Patents

Literature

49 results about "Solvent bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent bonding. Solvent bonding is one of several methods of adhesive bonding for joining plastics. Application of a solvent to a thermoplastic material softens the polymer, and with applied pressure this results in polymer chain interdiffusion at the bonding junction.

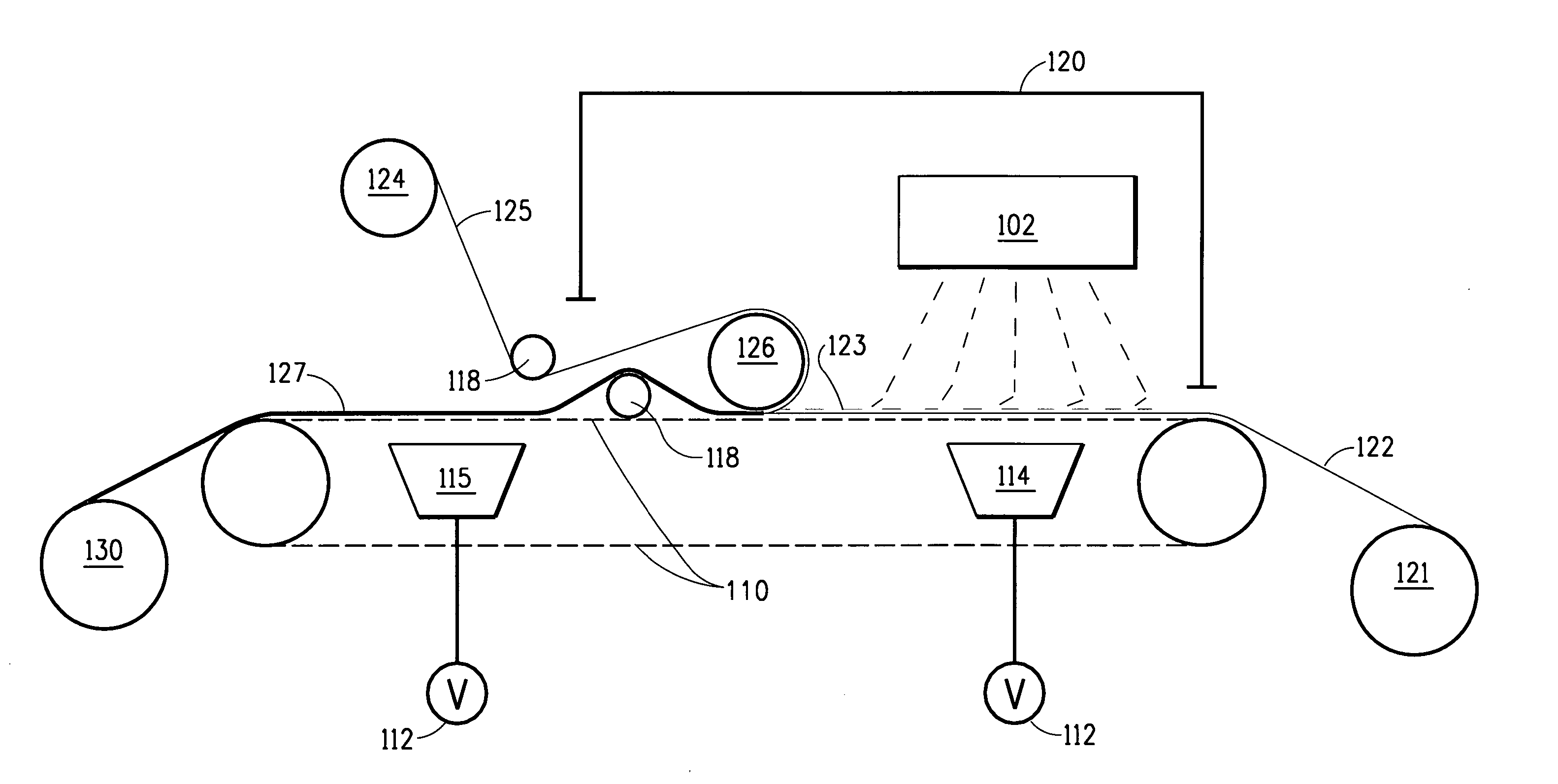

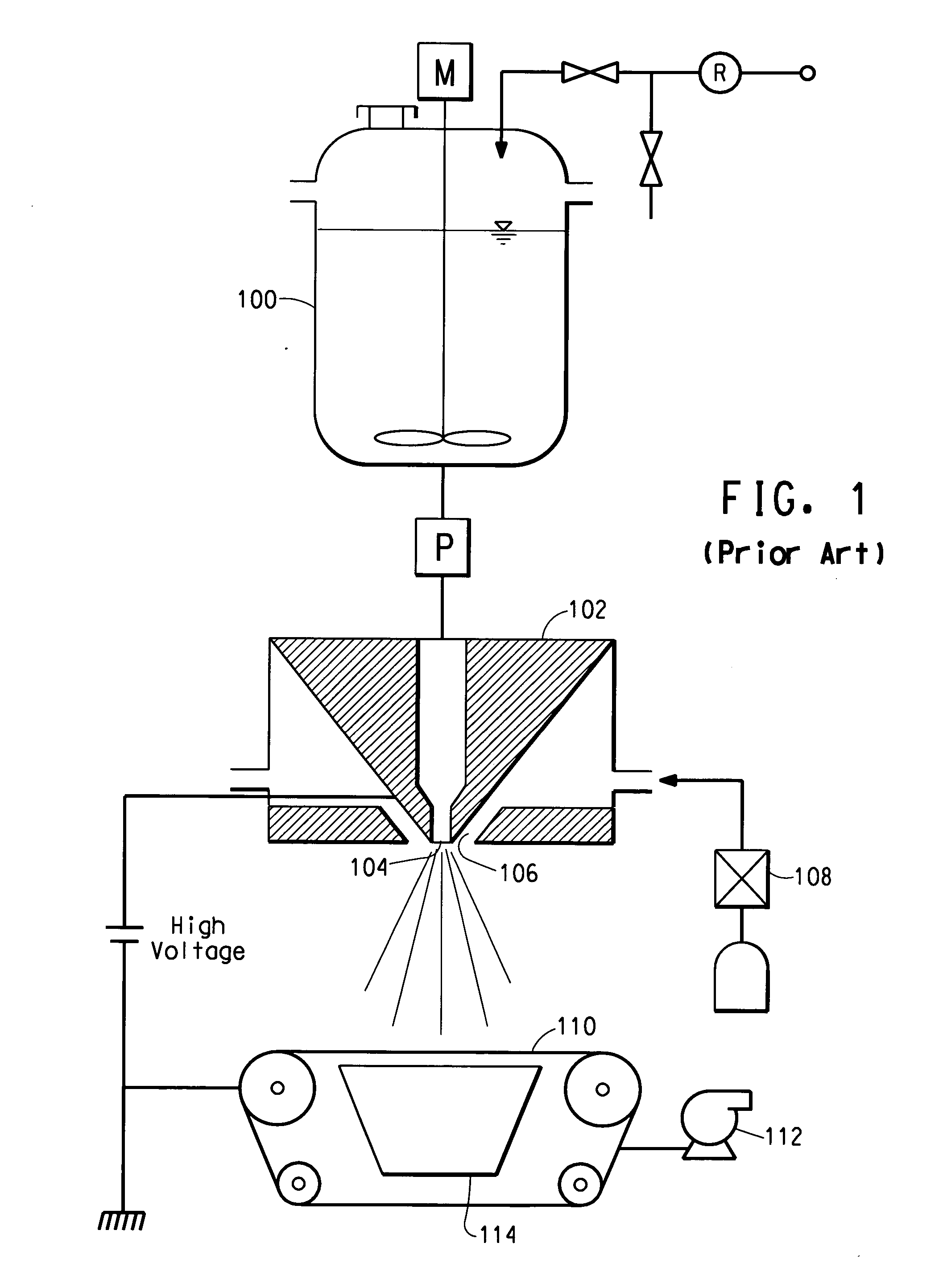

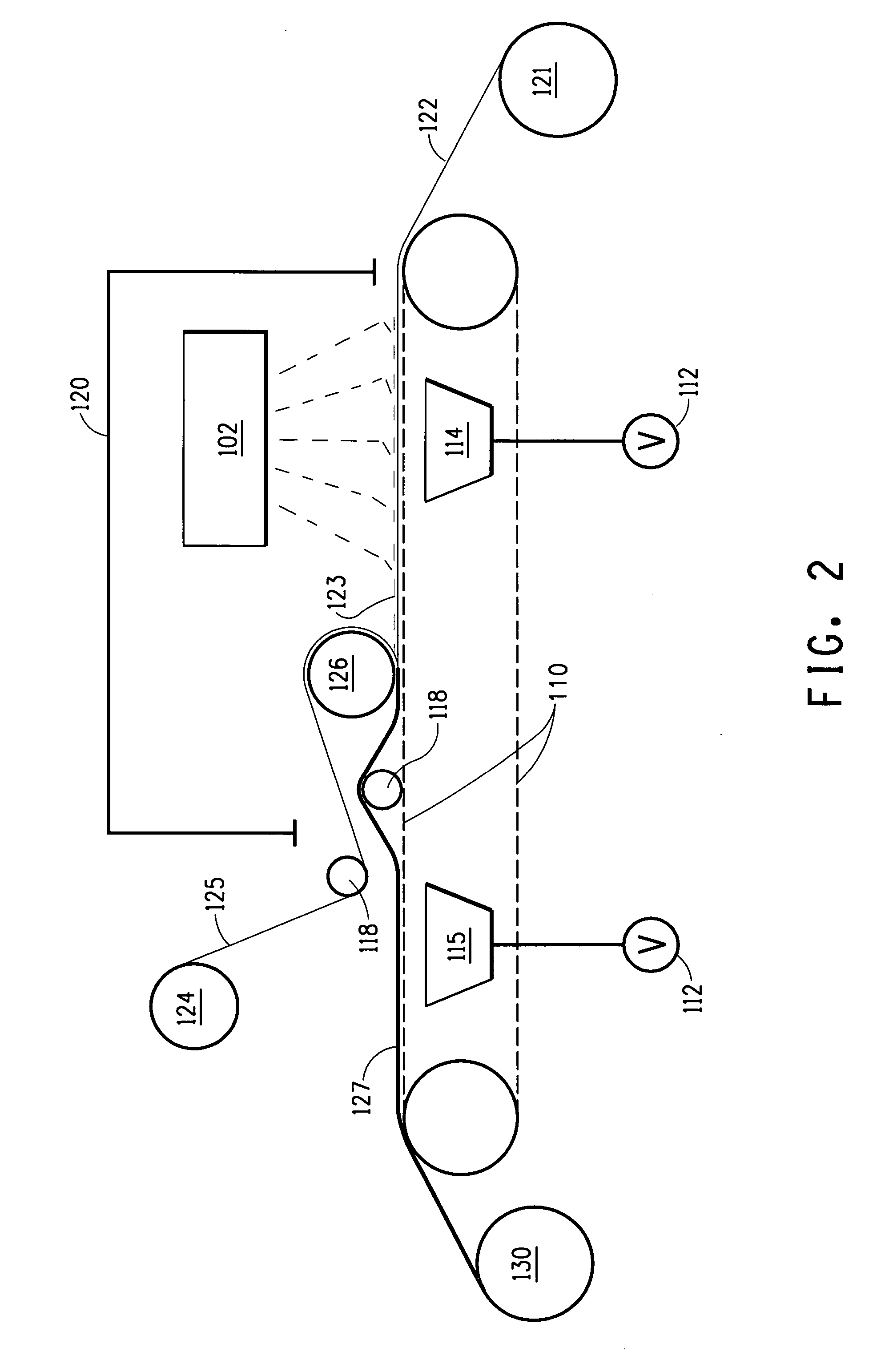

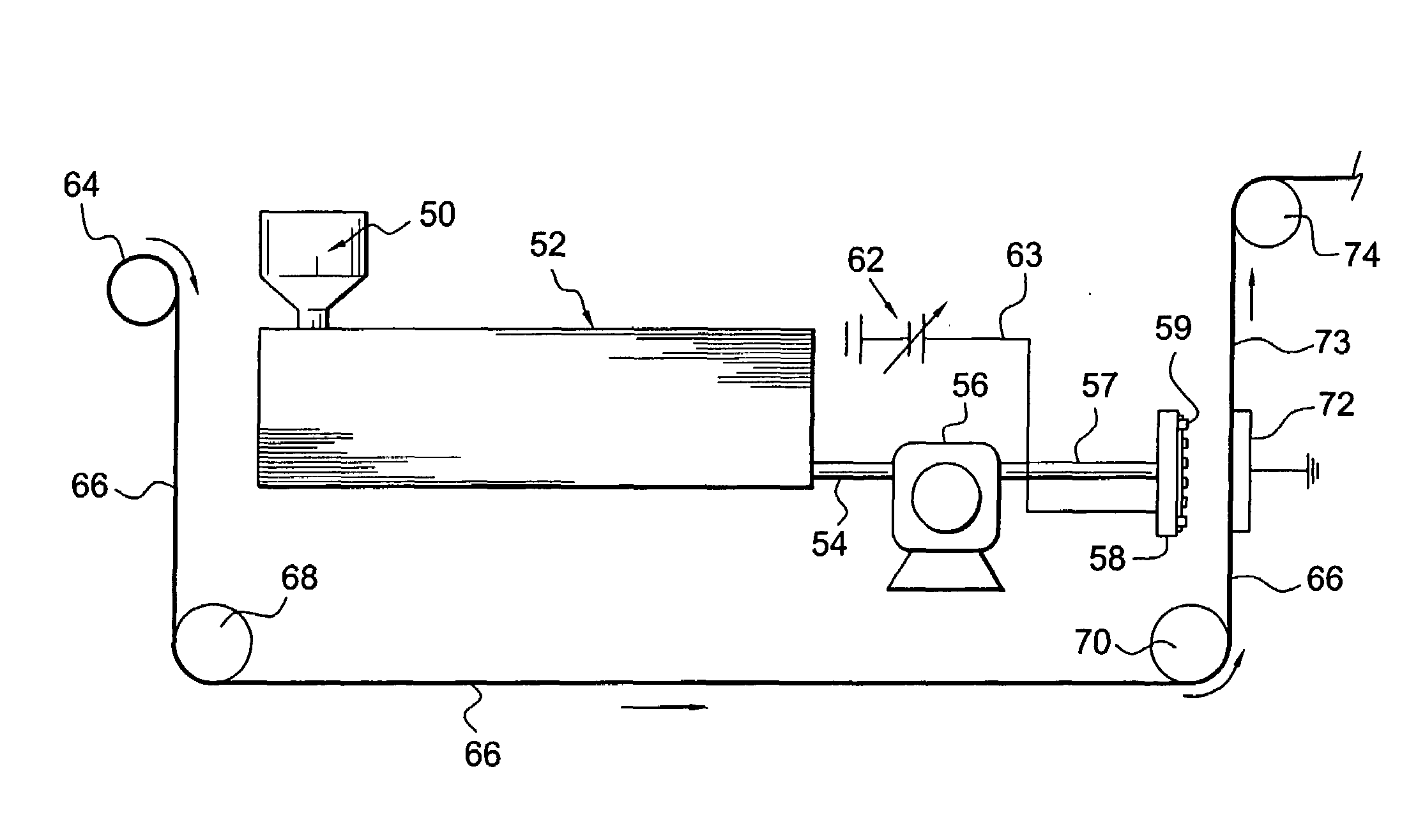

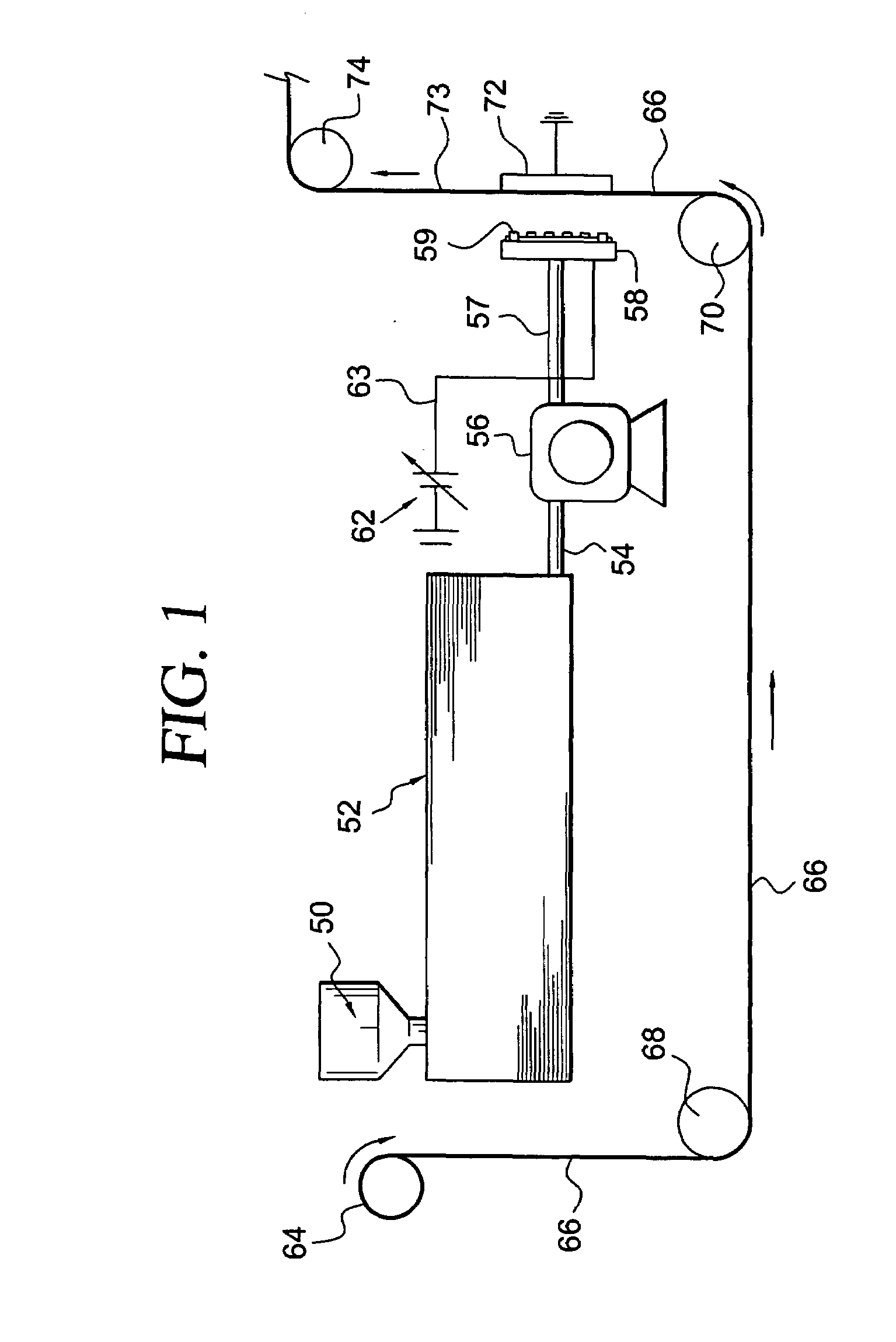

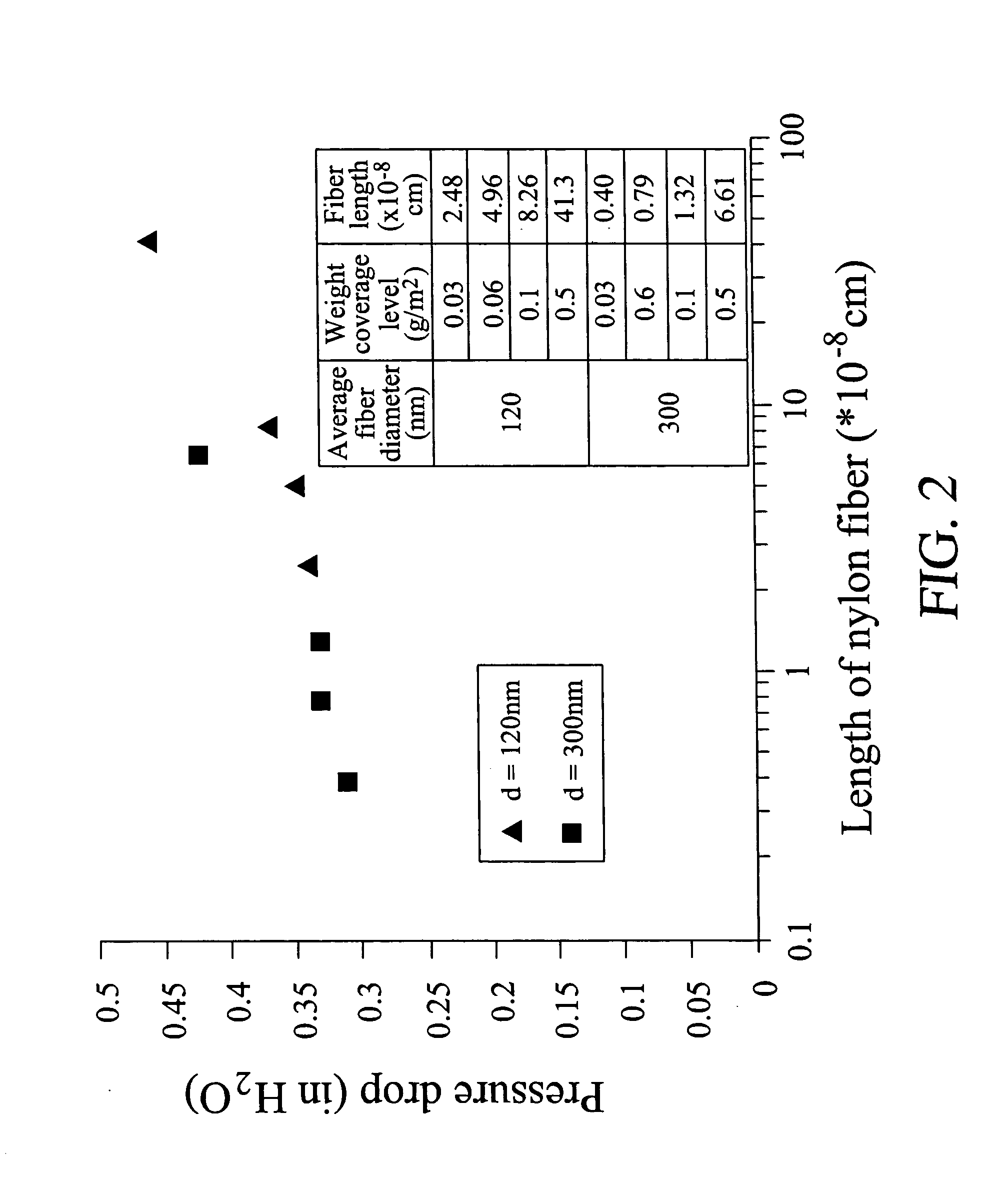

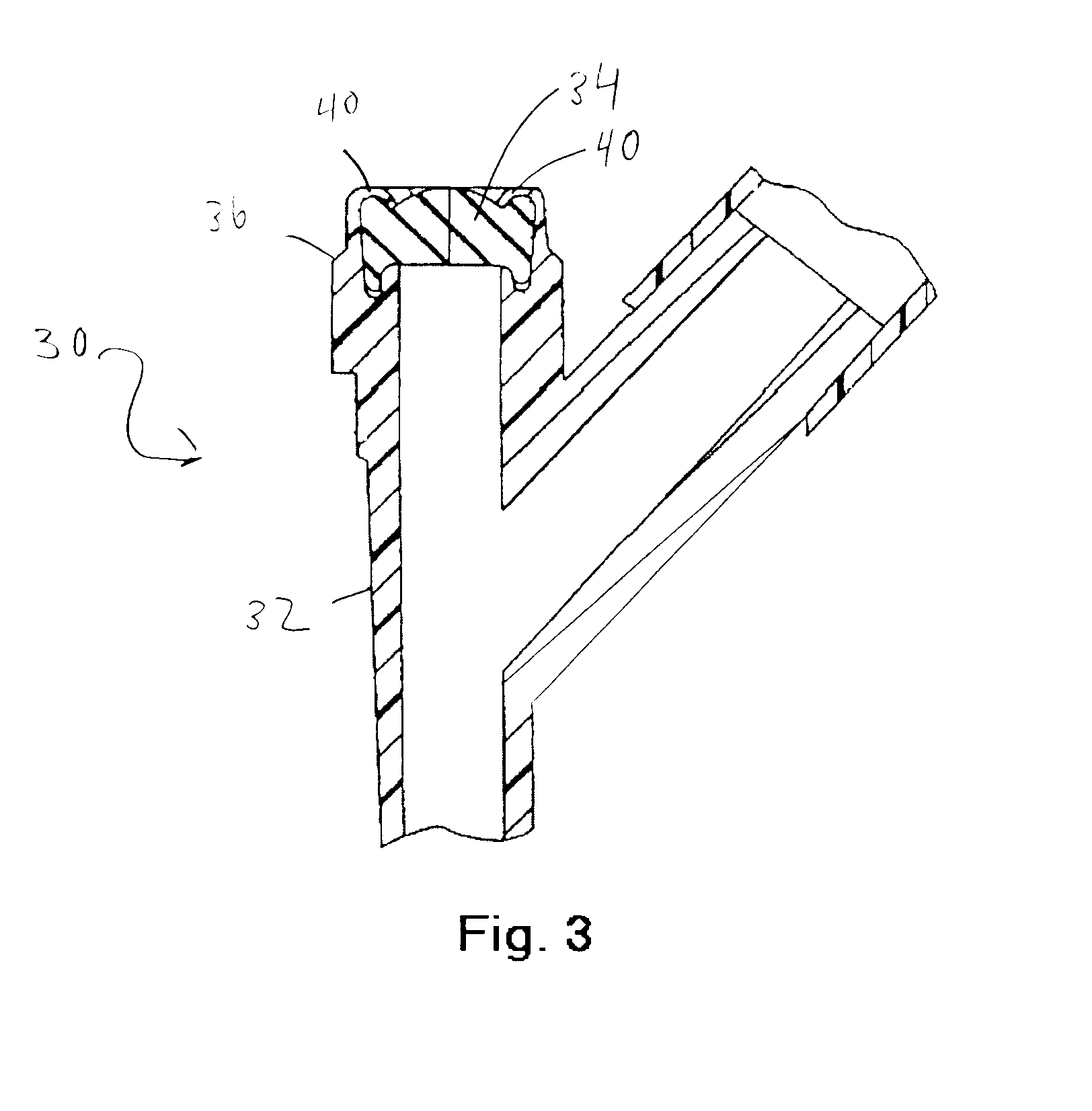

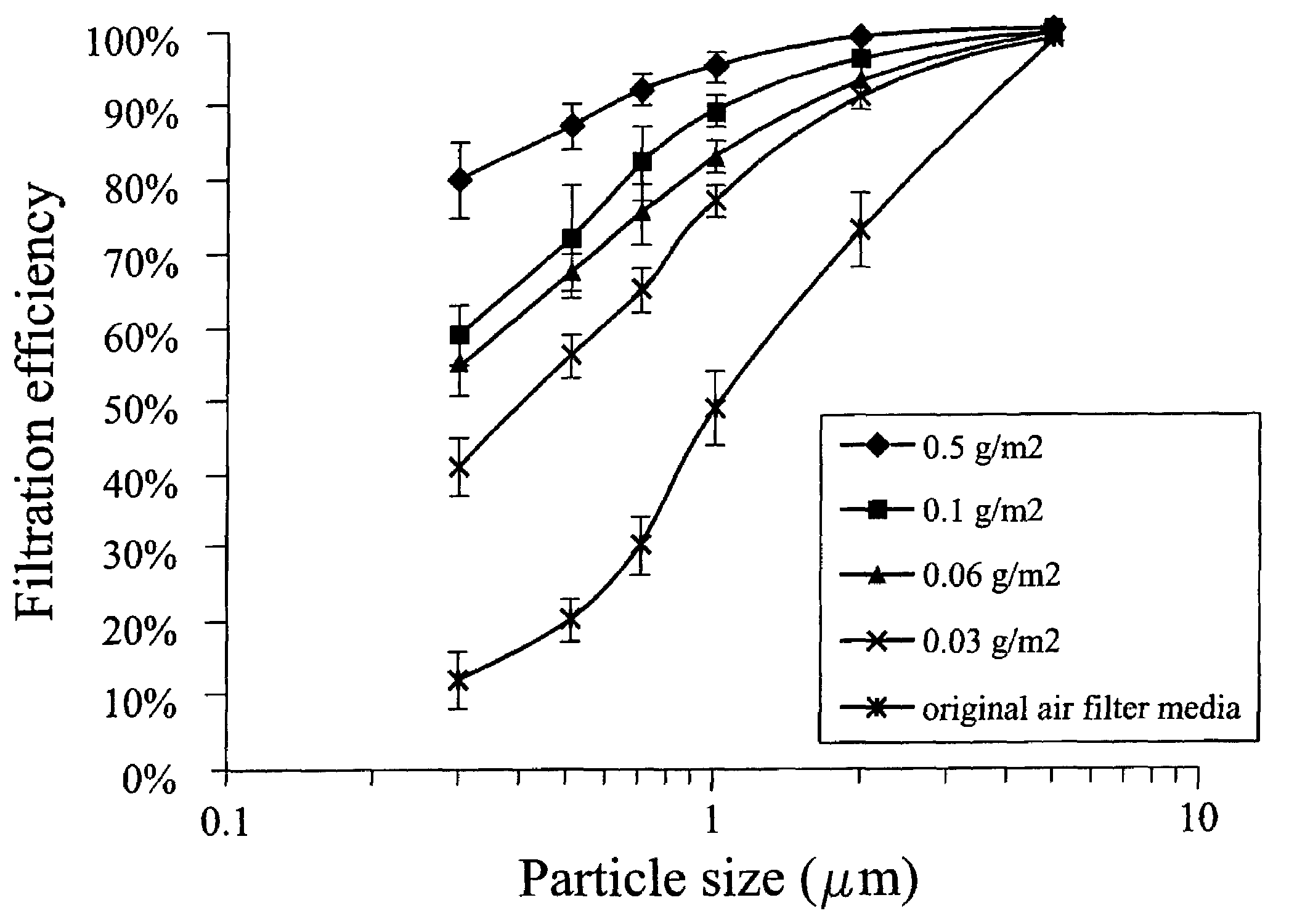

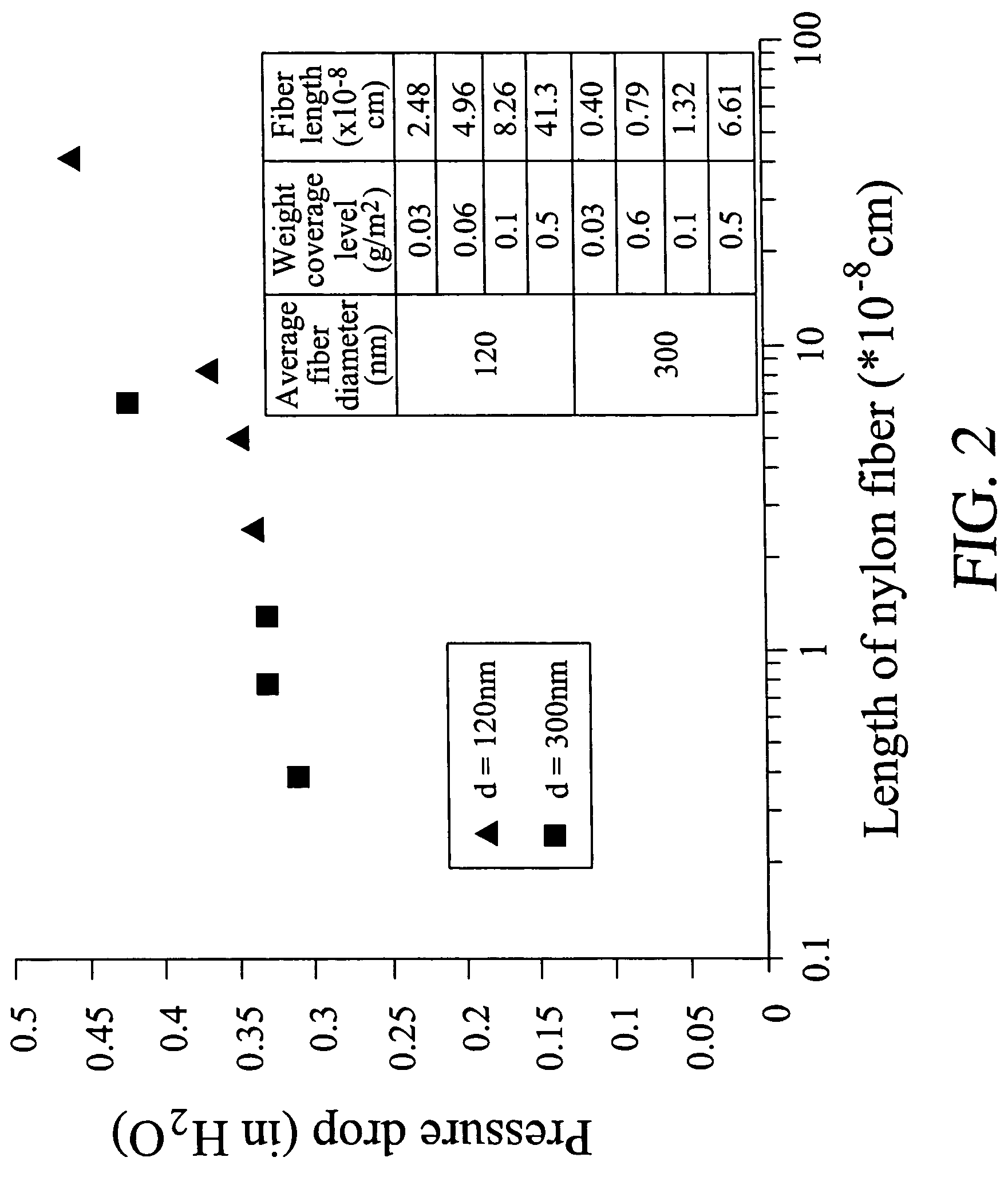

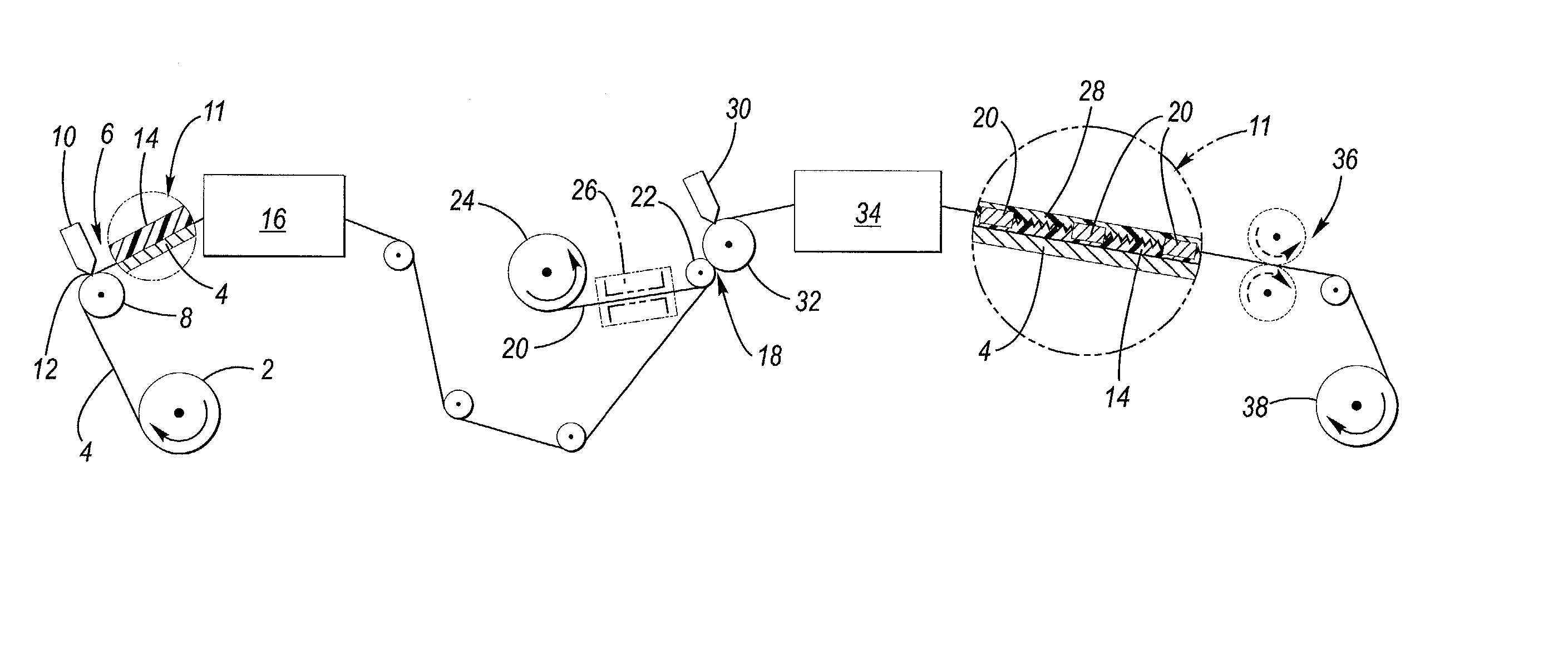

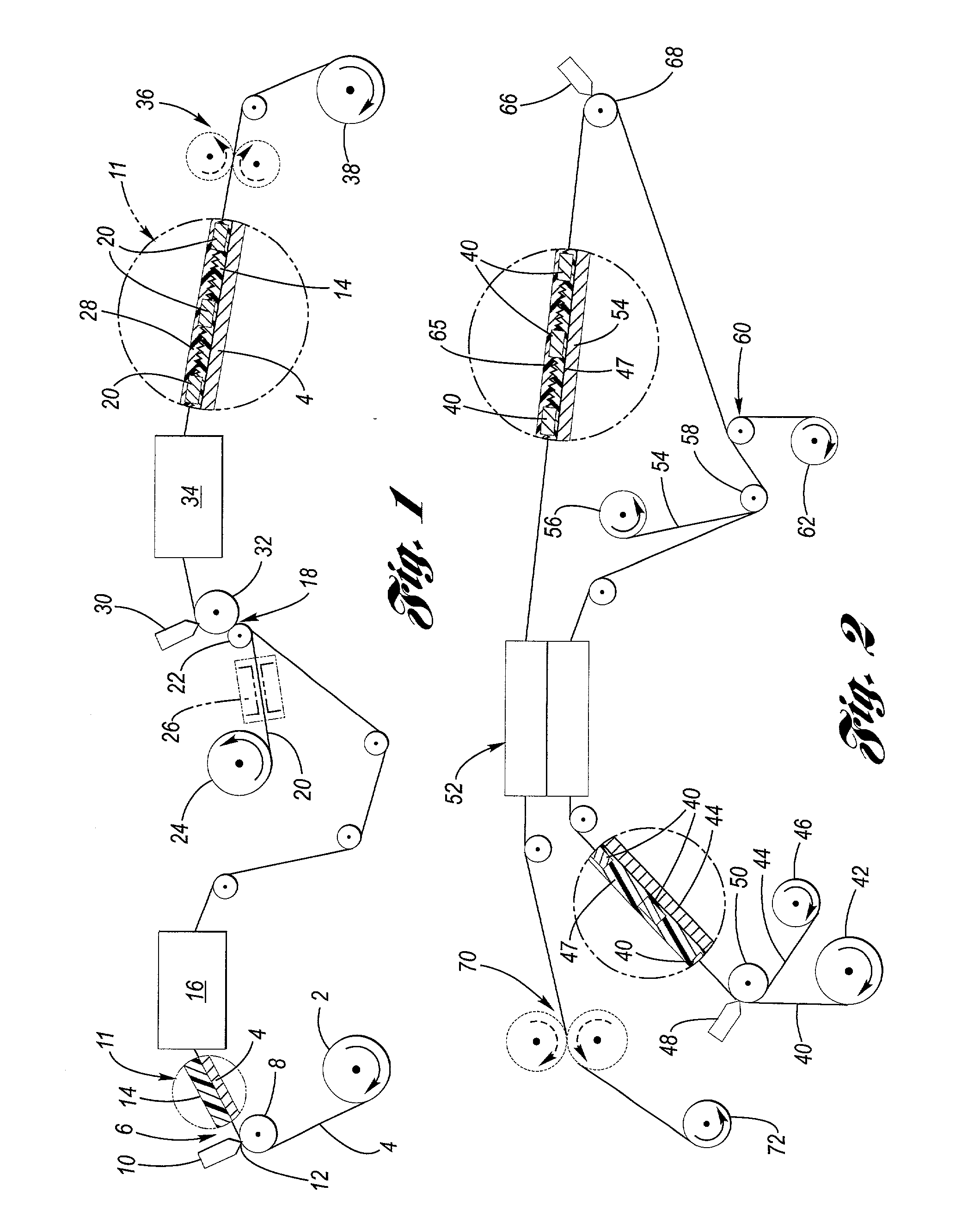

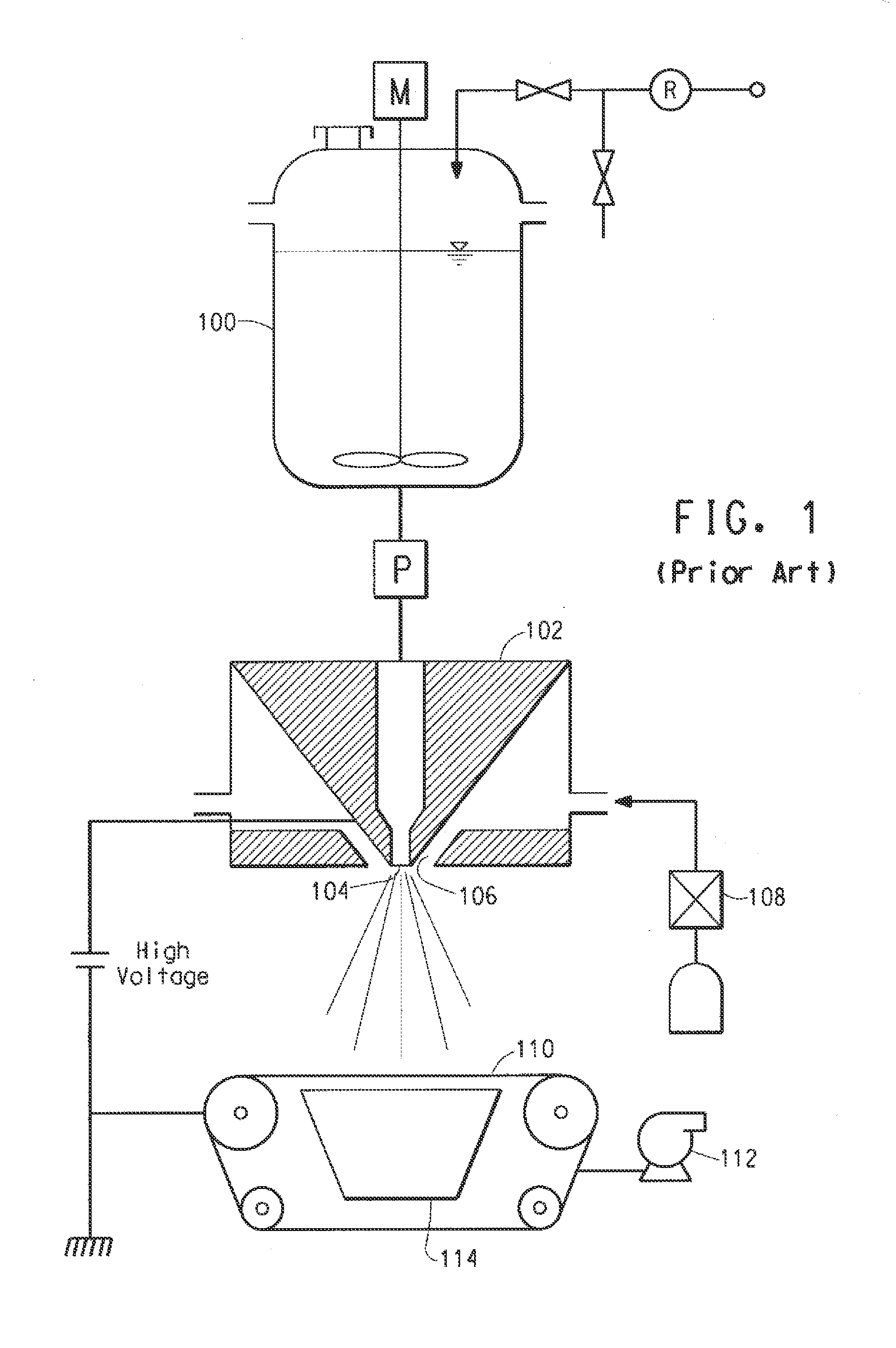

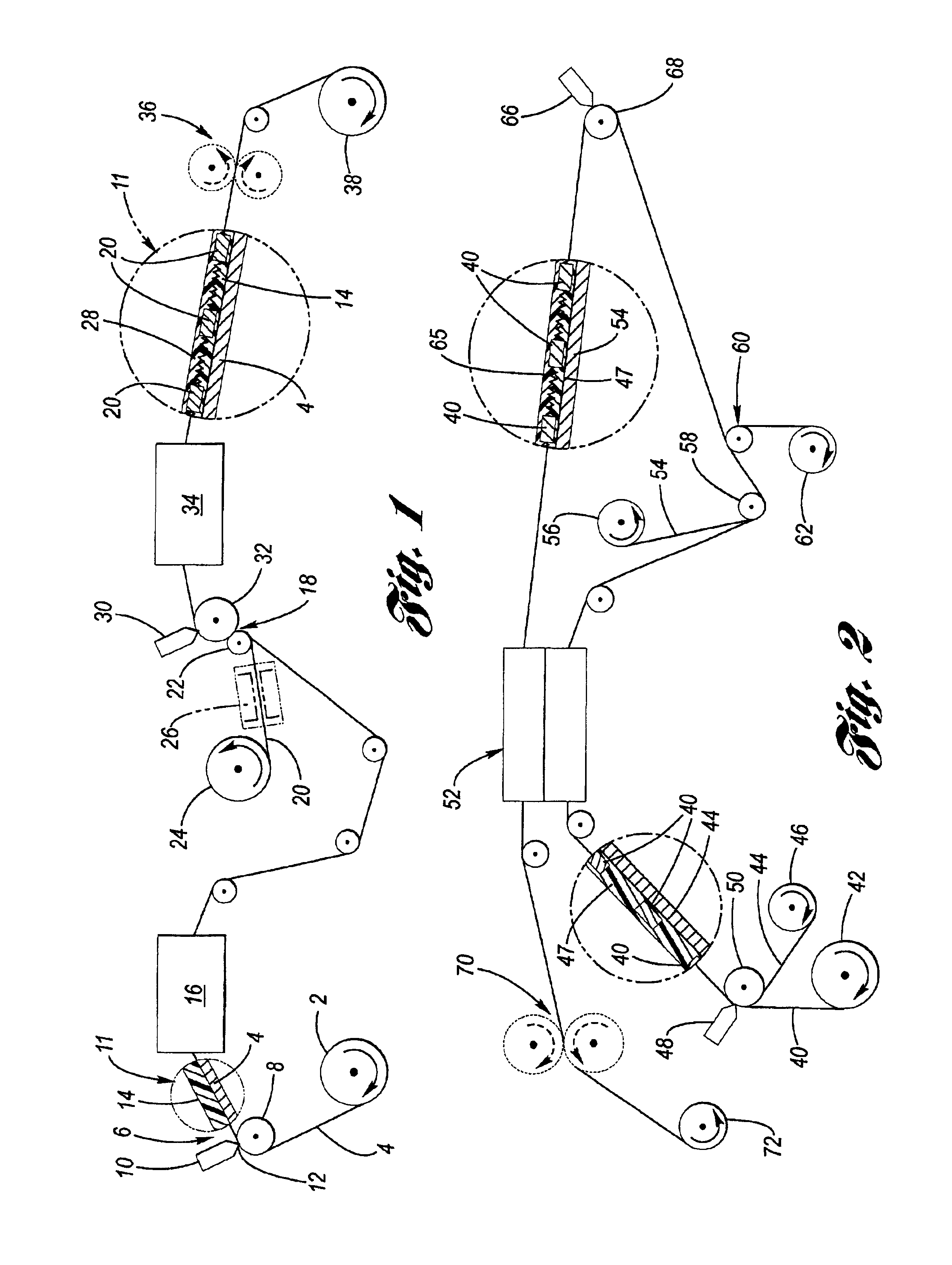

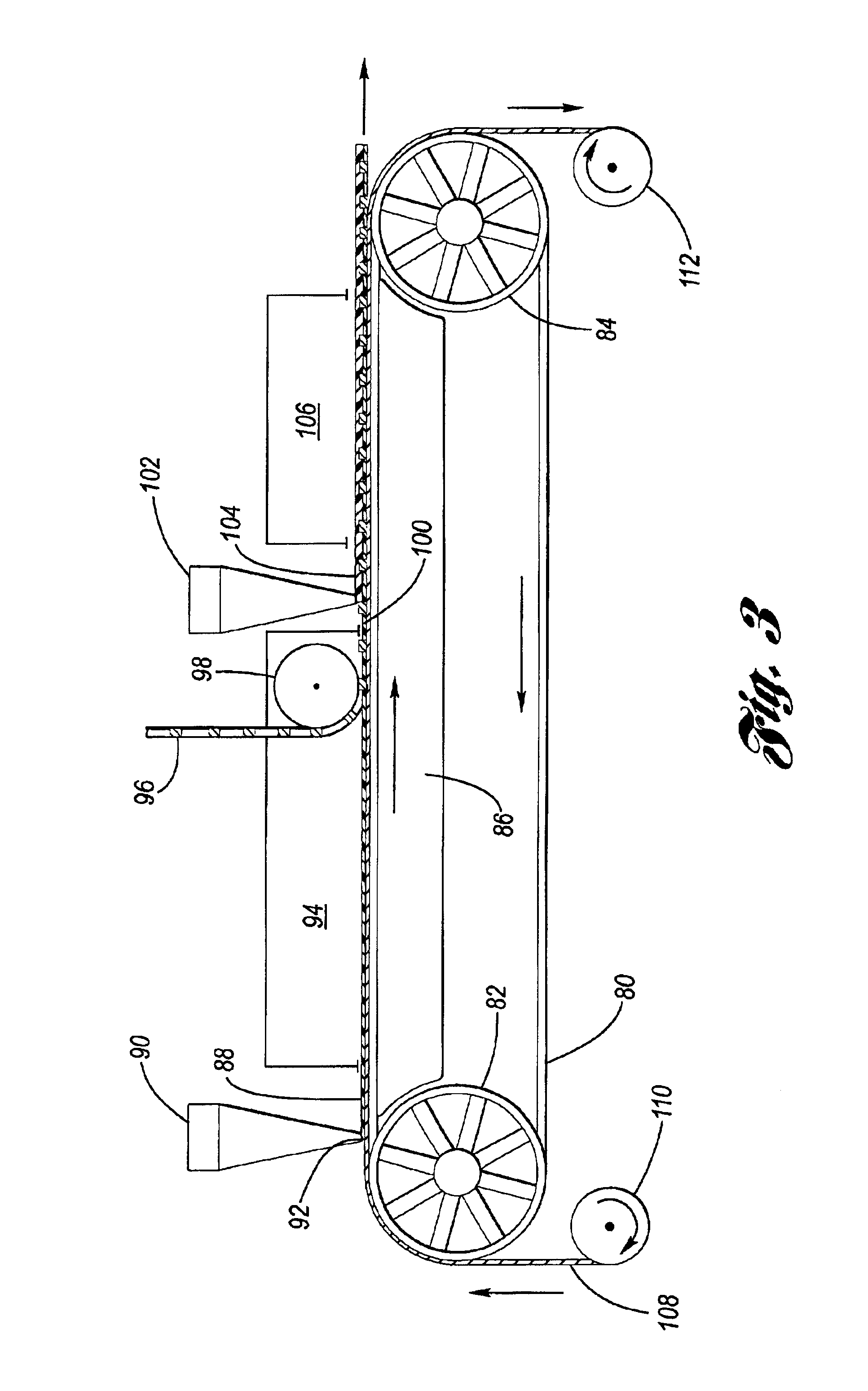

Filtration media for filtering particulate material from gas streams

A composite fabric formed by depositing a web of nanofibers electroblown from a first polymer onto a first support web comprising fibers of larger average diameter than the nanofibers spun from a compatible material, in the absence of an adhesive between the webs, and solvent-bonding the webs together.

Owner:DUPONT SAFETY & CONSTR INC

Cycloolefin blends and method for solvent bonding polyolefins

