Patents

Literature

44 results about "Blow fill seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blow-Fill-Seal (BFS) technology is a manufacturing technique used to produce small, (0.1mL) and large volume, (500mL +) liquid-filled containers. Originally developed in Europe in the 1930s, it was introduced in the United States in the 1960s, but over the last 20 years it has become more prevalent within the pharmaceutical industry and is now widely considered to be the superior form of aseptic processing by various medicine regulatory agencies including the U.S. Food and Drug Administration (FDA) in the packaging of pharmaceutical and healthcare products.

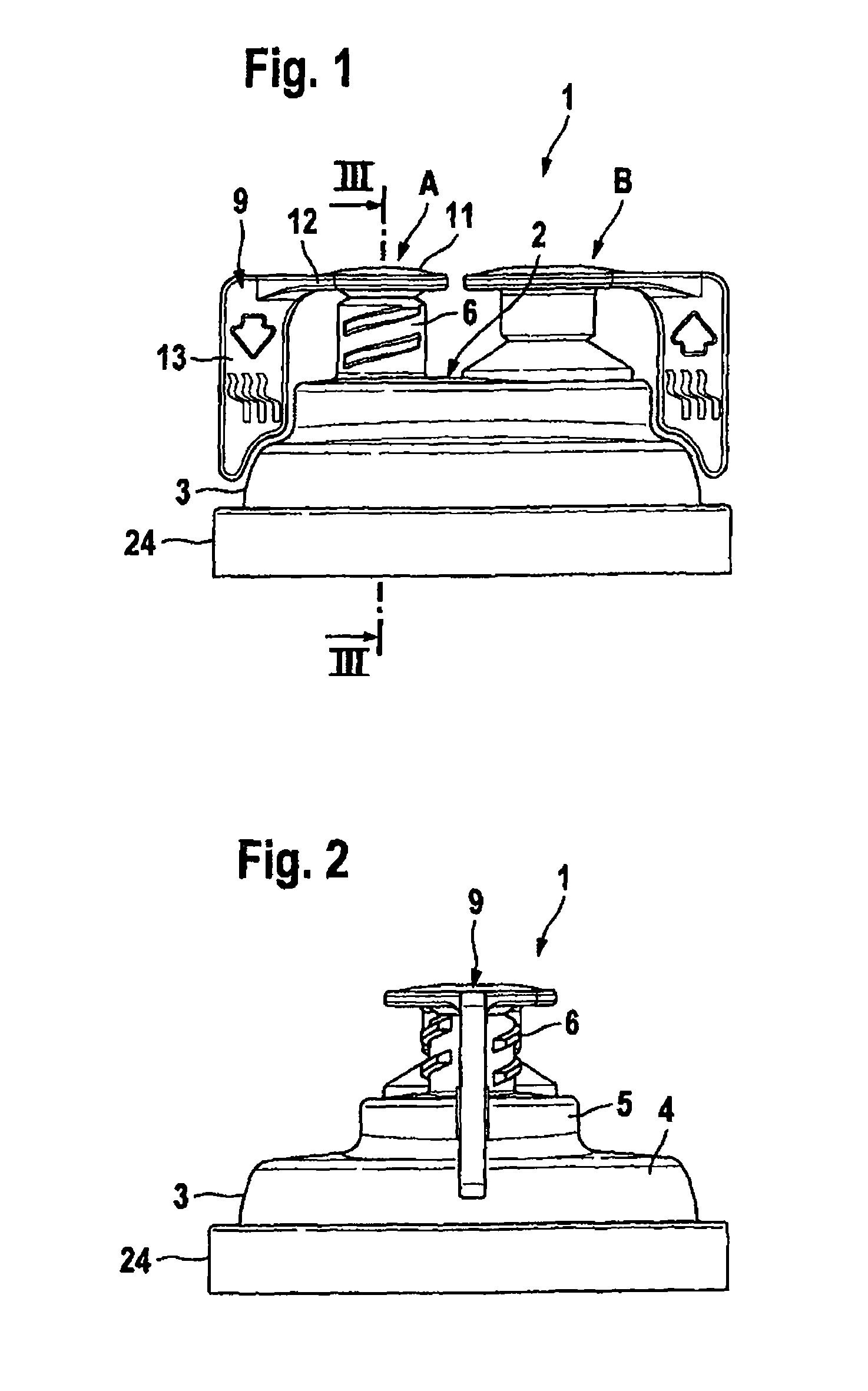

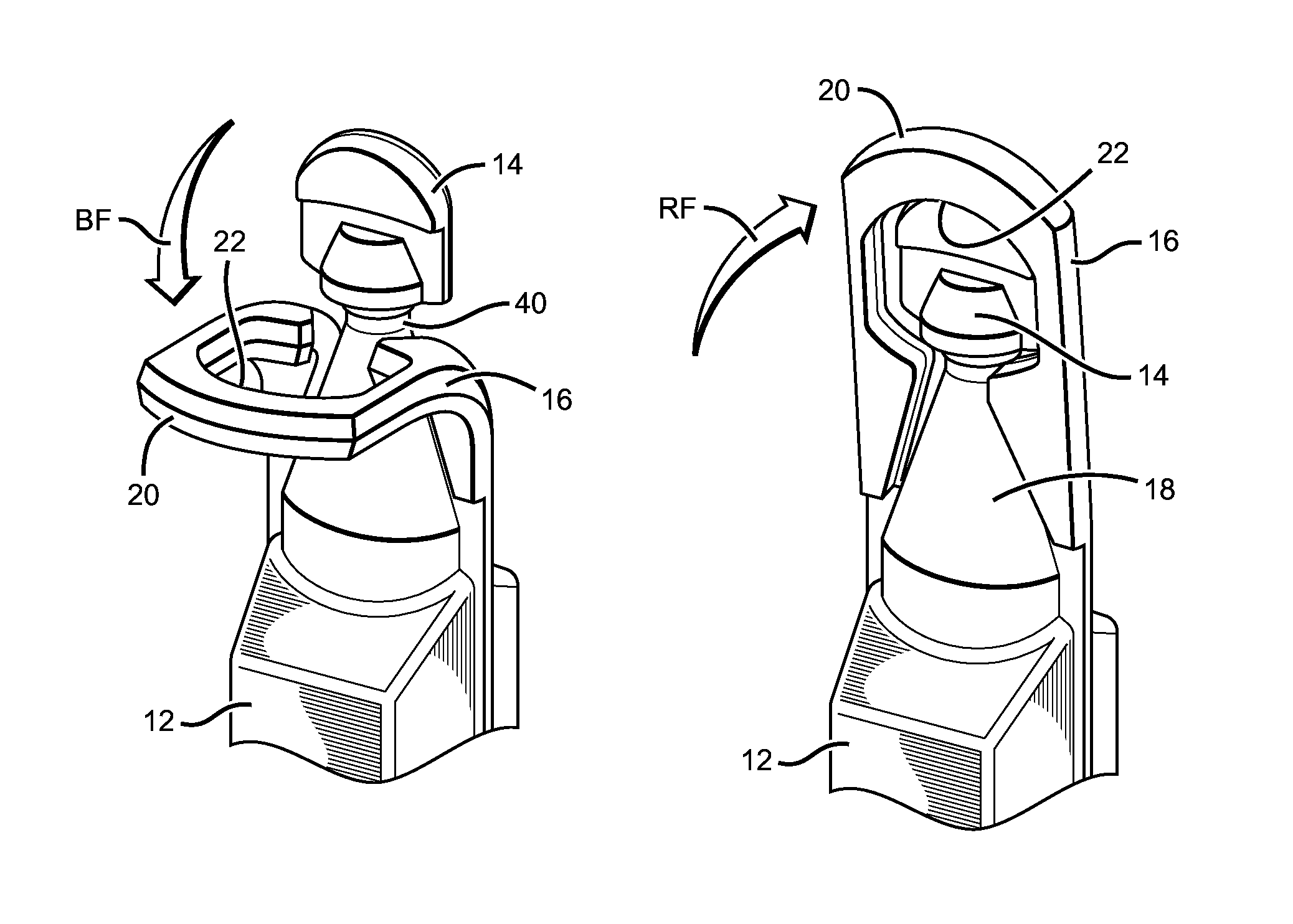

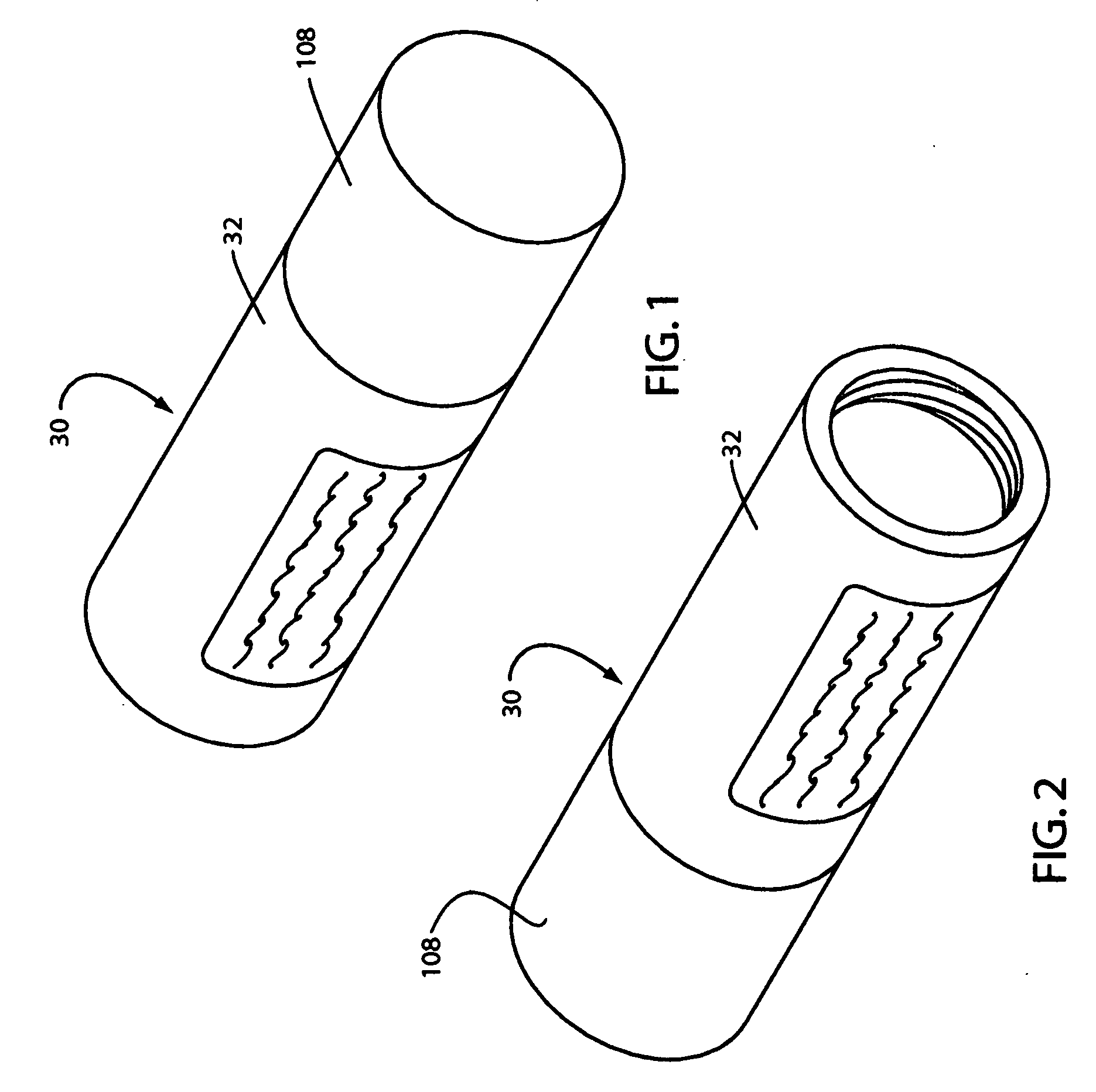

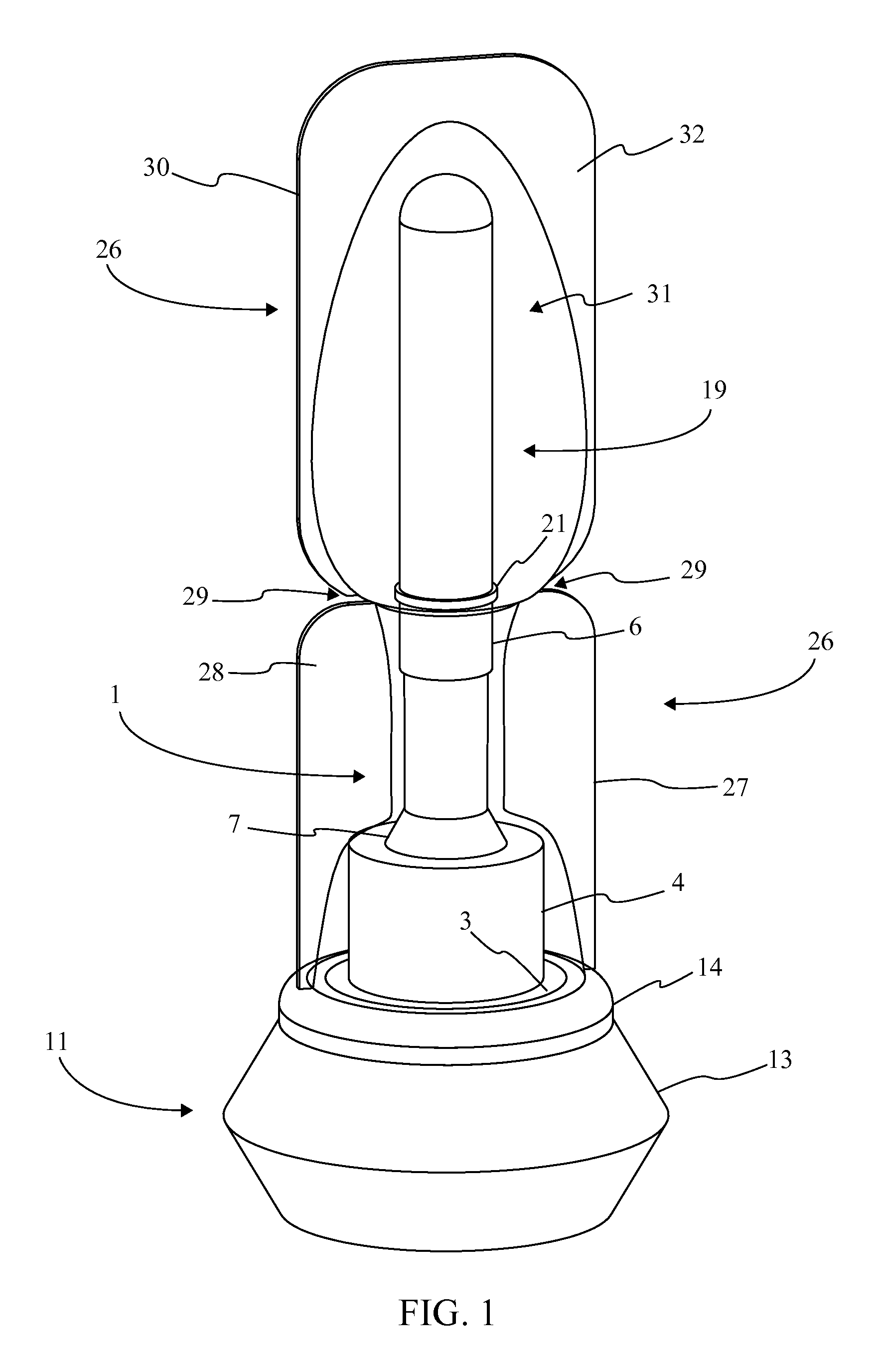

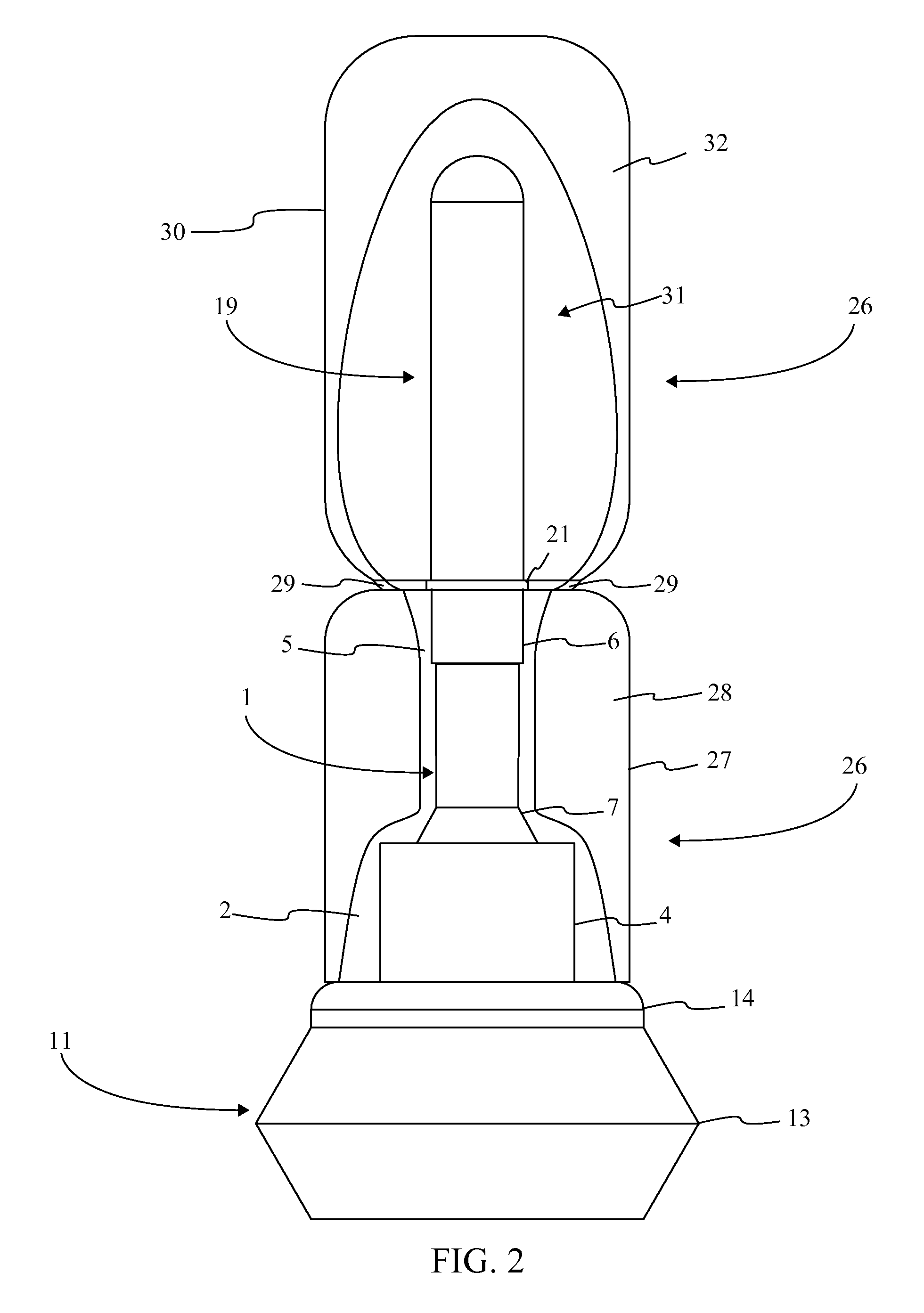

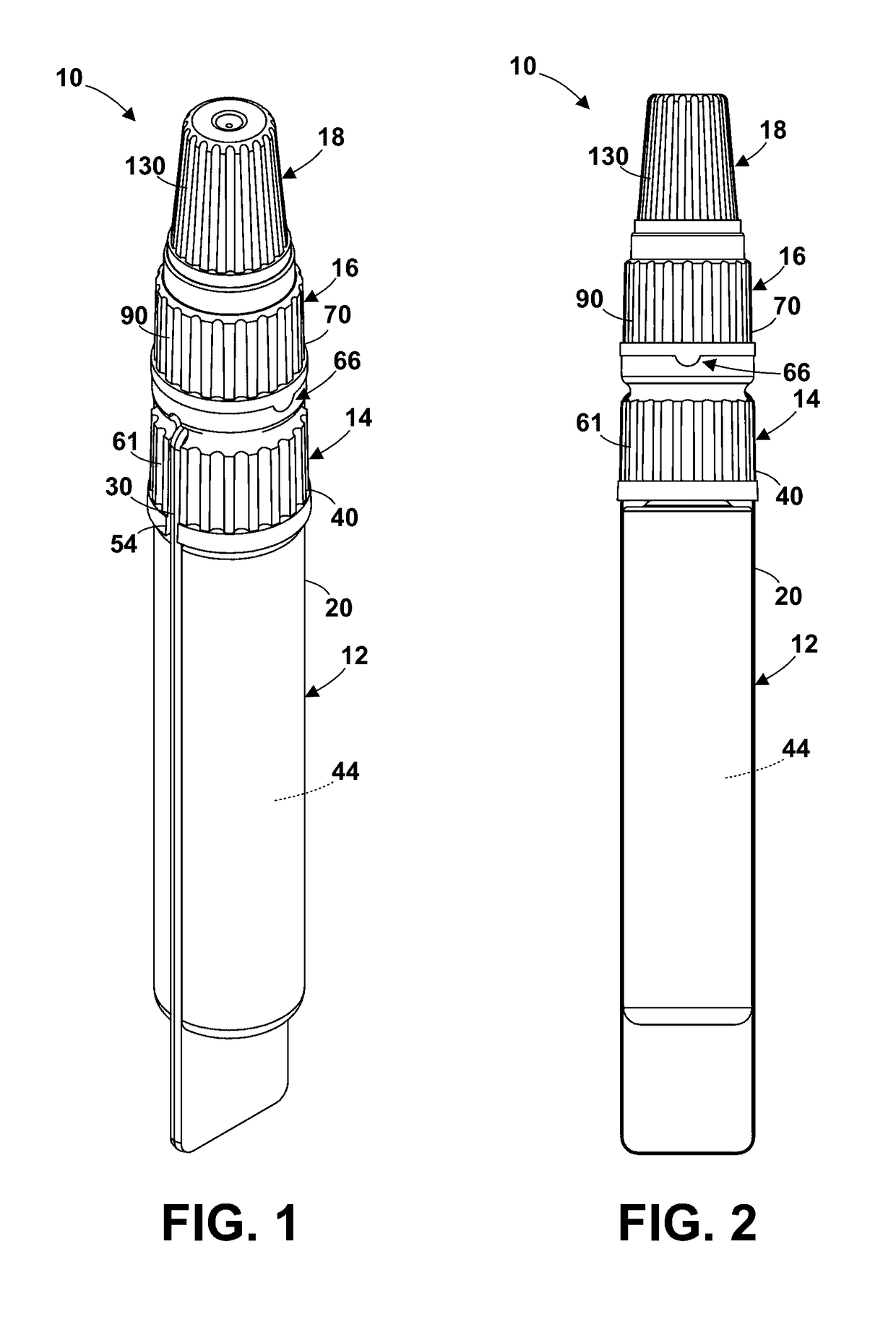

Blow fill sealed container with twist off top operated by overcap and method of forming the same

A container assembly includes a container body having a port or aperture adapted for use with a luer end of a needleless syringe. The aperture is sealed to a closure top by a first frangible seal. An overcap has a cap base sealed to the container body and an upper cap connected to the cap base by a second frangible seal, providing a sterile barrier surrounding the first frangible seal. The second frangible seal is broken by depressing the upper cap toward the container body. Alternatively, the second frangible seal is a removable tear strip broken by tugging on the tear strip. The upper cap includes a detent portion frictionally securing the upper cap to the closure top when the upper cap is depressed toward the container body. The upper cap and secured closure top are removed from container body by twisting the upper cap to break the first frangible seal and open the port.

