Patents

Literature

275results about "Affixing tags" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

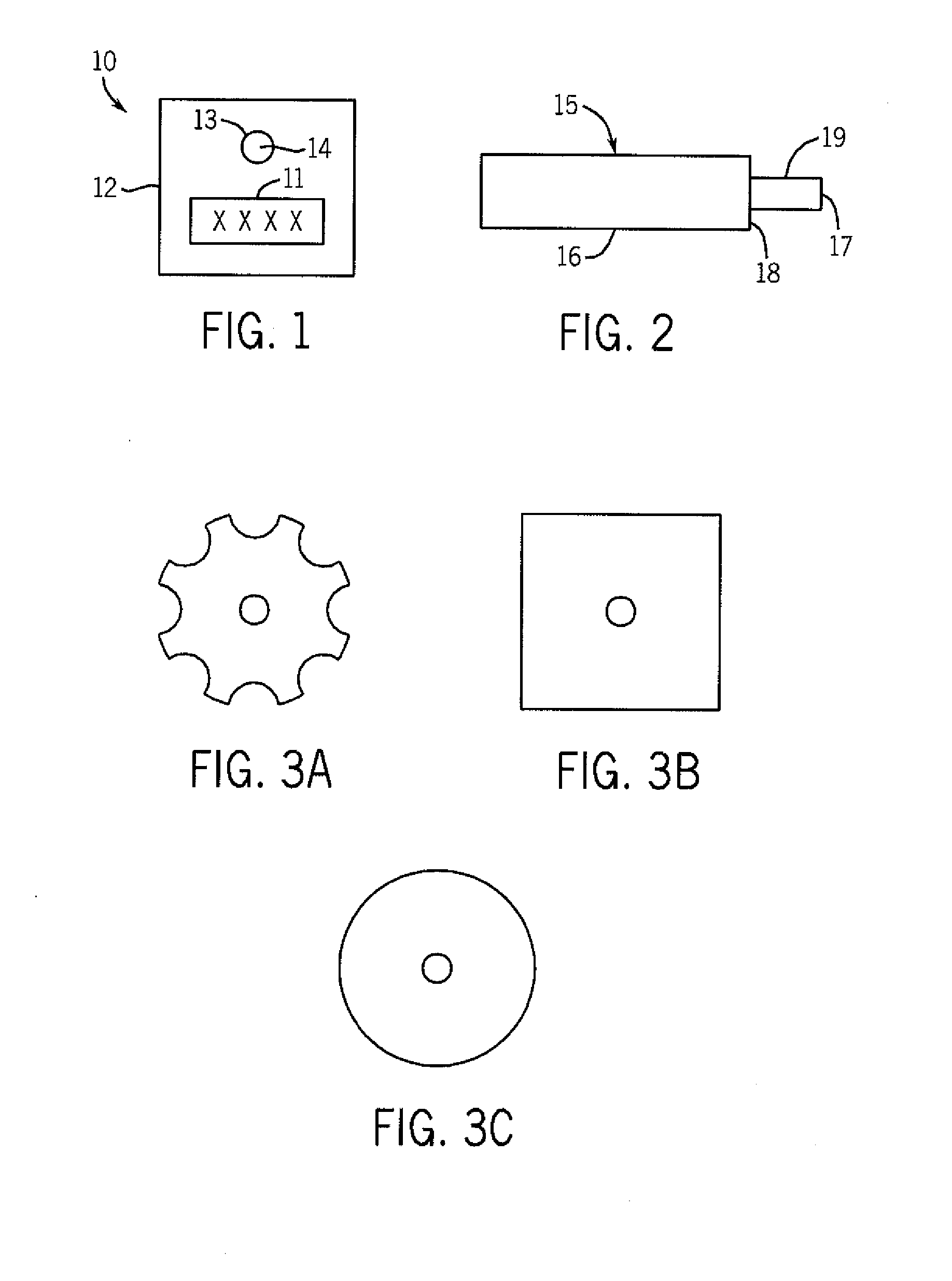

Device for dispensing plastic fasteners

ActiveUS7036680B1Easy to useReduce manufacturing costAffixing tagsCoin-freed apparatus detailsCross-linkEngineering

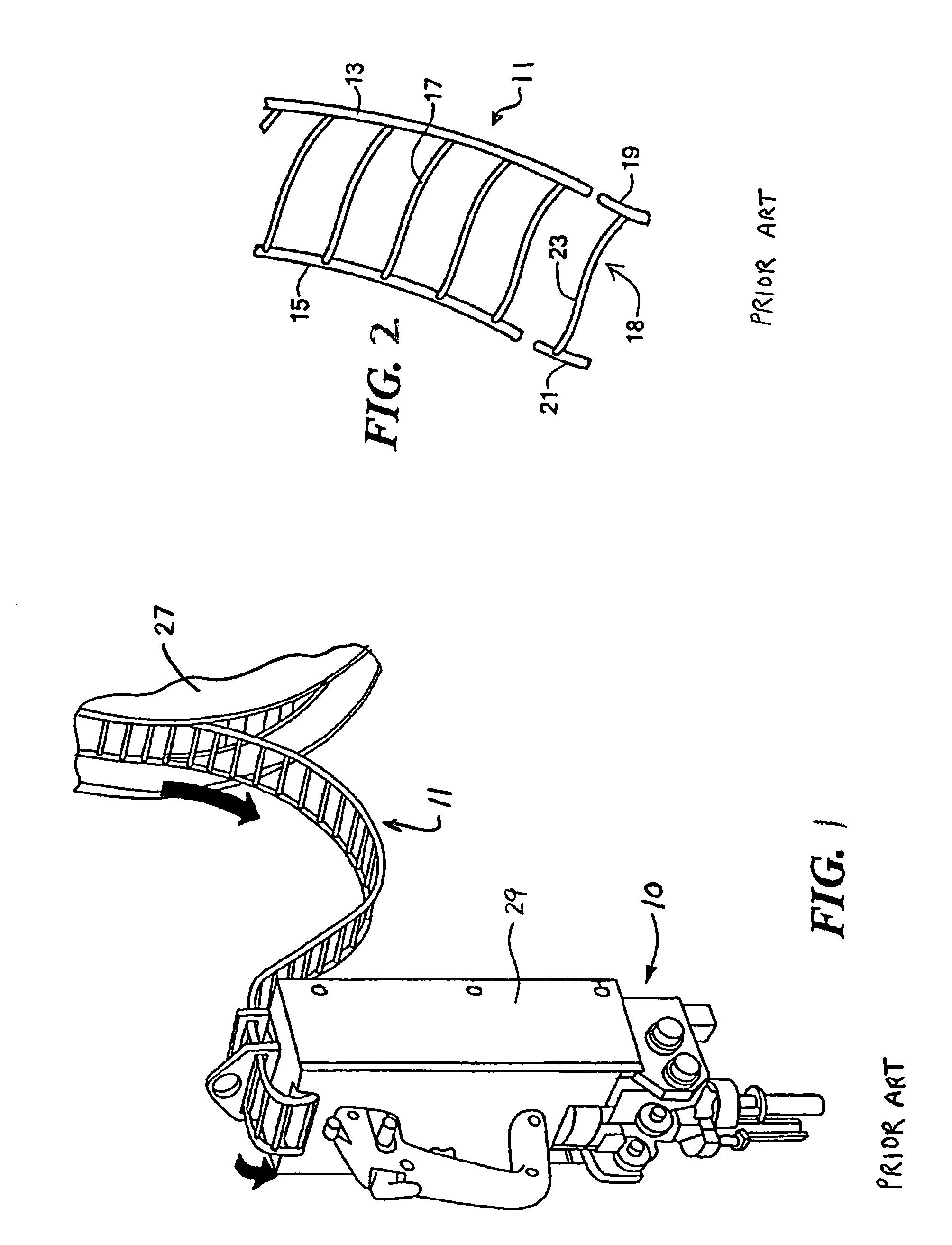

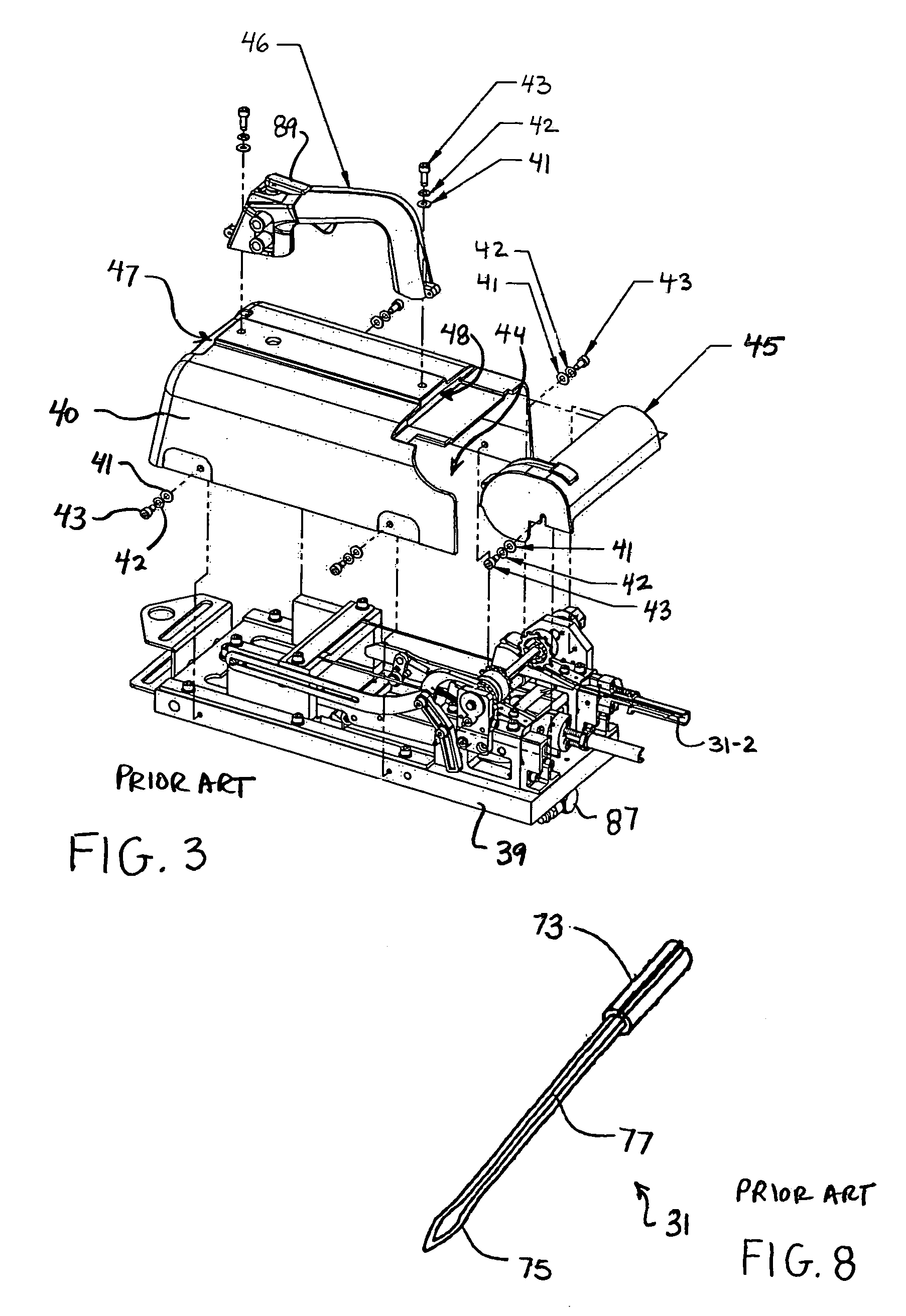

A device for dispensing an individual plastic fastener from a supply of fastener stock to couple together two or more objects. The supply of fastener stock includes a plurality of equidistantly spaced cross links which are coupled at one end to a continuous side rail. The fastener dispensing device includes a hollowed sharpened needle shaped to define a longitudinal bore and a feed mechanism for advancing the continuous side rail of the fastener stock into direct axial alignment behind the longitudinal bore of the hollowed needle. The feed mechanism includes a rotatably mounted feed shaft, a pair of feed wheels fixedly mounted on the feed shaft, each feed wheel comprising a plurality of sprockets which are sized and shaped to engage the supply of fastener stock, and first and second clutch wheels which are releasably matingly engageable with one another, the first clutch wheel being fixedly mounted on the feed shaft and the second clutch wheel being rotatably mounted on the feed shaft, each of the first and second clutch wheels including a plurality of ratchets. As a feature of the invention, the number of ratchets on each clutch wheel is at most equal to the number of sprockets on each feed wheel.

Owner:AVERY DENNISON CORP

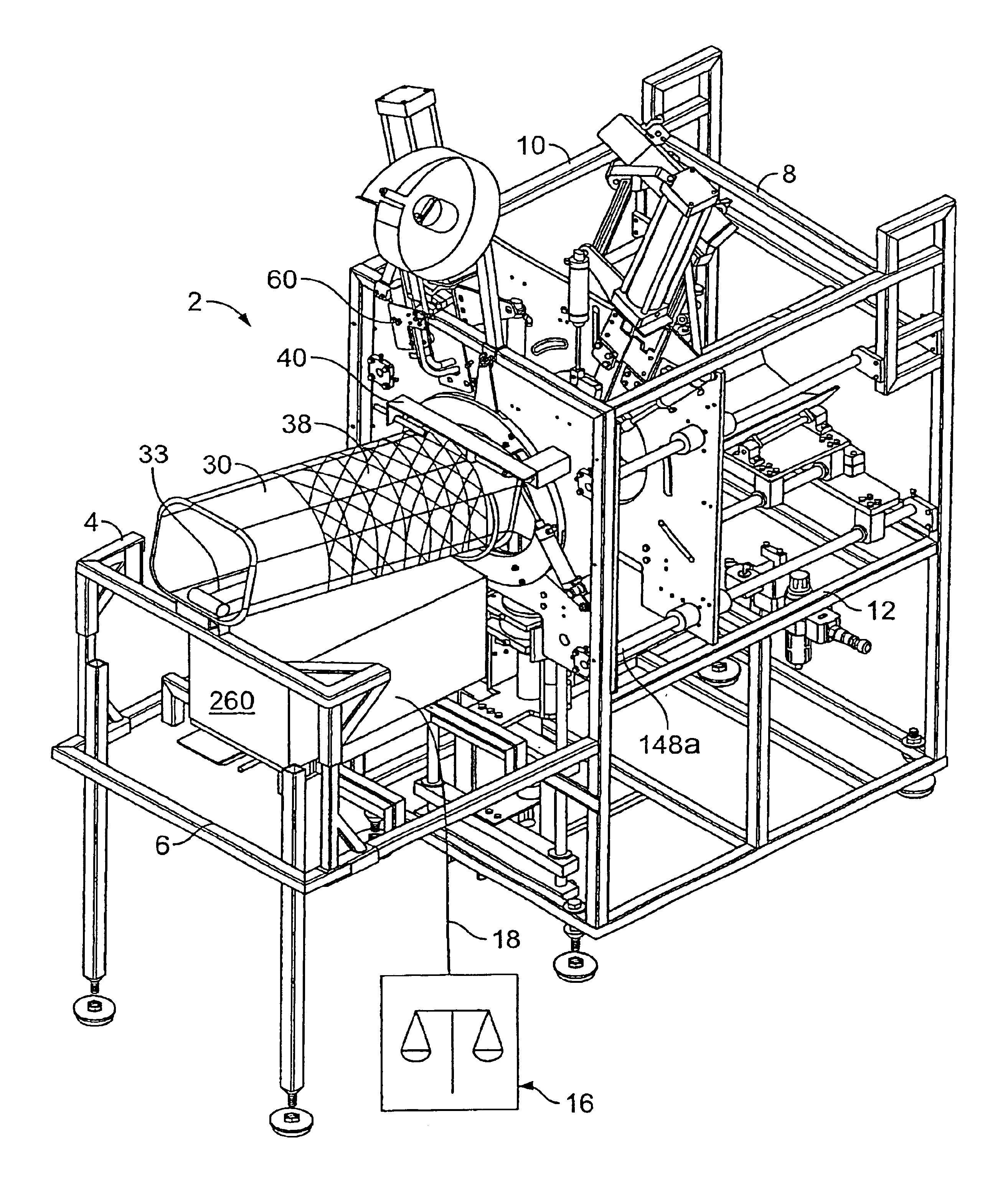

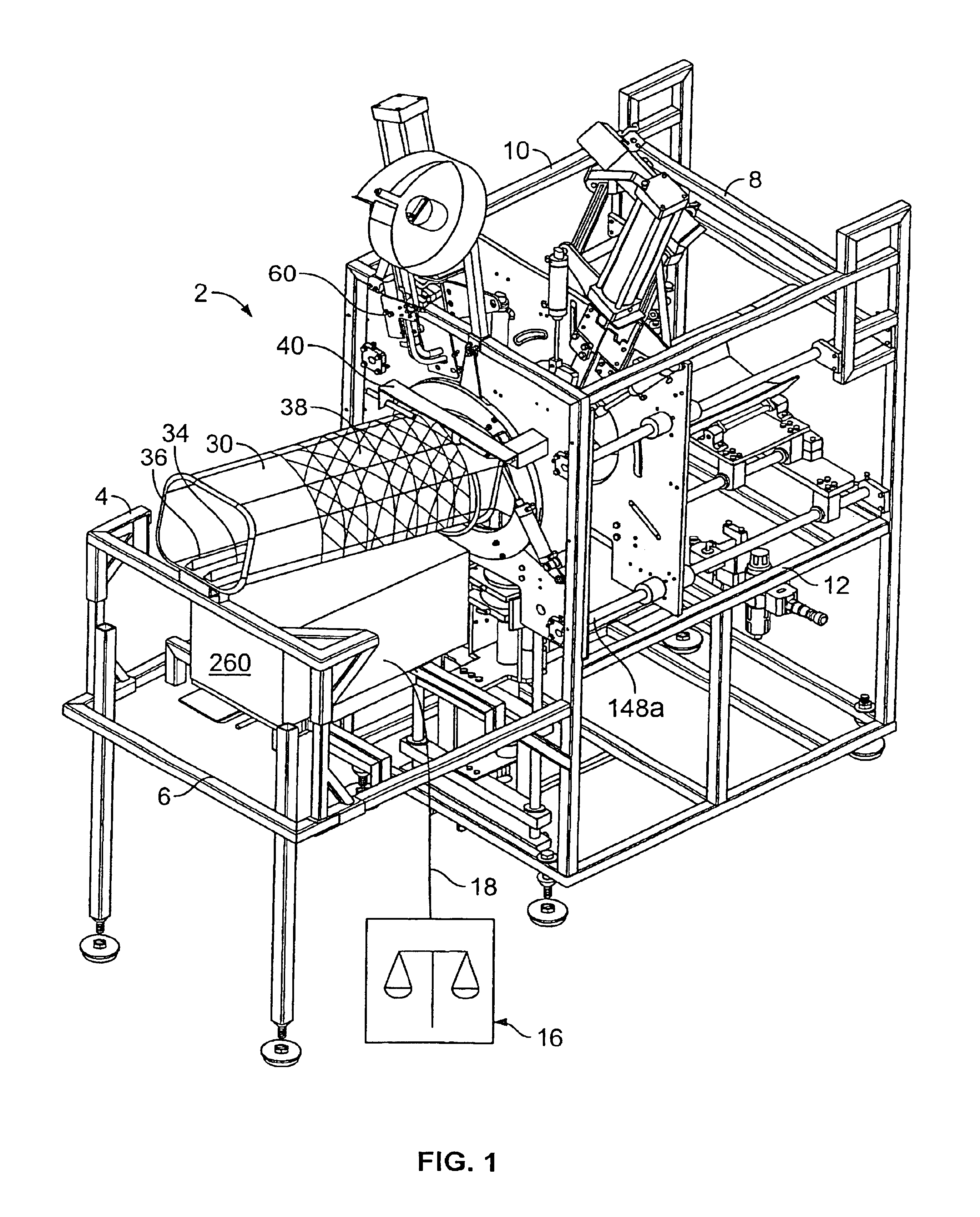

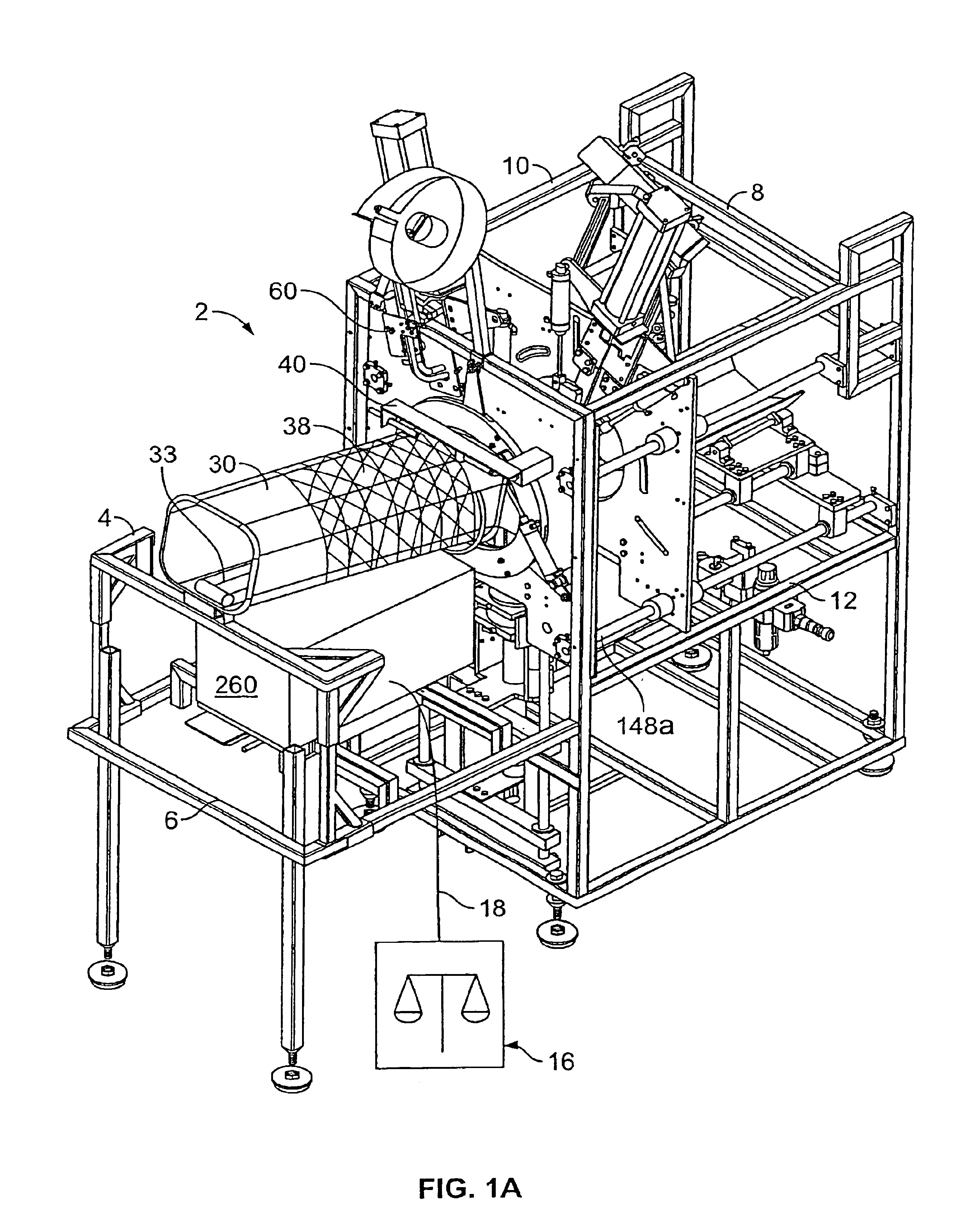

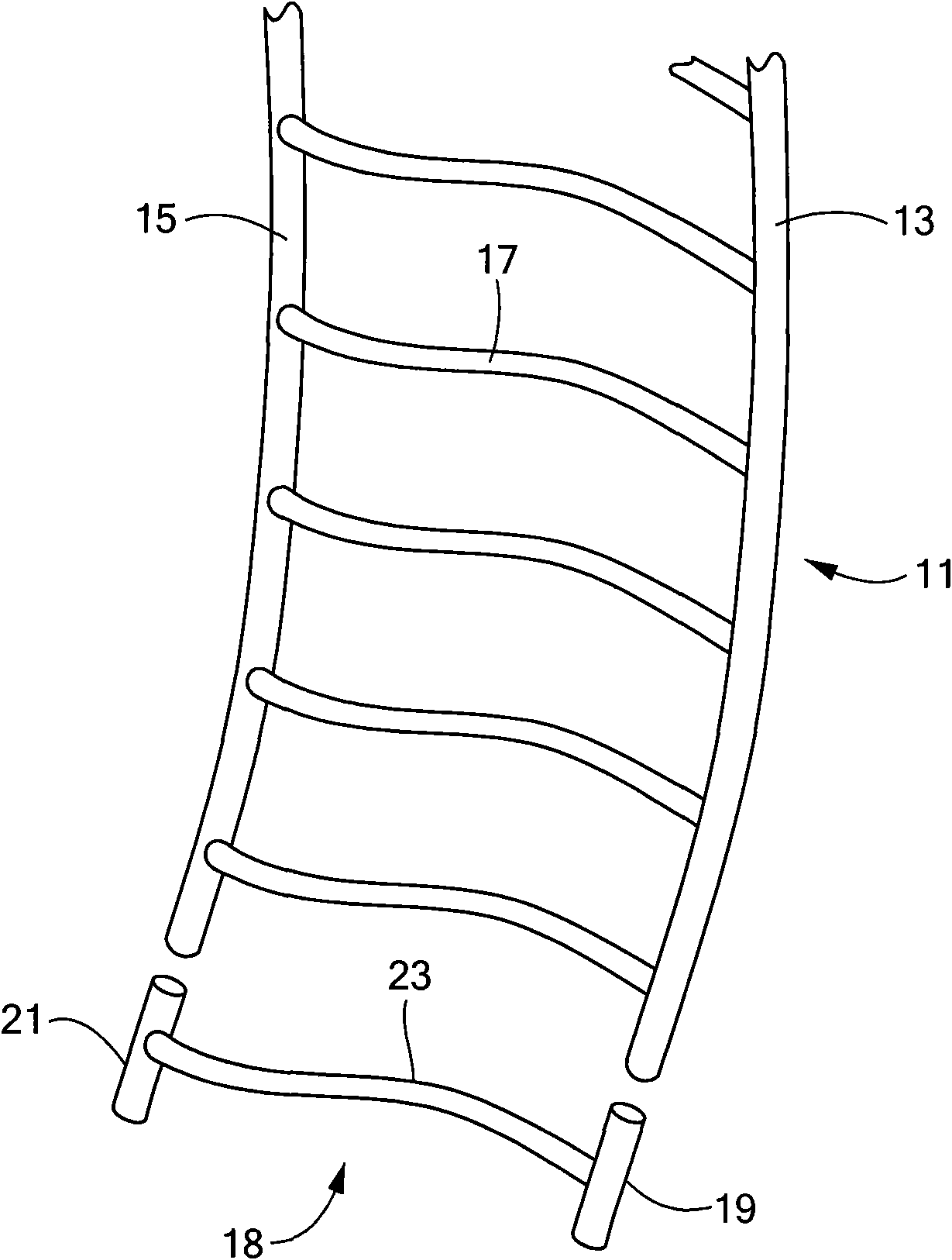

Apparatus for enclosing material in a net

InactiveUS6883297B2Uniform appearanceLighten the taskAffixing tagsSkinless sausage makingEngineeringMechanical engineering

An apparatus and method of enclosing material in a net and supplying a handle for ease of carrying the netted material, comprising clippers, irises, and a handle maker. A conveyor carries the material to a pair of irises. The irises gather the netting around the material, the first clipper cuts and closes the netting, and the handle maker forms a loop out of the severed netting. The second clipper attaches the loop back to the netting to form a handle. A scale can be used to weigh the material and a printer can create a label, with the weight or whatever other information is desired, for attachment to the netting.

