Patents

Literature

158results about How to "Strong oxidizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing trace of thallium in sewage

InactiveCN104773878AStrong oxidizingImprove adsorption capacityWater contaminantsMultistage water/sewage treatmentFenton reagentSulfate

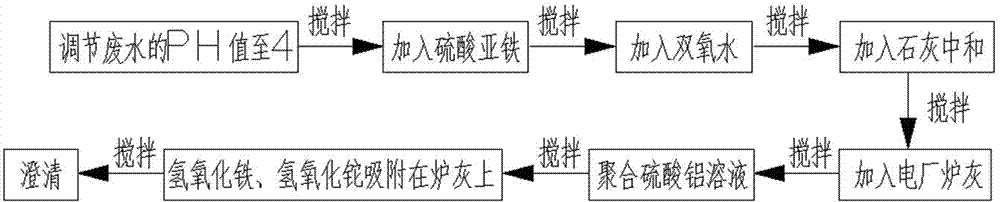

The invention relates to a method for removing a trace of thallium in sewage. The method includes the process steps of regulating the PH value of the thallium-contained sewage to 4, adding a ferrous sulfate solution to the sewage, evenly mixing the sewage with the ferrous sulfate solution, adding hydrogen peroxide to the sewage again, conducting stirring, oxidizing fluorosis univalence thallium (T1+) in the sewage into tervalence thallium (T13+), mixing ferrous iron and hydrogen peroxide into a fenton reagent, adding lime to the sewage and evenly conducting stirring so that the PH value of the sewage can be neutralized to be 7 to 9, hydrolyzing tervalence iron (Fe3+) in the sewage at the same time to form flocculent ferric hydroxide, adding an appropriate amount of power plant stove ash (electric duct collector stove ash) to the sewage, evenly conducting stirring, and adding a polyaluminium sulfate solution so that ferric hydroxide and thallium hydroxide can be adsorbed to the stove ash. Flocculent sediment generated through hydrolysis has the great surface area and quite strong adsorption capacity; the power plant stove ash can adsorb the flocculent sediment and colloid particles in the sewage and sink.

Owner:广东云测环境科技有限公司

Preparation method and application of biomass-based porous carbon/sulfur composite

InactiveCN106981644AHigh value utilizationImprove cycle stabilityHybrid capacitor electrodesCell electrodesBiomass carbonPorous carbon

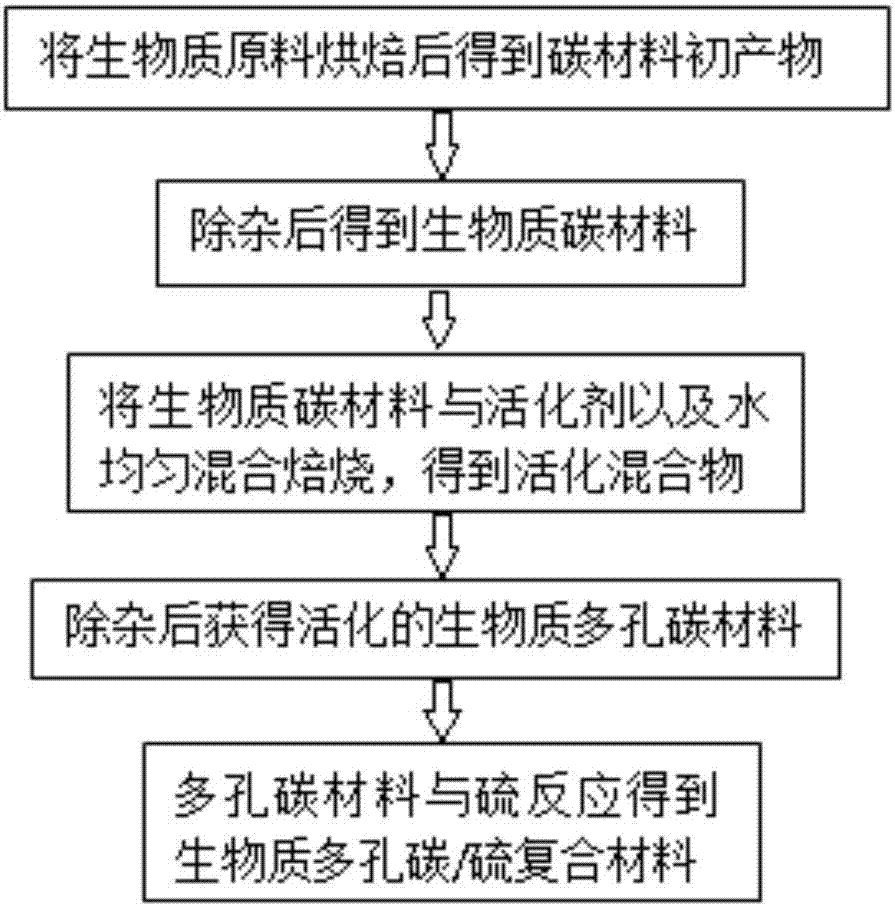

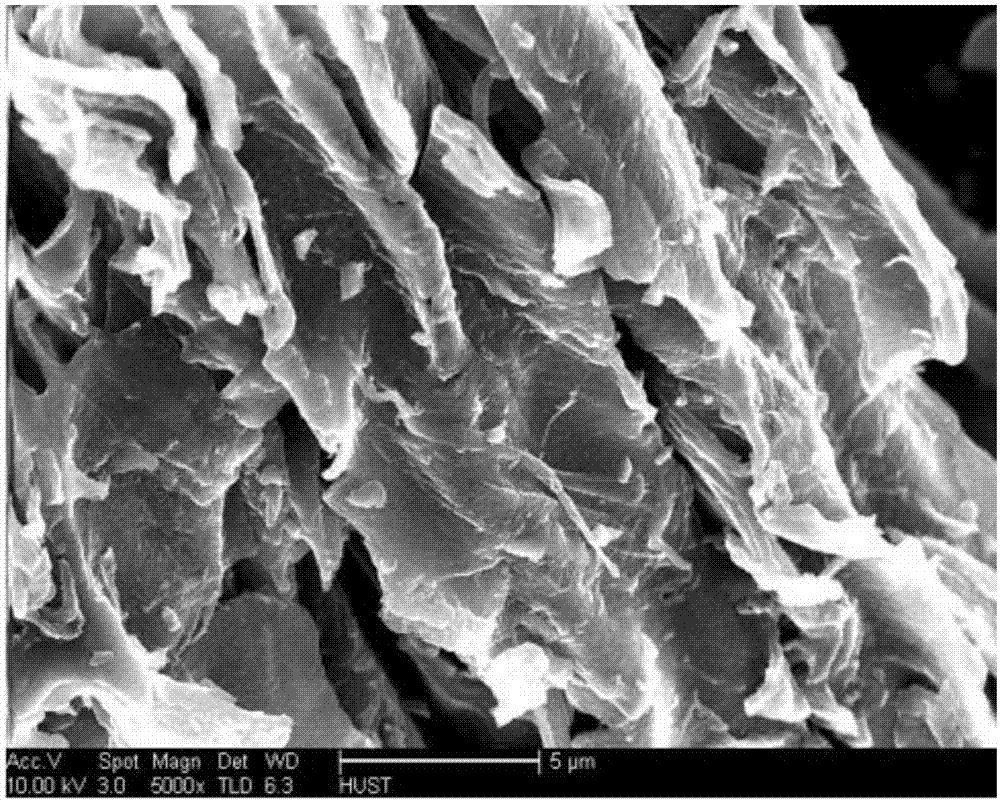

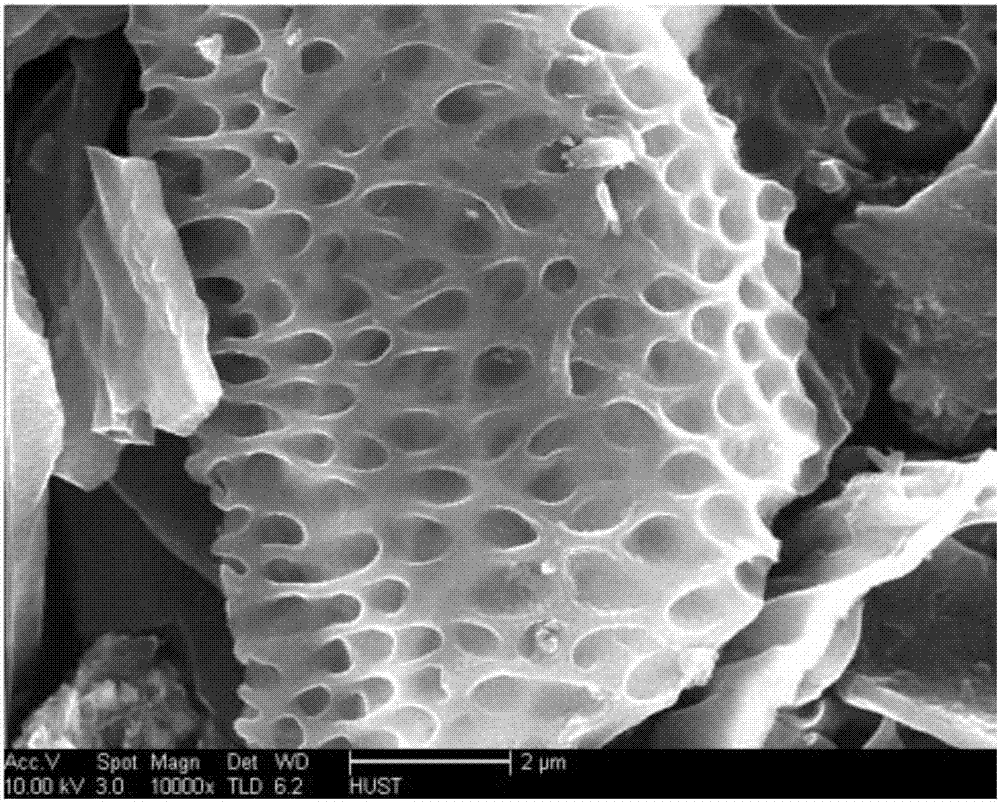

The invention belongs to the field of lithium-sulfur battery cathode materials and particularly relates to a preparation method of a preparation method of biomass-based porous carbon / sulfur composite, comprising the specific steps of S1, calcining biomass material to obtain a primary product of carbon material; S2, removing impurities from the primary product of carbon material to obtain biomass carbon material; S3, mixing well the biomass carbon material with an activator and water, and calcining to obtain activated mixture; S4, removing impurities from the mixture to obtain activated porous carbon material; S5, mixing the porous carbon material with sulfur for the purpose of reacting to obtain the porous carbon / sulfur composite. The invention also discloses application of the porous carbon / sulfur composite as a cathode material in batteries or supercapacitors. A battery prepared with the biomass carbon / sulfur composite prepared herein has high discharge capacity, good cycle stability and high coulombic efficiency, and has a promising application.

