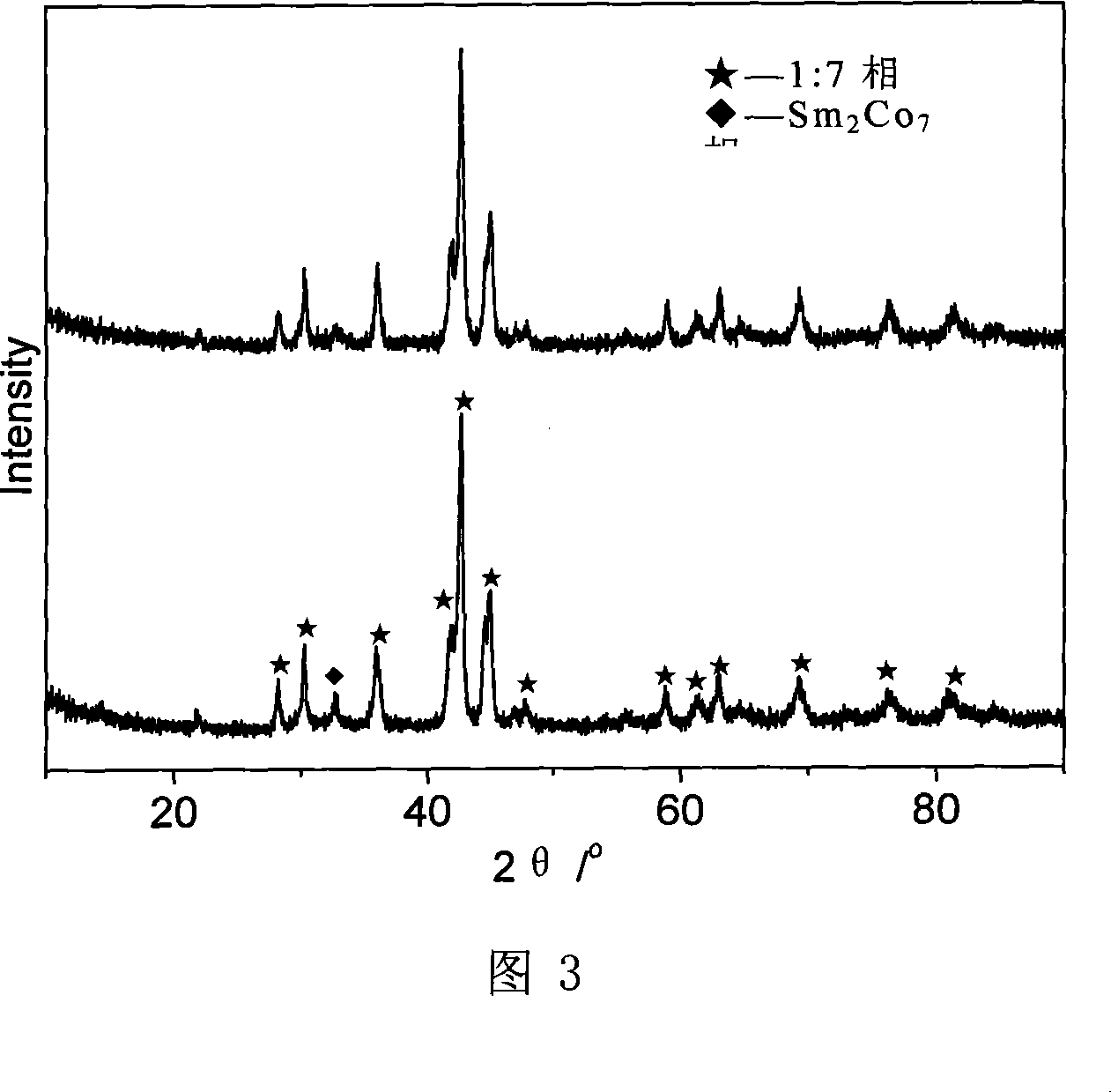

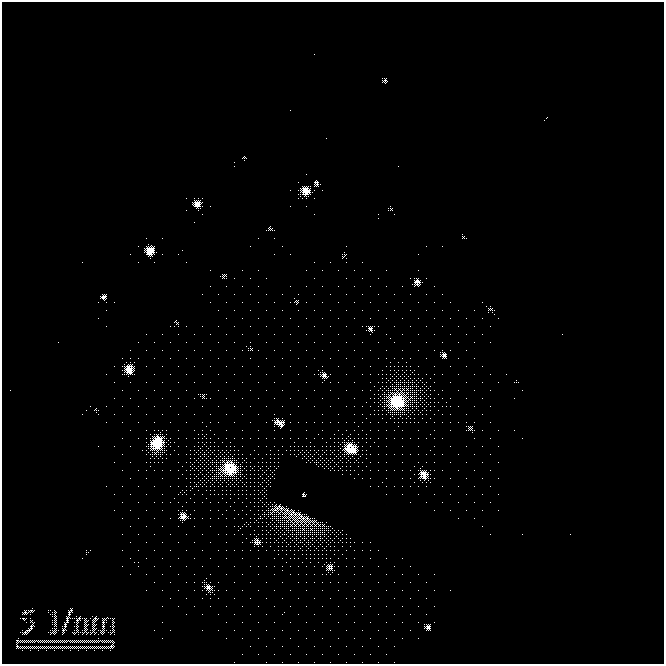

Method for preparing SmCo7 permanent-magnetic alloy with particle size smaller than 20nm

The invention discloses a preparing method of SmCo7 permanent magnet alloy whose grain size is smaller than 20nm, the RE, Co, Fe, Cu, T whose fineness is bigger than 99. 9% is mixed together just as proportion of RE(CobalFexCuyTw)z and placed in the induction furnace, the alloy ingoting which is after the fusion is cased into the quartz tube equipped with nozzle at the bottom to be melt, ejected to the surface of copper roller which is tail-wagging via the nozzle at the bottom of the quartz tube to form amorphous state alloy belt, the film belt obtained is airproofed in the quartz tube, then it is placed to the microwave welding furnace for crystal process, the temperature and time range of crystal process in the microwave welding furnace is 400-900deg.C and 10min-180min, then it is placed into water for cooling. The craftwork of the invention is simple, the cost is low, the grain size of nanometer crystal magnet which includes SmCo7 main phase is about 20nm, and it is lower than grain size obtained by general heat treatment method, the exchange coupled function between grains is increased greatly.

