Patents

Literature

267 results about "Trimethyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethyl phosphate is the trimethyl ester of phosphoric acid. It is a colourless, nonvolatile liquid. It has some specialized uses in the production of other compounds.

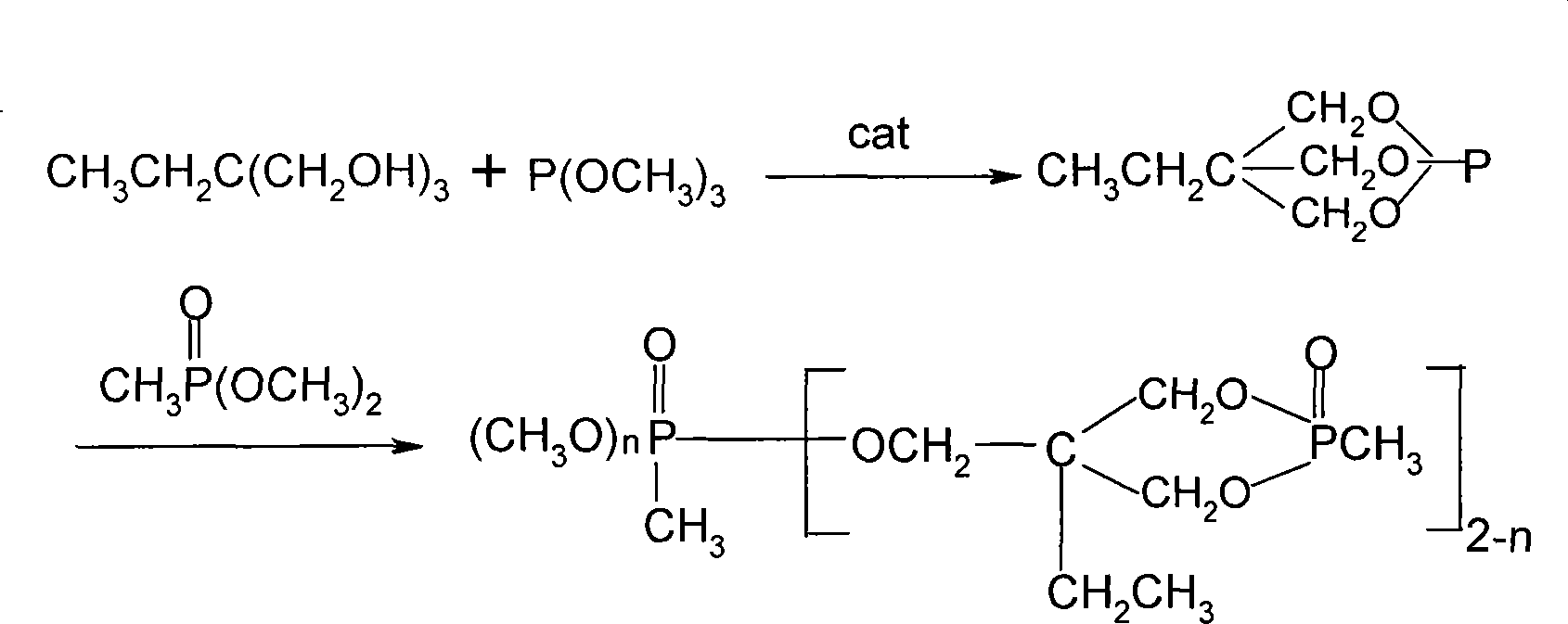

Method for preparing annular phosphonate or annular phosphate flame retardant

InactiveCN101230274AThe preparation method is simple and environmentally friendlyEasy to operateFlame-proof filament manufactureGroup 5/15 element organic compoundsDimethyl methylphosphonateTriethylphosphite

The invention provides a preparation method of annular phosphonate or annular organic phosphate flame retardant. The steps are that (1) trimethylolpropane and trimethyl phosphate or triethyl phosphate are taken as the material, and react to synthesize into midbody under the condition of catalyzer; (2) phosphonate or organic phosphate is added into the midbody and is heated, and then the product of annular phosphonate or annular organic phosphate flame retardant can be obtained. The phosphite ester is selected from trimethyl phosphate and triethyl phosphate. The phosphonate is selected from dimethyl-phosphine and diethyl ethyl phosphine. The organic phosphate is selected from trimethyl phosphate, triethyl phosphate, phosphate propyl, tributyl phosphate and tricresyl aromatic ester. The invention overcomes the shortcomings of the prior art, the new preparation method of annular phosphonate or annular organic phosphate flame retardant is environment-friendly, solution is not needed, and the operation is simple. The termination product has excellent color and luster, low acid value and excellent viscosity; and does not need additional decoloration.

Owner:NANJING NORMAL UNIVERSITY +1

Method for fabricating fiber reinforcement type microporous filter membranes of hollow fiber made from polyvinylidene fluoride

InactiveCN1695777AHigh tensile strengthTightly boundSemi-permeable membranesHollow fibrePolymer science

A fibre reinforced millipore filter membrane of hollow polyvinylidene fluoride fibre is prepared through preparing solution from polyvinylidene fluoride, solvent and additive, pretreating the reinforcing fibres, spinning, gelatinizing and post-treating. Said solvent, additive and reinforcing fibre are also disclosed.

Owner:TIANJIN UNIV

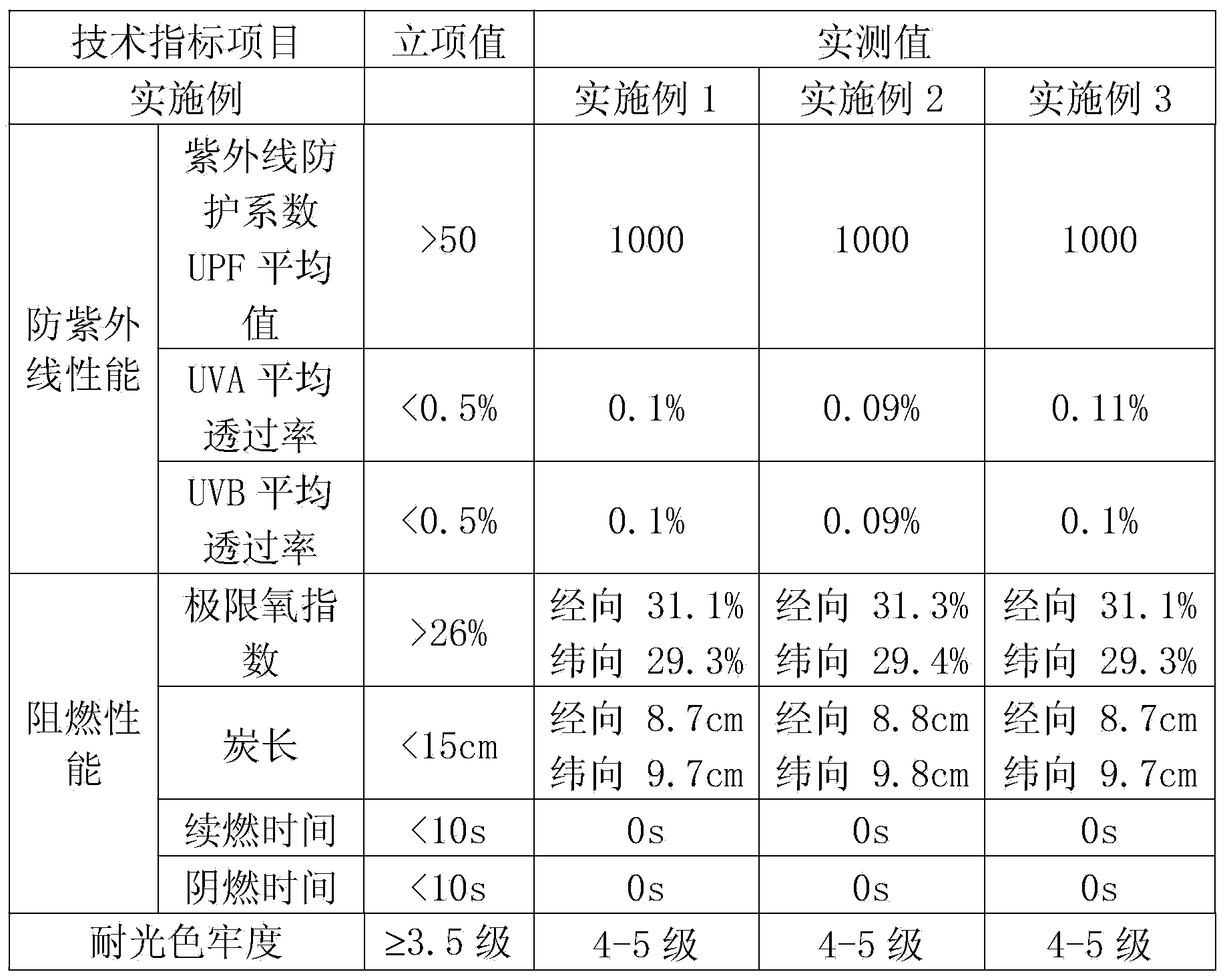

Production process for anti-ultraviolet flame-retardant light-resistant curtain shell fabric

The invention discloses a production process for an anti-ultraviolet flame-retardant light-resistant curtain shell fabric. The production process comprises the following steps: mixing and spinning flame-retardant polyester fiber, polyacrylonitrile fiber, refined sulfur cotton and flame-retardant nylon into yarns; spinning the yarns into a semi-finished shell fabric; padding the semi-finished shell fabric into a finishing solution for padding, and then drying and cooking the semi-finished shell fabric to obtain a finished curtain shell fabric, wherein the finishing solution comprises a coating, a Gemini cationic softener, a flame retardant, a micro-nano-oxide, polyoxyethylene alkyl ether sulfonates succinate and the like; the flame retardant is obtained by synthesizing trimethylolpropane, trimethyl phosphate and trimethyl phosphate in the molar ratio of 1:1:1; and the Gemini cationic softener is obtained by synthesizing stearyl amidopropyl dimethyl amine and bis(2-chloroethyl) ether in the molar ratio of 2:1. The curtain shell fabric prepared by the method has high ultraviolet resistance, high light resistance and high flame retardant performance.

