Patents

Literature

144 results about "Hexamethyldiamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

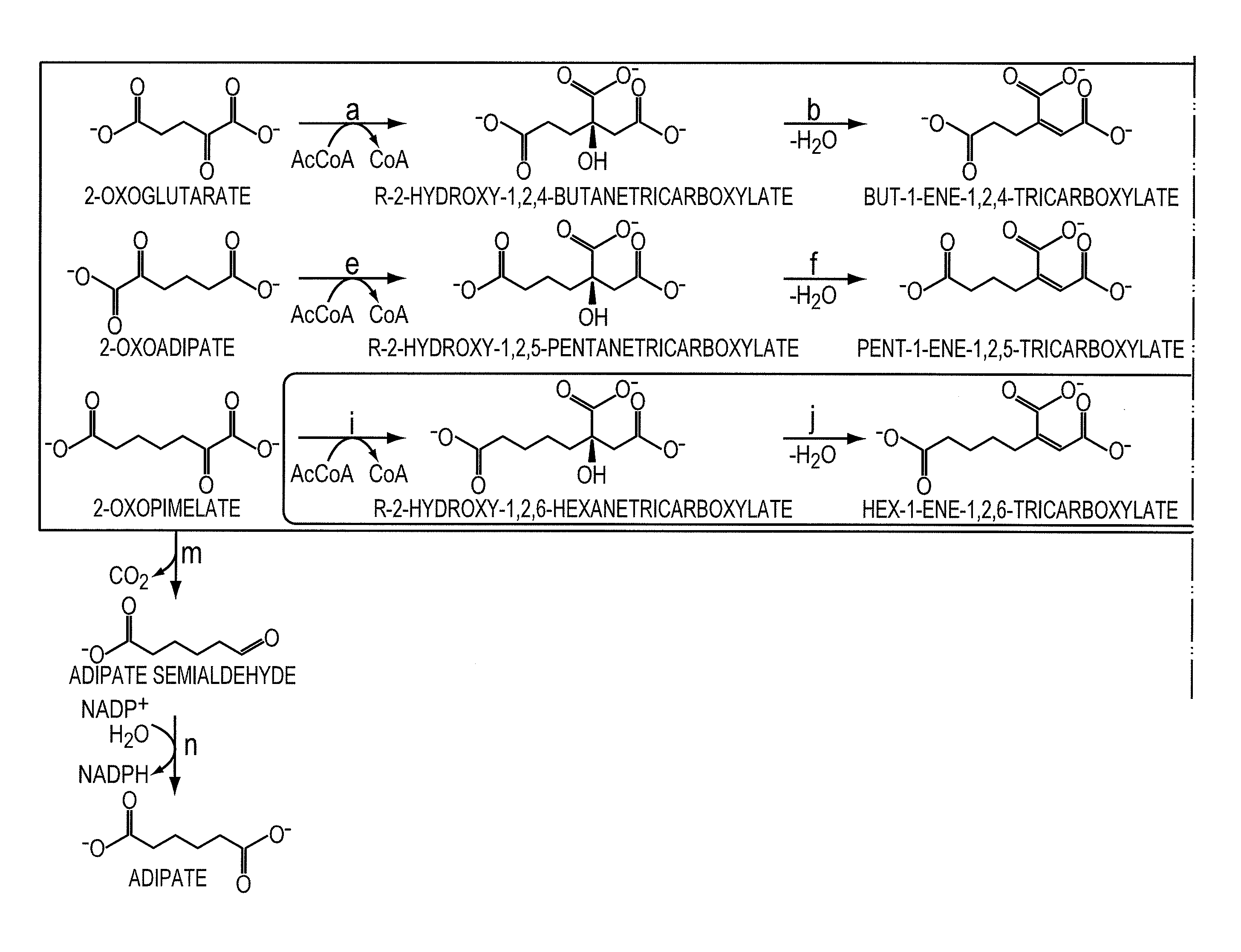

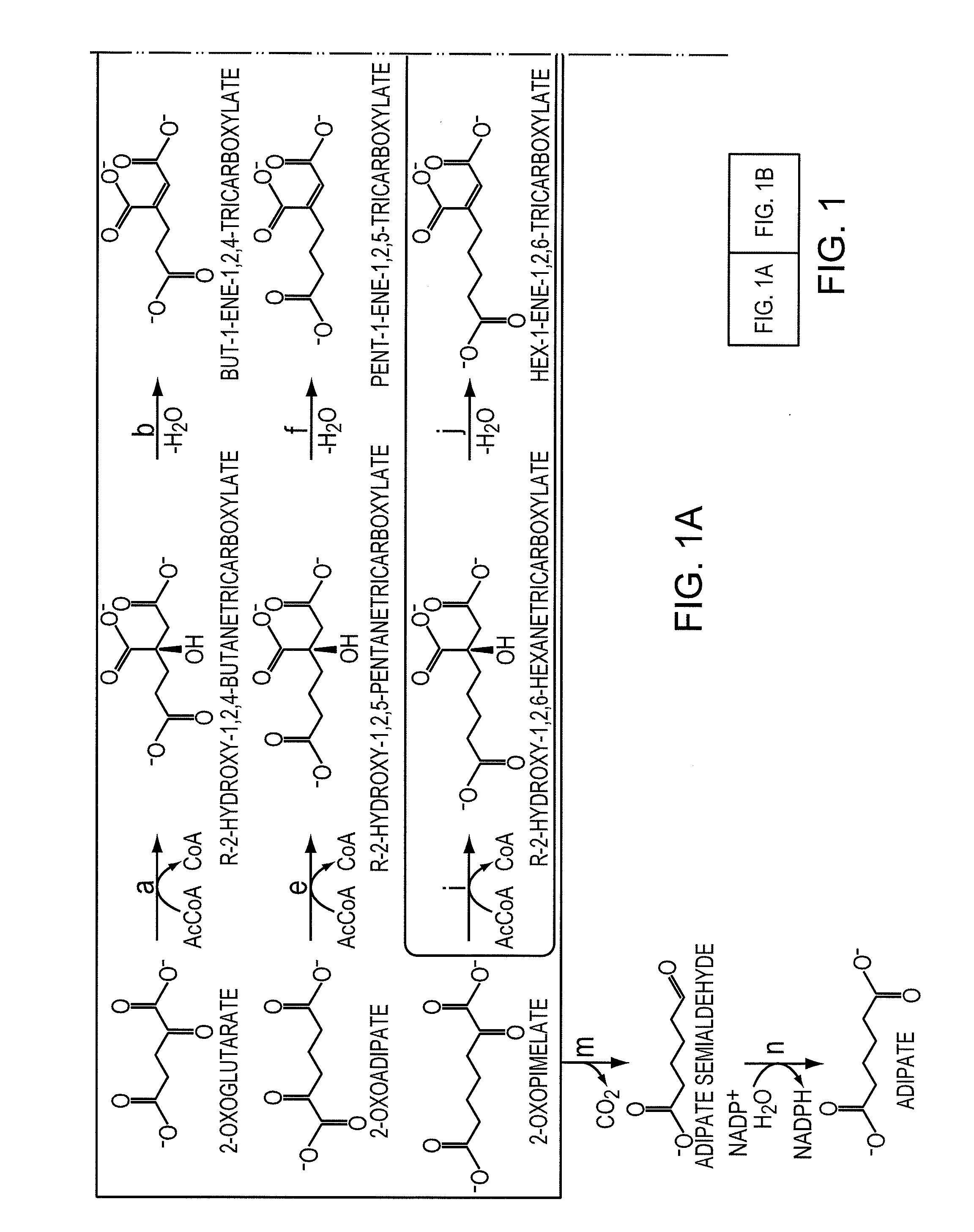

Biological Synthesis of Difunctional Alkanes from Carbohydrate Feedstocks

Aspects of the invention relate to methods for the production of difunctional alkanes in host cells. In particular, aspects of the invention describe components of genes associated with the difunctional alkane production from carbohydrate feedstocks in host cells. More specifically, aspects of the invention describe metabolic pathways for the production of adipic acid, aminocaproic acid, caprolactam, and hexamethylenediamine via 2-ketopimelic acid.

