High-toughness anti-corrosion 3D printing material for automobile manufacturing industry and preparation method of high-toughness anti-corrosion 3D printing material

A 3D printing and manufacturing technology, applied in the field of high-toughness anti-corrosion 3D printing materials for automobile manufacturing and their preparation, which can solve the problems of poor toughness and insufficient strength of polyphenylene sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

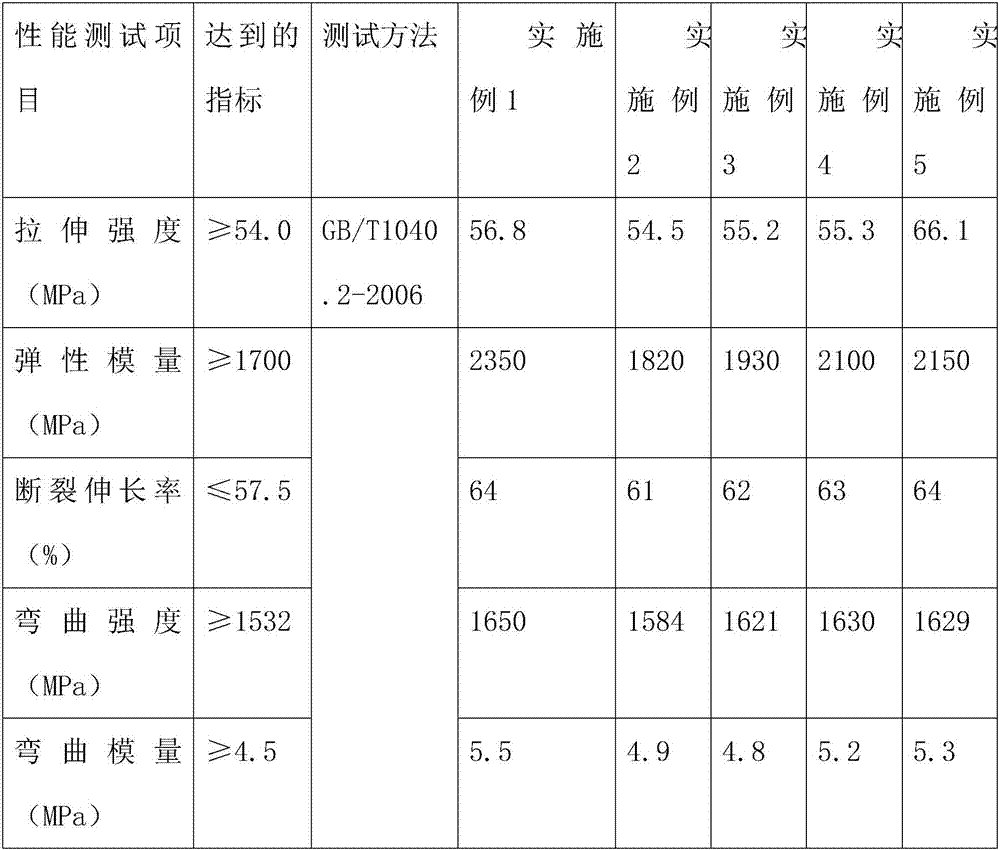

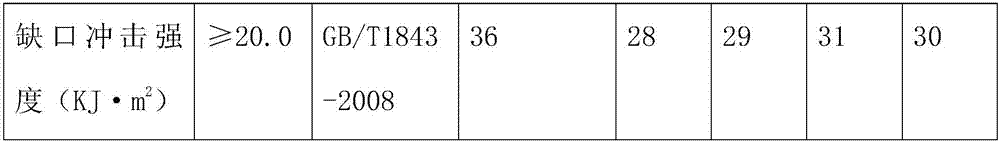

Examples

Embodiment 1

[0017] A high-toughness anti-corrosion 3D printing material for the automobile manufacturing industry proposed by the present invention, its raw materials include by weight: 100 parts of modified polyphenylene sulfide, 30 parts of phenolic resin, 25 parts of epoxy acrylic resin, 3 parts of amino resin, 4 parts of polyvinyl chloride, 5 parts of trimethyl phosphate, 12 parts of trimethyl phosphate, 6 parts of dioctyl phthalate, 3 parts of zinc borate, 3 parts of nano aluminum hydroxide, 6 parts of glass beads, polymer 4 parts of aluminum phosphate, 3.5 parts of titanium dioxide, 4.5 parts of glass fiber, 6 parts of carbon fiber, 3.5 parts of calcium sulfate whisker, 2.5 parts of carbon nanotube, 5 parts of jute fiber, 3 parts of L-polylactic acid, 3 parts of polyadipate, 6 parts of butylene terephthalate, 4.5 parts of polypropylene, 3.5 parts of maleic anhydride, 2.5 parts of antioxidant, 3.5 parts of silane coupling agent KH-570, 6 parts of modified toughening agent, 13.5 parts ...

Embodiment 2

[0019] A high-toughness anti-corrosion 3D printing material for the automobile manufacturing industry proposed by the present invention, its raw materials include by weight: 80 parts of modified polyphenylene sulfide, 40 parts of phenolic resin, 15 parts of epoxy acrylic resin, 5 parts of amino resin, 2 parts of polyvinyl chloride, 8 parts of trimethyl phosphate, 8 parts of trimethyl phosphate, 9 parts of dioctyl phthalate, 1 part of zinc borate, 5 parts of nano aluminum hydroxide, 4 parts of glass beads, polymer 6 parts of aluminum phosphate, 1 part of titanium dioxide, 6 parts of glass fiber, 4 parts of carbon fiber, 5 parts of calcium sulfate whisker, 1 part of carbon nanotube, 8 parts of jute fiber, 1 part of L-polylactic acid, 4 parts of polyadipic acid, 3 parts of butylene terephthalate, 6 parts of polypropylene, 2 parts of maleic anhydride, 4 parts of antioxidant, 2 parts of silane coupling agent KH-570, 8 parts of modified toughening agent, 9 parts of modified filler ....

Embodiment 3

[0024] The invention proposes a high-toughness anti-corrosion 3D printing material for the automobile manufacturing industry. The raw materials include: 120 parts of modified polyphenylene sulfide, 20 parts of phenolic resin, 35 parts of epoxy acrylic resin, 1 part of amino resin, 6 parts of polyvinyl chloride, 2 parts of trimethyl phosphate, 16 parts of trimethyl phosphate, 3 parts of dioctyl phthalate, 5 parts of zinc borate, 1 part of nano aluminum hydroxide, 8 parts of glass beads, polymer 2 parts of aluminum phosphate, 6 parts of titanium dioxide, 3 parts of glass fiber, 8 parts of carbon fiber, 2 parts of calcium sulfate whisker, 4 parts of carbon nanotube, 2 parts of jute fiber, 5 parts of L-polylactic acid, 2 parts of polyadipic acid, 9 parts of butylene terephthalate, 3 parts of polypropylene, 5 parts of maleic anhydride, 1 part of antioxidant, 5 parts of silane coupling agent KH-570, 4 parts of modified toughening agent, 18 parts of modified filler .

[0025] A prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com