Patents

Literature

2026results about "Heat resistant fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

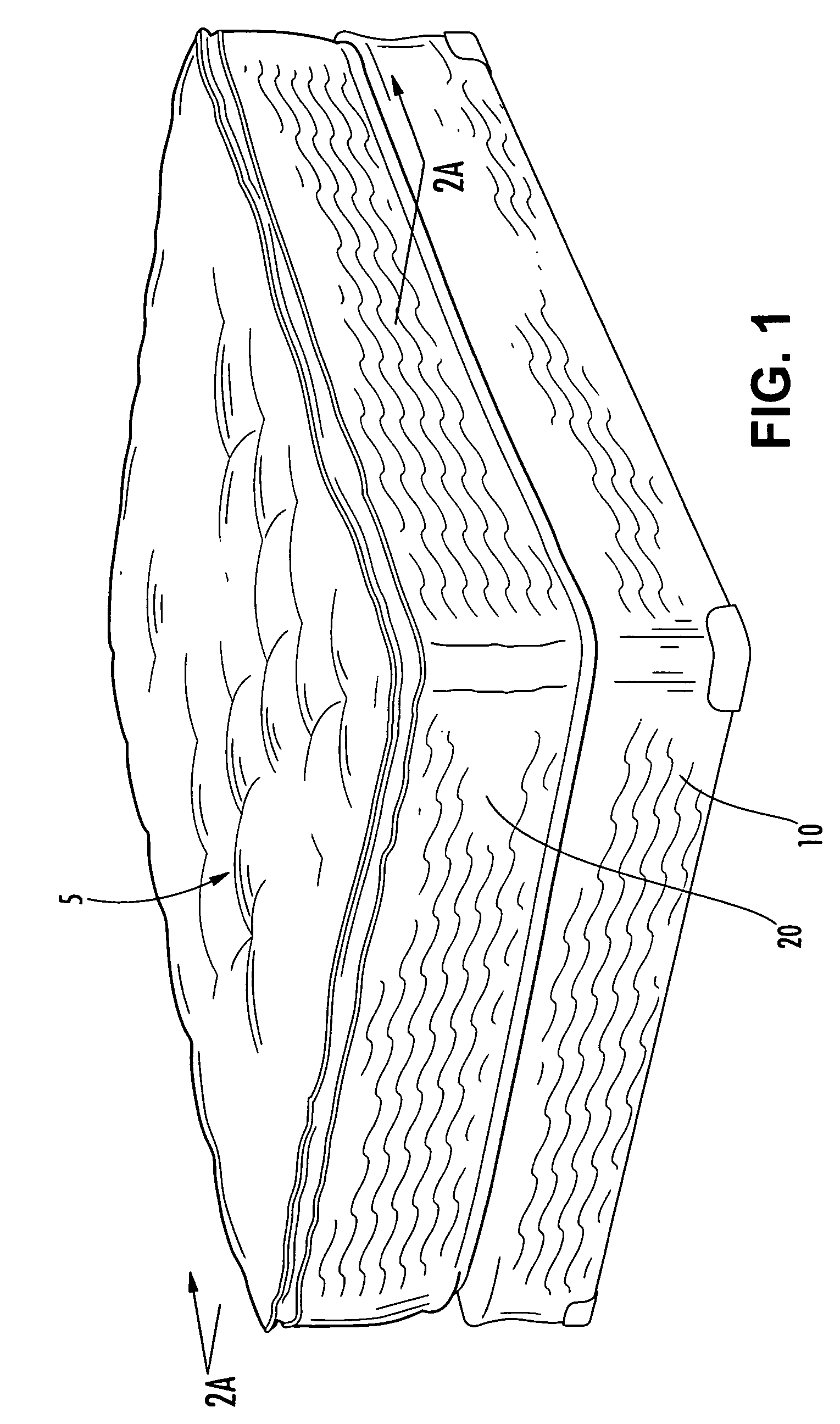

Nonwoven material for acoustic insulation, and process for manufacture

InactiveUS7837009B2Improve acoustic propertiesReduce weightLiquid surface applicatorsWallsMildewEngineering

