Patents

Literature

107 results about "Spin welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spin welding is a friction welding technique used on thermoplastic materials, in which the parts to be welded are heated by friction. The heat may be generated by turning on a lathe, a drill press, or a milling machine, where one part is driven by the chuck, and the other is held stationary with the spinning part driven against it. This is continued until the heat of friction between the parts reaches a sufficient level for the parts to weld. The stationary part is then released to spin as well, while pressure is applied along the axis of rotation, holding the parts together as they cool.

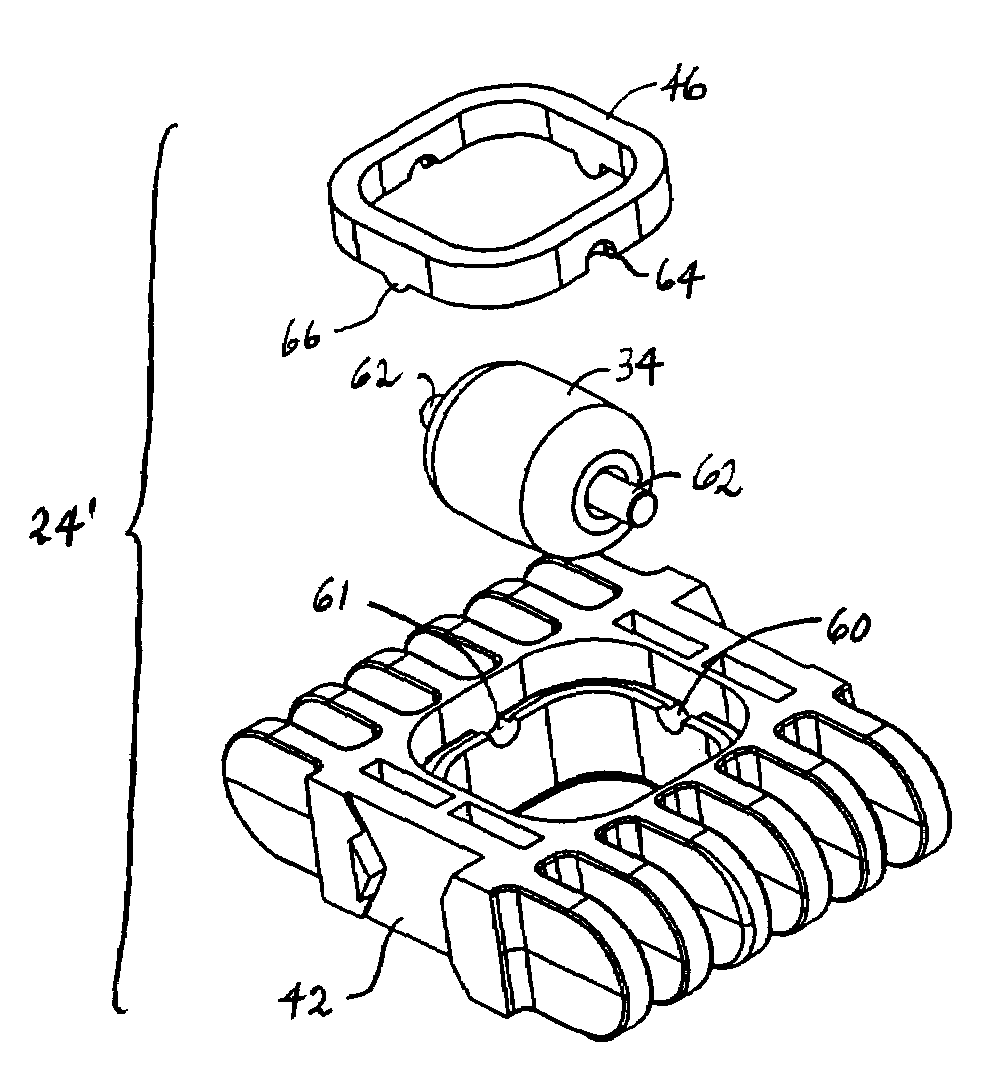

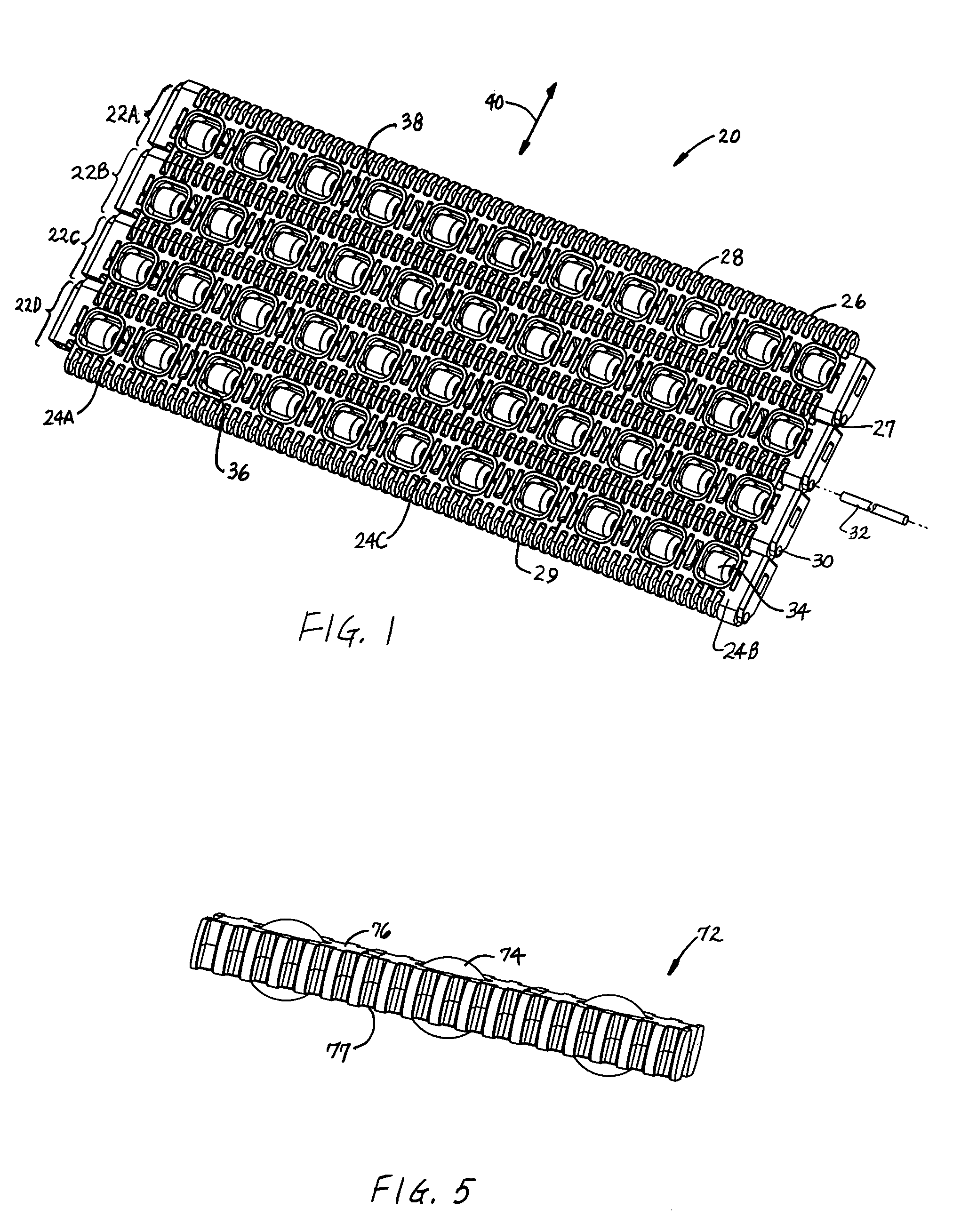

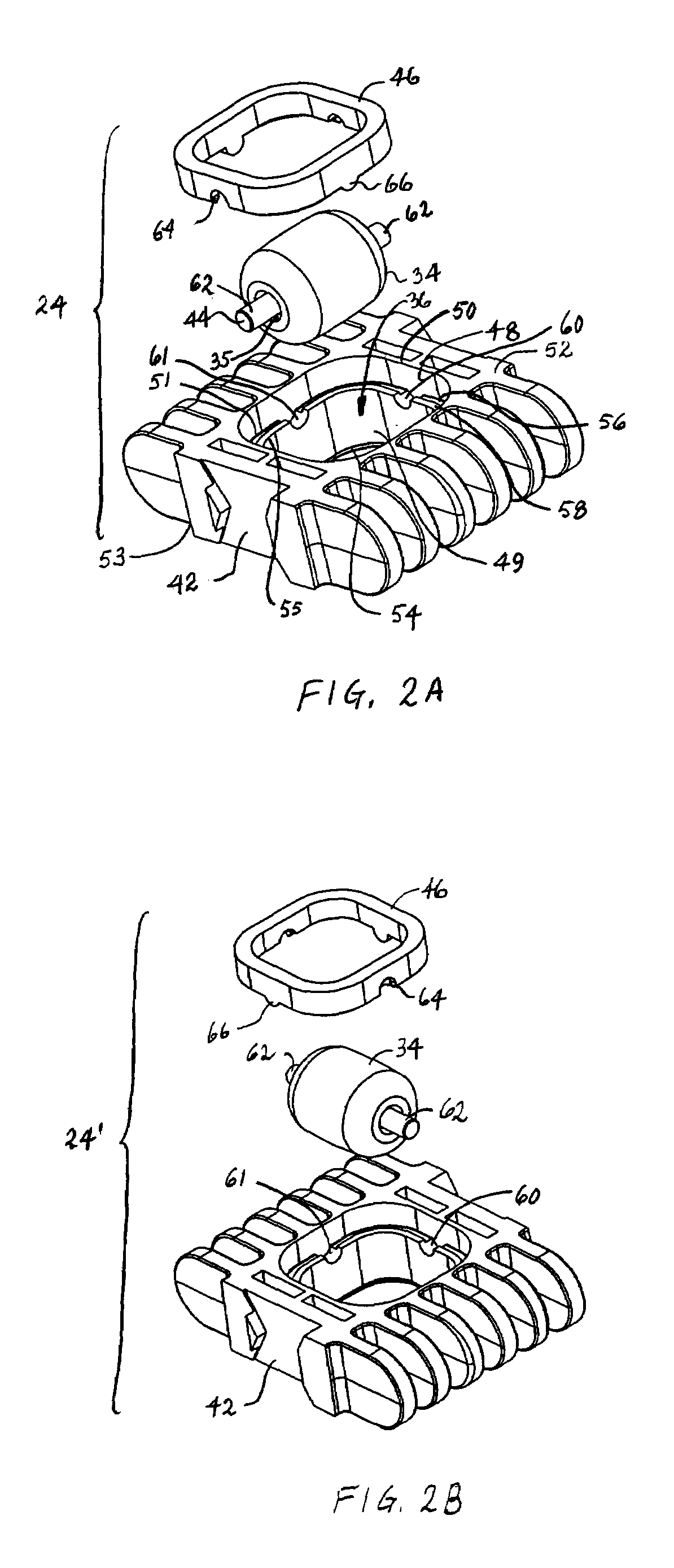

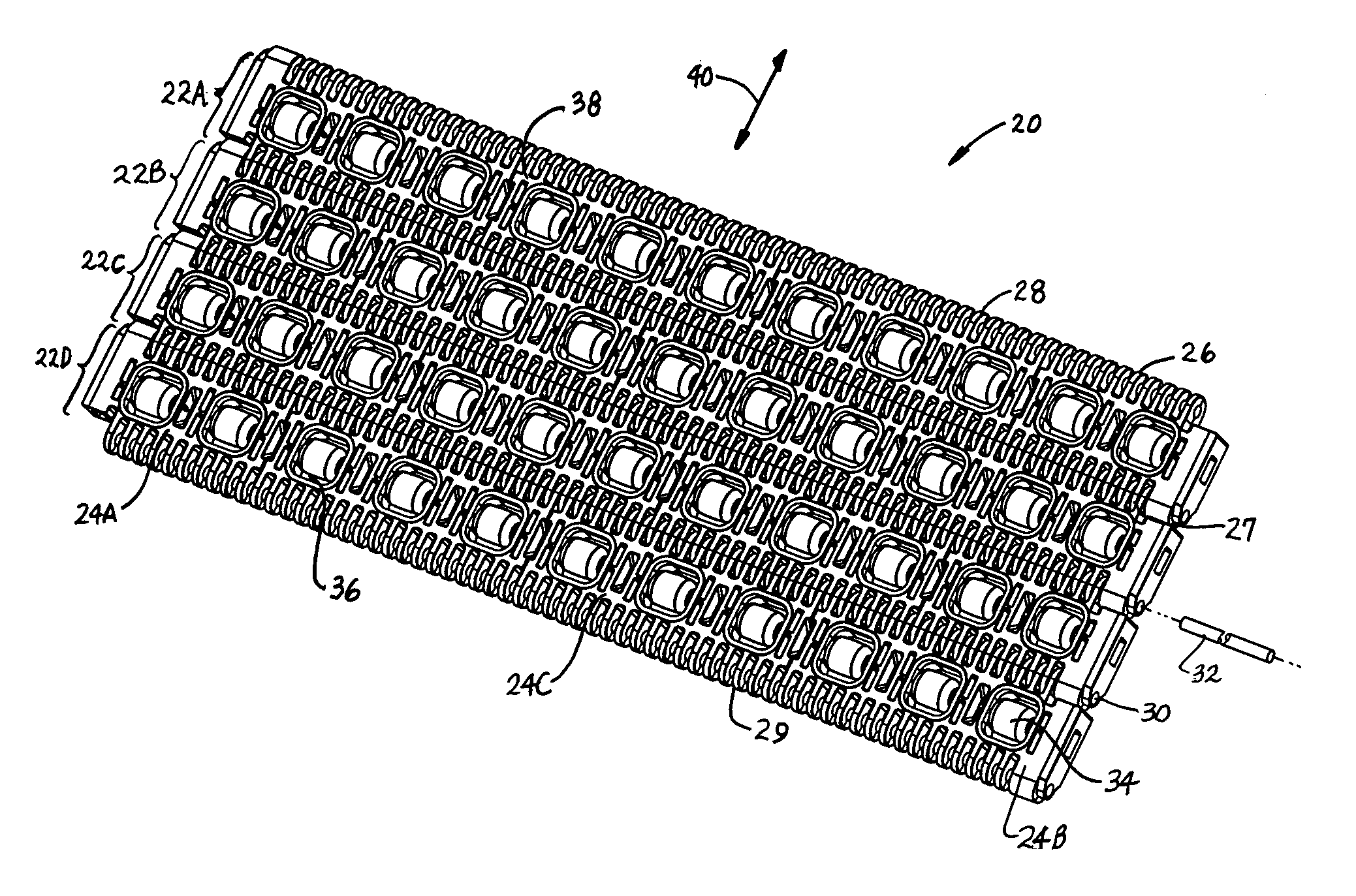

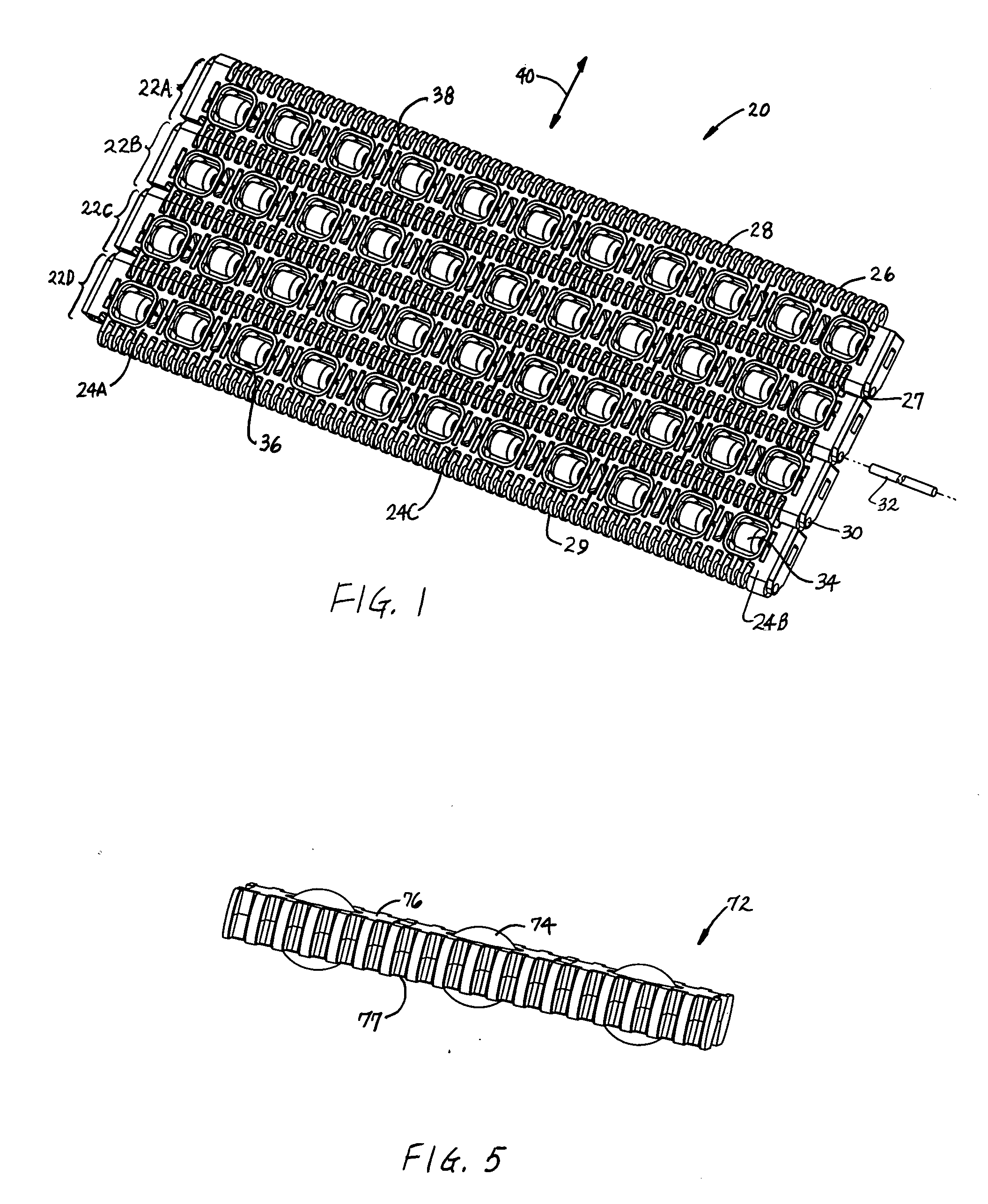

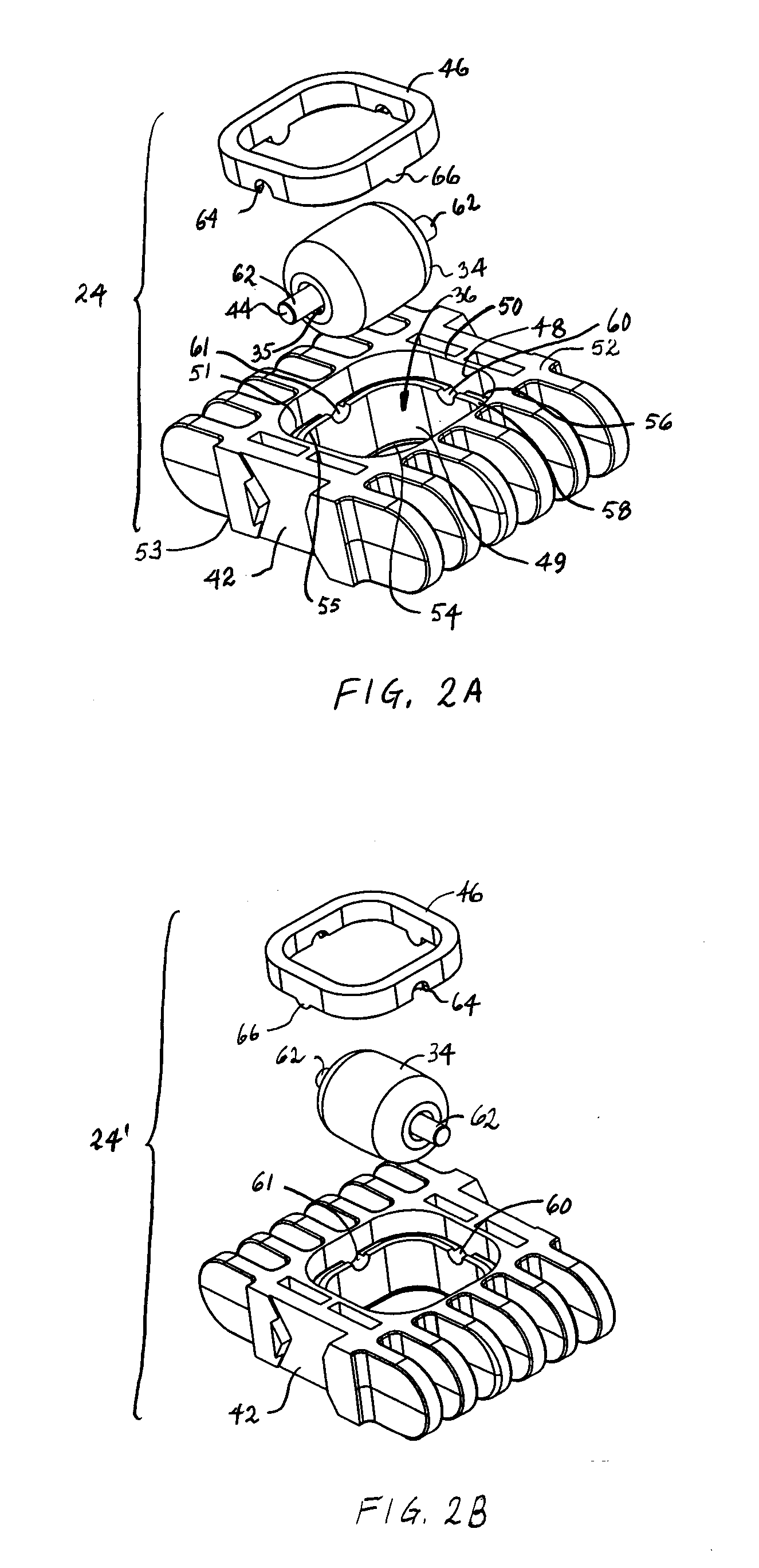

Conveyor belt modules with embedded rollers retained in the modules and associated method

A plastic conveyor belt module with embedded rollers retained in the module and a method for making such a module. The module includes a module body forming a cavity, a roller in the cavity, and a retainer received in the cavity to hold the roller rotatably in place. A salient portion of the roller extends outward from the cavity through the retainer past an outer surface of the module. The retainer is attached to the module body by ultrasonic welding, epoxy- or solvent-bonding, spin welding, electromagnetic welding, staking, screwing, or locking.

Owner:LAITRAM LLC

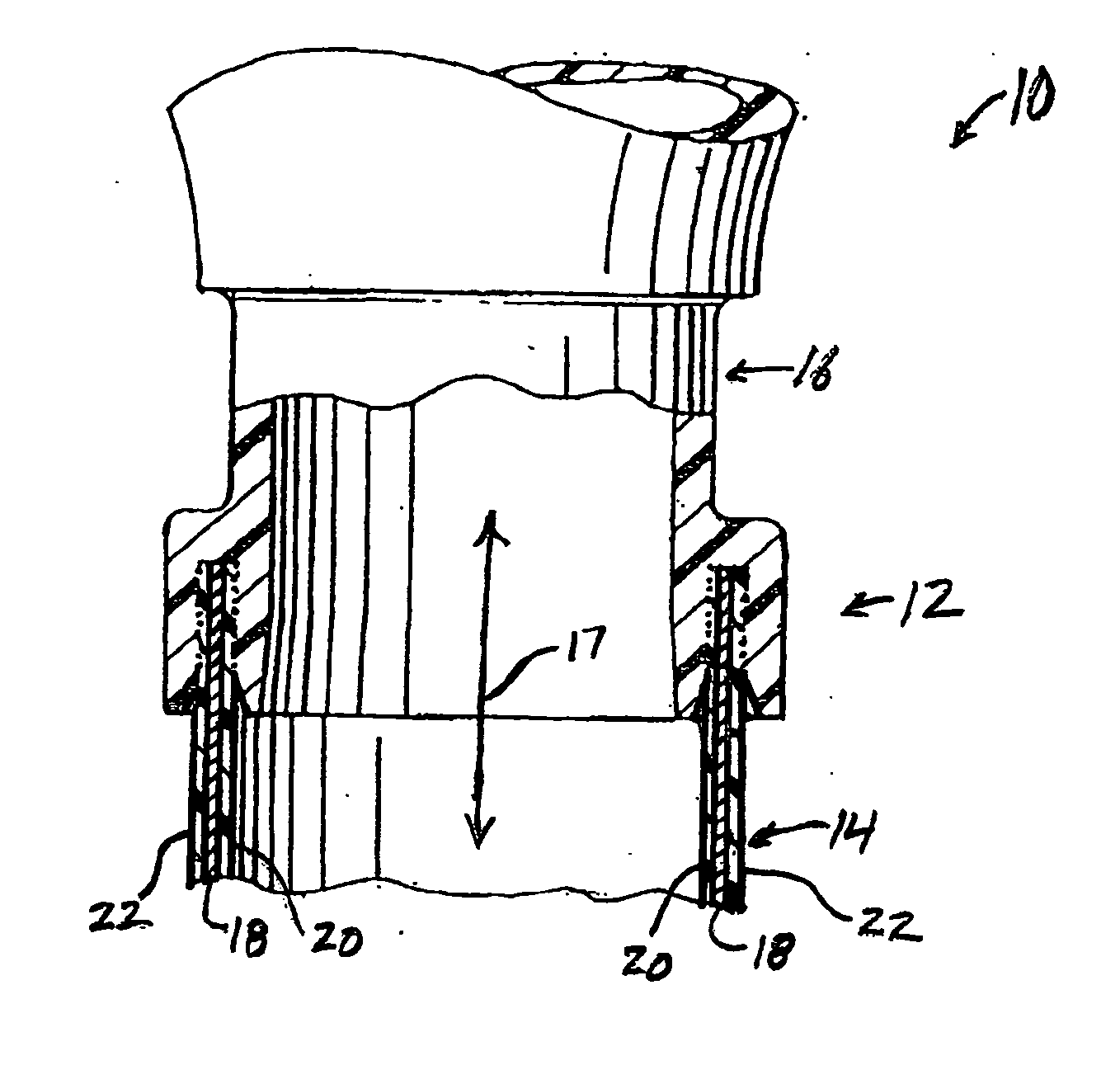

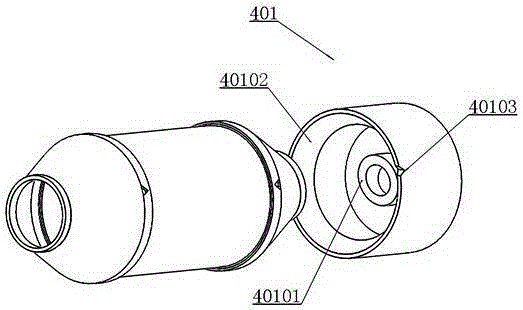

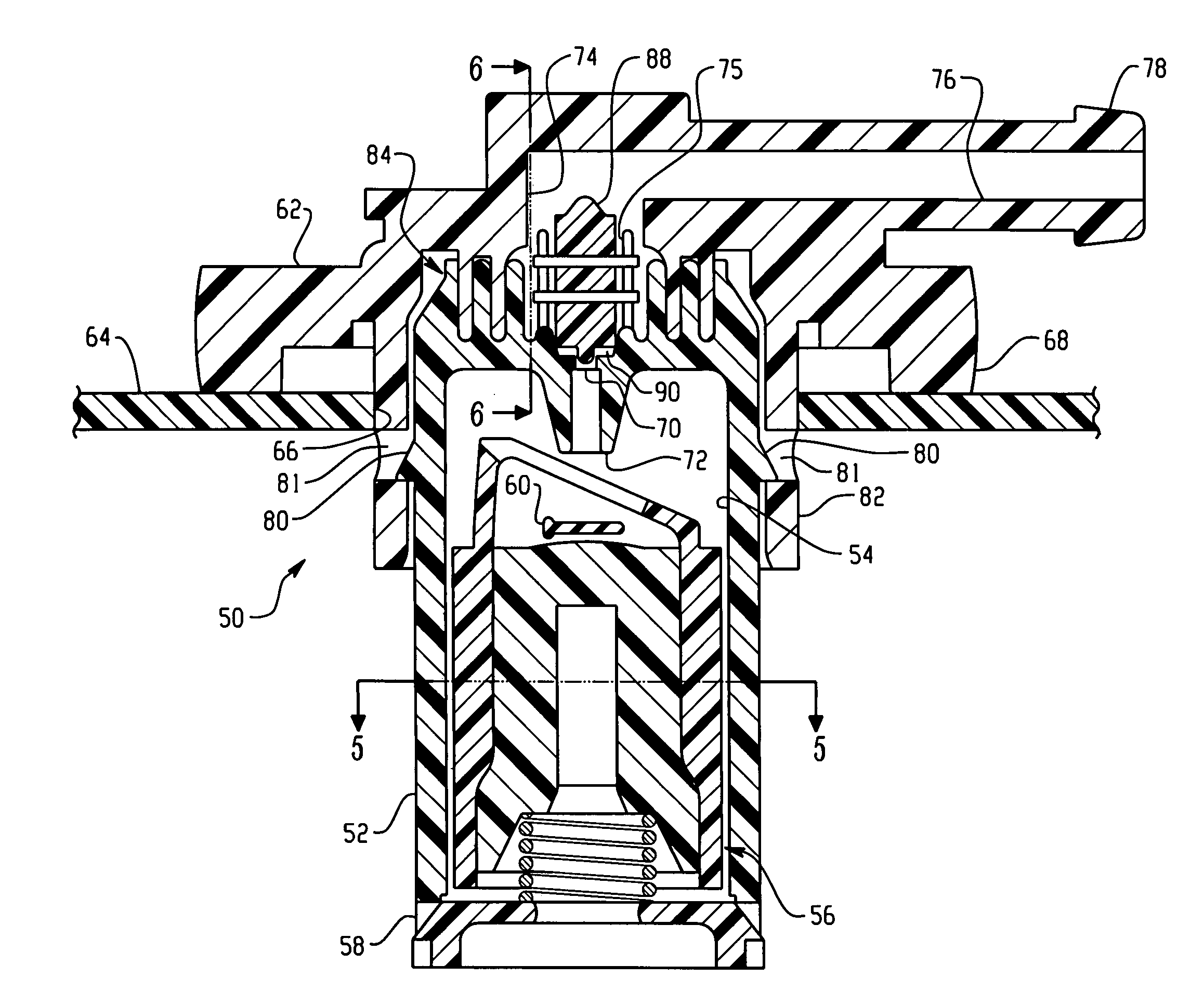

Container with integral module for heating or cooling the contents and method for its manufacture

InactiveUS6351953B1Exothermal chemical reaction heat productionOther heat production devicesSpin weldingChemical reaction

A container having a container body, a thermic module at one end of the body, and a closure at the other end of the body initiates an internal exothermic (or, alternatively, endothermic) chemical reaction to heat its contents when a user actuates the thermic module. A plastic thermic module body is spin-welded to a plastic container body by rotating one relative to and in contact with the other. The container body has multiple layers, including an inner layer such as a so-called oxygen barrier layer that inhibits oxidation and spoilage of the contents, and spin-welding the container body to the module body seals the otherwise-exposed oxygen barrier layer against air or moisture intrusion. The container includes a rotatable cover adhered to the container end over the closure with heat-sensitive adhesive that prevents a user from accessing the contents until a certain temperature is reached. The thermic module further includes a seal between an inner actuator button and an outer actuator button that seals the thermic module reactants against moisture intrusion prior to use, and is punctured when the thermic module is actuated. The thermic module may also include a filter disposed in interfering relation with the thermic module vents, including a portion between the inner and outer actuator buttons, to block egress of any particles of the solid reactant or the reaction product.