Owner:HUAZHONG UNIV OF SCI & TECH

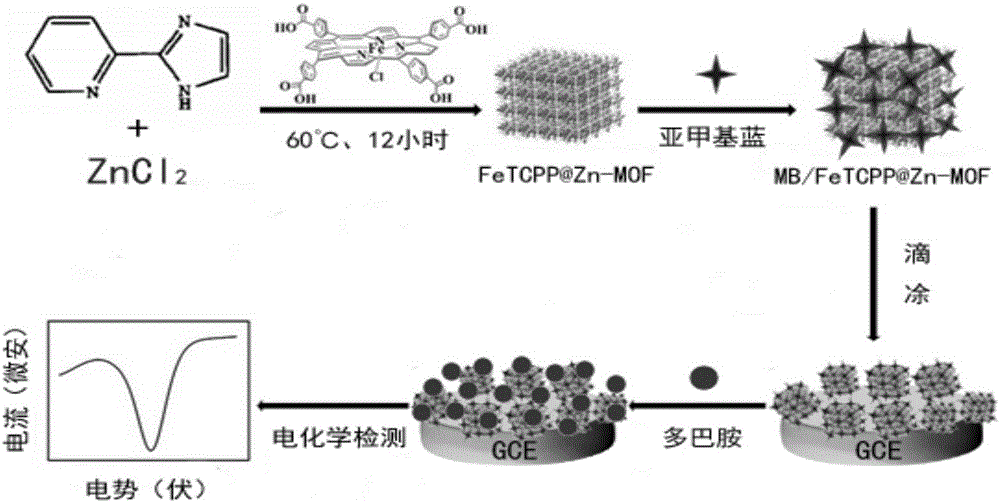

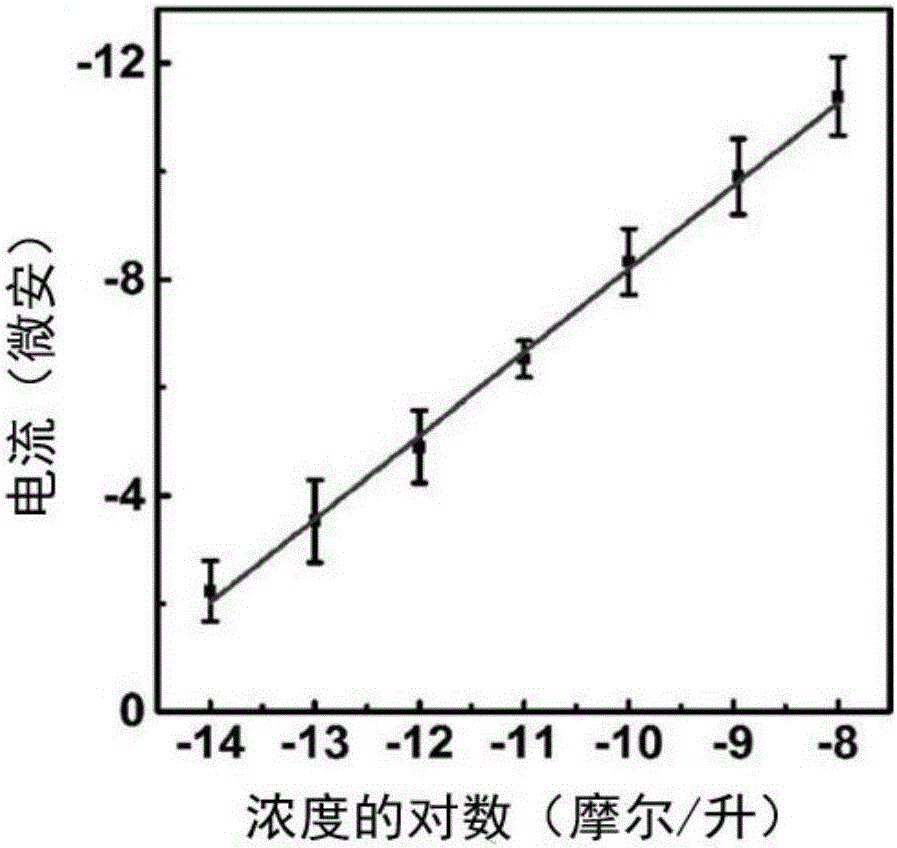

Preparation method and application of electrode of composite material of iron porphyrin chloride/methylene blue @metal-organic framework

ActiveCN106111196AStrong oxidizingAccurate detectionOrganic-compounds/hydrides/coordination-complexes catalystsMaterial electrochemical variablesOxidopamineMetal-organic framework

The invention provides a preparation method and application of an electrode of a composite material of an iron porphyrin chloride / methylene blue @metal-organic framework. Iron porphyrin chloride (FeTCPP) is encapsulated to a Zn metal-organic framework (MOF) by a one-pot method, a composite material of the metal-organic framework has negative charges in a solution, and cationic dye methylene blue (MB) with oxidation-reduction activity can be absorbed. The composite material is modified to the surface of a glass carbon electrode, and dopamine can be catalyzed and oxidized so that an electrical signal can be produced, sensitive detection for the dopamine is realized by an electrochemical method, the lowest detection limit can reach 0.48fM, and the detection range is wide. The composite material of the metal-organic framework disclosed by the invention is synthesized for the first time, and besides, the composite material of the metal-organic framework is also applied to the field of electrochemical sensing for the first time, the method is simple, the cost is low, and high electrochemical sensing sensitivity indicates that the composite material of the metal-organic framework functionalized by porphyrin and methylene blue has good application prospects in the field of electrochemical and biological sensing.

Owner:QINGDAO UNIV

Flat-plate type high-temperature SCR (Selective Catalytic Reduction) denitration catalyst and preparation method thereof

ActiveCN104741114ALarge specific surface areaImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryComposite oxide

The invention belongs to the field of environmental protection and environmental catalysis and particularly relates to a flat-plate type high-temperature SCR (Selective Catalytic Reduction) denitration catalyst and a preparation method thereof. The preparation method comprises the following steps of: by adopting a nano composite oxide CeO2-TiO2 or CeO2-ZrO2 as a carrier, and adopting WO3 as an active component, carrying out stepped mixing, rolling coating, pleating, shearing, drying and roasting to obtain the flat-plate type high-temperature SCR denitration catalyst on the basis of adopting CeO2-TiO2 or CeO2-ZrO2 composite oxide as the carrier. The product has excellent high-temperature denitration performance, and is applicable to flue-gas denitration under the temperature of 500-700 DEG C; and the product has excellent mechanical performance, sulfur-dioxide poisoning resistance and sintering resistance.

Owner:北京华电光大环境股份有限公司

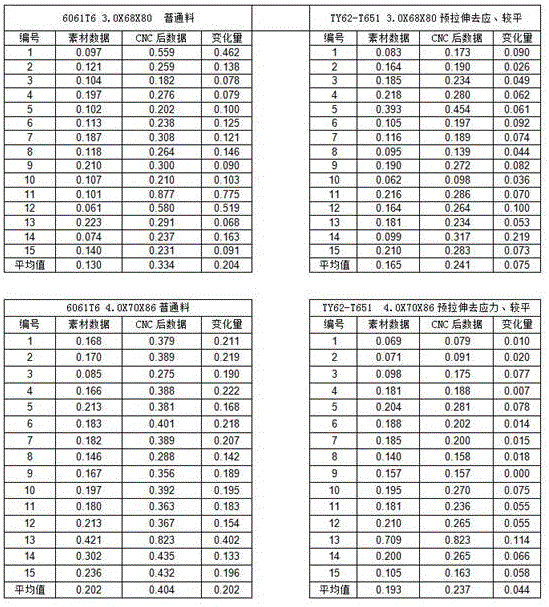

Manufacturing method of high-strength oxidable aluminum alloy plate strip

The invention discloses a manufacturing method of a high-strength oxidable aluminum alloy plate strip. The manufacturing method of the high-strength oxidable aluminum alloy plate strip comprises the following steps that (1) molten aluminum alloy is prepared, specifically, chemical elements are determined, and the aluminum alloy comprises, by mass, 0.6%-0.9% of Si, 0.1%-1.4% of Fe, 0.6%-0.9% of Cu, 0.2%-0.3% of Mn, 0.9%-1.1% of Mg, 0-0.05% of Cr, 0-0.05% of Zn, 0-0.05% of Ti, 0-0.05% of single impurities, 0-0.15% of blended impurities, and the balance Al; (2) casting is conducted; (3) hot rolling is conducted; (4) intermediate annealing is conducted; (5) cold rolling and finish rolling are conducted; and (6) continuous pull-correcting or predrawing is conducted. The aluminum alloy plate strip manufactured through the method has high strength, the tensile strength T.S(delta b / MPa) is equal to or higher than 350 MPa, the yield strength Y.S(delta 0.2 / MPa) is equal to or higher than 320 MPa, the extensibility (theta / %) is equal to or higher than 8%, and the surface hardness HV is equal to or higher than 120. The type of the aluminum alloy plate strip manufactured through the method is TY62-T651, the aluminum alloy plate strip is high in supporting strength and surface strength and oxidable when used for a side key of a mobile phone support, continuous punching can be achieved, and the production efficiency is high.

Owner:昆山灿鑫精密电子科技有限公司

Cobalt-load cerium manganese oxide catalyst and preparation method thereof

ActiveCN105289641AExcellent oxygen storage and release capacityGood catalytic oxidation performanceMetal/metal-oxides/metal-hydroxide catalystsCobalt oxideManganese oxide

The invention discloses preparation of a cobalt-load cerium manganese oxide catalyst. Cerium manganese oxide is prepared through an oxidization reduction method, then cobalt is loaded to the cerium manganese oxide through an equivalent-volume impregnation method, manganese oxide has good oxidization performance, cerium oxide has excellent oxygen storage and release capacity, cobalt oxide also has certain oxidization performance, the catalyst has good purifying efficiency on low-concentration nitric oxide, the conversation rate can be 96% at the temperature of 25 DEG C, long service life can also be kept, meanwhile raw materials for preparing the catalyst are easy to obtain, the technology is simple, cost is low, and industrial production can be achieved easily.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Diesel vehicle oxidized form catalyst having low temperature activity and preparation method thereof

ActiveCN105797767ALow ignition temperatureImprove conversion rateGas treatmentMolecular sieve catalystsSlurryComposite oxide

The invention relates to a diesel vehicle oxidized form catalyst having low temperature activity and a preparation method thereof.The catalyst comprises a carrier and a coating applied to the carrier, the coating is loaded with noble metal, the coating comprises tungsten-aluminum silicon composite oxide and molecular sieves, the noble metal is one of Pt and Pd or a mixture of the two types of substances, the coated weight of the coating is 80-180 grams / liter, and the coated weight of the noble metal is 0.5-4.5 grams / liter.The preparation method comprises the steps of firstly, preparing the tungsten-aluminum silicon composite oxide through an equivalent-volume impregnation method, then making slurry with the molecular sieves and the tungsten-aluminum silicon composite oxide according to the mass ratio of 1: (2-10), adding the noble metal Pt and Pd, finally immersing the carrier into the slurry, and conducting drying and sintering, so that the diesel vehicle oxidized form catalyst is obtained.The preparation method of the catalyst is simple, the steps are easy to operate, the prepared diesel vehicle oxidized form catalyst is low in combustion temperature, high in conversion rate and good in thermal stability, good capability for oxidizing HC and CO in tail gas of a diesel vehicle is achieved, and good sulfur resistance is achieved.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

