Patents

Literature

3518 results about "Adipic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

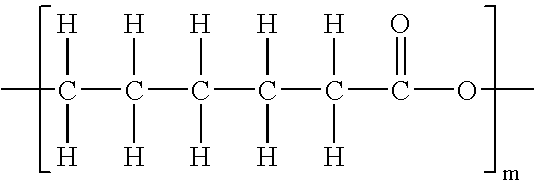

Adipic acid or hexanedioic acid is the organic compound with the formula (CH₂)₄(COOH)₂. From an industrial perspective, it is the most important dicarboxylic acid: about 2.5 billion kilograms of this white crystalline powder are produced annually, mainly as a precursor for the production of nylon. Adipic acid otherwise rarely occurs in nature, but it is known as manufactured E number food additive E355.

Synthetic fiber

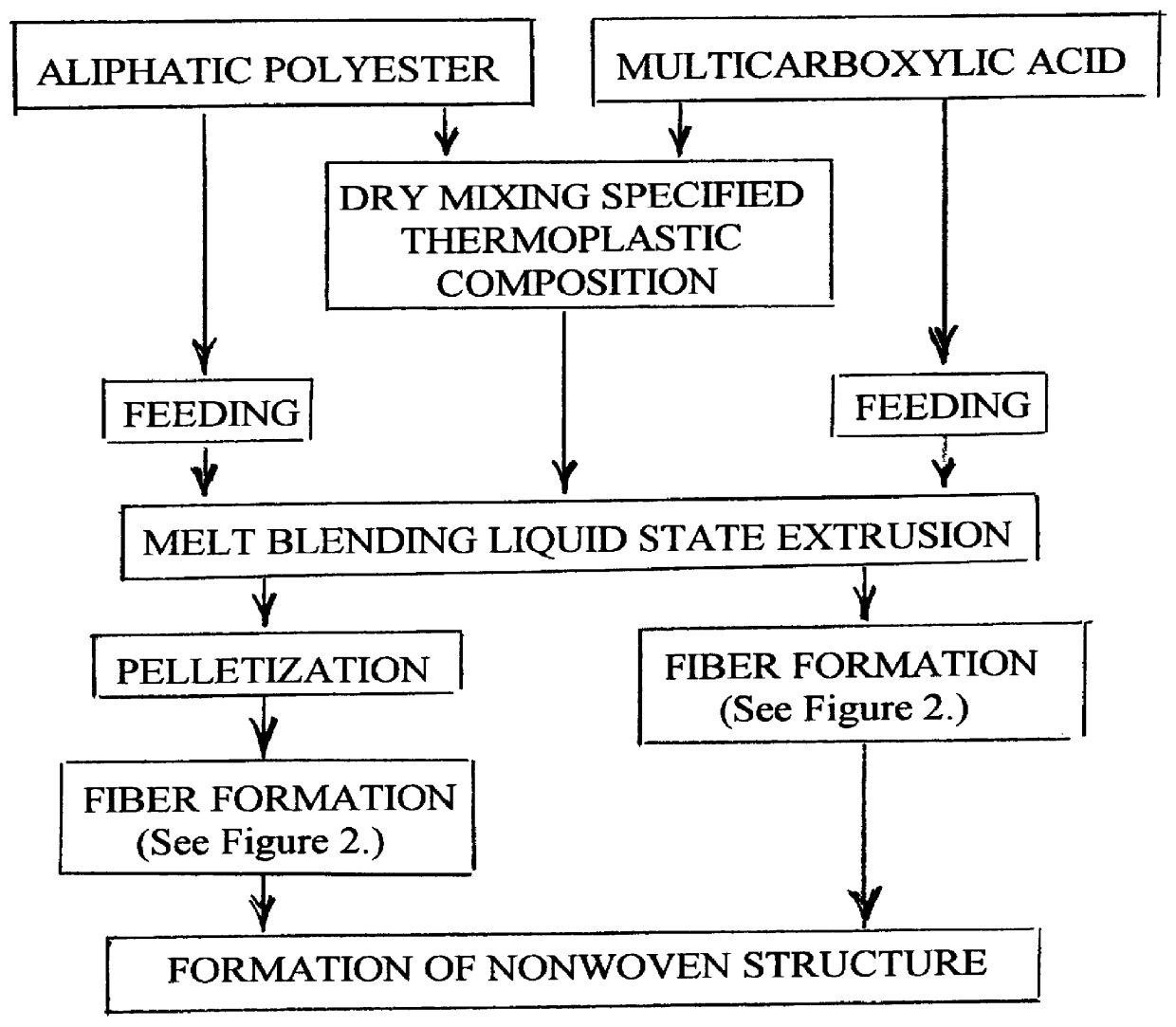

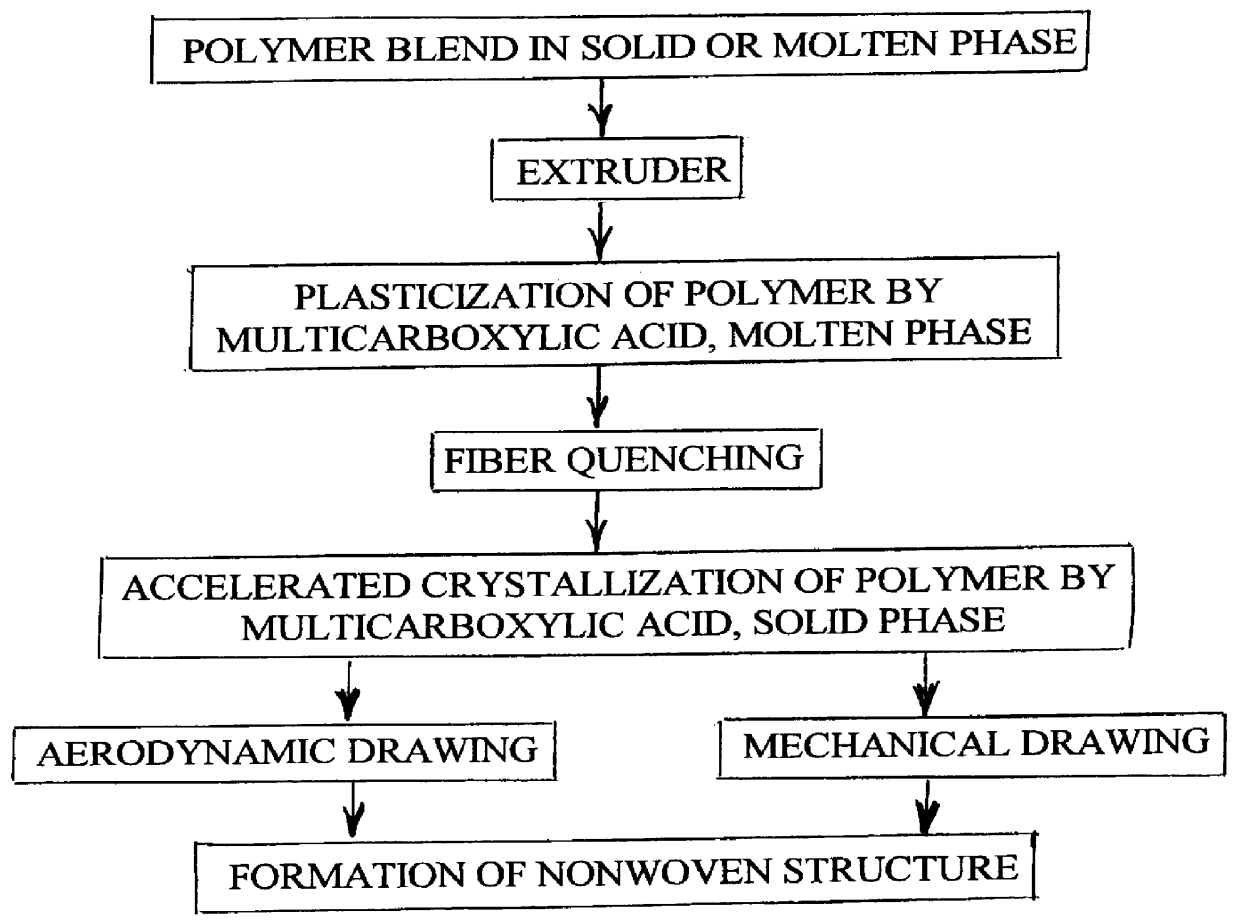

InactiveUS6135987AFormed easily and efficientlyCeramic shaping apparatusBaby linensPolyesterVitrification

