Patents

Literature

127 results about "Sterilization procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

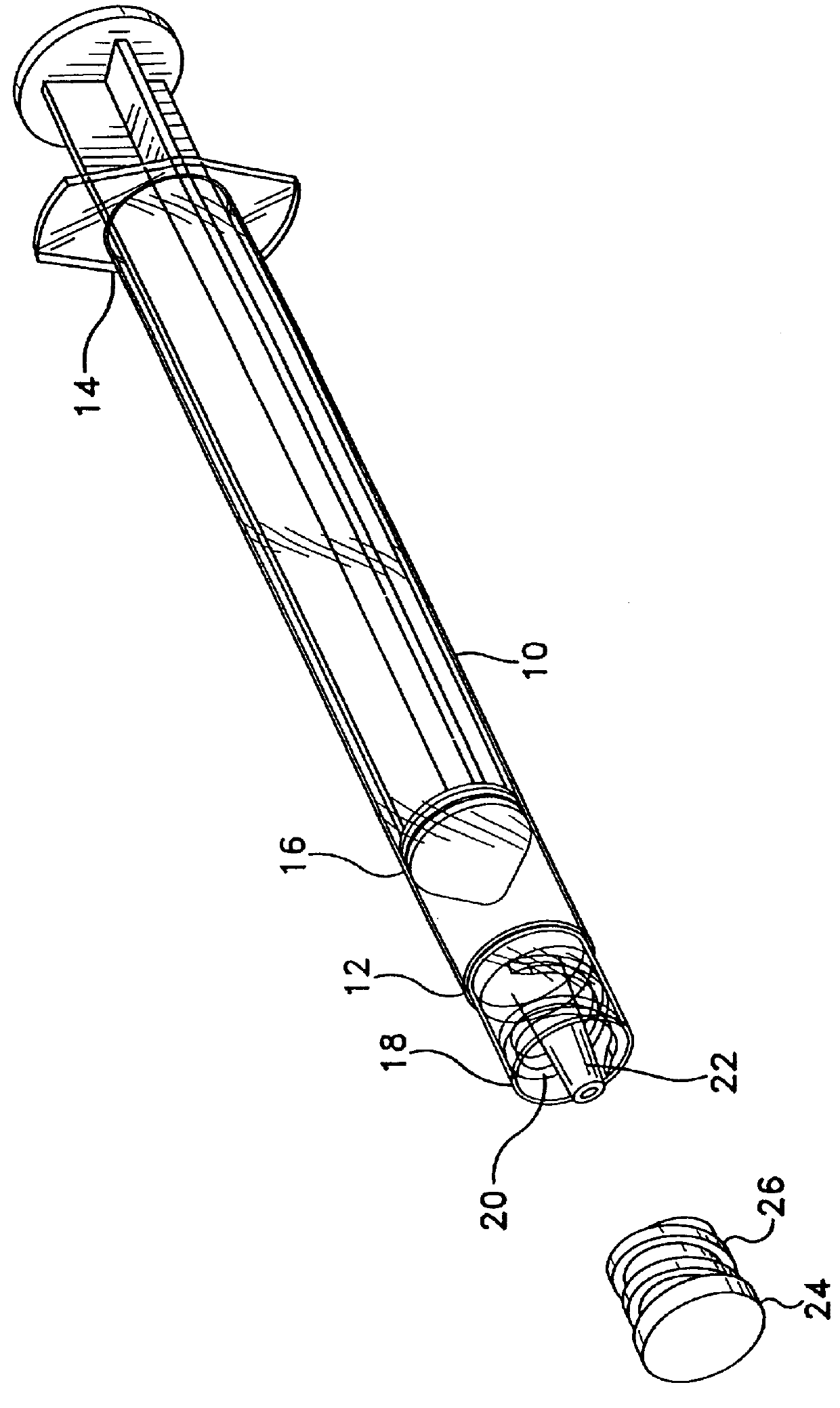

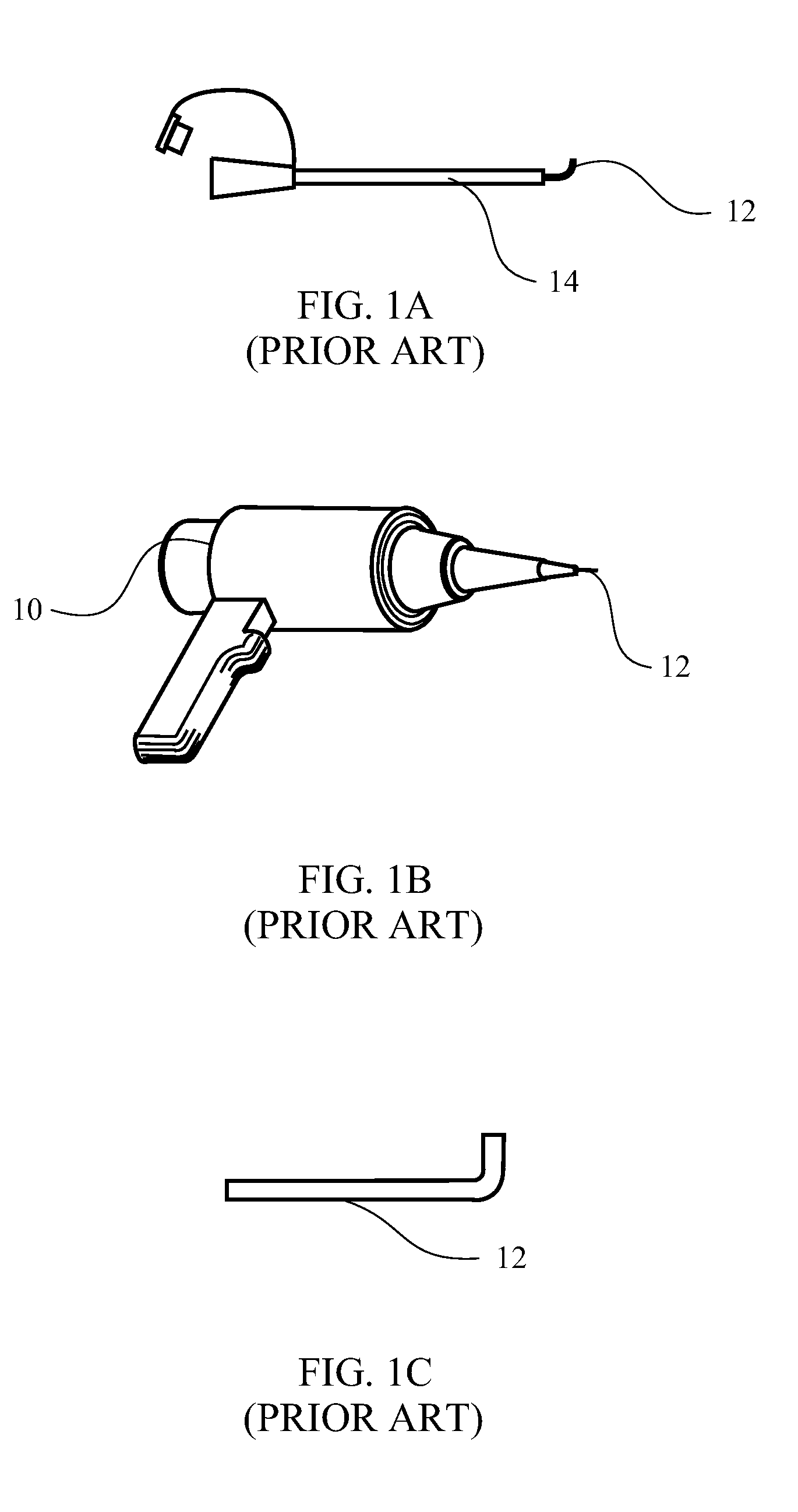

Protective sealing barrier for a syringe

InactiveUS6126640AEasy disposalEasy to operateInfusion syringesInfusion needlesBiomedical engineeringMembrane configuration

A protective sealing barrier for a syringe is disclosed. The protective sealing barrier can be configured to safeguard the sterility of the syringe and any contents held therein, as a barrier against leakage of any contents held within the syringe, or both. The syringe includes a luer tip and a collar having terminal ends which are preferably substantially co-planar with one another. The barrier consists of a membrane which is disposed in substantially entire surface contact with the terminal ends of both the luer tip and the collar. The membrane can be selected from a material permitting the syringe to be irradiated or heat sterilized. Likewise, the membrane can be chosen from a material permitting the syringe to be sterilized by various gas sterilization procedures. The membrane provides good tamper evidence of the syringe, can be stocked in a uniform size adaptable to various sizes of syringes, reduces the storage space required for the syringes, and can serve as a platform for printing information regarding contents held within the syringe.

Owner:BECTON DICKINSON & CO

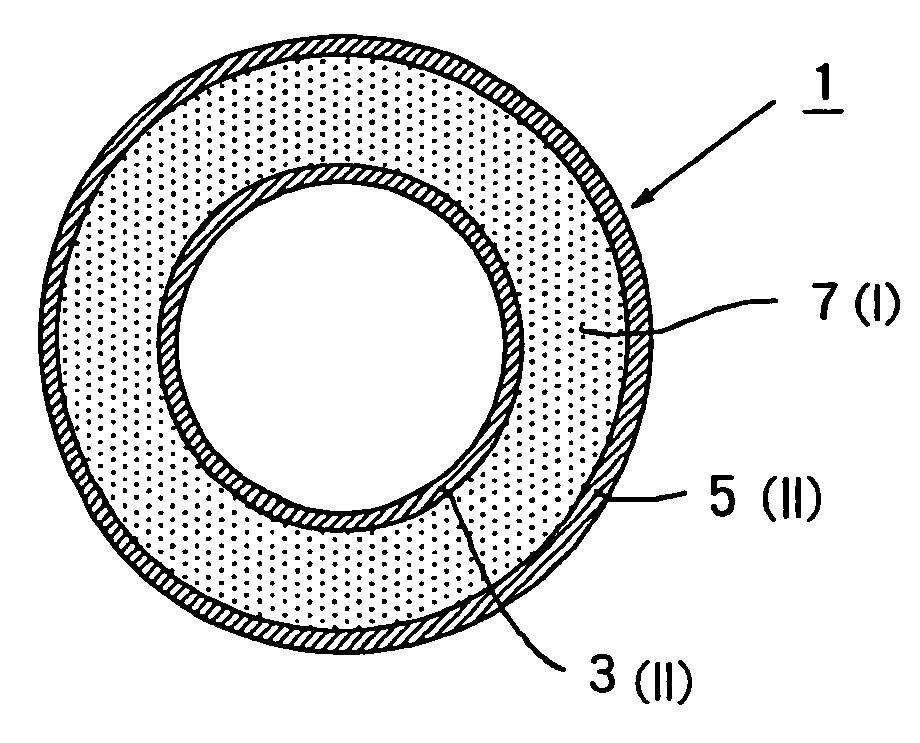

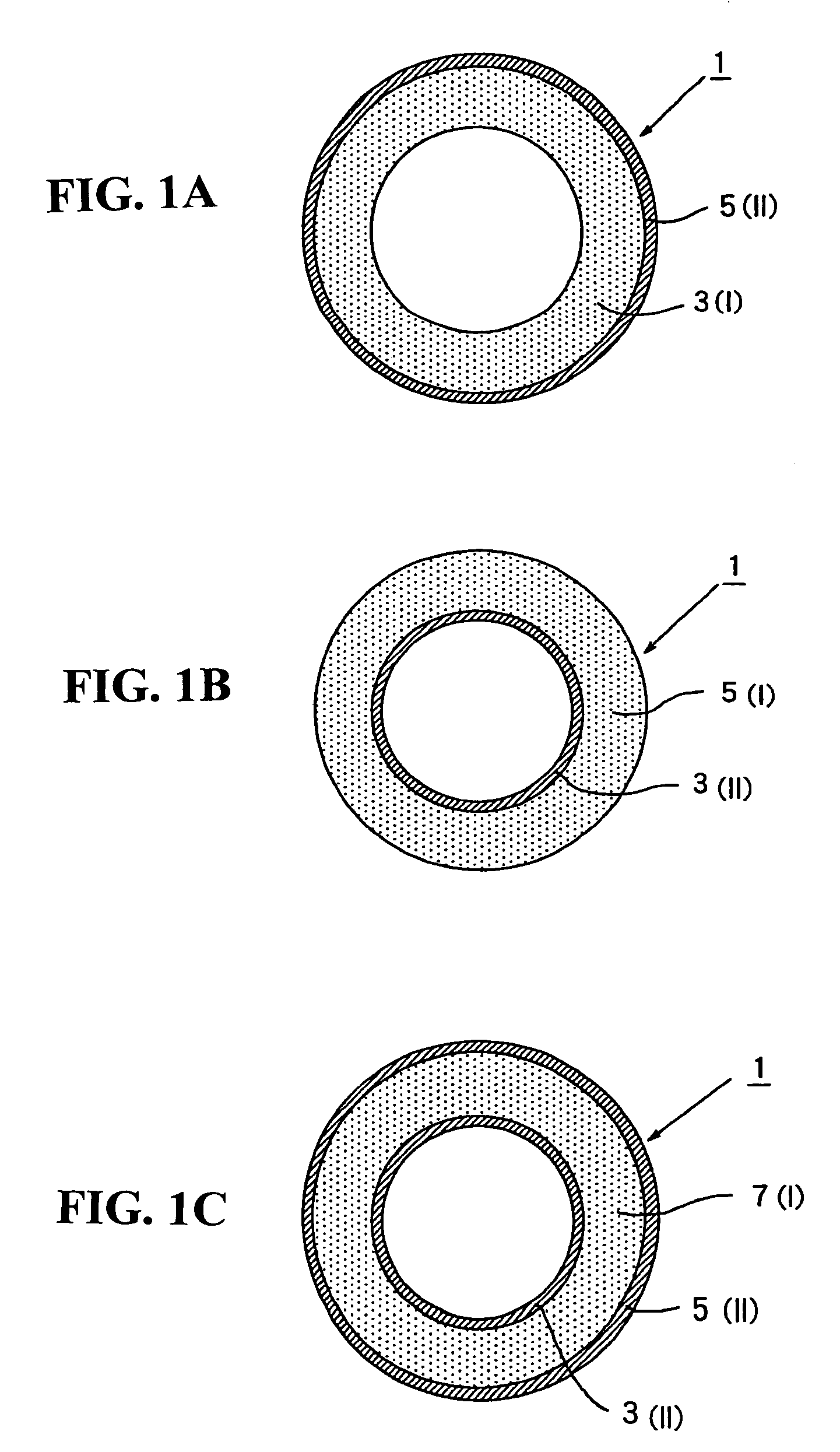

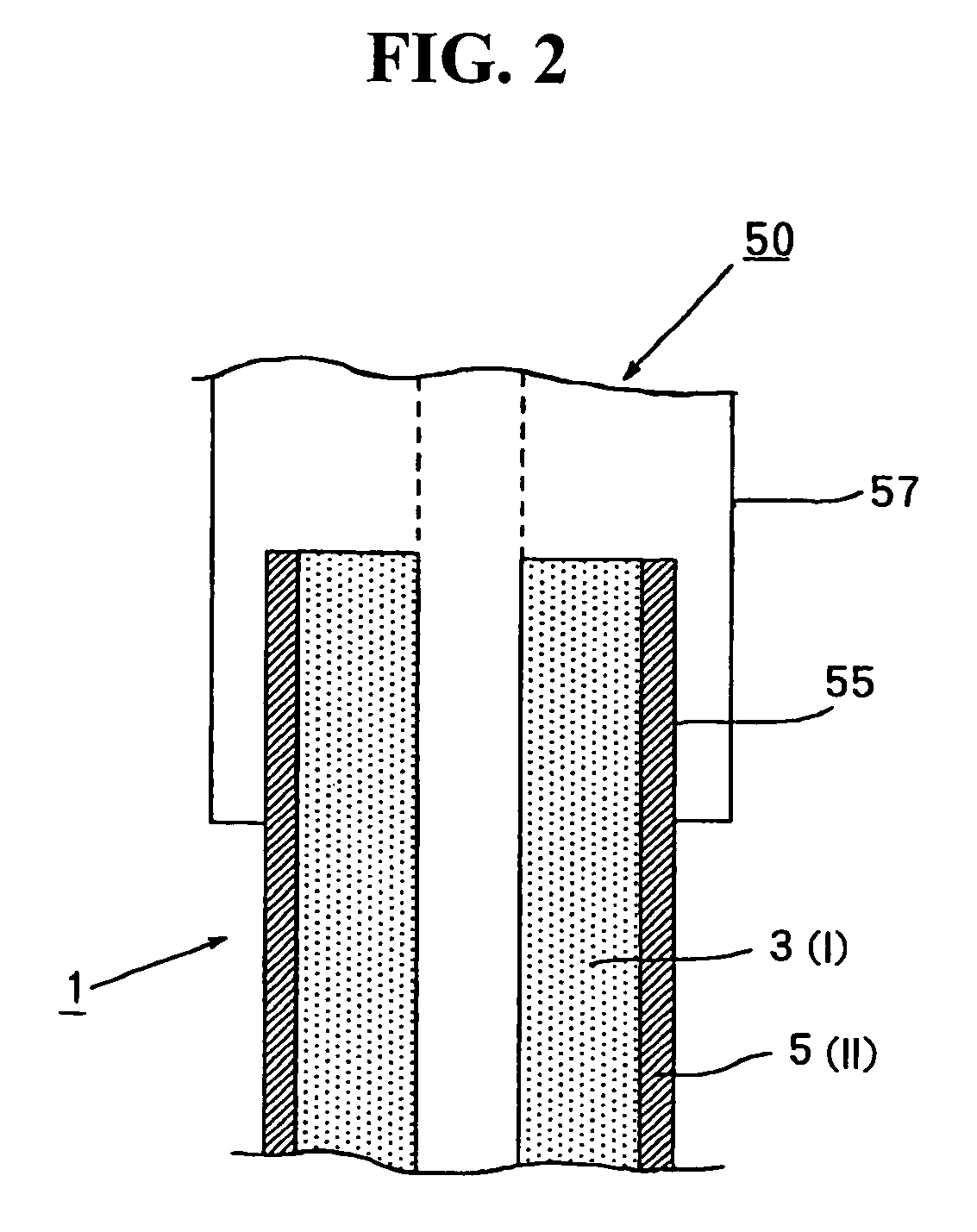

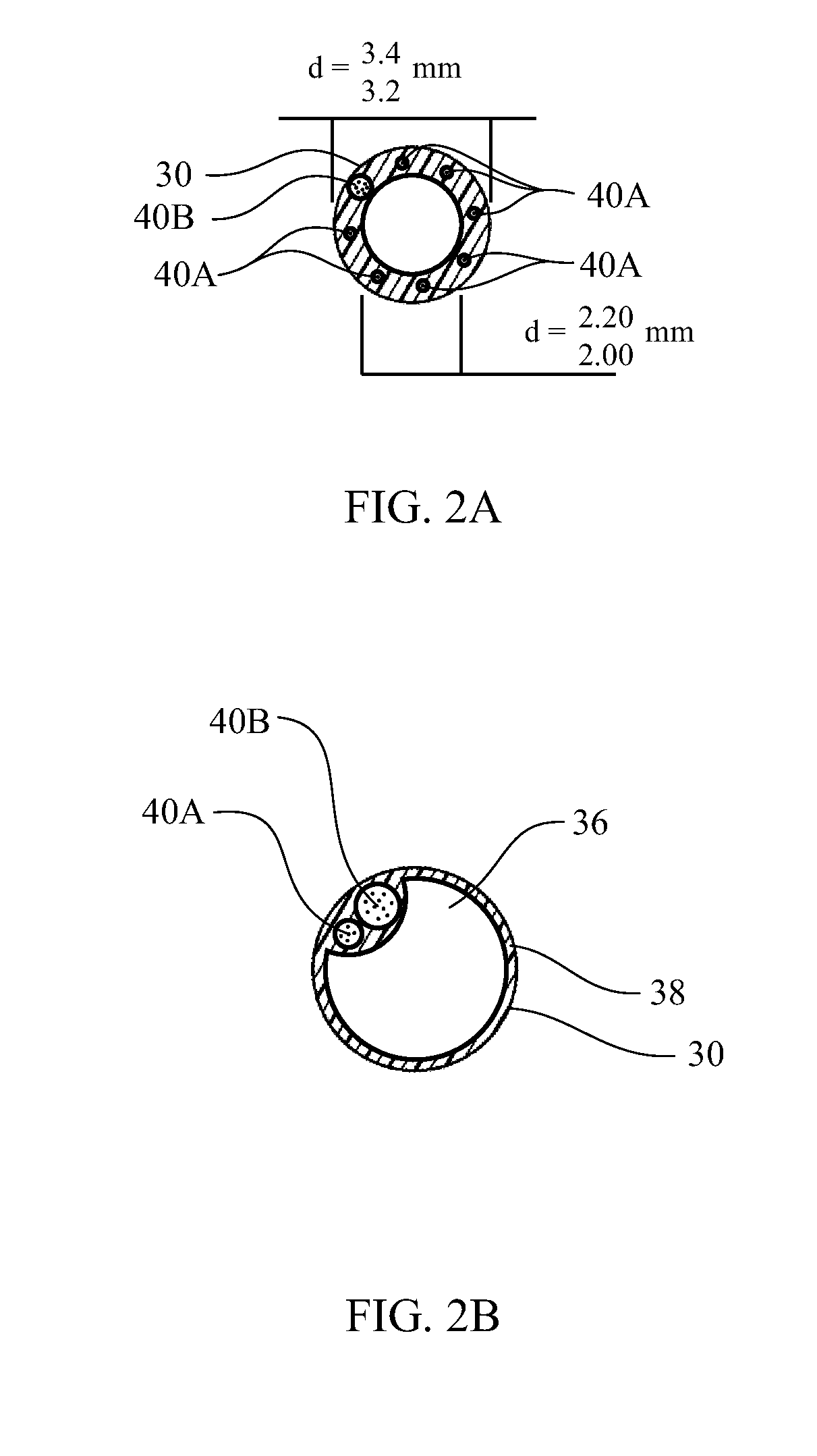

Multilayered tube and medical supply comprising multilayered tube

A multi-layered tube composed of at least two layers, each formed from a different resin, e.g. resin (I) or resin (II). Resin (I) contains 5 to 40 mass % of a polypropylene resin and 95 to 60 mass % of at least one hydrogenated copolymer. Resin (II) contains 45 to 100 mass % of a polypropylene resin and 55 to 0 mass % of a hydrogenated copolymer. The multi-layered tubes may be used in the field of medicine and provide tubing which is excellent in transparency, flexibility and anti-kinking properties, and which is durable during sterilization procedures with high-pressure steam. The multilayer tubing may also be safely disposed of as it generates no toxic gases, such as dioxin, when incinerated. The multilayered tubing has excellent connectability and may be bonded to other tubing using hot solvent bonding or solvent adhesion. The multilayered tubing which is free from generation of any toxic gas when incinerated, and which is excellent in hot solvent bonding or solvent adhesion to other tube.

Owner:KAWASUMI LABORITORIES INC +1

Method for rapidly growing and cultivating dendrobium officinale

InactiveCN101803515AShorten the maturity periodEasy to operateCultivating equipmentsSoilless cultivationMagnifying glassBottle

The invention discloses a method for rapidly growing and cultivating dendrobium officinale, which comprises the following steps of: taking back mature shadow fruit seeds in the country of origin for wild dendrobium officinale, and placing the seeds in a clean culture dish; after natural crack, pouring the seeds into a clean beaker, sealing the clean beaker, and storing the beaker in a low temperature box; performing a certain sterilization procedure on the stored seeds, placing the seeds in an MS minimal medium, performing seed germination cultivation, wherein the seeds gradually become green and form protocorm, and observing that needles appear in the protocorm by using magnifying glass; transferring the protocorm into the MS minimal medium, performing protocorm proliferation and differentiation culture, observing that plantlets are differentiated from the protocorm in a bottle along the production of partial new protocorm; and transferring the plantlets into the MS minimal medium, and performing strong seedling and rooting culture, seedling hardening and transplanting. The survival rate is over 97 percent without the seedling hardening process, and the yield is doubled. The growth speed is improved by 50 percent, the content of each component is equivalent to that of the wild dendrobium officinale, and the contents of amino acid and microelement are higher than those of the wild dendrobium officinale.

Owner:WUHAN ZHONGDA RUIFENG BIOENG

Fruit and vegetable juice, fruit and vegetable juice beverage and preparation method of fruit and vegetable juice

InactiveCN104664509AClearing heat and removing fireQuench thirstFood ingredient functionsFood preparationNutritive valuesAlcohol

The invention discloses a fruit and vegetable juice, a fruit and vegetable juice beverage and a preparation method of the fruit and vegetable juice. The preparation method of the fruit and vegetable juice comprises the following steps: (1) selecting and cleaning fruits and vegetables; (2) preparing raw fruit and vegetable juice; (3) carrying out cold enzyme deactivation and color protection treatment on the raw juice; (4) carrying out enzymolysis treatment; (5) carrying out refined filtration and hollow filtration; (6) carrying out low-temperature vacuum concentration; and (7) carrying out a cold sterilization procedure. According to the fruit and vegetable juice and the fruit and vegetable juice beverage prepared by the method, cold enzyme deactivation and cold sterilization technologies are adopted for the fruit and vegetable juice in enzyme deactivation and sterilization, so that the prepared fruit and vegetable juice and the fruit and vegetable juice beverage completely reserve nutritive value and health functions of fresh fruits and vegetables, and have the health functions of clearing heat, removing internal heat, promoting the secretion of saliva or body fluid, quenching thirst, moistening the lung, removing fat, lowering pressure, detoxifying, dispelling the effects of alcohol, inducing diuresis, reducing swelling, and losing weight.

Owner:宁夏天瑞产业集团现代农业有限公司

Preparation method of yak bone collagen peptide

InactiveCN103783254AEasy extractionShort manufacturing timeAnimal proteins working-upPectinaseEnzymatic hydrolysis

The invention discloses a preparation method of yak bone collagen peptide. The method is characterized by comprising the following technological processes: pretreatment of raw materials, gelatin extraction, separation of a collagen extracting solution, composite enzymatic hydrolysis, enzyme deactivation and sterilization, separation of a peptide solution, decoloring and deodorizing, concentrating and drying. The compound enzyme for composite enzymatic hydrolysis is prepared from protease, amylase, pectinase, cellulose and xylanase. The method has the advantages that the gelatin extraction process is simple, oil and gelatin are completely separated by using flow of a mixed solution, the enzymatic hydrolysis temperature is 48-52 DEG C, the time is 4-6 hours, the temperature is reduced in comparison with common enzymatic hydrolysis temperature, the preparation time of the product is shortened, and the method comprises enzyme deactivation and sterilization procedures, and decoloring and deodorizing procedures, so that the product is good in taste, and applicable to preparation of the yak bone collagen peptide.