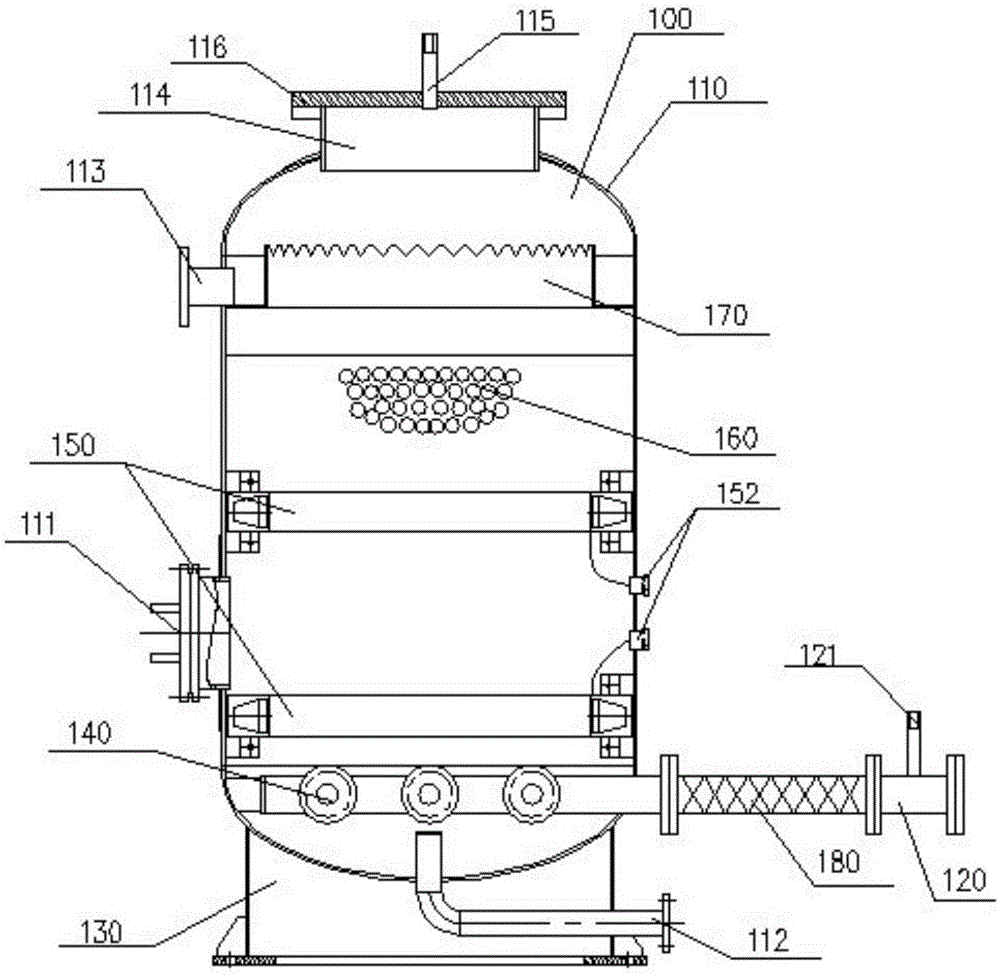

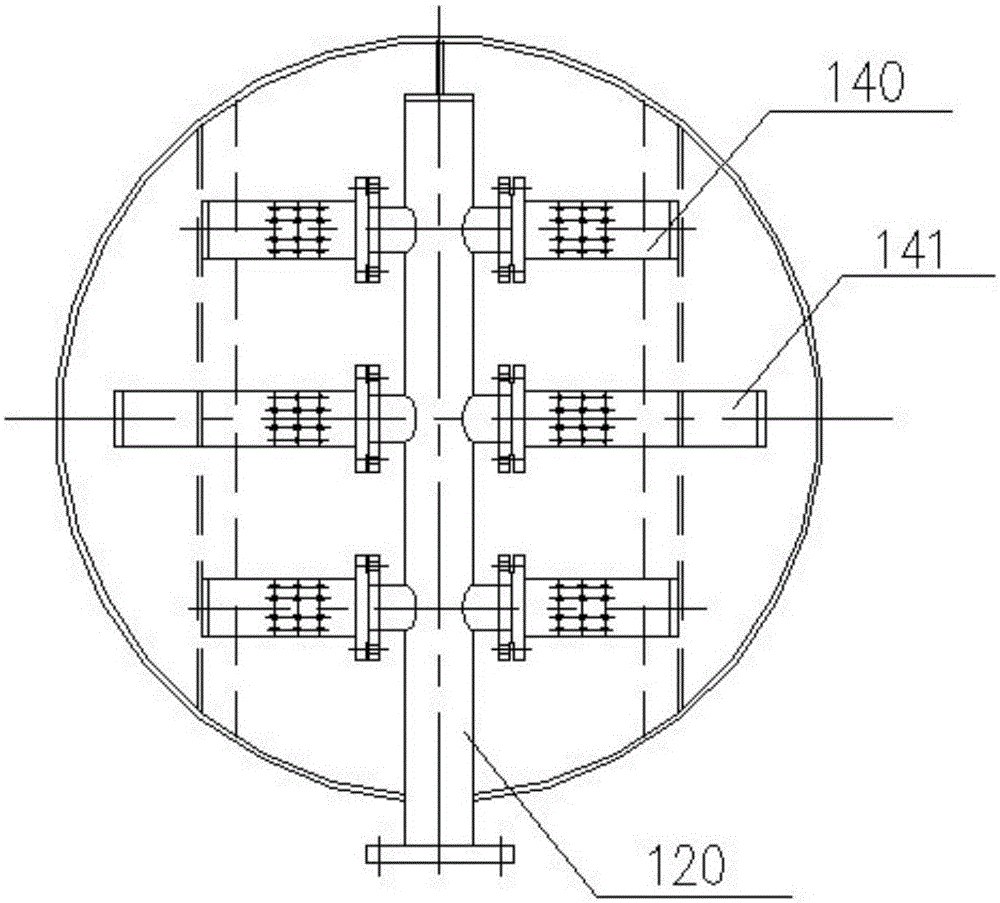

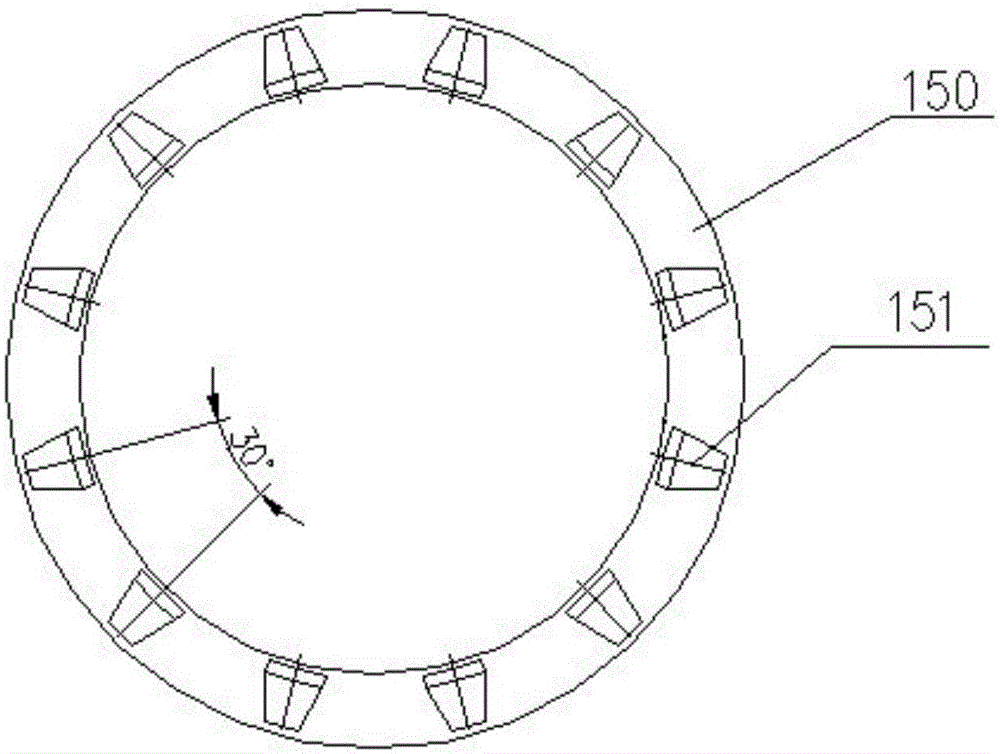

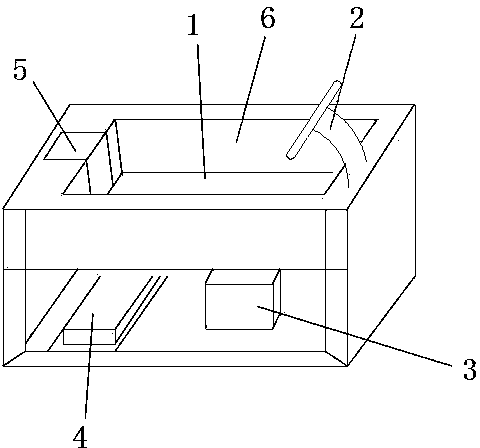

Ozone oxidation reactor

ActiveCN105000627AReal-time processingEasy to moveWaste water treatment from quariesWater/sewage treatment with mechanical oscillationsChemical oxygen demandUltrasonic cavitation

The invention discloses an ozone oxidation reactor. The ozone oxidation reactor comprises a tank body and a water inlet pipe communicated with the tank body. The water inlet pipe is provided with a water inlet and an ozone inlet. Ozone is fed in the ozone inlet. A hydrodynamic cavitation device allowing water and the ozone to generate hydrodynamic cavitation is arranged in the water inlet pipe. Ultrasonic oscillators allowing the water and the ozone to generate ultrasound cavitation are arranged in tank body and connected with an ultrasonic generator. A cavity of the tank body is filled with catalysts for motivating the ozone to generate hydroxyl radical. According to the ozone oxidation reactor, ozone oxidation is combined with an ultrasonic cavitation technology and a hydrodynamic cavitation technology to form a synergetic catalytic ozonation technology, the hydroxyl radical with the higher oxidation performance and lower reaction selectivity is generated, the oxidation potential of the hydroxyl radical can reach 2.8 V, the hydroxyl radical can generate a chain reaction with most of organic pollutants unselectively, hazardous substances are converted into CO2, H2O and mineral salt, the chemical oxygen demand is lowered, and meanwhile secondary pollution is avoided.