Owner:CENT SOUTH UNIV

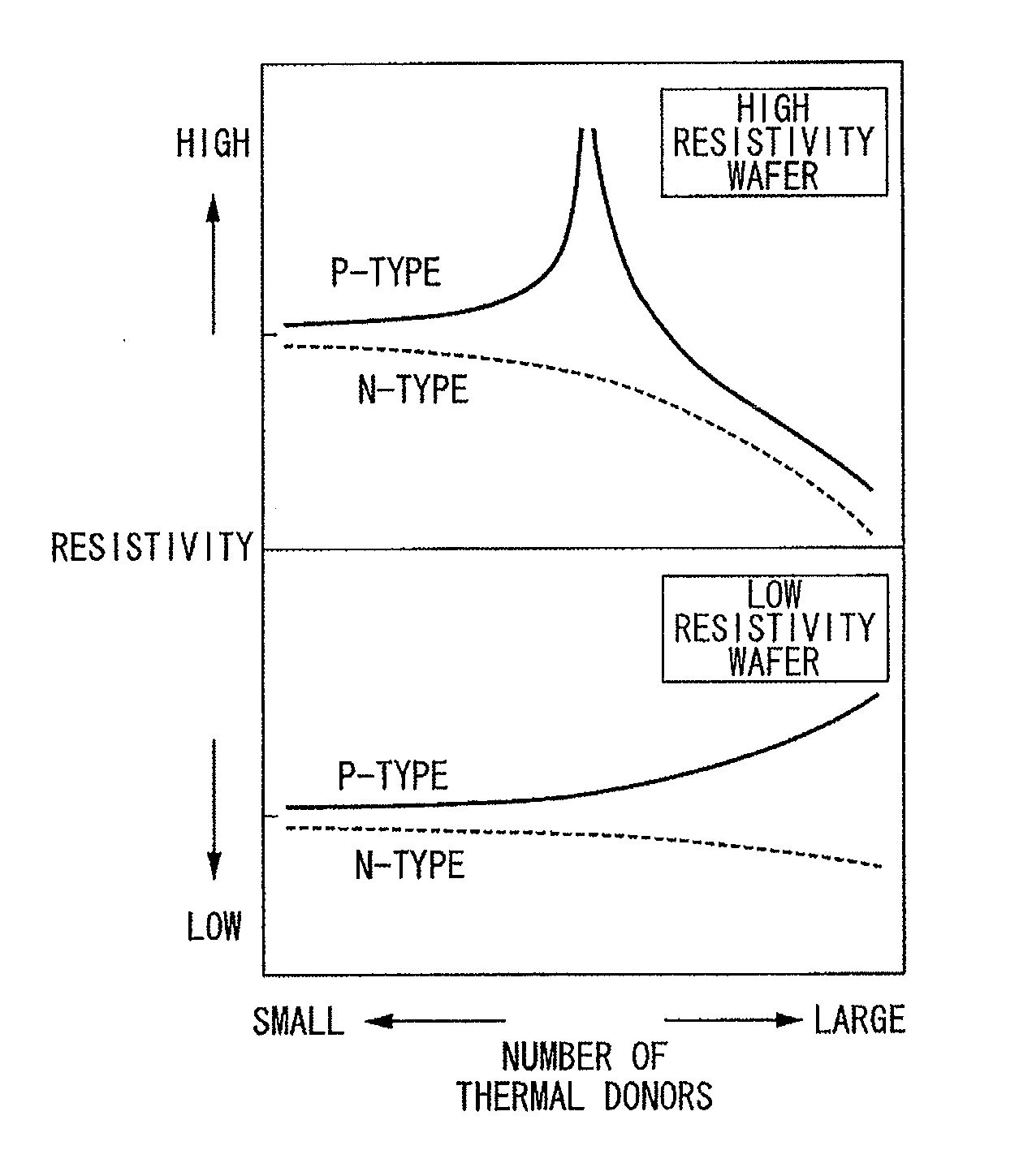

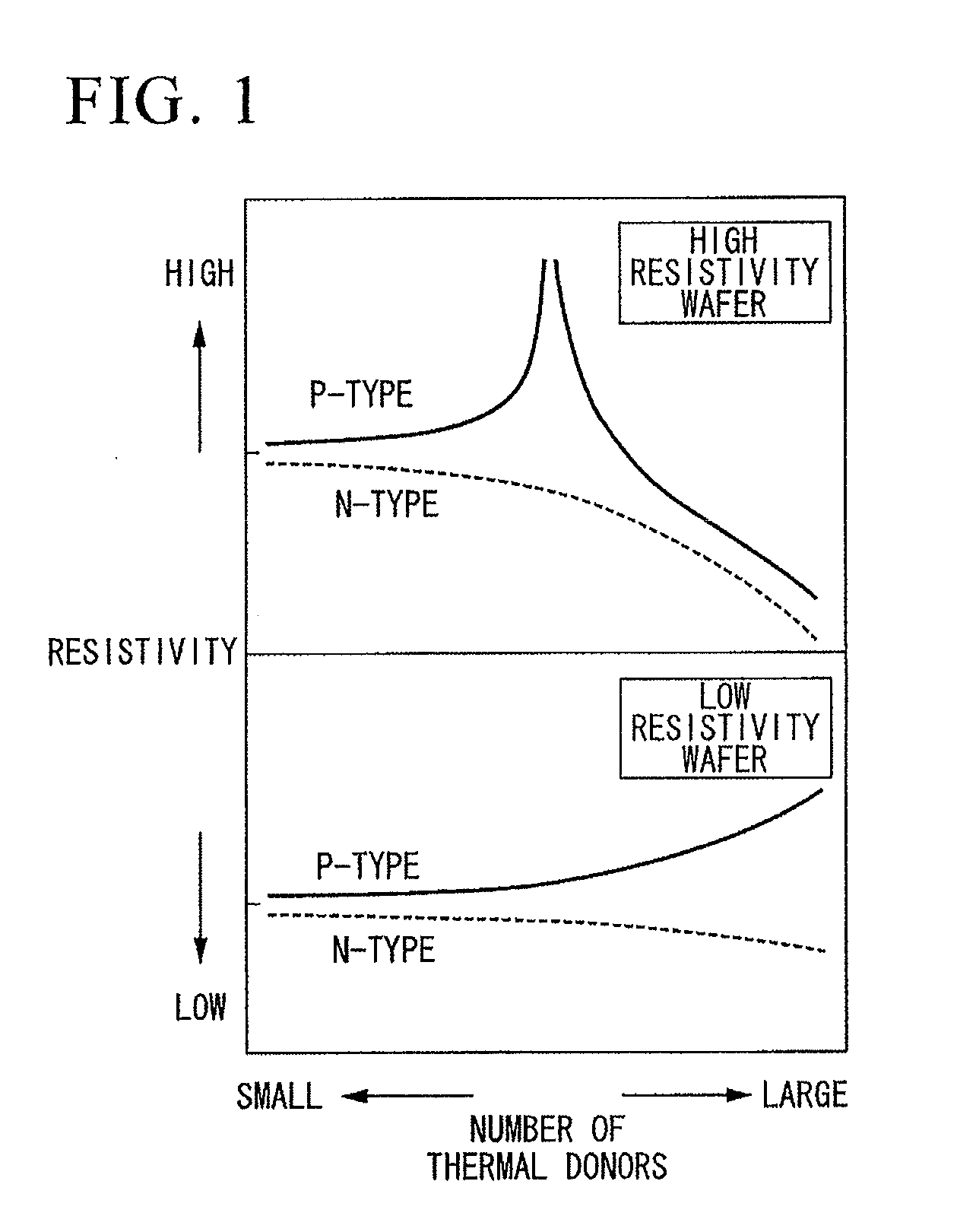

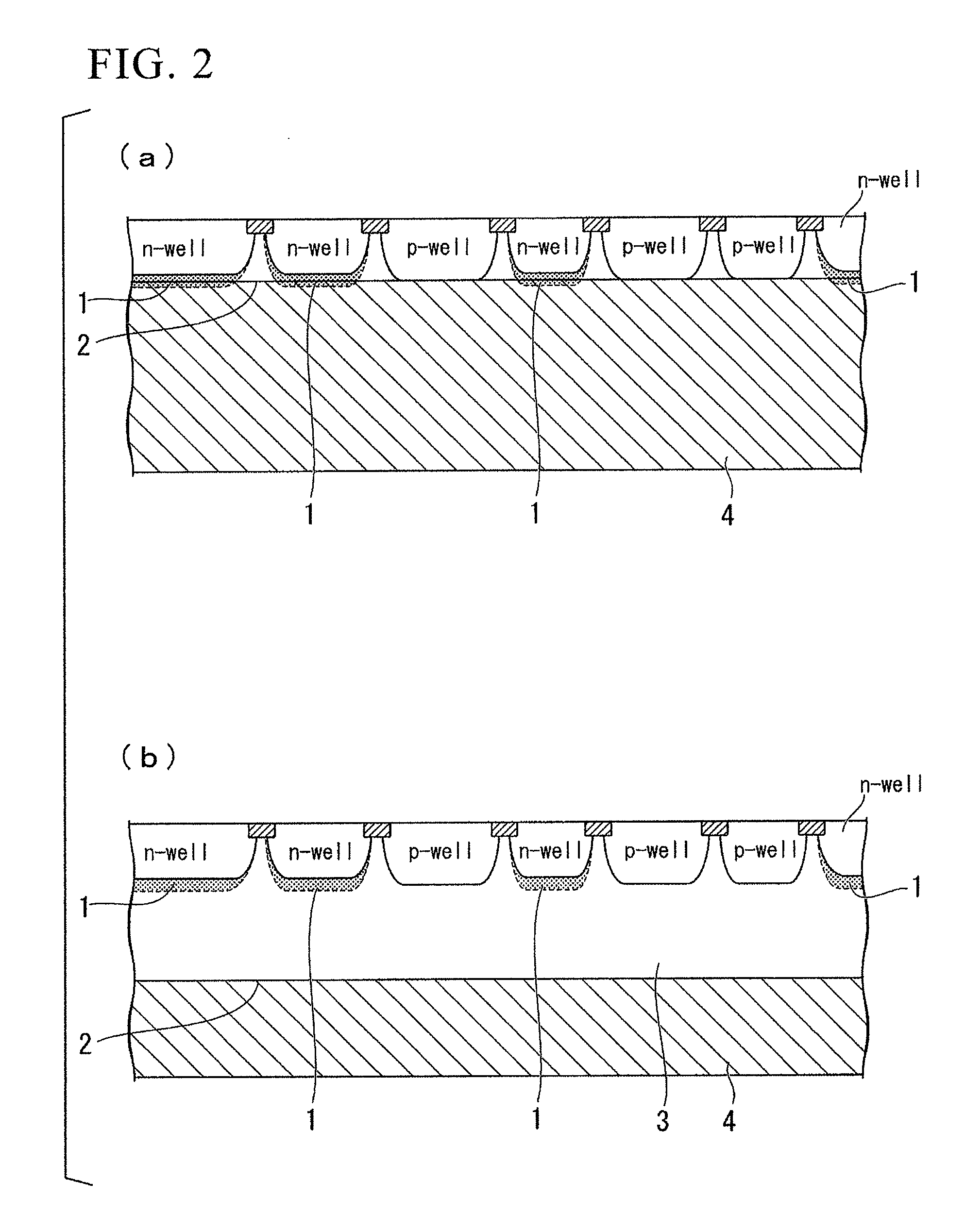

High resistivity silicon wafer and method for manufacturing the same

ActiveUS20100224968A1Avoid it happening againHigh mechanical strengthPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantCzochralski method

This method for manufacturing a high resistivity silicon wafer includes pulling a single crystal such that the single crystal has a p-type dopant concentration at which a wafer surface resistivity becomes in a range of 0.1 to 10 kΩcm, an oxygen concentration Oi of 5.0×1017 to 20×1017 atoms / cm3 (ASTM F-121, 1979), and either one of a nitrogen concentration of 1.0×1013 to 10×1013 atoms / cm3 (ASTM F-121, 1979) and a carbon concentration of 0.5×1016 to 10×1016 atoms / cm3 or 0.5×1016 to 50×1016 atoms / cm3 (ASTM F-123, 1981) by using a Czochralski method, processing the single crystal into wafers by slicing the single crystal, and subjecting the wafer to an oxygen out-diffusion heat treatment process in a non-oxidizing atmosphere. A peak position of a resistivity serving as a boundary between a p-type region of a wafer surface side and a p / n conversion region of an inner side of a thickness direction is adjusted by the nitrogen concentration or the carbon concentration such that the peak position is set to a boundary depth in a range of 10 to 70 μm from the wafer surface.

Owner:SUMCO CORP

6xxx aluminum alloys, and methods for producing the same

InactiveUS20120055591A1Easy to combineShort heat treatment timeSolar heating energySolar heat devicesHeat treatedAluminium alloy

New 6xxx aluminum alloy bodies and methods of producing the same are disclosed. The new 6xxx aluminum alloy bodies may be produced by preparing the aluminum alloy body for post-solutionizing cold work, cold working by at least 25%, and then thermally treating. The new 6xxx aluminum alloy bodies may realize improved strength and other properties.

Owner:ARCONIC INC

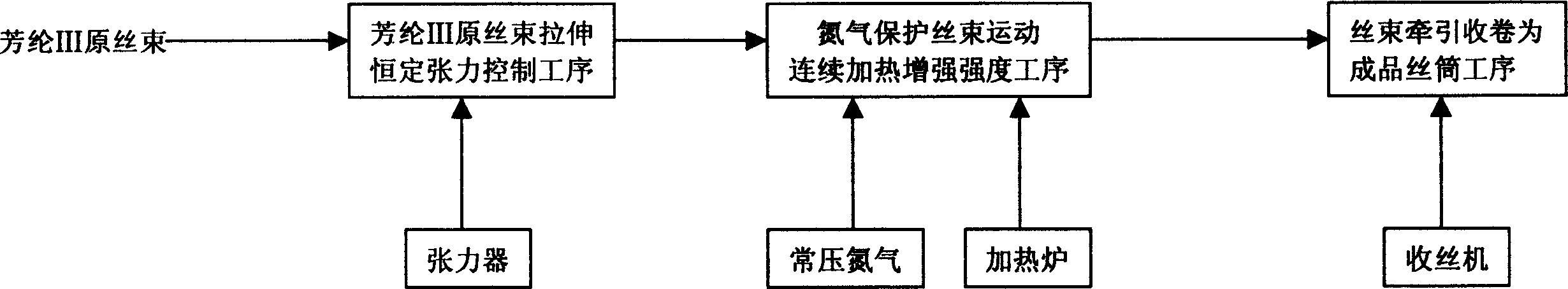

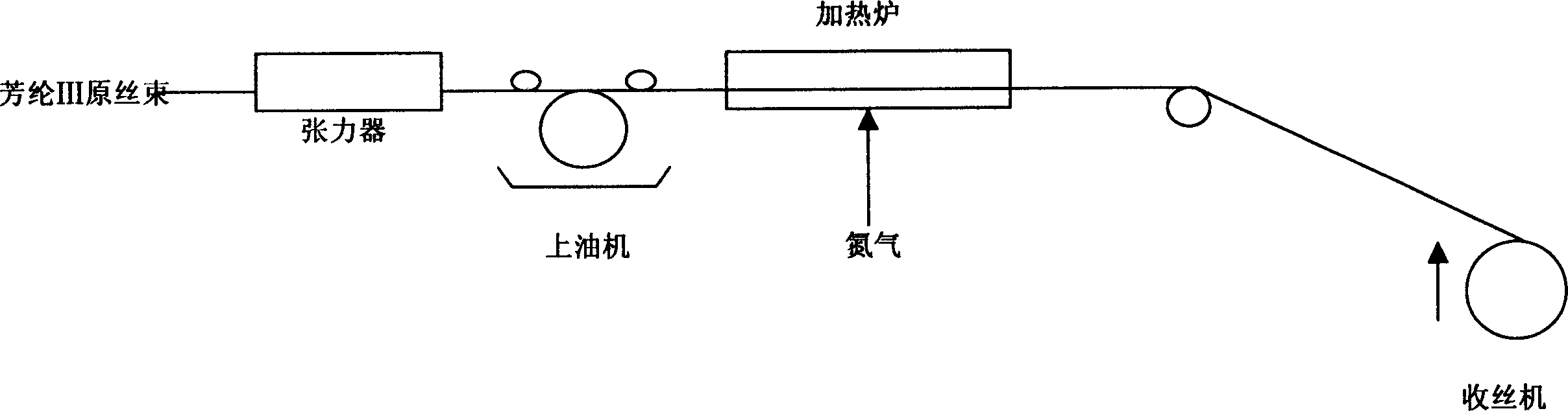

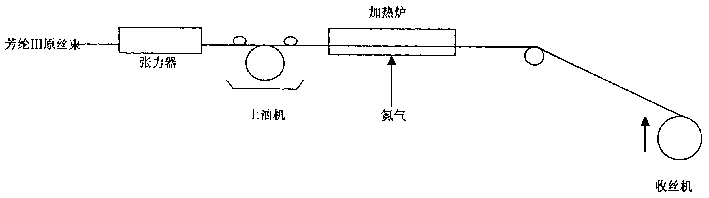

Post-treatment new process for aramid fibre III raw tow

InactiveCN1473969AGuaranteed uniformityImprove yieldArtificial filament heat treatmentMonocomponent polyamides artificial filamentNitrogen gasSolvent

The aramid III fiber as a new kind of high-strength material has wide application. Aramid III liquid is prepared with the materials including p-phenlenediamine, terephthalyl chloride and 5(6)-amino-2-(3-aminophenyl) benzimidazole and through low temperature copolymerization in dimethyl acetamide solvent; and is produced into aramid III fiber through serial spinning steps. The present invention provides the post-treatment technological process to raise the strength of aramid III fiber from 1.5 GPa to 4.5 GPa. The post-treatment process includes the treatment in the apparatus comprising tensioner, oiling machine, heating furnace and winding machine with the tension controlled in 0.2-1.0 CN / tex, temperature inside the nitrogen protected furnace 320-500 deg.c, and heating time 0.5-5 min. The raw tow is heated under motion inside the furnace homogeneously.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

6xxx aluminum alloys, and methods for producing the same

InactiveUS20140248177A1Short heat treatment timeImprove productivitySolar heating energyRigid pipesUltimate tensile strengthHeat treated