Owner:CELEXION

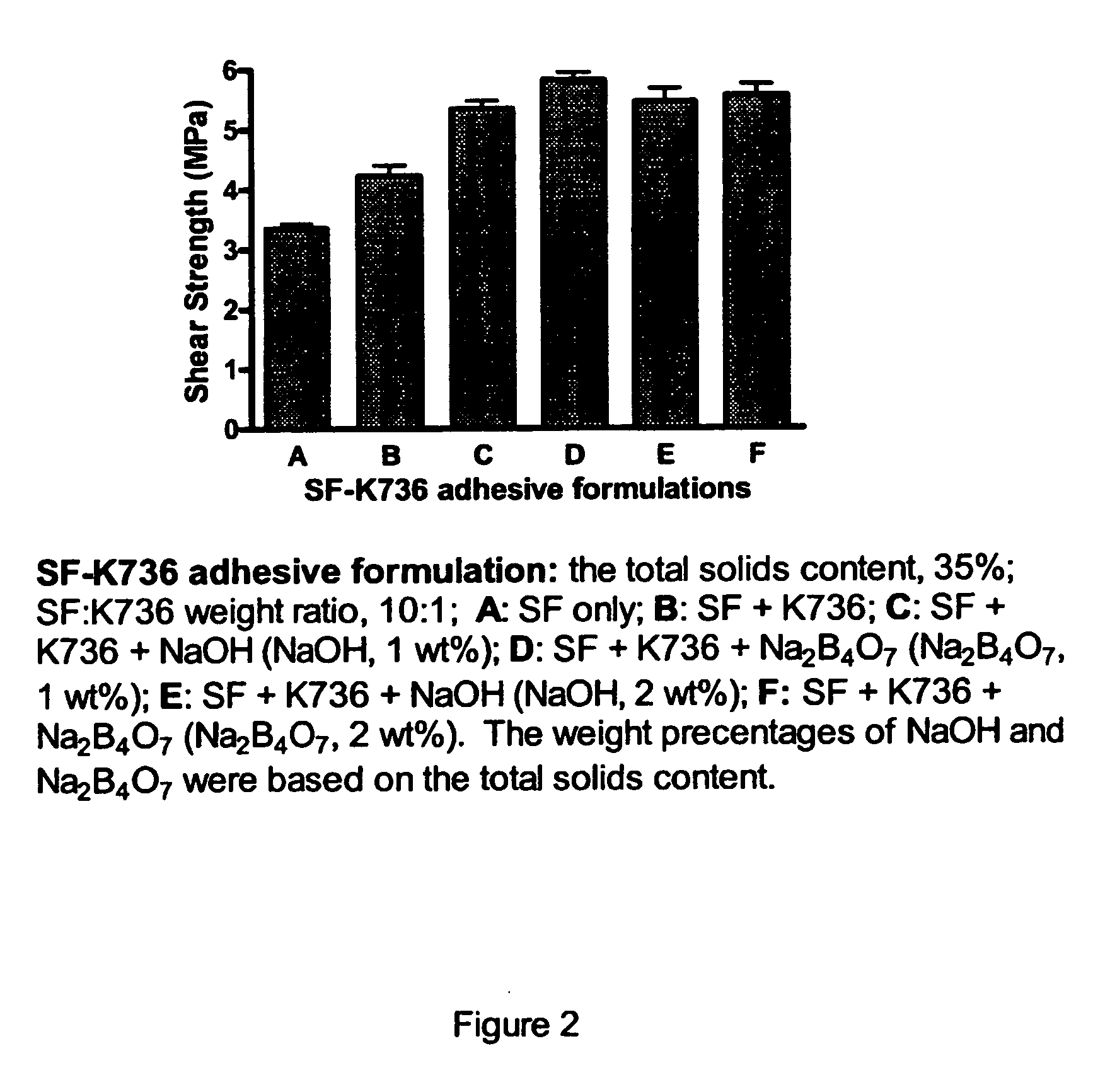

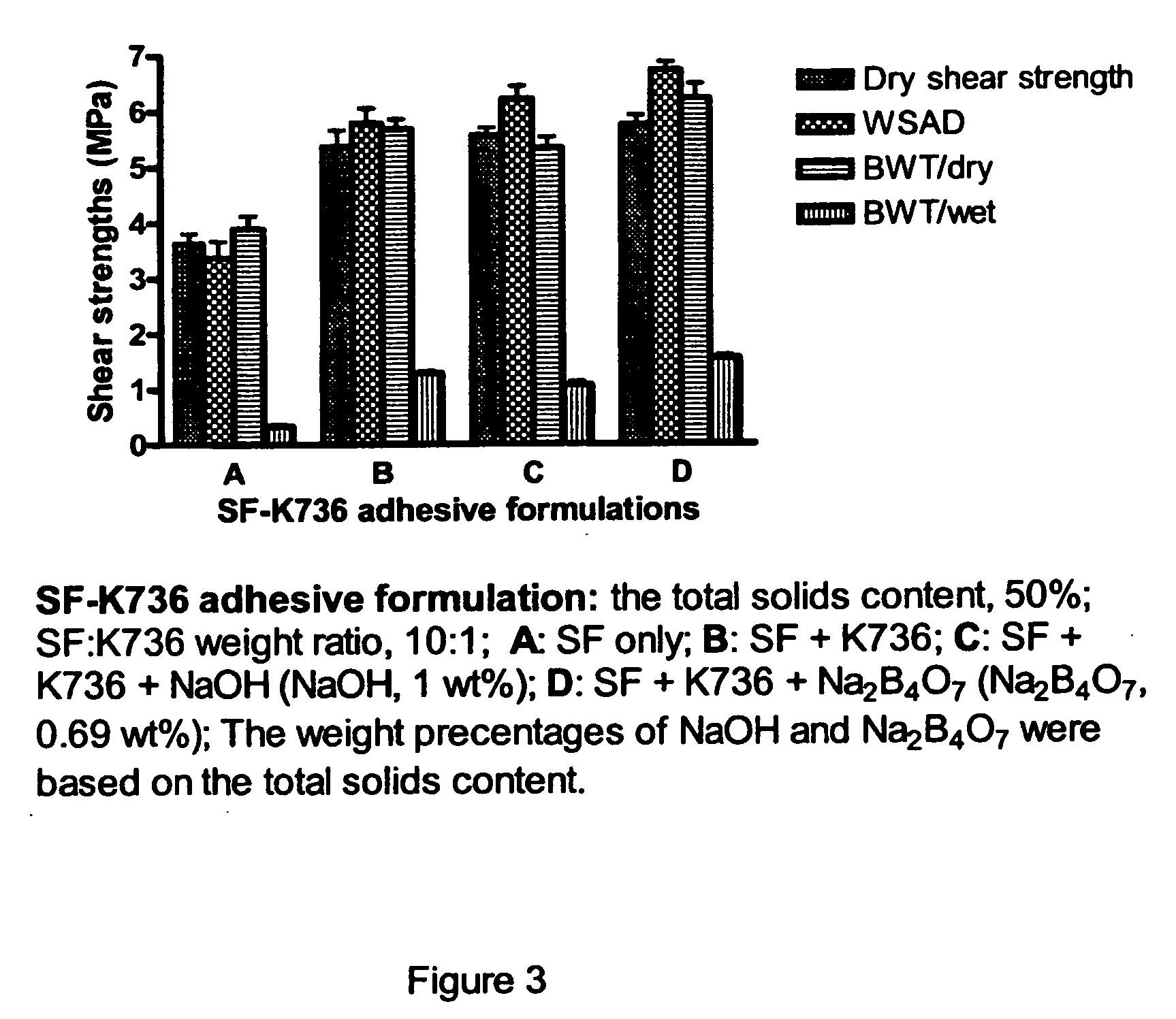

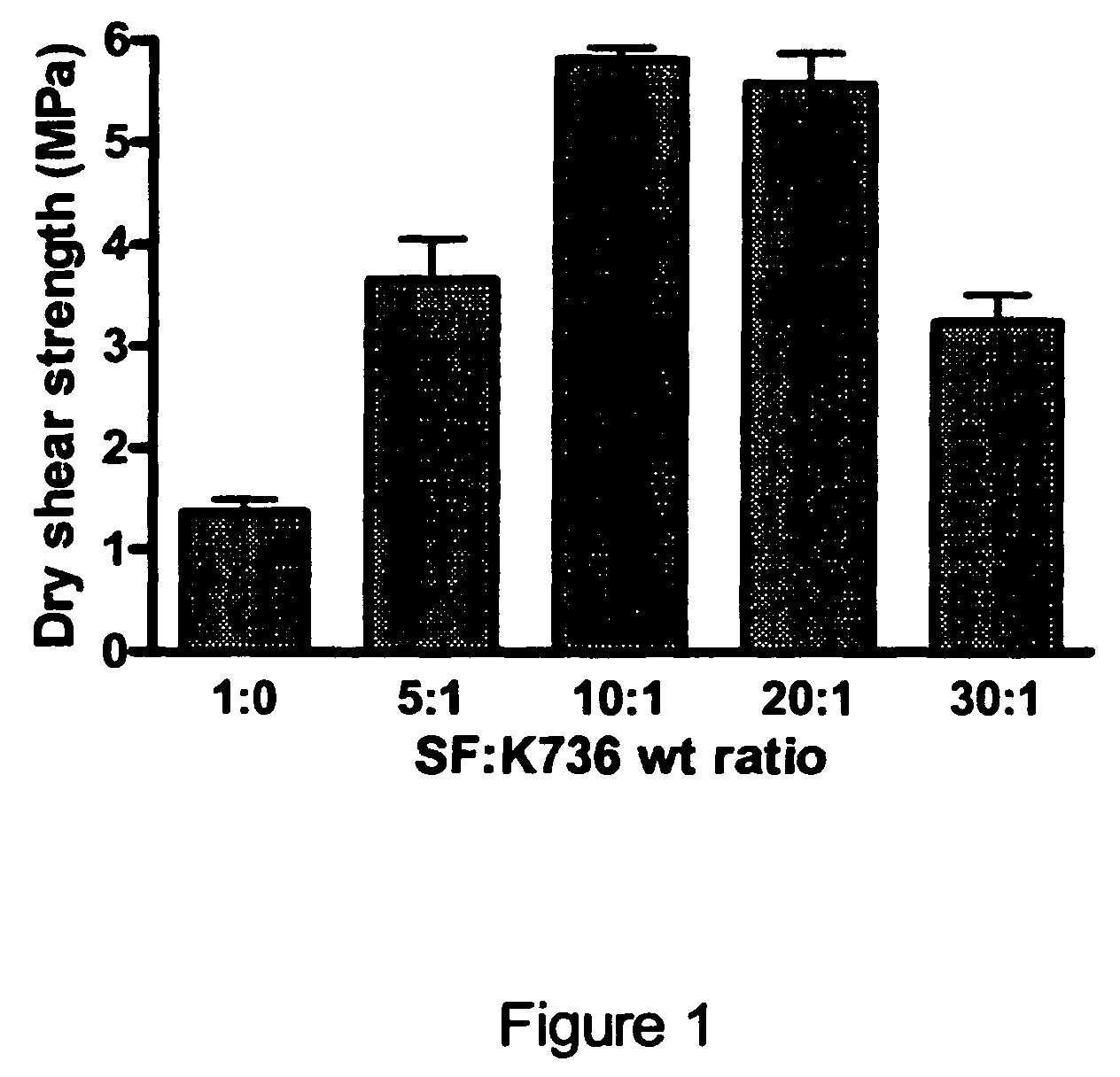

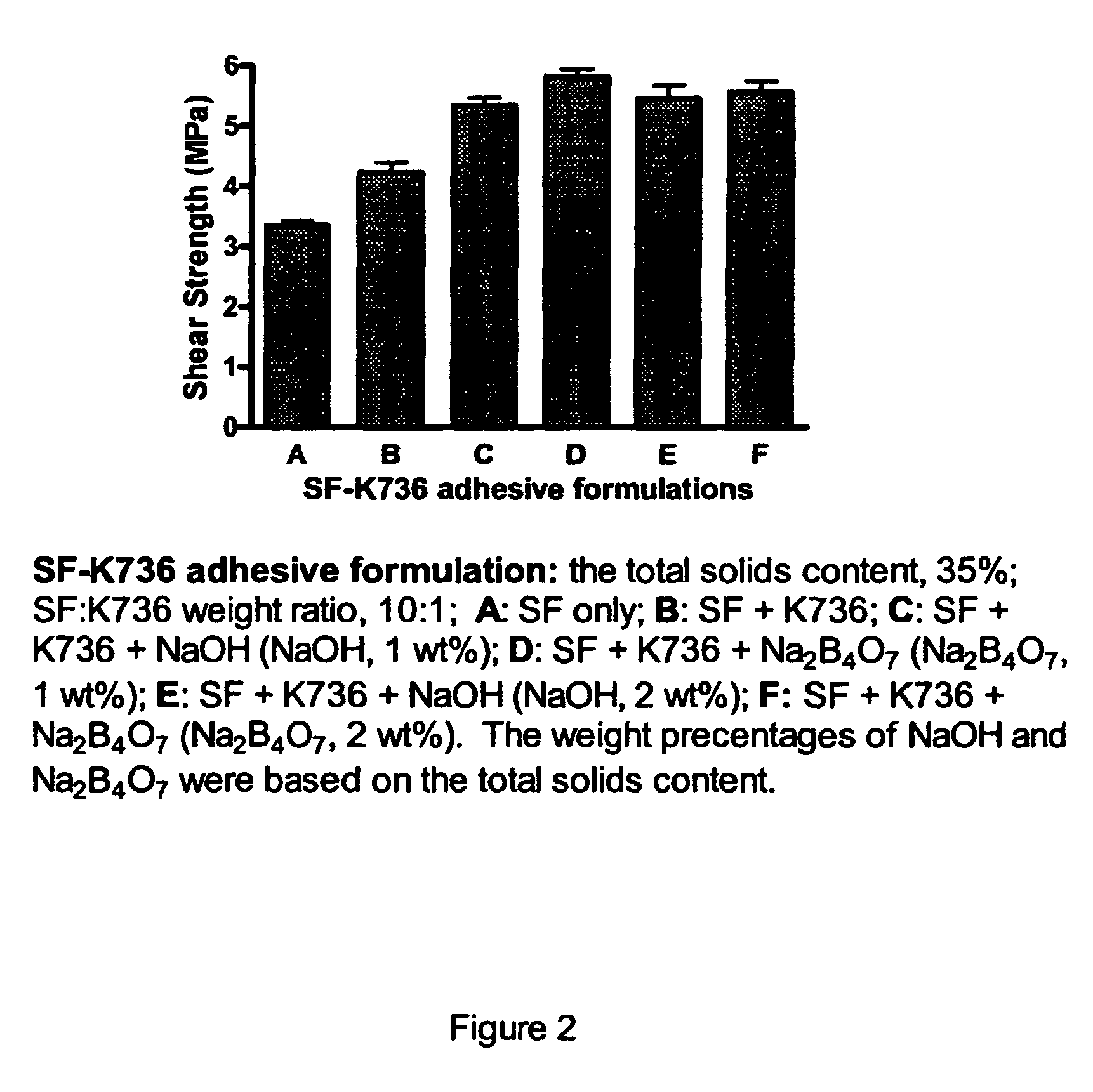

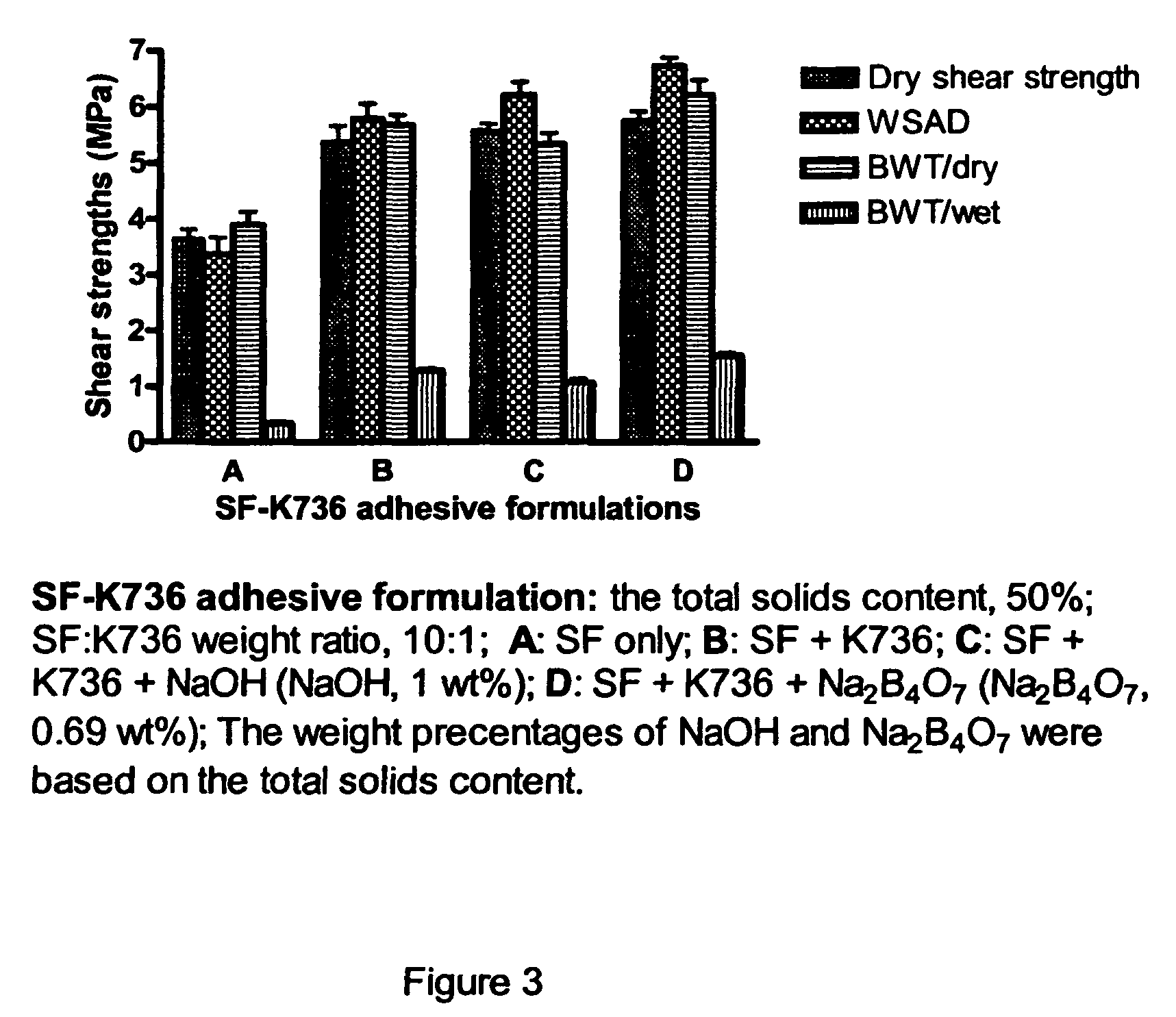

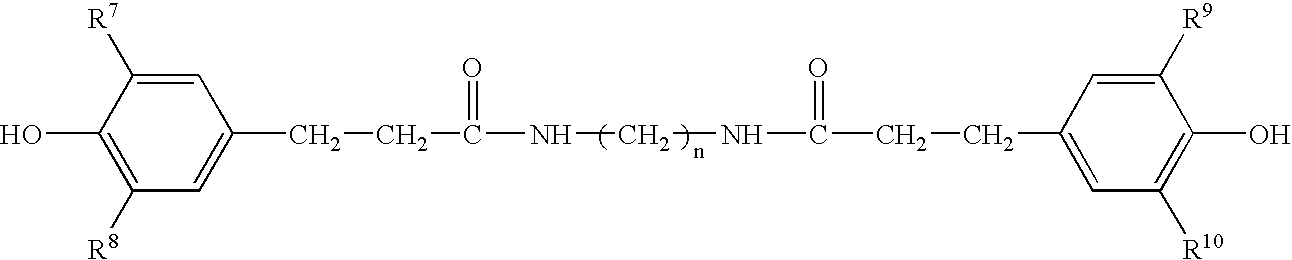

Formaldehyde-Free Adhesives and Lignocellulosic Composites Made from the Adhesives

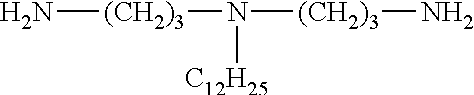

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

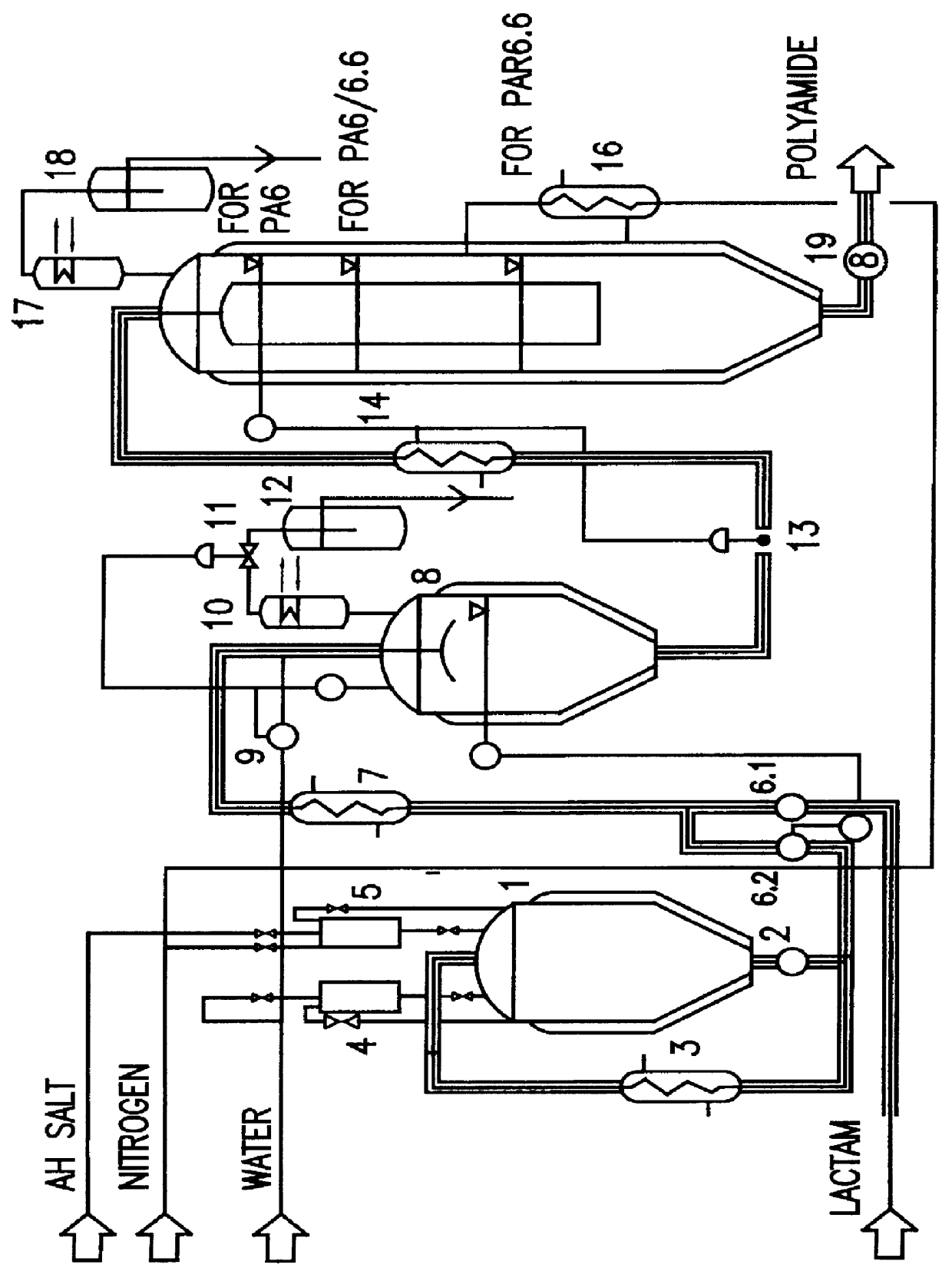

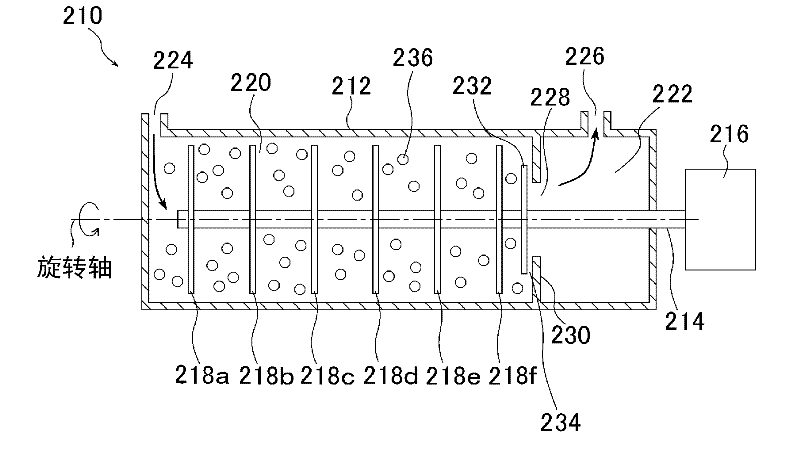

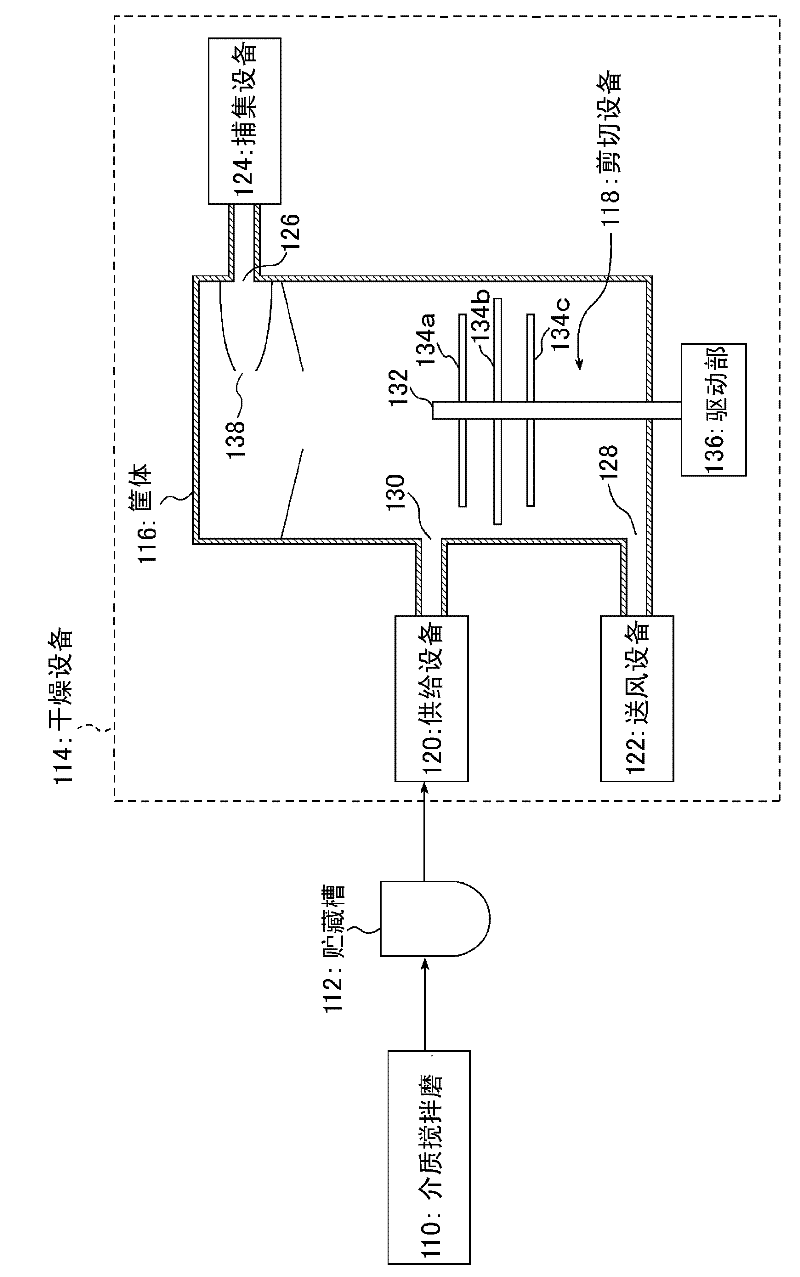

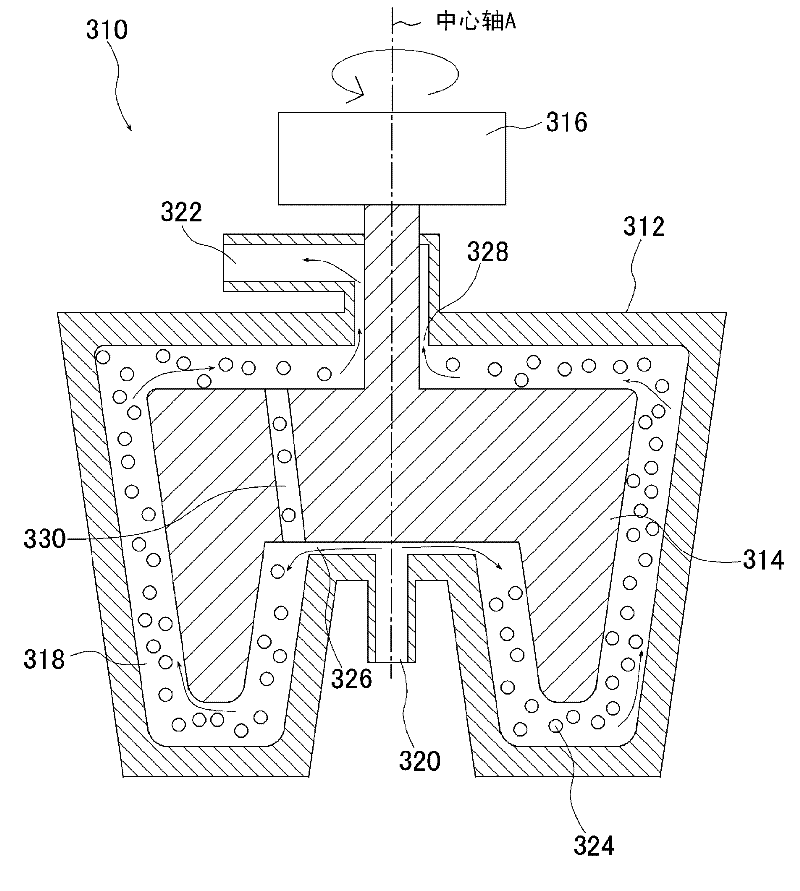

Process and device for the standardized continuous production of polyamides

InactiveUS6136947AHigh viscosityOvercome disadvantagesChemical recyclingHexamethyldiamineHexamethylenediamine