Owner:吴长海

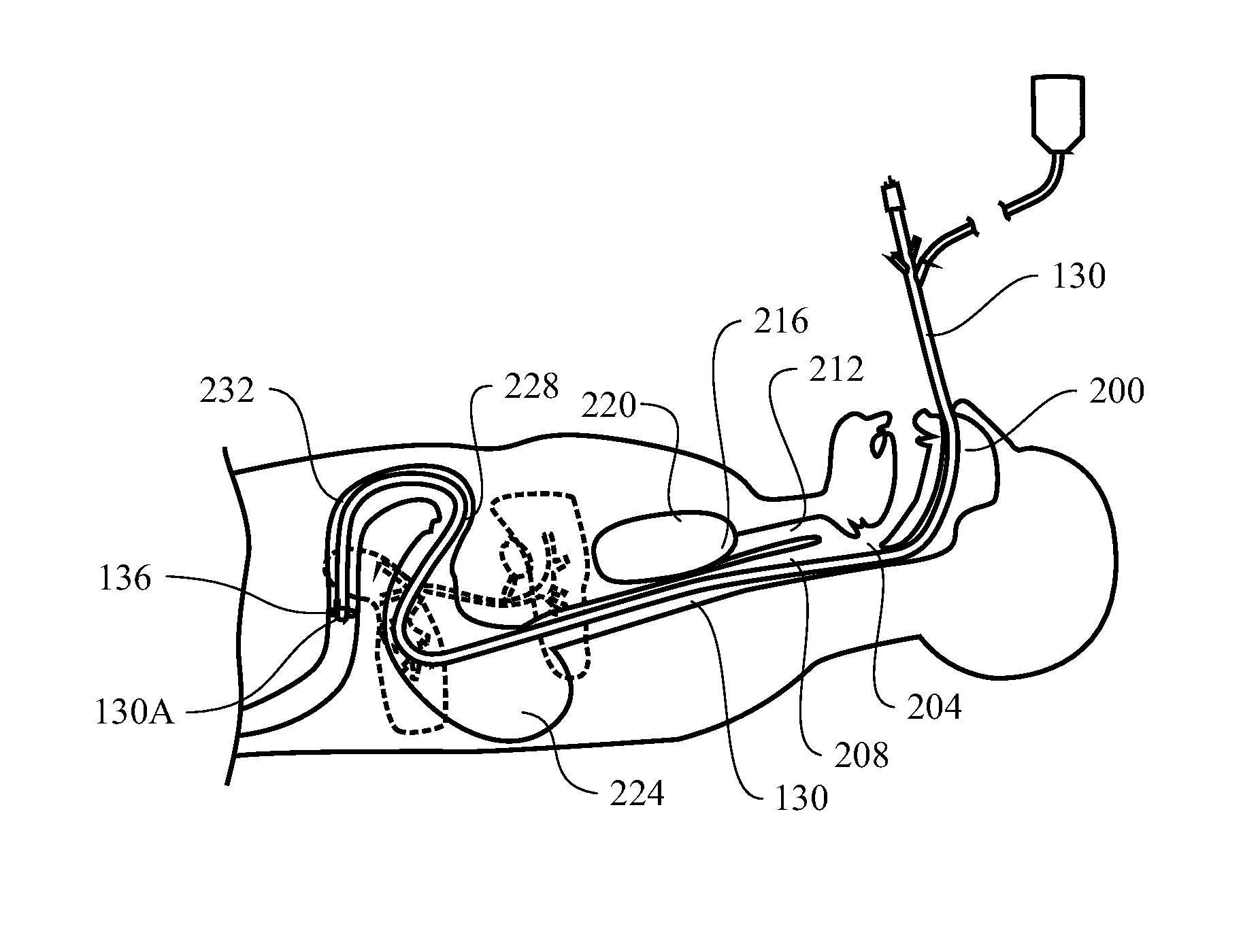

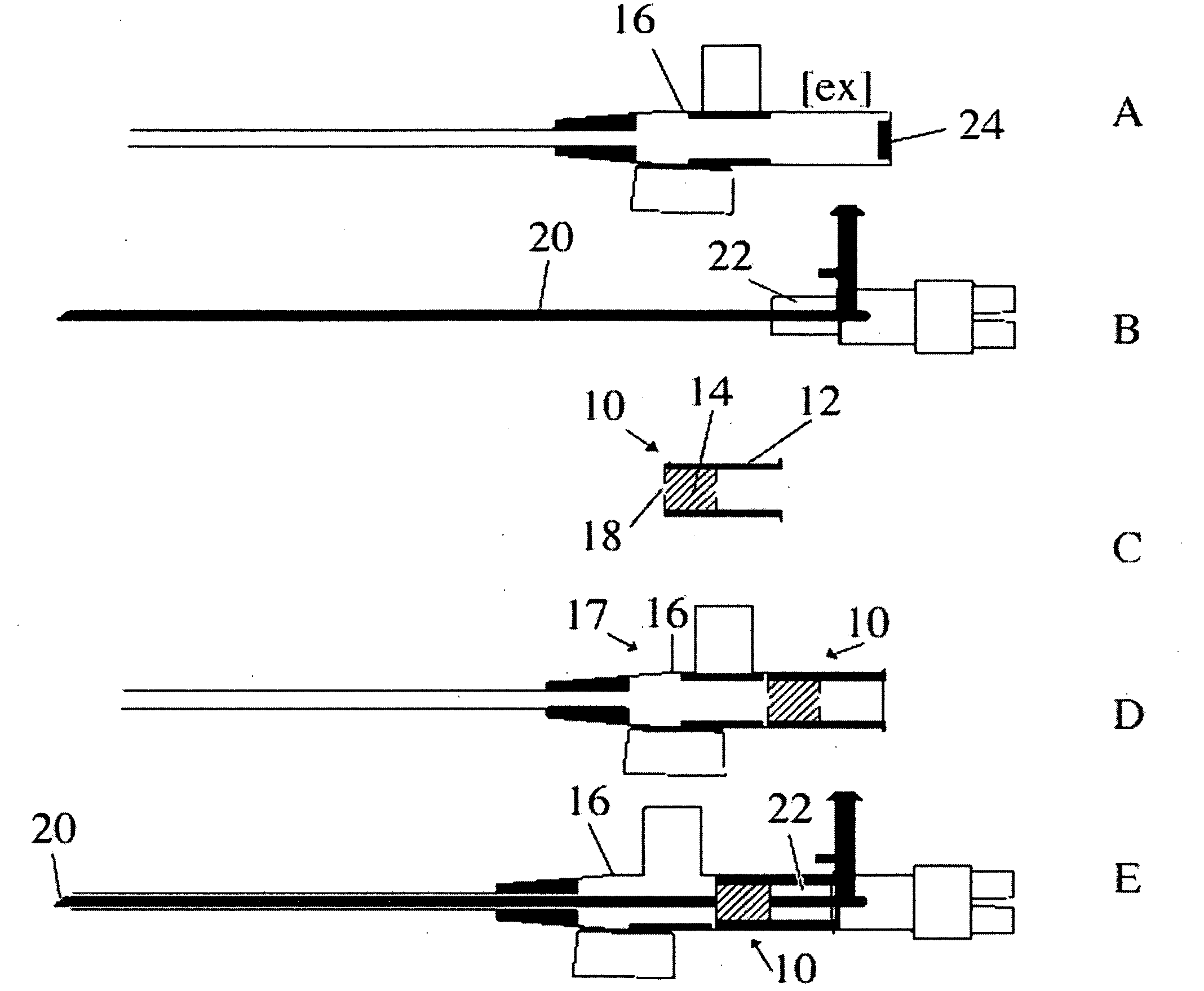

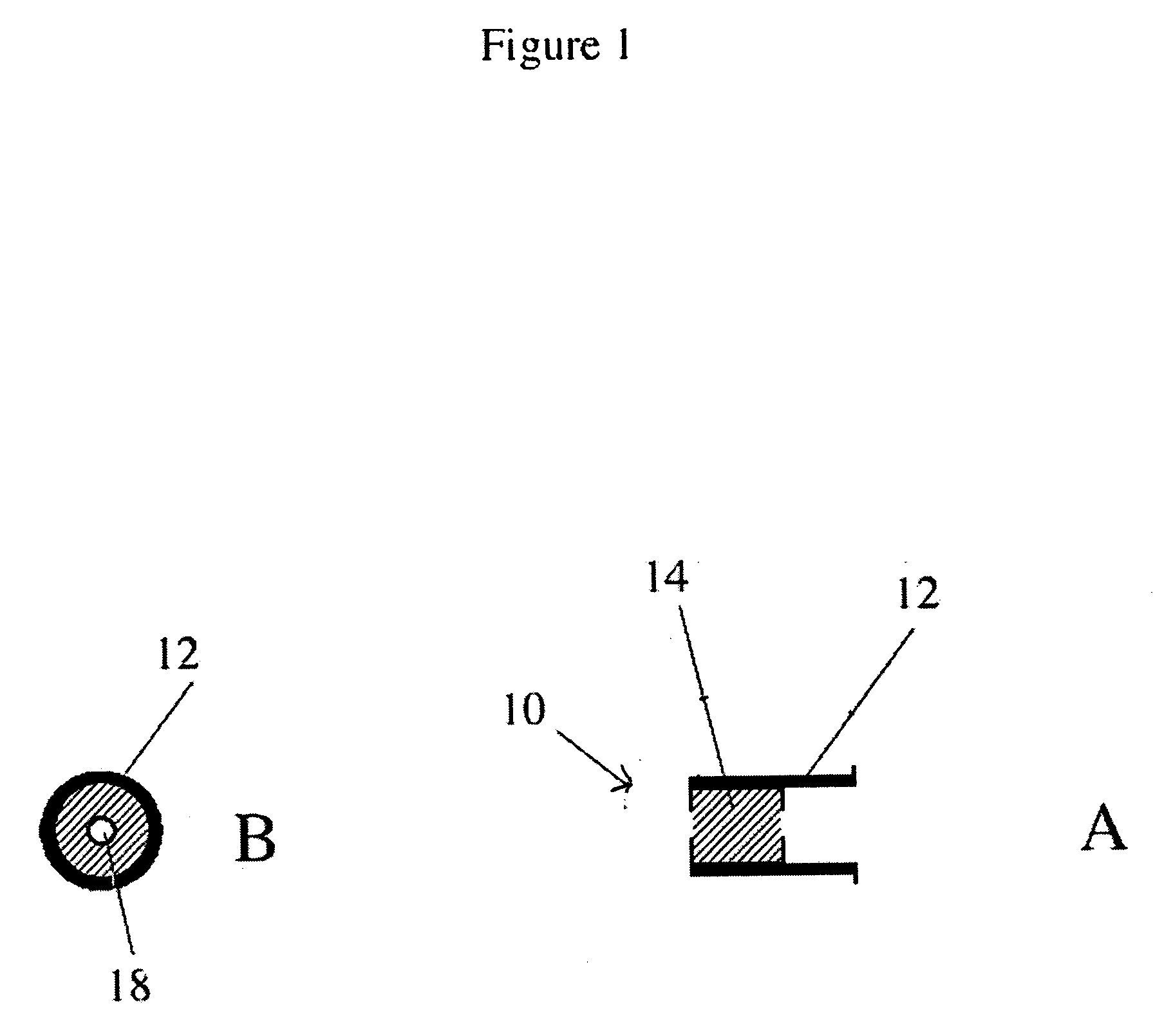

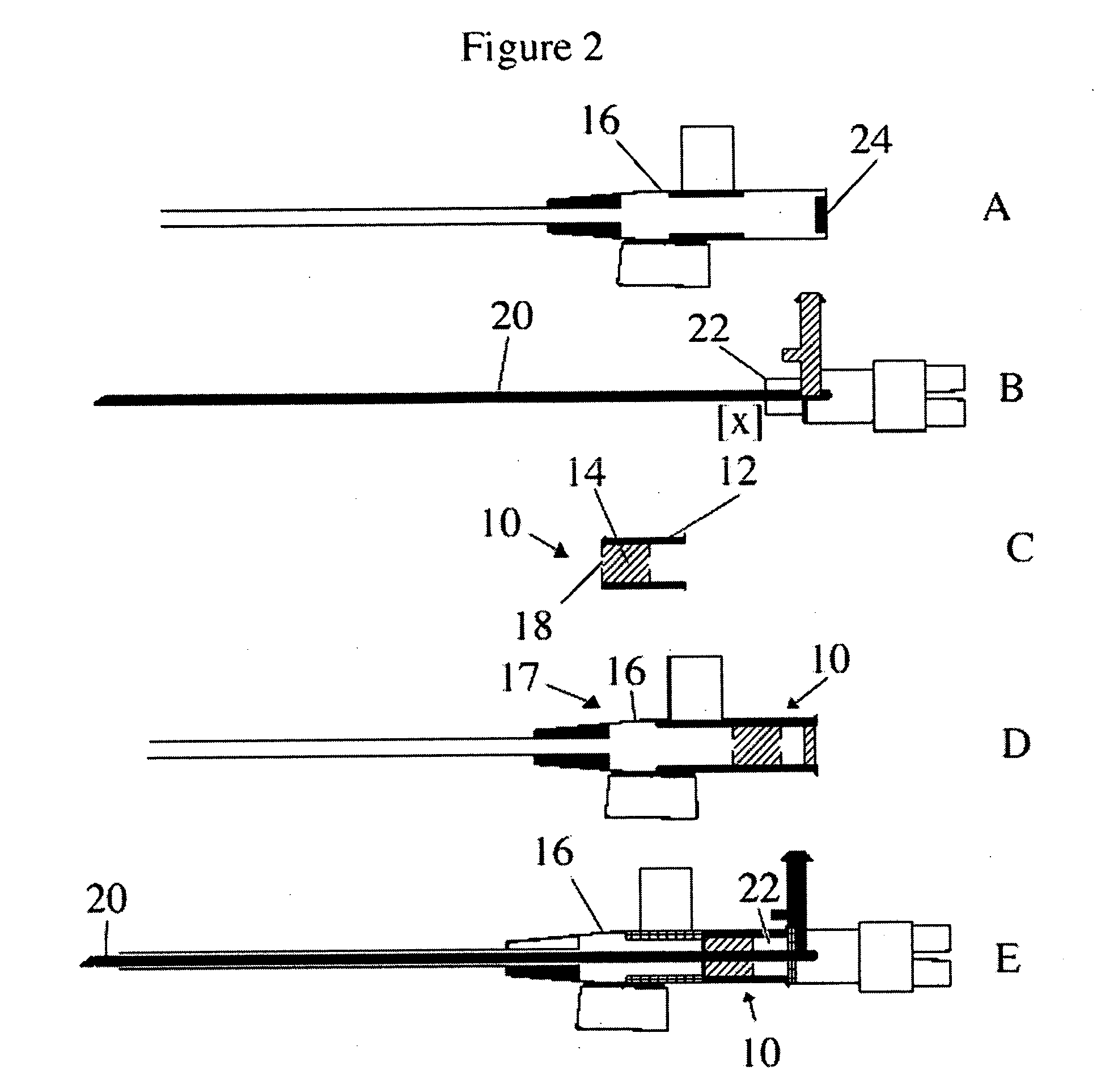

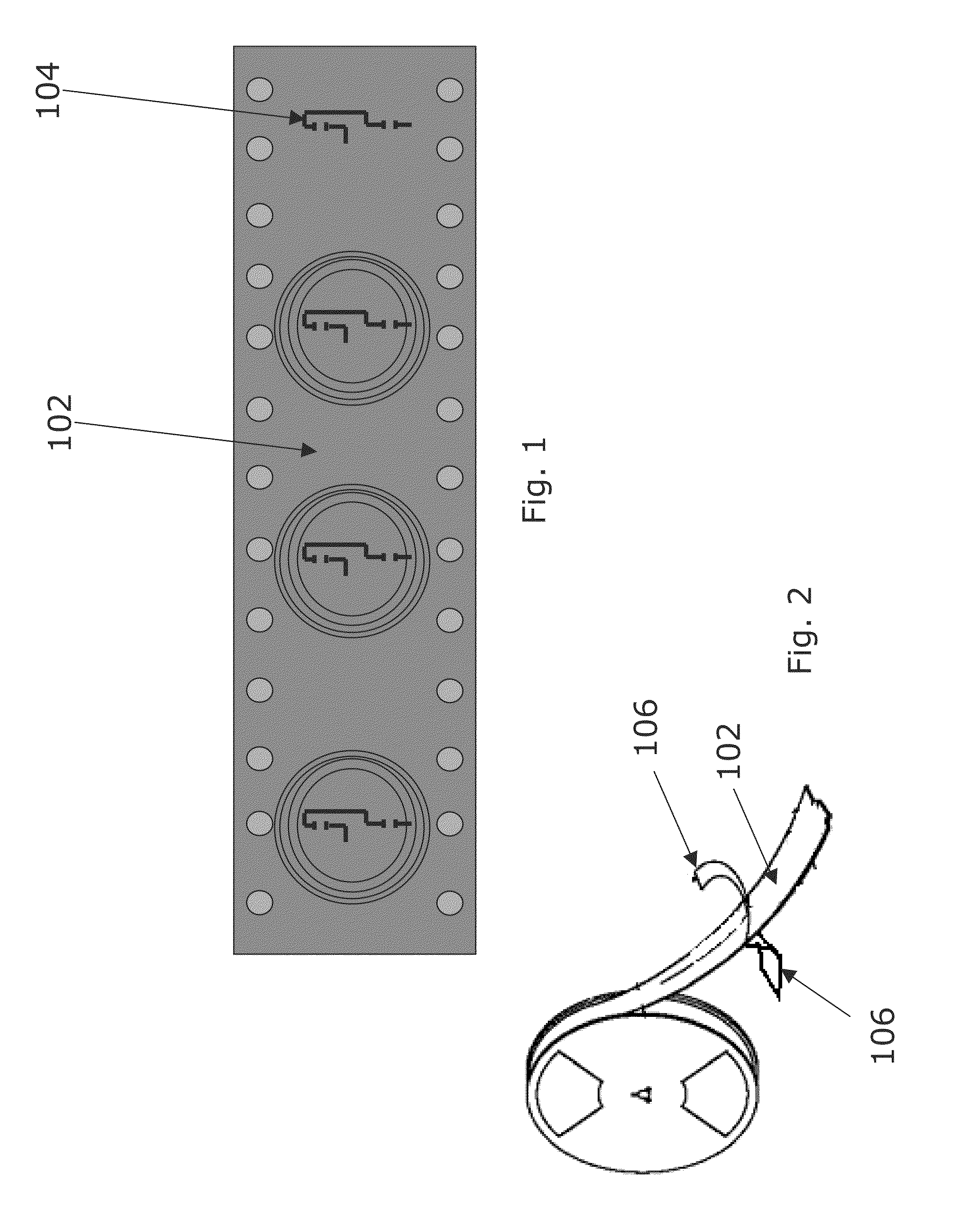

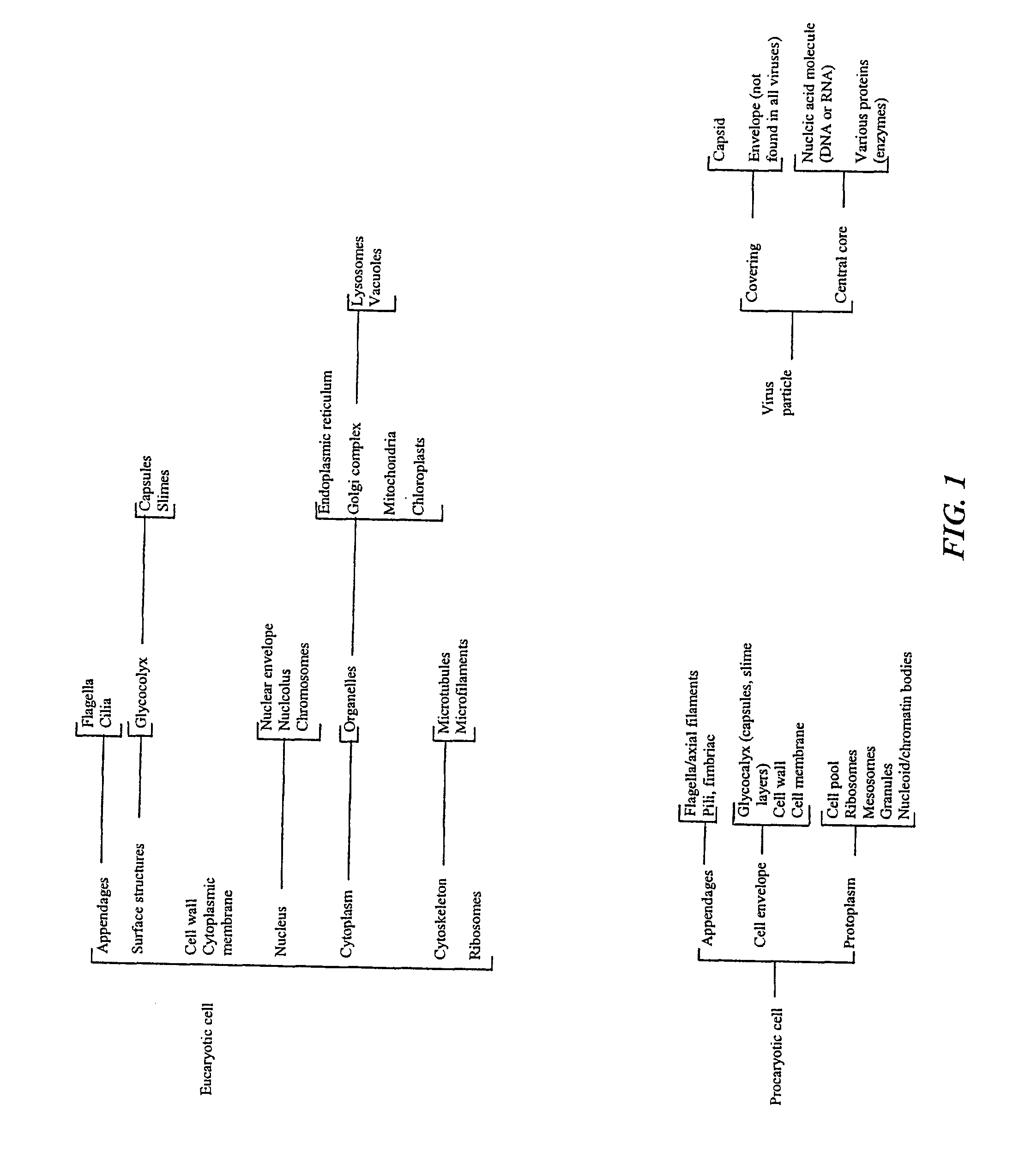

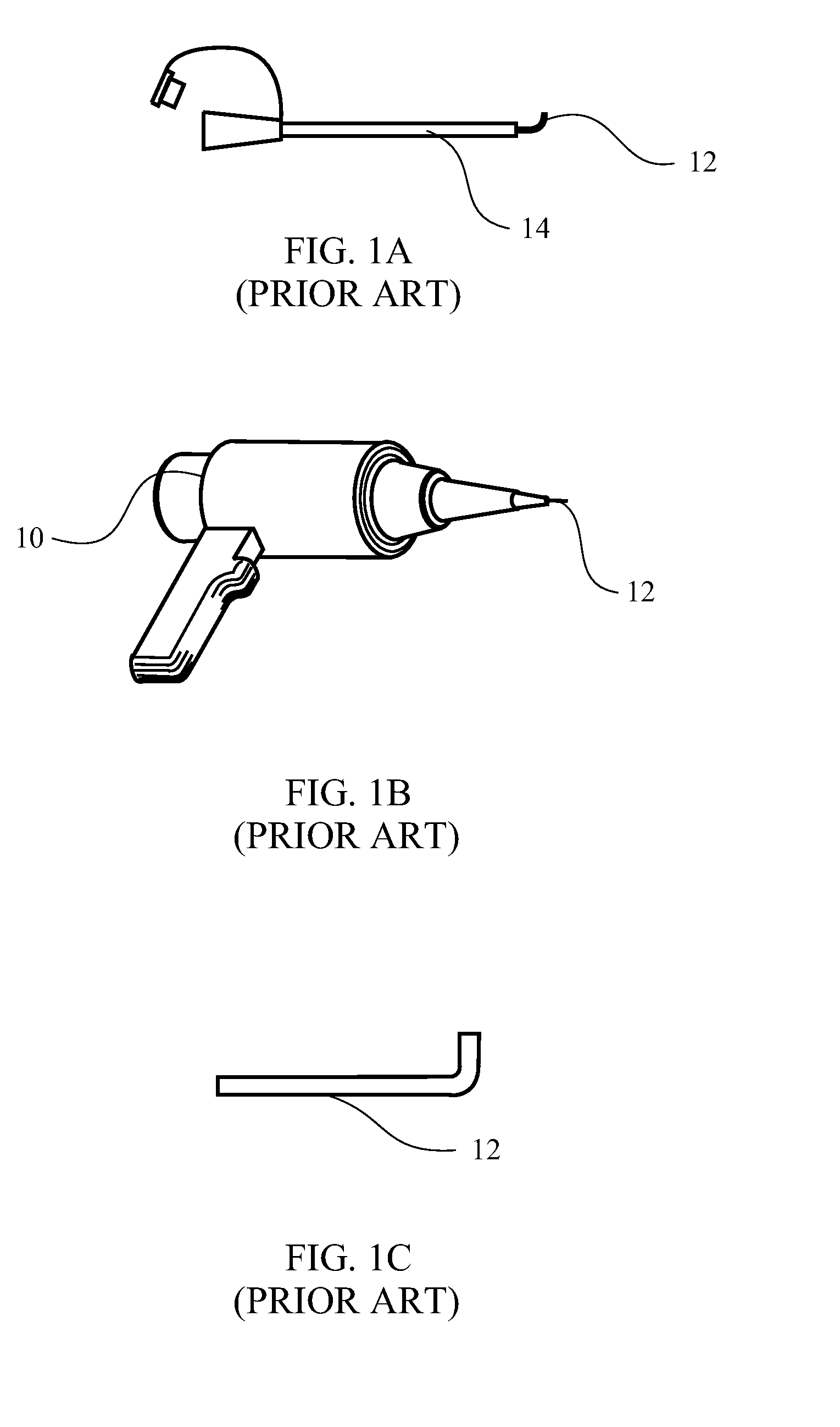

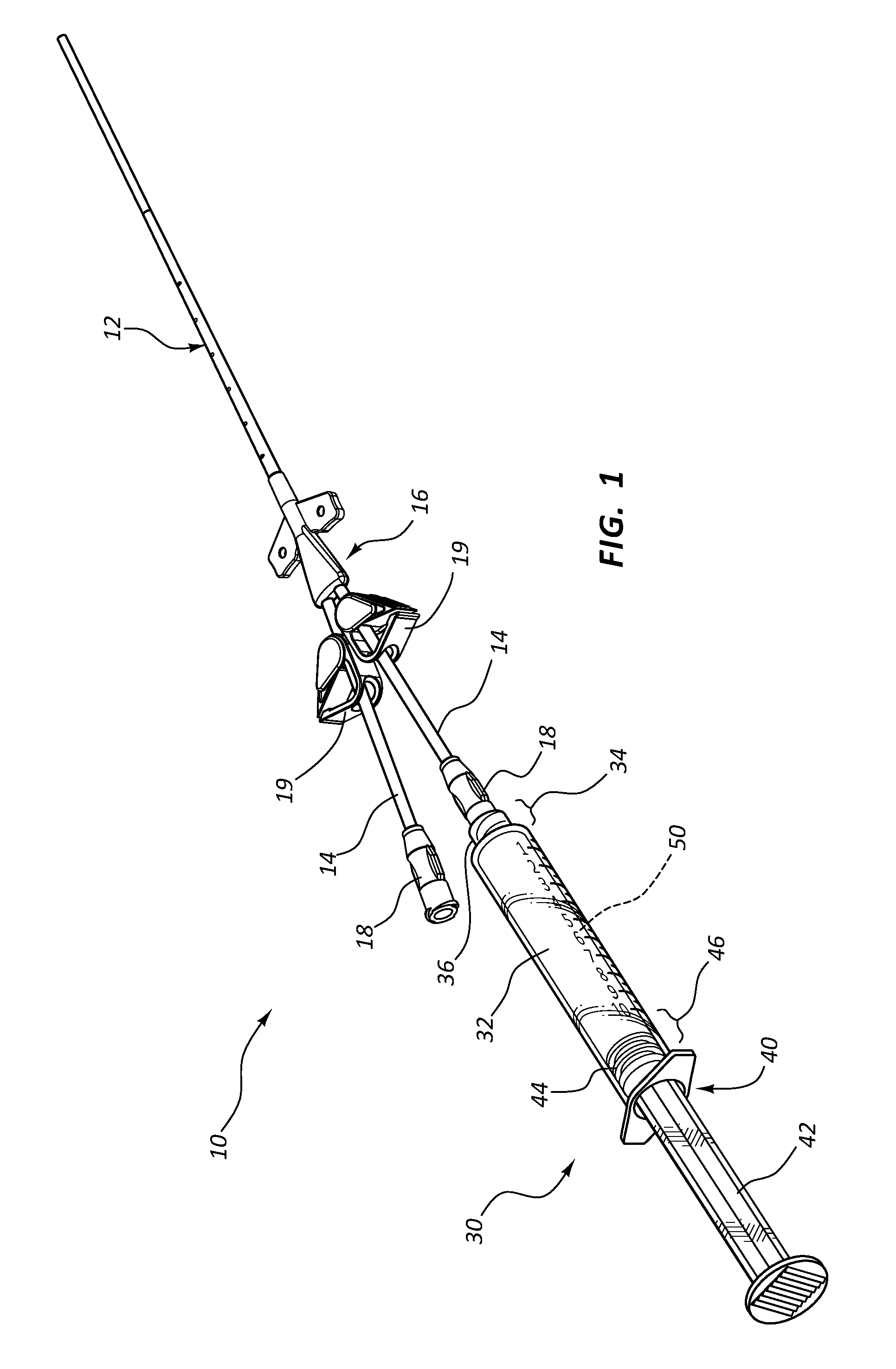

Optically guided medical tube and control unit assembly and methods of use

InactiveUS20120116160A1Solve the lack of spaceLarge outer diameterGastroscopesOesophagoscopesFeeding tubeBiomedical engineering

An optical medical tube and control unit assembly and methods of using the same are provided. The optical medical tube may include a steering mechanism and an imaging device which provides the user a visual aid when placing a tube in the body of a patient. The optical medical tube may be coupled to a coupling adaptor to enable quick and easy connecting of the imaging device and steering mechanism of the tube with a control unit such that a single control unit may be used to place multiple feeding tubes or confirm that a feeding tube remains in its proper position without the need for lengthy sterilization procedures between uses.

Owner:THE UNIV OF UTAH

Device to prevent blood leakage using intravenous catheters

InactiveUS20070196414A1Avoid blood leakagePrevent blood-leakageCapsInfusion syringesVeinIntravenous catheter

A device for preventing blood leakage during use of an intravenous catheter and needle using a stopper made of a material that is air permeable when dry; upon exposure to blood or other liquids bercomes rapidly liquid impermeable; is non-toxic and validated to use on humans; is inexpensive; is stable and withstands normal sterilization procedures such as heating and ionizing radiation; and is flexible and able to seal the hole when the needle is removed from the IV catheter during the cannulation process.

