Patents

Literature

204 results about "Chemical compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

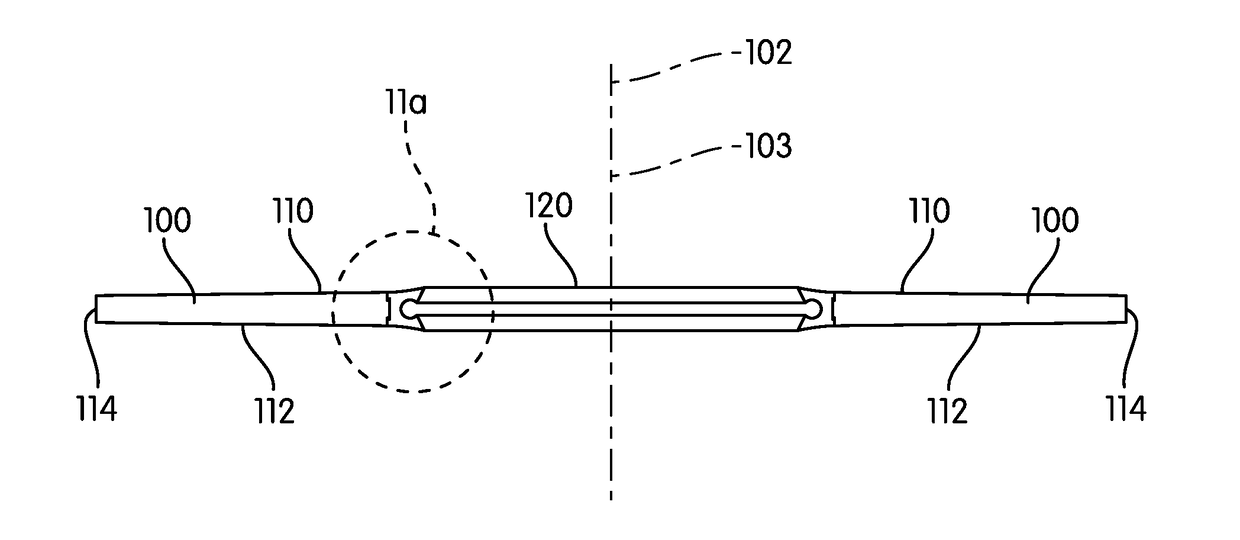

High temperature, high efficiency thermoelectric module

InactiveUS20100229911A1Low thermal conductivityImprove ZTThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsElectrical connection

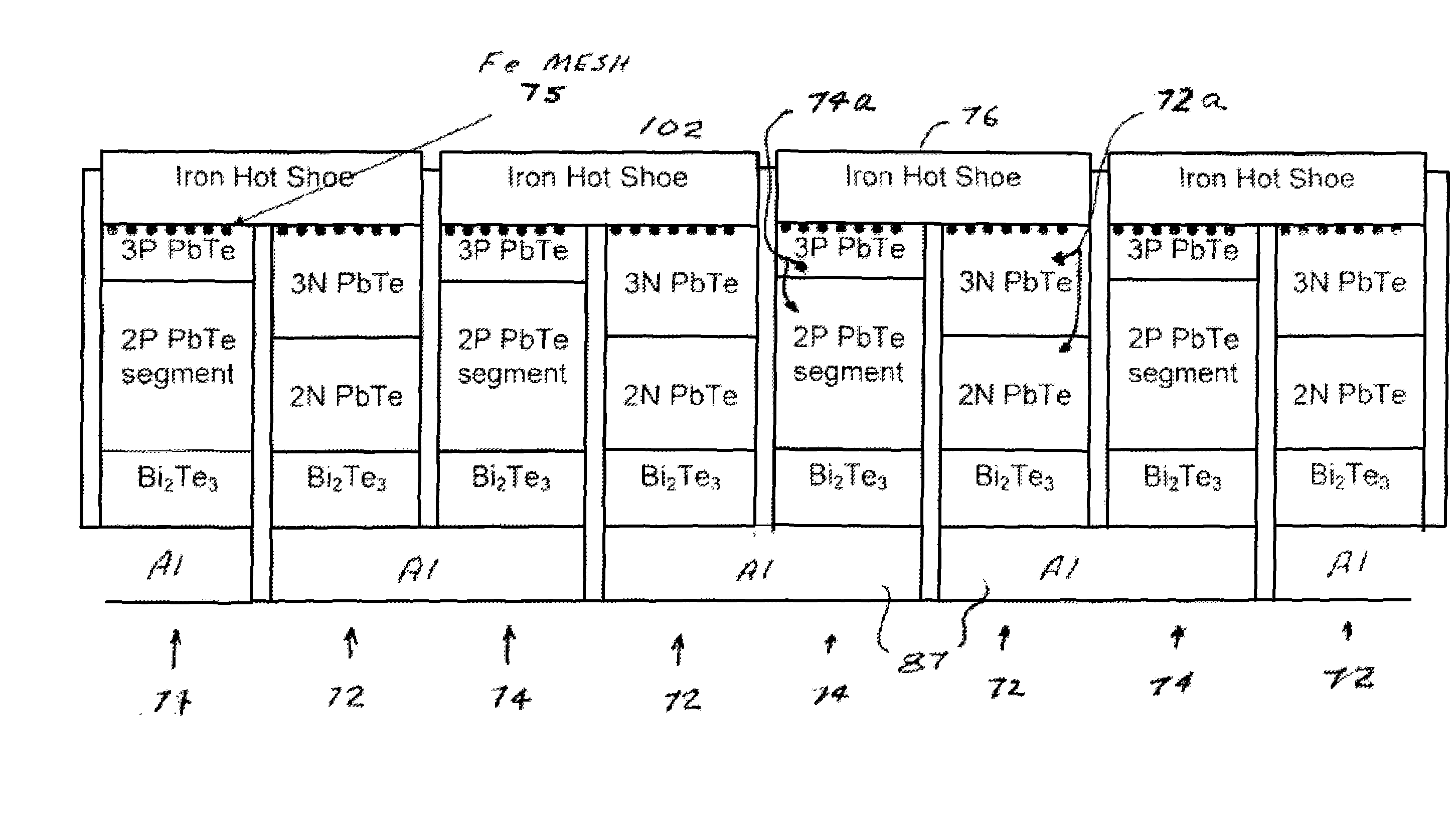

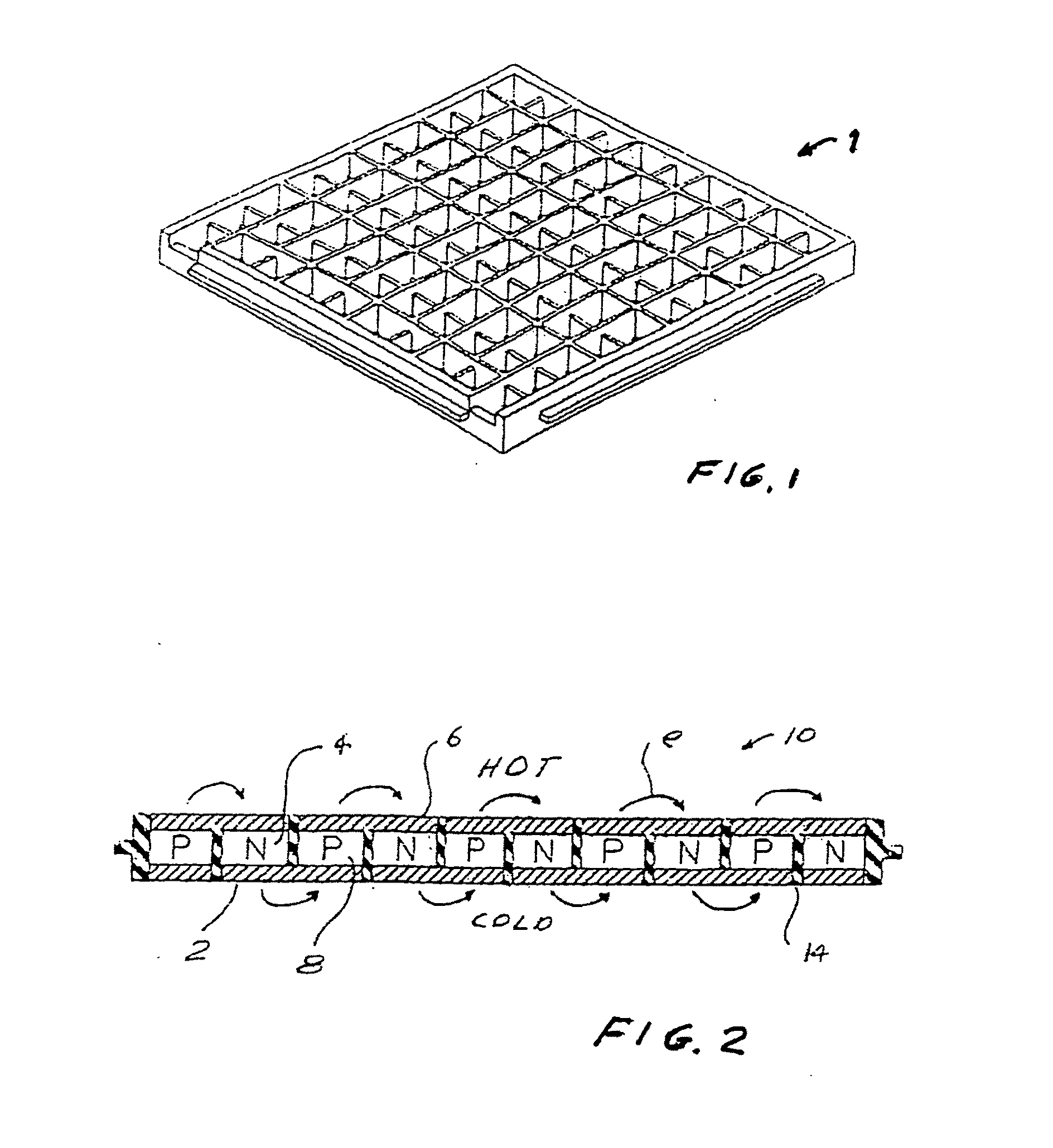

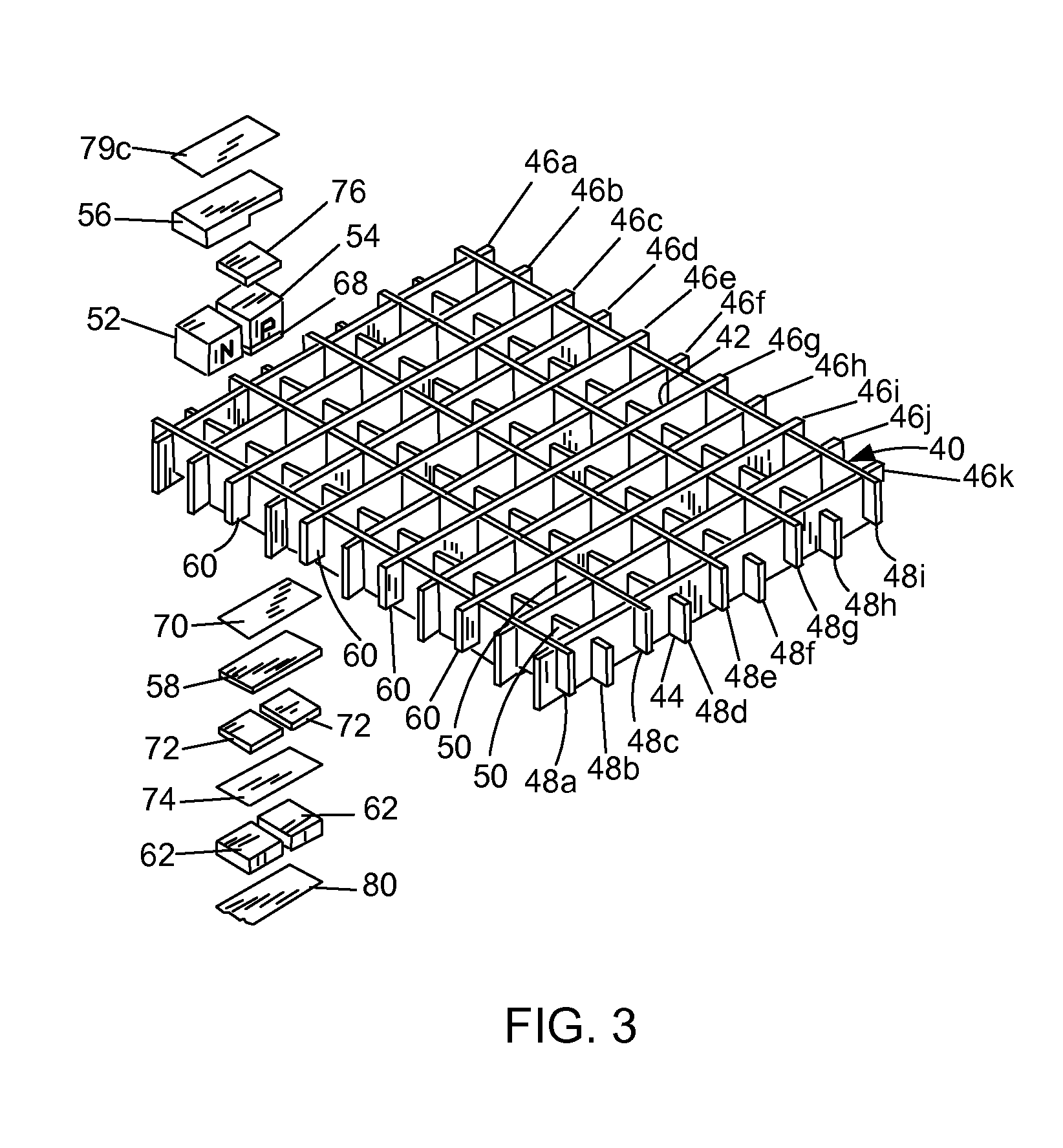

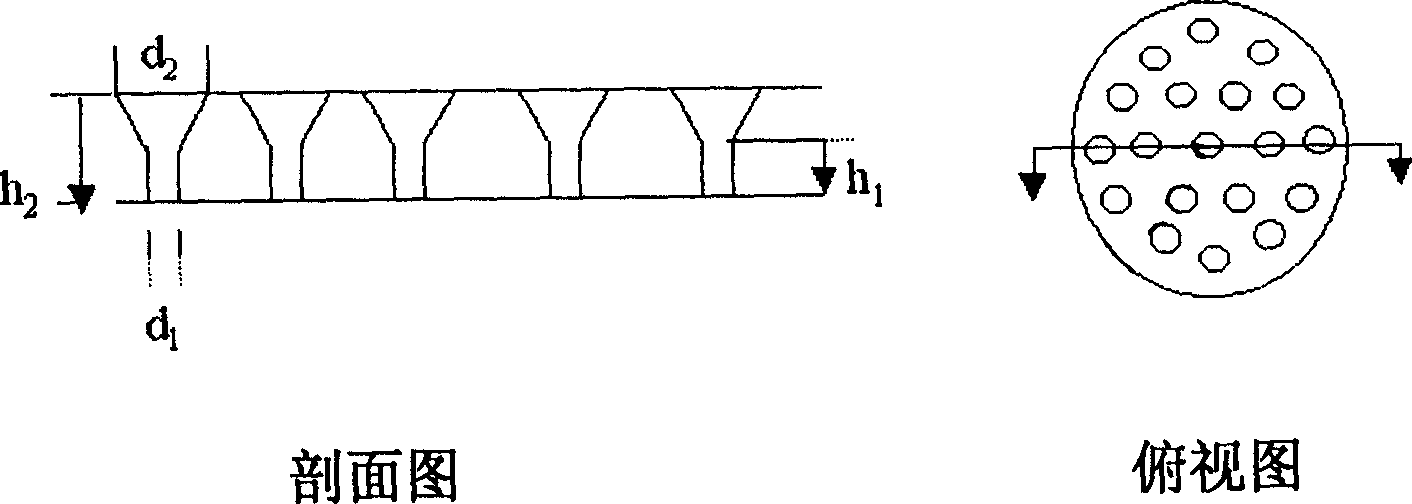

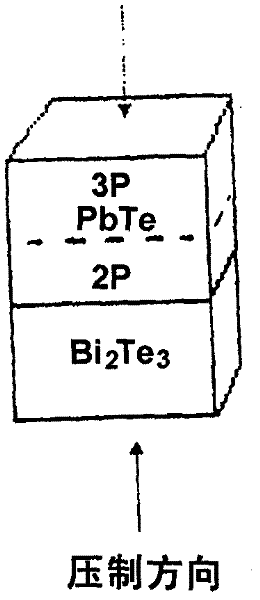

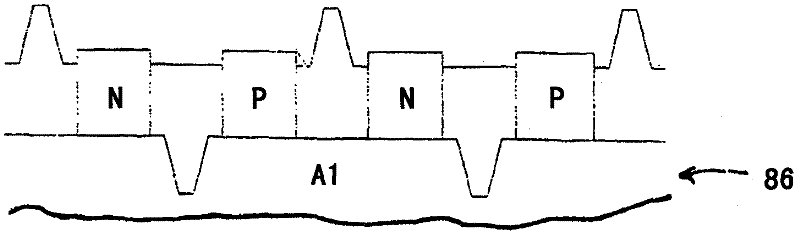

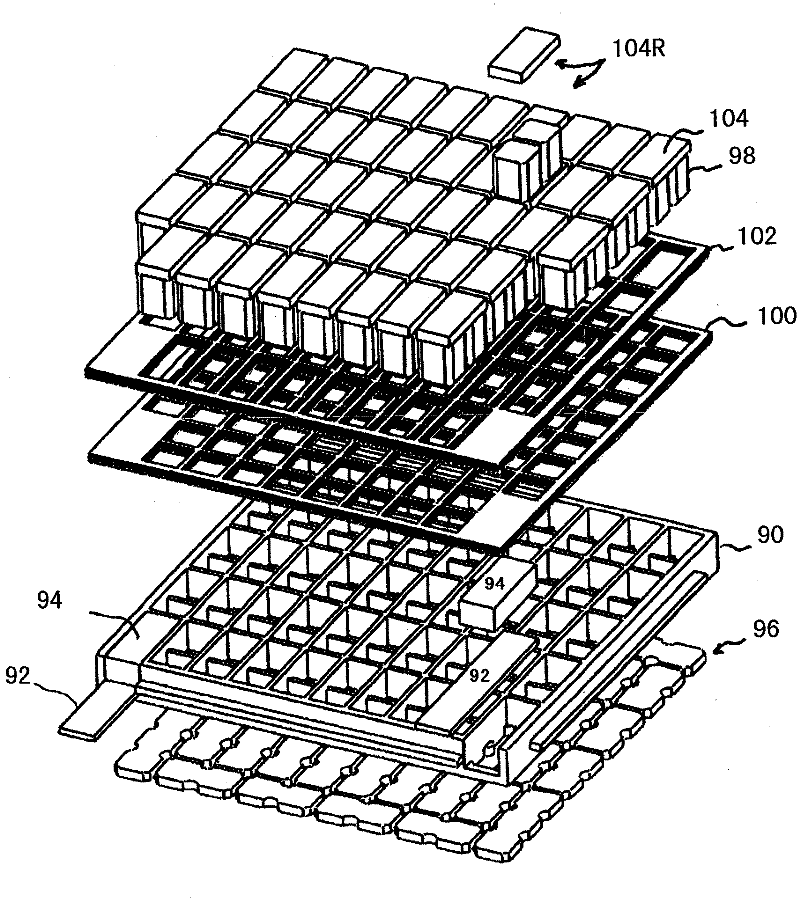

A long life, low cost, high-temperature, high efficiency thermoelectric module. Preferred embodiments include a two-part (a high temperature part and a cold temperature part) egg-crate and segmented N legs and P legs, with the thermoelectric materials in the three segments chosen for their chemical compatibility or their figure of merit in the various temperature ranges between the hot side and the cold side of the module. The legs include metal meshes partially embedded in thermoelectric segments to help maintain electrical contacts notwithstanding substantial temperature variations. In preferred embodiments a two-part molded egg-crate holds in place and provides insulation and electrical connections for the thermoelectric N legs and P legs. The high temperature part of the egg-crate is comprised of a ceramic material capable of operation at temperatures in excess of 500° C. and the cold temperature part is comprised of a thermoplastic material having very low thermal conductivity.

Owner:HI Z TECH +1

Skin care formulations

Disclosed are compositions and methods for treating skin comprising a chemically compatible combination of skin active ingredients comprising palmitoyl tetrapeptide-7, methylsilanol mannuronate, and Lactobacillus ferment, a chemically compatible combination of skin active ingredients comprising plant extracts from Punica granatum, Castanea sativa, Gossypium hirsutum, and Euterpe oleracea, and a dermatologically acceptable vehicle. The compositions can be substantive in that they can remain on a person's skin during sleep.

Owner:MARY KAY INC

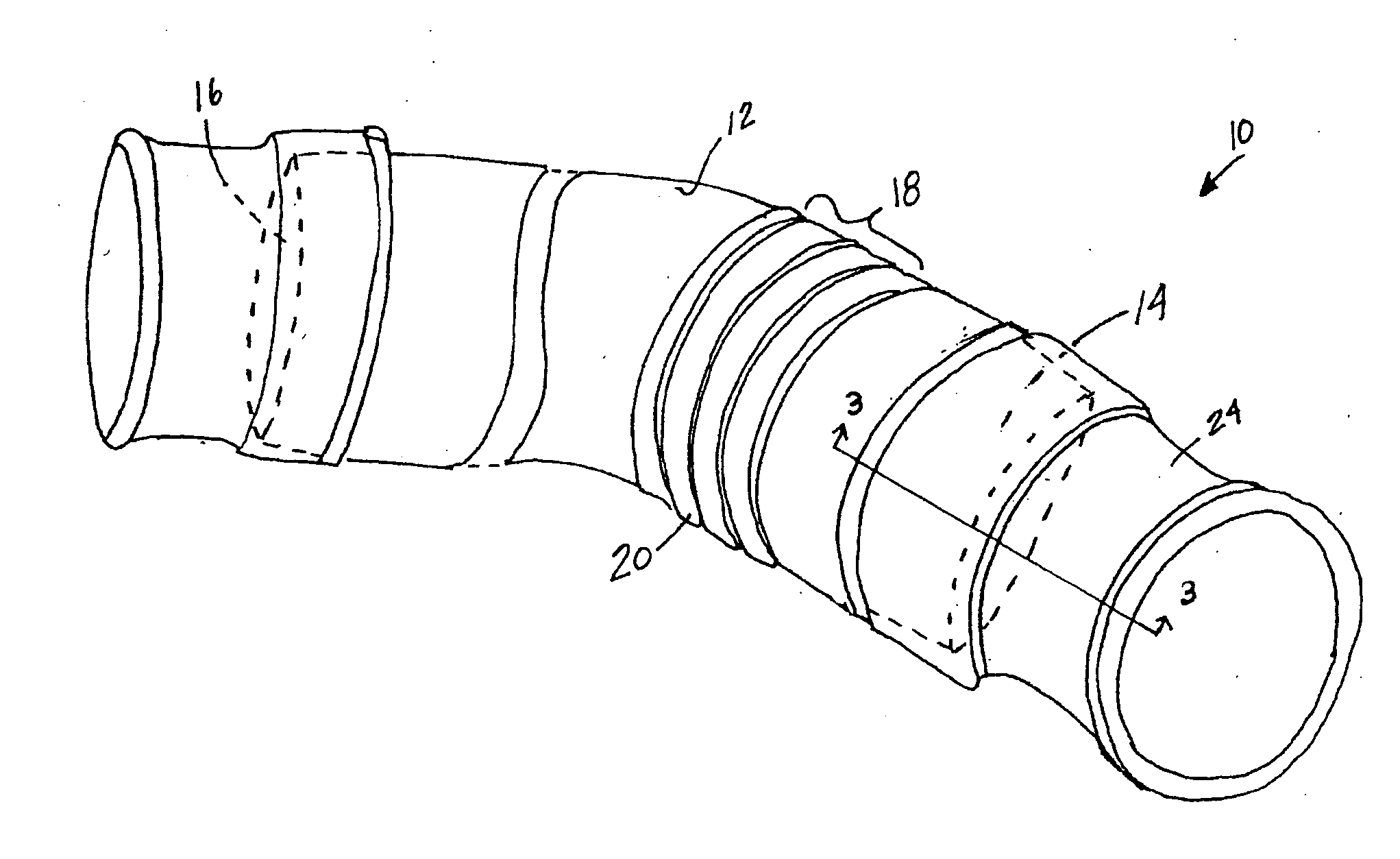

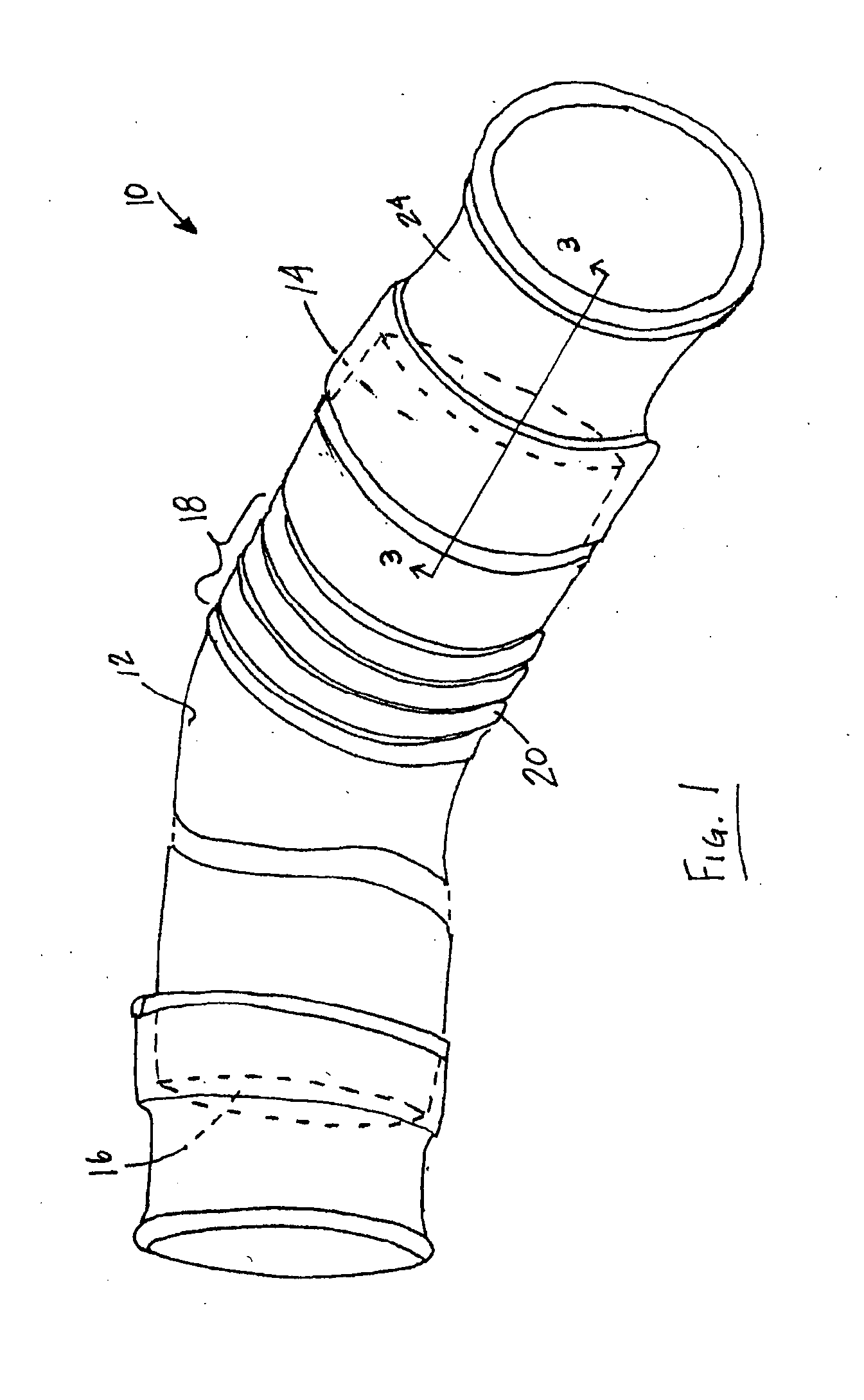

Two-shot or insert molded cuffs for welding onto clean air ducts

InactiveUS20060279084A1Simple interfaceWeld between the cuff member and the air duct body is improvedLighting and heating apparatusCombustion-air/fuel-air treatmentThermoplasticSpin welding

An air duct includes a rigid thermoplastic body having softer elastomeric cuff members welded to the ends thereof. The cuff members comprise an outer sealing component and a weldable insert bonded to at least a portion of the inner surface. The cuff members are adhered to the thermoplastic body at the weldable insert through a spin welding or other suitable welding process. The chemical compatibility between the insert and the thermoplastic body provides a robust weld at the interface.

