Preparation method of CuAlO2 monocrystal

A single crystal and drying technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of poor uniformity and repeatability, degradation of photoelectric performance of materials, etc., and achieve short reaction cycle, low preparation cost, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: Step 1: First, add analytically pure copper nitrate trihydrate and aluminum isopropoxide into ethylene glycol according to the copper-aluminum atomic ratio of 1:1, and prepare a blue transparent solution with a metal ion concentration of 0.6 mol / L. Solution A; step 2: then add citric acid to solution A with magnetic stirring to form a uniform precursor sol; wherein the molar ratio of citric acid to metal ions in solution A is 1:1; step 3: put the precursor sol in a drying oven Dry at 120°C for 10 hours to form a xerogel, and then grind the dried gel with an agate mortar; step 4: irradiate the ground xerogel with ultraviolet light for 60 minutes for photochemical reaction, and then put it into a silicon carbide rod Calcined in the furnace at 500°C for 4h, then cooled to room temperature with the furnace to obtain CuAlO 2 single crystal.

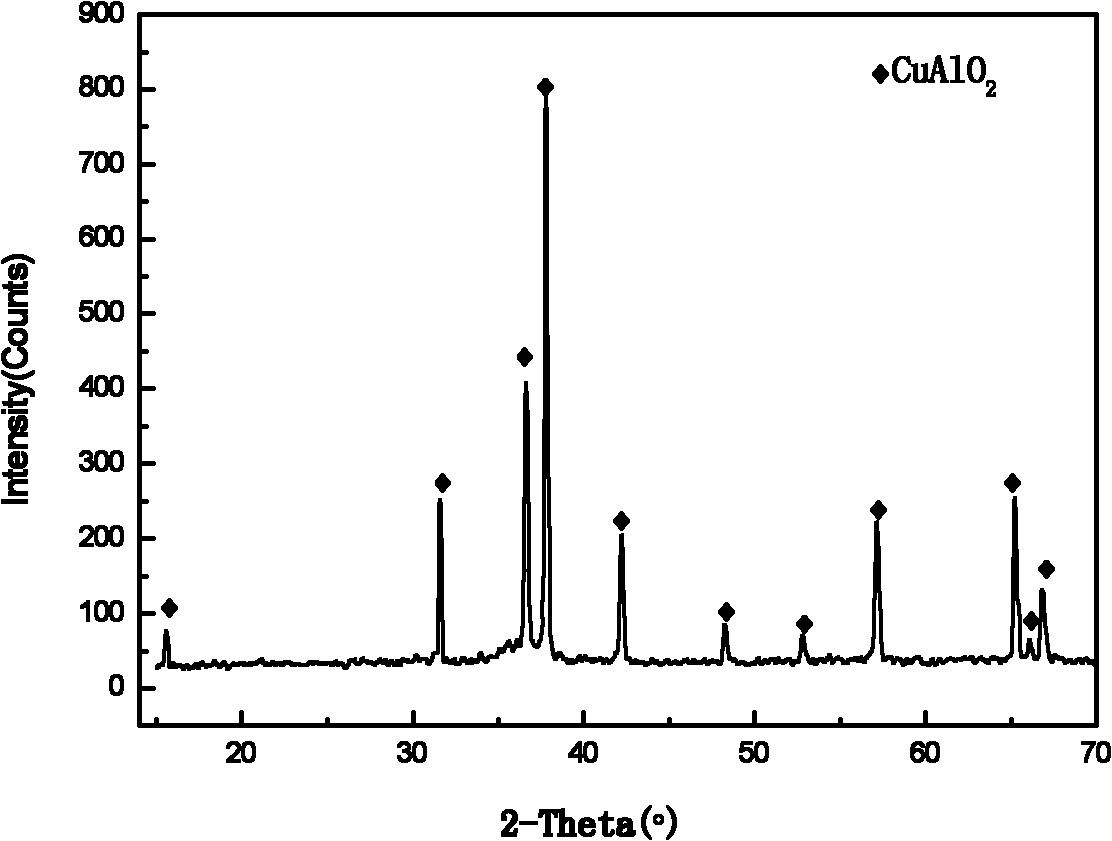

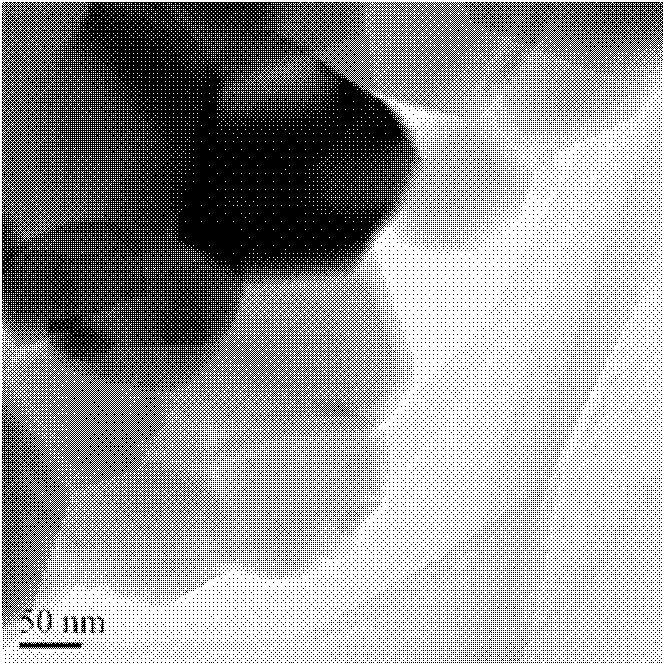

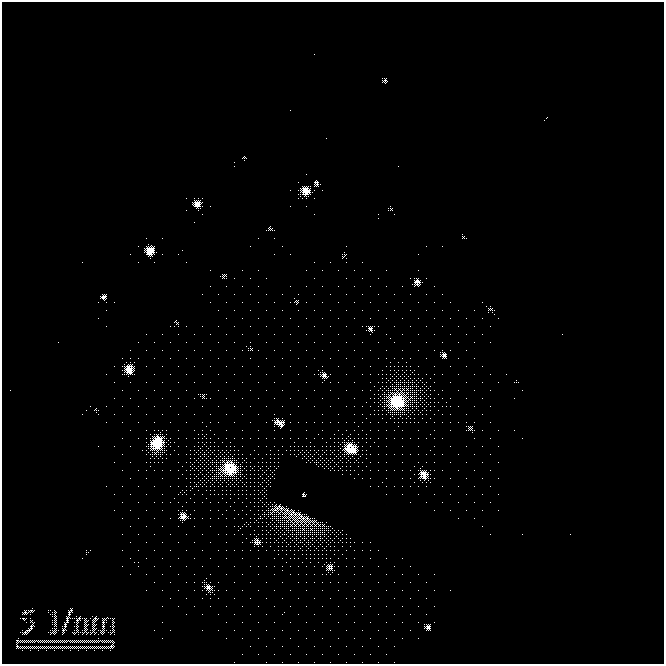

[0014] The CuAlO obtained in this example 2 The powder was analyzed by a Japanese Rigaku D / max2000PC X-ray diffractometer...

Embodiment 2

