Patents

Literature

1756 results about "Copper nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

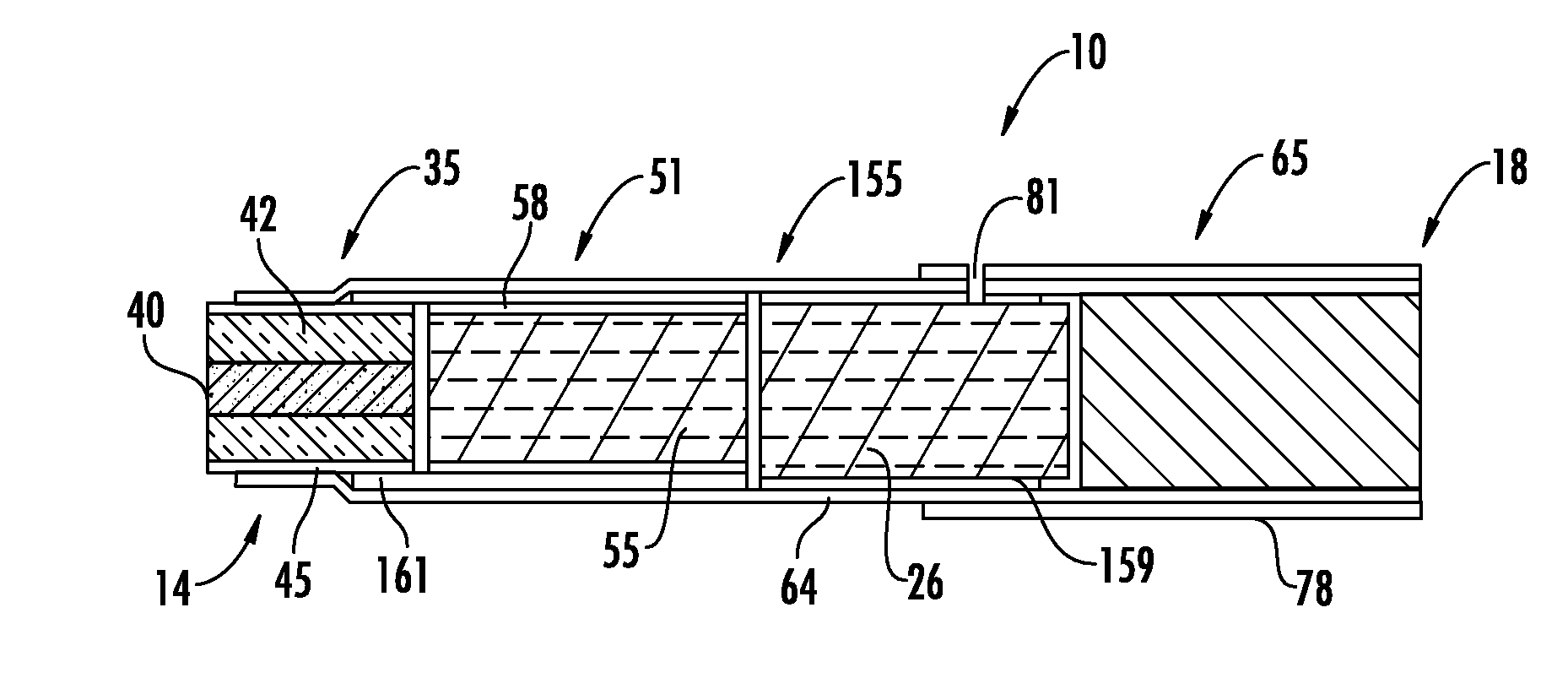

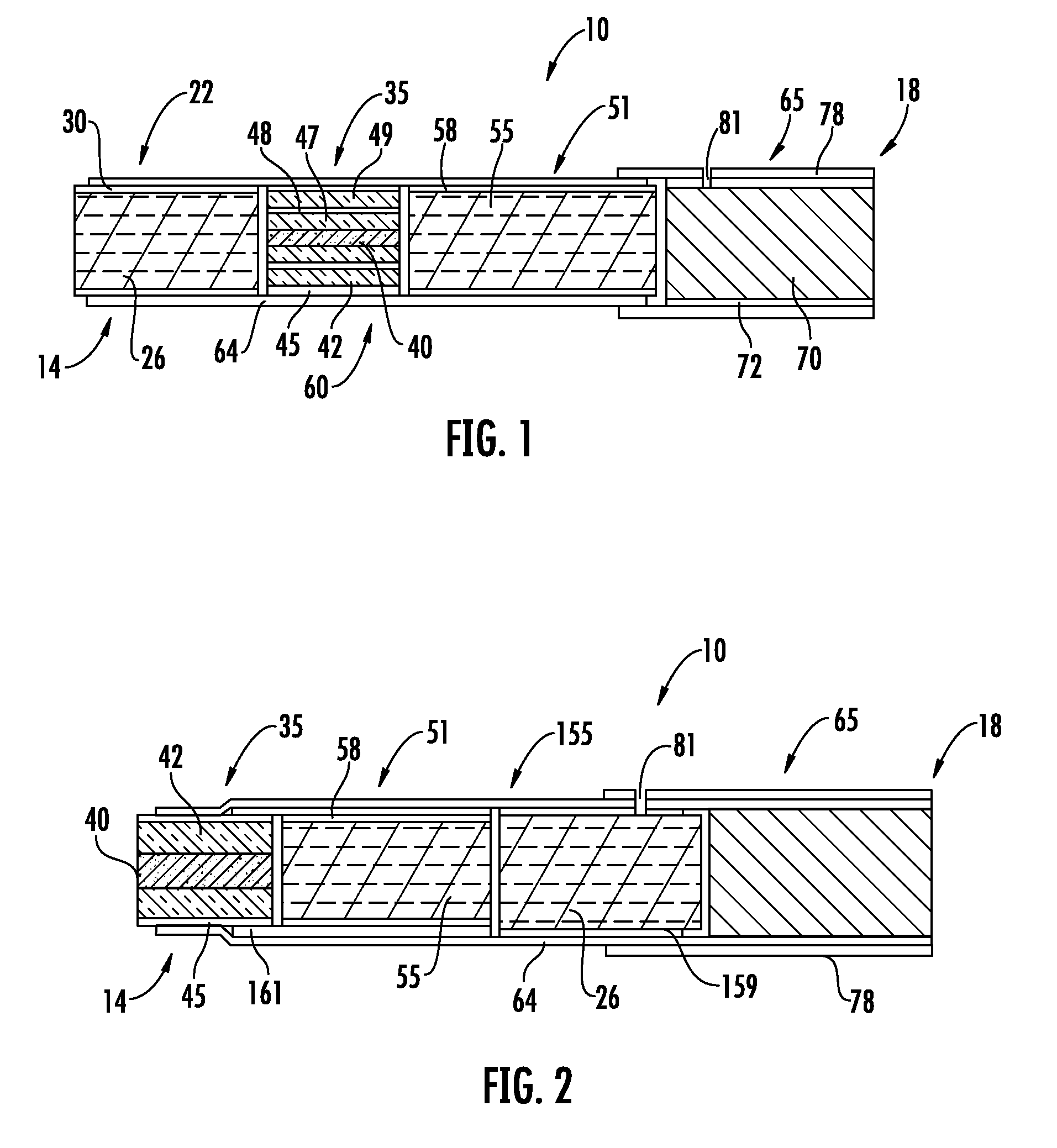

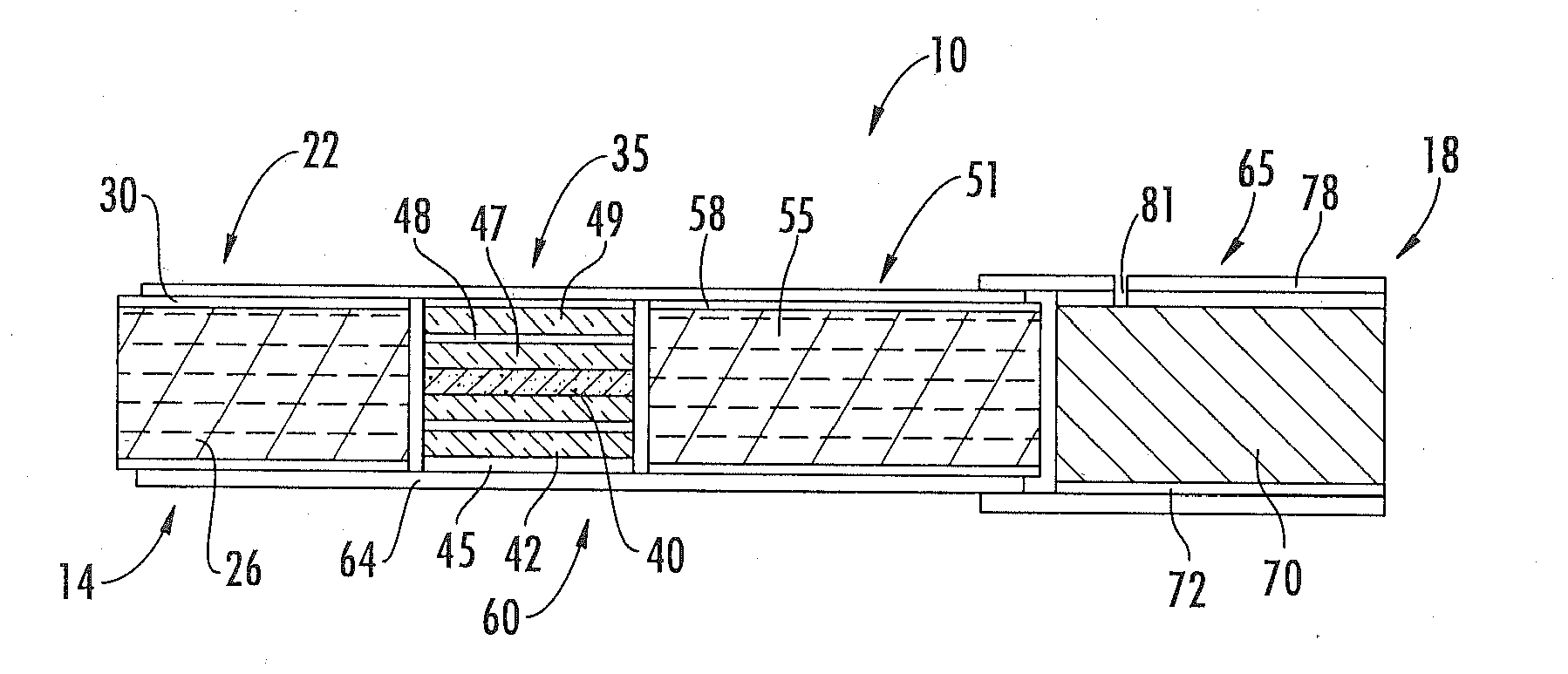

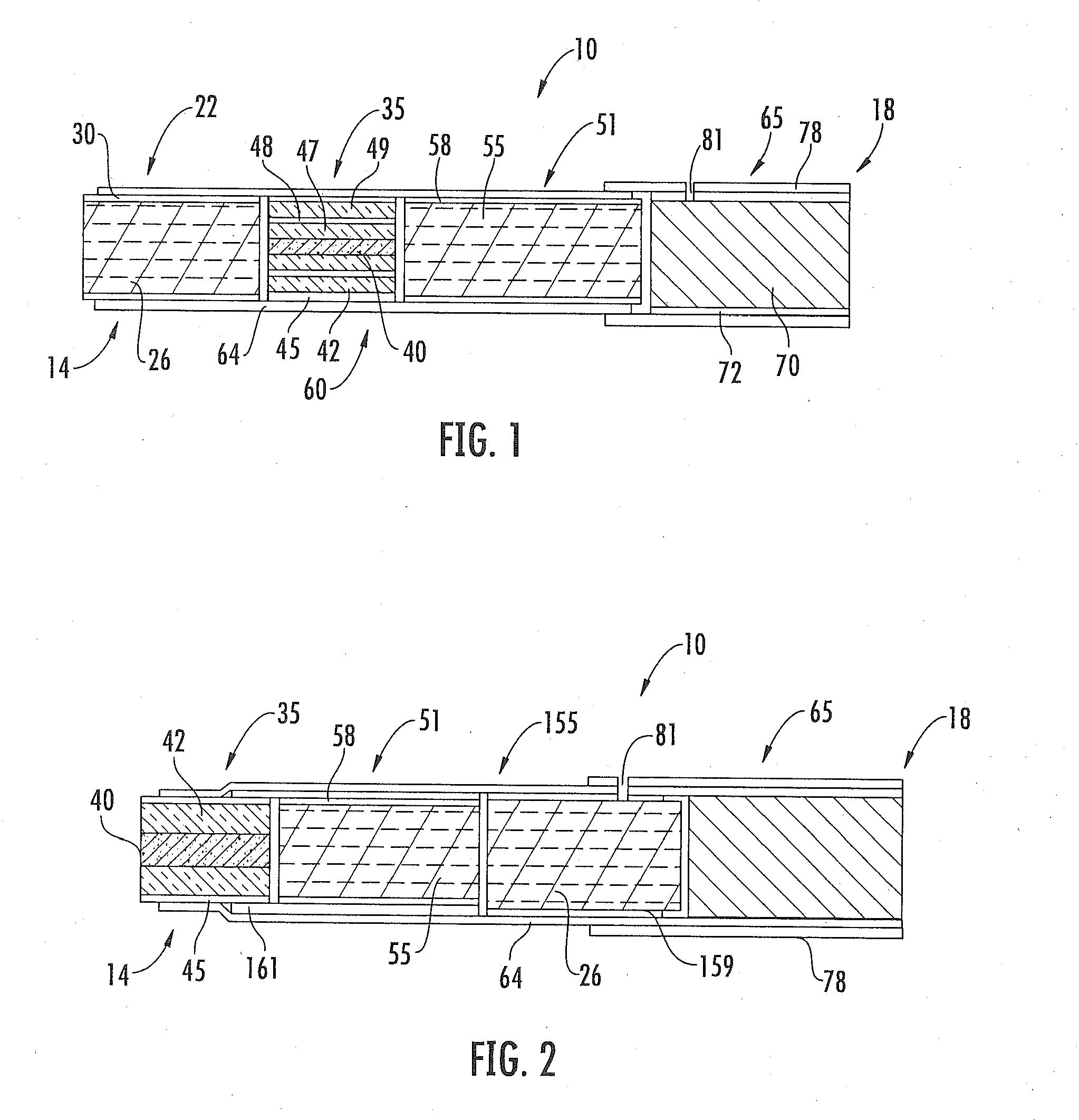

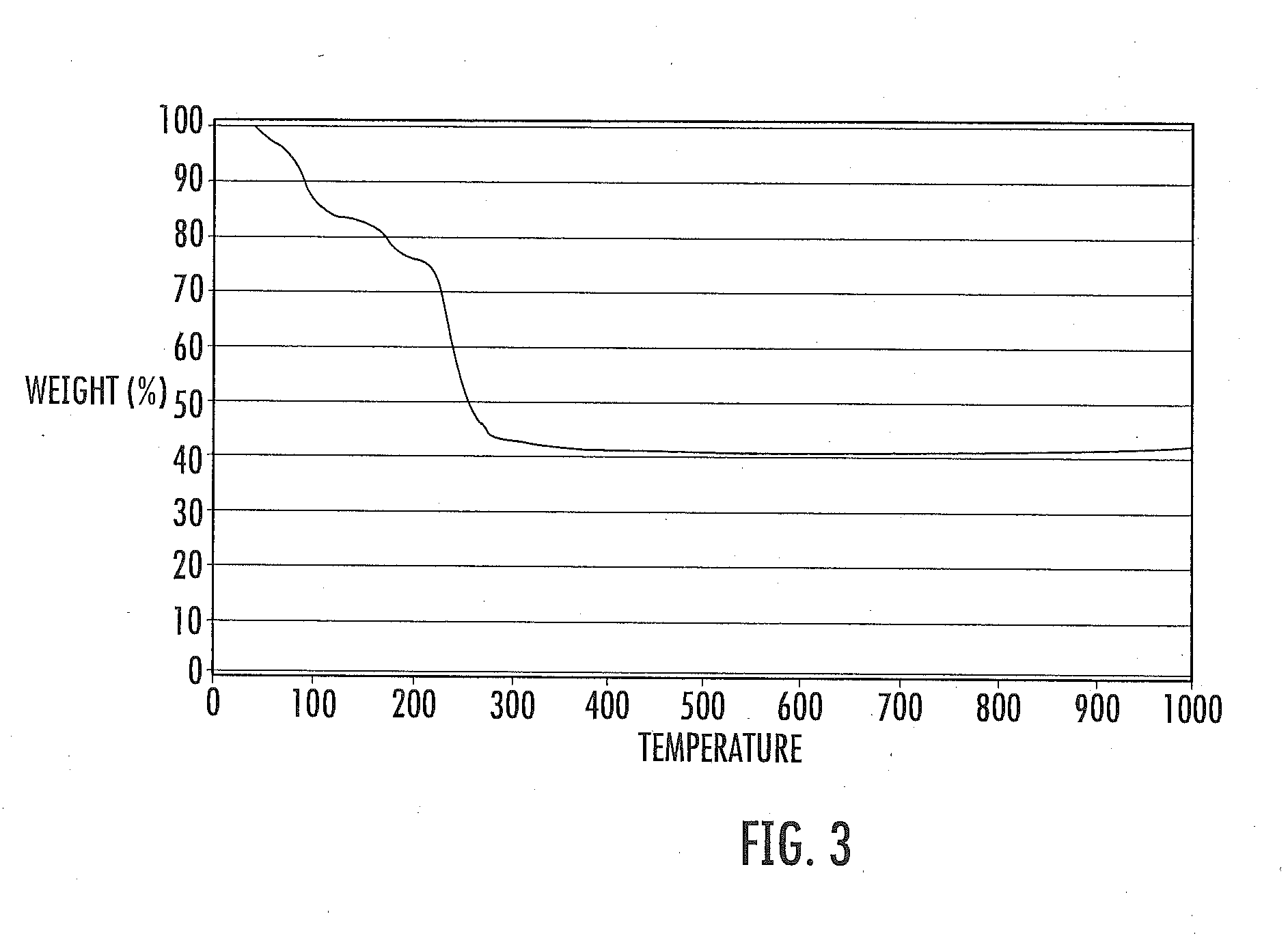

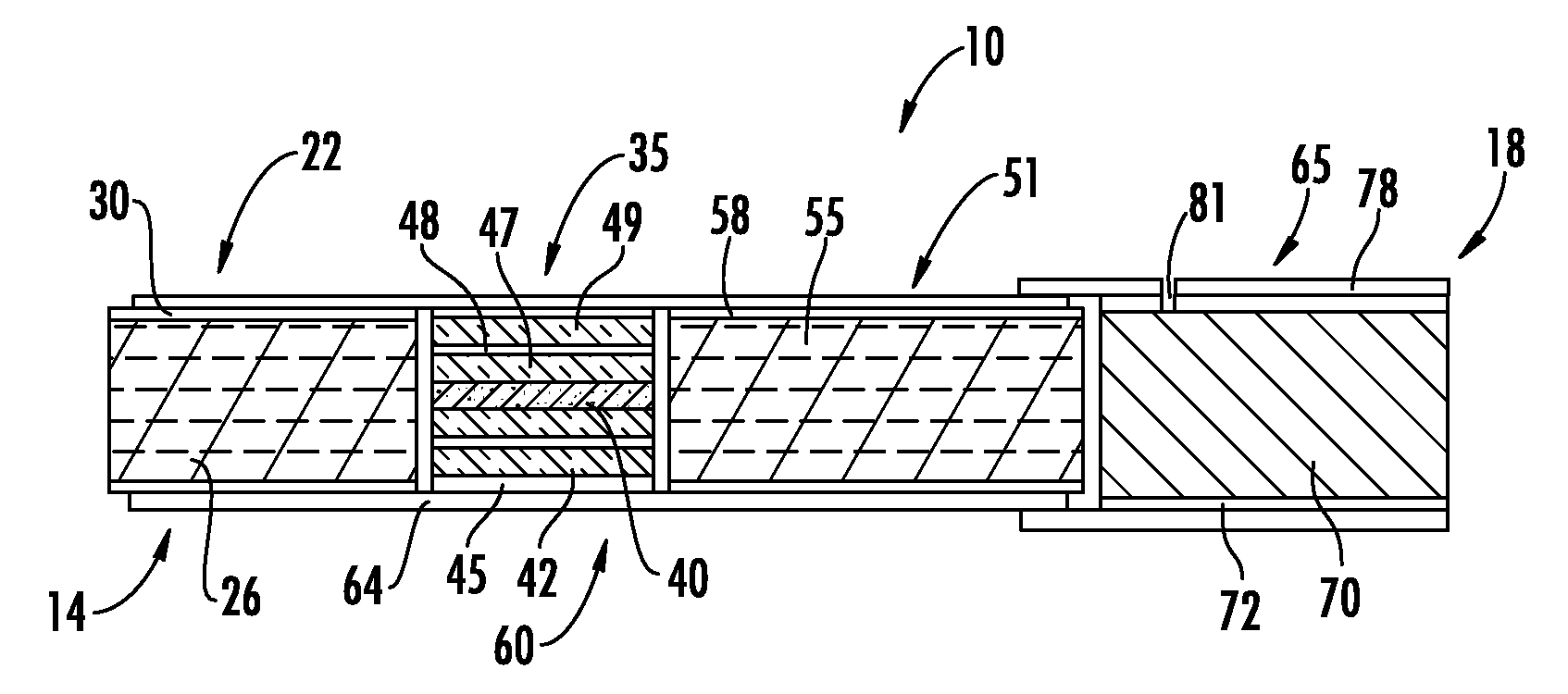

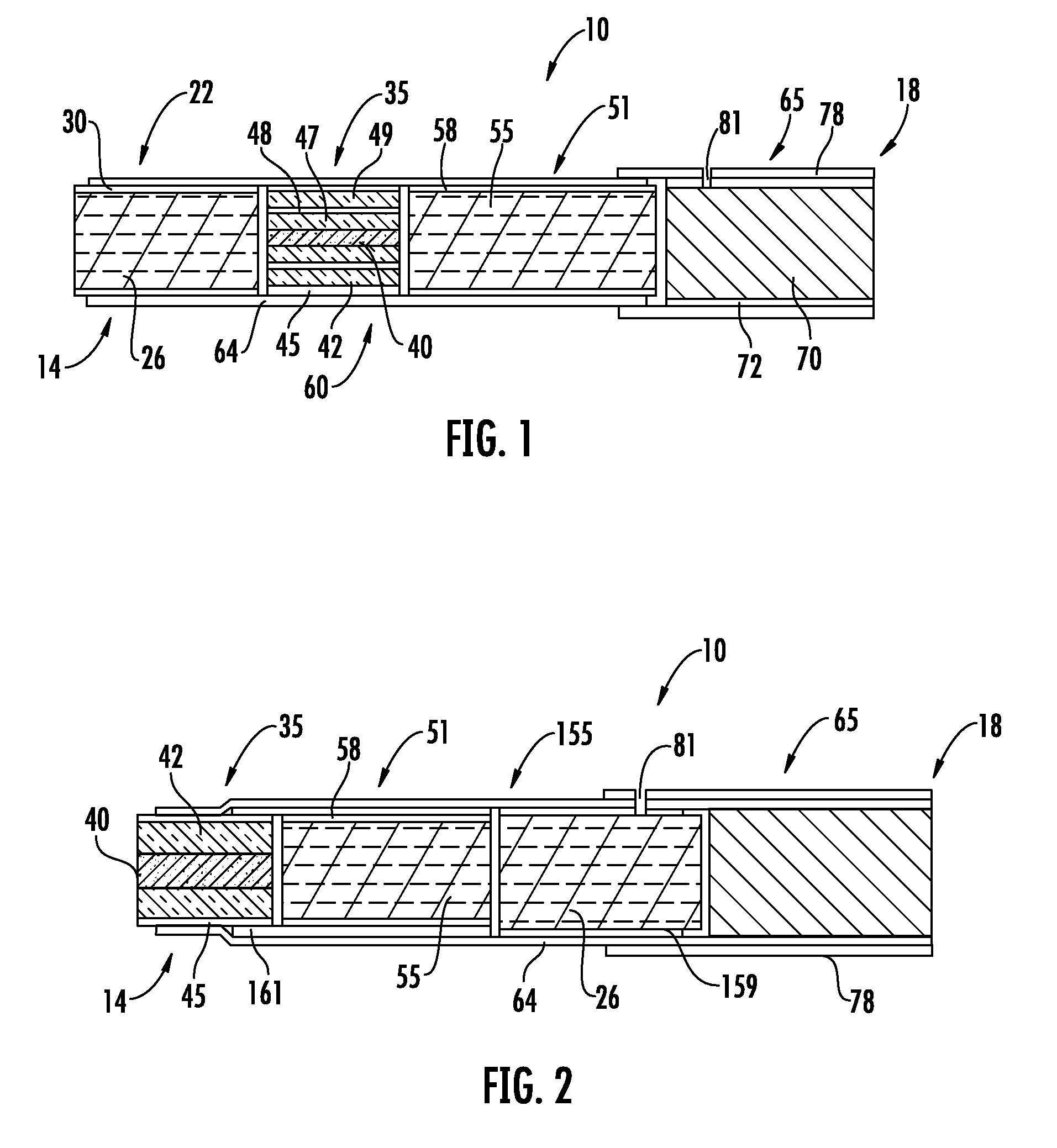

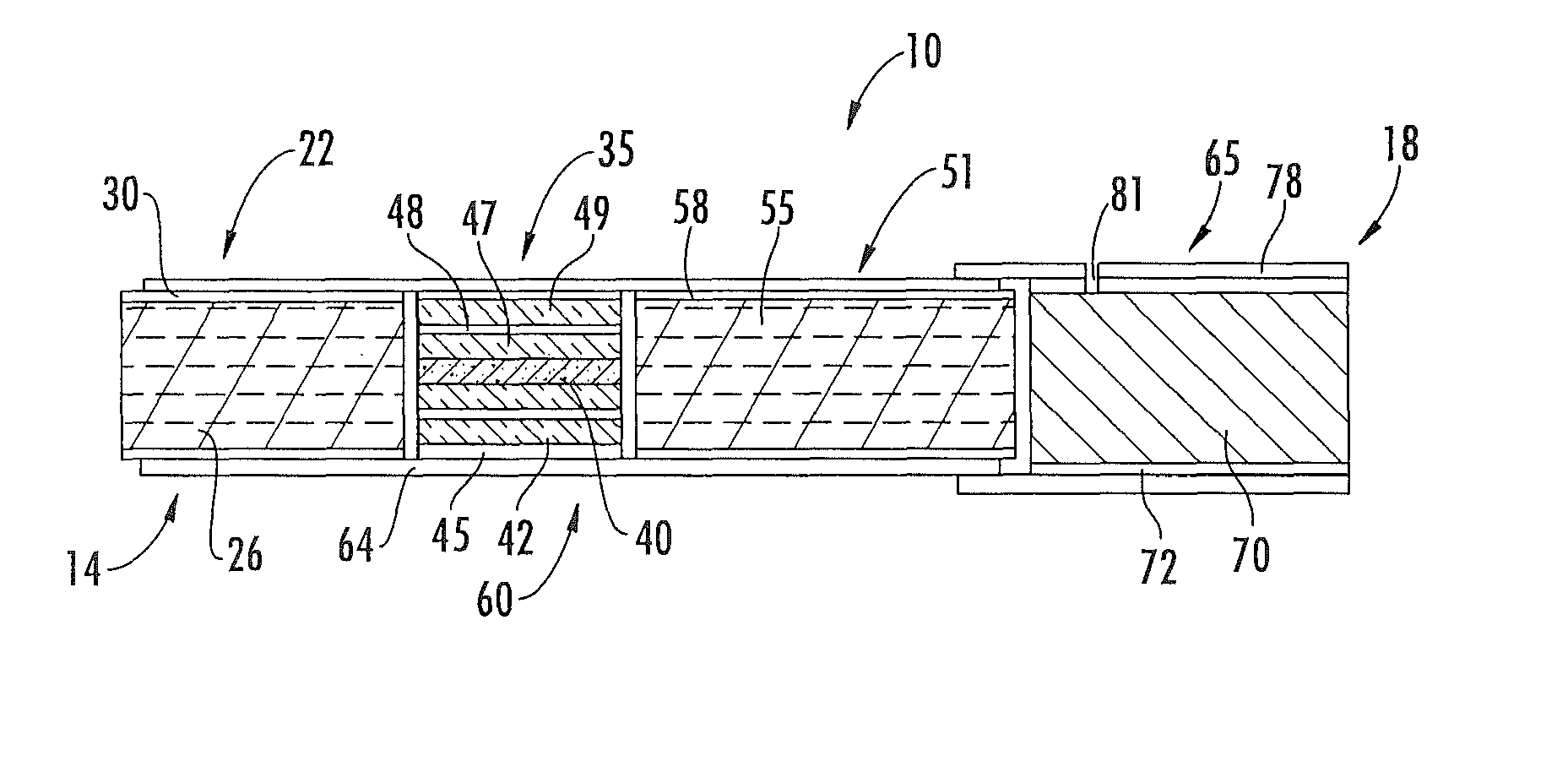

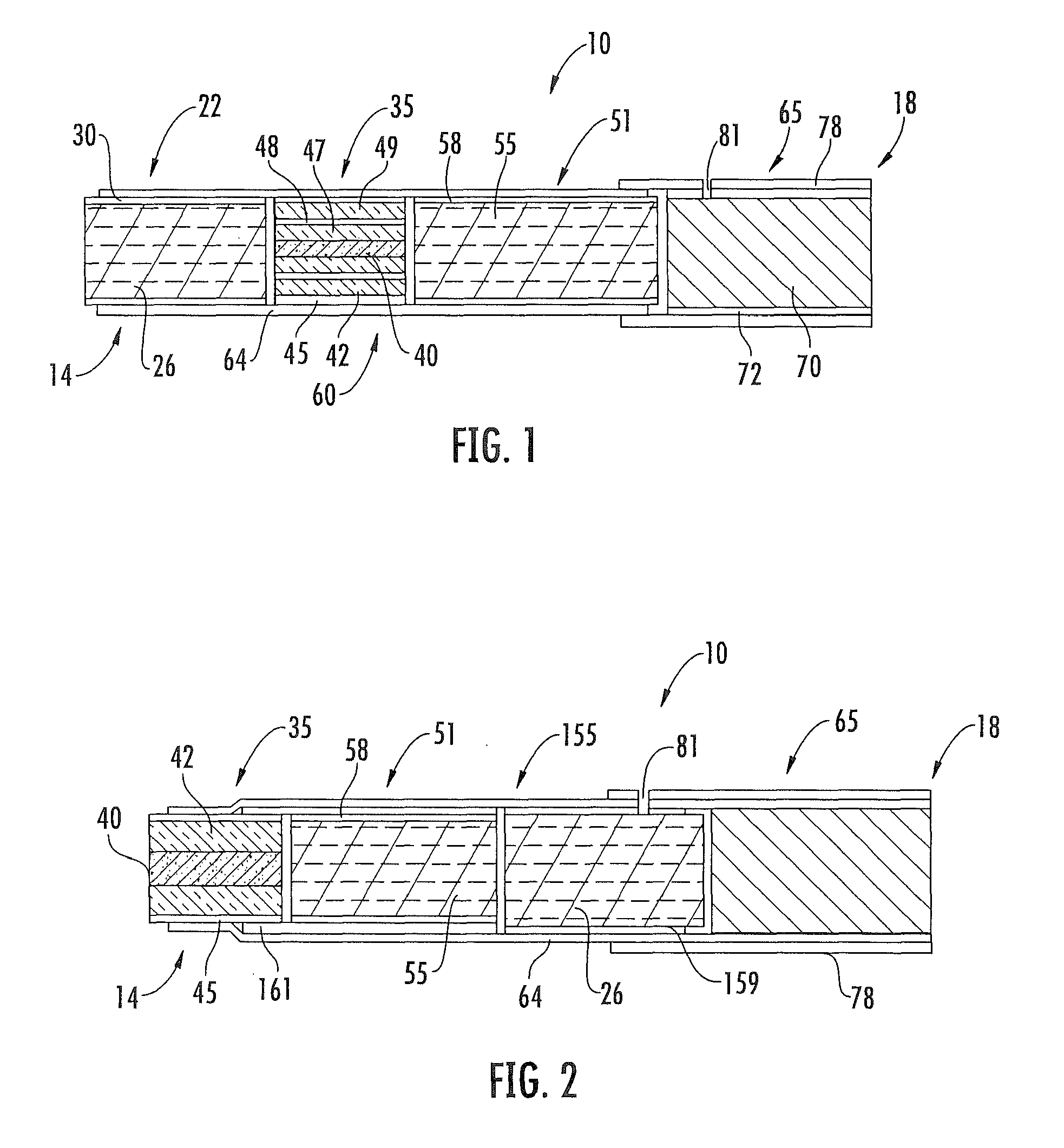

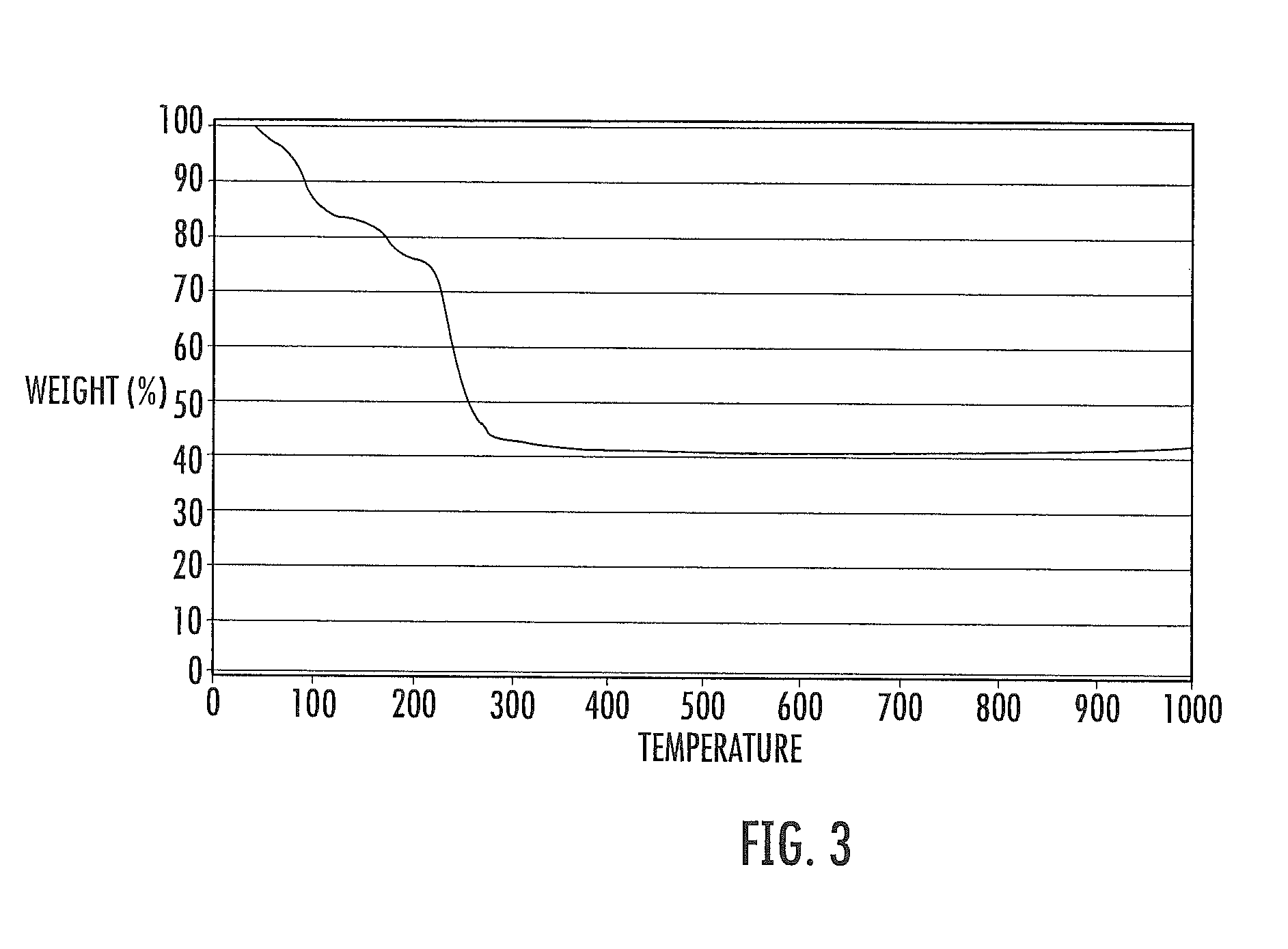

Method for Preparing Fuel Element For Smoking Article

ActiveUS20100065075A1Good water solubilityTobacco treatmentTobacco smoke filtersCerium nitrateCopper nitrate

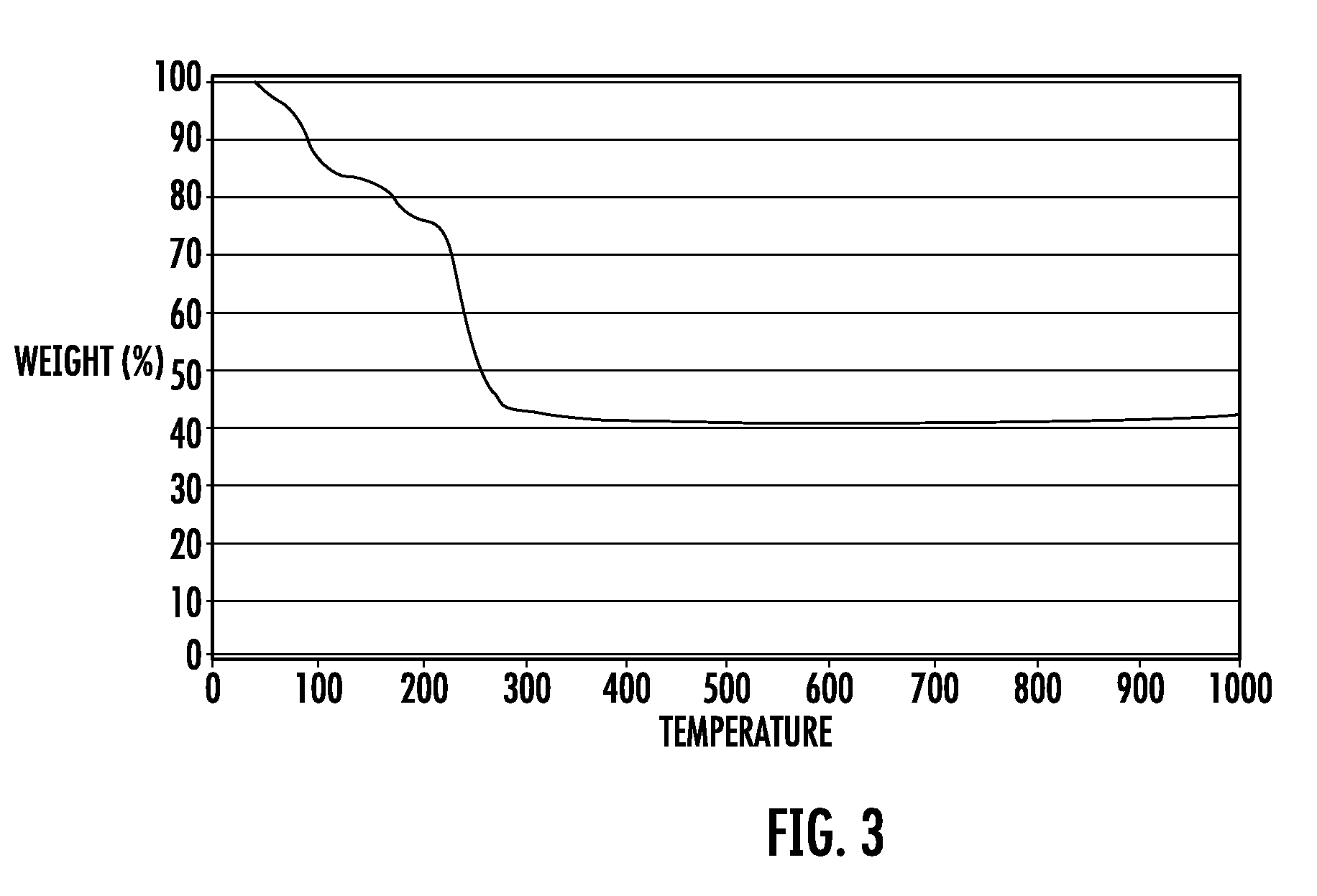

The invention provides a method for making a fuel element for a smoking article comprising forming a combustible carbonaceous material into a fuel element adapted for use in a smoking article; incorporating a metal-containing catalyst precursor into the fuel element or onto the surface thereof to form a treated fuel element, the incorporating step occurring before, during, or after said forming step; and optionally heating or irradiating the treated fuel element at a temperature and for a time sufficient to convert the catalyst precursor to a catalytic metal compound. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article including the steps of mixing a metal-containing catalyst precursor with a filler material or graphite or a combination thereof to form a pre-treated fuel element component; optionally calcining the pre-treated fuel element component in order to convert the catalyst precursor to a catalytic metal compound; after the optional calcining step, combining the pre-treated fuel element component with a carbonaceous material and a binder to produce a fuel element composition; and forming the fuel element composition into a fuel element adapted for use in a smoking article. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article comprising forming a combustible carbonaceous material into a fuel element adapted for use in a smoking article; incorporating a metal-containing catalyst precursor into the fuel element or onto the surface thereof to form a treated fuel element, the incorporating step occurring before, during, or after said forming step; and optionally heating or irradiating the treated fuel element at a temperature and for a time sufficient to convert the catalyst precursor to a catalytic metal compound. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Preparation method of nano cuprous oxide