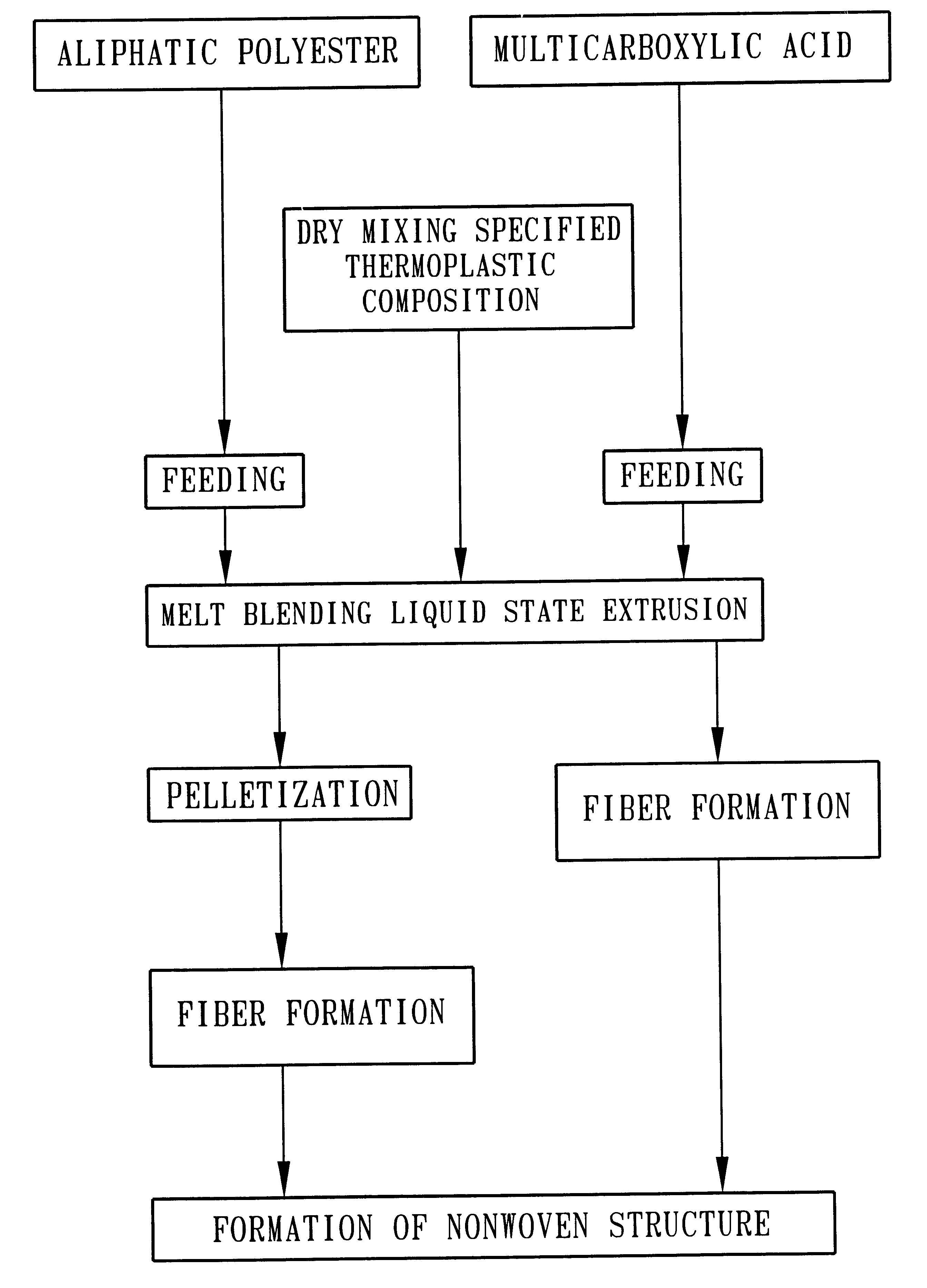

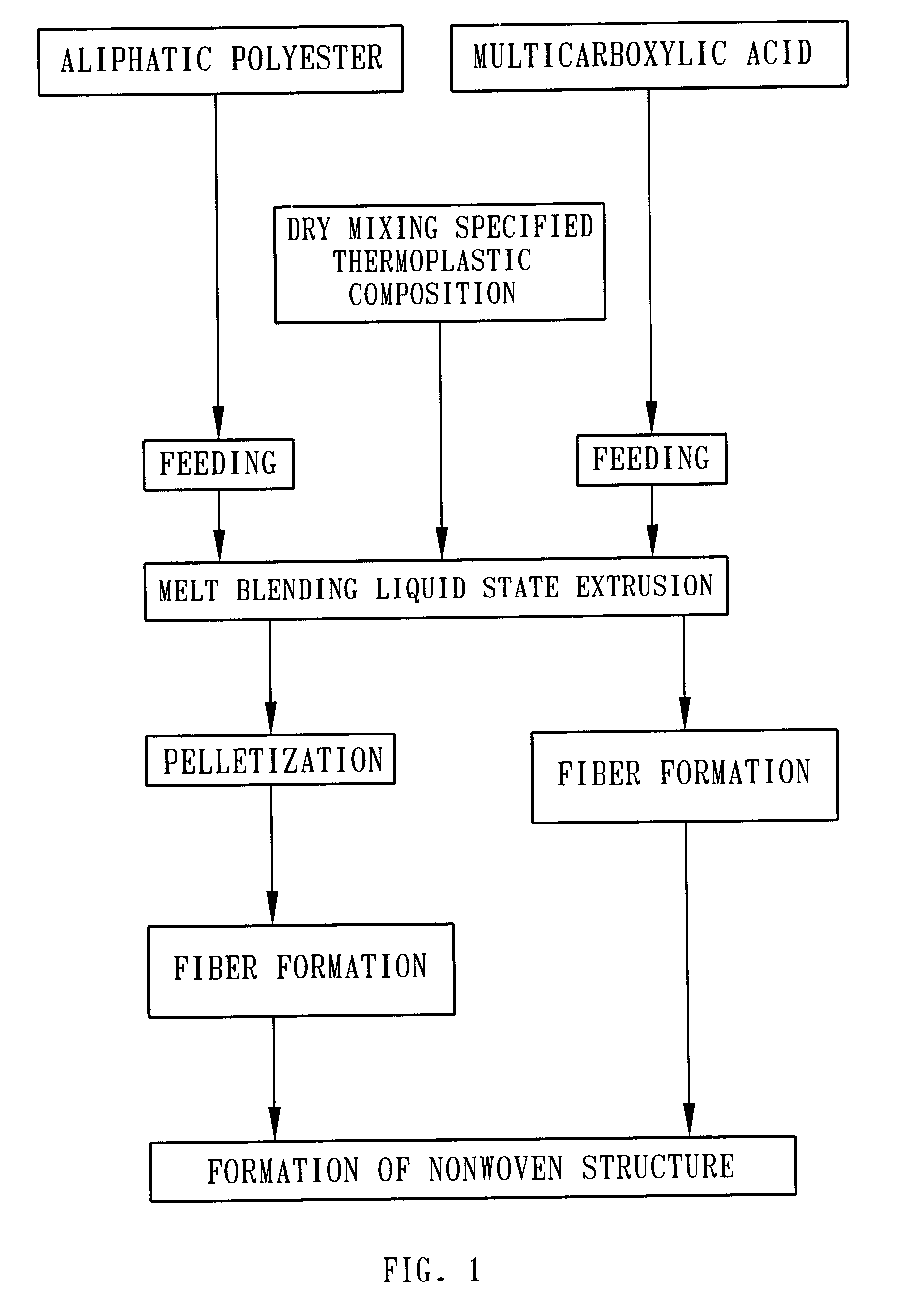

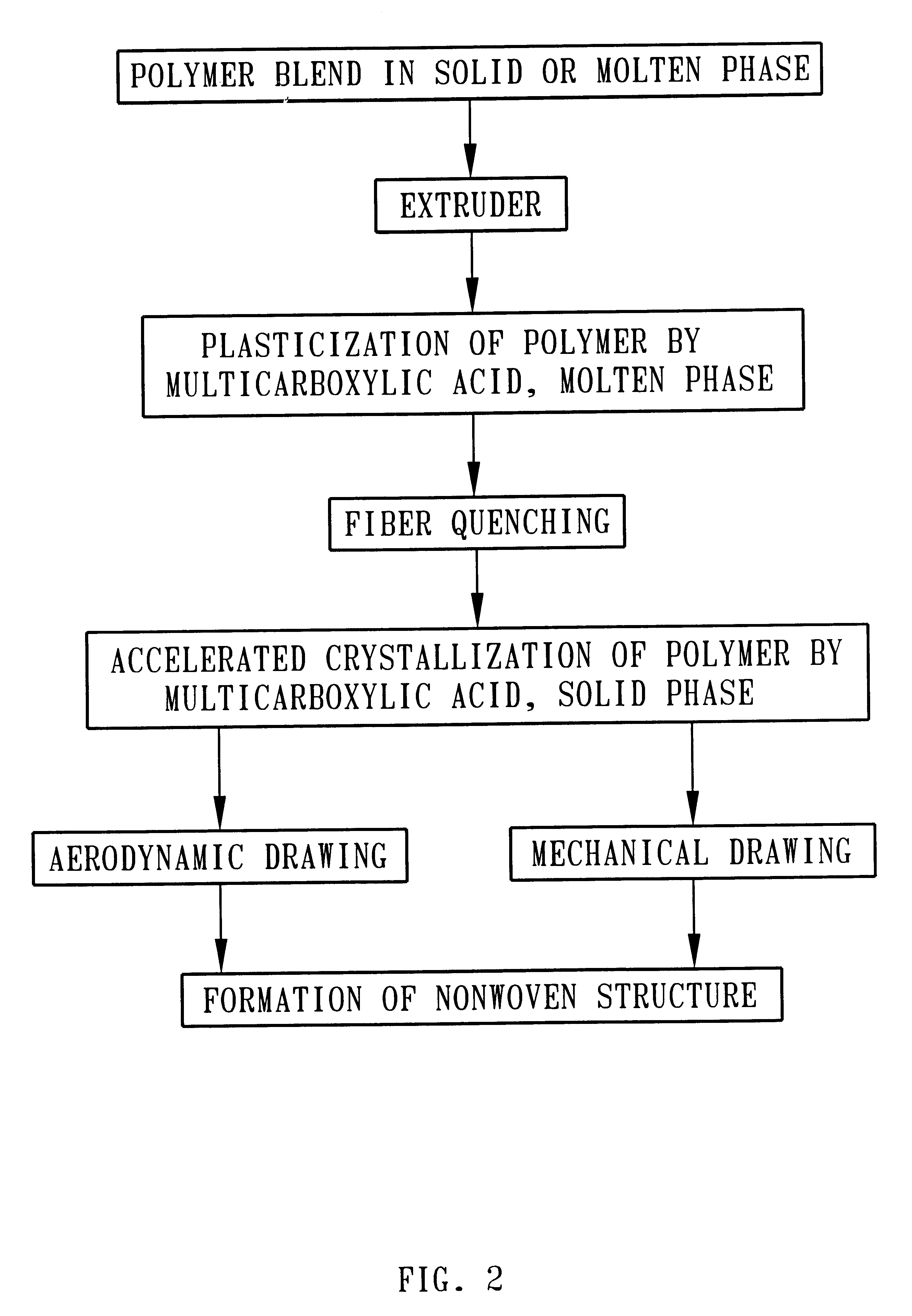

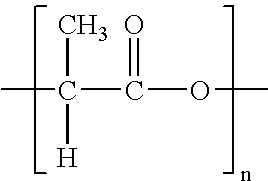

A process is disclosed for forming a synthetic fiber including providing a first component of an aliphatic polyester polymer a second component of a multicarboxylic acid, mixing the first component aliphatic polyester polymer and the second component multicarboxylic acid to form an unreacted specified thermoplastic composition, and melt blending the unreacted specified thermoplastic composition in an extruder or a mixer. The second component multicarboxylic acid lubricates the extruder and provides a nucleating agent for crystallizing the specified thermoplastic composition to form a mean crystal size less than about 120 Angstroms. Fiber composed of the specified thermoplastic composition has a mean crystal size less than about 120 Angstroms. The fiber has a glass transition temperature (Tg) less than about 55 DEG C. In one aspect, a first component of polylactic acid and a second component of adipic acid provide synthetic fibers in a nonwoven structure used in a biodegradable and compostable disposable absorbent product for the absorption and removal of body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

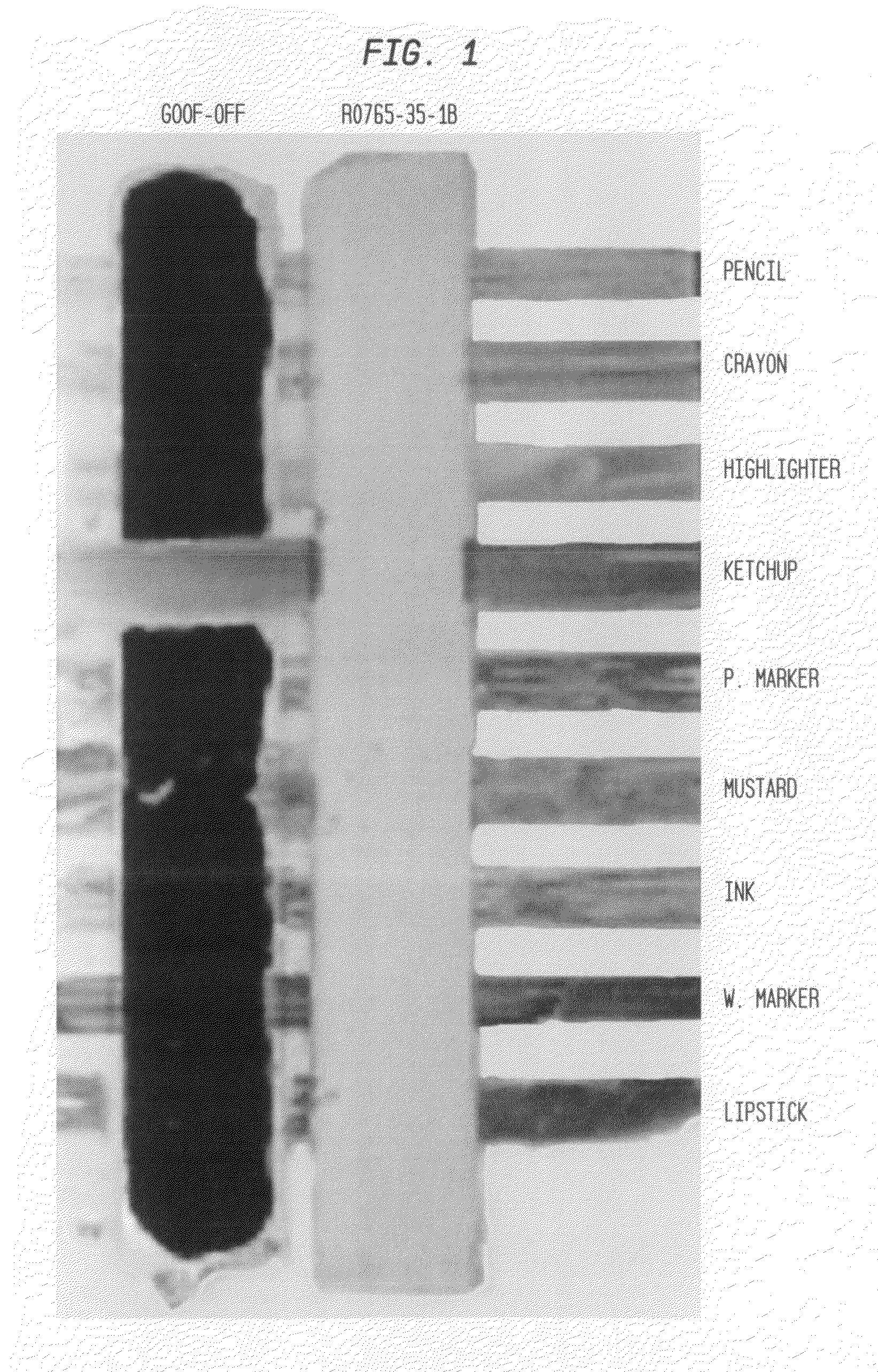

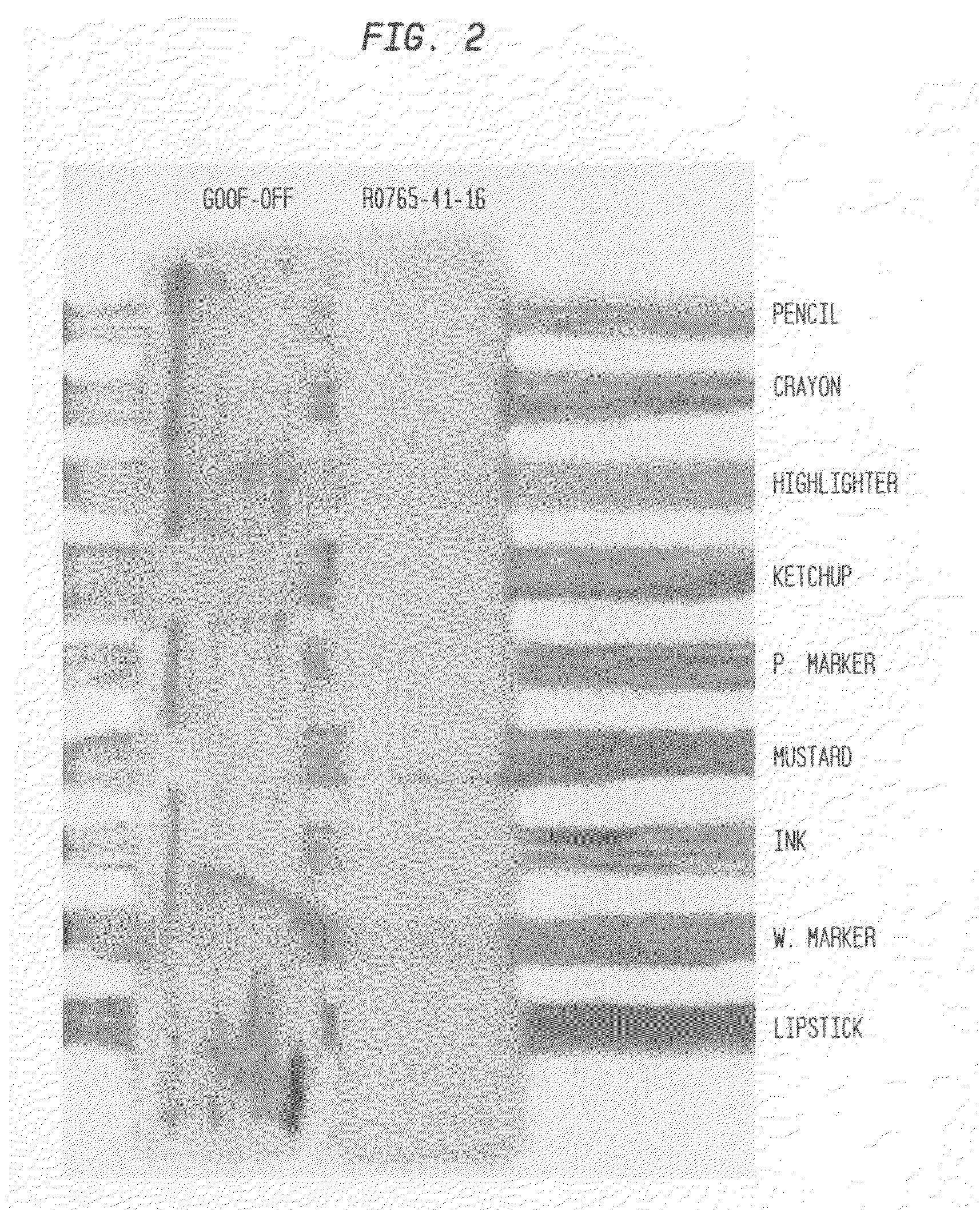

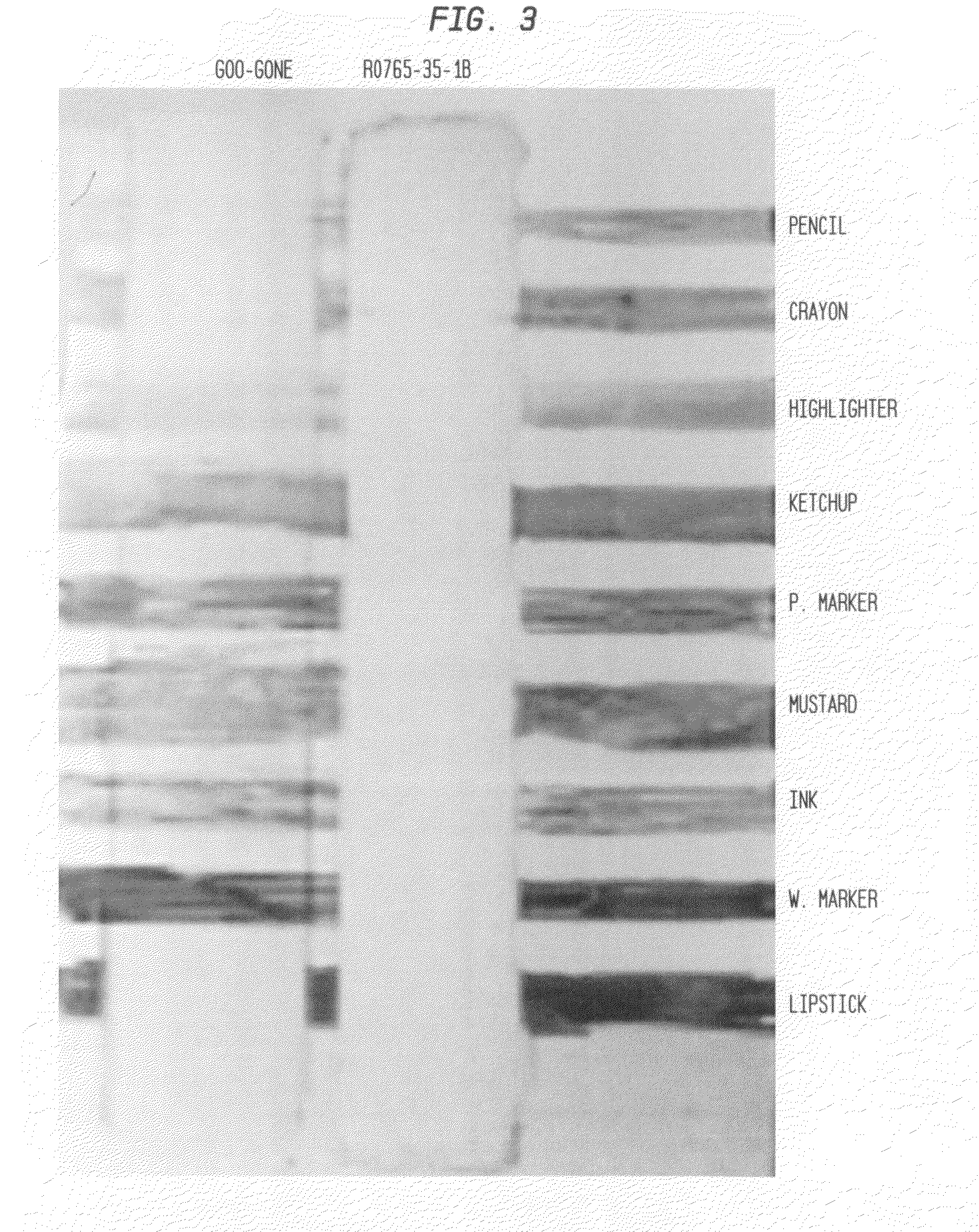

Cleaning compositions incorporating green solvents and methods for use

ActiveUS20090281012A1High flash pointLow vapor pressureOrganic detergent compounding agentsDetergent mixture composition preparationGlutaric acidActive agent