The present invention provides a polymer composition having a first component obtained by copolymerizing a norbornene monomer and an ethylene monomer, the first component being in an amount from about 1-99% by weight of the composition; and a second component of an ethylene and alpha-olefin copolymer, the alpha-olefin having 6 carbons, the second component being in an amount from about 99% to about 1% by weight of the composition.

Owner:BAXTER INT INC

Cycloolefin blends and method for solvent bonding polyolefins

Owner:BAXTER INT INC +1

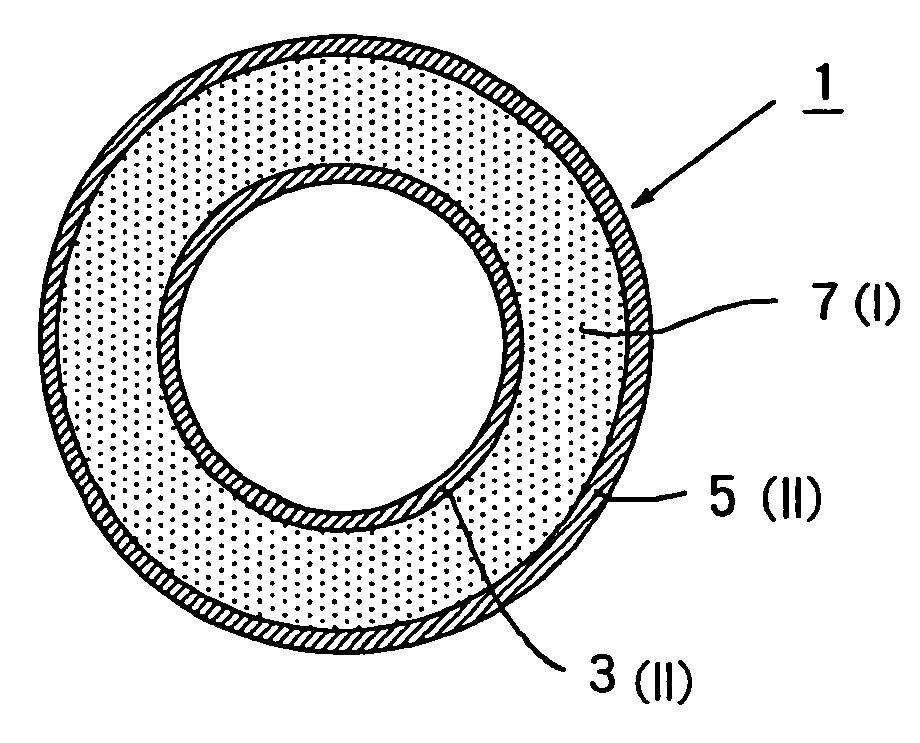

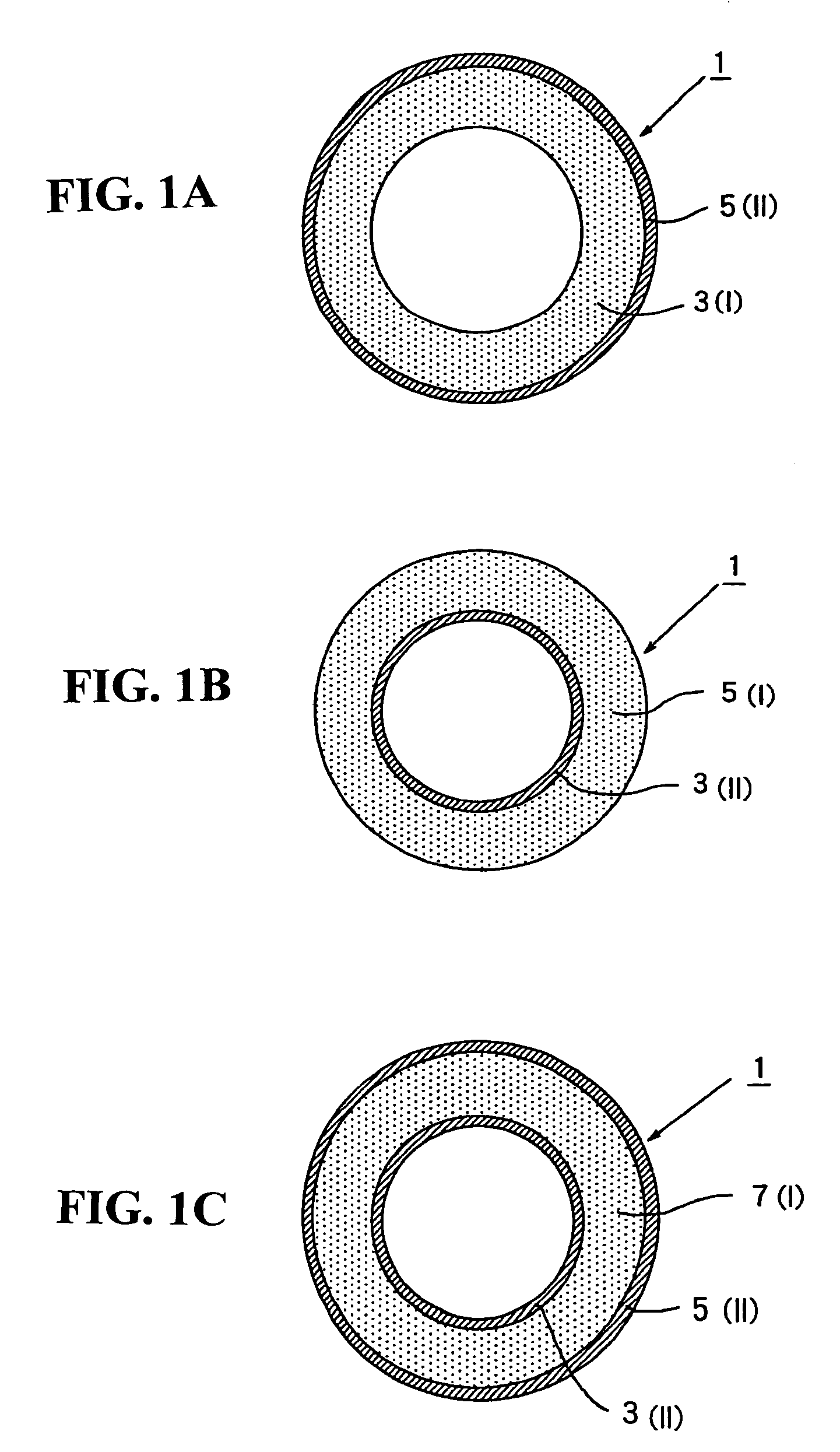

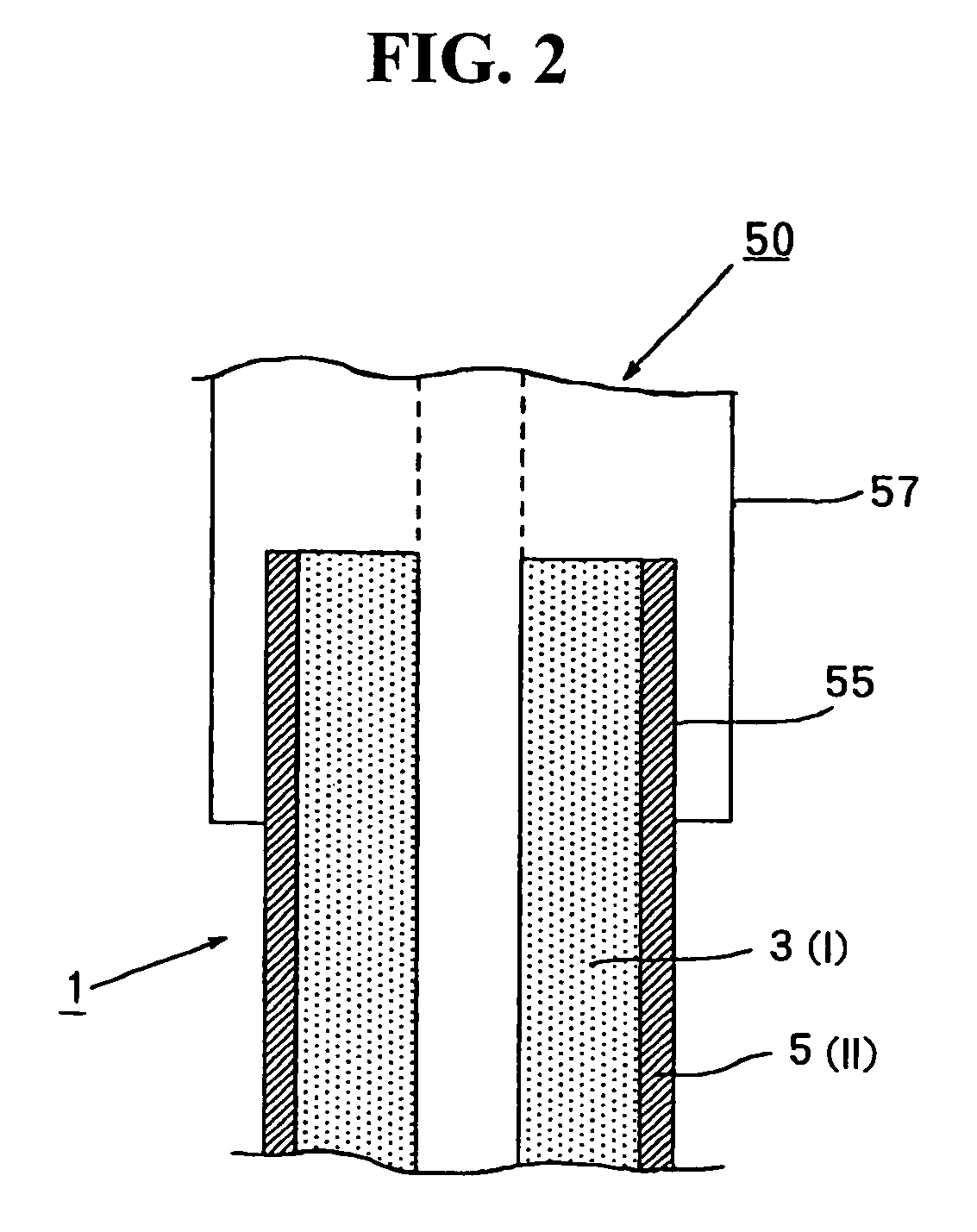

Multilayered tube and medical supply comprising multilayered tube

A multi-layered tube composed of at least two layers, each formed from a different resin, e.g. resin (I) or resin (II). Resin (I) contains 5 to 40 mass % of a polypropylene resin and 95 to 60 mass % of at least one hydrogenated copolymer. Resin (II) contains 45 to 100 mass % of a polypropylene resin and 55 to 0 mass % of a hydrogenated copolymer. The multi-layered tubes may be used in the field of medicine and provide tubing which is excellent in transparency, flexibility and anti-kinking properties, and which is durable during sterilization procedures with high-pressure steam. The multilayer tubing may also be safely disposed of as it generates no toxic gases, such as dioxin, when incinerated. The multilayered tubing has excellent connectability and may be bonded to other tubing using hot solvent bonding or solvent adhesion. The multilayered tubing which is free from generation of any toxic gas when incinerated, and which is excellent in hot solvent bonding or solvent adhesion to other tube.

