Patents

Literature

807 results about "Phosphonium salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

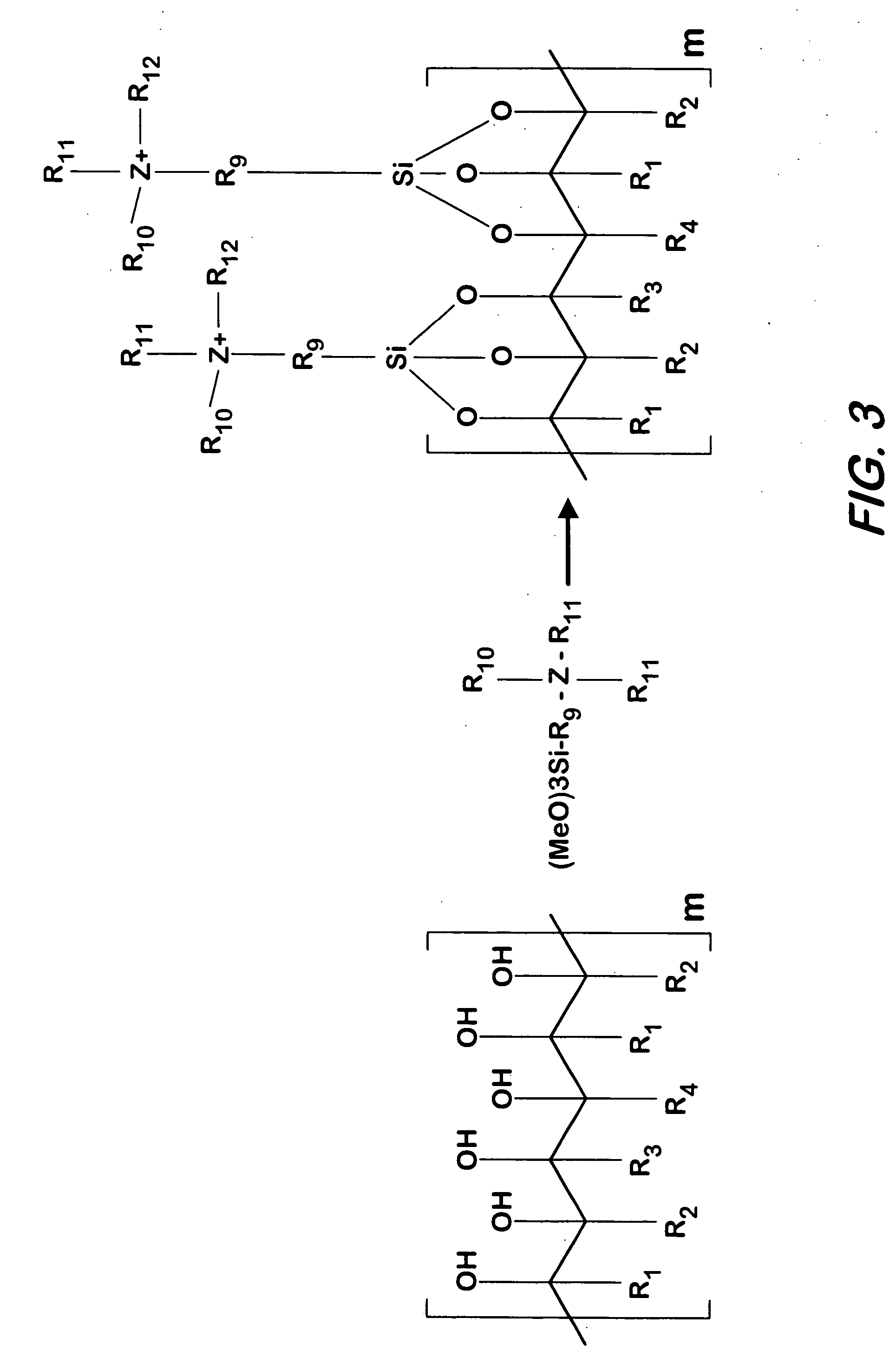

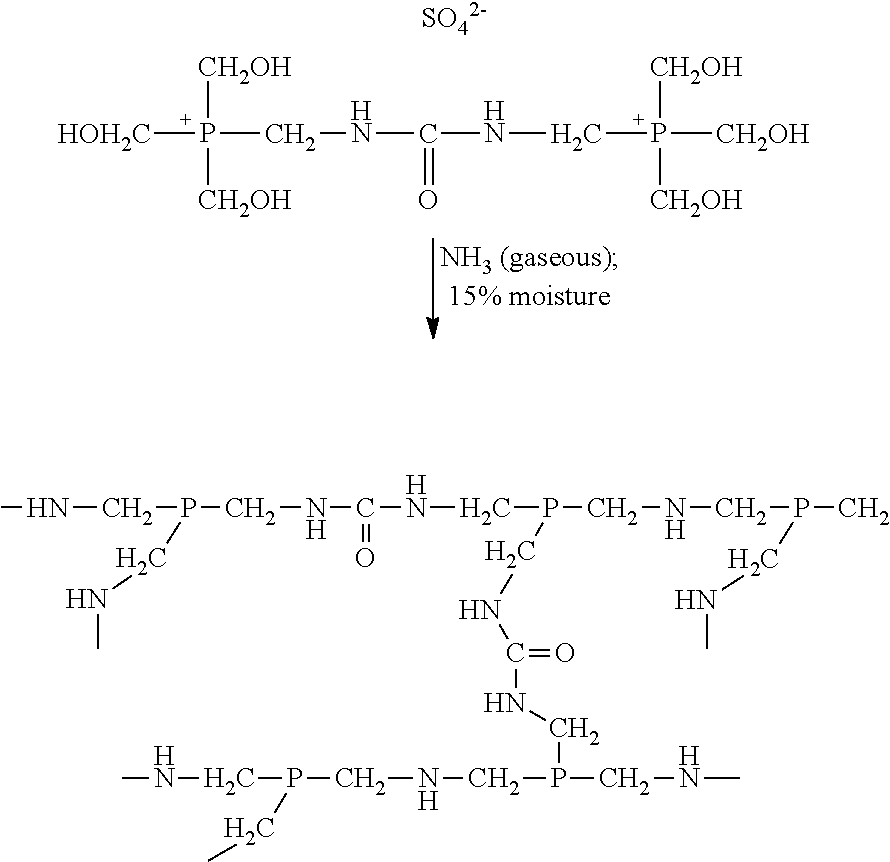

A phosphonium salt is a salt containing the phosphonium ion such as phosphonium iodide. More commonly, phosphonium refers to a quaternary organic derivative such as tetraphenylphosphonium chloride, (C₆H₅)₄P⁺ Cl⁻ and tetramethylphosphonium iodide, [P(CH₃)₄]⁺I−. Alkyltriphenylphosphonium salts are widely used for the preparation of Wittig reagents for the Wittig reaction. Such salts are readily made by the reaction of triphenylphosphine with an alkyl halide: Note that Ph stands for phenyl and X is a halide The reaction works well if the alkyl group is methyl or an unhindered primary alkyl group, but it is usually poor with secondary alkyl halides. Tertiary alkyl groups cannot form the ylide. The phosphonium salt is a stable compound which can often be purified by recrystallisation from ethanol. To form the Wittig reagent, the phosphonium salt is suspended in a solvent such as diethyl ether or THF and a strong base such as phenyllithium or n-butyllithium is added. One study demonstrates the use of benzyl alcohols as starting material for the synthesis of phosphonium acetates provided that the arene carries activating groups:

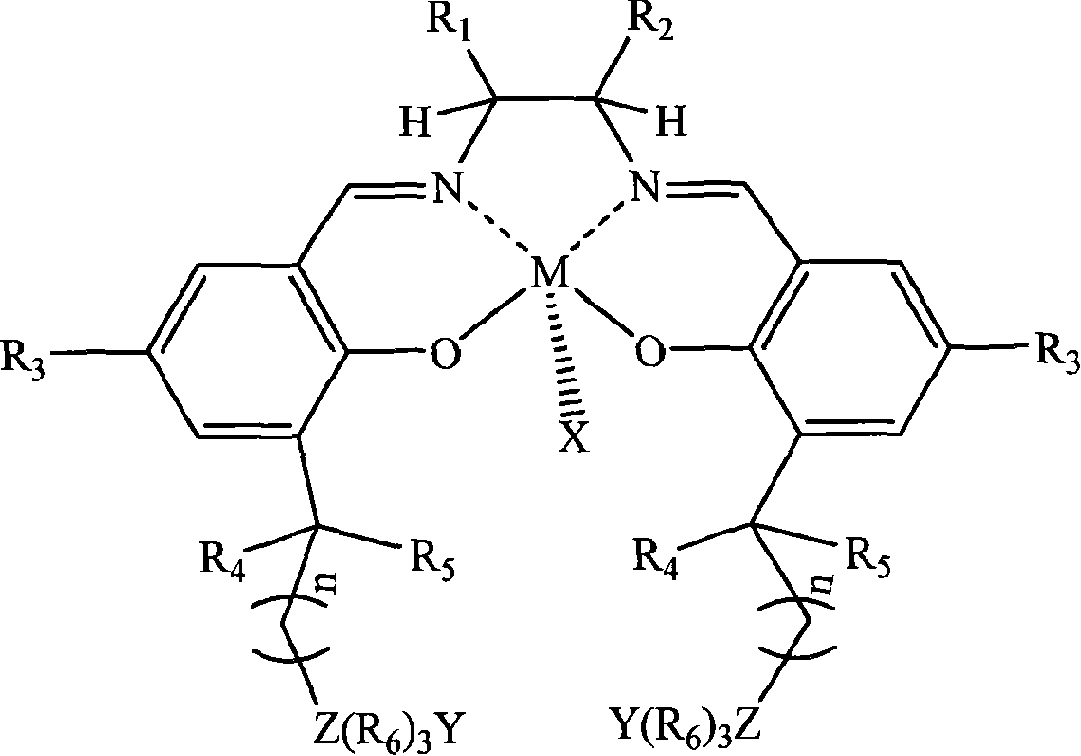

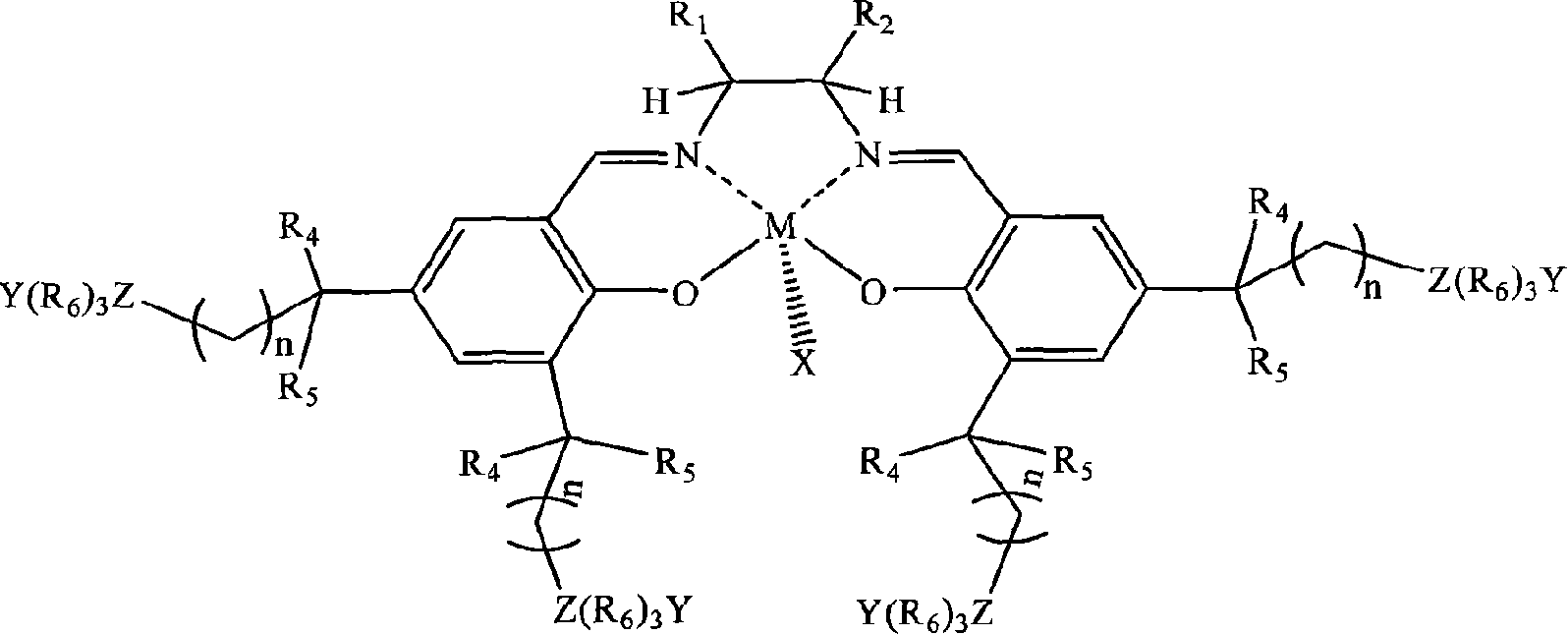

Double function catalyst for synthesizing polycarbonate

ActiveCN101020747AMild reaction conditionsThe process is simple and convenientAlkaneQuaternary ammonium cation

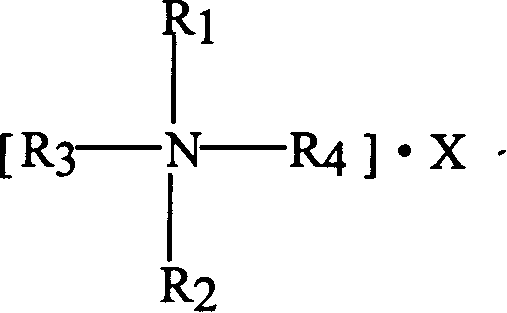

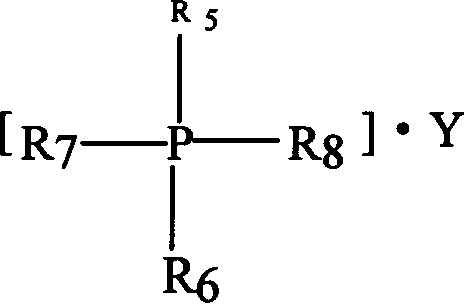

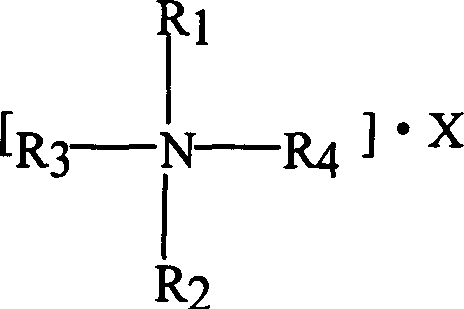

The present invention relates to one kind of high activity catalyst for catalyzing and activating CO2 to react with alkane epoxide to synthesize polycarbonate. The high activity catalyst is tetradentate Schiff base metal complex with double function, i. e., it has both electrophlic center originated from the metal ion in the complex and nucleophilic center originated from the quaternary ammonium salt or quaternary phosphonium salt connected to the benzene ring in the complex. The catalyst can catalyze the reaction of CO2 and alkane epoxide effectively to prepare polycarbonate.

Owner:DALIAN UNIV OF TECH

Process for producing fluoroolefins

InactiveUS20030060670A1Preparation by hydrogen halide split-offOrganic chemistry methodsPhosphonium saltPtru catalyst

A process for producing a fluoroolefin of the formula: CF.sub.3CY.dbd.CX.sub.nH.sub.p wherein Y is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); X is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); n and p are integers independently equal to 0, 1 or 2, provided that (n+p)=2; comprising contacting, in the presence of a phase transfer catalyst, a compound of the formula: CF.sub.3C(R.sup.1.sub.aR.sup.2.sub.b) C(R.sup.3.sub.cR.sup.4.sub.d), wherein R.sup.1, R.sup.2, R.sup.3, and R.sup.4 are independently a hydrogen atom or a halogen selected from the group consisting of fluorine, chlorine, bromine and iodine, provided that at least one of R.sup.1, R.sup.2, R.sup.3, and R.sup.4 is halogen and there is at least one hydrogen and one halogen on adjacent carbon atoms; a and b are independently=0, 1 or 2 and (a+b)=2; and c and d are independently=0, 1, 2 or 3 and (c+d)=3; and at least one alkali metal hydroxide. The alkali metal hydroxide can be, for example, potassium or sodium hydroxide and the phase transfer catalyst can be, for example, at least one: crown ether such as 18-crown-6 and 15-crown-5; or onium salt such as, quaternary phosphonium salt and quaternary ammonium salt. The olefin is useful, for example, as an intermediate for producing other industrial chemicals and as a monomer for producing oligomers and polymers.

Owner:HONEYWELL INT INC

Biodegradable resin composition for molding and object molded or formed from the same

Owner:UNITIKA LTD

Biodegradable resin composition for molding and molded object obtained by molding the same

InactiveUS20050043462A1Improve heat resistanceHigh mechanical strengthDyeing processPhosphoniumPhosphonium salt

A biodegradable resin composition and an object molded or formed from the composition. The resin composition comprises: 100 parts by weight of a biodegradable polyester resin comprising not smaller than 50% by weight of polylactic acid having a melting point of not lower than 160° C., the biodegradable polyester resin having a melt flow rate of 0.1 to 50 g / 10 min as measured under a load of 21.2 N at 190° C.; and 0.1 to 20 parts by weight of a phyllosilicate containing a primary, secondary or tertiary amine salt, a quaternary ammonium salt or a phosphonium salt ionically bonded between layers thereof.

