Method for producing H-shaped support piles

A production method and technology for supporting piles, which are applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of inability to meet the requirements of large-scale industrial production, low bending and shear resistance, and affecting the progress of the project. To achieve the effect of simple production, fast construction and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

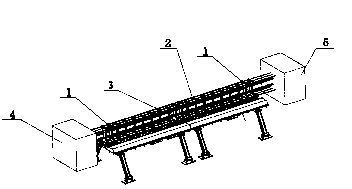

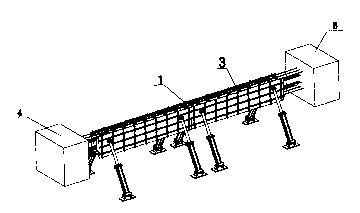

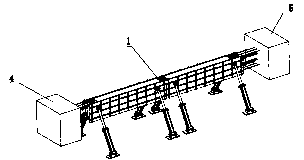

[0024] Attached below figure 1 To attach Figure 4 The invention is described in further detail.

[0025] The mold used in the present invention to produce the H-type support pile is commonly called the H-type support pile mold, and the mold structure adopted is that the application number is 201220469886.0, but the mold for actually producing the H-type support pile is not limited to the above-mentioned Mould, as long as can reach the mold of the utility model production effect all can.

[0026] A kind of production method of H type support pile, it is characterized in that: concrete manufacturing step comprises:

[0027] (1) Place the baffle 1 on the bottom plate of the H-shaped support pile mold or at both ends of the bottom plate. And through the hole on the baffle connected in series on the prestressed steel bar 2, at the same time several stirrups 3 are also connected in series on the prestressed steel bar 2, and one end of the prestressed steel bar is connected on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com