Owner:INST OF SINOPEC OILFIELD EQUIP CORP +1

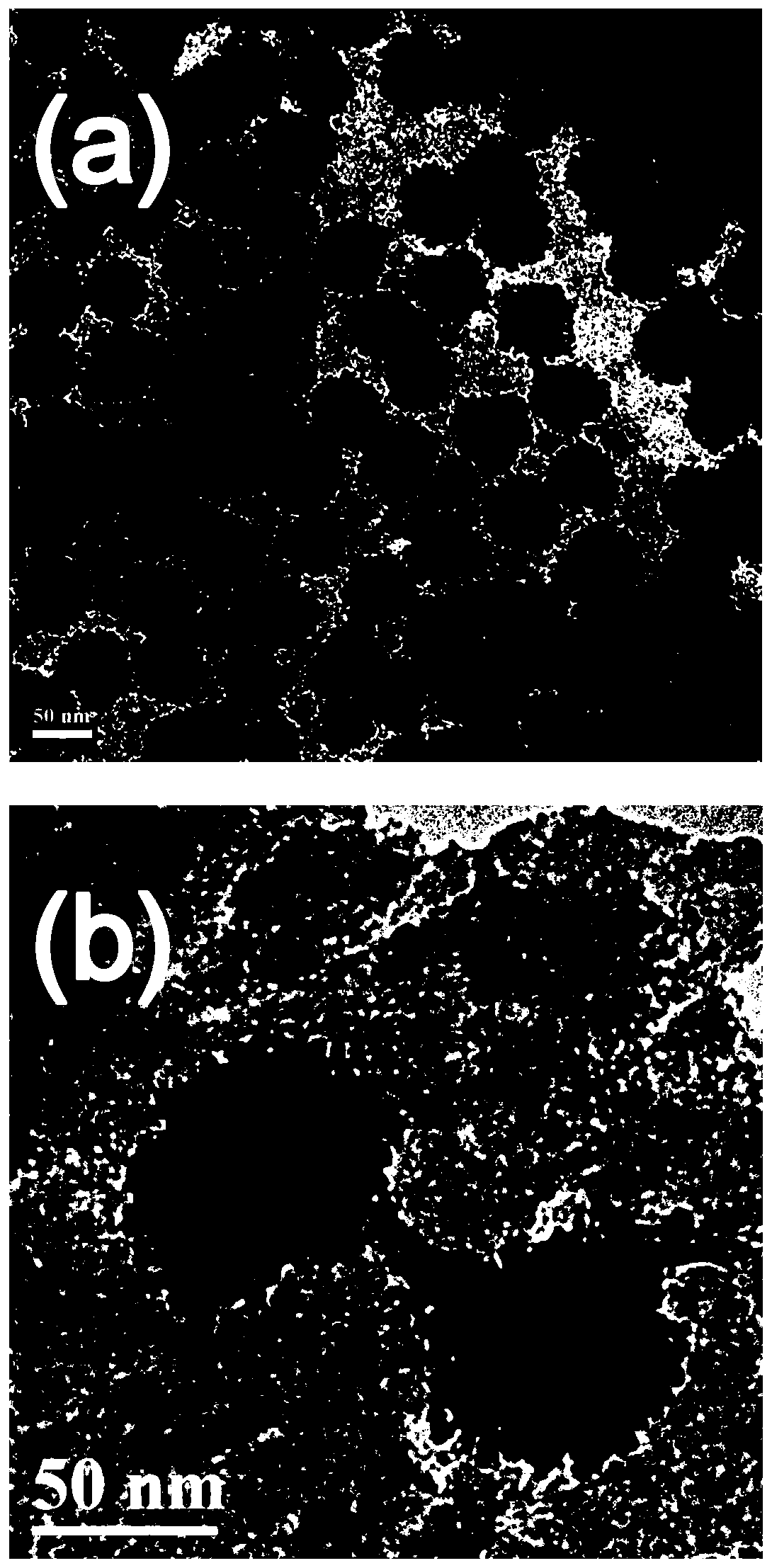

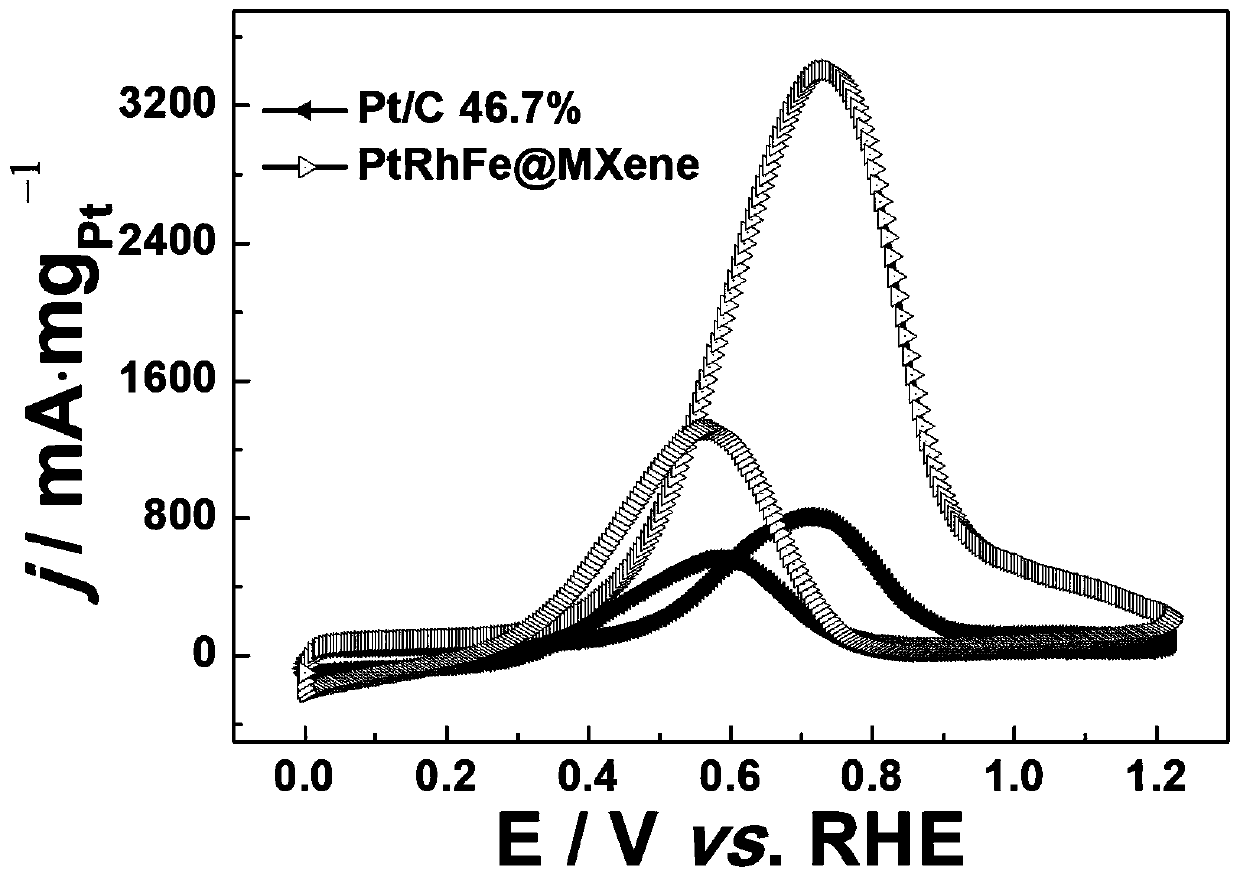

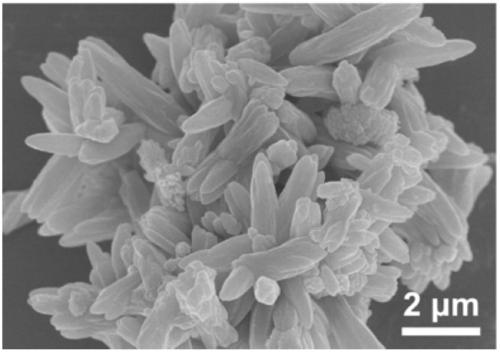

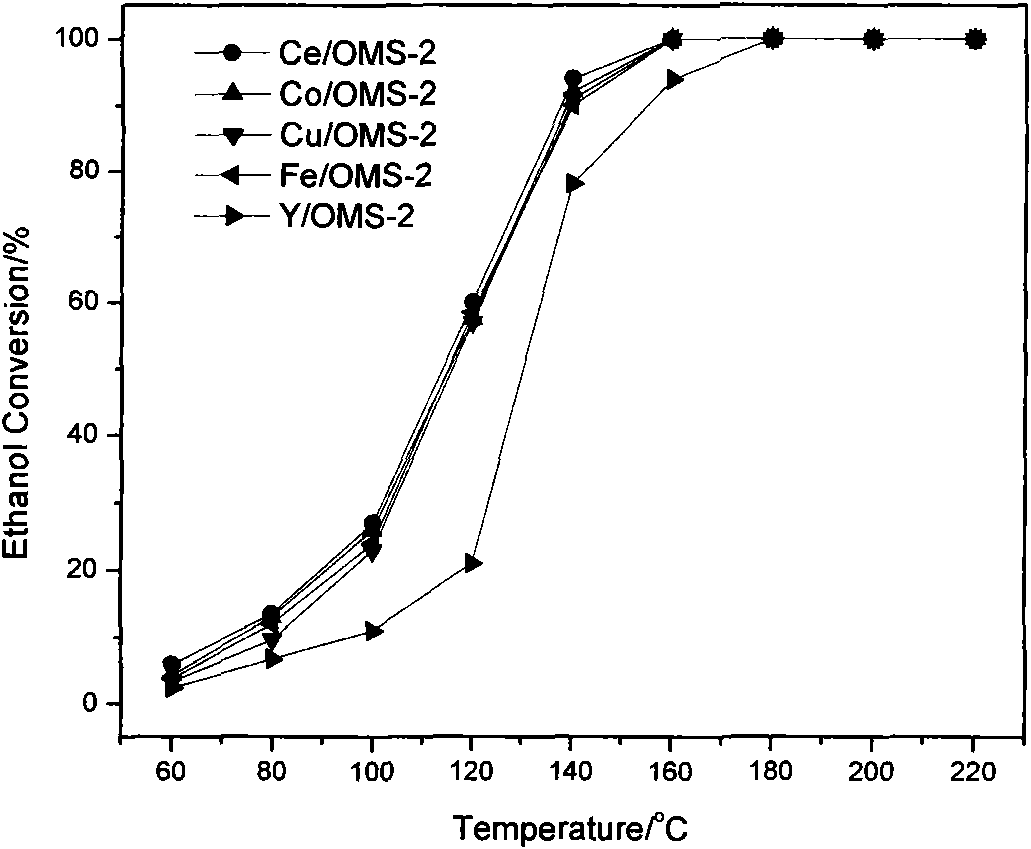

MXene loaded PtRhFe ternary alloy catalyst, and preparation method and formula thereof

ActiveCN109950564ASimple processGood repeatabilityMaterial nanotechnologyCell electrodesPotassium hydroxidePotassium

The invention discloses a preparation method of a MXene loaded PtRhFe ternary alloy catalyst. The method comprises that an organic solvent, a platinum source, a rhodium source, an iron source, a substrate material MXene powder and a surfactant are mixed and stirred uniformly, and make hydrothermal reaction; and centrifugation, washing, drying and grinding are carried out to obtain dry powder, namely a 2D material of MXene nanosheet loaded porous spherical PtRhFe ternary alloy particle product. The technology is simple, the repeatability is high, the prepared has an excellent enthanol oxidizability in an electrolyte including 1.0 mole / L potassium hydrate and 1.0 mole / L ethanol, and the peak current density can reach 3407milliampere / milligram which is 4.2 times of the peak current density ofa commercial platinum carbon catalyst in the platinum capacity of 46.7%. The catalyst can be widely applied to field of electrocatalysis enthanol oxidation, and enables large-scale commercializationof direct enthanol fuel cells.

Owner:SUN YAT SEN UNIV

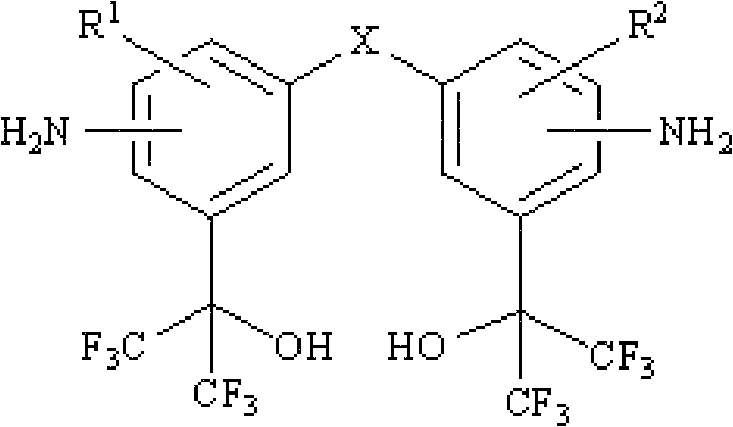

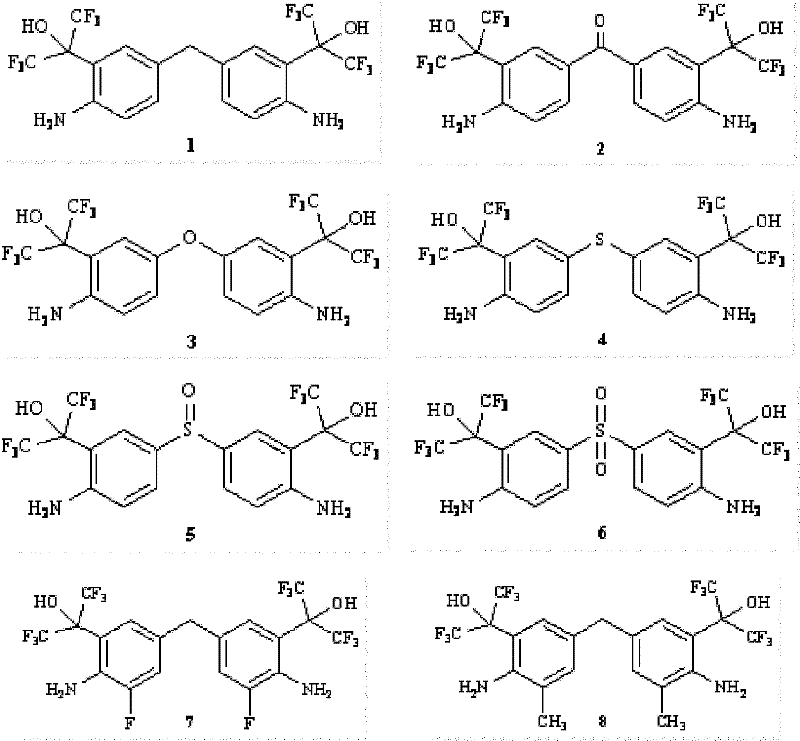

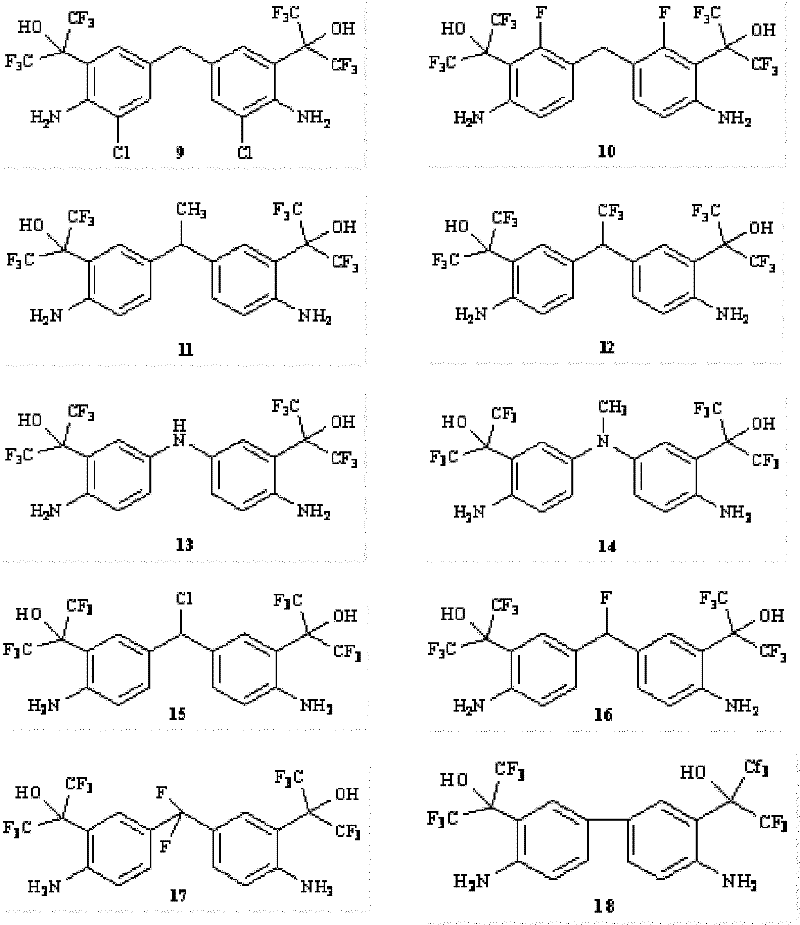

Membrane functional monomer containing hexafluoroisopropanol group and nanofiltration membrane preparation method thereof

ActiveCN102527265AImprove performanceImprove interception effectSemi-permeable membranesFunctional monomerMembrane surface

The invention relates to a membrane functional monomer containing a hexafluoroisopropanol group and a nanofiltration membrane preparation method thereof. A monomer which contains 1-hydroxy-1-trifluoromethyl-2,2,2-trifluoroethyl dianil compound as a nanofiltration membrane is designed and synthesized. The fluorine-containing nanofiltration membrane monomers are different monomers obtained from the reaction of a 4, 4'-dianil compound containing different substituent groups and hexafluoroacetone trihydrate. The nanofiltration membrane preparation method comprises the following steps of: fixing a basement membrane; soaking the basement membrane into a fluorine-containing monomer aqueous-phase solution; removing the superfluous aqueous-phase solution on the membrane surface, and then performing single interfacial polymerization on the basement membrane and a polybasic acyl chloride solution; drying for 1-5 minutes in air; performing heat treatment at 40-100 DEG C for 2-15 minutes; and rinsing, thereby obtaining the fluorine-containing nanofiltration membrane. The nanofiltration membrane preparation method has the advantages that the prepared fluorine-containing nanofiltration membrane has an excellent effect of retaining bivalent cations and anions and has ultrahigh property for resisting oxidation of free chlorine.