Owner:HAMMARSTEN OLA +1

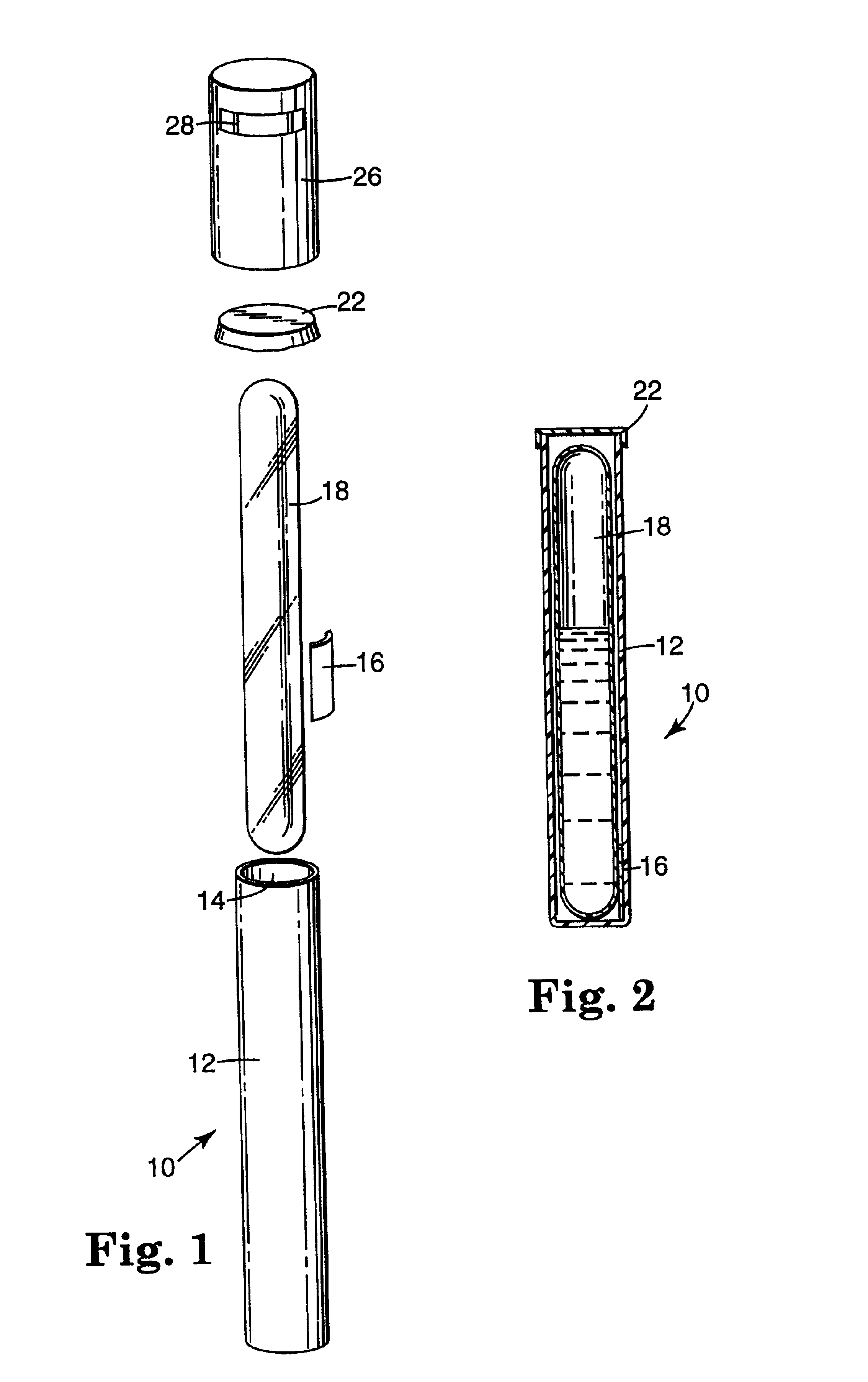

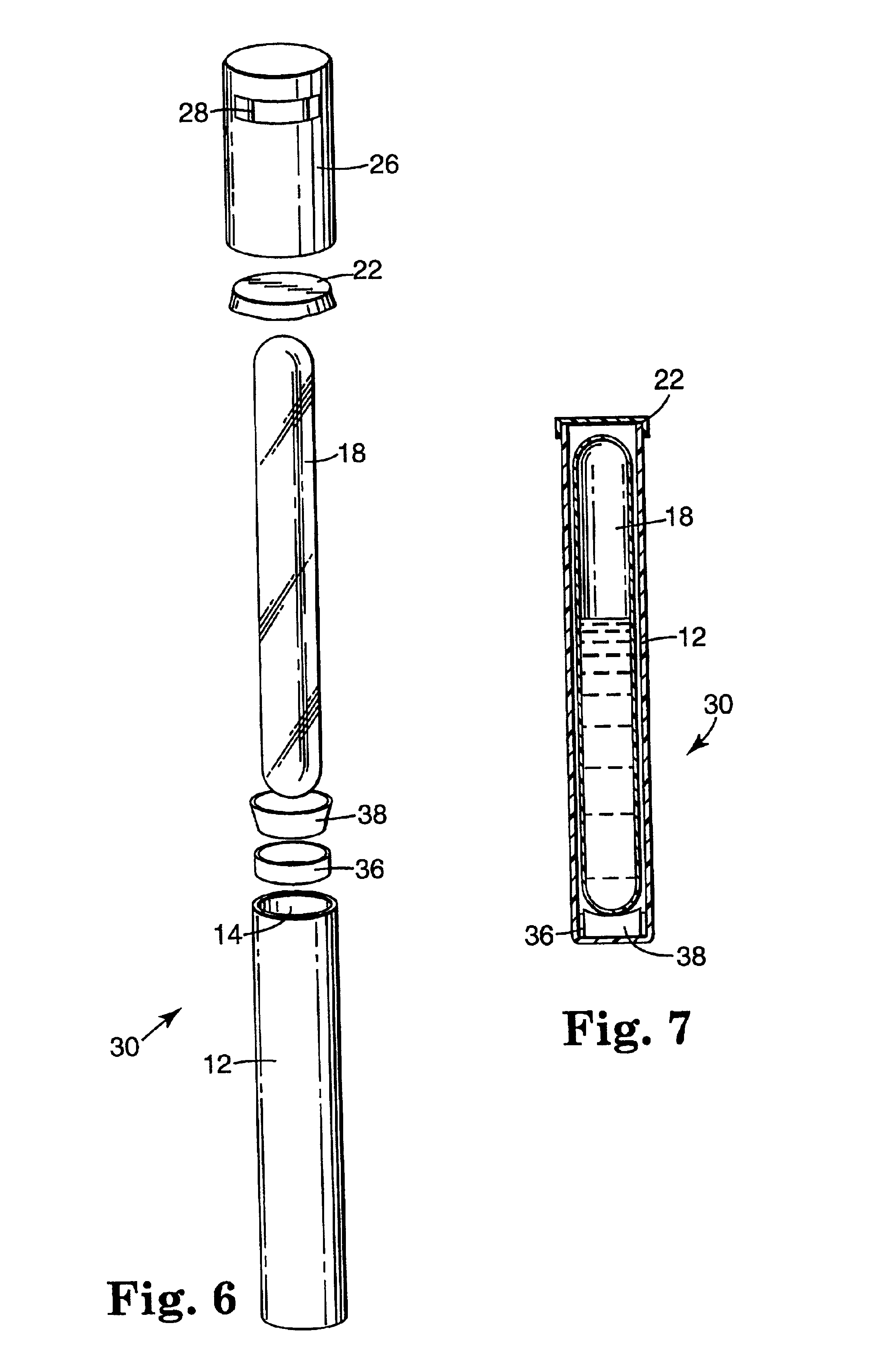

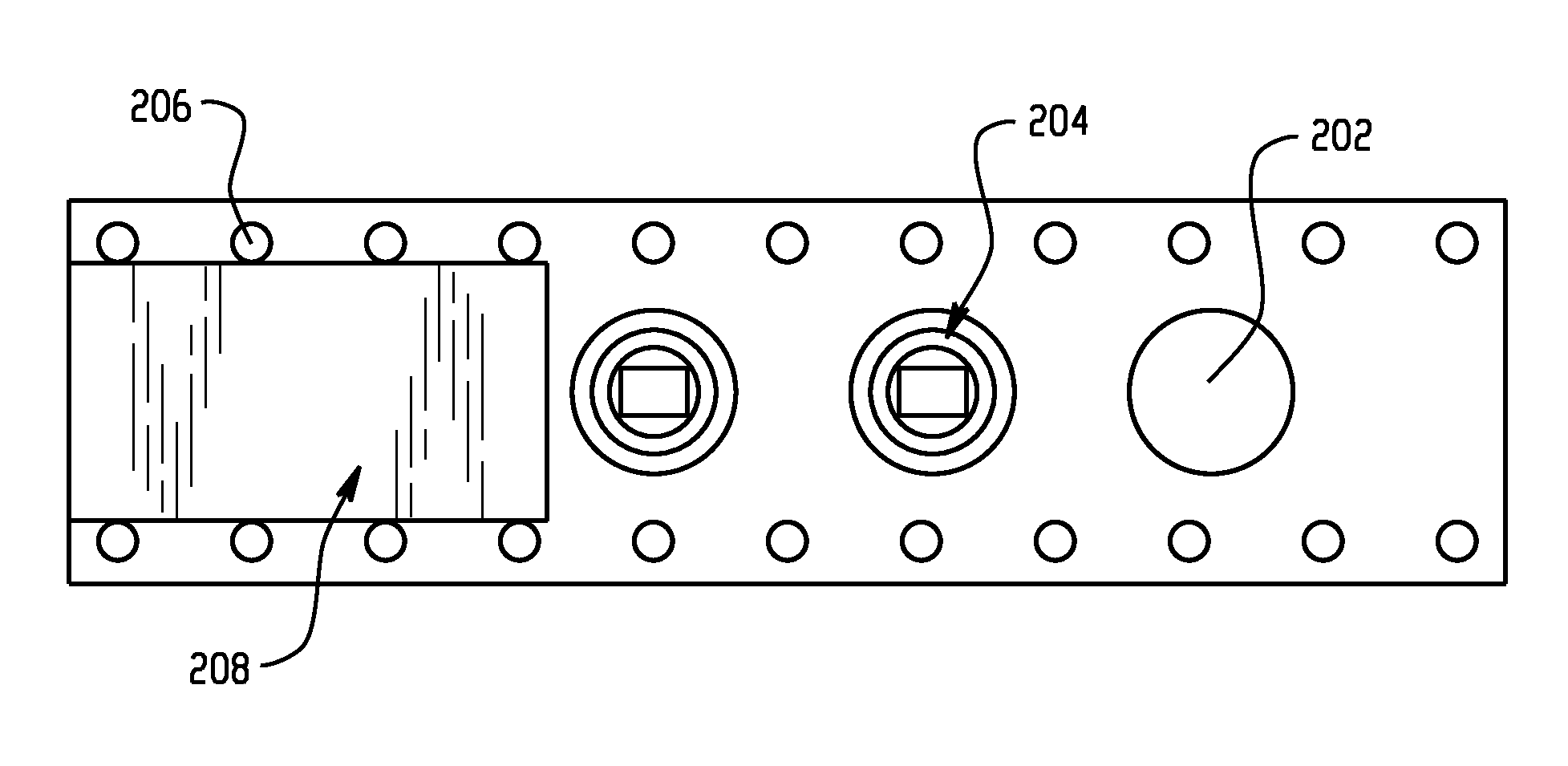

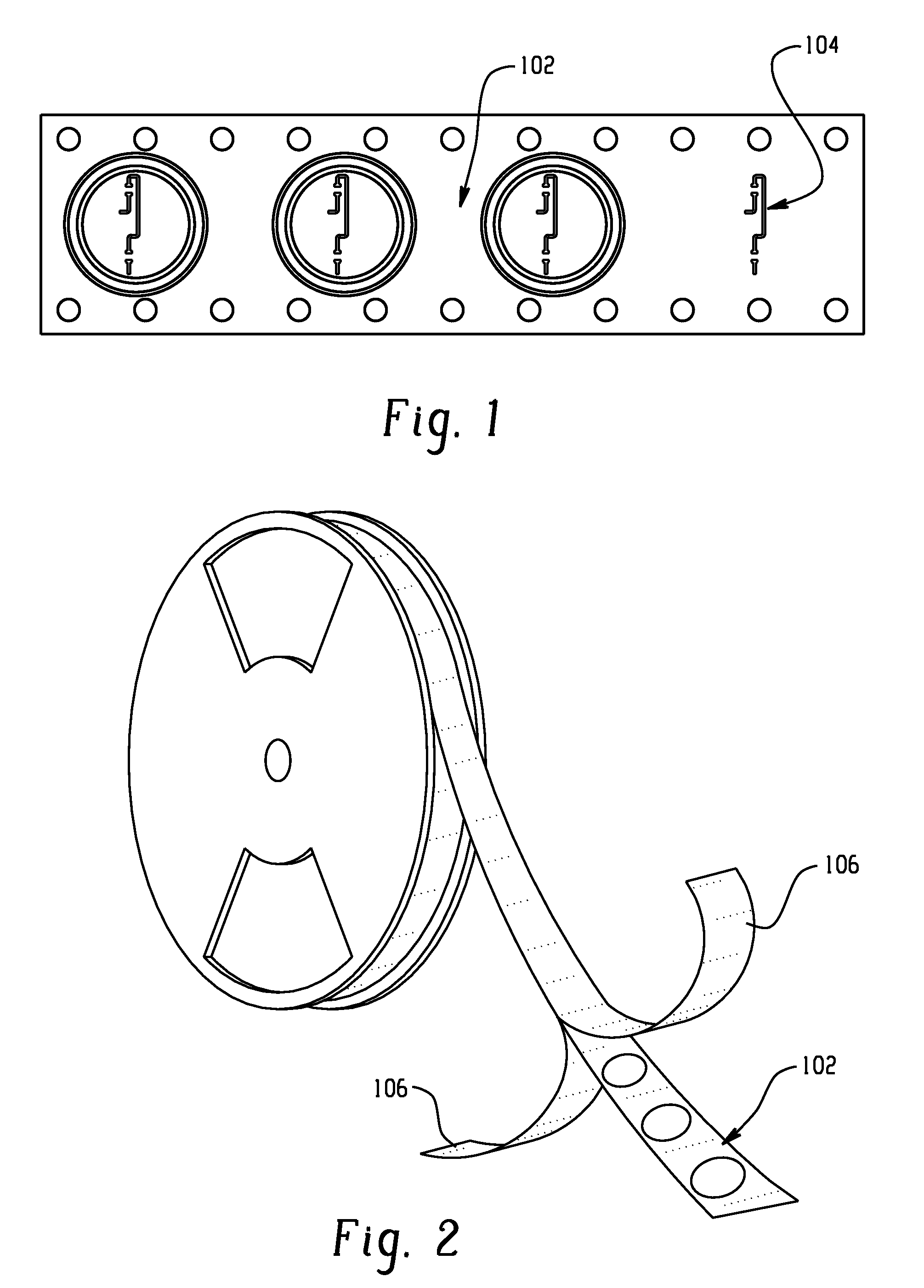

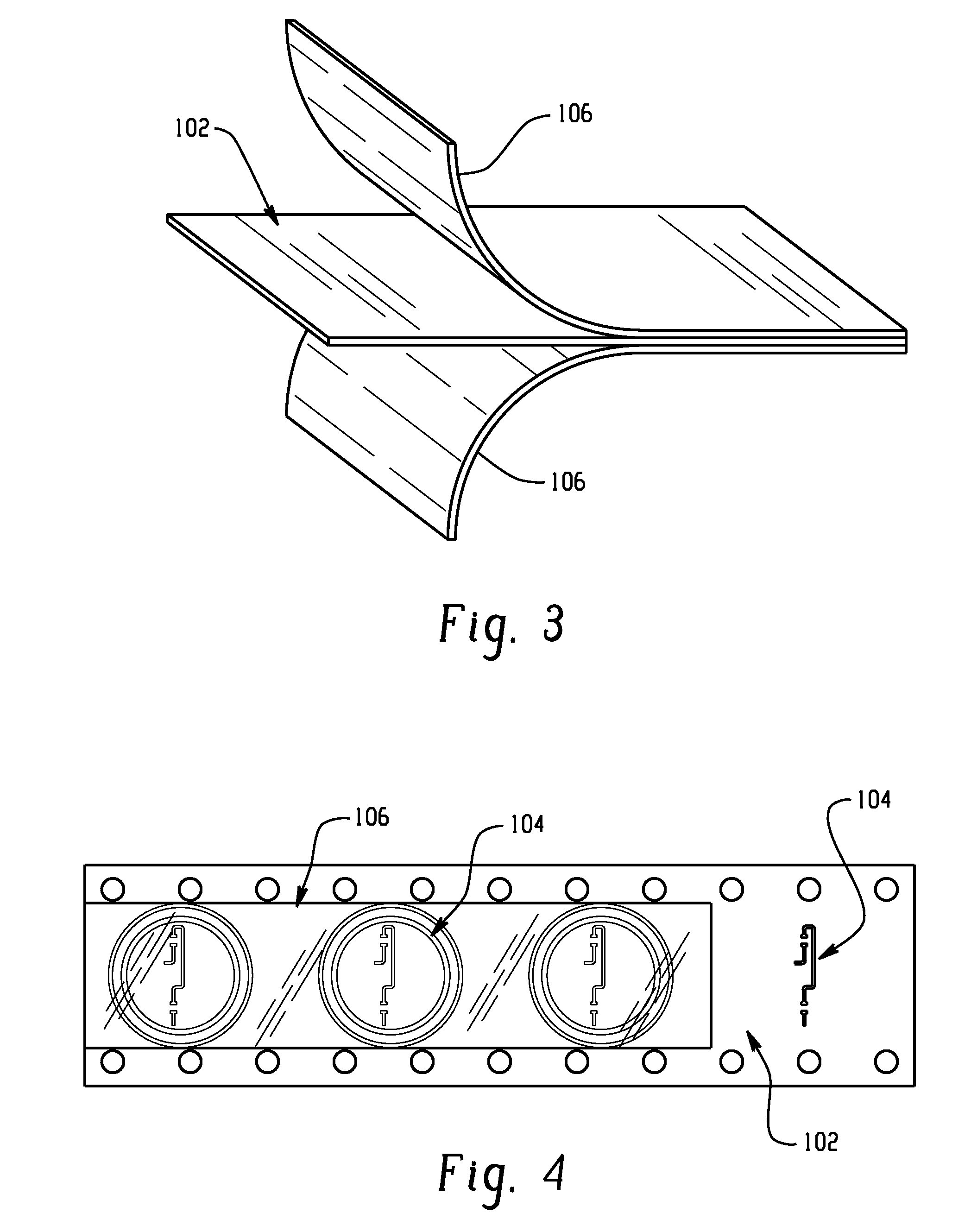

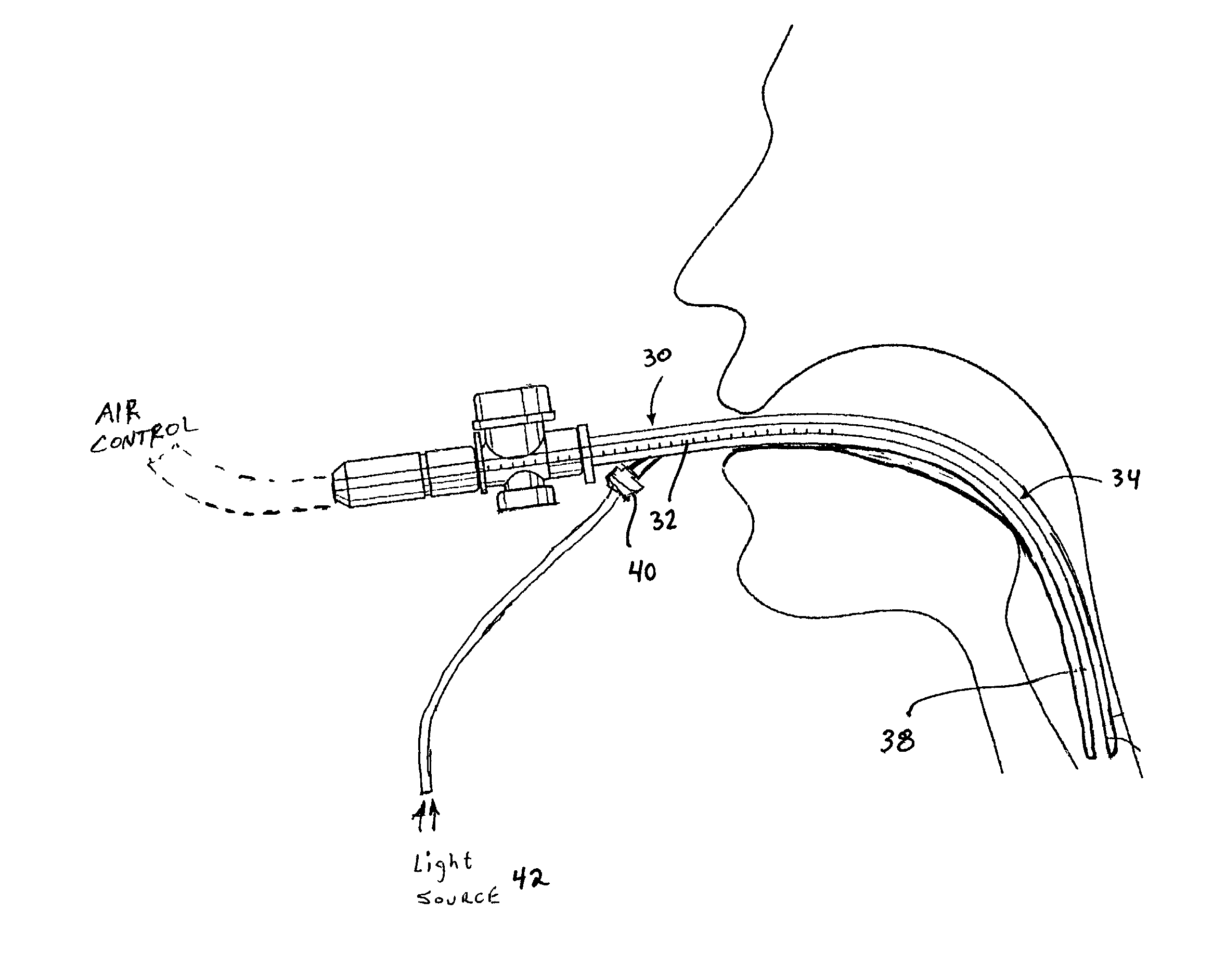

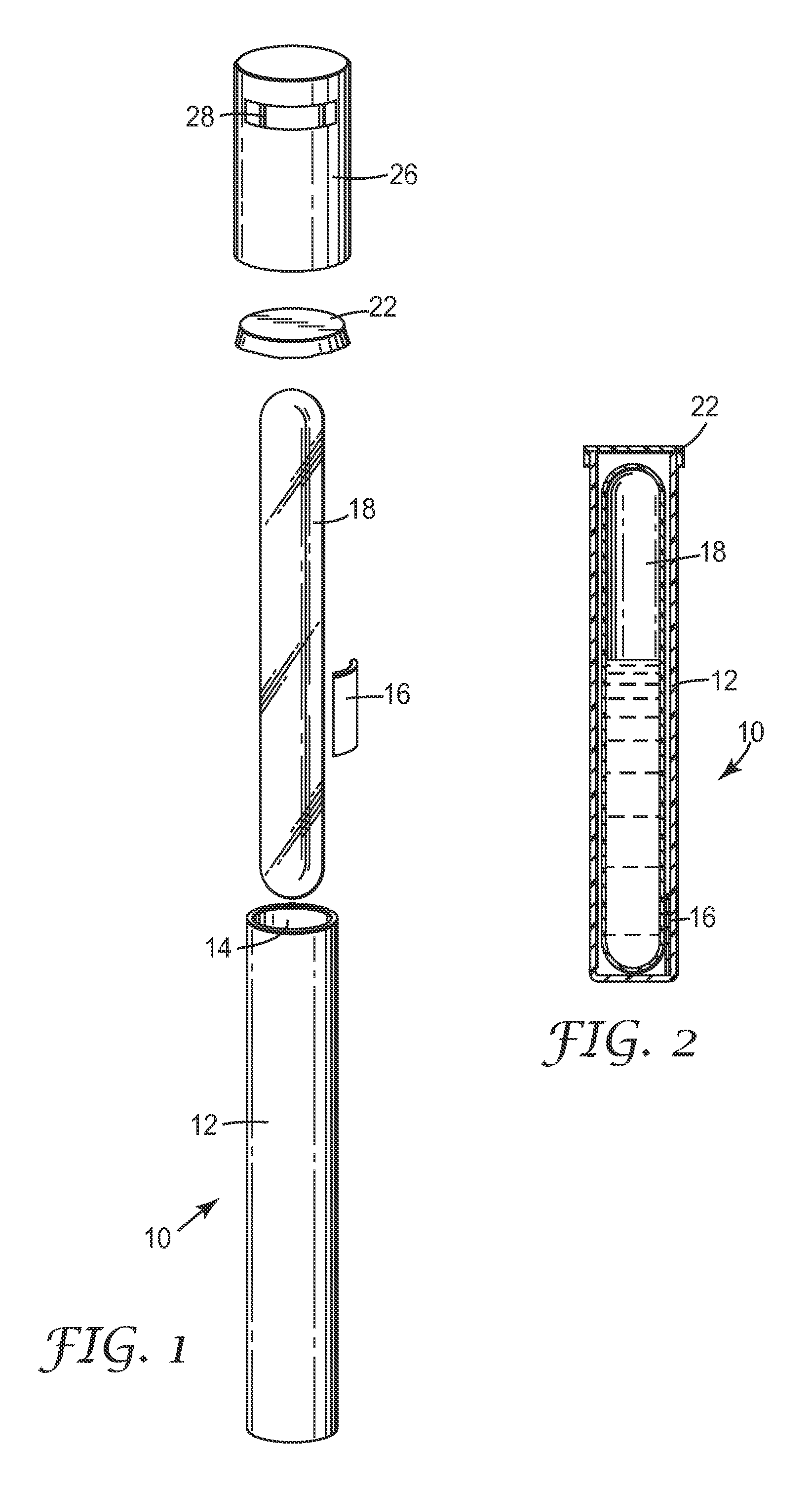

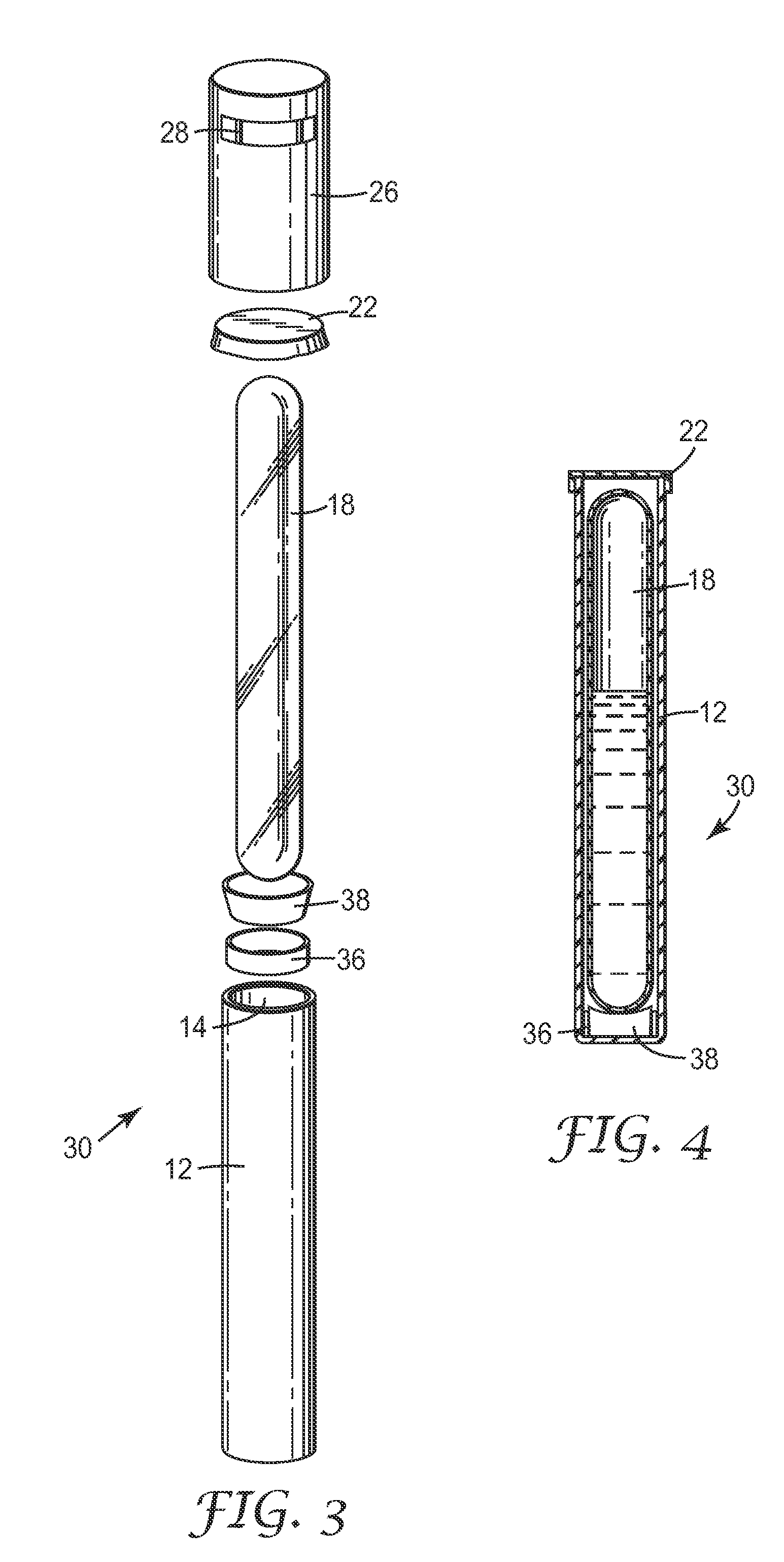

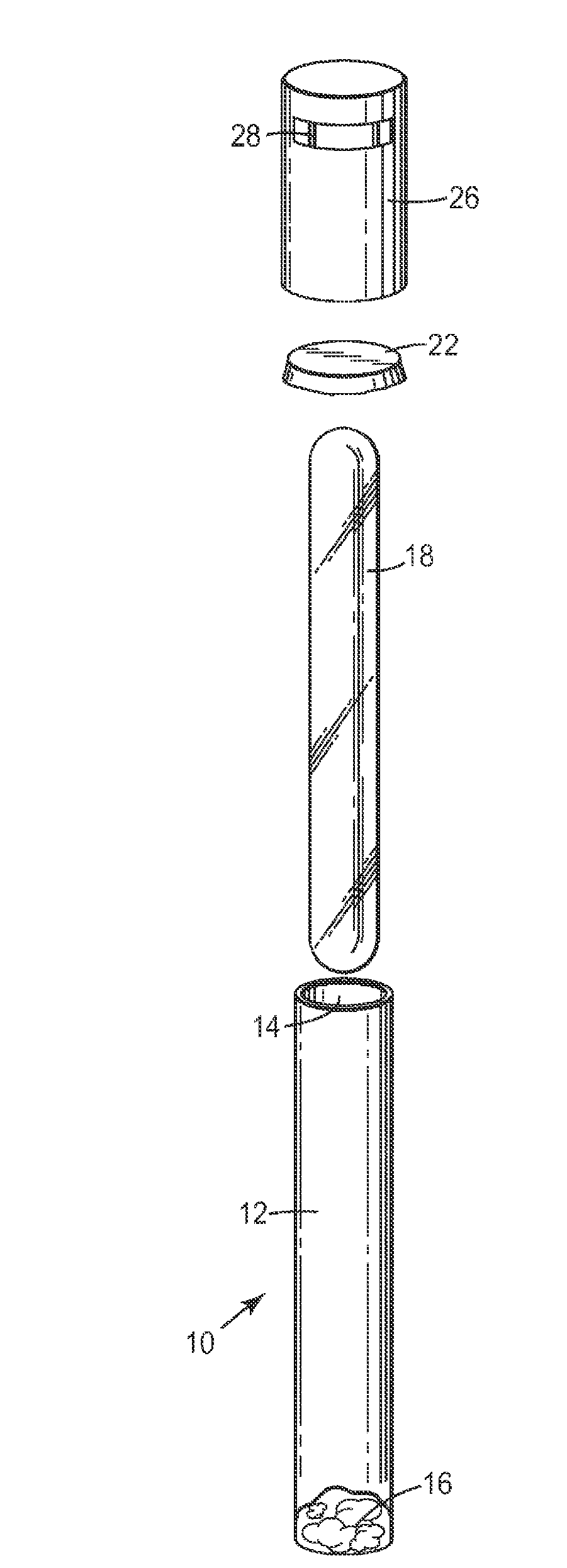

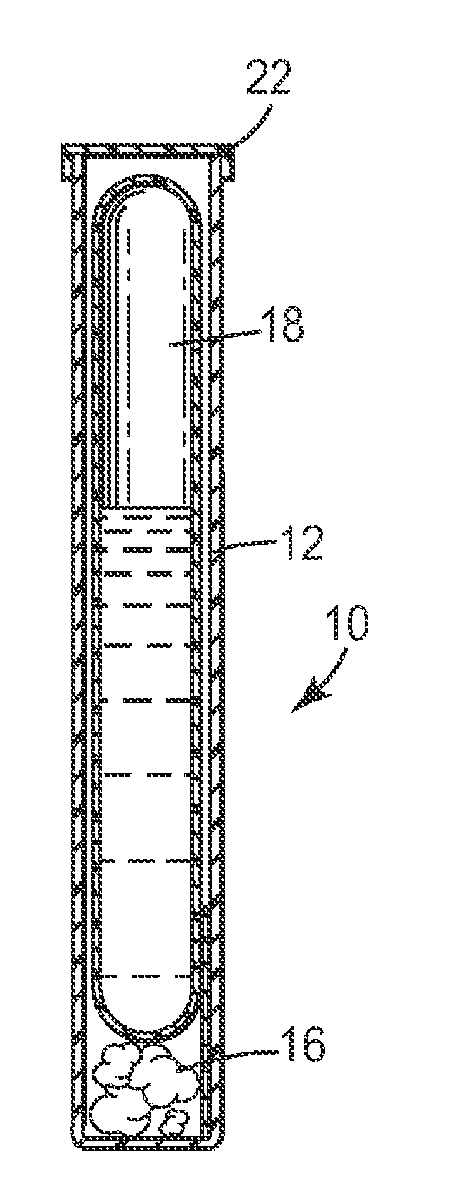

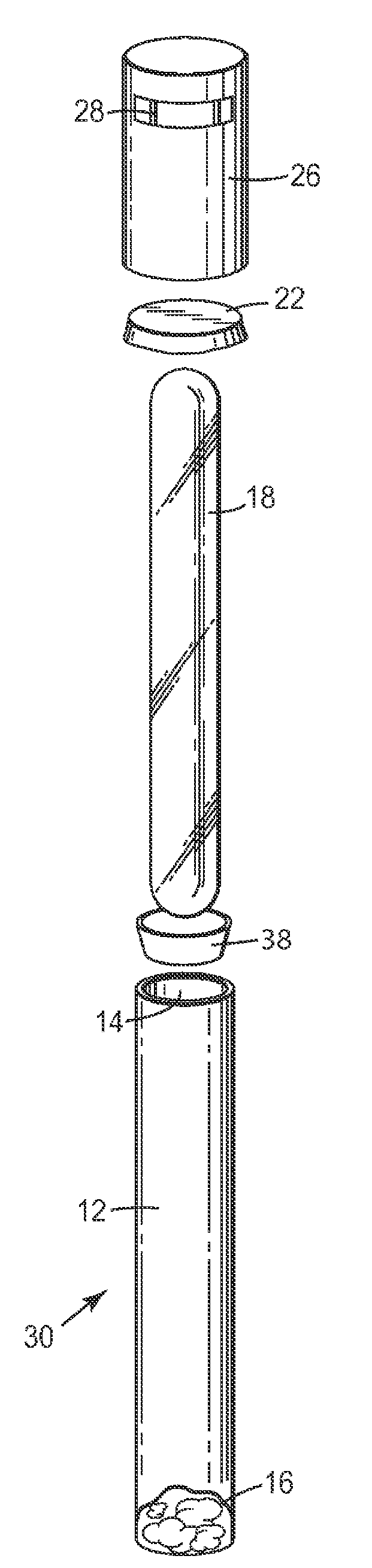

Sterilization indicator test packs

InactiveUS7045343B2Improve the immunityBioreactor/fermenter combinationsBiological substance pretreatmentsDefining lengthChallenge tests

Sterilization indicator test packs for testing the effectiveness of a sterilization procedure are provided. Both non-challenge and challenge-type test packs are disclosed. The non-challenge test packs include generally comprise a tray for holding a sterilization indicator the tray containing an elevated rim surface defining the perimeter of the tray and a recessed trough for receiving a sterilization indicator. The rim surface includes a plurality of spaced-apart grooves along its length extending through the rim to the recessed trough; a sterilization indicator within the recessed trough of the tray; and a lid that forms a plurality of channels with the grooves in the tray such that sterilant can enter the tray through the channels and contact the sterilization indicator.The challenge-type test packs generally include a tray for holding a sterilization indicator, the tray comprising a substantially planar surface, a recessed trough for receiving a sterilization indicator, and a recessed groove of a defined length and cross-sectional area extending through the recessed trough and penetrating the edge of the tray; a sterilization indicator within the recessed trough of the tray; and a lid forming a substantially sterilant-impermeable seal with the planar surface of the tray and forming a lumen path with the recessed groove in the tray.

Owner:3M INNOVATIVE PROPERTIES CO

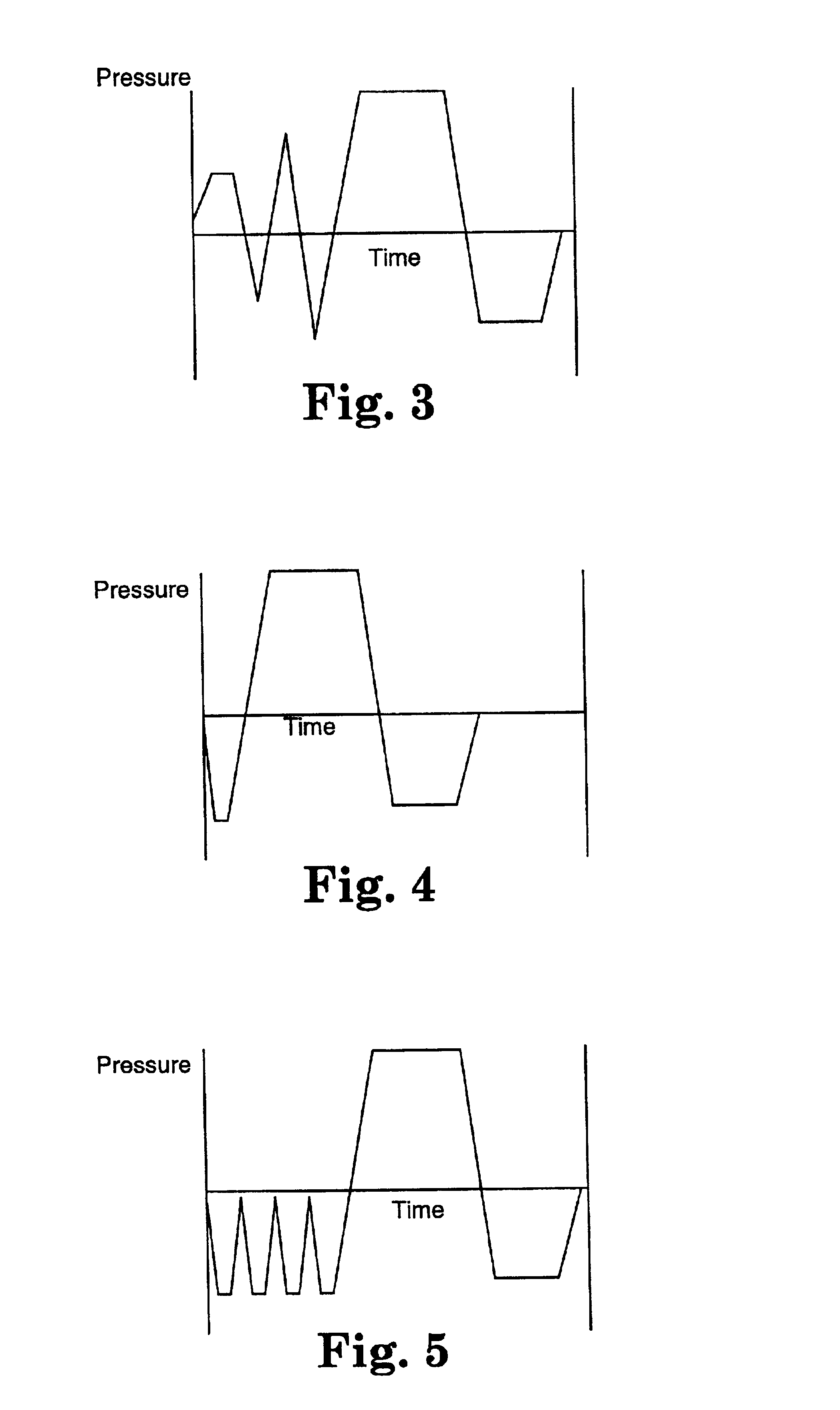

Method and apparatus for two-step sterilization

InactiveUS20080240978A1Maximize efficiencyEasy to processLavatory sanitoryMechanical vibrations separationWater basedProduct gas

The present invention relates to the field of sterilization of items that are sensitive to e.g. temperature, pH, positive or negative pressure, radiation or oxidation. More particularly, the invention concerns a method, the use of this method and an apparatus for sterilization or disinfection, comprising the steps of contacting one or more item or part of an item with (a) a water-based fluid containing at least one enzyme, and (b) a substantially water-free environment with a gas having oxidative properties, where said step (a) precedes said step (b). According to the invention, items can be sterilized that are otherwise impaired by conventional sterilization procedures, such as laboratory items, medical items, dental items, military items, biological items, and food processing-related items.