Owner:ARCONIC INC

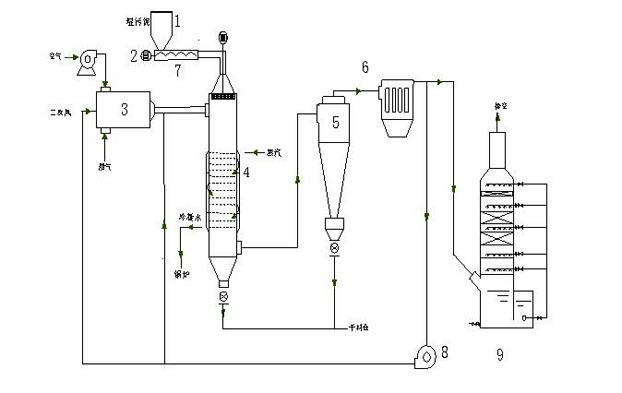

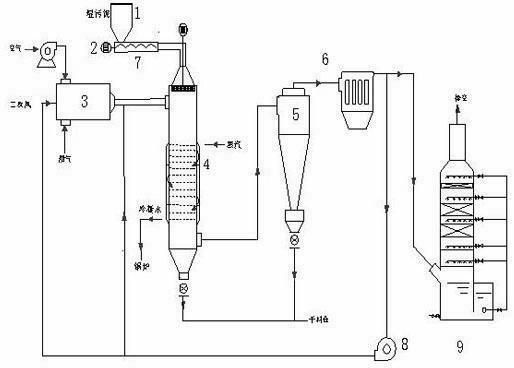

System and process for drying sludge using pulse combustion internal heating fluid bed

ActiveCN102690035AReduce loadImprove efficiencyCombination devicesSludge treatment by de-watering/drying/thickeningExhaust gasPulse combustion

The invention discloses a system for drying sludge using a pulse combustion internal heating fluid bed. The system comprises a pulse combustor, a wet sludge feeding granulating device, an internal heating fluid bed drier, a dust removing device and a deodorizing device. The invention also discloses a corresponding process for drying the sludge using the pulse combustion internal heating fluid bed. According to the invention, the process that the pulse combustion is combined with the heating fluid bed is adopted for sludge drying, so that the drying intensity is improved, the energy consumption is reduced, the treatment quantity of waste gas is reduced, and meanwhile the oxygen content of the system is reduced; dust combustion and explosion danger are prevented; and the system and the process are safe and reliable.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

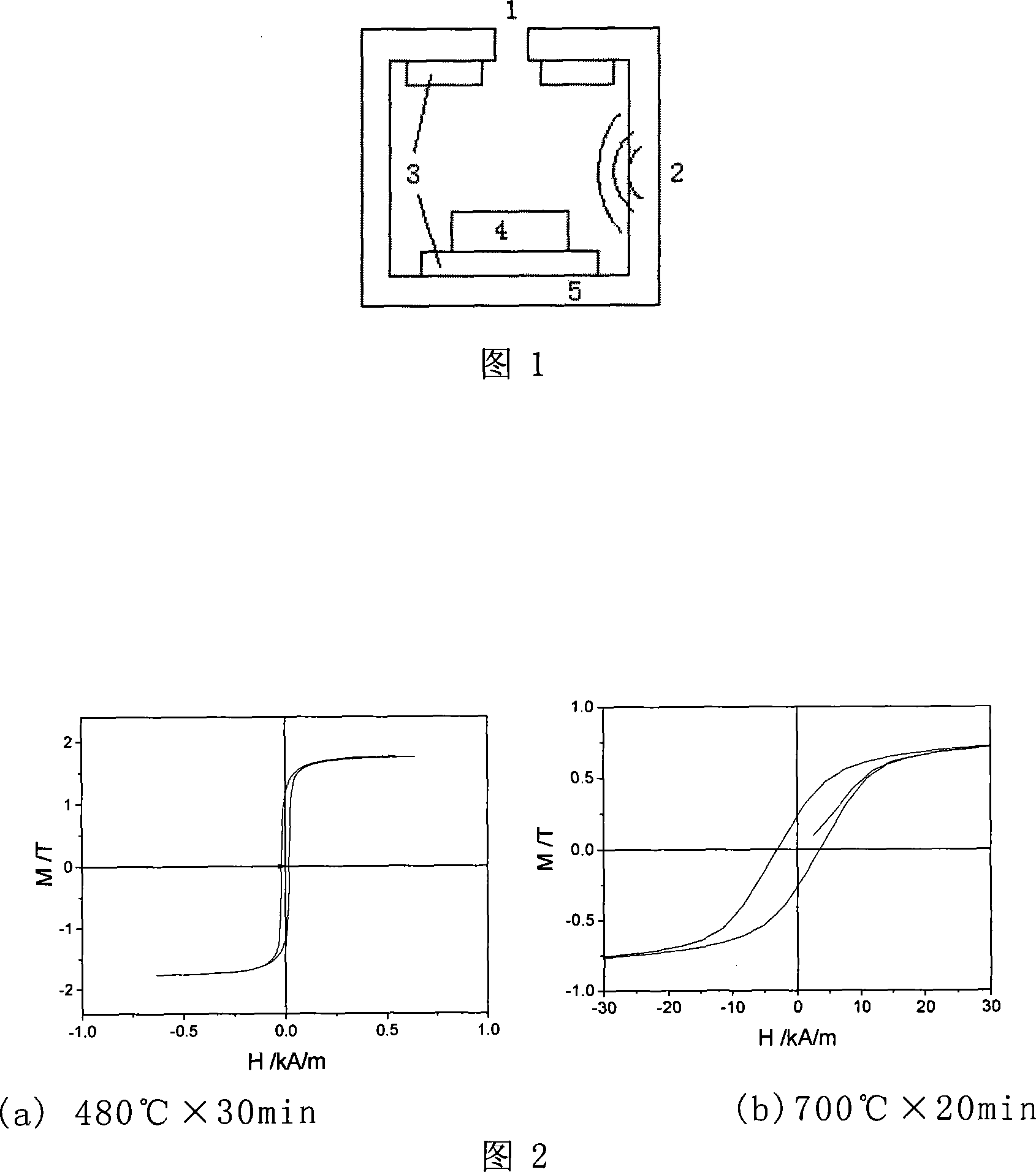

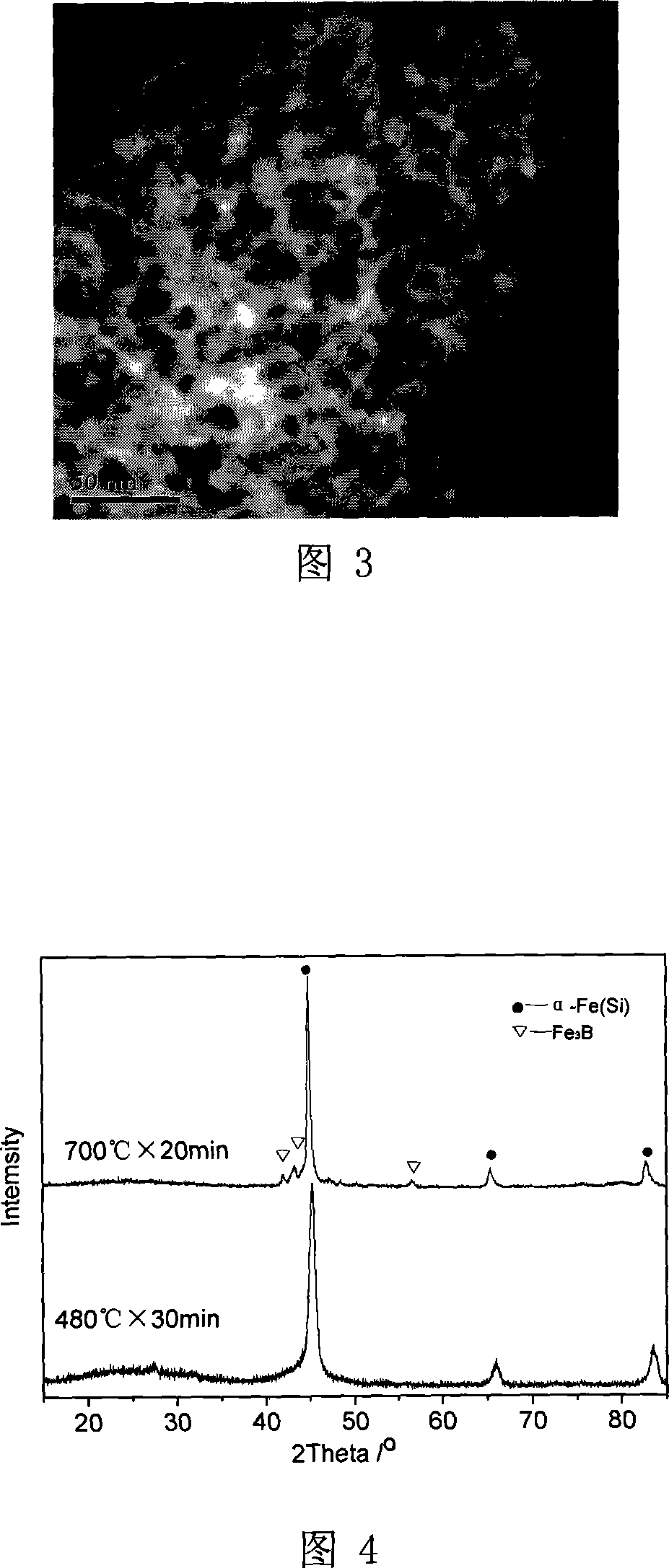

Fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy

The present invention discloses fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy. The technological process includes the following steps: 1. smelting alloy with Fe, Cu, Nb, Si and B in the ratio of Fe73.5Cu1Nb3Si13.5B9 in an induction furnace at vacuum 3-10 Pa in high purity Ar; 2. setting coarsely crushed alloy inside quartz pipe with nozzle in the bottom, setting the quartz pipe inside induction coil in a belt spinning machine, and melting the mother alloy in protecting Ar atmosphere; 3. spraying the alloy liquid under the pressure of Ar to the surface of rotating copper roller to form non-crystalline alloy belt; and 4. sealing the thin belt in quartz tube and crystallizing treatment in a microwave sintering furnace at 400-900 deg.c for 10-180 min to obtain ideal nanometer crystal structure.

Owner:CENT SOUTH UNIV

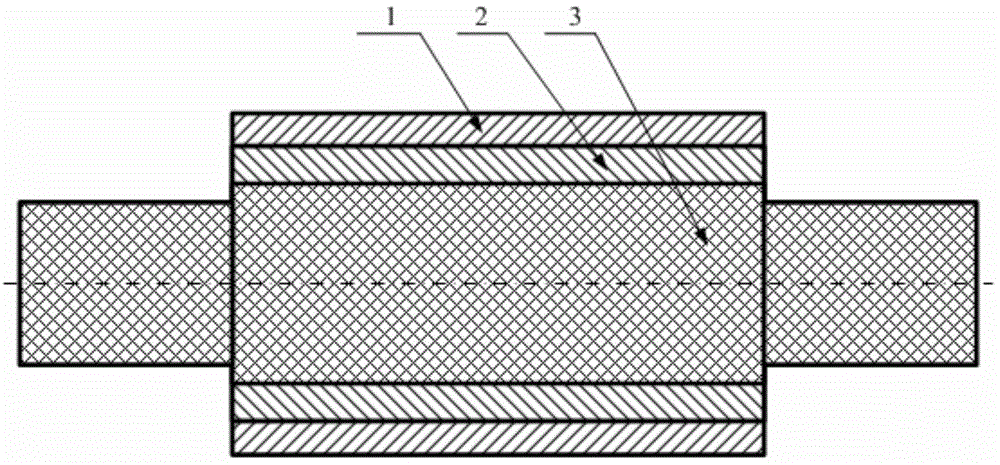

Wear-resisting roll used for steel rolling intermediate mill frame and manufacturing method thereof

ActiveCN104148399ASimple heat treatment processShort heat treatment timeRollsMetal rolling arrangementsSocial benefitsAlloy

A wear-resisting roll used for a steel rolling intermediate mill frame and a manufacturing method thereof belong to the technical field of steel rolling. The wear-resisting roll is composed of outer layer alloy nodular cast iron, inner layer high strength gray iron and a hot rolled middle carbon round steel roll shaft with high strength. The outer layer alloy nodular cast iron and the inner layer high strength gray iron are formed through centrifugal casting in a composite mode, and the inner layer high strength gray iron is integrated with the hot rolled middle carbon round steel roll shaft with high strength, and the composite wear-resisting roll with high strength is obtained. The wear-resisting roll has the advantages of being simple and convenient in production process, long in service life, low in production cost and the like. In addition, good economic and social benefits are achieved through application and popularization.