Owner:ADVANCED ELASTOMER SYST LP

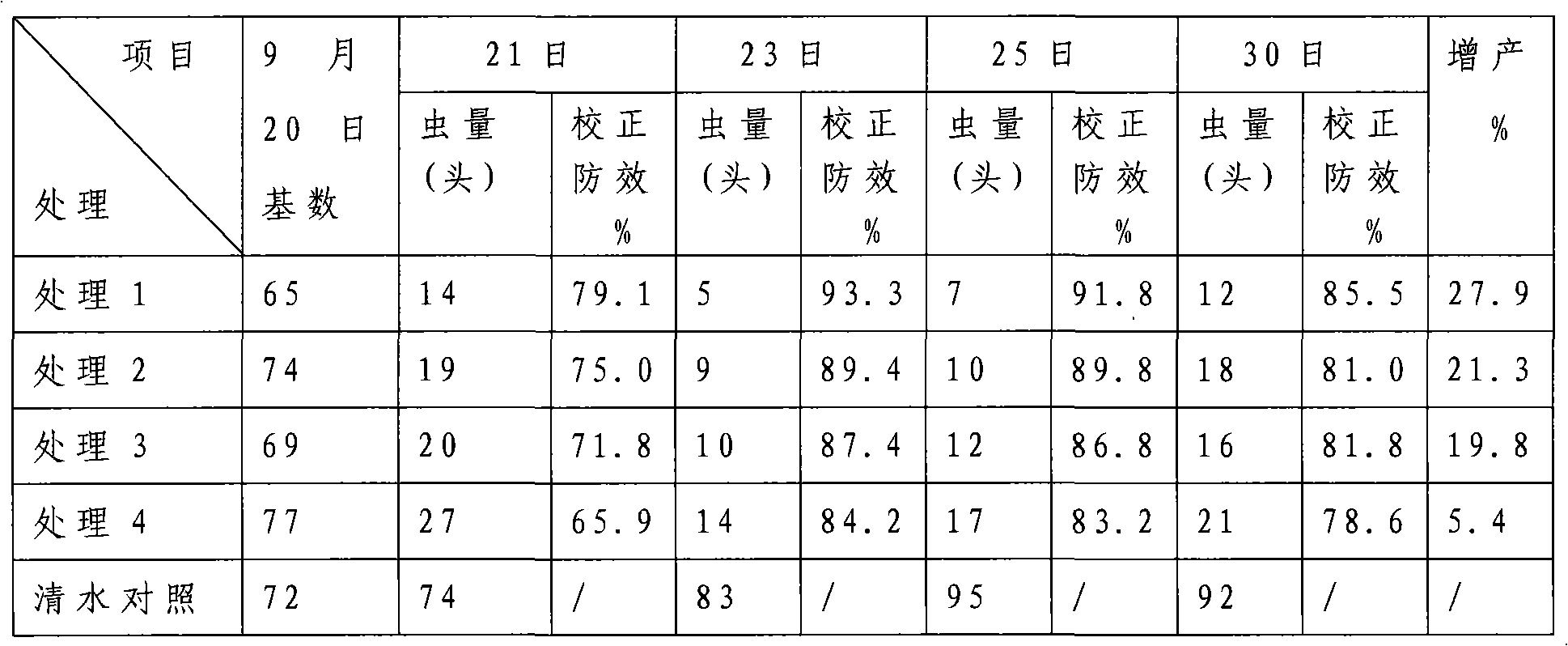

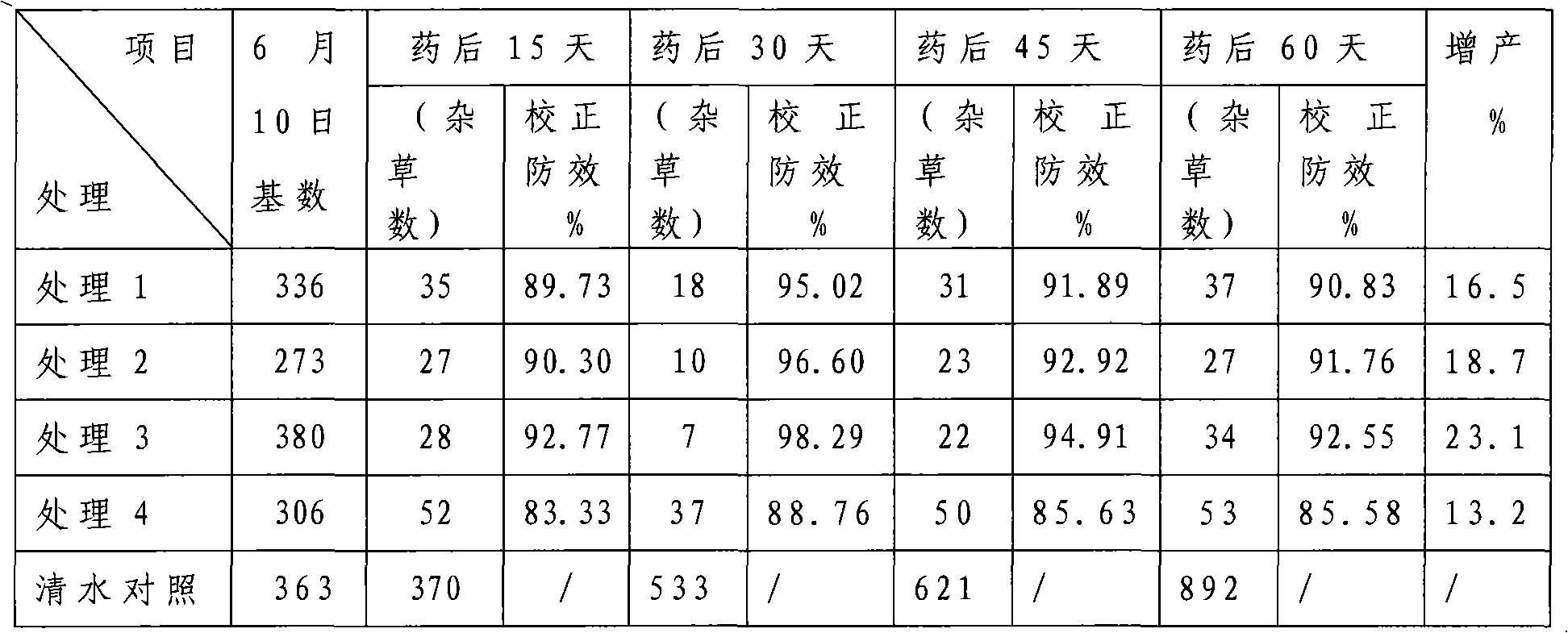

Microcapsule insecticide-fertilizer preparation, preparation method and application thereof

InactiveCN101857482ANo pollutionSlow release rateBiocidePlant growth regulatorsChemical compatibilitySolvent

The invention discloses a microcapsule insecticide-fertilizer preparation, a preparation method and application thereof. The preparation consists of the following components in part by weight: 1 to 30 parts of pesticide microcapsules and 70 to 99 parts of nutrient substance. The preparation method mainly comprises the following steps of: after fully dissolving a pesticide with a solvent, adding a wall material monomer into solution and mixing uniformly; transporting a mixture into a shear dispersion reaction kettle which is filled with smashed capsule bodies; stirring the mixture and the capsule bodies so that the capsules fully absorb the solution; performing a shear dispersion reaction to form capsules; performing solid-liquid separation and drying to prepare the pesticide microcapsules; adding the nutrient substances into the pesticide microcapsules; and fully stirring and uniformly mixing to prepare the microcapsule insecticide-fertilizer preparation. By using the microcapsule insecticide-fertilizer preparation and the preparation method, the problems of the chemical compatibility and the physical stability of the conventional insecticide-fertilizer preparation in the same system are solved effectively. A product of the invention has the advantages of: shielding and slow-releasing functions, high chemical compatibility and physical stability, lasting pesticide effect, natural degradability, no environment pollution, low use cost and simple production process.

Owner:侯金荣 +1

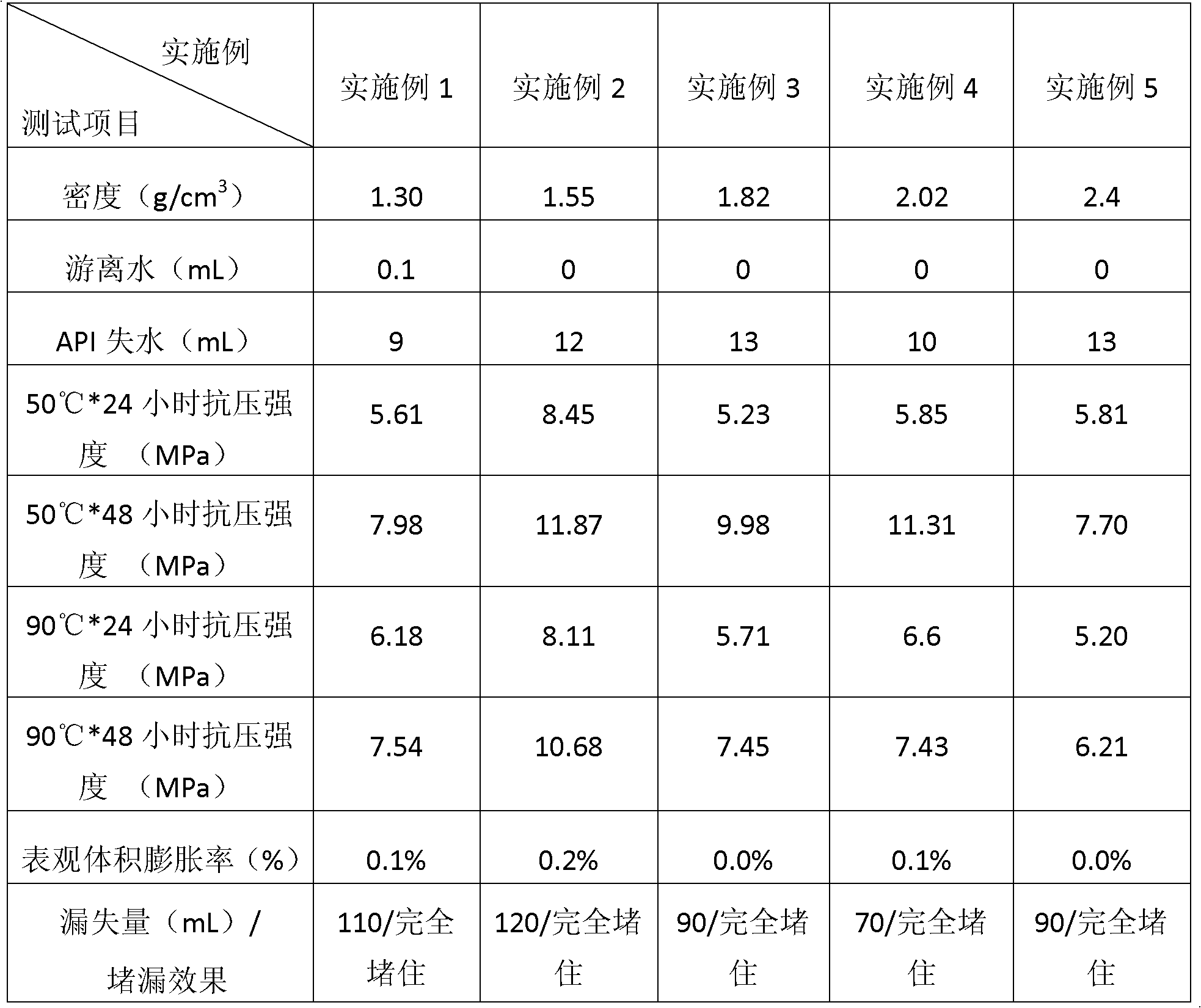

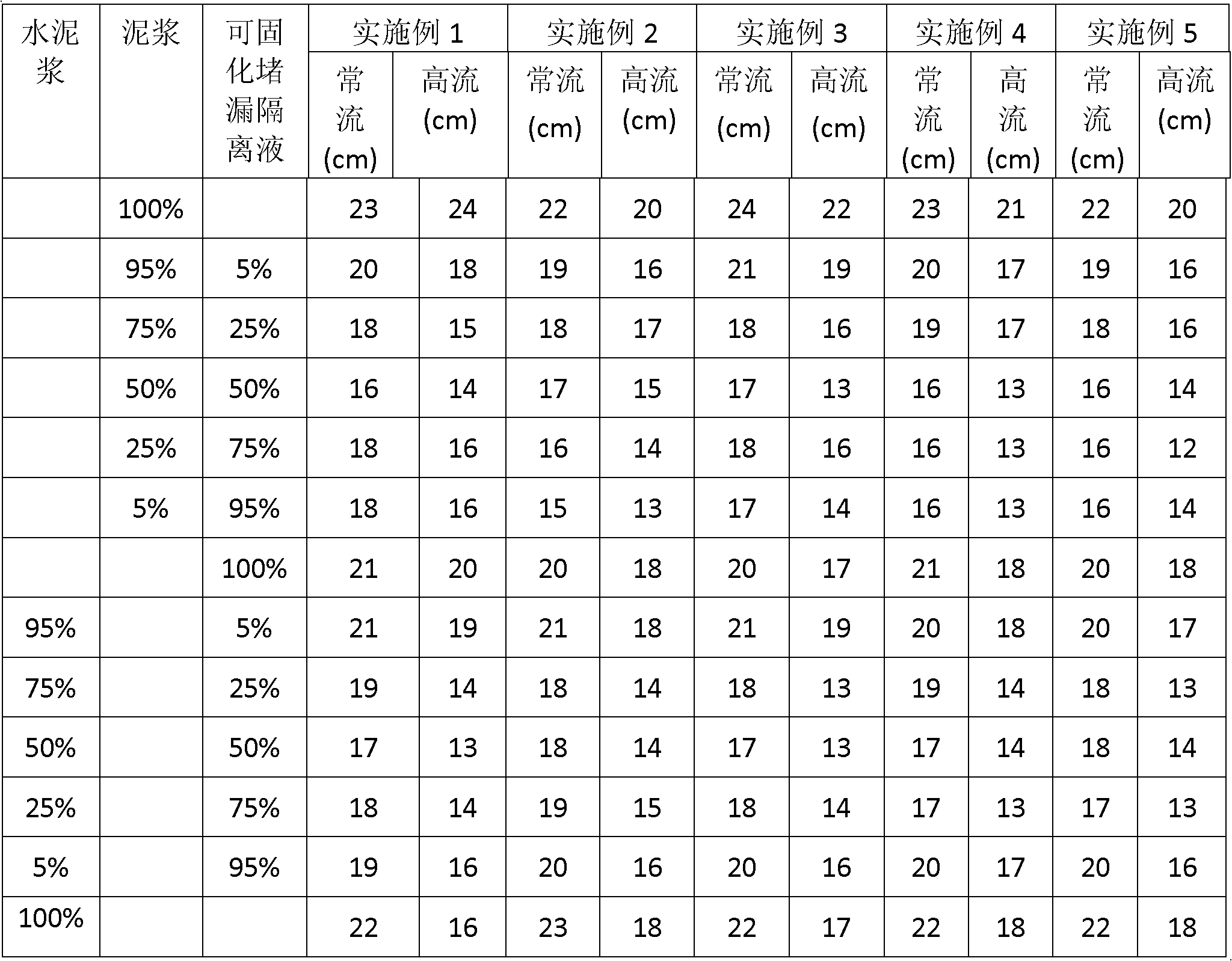

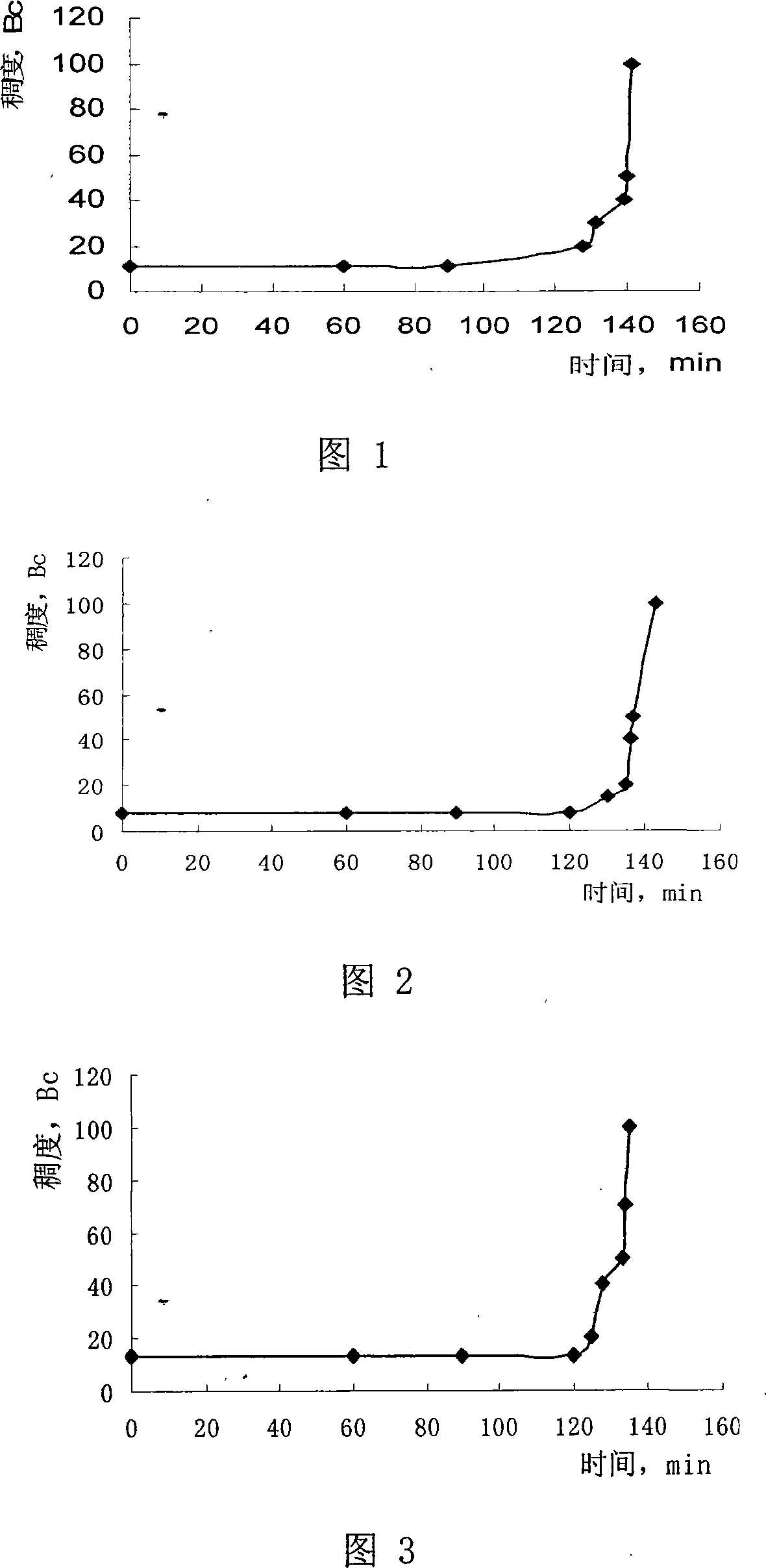

Curable leaking stoppage spacer fluid and preparation method thereof

The invention relates to a curable leaking stoppage spacer fluid and a preparation method thereof. The spacer fluid comprises the following components according to parts by weight: 450 parts of fresh water, 400-600 parts of curing agent, 3-10 parts of stabilizing agent, 2-20 parts of suspending agent, 10-40 parts of activating agent, 10-60 parts of activating auxiliary agent and 10-700 parts of density regulator, wherein the curing agent is slag powder; the stabilizing agent is clay; the suspending agent is sodium bentonite or calcium bentonite; the activating agent is the mixture of sodium hydroxide and sodium carbonate; the activating auxiliary agent is the mixture of sodium silicate and calcium oxide; and the density regulator can be iron ore powder for well cementation or coal ash hollow microsphere. After the curable leaking stoppage spacer fluid is cured, the lamination capability can reach more than 5MPa, the spacer fluid shows good chemical compatibility with mud and cement paste and good curing performance between 30-130 DEG C; after the spacer fluid is cured, the appearance of a formed cured body has non volume contraction; therefore, the spacer fluid can effectively pack a stratum dropping passage and provides guarantees for the follow-up operation of oil and gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