Owner:HOSPIRA INC

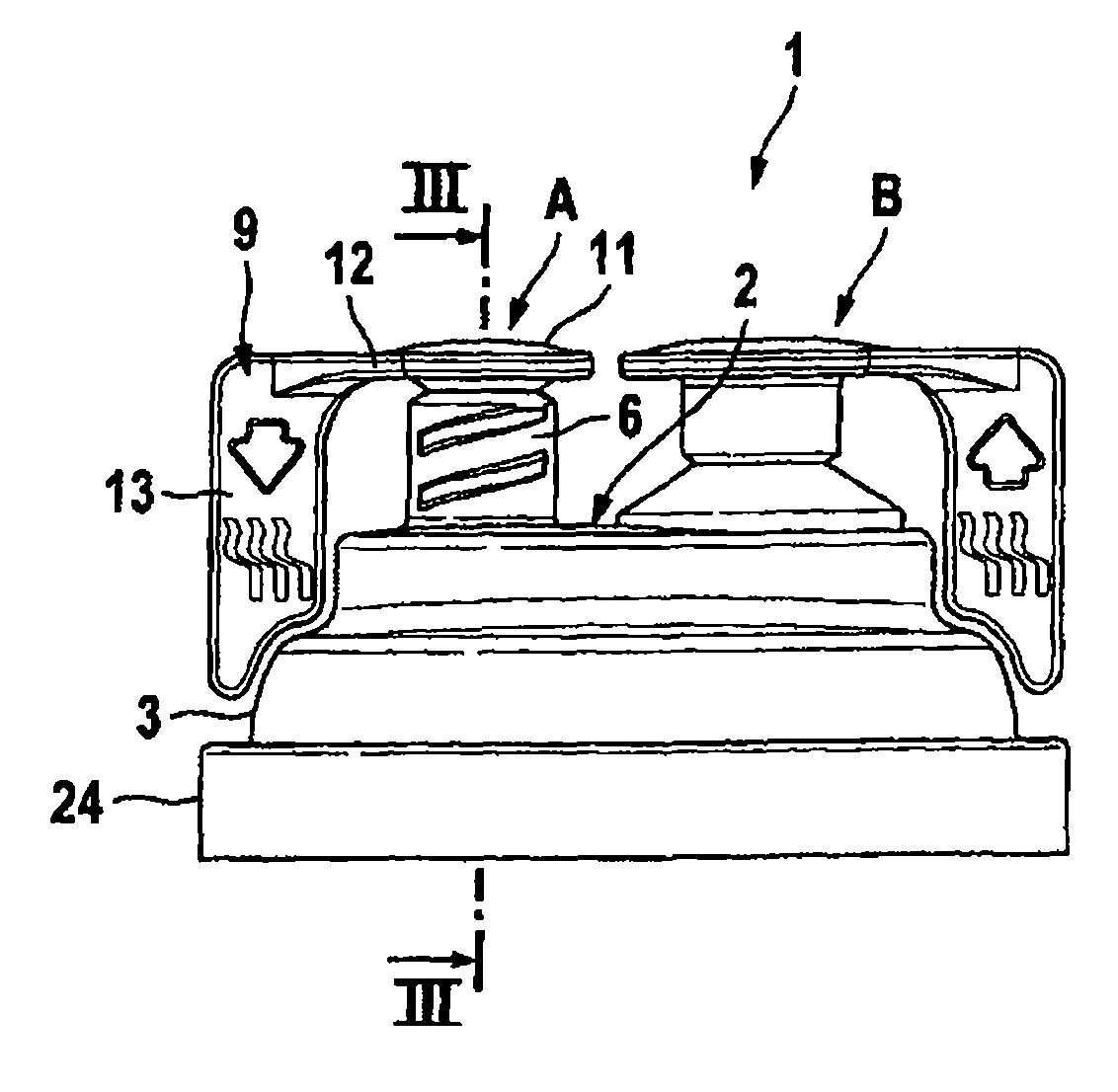

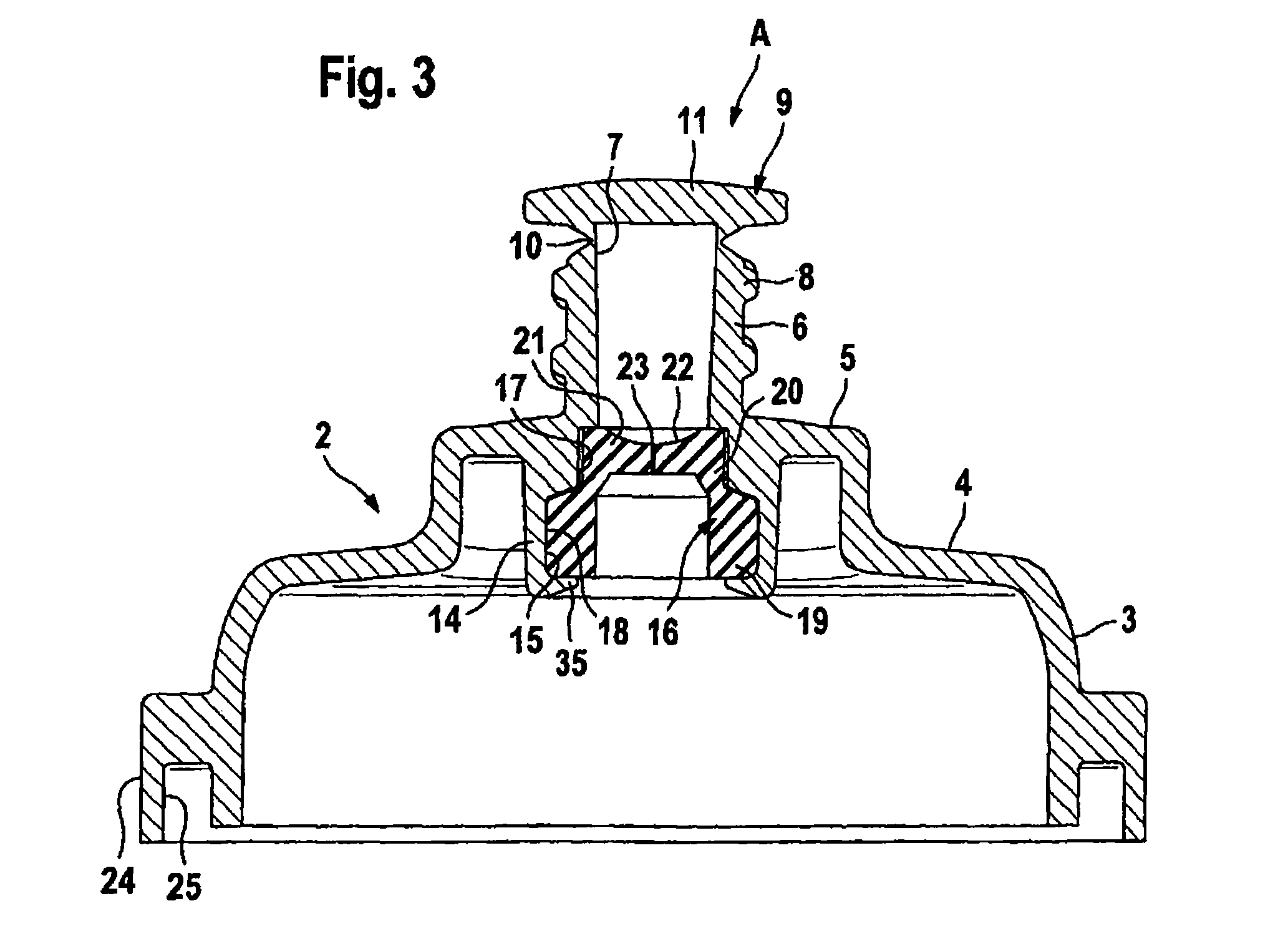

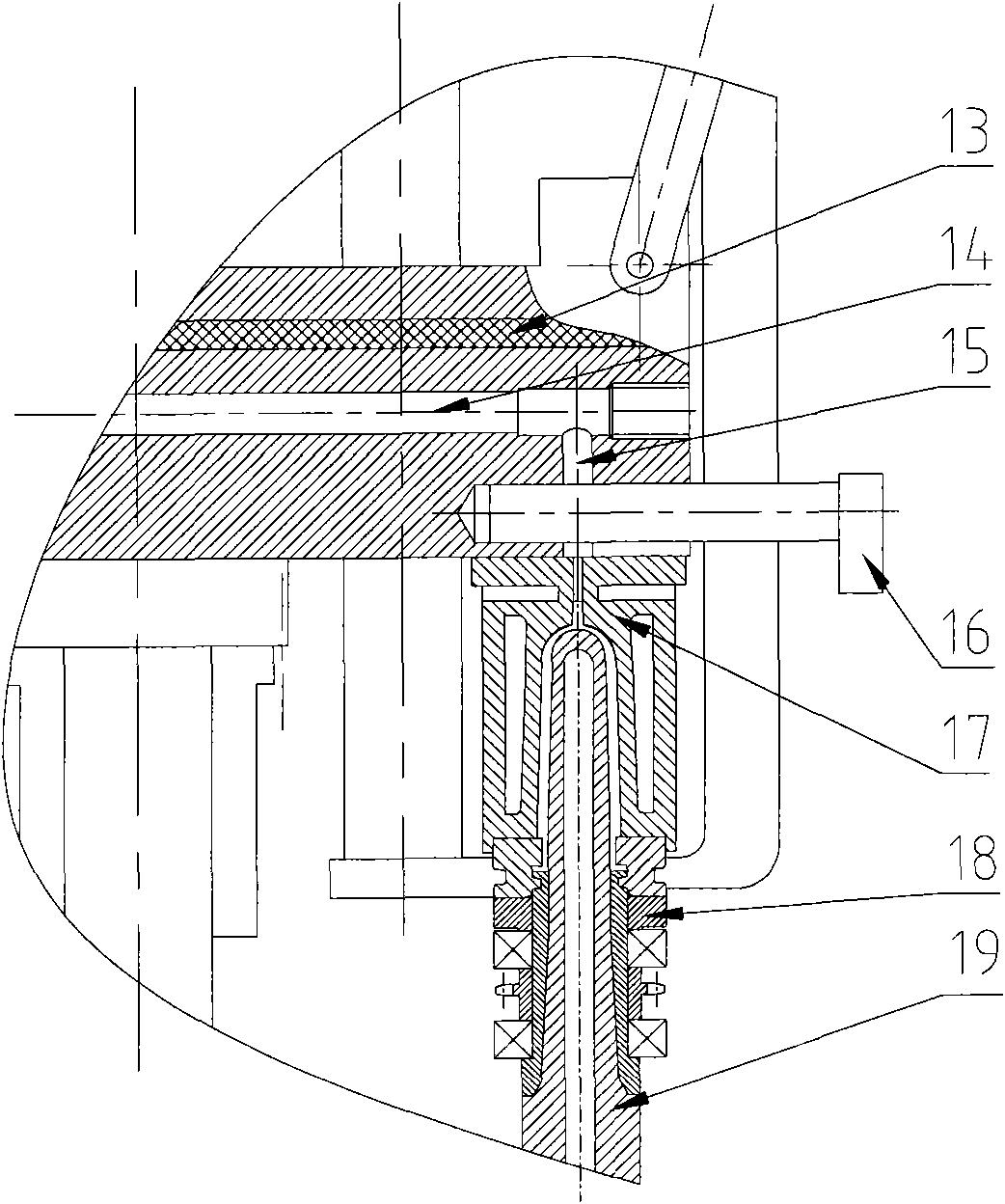

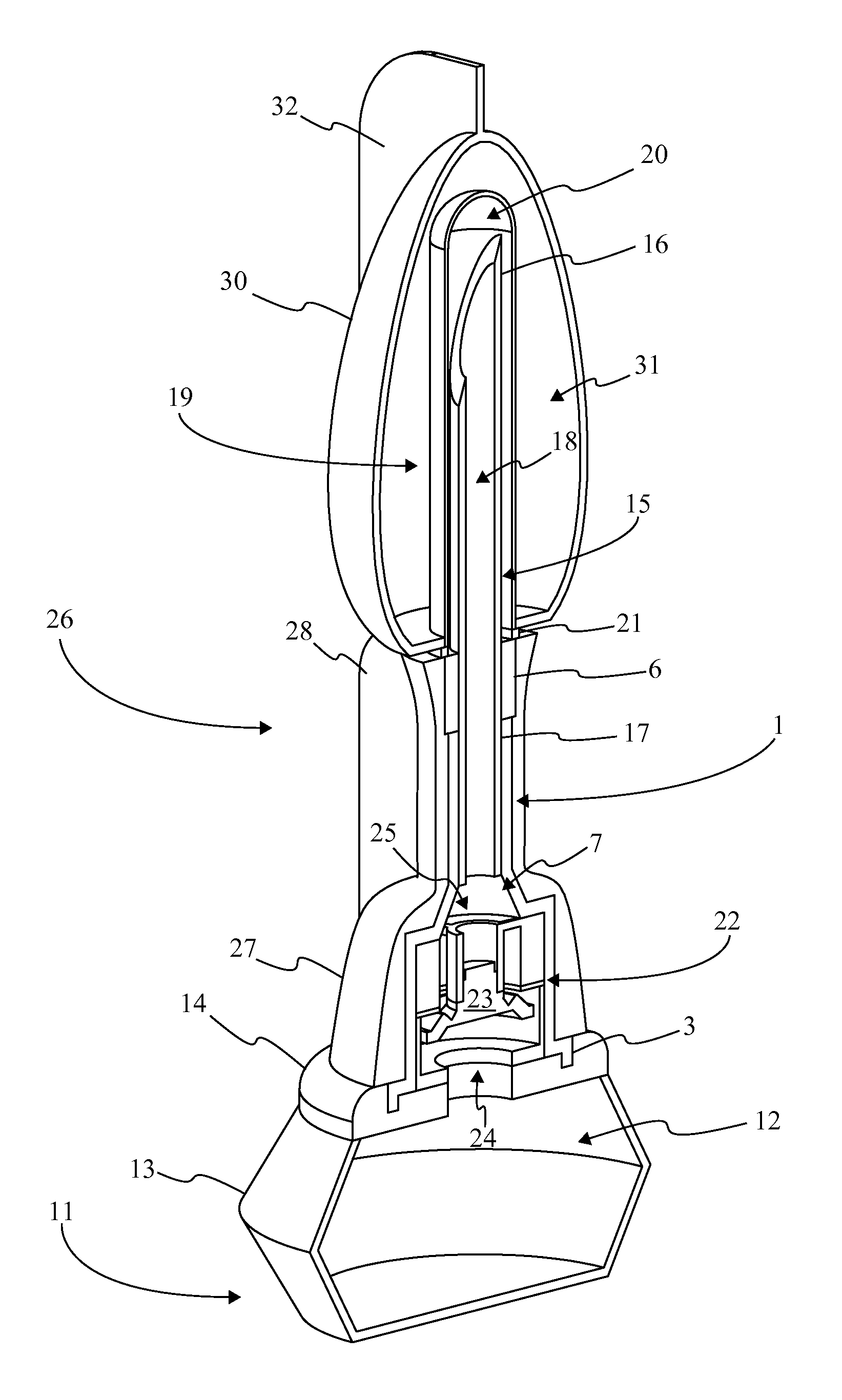

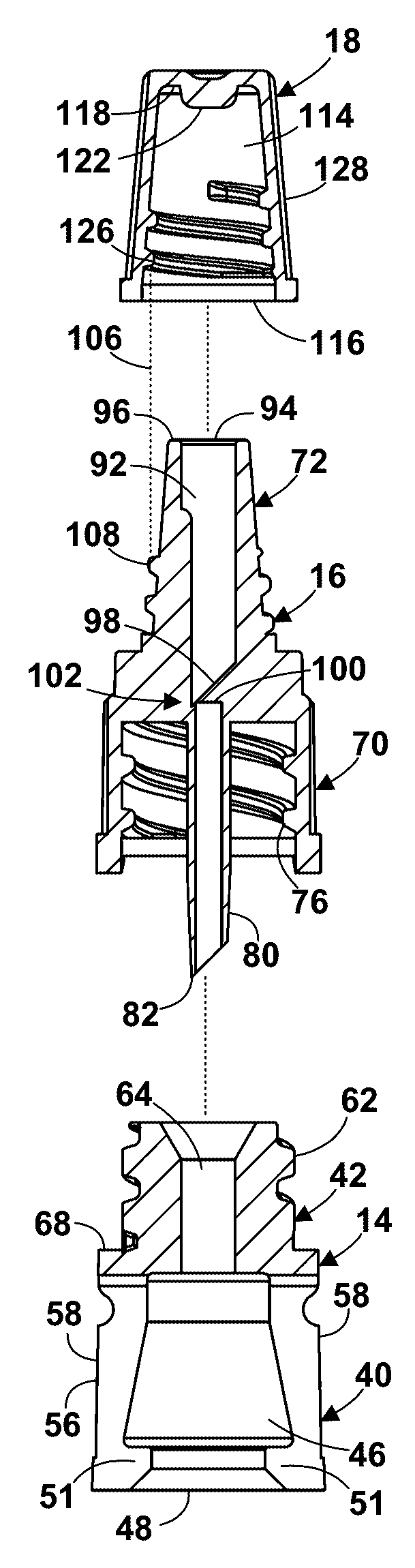

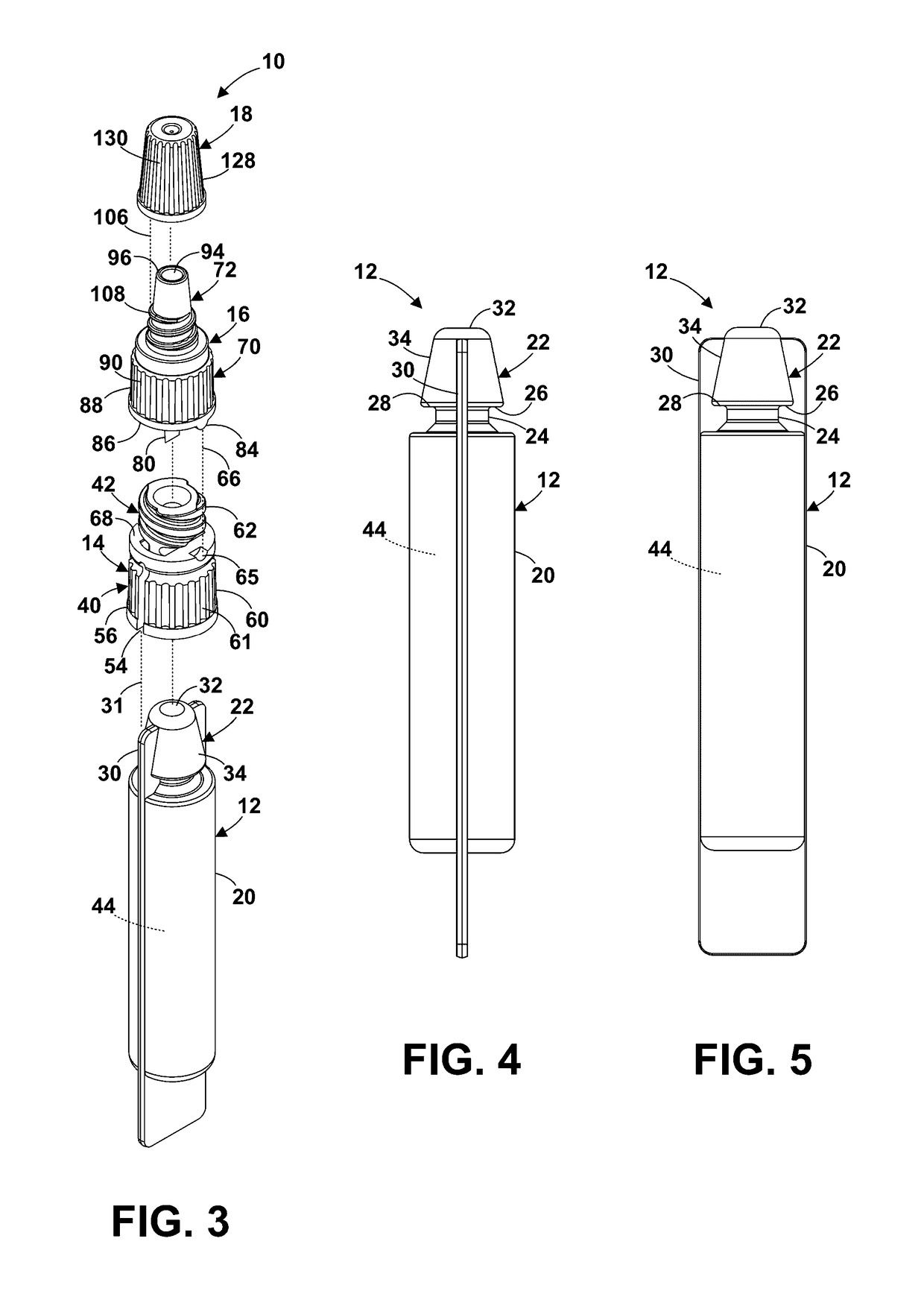

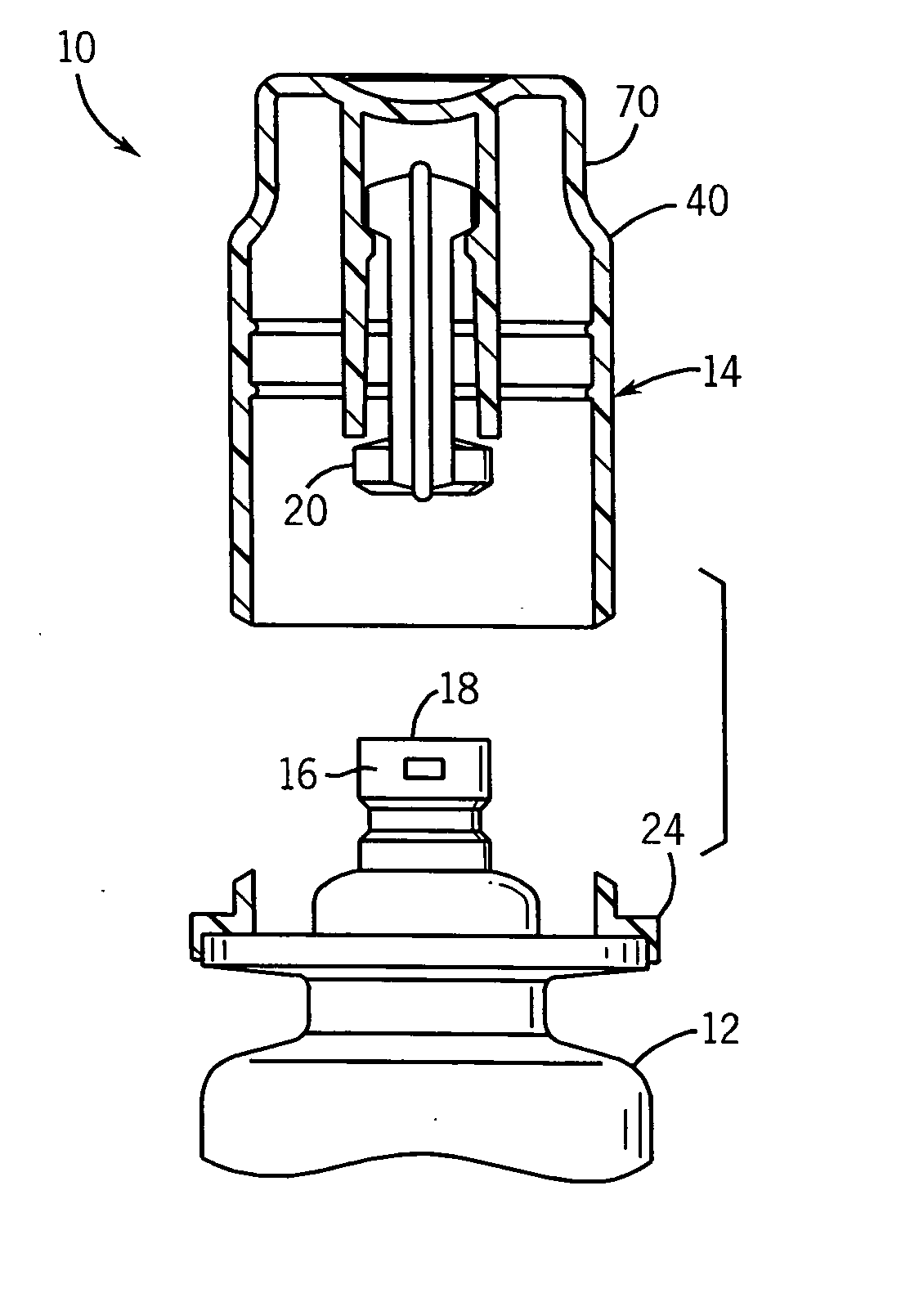

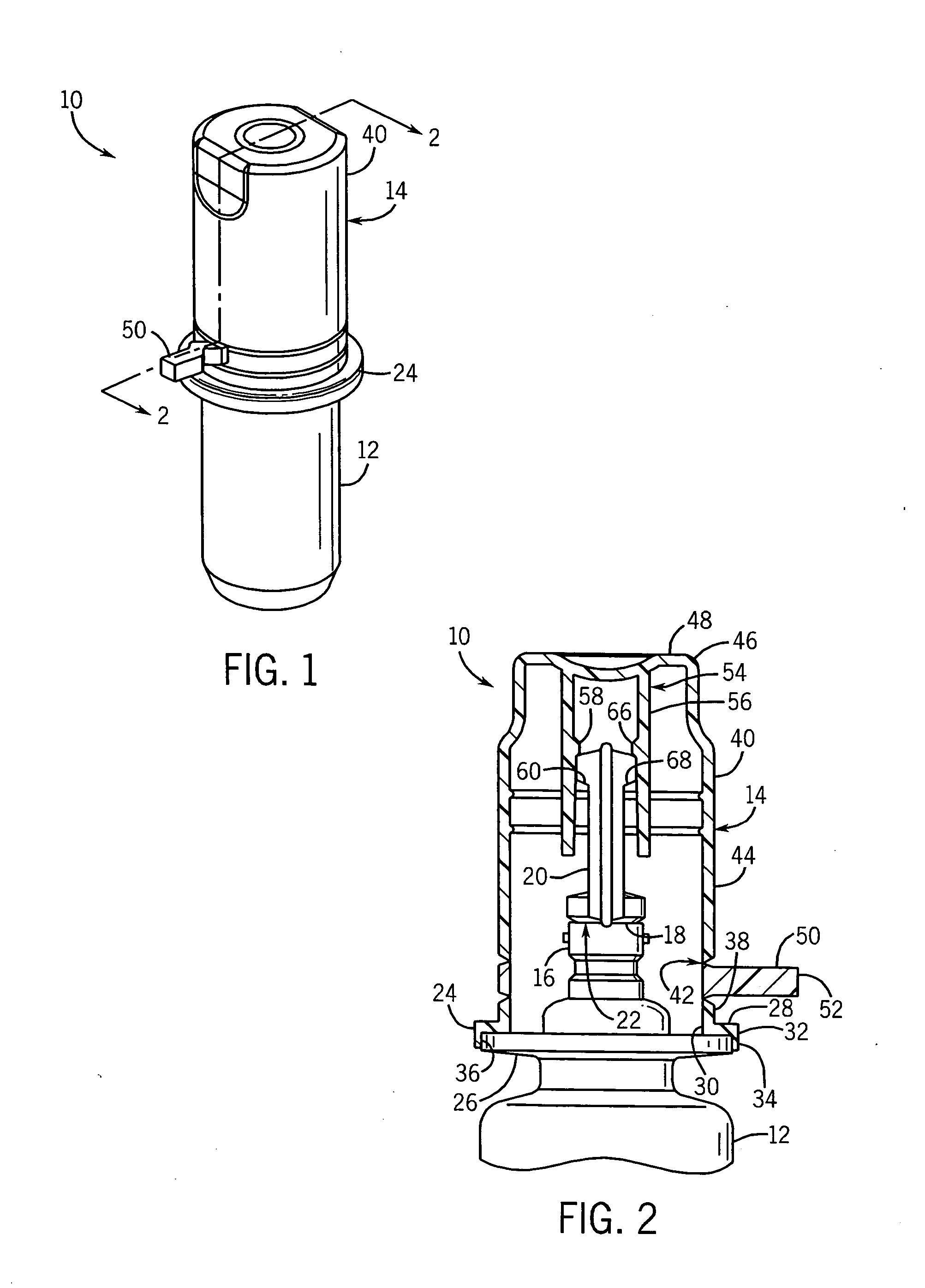

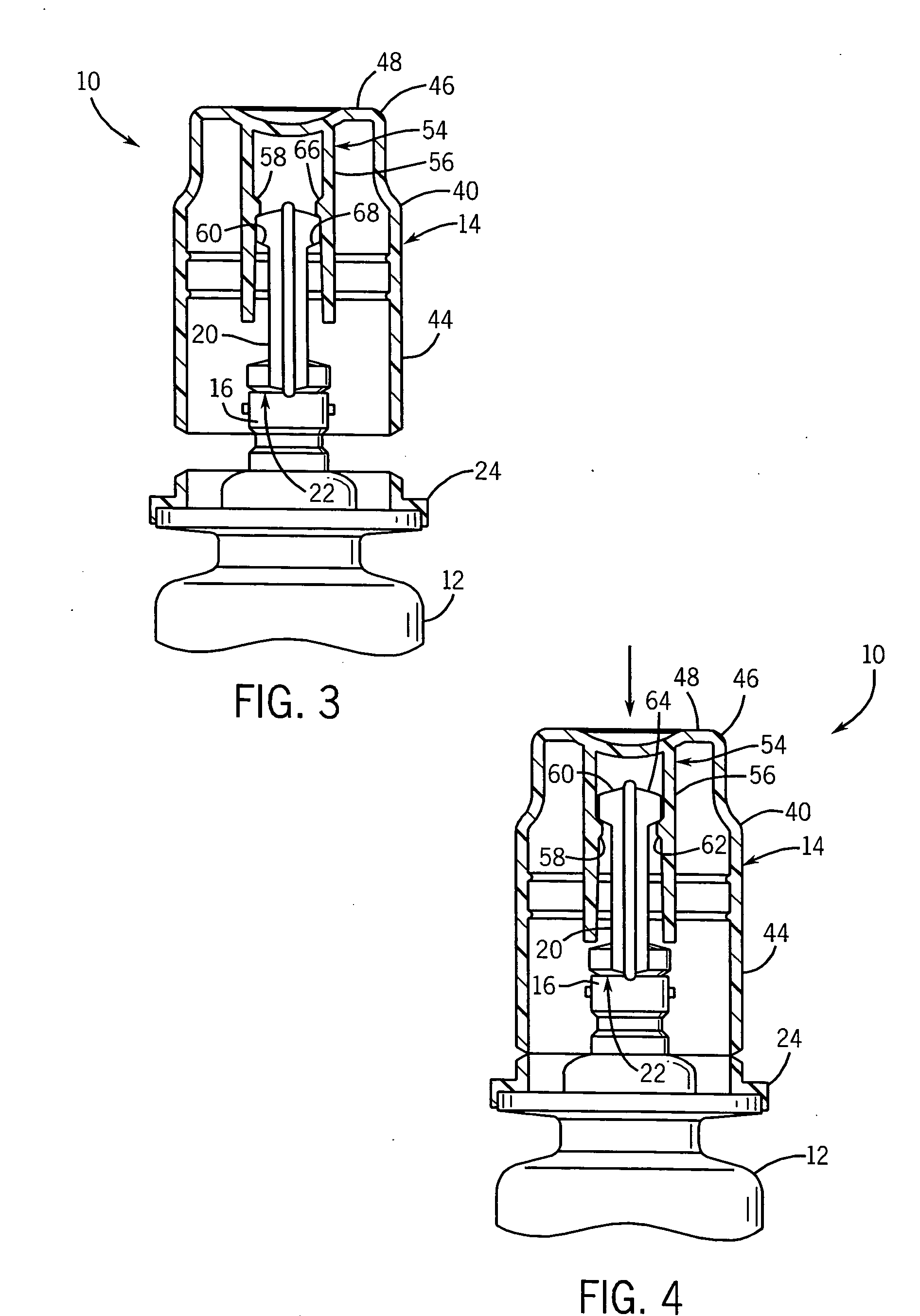

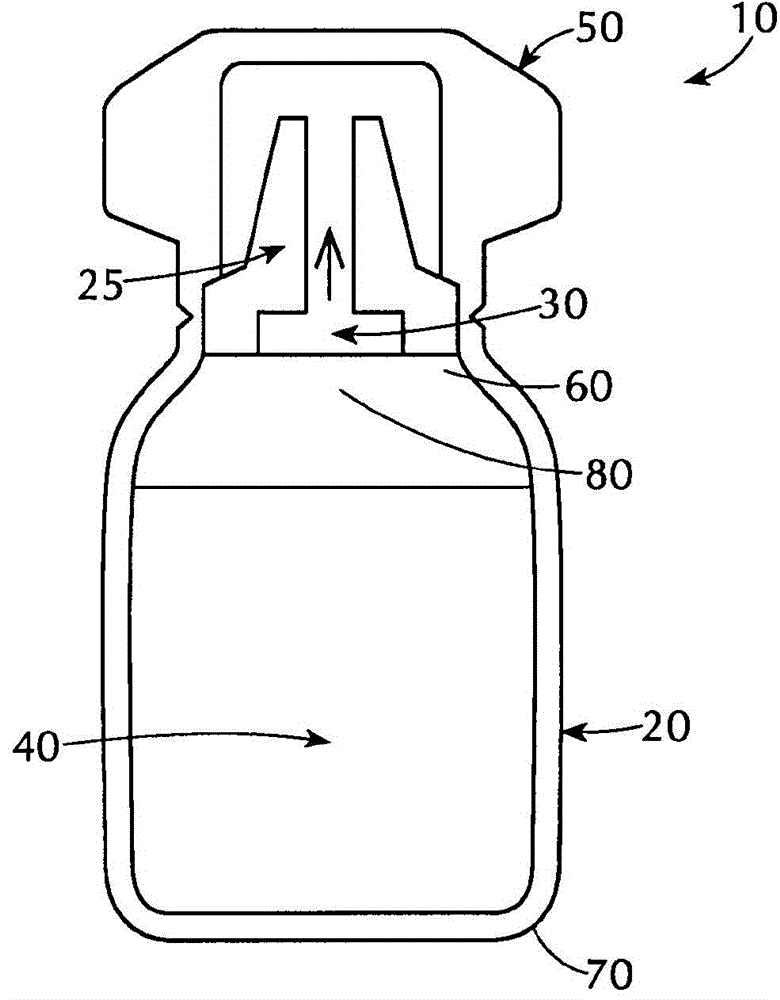

Closure cap for a container for receiving medical liquids, and container for receiving medical liquids

ActiveUS9095500B2Low cost manufacturingIncrease the number ofCapsDiagnosticsNeedle Free InjectionEngineering

The invention relates to a closure cap for a container for receiving medical liquids, in particular a BFS vial which is produced by a blow-fill seal process, and to a BFS container with such a closure cap. The closure cap according to the invention has a cover part and an edge part, with an injection part arranged in the cover part. The injection part has an outwardly directed connection part with a conical recess for receiving the cone stem of a needleless injection syringe in a seal-forming manner, and an inwardly directed closure part which has a self-sealing membrane for closing the recess of the connection part. The self-sealing membrane is slotted. The closure cap according to the invention allows a liquid to be injected without use of an injection needle.

Owner:FRESENIUS KABI DEUT GMBH

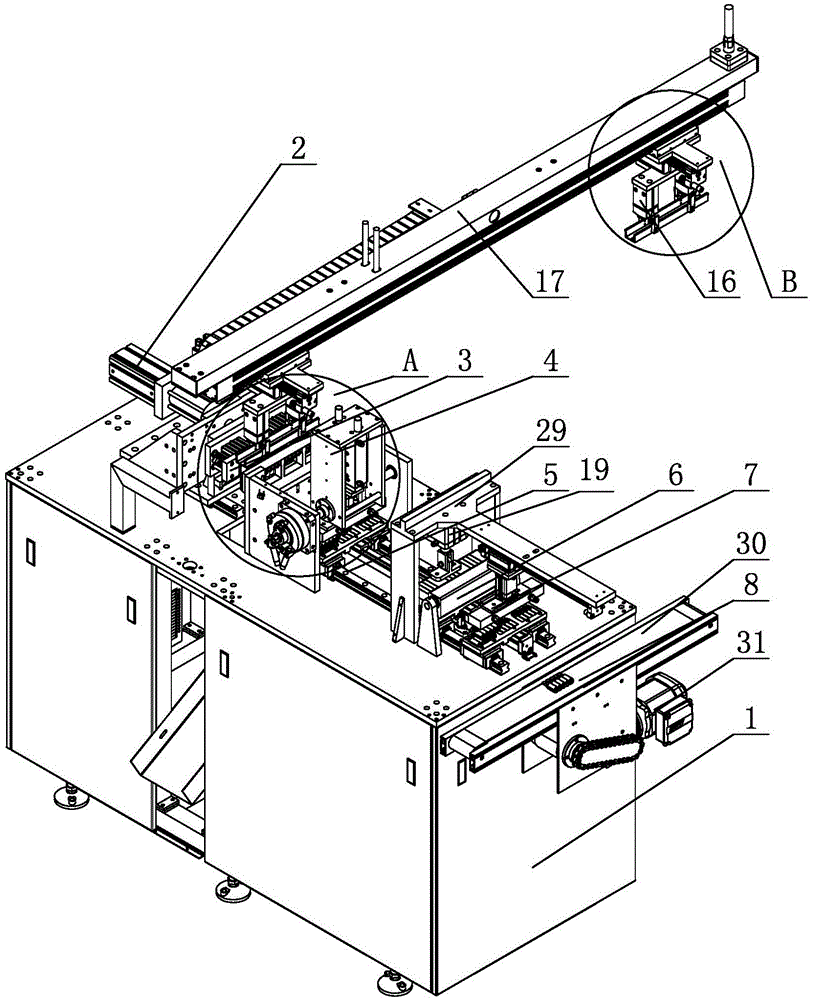

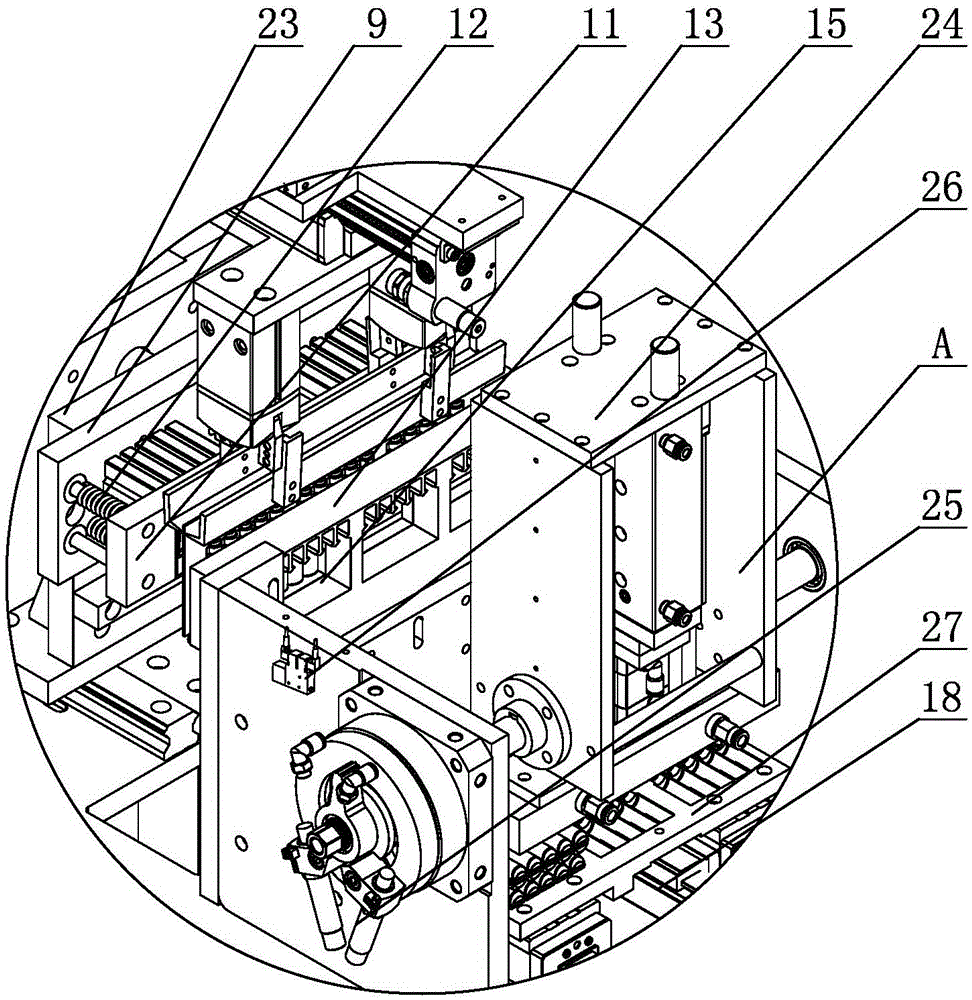

Filling machine integrated with blanking, bottle blowing, cleaning, filling and sealing

ActiveCN101664995AAchieve a clean effectBottle-handling machinesLiquid bottlingBiochemical engineeringCovering system

The invention provides a filling machine integrated with blanking, bottle blowing, cleaning, filling and sealing, comprising a blanking system, a heating system, a bottle blowing system, a cleaning system, a filling system, a sealing system, a covering system and a delivery system wich connects the blanking system, the heating system, the bottle blowing system, the cleaning system, the filling system, the sealing system and the covering system sequentially together; by adopting the filling machine integrated with blanking, bottle blowing, cleaning, filling and sealing, the problem that when the bottle blowing system is used, compression air for blowing bottle can be mixed with particles to pollute the bottle by using the blanking-bottle blowing-filling-sealing four-in-one machine manufactured by Hunan CHINASUN pharmaceutical machinery Co.,Ltd. is solved, thereby achieving the effect that the manufactured bottle is clean.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

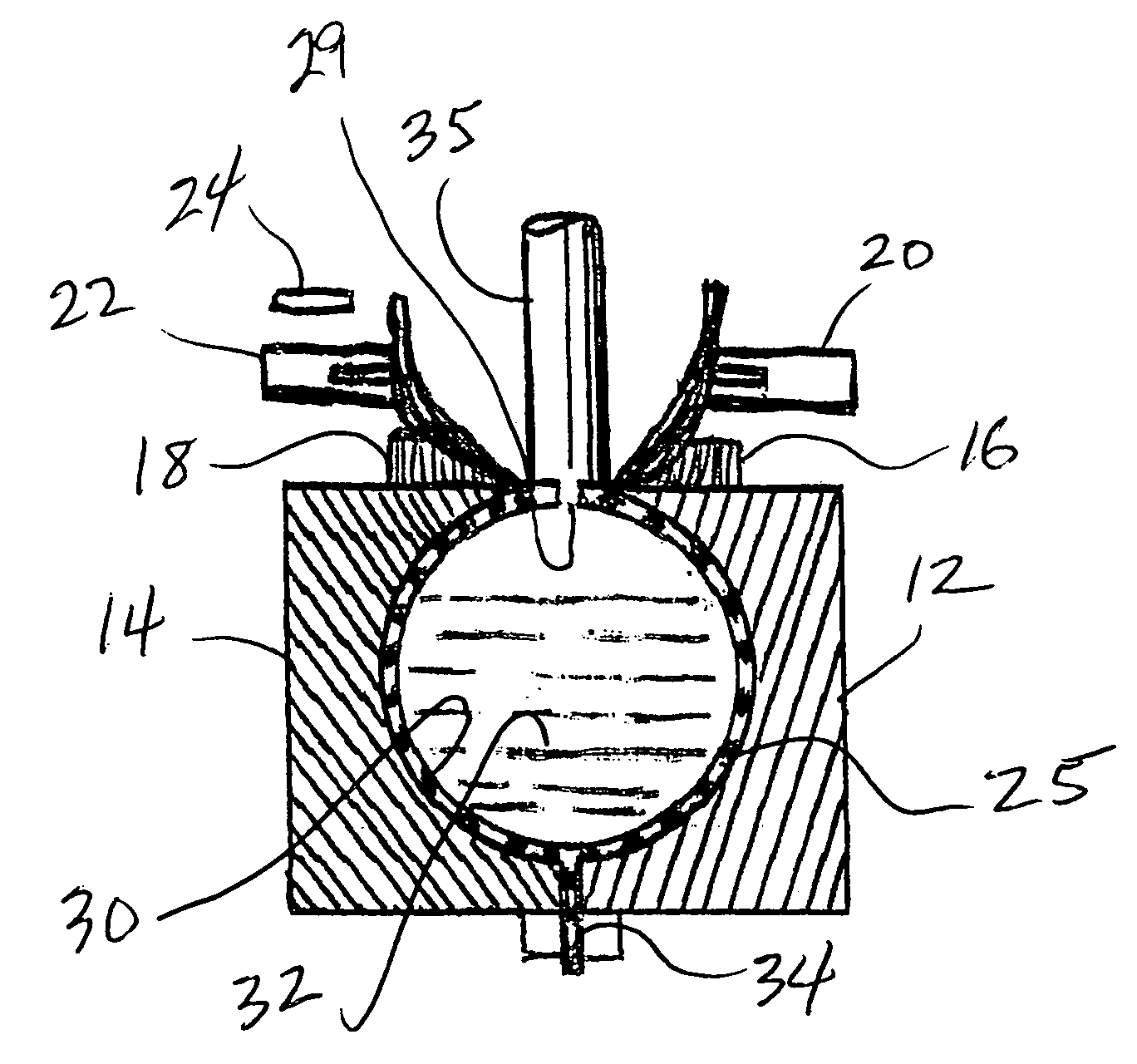

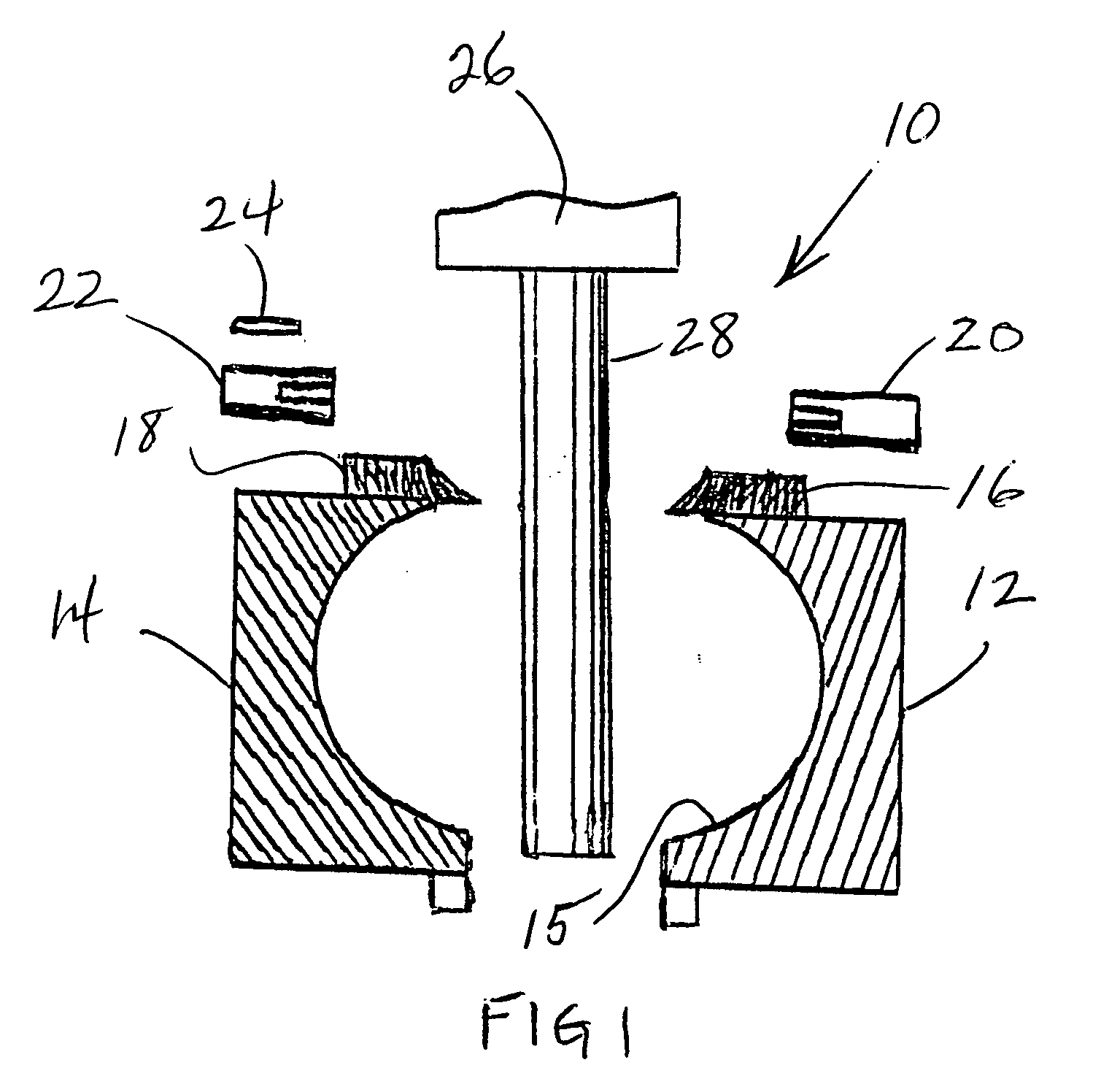

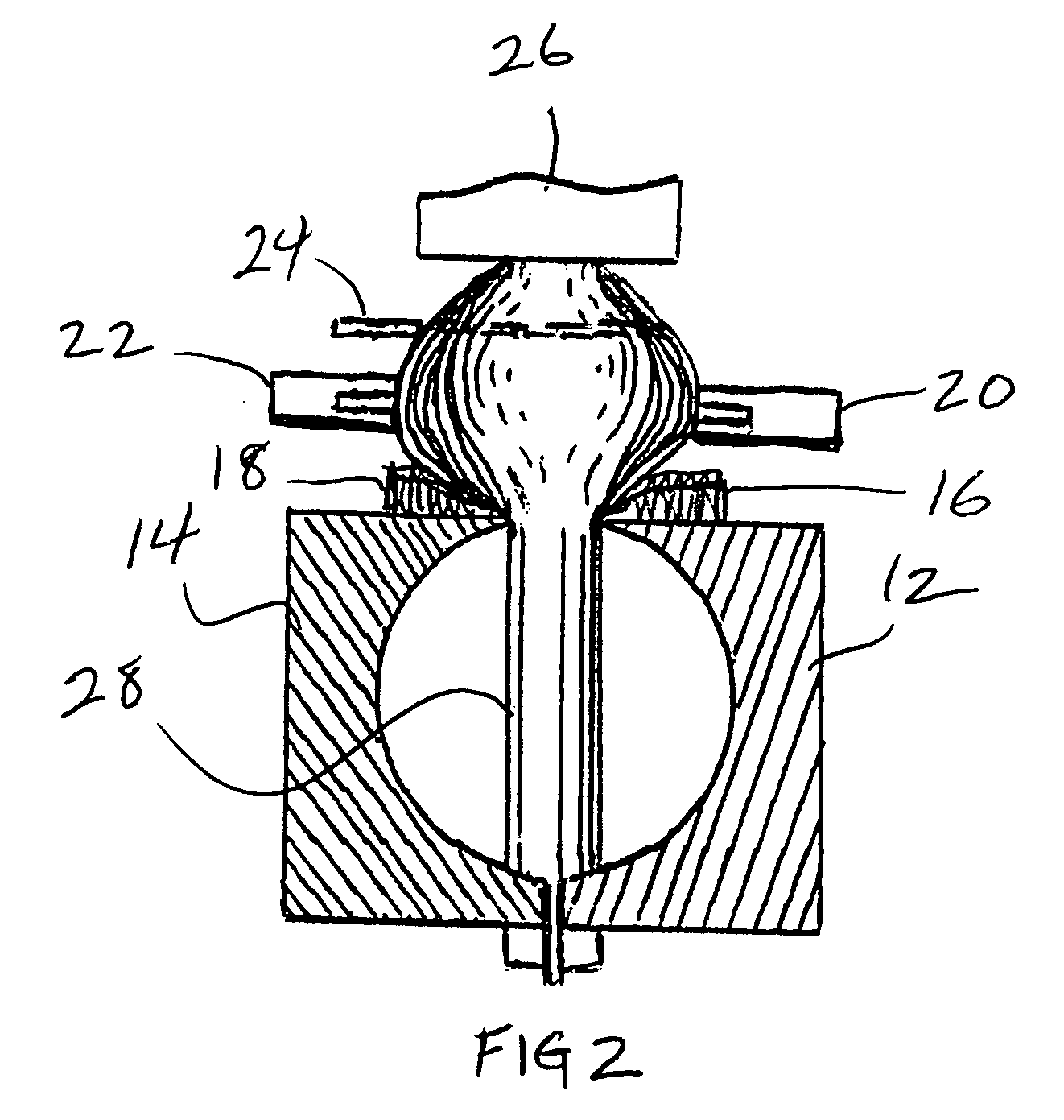

Blow-molded paintball and method of manufacture thereof

InactiveUS20060005732A1Without affecting performance of productHarness/breakability is easilyAmmunition projectilesTraining ammunitionBiomedical engineeringMedical treatment