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

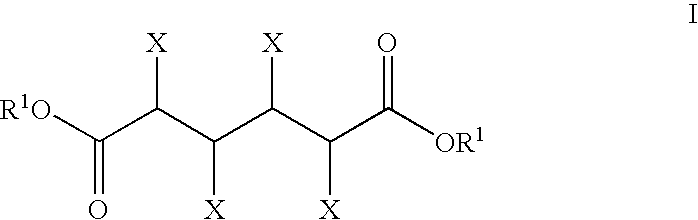

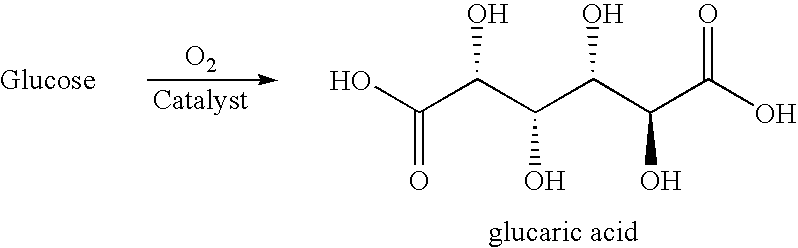

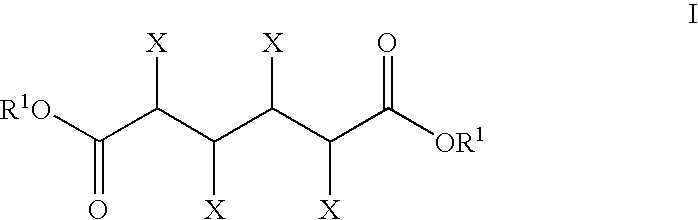

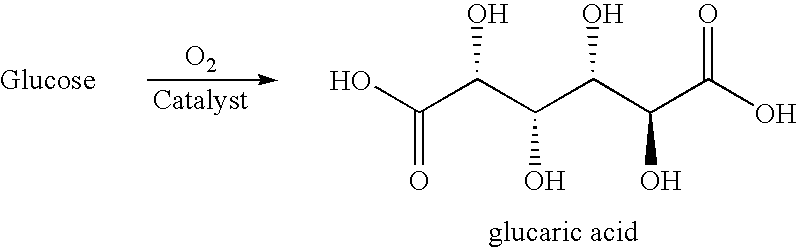

Production of adipic acid and derivatives from carbohydrate-containing materials

ActiveUS8669397B2Low costLactams preparationCarboxylic acid nitrile preparationCatalytic oxidationHydrodeoxygenation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

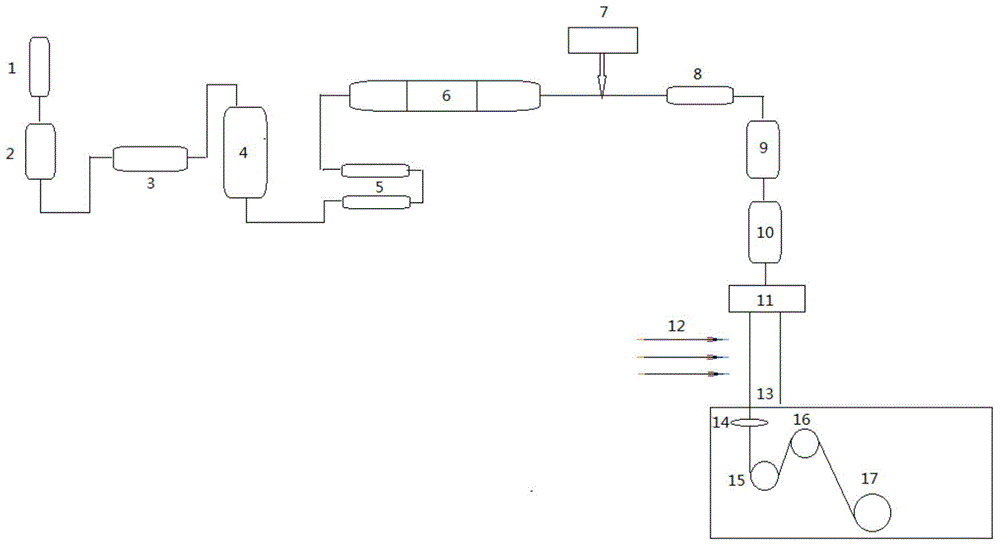

Nylon fibers and preparation method thereof

ActiveCN104562271AEmission reductionReduce pollutionFilament manufactureMonocomponent copolyamides artificial filamentYarnPolymer science

The invention discloses a preparation method of nylon fibers. The preparation method comprises the following steps: directly spinning after taking raw materials containing 1,5-pentamethylene diamine and adipic acid to react. The invention further provides the nylon fibers prepared by the method. The method adopts a manner of combining nylon polymerization and fusion direct spinning to prepare nylon 56 wires so that the production cost is reduced, the waste gas is reduced and the pollution to the environment is reduced. The high-performance nylon fibers prepared by the method can be further used for preparing textile materials including yarns, woven fabrics, knitted fabrics or non-woven fabrics, can be widely applied to the fields of clothing material industries, decoration carpets and the like, and has a wide industrial application prospect.

Owner:CATHAY R&D CENT CO LTD +1

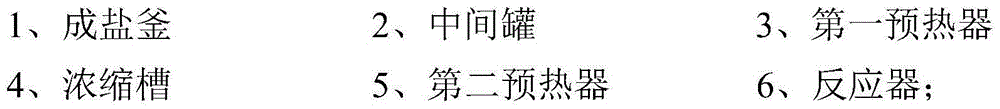

Biodegradable poly(lactic acid) polymer composition and films, coatings and products comprising Biodegradable poly(lactic acid) polymer compositions

InactiveUS7393590B2Improve ductilityIncrease flexibilitySynthetic resin layered productsThin material handlingPolyesterPolymer science

The present invention relates to biodegradable polymer compositions comprising poly(lactic acid) and poly(epsilon caprolactone) and co-polyester polymer with adipic acid mixed with organic peroxide and magnesium silicate minerals. In addition, the present invention relates to films, coatings and products made on the basis of said compositions and to a method for their preparation.

Owner:CEREPLAST INC

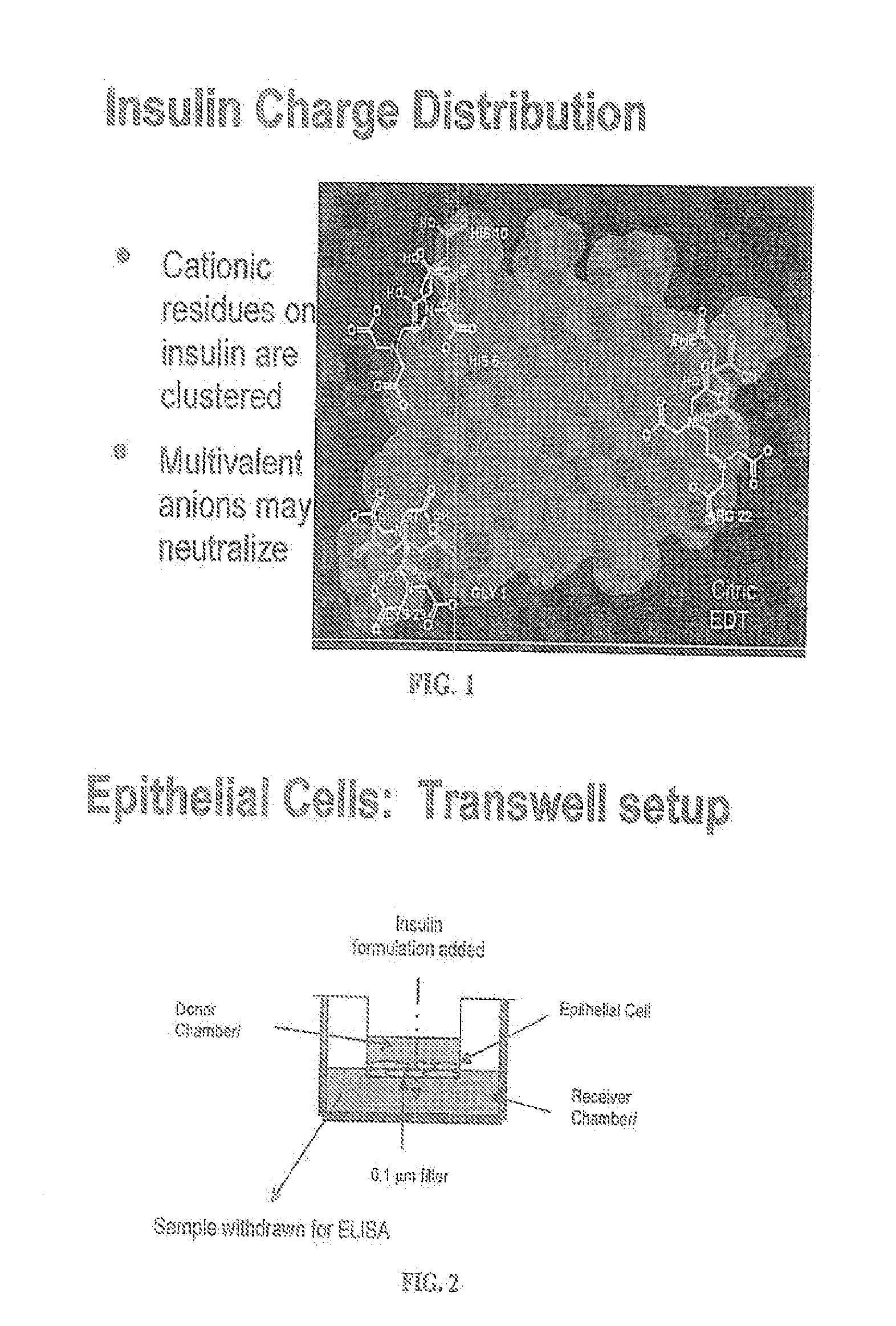

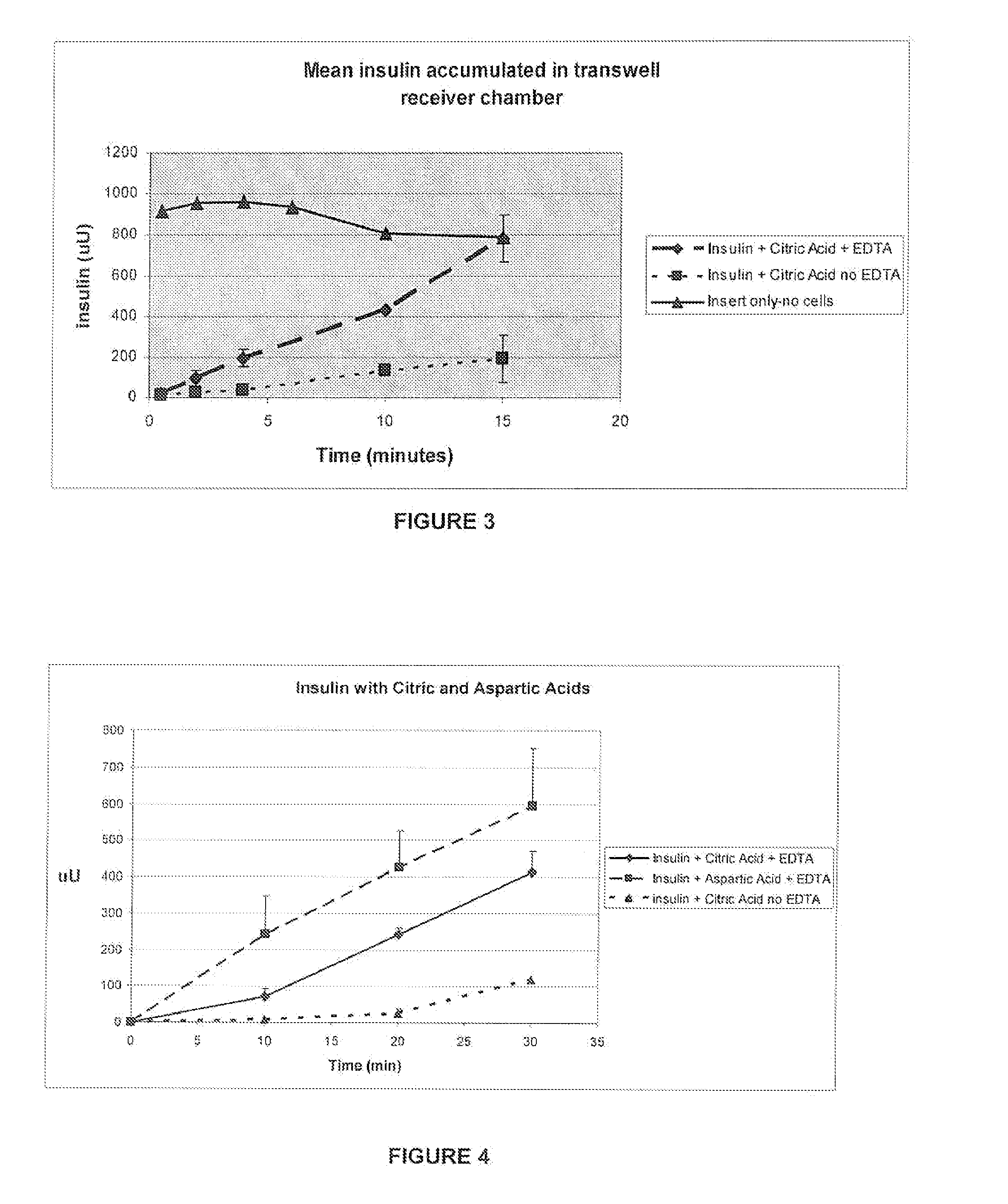

Rapid acting and long acting insulin combination formulations

ActiveUS20080039368A1Increase speedReduce the amount of solutionPeptide/protein ingredientsMetabolism disorderBefore BreakfastIntensive insulinotherapy