Owner:枣庄瑞兴机械制造有限公司

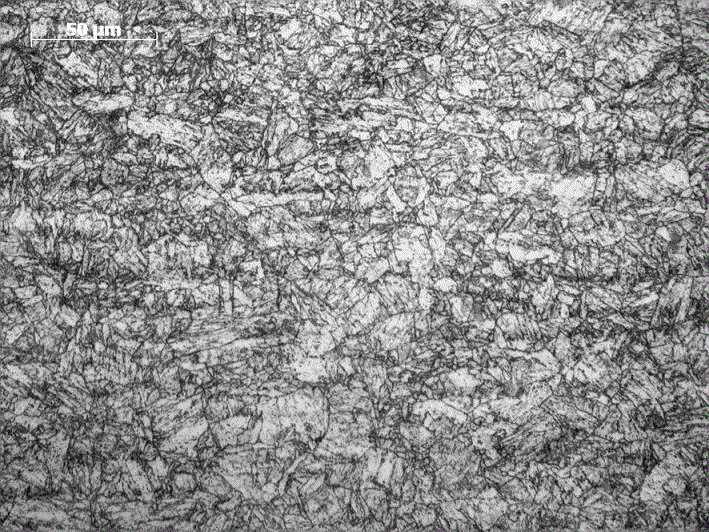

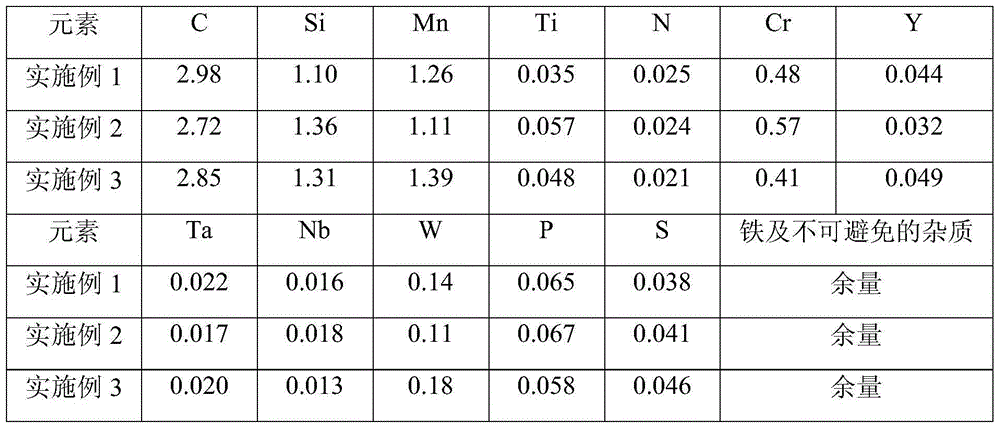

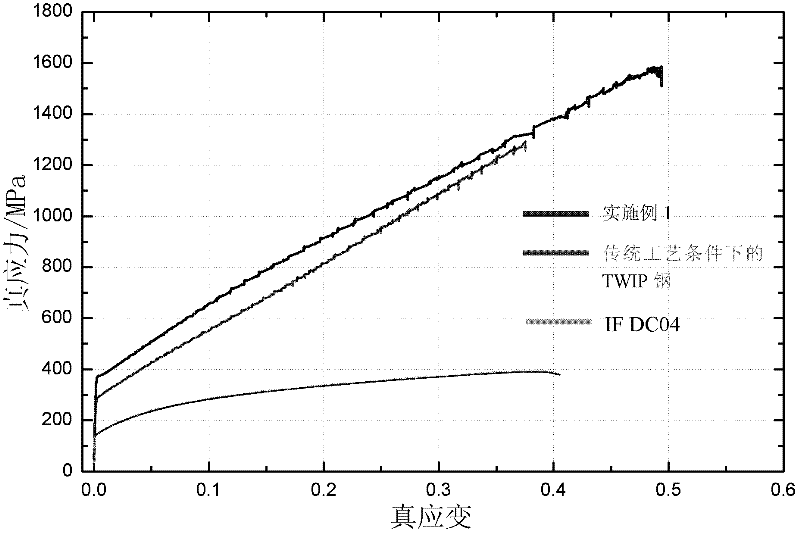

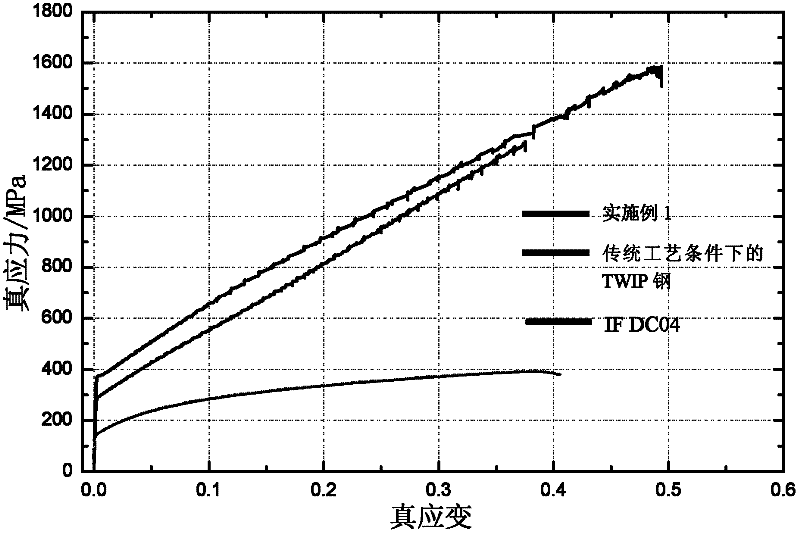

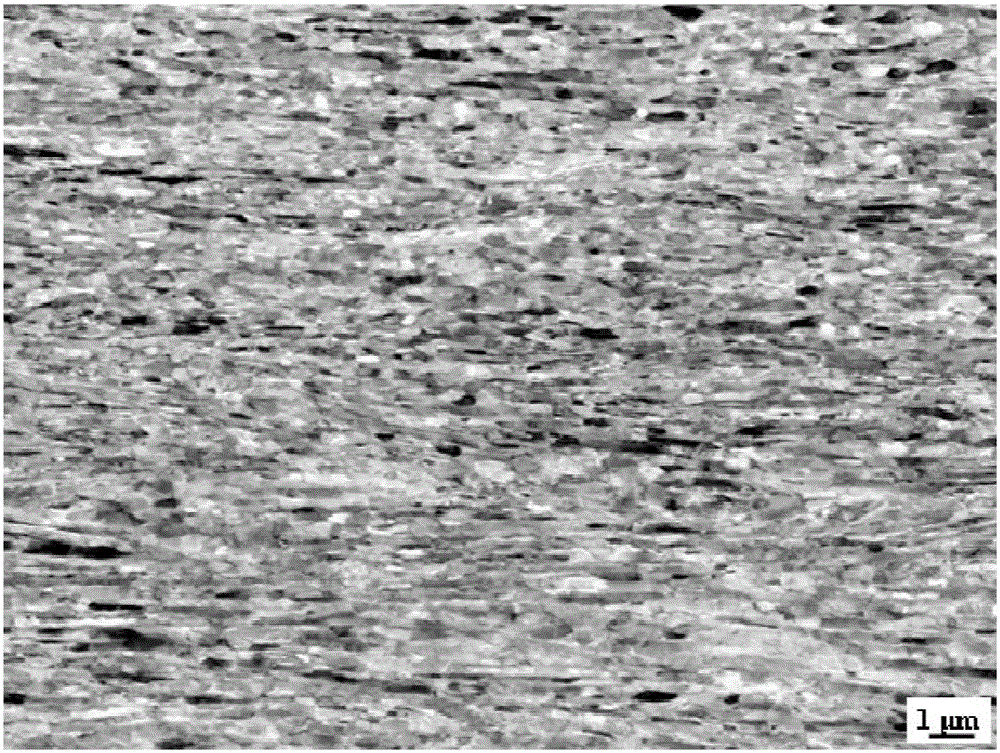

Annealing preparation process for enhancing product of strength and elongation of twinning-induced plasticity high-manganese steel board

The invention belongs to the field of metal material processing, and relates to an annealing preparation process for enhancing a product of strength and elongation of a twinning-induced plasticity (TWIP) high-manganese steel board. The high-manganese TWIP cold-rolled steel board comprises the following components in percentage by mass: 0.06-0.6% of C, not more than 3% of Si, not more than 3% of Al, 22-30% of Mn, not more than 0.1% of P, not more than 0.02% of S, and the balance of iron or inevitable impurities. The high-manganese TWIP cold-rolled steel board is prepared by the preparation steps of: smelting, carrying out die casting or continuous casting, hot rolling, cold rolling and heat treatment, carrying out heat insulation on the cold-rolled board in a heating furnace at 800-1000 DEG C for 0.1-0.5 hour, carrying out short-time heat treatment and rolling process multiple times, and carrying out air cooling to room temperature. According to the invention, by component and process control, the prepared material has superhigh strength and plasticity ratio, the tensile strength can reach 900-1020 MPa, the elongation can reach 70-80% and the strength and plasticity ratio can reach 80000 MPa.%; and the preparation process is simple and feasible as well as economical.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of 7Ni steel plate for liquefied natural gas storage tank

The invention discloses a preparation method of a 7Ni steel plate for a liquefied natural gas storage tank and belongs to the field of alloy steel manufacturing. The preparation method comprises the following steps: (1), smelting according to components of the 7Ni steel plate; (2), after heat preservation knobbling, carrying out hot rolling: rough rolling and finish rolling; and (3), cooling the hot rolled plate to a temperature of 20 to 300 DEG C at a super fast speed, then rising the temperature and keeping the temperature, and carrying out water cooling or air cooling to reach a room temperature so as to obtained a finished product, or carrying out air cooling to the hot rolled plate to reach a temperature of 660 to 700 DEG C, then quenching after heat preservation, rising the temperature and keeping the temperature, and then carrying out water cooling or air cooling to reach a room temperature, so as to obtained the finished product. The preparation method of the 7Ni steel plate for the liquefied natural gas storage tank has the beneficial effects as follows: (1), except for four elements such as C, Si, Mn and Ni in the components, only a small quantity of Cr element is added, stable control to components is facilitated, and the alloy cost is lowered; and (2), the TMCP technology is adopted, the hot rolling process is reasonably designed, the organization is detailed, and the low-temperature toughness and intensity of steel are improved; (3), after finally rolling, carrying out on-line quenching and tempering or air cooling to two-phase region heat preservation quenching and tempering, the heat processing time is short, and the product rhythm is compact.

Owner:NORTHEASTERN UNIV LIAONING

Lithium lanthanum bismuthate-based solid electrolyte material and preparation method thereof

InactiveCN102044700AIncreased overall conductivity at room temperatureReduce the temperatureFinal product manufactureElectrolyte accumulators manufactureWater soluble polymersWater soluble

The present invention discloses Lithium lanthanum bismuthate-based solid electrolyte material and preparation method thereof. The chemical formula of the material of Lithium lanthanum bismuthate-based solid electrolyte after the doping of lanthanum and the doping of lithium are conducted is La(3-x)AxLi(5+delta)Bi(2-y)ByO12. In the formula, A is the lanthanum position dopant, X is a value from 0 to 1.25, B is the bismuth position dopant, and Y is a value from 0 to 1.25. The preparation method of the material is as follows: according to the formula, weighing nitrates or carbonates or chlorides or acetates or alkoxides or oxides soluble in acids of lithium, lanthanum, bismuth, the lanthanum-position dopant and / or the bismuth-position dopant, preparing a solution by using the above chemicals,adding a lanthanum salt solution, a bismuth solution, a solution of lanthanum-position dopant and / or a solution of bismuth-position dopant dropwisely, adding citric acid and nitric acid successively to obtain a sol, adding a water-soluble polymer into the sol to form a gel, drying the gel, performing heat treatment to obtain nanocrystal powder, moulding the powder into a green body, and calciningto obtain the Lithium lanthanum bismuthate-based solid electrolyte material. The prepared material can be used as a solid electrolyte material and can be applied to all-solid-lithium ion battery.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Preparation method of carbon/carbon nanotube coated lithium iron phosphate composite material by in situ synthesis

ActiveCN106876705AHigh carbon coverageImprove electrochemical performanceCell electrodesSynthesis methodsPhosphate

The invention provides a preparation method of a carbon / carbon nanotube coated lithium iron phosphate composite material by in situ synthesis, and relates to the technical field of battery materials. The preparation method provided by the invention comprises the steps of weighing raw materials of a lithium source, iron powder, a phosphate and a carbon source; first performing ball-milling on the iron powder and the phosphate and adding hydrogen peroxide; and then adding the lithium source and the carbon source to obtain a slurry, drying and sintering under the protection of reducing / inert gas to obtain the composite material. According to the preparation method provided by the invention, the carbon / carbon nanotube coated lithium iron phosphate composite material is prepared by employing an in-situ synthesis method, so the heat treatment time is short; the composite material has relatively high carbon coating rate, stable electrochemical property and relatively good consistency, the cycle performance and the rate performance are greatly improved, the whole preparation process is simple, and the preparation method has the advantages of safety, high efficiency, low cost and environmental protection, etc.