Owner:KAWASUMI LABORITORIES INC +1

Cellulosic/polyamide composite

InactiveUS20070163217A1Prevent peelingCombination devicesSynthetic resin layered productsElectrospinningCellulose fiber

Composite of polyamide layer solvent bonded to cellulosic substrate is formed by solution electrospinning deposit of polyamide on cellulosic substrate with the solution subjected to electrospinning containing as solvent for polyamide one that swells cellulosic fibers on contact therewith and / or by depositing very long polyamide fibers of low average diameter.

Owner:CORNELL RES FOUNDATION INC +1

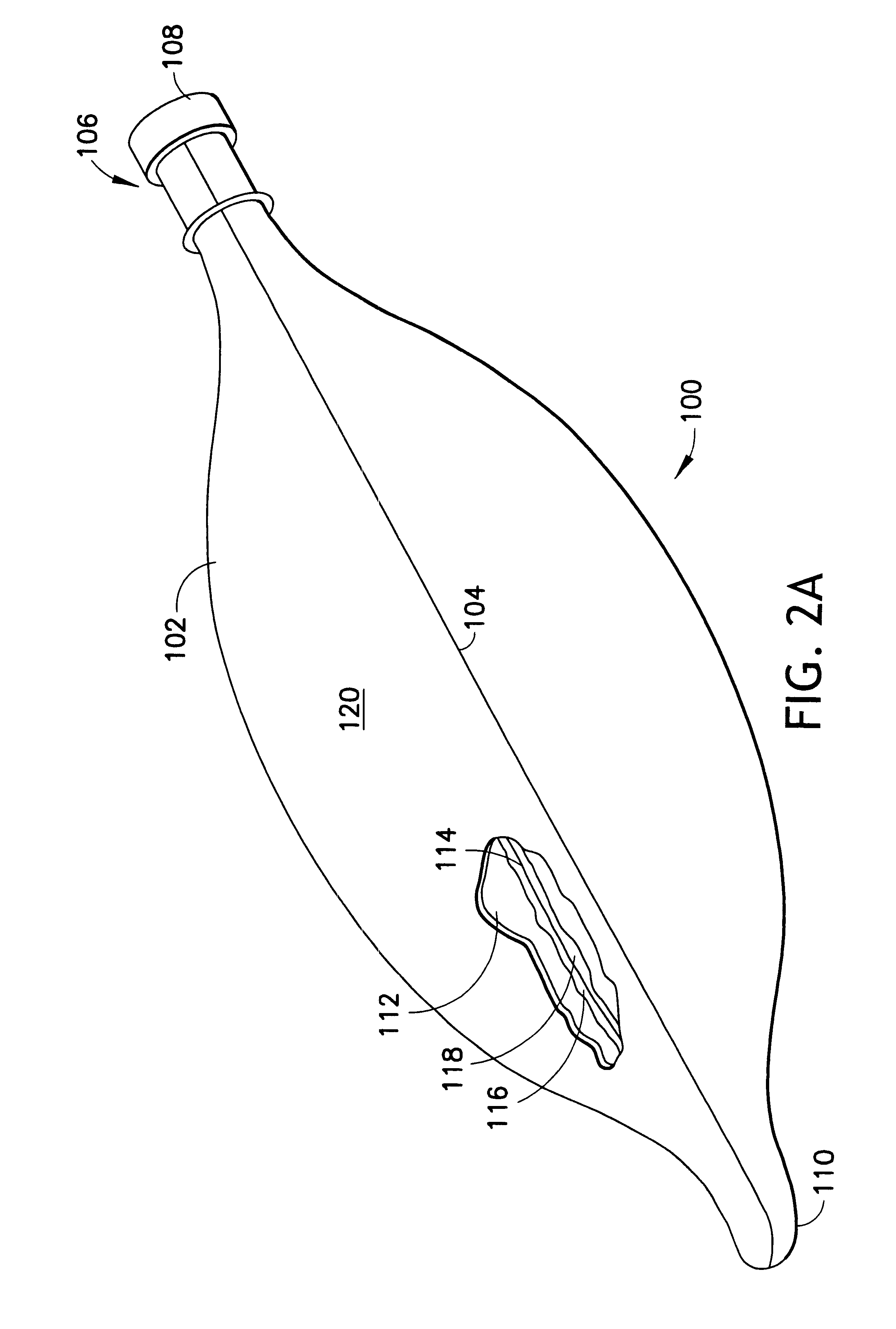

Film welded reservoir bag for breathing circuit and method of making the same

A pulmonarily sized bag formed of a non-latex material, including a bag body formed of panels of resin film material welded to one another along a weld line defining a seam of the bag body bounding an interior volume of the bag. The seam includes an interior seam portion in the interior volume, and an exterior seam portion at an exterior surface of the bag. One of the interior seam portion and exterior seam portion comprises free edges of the seam, and the other one of such seam portions is devoid of free edges. The bag is formable by various techniques, including radio frequency welding, impulse heating, solvent bonding, etc., and is usefully employed in a breathing circuit to obviate the necessity of using latex breathing bags.

Owner:POLYZEN INC

Solar module back veneer comprising non-solvent bonding layers and manufacturing method thereof

ActiveCN102569451AAvoid pollutionImprove performanceFinal product manufacturePhotovoltaic energy generationPolymer scienceAcrylic resin

The invention provides a solar module back veneer comprising non-solvent bonding layers. The solar module back veneer comprises: a base film layer, the bonding layers on two sides of the base film layer, a fourth thin layer and a fifth thin layer which are on another two sides of the bonding layers. The materials of the bonding layers are selected from one or more of the following components: polyethylene and a vinyl copolymer, polypropylene and modified polypropylene, thermoplastic polyurethane, acrylic resin and ABS series resin. The invention also provides a manufacturing method of the back veneer. According to the invention, a solvent adhesive can be completely avoided to be used. By using the method of the invention, pollution generated through volatilization and emission of the solvent to environment during a traditional back veneer manufacturing process can be avoided. Simultaneously, adhesive strength, ageing resistance, barrier performance and a long-term service ability can be increased. By using the non-solvent bonding layers, a fusion extrusion technology can be used during manufacturing the solar module back veneer, which substantially reduces production cost.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

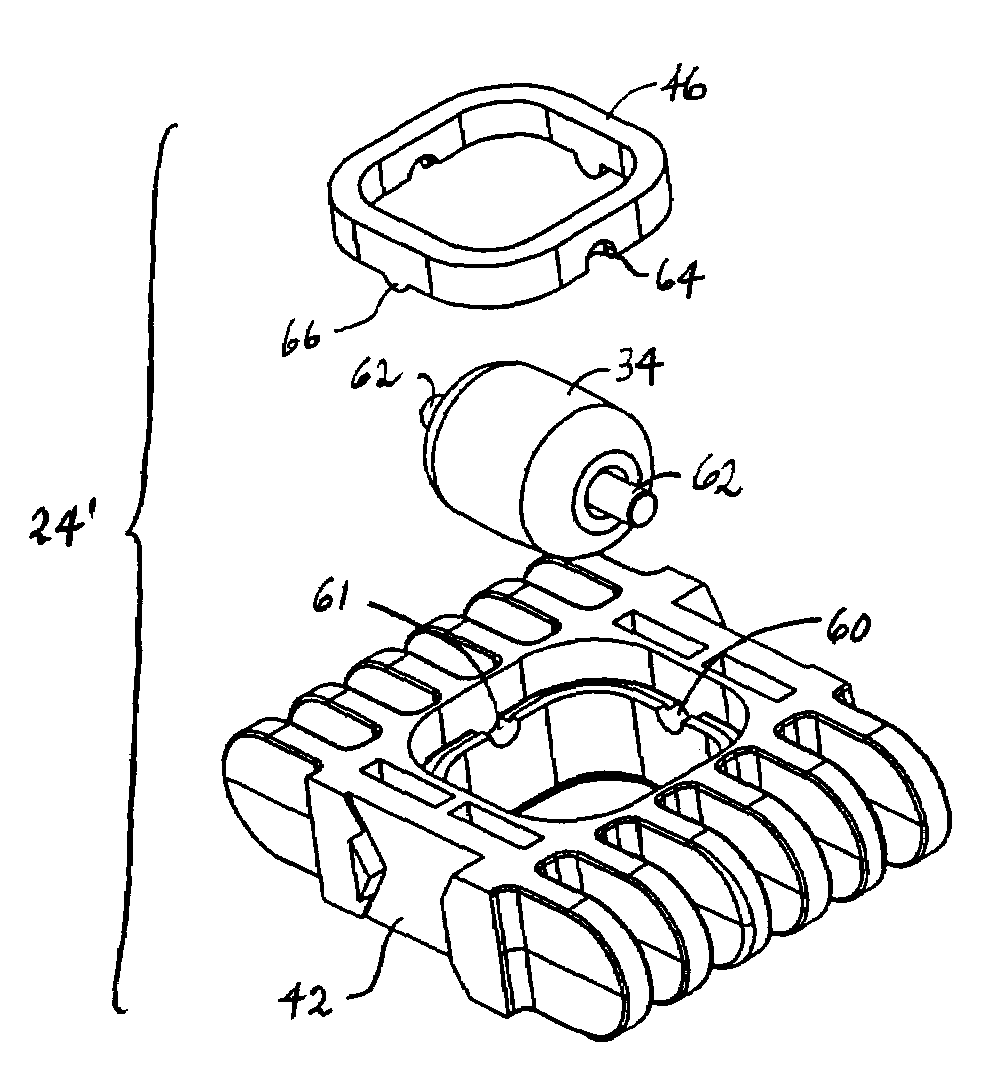

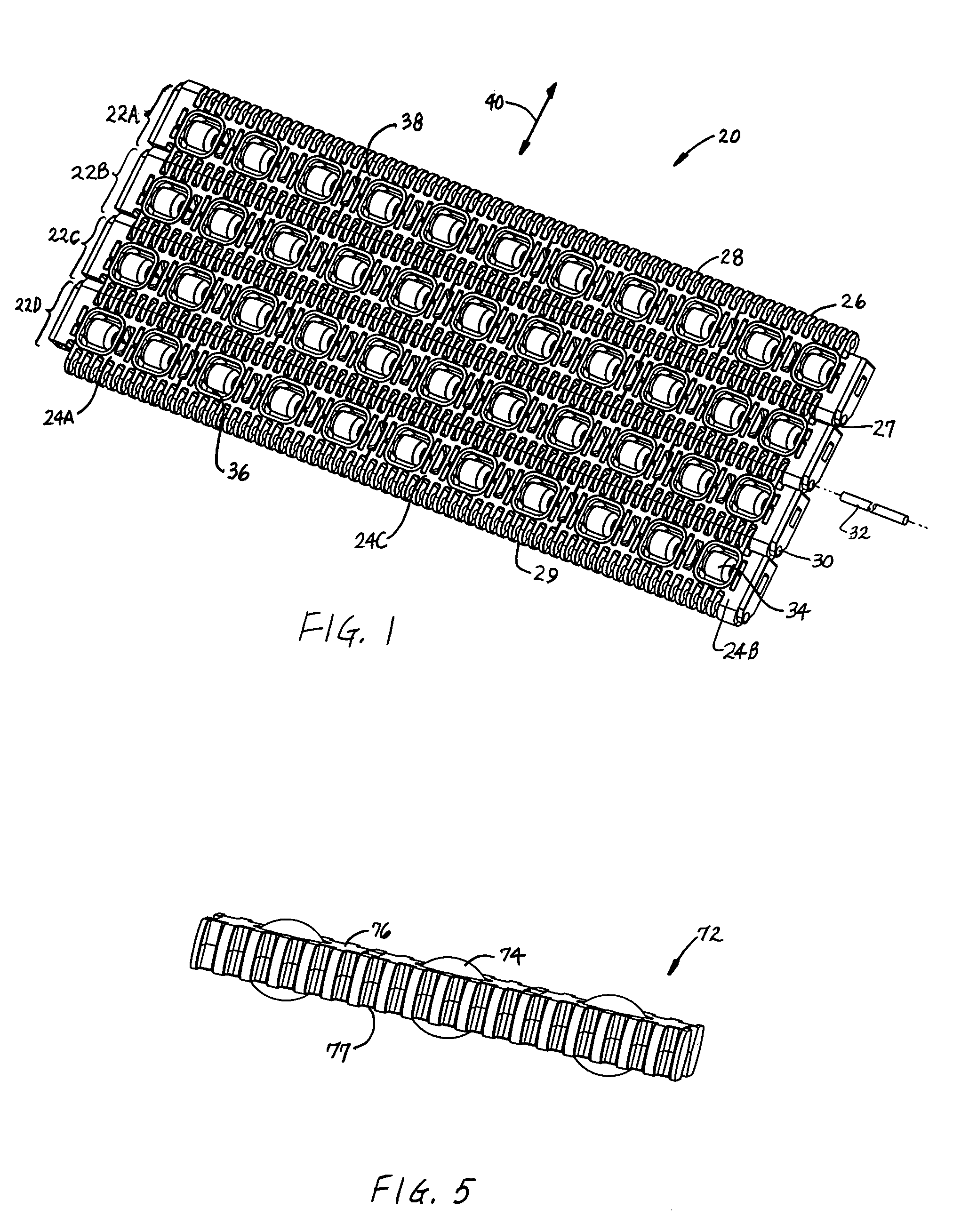

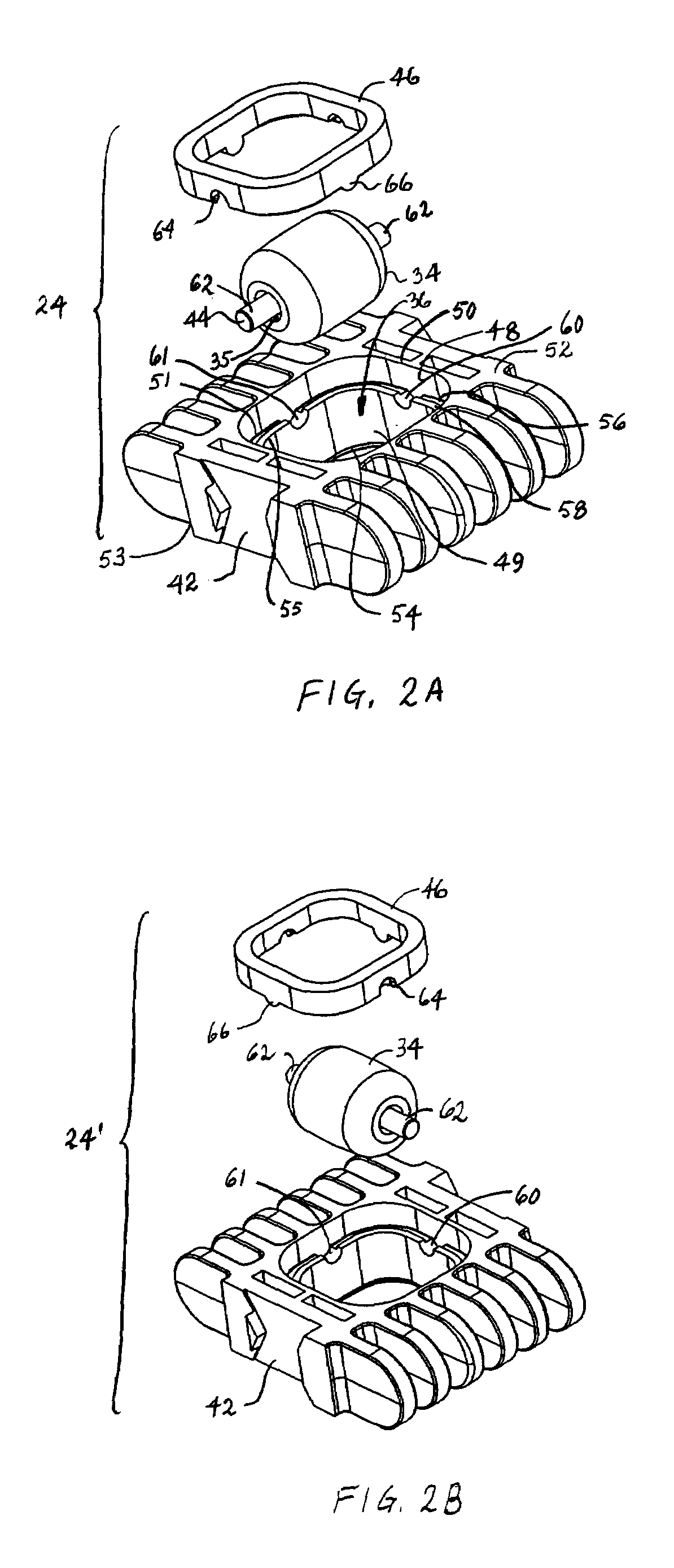

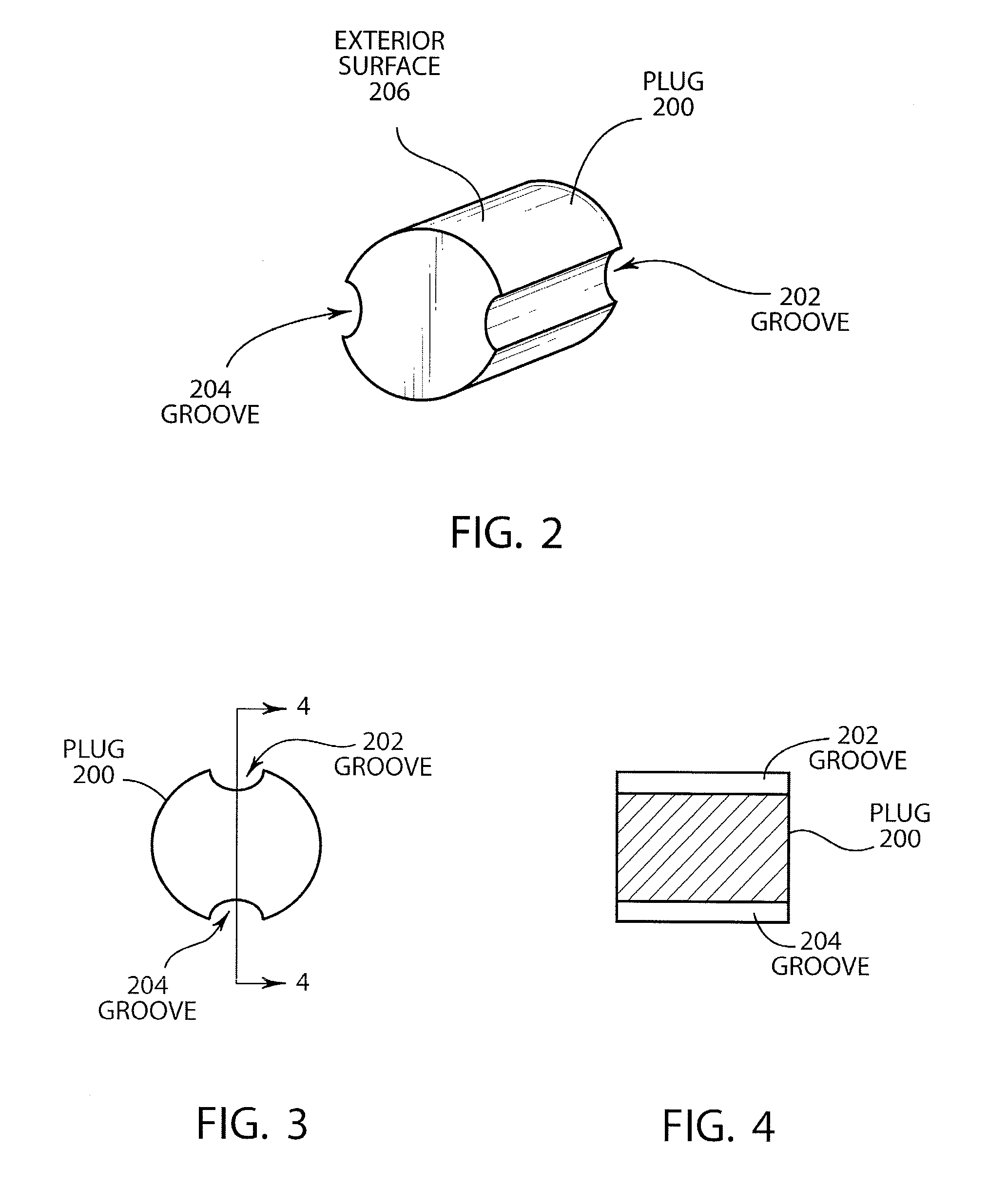

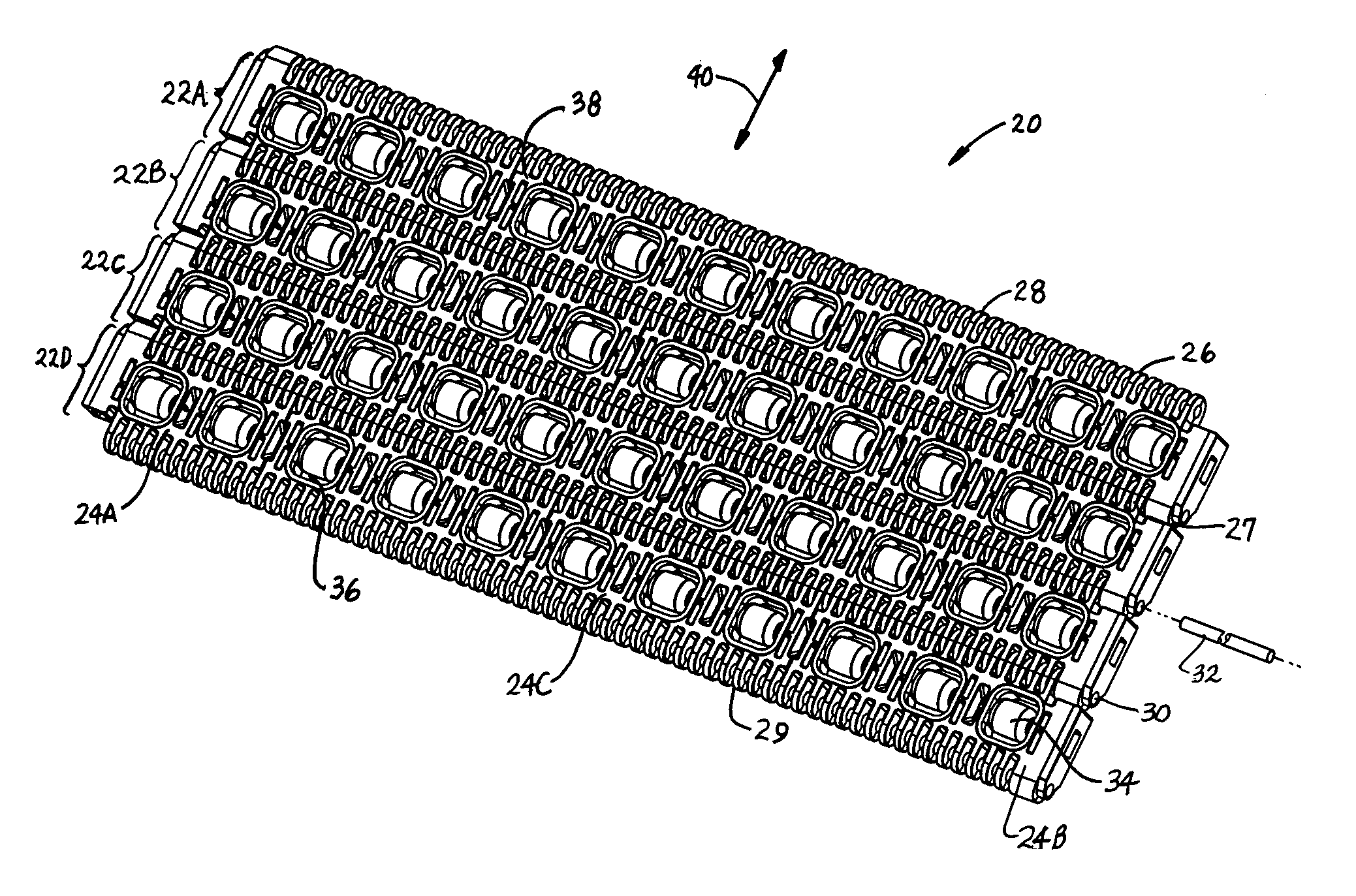

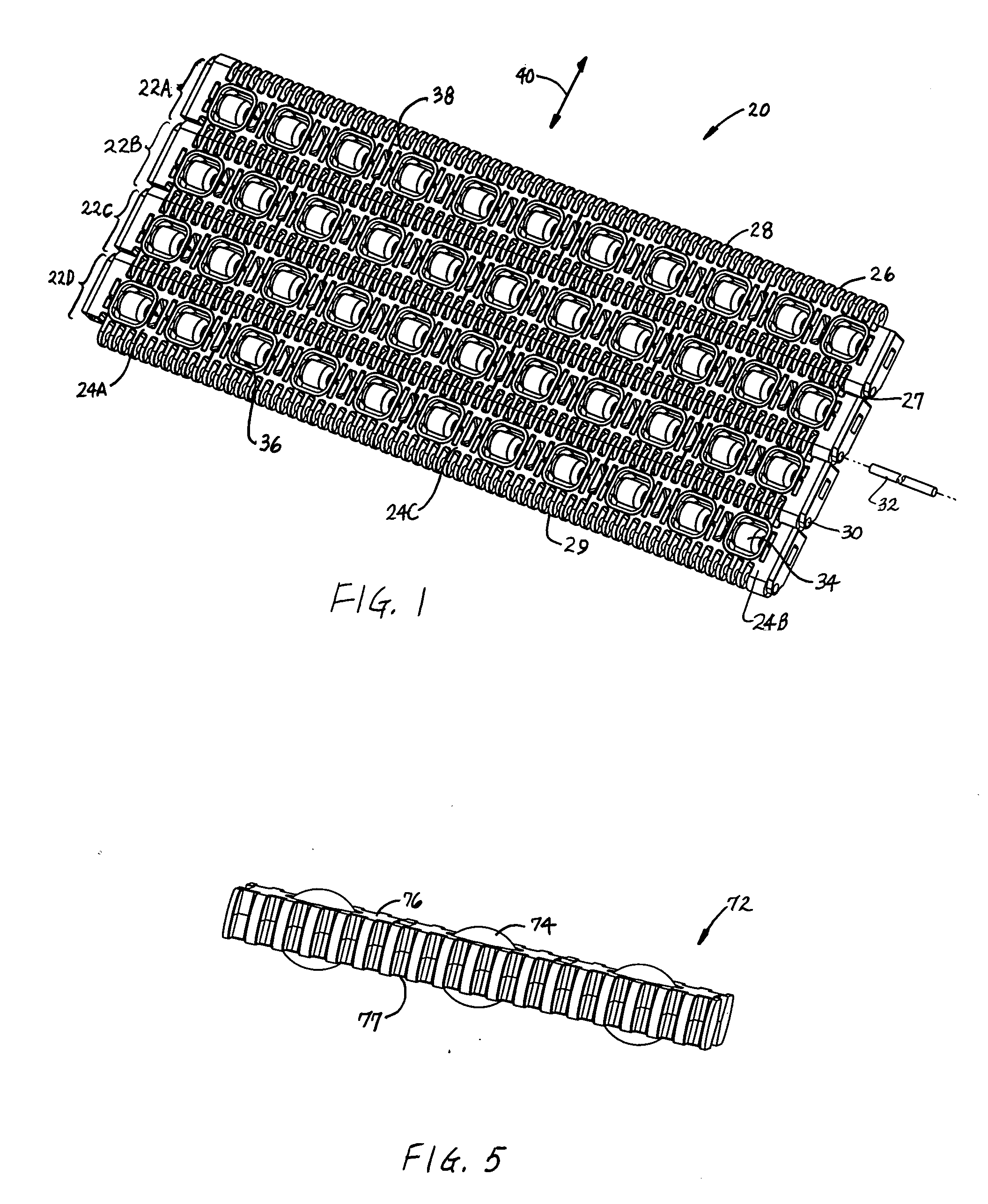

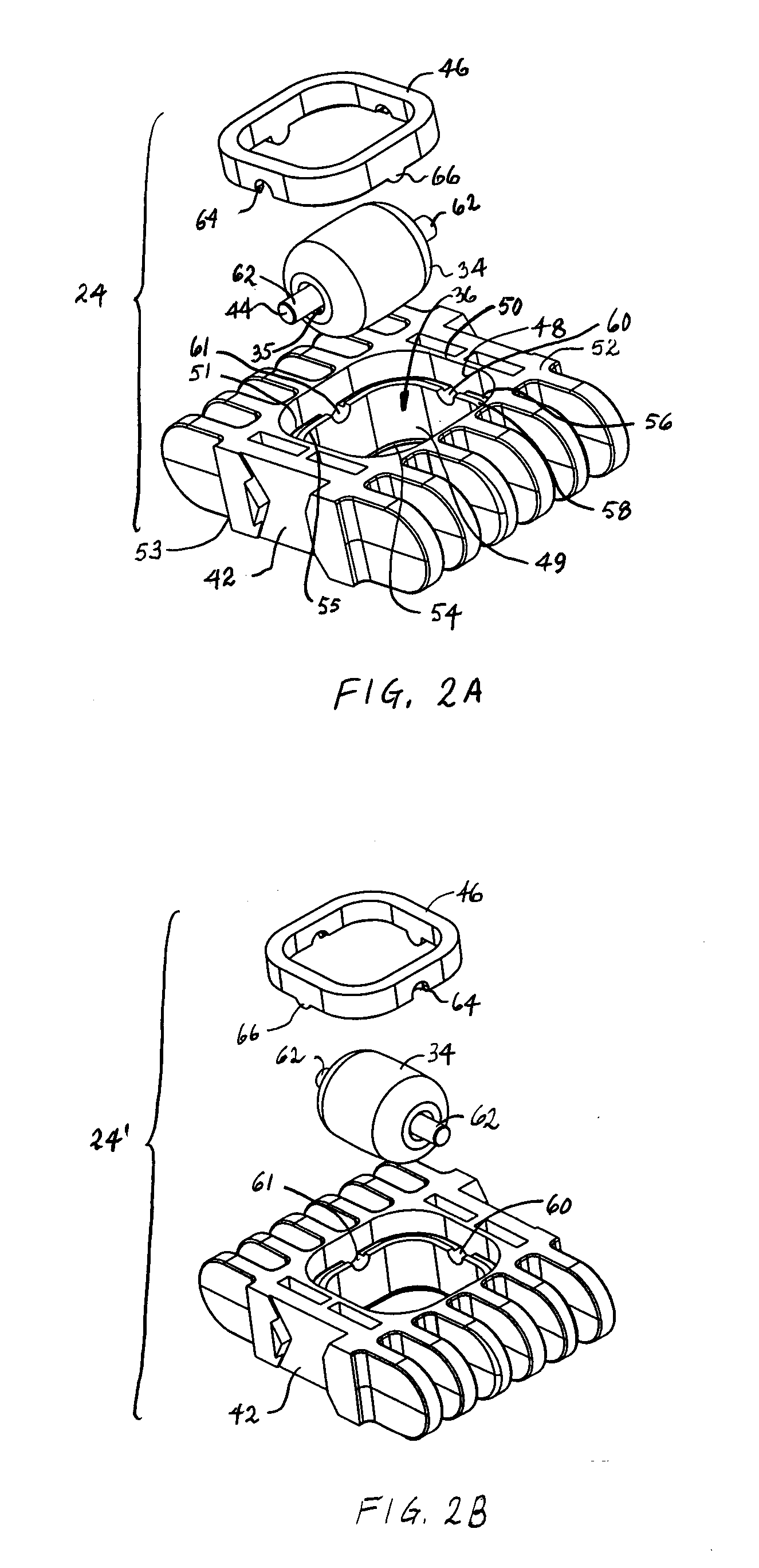

Conveyor belt modules with embedded rollers retained in the modules and associated method

A plastic conveyor belt module with embedded rollers retained in the module and a method for making such a module. The module includes a module body forming a cavity, a roller in the cavity, and a retainer received in the cavity to hold the roller rotatably in place. A salient portion of the roller extends outward from the cavity through the retainer past an outer surface of the module. The retainer is attached to the module body by ultrasonic welding, epoxy- or solvent-bonding, spin welding, electromagnetic welding, staking, screwing, or locking.

