Method for discoloring sulfuric acid by using potassium permanganate

A technology of potassium permanganate and sulfuric acid, which is applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problem that chroma and transparency affect the survival market of gypsum acid, the chroma and transparency cannot meet the standard sulfuric acid finished products, and cannot enter the ranks of the first-class product market, etc. problems, to achieve the effect of improving market competitiveness, strong oxidation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

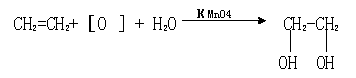

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] A saturated aqueous solution of potassium permanganate at room temperature was injected into the 99.6wt% sulfuric acid in a closed sulfuric acid decolorizing tank at a rate of 0.182L / min·t. The volume ratio of sulfuric acid to the saturated aqueous solution of potassium permanganate at room temperature was 1000: 2; At the same time, keep stirring at 10 revolutions per minute until the potassium permanganate solution is added; then let it stand for 1 day to obtain the finished sulfuric acid.

[0025] In this example, potassium permanganate KMn is consumed by 1 kg of finished sulfuric acid. 4 The solution is 0.15g, and the test results of decolorizing sulfuric acid are shown in Table 1. The results show that the amount of potassium permanganate KMn0 4 The solution oxidant has little effect on the internal quality of the sulfuric acid product, and does not affect the chemical composition and use performance of the sulfuric ...

Embodiment 2

[0028] This embodiment includes the following steps:

[0029] A saturated aqueous solution of potassium permanganate at room temperature was injected into the 99.5wt% sulfuric acid in a closed sulfuric acid decolorization tank at a rate of 0.455 L / min·t. The volume ratio of sulfuric acid to the saturated aqueous solution of potassium permanganate at room temperature was 1000: 5; At the same time, keep stirring at 15 revolutions per minute until the potassium permanganate solution is added; then let it stand for 2 days to obtain the finished sulfuric acid.

[0030] In this example, potassium permanganate KMn is consumed by 1 kg of finished sulfuric acid. 4 The solution is 0.32g. Such an amount of oxidant has little effect on the internal quality of the sulfuric acid product, and does not affect the chemical composition and use performance of the sulfuric acid product. Using potassium permanganate as a decolorizing agent, the production cost of sulfuric acid only increases by 2-3 yu...

Embodiment 3

[0032] This embodiment includes the following steps:

[0033] The saturated aqueous solution of potassium permanganate at room temperature was injected into the 99.5wt% sulfuric acid in a closed sulfuric acid decolorization tank at a rate of 0.728L / min·t. The volume ratio of sulfuric acid to the saturated aqueous solution of potassium permanganate at room temperature was 1000:8 ; Continuously stirring at the same time, the stirring speed is 8 revolutions / minute, until the potassium permanganate solution is added; then let stand for 2 days to obtain the finished sulfuric acid.

[0034] In this example, potassium permanganate KMn is consumed by 1 kg of finished sulfuric acid. 4 The solution is 0.50g. Such an amount of oxidant has little effect on the internal quality of the sulfuric acid product, and does not affect the chemical composition and use performance of the sulfuric acid product. Using potassium permanganate as a decoloring agent, the production cost of sulfuric acid onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com