Owner:UNITIKA LTD

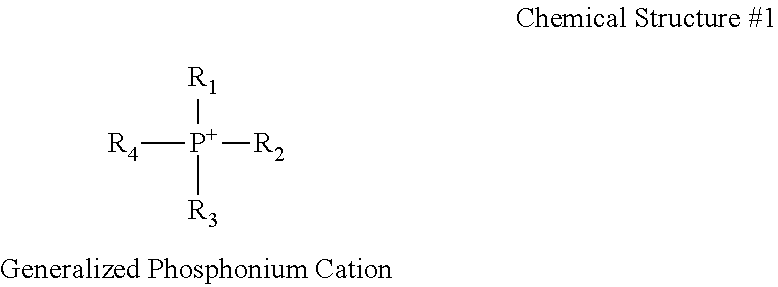

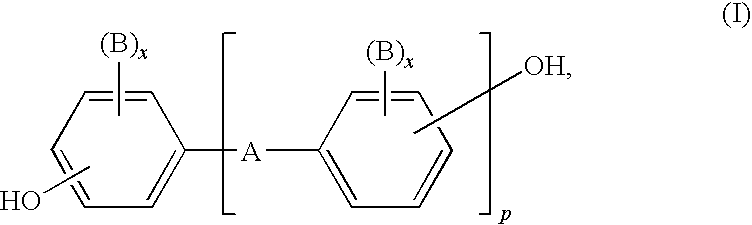

Quaternary phosphonium salt catalysts in catalytic hydrolysis of alkylene oxides

A process for the preparation of alkylene glycols by reacting an alkylene oxide with water in the presence of at least one ionic composition of a quaternary phosphonium cation of the general formula R1R2R3R4P+Whereby each of R1, R2, R3 and R4, independently, may be an alkyl, cycloalkyl, aryl, alkylaryl or arylalkyl group having from 1 to 10 carbon atoms, each of which may carry one or more substituents, or be attached to a polymer and an anion other than metalate or halogen.

Owner:SHELL OIL CO

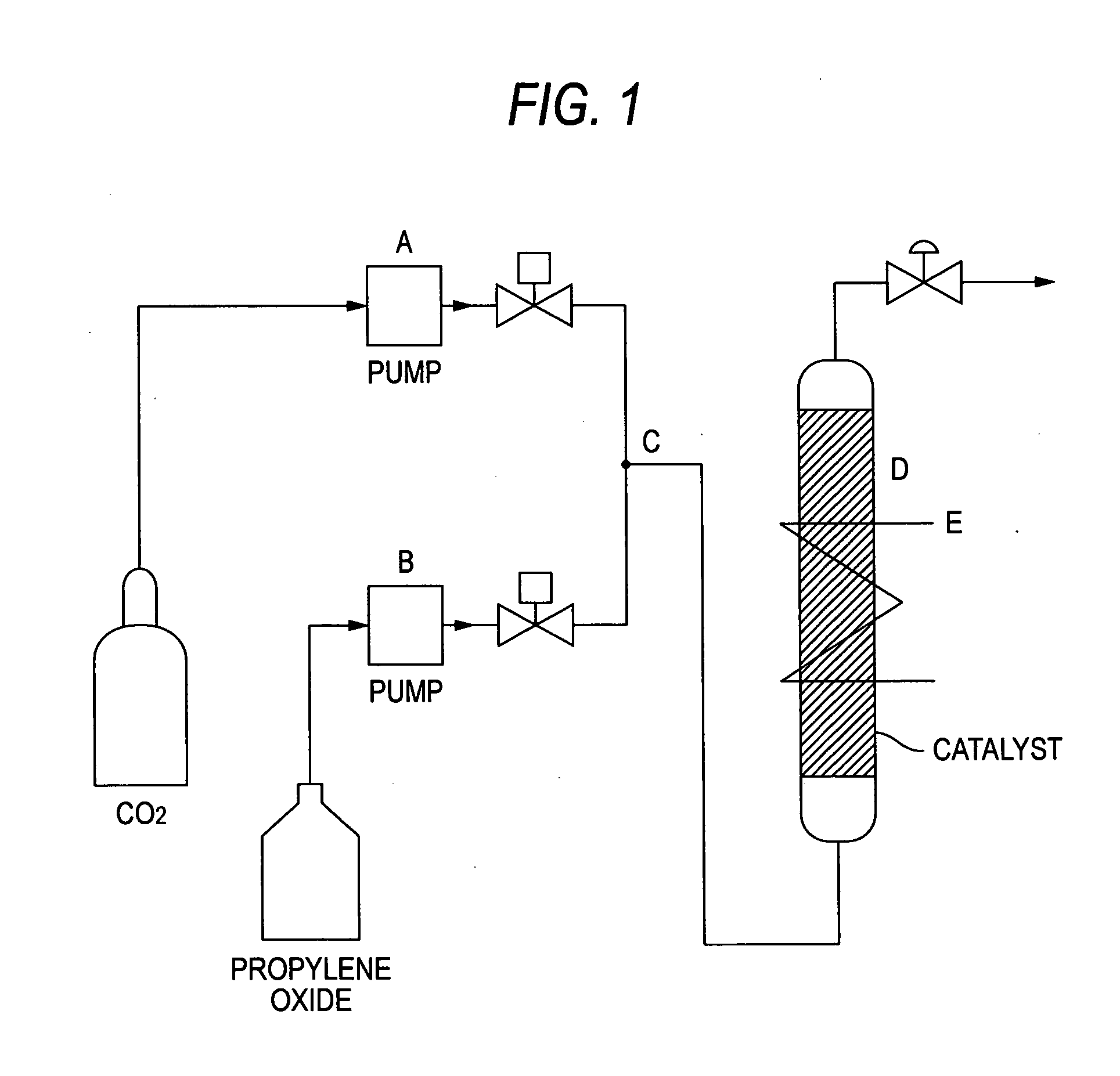

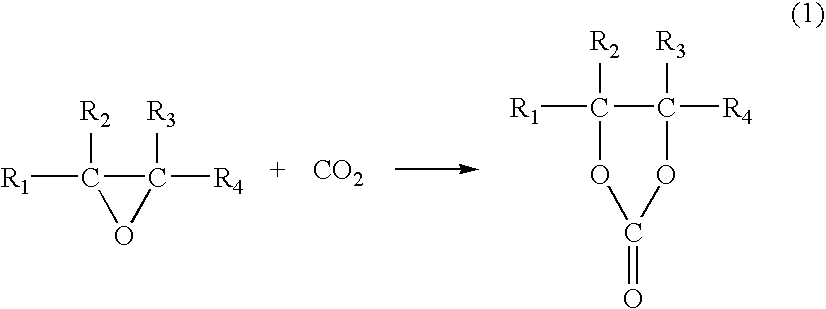

Catalyst for Cyclic Carbonate Synthesis

InactiveUS20080214386A1High yieldSolution to short lifeOrganic chemistryMolecular sieve catalystsPhosphoniumPhosphonium salt

Provided are a solid catalyst which gives a cyclic carbonate at a high yield and a high selectivity, which is stable and which may be readily separated after reaction; and a method of industrially advantageous, inexpensive and safe production of a cyclic carbonate by the use of the catalyst. The catalyst contains an inorganic solid substance having a surface modified with an ionic substance containing a Group 15 element; or contains an ionic substance containing a Group 15 element, and an inorganic solid substance. The modifying group for surface modification of an inorganic solid substance is an ionic substance containing a Group 15 element. The ionic substance containing a Group 15 element is at least one substance selected from organic phosphonium salts, organic ammonium salts, organic arsonium salts and organic antimonium salts.

Owner:NAT INST OF ADVANCED IND SCI & TECH

D1369 d radiation curable secondary coating for optical fiber

A new radiation curable Secondary Coating for optical fibers is described and claimed wherein said composition comprises a Secondary Coating Oligomer Blend, which is mixed with a first diluent monomer; a second diluent monomer; optionally, a third diluent monomer; an antioxidant; a first photoinitiator; a second photoinitiator; and optionally a slip additive or a blend of slip additives; wherein said Secondary Coating Oligomer Blend comprises:α) an Omega Oligomer; andβ) an Upsilon Oligomer;wherein said Omega Oligomer is synthesized by the reaction ofα1) a hydroxyl-containing (meth)acrylate;α2) an isocyanate;α3) a polyether polyol; andα4) tripropylene glycol; in the presence ofα5) a polymerization inhibitor; andα6) a catalyst;to yield the Omega Oligomer;wherein said catalyst is selected from the group consisting of dibutyl tin dilaurate; metal carboxylates, including, but not limited to: organobismuth catalysts such as bismuth neodecanoate; zinc neodecanoate; zirconium neodecanoate; zinc 2-ethylhexanoate; sulfonic acids, including but not limited to dodecylbenzene sulfonic acid, methane sulfonic acid; amino or organo-base catalysts, including, but not limited to: 1,2-dimethylimidazole and diazabicyclooctane; triphenyl phosphine; alkoxides of zirconium and titanium, including, but not limited to Zirconium butoxide and Titanium butoxide; and Ionic liquid phosphonium salts; and tetradecyl(trihexyl)phosphonium chloride; andwherein said Upsilon Oligomer is an epoxy diacrylate.

Owner:DSM IP ASSETS BV

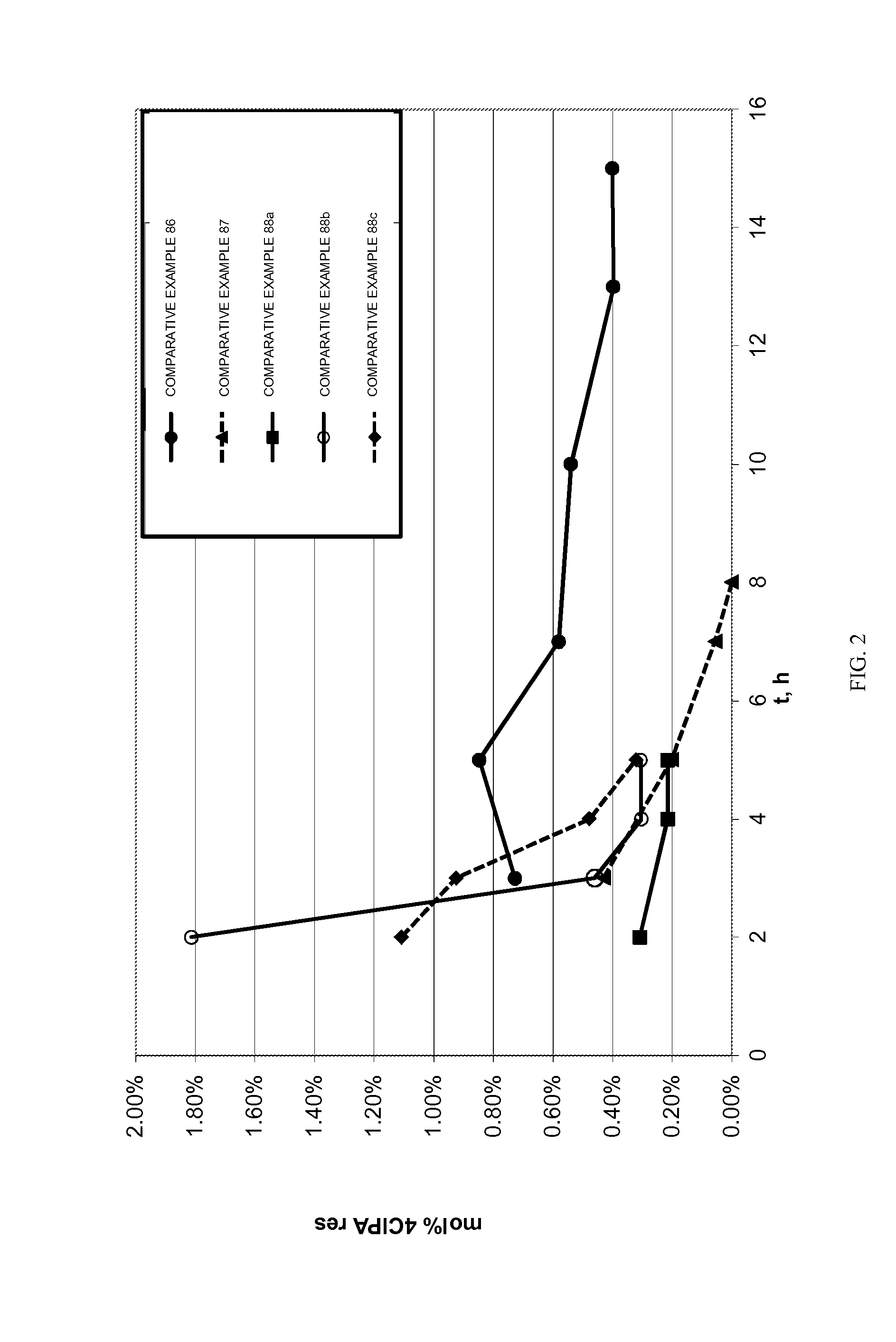

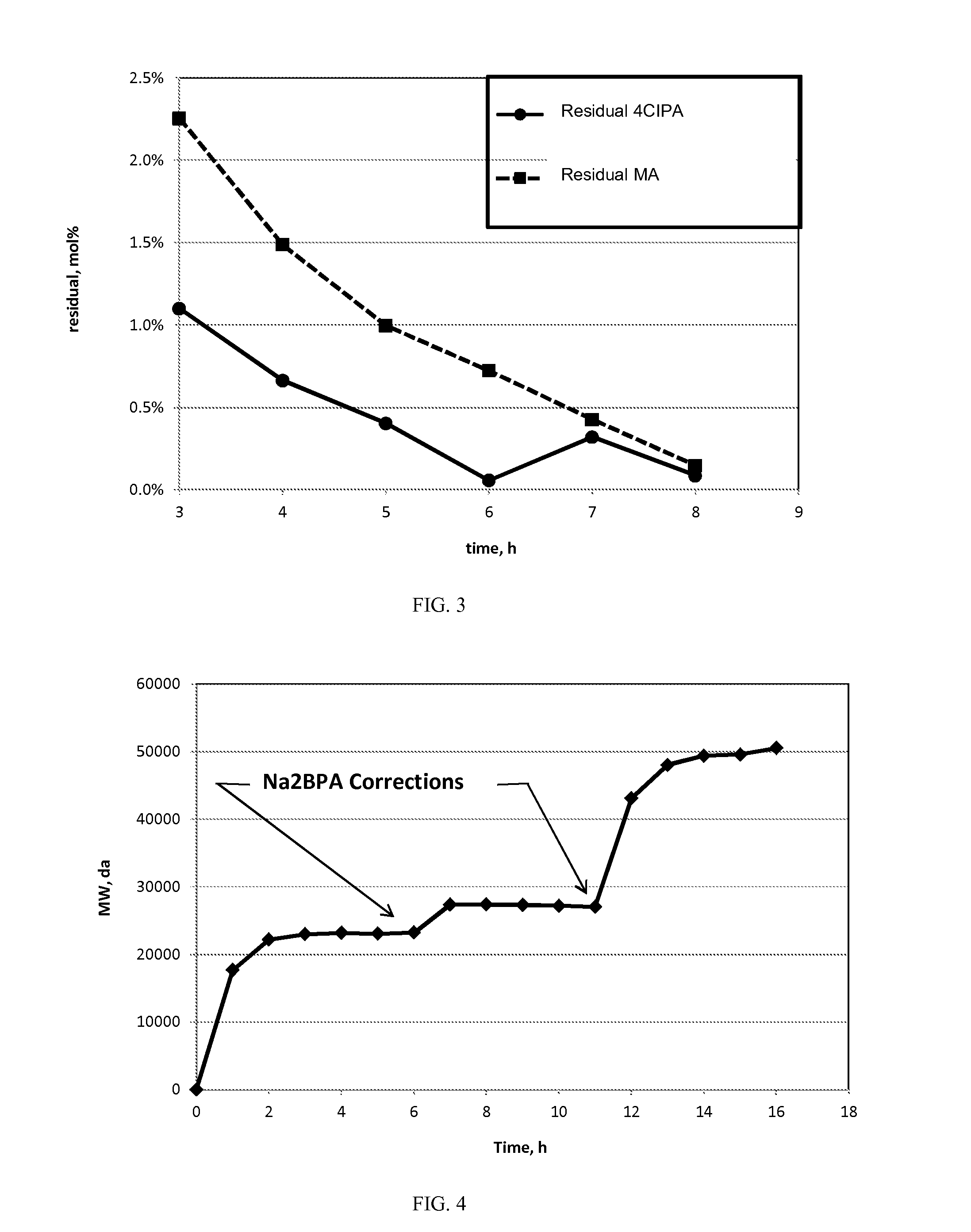

Methods of manufacture of bis(phthalimide)s and polyetherimides, and bis(phthalimide)s, and polyetherimides formed therefrom

A method of manufacture of a bis(phthalimide) composition includes reacting, in the presence of a solvent and a catalytically active amount of an imidization catalyst selected from quaternary ammonium salts, quaternary phosphonium salts, and combinations thereof, a substituted phthalic anhydride with an organic diamine, wherein conversion to the bis(phthalimide) is 99% complete in less than 6 hours.