Owner:AURA LTD

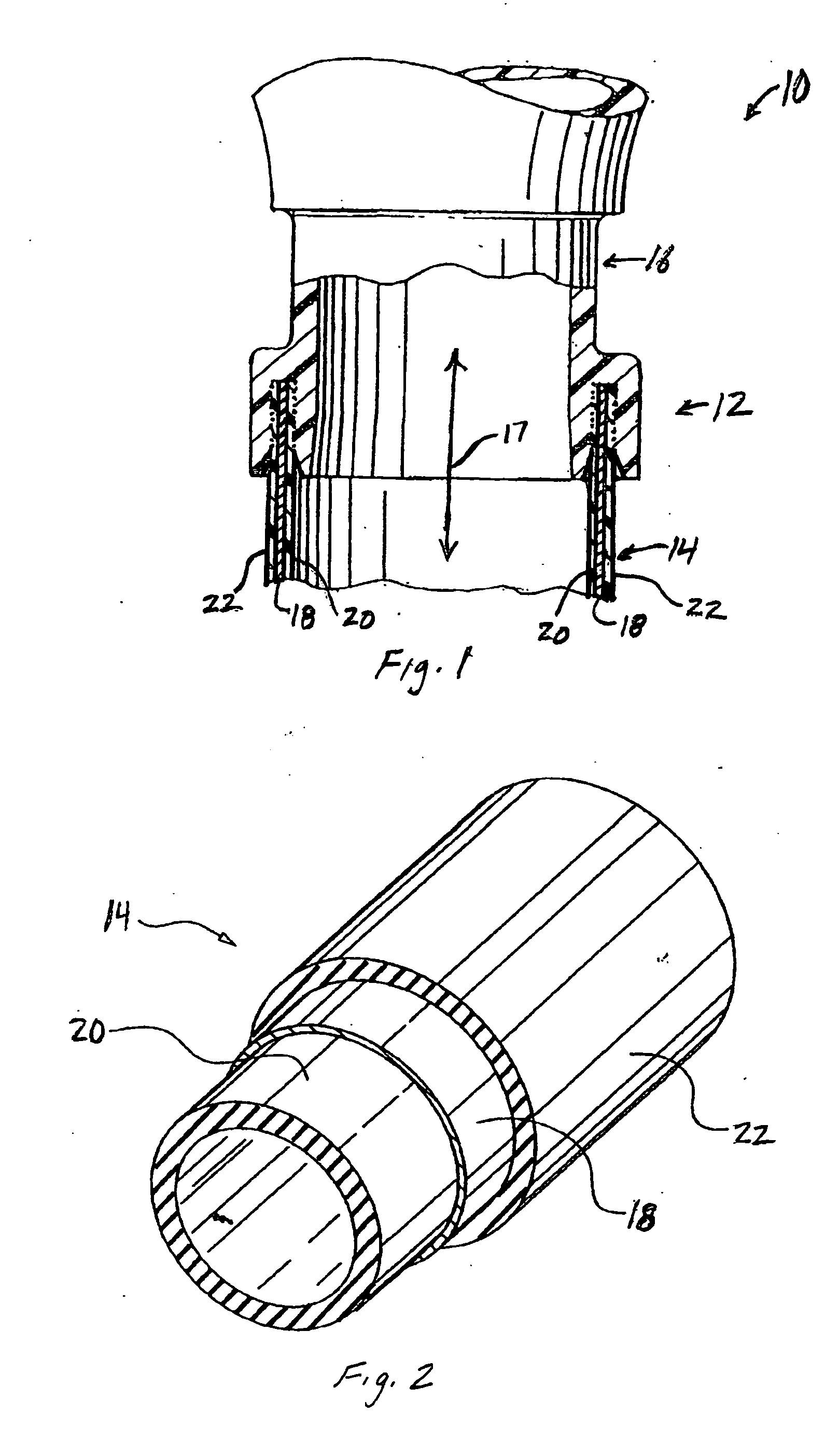

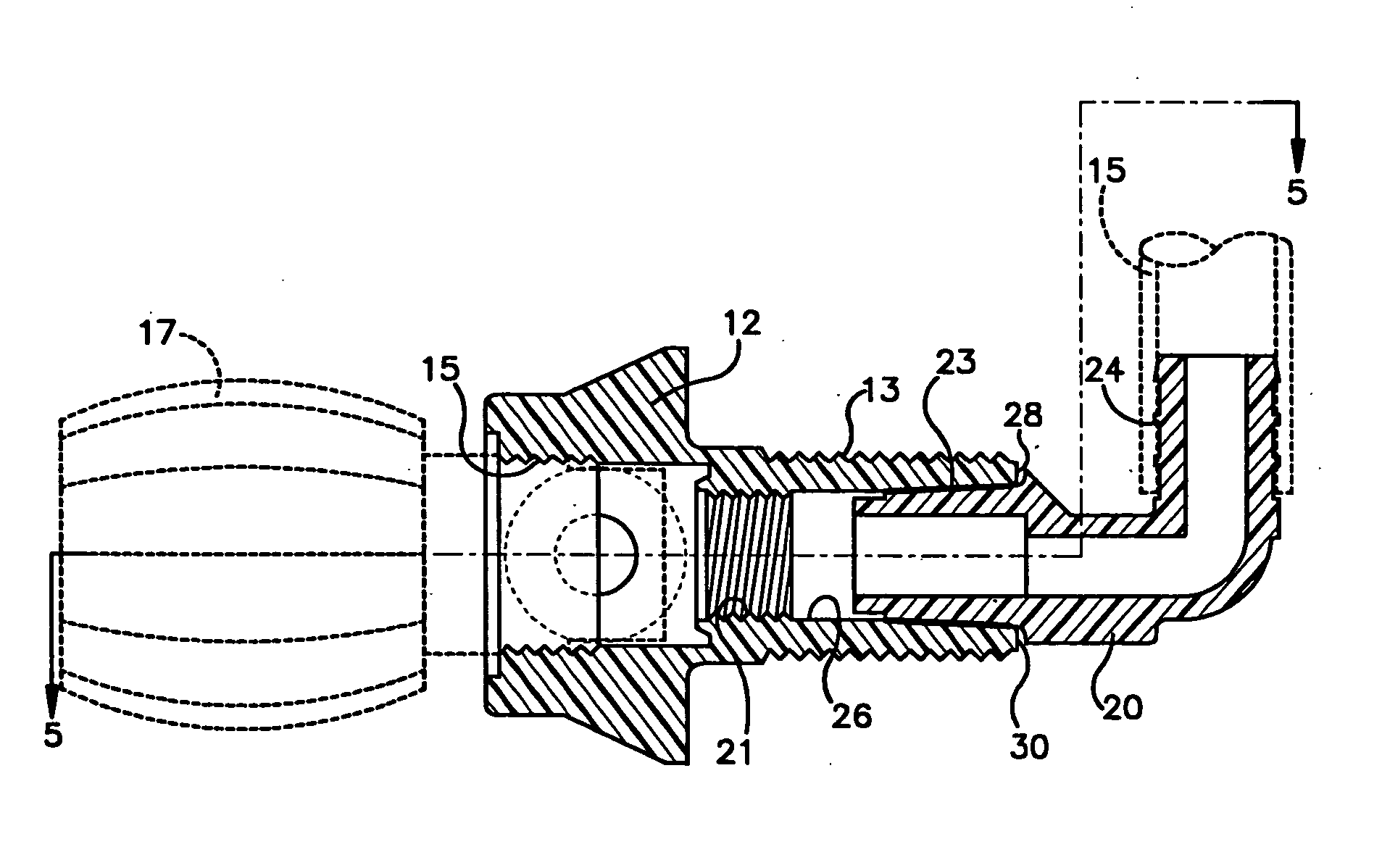

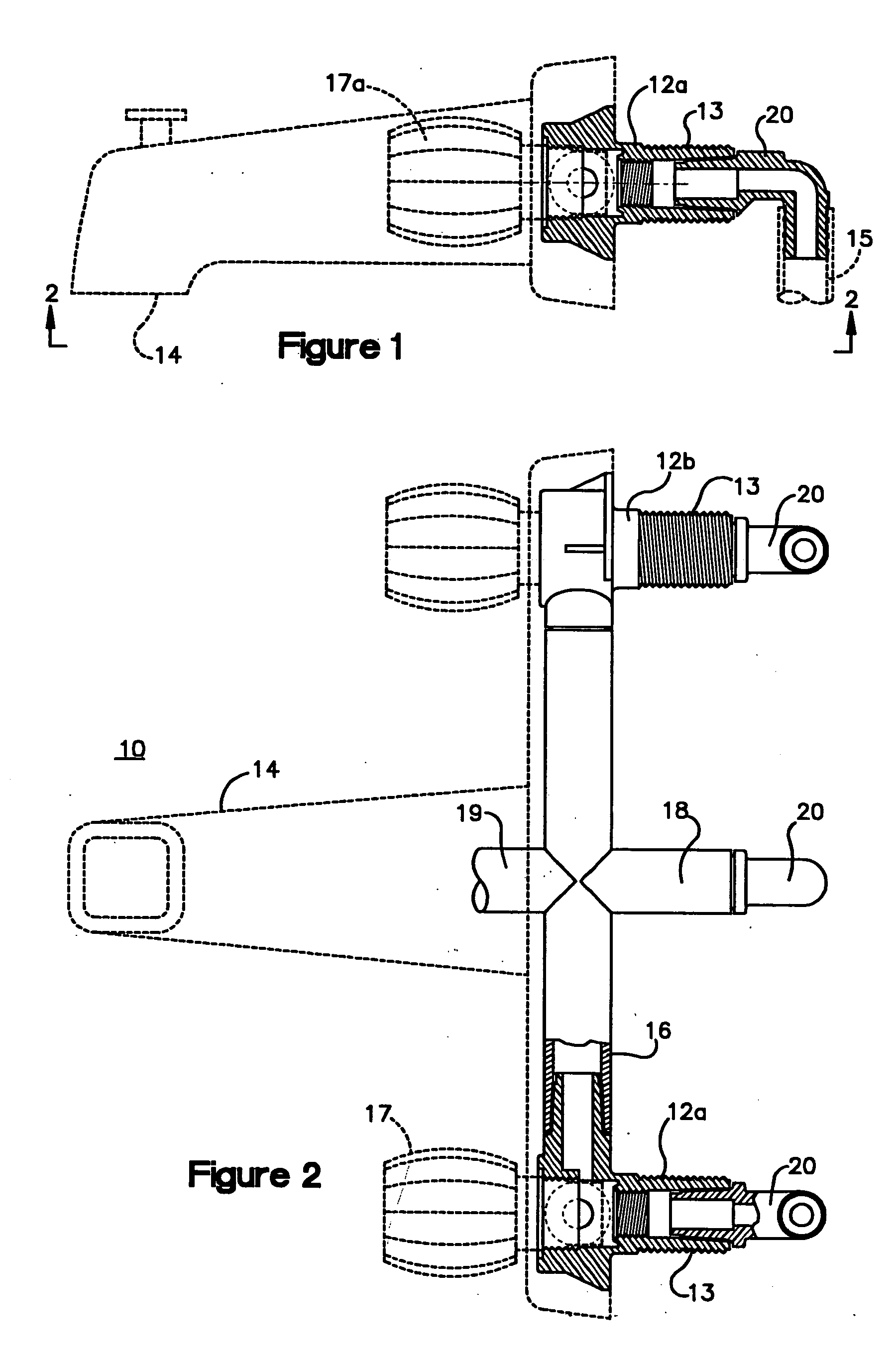

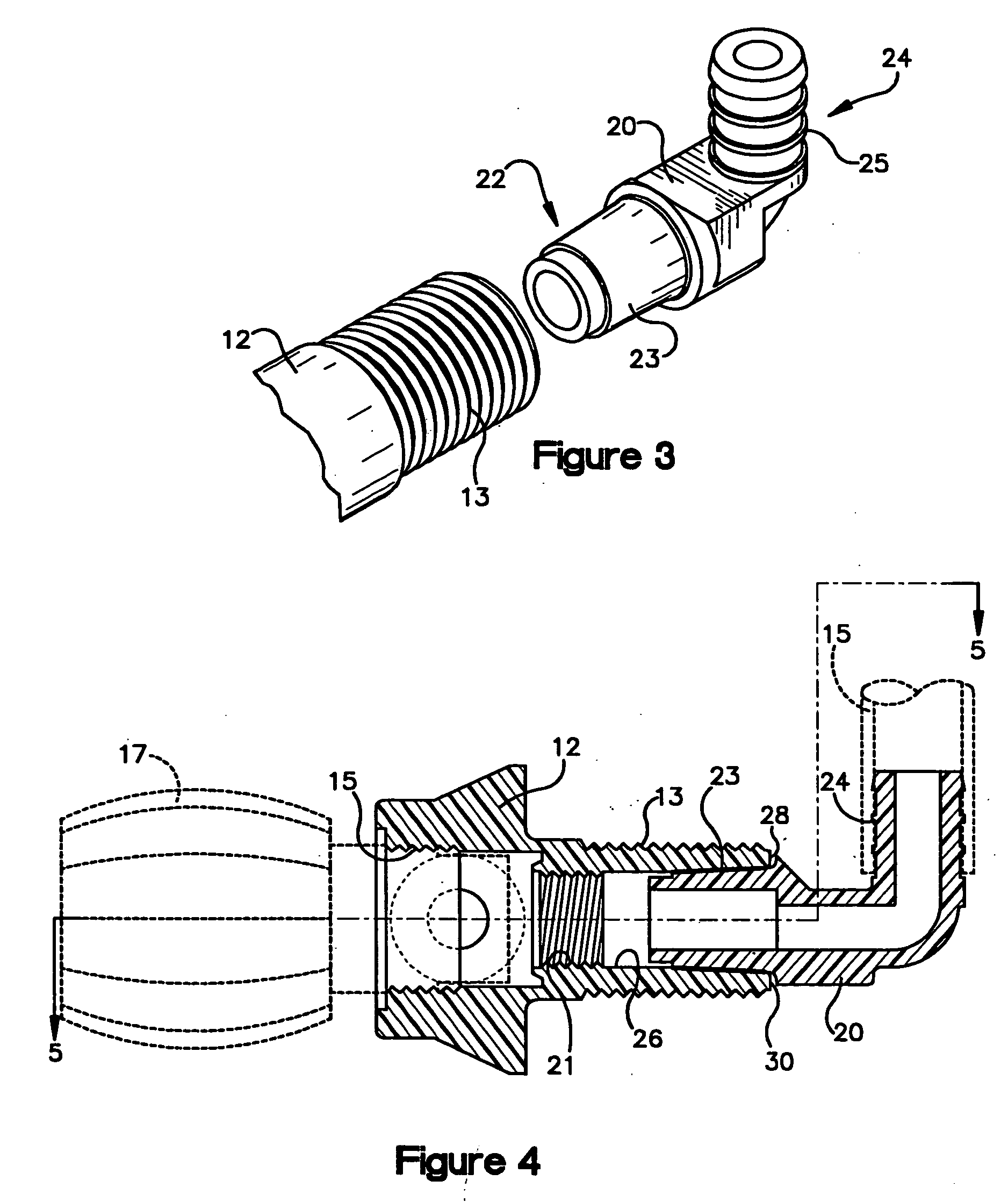

Gas impermeable tube joint and method of forming same

A method of forming a gas impermeable joint in a fluid system includes: providing a tube having a metallic barrier layer disposed between an inner plastic layer and an outer plastic layer; forcing at least one of the inner plastic layer and the outer plastic layer into contact with a plastic surface of a component; and welding the at least one of the inner plastic layer and the outer plastic layer with the plastic surface to form the gas impermeable joint. The welding may include: spin welding, hot plate welding, vibration welding, and ultrasonic welding. The metallic barrier layer extends substantially to the component, thus improving the gas impermeability of the joint between the tube and the component.

Owner:FLUID ROUTING SOLUTIONS

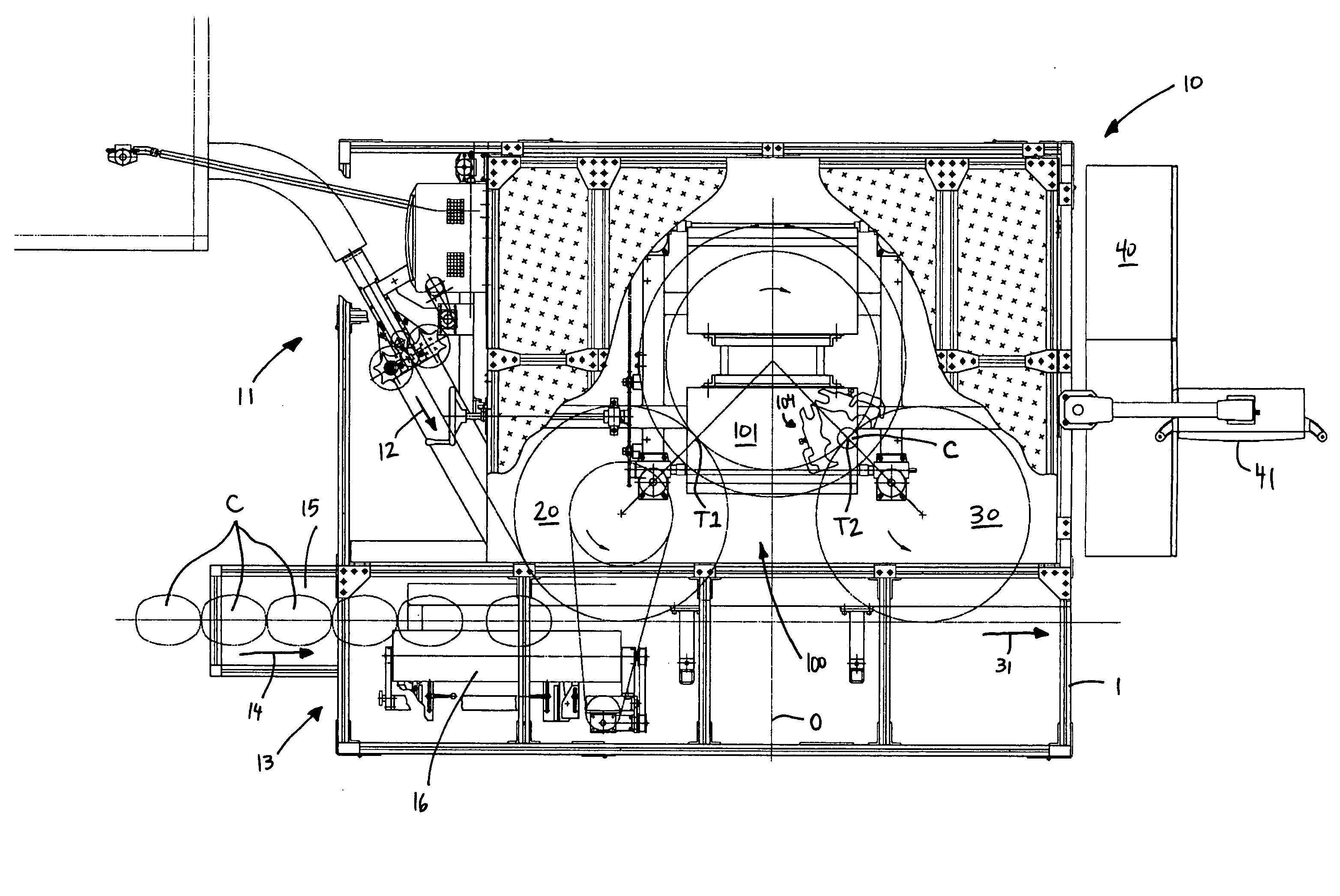

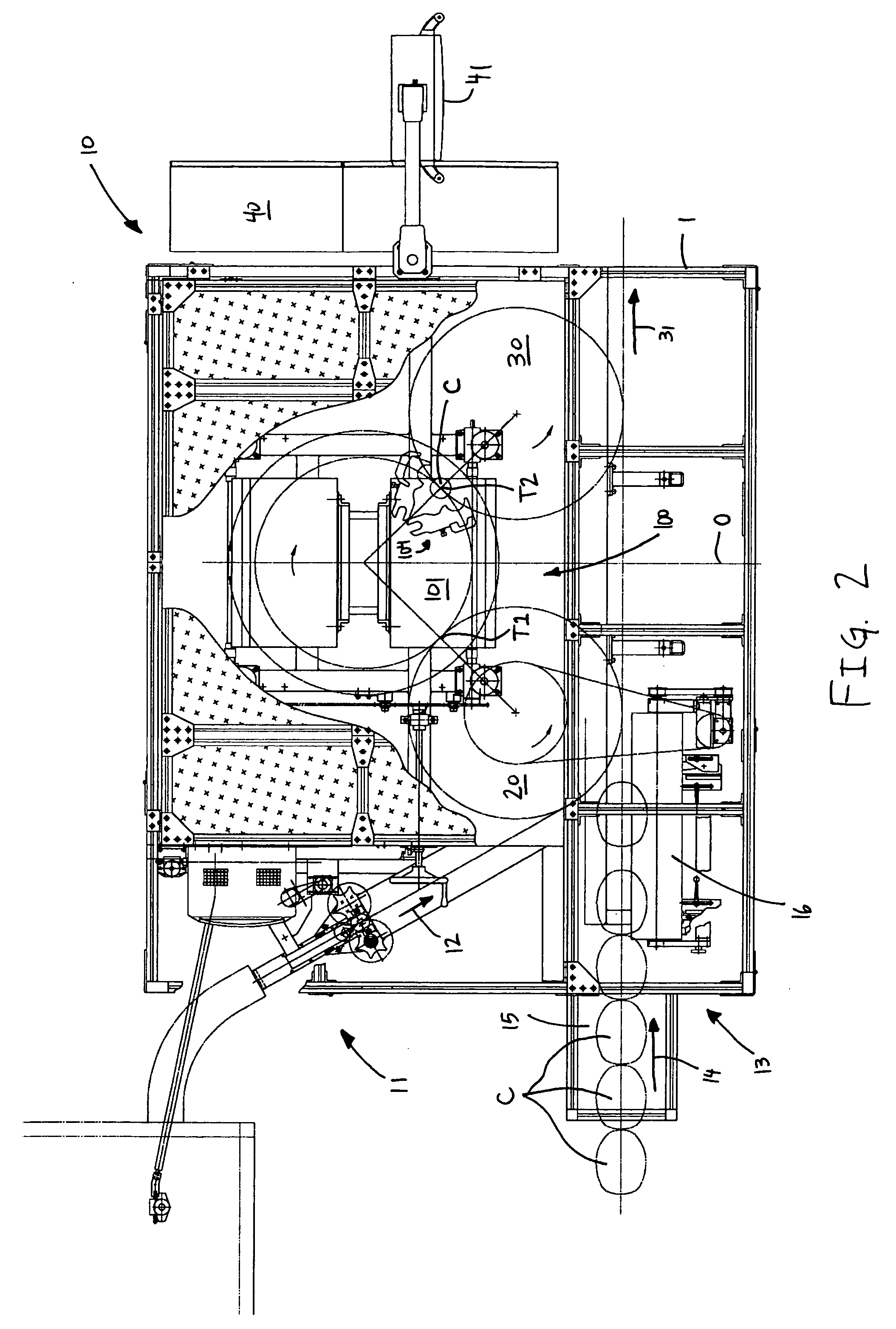

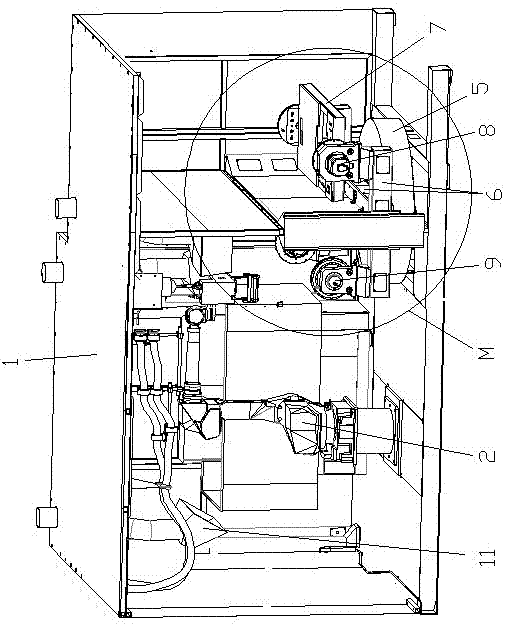

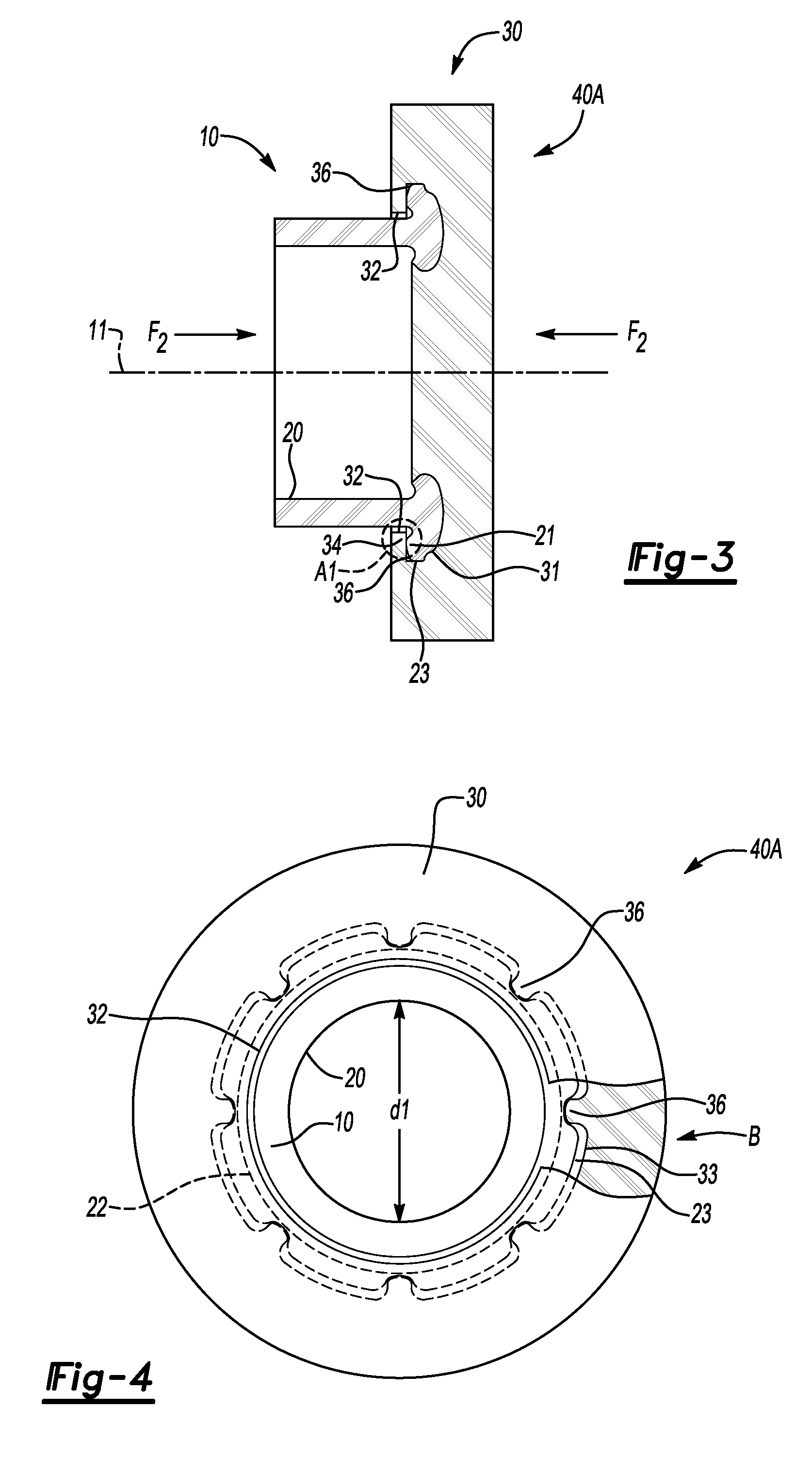

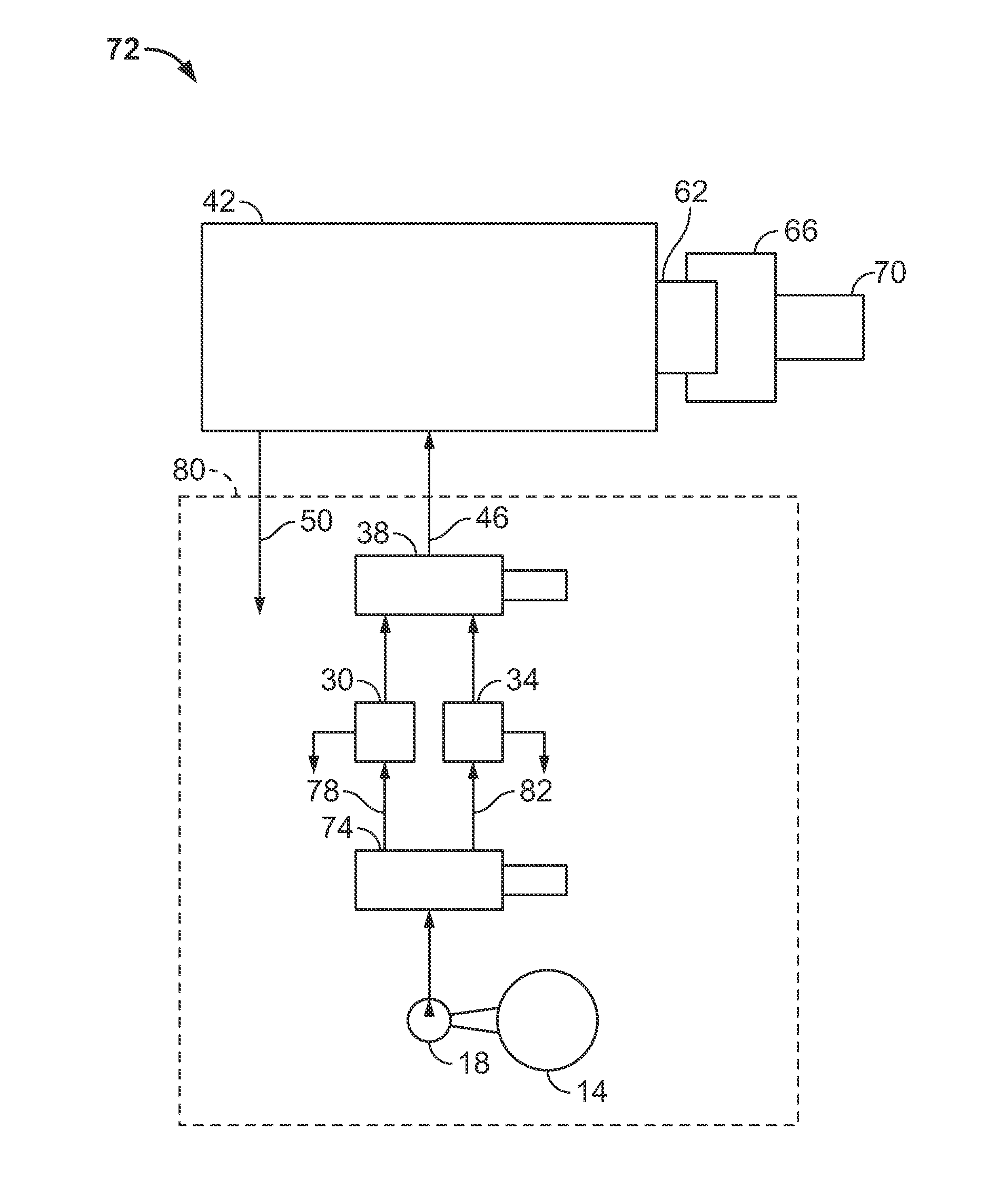

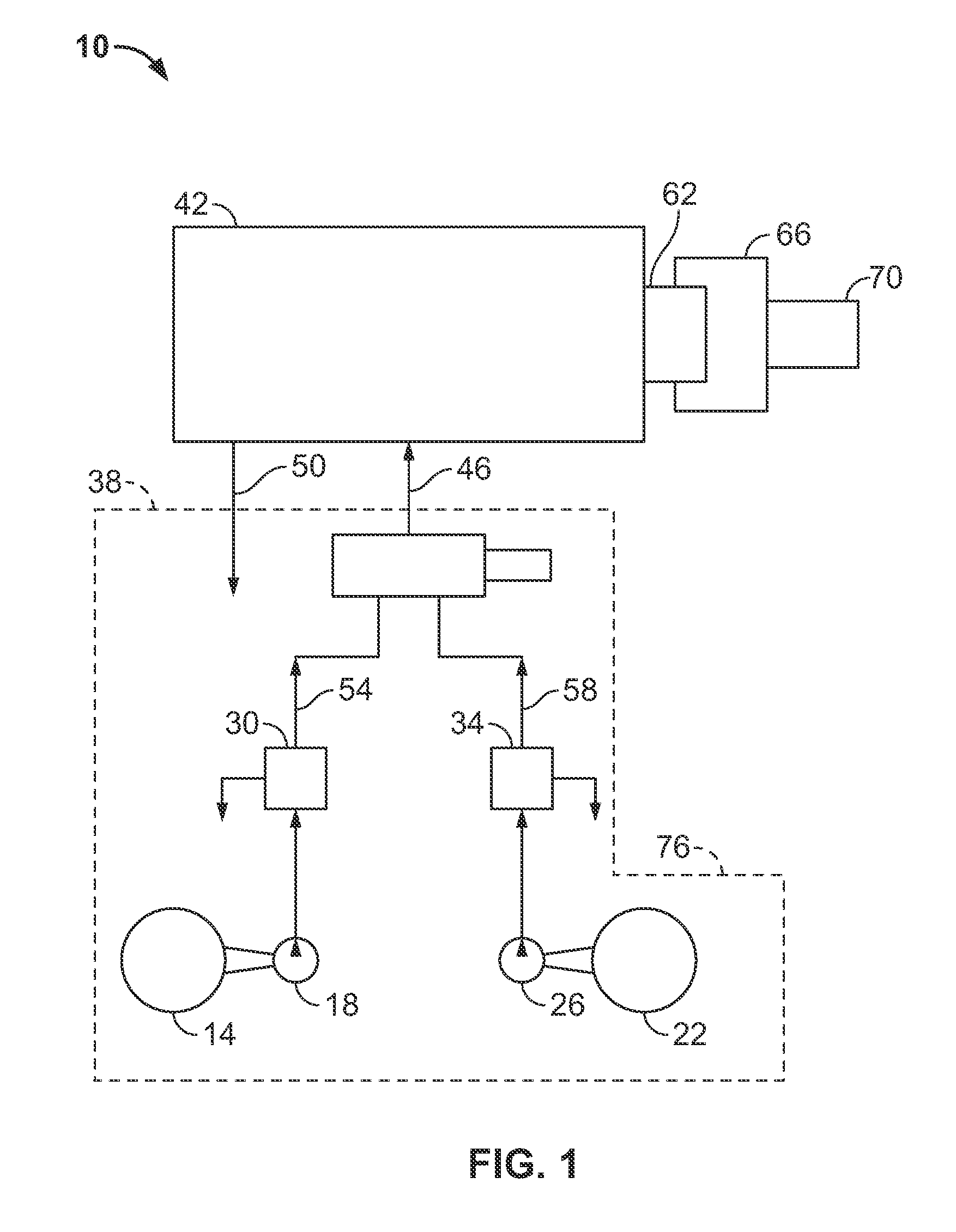

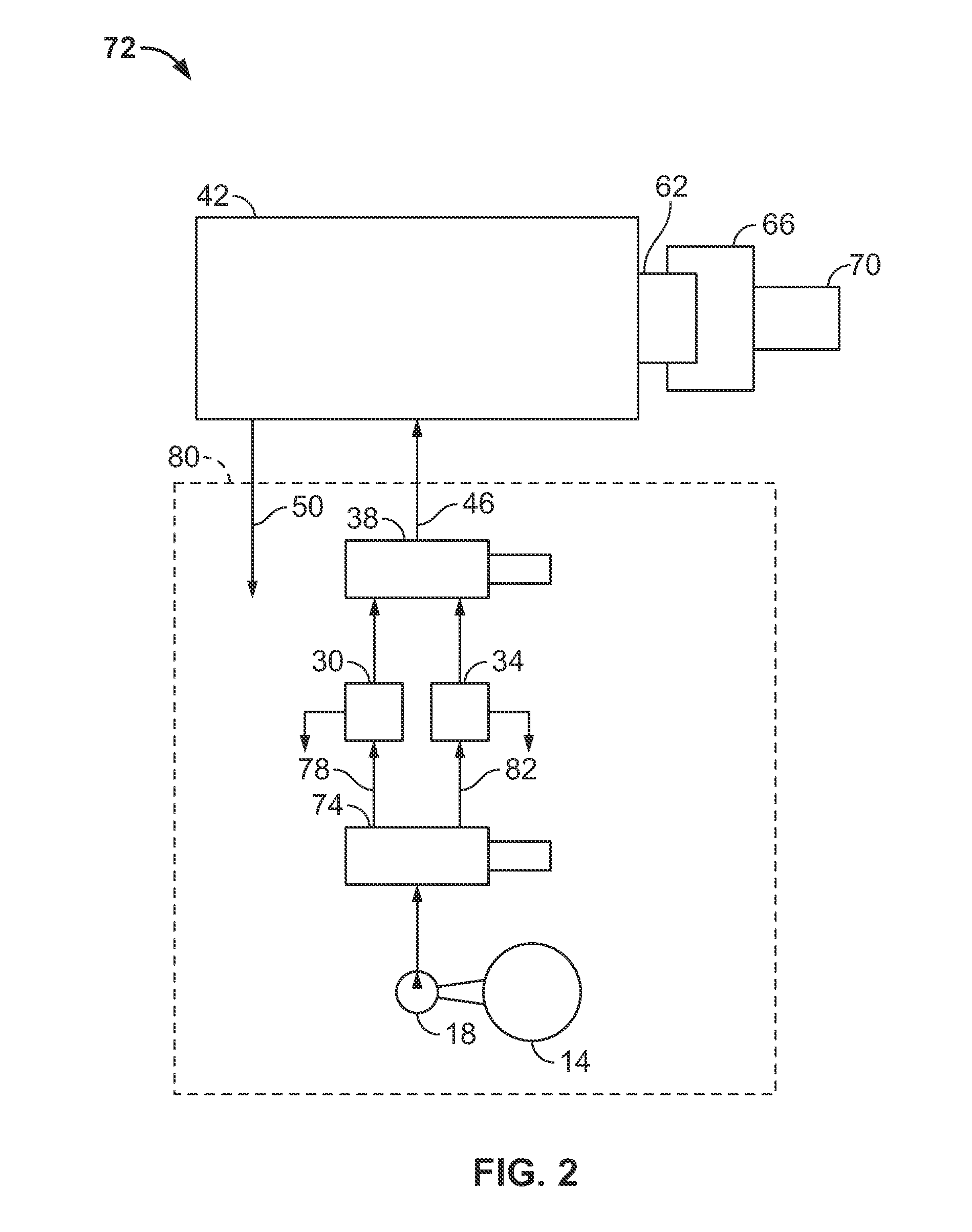

Continuous motion spin welding apparatus, system, and method

An apparatus, system, and method for friction (spin) welding separate parts of a plastic component to one another. The apparatus includes a rotational drive assembly coupled to a turret assembly arranged to be rotationally driven thereby about a longitudinal axis. The turret assembly includes at least one drive mechanism and a plurality of spindle assemblies disposed circumferentially around the longitudinal axis, each spindle assembly defining a spindle axis and including coupled to a chuck configured to receive and hold a first part of the plastic component. The chuck is configured to move along the respective spindle axis to contact the first part of the plastic component with a second part of the plastic component. The at least one drive mechanism is configured to move the chuck and the first part relative to the second part at a speed sufficient to permanently bond the first part to the second part during rotation of the turret assembly.