Owner:ZHEJIANG HUIDE NEW MATERIAL

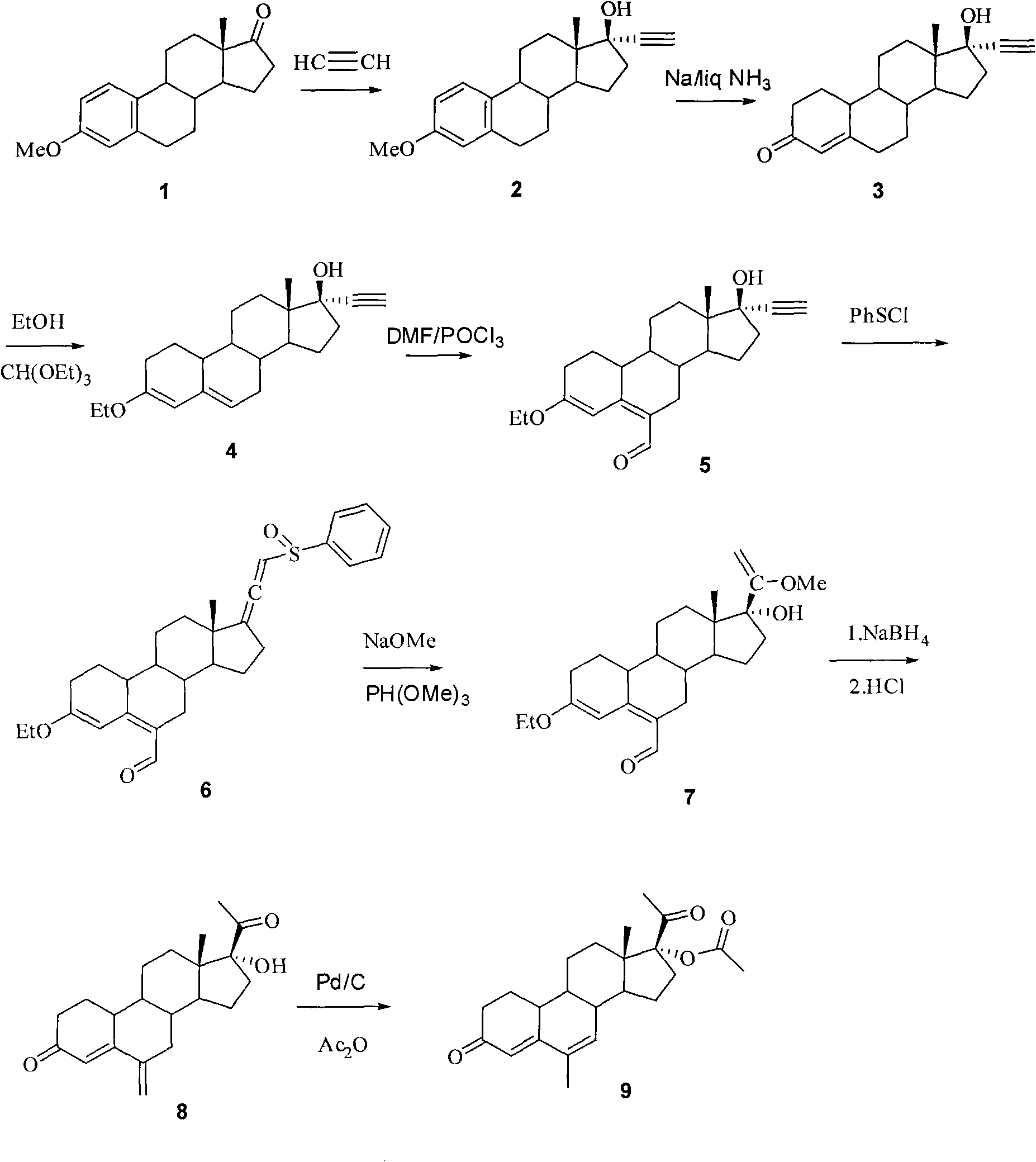

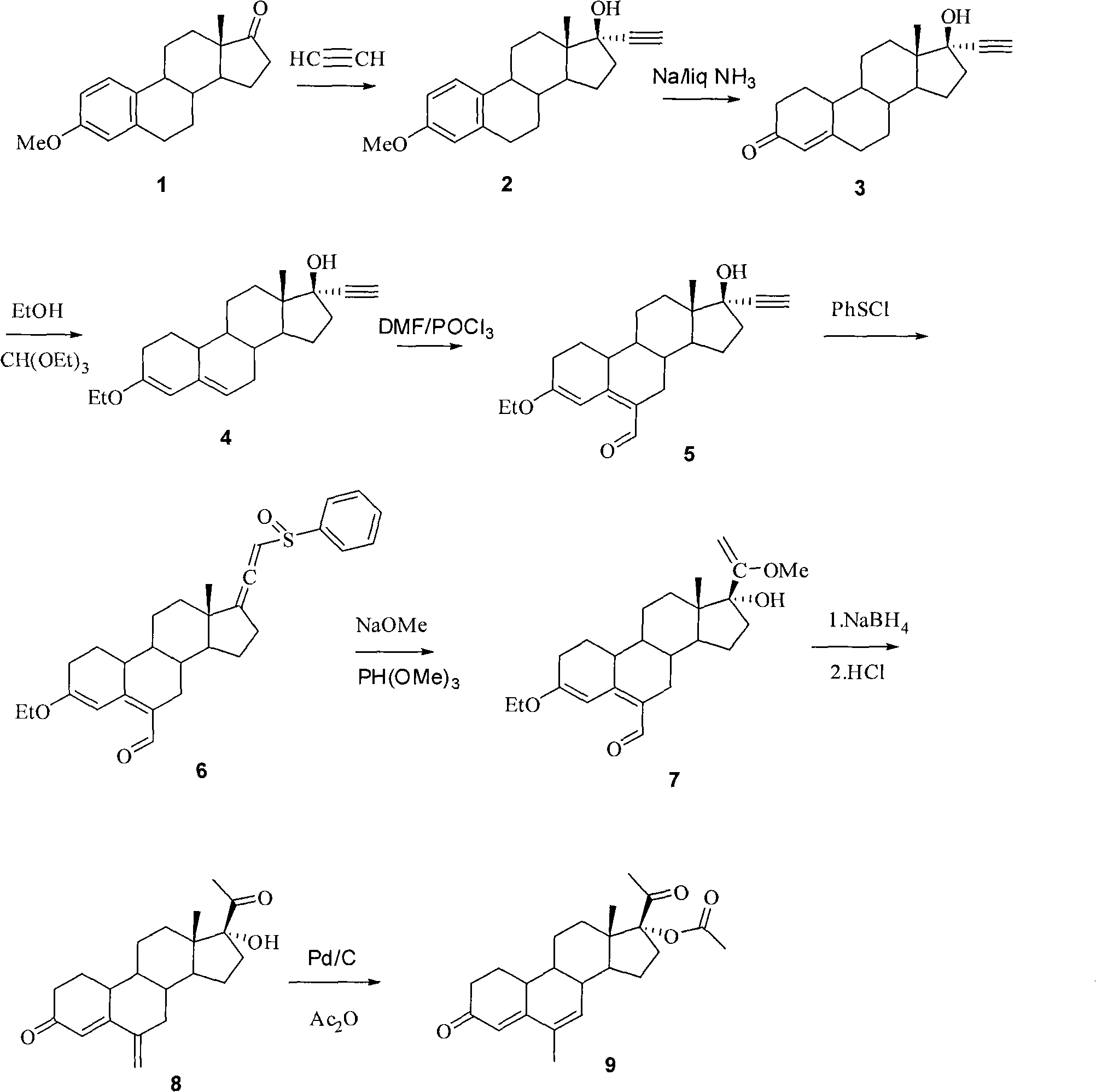

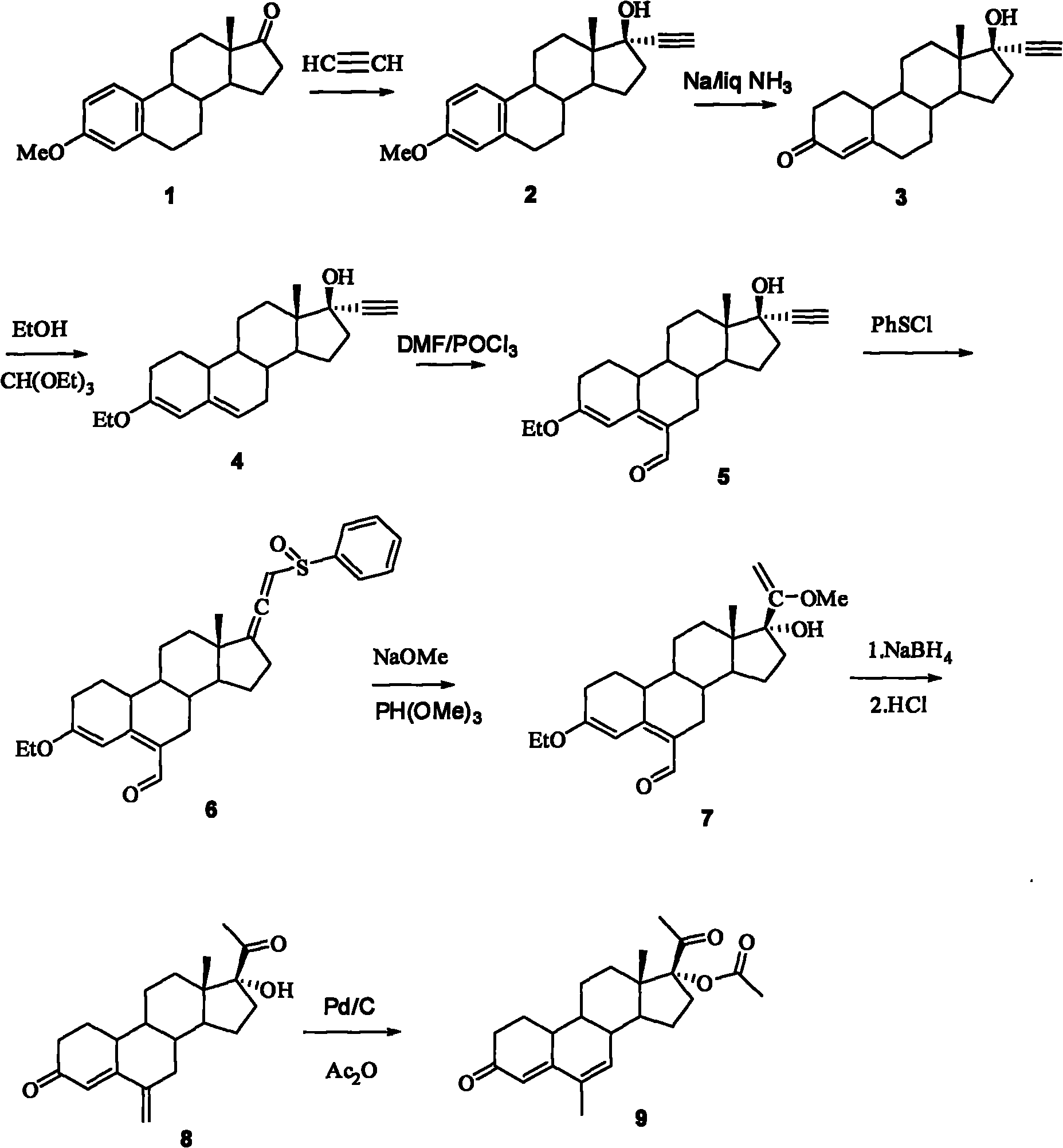

Method for synthesizing 6-methyl-17alpha-acetoxyl-19-norpregnane-4,6-diene-3,20-diketone

The invention relates to a method for synthesizing 6-methyl-17alpha-acetoxyl-19-norpregnane-4,6-diene-3,20-diketone. The method comprises the following steps: 1) reacting acetylene with estrone-3-methyl ether so as to obtain 17alpha-acetenyl estrone-3-methyl ether; 2) carrying out Birich reaction at a low temperature; 3) carrying out alkene etherification on the product obtained in the step 2); 4) carrying out a Vilsmeier reaction on the product obtained in the steps 3); 5) reacting the product obtained in the step 4) with benzene sulfenyl chloride; 6) reacting the product obtained in the step 5) with sodium methoxide and trimethyl phosphate; 7) reducing the formoxyl at the 6-position of the product obtained in the step 6); and 8) reacting the product obtained in the step 7) with Pd-C / cyclohexene, then reacting with acetic oxide so as to obtain the target product 6-methyl-17alpha-acetoxyl-19-norpregnane-4,6-diene-3,20-diketone. By using the method, the operation is simplified, and theproduction cost is reduced; and the reactions involved in the invention are simple to operate, and the yield is high.