Owner:SABIC GLOBAL TECH BV

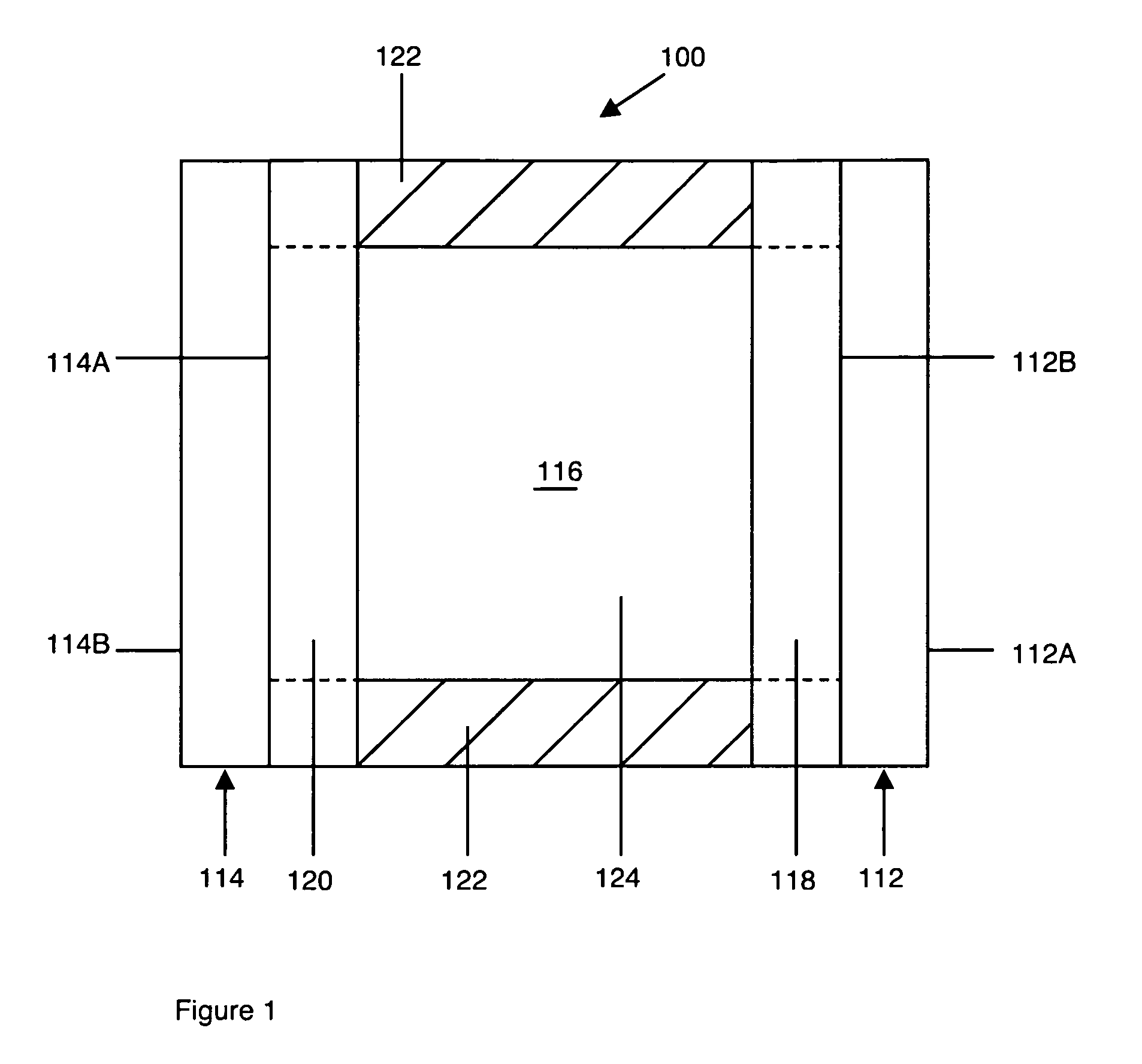

Electrochromic compounds and associated media and devices

An electrochromic device having an electrochromic medium which includes a compound represented by the following formula:wherein R1-R10 are the same or different and comprise H, an alkyl, cycloalkyl, polycycloalkyl, heterocycloalkyl, aryl, alkaryl, aralkyl, alkoxy, alkenyl, and / or alkynyl group containing approximately 1 to approximately 50 carbon atom(s), wherein the carbon atom(s) may be a linking group to, or part of, a halogen, a N, O, and / or S containing moiety, and / or one or more functional groups comprising alcohols, esters, ammonium salts, phosphonium salts, and combinations thereof; with the proviso that R2 and R7 each comprise at least two carbon atoms, at least one of R2 and R7 comprises less than 2 β hydrogen atoms and is void of a benzyl group.

Owner:GENTEX CORP

Preparation of permanent color inks from water-soluble colorants using specific phosphonium salts

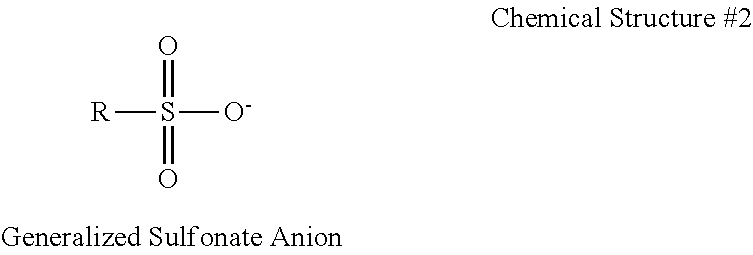

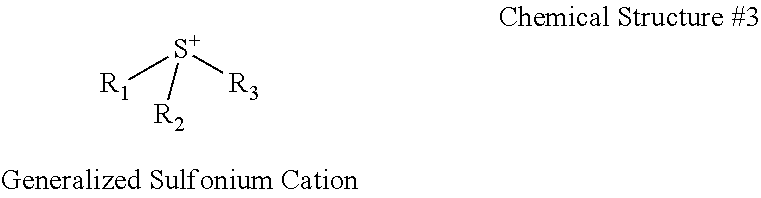

Water-fastness in aqueous ink-jet inks containing water-soluble dyes is achieved by using a specific ionic species having a charge opposite to that on the dye molecule. Anionic dyes typically contain sulfonate (or carboxylate) anionic groups. Using at least one specific ionic species of opposite charge, specifically, phosphonium salts, causes the colorant components to "crash" or precipitate out of the water-based ink onto the print medium due to the formation of a suitable charge complex between the ionic parts of the dye and the opposite charge of the counter-ion species. Other positively charged salts, such as quaternary ammonium salts, carbonium salts, iodonium salts, sulfonium salts, and pyrillium salts may be used to improve aqueous dispersion stability and thus printability. Such additional cationic salt partially replaces the phosphonium salt(s). Alternatively, certain surfactants, such as aromatic ethoxylates, polyethylene oxide ethers, or polypropylene oxide ethers may be used to improve print quality.

Owner:HEWLETT PACKARD DEV CO LP

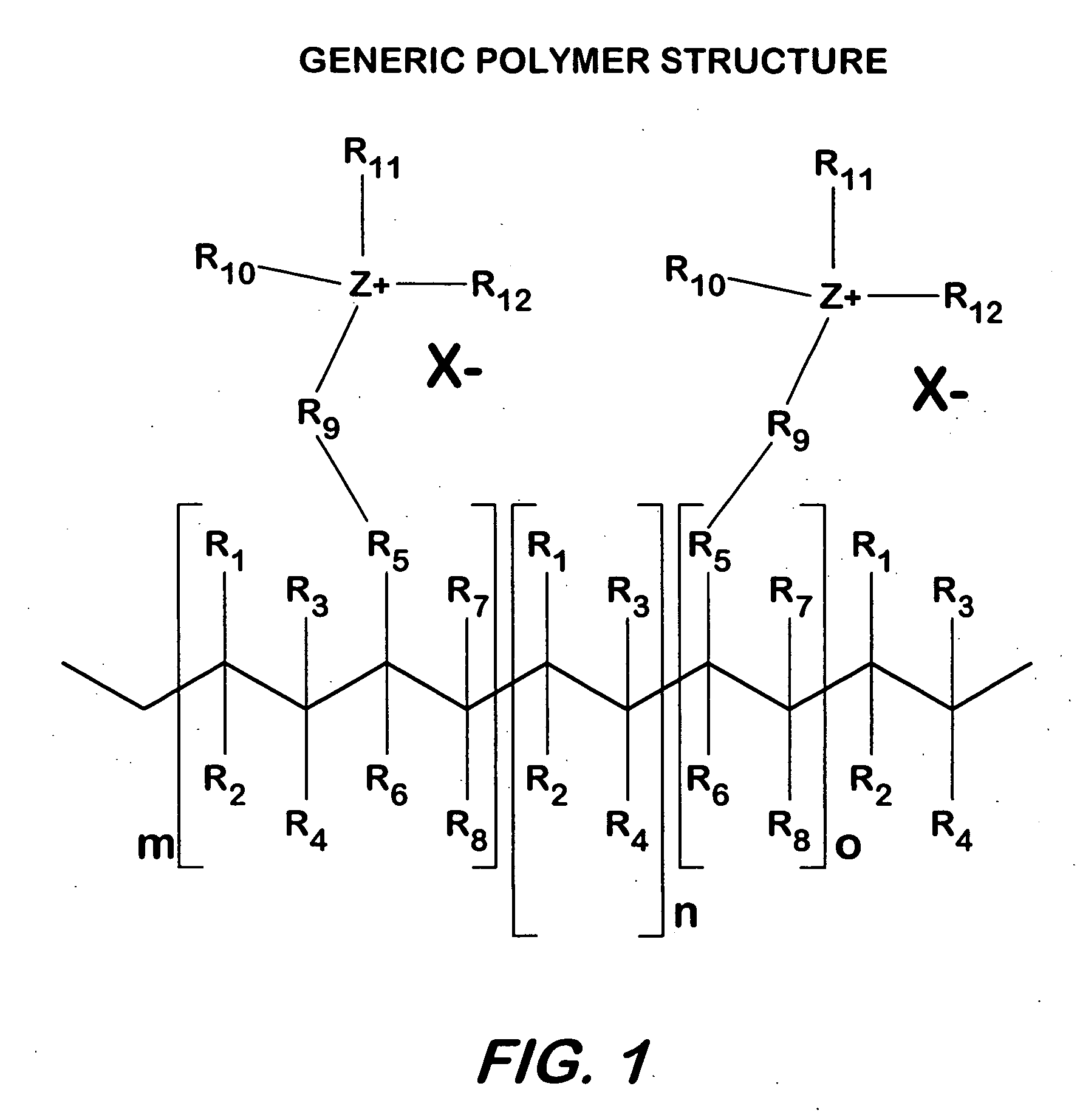

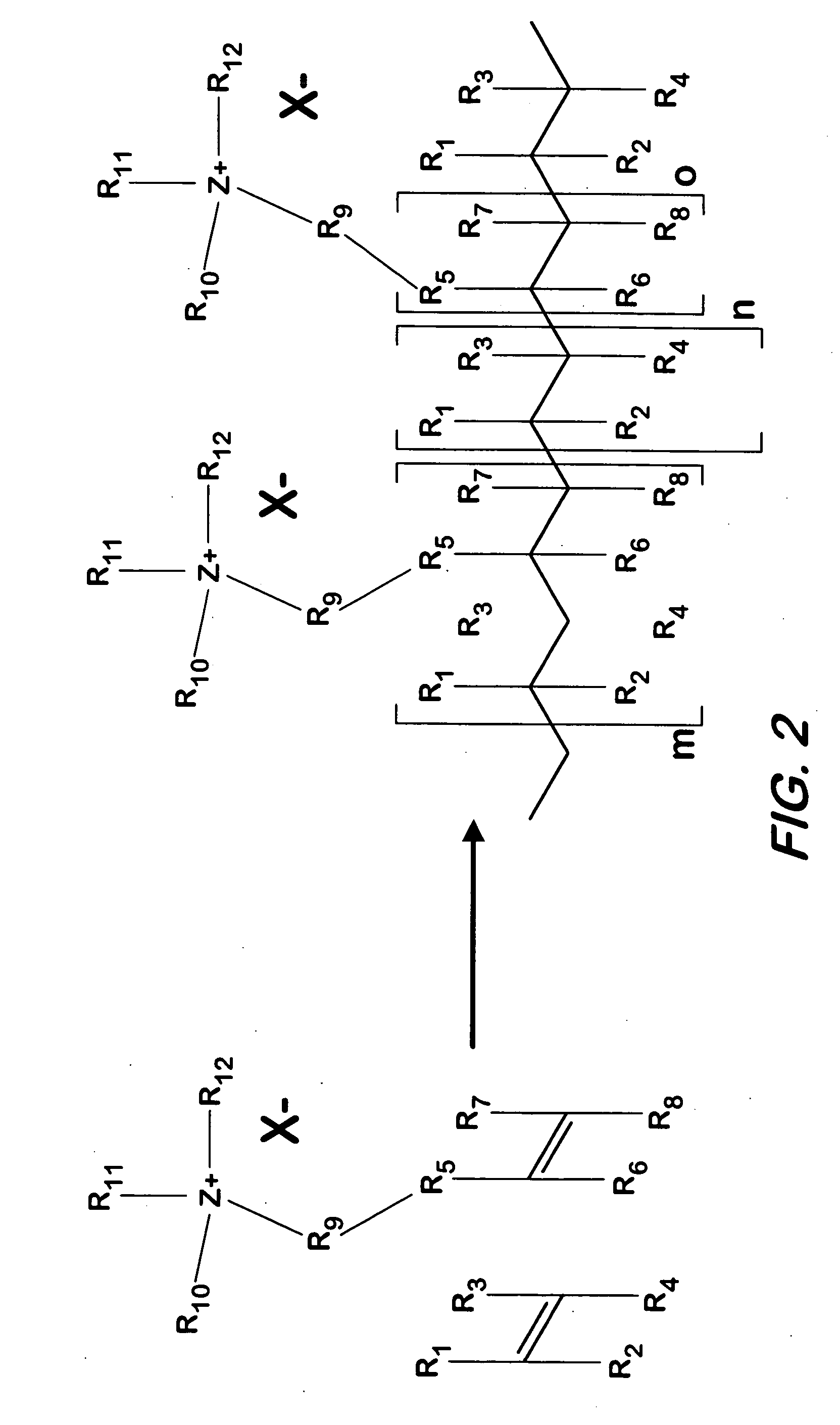

Method of preserving food using antimicrobial packaging

InactiveUS20050271780A1Extended shelf lifeReduce countBiocideFlexible coversPolymer sciencePhosphonium

The present invention relates to an anti-microbial packaging polymer and its method of use, and more particularly to a contact anti-microbial such as quaternary ammonium and phosphonium salts covalently bound to a polymeric material that may be suitable in a variety of applications such as film and container packaging of foodstuffs, cosmetics, medical equipment and devices, environmental, hygienic and sanitary applications, as well as other consumer and commercial use. This anti-microbial polymer has the benefit of being bactericidal, fungicidal, and / or viricidal. For example, this anti-microbial feature may result in additional shelf life of the foodstuff contained in the anti-microbial packaging polymer of the present invention.

Owner:BOSTON BRANDS

Phthalocyanine dyes suitable for use in offset inks

InactiveUS7559983B2Improve visibilityLess absorptionOrganic chemistryReactive dyesSulfonatePhosphonium

Owner:BASF SE

Composition for removing metal from hydrocarbon oil

ActiveCN1657596AReduce calcium concentrationReduce consumptionDewatering/demulsification with electric/magnetic meansHydrocarbon oils refiningDemulsifierPhosphonium salt

A composition for removing metals from masrolar D contains chelating agent, precipitant, optional surfactant and demulsifier, and at least one of mono-alcohol or biol polymer, quaternary ammonium salt, quaternary phosphonium salt and crown ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antifouling oligomerization catalyst systems

PendingUS20160367977A1Reduce polymeric foulingOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsSulfonatePhosphonium

A catalyst system that may reduce polymeric fouling may include at least one titanate compound, at least one aluminum compound, and an antifouling agent. The antifouling agent may be chosen from one or more of a phosphonium or phosphonium salt; a sulfonate or a sulfonate salt; a sulfonium or sulfonium salt; an ester including a cyclic moiety; an anhydride; a polyether; and a long-chained amine-capped compound. The catalyst system may further include a non-polymeric ether compound.

