A homogeneous conductive paste

A technology of conductive paste and functional phase, which is applied in the field of preparation of thick film electronic paste, and can solve problems that have not been solved well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

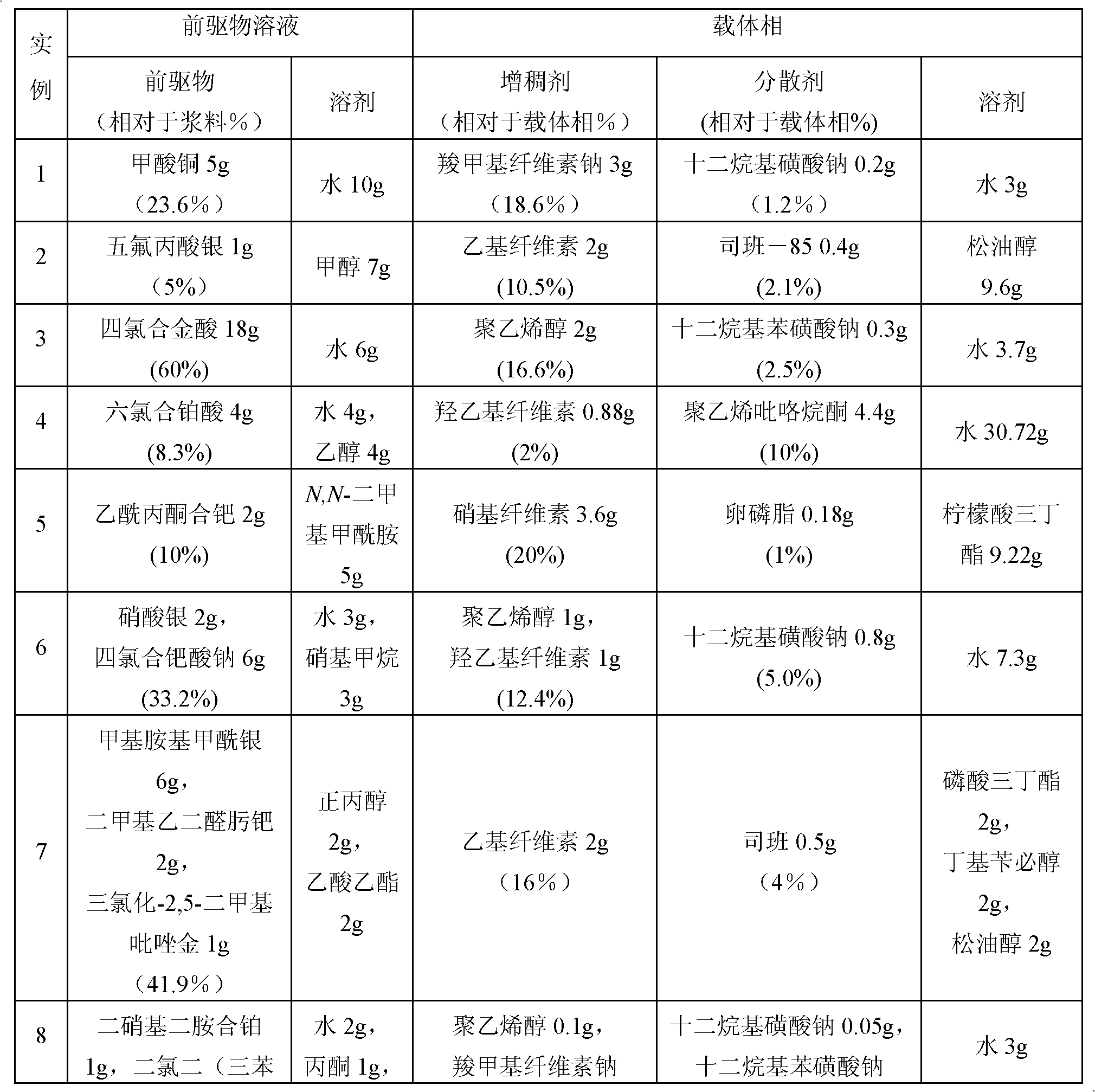

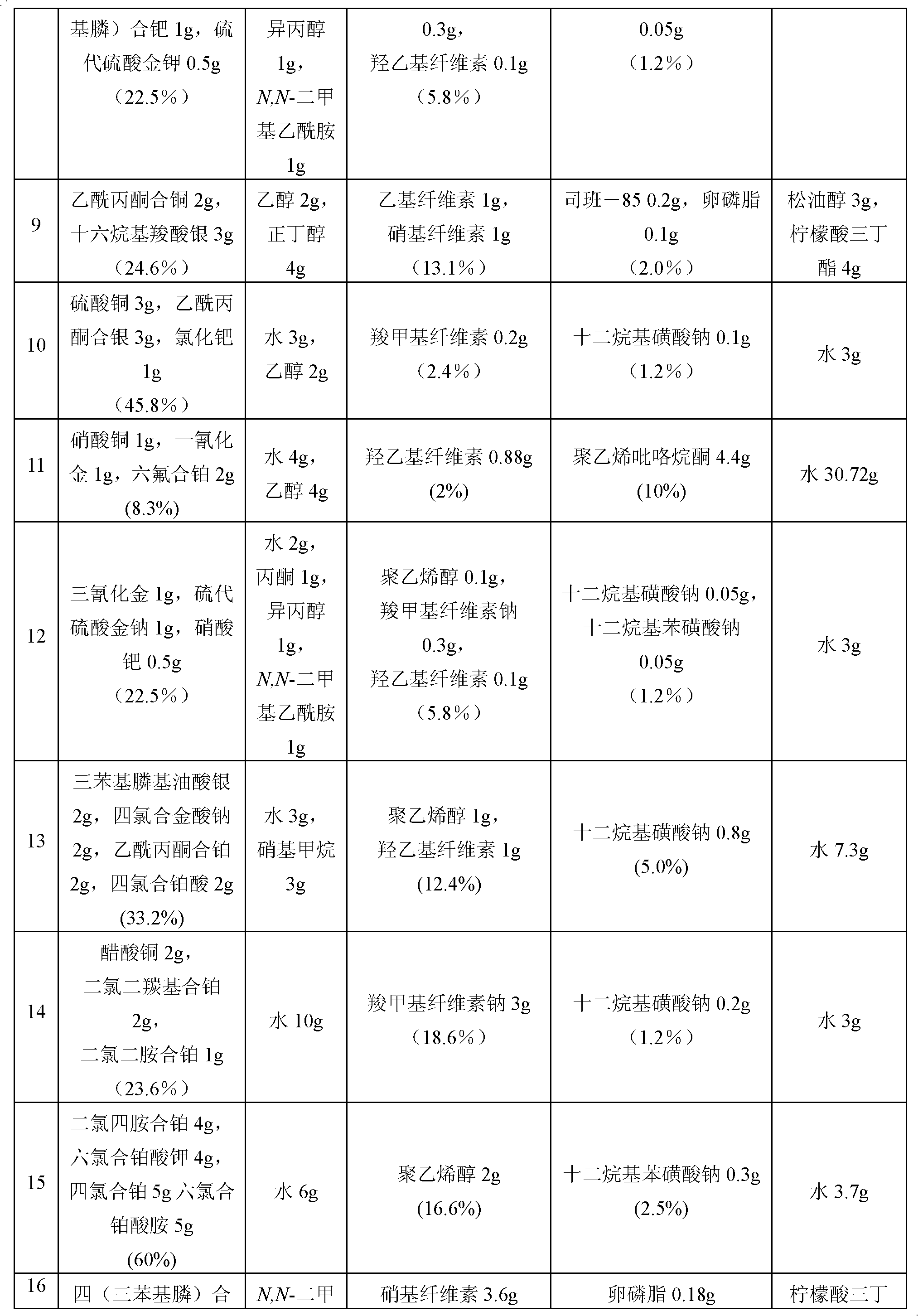

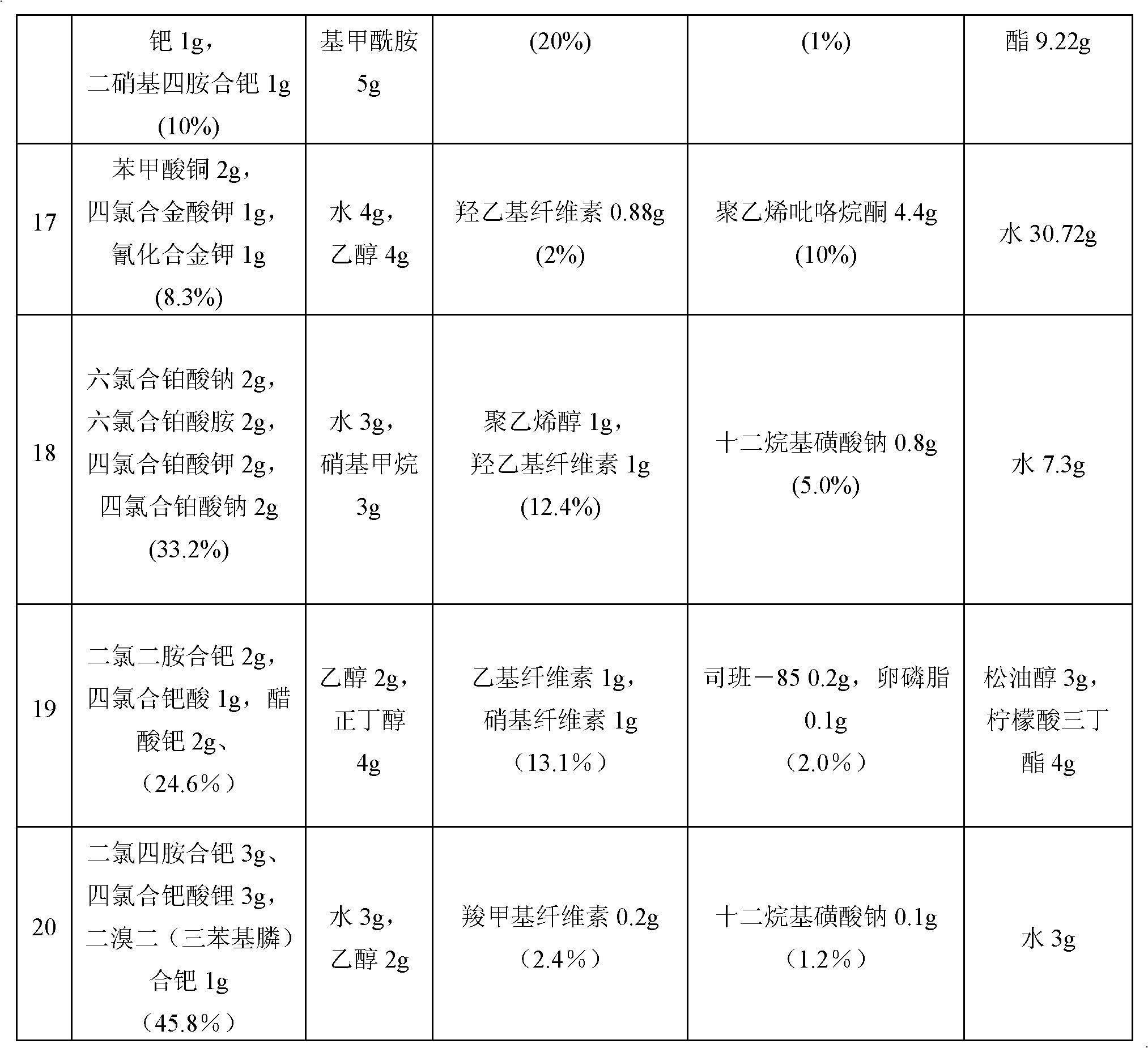

Examples

Embodiment 1

[0020] Dissolve 5 g of the precursor copper formate in 10 g of water to obtain an aqueous solution of copper formate; dissolve 3 g of sodium carboxymethyl cellulose in 3 g of water, add 0.2 g of sodium dodecylbenzene sulfonate, and dissolve to obtain a carrier phase; The aqueous solution of copper formate is mixed with the carrier, and mechanically stirred evenly to obtain the slurry of the present invention.

