A metal salt phosphate base electrolyte with high safety and high concentration in non-aqueous system

A technology of salt phosphate and phosphate, applied in the field of high-concentration metal salt phosphate-based electrolyte, can solve the problems of difficult to generate SEI film, reduce the flammability of electrolyte, and be difficult to achieve completely, and achieve excellent cycle stability and process. The parameters are easy to control and the equipment is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

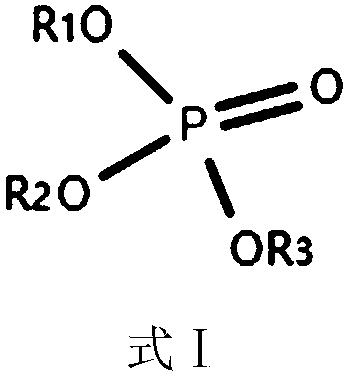

[0037] The preparation method of above-mentioned high-concentration phosphate-based electrolyte comprises the steps:

[0038] (1) Purify the organic solvent to remove impurities and remove water;

[0039] (2) In an argon-protected glove box, the conductive lithium salt is added to the solvent in the above (1);

[0040] (3) Stir for a period of time in an argon-protected glove box to obtain the electrolyte solution.

[0041] Purification in step (1) to remove impurities and remove water can be carried out by any one or Two or more are processed.

Embodiment 1

[0044] (1) Trimethyl phosphate (TMP) is first distilled and purified to remove impurities, and then lithium hydride is used to remove water;

[0045] (2) In an argon-protected glove box, add potassium bis(fluorosulfonyl)imide (KFSI) to the TMP in (1) above, so that the final concentration is 2.2mol / L, that is, a high concentration safe Phosphate-based electrolyte;