Owner:B K MEDICAL

Sterilization indicator with chemically stabilized enzyme

InactiveUS6897059B2Improve the immunityBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholPlasma sterilization

A sterilization indicator for testing the effectiveness of a sterilization procedure comprises a source of an enzyme, a sterilant-resistant chemical associated with the enzyme, and a substrate that reacts with the enzyme to form a detectable enzyme-modified product that provides an indication of the failure of the sterilization procedure. The sterilant-resistant chemical may be a polyglycerol alkyl ester, polyglycerol alkyl ether, an ethoxylated polyhydric alcohol ester, or a polyhydric alcohol ether. The indicator may be used to test the effectiveness of a hydrogen peroxide plasma sterilization procedure and may be provided with a non-challenge test pack or a lumen-challenge test pack.

Owner:3M INNOVATIVE PROPERTIES CO

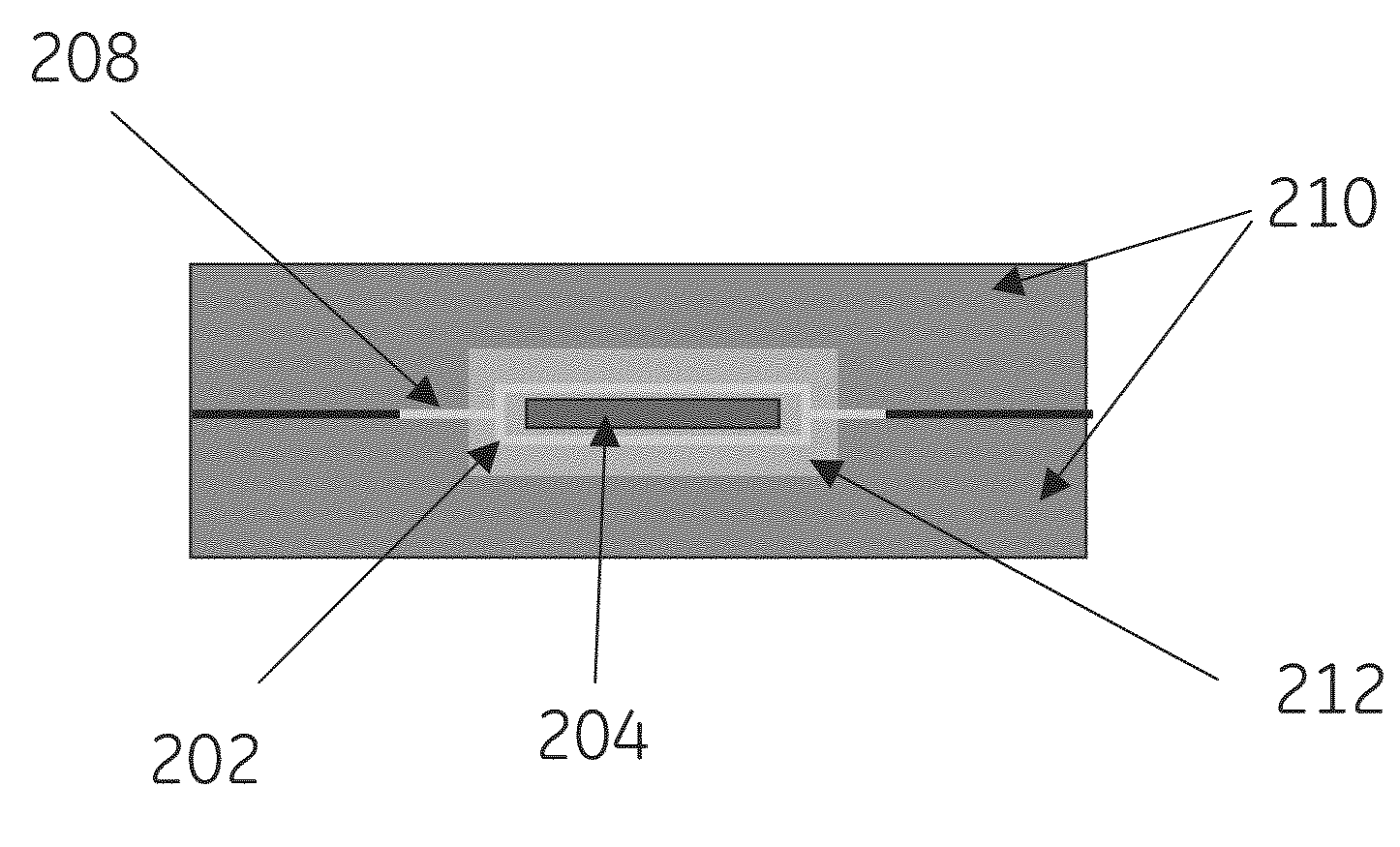

Encapsulated RFID tags and methods of making same

InactiveUS20100259393A1Increase resistanceHigh strengthSemiconductor/solid-state device detailsSynthetic resin layered productsBreaking strengthInjection molding process

Encapsulated radio frequency identification (RFID) articles having enhanced break strength and / or temperature resistance and methods of making these articles. The RFID articles include an RFID tag embedded within a thermoplastic substrate to form the RFID article. In one embodiment, the RFID article includes an over-molded barrier material that enables the RFID article to have enhanced temperature resistance such that the articles are able to sustain repeated exposure to high temperatures and / or sterilization procedures, thereby enabling the RFID articles to be utilized in applications heretofore unavailable. In other embodiments, the RFID articles are made using an injection molding process that provides very thin encapsulated RFID tags that also exhibit an increased level of temperature resistance.

Owner:SABIC GLOBAL TECH BV

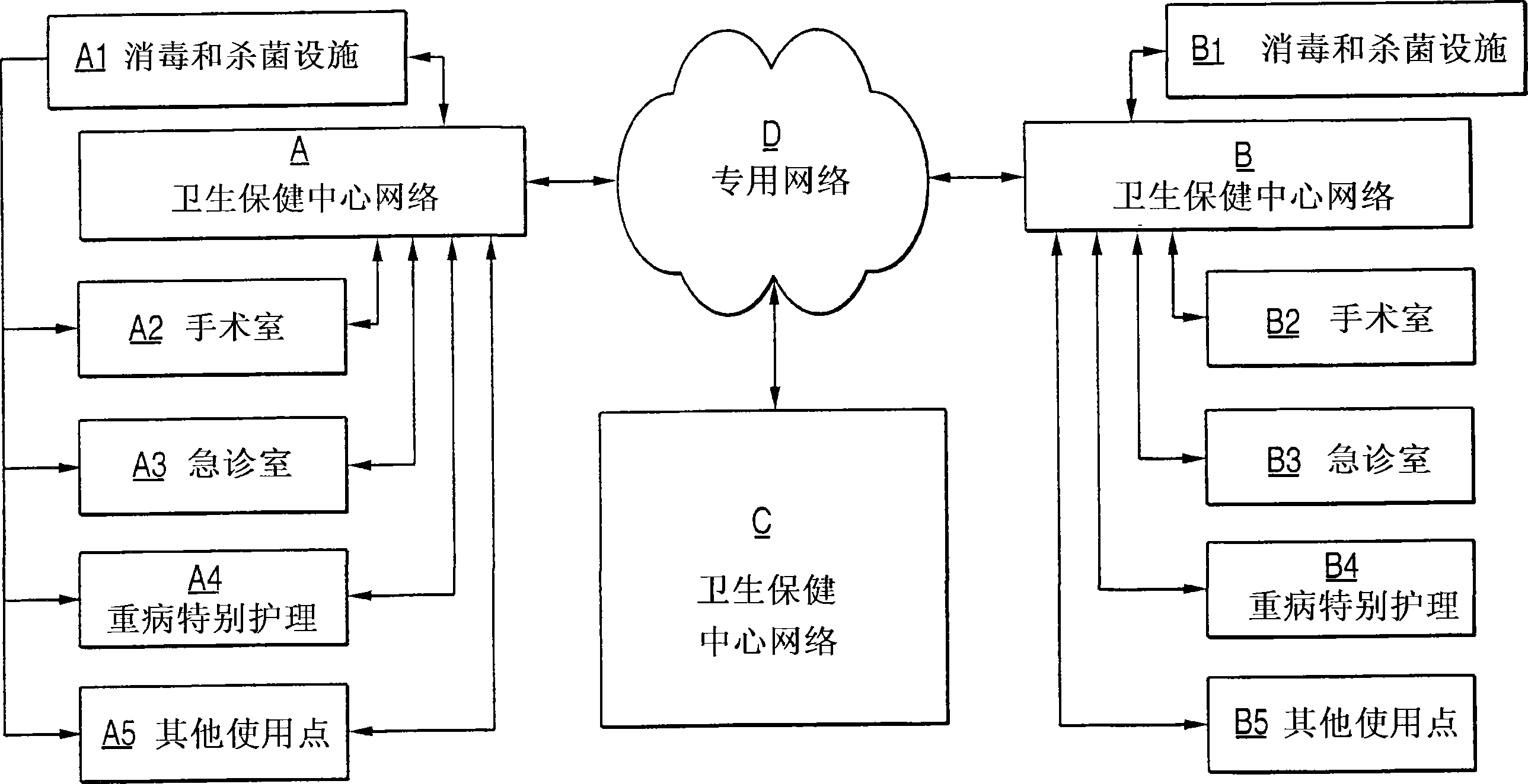

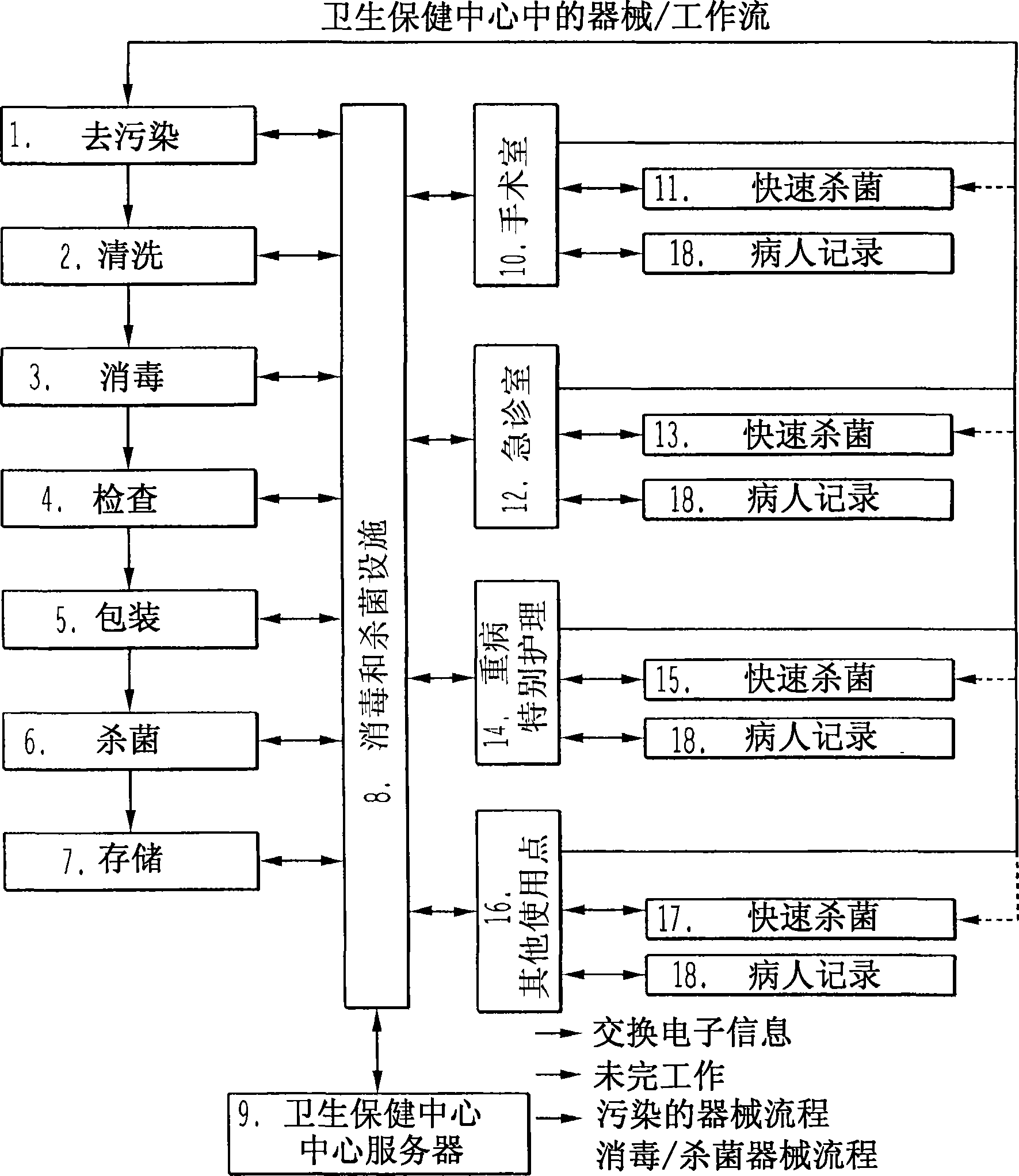

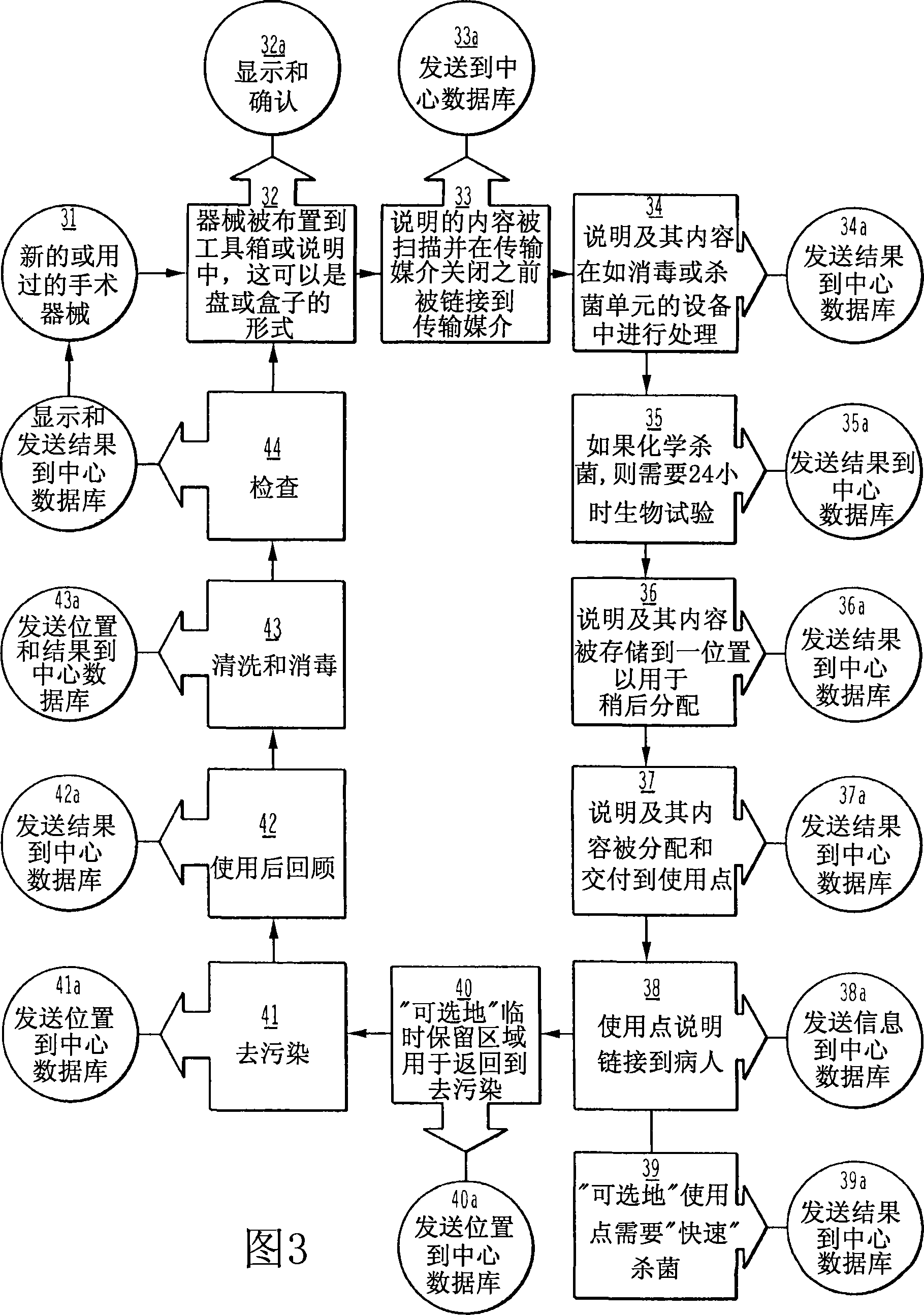

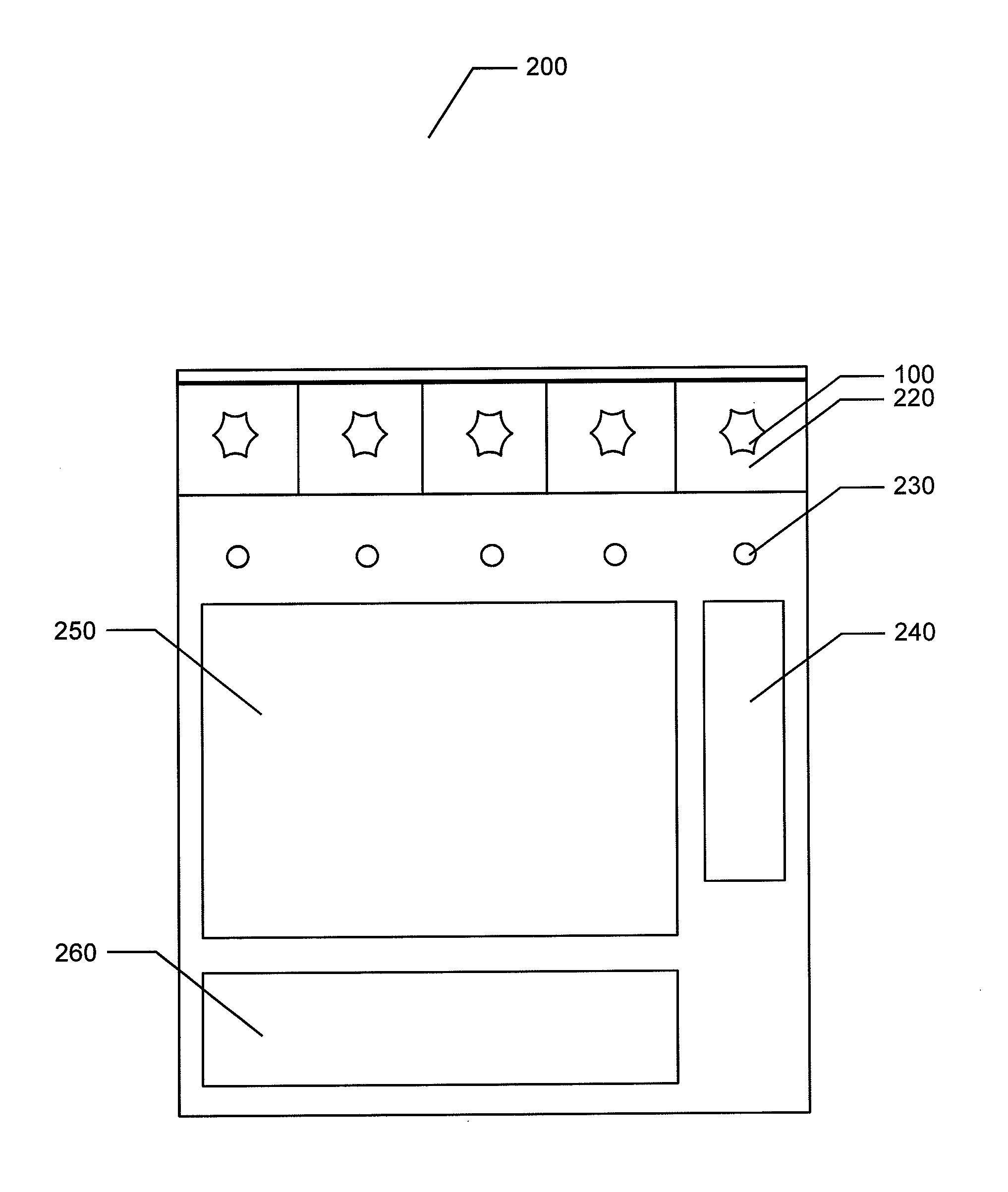

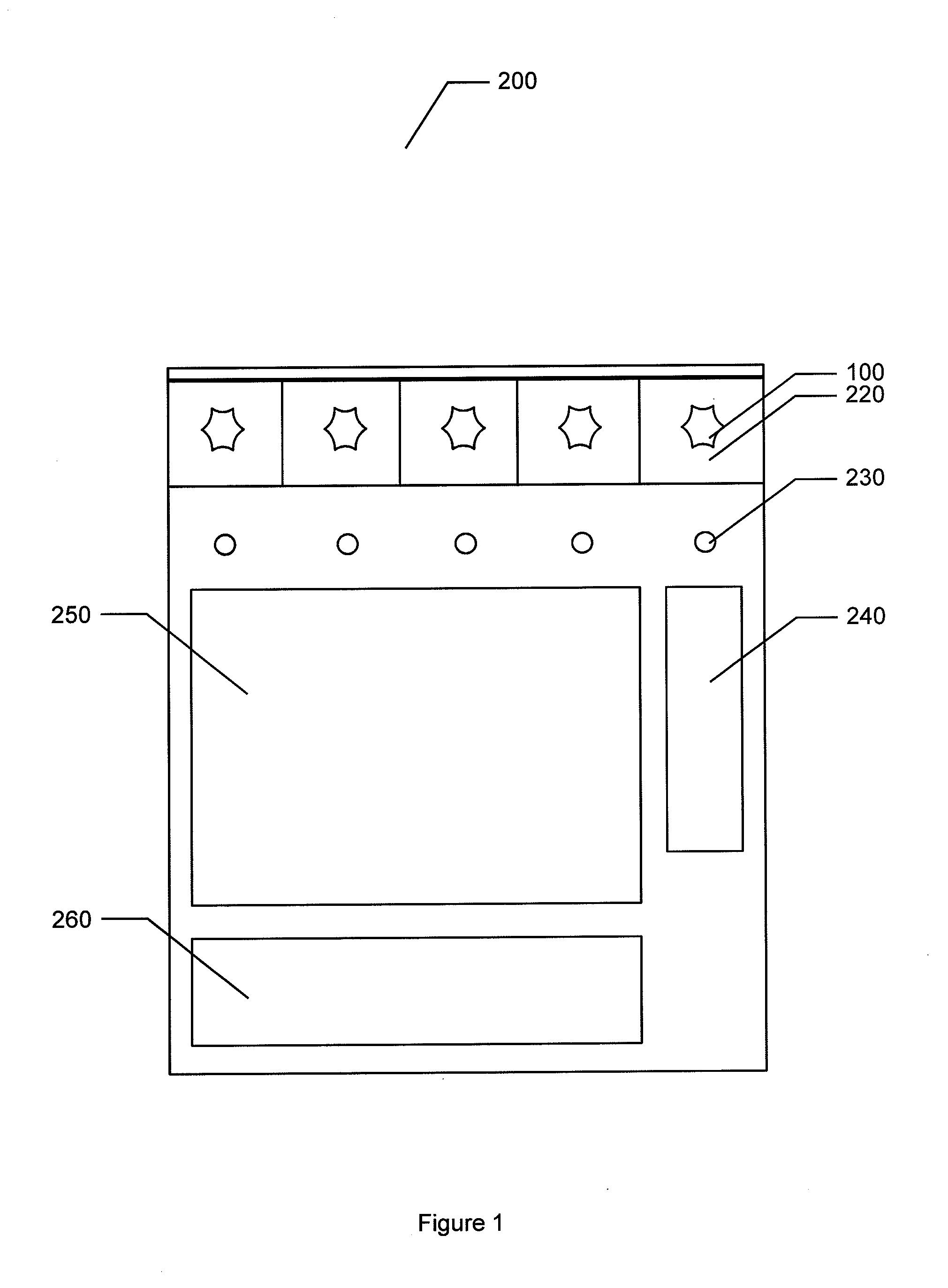

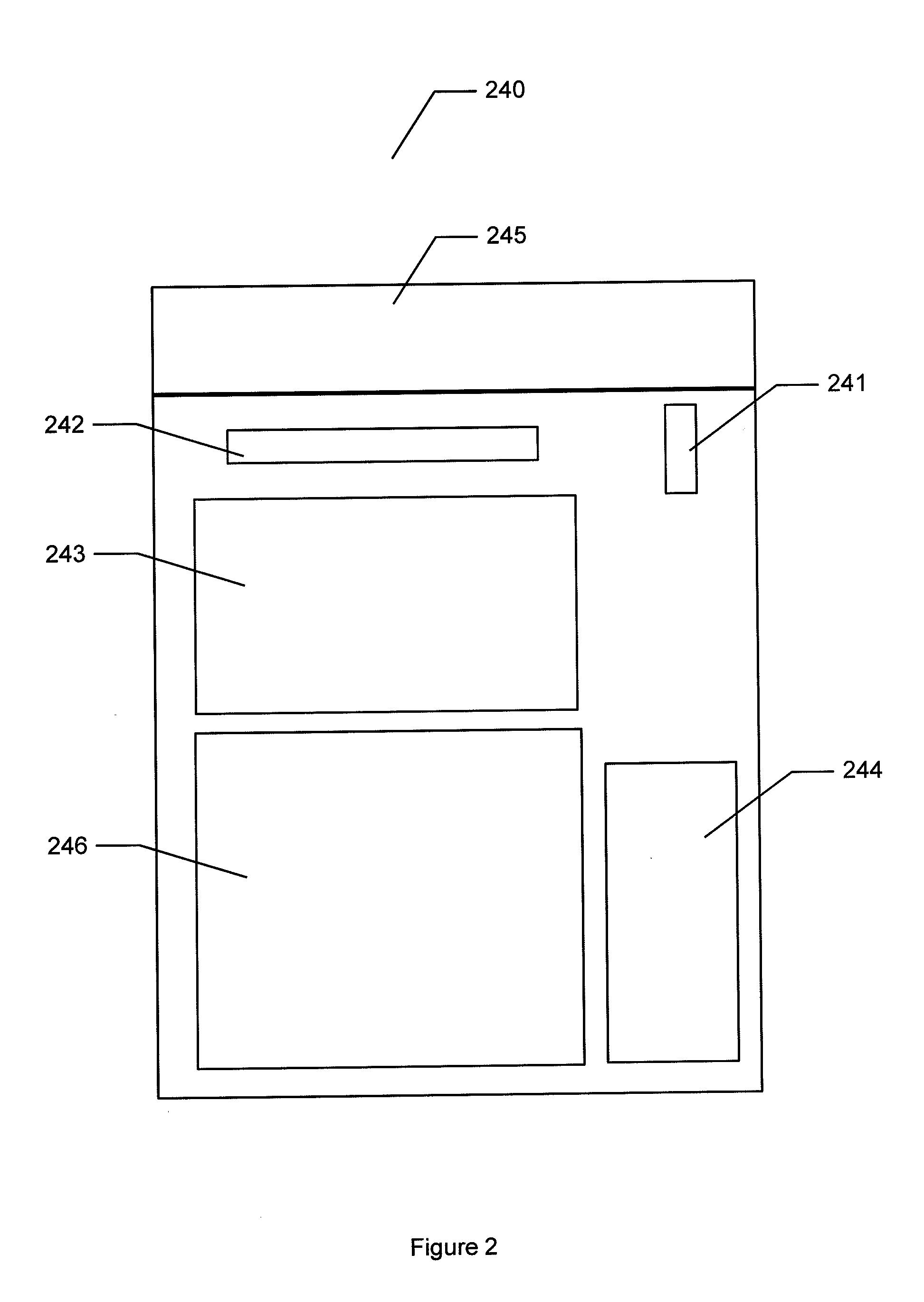

System for management of processed instruments

InactiveCN1918567AMemory record carrier reading problemsLavatory sanitoryComputer terminalHand held devices

An automated system to identify, analyze and record information associated with disinfection and / or sterilization procedures. Individual processing and client devices communicate via a computer network. The client devices such as desktop computers terminals, hand-held devices and / or process devices such as sterilizers, autoclaves, washing and / or disinfection devices are distributed among a health care facility more specifically disinfection and / or sterilization facilities that require processing of surgical instruments. The network server exchanges a variety of information with client devices as well as disinfection and / or sterilization equipment. In response to information from equipment and / or client devices, the network server may trigger decision messages to equipment and / or client devices, as well as generate reports for record keeping or maintenance purposes. The information distributed by the network server may pertain to the operation, maintenance and control of disinfection and sterilization equipment, characteristics and capabilities of instruments, and expert technical advice. The information received from the health care facilities includes requests for information, and process information documenting procedures performed within a health care, disinfection and / or sterilization facility.

Owner:赛康,勒克司和温根伯格有限公司分公司

Encapsulated RFID tags and methods of making same

InactiveUS8325047B2Increase resistanceHigh strengthSemiconductor/solid-state device detailsSynthetic resin layered productsBreaking strengthEngineering

Encapsulated radio frequency identification (RFID) articles having enhanced break strength and / or temperature resistance and methods of making these articles. The RFID articles include an RFID tag embedded within a thermoplastic substrate to form the RFID article. In one embodiment, the RFID article includes an over-molded barrier material that enables the RFID article to have enhanced temperature resistance such that the articles are able to sustain repeated exposure to high temperatures and / or sterilization procedures, thereby enabling the RFID articles to be utilized in applications heretofore unavailable. In other embodiments, the RFID articles are made using an injection molding process that provides very thin encapsulated RFID tags that also exhibit an increased level of temperature resistance.