Owner:EAST CHINA UNIV OF SCI & TECH

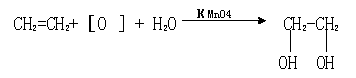

Method for discoloring sulfuric acid by using potassium permanganate

The invention relates to a method for discoloring sulfuric acid by using potassium permanganate. The method comprises the following steps of: filling potassium permanganate saturated water solution at normal temperature into sulfuric acid in a closed sulfuric acid discoloring tank at a speed of 0.1-0.8L / min.t, wherein the volume ratio of sulfuric acid to potassium permanganate saturated water solution at normal temperature is 1000: (2-8); and continuously stirring at a speed of 8-15 turns per minute, and statically placing the discolored sulfuric acid discharged from the sulfuric acid discoloring tank at least 1 day to obtain the finished product sulfuric acid. The method for discoloring sulfuric acid by using potassium permanganate has the advantages that since the potassium permanganate solution is used, the oxidizability is strong, the selectivity is good, the process is simple, convenient and flexible and the tawny or black brown sulfuric acid can be discolored; and the problem that the color and the clarity of the finished product sulfuric acid which is produced by using gypsum flue gas cannot satisfy the standard can be solved, the quality of the sulfuric acid which is produced by using the gypsum flue gas can be enabled to satisfy the standard on industrial concentrated sulfuric acid high-class products, the market competitiveness of the sulfuric acid which is produced by using gypsum is improved and the economic benefits of enterprises are increased.

Owner:刘立文

Catalytic oxidation type sludge conditioner and sludge conditioning method

InactiveCN110117149AImprove dehydration effectReduce dosageSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAluminium chlorohydrateSludge

The invention discloses a catalytic oxidation type sludge conditioner and a sludge conditioning method. The catalytic oxidation type sludge conditioner comprises an oxidant, a catalyst, a coagulant and a flocculating agent, wherein the oxidant is a peroxymonohydrosulfate composite salt, the catalyst is a cobalt salt, the coagulant is polyaluminum chloride, and the flocculating agent is polyacrylamide. According to the sludge conditioning method, sludge is conditioned by the catalytic oxidation type sludge conditioner, and the dewatering performance of the sludge is improved; in cooperation with mechanical dewatering, the water content of the discharged sludge is lowered to 60% or below. Meanwhile, the method solves the problems that the addition quantity of conditioners is large and the capacity of sludge is increased a lot in existing chemical sludge conditioning technologies; the method is beneficial to sludge disposal.

Owner:ZHEJIANG UNIV OF TECH

Composite carrier type SCR denitration catalyst capable of simultaneously removing nitrate and mercury, and preparation method thereof

InactiveCN105597732ALarge specific surface areaGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention discloses a composite carrier type SCR denitration catalyst capable of simultaneously removing nitrate and mercury, and a preparation method thereof. The catalyst comprises, by mass, 0.2 to 1.2% of V2O5 and 1.0 to 10% of WO3, with the balance being a TiO2-Ce2 composite oxide carrier. The nanometer TiO2-Ce2 composite oxide carrier has a higher specific surface area, enables active components to be better dispersed and has good water resistance and sulfur resistance; through interaction between the active components and the carrier, activity of the catalyst is further improved, and the catalyst has strong HgO oxidation activity in absence of HCl or under the condition of low HCl; and the catalyst simultaneously completes catalytic reduction of NOx and catalytic oxidation of HgO without additional installation of flue gas purifying facilities of a coal-fired power plant, thereby realizeing simultaneous controlling of NOx and HgO.

Owner:HUNAN UNIV

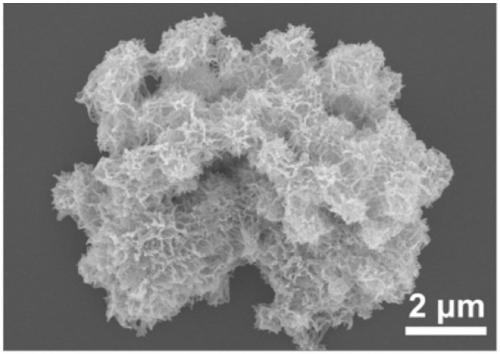

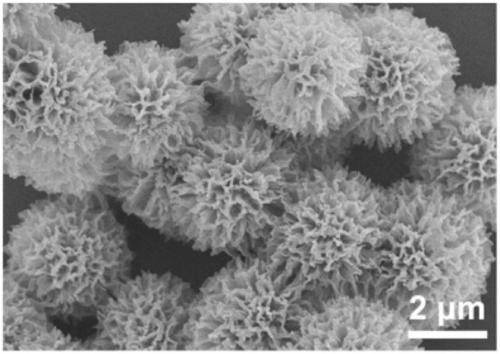

Double-functional amorphous FeMn-MOF-74 (ferromanganese-metal organic framework-74) nanoflower material and preparation method and application

InactiveCN109320736AEasy to operateNo secondary pollutionWater contaminantsWater/sewage treatment by sorptionMetal-organic frameworkChloride

The invention relates to a double-functional amorphous FeMn-MOF-74 (ferromanganese-metal organic framework-74) nanoflower material and a preparation method and application, and relates to a nanometermaterial and a preparation method and application, which aim at solving the problem of low adsorption capacity of existing MOF-based adsorbent to As(III). The double-functional amorphous FeMn-MOF-74 nanoflower material is prepared by taking 2,5-dihydroxy terephthalic acid as an organic ligand, anhydrous manganese chloride and anhydrous ferrous chloride as metal salt ligands, and N,N-dimethyl formamide and anhydrous ethanol as solvents through a solvothermal method. The preparation method comprises the following steps of 1, preparation of a mixed solution; 2, solvothermal reaction; 3, cleaningand drying. The double-functional amorphous FeMn-MOF-74 nanoflower material is used for removing poisonous metals in water, and oxidizing the poisonous metals in the water. The preparation method canbe used for preparing the double-functional amorphous FeMn-MOF-74 nanoflower material.

Owner:NORTHWEST A & F UNIV

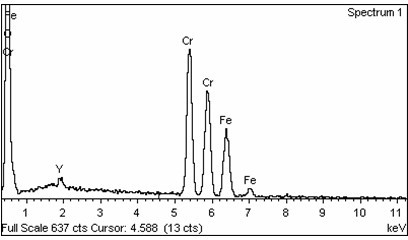

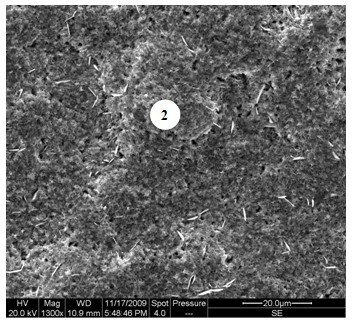

Method for adding rare earth to T91 and P91 steel for improving high temperature corrosion resistance

The invention relates to a method for adding rare earth to T91 and P91 steel for improving the high temperature corrosion resistance. The method comprises steps that: during a T91 and P91 steel smelting procedure, rare earth and / or corresponding oxides of rear earth are added to the steel, such that rear earth is dispersed in T91 steel. With the steps, T91 and P91 steel containing rear earth is prepared. The technical effects of the invention are that: 1, the T91 and P91 steel with the additive provided by the invention has excellent high-temperature vapor oxidation resisting capacity, and the oxidation speed of the type of material can be substantially reduced. When oxidized for 150 hours with a constant temperature under an environment of vapor with a temperature of 650 DEG C, an oxidation mass gain of a blank sample reaches 8.53mg / cm<2>, but an oxidation mass gain of a rear-earth-modified sample is only 0.12mg / cm<2>. No surface crack or oxide film exfoliation is found on the rear-earth-modified sample. 2, with the rear-earth-modified T91 and P91 steel provided by the invention, under an environment of high-temperature vapor, an oxide layer containing a large amount of chrome and a small amount of rear earth is formed on the surface of the sample.

Owner:NANCHANG HANGKONG UNIVERSITY

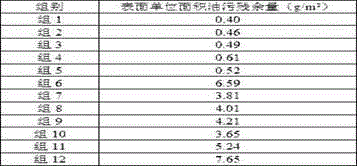

Easy-cleaning ceramic glaze as well as preparation method and application thereof

The invention discloses an easy-cleaning ceramic glaze as well as a preparation method and application thereof. The easy-cleaning ceramic glaze consists of the following raw materials in percentage by weight: 33-35% of potash feldspar, 10-12% of kaolin, 13-15% of calcium oxide, 8-10% of magnesium oxide, 6-8% of zinc oxide and 24-26% of quartz. All the raw materials are mixed and crushed to perform wet ball milling so as to obtain a glaze slip, and the glaze slip is subjected to iron removal, screening and aging for later use. According to the easy-cleaning ceramic glaze disclosed by the invention, various metal oxides are added in the formula of an easy-cleaning daily ceramic glaze to improve the easy-cleaning degree of the ceramic glaze and generate a synergistic action, the easy-cleaning degree and the glossiness of the obtained easy-cleaning ceramic glaze are much higher than those of the ceramic glaze in the past, and a glaze surface is smooth and nonstick to greasy dirt, so that the easy-cleaning ceramic glaze not only has significant self-cleaning capability and easy-cleaning property, but also has effective sterilizing, antibacterial, odor-removing and enzyme-preventing effects; and meanwhile, the obtained easy-cleaning ceramic glaze is leadless, green and safe.

Owner:GUANGDONG SHUNXIANG ENERGY SAVING LIGHTING TECH

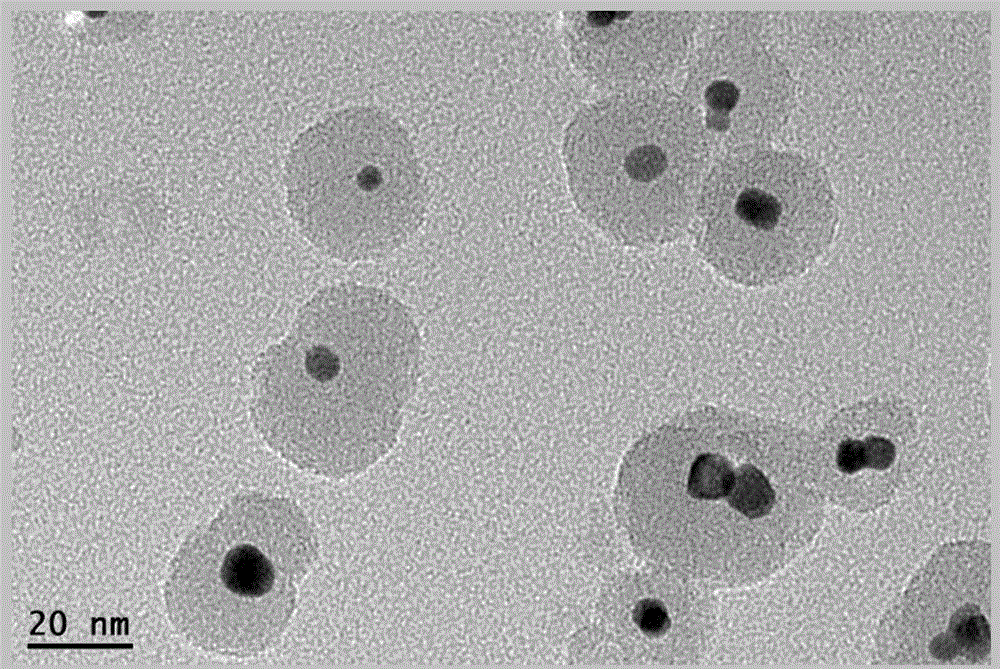

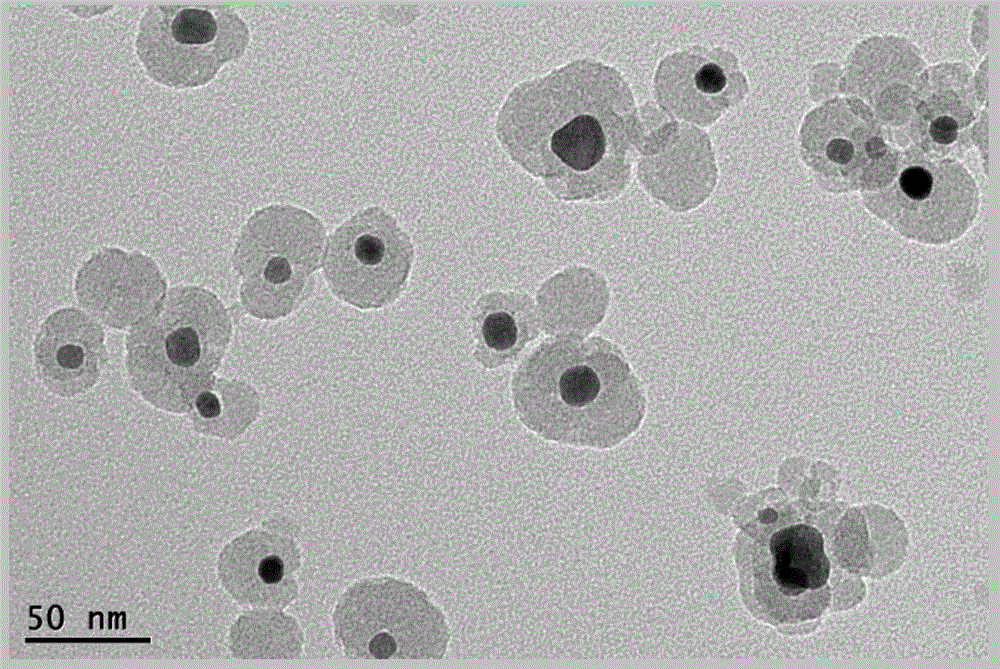

Acidity-controllable core-shell type platinum based catalyst and preparation and application thereof

ActiveCN106824175AHigh hydrothermal stabilityControlled AcidityNitrous oxide captureGas treatmentSilicon dioxideZirconium dioxide

The invention discloses the technical field of tail gas catalyst, and particularly relates to an acidity-controllable core-shell type platinum based catalyst for tail gas catalytic DOC (diesel oxidation catalyst) of a diesel vehicle and a preparation method thereof. The acidity-controllable core-shell type platinum based catalyst has the advantages that the nanometer platinum particles are used as an inner core, and the acid composite oxides, such as SiO2 (silicon dioxide)-Al2O3 (aluminum oxide), SiO2-TiO2 (titanium dioxide) and SiO2-ZrO2 (zirconium dioxide), are used as shells; under the existence of the catalyst, the diesel vehicle tail gas atmosphere is simulated, the temperature (T50) for converting 50% of propane (HC) is reduced to be lower than 250 DEG C, and more than 85% of NO is oxidized into NO2 (nitrogen dioxide) at the temperature below 200 DEG C; even after long-time high-temperature hydrothermal aging treatment at temperature of 800 DEG C, the original structure of the material can be still maintained, the excellent oxidizing activity is realized, and the use requirements of the DOC of the advanced diesel vehicle are met.