Owner:LAITRAM LLC

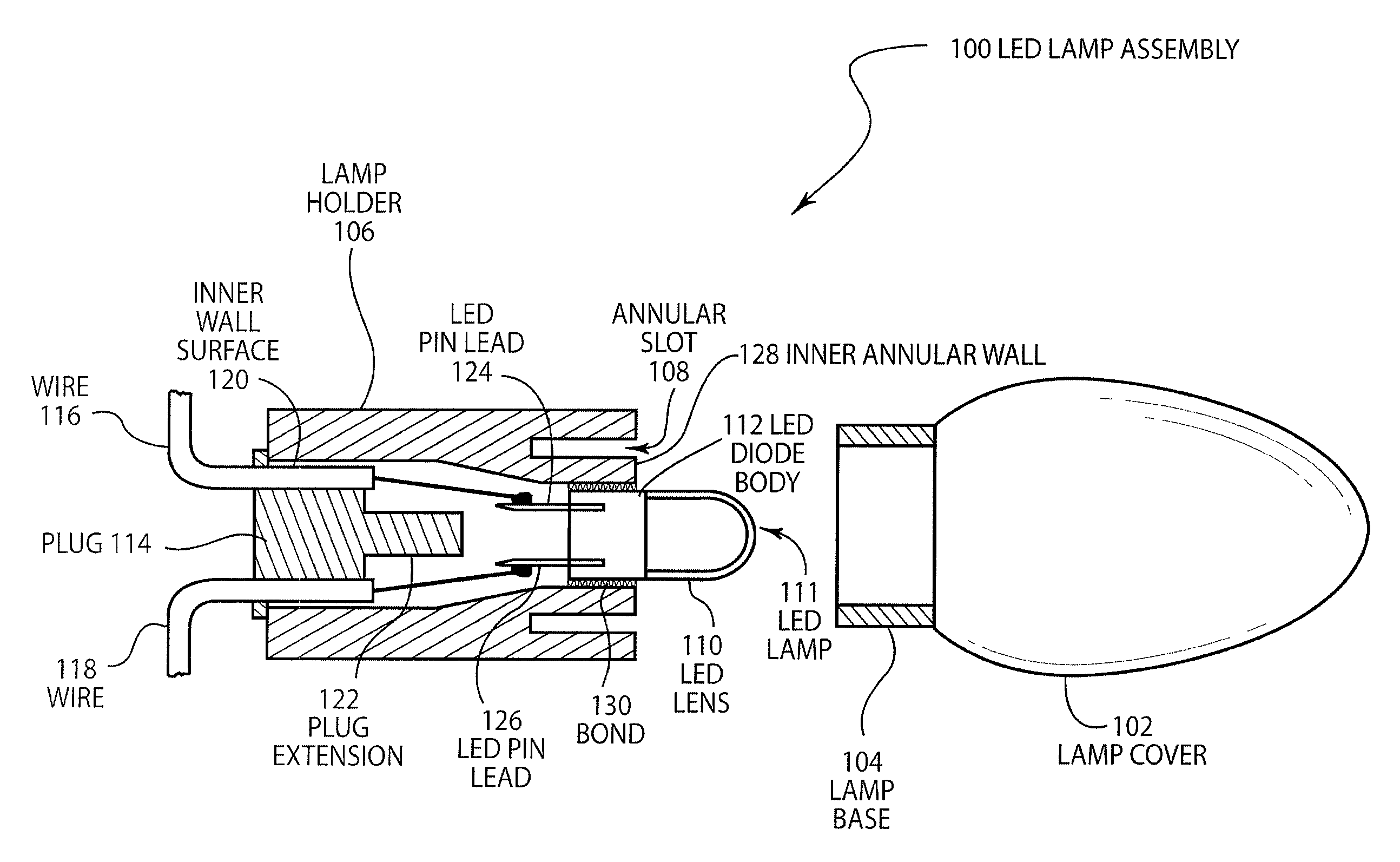

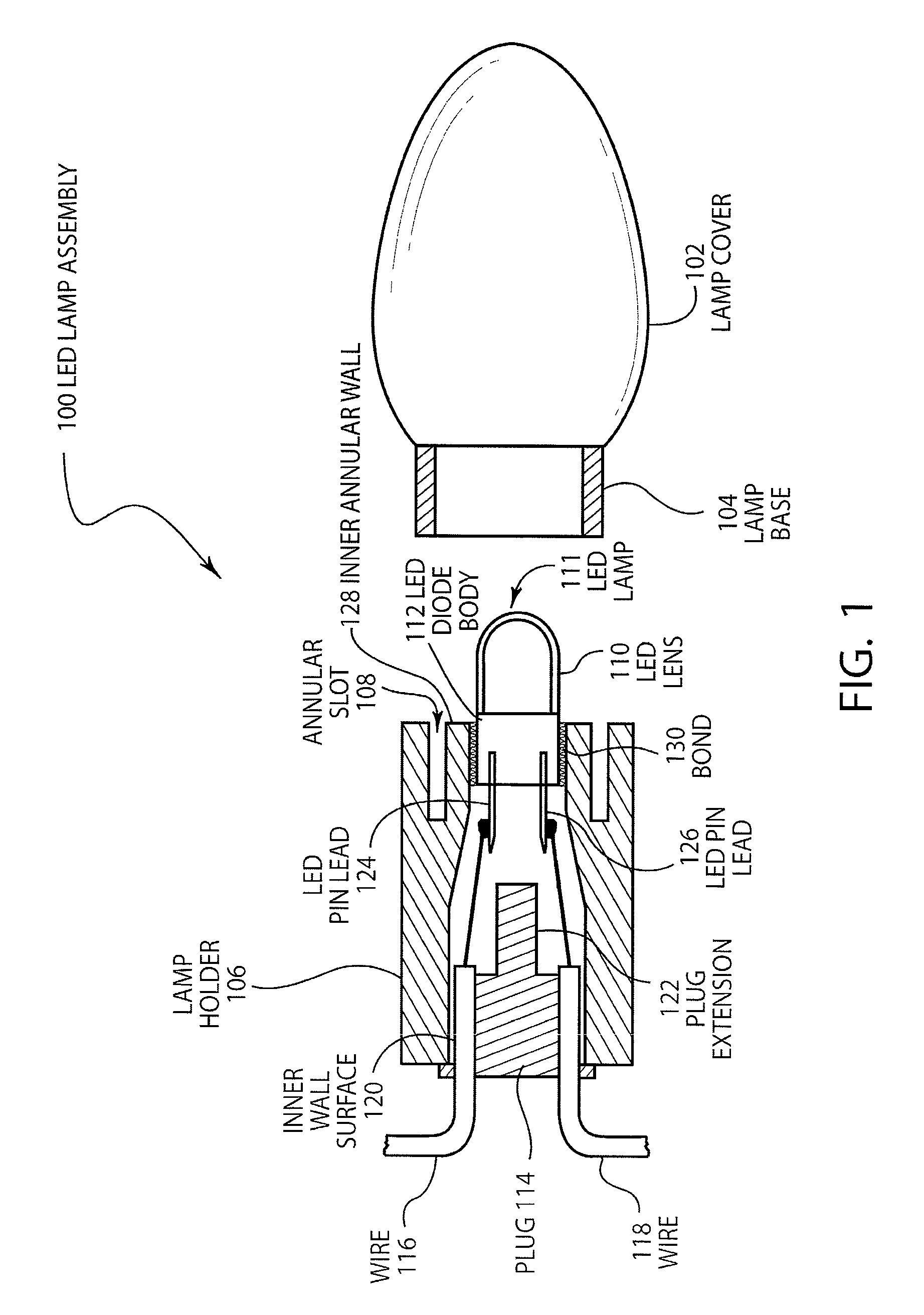

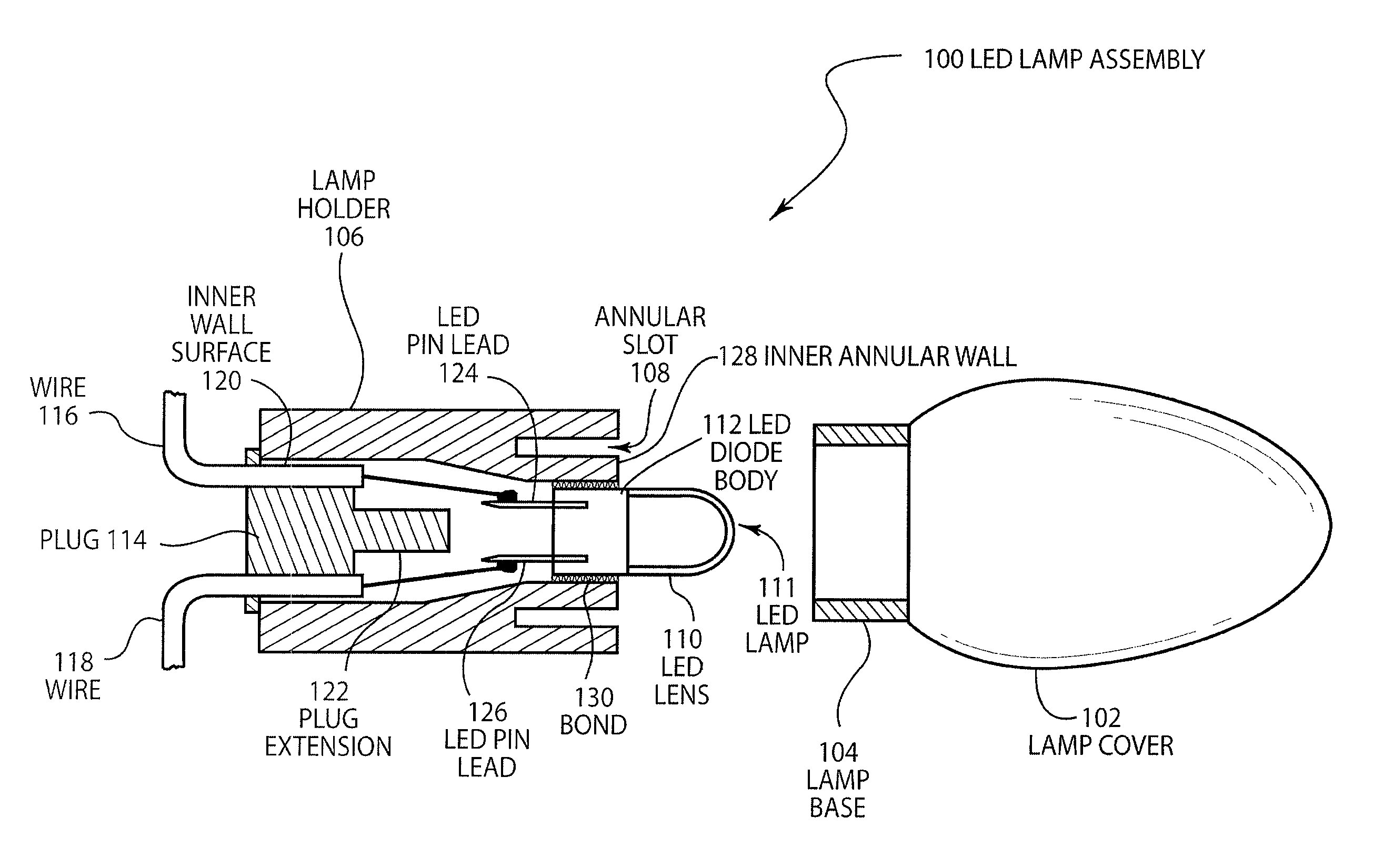

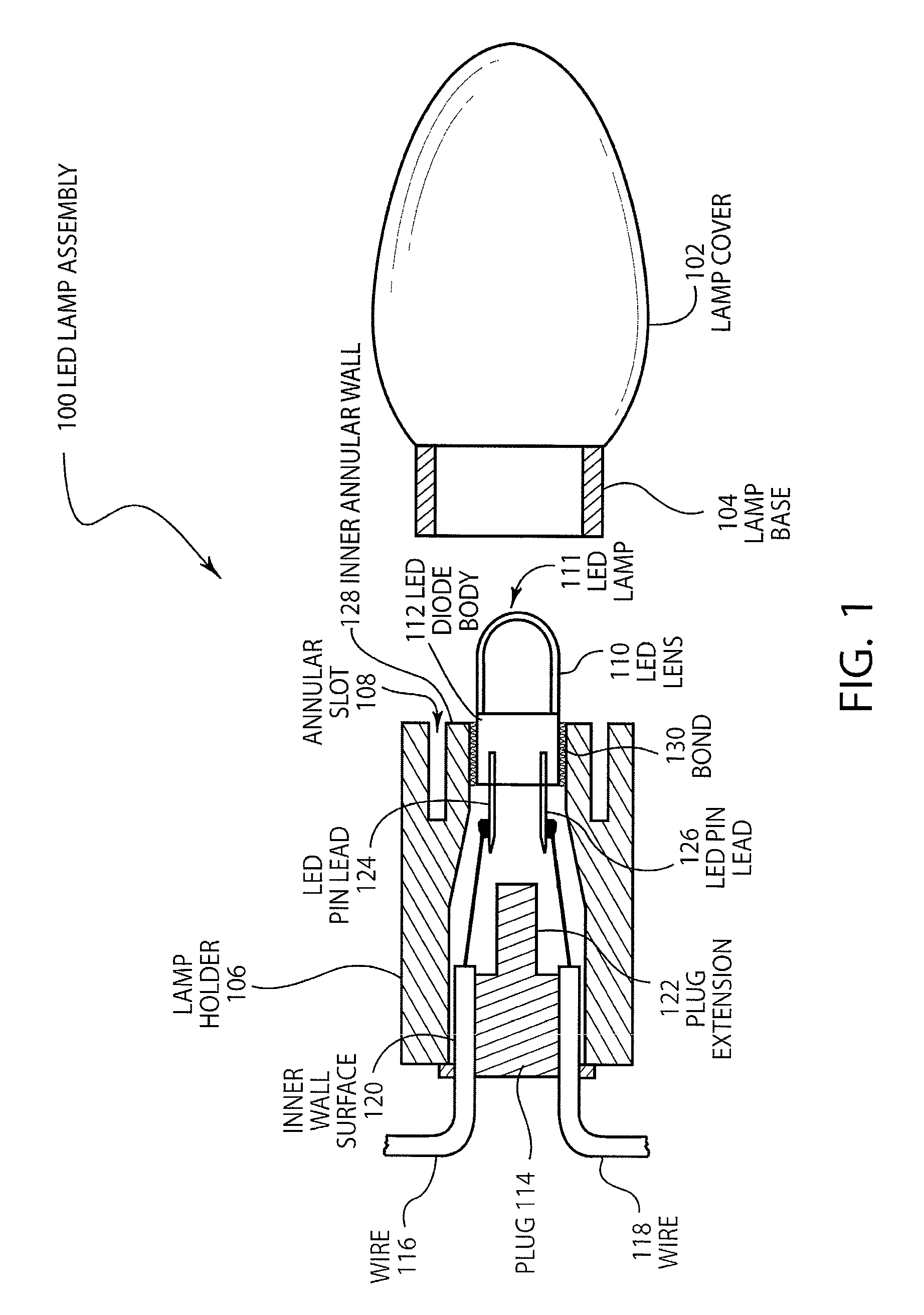

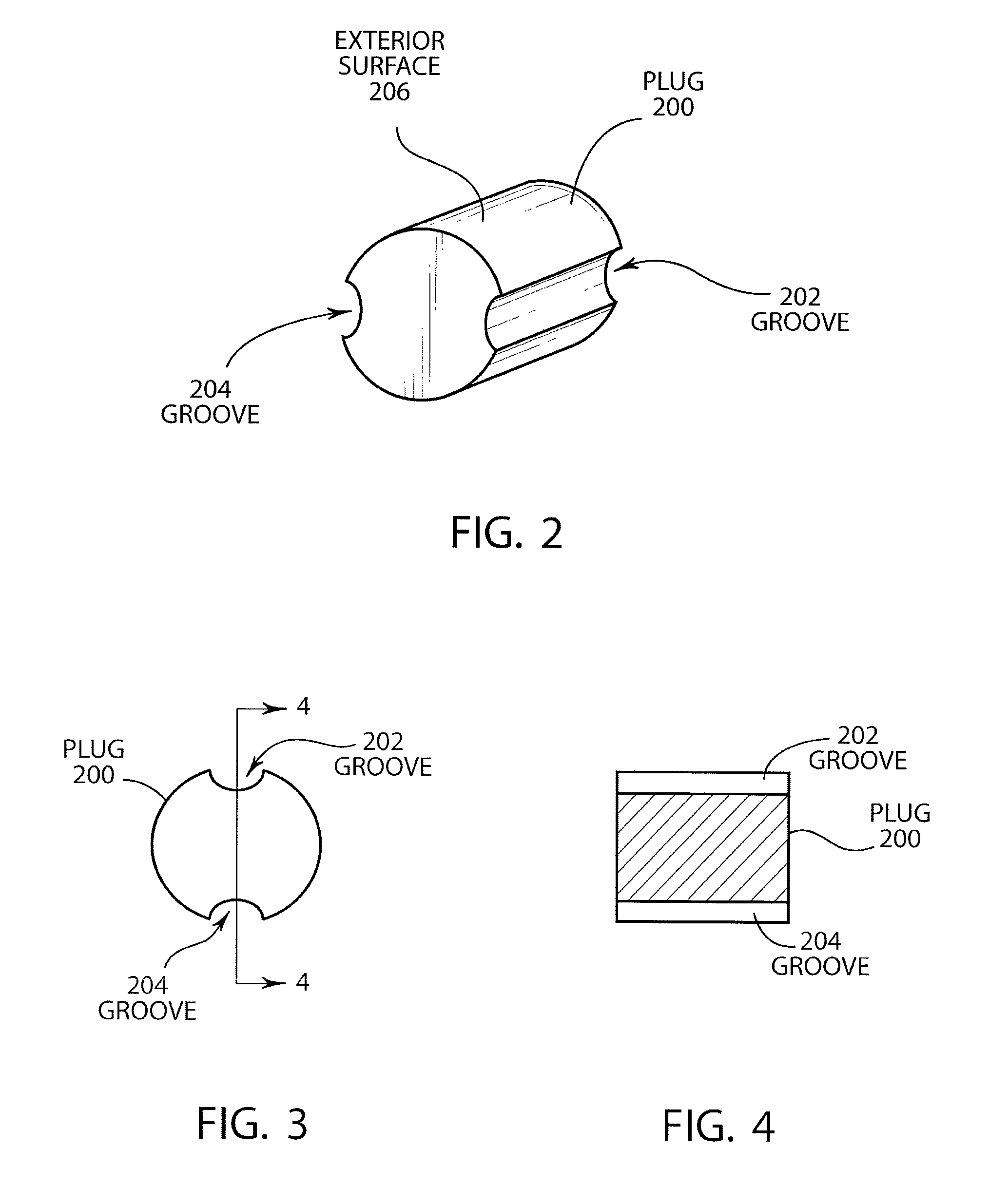

Substantially inseparable LED lamp assembly

ActiveUS20080143234A1Avoid disassemblyPoint-like light sourceThermionic cathodesInterference fitEngineering

Disclosed are LED lamp assemblies that are substantially inseparable. The LED lamp assemblies use discrete components that are individually manufactured and then assembled in a manner that substantially prevents disassembly or disengagement of components. An interference fit can be used to substantially secure components of the LED lamp assemblies. Bonding techniques can also be used, including adhesive and solvent bonds, as well as thermal bonds, including sonic bonds.

Owner:SANTAS BEST

Conveyor belt modules with embedded rollers retained in the modules and associated method

A plastic conveyor belt module with embedded rollers retained in the module and a method for making such a module. The module includes a module body forming a cavity, a roller in the cavity, and a retainer received in the cavity to hold the roller rotatably in place. A salient portion of the roller extends outward from the cavity through the retainer past an outer surface of the module. The retainer is attached to the module body by ultrasonic welding, epoxy- or solvent-bonding, spin welding, electromagnetic welding, staking, screwing, or locking.