Owner:SABIC GLOBAL TECH BV

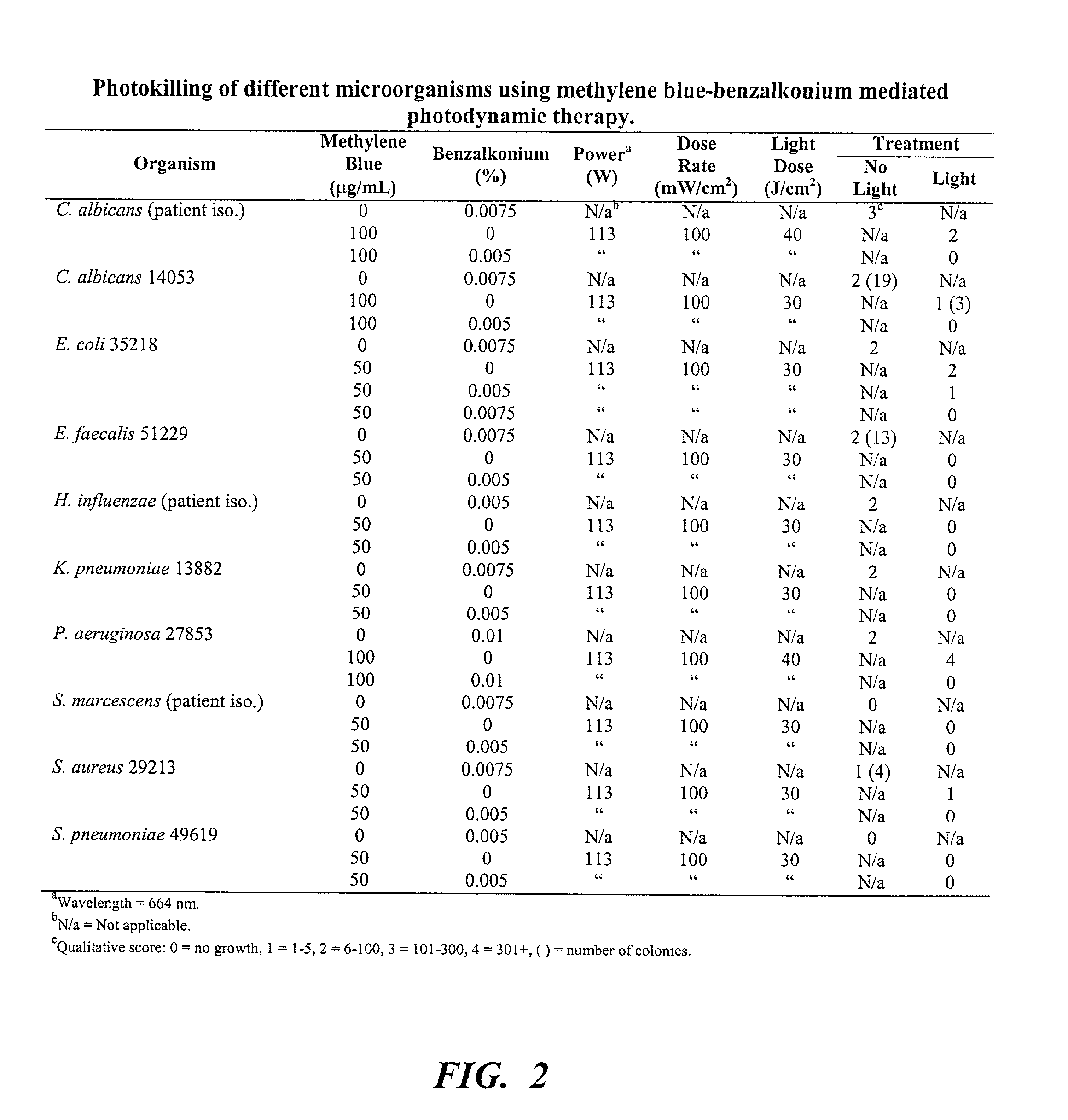

Photodynamic cellular and acellular organism eradication utilizing a photosensitive material and benzalkonium chloride

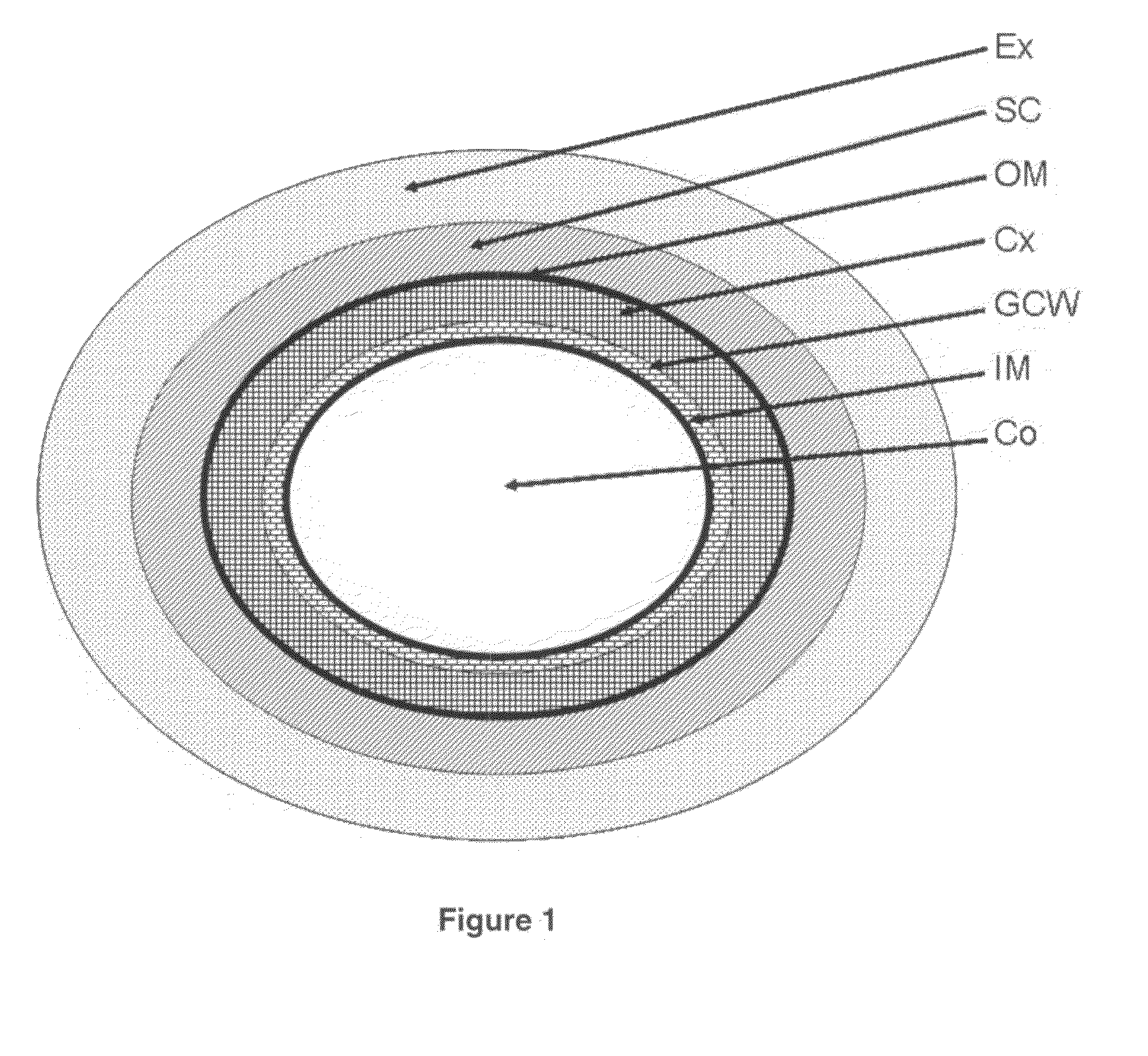

ActiveUS8187278B2Limited applicabilityReduce normal tissue toxicityPhotodynamic therapyLight therapyCancer cellOrganism

The invention relates to a method of photoeradication of cellular and acellular organisms including the steps of providing a surface acting agent containing benzalkonium chloride in association with a cellular or acellular organism, the surface acting agent disorienting a membrane structure so that said membrane no longer functions as an effective osmotic barrier; providing a photosensitive material in association with the cellular or acellular organism; and applying light in association with the cellular or acellular organism to cause a disruption of the organism. The method according to the present invention may be utilized in invitro and invivo treatment protocols for infections, sterilization procedures, cancer cell eradication, virus and fungus eradication, spore eradication, and biofilm organism eradication. Additional aspects of the invention include particular combinations of photosensitive materials and surfactants for use in photodynamic therapies.

Owner:ADVANCED PHOTODYNAMIC TECH

Methods for aseptic packaging of low-acid foods

ActiveUS20150239594A1Readily apparentPackage sterilisationStopper pretreatmentSterile environmentHermetic seal

The present disclosure relates to methods of maintaining sterility of an aseptic work zone of a blow-fill seal operation so that low acid foods may be aseptically processed and packaged. The methods of the present disclosure further provide for maintain the sterility of the aseptic work zone such that the aseptic work zone does not have to be enclosed in a separate sterile environment during the blow fill seal process. The methods of the present disclosure further provide a sterilization procedure that is compliant with FDA regulations related to the aseptic packaging of low acid food products. Further disclosed, are methods for producing a hermetically sealed container containing a low acid food product.

Owner:MEAD JOHNSON NUTRITION

Method for cultivating chicken leg mushroom under forest

InactiveCN101347079AReduce possessionPromote growth and developmentBio-organic fraction processingOrganic fertiliser preparationGrowth managementFermentation

The invention belongs to an edible fungi cultivation method, and in particular relates to a coprinus comatus underwood cultivation method, which comprises the following steps: the specific underwood condition of natural canopy under a forest is utilized, the corprinus comatus underwood cultivation method adopts two methods based on seasons, namely spring ridge planting and autumn bag cultivation, wherein the ridge planting method comprises the steps of preparing culture materials, digging holes, laying culture materials, seeding, mycelium growth management, soil covering, the management after covering soil, mushroom fruiting period management, inter-flush period management after harvest, and passing summer management; the autumn bag cultivation comprises the steps of preparing culture materials, stacking and fermentation, other management methods which are the same as those in the spring ridge planting method, bagging and sterilization, inoculation and cultivation, bag removal and soil covering, and the passing winter management. By adopting the two methods of the spring ridge planting and the autumn bag cultivation, the coprinus comatus underwood cultivation method does not need spring sterilization procedure, thus saving manpower and cost, and the autumn cultivation method can shorten mycelium growth time, so that the production cost can be reduced.

Owner:FUXIN SANJIANG EDIBLE FUNGUS SCI & TECHDEV

Sanitary dispensing device with removable display

InactiveUS20120286038A1Increase consumer confidenceFast and effective and inexpensiveStampsArticle advertisingPaymentProduct selection

A sanitary dispensing device for dispensing and storing products is disclosed. The sanitary dispensing device comprises a product display area for displaying products or pictures of products, product selection switches for selecting a product for purchase, a payment exchange area for receiving payment, and a product retrieval area for retrieving purchased products. The sanitary dispensing device further comprises a removable display for displaying information such as product information, instructional information, or dynamic advertising. The sanitary dispensing device further comprises an ultraviolet light module for performing sterilization procedures on the products, product packages, and currency. The sanitary dispensing device further comprises a hands sterilization module for sterilizing a user's hands.

Owner:WU MING YUAN

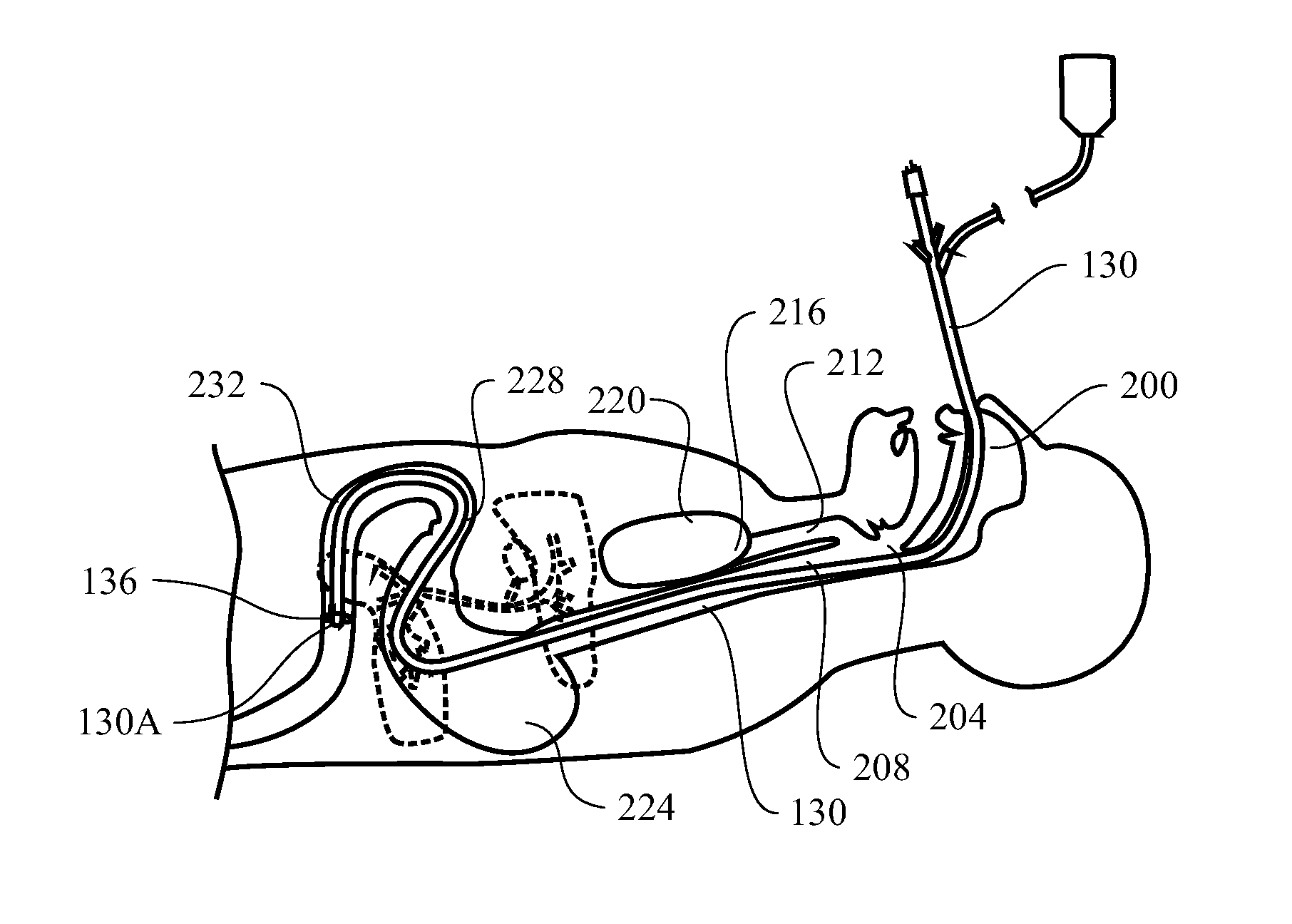

Optically guided medical tube and control unit assembly and methods of use

ActiveUS20120116161A1Solve the lack of spaceLarge outer diameterGastroscopesOesophagoscopesFeeding tubeBiomedical engineering

An optical medical tube and control unit assembly and methods of using the same are provided. The optical medical tube may include a steering mechanism and an imaging device which provides the user a visual aid when placing a tube in the body of a patient. The optical medical tube may be coupled to a coupling adaptor to enable quick and easy connecting of the imaging device and steering mechanism of the tube with a control unit such that a single control unit may be used to place multiple feeding tubes or confirm that a feeding tube remains in its proper position without the need for lengthy sterilization procedures between uses.