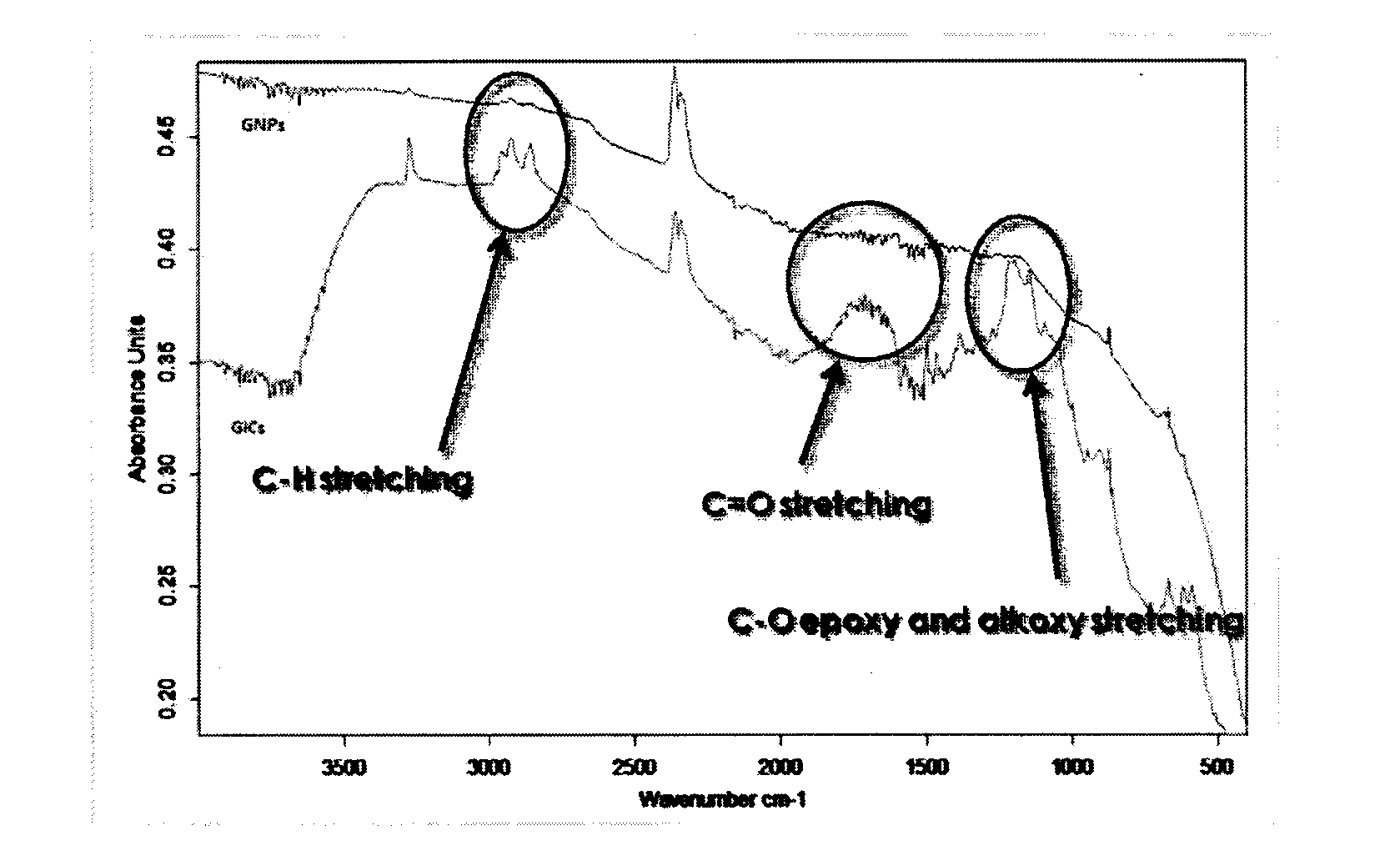

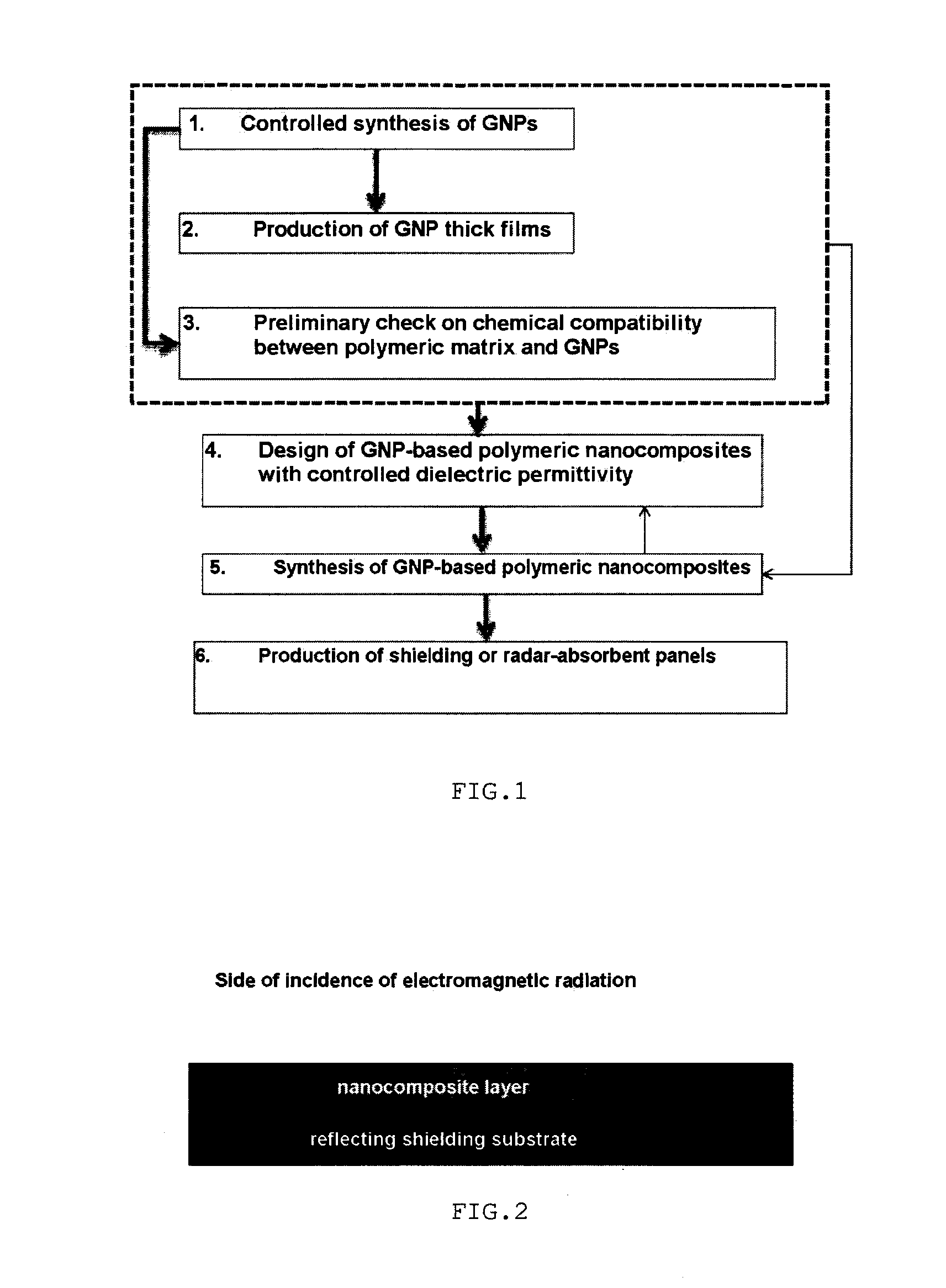

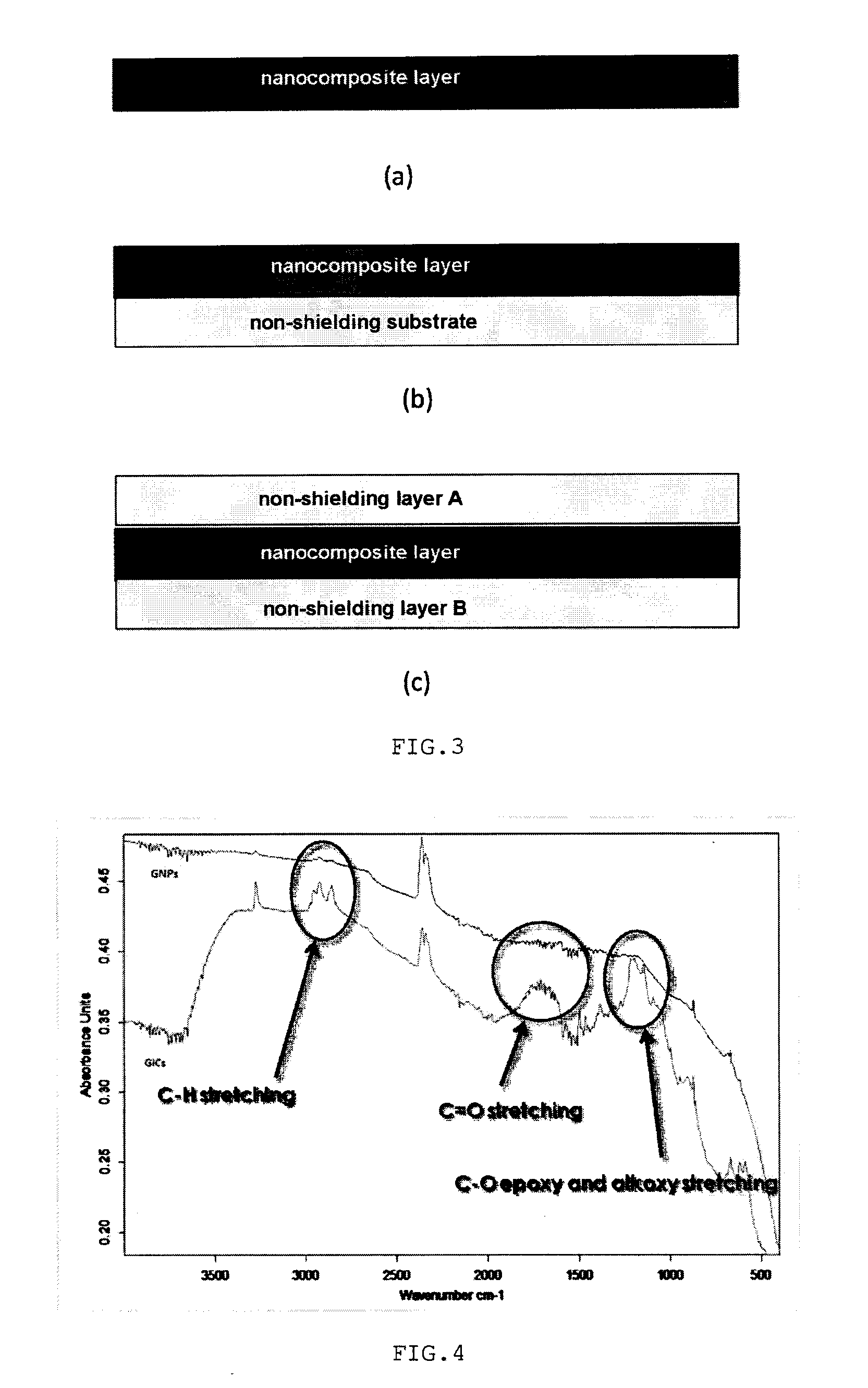

Graphene nanoplatelets- or graphite nanoplatelets-based nanocomposites for reducing electromagnetic interferences

InactiveUS20150305212A1Easy to operateSuitable for low-cost mass productionMaterial nanotechnologyNon-metal conductorsModel parametersChemical compatibility

A process for producing GNP-based polymeric nanocomposites for electromagnetic applications such as shielding and / or absorption of the energy associated to electromagnetic fields envisages a plurality of steps that include: controlled synthesis, for optimizing the morphological and electrical properties thereof, of graphene nanoplatelets (GNPs) to be used as nanofillers in a polymeric matrix; selection of the polymeric matrix so as to optimize its chemical compatibility with the type of GNPs thus obtained; production via the solution-processing technique of GNP-based polymeric nanocomposites with dielectric permittivity and electric conductivity controlled and predictable via the equivalent-effective-medium model by calibrating the parameters of the model for the specific type of polymeric matrix and GNPs used.

Owner:UNIV DEGLI STUDI DI ROMA LA SAPIENZA

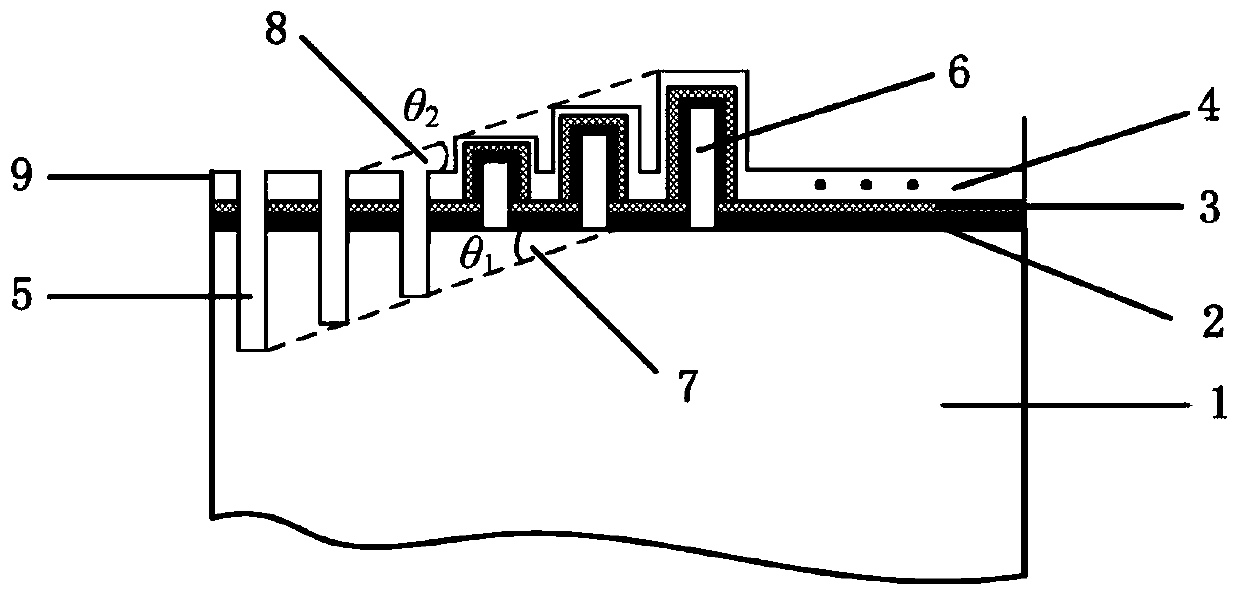

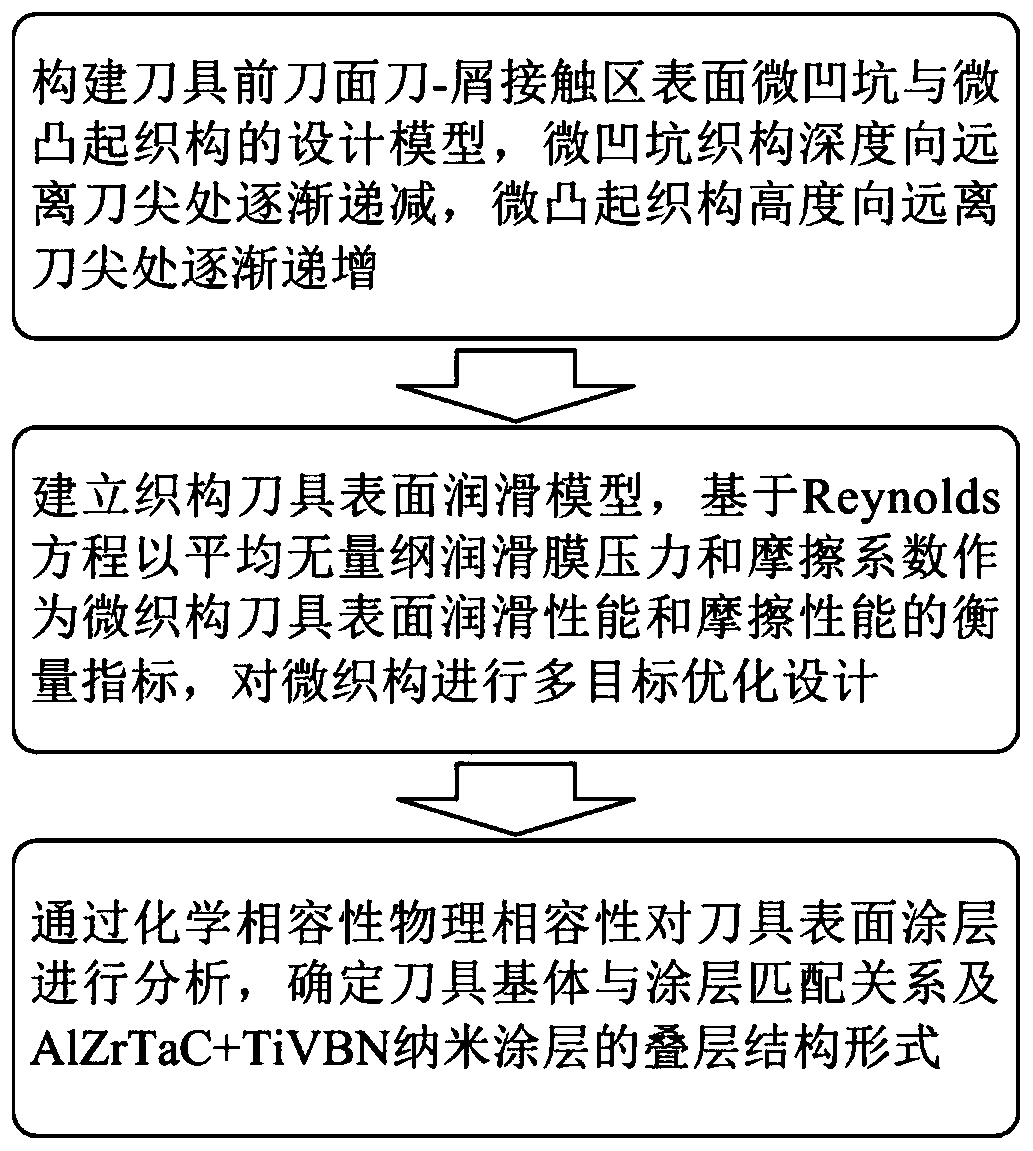

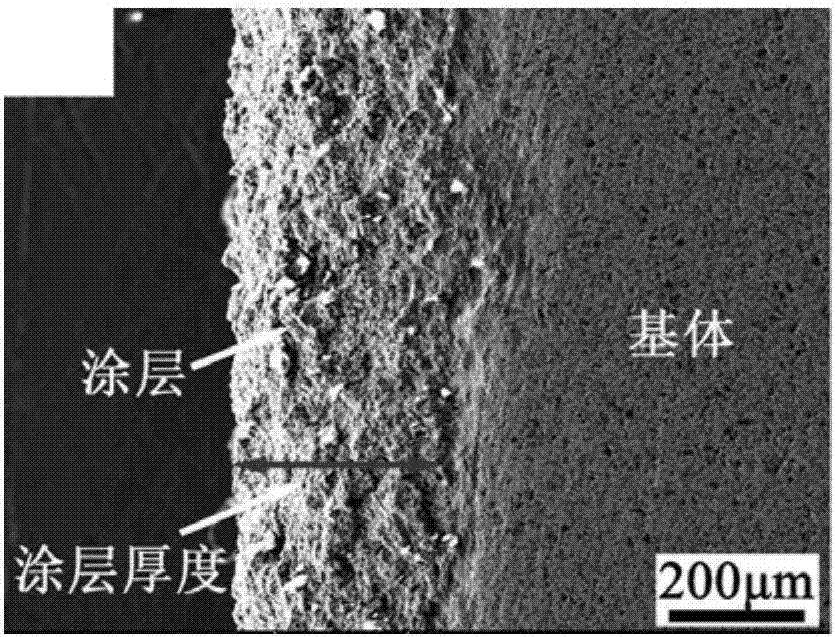

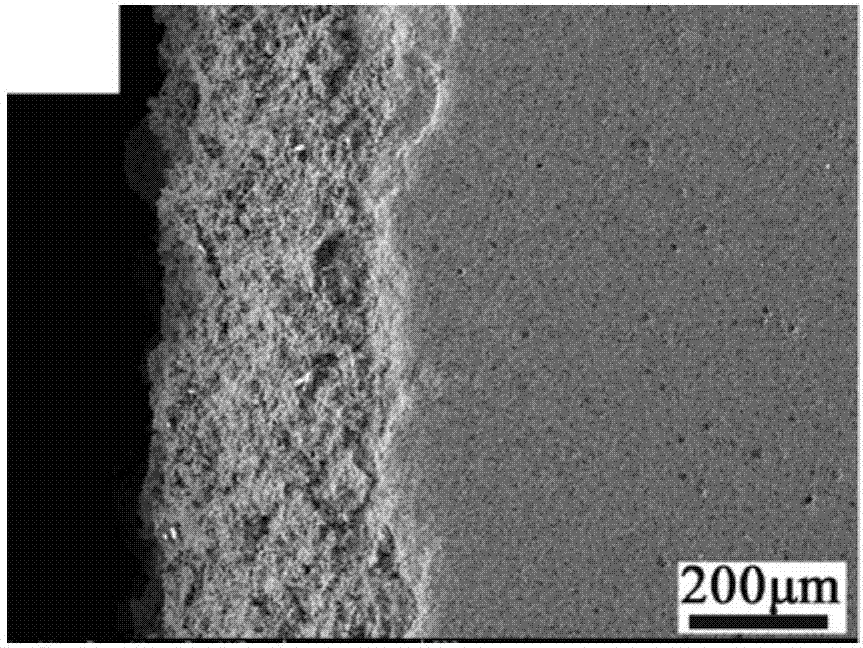

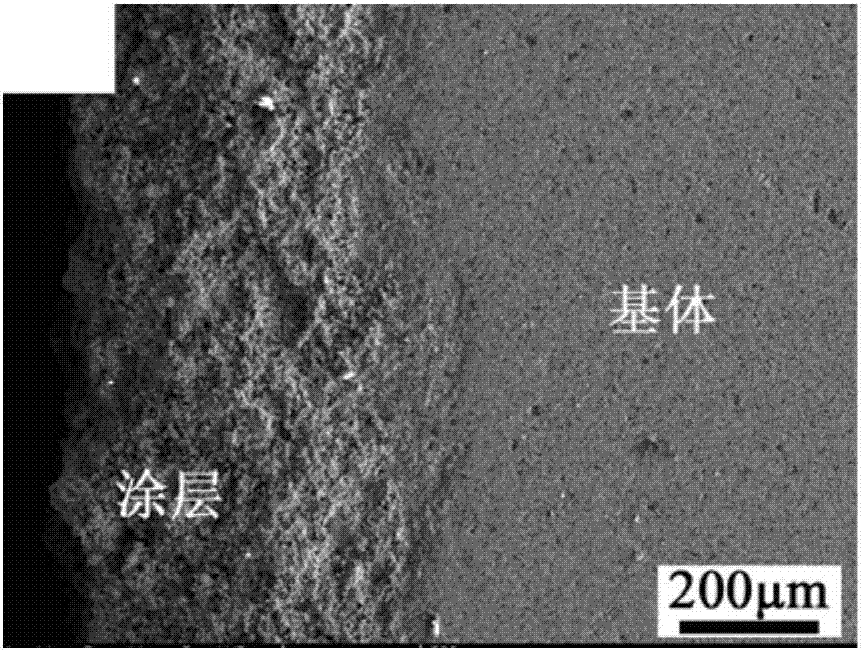

Bionic texture and coating layer cooperated anti-friction cutter and design method thereof

The invention discloses a bionic texture and coating layer cooperated anti-friction cutter and a design method thereof. The cutter adopts a basal body material of high-speed steel, hard alloys or ceramic; a bionic micro pit and micro projection composite texture is arranged in a cutter-chip contact area on the front cutter surface of the basal body material of the cutter; AlZrTaC+TiVBN alternate-distributed nanometer laminate coating layers are arranged on the surfaces of the texture and a basal body; the alternate laminate coating layers at least comprise single layers of 10 AlZrTaC layers and 10 TiVBN layers; and the thickness of the single layers of AlZrTaC and TiVBN is not bigger than100 nm. The design method of the cutter comprises the following steps: a design model of a micro texture on the surface of the cutter-chip contact area on the front cutter surface of the cutter is built; the oil film pressure and the friction coefficients of the cutter-chip contact interface are analyzed based on a Reynolds equation to optimize the geometric size of the micro texture and the depth or height gradual change dip angles theta 1 and theta 2; and through physical compatibility and chemical compatibility analysis, a laminate structural form of AlZrTaC+TiVBN coating layers is built. The cutter synthesizes the characteristics of the micro texture and the nanometer laminate coating layers, can reduce the friction and the wear of the cutter in the lubricating liquid cutting process, and can be widely applied to the cutting in the cutting liquid mode.

Owner:SOUTHEAST UNIV

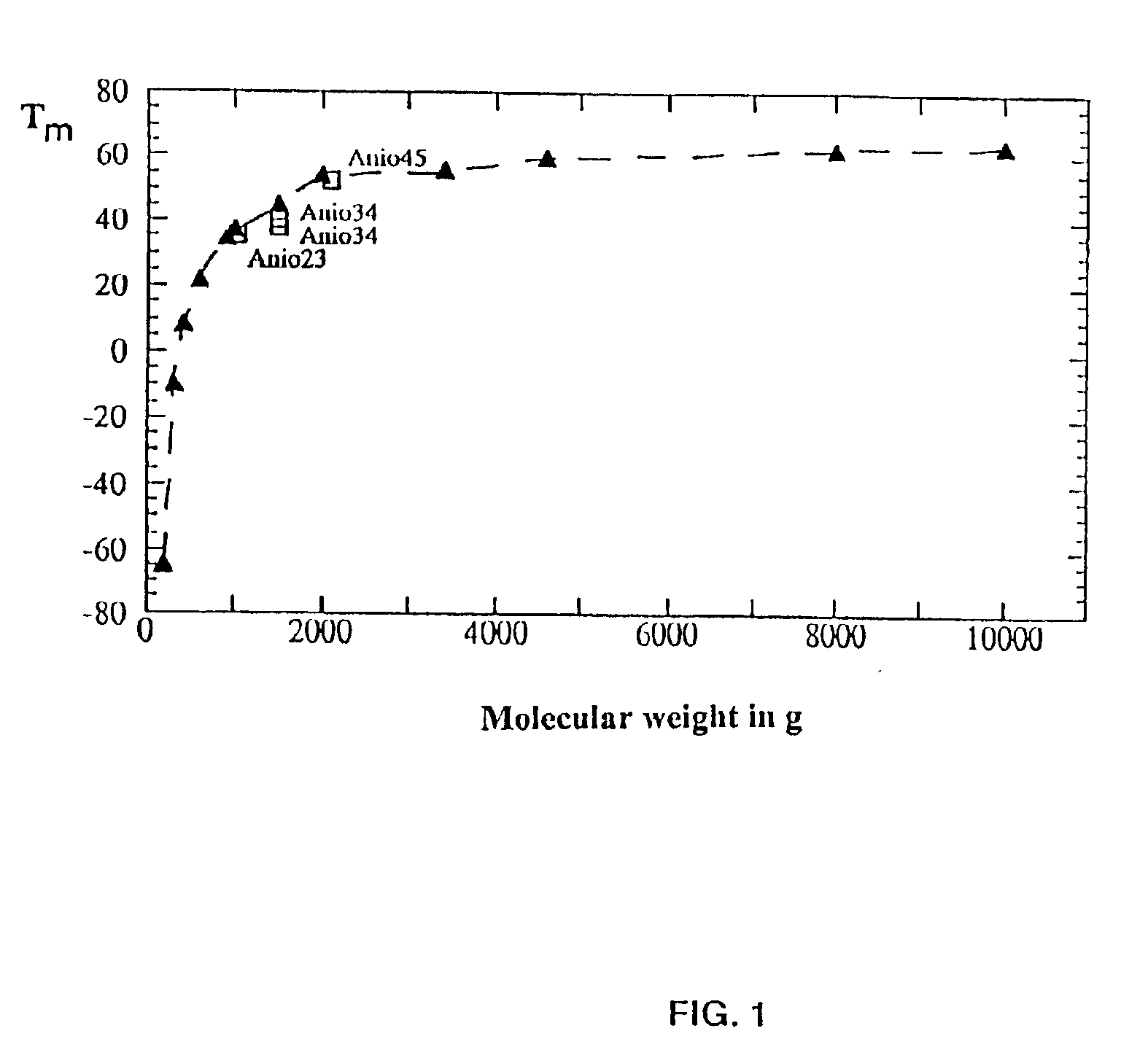

Copolymer of ethylene oxide and at least one substituted oxirane carrying a cross-linkable function, process for preparation thereof and use thereof for producing materials with ionic conduction

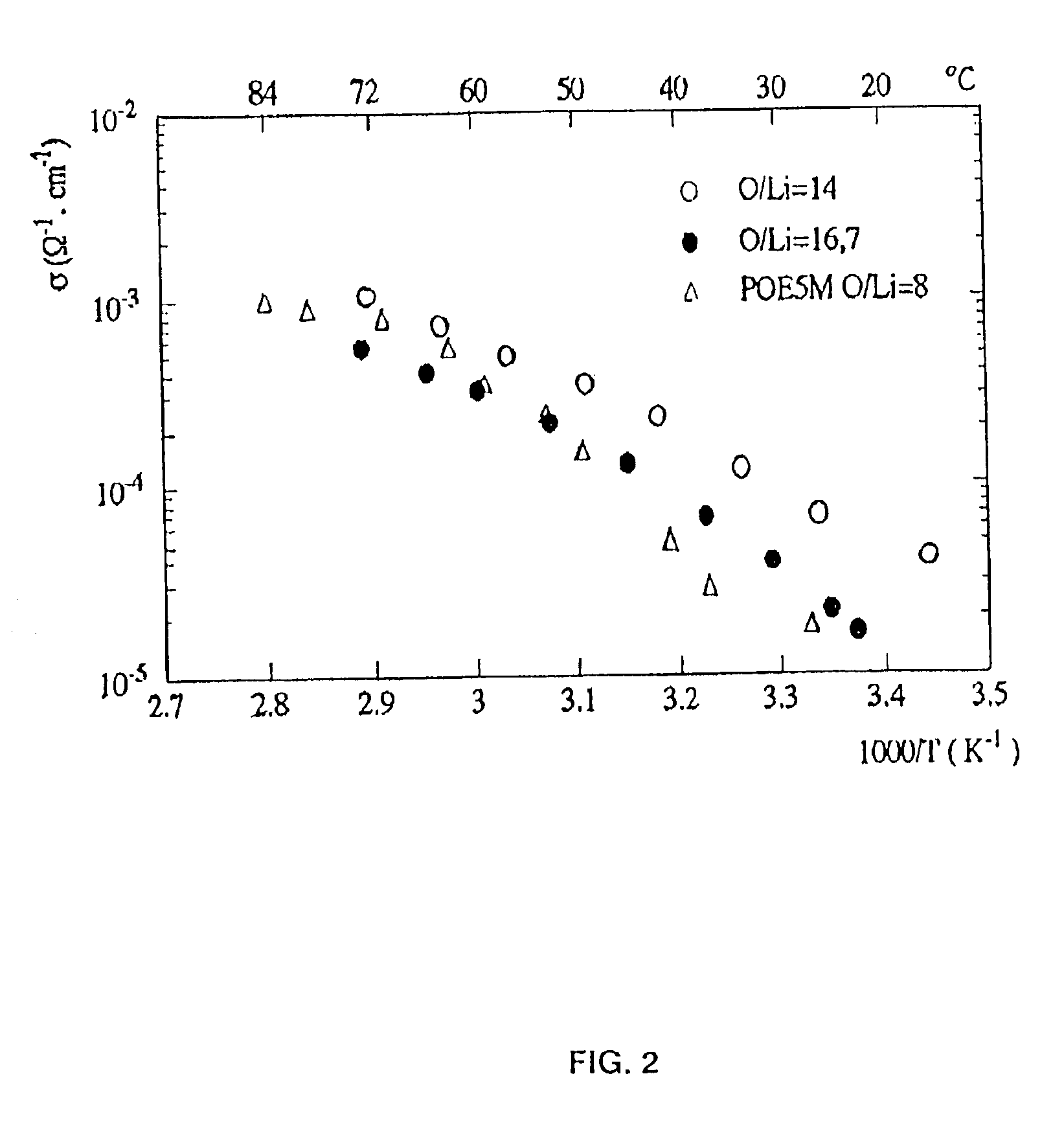

InactiveUS6903174B2High reaction yieldLess impuritiesConductive materialSolid electrolyte cellsLithiumEthylene oxide