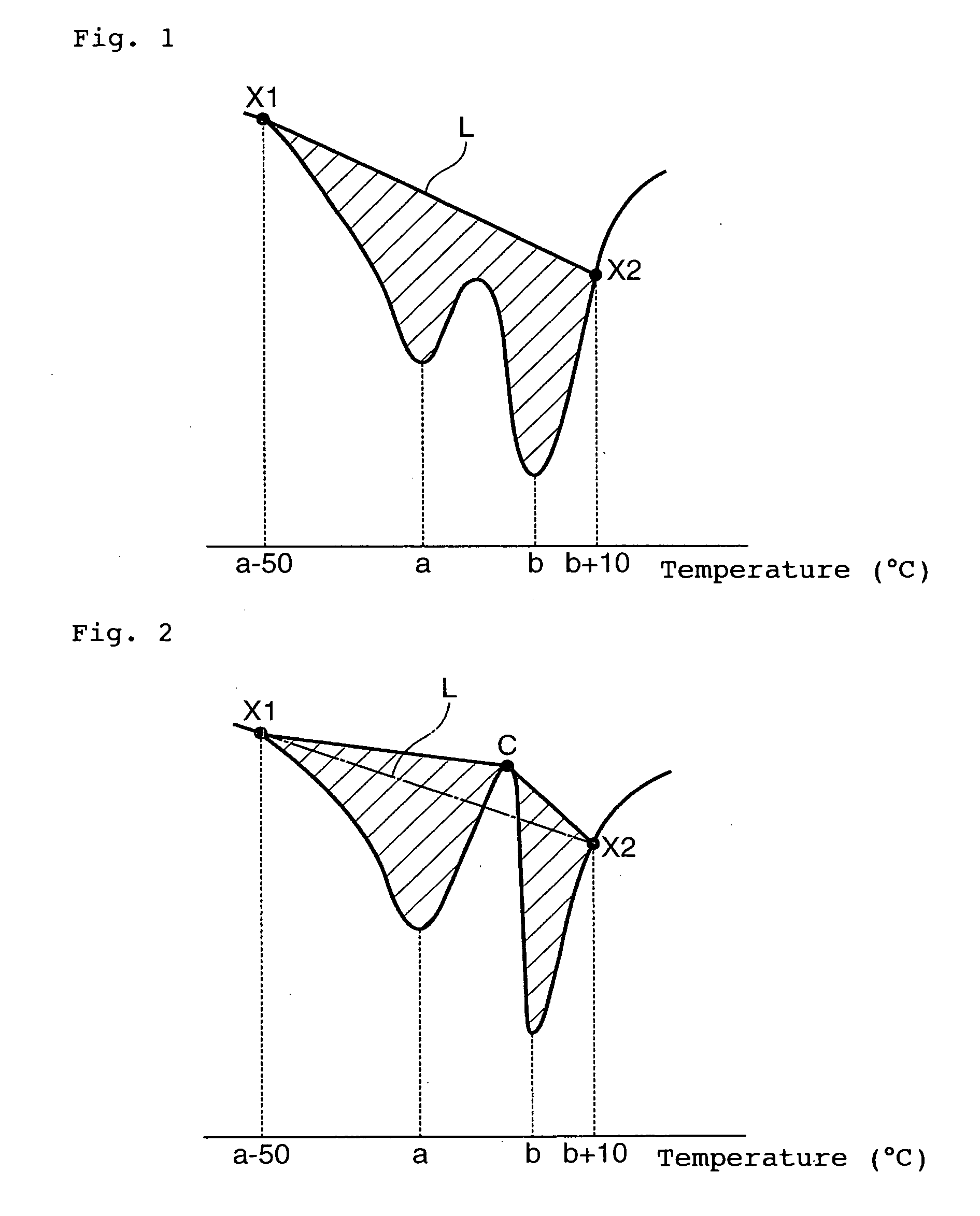

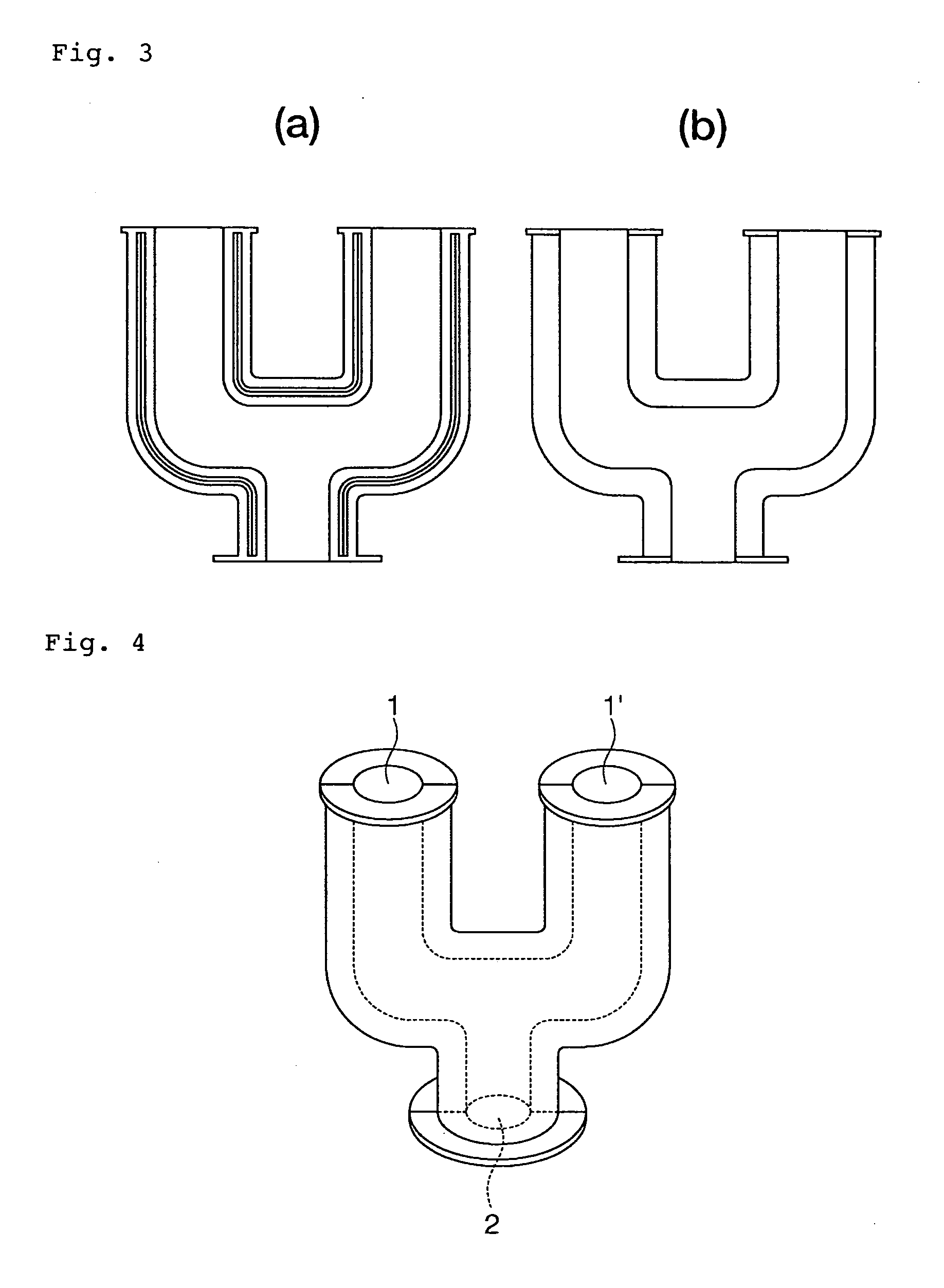

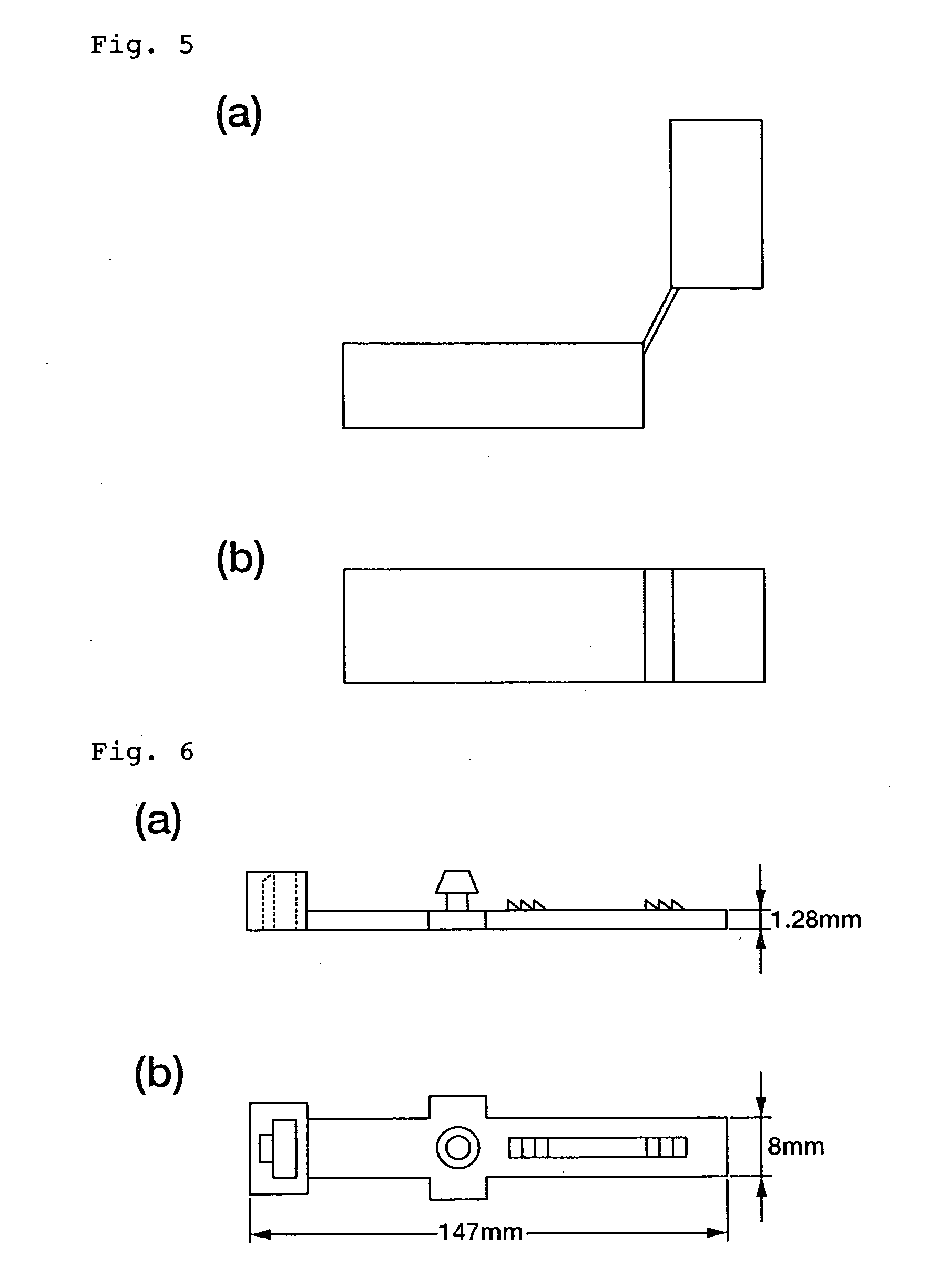

PCT No. PCT / EP96 / 05514 Sec. 371 Date Nov. 13, 1998 Sec. 102(e) Date Nov. 13, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO90 / 21758 PCT Pub. Date Jun. 19, 1997A process and device for the standardised continuous production of polyamide 6, polyamide 6.6 and / or copolyamides from e-caprolactam and / or adipic acidic hexamethylenediamine or adipic acid and hexamethylenediamine uses a combination of known specific processes to design a polymerisation reactor in which product with sufficiently high quality can be produced with the most efficient possible use of the energy applied and in such a way that the initial substances can be used alternately in the individual processing stages: pre-heating of the initial products using a common heat exchanger to 190-300 DEG C.; polymerisation of the initial products in a pressure stage with or without elimination of water and product recycling at 150-280 DEG C. and a pressure of <20 bar, dewatering of the polymer melt in a one to five turn coil under slow pressure reduction; and final condensation of the melt in at least one common vertical reactor at temperatures of between 210 and 285 DEG C.

Owner:POLYMER ENG

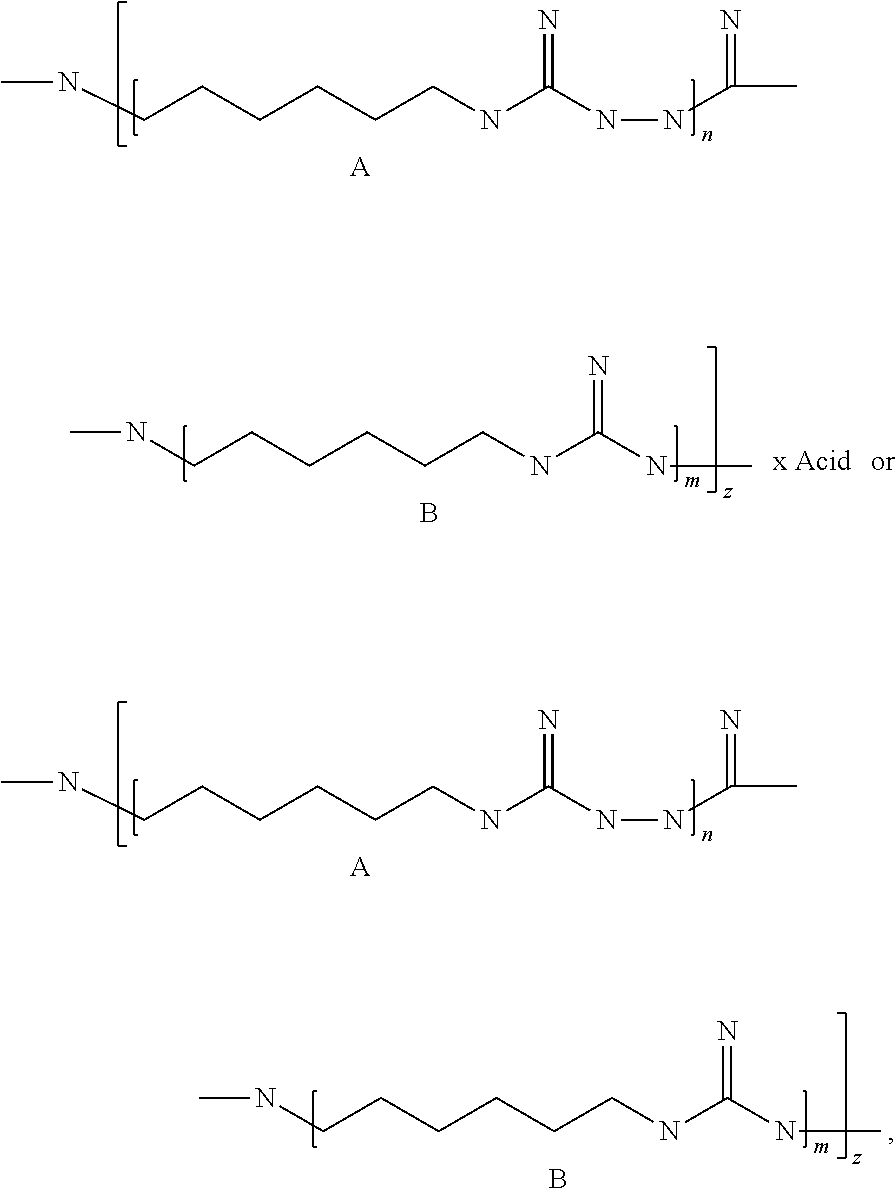

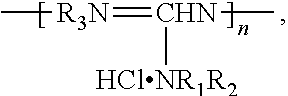

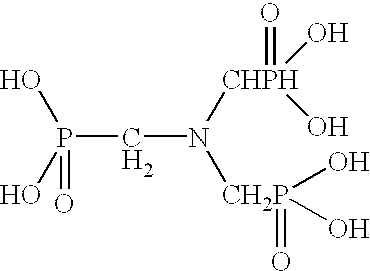

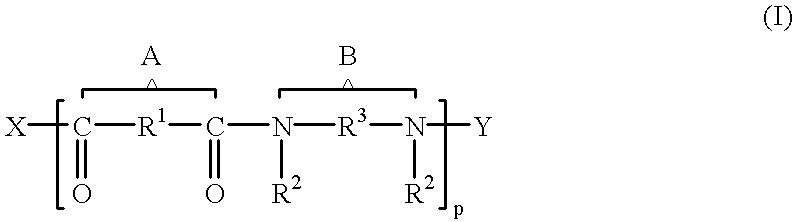

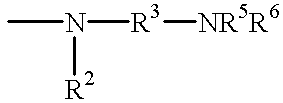

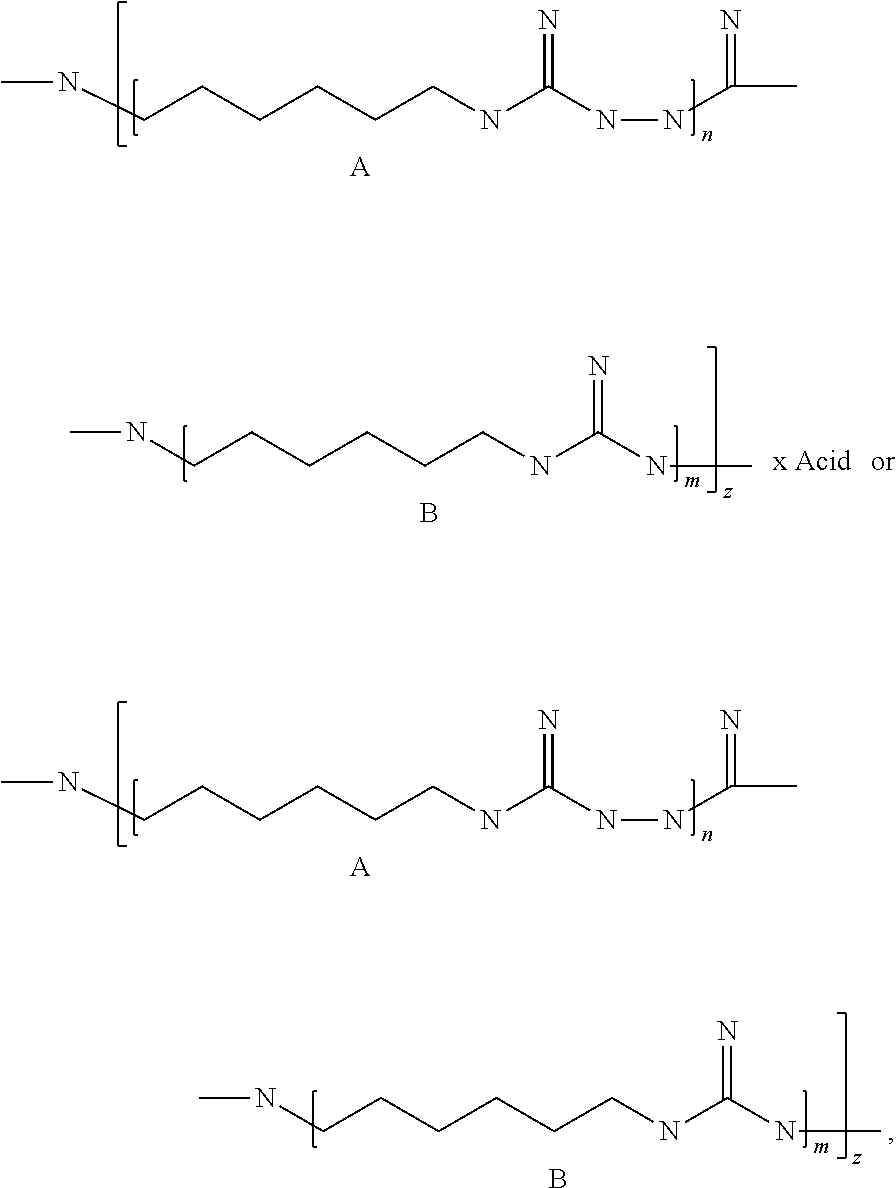

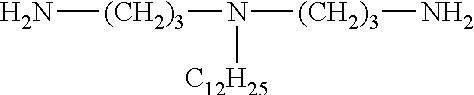

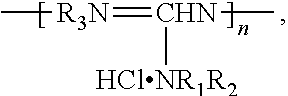

Method for Producing Biocidal Polyguanidine, and Biocidal Polyguanidine

ActiveUS20110269936A1High activityOrganic active ingredientsOrganic chemistryMicroorganismHexamethyldiamine

The inventions relate to antiseptic agents and the method for producing thereof and can be used as a broad-spectrum disinfectant in medicine, veterinary medicine, agriculture etc.The method for producing of biocidal polyguanidine that comprises condensation polymerization of hexamethylenediamine with guanine salt additionally uses hydrazine hydrate during the condensation polymerization process, at the following ratio of components, mass %:hexamethylenediamine 20-55guanidine salt 25-65hydrazine hydrate the rest.Biocidal polyguanidine obtained by means of the above-mentioned method, with the following formula:wheren—the number of links A in a single unit of the polymer chain, n=1-3;m—the number of links B in a single unit of the polymer chain, m=2-10;z—the number of single units in the polymer chain, z=4-20;Acid—an acid.The inventions allow obtaining a biocidal polyguanidine with high level of broad-spectrum antimicrobial activity.