Owner:THE UNIV OF UTAH

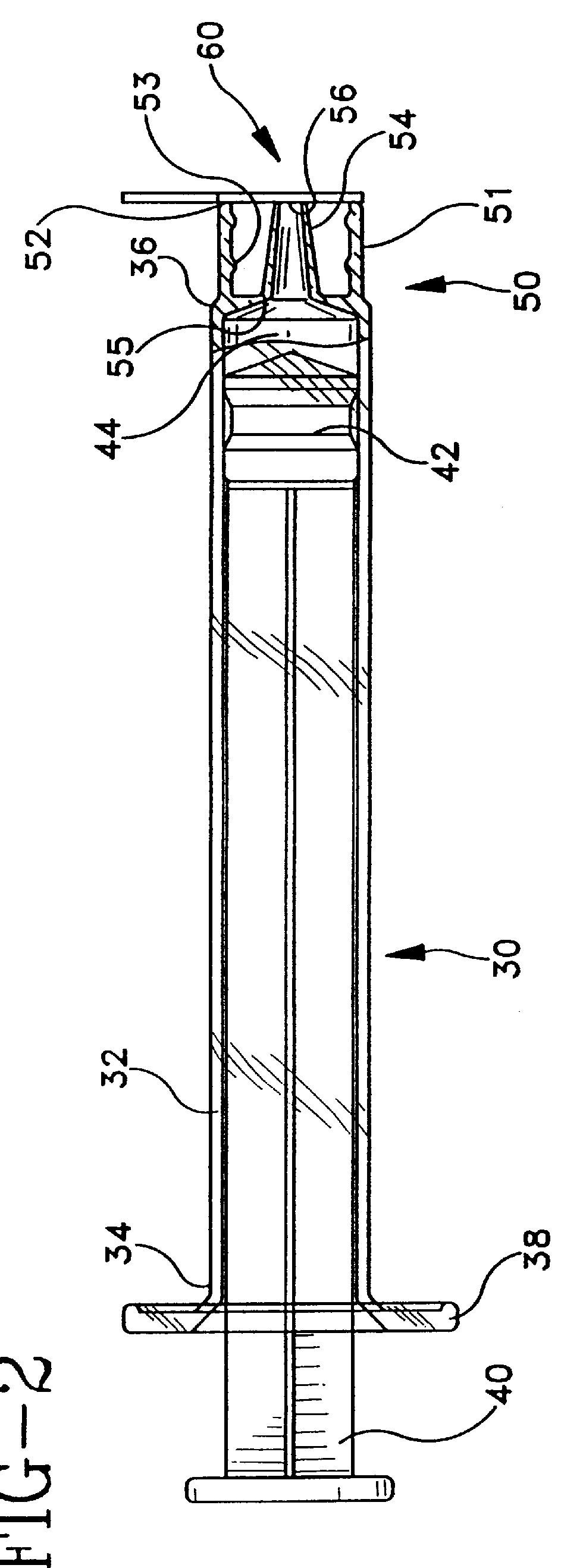

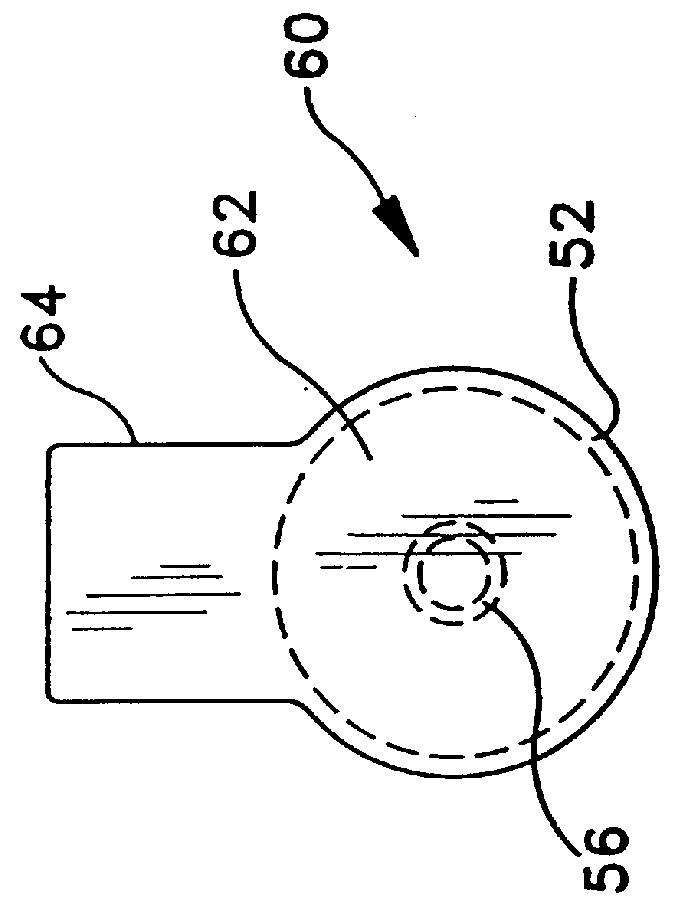

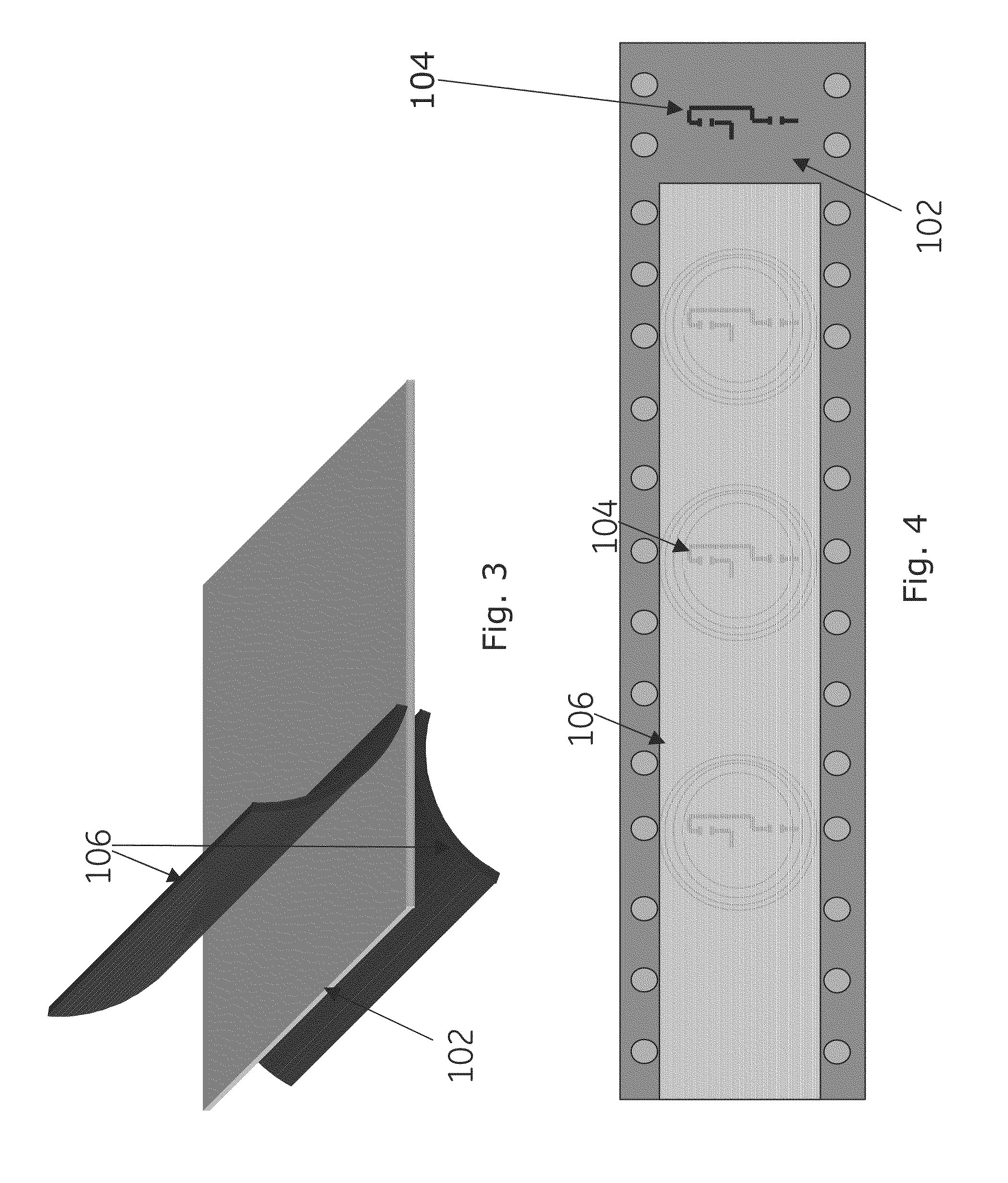

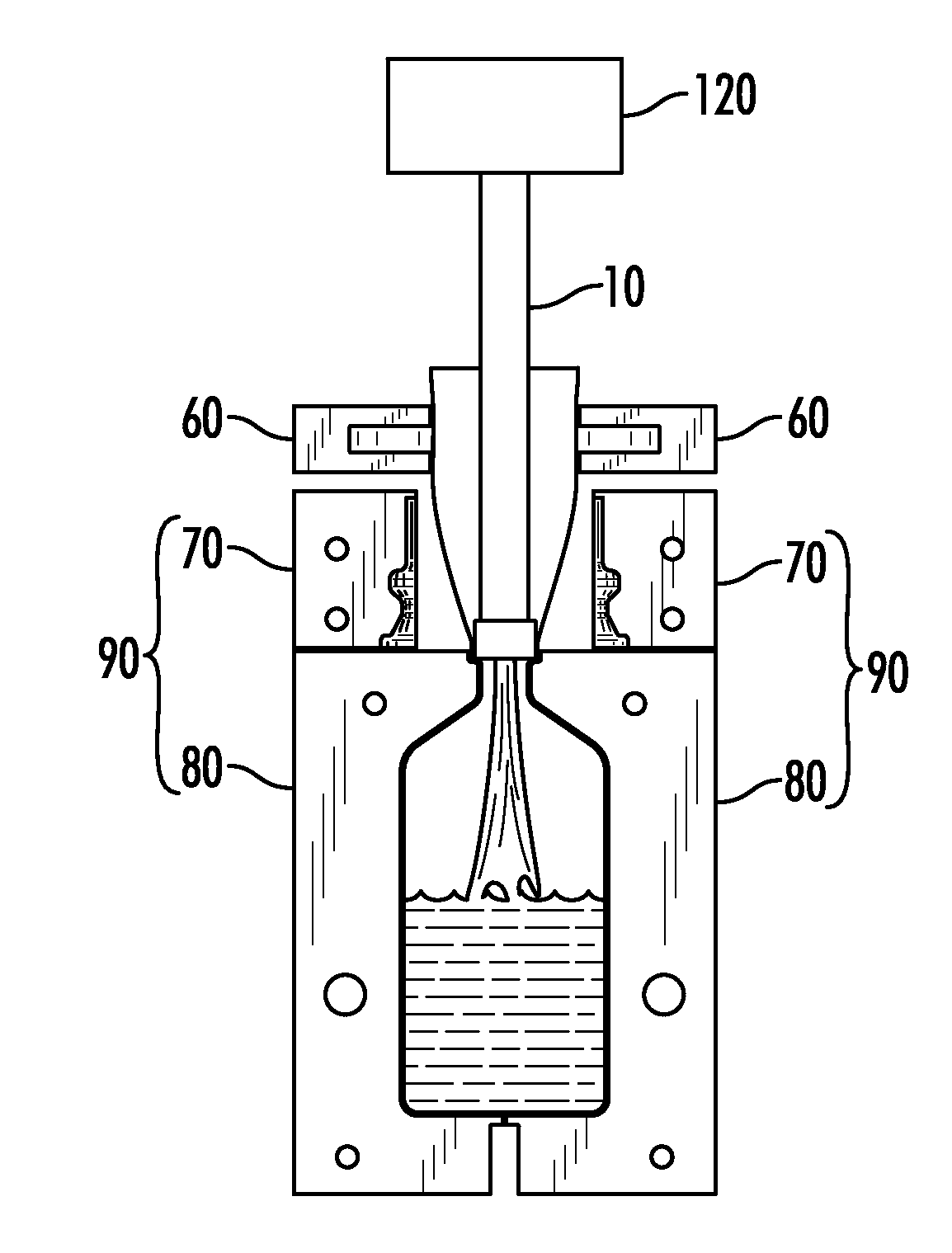

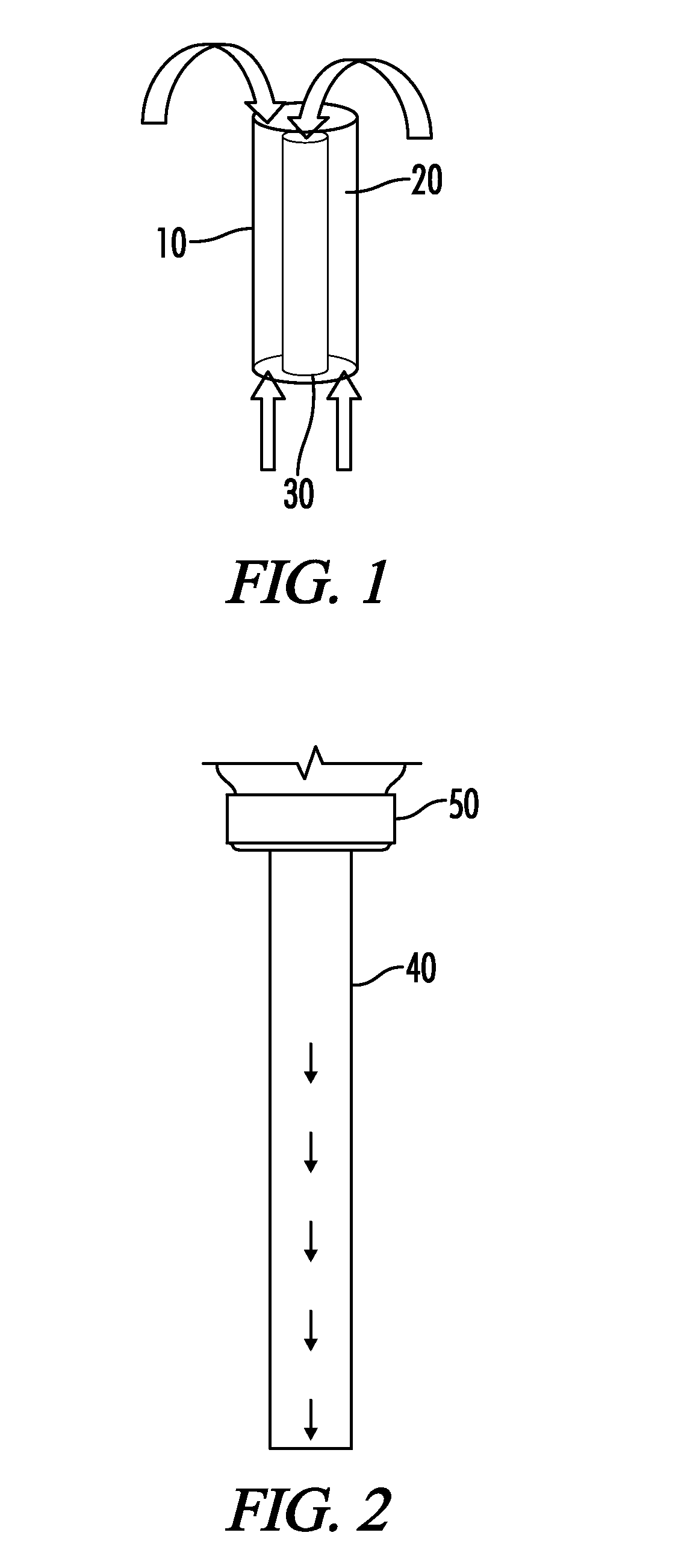

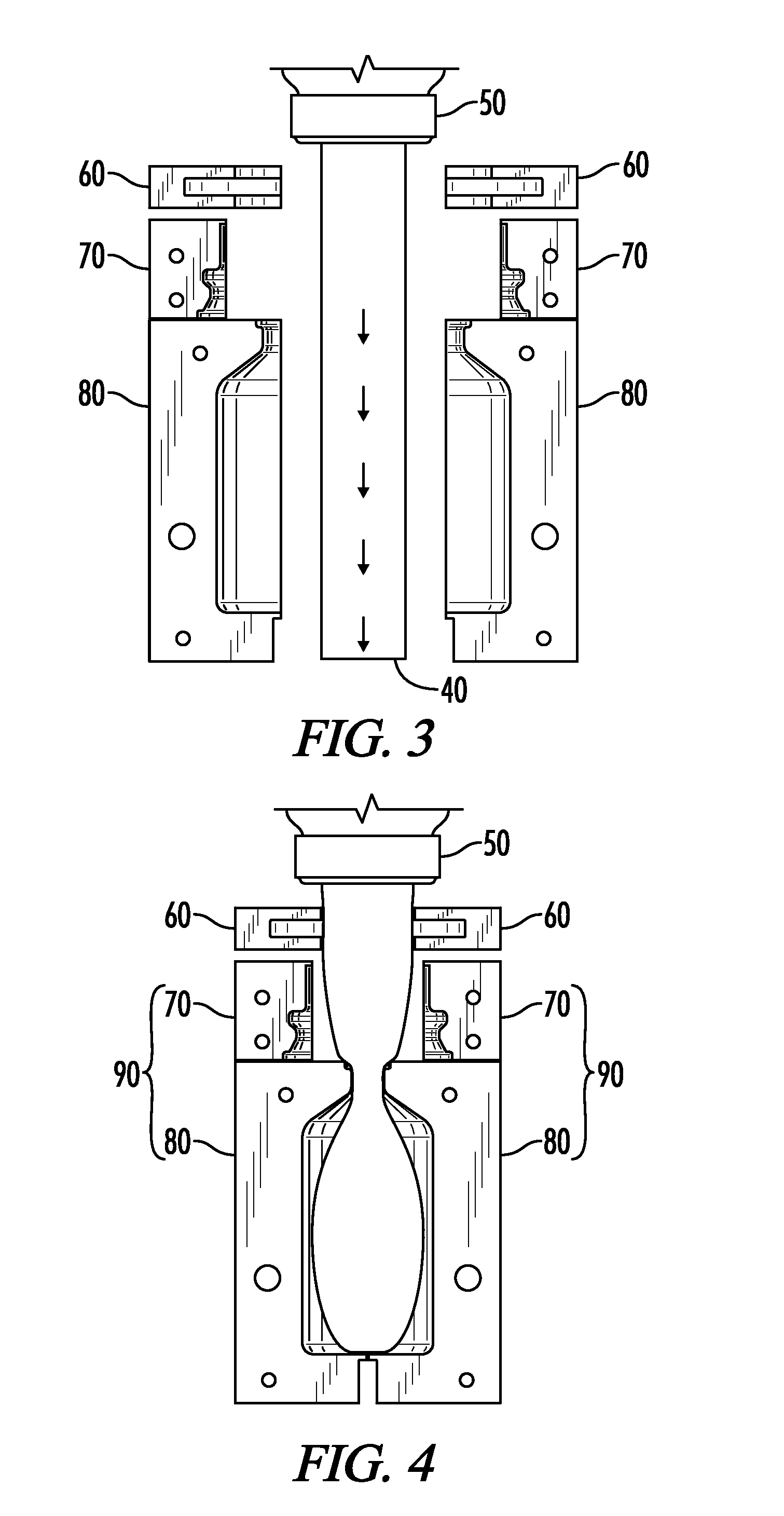

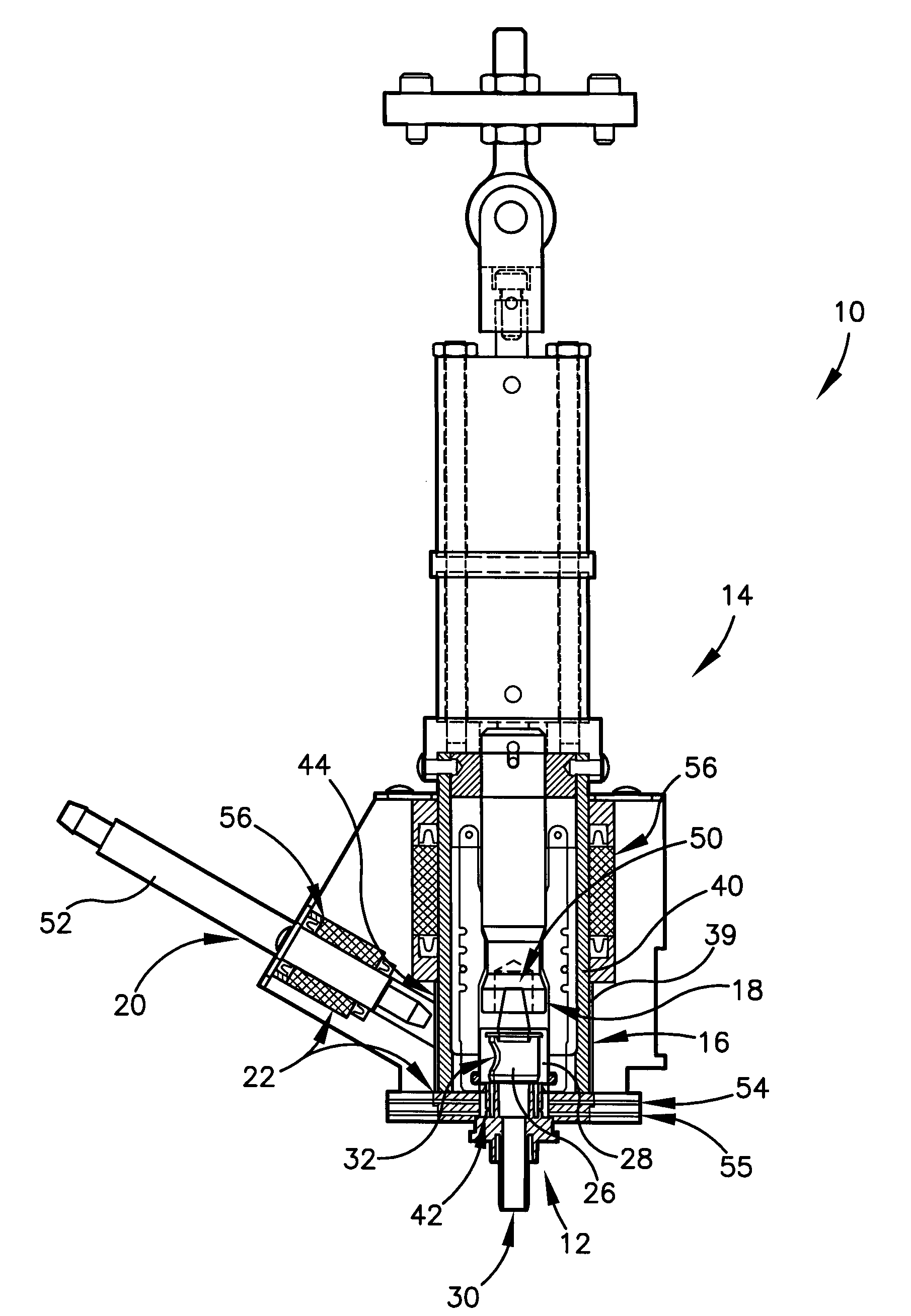

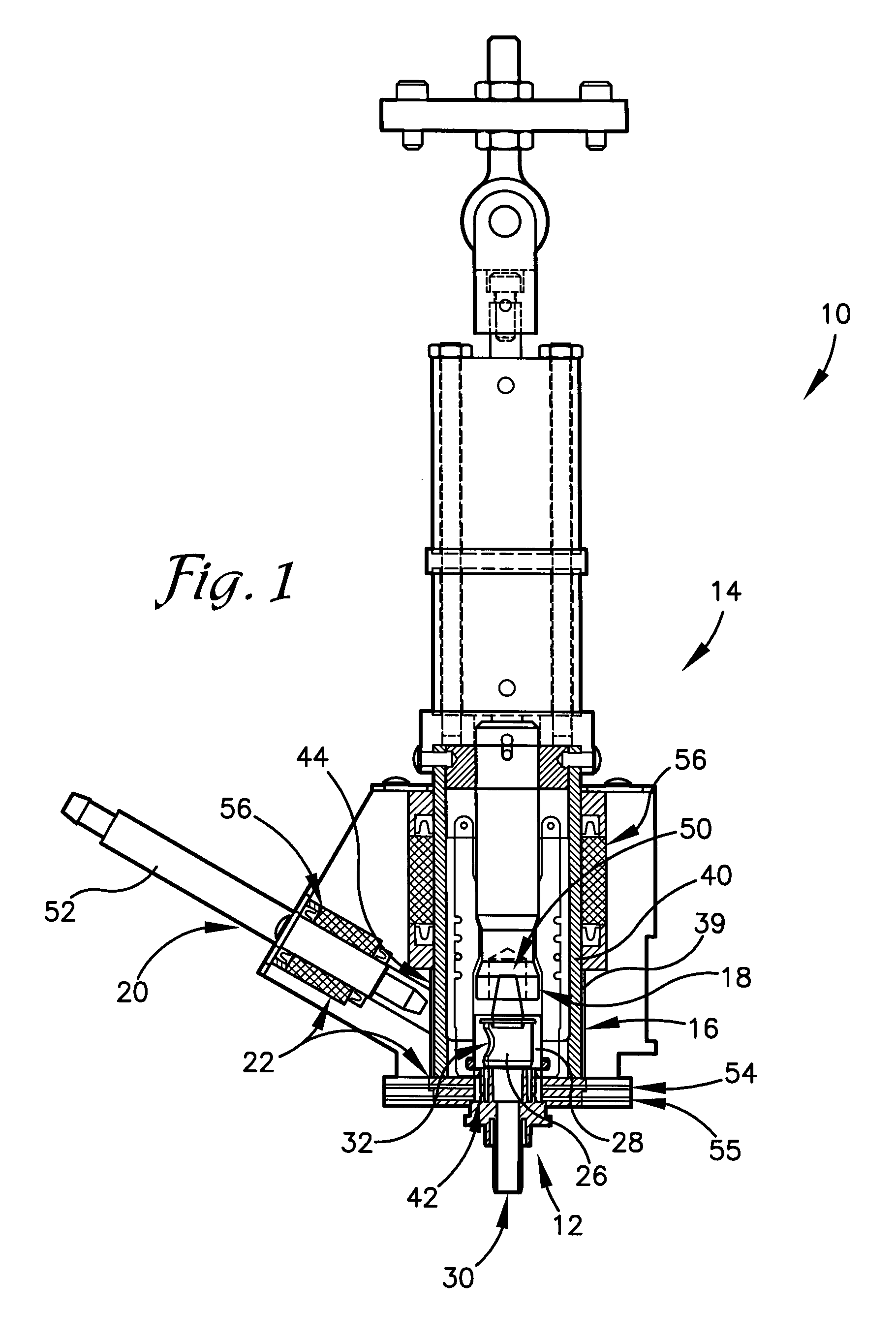

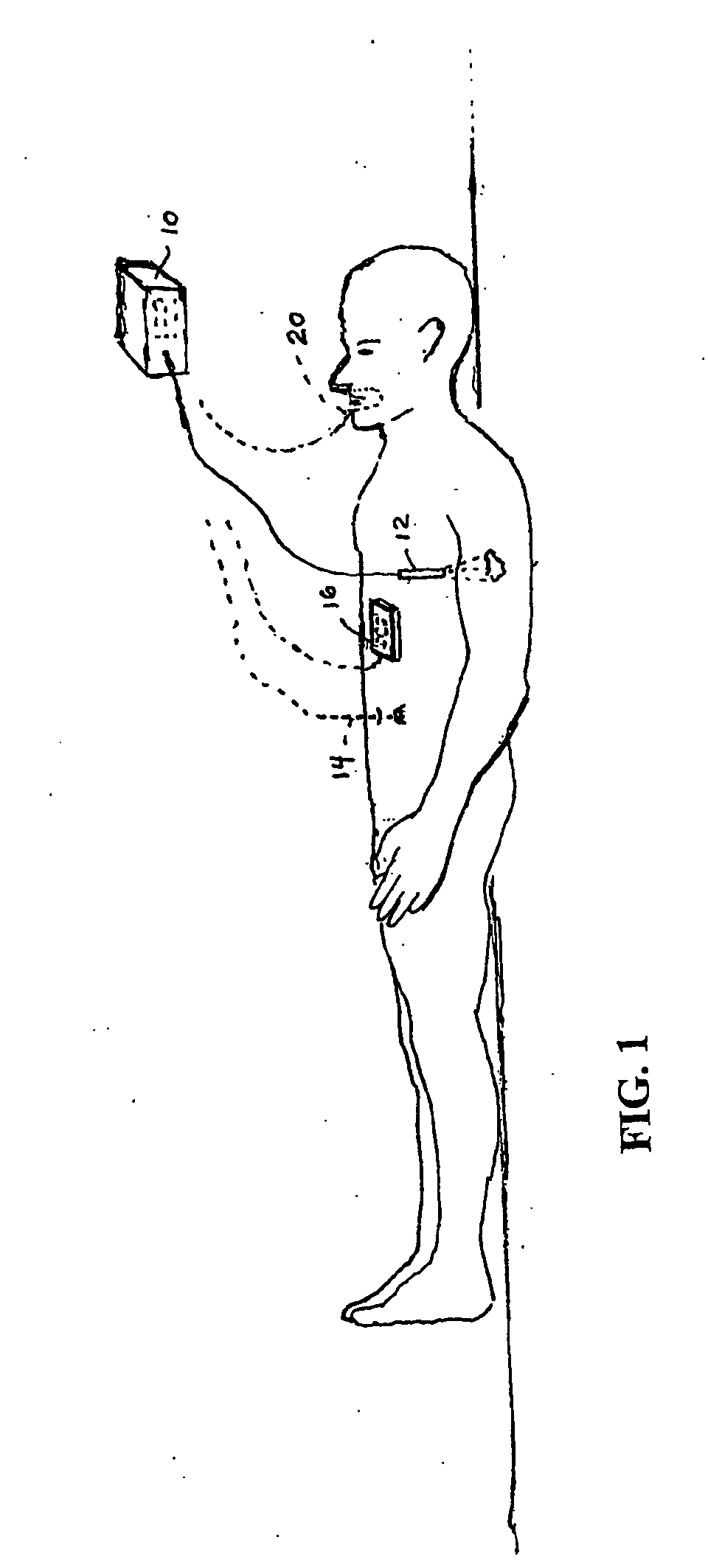

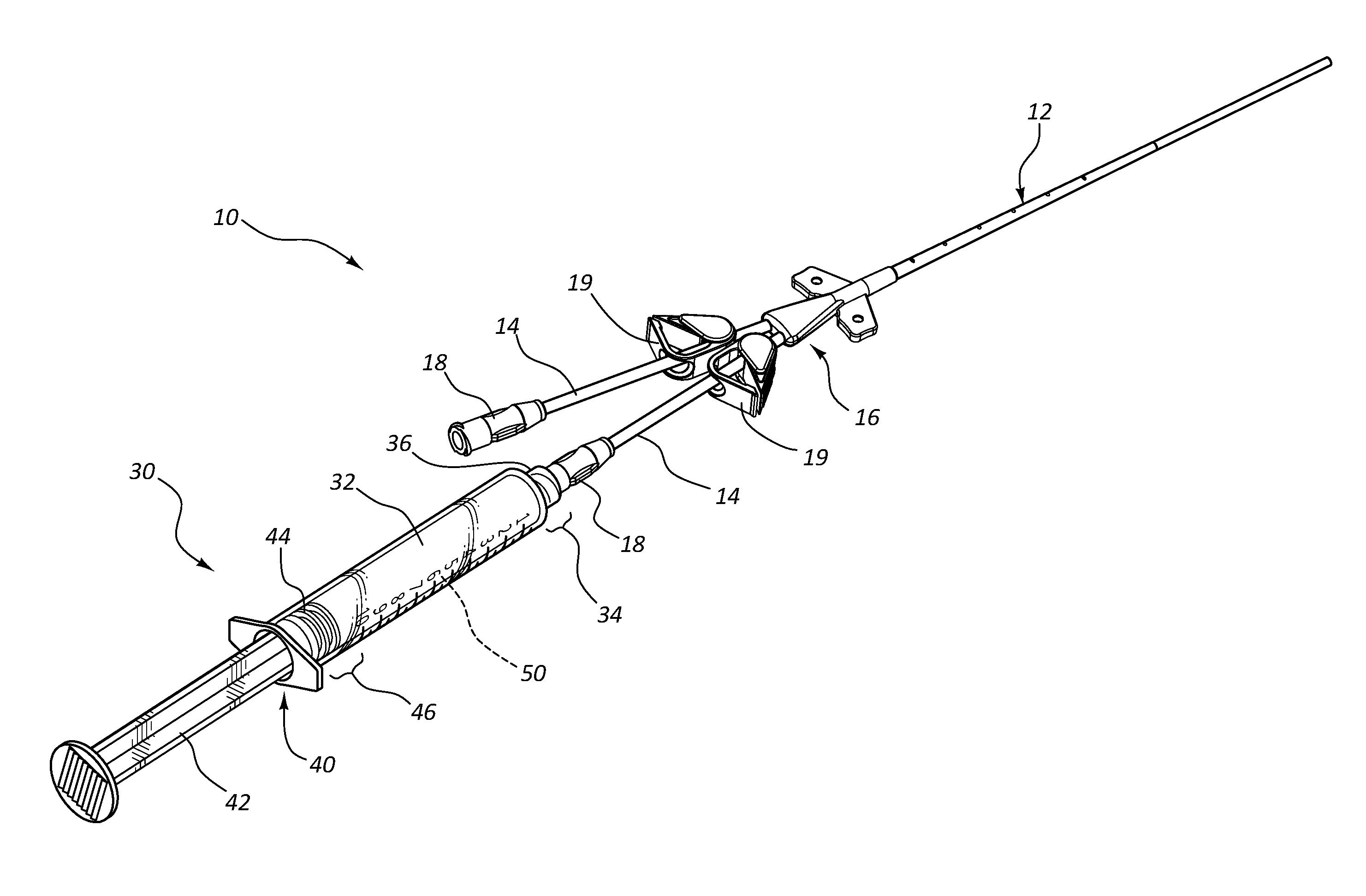

System and method for filling containers

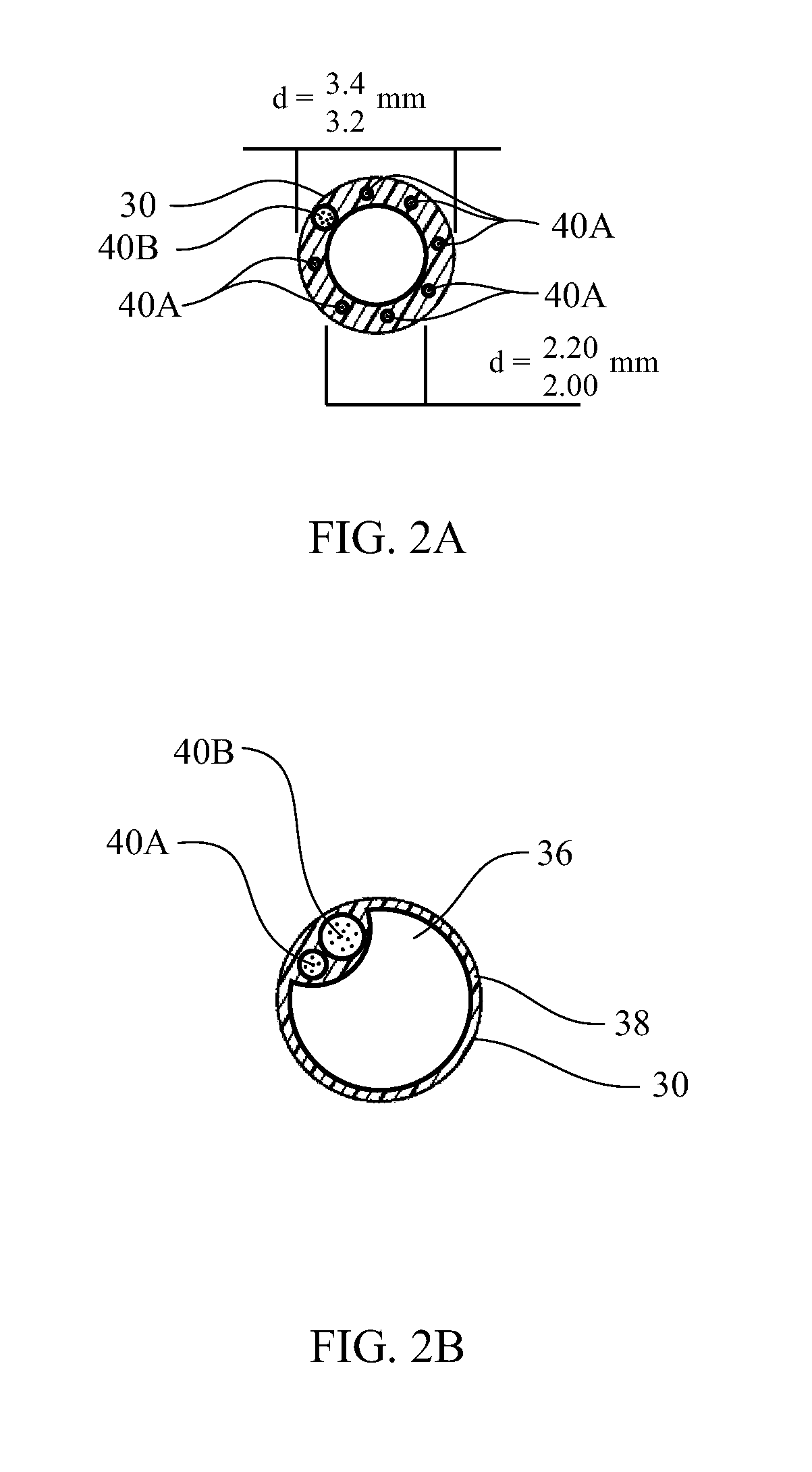

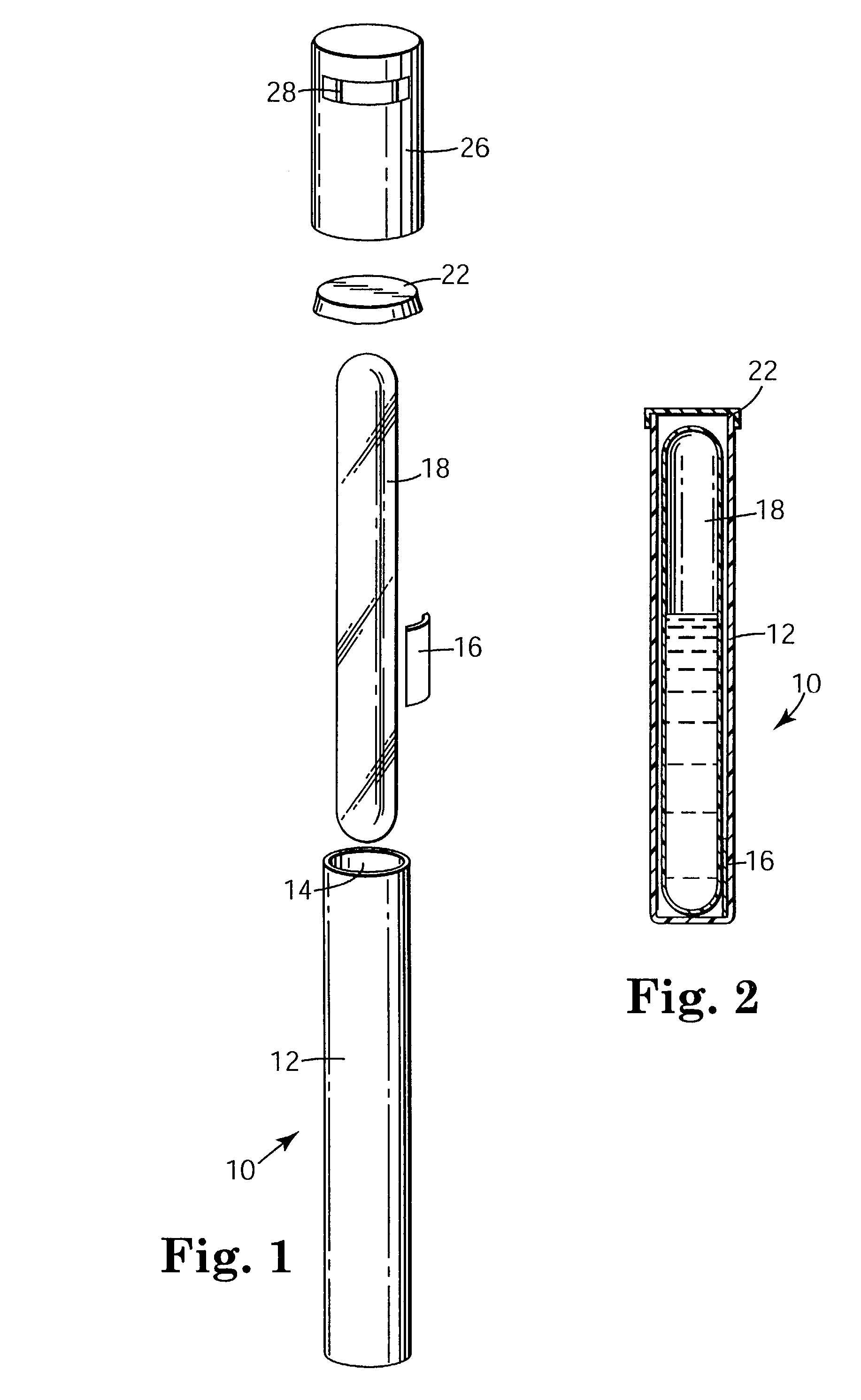

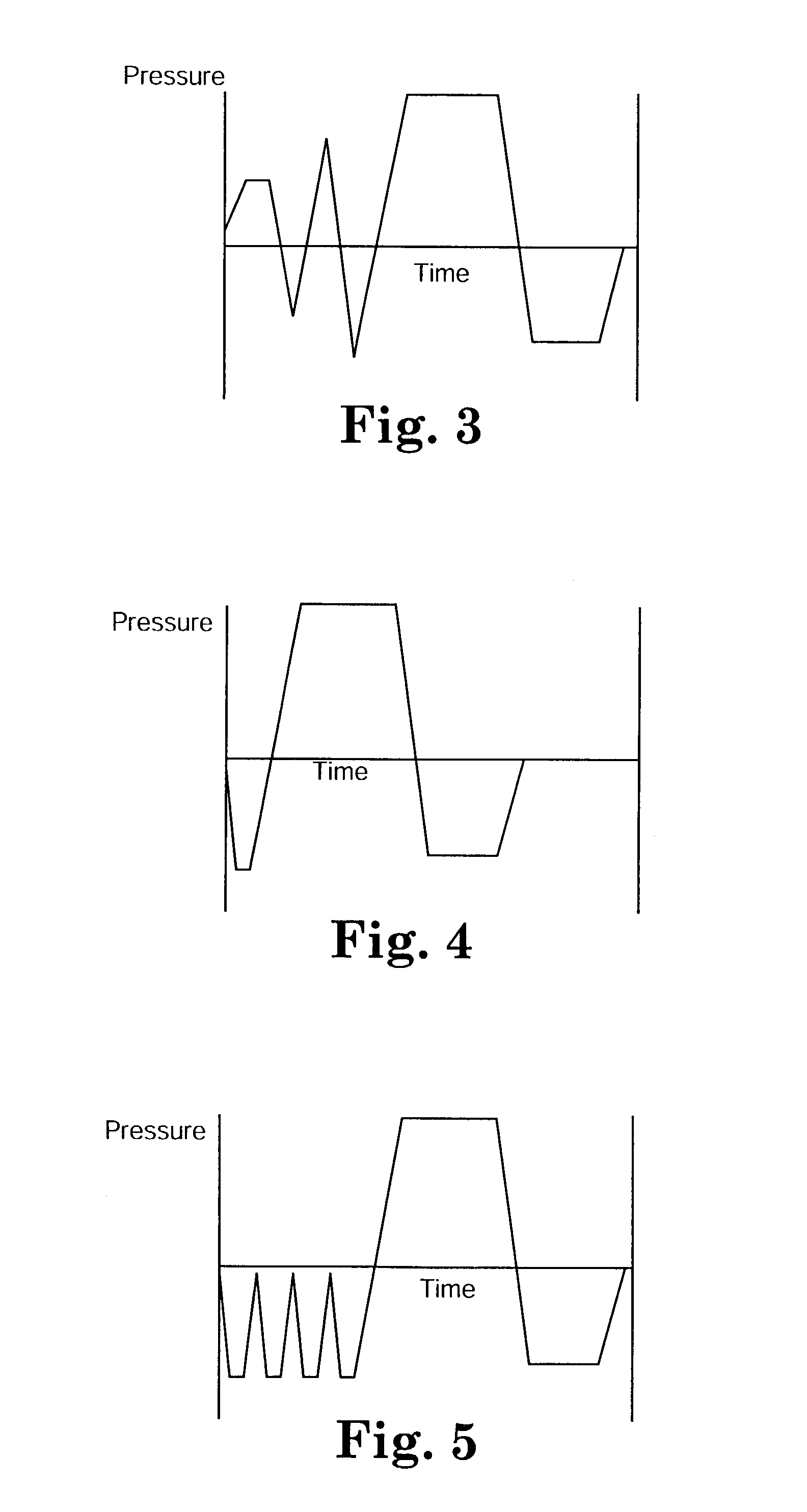

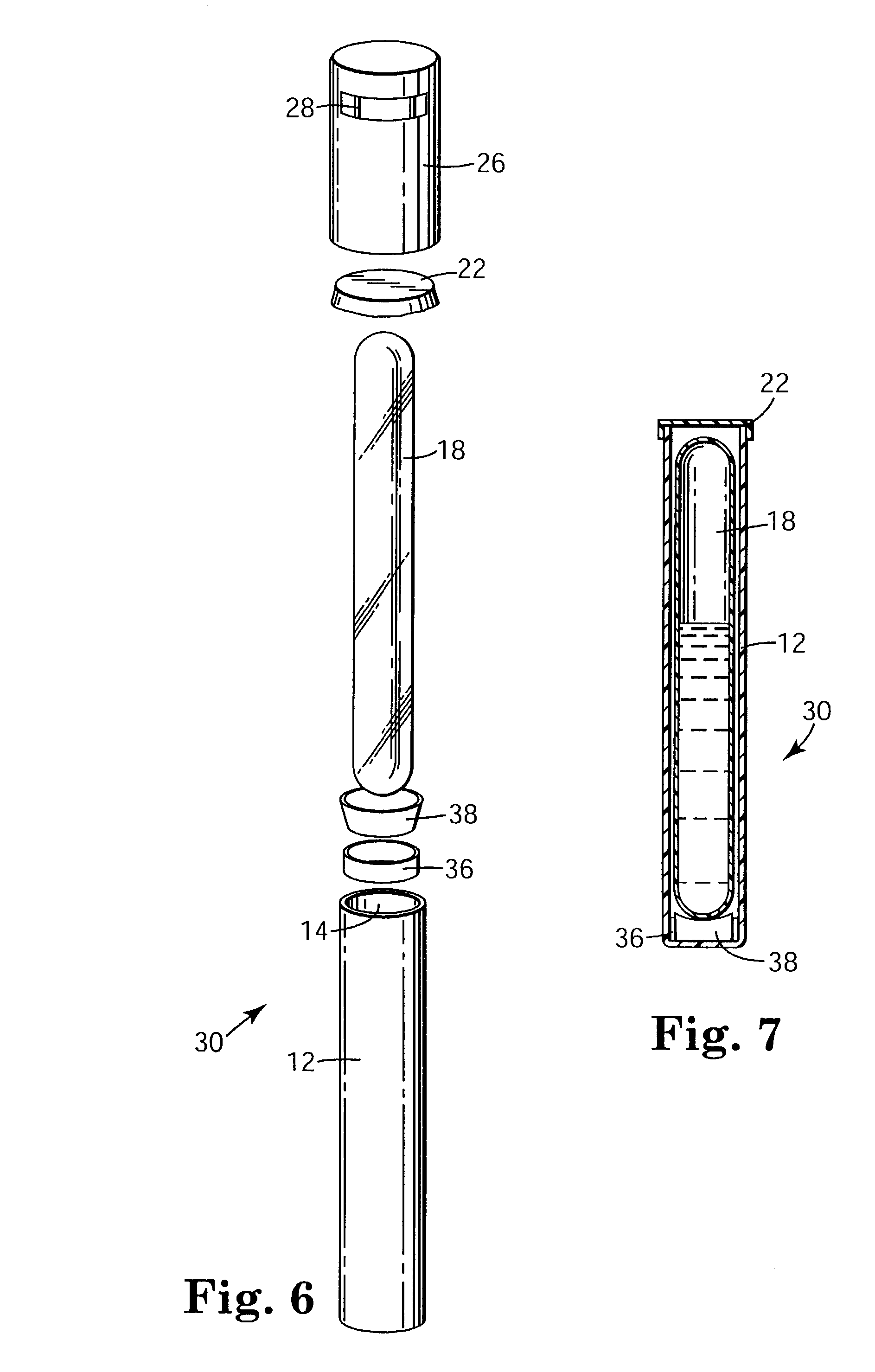

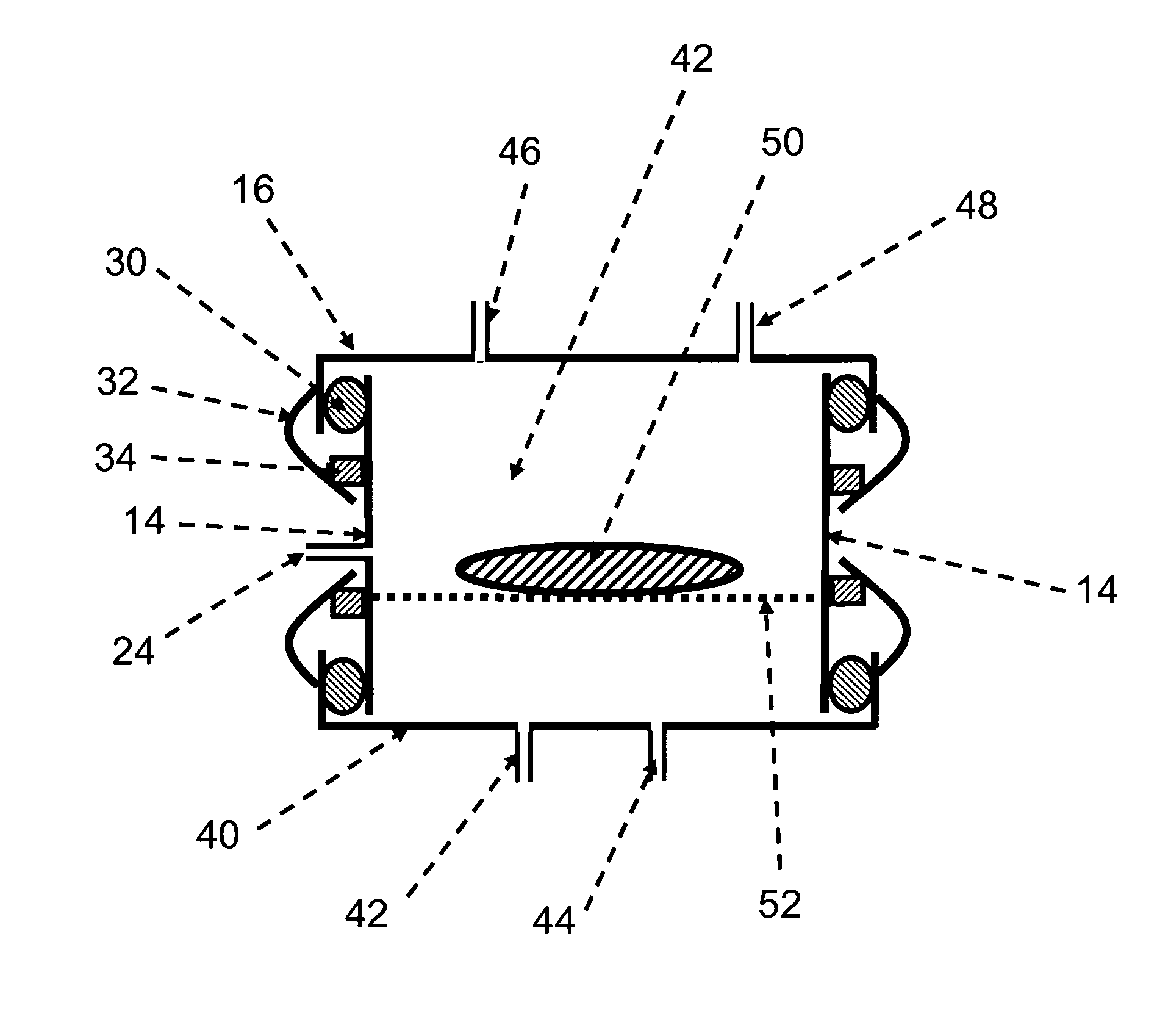

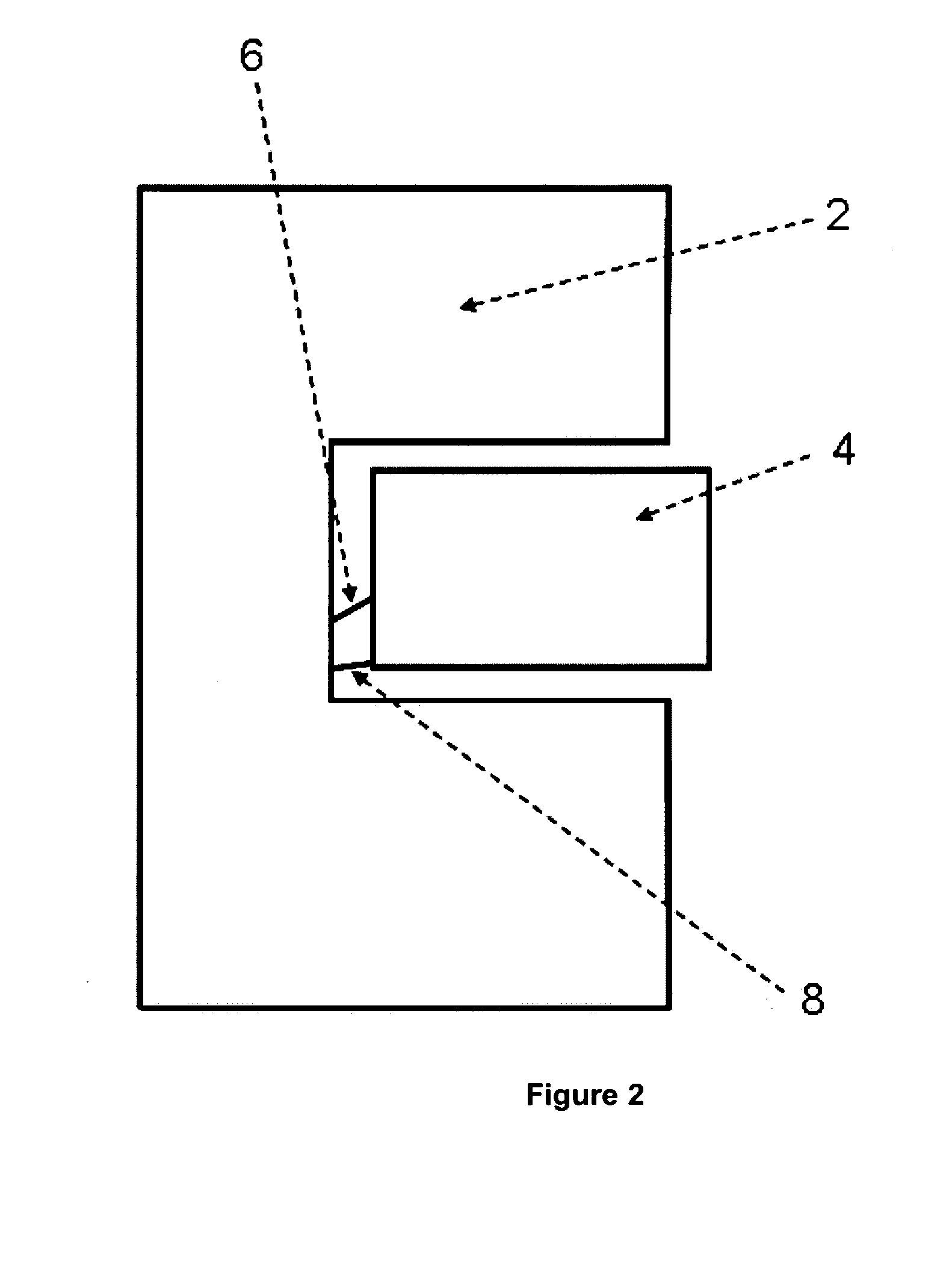

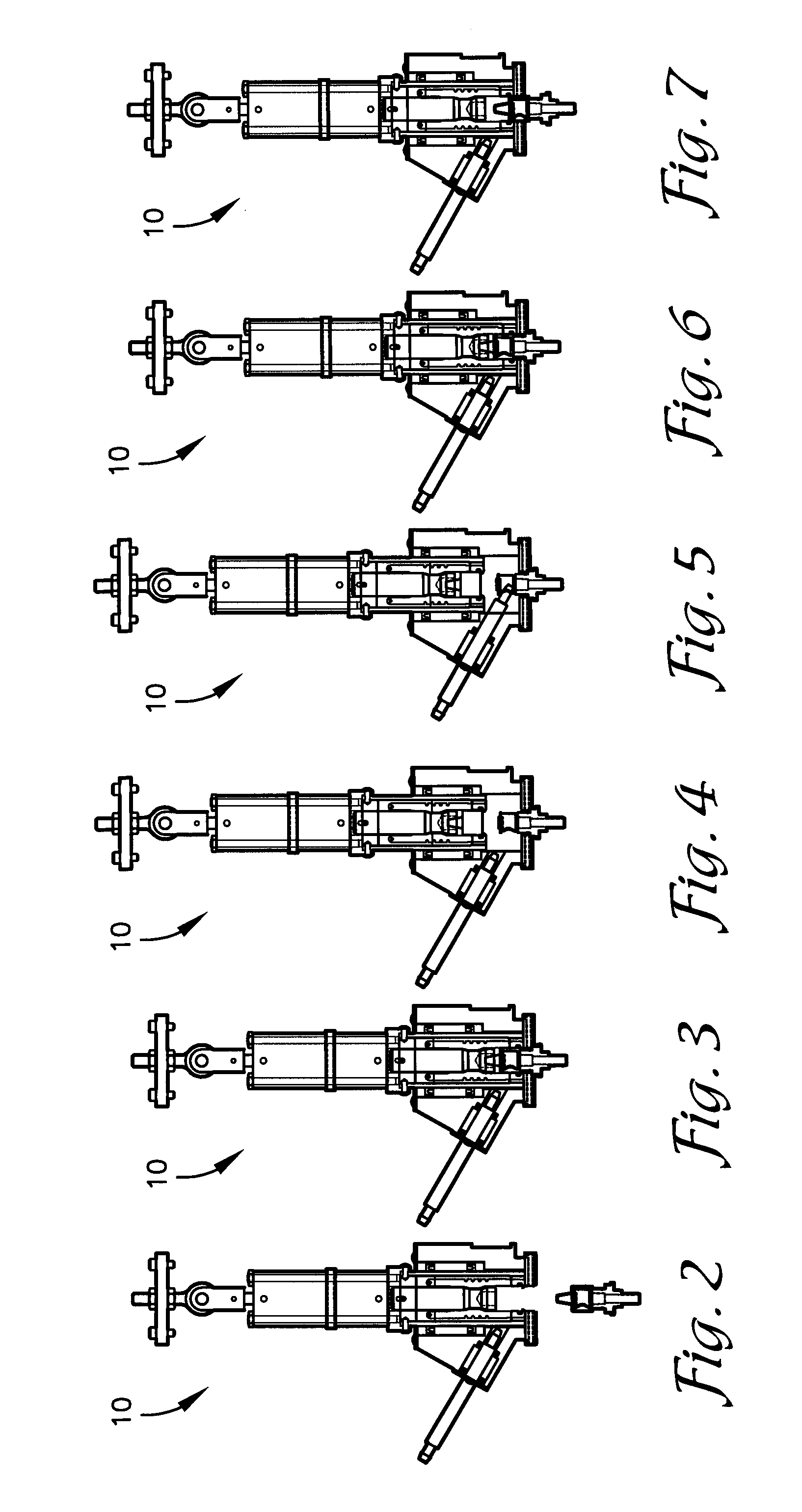

ActiveUS20070277904A1Eliminate wasteMore transfer of fluidPlug valvesBarrels/casks fillingEngineeringSterilization procedure

A system (10) and method for substantially automatically aseptically or non-aseptically filling a container with a fluid. The transfer of fluid occurs via a movable nozzle mechanism (20) substantially automatically inserted into a side opening (32) in a connector (12) attached to the container. More specifically, the side opening (32) in the connector (12) is exposed, the nozzle mechanism (20) is moved into the side opening (32), the fluid is transferred into the container via the nozzle mechanism (20) and the connector (12), the nozzle mechanism (20) is removed from the side opening (32) in the connector (12), and the side opening (32) in the connector (12) is closed. The aseptic transfer of fluid includes a substantially automatic sterilization procedure accomplished by both spray and contact components (54,56).

Owner:ADVANCED SCIENTIFICS INC

Sterilization indicators including a neutralizer and methods

ActiveUS20130273593A1Avoid painBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismActive enzyme

