Patents

Literature

80results about How to "Guaranteed crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

900MPa high-strength steel preheating-free combined welding method

The invention discloses a 900MPa high-strength steel preheating-free combined welding method. 700-800 MPa low-hydrogen type high-tenacity shielded metal arc welding is adopted for backing welding, then a 900MPa high-tenacity solid wire is matched with Ar+CO2 mixed gas shielded welding for implementing filling welding, and a 800MPa flux-cored wire is matched with CO2 gas shielded welding for cosmetic welding. A crack-free welding joint can be obtained by welding 900MPa high-strength steel through adopting a preheating-free and postweld heat treatment free combined welding process, and a joint region is smooth and clean, and can meet operating requirements on a high-strength steel welding structure for higher bearing capacity because the room temperature tensile strength of weld metal is more than 860MPa and the damping power of a V-shaped notch of the weld metal with the test temperature of 0 DEG C is more than 90J; and meanwhile, the method has welding cost reduced by about 25 percent, simple and convenient operation and easy popularization.

Owner:SHANDONG UNIV

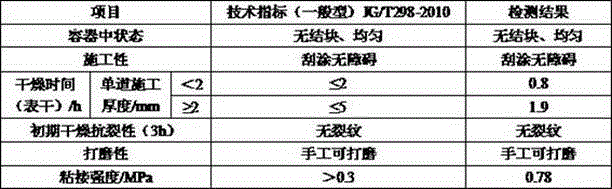

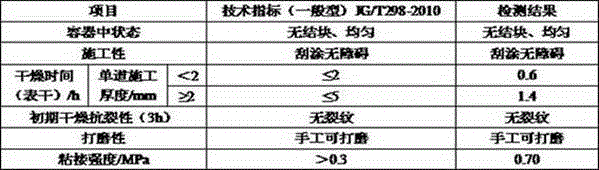

Putty powder used for walls in house

InactiveCN101705027AExcellent scratch coating construction performanceGuaranteed crack resistanceFilling pastesCalcium hydroxideSodium Bentonite

The invention provides putty powder used for walls in a house. The putty powder comprises the following ingredients: ground calcium carbonate, sodium-base bentonite, 1788 powder of polyving akohol, hydroxypropyl methyl cellulose and talcum powder, besides, white cement or / and calcium hydroxide powder is / are added therein as a reinforcing material, and also, sodium hexametaphosphate powder and / or tourmaline powder are / is added in the product. The putty powder has excellent scraping construction performance, long-acting mould-proof performance and excellent dense degree of the putty coating as well as the function of releasing negative ions for a long time, can effectively adsorb various harmful substances in the air and purify the air, and has excellent environment-friendly performance.

Owner:毕家新

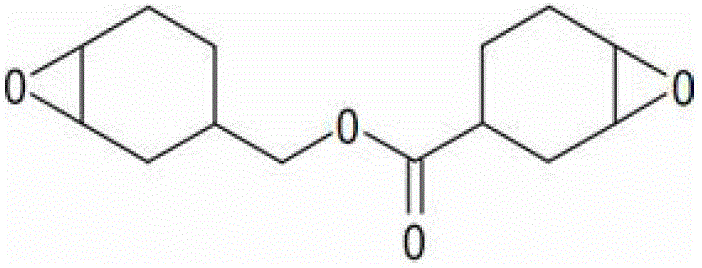

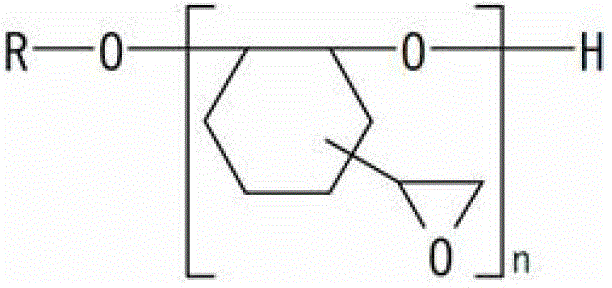

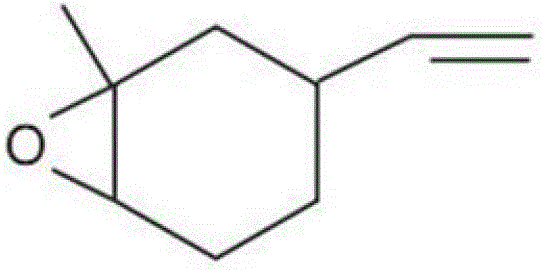

LED-packaging epoxy resin composition

InactiveCN102746487AGuaranteed crack resistanceGuaranteed craftsmanshipNon-macromolecular adhesive additivesEpoxy resin adhesivesPhosphonium saltPhosphate

The invention discloses a method for improving the performance of a large-power high-light-transmittance LED packaging epoxy resin composition. The composition is composed of a component A and a component B. The composition has excellent UV resistance and yellowing resistance. The composition is advantaged in good manufacturability, good light transmittance, and low light failure. The composition can be used in white-light and blue-light LED packaging. Compared with organosilicon, the composition is advantaged in low price. Innovatively, the component A of the composition is composed of liquid cycloaliphatic epoxy resin, solid cycloaliphatic epoxy resin, and hydrogenated bisphenol A epoxy resin. An anti-forming agent, a color complementary agent, and a dispensing agent are adopted in auxiliary. The system does not contain benzene ring, and yellowing is not easy to occur. The component B is prepared through the steps that: methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride are subjected to a polymerization reaction with promoting agents or cationic initiators such as quaternary phosphonium salt, quaternary ammonium salts, DBU salt, and imidazole; with added phosphate antioxidant, a thermal yellowing capacity is improved. With the applications of an ultraviolet absorber and a light stabilizer, a UV yellowing resisting effect is further improved.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS +1

Protuberant hot-melt road marking coating, and preparation method and construction method thereof

ActiveCN109021830AGood formabilityImprove deformation resistanceRosin coatingsTraffic signalsHot meltRosin

The invention discloses a protuberant hot-melt road marking coating, and a preparation method and a construction method thereof, and relates to the technical field of road marking construction. The protuberant hot-melt road marking coating is mainly prepared from the following raw materials by the weight percentage: 3-8% of petroleum resin, 3-8% of rosin resin, 2-6% of polyamide resin, 0.5-1.5% ofalkyd resin, 20-50% of a reflective material, 1-10% of a pigment, 0-1.5% of an anti-sedimentation agent, and the balance a filler. The defects of poor formability, poor cohesion, poor low temperatureresistance, easy cracking when being used in winter and poor deformation resistance at high temperature of a traditional road marking coating are alleviated. The formula of the protuberant hot-melt road marking coating improves the performance of the coating through the cooperative use of petroleum resin, rosin resin, polyamide resin and alkyd resin; pigments and fillers, the reflective materialand the optional anti-sedimentation agent are added for compounding, so the product has the advantages of good performance, improved high temperature anti-compressive performance, no cracking in winter and no collapse when being pressed in summer.

Owner:河北新思维创业空间服务有限公司 +1

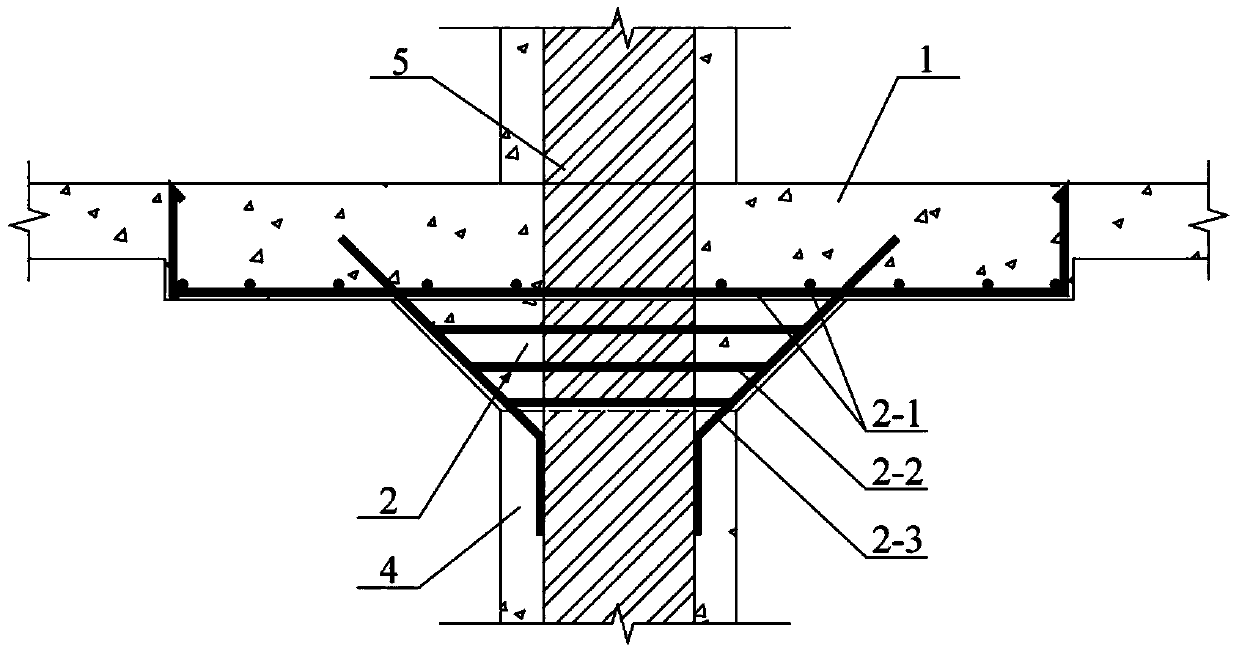

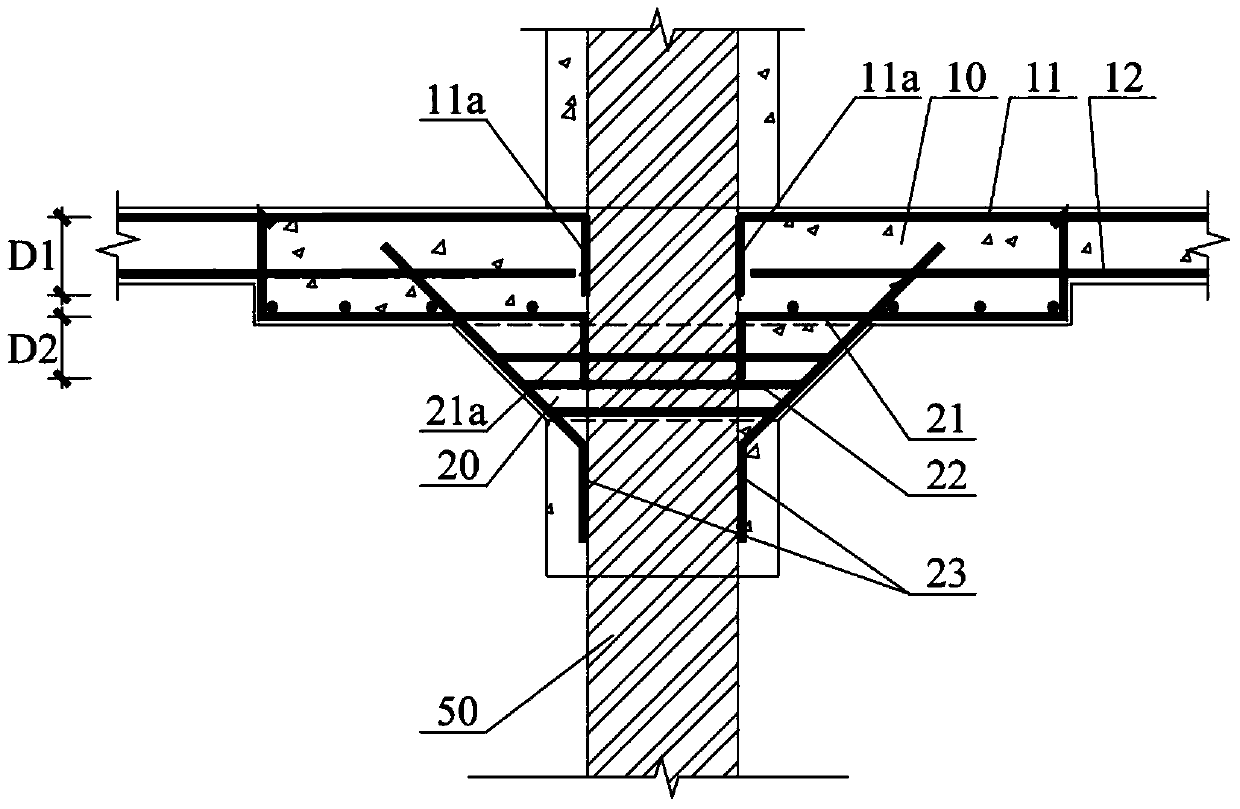

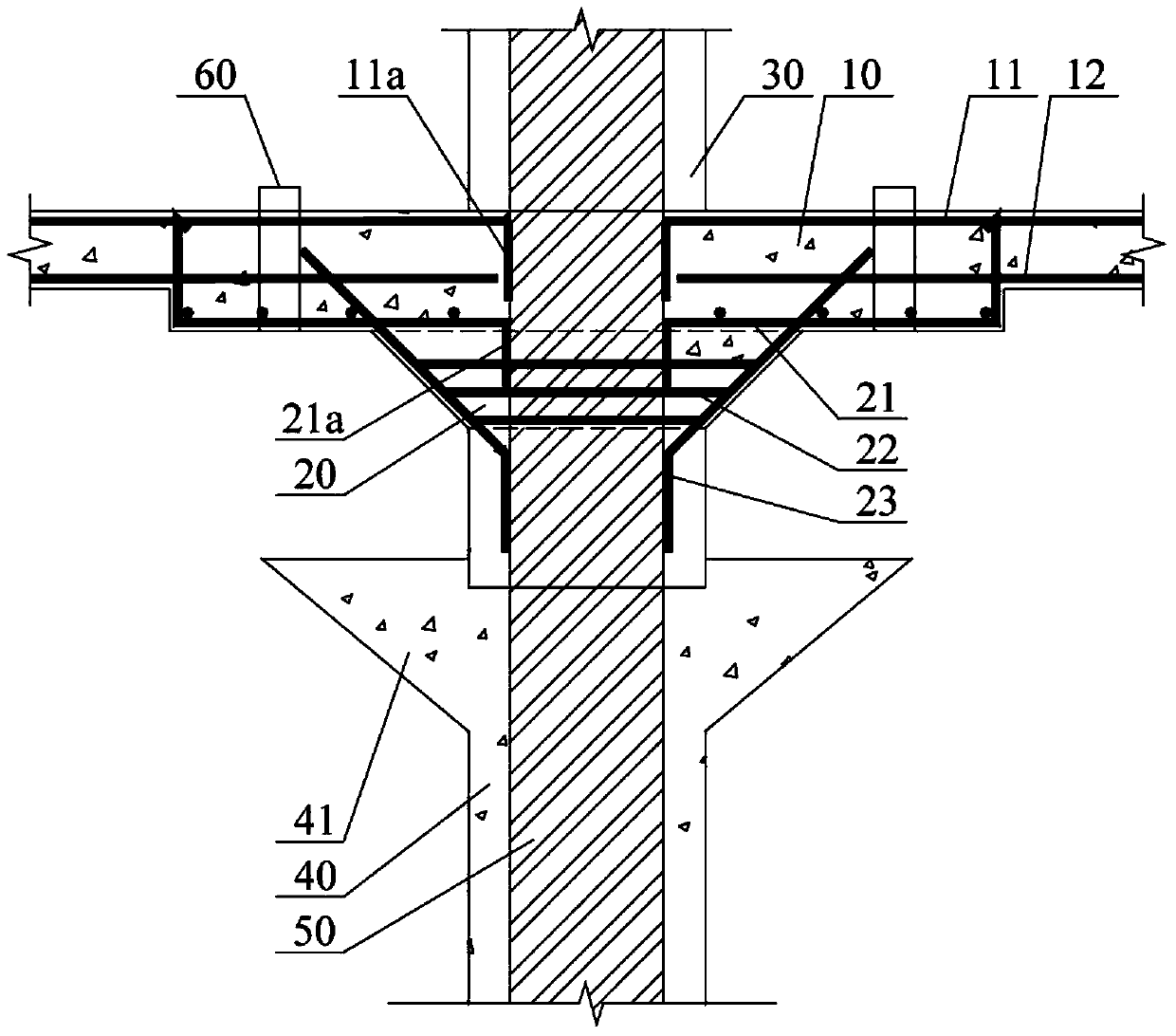

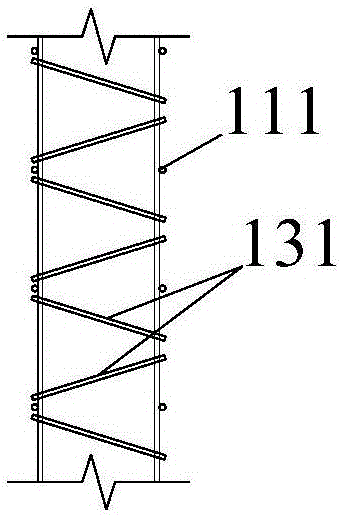

Method for constructing connection joint between flat slab and post cap in reverse construction method