Owner:TETS VIKTOR VENIAMINOVICH

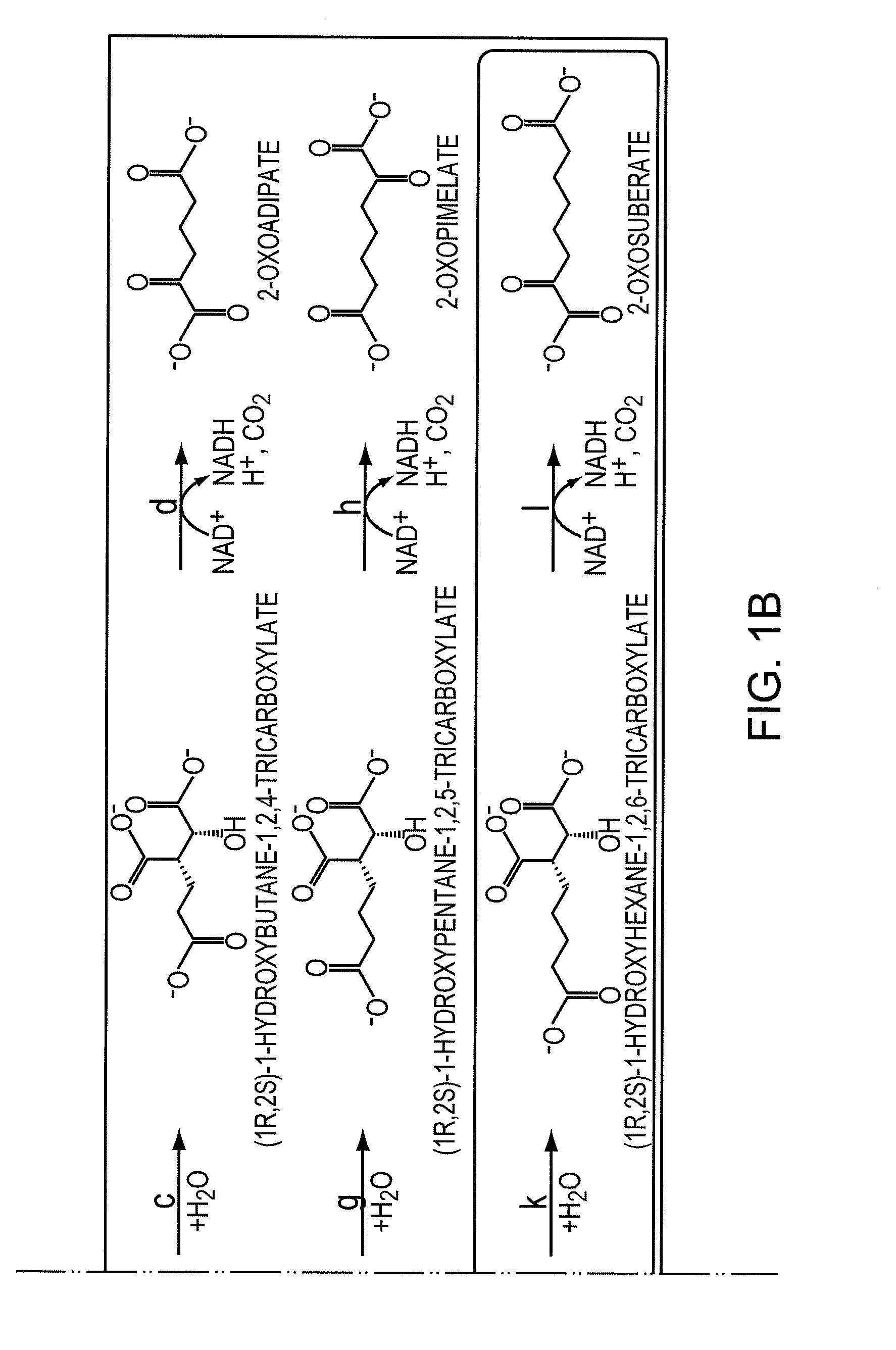

Formaldehyde-free adhesives and lignocellulosic composites made from the adhesives

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

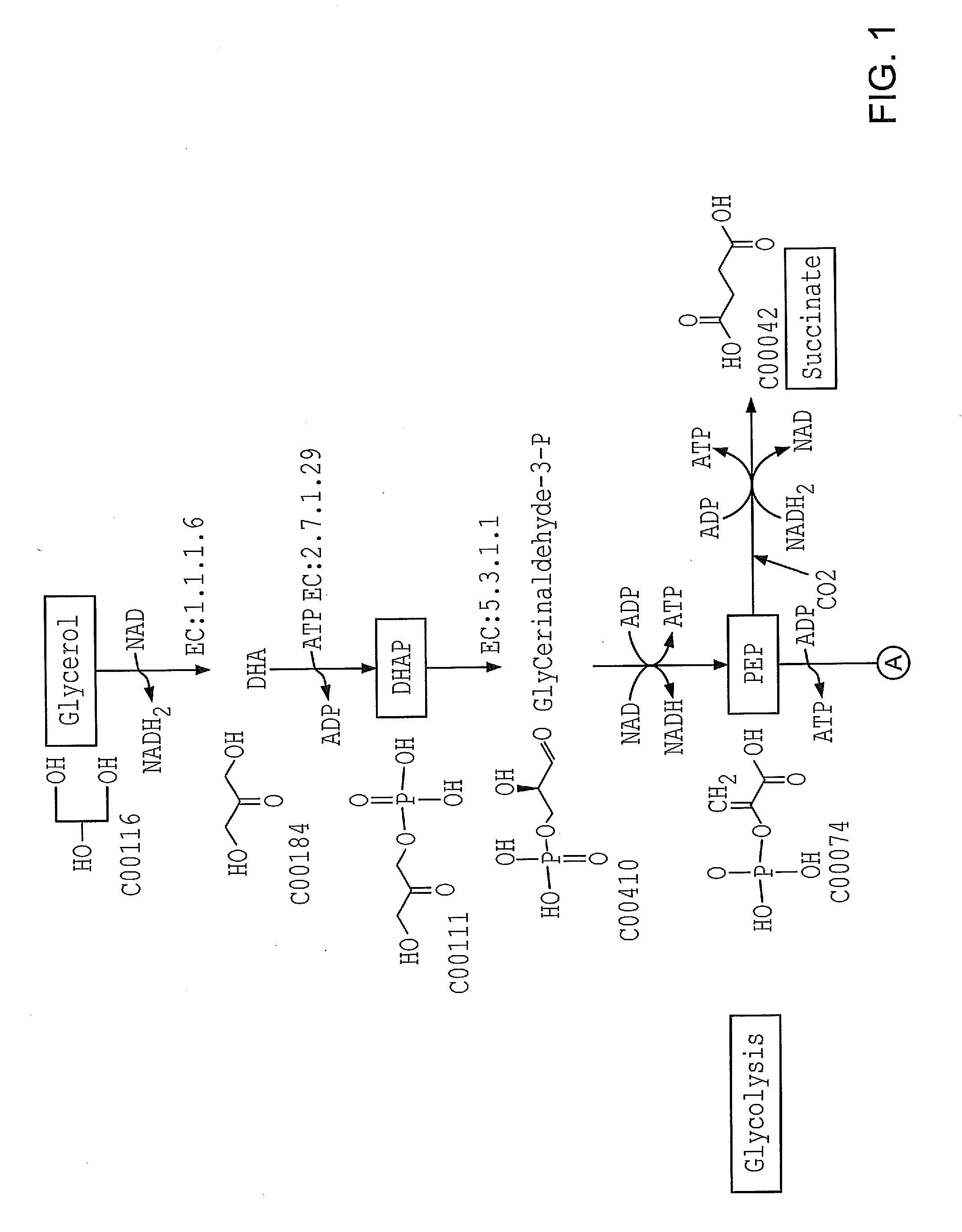

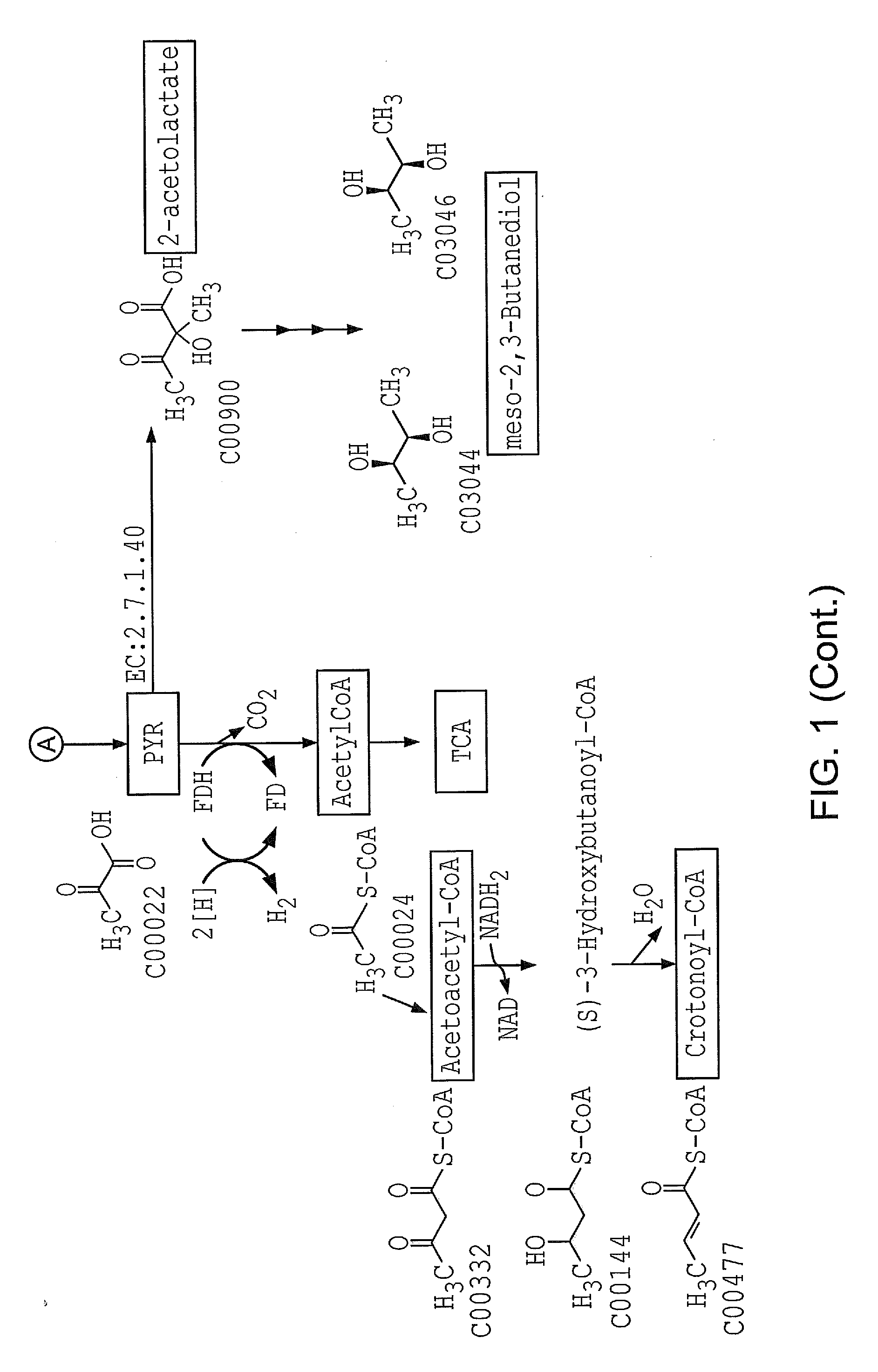

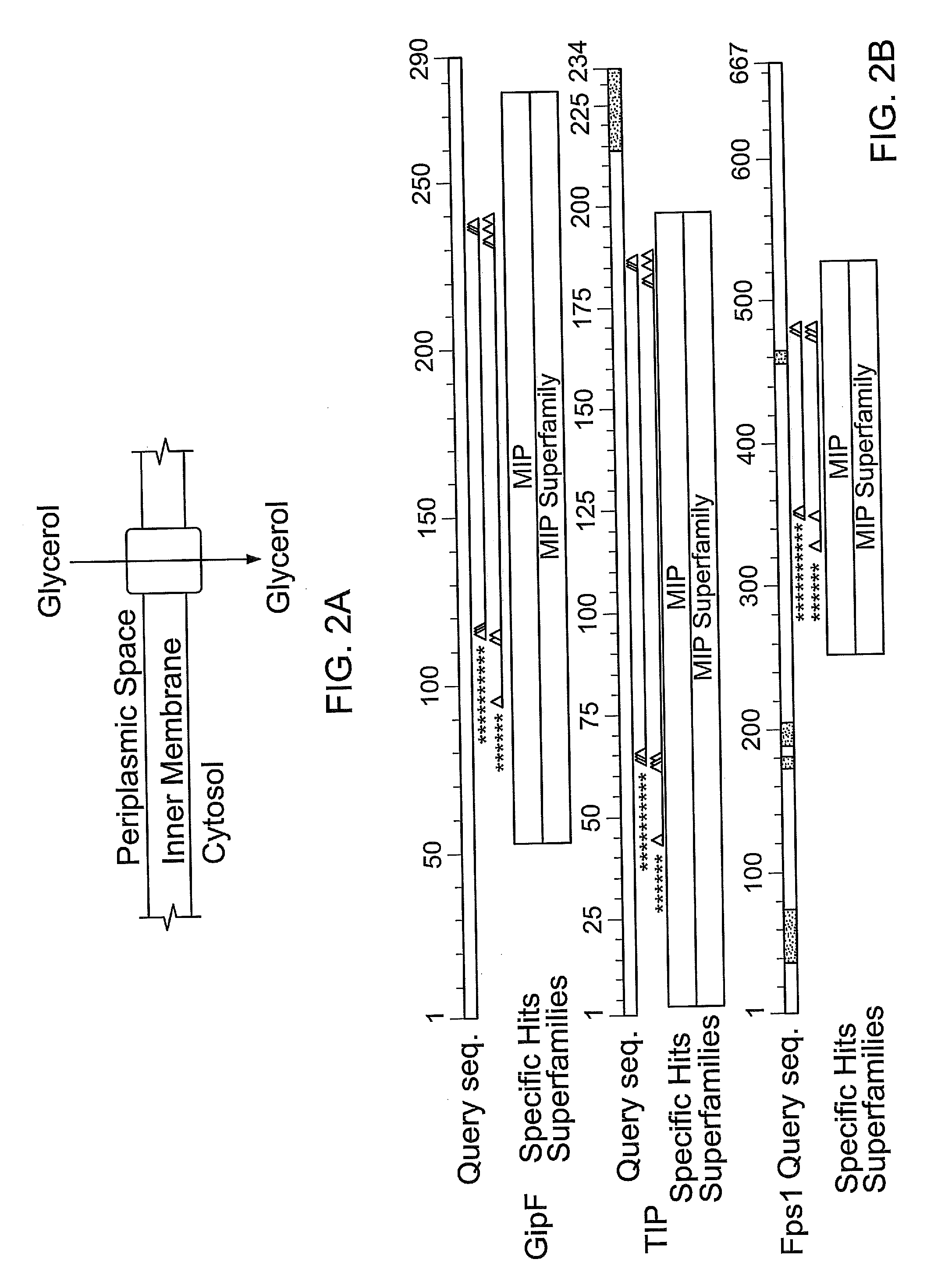

Methods of making nylon intermediates from glycerol

ActiveUS20130210090A1Reduce usageRate minimisedBacteriaHydrolases3-Hydroxypropionic acid2,3-Butanediol

Embodiments of the invention relate to the enzymatic conversion of bioderived feedstocks to commercially valuable chemicals. The enzymatic conversions of the embodiments of the invention offer the potential for lower cost routes to these value-added chemicals. Some of the chemicals that are useful include nylon intermediates such as caprolactam, adipic acid, 1,6-hexamethylene diamine; butanediols such as 1,4-butanediol, 1,3-butanediol, and 2,3-butanediol; butanols such as 1-butanol, and 2-butanol; succinic acid, butadiene, isoprene, and 3-hydroxypropanoic acid.

Owner:INV NYLON CHEM AMERICAS LLC

Composite having two or more layers, including an EVOH layer

InactiveUS20060141188A1Solve the lack of resistanceSynthetic resin layered productsFlexible pipesLaurolactamHexamethylenediamine

The present invention provides a layered composite, which includes the following layers: (I) a layer I composition including: (a) from 0 to 80 part by weight of at least one polyamide selected from the group including PA6, PA66, PA6 / 66 and mixtures thereof; (b) from 0 to 100 parts by weight of at least one polyamine-polyamide copolymer that includes the following monomer units: (α) from 0.5 to 25% by weight, based on the weight of the polyamine-polyamide copolymer, of at least one polyamine having at least 4 nitrogen atoms and having a number-average molar mass Mn of at least 146 g / mol, and (β) at least one polyamide-forming monomer selected from the group including lactam, ω-aminocarboxylic acid, equimolar combination of diamine and dicarboxylic acid, and mixtures thereof; and (c) from 0 to 80 parts by weight of at least one polyamide selected from the group including PA11, PA12, PA612, PA1012, PA1212 and wherein, in the layer I, a total of the parts by weight of (a), (b) and (c) is 100; wherein within an entirety of (a) and (b), at least 20 parts by weight of the entirety include monomer units selected from the group including caprolactam, combination of hexamethylenediamine / adipic acid, and mixtures thereof; and wherein within an entirety of (b) and (c), at least 20 parts by weight of the entirety include monomer units selected from the group including ω-aminoundecanoic acid, laurolactam, combination of hexamethylenediamine / 1,12-dodecanedioic acid, combination of 1,10-decanediamine / 1,12-dodecanedioic acid, combination of 1,12-dodecanediamine / 1,12-dodecanedioic acid, and mixtures thereof; and (II) a layer II composition which includes at least one ethylene-vinyl alcohol copolymer.