Sterilization indicators that include a neutralizer, such indicators useful for testing the effectiveness of a sterilization procedure by measuring the activity of an active enzyme whose activity is correlated with the survival of microorganisms.

Owner:3M INNOVATIVE PROPERTIES CO

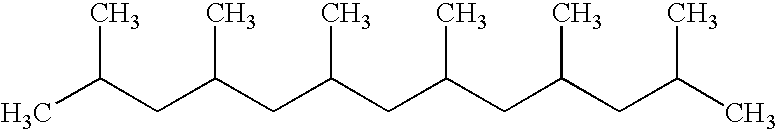

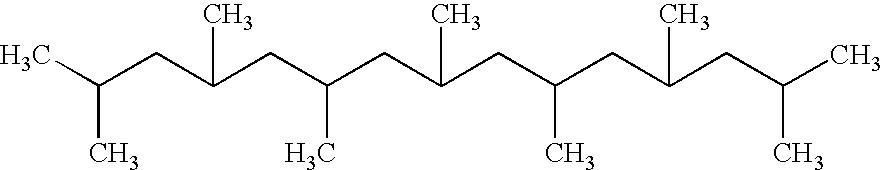

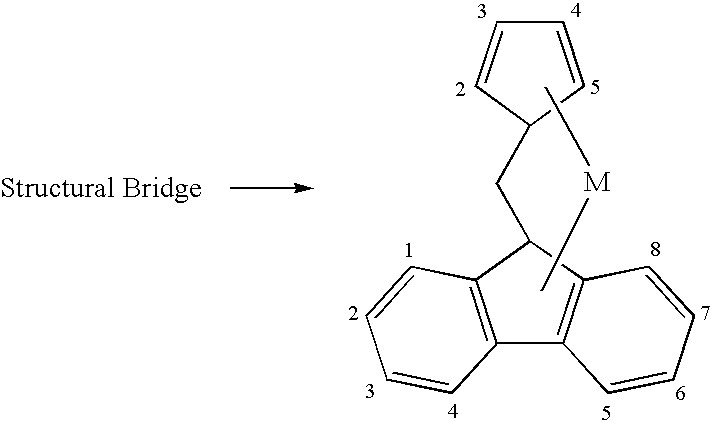

Radiation Resistant Polypropylene Materials

A polypropylene material is provided having increased radiation resistance compared to solely isotactic polypropylene. The material is formed by utilizing a syndiotactic polypropylene. The isotactic polypropylene may be an isotactic metallocene or Ziegler-Natta catalyzed polypropylene and may include an amount of syndiotactic polypropylene. The material may be used in forming a variety of materials that may undergo exposure to radiation, such as sterilization procedures using radiation. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:FINA TECH

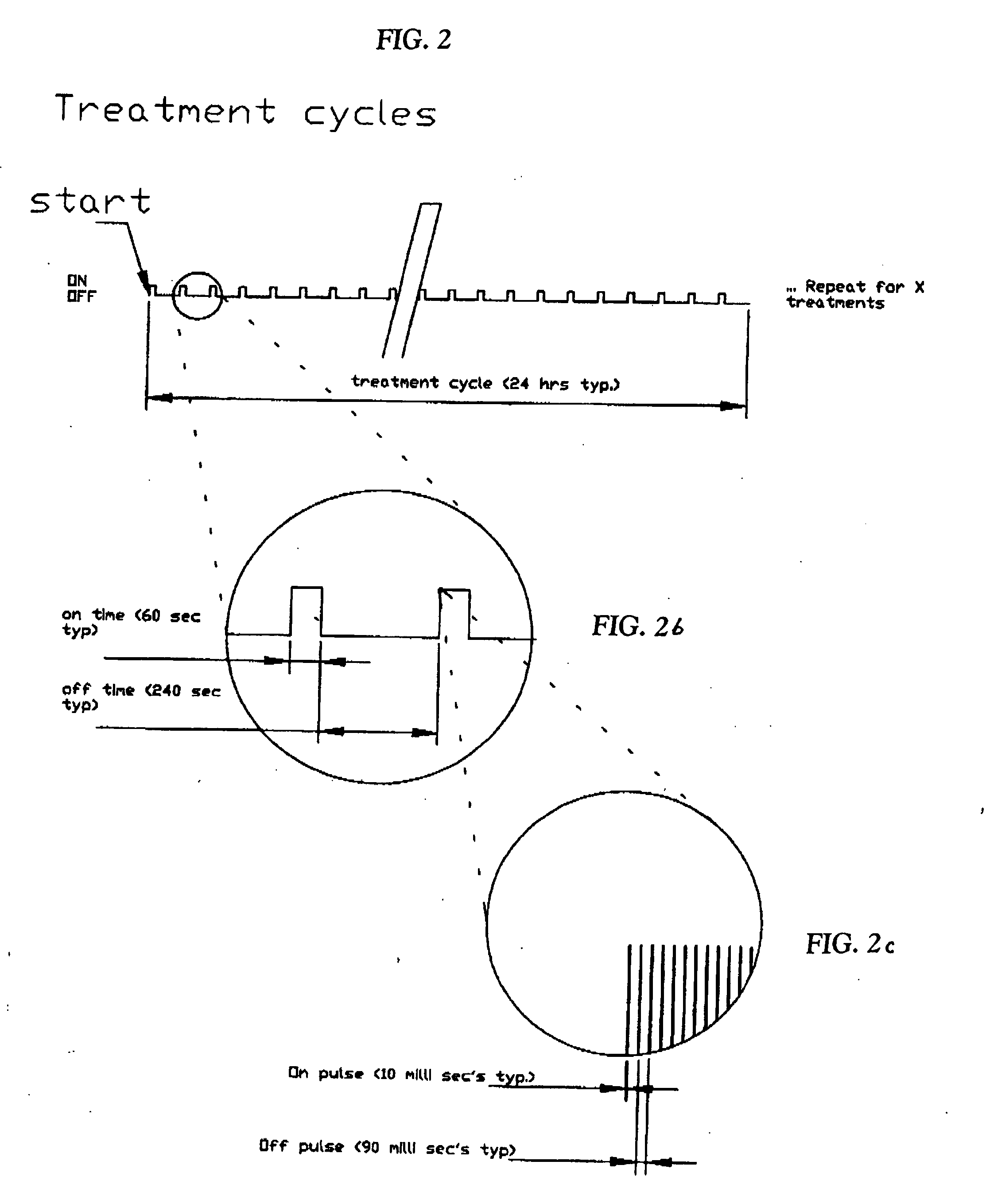

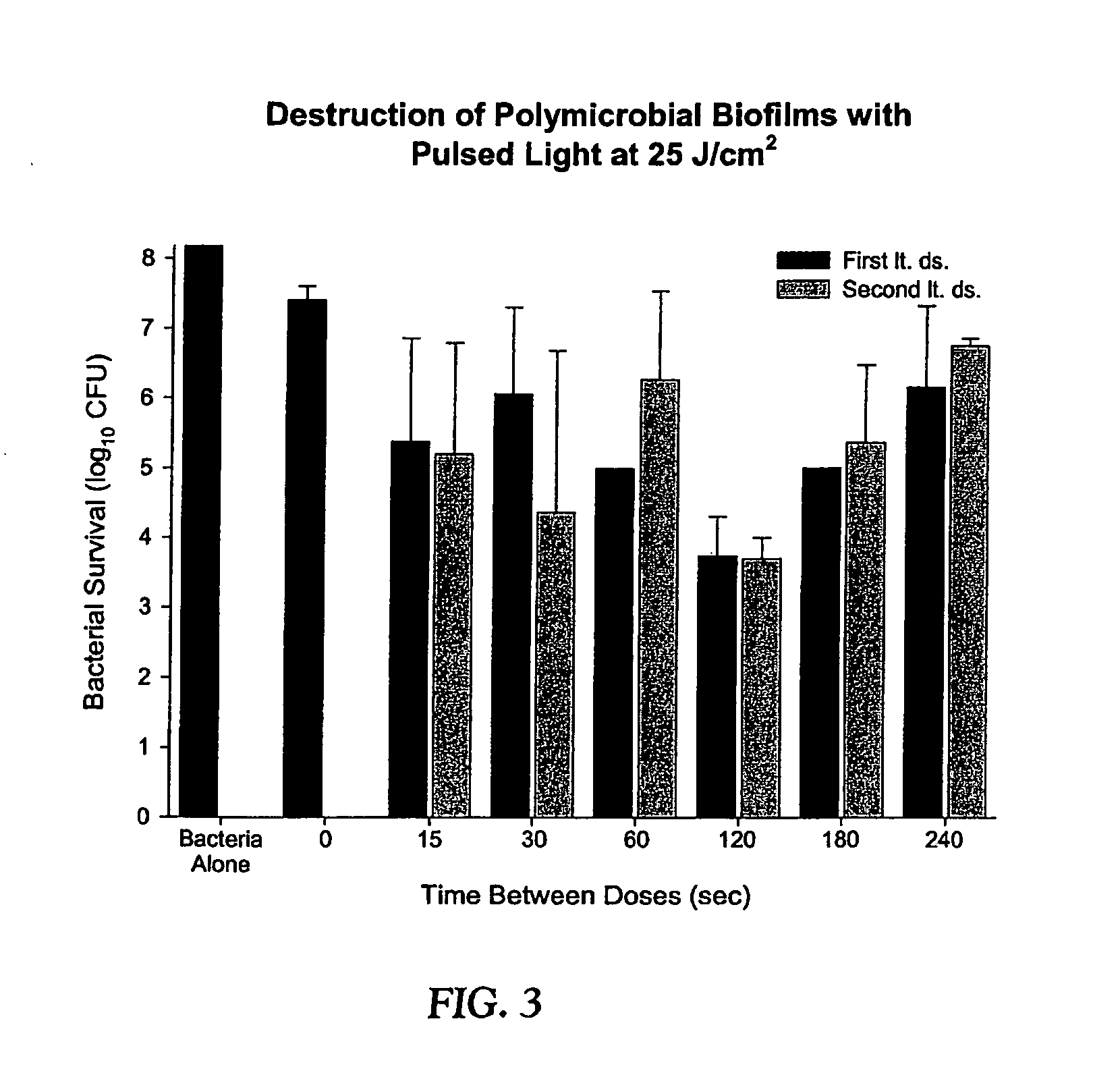

Photodynamic therapy utilizing multiple duty cycle light modulation

InactiveUS20060234959A1Improve efficiencyGood curative effectBiocideCavity massageCancer cellLight modulation

A method of photodynamic disruption of target cells within a target cell site wherein the target cells are associated with one or more of a sterilization procedure, a biofilm eradication procedure, a sterilization procedure of a medical prosthesis, a treatment of an infection at a tissue site, eradication of cancer cells and a fluid or food decontamination process. Surface acting agents such as benzalkonium chloride or polymyxin B sulfate or both may be utilized. A controllable light source capable of delivering light at a plurality of duty cycles is utilized to cause photoactivation of the photosensitive material resulting in degradation of target cells within the site.