Owner:黄云生 +1

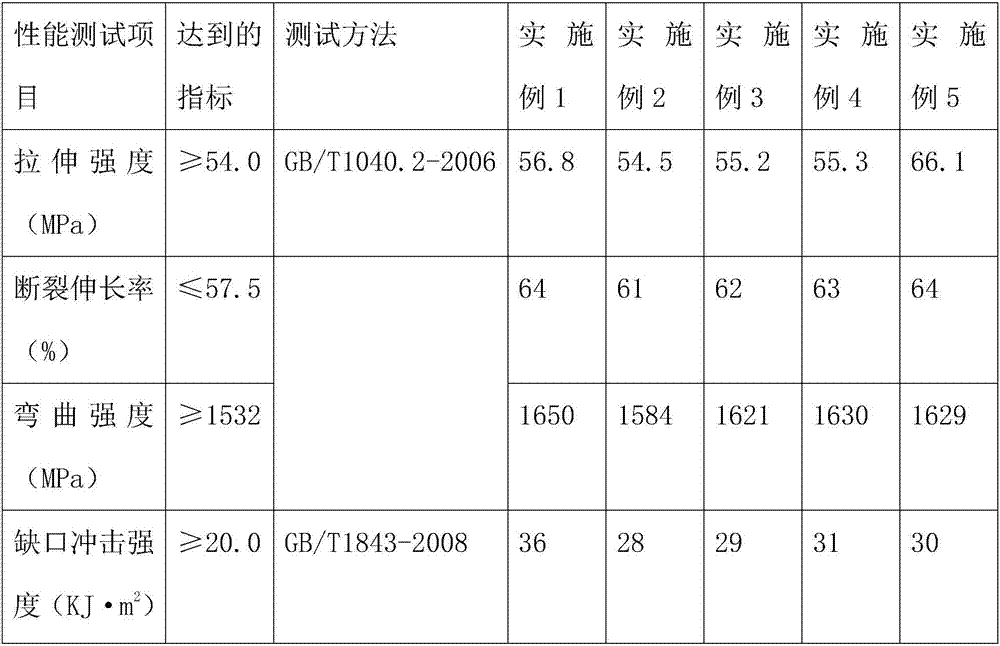

Anti-oxidization and high-intensity 3D printing material for building engineering and preparation method of printing material

InactiveCN107141799AImprove oxidation resistanceHigh strengthAdditive manufacturing apparatusSodium BentonitePolyvinyl chloride

The invention discloses an anti-oxidization and high-intensity 3D printing material for building engineering. The anti-oxidization and high-intensity 3D printing material is prepared from the following raw materials: modified polyphenylene sulfide, polyethylene sulfone, polycarbonate, polyvinyl chloride resin, diisocyanate, trimethyl phosphate, chlorinated polyethylene, polytetrafluoroethylene fine powder, hydroxypropyl methyl cellulose, nano titanium dioxide, zinc borate, antimonous oxide, organic bentonite, glass fiber, nano-zinc oxide, basalt plain fiber cloth, nanosilicon dioxide, tetraethoxysilane, a silane coupling agent KH-570, glycerinum, a defoaming agent, an anti-oxidization modifier and a modifier filler. The invention further provides a preparation method of the anti-oxidization and high-intensity 3D printing material for building engineering. The prepared 3D printing material is excellent in oxidization resistance and intensity.

Owner:HEFEI SKE INTELLIGENT TECH

Heat-resistant and corrosion-resistant epoxy coating for heat-resistant and corrosion-resistant power distribution cabinet shell

InactiveCN106833261AImprove mechanical propertiesEffective in promoting dispersionAnti-corrosive paintsEpoxy resin coatingsPolyvinyl alcoholPolyphenol

The invention discloses a heat-resistant and corrosion-resistant epoxy coating for a heat-resistant and corrosion-resistant power distribution cabinet shell. The heat-resistant and corrosion-resistant epoxy coating is prepared from the following raw materials in parts by weight: 20-40 parts of bisphenol A type epoxy resin, 10-20 parts of polyphenols glycidyl ether epoxy resin, 5-15 parts of novolac epoxy, 6-14 parts of aminoethyl piperazine, 1-2 parts of coalescing agent, 2-4 parts of trimethyl phosphate, 2-6 parts of modified asbestos, 2-4 parts of zeolite powder, 6-10 parts of mica powder, 2-4 parts of glass beads, 1-6 parts of porous powder quartz, 2-6 parts of coal ash, 1-4 parts of cornstalk, 2-5 parts of bentonite, 1-4 parts of carbon black, 5-12 parts of zinc phosphate, 0.5-1.5 parts of antibacterial agent, 2-4 parts of defoaming agent, 5-15 parts of polyvinyl alcohol, and 40-80 parts of water. The epoxy coating disclosed by the invention has extremely high heat stability and corrosion resistance, is not only excellent in airtightness, and but also strong in surface adhesion; and meanwhile, the smearing tenacity can be effectively enhanced, and the smeared coating is hard to break even encountering strong impact.

Owner:ANHUI LIAOYUAN ELECTRIC EQUIP MFG

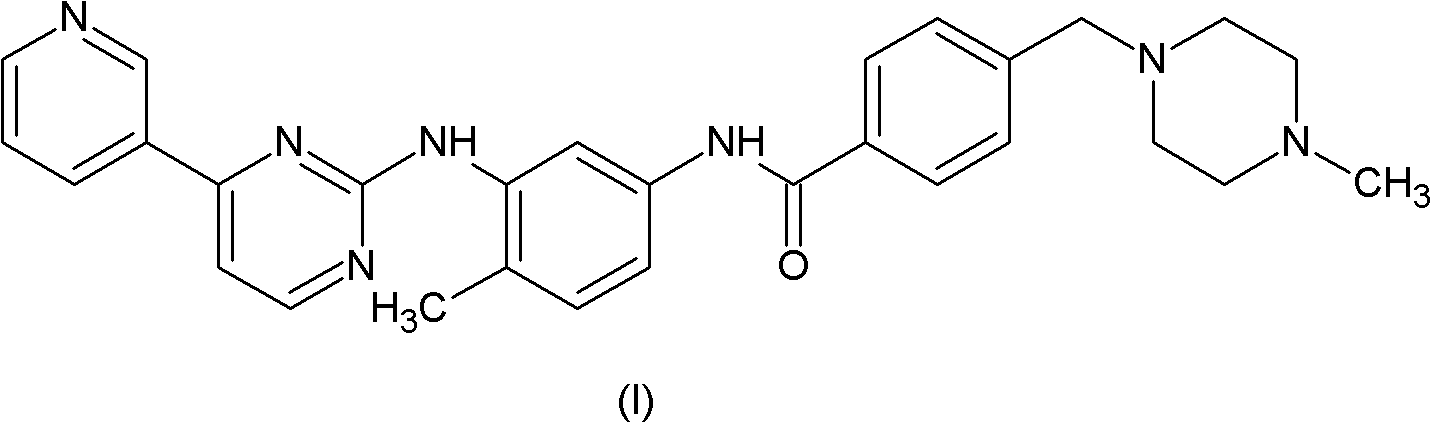

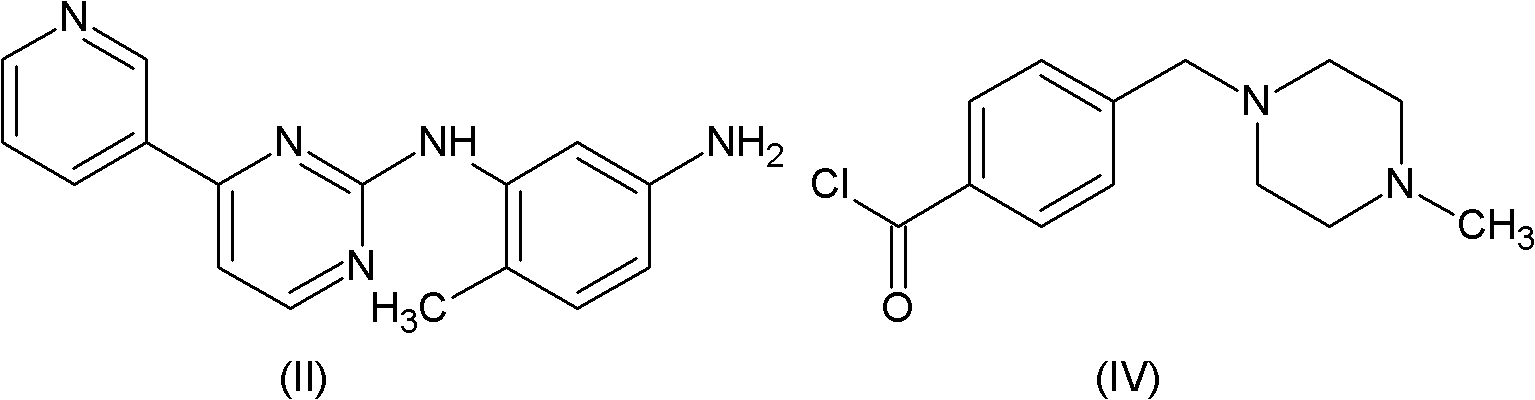

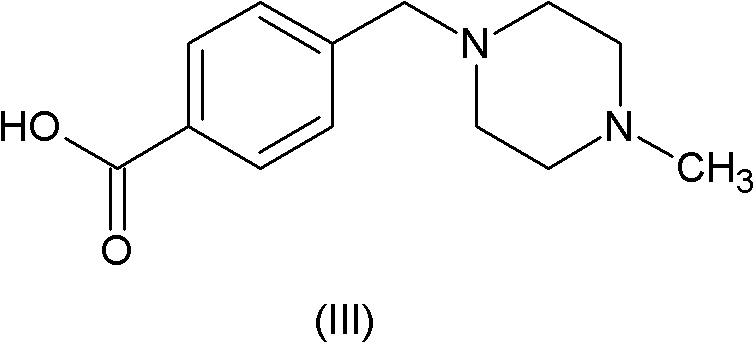

Method for preparing imatinib

ActiveCN101921260AThe reaction steps are simpleShorten the production cycleOrganic chemistryBenzoic acidN dimethylformamide

The invention relates to a method for preparing imatinib, which comprises the following steps of: with a compound N-(5-Amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidineamine shown as the structural formula (II) and a compound 4-[(4-Methylpiperazin-l-yl)methyl]benzoic acid shown as the structural formula (III) as initial raw materials, dropwise adding phosphite ester at 50-90 DEG C for 1-2 hours inthe presence of a catalyst in an organic solvent; and continuously insulating and reacting at 50-90 DEG C to obtain the compound imatinib shown as the structural formula (I). The organic solvent is N,N-dimethylformamide, N,N-dimethylacetylamide or N-methylpyrrolidone. The catalyst is pyridine; and the phosphite ester is trimethyl phosphate, triethyl phosphate or triphenyl phosphate. The technical scheme of the invention has the advantages of simple reaction step, easy control of reaction, short production cycle, low toxicity of used raw materials, less pollution to the environment and higher product quality, and the yield can reach 95 percent, and the purity reaches 99.5 percent.