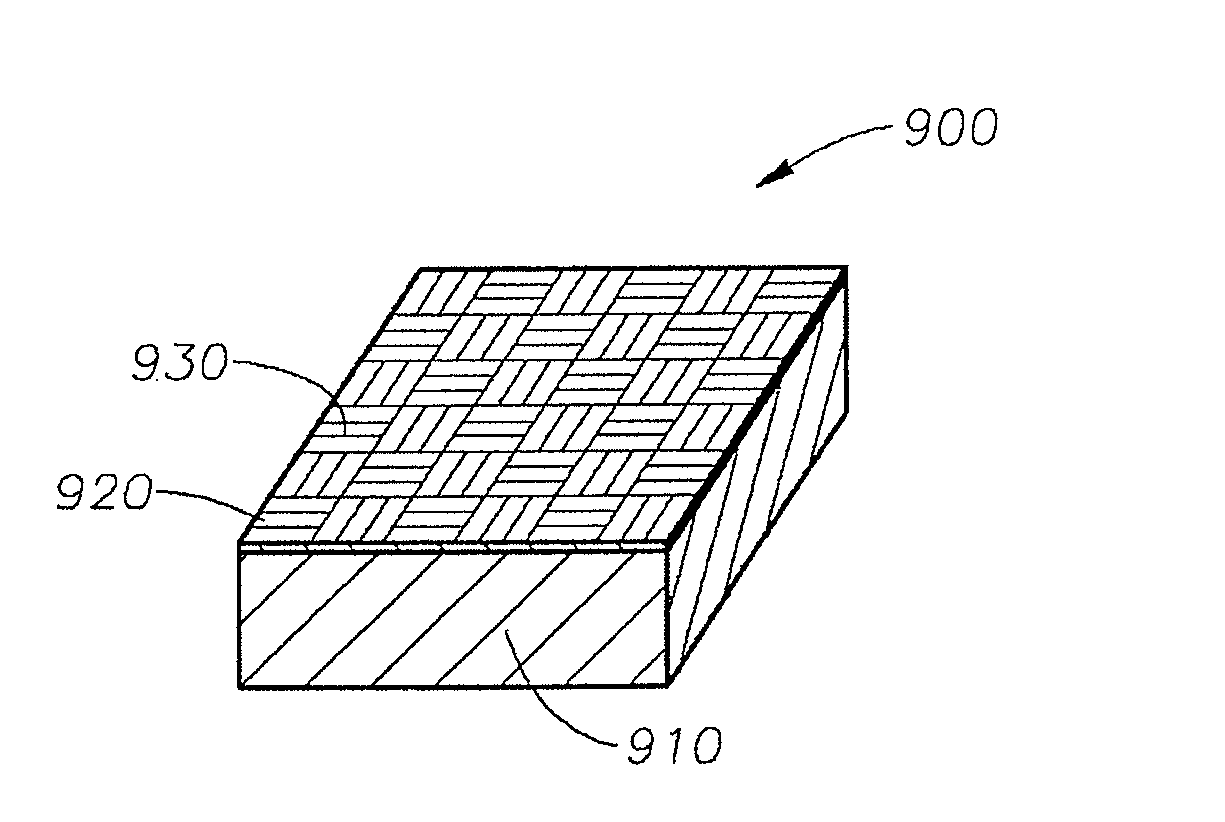

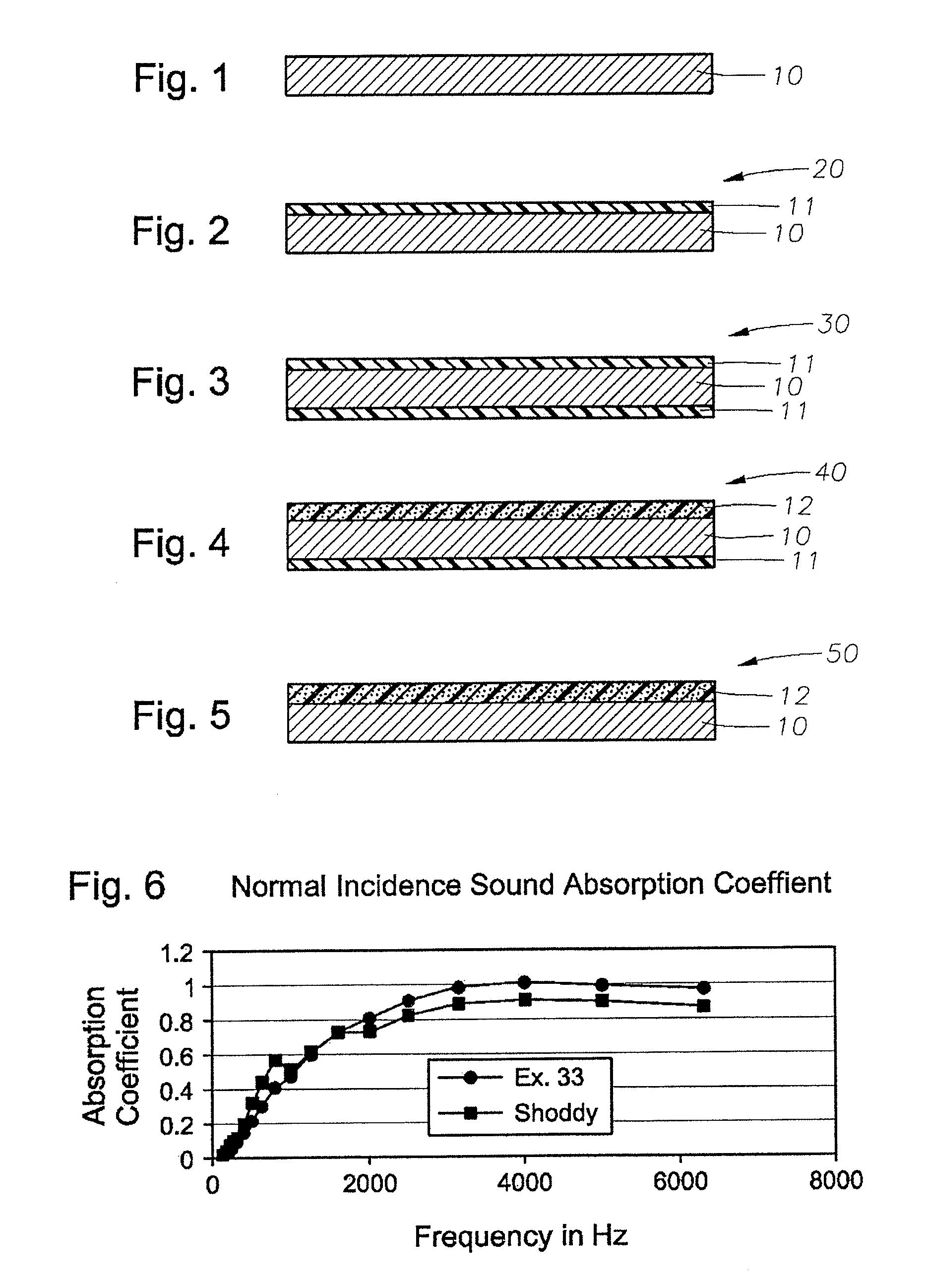

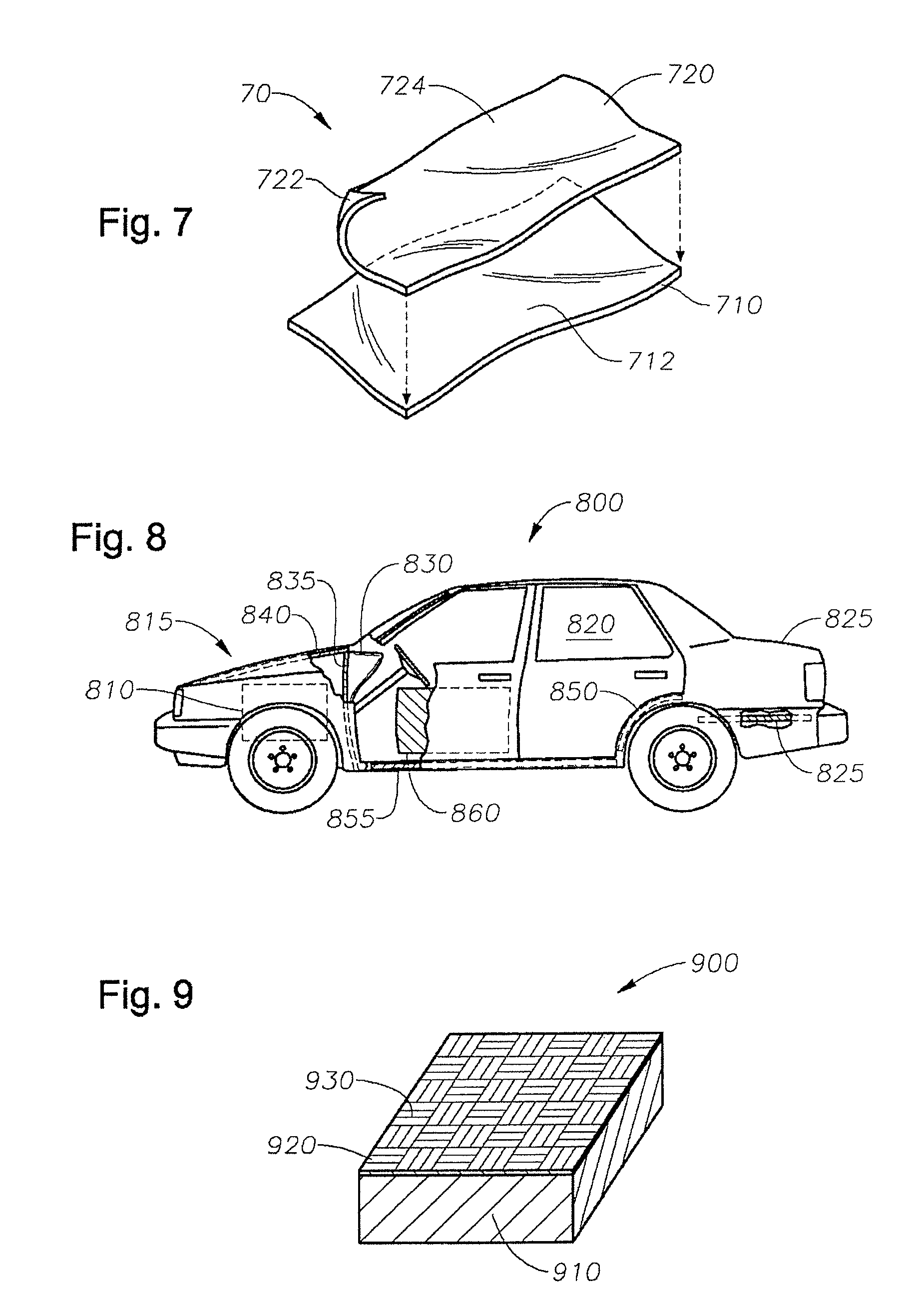

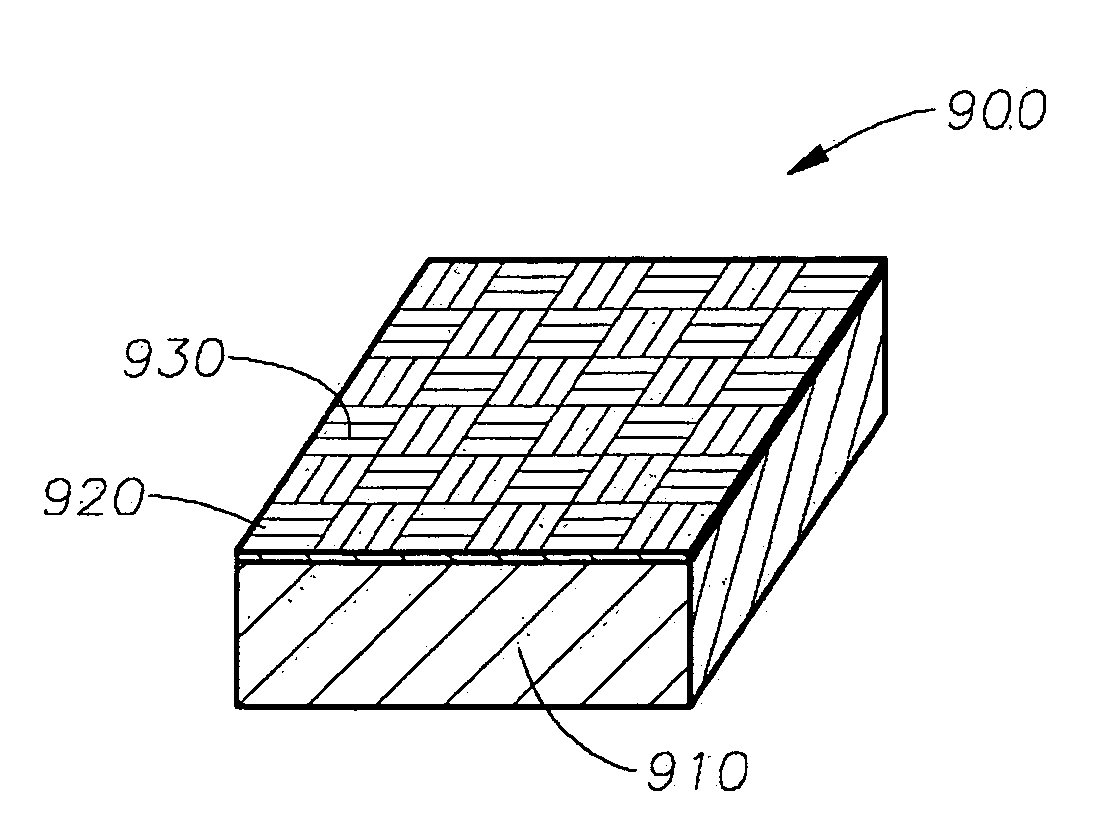

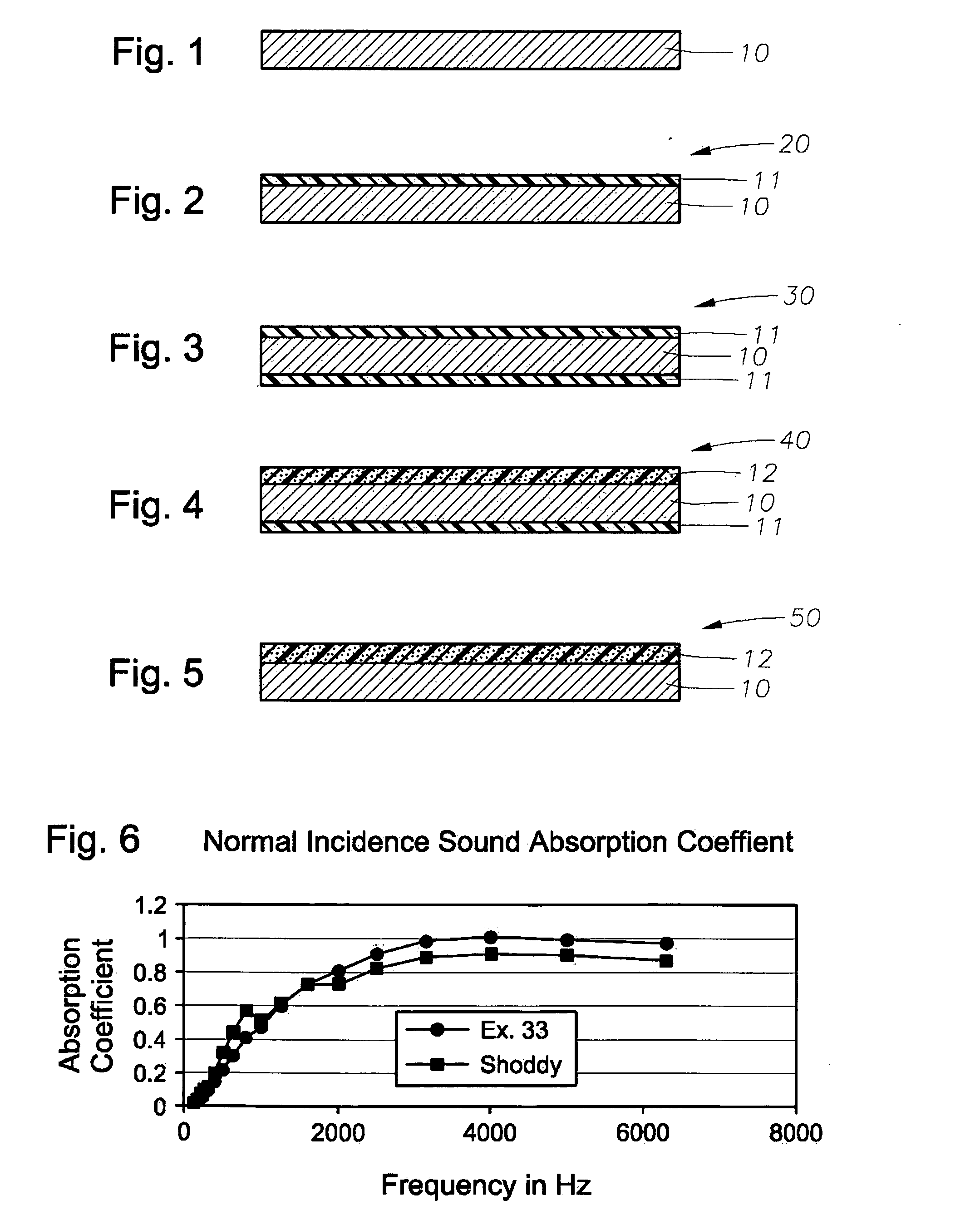

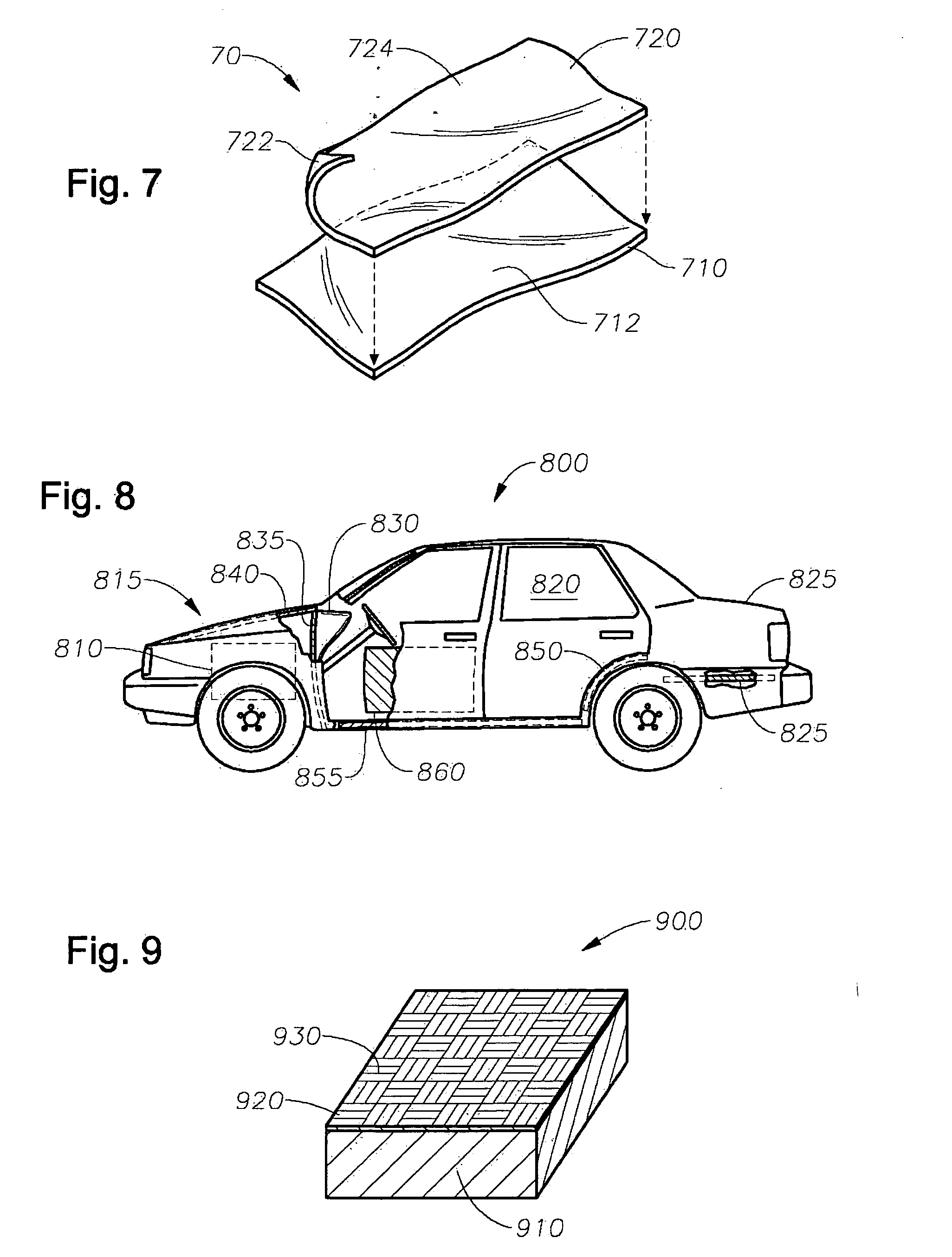

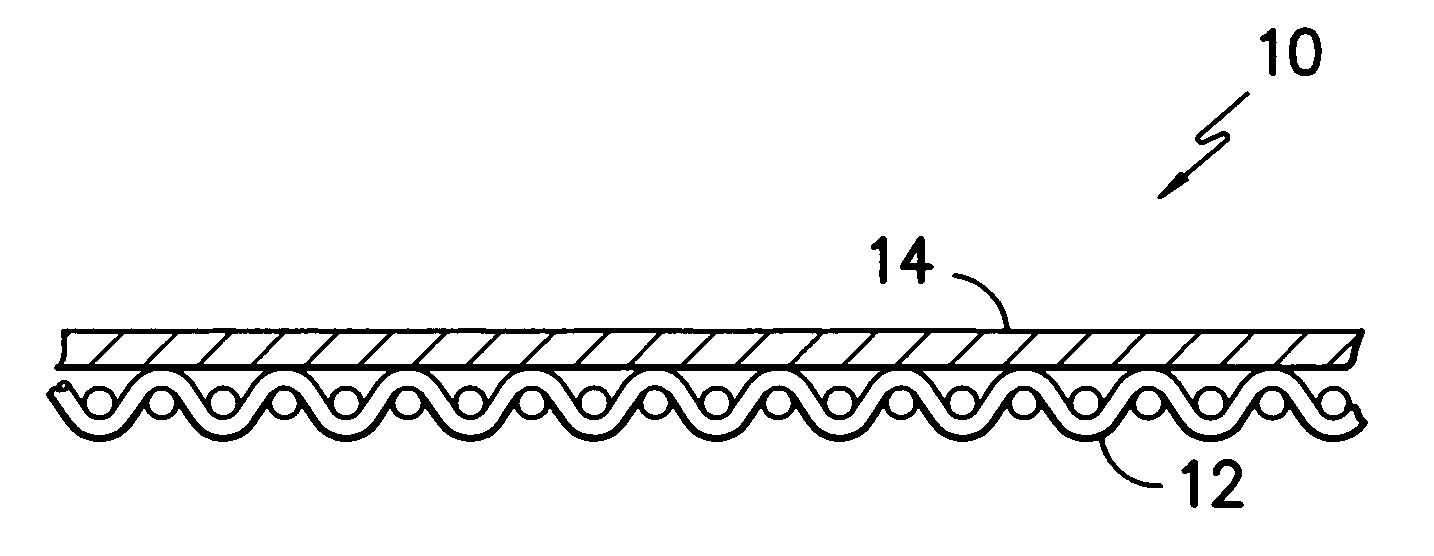

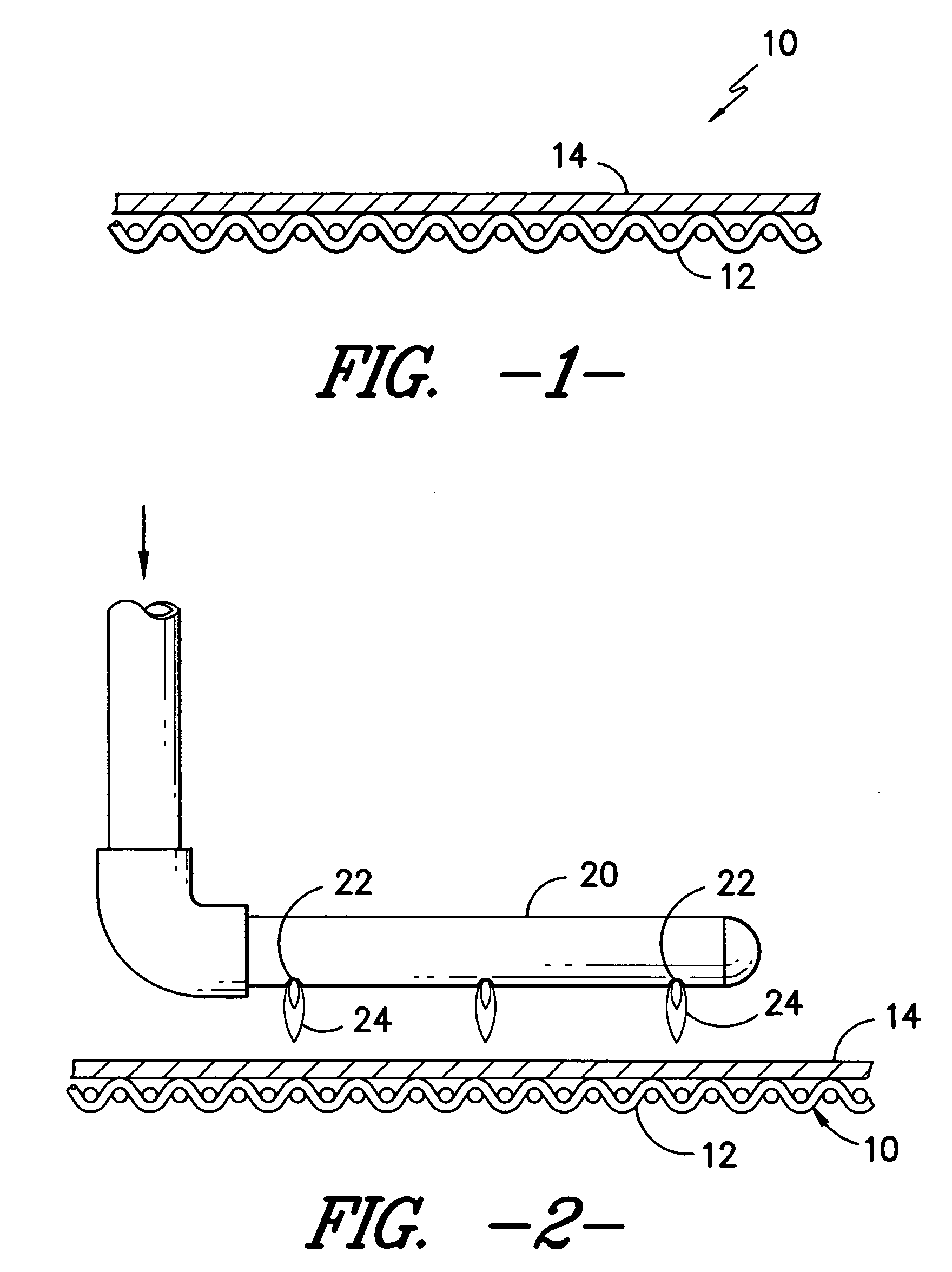

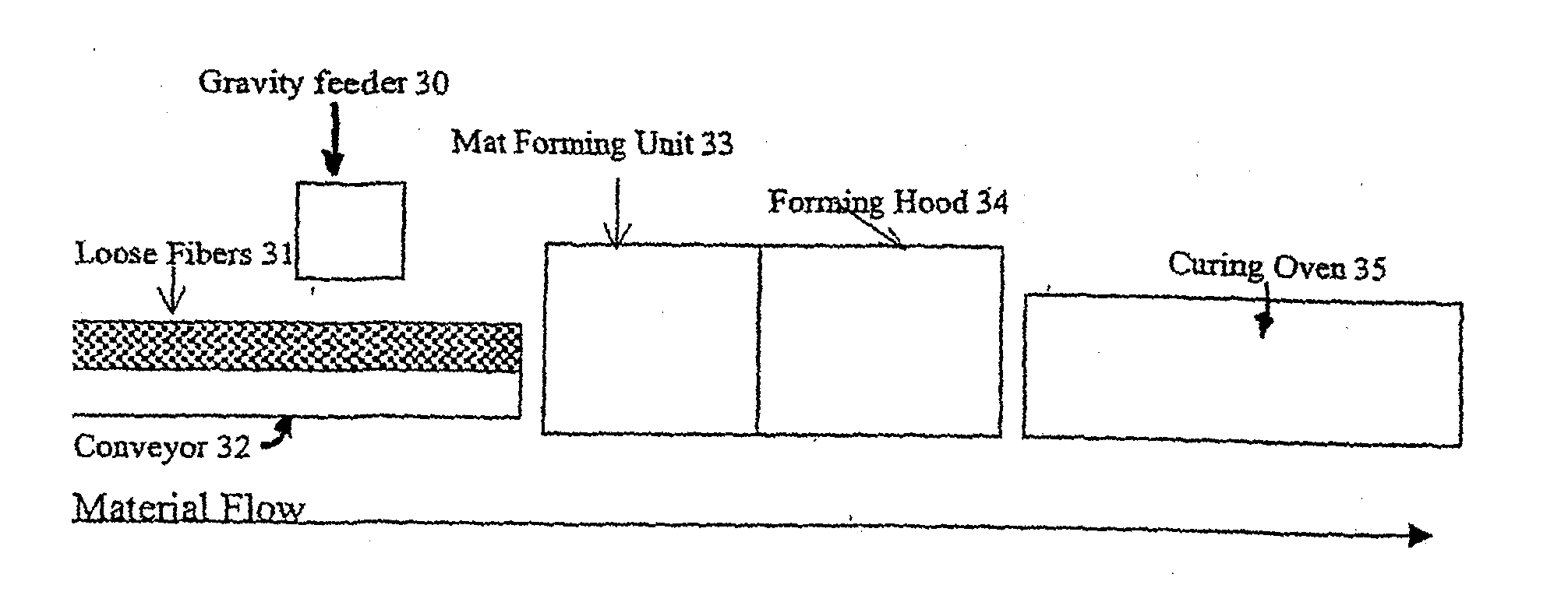

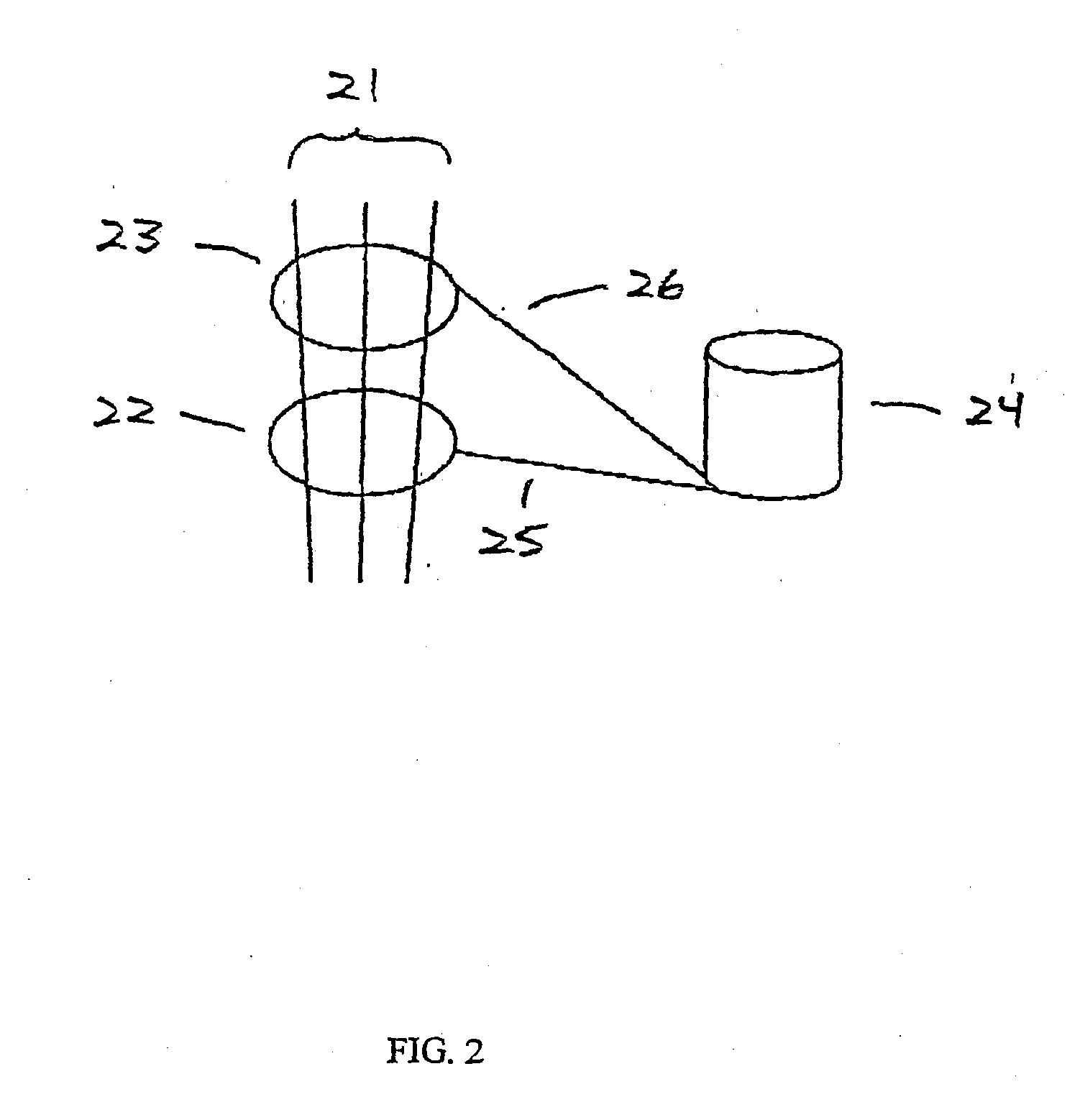

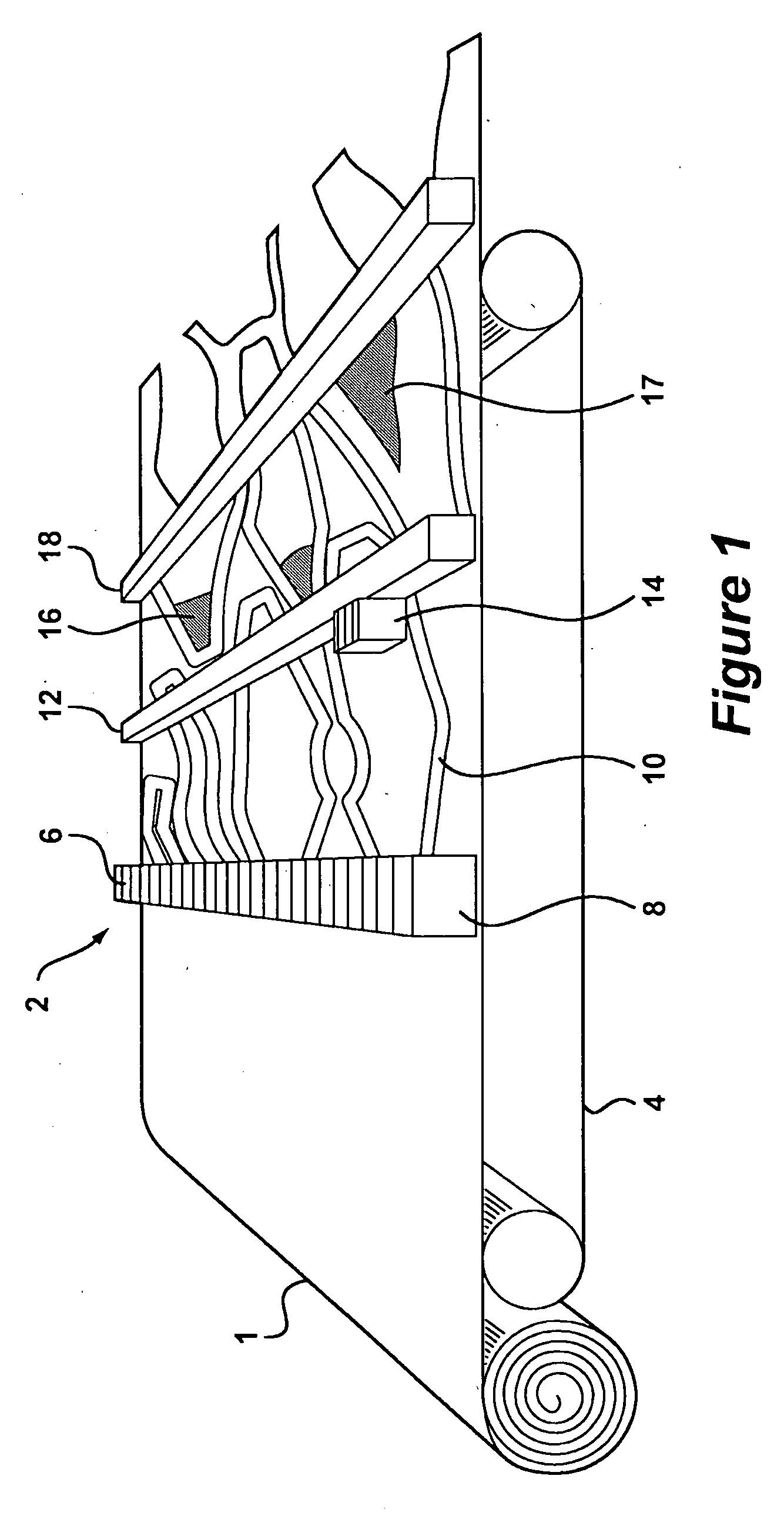

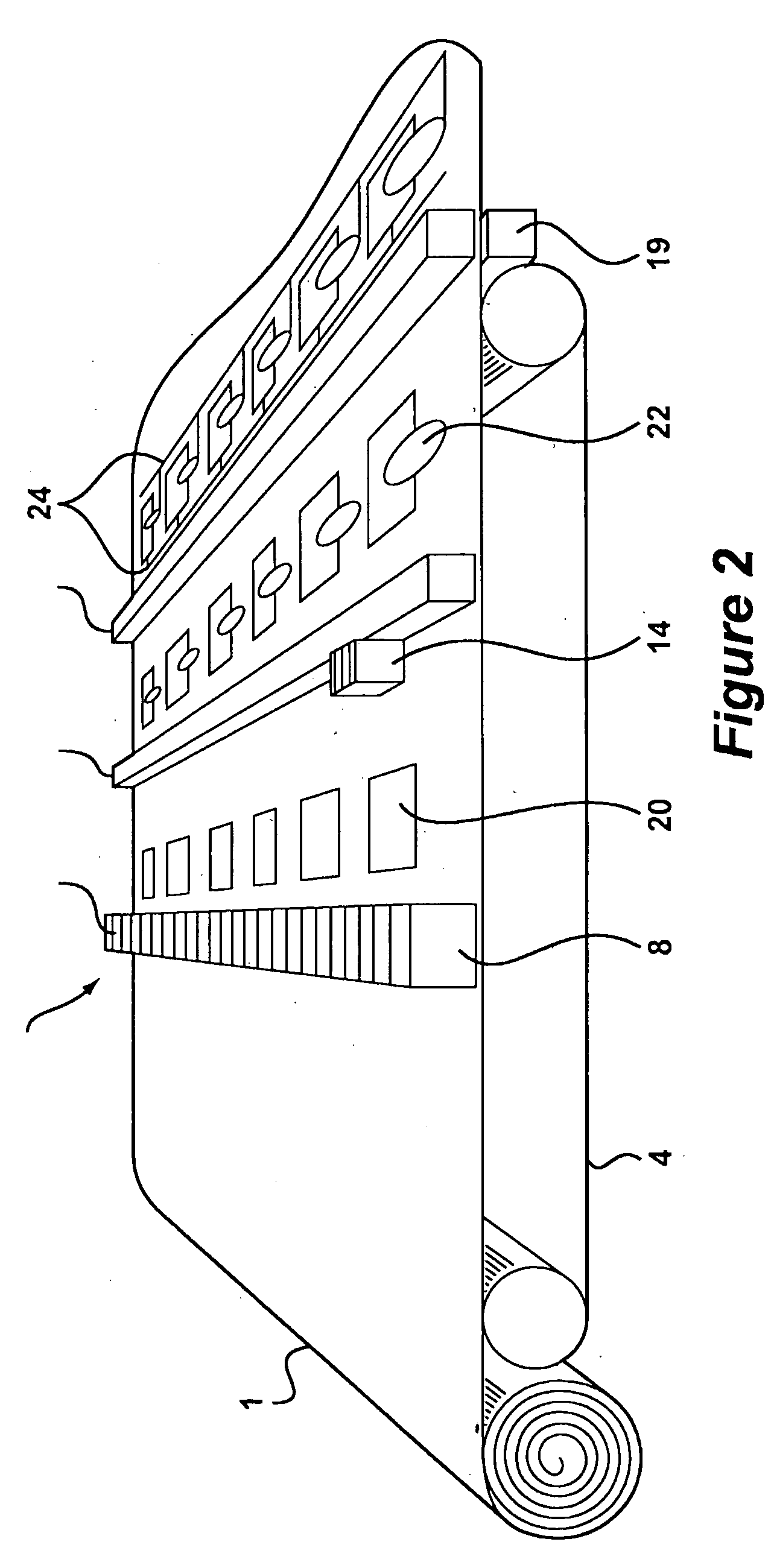

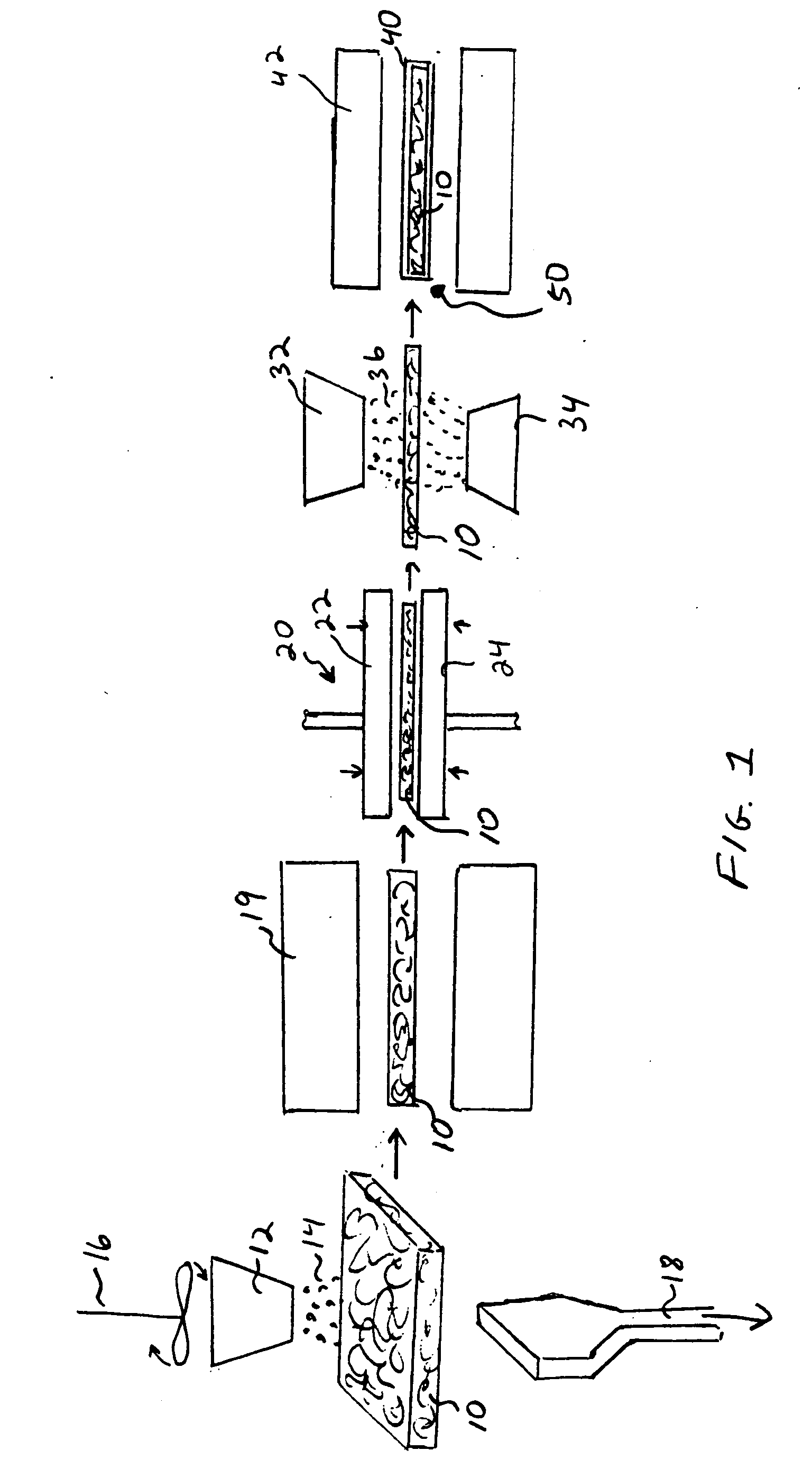

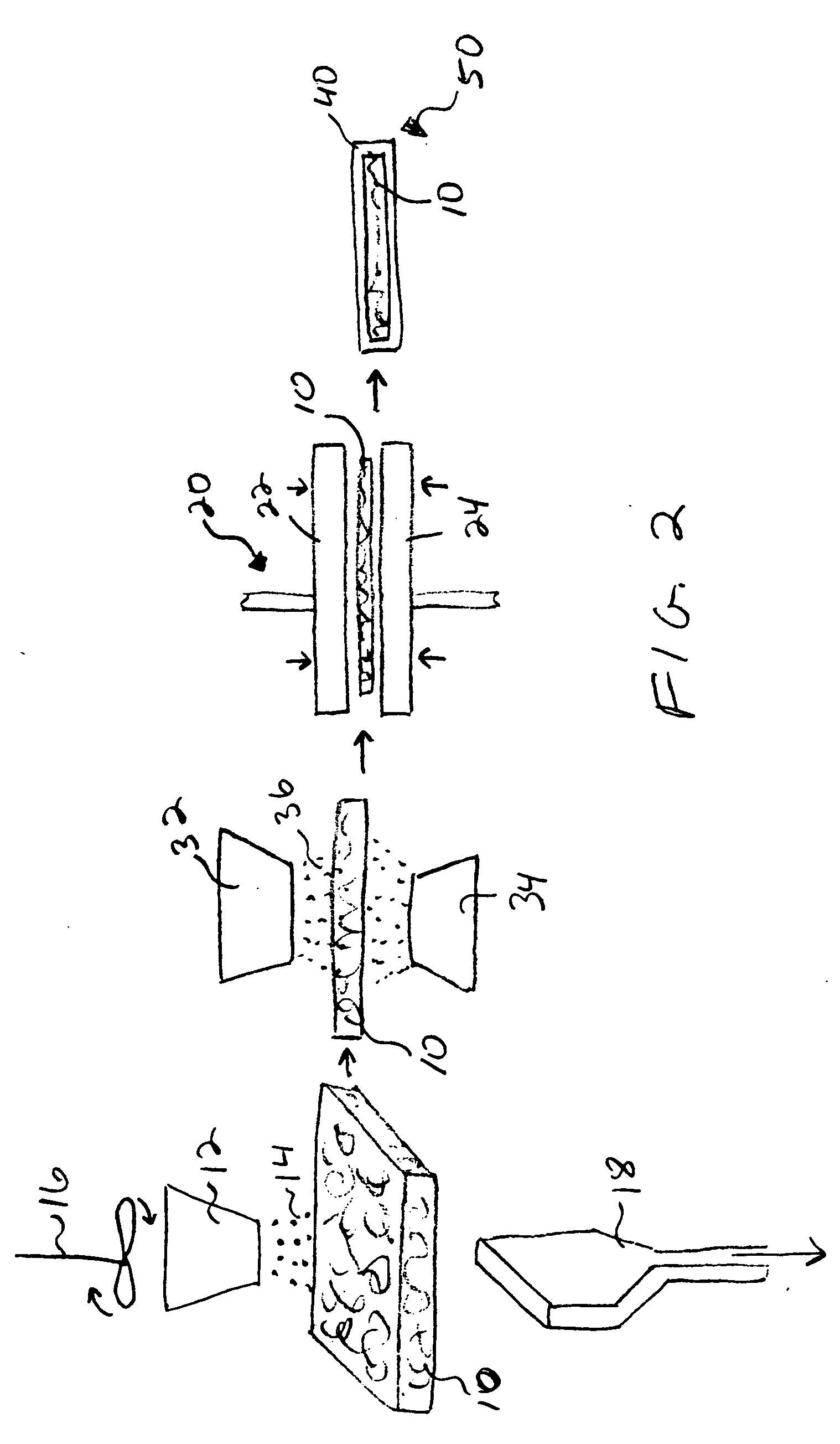

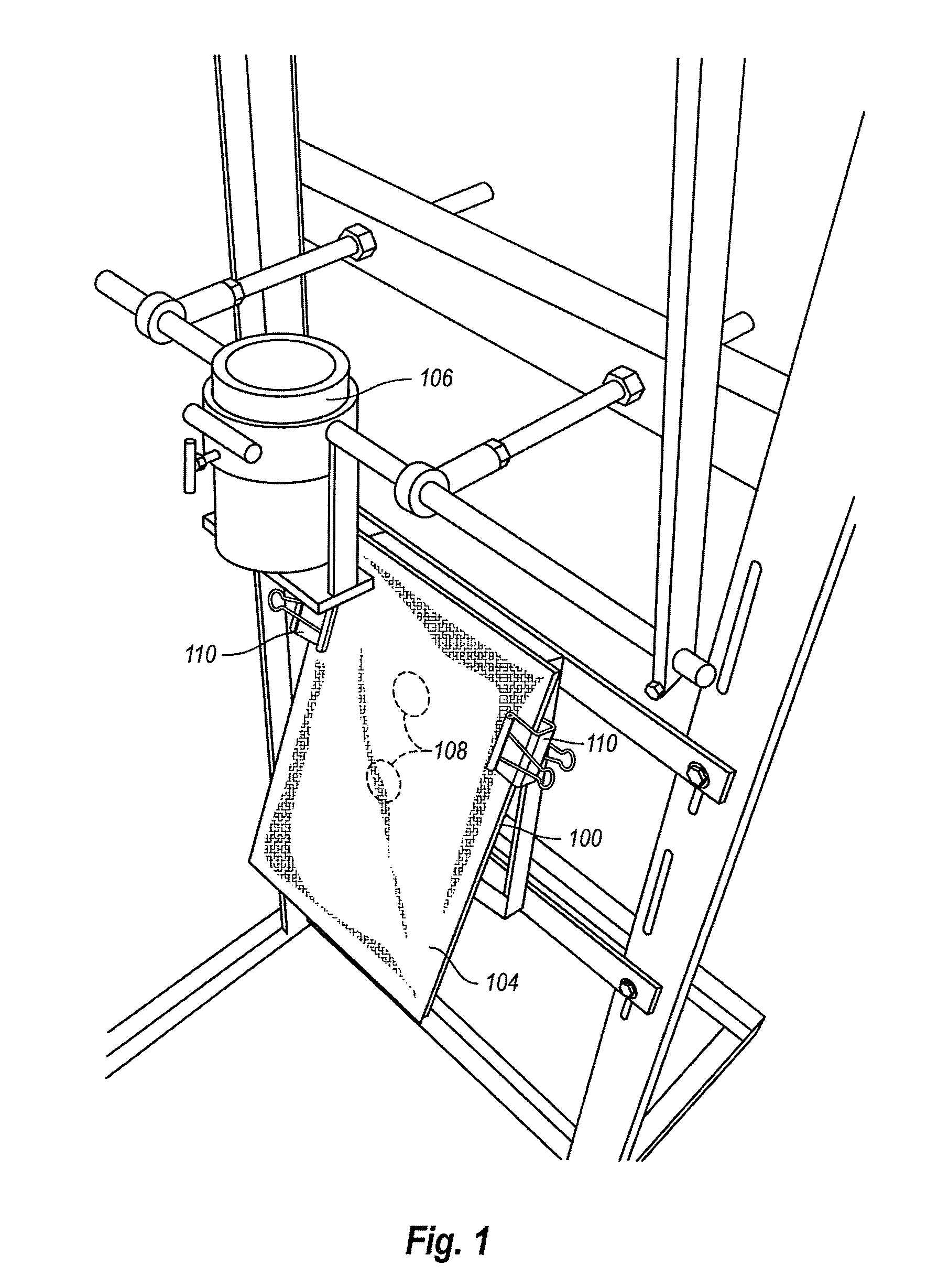

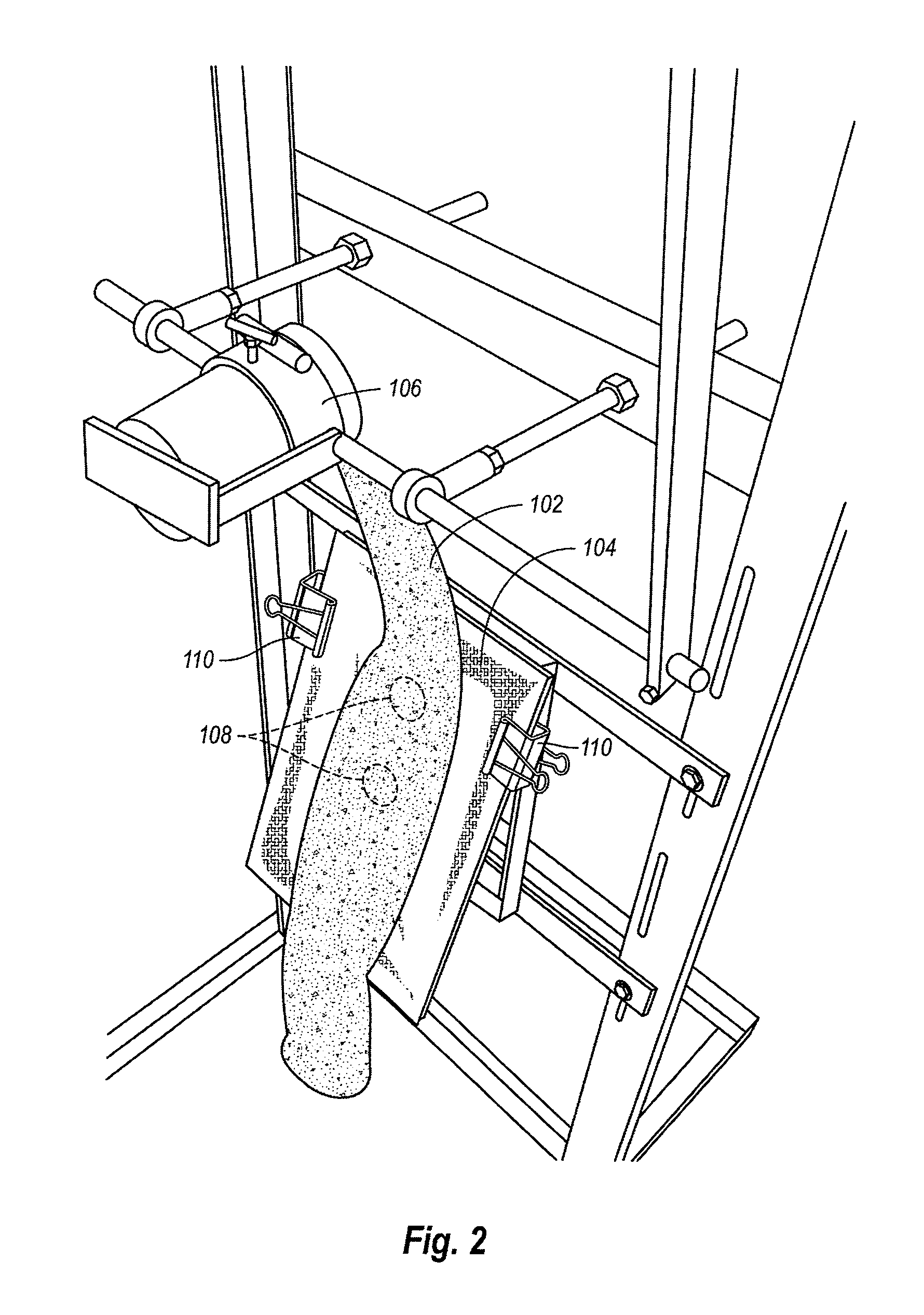