ActiveCN103790379AClosely connectedImprove mechanical performanceBuilding material handlingPunchingSteel columns

The invention provides a method for constructing a connection joint between a flat slab and a post cap in a reverse construction method, and relates to the technical field of concrete supporting components. The method aims to solve the problems that in the prior art, a flat slab and a post cap are poured and constructed successively, accordingly, shrinkage cracks are prone to being formed a connection joint, bearing capacity, rigidity and punching-resistant capacity of the flat slab are reduced, reverse construction operations are extremely inconvenient and operation efficiency is reduced. The method includes the following steps that firstly, an upper-layer steel bar and a lower-layer steel bare of the flat slab to be poured and an embedded steel bar, a horizontal hoop rib and radial inclined ribs of the post cap to be poured are distributed surrounding a reserved steel column; a formwork is erected, concrete is poured, the formwork is dismantled after the concrete is hardened, and the flat slab and the post cap, which are connected into a whole, are manufactured. Through the method, the flat slab and the post cap can be poured to form a whole and are connected more tightly, the punching-resistant requirement can be met and stress performance of the connection joint is improved.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

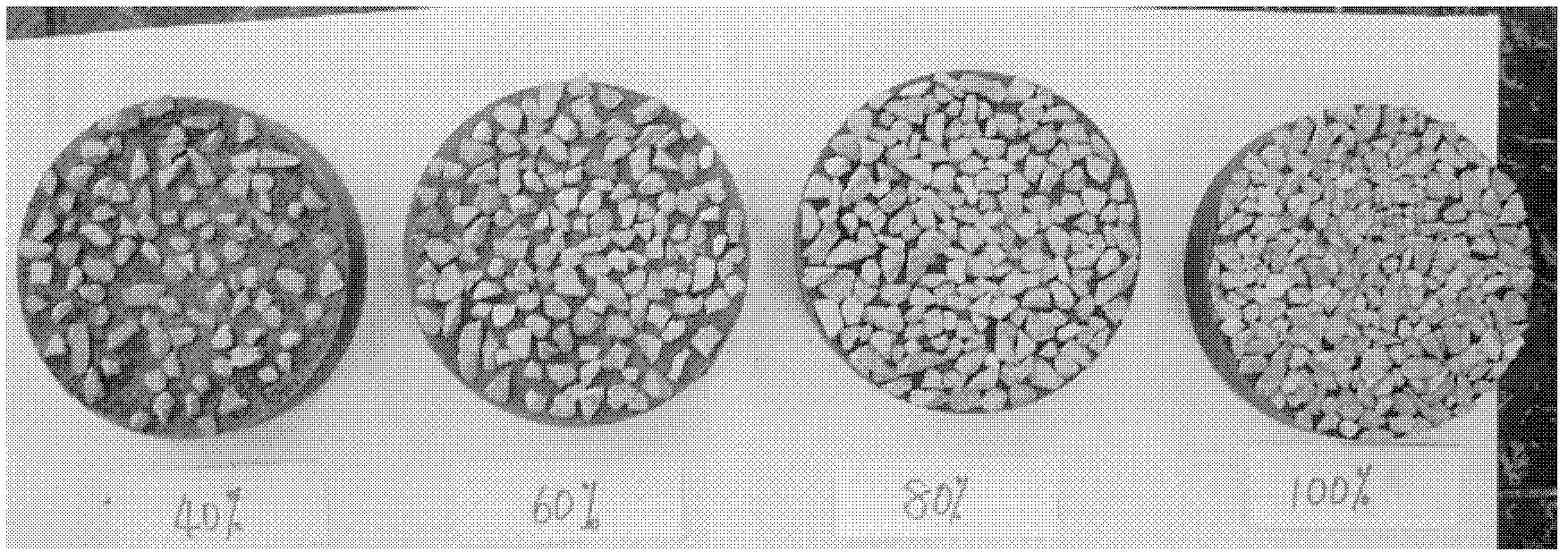

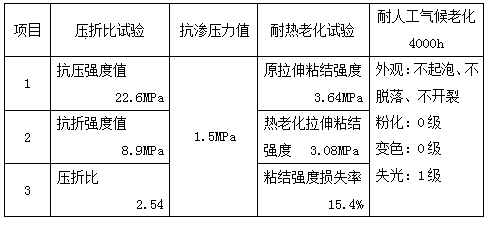

Composite waterproof adhesive layer and preparation method thereof

ActiveCN102433817AGuaranteed crack resistanceImprove crack resistanceIn situ pavingsChipsealAdhesive

The invention relates to a ''composite waterproof adhesive layer and a preparation method thereof'', and belongs to the technical field of road construction. The composite waterproof adhesive layer comprises the following three structural layers from bottom to top: a glass fiber geogrid layer, a rubber asphalt layer and a single grain diameter gravel layer; the glass fiber geogrid is formed by bidirectional warp knitting, the longitudinal and transverse tensile strength at break in each linear meter is not less than 25kN / m, and the longitudinal and transverse elongation at break is not more than 4 percent; the rubber asphalt is high-viscosity asphalt, and the spray value is 2.0 to 2.6kg / m<2>; and the grain diameter range of the single grain diameter gravel is 13.2 to 19 millimeters, the single grain diameter gravel exceeding the grain diameter range is not more than 10 percent, and the spread area is 60 to 85 percent. The composite waterproof adhesive layer has strong bonding capacity with an upper bearing layer or a lower bearing layer, can integrally improve the adhesion and the waterproof performance among pavement structure layers, and obviously improves the integral cracking resistance of the pavement structure.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

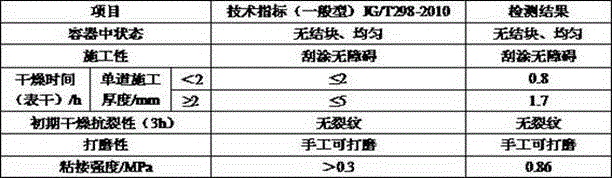

Method for preparing interior wall putty powder from semi-dry desulfurization ash

ActiveCN105949864AShort processReduce manufacturing costFilling pastesPolyvinyl alcoholMethyl cellulose

The invention discloses a method for preparing interior wall putty powder from semi-dry desulfurization ash. The method is characterized by including steps: screening the semi-dry desulfurization ash through a square-hole sieve; mixing, by weight, 80-100 parts of the semi-dry desulfurization ash, 0-20 parts of white cement or ash calcium powder, 0.8-5 parts of redispersible latex powder, 0-0.2 part of polyvinyl alcohol, 0.3-0.35 part of hydroxypropyl methyl cellulose ether and 0.02-0.05 part of starch ether, and stirring for 5-10min. The semi-dry desulfurization ash can be used as a raw material of the interior wall putty powder only by screening treatment without calcining, drying and grinding, and accordingly procedure simplicity, easiness in operation, low energy consumption and effectiveness in control of production cost are realized. In addition, with a small amount of inorganic cementing material or without the same, the semi-dry desulfurization ash is taken as filler with a small amount of additives to prepare the interior wall putty powder, so that the semi-dry desulfurization ash can be used effectively and substantially to realize recycling of the semi-dry desulfurization ash.