Owner:POLY CLIP SYST

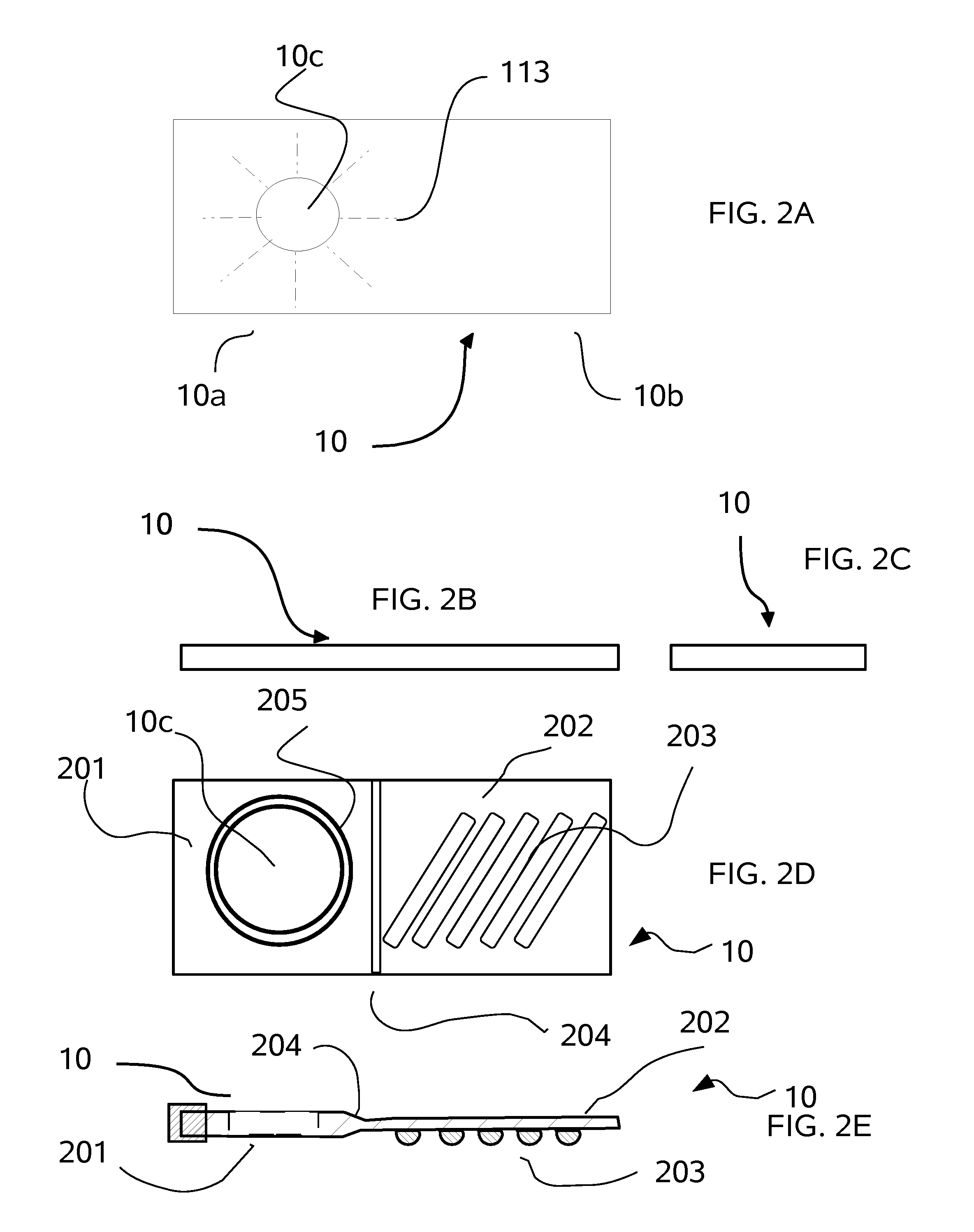

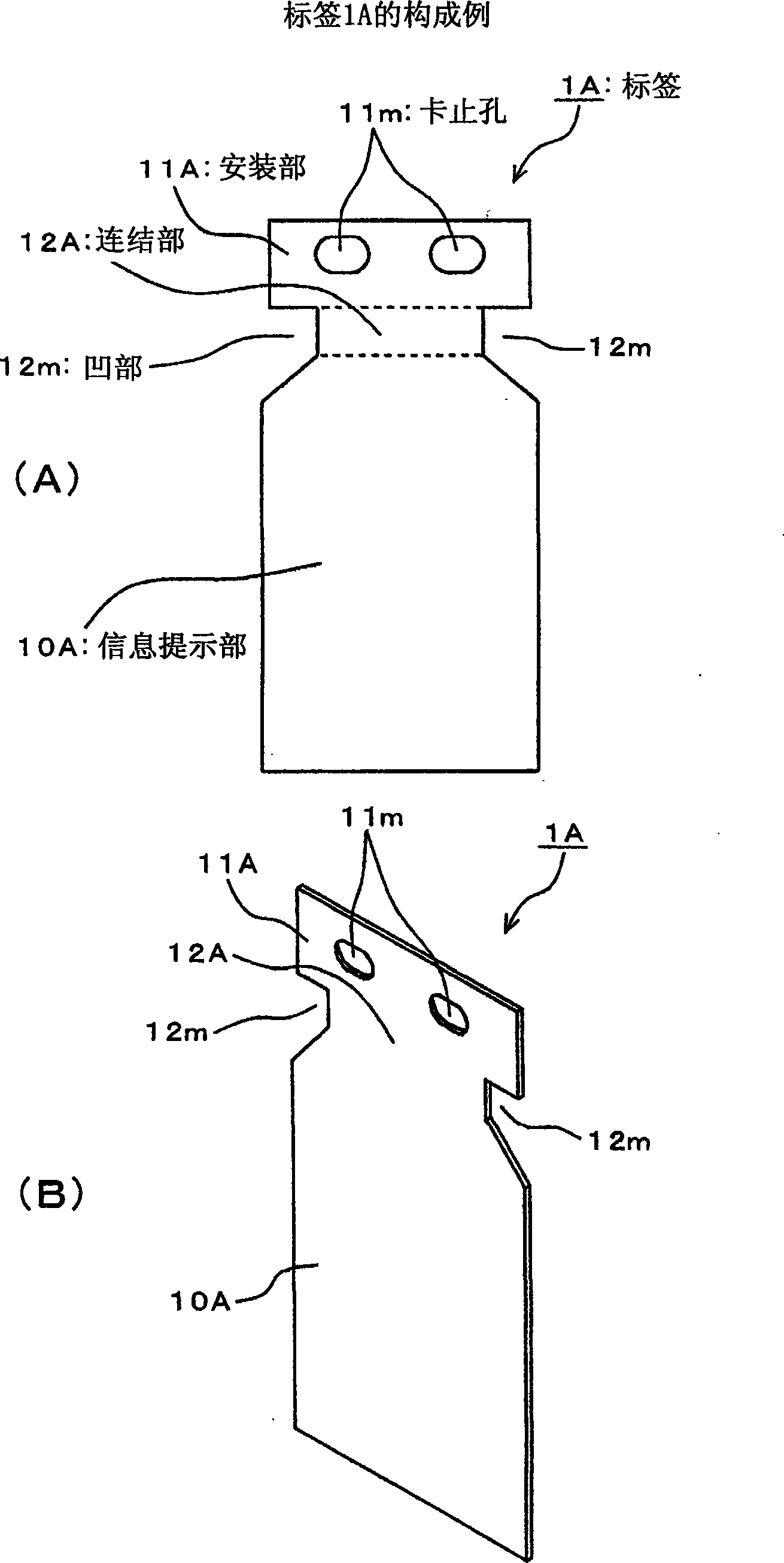

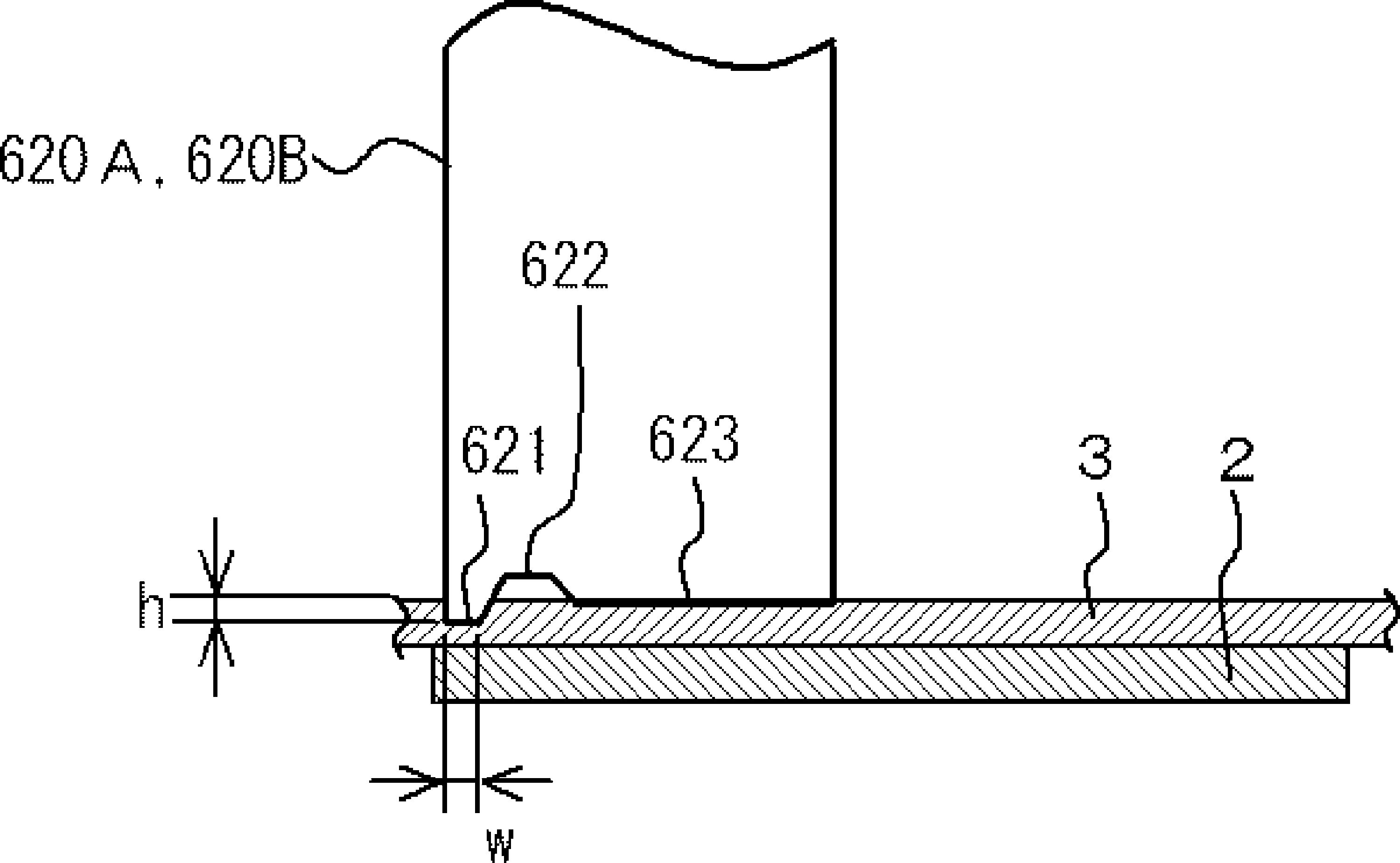

Label

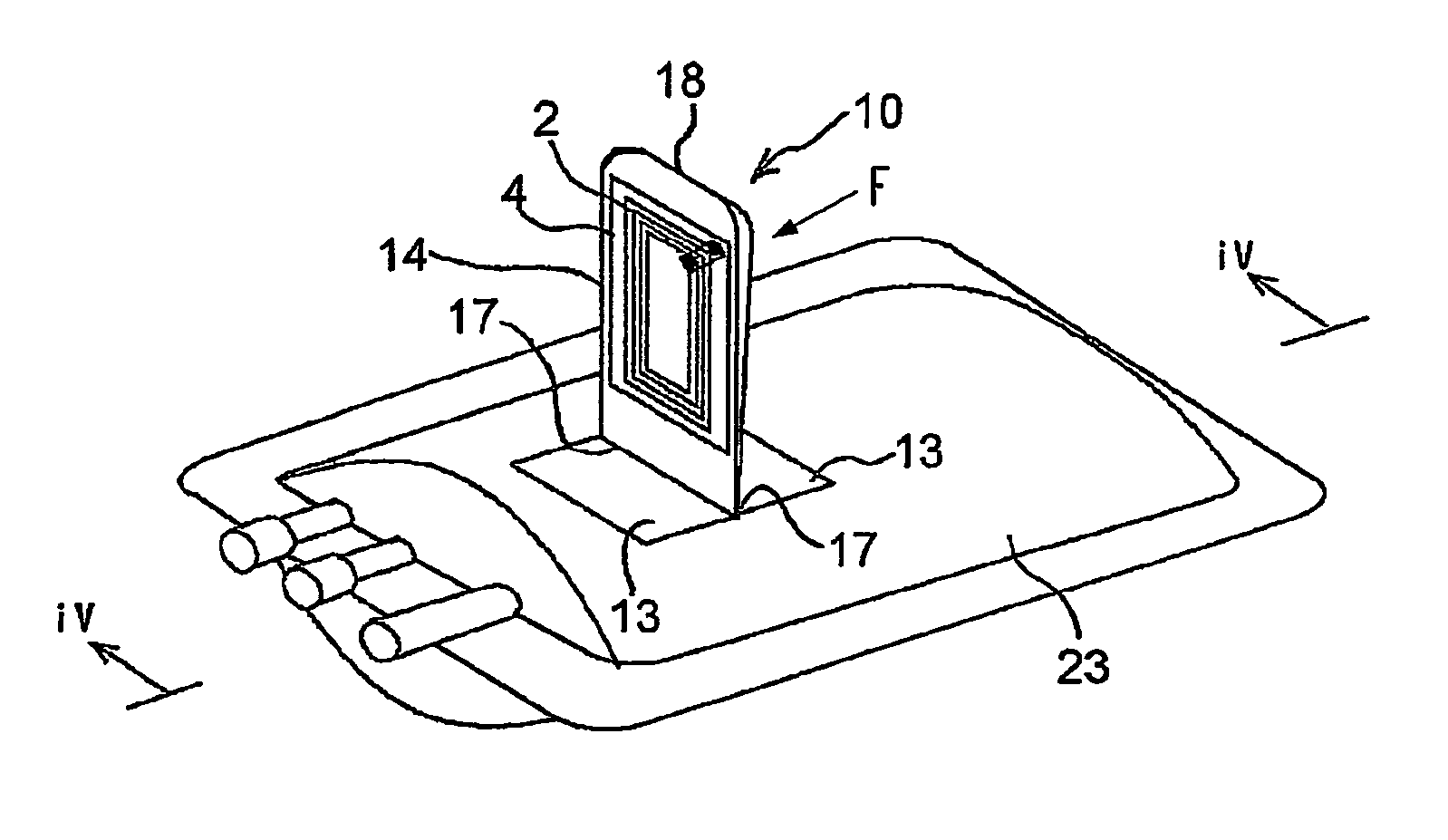

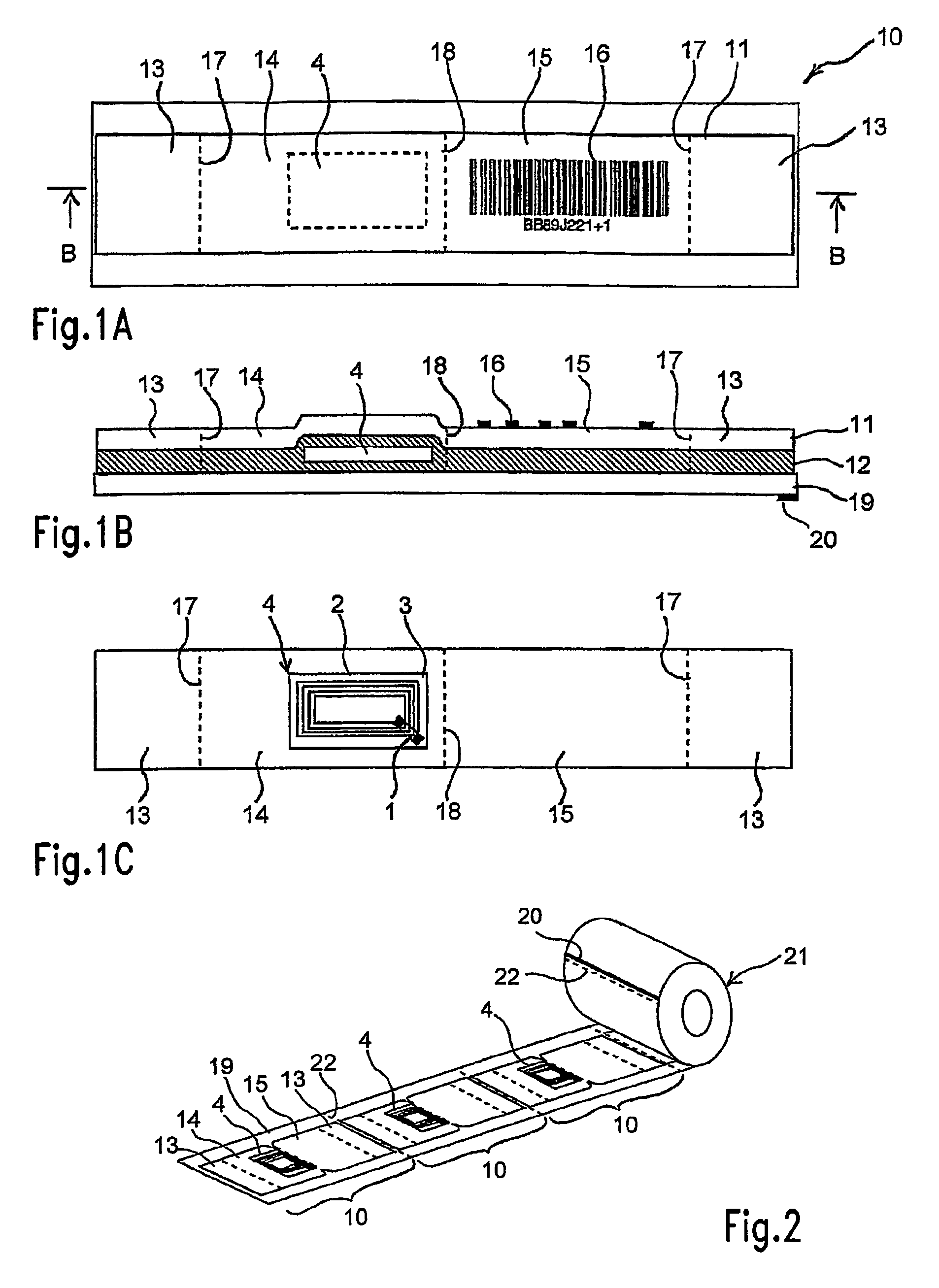

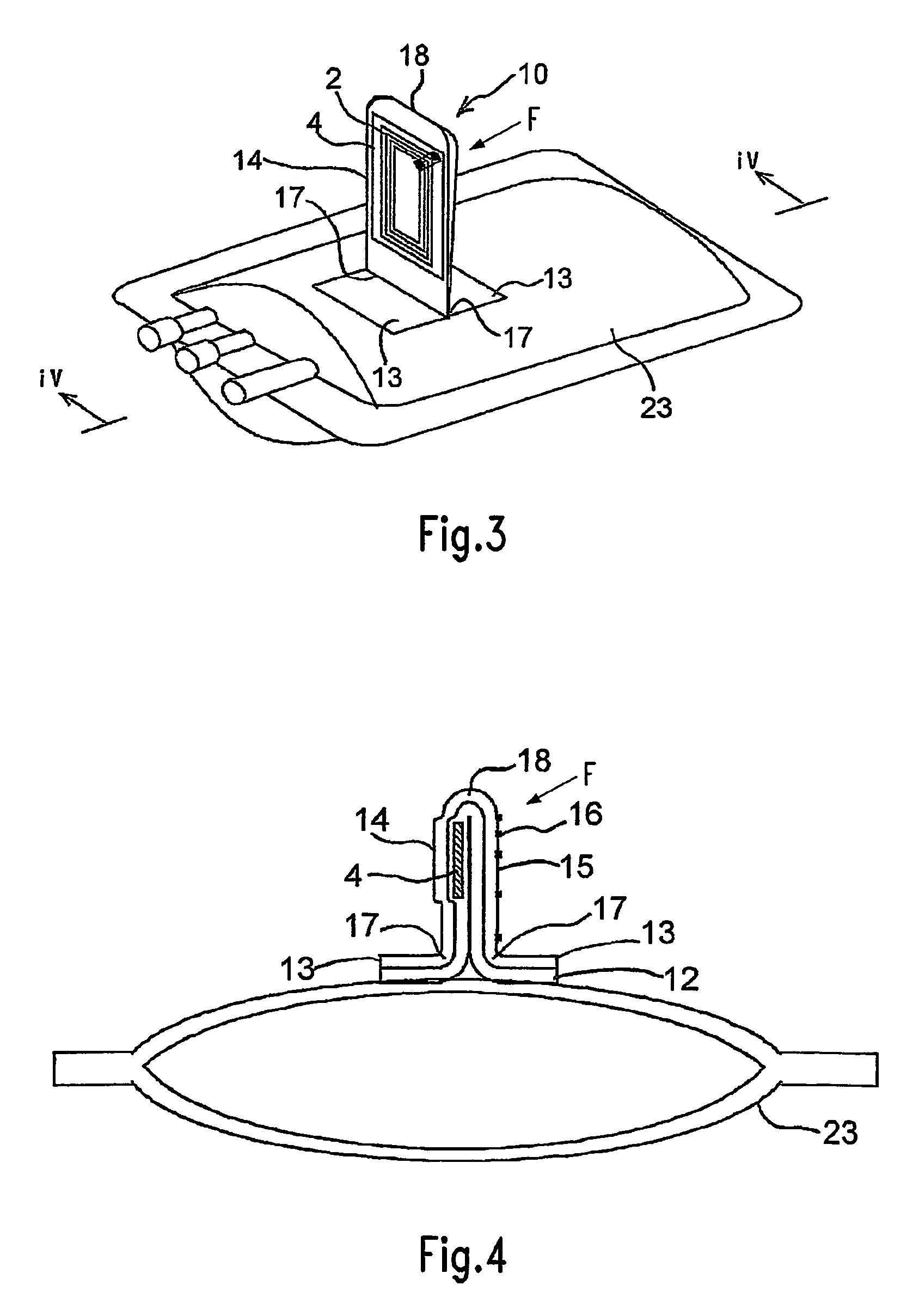

The present invention refers to a label comprising a pasting part for pasting said label to an object and comprising an electronic device preferably for a radio frequency identification (RFID). In order to improve such a label, it is suggested that the electronic device is pivotably connected to said pasting part.

Owner:SATO CO LTD

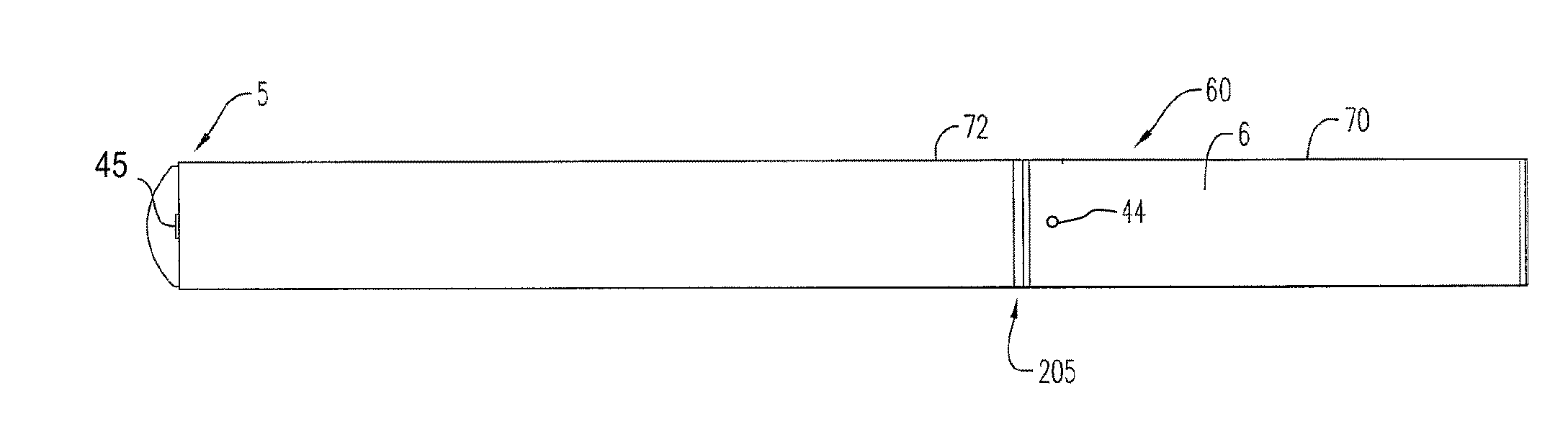

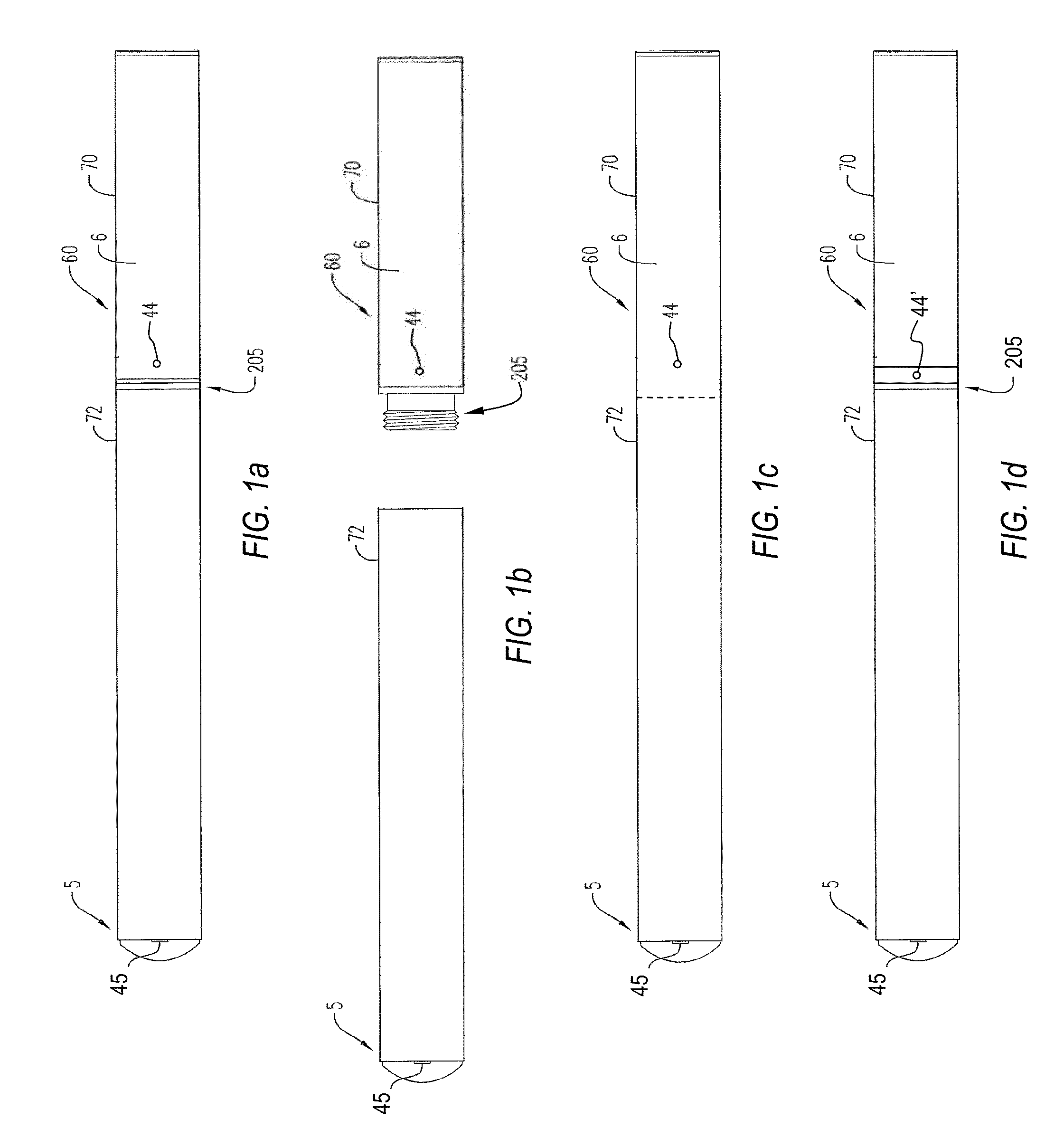

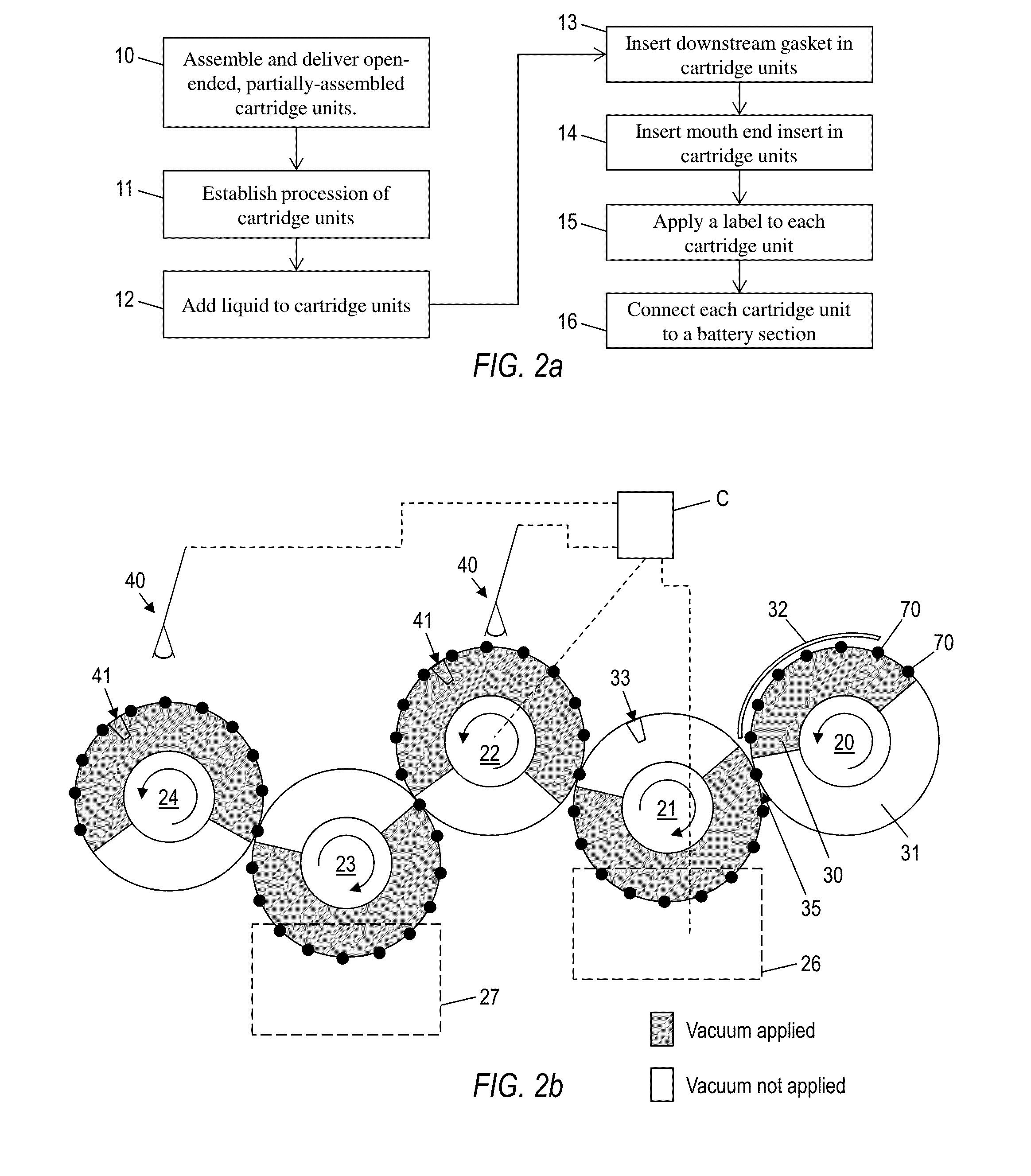

System and method for applying a label for the automated production of e-vapor devices

A system for use in manufacturing vapor-generating articles may include a rotatable drum that is configured to hold a plurality of the vapor-generating articles. The system may also include a tagging drum that is configured to tag a respective label to a housing of each of the vapor-generating articles. The system may also include a pressing roller that is configured to press a leading edge of the label against the housing after the tagging. The system may further include a rolling drum that is configured to roll the label around the housing after the pressing.

Owner:AKRIA CLIENT SERVICES LLC

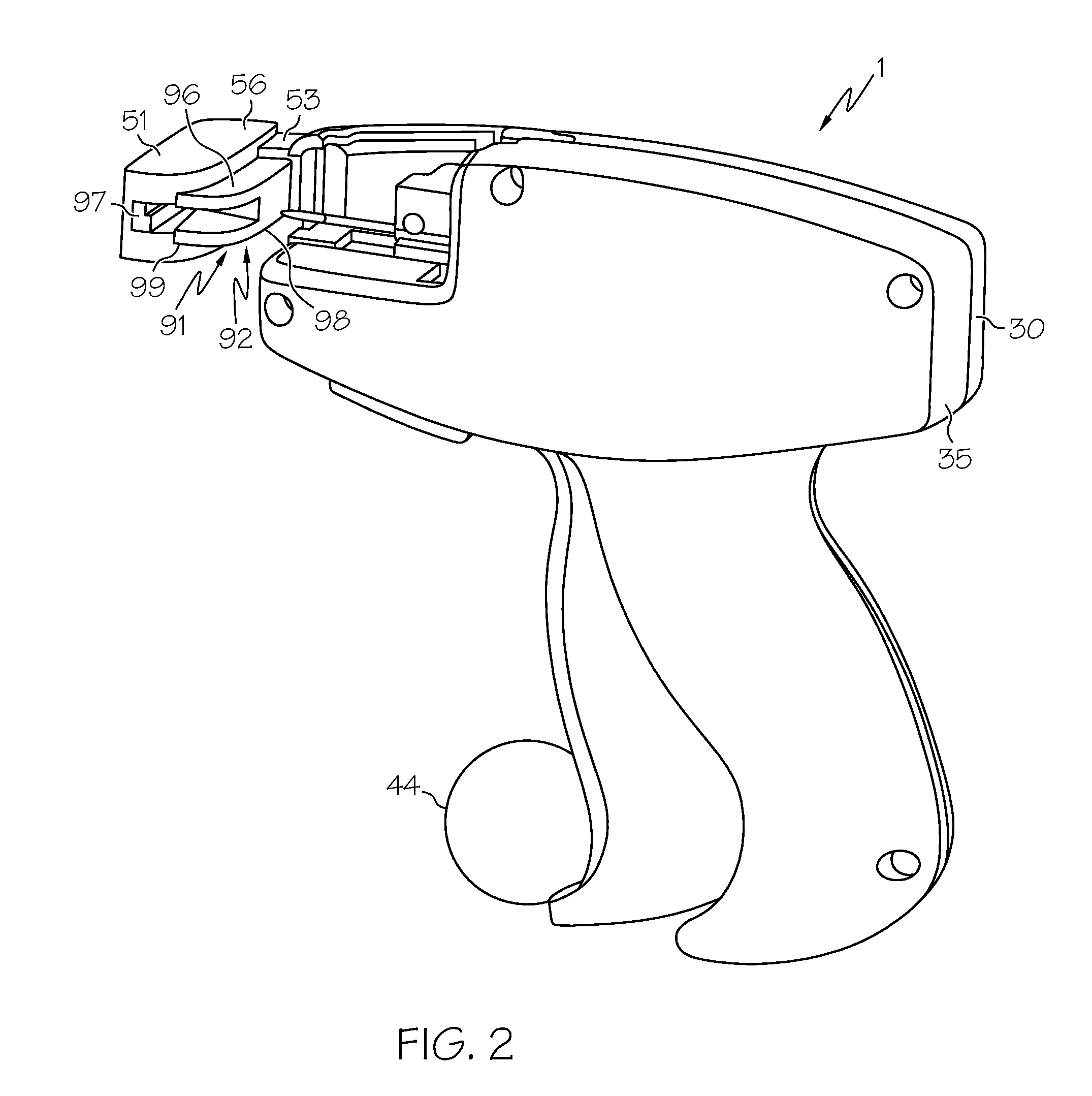

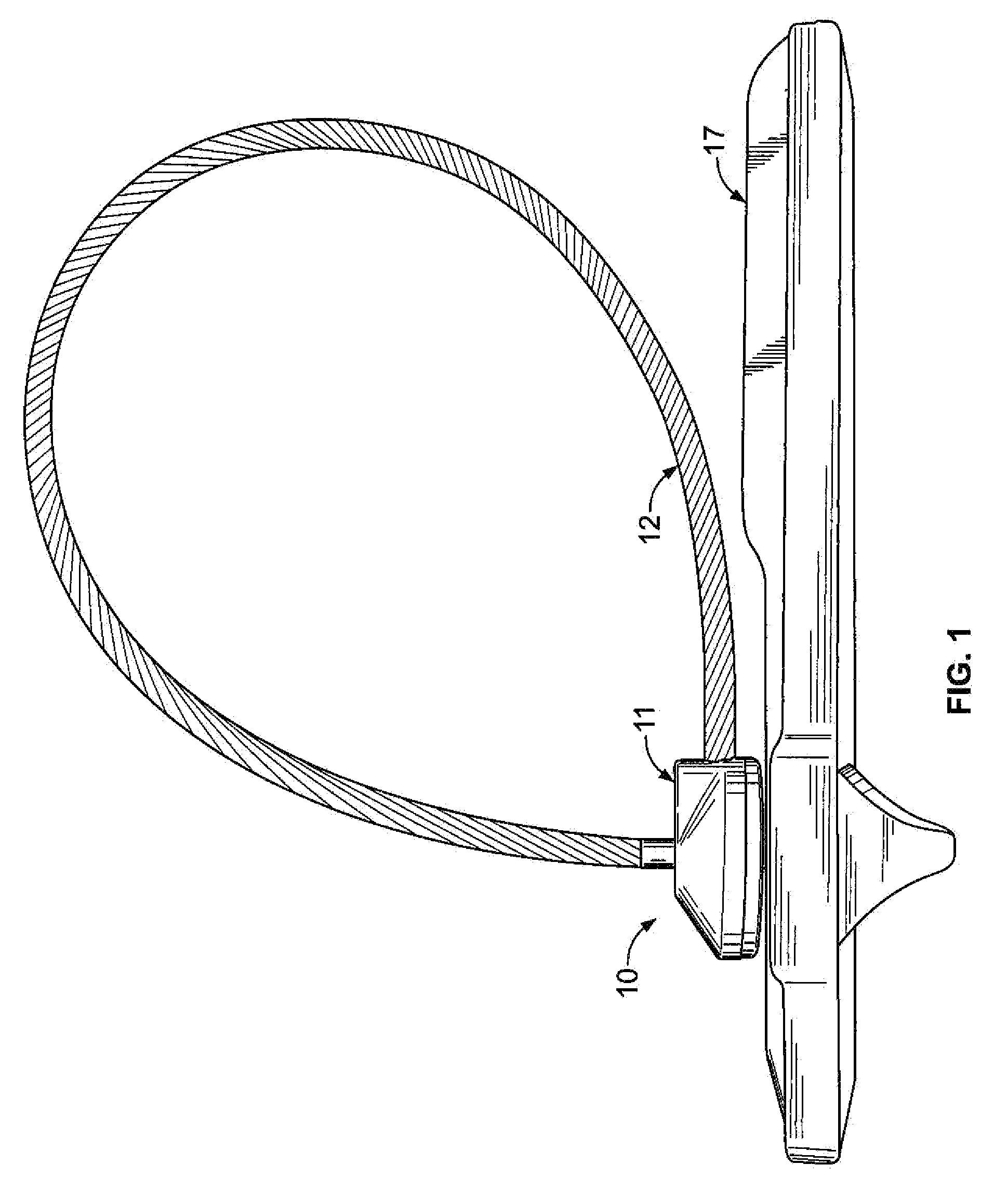

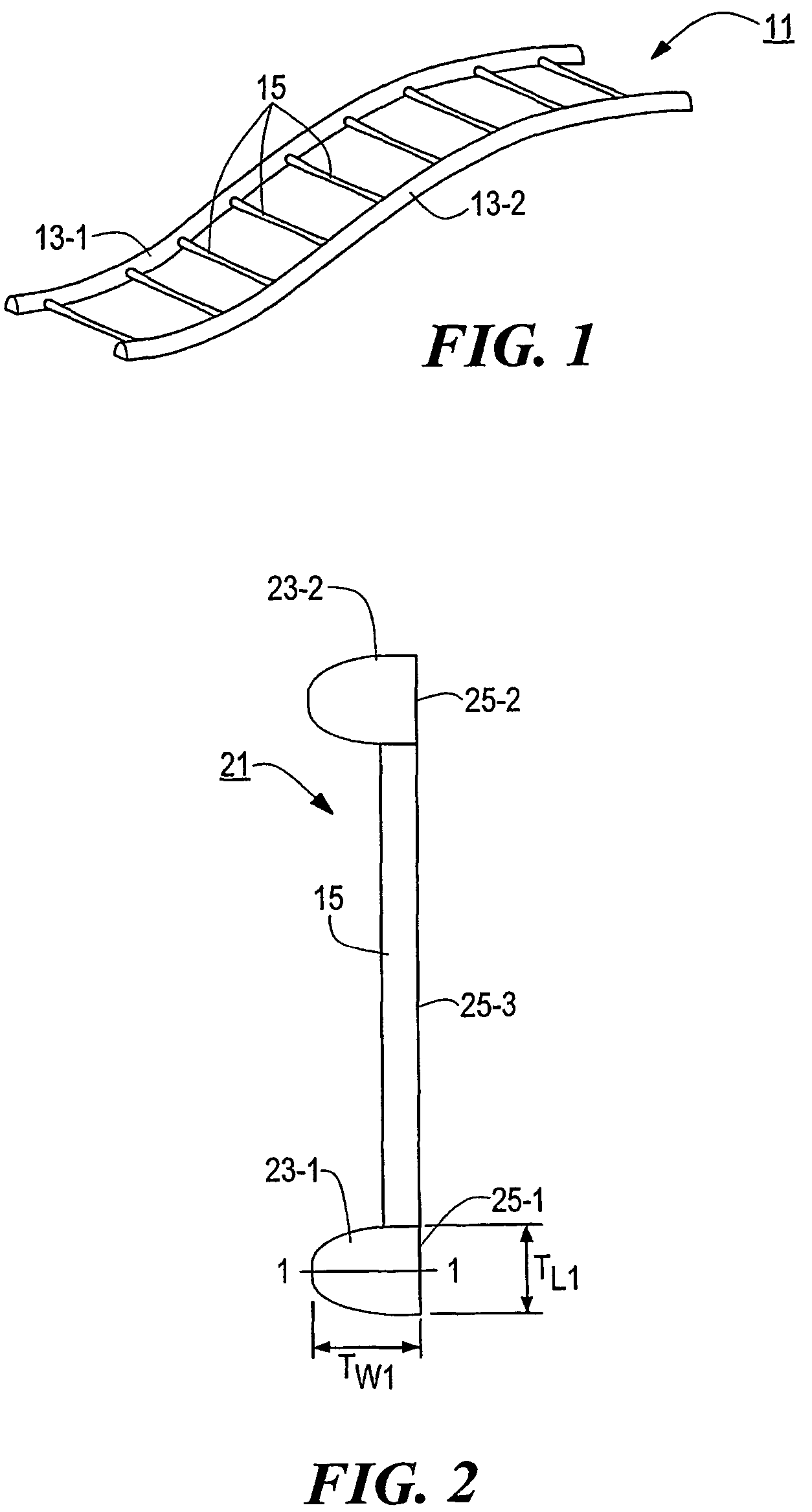

Tool for dispensing plastic fasteners

ActiveUS7331497B2Smooth trigger strokeReduce in quantityLabelling deformable materialsAffixing tagsSyringe needleBiomedical engineering

A tool for dispensing fasteners from a fastener clip having a runner bar comprises a housing shaped to include a handle portion, a barrel portion and a guide channel for receiving the used portion of the runner bar. A trigger assembly is pivotally mounted in the handle portion. The tool also includes a needle slide slidably mounted in the barrel portion, a needle coupled to the needle slide, and a needle slide link coupling the needle slide to the trigger assembly. An ejector slide is slidably mounted within the needle slide and adapted to receive an ejector rod which is insertable back and forth through the hollow needle. The needle slide and the ejector slide are independently coupled to the trigger assembly. An anvil extends out in front of the barrel portion and is adapted to receive a removable brush, the needle being aligned to selectively project into the brush.

Owner:AVERY DENNISON CORP

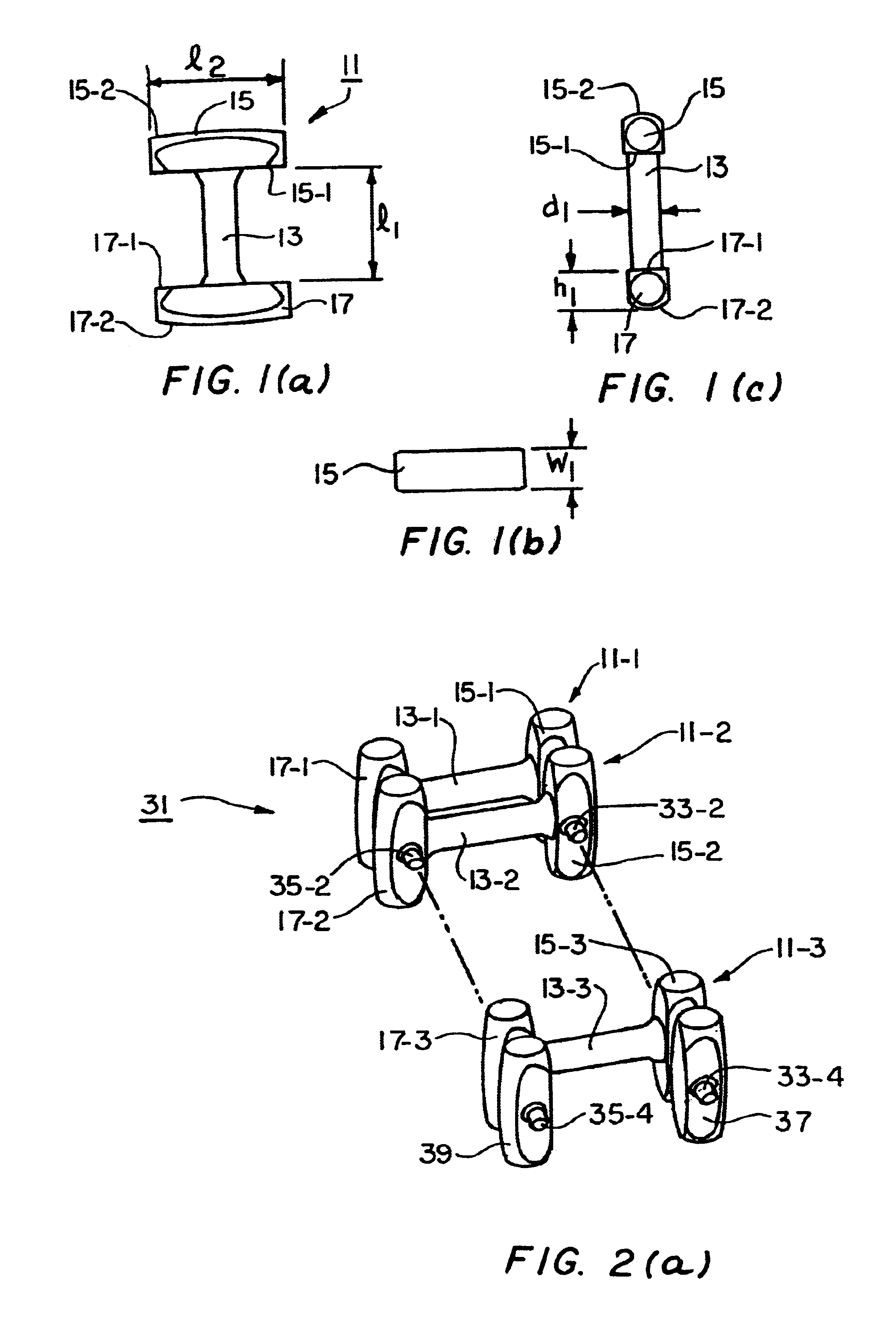

Plastic fastener, fastener clip, fastener dispensing tool and method of fastening objects

According to one embodiment, the plastic fastener comprises a flexible filament having a length of about 4.3 mm and a tensile strength of about 2 pounds, a first transverse bar located at one end of the flexible filament, and a second transverse bar located at the opposite end of the flexible filament. The fastener clip, which preferably does not contain a runner bar, comprises a plurality of identical fasteners of the aforementioned type, each of the fasteners being arranged in a parallel, side-by-side, spaced relationship. A connector post connects the first transverse bars of adjacent fasteners, and a connector post connects the second transverse bars of adjacent fasteners. An extra transverse bar is connected by a connector post to the first transverse bar of the last fastener, and another extra transverse bar is connected by a connector post to the second transverse bar of the last fastener, the extra transverse bars not being interconnected by a flexible filament.