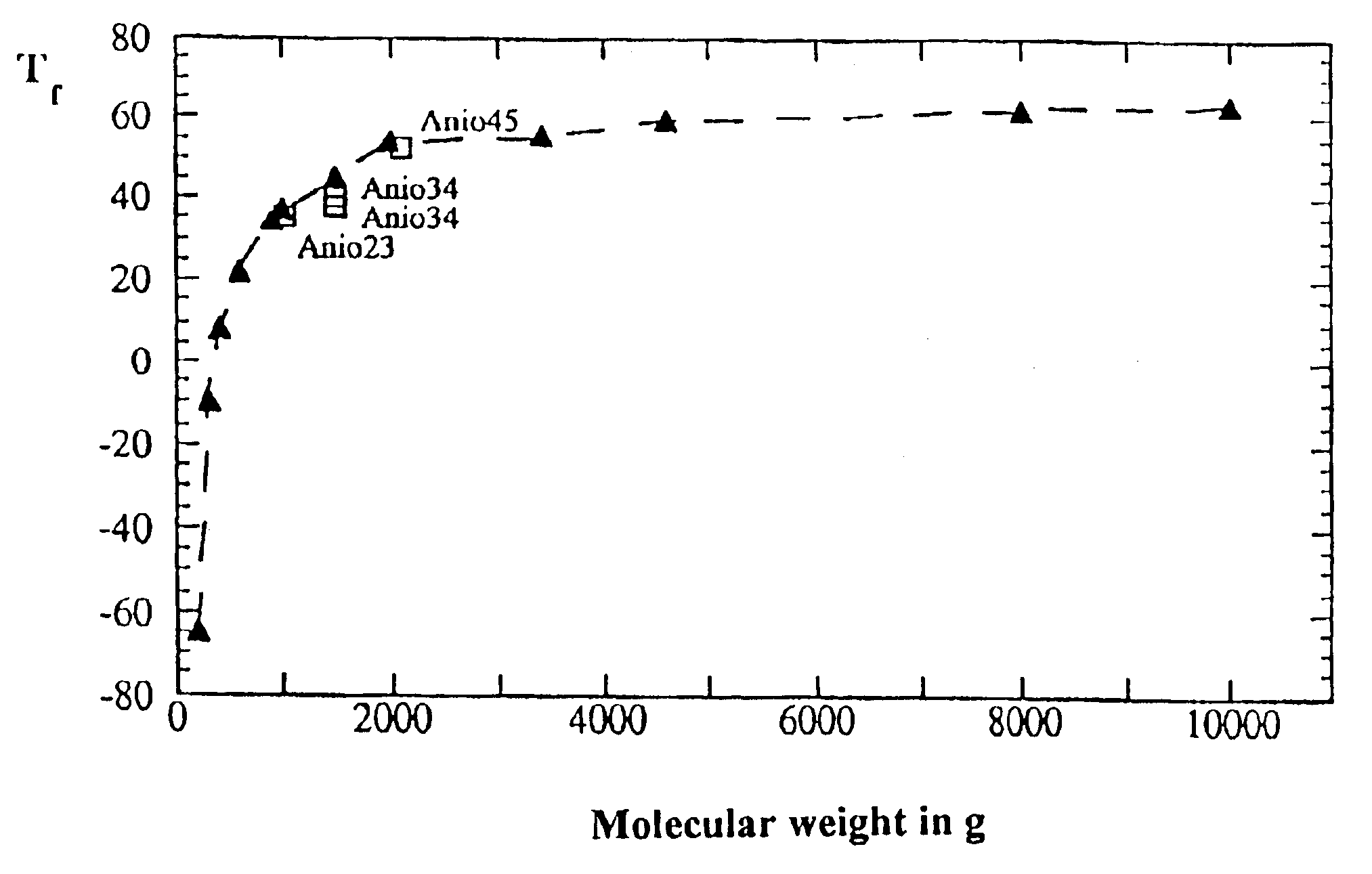

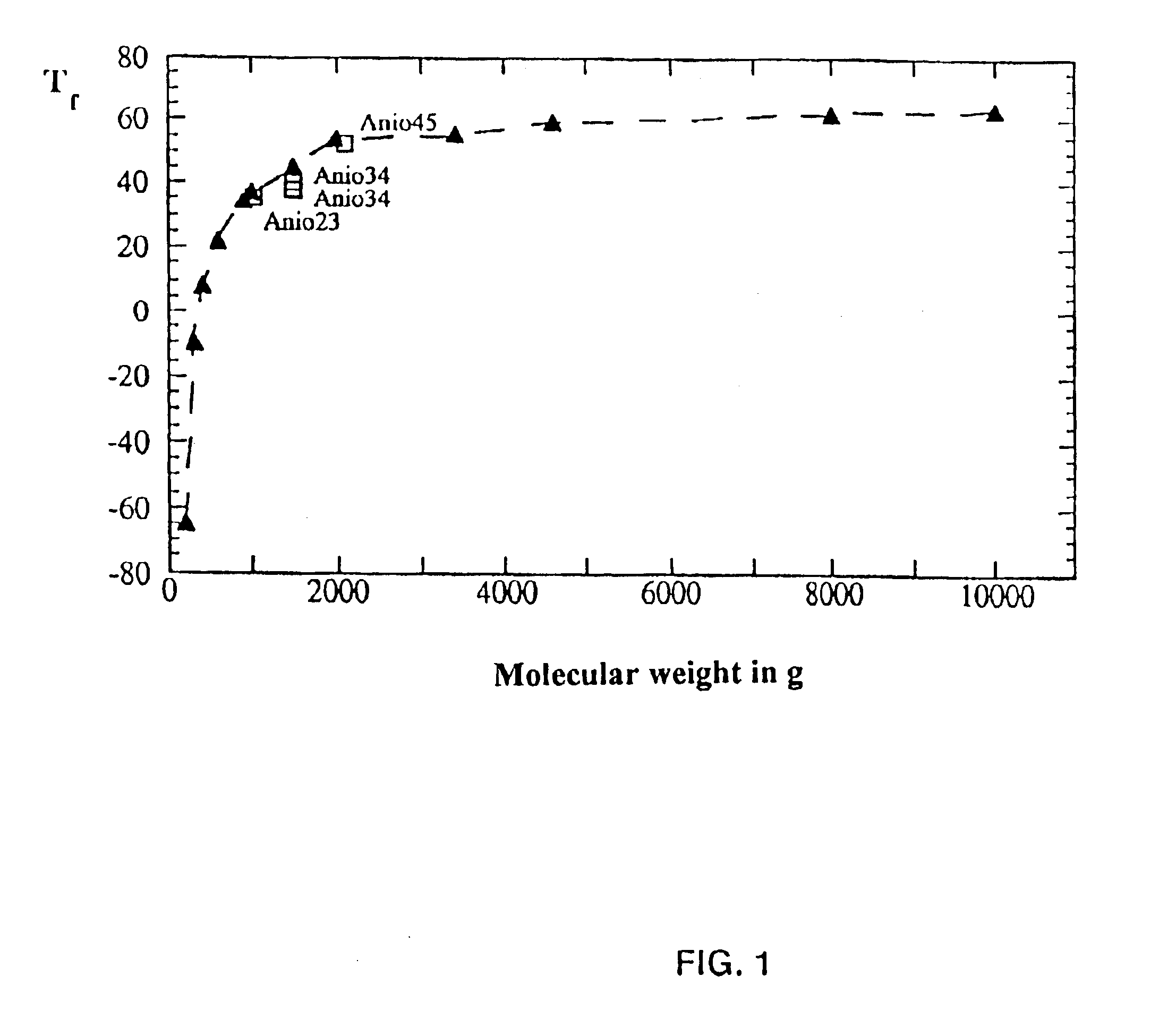

The invention concerns a copolymer of ethylene oxide and at least one substituted oxirane carrying a cross-linkable function. The copolymer comprises ethylene oxide, —O—CH2—CHR— units in which R is a substituent containing a reactive function which is cross-linkable by free radical process, R may be different from one unit to the other, and possibly —O—CH2—CHR′— units in which R′ is a substituent containing no reactive function which is cross-linkable by means of a free radical process, R′ may be different from one unit to the other. It is characterized by an excellent polymolecularity index I=Mw / Mn and a statistical distribution of the different monomer units. The copolymer is prepared by an anionic copolymerization process. The copolymer is useful for preparing a solid electrolyte having good mechanical properties, a good cationic conductivity and a good chemical compatibility with the electrodes of a generator operating with alkali metals such as lithium and sodium.

Owner:BATHIUM CANADA

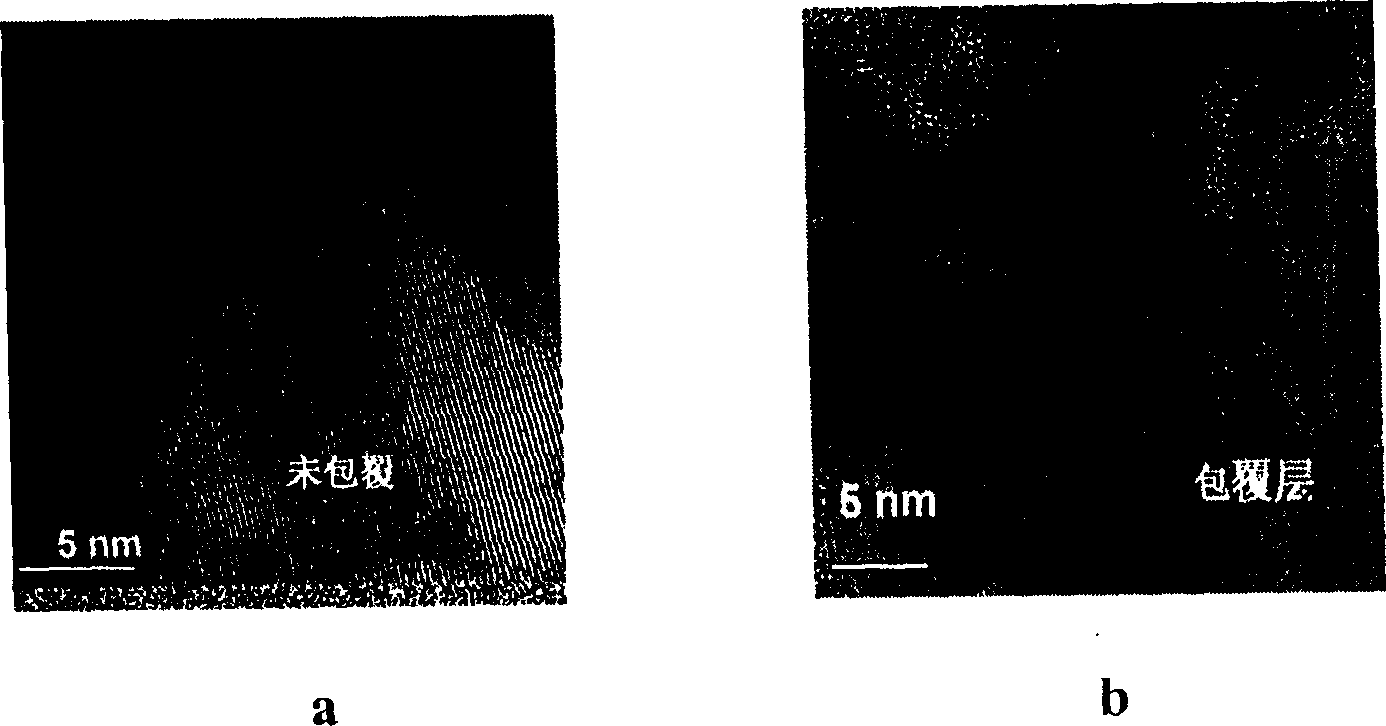

Nano particle surface physicochemical structure cutting and coating method

InactiveCN1488462AEasily brokenPromote infiltrationVacuum evaporation coatingSputtering coatingChemical structureSurface roughness

The invention is a cutting and coating method for surface physical and chemical structure of nano particles. Through confecting the radio frequency plasma to control pulse ratio, time, power, and furthermore control the kind, content, sediment layer thickness the coarse rate of packing film of functional group, it can cut and coat the special monomer molecular functional group film on the surface of the nano particles, and adjusts the thickness, surface coarse rate and so on, gets the coating film with special physical and chemical structure, changes the physical and chemical structure of nano particles.

Owner:DONGHUA UNIV

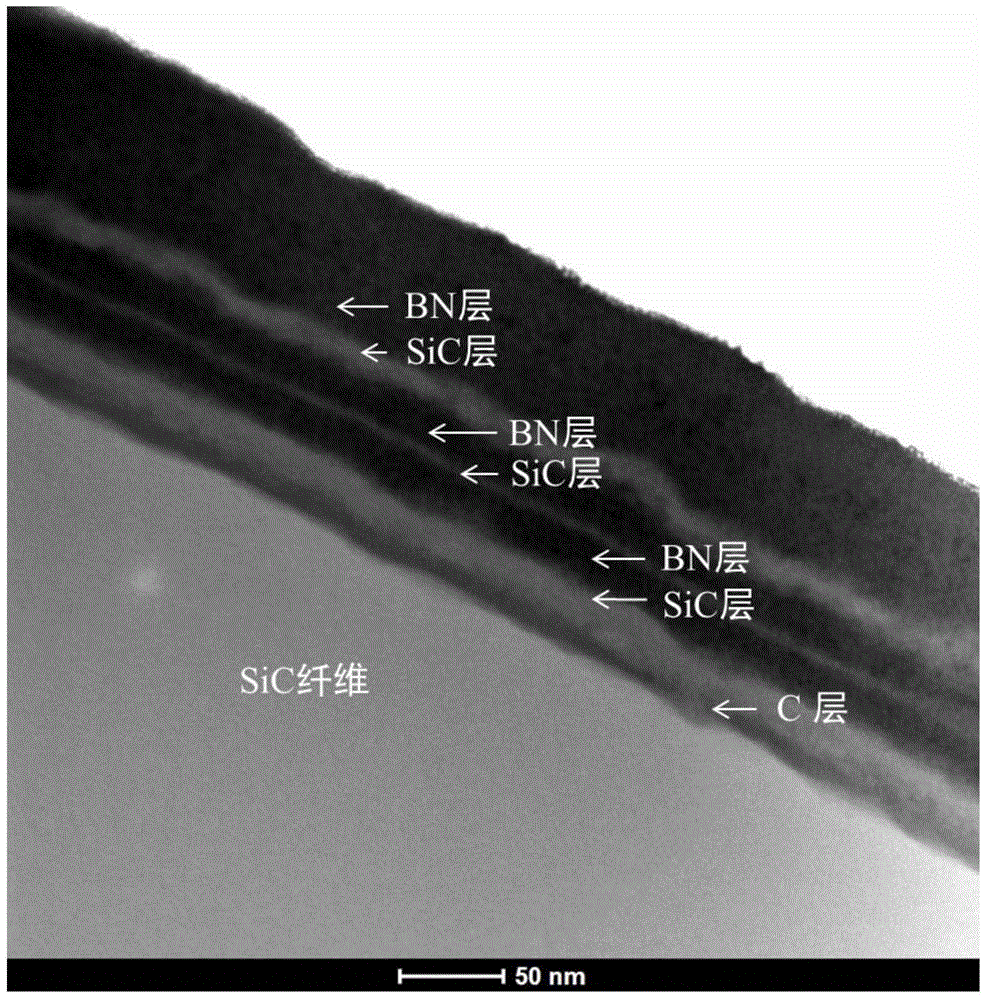

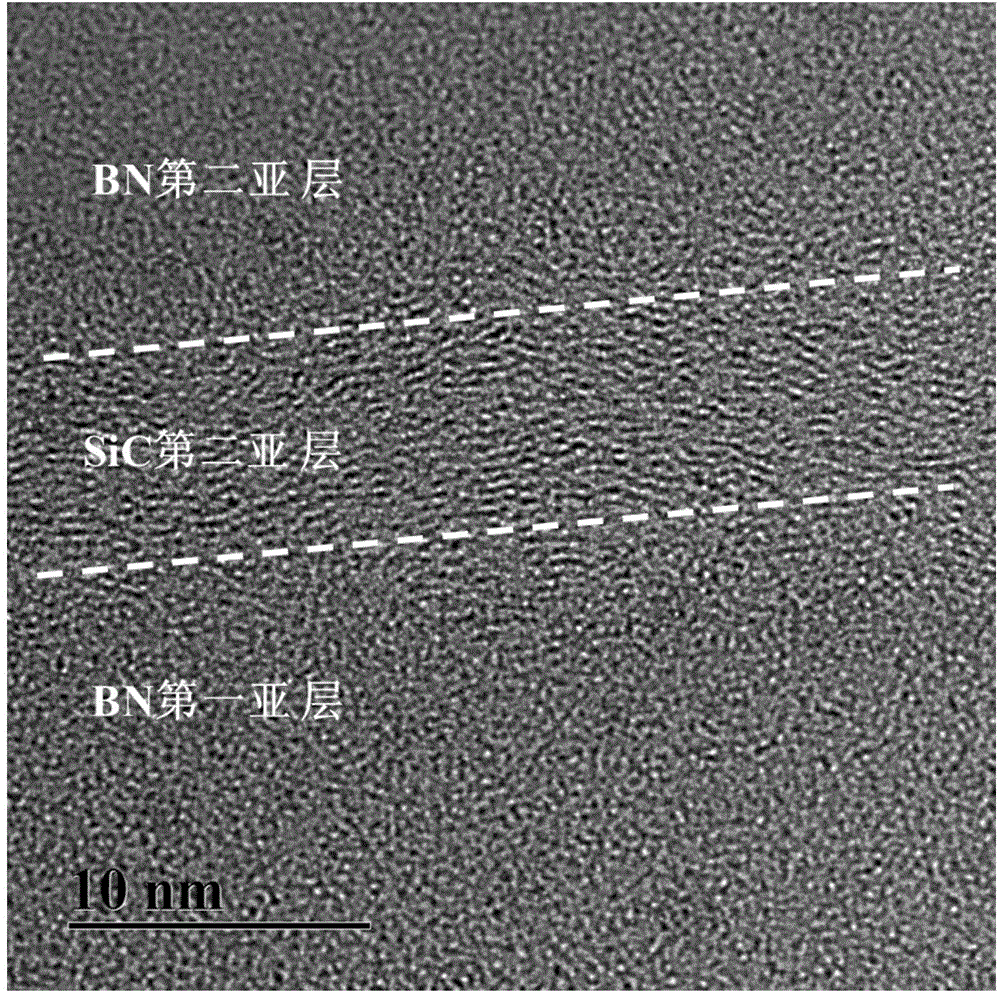

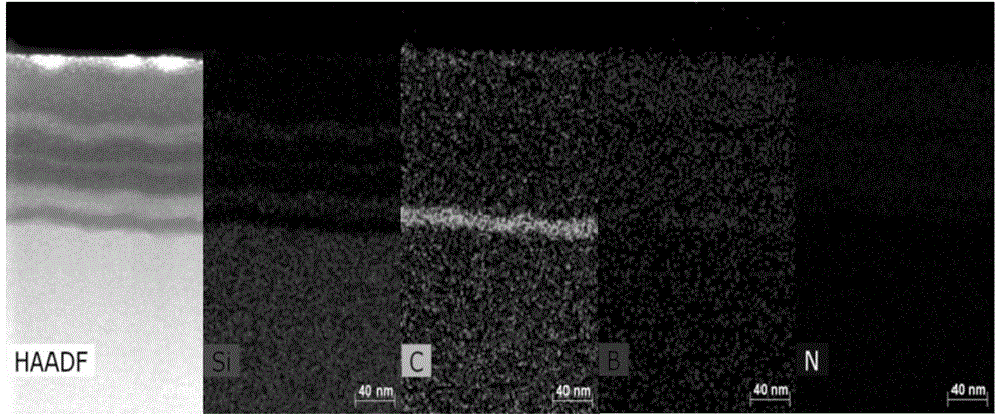

C/(SiC/BN)n compound interface phase coating, coating fiber and preparation method of coating fiber

The invention discloses a C / (SiC / BN)n compound interface phase coating which comprises a C layer and a periodic superposed layer, wherein the periodic superposed layer refers to alternative periodic superposition of SiC layers and BN layers. The coating fiber comprises a fiber base body and the C / (SiC / BN)n compound interface phase coating applied to the surface of the base body, wherein the fiber base body is selected from one of mullite fiber, carbon fiber, silicon carbide fiber and quartz fiber. The preparation method of the coating fiber comprises the following steps: preparing a fiber base body material, and depositing the C layer on the surface of the fiber base body with a chemical vapor deposition method at first; then alternatively depositing the SiC layers and the BN layers on the surface of the C layer with the chemical vapor deposition method, repeating the alternative depositing process 3-5 times, and obtaining the coating fiber. The coating fiber has the advantages of good physical and chemical compatibility, high temperature resistance, oxidation resistance, good toughening effect and the like.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of ZrC ceramic material surface ZrB2-SiC composite coating

ActiveCN107056334ASolve the problem of cracking or even peelingGood chemical compatibilityComposite ceramicSlurry

The invention relates to a preparation method of ZrB2-SiC composite ceramic coating, in particular to a preparation method of ZrC ceramic material surface ZrB2-SiC composite coating, and solves the problem that ZrC superhigh-temperature ceramic has poor high temperature protection. The preparation method comprises the specific steps of weighing raw powders in molar percentage, ball-milling, and wet-stirring to obtain a slurry; evaporatively drying the slurry, and grinding to obtain mixed powder; subjecting the mixed powder to hot-pressing sintering, cooling with a furnace, taking out to obtain ZrB2-SiC-ZrC superhigh-temperature ceramic block material; crushing the ceramic block material, grinding, and screening to obtain ZrB2-SiC-ZrC mixed spraying powder; pretreating a ZrC-SiC composite ceramic base, washing, and drying for use; spraying the ZrB2-SiC-ZrC composite coating to the pretreated ZrC-SiC base by means of plasma spraying technique. Interfacial bonding is enhanced through good chemical compatibility of ZrB2 and ZrC.

