Blow-molded paintball and method of manufacture thereof

a technology of blow molding and paintball, which is applied in the field of blow molding paintball and paintball projectile, can solve the problems that paintballs are formed without any drawbacks, and achieve the effects of flying farther and much more accurately, long shelf life, and avoiding affecting the performance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

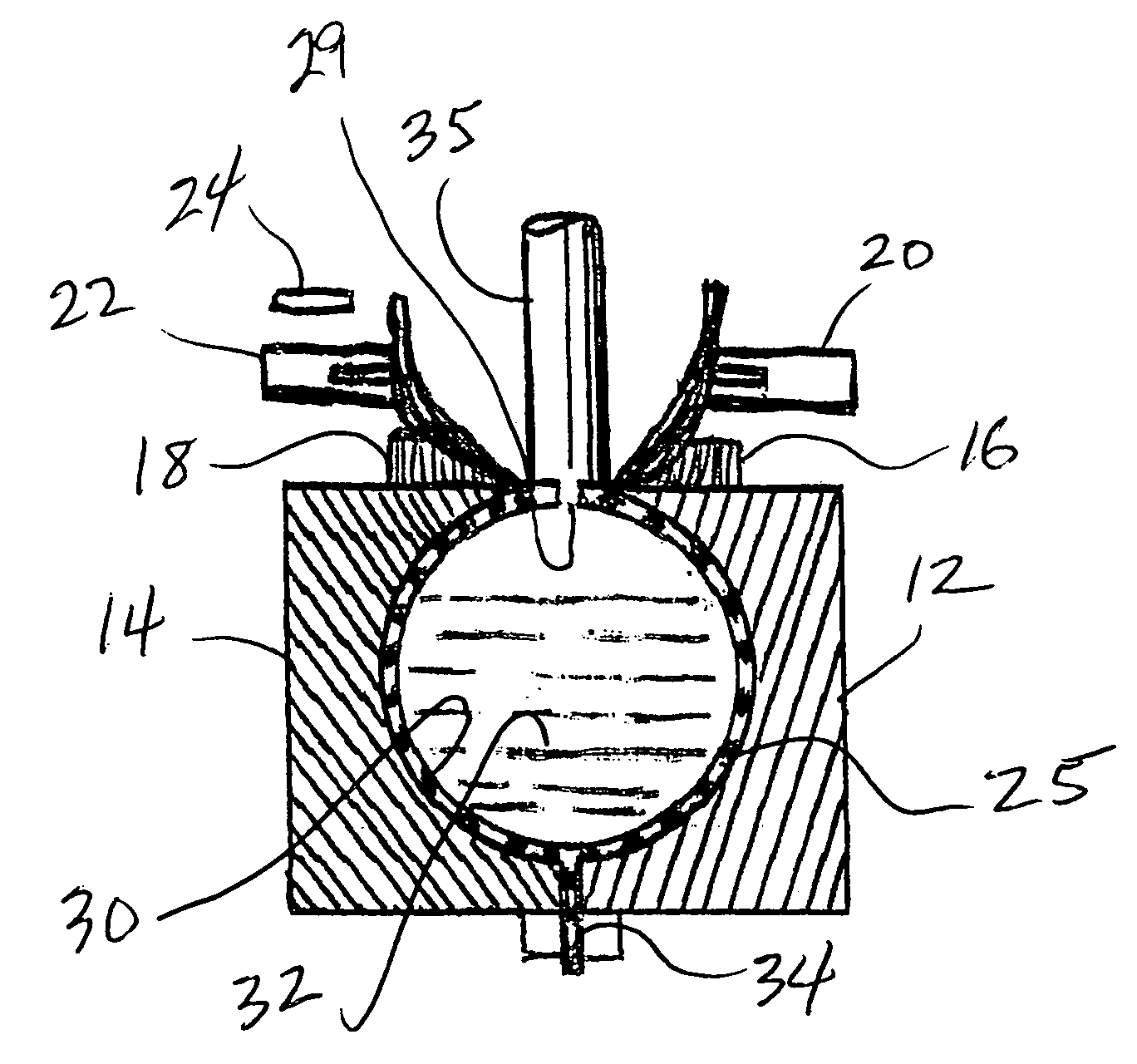

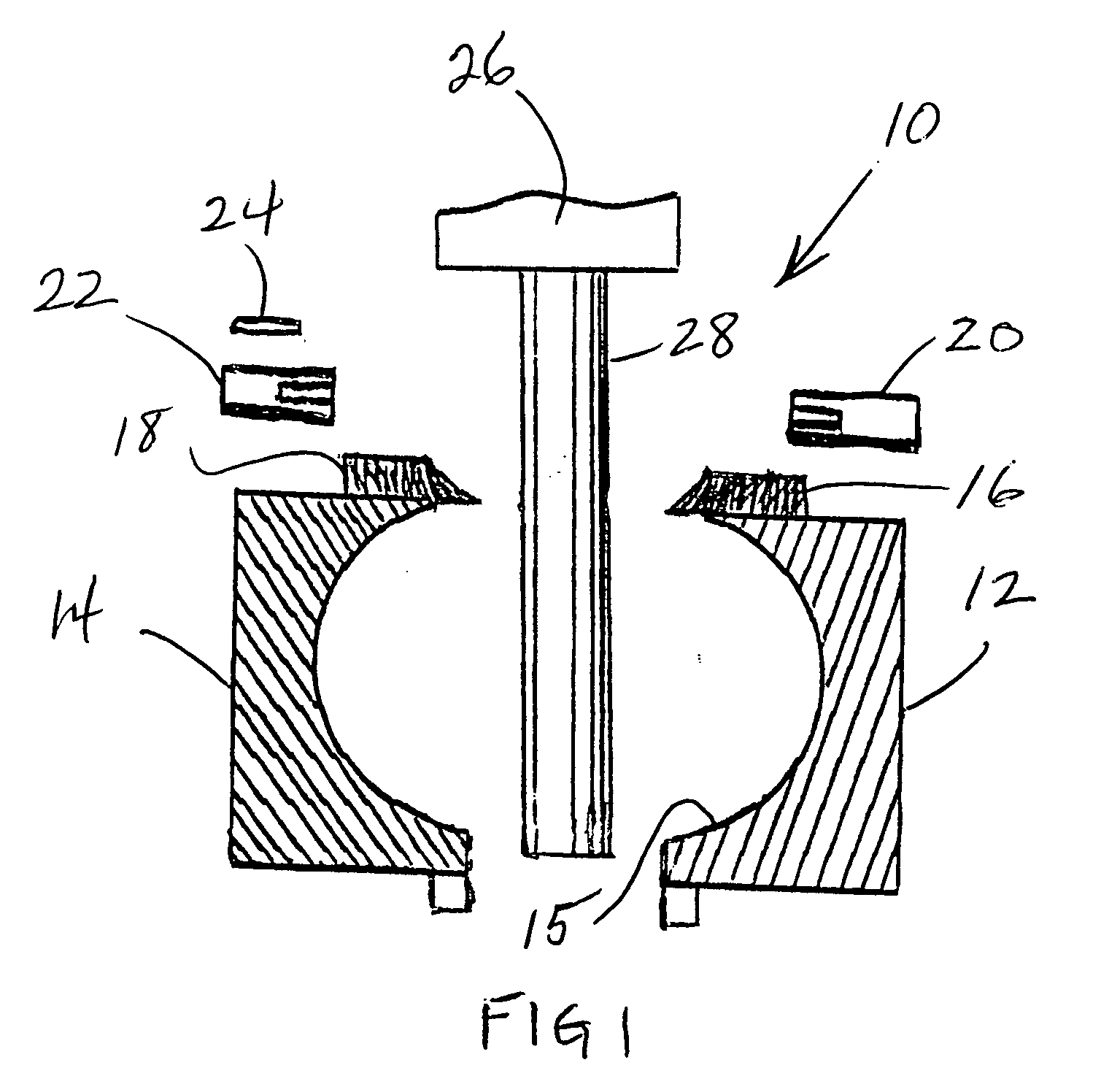