Owner:SUMITOMO CHEM CO LTD

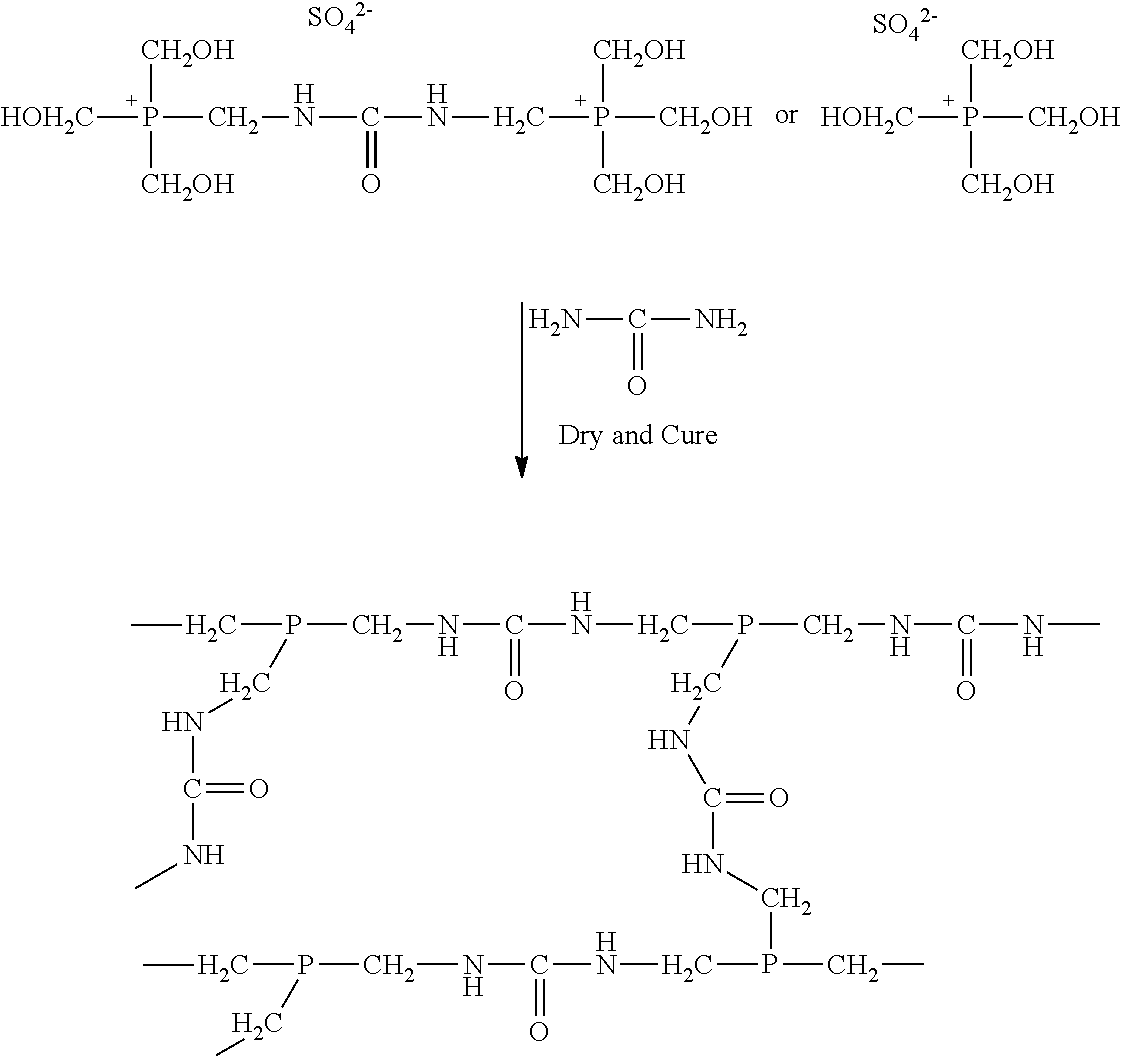

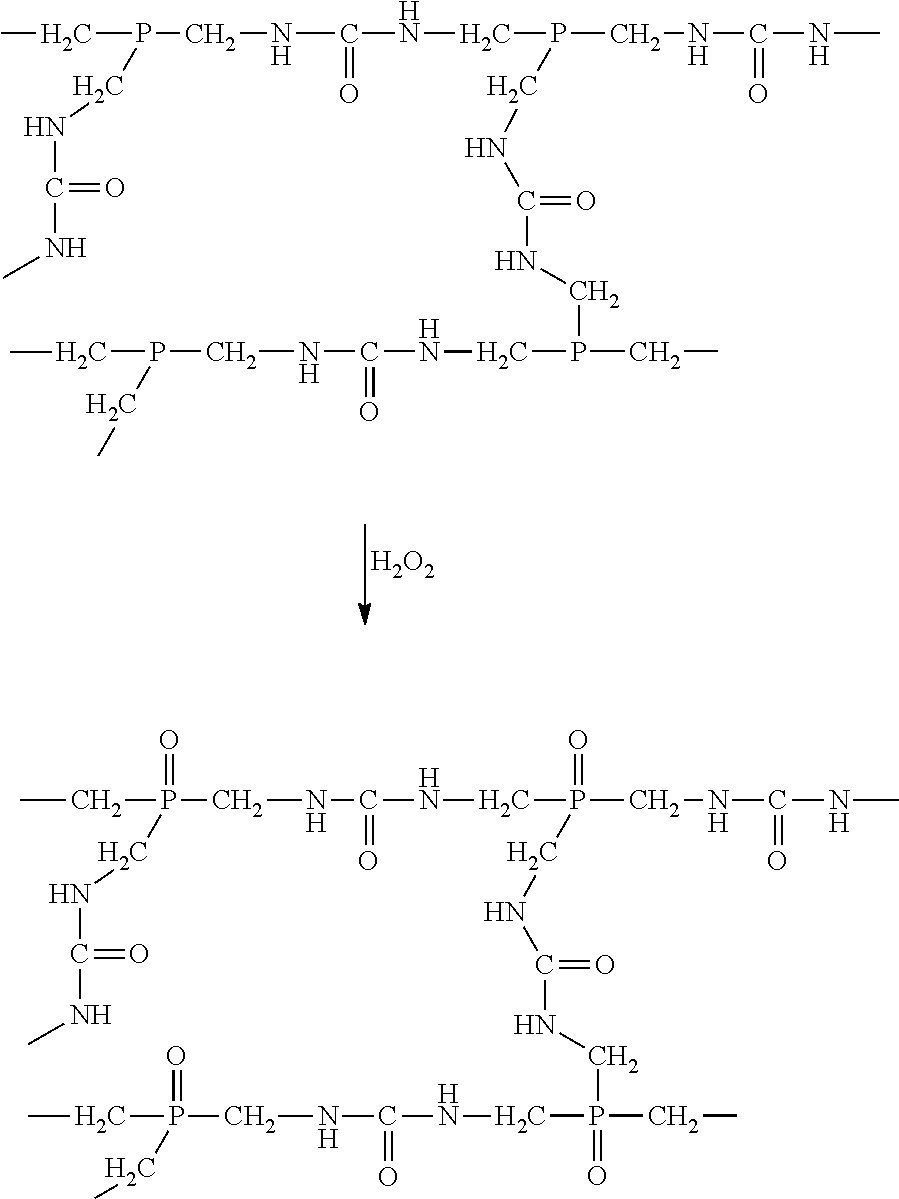

Flame resistant textile

A flame resistant textile is provided. The textile is a sateen weave fabric containing cellulosic fibers, where the sateen weave fabric has a thickness of at least 19.5 mils, a thickness of at least 25 mils after 3 home washes at 120° F., an air permeability of at least 60 cfm, and a weight of less than about 7 oz / yd2. The sateen weave fabric also contains a treatment, where the treatment contains a tetramethylhydroxy phosphonium salt or its condensate and chemical selected from the group consisting of urea, guanidines, guanyl urea, glycoluril, and polyamines. When the sateen weave fabric to which the treatment has been applied has been heat-cured and oxidized at least a portion of the cellulosic fibers have a pentavalent phosphate compound polymerized therein. The method for producing the flame resistant textile is also provided.

Owner:MILLIKEN & CO

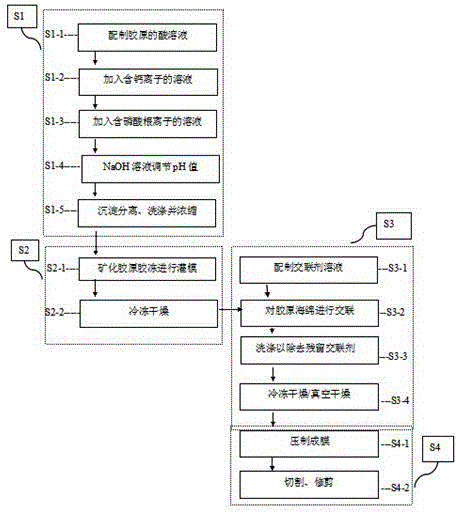

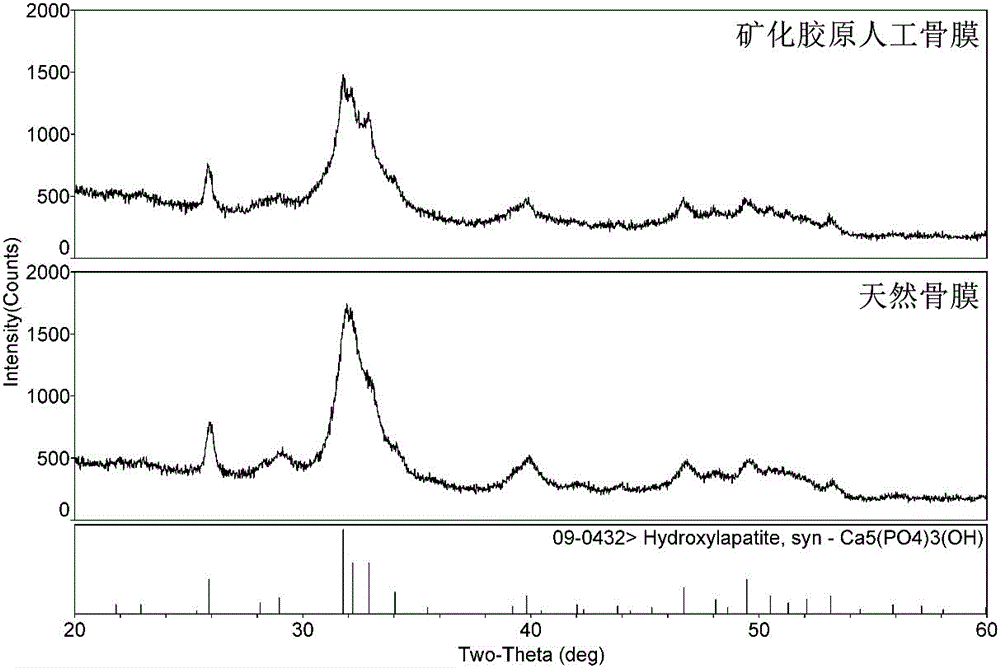

Mineralized collagen artificial periosteum and preparation method thereof

The invention provides a mineralized collagen artificial periosteum. The artificial periosteum is prepared from mineralized collagen in which nano calcium phosphonium salt and collagen fibers are arranged in order, has substances and micro and macro structures, which are the same as a natural periosteum, also has a favorable mechanical property and biodegradation properties, and can be used for replacing and restoring the periosteum. The artificial periosteum can limit other bone grafting materials in the bone fracture parts in the restoring process to prevent the bone grafting materials from coming out and muscles, fat and other tissues from being extruded into the bone fracture parts, so that the restoring effect cannot be influenced. The pore structure of the artificial periosteum facilitates revascularization and conveying of nutrient substances, thereby benefiting restoring of bone fractures. Since the mineralized collagen artificial periosteum consists of nano calcium phosphonium salt and the collagen fibers, the artificial periosteum can be gradually degraded along with regeneration of bone tissues and the periosteums in the body. The invention also provides a preparation method of the artificial periosteum.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

Impact-modified polycarbonate compositions having a good combination of natural color, hydrolytic stability and melt stability

The present invention relates to polycarbonate compositions comprisingA) from 10 to 99 parts by weight, in each ease based on the sum of components A+B+C, of aromatic polycarbonate and / or aromatic polyester carbonate,B) from 1 to 35 parts by weight, in each case based on the sum of components A+B+C, of rubber-modified graft polymer ofB.1 from 5 to 95 wt. % of at least one vinyl monomer onB.2 from 95 to 5 wt. % of one or more graft bases having a glass transition temperature <10° C.,C) from 0 to 40 parts by weight, in each case based on the sum of components A+B+C, of vinyl (co)polymer and / or polyalkylene terephthalate,D) from 0 to 50 parts by weight, in each case based on the sum of components A+B+C, of phosphorus-containing flameproofing agent,E) from 0 to 1.0 part by weight, in each case based on the sum of components A+B+C, of acidic additives, andF) from 0 to 50 parts by weight, in each case based on the sum of components A+B+C, of additives,wherein component B is obtainable by reacting component B.1 with the graft base B.2 by means of emulsion polymerization, with the proviso that in those compositions that are free of components D) and E), the graft polymer dispersion in the spray drying or in the precipitation has a pH value of less than 7,characterized in that there are used in the graft reaction from 0.1 to 5 parts by weight (based on the sum of the parts by weight of the monomers B.1 and of the graft base B.2 that are used=100 parts by weight) of at least one emulsifier selected from the group consisting of alkali, alkaline earth, ammonium and phosphonium salts of a saturated fatty acid having from 10 to 50 carbon atoms, wherein the emulsifier or emulsifiers remains or remain in component B,and also to a process for the preparation of these polycarbonate compositions and to the use of the polycarbonate compositions in the production of molded bodies, and to the molded bodies themselves.

Owner:BAYER MATERIALSCIENCE AG

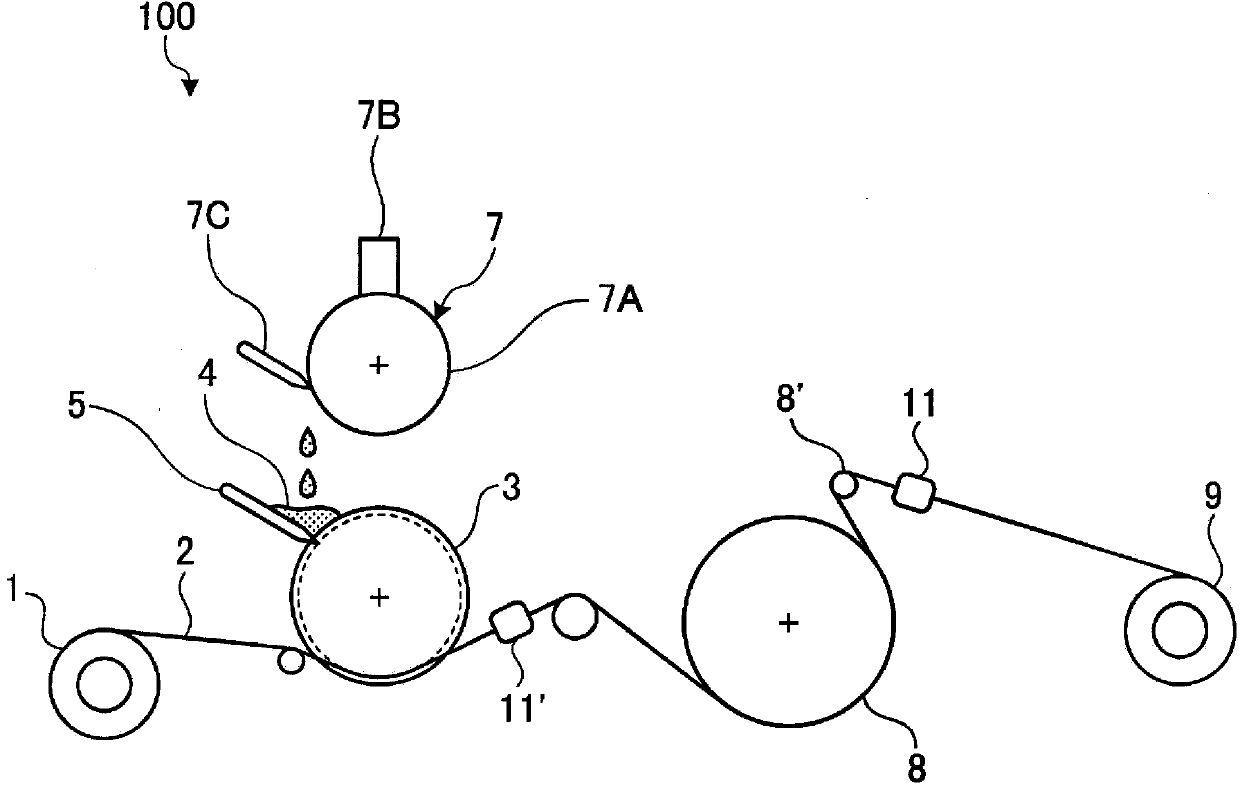

Carbon fiber molding material, molding material, and carbon fiber-strengthening composite material

InactiveCN103975003AGood adhesionCovalent bond formation promotionFibre typesWoven fabricsFiberPolymer science

A carbon fiber molding material is provided that exhibits excellent interfacial adhesion between the carbon fibers and a thermosetting resin, and that yields a molded product exhibiting excellent mechanical properties. The carbon fiber molding material is either (Z) a prepreg containing sizing agent-coated carbon fibers and a thermosetting resin, or (Y) a material for forming woven fabric or braided cords that employs sizing agent-coated carbon fibers. The sizing agent is characterized by containing the following components (A) and (B): component (A) is an epoxy compound having two or more epoxy groups, or two or more functional groups; component (B) is a compound containing one or more of the group consisting of a tertiary amine compound, a tertiary amine salt, a quaternary ammonium salt, a quaternary phosphonium salt, and a phosphine compound. The sizing agent is obtained by blending 0.1-25 parts by mass of the compound (B) with 100 parts by mass of the compound (A).