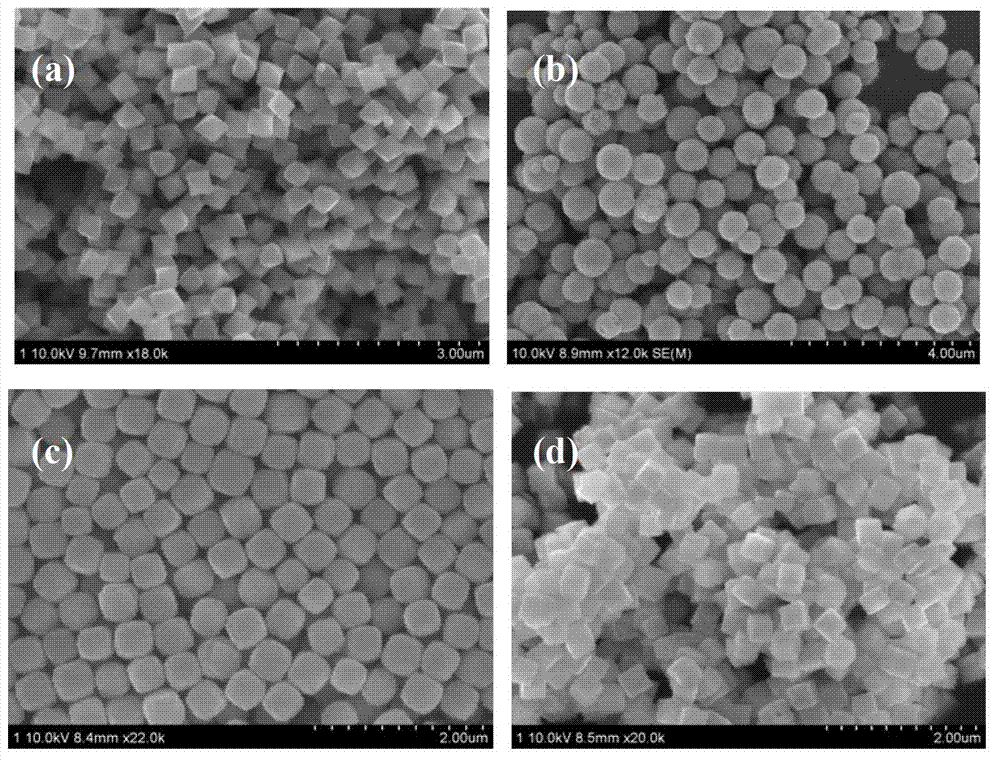

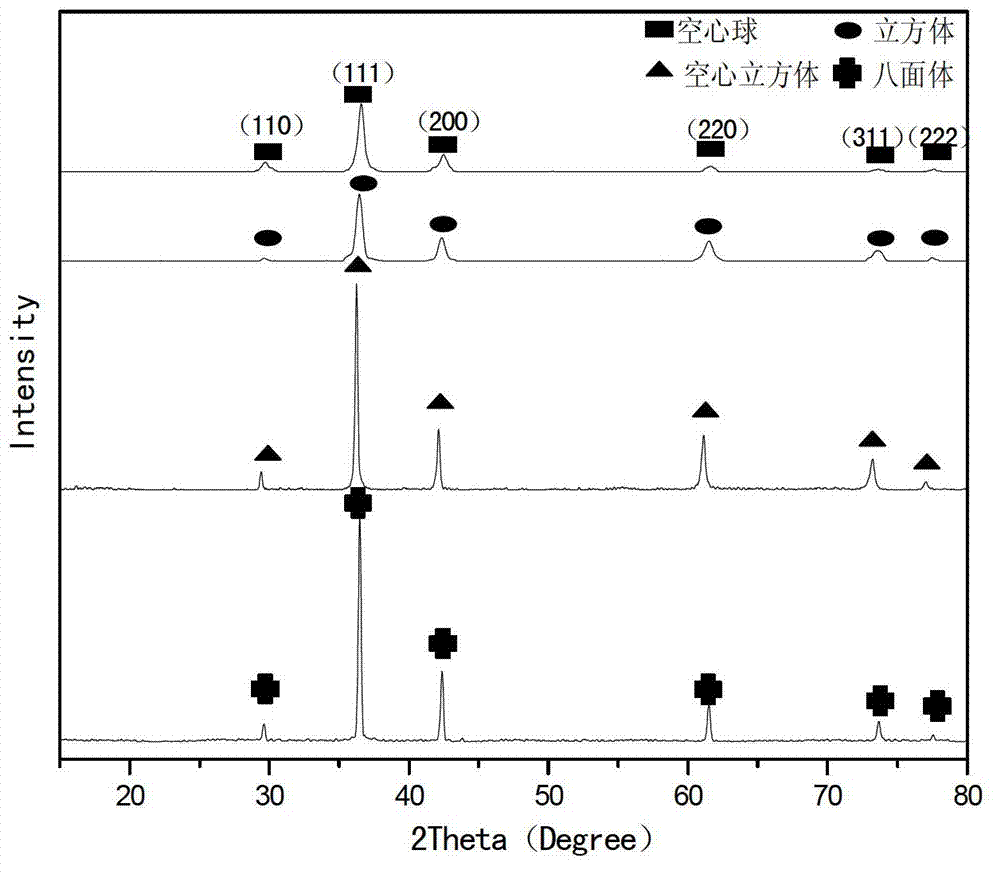

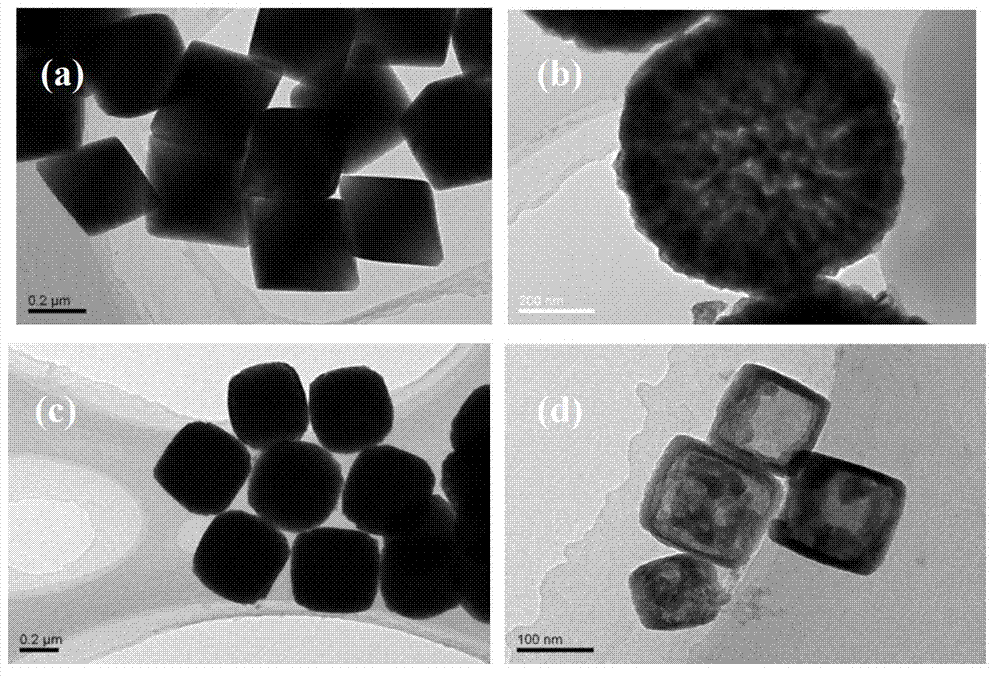

InactiveCN103172104AHigh purityNothing producedMaterial nanotechnologyCopper oxides/halidesOctahedronCopper nitrate

Owner:ZHEJIANG SCI-TECH UNIV

Use of sub-micron copper salt particles in wood preservation

InactiveUS20060062926A1Little dangerSmall particle sizeBiocideLiquid surface applicatorsPhosphateCopper nitrate

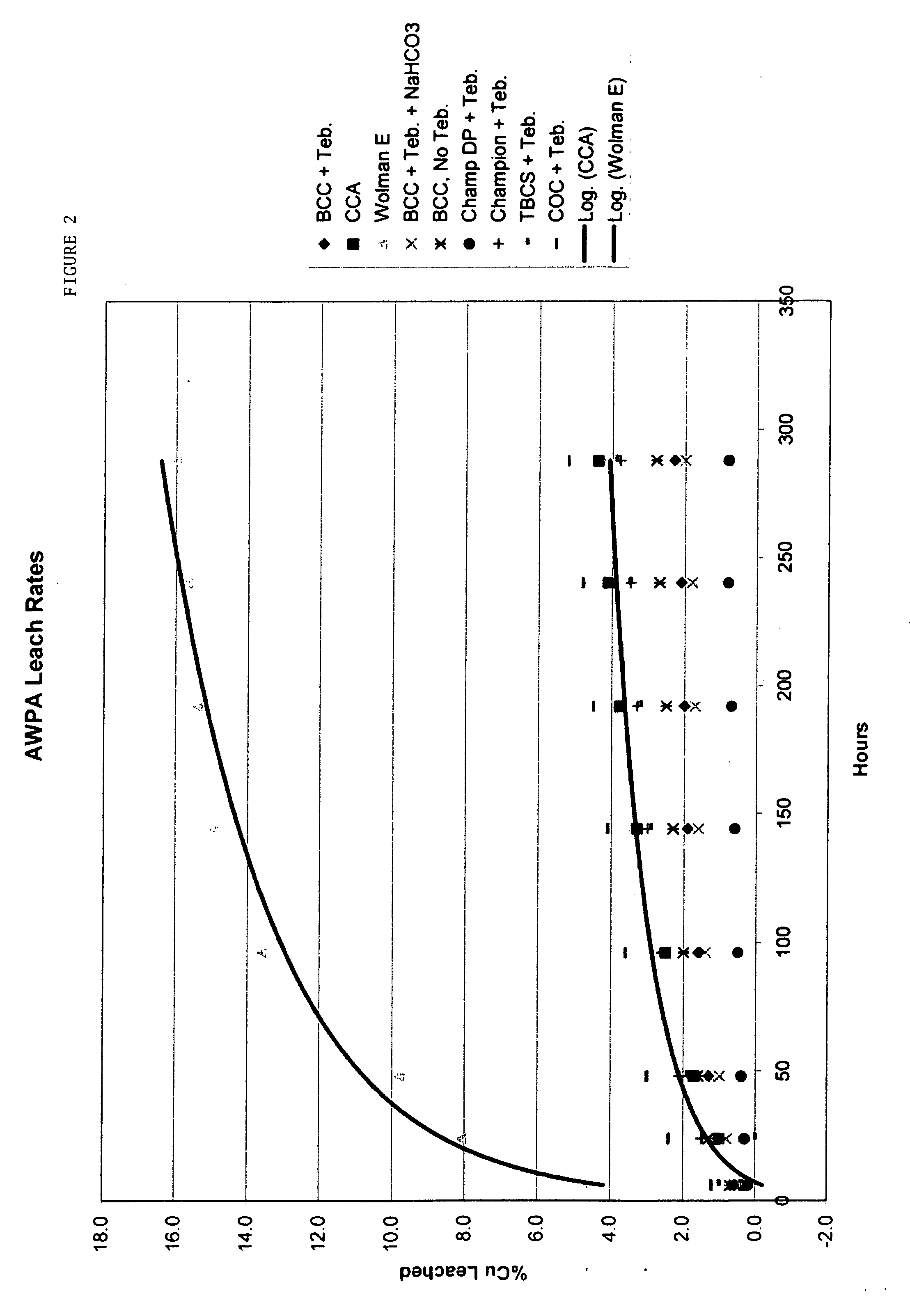

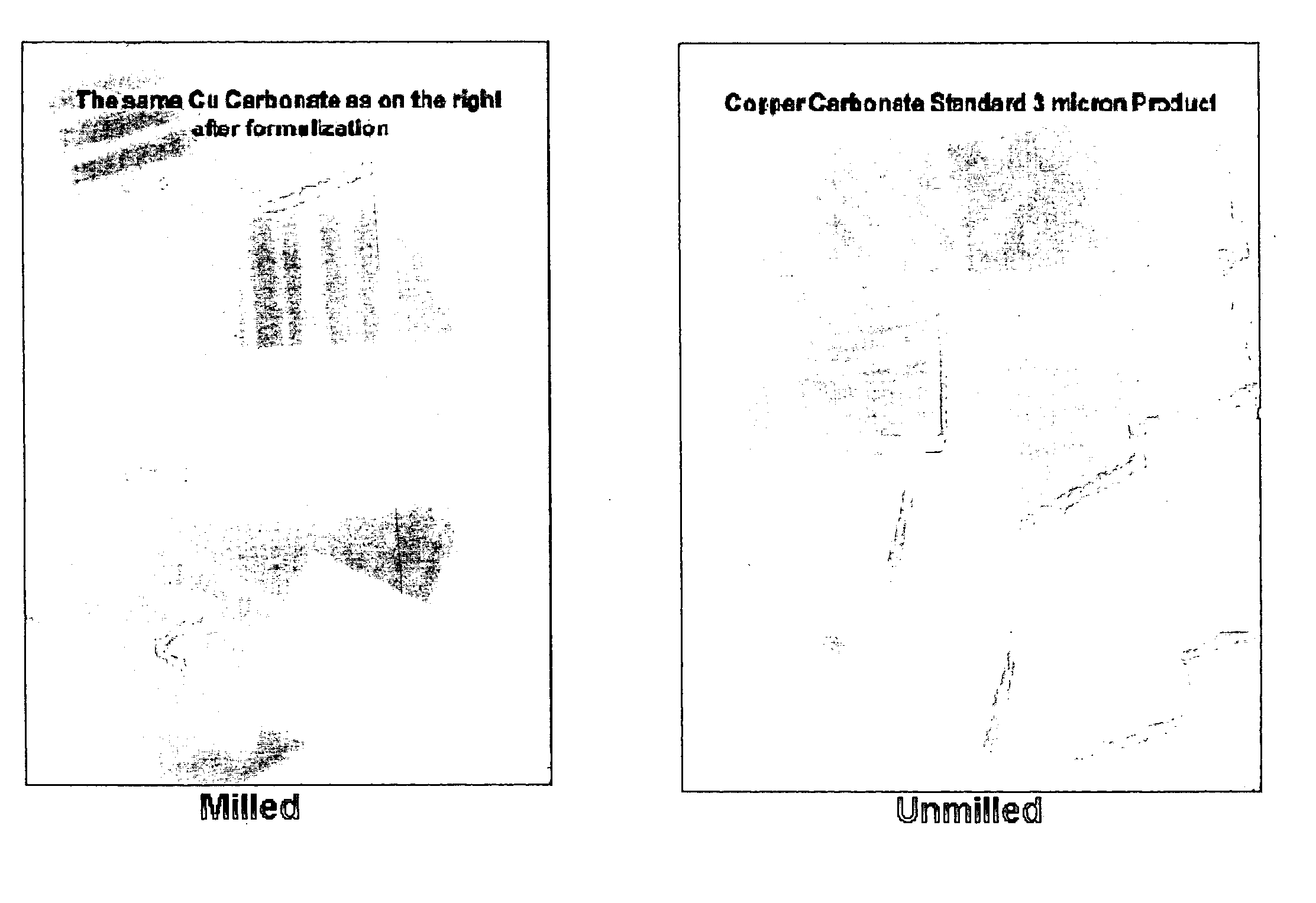

A method for preserving wood by injecting into the wood a slurry having: particles of a sparingly soluble copper salt, copper hydroxide, or both, wherein the weight average diameter d50 of the particles in the slurry is between 0.1 microns and 0.7 microns and the d98 of the particles in the slurry is less than about 1 micron; a dispersant; and water. The dispersant is anionic or a mix of anionic and non-ionic. Advantageously, less than 20% by weight of the particles have a diameter less than 20 nanometers. Useful copper salts include basic copper carbonate, tri-basic copper sulfate, copper oxychloride, basic copper nitrate, basic copper borate, copper borate, basic copper phosphate, or copper silicate. The slurry most preferably includes copper hydroxide particles. The slurry further advantageously includes at least one organic biocide, wherein at least a portion of the organic biocide is coated on the particles.

Owner:OSMOSE

Particulate wood preservative and method for producing same

InactiveUS20050252408A1Reduce the amount requiredWide particle size distributionBiocideAntifouling/underwater paintsCopper(II) hydroxideBasic copper carbonate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:OSMOSE

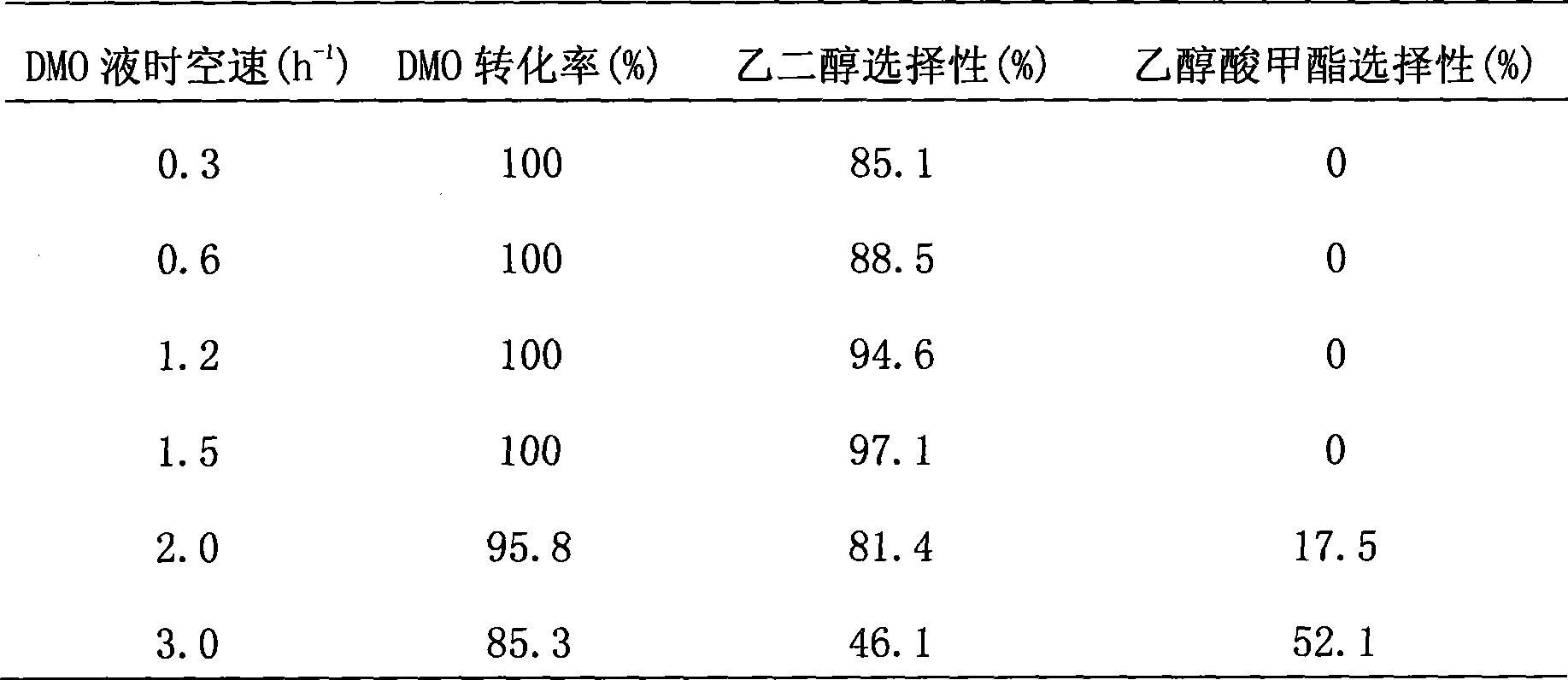

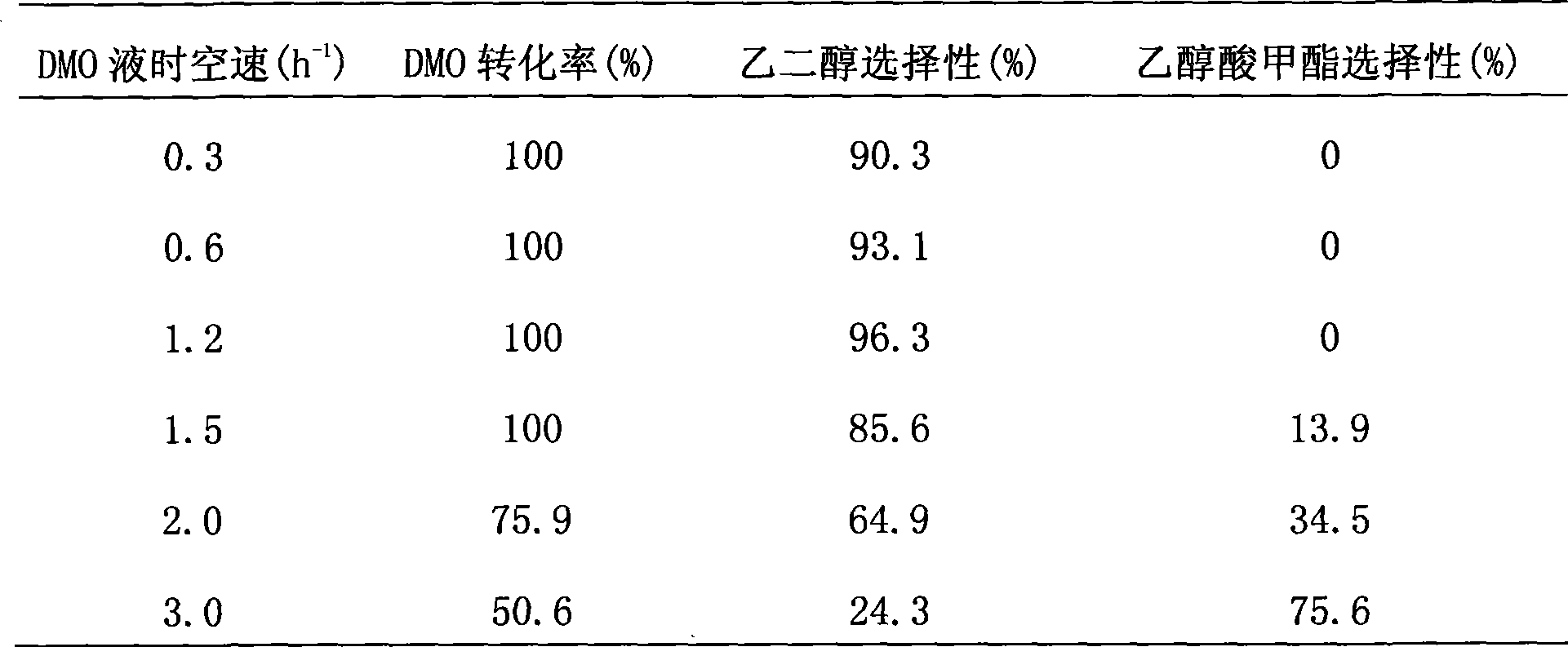

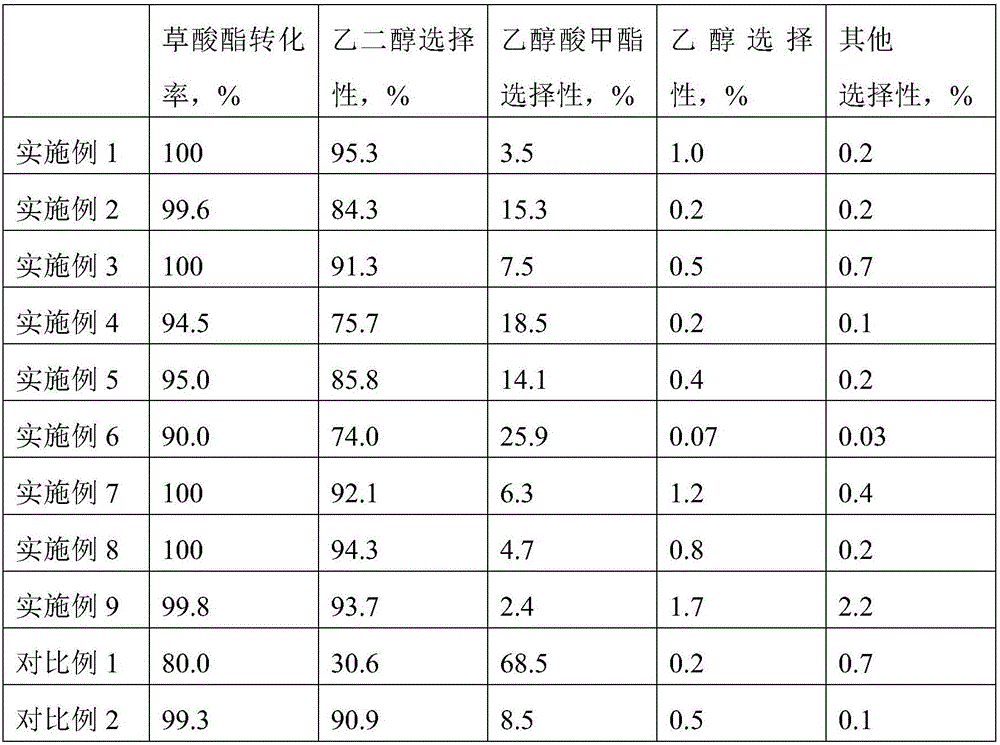

Method for preparing catalyst used in method for preparing ethanediol by dimethyl oxalate hydrogenation