Owner:LAITRAM LLC

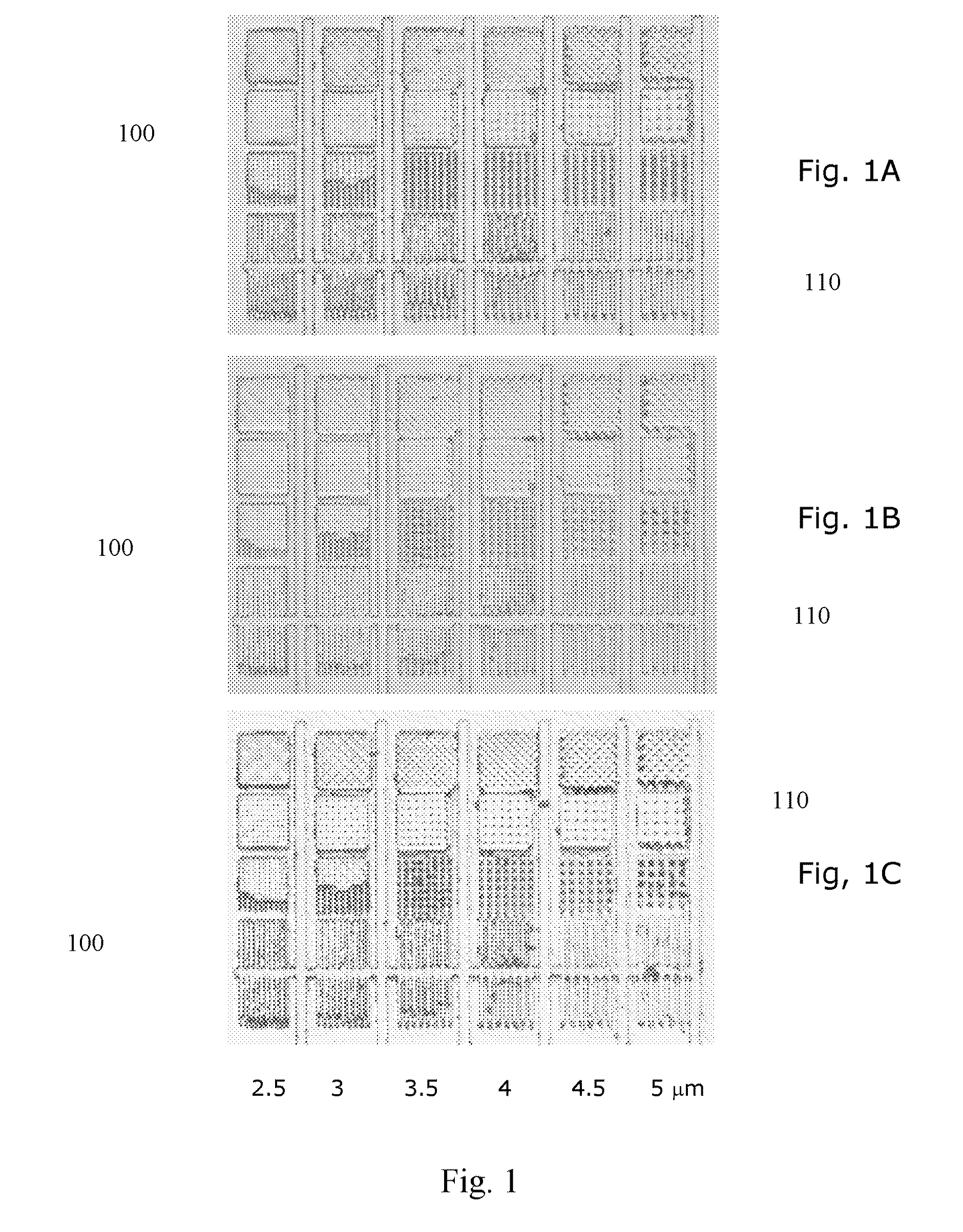

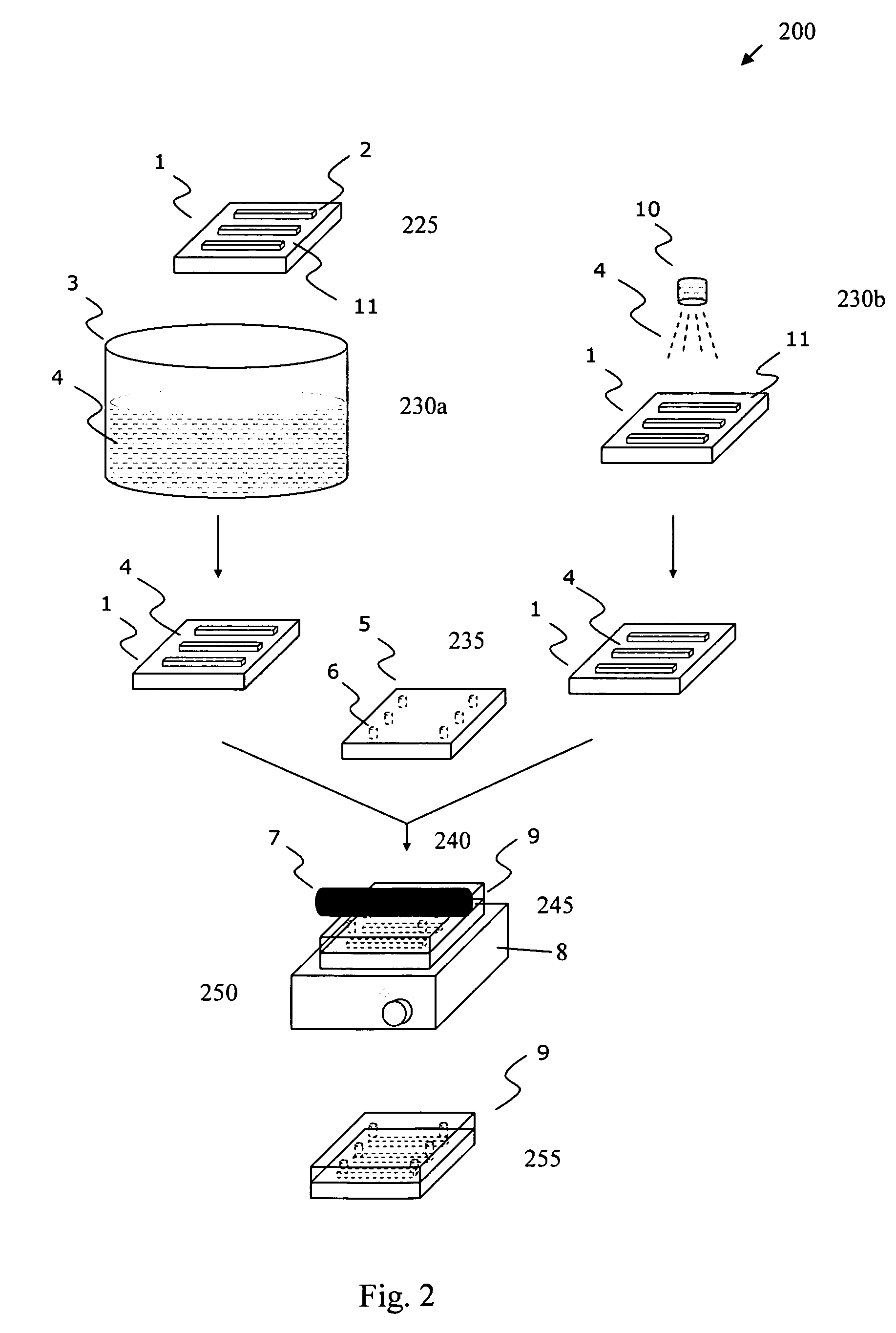

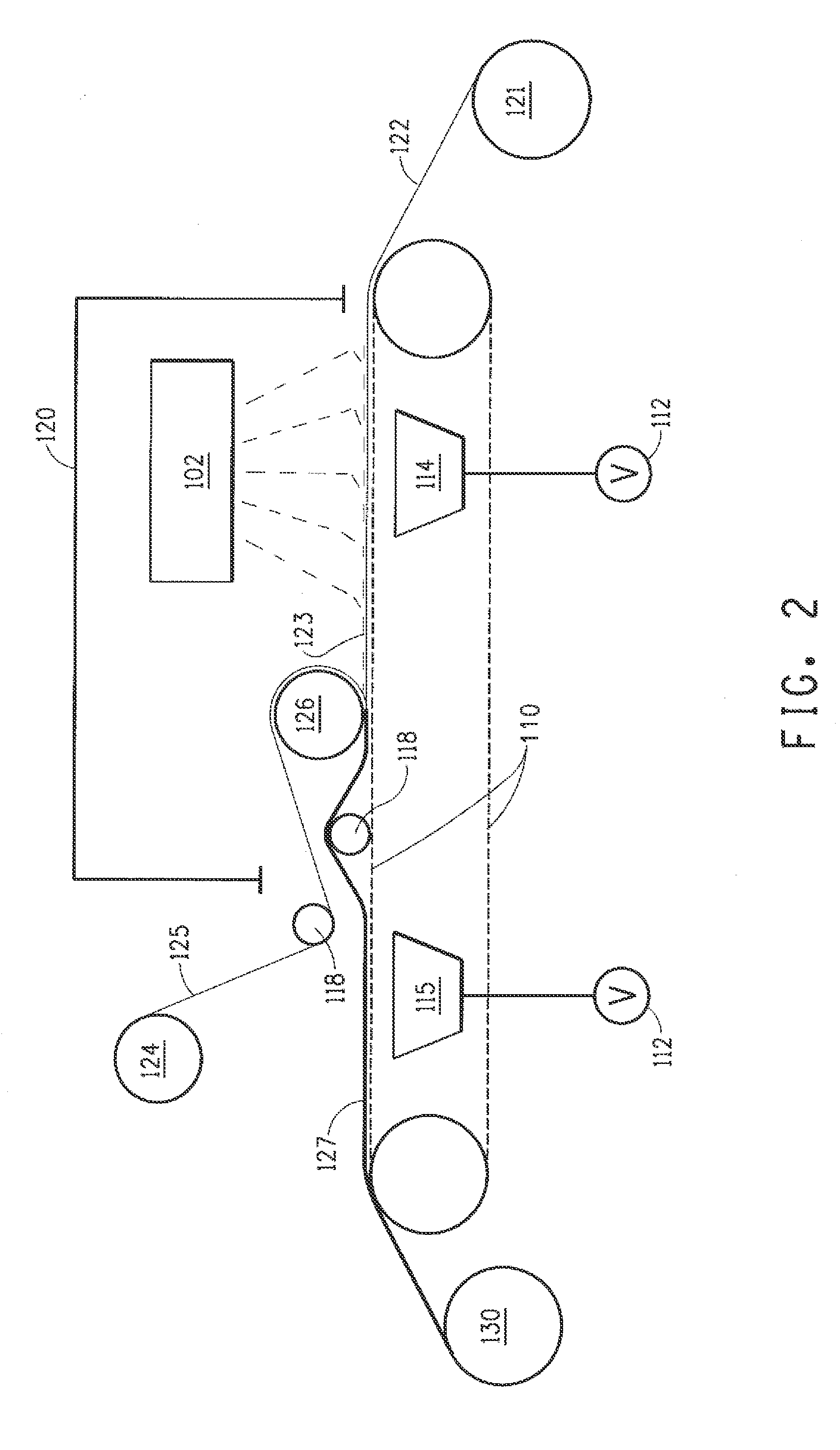

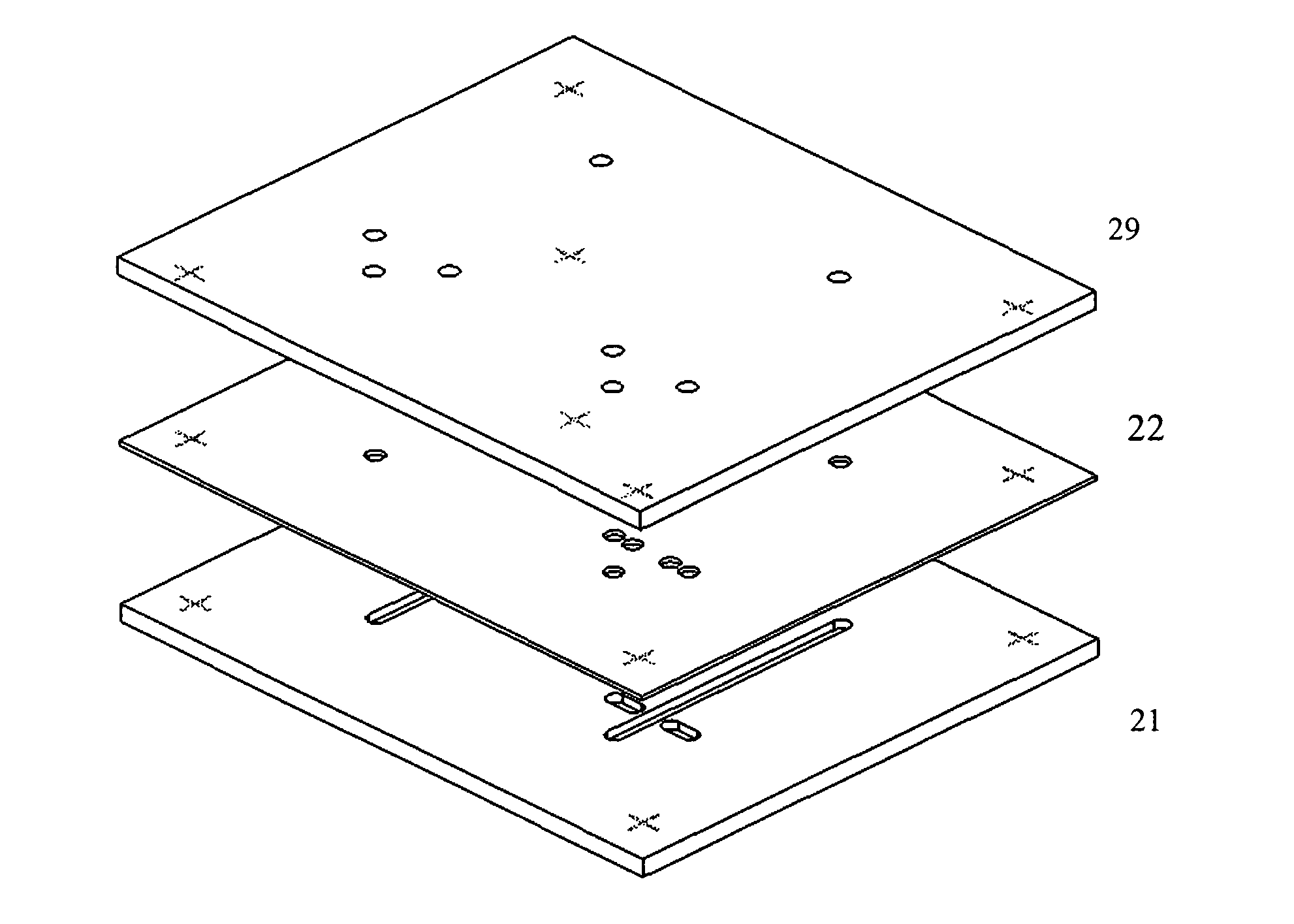

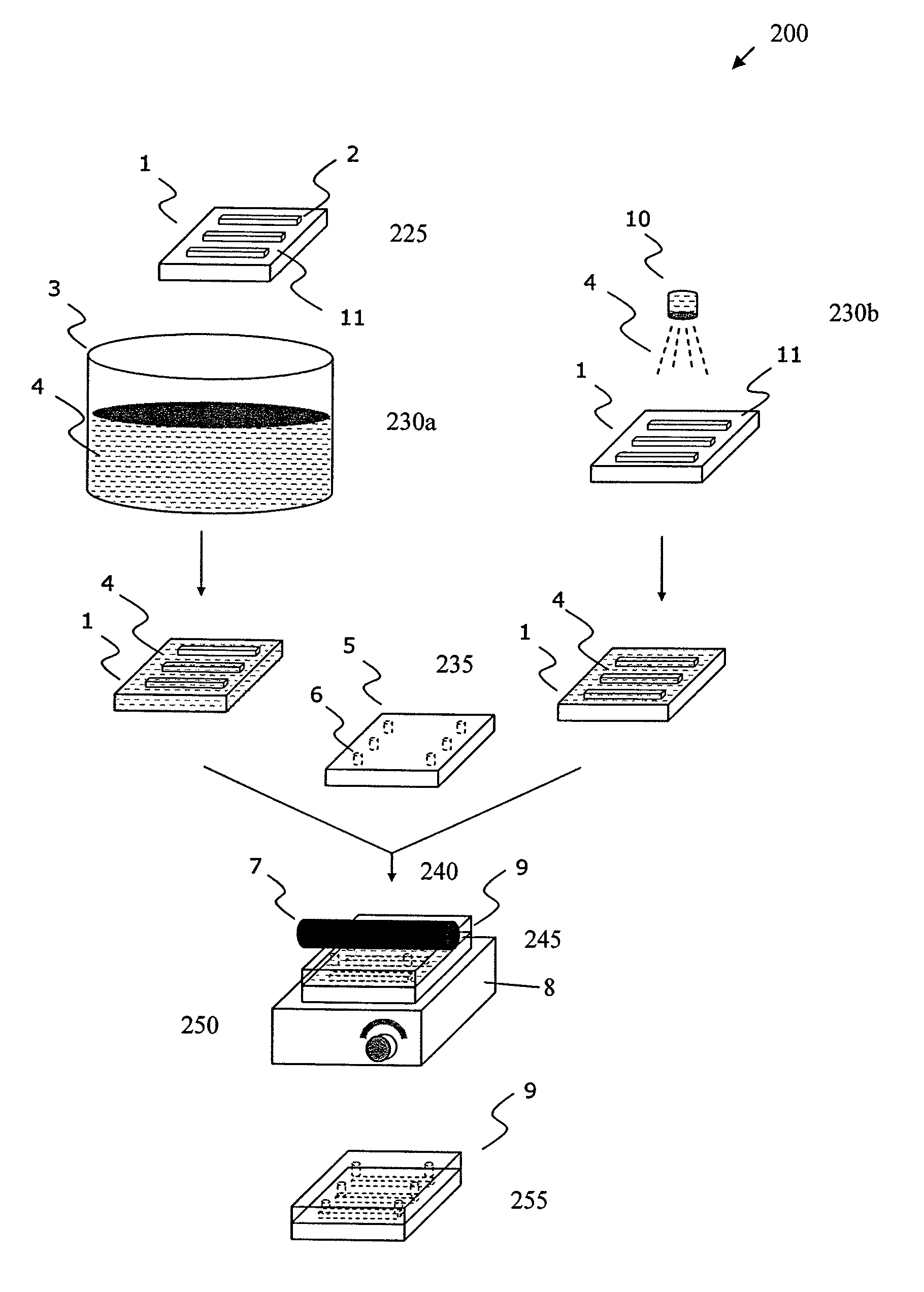

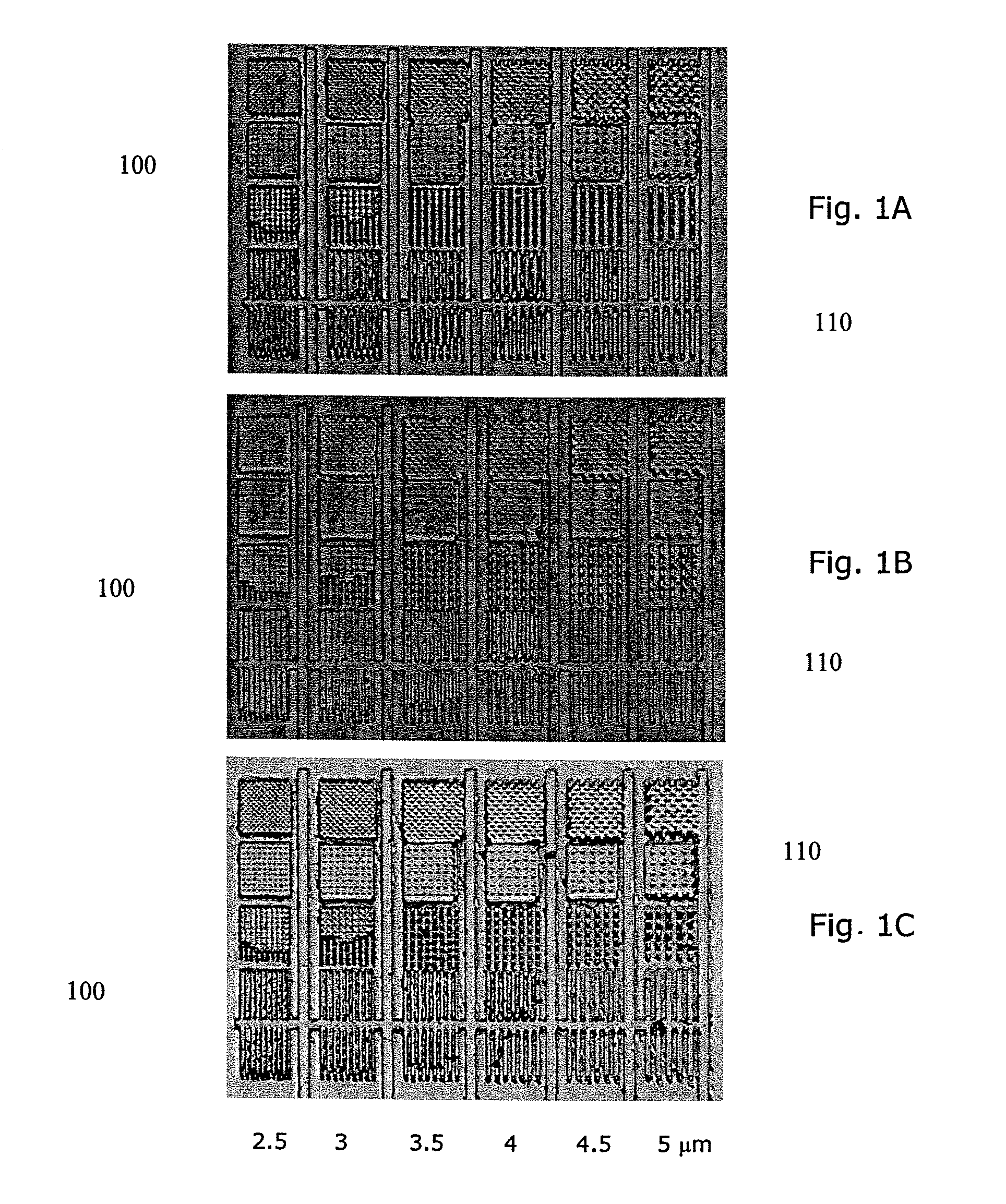

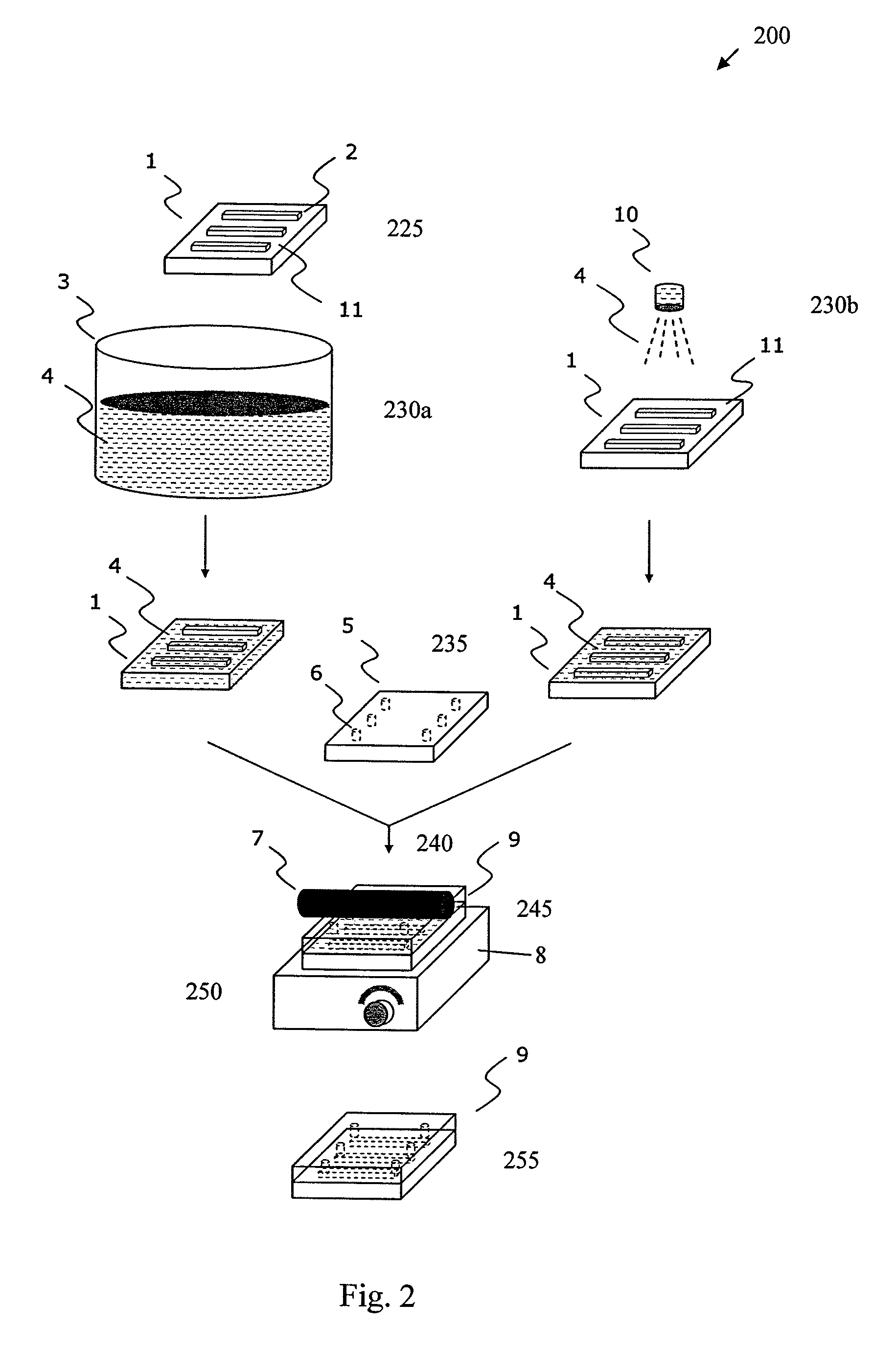

Laminated microfluidic structures and method for making

ActiveUS20060078470A1Valve arrangementsShaking/oscillating/vibrating mixersPolymer substratePolystyrene

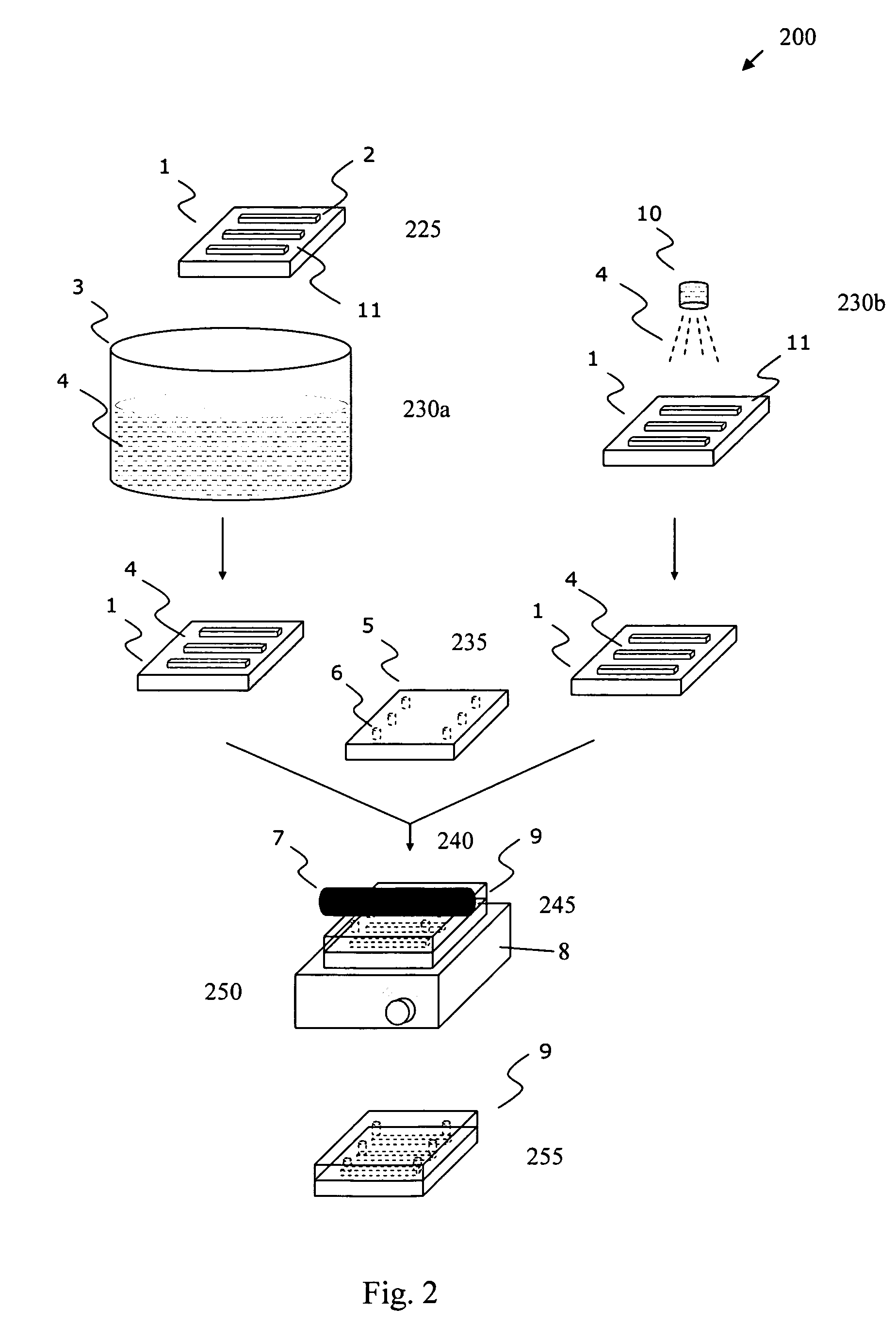

A method for making a polymeric microfluidic structure in which two or more components (layers) of the microfluidic structure are fixedly bonded or laminated with a weak solvent bonding agent, particularly acetonitrile or a mixture of acetonitrile and alcohol. In an aspect, acetonitrile can be used as a weak solvent bonding agent to enclose a microstructure fabricated in or on a non-elastomeric polymer such as polystyrene, polycarbonate, acrylic or other linear polymer to form a three-dimensional microfluidic network. The method involves the steps of wetting at least one of the opposing surfaces of the polymeric substrate components with the weak solvent bonding agent in a given, lower temperature range, adjacently contacting the opposing surfaces, and thermally activating the bonding agent at a higher temperature than the lower temperature range for a given period of time. The contacted polymeric substrates may also be aligned prior to thermal activation and compressed during thermal activation. A laminated, polymeric microfluidic structure is also disclosed.

Owner:RHEONIX

Laminated microfluidic structures and method for making

Owner:RHEONIX INC

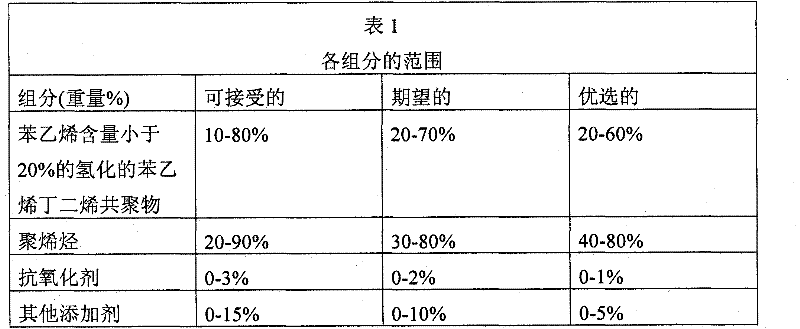

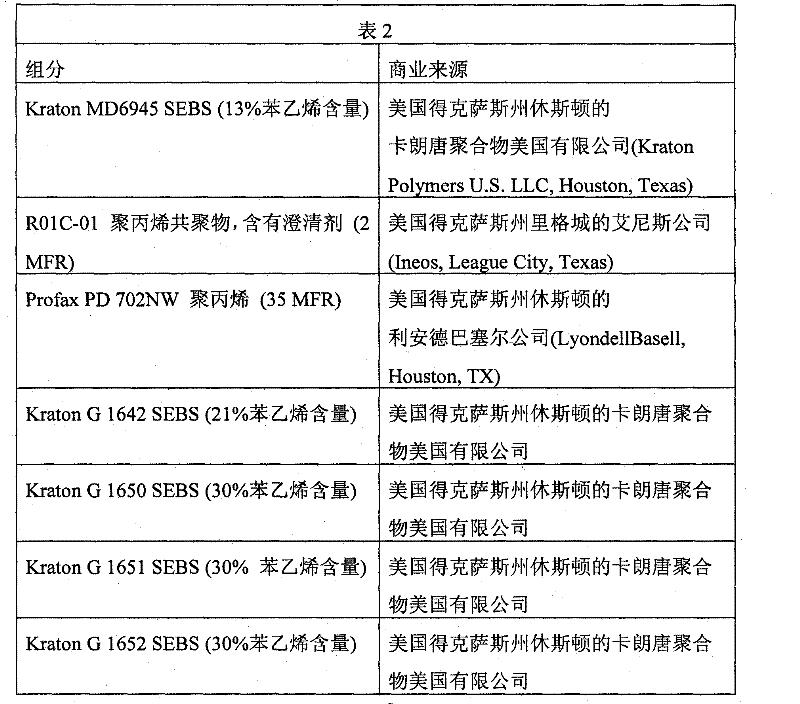

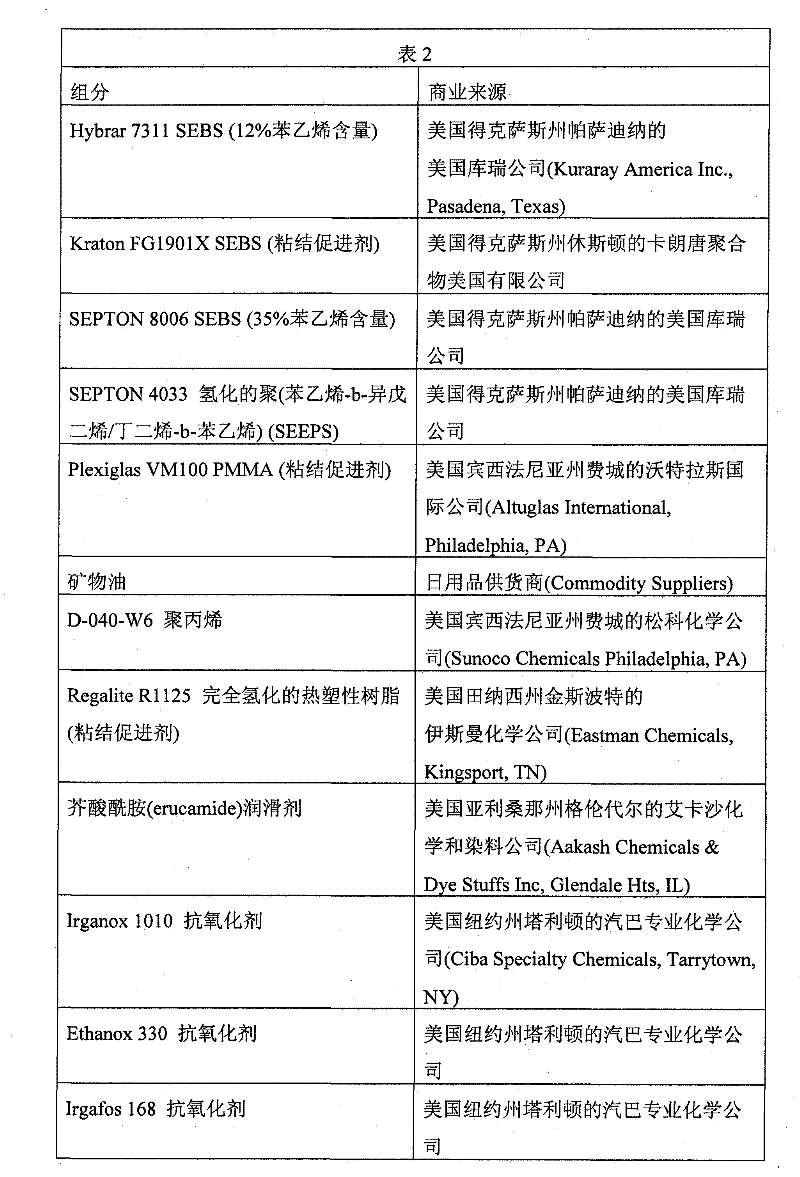

Solvent bondable thermoplastic elastomers

An essentially halogen-free, plasticizer-free thermoplastic elastomer compound is disclosed. The compound has from 10-80 weight percent of a hydrogenated styrene butadiene copolymer having a styrene content of less than 20 weight percent; from 20-90 weight percent of a polyolefin; and less than about 3 weight percent of antioxidant. The compound is capable of being solvent bonded or welded to another thermoplastic material using cyclohexanone alone or with methyl ethyl ketone. The compound is especially useful as medical tubing connected to other parts of medical equipment. The bond strength of the compound to the other thermoplastic material is properly determined only after multiple days of bonding.

Owner:AVIENT CORP

Cycloolefin blends and method for solvent bonding polyolefins

The present invention provides a polymer composition having: a first component selected from homopolymers and copolymers of cyclic olefin containing polymers and bridged polycyclic hydrocarbon containing polymers, the first component being present in an amount from about 1-99% by weight of the composition; and a second component is selected from homopolymers and copolymers of a diene having from 4 to 12 carbons, the second component being present in an amount from about 99% to about 1% by weight of the composition.

Owner:BAXTER INT INC

Cellulosic/polyamide composite

InactiveUS7618702B2Prevent peelingCombination devicesSynthetic resin layered productsElectrospinningCellulose fiber

Composite of polyamide layer solvent bonded to cellulosic substrate is formed by solution electrospinning deposit of polyamide on cellulosic substrate with the solution subjected to electrospinning containing as solvent for polyamide one that swells cellulosic fibers on contact therewith and / or by depositing very long polyamide fibers of low average diameter.