Owner:AVERY DENNISON CORP

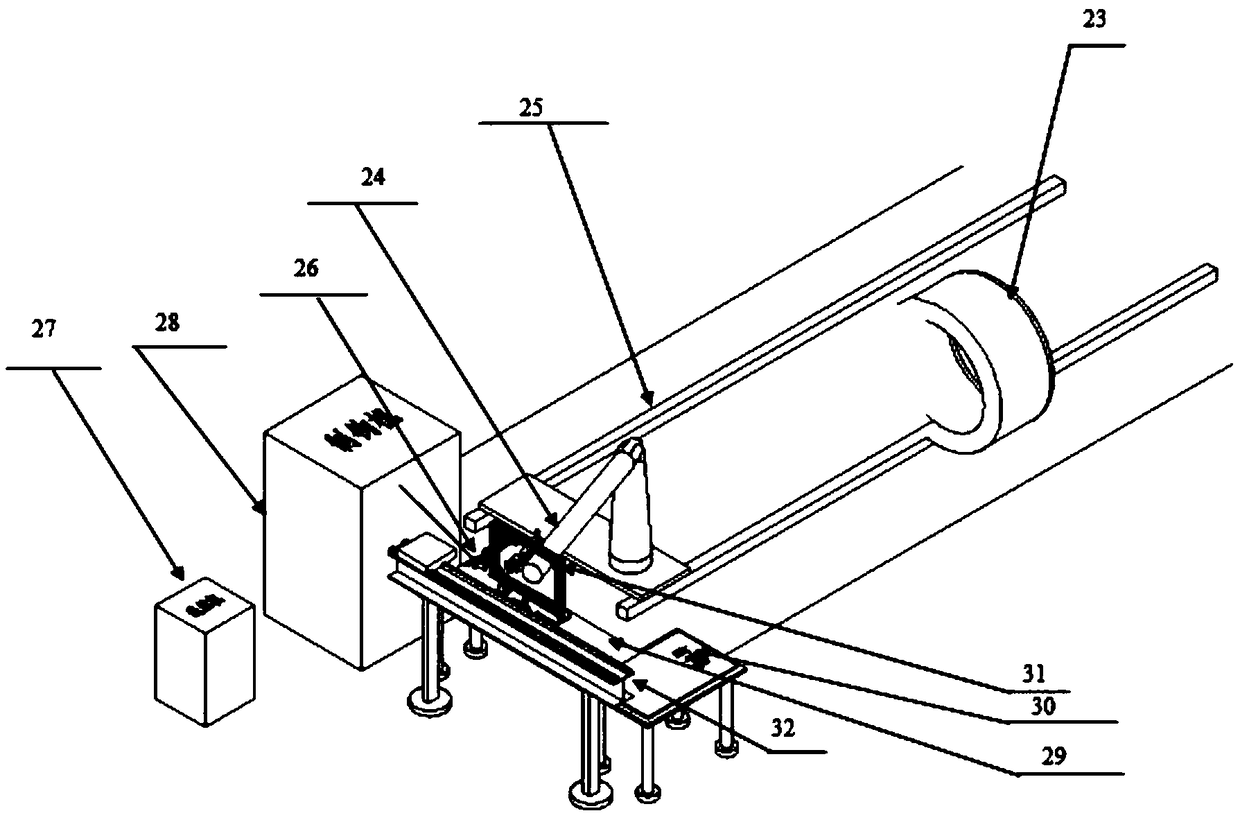

Binding equipment for textile industry

InactiveCN101450719ALow costOptimize layoutLabelling deformable materialsAffixing tagsSOCKSElectric machinery

The invention relates to binding equipment in the textile industry, which comprises a frame, an actuating unit, a hold-down mechanism, a steel needle movement mechanism and a plastic pin extruding mechanism, wherein the hold-down mechanism, the steel needle movement mechanism and the plastic pin extruding mechanism which are connected to the actuating unit are driven by the actuating unit to reciprocate up and down along a guide rail on a guide rail support of the frame; and the actuating unit is fixed on the frame. The binding equipment is characterized in that the actuating unit is an electric mechanism. The equipment is suitable for binding clothes, shoes and hats, and socks in families or individual workshops, and can be used for binding hangtags or a plurality of pairs of socks. The equipment is suitable for binding products with different thicknesses, and can bind plastic pins with different specifications through adjustment. The equipment is operated by means of driving two cams and a connecting rod by a motor, and changes the phenomenon that the prior equipment realizes binding through three cylinders. The binding equipment has the advantages of no air source limitation tooperation places and simple and reliable operation.

Owner:上海允科自动化有限公司

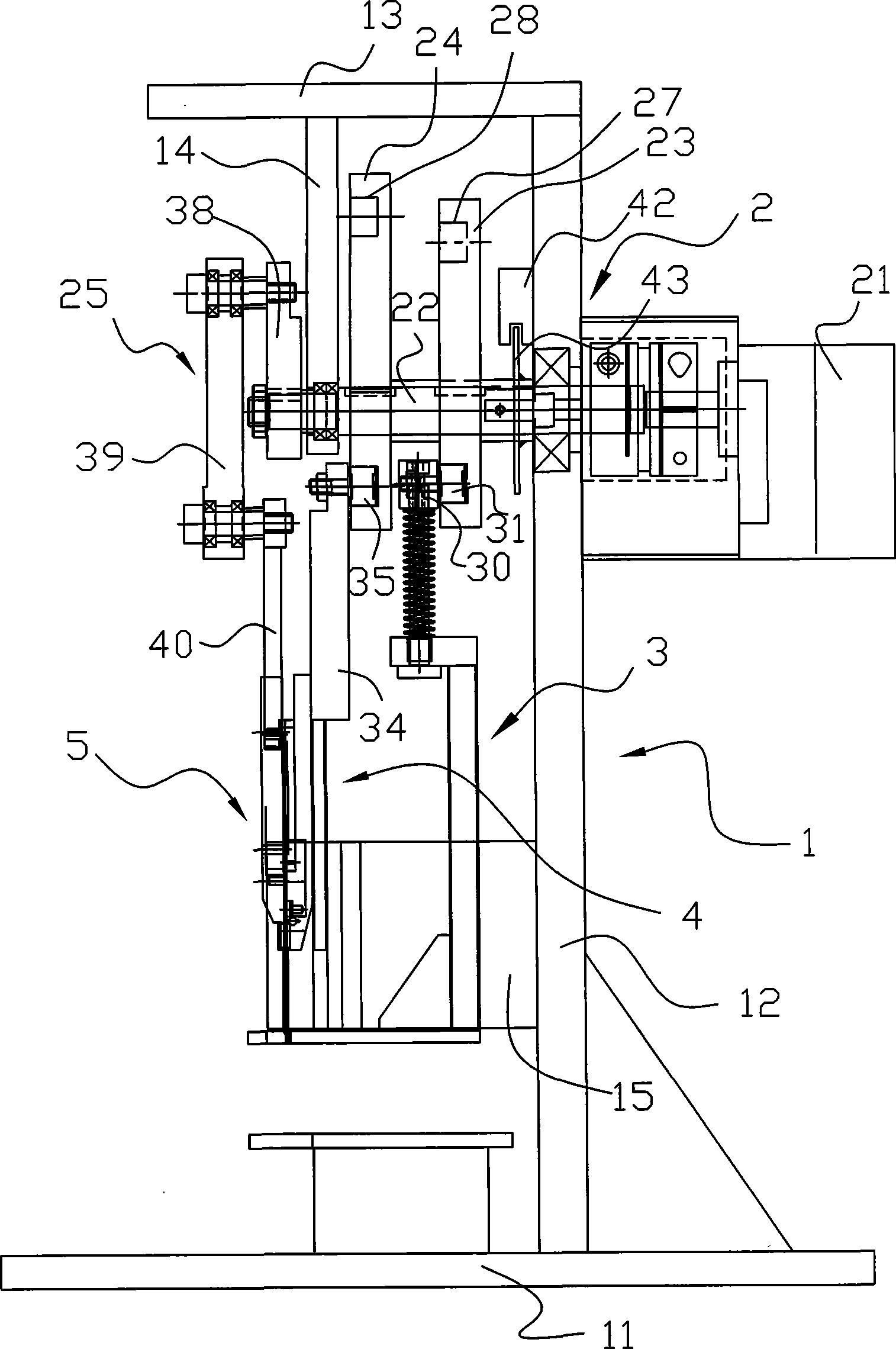

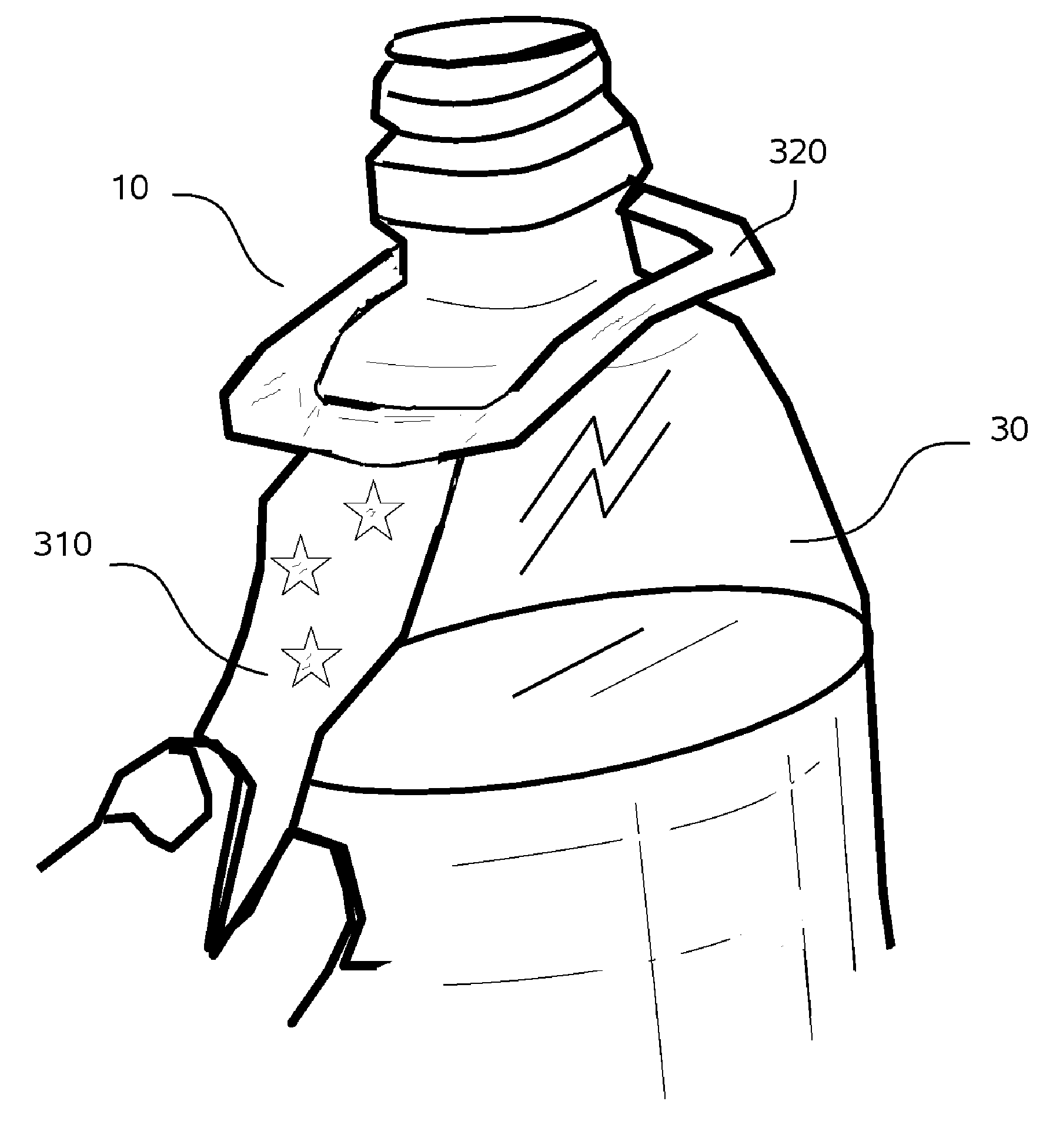

Method of Attaching a Label to a Thermoplastic Substrate

InactiveUS20080053605A1Reliable methodLamination ancillary operationsAffixing tagsThermoplasticEdge surface

A label with top, bottom and edge surfaces is attached to a thermoplastic substrate by a method comprising the steps of:A. Placing the bottom surface of the label in contact with a surface of the substrate;B. Melting a portion of the substrate beneath the label or adjacent to an edge of the label;C. Drawing a portion of the melted substrate over an edge of and onto the top surface of the label such that the portion of the melted substrate on the top surface of the label is continuous with the substrate; andD. Solidifying the melted substrate.The attachment does not require adhesive or mechanical fasteners, and the label and thermoplastic substrate can be made of any material that will withstand the conditions of the environment to which they will be exposed.

Owner:BRADY WORLDWIDE INC

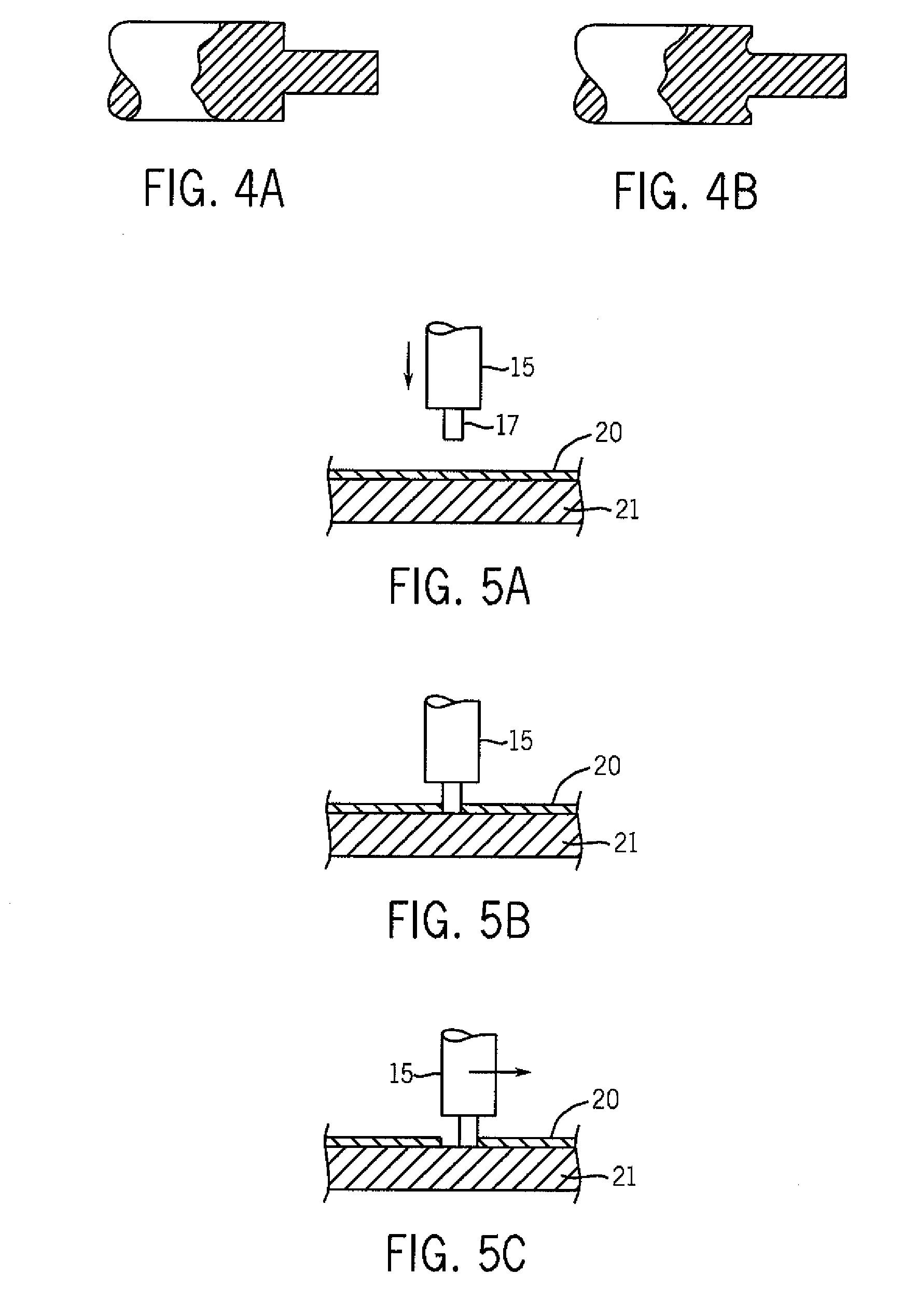

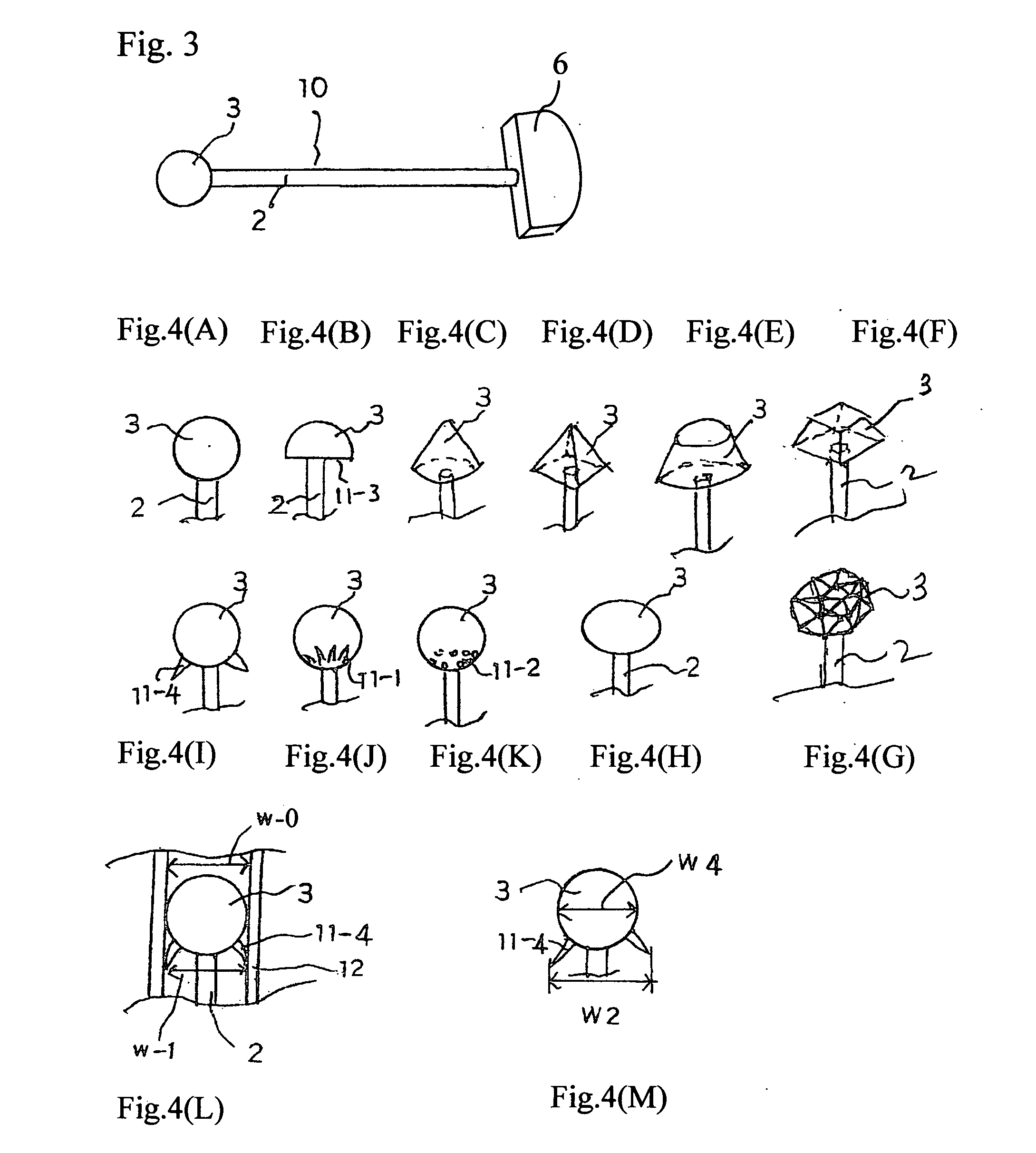

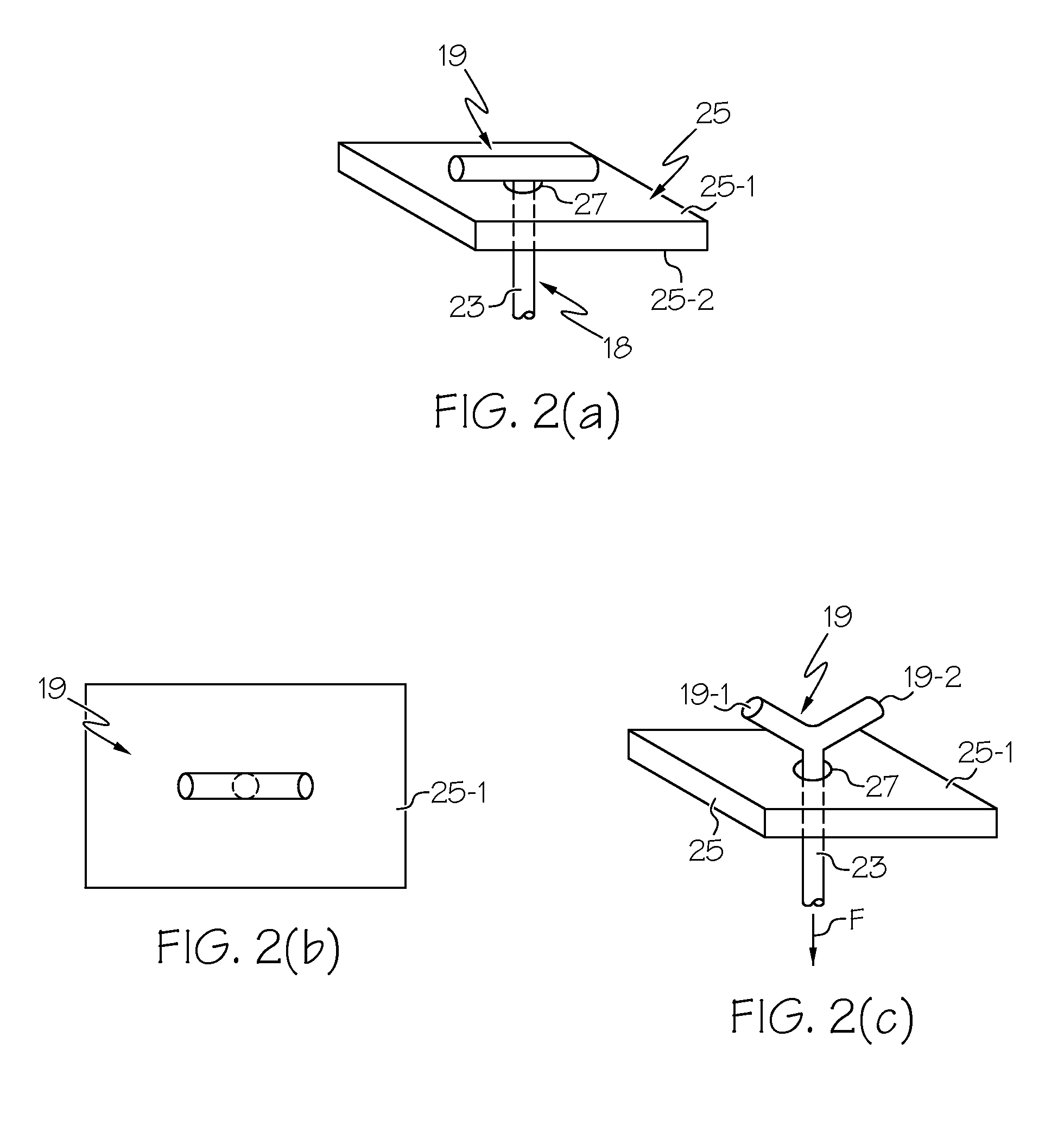

Fastener, a fastener assembly and a fastener attaching device

A fastener and a fastener assembly for fastening a plurality of layered goods or for attaching a tag to a good has at least one bulged massive portion provided at one end of a filament portion instead of a conventional T-bar end. A fastener attaching device shoots the fastener of the present invention through the goods to attach the fasteners.