Owner:TORAY IND INC

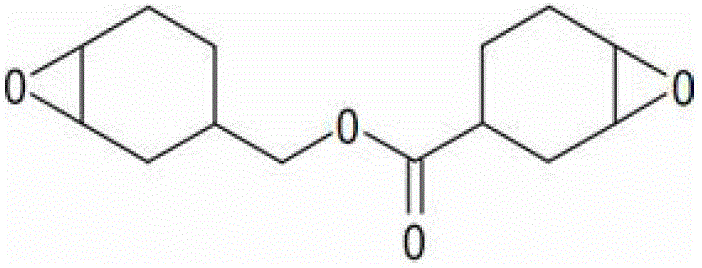

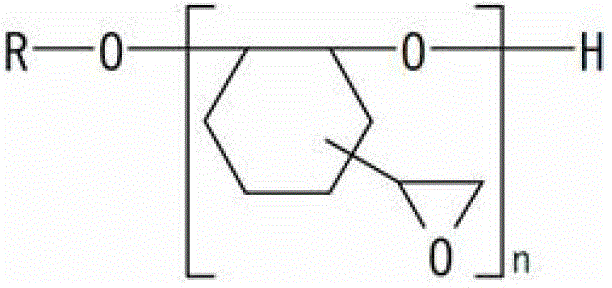

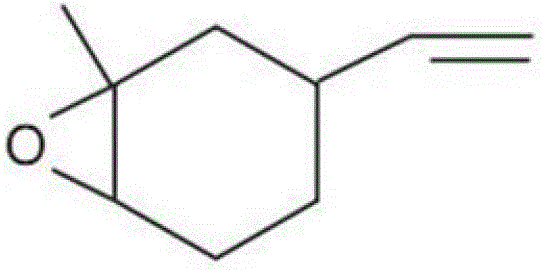

LED-packaging epoxy resin composition

InactiveCN102746487AGuaranteed crack resistanceGuaranteed craftsmanshipNon-macromolecular adhesive additivesEpoxy resin adhesivesPhosphonium saltPhosphate

The invention discloses a method for improving the performance of a large-power high-light-transmittance LED packaging epoxy resin composition. The composition is composed of a component A and a component B. The composition has excellent UV resistance and yellowing resistance. The composition is advantaged in good manufacturability, good light transmittance, and low light failure. The composition can be used in white-light and blue-light LED packaging. Compared with organosilicon, the composition is advantaged in low price. Innovatively, the component A of the composition is composed of liquid cycloaliphatic epoxy resin, solid cycloaliphatic epoxy resin, and hydrogenated bisphenol A epoxy resin. An anti-forming agent, a color complementary agent, and a dispensing agent are adopted in auxiliary. The system does not contain benzene ring, and yellowing is not easy to occur. The component B is prepared through the steps that: methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride are subjected to a polymerization reaction with promoting agents or cationic initiators such as quaternary phosphonium salt, quaternary ammonium salts, DBU salt, and imidazole; with added phosphate antioxidant, a thermal yellowing capacity is improved. With the applications of an ultraviolet absorber and a light stabilizer, a UV yellowing resisting effect is further improved.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS +1

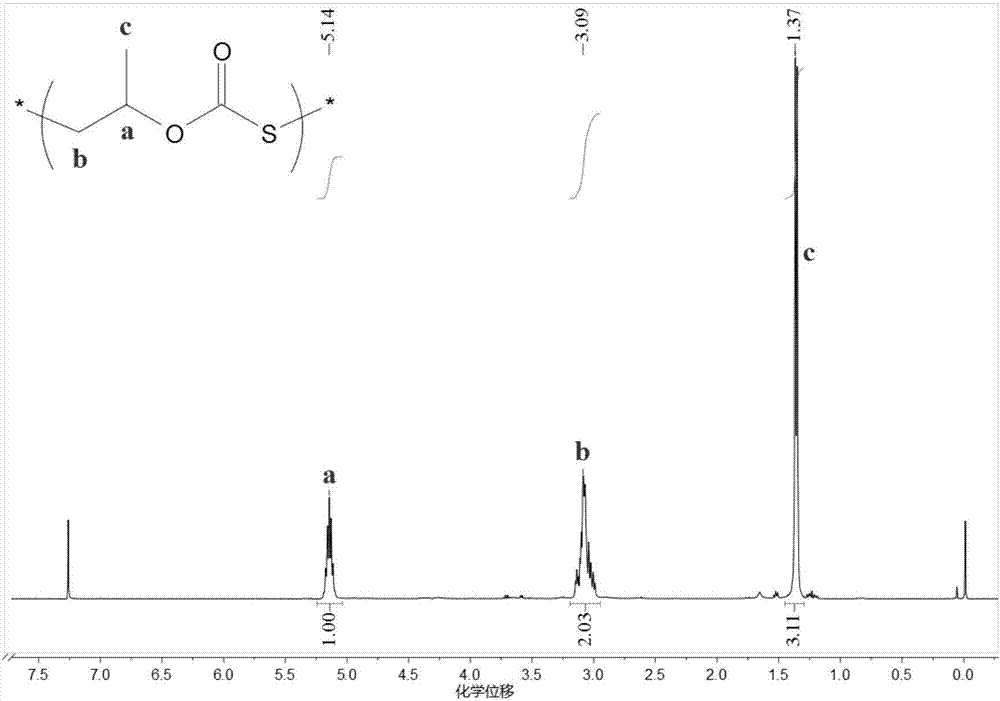

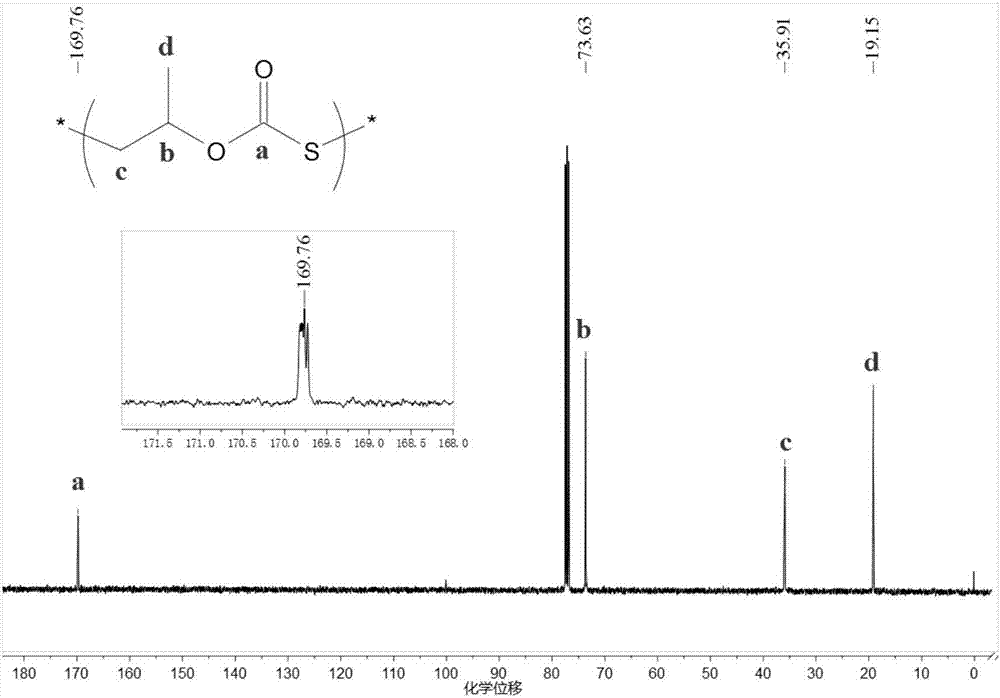

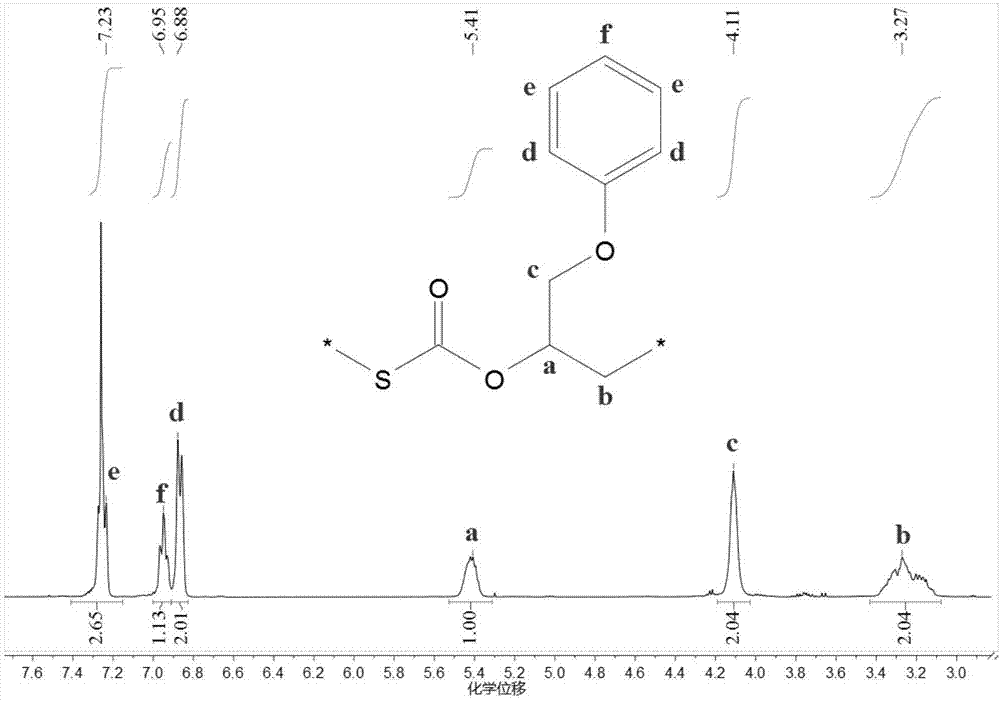

Method for preparing poly(monothiocarbonate)

ActiveCN106866952AImprove adaptabilityImprove catalytic performancePolycarbonate coatingsPhosphonium saltPhosphonium

The invention discloses a method for preparing poly(monothiocarbonate). According to the method, carbon oxysulfide and oxygen-containing monomers are used as raw materials; a catalysis system consisting of initiators and Lewis acid is used; after the bulk polymerization or solution polymerization, poly(monothiocarbonate) is obtained; the oxygen-containing monomers are selected from at least one kind of materials of epoxy compounds, oxetane and 3-substituted oxetane; the initiators are selected from quaternary ammonium salt, quaternary phosphonium salts or organic alkali. The preparation method of synthesizing the poly(monothiocarbonate) through anion ring-opening polymerization by using a catalytic system formed by at least one kind of materials from quaternary ammonium salt, quaternary phosphonium salts or organic alkali, and the Lewis acid; the poly(monothiocarbonate) with the specific chain structures can be obtained through preparation. The catalysis system can be obtained only through compounding; the metal residue and color residue problems do not exist.

Owner:ZHEJIANG UNIV

Process for producing fluoroolefins

InactiveCN1589248APreparation by hydrogen halide split-offOrganic chemistry methodsPhosphonium saltPotassium

A process for producing a fluoroolefin of the formula: CF3CY=CXnHp wherein Y is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); X is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); nand p are integers independently equal to 0, 1 or 2, provided that (n + p) = 2; comprising contacting, in the presence of a phase transfer catalyst, a compound of the formula: CF3C (R<l>aR<2>b) C (R<3>CR<4>d) , wherein R<1>, R<2>, R<3>, and R<4> are independently a hydrogen atom or a halogen selected from the group consisting of fluorine, chlorine, bromine and iodine, provided that at least one of R<1>, R<2>, R<3>, and R<4> is halogen and there is at least one hydrogen and one halogen on adjacent carbon atoms; a and b are independently = 0, 1 or 2 and (a+b) = 2; and c and d are independently = 0, 1, 2 or 3 and (c+d) = 3; and at least one alkali metal hydroxide. The alkali metal hydroxide can be, for example, potassium or sodium hydroxide and the phase transfer catalyst can be, for example, at least one: crown ether such as 18-crown-6 and ls-crown-S; or onium salt such as, quaternary phosphonium salt and quaternary ammonium salt. The olefin is useful, for example, as an intermediate for producing other industrial chemicals and as a monomer for producing oligomers and polymers.