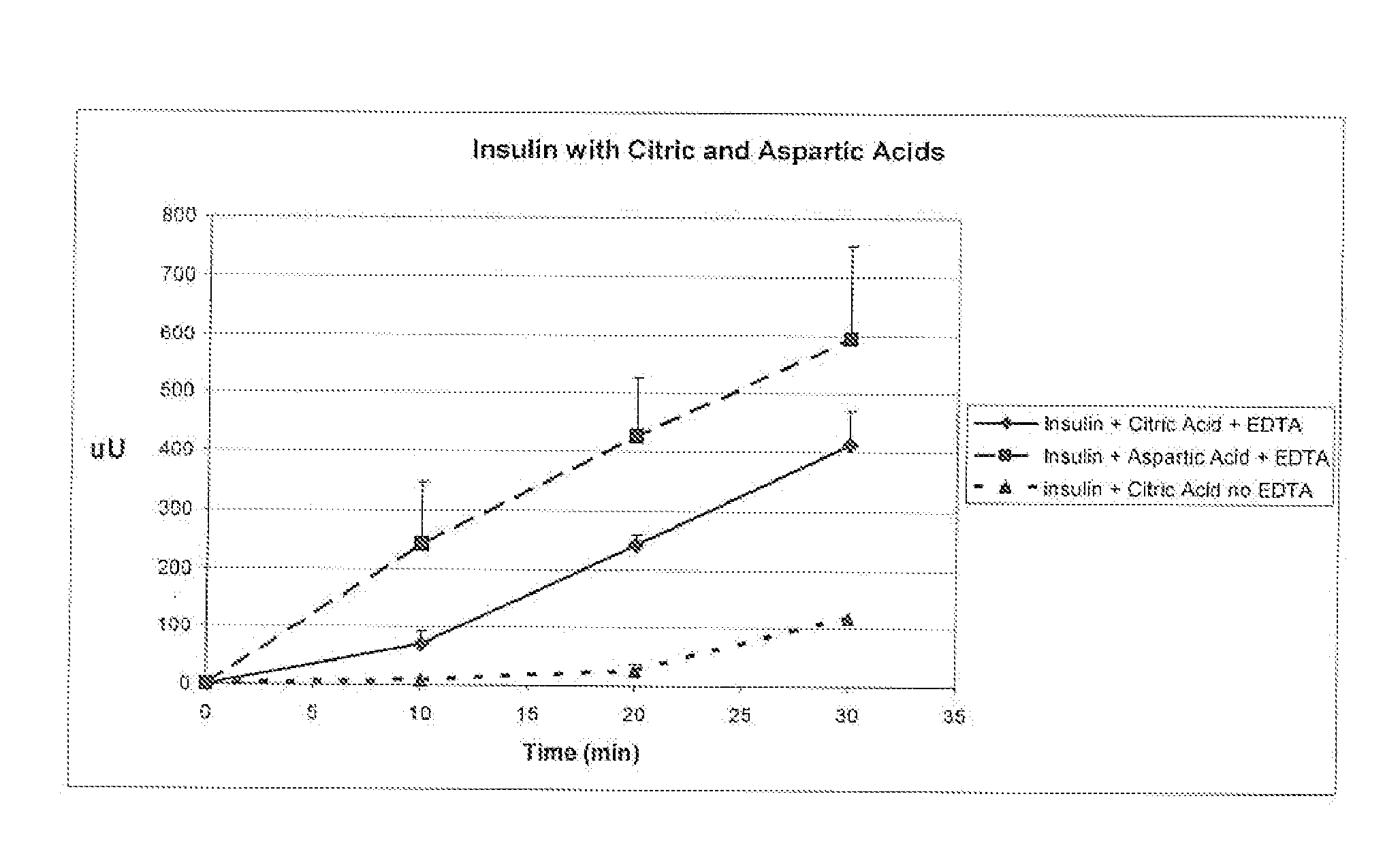

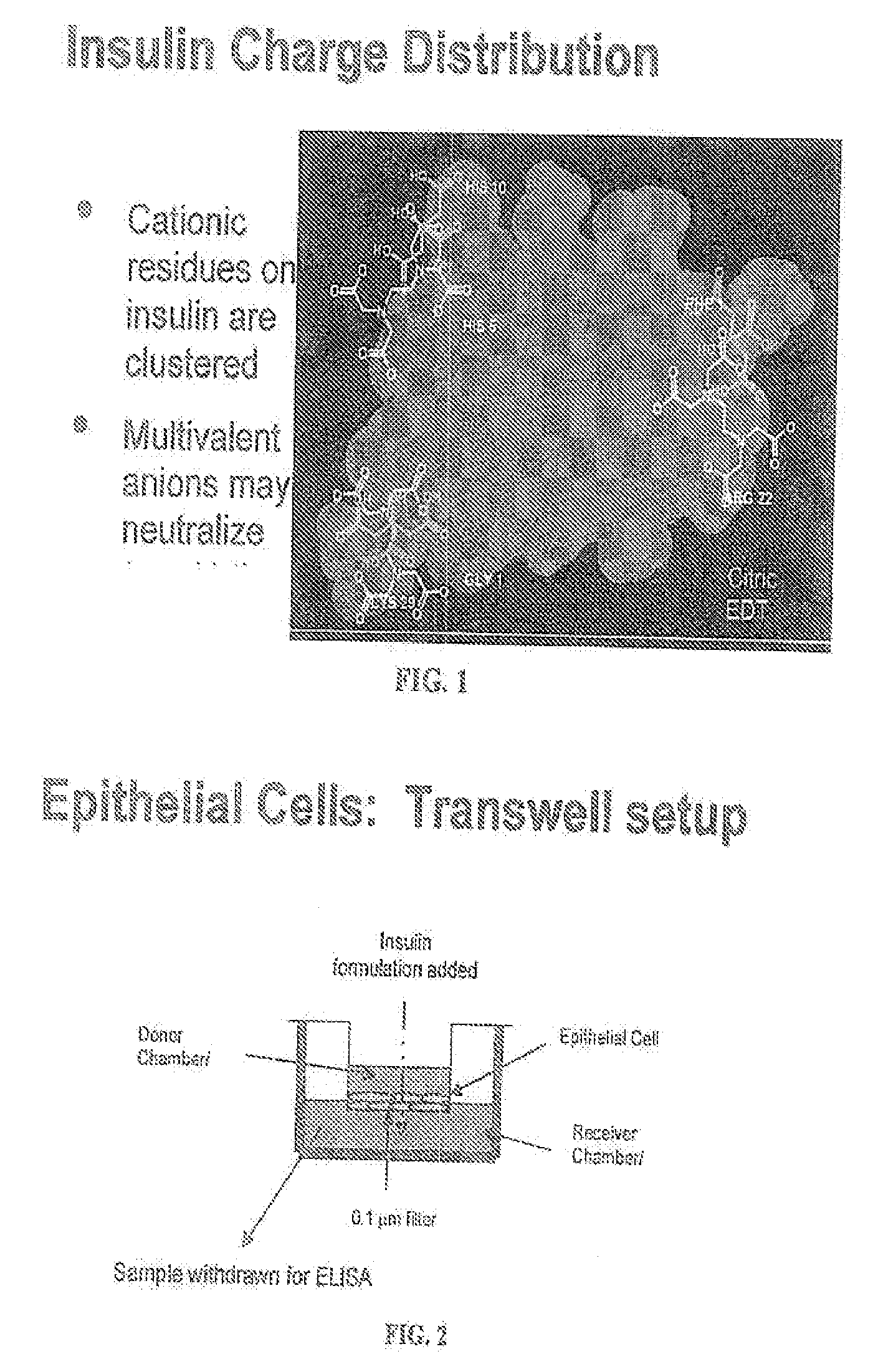

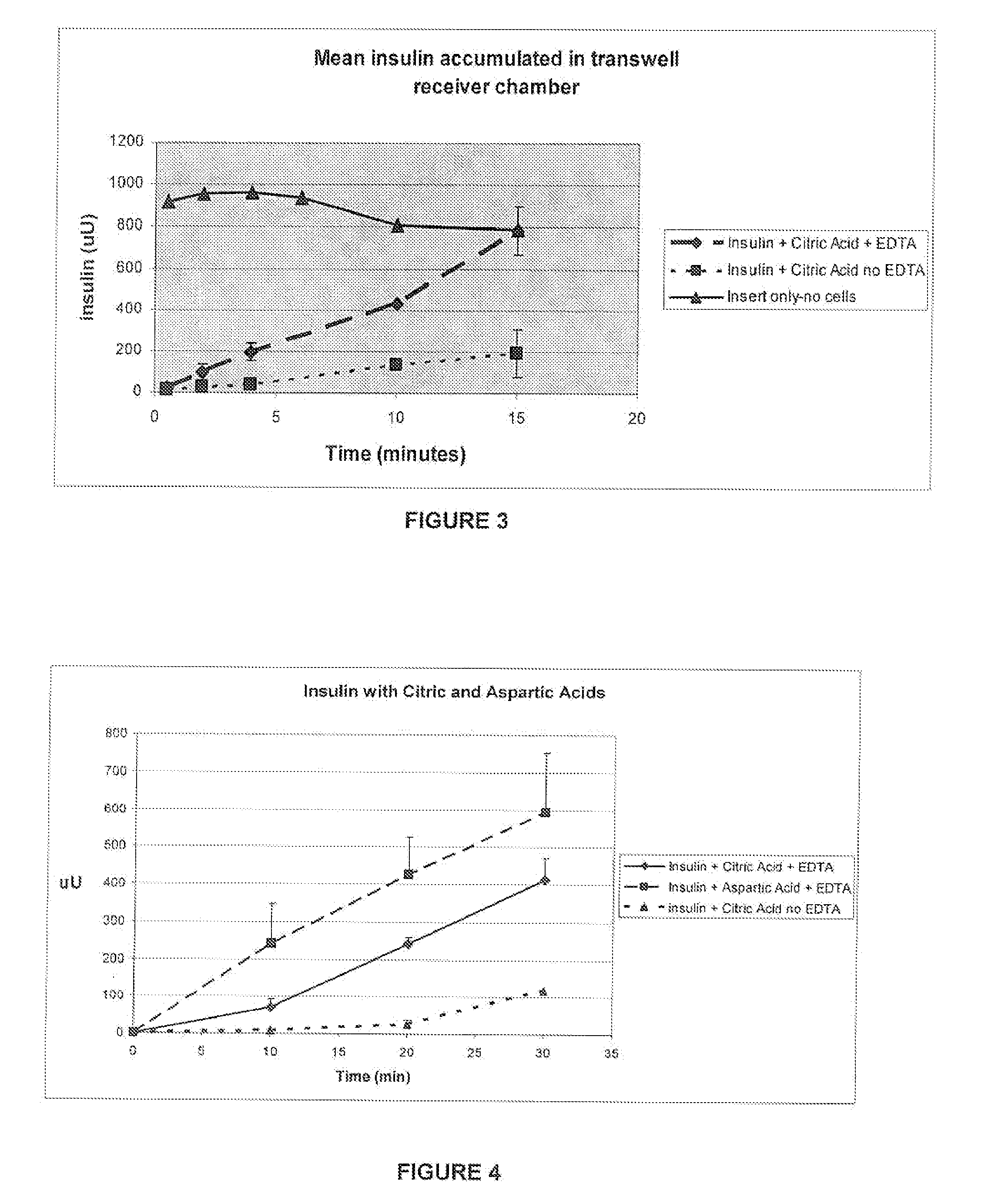

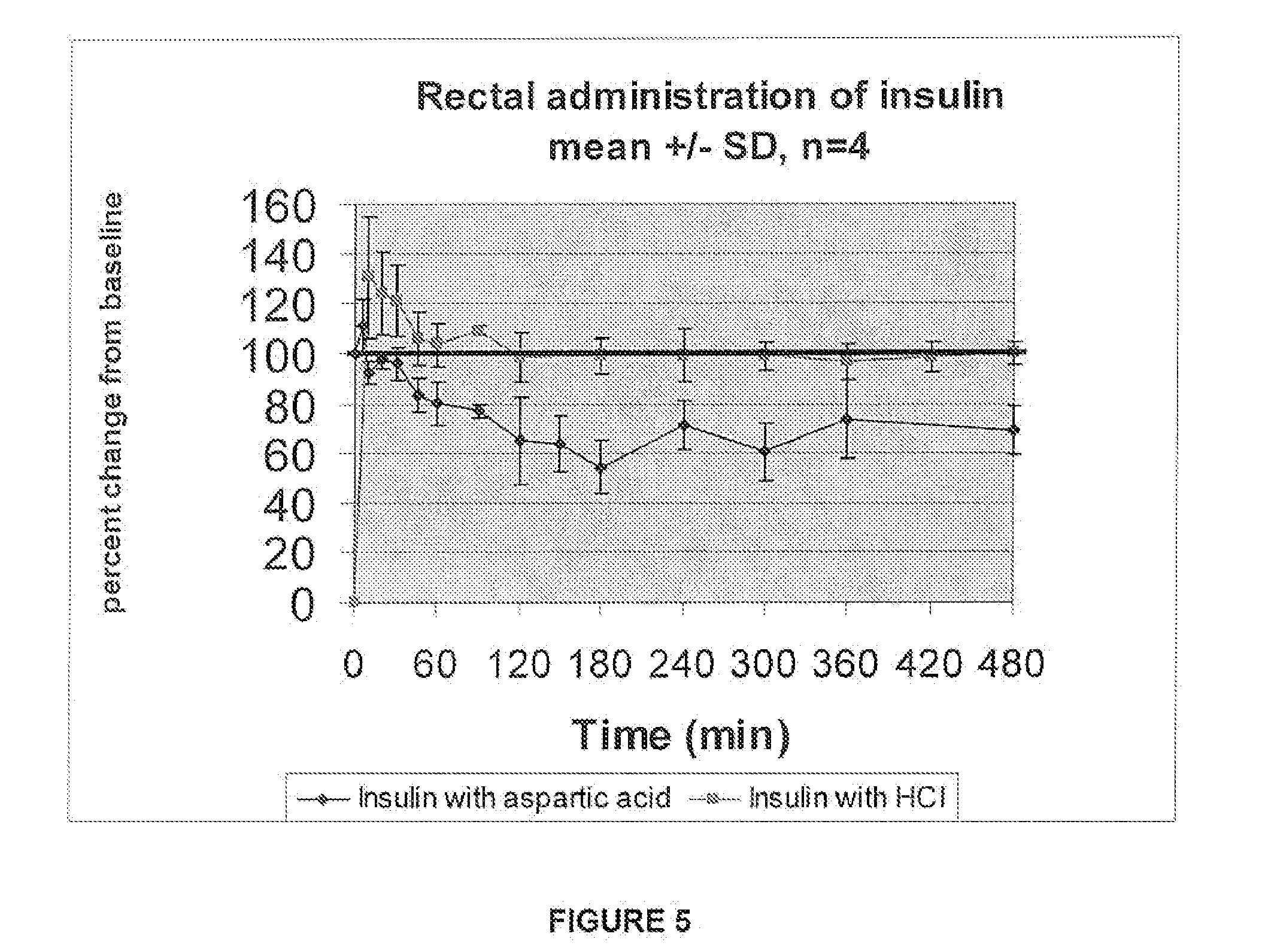

A combined rapid acting-long acting insulin formulation has been developed wherein the pH of the rapid acting insulin is adjusted so that the long acting glargine remains soluble when they are mixed together. In the preferred embodiment, this injectable basal bolus insulin is administered before breakfast, provides adequate bolus insulin levels to cover the meal, does not produce hypoglycemia after the meal and provides adequate basal insulin for 24 hours. Lunch and dinner can be covered by two bolus injections of a fast acting, or a rapid acting or a very rapid acting insulin. As a result, a patient using intensive insulin therapy should only inject three, rather than four, times a day. Experiments have been performed to demonstrate, the importance of the addition of specific acids to hexameric insulin to enhance speed and amount of absorption and preserve bioactivity following dissociation into the monomeric form by addition of a chelator such as EDTA. As shown by the examples, the preferred acids are aspartic, maleic, succinic, glutamic and citric acid. These are added in addition to a chelator, preferably ethylenediaminetetraacetic acid (EDTA). The results show that the citric acid formulation was more effective at dropping the blood glucose rapidly than the identical rapid acting formulation prepared with HCl in swine. Charge masking by the polyacid appears to be responsible for rapid insulin absorption. EDTA was not effective when used with adipic acid, oxalic acid or HCl at hastening the absorption of insulin. These results confirm the results seen in clinical subjects and patients with diabetes treated with the rapid acting insulin in combination with citric acid and EDTA.