Owner:DESCHENES CHARLES L

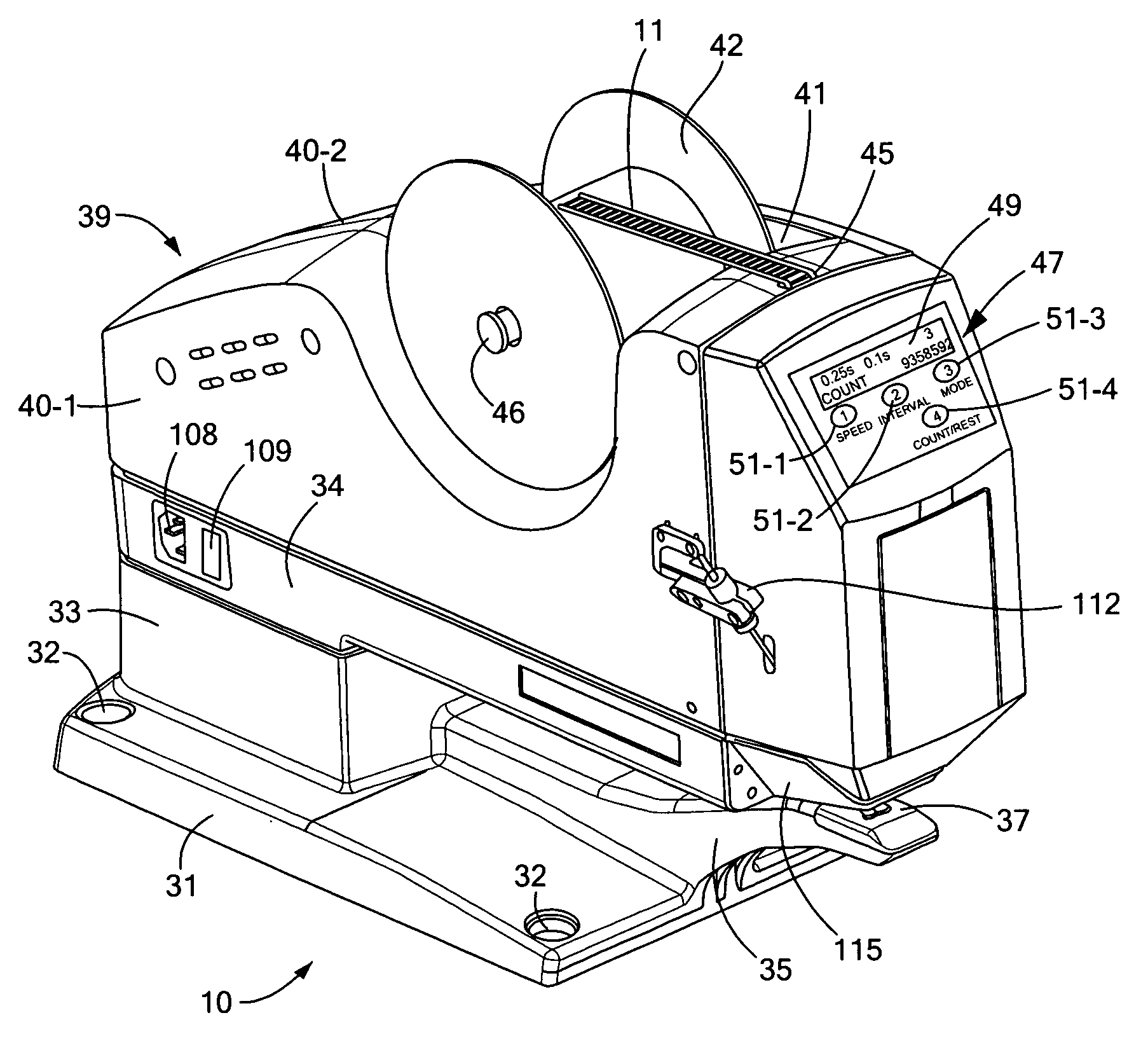

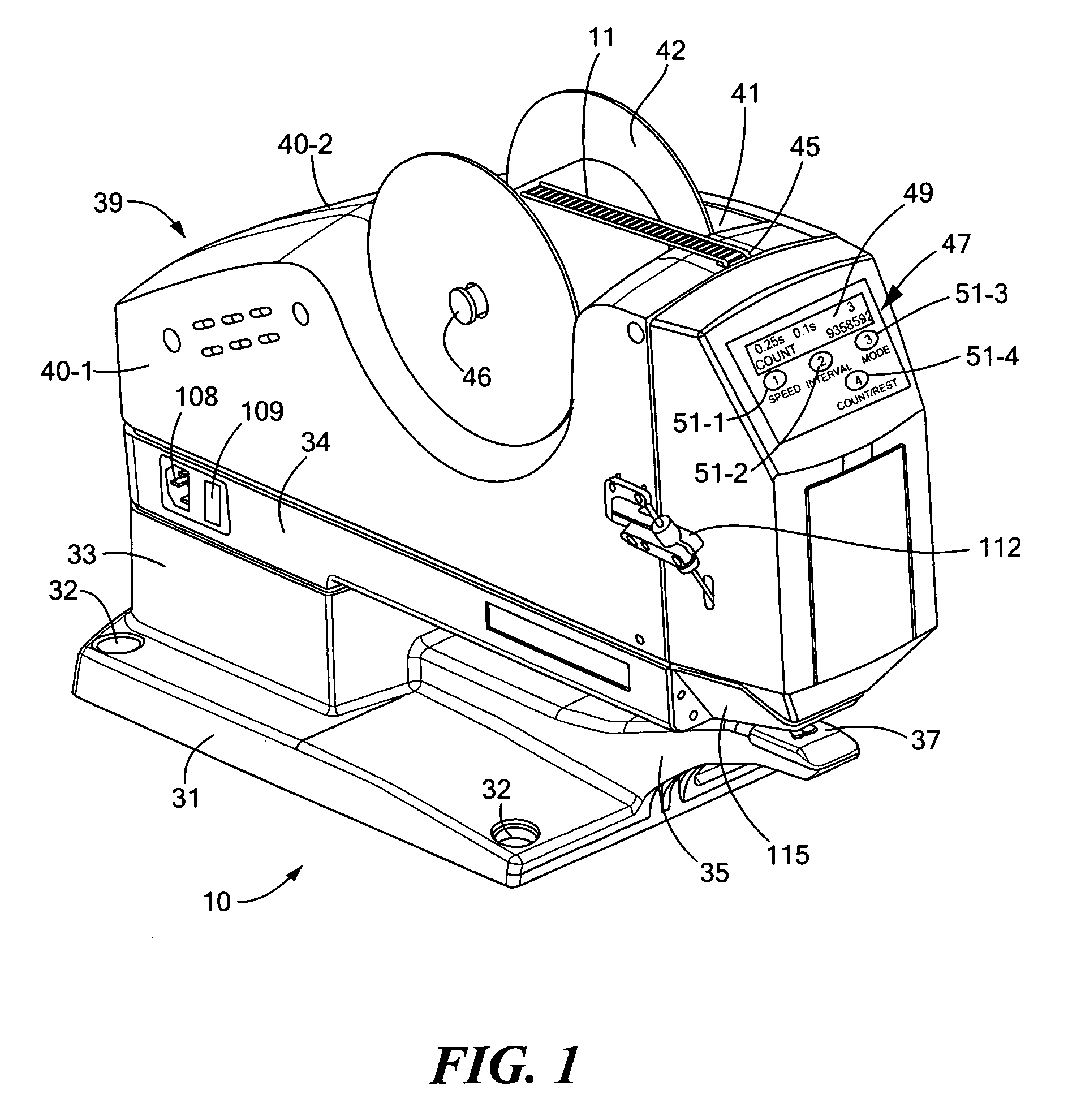

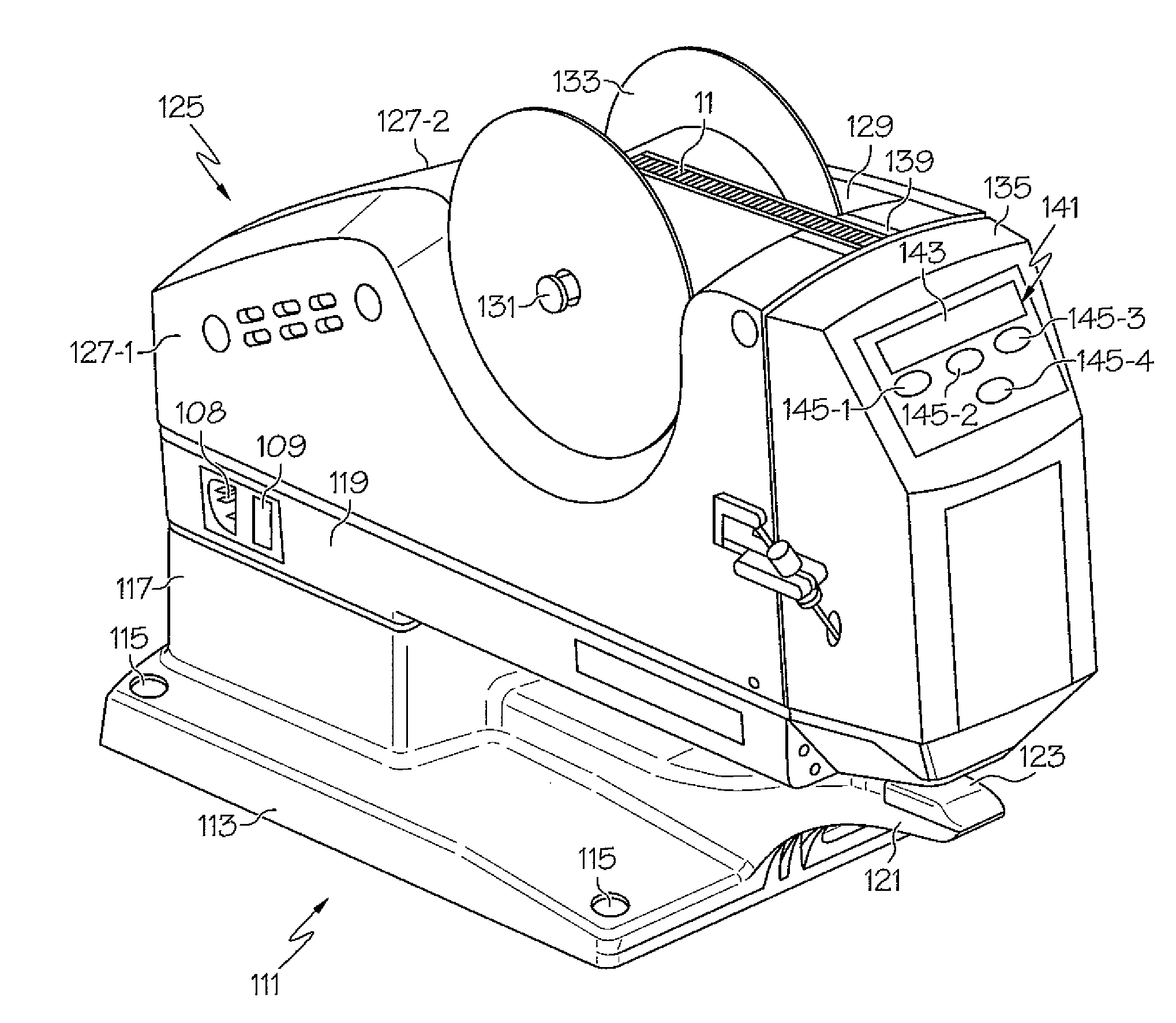

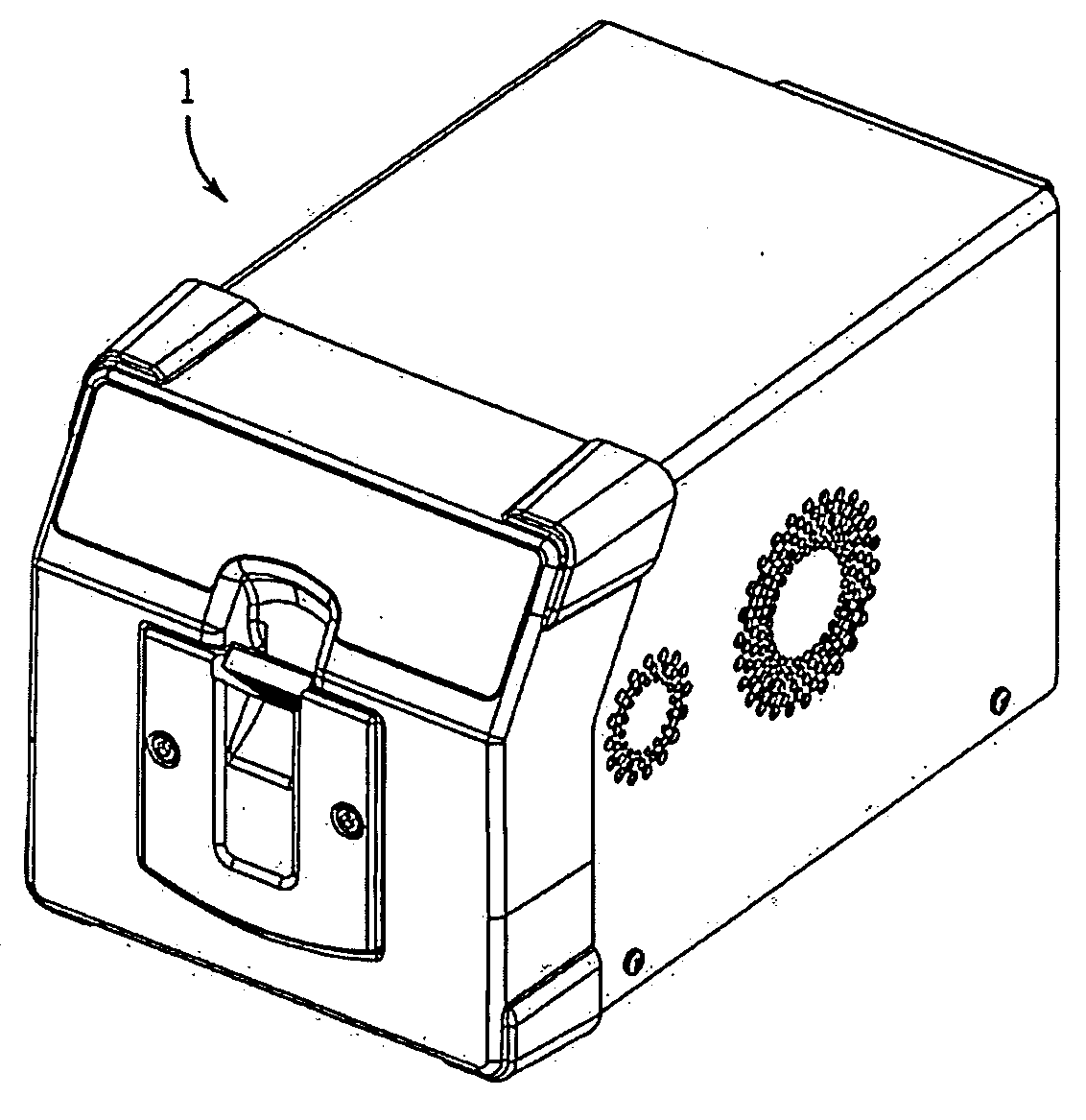

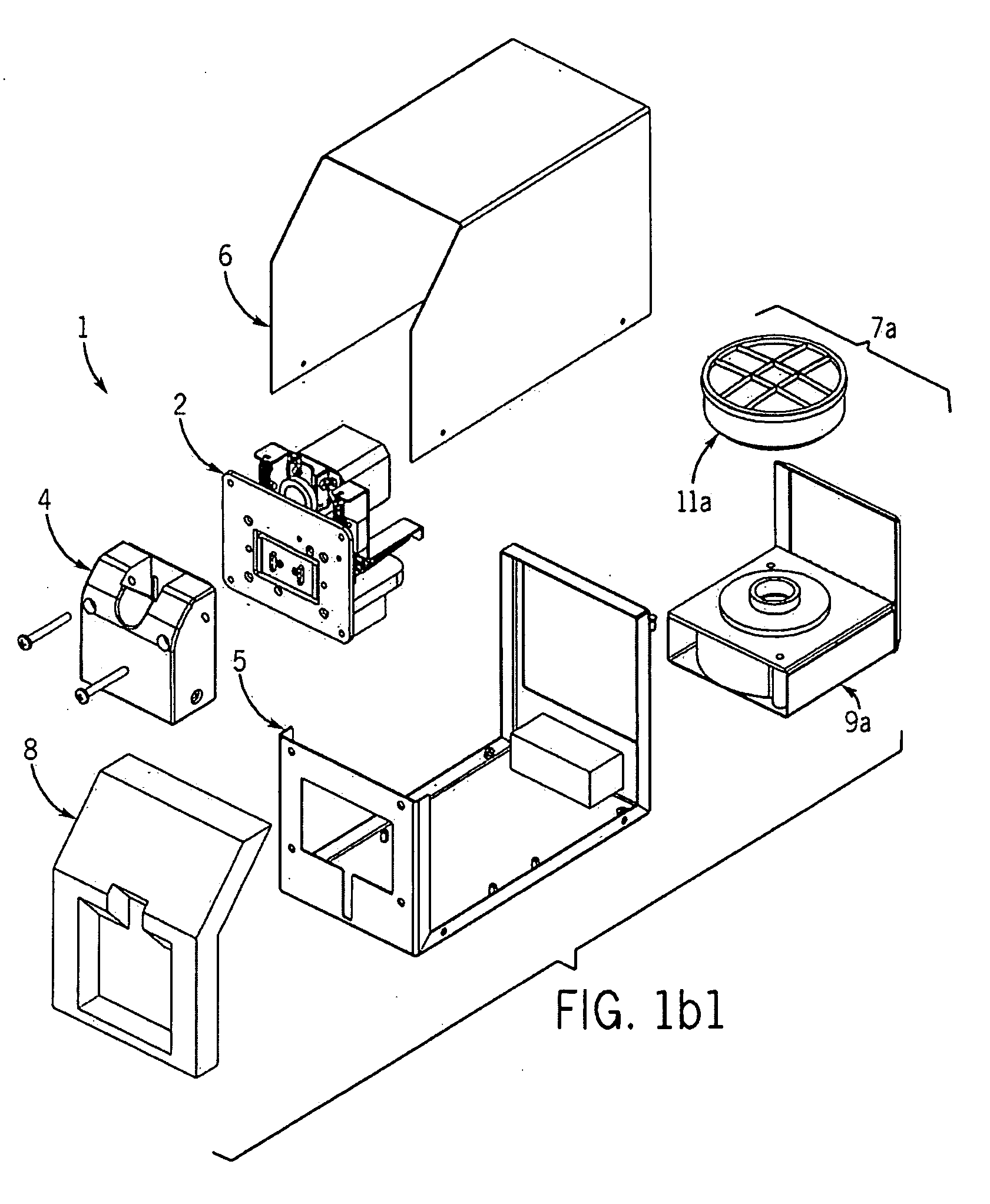

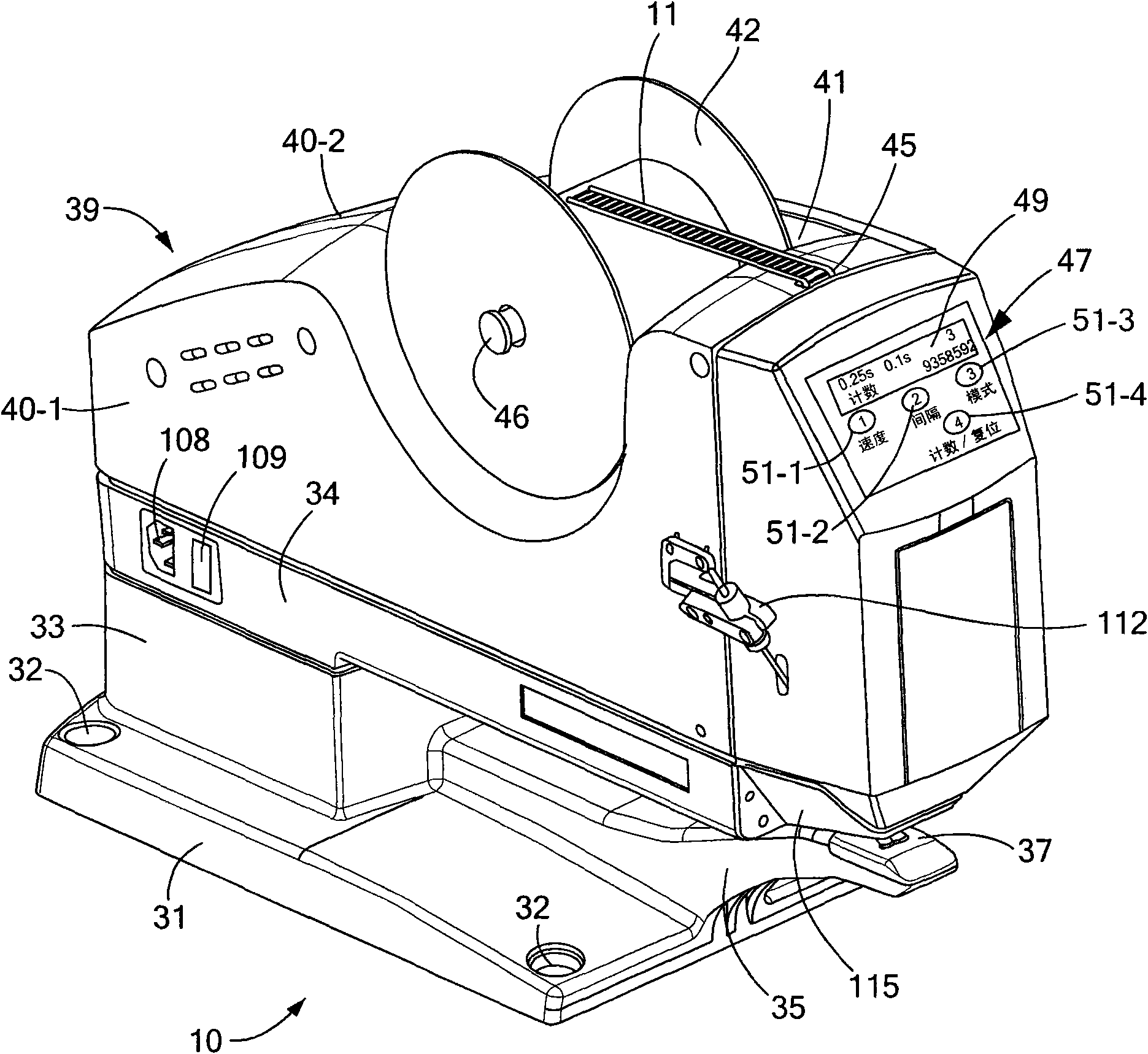

Device for dispensing plastic fasteners

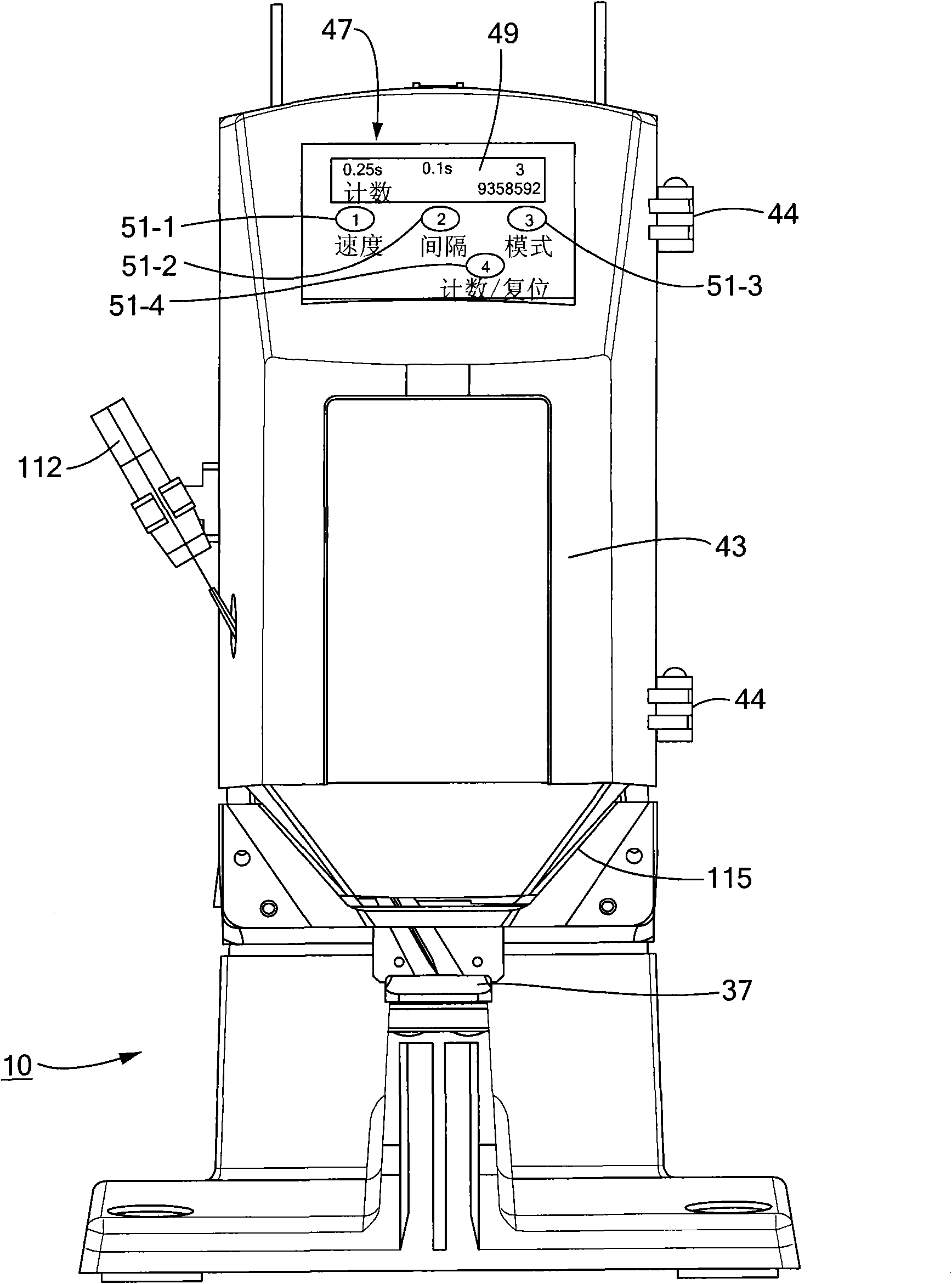

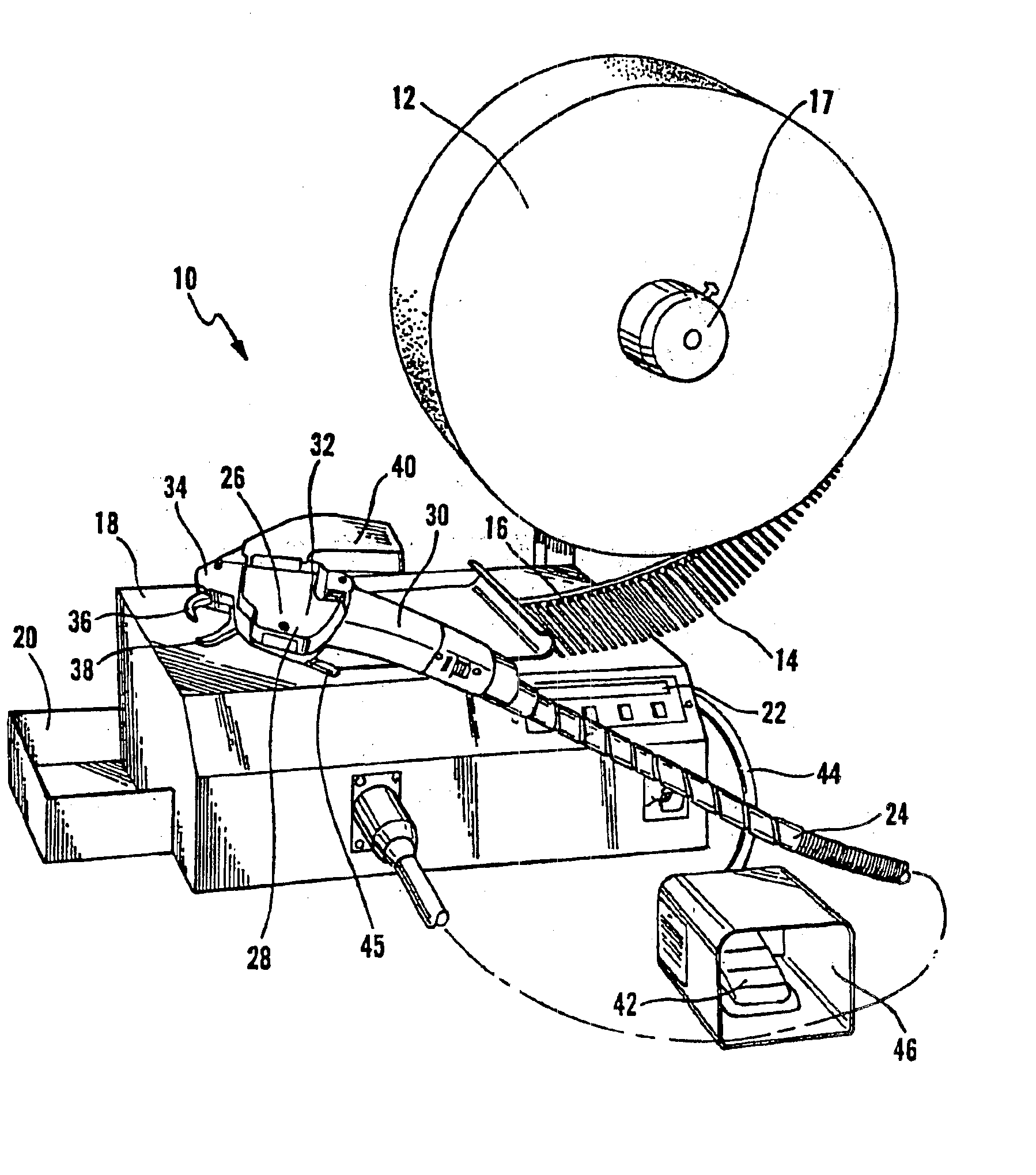

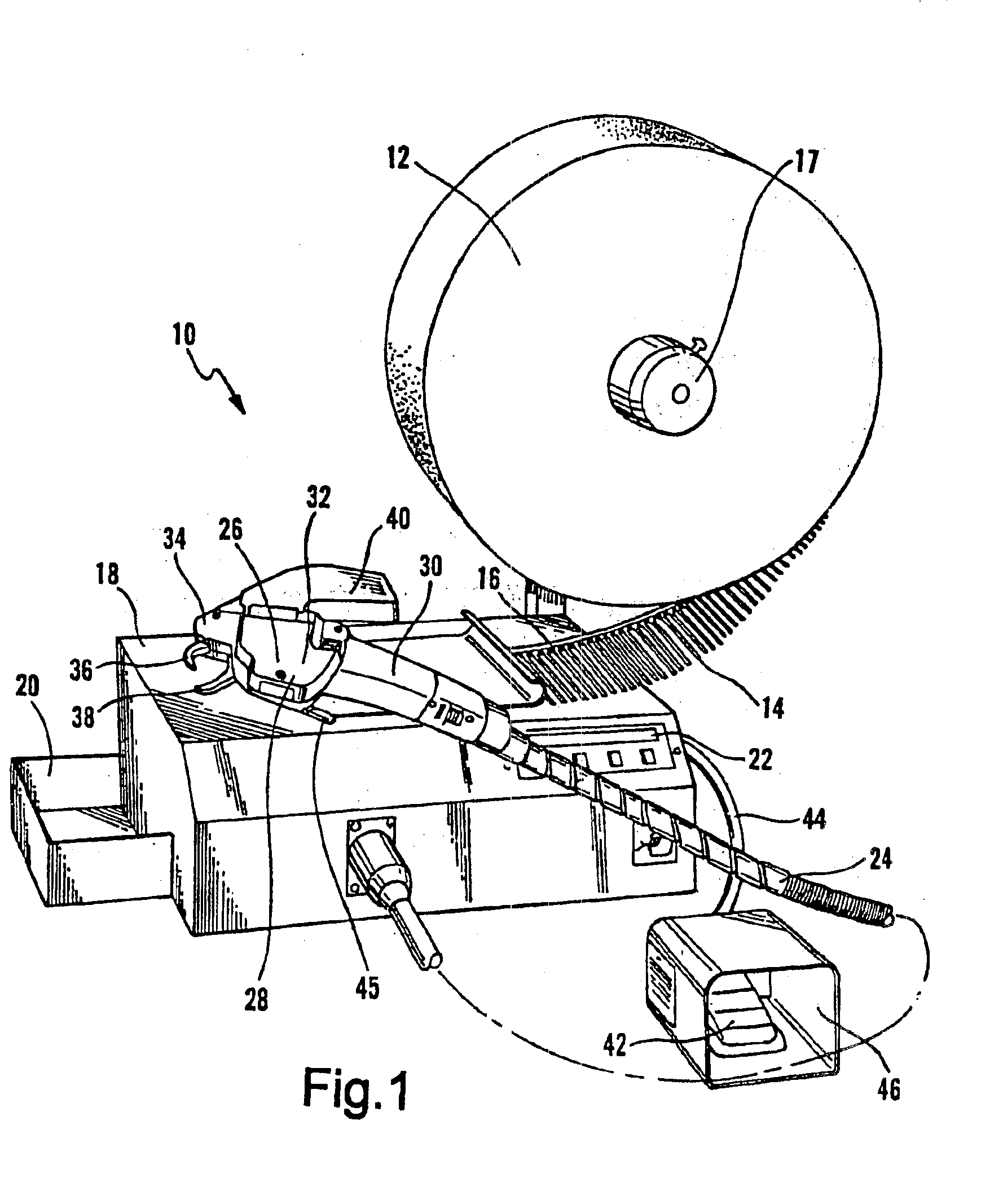

ActiveUS20080164271A1Maximize productivityEnergy efficiencyStampsAffixing tagsPower switchingControl theory

A device for dispensing individual plastic fasteners from a continuous supply of 0.1875 inch pitch ladder stock includes a head assembly that is designed to receive the supply of ladder stock, sever an individual fastener from the supply ladder stock and eject the individual fastener during a single stroke of its actuation cycle. The device also includes a stepper motor for driving the head assembly through its actuation cycle, a DC power switching supply for regulating the power supplied to the stepper motor from an AC input power source, and a controller for collecting historical data relating to usage of the device and for regulating operation of the stepper motor. The controller is programmed to enable certain operational characteristics, such as stroke speed and mode, to be regulated through a user interface which includes a screen display and a plurality of control buttons.

Owner:AVERY DENNISON CORP

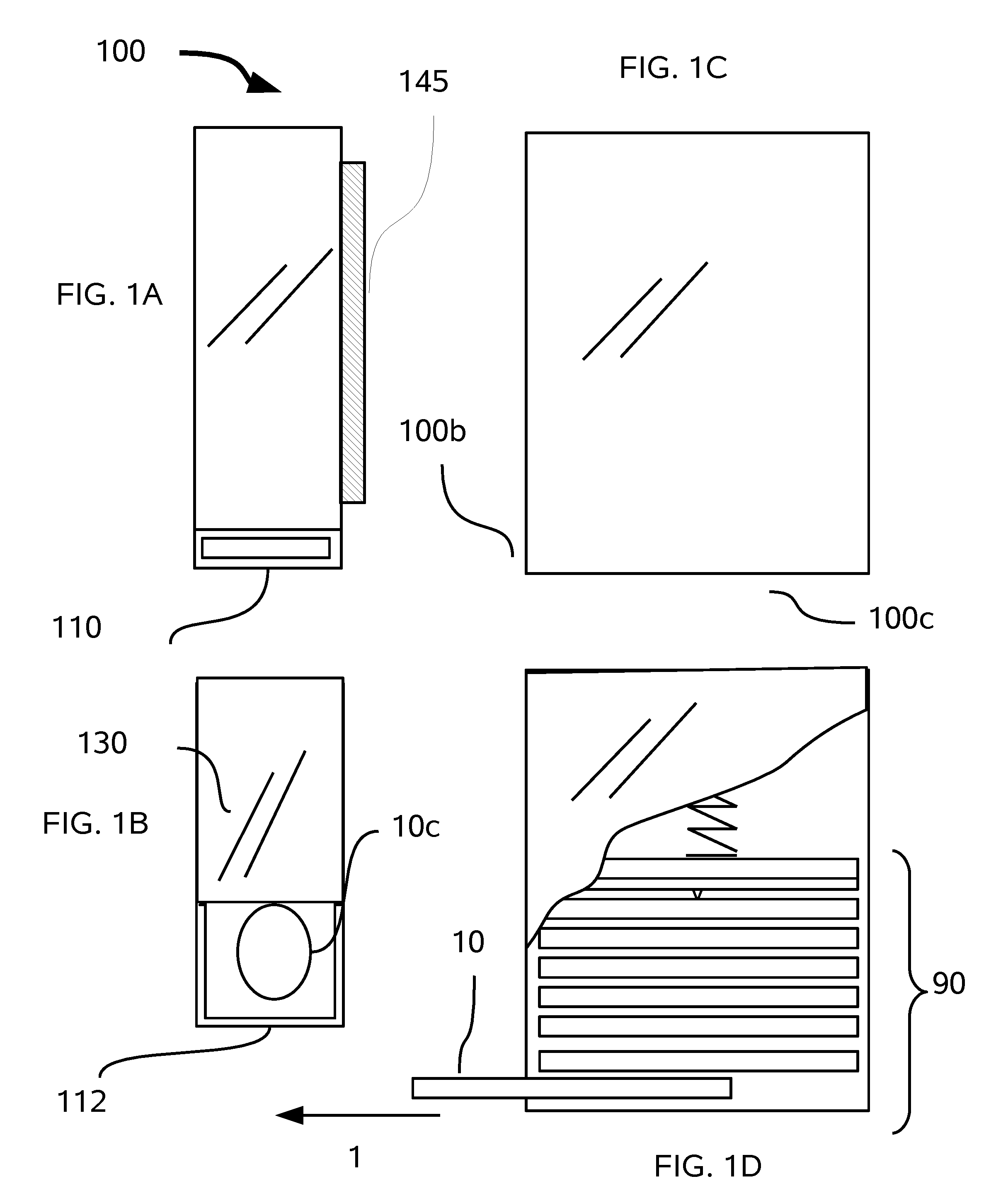

Beverage Label System and Dispenser

A bottle label means having a hole on one side and an ID means on the other is optionally dispensed from a roll or stack by inserting the neck of the bottle into the hole whereby the removal provide another label that is ready for removal by a second bottle. Preferably, the labels are not identical so that each bottle has a unique identification on it without the need to write on the label.