Owner:HONEYWELL INT INC

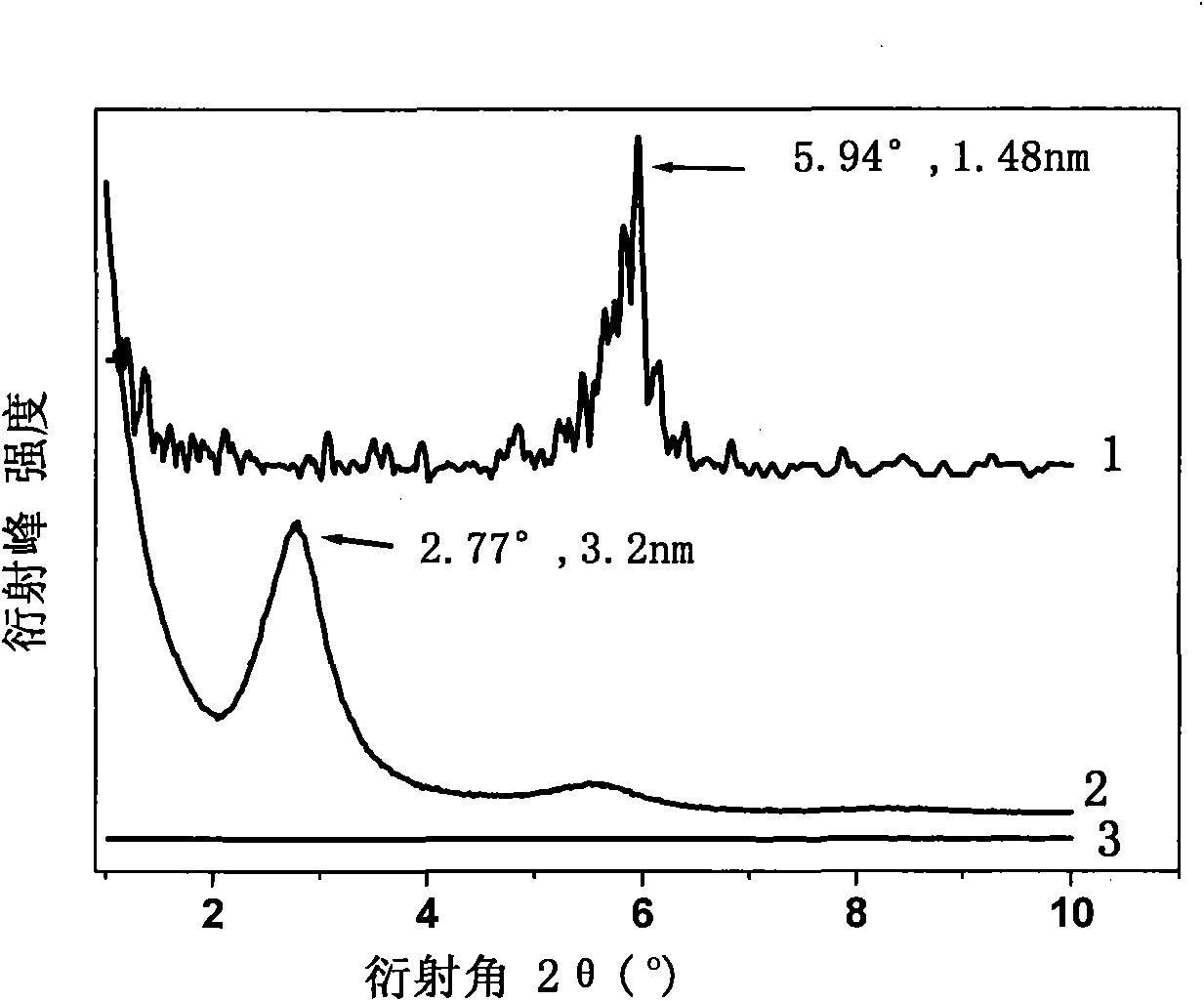

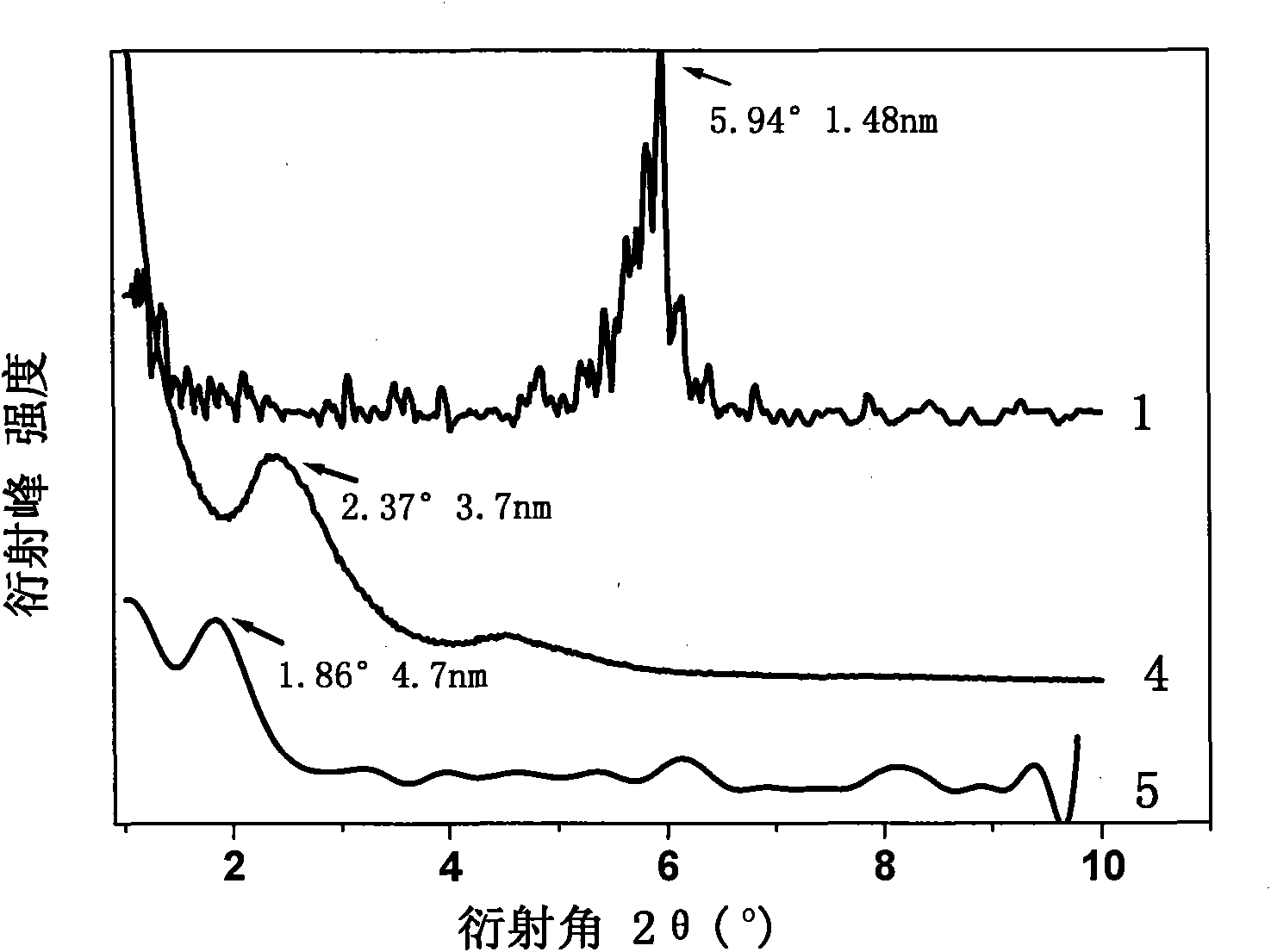

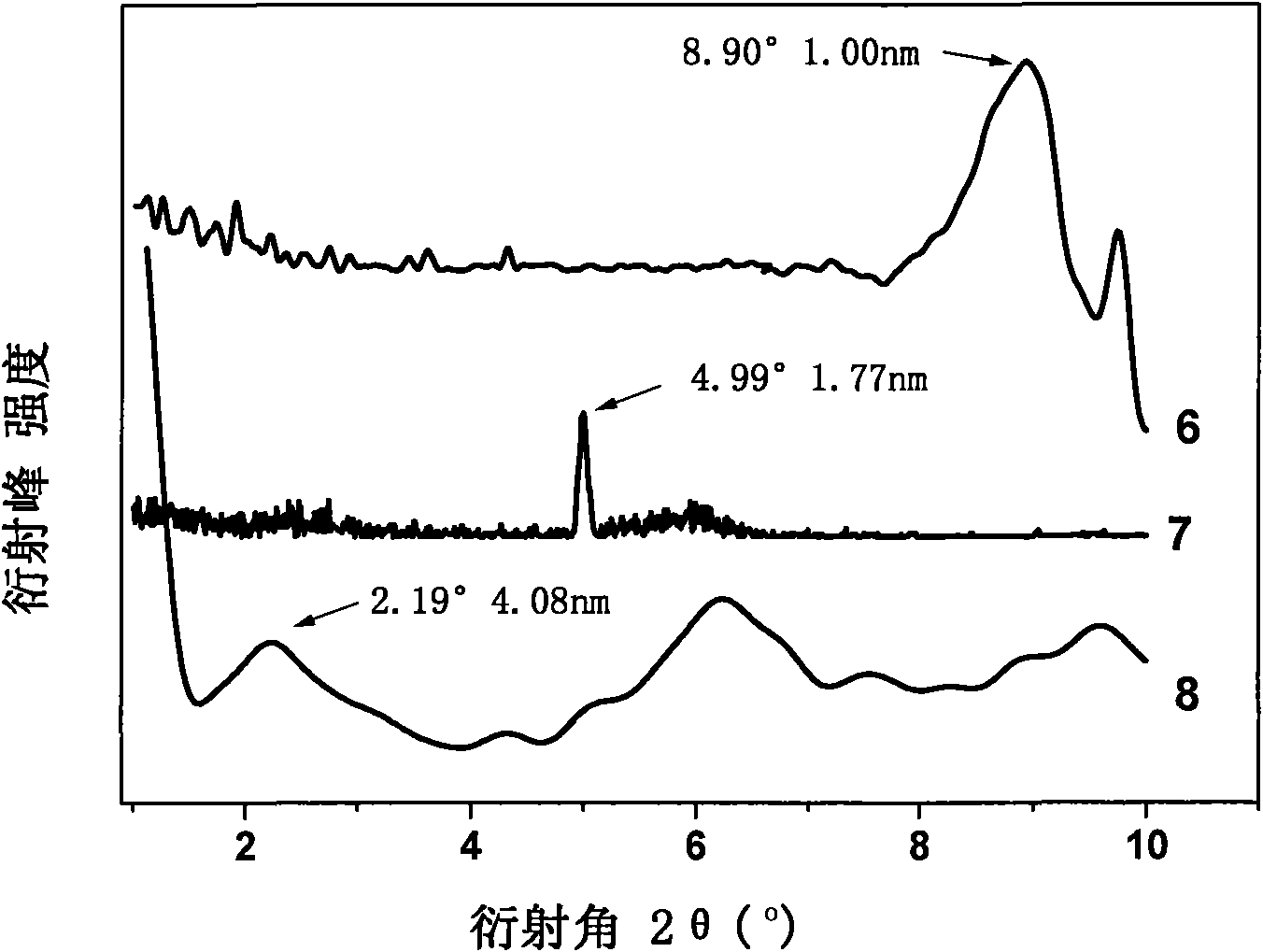

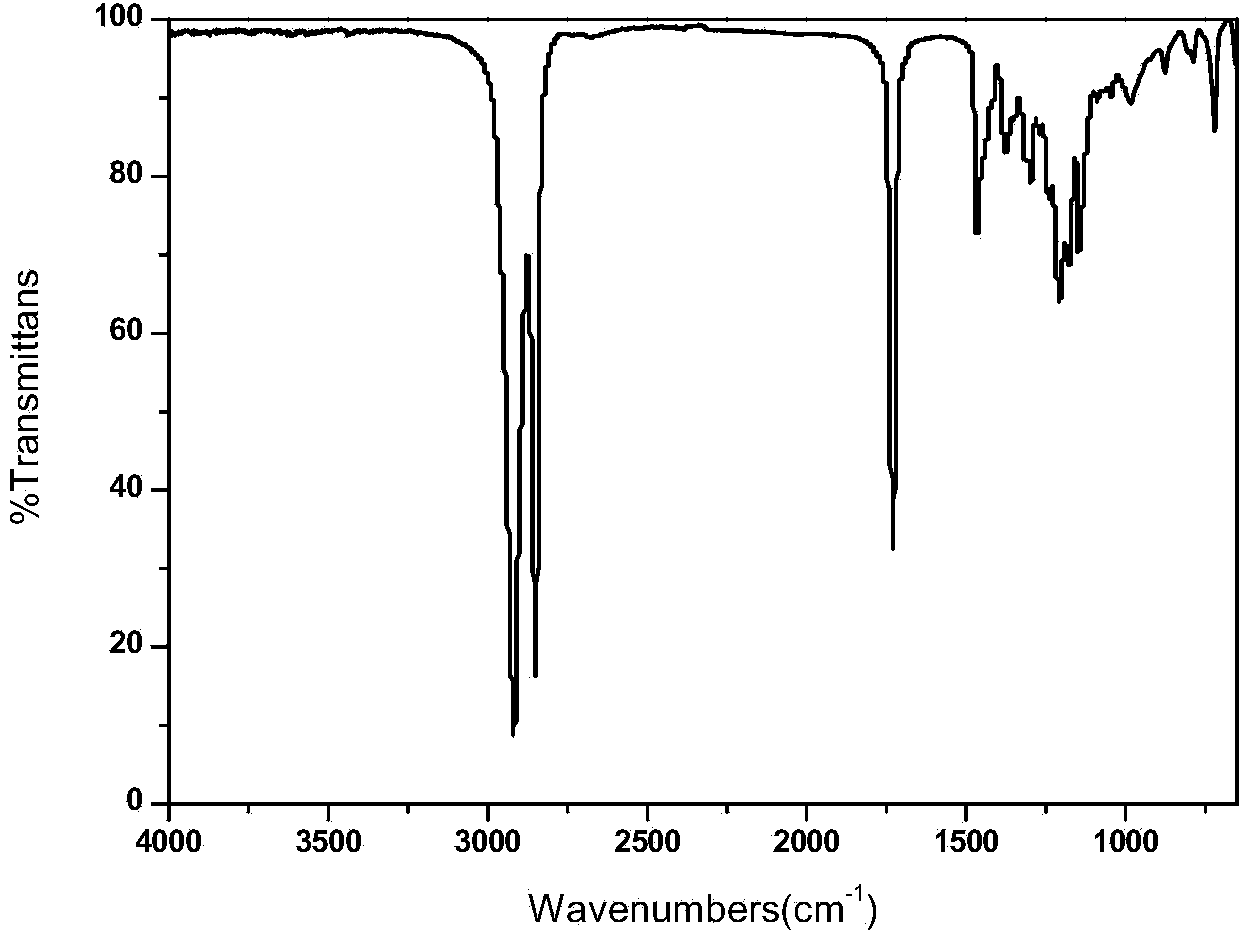

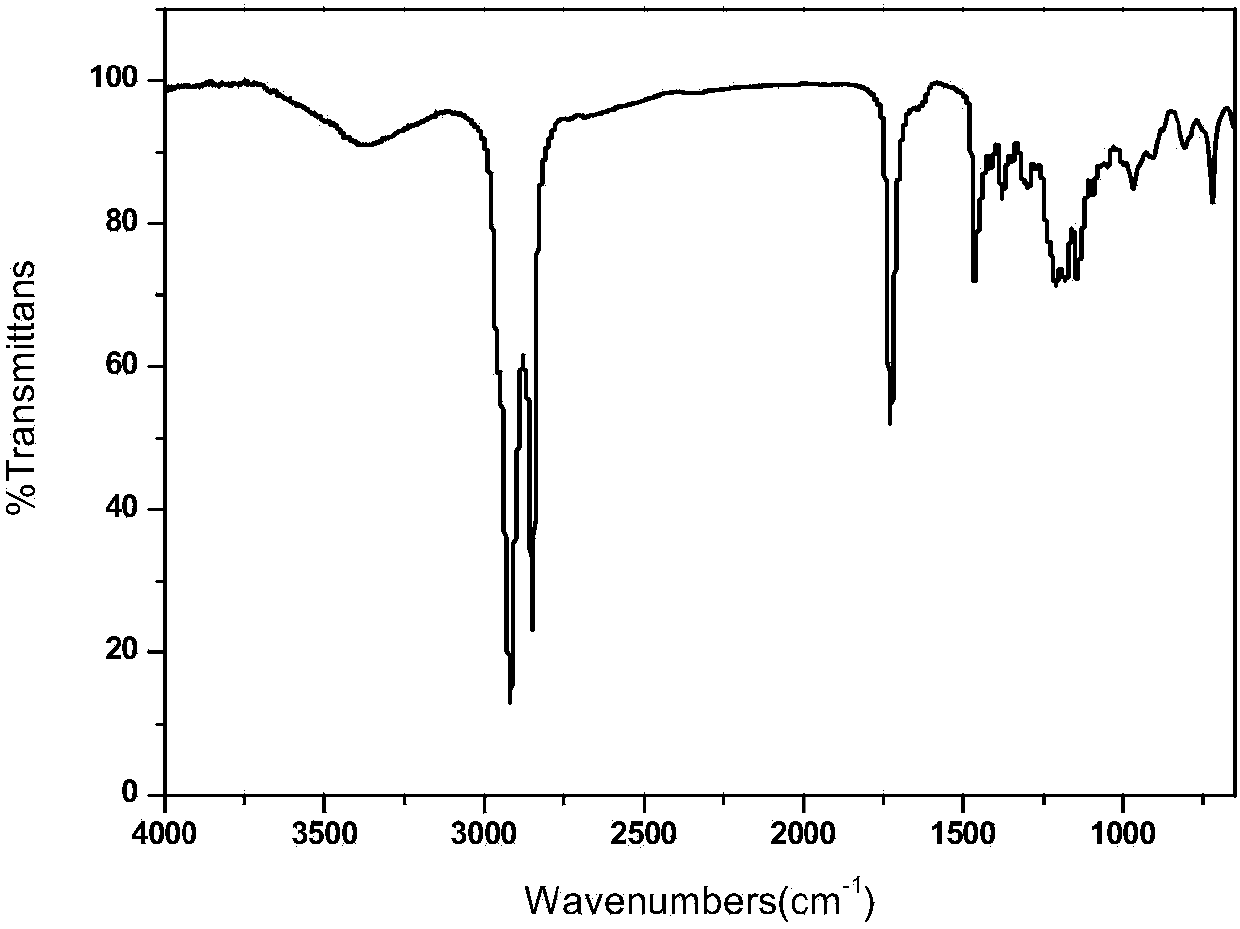

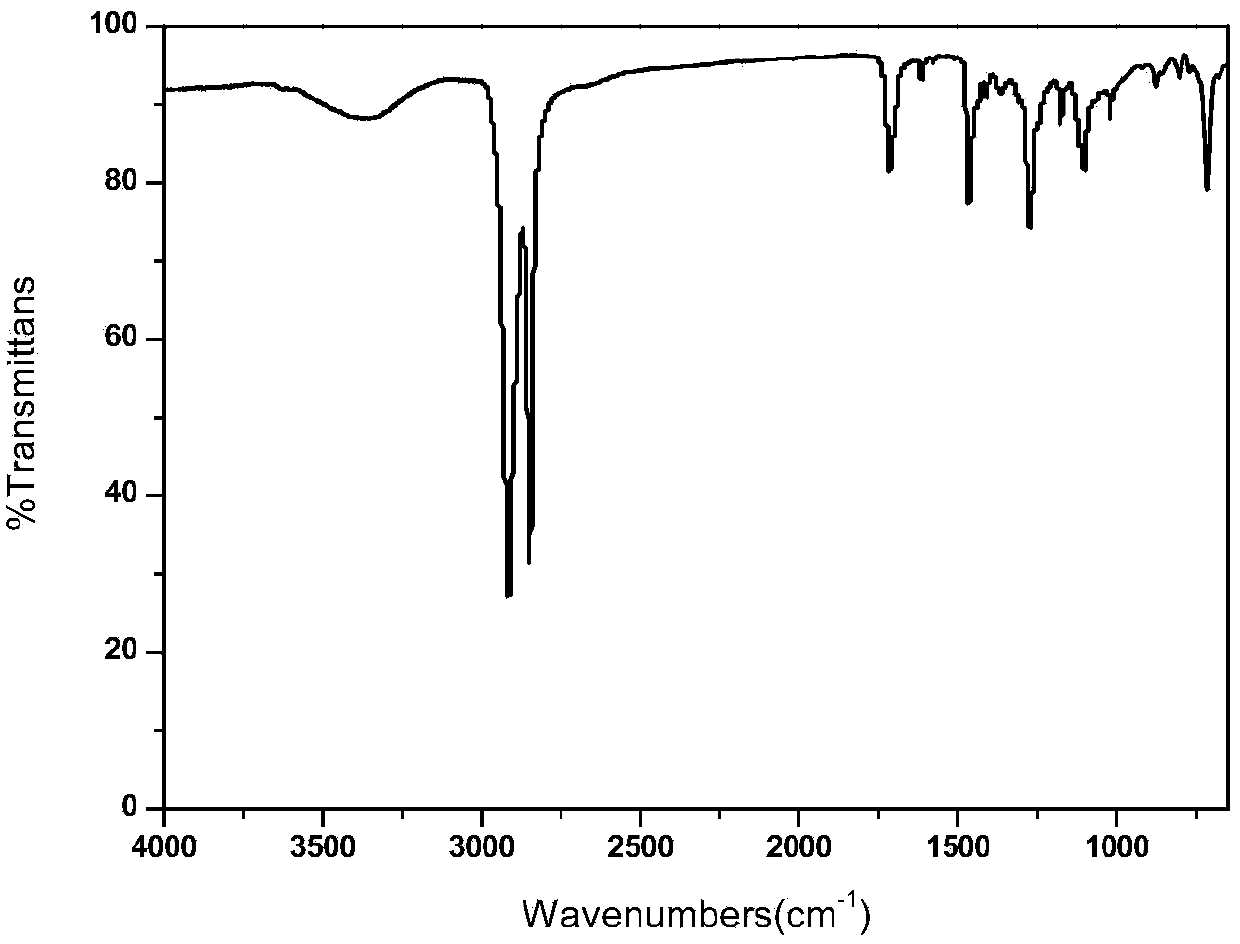

Methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and polymer/montmorillonite nanocomposite

InactiveCN101979444AGood physical and chemical stabilityGreen chemical reagents are goodFibre treatmentCoatingsPhosphonium saltEngineering plastic

The invention relates to the field of polymer / montmorillonite nanocomposites, and discloses methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and the polymer / montmorillonite nanocomposite. The method for preparing the polymer / montmorillonite nanocomposite comprises the steps of performing pillaring-modification on montmorillonite by using quaternaryphosphonium salt ionic liquid and then intercalating the quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and a polymer or a polymeric monomer. In the methods, the montmorillonite is pillaring-modified directly by the quaternary phosphonium salt ionic liquid without water and any other solvent, and the ionic liquid can be recycled; the methods are simple, convenient to operate and environmentally-friendly, reduces the cost and saves energy consumption; and the quaternary phosphonium salt ionic liquid has more stable chemical properties and higher thermal stability, greatly improves the mechanical properties of the polymer material, can be applied to engineering plastics and heat-resisting polymers, and greatly expands the application range of the montmorillonite.

Owner:SOUTH CHINA UNIV OF TECH

High polymer quaternary phosphonium salt antibacterial material and preparation method thereof

ActiveCN103739786AEasy to cleanImprove antibacterial functionBiocideFungicidesEscherichia coliPhosphonium

The invention discloses a high polymer quaternary phosphonium salt antibacterial material and a preparation method thereof. The high polymer quaternary phosphonium salt antibacterial material is prepared by bonding halogenacylhalide type monomers onto macromolecules of an ethylene-vinyl alcohol copolymer (EVOH) through grafting reaction and further performing quaternary phosphonium reaction with trialkylphosphine. The high polymer quaternary phosphonium salt antibacterial material disclosed by the invention has the advantages of broad-spectrum, high-efficient and lasting antibacterial function and good safety, can be shaped and processed into products with the antibacterial function alone, and mixed with polyethylene, polypropylene and other non-polar resin and other types of resin for being shaped and processed into the products with the antibacterial function, and further has broad application prospects. The sterilization efficiency of the high polymer quaternary phosphonium salt antibacterial material prepared by the preparation method disclosed by the invention against escherichia coli, staphylococcus aureus and a variety of bacteria is more than 99%, and the mildew-resistant grade against aspergillus niger, aspergillus terreus and a variety of mildew is 1-0 grade.

