Patents

Literature

200 results about "2,3-Butanediol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2,3-Butanediol is the organic compound with the formula (CH₃CHOH)₂. It is classified as a vic-diol (glycol). It exists as three stereoisomers, a chiral pair and the meso isomer. All are colorless liquids. Applications include precursors to various plastics and pesticides.

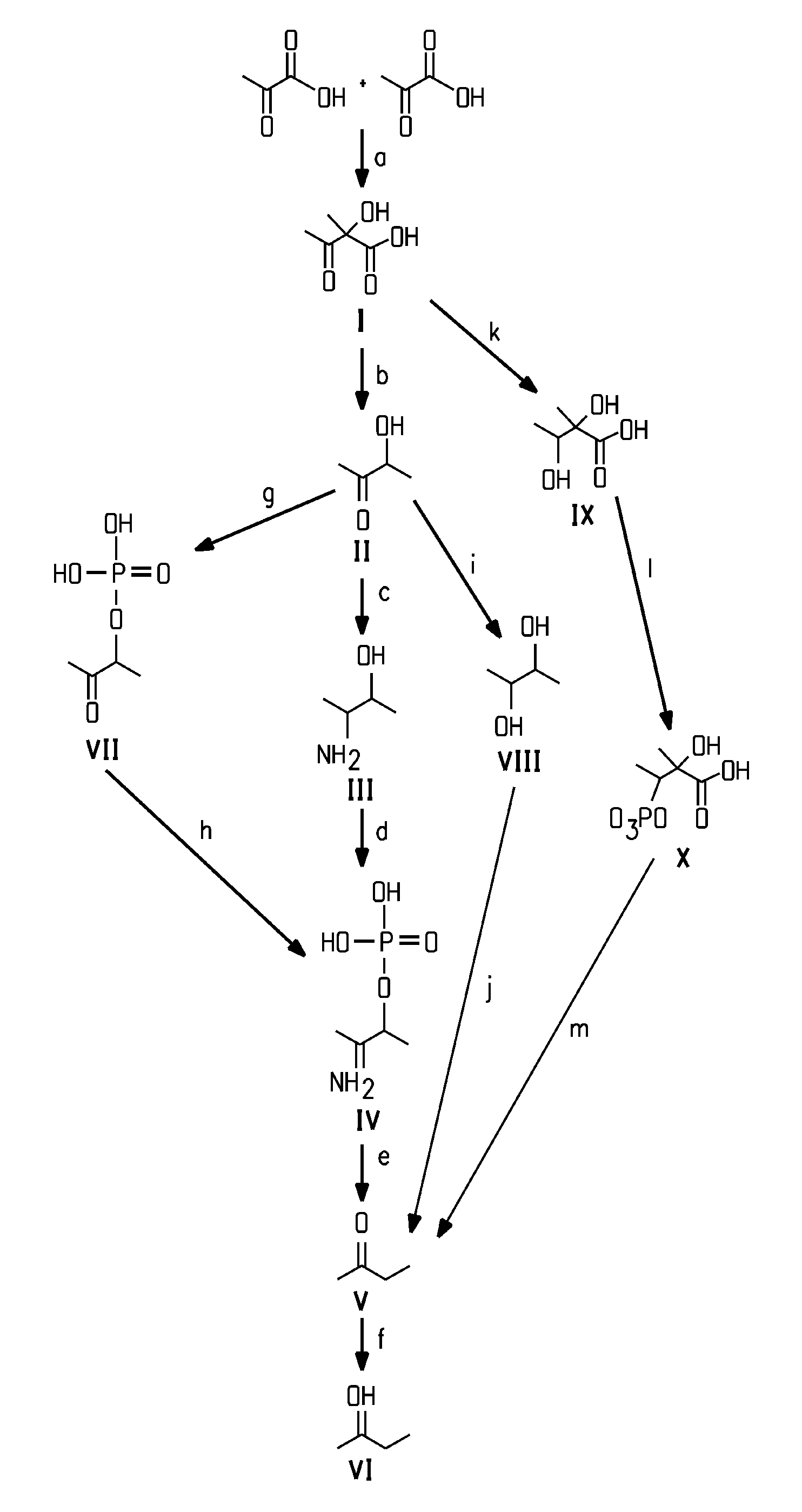

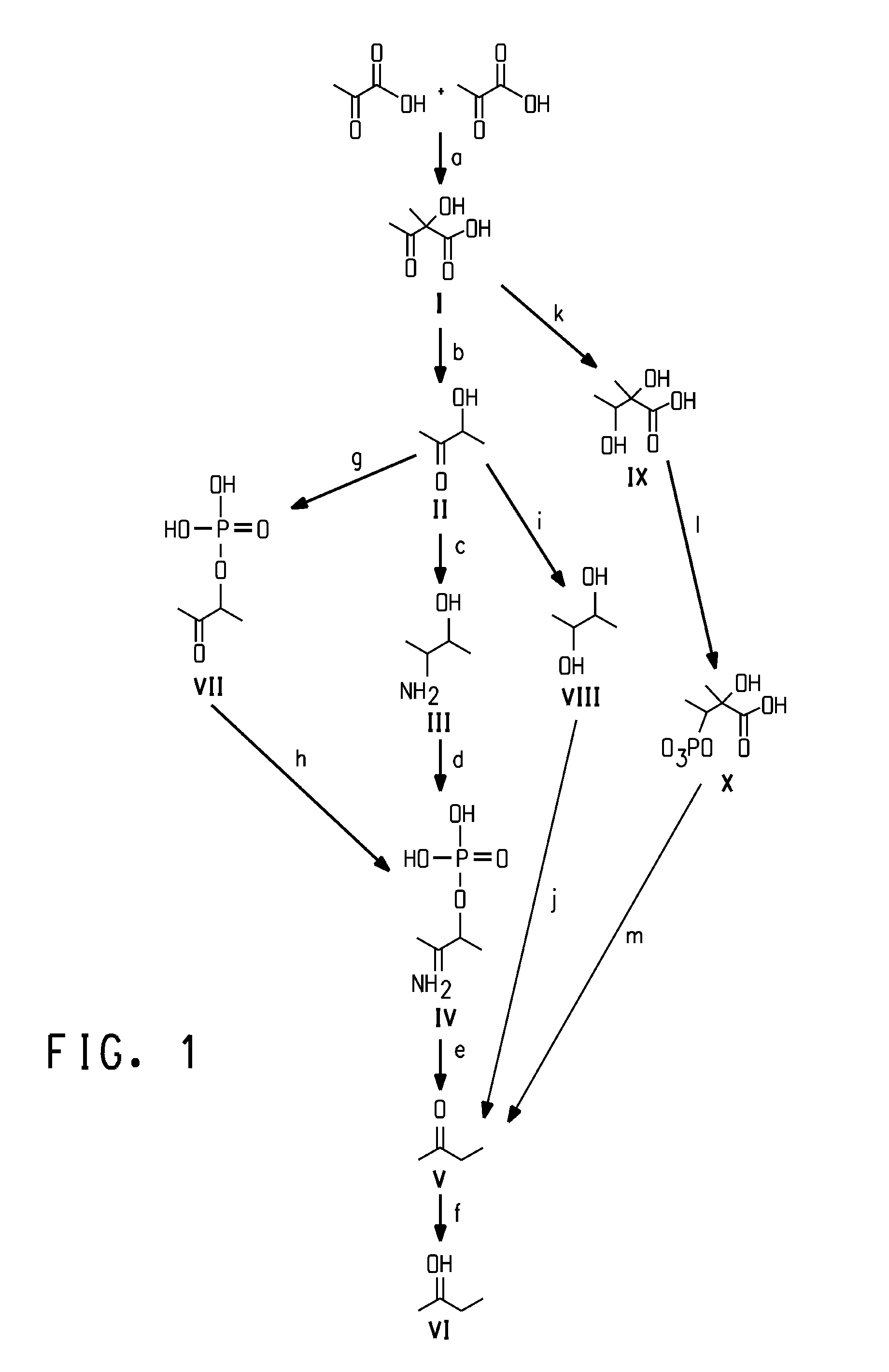

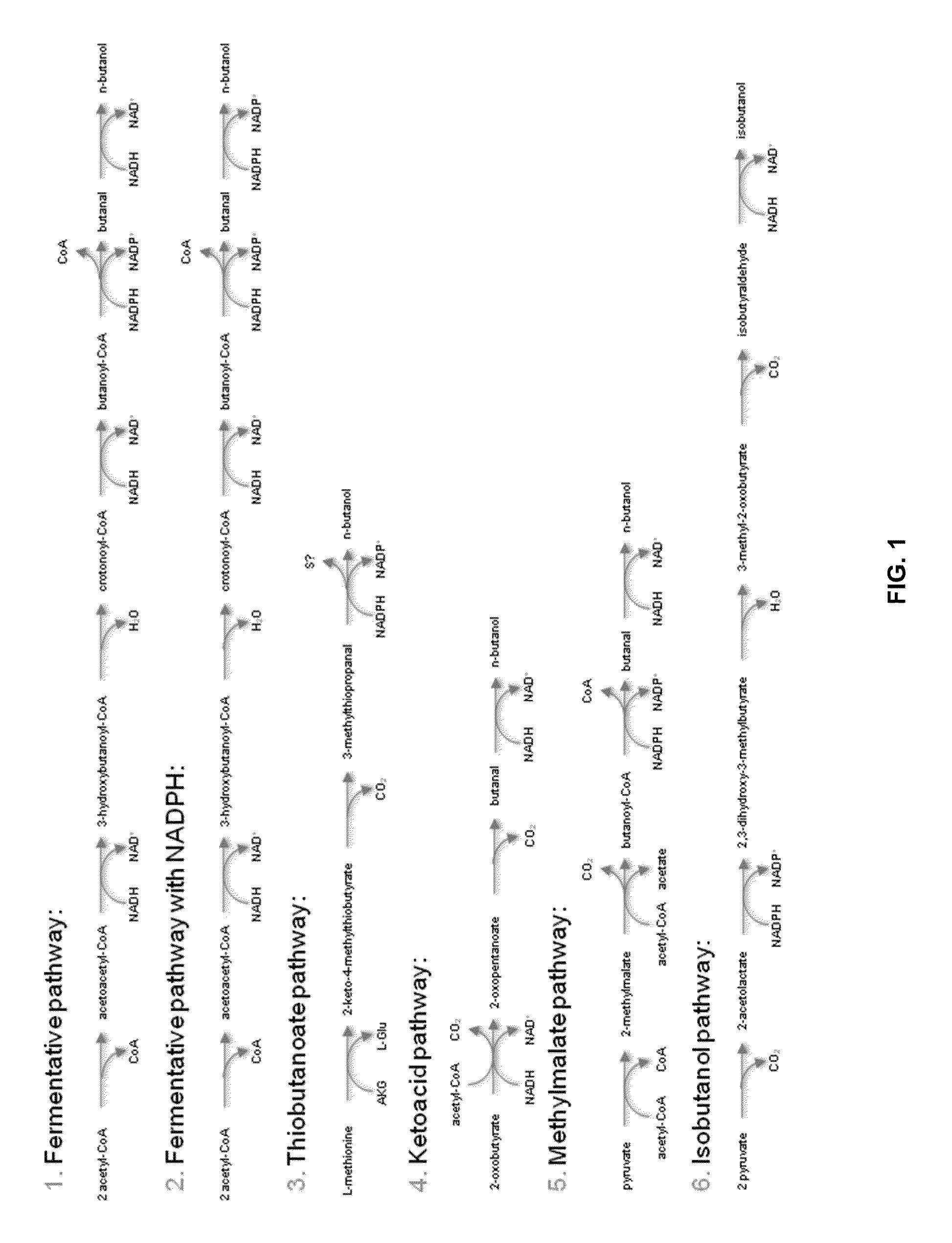

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein. Specifically disclosed herein are the use of coenzyme B12-independent butanediol dehydratases that catalyzes the substrate to product conversion of 2,3-butanediol to 2-butanone in the process of producing 2-butanol and 2-butanone.