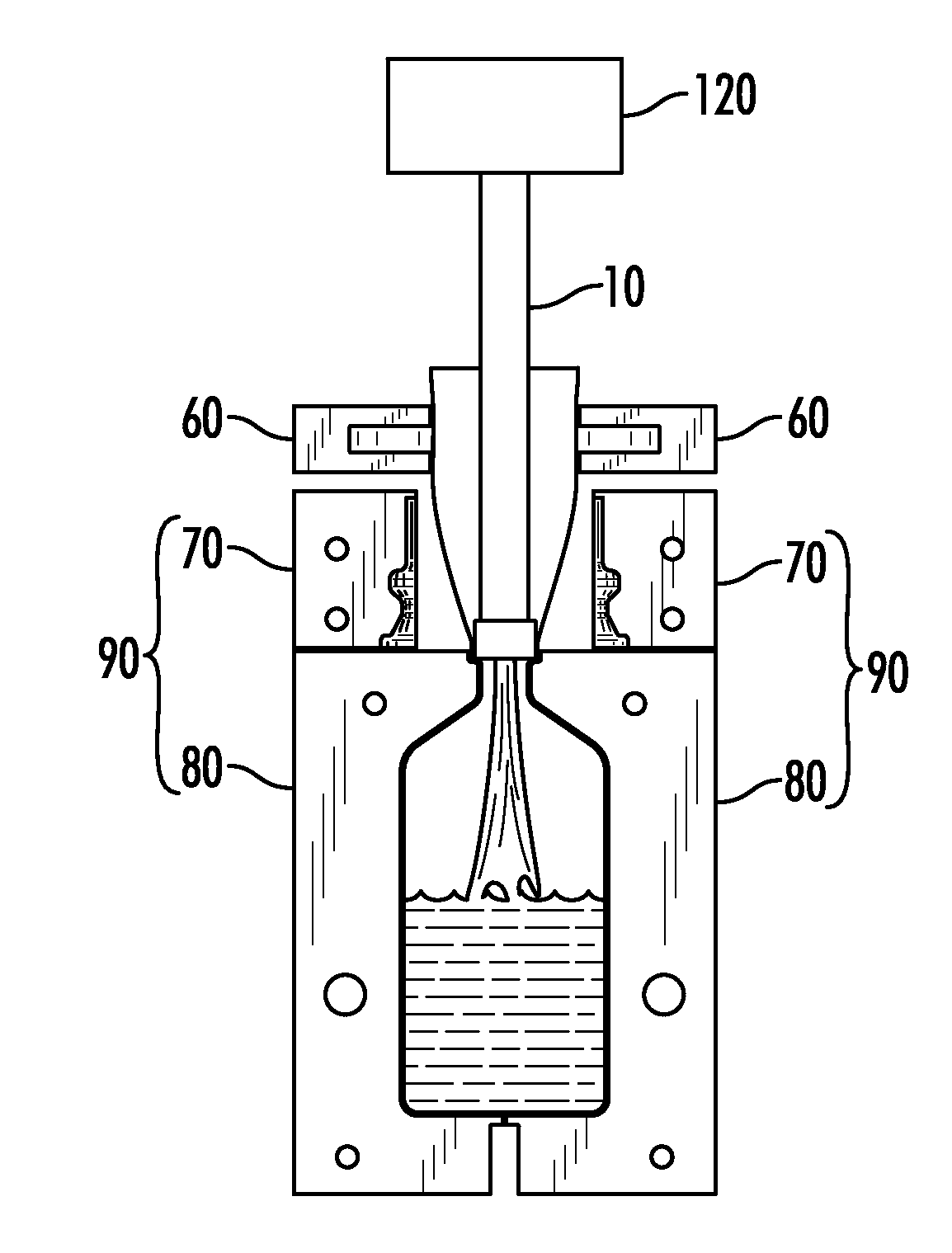

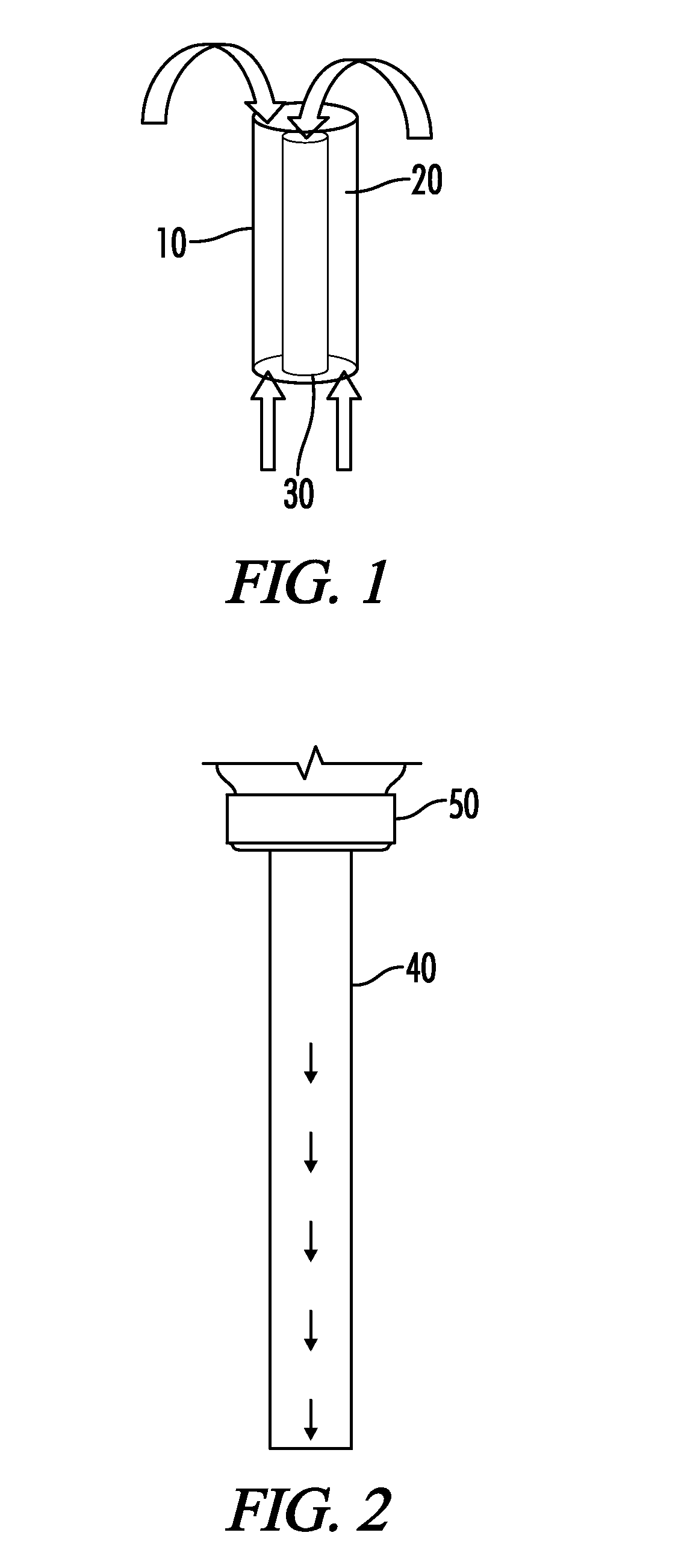

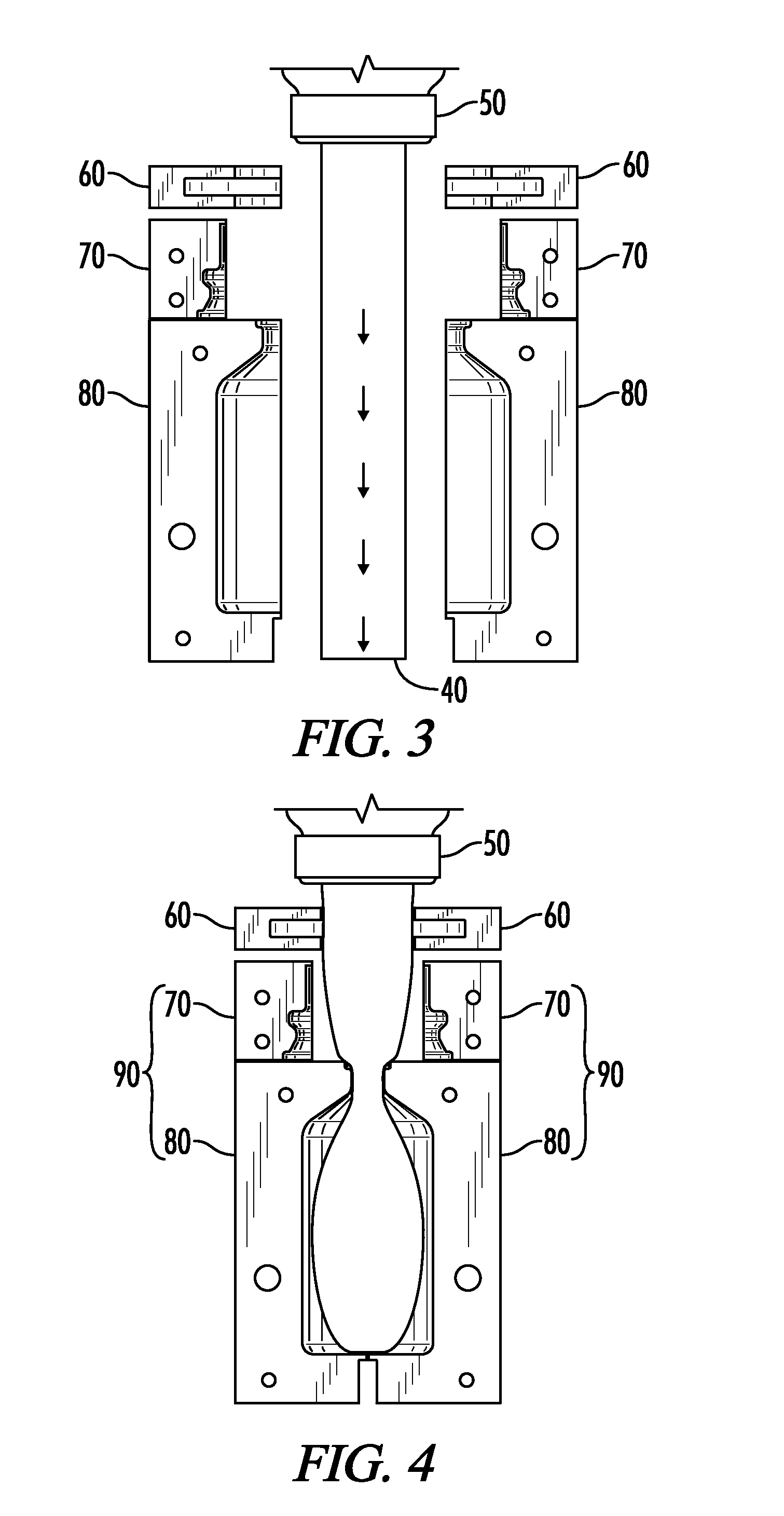

Blow-fill-seal processing is employed to fabricate fully formed and filled paintballs. A blow-fill-seal machine, known in the field of medical container and syringe manufacture, is adapted for making paintballs by employing spherical surface main molds which form blow-molded shells and permit the shells to be filled with suitable paintball dye and then sealing molds are used to seal the filled paintball shell thereby resulting in a fully formed paintball having an accurate spherical surface.

Owner:FORSTER GLENN

Methods for aseptic packaging of low-acid foods

ActiveUS20150239594A1Readily apparentPackage sterilisationStopper pretreatmentSterile environmentHermetic seal

The present disclosure relates to methods of maintaining sterility of an aseptic work zone of a blow-fill seal operation so that low acid foods may be aseptically processed and packaged. The methods of the present disclosure further provide for maintain the sterility of the aseptic work zone such that the aseptic work zone does not have to be enclosed in a separate sterile environment during the blow fill seal process. The methods of the present disclosure further provide a sterilization procedure that is compliant with FDA regulations related to the aseptic packaging of low acid food products. Further disclosed, are methods for producing a hermetically sealed container containing a low acid food product.