Owner:EVONIK OPERATIONS GMBH

Methods for producing dodecanedioic acid and derivatives thereof

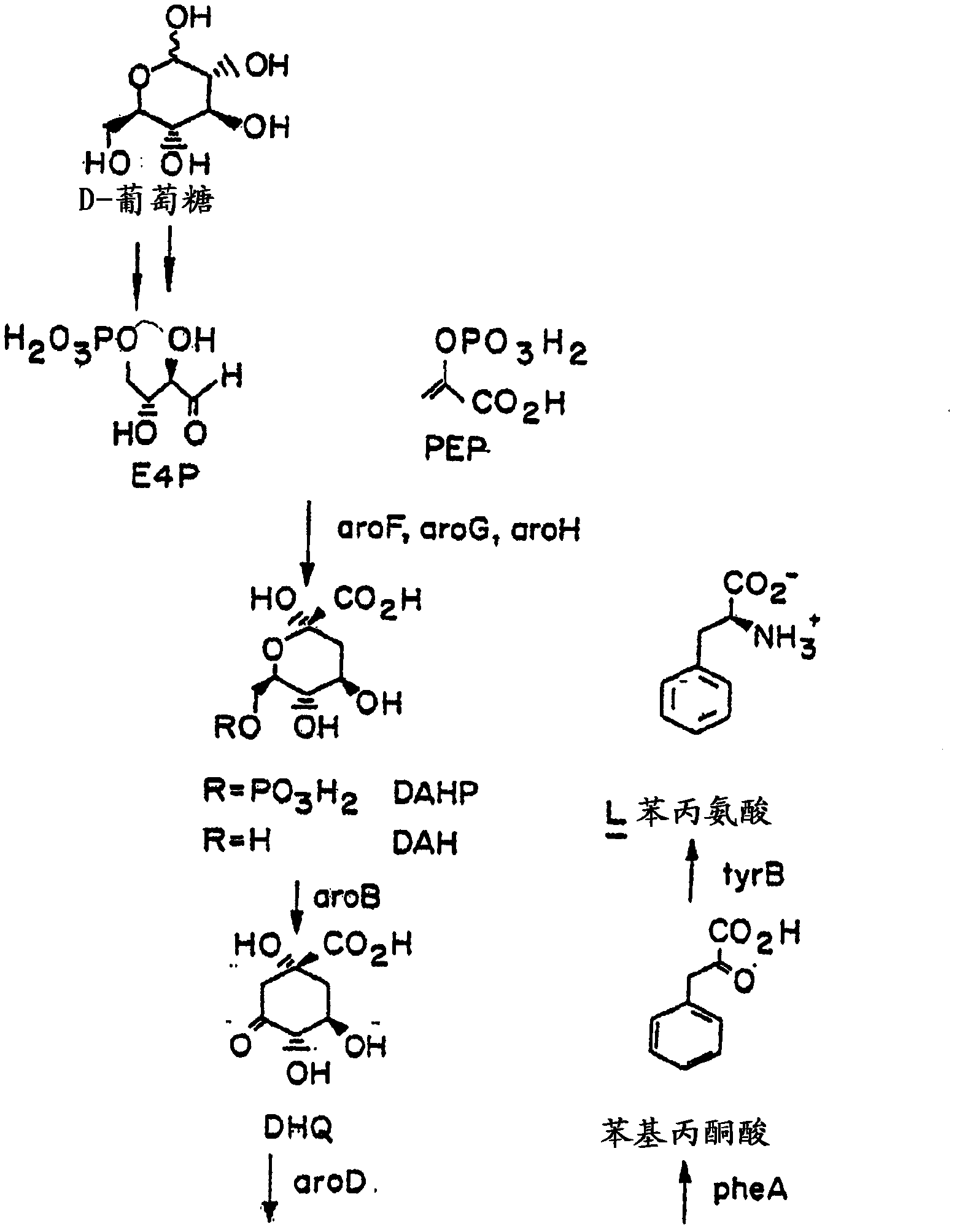

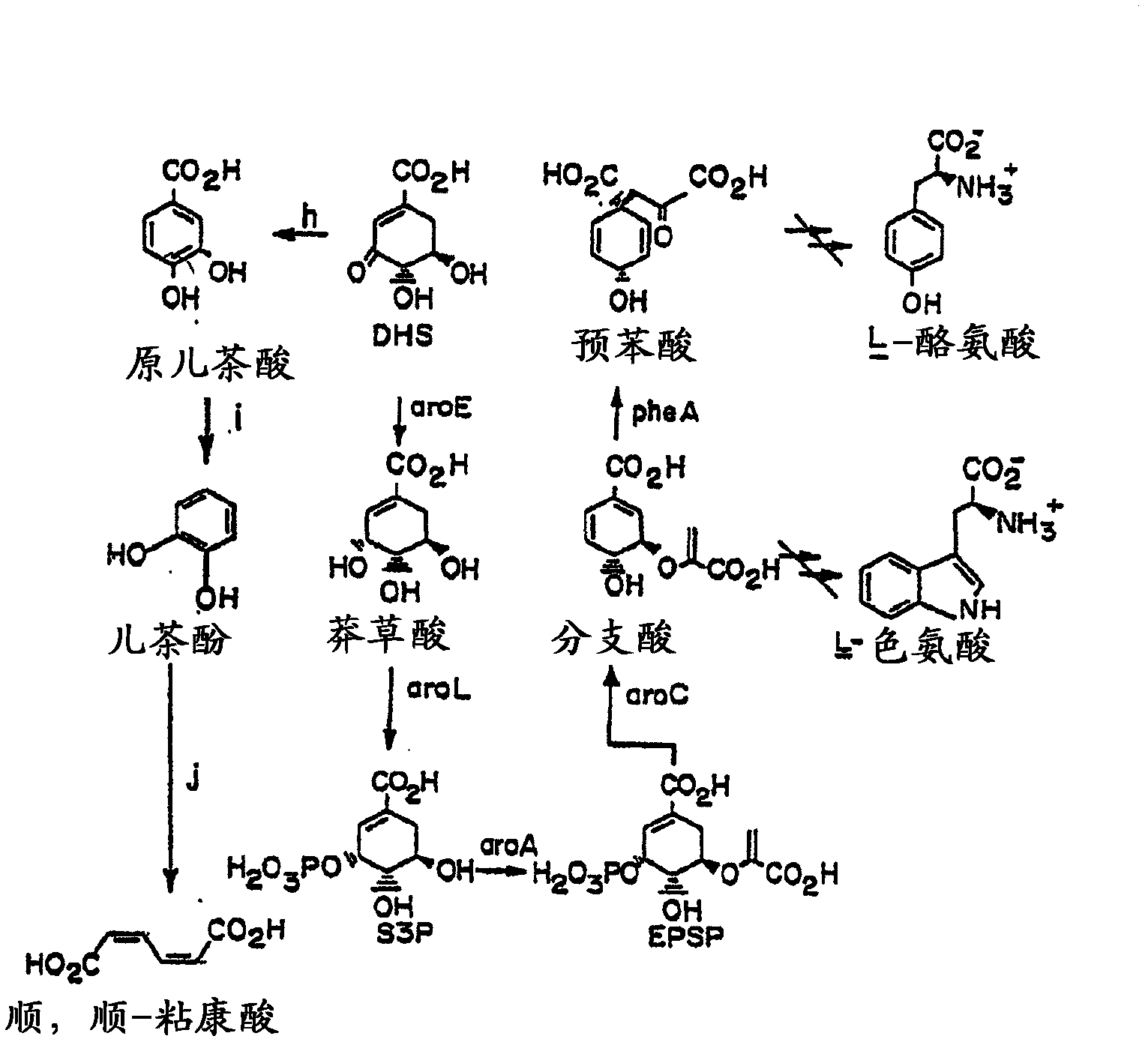

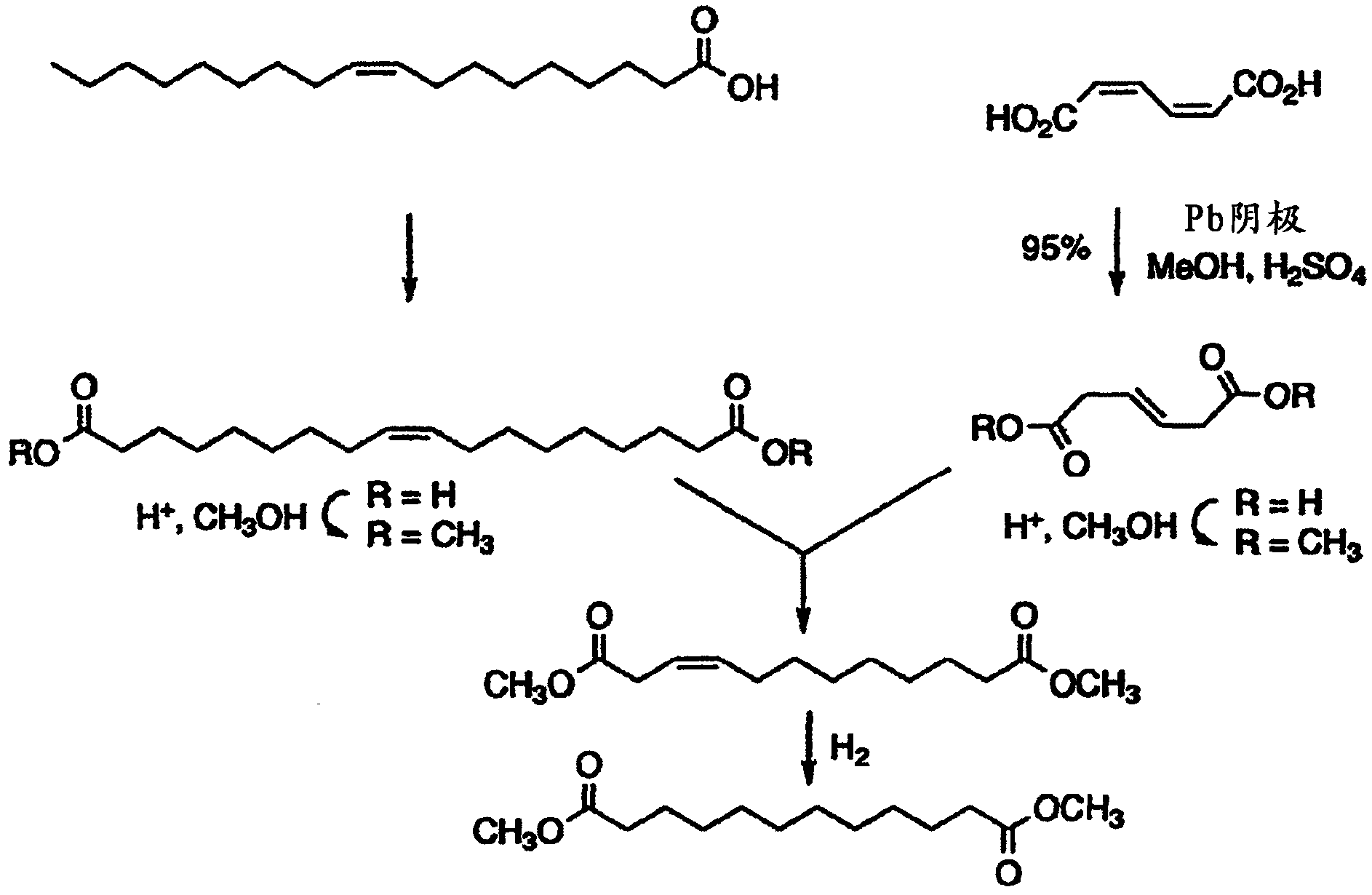

InactiveCN102498086AOrganic compound preparationCarboxylic acid esters preparationHexamethyldiamineMuconic acid

Methods for producing biosourced dodecanedioic acid and compositions comprising biosourced dodecanedioic acid are provided. In some embodiments, the method comprises first forming muconic acid biologically from a renewable carbon source, reducing the muconic acid to hexenedioic acid, and then reacting the hexenedioic acid with an unsaturated fatty acid, typically a Delta9 unsaturated fatty acid, in a metathesis reaction to produce dodecenedioic acid. Dodecenedioic acid is then reduced to dodecanedioic acid. Dodecanedioic acid is can be used to form polymers, such as polyamides. Examples of polyamides include nylon, such as nylon 6,12. Nylon 6,12 can be formed by reacting dodecanedioic acid with 1,6-hexamethylene diamine.

Owner:AMYRIS INC

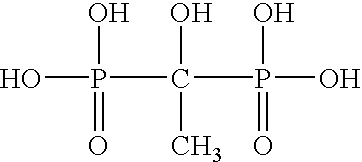

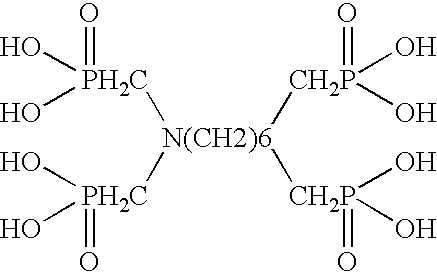

Ammonium polyphosphate solutions containing multi-functional phosphonate corrosion inhibitors

InactiveUS6846437B2Reduce corrosionOther chemical processesLiquid fertilisersSuspending AgentsFerrous Gluconate

A corrosion-inhibited fire retardant composition is provided that comprises at least one ammonium polyphosphate, at least one suspending agent, at least one phosphonate selected from a group consisting of aminotri(methylenephosphonic acid), 1-hydroxyethylidene-1,1-diphosphonic acid, hexamethylenediaminetetra(methylenephosphonic acid), diethylenetriaminepenta(methylenephosphonic acid), salts thereof, and mixtures thereof and a corrosion inhibiting system. The corrosion inhibiting system is comprised of at least one corrosion inhibiting compound selected from a group consisting of azoles, insoluble ferric pyrophosphate, soluble ferric pyrophosphate, ferrous oxalate, ferric citrate, ferrous sulfate, ferric ammonium citrate, insoluble ferric orthophosphate, soluble ferric orthophosphate, ferric ammonium oxalate, ferric ammonium sulfate, ferric bromide, ferric sodium oxalate, ferric stearate, ferric sulfate, ferrous acetate, ferrous ammonium sulfate, ferrous bromide, ferrous gluconate, ferrous iodide, ferric acetate, ferric fluoroborate, ferric hydroxide, ferric oleate, ferrous fumarate, ferrous oxalate, ferrous oxide, ferric lactate, ferric resinate, and any combination thereof. Methods of making and using the same are also described. In addition, agricultural plant nutrients comprising the same are provided.

Owner:PERIMETER SOLUTIONS LP

Powdered solid cosmetic and manufacturing method therefor

ActiveCN102395351AExcellent shine prevention effectCosmetic preparationsBody powdersClay mineralsHexamethyldiamine

Provided is a powdered solid cosmetic that lasts well and is excellent at preventing makeup running and oily shininess. Said powdered solid cosmetic is characterized by containing: a powder component; an oil-based component that serves as a binder; and a mixture of hexamethylenediamine and bis(aminomethyl)cyclohexane which has been amidated in hydrogenated castor oil fatty acid, resulting in an amide mixture. The amide mixture preferably constitutes 1.0-15% by mass of the cosmetic. As a powder component, spherical poly(metha)acrylate particles are preferably included, constituting 1-20% by mass of the cosmetic. An organically-denatured clay mineral is preferably included such that the mass thereof and the mass of the amide mixture total 1.0-15% of the total mass of the cosmetic. As a powder component, a powder treated by a fluorine compound is preferably included, constituting 5-97% by mass of the cosmetic.

Owner:SHISEIDO CO LTD

Developing solution for photoresist

InactiveUS20050130082A1Good storage stabilityPrevent precipitationPhotoprinting processesSemiconductor/solid-state device manufacturingHexamethyldiamineTricarboxylic acid

A novel developing solution for photoresists which is suitable for use as a developing solution for a photoresist formed on an aluminum-containing base formed on a wafer. It comprises an alkali builder, a calcium compound, and a chelating agent, the chelating agent being selected from the group consisting of 1-hydroxyethylidene-1,1-diphosphonic acid, aminotrimethylenephosphonic acid, 2-phosphonobutane-1,2,4-tricarboxylic acid, ethylenediaminetetramethylenphosphonic acid, diethylencetriaminepentamethylenephosphonic acid, hexamethylenediaminetetraethylenephosphonic acid, and diethylenetriaminepenta(methylenephosphonic acid).

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Water concentration reduction process