[0015] Example 2: Step 1: First, add analytically pure copper nitrate trihydrate and aluminum isopropoxide into ethylene glycol according to the copper-aluminum atomic ratio of 1:1, and prepare a blue transparent solution with a metal ion concentration of 0.5 mol / L. Solution A; step two: then add citric acid to solution A with magnetic stirring to form a uniform precursor sol; wherein the molar ratio of citric acid to metal ions in solution A is 0.8:1; step three: put the precursor sol in a dry box Dry at 140°C for 9 hours to form a xerogel, and then grind the dried gel with an agate mortar; step 4: irradiate the ground xerogel with ultraviolet light for 55 minutes for photochemical reaction, and then put it into a silicon carbide rod Calcined in the furnace at 550°C for 3h, then cooled to room temperature with the furnace to obtain CuAlO 2 single crystal.

Embodiment 3

[0016] Example 3: Step 1: First, add analytically pure copper nitrate trihydrate and aluminum isopropoxide into ethylene glycol according to the copper-aluminum atomic ratio of 1:1, and prepare a blue transparent solution with a metal ion concentration of 0.4 mol / L. Solution A; step two: then add citric acid to solution A with magnetic stirring to form a uniform precursor sol; wherein the molar ratio of citric acid to metal ions in solution A is 1.2:1; step three: put the precursor sol in a dry box Dry at 160°C for 8 hours to form a xerogel, and then grind the dried gel with an agate mortar; step 4: irradiate the ground xerogel with ultraviolet light for 50 minutes for photochemical reaction, and then put it into a silicon carbide rod Calcined in the furnace at 600°C for 2h, then cooled to room temperature with the furnace to obtain CuAlO 2 single crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com