Owner:MEAD JOHNSON NUTRITION

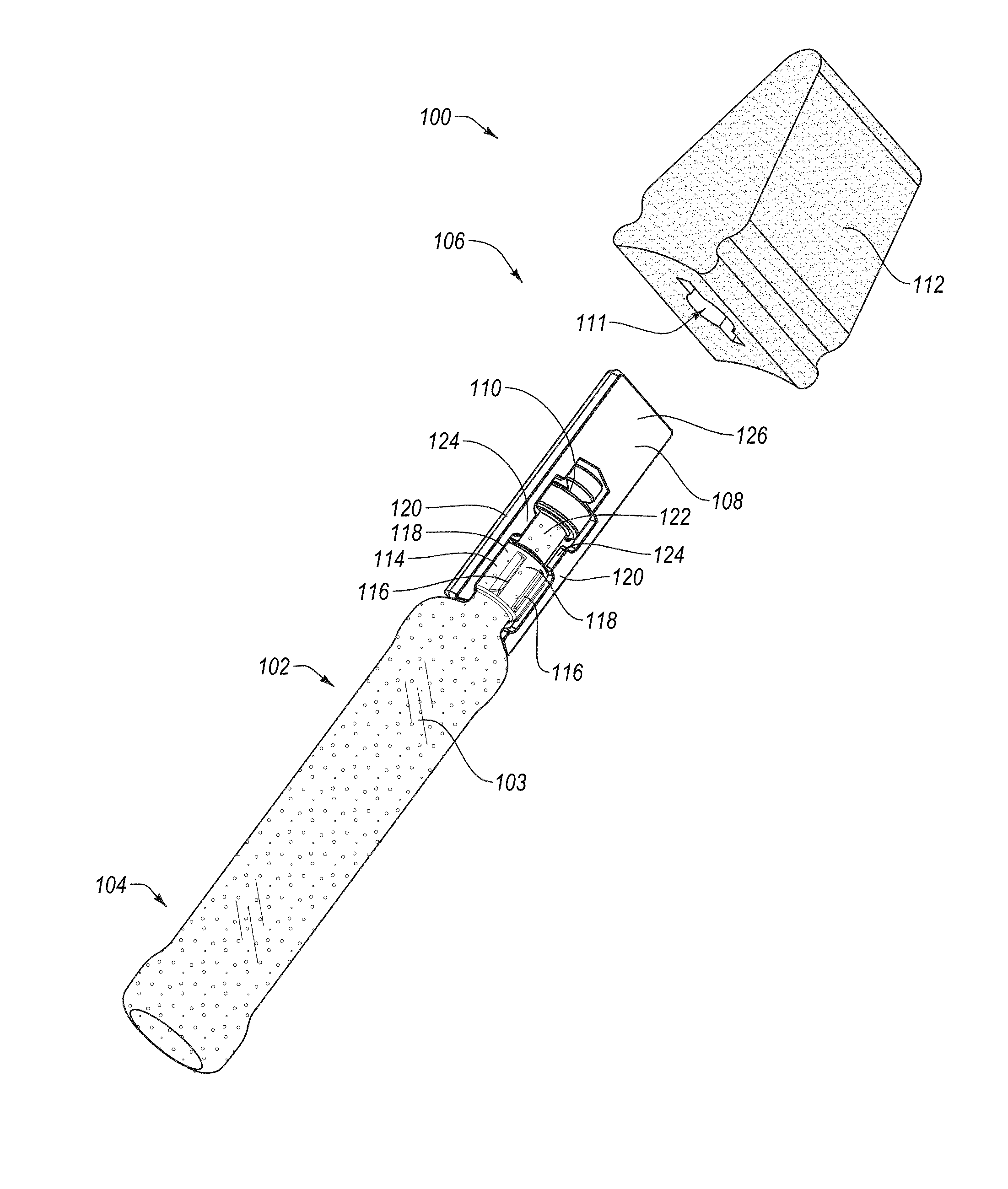

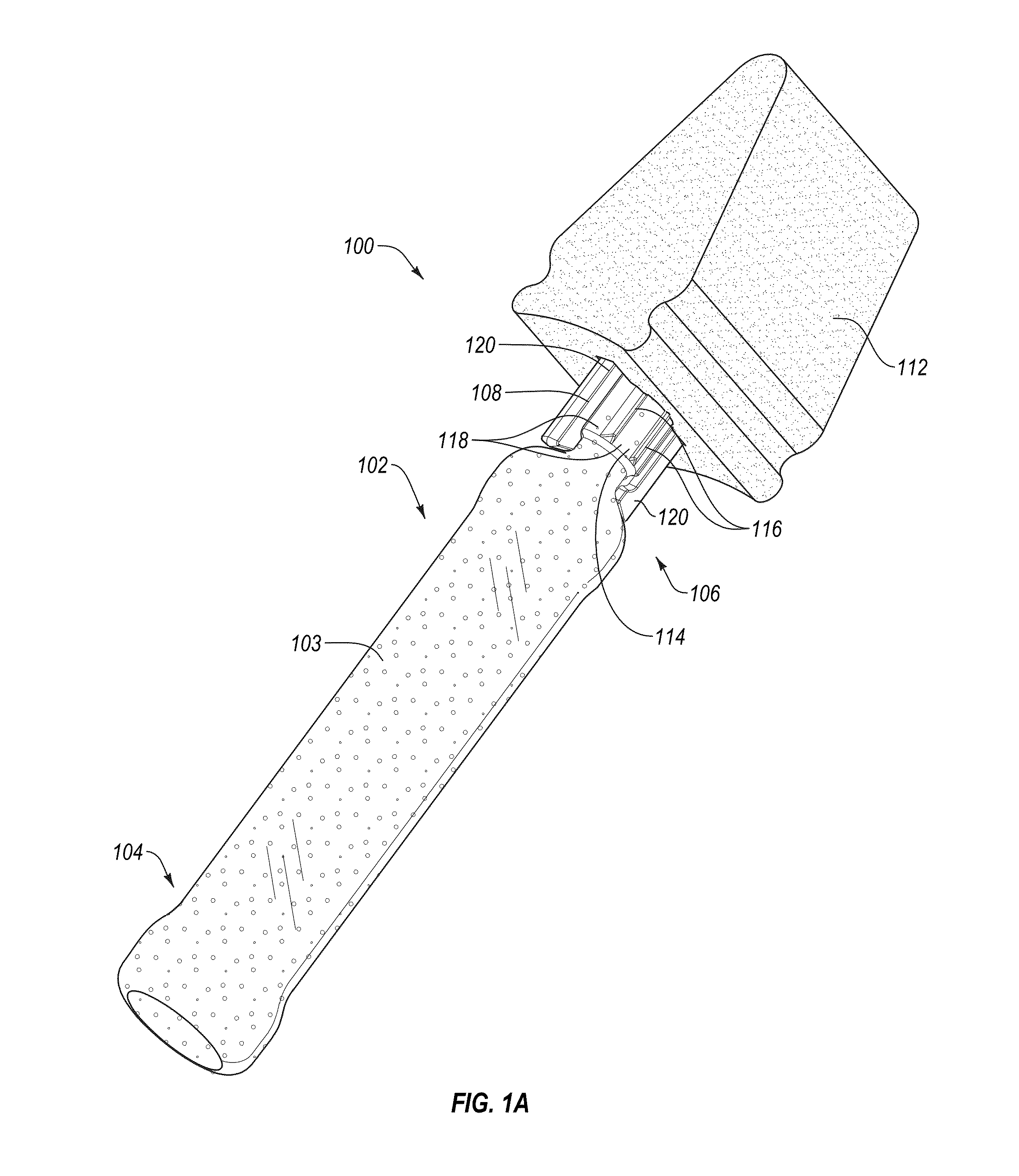

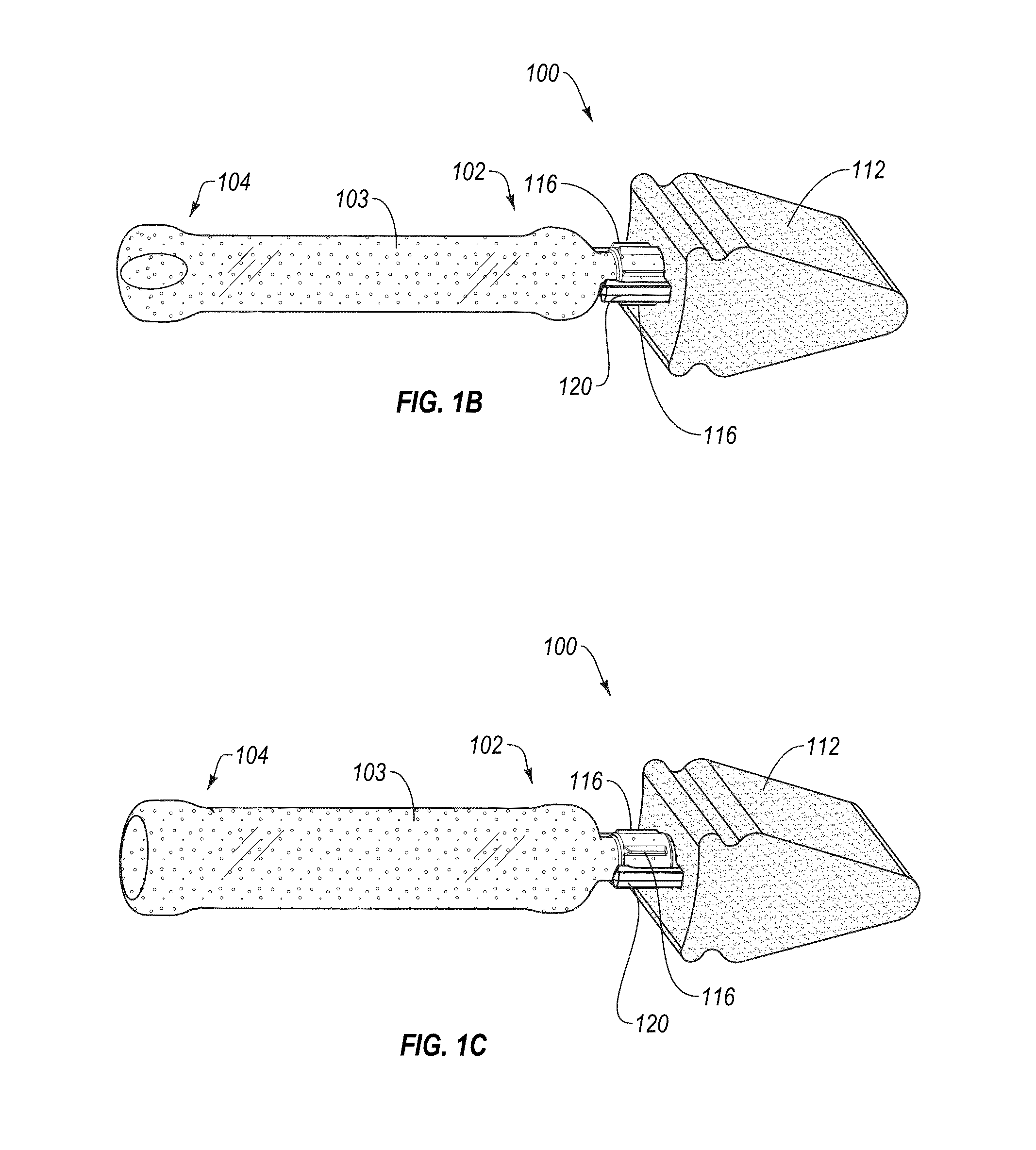

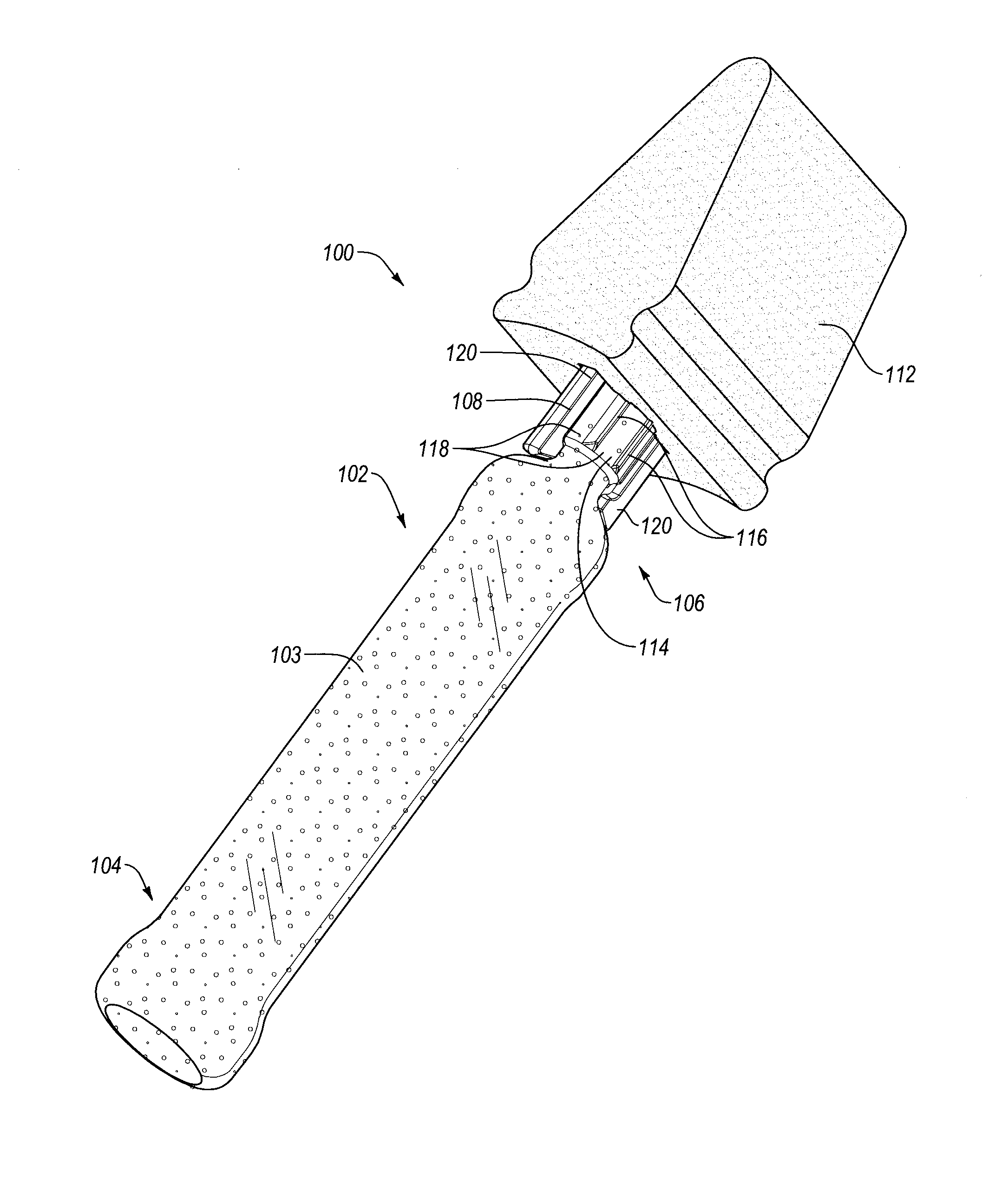

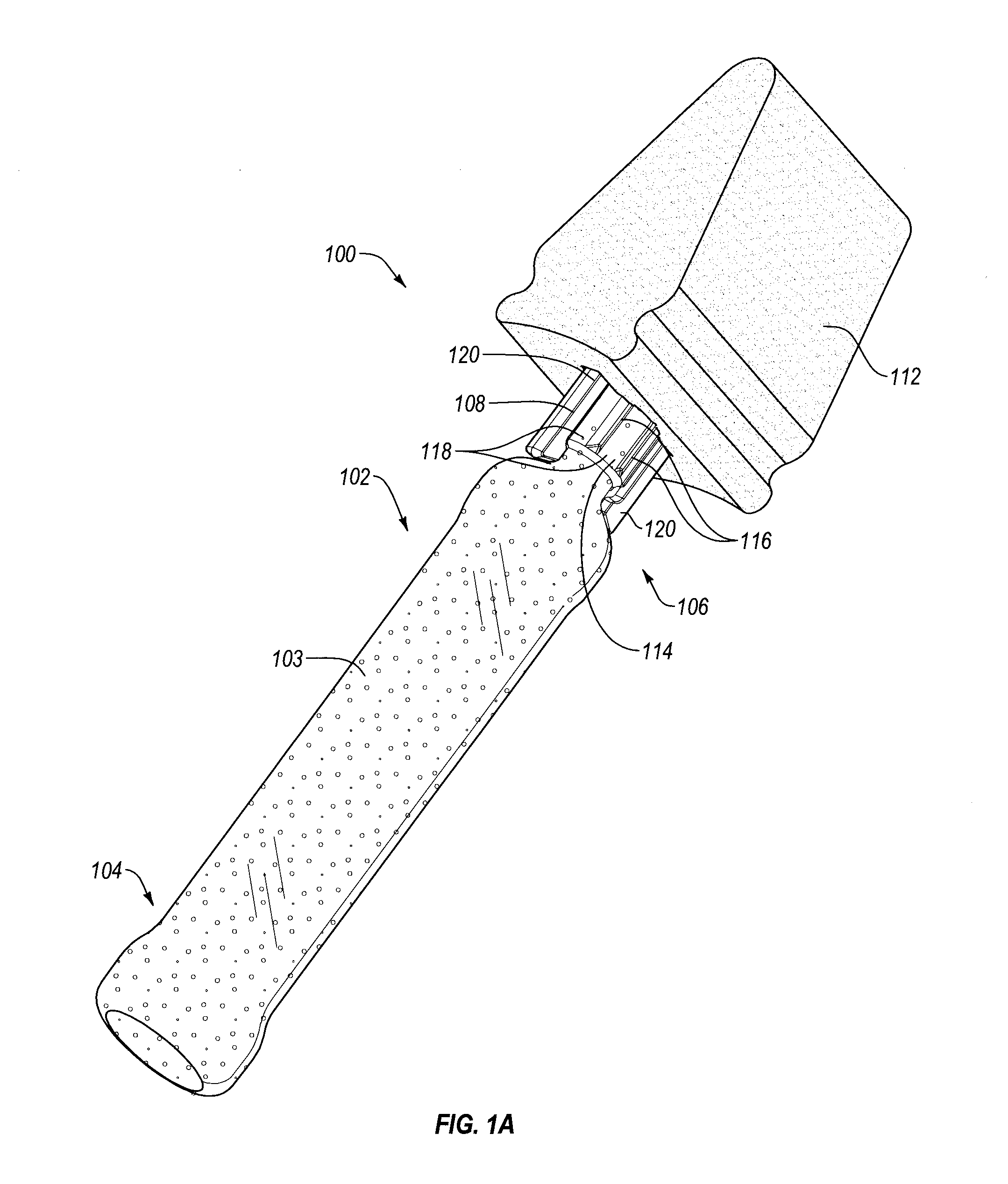

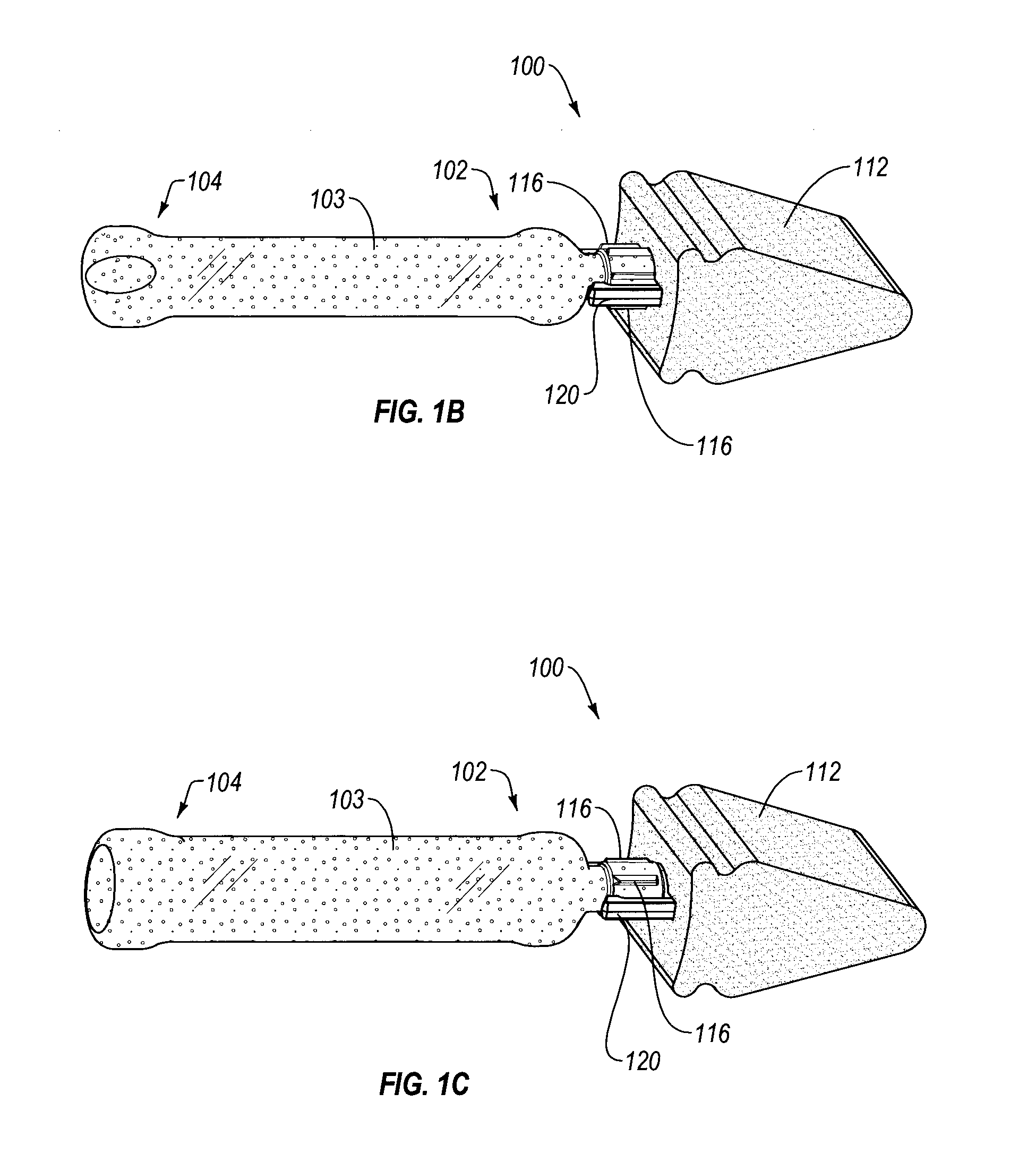

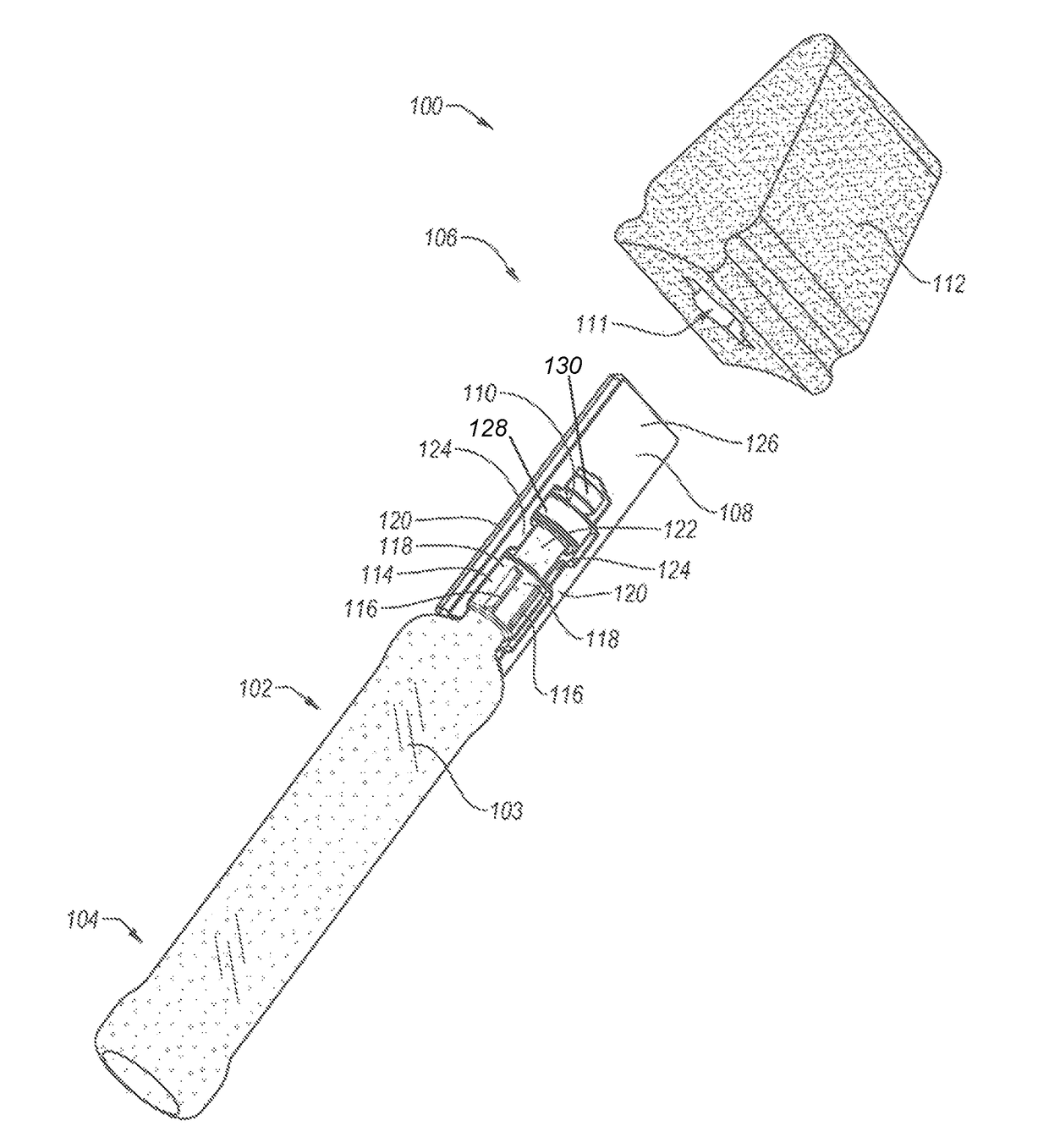

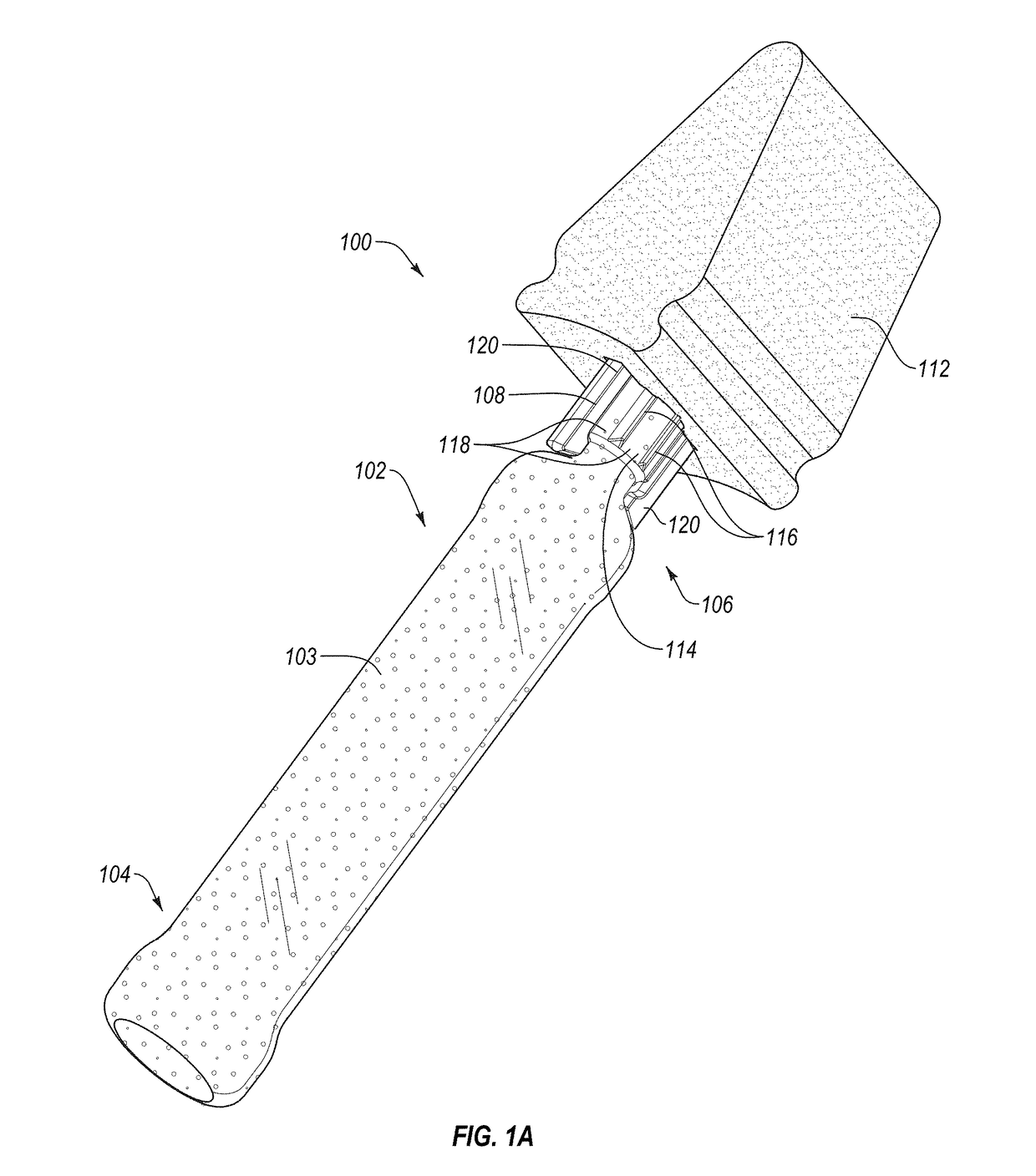

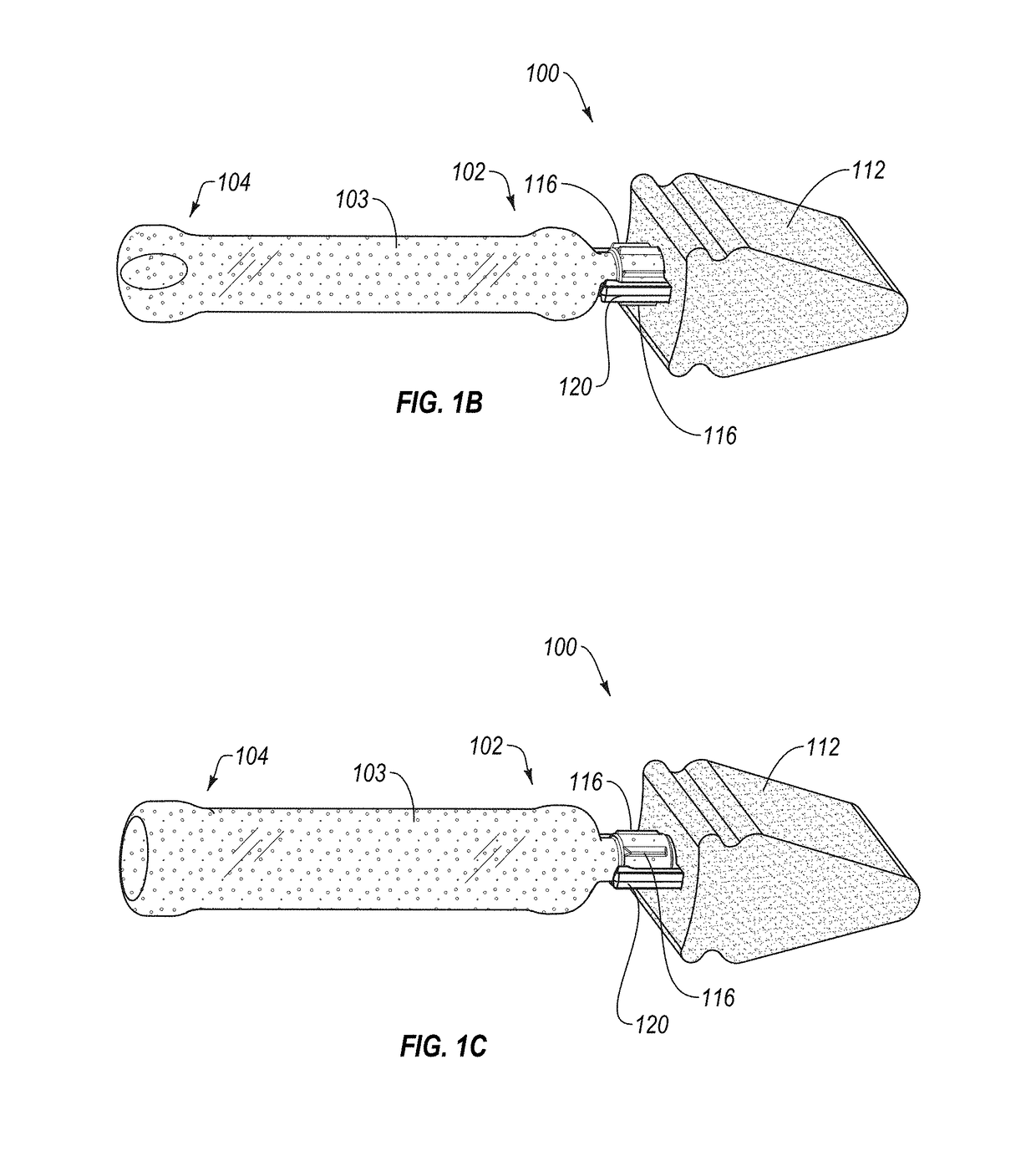

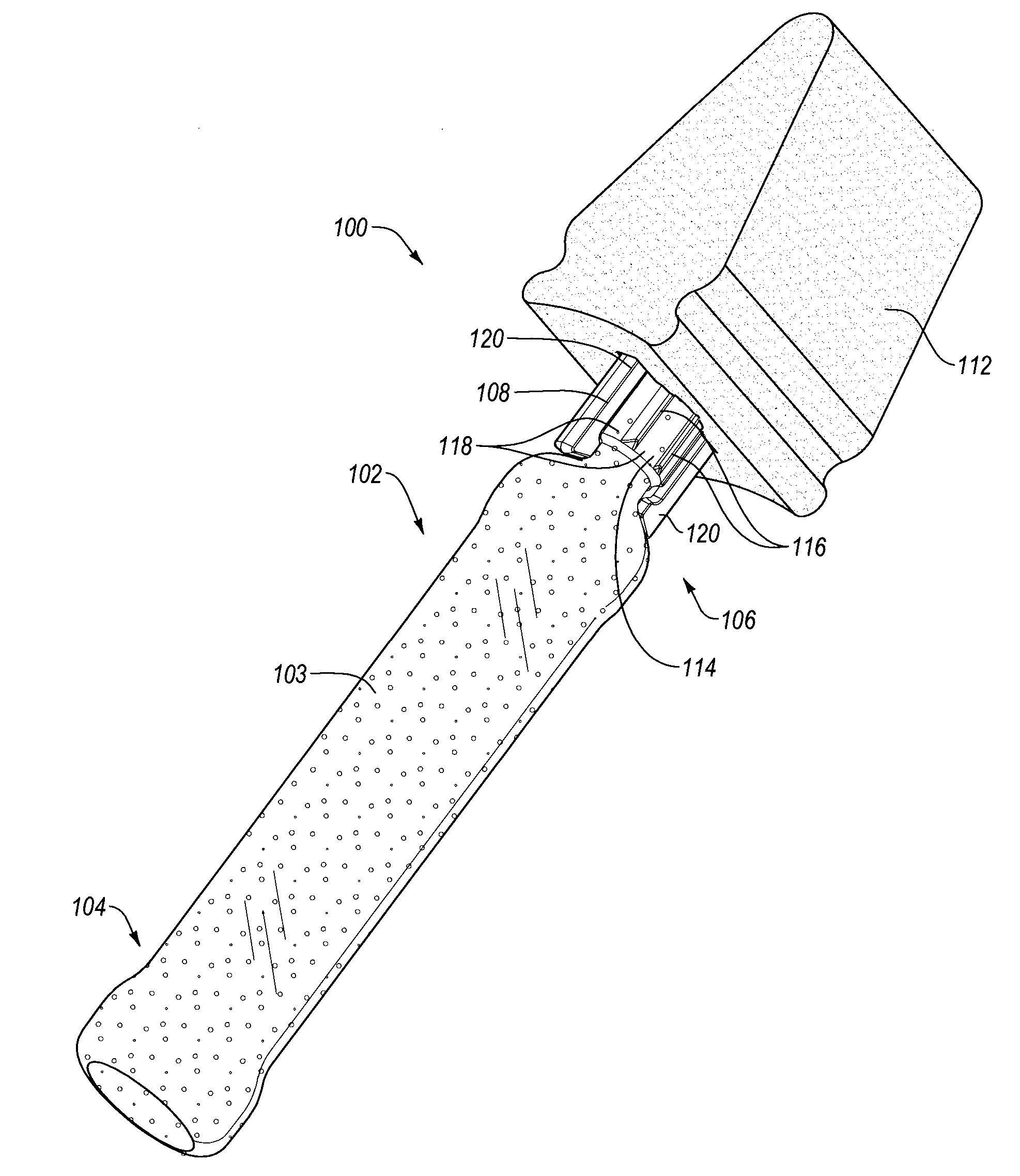

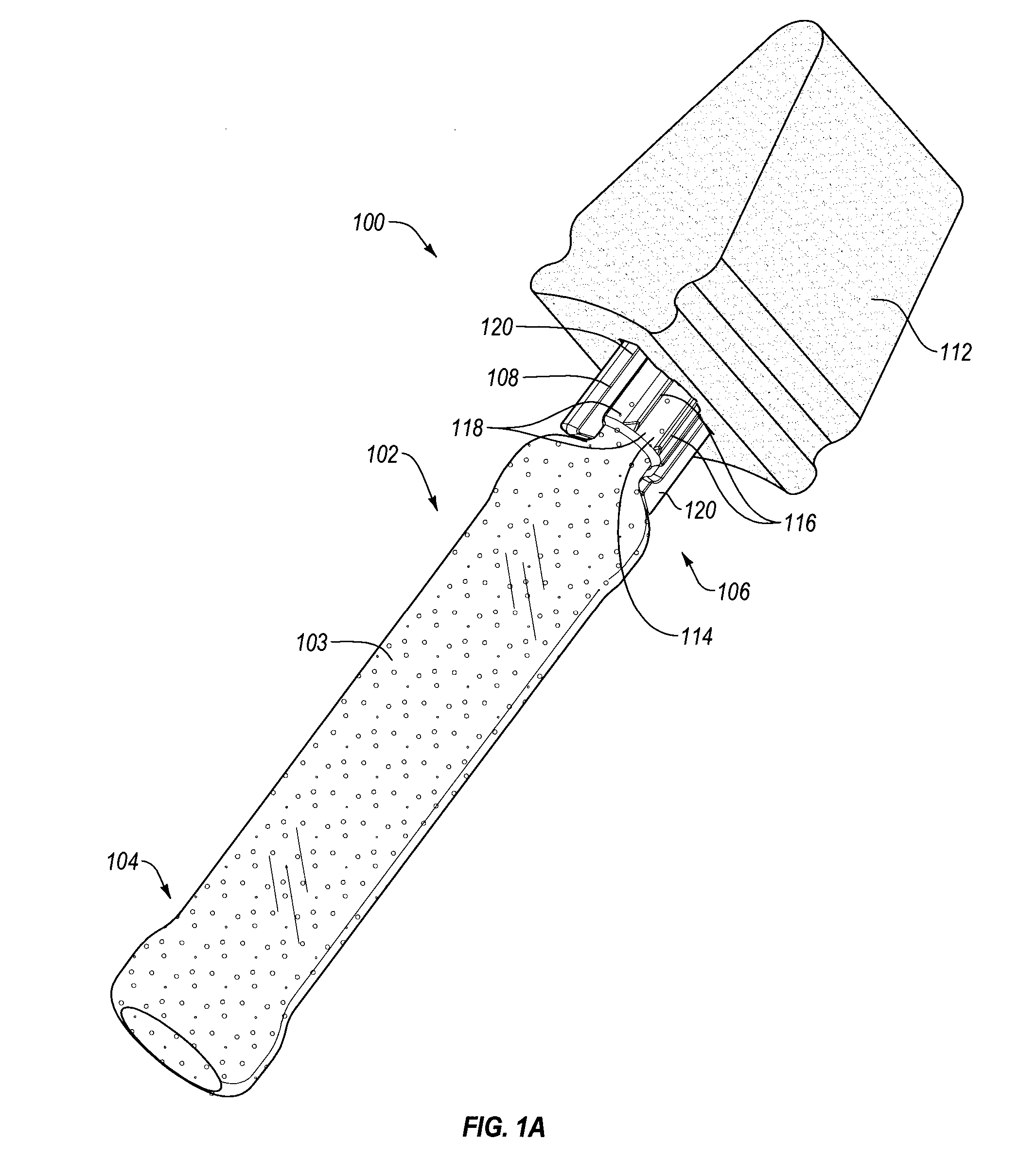

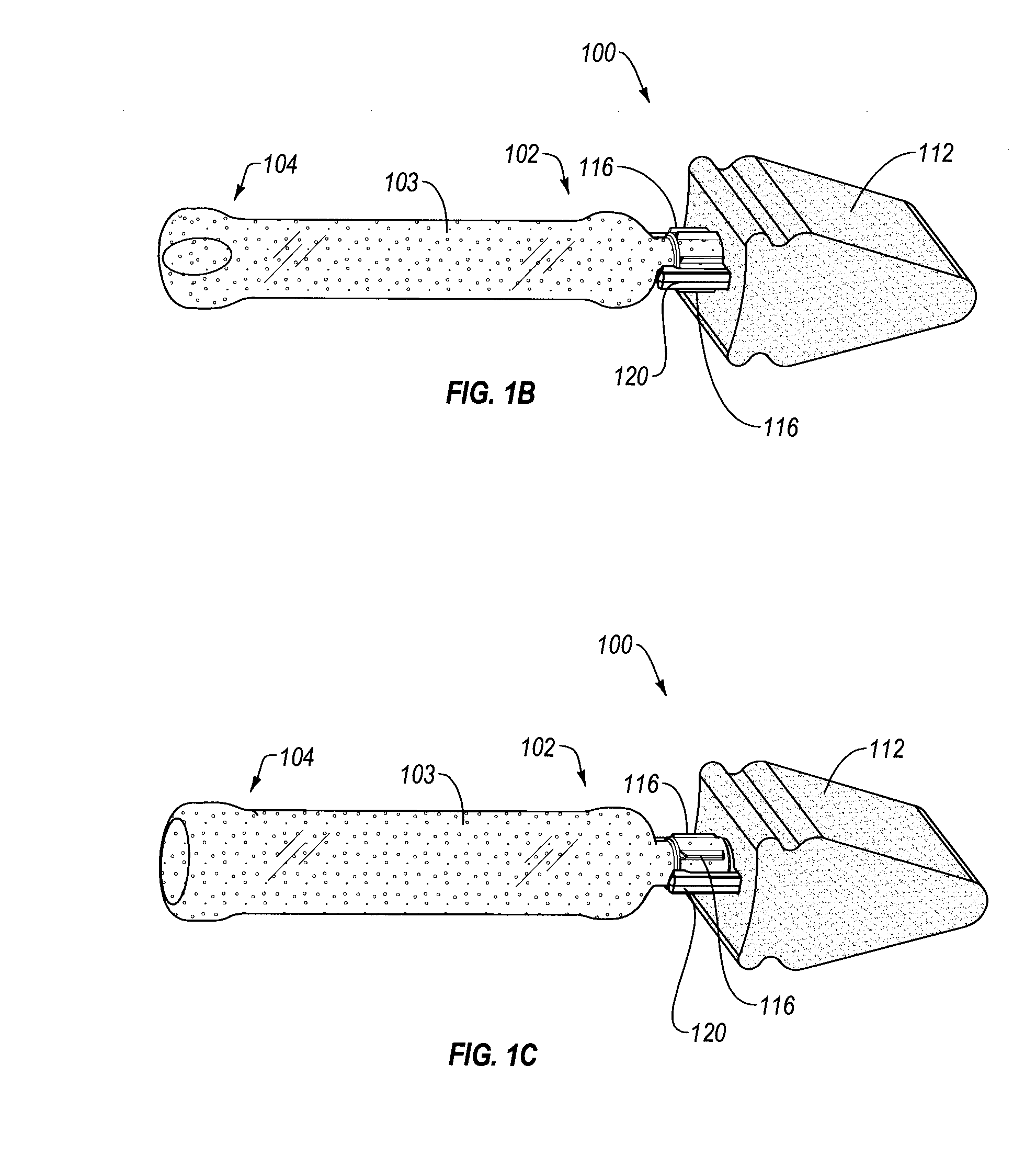

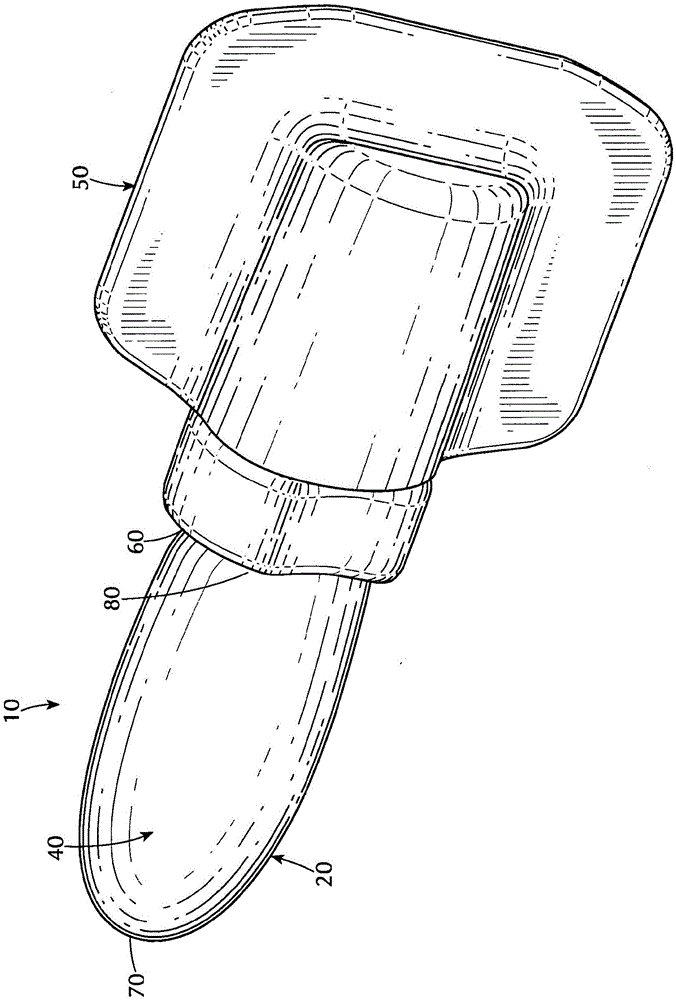

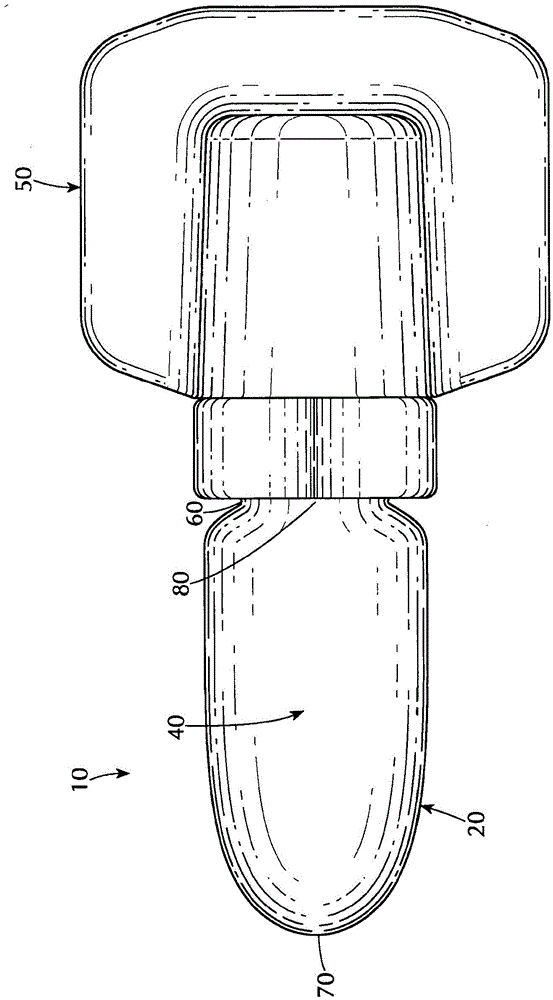

Skin antiseptic applicator and methods of making and using the same

ActiveUS20140371694A1Minimize ethylene oxide penetrationMedical applicatorsDomestic articlesBlow fill sealBiomedical engineering

The invention relates to applicators for applying a solution or other composition (e.g., an antiseptic composition) to skin of a patient. The applicator may include a container body having a proximal end, a distal end, and a frangible member disposed at the distal end of the body. The applicator includes a first position where the container body and frangible member are a unitary piece (e.g., blow molded as a single piece), and a second position when the frangible member is rotated relative to the body to irreversibly break a weak point therebetween, releasing the composition in the hollow body through an opening. A porous applicator head may be positioned adjacent the distal end of the body and frangible member, so that the composition flows out the body, through the opening, and onto the head. The applicator may be formed in a blow-fill-seal process for improved sterility and ease of manufacture.

Owner:MEDLINE IND LP

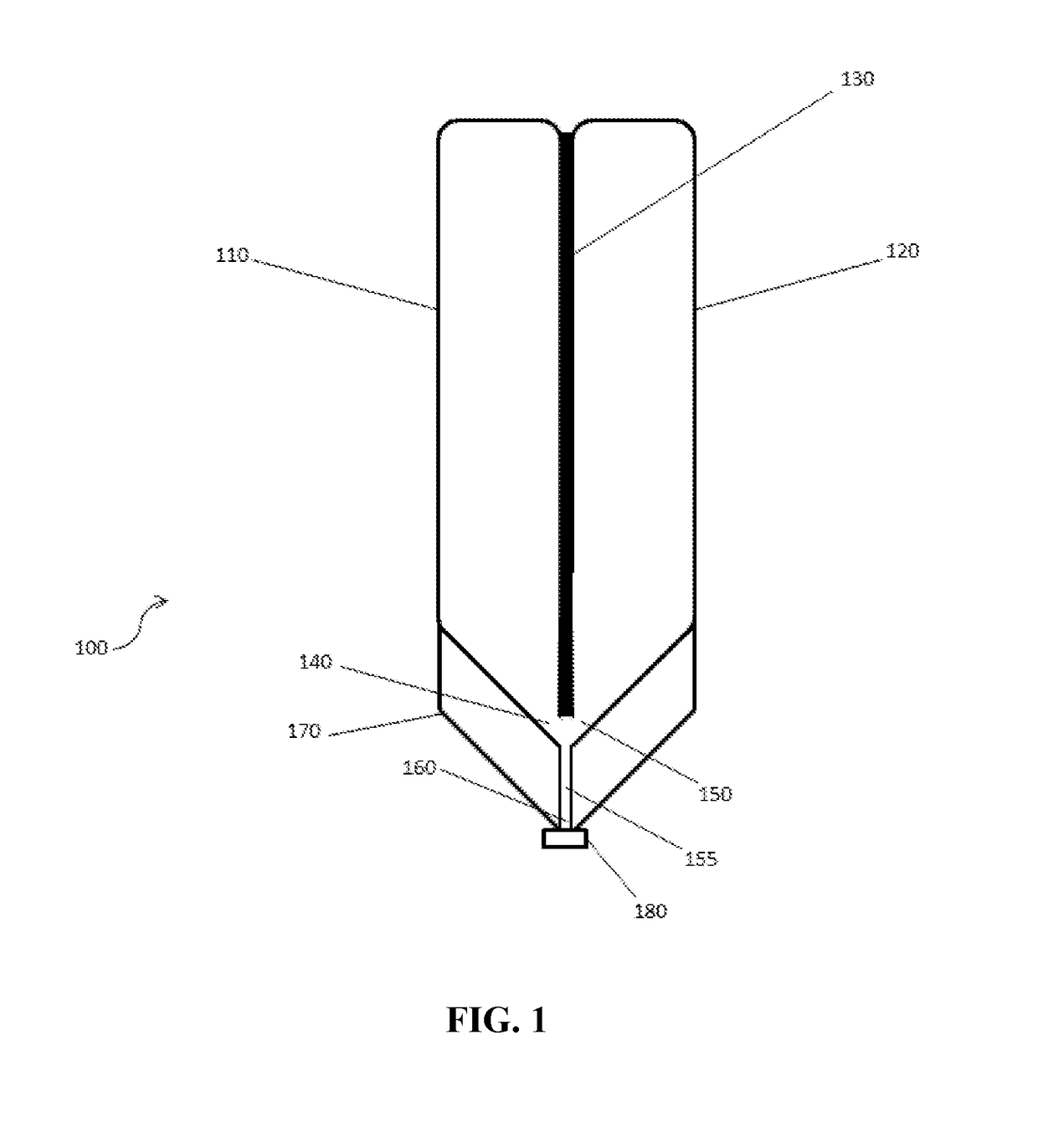

Child resistant blow-fill seal container

ActiveUS9108777B1Low production costSuitable for packagingClosuresChild proof meansEngineeringSingle use

A child resistant container made from blow-molded plastic which comprises: a vial having an outlet port; a pre-determined volume of aseptic fluid disposed sealed within the vial; a cap detachable from the vial; and, a resilient guard having a first and second ends which are integral to the vial on opposing sides. The resilient guard is designed to not be separated from contact with the vial and has a mid-portion which is initially positioned above the top of the cap to prevent cap removal. The safety container is preferably single use.

Owner:NEW VISION PHARM LLC

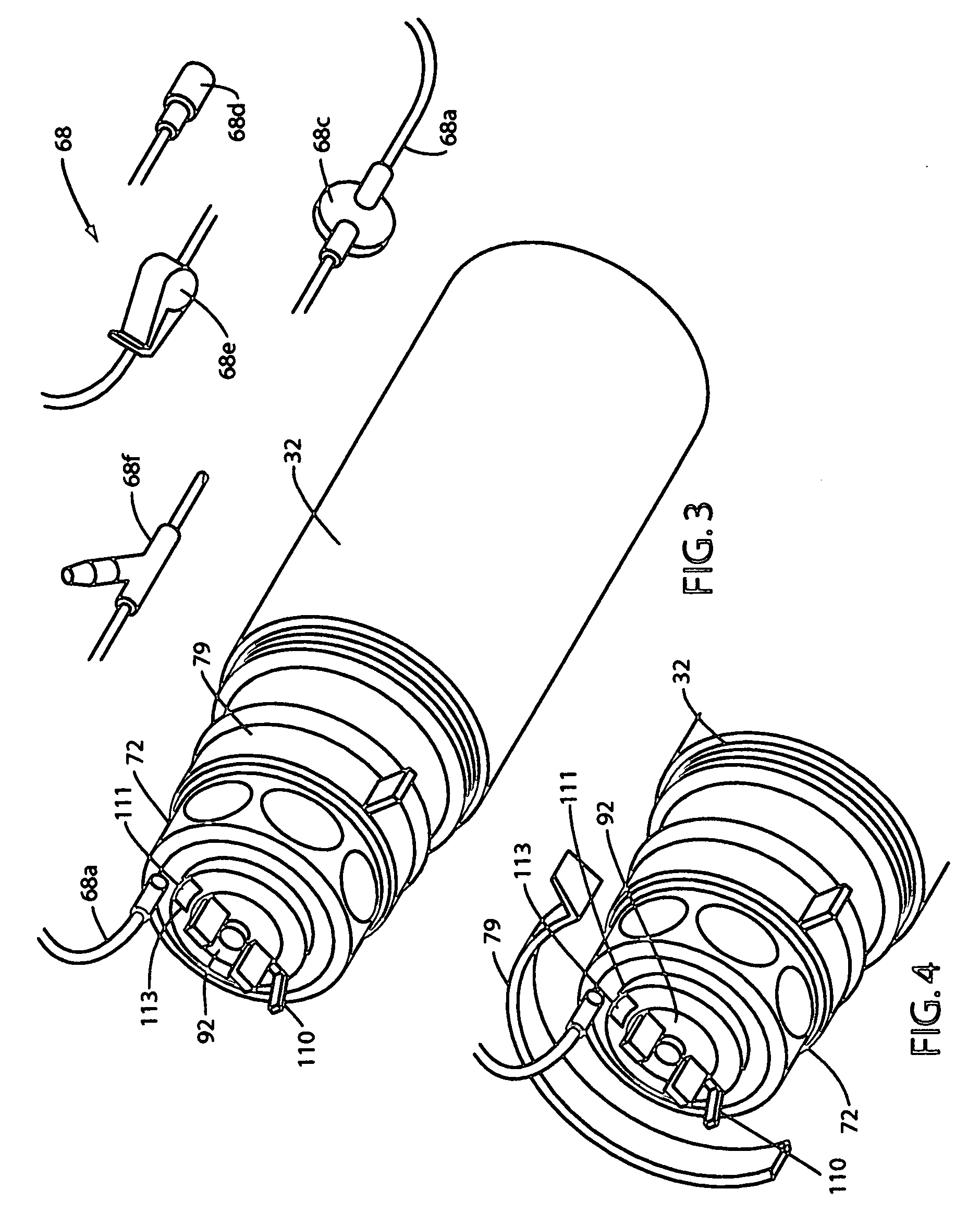

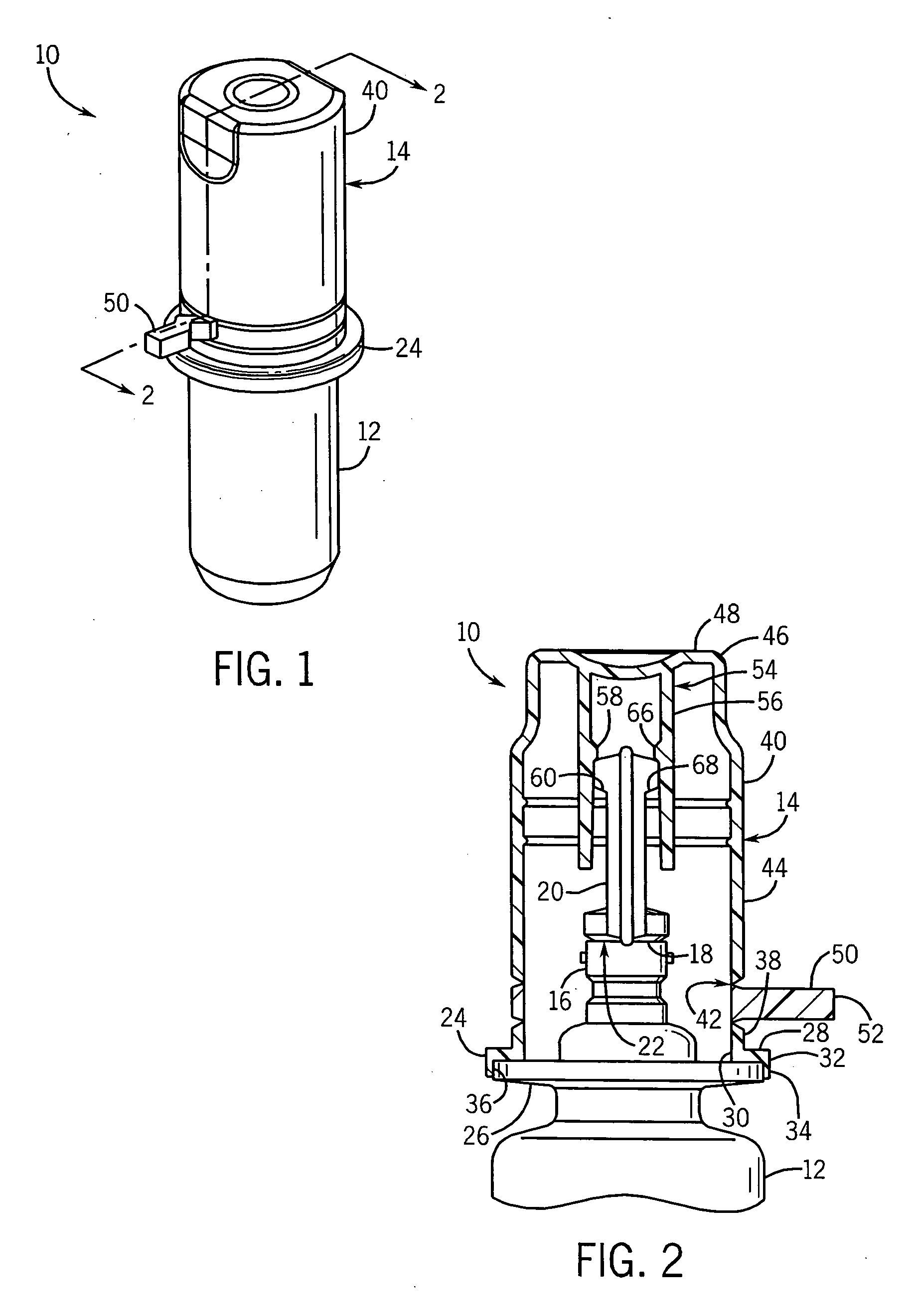

Prefilled Medical Injection Device

A prefilled medical injection device with production specific elements is provided as a single use disposable injection device that is optimally suited for mass production through the Blow Fill Seal manufacturing process. The device utilizes a valve and a needle assembly fused to an insert. The valve and the needle assembly are positioned within the insert forming a conduit. The needle assembly is covered with a needle cap that is detachably coupled to protecting the needle assembly from contamination and a user from accidental needle stick. The insert is engaged to the bellows during the BFS manufacturing process and hermetically sealed by a parison layer that covers exterior portion of the insert and the needle cap. The parison layer is formed and trimmed creating exterior features that facilitate the use of the prefilled medical injection.

Owner:ADAR MEDTECH

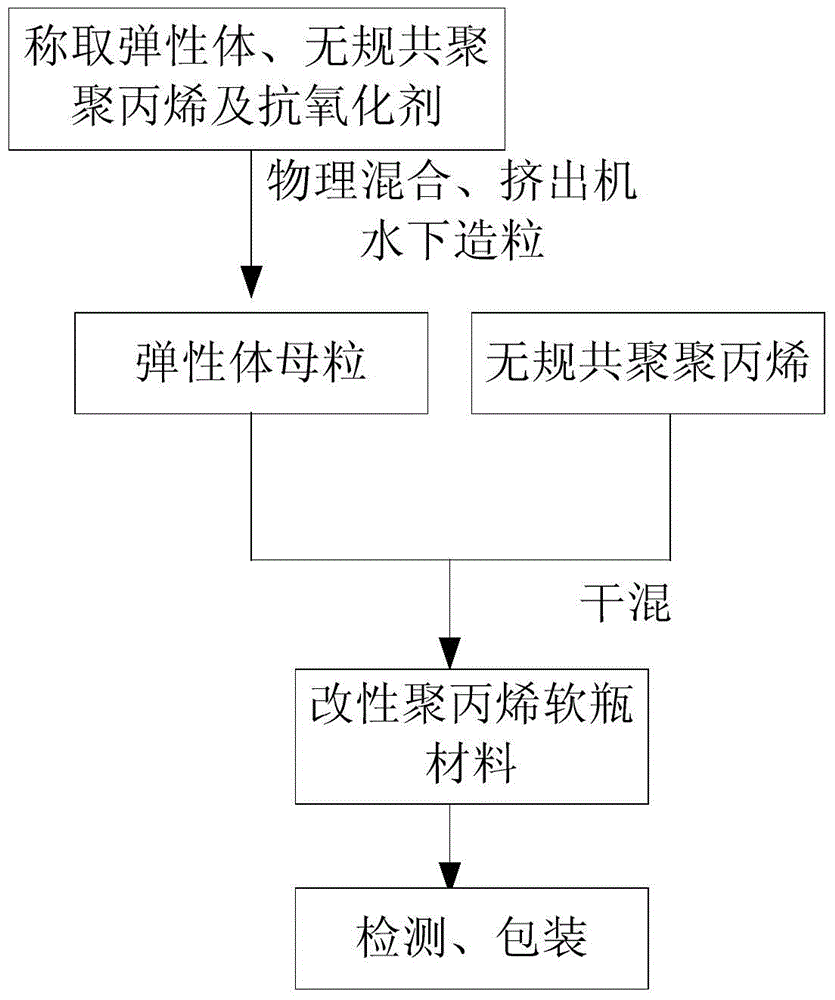

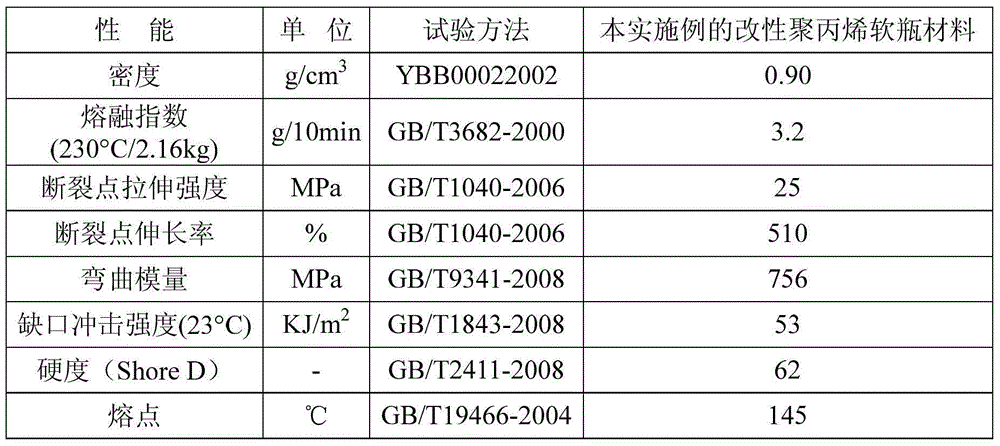

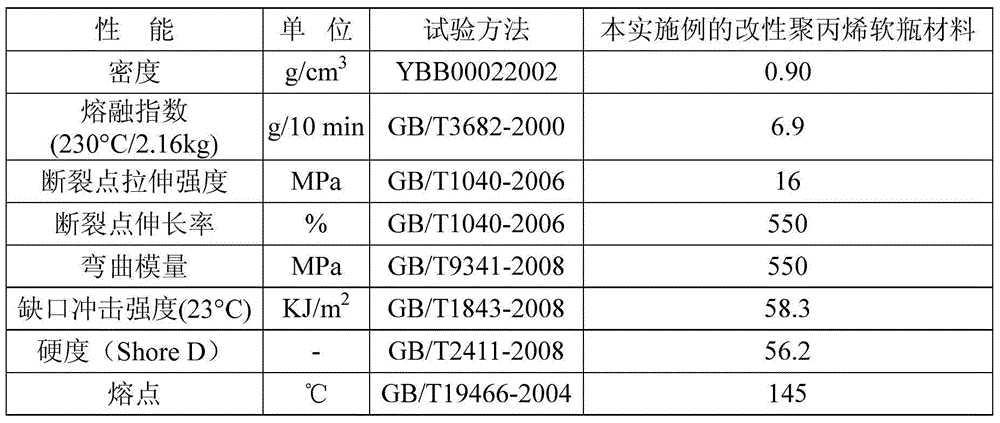

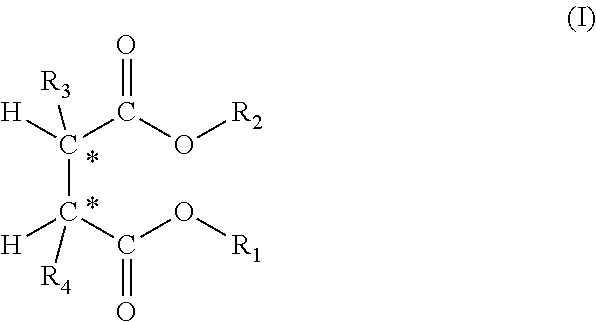

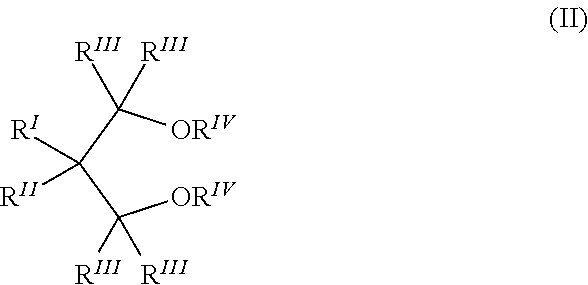

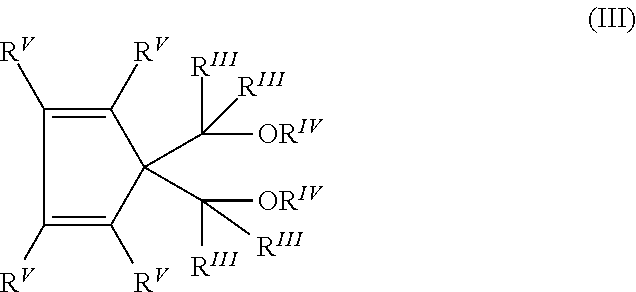

Modified polypropylene soft bottle material, as well as preparation method and applications thereof

ActiveCN104086905AQualified physical and mechanical propertiesIncrease productivityElastomerAntioxidant

The invention relates to a modified polypropylene soft bottle material, as well as a preparation method and applications thereof. The preparation method of the modified polypropylene soft bottle material comprises the following steps: (1) mixing ethylene-propylene type propenyl thermoplastic elastomer or styrenic thermoplastic elastomer with polypropylene random copolymer, phenols antioxidant and phosphite ester antioxidant, then pelletizing underwater through an extruder, to obtain granular elastomer master batch; and (2) conducting dry blending to the polypropylene random copolymer and the elastomer master batch to obtain the modified polypropylene soft bottle material, wherein the amount of the polypropylene random copolymer adopted in the step (2) is greater than that of the polypropylene random copolymer adopted in the step (1). The obtained modified polypropylene soft bottle material has excellent physical performance and safety performance in contact with liquor, and can meet the blowing-filling-sealing technological requirements in preparation of soft bottles (bags), and the obtained polypropylene soft bottle (bag) is soft, good in self-sealing effect, has high qualification rate of 99% in the emptying test, high safety and high anti-impact strength.