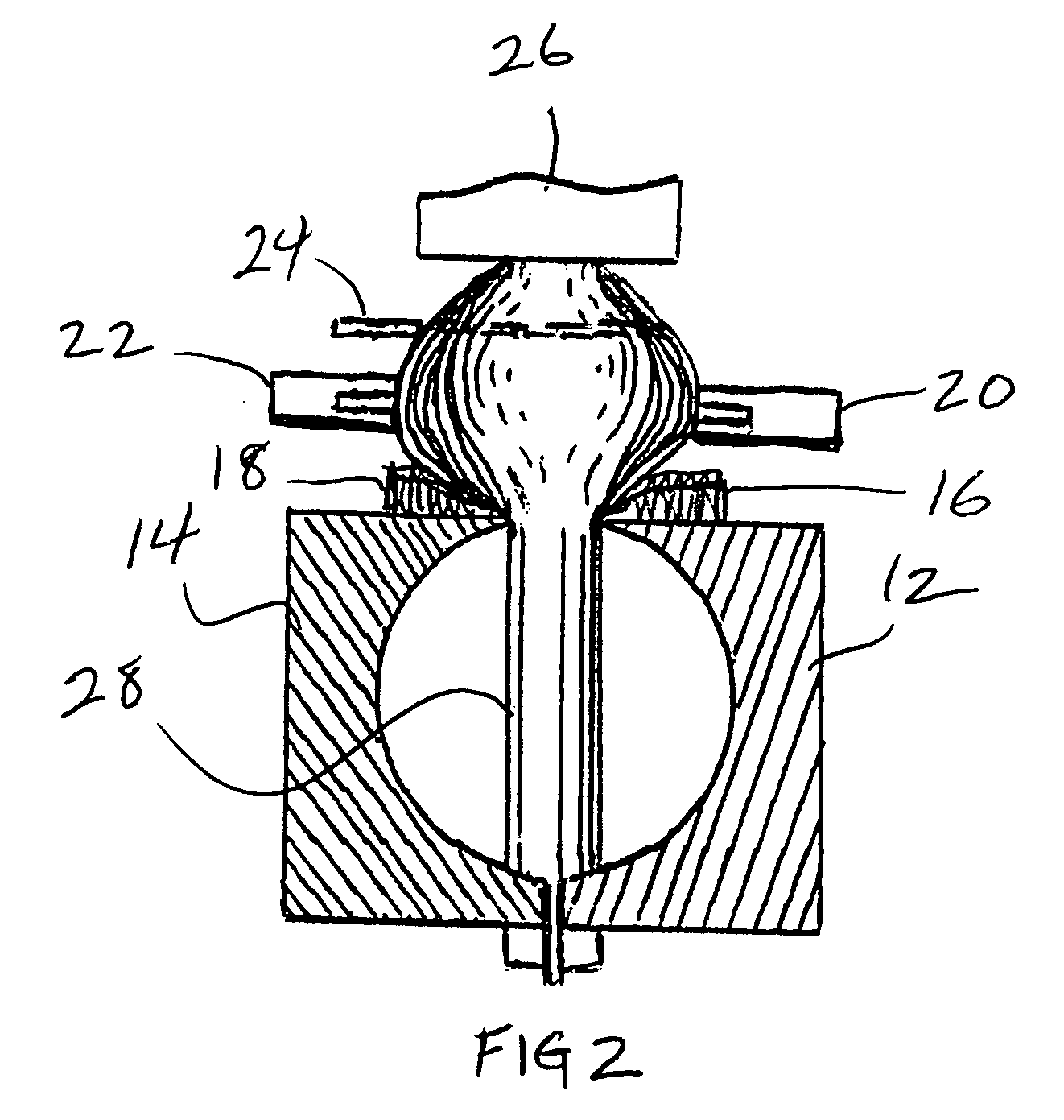

[0013] Blow-fill-seal technology, originally developed in Europe in the 1930's and introduced in the United States in the 1960's, has emerged as a preferred method for aseptic packaging of pharmaceutical and healthcare products due to unrivaled flexibility in container design, overall product quality, product output and low operational costs. The multi-step process of blow molding, aseptic filling and hermetic sealing of liquid products may be achieved in one sequential operation on a compact, automated machine frame with fill volumes ranging from 0.1 milliliter (ml) to 1,000 ml.

[0014] A variety of polymers may be used in the process, low and high-density polyethylene and polypropylene being the most popular. The innate ability to form the container / closure during the actual aseptic packaging process allows for custom design of the product to meet the specific needs of the application.

[0015] Recent advancements in machine design allow for insertion of pre-molded, pre-sterilized co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com