Owner:杭州尚杰装备科技有限公司

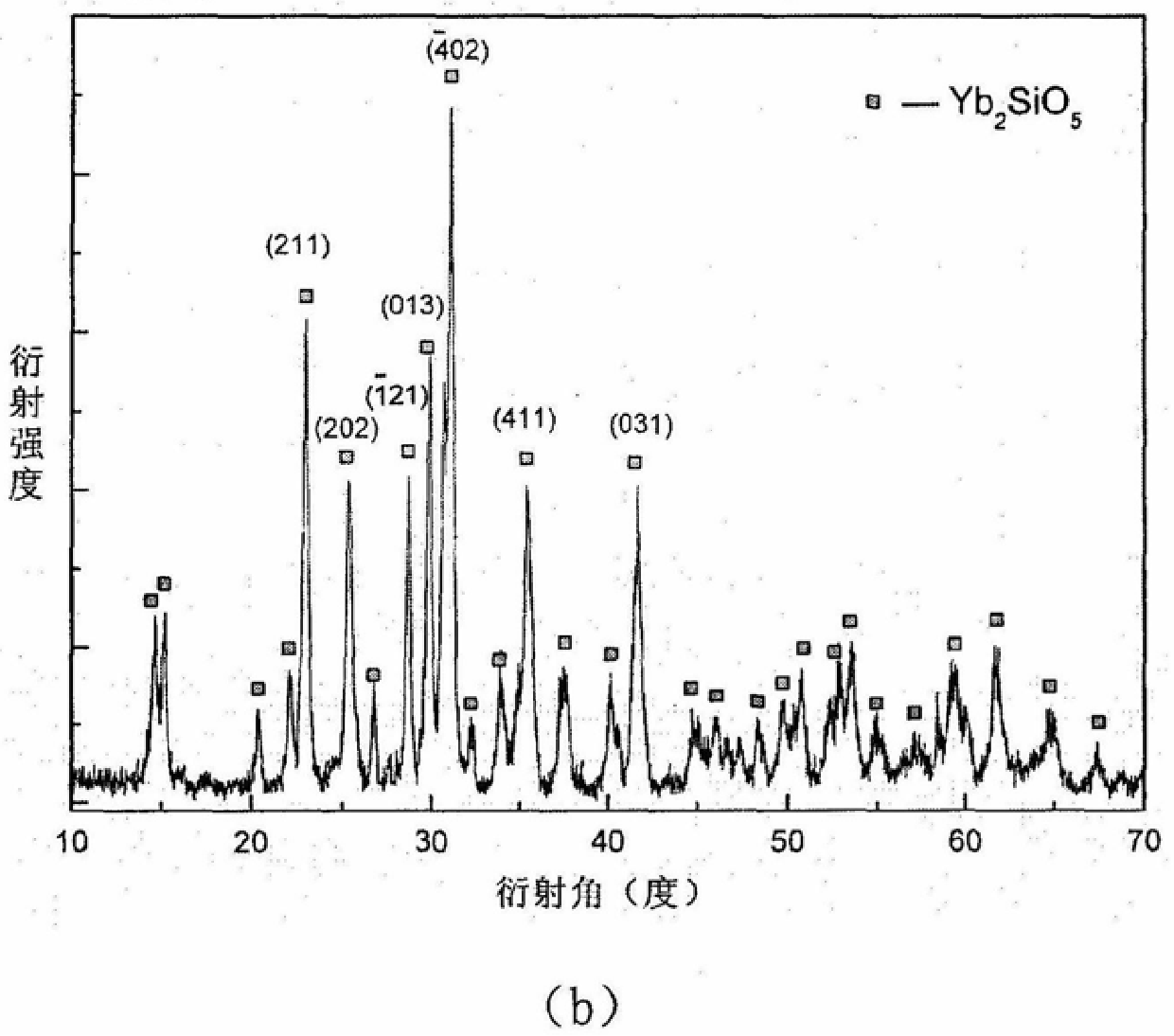

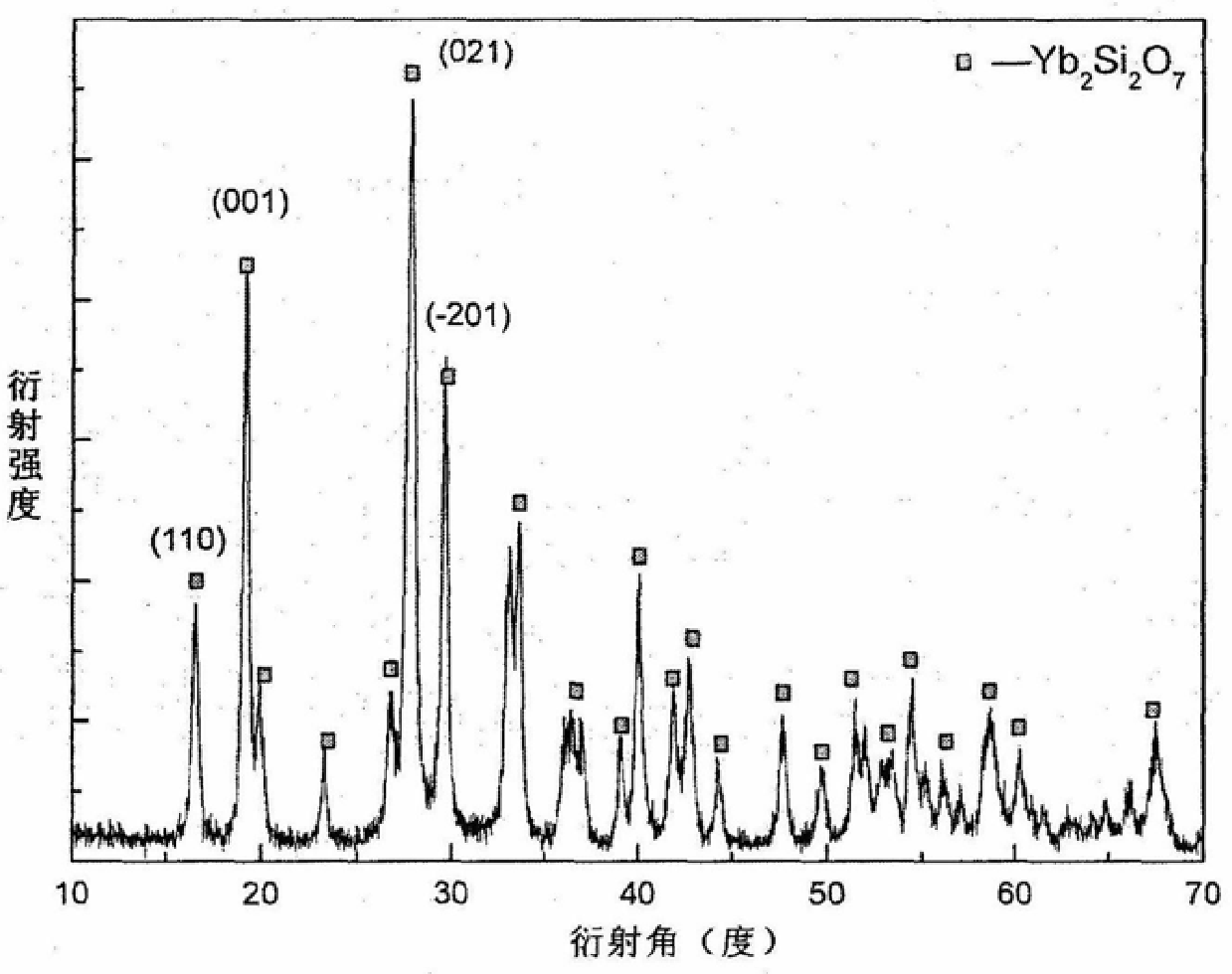

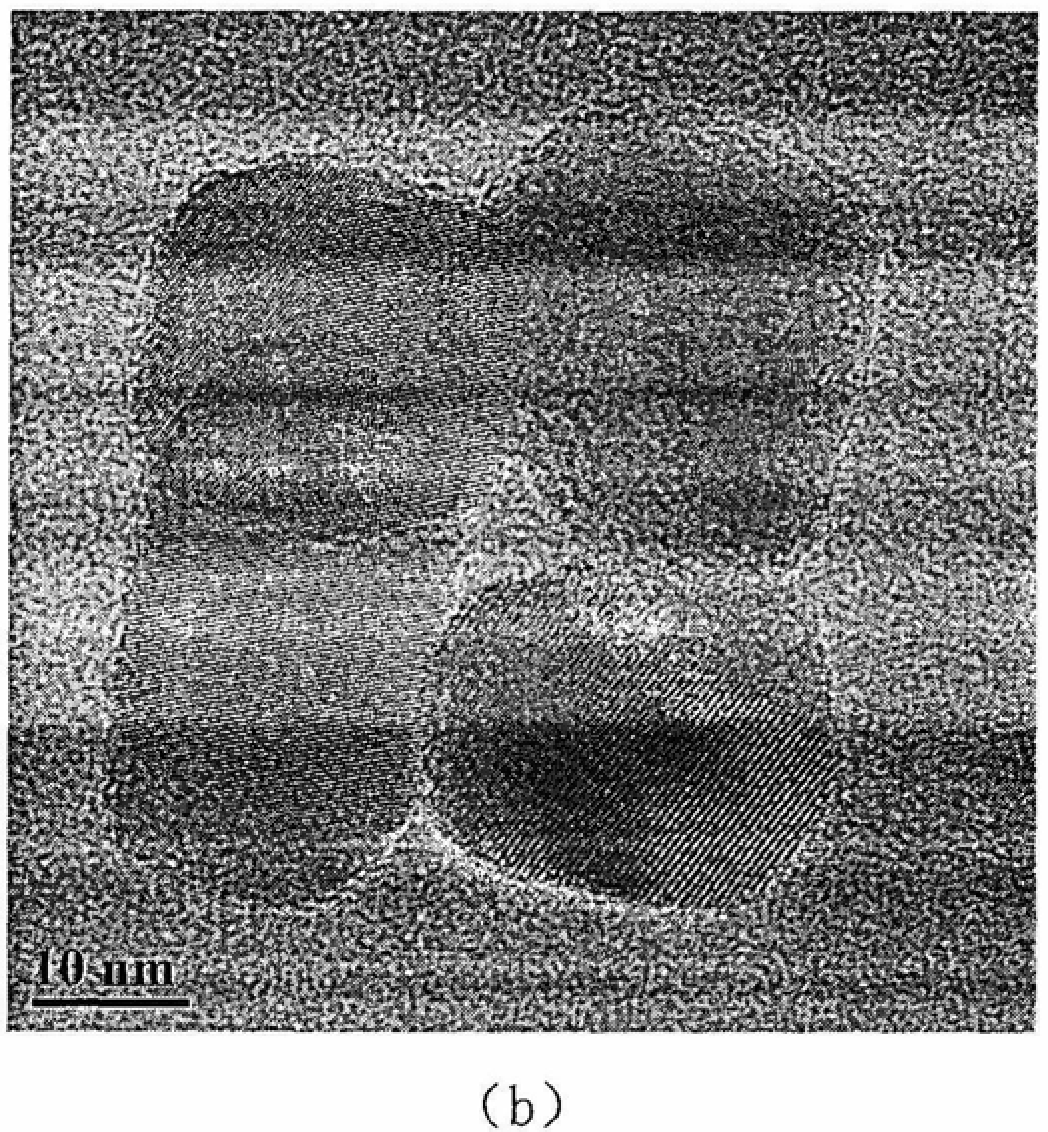

Preparation method of nanometer rare earth silicate powder

InactiveCN106342075BGood heat insulationNarrow particle size distributionRare earth metal compoundsSilicon compoundsFiltrationSynthesis methods

The invention relates to a preparation method of nano-rare earth silicate powder, which is characterized in that a certain stoichiometric ratio of rare earth oxides or rare earth soluble salts and silicon sources are formulated into solutions respectively, and the two solutions are mixed, and continuously After reacting for 6-24 hours, filtering and drying, monodisperse particles with a particle diameter of 20-30 nm can be obtained. Compared with the commonly used solid-phase reaction method and co-precipitation-calcination method, the synthesis method provided by the present invention has a synthesis temperature lowered by 1000-1300°C, which is more environmentally friendly and energy-saving; the obtained product has good oxidation resistance and compatibility with the substrate Physical and chemical compatibility of materials. The powder obtained by the method of the invention can be used to prepare the anti-oxidation coating on the surface of C / C composite materials and non-oxide silicon-based ceramic materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

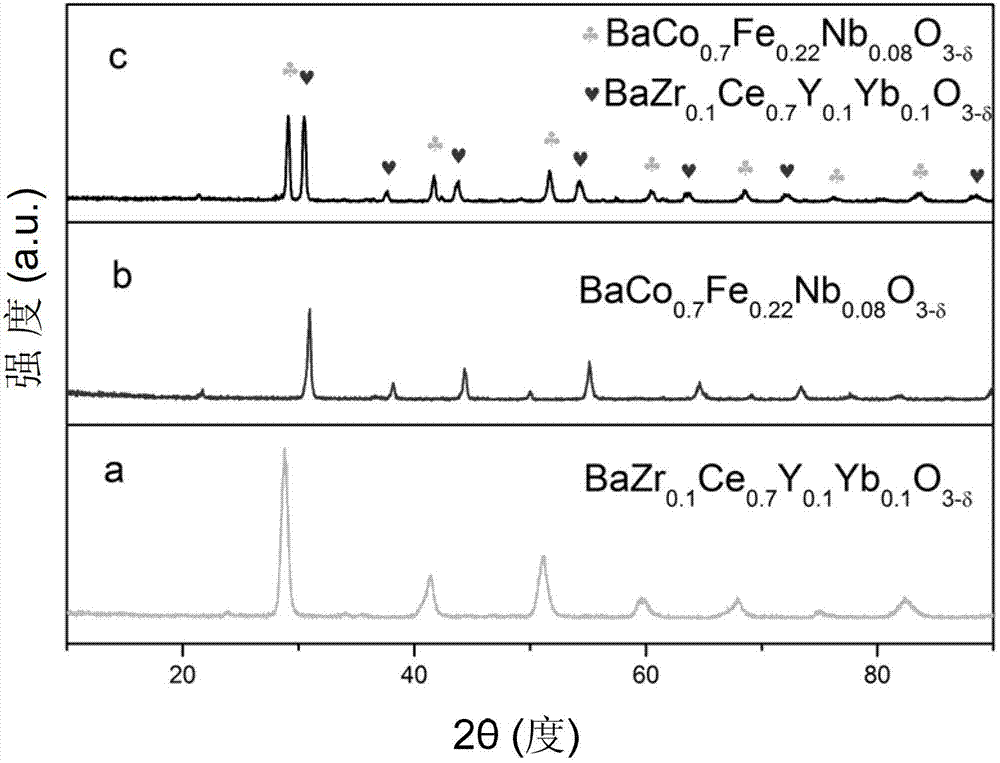

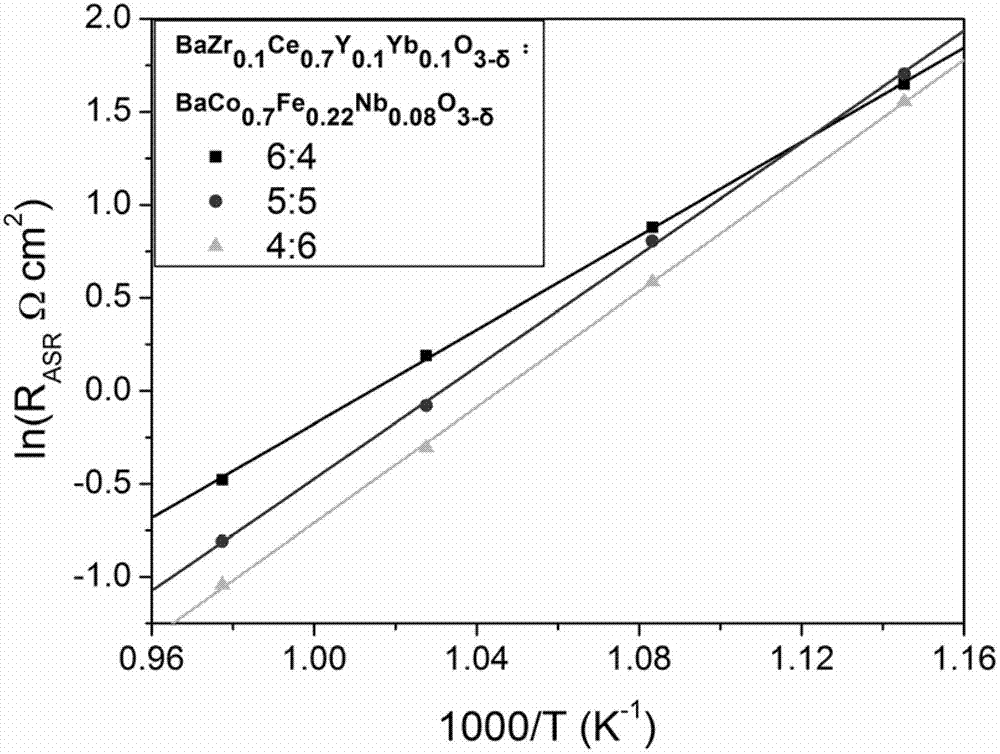

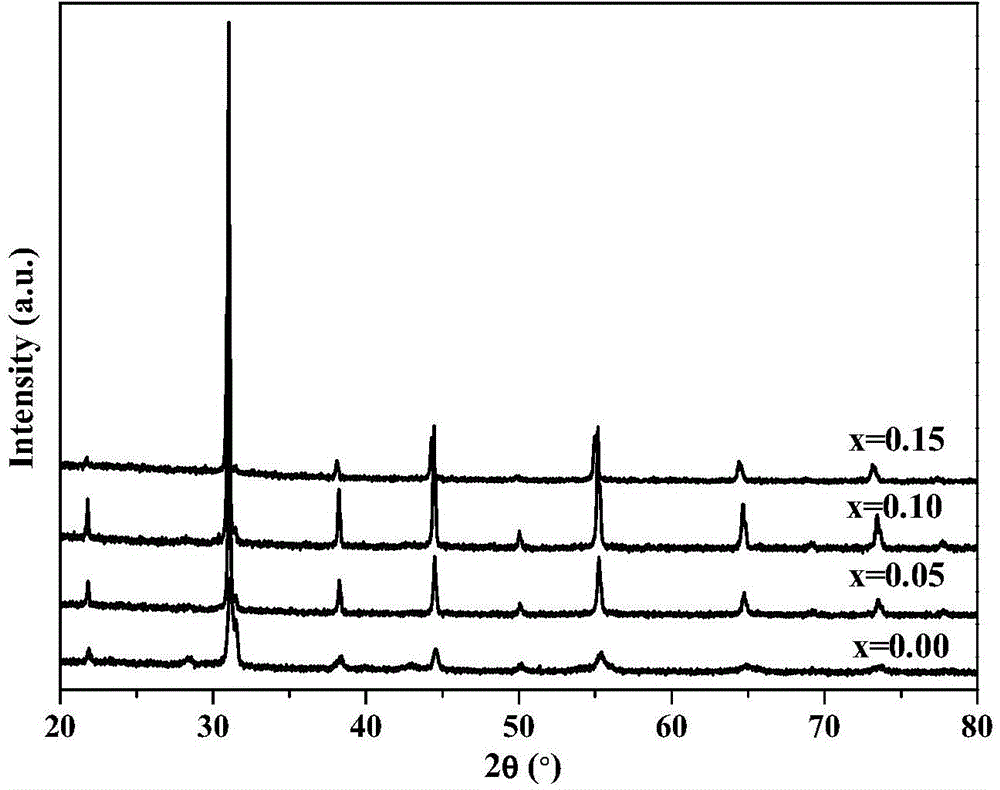

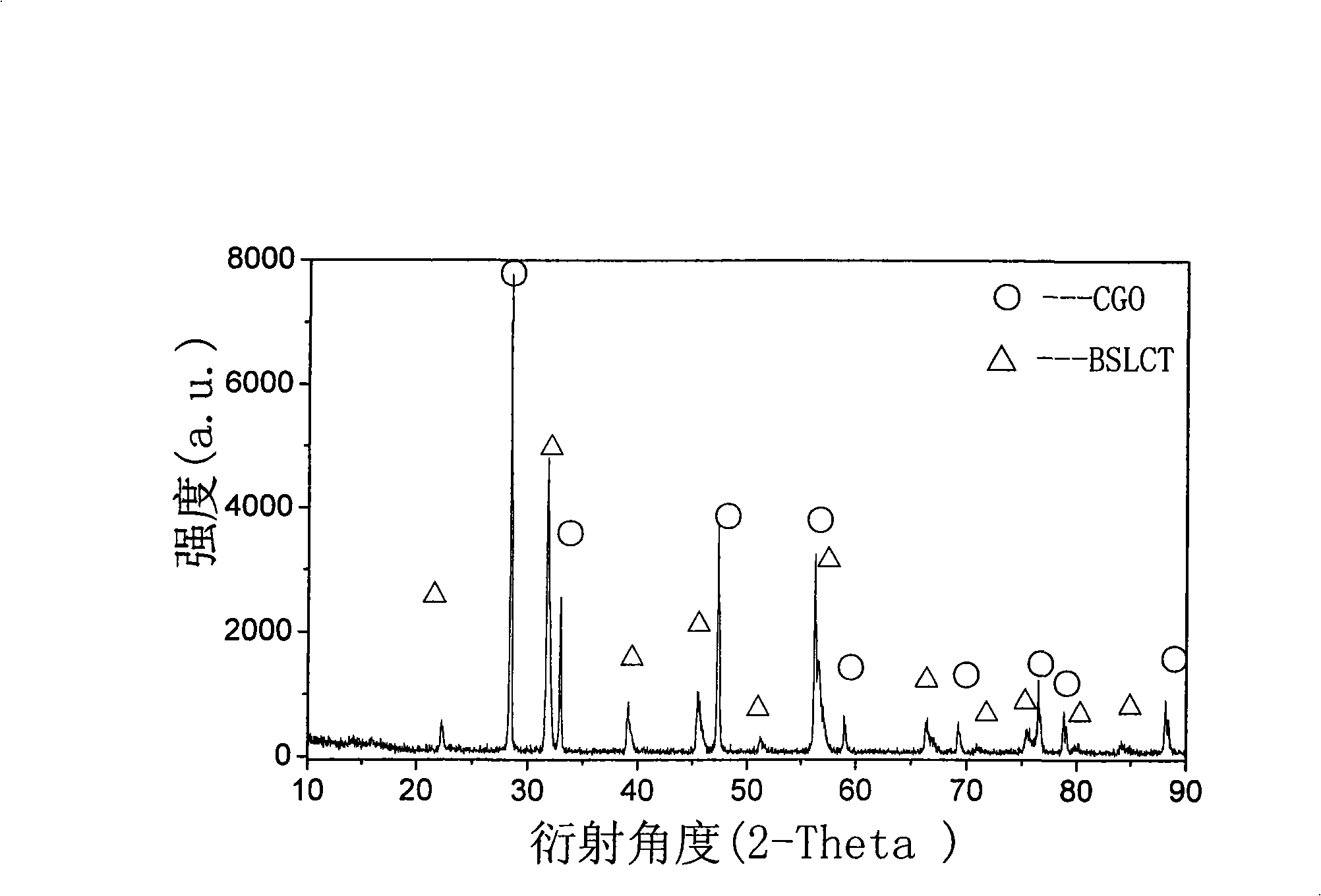

Composite cathode material for medium and low-temperature proton-conductive solid oxide fuel cells

ActiveCN103208634AInhibition of phase transitionImprove electrocatalytic performanceCell electrodesChemical compatibilityElectron

The invention discloses a composite cathode material for medium and low-temperature proton-conductive solid oxide fuel cells, and belongs to the field of fuel cells. The composite cathode material is characterized in that BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> with high oxygen ionic conductivity and high electronic conductivity and BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> with high proton conductivity are composited with each other to manufacture the novel cathode material, a chemical formula of the novel cathode material is BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta>-BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta>, and a ratio of the phase BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> to the phase BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> is changeable. The composite cathode material can be used for the medium and low-temperature proton-conductive solid oxide fuel cells. The composite cathode material has the advantages that after the BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> and the BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> are composited, the cathode material has oxygen ionic conductivity, proton conductivity and electronic conductivity, a three-phase interface is expanded, the composite cathode material is excellent in electrode performance, the two phases of the composite cathode material are excellent in chemical compatibility and stable in performance, the cathode material is good in electro-catalysis performance owing to the presence of Co in the phase BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta>, interface resistance of each cell can be reduced, and the working performance of each cell can be improved.