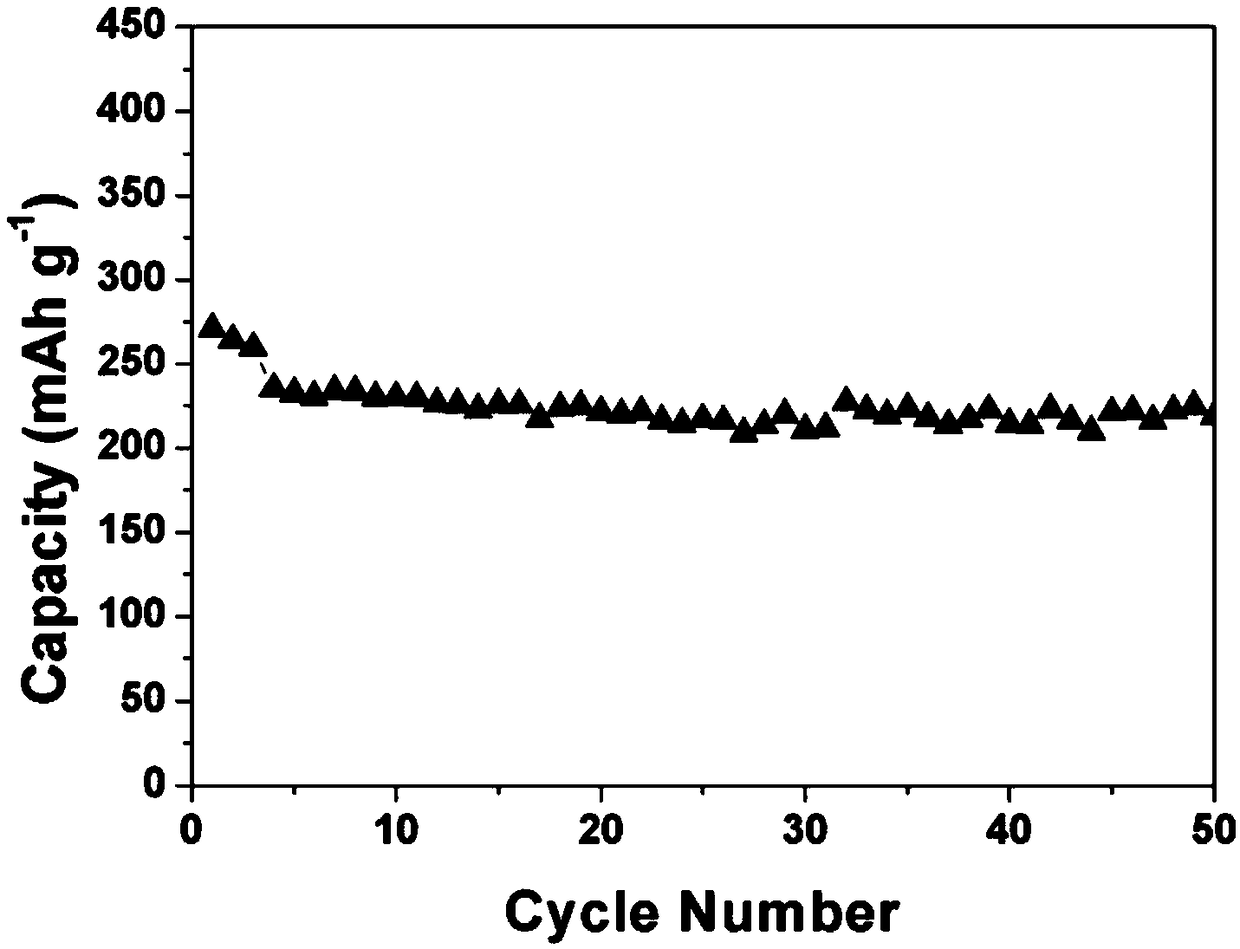

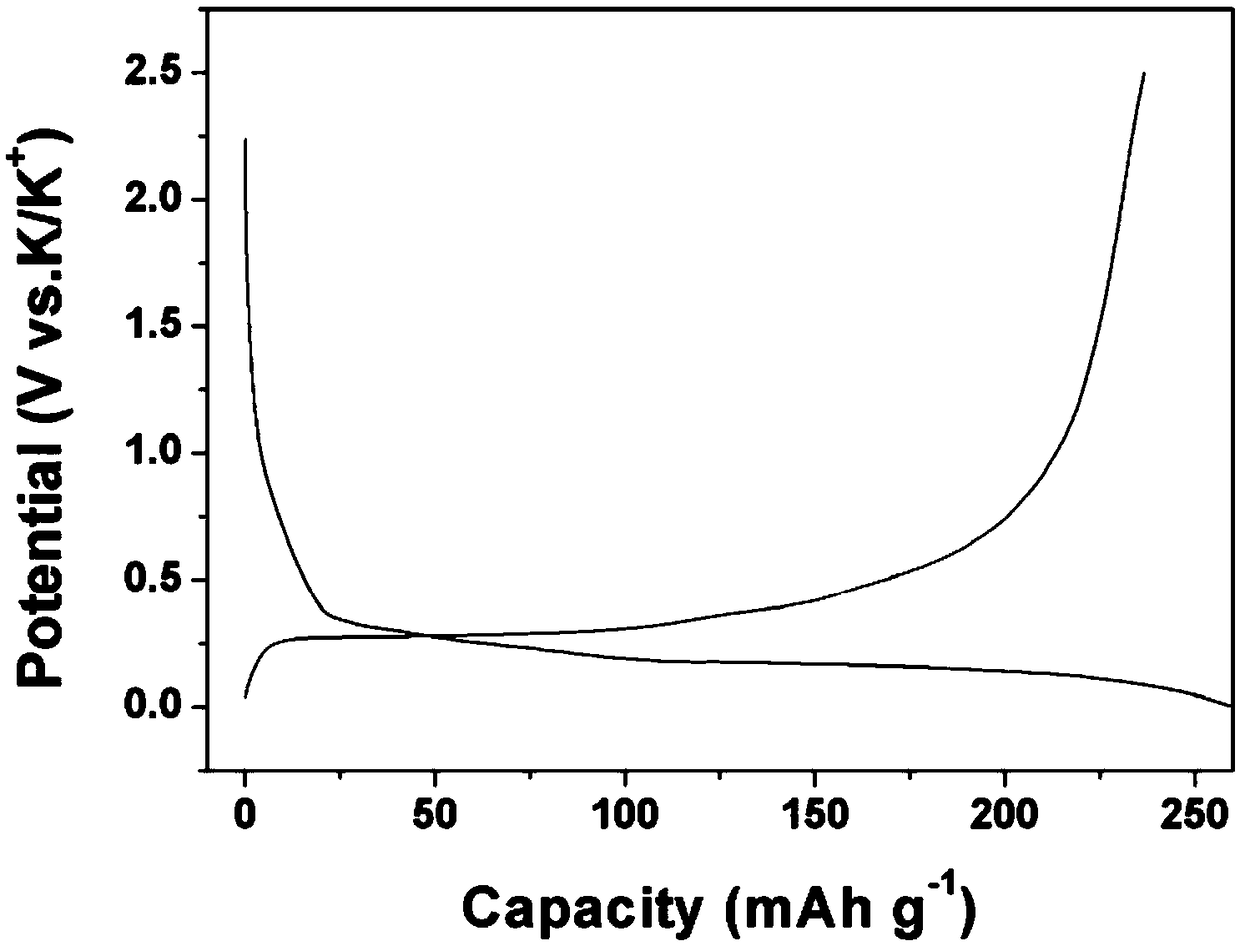

[0046] (3) Electrochemical performance test

[0047] Negative electrode: Spherical graphite is used as the active material, SP is the conductive agent and CMC is used as the binder, and the slurry is prepared according to the mass ratio of 8:1:1, and coated on the copper foil to make an electrode sheet. Potassium flakes, separators and spherical graphite pole pieces were assembled into a button battery for testing with a current density of 60mA g -1 .

Embodiment 2

[0049] (1) Distill and purify trimethyl phosphate (TMP) to remove impurities, and then add 4A molecular sieves to remove moisture and impurity alcohols in the solvent;

[0050] (2) In an argon-protected glove box, lithium hexafluorophosphate (LiPF 6 ) is added to the TMP in the above (1), so that the final concentration is 2.2mol / L, to obtain a high-concentration safe phosphate-based electrolyte;

[0051] (3) Electrochemical performance test

[0052] Negative electrode: Spherical graphite is used as the active material, SP is the conductive agent and CMC is used as the binder, and the slurry is prepared according to the mass ratio of 8:1:1, and coated on the copper foil to make an electrode sheet. Lithium sheet, separator and spherical graphite pole piece were assembled into a button battery for testing, and the current density was 60mA g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com