Owner:西昌市蓝鼎环保科技有限公司 +1

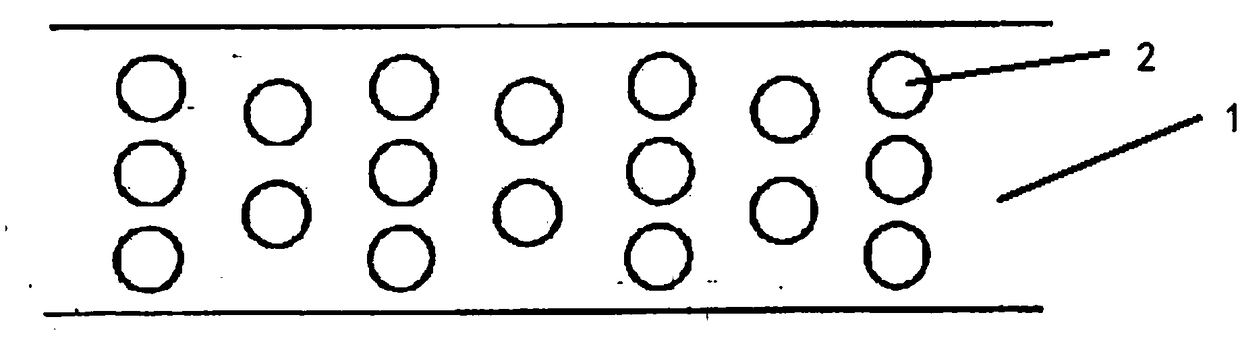

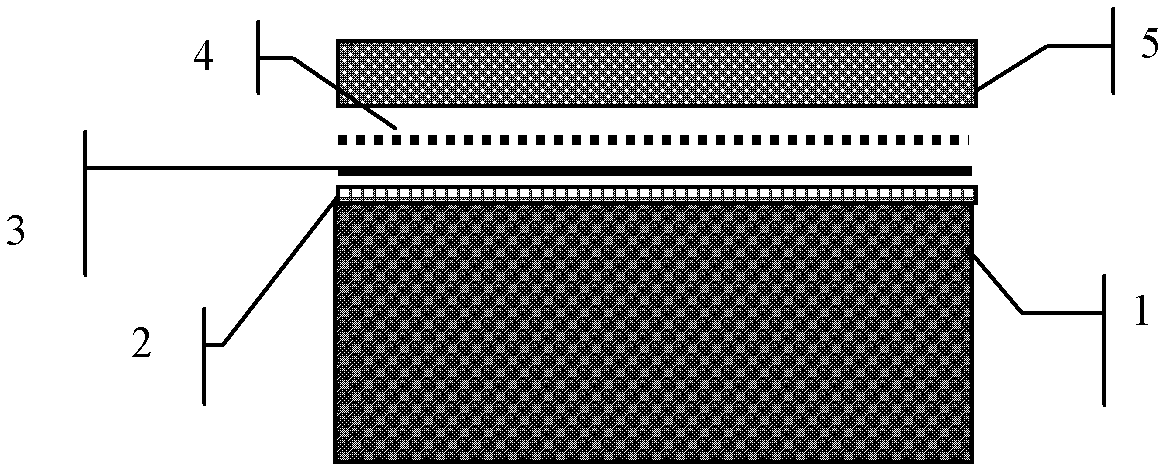

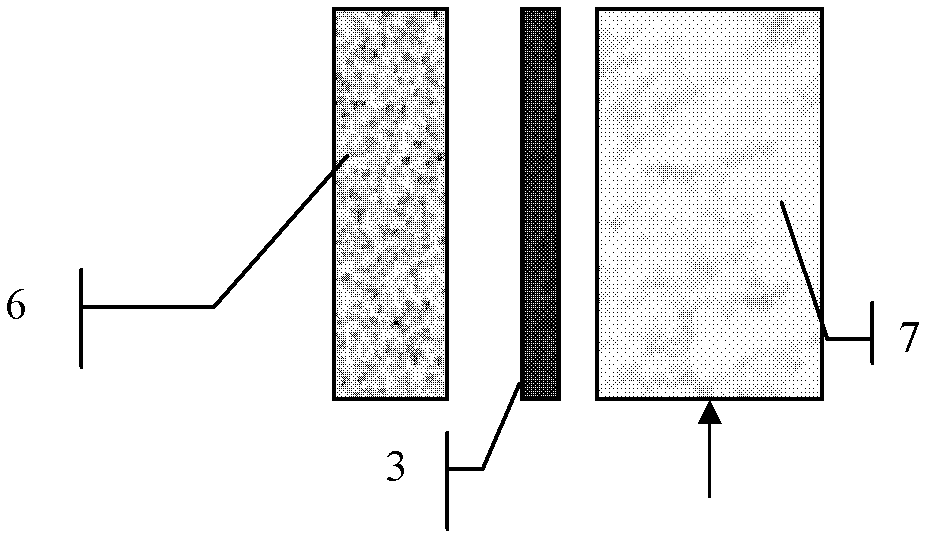

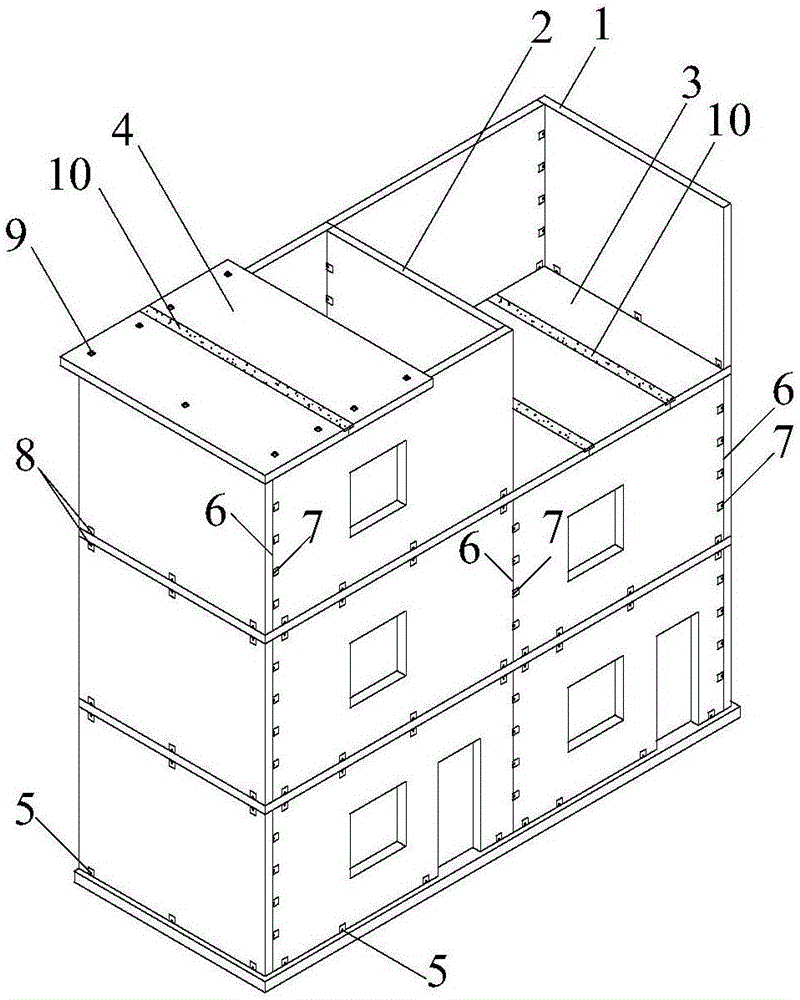

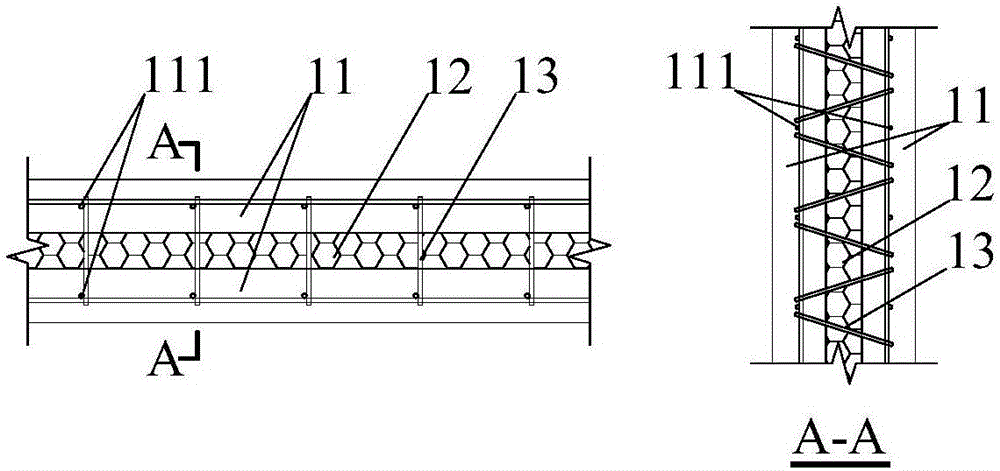

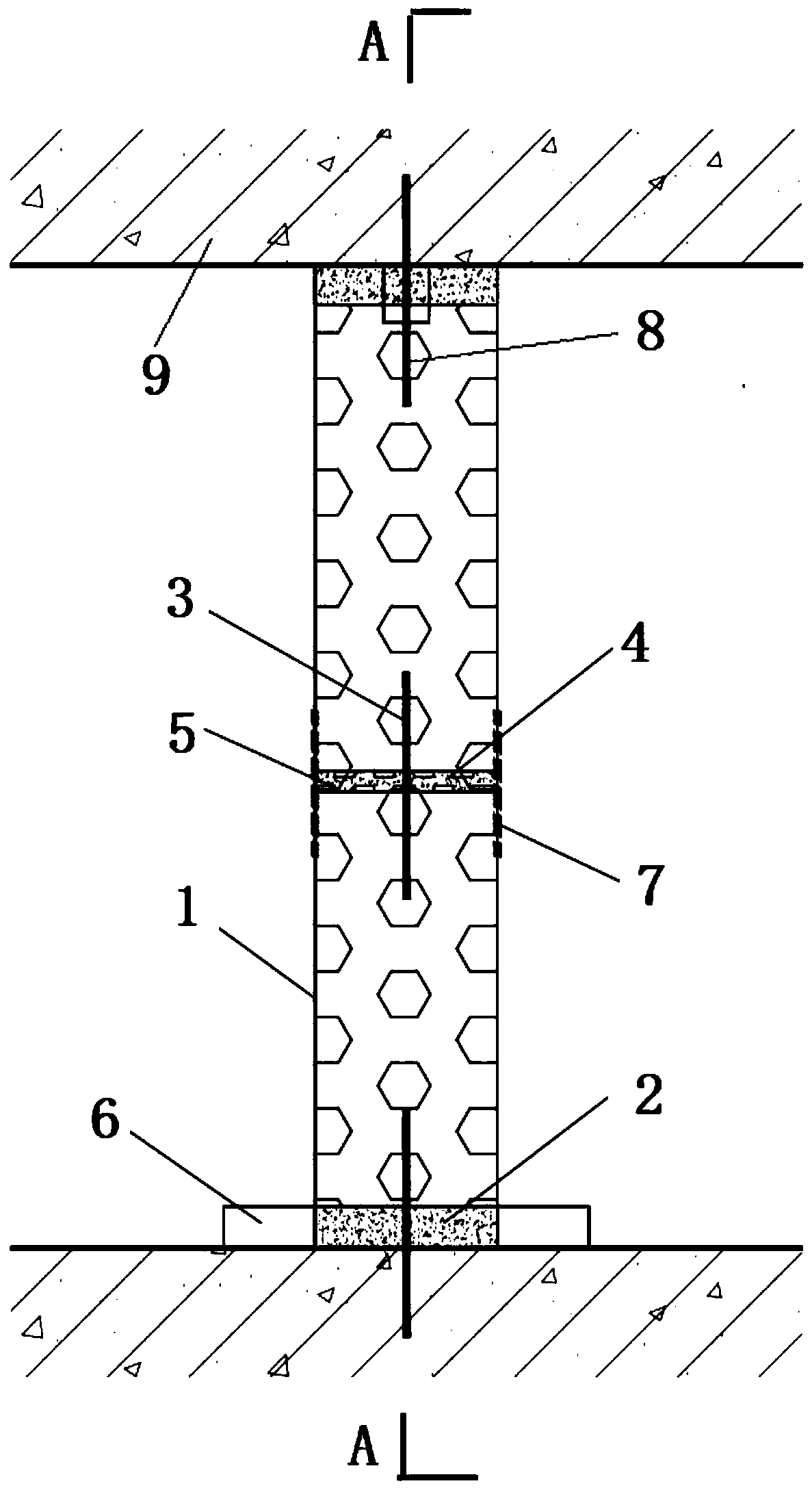

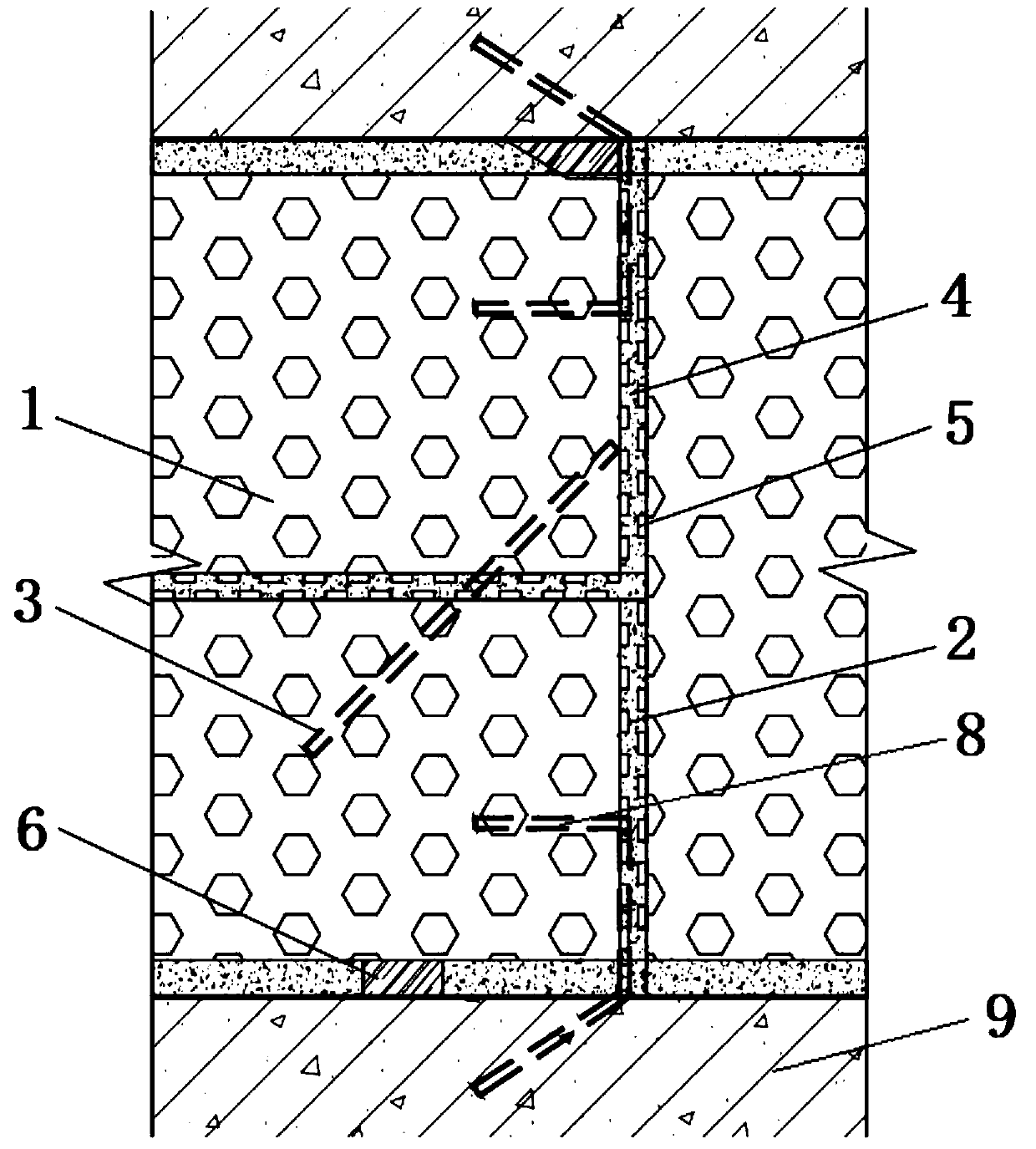

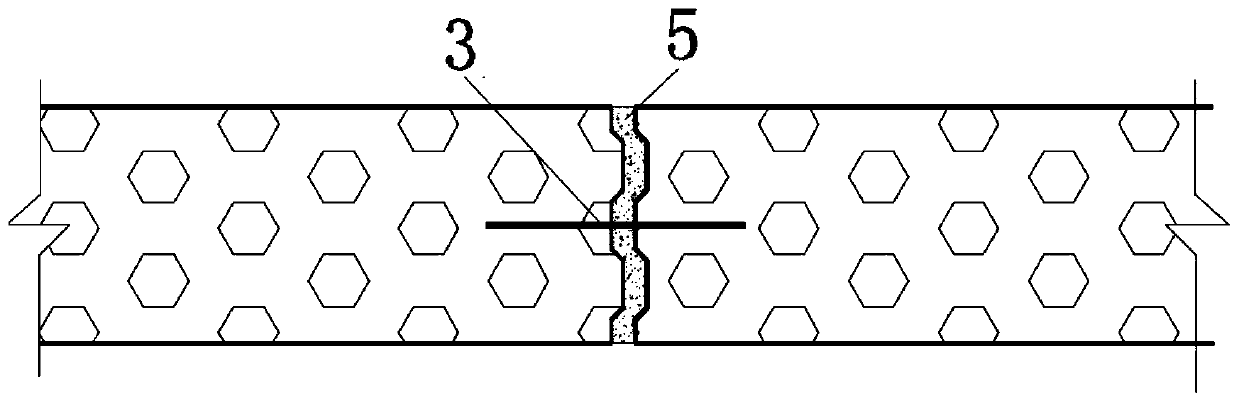

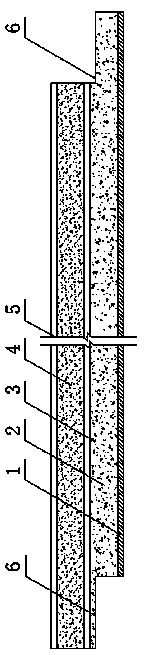

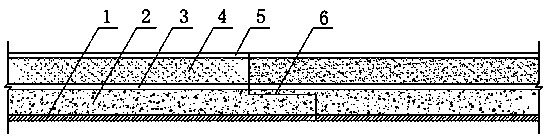

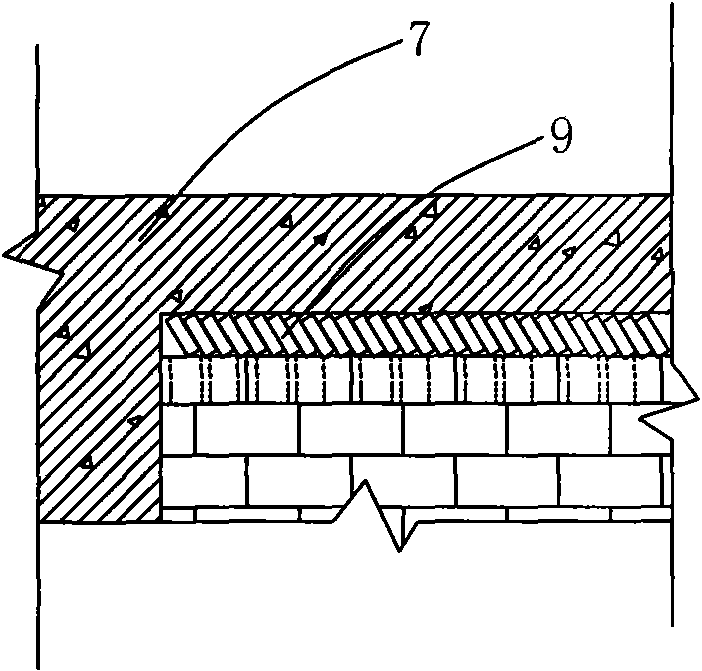

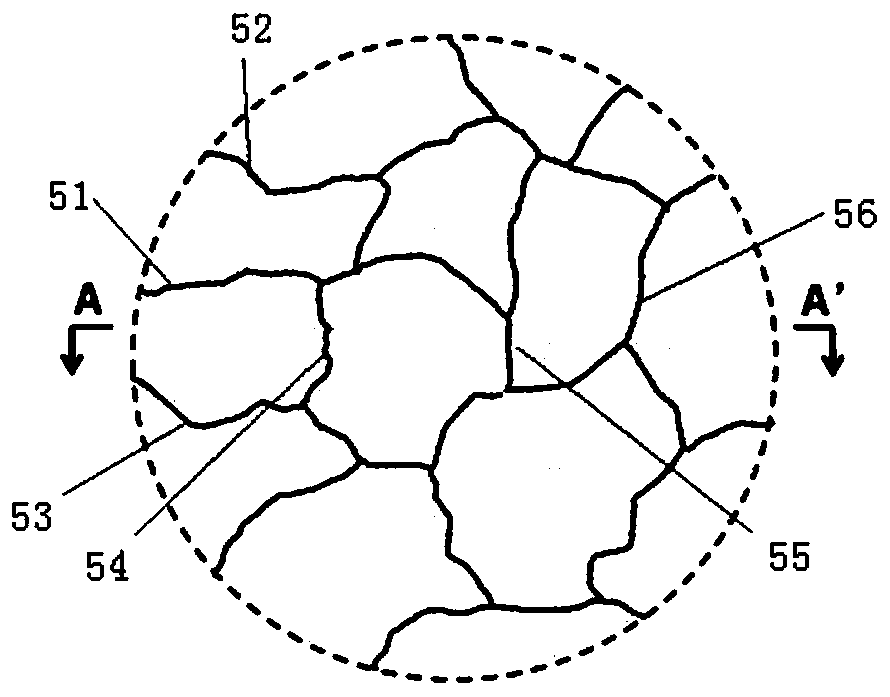

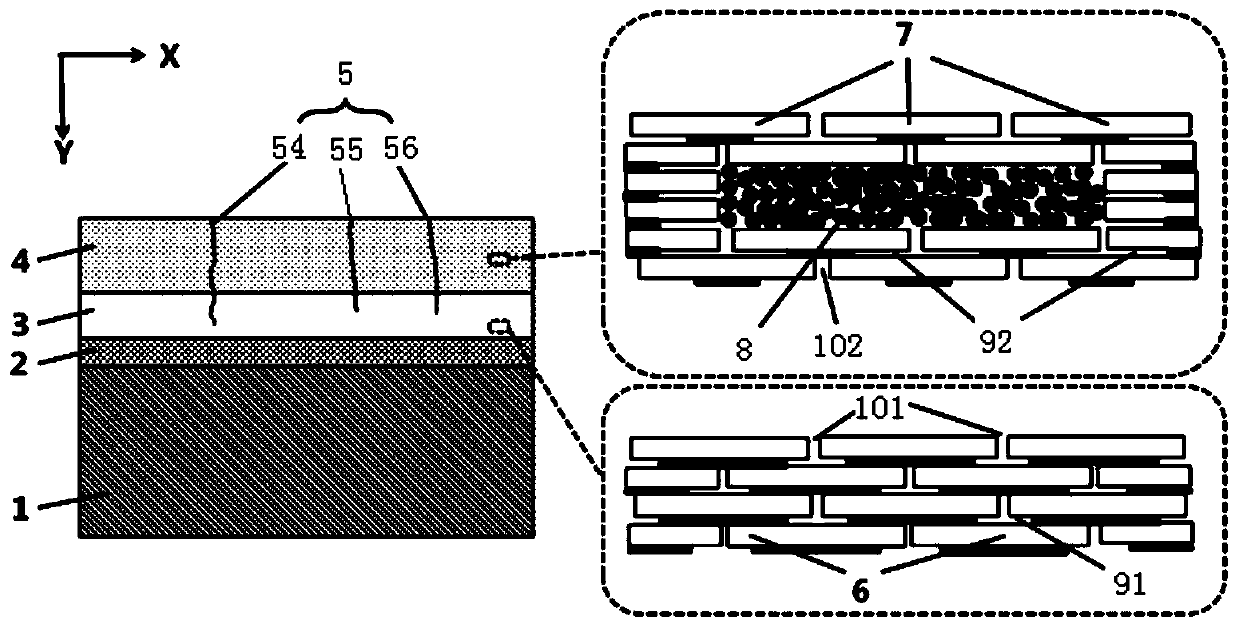

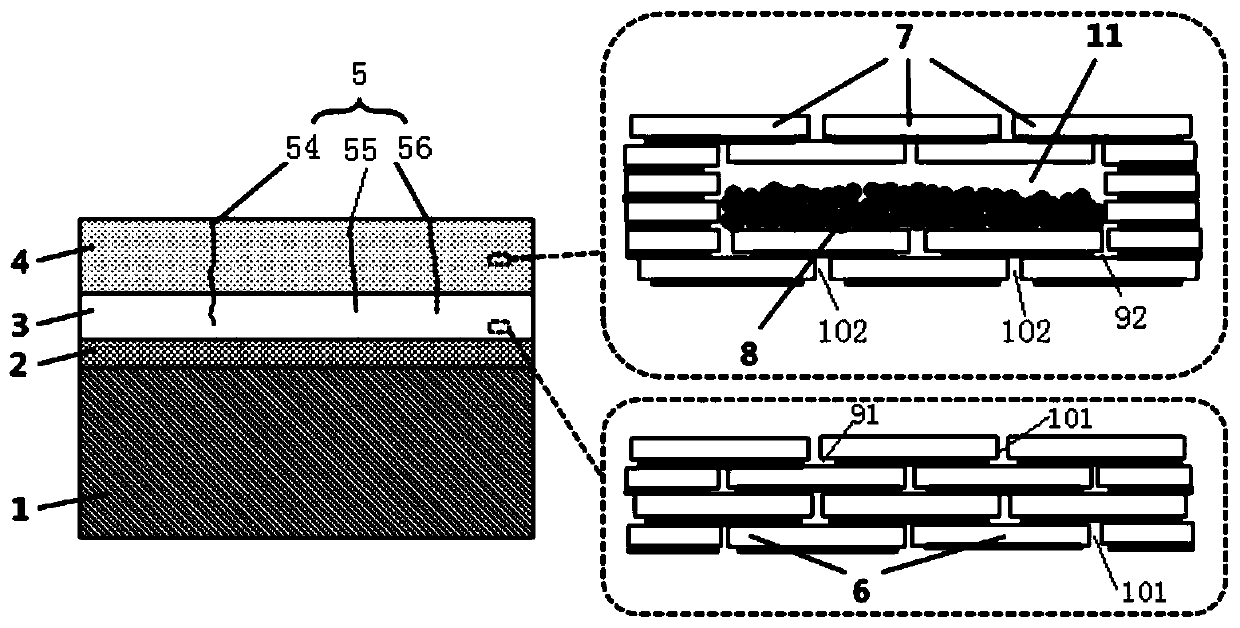

Lower multi-layer assembly type heat insulation and energy saving building

PendingCN106836468AReduce waste and other issuesAvoid Bricklaying and Plastering JobsRoof covering using slabs/sheetsBuilding componentsInsulation layerSandwich board

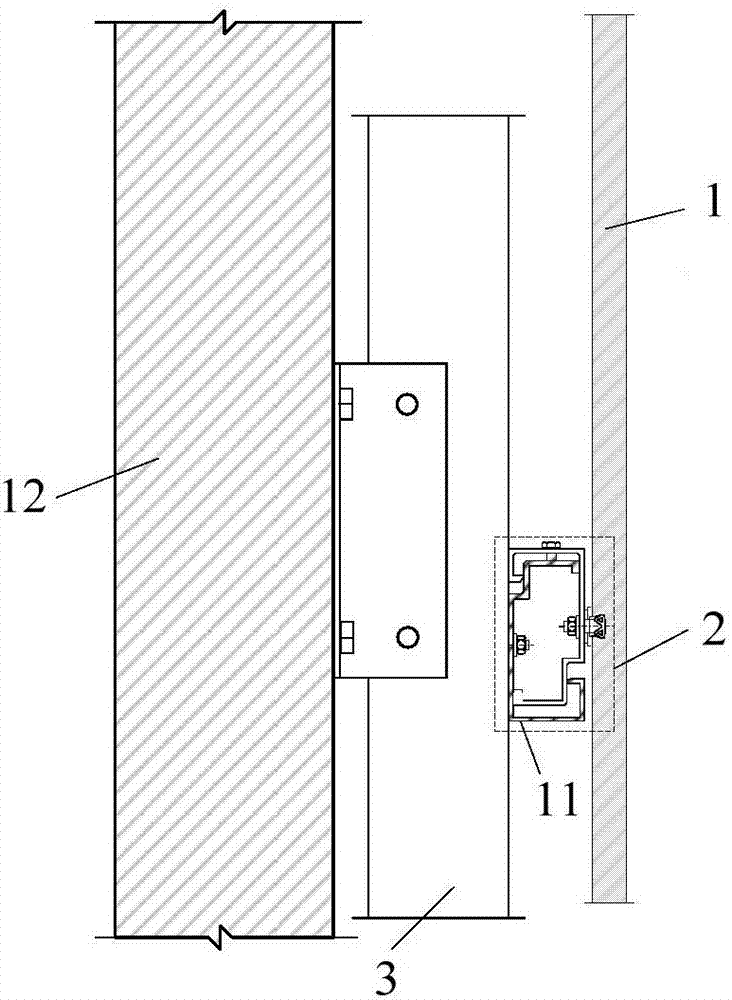

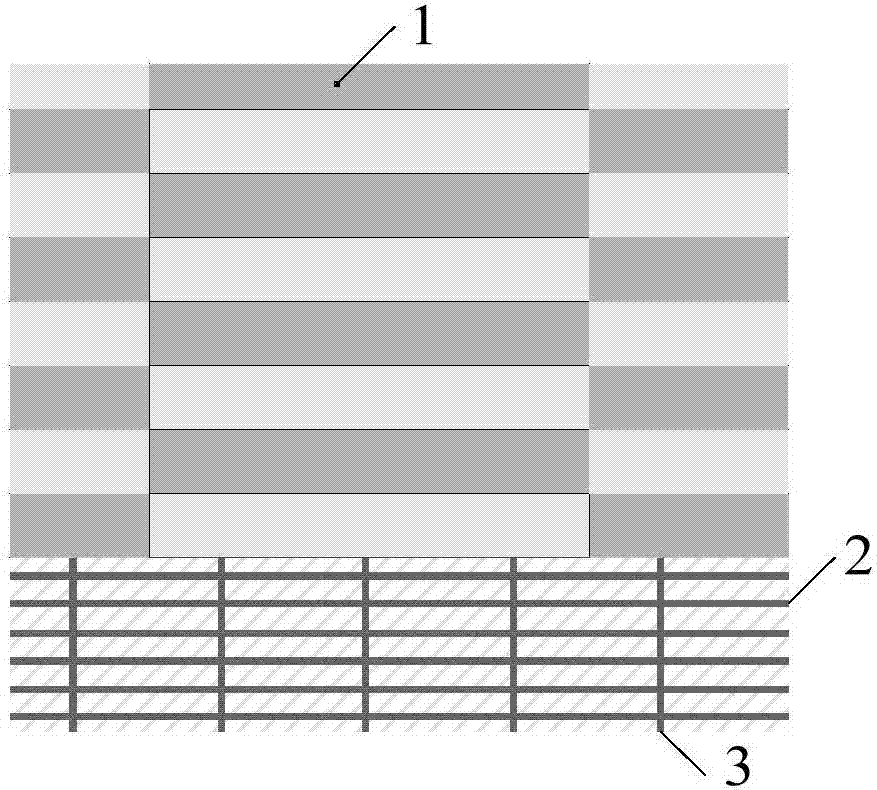

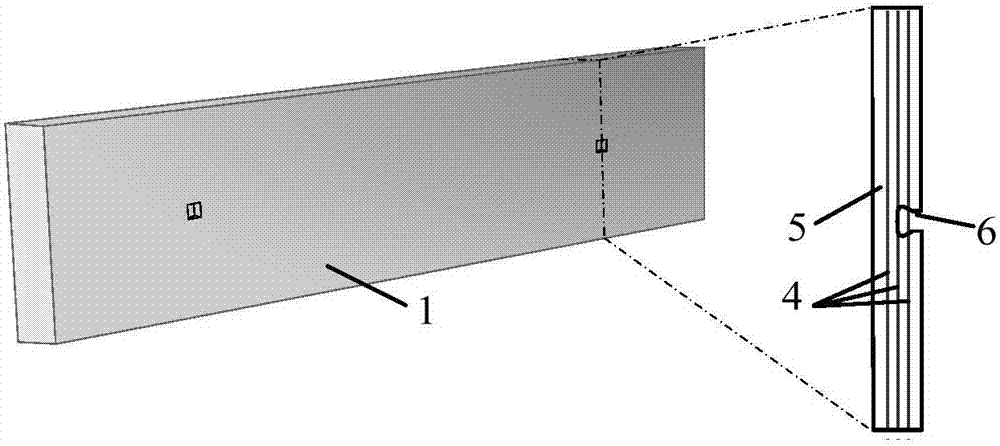

The invention provides a lower multi-layer assembly type heat insulation and energy saving building which comprises a wall body, a floor and a roof. The wall body, the floor and the roof adopt amode of prefabricated slabswhich comprise prefabricated outer wallboards (1), prefabricated inner wallboards (2), prefabricated floor boards (3) and prefabricated roof boards (4), and comprise prefabricated sandwich boards with heat insulation layers; the prefabricated wallboards and a foundation are connected through vertical connection devices (5) evenly arranged at the bottoms of the prefabricated wallboards; the adjacent prefabricated wallboards are connected through joints (6); the joints (6) are evenly provided with horizontal connection devices (7) in the height direction; the upper and lower layers of prefabricated