Plastic ampoule blanking slitting transfer all-in-one machine

It is an all-in-one machine and punching technology, which is applied in labeling, metal processing, fixed labels, etc. It can solve the problems of low work efficiency, large manpower and time consumption, and waste edges of products, and achieve high work efficiency, compact structure, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

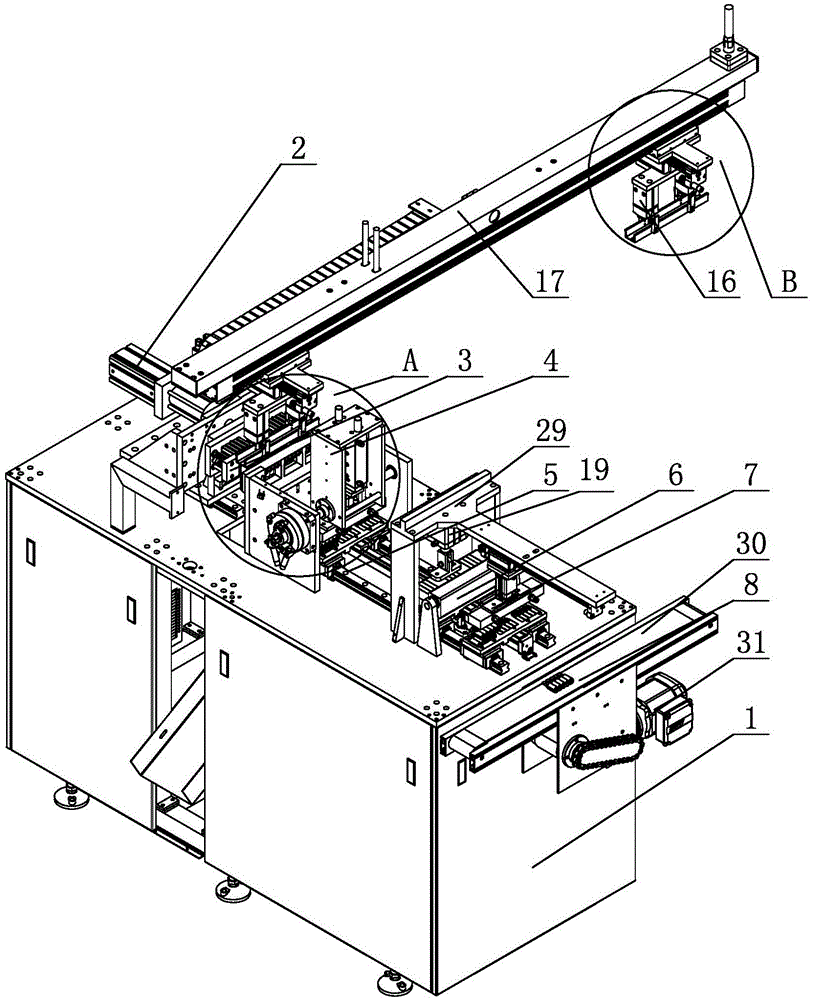

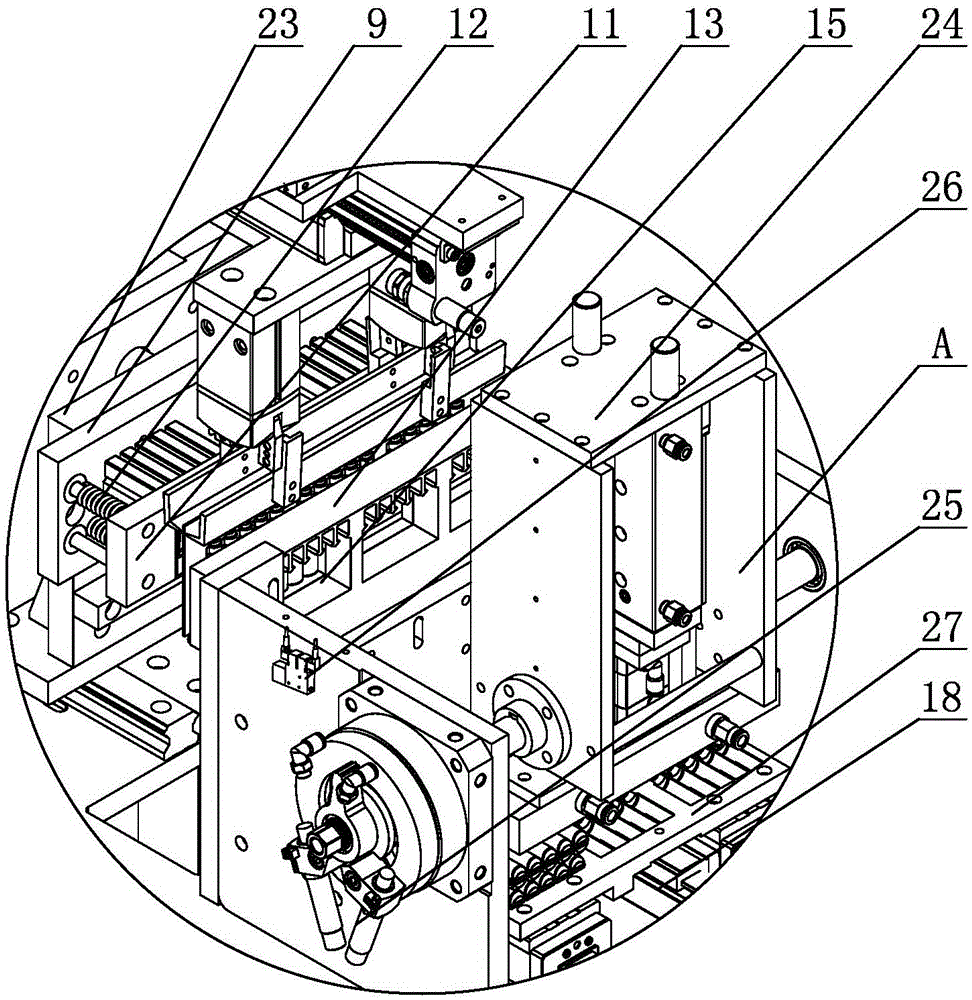

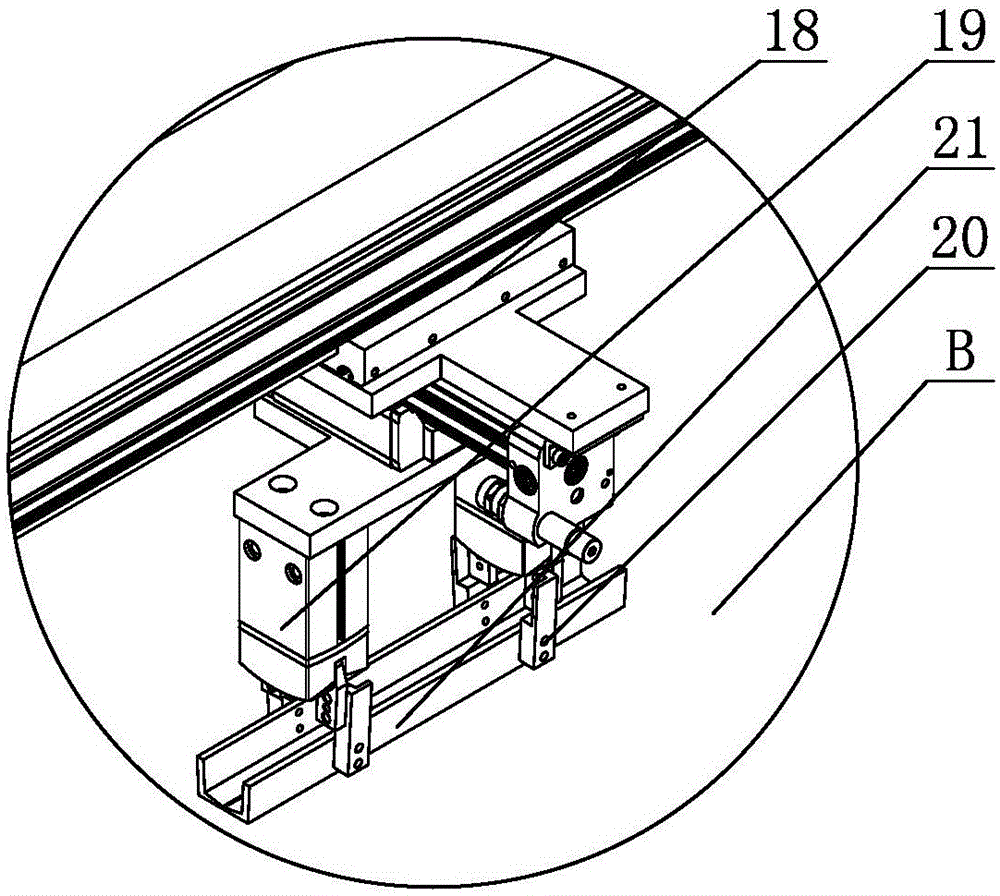

[0025] like Figure 1-4 As shown, the plastic ampoule punching, slitting and transferring all-in-one machine of the present invention includes a frame 1 on which a push assembly 2, a punching die assembly 3, a suction cup assembly 4, and a virtual-cut product transfer assembly are sequentially arranged. 5. Cutter assembly 6, finished product transfer assembly 7 and delivery assembly 8, said punching die assembly 3 includes punching die fixing plate 9, punching die 10, punching die inserting plate 11, compression spring 12 and punching die The support plate 13, one side of the punching die fixing plate 9 is fixedly connected with the push assembly 2, the other side of the punching die fixing plate 9 is fixedly connected with the punching die 10, the punching die fixing plate 9 and the punching die inserting plate 11 pass through the guide shaft 14 is connected, the guide shaft 14 is provided with a compression spring 12, punching holes are set on the punching die inserting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com