Owner:RENOLIT PLASTICS TECH BEIJING CO LTD

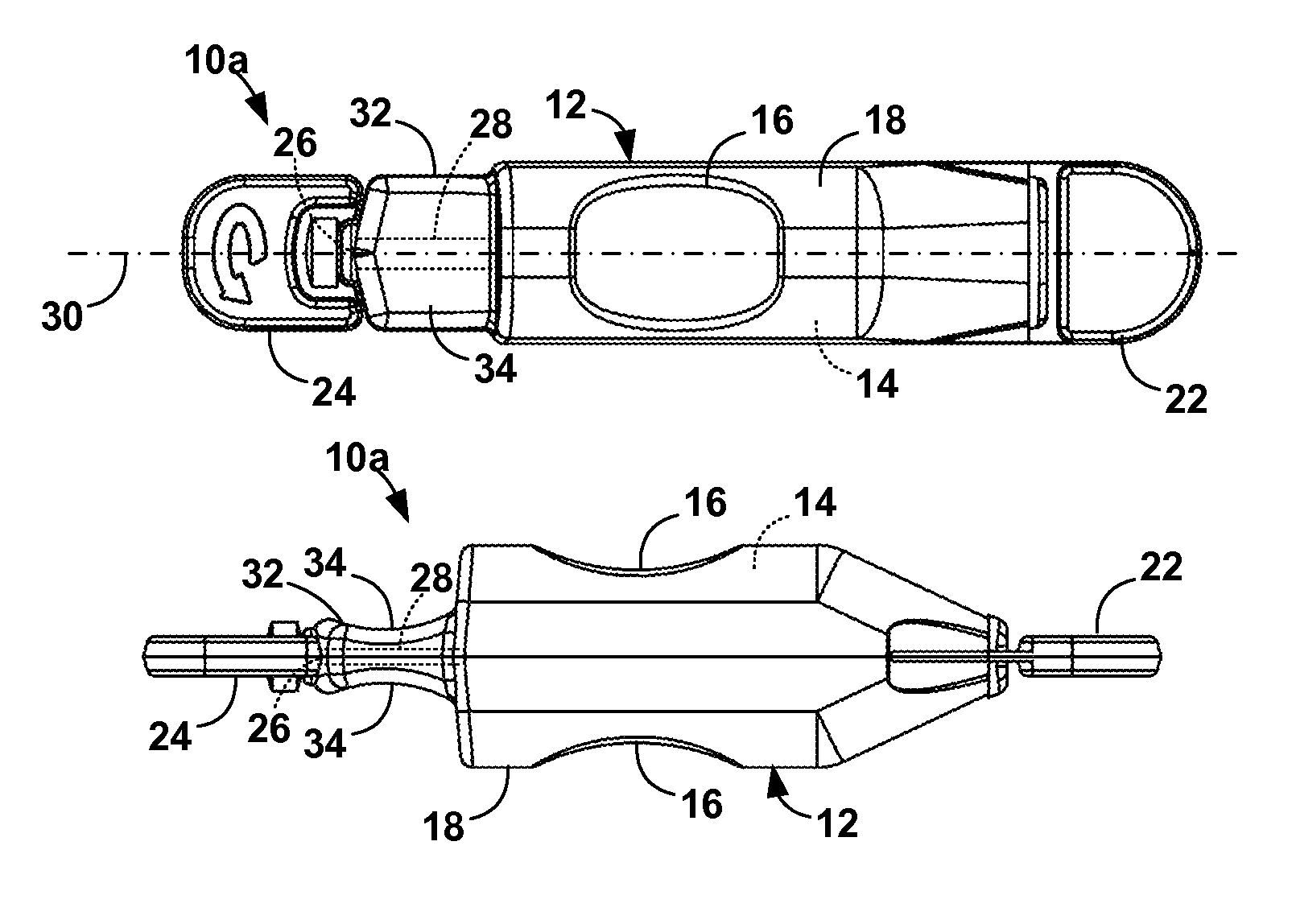

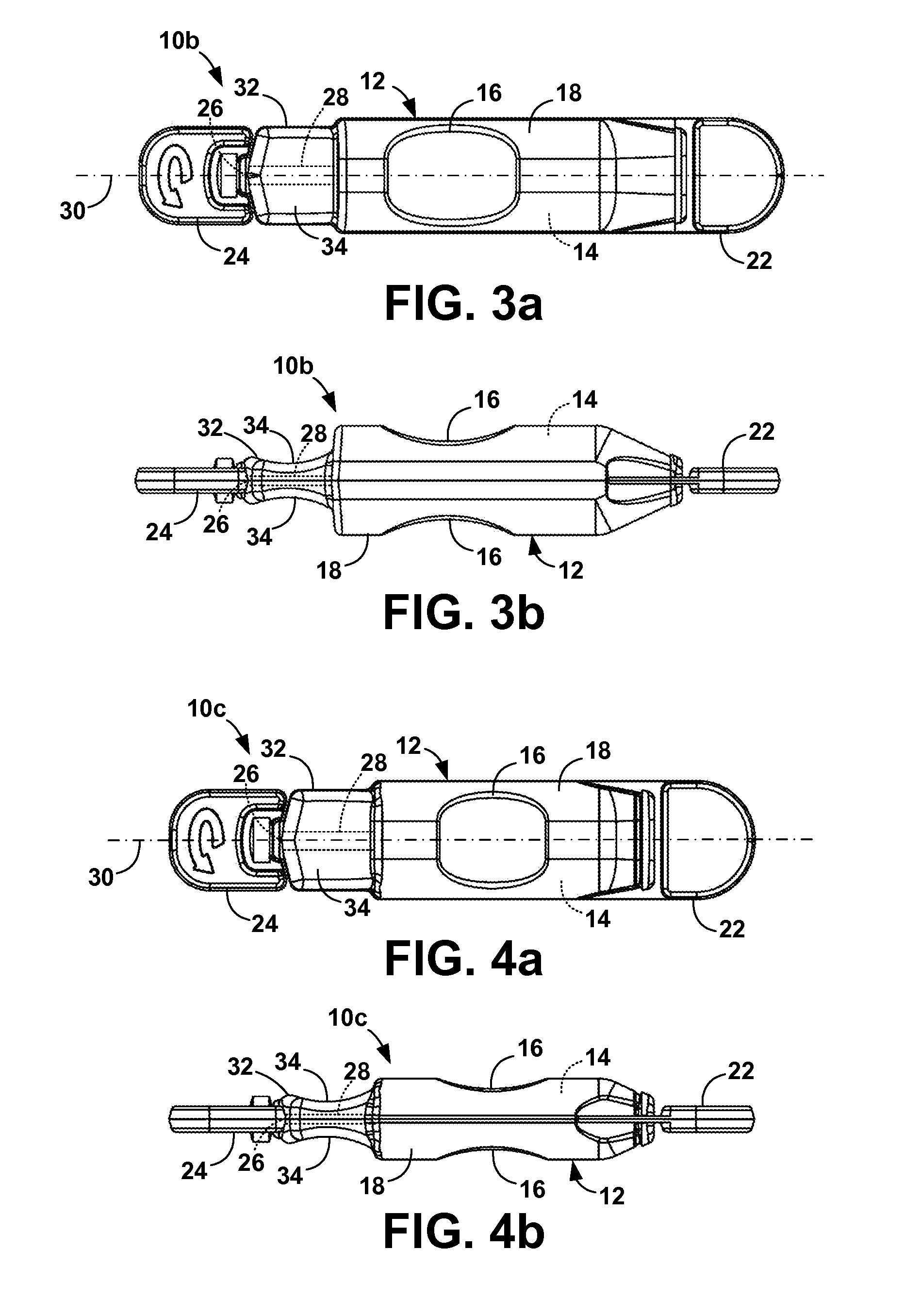

Skin antiseptic applicator and methods of making and using the same

ActiveUS20140366485A1Minimize ethylene oxide penetrationMedical applicatorsWrapper twisting/gatheringBiomedical engineeringBlow fill seal

The invention relates to applicators for applying a solution or other composition (e.g., an antiseptic composition) to skin of a patient. The applicator may include a container body having a proximal end, a distal end, and a frangible member disposed at the distal end of the body. The applicator includes a first position where the container body and frangible member are a unitary piece (e.g., blow molded as a single piece), and a second position when the frangible member is rotated relative to the body to irreversibly break a weak point therebetween, releasing the composition in the hollow body through an opening. A porous applicator head may be positioned adjacent the distal end of the body and frangible member, so that the composition flows out the body, through the opening, and onto the head. The applicator may be formed in a blow-fill-seal process for improved sterility and ease of manufacture.

Owner:MEDLINE IND LP

Skin antiseptic applicator and methods of making and using the same

The invention relates to applicators for applying a solution or other composition (e.g., an antiseptic composition) to skin of a patient. The applicator may include a container body having a proximal end, a distal end, and a frangible member disposed at the distal end of the body. The applicator includes a first position where the container body and frangible member are a unitary piece (e.g., blow molded as a single piece), and a second position when the frangible member is rotated relative to the body to irreversibly break a weak point therebetween, releasing the composition in the hollow body through an opening. A porous applicator head may be positioned adjacent the distal end of the body and frangible member, so that the composition flows out the body, through the opening, and onto the head. The applicator may be formed in a blow-fill-seal process for improved sterility and ease of manufacture.

Owner:MEDLINE IND LP

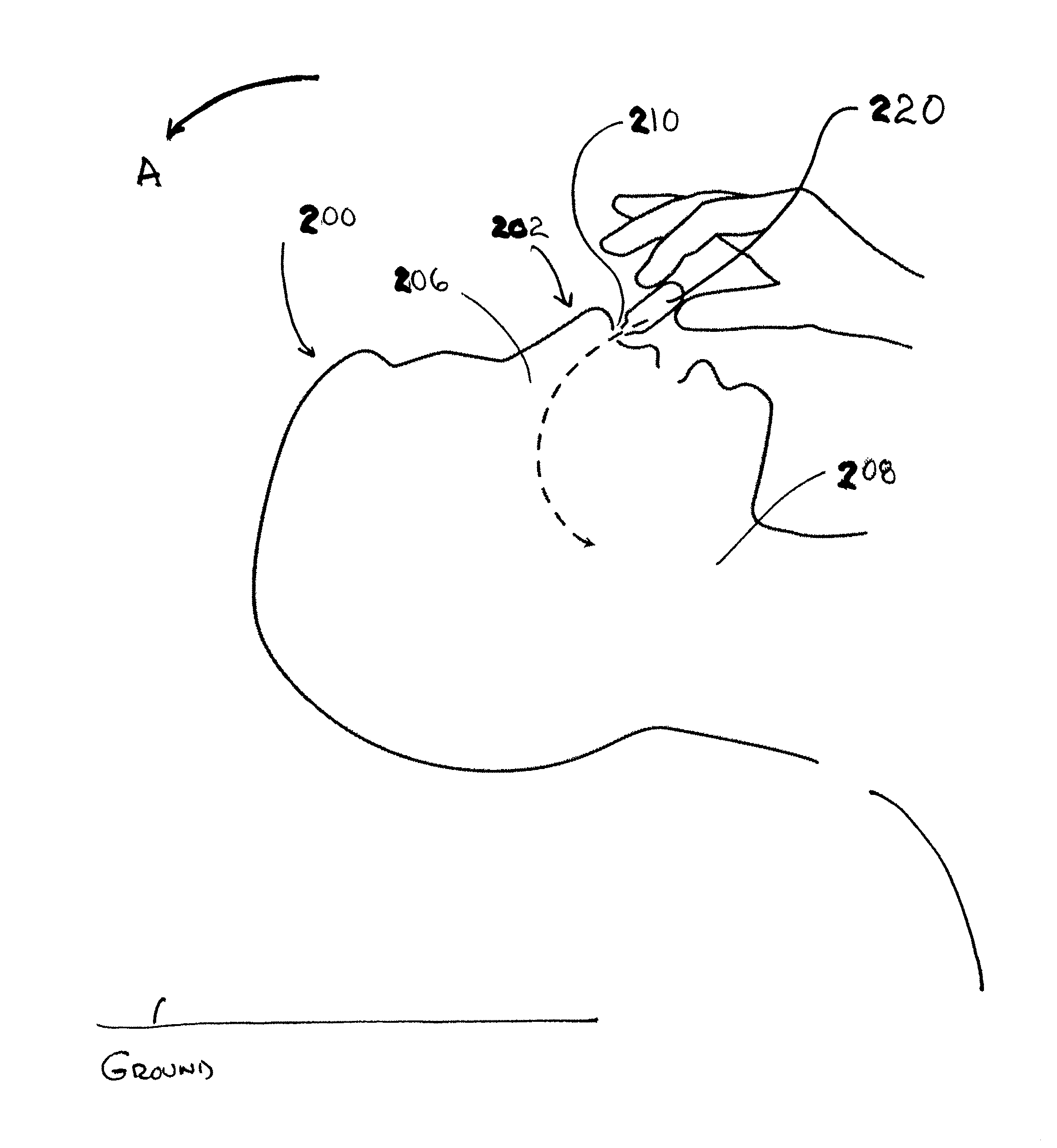

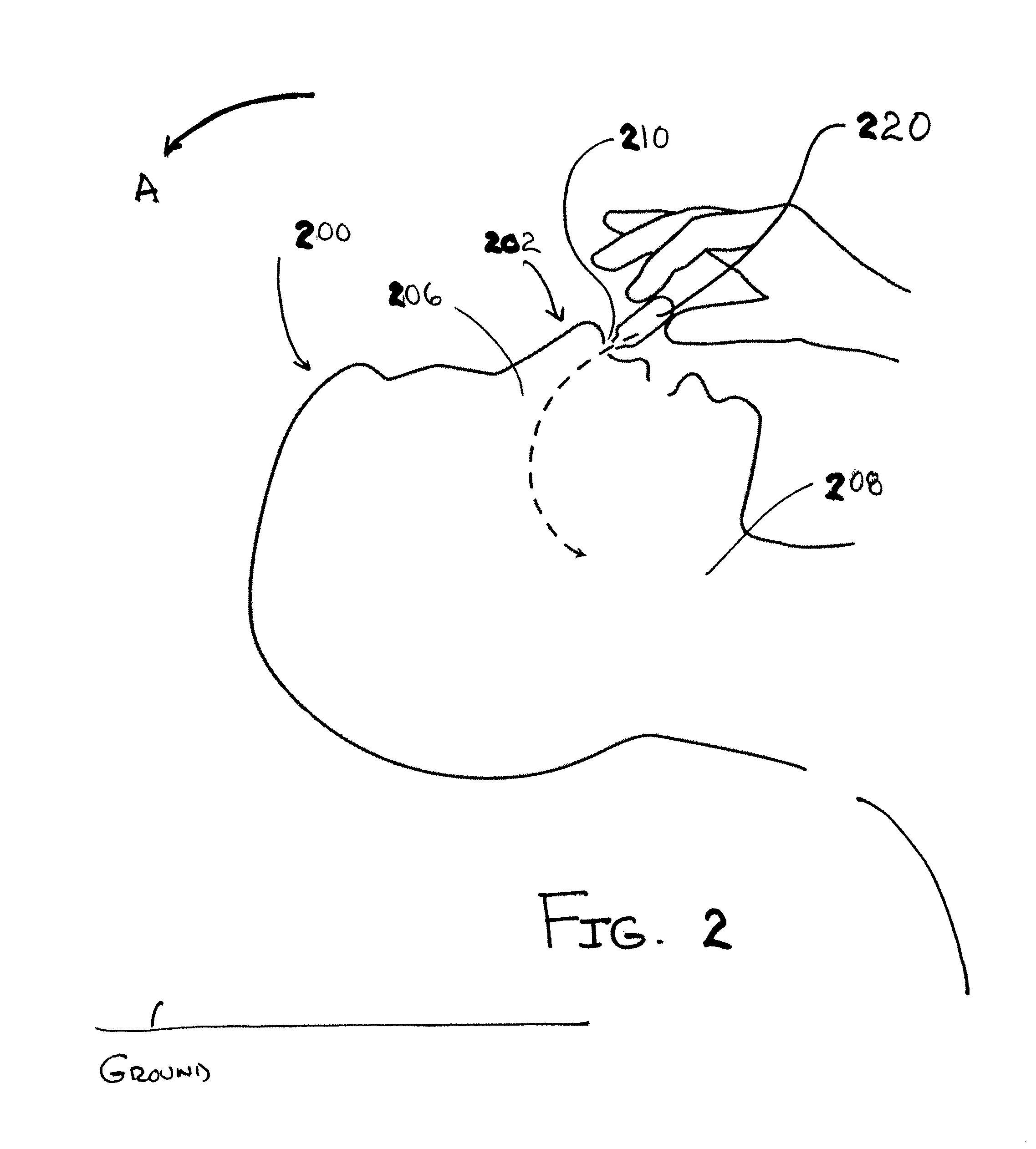

Method of administering a substance to the throat

A pharmaceutical product in the form of an anti-snoring substance includes a container containing the anti-snoring substance, the anti-snoring substance being in the form of a solution pre-concentrate. The container is made by a blow-fill-seal technology, wherein the container material is Polyethylene or Polypropylene. The container includes a body portion containing the anti-snoring substance and a fluid outlet portion configured to deliver the anti-snoring substance.

Owner:TANNER MEDICO

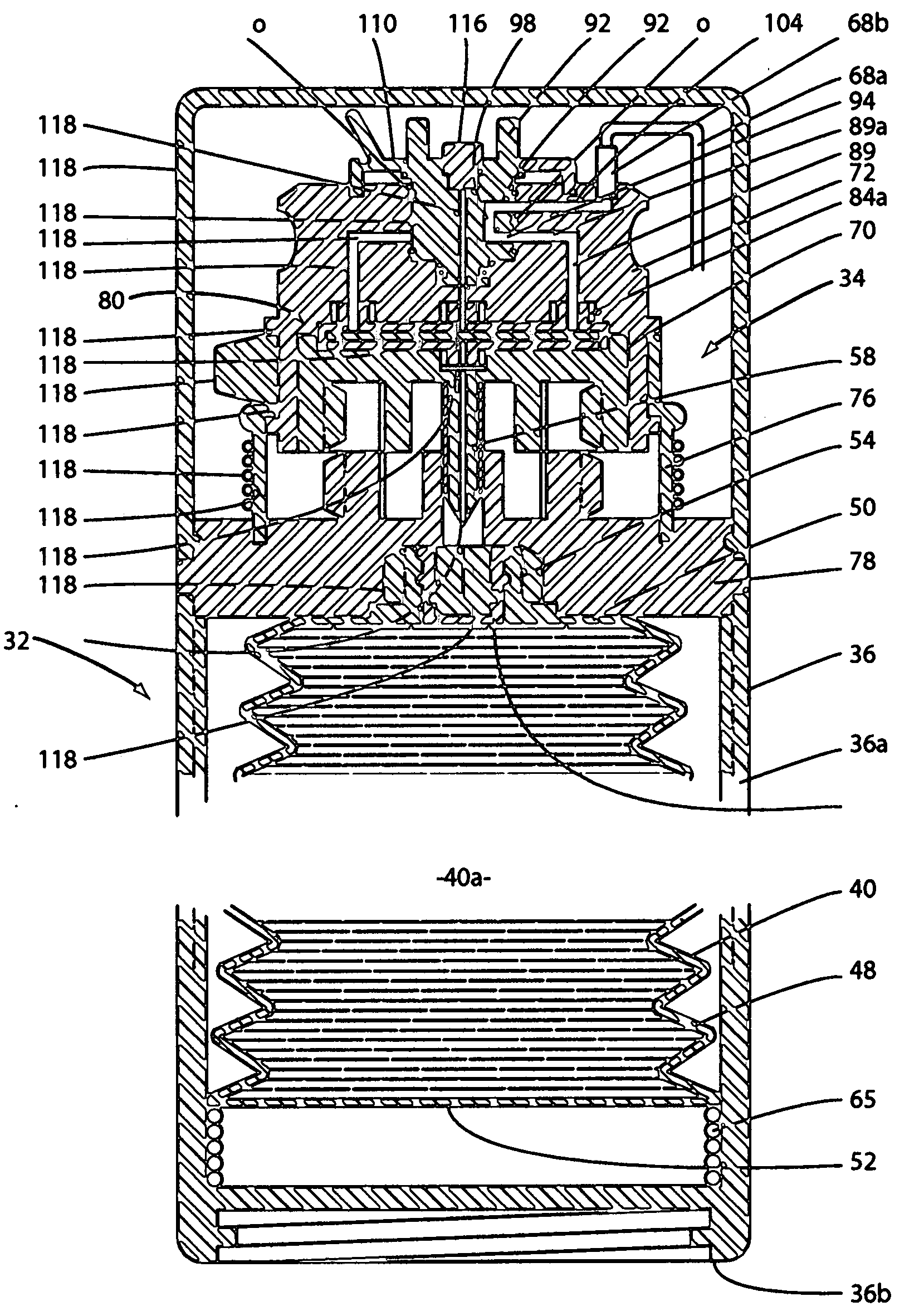

Fluid dispenser with uniformly collapsible reservoir

InactiveUS20080243077A1Easy constructionEasy to handleMedical devicesMedical applicatorsBiomedical engineeringElastance