Owner:合肥国轩科宏新能源科技有限公司

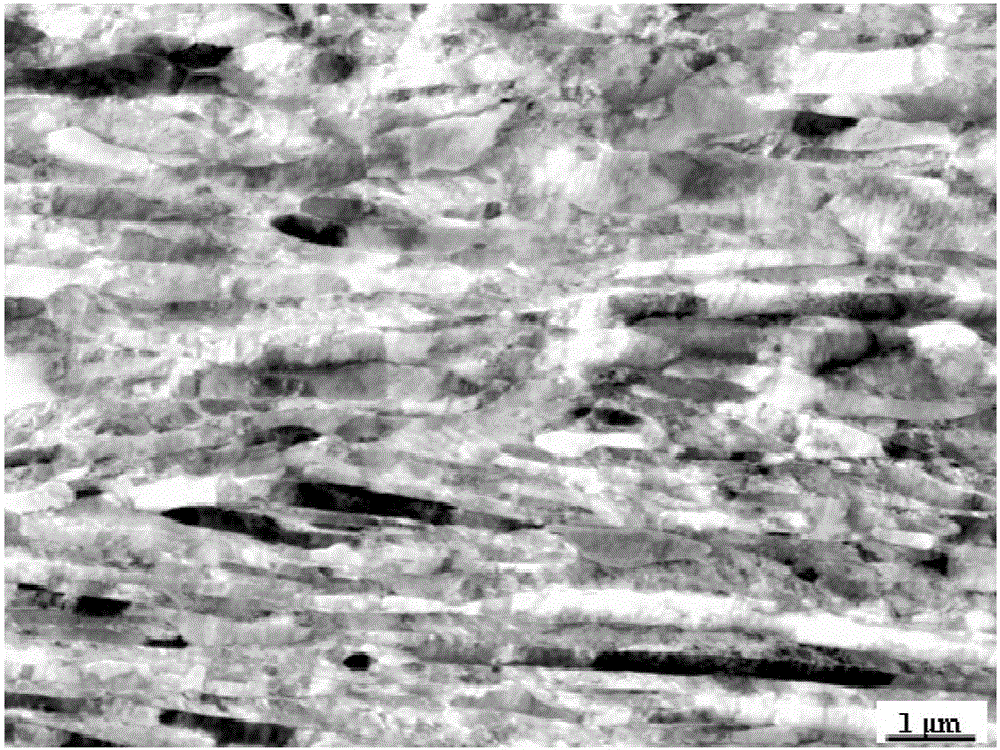

Nano/superfine medium-manganese TRIP (transformation induced plasticity) steel plate and warm-rolling preparation method thereof

The invention relates to a nano / superfine medium-manganese TRIP (transformation induced plasticity) steel plate and a warm-rolling preparation method thereof, belonging to the technical field of ultrahigh-strength steel. The nano / superfine medium-manganese TRIP steel plate comprises the following chemical components in percentage by weight: 0.17-0.25wt.% of C, 0.00-0.50wt.% of Si, 5.00-7.00wt.% of Mn, 1.00-1.50wt.% of Al, 0.014-0.03wt.% of N, 0.00-0.06wt.% of Nb, 0.00-0.25wt.% of Mo, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, forging, carrying out hot rolling, and carrying out warm rolling to obtain the nano / superfine medium-manganese TRIP steel plate; and carrying out heat treatment on the steel plate to obtain the nano / superfine medium-manganese TRIP heat-treated steel plate. By using the warm-rolling technique instead of the typical technique for producing manganese steel, the method provided by the invention has the advantages of simple technique, short production cycle and controllable plate shape. The prepared steel plate has a nano / superfine structure, has the advantages of high strength and favorable properties, and satisfies the target requirements of resource saving, energy consumption reduction, light weight and crash safety enhancement for automobile industry.

Owner:NORTHEASTERN UNIV

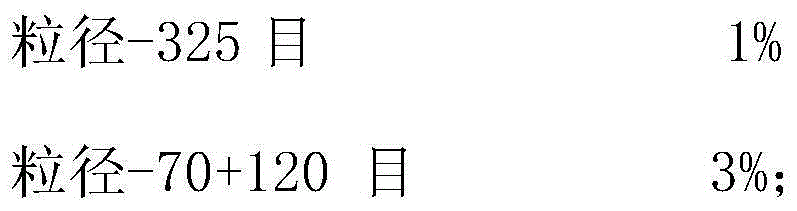

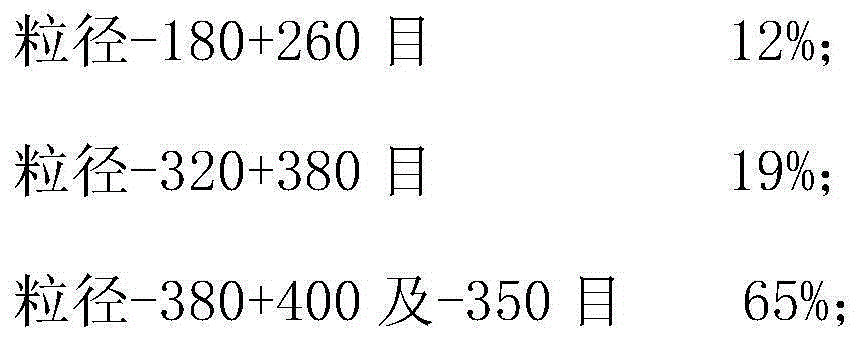

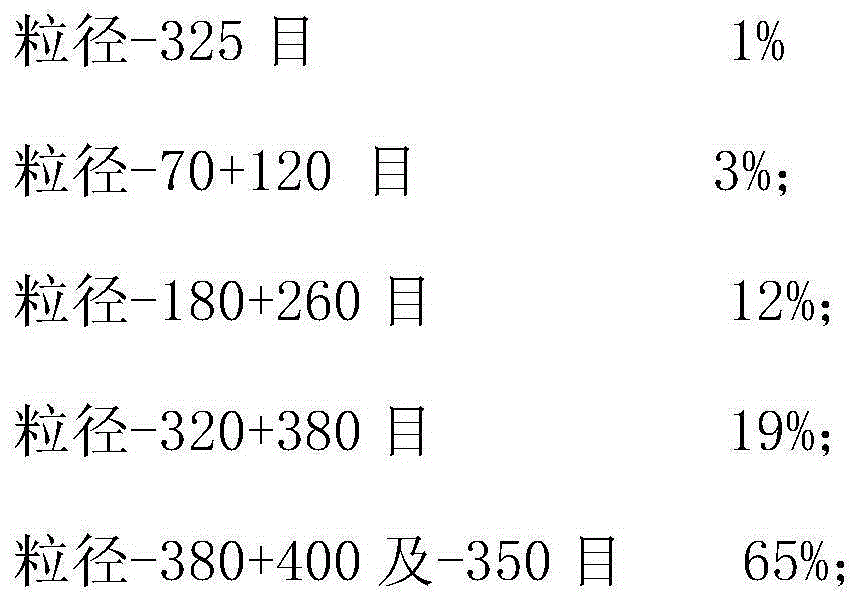

Fe-Si-Al soft magnetic powder

ActiveCN105014065ALow oxygenReduce permeabilityInorganic material magnetismPhosphoric acidNitrogen gas

The invention discloses a manufacturing method for Fe-Si magnetic powder. The method includes the steps that the powder is smelted through a vacuum induction furnace and comprises the chemical composition of Si, Al, Ni, Cr, Mn, C and the balance Fe, the content of C is controlled to range from 0.015% to 0.018%, the powder is cast in vacuum to form a cast ingot, the alloy cast ingot is roughly crushed and conveyed into a ball mill so as to be ground into powder of different grain diameters, and pure nitrogen protective thermal treatment is then performed; alloy smelting is performed in a magnesia crucible open-type medium-frequency induction furnace, after alloy smelting is finished, the alloy is manufactured into a strip through a strip flinging machine according to a high-speed cooling method, and the strip is crushed into powder; and the Fe-Si powder is added to a 0.25% phosphoric acid solution when parched and fried to be at the temperature of about 80 DEG C, and surface passivation treatment is performed. The powder can be further pressed into a powder core. The limitation of the content of an impurity of C is broken, a novel high-quality Fe-Si-Al soft magnetic material which is low in oxygen content, magnetic conductivity and power consumption can be manufactured, thermal treatment time is short, the temperature is low, energy is saved, and environmental friendliness is achieved.

Owner:江苏启诚磁业有限公司

Method for preparing silicon carbon particulate reinforced composite material containing silicon-aluminum alloy by using crystalline silicon cutting waste

The invention belongs to the technical field of the comprehensive utilization of secondary resource and particularly relates to a method for preparing a silicon carbon particulate reinforced composite material containing silicon-aluminum alloy by utilizing crystalline silicon cutting waste. The method comprises the following steps: firstly, pickling the crystalline silicon cutting waste to remove impurities such as iron oxide, metal impurities and a small amount of silicon dioxide in cutting waste, washing with water, filtering and drying to obtain a mixed micro-powder of silicon carbide and silicon with the particle size in the range of 0.5-10 mu m, mixing the silicon carbide micro-powder which accounts for 4.5-32.5% of the total mass fraction of the composite material and free silicon which accounts for 0.2-9.8% of the total mass fraction of the composite material with aluminum or aluminum alloy, performing strong stirring at a high temperature until silicon carbide is evenly dispersed and silica powder is dissolved, and rapidly solidifying to obtain the final product. The silicon carbide and silicon powder is waste in industrial production and widely available. The silicon carbon particulate reinforced composite material has the beneficial effects of high strength, fine grain size, low manufacturing cost and the like.