Owner:CORNELL RES FOUNDATION INC +1

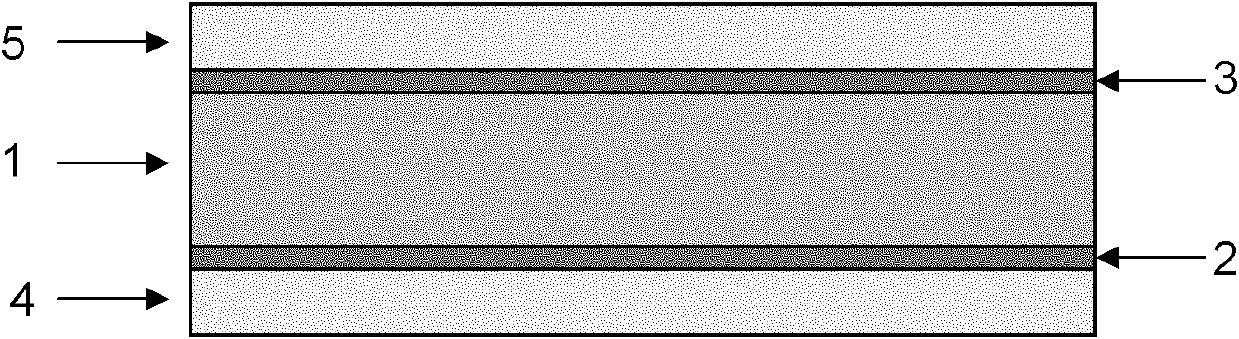

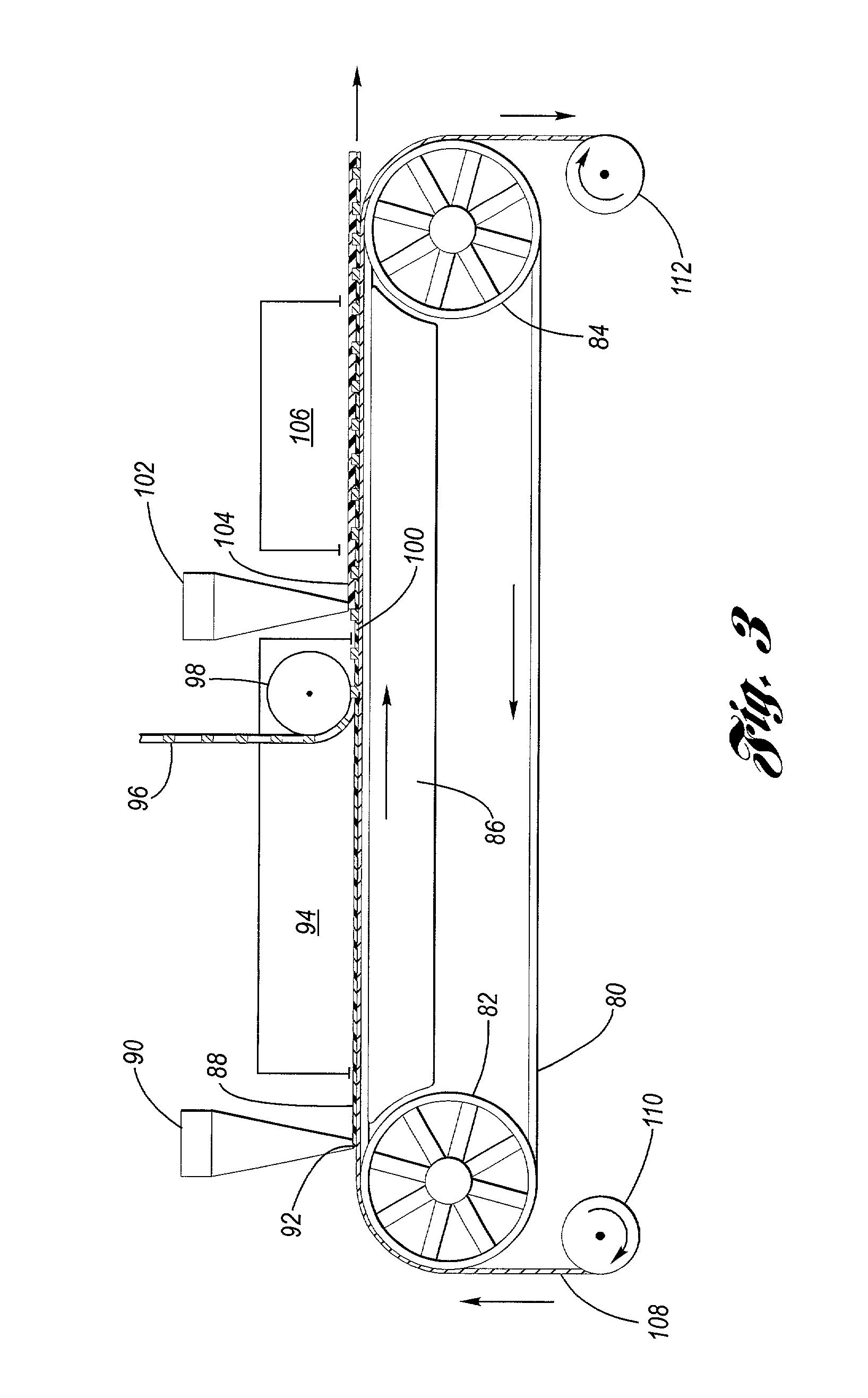

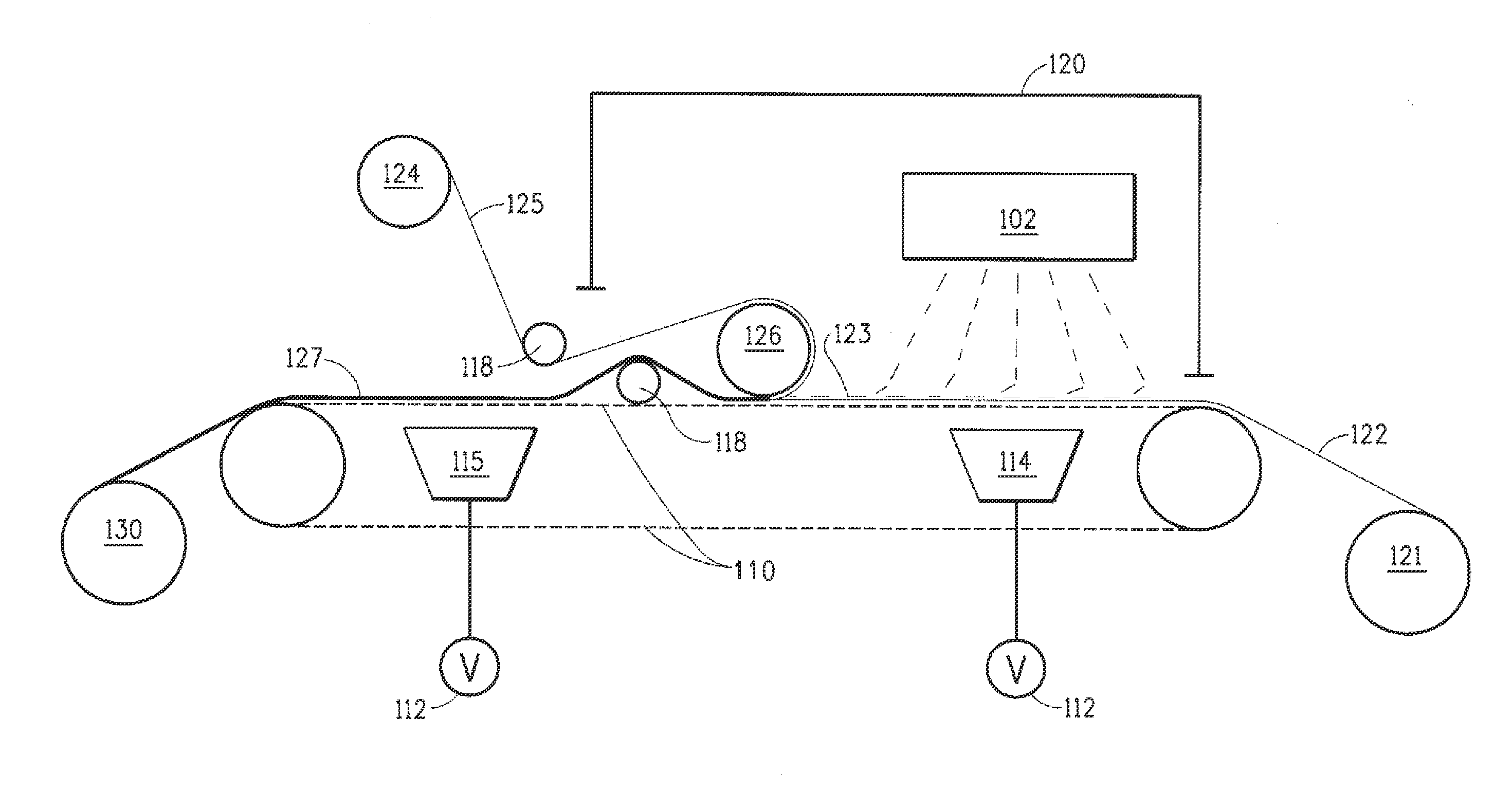

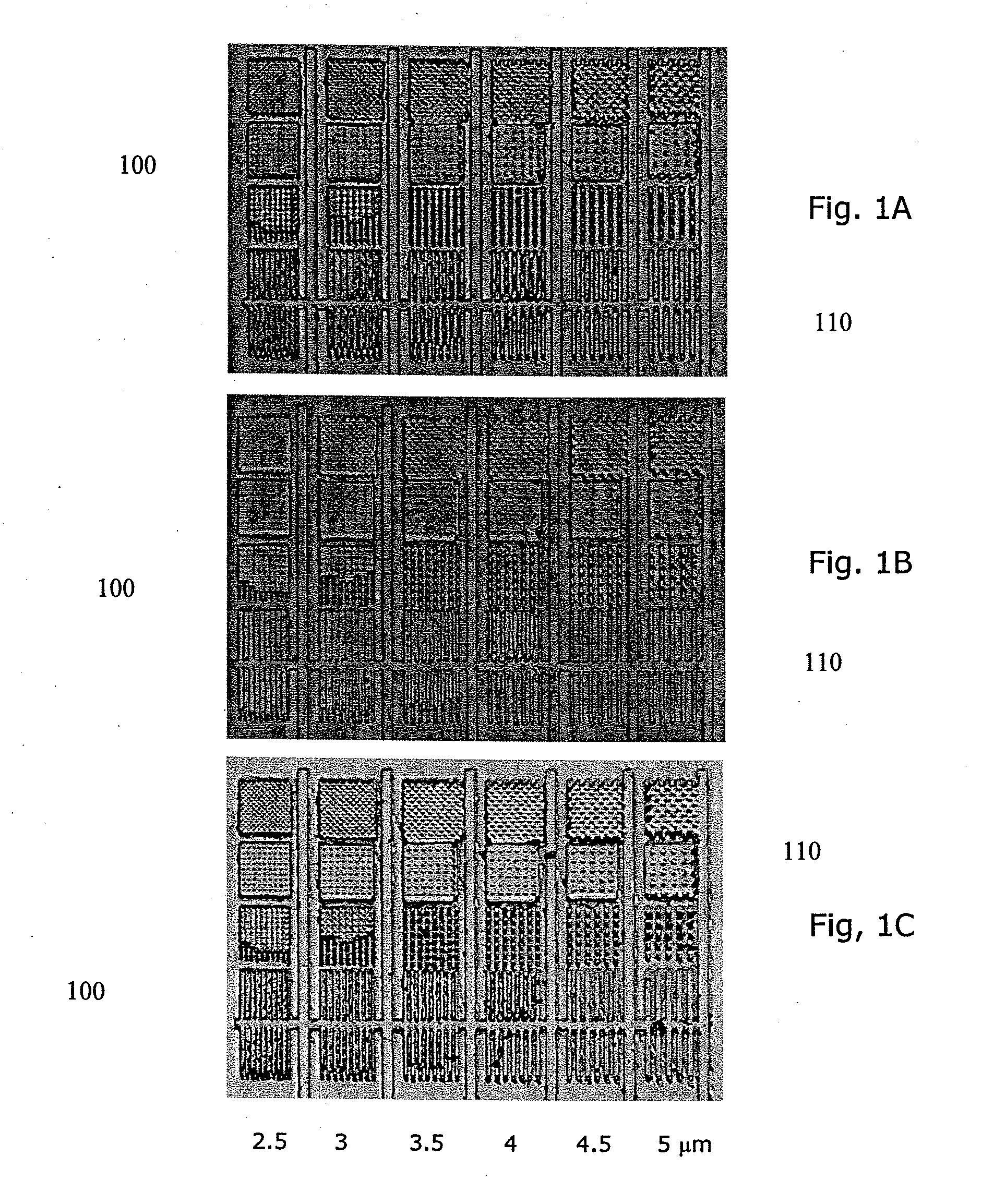

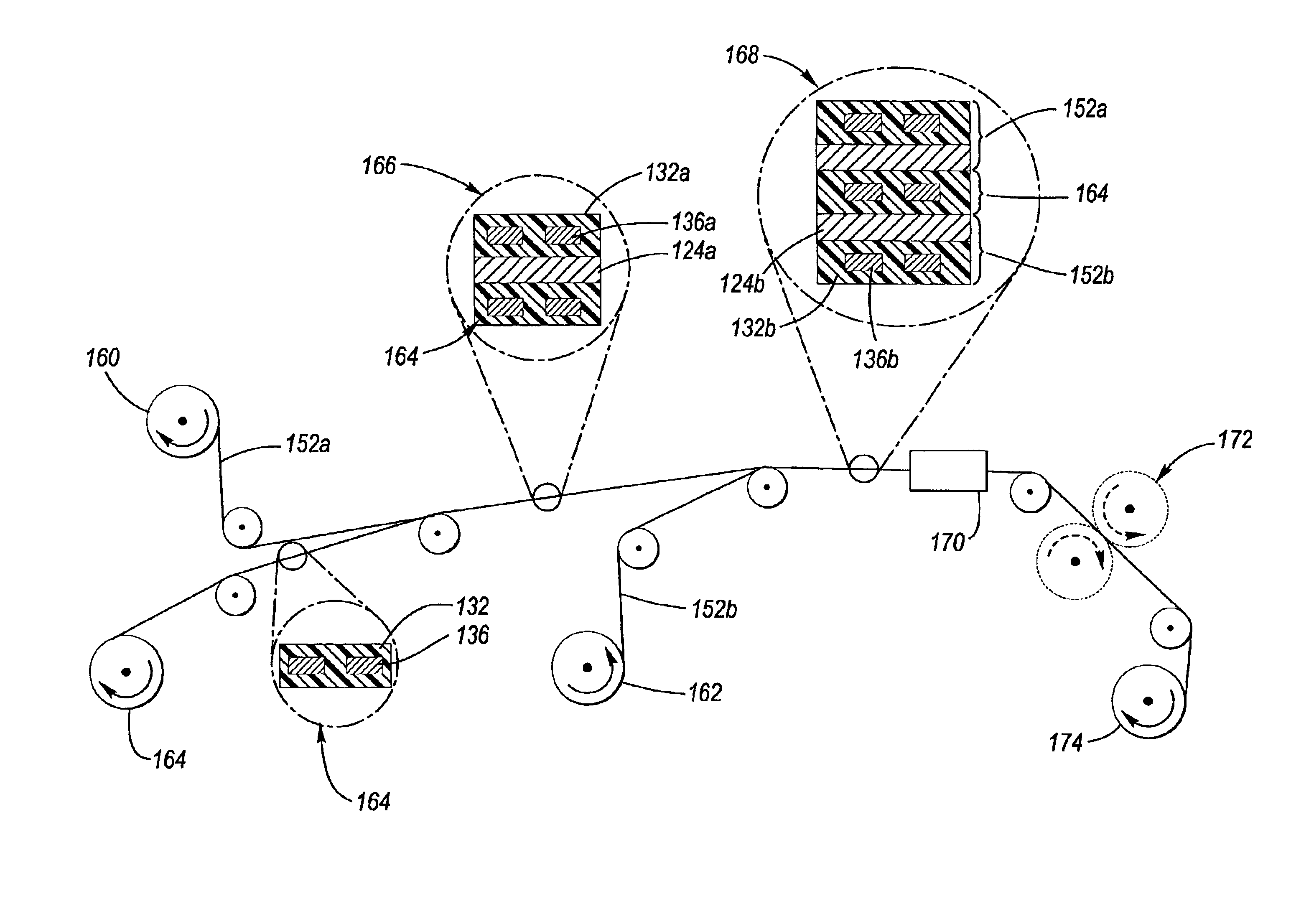

System and method for multilayer fabrication of lithium polymer batteries and cells using surface treated separators

InactiveUS20020170169A1Electrode thermal treatmentFinal product manufacturePlasticizerPhysical chemistry

Method of making Li-intercalateable electrodes for a lithium-ion battery by applying a first film onto a first face of an electrically conductive grid, which film comprises a plurality of Li-intercalateable particles dispersed throughout a mixture of a polymeric binder and a plasticizer for the binder. Thereafter, a film-forming slurry having the same composition as the first film, plus a solvent therefor, is applied to a second face of the grid opposing the first face so as to provide a second film and such that the solvent in the slurry dissolves at least a portion of the first film and promotes solvent bonding of the films with the grid embedded therein. A polymeric backing film treated with plasma and defining a separator is used as a manufacturing process aid, thereby eliminating the step of using a carrier film onto which the electrodes are fabricated and stripping off the carrier and discarding the same. Treating the separator with plasma enhances surface energy thereby improving the lamination process of the film-forming slurries to the separator and reducing degradation of the separator.

Owner:ENERDEL

Filtration media for filtering particulate material from gas streams

A composite fabric formed by depositing a web of nanofibers electroblown from a first polymer onto a first support web comprising fibers of larger average diameter than the nanofibers spun from a compatible material, in the absence of an adhesive between the webs, and solvent-bonding the webs together.

Owner:DUPONT SAFETY & CONSTR INC

Laminated microfluidic structures and method for making

A method for making a polymeric microfluidic structure in which two or more components (layers) of the microfluidic structure are fixedly bonded or laminated with a weak solvent bonding agent, particularly acetonitrile or a mixture of acetonitrile and alcohol. In an aspect, acetonitrile can be used as a weak solvent bonding agent to enclose a microstructure fabricated in or on a non-elastomeric polymer such as polystyrene, polycarbonate, acrylic or other linear polymer to form a three-dimensional microfluidic network. The method involves the steps of wetting at least one of the opposing surfaces of the polymeric substrate components with the weak solvent bonding agent in a given, lower temperature range, adjacently contacting the opposing surfaces, and thermally activating the bonding agent at a higher temperature than the lower temperature range for a given period of time with RF or ultrasonic energy. The contacted polymeric substrates may also be aligned prior to thermal activation and compressed during thermal activation. A laminated, polymeric microfluidic structure is also disclosed.

Owner:RHEONIX

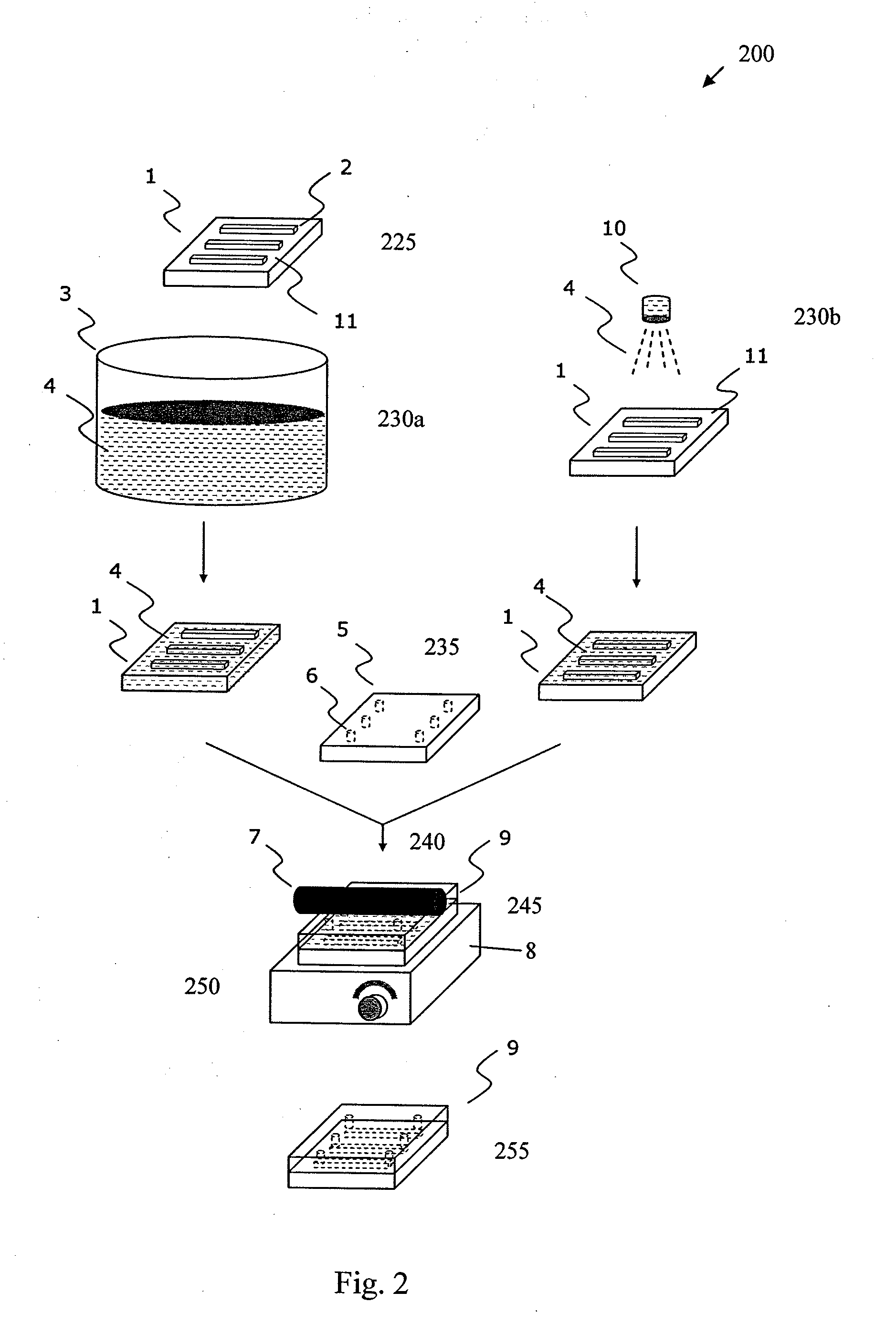

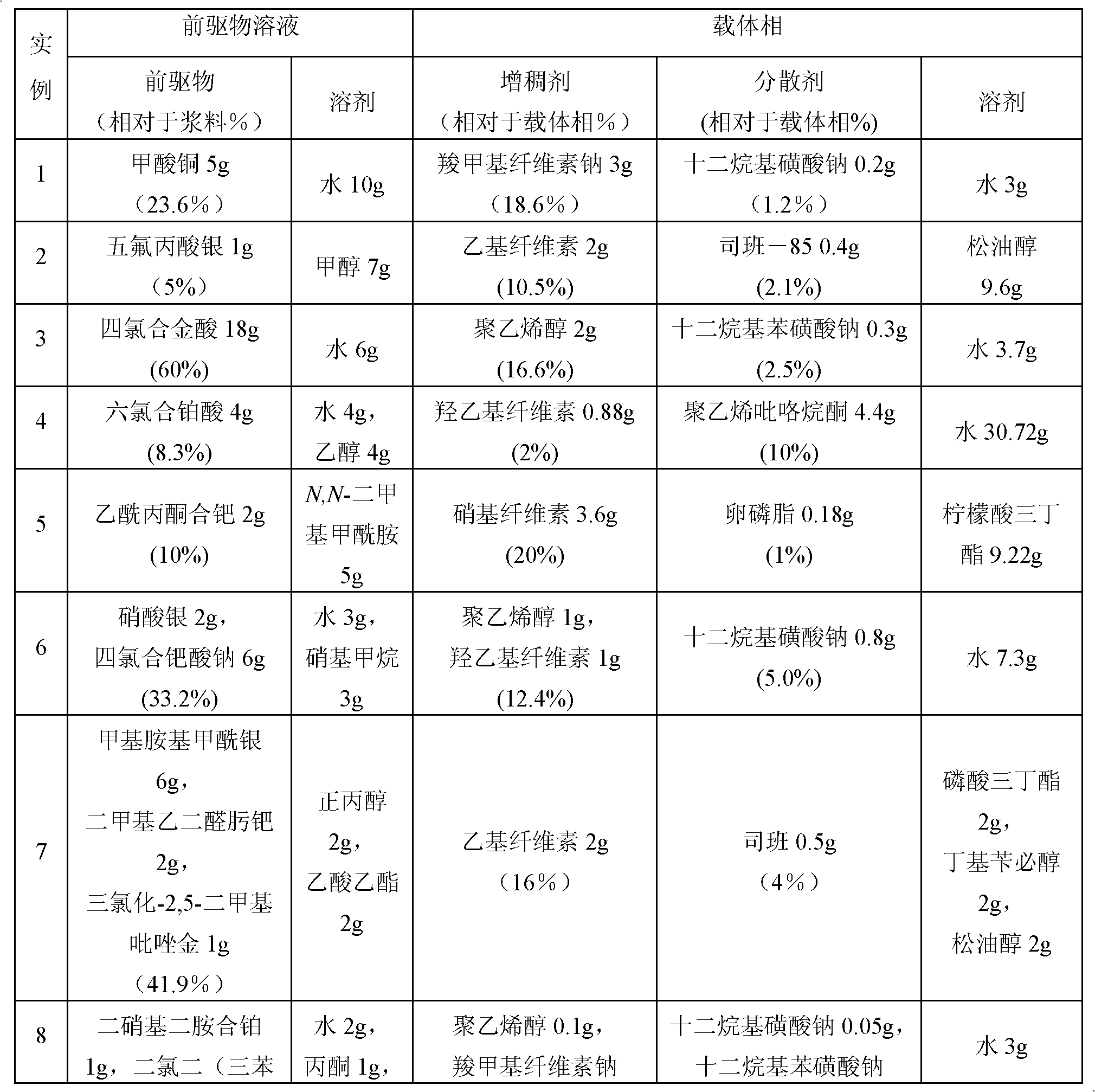

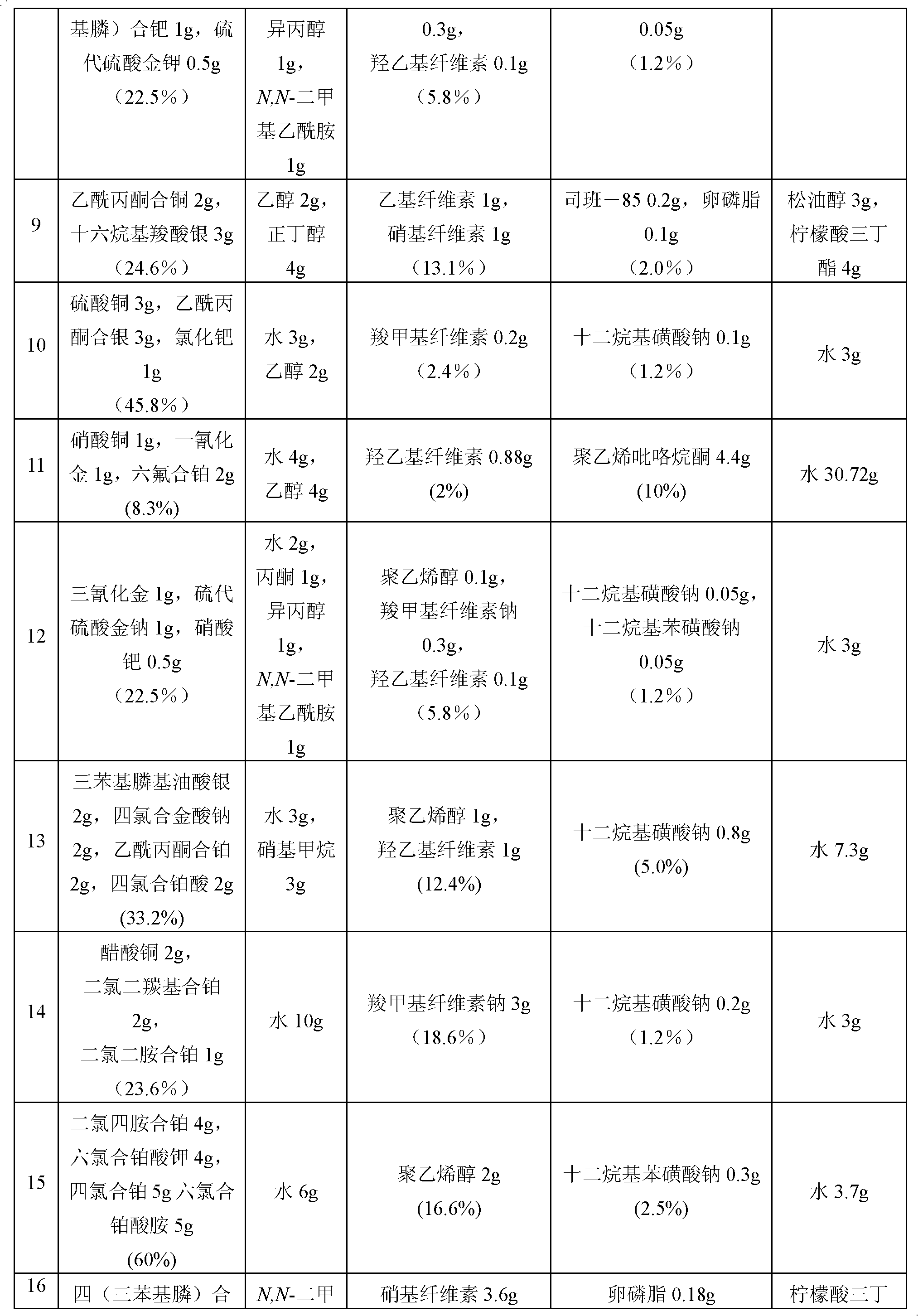

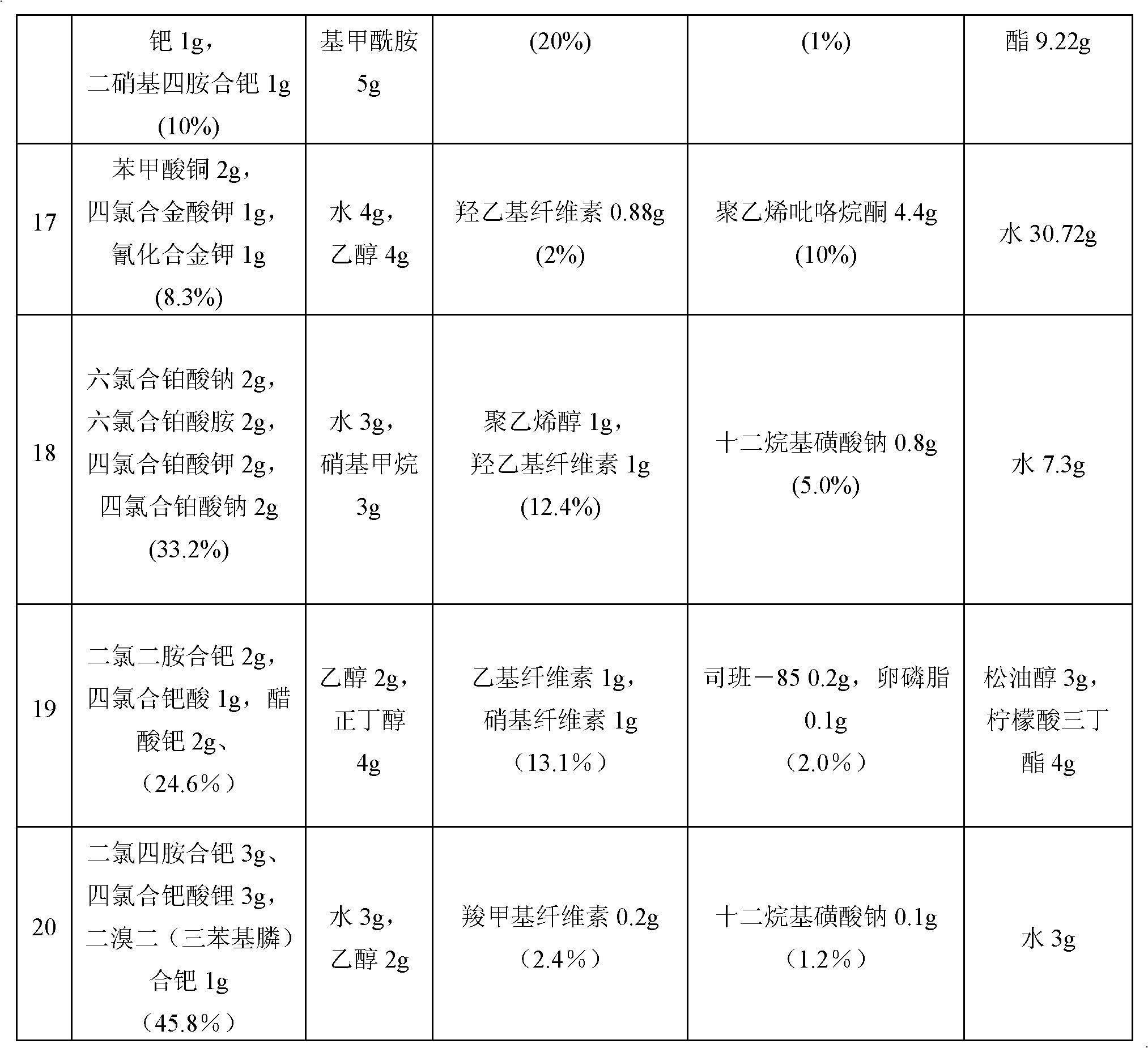

A homogeneous conductive paste

InactiveCN102270514AHigh resolutionNon-conductive material with dispersed conductive materialParticulatesDirect writing

The invention discloses a homogeneous conductive paste, which is composed of a precursor of a conductive functional phase and a carrier phase: the mass percentage of the precursor of a conductive functional phase is 5-60%, and the rest is a carrier phase; the carrier The phase is composed of multiple components, and the mass fraction of each component relative to the carrier phase is respectively: thickener 2-20%, dispersant 1-10%, and the rest is solvent. The homogeneous conductive paste does not contain particle functional phases and other solid phases, but contains functional phase precursors, which can be well dissolved in the solvent of the binder phase, and can be used in the subsequent post-treatment process In the process, it can be converted into a conductive functional phase; the slurry avoids the problem of particle settling and agglomeration during the preparation and storage of the traditional slurry containing the particle functional phase; It can be processed and formed by methods such as micro-spraying and direct writing, and after post-treatment such as drying and sintering, a conductive line or pattern with good conductivity and high resolution can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

Heat shrinkable film

InactiveUS20070071967A1Outstanding processing suitabilityHigh transparencySynthetic resin layered productsCoatingsPolyesterEngineering

[PROBLEMS]To provide a heat shrinkable film that, when used as a label of beverage container, enhances the smoothness of external surface side to thereby prevent merchandise jamming in an automatic vending machine of beverage and that is fully satisfactory in solvent bonding capability and excels in processability. [MEANS FOR SOLVING PROBLEMS]There is provided a heat shrinkable polyester film characterized in that (A) at least one major surface thereof is overlaid with 0.002 to 0.5 g / m2, in terms of solid content coating amount of a silicone containing easily slipping layer, (B) a friction coefficient between one and the same easily-slipping layer satisfies a relationship of μd≦0.27, and that (C) the heat shrinkable polyester film exhibits a heat shrinkage percentage of not less than 50% in a maximum shrinkage direction, after immersion in hot water at 95° C. for 10 seconds. Thus, there is provided the heat shrinkable film that when used as a label of beverage container, enhances the smoothness of external surface side to thereby prevent merchandise jamming in an automatic vending machine of beverage and that is fully satisfactory in solvent bonding capability and excels in processability.

Owner:TOYOBO CO LTD

Substantially inseparable LED lamp assembly

Disclosed are LED lamp assemblies that are substantially inseparable. The LED lamp assemblies use discrete components that are individually manufactured and then assembled in a manner that substantially prevents disassembly or disengagement of components. An interference fit can be used to substantially secure components of the LED lamp assemblies. Bonding techniques can also be used, including adhesive and solvent bonds, as well as thermal bonds, including sonic bonds.