InactiveCN101411990AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsOrganic compound preparationCopper nitrateMesoporous silica

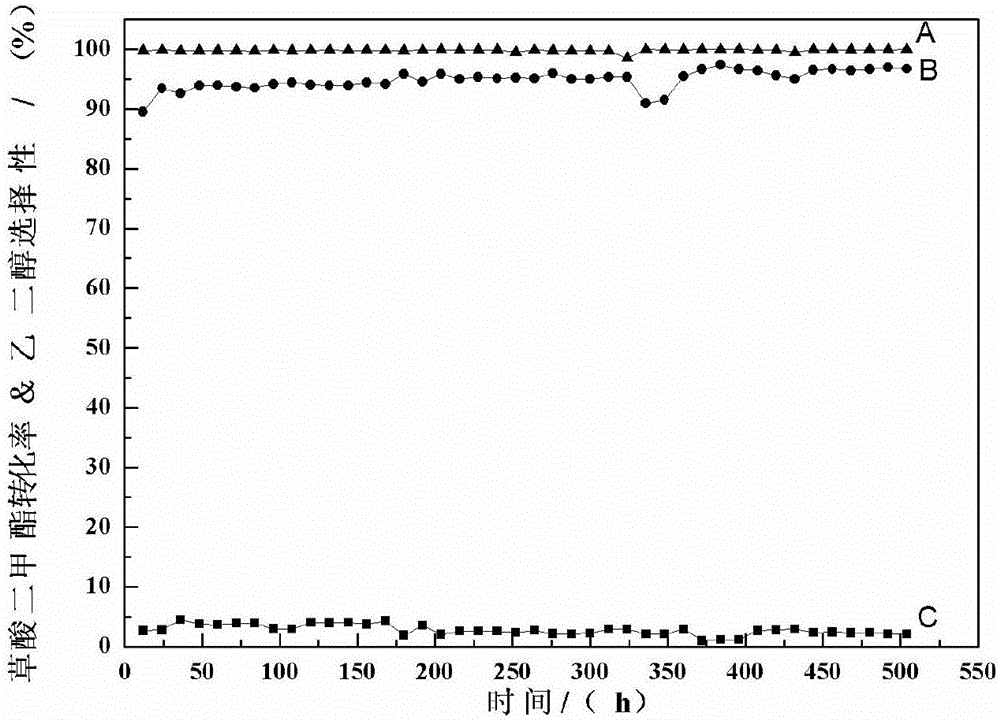

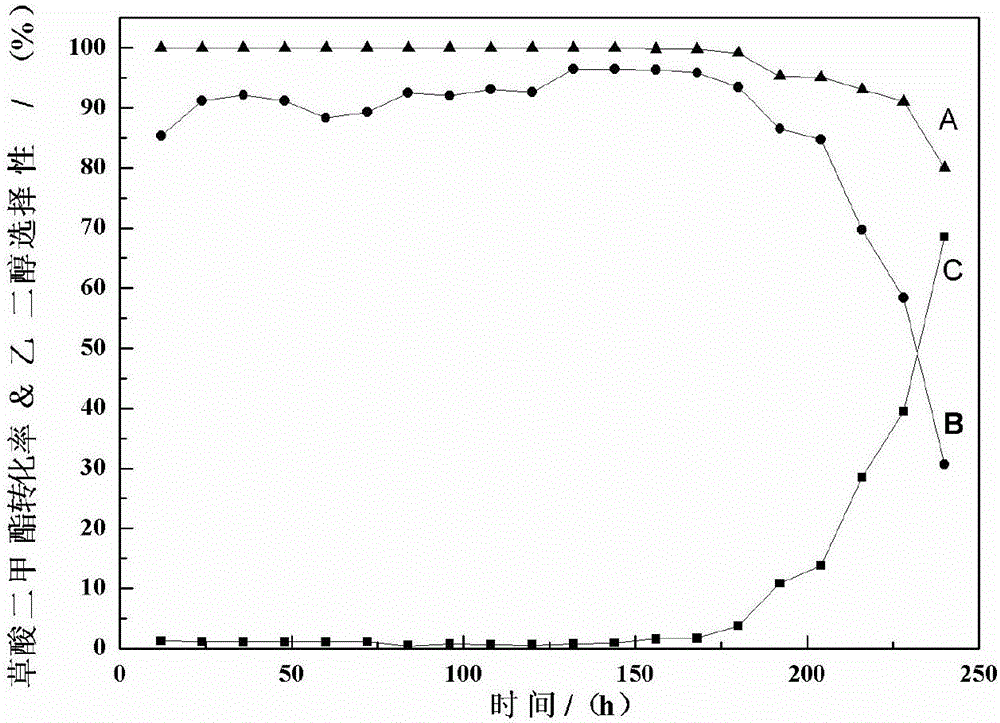

The invention relates to the field of chemical technology, in particular to a method for preparing a catalyst for hydrogenating dimethyl oxalate to prepare glycol. The method comprises the following steps: step one, copper nitrate is used to prepare a cuprammonium complex compound; step two, the cuprammonium complex compound is added with a mesoporous silica molecular sieve, is dripped with distilled water, and is filtered, washed, dried and roasted to prepare a catalyst precursor; and step three, the catalyst precursor is reduced in a hydrogen-nitrogen mixed atmosphere to prepare the catalyst. In the catalyst, according to mass percentage, the content of copper is between 5 and 40 percent; and the content of the mesoporous silica molecular sieve is between 60 and 95 percent. The method has the advantages that a silicon copper catalyst prepared through the new method has high catalytic activity and glycol selectivity in the reaction of hydrogenating the dimethyl oxalate to prepare the glycol, has long service life, smooth reaction performance and easy control.

Owner:FUDAN UNIV

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article including the steps of mixing a metal-containing catalyst precursor with a filler material or graphite or a combination thereof to form a pre-treated fuel element component; optionally calcining the pre-treated fuel element component in order to convert the catalyst precursor to a catalytic metal compound; after the optional calcining step, combining the pre-treated fuel element component with a carbonaceous material and a binder to produce a fuel element composition; and forming the fuel element composition into a fuel element adapted for use in a smoking article. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

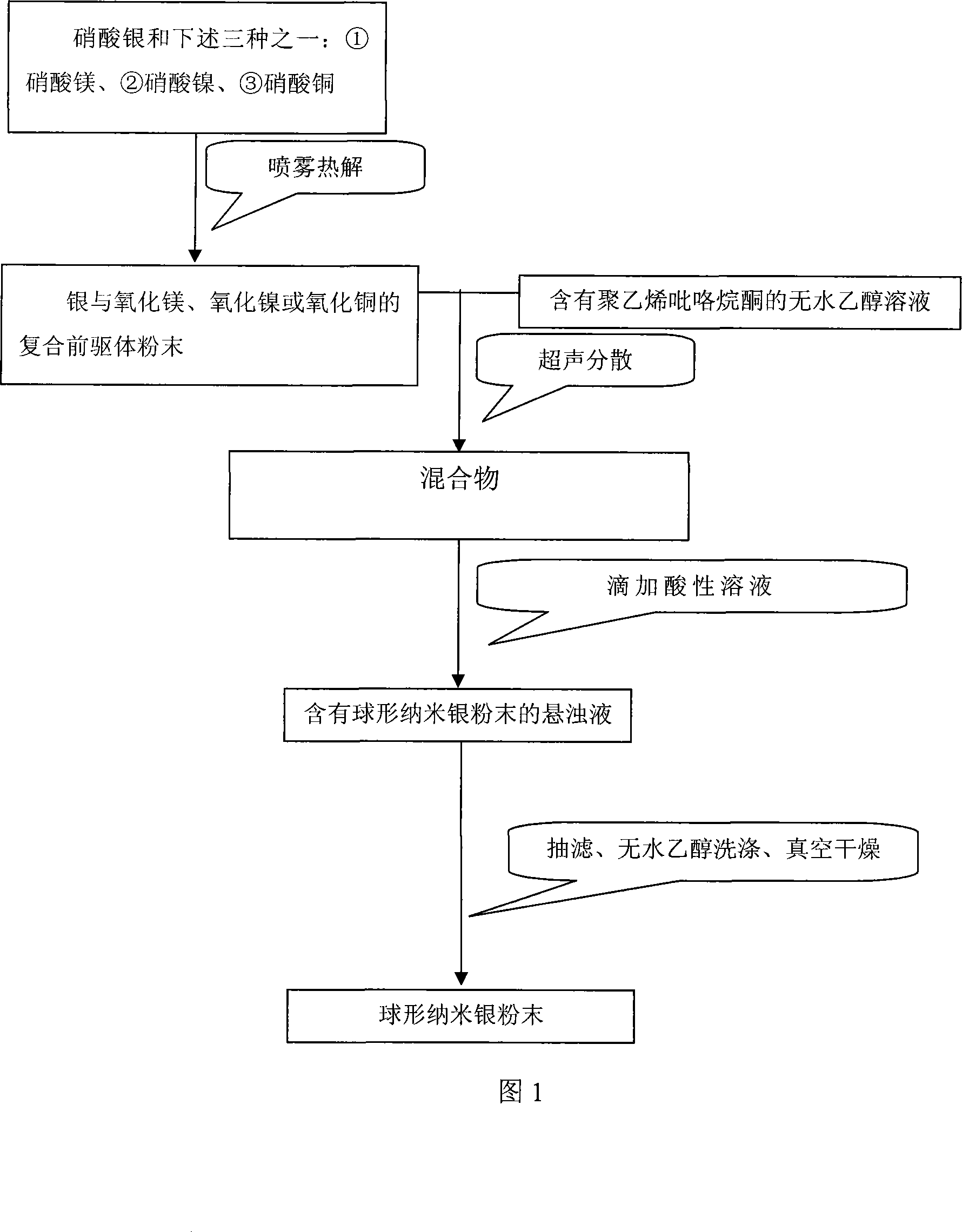

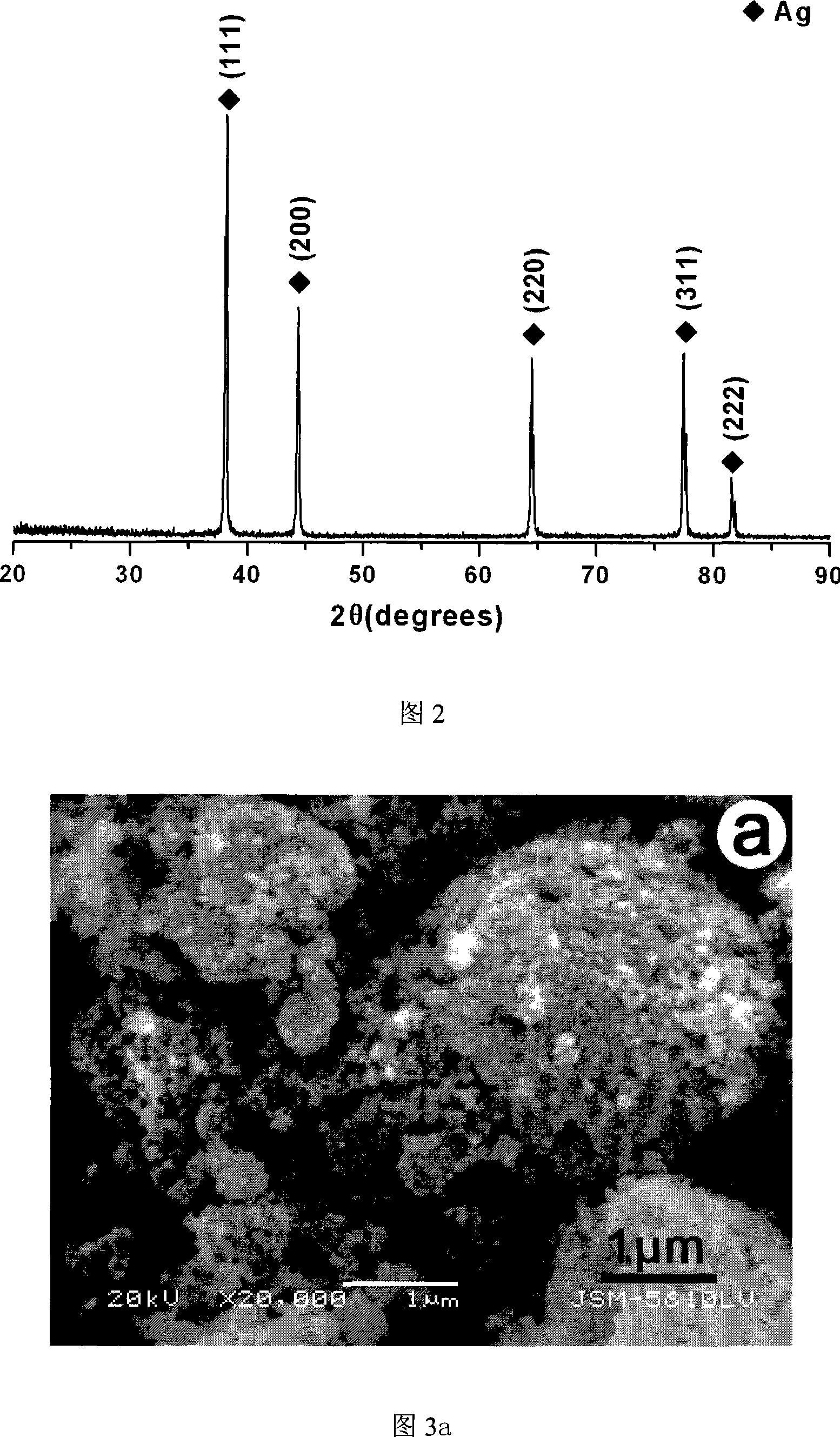

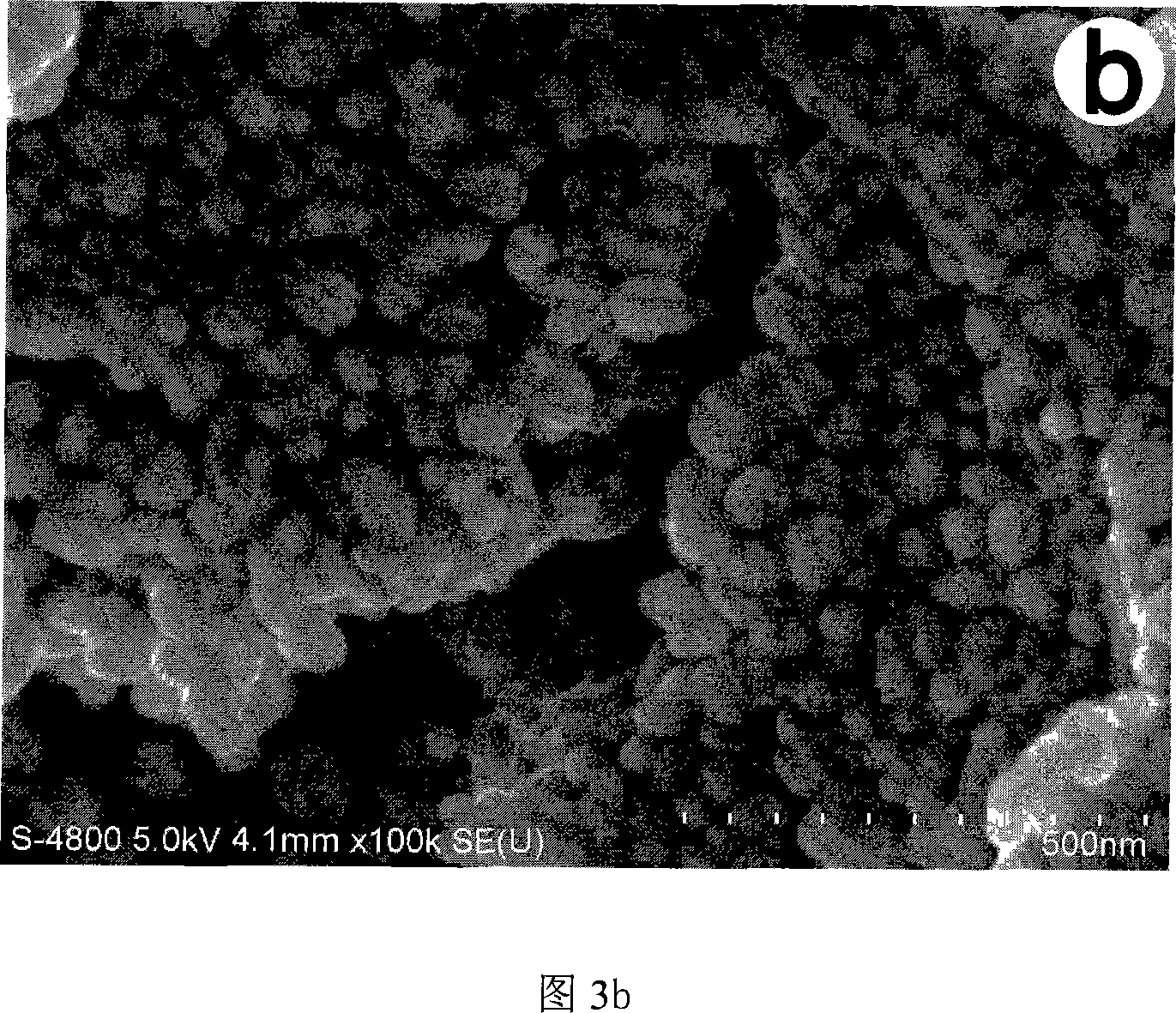

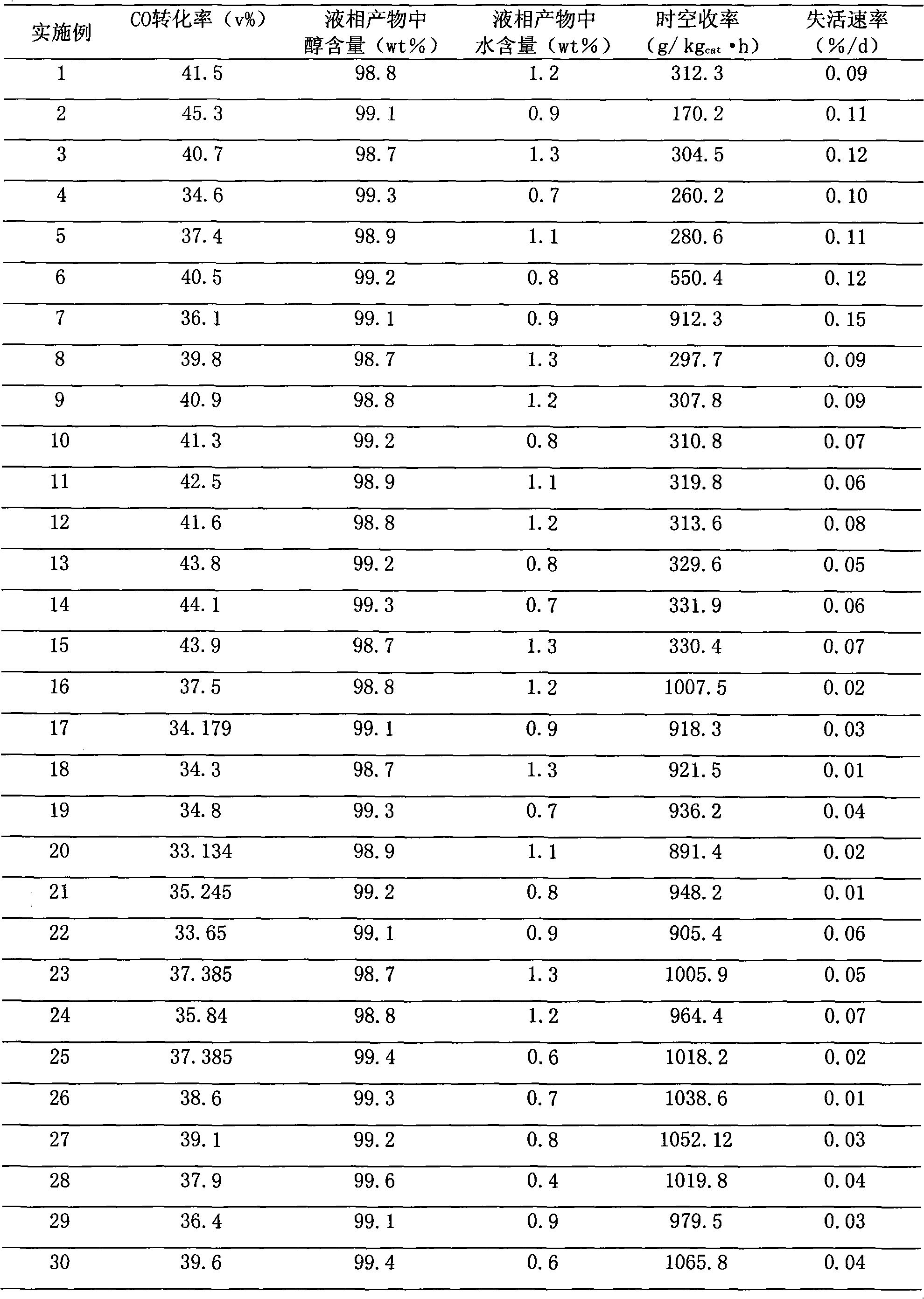

Method for preparing spherical nano silver powder

The invention relates to a method for preparing a spherical nanometer sliver powder. A method for preparing a spherical nanometer sliver powder is characterized in that the invention includes the following steps: 1) spraying and pyrolyzing: a, dissolving silver nitrate with one of the three: {1}magnesium nitrate, {2}nickel nitrate, {3}copper nitrate into water to prepare into a water liquor with a consistency of 10 to 40wt percent; the mol ratio of magnesium ion, nickel ion or copper ion in the liquor is 0.05 to 1 :4; then spraying for pyrogenation; b, under the existence of a dispersant and protecting agent, adding into a non-water ethanol to disperse to acquire a mixture; 2) preparing the spherical nanometer sliver powder: a, dripping acid liquor into the mixture and adjusting a PH value between 3 to 5 to acquire a suspension containing the spherical nanometer sliver powder; b, pumping filtration, washing and drying to acquire the spherical nanometer sliver powder. The preparing method is simple and easy to be controlled, has no pollution and low cost, is suitable for industrialization scale production. The prepared spherical nanometer sliver powder belongs to the nanometer grade and the powder has uniform distribution of the grain diameter, regular shape and high yield.