Owner:GRAHAM PACKAGING CO LP

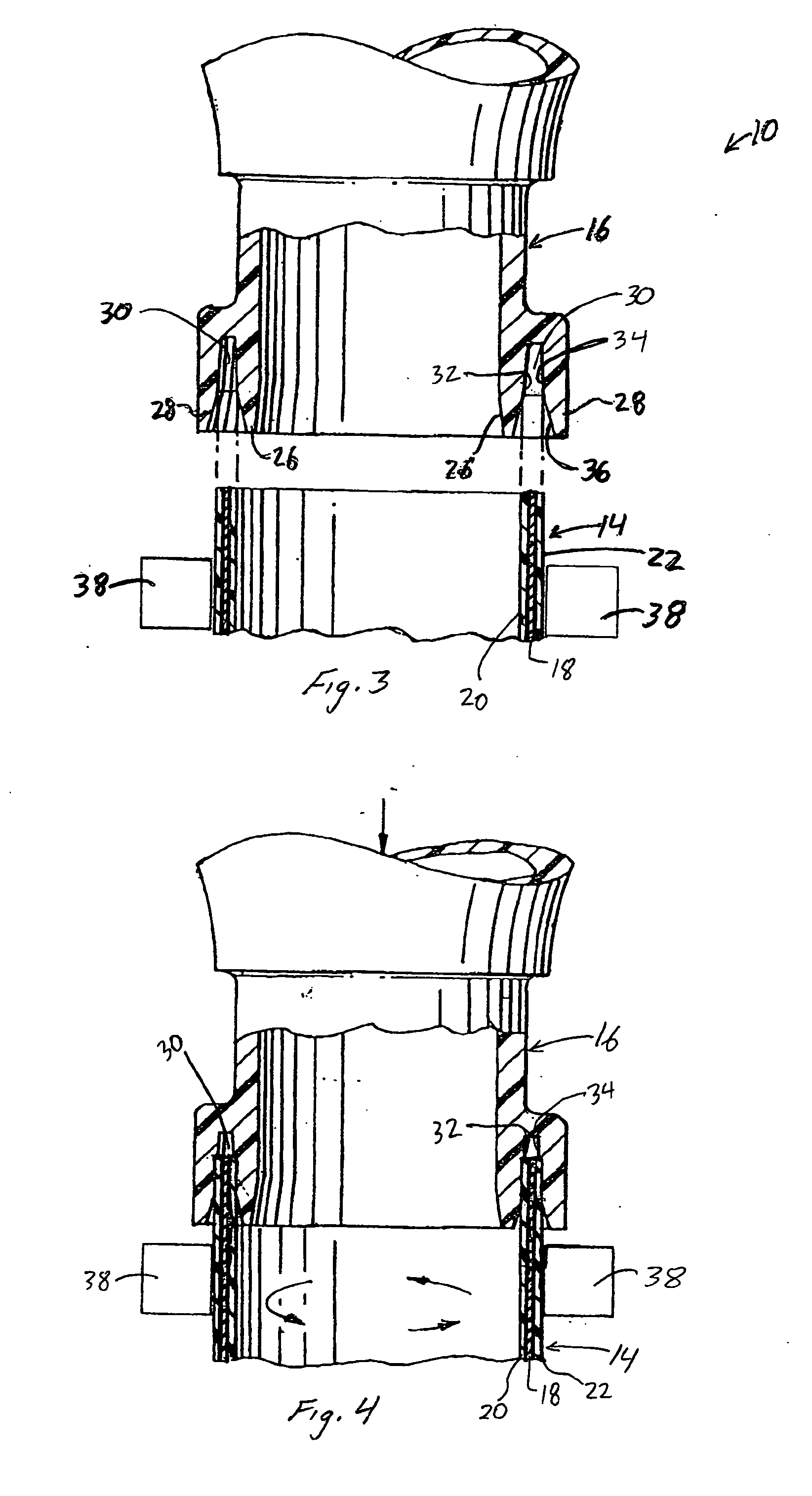

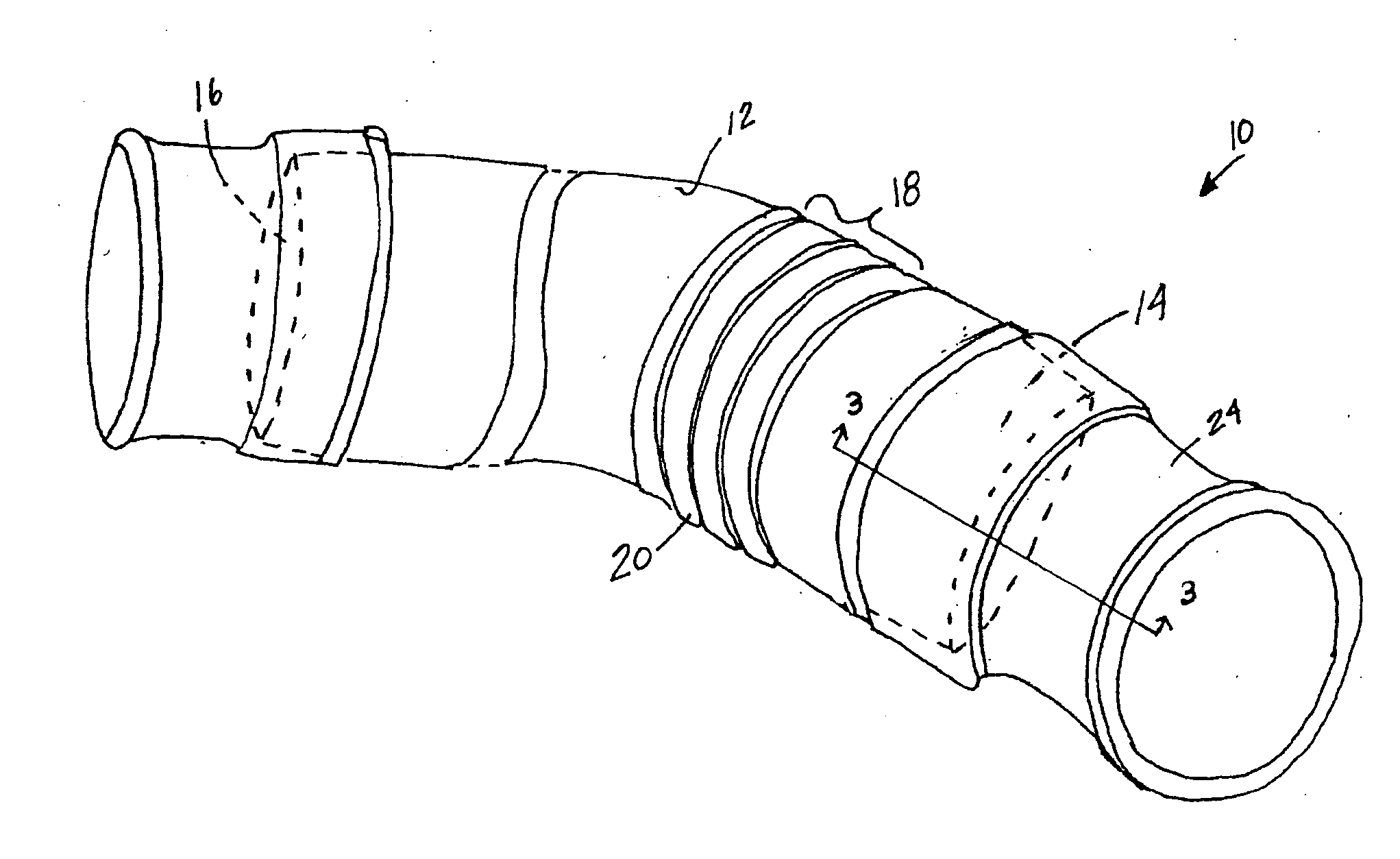

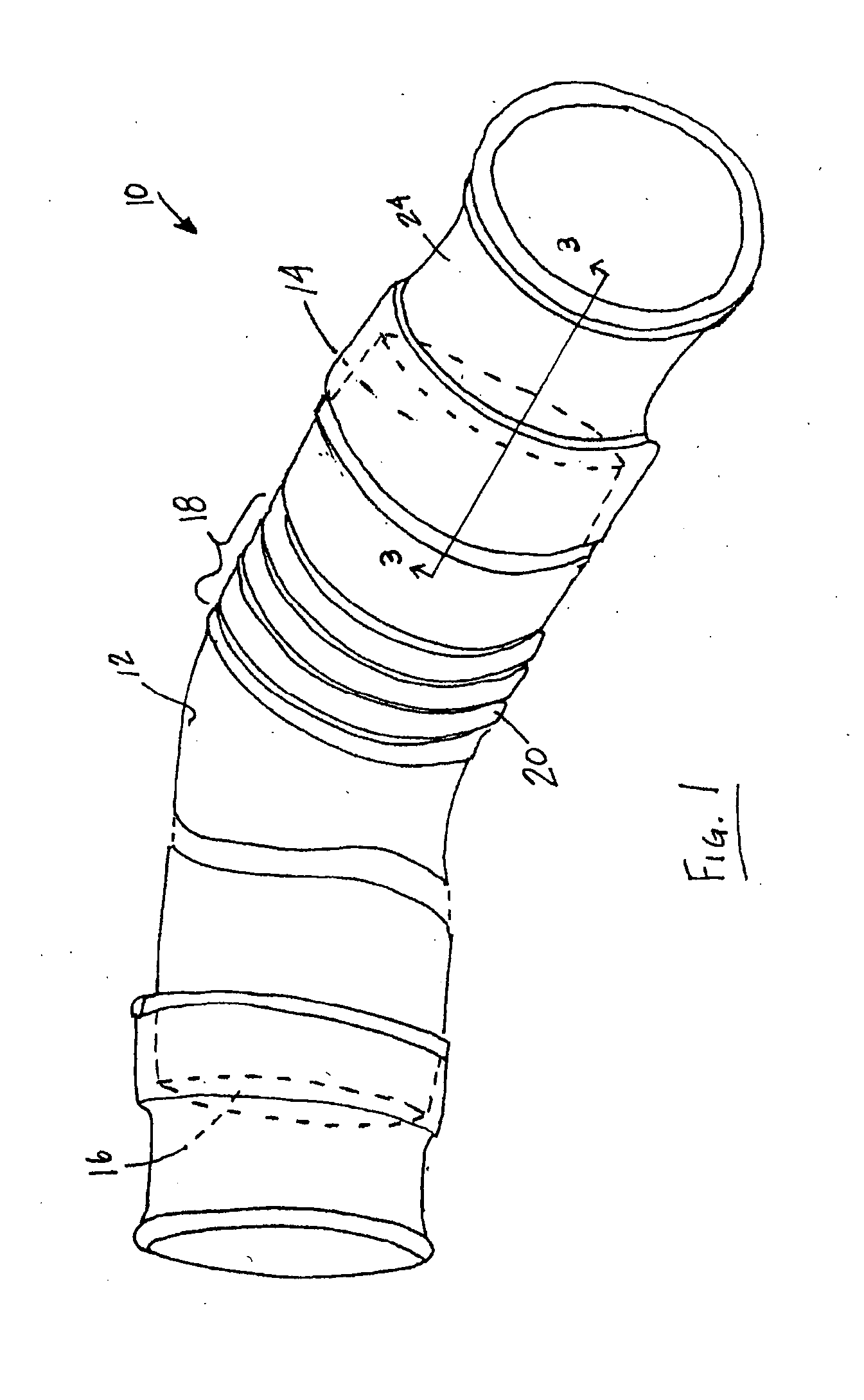

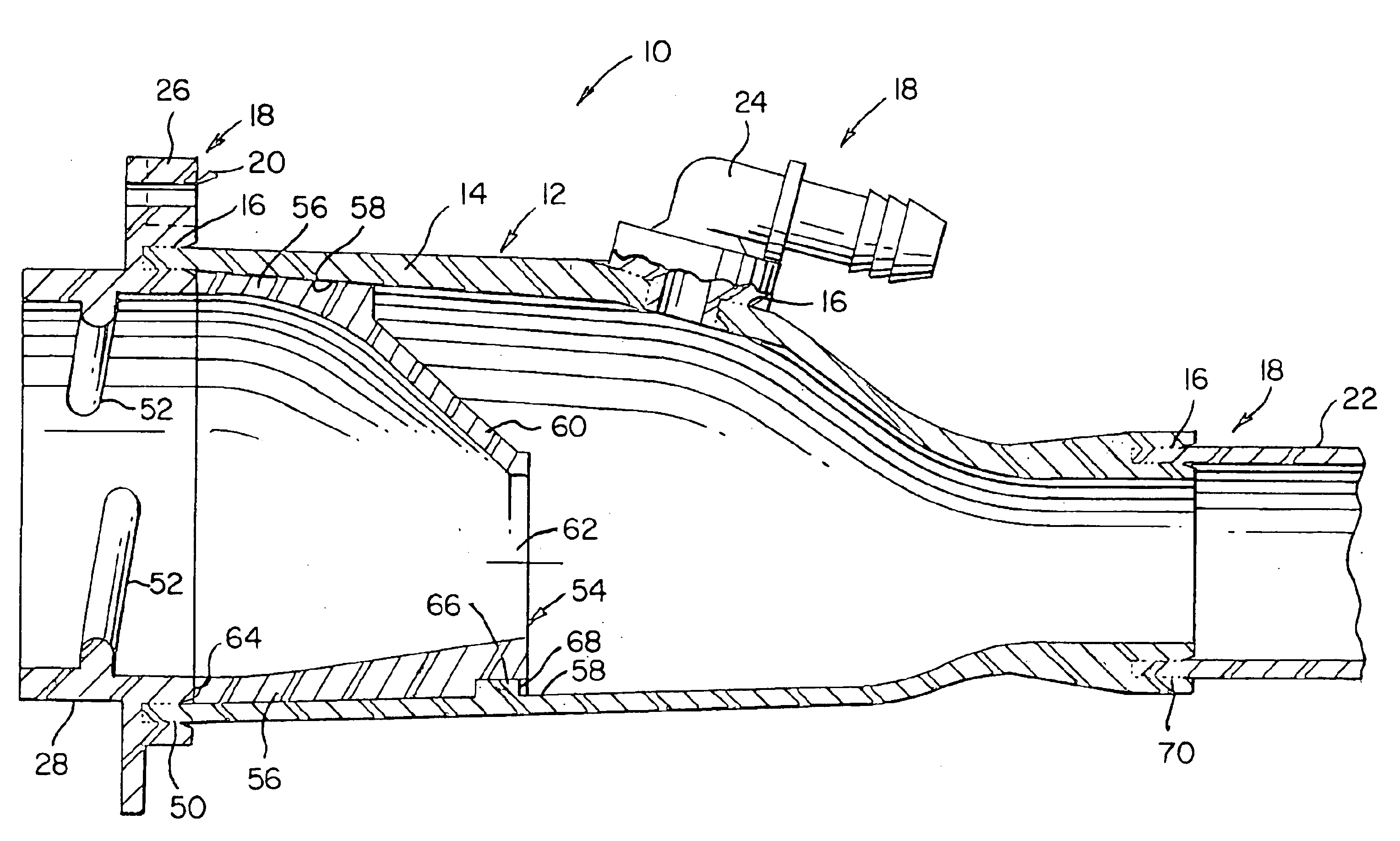

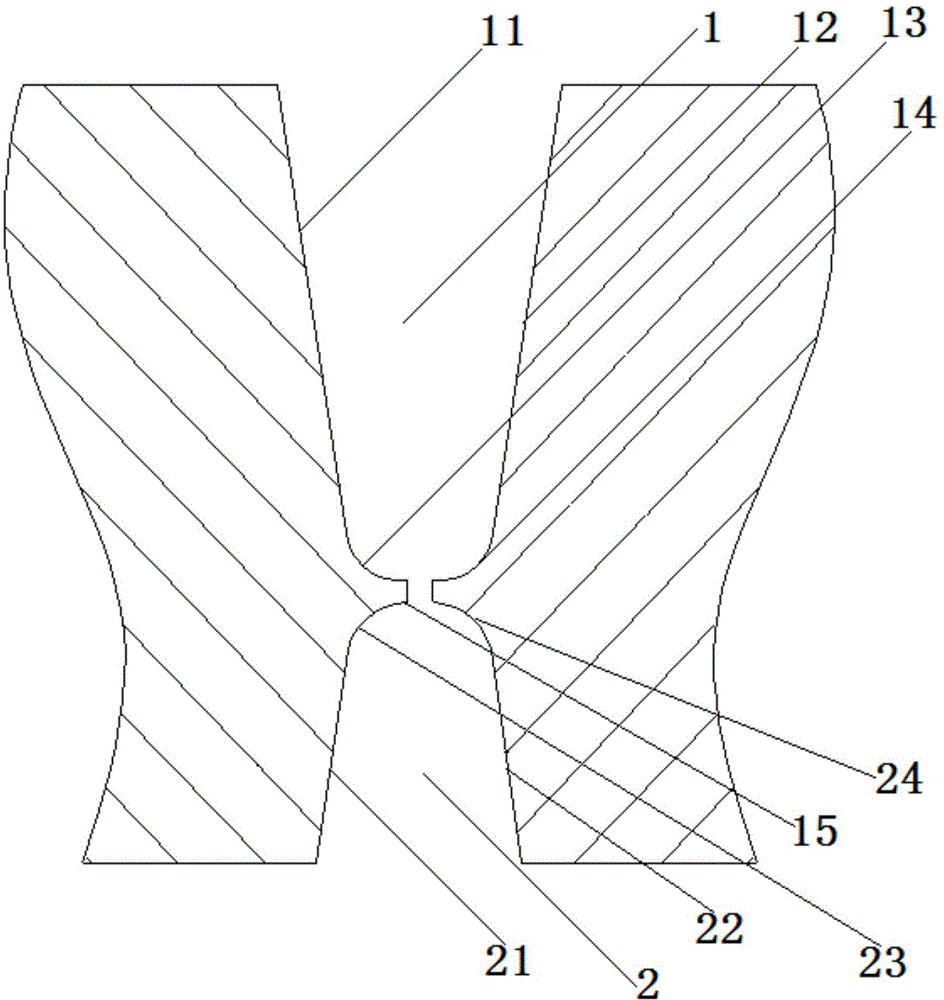

Two-shot or insert molded cuffs for welding onto clean air ducts

InactiveUS20060279084A1Simple interfaceWeld between the cuff member and the air duct body is improvedLighting and heating apparatusCombustion-air/fuel-air treatmentThermoplasticSpin welding

An air duct includes a rigid thermoplastic body having softer elastomeric cuff members welded to the ends thereof. The cuff members comprise an outer sealing component and a weldable insert bonded to at least a portion of the inner surface. The cuff members are adhered to the thermoplastic body at the weldable insert through a spin welding or other suitable welding process. The chemical compatibility between the insert and the thermoplastic body provides a robust weld at the interface.

Owner:ADVANCED ELASTOMER SYST LP

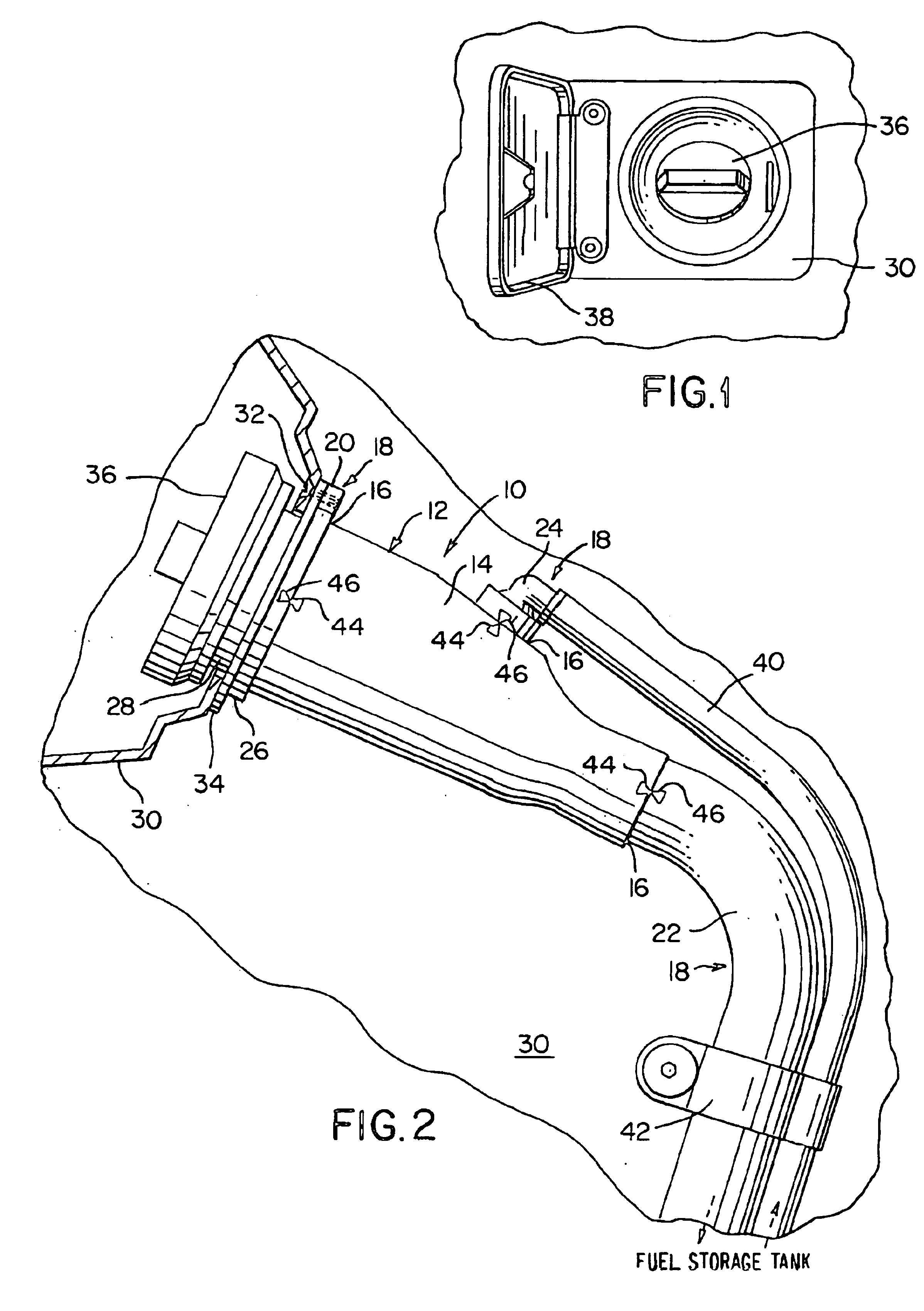

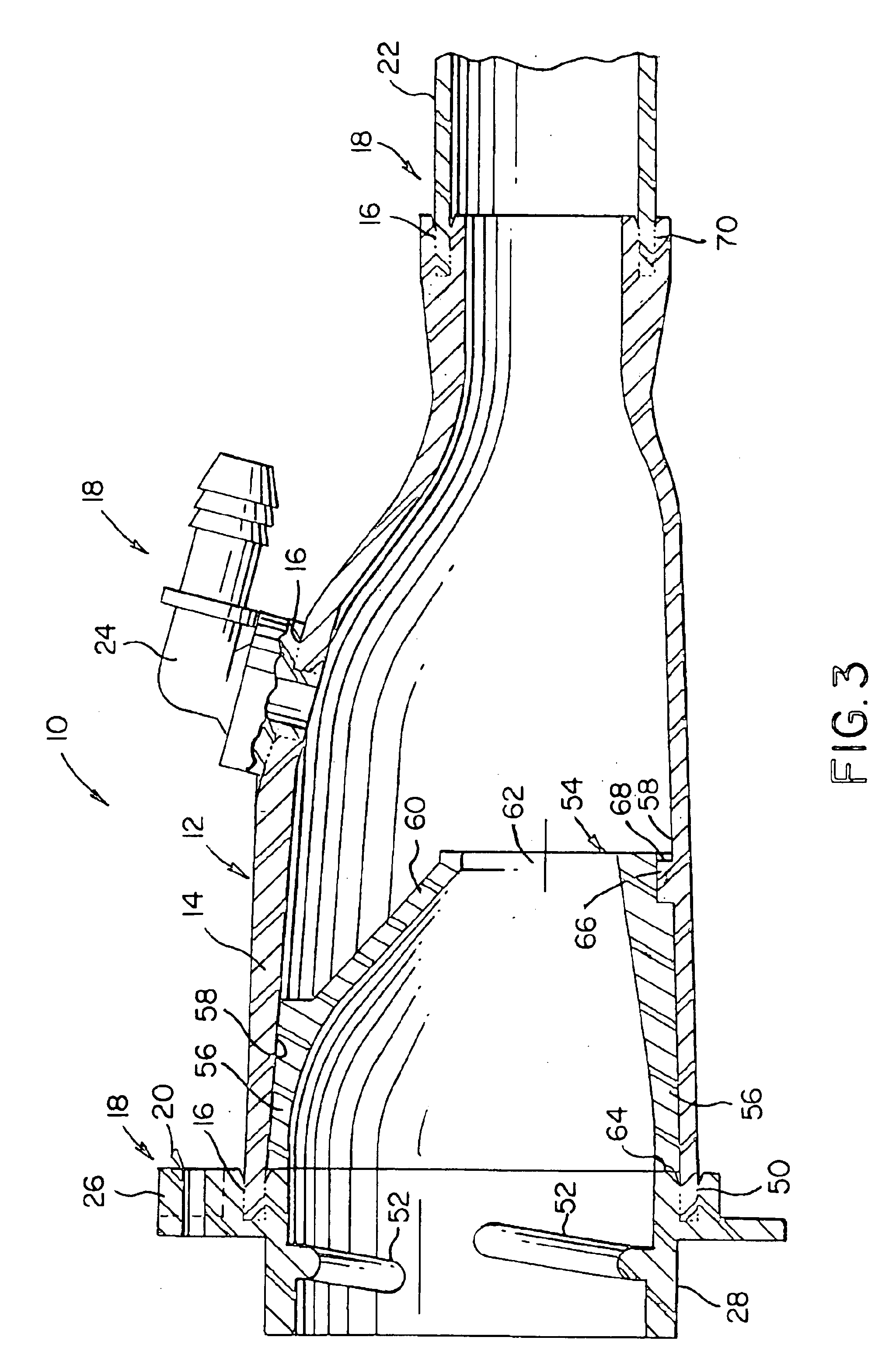

Fuel fill system

A fuel fill system includes an outer funnel and one or more components, each formed from a thermoplastic material. The components, which may include a flange, a tube, and a vapor recirculation fitting, are in fluid communication with the outer funnel via welded joints. The welded joints may be formed by at least one of: spin welding, hot plate welding, laser welding, vibration welding, and ultrasonic welding. The plastic to plastic weld provides an electrically conductive, substantially seamless, vapor permeation resistant joint between each of the components and the outer funnel.

Owner:FLUID ROUTING SOLUTIONS

Conveyor belt modules with embedded rollers retained in the modules and associated method

A plastic conveyor belt module with embedded rollers retained in the module and a method for making such a module. The module includes a module body forming a cavity, a roller in the cavity, and a retainer received in the cavity to hold the roller rotatably in place. A salient portion of the roller extends outward from the cavity through the retainer past an outer surface of the module. The retainer is attached to the module body by ultrasonic welding, epoxy- or solvent-bonding, spin welding, electromagnetic welding, staking, screwing, or locking.

Owner:LAITRAM LLC

Gas impermeable tube joint and method of forming same

A method of forming a gas impermeable joint in a fluid system includes: providing a tube having a metallic barrier layer disposed between an inner plastic layer and an outer plastic layer; forcing at least one of the inner plastic layer and the outer plastic layer into contact with a plastic surface of a component; and welding the at least one of the inner plastic layer and the outer plastic layer with the plastic surface to form the gas impermeable joint. The welding may include: spin welding, hot plate welding, vibration welding, and ultrasonic welding. The metallic barrier layer extends substantially to the component, thus improving the gas impermeability of the joint between the tube and the component.

Owner:FLUID ROUTING SOLUTIONS

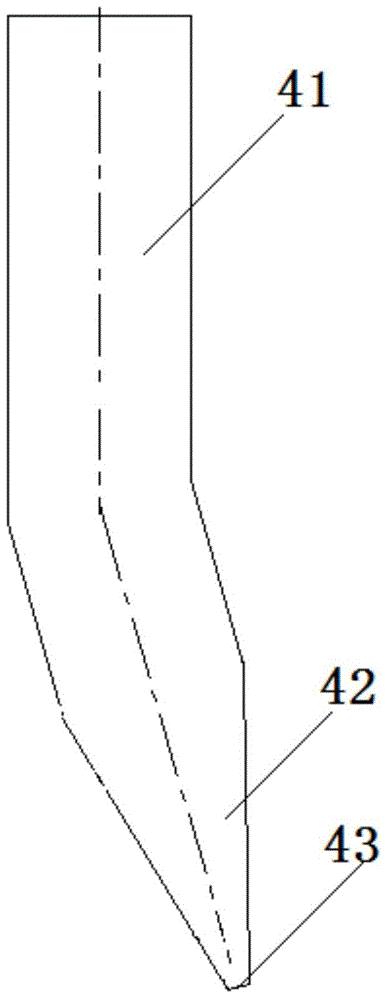

Full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding

ActiveCN104084678AImprove welding efficiencyReduce welding distortionArc welding apparatusWorkpiece edge portionsSpin weldingArchitectural engineering

The invention discloses a full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding. According to the method, nickel base alloy serves as an isolating layer to carry out machining on a connecting pipe and a safety end so that a welding groove can be formed by the connecting pipe and the safety end during assembling, and the welding groove is welded. A plurality of weld beads are welded during welding, the bottom end of a part to be welded is arced during welding, spin welding is carried out along one side of the part to be welded to the top end of the part to be welded, arcing is stopped, the bottom end of the part to be welded is arced again, spin welding is carried out along the other side of the part to be welded to the top end of the part to be welded, and arcing is stopped. When the welding groove is a double-faced U-shaped narrow gap groove, an outer groove is welded but not completely welded, back chipping and complete welding are carried out on an inner groove, and then complete welding is carried out on the outer groove. When the welding groove is a single-faced narrow gap groove, the groove is completely welded, a cushion plate is removed, and back chipping is carried out.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