Owner:BIVIN DONALD B +3

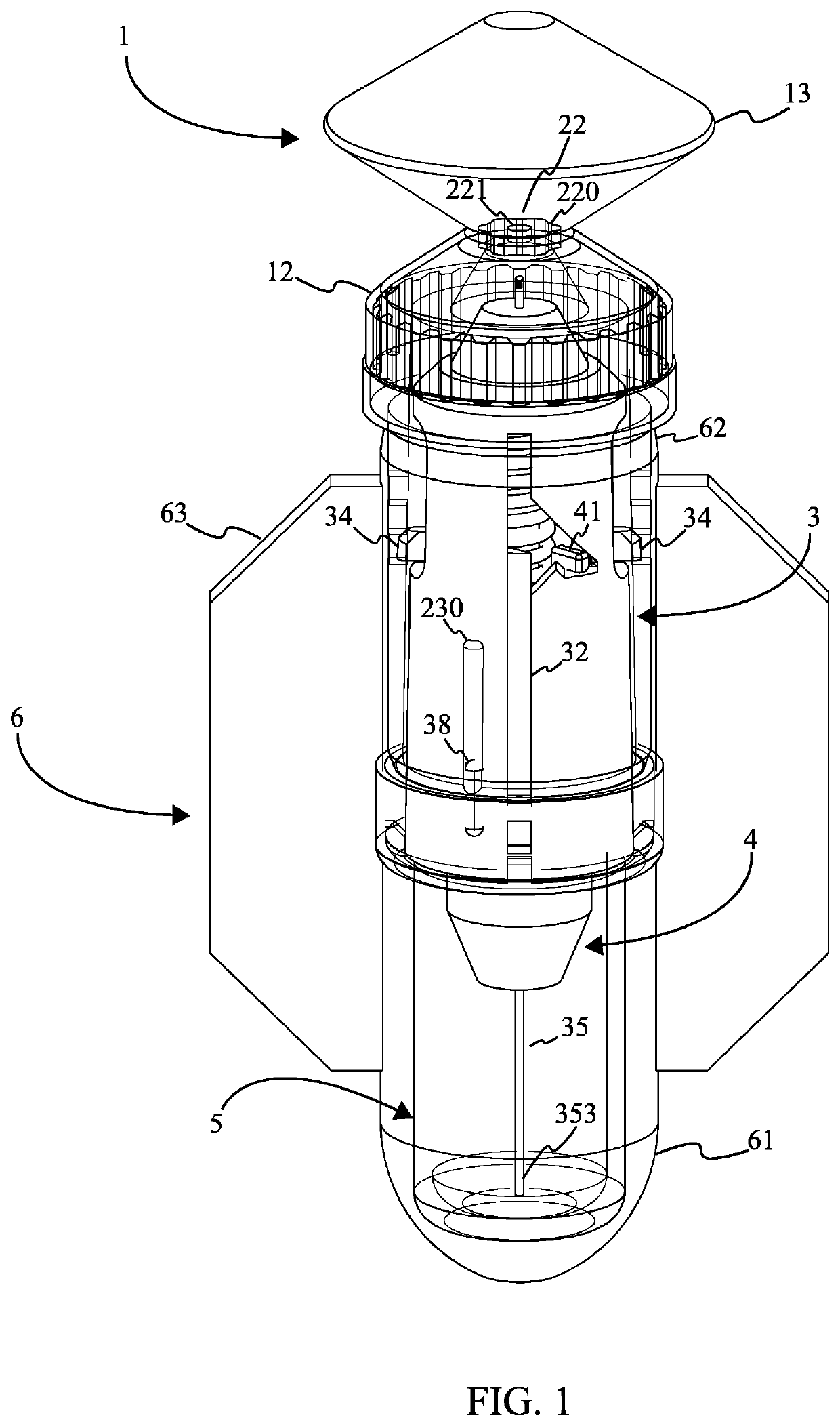

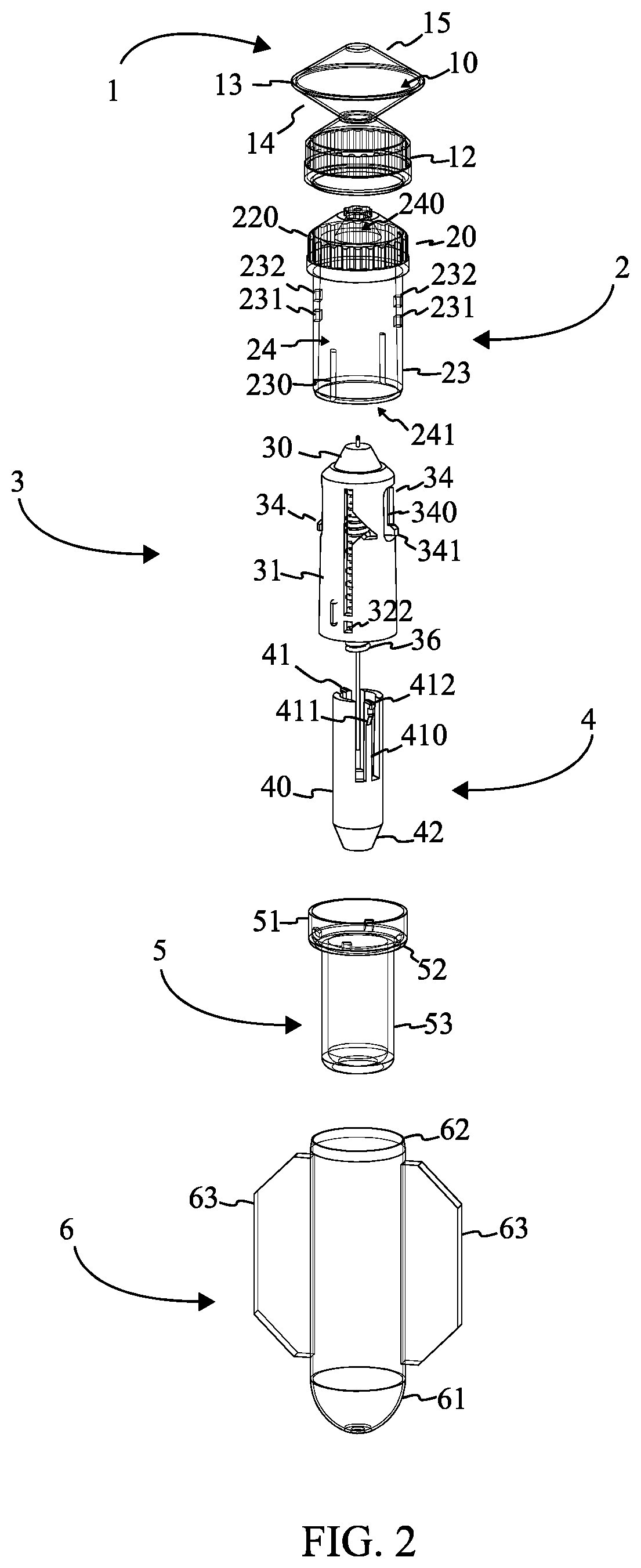

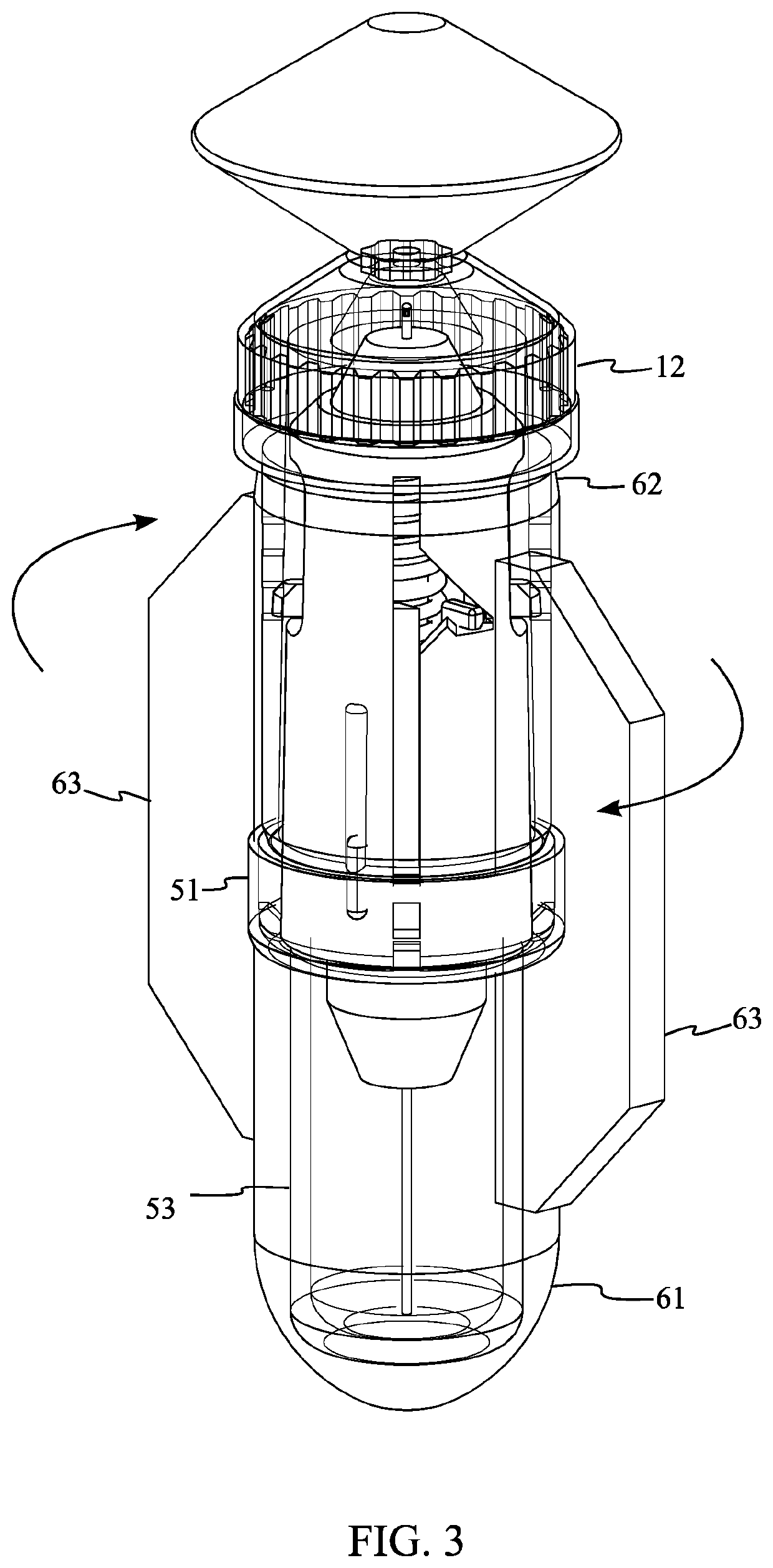

Prefilled medical injection device

Owner:ADAR MEDTECH

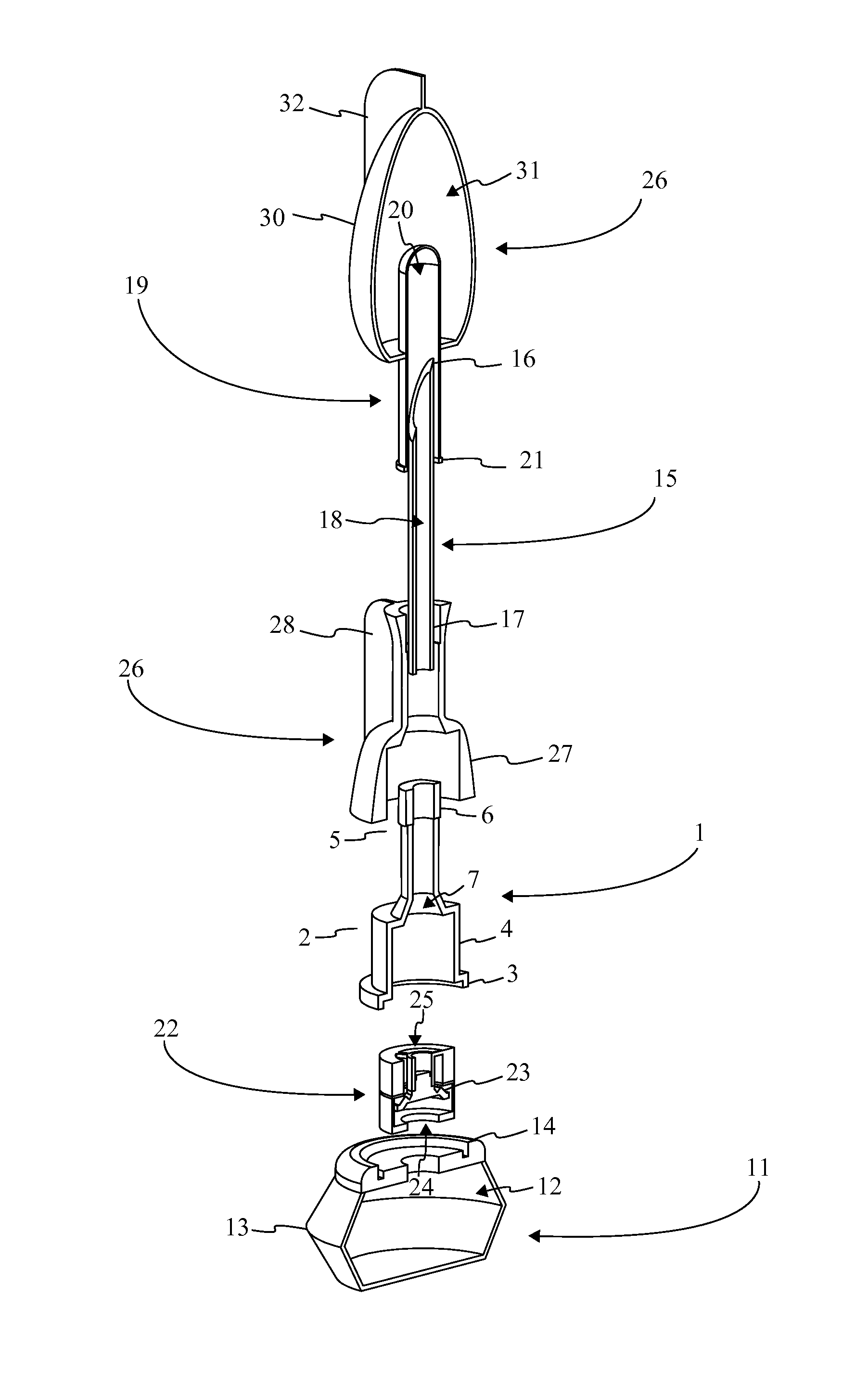

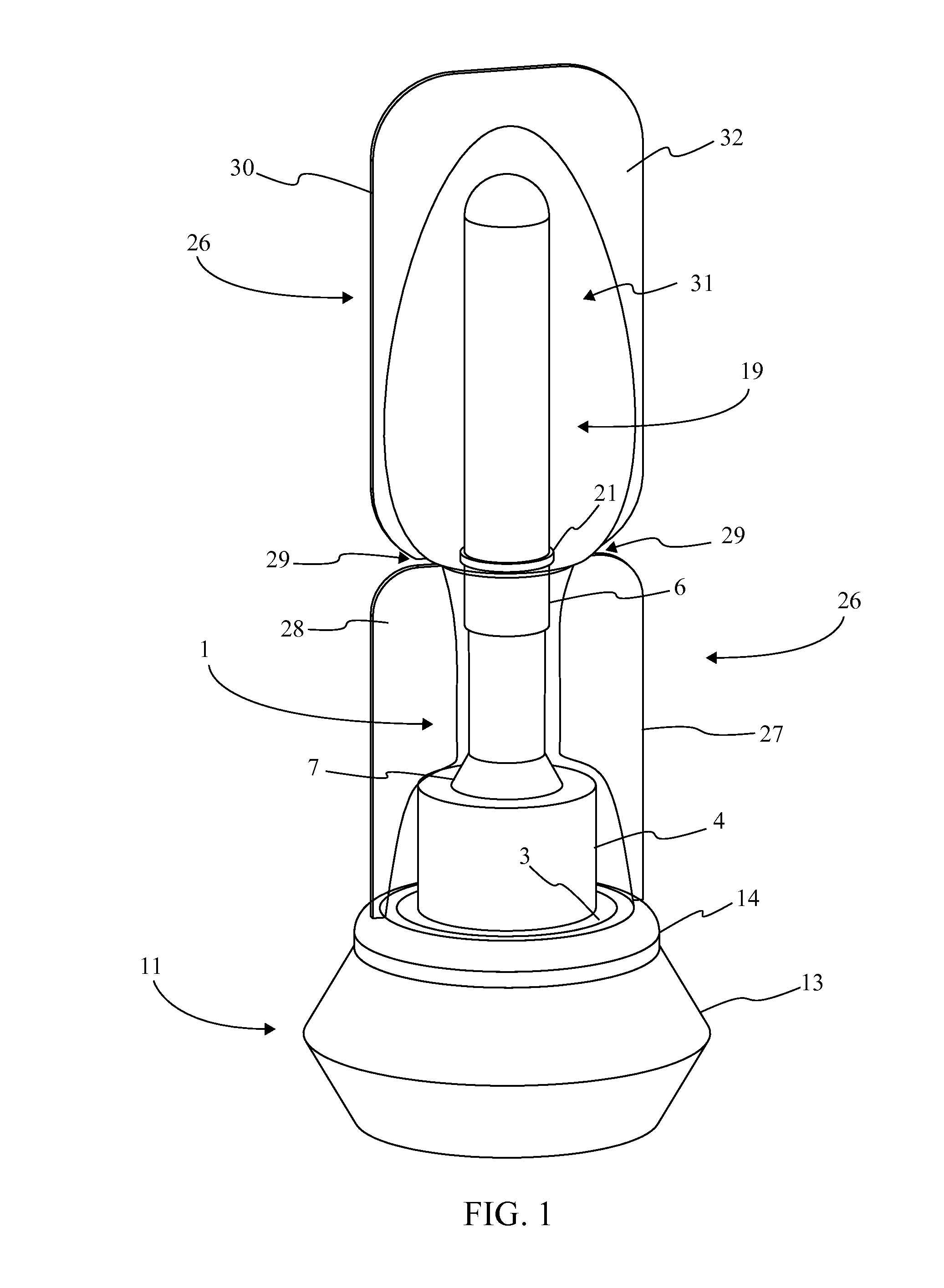

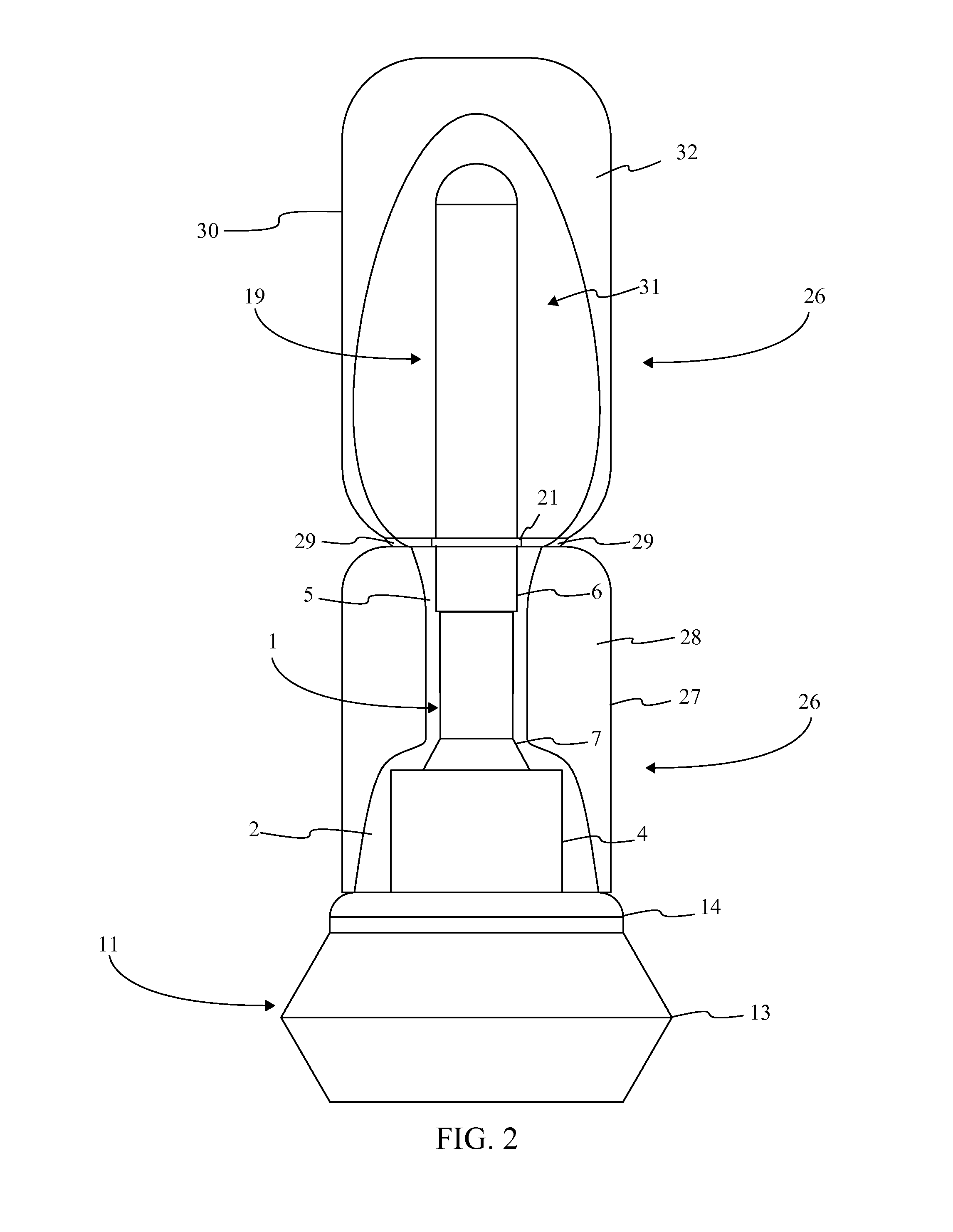

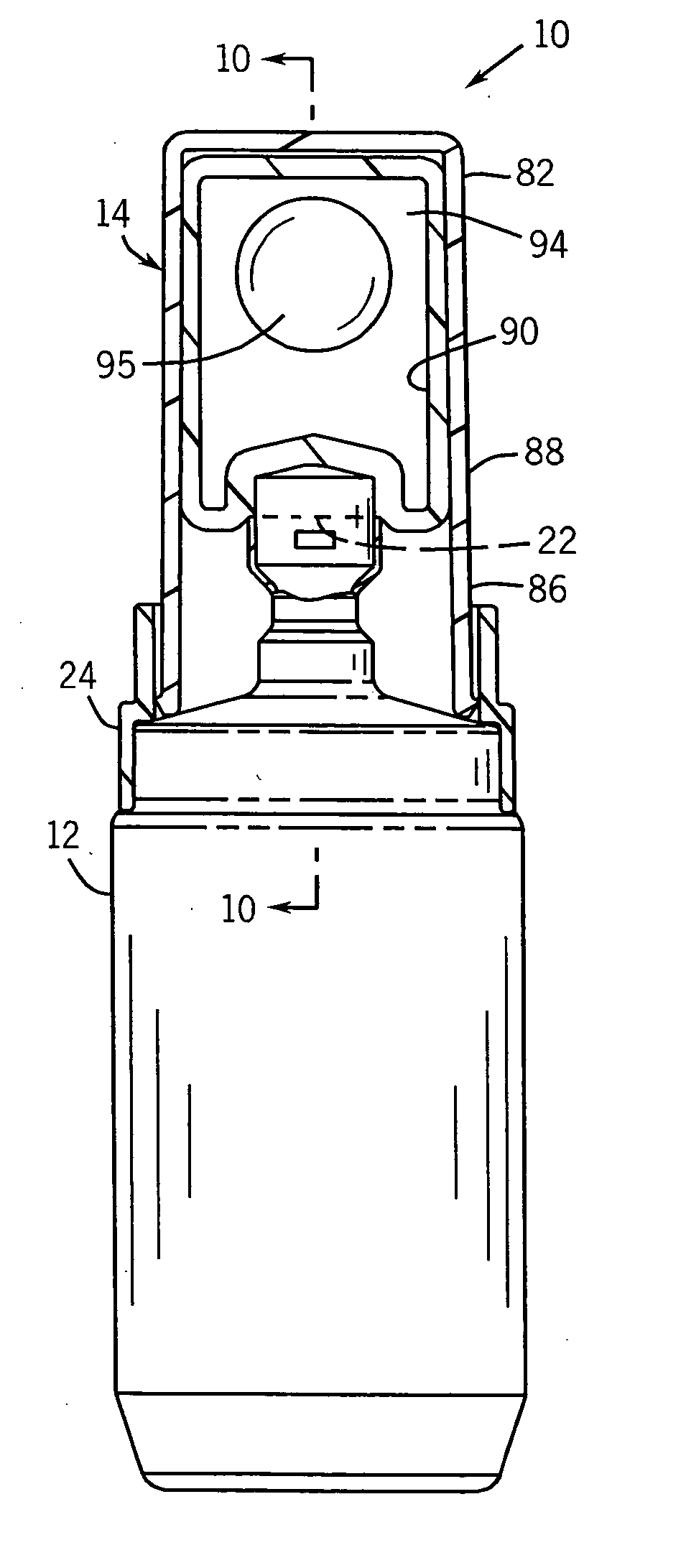

Single Use Injector

A single use injector is a disposable injection device that is specifically optimized for production using the blow fill seal (BFS) manufacturing process and includes various mechanisms that render the device inoperable and facilitate its safe disposal after use. The single use injector incorporates an ampoule aseptically filled with a medication that is coupled to a hermetically sealed component system. The hermetically sealed component system incorporates various mechanisms that are actuated during the use of the injection device. The injection device is encased in a removable overtube that prevents contamination. upon removal of the overtube, the injection device is activated, by compression of a needle cap that irreversible punctures the ampoule in order to inject the medication through a needle. The injection device additionally incorporates a shield that deploys over the needle following injection of the medication into a patient.

Owner:ADAR MEDTECH

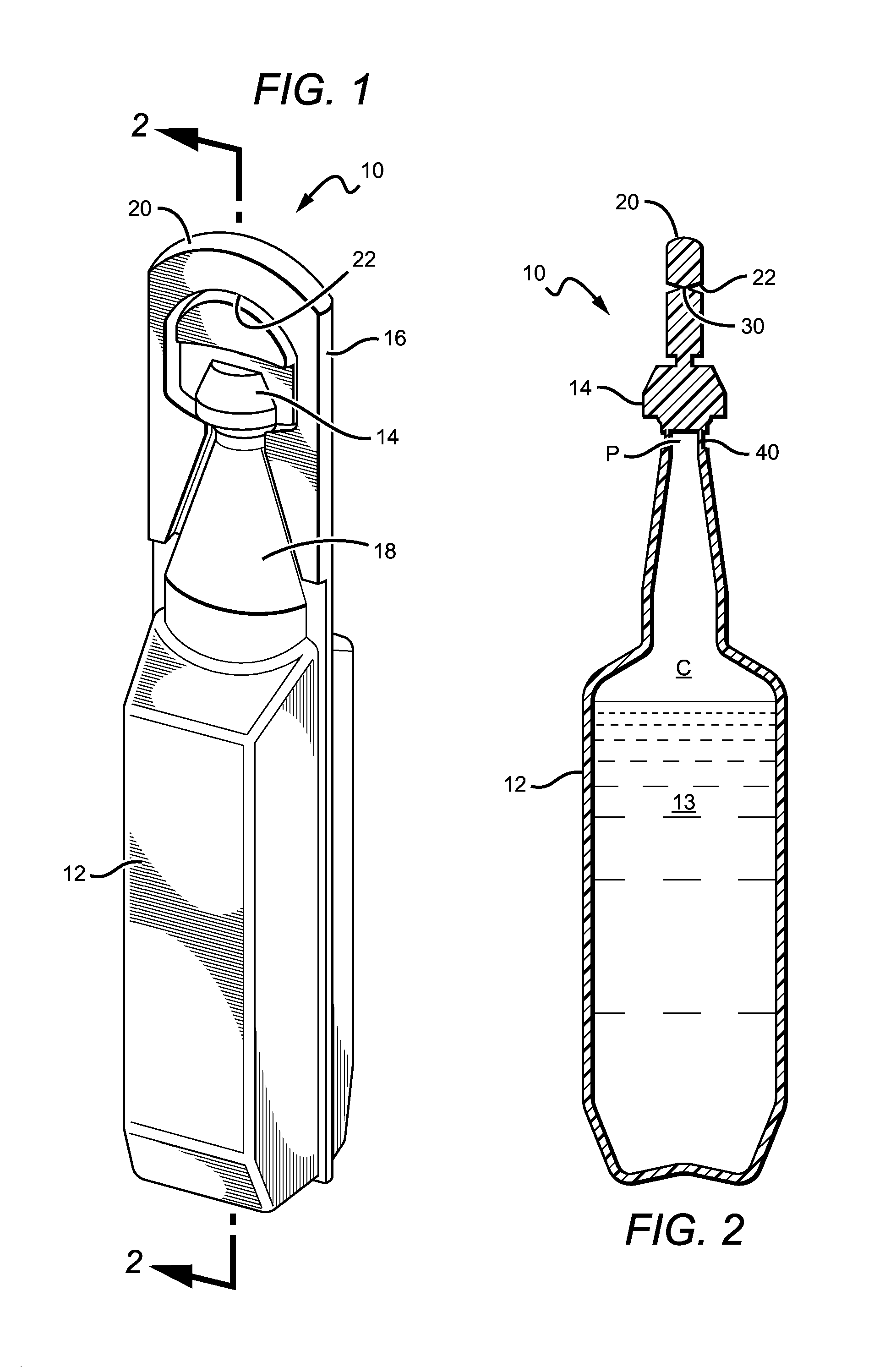

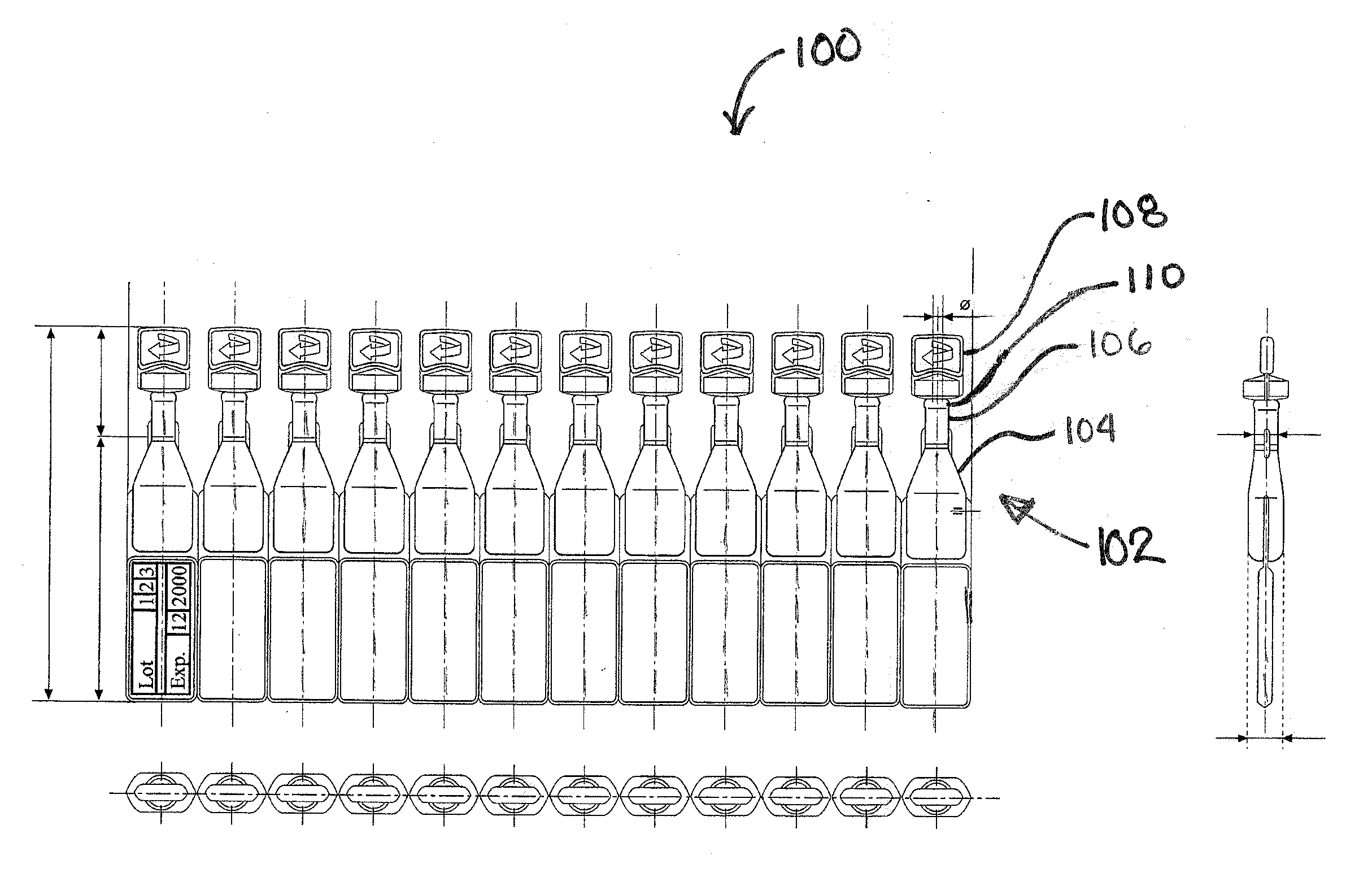

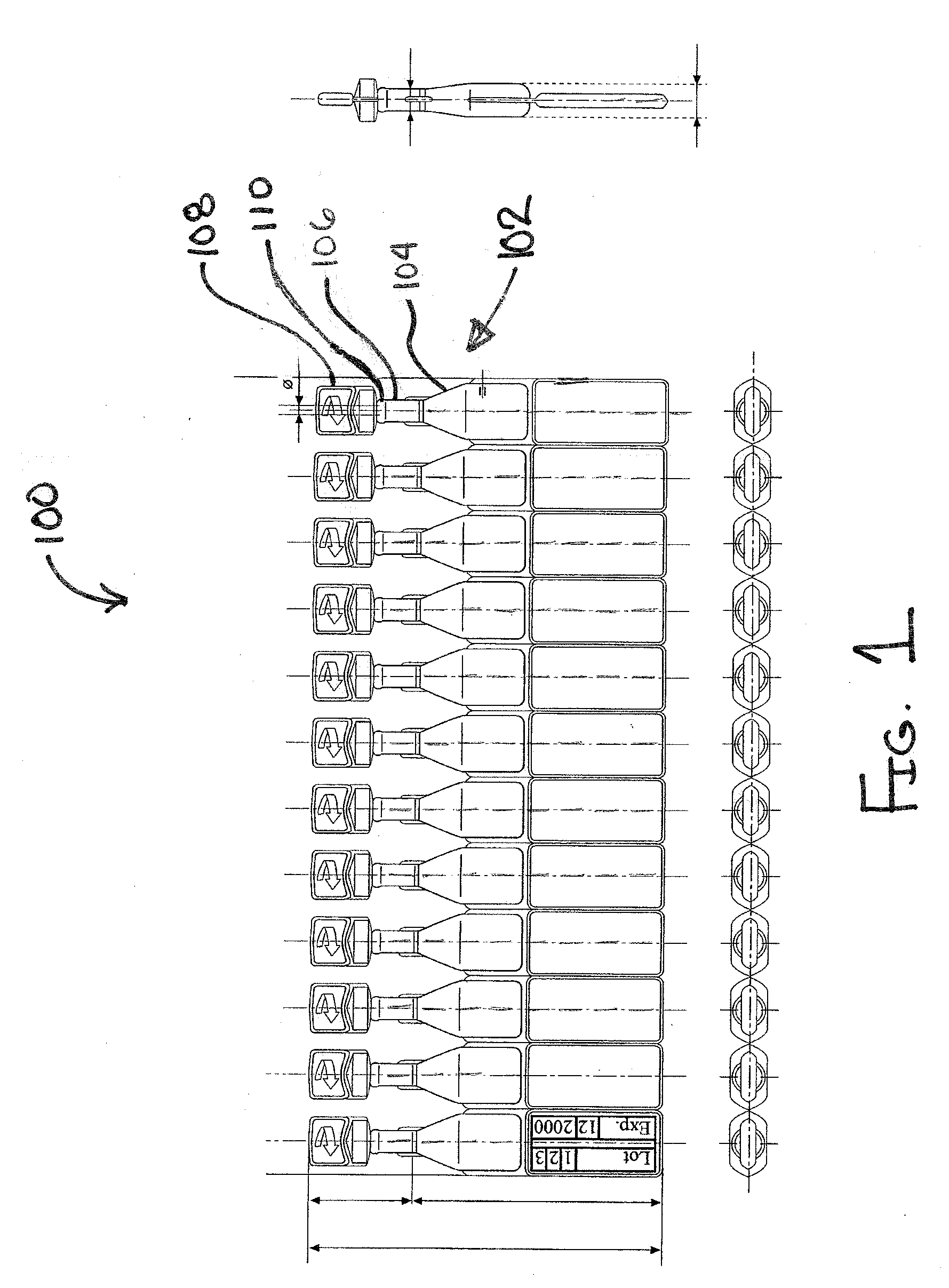

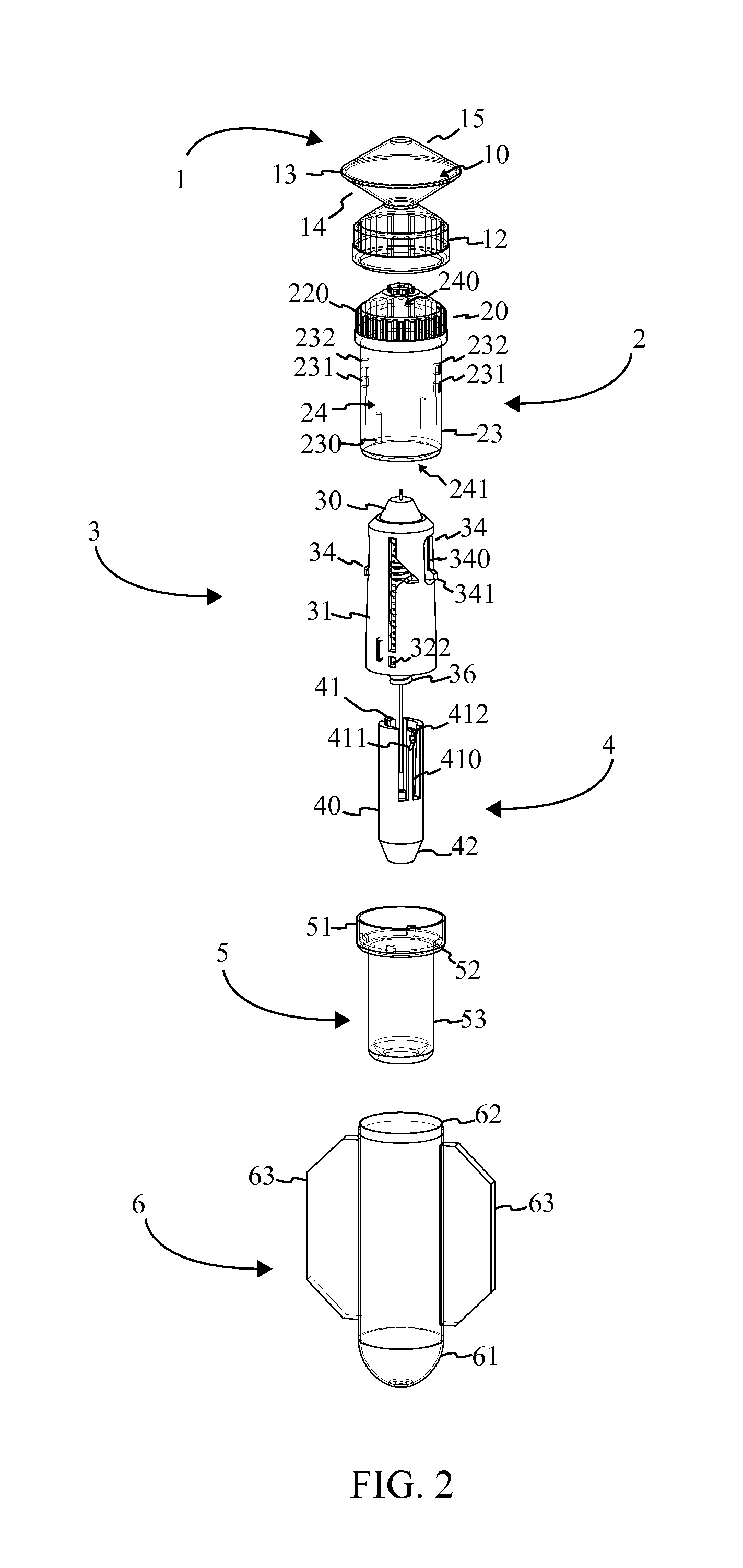

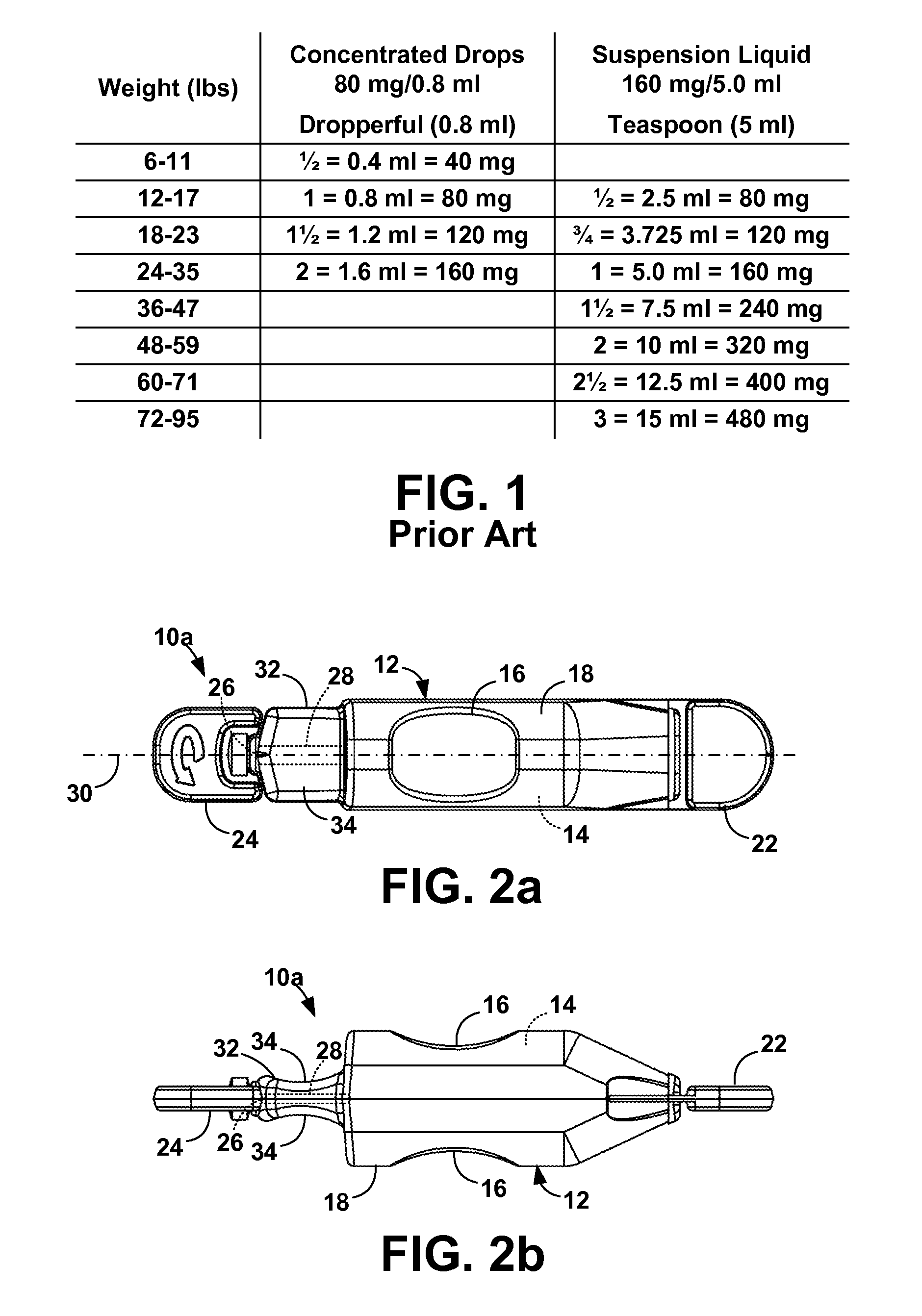

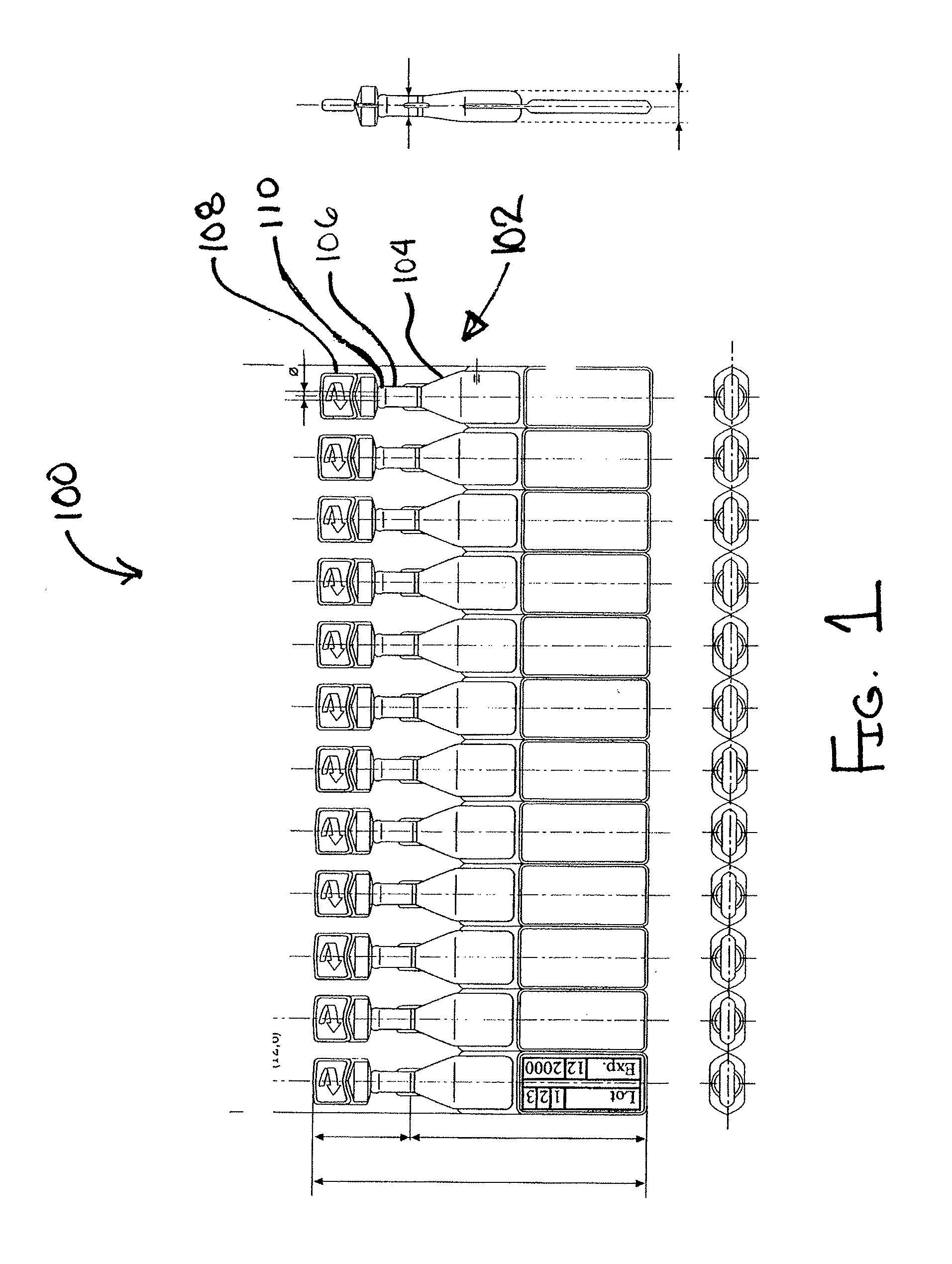

Packaging system for liquid medications

ActiveUS9364393B1Prevent overdosingAvoid contaminationClosuresPharmaceutical containersEngineeringViscosity

A dosing system for analgesic liquid suspensions including unit dose containers made using blow-fill-seal (BFS) technology. The containers come in various sizes and hold appropriate doses for specific weight ranges. Each container has body with a compartment for holding the liquid, finger rests for squeezing the container to expel the liquid, a tab at one end for labeling, and a twist-off closure at the other end. In the larger containers, the opening end has a lip rest, which is a flattened section that includes opposed, curved depressions. In the smallest container, the opening end has a long tapered neck. The suspension has a relatively low viscosity to ensure more complete dose evacuation from the container. The containers will be sold in assemblages of various combinations of sizes.

Owner:HEALTHSTAR

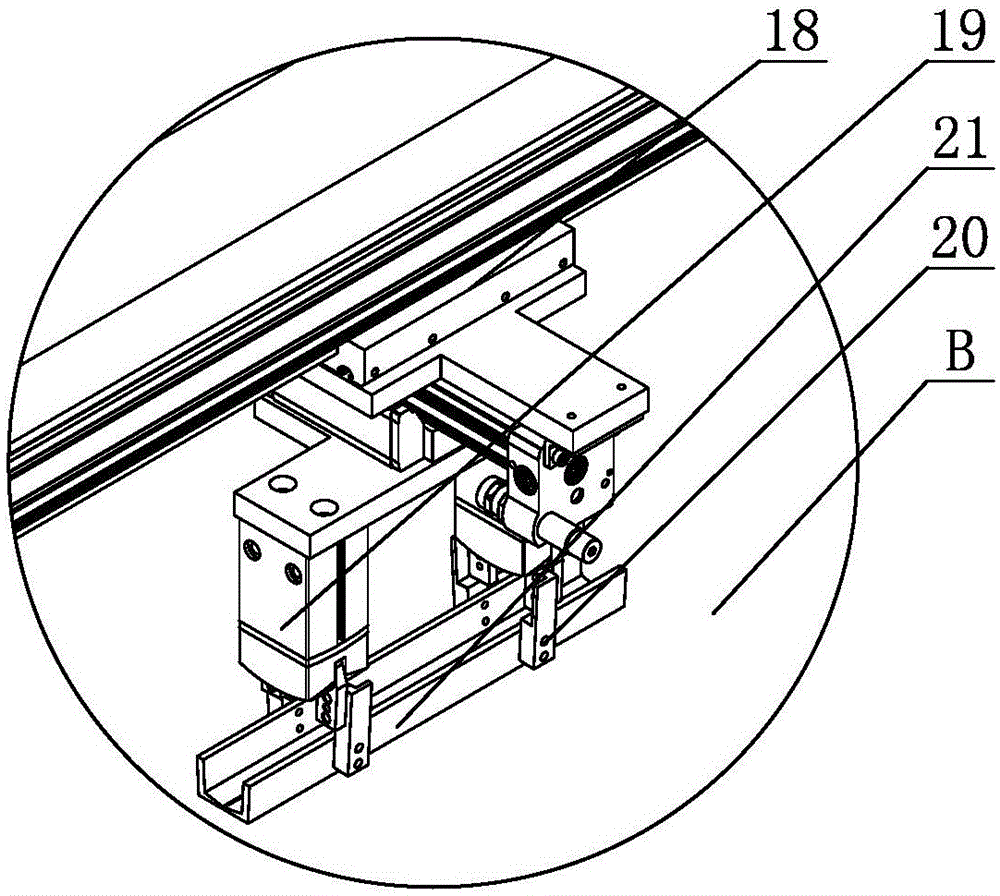

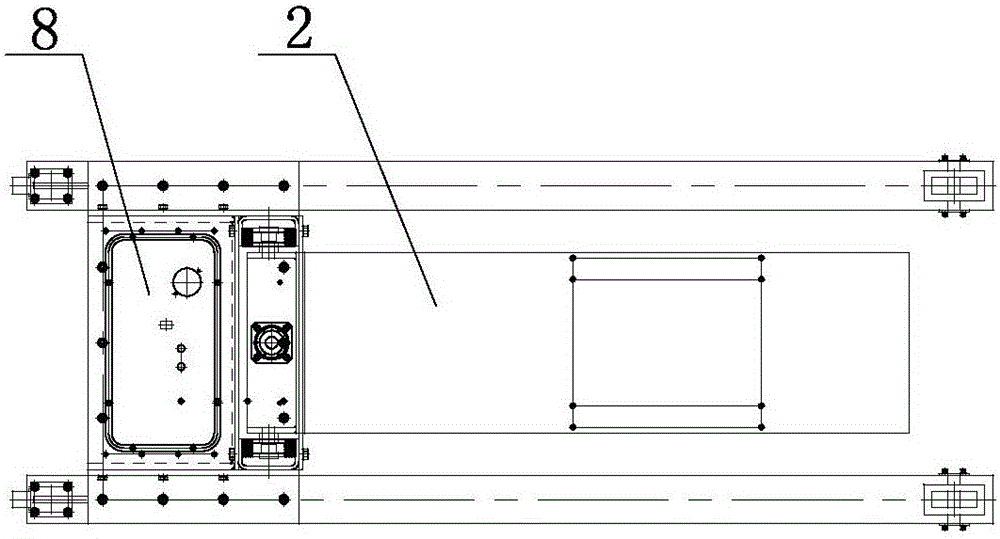

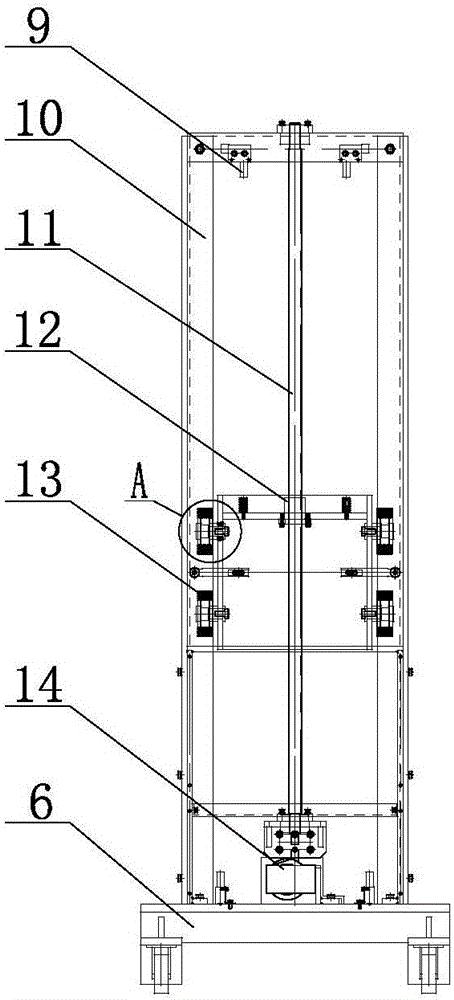

Plastic ampoule blanking slitting transfer all-in-one machine

ActiveCN105058501AMeet production speed requirementsCompact structureAffixing tagsMetal working apparatusEngineeringAmpoule

The invention relates to subsequent processing equipment of products produced by blowing-filling-sealing integrated equipment, in particular to a plastic ampoule blanking slitting transfer all-in-one machine. The plastic ampoule blanking slitting transfer all-in-one machine comprises a rack; a push assembly, a punch die assembly, a sucker assembly, a virtual cutting product transfer assembly, a cutter assembly, a finished product transfer assembly and a conveying assembly are sequentially arranged on the rack; the punch die assembly comprises a punch die fixing plate, a punch die, a punch die embedding plate, a compression spring and a punch die supporting plate; two sides of the punch die fixing plate are connected with the push assembly and the punch die respectively; the punch die fixing plate is connected with the punch die embedding plate through a guide shaft; the compression spring is disposed on the guide shaft; a straight slot which corresponds to the punch die is formed in the punch die embedding plate; the punch die supporting plate is disposed on the opposite side of the punch die; a claw assembly is arranged above the rack; the claw assembly is disposed on a transverse beam. The plastic ampoule blanking slitting transfer all-in-one machine is compact in structure, easy to operate, high in working efficiency and capable of excellently meeting the requirements for production speed of products by the blowing-filling-sealing equipment.

Owner:SHINVA MEDICAL INSTR CO LTD

Delayed pierce, sealed container

A sealed liquid container with a bottle, base, piercer, and cap. The bottle is a blow-fill-seal container with a body, dispensing head connected to the body by a neck, and a fluid chamber. The base has a socket that accepts the dispensing head and permanently attaches to the bottle by one or more fingers extending radially into the socket and under the shoulder of the dispensing head. A keying mechanism prevents the base from rotating on the bottle. The piercer has an axially-extending, sharpened, hollow tube. In shipping mode, the piercer is turned onto the base until the tube tip is touching the dispensing head. To use, the piercer is turned until the tube tip penetrates the dispensing head into the fluid chamber, and the piercer locking mechanism is engaged to prevent removal of the piercer. A cap turns onto the piercer.