Owner:NEWMARK CHARLES M

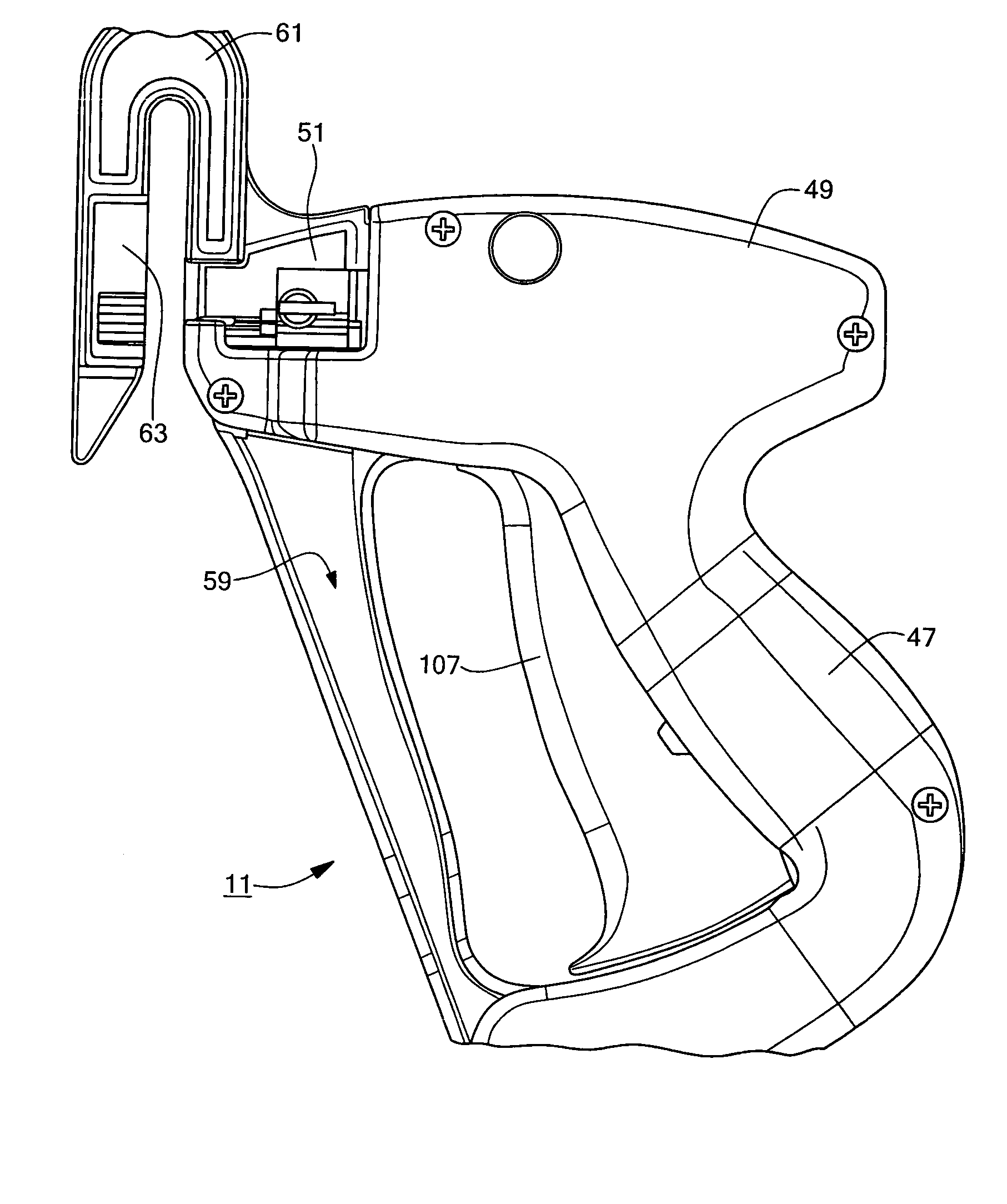

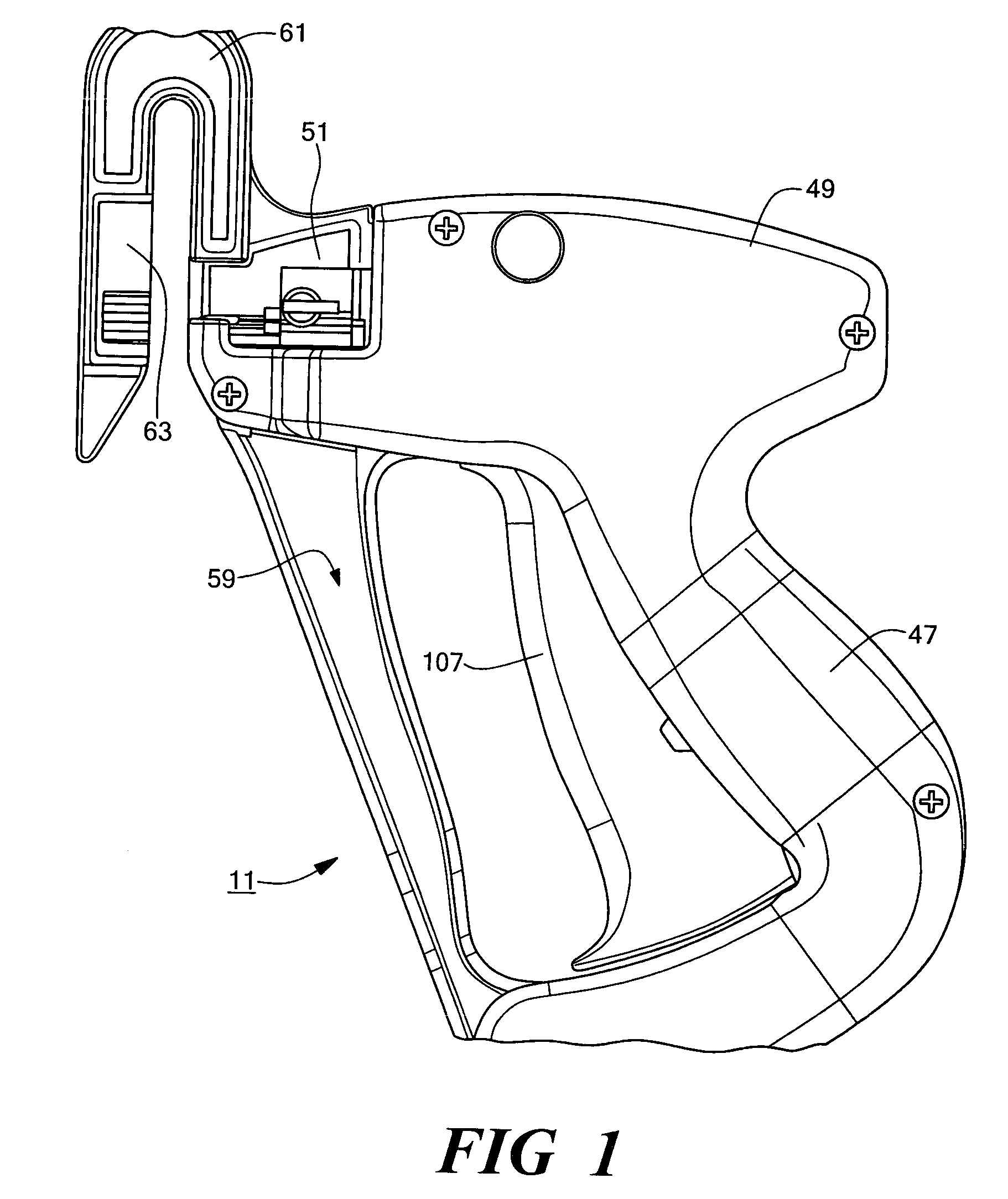

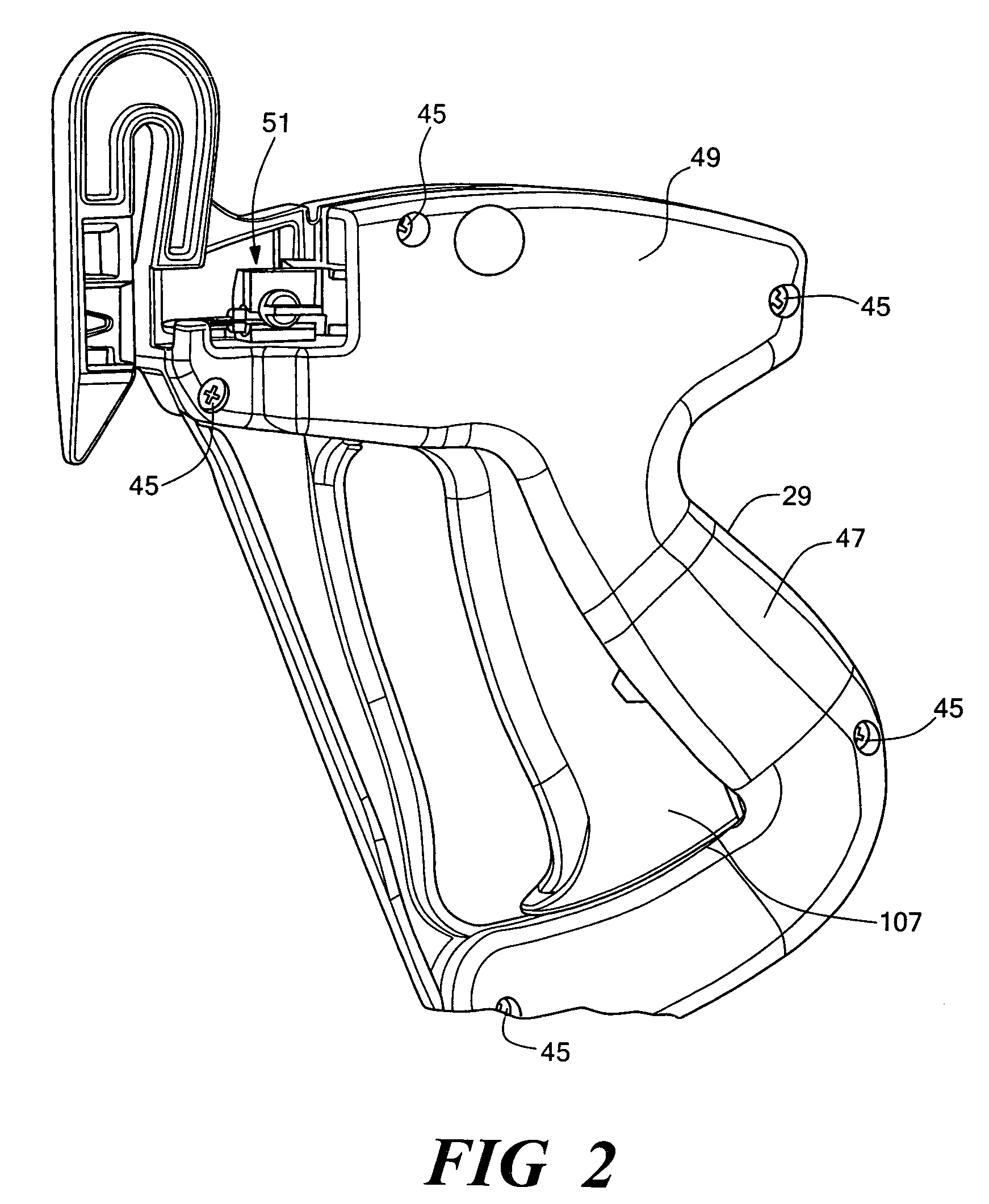

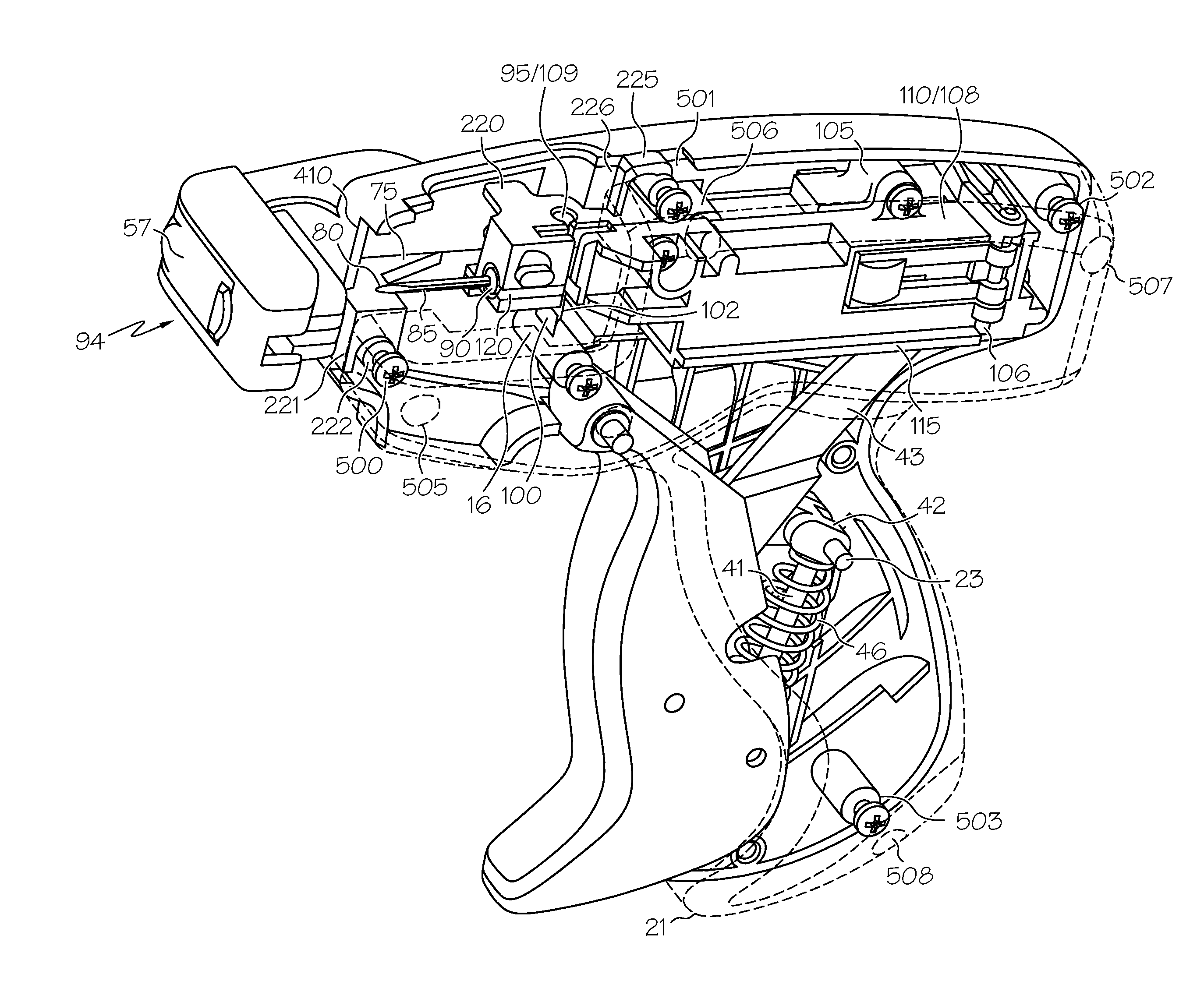

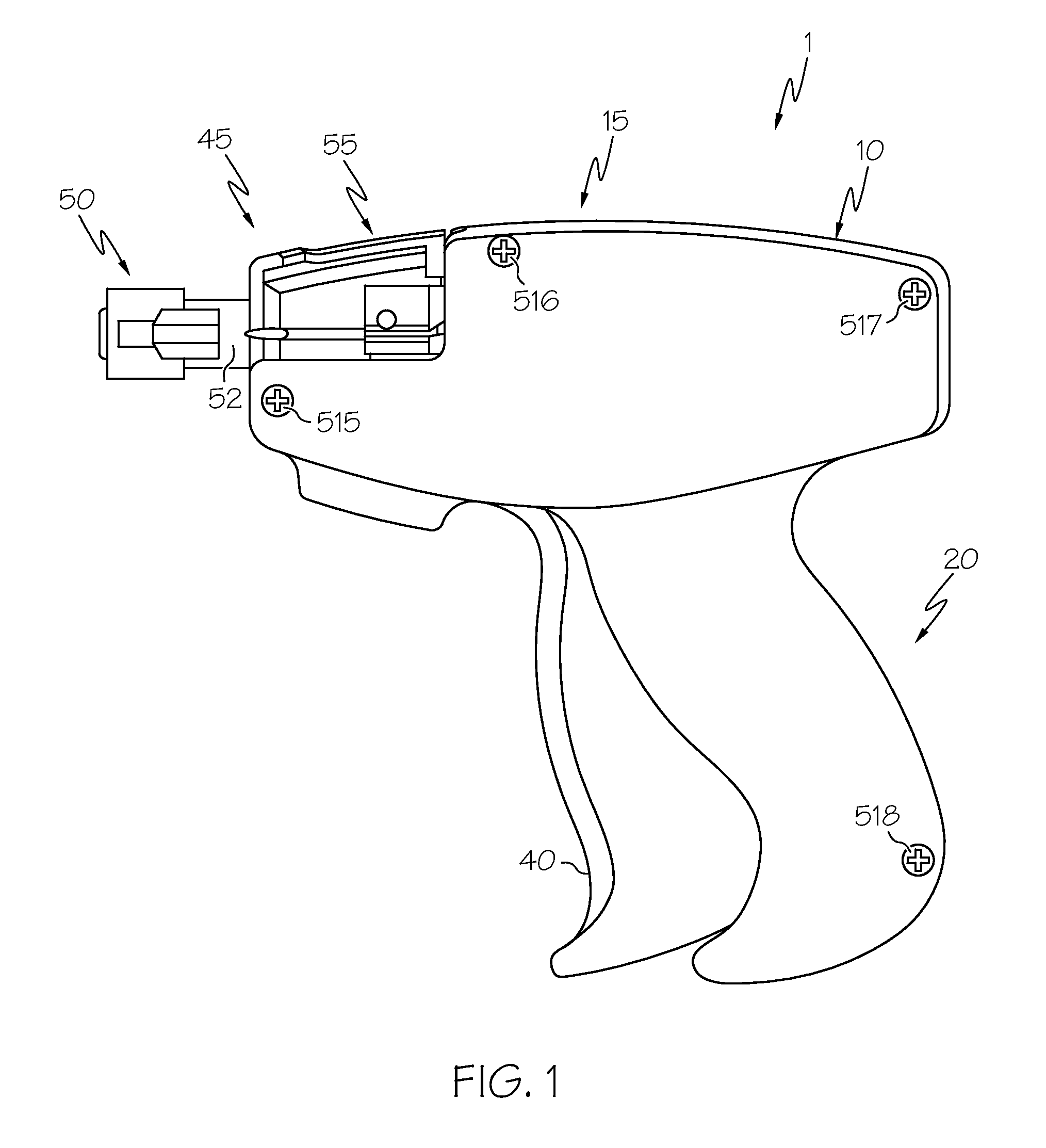

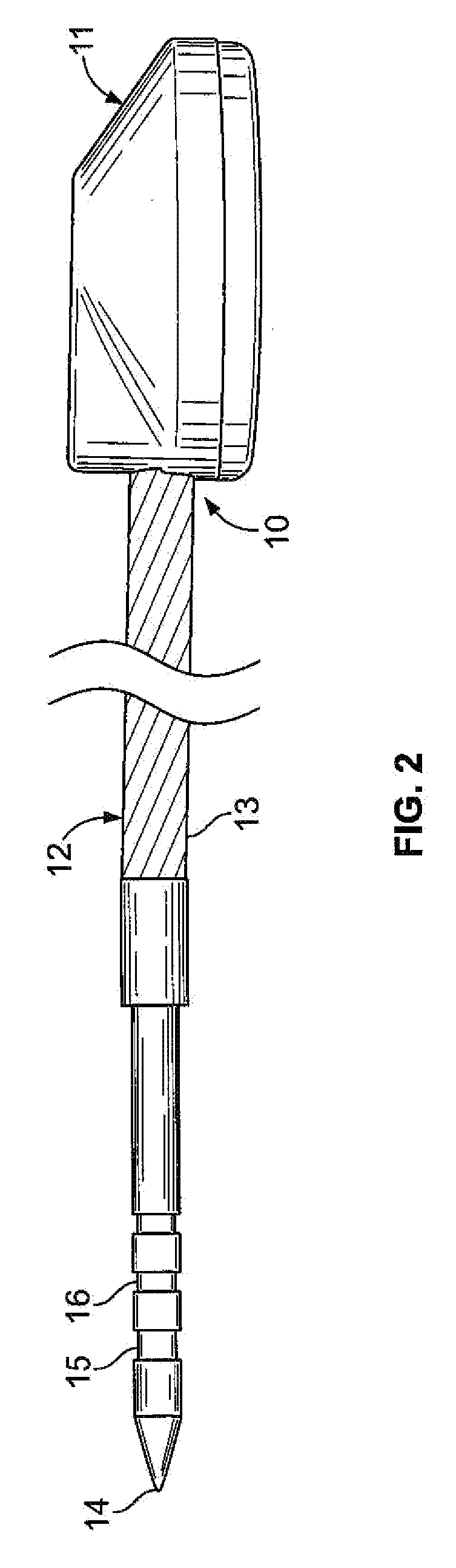

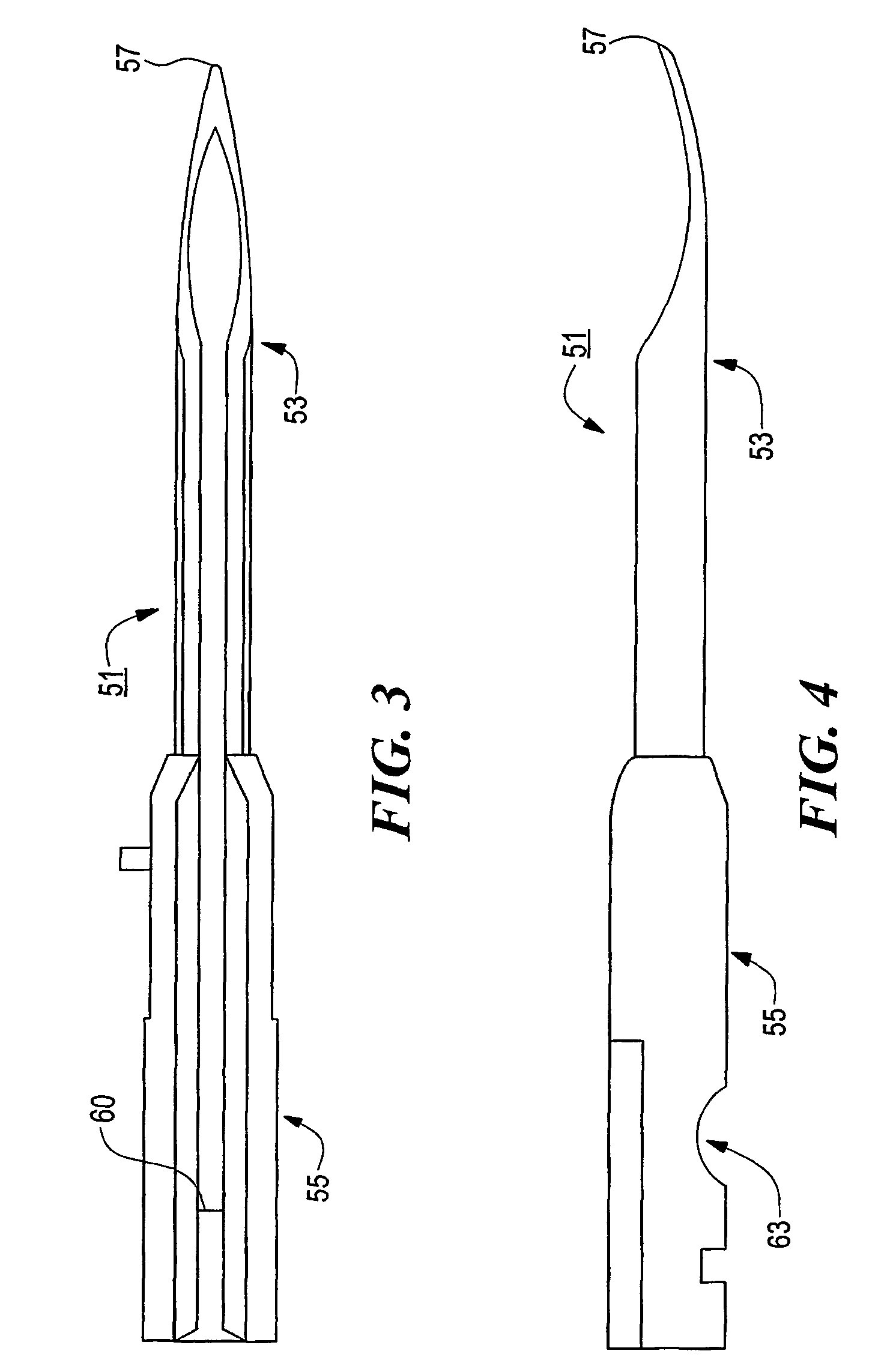

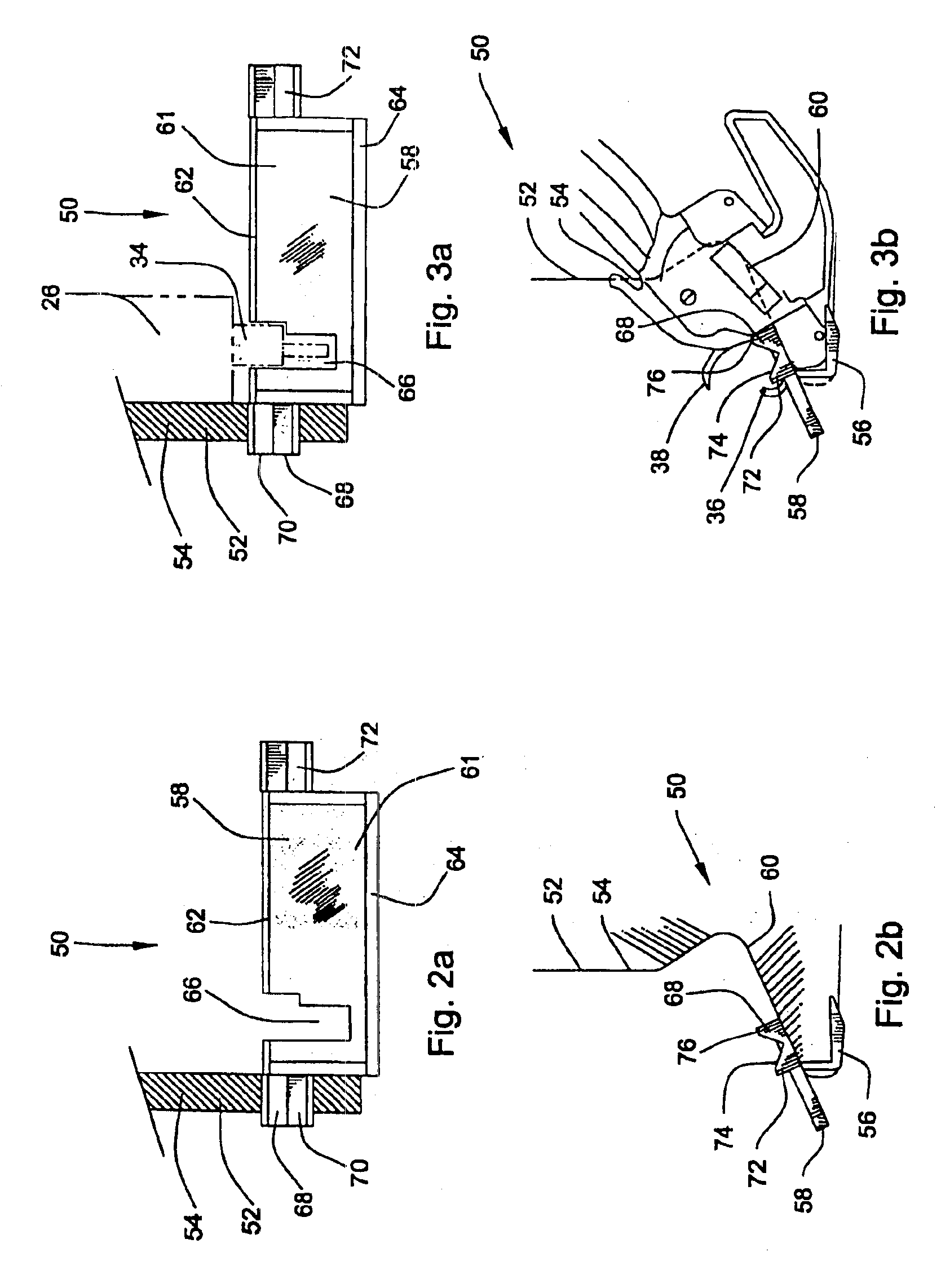

Plastic Fastener Dispensing Hand Tool Having a Novel Anvil Design to Reduce Needle Sticks

ActiveUS20110220701A1Inadvertent cutAffixing tagsPortable labelling toolsSyringe needleBiomedical engineering

An improved hand tool for dispensing plastic fasteners having a novel anvil design that reduces inadvertent user needle sticks during operation of the hand tool and a needle having a novel casing that further reduces inadvertent user needle sticks during the replacement of the hand tool needle. The hand tool has a gun shaped casing with a barrel portion and a handle portion. The casing has a needle assembly opening at the front of the barrel portion and a trigger slot at the front of the handle portion. The hand tool further has a hollow needle disposed on one end of a needle assembly. The needle assembly is slidably movable back and forth between a retracted position disposed substantially within casing and an extend position disposed substantially out of the casing through the needle assembly opening. The hand tool further has a trigger that is pivotally mounted within the casing that extends out from the trigger slot. The trigger is capable of moving the needle assembly between the retracted and extended positions. The hand tool further has an anvil. The anvil has a finger guide portion, a main portion, and a tag slot. The tag slot separates the finger guide portion from the main portion.

Owner:AVERY DENNISON CORP

Fastener assembly

A fastener assembly for coupling together two or more articles includes a plastic fastener and an anchoring member. The plastic fastener includes a pair of parallel cross-bars that are interconnected by a transverse filament. The anchoring member is constructed as a unitary, solid, plastic disc with opposing flattened surfaces. In use, the anchoring member is disposed against an outer surface of the articles to be coupled together. During the fastener dispensing process, the ejected cross-bar penetrates through the articles as well as the anchoring member. Upon completion, the ejected cross-bar lies directly upon the exposed surface of the anchoring member. As such, the stiffened anchoring member provides structural integrity to articles that are deformable in construction. In this manner, the anchoring member prevents intact removal of a dispensed fastener by either intentional or unintentional widening of the hole in the articles through which the fastener extends.

Owner:AVERY DENNISON CORP

Automatic signage hooking system

The invention belongs to the field of automation, in particular to an automatic signage hooking system which includes a manipulator, a hook taking-off device, a positioning device, a wire transmissiondevice, a signage suction mechanism and a control device, the wire transmission device is used for outputting the wire to be marked, the signage suction mechanism is used for sucking the signage andmoving to the hook position, the hook taking-off device is used for clamping a hook and hanging the signage on the hook, the manipulator is used for hanging the hook with the signage on the wire, thecontrol device is connected with the manipulator, the hook taking-off device, the positioning device, the wire transmission device, and the signage suction mechanism, and the positioning device is used for obtaining position information of the wire to be hooked with the signage; and the control device is used for controlling the manipulator, the hook taking-off device, the wire transmission device, and the signage suction mechanism according to the position information obtained by the positioning device.

Owner:BEIJING ZHONGYUANTONG SCI & TECH

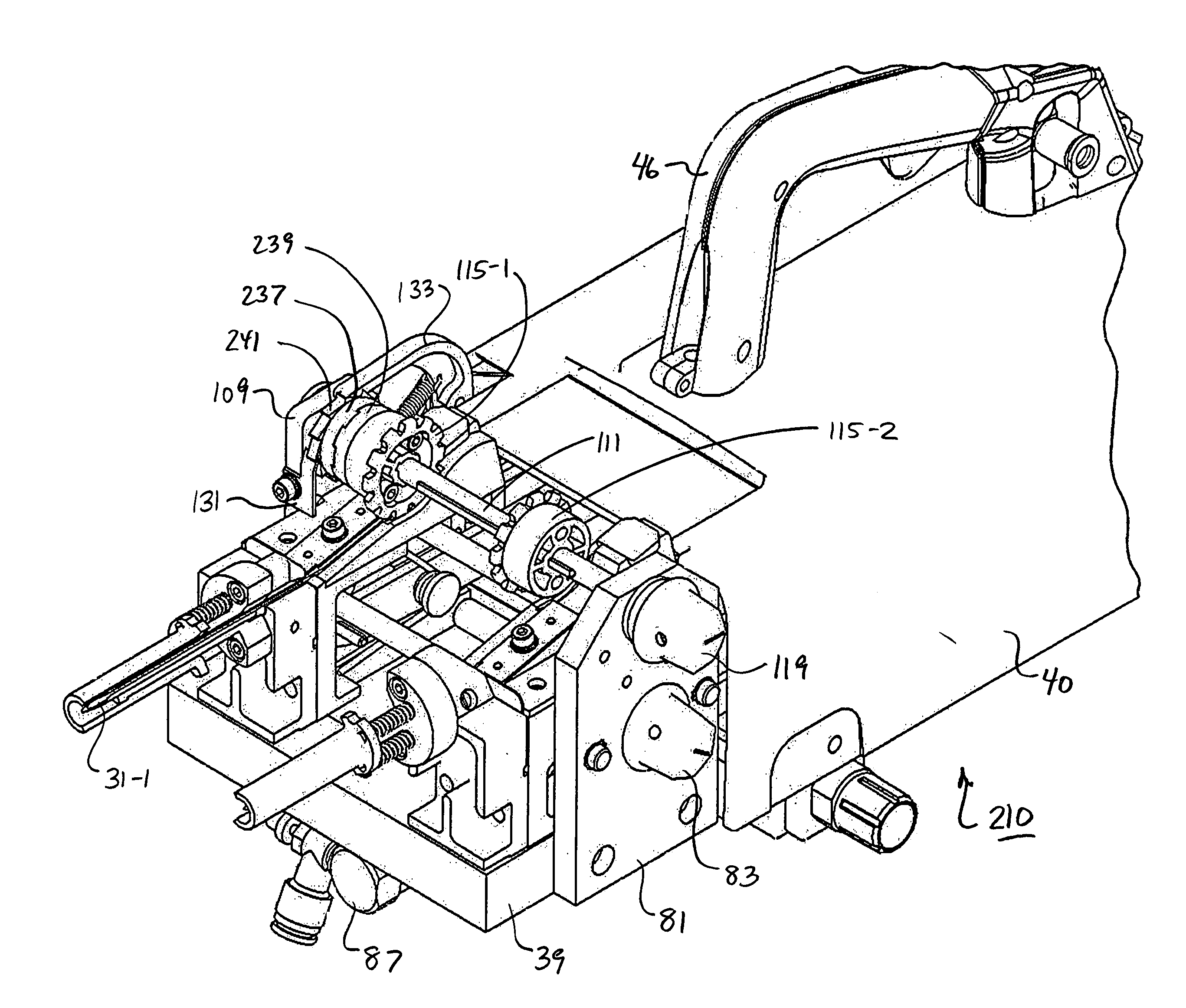

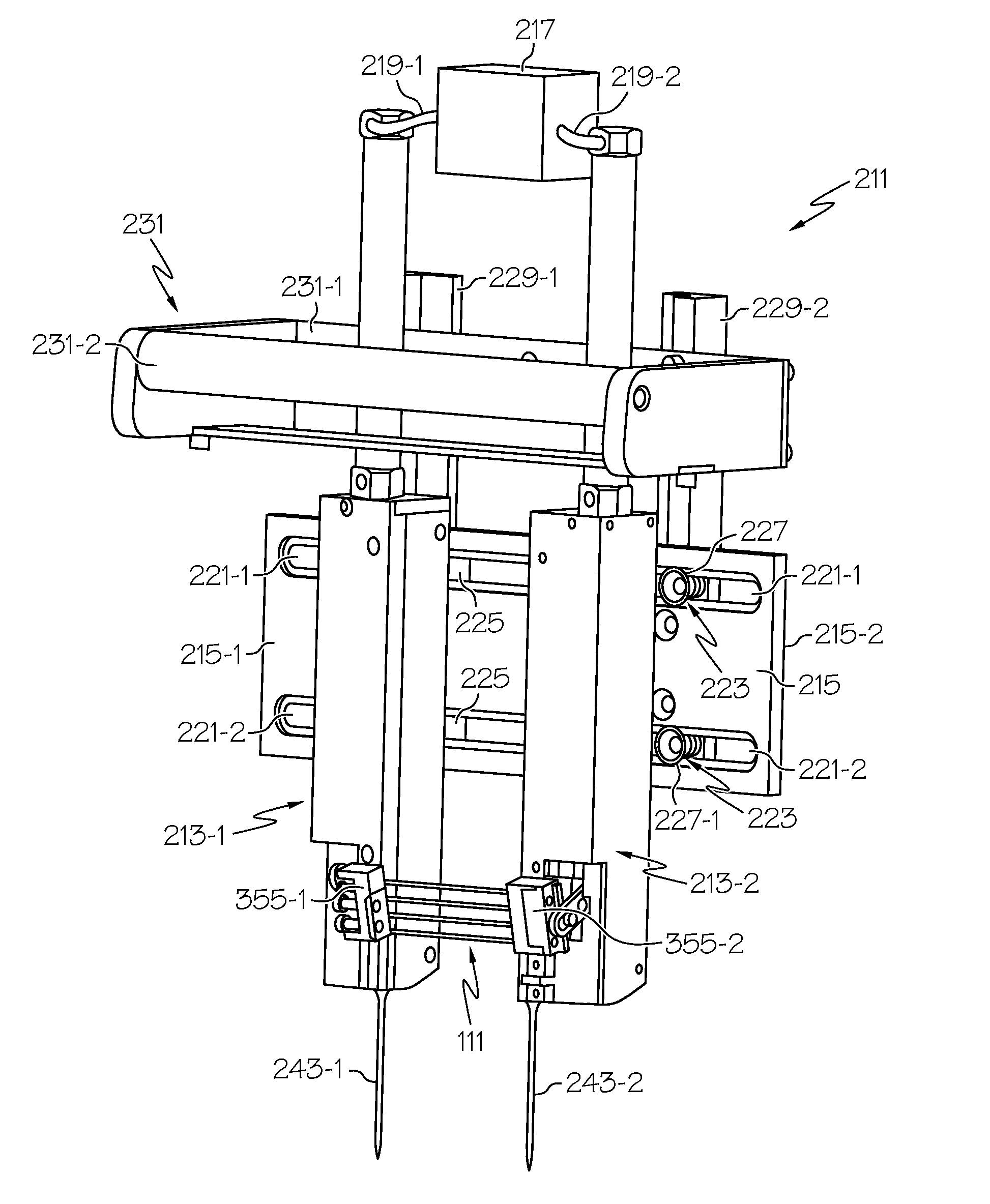

Device for dispensing plastic fasteners

A device for dispensing an individual plastic fastener from a supply of fastener stock includes a motor-driven head assembly adapted to receive the supply of fastener stock, sever an individual fastener from the supply and in turn eject the severed fastener. The head assembly includes a pair of needle block assemblies that retain corresponding hollow needles, each needle block assembly being shaped to define a feed channel that transitions a side rail for the fastener stock into axial alignment behind its corresponding needle. In addition, at least one needle block assembly includes a rearward shelf and a forward bowing plate. In use, the lowermost cross-links of the fastener stock fittingly align between the shelf and the bowing plate. In this manner, the lowermost cross-links are limited to distort uniformly upward within the single plane defined by the pair of feed channels, thereby optimizing feed reliability of the device.

Owner:AVERY DENNISON CORP

Unitary Lanyard and Base for Electronic Surveillance Tag

Owner:BEST SECURITY ACQUISITION LLC

Device for Attaching a Label to a Substrate

InactiveUS20090117387A1Lamination ancillary operationsControlling laminationHigh humidityBiomedical engineering

Labels are permanently attached to a substrate, e.g., a tissue cassette, by use of a staking device. The device comprises a staker assembly and a cassette fixture assembly. The cassette fixture assembly includes a slot and a clamping assembly for securing the cassette within the device. The staker assembly includes a set of probes that are heated and sequentially moved into a position to burn a hole in a label that is provisionally attached to the cassette, and then the substrate is melted and displaced through the hole to form a collar bond that permanently attaches the label to the cassette. The label remains attached to the cassette when exposed to harsh environmental conditions, e.g., high heat, high humidity, solvents, etc.