Owner:GEVO INC

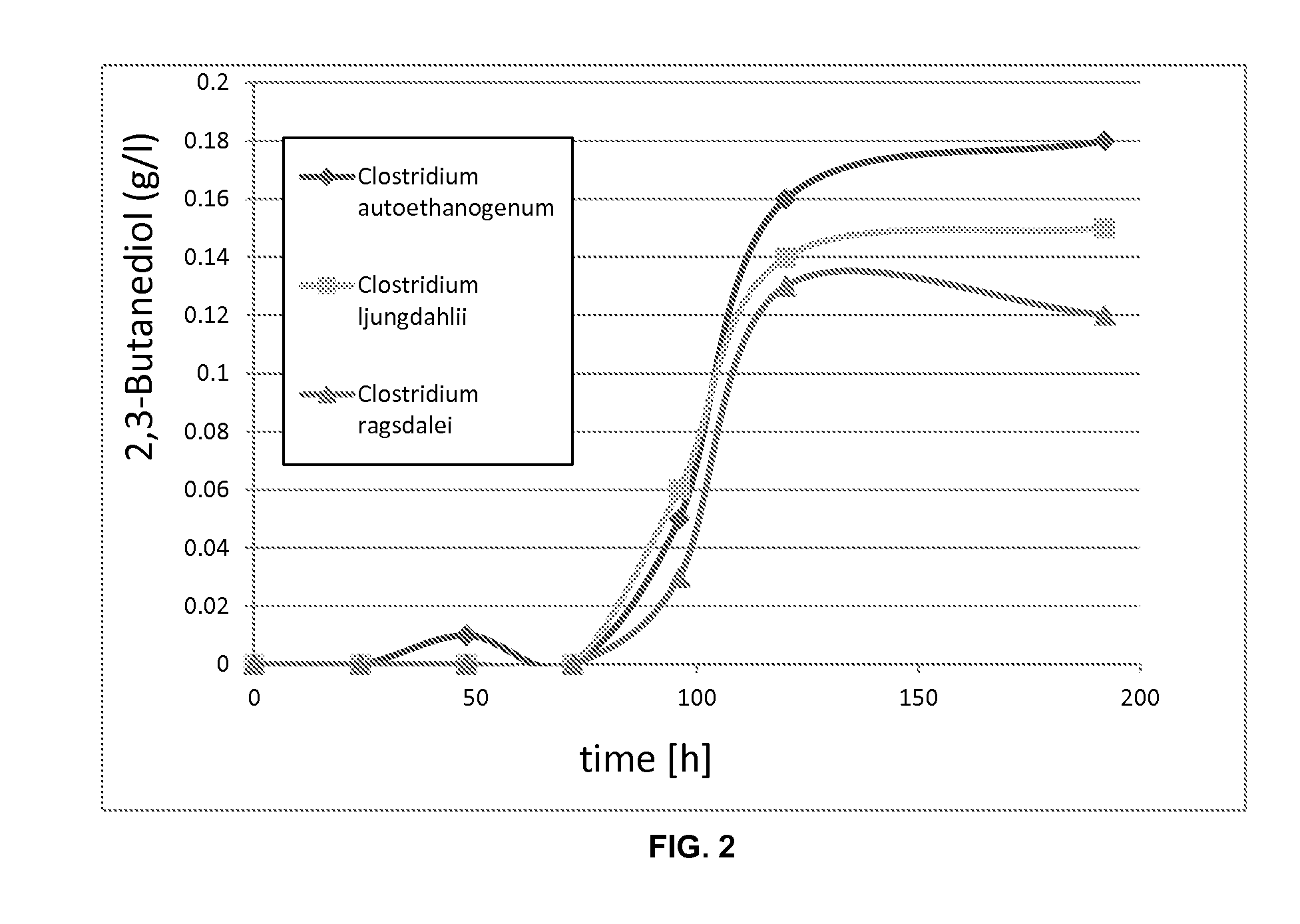

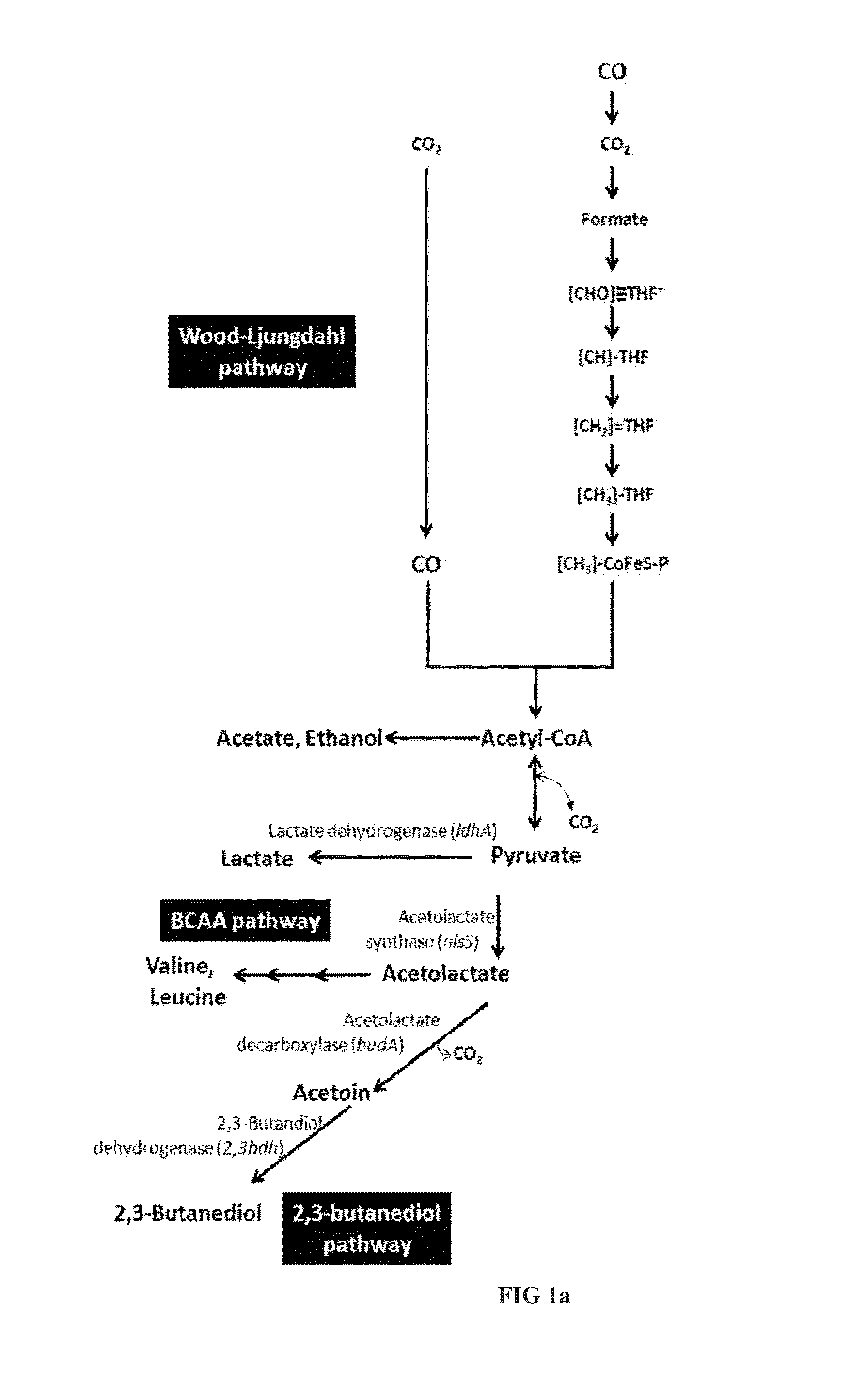

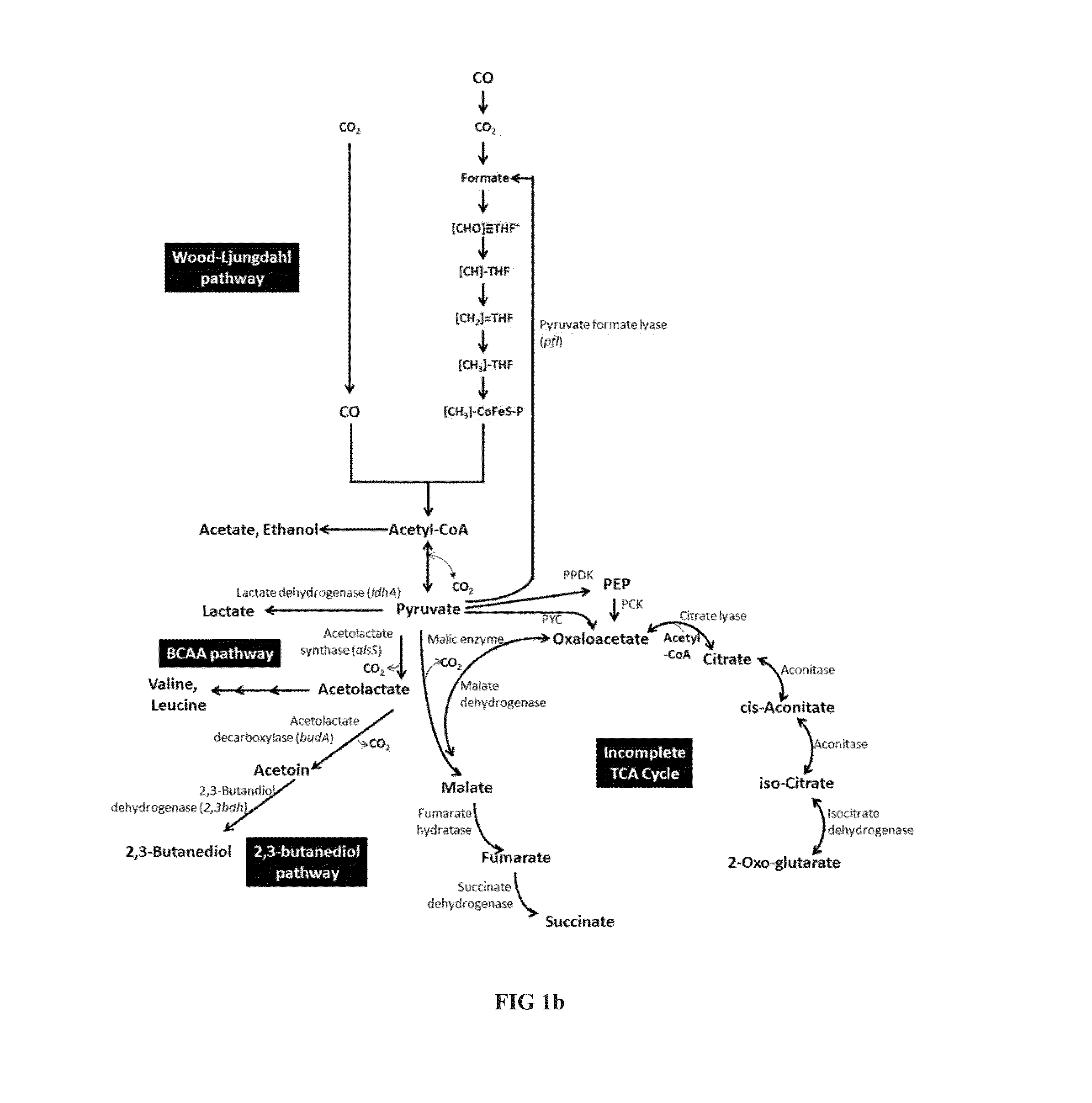

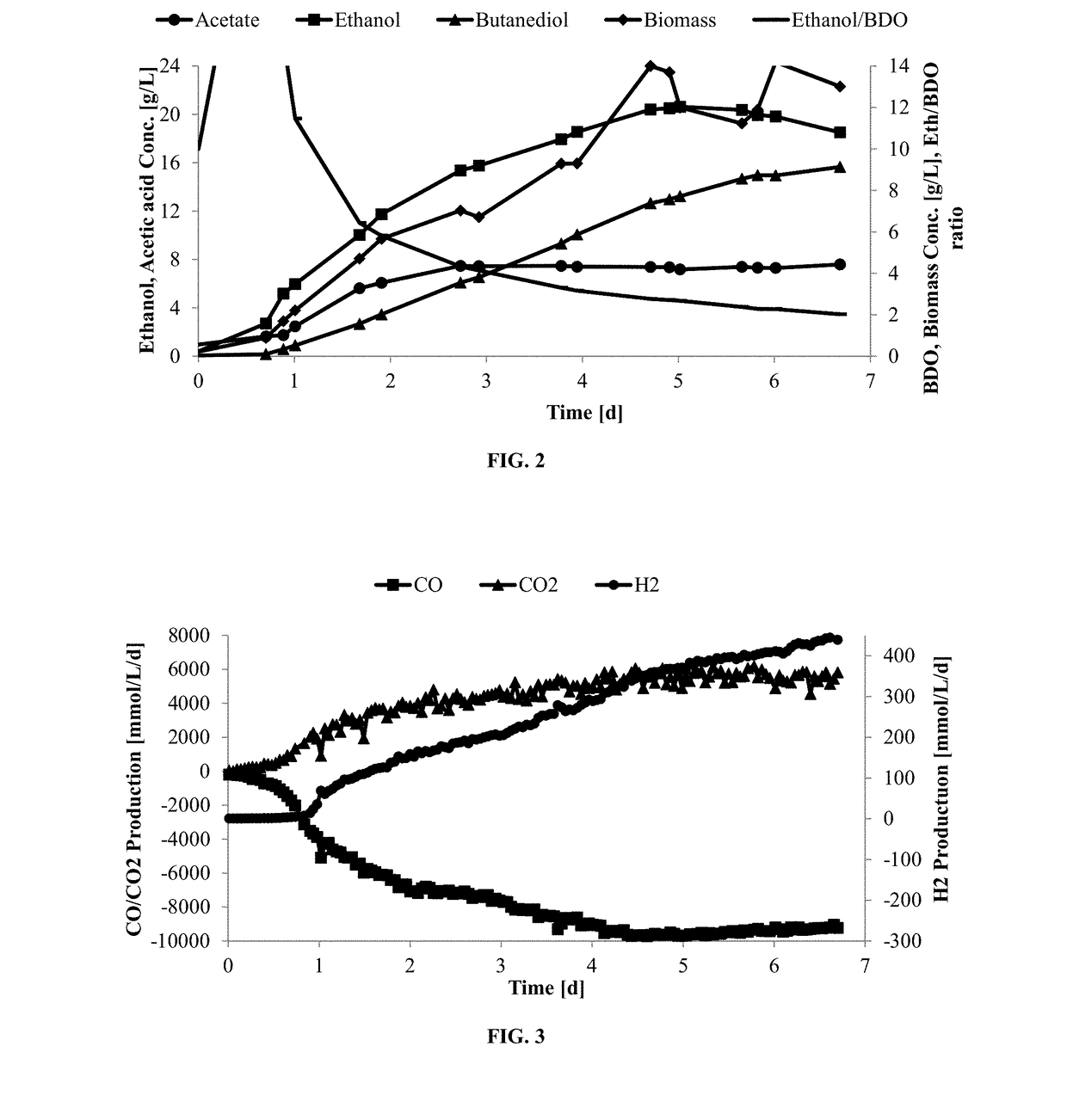

Process for producing chemicals using microbial fermentation of substrates comprising carbon monoxide

InactiveUS20120045807A1Organic compound preparationMicroorganismsClostridium ragsdalei2,3-Butanediol

A process for converting a substrate such as carbon monoxide to useful chemicals has been developed. The process involves providing a substrate comprising CO to a bioreactor which contains a culture of one or more micro-organisms and anaerobically fermenting the substrate to produce 2,3-butanediol (BDO). The BDO is next converted to one or more of butane, butadiene and / or methyl ethyl ketone which in turn can be converted to other compounds. The source of the CO can be an industrial process such as the ferrous metal products manufacturing. The microorganism can be Clostridium autoethanogenum, Clostridium ljundahlii or Clostridium ragsdalei.

Owner:LANZATECH NZ INC

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein. Specifically disclosed herein are the use of coenzyme B12-independent butanediol dehydratases that catalyzes the substrate to product conversion of 2,3-butanediol to 2-butanone in the process of producing 2-butanol and 2-butanone.