Owner:HEALTHSTAR

Blow fill sealed container with twist off top operated by overcap and method of making the same

Owner:HOSPIRA INC

Single use injector

A single use injector is a disposable injection device that is specifically optimized for production using the blow fill seal (BFS) manufacturing process and includes various mechanisms that render the device inoperable and facilitate its safe disposal after use. The single use injector incorporates an ampoule aseptically filled with a medication that is coupled to a hermetically sealed component system. The hermetically sealed component system incorporates various mechanisms that are actuated during the use of the injection device. The injection device is encased in a removable overtube that prevents contamination. upon removal of the overtube, the injection device is activated, by compression of a needle cap that irreversible punctures the ampoule in order to inject the medication through a needle. The injection device additionally incorporates a shield that deploys over the needle following injection of the medication into a patient.

Owner:ADAR MEDTECH

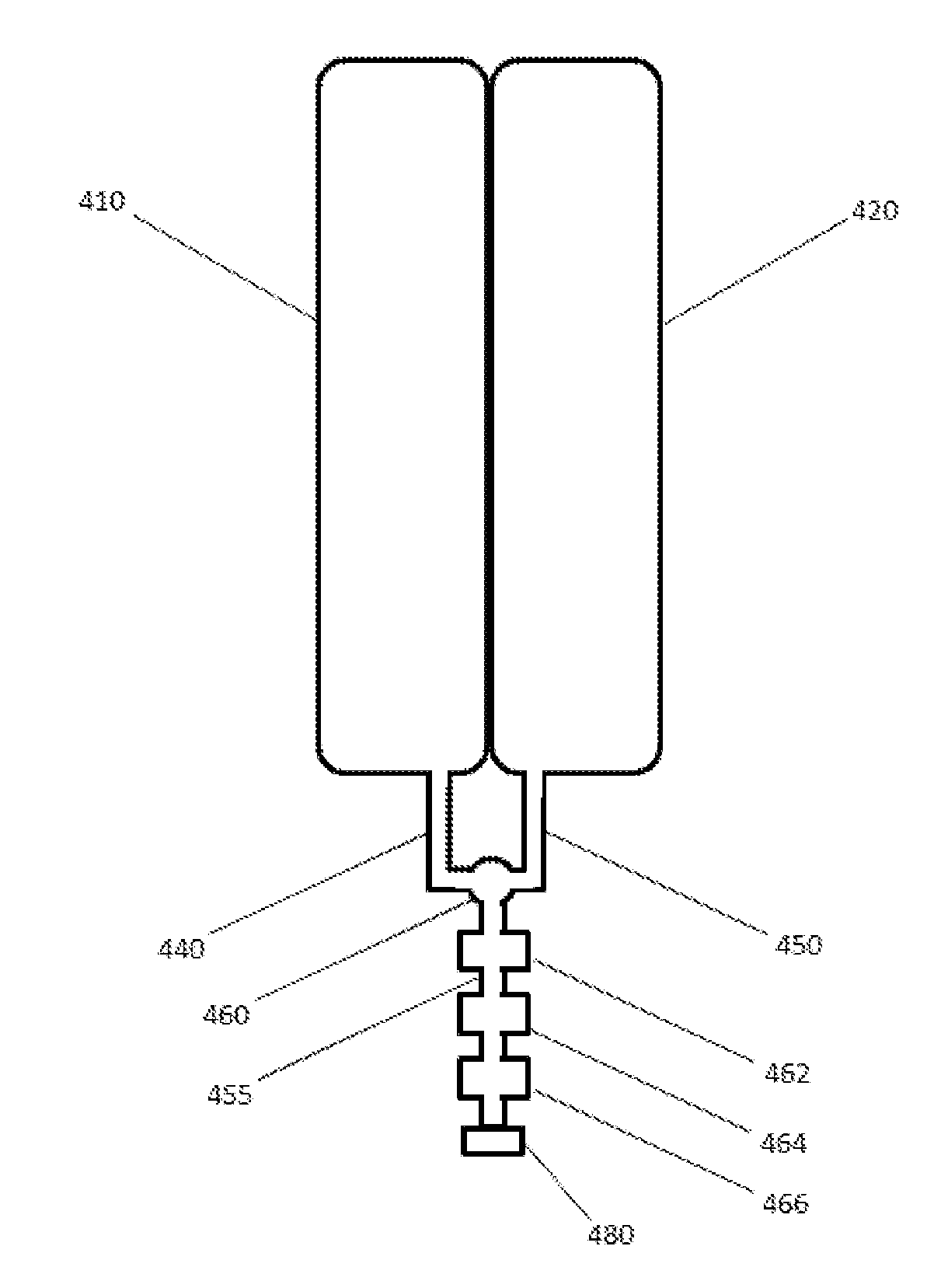

Dual Container for Sterile Fabrication and Filling

InactiveUS20180235839A1Reduce consumptionFlow mixersPharmaceutical containersEngineeringPharmaceutical formulation

A multi-reservoir dispensing, disposable and sterile container has at least two separate and distinct reservoirs positioned adjacent to one another, and which can be readily manufactured using blow-fill-seal technology. The reservoirs contain components of a mixed pharmaceutical formulation, which is prepared at the time of dispensing from the container by blending of the contents of the reservoirs. Liquid flow channels extend from each reservoir and merge together at or near an exit aperture of the container, and a mixing feature can be employed at or downstream of the point of merging. In the container as provided to a user the exit aperture is blocked by a seal, which is removed prior to dispensing.

Owner:JOHNSON LIVING TRUST

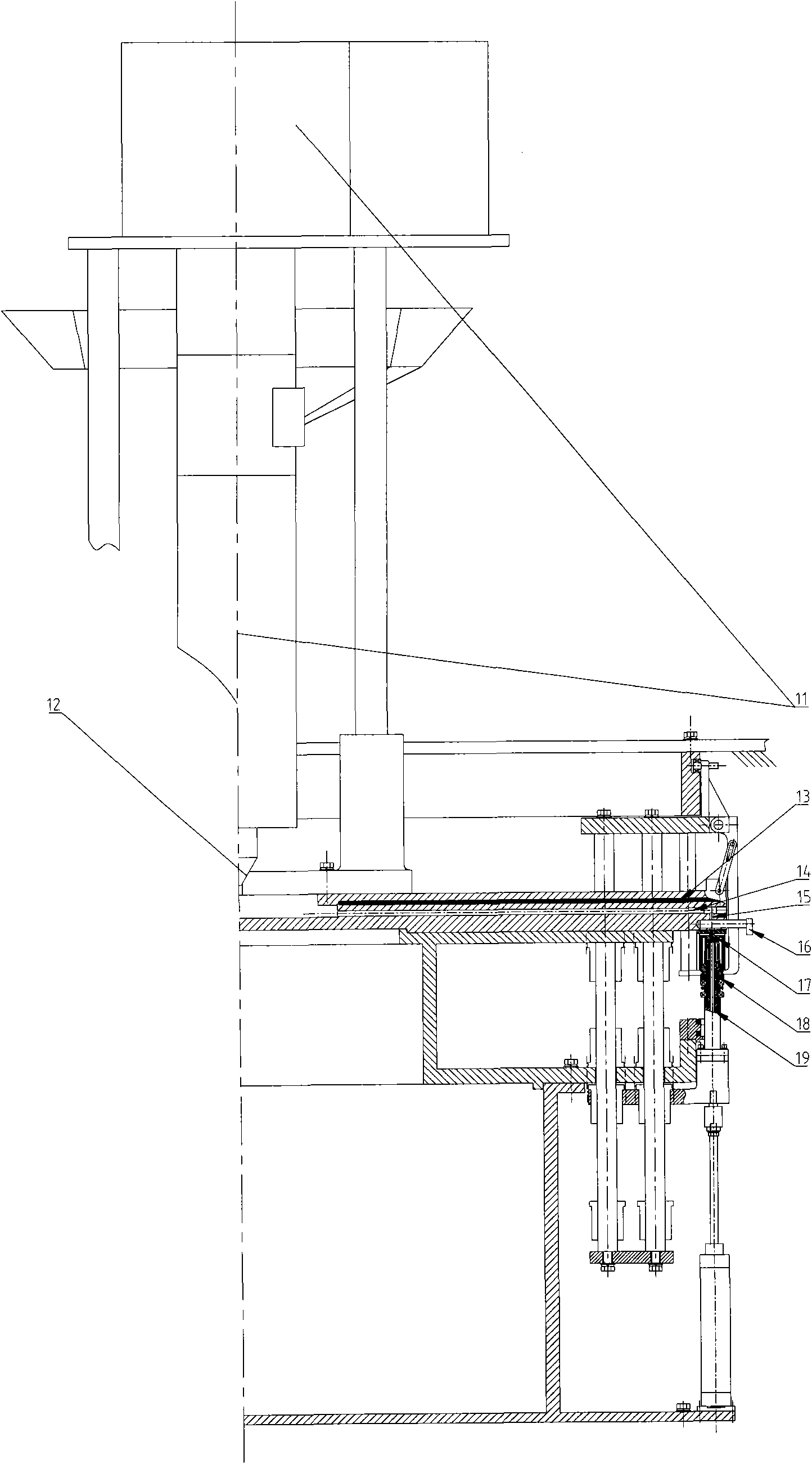

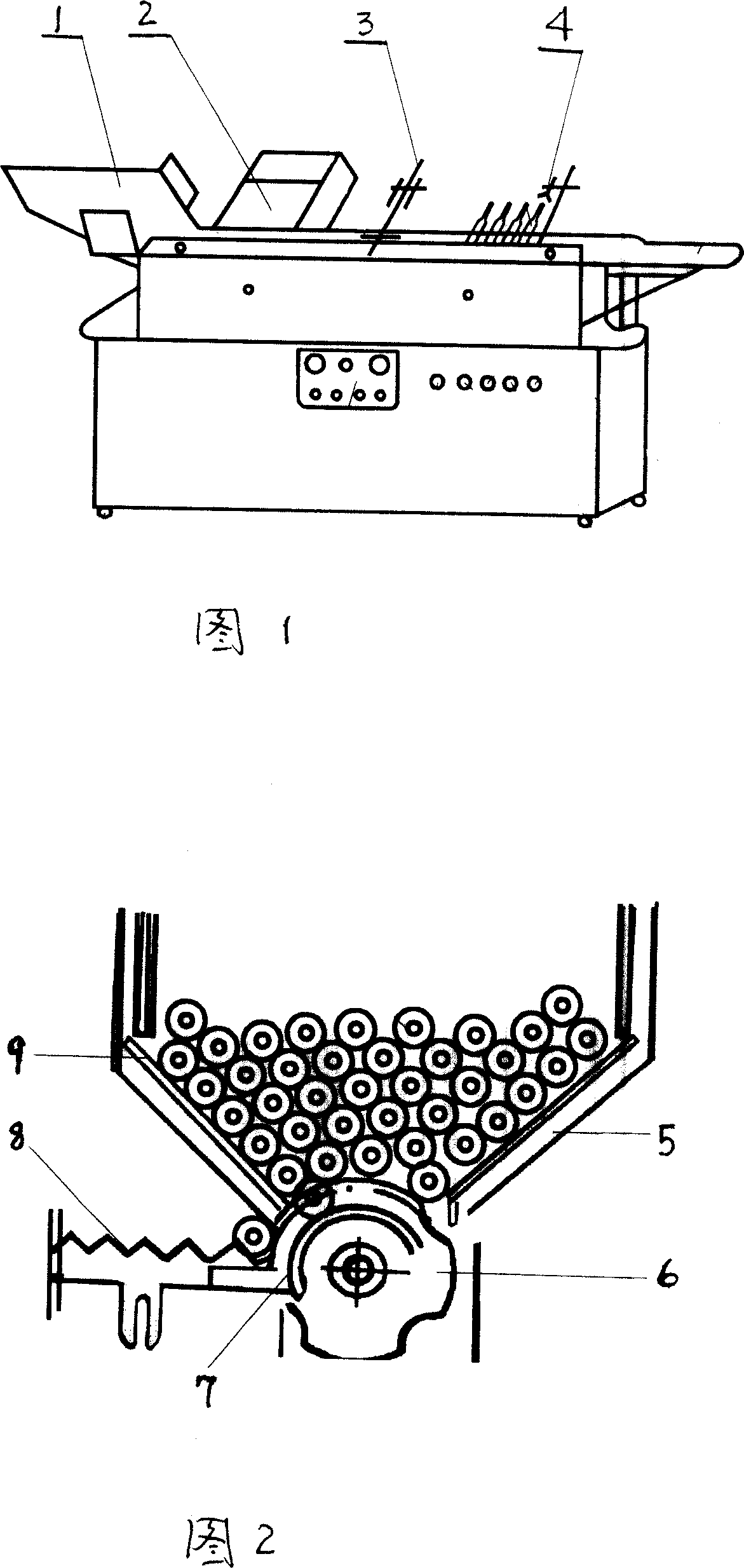

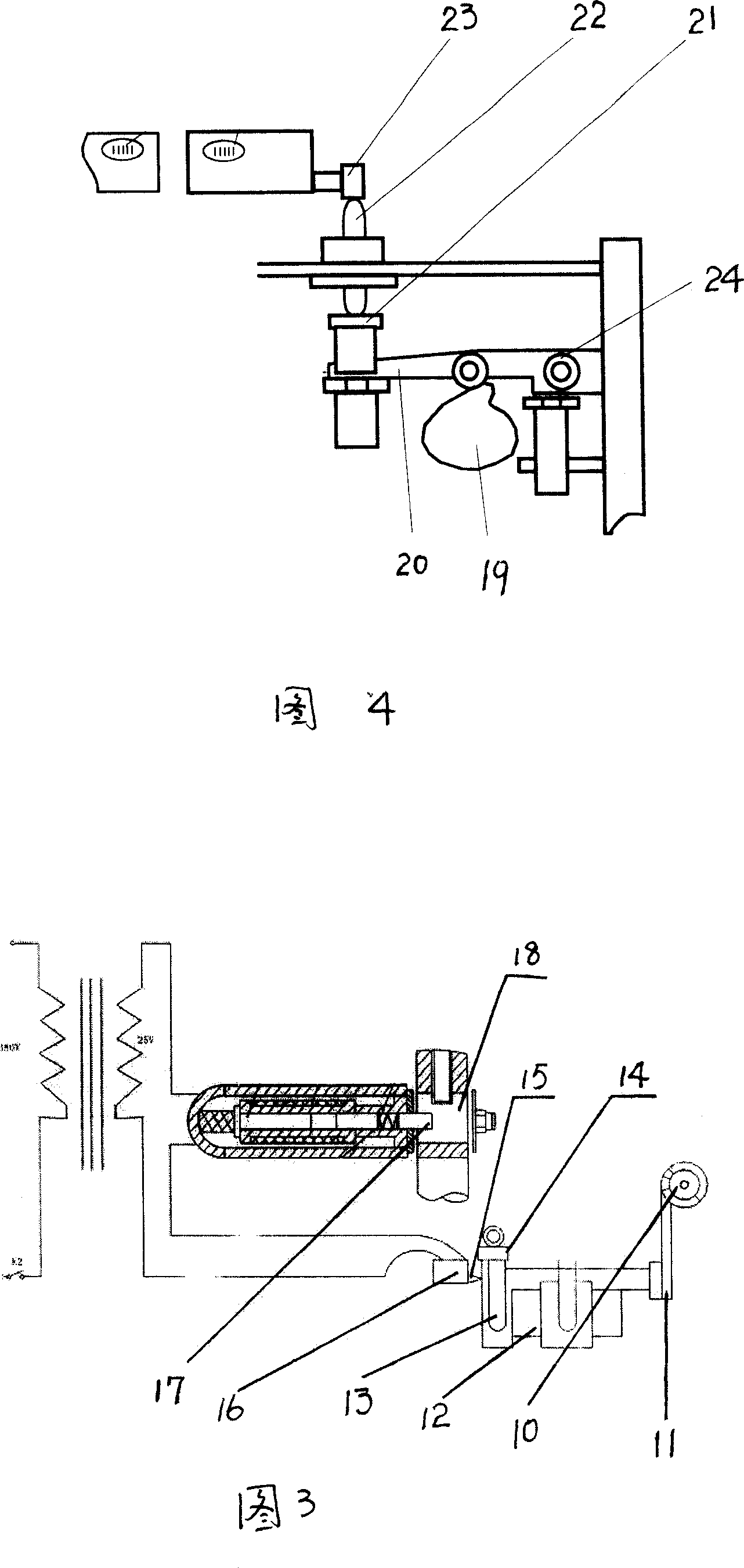

Automatic washing blowing filling sealing machine for injection bottle

InactiveCN101016144AImprove work efficiencyImprove potting qualityBottle-handling machinesGlass reforming apparatusEngineeringBottle

The invention relates to an automatic washing drying drug filling sealing machine of injection bottle, comprising a bottle feeder, a washing drier, a filling device and a sealing device which are geared serially. The bottle feeder comprises a bottle feeding hopper, a disc, an adjusting rod, and a positioning tooth plate, the inner wall of the bottle feeding hopper is disposed with a movable bar plate, the adjustable distance between the movable bar plate and the disc can pass different injection bottle, the disc is connected with the positioning tooth plate, the adjusting rod is opposite to the bottleneck of the injection bottle, and the filling device is disposed with an automatic filling stopper. The invention can reduce cost and volume, reduce structure complexity, and combine drug washing, filling and sealing processes, to improve efficiency and quality, with high automatic degree and reliability.

Owner:中国人民解放军第一一八医院

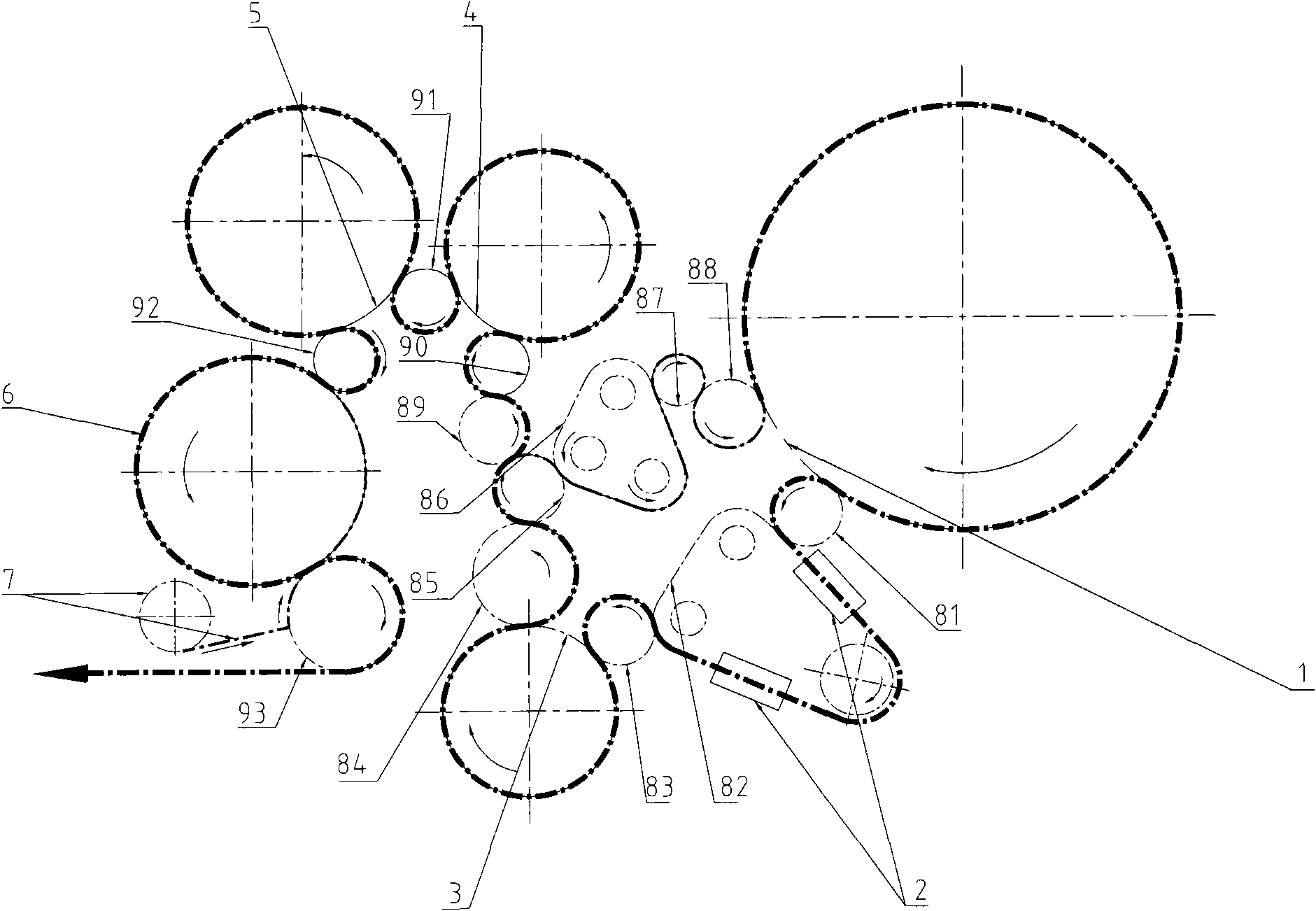

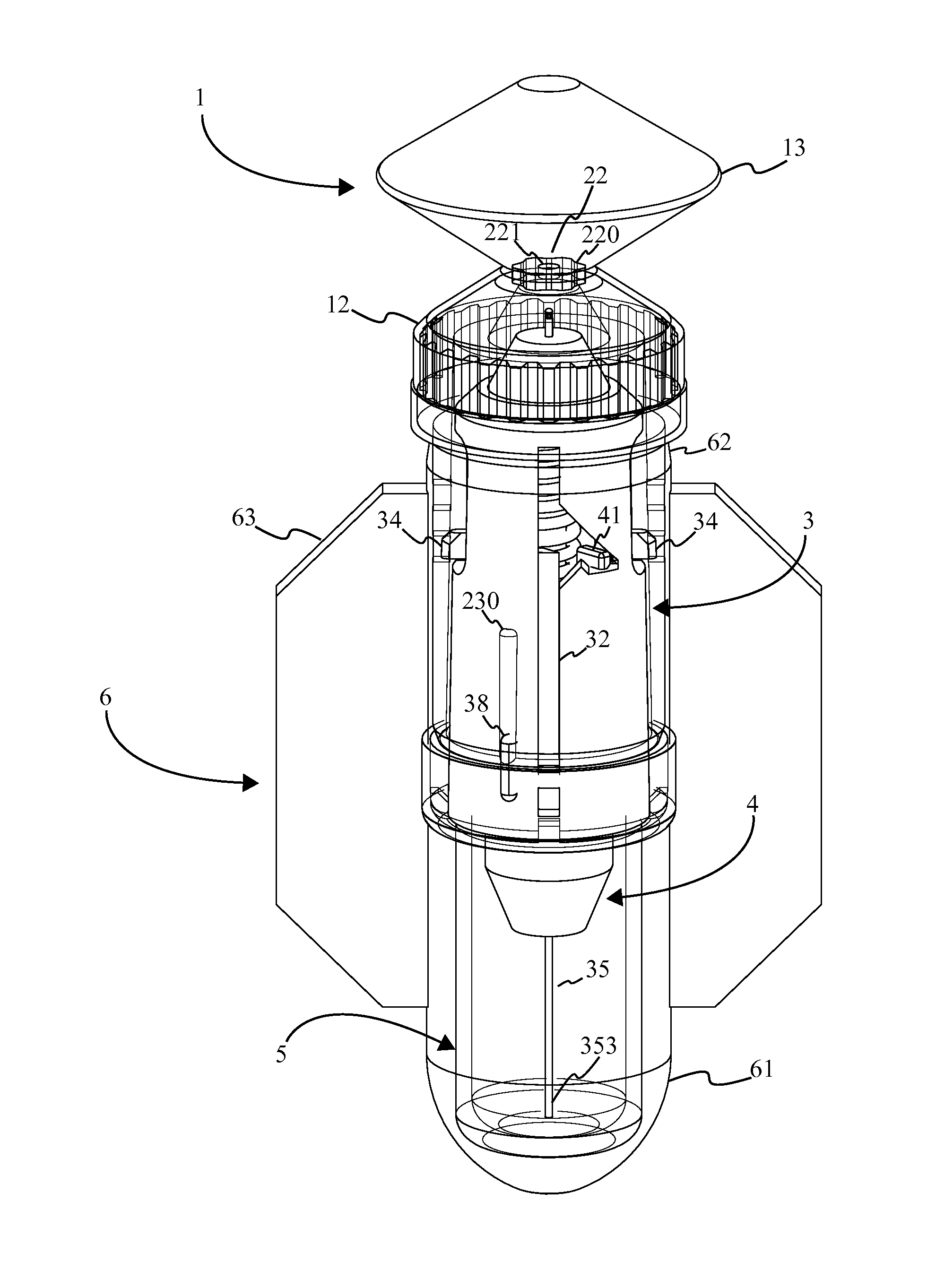

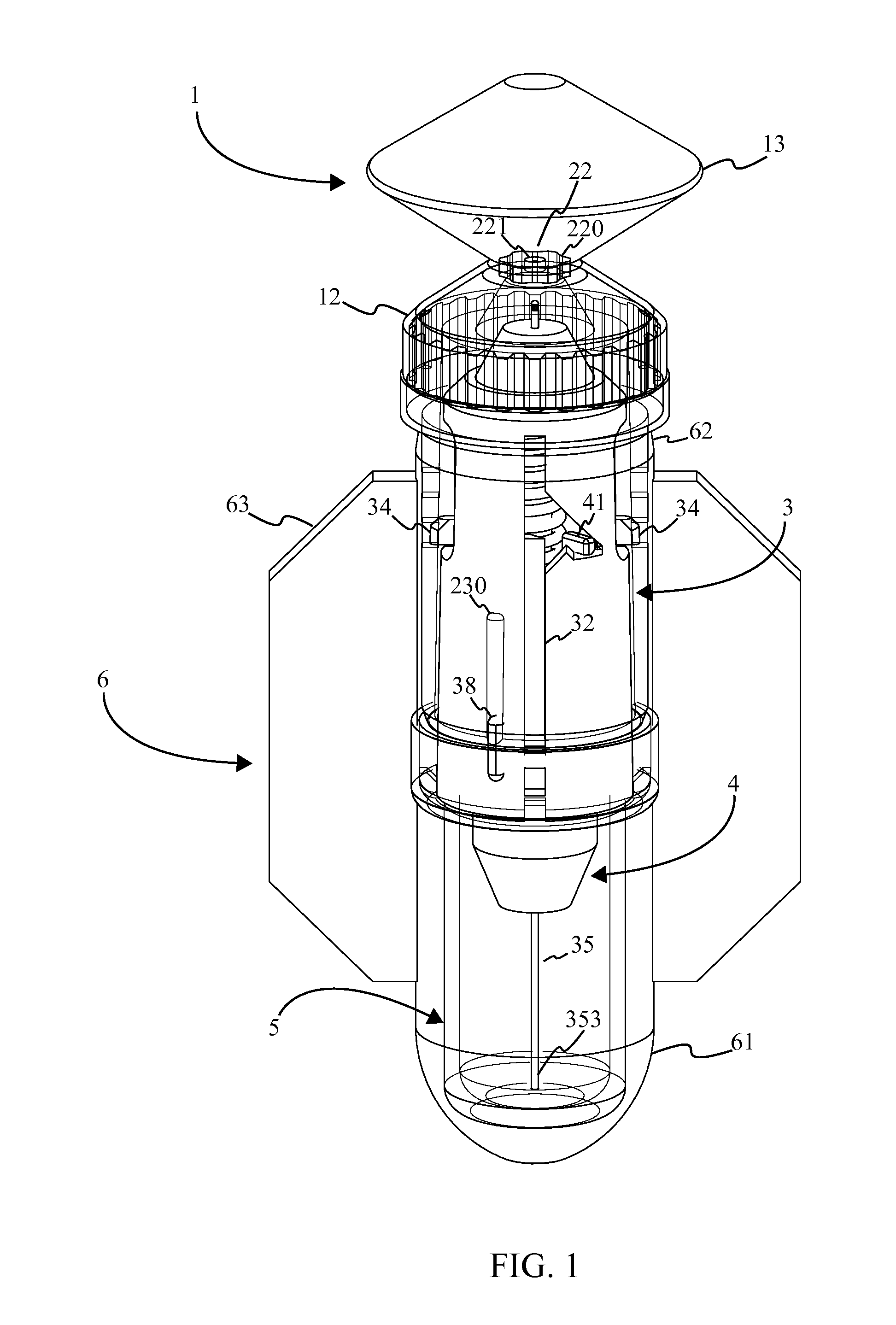

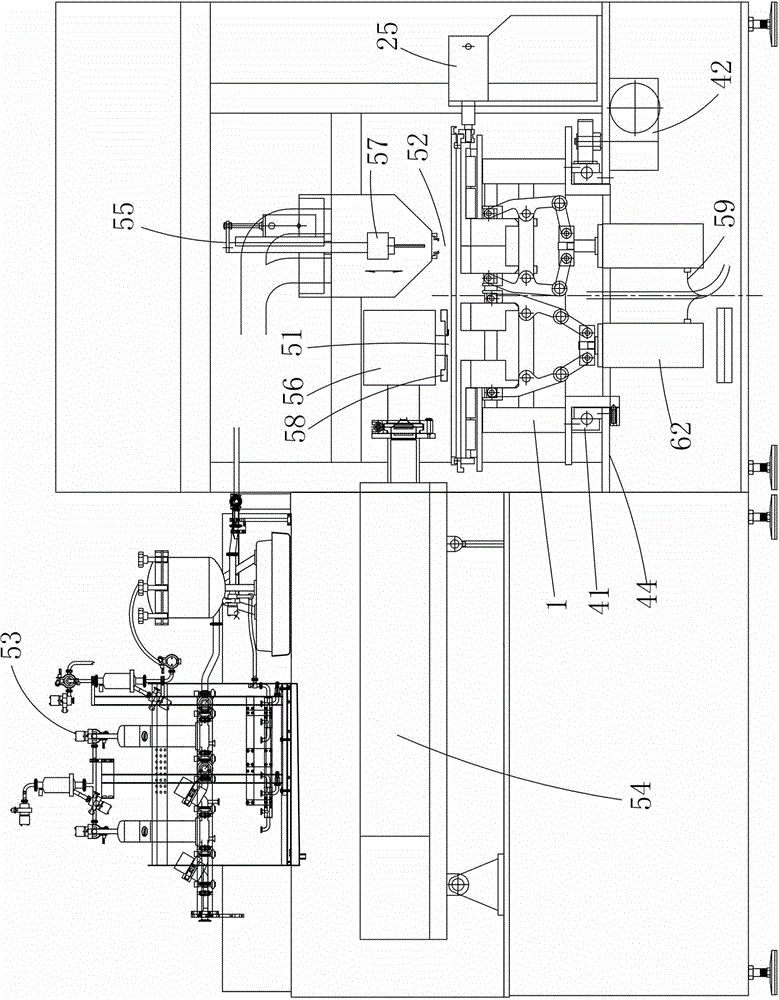

Blowing-filling-sealing integrated machine

ActiveCN104030224AReduce manufacturing costIncrease productivityBottle-handling machinesLiquid materialBlow fill sealSmall footprint

A blow-fill-seal integrated machine, comprising a rack (44), a parison receiving station (51), a fill-seal station (52), and a revolving base (1) capable of turning 180 degrees back and forth around a rotation center (11); the revolving base (1) is provided with two mold groups thereon, the two mold groups being arranged at 180-degree angles along the peripheral turning direction of the revolving base (1); during the turning of the revolving base (1), the two mold groups move alternatively to the parison receiving station (51) and the fill-seal station (52). The integrated machine has a small footprint, low manufacturing costs, high production efficiency, and high reliability.