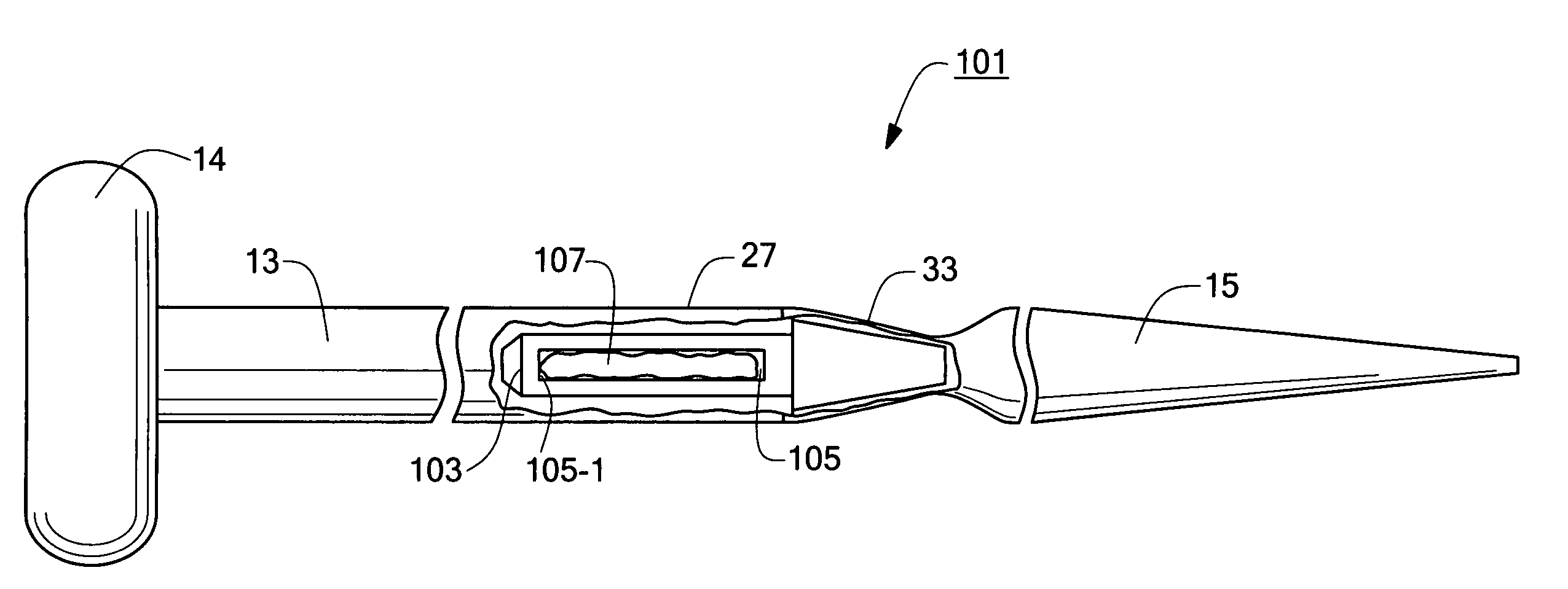

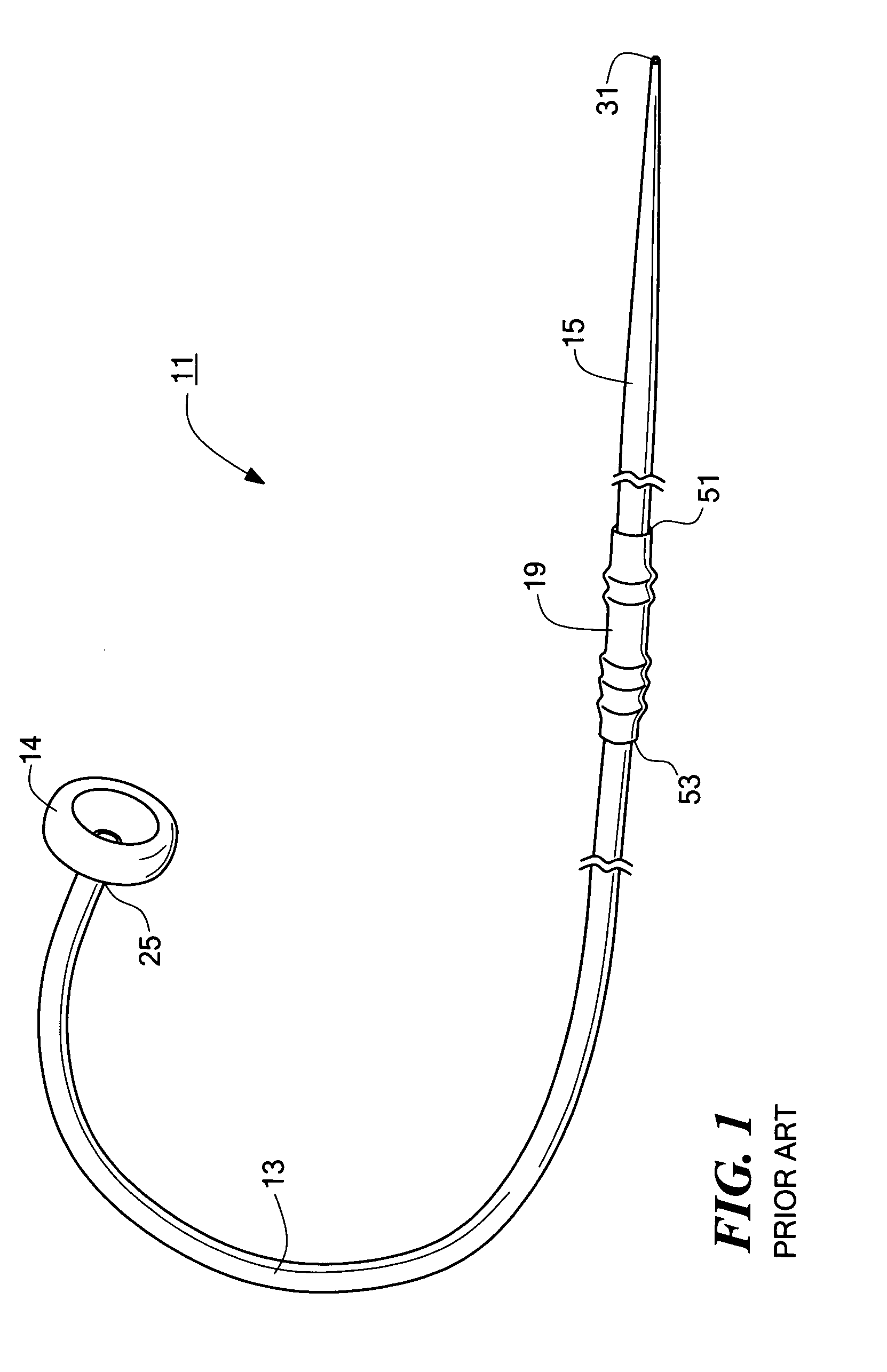

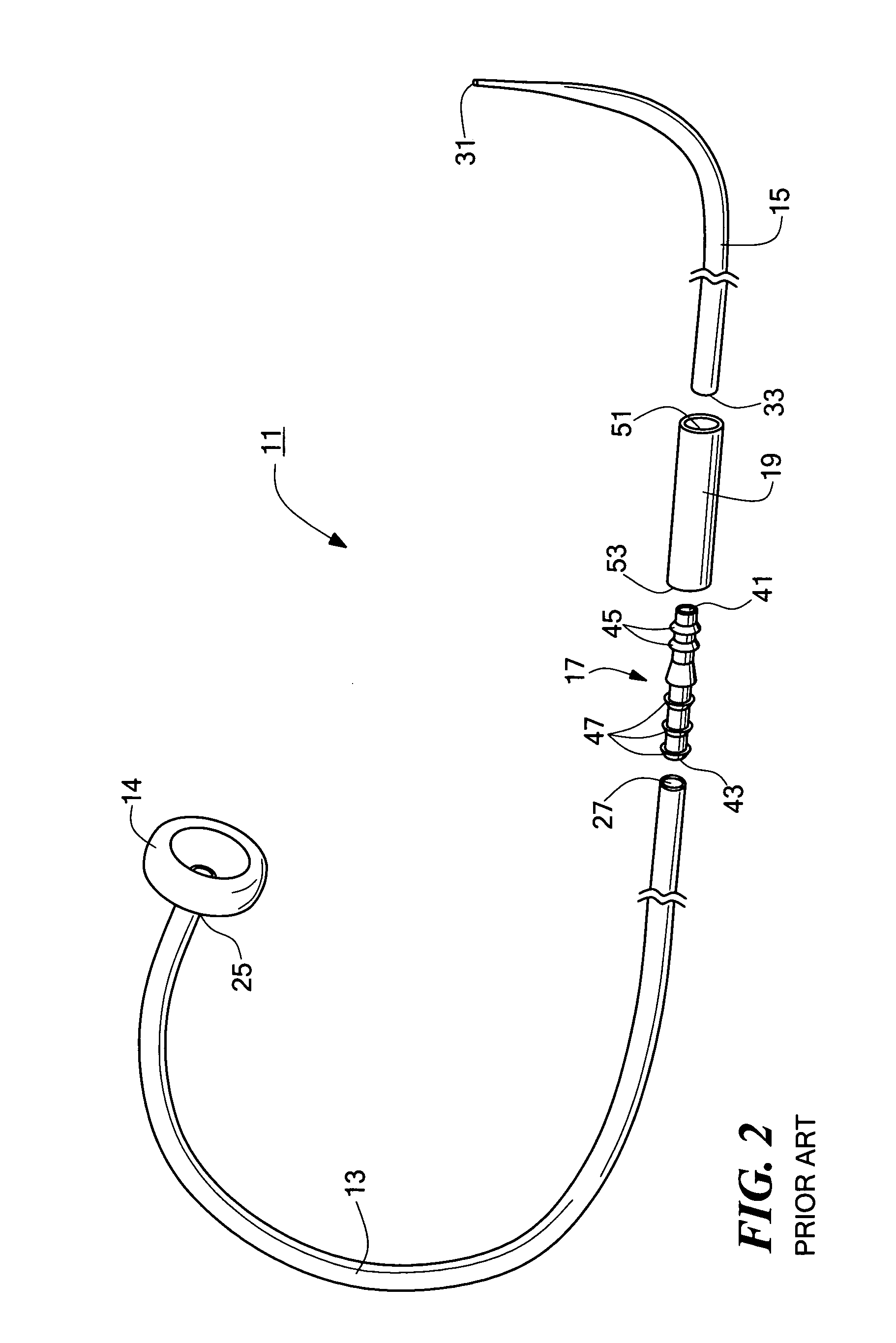

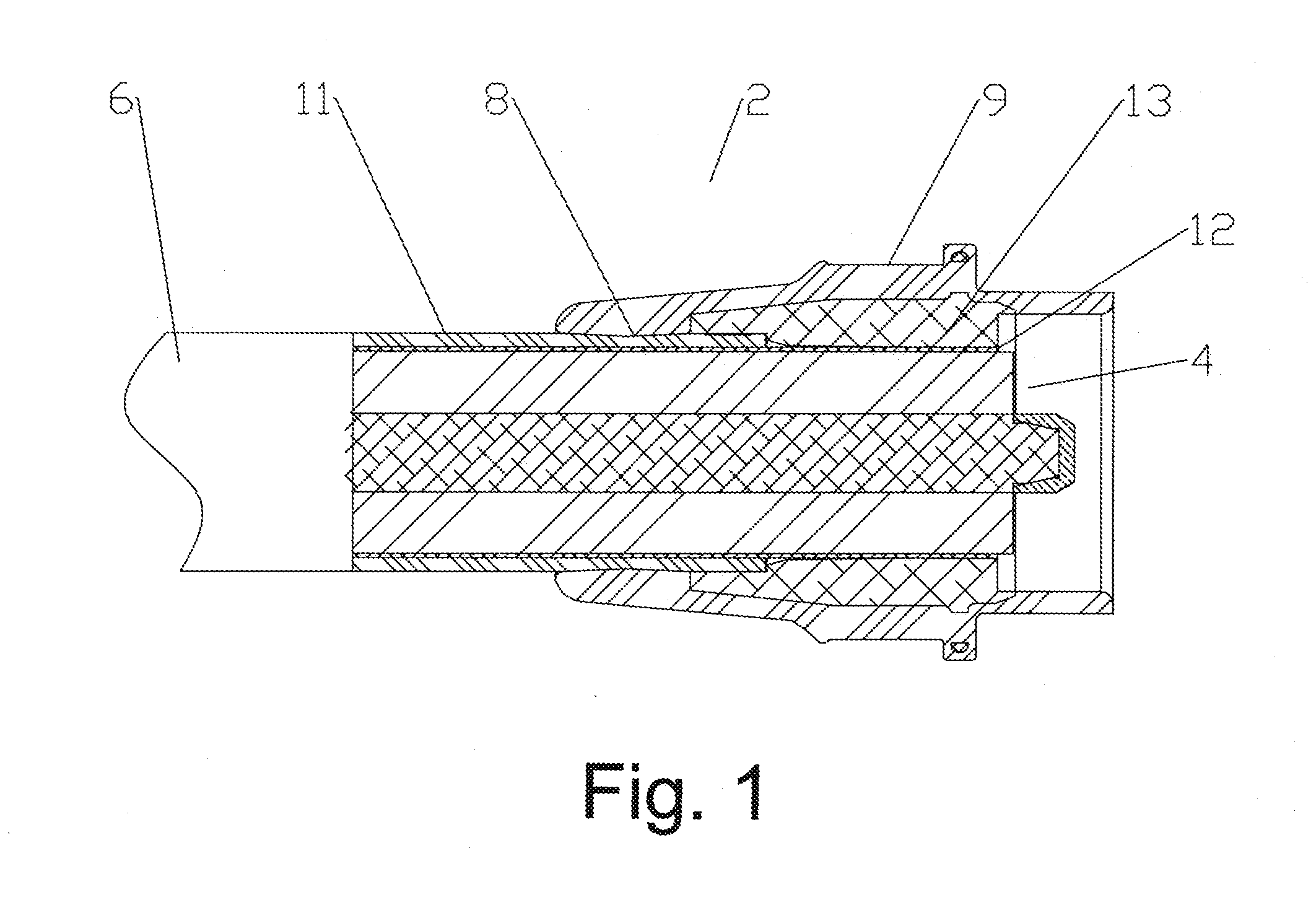

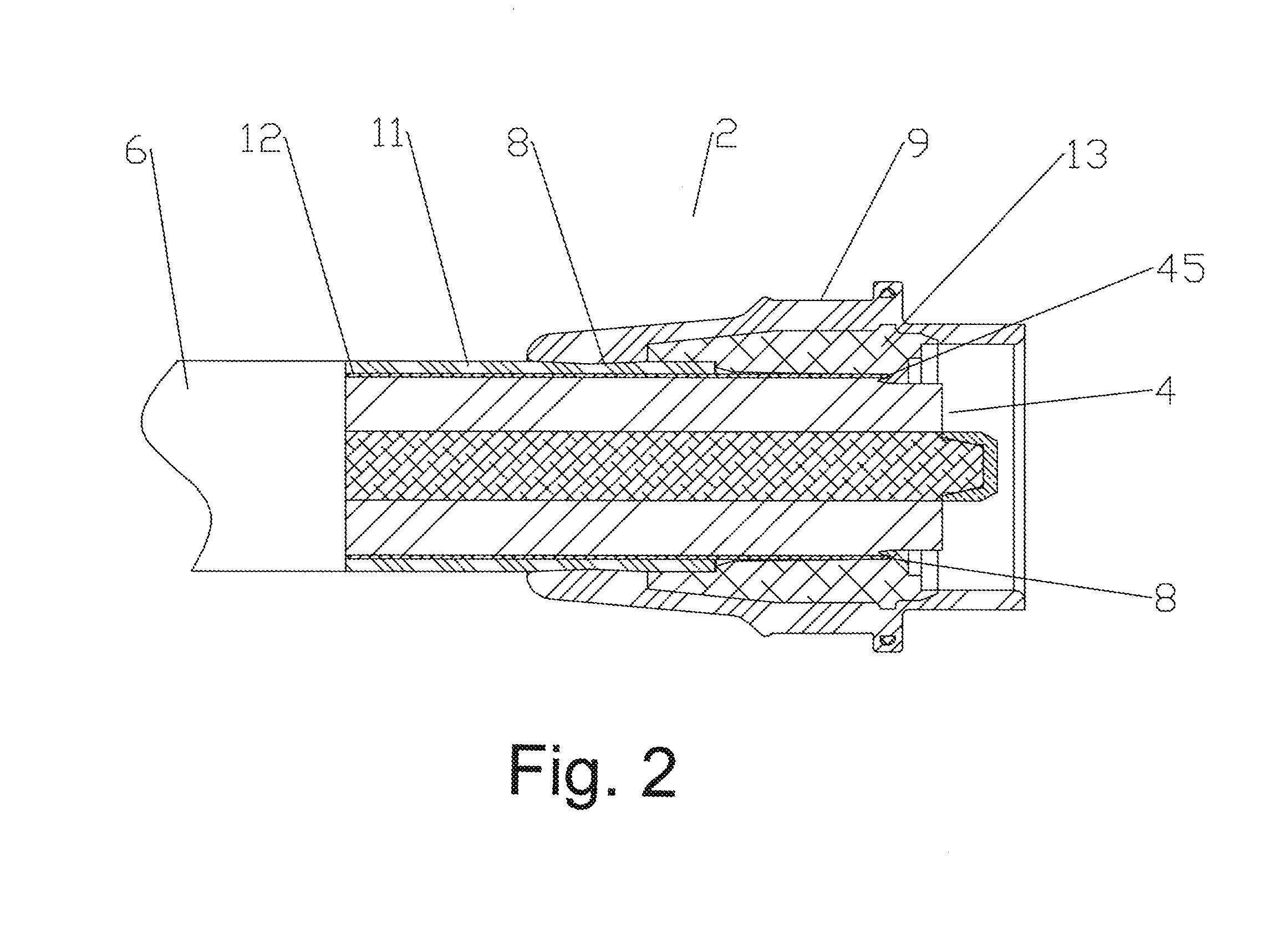

Connector for use with a medical catheter and medical catheter assembly

Connector for use with a medical catheter assembly and medical catheter assembly including the connector. In one embodiment, the connector comprises a rear portion, an intermediate portion, and a front portion. The rear portion is frusto-conical in shape and tapers rearwardly in cross-sectional diameter from its front end. A centrally-disposed, smaller-diameter, longitudinal bore is provided in the rear portion, the bore being appropriately dimensioned to receive a guidewire therethrough. The intermediate portion is generally cylindrical and is shaped to include a centrally-disposed, larger-diameter longitudinal bore and a pair of longitudinally-extending slots providing access to the larger-diameter bore. The front portion is frusto-conical in shape and tapers forwardly in cross-sectional diameter from its rear end. In use, a silicone tube is inserted into the larger-diameter bore of the intermediate portion, and the rear and intermediate portions of the connector are inserted into a gastrostomy feeding tube. A silicone glue is then used to bond the silicone tube to the gastrostomy feeding tube. The front end of the connector is inserted into a dilator and is secured thereto by spin-welding.

Owner:BOSTON SCI SCIMED INC

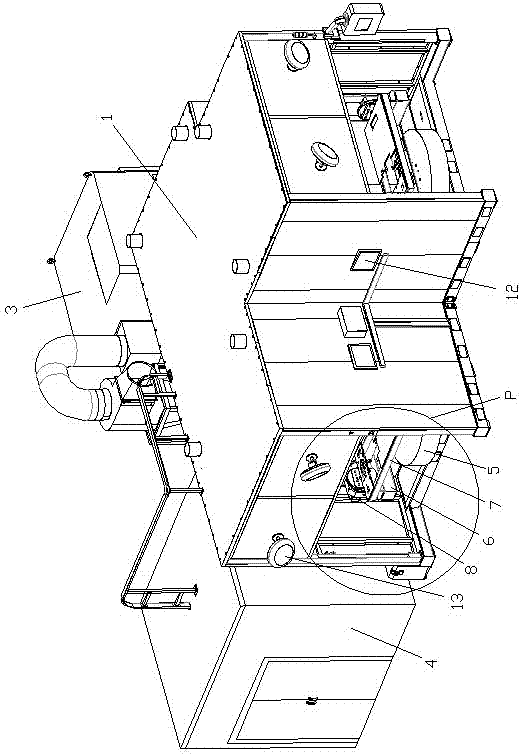

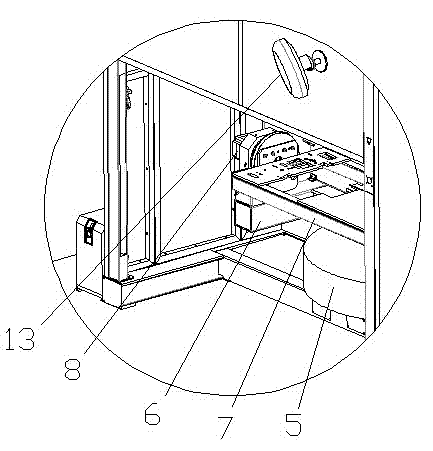

Dashboard beam frame laser welding system

ActiveCN102825387ARealize simultaneous weldingSimple welding processLaser beam welding apparatusDashboardAutomatic control

The invention discloses a dashboard beam frame laser welding system comprising a welding room, a laser welding mechanical arm, a spin welding post, an exhaust dust removing system and an automatic control system, wherein the spin welding post comprises a post platform, a first servo motor, a supporting beam and welding fixture mounting platforms; the exhaust tube inlet of the exhaust dust removing system is arranged in the welding room; and the automatic control system is used for controlling the laser welding mechanical arm, the first servo motor and a second servo motor. According to the dashboard beam frame laser welding system, the independent fixtures of the dashboard beam frame can be intensely arranged on the two welding fixture mounting platforms, and a plurality of parts can be intensely welded on the same post in the same process, so that the welding process can be optimized greatly and the welding efficiency is improved; and the laser welding is adopted to replace the traditional arc welding, so that the degree of automation is higher, the work efficiency is higher and the welding quality is better.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

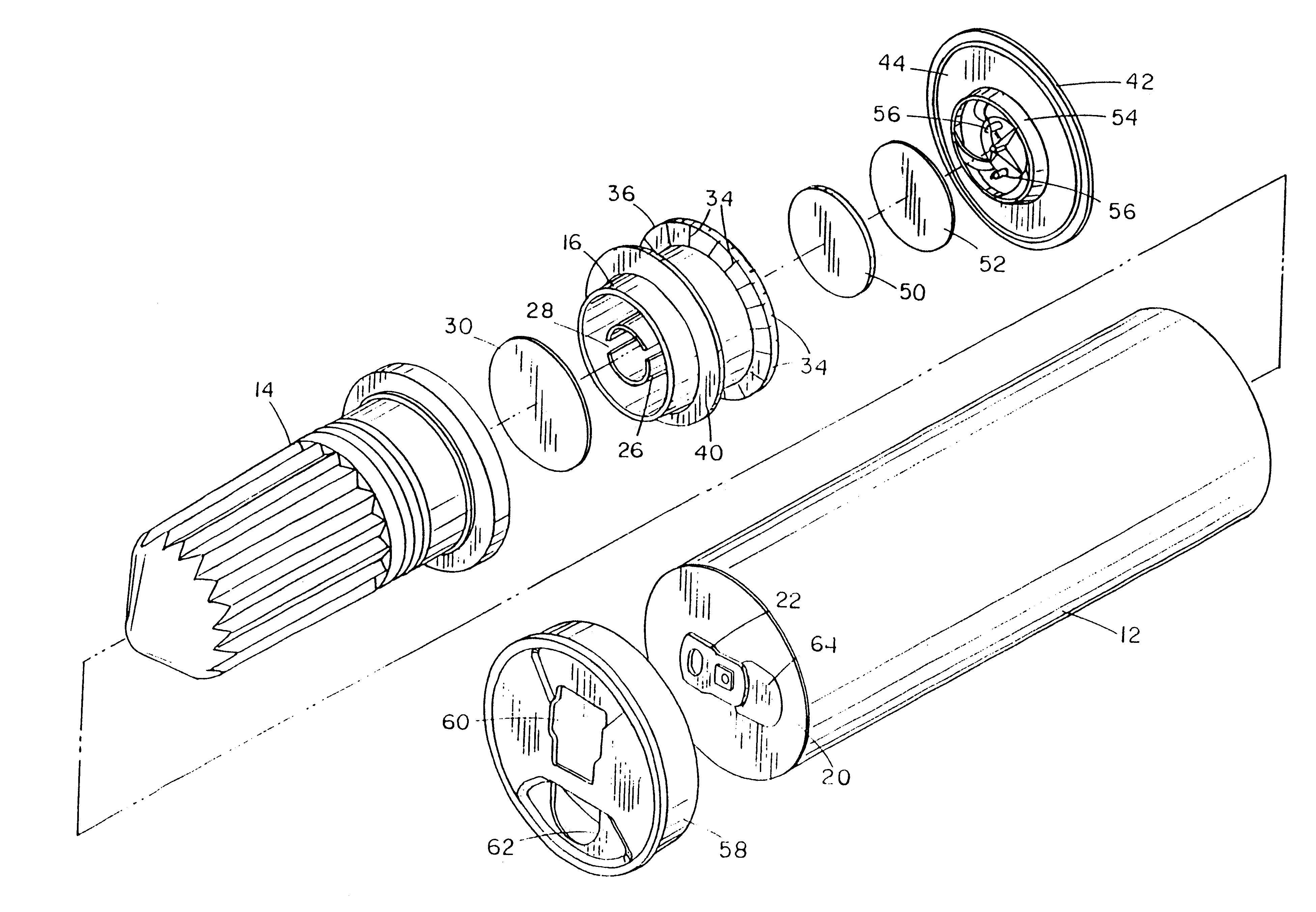

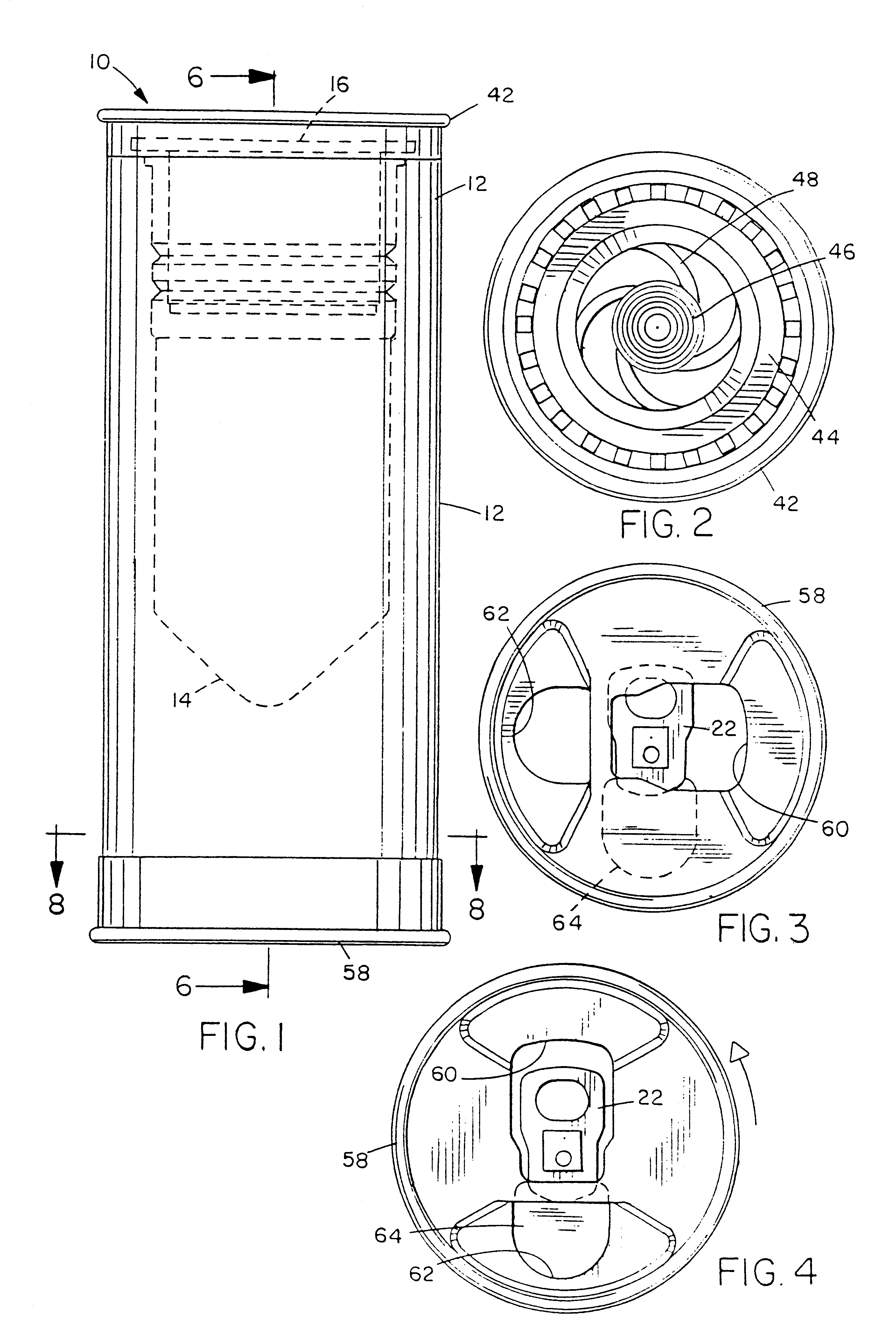

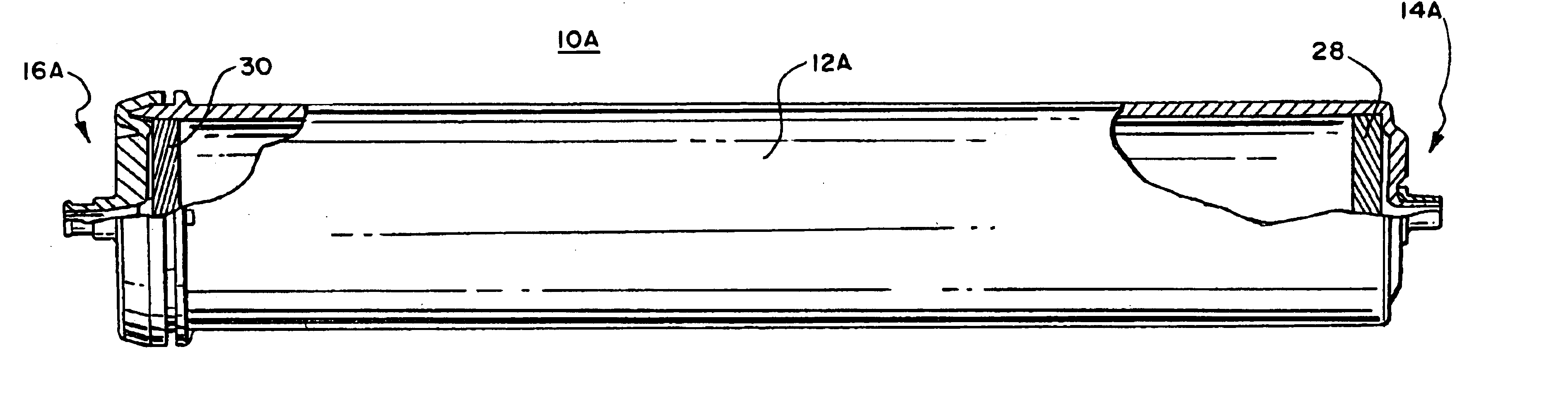

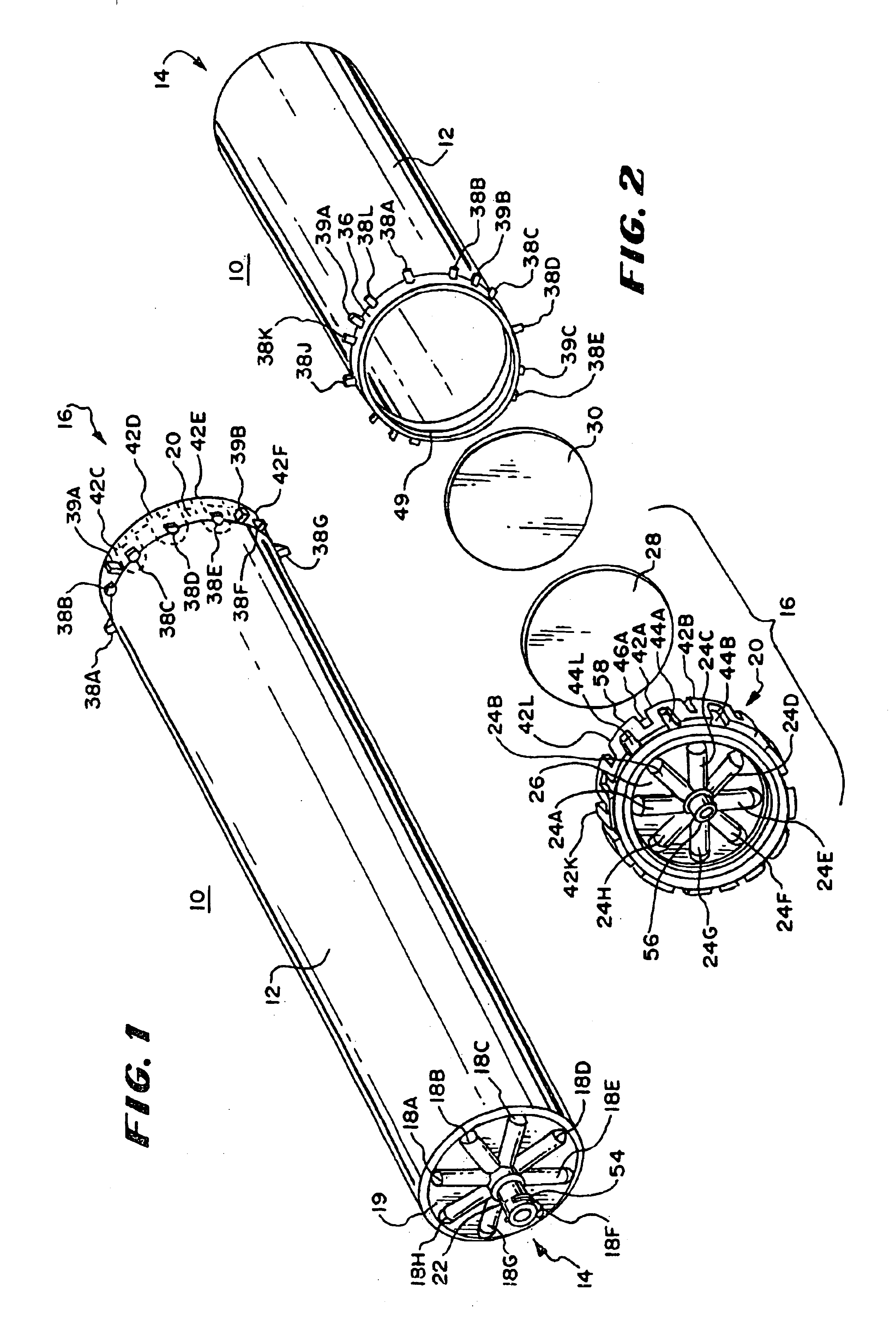

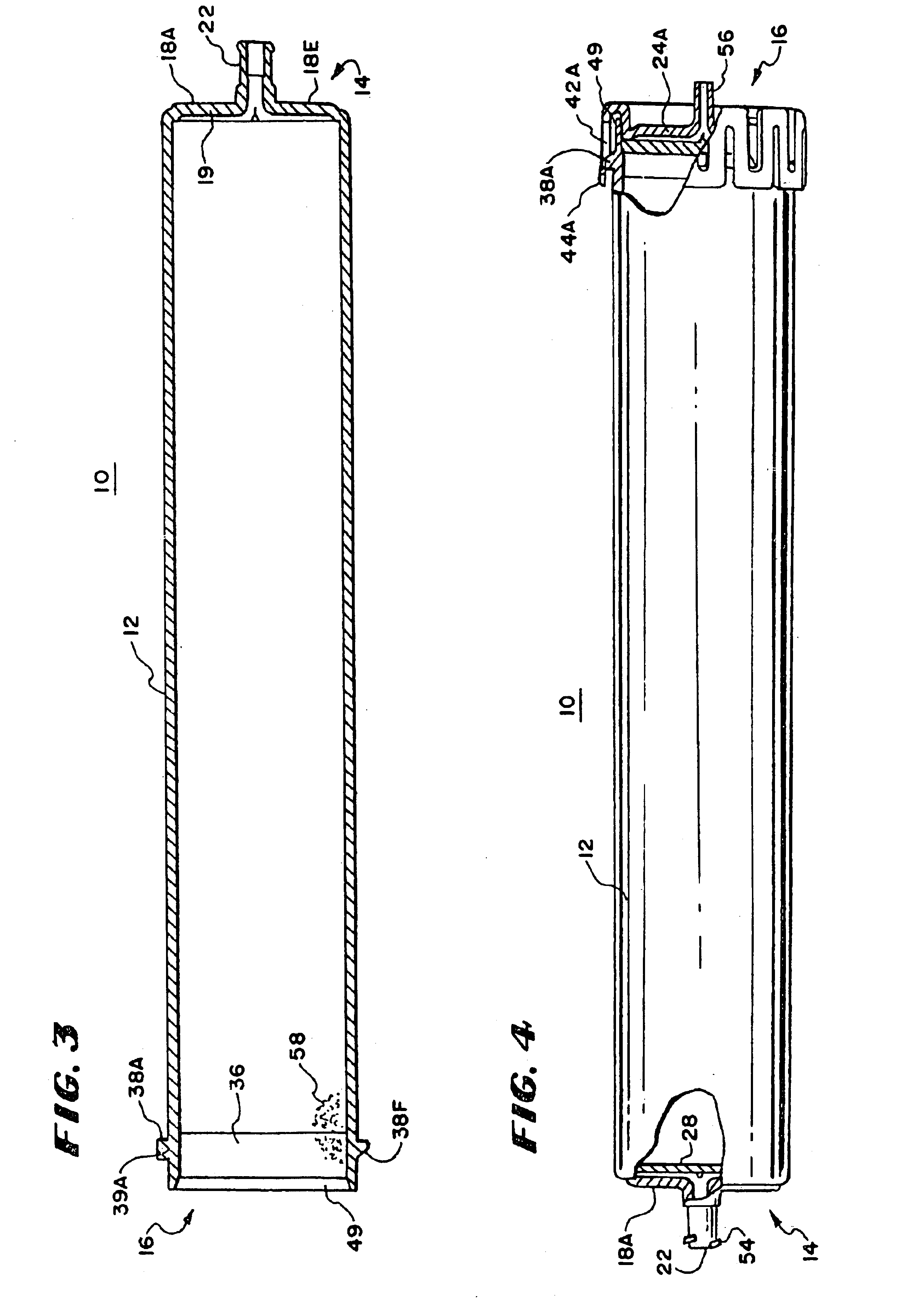

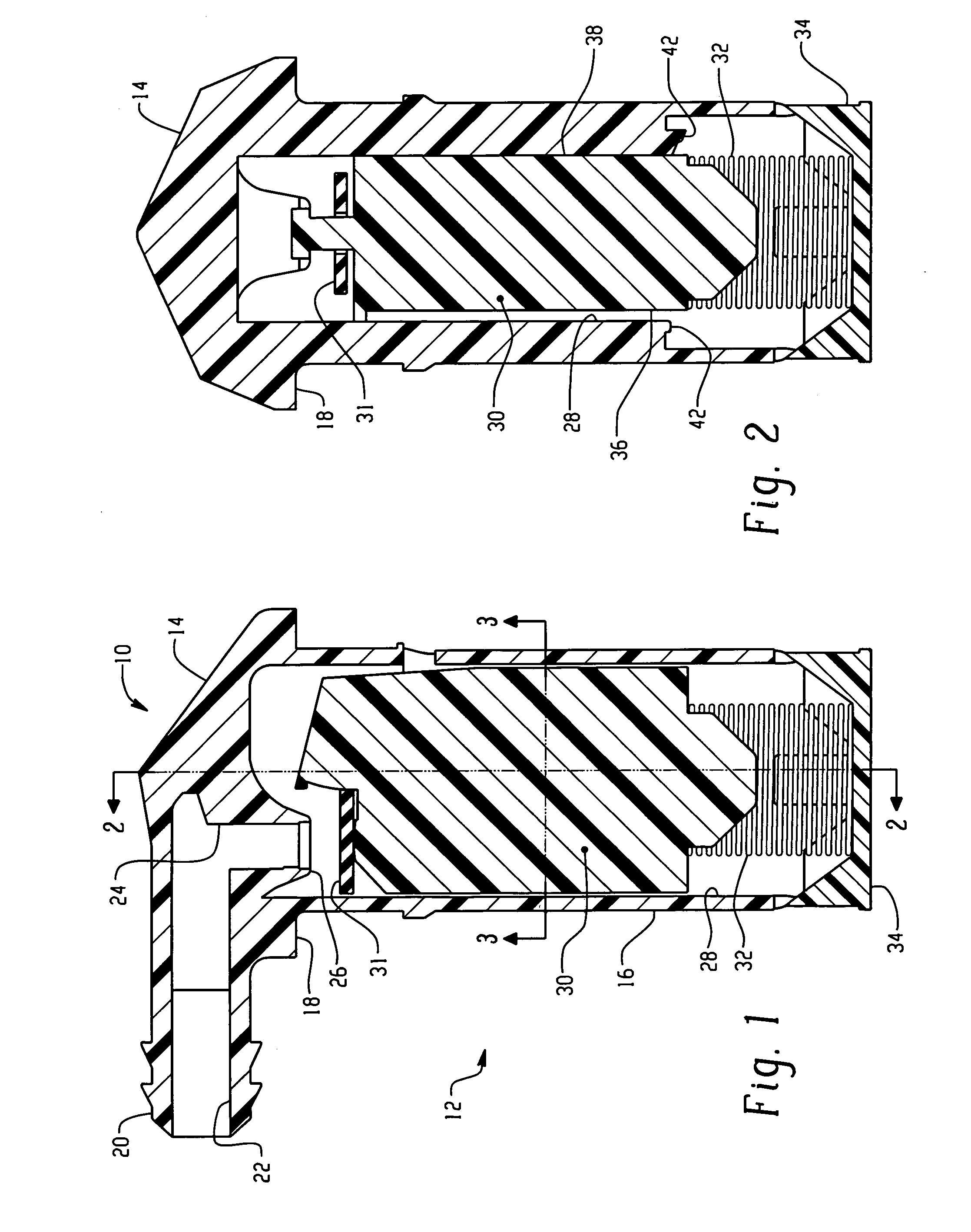

Disposable chromatographic columns

InactiveUS7008541B2High pressureInexpensive materialsIon-exchange process apparatusComponent separationSpin weldingFilling materials

To make an inexpensive chromatographic column and perform chromatography with it, column walls and a column end with a port are molded integrally from plastic. A closure is integrally molded with a port as well. One type of closure includes part of a snap-on fastener integrally molded to it to cooperate with corresponding parts molded integrally with the column walls and another type of closure is welded to the tubular walls. In the preferred embodiment the welding is spin welding. The end and closure have channels molded into them radiating from a port and opening toward packing material such as silica beads or porous polymeric plugs. Filters and secondary seals may be located at the ends to prevent leakage of packing material.