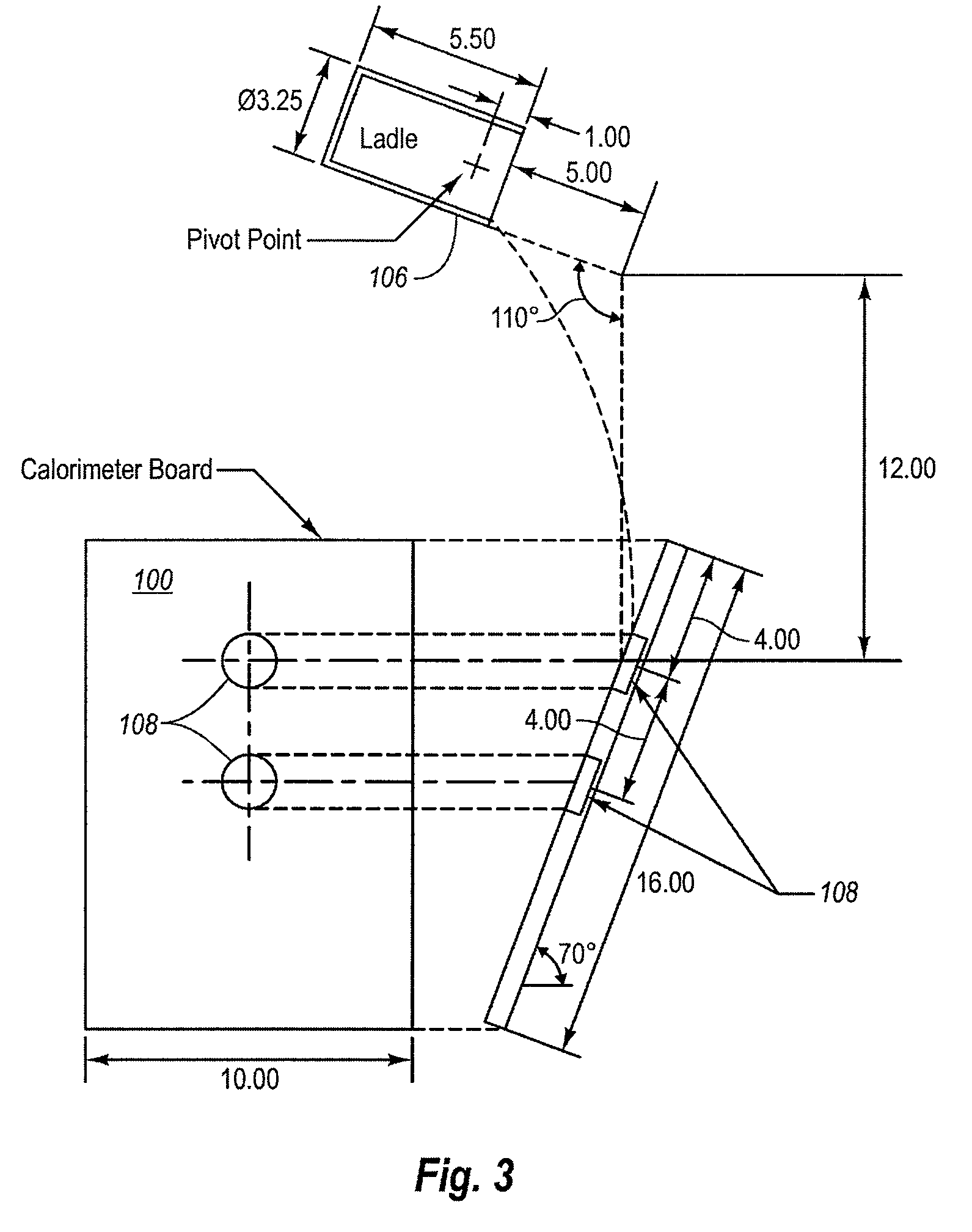

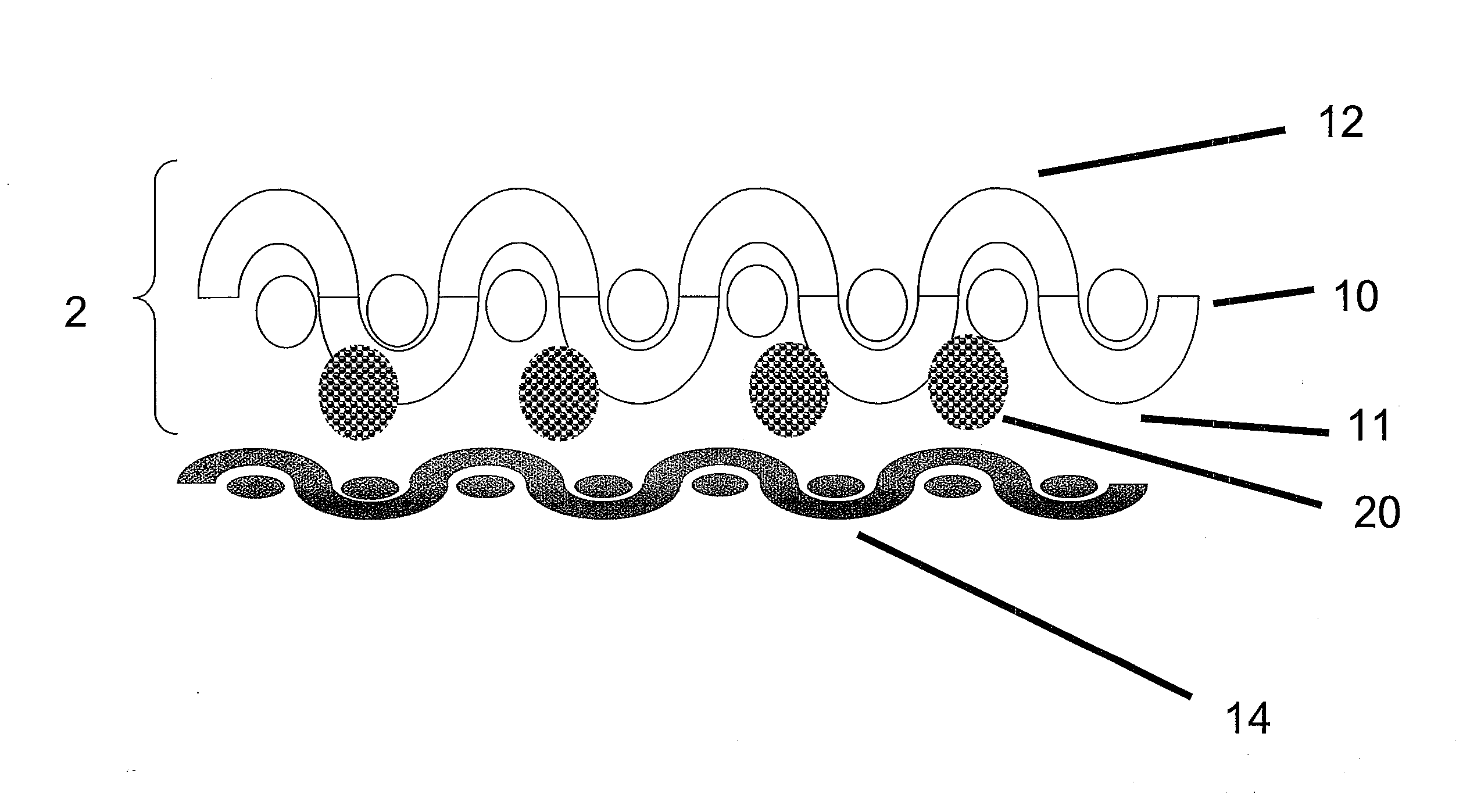

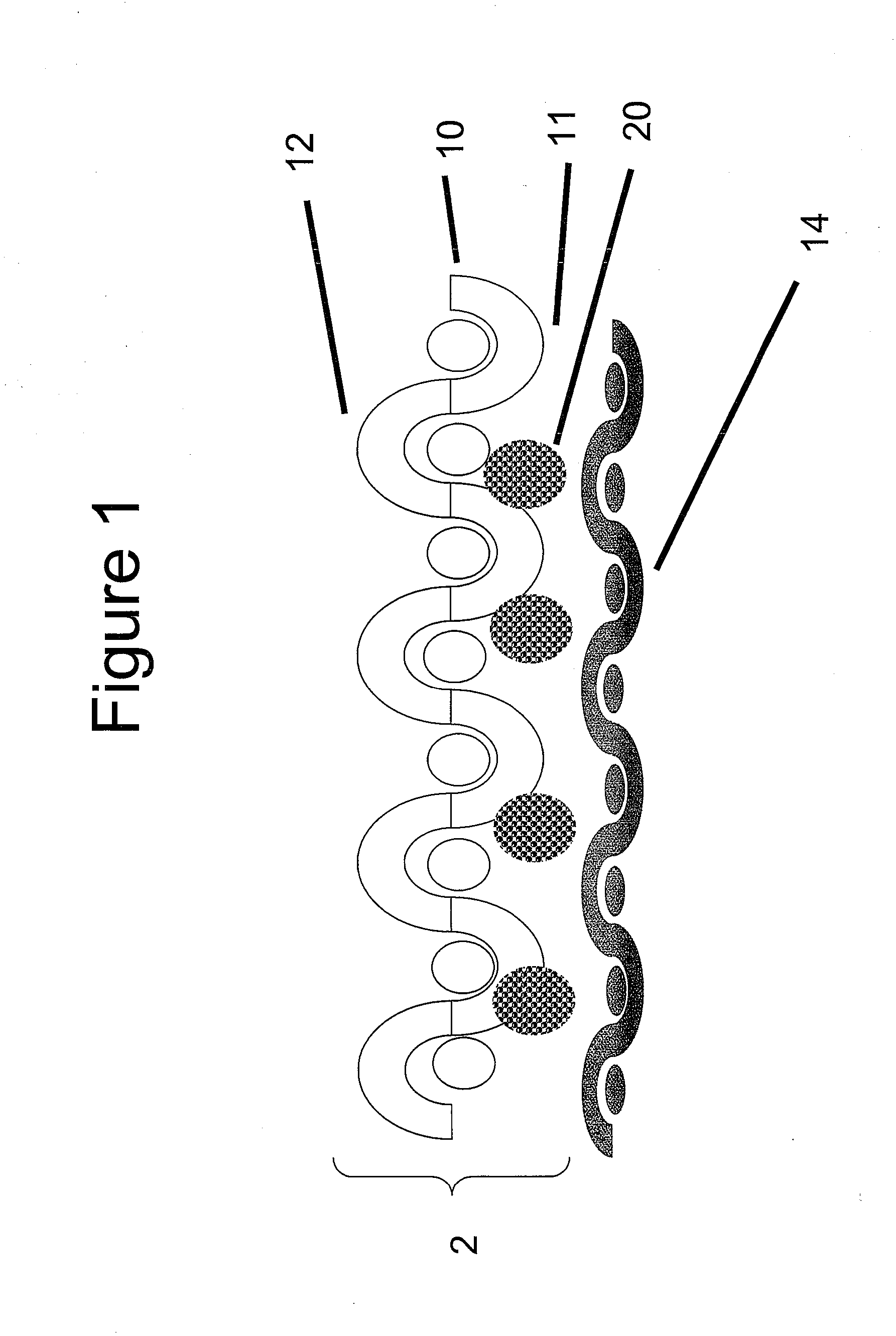

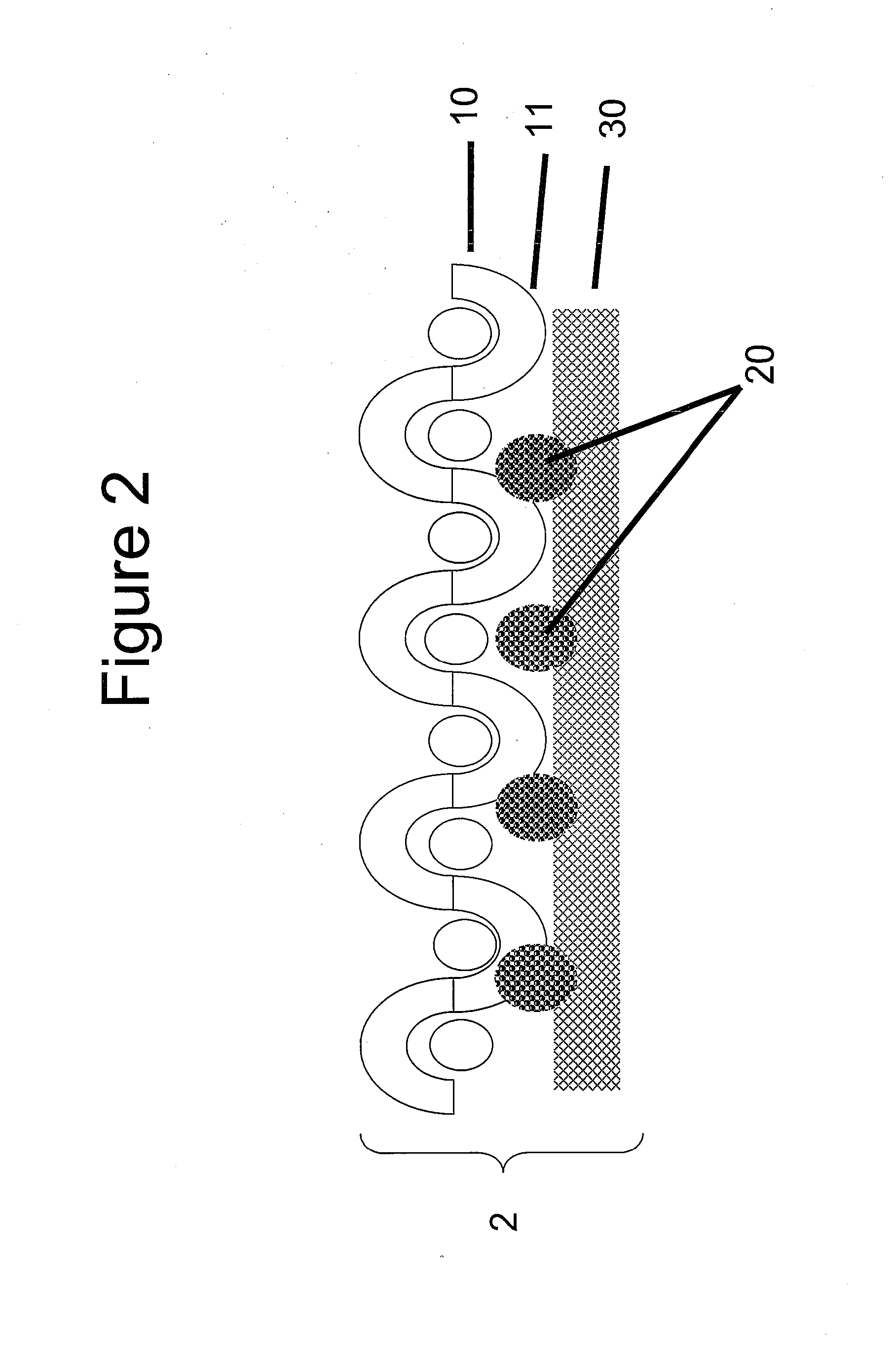

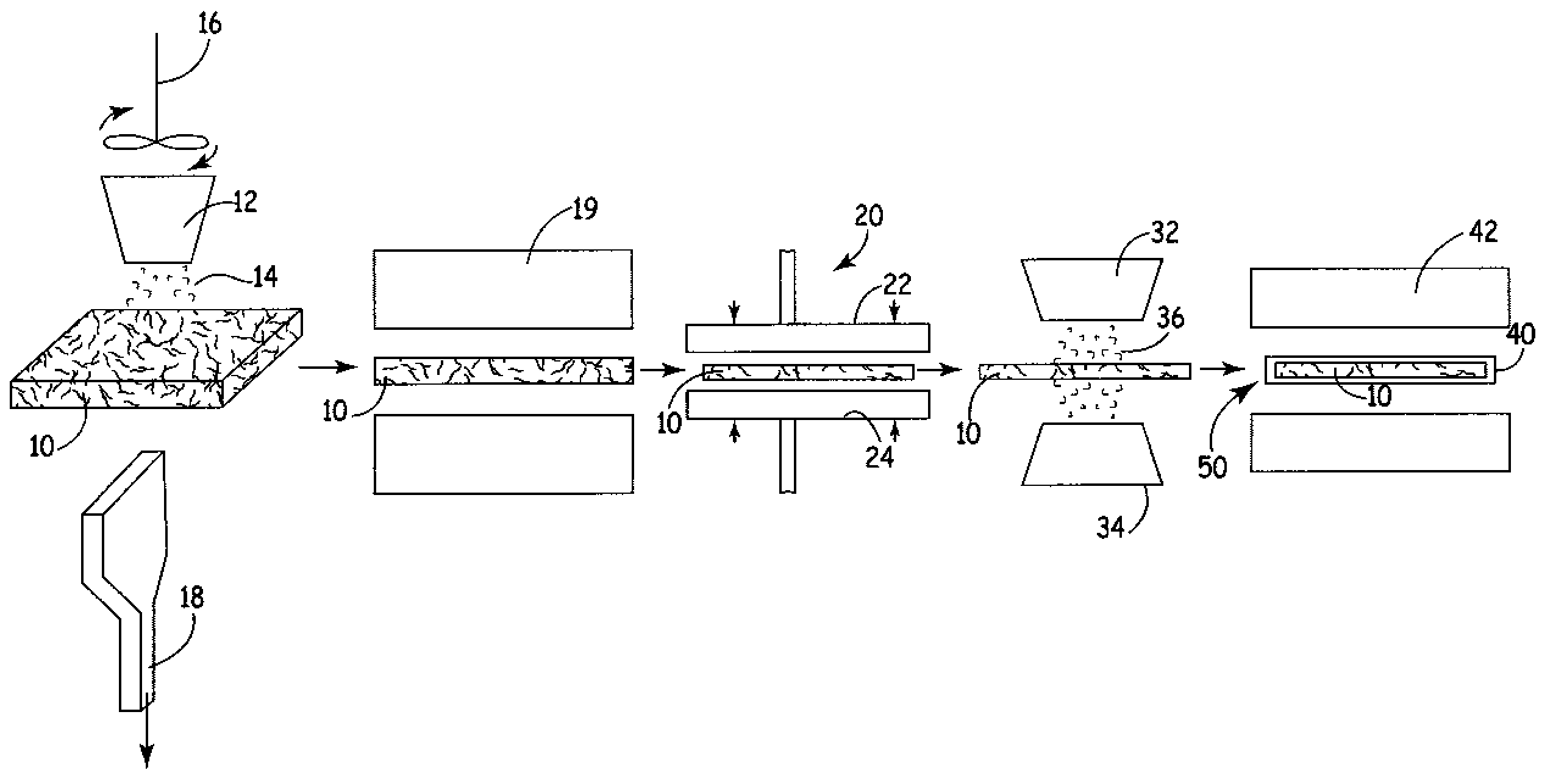

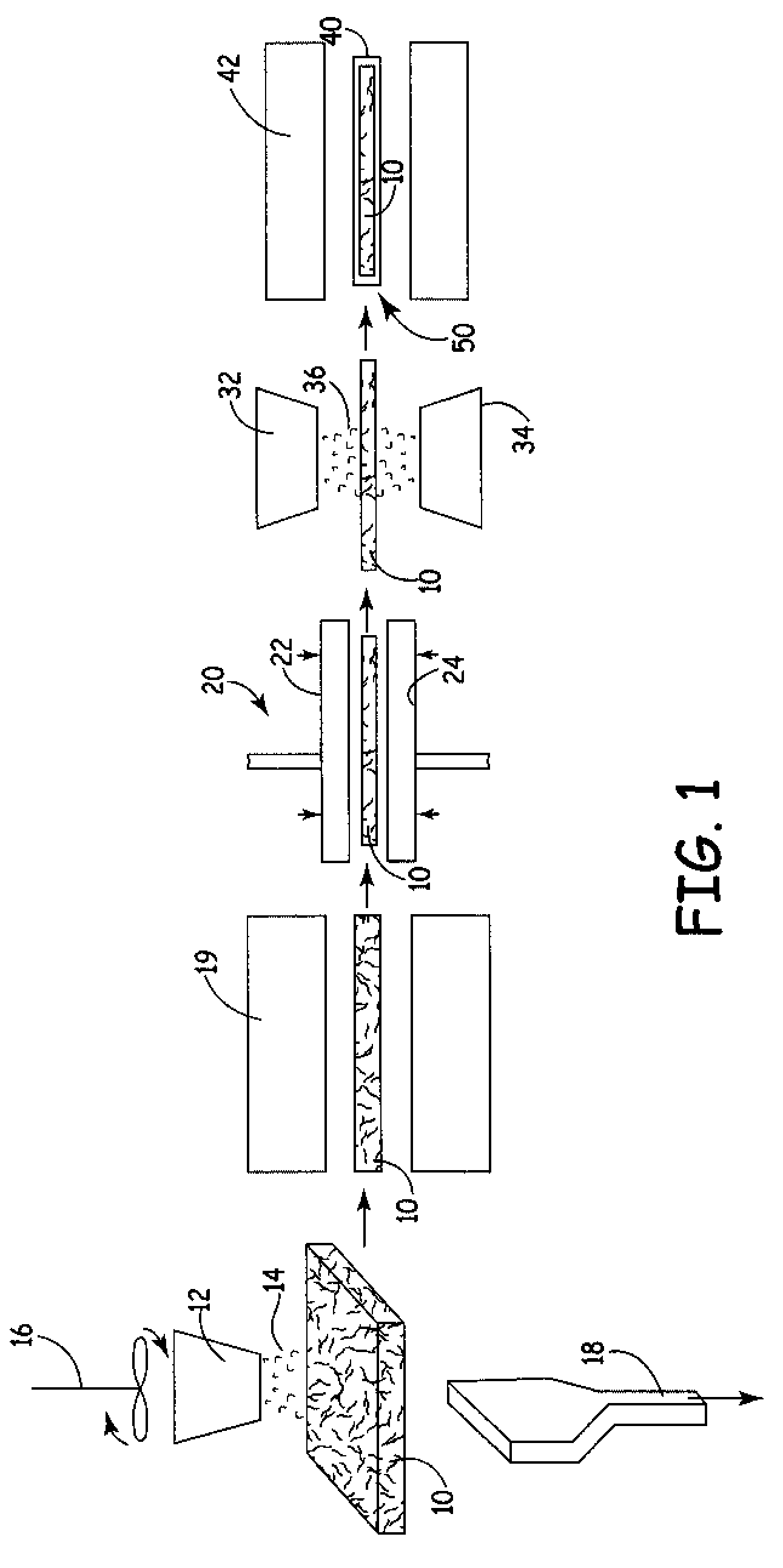

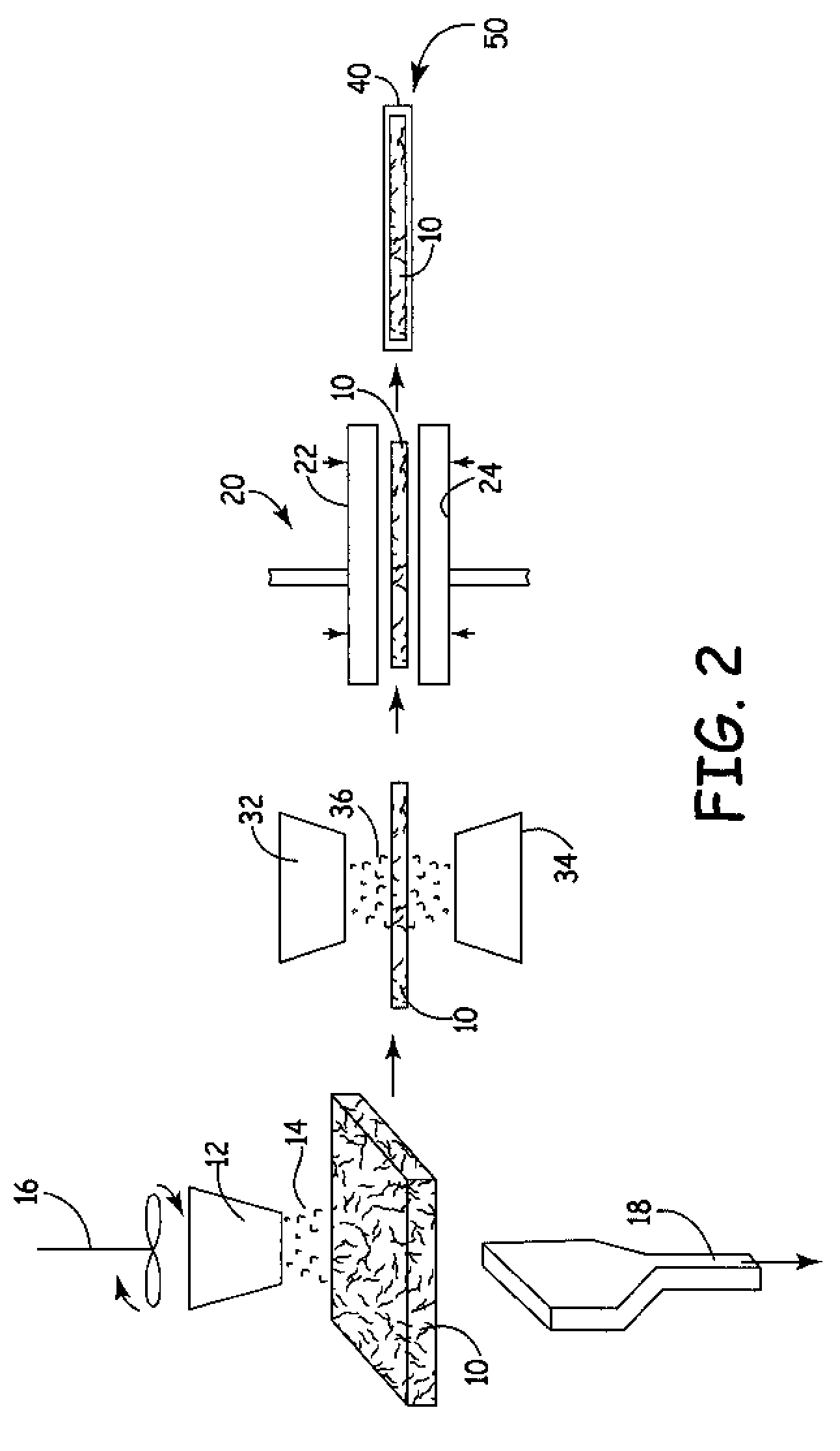

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GEORGIA PACIFIC NONWOVENS LLC

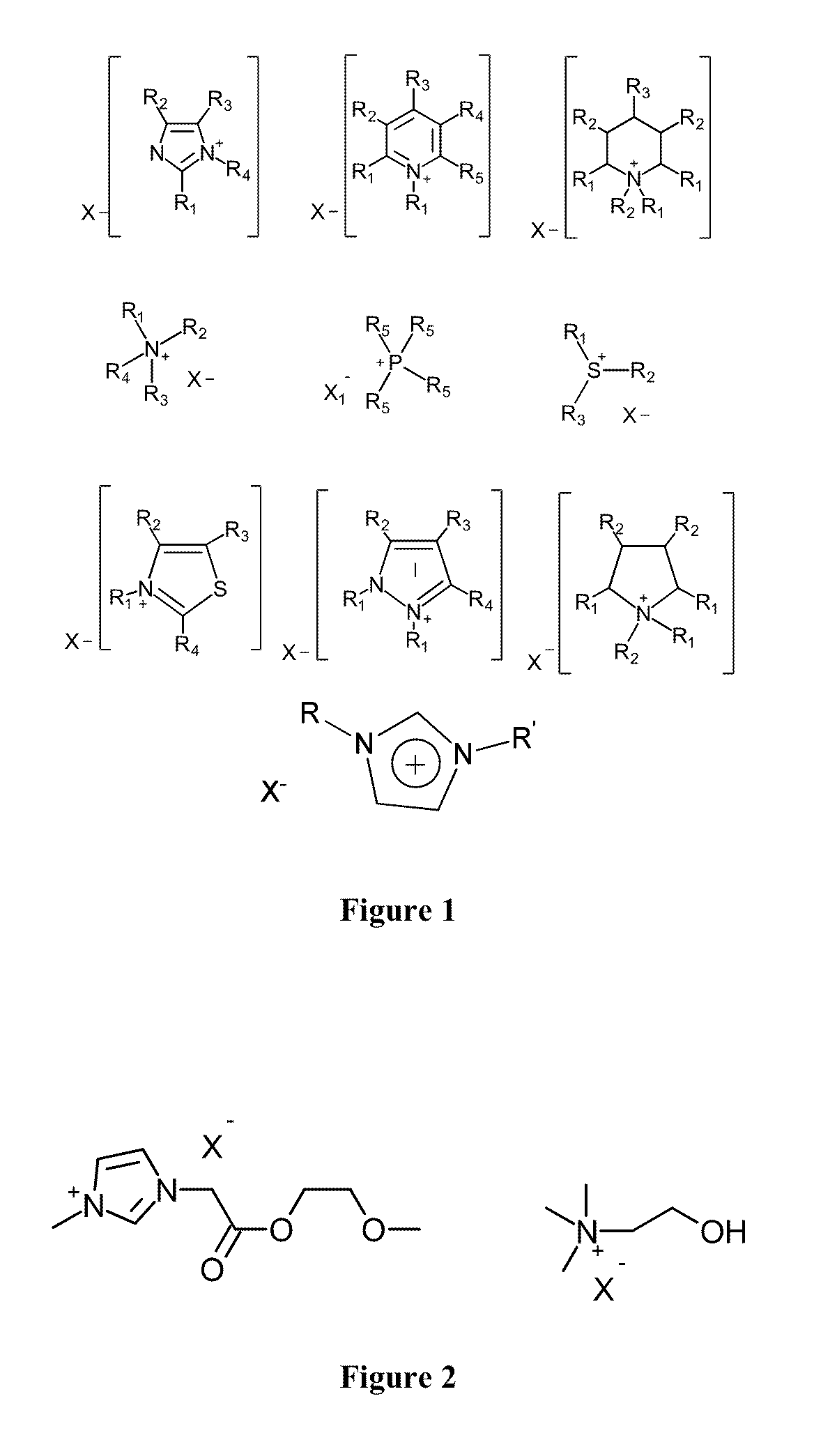

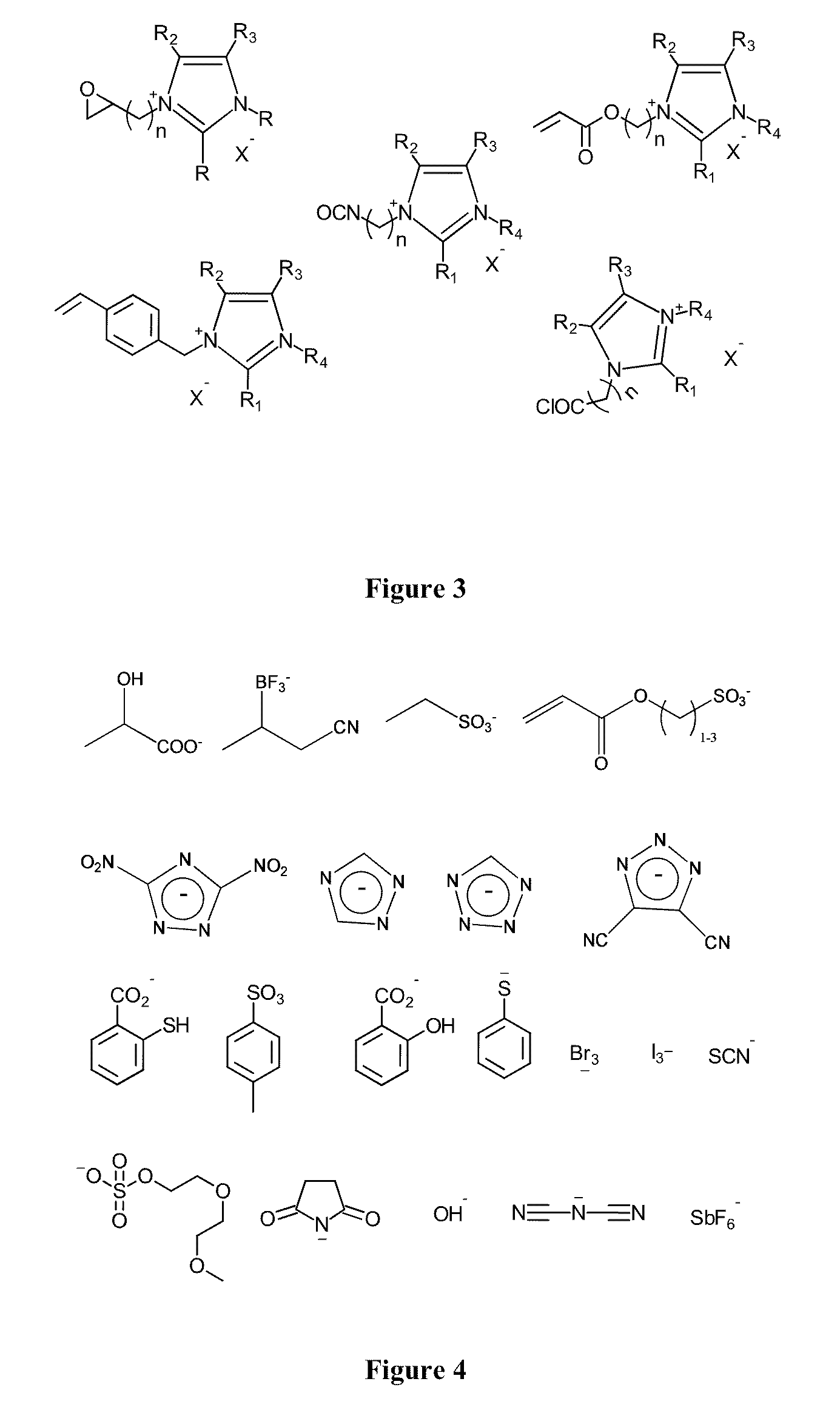

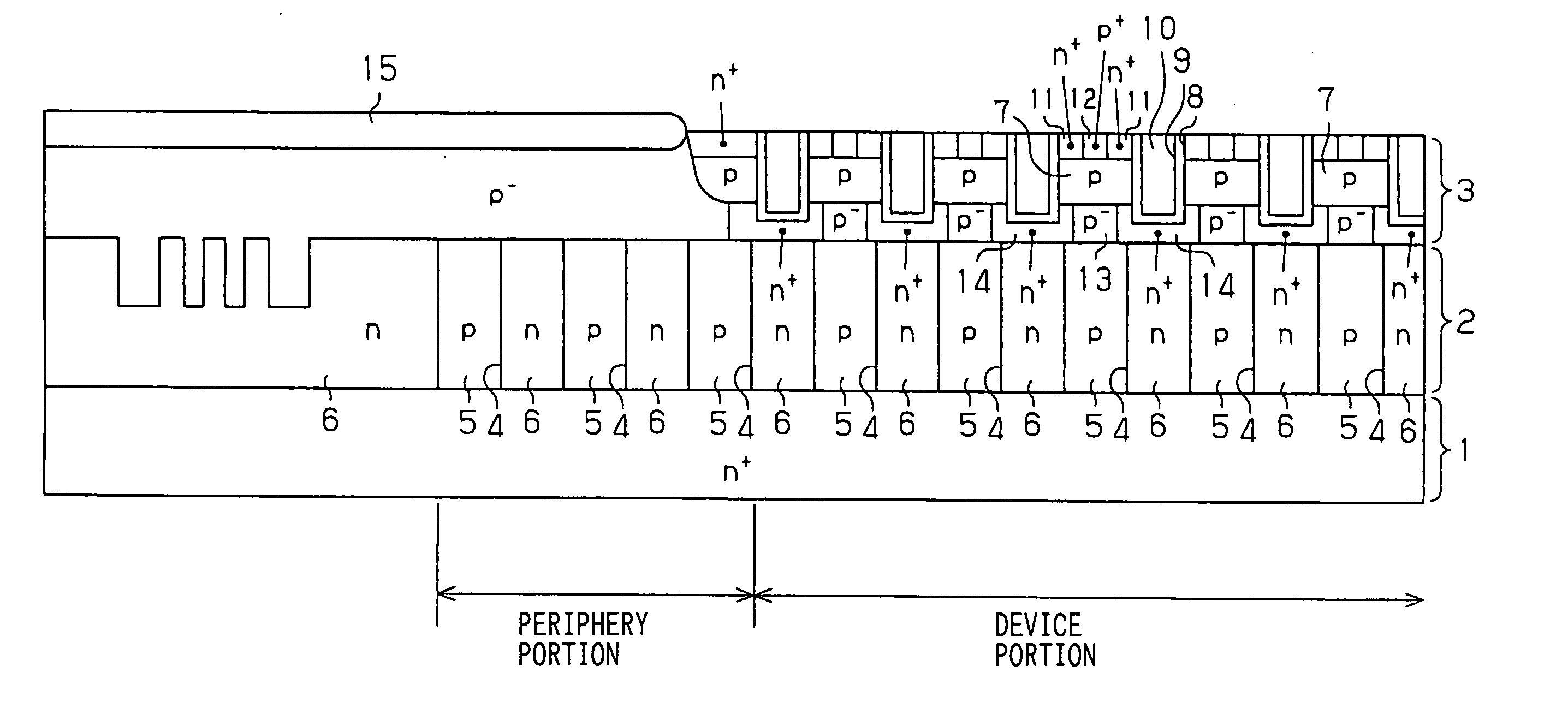

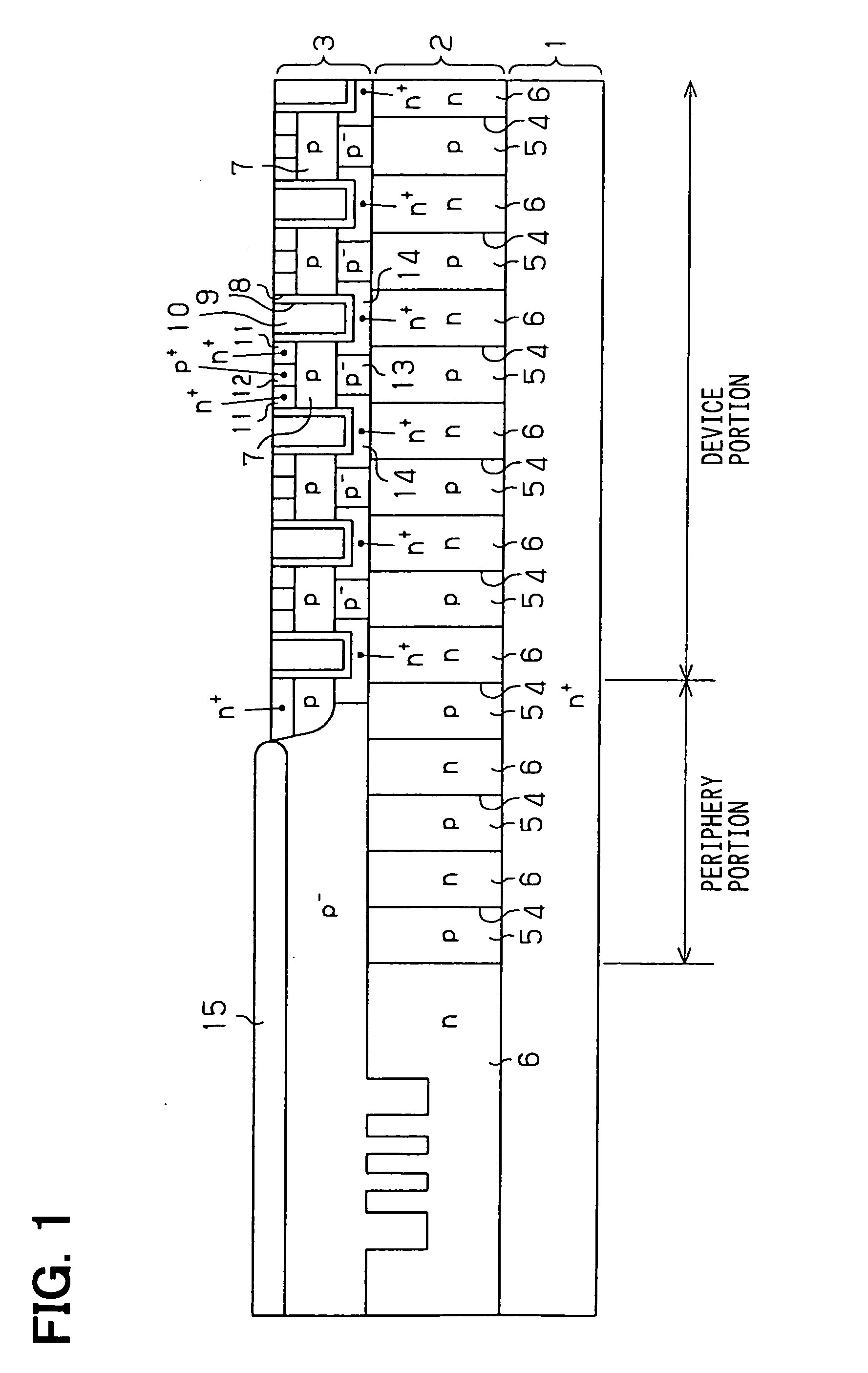

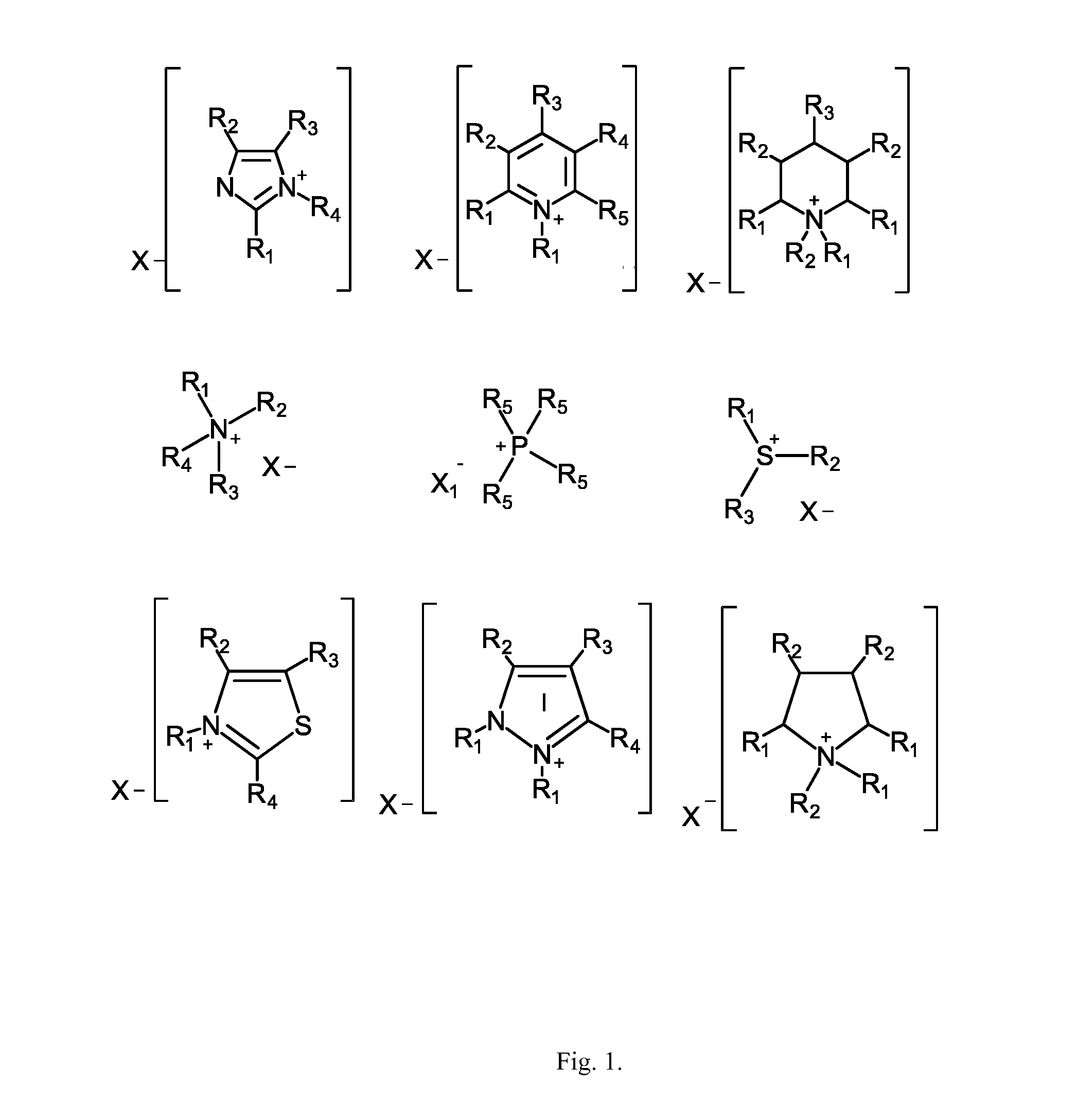

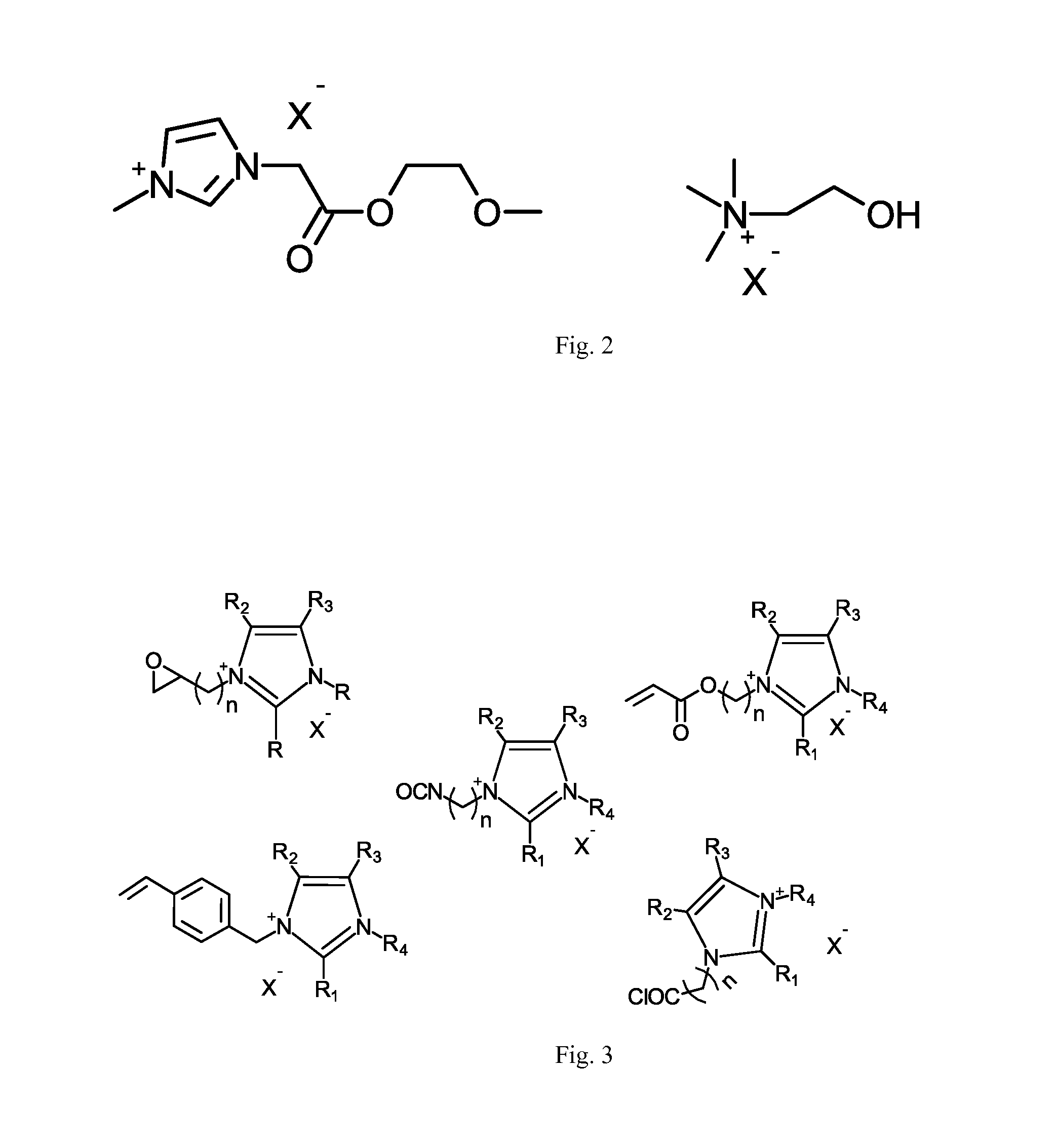

Ionic Liquid Flame Retardants