Owner:WUHAN UNIV OF TECH

Substituted basic metal nitrates in gas generation

A material for a pyrotechnic composition and related pyrotechnic compositions are provided in which the material includes a substituted basic metal nitrate including a reaction product of an acidic organic compound and a basic metal nitrate. A method for enhancing a burn rate of a gas generant composition and a burn rate enhanced gas generant composition including a reaction product of basic metal nitrate and tetrazoles, tetrazole derivatives, and combinations thereof, and a nitrogen-containing co-fuel such as guanidine nitrate are also disclosed. The burn rate enhance gas generant composition may optionally include an additional oxidizer such as basic copper nitrate.

Owner:AUTOLIV ASP INC

Method for preparing methanol synthesizing catalyst

InactiveCN101584986AEvenly distributedUniform particle size distributionOrganic compound preparationHydroxy compound preparationCopper nitrateSlurry

According to a method for preparing methanol synthesizing catalyst, a water solution which contains copper nitrate, zinc nitrate, aluminum nitrate and a fourth component with a total concentration of 0.5-2.0mol / L and a water solution that contains the sodium carbonate with a concentration of 0.5-2mol / L are prepared. At a state that the temperature is controlled to 50-80 DEG C with the microwave, the pH value is controlled to 6.5-8.5 for executing coprecipitation reaction. Then the water solution is aged for 0.5-3 hours in the temperature of 60-90 DEG C, which is controlled with the microwave. Then the precipitate is washed and filtered with the de-ionized water. Then the filter cake is dried for 1-11 hours at the condition that the temperature is controlled to 70-150 DEG C with the microwave. Finally the dried precipitate is calcined for 1-5 hours at the condition that the temperature is controlled to 300-400 DEG C with the microwave for obtaining the target catalyst. The method of the invention has the advantages of simple technique, moderate operation condition, smaller and more uniform catalyst particle particularly when the microwave heating is introduced and higher mechanical strength of the catalyst. The test through the static bed and the slurry-bed reactor shows that the activity and the stability of the catalyst are better than those of the catalyst prepared through the conventional heating and the bottleneck of incapability for industrializing of the slurry-bed caused by the easy inactivation is broken through.

Owner:TAIYUAN UNIV OF TECH

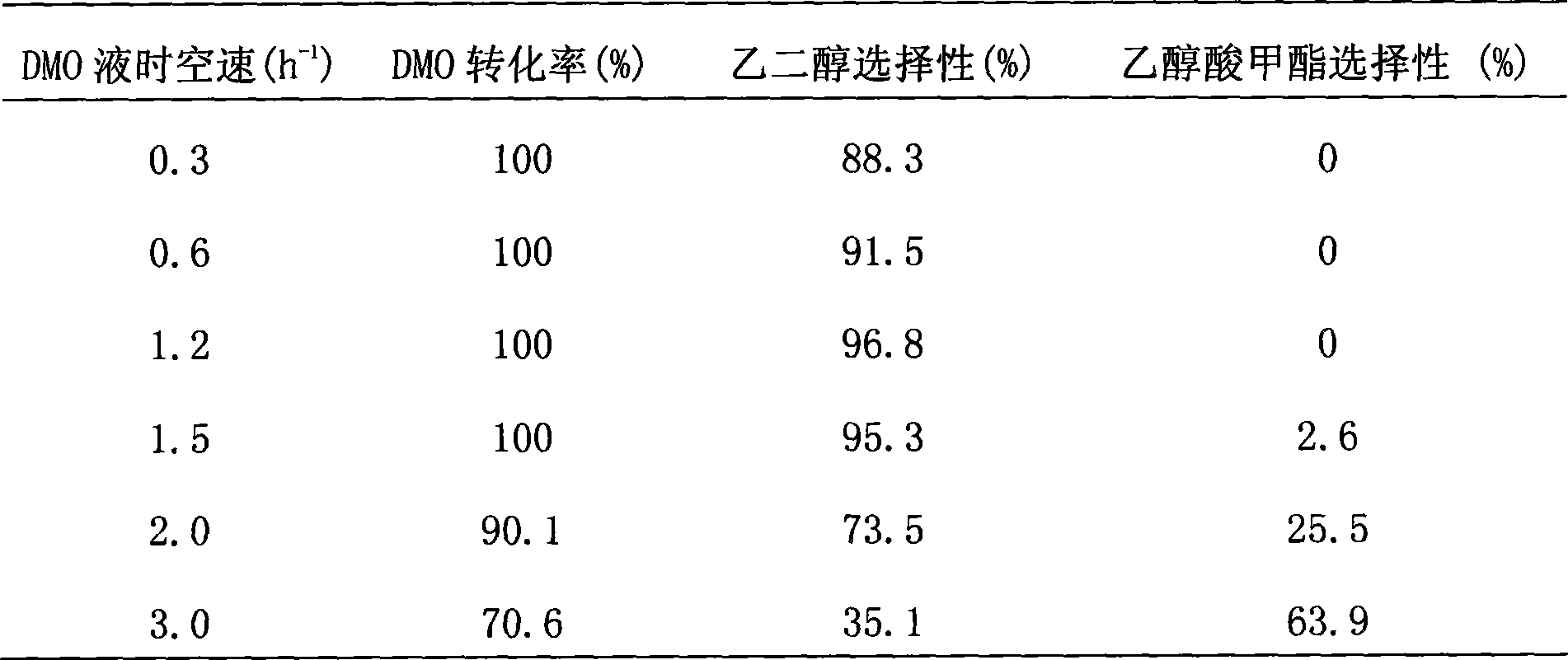

Glycol catalyst prepared by dimethyl oxalate hydrogenation and preparation method thereof

ActiveCN101607205AAvoid structural damageHigh activityOrganic compound preparationHydroxy compound preparationHydrogenCopper nitrate

The invention discloses a glycol catalyst prepared by dimethyl oxalate hydrogenation and a preparation method thereof, which is characterized in that the catalyst takes copper nitrate or copper acetate as copper source, ludox as silicon source, ammonia, ammonium bicarbonate or urea as precipitant which are coprecipitated to prepare CuSi catalyst forerunner; one or two of Zn, Fe, Ag, and Pd is soaked in the catalyst forerunner and used as additive agent, and then mixture is baked in the temperature of 200 to 500 DEG C, and finally is beaten into pieces and formed to obtain the catalyst. The catalyst comprises 20-50% of Cuo, 0.005%-3% of additive agent and the rest of SiO2 according to mass percent of oxygen compound, wherein additive agent is oxidate of one or two of Zn, Fe, Ag, and Pd. Before using, the catalyst is reduced by hydrogen and nitrogen combination gas containing 1% to 90% of hydrogen; and the reduction temperature is 150 to 500 DEG C.

Owner:HAISO TECH

Preparation method and application of carbon-based copper-cobalt oxide nanosheet catalyst

InactiveCN107442125ARegular shapeLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsWater basedFiber

The invention discloses a preparation method of a carbon-based copper-cobalt oxide nanosheet catalyst and application to oxygen evolution by electrolyzing water based on the catalyst, and belongs to the technical fields of nano catalysis, nano materials and metal-organic framework (MOF) materials. The preparation method comprises the following main steps of blending an aspartic acid alkaline solution with a copper nitrate-cobalt nitrate solution at a room temperature, generating a sediment at the room temperature, carrying out suction filtration, and drying, so that a Cu-MOF nano fiber loaded Co(II) ion, namely a CuCo-MOF nano fiber, is prepared; heating the CuCo-MOF nano fiber in an air atmosphere, so that the carbon-based copper-cobalt oxide nanosheet catalyst is prepared. The cost of raw materials used for the preparation of the catalyst is low; the preparation process is simple; the reactive energy consumption is low; the carbon-based copper-cobalt oxide nanosheet catalyst has an industrial application prospect. The catalyst is used for efficiently catalyzing and hydrolyzing the water for the oxygen evolution and has favorable oxygen-evolution electrocatalytic activity and electrochemical stability.

Owner:UNIV OF JINAN

Catalyst for synthesizing ethylene glycol by oxalate hydrogenation, and preparation method and application method of catalyst

ActiveCN106563449AGood dispersionHigh activityOrganic compound preparationCarboxylic acid esters preparationDispersityReaction temperature

The invention provides a catalyst for synthesizing ethylene glycol by oxalate hydrogenation, and a preparation method and an application method of the catalyst. The preparation method comprises the steps of taking copper nitrate and copper acetate as copper sources, taking alkaline silica gel as a silicon source, and taking urea and ammonia water as a precipitant; adding a multi-hydroxyl organic matter; and preparing a Cu / SiO2 catalyst with a deposition-precipitation method. According to the method, the dimension and dispersity of copper species are adjusted and controlled by adding the multi-hydroxyl organic matter in the preparation process, and the aggregation of the copper species is inhibited by utilizing carbon deposition, so that the problem of easy sintering of the copper species at a high temperature is better solved. The application method for applying the catalyst to the synthesis of ethylene glycol by oxalate hydrogenation comprises the steps of firstly enabling the organic matter on the catalyst to form the carbon deposition at a relatively high temperature in an inert atmosphere; secondly switching inert gas to hydrogen in a cooling process after carbon deposition formation; and finally when the temperature is reduced to a reaction temperature, performing subsequent hydrogenation synthesis. The method has the characteristics that the catalyst does not need to be pre-roasted before use, and hydrogen pre-reduction does not need to be carried out for a long time, so that the preparation and use costs of the catalyst can be reduced.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

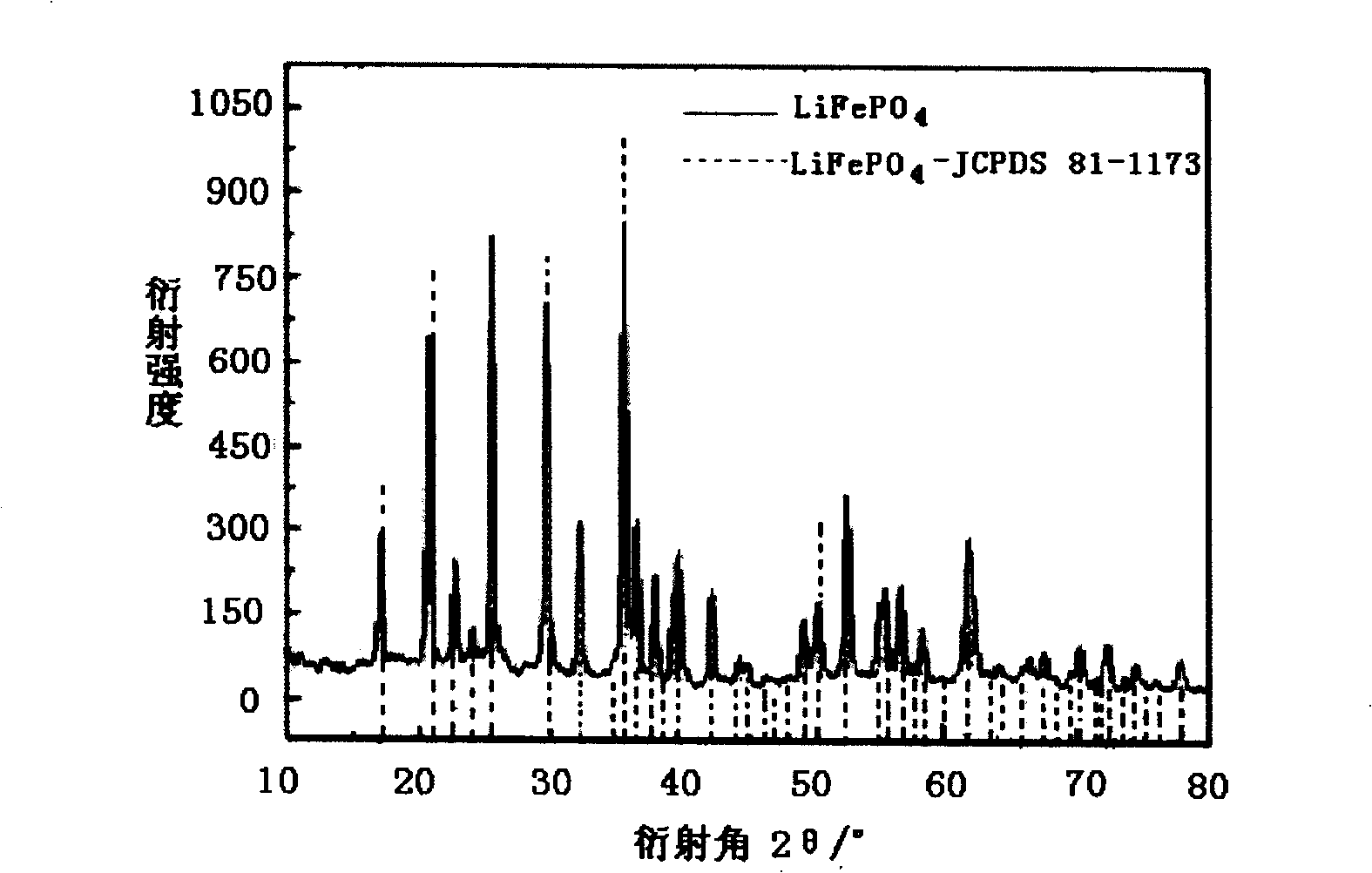

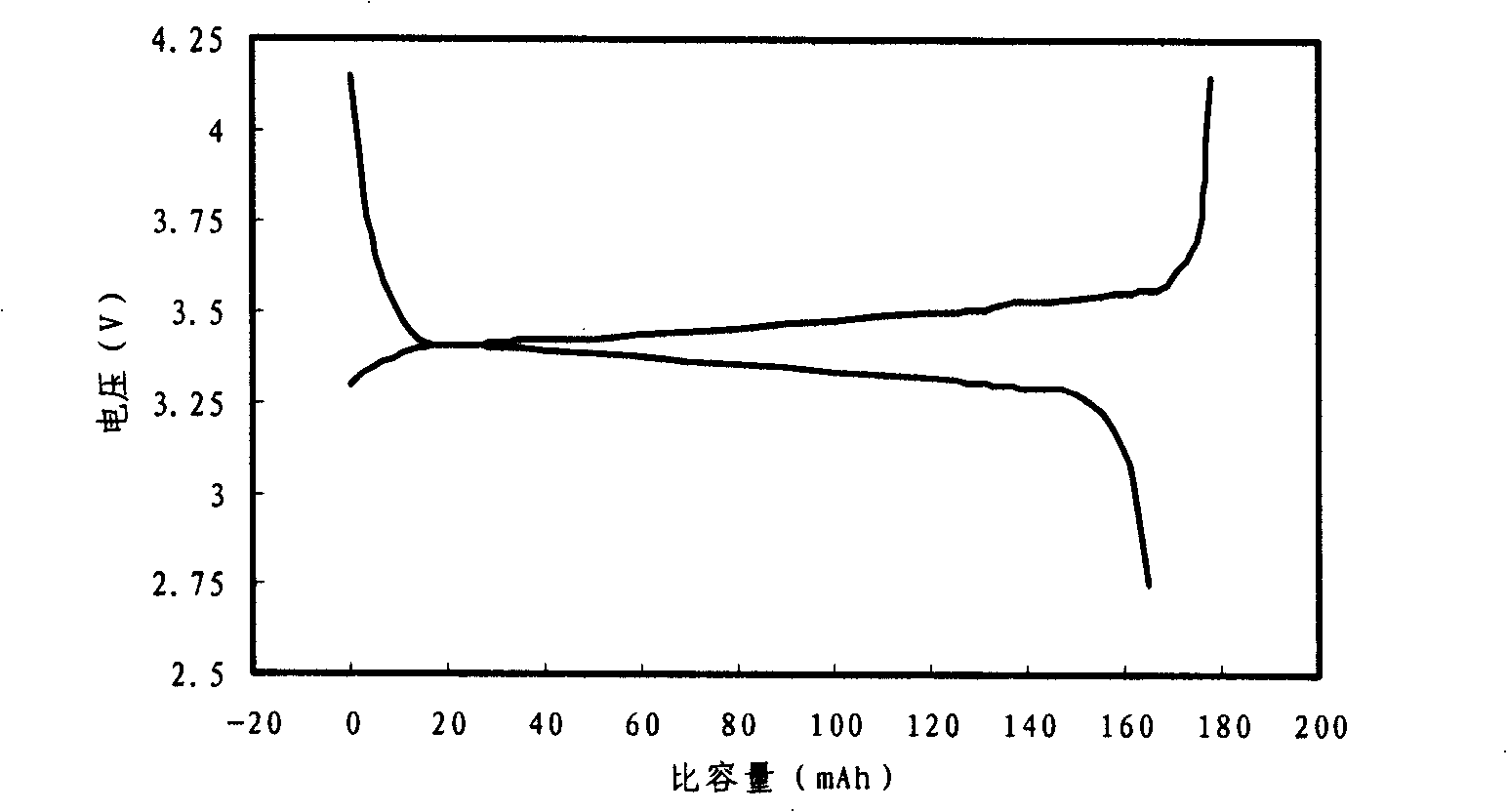

Positive electrode material of lithium ion cell and its preparation method

InactiveCN101339988ASolve the control puzzleWell mixedElectrode manufacturing processesPhosphorus compoundsPhosphateCopper nitrate

The invention discloses an electrode material of a lithium-ion battery and a preparation method thereof. The electrode material is lithium iron phosphate (LiFePO4) with the surface coated with nano-copper and is prepared by using the following method: water solution of ferrous phosphate and lithium phosphate is evenly mixed according to a chemical formula, and is added with a stabilizer OP-10 water solution for mixing and stirring, the mixed solution is controlled at a certain temperature for precipitation, and then the precipitate is filtered, rinsed and aired. Heat treatment is carried out for an aired precursor obtained from the previous step at high temperature, therefore a lithium iron phosphate semi-finished product is obtained. The problem of the imperfect particle size of the lithium iron phosphate is solved by controlling the process conditions. Copper nitrate solution is mixed with the lithium iron phosphate semi-finished product and is added with vitamin C for reducing to obtain the copper; metal copper is evenly clad on the surface of the lithium iron phosphate particles. The preparation method has simple operational procedure; the lithium-ion battery anode material of the prepared lithium-ion battery electrode material has high ionic conductivity and electron conductivity, the 1C initial specific capacity is not less than 162mAh / g and the lC tap density is not less than 1.5g / cm<3>.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

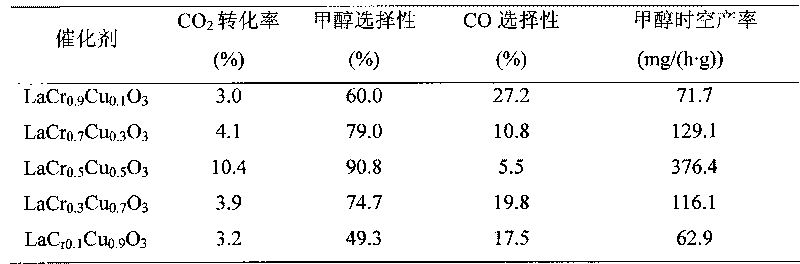

Catalyst for synthesizing methanol by direct hydrogenation of carbon dioxide and preparation method thereof

InactiveCN101690894AImprove performanceOvercome the disadvantages of low conversion rate and poor selectivity of methanolOrganic compound preparationHydroxy compound preparationCopper nitrateHYDROSOL

The invention discloses a catalyst for synthesizing methanol by direct hydrogenation of carbon dioxide and a preparation method thereof and relates to the catalyst. The invention provides the catalyst for synthesizing the methanol by direct hydrogenation of the carbon dioxide and the preparation method thereof. The catalyst is LaCr1-xCuxO3, wherein x is the relative mole fraction of a main component of Cu, x is equal to 0.1-0.9, and La: Cr: Cu is equal to 1: (1-x): x. The preparation method comprises the steps of preparing copper nitrate, chromium nitrate, lanthanum nitrate and citric acid into water solution, forming a sol under the radiation of an infrared lamp, heating, decomposing nitrogen oxides and organic acids, pre-baking in an atmosphere furnace at the temperature of 350-450 DEG C for 2-4h, baking at the temperature of 700-800 DEG C, and obtaining the catalyst for synthesizing the methanol by direction hydrogenation of the carbon dioxide. The citric acid complexation-rapid combustion method is adopted for overcoming the disadvantages of lower conversion rate, poorer selectivity of the methanol and the like during the catalysis of the carbon dioxide by using the existing catalyst for synthesizing the methanol by hydrogenation of the carbon dioxide, and the prepared catalyst has stable performances.