wallboards and the prefabricated floor boards (3) are connected through a plurality of vertical connection devices (8); the prefabricated wallboards and the prefabricated roof boards (4) are connected through vertical connection devices (9) evenly arranged at the tops of the prefabricated wallboards; and the adjacent prefabricated floor boards (3) or the adjacent prefabricated roof boards (4) are connected through joints (10). The building achieves integrated organic combination of whole assembling of a main body structure and a heat insulation structure, so that the field construction speed is high, and the heat insulation and energy saving effects are good.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

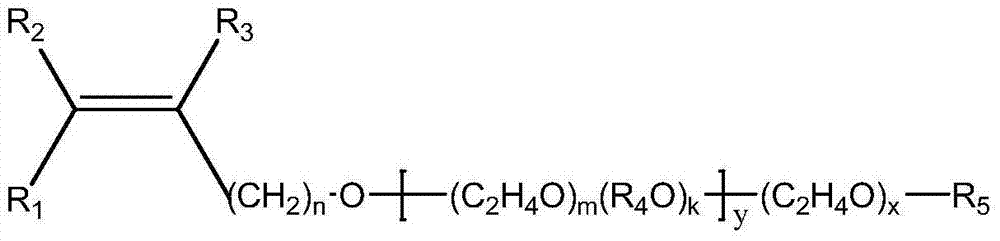

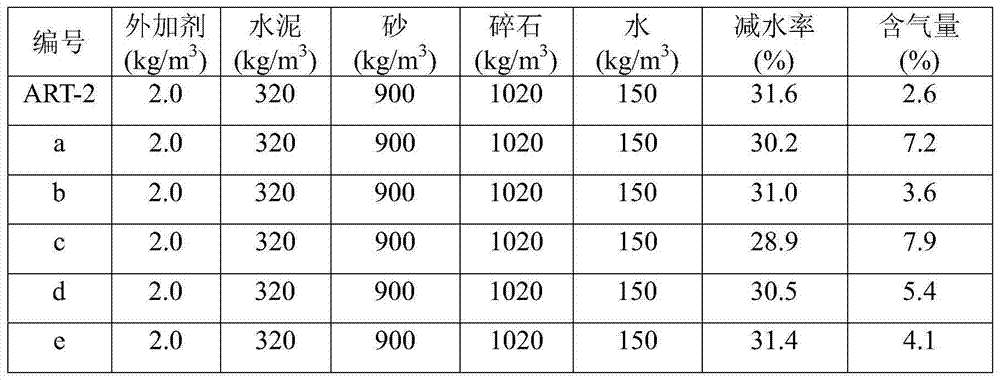

Block polyether, air entrained type polycarboxylate water reducing agent prepared by block polyether and preparation method thereof

The present invention provides a block polyether, an air entrained type polycarboxylate water reducing agent prepared by the block polyether and a preparation method thereof, the air entrained type polycarboxylate water reducing agent not only has excellent work performance, also has the function of improving the air content in concrete, can not only avoid the a series of compatibility problems caused by compounding with an initiator, also can replace a calcium lignosulphonate water reducer and can ensure the concrete strength and anti cracking performance. In addition, due to the polyether special block structure, the air entrained type polycarboxylate water reducing agent has surface activity different from that of unsaturated polyglycol ether, and can be soluble in an aqueous solution so as to avoid the occurrence of delamination and other situations.