Owner:山东金城昆仑药业有限公司

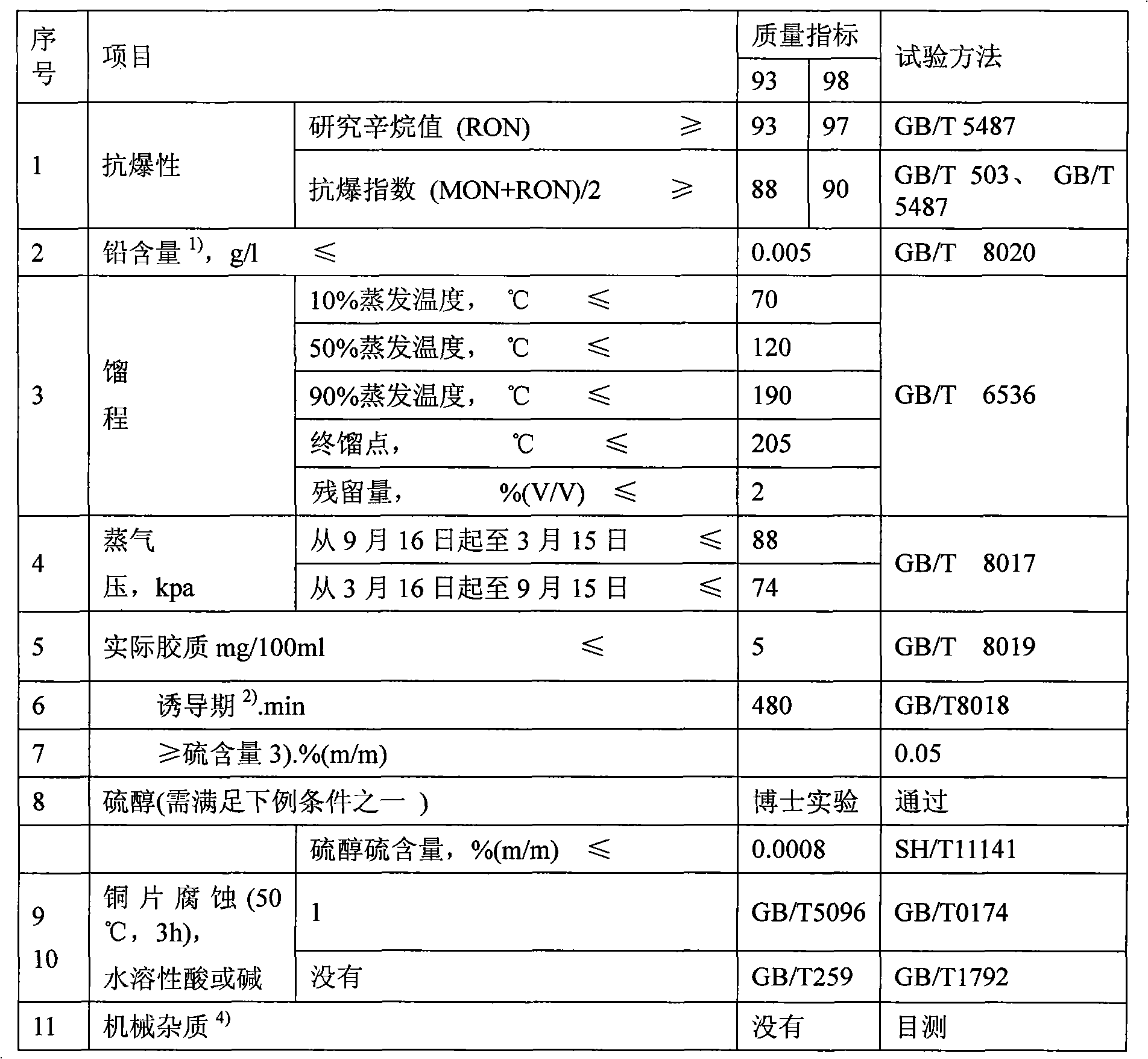

Alcohol ether gasoline used in new energy vehicles

InactiveCN101538491AReduce consumptionReduce pollutionLiquid carbonaceous fuelsNew energyLiquid fuel

The invention relates to a liquid fuel, and particularly a liquid carbonaceous fuel of the mixture of hydrocarbons and alcohol ether. The alcohol ether gasoline used in new energy vehicles comprises 25 to 85 percent of gasoline constituents and 15 to 75 percent of alcohol ether-major other chemical raw materials by weight percentage, wherein the components of the alcohol ether-major other chemical raw materials and the weight proportions thereof in the alcohol ether gasoline used in new energy vehicles are as follows: industrial methanol: 10 to 60 percent, n-hexane: 0 to 3 percent, isopropyl chloride: 0 to 1 percent, trichloroethylene: 0 to 1 percent, epichlorohydrin: 0.2 to 3 percent, bromoethanol: 0.2 to 2 percent, isodibutyl ether: 0.5 to 2 percent, ethylene glycol monobutyl ether: 0 to 1 percent, lauric acid : 0.4 to 2 percent, methyl chloroacetate: 0 to 4 percent, isopropyl nitrate: 0.2 to 4 percent, trimethyl phosphate: 0 to 3 percent, nitromethane: 0.1 to 1 percent, nitroethane: 0 to 1 percent, nitroguanidine: 0 to 3 percent, cyclopentadiene: 0 to 4 percent, and n-butylamine: 0 to 1 percent.

Owner:陈斌

Heat-resistant flame-retardant power cable protective pipe

InactiveCN105400069AImprove heat resistanceIncrease elasticityPlastic/resin/waxes insulatorsSodium phosphatesAluminium hydroxide

The invention discloses a heat-resistant flame-retardant power cable protective pipe, which comprises polypropylene, nylon, ethylene-octene copolymer grafted maleic anhydride, acfylonitrile-butadiene-styrene copolymer, polyethylene glycol terephthalate, nano-silica sol, graphene oxide, nanosized mesoporous silicon dioxide, nano calcium carbonate, wollastonite, nano-aluminium hydroxide, carbon nanofibres, trimethyl phosphate, zinc borate, expansible graphite, naphthenic oil, maleimide, antioxygen, lanthanum stearate, (3, 4 - dimethyl) dibenzylidene sorbitol and 2, 2 - methylene - double (4, 6-2 tert butyl phenoxy) sodium phosphate. The heat-resistant flame-retardant power cable protective pipe is excellent in flame retardant, perfect in heat resistance and aging resistance, can meet the use demands in various fields, and is long in service life.

Owner:安徽宁国市高新管业有限公司

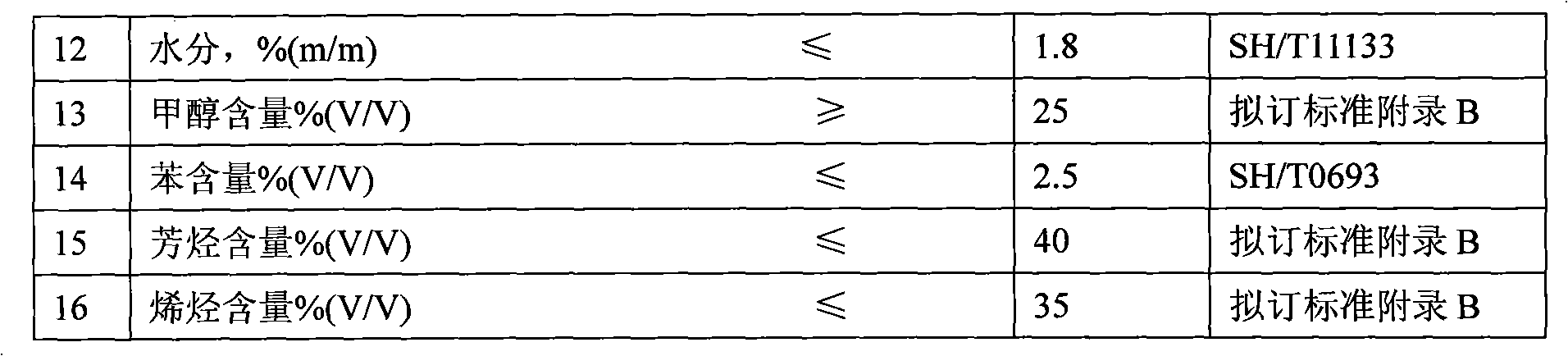

Refining process method of by-product salt on production line of glyphosate

ActiveCN105036155ARealize resource utilizationTo achieve the purpose of purifying solid saltAlkali metal halide purificationResource utilizationToxic industrial waste

The invention belongs to the technical field of environment protection and relates to a refining process method of by-product salt on a production line of glyphosate. The method is specifically applied to the treatment of waste water of glycine glyphosate mother liquor and treatment of by-product salt in the industries of PMIDA mother liquor, iminodiacetic acid mother liquor, trimethyl phosphate mother liquor and chlor-alkali; due to the fact that the solid waste salt on the production process line of glyphosate contains a large amount of organic matters, the solid waste salt can not be applied but serve as industrial waste salt. By means of the process method, most organic matters in the solid salt can be removed, the purpose of purifying the solid salt is achieved, the purified solid salt or refined saline water can be used for other industries such as chlor-alkali production and caustic soda production, the resource utilization of the waste is achieved, and great economic benefit and social benefit are achieved.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