Owner:XIAMEN UNIV

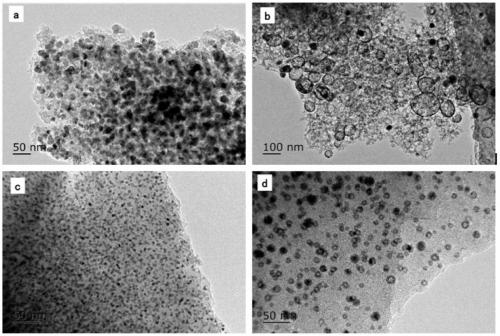

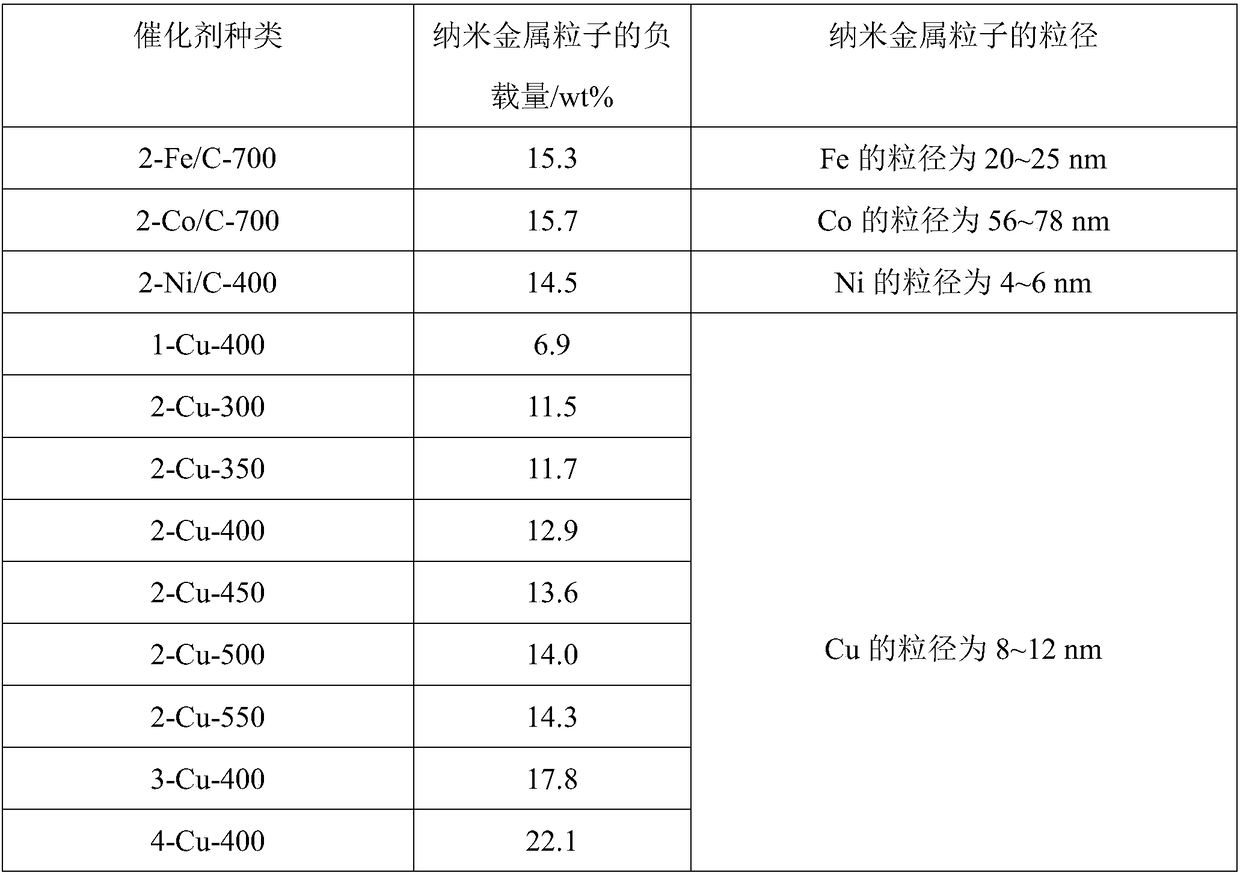

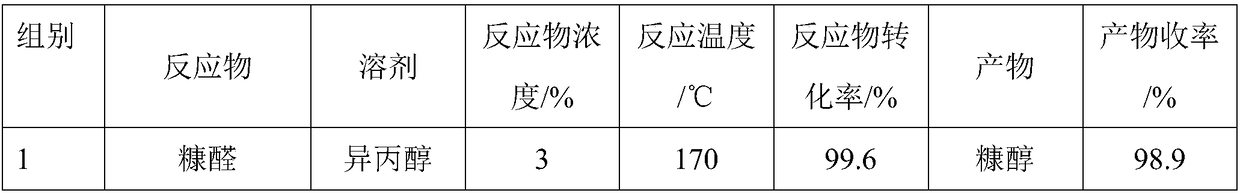

Biomass carbon-base material high-load nano-metal catalyst, as well as preparation method and application thereof

ActiveCN109364922ARaw greenEasy to makeMaterial nanotechnologyCatalyst carriersSimple componentCopper nitrate

The invention discloses a biomass carbon-based material high-load nano-metal catalyst, as well as a preparation method and application thereof. The catalyst is prepared by soaking shaddock peel powderin a nitrate solution having a certain concentration, drying and calcining, metal simple component serves as the active component, and organic carbon serves as the carrier; the nitrate is ferric nitrate, cobalt nitrate, nickel nitrate or copper nitrate; and the metal simple component is iron, cobalt, nickel or copper. The catalyst has the characteristics of environment-friendly raw materials, simple preparation process and high hydrogenation selectivity, has a good effect when being applied to a hydrogenation reaction of biomass derivatives, for instance, the furfuryl alcohol yield at a relatively low temperature of 170 DEG C can be 98,9 percent when the furfuryl alcohol is prepared by a furfuryl alcohol selective hydrogenation reaction.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

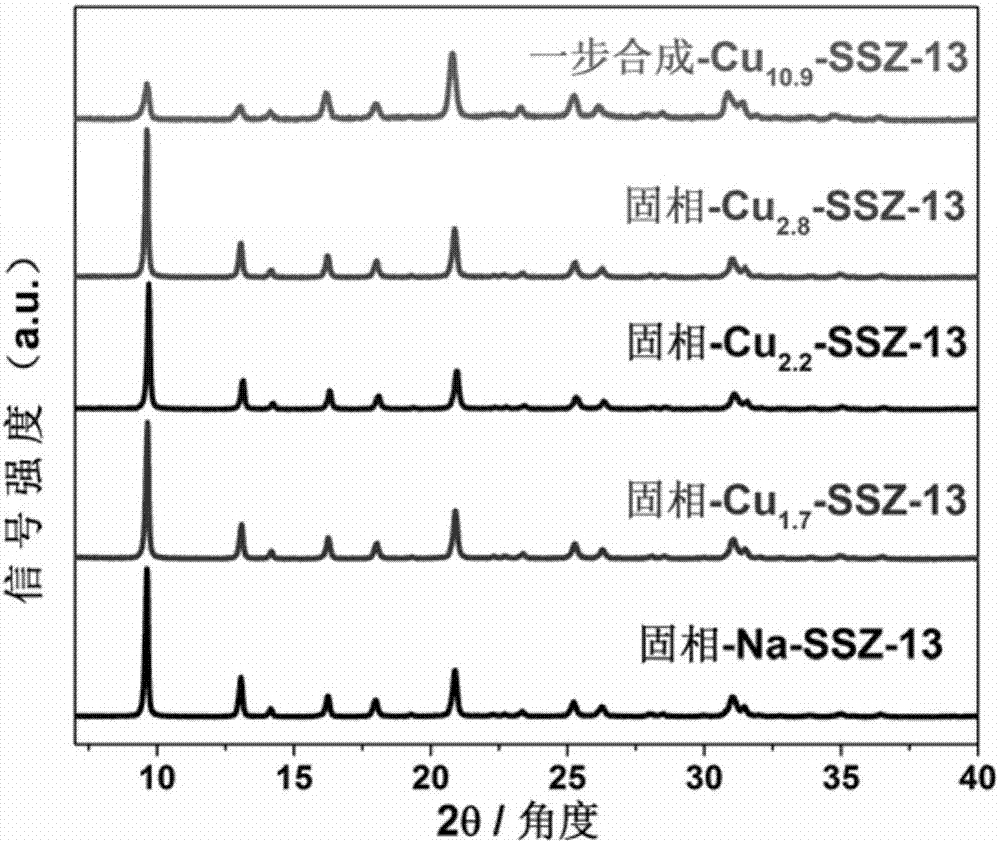

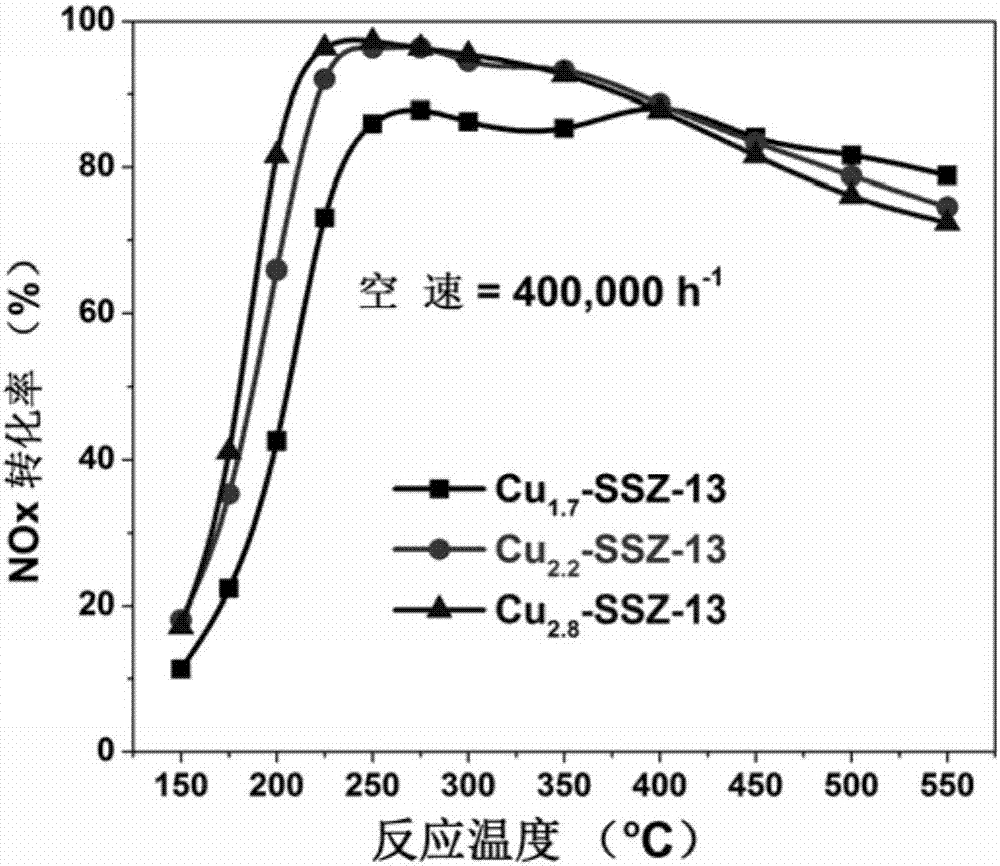

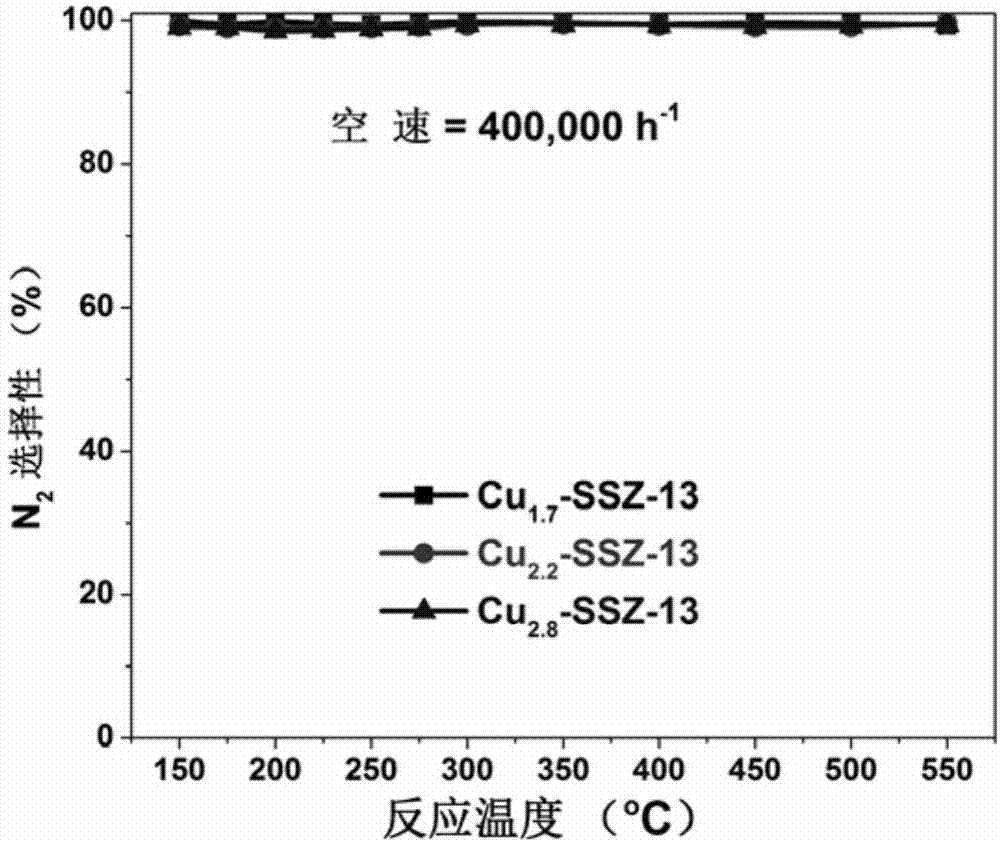

Preparation method and application of Cu-SSZ-13 catalyst

InactiveCN107115888AHigh catalytic activityExcellent resistance to high airspeedGas treatmentMolecular sieve catalystsIon exchangeCopper nitrate

The invention provides a preparation method and application of a Cu-SSZ-13 catalyst. The preparation method comprises the following steps: 1) putting raw materials including a silicon source, an aluminum source, a template agent and seed crystals into a mortar, and grinding to form a uniform mixture; 2) feeding the mixture into a reaction kettle and crystallizing; after cooling, washing and drying, roasting to obtain an Na-SSZ-13 molecular sieve carrier; 3) preparing an ammonium nitrate solution, and adding into the Na-SSZ-13 molecular sieve carrier; after carrying out ion exchange, filtering, washing and drying to obtain an NH4-SSZ-13 molecular sieve; 4) preparing a copper nitrate solution and adding into the NH4-SSZ-13 molecular sieve; after carrying out ion exchange, filtering, drying and roasting to obtain the Cu-SSZ-13 catalyst. The Cu-SSZ-13 catalyst prepared by the preparation method has excellent NH3-SCR (Selective Catalytic Reduction) catalytic activity, N2 selectivity, hydrothermal stability, and H2O and SO2 positioning resisting properties, and is applicable to purification of tail gas of diesel vehicles.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method and applications of ternary composite material

InactiveCN104324762AEfficient preparationPromote growthOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsSimple Organic CompoundsMaterials preparation

The present invention relates to a ternary composite material preparation method, and belongs to the technical field of material science, nanometer materials, catalysis and the like. According to the present invention, a cyanuric chloride hexahydroxy carboxylic acid ligand and copper nitrate are adopted as raw materials to prepare the hydrothermally stable porous metal organic framework material Cu-MOF, Cu-MOF is adopted as a carrier, nanometer silver is anchored on the surface of the carrier, and a porous titanium dioxide shell layer is coated to prepare the ternary composite material Cu-MOF@Ag@TiO2. The composite material has the excellent performance of catalytic reduction of unsaturated organic compounds, and has good application prospects in heterogeneous catalytic reduction reactions.

Owner:UNIV OF JINAN

Ultrahigh-Purity Copper and Process for Producing the Same, and Bonding Wire Comprising Ultrahigh-Purity Copper

InactiveUS20090272466A1Efficient preparationReduce hardnessCellsSolid-state devicesElectrolysisCopper nitrate

Provided is ultrahigh purity copper having a hardness of 40 Hv or less, and a purity of 8N or higher (provided that this excludes the gas components of O, C, N, H, S and P). With this ultrahigh purity copper, the respective elements of O, S and P as gas components are 1 wtppm or less. Also provided is a manufacturing method of ultrahigh purity copper based on two-step electrolysis using an electrolytic solution comprised of copper nitrate solution, including the procedures of adding hydrochloric acid in an electrolytic solution comprised of copper nitrate solution; circulating the electrolytic solution; and performing two-step electrolysis while eliminating impurities with a filter upon temporarily setting the circulating electrolytic solution to a temperature of 10° C. or less. The present invention provides a copper material that is compatible with the thinning (wire drawing) of the above, and is capable of efficiently manufacturing ultrahigh purity copper having a purity of 8N (99.999999 wt %) or higher, providing the obtained ultrahigh purity copper, and providing a bonding wire for use in a semiconductor element that can be thinned.

Owner:JX NIPPON MINING& METALS CORP

Production and use for dimethyl ether by methanol dewater

InactiveCN1745894AEasy to makeEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsEther preparation by compound dehydrationCopper nitrateSolvent

A catalyst for preparing dimether by dewatering methanol contains CuO (20-40 Wt%), ZnO (5-30), La2O3 (1-10), Sm2O3 (1-10), V2O5 (1-10) and carrier (40-60). Its preparing process includes such steps as dissolving copper nitrate (or acetate), Zinc nitrate (or acetate) and lanthanum nitrate in solvent, adding carrier, stirring, adding superfine (250 meshes) particles of Sm2O3 and V2O5, stirring, infrared drying at 60-100 Deg C., calcining at 350-500 Deg C., pressing and sieving.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