Owner:UNIV OF SCI & TECH BEIJING

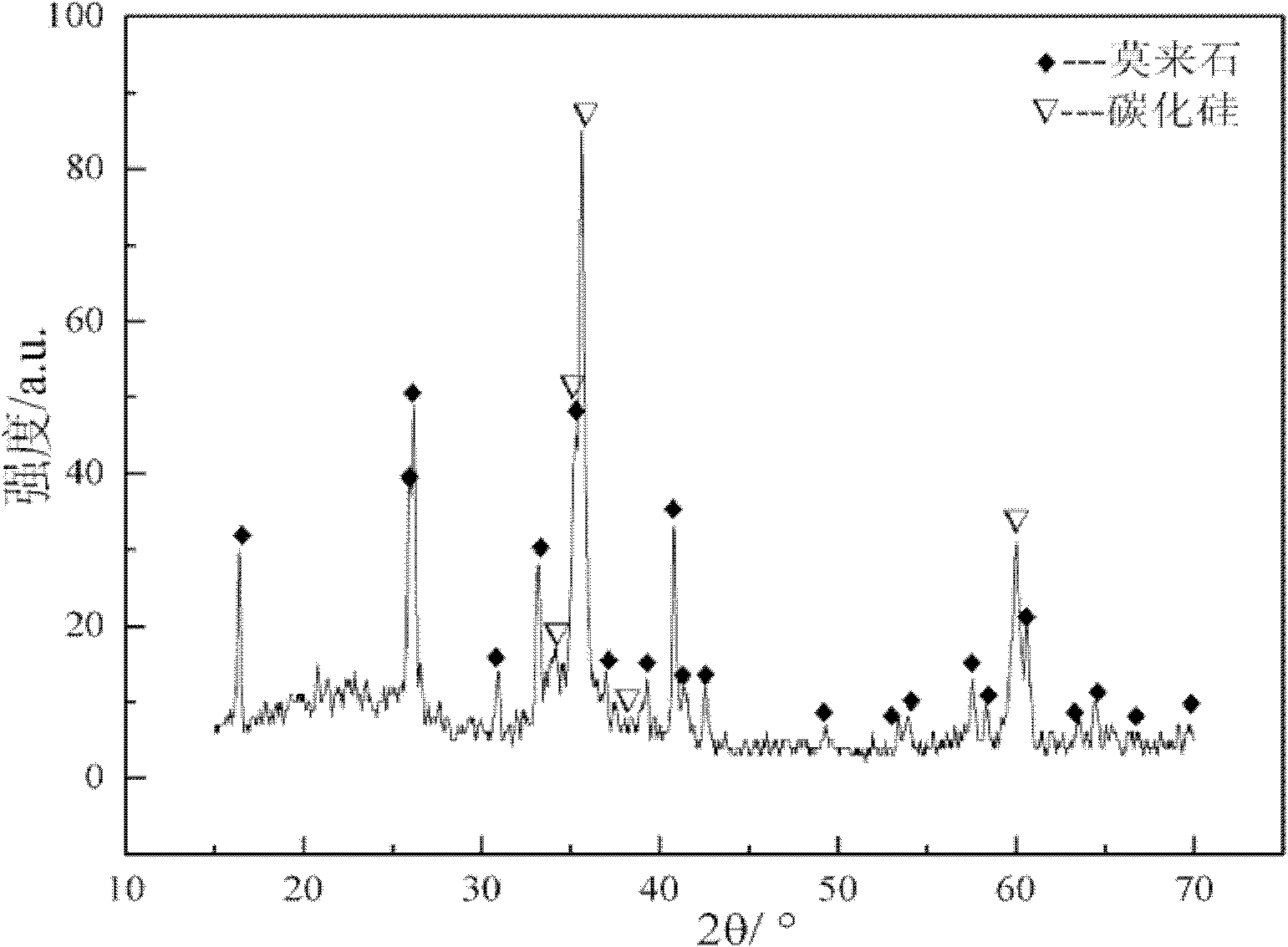

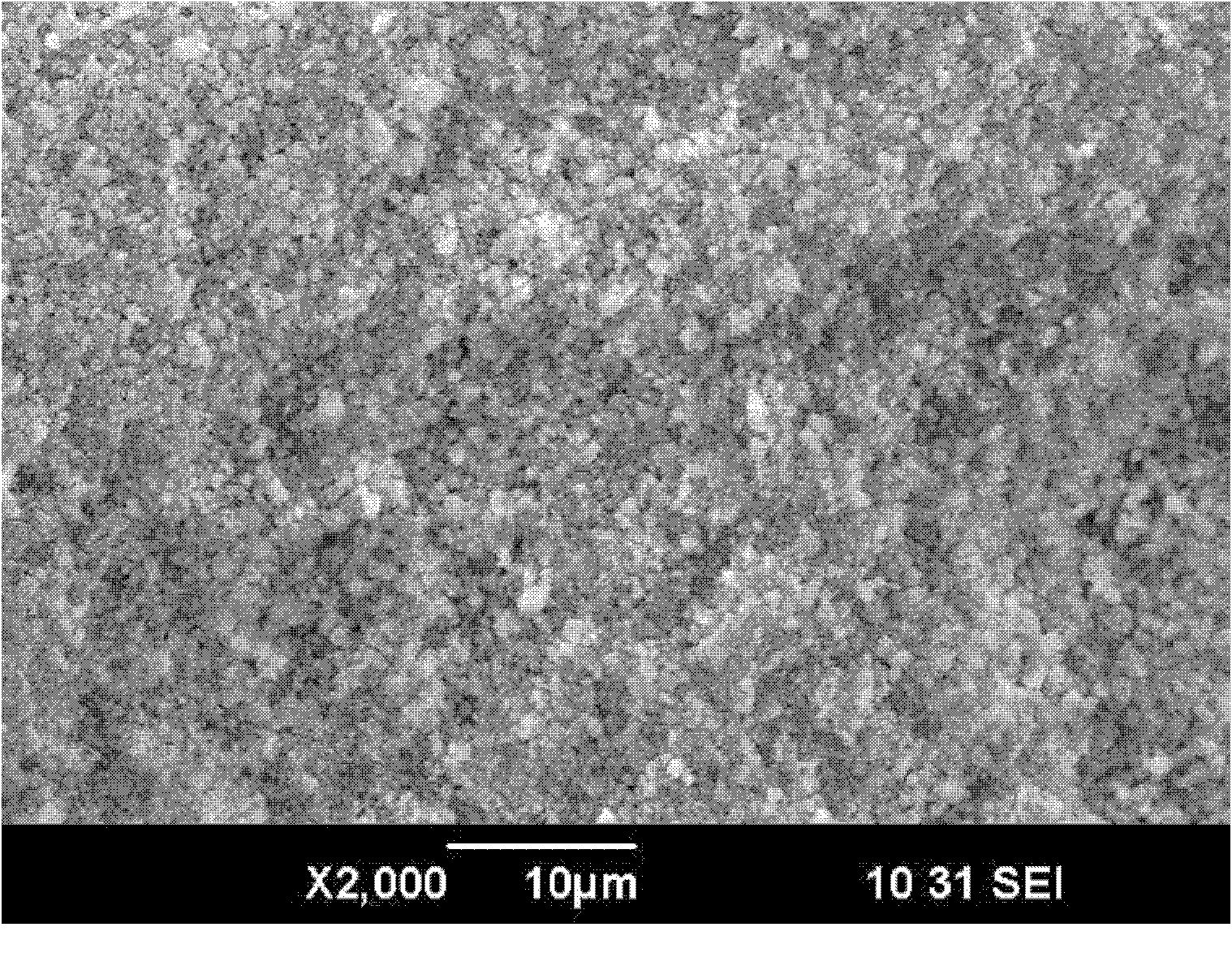

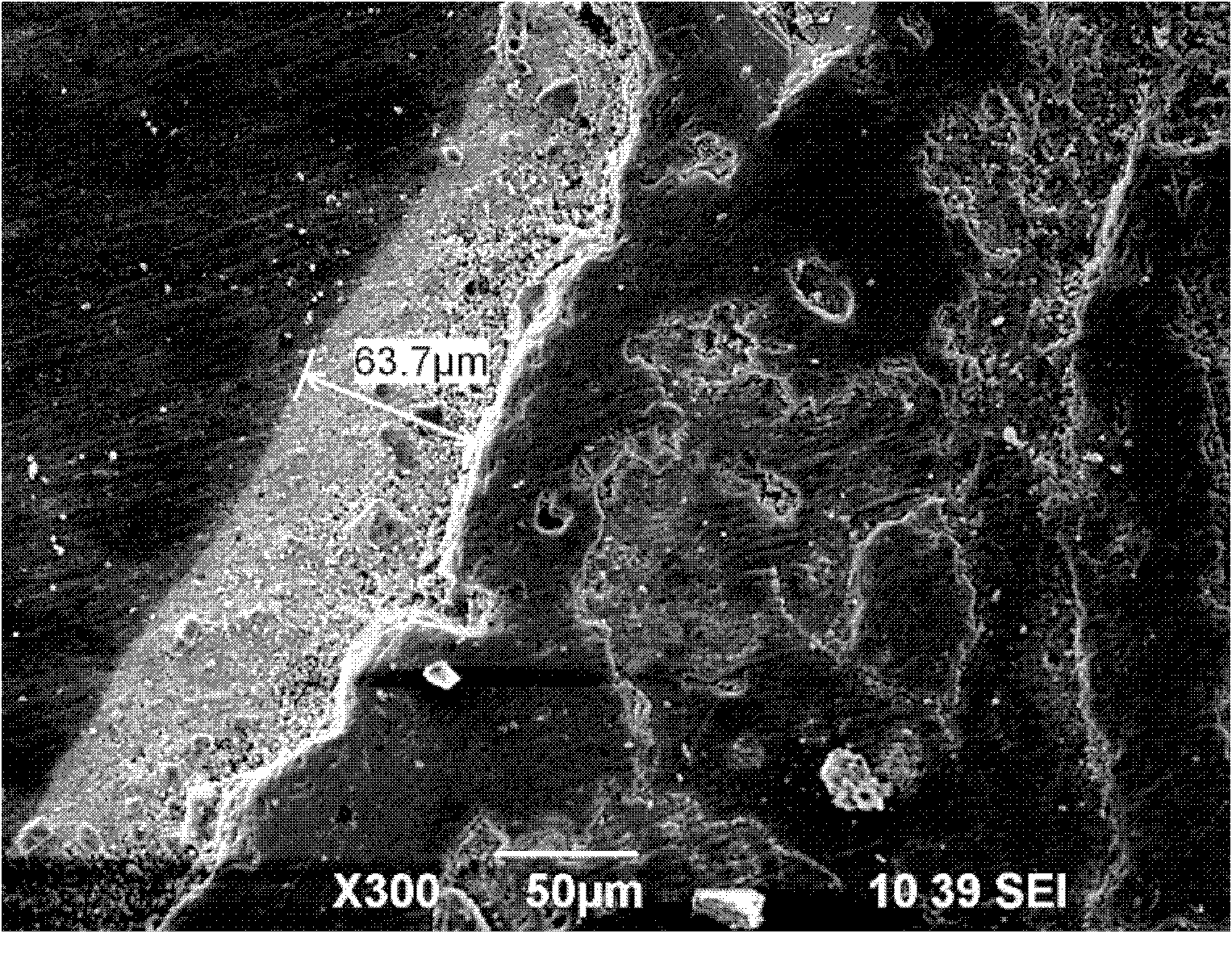

Preparation method of SiC coated mullite complex coating of C/C composite material

The invention discloses a preparation method of a SiC coated mullite complex coating of a C / C composite material, which comprises the following steps: evenly mixing tetraethoxysilane, absolute ethyl alcohol and distilled water to obtain a tetraethoxysilane solution; mixing Al(NO3)3 aqueous solution with the tetraethoxysilane solution to obtain sol; dispersing nano SiC powder into the sol to obtain a suspension sol; aging and drying the suspension sol into dried gel, grinding the dried gel in an agate mortar, and then putting the ground dried gel into a crucible and sintering to obtain SiC coated mullite powder; dissolving the coated mullite powder into isopropanol to prepare into suspension and then adding iodine simple substance, clipping C / C composite material samples with a SiC inner coating on the cathode clip in a hydrothermal kettle; putting the hydrothermal kettle in an oven for hydrothermal electrophoresis reaction and then naturally cooling to room temperature; and taking out the samples and drying to obtain the SiC coated mullite complex coating of the C / C composite material. The prepared SiC coated mullite complex coating of the C / C composite material has excellent bond, even thickness, compact surface and excellent physical and chemical compatibility.

Owner:SHAANXI UNIV OF SCI & TECH

Bendable low-emission coated glass

The invention relates to a bendable low-emission coated glass. A film structure of the bendable low-emission coated glass is as follows from glass substrate to outside: a glass substrate, a first dielectric layer, a low-emission layer, a second dielectric layer, and a protection layer. Compared with the prior art, the bendable low-emission coated glass of the invention utilizing chemical compatibility has excellent physical performance, flexible configuration, convenient control, higher deposition efficiency, and good bend resistance. Key performance indicators of the glass after being bent do not change. The glass has low emission. Visible light transmittance of laminated glass composed of the bendable low-emission coated glass is above 76%, and solar transmittance thereof is less than 48%; or the visible light transmittance is above 70% and the solar transmittance is less than 43%. The glass is suitable for the windshield glass of an automobile.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

High temperature, high efficiency thermoelectric module

InactiveCN102308400AInhibit growthAvoid spreadingThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsThermoelectric cooling

A long life, low cost, high-temperature, high efficiency thermoelectric module. Preferred embodiments include a two-part (a high temperature part and a cold temperature part) egg-crate and segmented N legs and P legs, with the thermoelectric materials in the three segments chosen for their chemical compatibility or their figure of merit in the various temperature ranges between the hot side and the cold side of the module. The legs include metal meshes partially embedded in thermoelectric segments to help maintain electrical contacts notwithstanding substantial temperature variations. In preferred embodiments a two-part molded egg-crate holds in place and provides insulation and electrical connections for the thermoelectric N legs and P legs. The high temperature part of the egg-crate is comprised of a ceramic material capable of operation at temperatures in excess of 5000C and the cold temperature part is comprised of a thermoplastic material having very low thermal conductivity.

Owner:HI Z TECH

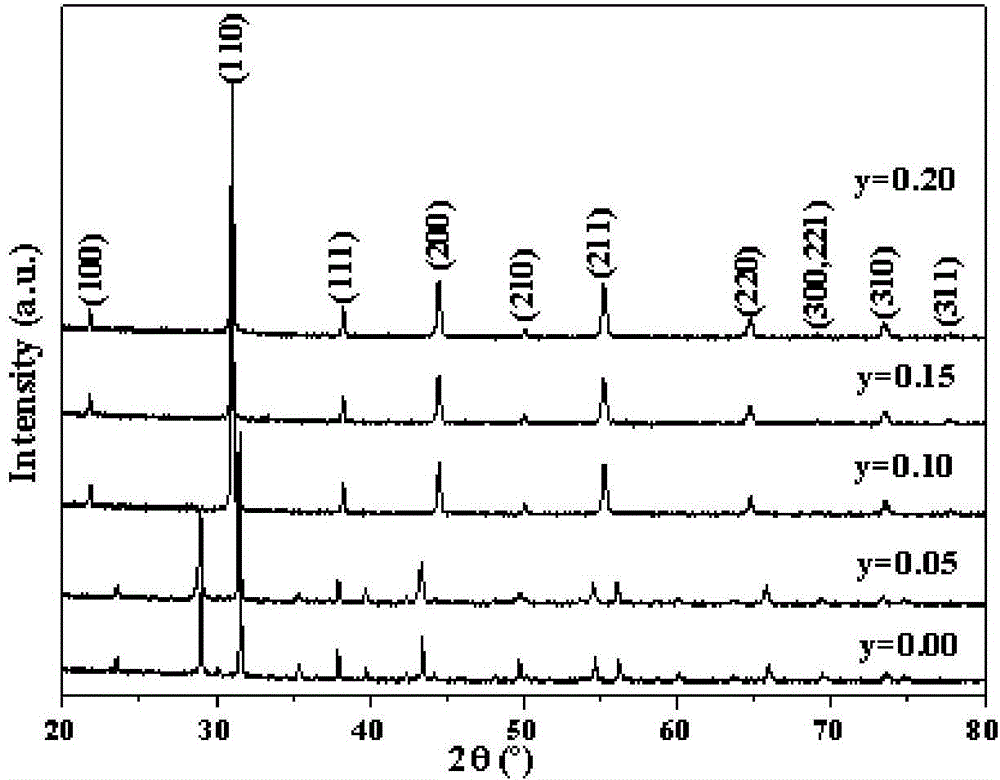

BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, preparation method and applications thereof

InactiveCN104409742AImprove structural stabilityCo-doping improvesCell electrodesOxygen ionsChemical compatibility

The invention discloses a BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, a preparation method and applications thereof. The provided cathode material has a perovskite type structure and is represented by a chemical formula: BaBi<x>Nb<y>Co<1-x-y>O<3-delta>, wherein the delta represents oxygen excess or oxygen deficiency (-1=<delta=<1), the x represents the doping amount of Bi2O3 (0=<x=<0.15), and the y represents the doping amount of Nb2O5 (0=<y=<0.2). The chemical compatibility between the provided BaBi<x>Nb<y>Co<1-x-y>O<3-delta> cathode material and the conventional electrolyte material such as GDC, and the like is good. In the air the current can be well conducted by the oxygen ions and electrons. In the temperature range of 450 to 850 DEG C, the provided cathode material has a very good oxidation-reduction catalytic activity. The cathode material is suitable for a solid oxide fuel cell used at a mid-low temperature.

Owner:HARBIN INST OF TECH

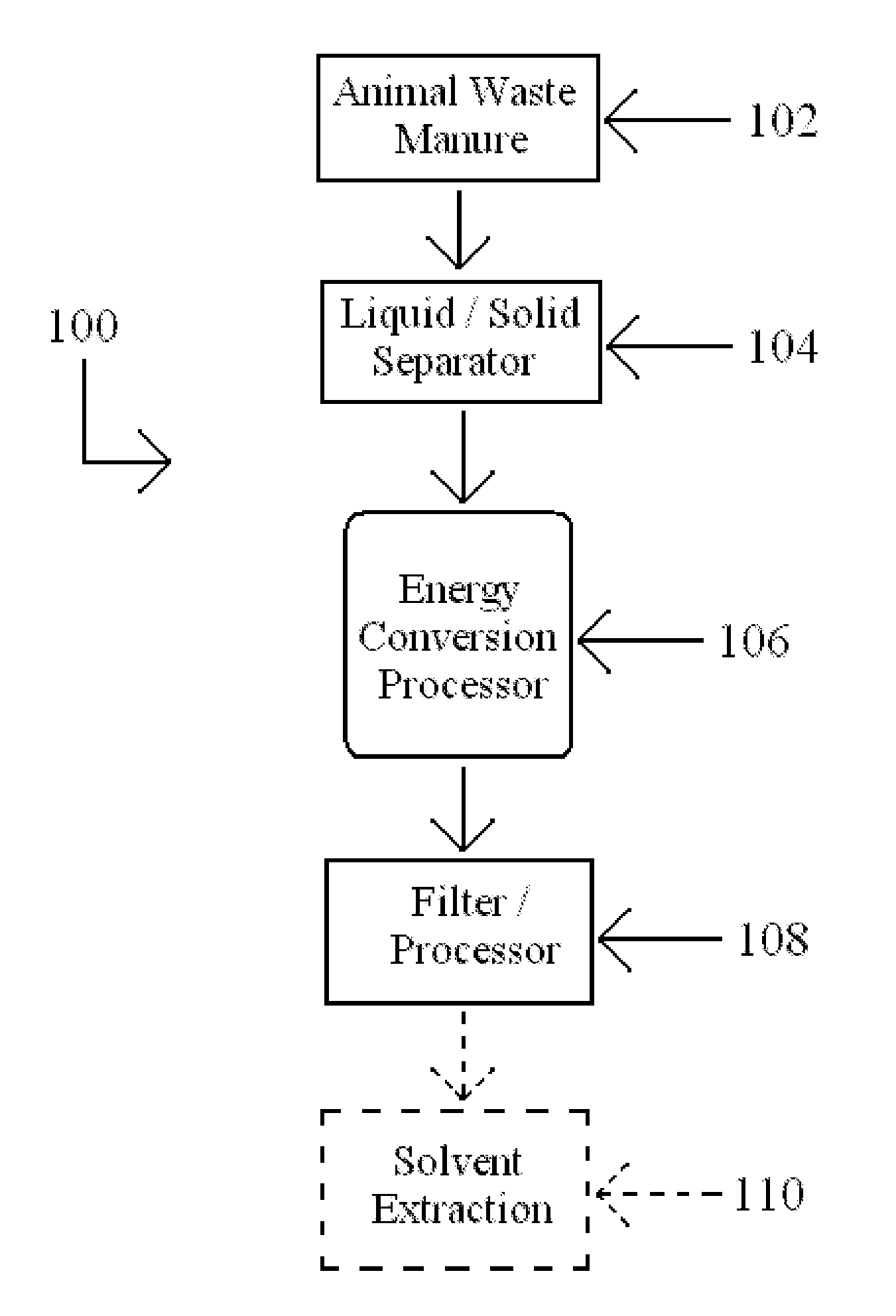

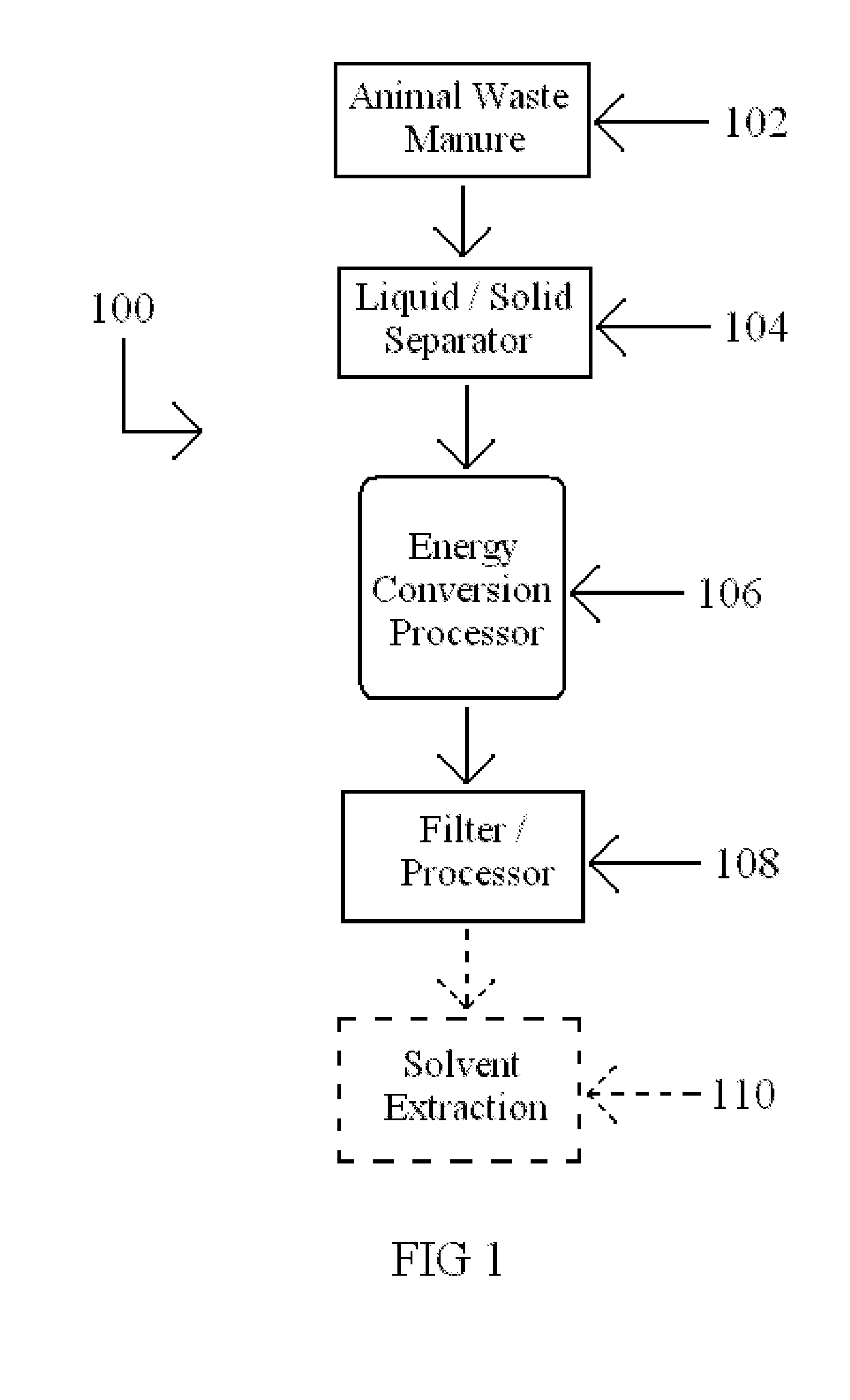

Asphalt compositions with resinous addition derived from animal waste

InactiveUS20130319289A1Good chemical compatibilityFatty acid chemical modificationInksEngineeringChemical compatibility

A bio-resource resin for use as a replacement for a portion of asphalt in asphalt compositions includes a bio-oil derived from animal waste and including hydrocarbons; and a compatibilizing agent. The bio-oil is derived from animal waste by subjecting the animal waste to a conversion process selected from a hydrothermal conversion process and a thermochemical conversion process. This bio-resource resin can be employed as a substitute for a portion of asphalt in common asphalt compositions, and the compatibilizing agent improves the chemical compatibility between the bio-oil and the asphalt.

Owner:IMPERIAL COMMODITIES

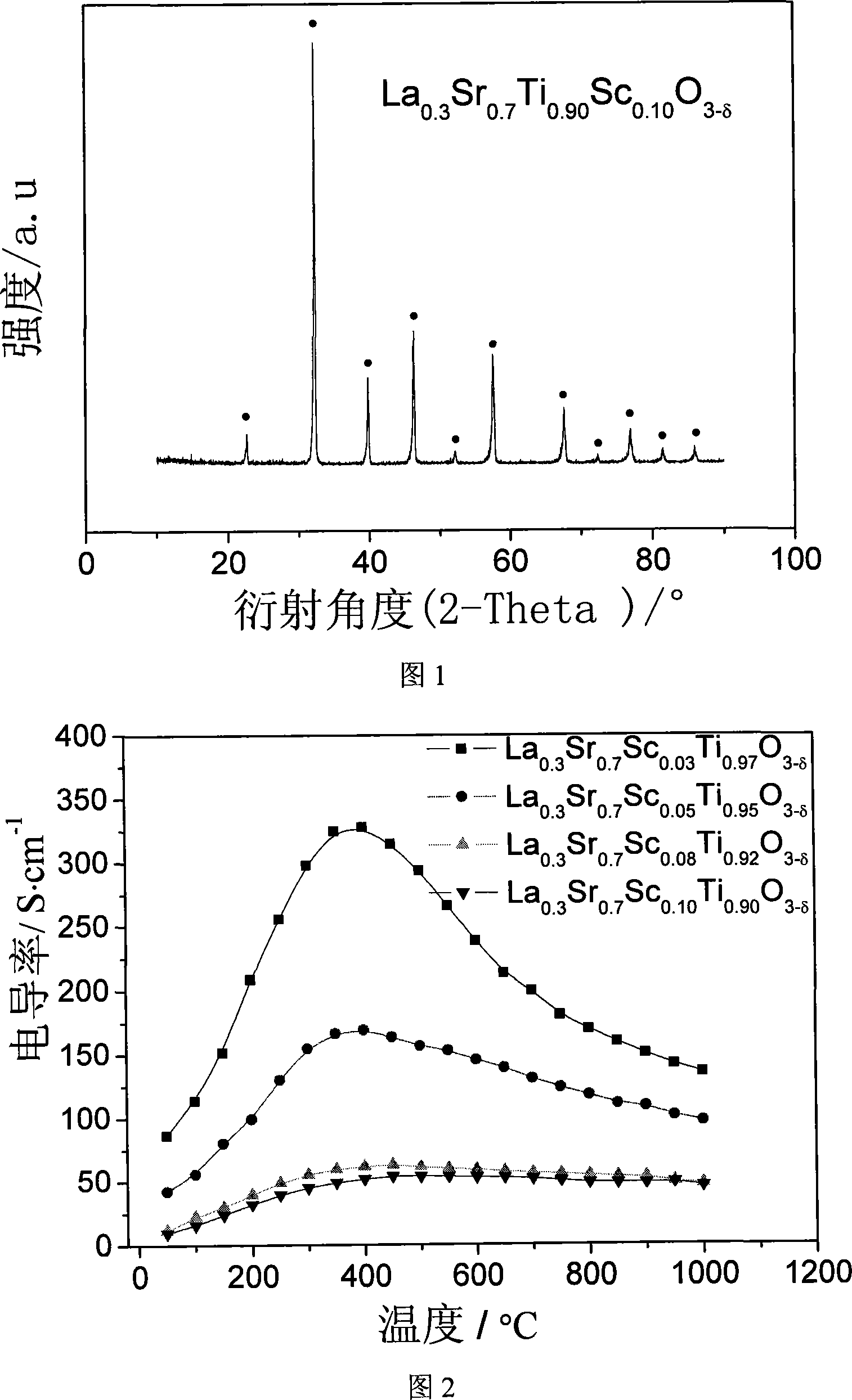

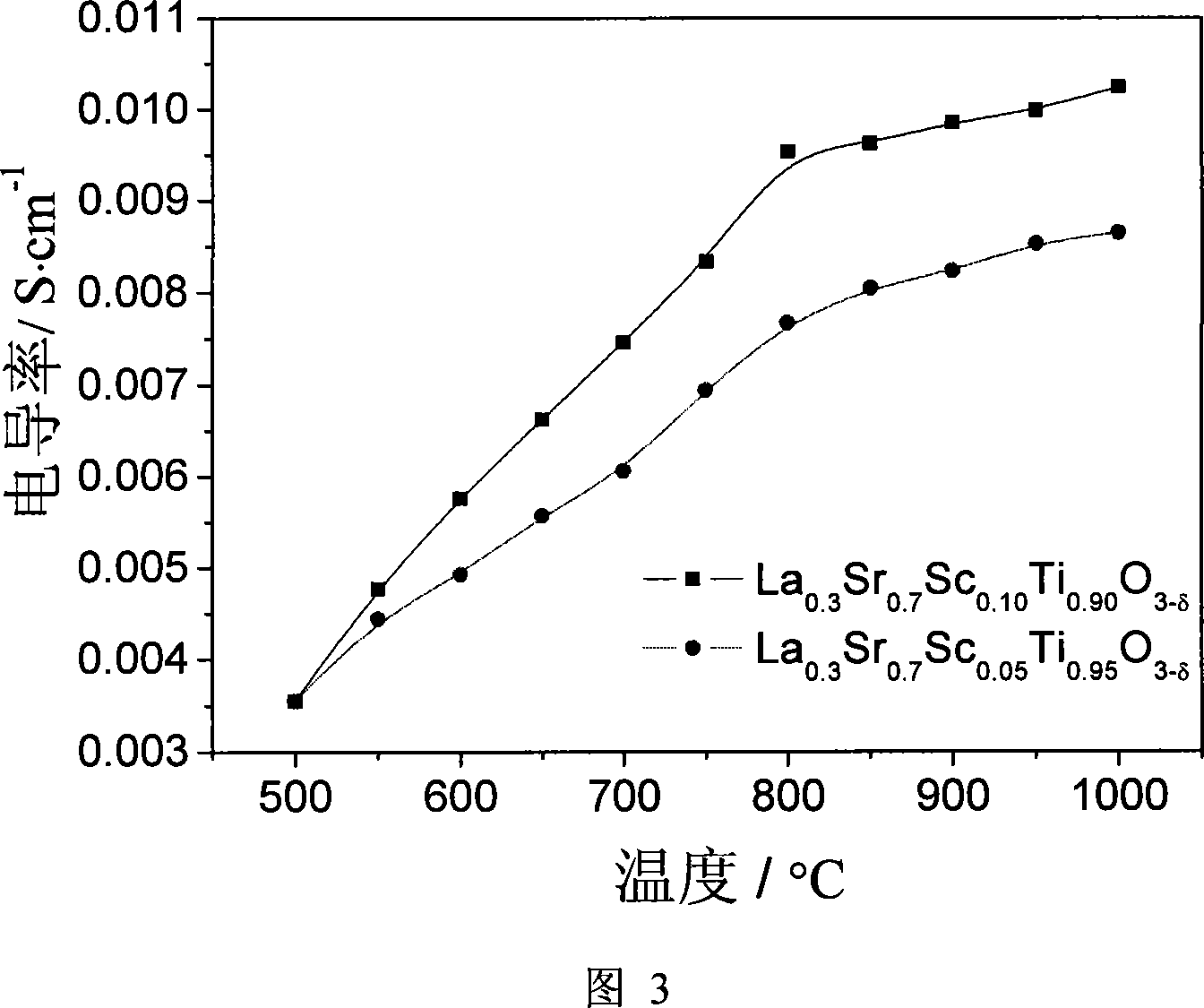

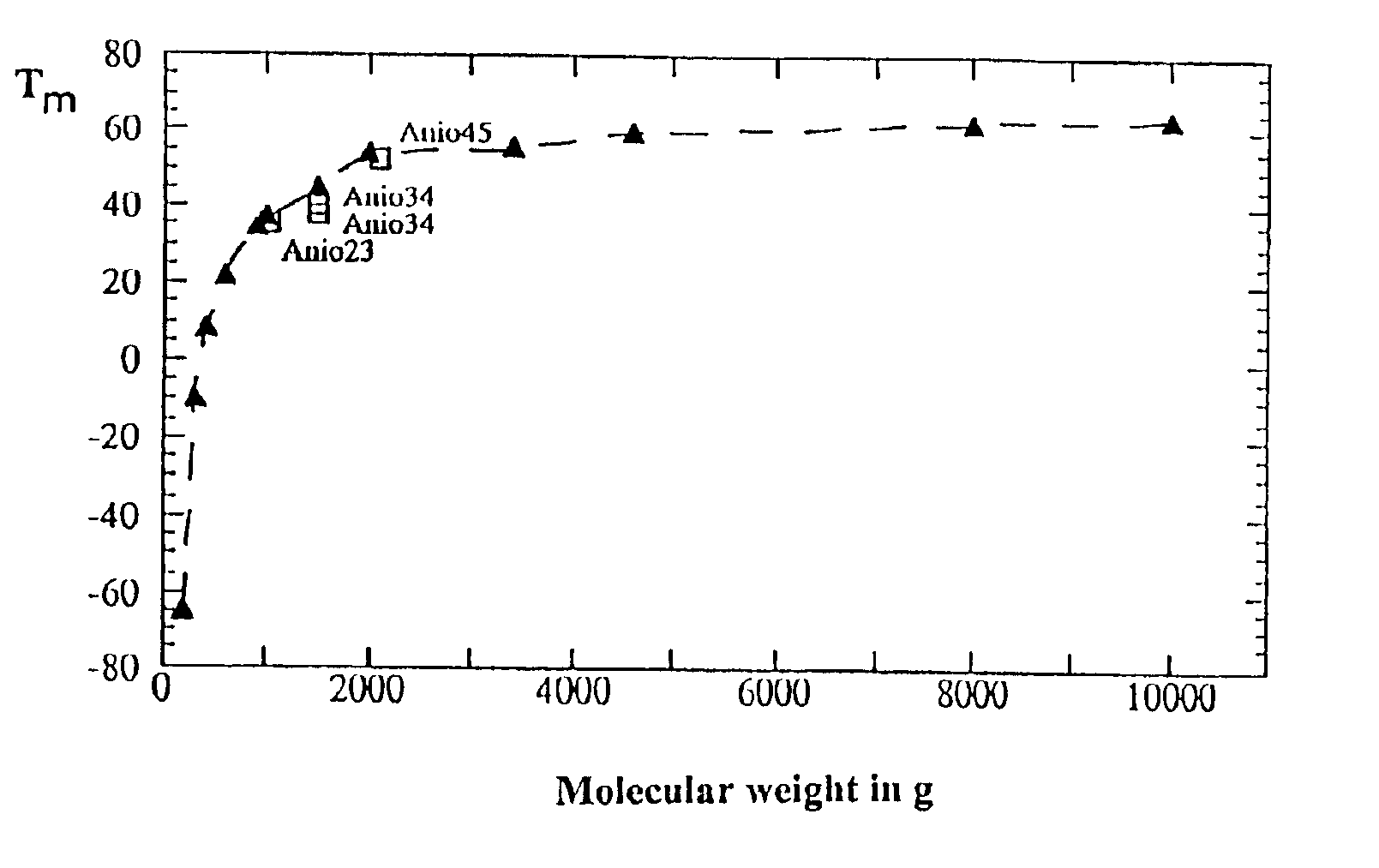

A cathode material for A and B adulterated SrTiO3 solid oxide fuel battery

InactiveCN101237046AControl the amount of incorporationImprove ionic conductivityCell electrodesFuel cell detailsStrontium titanateWork performance

The present invention relates to an anode material, in particular to a solid oxide fuel battery anode material. The anode material is characterized in that: the co-doping of an A-site La and a B-site Sc is carried out for the perovskite type SrTiO3; the molecular formula after doping is La0.30Sr0.70ScxTi1-xO3-delta, wherein, x is equal to 0.001-0.10. The A-site and the B-site co-doped anode material prepared by the present invention can be used for solid oxide fuel batteries, having stable performance and good chemical compatibility with electrolytes YSZ and LSGM. Along with the increase of Sc doping amount, the ionic conductivity of La0.30Sr0.70ScxTi1-xO3-delta is increased, and the ionic conductivity of La0.30Sr0.70ScxTi1-xO3-delta (x is equal to 0.10) at 800 DEG C is increased to 0.0095S.cm-1, so as to improve the work performance of SOFC and promote the practical process of SOFC.