Owner:SANTAS BEST

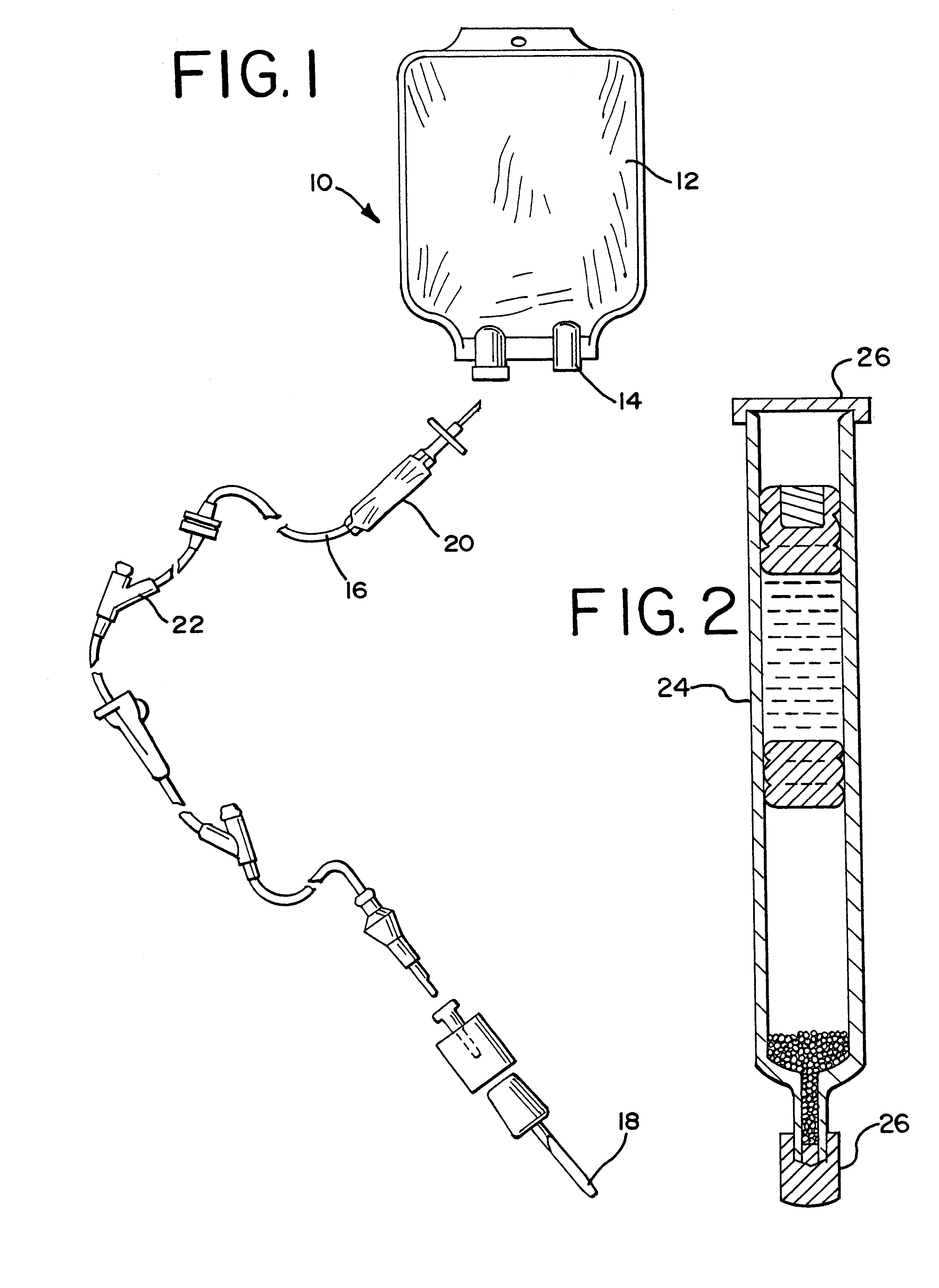

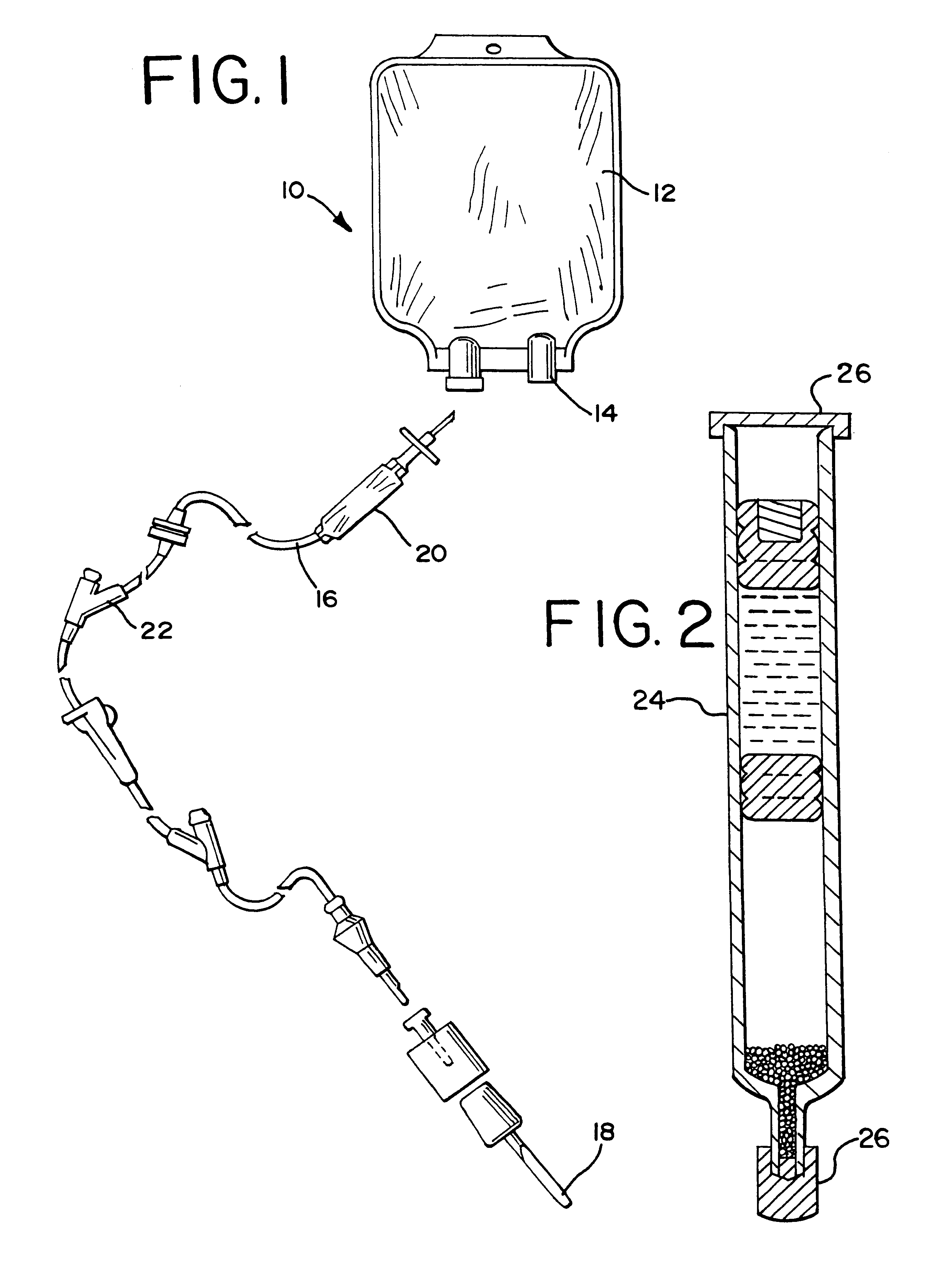

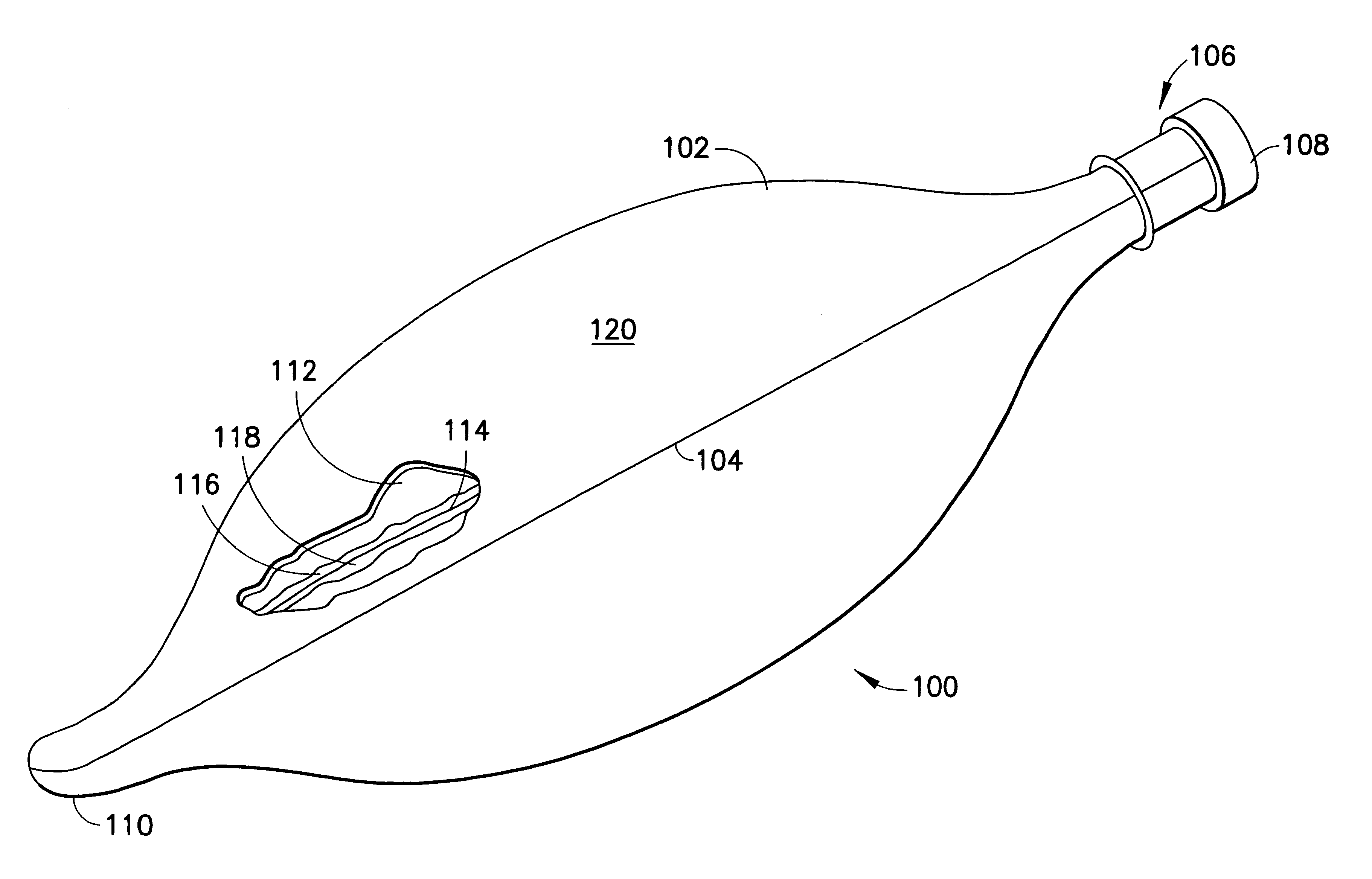

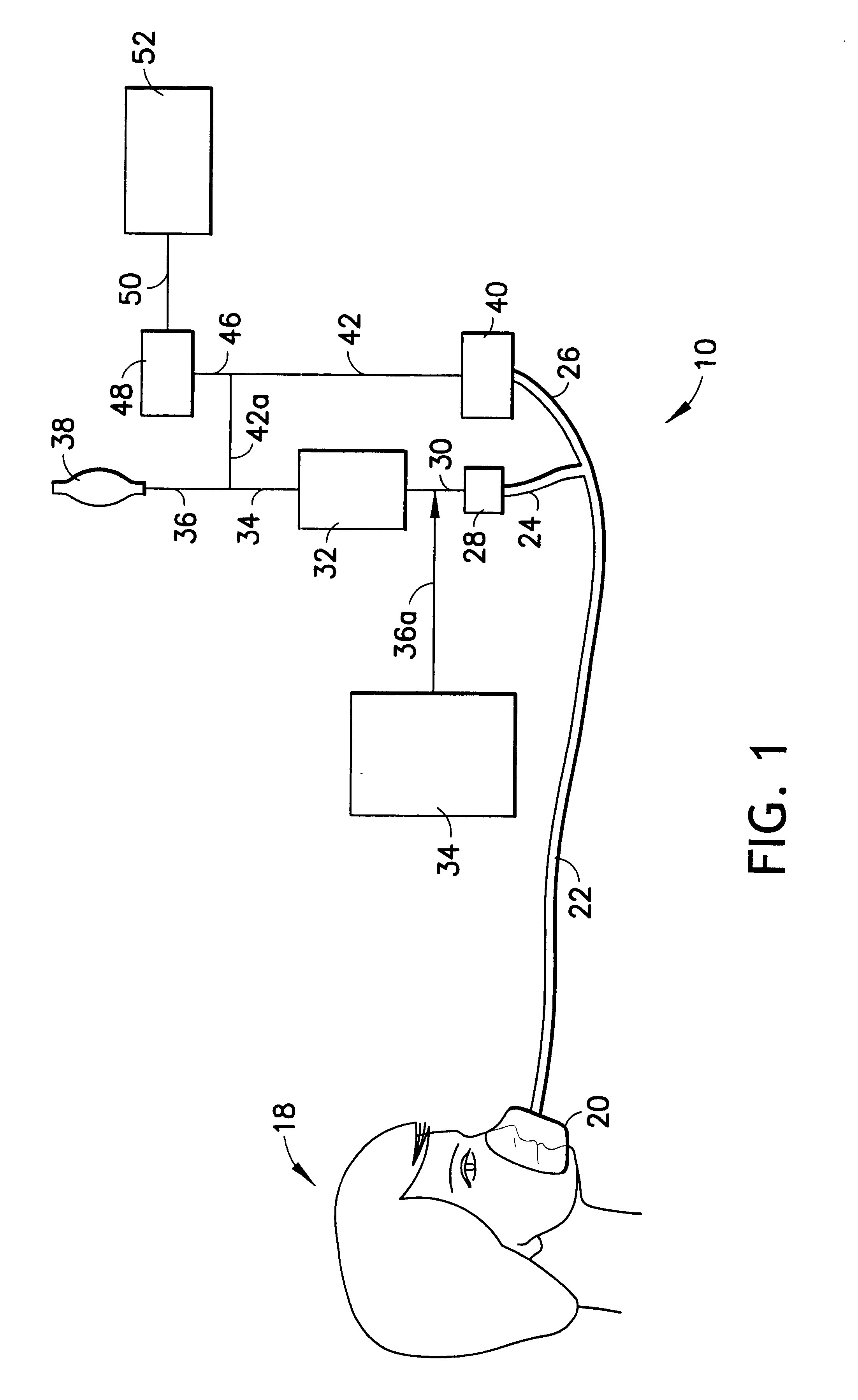

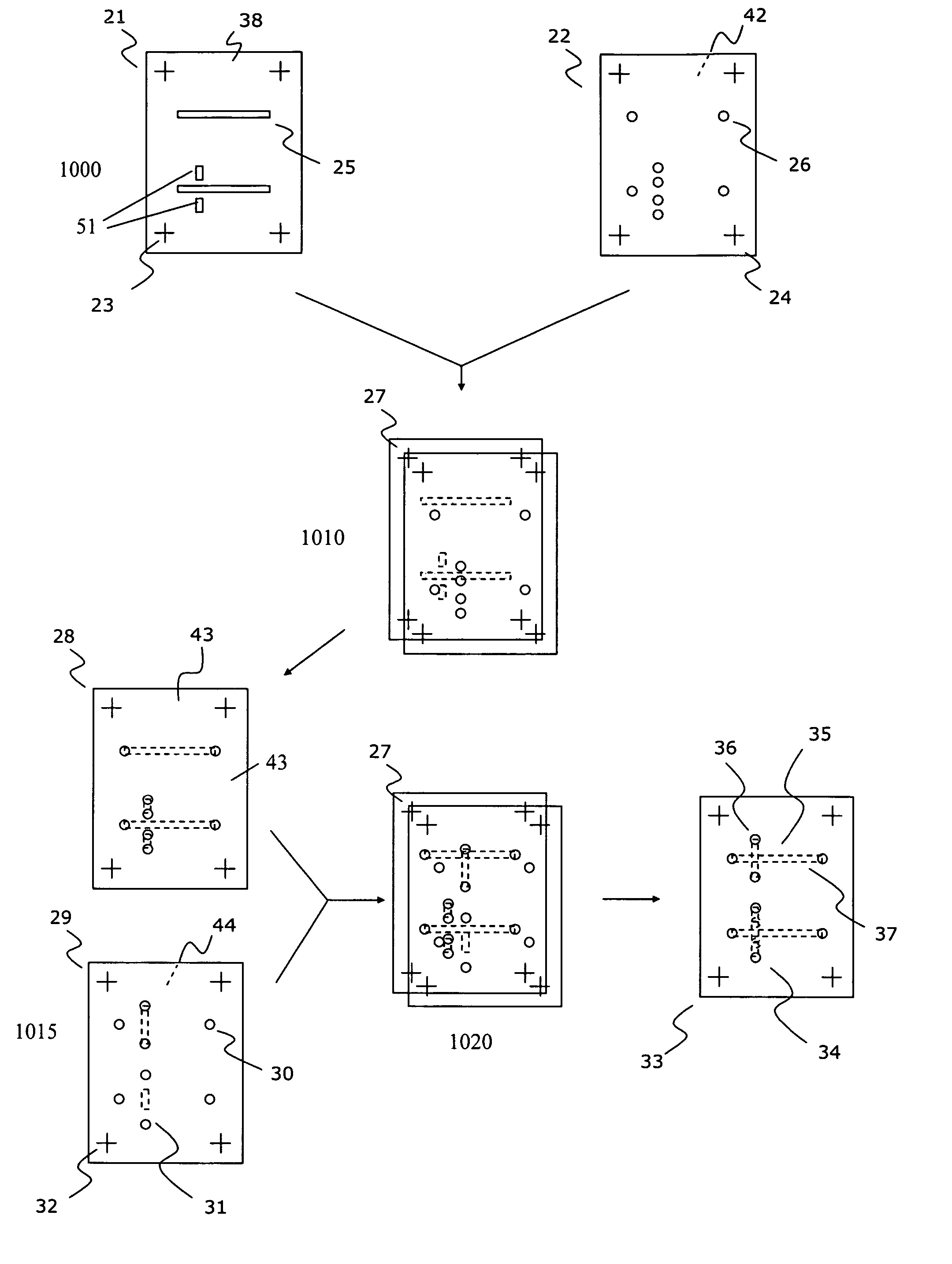

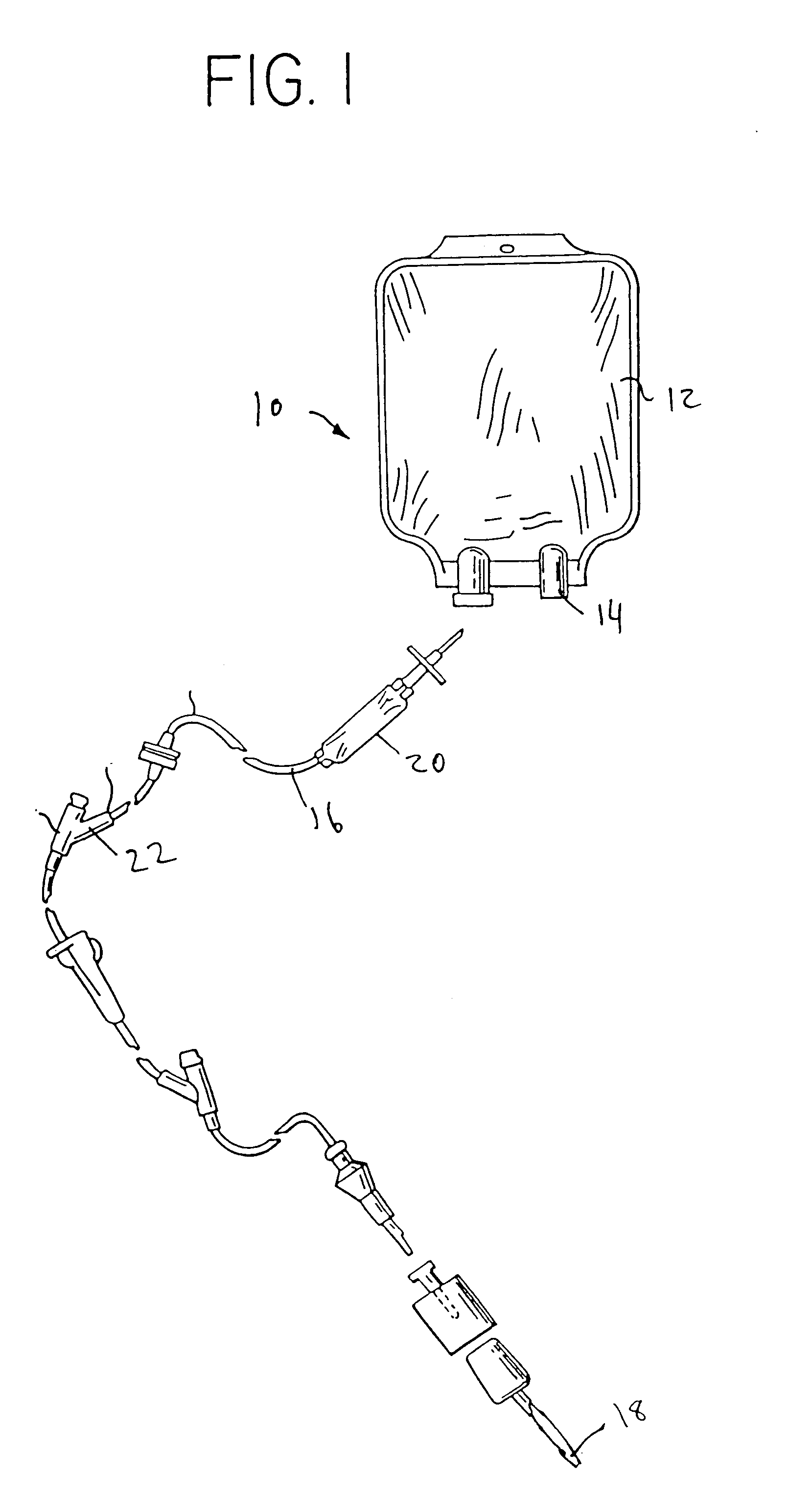

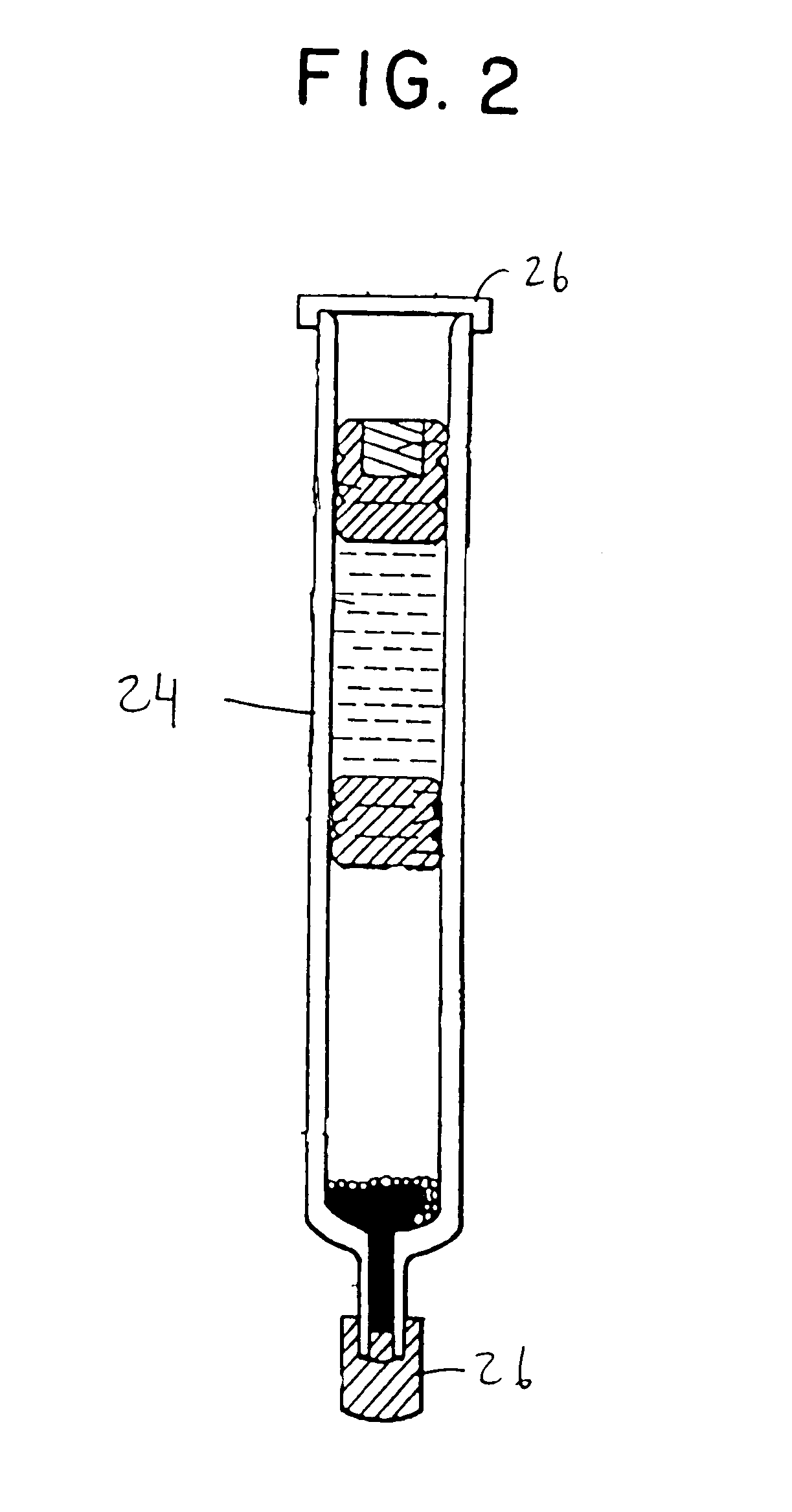

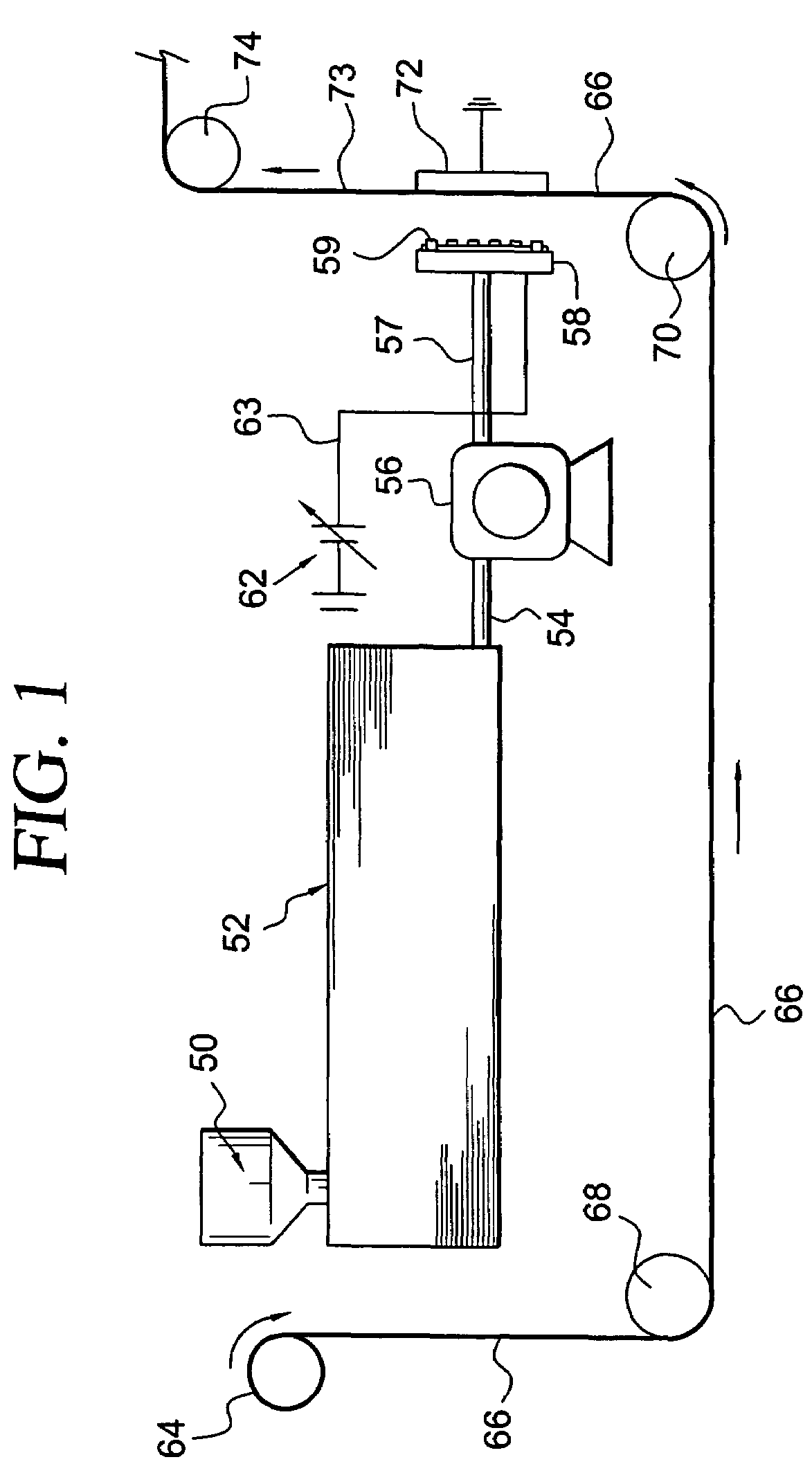

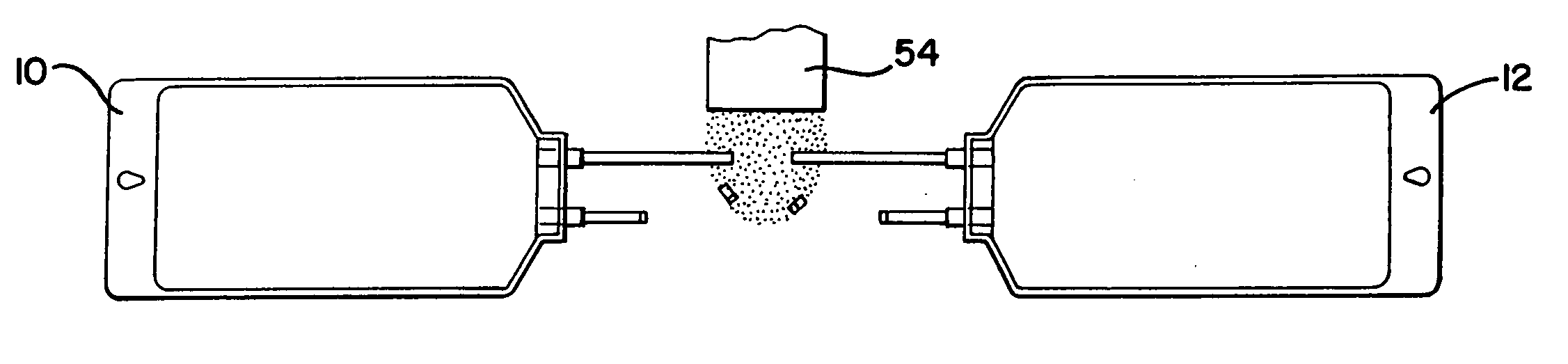

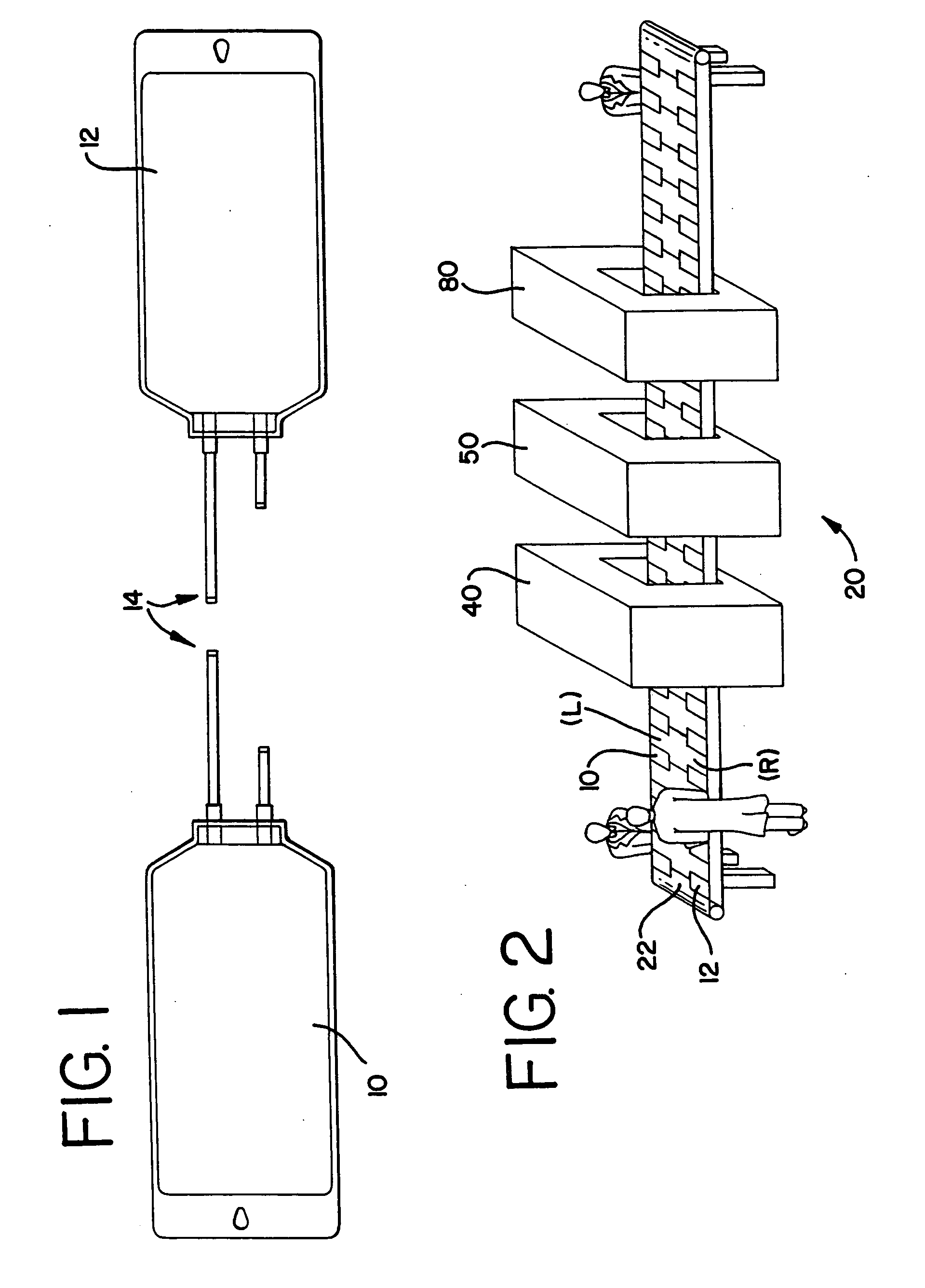

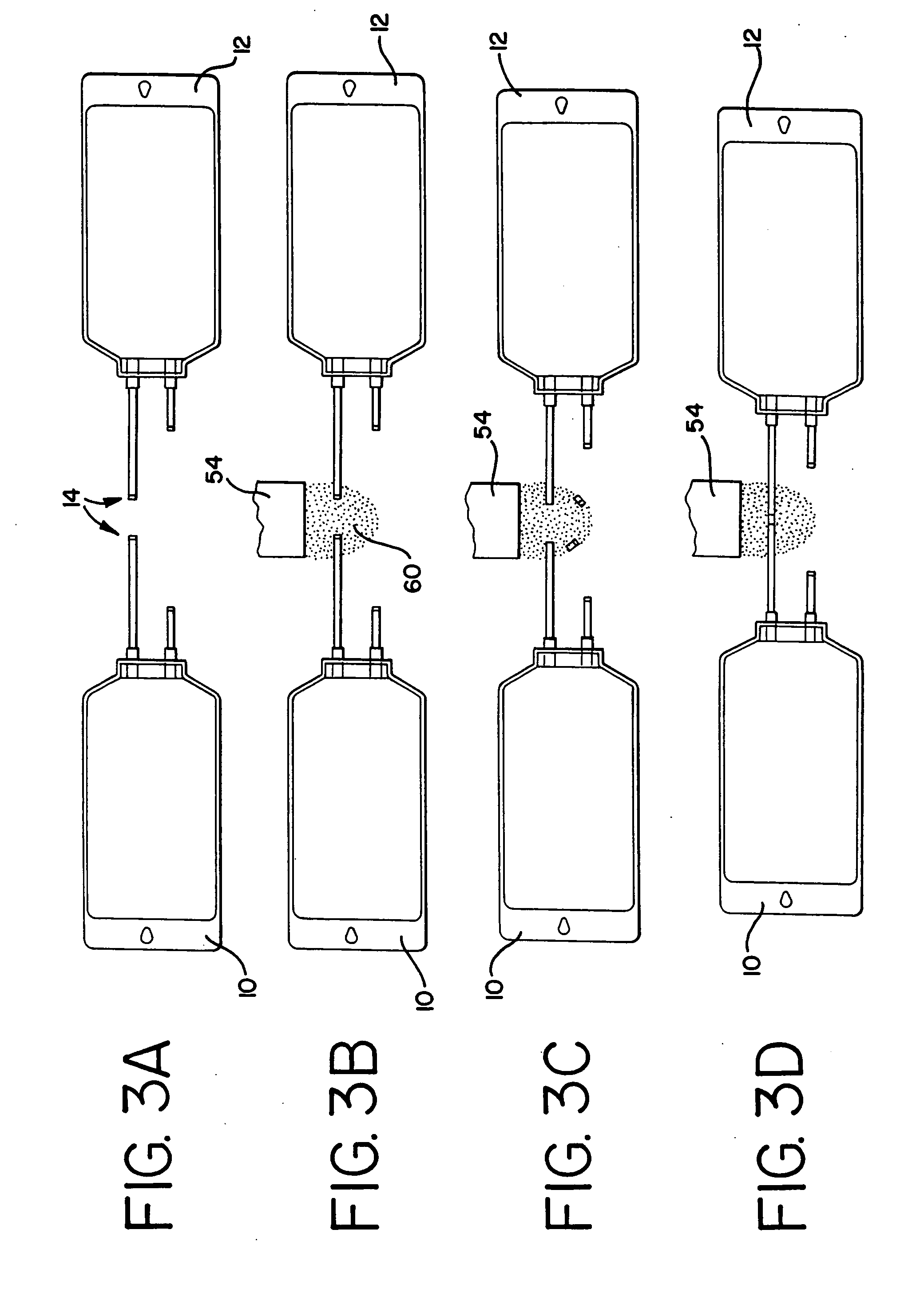

Method and apparatus for manipulating pre-sterilized components in an active sterile field

The connection, assembly, or fill of two or more pre-sterilized components having at least one terminal end each for attachment to another component, and an apparatus for performing such a connection, while maintaining the sterility of the components is disclosed. The resulting connection is made permanent by bonding the contacting components together using either a solvent bonding technique, a radio frequency sealer, a heat sealer, or any other suitable process. The connection is preferably made within an active sterile field. Using a low-voltage electron beam instrument, such as the MIN-EB™, a suitable sterile field sphere can be created. The terminal ends of the multiple components remain within the sterile field sphere until the possibility of contamination within the sealed components is significantly reduced to industry acceptable standards.

Owner:BAXTER INT INC

Laminated microfluidic structures and method for making

A method for making a polymeric microfluidic structure in which two or more components (layers) of the microfluidic structure are fixedly bonded or laminated with a weak solvent bonding agent, particularly acetonitrile or a mixture of acetonitrile and alcohol. In an aspect, acetonitrile can be used as a weak solvent bonding agent to enclose a microstructure fabricated in or on a non-elastomeric polymer such as polystyrene, polycarbonate, acrylic or other linear polymer to form a three-dimensional microfluidic network. The method involves the steps of wetting at least one of the opposing surfaces of the polymeric substrate components with the weak solvent bonding agent in a given, lower temperature range, adjacently contacting the opposing surfaces, and thermally activating the bonding agent at a higher temperature than the lower temperature range for a given period of time. The contacted polymeric substrates may also be aligned prior to thermal activation and compressed during thermal activation. A laminated, polymeric microfluidic structure is also disclosed.

Owner:北京博昂尼克微流体技术有限公司

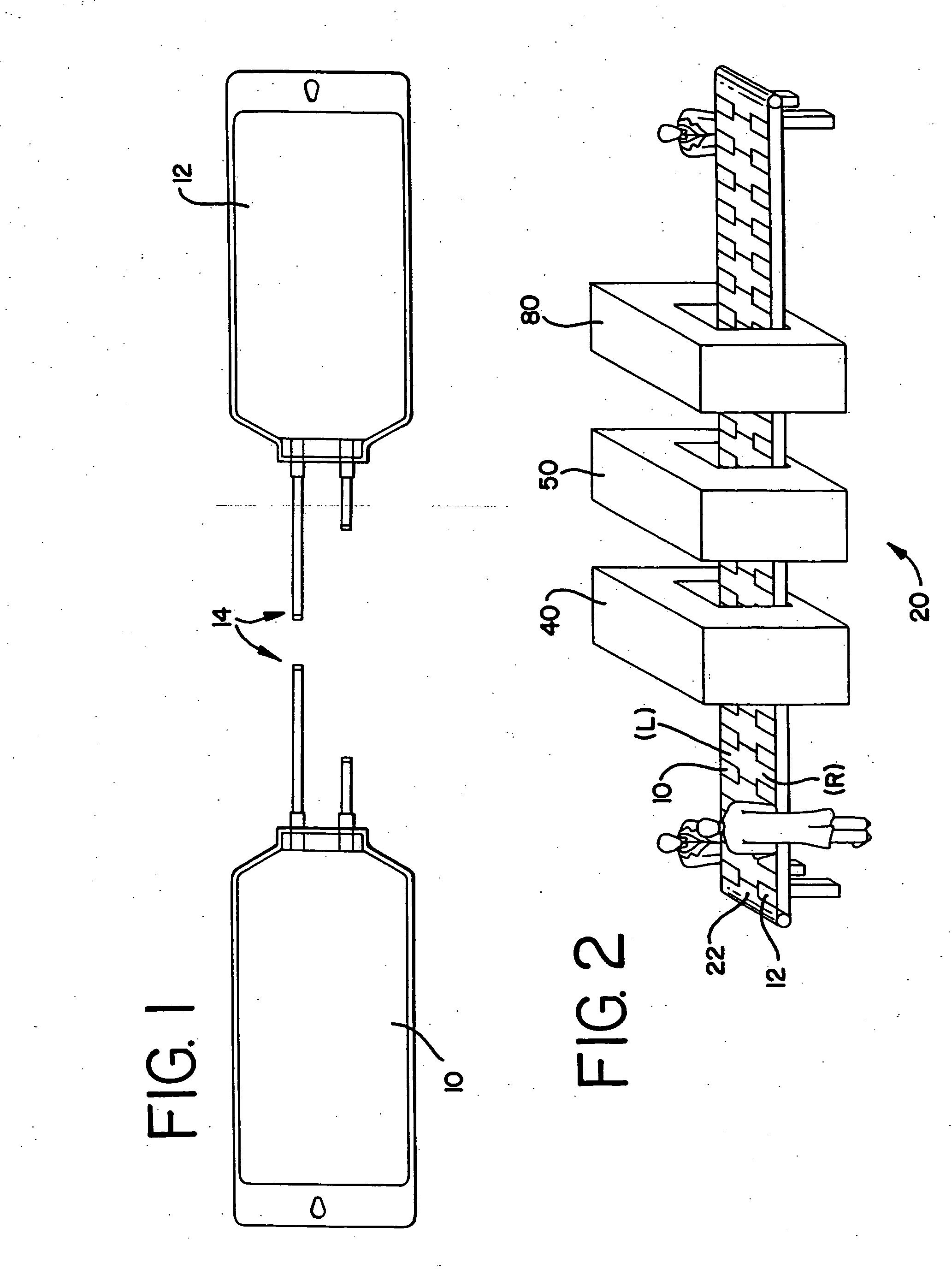

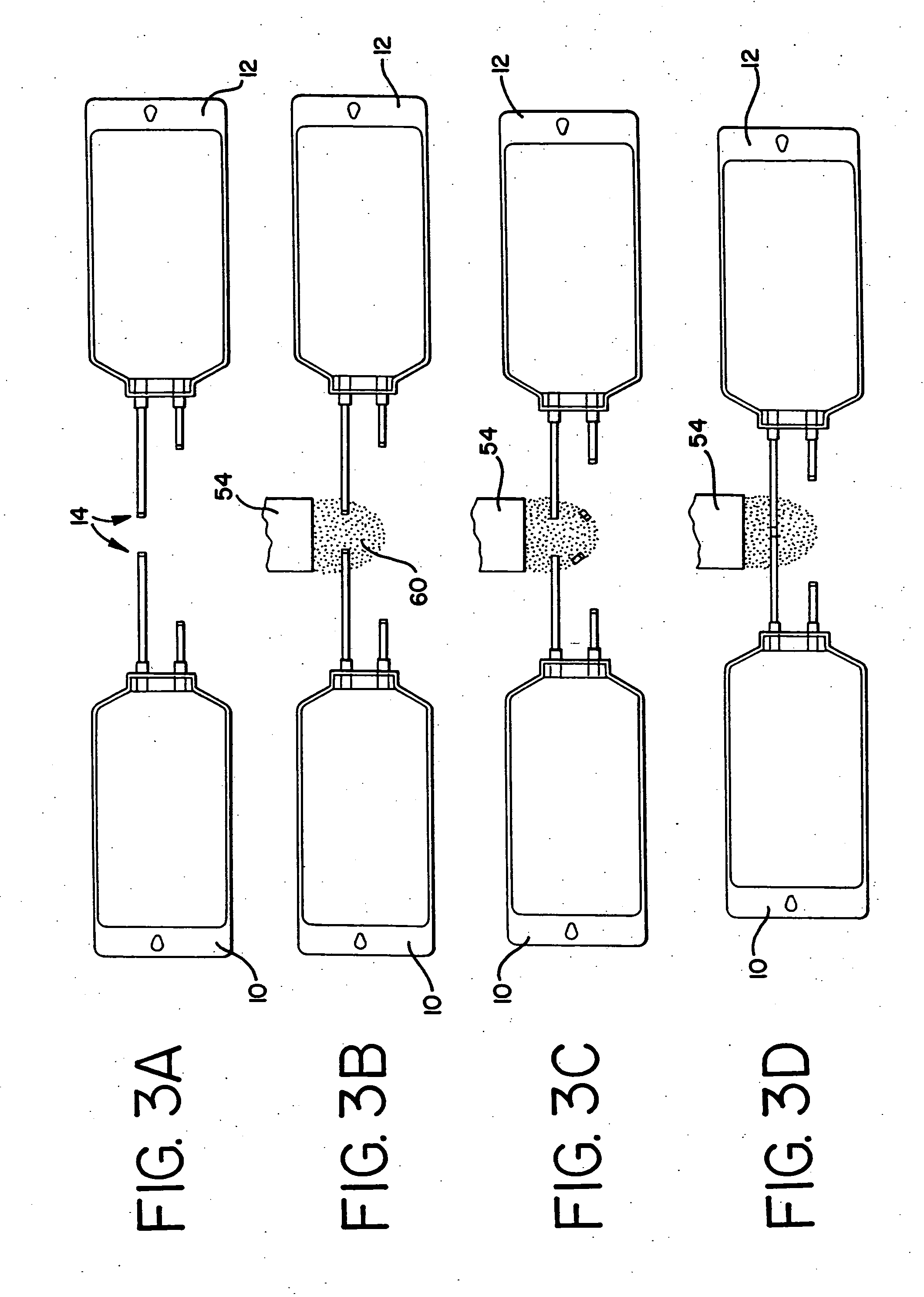

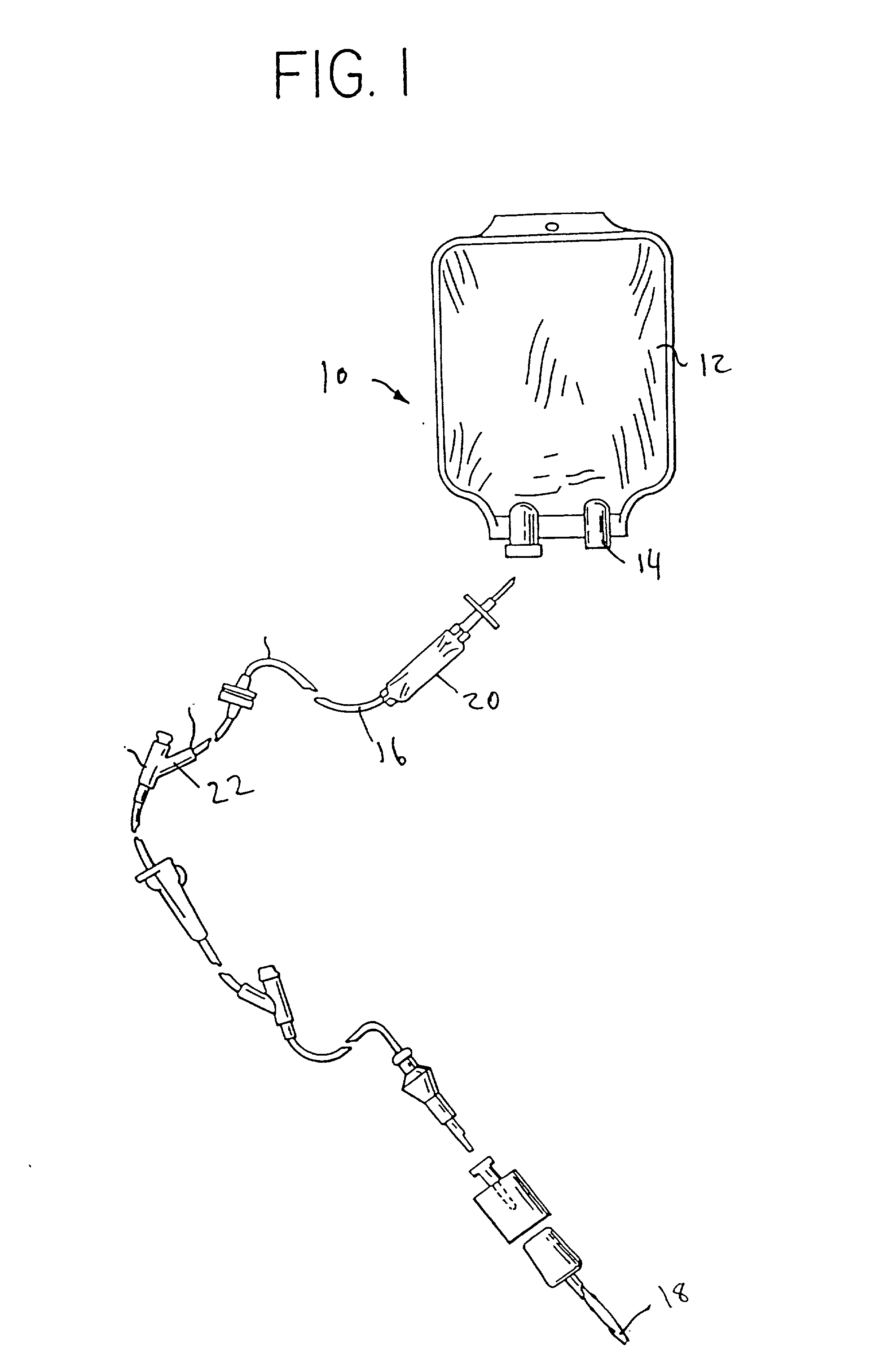

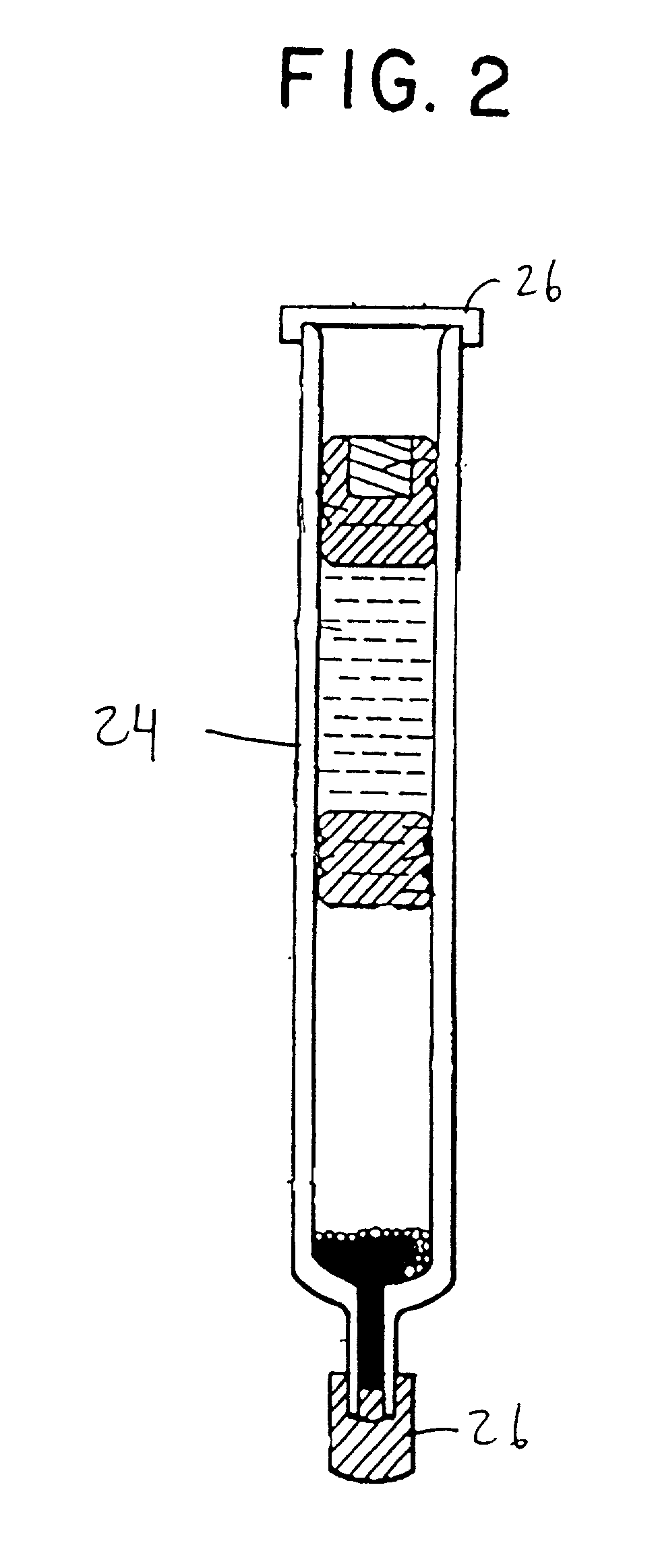

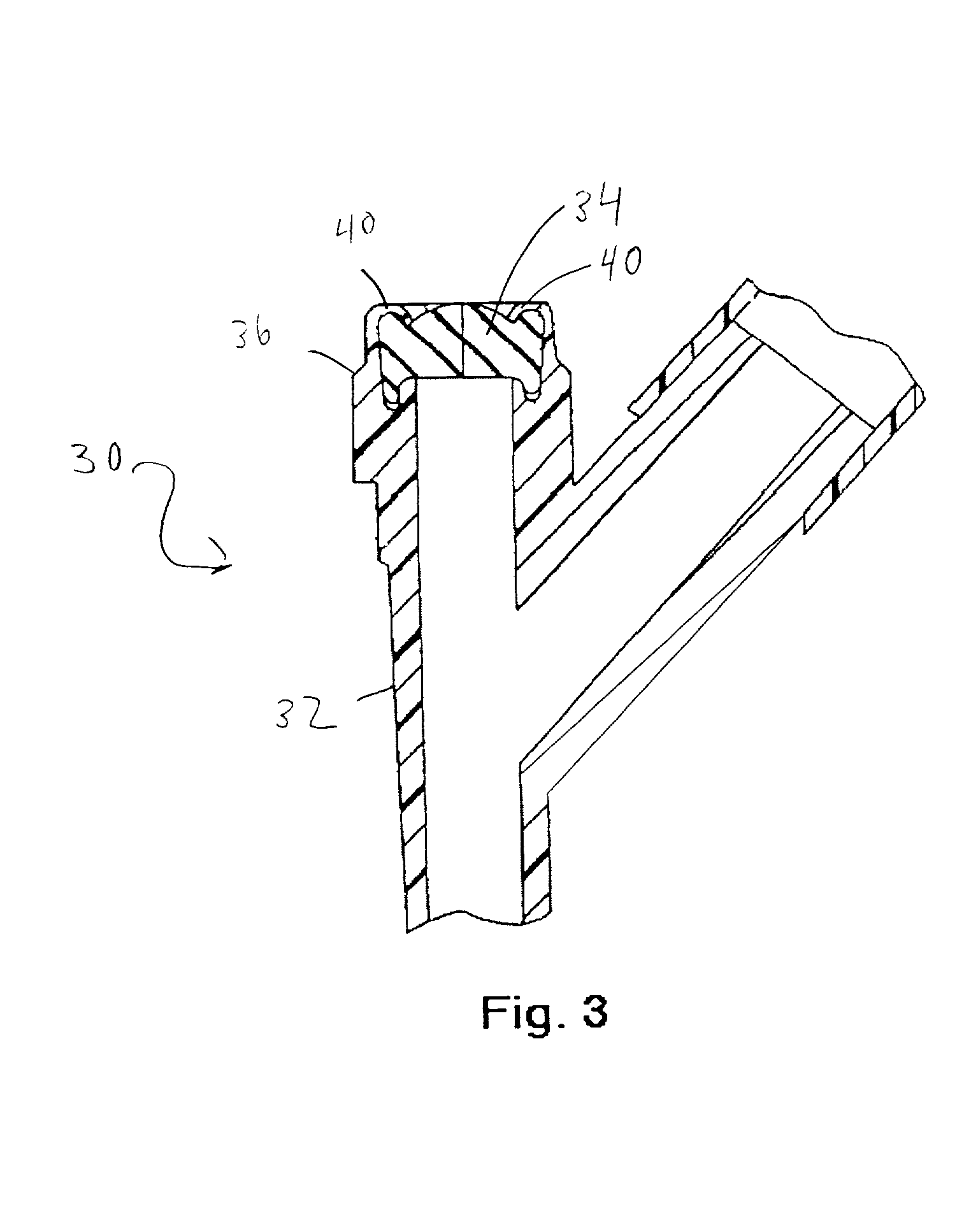

Apparatus for manipulating pre-sterilized components in an active sterile field

InactiveUS20050161614A1Material analysis using wave/particle radiationElectric discharge tubesHeat sealerLow voltage

The connection, assembly, or fill of two or more pre-sterilized components 10, 12 having at least one terminal end 14 each for attachment to another component, and an apparatus for performing such a connection, while maintaining the sterility of the components is disclosed. The resulting connection is made permanent by bonding the contacting components 10, 12 together using either a solvent bonding technique, a radio frequency sealer, a heat sealer, or any other suitable process. The connection is preferably made within an active sterile field 60. Using a low-voltage electron beam instrument 54, such as the MIN-EB™, a suitable sterile field sphere can be created. The terminal ends 14 of the multiple components 10, 12 remain within the sterile field sphere 60 until the possibility of contamination within the sealed components is significantly reduced to industry acceptable standards.