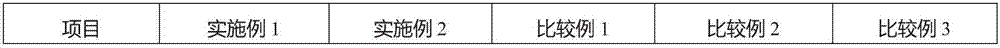

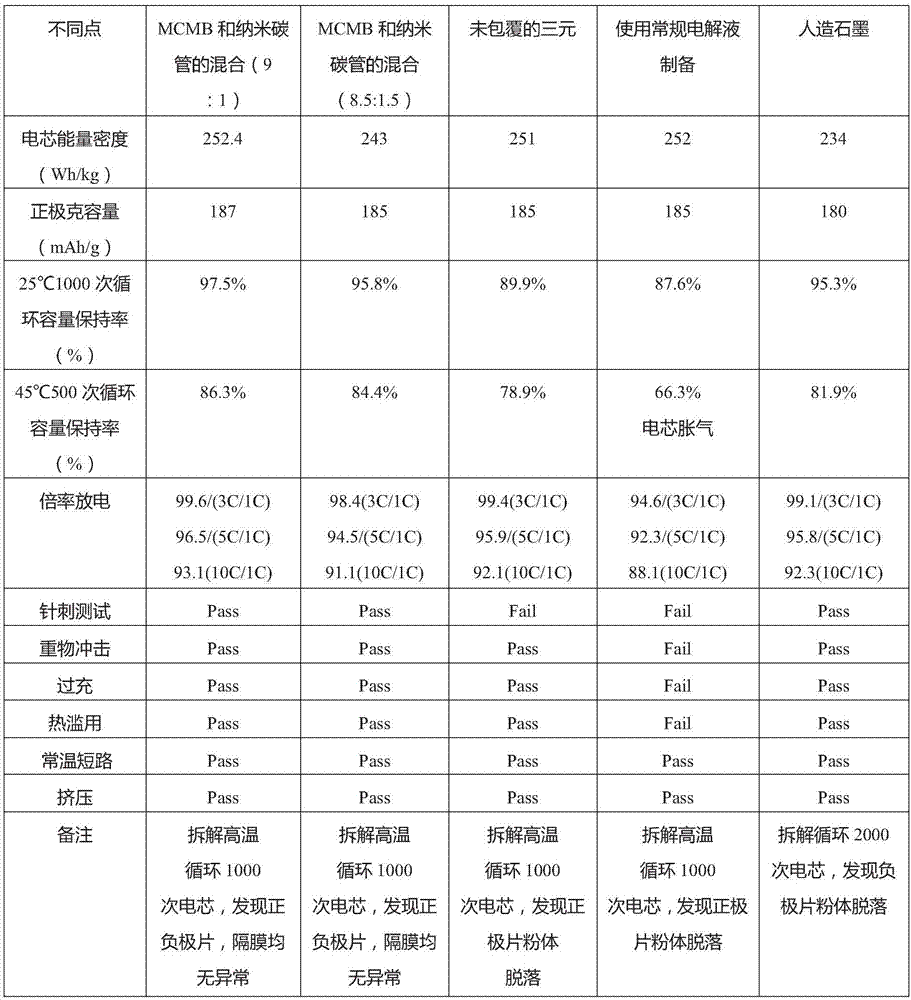

Ternary lithium battery electrolyte and high-temperature resistant, high-capacity and high-safety lithium battery core

InactiveCN107978794AImprove securityImprove high temperature resistanceMaterial nanotechnologyCell electrodesCarbon nanotubeCarbonate

The invention discloses a ternary lithium battery electrolyte and a high-temperature resistant, high-capacity and high-safety lithium battery core. According to the lithium battery core, a high-temperature resistant high-safety electrolyte is prepared by adopting a novel lithium salt of a conductive lithium salt LiBOB (lithium bis(oxalate)borate) and a lithium salt LiFSI (lithium bis(fluorosulfonyl)imide) and adding a proper amount of additive of FEC (fluoroethylene carbonate), MMDS (methylene methanedisulfonate) and TMP (trimethyl phosphate). A novel ternary positive electrode material coatedwith a mixture of nano titanium dioxide and a ternary material (LiNi0.8Co0.1Mn0.1O2) is adopted by a positive electrode, and a mixture of mesocarbon microbeads MCMB and carbon nanotubes is adopted bya negative electrode, thereby preparing the novel high-temperature resistant high-capacity lithium-ion power battery core for an automobile. According to the prepared battery core, the cycle performance is improved, and meanwhile, the problem of high-temperature air expansion is well solved.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

Method for preparing calcium phosphate series bioceramic nano-powder

The present invention is the preparation process of serial calcium phosphate bioceramic powder, including hydroxyapetite, beta-tricalcium phophate and biphase hydroxyapetite / beta-tricalcium phophate ceramic. The preparation process includes: weighing calcium nitrate and trimethyl phosphate in the molar Ca / P ratio of 1.5-1.67 and dissolving in distilled water and alcohol separately; adding citric acid in the equal molar amount of calcium ion to calcium nitrate aqua and dissolving fully; mixing the calcium nitrate aqua and trimethyl phosphate alcohol solution, regulating the pH value of the mixed solution with ammonia water to 3-11 and ageing at room temperature for 12-48 hr; drying at 80-190 deg.c for 2-10 hr to produce dry gel; and calcining at 500-600 deg.c for 1-3 hr to obtain required nano powder.

Owner:SOUTHEAST UNIV

Preparation method of environment-friendly special modified polyester chip for iron coating

The invention discloses a preparation method of an environment-friendly special modified polyester chip for iron coating. The preparation method comprises the following steps of adding ethylene glycol into a pulping kettle and then sequentially adding terephthalic acid, isophthalic acid, 1,4-cyclohexanedimethanol and neopentyl glycol into the pulping kettle to prepare slurry; adding ethylene glycol into a catalyst preparation kettle, then adding a titanium catalyst and uniformly stirring to prepare catalyst liquid; adding ethylene glycol into an additive preparation kettle, then adding silicon dioxide and uniformly stirring to prepare additive liquid; leading the slurry and the catalyst liquid into a first esterification kettle, heating to perform the esterification reaction, then leading the obtained product into a second esterification kettle, adding trimethyl phosphate and the additive liquid and uniformly mixing; leading ester into a condensation polymerization kettle to carry out condensation polymerization, and vacuumizing to the degree of polymerization of 70 to 110 in the reaction process so as to obtain high-molecular polymer melt; and preparing the high-molecular polymer melt into the chip in the cooling process. The polyester chip can be widely used for iron canned products such as foods, beverages, drugs, chemical products and the like; moreover, the polyester chip also can be used for packaging of powder or emulsion pesticides and the like; discharge of an organic solvent is greatly reduced; and the environment-friendly special modified polyester chip for iron coating can replace foreign products.

Owner:TIANJIN HUAXIN YINGJU POLYESTER MATERIAL SCI & TECH

Modified plastic material with high strength and aging resistance

The invention discloses a modified plastic material with high strength and aging resistance. The modified plastic material is prepared from the following raw materials: acrylonitrile butadiene styrene (ABS) resin, modified polyvinyl chloride, acrylic resin, polyhydroxybutyrate, urea resin, trimethyl phosphate, glass fibers, nano zinc oxide, organic silicon, nano diamond, nano diatomaceous earth, montmorillonite, quartz powder, ceramic micro-powder, silicon carbide, lignocellulosic powder, clay, white carbon black, glycerol, zinc stearate, a dispersing agent, a silane coupling agent KH-560 and a modifying aid. The modified plastic material provided by the invention is high in strength and good in aging resistance.