[0021] After the slurry was spin-coated on a quartz glass substrate to form a film, it was dried at 65°C for 30 min, and then 2 Laser or Nd:YAG treatment, can get conductive layer or conductive line, its volume resistivity is about 4.7×10 -5 Ω·cm.

Embodiment 2

[0023] Dissolve 1 g of the precursor silver pentafluoropropionate in 7 g of methanol to obtain a methanol solution of the precursor; dissolve 2 g of ethyl cellulose in 9.6 g of terpineol, add 0.4 g of Span-85 to obtain a carrier phase; Mix the methanol solution of the substance with the carrier, continue stirring evenly, and then ultrasonically disperse to obtain the slurry of the present invention.

[0024] The slurry is directly written on the ceramic substrate with a micro-pen (tip inner diameter of 20 μm) direct writing device, first dried at 50°C for 20 minutes, and then sintered at 450°C for 30 minutes to obtain a conductive pattern with a resolution of up to 20 μm Around, the volume resistivity is about 6.2×10 -5 Ω·cm.

Embodiment 3

[0026] Dissolve 18g of precursor tetrachloroalloy acid in 6g of water to obtain the aqueous solution of precursor; dissolve 2g of polyvinyl alcohol in 3.7g of water, add 0.3g of sodium dodecylbenzenesulfonate, and dissolve to obtain a carrier phase; The above-mentioned precursor aqueous solution is mixed with the carrier, and mechanically stirred evenly to obtain the slurry of the present invention.

[0027] The slurry is screen printed on the ceramic substrate, dried at 70°C for 20 minutes, and then sintered at 350°C for 40 minutes to obtain a conductive pattern with a volume resistivity of about 8.3×10 -5 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com