Owner:TELEDYNE INSTR INC

Integral barbed fitting

InactiveUS20050127664A1Reduce componentsReduce labor costsHose connectionsDomestic articlesSpin weldingCoupling

Disclosed is a coupling for a direct connection of supply tubing to a faucet assembly. The direct connection includes a barbed fitting that is integrally formed into the valve body to produce a one-piece unit. The integration of the fitting to the valve body is accomplished through either spin welding, sonic welding or hot-plate welding.

Owner:PHOENIX PRODS

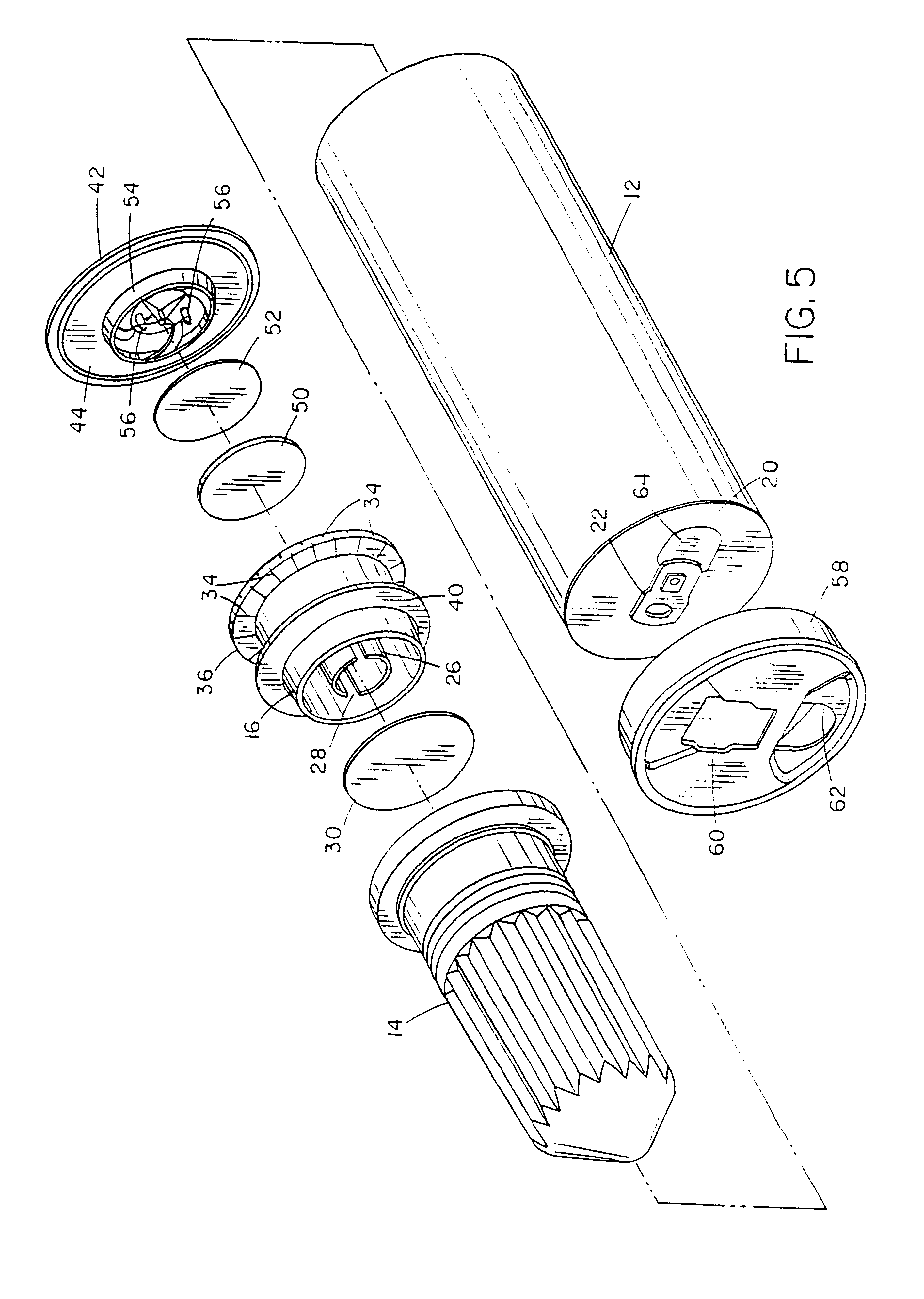

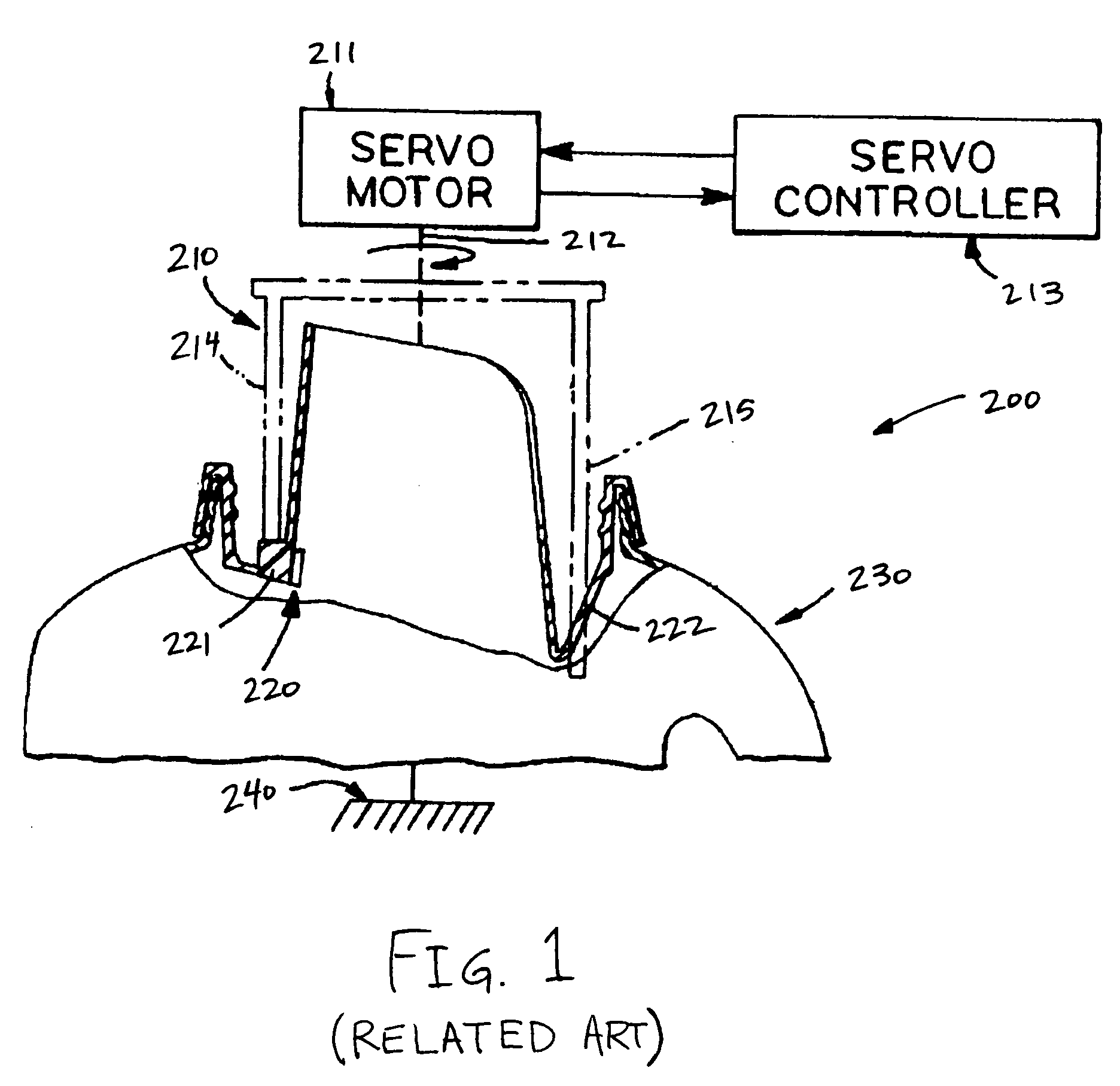

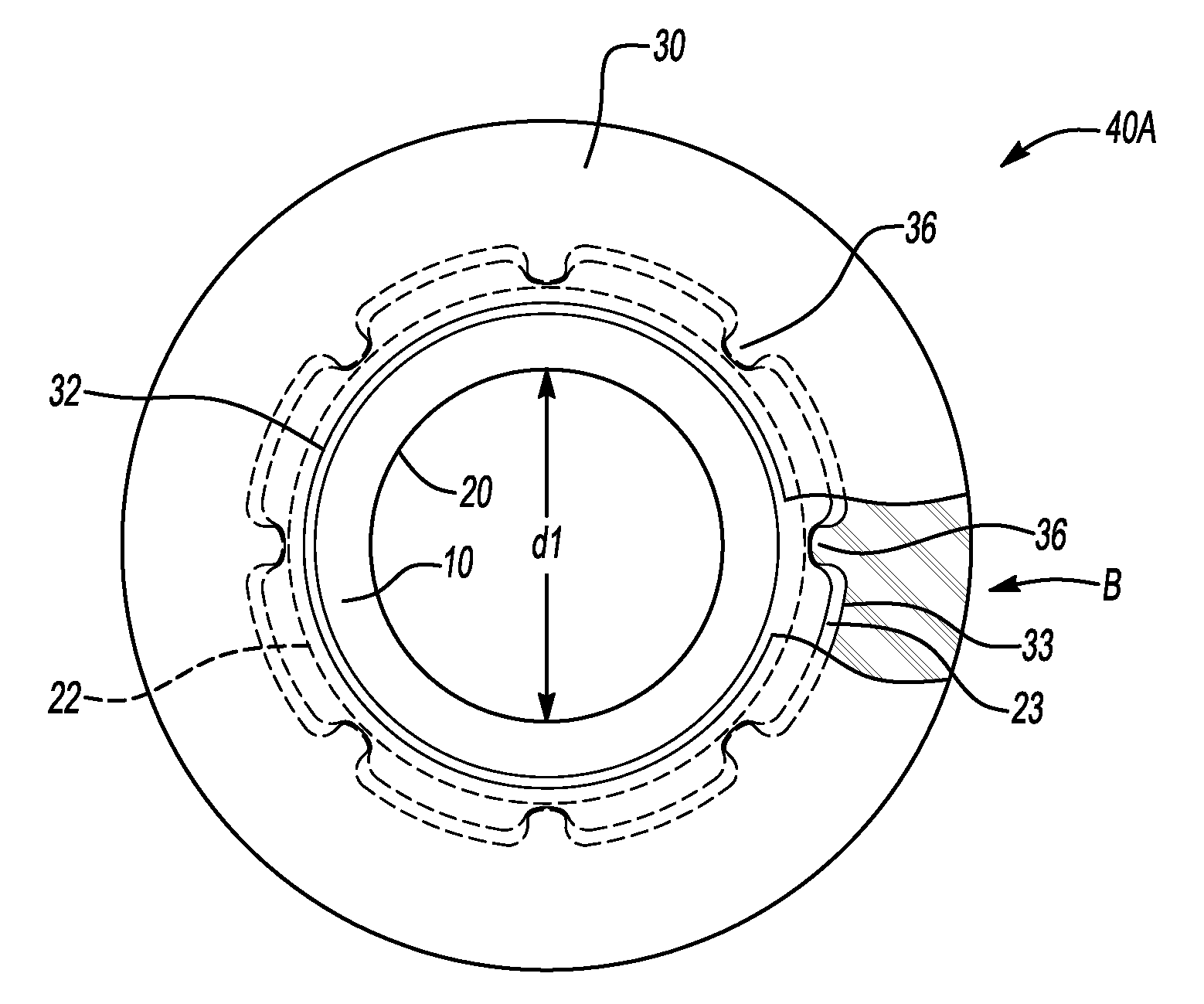

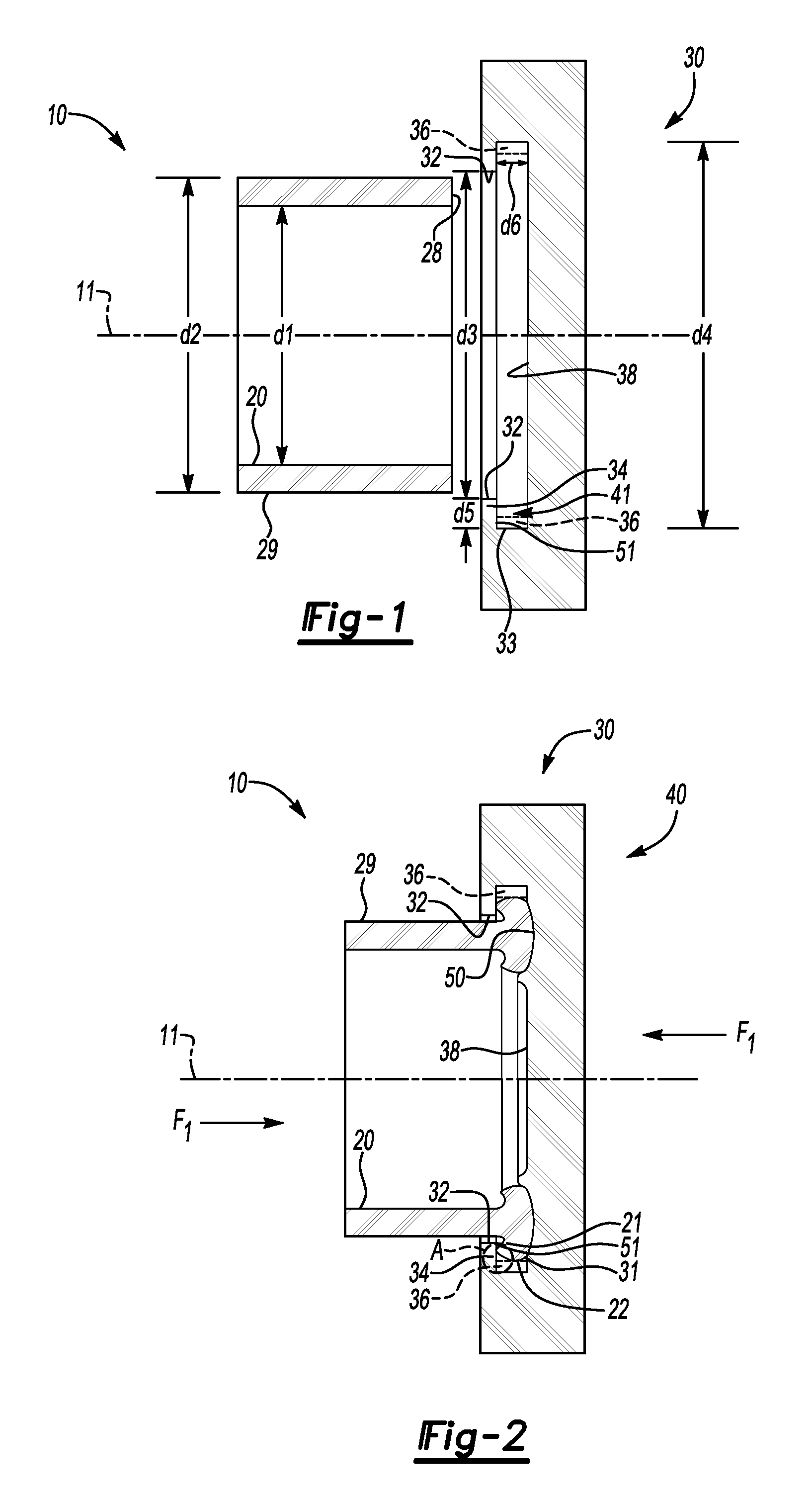

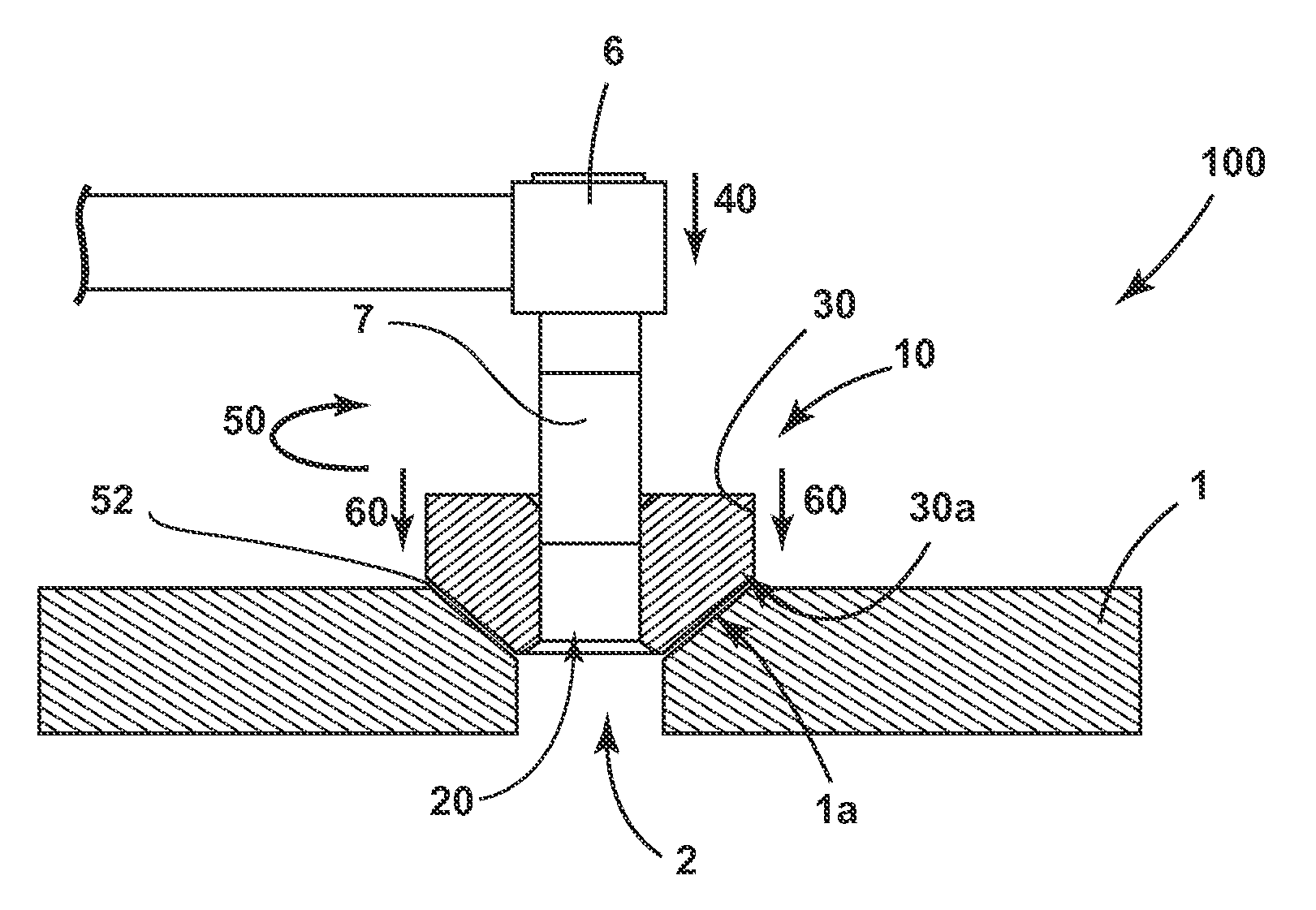

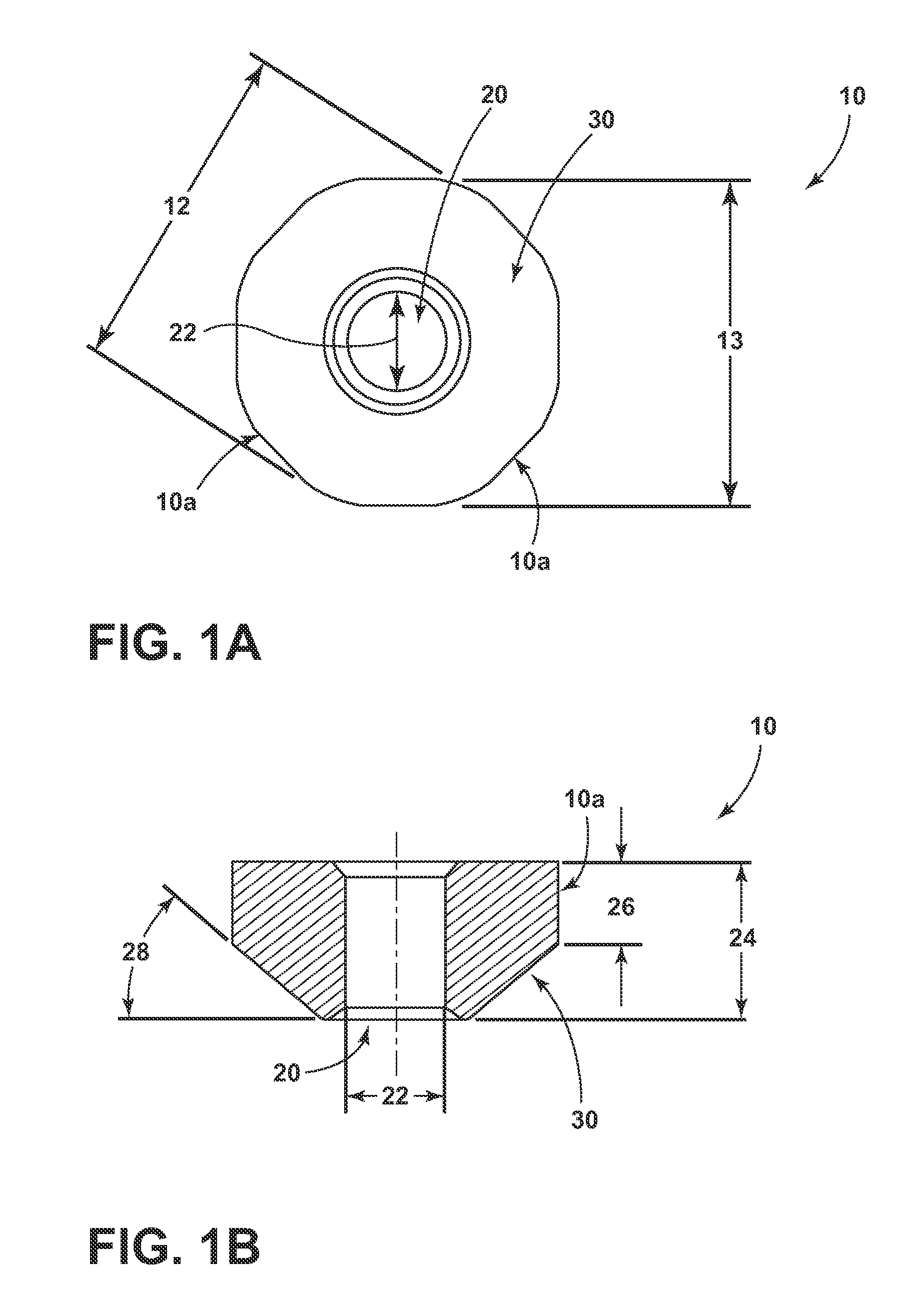

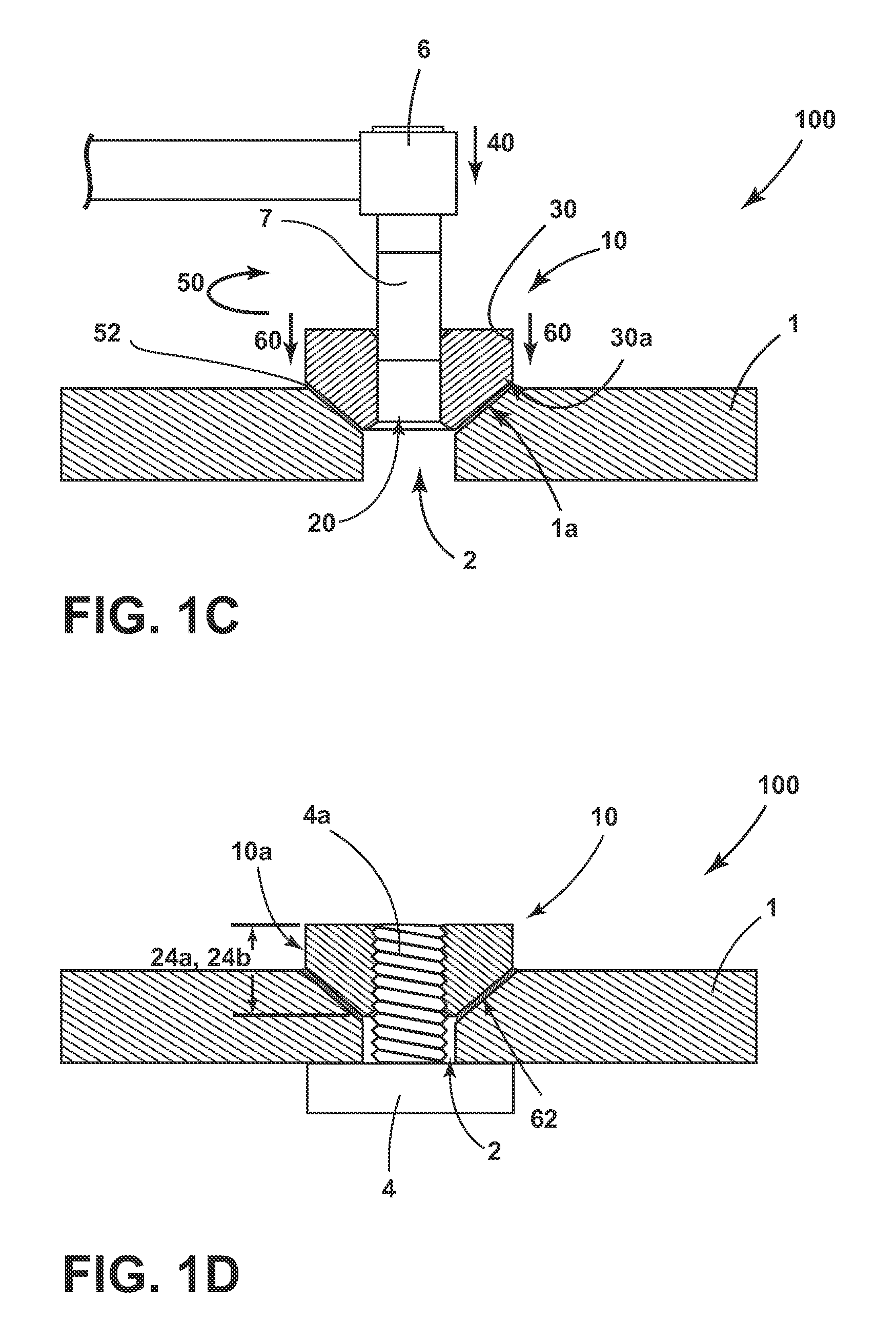

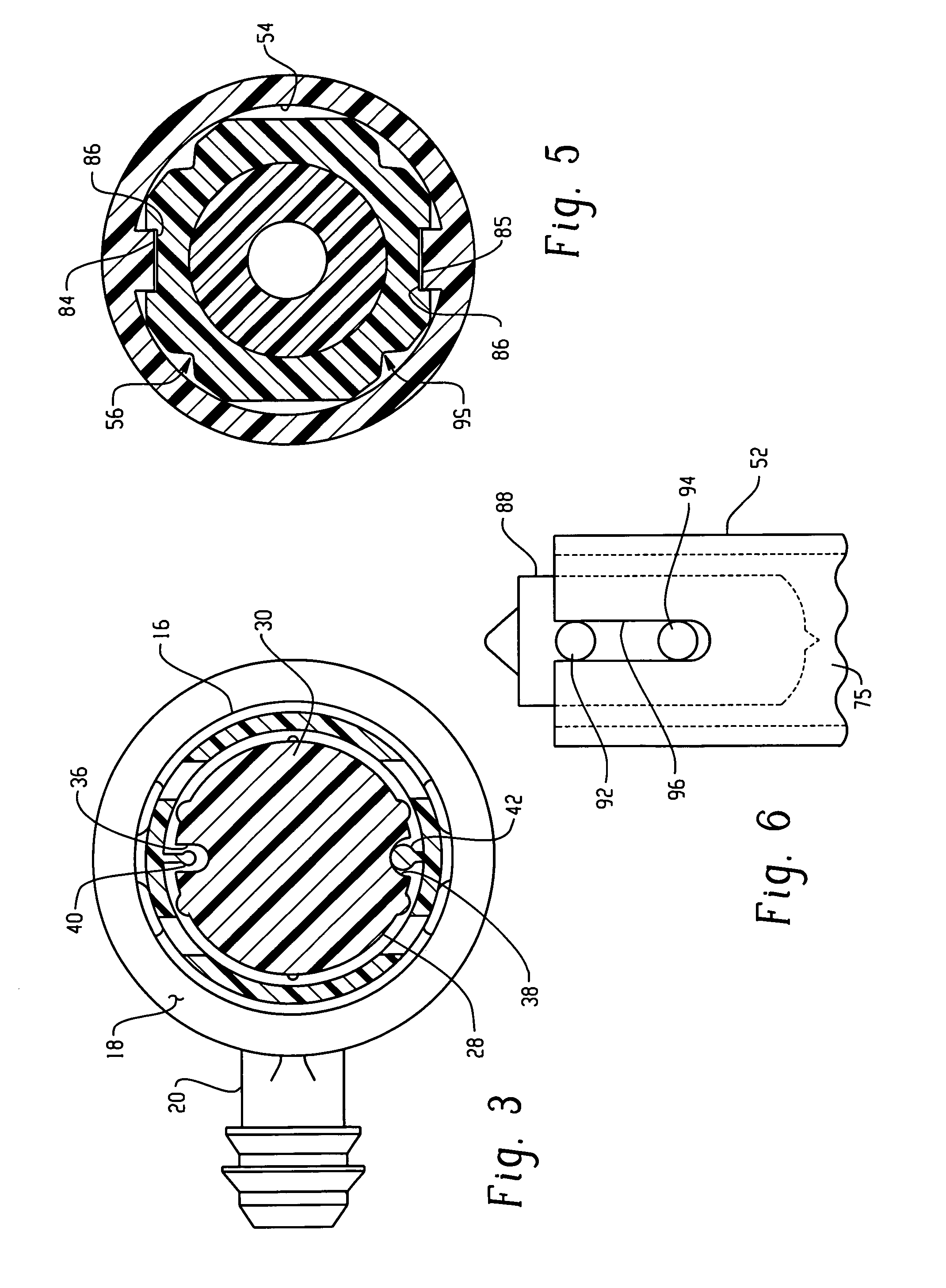

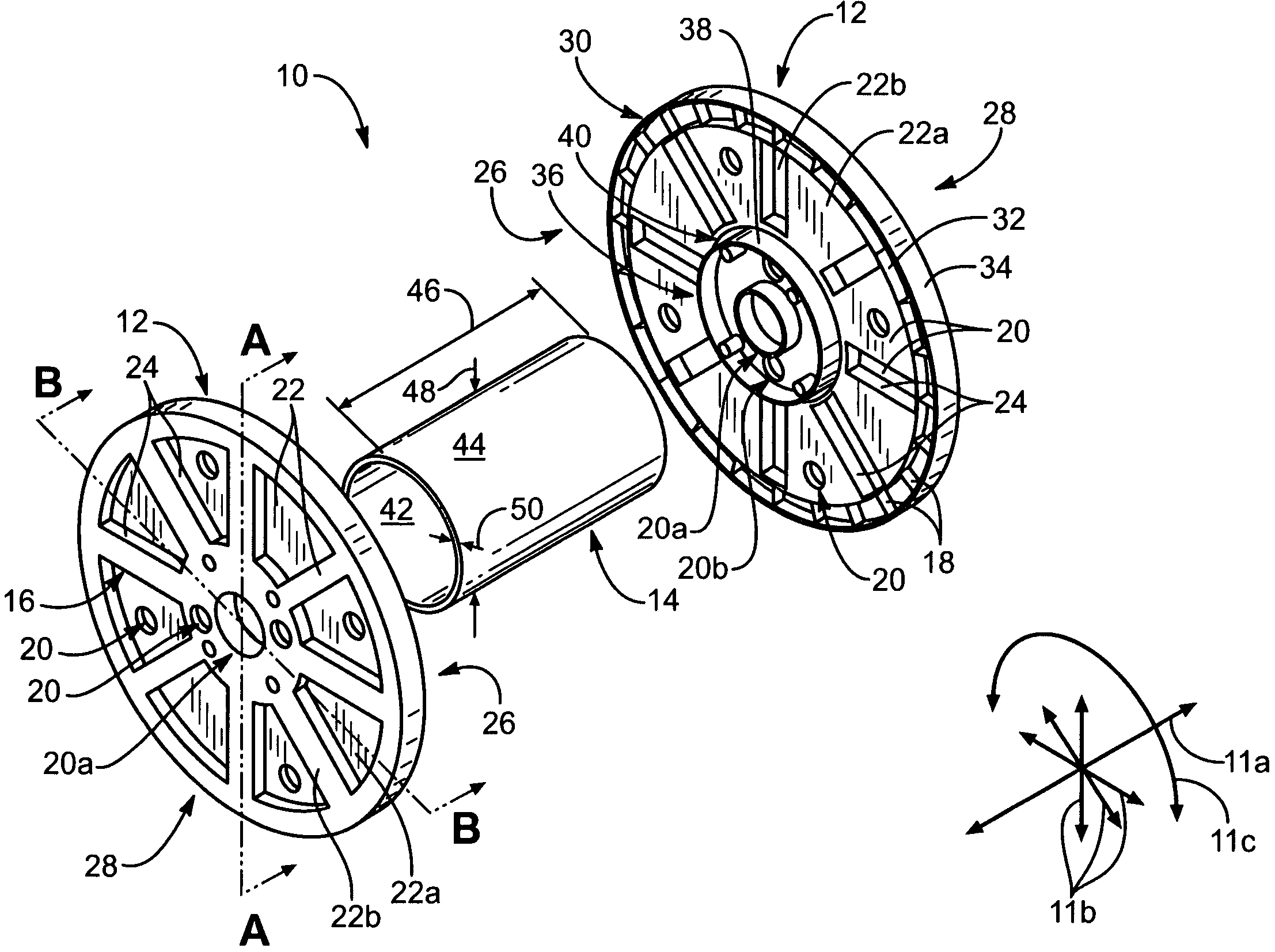

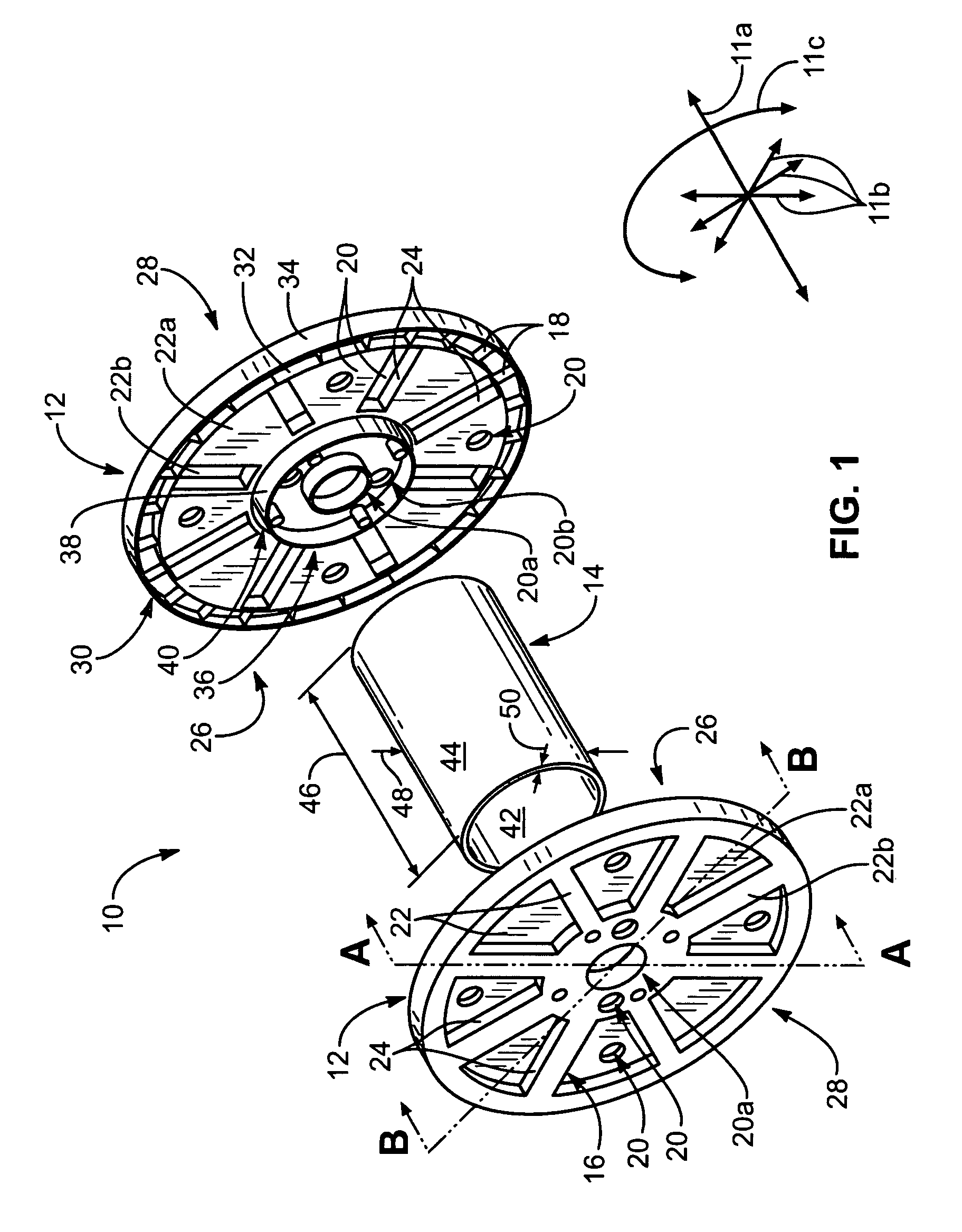

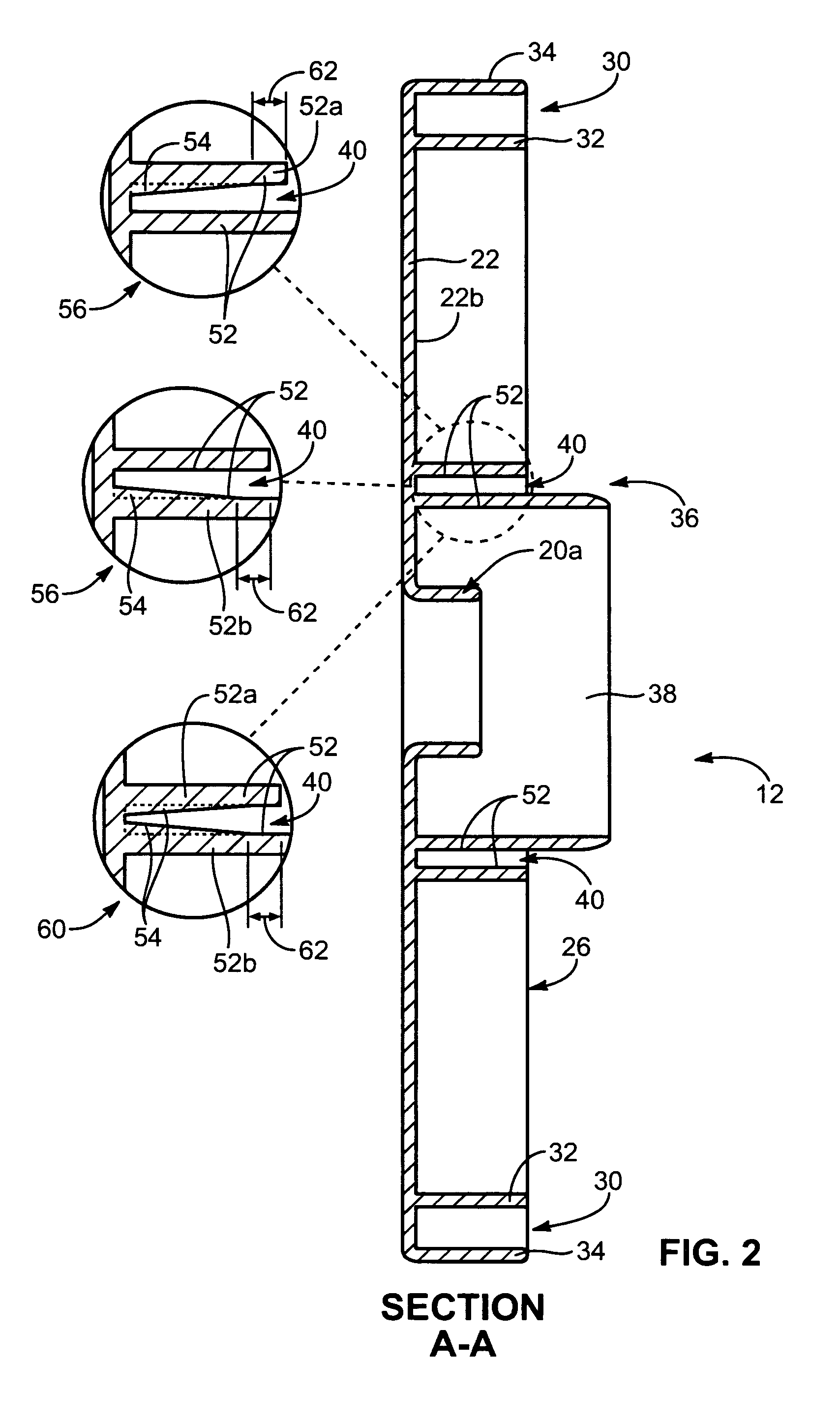

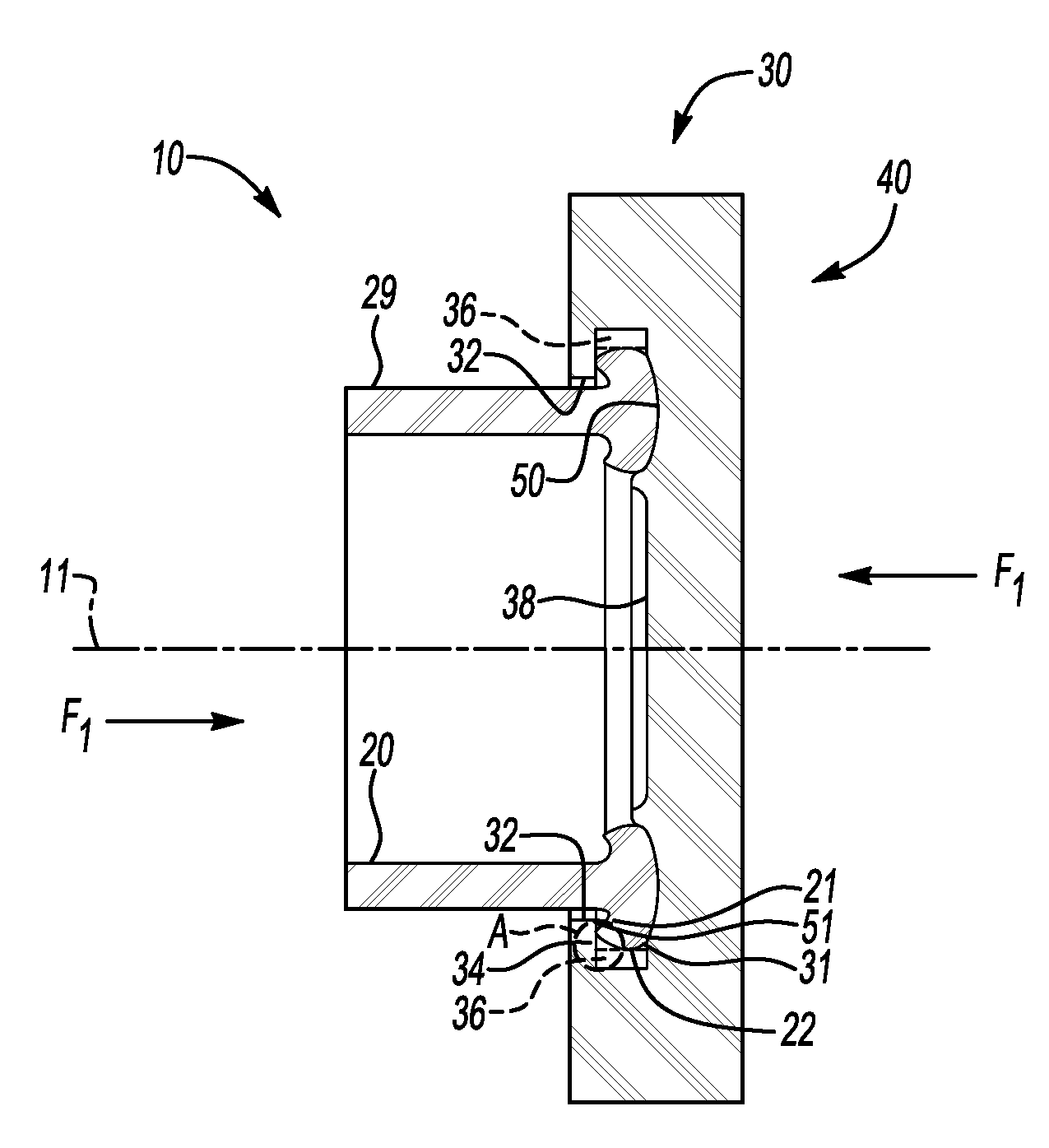

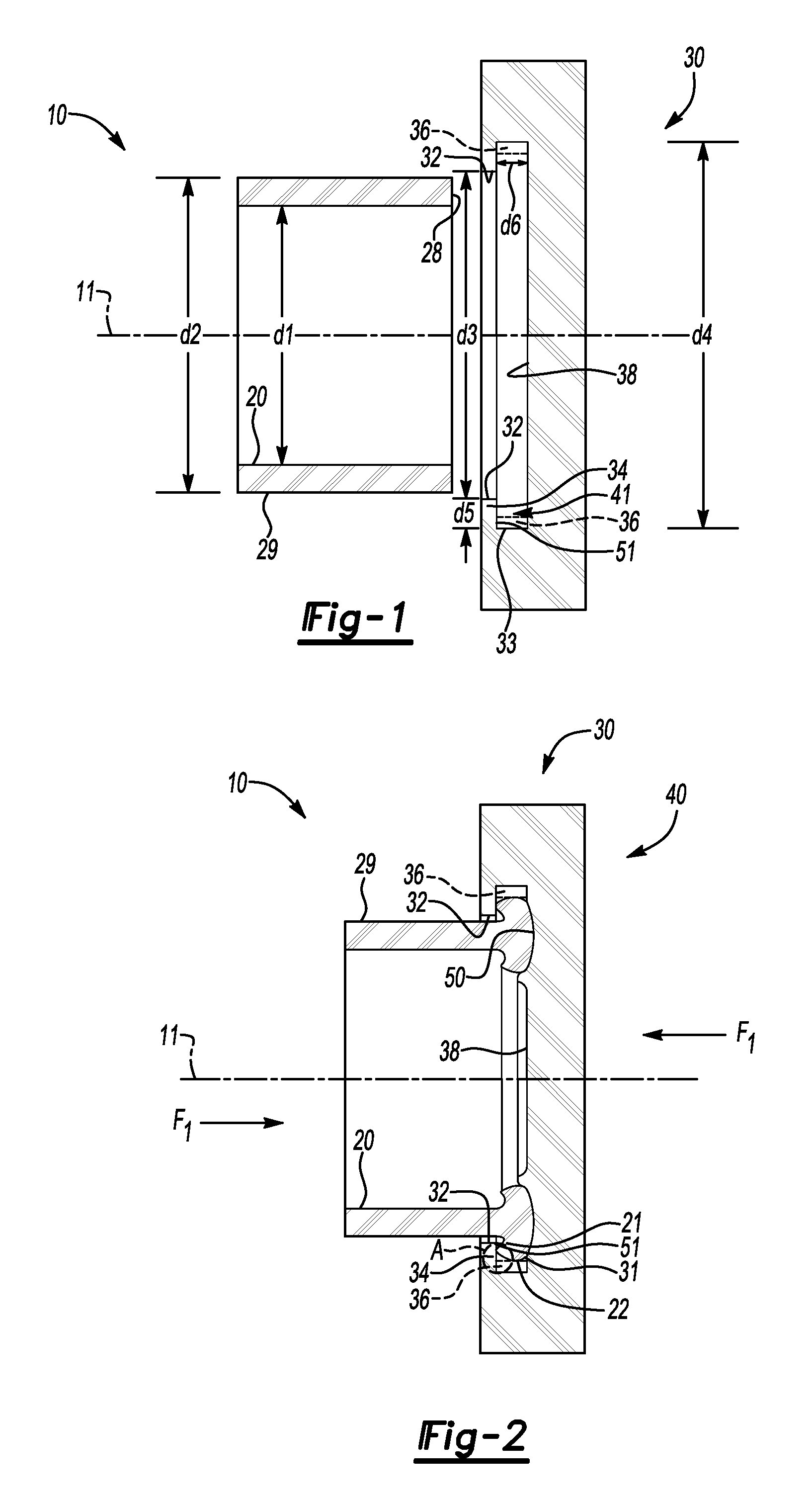

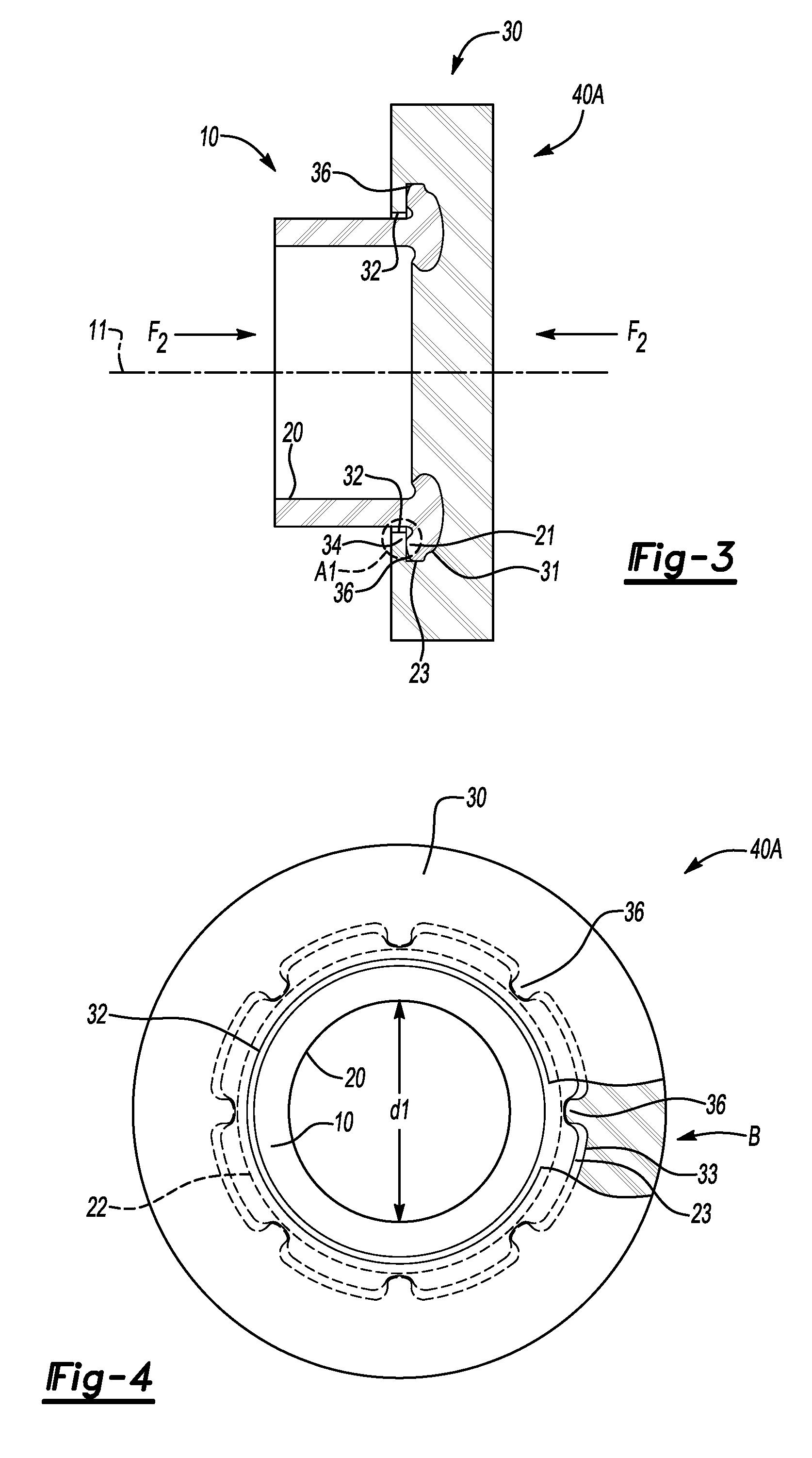

Friction-Welded Assembly with Interlocking Feature and Method for Forming the Assembly

ActiveUS20090324986A1Increased durabilityStrength optimizationEngine sealsVehicle sealing arrangementsCircular discFriction welding

A welded assembly includes a weld joint formed via a spin-welding process. A disc receives a cylinder prior to spin-welding, with the disc having a circumferential groove undercutting or defining an annular shelf. An interlocking feature retaining the cylinder and disc is formed between a flow pattern of the cylinder and the annular shelf upon cooling of molten flash in the groove underneath the annular shelf. Teeth can be formed integrally with the disc to provide a torsional interlocking feature between the disc and cylinder. A method for forming a weld joint between a plastic cylinder and disc includes providing the disc with a circumferential groove forming an annular shelf, and rotating the cylinder with respect to the disc under an axial force to thereby form an outflow of molten flash. The flash forms an interlocking feature when cooled after flowing into the groove underneath the shelf.