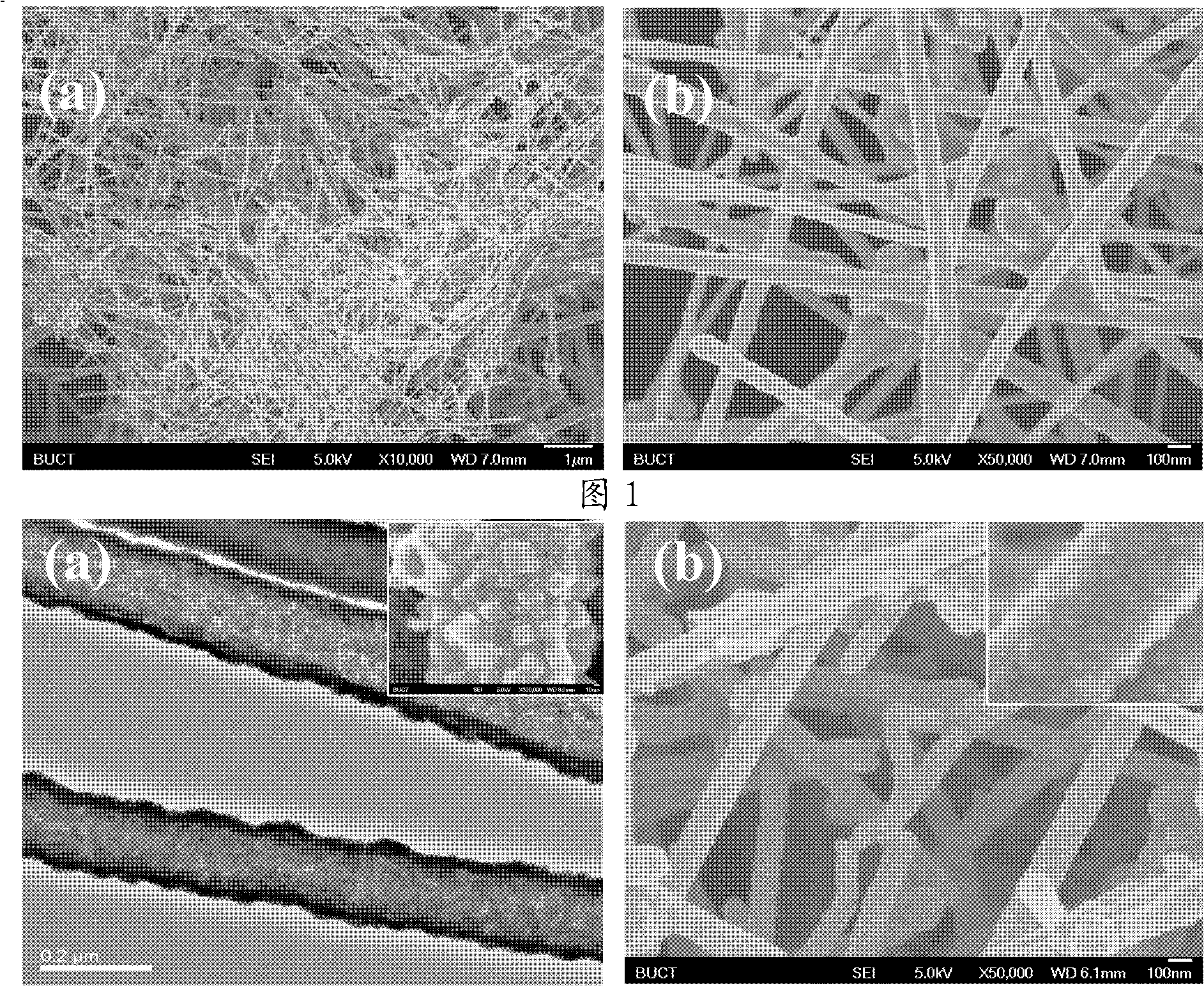

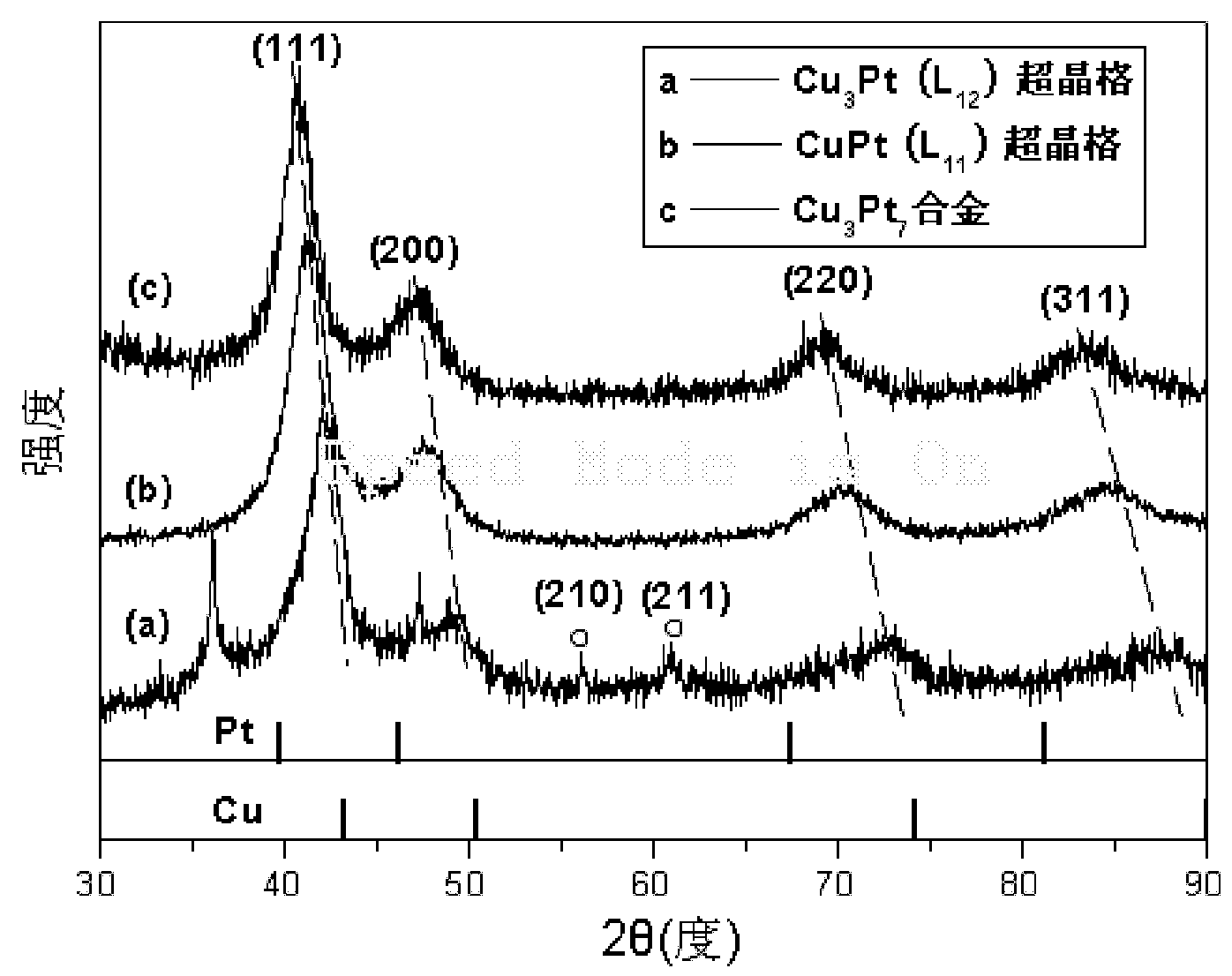

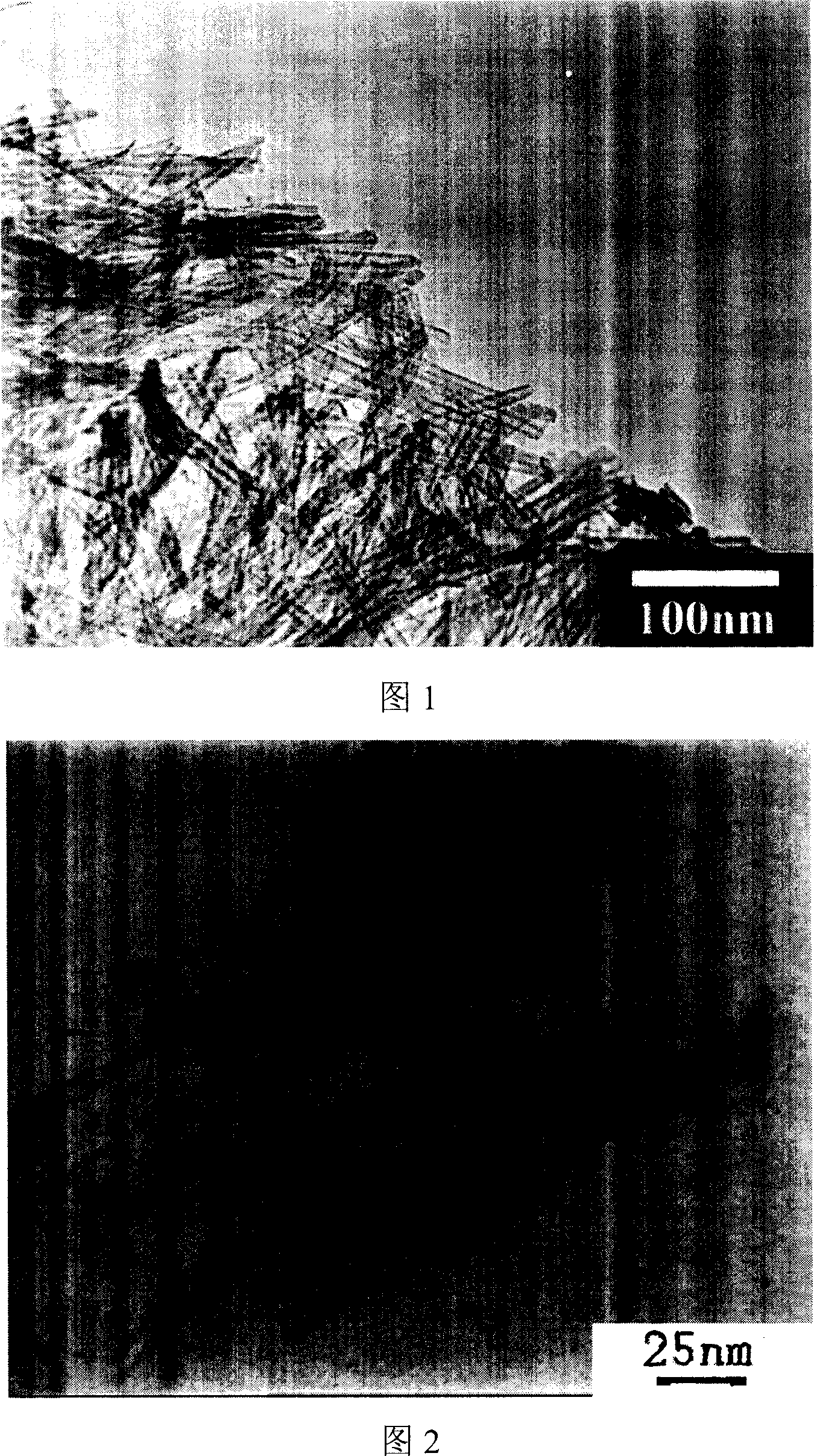

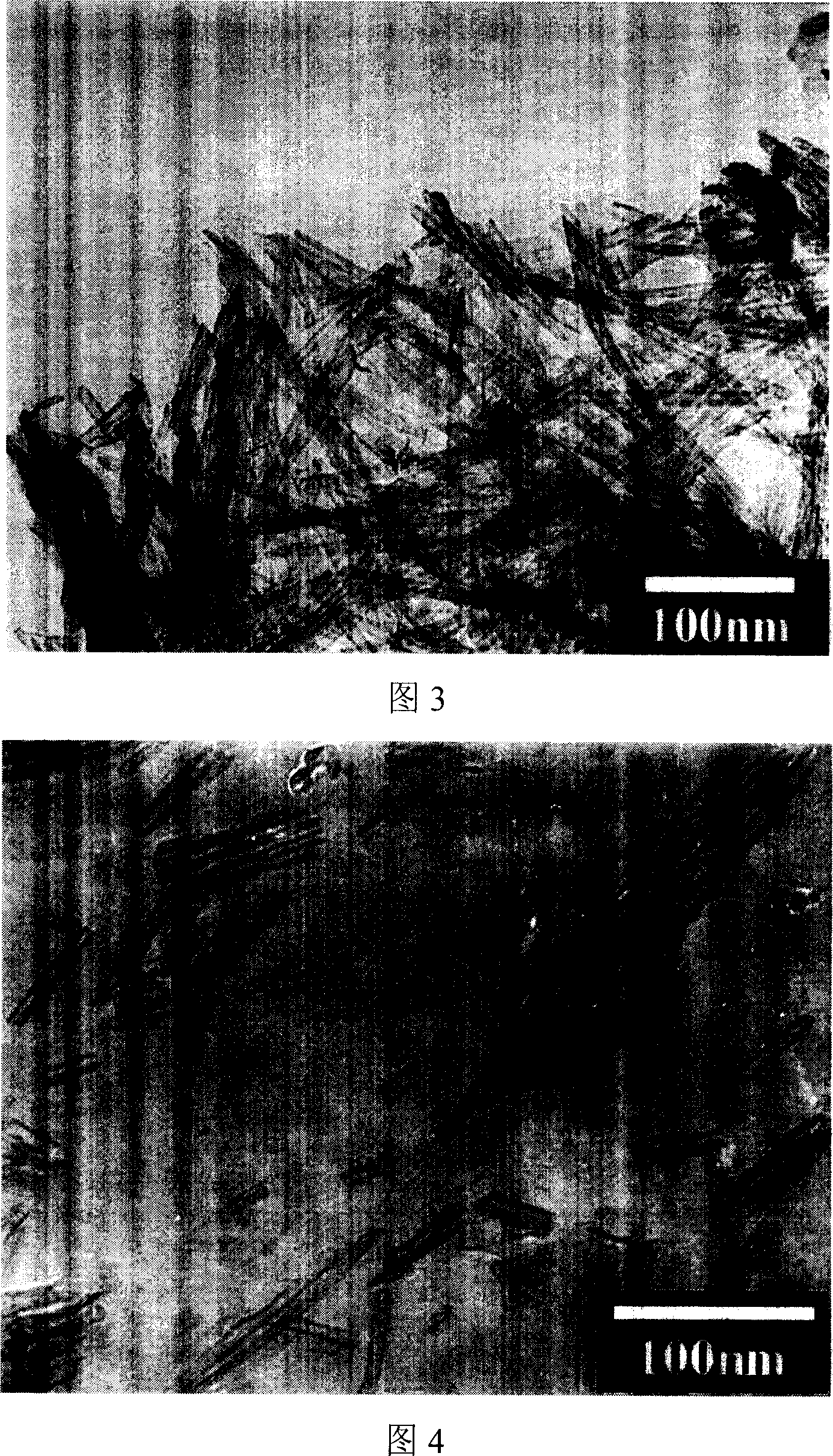

A kind of copper-platinum superlattice alloy nanotube and preparation method thereof

ActiveCN102277622AImprove conversion rateImprove responseMaterial nanotechnologyPolycrystalline material growthEthylenediamineCopper nitrate

The invention provides a copper-platinum superlattice alloy nano-tube and a preparation method thereof, and belongs to the technical field of alloy nano-tube preparation. The preparation method comprises the following steps: firstly, a sodium hydroxide solution is used as a pH regulating agent, anhydrous ethylenediamine is used as a morphological controlling agent, and a hydrazine hydrate solution is used as a reducing agent to reduce a copper nitrate solution to prepare a copper nano-wire; the copper nano-wire is treated with hydrochloric acid and water respectively and dried, and is dispersed in deionized water, in which nitrogen is introduced to remove oxygen; and a chloroplatinic acid solution is added to ensure the molar ratio of chloroplatinic acid to copper is 1:5 or 1:3, reaction is carried out for 20 to 60 minutes, and then filtering, cleaning and drying are carried out. The prepared copper-platinum superlattice alloy nano-tube has a hollow nano-tube structure with the lengthof between 3 and 5 mu m and an outer diameter of between 80 and 150 nm, and the alloy tube wall consists of alloy cubic particles with the particle diameter less than 20 nanometers. The preparation method has the advantages of simple condition, quick reaction and high product conversion rate.

Owner:BEIJING UNIV OF CHEM TECH

Gasoline desulfurization adsorbent and preparation method thereof

ActiveCN103394322AAvoid reunionIncrease the areaOther chemical processesHydrocarbon oils refiningSorbentGraphene flake

The invention provides a gasoline desulfurization adsorbent and a preparation method thereof, overcoming the defect that graphene in the prior art is easy to agglomerate in the using process. The gasoline desulfurization adsorbent takes attapulgite and graphene as carriers and cuprous oxide and manganese dioxide as active ingredients. The preparation method comprises the following steps of: (1) adding graphite and copper nitrate to concentrated sulfuric acid, then slowly adding potassium permanganate, then adding attapulgite slurry with concentration of 0.5-3g / L, and carrying out ultrasonic dispersion; adding an alkali solution to regulate the pH value, thus preparing composite suspension; and (2) adding a reducing agent solution under the condition of stirring, reacting, filtering, washing and drying, thus preparing the composite desulfurization adsorbent. The gasoline desulfurization adsorbent and the preparation method have the beneficial effects that one-dimensional rod-like attapulgite can be inserted between graphene oxide sheet layers, and attapulgite monocrystals are intercalated into graphene to prevent mutual superimposition of the graphene sheets so as to avoid the problem that graphene is easy to agglomerate in the using process.

Owner:江苏纳欧新材料有限公司

Metal oxide-loaded molecular sieve catalyst and preparation method thereof

ActiveCN101711990AStrong oxidizingReduce exhaust temperatureMolecular sieve catalystsDispersed particle separationMANGANESE ACETATECerium

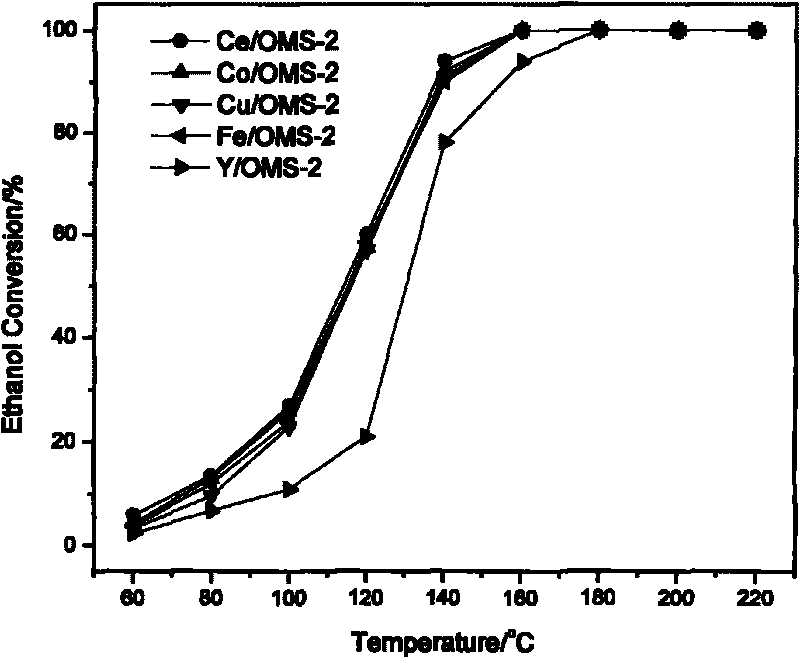

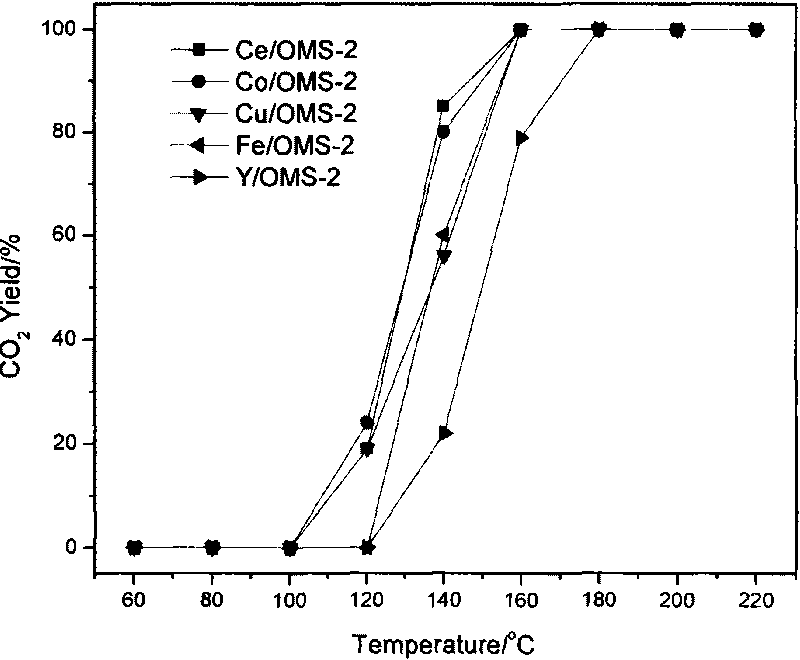

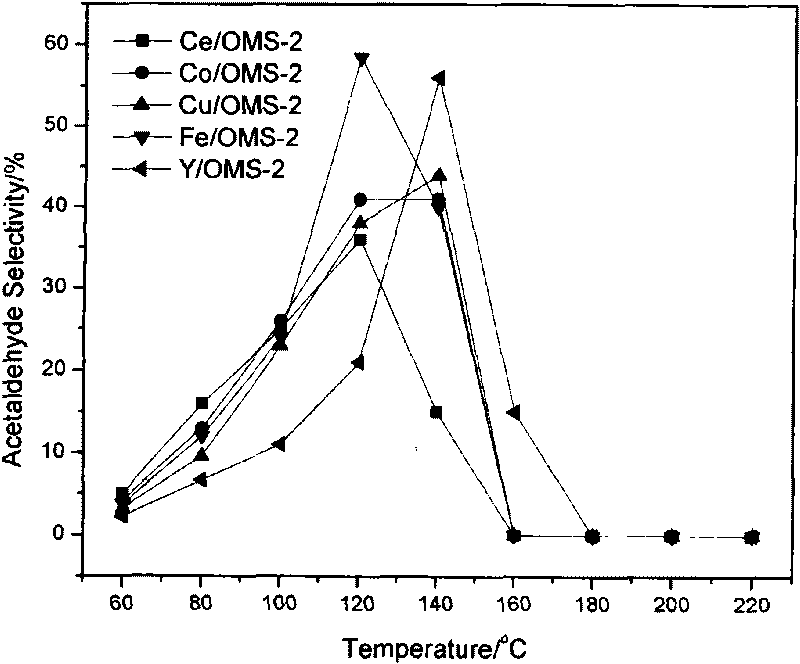

A metal oxide-loaded molecular sieve catalyst comprises pure cryptomelane type manganese dioxide and transition metal. A method for preparing the molecular sieve catalyst comprises the following steps: 1, preparing solution of potassium permanganate; 2, preparing solution of manganese acetate; 3, adding the solution obtained by the step one into a three-neck flask, and heating, condensing and refluxing the solution; 4, adding the solution obtained by the step two into the three-neck flask of the step three, condensing and refluxing the solution, filtering and drying the obtained black pasty sediment, and roasting the sediment to obtain an octahedral manganese oxide molecular sieve catalyst (OMS-2) solid; 5, adding cerium ammonium nitrate, cobalt nitrate hexahydrate, copper nitrate trihydrate, ferric nitrate nonahydrate or yttrium nitrate into deionized water to form solution; and 6, mixing the solid taken from the step four and the solution in the step five, soaking cerium on the octahedral manganese oxide molecular sieve catalyst (OMS-2) solid, and drying and roasting the obtained solid to obtain the metal oxide-loaded molecular sieve catalyst. The metal oxide-loaded molecular sieve catalyst has the characteristics of high purification efficiency, low price and good thermal stability.