Owner:GEVO INC

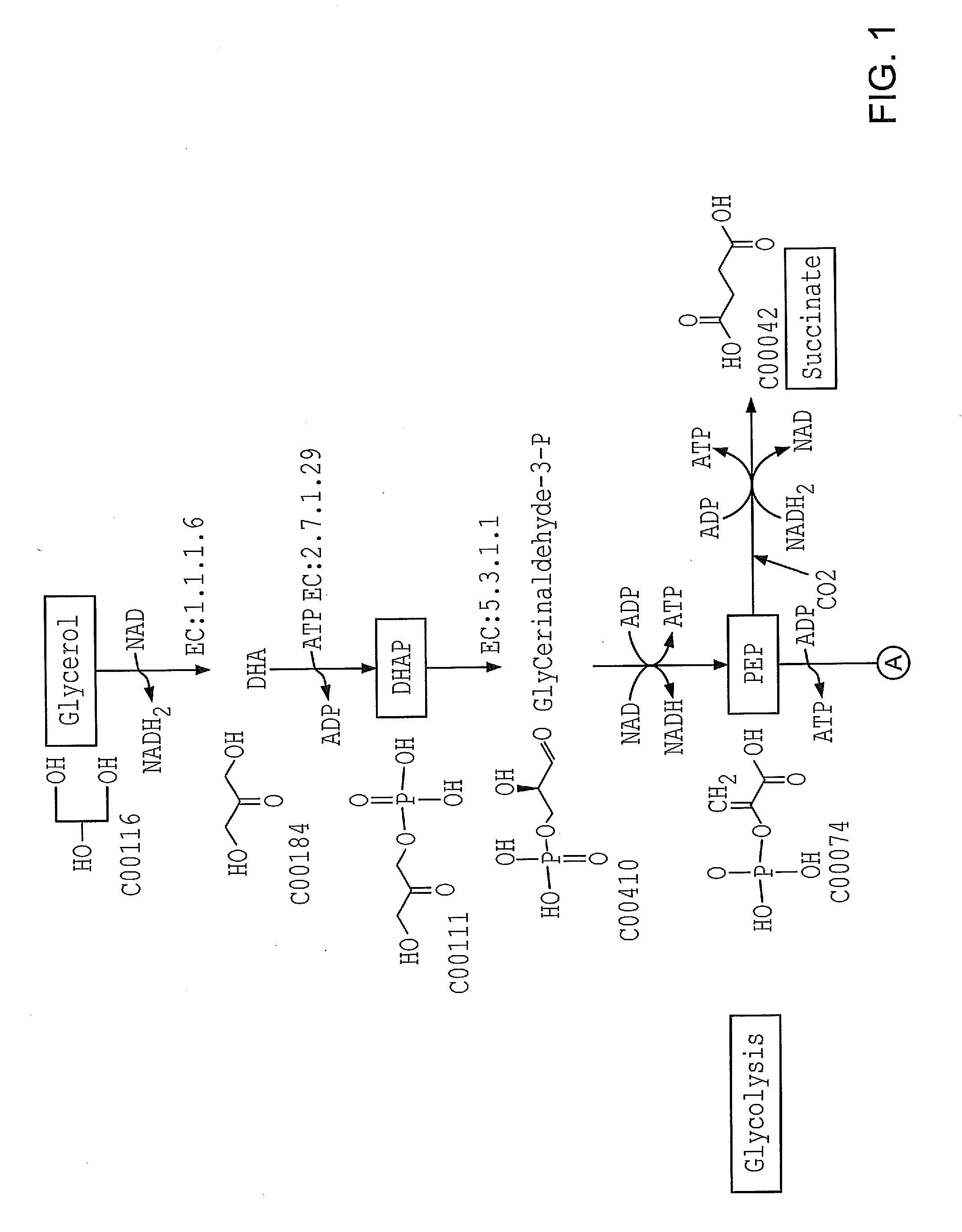

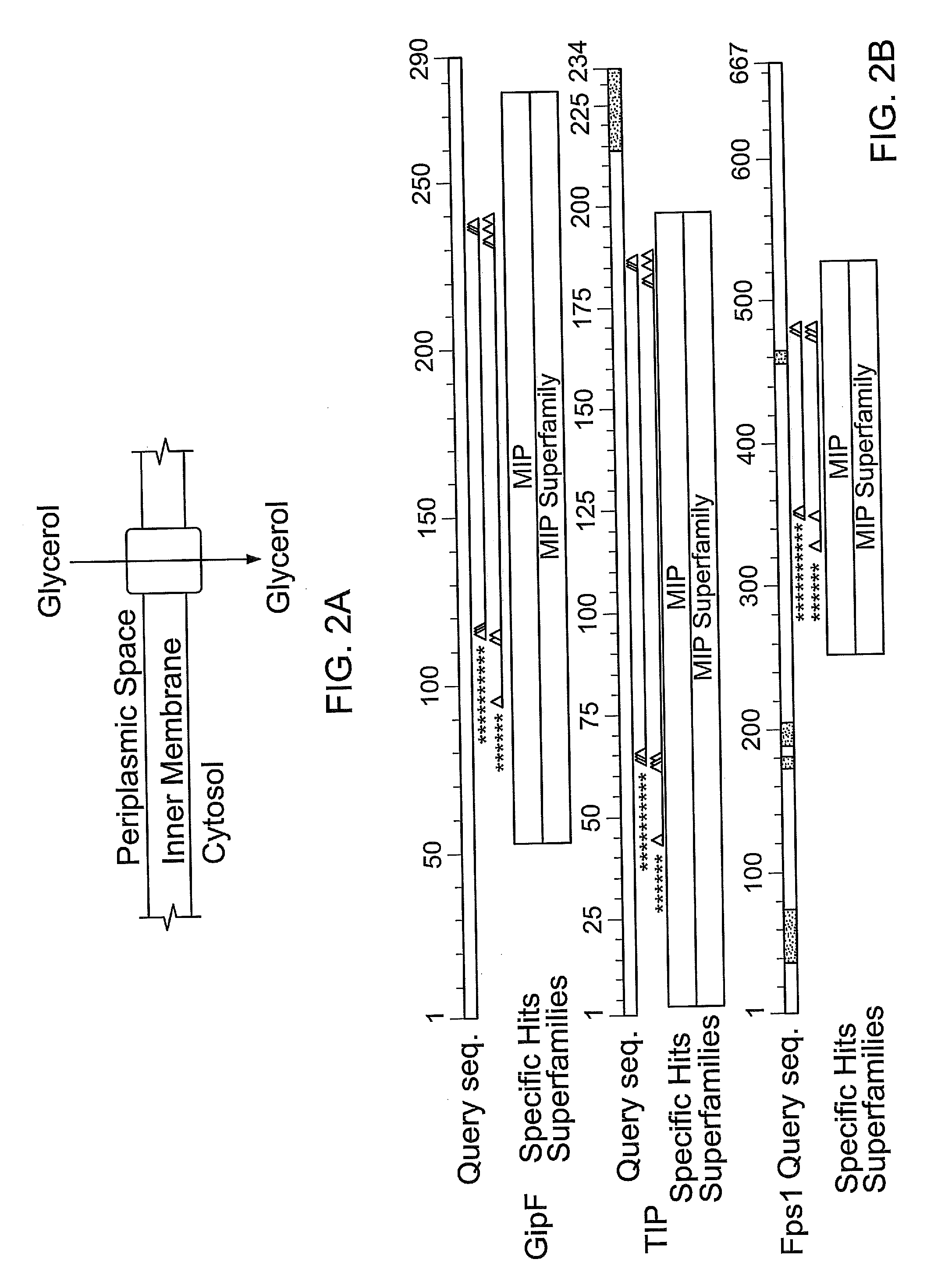

Methods of making nylon intermediates from glycerol

ActiveUS20130210090A1Reduce usageRate minimisedBacteriaHydrolases3-Hydroxypropionic acid2,3-Butanediol

Embodiments of the invention relate to the enzymatic conversion of bioderived feedstocks to commercially valuable chemicals. The enzymatic conversions of the embodiments of the invention offer the potential for lower cost routes to these value-added chemicals. Some of the chemicals that are useful include nylon intermediates such as caprolactam, adipic acid, 1,6-hexamethylene diamine; butanediols such as 1,4-butanediol, 1,3-butanediol, and 2,3-butanediol; butanols such as 1-butanol, and 2-butanol; succinic acid, butadiene, isoprene, and 3-hydroxypropanoic acid.