Owner:ELI LILLY & CO

Synthetic fiber

A novel synthetic fiber is disclosed including a first component of an aliphatic polyester polymer, a second component of a multicarboxylic acid, an admixture of the first component aliphatic polyester polymer and the second component multicarboxylic acid to form an unreacted specified thermoplastic composition, and melt blending the unreacted specified thermoplastic composition in an extruder or a mixer. The second component multicarboxylic acid lubricates the extruder and provides a nucleating agent for crystallizing the specified thermoplastic composition to form a mean crystal size less than about 120 Angstroms. Fiber composed of the specified thermoplastic composition has a mean crystal size less than about 120 Angstroms. The fiber has a glass transition temperature (Tg) less than about 55° C. In one aspect, a first component of polylactic acid and a second component of adipic acid provide synthetic fibers in a nonwoven structure used in a biodegradable and compostable disposable absorbent product for the absorption and removal of body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

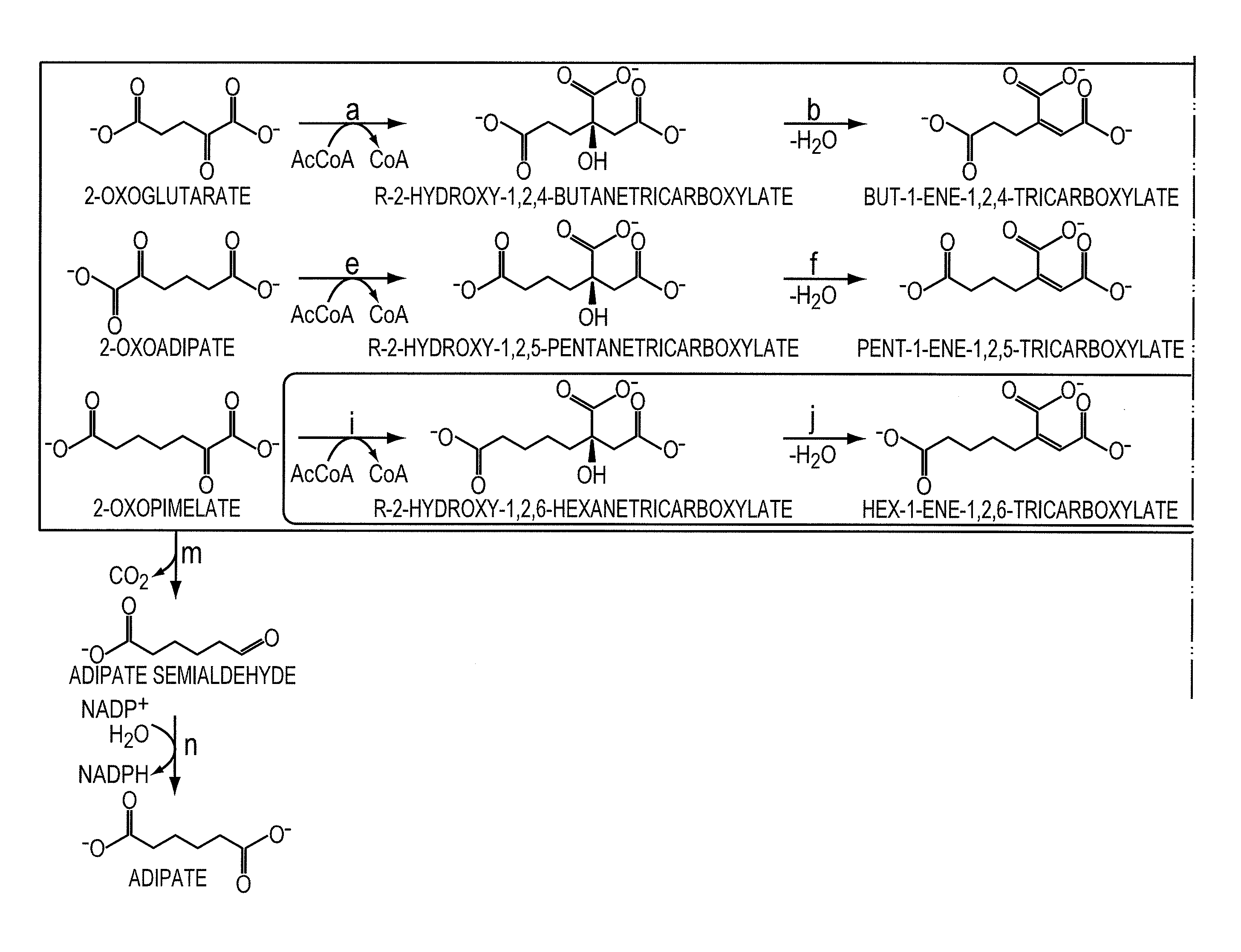

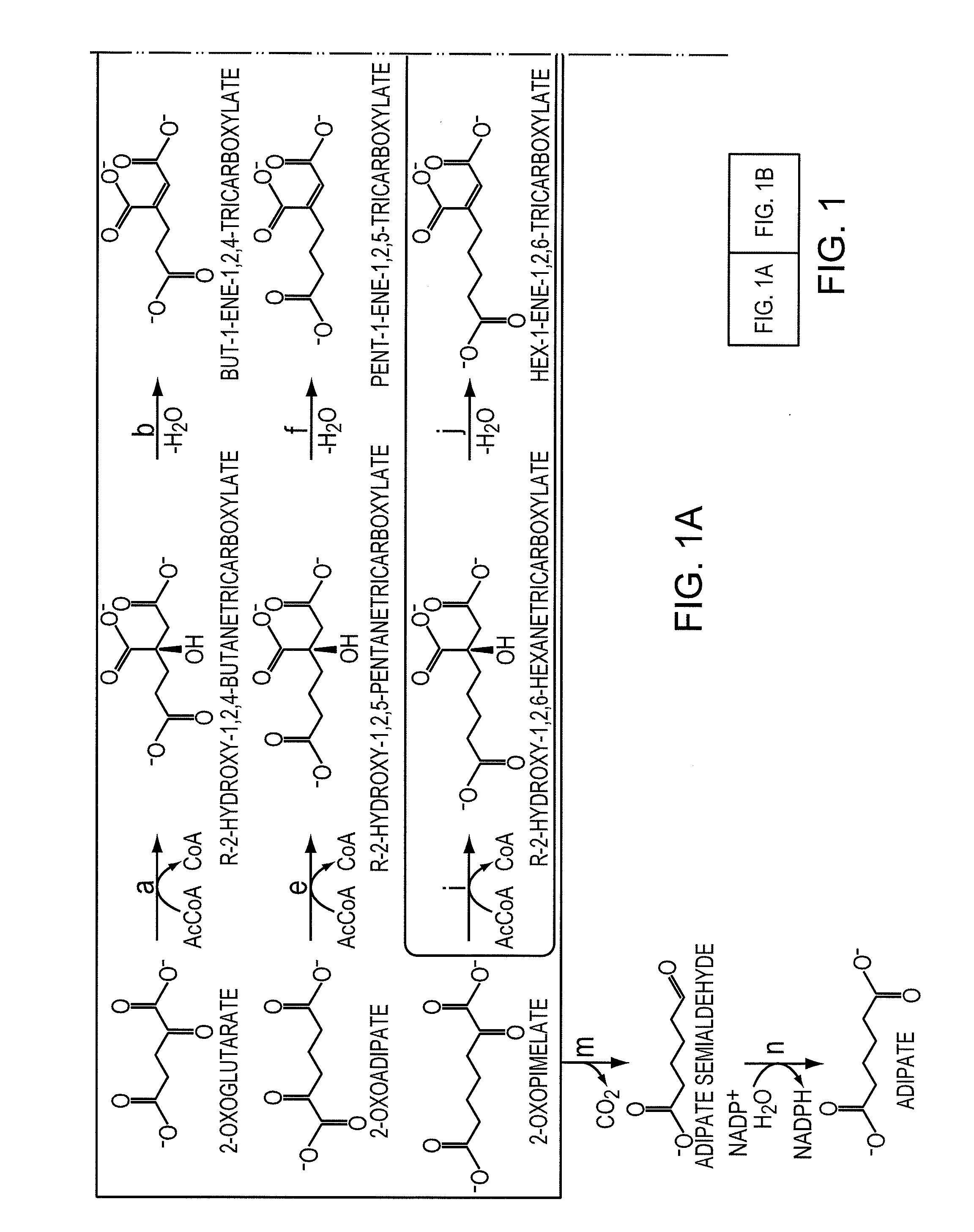

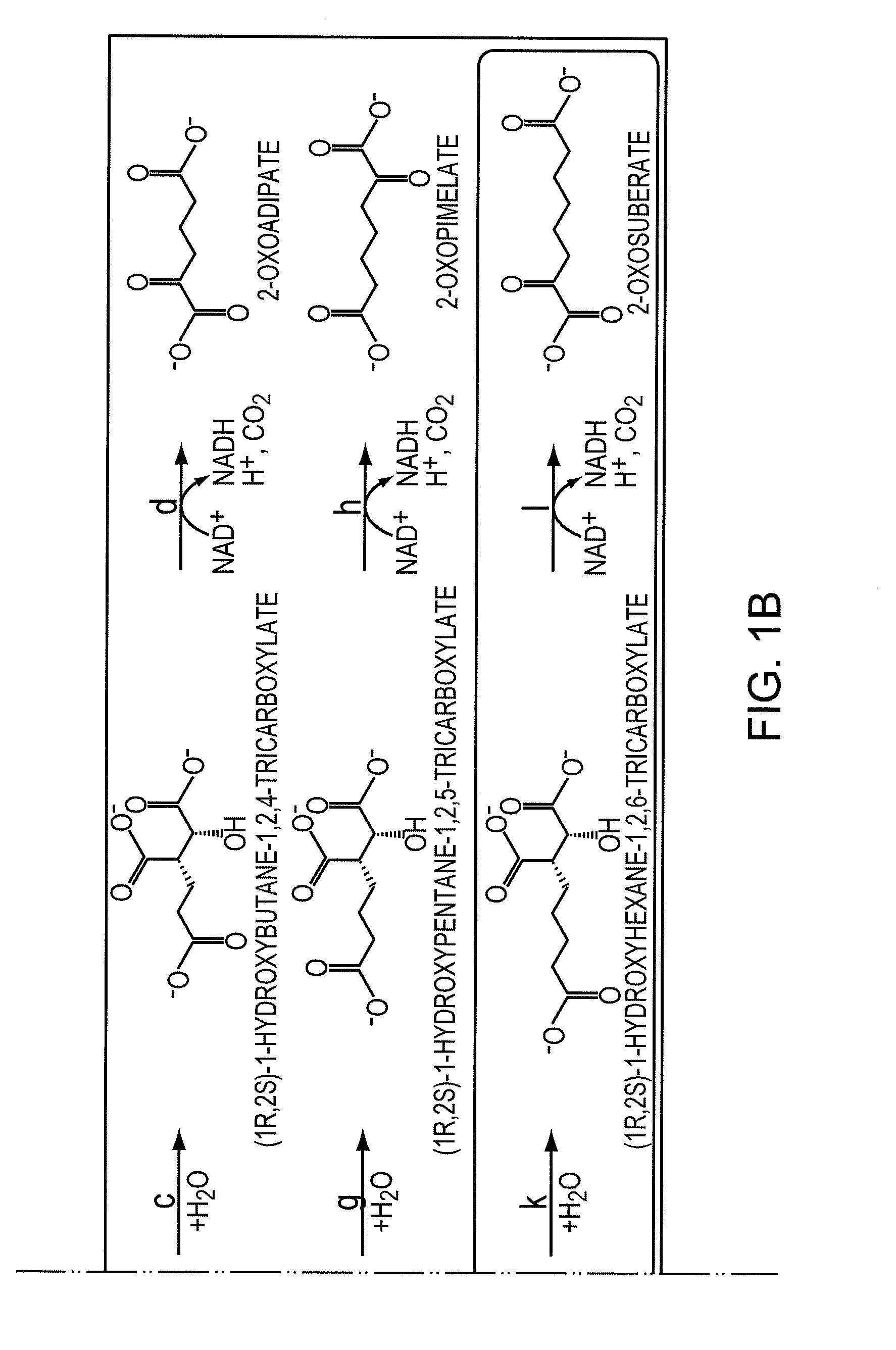

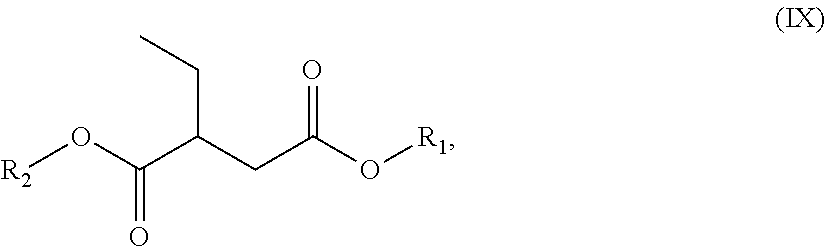

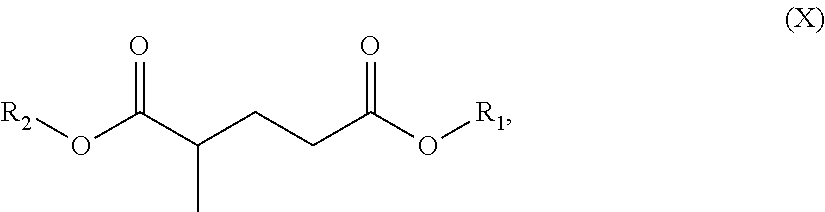

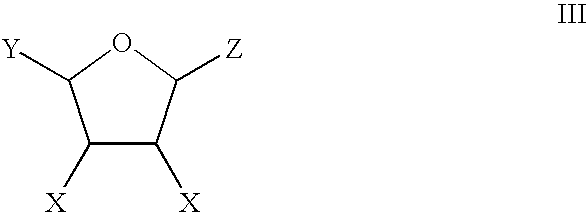

Biological Synthesis of Difunctional Alkanes from Carbohydrate Feedstocks

Aspects of the invention relate to methods for the production of difunctional alkanes in host cells. In particular, aspects of the invention describe components of genes associated with the difunctional alkane production from carbohydrate feedstocks in host cells. More specifically, aspects of the invention describe metabolic pathways for the production of adipic acid, aminocaproic acid, caprolactam, and hexamethylenediamine via 2-ketopimelic acid.