Owner:GM GLOBAL TECH OPERATIONS LLC

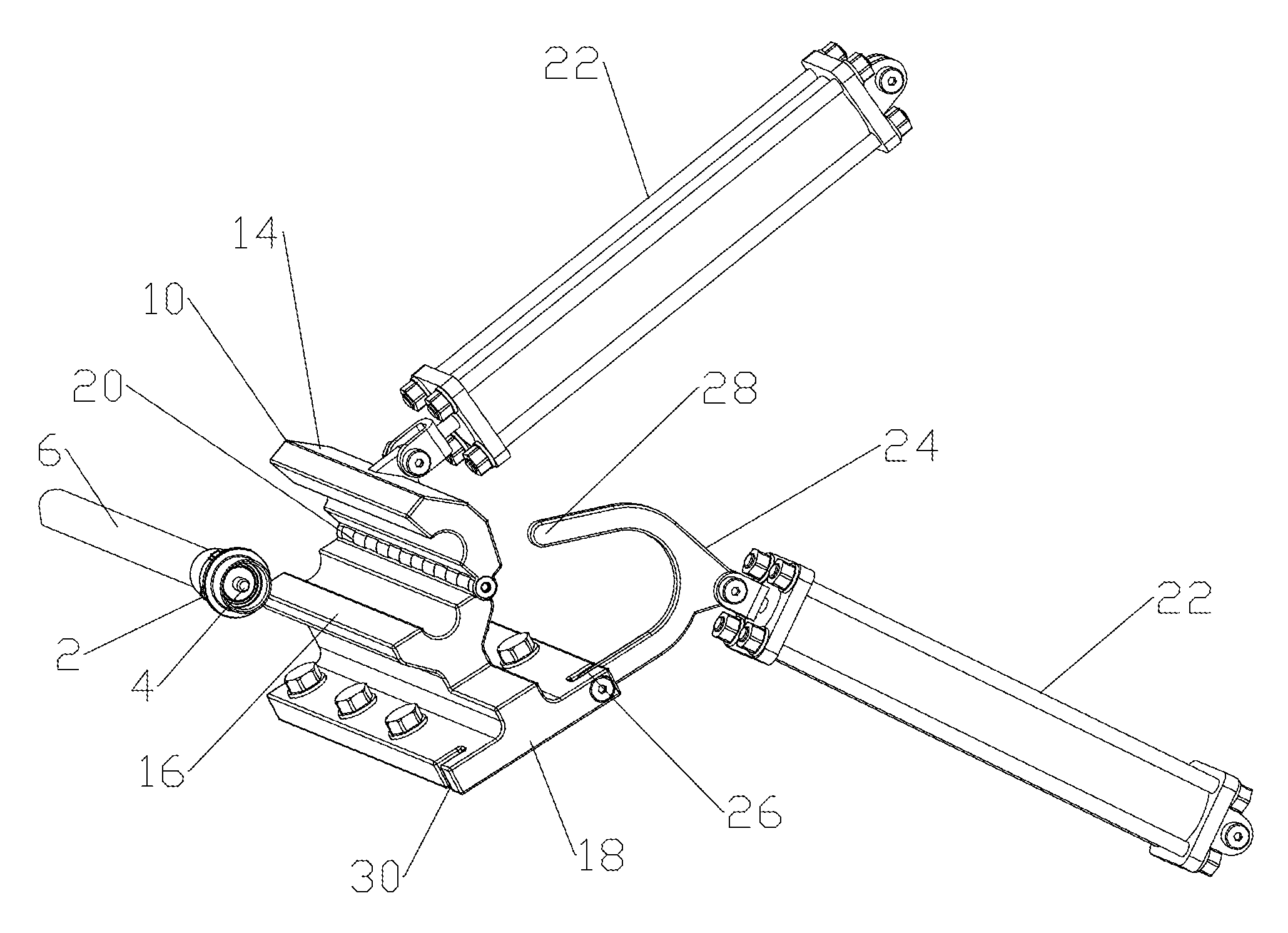

Double-gun girth welding device used for barrel body and end cover

ActiveCN105215613AGood alignment and clamping effectSimple structureWelding/cutting auxillary devicesAuxillary welding devicesSpin weldingWeld seam

The invention belongs to the technical field of automobile exhaust pipe component welding and particularly relates to a double-gun girth welding device used for a barrel body and an end cover. The device comprises a base and a welding mechanism fixed to the base, a first positioning and clamping mechanism, a second positioning and clamping mechanism and a sliding support mechanism are arranged on the base, a first end cover positioning and clamping sleeve is arranged on the first positioning and clamping mechanism, a second end cover positioning and clamping sleeve is arranged on the second positioning and clamping mechanism, and the first positioning and clamping mechanism and the second positioning and clamping mechanism are arranged at the two sides of the welding mechanism. By means of the detachable base, the barrel body and the end cover can be well aligned and clamped, spin welding can be conducted on two formed welding seams to be welded, and the detachable base has the advantages of being simple and reasonable in structure, convenient to operate, good in aligning, clamping and welding effect and high in efficiency.

Owner:ZHEJIANG DA FENG AUTOMOBILE TECH

Cylindrical Surface Spin Weld Apparatus and Method of Use

ActiveUS20120125513A1Reduce chanceRepeatable spin weldingLine/current collector detailsElectrically conductive connectionsSpin weldingCoaxial cable

A spin weld apparatus for spin welding a prepared end of a coaxial cable with a coaxial connector includes a cable clamp dimensioned to grip the coaxial cable and a drive collet dimensioned to enclose and rotationally interlock with a lateral surface of the coaxial connector. The drive collet is dimensioned to rotationally interlock with an interlocking portion of a spin welder. The spin welder is dimensioned to axially align the coaxial connector with the coaxial cable for spin welding when the drive collet is rotationally interlocked with the spin welder.