Owner:TIANCHANG KANGNING PLASTIC TECH

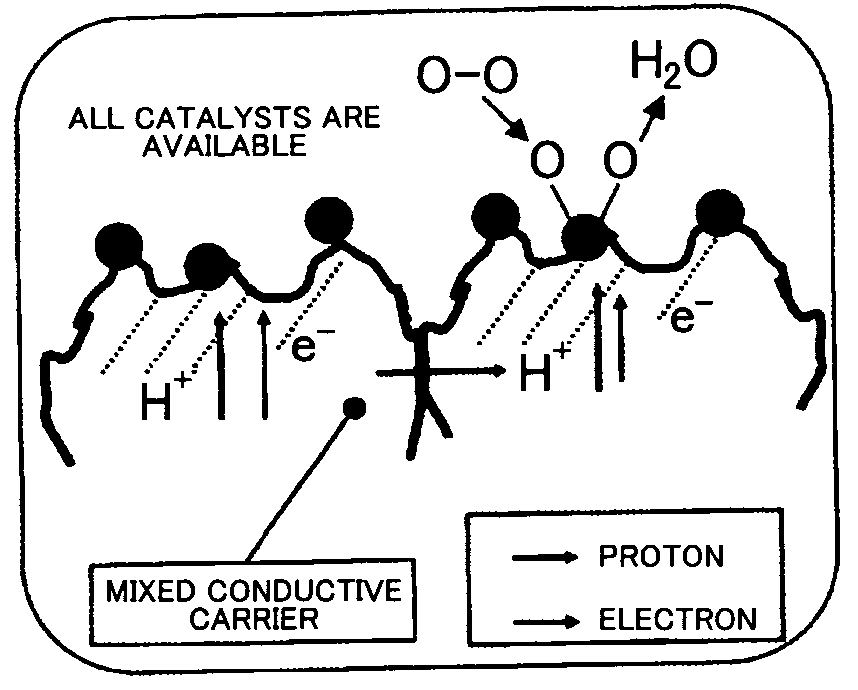

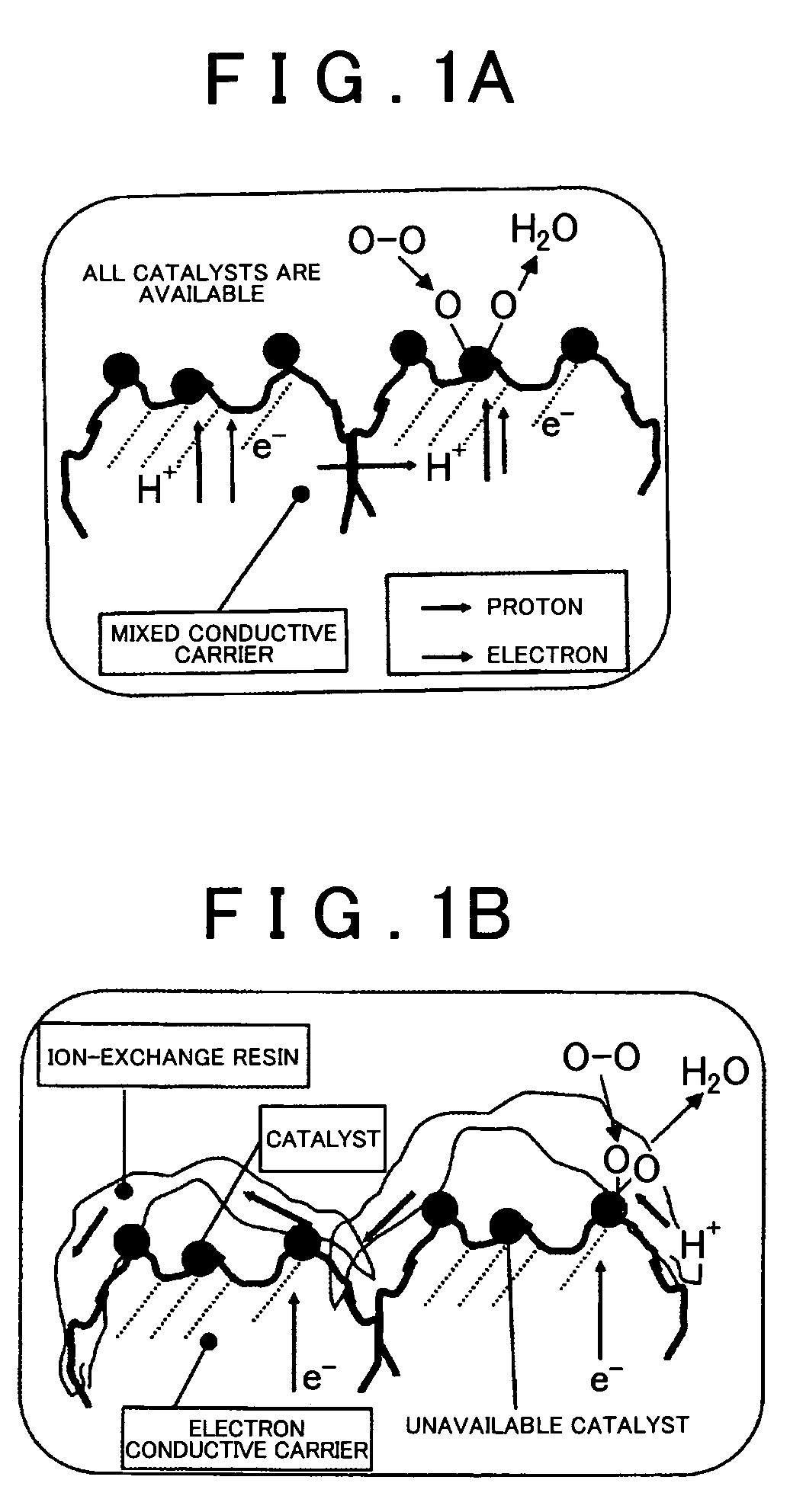

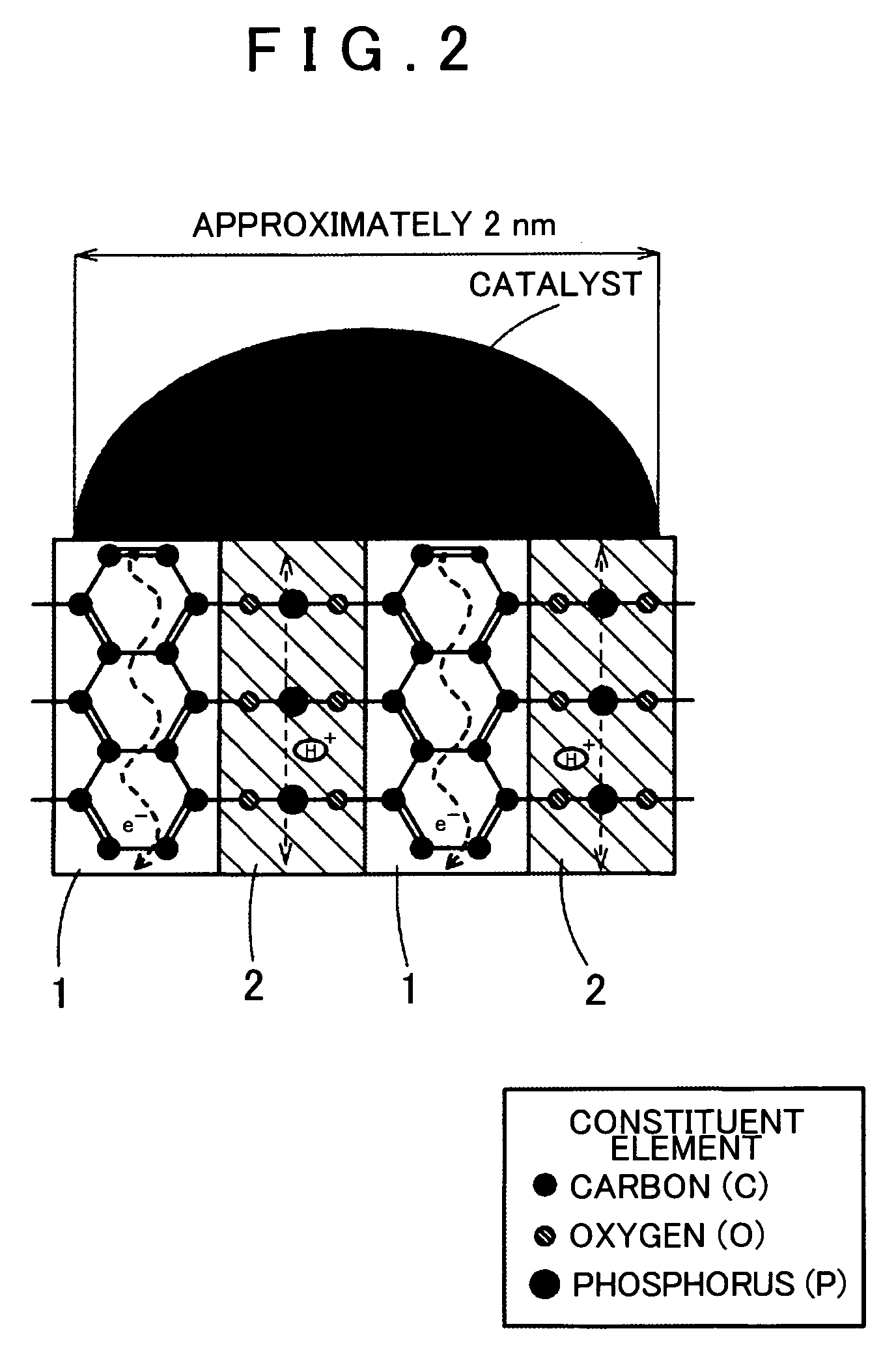

Fuel Cell Reaction Layer, Fuel Cell, and Method for Producing Fuel Cell Reaction Layer

ActiveUS20090162735A1Improve electronic conductivityImprove proton conductivityActive material electrodesSolid electrolyte fuel cellsReaction layerElectrical conductor

Disclosed is a fuel cell reaction layer which is excellent in durability and heat resistance while having a low operation temperature. In addition, supply of an oxygen gas to the fuel cell reaction layer is hardly disturbed. Also disclosed are a fuel cell and a method for producing such a fuel cell reaction layer. Specifically disclosed is a fuel cell reaction layer wherein a mixed conductive catalyst, which is obtained by loading a Pt catalyst onto a mixed conductive carrier wherein an electron conductor composed of carbon and a proton conductor composed of a phosphoric acid condensate are hybridized, is used. In addition, a water-repellent carbon is further blended in this fuel cell reaction layer. The mixed conductive carrier is obtained by carbonizing a polymer precursor which is obtained by mixing and copolymerizing a resorcinol and trimethyl phosphate.

Owner:EQUOS RES

High-toughness anti-corrosion 3D printing material for automobile manufacturing industry and preparation method of high-toughness anti-corrosion 3D printing material

InactiveCN107141798AImprove toughnessImprove anti-corrosion performanceAdditive manufacturing apparatusAntioxidantPolyvinyl chloride

The invention discloses a high-toughness anti-corrosion 3D printing material for automobile manufacturing industry. The high-toughness anti-corrosion 3D printing material comprises the following raw materials: modified polyphenylene sulfide, phenolic resin, epoxy acrylic resin, amino resin, polyvinyl chloride, trimethyl phosphate, dioctyl phthalate, zinc borate, nano aluminum hydroxide, glass beads, aluminum polyphosphate, titanium dioxide, glass fiber, carbon fiber, calcium sulfate whiskers, carbon nanotube, jute fibers, levorotatory polylactic acid, poly adipic acid, butylene terephthalate, polypropylene, maleic anhydride, an antioxidant, a silane coupling agent KH-570, a modified toughening agent and modified fillers. The invention also proposes a preparation method of the high-toughness anti-corrosion 3D printing material for automobile manufacturing industry. The prepared 3D printing material has high toughness and corrosion resistance.

Owner:HEFEI SKE INTELLIGENT TECH

High-temperature-resistant tensile control cable material

The invention discloses a high-temperature-resistant tensile control cable material. The high-temperature-resistant tensile control cable material is prepared from phenolic resin, silicon rubber, butadiene rubber, alkyd resin, chloroprene rubber, epoxy resin, coumarone resin, trimethyl phosphate, zinc borate, carbon black, vermiculite, zinc borate, nano silicon carbide, glass fibers, nano magnesium oxide, sodium metaborate, wood fiber powder, antimonous oxide, nano aluminium hydroxide, isocyanate, polysiloxane, diisooctyl phthalate, a silane coupling agent KH-550, chlorinated paraffin, ammonium polyphosphate, styrene, a vulcanizing agent DTDM, a plasticizer, high-temperature-resistant modification additives and tensile modification additives. The control cable material has excellent high temperature resistance and tensile performances.

Owner:安徽华海特种电缆集团有限公司

High-strength ultraviolet-resistant 3D (three-dimensional) printing material for building field and preparation method thereof

InactiveCN107177155AWell mixedImprove rigidityAdditive manufacturing apparatusPolyvinyl chlorideDibenzoyl Peroxide

The invention discloses a high-strength ultraviolet-resistant 3D (three-dimensional) printing material for the building field. The high-strength ultraviolet-resistant 3D printing material is prepared from the following raw materials including ABS resin, polyvinyl chloride, polypropylene, polycarbonate, maleic anhydride, phenolic resin, trimethyl phosphate, glass fiber, carbon fiber, methyl laurate, N,N'--4,4'--diphenylmethane-bismaleimide, 5-sulfonic acid mono-potassium terephthalate, 2,5-dihydroxyterephthalic acid, benzotriazole, polytetrafluoroethylene, sodium allylsulfonate, methyl acrylate, n-propyl acrylate, magnesium stearate, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, silane coupling agents KH-560, benzoyl peroxide, hardness enhancing modifying agents, modification auxiliary agents and modification fillers. The invention also provides a preparation method of the high-strength ultraviolet-resistant 3D printing material for the building field. The prepared 3D printing material has high strength and excellent ultraviolet-resistant performance.

Owner:HEFEI SKE INTELLIGENT TECH

Alcohol ether fuel additive

InactiveCN1876774ARaise MethanolIncrease ethanol contentLiquid carbonaceous fuelsAlcohol fuelDiethyl carbonate

The invention relates the alcohol ether fuel and addition agent. The addition agent comprises methyl formate, methyl methacrylate, trimethyl phosphate, dimethyl carbonate or 10-50wt% diethyl carbonate, dimethyl ether, isopropyl ether, propyl ether, 15-40wt% ethyl ether, isoamyl alcohol, isobutyl alcohol or 15-50wt% isoheptyl alcohol, aminoethyl alcohol, diethyl ethanolamine, triethylamine, hexadecylamine, octadecyl ammonium, 0.5-5wt% nitroaniline, and 0.1-1wt% nufenoxole. The invention has the advantages of non emulsification, non three wastes, low energy consumption and high productivity.

Owner:SHANGHAI FINE ALCOHOL PETROCHEM TECH DEV

High impact resistance flame-retardant modified plastic material

The invention discloses high impact resistance flame-retardant modified plastic material, which is prepared from the following raw materials: polyvinyl chloride resin, modified polyester resin, polypropylene resin, acrylic resin, trimethyl phosphate, chlorinated polyethylene, polycarbonate, polytetrafluoroethylene micro-powder, hydroxypropyl methyl cellulose, titanium dioxide, conductive carbon black, antimony trioxide, talcum powder, mica iron oxide, nano zinc oxide, quartz sand, nano silicon dioxide, ethyl orthosilicate, a silane coupling agent KH-570, glycerol, epoxy vegetable oil, a dispersing agent, a plasticizer and a modifying aid. The modified plastic material provided by the invention has excellent impact resistance and good flame retardant property.