Owner:XINJIANG JOINWORLD CO LTD

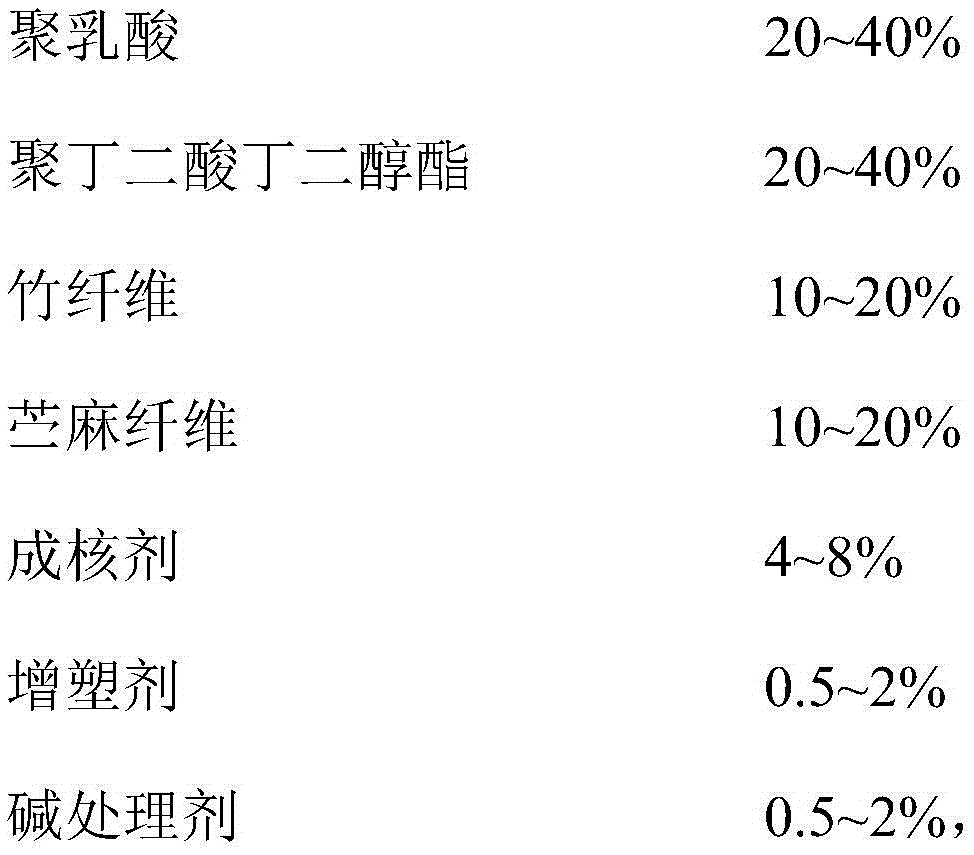

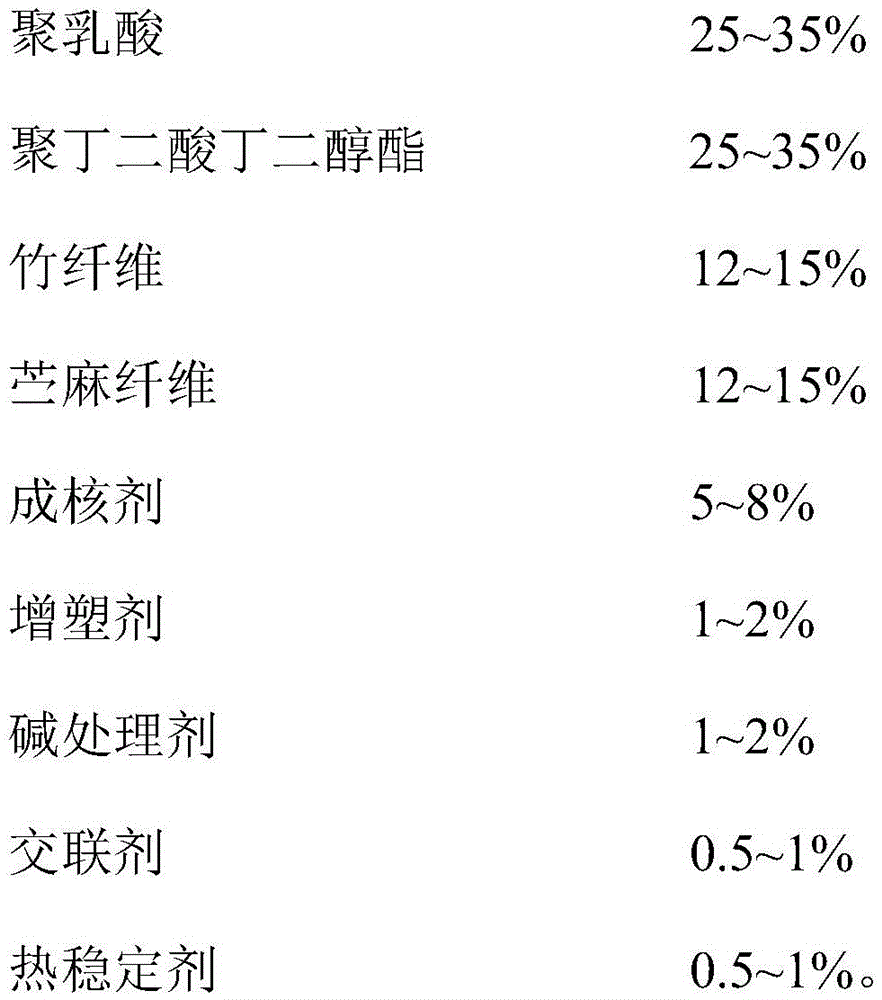

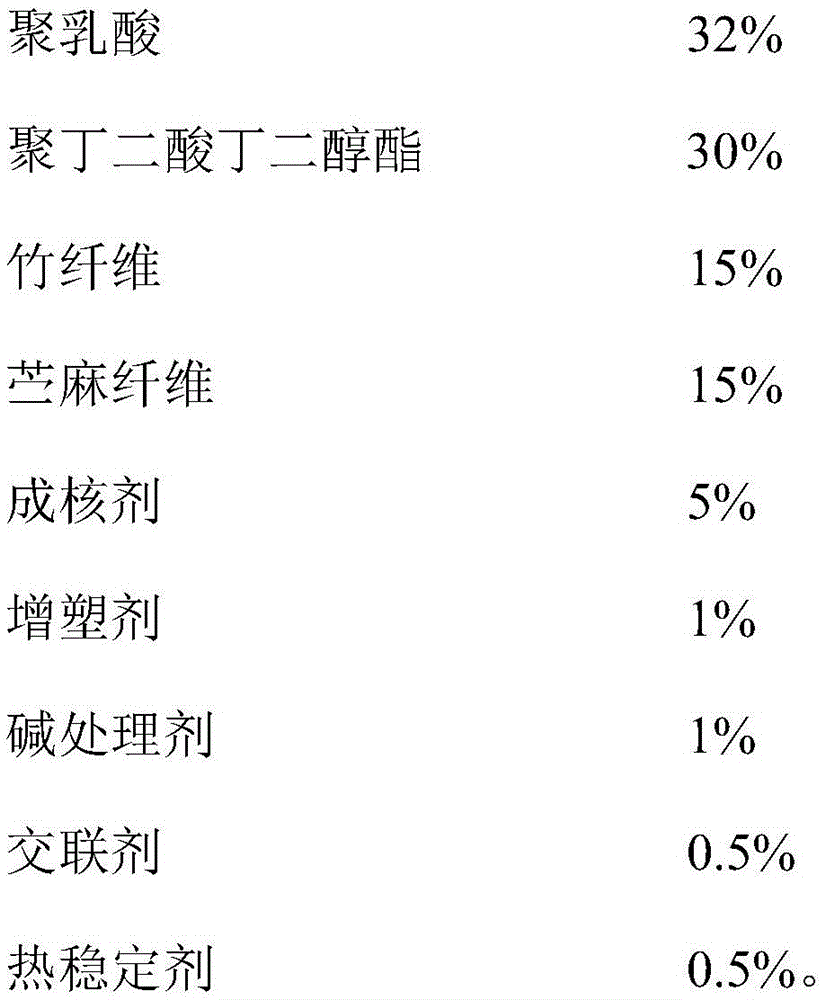

Full-degradable injection product and preparation method therefor

The invention relates to the technical field of full-degradable composite materials, in particular to a full-degradable injection product. The full-degradable injection product comprises the following raw materials in percentage by weight: 20-40% of polylactic acid, 20-40% of polybutylene succinate, 10-20% of bamboo fibers, 10-20% of ramine fibers, 4-8% of a nucleating agent, 0.5-2% of a plasticizer and 0.5-2% of an alkali treating agent. Various components are reasonably combined; and especially the alkali treating agent is added, so that the product is improved in elongation, flexibility and physical and mechanical properties while keeping good biodegradability and compatibility. In addition, the invention provides a preparation method for the full-degradable injection product. the preparation method comprises the steps of preparing the raw materials in proportion, weighing the raw materials and mixing the raw materials in a high mixing machine; granulating the mixed raw materials in a double-screw extruder; putting the formed granules into an injection machine and performing injection forming by a required product mould; and performing secondary heating on an injection product in a drying tunnel furnace. The technological process is simple, the heat treatment time is short, the machining performance is good, and the production cost is low.

Owner:东莞市恒丰高新技术开发有限公司

Electric field-assisted thermal treatment method of ZrTiAlV alloy sheets

The invention relates to an electric field-assisted thermal treatment method of ZrTiAlV alloy sheets. The thermal treatment method mainly comprises the following steps: performing vacuum hotpressing deformation on 47Zr-45Ti-5Al-3V alloy sheets with the thickness of 1-2mm at 750DEG C-800DEG C by adopting a vacuum hot-pressing technology, wherein the deformation quantity is 10-30% of the initial thickness of the original sheets; filling the deformed sheets into a mold made of graphite materials, placing on spark plasma sintering equipment, applying mechanical pressure of 5MPa, loading pulse current onto 47Zr-45Ti-5Al-3V alloy sheets under the vacuum state of less than10<-2> Pa by utilizing a vertical pressure head and an electrified electrode so that the alloy sheets are discharged and heated the temperature of the 47Zr-45Ti-5Al-3V alloy sheets is fast raised to 600-700DEG C, performing heat preservation for 20min and then disconnecting and cooling to 20DEG C. The treated 47Zr-45Ti-5Al-3V alloy sheets have excellent comprehensive mechanical performance, the yielding strength is 1082MPa-1190MPa, the tensile strength is 1220MPa-1352MPa, the elongation after fracture is 7.5%-12.7%, and the applications of the 47Zr-45Ti-5Al-3V alloy in the engineering field can be realized.

Owner:YANSHAN UNIV

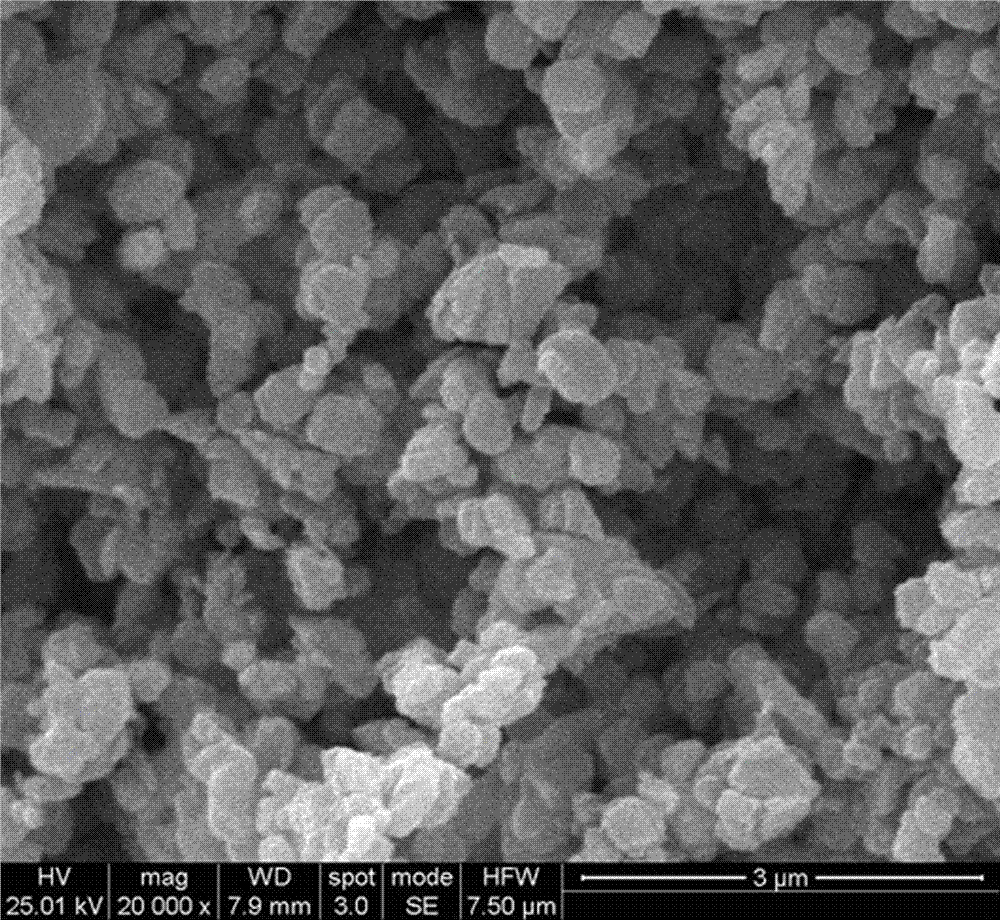

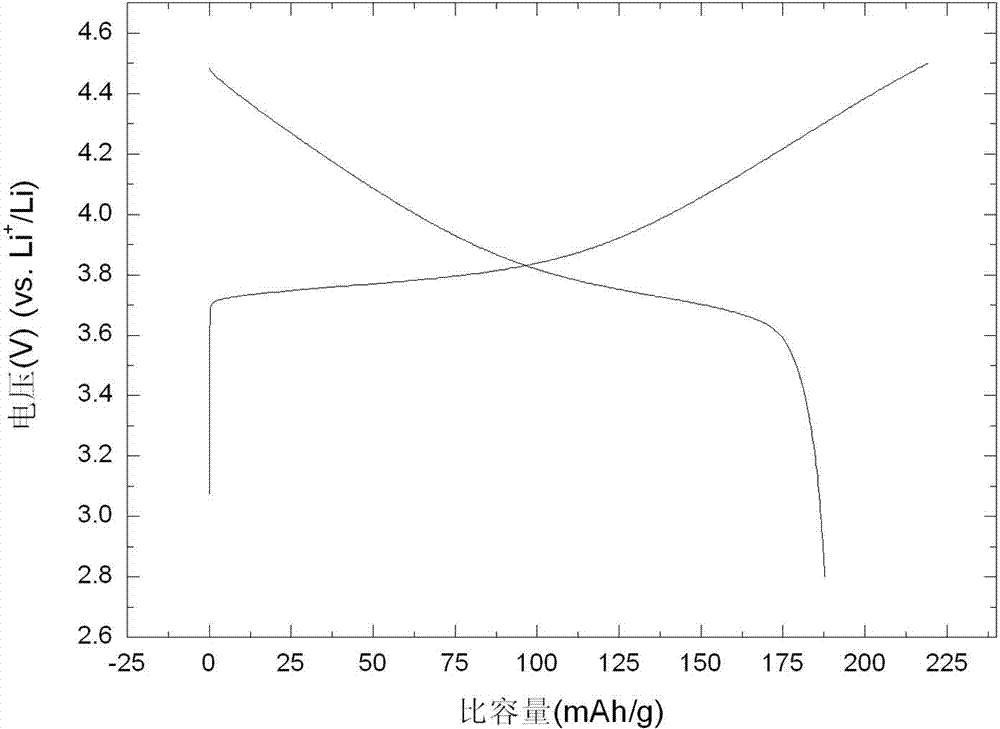

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381BShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltSodium-ion battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