Owner:UNIV OF SCI & TECH BEIJING

Copolymer of ethylene oxide and at least one substituted oxirane carrying a cross-linkable function, process for preparation thereof, and use thereof for producing ionically conductive materials

InactiveUS6855788B2High reaction yieldLess impuritiesCell electrodesConductive materialChemical compatibilityConductive materials

Owner:BATHIUM CANADA

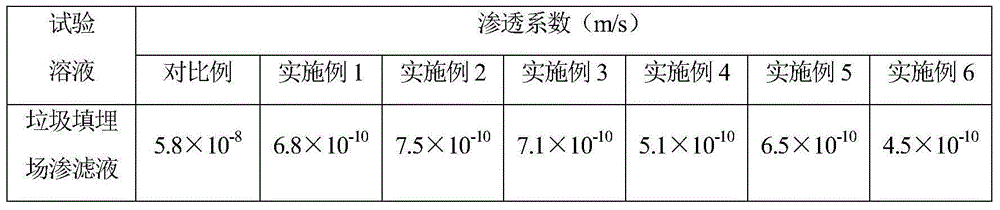

Organic pollutant-resistant polymer bentonite nanocomposite material and preparation method thereof

ActiveCN105199288ABroad application prospectsBroad protectionOsmotic coefficientChemical compatibility

The invention discloses an organic pollutant-resistant polymer bentonite nanocomposite material which comprises bentonite and cationic polyacrylamide, wherein the mass of the cationic polyacrylamide is 0.1 to 10 percent of that of the bentonite. The material can effectively improve the chemical compatibility of the bentonite, improve the capability of resisting organic pollutants, and can still maintain a very low permeability coefficient under the effect of contaminating fluid, so the impermeable property of bentonite type separation facilities is greatly improved, the effective service life of the separation facilities is prolonged, and the engineering cost is reduced. Meanwhile, a preparation method of the organic pollutant-resistant polymer bentonite nanocomposite material is provided, and the method is simple and easy.

Owner:SOUTHEAST UNIV

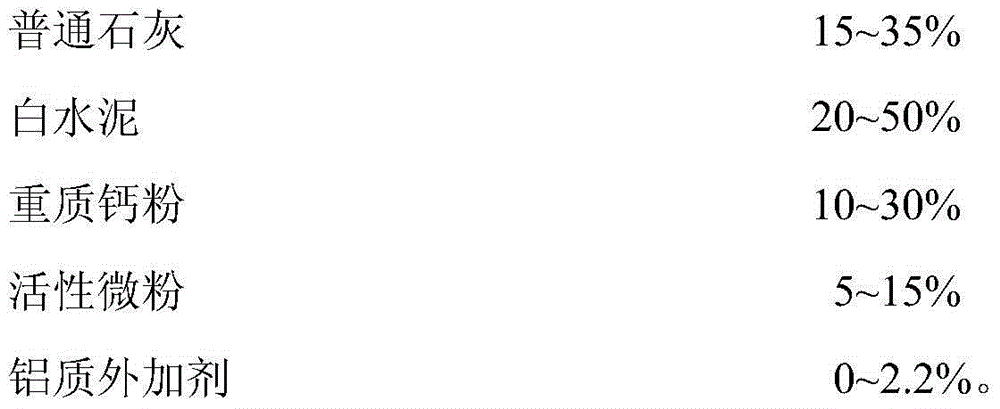

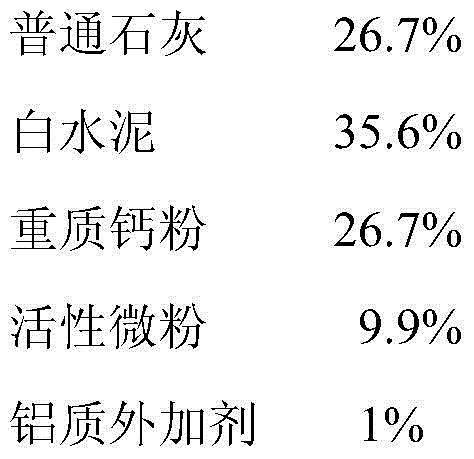

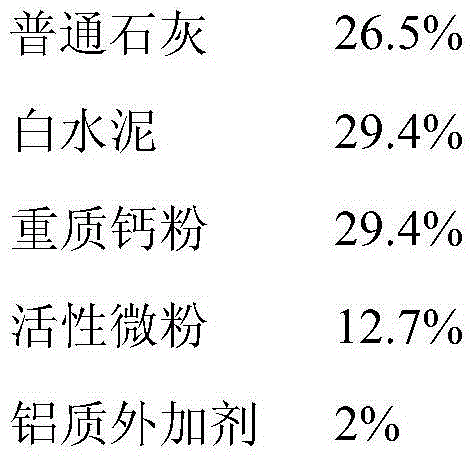

Protection brick and stone ancient building repair lime bonding material

The invention discloses a protection brick and stone ancient building repair lime bonding material, the hydraulic lime material comprises the following components by mass: 15-35% of lime, 20-50% of white cement, 10-30% of heavy calcium powder, 5-15% of active micro powder, and 0-2.2% of an aluminium additive, and the chemical composition, mineral composition and physical and mechanical properties of the hydraulic lime material are similar to that of ancient brick / stone building lime slurry in China, the hydraulic lime material solves the key problems of mismatching strength of cement mortar or polymer mortar in the prior art and ancient brick / stone, poor chemical compatibility and low longterm durability and the like, and overcomes the shortcomings of slow hardening, low strength, too large shrinkage, and the poor water resistance of the ordinary lime, and a new type inorganic cementing material is provided for protection brick and stone ancient building repair.

Owner:SOUTHEAST UNIV

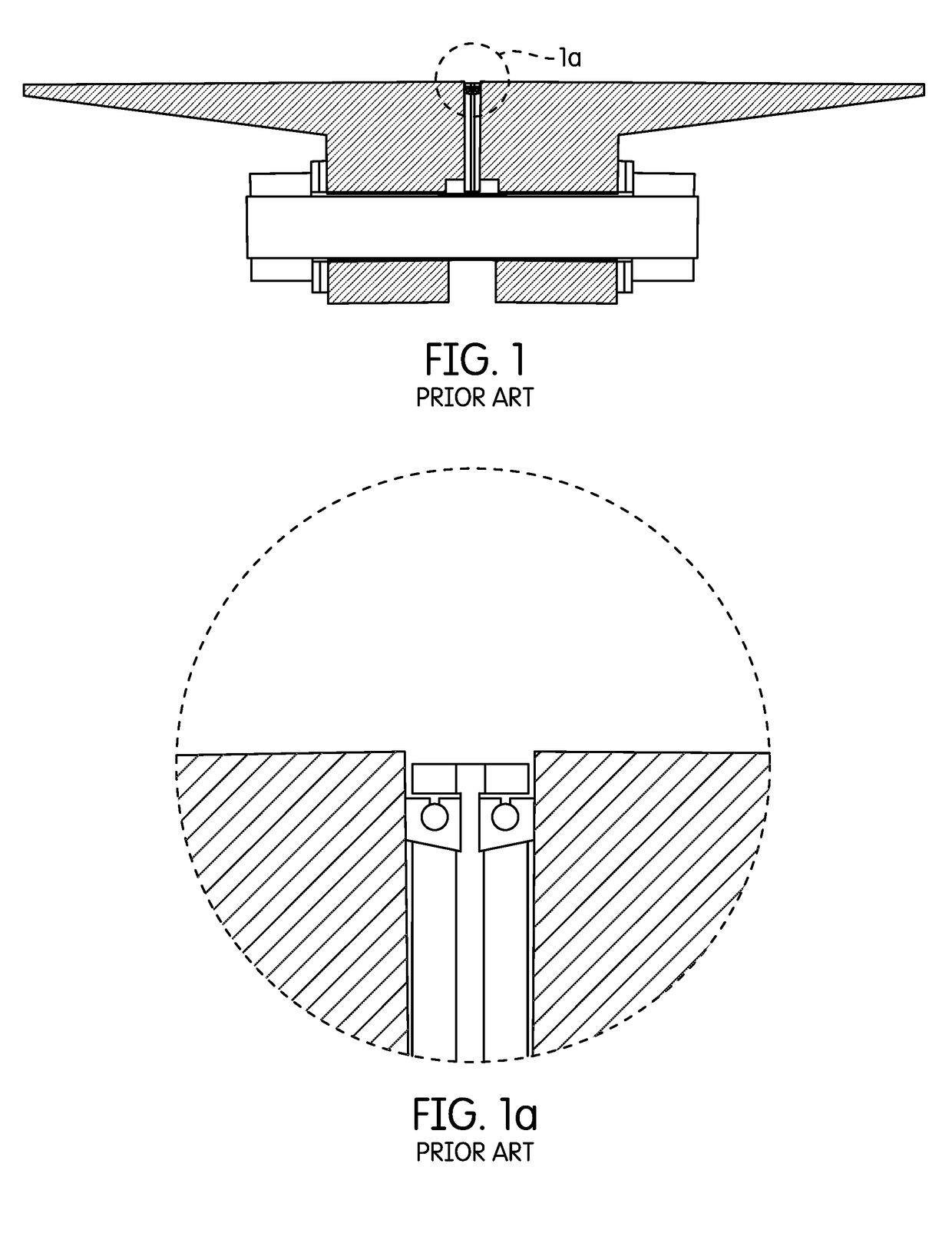

Non-metallic high pressure high temperature high chemical compatibility flange isolation gasket

ActiveUS20180058616A1Prevent escapeIncrease pressureEngine sealsFlanged jointsElectricityEngineering

A non-metallic flange isolation gasket kit sealing flanged pipeline connections and flanged vessel connections while providing electrical isolation protection between flanges suited for high-pressure and high-temperature cathodic protection applications is presented. The invention protects flange faces from media induced corrosion and mitigates flange rotation induced fatigue and failures. The invention comprises of a retainer, a seal, and a seal pre-load structural ring. The seal pre-load structural ring is inserted into the seal, and seal outer diameter surface is joined to the retainer inner diameter surface. A second embodiment comprises of a composite gasket blank, comprising of a retainer and a seal, and a seal pre-load structural ring. The seal outer diameter surface and the retainer inner diameter surface are joined by thermal fusion bonding. The invention may further comprise one or more gasket seating stress stabilizers and / or a centering ring. Tapered retainer upper and lower surfaces decrease flange rotation.

Owner:ROWLEY MARC +1

Salt-containing separating liquid system and its prepn process

InactiveCN101089114AMeet the water loss requirementsWith fluid loss controlDrilling compositionClay mineralsEngineering

The present invention is salt-containing separating liquid system for cementing shaft wall and its preparation process. It is prepared with water 100 weight portions, clay mineral 1-5 weight portions, tackifier 0.05-0.25 weight portion, dehydration reducing agent 0.1-0.3 weight portion, flow form regulator 0.1-1.5 weight portions, weight additive 30-333 weight portions, NaCl 1-35 weight portions, Na2CO3 0.06-0.3 weight portion and defoaming agent in small amount. It is prepared through mixing all the said materials. It has relatively capacity of resisting pollution of soluble salts, wide density regulating range, flexible rheological property regulating capacity and high fluid chemical compatibility.

Owner:SOUTHWEST PETROLEUM UNIV

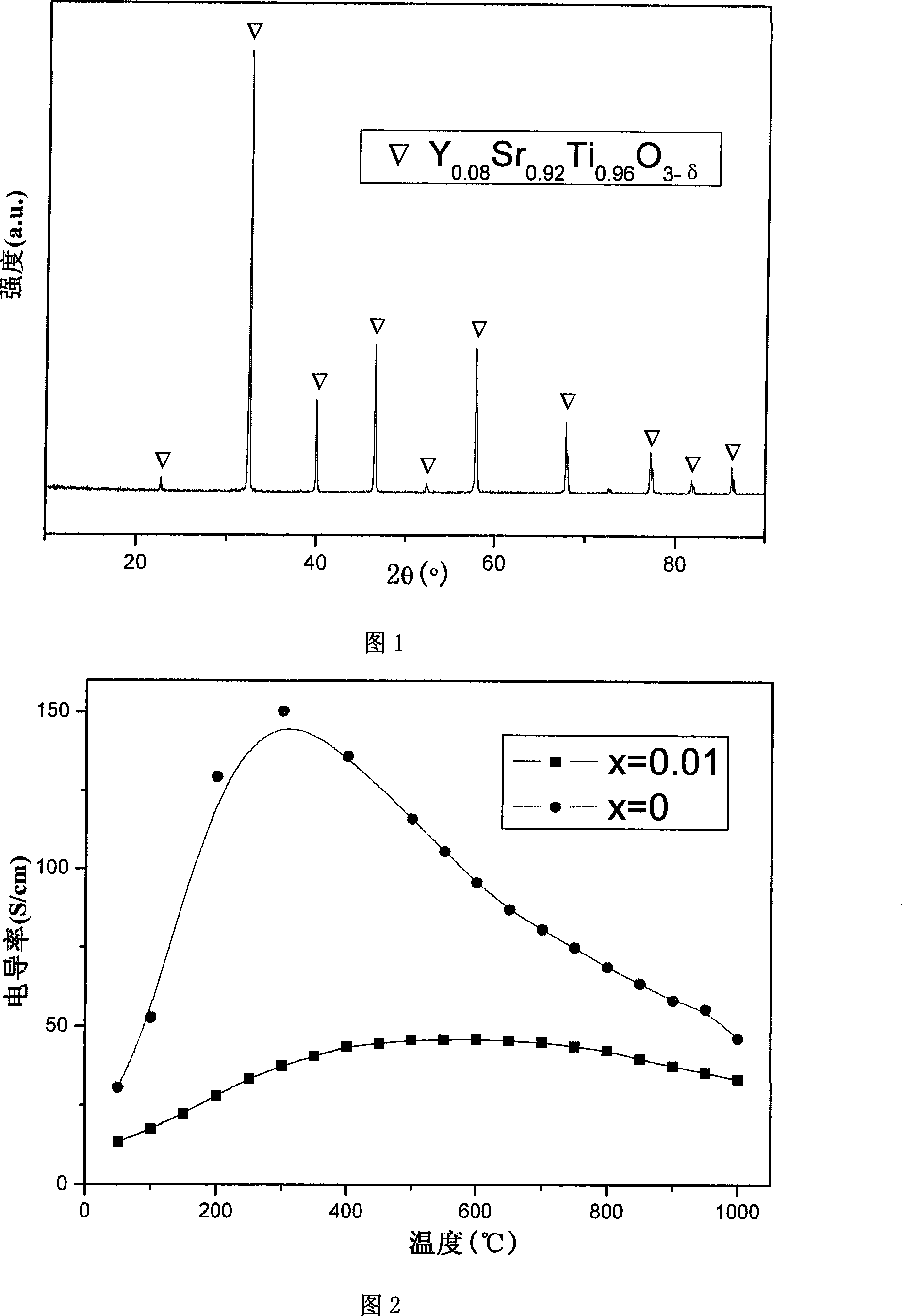

B-position omission perovskite anode material used for solid-oxide fuel battery

InactiveCN101222059AImprove performanceGood chemical compatibilityCell electrodesFuel cell detailsFuel cellsIonic conductance

The invention relates to a B-site omission perovskite anode material used for a solid oxide fuel cell, belonging to the fuel cell field. The invention is characterized in that: an A site of perovskite SrTiO3 is adulteration of Y (8 mole percent); Ti omission exists on a B site; molecular formula after omission adulteration is Y0.08Sr0.92Ti1-xO3-delta, wherein, x is equal to 0 to 0.05; a transition element for A-site adulteration is yttrium. The omission adulteration anode material prepared by the invention can be used for the solid oxide fuel cell and has stable performance and good chemical compatibility with electrolyte YSZ and LSGM, and ionic conductivity of the material is greatly improved. Compared with data of a material Y0.08Sr0.92TiO3-delta which has no omission adulteration, the ionic conductivity is raised by two order of magnitudes, thereby working performance of the anode material is improved and foundation is laid for practicality of the SOFC.

Owner:UNIV OF SCI & TECH BEIJING

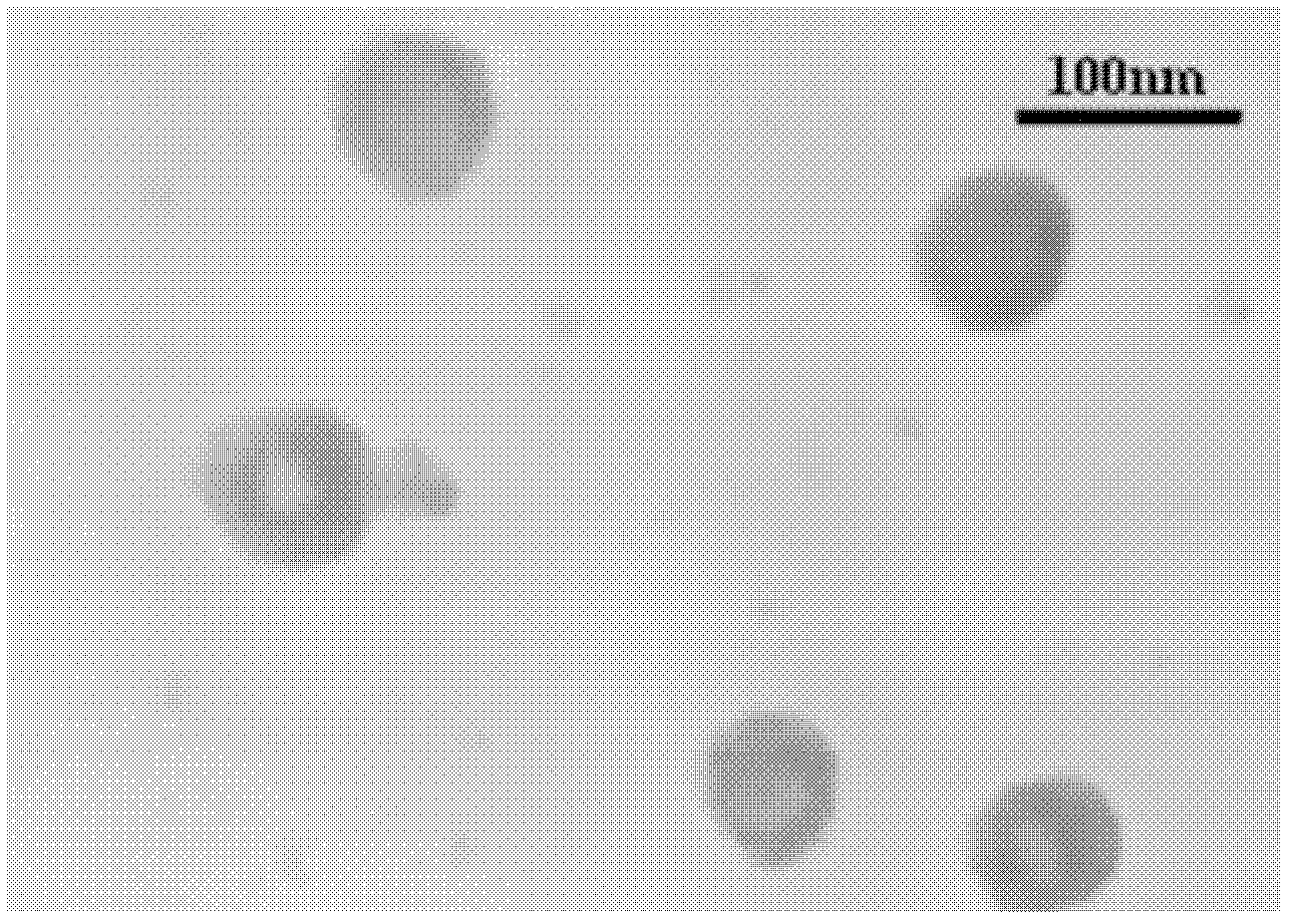

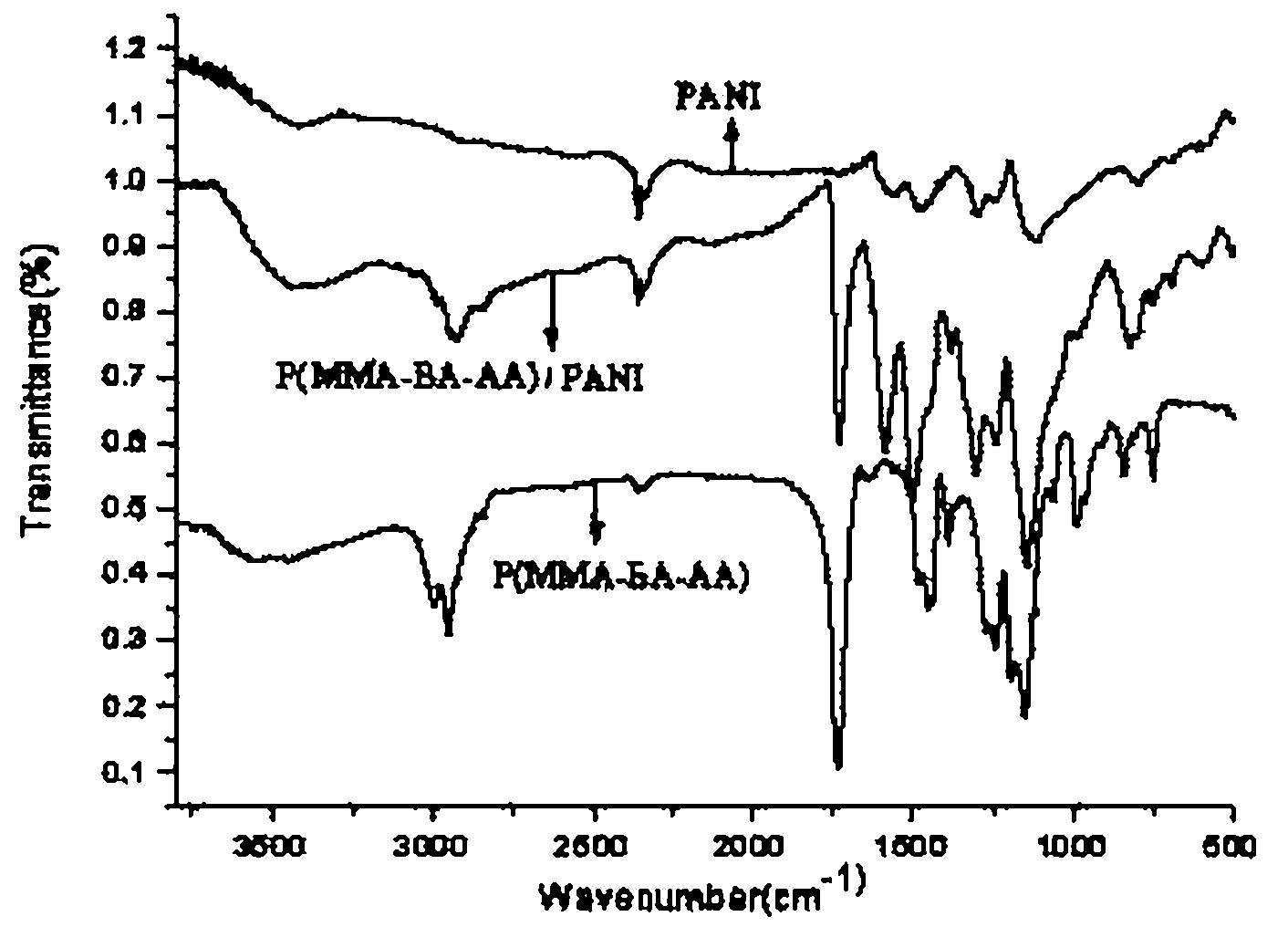

Aqueous epoxy antistatic coating with nano-core-shell structural conductive polyaniline and preparation method thereof

The invention discloses an aqueous epoxy antistatic coating with nano-core-shell structural conductive polyaniline and a preparation method thereof. According to the preparation method, a self-made emulsifying agent is synthesized by taking epoxy resin and polyethylene glycol as raw materials; the nano-core-shell structural conductive polyaniline is synthesized by a miniemulsion method and takingthe emulsifying agent and sodium dodecyl sulfate as emulsifying agents; and the aqueous epoxy antistatic coating with the nano-core-shell structural conductive polyaniline is prepared by taking the core-shell structural polyaniline as a filler. The preparation method disclosed by the invention is simple in preparation process and low in cost, and the conductivity can be controllable through adjusting the quantity of addition of the polyaniline. The aqueous epoxy antistatic coating prepared by the preparation method disclosed by the invention has the advantages of high content of polyaniline, good chemical compatibility and remarkable antistatic property, and the dispersion and the stability of the polyaniline in an aqueous epoxy emulsion are excellent, so that the aqueous epoxy antistaticcoating with the nano-core-shell structural conductive polyaniline has an important industrial application value.