Owner:JINYU HENAN PACKAGING

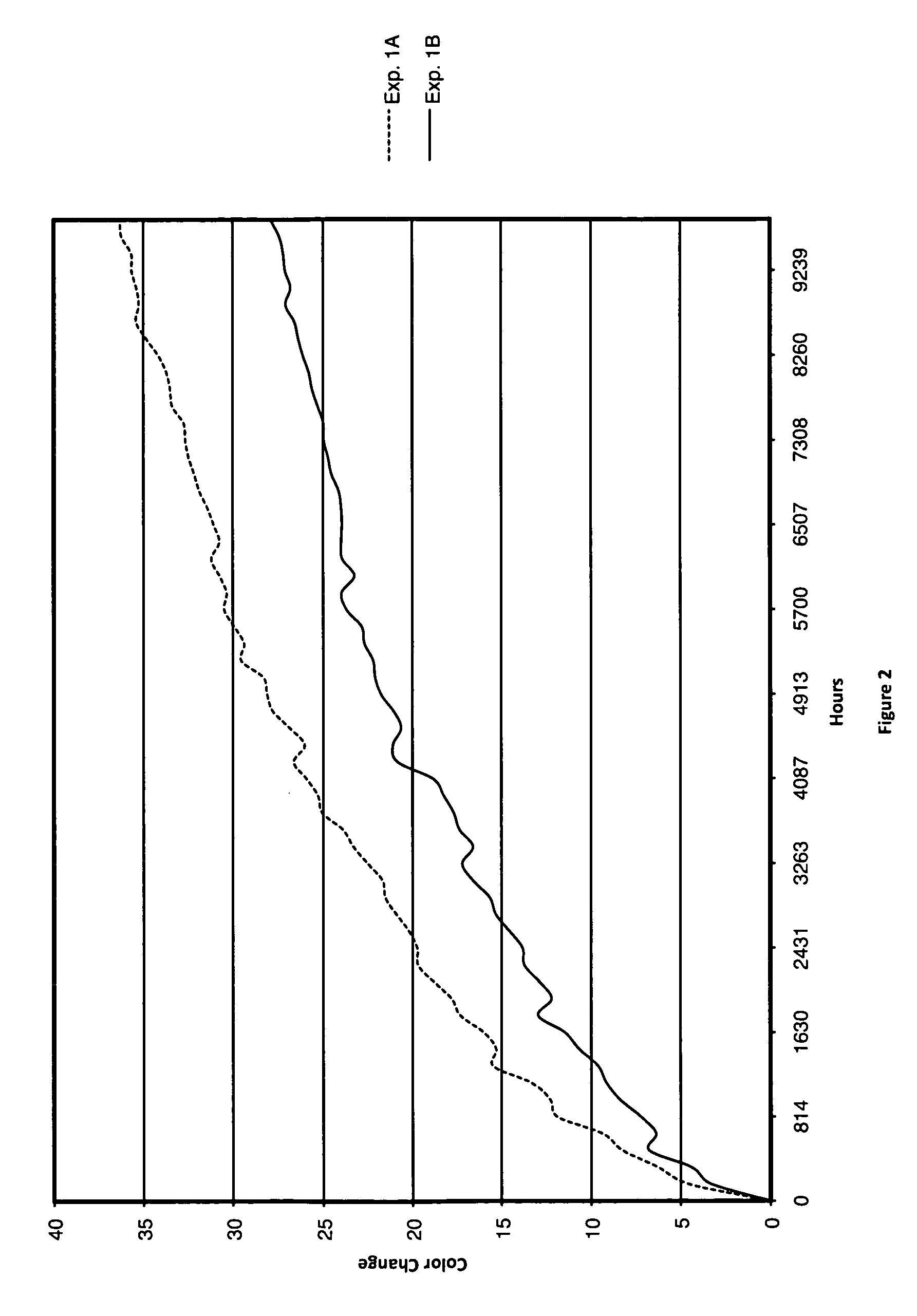

Treatment method for a hydrocarbon-containing system using a biocide

ActiveUS20140080792A1Low costSimple procedureWaste water treatment from quariesBiocidePhosphonium saltEvaluation system

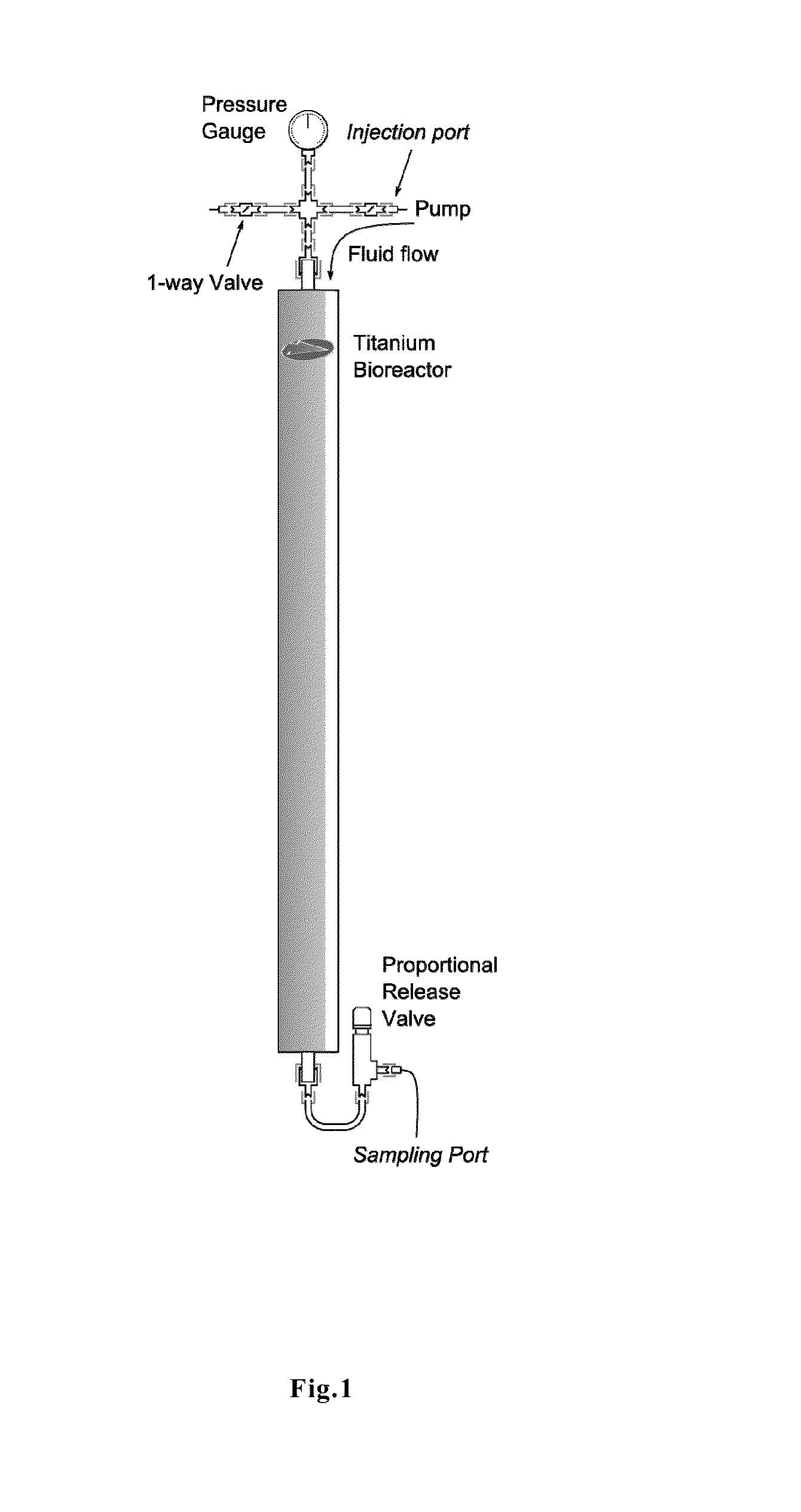

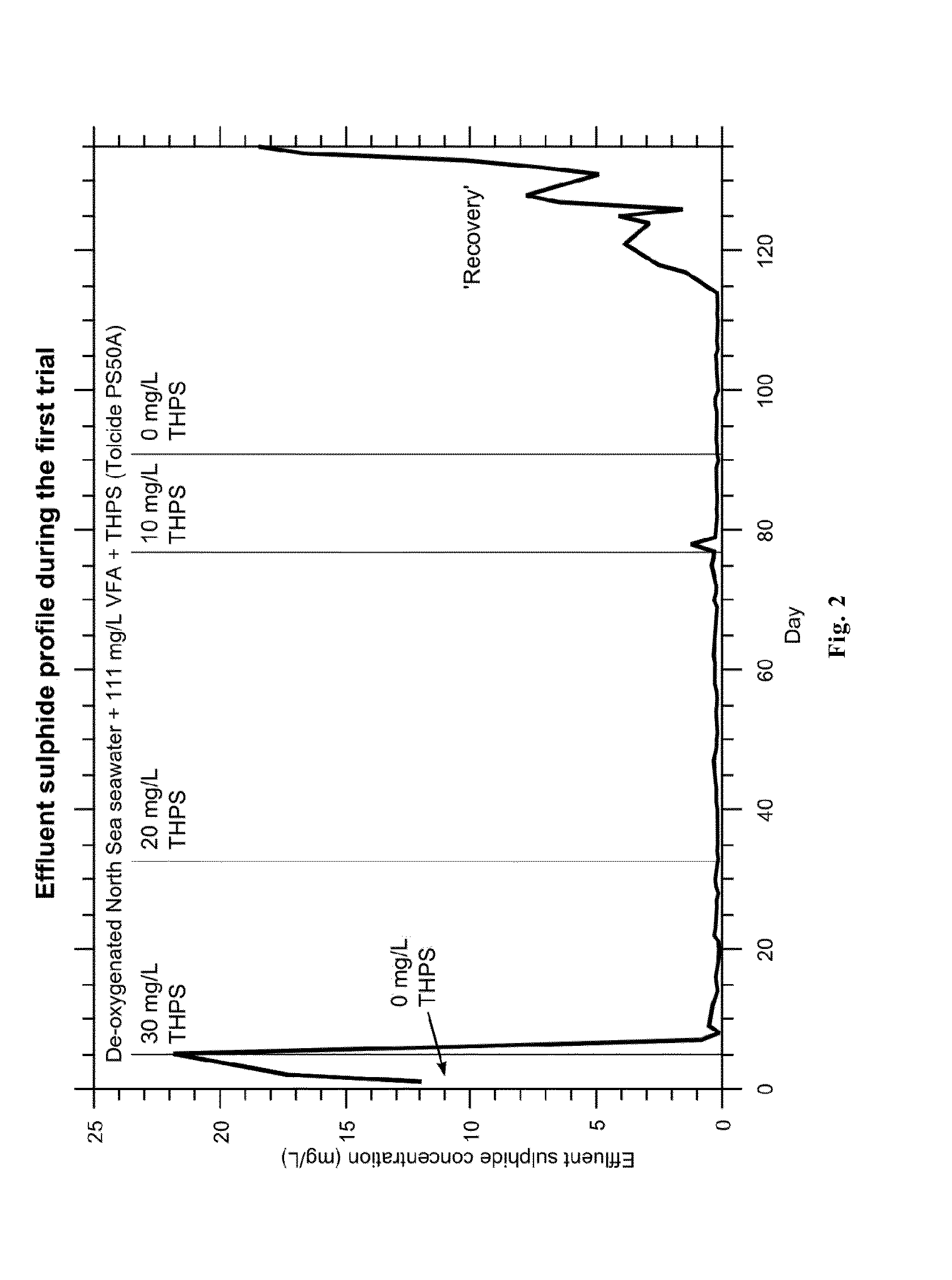

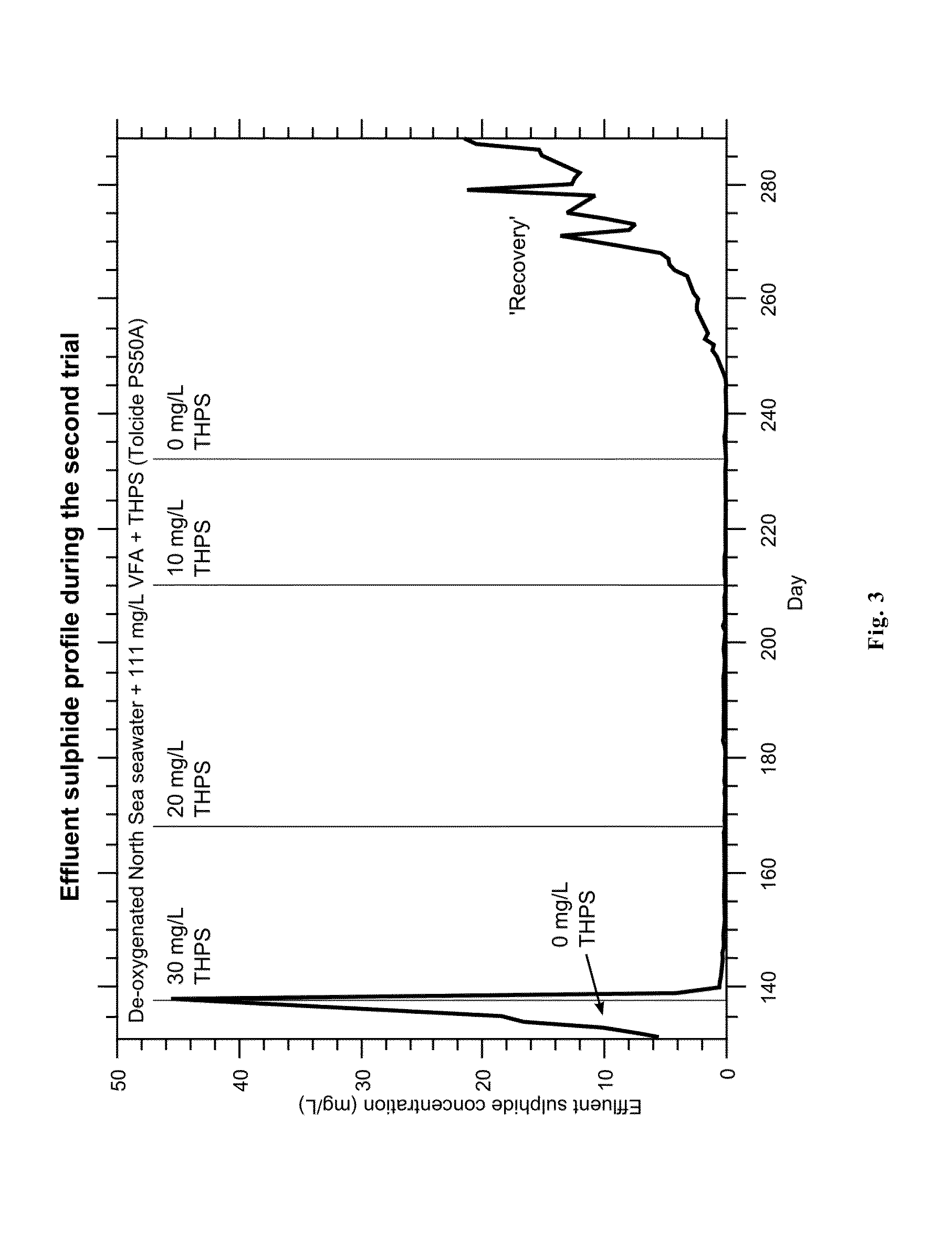

A method for reducing the effects of biological contamination in a hydrocarbon-containing system comprising the steps of continuously adding a formulation comprising tris(hydroxymethyl)phosphine or a tetrakis(hydroxymethyl)phosphonium salt to the system for one day or more; monitoring the efficacy of the continuous treatment by an assessment of the extent to which there is any effect on the environment that is attributable to metabolic activity of active microbes present in the system; wherein the tris(hydroxymethyl)phosphine or tetrakis(hydroxymethyl)phosphonium salt is added at a concentration of from 1 to 30 ppm based on the total volume of aqueous fluid added to the system, and wherein the formulation is added to the system at a stage to minimize incompatibility with any other chemicals that are added to the aqueous fluid. The treatment disrupts the microbial activity of active microbes in the hydrocarbon-containing system and can prevent or reduce detrimental effects arising from the presence of active microbes in the system.

Owner:ENERGY SOLUTIONS (US) LLC

Polyetherimide compositions, methods of manufacture, and articles formed therefrom

A method for the manufacture of a polyetherimide composition includes catalyzing the reaction of a dianhydride and an organic diamine with a catalyst selected from guanadinium salts, pyridinium salts, imidazolium salts, tetra(C6-24)aryl ammonium salts, tetra(C7-24 arylalkylene)ammonium salts, dialkyl heterocycloaliphatic ammonium salts, bis-alkyl quaternary ammonium salts, (C7-24arylalkylene)(C1-16alkyl)phosphonium salts, (C6-24aryl)(C1-16alkyl)phosphonium salts, phosphazenium salts and combinations thereof, optionally in the presence of a solvent.