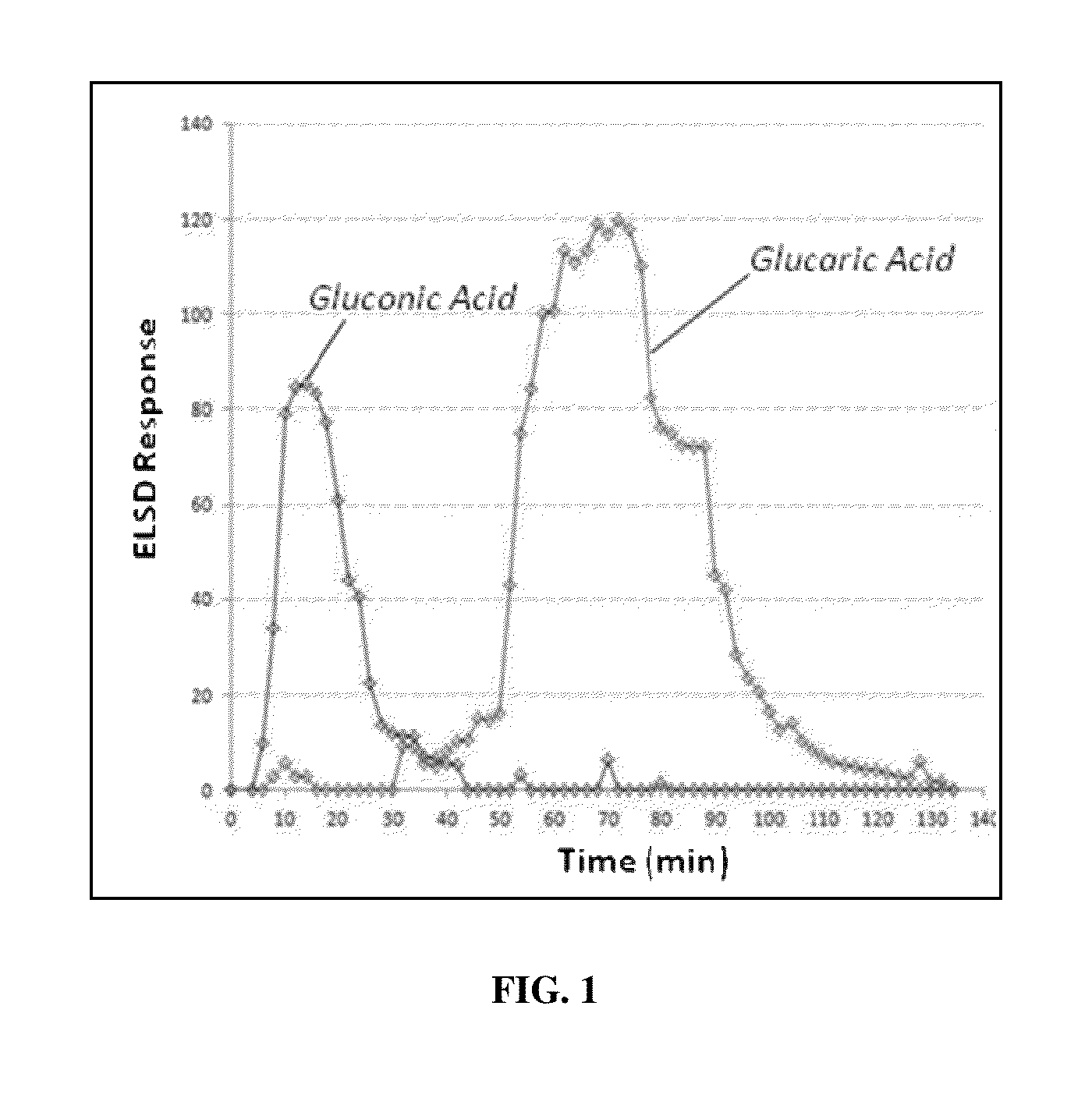

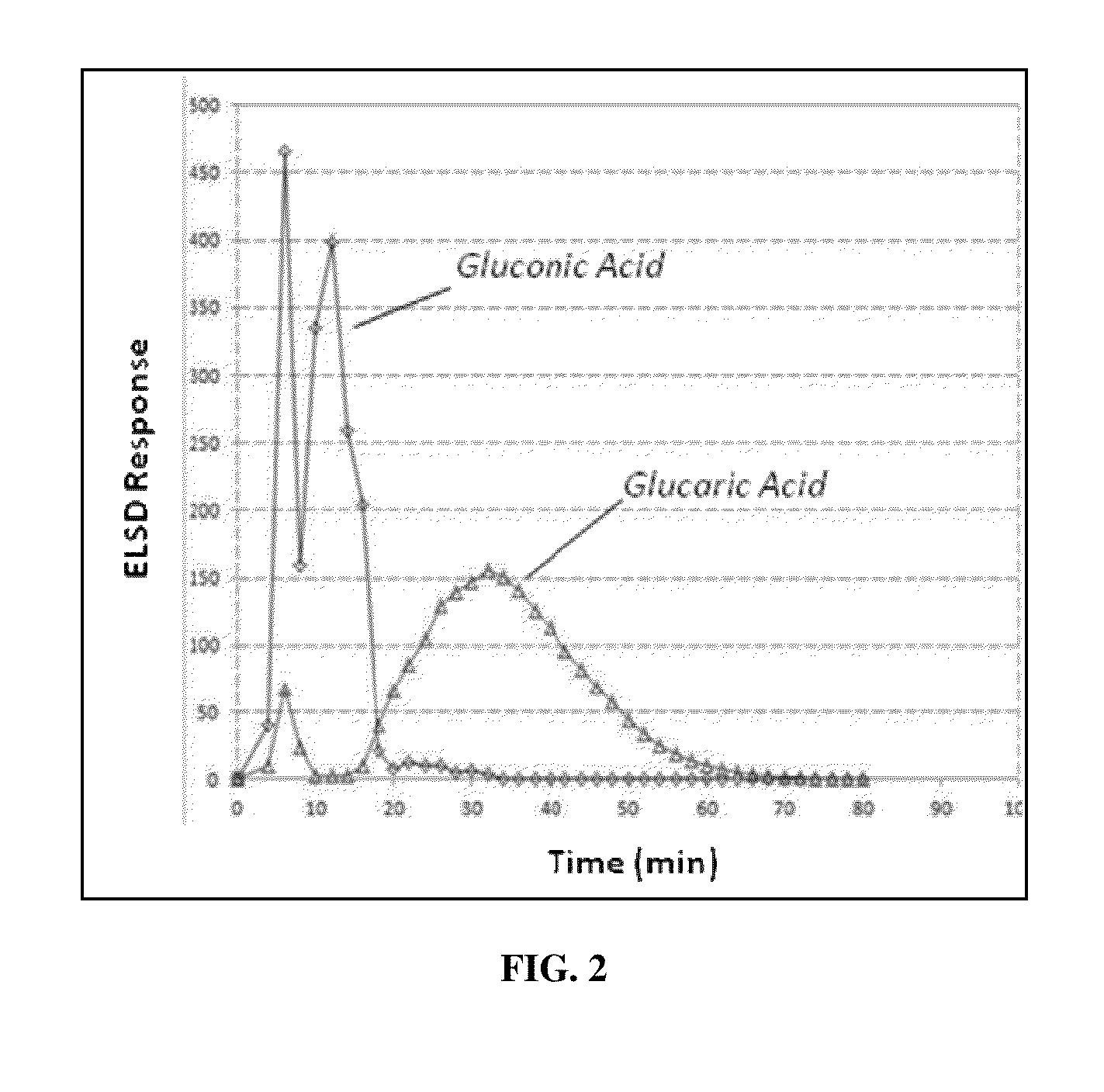

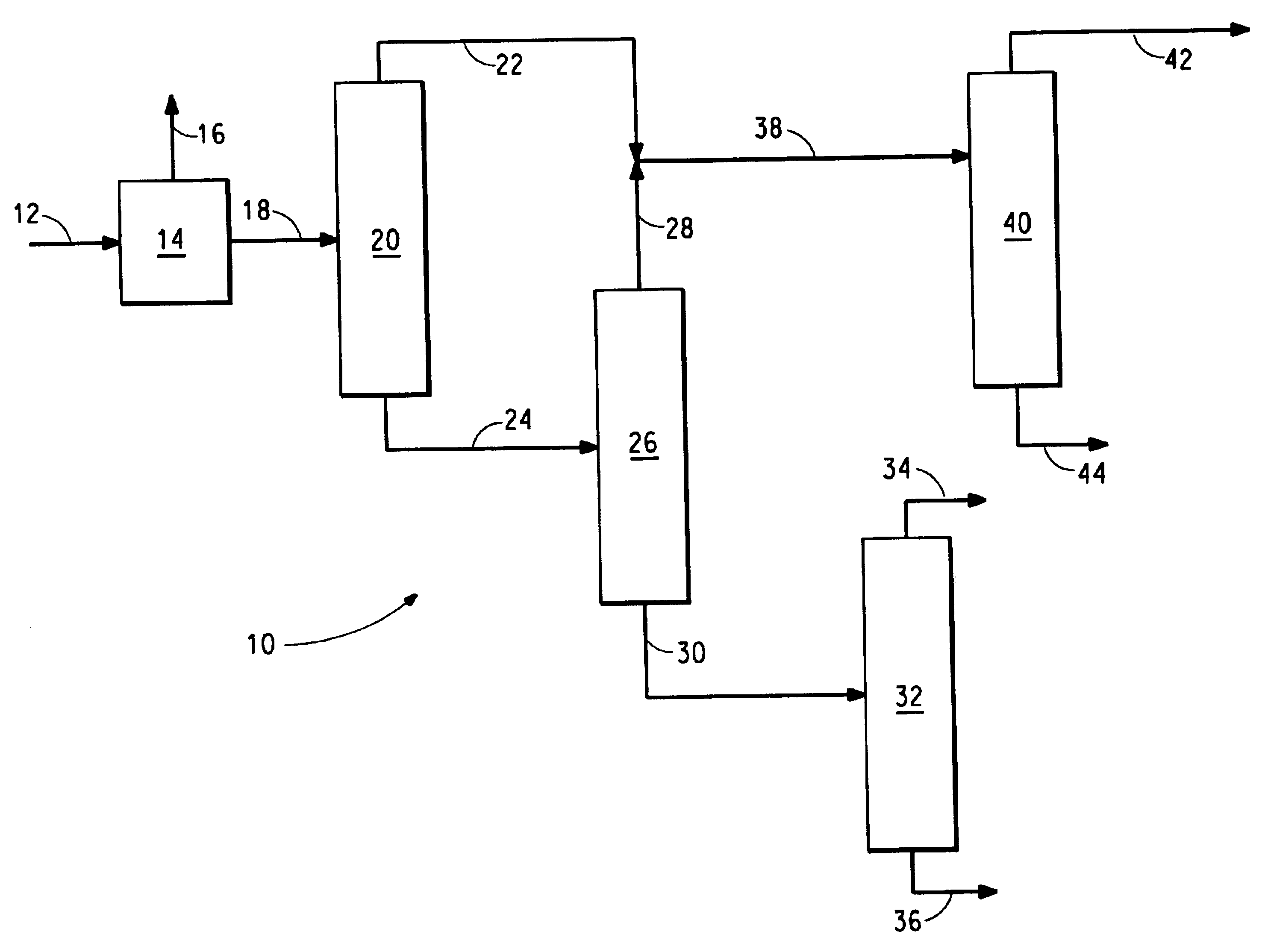

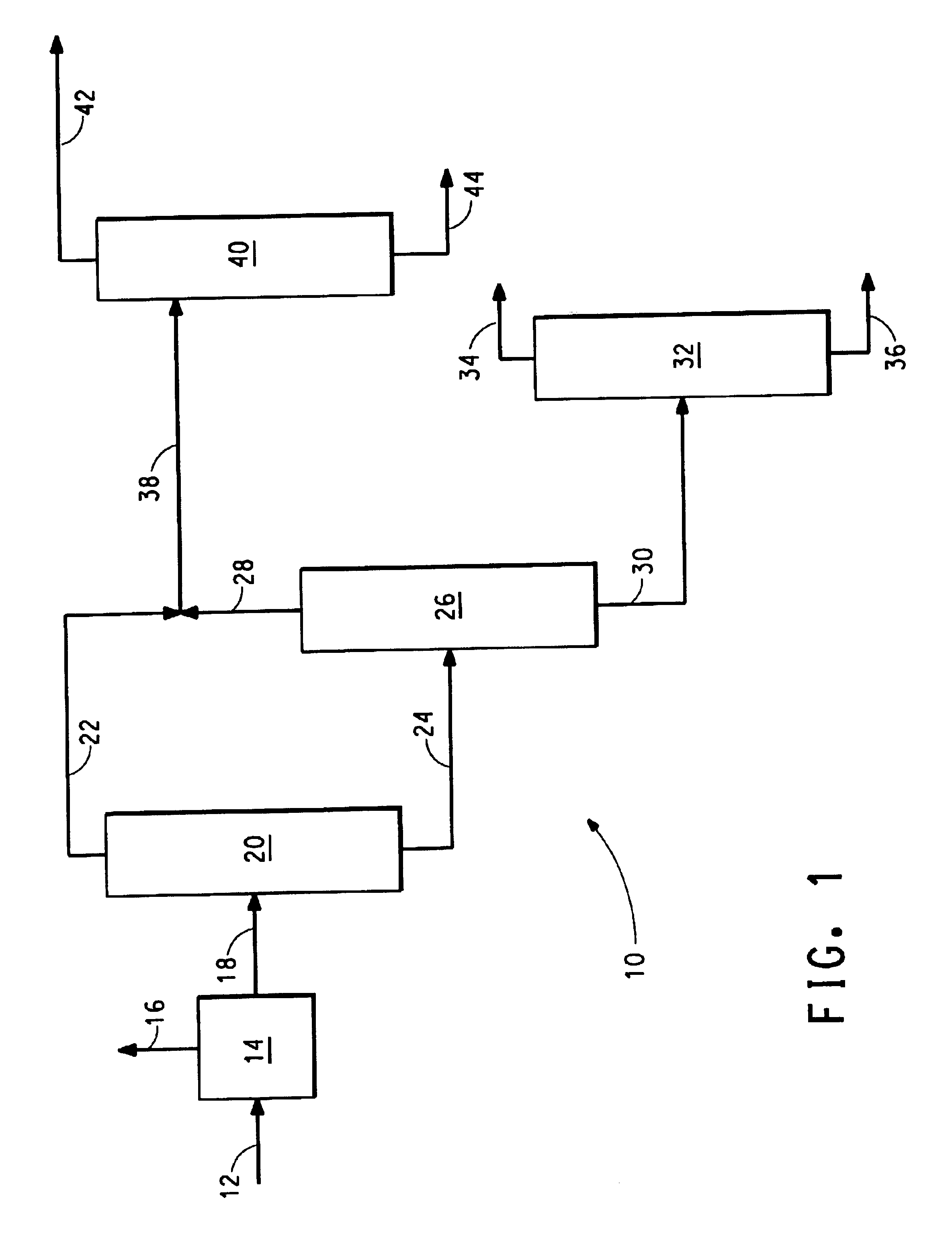

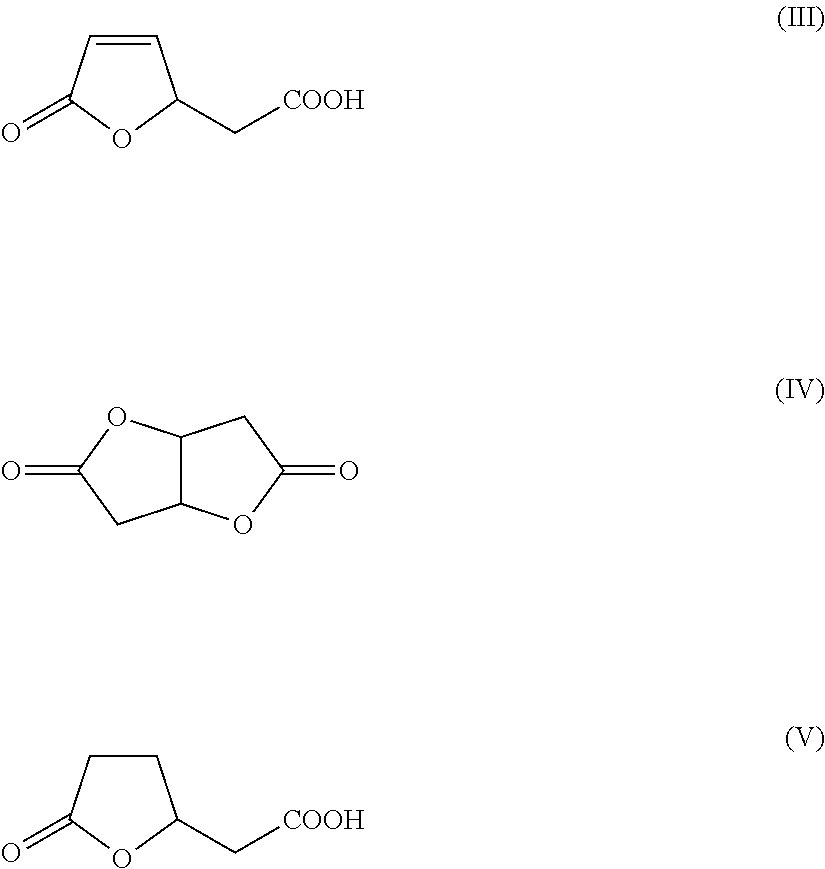

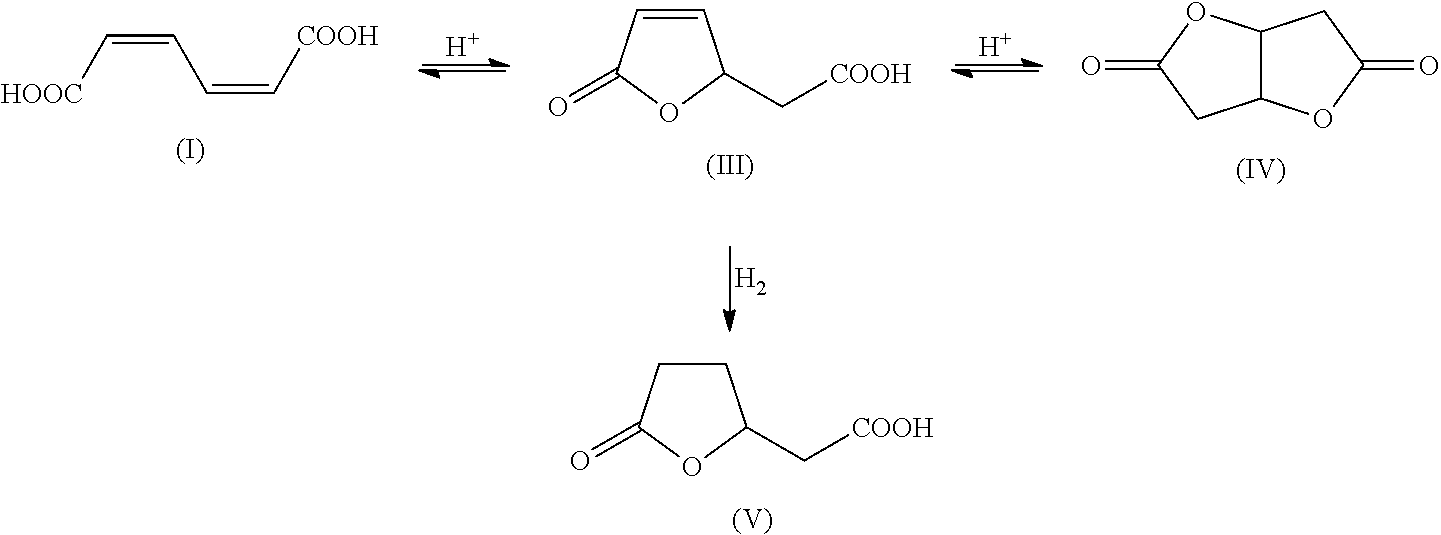

ActiveUS20130158255A1Speed up the processOrganic compound preparationPreparation from carboxylic acid esters/lactonesHexamethyldiamineWater concentration

The present disclosure relates generally to water concentration reduction processes within an adipic acid process. The present invention also includes process for converting a glucose-containing feed derived from a carbohydrate source to an adipic acid product wherein the process includes the steps of: converting glucose in the feed to a reaction product including a hydrodeoxygenation substrate and a first concentration of water; reducing the concentration of water in the reaction product to produce a feedstock including the hydrodeoxygenation substrate and second concentration of water, wherein the second concentration of water is less than the first concentration of water; and converting at least a portion of the hydrodeoxygenation substrate in the feedstock to an adipic acid product. Processes are also disclosed for producing hexamethylene diamine and caprolactam from the adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Polyamide Resin and Hinged Molded Product

InactiveUS20070249783A1Excellent vibration welding strengthHigh hinge propertyNon-fibrous pulp additionMonocomponent copolyamides artificial filamentHexamethyldiamineHexamethylenediamine

A polyamide resin comprising a dicarboxylic acid constitutional unit comprising an adipic acid unit and a diamine constitutional unit comprising a pentamethylenediamine unit and a hexamethylenediamine unit wherein a weight ratio of the pentamethylenediamine unit to the hexamethylenediamine unit being in the range of 95:5 to 60:40; a vibration-welded molded product having an excellent vibration welding strength, a hinged molded product and a binding band having an excellent low-temperature toughness, and a filament having an excellent transparency which are obtained from the polyamide resin; and a hinged molded product comprising a polyamide resin constituted of an adipic acid unit and a pentamethylenediamine unit.

Owner:MITSUBISHI CHEM CORP

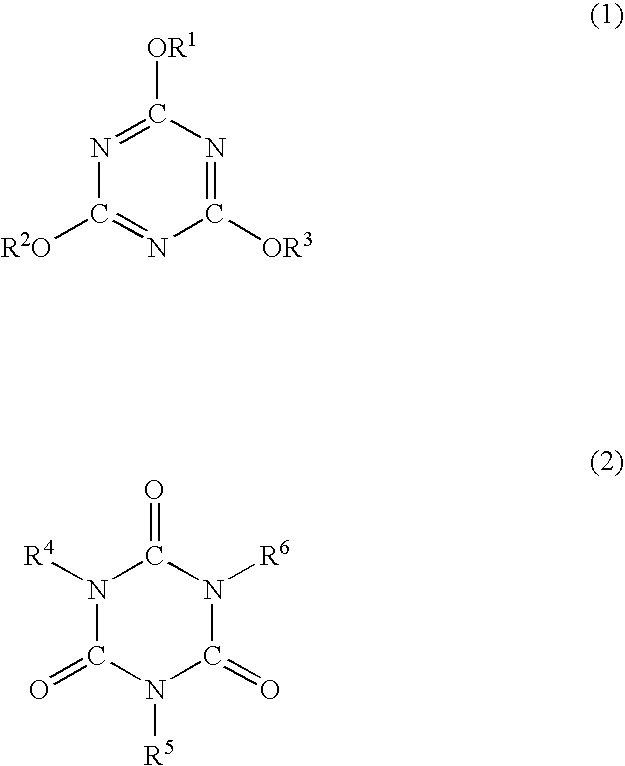

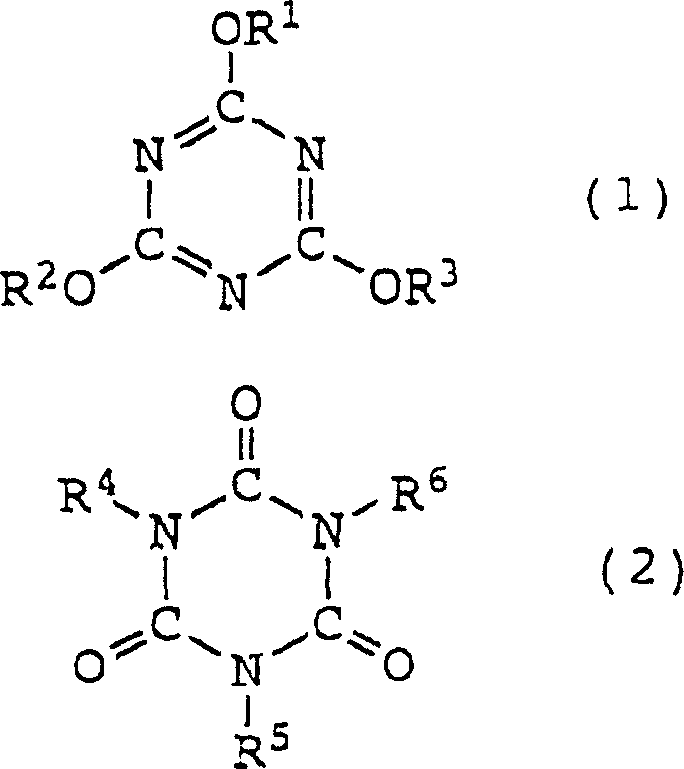

Flame-retardant polyamide resin composition and extrusion-molded product

InactiveUS20050203223A1Excellent in combustibilityImprove flame retardant performanceCarbon numberHexamethyldiamine

The present invention relates to a polyamide resin composition comprising 99 to 80 parts by weight of a polyamide base resin comprising at least one polyamide resin and 1 to 20 parts by weight of a triazine-based flame retardant, the total amount of polyamide base resin and triazine-based flame retardant being 100 parts by weight, said polyamide base resin having constituting units comprising (a) polyamide 6 constituting units comprising a polycondensate of ε-caprolactam and (b) two or more kinds of polyamide constituting units comprising a polycondensate of hexamethylenediamine and a dicarboxylic acid having a carbon number of 6 to 11.