Owner:BRADY WORLDWIDE INC

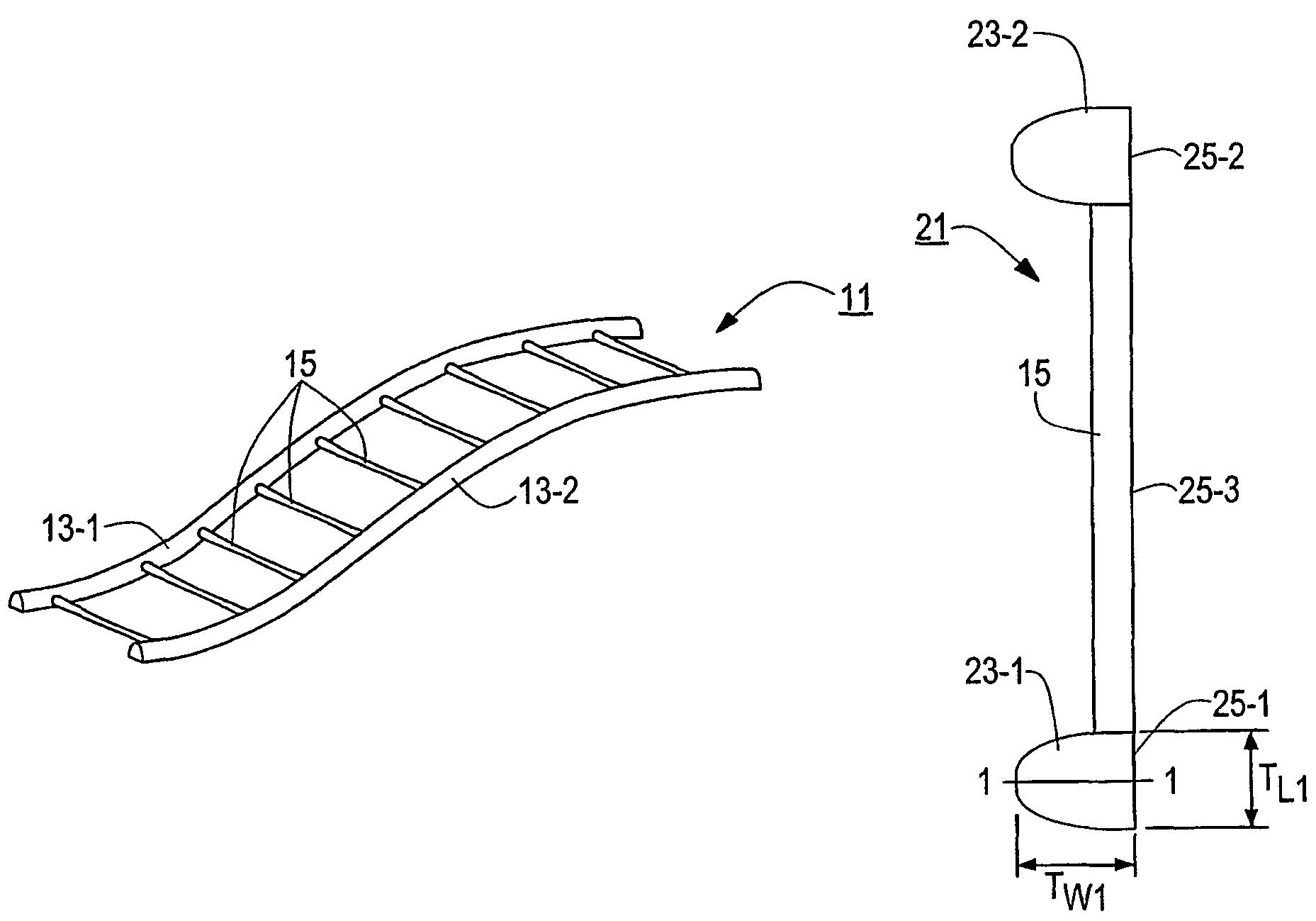

Plastic fasteners, needles for dispensing and method of manufacture

Owner:AVERY DENNISON CORP

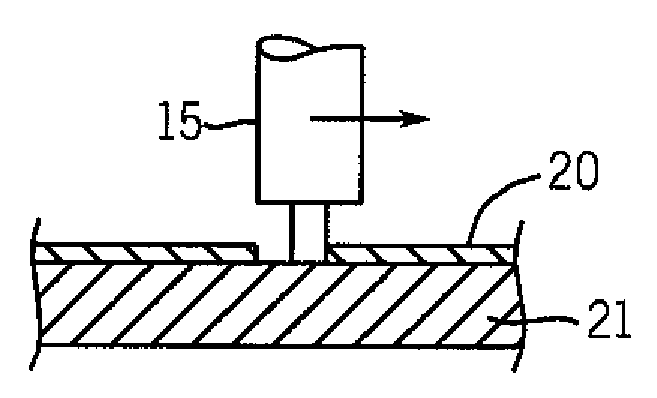

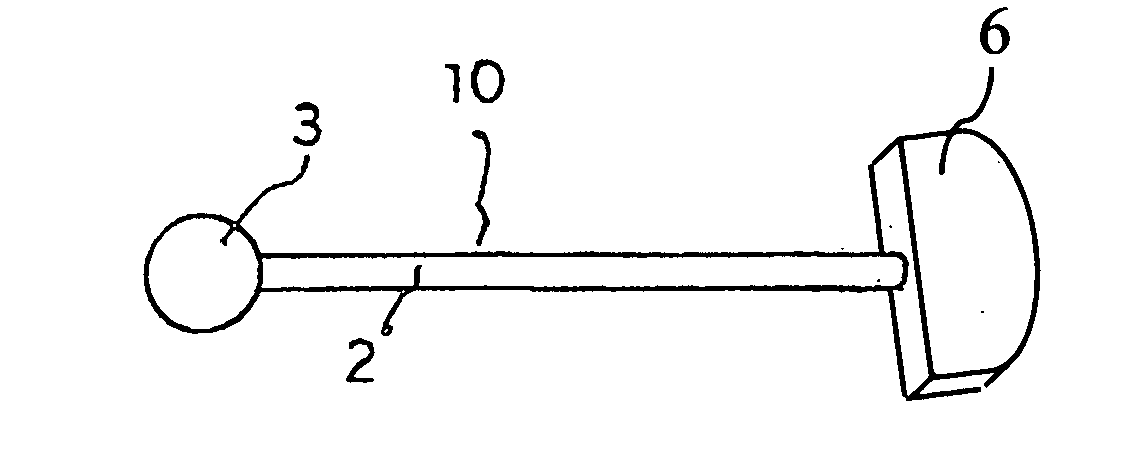

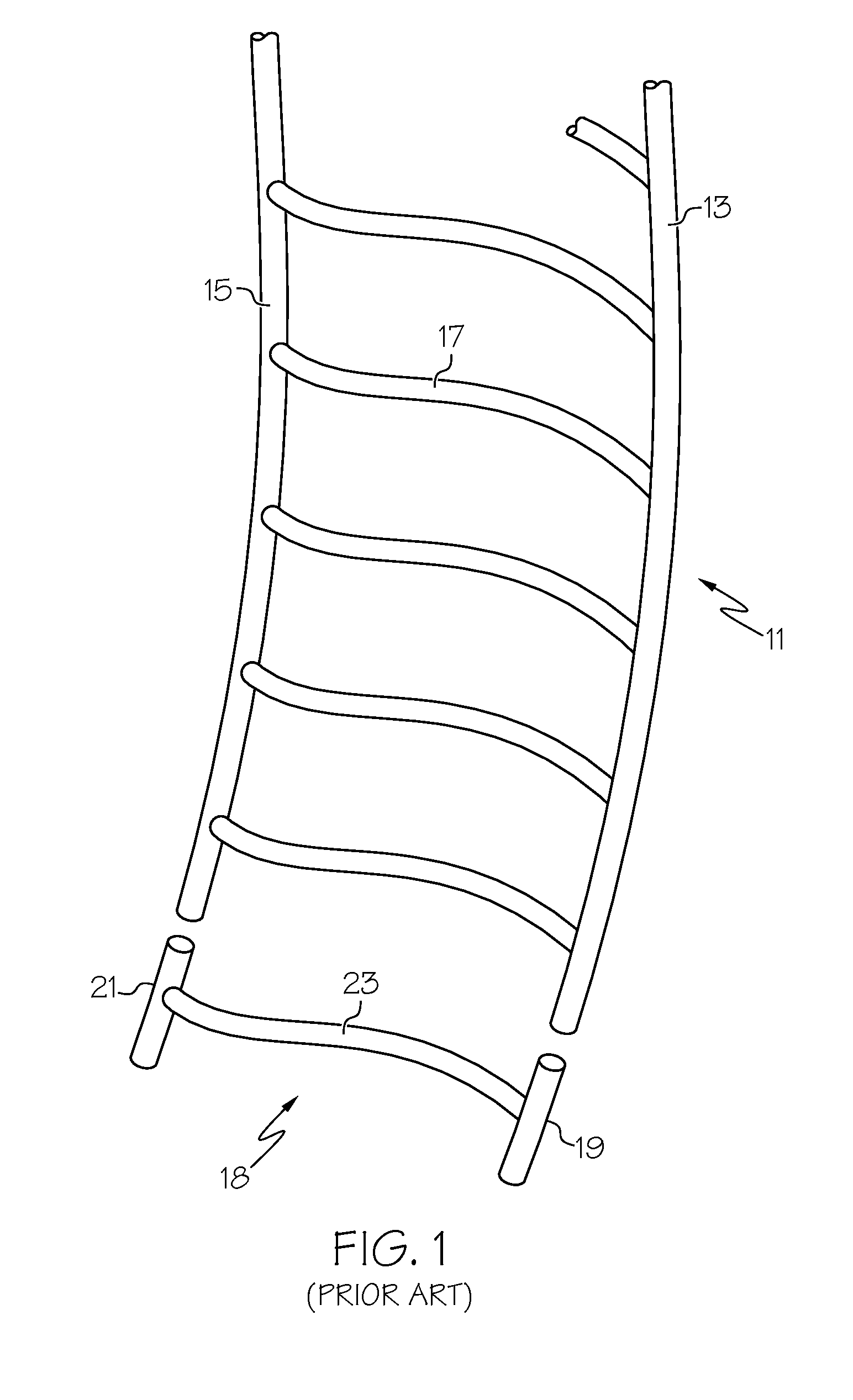

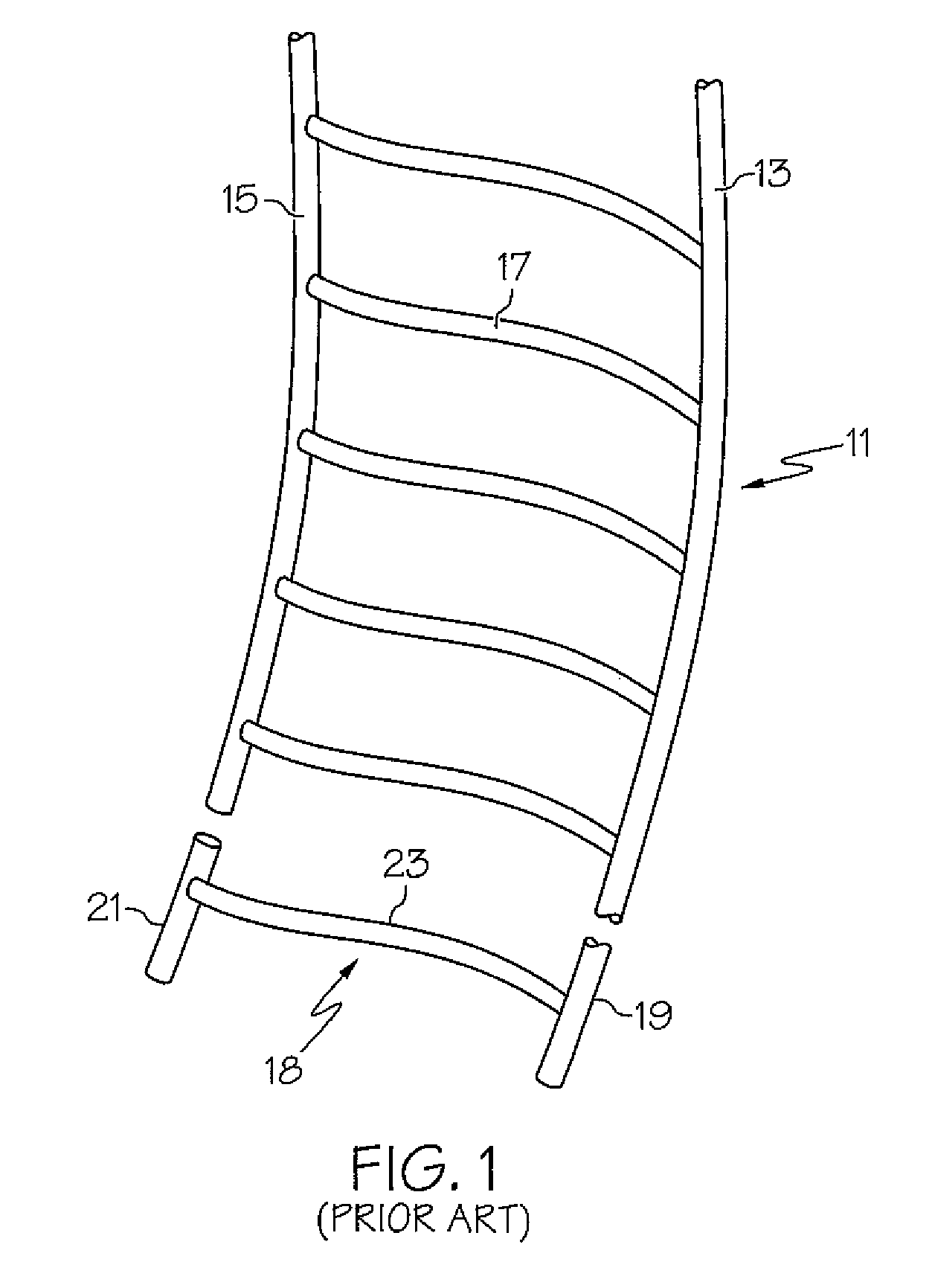

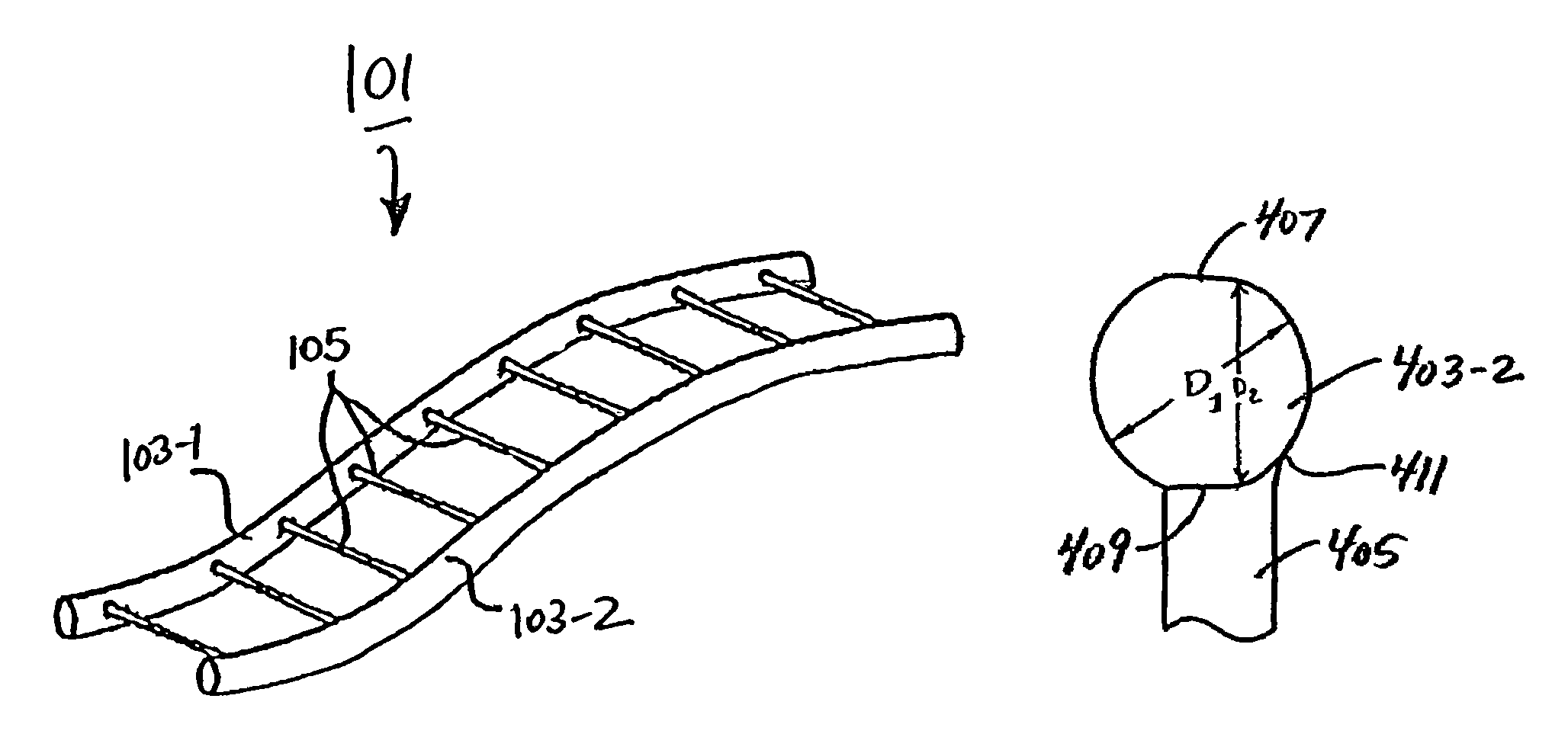

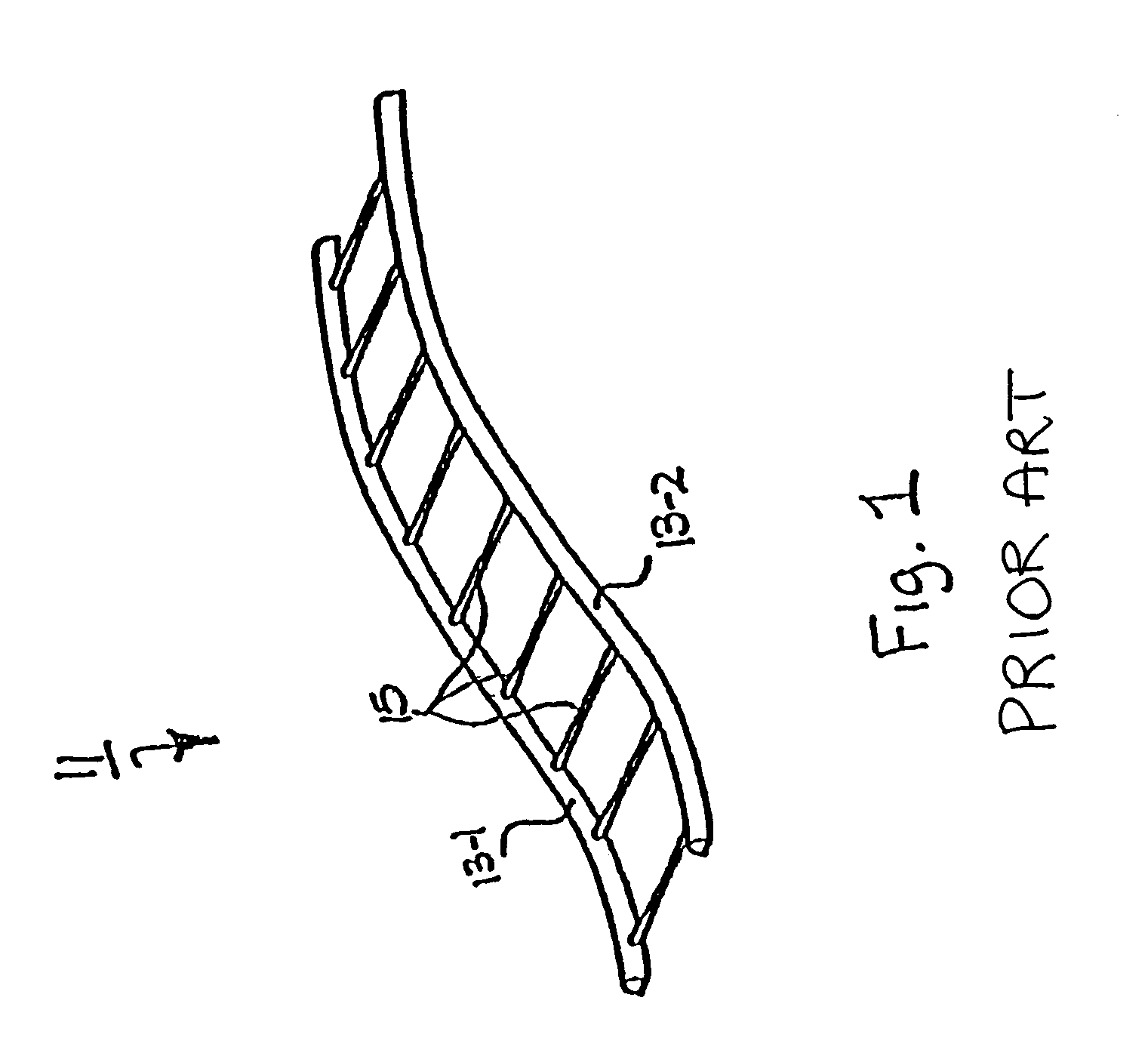

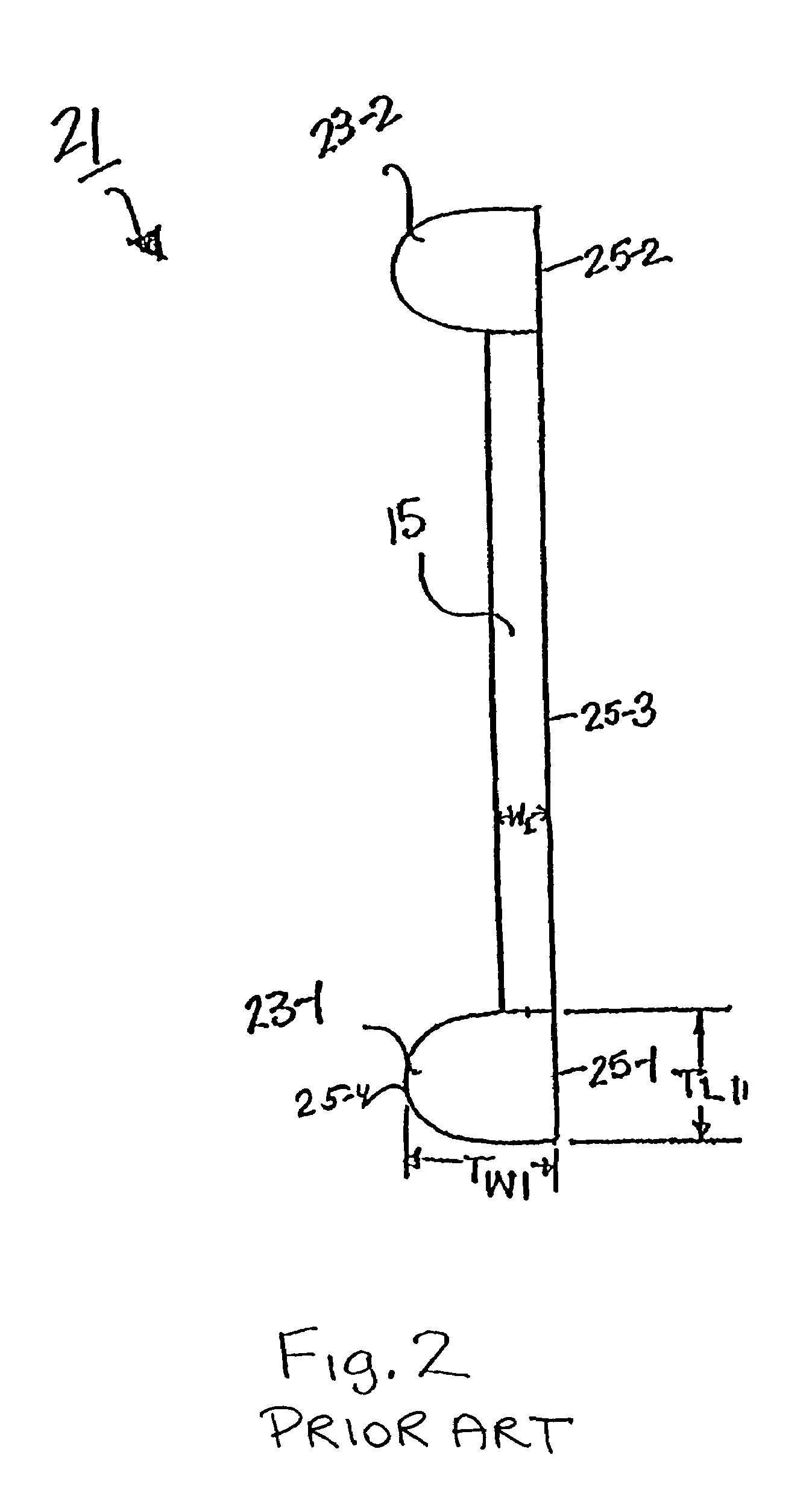

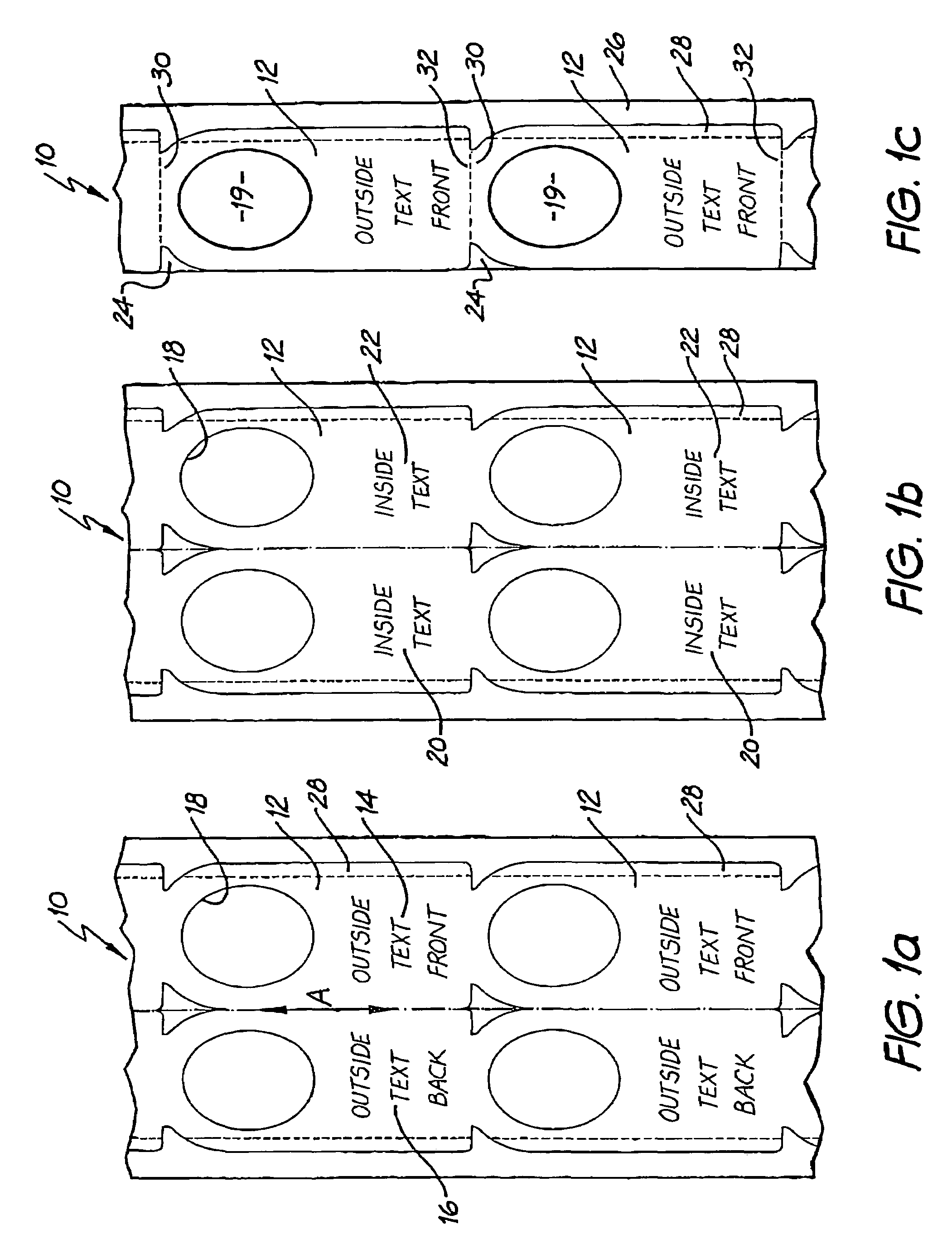

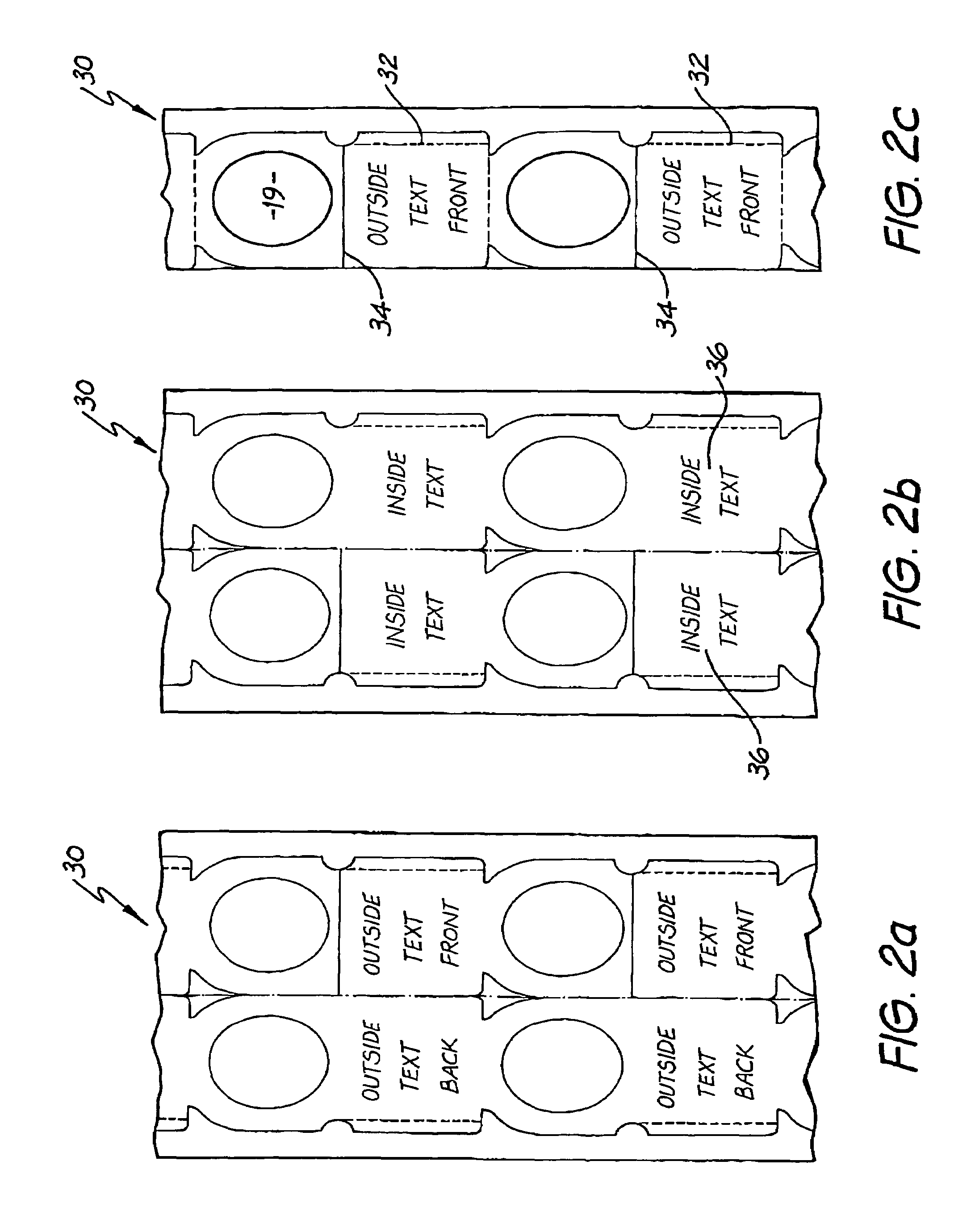

Continuously connected fastener stock and method of manufacturing the same

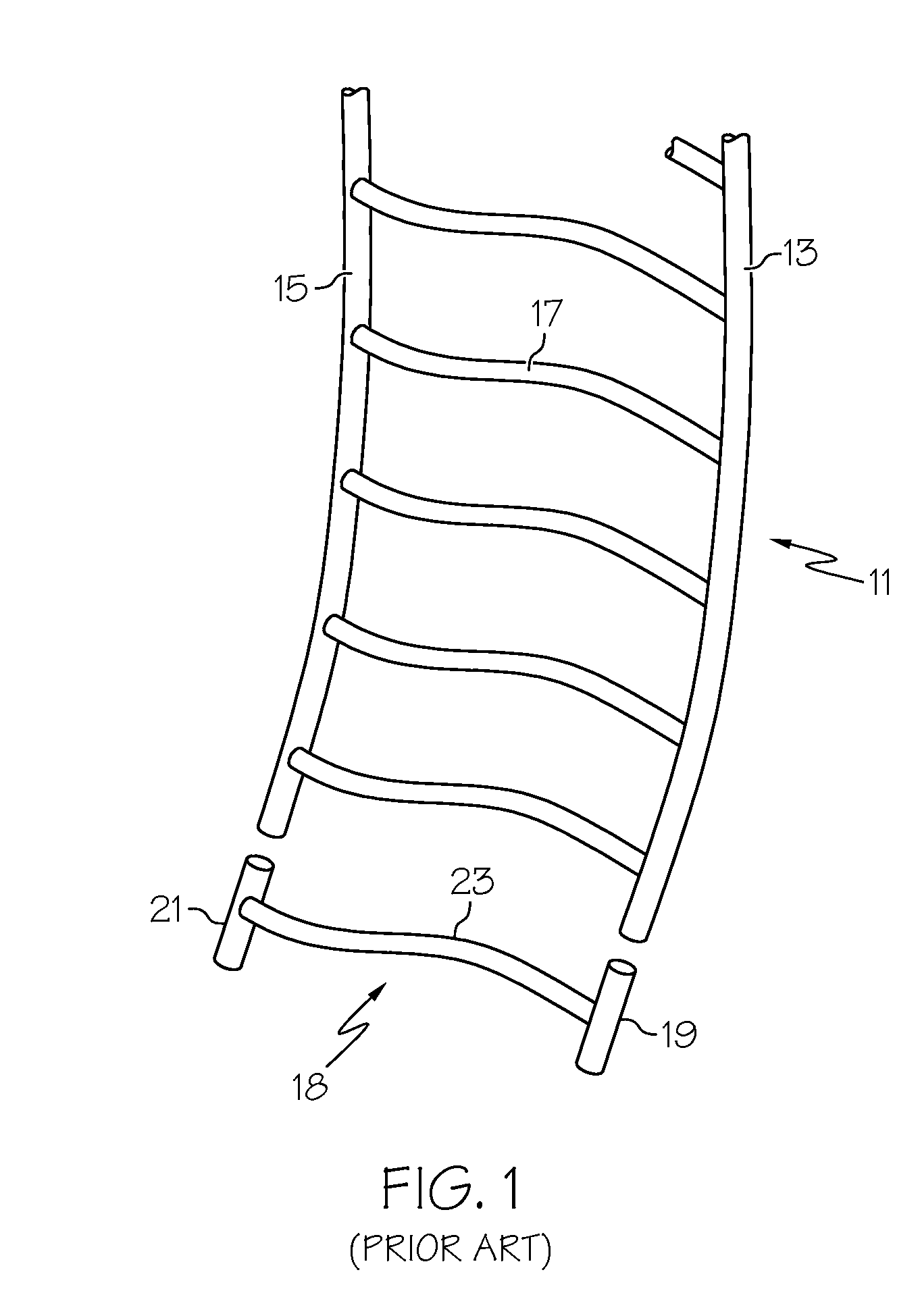

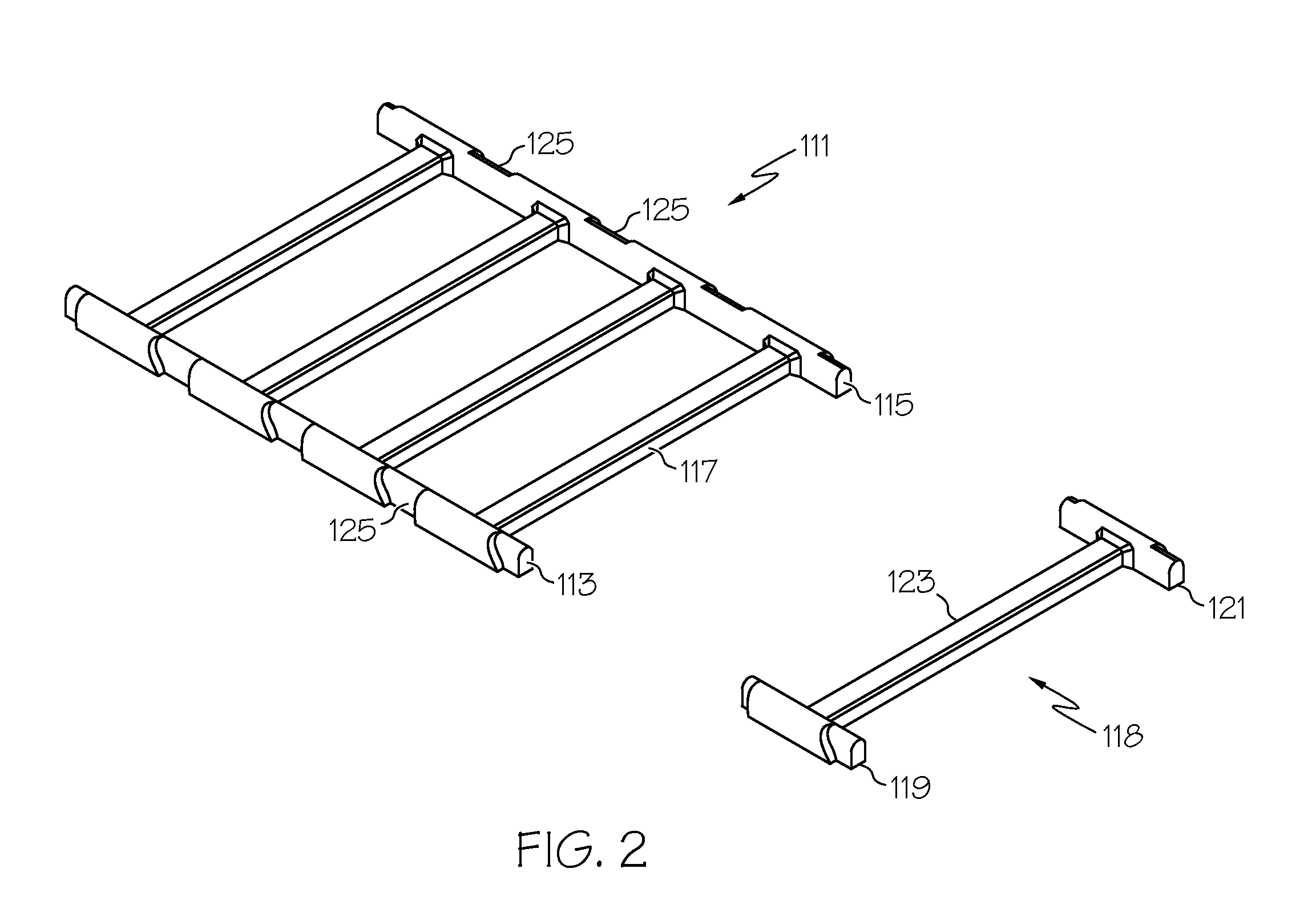

InactiveUS7308983B2Increasing cross-sectional sizeOvercome problemsAffixing tagsOther accessoriesCross-linkEngineering

Continuously connected fastener stock and a method of making same. The method, in one embodiment involves providing a rotating molding wheel, the wheel being provided with a peripheral impression comprising a pair of peripherally-extending side members interconnected by a plurality of cross-links. Molten plastic is extruded into the peripheral impression of the wheel, with a layer of controlled film overlying the peripheral impression. The molten plastic is then allowed to solidify. A knife in substantially elliptical contact with the peripheral impression is then used to skive excess plastic from the rotating molding wheel. The knife is provided with a pair of cut-out portions along its bottom edge, each cut-out portion being aligned with one of the peripherally-extending side members so as to augment the transverse cross-sectional size thereof. The continuously connected fastener stock thus formed is then removed from the rotating molding wheel. The fastener stock includes in one embodiment first and second side members each being generally circular in cross-section and a plurality of cross-links each having a flat surface.

Owner:AVERY DENNISON CORP

Method of producing a squeeze tube with maximally labeled surface area

Owner:CCL LABEL INC

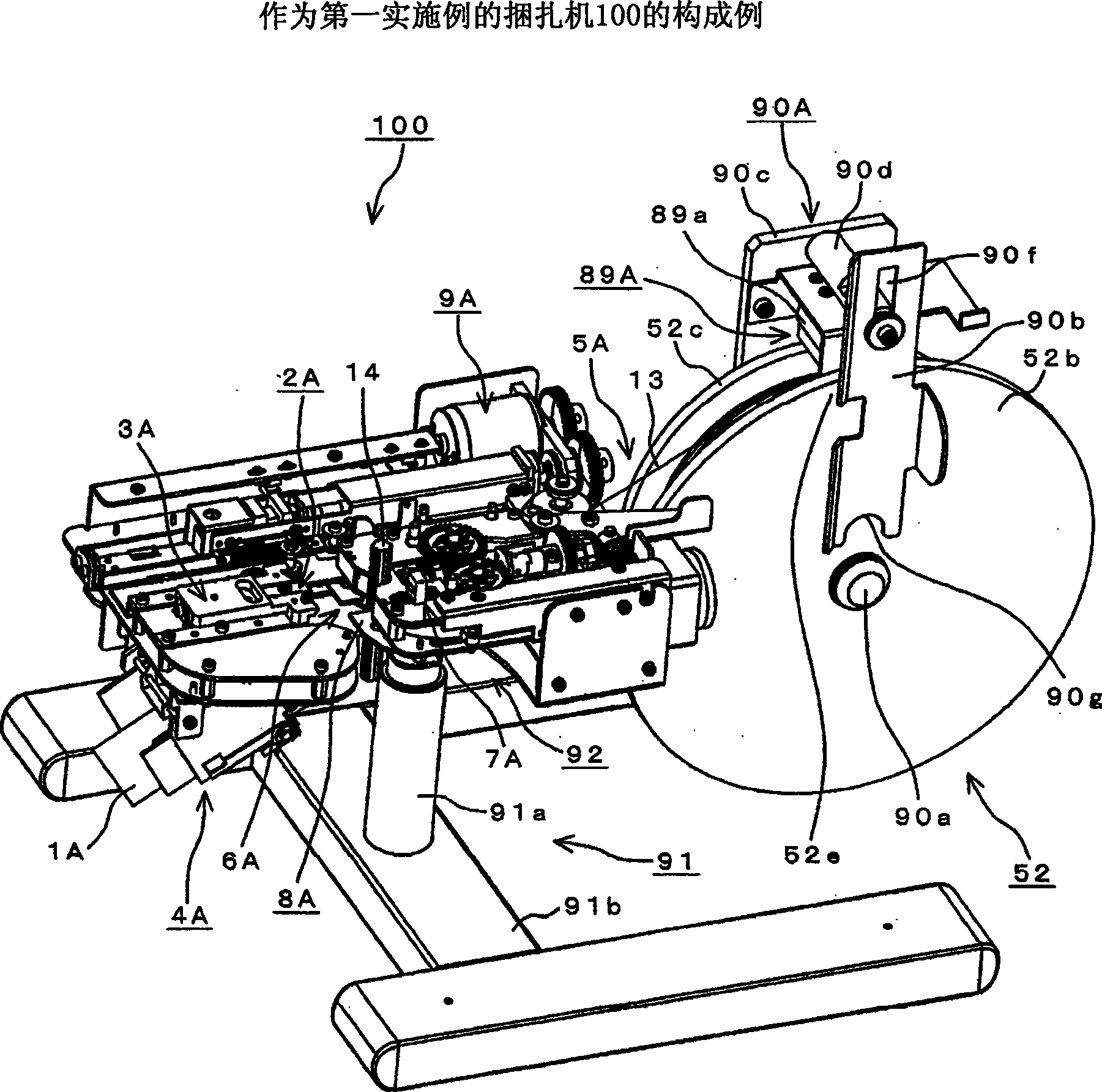

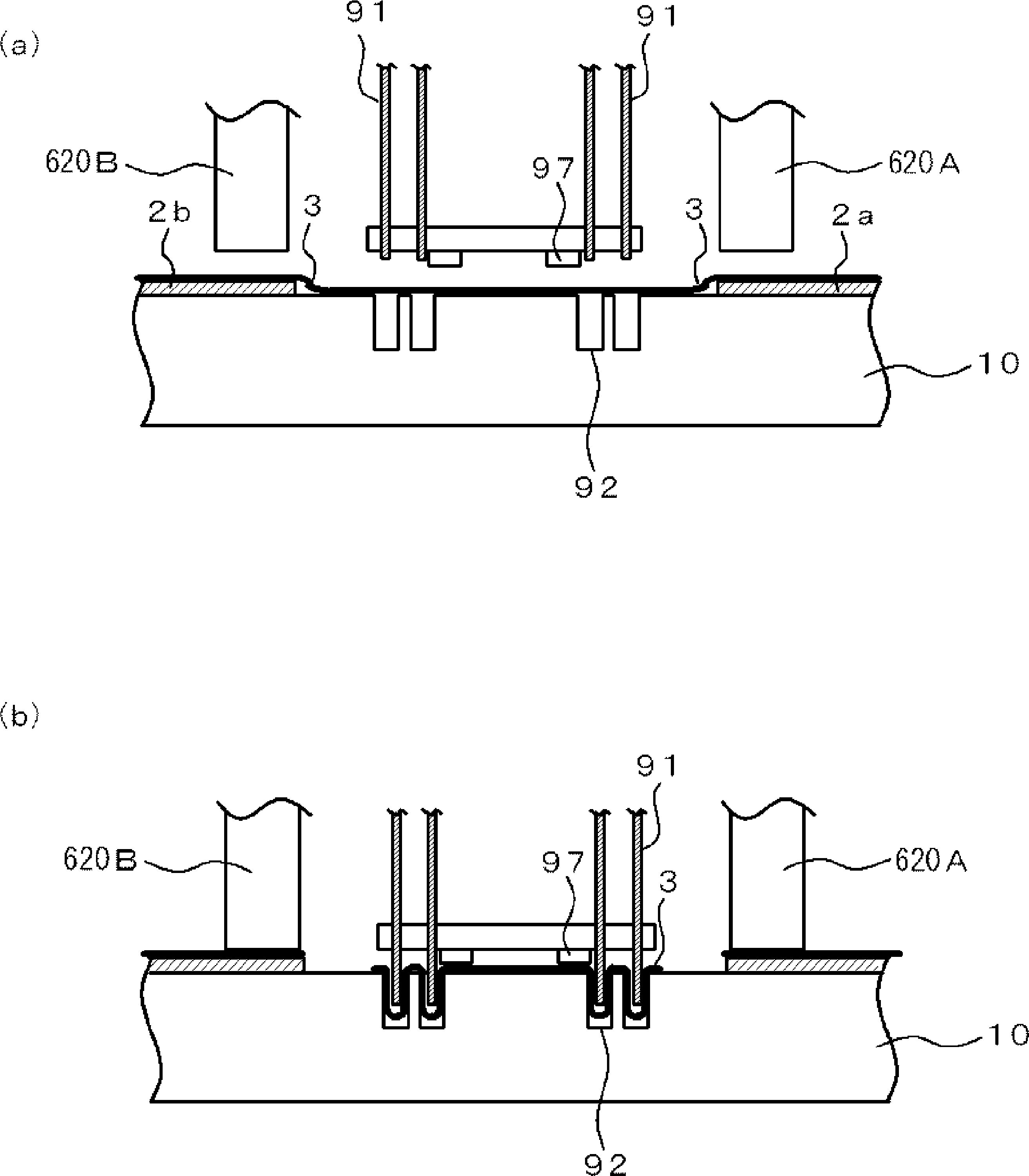

Coiler

InactiveCN101544286AInhibit wearAvoid partial wearAffixing tagsWrapper twisting/gatheringCircular discBobbin

The present invention provides a coiler which can increase the braking force of the coiler and can restrain the coiler abrasion and deformation caused by the braking. The coiler is provided with a bobbin (52) which has a disc outside plate (52b) that is formed to a large shape compared with a disc inner plate (52c). A braking mechanism (89A) clamps a large-shaped part (52e) of the disc outside plate (52b) that has a shape larger than that of the disc inner plate (52c) for braking the bobbin (52). In an embodiment of the invention, the braking mechanism (89A) clamps the disc outside plate (52b) through a braking disc (90h) and a pressure lever (90b) of a solenoid (89a) in power failure.