Owner:SHANDONG UNIV

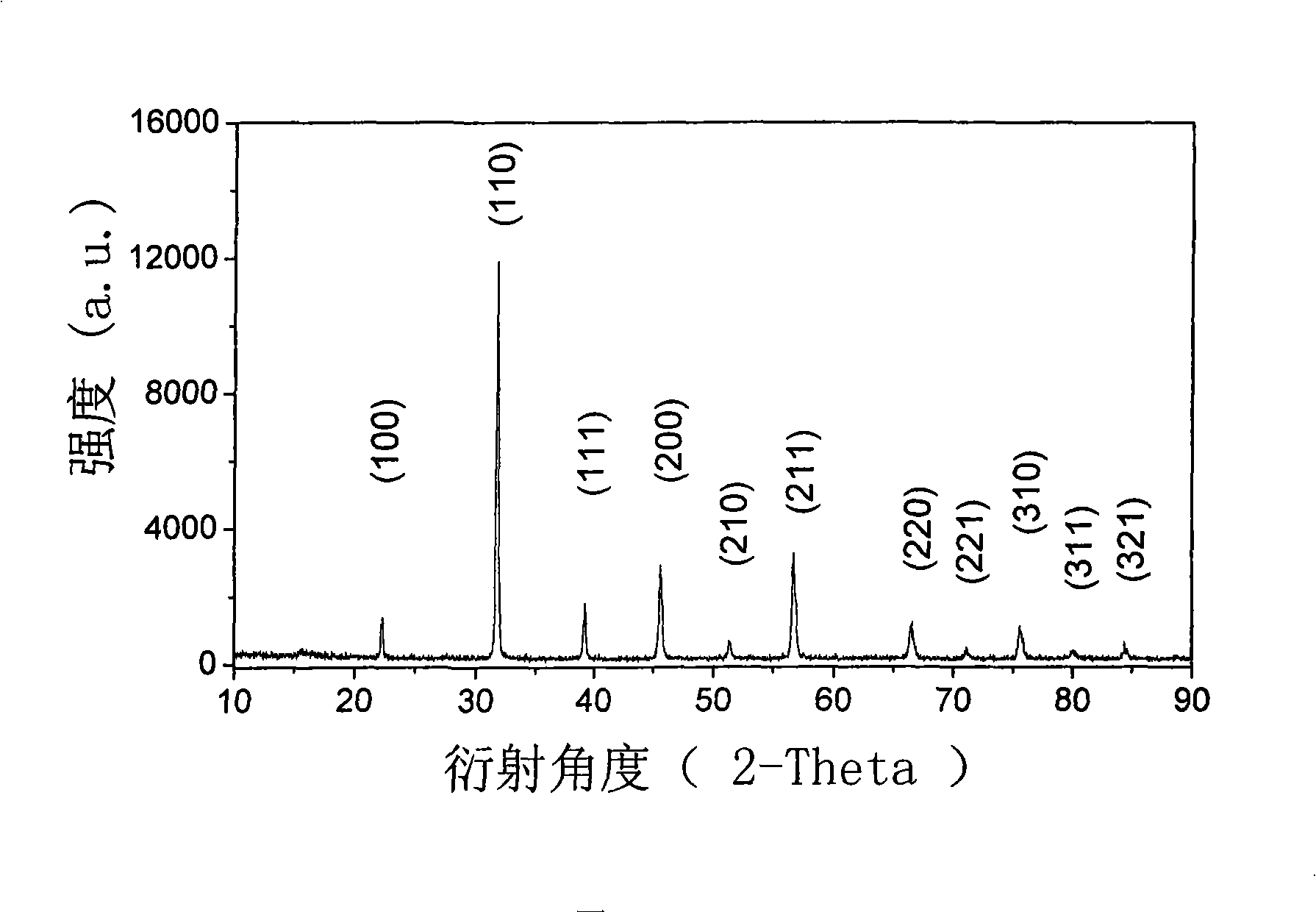

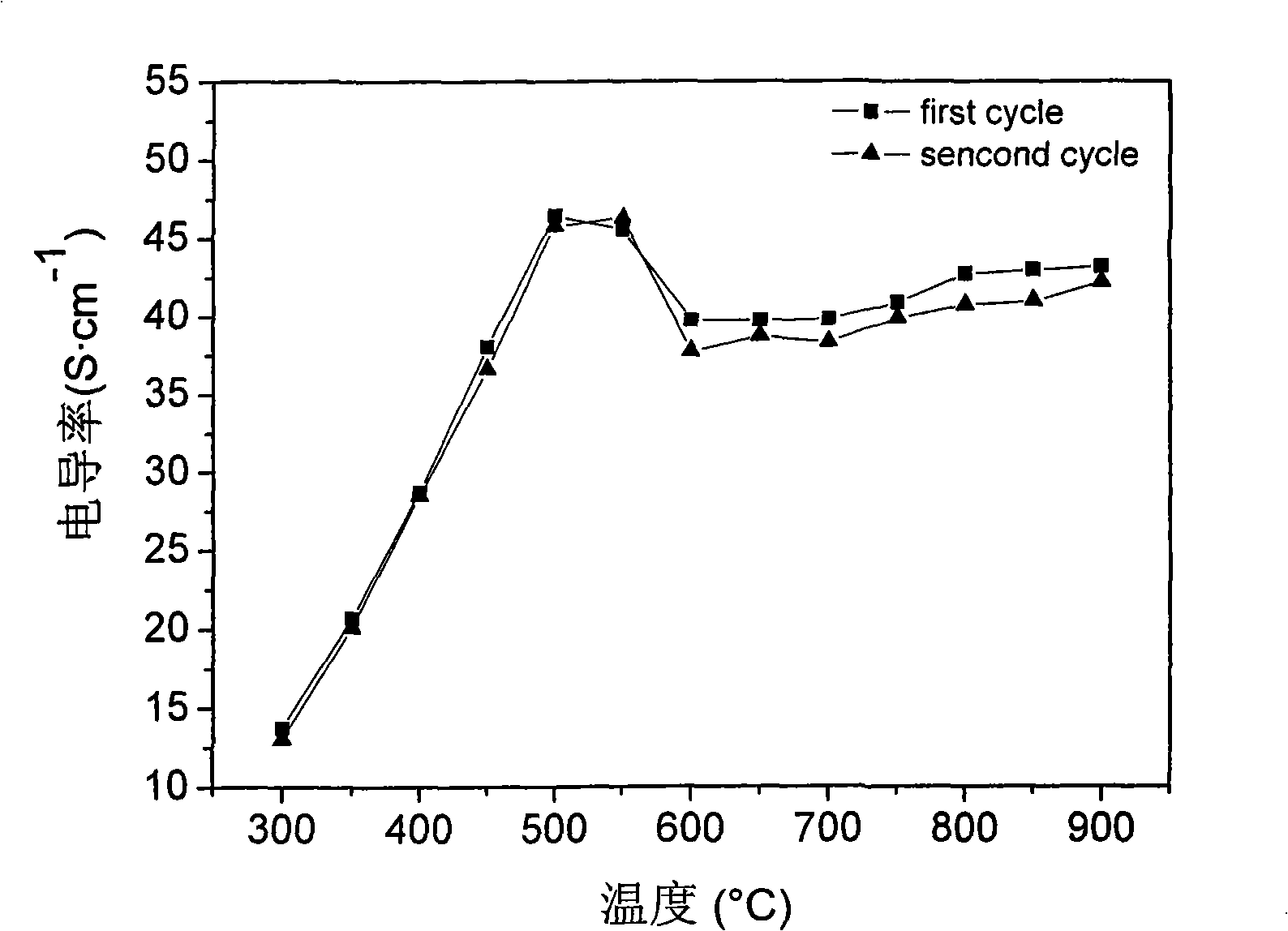

Cathode material for middle and low-temperature solid oxide fuel battery

InactiveCN101267038AGood compatibilityHigh oxygen ionCell electrodesTitanium compoundsChemical compatibilityThermal stability

The present invention provides a La doped low-to-intermediate temperature solid state oxide fuel cell, which molecular formula is (Ba0.6Sr0.4)1-xLaxCo0.85Ti0.15O3-theta, 0.052-based electrolyte, stably existing with CGO under 900 DEG C. The conductivity of the cathode material under the temperature 500 DEG C is 46.42S.cm-1, compared with the material having no La doping, the conductivity is enhanced about 150%. The cathode material is fit for low medium temperature solid oxide fuel cell.

Owner:UNIV OF SCI & TECH BEIJING

Novel medical powder injection rubber plug and manufacturing method thereof

ActiveCN101851377AGood chemical resistanceImprove cleanlinessPharmaceutical containersMedical packagingEngineeringPack material

The invention discloses a novel medical powder injection rubber plug and a manufacturing method thereof, which belong to the technical field of medical packaging materials. The invention is characterized in that the rubber plug is manufactured by using the following raw materials in part by weight: halogenated butyl rubber 50-60, argil 30-40, carbon black 0.5-1.0, magnesium oxide 2.0-3.0, vulcanizing agent 0.1-0.3, titanium white 0.5-2.5, and carbon black master batch 0.2-1.0. The halogenated butyl rubber may be chlorinated butyl rubber or brominated butyl rubber. The rubber plug of the invention has high chemical resistance, high chemical compatibility, high biological safety and good chemical properties.

Owner:SHANDONG PHARMA GLASS

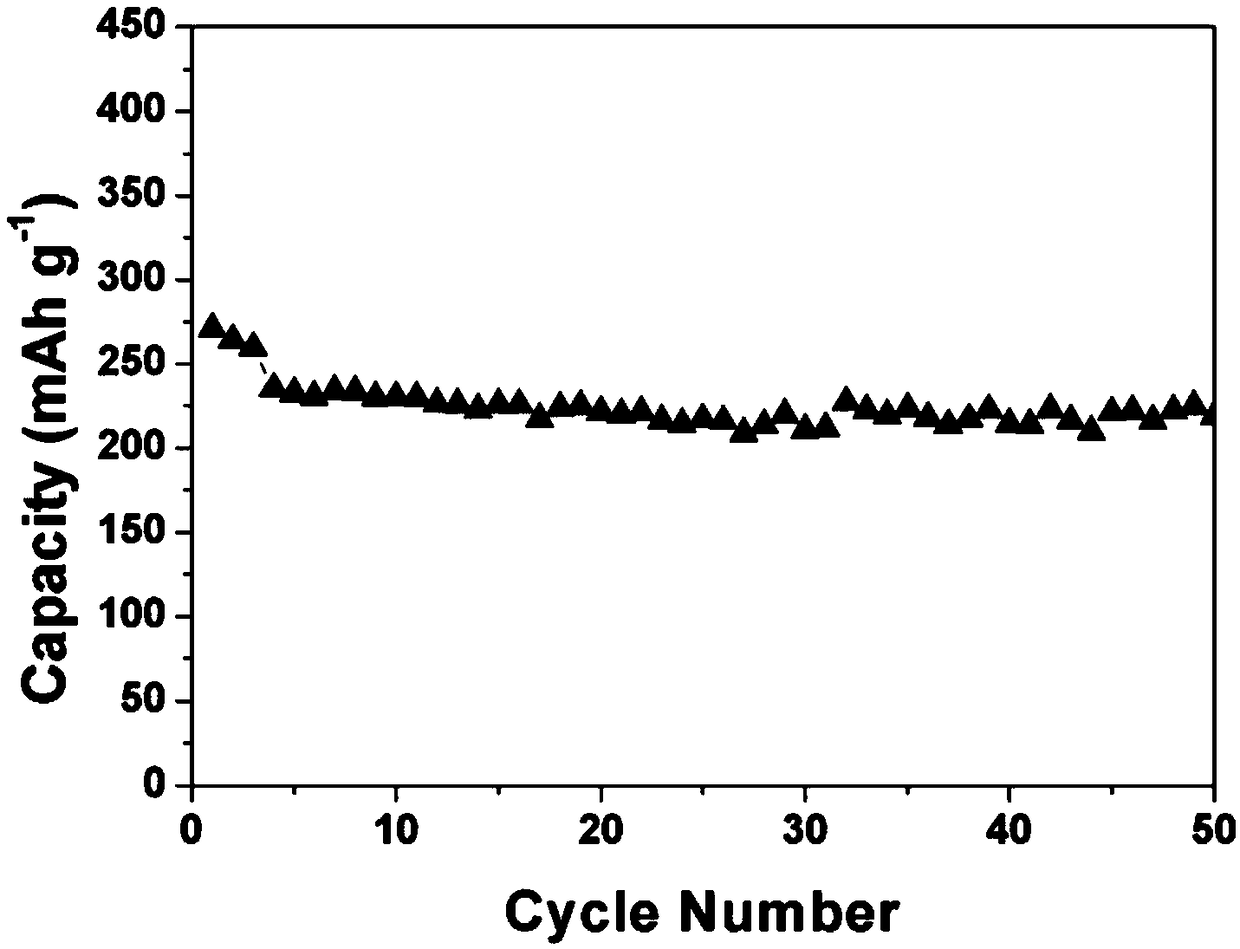

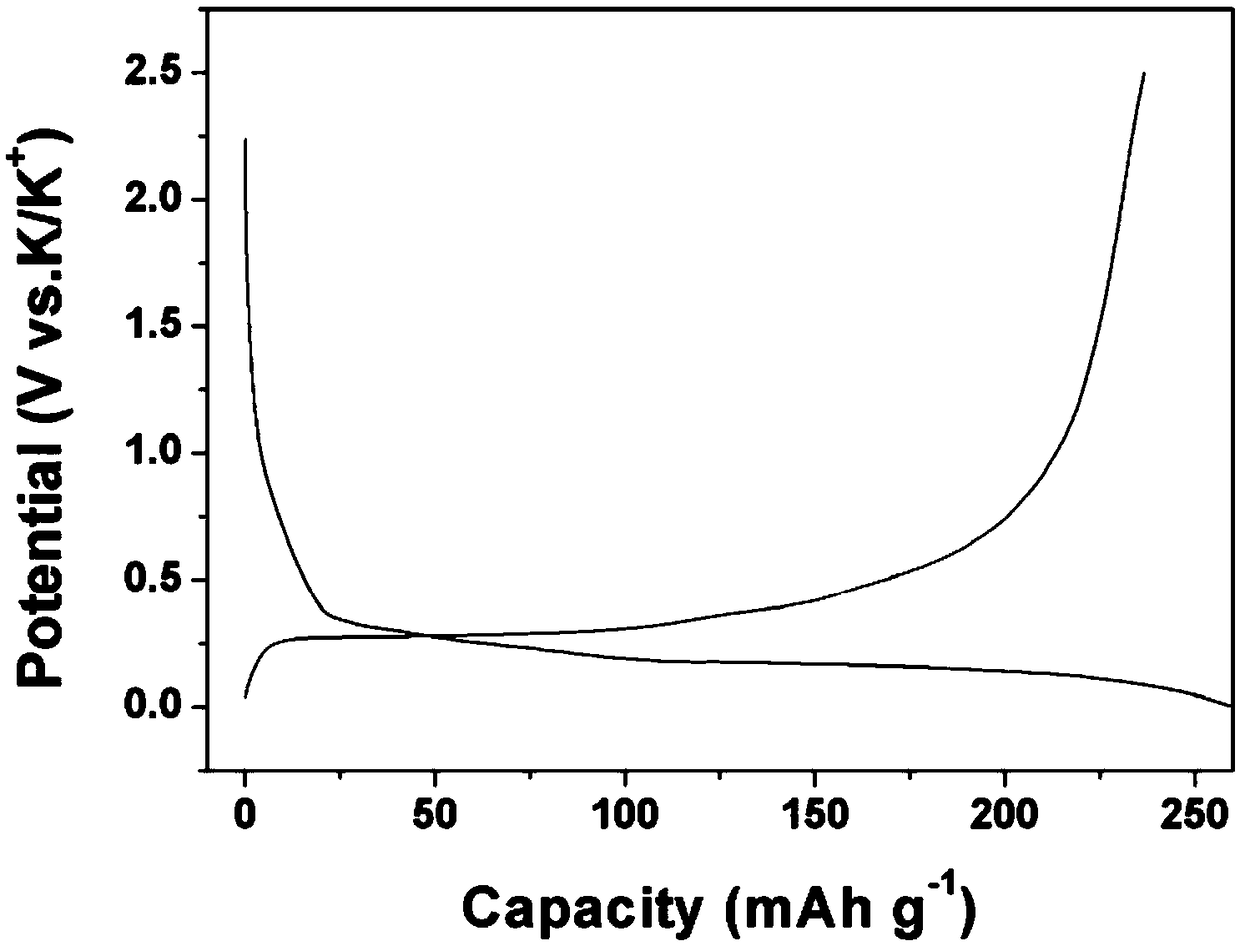

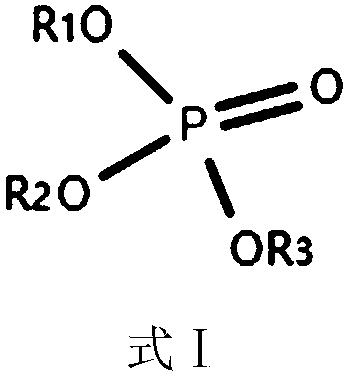

A metal salt phosphate base electrolyte with high safety and high concentration in non-aqueous system

A metal salt phosphate base electrolyte with high safety and concentration in non-aqueous system includes metal salt and phosphate ester. When the electrolyte is applied to a lithium ion battery by adding a high concentration of metal salt, the high concentration electrolyte exhibits enhanced reduction / oxidation resistance, good chemical compatibility with the electrode and high non-combustibilityas compared with a conventional electrolyte. The invention uses high-concentration metal salt as solute and has the function of widening electrochemical window of electrolyte. Solute-derived inorganic SEI membranes were formed on the anode, which were compared with solvent-derived organic SEI membranes. Inorganic SEI membrane, inorganic SEI membrane has more excellent cycle stability; Compared with common carbonate electrolyte, high concentration metal salt electrolyte has good compatibility with graphite anode.

Owner:SHANDONG UNIV

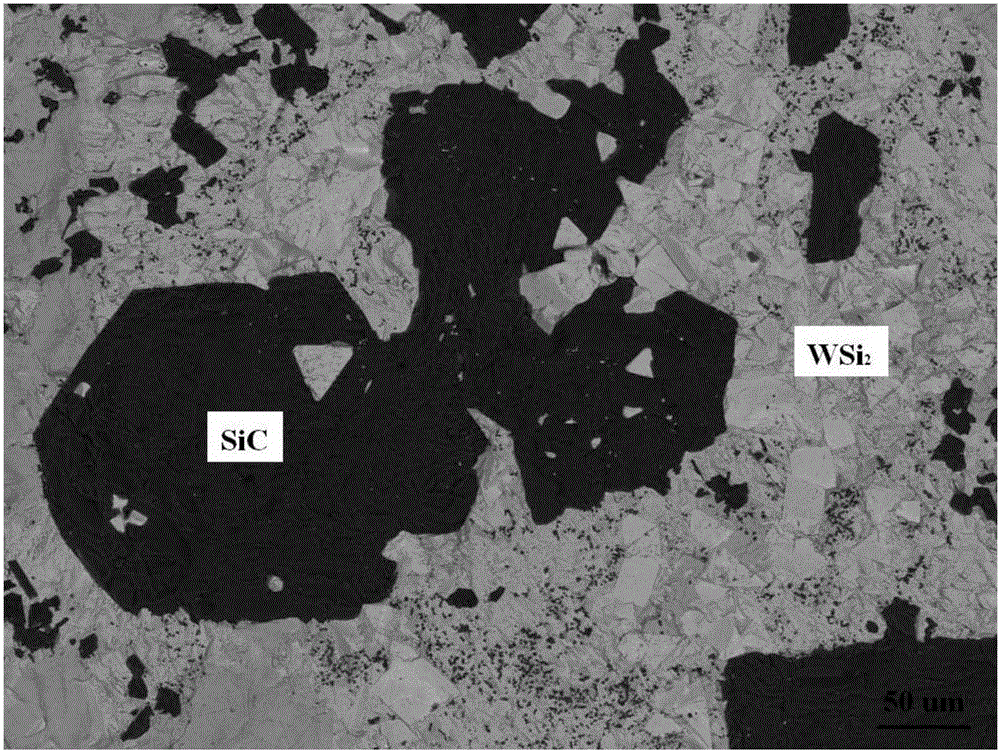

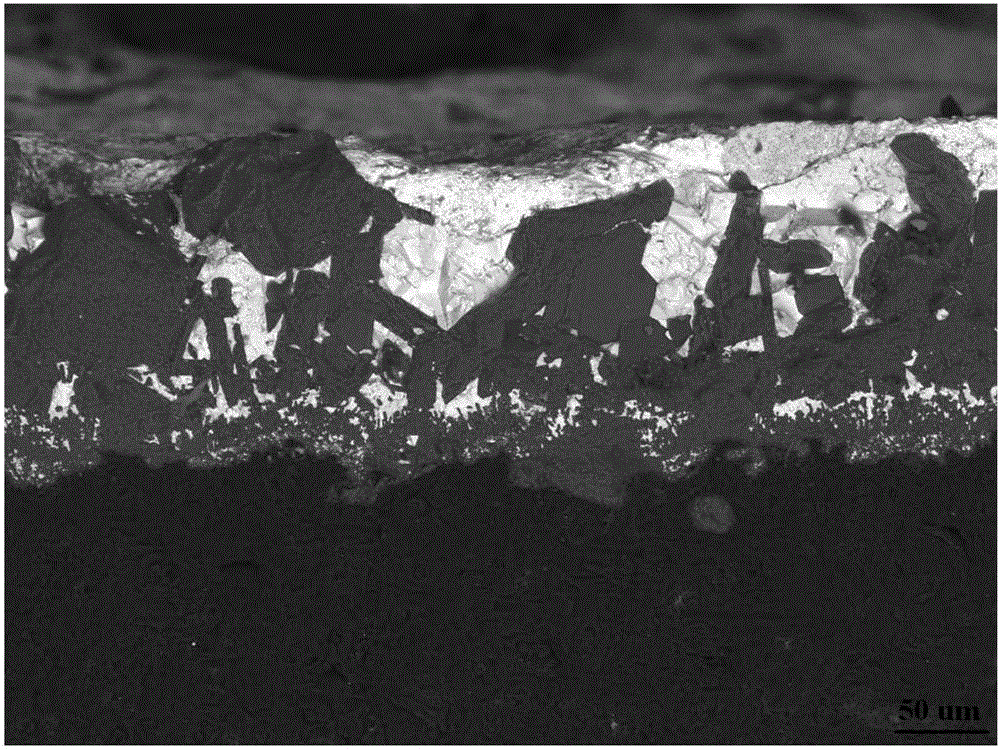

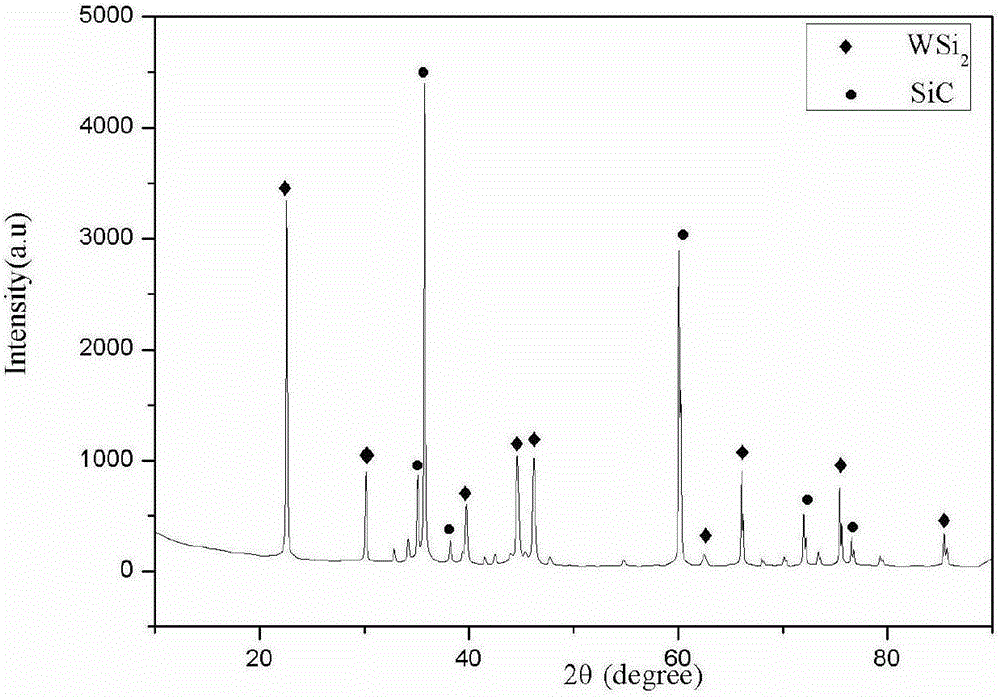

Preparation method of carbon/carbon composite material surface metal tungsten gradient coating

The invention relates to a preparation method of a carbon / carbon composite material surface metal tungsten gradient coating, which aims to solve the problems of poor compatibility between the C / C composite material and W, high tendency to generating the WC brittle phase and the like. The method comprises the following steps: previously preparing a SiC / WSi2 transition layer on the C / C composite material surface by a two-step embedding process to improve the physicochemical compatibility between the C / C composite material and metal W; and finally, successfully preparing a W coating on the C / C composite material surface coated with the SiC / WSi2 transition layer by an ultrasonic plasma spraying process, thereby preparing the C-Si-W gradient coating on the C / C composite material surface. The SiC / WSi2 transition layer and sprayed W overcoating have compact structure, and are firmly combined with the base. The C / C composite material with the C-Si-W gradient coating maintains the advantages of high strength, low specific gravity and the like, and also has excellent properties of the metal W.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com