Owner:INV NYLON CHEM AMERICAS LLC

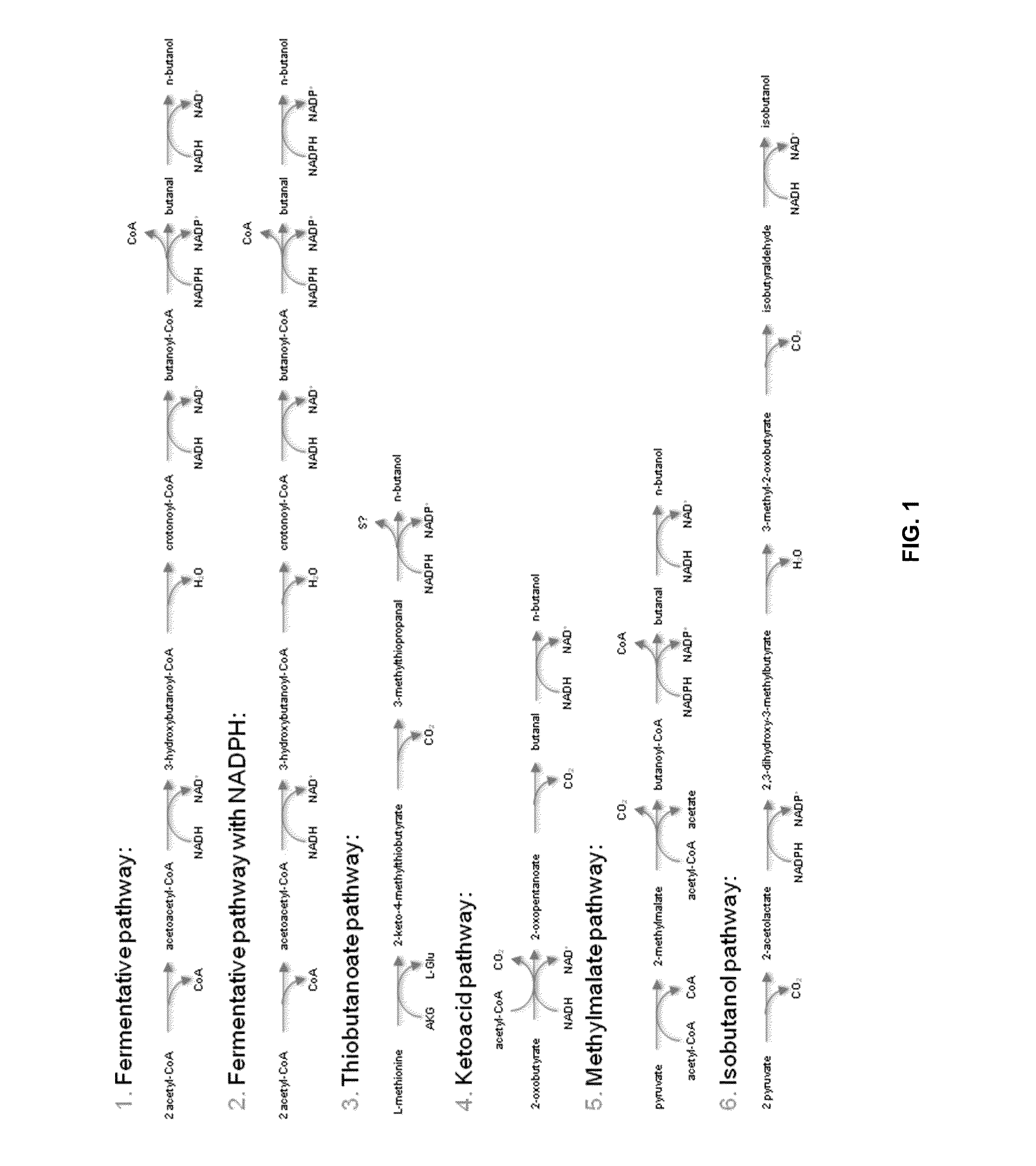

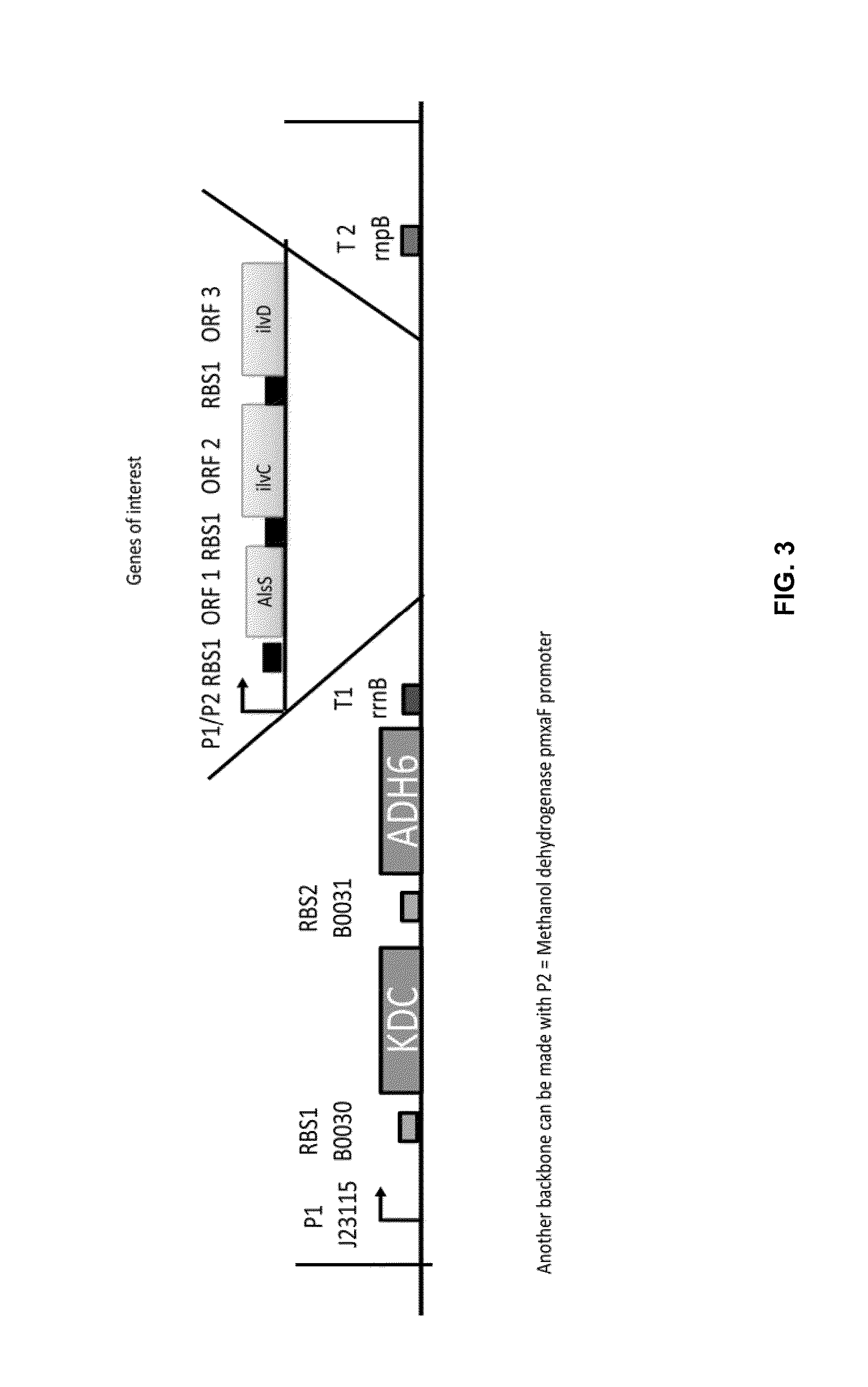

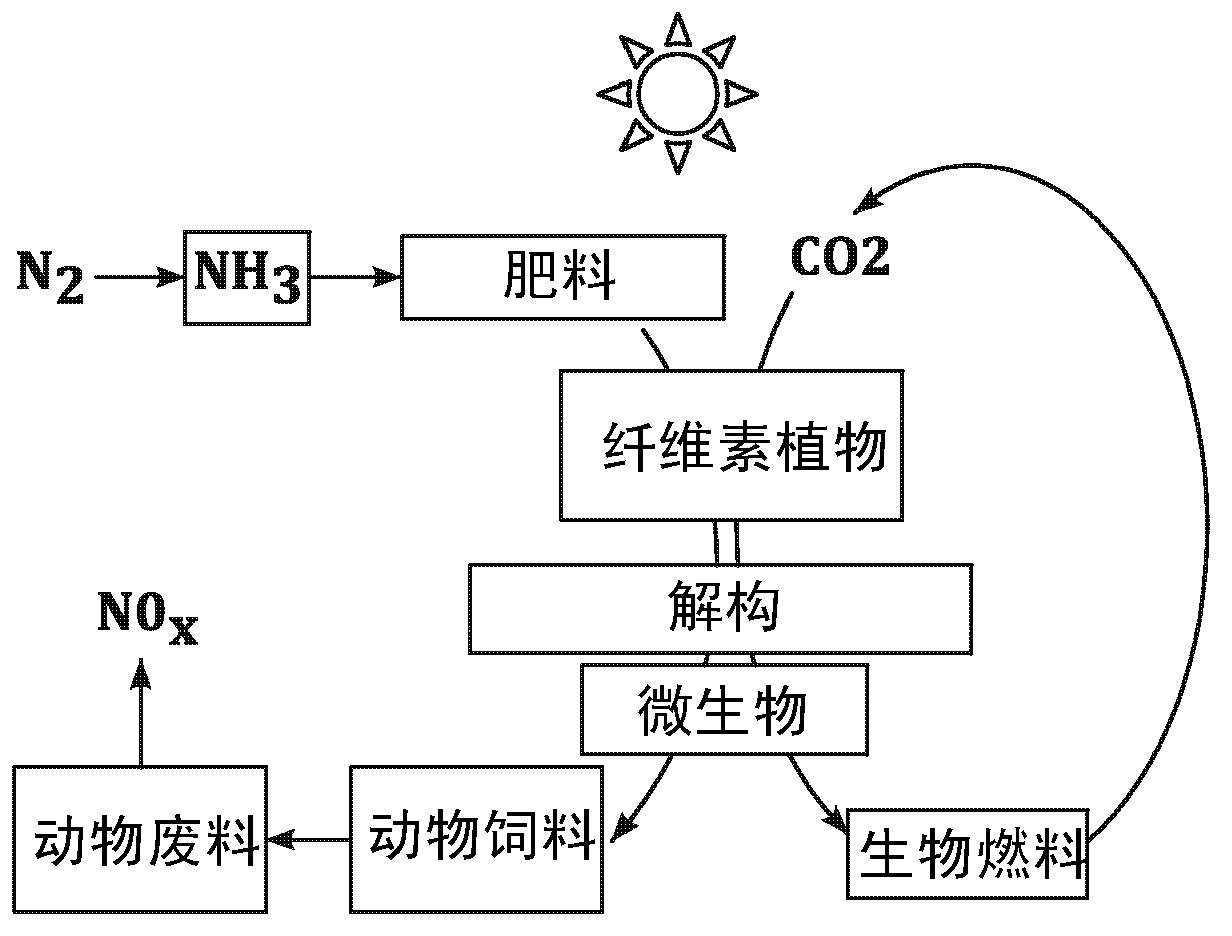

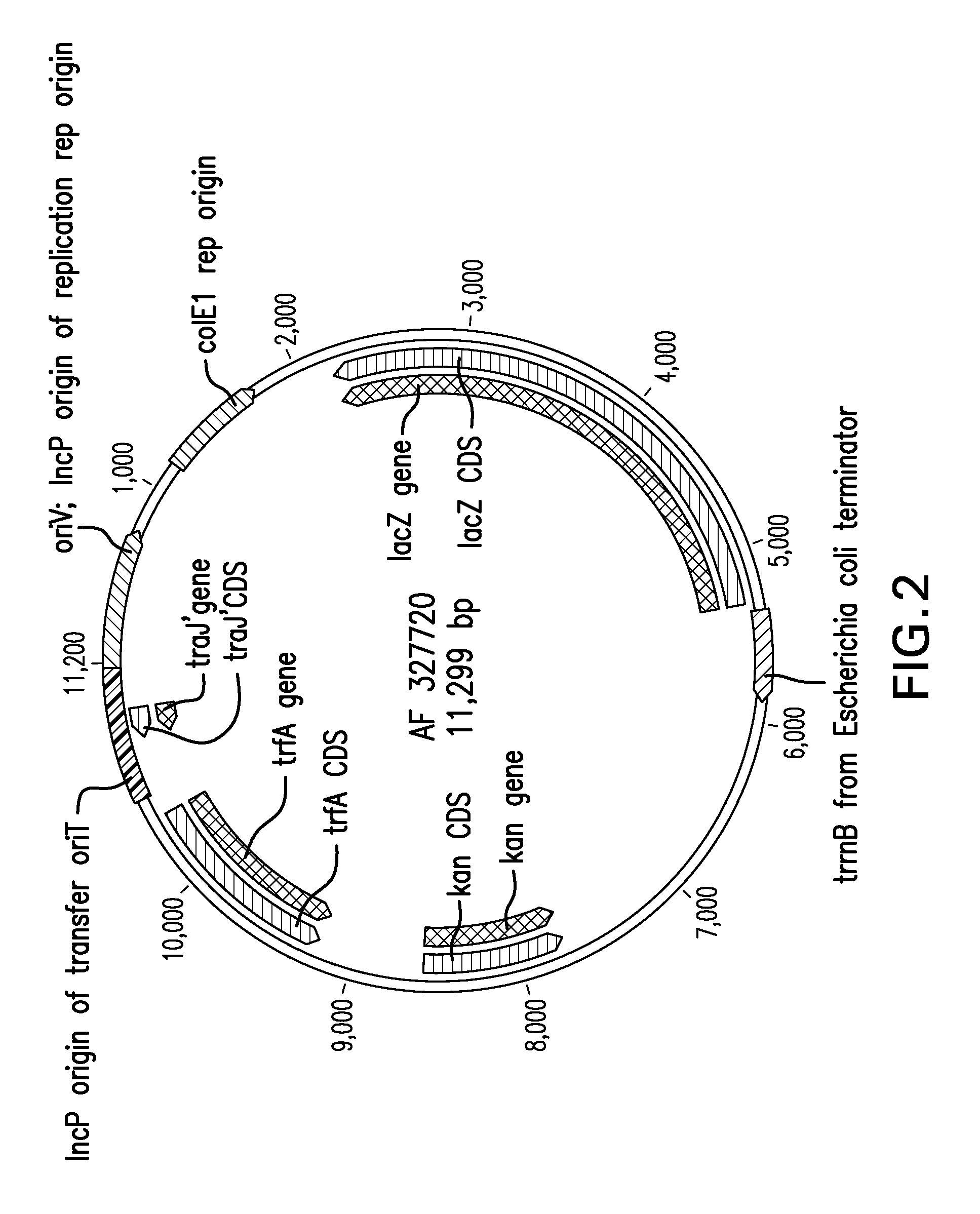

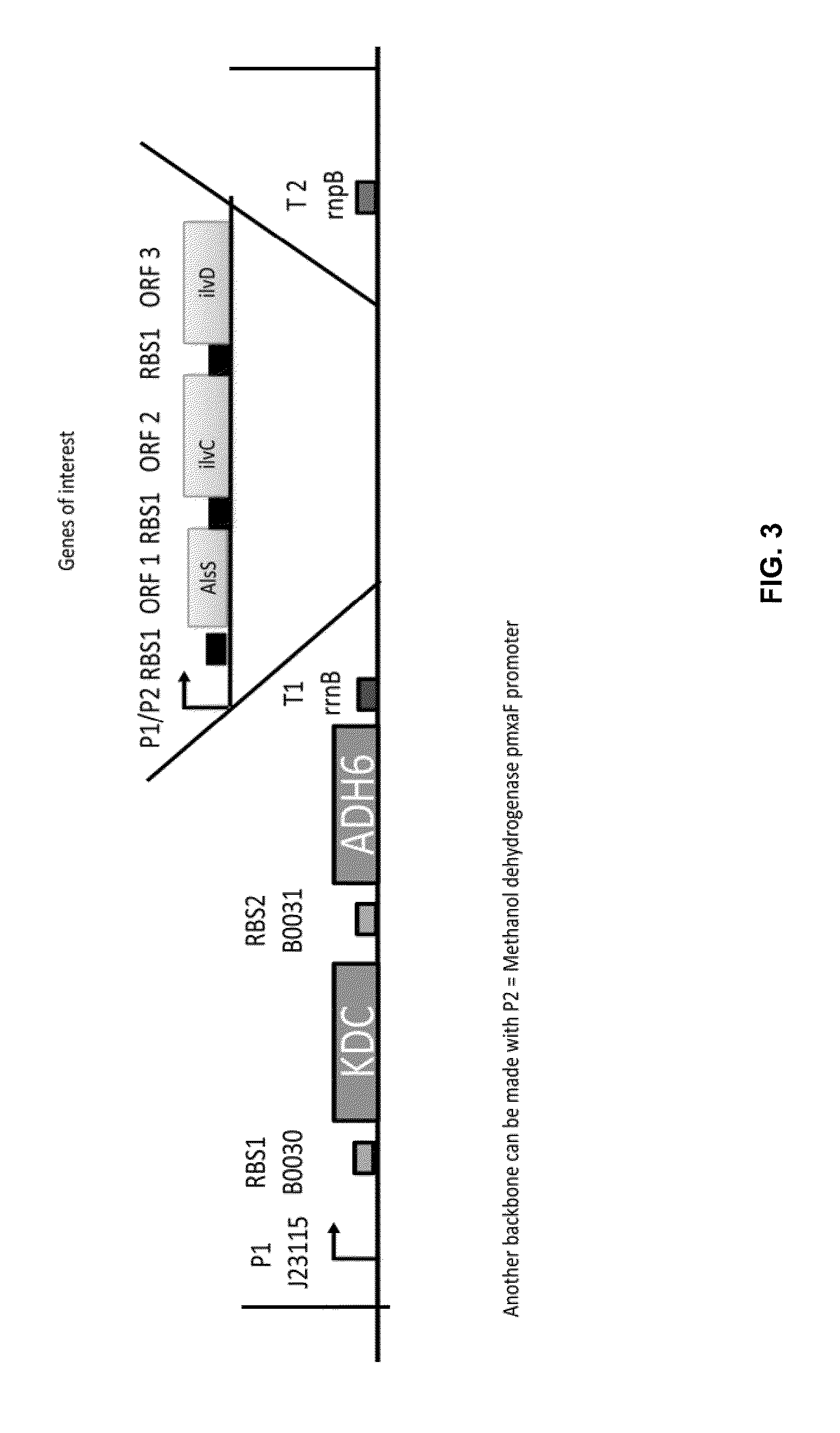

Biological Conversion of Multi-Carbon Compounds from Methane

Multi-carbon compounds such as ethanol, n-butanol, sec-butanol, isobutanol, tert-butanol, fatty (or aliphatic long chain) alcohols, fatty acid methyl esters, 2,3-butanediol and the like, are important industrial commodity chemicals with a variety of applications. The present invention provides metabolically engineered host microorganisms which metabolize methane (CH4) as their sole carbon source to produce multi-carbon compounds for use in fuels (e.g., bio-fuel, bio-diesel) and bio-based chemicals. Furthermore, use of the metabolically engineered host microorganisms of the invention (which utilize methane as the sole carbon source) mitigate current industry practices and methods of producing multi-carbon compounds from petroleum or petroleum-derived feedstocks, and ameliorate much of the ongoing depletion of arable food source “farmland” currently being diverted to grow bio-fuel feedstocks, and as such, improve the environmental footprint of future bio-fuel, bio-diesel and bio-based chemical compositions.