Owner:ADVANCED PHOTODYNAMIC TECH

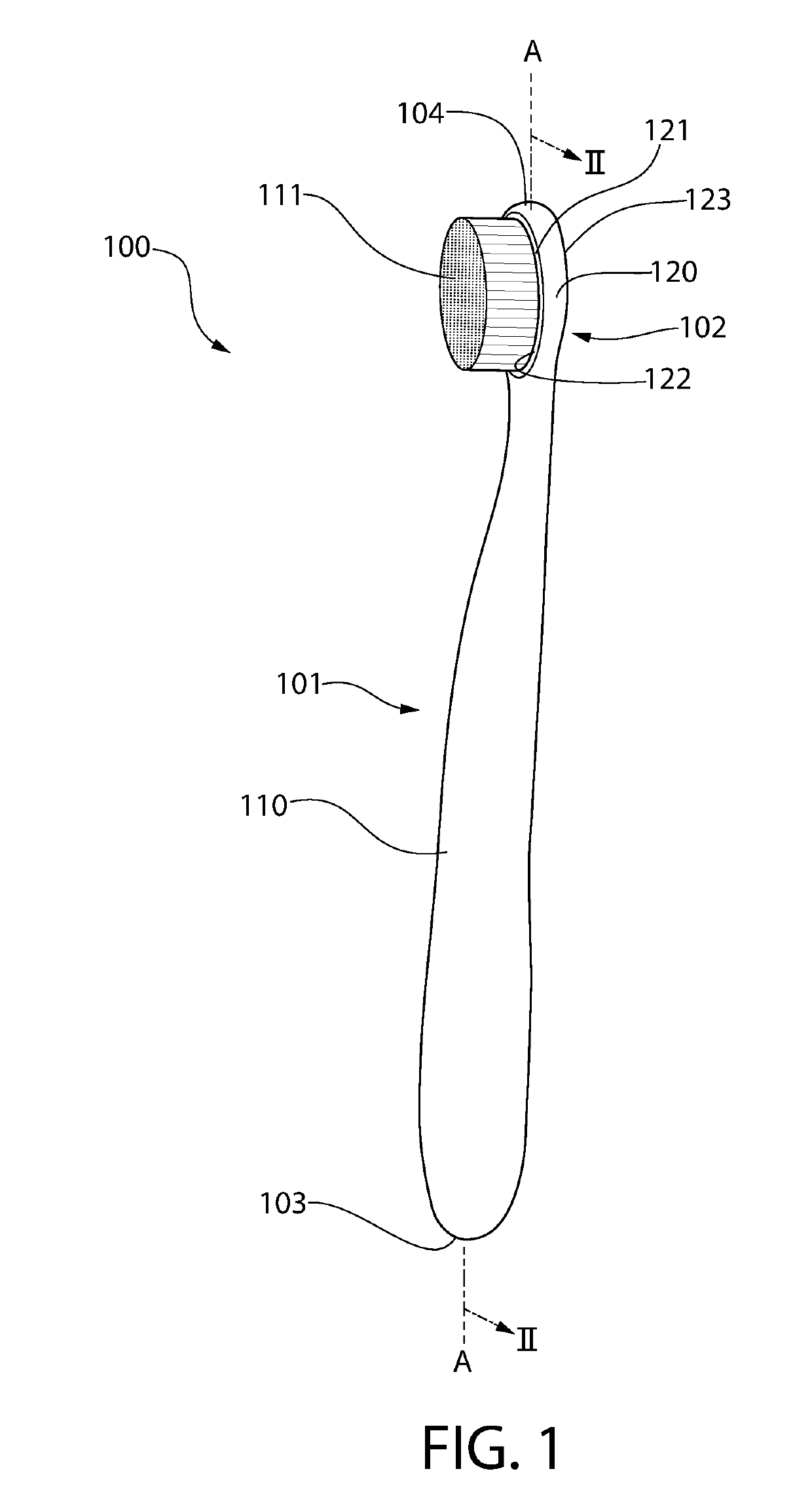

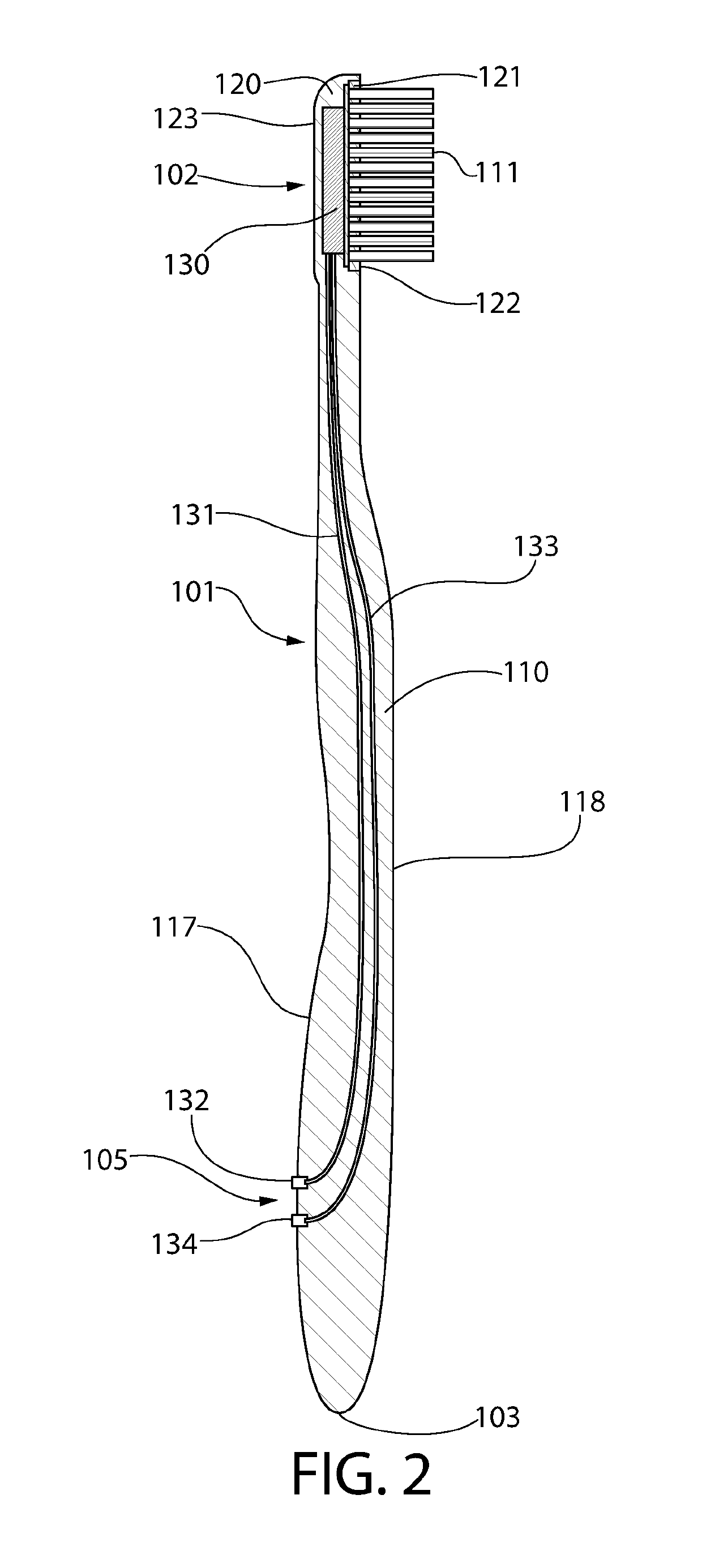

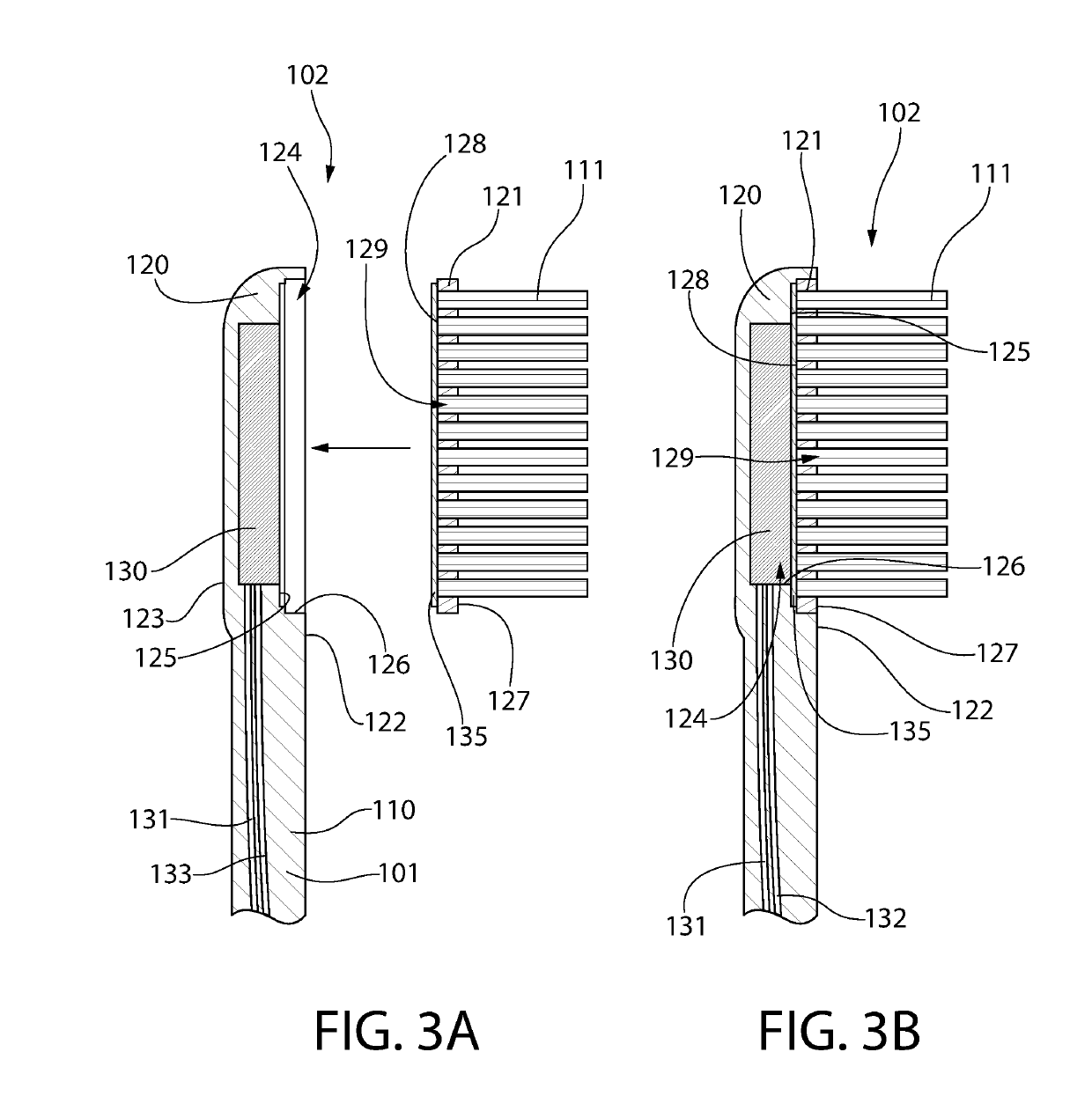

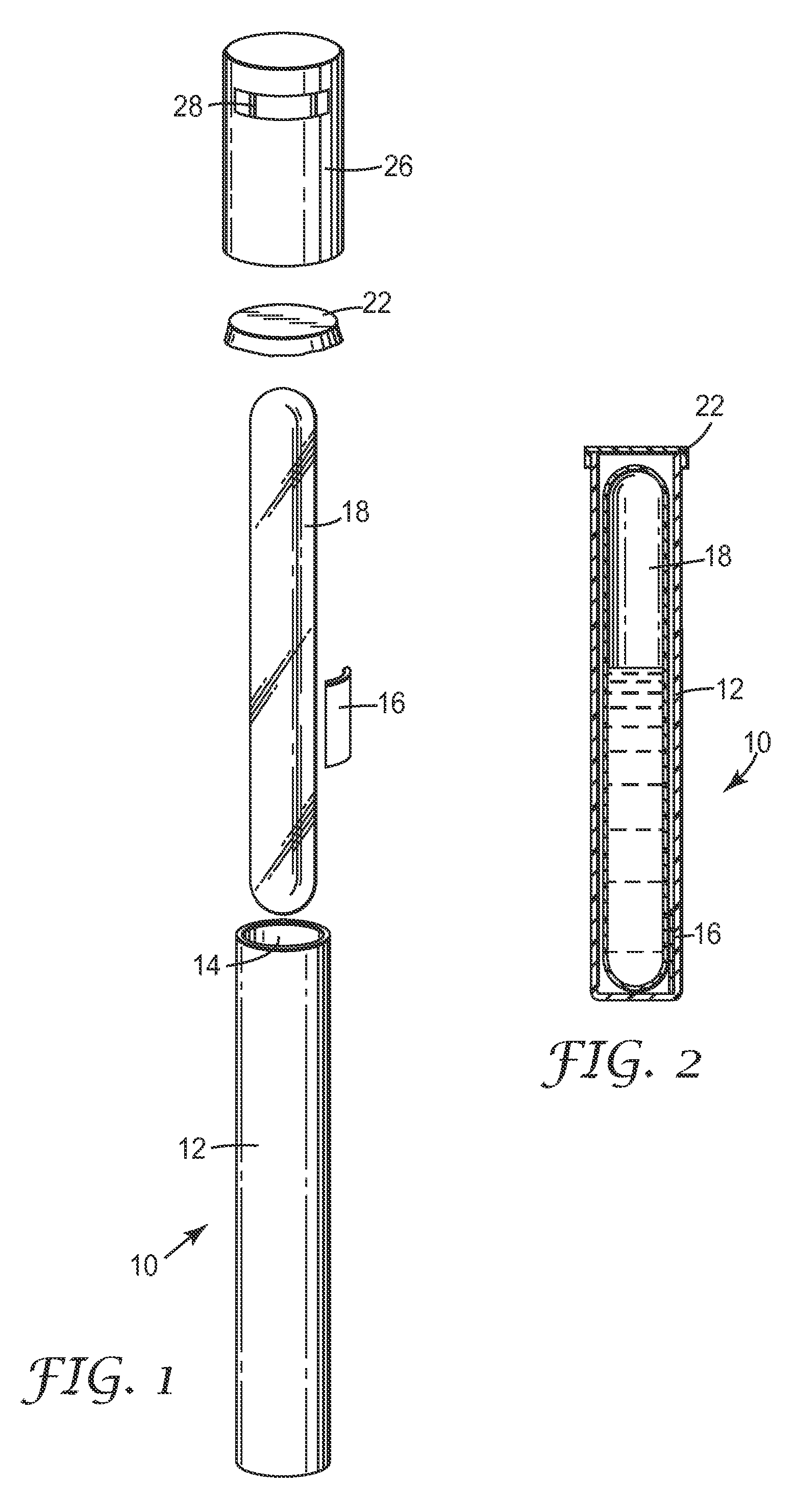

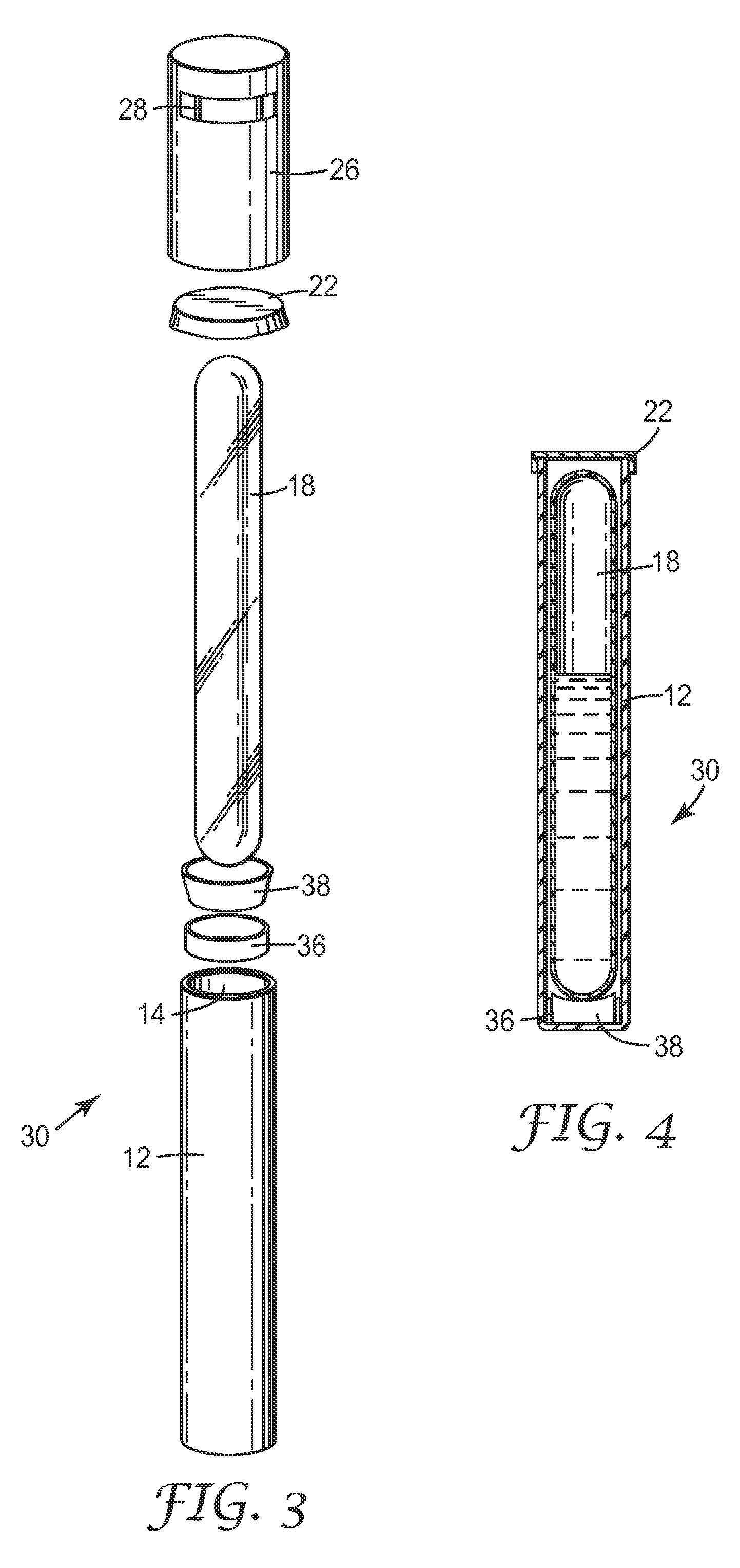

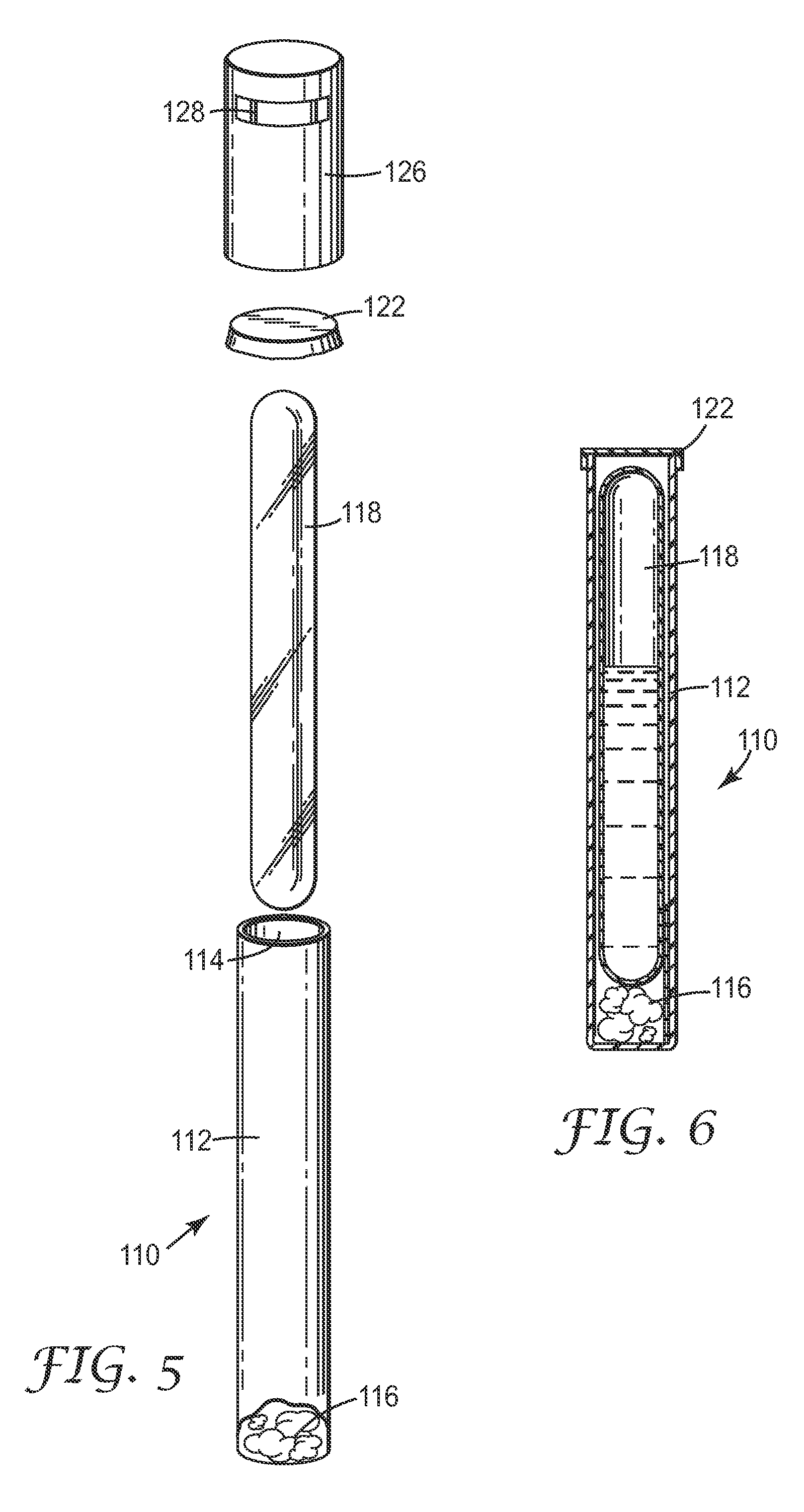

Oral Care Implement

An oral care implement sanitization system that includes an oral care implement and a case for storing the oral care implement and activating a sanitization or sterilization procedure. The oral care implement may include tooth cleaning elements, a light source, and a first electrical coupling element operably coupled to the light source. The case may include a housing having a cavity for holding the oral care implement, a power source, and a second electrical coupling element operably coupled to the power source. When the oral care implement is positioned within the cavity of the housing of the case, the first and second electrical coupling elements are operably coupled together. Operable coupling of the first and second electrical coupling elements initiates, either immediately or upon the occurrence of some additional action, activation of the light source for sanitizing or sterilizing the tooth cleaning elements.

Owner:COLGATE PALMOLIVE CO

Self-contained sterilization indicators including a neutralizer for residual oxidizing sterilant

ActiveUS8975067B2Bioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismActive enzyme

Sterilization indicators that include a neutralizer, such indicators useful for testing the effectiveness of a sterilization procedure by measuring the activity of an active enzyme whose activity is correlated with the survival of microorganisms.

Owner:3M INNOVATIVE PROPERTIES CO

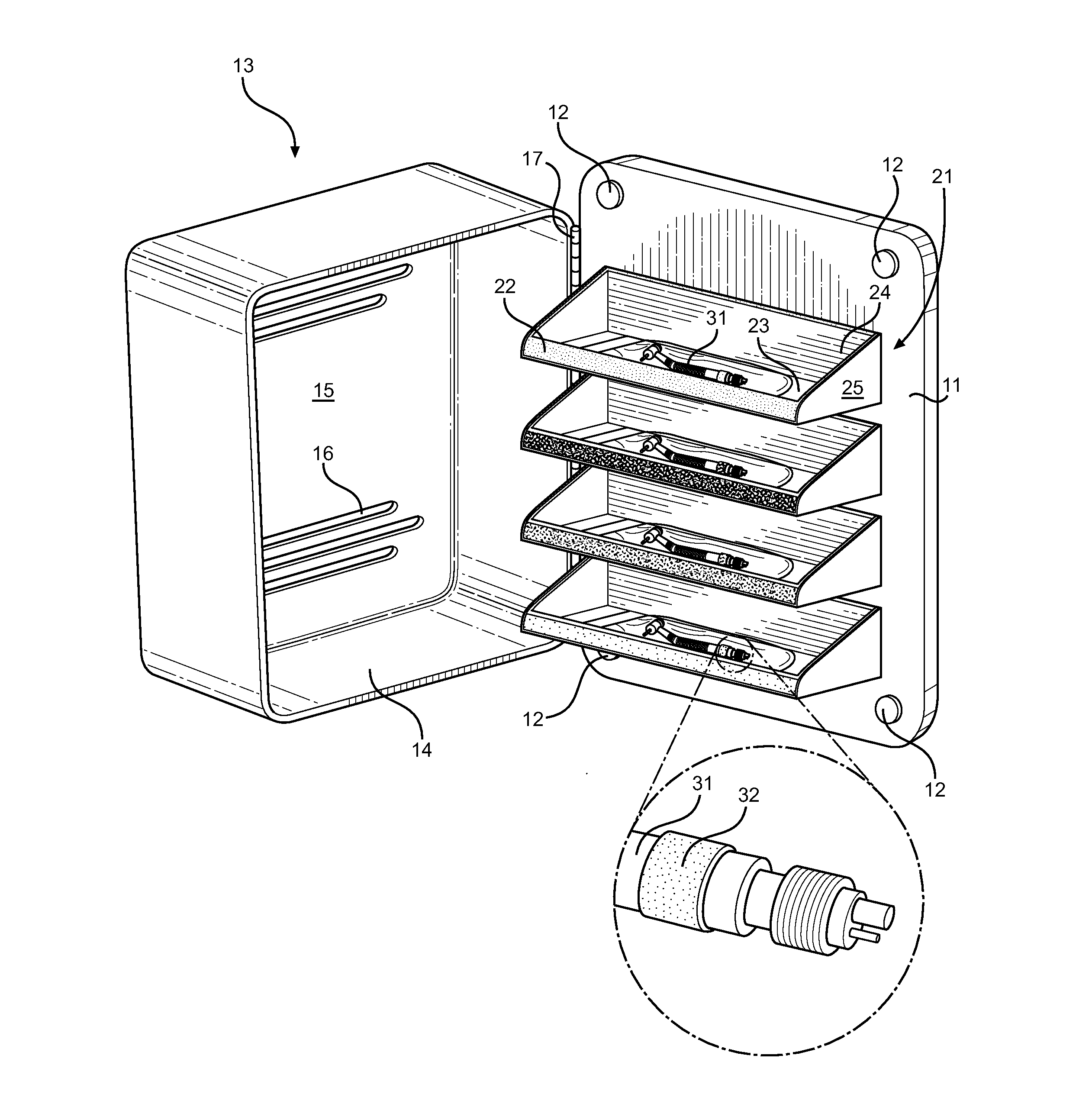

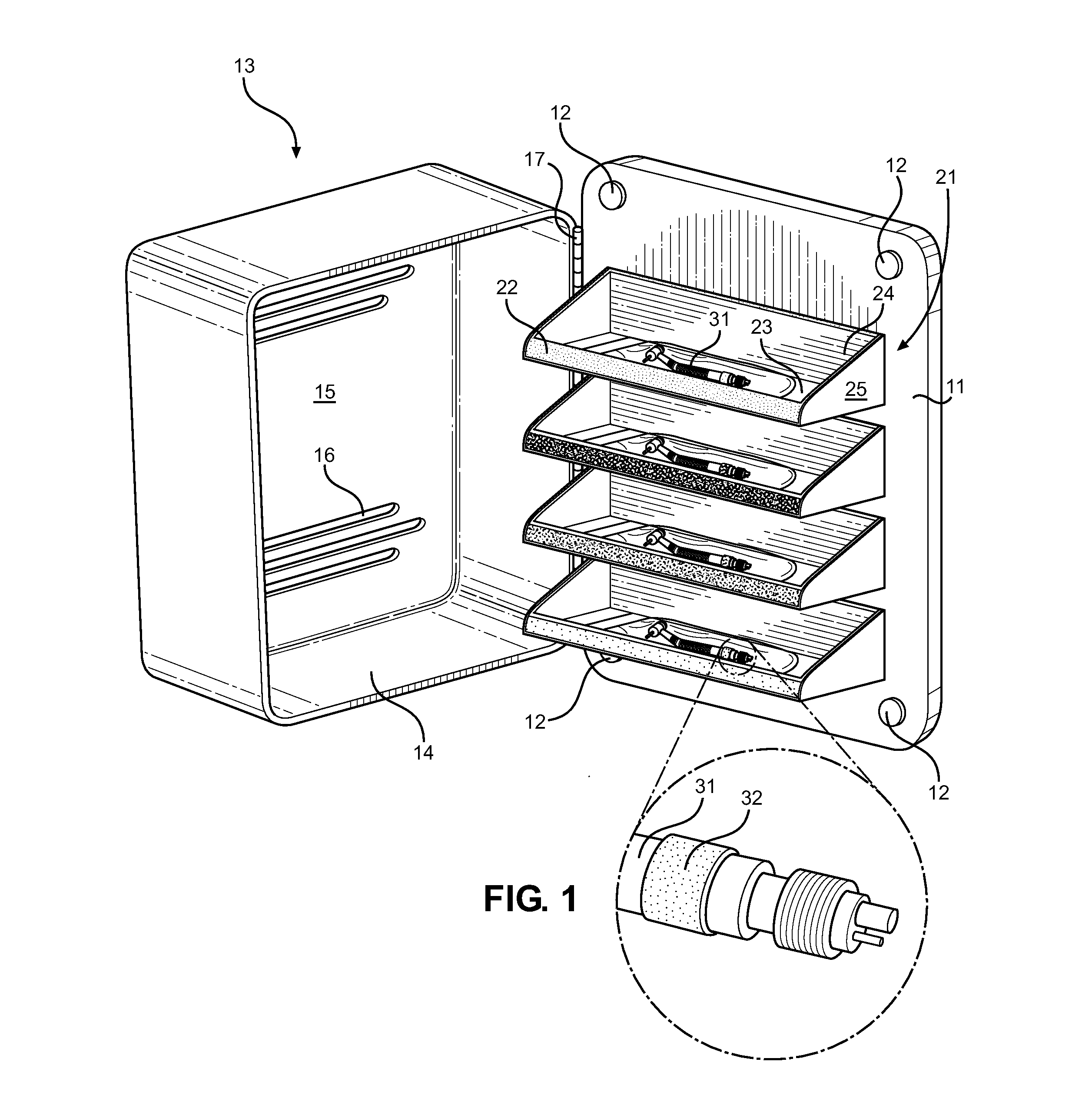

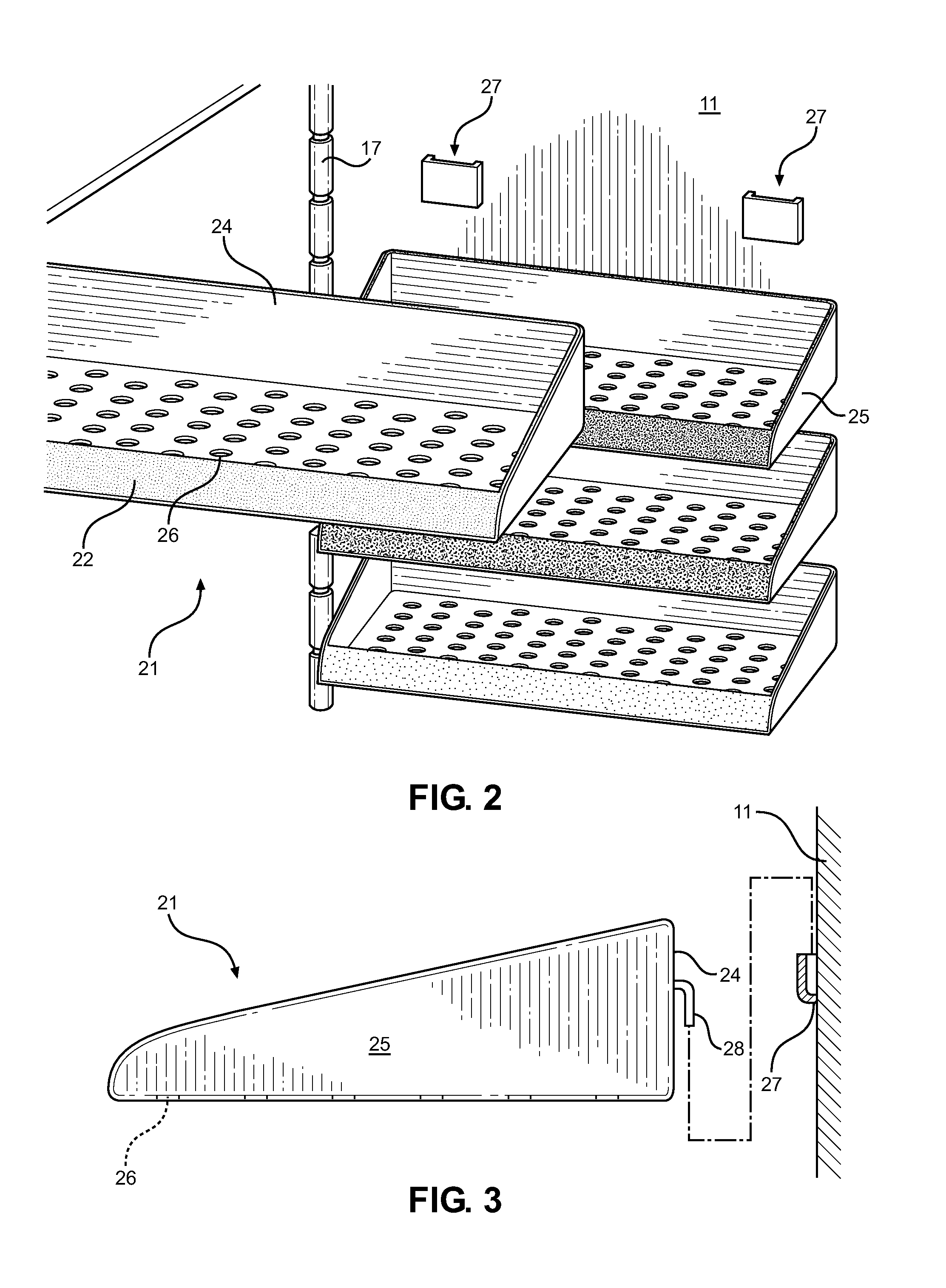

Dental Handpiece Rack and Method of Storing Dental Handpieces

InactiveUS20140242542A1Easy to makeExtended service lifeSurgical furnitureOperating chairsEngineeringMoisture

A dental handpiece and general implement rack is provided, along with a method of tracking implement use in a patient environment. The rack comprises a housing having a plurality of removable trays therein, the trays being adapted to support a dental implement thereon. Each tray includes a visual indicator that matches a marker placed on an implement being stored in that tray. The tray indicators are utilized to determine which implement has been utilized during the course of the day in order to implement sterilization procedures for only those implements that have been used on patients and are now unsterile. The device and associated method prevent sterilization by autoclave for implements that do not require cleaning, thereby extending their useful life and preventing over-cleaning thereof. The housing is preferably a wall-mountable structure having a hinged lid closure and a ventilated design to prevent moisture capture therein.

Owner:JUBENVILLE JASON

Method for producing PHA by continuous treatment of molasses alcohol wastewater via mixed halophilic bacteria

ActiveCN104178529AFacilitated releaseEasy to recycleSustainable biological treatmentFermentationActivated sludgeAutomatic control

The invention relates to a method for producing PHA by continuous treatment of molasses alcohol wastewater via mixed halophilic bacteria and belongs to the technical field of production of PHA. The method comprises the following steps of carrying out activation culture on mixed halophilic sludge to obtain halophilic activated sludge, carrying out enrichment culture on the molasses alcohol wastewater inside an SBR reactor by virtue of mixed halophilic bacteria colony, carrying out continuous PHA production on molasses wastewater inside a continuous flow reactor and recovering PHA in the discharged residual sludge. The PHA is synthesized by virtue of the mixed bacteria colony instead of a pure bacteria colony, strict sterilization procedures is not required, the process is simplified and the cost is saved; the continuous flow process is simple, compared with the fermentation process, the repeated replacement of the fermentation broth is not required, the repeated inoculation of bacterial sludge is not required, the continuous water inlet and continuous water outlet are achieved, respective process parameters tend to a constant value and is simply implemented, the automatic control is facilitated, the method is easily operated in engineering, the yield of PHA is high, the continuous production of PHA is achieved and the resource utilization of residual sludge is also achieved.

Owner:北京中汉汇德环境科技有限公司

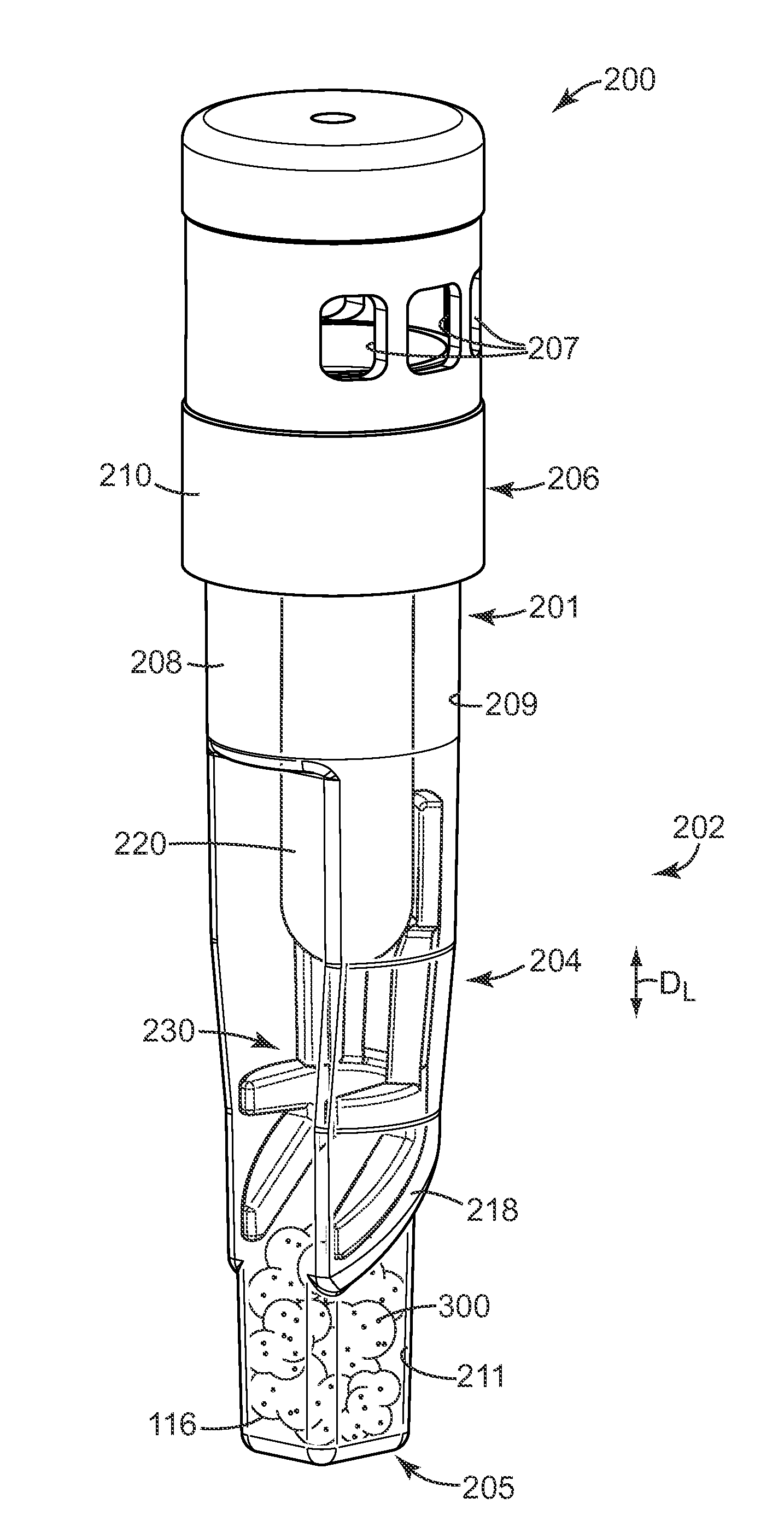

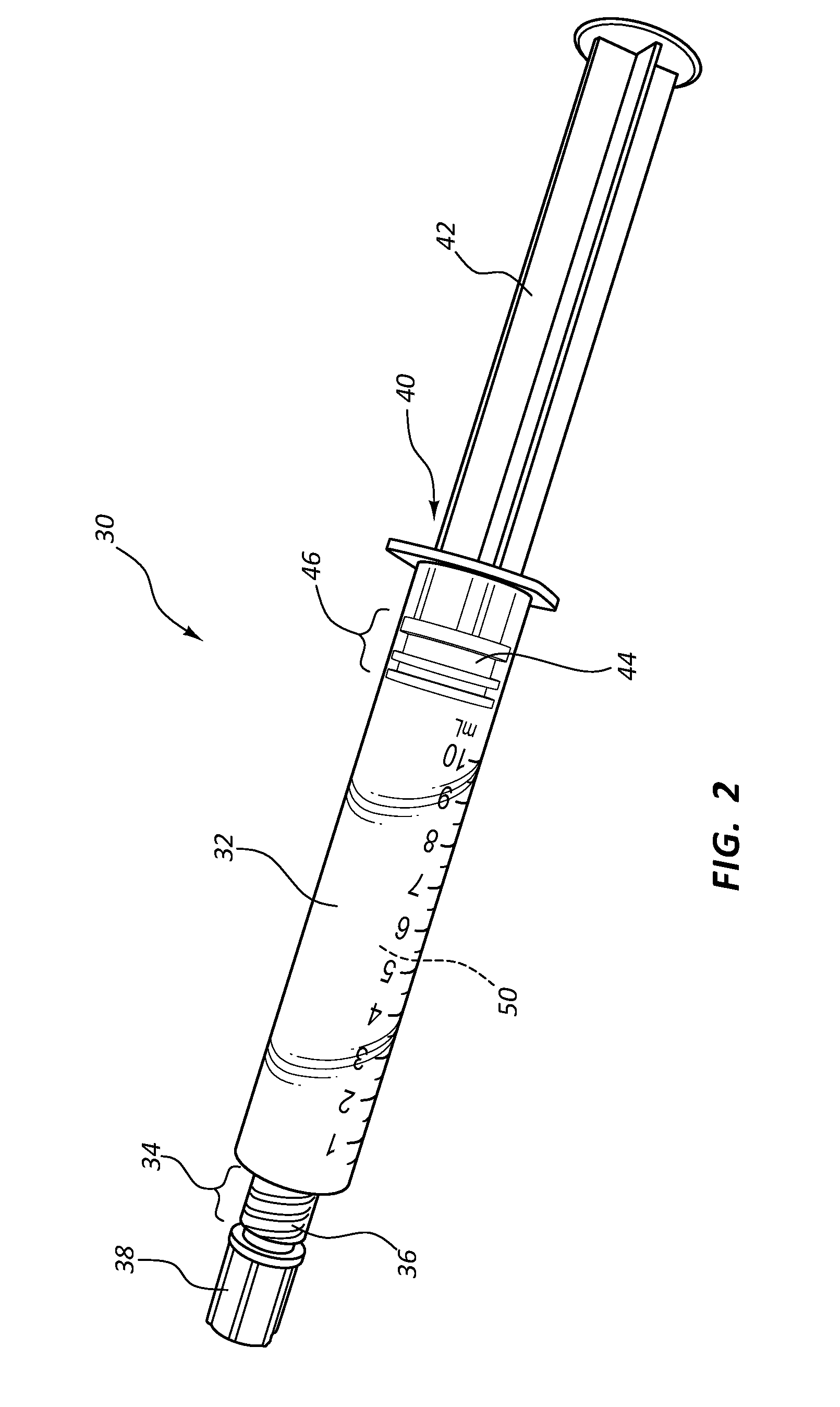

Infusates with Enhanced pH Stability Under Ethylene Oxide Sterilization

Normal saline and other infusate solutions for infusion into the body of a patient during medical treatment are disclosed. In particular, infusates are disclosed that are formulated to resist changes to the pH of the solution when subjected to sterilization procedures that employ ethylene oxide gas. In one embodiment, a buffered infusate suitable for disposal in a syringe or other container is disclosed. The syringe is sterilizable using ethylene oxide. The buffered infusate comprises an aqueous solution that is disposed in the syringe and is suitable for infusion into a body of a patient. A buffer component is added to the aqueous solution to form a buffered solution. The buffer component is configured to resist a change in the pH of the buffered solution upon exposure of the buffered solution to the ethylene oxide during sterilization of the syringe.

Owner:CR BARD INC

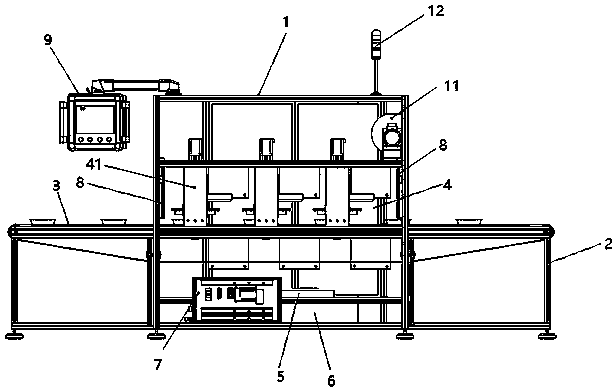

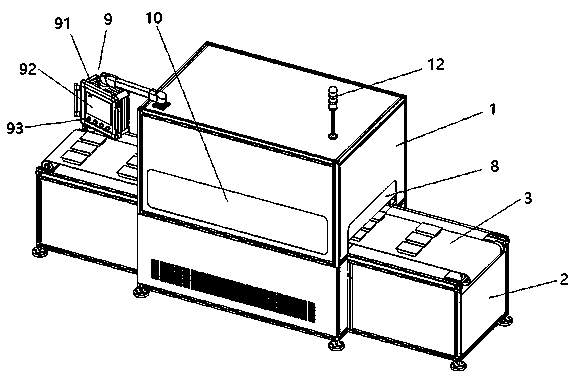

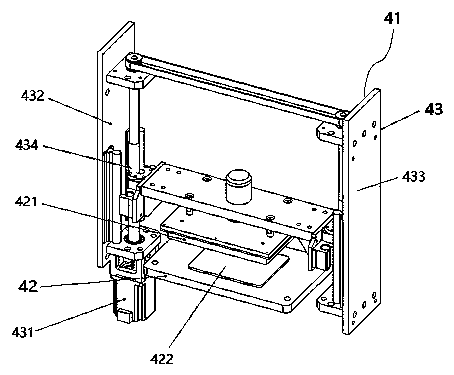

High-voltage electric field and low-temperature plasma cold sterilization production line equipment

PendingCN109221874AAdapt to the requirements of automated productionImprove efficiencyFood preservationProduction lineHigh pressure

The invention discloses high-voltage electric field and low-temperature plasma cold sterilization production line equipment. The high-voltage electric field and low-temperature plasma cold sterilization production line equipment comprises a machine case, a rack, a conveyor belt mechanism, high-voltage electric field and low-temperature plasma cold sterilization core devices, a high-voltage transformer, a high-voltage control cabinet, high-voltage electric field shielding doors and a control device. The high-voltage electric field and low-temperature plasma cold sterilization core devices are arranged in the machine case above the rack and 2 to 5 groups of the high-voltage electric field and low-temperature plasma cold sterilization core devices are arranged at a certain distance along a movement direction of the conveyor belt mechanism; each high-voltage electric field and low-temperature plasma cold sterilization core device is composed of a plurality of groups of high-voltage electrode assemblies which are arrayed in one row in parallel at an equal distance; the high-voltage electric field shielding doors are arranged at an entrance and an exit of a sterilized packaging part on the rack respectively in a hoistable manner. The high-voltage electric field and low-temperature plasma cold sterilization production line equipment is used for carrying out a plurality of times of low-temperature plasma continuous sterilization treatment on a packaging product; the sterilization time is short, the effect is good, and the efficiency is high; a sterilization procedure is accurate and controllable, is simple to operate and can be adaptive to automatic production requirements of large-scale cold sterilization and fresh-keeping packaging of foods.

Owner:SUZHOU YIRUN FOOD TECH CO LTD +1

Sterilization indicators including a porous carrier and methods

InactiveCN103269726ABioreactor/fermenter combinationsBiological substance pretreatmentsActive enzymeBiology

Sterilization indicators that include a unique porous carrier, such indicators useful for testing the effectiveness of a sterilization procedure by measuring the activity of an active enzyme whose activity is correlated with the survival of microorganisms.

Owner:3M INNOVATIVE PROPERTIES CO

Plastic bottle cap and production technique thereof

The invention relates to the technical field of bottle caps, particularly a plastic bottle cap and a production technique thereof. The plastic bottle cap is prepared by carrying out injection molding on mixed plastic granules. The mixed plastic granules are prepared from plastics, tetrabutyl stannate, water, a silane coupling agent, a catalyst and a dispersing agent. The plastic bottle cap can resist the temperature of 200 DEG C, and thus, is suitable for filling food and carrying out high-temperature sterilization. The plastic bottle cap has the advantage of favorable high-temperature-resistant effect, and can not easily deform in the high-temperature sterilization procedure, thereby ensuring the sealing property of the plastic bottle cap, and greatly lowering the fraction defective of the product. The production technique has the characteristics of simple process and low production cost, and is suitable for large-scale production.

Owner:湖南金富包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com