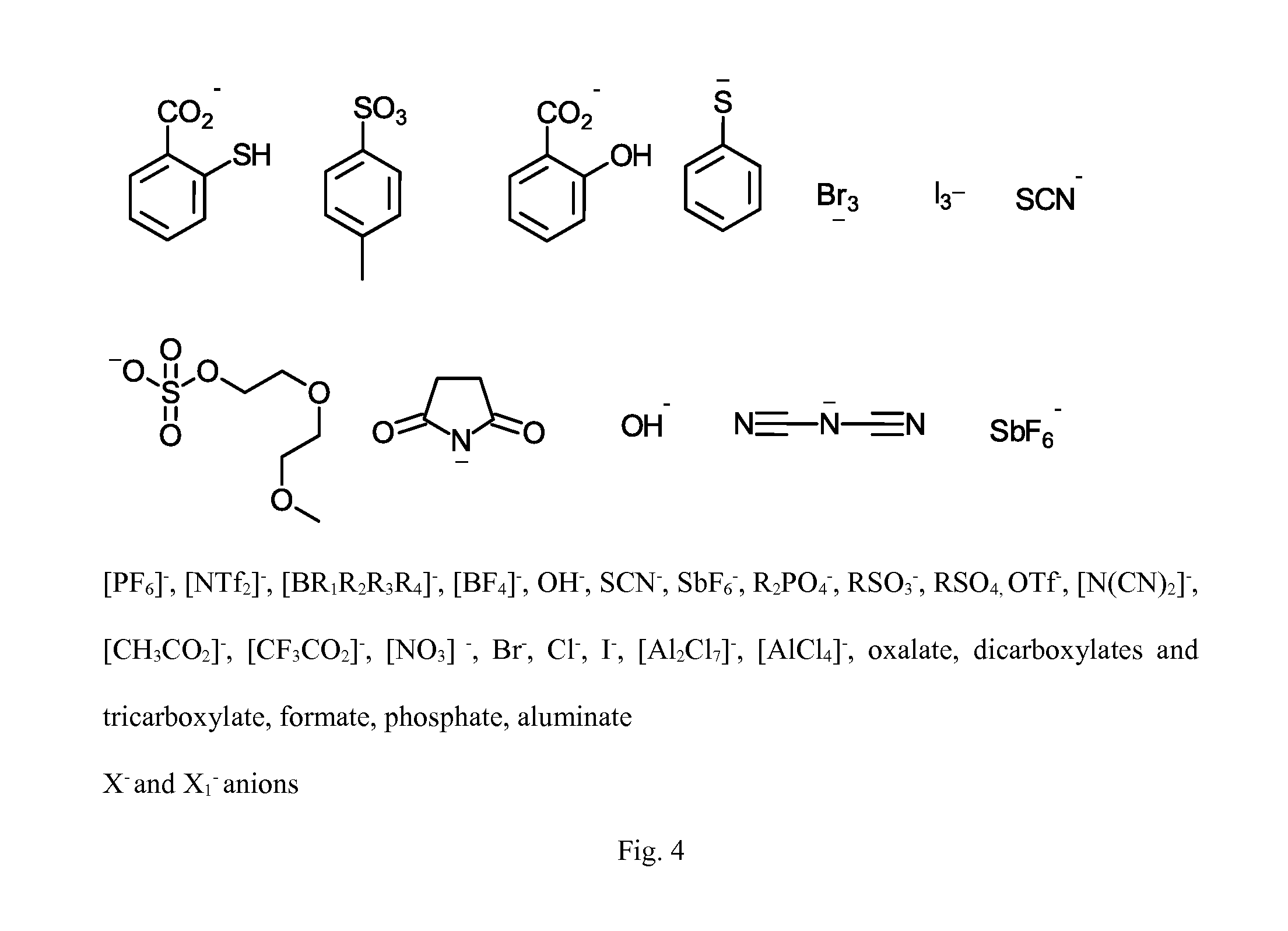

ActiveUS20110073331A1Excellent resistance to migrationPromote leachingPretreated surfacesHeat resistant fibresFire retardantIonic liquid

The present invention relates to the use of ionic liquids as flame retardants. The compounds of the invention may be used as flame retardants in various materials without causing damage to the environment and or health of humans or animals. Ionic liquid flame retardants maybe applied alone or in combination with traditional flame retardants. Ionic liquid flame retardants can be applied to finish textile, plastic, leather, paper, rubber or as wild fire flame retardants.