Owner:TSINGHUA UNIV

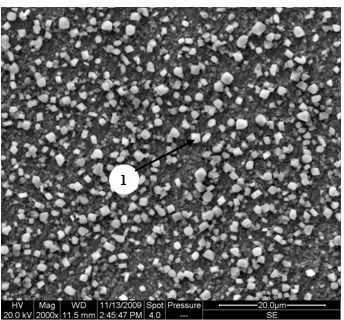

Oxide ceramic filtering material and preparation method thereof

InactiveCN101450856ASufficient service lifeStrong oxidizingOther chemical processesOxide ceramicFiltration

The invention discloses an oxide ceramic filter material and a preparation method. The oxide ceramic filter material comprises the following compositions by weight portion: 10 to 60 portions of CaO, 1 to 60 portions of MgO, 10 to 40 portions of SiO2, 5 to 20 portions of Al2O3, 0 to 15 portions of TiO2, 0 to 25 portions of ZnO and 0.1 to 1 portion of Fe2O3. The basic principle of the filter material is to complete the function of high-efficiency filtration by the function that adsorbed antibacterial materials subjected to physical filtration release active oxygen when reacting with water. The oxide ceramic filter material mainly aims to solve the problem of water quality deterioration caused by various pollutants in water bodies, and simultaneously has strong sterilization and algae removal properties.