Owner:CELEXION

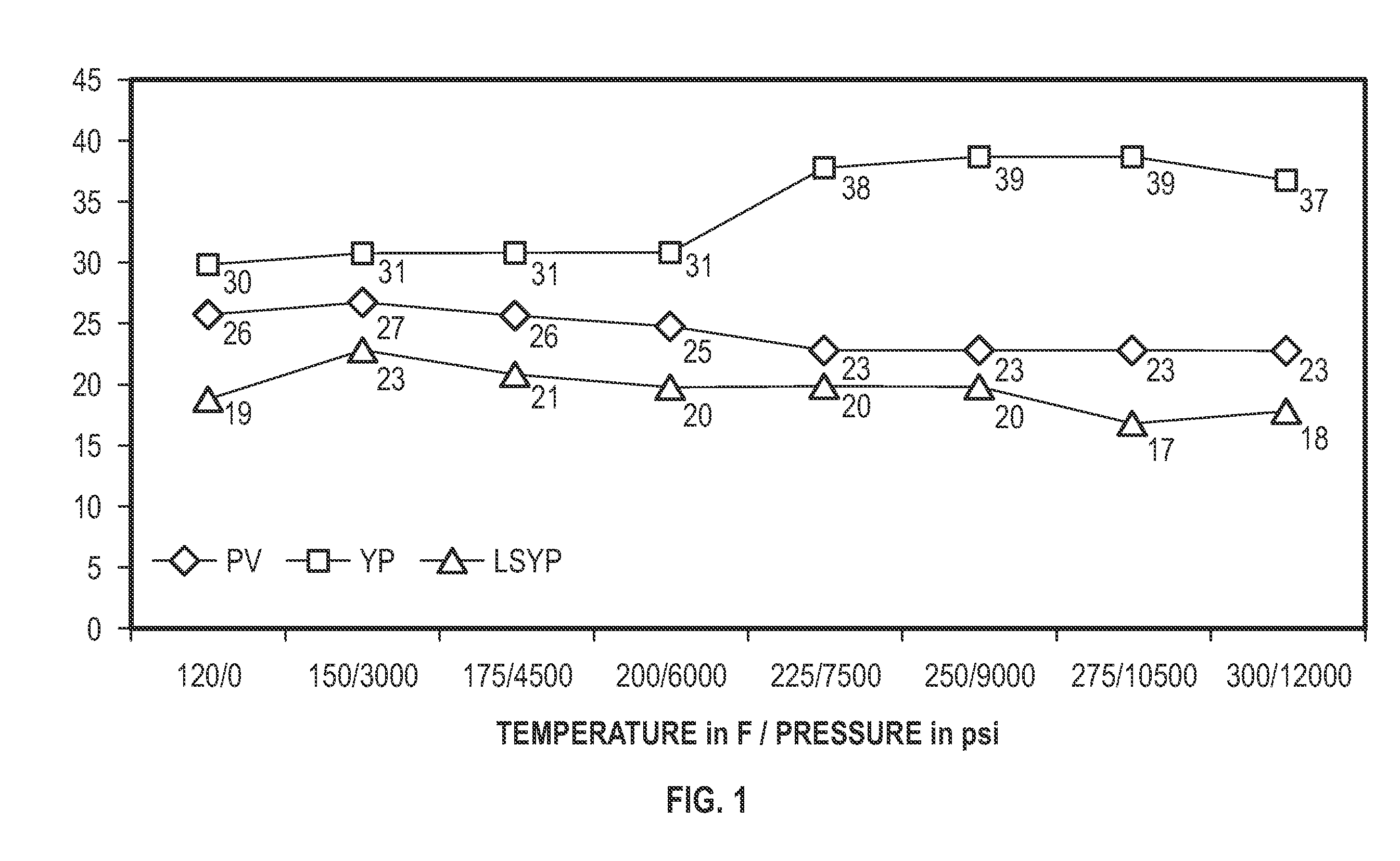

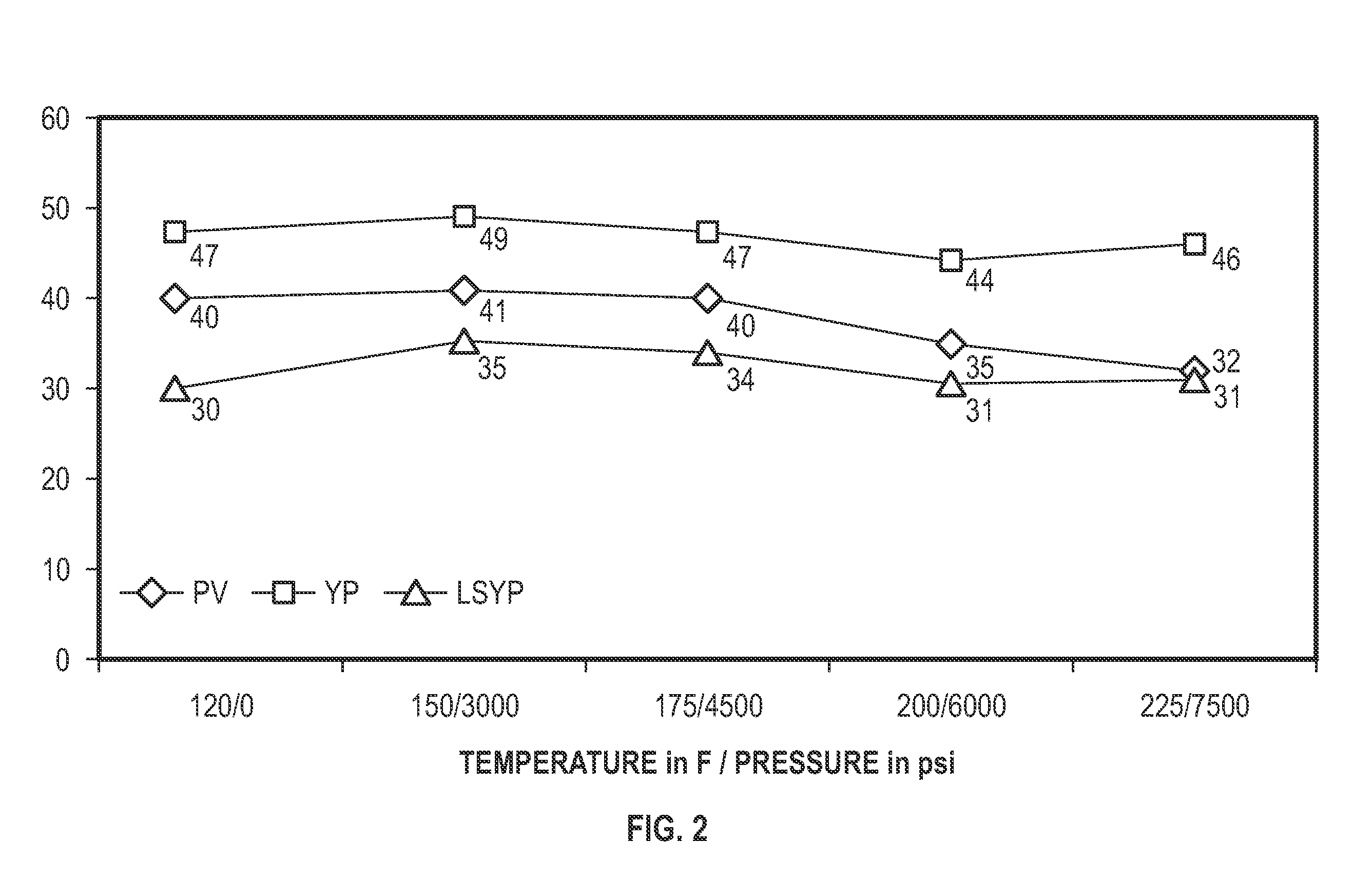

Environmentally Friendly Solvent Systems/Surfactant Systems For Drilling Fluids

InactiveUS20140005079A1Good for healthImprove securityFlushingDrilling compositionGlutaric acidActive agent

A oil field production fluid, namely a drilling mud composition, comprising a mixture of: (a) at least one base oil component; and (b) an additive component comprising a blend of dibasic esters. The functional fluid can optionally comprise additional additive components. The blend of dibasic esters comprises two or more of dialkyl methylglutarate, dialkyl adipate, dialkyl ethylsuccinate, dialkyl succinate, dialkyl glutarate.

Owner:RHODIA OPERATIONS SAS

Use of eco-friendly microemulsions in oil cleaning applications

InactiveUS20130146545A1Easily biodegradablePoint becomes highSurface-active detergent compositionsTransportation and packagingDibasic esterPhenol

An environmentally-friendly cleaning composition for oil cleaning comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition.

Owner:RHODIA OPERATIONS SAS

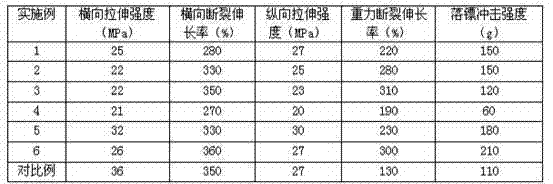

Full-biodegradable film and preparation method thereof

The invention relates to a composition of a high-tenacity full-biodegradable film and a preparation method thereof. The film is prepared from polylactic acid (PLA), poly propylene carbonate (PPC), polybutylene adipate terephthalate (PBAT) and a heat stabilizer. Blending modification sections are prepared by adopting a twin-screw extruder, blow molding is carried out by adopting a single-screw extruder, the prepared film has excellent tenacity and full biodegradable performance, and meanwhile the cost is low, so that the film is an ideal substitute for a current non-degradable film packing material.

Owner:NANTONG LONGDA BIO TECH NEW MATERIALS CO LTD

Methods and Materials to Enhance High Temperature Rheology in Invert Emulsions

ActiveUS20130303411A1Quantity minimizationLow pour pointFlushingDrilling compositionOrganic acidEmulsion

An invert emulsion drilling fluid, and a method of drilling with such fluid, having improved rheology at low mud weights and high temperatures. The improved rheology is effected with addition of a rheology additive of the invention comprising fatty dimer diamines or dimer diamines and an organic acid or ester of the acid. A nonlimiting example of such a rheology additive comprises a C36 fatty dimer diamine and adipic acid or dimethyl adipate.

Owner:HALLIBURTON ENERGY SERVICES INC

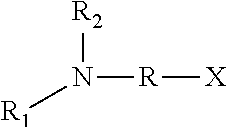

Plasticizer Blends and Use Thereof

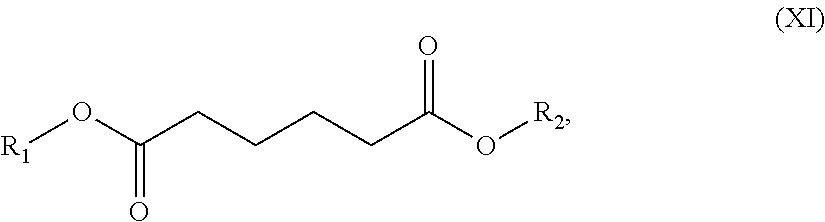

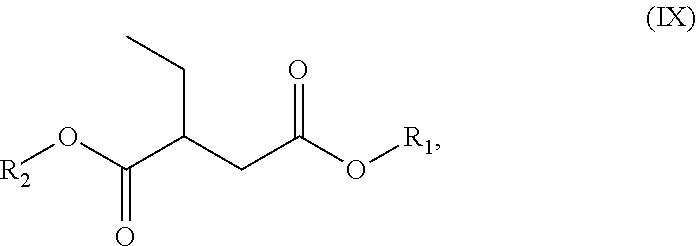

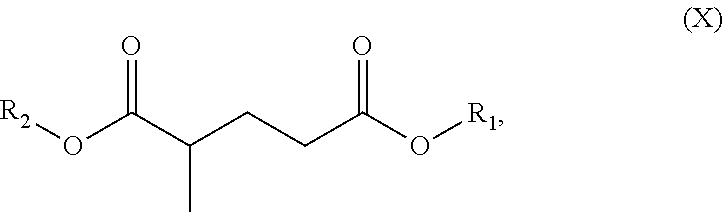

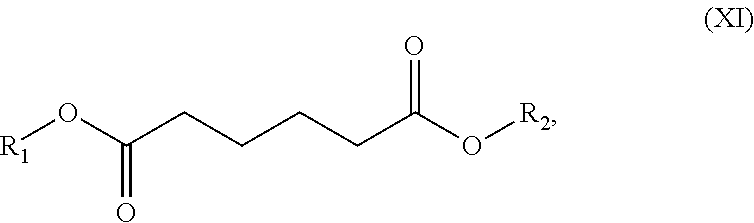

Provided are mixtures of 1) compounds of the formula:wherein R1 is a saturated or unsaturated cyclic hydrocarbon optionally substituted with an alkyl and / or an OXO-ester, and R2 is a C4 to C14 hydrocarbyl; and 2) one or more second plasticizers selected from the group consisting of alkyl terephthalates, alkyl phthalates, alkyl benzoate esters, di-benzoate esters, esters of cyclohexane polycarboxylic acids, and dialkyl adipates. Also provided are plasticized polymer compositions containing said mixtures.

Owner:EXXONMOBIL CHEM PAT INC

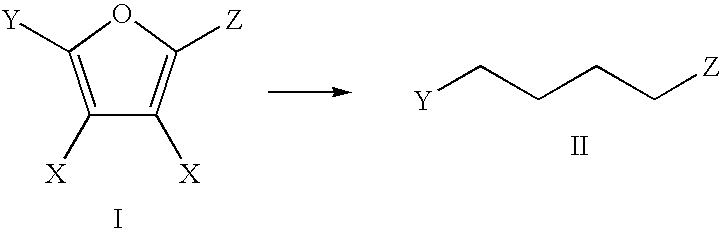

Production of Adipic Acid and Derivatives from Carbohydrate-Containing Materials

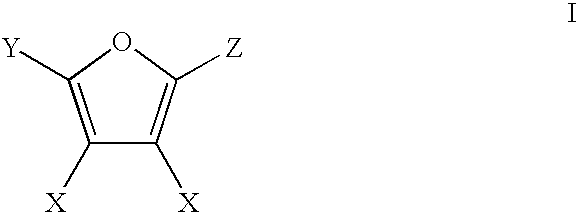

The present invention generally relates to processes for the chemocatalytic conversion of a carbohydrate source to an adipic acid product. The present invention includes processes for the conversion of a carbohydrate source to an adipic acid product via a furanic substrate, such as 2,5-furandicarboxylic acid or derivatives thereof. The present invention also includes processes for producing an adipic acid product comprising the catalytic hydrogenation of a furanic substrate to produce a tetrahydrofuranic substrate and the catalytic hydrodeoxygenation of at least a portion of the tetrahydrofuranic substrate to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