Owner:INOVIA MATERIALS (HANGZHOU) CO LTD

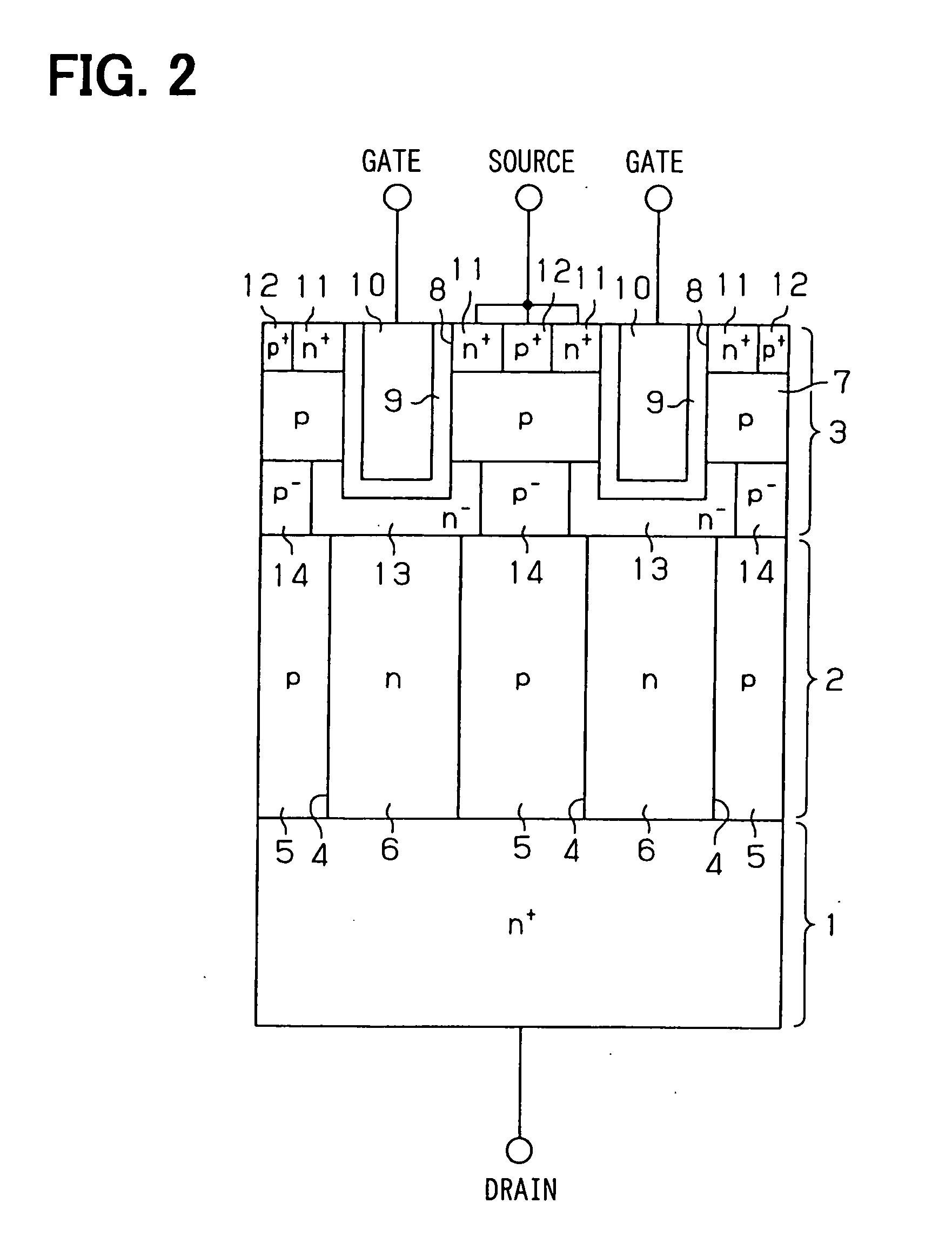

Method for manufacturing semiconductor device

ActiveUS20050221547A1Increase etch rateSemiconductor/solid-state device manufacturingHeat resistant fibresDevice materialSemiconductor

A method for manufacturing a semiconductor device includes the steps of: forming a trench in a semiconductor substrate; and forming an epitaxial film on the substrate including a sidewall and a bottom of the trench so that the epitaxial film is filled in the trench. The step of forming the epitaxial film includes a final step before the trench is filled with the epitaxial film. The final step has a forming condition of the epitaxial film in such a manner that the epitaxial film to be formed on the sidewall of the trench has a growth rate at an opening of the trench smaller than a growth rate at a position of the trench, which is deeper than the opening of the trench.

Owner:SUMCO CORP +1

Nonwoven material for acoustic insulation, and process for manufacture

InactiveUS20080121461A1Improve acoustic propertiesReduce weightLiquid surface applicatorsWallsVolumetric Mass DensityEngineering

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GEORGIA PACIFIC NONWOVENS LLC

Thermally protective materials

InactiveUS20090111345A1Improve protectionFlexibilityChemical protectionHeat protectionPolymer resinGraphite

A mixture comprising an expandable graphite and a polymer resin is described wherein the polymer resin-expandable graphite mixture has a volume increase and structural integrity after exposure to heat. Methods are described for increasing the thermal protective performance (TPP) of textiles and laminates while optionally maintaining comfort, flexibility, and liquid protective properties.

Owner:W L GORE & ASSOC GMBH +1

Molded object having nonwoven fibrous structure

ActiveUS20090130939A1Increased bending stressImprove toughnessErasing devicesConstruction materialPolyesterApparent density

To prepare a shaped product comprising a thermal adhesive fiber under moisture and having a fiber aggregate nonwoven structure. In the shaped product, the thermal adhesive fibers under moisture are melted to bond to fibers constituting the fiber aggregate nonwoven structure and the bonded fiber ratio is not more than 85%. The shaped product has an apparent density of 0.05 to 0.7 g / cm3, a maximum bending stress of not less than 0.05 MPa in at least one direction, and a bending stress of not less than ⅕ of the maximum bending stress at 1.5 times as large as the bending deflection at the maximum bending stress. The moistenable-thermal adhesive fiber may be a sheath-core form conjugated fiber comprising a sheath part comprising an ethylene-vinyl alcohol-series copolymer and a core part comprising a polyester-series resin. Such a shaped product can be used for a building board or the like since the shaped product has a high bending stress although the product is light and has a low density.

Owner:KURARAY CO LTD

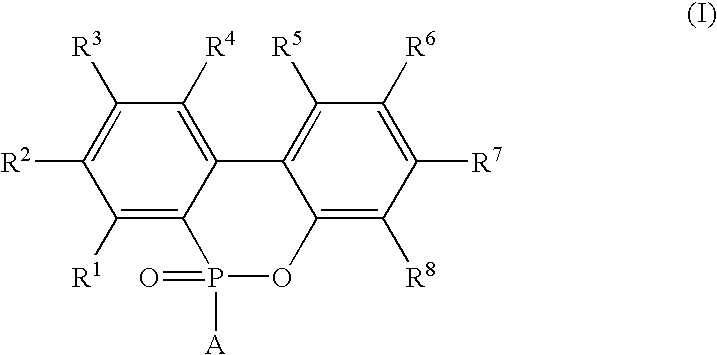

Artificial sueded leather being excellent in flame retardance and method of producing the same

ActiveUS20090258182A1Increase resistanceSynthetic resin layered productsHeat resistant fibresSolubilityCompound a

It is intended to provide a novel artificial sueded leather having flame retardance, which is excellent inflame retardance, light resistance and abrasion resistance, suffers from no water spot and is free from any halogenated chemical (i.e., one having been treated with a so-called non-halogenated flame retardant), and a method of producing the same. The above artificial sueded leather comprises a thermoplastic synthetic fiber cloth made of a woven fabric, a knitted web or a nonwoven fabric, which has a raised-fiber or napped-fiber surface and has been impregnated with a polyurethane resin, and a flame retardant which contains at least a phosphate compound A having a solubility in water of 1% or less, a vinyl group-containing resin C capable of forming a carbonization skeleton in burning and a water-insoluble thickener D and is imparted to one face of the thermoplastic synthetic fiber cloth. A method of producing the artificial sueded leather as described above comprises imparting an flame retardant, which contains at least a phosphate compound A having a solubility in water of 1% or less, a vinyl group-containing resin C capable of forming a carbonization skeleton in burning and a water-insoluble thickener D, to one face of a thermoplastic synthetic fiber cloth made of a woven fabric, a knitted web or a nonwoven fabric which has a raised-fiber or napped-fiber surface and has been impregnated with a polyurethane resin.

Owner:TORAY IND INC

Articles of enhanced flamability resistance

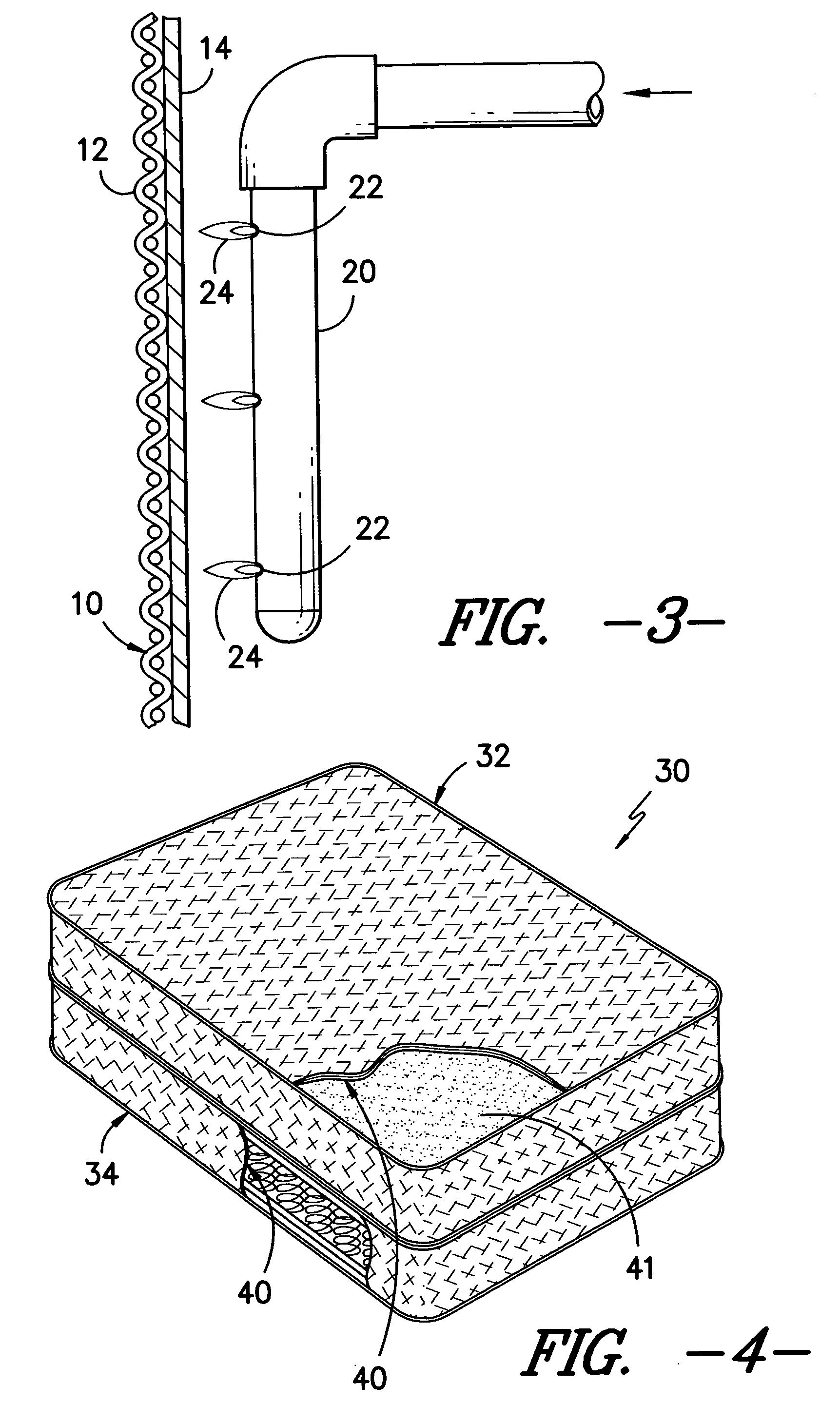

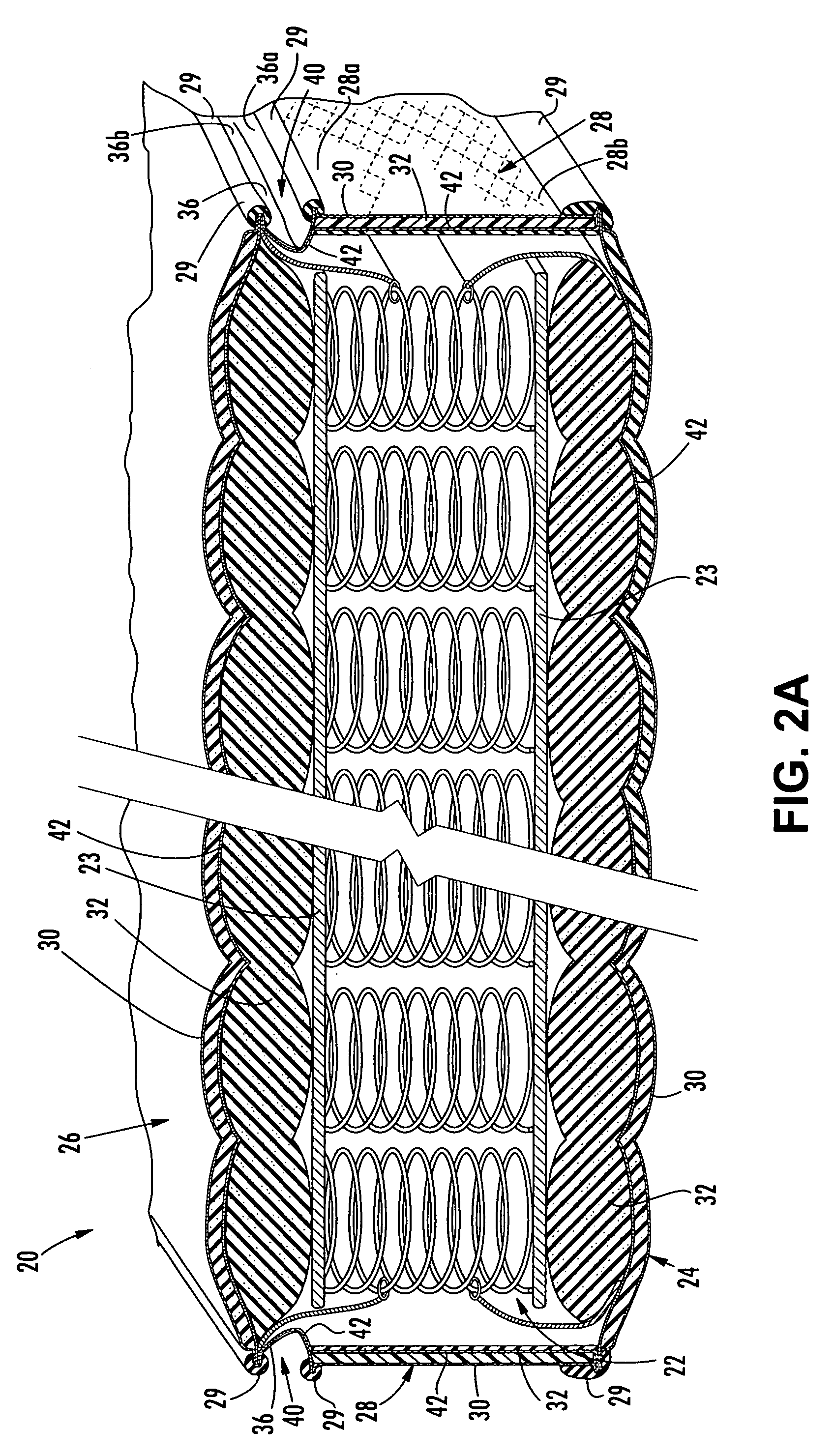

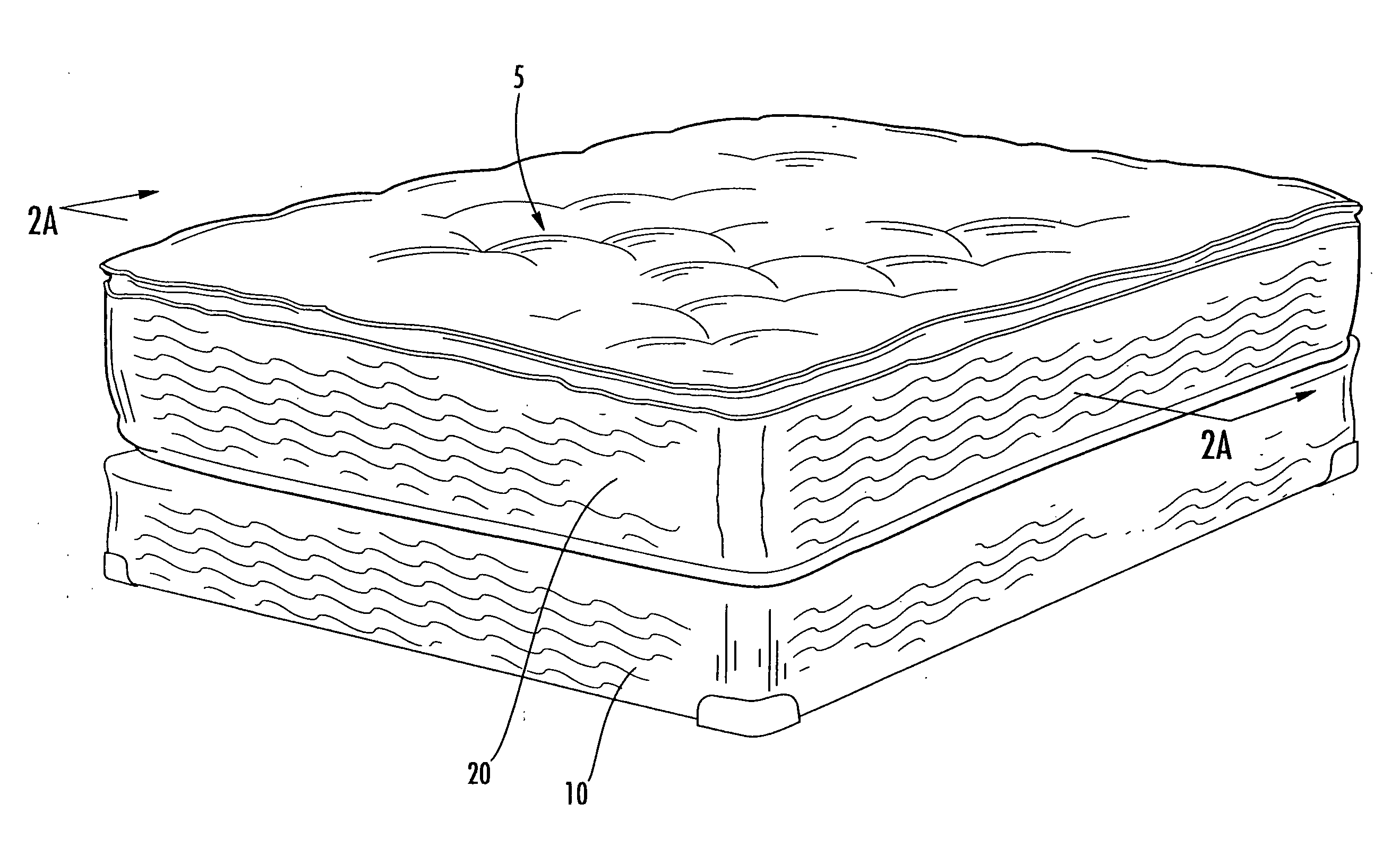

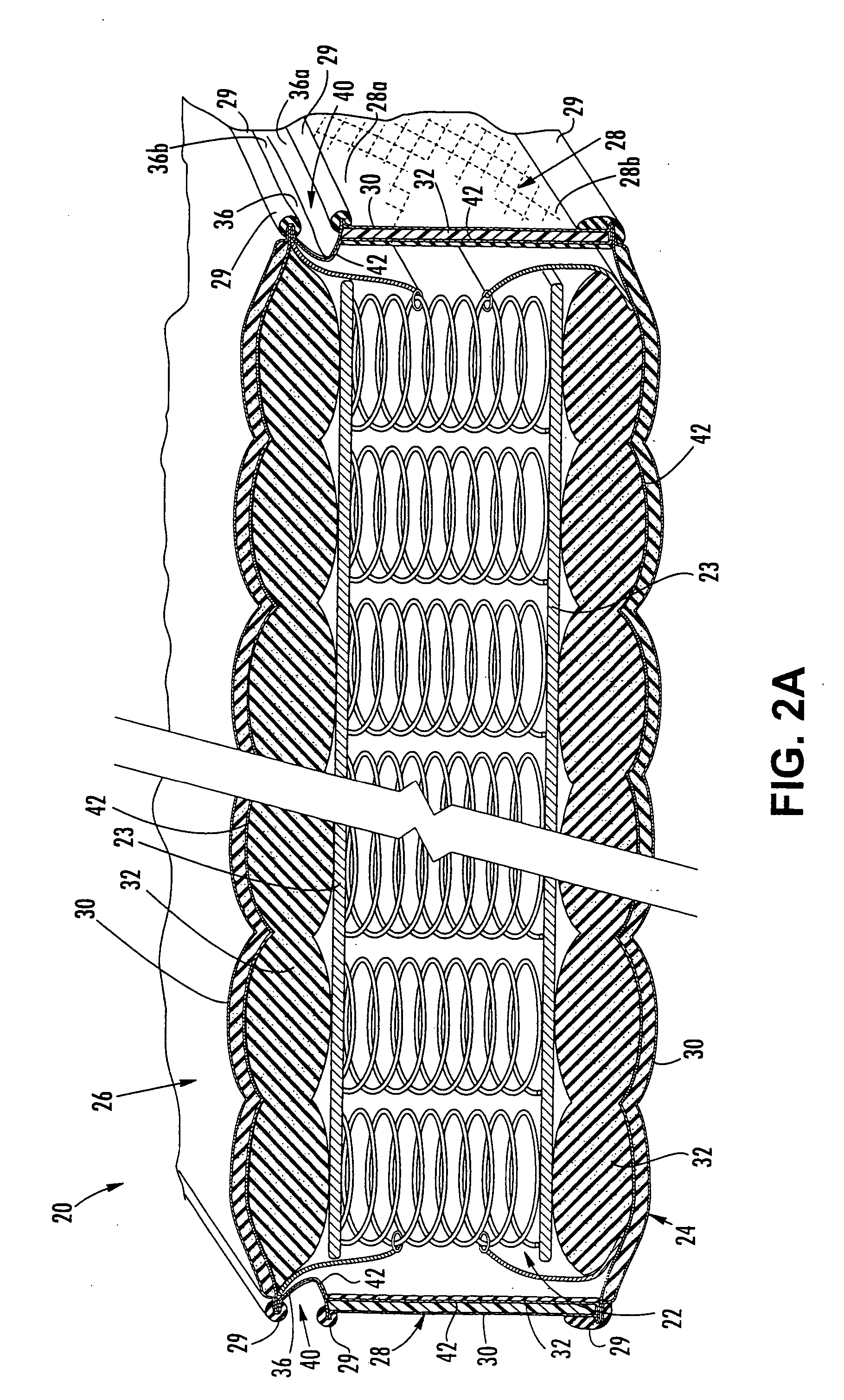

InactiveUS20050287894A1Substantial flame resistanceStuffed mattressesSynthetic resin layered productsEngineeringFlame resistance

Owner:BURNS JOHN +3

Water-soluble flame-retardant polyester resin, resin composition containing the resin, and fiber product treated with the resin composition

InactiveUS7358323B2Improve flame retardant performanceEliminate the problemSynthetic resin layered productsHeat resistant fibresSolubilityFiber

A water-soluble, flame retardant polyester resin is obtained by a condensation reaction or a polycondensation reaction of a dicarboxylic-acid component, a glycol component, a water-solubility imparting component and a reactive phosphorus-containing compound such that a ratio of the water-solubility imparting component in a total of the dicarboxylic-acid component and the water-solubility imparting component is in a range of 1 to 60 mol %. Since this polyester resin can be dissolved in a solvent by allowing a halogen-free, phosphorus-containing polyester with excellent flame resistance to have water solubility, it is possible to improve applicability and eliminate problems of working environment and environmental destruction resulting from organic solvents. In addition, even when treating substrates such as fibers and PET films with the polyester resin, there is no deterioration of these substrates.