Owner:GRIMAT ENG INST CO LTD

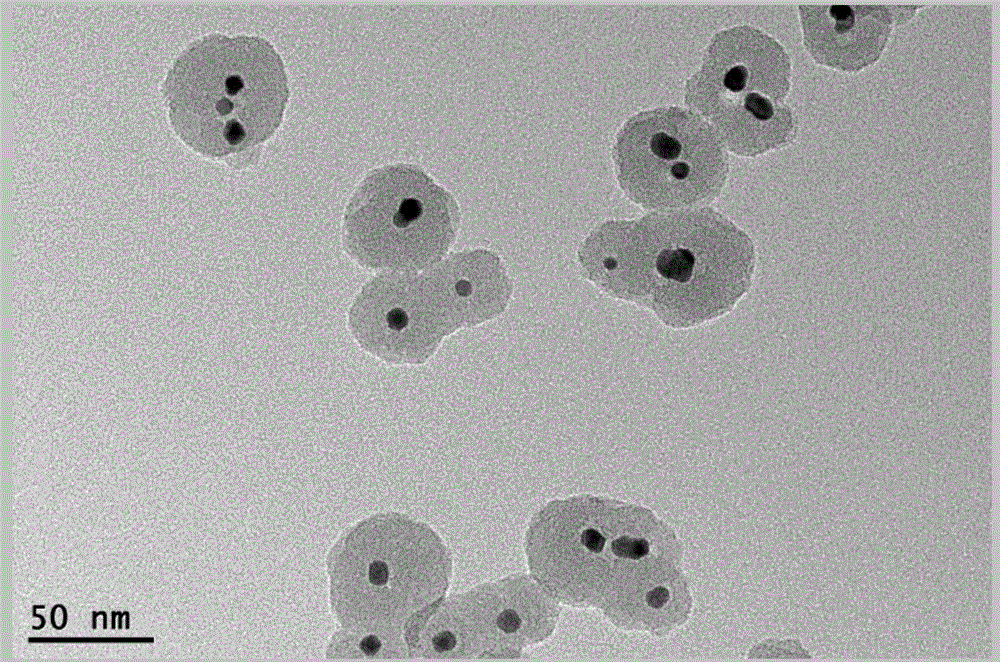

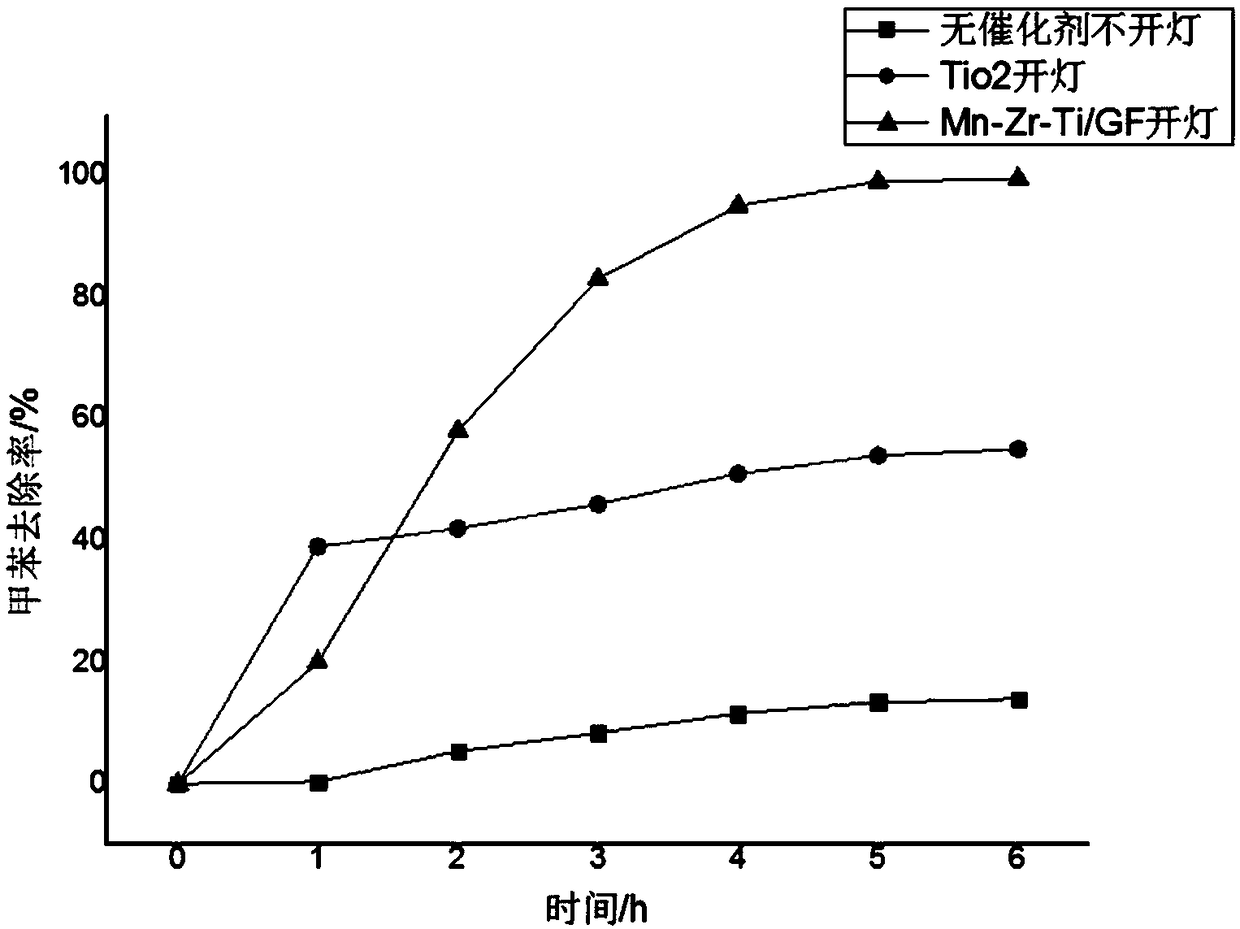

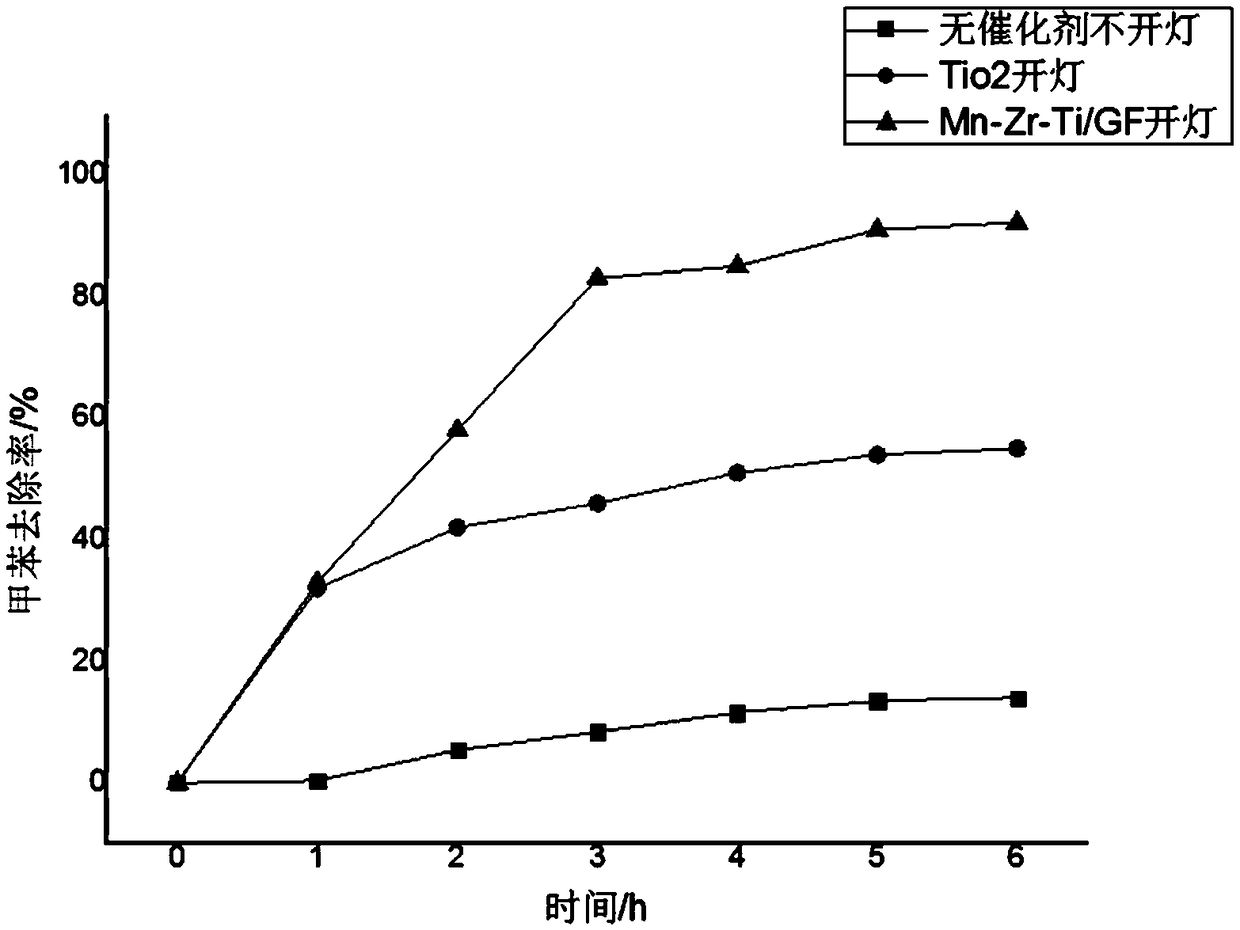

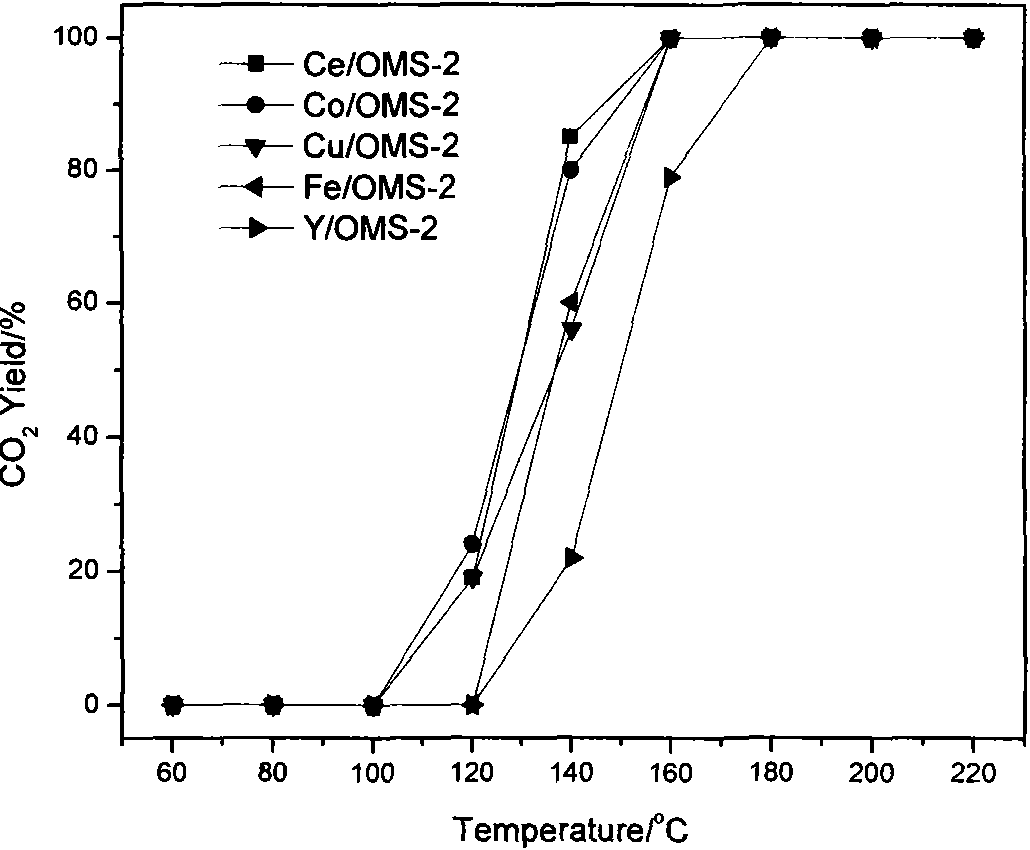

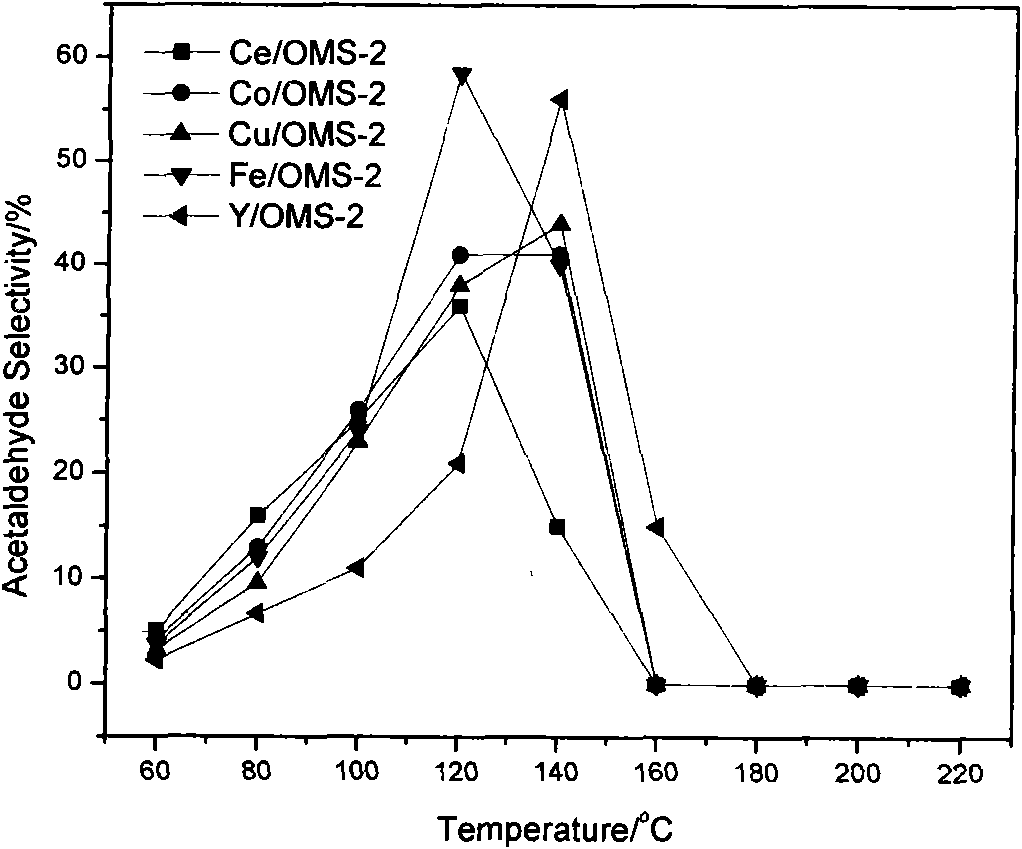

VOCs catalyst for synergistic catalytic oxidation of ultraviolet-light self-excited ozone and preparation method and application thereof

InactiveCN109364913AEfficient processingReduce concentrationGas treatmentDispersed particle separationIonMuffle furnace

The invention relates to a VOCs catalyst for synergistic catalytic oxidation of ultraviolet-light self-excited ozone and a preparation method and application thereof. Alkali-free wax-free glass fiberis taken and cooked with a nitric acid solution, then is washed with ionized water to be neutral, and is dried; tetrabutyl titanate is used as a precursor and is mixed with anhydrous ethanol to obtaina solution A; deionized water, zirconium oxychloride and acetic acid are dissolved in ethanol, and a solution B is obtained by stirring; the solution A is evenly stirred and then the solution B is added to get a light yellow precursor C; the glass fiber is soaked in the light yellow precursor C, drying is performed after impregnation, ageing is performed at room temperature, vacuum drying is executed in a vaccum drying oven, roasting is carried out in a muffle furnace, and natural cooling is executed to room temperature to obtain Zr-Ti supported glass fiber; a solution D is obtained by mixingthe manganese nitrate, ethanol, acetic acid and deionized water; the Zr-Ti supported glass fiber is impregnated in solution D, aged, dried and roasted to obtain the VOCs catalyst for synergistic catalytic oxidation of ultraviolet-light self-excited ozone.

Owner:NANJING UNIV OF TECH +1

Soil improvement material suitable for oxidative soil

InactiveCN101928566AGood slow releaseIncreased cation exchange capacityAgriculture tools and machinesOrganic compound preparationTarChemistry

The invention relates to a soil improvement material suitable for oxidative soil. A method comprises the following steps of: 1, sieving clay minerals through a screen of over 40 meshes for later use; 2, uniformly stirring biomass, the clay minerals and a catalyst to obtain a preprocessed biomass raw material; 3, collecting solid residue biological cokes as the raw material for preparing a soil structure conditioner from a discharge port on the tail part of a cracking unit; and 4, using the neutralized biological cokes as the structure conditioner of multiple kinds of oxidative soil. The invention has the advantages that: 1, the return utilization of the biological cokes which are modified reasonably is a main feasible approach of solving the problem that the biomass is excessively developed and utilized to possibly cause nutrient loss of the soil and cause balance destruction of soil organic matters; 2, the soil improvement material is particularly effective for structure improvement of the oxidative soil with obvious desilicication and aluminum enrichment trend, such as yellow soil, red soil, laterite and the like; and 3, due to the application of clay in biomass cracking, a tar substance, particularly condensed nuclear hydrocarbon is avoided.