Owner:TRUKING TECH LTD

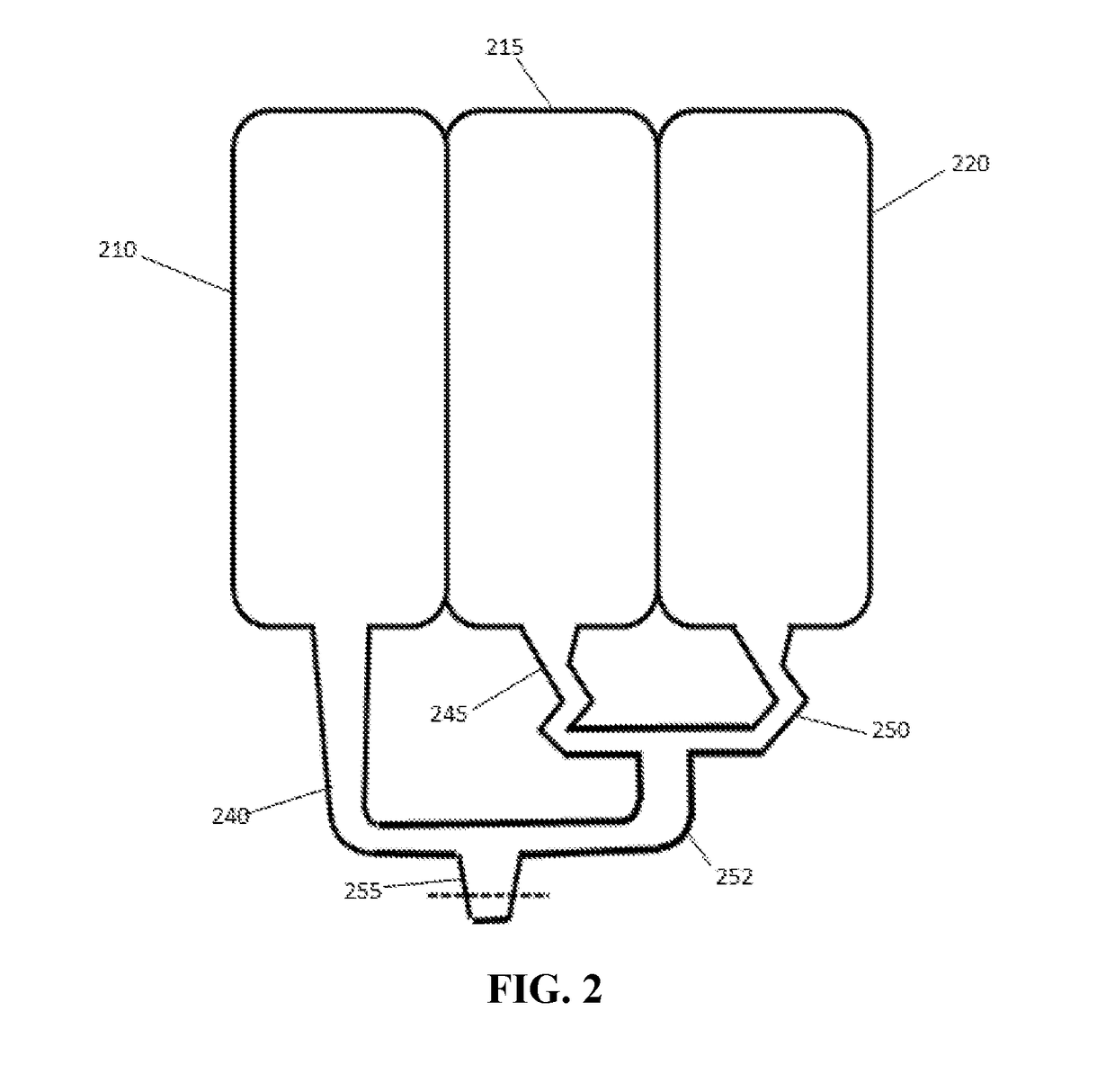

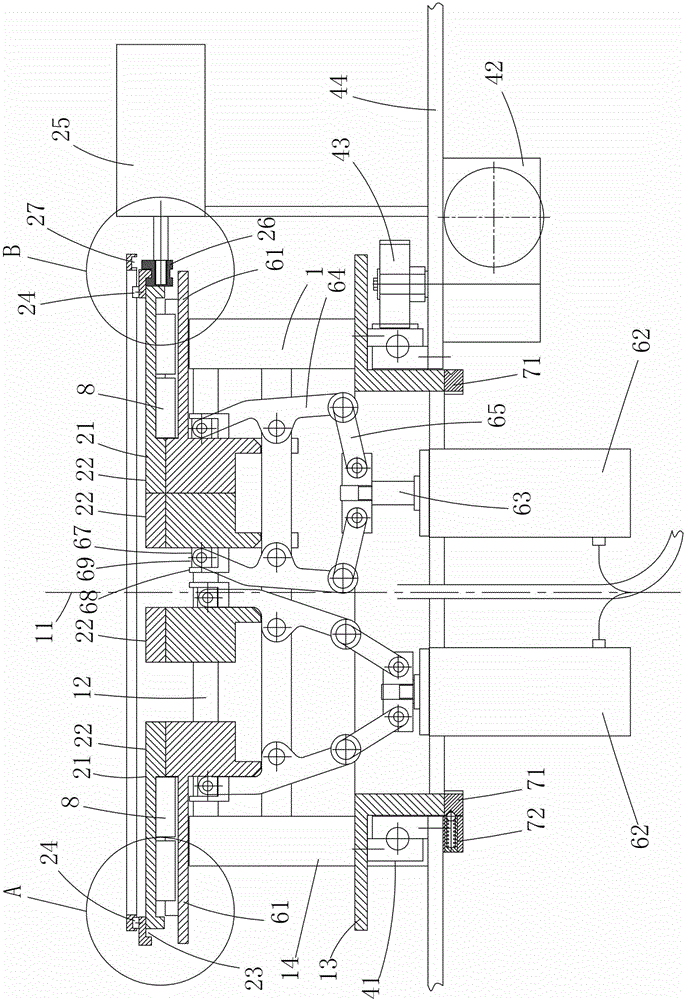

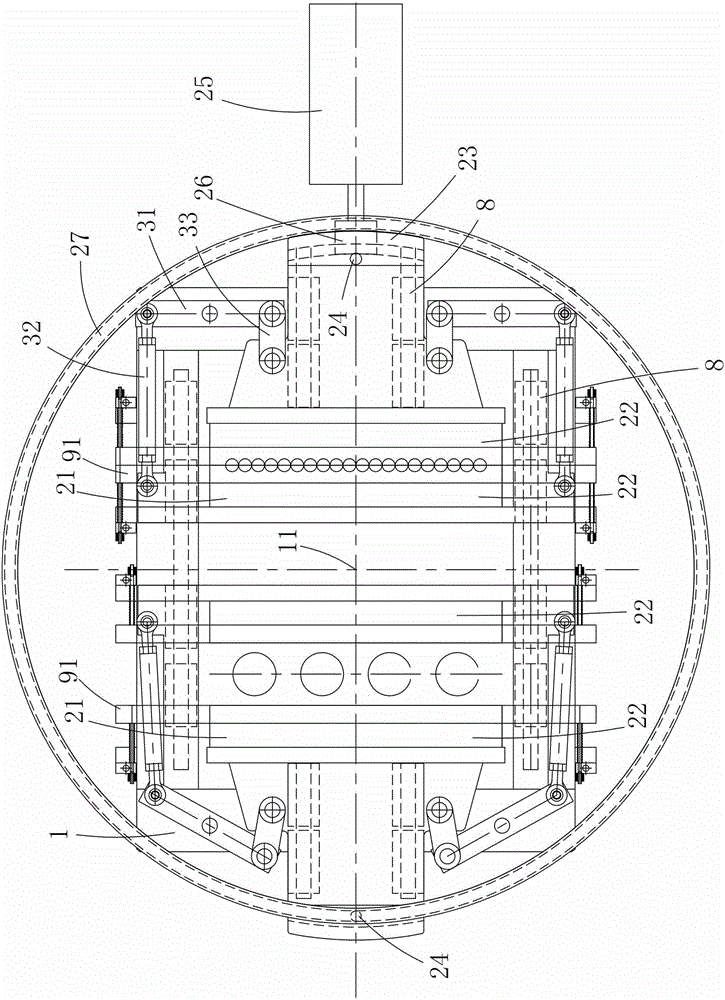

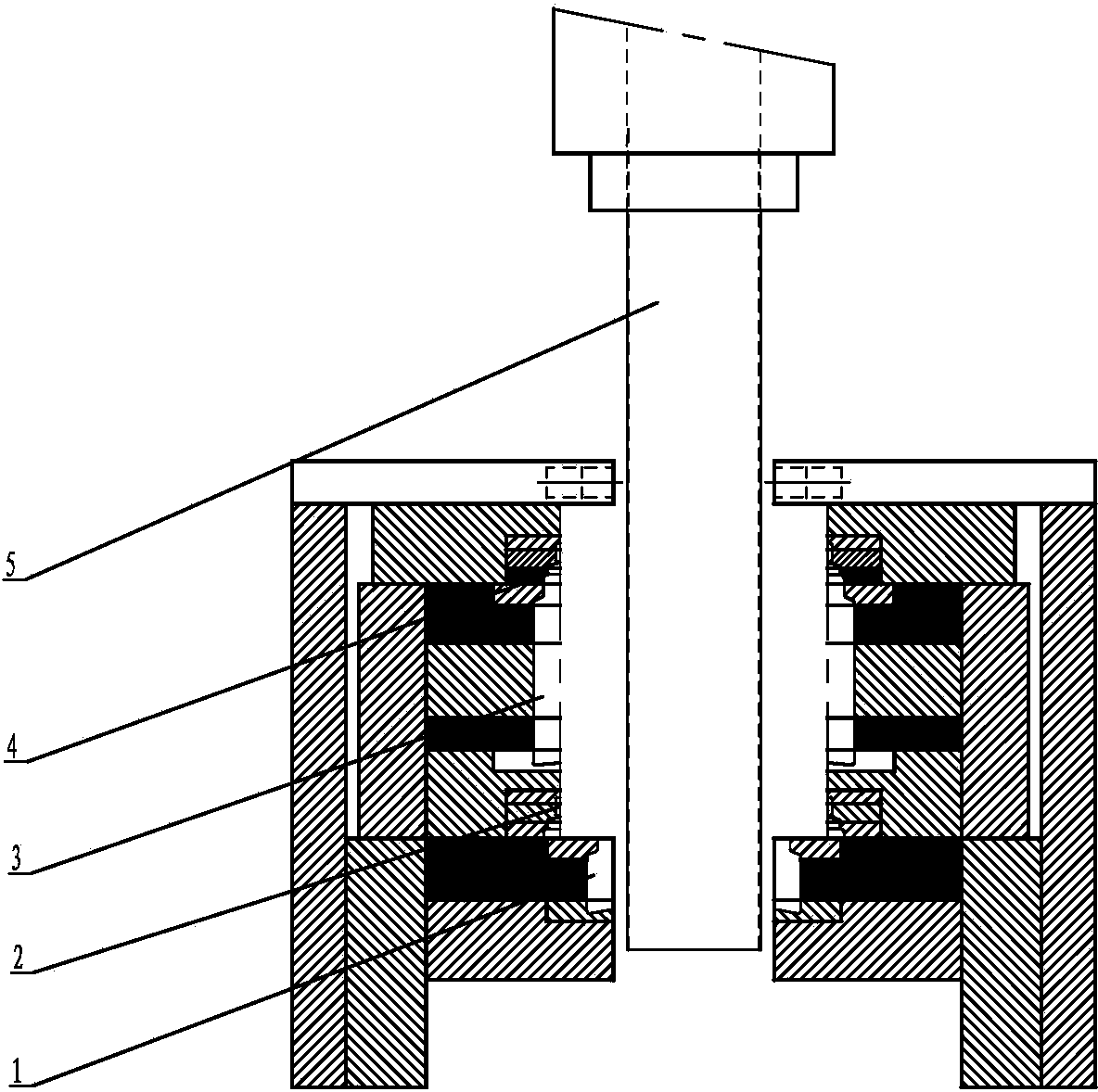

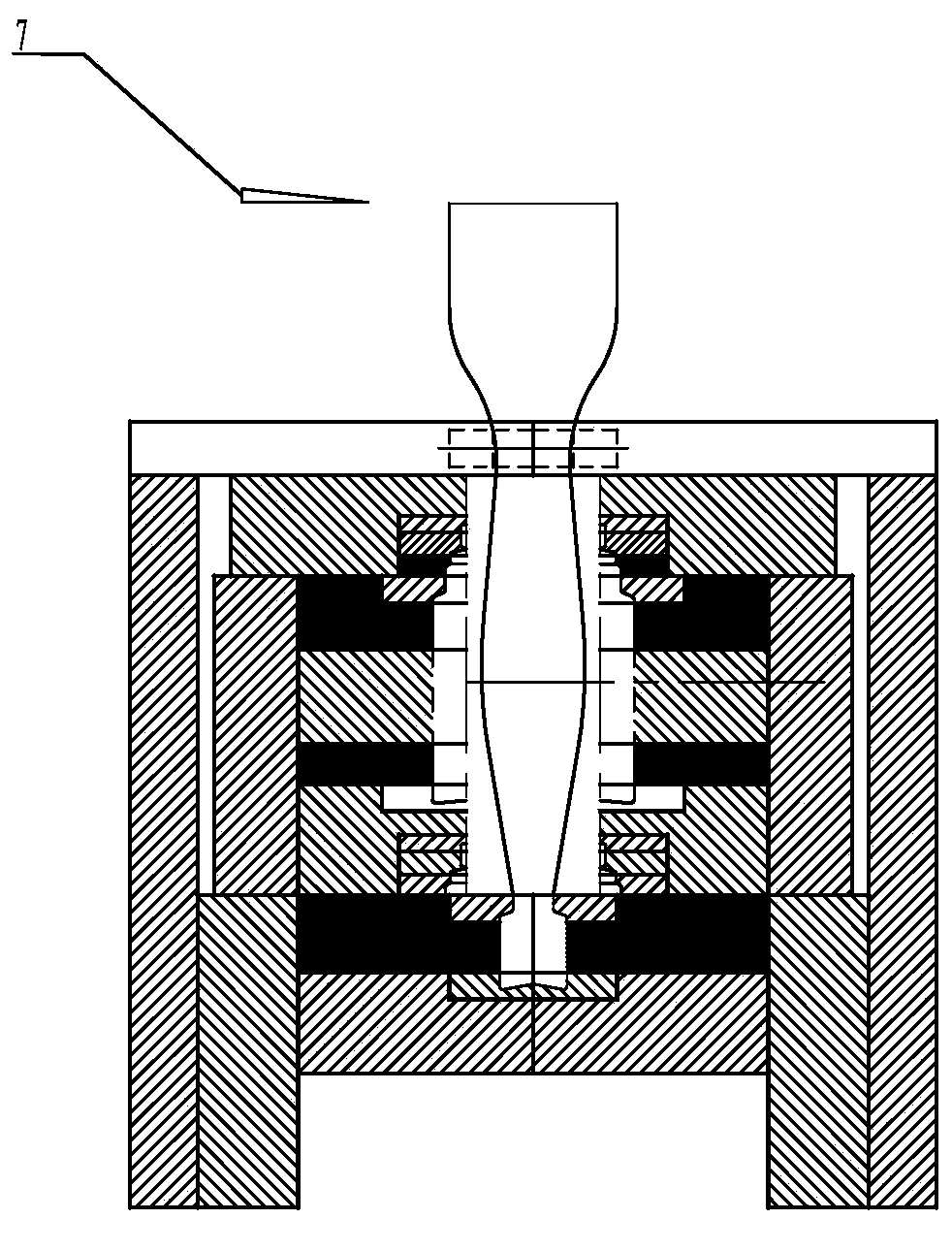

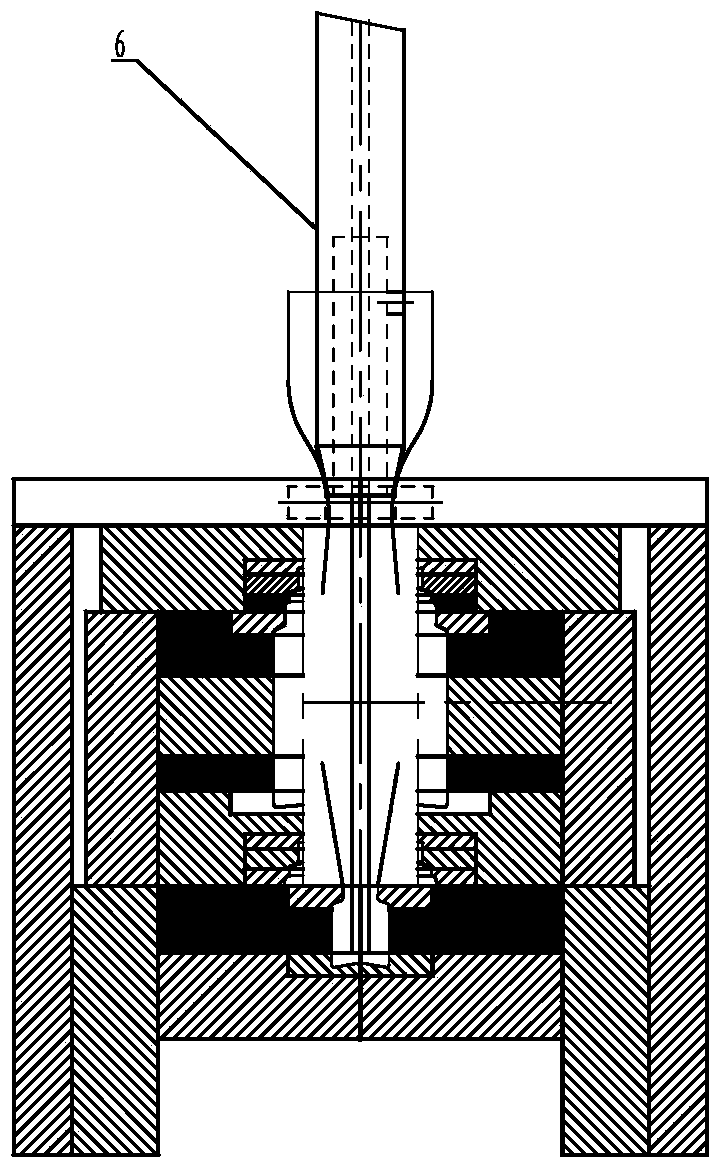

Blowing-filling-sealing multi-row combined mold for plastic ampoule and production method for ampoule by using mold

ActiveCN104085847AIncrease profitIncrease productivityBottle-handling machinesBottleMaterials science

The invention relates to a blowing-filling-sealing multi-row combined mold for a plastic ampoule and a production method for the ampoule by using the mold, and belongs to the field of foodstuff, medicine packaging machineries. The mold comprises a left-half mold and a right-half mold which are symmetrically arranged, the left-half mold and the right-half mold are both symmetrically provided with a lower-row bottle-body mold, a lower-row bottleneck mold, an upper-row bottle-body mold and an upper-row bottleneck mold from bottom to top; the lower-row bottleneck mold and the corresponding upper-row bottle-body mold are fixed together; the lower-row bottleneck mold and the corresponding lower-row bottle-body mold are matched with each other through a slide rail and a slide groove, and the upper-row bottleneck mold and the upper-row bottle-body mold are also matched with each other through a slide rail and a slide groove. Raw materials are saved and production efficiency is high.

Owner:SHINVA MEDICAL INSTR CO LTD

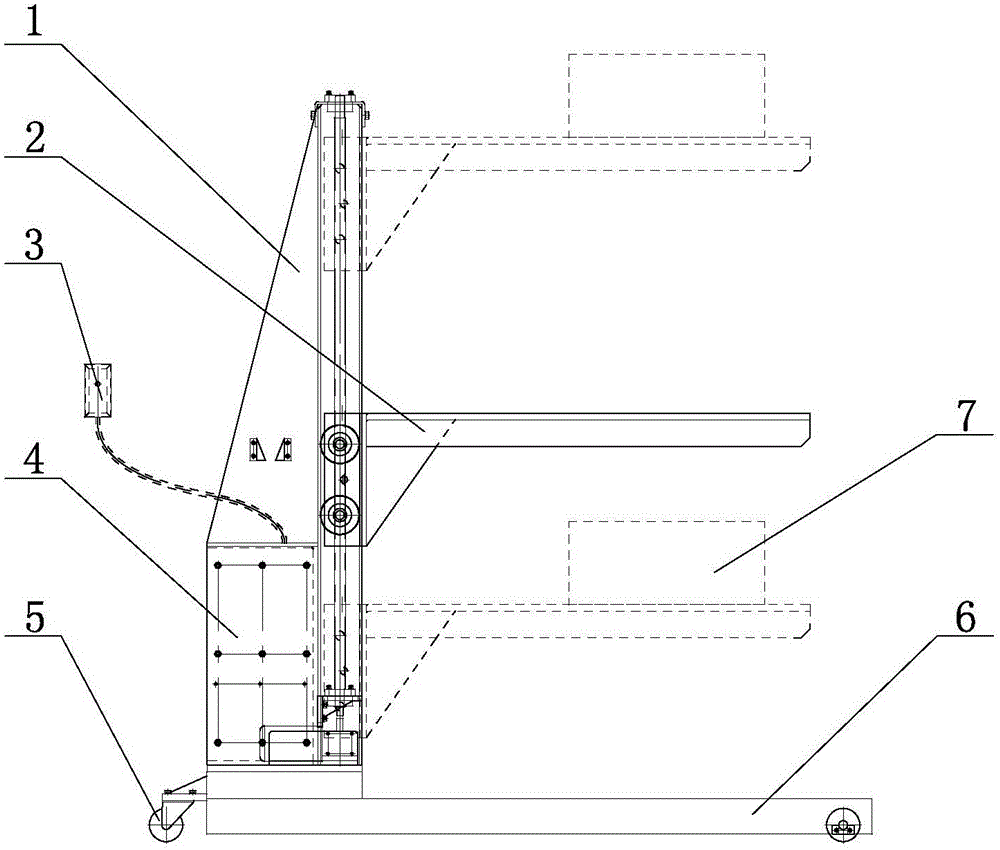

A mold replacing vehicle used for plastic ampoule blowing-filling-sealing three-in-one equipment

The invention relates to a mold replacing vehicle used for plastic ampoule blowing-filling-sealing three-in-one equipment, and belongs to the technical field of plastic forming mold replacing devices. The mold replacing vehicle comprises a mobile pedestal. Mobile wheels are disposed under the mobile pedestal. The mobile pedestal is provided with a lifting support. The lifting support is provided with guide rails and a ball screw. The guide rails are at two sides of the ball screw. One side of the lifting support is provided with a horizontally disposed lifting platform. The lifting platform is provided with a mold mounting hole. One end of the lifting platform is provided with screw nuts and lifting and descending guide wheels. The screw nuts are matched with the ball screw. The lifting and descending guide wheels are matched with the guide rails. The lower end of the ball screw is connected to a drive motor. The drive motor is mounted to the mobile pedestal and is connected to a power supply control module. The mold replacing vehicle is convenient to operate and meets mold replacing needs for the plastic ampoule blowing-filling-sealing three-in-one equipment.

Owner:SHINVA MEDICAL INSTR CO LTD

Skin antiseptic applicator and methods of making and using the same

InactiveUS20140371695A1Minimize ethylene oxide penetrationMedical applicatorsDomestic articlesBiomedical engineeringSkin disinfection

The invention relates to applicators for applying a solution or other composition (e.g., an antiseptic composition) to skin of a patient. The applicator may include a container body having a proximal end, a distal end, and a frangible member disposed at the distal end of the body. The applicator includes a first position where the container body and frangible member are a unitary piece (e.g., blow molded as a single piece), and a second position when the frangible member is rotated relative to the body to irreversibly break a weak point therebetween, releasing the composition in the hollow body through an opening. A porous applicator head may be positioned adjacent the distal end of the body and frangible member, so that the composition flows out the body, through the opening, and onto the head. The applicator may be formed in a blow-fill-seal process for improved sterility and ease of manufacture.

Owner:MEDLINE INDUSTRIES

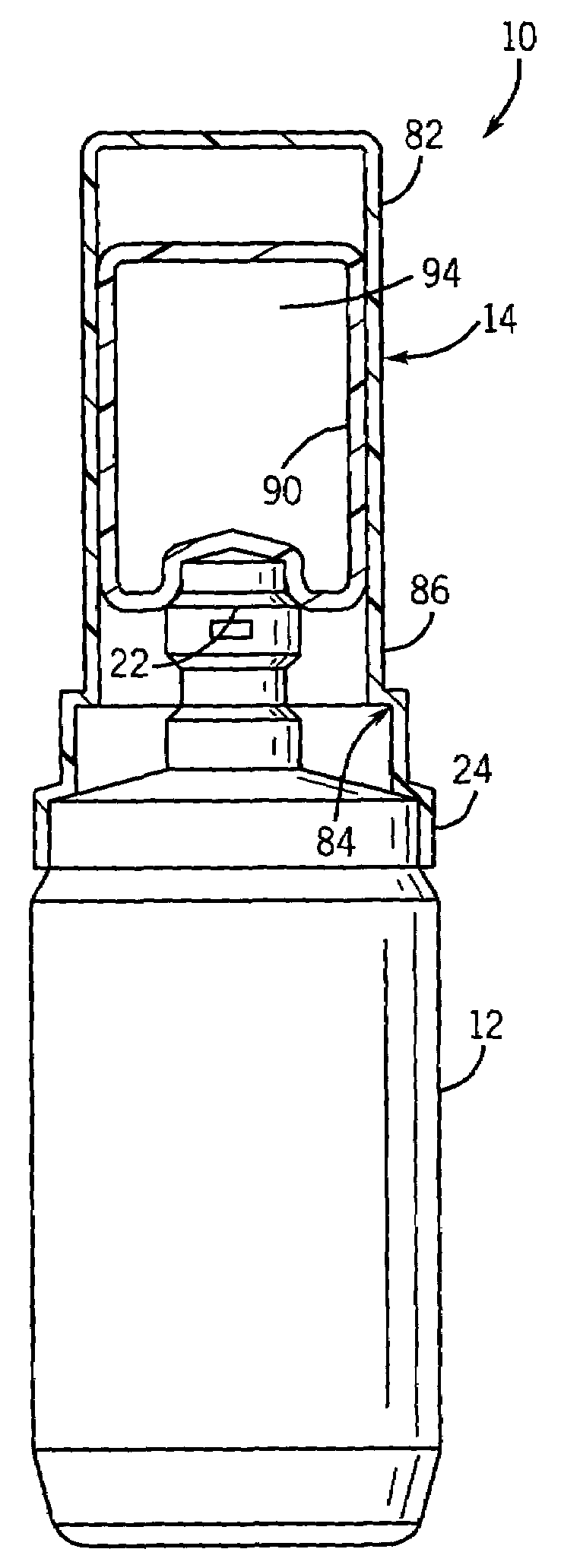

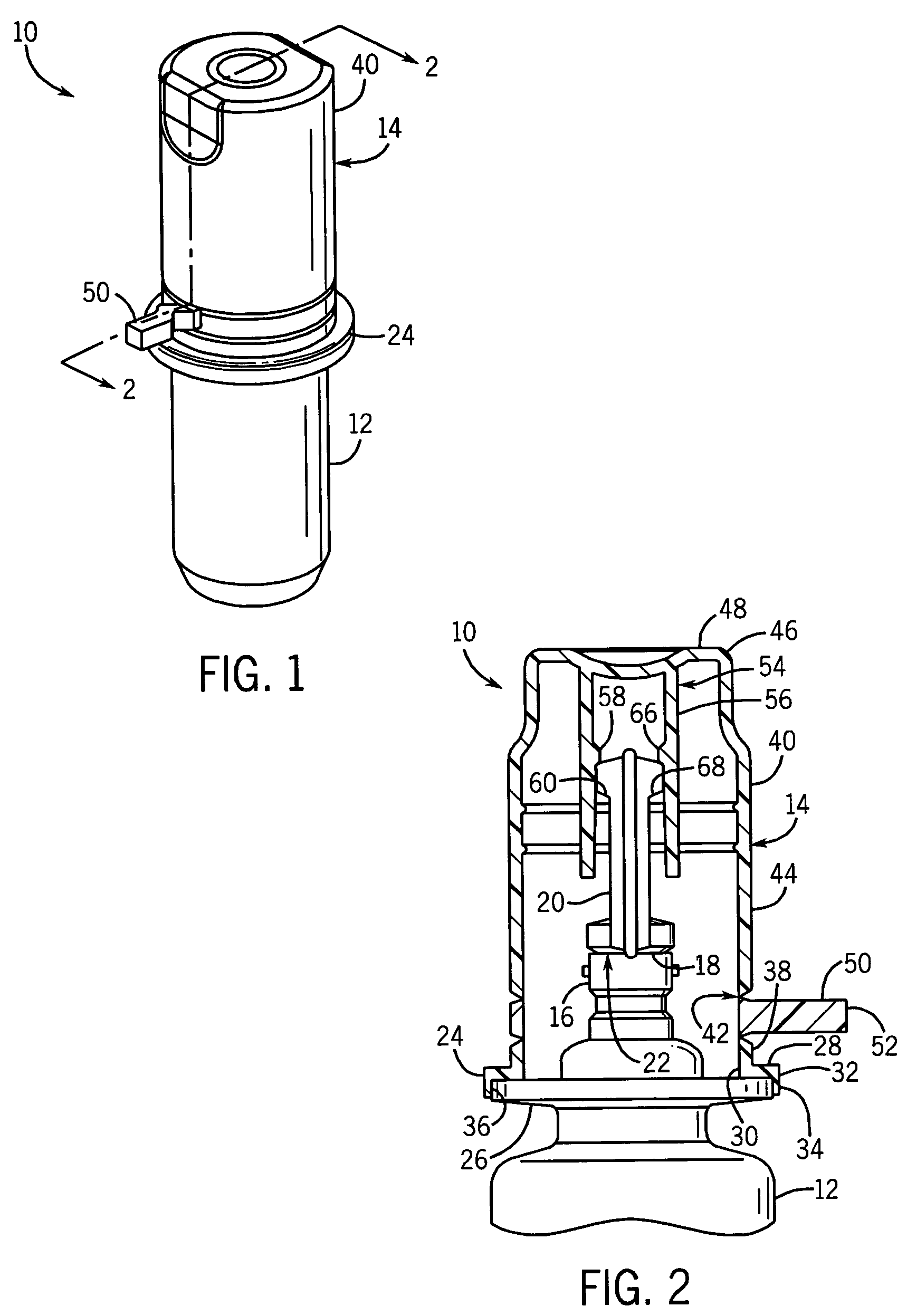

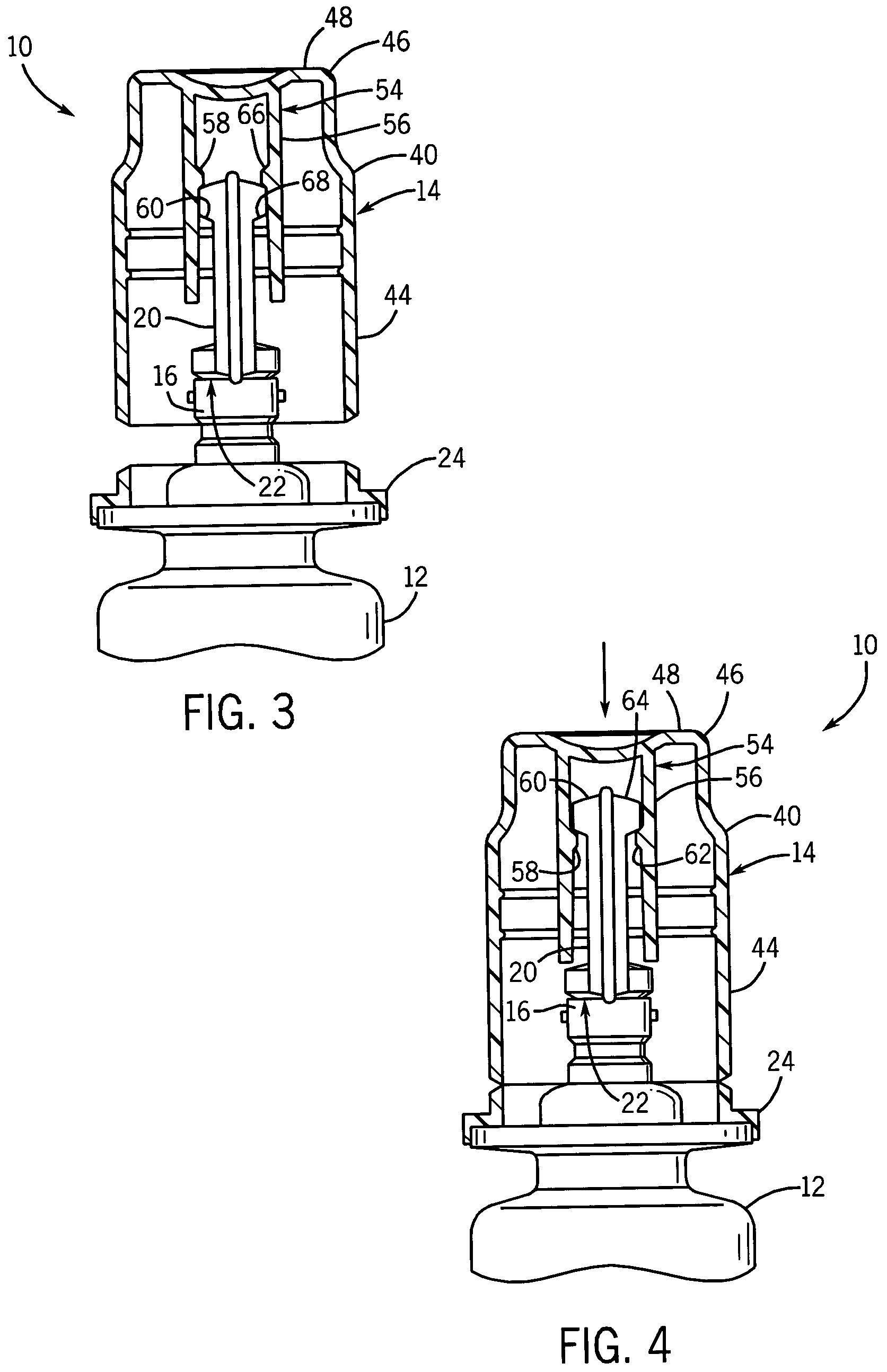

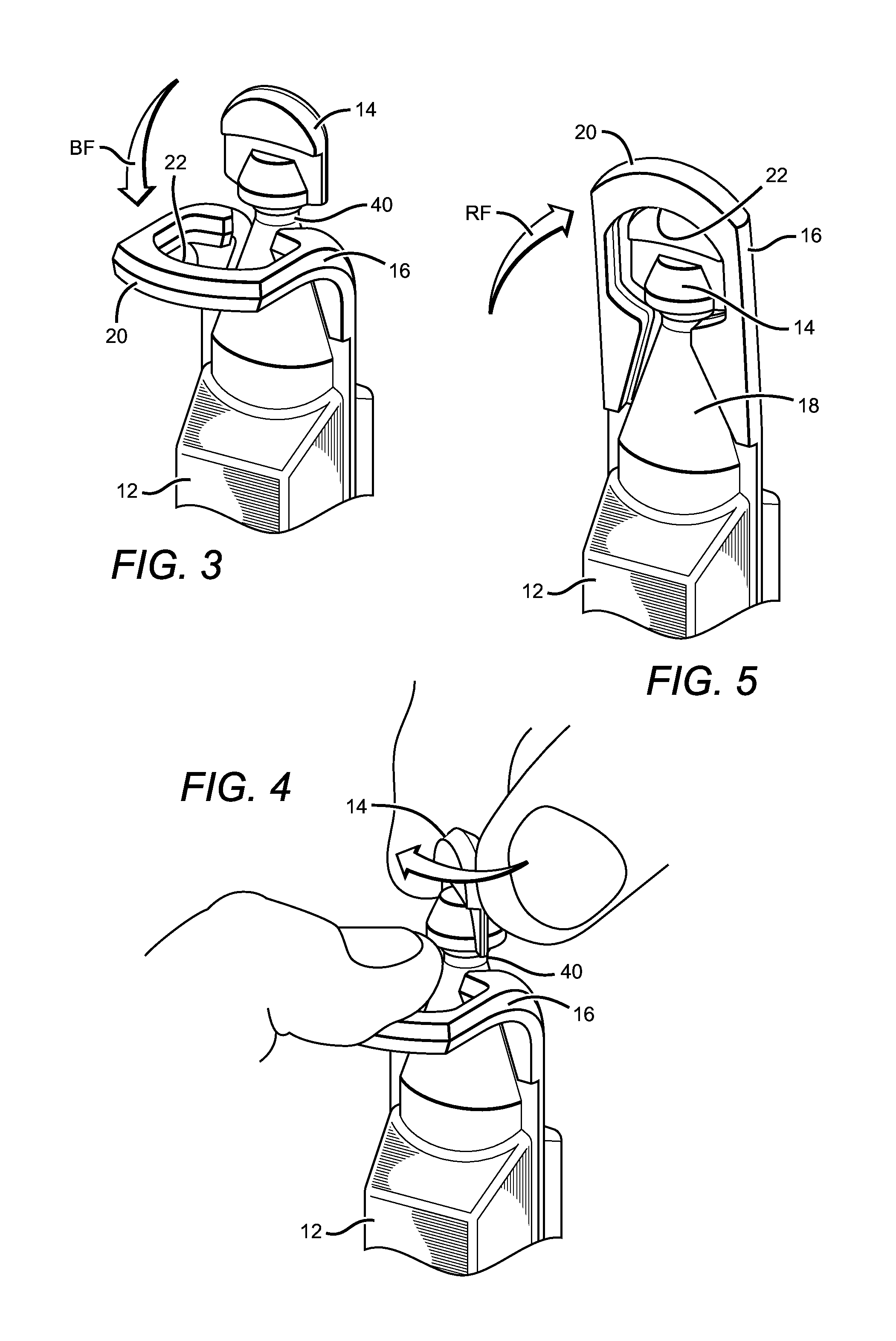

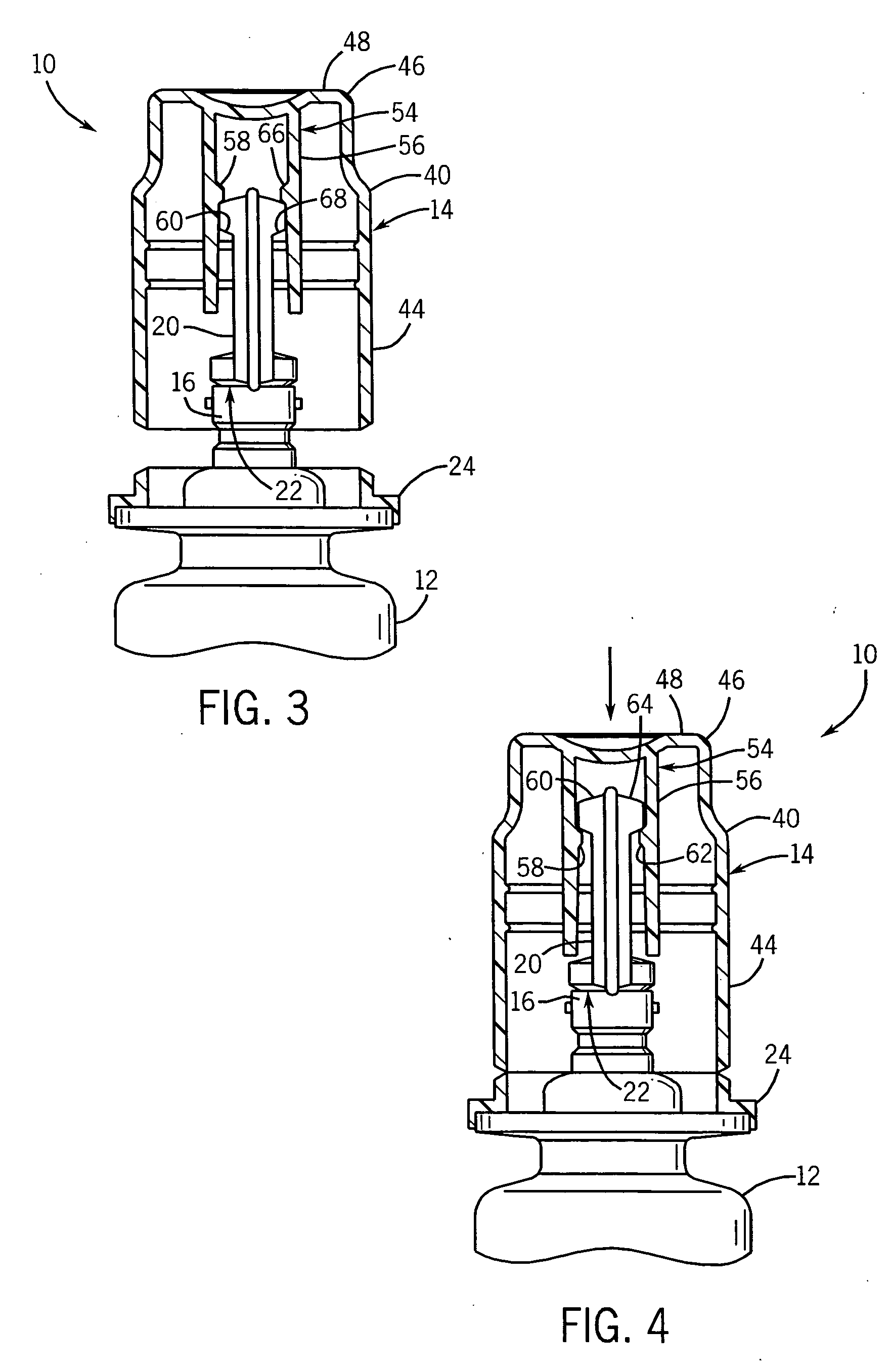

Blow fill sealed container with twist off top operated by overcap and method of making the same

A container assembly includes a container body having a port or aperture adapted for use with a luer end of a needleless syringe. The aperture is sealed to a closure top by a first frangible seal. An overcap has a cap base sealed to the container body and an upper cap connected to the cap base by a second frangible seal, providing a sterile barrier surrounding the first frangible seal. The second frangible seal is broken by depressing the upper cap toward the container body. Alternatively, the second frangible seal is a removable tear strip broken by tugging on the tear strip. The upper cap includes a detent portion frictionally securing the upper cap to the closure top when the upper cap is depressed toward the container body. The upper cap and secured closure top are removed from container body by twisting the upper cap to break the first frangible seal and open the port.

Owner:HOSPIRA INC

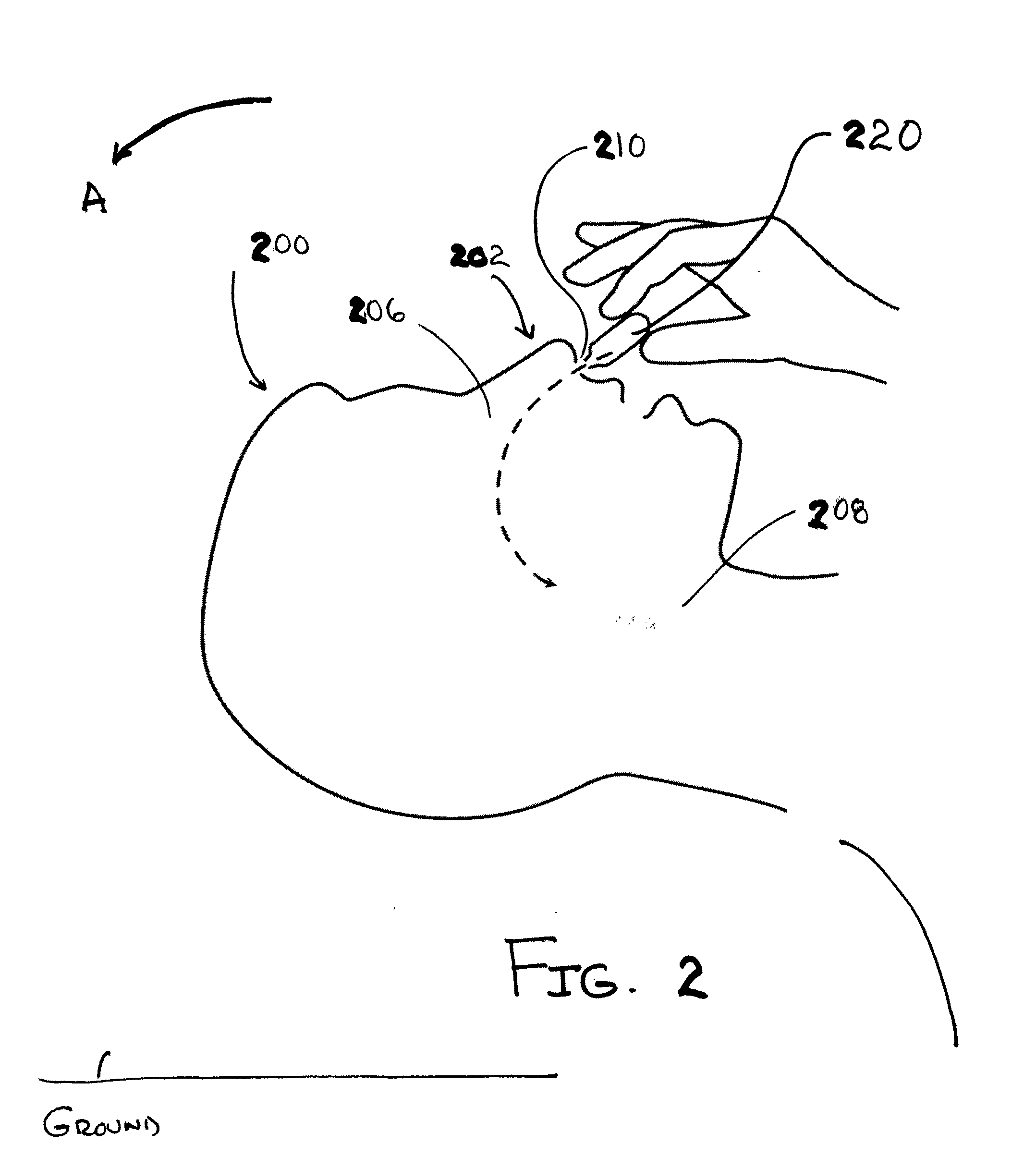

Nasal spray apparatus

A pharmaceutical product in the form of an anti-snoring substance includes a container (220) containing the anti-snoring substance, the anti-snoring substance being in the form of a solution pre-concentrate. The container (220) is made by a blow-fill-seal technology, wherein the container material is Polyethylene or Polypropylene. The container (220) includes a body portion (104) containing the anti-snoring substance and a fluid outlet portion (106) configured to deliver the anti-snoring substance.

Owner:TANNERMEDICO

Blow fill seal luer syringe

A single use pre-filled delivery device comprising a deformable container, a one-way valve, and male luer connector is described. Also described are methods of flushing vascular access devices using a single use pre-filled delivery device as described herein is also disclosed.

Owner:BECTON DICKINSON & CO

Sterilizable article made of propylene copolymer

ActiveUS10155829B2Good optical performanceHigh transparencyPharmaceutical containersMedical packagingOptical propertyMedicine

Owner:BASSELL POLIOLEFINE ITAL SRL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com