Owner:GOO CHEM IND

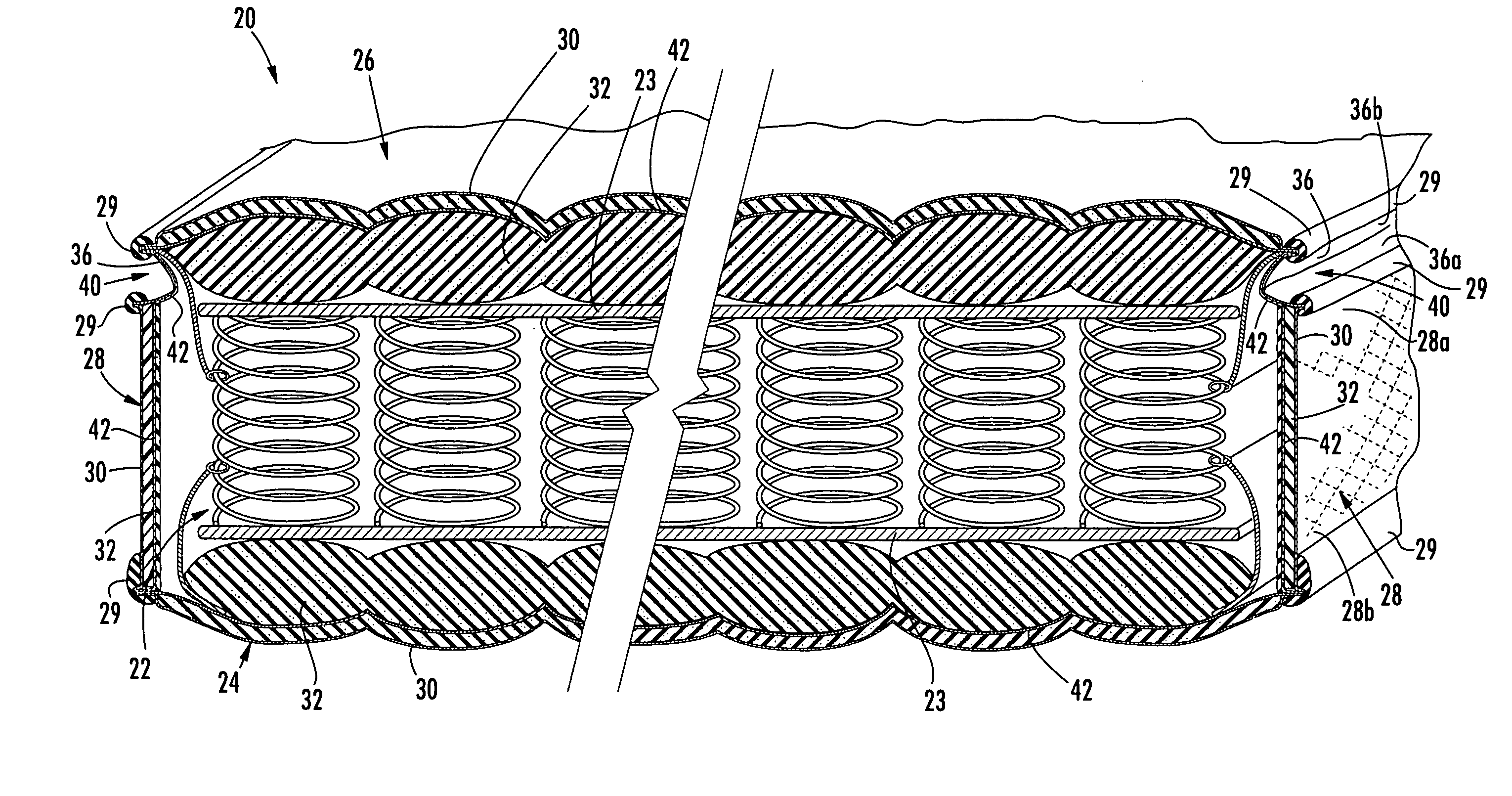

Heat and flame-resistant materials and upholstered articles incorporating same

ActiveUS7150059B2Improve performanceAvoid burnsStuffed mattressesSynthetic resin layered productsCombustionConus californicus

A mattress, foundation, or other upholstered sleep product or article includes a core and barrier material surrounding the core. The barrier material includes flame and heat-resistant material that is configured to prevent combustion of the core when the upholstered article is impinged with a gas flame according to California Technical Bulletin 603 of the State of California Department of Consumer Affairs. The barrier material may include an intumescent material that is configured to swell and char in the presence of a flame so as to form a barrier to the flame and to heat generated by the flame.

Owner:ADVANCED MICRO DEVICES INC +1

Heat and flame-resistant materials and upholstered articles incorporating same

InactiveUS20050227558A1Improve performanceAvoid burnsStuffed mattressesSynthetic resin layered productsCombustionEngineering

A mattress, foundation, or other upholstered sleep product or article includes a core and barrier material surrounding the core. The barrier material includes flame and heat-resistant material that is configured to prevent combustion of the core when the upholstered article is impinged with a gas flame according to California Technical Bulletin 603 of the State of California Department of Consumer Affairs. The barrier material may include an intumescent material that is configured to swell and char in the presence of a flame so as to form a barrier to the flame and to heat generated by the flame.

Owner:PRECISION FABRICS GROUP

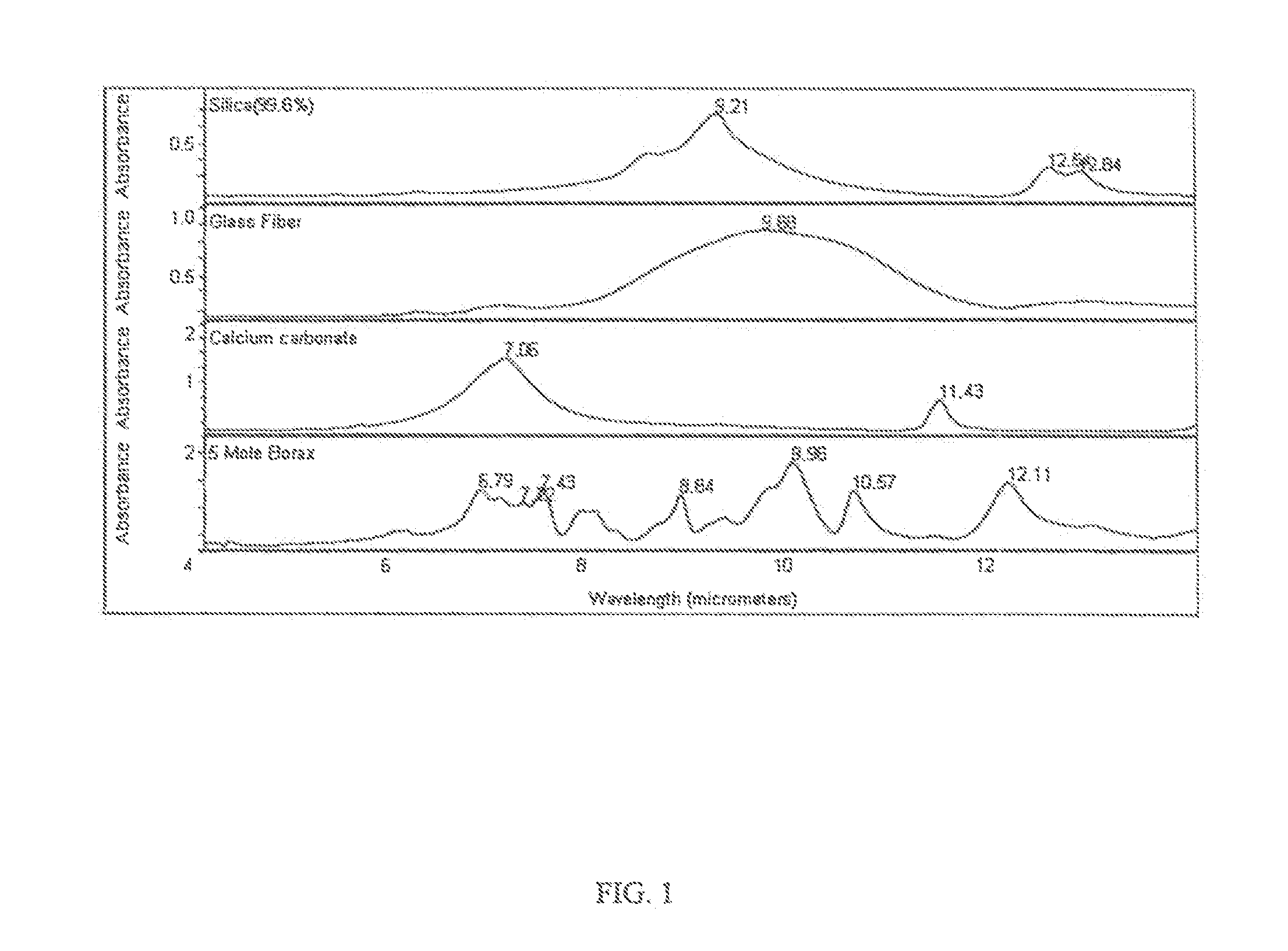

Thermal insulation containing supplemental infrared radiation absorbing material

InactiveUS20110256790A1Reduce heat lossEffective wavelength rangeHollow filament manufactureClimate change adaptationFiberRadar-absorbent material

Owner:SAINT-GOBAIN GLASS FRANCE

Near Infrared Absorbing Fiber and Fiber Article Using Same

ActiveUS20080308775A1Effective heat absorptionSatisfactory weather resistanceEngine sealsHeat resistant fibresPolyesterYarn

An inexpensive fiber that has heat retaining properties, satisfactory weather resistance and heat absorption efficiency, and includes a heat absorbing material having excellent transparency; and a fiber article that uses the fiber. A particle dispersion of Cs0.33WO3 is obtained by mixing Cs0.33WO3 microparticles, toluene, and a microparticle dispersing agent to create a liquid dispersion, and then removing the toluene. The particle dispersion is added to and uniformly mixed with pellets of polyethylene terephthalate resin, after which the mixture is extruded, the strands thus obtained are formed into pellets, and a master batch including Cs0.33WO3 microparticles is obtained. This master batch is mixed with a master batch to which inorganic microparticles have not been added, and the mixture thus obtained is melt spun and stretched to manufacture a polyester multifilament yarn. The polyester multifilament yarn is cut, polyester staple fibers are created, and a spun yarn is manufactured. A heat retentive knit article is obtained using the spun yarn.

Owner:SUMITOMO METAL MINING CO LTD

Use of rhamnolipid-based formulations for fire suppression and chemical and biological hazards

InactiveUS20090126948A1Effective applicationFireproof paintsChemical protectionEngineeringBiological hazard

The present invention relates to rhamnolipid-based formulations for bio-hazard coatings and fire extinguishing compositions. In addition, the present invention relates to the methods of extinguishing fires and protecting objects by using the formulations of the present invention.

Owner:DESANTO KEITH

Method for Providing a Localised Finish on Textile Article

A method of producing a textile article having a localised finish is described. The method comprises providing a continuous supply of a textile substrate, providing an array of digital nozzles, supplying a finishing composition to the nozzles and selectively depositing the finishing composition from the nozzles in a series of droplets to deposit a first predetermined pattern of droplets on a selected area of the substrate to endow a functional characteristic on the selected areas. In this way, it is possible to ensure that only those areas receive the finishing composition that ultimately require it. Usage of valuable chemicals and process time can hereby be reduced.

Owner:TEN CATE ADVANCED TEXTILES BV

Flame resistant fabric having antimicrobials and methods for making them

Owner:SOUTHERN MILLS

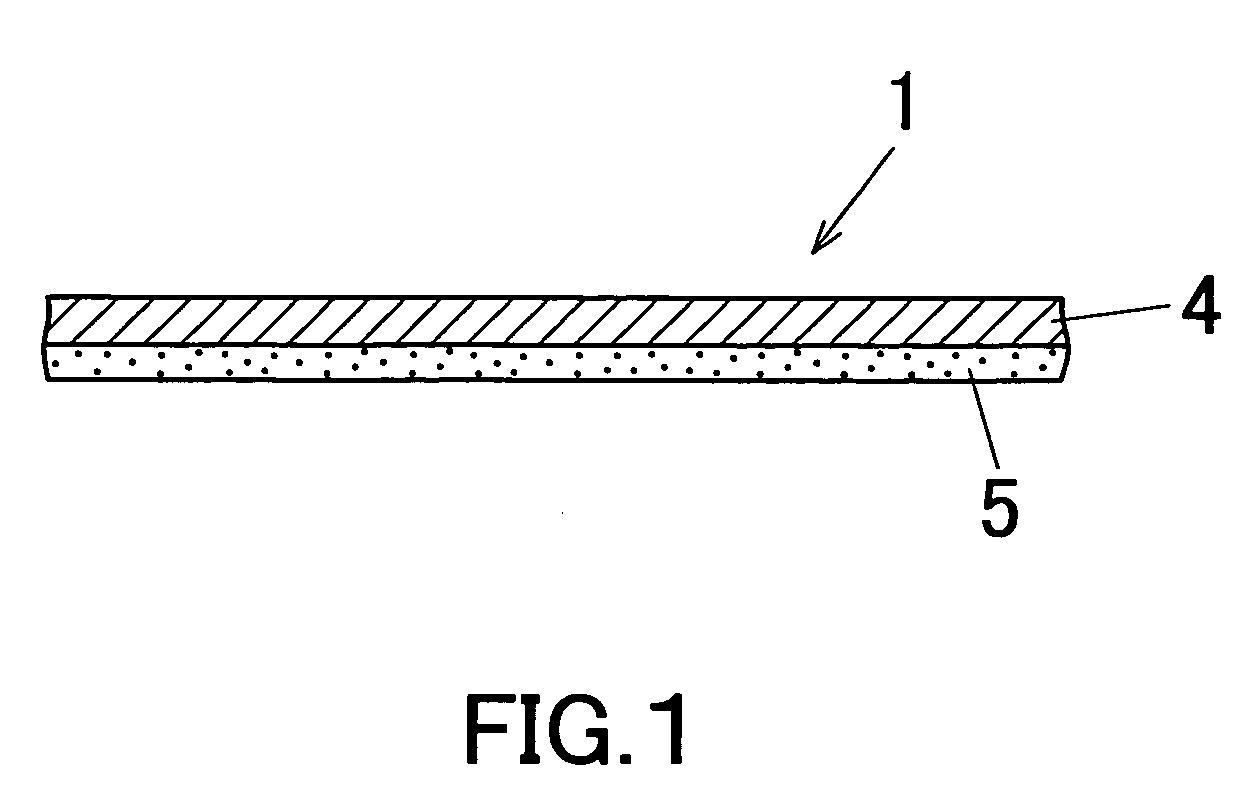

Flame-retardant fabric and method for manufacturing the same

A flame-retardant fabric 1 of the present invention comprises: a fiber fabric 4; and a back layer 5 formed on the back surface of the fiber fabric 4 and containing at least one of inorganic compound selected from the group consisting of calcium carbonate and magnesium hydroxide, thermally expansive graphite and a polymer substance. The adhering amount of solid of the back layer 5 is 50 to 150 g / m2. The adhering amount of the thermally expansive graphite is 15 to 60 g / m2. The adhering amount of the inorganic compound is 10 to 60 g / m2. The flame-retardant fabric causes no generation of noxious substances in case of fire and at incineration disposal, can impart sufficient initial flame retardancy, and has excellent flame-retardant performance in heat aging.

Owner:TOYOTA JIDOSHA KK +1

Flame resistant filler cloth and mattresses incorporating same

ActiveUS20050144728A1Low heat shrinkageStuffed mattressesSynthetic resin layered productsHeat resistanceEngineering

A filler cloth includes cellulosic fibers treated with a flame retardant chemistry such that the filler cloth has a char length of less than about nine inches when tested in accordance with NFPA 701, such that thermal shrinkage of the filler cloth at 400° F. is less than about 35% in any direction, and such that the filler cloth maintains flame and heat resistant integrity when impinged with a gas flame in accordance with testing protocols set forth in Technical Bulletin 603 of the State of California Department of Consumer Affairs. The filler cloth cellulosic fibers are treated with a flame retardant chemistry such that the filler cloth has a Frazier air permeability of less than about 400 cfm and a thermal resistance rating of at least about 3 when tested according to NFPA 2112.

Owner:PRECISION FABRICS GROUP

Flame retardant compositions

Novel formulations comprising pentabromobenzylbromide (PBBBr) and a carrier, for use as a flame retardant for application on a substrate, and processes for their preparation are disclosed. Further disclosed are articles-of-manufacture having these formulations applied thereon, and the use of PBBBr as a flame retardant for application on a substrate. These novel formulations are particularly effective as flame retardants for textiles, and are characterized by a low add-on and a high washing fastness.

Owner:BROMINE COMPOUNDS

Fire resistant composite material and fabrics therefrom

The present invention relates to fire resistant composite materials and to fire resistant fabric materials and mattresses made therefrom. The composite materials include (a) a substrate selected from the group consisting of cotton, rayon, lyocell, wool, silk and blends thereof; and (b) a coating consisting essentially of water, ammonium polyphosphate, binder material and cellulose filler material. The binder material bonds the ammonium polyphosphate and cellulose filler materials together and to the substrate such that the substrate is coated with the coating.

Owner:ELCOR CORP

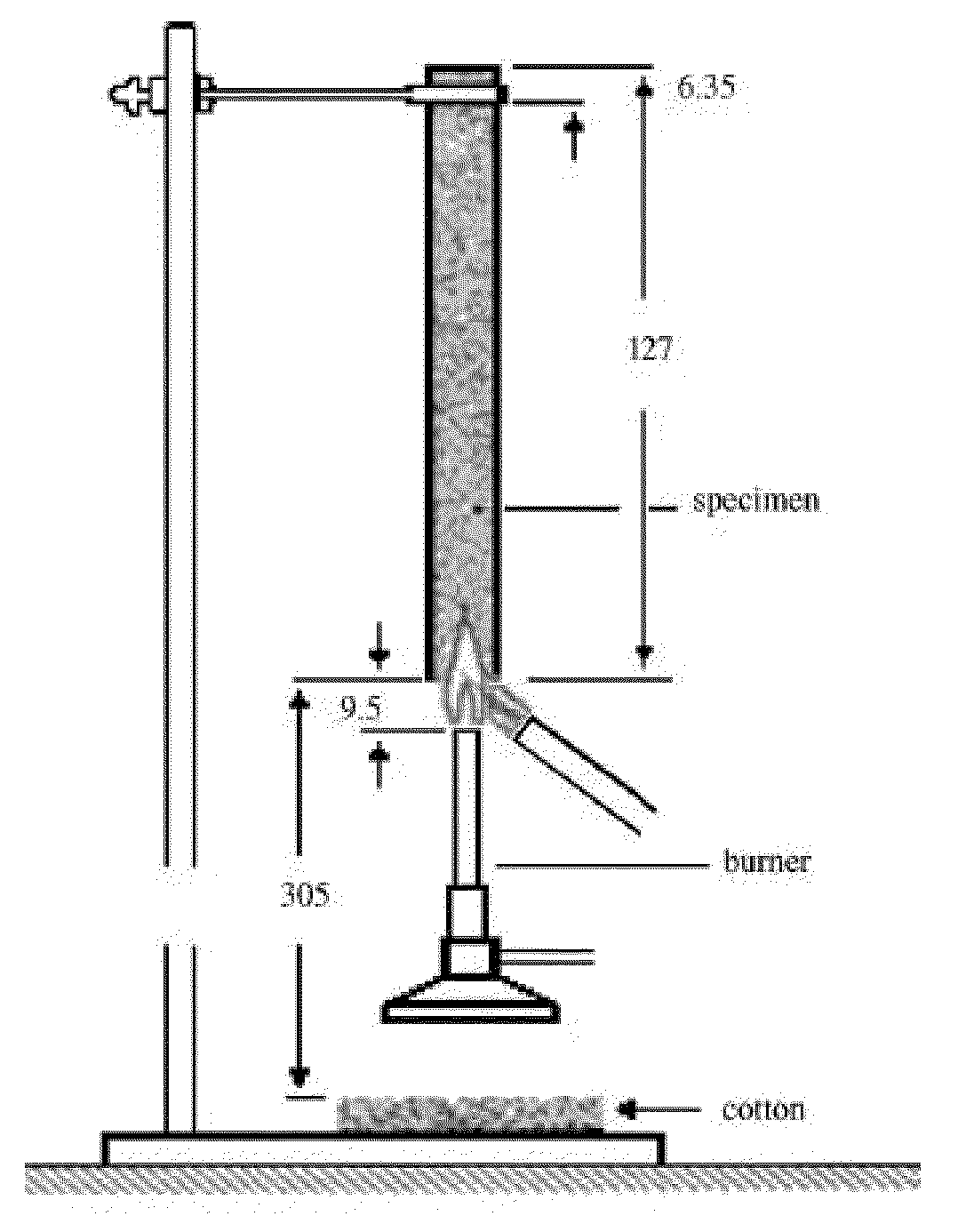

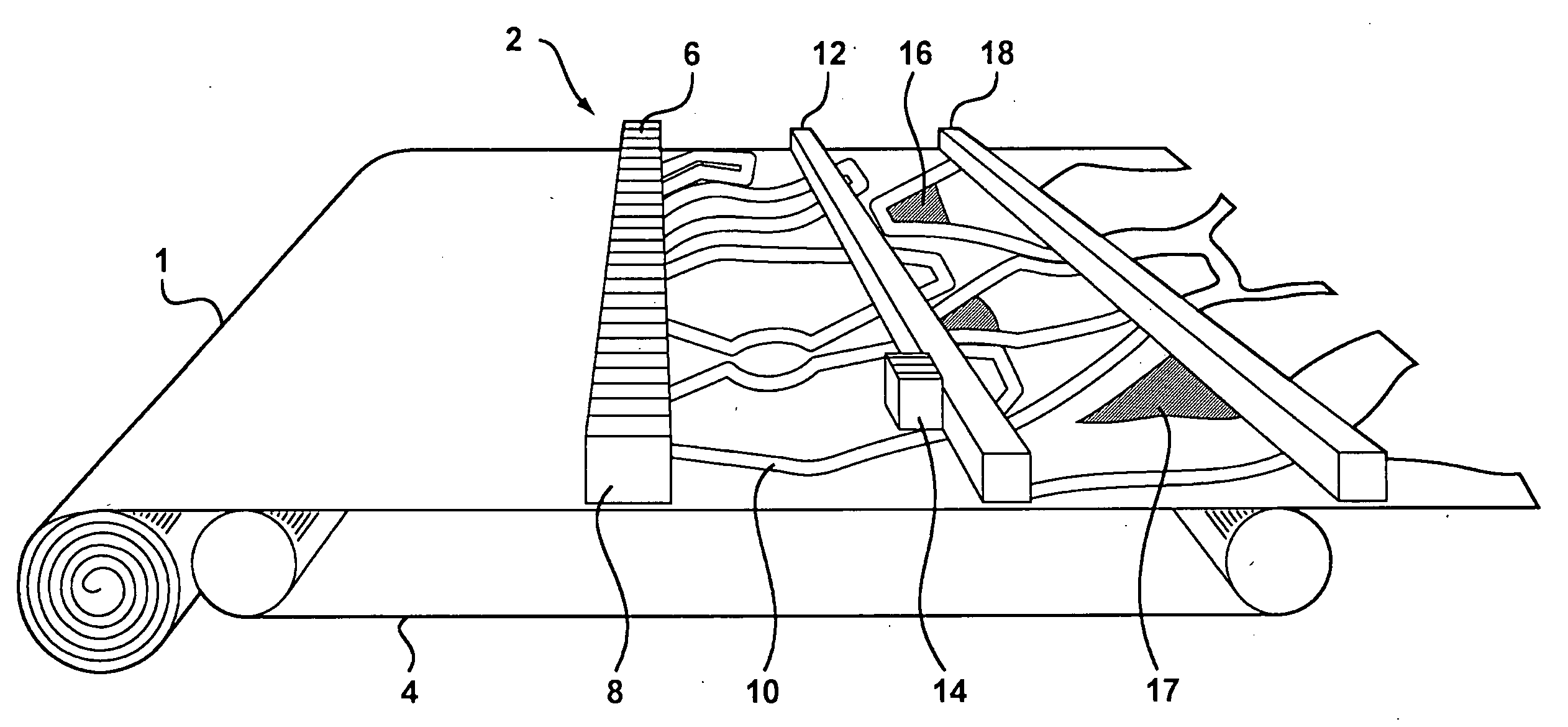

Fire-resistant fiber-containing article and method of manufacture

InactiveUS20060182940A1Meet standardClimate change adaptationHeat resistant fibresFiberFire retardant

A fire resistance article comprises a bast fiber component, a thermoplastic component that acts as a binder, and a first fire retardant component, the article having a coating of a second fire retardant component, such that the article can be used in the manufacture of structures having a Class A fire resistance rating. In one method of manufacture, a fibrous mass of the bast fiber component and the thermoplastic binder has the first fire retardant dispersed therethrough, and is then heated, compressed to a desired thickness and density, and coated with the second fire retardant component.