Owner:MAX CO LTD

Method and device for knotting the ends of a thread to flat articles

Owner:茶叶包装专用机械两合公司

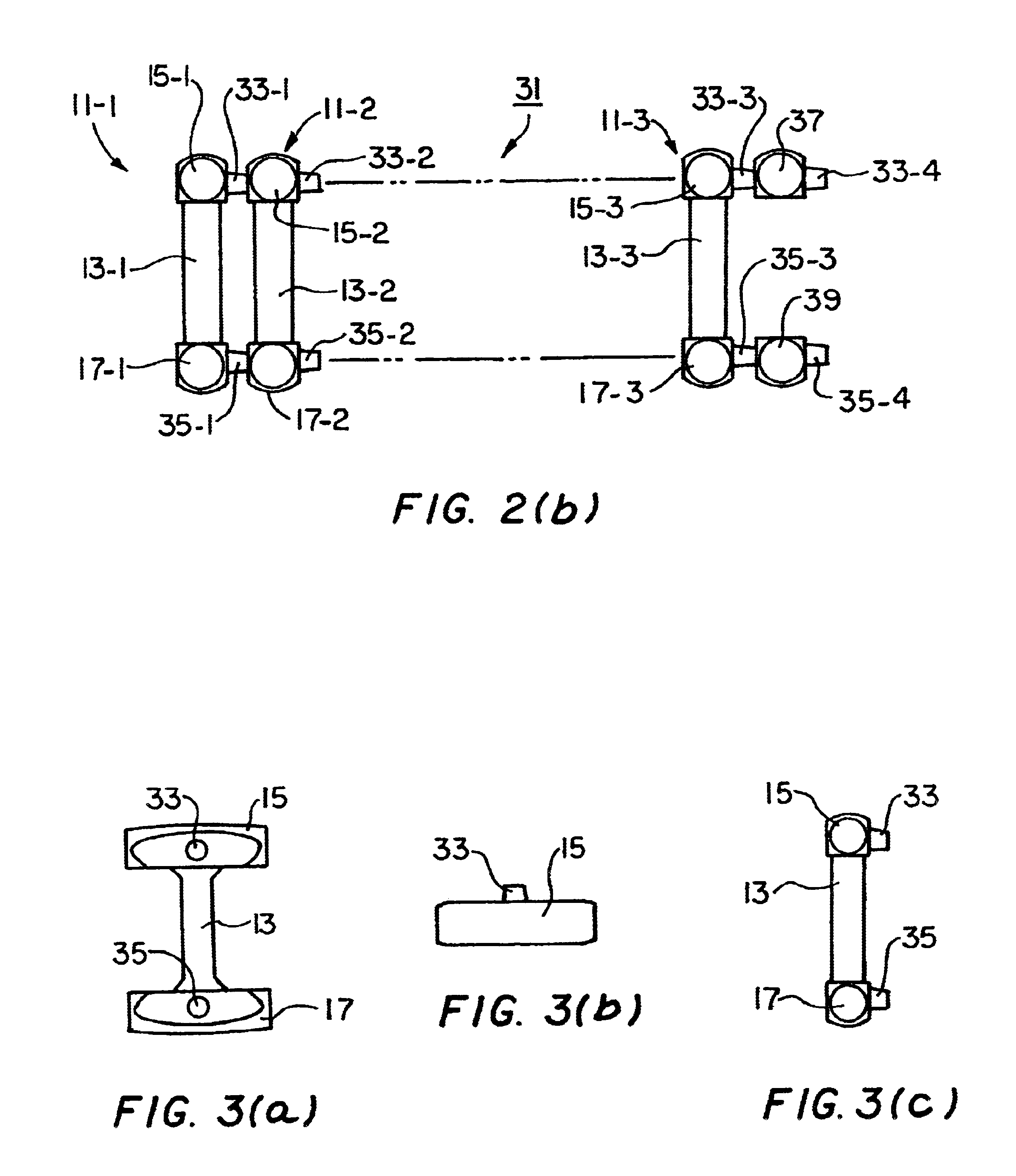

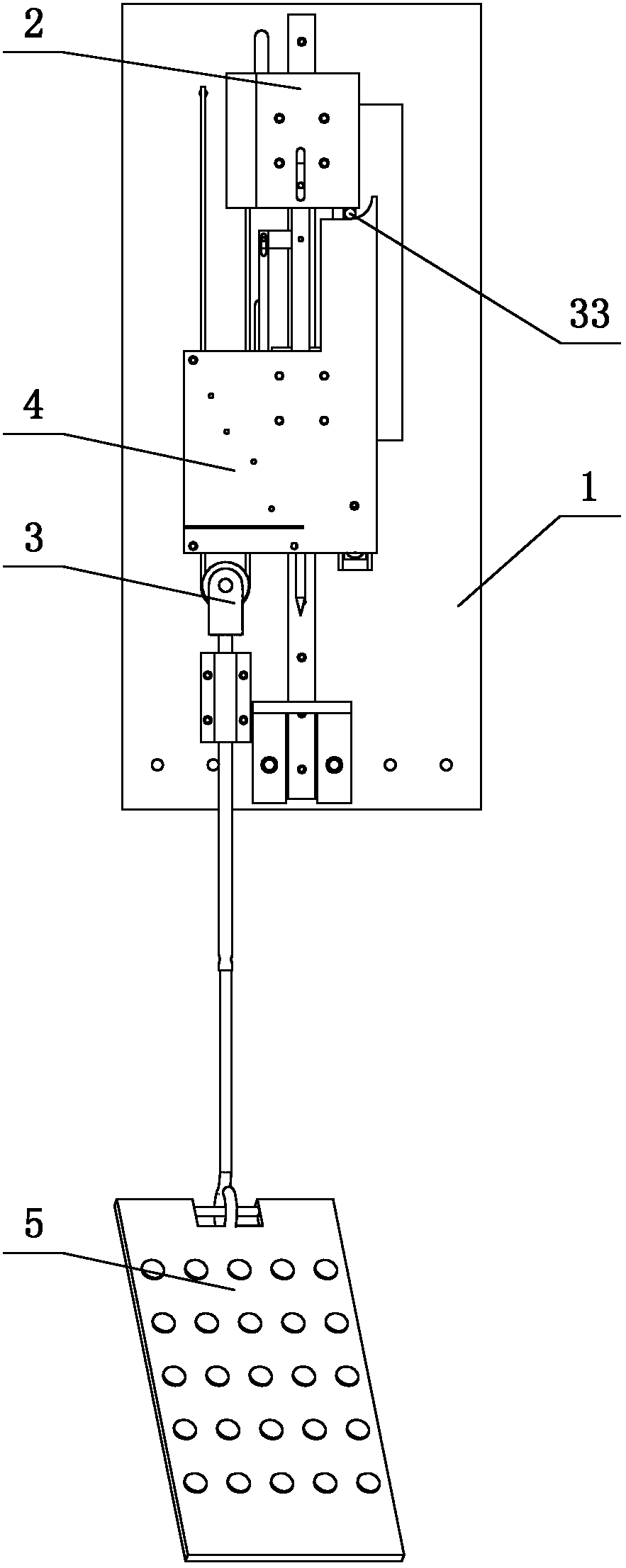

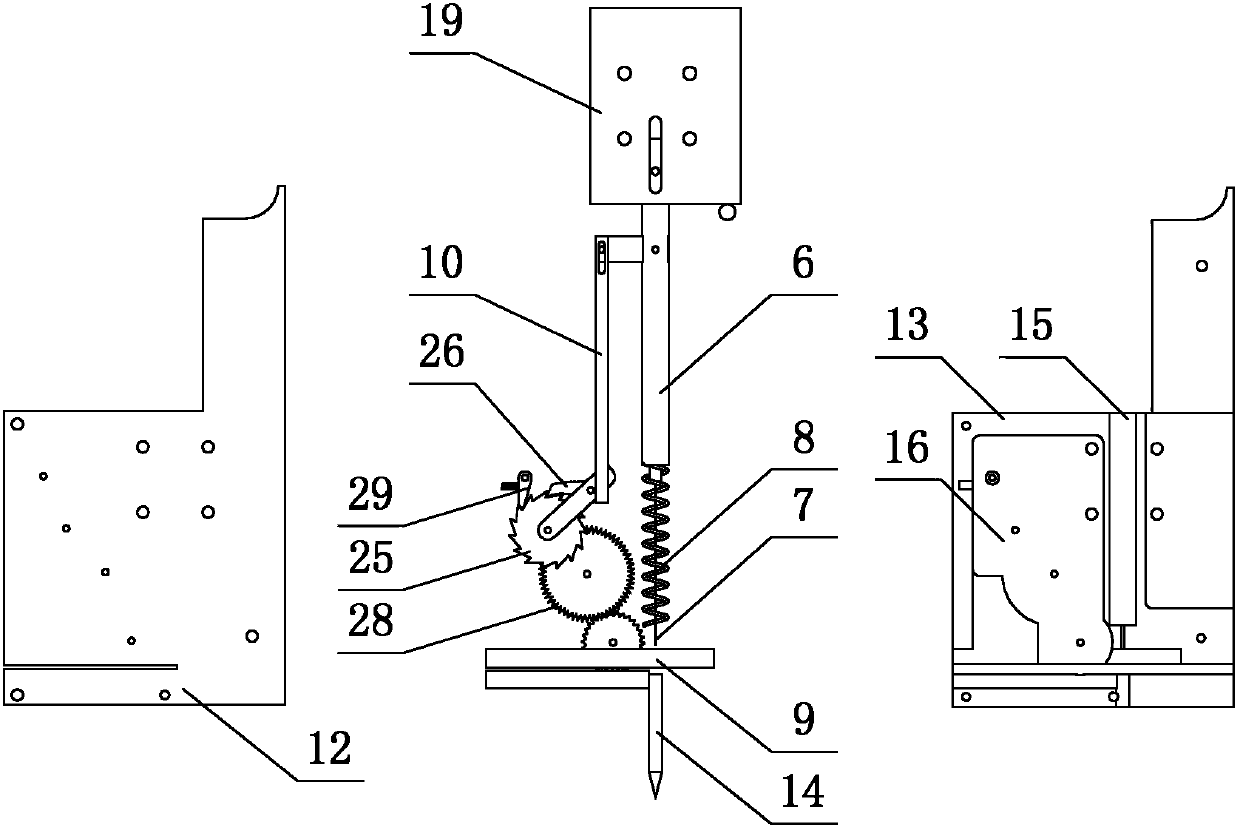

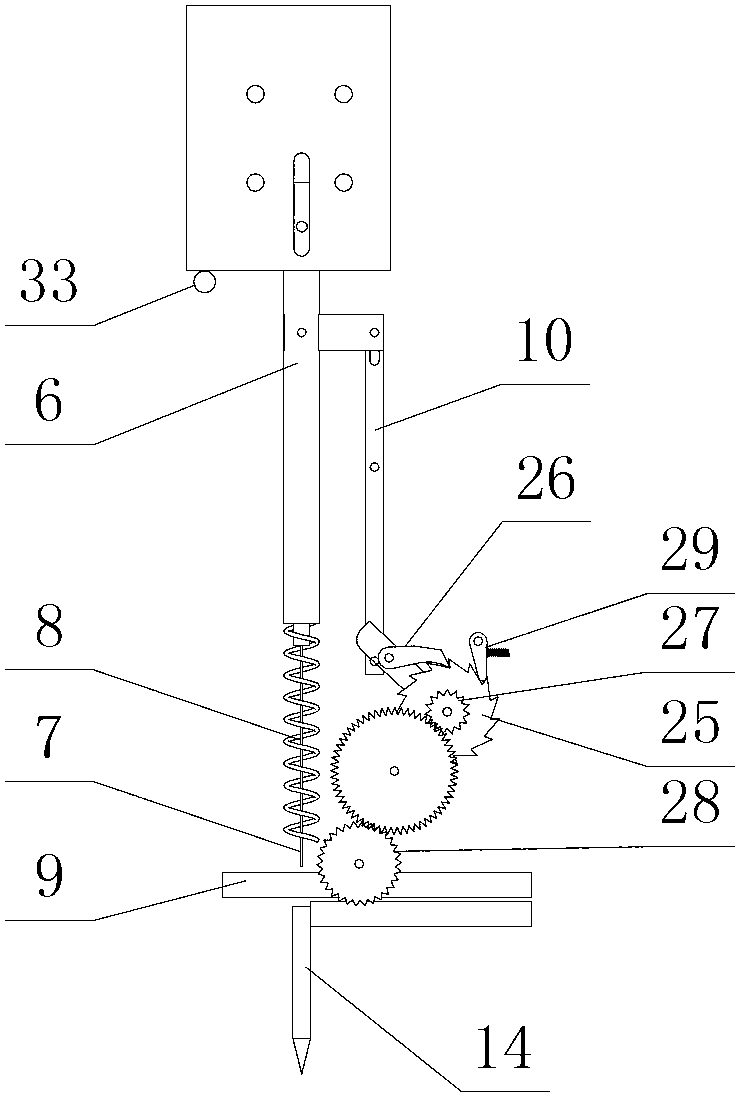

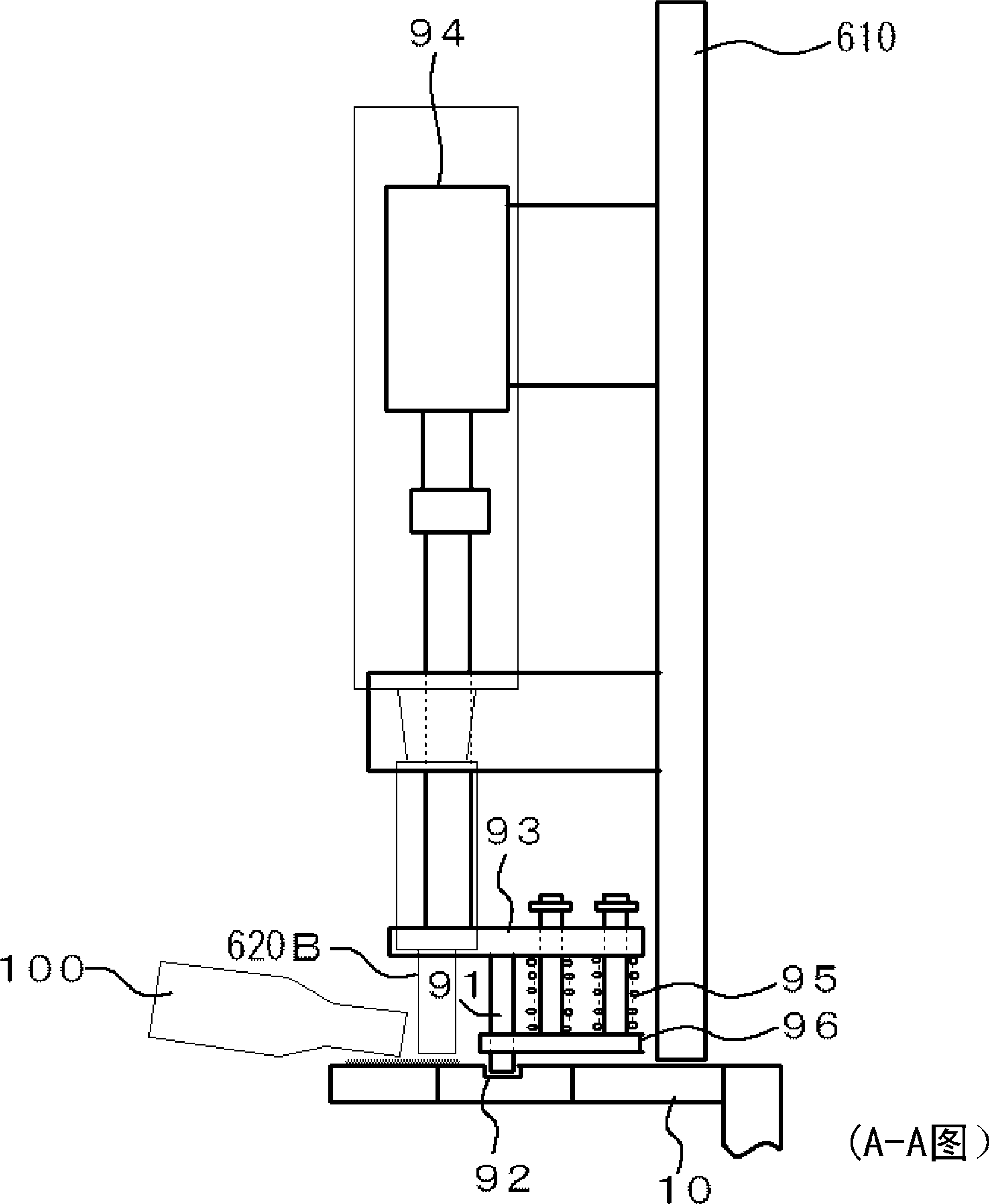

Tag binding machine

InactiveCN103129793AOvercome the shortcomings of small mechanical strength and inability to bind multiple pieces at a timeCompact structureAffixing tagsControl engineeringProcess engineering

The invention discloses a tag binding machine comprising a frame, a linkage assembly slidably arranged on the frame, a differential power assembly driving the linkage assembly to move, a plastic pin extrusion mechanism driven by the linkage assembly, and a pedal driving the differential power assembly to move. The pedal is connected to the differential power assembly. The machine is advantaged in that: tag binding is realized with the mechanical force of the pedal, such that defects of small mechanical force and incapability of binding a plurality parts in one time of a traditional gun-type tag machine are overcome. Also, cost is saved, and other power is not needed. The mechanical-transmission tag machine has the advantages of compact structure and long service life. With the machine, tag binding of various plastic pin bullets and fabrics can be achieved.

Owner:ZHEJIANG YUEYANG HLDG GRP

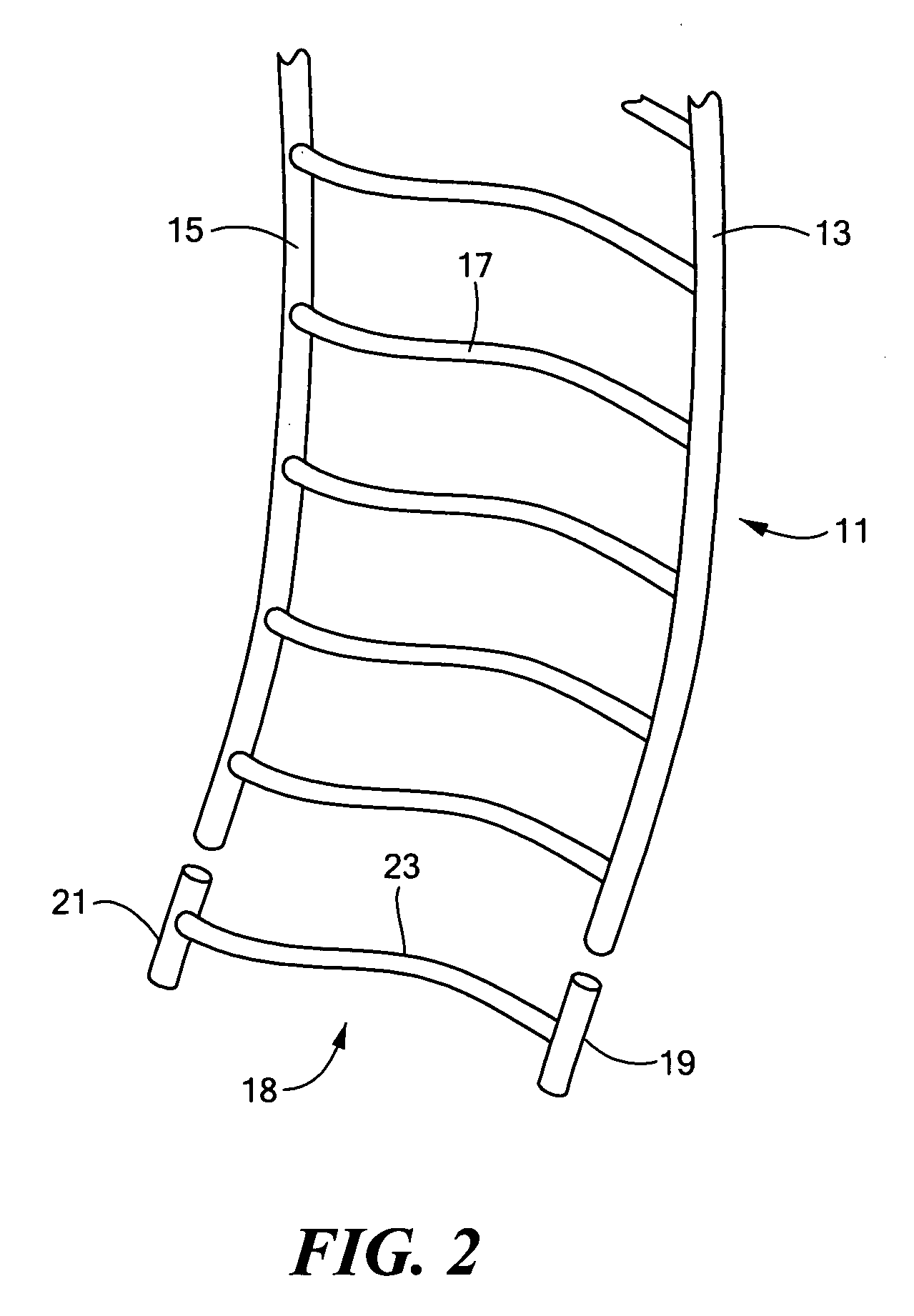

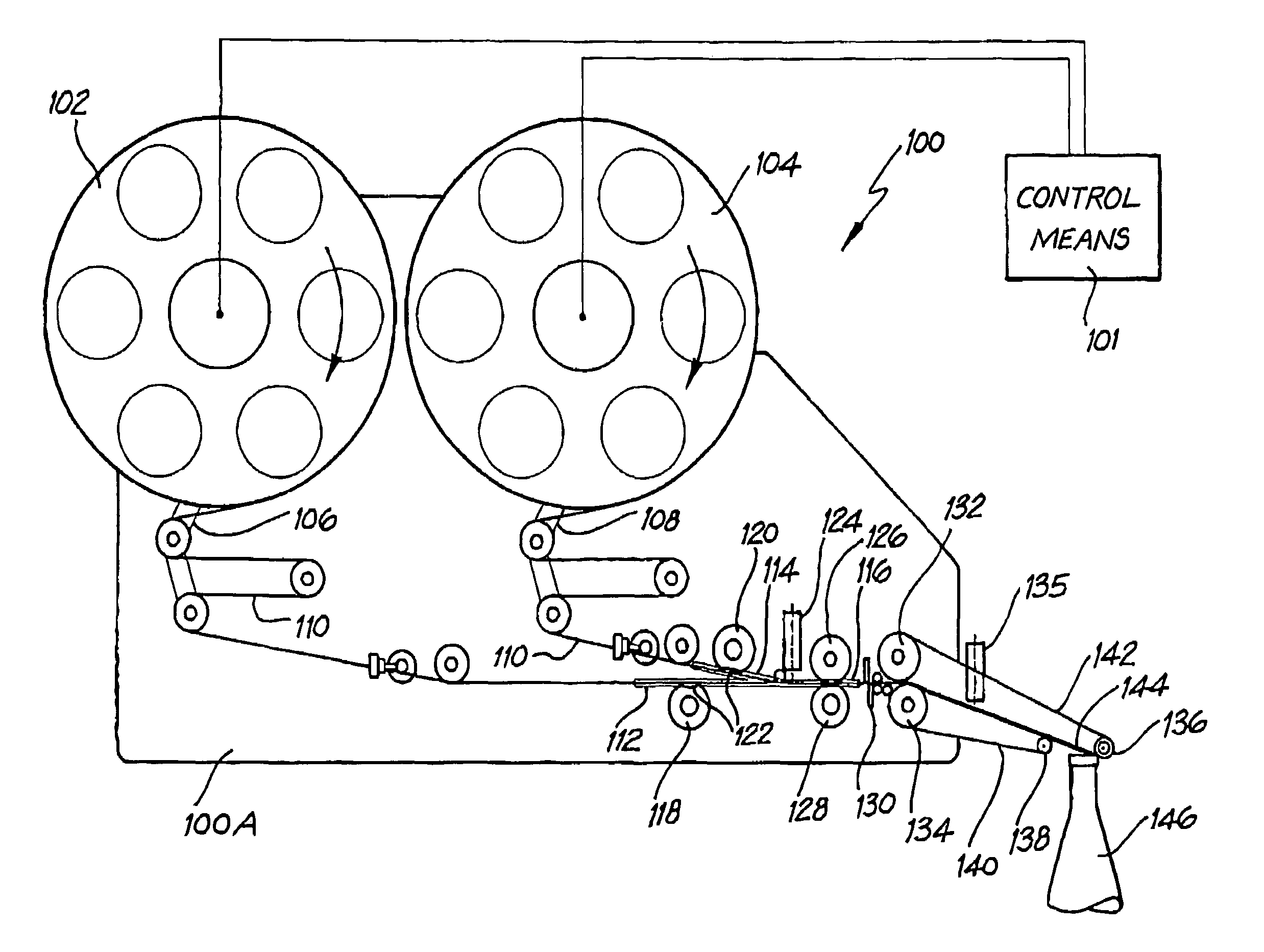

Methods and apparatus for producing and for applying labels

An apparatus for applying labels including hanging labels, in the form of a continuous web of material to containers is defined. The apparatus includes first and second reels on which the continuous web material is wound for application to containers by the apparatus. The apparatus includes an automatic splicing arrangement for feeding web material from a second reel after the first reel is exhausted. The labels are in the form of a continuous web of material and no separate support web is provided for the labels. The apparatus includes a pair of interchange rollers and a pair of associated guide means which merge to define a single guide means, and an indexing means disposed adjacent the point where the guide means merge. The interchange rollers are synchronously driven by a single drive means via a servo means or the like. The web of labels is made by printing on one or both sides of the web of material and plough-folding the web of material parallel to the longitudinal axis of the material to generate a succession of joined multi-layer labels or leaflets.

Owner:BAUMLI PETER J

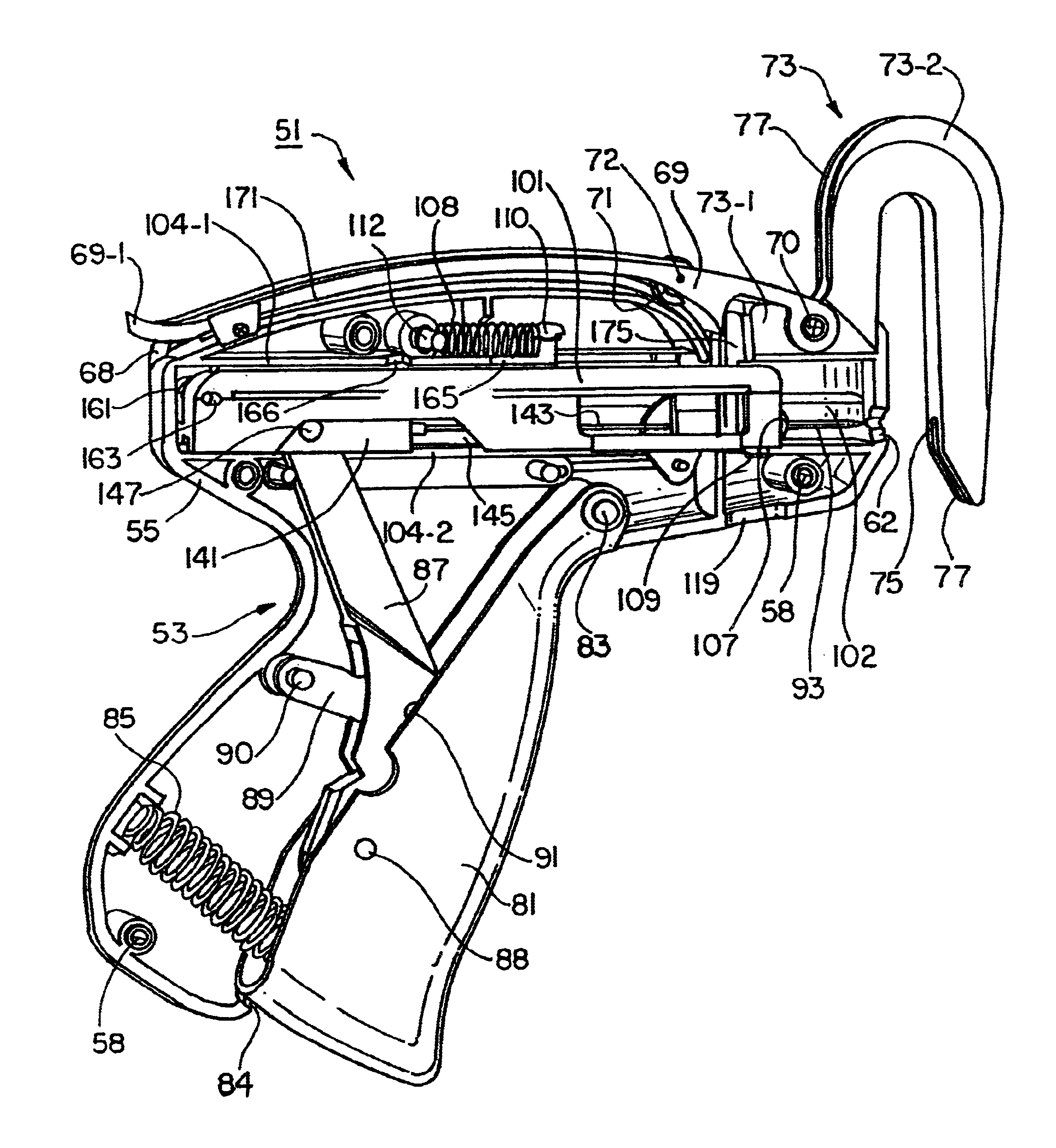

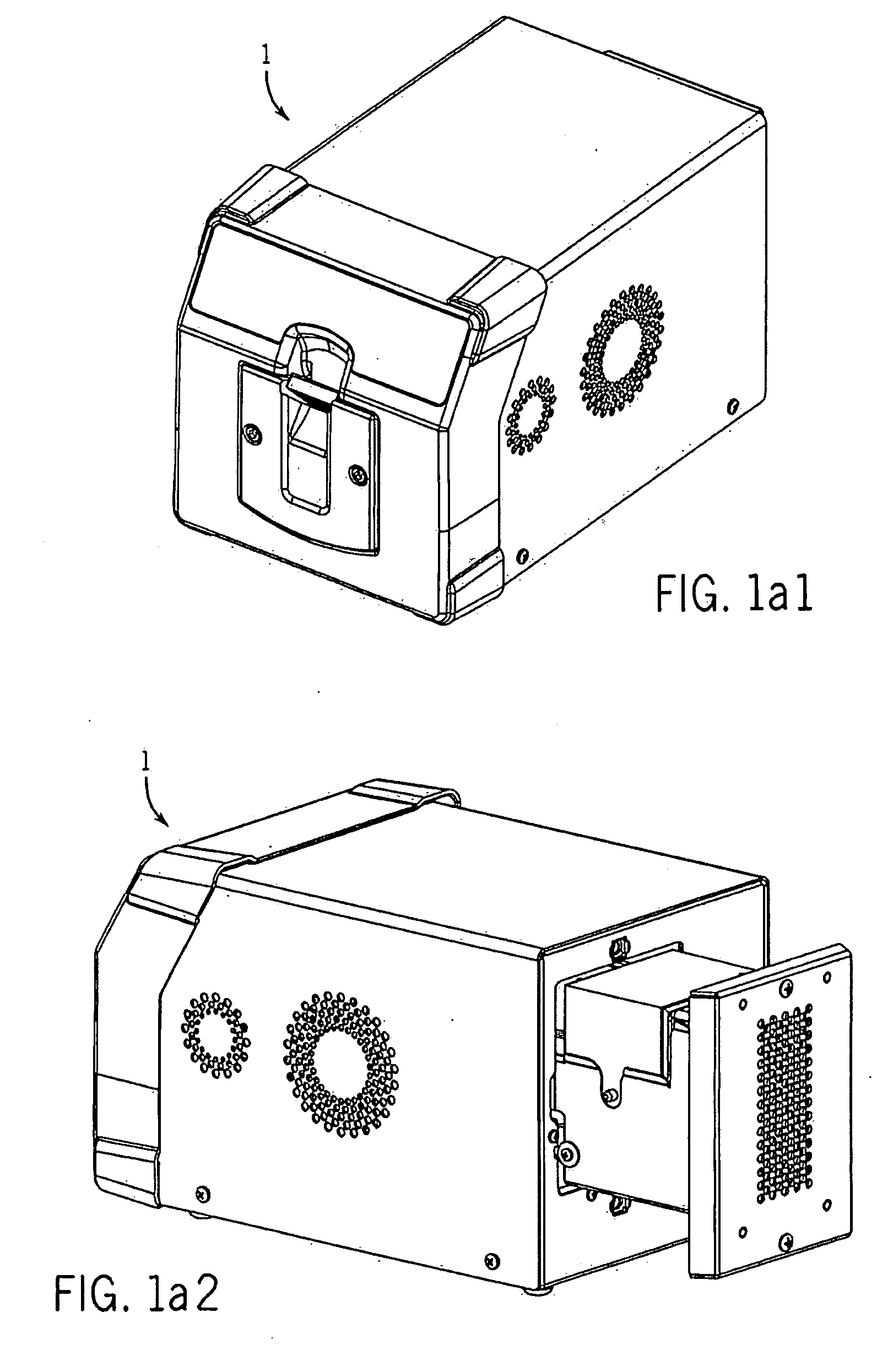

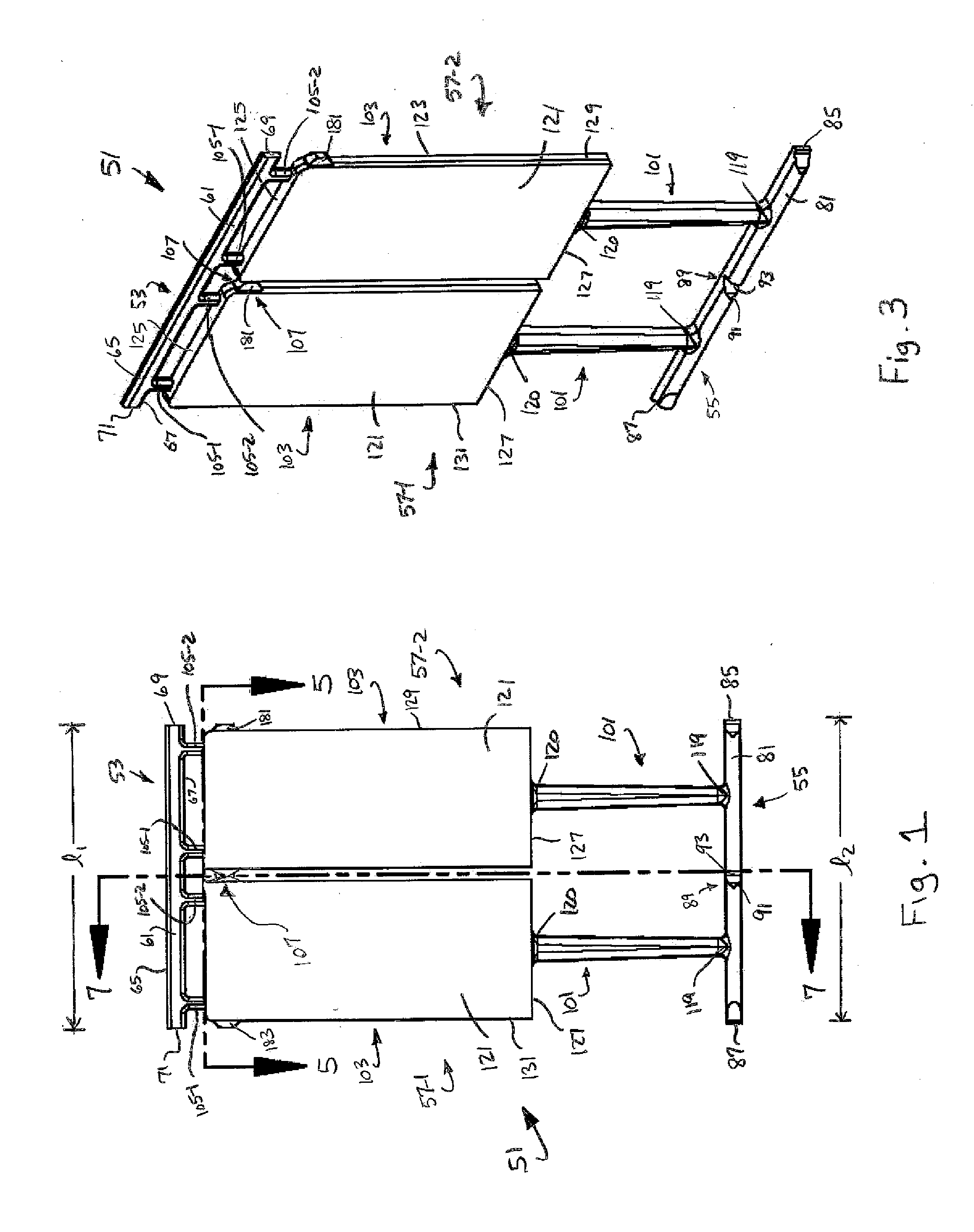

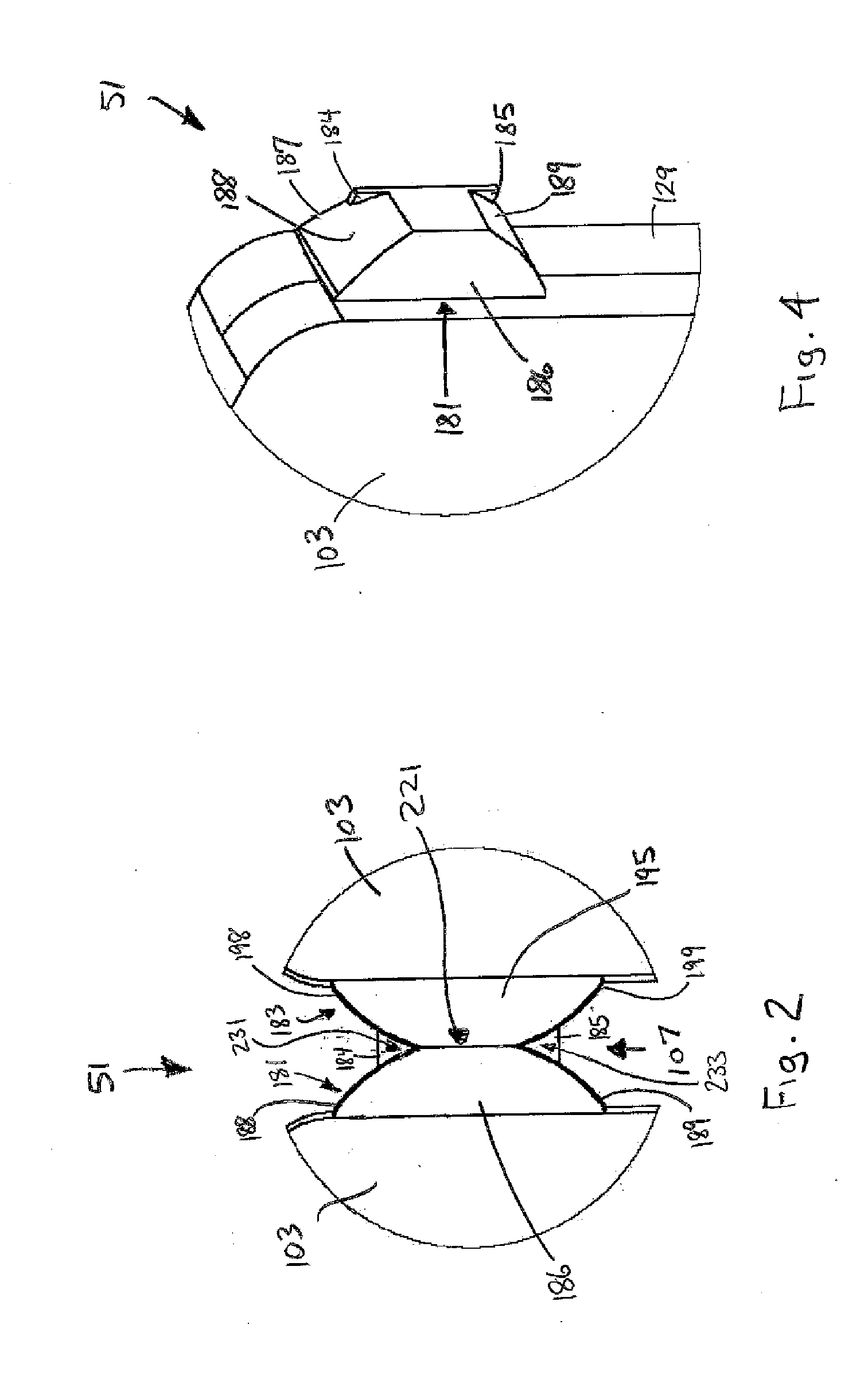

Device for dispensing plastic fasteners

A device for dispensing individual plastic fasteners from a continuous supply of ladder stock includes a head assembly (53) that is designed to receive the supply of ladder stock, sever an individual fastener from the supply ladder stock and eject the individual fastener during a single stroke of its actuation cycle. The device also includes a stepper motor (103) for driving the head assembly through its actuation cycle, a DC power switching supply for regulating the power supplied to the stepper motor from an AC input power source, and a controller (105) for collecting historical data relating to usage of the device and for regulating operation of the stepper motor. The controller (105) is programmed to enable certain operational characteristics, such as stroke speed and mode, to be regulated through a user interface which includes a screen display and a plurality of control buttons. The device can be configured to dispense a double fastener or a fastener of which the first end of a filament (217) is branched.