Owner:SABIC GLOBAL TECH BV

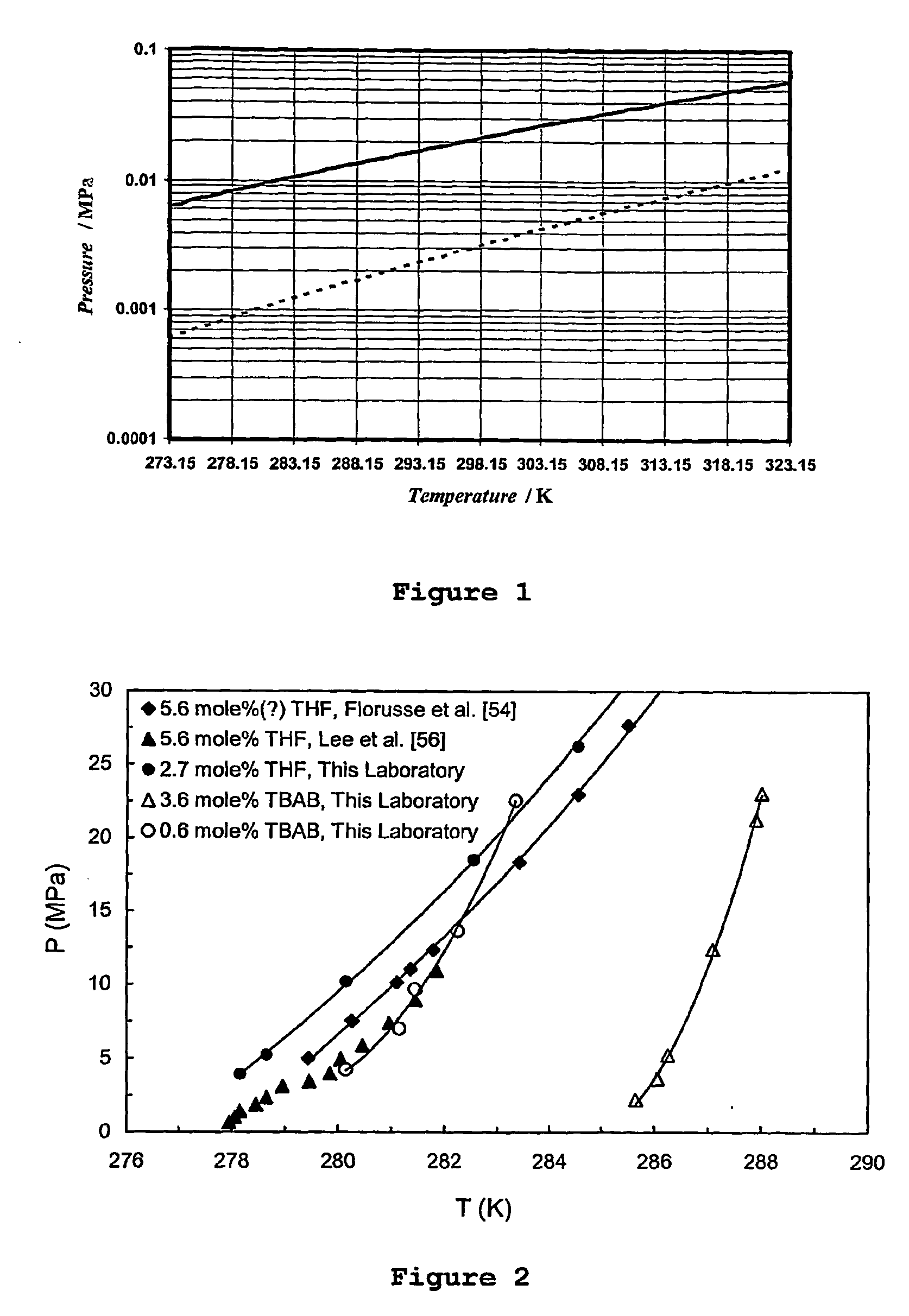

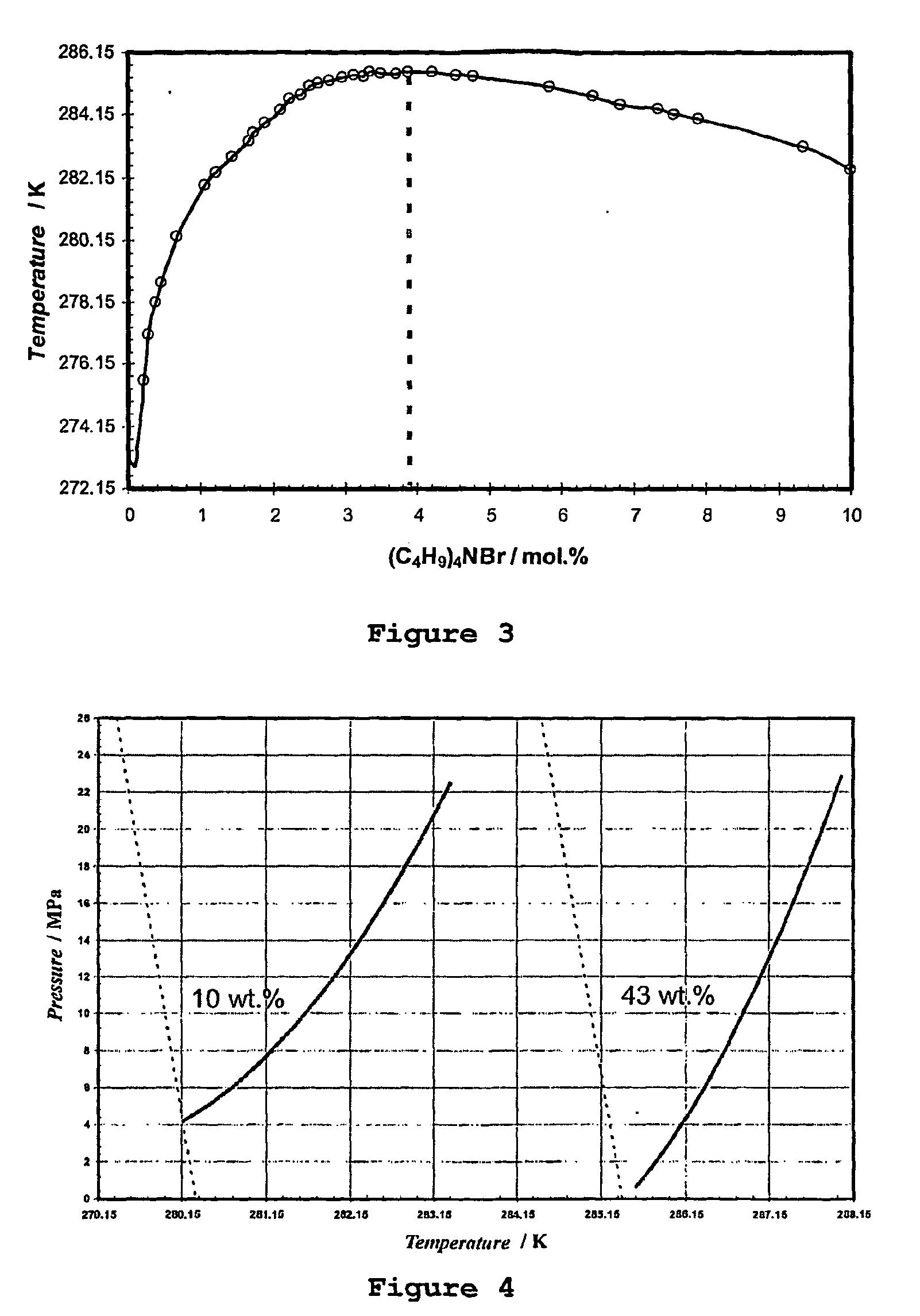

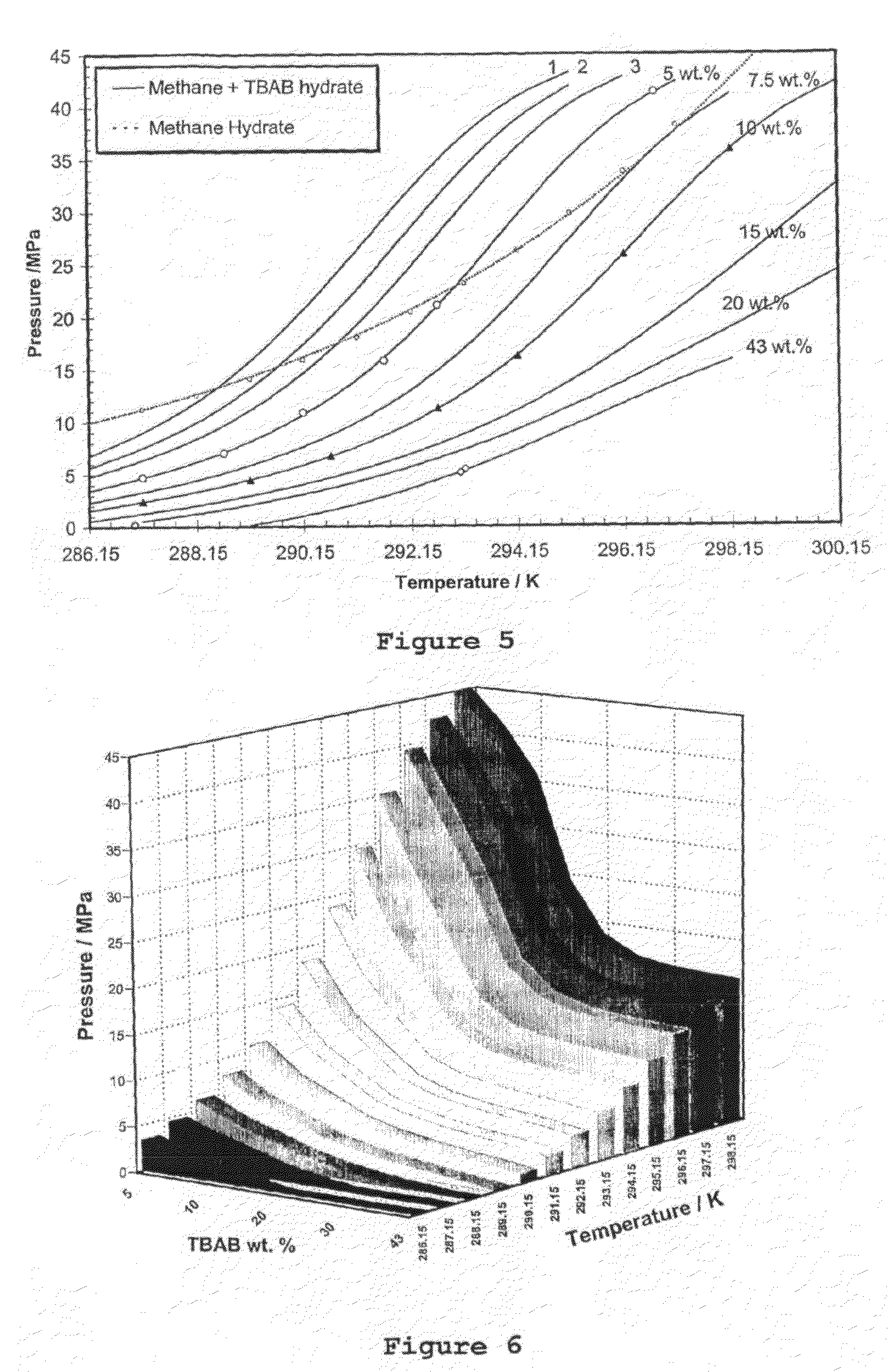

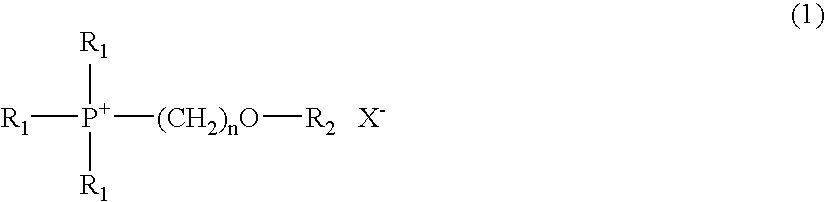

Method for gas storage, transport, and energy generation

The invention provides semi-clathrate hydrate compositions formed from water, a semi-clathrate hydrate forming compound and a gas. The semi-clathrate hydrate forming compounds can be ammonium salts, sulphonium salts, phosphonium salts or amines. The semi-clathrate hydrate compositions can be used to store gases including hydrogen, methane and carbon dioxide. Methods of manufacture of the compositions and their uses in energy storage and generation, and for the separation of gases are also described.

Owner:HERIOT WATT UNIV

Vulcanized rubber laminate

The invention provides a vulcanized rubber laminate obtained by firmly bonding an unvulcanized epichlorohydrin rubber layer and an organic peroxide-containing fluororubber layer. The laminate is obtained by thermal adhesion a layer of an unvulcanized epichlorohydrin rubber composition to a layer of an unvulcanized fluororubber composition. The epichlorohydrin rubber composition comprises 1) an unvulcanized epichlorohydrin rubber containing 3 to 15 mol % of allyl glycidyl ether unit, 2) quinoxaline-based vulcanizing agents, mercaptotriazine-based vulcanizing agents or bisphenol-based vulcanizing agents, and 3) 1,8-diazabicyclo(5,4,0)undecene-7 salts, 1,5-diazabicyclo(4,3,0)nonene-5 salts, quaternary ammonium salts, quaternary phosphonium salts, basic white carbons or an alkaline metal salt of higher fatty acid the fluororubber composition comprises an fluororubber and an organic peroxide-based vulcanizing agent.

Owner:OSAKA SODA CO LTD

Adsorbent for simultaneously removing heavy metals and phenol organics in mineral processing wastewater and preparation method thereof

InactiveCN102580682ALong-lastingNot easy to precipitateOther chemical processesWater/sewage treatment by sorptionSodium BentonitePhosphonium salt

The invention discloses an adsorbent for simultaneously removing heavy metals and phenol organics in wastewater. The adsorbent is obtained by modifying bentonite with a quaternary phosphonium salt cationic surfactant and a chelating agent. The invention also discloses a preparation method of the adsorbent. The preparation method comprises the following steps of: 1) throwing the surfactant into water and heating and stirring the surfactant until the surfactant is completely dissolved; 2) throwing original bentonite into the solution and stirring the original bentonite under room temperature; 3) adding the chelating agent and continuing stirring under room temperature; and 4) drying the product after washing and filtering, grinding and sieving the product with a 100-mesh sieve and placing the obtained product in a dryer under room temperature for later use. The adsorbent and the preparation method have the following advantages that the quaternary phosphonium salt cationic surfactant is firstly exchanged into interlayers of bentonite and the chelating agent also enters the interlayers through hydrophobic bond of the cationic surfactant, thus enlarging the layer distances and ensuring the interlayers to have hydrophobicity and enhancing adsorption of the phenol organics; meanwhile, the chelating agent and the heavy metals form coordination complexes; the adsorbent has a good effect on simultaneously removing heavy metals and phenol organics in mineral processing wastewater; and the removal rates of Cd2<+> and phenol organics in the actual mineral processing wastewater are respectively 88.1% and 99.9%.

Owner:XIANGTAN UNIV

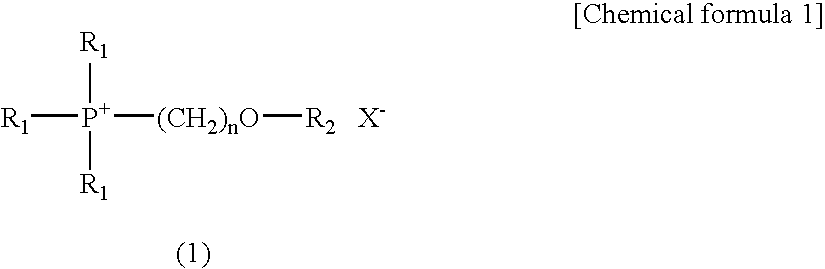

Electrolyte composition used in charge storage device and storage device using the same

InactiveUS20090053597A1Low viscosityImprove ionic conductivityHybrid capacitor electrolytesElectrolytic capacitorsPhosphonium saltEthyl group

The present invention provides an electrolyte composition used in a charge storage device, which comprises an ionic liquid that has high ionic conductivity and is highly safe with no risks of inflammation and the like. It is an electrolyte composition used in a charge storage device, which comprises a quaternary phosphonium salt ionic liquid represented by general formula (1) as described below. The viscosity at 25° C. of this ionic liquid is preferably 200 mPa·sec or less. In the general formula (1), it is preferable that the alkoxyalkyl group be a methoxymethyl group and that all the alkyl groups be ethyl groups.wherein R1 represents a linear or branched alkyl group containing 1 to 3 carbon atoms; R2 represents a methyl group or an ethyl group; n represents an integer between 1 and 3; and X represents N(SO2CF3)2.

Owner:NIPPON CHECMICAL IND CO LTD

Preparation method of flame resistance core-shell type aqueous acrylic ester resin coating

ActiveCN104031514AImprove the defect of "hot sticky and cold brittle"Improve flame retardant performanceFireproof paintsPolymer sciencePhosphonium salt

The invention relates to a preparation method of a flame resistance core-shell type aqueous acrylic ester resin coating. Water, emulsifiers, methacrylic acid and a monomer A are added and emulsified, an initiator starts to be added dropwise for 1-3 hours when the temperature is 75 DEG C, reaction is carried out for 3-5 hours with the temperature kept at 75 DEG C, quaternary phosphonium salt is added to react for 1-3 hours, and core layer emulsion is obtained; a monomer B and an initiator are added into the core layer emulsion dropwise for 1-3 hours at the same time and react for 2 hours with the temperature kept at 75-85 DEG C, borane is added dropwise, reaction is carried out for 1-3 hours with the temperature kept at 75-85 DEG C, then cross-linking agents are added dropwise, reaction is carried out for 1-2 hours with the temperature kept at 75-85 DEG C, the temperature is decreased to be 50 DEG C, an emulsifier is added into a reaction system, the reaction time is 30 minutes, ammonium hydroxide is added to adjust the pH value to be 7-8, and the flame resistance core-shell type aqueous acrylic ester resin coating is obtained. The flame resistance of obtained flame resistance core-shell type aqueous acrylic ester resin can be greatly improved, and the defect that traditional acrylic ester resin is sticky at high temperature and crisp at low temperature is also overcome.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com