Owner:HNI TECH INC

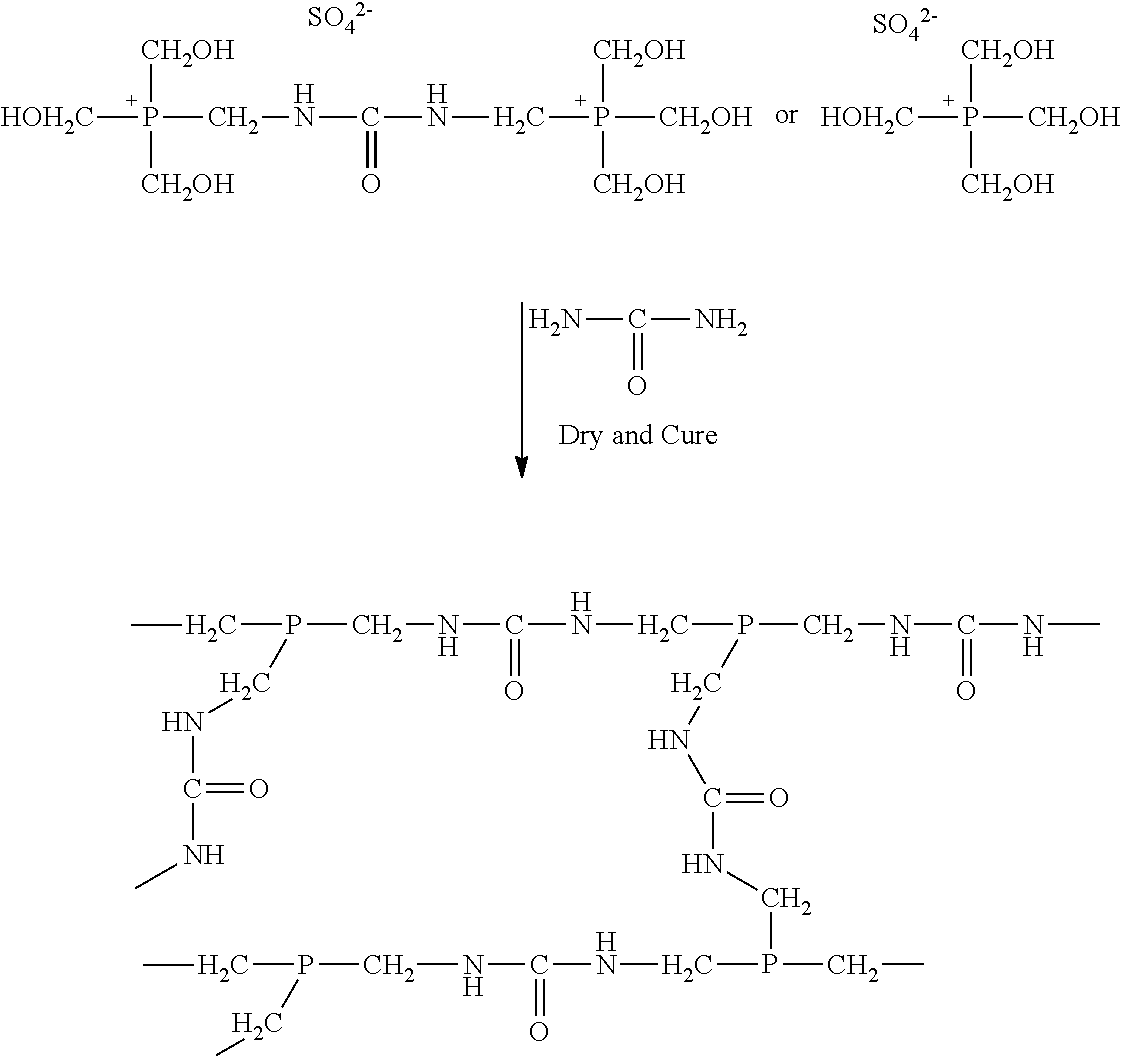

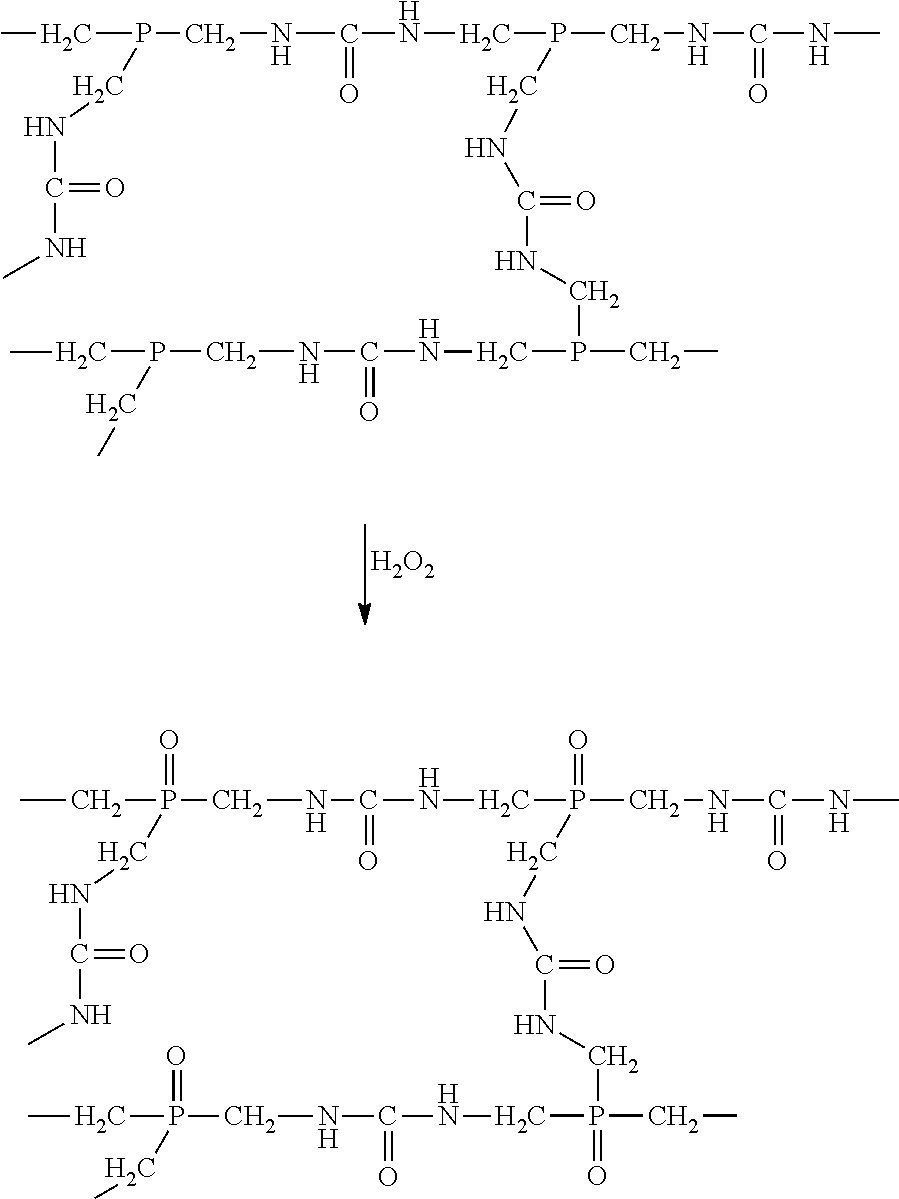

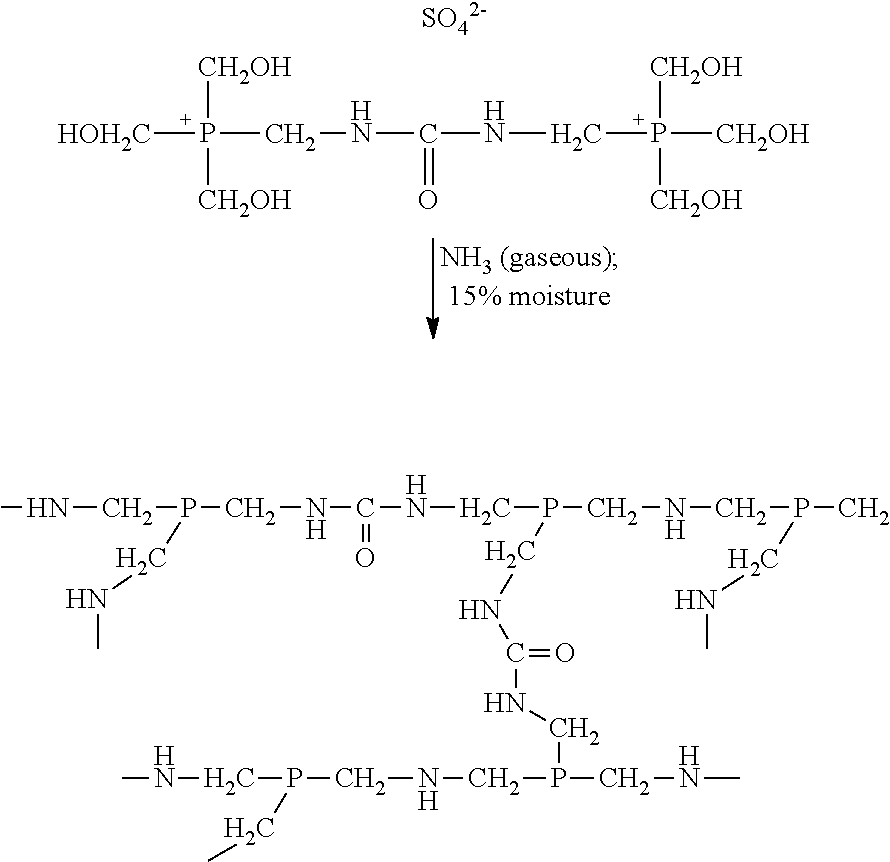

Flame resistant textile

A flame resistant textile is provided. The textile is a sateen weave fabric containing cellulosic fibers, where the sateen weave fabric has a thickness of at least 19.5 mils, a thickness of at least 25 mils after 3 home washes at 120° F., an air permeability of at least 60 cfm, and a weight of less than about 7 oz / yd2. The sateen weave fabric also contains a treatment, where the treatment contains a tetramethylhydroxy phosphonium salt or its condensate and chemical selected from the group consisting of urea, guanidines, guanyl urea, glycoluril, and polyamines. When the sateen weave fabric to which the treatment has been applied has been heat-cured and oxidized at least a portion of the cellulosic fibers have a pentavalent phosphate compound polymerized therein. The method for producing the flame resistant textile is also provided.

Owner:MILLIKEN & CO

Ionic liquid flame retardants

InactiveUS20110039467A1Excellent resistance to migrationPromote leachingNatural cellulose pulp/paperSpecial paperFire retardantIonic liquid

The present invention relates to the use of ionic liquids as flame retardants. The compounds of the invention may be used as flame retardants in various materials without causing damage to the environment and or health of humans or animals. Ionic liquid flame retardants maybe applied alone or in combination with traditional flame retardants. Ionic liquid flame retardants can be applied to finish textile, plastic, leather, paper, rubber, or as wild fire flame retardants.

Owner:H&C CHEM

Synergistic flame retardant compositions and fiber blends including the same

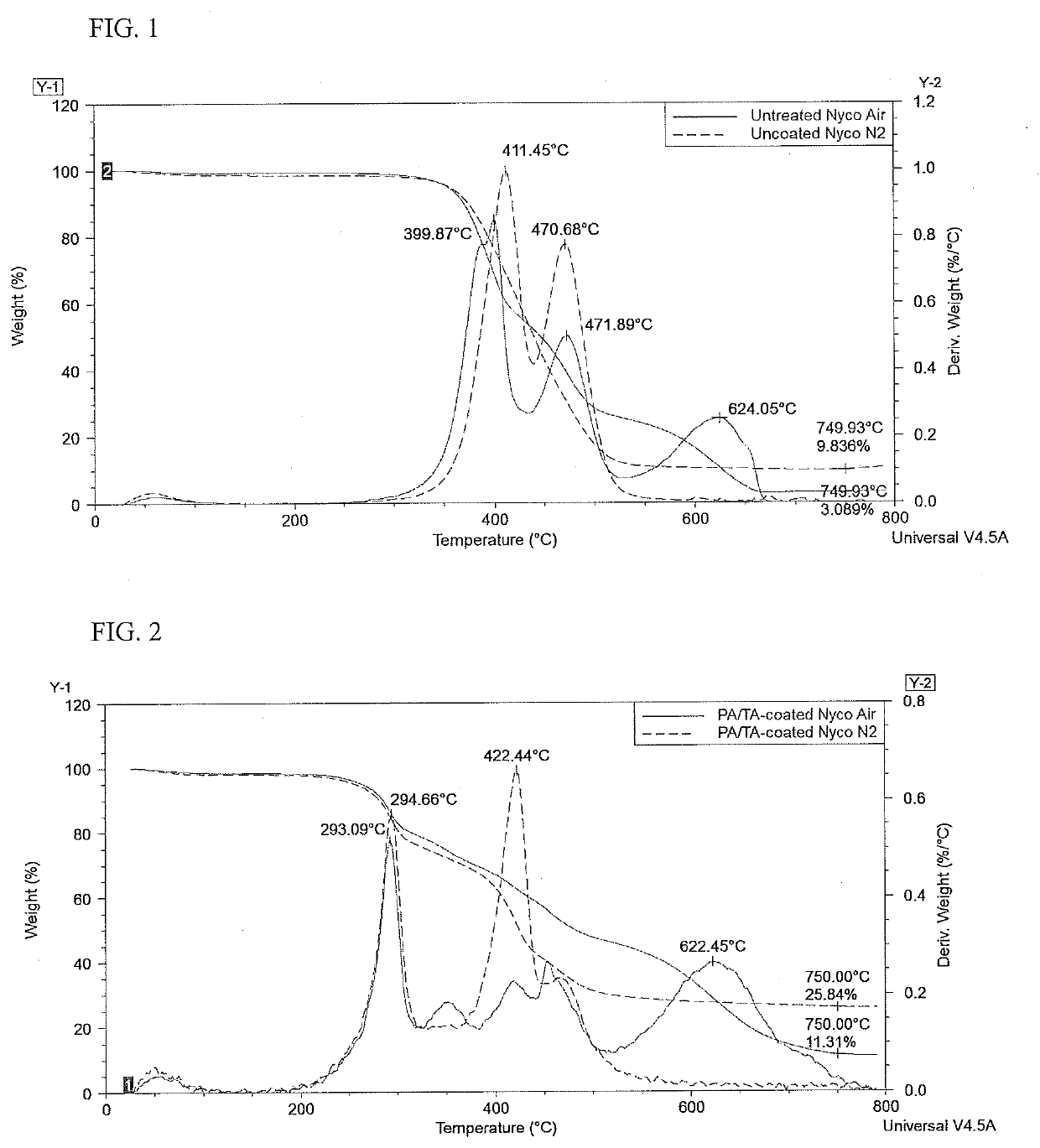

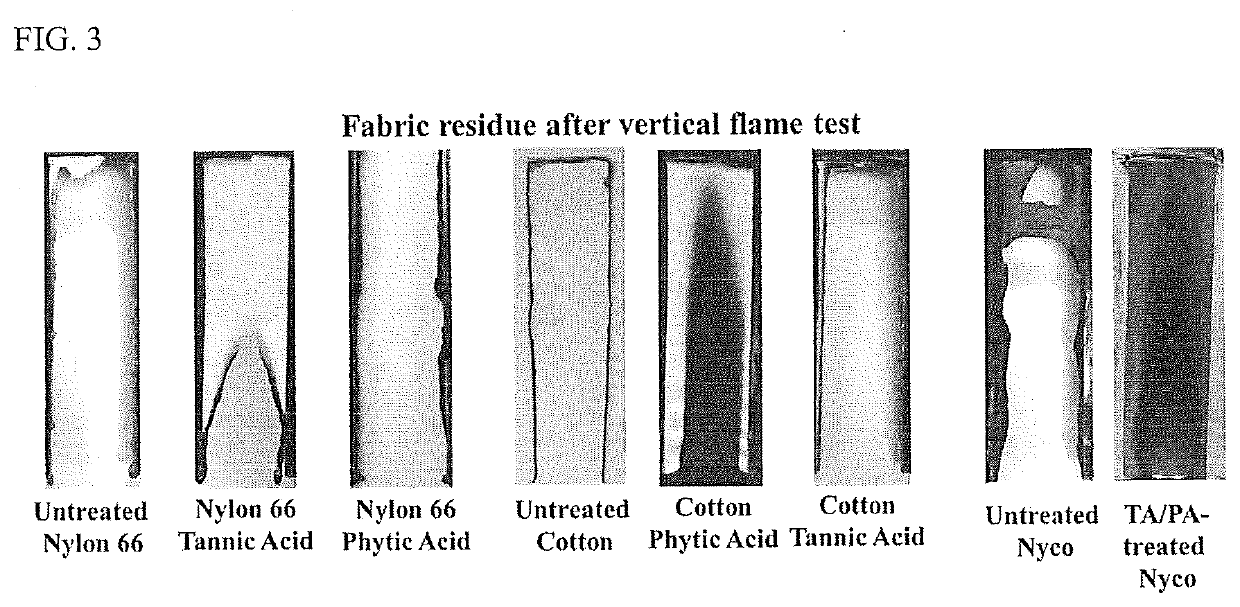

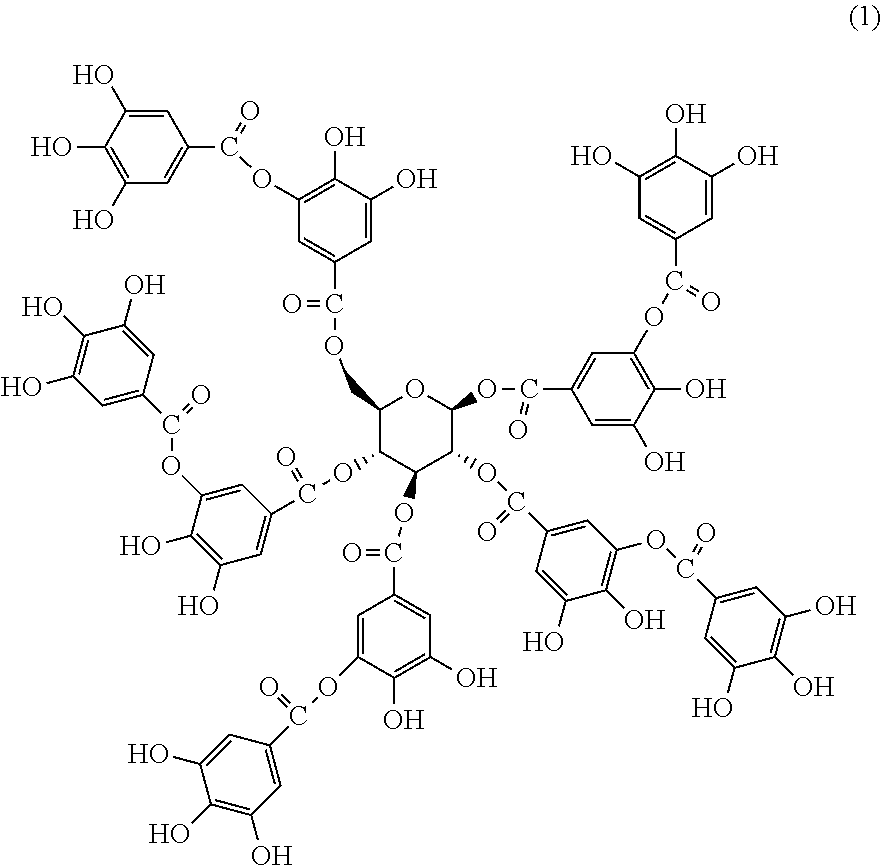

A synergistic flame retardant composition comprising a phenolic compound comprising condensed tannin, hydrolysable tannin, lignin, cardanol, quercetin, catechin, epicatechin, anthocyanidin, catechol, dopamine, hydroxytyrosol, adrenaline, 4-hydroxyphenylacetic acid, gallic acid, digallic acid, methyl gallate, ellagic acid, phloroglucinol, hexahydroxydiphenic acid, luteic acid, casuarictin, or a combination thereof; and a phosphorus-containing compound comprising a C5-7 carbocyclic polyol substituted with at least one phosphate group.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY +1