Low-temperature semi-quenched and wear-resistant steel with brinell hardness of 400 HB and production method thereof

The invention discloses a low-temperature semi-quenched and wear-resistant steel with the brinell hardness of 400 HB. The low-temperature semi-quenched and wear-resistant steel with the brinell hardness of 400 HB is prepared from the following components of, in percentage by weight, 0.08%-0.25% of C, 0.30%-0.50% of Si, 0.5%-1.0% of Mn, less than or equal to 0.01% of P, less than or equal to 0.005%of S, 0.60%-0.80% of Cr, 0.03%-0.05% of Al, 0.01%-0.02% of Ti, 0.02%-0.03% of Nb and 0.001%-0.004% of B; the production method comprises the following steps of performing RH vacuum treatment after conventional converter combined blowing and LHF furnace treatment; heating a casting blank; performing rough rolling; carrying out finish rolling; quenching; tempering at low temperature; and finishingfor later use. On the premise of ensuring the hardness value, a relatively soft bainite or sorbite metallographic structure is obtained at the core part of the steel plate, the surface of the steel plate is tempered martensite metallographic structure, so that the brinell hardness of the surface of the steel plate is greater than 400HBW, and the production cost is reduced by at least 10% comparedwith that of the prior art due to the addition of the alloy elements.

Owner:武汉钢铁有限公司

A kind of heat-resistant polylactic acid composite material and preparation method thereof

The invention provides a heat-resistant polylactic acid composite material and a preparation method thereof, belonging to the technical field of polymer materials. It solves the technical problems such as poor biodegradability, high cost and poor mechanical properties of existing methods for preparing polylactic acid cross-linked materials and products in polymer cross-linked materials. The heat-resistant polylactic acid composite material includes the following components by weight: 50-99 parts of polylactic acid resin with oligo-D lactic acid content; 0.1-15 parts of nucleating agent; 1-50 parts of starch or modified starch; The poly-D lactic acid content in the polylactic acid resin with the oligo-D lactic acid content is lower than 5wt%. The preparation method of the composite material comprises the following steps: a. mixing and granulating; b. injection molding; c. heat treatment. The composite material has excellent mechanical properties and good heat resistance. The preparation method of the composite material has the advantages of simple technological process, strong processability and low cost, and can realize large-scale industrialized production.

Owner:ZHEJIANG HISUN BIOMATERIALS

Low-yield ratio and high-strength stirrup provided with bainite structure and used for buildings and production process

The invention discloses a low-yield ratio and high-strength stirrup which is provided with a bainite structure and is used for buildings and a production process. The stirrup can improve the earthquake resistant performance of the buildings obviously, so that the collapse time of the buildings can be delayed under the condition of high-intensity earthquake levels or the buildings are not collapsed to provide escape opportunity for life. According to the production process, a ferrite and a hot-rolled steel bar with a pearlitic structure are used as raw materials, and the stirrup comprises the following chemical ingredients in percentage by weight: 0.15 to 0.30 percent of C, less than or equal to 1.5 percent of Si, 0.5 to 1.5 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S and the balance of Fe and impurities, wherein one of V and B is added appropriately according to requirements. According to the process, the raw materials are subjected to isothermal treatment to prepare the finished product; and during isothermal treatment, the processed steel bar is heated to above 850 DEG C, and then is water-cooled to 350 to 400 DEG C to obtain dual-phase steel with the ferrite and the bainite structure, wherein the isothermal treatment is completed within one minute. The strength level of the stirrup serving as the finished product is 800 to 1,100 MPa, the yield ratio is about 0.8 to 0.85, A is more than or equal to 12 percent, Agt is more than or equal to 3.5 percent, cracks at the bending position after the stirrup is bent 180 degrees are avoided, and the diameter of the finished product is 5 to 12 millimeters.

Owner:ANYANG LONGTENG SPECIAL STEEL MFG +3

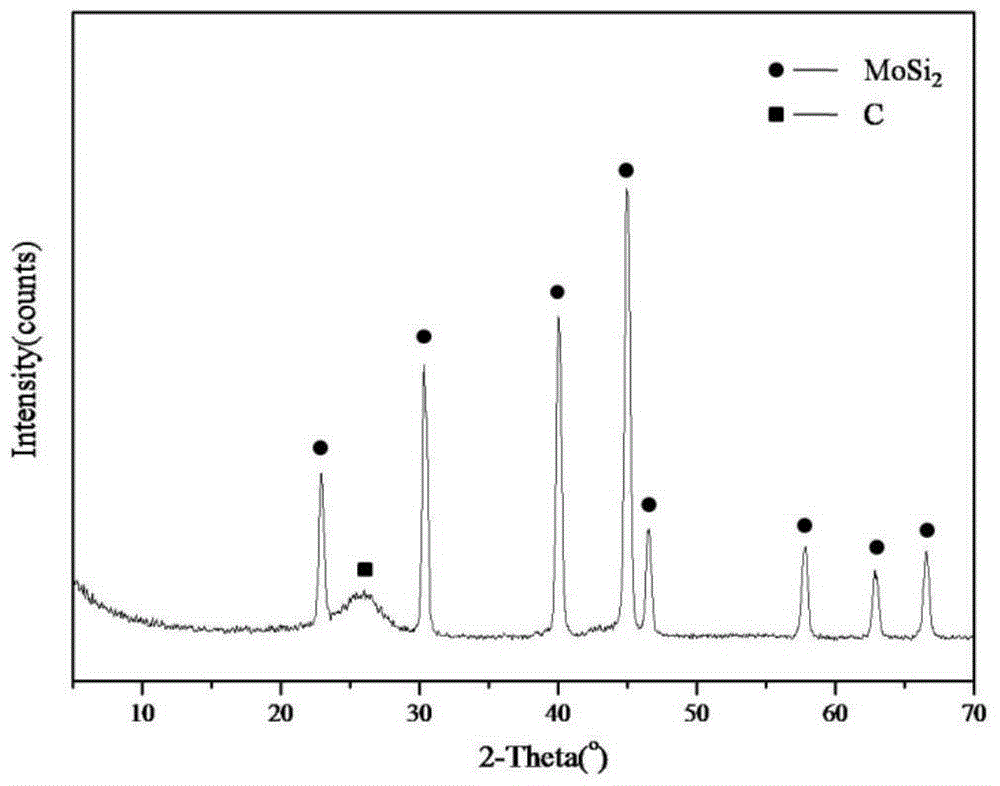

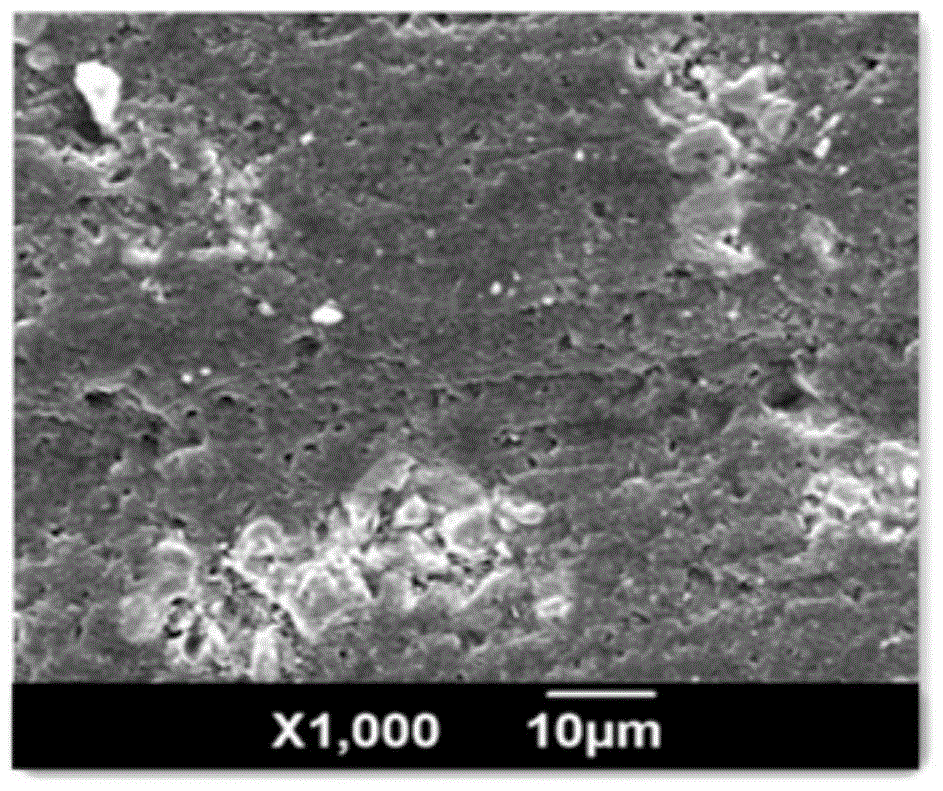

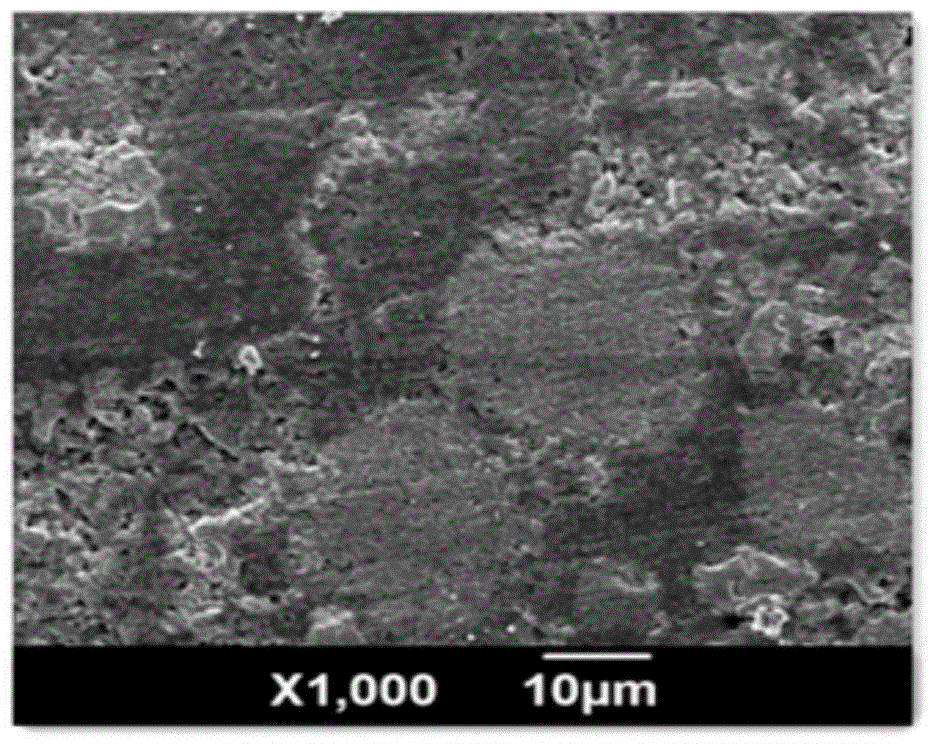

Preparation method of sheet-shaped C/C-MoSi2 composite

The invention provides a preparation method of a sheet-shaped C / C-MoSi2 composite. The method includes the steps of conducting ultrasonic oscillation and stirring to obtain suspension liquid after molybdenum disilicide powder is dispersed in isopropanol, increasing the density of carbon fiber three-dimensional fabric through a hydrothermal glucose osmosis, placing the carbon fiber three-dimensional fabric in a glass sand core pumping filtration device, pouring the suspension liquid in a pumping filtration flat-bottom funnel so that all the suspension liquid can completely penetrate through a C / C composite, placing a sample in a glucose solution to be subjected to a homogeneous phase hydrothermal reaction so that the density of the composite can be further increased, taking out the sample after the reaction to be dried, and finally conducting thermal treatment. The prepared C / C-MoSi2 composite is moderate in density and compact in structure, and the interfaces of C / C and MoSi2 are well bonded. The C / C-MoSi2 composite good in performance can be obtained at a low temperature; experiment raw materials are easy to obtain, the preparation process is simple, operation is easy and convenient, cost is low, and the preparation method is friendly to the environment and free of pollution.