Owner:COMMSCOPE TECH LLC

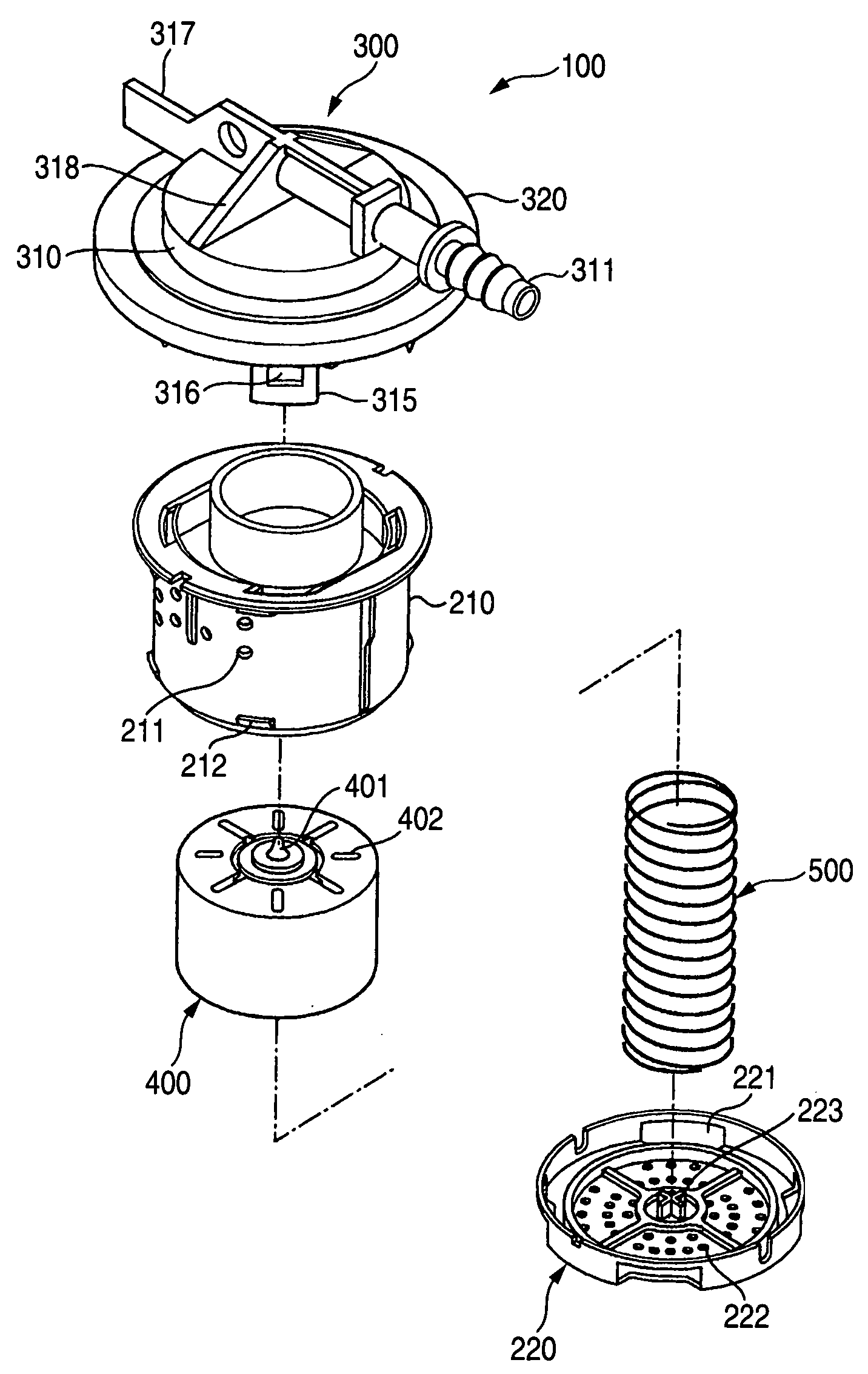

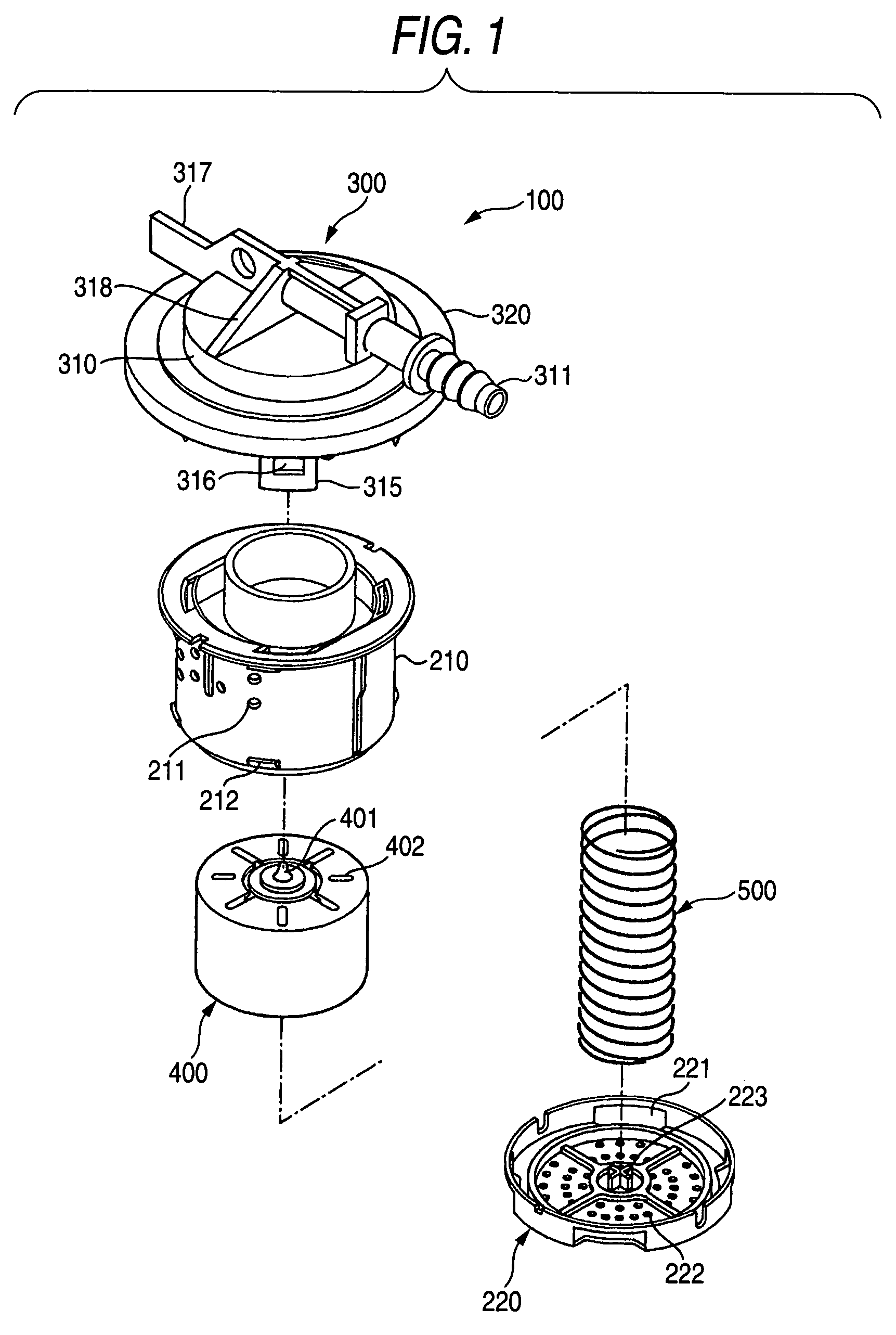

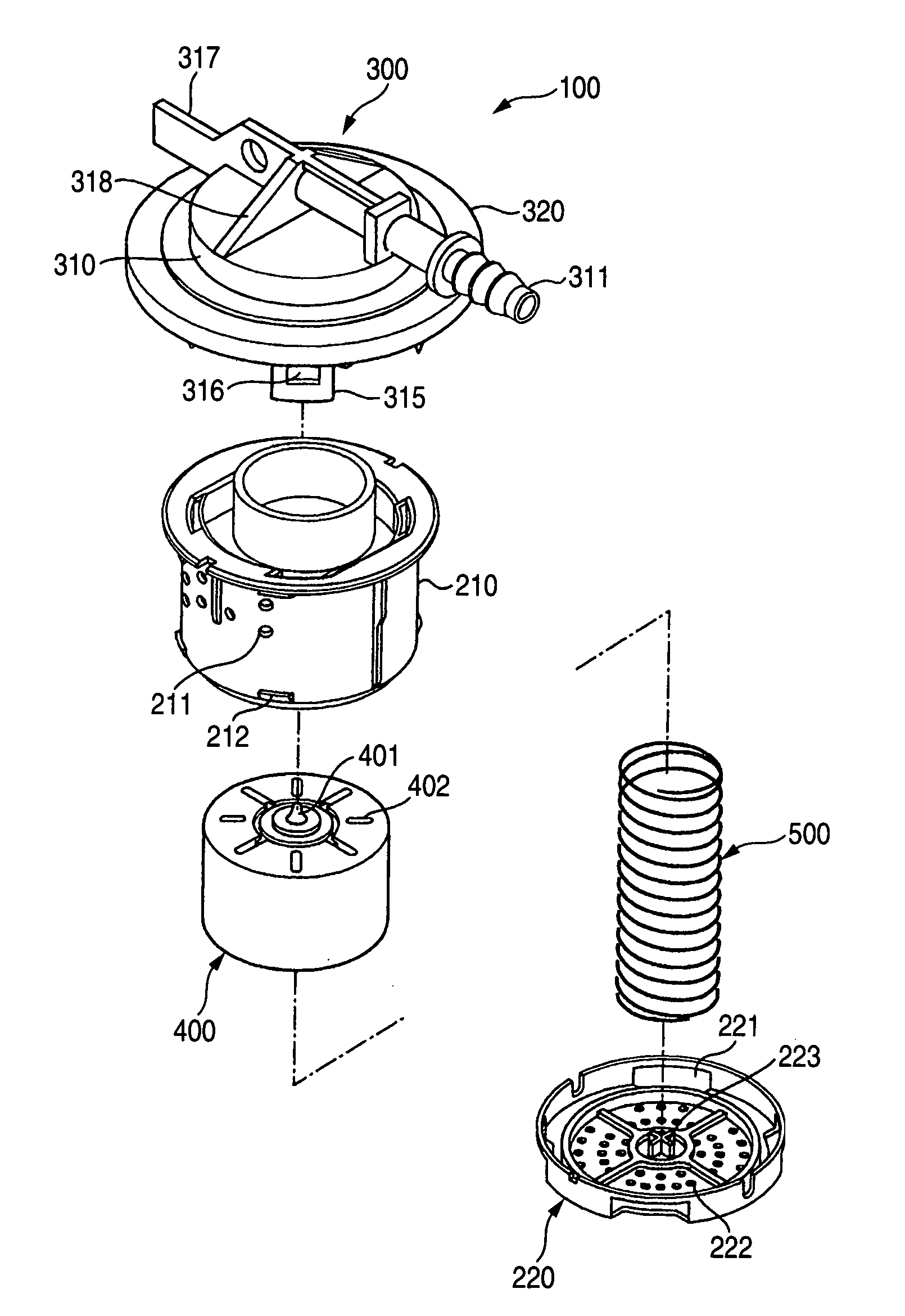

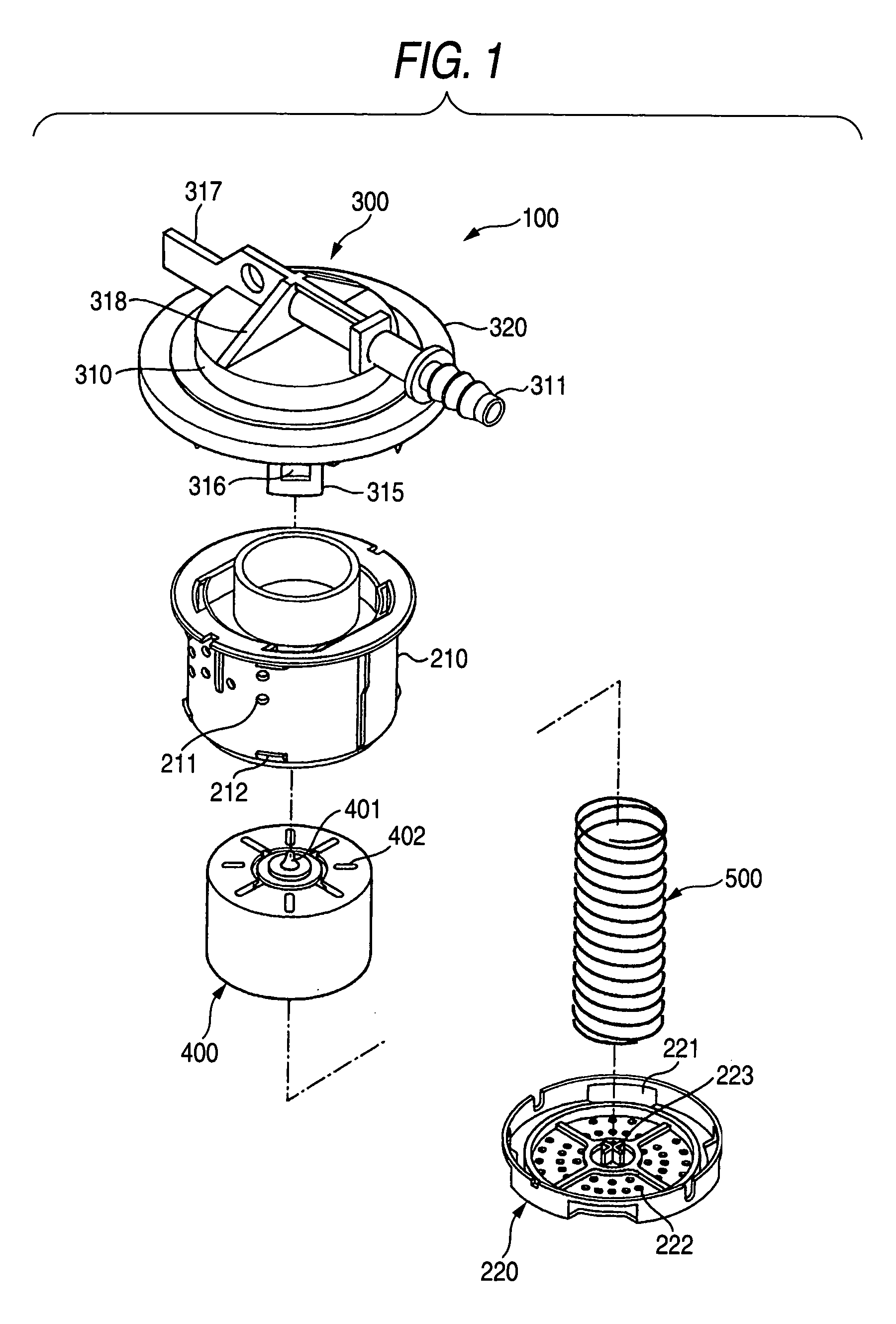

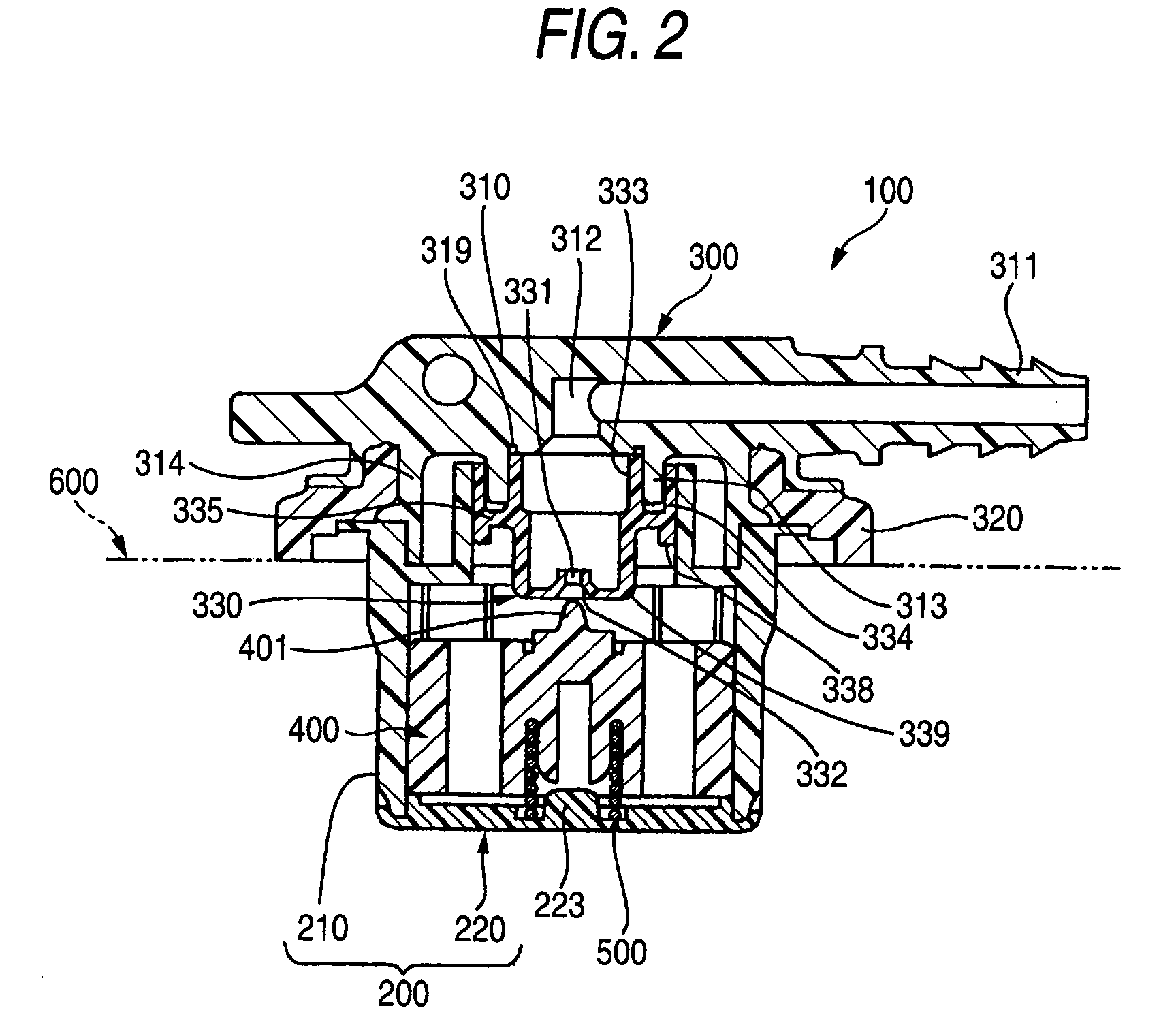

Method for manufacturing float valve apparatus

InactiveUS7661193B2Minimize occurrenceImprove adhesionOperating means/releasing devices for valvesWelding/cutting auxillary devicesSpin weldingEngineering

In a method for manufacturing a float valve apparatus including a valve case, an upper lid incorporated into this valve case to form a valve chamber, and a float valve liftably arranged inside the valve chamber, the upper lid being provided with a lead-out pipe connected to piping of the outside, an exhaust hole which communicates with this lead-out pipe and is opened in an inner surface of the upper lid, and a seal cap which is mounted so as to enclose this exhaust hole and forms a valve seat on which the float valve abuts, the seal cap is welded to an inner surface of the upper lid by spin welding.

Owner:PIOLAX CO LTD

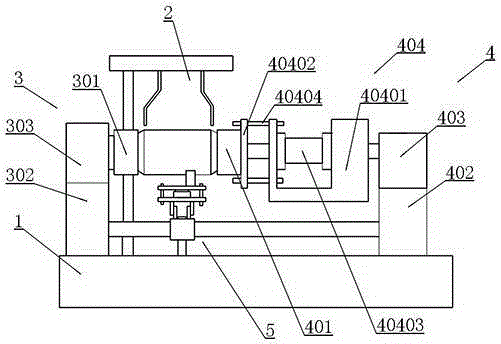

Spin welding oil cup clamp capable of preventing welding oxidation and control method

ActiveCN106881549AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesSpin weldingCarbon Dioxide / Helium

The invention relates to a spin welding oil cup clamp capable of preventing welding oxidation and a control method. The clamp comprises a hanging basket part, a left clamp part, a right clamp part and shielding gas passages; the left clamp part and the right clamp part are respectively installed at two sides of the hanging basket part; the shielding gas passages are respectively installed in the middle part of the left clamp part and the middle part of the right clamp part; the shielding gas passages are used for blowing protecting gas out when welding to prevent oxidation stain of workpieces during welding and keep the surface of workpieces clean; the oil cup is placed on the clamp; a workpiece is tightly clamped with the left clamp part and the right clamp part at the same time; the hanging basket part rotates and the workpiece rotates along with the turning axle of the hanging basket; through welding heads, welding of multi edges sharing a same cross section is realized; and the left end and the right end can be welded at the same time. Compared with traditional welding devices, the clamping is easy and quick and is accurate in positioning; combined with modern laser welding technology, quick welding is realized; the welding quality is reliable; disability rate is as low as zero; the production efficiency is high and labor intensity is low.

Owner:WUHAN CHUTIAN IND LASER EQUIP

Spin-welded electrical ground and spin welding methods

ActiveUS20150222027A1Vehicle connectorsSoldered/welded conductive connectionsFriction weldingSpin welding

A friction-welded ground assembly that includes an alloy substrate with a clearance hole; an aluminum alloy weld nut having a bolt bore and an outer wall; and a grounding bolt. The bore is located substantially within the clearance hole and a portion of the outer wall is joined to the substrate at a friction-welded attachment. Further, the bolt is threaded within the bore. In addition, a method for making a ground includes the steps: rotating an aluminum alloy weld nut having an outer wall at a predetermined speed; lowering the outer wall of the rotating nut into contact with an aluminum alloy substrate to generate a frictional force for a friction time; arresting the rotation of the nut; and applying an axial forging force to the outer wall and the substrate for a forging time.

Owner:FORD GLOBAL TECH LLC

Method for manufacturing float valve apparatus

InactiveUS20050022383A1Avoid glitchesAvoid leaningOperating means/releasing devices for valvesWelding/cutting auxillary devicesSpin weldingVALVE PORT

In a method for manufacturing a float valve apparatus including a valve case, an upper lid incorporated into this valve case to form a valve chamber, and a float valve liftably arranged inside the valve chamber, the upper lid being provided with a lead-out pipe connected to piping of the outside, an exhaust hole which communicates with this lead-out pipe and is opened in an inner surface of the upper lid, and a seal cap which is mounted so as to enclose this exhaust hole and forms a valve seat on which the float valve abuts, the seal cap is welded to an inner surface of the upper lid by spin welding.

Owner:PIOLAX CO LTD

Fuel vapor vent valve and method of attaching same to a tank

InactiveUS7146729B2Prevent rotationNon-fuel substance addition to fuelAssembly machinesSpin weldingEngineering

A float operated fuel vapor vent valve has body structure with an annular mounting flange formed of material weldable to a fuel tank and the flange is spin welded to the tank. The float has surfaces thereon which slidably engage corresponding surfaces in the float chamber to prevent relative rotation of the float with respect to the valve body during spin welding. An optional pressure relief valve in the vent outlet also has surfaces slidably engaging the vent passage to prevent relative rotation during spin welding.

Owner:EATON CORP

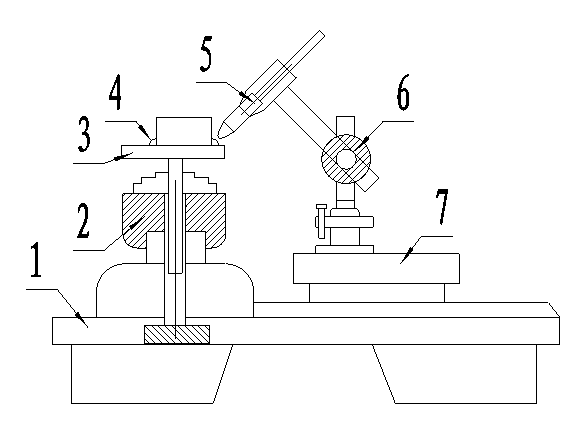

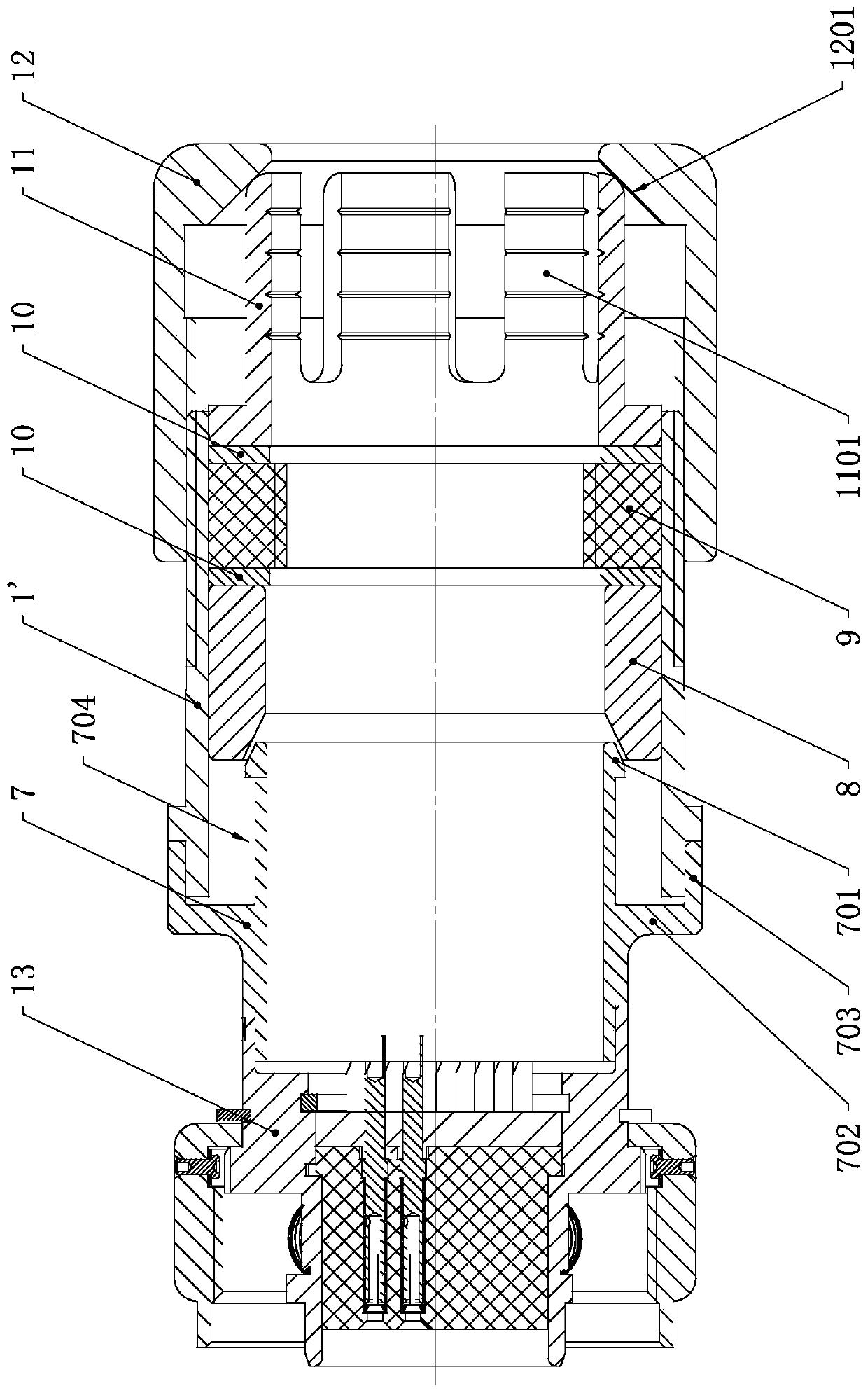

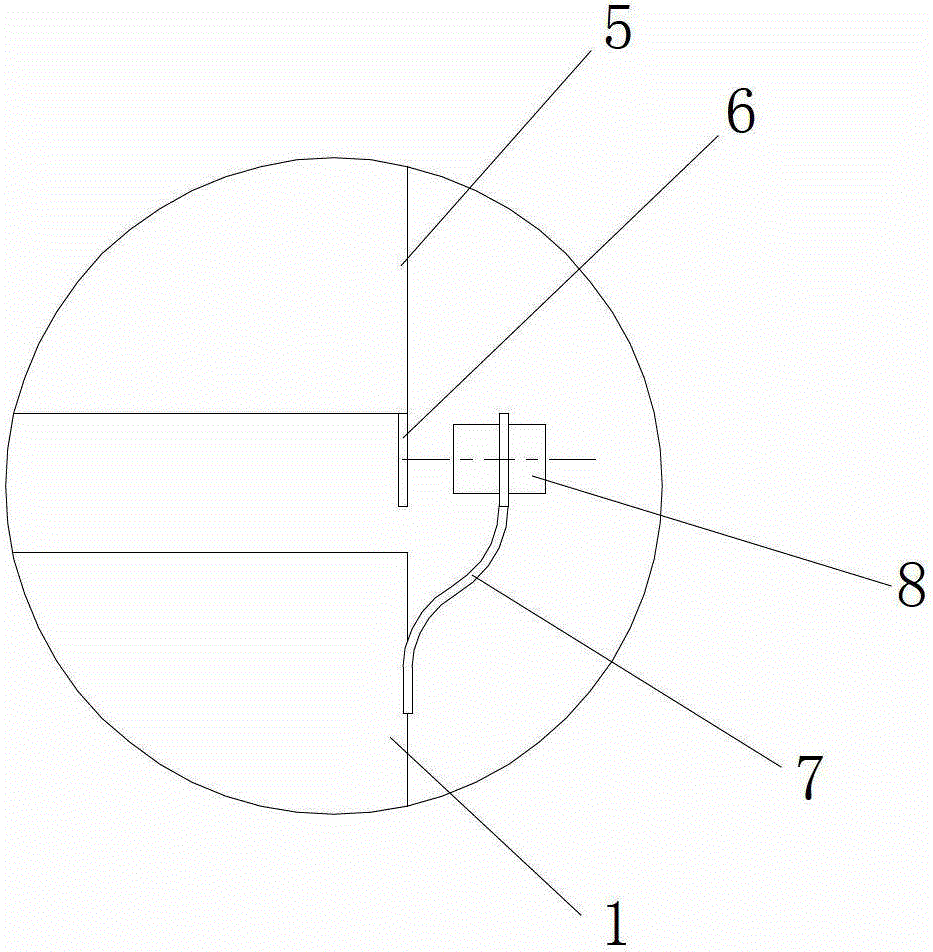

Spin welding device

InactiveCN103659064AImprove welding qualityImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesLow speedSpin welding

The invention relates to a spin welding device. A low-speed variable-frequency motor and a movable platform are arranged on a working table, a welding part and a welded joint are fixed to the low-speed variable-frequency motor, a welding gun and a welding gun lifting motor are fixed to a movable platform, and the welded joint on the welding part is driven to rotate at a constant speed through the low-speed variable-frequency motor; meanwhile, the welding gun is controlled through the welding gun lifting motor and the movable platform, a stable welding work distance is kept between the welding gun and the welded joint all the time, and therefore continuous automatic welding of the welding part and the special-shaped welded joint is achieved, stable welding quality is more efficiently achieved, and the efficient production of the spin welding device is achieved.