Owner:LIAONING OXIRANCHEM INC

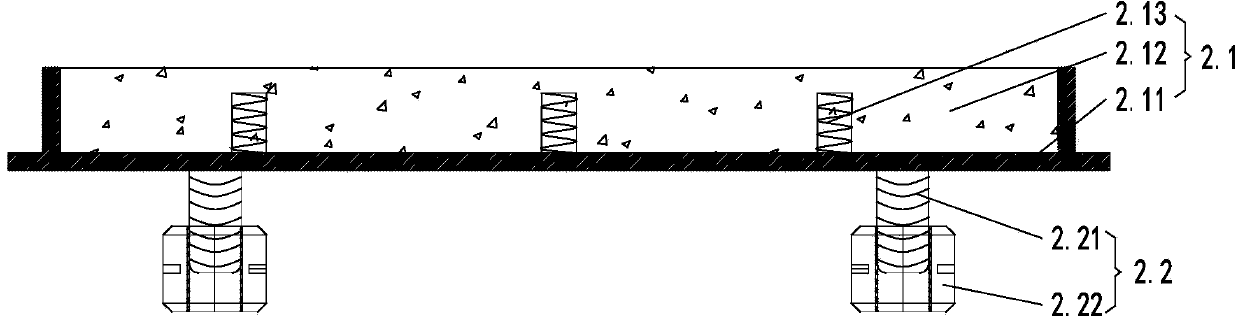

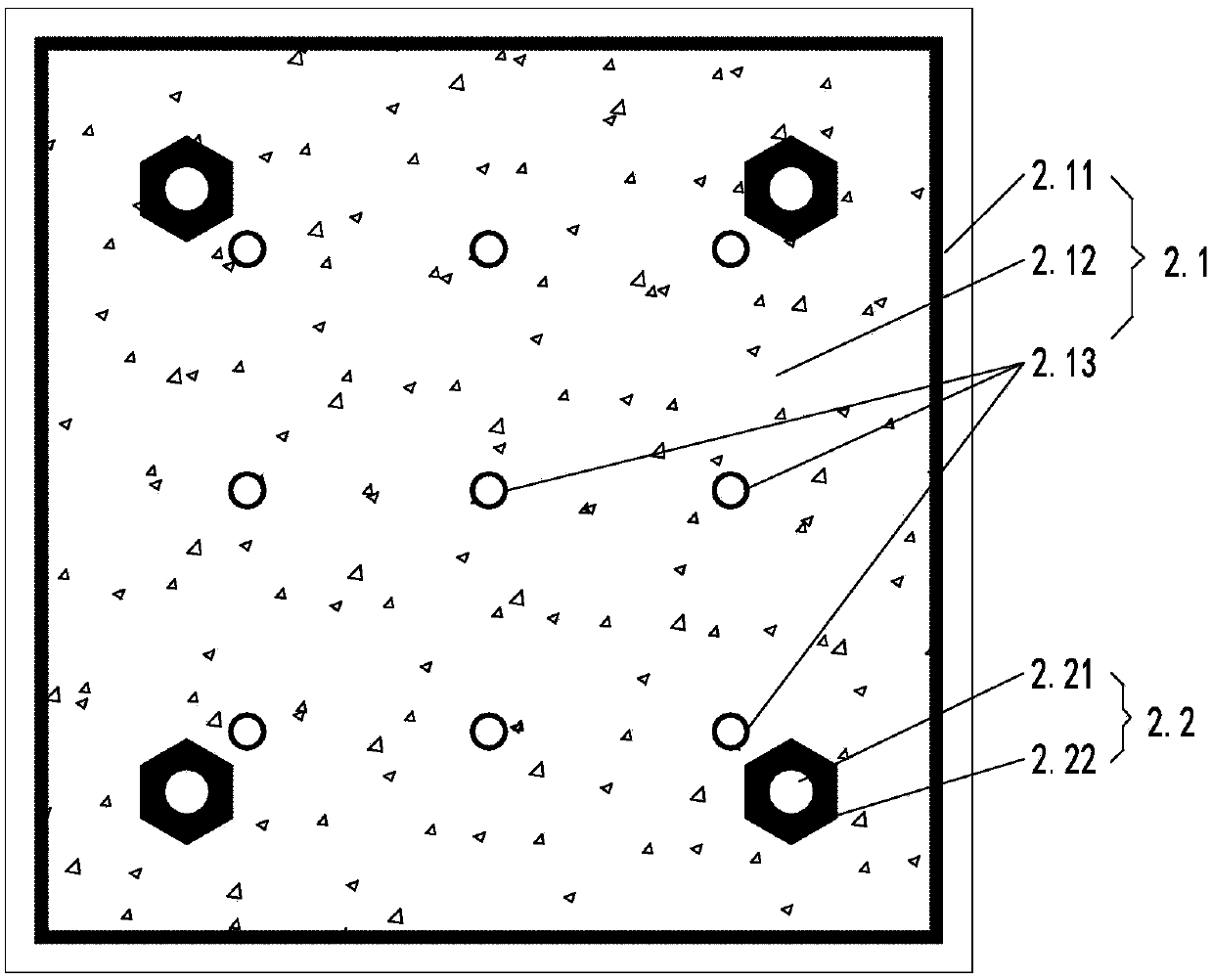

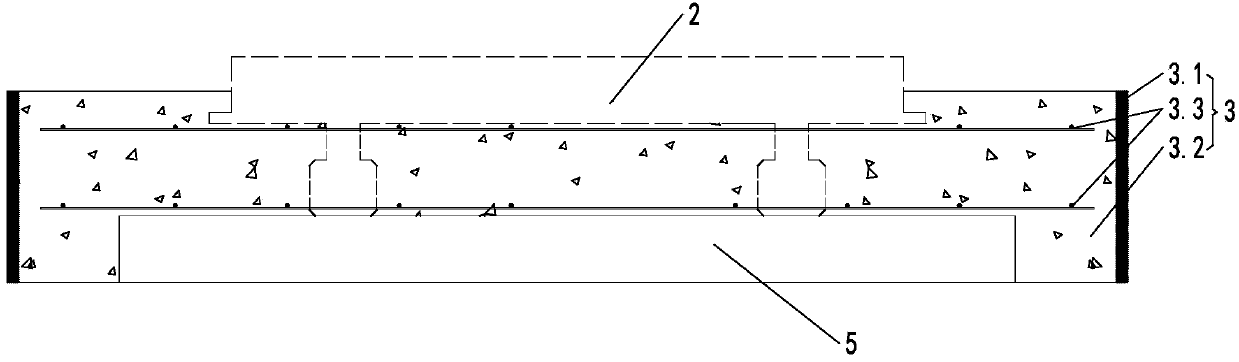

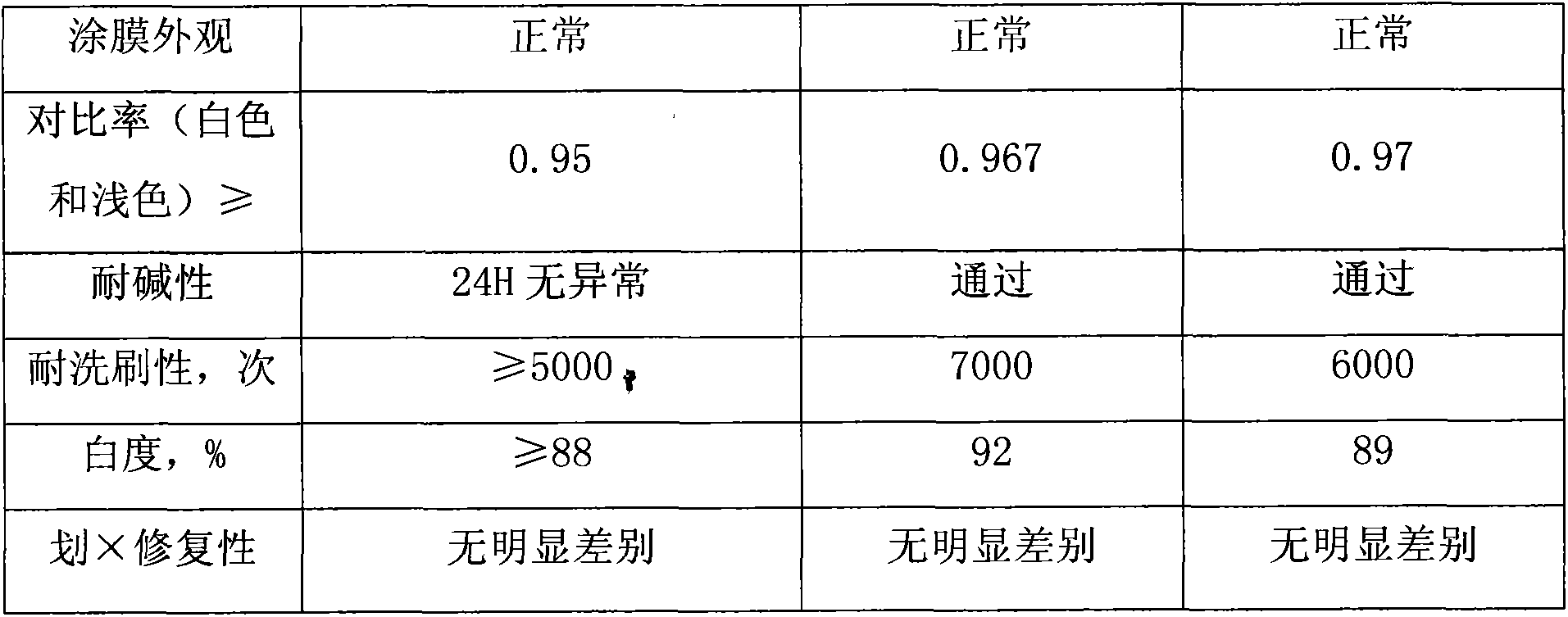

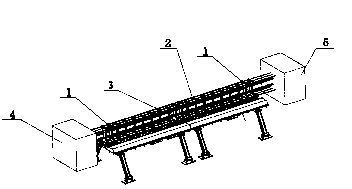

Simply-supported slab bridge jack-up method and height-adjustable combined cushion structure applied therein

ActiveCN103726450AImprove applicabilityImprove construction accuracyBridge erection/assemblyBridge strengtheningOperabilityRisk stroke

The invention discloses a simply-supported slab bridge jack-up method and a height-adjustable combined cushion structure applied therein. The simply-supported bridge jack-up method includes: firstly, setting up distributive girders under a girder, arranging jacks and putting up temporary supports, and then entirely synchronously jacking up a simply-supported slab to the height 1-3mm higher than design elevation; preliminarily supporting the bridge by the aid of the height-adjustable combined cushion structure and supports prior to performing zero-clearance girder falling to the designed elevation, and then demounting the jacks and the temporary supports. The height-adjustable combined cushion structure comprises a precast portion composed of precast supports and a height-adjustment combined mechanism capable of adjusting the height of the precast supports and a cast-in-situ portion coating a height-adjustable mechanism and part of the precast supports. The simply-supported slab bridge jack-up method and the height-adjustable combined cushion structure applied therein have the advantages of high applicability, controllable security, high construction precision, high operability, high economical efficiency, good application prospect and the like, thereby being capable of being used in support replacement projects of expressways and the bridges of urban roads and especially applicable to jack-up engineering when jack-up height of a sole-across simply-supported girder (slab) is larger than the stroke of one jack.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Low magnetic permeability stainless electrode and preparation method thereof

ActiveCN101386114AEasy to promote and useGuaranteed crack resistanceWelding/cutting media/materialsSoldering mediaMetallic NickelQuartz

The invention discloses a stainless steel welding electrode with low magnetic permeability and a preparation method thereof. The welding electrode of the invention is composed of an H06Cr21Ni10 welding core and a coating. The coating comprises components according to the following weight percentages: 45 percent to 53 percent of TiO2, 10 percent to 13 percent of CaCO3, 10 percent to 13 percent of CaF2, 0.6 percent to 1 percent of alkali powder , 5 percent to 7 percent of quartz, 2 percent to 3 percent of talc, 6 percent to 8 percent of chromium metal, 7.5 percent to 8.5 percent of manganese metal, 2.8 percent to 3.6 percent of metallic nickel and 1 percent to 2 percent of Cr2O3. The weld metal of the welding electrode of the invention has low magnetic permeability, meets the required mechanical properties and can be used for welding stainless steel structures of 1Cr18Ni9Ti and 0Cr18Ni9 with low magnetic permeability. The price of the welding electrode is considerably lower than that of the existing stainless steel welding electrode E310-16 with low magnetic permeability. The welding electrode of the invention has welding technological properties and mechanical properties of weld metal which are similar to the existing E308-16 stainless steel welding electrode, thereby being convenient for wide application.

Owner:TIANJIN BRIDGE WELDING MATERIALS GROUP

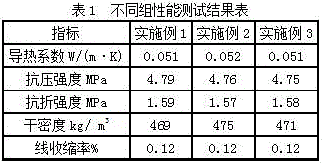

Novel energy-saving thermal insulation mortar and preparation method thereof

The invention relates to novel energy-saving thermal insulation mortar, which is prepared from the following components in parts by weight: 45 to 53 parts of ordinary Portland cement, 8 to 10 parts of wollastonite, 6 to 8 parts of vermiculite power, 12 to 15 parts of ceramic polished waste residue, 15 to 18 parts of vitrified light hollow microsphere, 8 to 10 parts of fly ash hollow cenosphere, 4 to 6 parts of alumina bubble, 2 to 3 parts of lignin fibre, 2 to 3 parts of polyvinyl alcohol fibre, 1 to 1.5 parts of sucrose fatty acid ester, 4 to 5 parts of hydroxypropyl guar gum, 1 to 1.5 parts of sodium dehydroacetate, 2 to 3 parts of strontium carbonate and 3 to 4 parts of poly carboxylic acid water reducing agent. The novel energy-saving thermal insulation mortar disclosed by the invention is prepared by adopting a special formula and an optimized proportion; waste, such as the ceramic polished waste residues, is utilized, and an excellent comprehensive performance index is achieved; the novel energy-saving thermal insulation mortar is ensured to have an unexpected thermal insulation effect and a crack resistance effect, and is very suitable for various building thermal insulation projects with high requirements.

Owner:东莞市鑫燕建筑节能材料有限公司

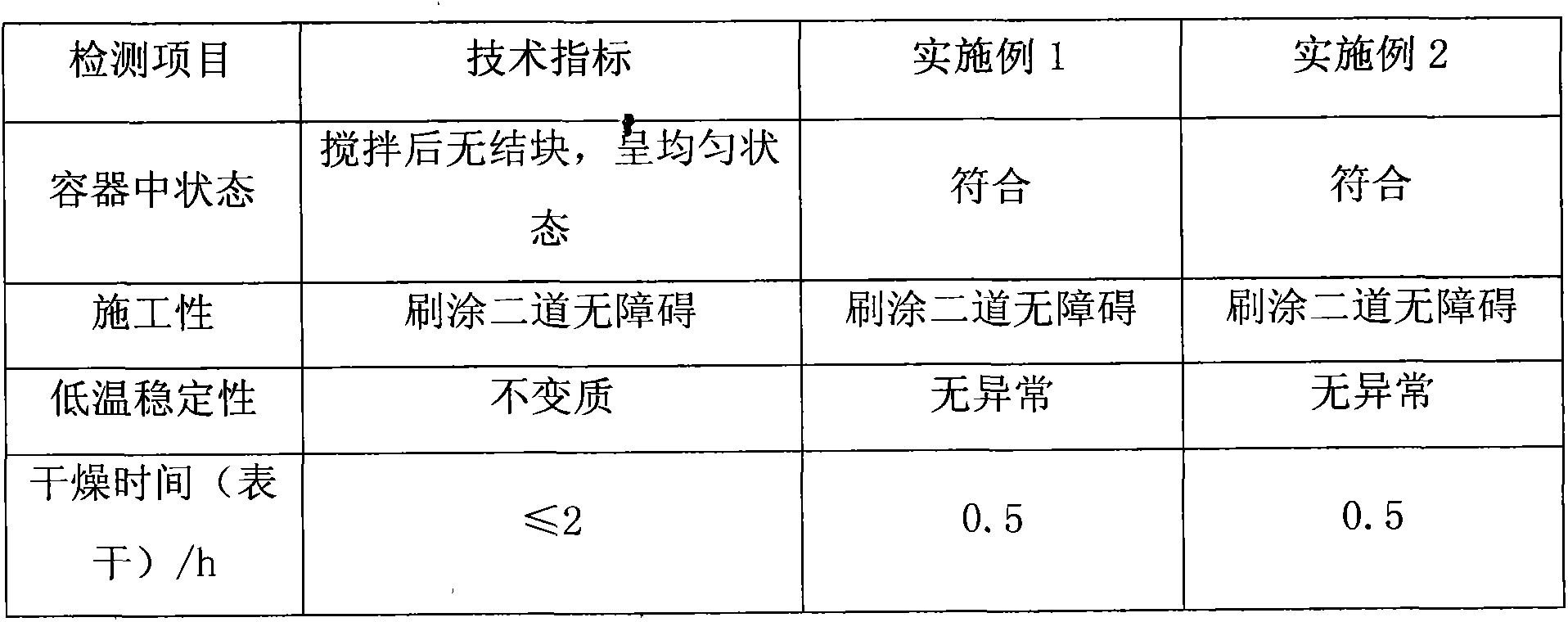

Home decoration coating and preparation method thereof

InactiveCN103725122AGuaranteed low temperature film formationGuaranteed low temperature repairabilityCoatingsCrack resistanceDefoaming Agents

The invention discloses a home decoration coating and a preparation method thereof, relating to the field of coatings. The invention provides the home decoration coating comprising the following components in parts by weight: 250-300 parts of VAE (vinyl acetate-ethylene) emulsion, 200-220 parts of titanium dioxide, 70-100 parts of kaolin, 80-120 parts of ground calcium carbonate, 300-350 parts of water, 1-5 parts of a surfactant, 5-6 parts of a dispersant, 1-3 parts of a pH regulator, 2-5 parts of a defoaming agent, 2-4 parts of a preservative and 5-10 parts of a thickening agent. The home decoration coating adopts the VAE emulsion to ensure that the low-temperature film forming property and low-temperature repairing property of film coating, cracking resistance, scrub resistance and self film-forming capacity of the coating are ensured, and a film forming auxiliary agent is not added, so that the VOC (volatile organic compound) content of the coating is reduced.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Method for producing H-shaped support piles

The invention provides a method for producing H-shaped support piles which are low in cost, bending resistant, shearing resistant and high in intensity. The technical scheme includes that the method specifically includes: (1) placing stop plates on the baseplate of an H-shaped support pile die or at two ends of the baseplate, serially connecting the stop plates on prestressed steel via holes on the stop plates, serially connecting a plurality of stirrups on the prestressed steel, connecting one end of the prestressed steel on a first tensioning device, and connecting the other end of the prestressed steel on a second tensioning device; and (2) adjusting distributing distance of the stop plates and the stirrups, closing the H-shaped support pile die to tension the prestressed steel, and the like.