Owner:AVERY DENNISON CORP

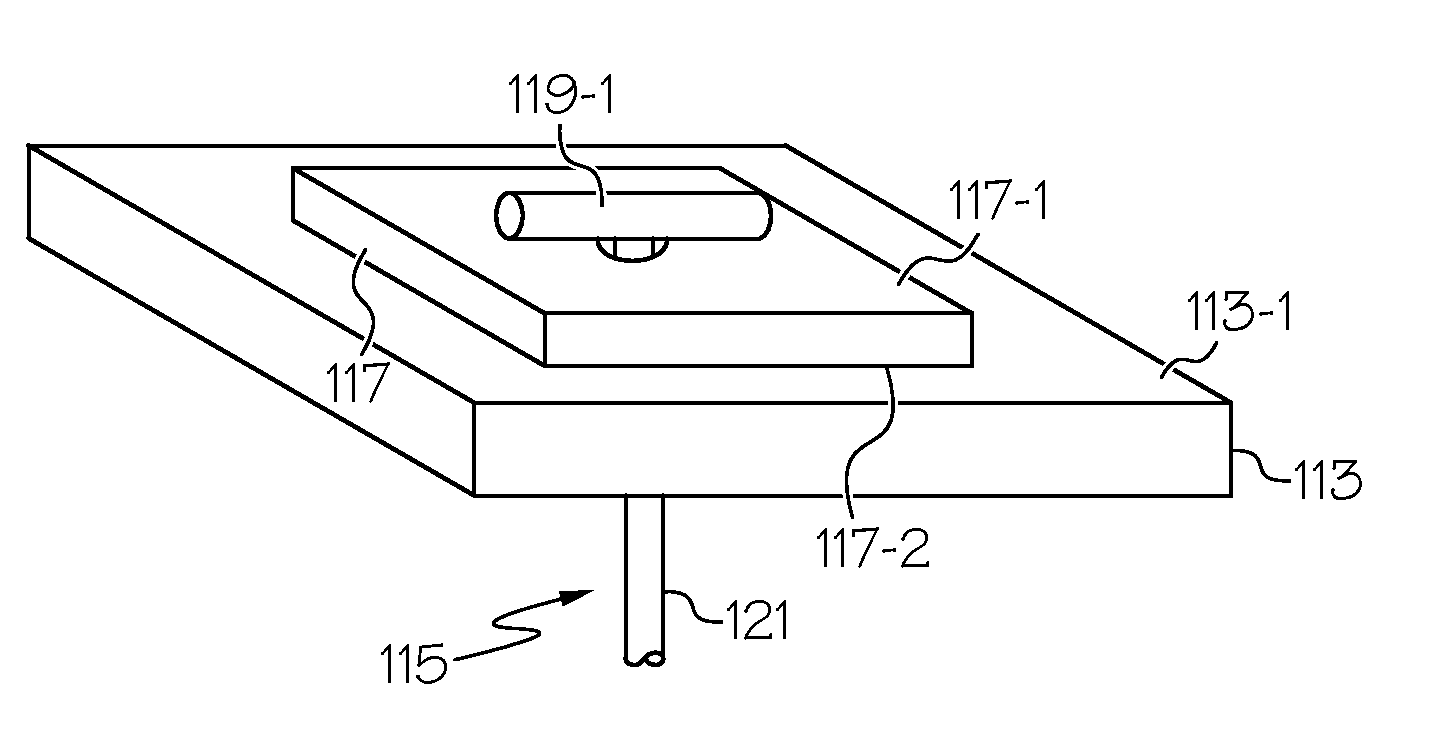

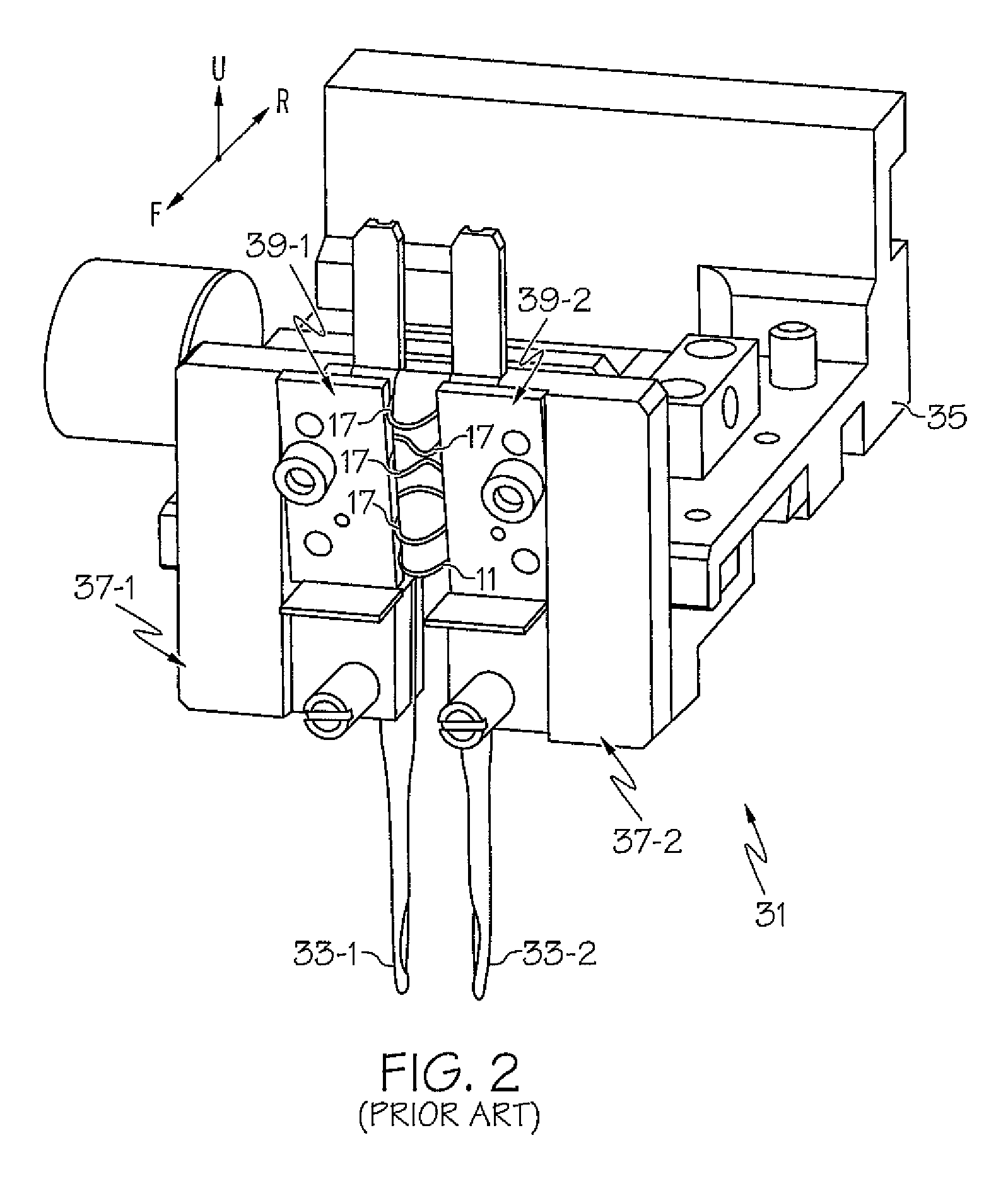

Fastener stock and device for use in dispensing plastic fasteners therefrom

ActiveUS20130134205A1Limited amountIncrease flexibilityStampsDispensing apparatusComputer moduleAngular orientation

A device for dispensing a plastic fastener from a supply of ladder-type fastener stock includes a pair of separate modules that are independently pneumatically powered by a common air source. Each module is adapted to receive and index a corresponding side rail of the fastener stock, separate a cross-bar therefrom and eject the separated cross-bar out through a sharpened needle. As a feature of the invention, the pair of modules ejects the cross-bars of the dispensed fastener in an offset relationship to minimize fastener stress. As another feature of the invention, the pair of modules is independently slidably coupled to a common mounting plate. In this manner, the spacing and angular orientation between the modules are adjustable. As another feature of the invention, the feed mechanism includes a feed pawl that selectively engages outwardly facing notches formed in the side rail to ensure accurate alignment prior to the severing process.

Owner:AVERY DENNISON CORP

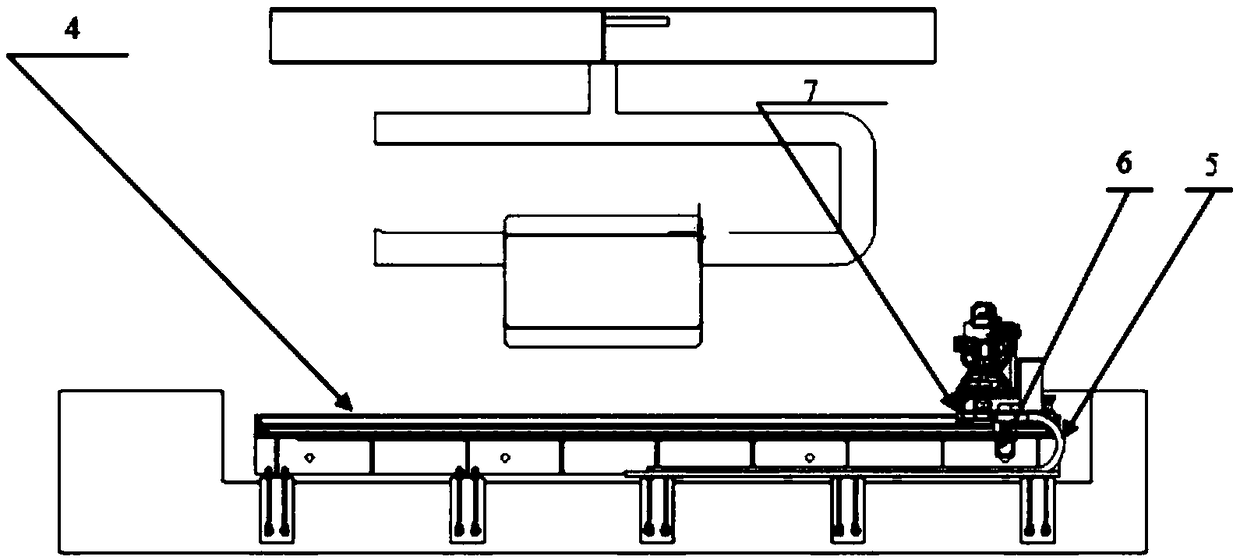

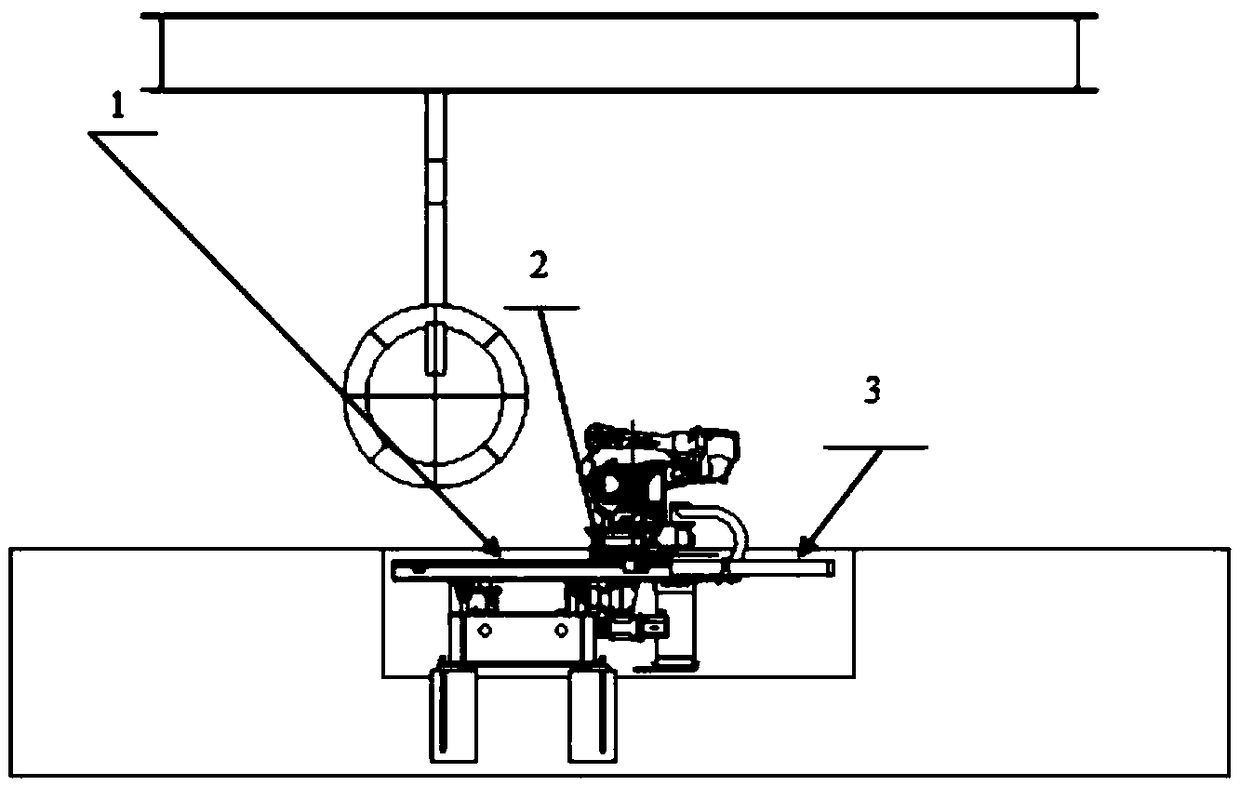

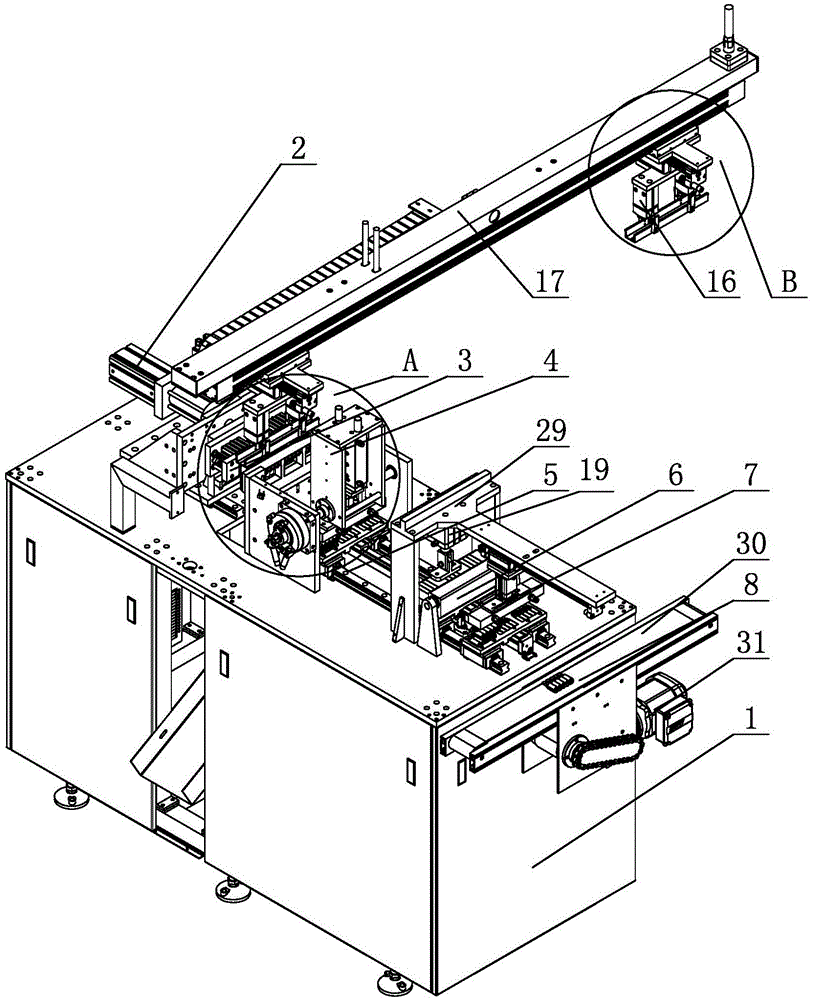

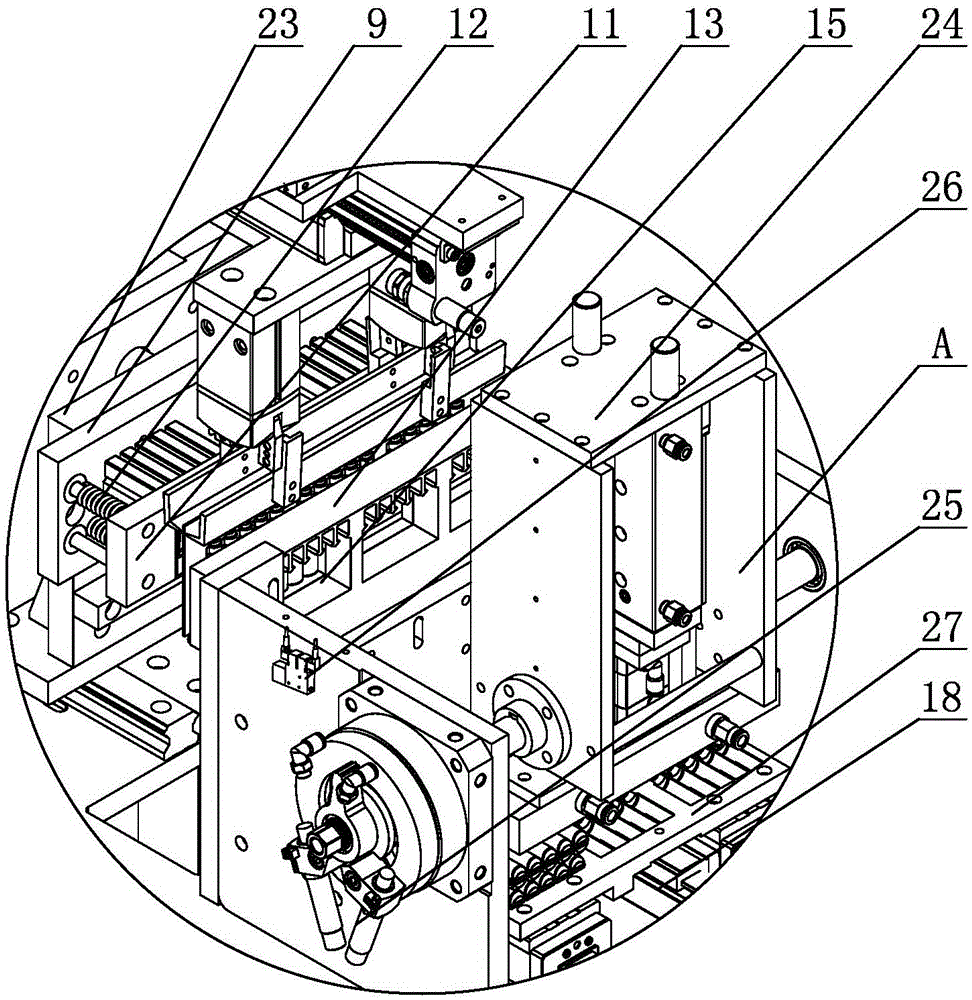

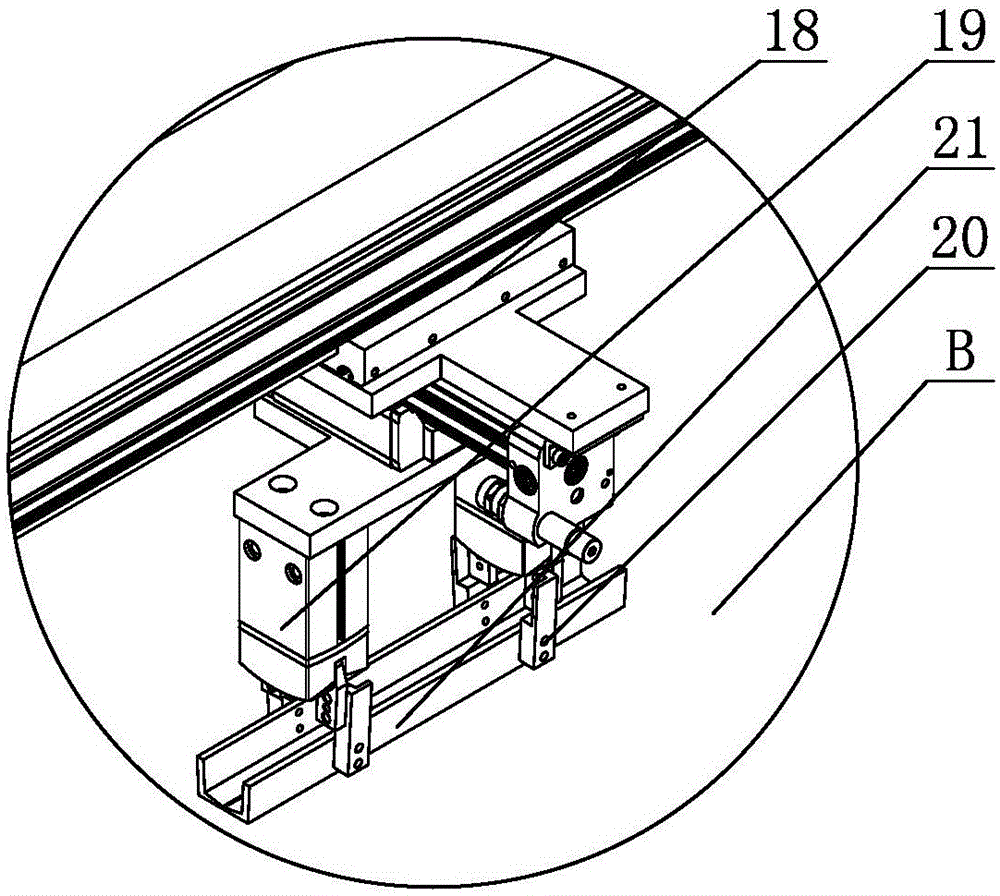

Plastic ampoule blanking slitting transfer all-in-one machine

ActiveCN105058501AMeet production speed requirementsCompact structureAffixing tagsMetal working apparatusEngineeringAmpoule

The invention relates to subsequent processing equipment of products produced by blowing-filling-sealing integrated equipment, in particular to a plastic ampoule blanking slitting transfer all-in-one machine. The plastic ampoule blanking slitting transfer all-in-one machine comprises a rack; a push assembly, a punch die assembly, a sucker assembly, a virtual cutting product transfer assembly, a cutter assembly, a finished product transfer assembly and a conveying assembly are sequentially arranged on the rack; the punch die assembly comprises a punch die fixing plate, a punch die, a punch die embedding plate, a compression spring and a punch die supporting plate; two sides of the punch die fixing plate are connected with the push assembly and the punch die respectively; the punch die fixing plate is connected with the punch die embedding plate through a guide shaft; the compression spring is disposed on the guide shaft; a straight slot which corresponds to the punch die is formed in the punch die embedding plate; the punch die supporting plate is disposed on the opposite side of the punch die; a claw assembly is arranged above the rack; the claw assembly is disposed on a transverse beam. The plastic ampoule blanking slitting transfer all-in-one machine is compact in structure, easy to operate, high in working efficiency and capable of excellently meeting the requirements for production speed of products by the blowing-filling-sealing equipment.

Owner:SHINVA MEDICAL INSTR CO LTD

Plastic fastener and plastic fastener assembly

Plastic fastener and plastic fastener assembly. The plastic fastener assembly may be a length of continuously connected fastener stock and may include a first flexible filament having a first end and a second end, a first cross-bar disposed at the first end of the first flexible filament, and a first paddle disposed at the second end of the first flexible filament. The plastic fastener assembly may further include a second flexible filament, the second flexible filament having a first end and a second end, a second cross-bar disposed at the first end of the second flexible filament, and a second paddle disposed at the second end of the second flexible filament. The plastic fastener assembly may further include a first severable connector interconnecting the first and second paddles. The first severable connector may include a pair of generally frusto-semi-circular members joined to one another at a generally planar break region.

Owner:AVERY DENNISON CORP

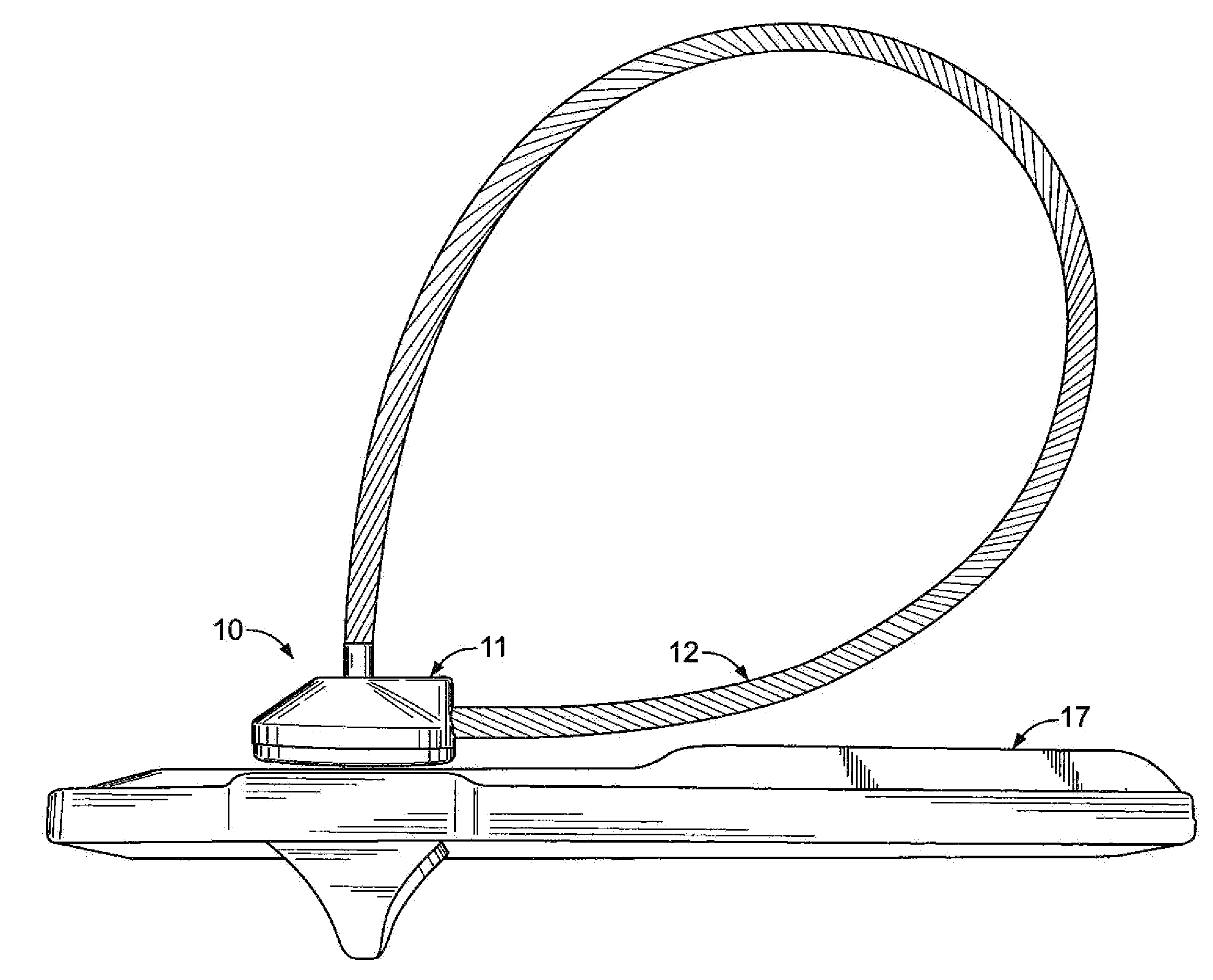

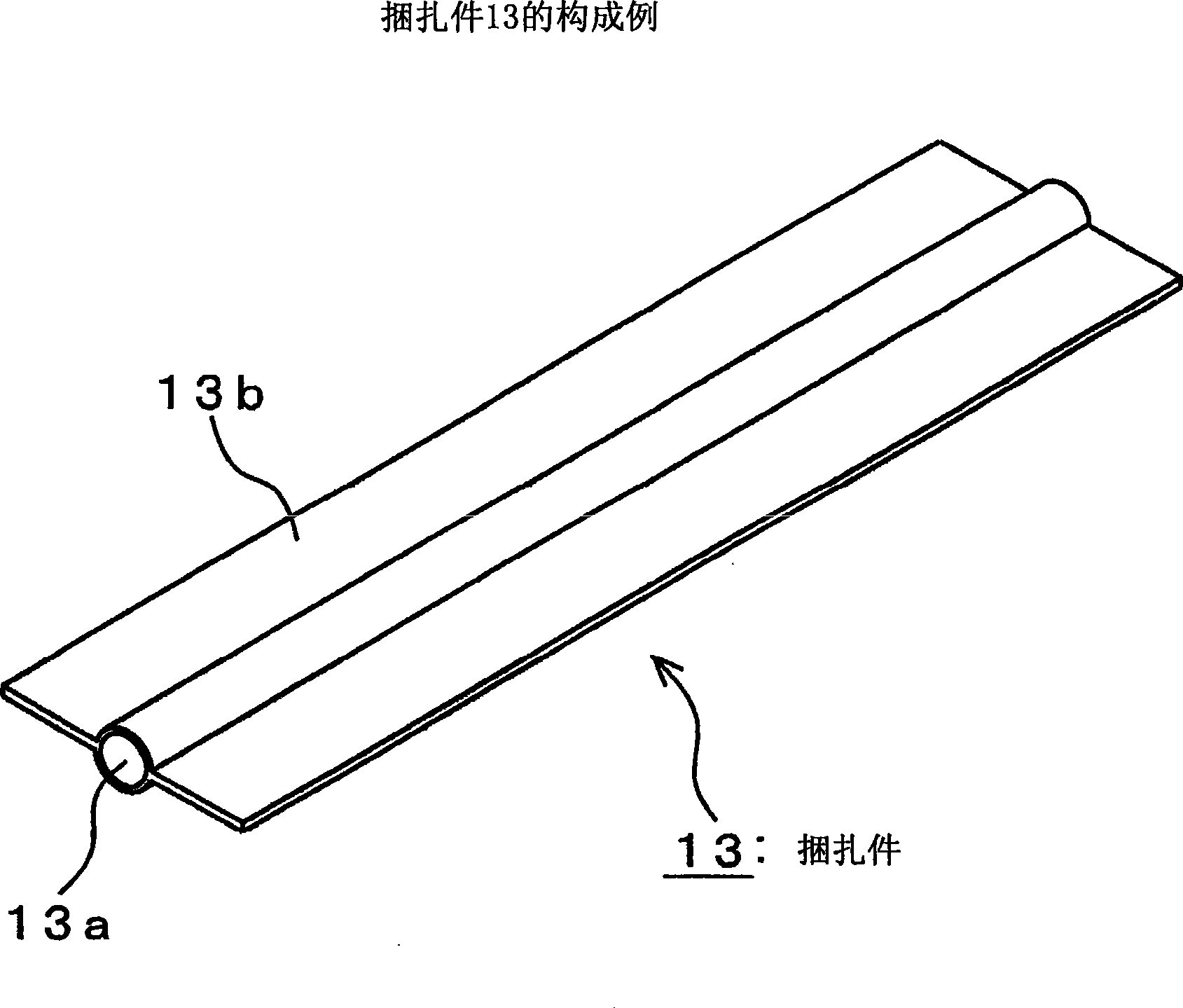

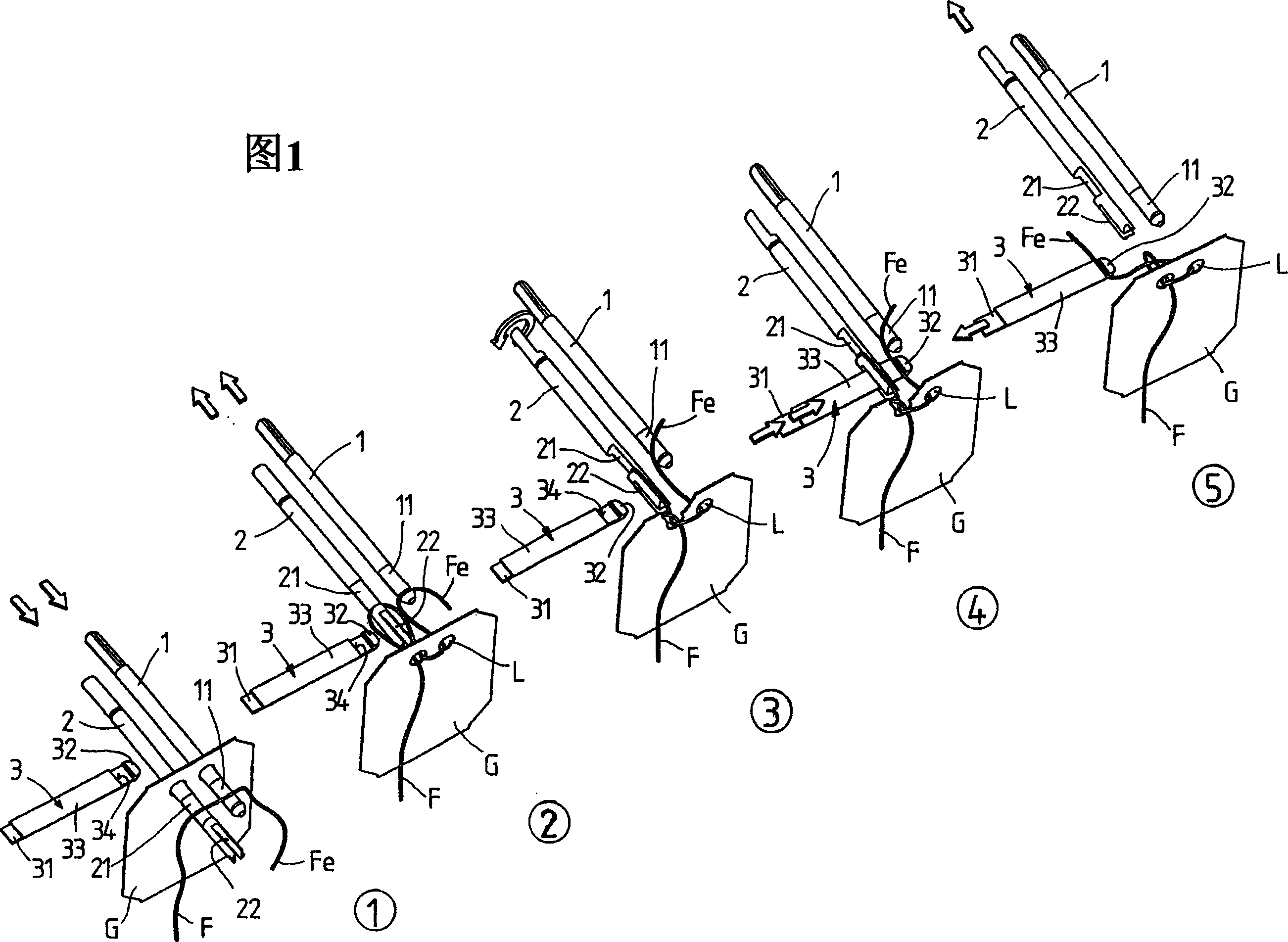

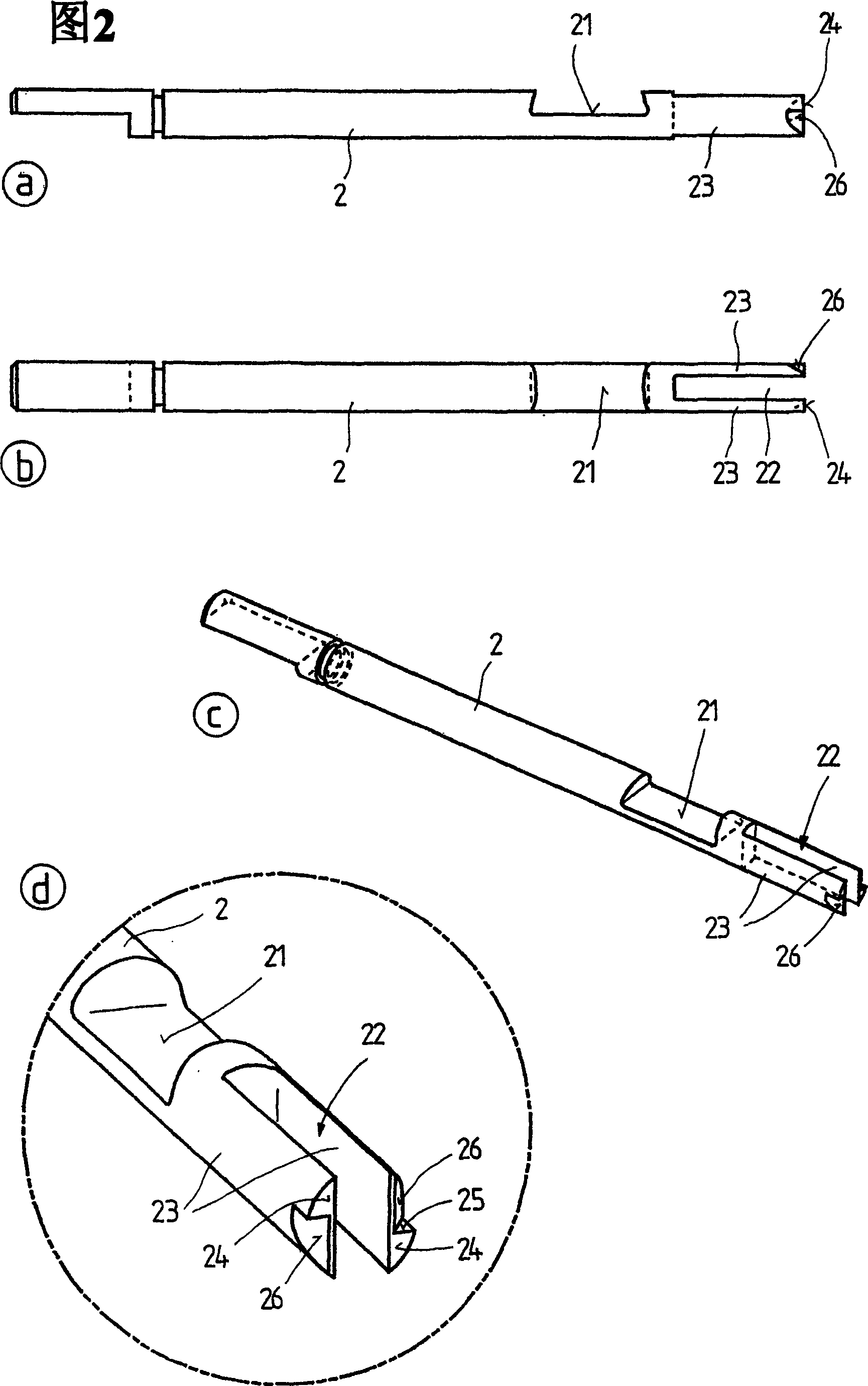

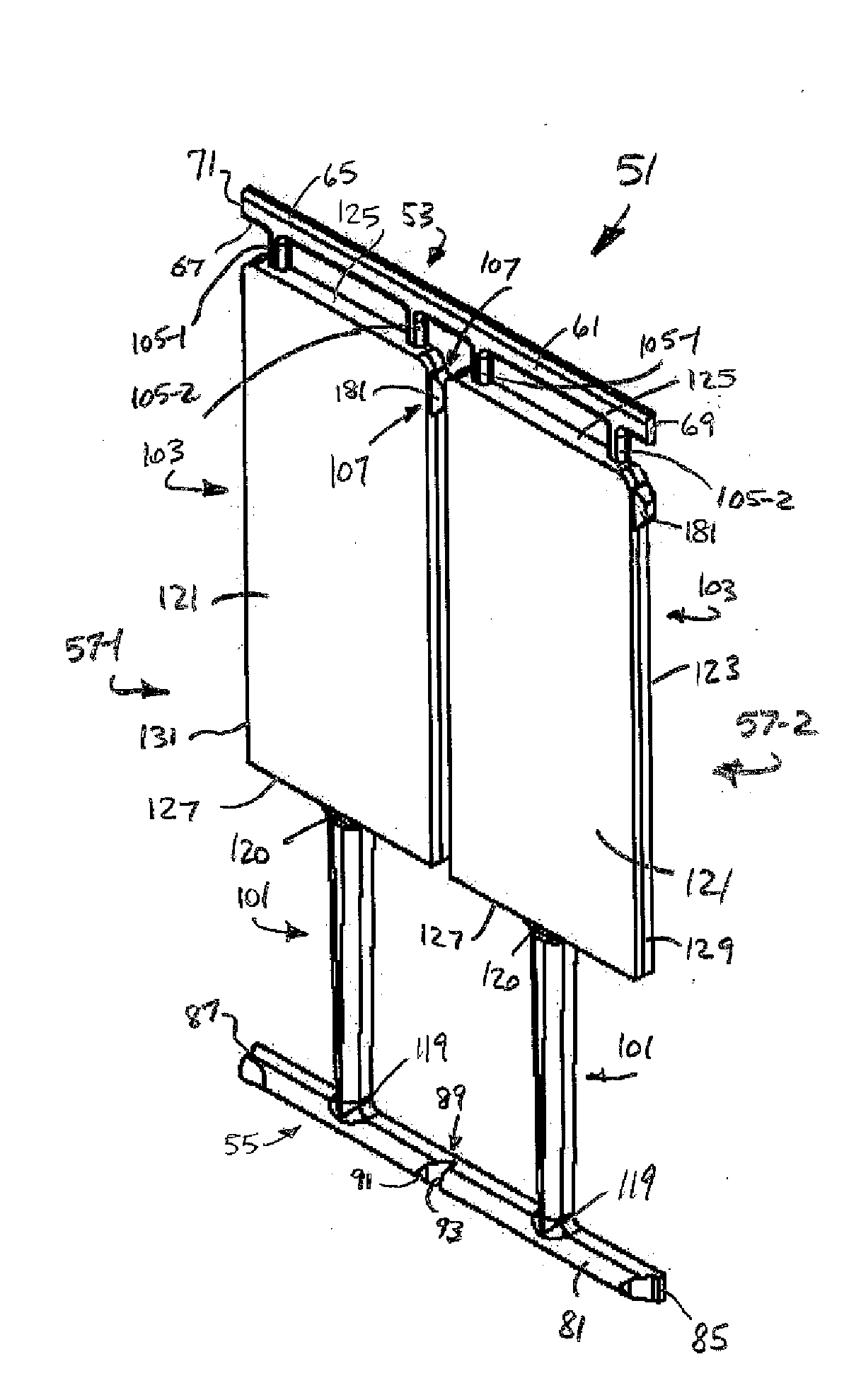

Hang tag and method of applying hang tag to an elongated object

A hang tag is disclosed. The hang tag has first and second surfaces, which are preferably planar. A slot is defined between the first and second surfaces. Desirably, the slot extends at least about 0.25 inches in one direction and at least about 1 inch in another direction. Also disclosed is a method and an apparatus for automatically applying a hang tag to an elongated object (e.g., an electrical cord such as a cord set), with a machine that is suitable for applying a securement strap to an object. The method includes providing a hang tag having a slot therein. The hang tag is aligned with the machine so that when the securement strap is ejected from the machine, it passes through the slot, forms a loop around the elongated object, and is tensioned around the object. As such, the securement strap serves to attach the hang tag to the elongated object in a stationary manner.

Owner:WS PACKAGING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com