Owner:TIANCHANG KANGNING PLASTIC TECH

Heat-resistant modified plastic material with high abrasion resistance and high toughness

The invention discloses a heat-resistant modified plastic material with high abrasion resistance and high toughness. The heat-resistant modified plastic material is prepared from the following raw materials: modified urea-formaldehyde resin, polyvinyl chloride, polystyrene, trimethyl phosphate, polyvinyl chloride, barium sulfate, low-density polyethylene, polystyrene, calcium sulfate whiskers, talcum powder, heavy calcium carbonate, nano calcium carbonate, magnesium hydroxide, aluminum hydroxide, zinc borate, nano zinc powder, antimony trioxide, aluminum powder, asbestos fibers, jute fibers, ethyl trimethoxysilane, trifluoropropyl methyl silicone oil, zinc sulfate, a compatibilizer, a crosslinking agent, an antioxidant, a modifying auxiliary agent and glycerin. The modified plastic material provided by the invention has excellent abrasion resistance and heat resistance as well as good toughness.

Owner:TIANCHANG KANGNING PLASTIC TECH

Non-aqueous electrolyte and lithium secondary battery using the same

InactiveCN102195084AAchieve long lifeLi-accumulatorsSecondary cells servicing/maintenancePhosphateCharge discharge

A non-aqueous electrolyte and a lithium secondary battery using the same are provided, which satisfy both flame retardancy and charge-discharge cycle characteristics, and attain a longer lifetime of the battery. A mixture of a chain carbonate, vinylene carbonate, a fluorinated cyclic carbonate and a phosphate ester is used as the non-aqueous electrolyte. It is desirable that the phosphate ester includes trimethyl phosphate and a fluorinated phosphate ester. Further, it is desirable that ethylene carbonate is further contained.

Owner:HITACHI LTD

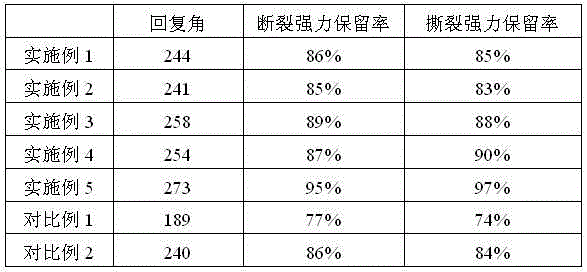

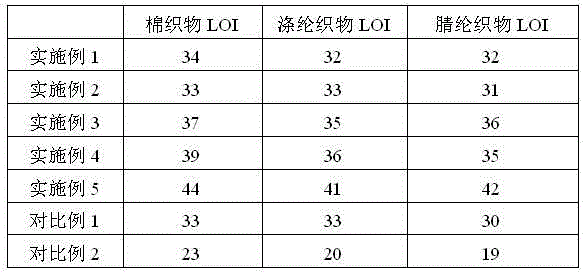

Flame-retardant anti-wrinkle finishing agent for fabric and preparation method and application thereof

ActiveCN104695233AIncreased flame retardant strengthImprove wrinkle resistanceVegetal fibresPhosphorous acidPhosphoric Acid Esters

The invention discloses a flame-retardant anti-wrinkle finishing agent for fabrics and a preparation method and application thereof. The flame-retardant anti-wrinkle finishing agent for fabrics comprises the following components in parts by weight: 8-15 parts of trimethyl phosphite, 4-9 parts of tri-isopropyl phosphite, 4-7 parts of triisopropyl borate, 3-7 parts of amino propanol ascorbyl phosphate, 8-15 parts of polyglycerol polyricinoleate, 14-20 parts of dimethyl silicone, 5-13 parts of dimethiconol stearate, 4-8 parts of secondary alcohol ethoxylate, 12-20 parts of propylene glycol and 300-400 parts of water. The preparation method comprises the following steps: mixing, heating, performing magnetic stirring, and the like. The anti-wrinkle property and the flame retardancy of a fabric treated by using the finishing agent are remarkably improved.

Owner:SUZHOU INST OF TRADE & COMMERCE

High-strength and high-toughness 3D printing material used for buildings

The invention discloses a high-strength and high-toughness 3D printing material used for buildings. The 3D printing material includes polyester resin, urea resin, polysulfide rubber, phenolic resin, nitrile butadiene rubber, polyamide resin, chlorinated polyethylene, microcrystalline cellulose, nano-silicon carbide, ramie fibers, zinc stearate, barite powder, aluminum polyphosphate, nano-aluminumhydroxide, carbon black, trioctyl trimellitate, trimethyl phosphate, stearic acid, chlorinated paraffin, a silane coupling agent KH-570, a strength increasing filler and a toughness enhancing aid. The3D printing material has high strength and high toughness.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

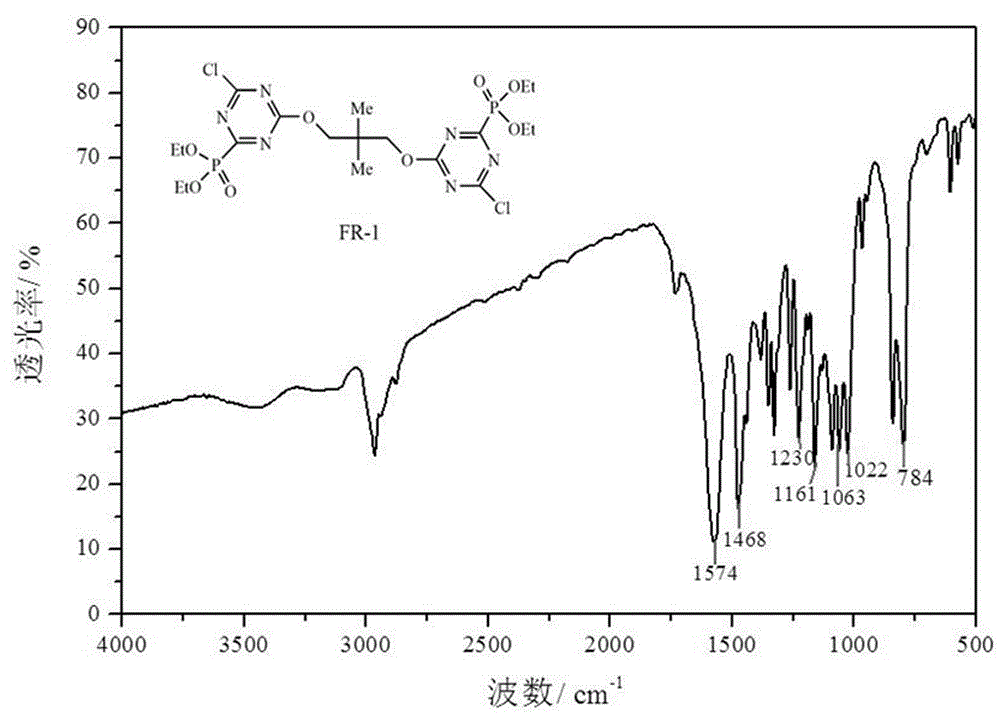

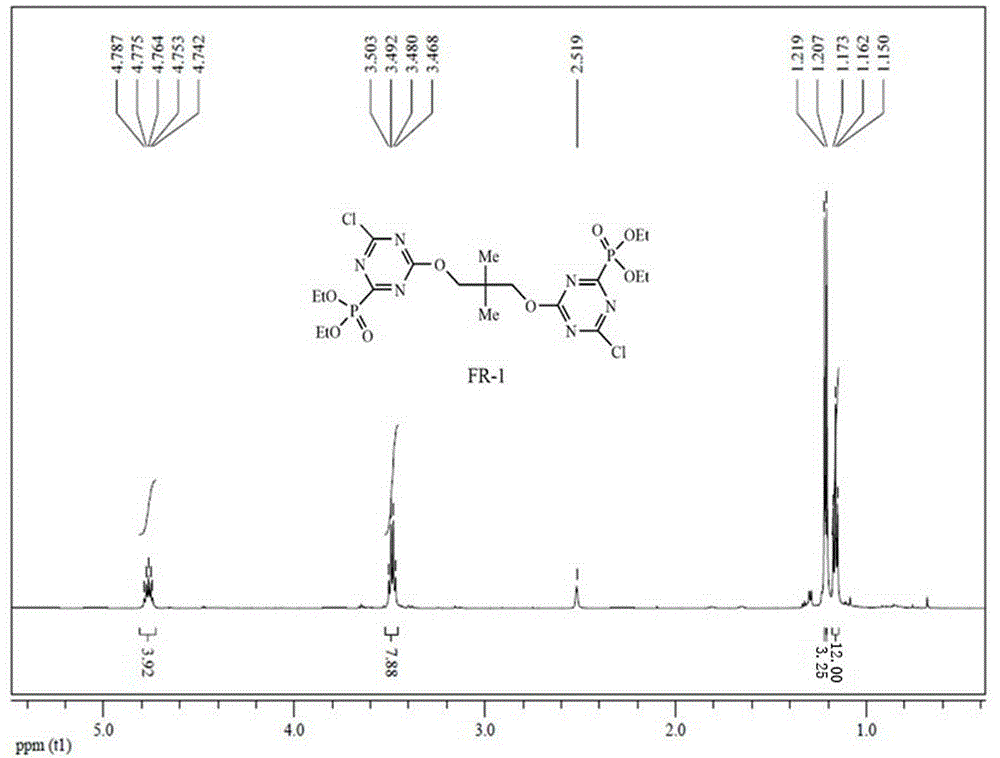

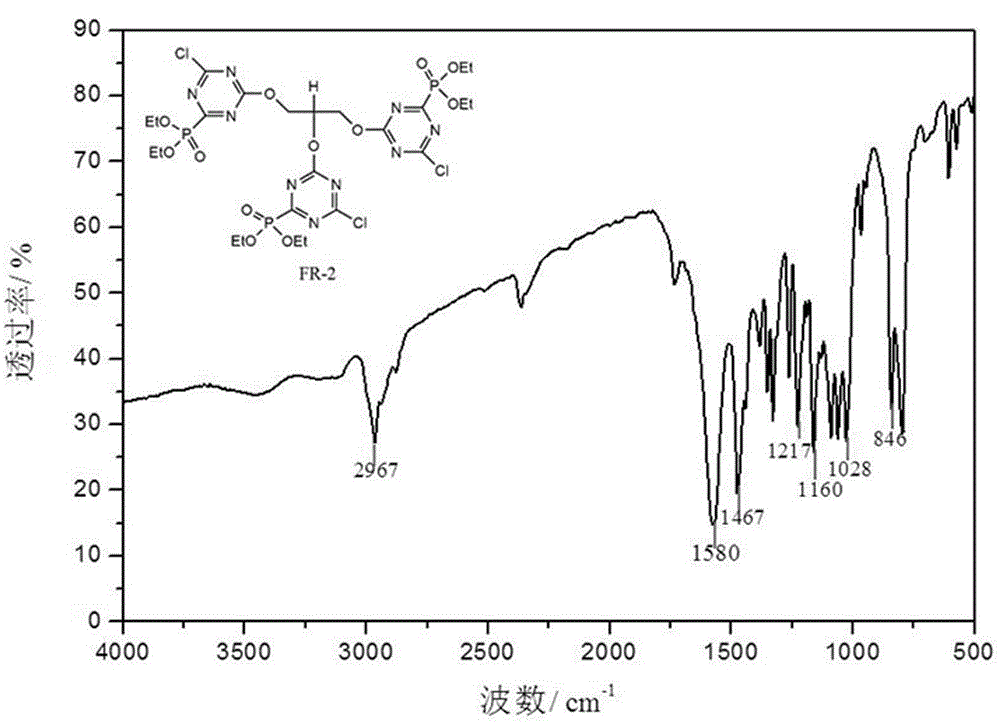

Compound with a plurality of active groups and preparation method of compound

InactiveCN103980314AImprove flame retardant performanceImprove thermal stabilityGroup 5/15 element organic compoundsElectrophilic additionPhosphorous acid