Owner:俞晓东 +2

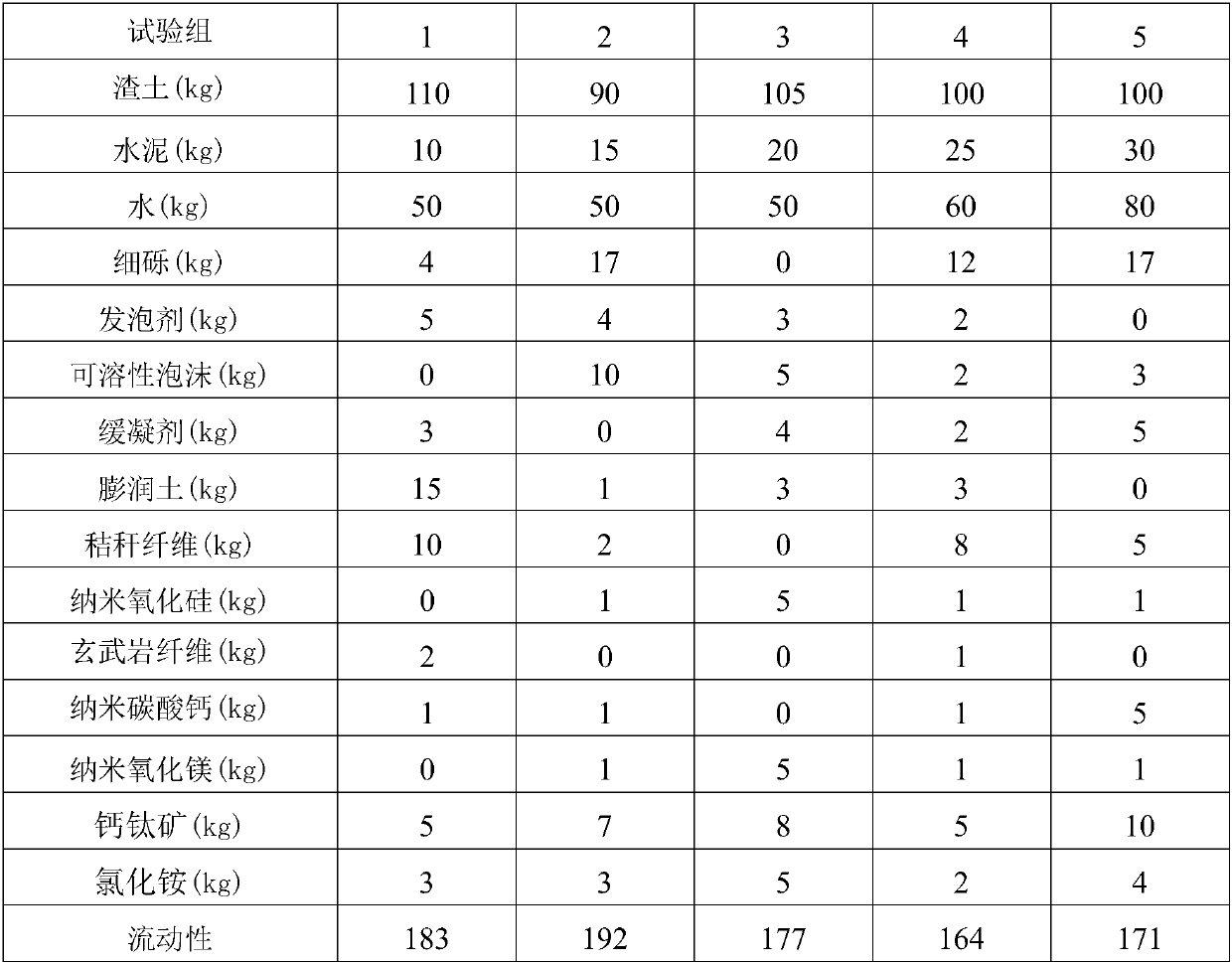

Fluidized roadbed soil and construction method

The invention discloses fluidized roadbed soil and a construction method. The fluidized roadbed soil comprises the following raw materials, in parts by weight: 90-110 parts of residue soil, 10-30 parts of cement, 50-80 parts of water, 0-20 parts of fine gravel, 0-5 parts of a foaming agent, 0-10 parts of soluble foam particles, 0-5 parts of a retarder, 0-15 parts of bentonite, 0-10 parts of straw fibers, 0-5 parts of nano silicon oxide, 0-2 parts of basalt fibers, 0-5 parts of nano calcium carbonate, 0-5 parts of nano magnesium oxide, 5-10 parts of perovskite, and 2-5 parts of ammonium chloride. The fluidized roadbed soil is obtained by the steps of mixing the above raw materials, performing sieving, performing mud scattering and the like. The fluidized roadbed soil provided by the invention has the following advantages: the fluidized roadbed soil has a wide application range: the fluidized roadbed soil is in a flowing state and has no special requirements for formation flatness; the fluidized roadbed soil has good water permeability: the fluidized roadbed soil has good water permeability, the water permeability coefficient can reach 12 m / s<-4>, and a water body can be dispersed more quickly; the fluidized roadbed soil has high strength: the unconfined compressive strength under fluidity of 185 reaches 362 kPa; and the fluidized roadbed soil is convenient for construction and has high economic benefits.

Owner:JIANGSU UNIV OF SCI & TECH

Fabricated light-weight interior partition wall joint structure and construction method thereof

The invention relates to the technical field of construction engineering, and discloses a fabricated light-weight interior partition wall joint structure and a construction method thereof. The fabricated light-weight interior partition wall joint structure comprises a concrete floor or beam and two or more light-weight interior partition wall precast slabs, fiber cement wedge plugs are embedded between the concrete floor or beam and the light-weight interior partition wall precast slabs, and meanwhile, '7'-shaped anchoring steel bars are implanted between the concrete floor or beam and the light-weight interior partition wall precast slabs. According to the fabricated light-weight interior partition wall joint structure, the construction methods of a light-weight interior partition wall construction column, a ring beam and the like are canceled, an interior partition wall precast slab joint, an interior partition wall rabbet, a wall body driving anchoring steel bar and nailing alkali resistant and crack resistant grid cloth, the overall stability and crack resistance of an interior partition wall body are effectively ensured, the construction quality problem of the expansion crackat the joints between the inner partition wall and the concrete structure, and between the wall and the wall is avoided, the whole assembly process is simple, operation is convenient, the constructionperiod is shortened, and the cost is low.

Owner:CCFED THE FIRST CONSTR & ENG

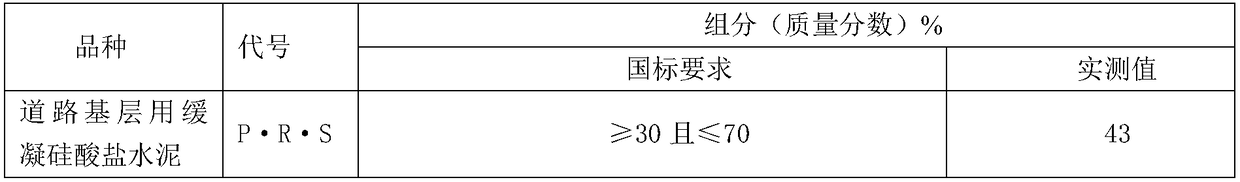

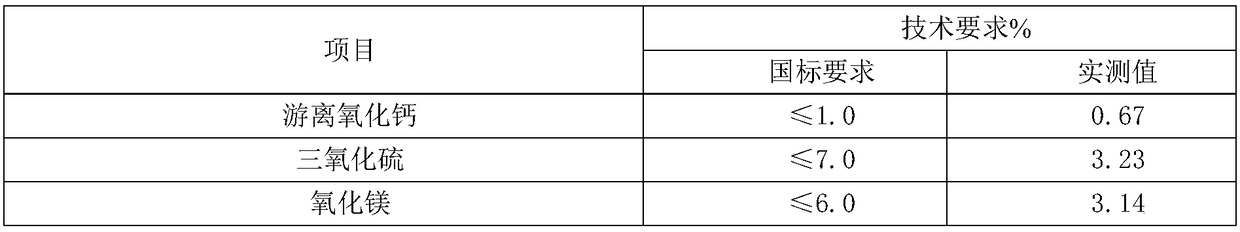

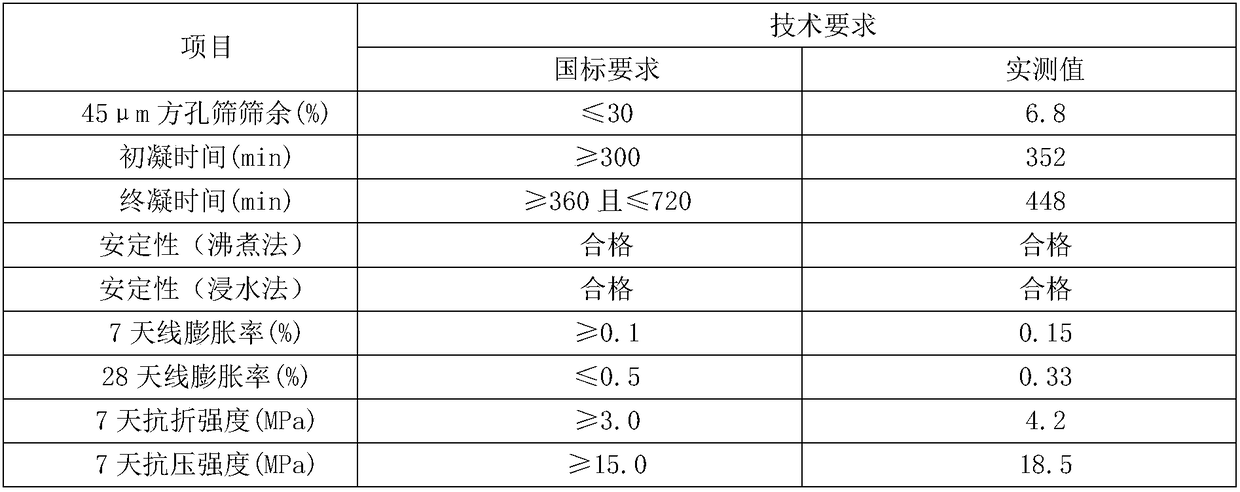

Delayed coagulation Portland cement for road base layer and production method

InactiveCN109503006AGuaranteed frost resistanceGuaranteed crack resistanceCement productionCrack resistanceSlag

The invention discloses delayed coagulation Portland cement for a road base layer and a production method. The delayed coagulation Portland cement comprises the following raw materials in percentage by mass: 50% of clinker, 7% of flue gas desulfurization gypsum, 7% of limestone, 6% of slag, 30% of coal ash and 0.8% of grinding aids. The production method comprises the following steps: crushing theclinker, the flue gas desulfurization gypsum, the limestone, the slag and the coal ash, pre-homogenizing, carrying powder grinding, and making a crude material by using a conventional method; preheating and partially decomposing the crude material by using a cycle preheater; sintering in a cement rotary furnace so as to obtain clinker, further rapidly decomposing carbonate in the rotary furnace,and carrying out a series of solid phase reactions; putting the cement clinker and the grinding aids into a ball mill, and finally milling the cement clinker into appropriate granularities by using the ball mill. By adopting the delayed coagulation Portland cement for the road base layer, multiple use function property requirements such as freezing resistance, cracking resistance, permeation resistance, impact resistance, wearing resistance and erosion resistance of the cement can be ensured, resources can be comprehensively utilized, and remarkable social benefits can be made.