Owner:C R F SOC CONSORTILE ER AZIONI +1

Heat shrinkable film

To provide a heat shrinkable film that, when used as a label of beverage container, enhances the smoothness of external surface side to thereby prevent merchandise jamming in an automatic vending machine of beverage and that is fully satisfactory in solvent bonding capability and excels in processability. There is provided a heat shrinkable polyester film characterized in that (A) at least one major surface thereof is overlaid with 0.002 to 0.5 g / m2, in terms of solid content coating amount of a silicone containing easily slipping layer, (B) a friction coefficient between one and the same easily-slipping layer satisfies a relationship of μd≦0.27, and that (C) the heat shrinkable polyester film exhibits a heat shrinkage percentage of not less than 50% in a maximum shrinkage direction, after immersion in hot water at 95° C. for 10 seconds. Thus, there is provided the heat shrinkable film that when used as a label of beverage container, enhances the smoothness of external surface side to thereby prevent merchandise jamming in an automatic vending machine of beverage and that is fully satisfactory in solvent bonding capability and excels in processability.

Owner:TOYOBO CO LTD

Cycloolefin blends and method for solvent bonding polyolefins

The present invention provides a polymer composition having: a first component selected from homopolymers and copolymers of cyclic olefin containing polymers and bridged polycyclic hydrocarbon containing polymers, the first component being present in an amount from about 1-99% by weight of the composition; and a second component is selected from homopolymers and copolymers of a diene having from 4 to 12 carbons, the second component being present in an amount from about 99% to about 1% by weight of the composition.

Owner:BAXTER INT INC

Solvent bondable thermoplastic elastomers

Owner:AVIENT CORP

Solvent bondable thermoplastic elastomers

An essentially halogen-free, plasticizer-free thermoplastic elastomer compound is disclosed. The compound has from 10 - 80 weight percent of a hydrogenated styrene butadiene copolymer having a styrene content of less than 20 weight percent; from 20 - 90 weight percent of a polyolefin; and less than about 3 weight percent of antioxidant. The compound is capable of being solvent bonded or welded to another thermoplastic material using cyclohexanone alone or with methyl ethyl ketone. The compound is especially useful as medical tubing connected to other parts of medical equipment. The bond strength of the compound to the other thermoplastic material is properly determined only after multiple days of bonding.

Owner:AVIENT CORP

Laminated microfluidic structures and method for making

Owner:RHEONIX INC

System and method for multilayer fabrication of lithium polymer batteries and cells

Method of making Li-intercalateable electrodes for a lithium-ion battery by applying a first film onto a first face of an electrically conductive grid, which film comprises a plurality of Li-intercalateable particles dispersed throughout a mixture of a polymeric binder and a plasticizer for the binder. Thereafter, a film-forming slurry having the same composition as the first film, plus a solvent therefor, is applied to a second face of the grid opposing the first face so as to provide a second film and such that the solvent in the slurry dissolves at least a portion of the first film and promotes solvent bonding of the films with the grid embedded therein. A polymeric backing film defining a separator is used as a manufacturing process aid, thereby eliminating the step of using a carrier film onto which the electrodes are fabricated and stripping off the carrier and discarding the same.

Owner:ENERDEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com