The invention relates to a reaction type phosphorus-nitrogen flame retardant and in particular to a compound with a plurality of active groups and a preparation method of the compound. The preparation method comprises the following steps: (1) weighing cyanuric chloride, dissolving cyanuric chloride into a first solvent, stirring till being completely dissolved, slowly heating to be 60 DEG C, preserving heat while continuously stirring to uniformly disperse reactant; and (2) in the presence of nitrogen, adding a phosphite ester solution which is dissolved in the first solvent, reacting for 4-6 hours, and keeping stirring in the reaction process. Compared with the prior art, the compound with the plurality of active groups has the beneficial effects that the compound is prepared from raw materials, namely, cyanuric chloride, phosphite ester compounds (trimethyl phosphate or triethyl phosphate) and polyhydric alcohol compounds (neopentyl glycol, glycerol or pentaerythritol) with quaternary carbon (or secondary carbon) atoms, through Michaelis-Arbuzov electrophilic addition reaction and nucleophilic substitution reaction.

Owner:ZHONGBEI UNIV

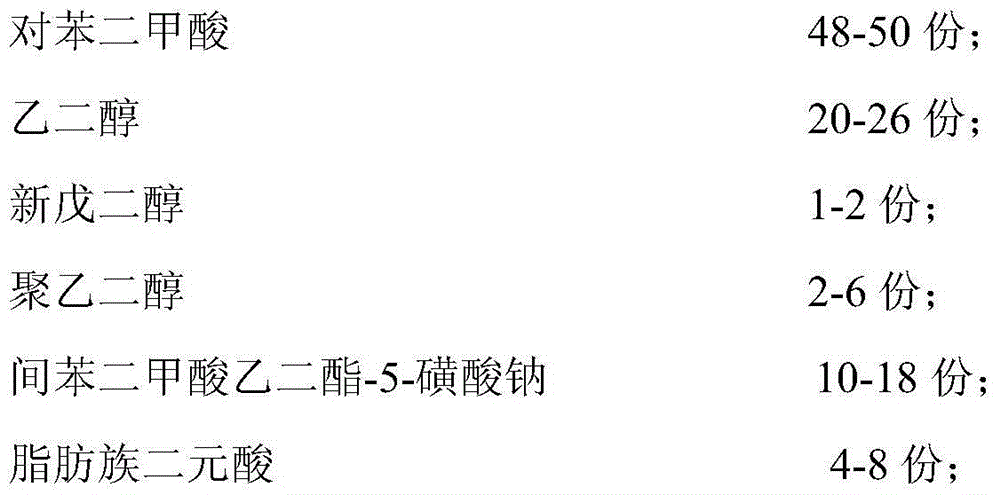

Sea-island fiber water-soluble polyester and preparation method thereof

The invention discloses sea-island fiber water-soluble polyester and a preparation method thereof. The sea-island fiber water-soluble polyester is characterized in that the sea-island fiber water-soluble polyester is prepared by taking terephthalic acid, ethylene glycol, neopentyl glycol, polyethylene glycol, diethyl m-phthalate-5-sodium sulfonate and aliphatic binary acid as monomers, antimonous oxide or antimony acetate as catalyst and trimethyl phosphate as stabilizer through esterification, polymerilization and post-treatment. The sea-island fiber water-soluble polyester can be dissolved in hot water at temperature of 80 DEG C without alkali liquor, and sea-island fibers are not damaged in the process of fiber splitting of the sea-island fibers.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

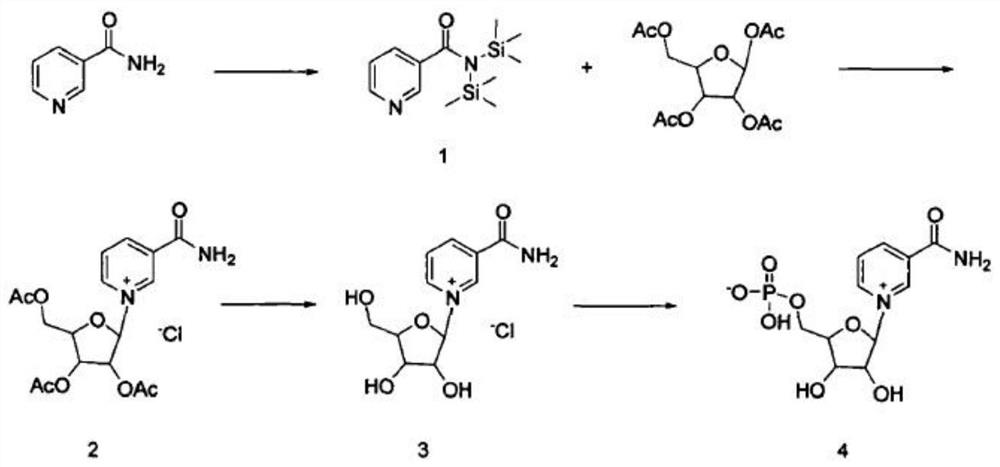

Synthesis method of beta-nicotinamide mononucleotide

ActiveCN111647032AStereoselectiveShort reaction timePhysical/chemical process catalystsSugar derivativesPtru catalystNicotinamide riboside

The invention discloses a synthesis method of beta-nicotinamide mononucleotide, and relates to the technical field of drug synthesis. The synthesis method mainly comprises the following steps of S1, mixing and reacting nicotinamide, hexamethyldisilazane and a catalyst I in a reaction kettle to obtain silanization-protected nicotinamide; S2, adding tetraacetyl ribose, a solvent, a catalyst II and methanol for reaction so as to generate nicotinamide triacetyl riboside; S3, adding methanol and n-propylamine to generate nicotinamide riboside; S4, adding trimethyl phosphate and phosphorus oxychloride to generate beta-nicotinamide mononucleotide; and S5, separating and purifying the beta-nicotinamide mononucleoside acid. According to the invention, a plurality of continuous steps are controlledto be carried out in one reaction container, and the steps of separating and purifying an intermediate are avoided, so that the method has the advantages of high yield and high production efficiency.

Owner:上海舒泽生物科技研究所

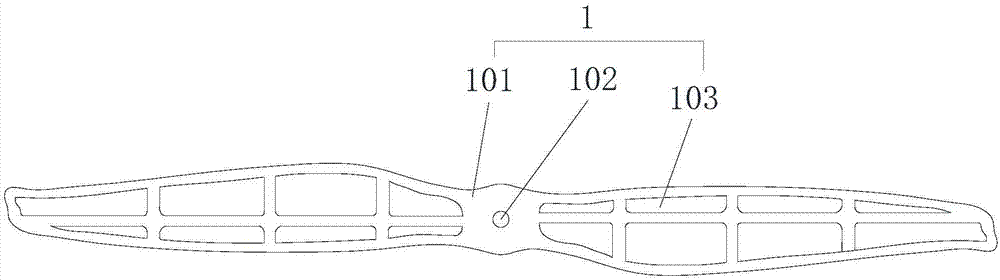

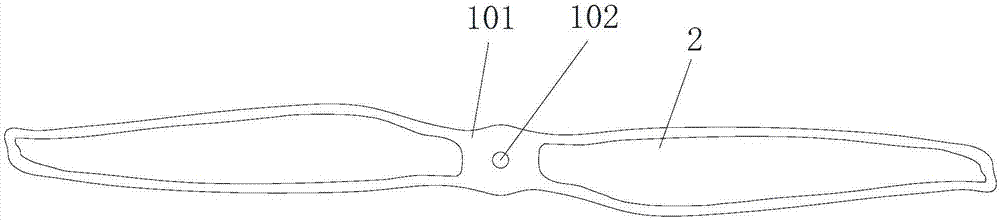

Novel compound material propeller

InactiveCN107380404AImprove mechanical propertiesGood weather resistancePropellersFiberCarbon fibers

The invention discloses a novel compound material propeller. The novel compound material propeller comprises a framework and a and covering layer, wherein the framework comprises a framework body, a mounting hole and cutouts, wherein the covering layer is adhered to the cutouts; raw materials of the framework body comprise polystyrene, polymethyl methacrylate, polystyrene, polyvinyl chloride, polyolefine, unsaturated polyester resins, styrene-butadiene-styrene triblock copolymer, ethylene-vinyl acetate copolymer, polytetrafluoroethylene resins, polyhydroxybutyrate, short-cut carbon fibers, urea-formaldehyde resins, trimethyl phosphate, zinc stearate, a dispersing agent, a silane coupling agent KH-560, and rigidity strengthening addition agents. The novel compound material propeller disclosed by the invention is high in strength, good in rigidity, light in weight, stable in structure, and excellent in weatherability, and the service life is prolonged.

Owner:安徽劲旋风航空科技有限公司

Low pressure resistant polyethylene terephthalate resin and producing method thereof

A low-pressure-resisting polypara-formate ethylene glycol ester resin contains isophthalic acid, ethylene glycol, diglycol, catalyst, stabilizer and p-phthalic acid; catalyst is antimony or cellulose antimony or Germanic oxide, stabilizer is phosphoric acid or poly-phosphoric acid or phosphorous acid or tri-methyl phosphate or tri-phenyl phosphate. The process is carried out by beating, esterification reacting, polymerization reacting, dicing, pre-crystallizing, crystallizing, solid-phase polymerizing, and fluidized cooling to obtain final product. It costs low and can be used to produce soda beverage bottle.

Owner:新疆维格瑞生物科技有限公司

Antibacterial 3D printing material for medical products

InactiveCN107118502AImprove antibacterial propertiesWell mixedAdditive manufacturing apparatusMedical productAntimony trioxide

The invention discloses an antibacterial 3D printing material for medical products, which comprises the following raw materials: ABS resin, organic fluorinated epoxy, acrylic resin, urea-formaldehyde resin, polyhydroxybutyrate, antibacterial reinforcer, modified zeolite, calcium molybdate, calcined whiting powder, zeolite powder, nitrocotton, zinc phosphate, bentonite, antimony trioxide, zinc oxide, seaweed meal, diatomite, antimony trioxide, zirconium oxide, aluminum sulfate, aluminum oxide, hydroxyethyl cellulose (HEC), lauryl acrylate, trimethyl phosphate, acrylonitrile, silane coupling agent KH-560, sulfonated oil, an antifoamer, and a modifying additive. The antibacterial 3D printing material disclosed by the invention has excellent antibacterial property.

Owner:HEFEI SKE INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com