Owner:DATONG JIDONG CEMENT CO LTD

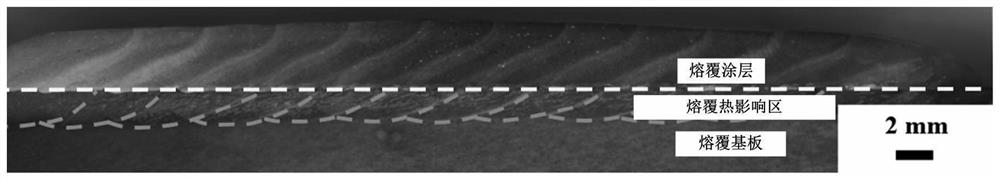

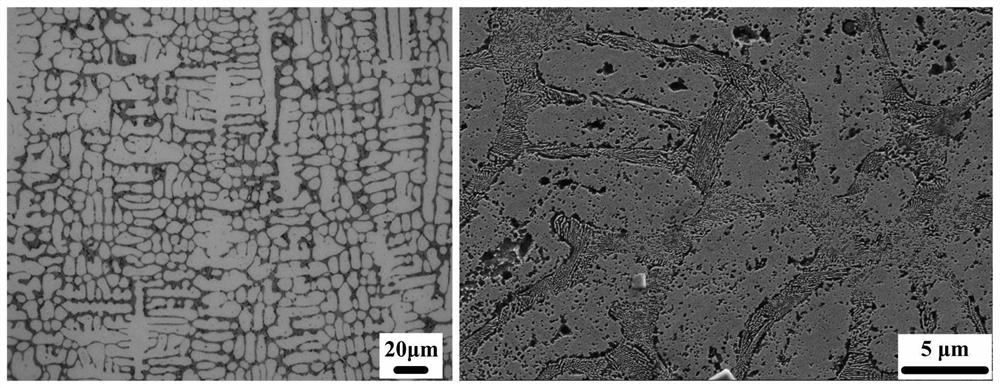

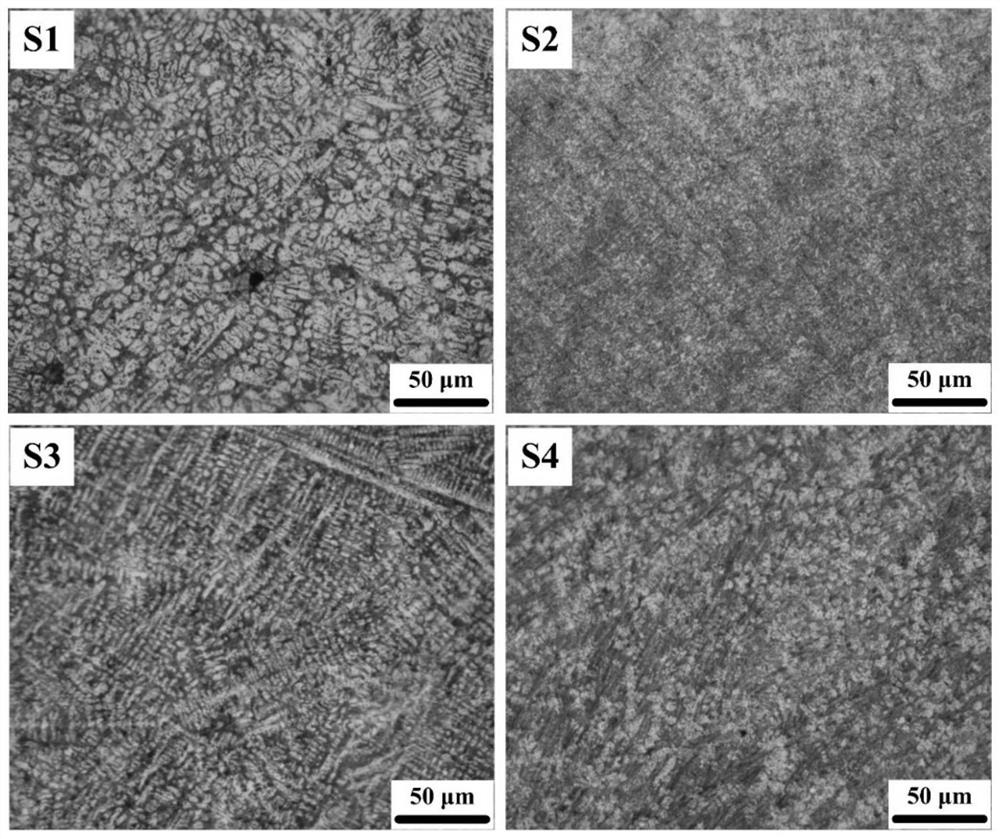

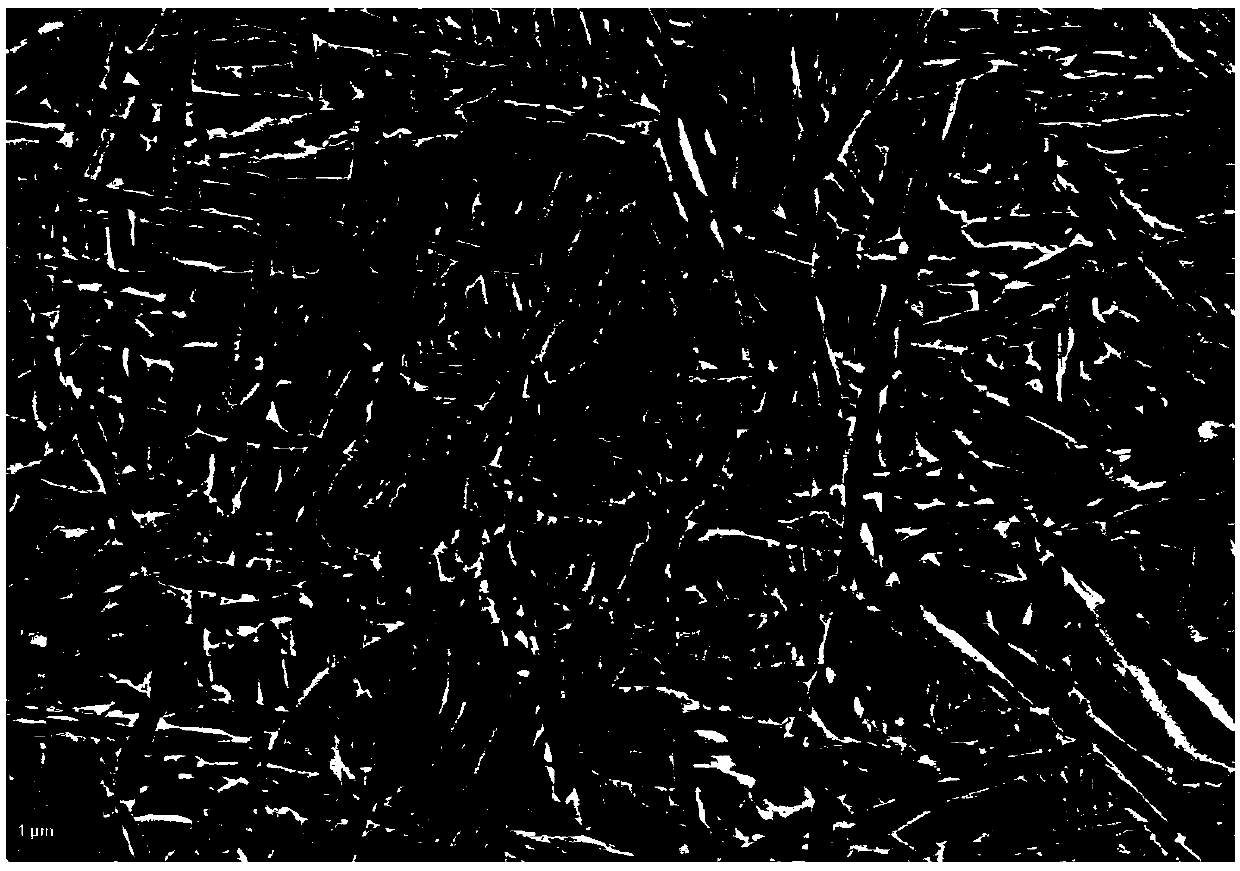

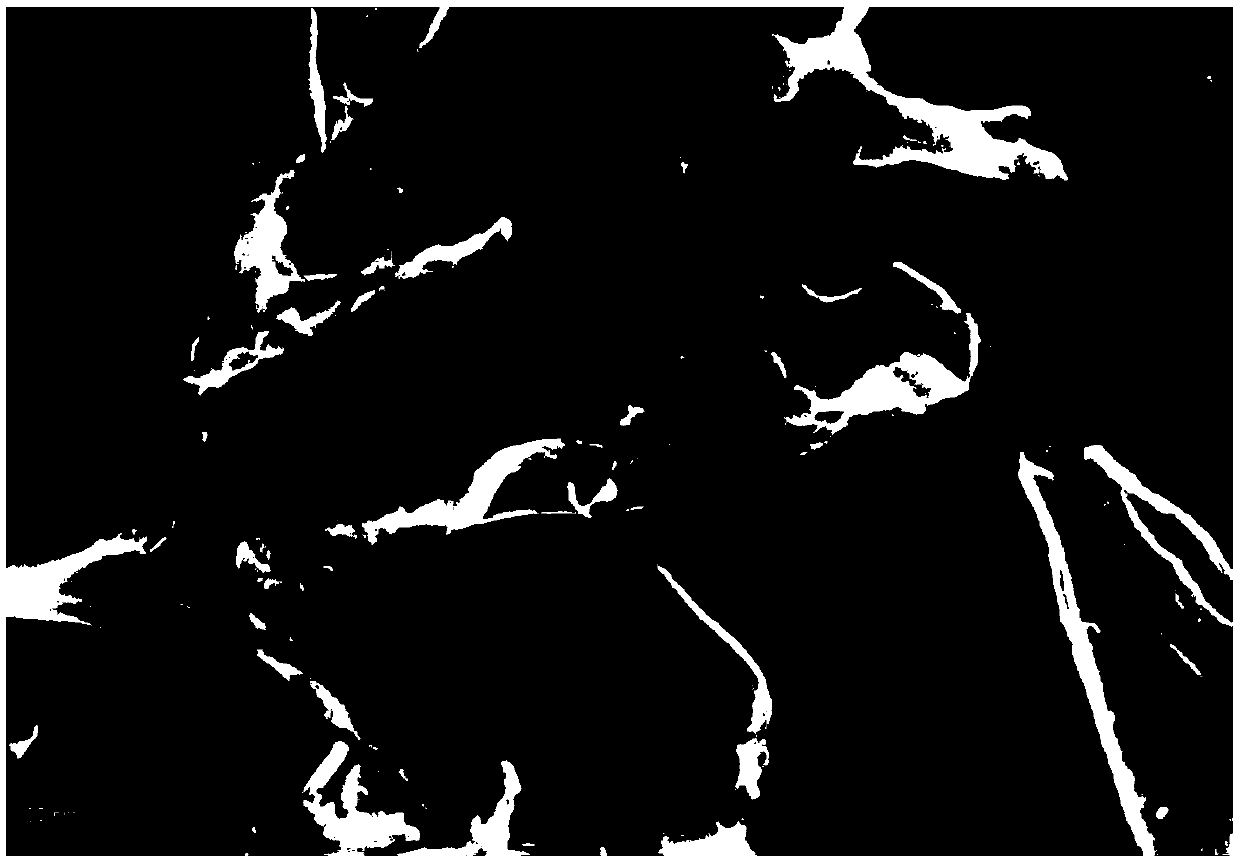

Iron-based alloy powder, laser cladding coating and preparation method of iron-based alloy powder

PendingCN114411056AHigh thermodynamic affinityRetain plasticityMetallic material coating processesCrack resistanceWear resistance

The invention discloses iron-based alloy powder, a laser cladding coating and a preparation method of the iron-based alloy powder and the laser cladding coating. The iron-based alloy powder is composed of, by mass, 1.5%-3.0% of C, 0.5%-1.5% of Si, 16%-18% of Cr, 1%-4% of Ni, 1%-3% of Mo, 0.2%-1% of Mn, 0.2%-1% of the total amount of Nb and V and the balance Fe. According to the invention, the laser cladding coating is formed by adopting the iron-based alloy powder and a laser cladding process, so that good balance of wear resistance, corrosion resistance and cracking resistance can be realized.

Owner:上交(徐州)新材料研究院有限公司 +2

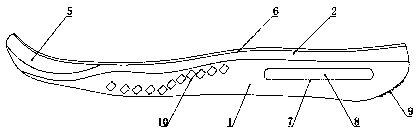

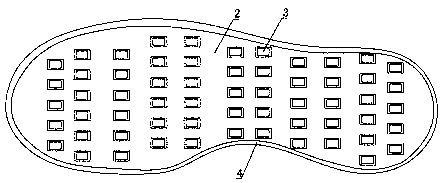

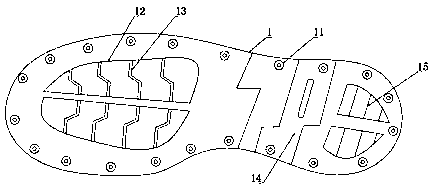

Light foaming TPU shoe sole and manufacturing process thereof

InactiveCN111109759AIncrease contactNormal contactSolesDomestic footwearMechanical engineeringComposite material

The invention discloses a light foaming TPU shoe sole which comprises a TPU shoe sole base body, a foam pad adheres to the top end of the TPU shoe sole base body, a plurality of cavities are formed inthe bottom end of the foam pad, an adhesive layer adheres to the edge of the foam pad, a resin layer adheres to the front end of the foam pad in an embedded mode, and an insole layer adheres to the top end of the foam pad. A damping cavity is formed in the heel position of the TPU shoe sole base body, the damping cavity is filled with elastic cotton, and a plurality of TPU foaming particles are embedded in the sole position of the TPU shoe sole base body. The structure is scientific and reasonable, safe and convenient use, normal sole contact can be facilitated through the foam pad; the hardeffect of the front end of the shoe sole can be improved through the resin layer, the toes are protected and prevented from being injured by collision, and the vibration feeling generated when the shoe sole makes contact with the ground in the walking process can be improved through mutual cooperation of the cavity, the damping cavity and the elastic cotton.

Owner:JINJIANG FEIYANG SHOES MATERIALS CO LTD

Texture paint decoration prefabricated coiled material for exterior wall of building and method for preparing same

A texture paint decoration prefabricated coiled material for an exterior wall of a building comprises an organic polymer non-woven fabric bearing layer, a toughness base material layer is arranged on the organic polymer non-woven fabric bearing layer, a waterproof base coat layer is sprayed on the toughness base material layer, a texture paint main paint layer is arranged on the waterproof base coat layer, and a finish-coat paint layer is arranged on the texture paint main paint layer. A method for preparing the texture paint decoration prefabricated coiled material for the exterior wall of the building includes the following steps that (1) the toughness base material layer is prepared, wherein powdery matter is metered and sequentially added according to sequences of quartz sand with the number of meshes ranging from 80 to 150 in per square inch, sub-nanometer ferronickel blast furnace slag ultrafine powder, 52.2 R Portland cement and hydroxypropyl methyl cellulose, stirring begins to be carried out from the moment when the powder is added, and stirring is conducted for another 4-6 minutes after the hydroxypropyl methyl cellulose is added; emulsion A is added to the mixture and stirred for about 3-5 minutes, then emulsion B and a proper amount of water are added and stirred for 6-8 minutes, and toughness base material mortar suitable for being sprayed and rolled is prepared.

Owner:山东省建筑科学研究院有限公司 +1

Functional terrace dividing strip and construction method thereof

The invention provides a functional terrace dividing strip and a construction method thereof. The functional terrace dividing strip is prepared from 300-400 parts of cement, 60-80 parts of inorganic mineral reinforcing materials, 50-100 parts of coal ash microspheres, 400-550 parts of quartz sand, 3-6 parts of thickening agents, 1-2 parts of a water reducing agent, 1-2 parts of a defoaming agent,4-8 parts of an early strength agent, 3-5 parts of fibers, 0-15 parts of rubber powder, 1-2 parts of a retarders, and 0-3 parts of pigment. The dividing strip is based on dry-mixed mortar which is high in early strength, rapid in setting, high in bonding strength and good in plasticity; therefore, efficient and rapid construction is achieved in cooperation with a specific construction method, thedividing strip can be shoveled or retained, and shoveled waste can serve as filler of common mortar or concrete to be reused after being collected and crushed.

Owner:武汉富洛泰克材料科技有限公司

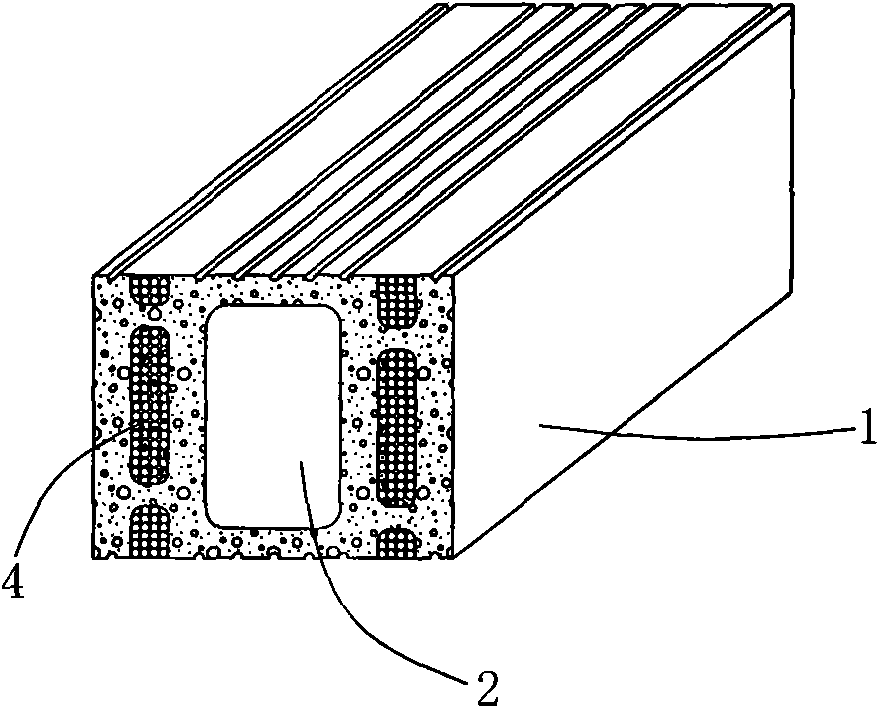

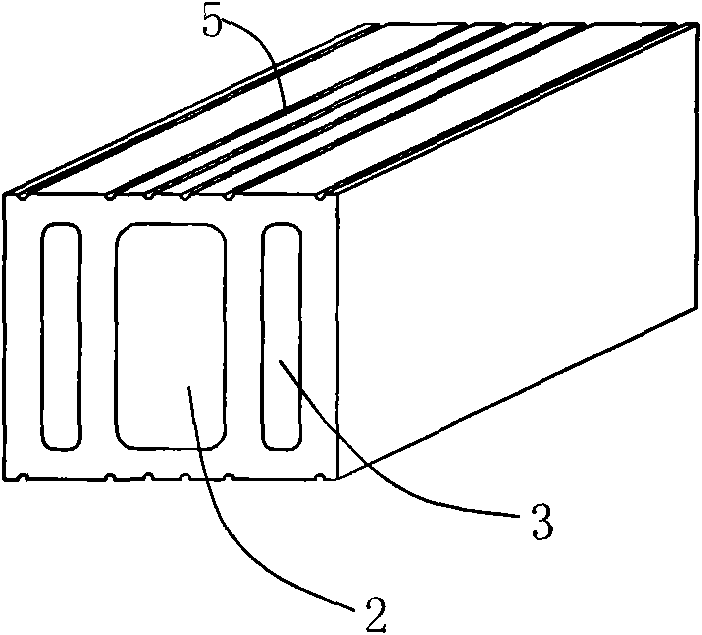

Transverse self-heat-preservation energy-saving concrete block

The invention discloses a transverse self-heat-preservation energy-saving concrete block. A length direction of the concrete block is set to be parallel to the length direction of a wall formed by piled blocks, through holes penetrating the concrete block are arranged in the middle of the concrete block along the length direction, heat preservation holes used for filling heat preservation materials are arranged at two sides of the through holes along the length direction of the concrete block, and the top surface and the bottom surface of the concrete block are provided with a plurality of parallel grout grooves that are arranged along the length direction of the block.