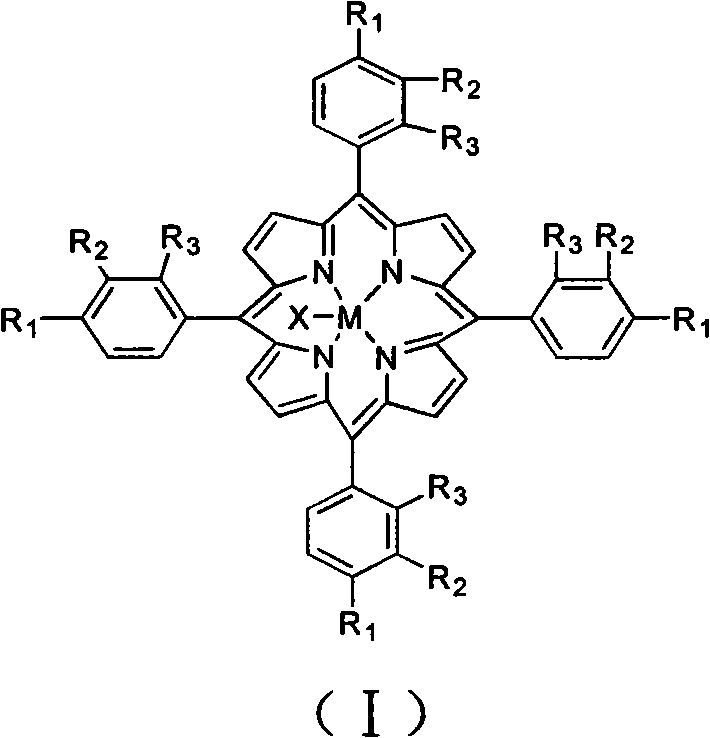

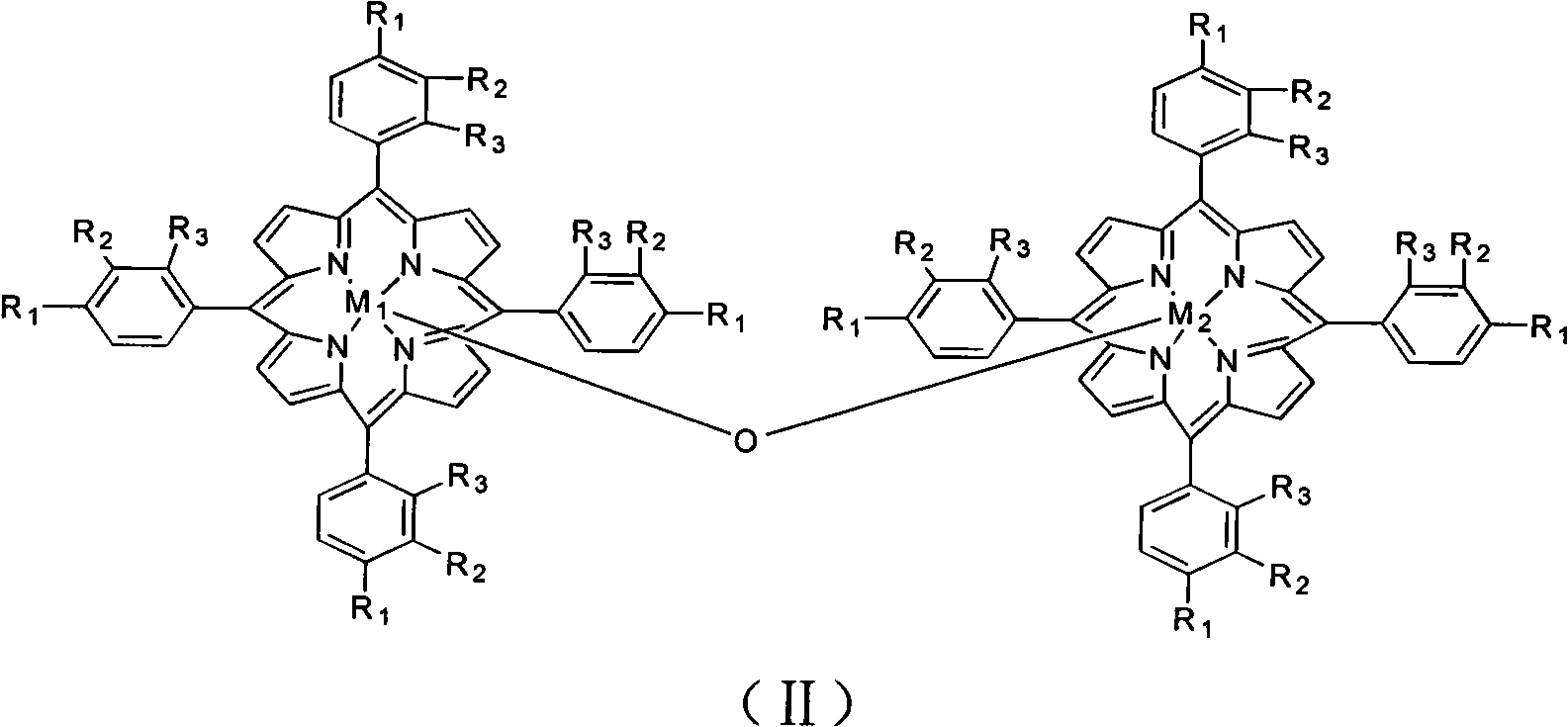

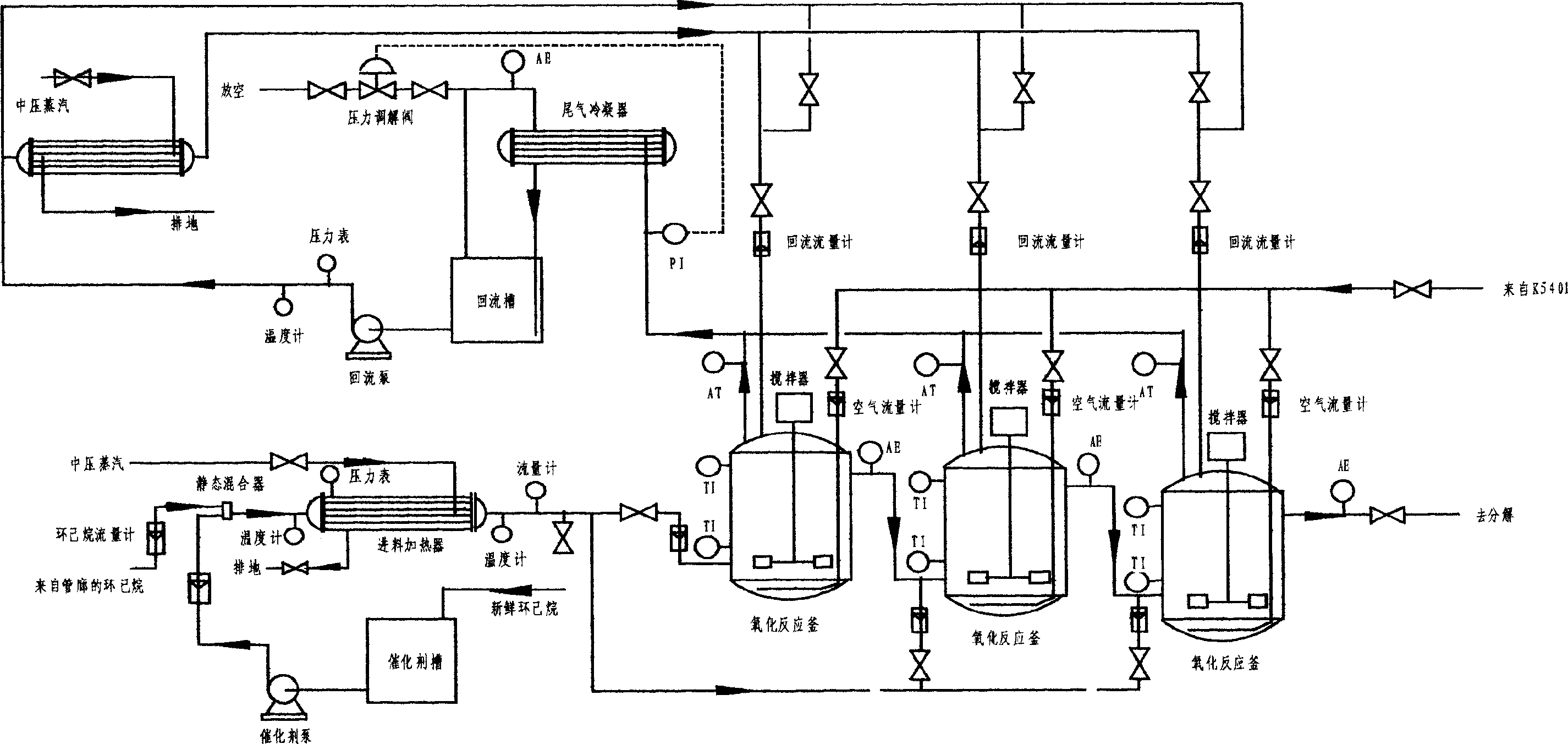

Process and equipment for preparing adipic acid by catalyzing air and oxidizing cyclohexane

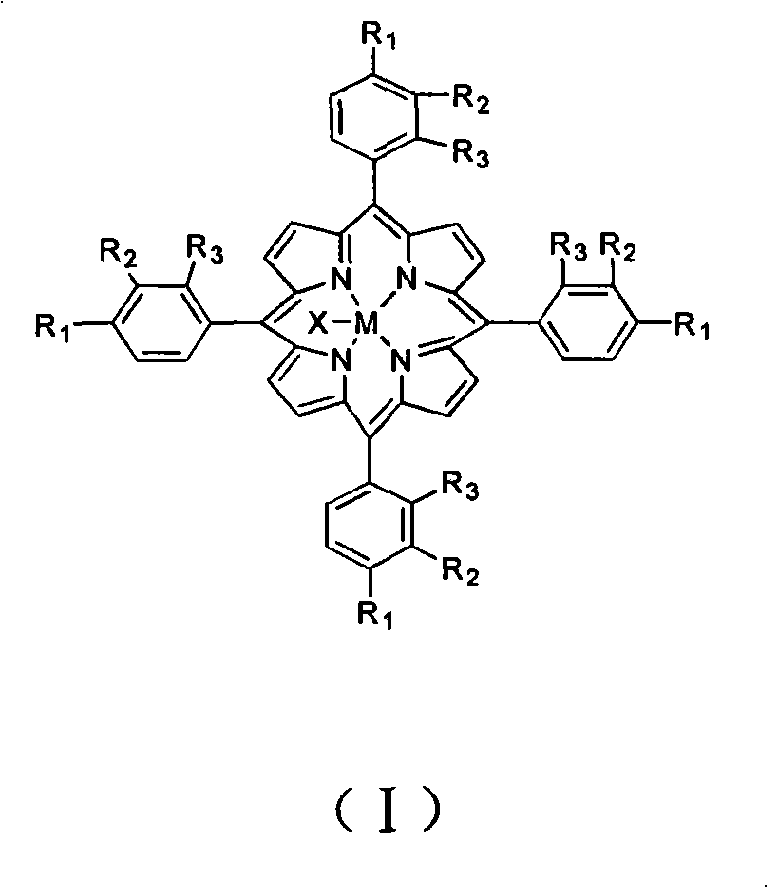

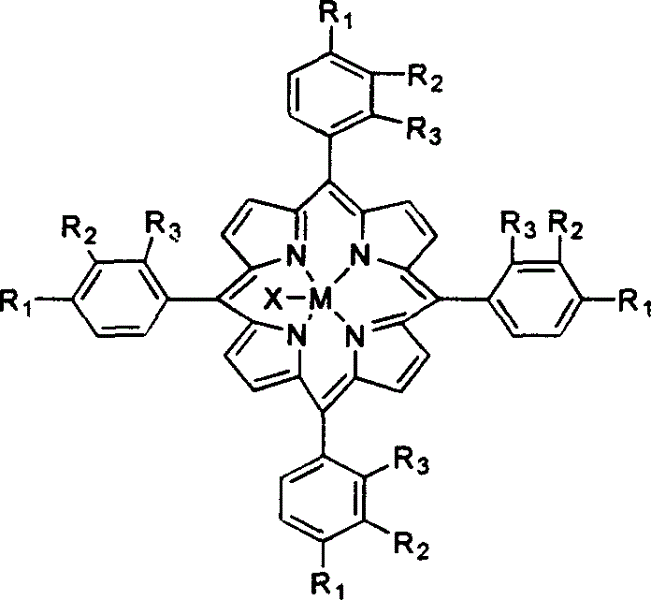

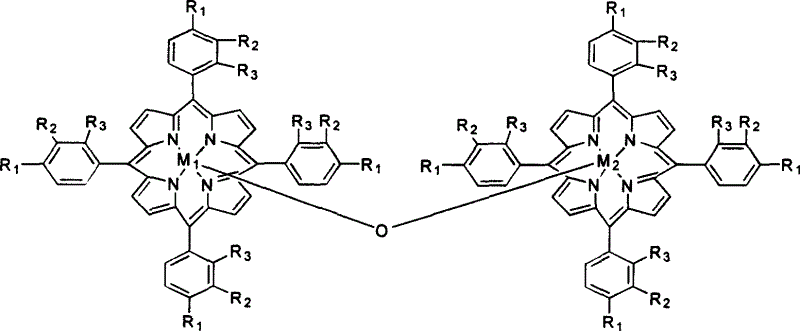

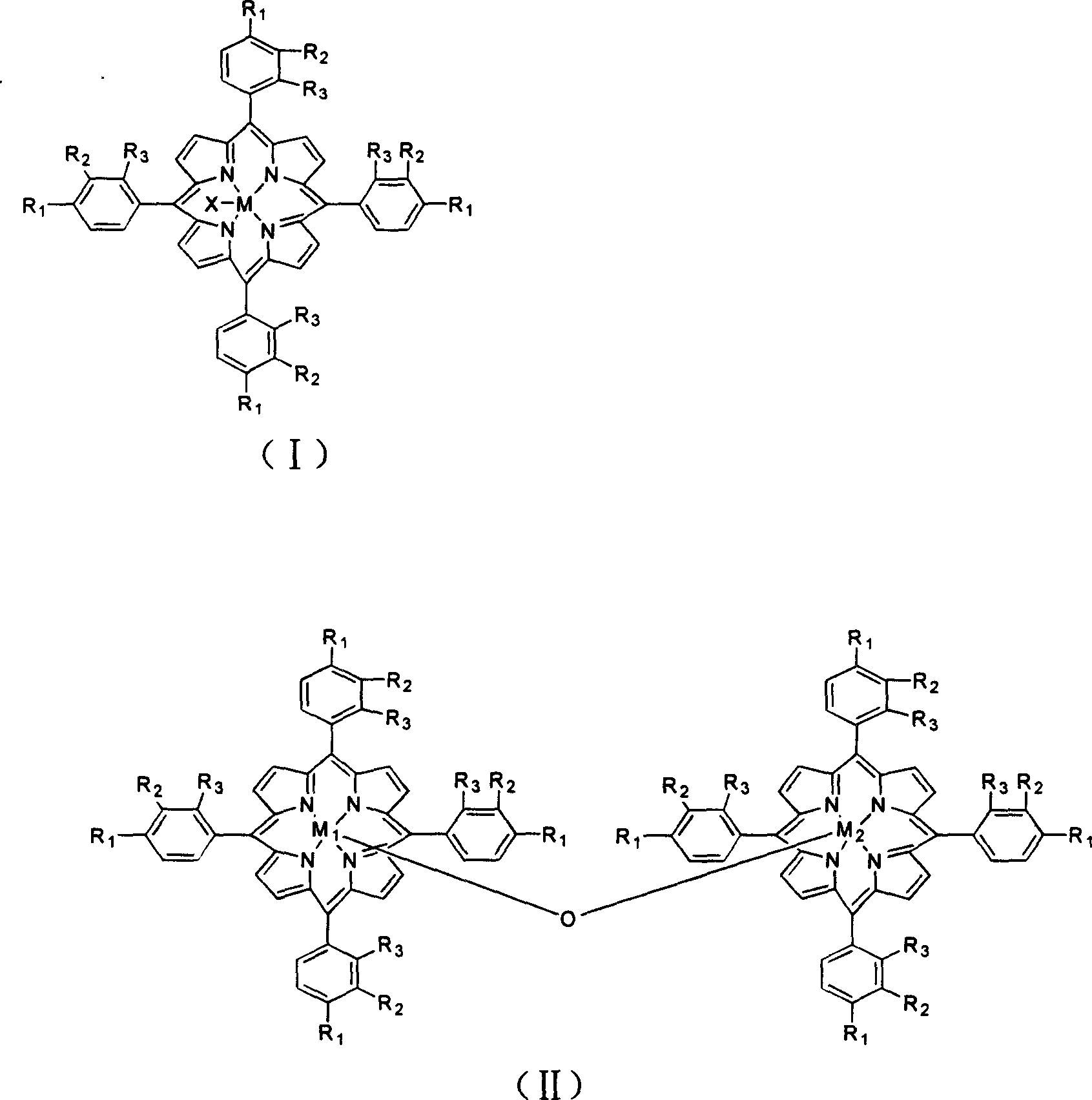

InactiveCN101337879AImprove conversion rateHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexanoneBoiling point

The invention discloses a process and a plant for preparing adipic acid by catalytically aerobically oxidizing cyclohexane. The process comprises the following steps: dissolving 1 to 50 PPM of a catalyst including single metalloporphyrin or mu-oxo bimetallic porphyrin or a mixture of single metalloporphyrin, mu-oxo bimetallic porphyrin and transition metal salt or oxide in cyclohexane; introducing 5 to 12 atm of air or oxygen-rich or oxygen-poor air into a multi-stage oxidation reactor with a gas distributor; controlling the reaction temperature at 140 to 160 DEG C; oxidizing cyclohexane for 45 to 120 min; feeding the mixture of the oxidation reaction into a flash separator to carry out flash evaporation at the temperature of 78 to 155 DEG C and under the pressure of 0.1 to 1.0 atm, so that the low-boiling-point products such as cyclohexane, cyclohexanol and cyclohexanone change to gas and are separated from adipic acid with the content above 80%; continuously circularly oxidizing the low-boiling-point products to separate and purify the high-boiling-point oxidation product; and purifying and separating by the existing technique to obtain fine adipic acid product. The process can directly prepare adipic acid by aerobically oxidizing cyclohexane, wherein the conversion rate of cyclohexane is up to 95%, and the yield of adipic acid is up to 70%.

Owner:HUNAN UNIV

Thermoplastic polyurethane elastomer and manufacturing method thereof

The invention relates to the manufacturing field of a special extrusion grade T-die thermoplastic elastomer, in particular to a manufacturing formula and a manufacturing method thereof. The formula comprises the following components: 20-40% of 4,4'-diphenylmethane-diisocyanate, 15-70% of polybutylene adipate the molecular weight of which is 1000 or 2000, 0-50% of poly butylene glycol adipate the molecular weight of which is 2000, 5-15% of 1,4-butanediol, 0-5% of glycol, 0.1-1.0% of antioxidant, 0.1-1.0% of lubricant, 0.001-0.1% of environment-friendly catalyst, 0.1-1.0% of ultraviolet absorbent, 0.1-1.0% of light stabilizer and 0.1-1.0% of hydrolysis resistant agent. Continuous production processes are used for synthesizing TPU (thermoplastic polyurethane). The product of the invention has the advantages of stable quality, excellent performance, few T-die extrusion crystal points, good transparency (more than 4mm), stable extrusion, no occurrence of separation of additives, high hydrolysis resistance and high UV (ultraviolet) resistance, and the indexes and the performance of the product can reach the indexes of international like products. The invention provides a thermoplastic polyurethane elastomer and a manufacturing method thereof.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