Owner:MITSUBISHI ENG PLASTICS CORP

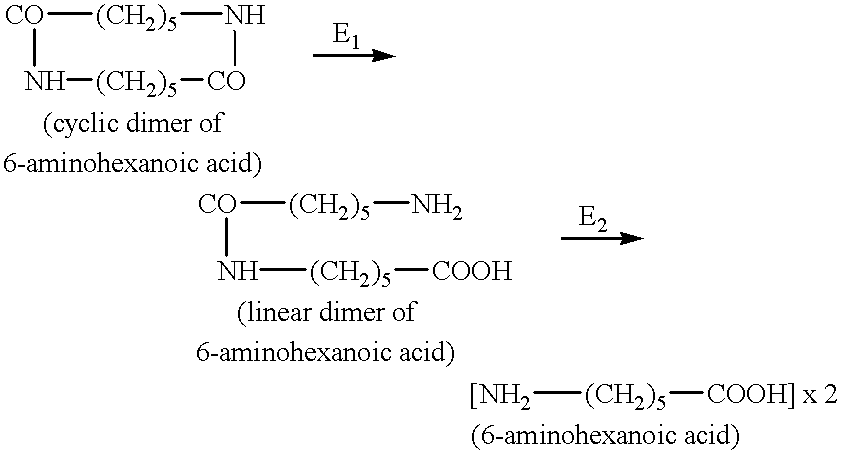

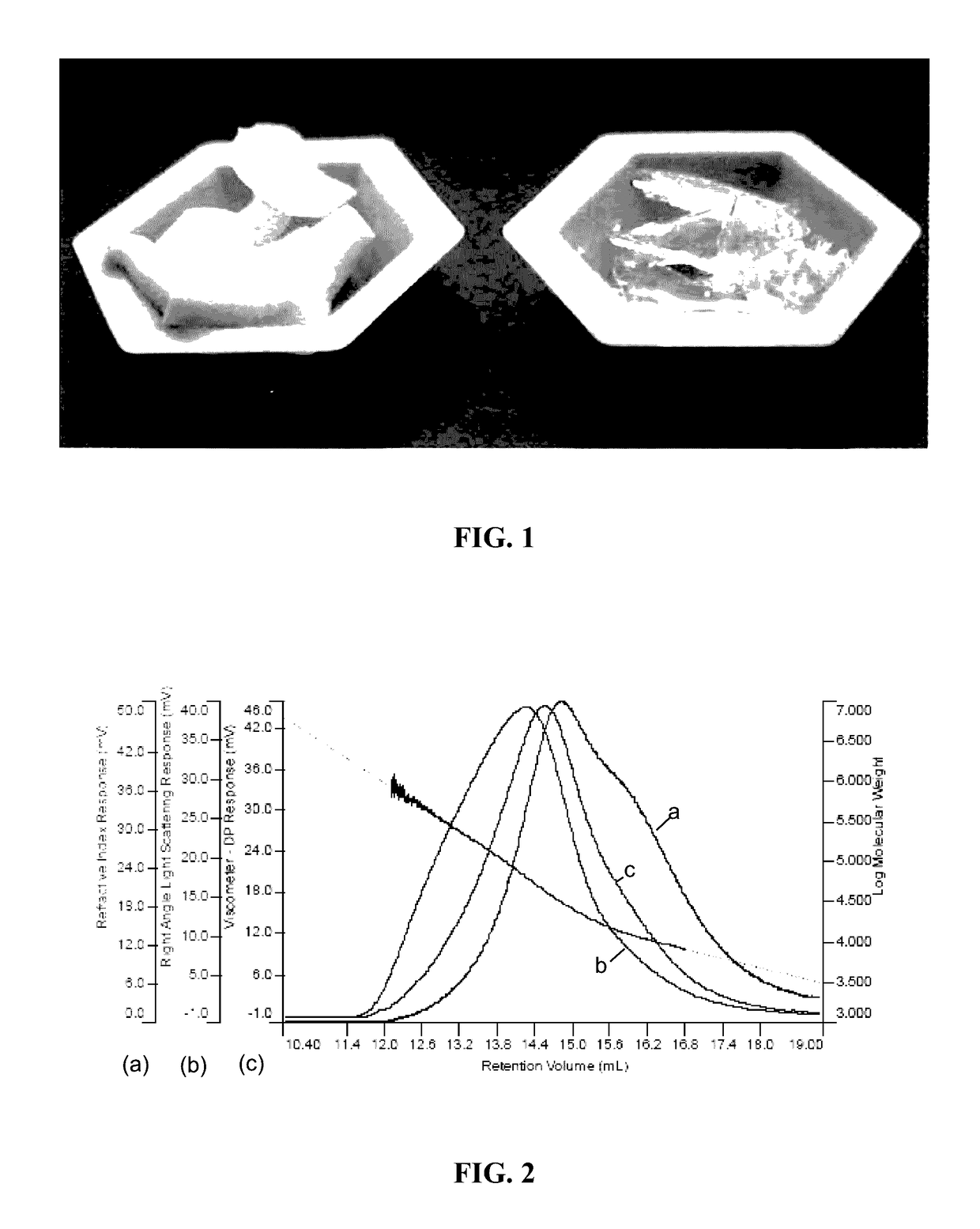

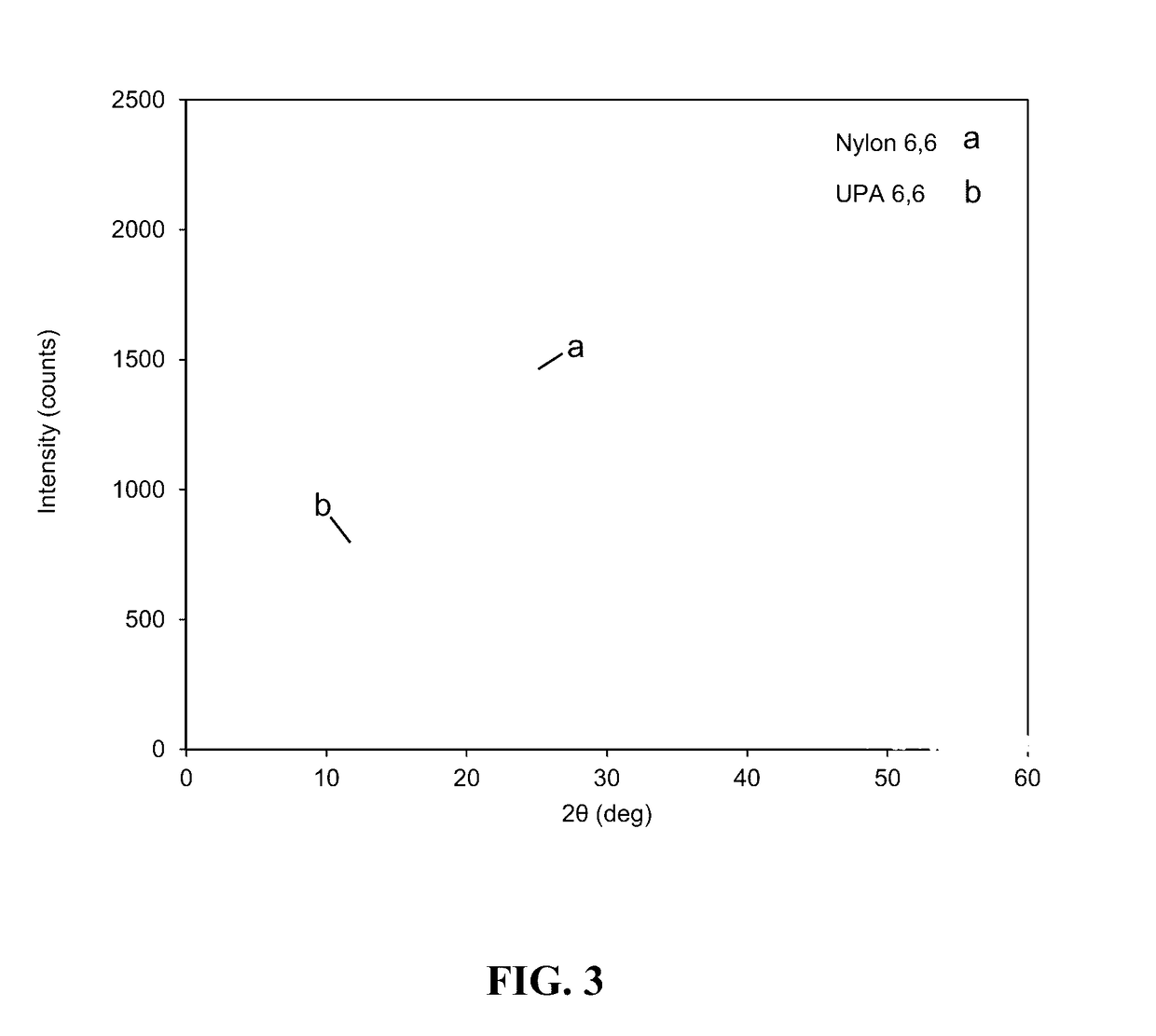

Enzymes and micro organisms with amidase activity which hydrolyze polyamides

The present invention relates to a process for the enzymatic hydrolysis of polyamides 6.6 to give adipic acid monomers and hexamethylenediamine monomers. The present invention further relates to an enzyme with amidase activity particularly towards substrates of the oligomer type derived from PA 6.6 and / or PA 6, said enzyme being characterized in that it consists of a peptide sequence corresponding to SEQ ID NO: 1 in the attached sequence listing and / or at least one polypeptide homologous to this sequence. The invention further relates to the DNA coding for said enzyme and to the biological precursors thereof The invention further relates to the microorganisms capable of producing this enzyme and to the hydrolysis process in which this enzyme and / or these microorganisms are applied.

Owner:RHONE POULENC FIBERS & POLYMERES

Polyamide composite material with double or multiple layers

InactiveCN1361005ASynthetic resin layered productsThin material handlingLaurolactamHexamethyldiamine

A good layer adhesion can be achieved in a composite having two or more layers wherein a layer I is obtained from a molding composition which has the following components: a) from 0 to 80 parts by weight of a polyamide selected from the group consisting of PA6, PA66, PA6 / 66 and a mixture thereof; b) from 0 to 100 parts by weight of a polyamine-polyamide copolymer; and c) from 0 to 80 parts by weight of a polyamide selected from the group consisting of PA11, PA12, PA612, PA1012, PA1212 and a mixture thereof; wherein a total of the parts by weight of components a), b) and c) is 100; wherein at least 20 parts by weight of components a) and b) is a monomer unit which is obtained from caprolactam and / or from a combination of hexamethylenediamine / adipic acid; and wherein at least 20 parts by weight of components b) and c) is a monomer unit which is obtained from omega-aminoundecanoic acid, laurolactam, a mixture of hexamethylenediamine and 1,12-dodecanedioic acid, a mixture of 1,10-decanediamine and 1,12-dodecanedioic acid, and / or a mixture of 1,12-dodecanediamine and 1,12-dodecanedioic acid.

Owner:EVONIK DEGUSSA GMBH

Diamine purification method

InactiveCN1829680AAmino compound purification/separationOrganic compound preparationHexamethyldiaminePurification methods

The invention relates to a method of purifying diamines which are obtained by hydrogenation of dinitriles. More specifically, the invention relates to the purification of hexamethylene diamine which is obtained by hydrogenation of adiponitrile. The inventive method consists in treating at least one part of the hexamethylene diamine flow drawn from the distillation column and re-injecting the treated flow back into the column.

Owner:RHODIA POLYAMIDE INTERMEDIATES

Distillative method for separating hexamethylenediamine from a mixture comprising hexamethylenediamine, 6-aminocapronitrile and tetrahydroazepine

InactiveUS6887352B2Minimizes isomerizationAmino compound purification/separationOrganic compound preparationIsomerizationHexamethyldiamine

A method for recovering hexamethylene diamine (HMD) from a mixture comprising HMD, 6-aminocapronitrile (ACN) tetrahydroazepine (THA), and adiponitrile (ADN) is disclosed.The method includes introducing the mixture into a first distillation column, separating as a group the HMD, ACN and at least a portion of the THA as distillate from the ADN. The first distillation column is operated at a temperature and pressure to minimize isomerization of the ADN into 2-cyanocyclopentylideneimine(CPI). The distillate of the first distillation column is introduced into a subsequent distillation column and the HMD is separated from the ACN and THA.

Owner:INVISTA NORTH AMERICA R L

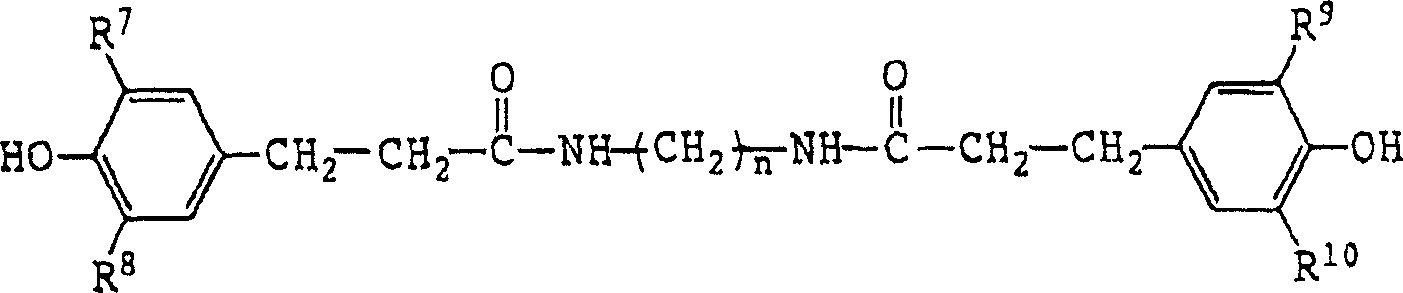

Polyamide composition for blow molded articles

High temperature polyamide resin compositions for blow molding and articles blow molded from such compositions are provided. The blow molded articles exhibit excellent heat resistance, chemical resistance, and dimensional stability. The composition has a melting point of at least 275° C. and a glass transition temperature of at least 60° C. The composition comprises an aromatic polyamide, an impact modifier, and a stabilizer. The aromatic polyamide is a polymer or copolymer having repeating units derived from a carboxylic acid component and an aliphatic diamine component, the carboxylic component being terephthalic acid or a mixture of terephthalic acid and one or more other carboxylic acids, and the aliphatic diamine component being hexamethylene diamine or a mixture of hexamethylene diamine and 2-methyl pentamethylene diamine or 2-ethyltetramethylene diamine. The impact modifier is selected from the group of (i) ethylene polymers and copolymers grafted with carboxylic acid, an anhydride thereof, maleimide or an epoxy compound; (ii) olefin / arcylic acid / anhydride terpolymers and ionomers; and (iii) styrenic thermoplastic elastomers grafted with an anhydride of a carboxylic acid. The stabilizer is selected from the group of (i) phosphite and phosphonite stabilizers; (ii) hindered phenol stabilizers; (iii) hindered amine stabilizers; and (iv) aromatic amine stabilizers.

Owner:TOPOULOS GEORGIOS

Method for producing foods from culture of Bacillus natto

ActiveUS20060141095A1Prevent excessive intakeSafely intakeBacteriaWort preparationVitamin K2Hexamethylenediamine

The present invention provides a method for producing a food product containing nattokinase but containing little or none vitamin K2, comprising treating a Bacillus natto culture or culture supernatant with at least one coagulant selected from the group consisting of an inorganic coagulant and a cationic polymer coagulant (excluding chitosan). As the inorganic coagulant, calcium chloride or poly aluminum chloride is preferable, and their mixtures with a phosphorus coagulant are also preferably used. As the cationic polymer coagulant, cationic polysaccharides, hexamethylenediamine / epichlorohydrin polycondensates or dimethylamine / epichlorohydrin polycondensates are preferably used, and their mixtures with a polyacrylate are also preferably used.

Owner:AMANO ENZYME INC +1

Method of manufacturing cured ethylene acrylic and polyacrylate elastomers

An improved method of making an ethylene acrylate (AEM) elastomer or a polyacrylate (ACM) elastomer wherein an aqueous solution of hexamethylene diamine (HMDA) is employed as the curative agent rather than hexamethylene diamine carbamate (HMDAC). The HMDA reacts with the curative-site monomer derived from the monoalkyl ester of a 1,4-butene-dioic acid in the presence of water, producing (i.e., after press-curing and any secondary heat-curing) a crosslinked elastomer with properties essentially indistinguishable from that produced using HMDAC as the curative agent. Advantageously, the aqueous solution of HMDA can be blended directly into the compound or it can be deposited on an additive such as silica or carbon black prior to blending. Elastomers produced by the improved method according to the present invention are particularly useful in automotive applications requiring oil resistant compositions.

Owner:DUPONT POLYMERS INC

Method for producing hexamethylenediamine

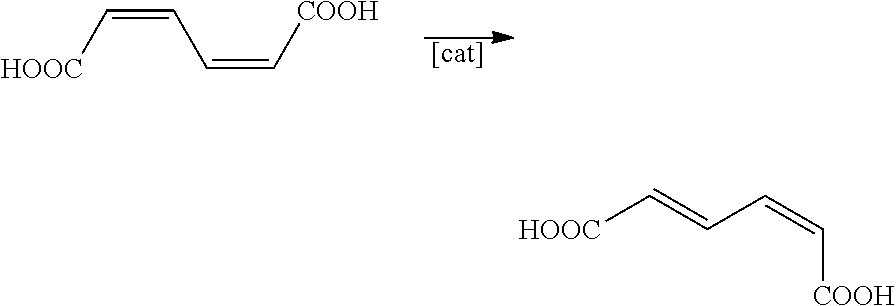

InactiveUS20160326092A1Adipic acid yieldHigh melting pointAmino compound purification/separationOrganic compound preparationMuconic acidHexamethyldiamine

The invention relates to a method for producing hexamethylenediamine, wherein a) a muconic acid starting material is provided, which is selected from among muconic acid, esters of muconic acid, lactones of muconic acid, and mixtures thereof, b) the muconic acid starting material is subjected to a reaction with hydrogen in the presence of at least one hydrogenation catalyst in order to form 1,6-hexanediol, and c) the 1,6-hexanediol obtained in step b) is subjected to amination in the presence of an amination catalyst in order to obtain hexamethylenediamine. The invention further relates to hexamethylenediamine which can be produced by means of said method.

Owner:BASF AG

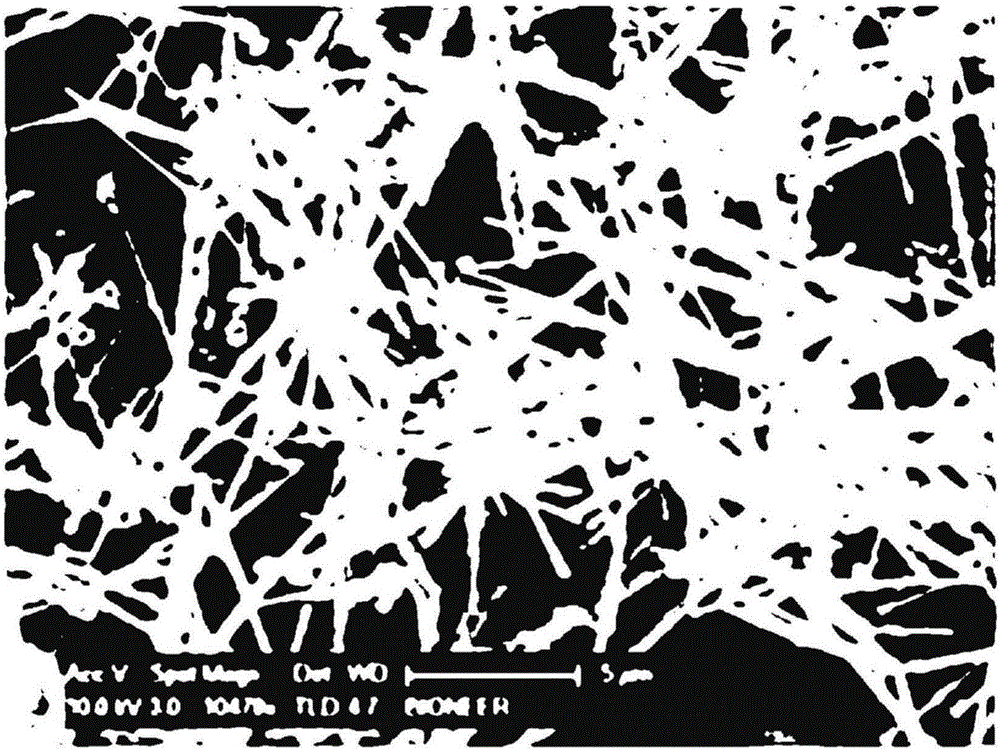

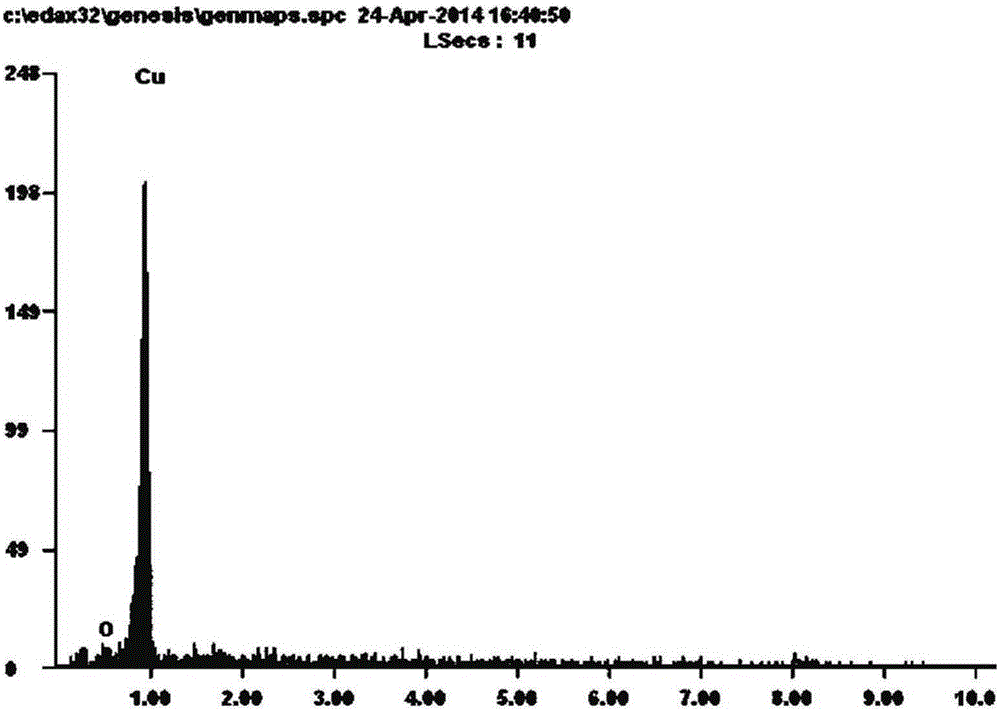

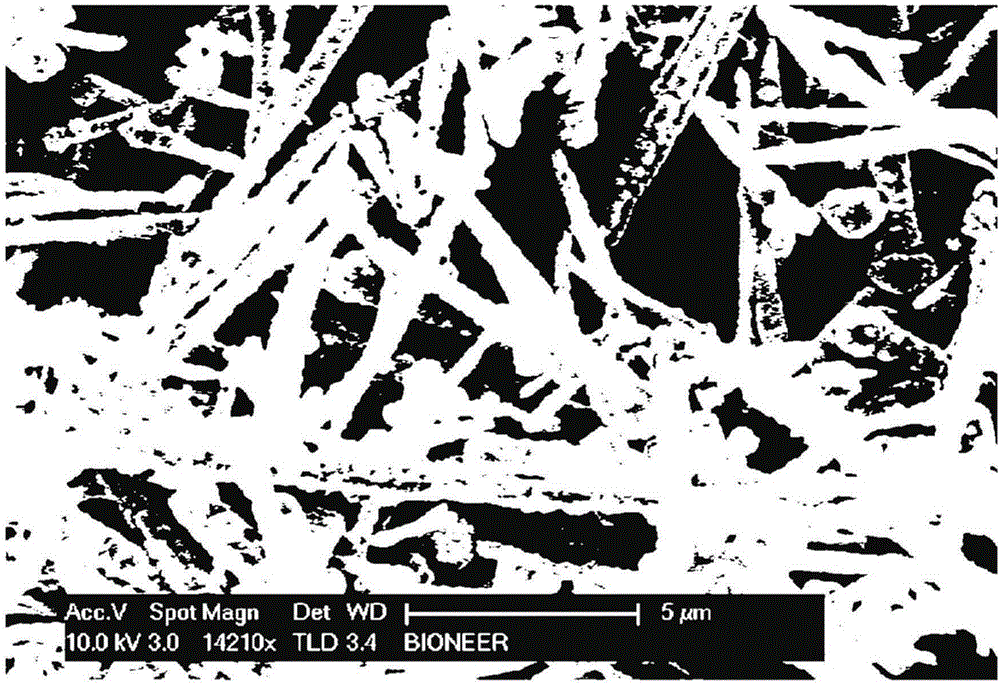

Silver-coated copper nanowire and preparation method therefor

ActiveCN106536094ANanostructure manufactureTransportation and packagingHexamethyldiamineChemical plating

The present invention relates to a silver-coated copper nanowire and a preparation method therefor and, more specifically, is characterized by synthesizing a copper nanowire through a chemical method by using piperazine (C4H10N2) and / or hexamethylenediamine (C6H16N2), which are novel copper capping agents, and then coating the same with silver by using a chemical plating method in order to prevent the oxidation of the copper nanowire.