Owner:王荣树

Anti-cracking green environment-friendly spray coating paint and preparation method thereof

The invention provides anti-cracking green environment-friendly spray coating paint and a preparation method thereof. The anti-cracking green environment-friendly spray coating paint is prepared fromthe following ingredients in parts by weight: 10 to 12 parts of water soluble acrylic resin, 5 to 8 parts of titanium dioxide, 3 to 6 parts of linseed oil, 2 to 5 parts of natural resin, 2 to 4 partsof cobalt iso-octoate, 8 to 12 parts of tung oil, 5 to 10 parts of calcium oxide, 3 to 6 parts of turpentine, 4 to 8 parts of stabilizing agents, 6 to 8 parts of glycerol, 2 to 4 parts of curing agents, 5 to 8 parts of epoxy resin curing glue and optional auxiliary materials. The linseed oil, the natural resin, the tung oil and the turpentine are added in the paint, so that the problems of cracking, layering and the like cannot occur with the use time increases; in addition, the paint obtained by using the formula is safe, environmental friendly, non-toxic and harmless; in addition, the concentration is low; a spray coating manner can be used; the uniformity is high; the furniture spray coating is facilitated; the application range is wide.

Owner:CARPOLY CHEM GRP

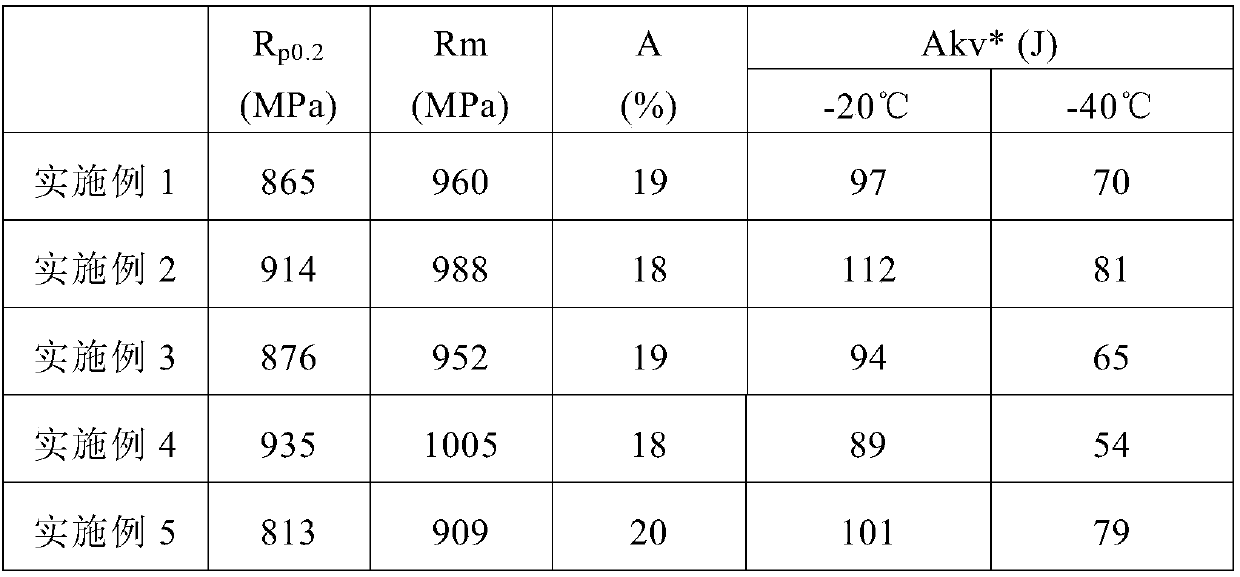

Ultrahigh-strength gas shielded welding wire and wire rod

ActiveCN110640350ALow costGuaranteed welding effectWelding/cutting media/materialsSoldering mediaWire rodCrack resistance

The invention relates to an ultrahigh-strength gas shielded welding wire and wire rod. The welding wire comprises the following chemical components, in percentage by mass, of 0.05%-0.15% of C, 0.65%-0.80% of Si, 1.7%-2.0% of Mn, less than or equal to 0.01% of S, less than or equal to 0.015% of P, 0.18%-0.28% of Cr, 1.4%-1.8% of Ni, 0.2%-0.6% of Mo, 0.10%-0.20% of Ti, 0.01%-0.05% of V, 0.007%-0.014% of N, and the balance Fe and inevitable impurities, and meanwhile, it is desirable to satisfy that Si / 24+Mn / 6+Ni / 40+Cr / 5+Mo / 4=0.45%-0.55%, and Ti+6V+15N=0.3%-0.6%. According to the welding wire andthe wire rod, the yield strength of the weld metal of the welding wire is larger than or equal to 800 MPa, the tensile strength is larger than or equal to 900 MPa, the elongation A is larger than or equal to 18%, the impact energy Akv of -40 DEG C is larger than or equal to 50 J, and the welding performance and the crack resistance of the welding wire and the strong plasticity and toughness of theweld metal are both considered.

Owner:BAOSHAN IRON & STEEL CO LTD

Anti-sintering long-life double-layer columnar structure thermal barrier coating and preparation method thereof

PendingCN109763091ATo achieve the purpose of anti-sinteringHigh feasibilityMolten spray coatingCrack resistanceInsulation layer

The invention discloses an anti-sintering long-life double-layer columnar structure thermal barrier coating and a preparation method thereof. The anti-sintering long-life double-layer columnar structure thermal barrier coating comprises a toughening layer located inside and a heat insulation layer located outside, the heat insulation layer comprises a longitudinal gap in the heat flow direction, and the heat insulation layer is composed of composite stacking of compact sheet-layer units and loose nano particle piles; the toughening layer accounts for 10%-50% of the total thickness of the double-layer structure thermal barrier coating, wherein the fracture toughness of a first thermal barrier coating material is greater than or equal to 2.5MPa.m<1 / 2>; and the heat insulation layer accountsfor 50%-90% of the total thickness of the double layers, and the thermal conductivity of a second thermal barrier coating material and a third thermal barrier coating material at the temperature of 1000-1600 DEG C does not exceed 2.5W / m.K. According to the double-layer columnar structure thermal barrier coating provided by the invention, the purpose of resisting sintering of the ceramic coating ina high-temperature environment can be achieved, and the cracking resistance of the coating is enhanced through the design of the toughening layer and the columnar structure, so that the anti-sintering and long-life collaborative design of the novel structure thermal barrier coating is realized.

Owner:XI AN JIAOTONG UNIV

Special pointing adhesive for decorative aerated concrete block exterior wall

InactiveCN102485819AHigh tensile strengthHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyvinyl alcoholPliability

The invention discloses a special pointing adhesive for a decorative aerated concrete block exterior wall. The pointing adhesive is an organic-inorganic compound with an organic component of butylbenzene latex and an inorganic component of cement. As performance of the butylbenzene latex and introduction of a plurality of multifunctional assistants, the pointing adhesive has better flexibility, bonding strength and wellability to the aerated concrete block than an ordinary pointing adhesive. The pointing adhesive of the invention contains two components of a slurry and a powder in separate packages. The slurry comprises water, butylbenzene latex, wetting agent, 1788 type polyvinyl alcohol aqueous solution, antifoaming agent and mildew inhibitor; and the powder comprises cement, fly ash and calcium carbonate powder. The slurry and the powder are cooperatively packaged according to a proportion.

Owner:ANHUI INST OF BUILDING RES & DESIGN

Thermal insulation mortar with lower thermal conductivity coefficient and preparation method thereof

The present invention discloses a thermal insulation mortar with a lower thermal conductivity coefficient and belongs to the technical field of building materials. The thermal insulation mortar is prepared from the following raw materials: 250-350 parts of silicate cement, 180-240 parts of river sand, 160-240 parts of construction waste residues, 120-170 parts of talc, 10-20 parts of asphalt, 30-80 parts of thermal insulation aggregate, 6-9 parts of mineral wool, 8-12 parts of lignocellulose, 3-8 parts of a water resistant agent and 3-5 parts of an admixture. The thermal insulation aggregate is composed of expanded perlite and hollow glass micro-beads in a weight ratio of 1:(0.1-0.3). The hollow glass micro-beads are compounded with the expanded perlite and mineral wool. The prepared thermal insulation mortar has a thermal conductivity coefficient obviously lower than that of thermal insulation mortar compounded by the expanded perlite and mineral wool, and also has higher strength andhigher use value.

Owner:芜湖市颂晖商贸有限公司

Textile concrete externally-hung curtain wall and preparation method thereof

InactiveCN106968374AImprove bearing capacityStrong crack control abilityConstruction materialWallsFiberCrack resistance

The invention belongs to the technical field of building materials and relates to a textile concrete externally-hung curtain wall. The curtain wall is formed by compounding textiles and high-performance fine concrete externally doped with chopped fibers. The number of layers of the textiles in the curtain wall can be adjusted according to the actual project needs; and the appearance modeling of the curtain wall can be determined by manufacturing corresponding formworks according to actual projects during test block pouring. The novel curtain wall disclosed by the invention can effectively replace a traditional curtain wall material, can be widely applied to high-rise building outer wall vertical faces under various complex environments, and has wide application prospects. The curtain wall disclosed by the invention has the advantages of being easy and convenient to manufacture, thin in wall, low in weight, low in installation and transportation expense, convenient to assemble and the like during manufacturing and installation, and has the characteristics of being high in bearing force, good in crack resistance, good in durability, attractive in appearance and the like in the use performance.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Repairing agent for subway shield segments and preparation method of repairing agent

InactiveCN111995349AGuaranteed crack resistanceImprove compactnessSolid waste managementAluminateCellulose

The invention discloses a repairing agent for subway shield segments and a preparation method of the repairing agent. The repairing agent is prepared from the following raw materials in parts by mass:200 to 300 parts of ordinary Portland cement; 150-200 parts of white cement; 100 to 250 parts of sulphoaluminate cement; 20-50 parts of microbeads; 50 to 100 parts of silica fume (silica powder); 150to 250 parts of active glass powder; 1 to 10 parts of excitant; 50 to 100 parts of concrete expanding agent; 0.1 to 0.4 part of plastic expanding agent; 1 to 5 parts of water reducing agent; 0.1 to 0.4 part of defoaming agent; 0 to 0.5 part of cellulose; 15 to 35 parts of redispersible latex powder; and A parts of water. The sum of the dosages of the components excepting water, namely the sum ofthe parts of the components excepting water is B, and the water-material ratio, namely the ratio of A to B, is 0.15-0.20: 1. The invention further provides a preparation method of the repairing agent.Through the synergistic effect of all the components, the repairing agent is high in early and later compressive strength, good in wear resistance and small in color difference with old concrete repairing, has the characteristics of good bonding performance and crack resistance, and is convenient to apply and popularize.

Owner:刘翠芬

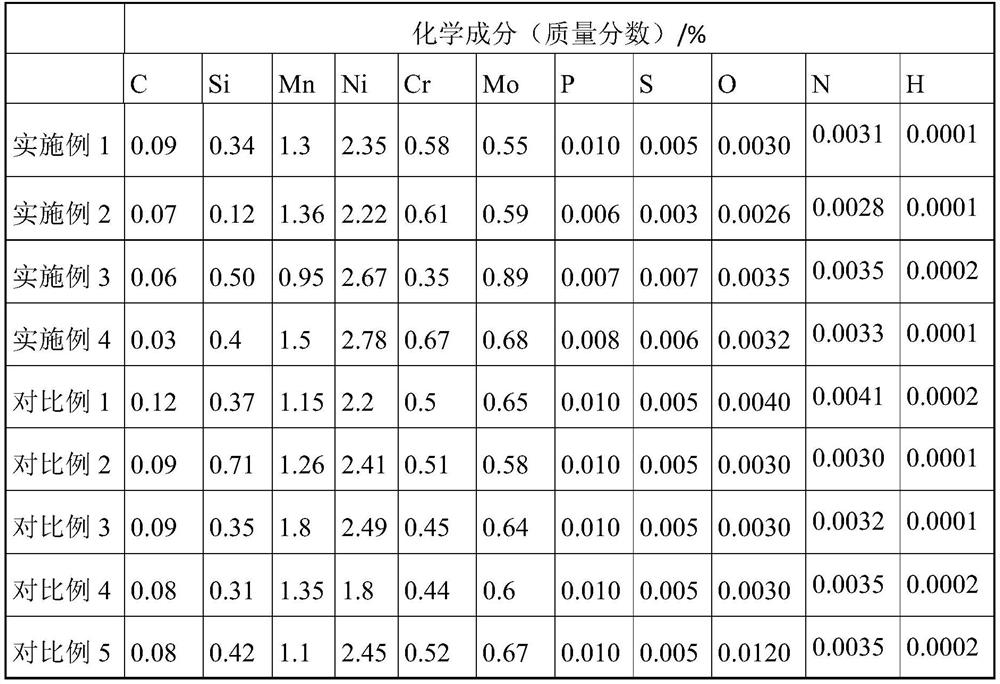

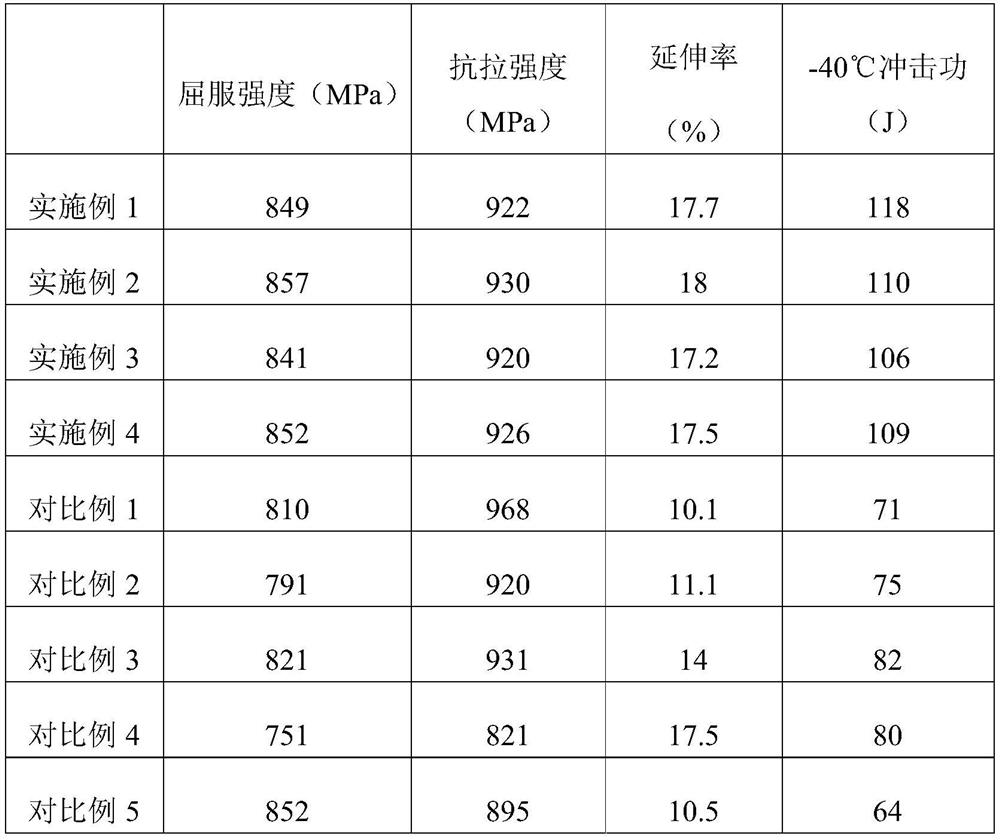

High-strength high-toughness low-alloy steel wire as well as preparation method and application thereof

InactiveCN112853216AHigh strengthHigh tensile strengthAdditive manufacturing apparatusFurnace typesWire rodIngot

The invention discloses a high-strength high-toughness low-alloy steel wire which comprises the following components in percentage by mass: 0.03-0.09% of C, 0.1-0.5% of Si, 0.9-1.5% of Mn, 0.5-0.9% of Mo, 2.2-2.8% of Ni, 0.3-0.7% of Cr, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance of Fe and inevitable impurities. The invention also discloses a preparation method of the wire, which comprises the following steps: a, carrying out vacuum melting on the raw materials with a designed ratio to obtain a cast ingot; B, forging the cast ingot to obtain a bar; C, rolling the bar to obtain a wire rod; and d, annealing the wire rod, and then drawing the wire to obtain the wire . The high-strength high-toughness low-alloy steel wire can adapt to an inert gas environment in laser additive manufacturing, does not need special deoxidation and deslagging, can continuously work, does not need copper plating, and is environment-friendly.

Owner:ANSTEEL BEIJING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com