Owner:TSINGHUA UNIV

Iron catalyst containing titanium deposition for catalyzing Fischer-Tropsch synthesis reaction and method for producing the same

ActiveCN101298046ALarge specific surface areaGood choiceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsNitrateCopper nitrate

The invention relates to an iron catalyst which contains an assistant and used for catalyzing the Fischer-Tropsch reaction, which is characterized by comprising the components with mass ratios of Fe: Cu; K: Ti: SiO2 equal to 100: (0.1-10): (0.1-10): (0.01-5): (5-30), wherein, Fe, Cu, K and Ti exist in the form of oxides. The invention also relates to a preparation method for the catalyst, which comprises the steps that: at the presence of a precipitator with a pH value of 6-9, ferric nitrate, copper nitrate and a titanium compound are deposited in water; a deposit is separated and mixed with potassium carbonate and silica sol after being washed; a mixture obtained is dried and calcined. The iron catalyst with the assistant of titanium structure has relatively large specific surface area, CO conversion activation and antiwelding and antisulphour properties.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

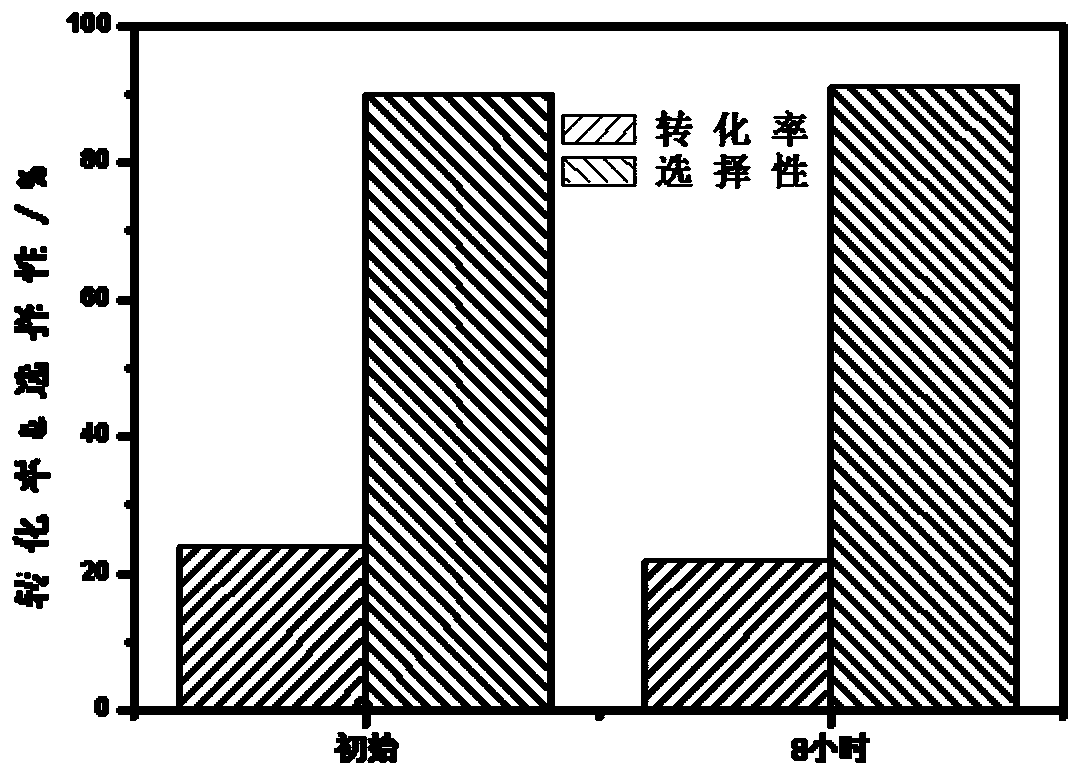

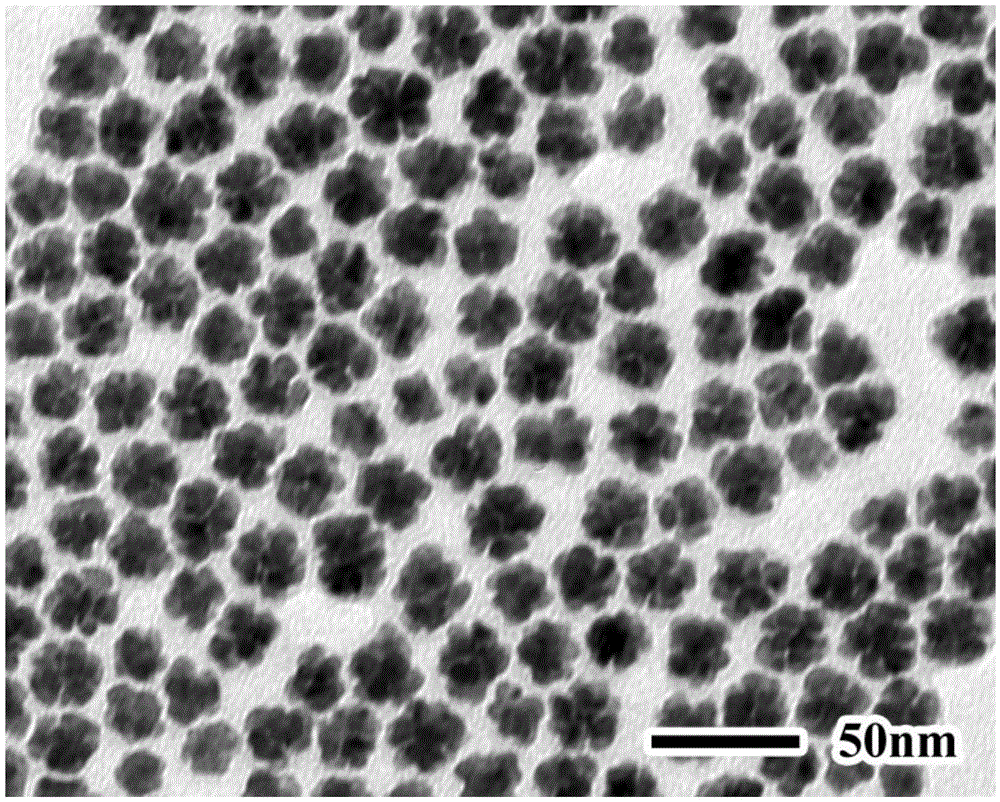

Aluminum oxide loaded PtCu monatomic alloy catalyst and preparation method and application thereof

ActiveCN108620092AHigh activityPt content decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention discloses an aluminum oxide loaded PtCu monatomic alloy catalyst and a preparation method and application thereof. The catalyst takes Al2O3 as a carrier, takes Cu as an auxiliary, and loads a small amount of active components Pt; the mass percent of Pt is 0.025%-0.15%, and the mass percent of Cu is 5%-20%; and during preparation, a co-impregnation method is used, the Al2O3 carrier isimpregnated in an aqueous solution of chloroplatinic acid and copper nitrate, the PtCu / Al2O3 catalyst is obtained after drying and roasting and high-temperature reduction, and the catalyst has high activity and high stability, and is low in price and low in toxicity. The catalyst is suitable for reaction for producing olefin by dehydrogenation through low alkane, and is particularly suitable forreaction for producing propylene by dehydrogenation through propane in a hydrogenation atmosphere, the dehydrogenation activity is quite high under the condition of high temperature, the selectivity of the propylene can reach 90% or above, the stability is good, the use amount of Pt is small, the utilization rate is high, and compared with an industrial Pt series catalyst, the aluminum oxide loaded PtCu monatomic alloy catalyst is cheaper.

Owner:TIANJIN UNIV

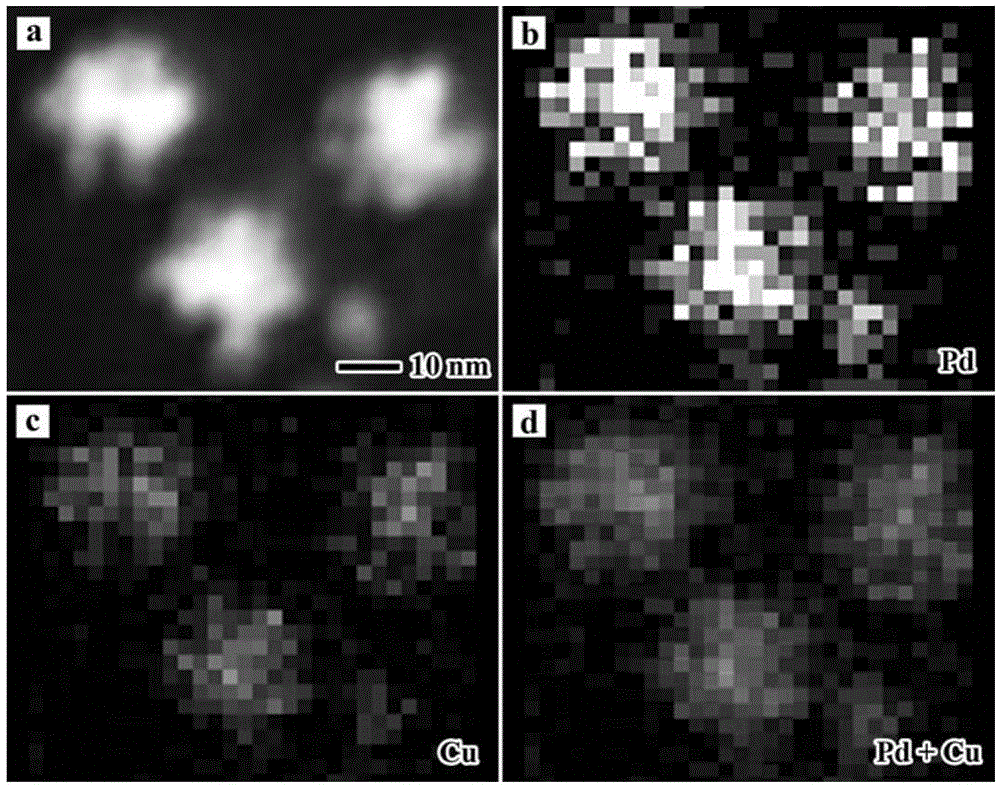

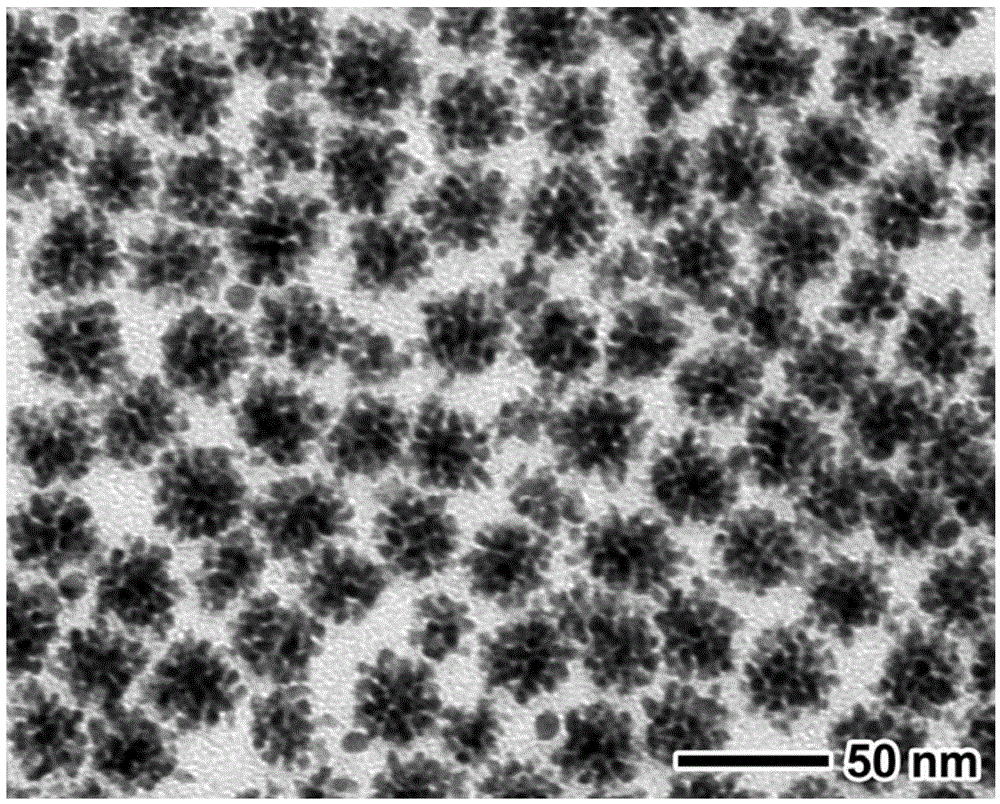

Preparation method for dendritic copper-palladium nanocrystalline alloy and product of preparation method

InactiveCN105618784AEasy to operateMild reaction conditionsTransportation and packagingMetal-working apparatusCopper chlorideCopper nitrate

The invention relates to a preparation method for a dendritic copper-palladium nanocrystalline alloy, which comprises the following steps: dissolving a palladium precursor, a copper precursor and a dispersant into a solvent, then adding a reducing agent, performing a reaction at 120-160 DEG C for 1-2 h, and performing centrifugal separation to obtain a dendritic copper-palladium nanocrystalline alloy, wherein the palladium precursor is palladium acetylacetonate, palladium acetate or palladium nitrate; and the copper precursor is copper acetylacetonate, copper chloride, copper nitrate or copper sulfate. The invention further relates to the dendritic copper-palladium nanocrystalline alloy. Dendritic nanocrystals with adjustable sizes and good dispersibility can be prepared according to the preparation method, and the preparation method is simple, has high repeatability and is low in cost.

Owner:ZHEJIANG UNIV

Method for preparing Nano tube of titanate

InactiveCN101003385ALarge specific surface areaImproved electrical and catalytic propertiesPolycrystalline material growthTitanium compoundsCopper nitrateSodium titanate

This invention discloses a method for preparing titanate nanotubes. The method comprises: uniformly mixing nitrate and power of sodium titanate nanotubes at a mol ratio of (5-100):1, performing melt-reaction at 50-450 deg.C for 3-48 h, cooling, washing to remove unreacted nitrate, and drying to obtain titanate nanotubes. The nitrate is lithium nitrate, and drying to obtain titanate nanotubes. The nitrate is lithium nitrate, potassium nitrate, rubidium nitrate, cesium nitrate, silver nitrate, nickel nitrate, thallium nitrate, copper nitrate, zinc nitrate or cobalt nitrate. The precursor of sodium titanate nanotubes is prepared by: reacting titanium dioxide, metatitanic acid or titanate ester in 20-80 wt. % NaOH aqueous solution at 100-140 deg.C for 12-72 h, washing with water, filtering and drying. This invention can prepare titanate nanotubes with large specific surface area by melt-exchange method.

Owner:HENAN UNIVERSITY

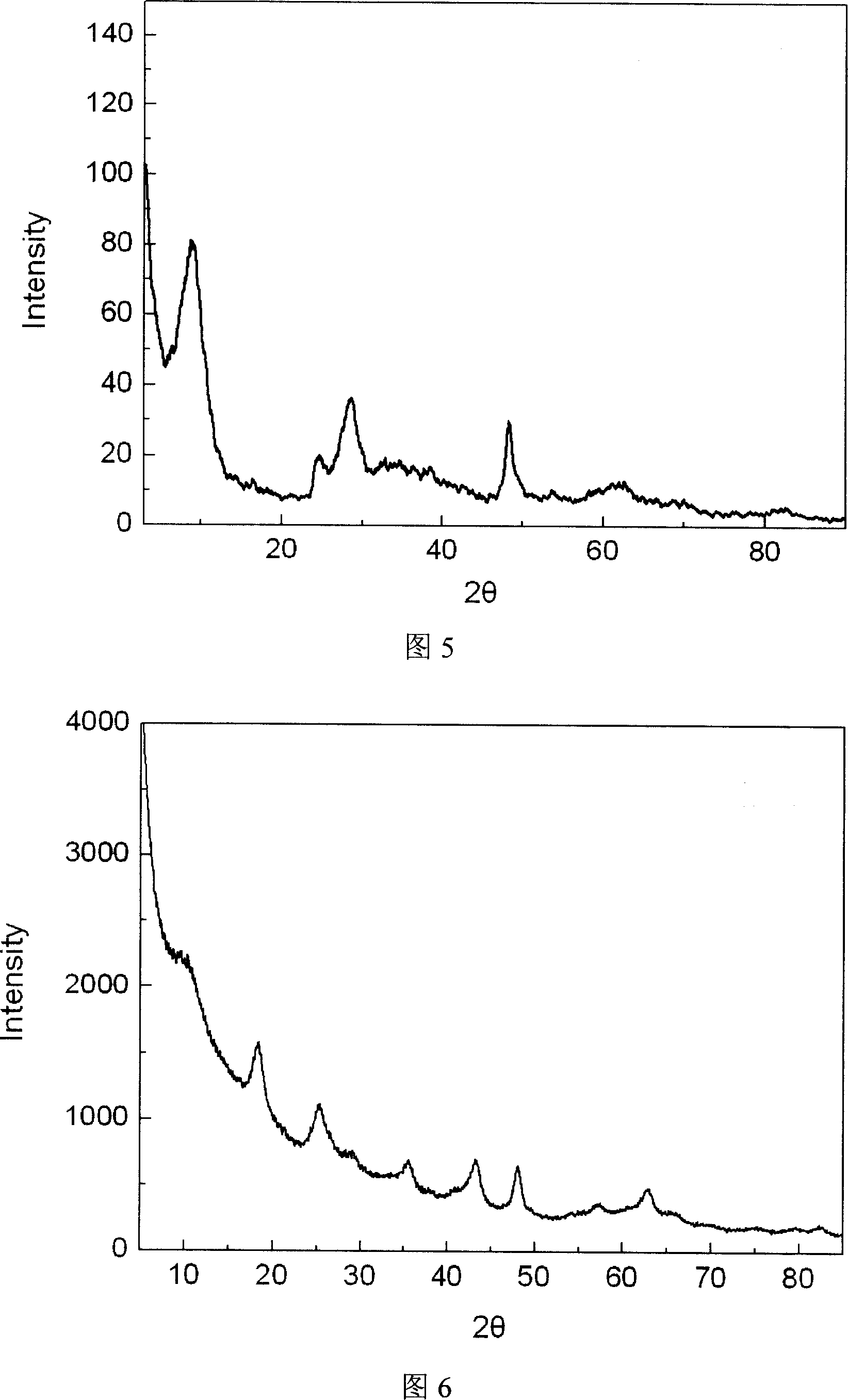

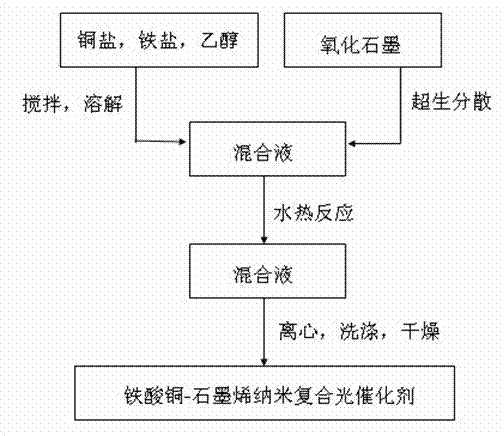

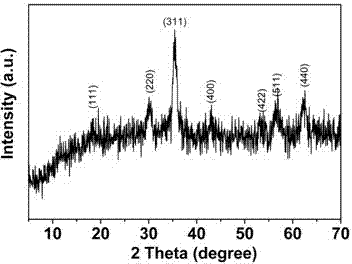

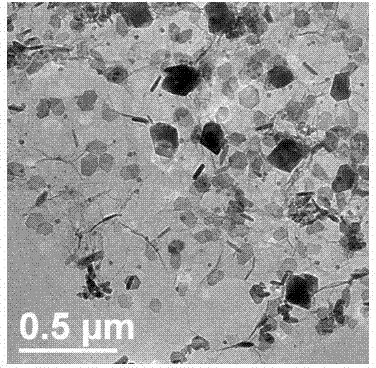

Copper ferrite-graphene nano complex and preparation method thereof

InactiveCN102527387AEvenly dispersedNo pollution in the processWater/sewage treatment by irradiationCell electrodesCopper nitrateHydrothermal synthesis

The invention discloses a copper ferrite-graphene nano complex and a preparation method of the copper ferrite-graphene nano complex. The preparation method comprises the steps of: ultrasonically dispersing graphite oxide in ethanol, adding ferric nitrate and copper nitrate to ethanol, stirring for dissolving, then mixing two systems, transferring the mixed system to a hydrothermal kettle for reaction, after reaction is finished, centrifugally separating the product, washing and drying to obtain the copper ferrite-graphene nano complex. According to the invention, copper ferrite nano sheets with uniform size and uniform dispersing are prepared with graphene as a supporting material by a hydrothermal synthesis method. The copper ferrite-graphene nano complex prepared by the preparation method disclosed by the invention has better application prospects and economic benefits in the aspects of sewage treatment and lithium ion cells.

Owner:NANJING UNIV OF SCI & TECH

Application of nanometer copper oxide and the method of preparing the same

InactiveCN101041119AHigh desulfurization precisionSimple preparation processNanostructure manufactureDispersed particle separationLow demandSulfur

The invention relates to an application of nanometer copper oxide and the preparing method, belonging to an application of compound and the preparing method. Before the invention, there are not reports that single nanometer copper oxide is used as ambient temperature desulfurizer and the purity of nanometer copper oxide prepared by prior preparing method for nanometer copper oxide is low. In the invention, the nanometer copper oxide is used as the ambient temperature desulfurizer and the nanometer copper oxide is the only component of ambient temperature desulfuizer. The preparation of nanometer copper oxide is that sodium hydroxide is added in the copper nitrate solution and then it is filtered, dried and baked or the preparation of nanometer copper oxide is that sodium hydroxide is added in the copper nitrate solution and then it is filtered and dried. The desulfurization accuracy of nanometer copper oxide in the invention is high in ambient temperature condition and the sulfur capacity is high to 18.3%-28.7%. The purity of nanometer copper oxide prepared in the invention is higher than 99.9%. It is provided with simple preparing process, low demand for machining equipment, small energy consumption and low production cost. It is easy to be developed and implemented.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com