Owner:BIONEER

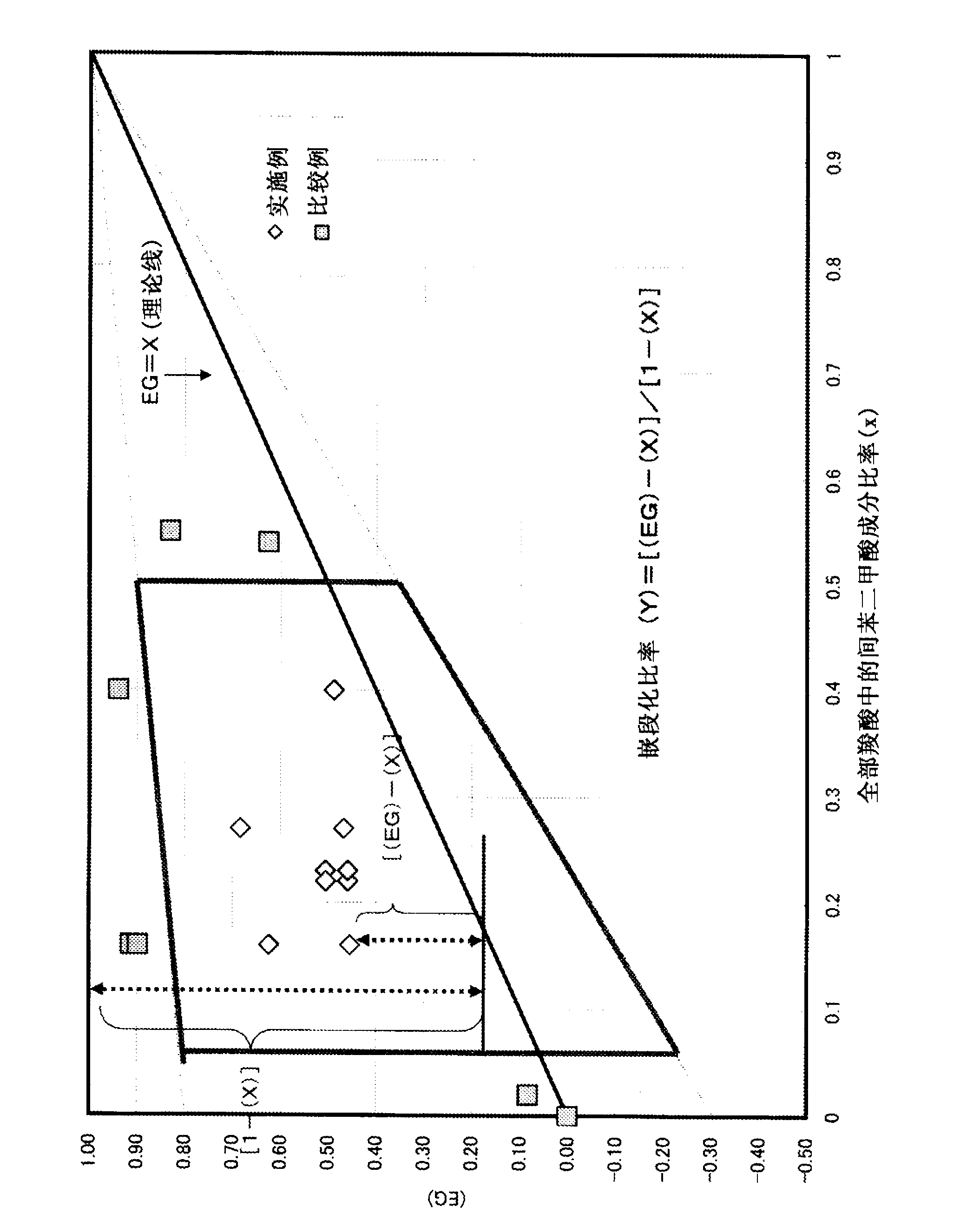

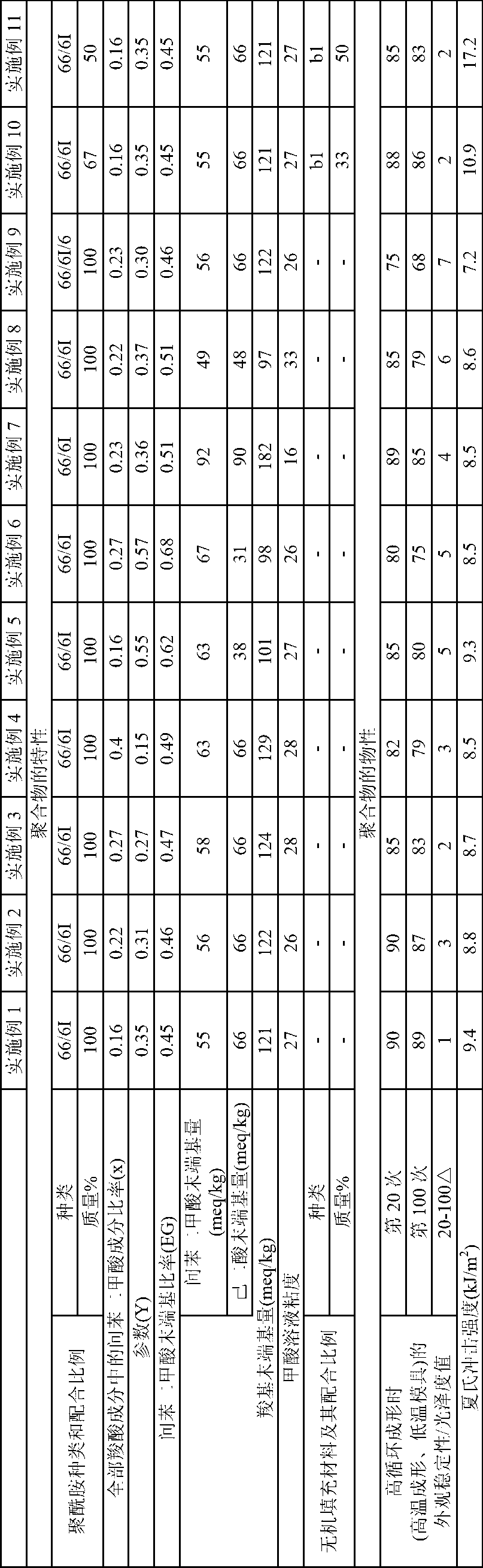

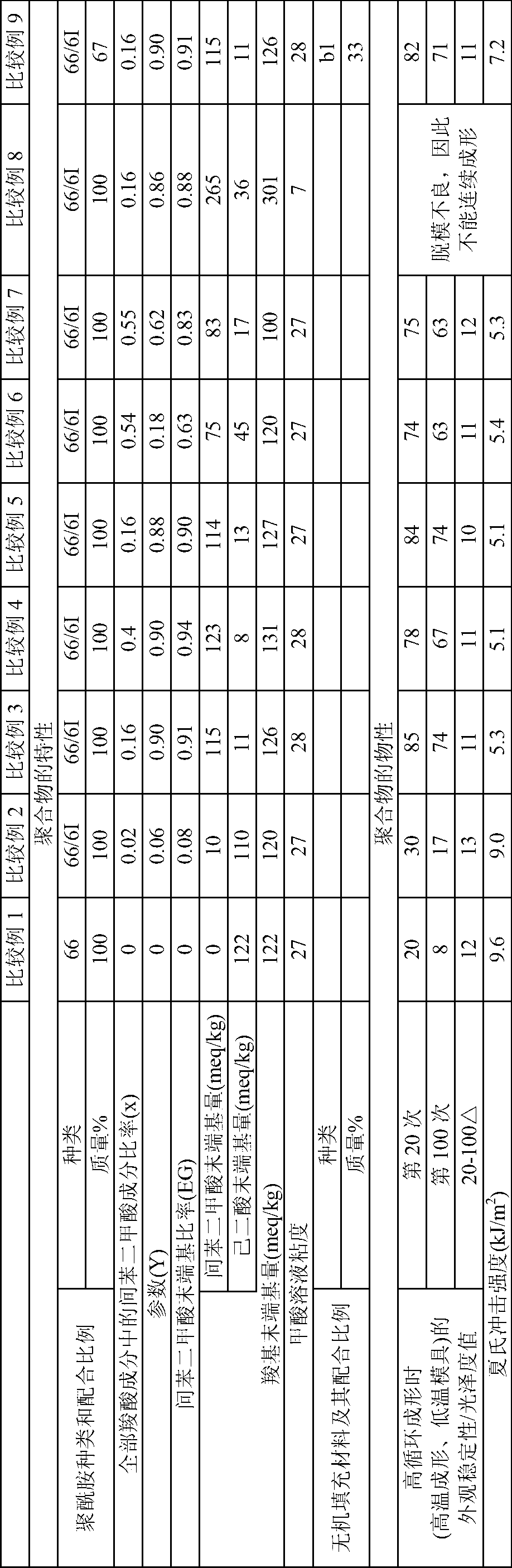

Polyamide and polyamide composition

ActiveCN102933638AStable surface appearanceGood impact resistanceHexamethyldiamineHexamethylenediamine

Provided are a polyamide and a polyamide composition which, even when molded under severe molding conditions, attain satisfactory stability with respect to the surface appearance of the molded objects and which have excellent impact resistance. The polyamide (A) comprises units (a) formed from adipic acid and hexamethylenediamine and units (b) formed from isophthalic acid and hexamethylenediamine, wherein the proportion (x) of isophthalic acid units to all carboxylic acid units in the polyamide is 0.05=(x)=0.5 and the block ratio (Y) is -0.3=(Y)=0.8. The polyamide composition comprises 30-95 mass% the polyamide and 5-70 mass% inorganic filler (B).

Owner:ASAHI KASEI KK

Method for producing biocidal polyguanidine, and biocidal polyguanidine

The inventions relate to antiseptic agents and the method for producing thereof and can be used as a broad-spectrum disinfectant in medicine, veterinary medicine, agriculture etc.The method for producing of biocidal polyguanidine that comprises condensation polymerization of hexamethylenediamine with guanine salt additionally uses hydrazine hydrate during the condensation polymerization process, at the following ratio of components, mass %:hexamethylenediamine 20-55guanidine salt 25-65hydrazine hydrate the rest.Biocidal polyguanidine obtained by means of the abovementioned method, with the following formula:wheren—the number of links A in a single unit of the polymer chain, n=1-3;m—the number of links B in a single unit of the polymer chain, m=2-10;z—the number of single units in the polymer chain, z=4-20;Acid—an acid.The inventions allow obtaining a biocidal polyguanidine with high level of broad-spectrum antimicrobial activity.

Owner:TETS VIKTOR VENIAMINOVICH

Flame-retardant polyamide resin composition and extrusion-molded product

InactiveCN1667023AIncrease flame retardancyGood flexibilityTubular articlesCarbon numberHexamethyldiamine

The present invention relates to a polyamide resin composition comprising 99 to 80 parts by weight of a polyamide base resin and 1 to 20 parts by weight of a triazine-based flame retardant, said polyamide base resin having constituting units comprising (a) polyamide 6 constituting units comprising a polycondensate of epsilon -caprolactam and (b) two or more kinds of polyamide constituting units comprising a polycondensate of hexamethylenediamine and a dicarboxylic acid having a carbon number of 6 to 11.

Owner:MITSUBISHI ENG PLASTICS CORP

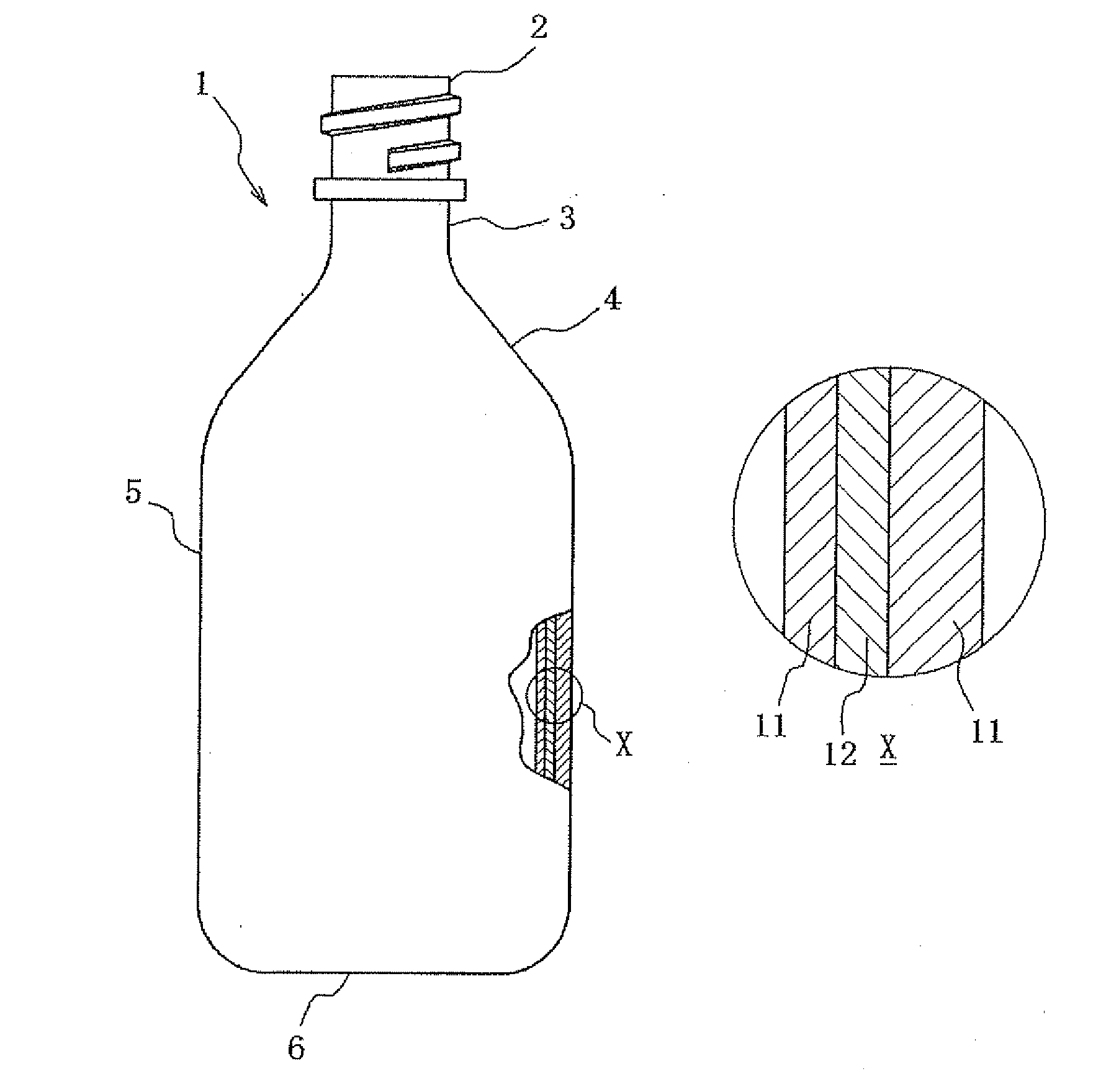

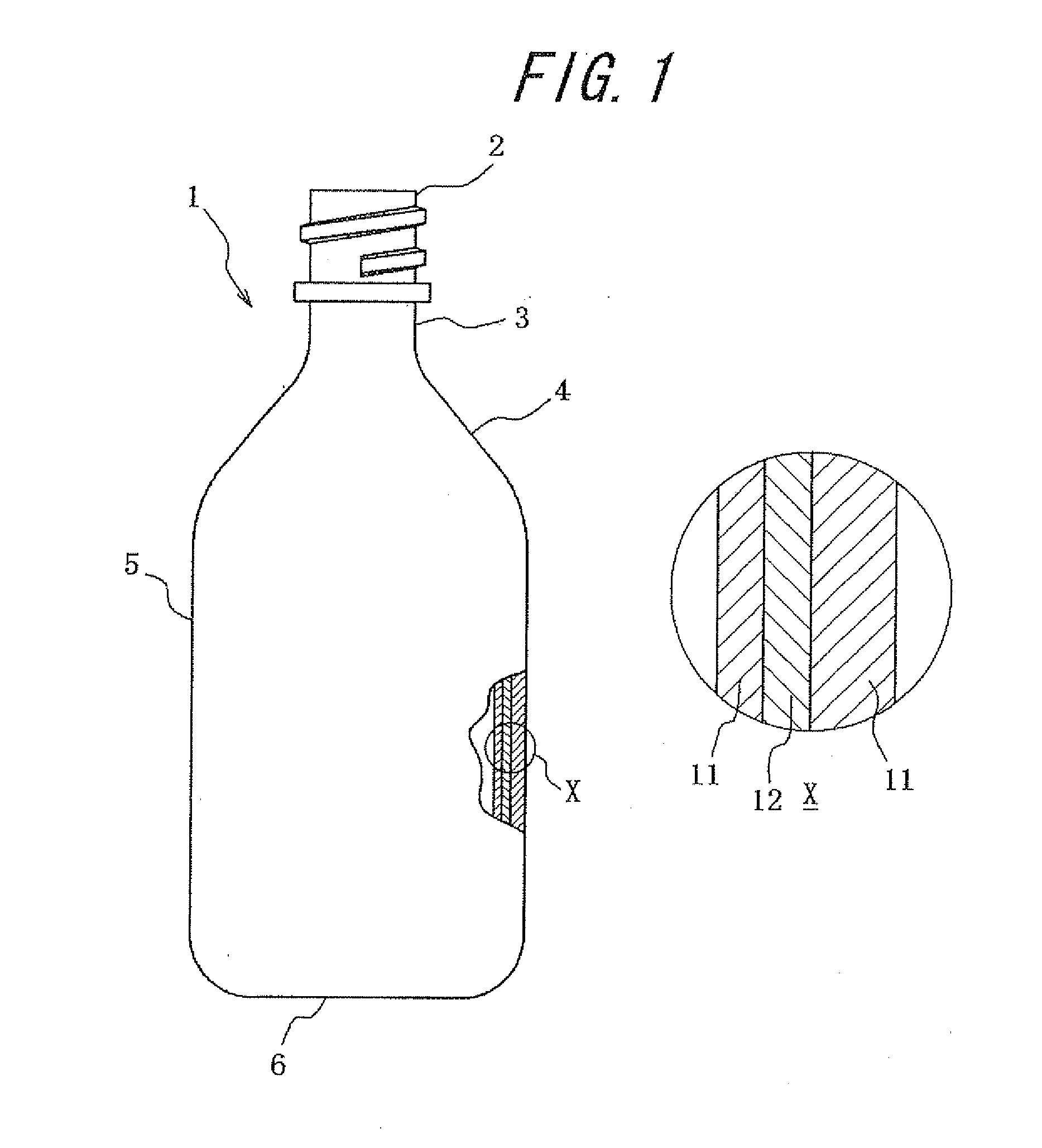

Synthetic resin container with high barrier properties

ActiveUS20110036850A1Suppress white opacityImprove barrier propertiesBottlesSynthetic resin layered productsHexamethyldiamineHexamethylenediamine

A container made of synthetic resin which does not cause whitening or clouding in an unstretched portion even after long-period storage and which has excellent barrier properties. A PET bottle comprising a substrate layer made of PET and a barrier layer having a gas permeability lower than that of the substrate layer, wherein the barrier layer is made of a barrier material prepared by incorporating a polyamide containing m-xylene groups with an amorphous polyamide comprising both m-xylene isophthalamide structures and hexamethylene isophthalamide structures. A copolyamide composed of both a copolymer of m-xylenediamine and isophthalic acid and a copolymer of hexamethylenediamine and isophthalic acid is used as the amorphous polyamide. The content of the amorphous polyamide in the barrier layer is adjusted to 15 to 25 wt %.

Owner:YOSHINO KOGYOSHO CO LTD

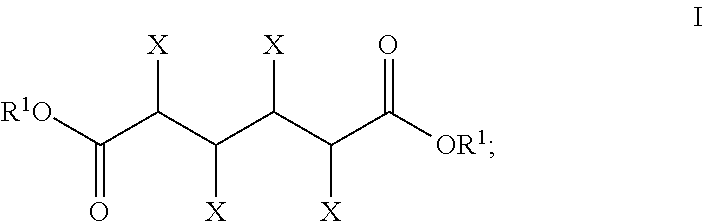

Bioadvantaged nylon: polycondensation of 3-hexenedioic acid with hexamethylenediamine

The present invention relates to a polymer comprising a repeating group having the structure of formula (I)wherein R, R1, R2, R3, R4, X, and s are as described herein and salt thereof. Also disclosed is a process of synthesizing such polymers.

Owner:IOWA STATE UNIV RES FOUND

Multilayer composite comprising a polyester layer

ActiveUS20160271921A1High heat distortion temperatureGood adhesion between layersFlexible coversWrappersHexamethylenediamineCarboxylic acid

A multilayer composite containing the following layers: I. a first layer (layer I) of a moulding compound containing at least 40 wt. % of the following components: 1) 60 to 99 parts by wt. of a copolyamide based on hexamethylenediamine, terephthalic acid and an aliphatic dicarboxylic acid having 8 to 19 carbon atoms and 2) 40 to 1 parts by wt. of an olefinic copolymer as impact modifier, wherein the parts by wt. of 1) and 2) sum to 100; and II. a second layer (layer II) of a moulding compound containing at least 60 wt. % of thermoplastic polyester, has a high heat distortion temperature, a very good impact resistance, a high elongation at break and good layer adhesion.

Owner:EVONIK OPERATIONS GMBH

Moulding compound based on a partially aromatic copolyamide

A moulding composition, comprising at least 40 wt. % of the following components:a) 60 to 99 parts by wt. of a partially aromatic copolyamide which comprises as polymerized monomer units:I. 30 to 90 mol % of a combination of hexamethylenediamine and terephthalic acid; andII. 70 to 10 mol % of a lactam and / or of an ω-aminocarboxylic acid with 11 or 12 C atoms; andb) 40 to 1 parts by wt. of an olefinic copolymer comprising as polymerized monomer units:i) 35 to 94.9 wt. % of ethene-based monomer units,ii) 5 to 65 wt. % of monomer units based on a 1-alkene with 4 to 8 C atoms,iii) 0 to 10 wt. % of monomer units based on an olefin different from i) and ii), andiv) 0.1 to 2.5 wt. % of monomer units based on an aliphatically unsaturated dicarboxylic acid anhydride,wherein a sum of the weight % values of i), ii), iii) and iv) is 100%, and the sum of the parts by wt. of a) and b) is 100; which can is processed into moulded articles with improved thermal aging resistance is provided.

Owner:EVONIK OPERATIONS GMBH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com