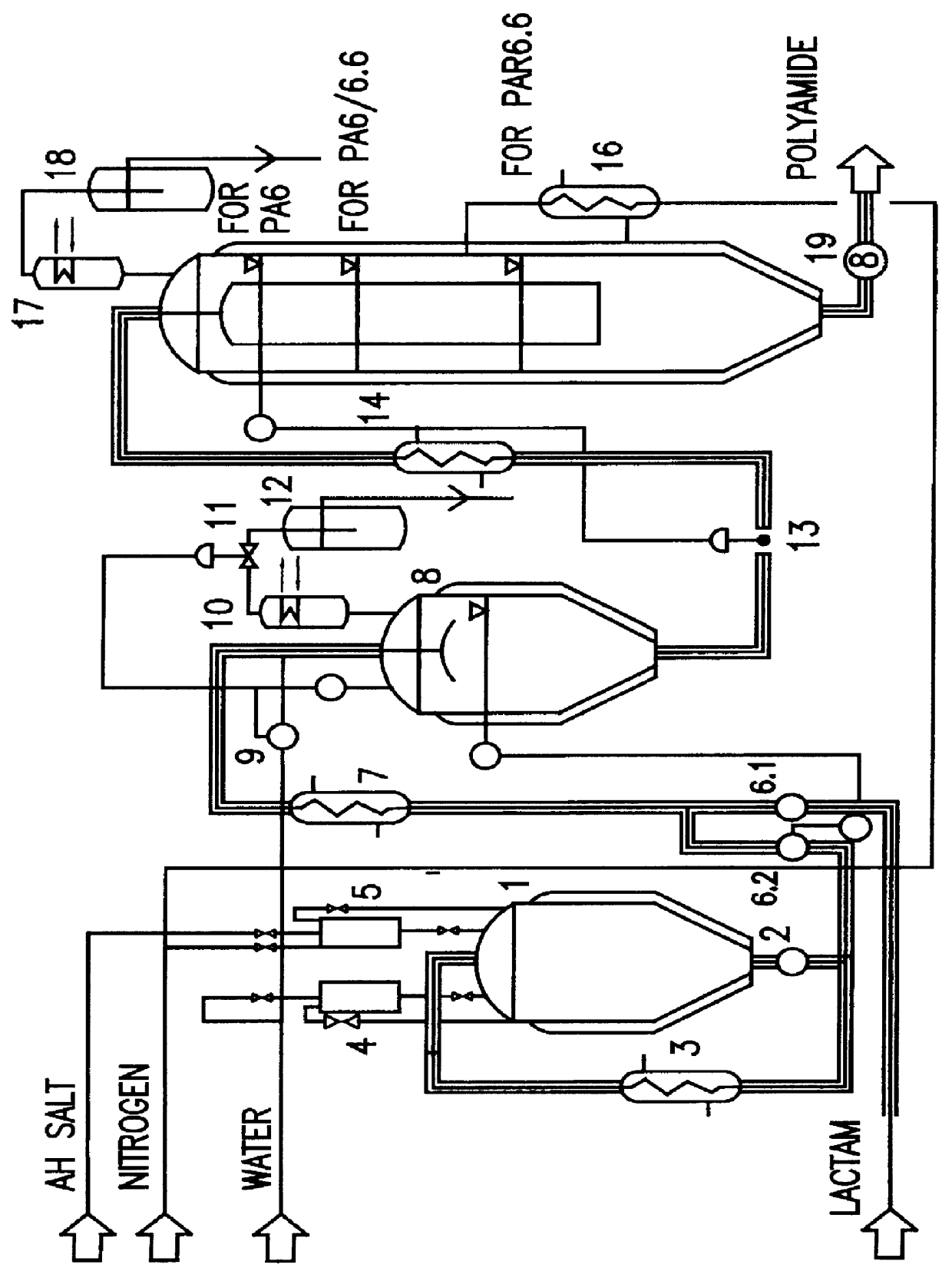

Process and device for the standardized continuous production of polyamides

InactiveUS6136947AHigh viscosityOvercome disadvantagesChemical recyclingHexamethyldiamineHexamethylenediamine

PCT No. PCT / EP96 / 05514 Sec. 371 Date Nov. 13, 1998 Sec. 102(e) Date Nov. 13, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO90 / 21758 PCT Pub. Date Jun. 19, 1997A process and device for the standardised continuous production of polyamide 6, polyamide 6.6 and / or copolyamides from e-caprolactam and / or adipic acidic hexamethylenediamine or adipic acid and hexamethylenediamine uses a combination of known specific processes to design a polymerisation reactor in which product with sufficiently high quality can be produced with the most efficient possible use of the energy applied and in such a way that the initial substances can be used alternately in the individual processing stages: pre-heating of the initial products using a common heat exchanger to 190-300 DEG C.; polymerisation of the initial products in a pressure stage with or without elimination of water and product recycling at 150-280 DEG C. and a pressure of <20 bar, dewatering of the polymer melt in a one to five turn coil under slow pressure reduction; and final condensation of the melt in at least one common vertical reactor at temperatures of between 210 and 285 DEG C.

Owner:POLYMER ENG

Rapid Acting and Long Acting Insulin Combination Formulations

InactiveUS20080039365A1Promote absorptionAct quicklyBiocidePeptide/protein ingredientsBefore BreakfastIntensive insulinotherapy

A combined rapid acting-long acting insulin formulation has been developed wherein the pH of the rapid acting insulin is decreased so that the long acting glargine remains soluble when they are mixed together. In the preferred embodiment, this injectable basal bolus insulin is administered before breakfast, provides adequate bolus insulin levels to cover the meal, does not produce hypoglycemia after the meal and provides adequate basal insulin for 24 hours. Lunch and dinner can be covered by two bolus injections of a fast acting, or a rapid acting or a very rapid acting insulin. As a result, a patient using intensive insulin therapy should only inject three, rather than four, times a day. Experiments have been performed to demonstrate the importance of the addition of specific acids to hexameric insulin to enhance speed and amount of absorption and preserve bioactivity following dissociation into the monomeric form by addition of a chelator such as EDTA. As shown by the examples, the preferred acids are aspartic, glutamic and citric acid. These are added in addition to a chelator, preferably ethylenediaminetetraacetic acid (EDTA). The results show that the citric acid formulation was more effective at dropping the blood glucose rapidly than the identical rapid acting formulation prepared with HCl in swine. Charge masking by the polyacid appears to be responsible for rapid insulin absorption. EDTA was not effective when used with adipic acid, oxalic acid or HCl at hastening the absorption of insulin. These results confirm the results seen in clinical subjects and patients with diabetes treated with the rapid acting insulin in combination with citric acid and EDTA.

Owner:ELI LILLY & CO

Polyester plasticizer and chlorine-containing resin compositions

ActiveUS20060025544A1Superior in plasticization efficiencyGood oil resistancePlastic/resin/waxes insulatorsLavatory sanitoryPolyesterAdipic acid

A polyester plasticizer which is obtained by reacting a diol component (a) consisting of 100 parts by mole of 2-methyl-1,3-propanediol, 10 to 1000 parts by mole of 3-methyl-1,5-pentanediol and 0 to 1000 parts by mole of other aliphatic diol with an organic dicarboxylic acid components (b) consisting of 100 parts by mole of adipic acid and 0 to 100 parts by mole of other organic dicarboxylic acid and a chain terminator (c) consisting of a monovalent aliphatic alcohol or a monovalent aliphatic organic acid and which has an average molecular weight of 500 to 5000. This plasticizer is excellent in plasticizing efficiency and can impart excellent oil resistance to synthetic resins such as chlorine-containing resins.

Owner:ADEKA CORP

Biodegradable polymeric nanocomposite compositions particularly for packaging

Specific polymer blends of polylactic acid (PLA) and polyhydroxybutyrate (PHB) and poly-(butylenes adipate-co-terephthalate (PBAT) as a fatty acid quaternary ammonium modified clay. The blends are particularly useful for barrier packaging.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Fully biodegradable material with polylactic acid/polyterephthalic dibutyl adipate used as base materials and preparation method thereof

The invention discloses a fully biodegradable material with polylactic acid / polyterephthalic dibutyl adipate used as base materials and a preparation method thereof. The material provided by the invention is composed of polylactic acid, polyterephthalic dibutyl adipate, a bio-based filler, an inorganic filler and a few amount of auxiliaries. The material has been certified by American ASTMD6400, European EN13432 and Australian AS4736 and is a fully biodegradable material. The fully biodegradable material contains the following ingredients, by weight, 5-60 parts of polylactic acid (PLA), 5-60 parts of polyterephthalic dibutyl adipate, 5-40 parts of the bio-based filler, 5-45 parts of the inorganic filler and 0.3-10 parts of the auxiliaries. The above ingredients are fully mixed, and the mixture undergoes melt plastification by a screw and then is directly extruded to obtain a board of 0.2-2mm thick. The board can undergo embossed work to obtain fruit trays, vegetable trays, disposable knives and forks and the like.

Owner:江苏天仁生物材料有限公司

Catalyst oxdie cyclohexane process

ActiveCN1530358AIncrease conversion rate per passImprove one-way yieldOxygen compounds preparation by hydrocarbon oxidationCyclohexanonePorphyrin

A process for preparing cyclohexanol, cyclohexanone and adipic acid by catalytic oxidization of cyclohexane under existance of metallic porphyrin catalyst and a certain temp and pressure through combination of different reactors is disclosed. Its advantages are high single-pass conversion rate of cyclohexane and total output rate, low energy consumption and cost, and no need of cyclohexanol or acetone solvent and cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP

Production of Adipic Acid and Derivatives from Carbohydrate-Containing Materials

ActiveUS20100317823A1Increase costLow costCarboxylic acid nitrile preparationOrganic chemistry methodsCatalytic transformationCatalytic oxidation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Biodegradable compounds including poly(lactic acid) polymer compositions and products

InactiveUS20050192377A1Increase flexibilityImprove ductilityDyeing processFruits/vegetable preservation by coatingPolyesterPolymer science

The present invention relates to biodegradable polymer compositions comprising poly(lactic acid) and co-polyester polymer with adipic acid mixed with organic peroxide and mineral particles. In addition, the present invention relates to products made on the basis of such compositions, such as molded and extruded articles.

Owner:CEREPLAST INC

Scaling powder for no-clean lead-free low-silver welding paste

ActiveCN104400257AImprove printing qualityEasy to shapeWelding/cutting media/materialsSoldering mediaBenzoic acidOXALIC ACID DIHYDRATE

The invention discloses scaling powder for no-clean lead-free low-silver welding paste. The scaling powder comprises, by weight percentage, 3-13% of active agent, 0.2-1.5% of surface active agent, 0.2-3.0% of emulgator, 3.0-10.0% of thixotropic agent, 3-8% of film-forming agent, 0.1-1% of antioxidant, 0.1-0.5% of corrosion inhibitor and the rest of solvent. The active agent is composed of four or five components in succinic acid, oxalic acid, salicylic acid, glutaric acid, citric acid, adipic acid, lactic acid, benzoic acid, malic acid and triethanolamine. The scaling powder for the no-clean lead-free low silver welding paste does not contain halogen, the corrosion to a circuit board is greatly lowered, the printing quality of the welding paste is good without bridging or turned-down edges, a welding point is good in forming after returning, the brazing connecting defect is greatly lowered, the residue is small without solder balls, the cleaning is not needed, the welding paste is directly used for assembling, the Sn-0.45 Ag-0.68 Cu or Sn-0.3 Ag-0.7 Cu low silver welding paste manufactured by using the scaling powder does not contain the halogen and rosin, the organic chemistry smoke is small, and the pollution to the environment is small.

Owner:CHONGQING UNIV OF TECH

Method of preparing adipic acid by air-oxidating hexacarbocyclic compound

InactiveCN1535947AReduce dosageHigh catalytic efficiencyOrganic compound preparationCarboxylic compound preparationCyclohexanoneCyclohexene

The present invention relates to a new process for preparing adipic acid by air oxidating cyclohexane, cyclohexanol, cyclohexanone and cyclohexene or mixture of cyclohexanol and cyclohexanone under the catalysis of metal porphyrin. Under the condition of 1-20 atm air and reaction temp. is 50-200 deg.C it can select and use mu-oxidized metal porphyrin and monometal porphyrin or their fixed carrier material as catalyst independently, also can select and use metal porphyrin or their fixed carrier material as main catalyst, and use transition metal salt or oxide as co-catalyst. The metal porphyrin like biological-enzyme can high-effectively and high-selectivity catalyze air under the biologicae concentration to directly oxidate the cyclohexane into adipic acid. Said invented dose of metal porphyrin is less, and its catalytic effect is good, it can make homogeneous catalysis, also can make heterogeneous catalysis after the carrier is fixed.

Owner:HUNAN UNIV

Long chain fatty acids for reducing off-taste of non-nutritive sweeteners

InactiveUS20080226790A1Food ingredient as taste affecting agentFood preparationArachidic acidAdipic acid

Aspects of the invention relate to beverage compositions, including, for example, concentrated and ready-to-drink formulations sweetened with at least one non-nutritive sweetener and further including a long chain fatty acid compound in an amount sufficient to reduce the off-note taste of the non-nutritive sweetener. In certain embodiments, the long chain fatty acid may be one or more of the following: lauric acid, myristic acid, palmitic acid, stearic acid, arachidic acid, behenic acid, oleic acid, linoleic acid, alpha-linolenic acid, arachidonic acid, eicosapentaenoic acid, docosahexaenoic acid, erucic acid, adipic acid, and palmitic acid. In certain exemplary embodiments, a plurality of different long chain fatty acids are utilized. In another embodiments, the long chain fatty acids comprise both natural and synthetic fatty acids.

Owner:CONCENTRATE MFG OF IRELAND

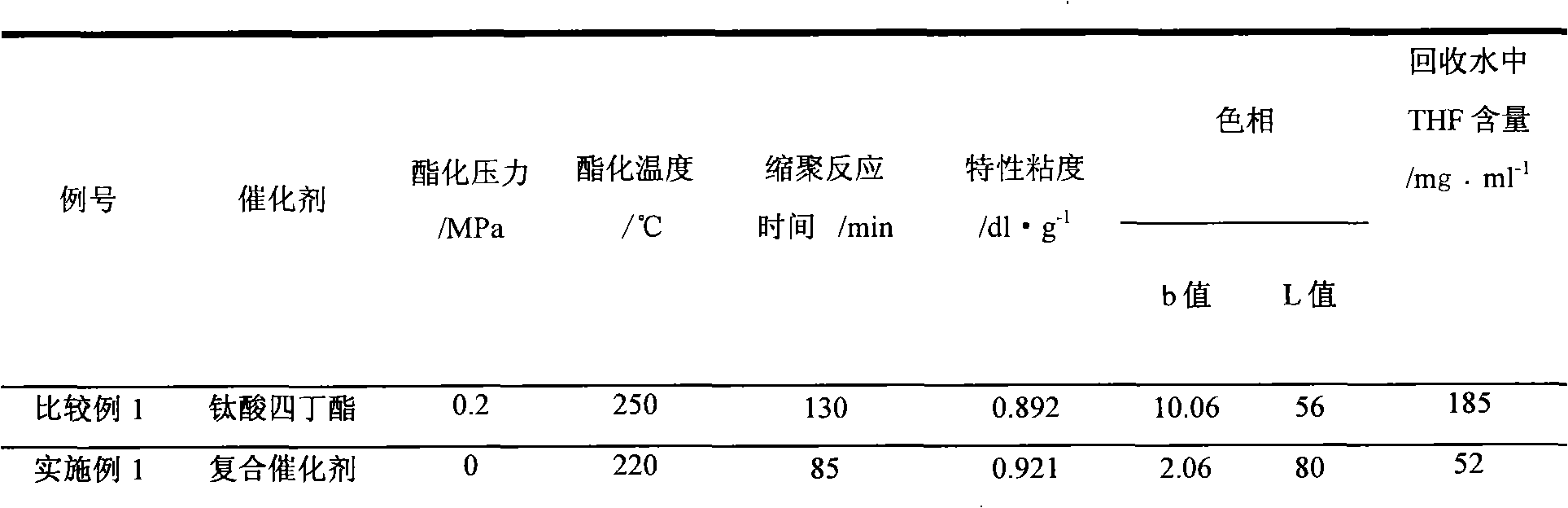

Preparation method of polybutylene terephthalate/adipate butanediol copolyester

The invention relates to a preparation method of polybutylene terephthalate / adipate butanediol copolyester, which utilizes a titanium compound and an antimony compound as the composite catalyst, the mole ratio of terephthalic acid to adipate is 3:7-8:2, the ratio of the total mole of the terephthalic acid and the adipate to the mole of 1,4-butanediol is 1:1.0-1.8, esterification is carried out at normal pressure and the temperature of 150-220 DEG C, the pressure is reduced to high vacuum 10-150 Pa for the reaction, the final temperature for the reaction is 265-280 DEG C, and inert gas is utilized to recover the pressure to be normal to obtain the copolyester. The reaction time is shortened, the production amount of tetrahydrofuran is small, the intrinsic viscosity of copolyester chips is 0.90-1.32 dL / g, the hue b value of the product is between 0 and 8, the L value is between 68 and 85, and the product of the polybutylene terephthalate / adipate butanediol copolyester can be used in the fields of various soft package plastic products.

Owner:PETROCHINA CO LTD

Aqueous dispersion for chemical mechanical polishing

InactiveUS20010039766A1Improve balanceImprove accuracyPigmenting treatmentOther chemical processesOXALIC ACID DIHYDRATEColloidal silica

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com