Owner:重庆针尖内燃机部件制造有限公司

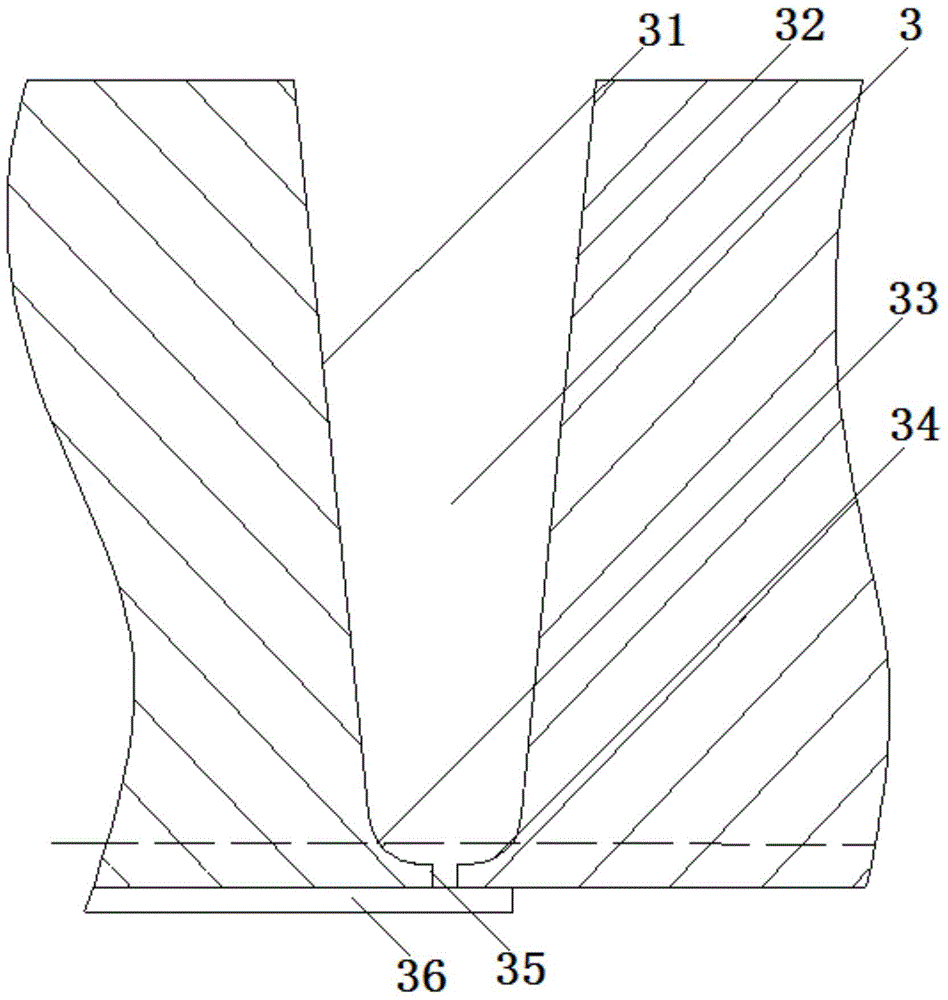

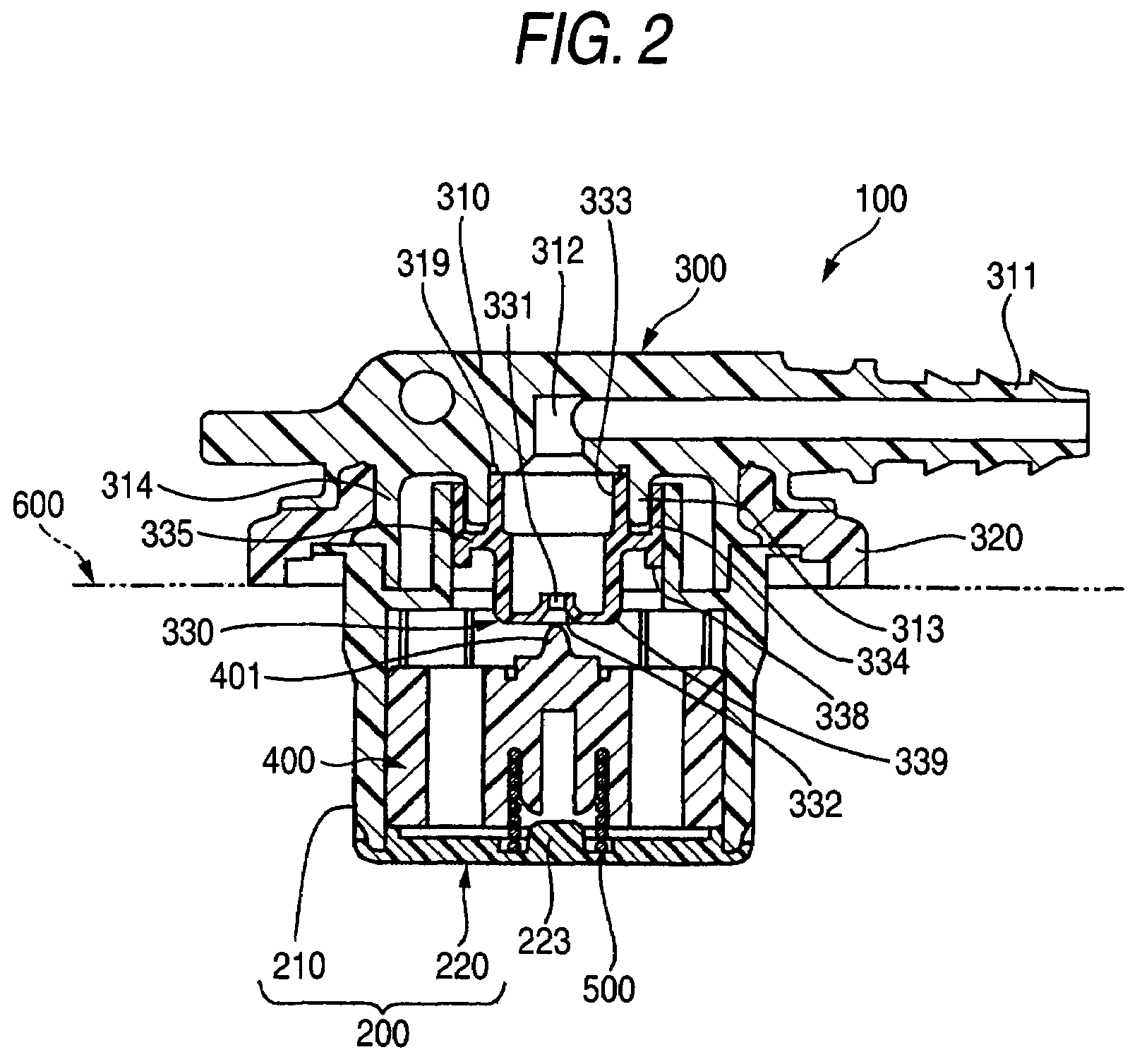

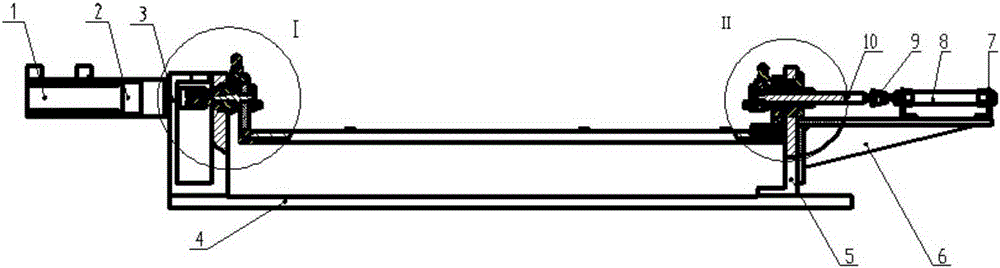

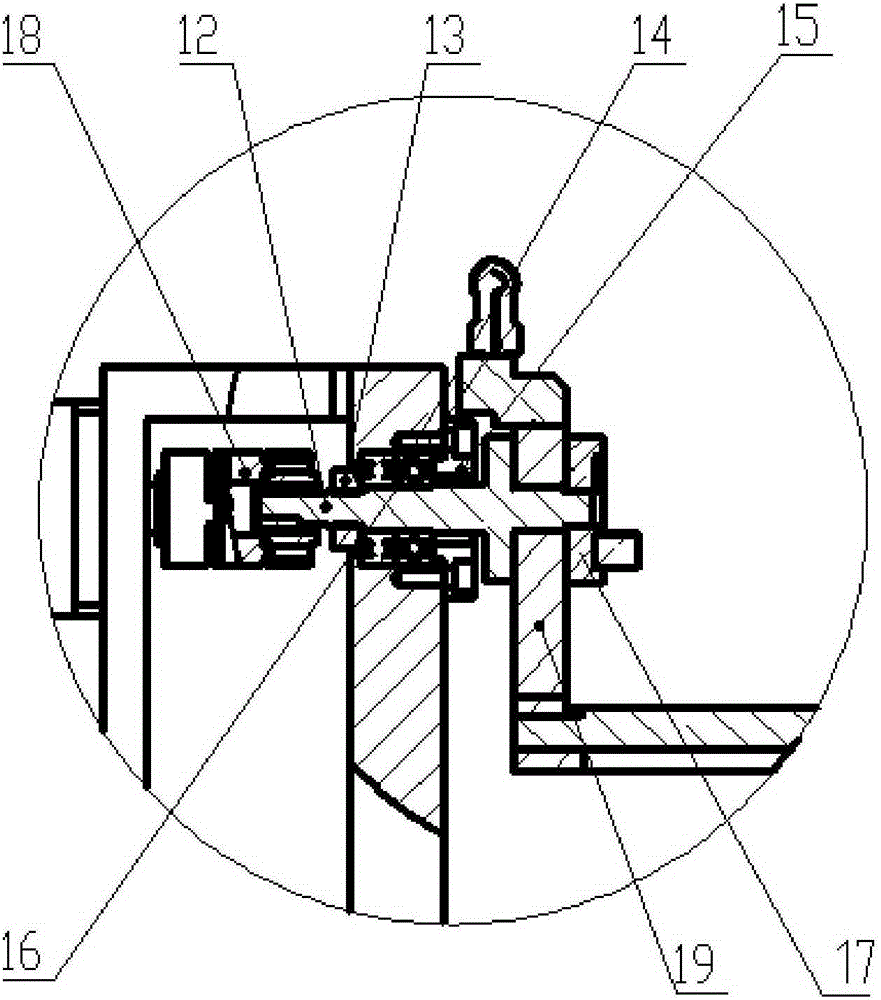

Cross-grade spin welding apparatus and method

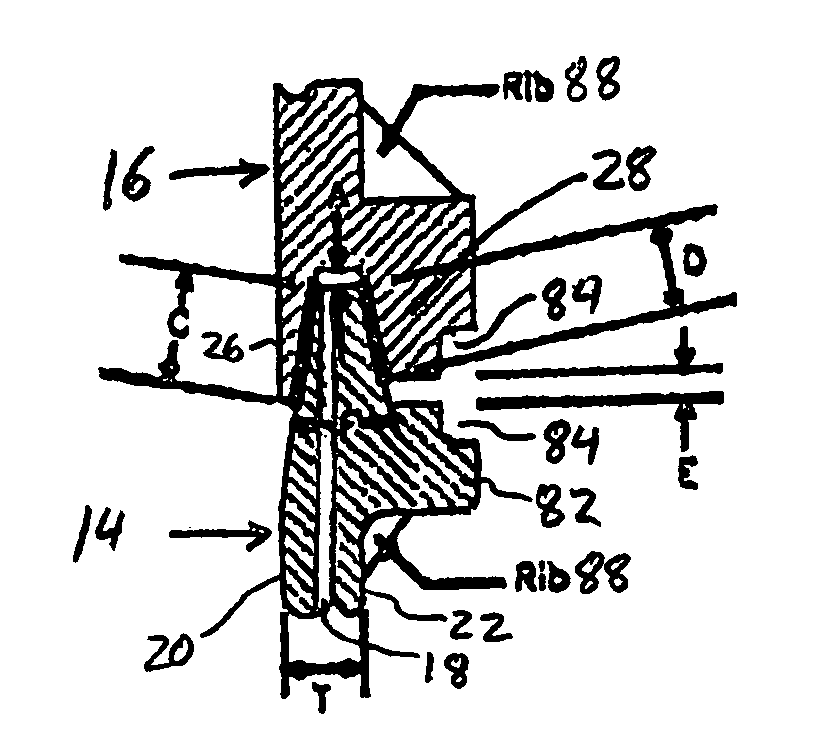

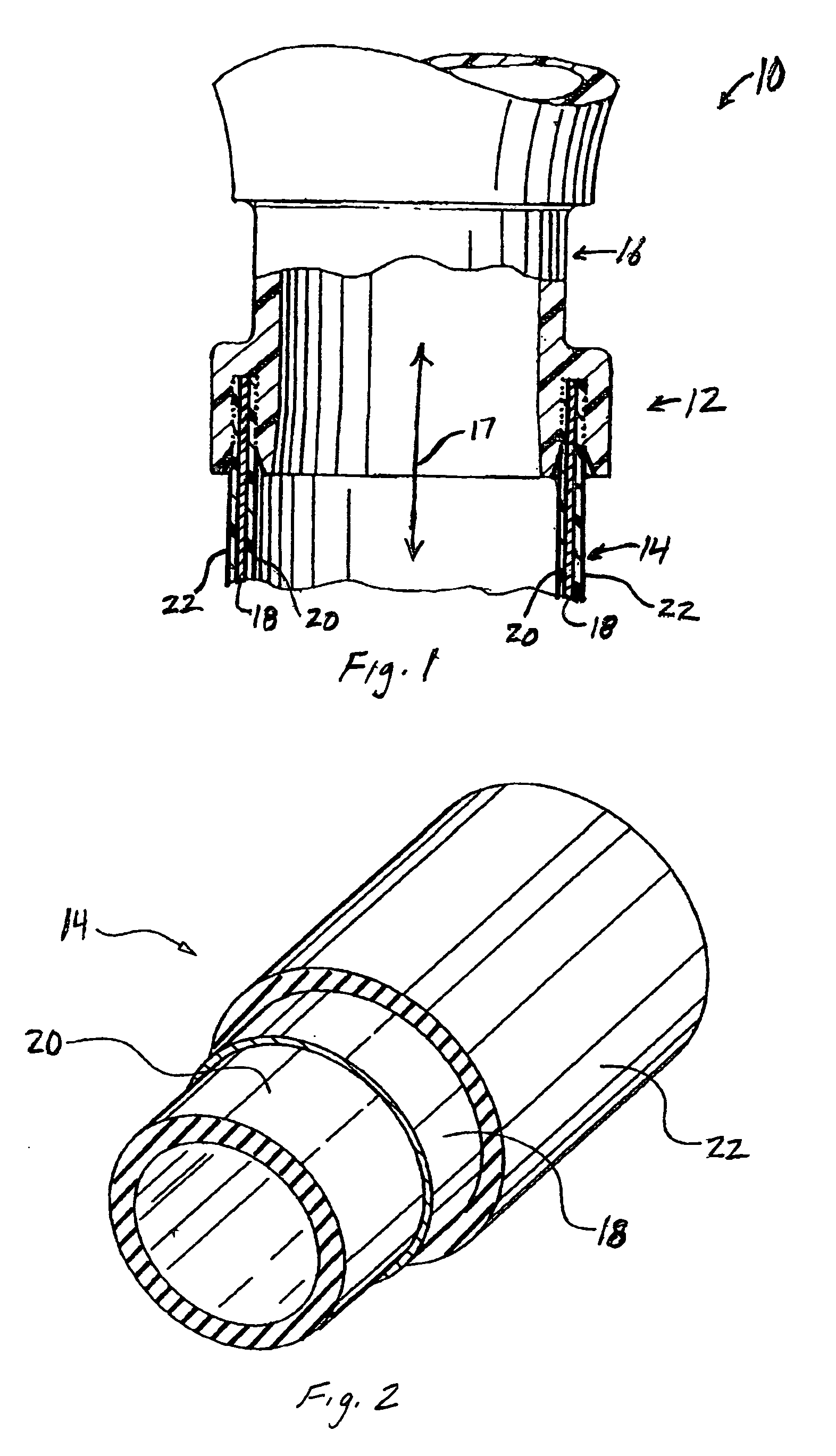

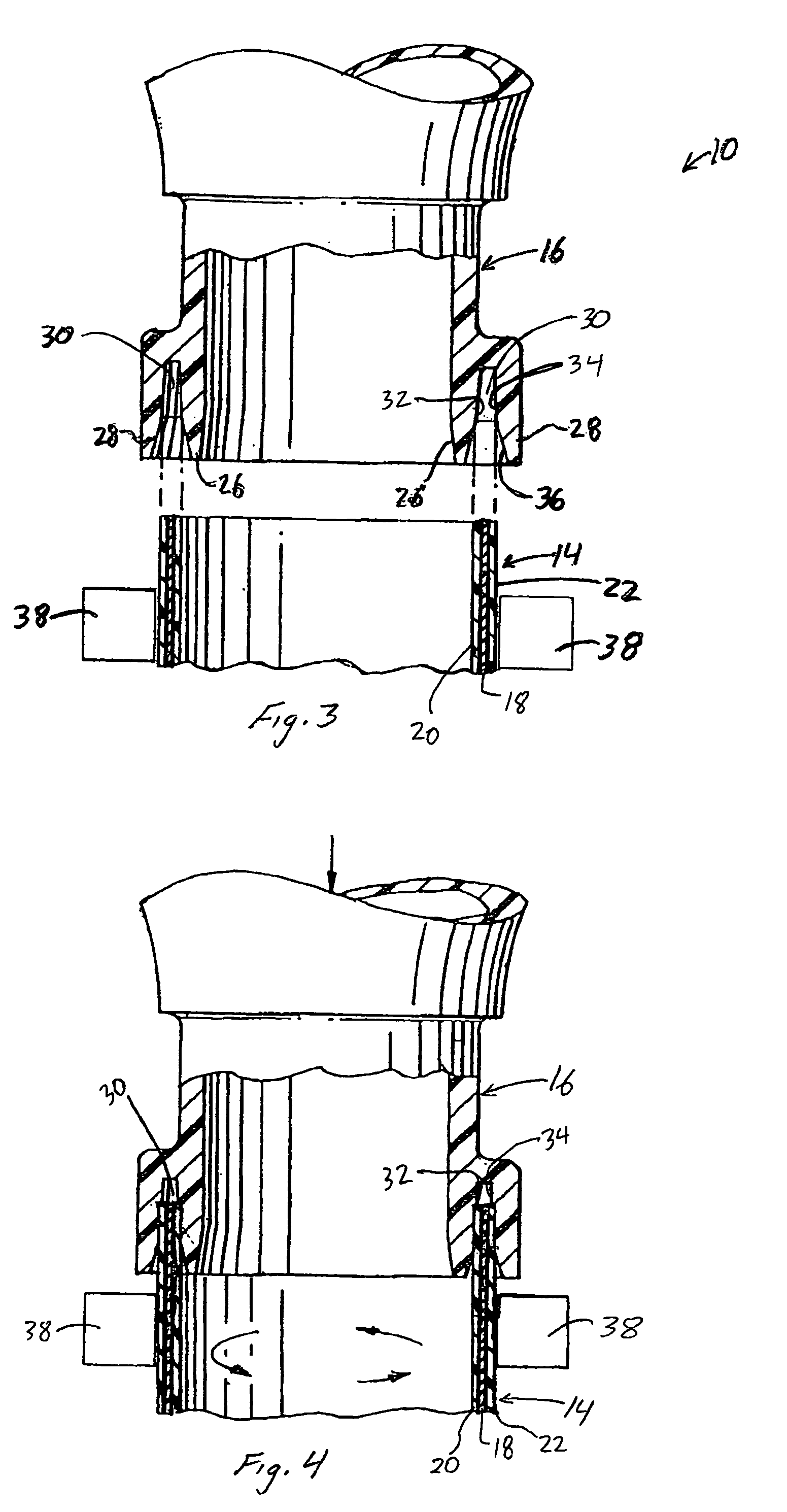

ActiveUS7534316B2Less cost-effectiveEncouraging meltingLaminationLamination apparatusThermoplasticPolymer resin

A method for welding parts formed of polymeric resins having different melt-index grades. The method may include the steps of selecting a tube formed of a first thermoplastic in an extrusion process, selecting a first flange formed of a second thermoplastic in an injection molding process and having a containment region sized to receive an end of the tube, inserting an end of the tube within the containment region of the first flange, and welding the tube to the flange by inducing relative rotation between the flange and the tube. The containment region may have a depth more than two times the wall thickness of the tube. Moreover, the containment region may maintain its shape and support friction pressure on a significant portion of melted material within the weld zone, so the material may continue to generate heat and conduct the same to the less easily melted material.

Owner:SONOCO DEV INC

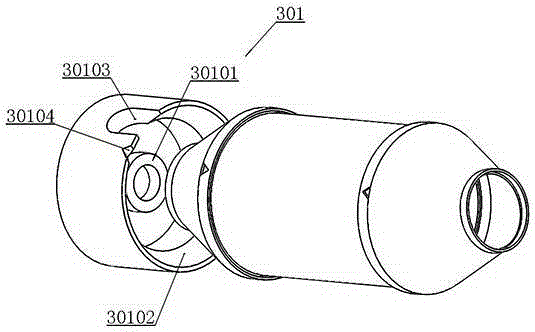

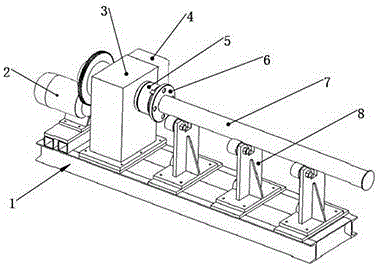

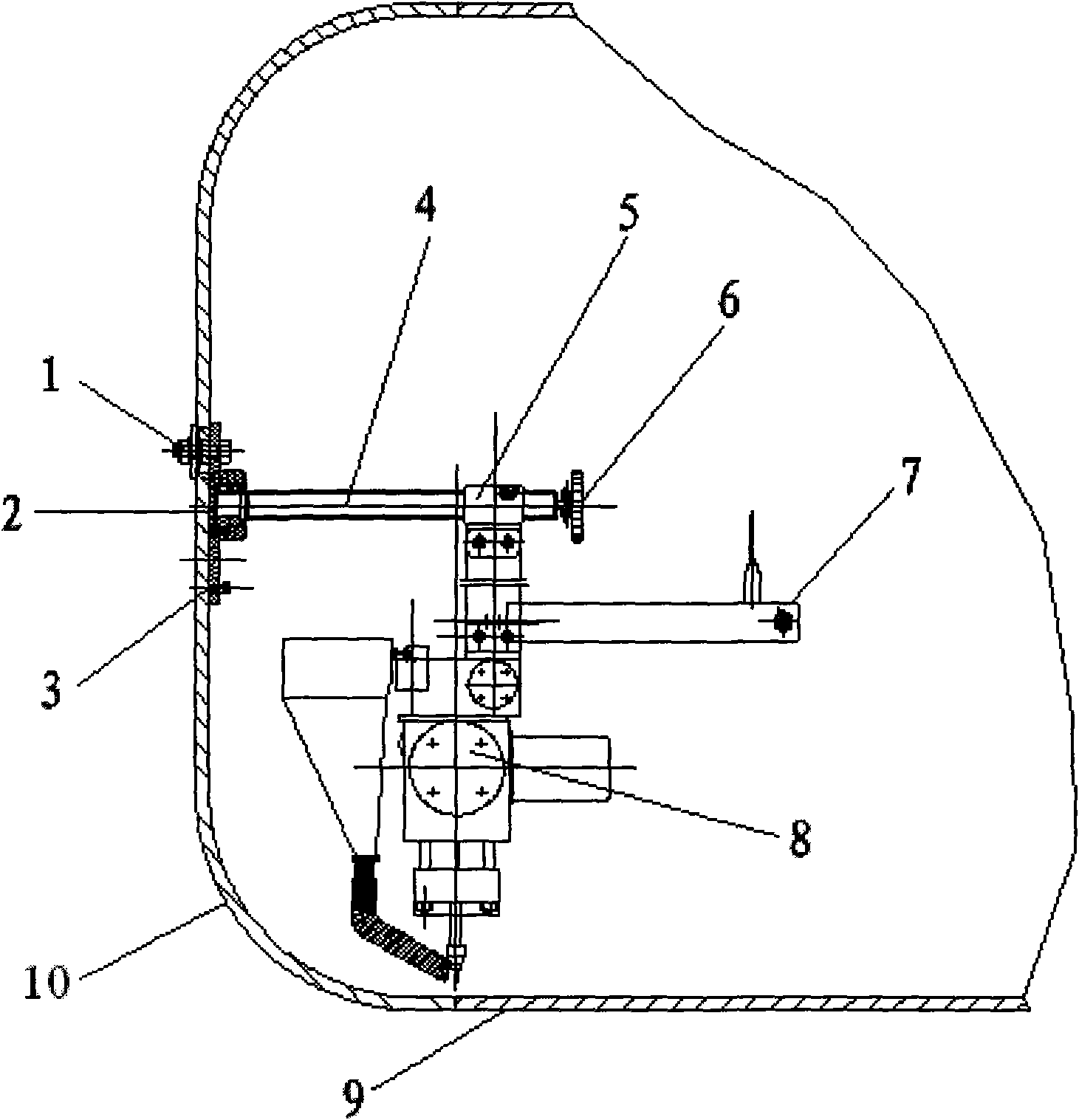

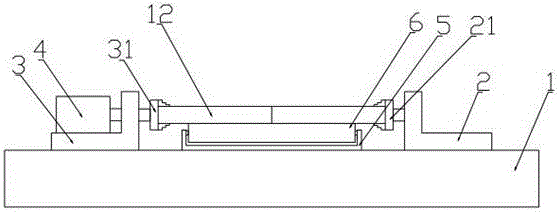

Automatic spin welding tool for circular seams of pipe fittings

InactiveCN106392456AReduce labor intensityUniform and beautiful girth weldWelding/cutting auxillary devicesAuxillary welding devicesElectricitySpin welding

The invention belongs to the technical field of welding and specifically relates to an automatic spin welding tool for circular seams of pipe fittings. The automatic spin welding tool comprises a base. The base is provided with a variable frequency motor, a transmission case and an electric control cabinet. The variable frequency motor is arranged on one side of the base, and the transmission case and the electric control cabinet are arranged on the right side of the variable frequency motor side by side. The transmission case and the variable frequency motor are connected through a gear in an engaged manner. The electric control cabinet is electrically connected with the variable frequency motor. An output shaft of the transmission case is connected with a chuck. When the automatic spin welding tool for the circular seams of the pipe fittings is used for welding a flange and a steel pipe, the circular welding seams can be continuously formed, the number of welding connectors is reduced, and only one connector is arranged; and due to the fact that the flange and the steel pipe rotate at a constant speed, the circular welding seams formed during welding are relatively uniform and attractive. In addition, by means of the automatic spin welding tool for the circular seams of the pipe fittings, the production efficiency is greatly improved while the labor intensity of workers is reduced.

Owner:中电装备青岛豪迈钢结构有限公司

Friction-welded assembly with interlocking feature and method for forming the assembly

ActiveUS7726542B2Increased durabilityStrength optimizationVehicle componentsWelding/soldering/cutting articlesFriction weldingCircular disc

Owner:GM GLOBAL TECH OPERATIONS LLC

Hydrostatic arrangement for a spin welding machine and method of supporting spindle for the same

A hydrostatic arrangement for a spin welding machine includes, a spindle rotationally supported with at least one of a thrust hydrostatic bearing and a journal hydrostatic bearing, and a hydraulic unit configured to supply liquid to the at least one of a thrust hydrostatic bearing and a journal hydrostatic bearing at at least two different pressures.

Owner:ELKA PRECISION

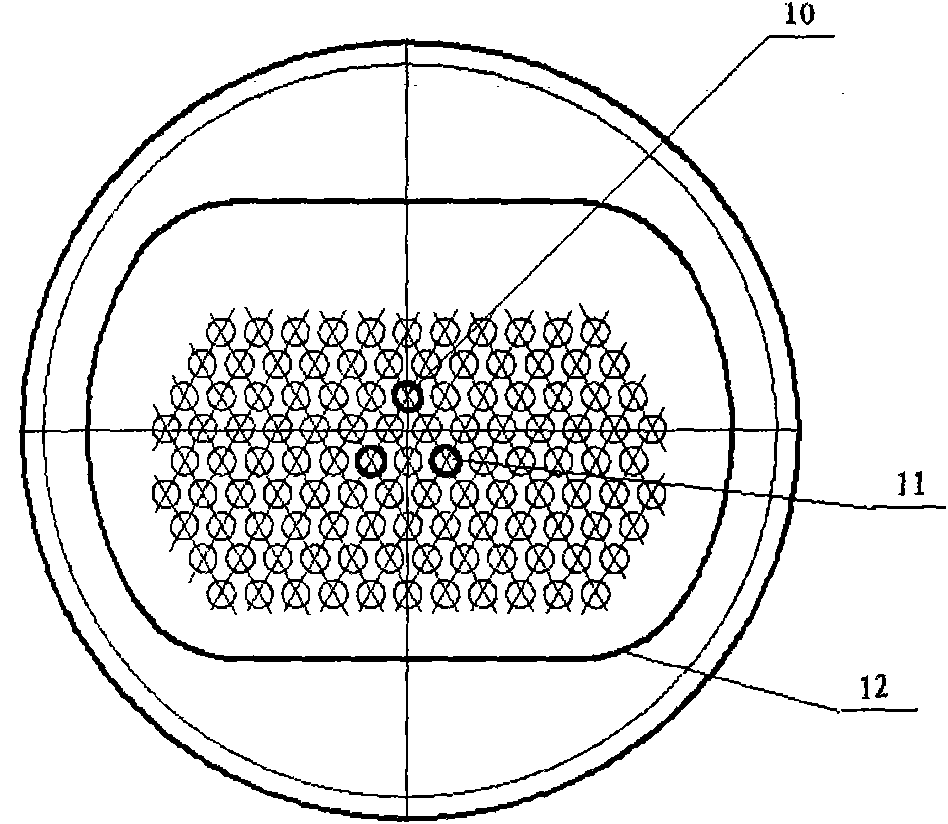

Novel inner circular seam automatic welding mechanism for cylinder assembly

InactiveCN101837498AReduce workloadImprove efficiencyArc welding apparatusDomestic vesselsStable stateSpin welding

The invention discloses a novel inner circular seam automatic welding mechanism for a cylinder assembly. Three seal head holes on an arched tube plate seal head are selected as positioning references. Through a positioning liner plate which is provided with a right opening and is generally used by the three seal head holes, a base plate and the arched tube plate seal head on a positioning bearing block are connected with each other in a positioning mode by using bolts. A cantilever screw rod is arranged on the positioning bearing block and is ensured to be coaxial with a seal head cylinder body. A hand piece of a suspended type submerged arc welding machine is fixed on a nut connecting plate. When a hand wheel is toggled, the nut connecting plate drives the hand piece of the suspended type submerged arc welding machine and a wire reel bracket to move axially. When the positioning bearing block is in spin welding along with the cylinder body, a cantilever screw rod shaft is in a relatively stable state to satisfy automatic welding. The hand piece of the suspended type submerged arc welding machine and an accessory enter the cylinder body through pipe orifices. A cable wire is penetrated into the cylinder body from a pipe orifice close to the central part of the arched tube plate seal head, and is connected and fixed with the hand piece of the suspended type submerged arc welding machine. The cylinder body rotates on a roller frame to perform debugging and alignment on a fixture.

Owner:尹克芳

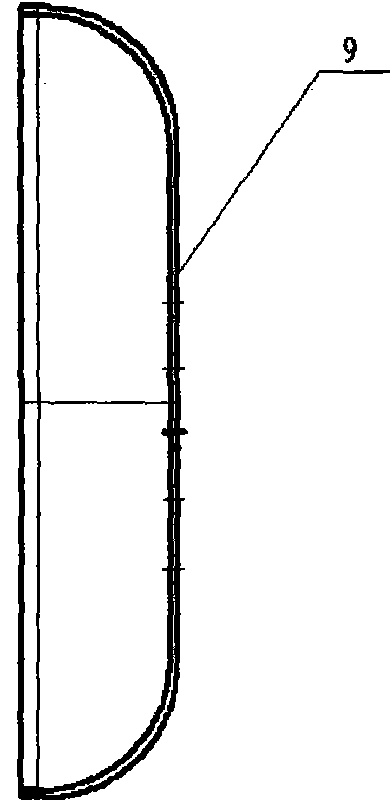

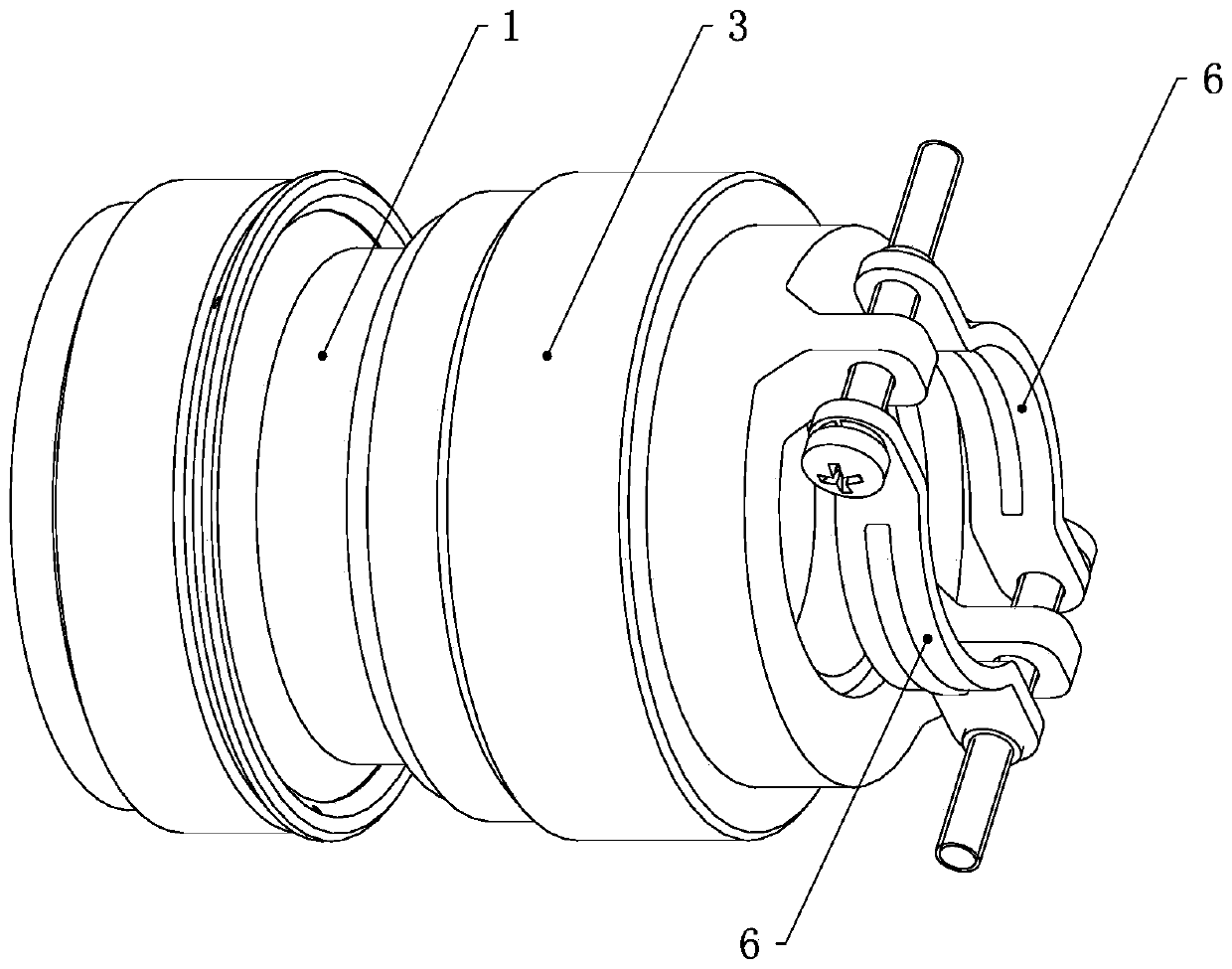

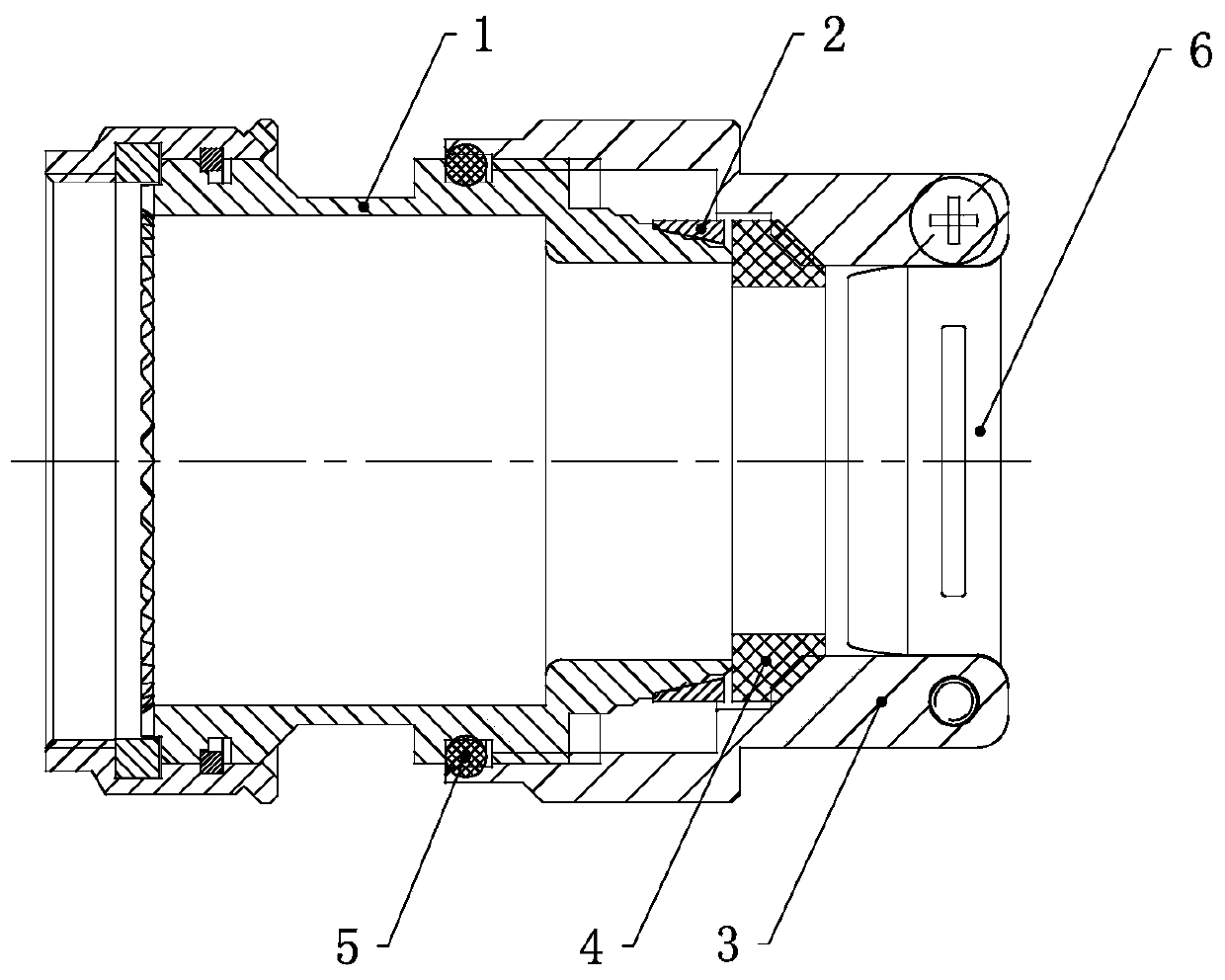

Cable sealing clamping and shielding woven layer compaction one-key tail clamp

PendingCN109980431ACompact structureEasy to operateRelieving strain on wire connectionCouplings bases/casesRubber ringSpin welding

The cable sealing clamping and shielding woven layer compaction one-key tail clamp comprises a sleeve, a shielding ring and a rubber ring which are successively arranged in the sleeve in the axial direction, a line clamping ring having a plurality of claws arranged at its rear end in the circumferential direction. The front end of the sleeve is welded and fixed to a mounting portion protruding from the outer wall of a spin welding sleeve. A tail clamp nut is detachably mounted on the rear end of the sleeve. When mounted, the tail clamp nut is movable in the axial direction of the sleeve to beabutted against the rear end of the line clamping ring such that each claw retracts inwardly in the radial direction to clamp a cable passing through the sleeve, and applies axial pressure to the rubber ring to cause radial deformation to seal the cable passing through the sleeve. The axial pressure is applied to the shielding ring in order that the conical surface at the front end of the inner wall of the shielding ring matches the conical surface of the boss at the rear end of the spin welding sleeve to compact a cable shielding woven layer. The tail clamp can realize functions of cable shielding woven layer compaction, cable sealing, cable clamping and the like by assembling the tail clamp nut, thereby shortening the assembly time and improving the assembly efficiency.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

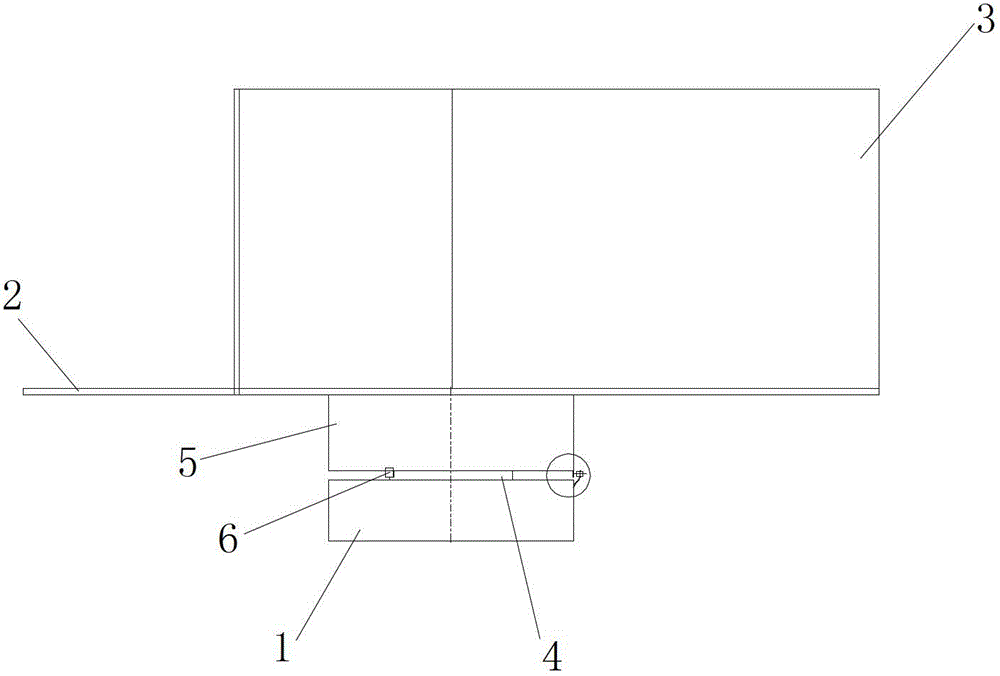

Fixing device for spin welding of pipe

InactiveCN105945504AReduce labor intensitySimple structureWelding/cutting auxillary devicesAuxillary welding devicesSpin weldingEngineering

The invention discloses a fixing device for spin welding of a pipe, and relates to the technical field of welding. The fixing device comprises a workbench, and a fixed seat and a movable seat are oppositely arranged in the horizontal direction of the workbench. The fixed seat is provided with a first rotary claw. A rotary motor is mounted on the movable seat. The fixed seat and the movable seat are both in an L shape. A rotary shaft of the rotary motor penetrates the movable seat to be fixedly connected with a second claw. The first claw and the second claw are oppositely mounted. A part to be welded is fixedly arranged between the first claw and the second claw. A pair of carrier rollers is arranged in the feeding direction of the workbench, each carrier roller is mounted on the workbench through a mounting seat, a cooling device is arranged in each carrier roller, and the axis of each carrier roller is parallel to that of the part to be welded. The fixing device is simple in locating, convenient to control and operate and stable in running.

Owner:成都浩方机电有限责任公司

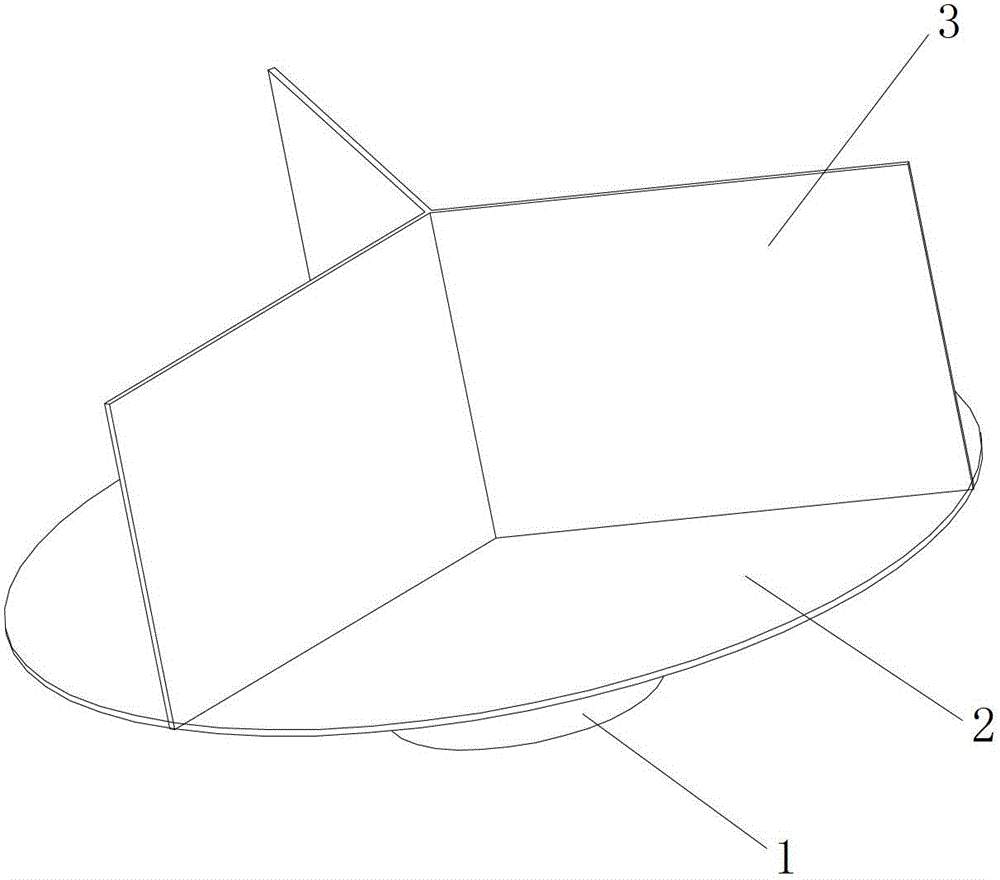

Multi-station spin welding platform

InactiveCN102873480ASimple structureLow costWelding/cutting auxillary devicesAuxillary welding devicesSpin weldingEngineering

The invention relates to a welding platform, in particular to a multi-station spin welding platform which comprises a turntable base, a turntable rotating shaft connected onto the turntable base, a turntable supporting base, a tooling placing table and a light-shading plate grid, wherein the turntable supporting base is connected with the upper end of the turntable rotating shaft and can rotate together with the turntable rotating shaft, the tooling placing table is fixedly connected onto the turntable supporting base, and the light-shading plate grid is arranged on the tooling placing table and evenly separates the tooling placing table into n equal parts. A servo motor used for driving the turntable rotating shaft to rotate is arranged in the turntable base, n position detection plates are arranged on the lower side of the turntable supporting base in protruding mode, a photoelectric detection switch used for detecting the positions of the position detection plates arranged on the lower side of the turntable supporting base is connected on one side of the turntable base, and n is a natural number equal to or larger than 2. The multi-station spin welding platform has the advantages of being capable of effectively improving work efficiency and reducing worker labor intensity, being low in cost and little in production area occupation, ensuring welding accuracy easily and the like.

Owner:LIUZHOU SHANCHUAN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com