Owner:博兴瑞峰新材料有限公司

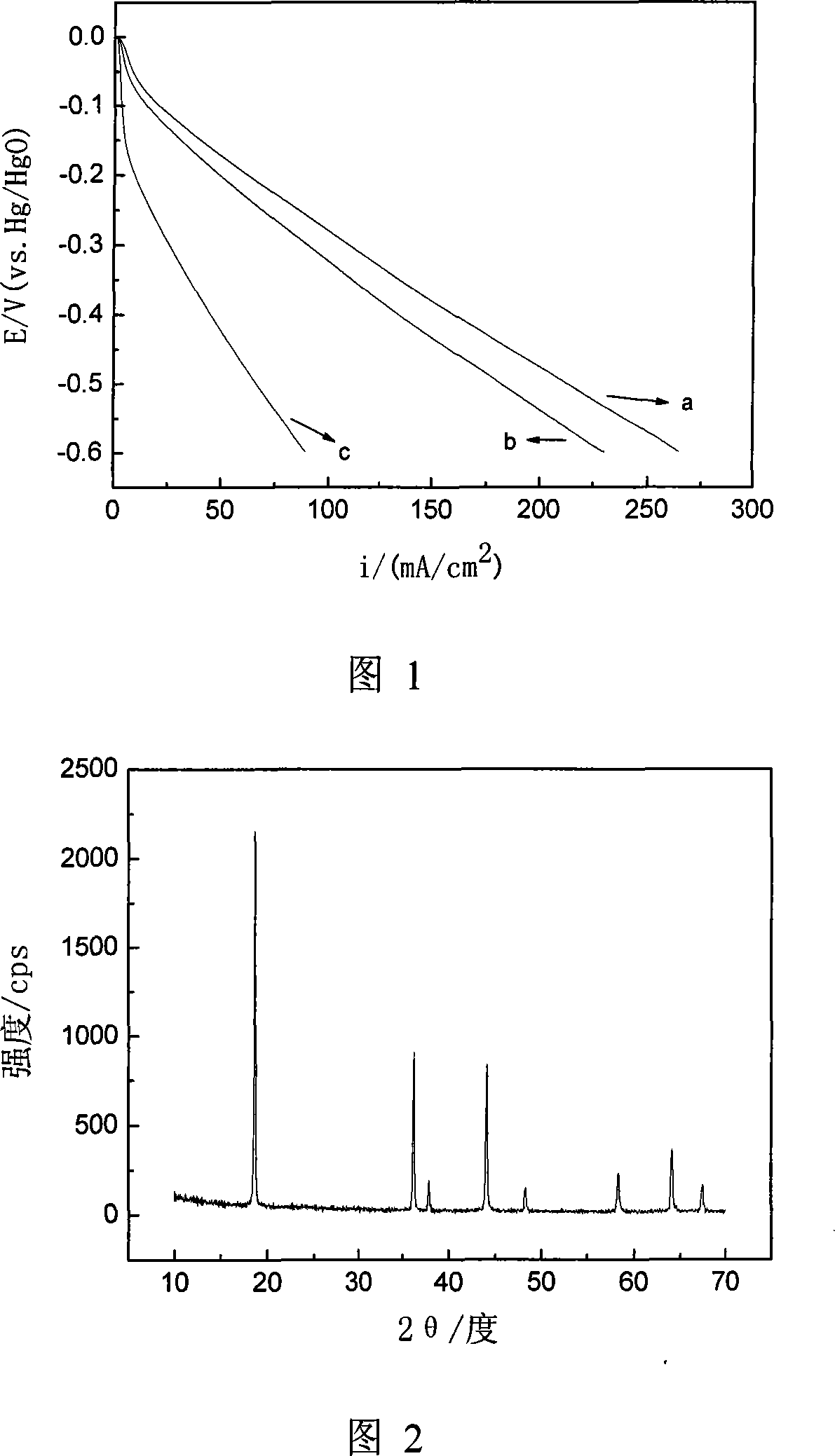

Electro-catalyst of zinc-air battery and method for making same

InactiveCN101114714AImprove electrocatalytic activityGood chemical stabilityCell electrodesCatalyst activation/preparationMolecular levelZinc–air battery

The invention discloses a clectrocatalyst for zinc-air batteries and a preparation method. The general formula of the clectrocatalyst is LiNixCoyFezMn2-x-y-zO4, wherein x is more than or equal to 0.10 and less than or equal to 0.50, y is more than or equal to 0 and less than or equal to 0.50, and z is more than or equal to 0 or less than or equal to 0.50. The crystalline structure of the clectrocatalyst is spinel-type crystalline structure. The clectrocatalyst of the invention has high electro-catalytic activity and good chemical stability, and the raw materials needed for the preparation of the clectrocatalyst has rich reserves and low prices; and the uniform doping of different metals in the clectrocatalyst outcome can be realized and an outcome with uniform structure at the molecular level can be obtained within a short time. The clectrocatalyst of the invention requires low heat treatment temperature and short heat treatment time, and the obtained outcome has high purity and narrow particle size distribution. And the reaction process and the microstructure of the sol-gel are easy to be controlled, resulting in little side effects, high outcome conversion rate, and thus having high outcome quality and production efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Magnetic body and electronic component using the same

A magnetic body constituted by magnetic grains bonded together via oxide film, which magnetic grains contain a Fe—Si-M soft magnetic alloy (where M is a metal element more easily oxidized than Fe) that contains sulfur atoms (S). The magnetic body preferably contains 0.004 to 0.012 percent by weight of S, 1.5 to 7.5 percent by weight of Si, and 2 to 8 percent by weight of metal M.

Owner:TAIYO YUDEN KK

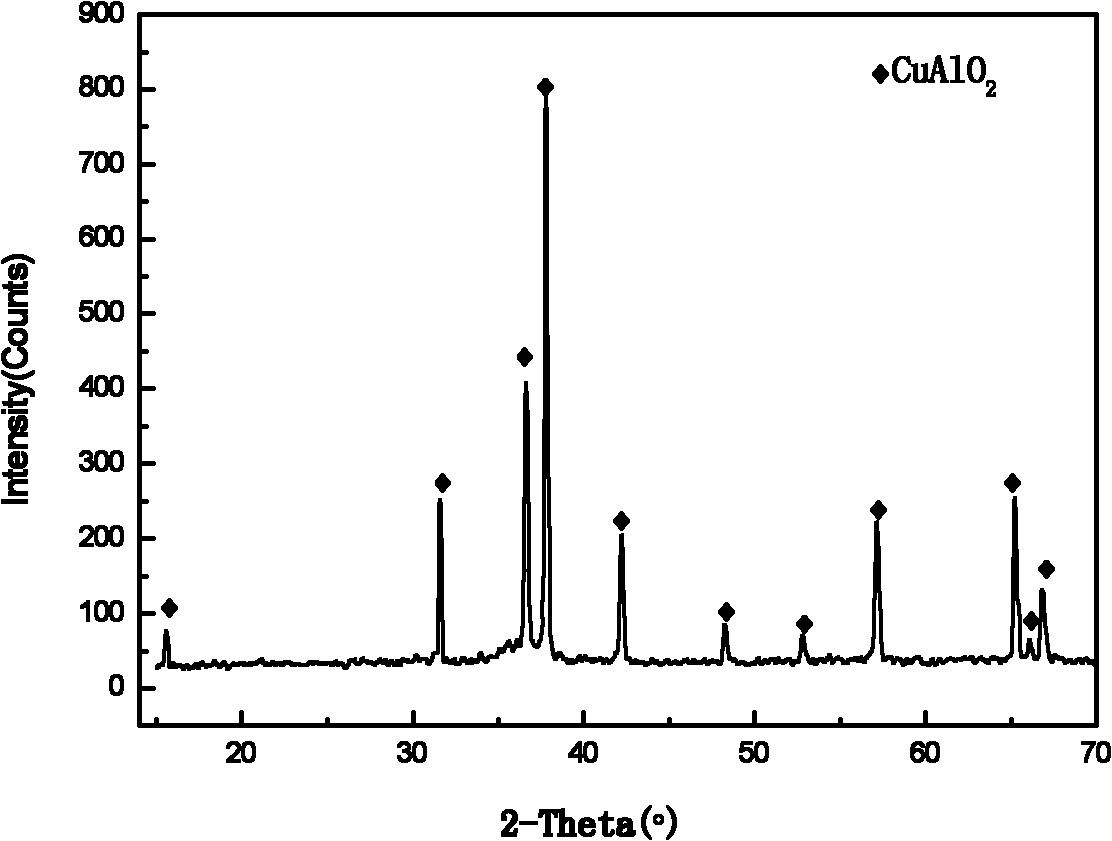

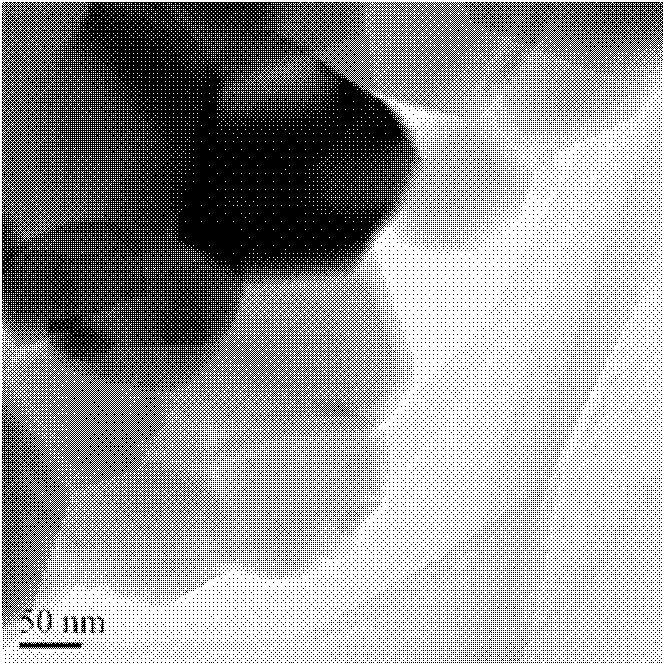

Preparation method of CuAlO2 monocrystal

InactiveCN101838849AReduce manufacturing costEasy to operateFrom gel statePolycrystalline material growthChemical reactionUltraviolet lights

The invention relates to a preparation method of CuAlO2 monocrystal, which comprises the following steps that: first, copper nitrate trihydrate and aluminum isopropoxide are added into glycol to prepare blue transparent solution A; then citric acid and water are added into the solution A to be magnetically stirred into uniform precursor sol; the precursor sol is dried to form dry gel, and then an agate mortar is adopted to grind the dried gel; and the ground dry gel is radiated by ultraviolet light, has photochemical reaction, and then put into a silicon carbide rod furnace to be calcined, and the CuAlO2 monocrystal is obtained. The preparation method integrates a citric sol-gel method and the photochemical reaction, and prepares the CuAlO2 monocrystal; and by integrating the citric sol-gel method and the photochemical reaction, the preparation method of the CuAlO2 monocrystal not only has the advantages of low preparation cost, simple operation and short reaction cycle, but also can synthesize the CuAlO2 monocrystal at lower temperature and within shorter heat treatment time.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing a complex oxygen ion conductor electrolyte film by quick heat treatment of collosol and gel

InactiveCN1571203AAchieve preparationAccurate control of stoichiometric ratioFinal product manufactureSolid electrolyte fuel cellsElectrical conductorFilm material

The invention relates to a method for preparing multilayer compound nano oxygen ion conductor electrolyte film material, adopting rapid heat treatment sol-gel methd to prepare a multilayer film A / (B / A)n (A and B stand for YSZ or RCO, n>=1), where the preparing process for each film layer: sole precursor preparing, spin-spreading coating, rapid heat treatment, and film forming, in which, YSZ film preparation adopts ZrOCl2. 8H2O and Y(NO3)3.6H2O, uses ammonia as precipitator, uses thin hydrochloric acid to regulate pH value of solution, and uses glycol as metal chelating agent and the YSZ film is 10-400 nm thick; RCO film preparation adopts Ce(NO3)3.6H2O and R2O3, uses oxalic acid as precipitator and citric acid as metal chelating agent, and the RCO film is 10-400 nm thick. Circulating the above steps can prepare uniformly thick, compact, high-quality multilayer compound nano electrolyte film, shortening film making cycle, raising the efficiency, and reducing the cost.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com