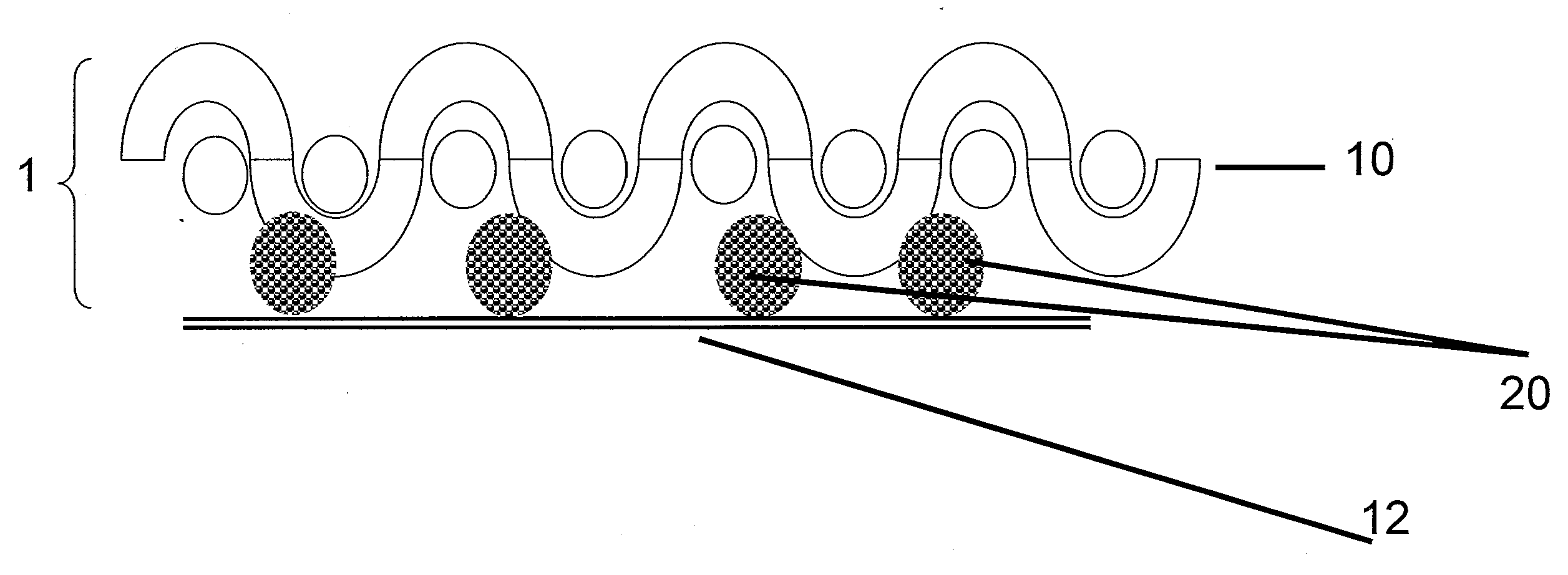

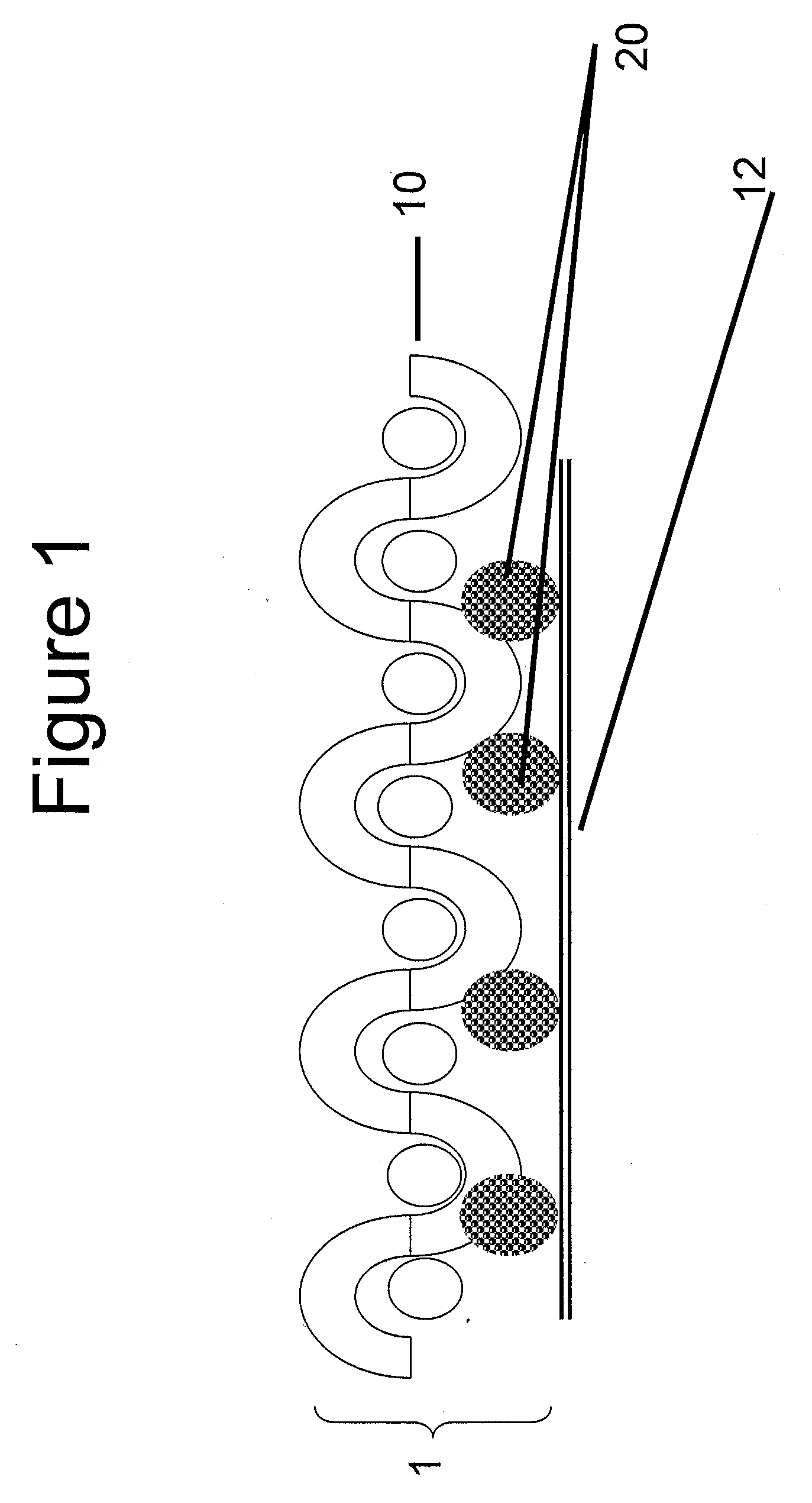

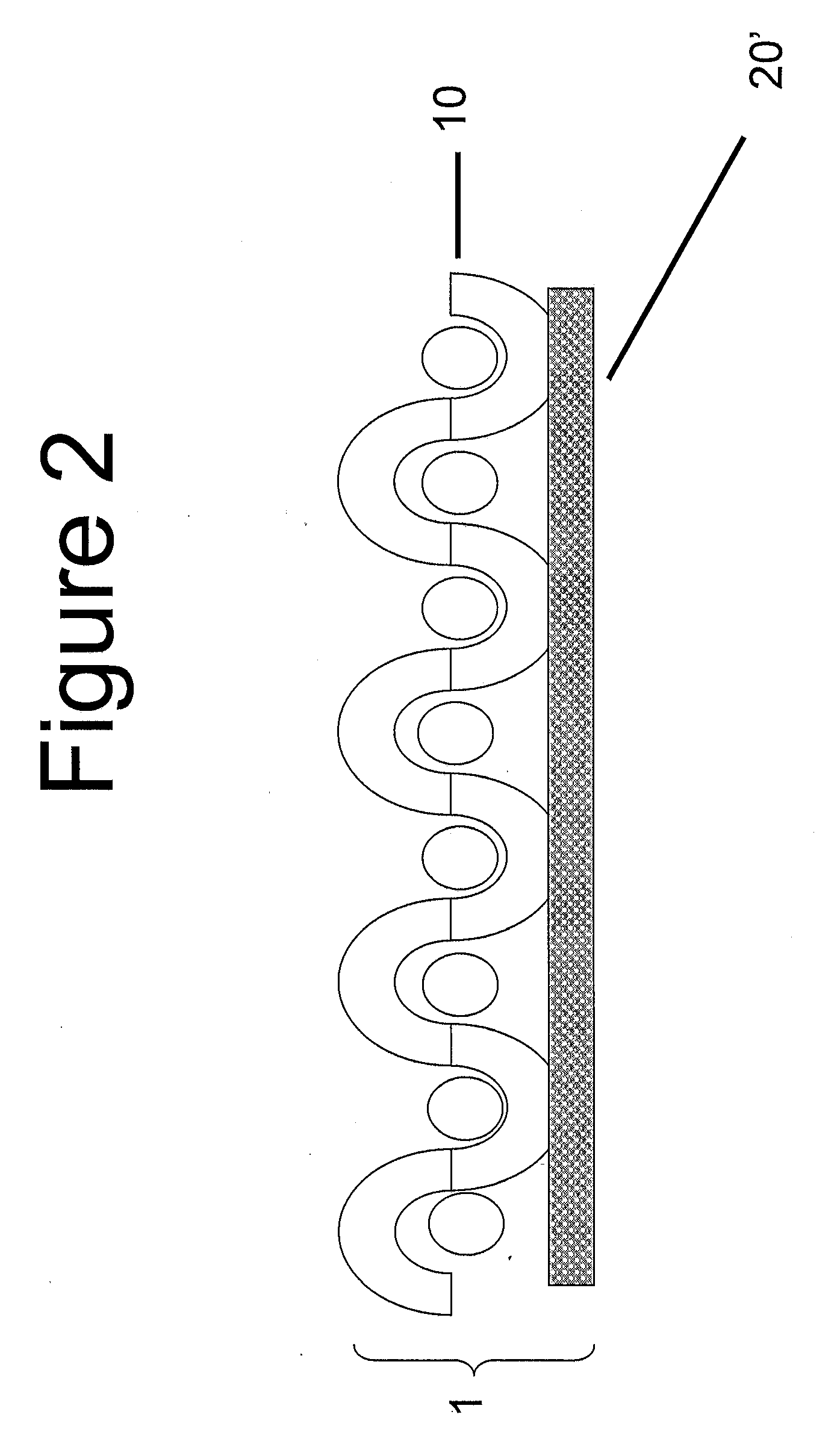

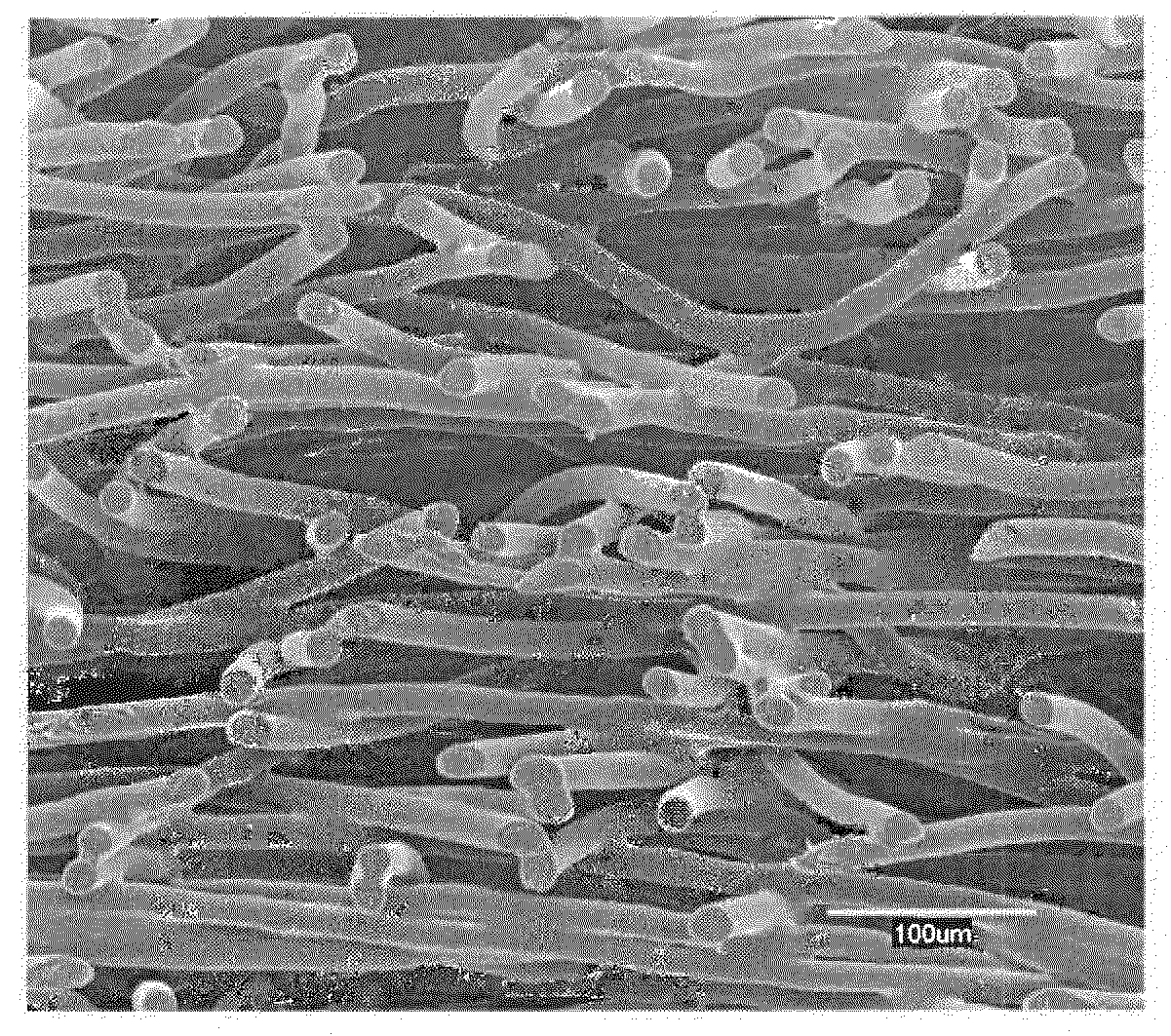

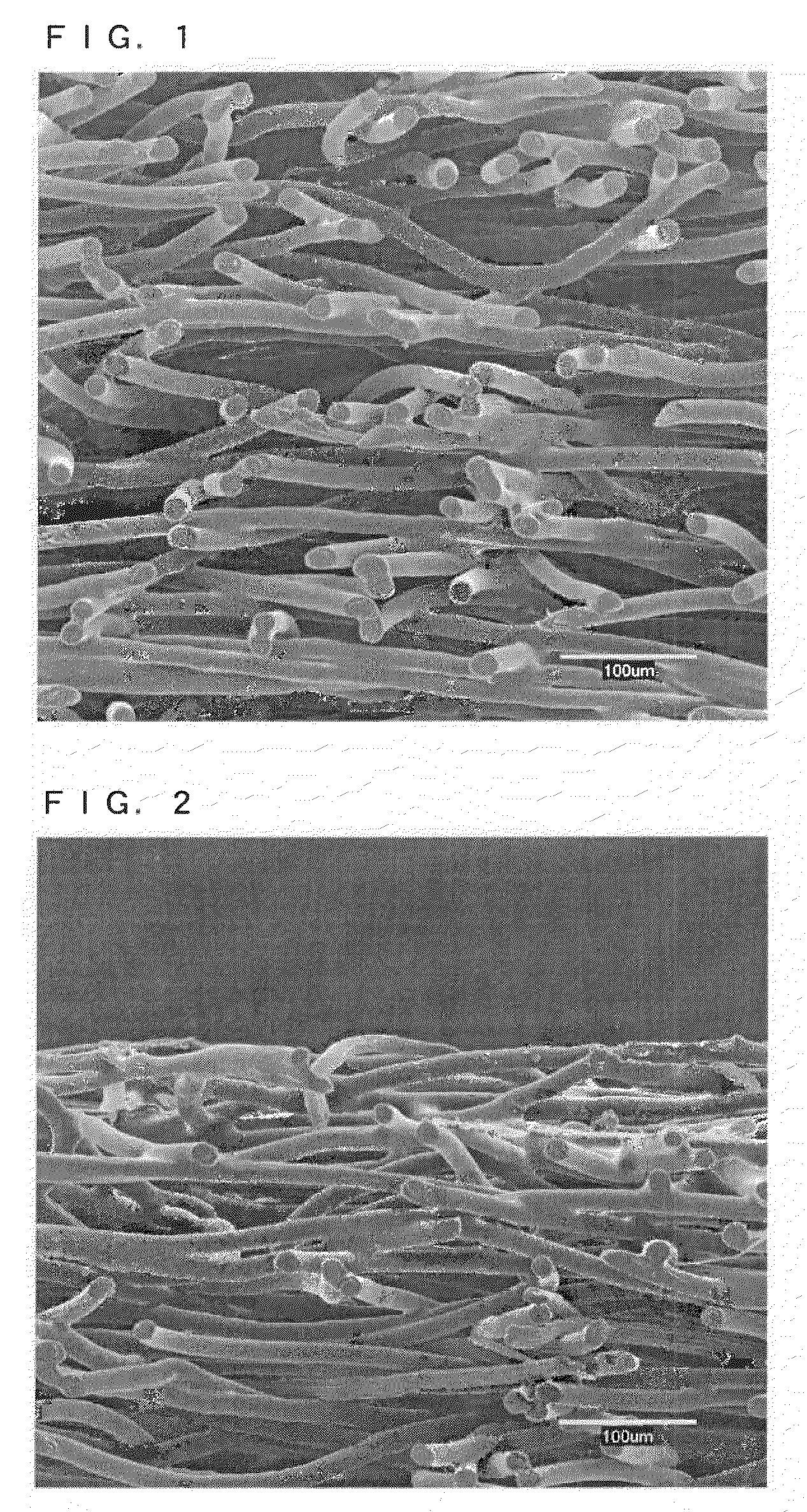

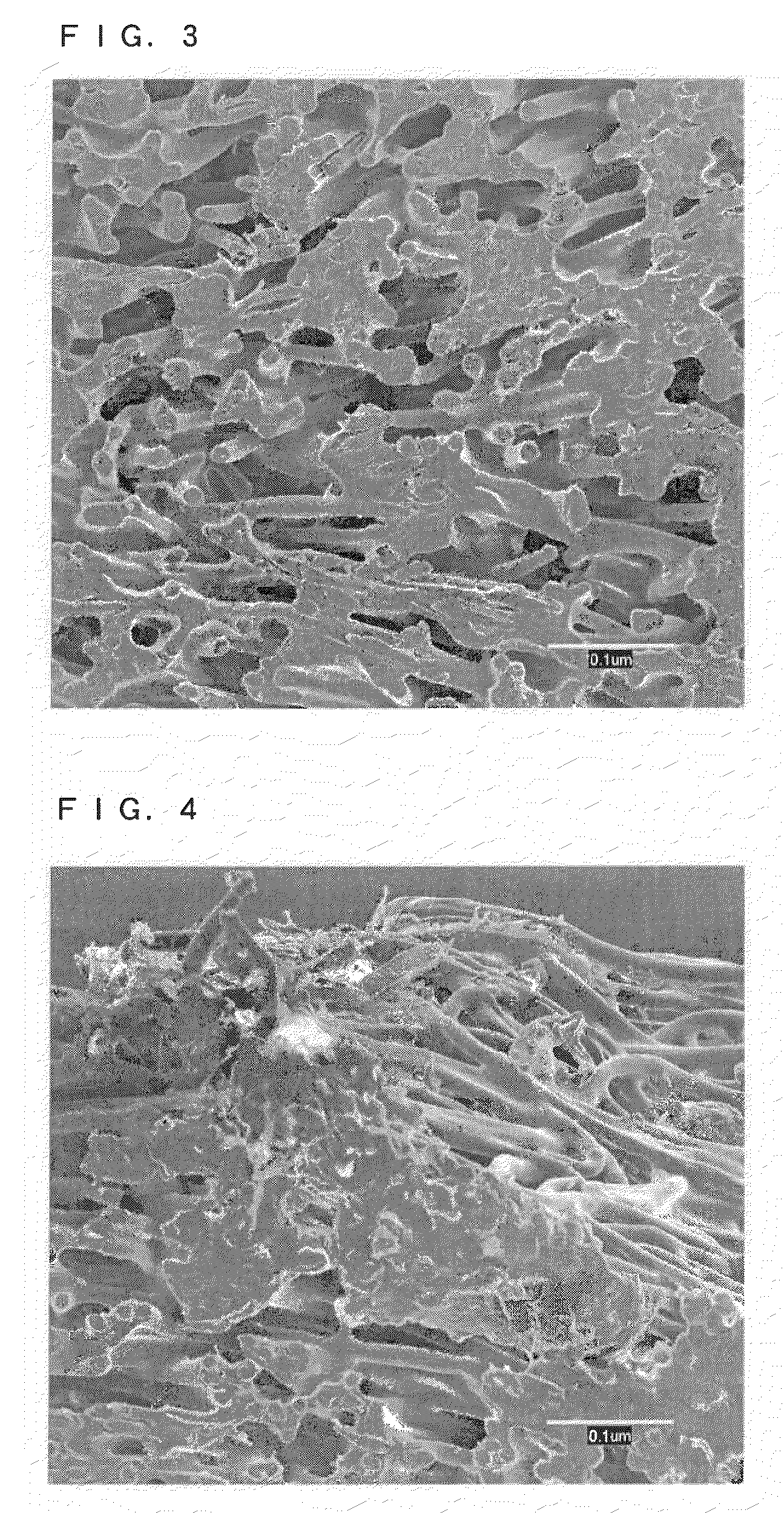

Yarns and fabrics that shed liquids, gels, sparks and molten metals and methods of manufacture and use

Fire retardant and heat resistant yarns and fabrics include a fabric or yarn comprised of oxidized polyacrylonitrile at least partially coated or encapsulated by a strengthening polymer material that helps the fabric or yarn shed liquids, gels, sparks, and molten metals. The polymer material includes one or more types of cured silicone polymer resin. A fluorochemical may be at least partially impregnated into the fabric or yarn prior to applying the strengthening polymer material in order to further enhance the shedding properties of the yarns or fabric. In one embodiment, the silicone polymer resin only coats or encapsulates the yarn, but does not form a continuous coating over the whole fabric, so that the treated fabric is still able to breath through pores and spaces between individual yarn strands that make up the fabric. The polymer material increases the strength, abrasion resistance, durability and shedding capability of the fire retardant heat resistant yarn or fabric.

Owner:CHAPMAN THERMAL PRODS

Fire-Resistant Cellulose Material

A fire-resistant cellulose material composed of a liquid acid fire-retardant chemical composition and methods of producing the cellulose material are disclosed.

Owner:INVESTORS COMMUNITY BANK

Burn protective materials

InactiveUS20090110919A1Comfortable to wearPretreated surfacesHeat resistant fibresPolymer resinGraphite

A method is described for reducing the afterflame of a flammable, meltable material. A textile composite is described comprising an outer textile comprising a flammable, meltable material, and a heat reactive material comprising a polymer resin-expandable graphite mixture.

Owner:WL GORE & ASSOC INC

Phosphorus and nitrogen containing flame-retardant finishing agent and flame-retardant cellulose fiber fabric preparation method

InactiveCN108049173AAvoid defects that release toxic substancesSolve the problem of not being washedHeat resistant fibresVegetal fibresNitrogenPhytic acid

The invention discloses a phosphorus and nitrogen containing flame-retardant finishing agent and a flame-retardant cellulose fiber fabric preparation method. The flame-retardant finishing agent is a mixed solution of ammonium phytate, urea and dicyandiamide. A preparation method of the flame-retardant finishing agent comprises the following steps: firstly, utilizing phytic acid and nitrogen containing compound as raw materials to synthesize flame retardant ammonium phytate; secondly, dissolving the synthesized flame retardant ammonium phytate into water and adding the certain amount of the urea and the certain amount of a crosslinking agent to prepare a flame-retardant finishing agent with a corresponding concentration; finally, utilizing a padding-drying-baking finishing technology to apply the flame-retardant finishing agent to flame-retardant finishing of cellulose fiber / fabric. The flame-retardant finishing agent disclosed by the invention has the advantages that greenness and environmental friendliness are achieved in the utilized raw materials, a finishing technology is simple and easy to operate, and no any toxic and harmful matters to the human body and the environment is not generated in an operational process and a using process; the finished cellulose fiber / fabric has the advantages of excellent flame retardance, good washing resistance and wide market application prospect.

Owner:TIANJIN POLYTECHNIC UNIV

Fiber-containing article and method of manufacture

InactiveUS20060252323A1Climate change adaptationSynthetic resin layered productsFiberVolumetric Mass Density

A fire resistance or acoustical absorbing article comprises a bast fiber component, a thermoplastic material that acts as a binder, and a first fire retardant component, the article having a coating of a second fire retardant component, such that the article may be used in the manufacture of structures having a Class A fire resistance rating. In one method of manufacture, a fibrous mass of the bast fiber component and the thermoplastic binder has the first fire retardant dispersed therethrough, and is then heated, compressed to a desired thickness and density, and coated with the second fire retardant component.

Owner:HNI TECH INC

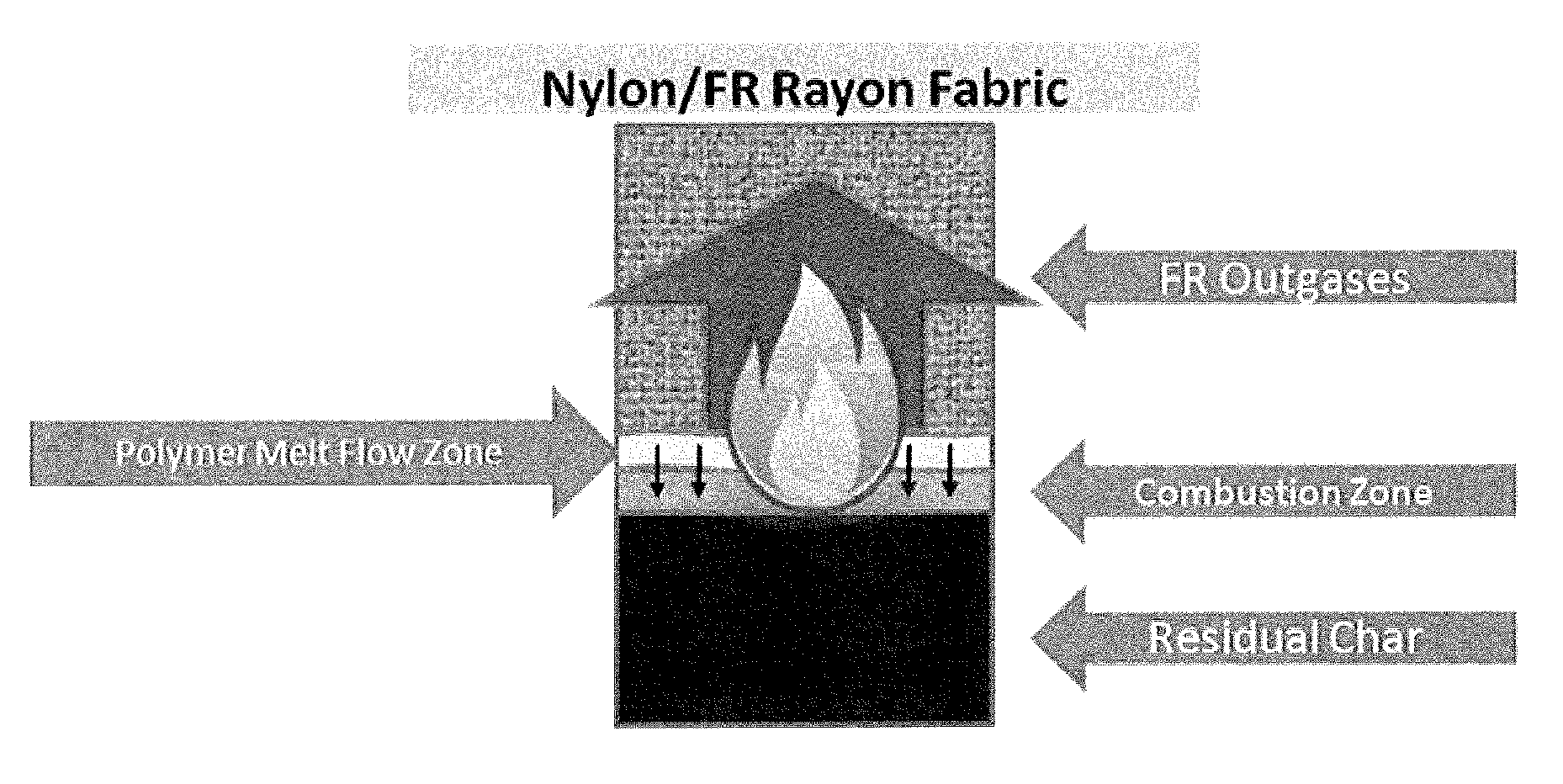

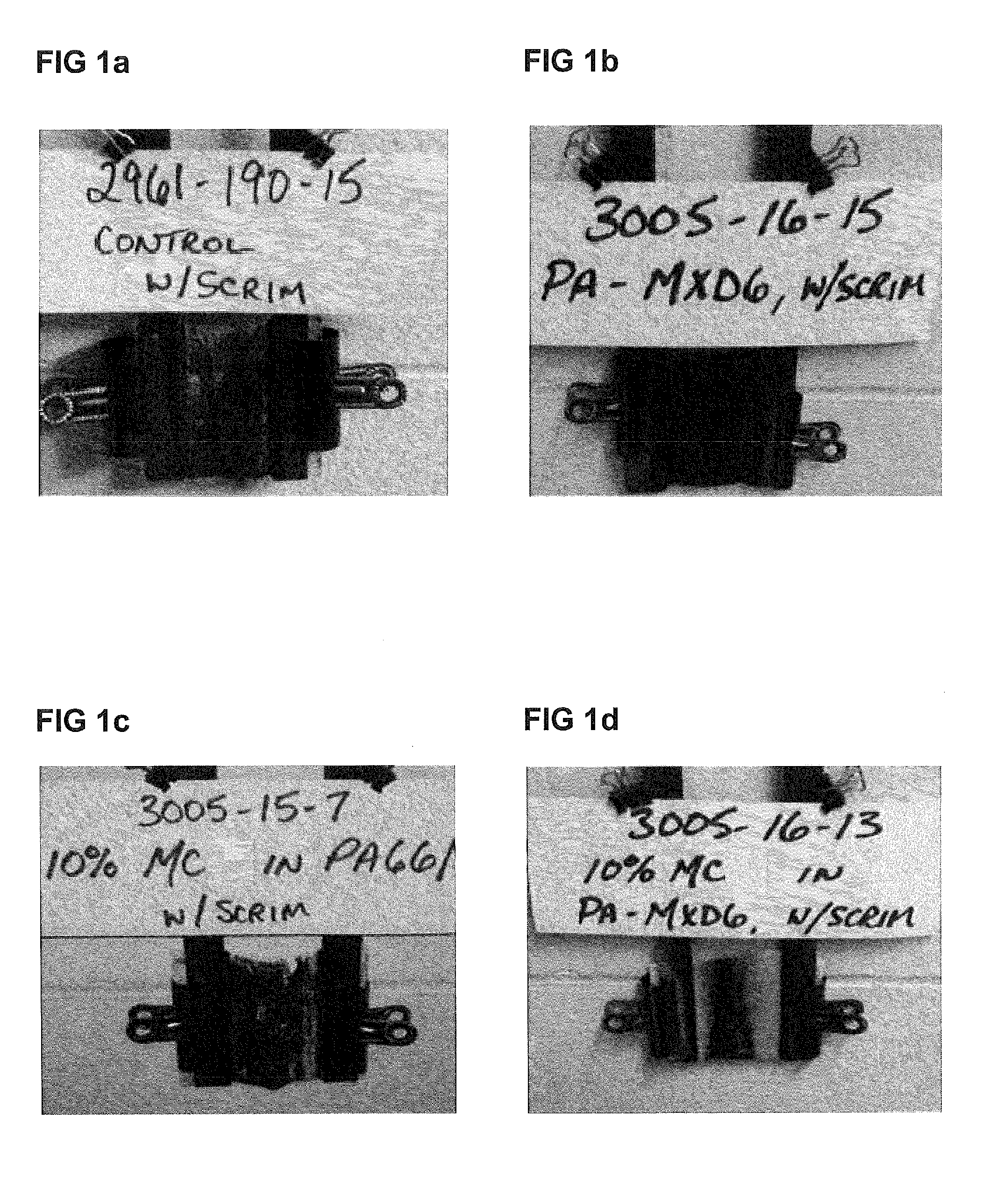

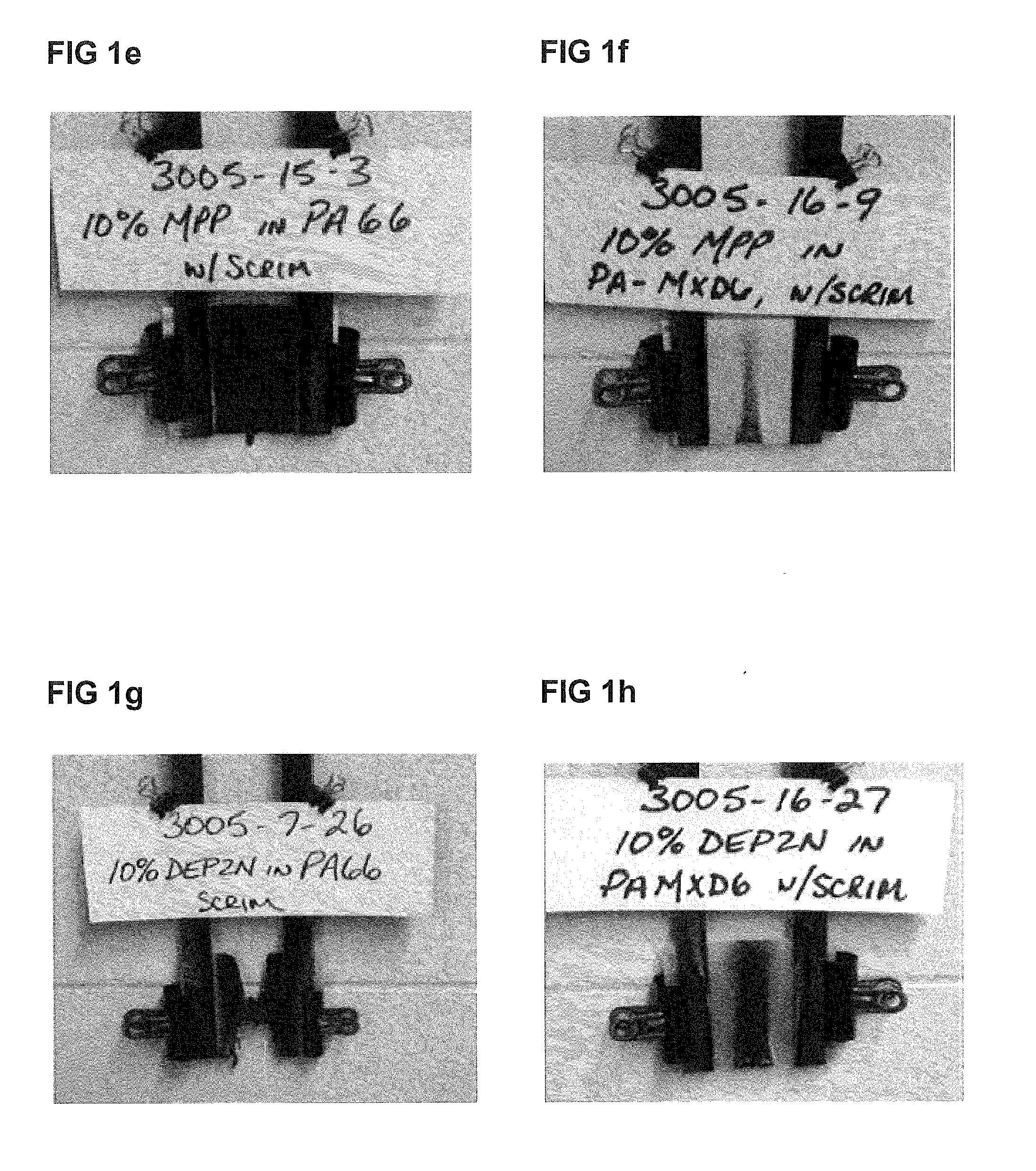

Flame retardant fibers, yarns, and fabrics made therefrom

ActiveUS20130244527A1Eliminate the effects ofImprove flame retardant performanceFlame-proof filament manufactureHeat resistant fibresFiberYarn

Disclosed are technical fibers and yarns made with partially aromatic polyamides and non-halogenated flame retardant additives. Fabrics made from such fibers and yarns demonstrate superior flame retardancy over traditional flame retardant nylon 6,6 fabrics. Further, the disclosed fibers and yarns, when blended with other flame retardant fibers, do not demonstrate the dangerous “scaffolding effect” common with flame retardant nylon 6,6 blended fabrics.

Owner:INV PERFORMANCE MATERIALS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com