Owner:NANCHANG UNIV

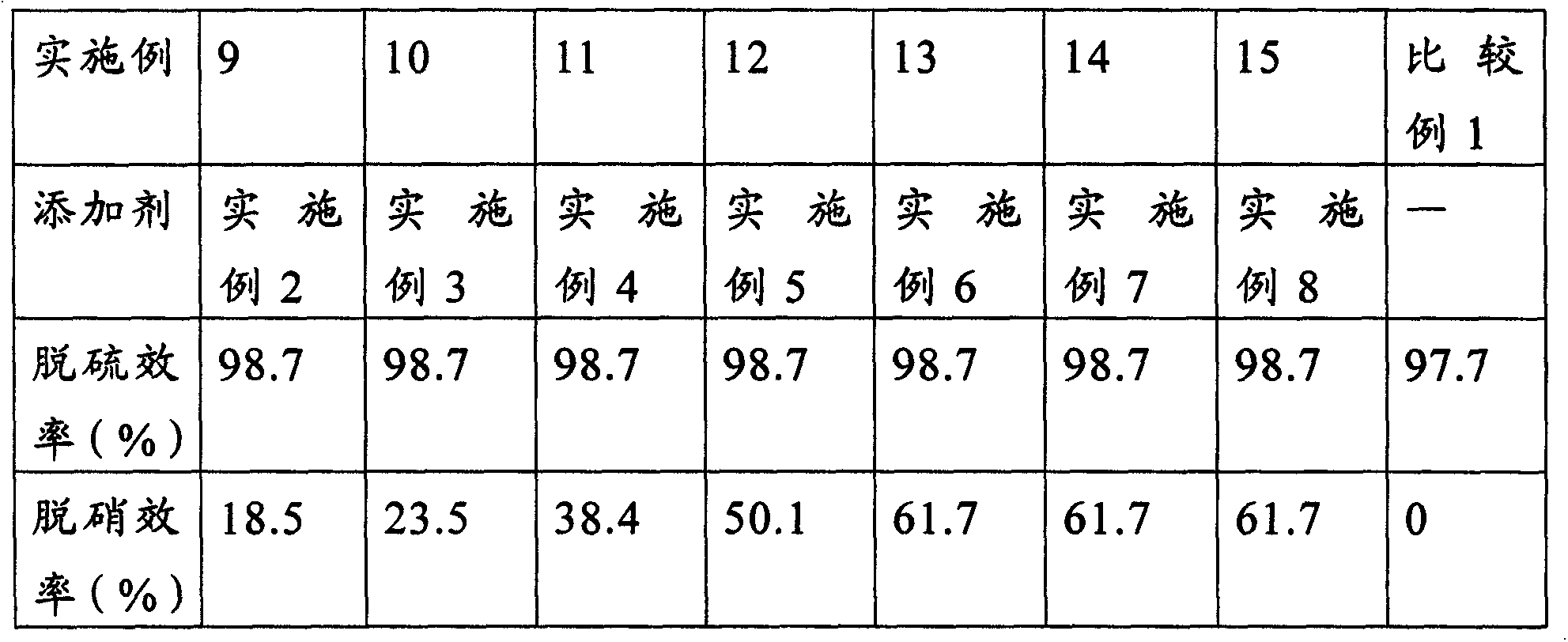

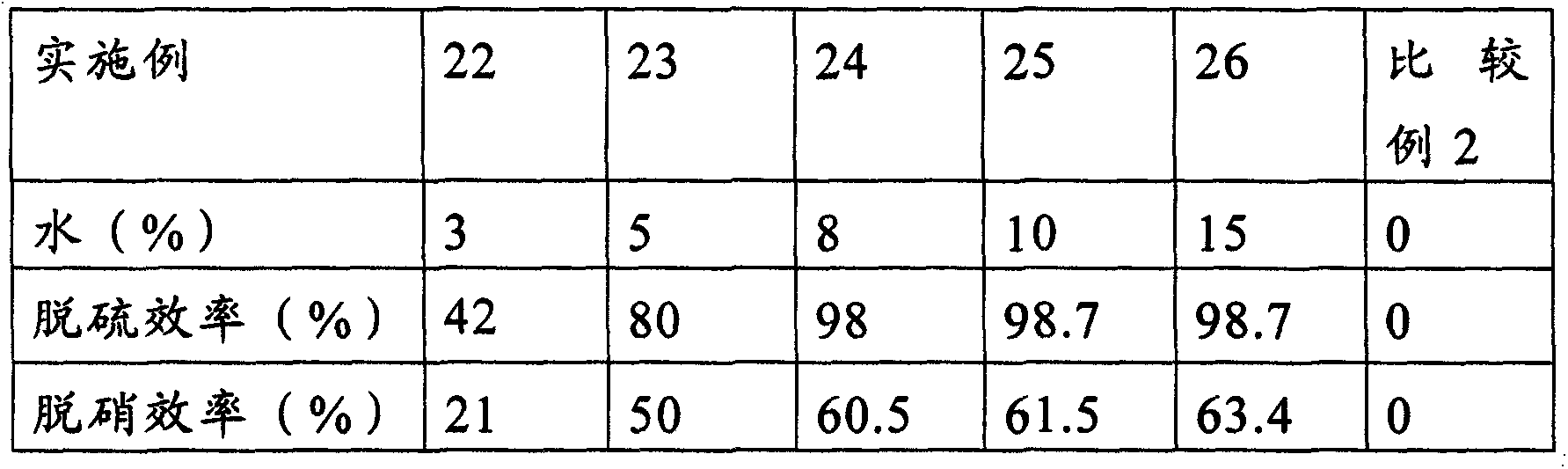

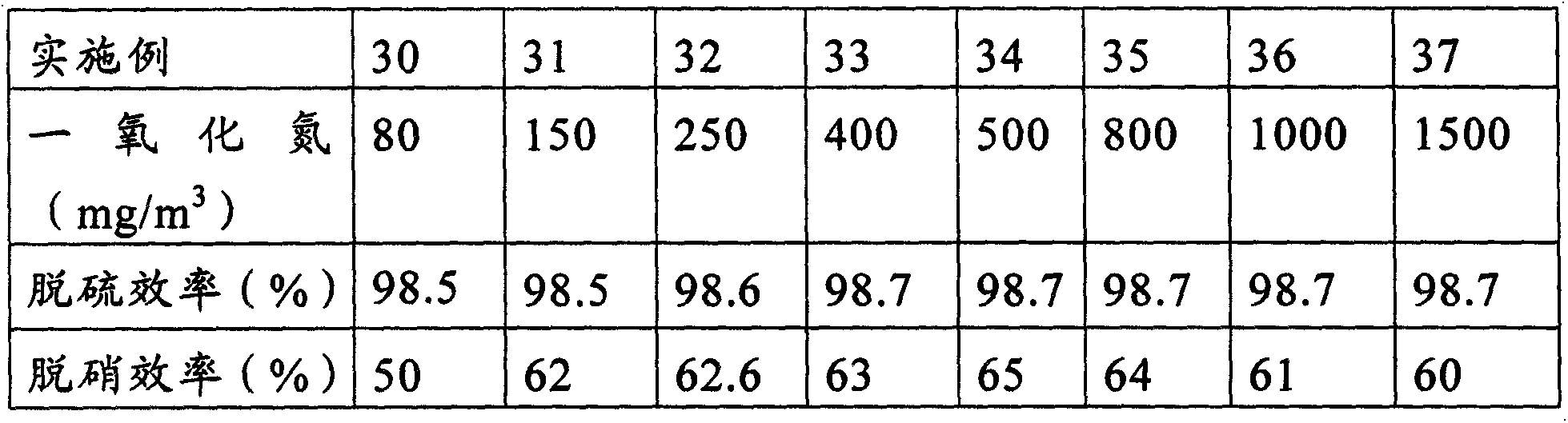

Additive for flue gas desulfurization and denitration and flue gas desulfurization and denitration method

InactiveCN103406020AStrong oxidizingHigh simultaneous desulfurization and denitrification efficiencyDispersed particle separationAir quality improvementCalcium hydroxideFlue gas

The invention provides an additive for flue gas desulfurization and denitration, which comprises a calcium-based sorbent and a tetravalent cerium compound. The invention also provides a flue gas desulfurization and denitration method. According to the invention, the tetravalent cerium compound is taken as an oxidant, and after the tetravalent cerium compound is mixed with the calcium-based sorbent, the obtained mixture is applied to a flue gas desulfurization and denitration dry process, and then the tetravalent cerium compound and the calcium-based sorbent play roles together in simultaneously removing sulfur dioxide and nitric oxide in flue gas, so that the additive has high simultaneous desulfurization and denitration efficiency and good security and stability. Experimental results show that when the additive comprises 2.3 wt % of the tetravalent cerium compound and 97.7 wt % of calcium hydroxide, the reaction temperature is 50-60 DEG C, and water accounts for 8 wt % of the total mass of the water, flue gas and the additive, the average efficiencies of desulfurization and denitration can respectively reach 98.7% and 61.5%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Metal oxide-loaded molecular sieve catalyst and preparation method thereof

ActiveCN101711990BStrong oxidizingReduce exhaust temperatureMolecular sieve catalystsDispersed particle separationMANGANESE ACETATECerium

Owner:TSINGHUA UNIV

Method for preparing porous starch microsphere loaded potassium ferrate sewage treatment complexing agent

InactiveCN103803693AReduce oxidation rateImprove water treatment effectWater/sewage treatment by sorptionWater/sewage treatment by oxidationMicrospherePorous starch

The invention discloses a method for preparing a porous starch microsphere loaded potassium ferrate sewage treatment complexing agent. The porous starch microsphere loaded potassium ferrate sewage treatment complexing agent comprises the following components in percentage by mass: 50-70 percent of porous starch microsphere loaded potassium ferrate complex, 20-40 percent of polymeric ferric sulfate and 10-20 percent of diatomite, wherein the porous starch microsphere loaded potassium ferrate complex is a complex prepared by dissolving potassium ferrate in an aqueous solution of KOH with the pH of 12, adding porous starch microspheres for complexing and adsorbing. According to the novel water treatment complexing agent, a slow release effect on the oxidizing ability of the potassium ferrate is realized, and the sewage treatment capacity of the potassium ferrate is improved. In addition, due to addition of the polymeric ferric sulfate and diatomite, the complexing and adsorbing capacity of the complexing agent can be further improved, and the sewage treatment effect is improved.

Owner:XIJING UNIV

Denitration catalyst with high sulfur resistance and high alkali metal resistance, and preparation method thereof

PendingCN110721669AImprove denitrification efficiencyImprove stabilityGas treatmentHeterogenous catalyst chemical elementsCerium nitratePtru catalyst

The invention discloses a denitration catalyst with high sulfur resistance and high alkali metal resistance, and a preparation method thereof. The catalyst is prepared by taking tetrabutyl titanate and tetraethyl silicate as carrier precursors, vanadyl sulfate and neodymium nitrate as active component precursors and cerium nitrate and ammonium molybdate as assistant precursors through centrifuging, drying and calcining by adopting a sol-gel process and a coprecipitation process. The prepared denitration catalyst with high sulfur resistance and high alkali metal resistance effectively overcomesthe defects of narrow temperature window, poor alkali metal resistance and poor sulfur resistance of a traditional denitration catalyst. When the temperature is 150-450 DEG C, the air speed is 1000-100000 h<-1>, the SO2 concentration is 0-3000 mg / m<3>, and the K2O concentration of the catalyst is 0-1.5%, the catalyst has an excellent denitration efficiency and an excellent N2 selectivity, and issuitable for nitrogen oxide emission control under flue gas conditions of a coal-fired power plant, a coking plant, a glass kiln, a cement kiln and the like.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

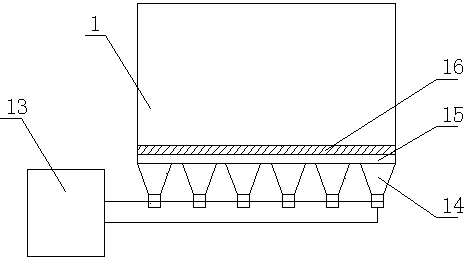

Polytetraurea lubricant grease

InactiveCN105779083AStrong viscosity retention at high temperatureLow pour pointLubricant compositionFood industryAntioxidant

The invention discloses polytetraurea lubricant grease. The polyurea lubricant grease disclosed by the invention is obtained through taking low-viscosity lubricating oil prepared from ester oil and poly alpha olefin as base oil, taking synthesized polytetraurea as a thickener and adding a friction modifier and an antioxidant. According to the ureido-based lubricant grease disclosed by the invention, the thickening effect is greatly increased without increasing the cost, the comprehensive performance is good, and the lubricant grease can be applied to machinery in the fields of electrical appliance industry, metallurgical industry, food industry, paper-making industry, automobile industry, airplane industry and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

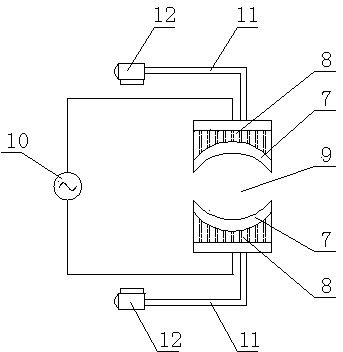

Device and method for degrading pesticide residues in traditional Chinese medicinal materials

InactiveCN103656957AImprove the effect of removing pesticide residues in Chinese herbal medicinesAggressiveChemical protectionPesticide residueHydroxyl radical

The invention discloses a device for degrading pesticide residues in traditional Chinese medicinal materials. The device comprises a cleaning water tank, a hydroxyl radical generator, an ultrasonic system and a photocatalyst. Meanwhile, the invention provides a method for degrading pesticide residues in traditional Chinese medicinal materials. The method comprises the steps of soaking; hydroxyl radical oxidation; ultrasonic cleaning and the like. The device can be used for safely and efficiently cleaning the traditional Chinese medicinal materials and has a favorable pesticide residue removal effect.

Owner:长沙安迪生物科技有限公司

A processing method of modified soybean fibers

InactiveCN107700203AHigh tensile strengthImproves tensile strength propertiesBiochemical fibre treatmentHeat resistant fibresFiberBiological activation

A processing method of modified soybean fibers is disclosed. The method is characterized in that the method includes (1) a step of surface etching, namely a step of adding soybean fibers into a plasmamachine and performing surface treatment; (2) a soaking step, namely a step of soaking the etched soybean fibers into an activating agent solution, performing activation, and then soaking the soybeanfibers in an antibacterial solution; (3) a step of ionization treatment, namely a step of soaking the soaked soybean fibers into a treating agent, performing ionization treatment, adding a sodium silicate solution into an ionization tank, and performing a second time of ionization; (4) a step of high-pressure temperature changing, namely a step of drying the ionized soybean fibers until the watercontent is 7-9%, then putting the soybean fibers into a temperature changing oven, and performing temperature changing treatment; and (5) a step of oxidation, namely a step of oxidizing the temperature-changed soybean fibers in a vacuum tank.

Owner:安徽华祺汽车装饰有限公司

CrXCo3-XO4 spinel type catalyst and preparation method thereof

InactiveCN101722004AImprove thermal stabilitySimple structureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHeat stabilitySpinel

The invention relates to a CrXCo3-XO4 spinel type catalyst for purifying tail gas of gas-fueled vehicles. An A site of a spinel AB2O4 structure comprises positive divalent cobalt elements, and a B site comprises chromium elements or chromium elements and positive divalent cobalt elements, wherein the molar ratio of the positive divalent cobalt elements to the sum of positive trivalent cobalt elements and the chromium elements to oxygen elements is 1:2:4. The preparation method of the CrXCo3-XO4 spinel type catalyst comprises the steps of: (1) respectively preparing a chromic nitrate solution and a cobalt nitrate solution with deionized water; (2) according to the proportion of the cobalt elements and the chromium elements, weighing the chromic nitrate solution and the cobalt nitrate solution which are prepared in the step (1), and uniformly mixing the two solutions by magnetic stirring; (3) adding an ammonia solution to regulate the pH value to obtain a suspension; and (4) carrying out vacuum filtration on the suspension obtained in the step (3), putting filter cakes in a drying box for drying, and then, transferring the filter cakes into a muffle furnace for roasting. The CrXCo3-XO4 spinel type catalyst has the characteristics of good heat stability, simple structure, low cost and wide application prospects.

Owner:TSINGHUA UNIV

Oxide ceramic powder capable of perpetually releasing active oxygen when suffering from water

The invention discloses inorganic ceramic powder and discloses the performance of the inorganic ceramic powder for slowing hydrolyzing and releasing active oxygen when suffering from water and a preparation method thereof. Through controlling the sintering temperature and time and performing surface packaging treatment by different methods, the hydrolization process can be ensured to be performed slowly and the active oxygen can be released for a long time, thereby the application value of the powder on engineering is ensured. The release of the active oxygen can provide a powerful oxygenation mechanism for sterilizing, killing algae and lowering the pollution in water (lowering the COD index). When the powder is used for preparing various other water treatment filter materials, the range of the powder applied to the field of water treatment engineer can be expanded.

Owner:BEIJING HUADE MAITUO TECH DEV

Method for recovering vanadium, aluminum and molybdenum from waste catalyst

ActiveCN112048622AGood diffusion performanceStrong oxidizingProcess efficiency improvementAluminiumVanadium atom

The invention provides a method for recovering vanadium, aluminum and molybdenum from a waste catalyst. According to the method, the oxidizing leaching of an alkaline solution is enhanced through an aeration process, and the solubility of oxygen, and the leaching rate of vanadium, aluminum and molybdenum are improved; and the reaction time is shortened, so that the reaction and energy consumptionof alkaline solution evaporation are reduced. Finally, leachate containing the vanadium, aluminum and molybdenum, and tailings enriched with other valuable elements can be obtained, and resource utilization of the waste catalyst is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com