Owner:PRECIGEN INC

Environmentally-friendly breeding of bacillus subtilis for producing 2,3-butanediol by fermentation with glucose substrate

InactiveCN101851598AImprove protectionHigh utilization rate of raw materialsBacteriaMicroorganism based processesChemical synthesisPolyester

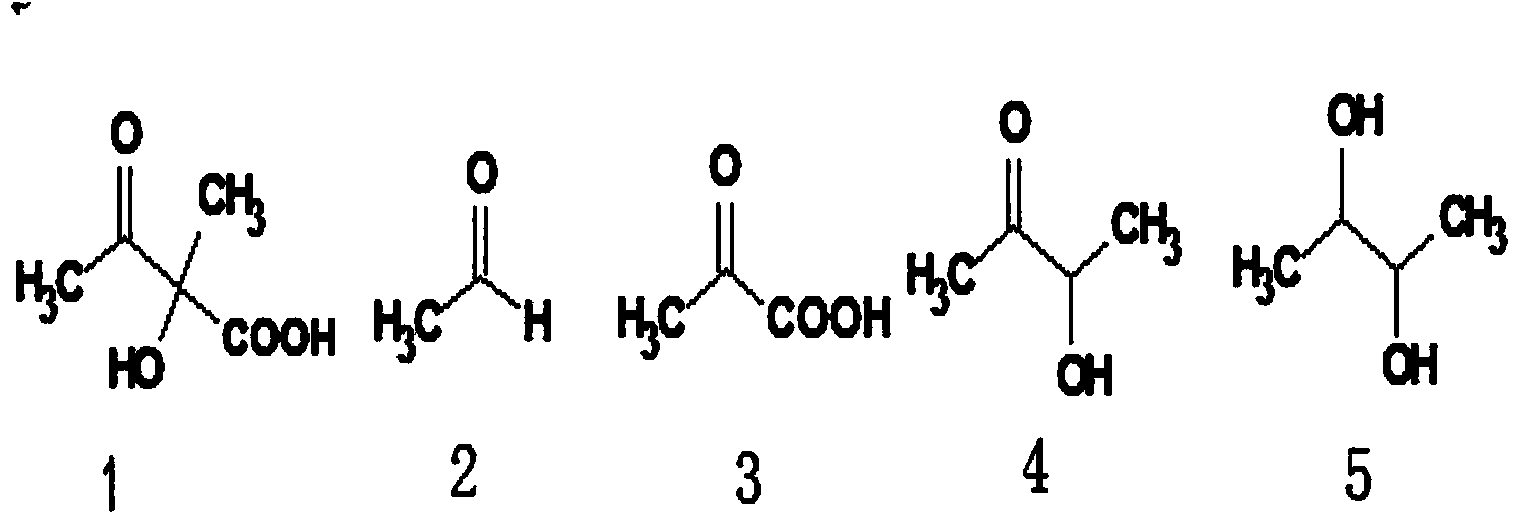

2,3-BDO is important industrial chemicals and a medicinal precursor, for example, the 2,3-BDO can form 1,3-butadiene through dehydration and can be used for synthesizing rubber, polyester and polyurethane; the esterified 2,3-BDO is a precursor of synthetic polyimine, and can be applied to medicaments, cosmetics, washing liquor liquid and the like; and in addition, the 2,3-BDO can also be used as a flavor substance to be added into distilled spirit and cream. The 2,3-BDO can be prepared by a chemical synthesis method and a microorganism production method, and due to a special structure of 2,3-butanediol, in the chemical method for producing the 2,3-butanediol, the 2,3-butanediol is mainly prepared by hydrolyzing four-carbon hydrocarbon generated during the splitting decomposition of petroleum at the high temperature and under the high pressure and has the disadvantages of high cost, complicated processes and difficult operation, so the large-scale industrial production is difficult to realize all the time. With the increasing rise in oil price, people pay close attention to the production of the 2, 3-butanediol by using the microbial fermentation method and the developmental research of derivatives thereof gradually. The fermentation method for producing the 2,3-butanediol has the following advantages that: firstly, the fermentation method has the superiority in cost, and the chemical method has high production cost; secondly, the fermentation method has an environmental-friendly characteristic, and the 2,3-butanediol is used as an organic synthesis intermediate to occupy markets of a number of compounds and other petroleum chemicals, has wide prospect, obvious social and environmental benefits, and is particularly favorable for the extensive application of the products; and thirdly, in the fermentation method for producing the 2,3-butanediol, renewable resources are used as raw materials, so the fermentation method does not depend on the petroleum chemicals.

Owner:JIANGNAN UNIV

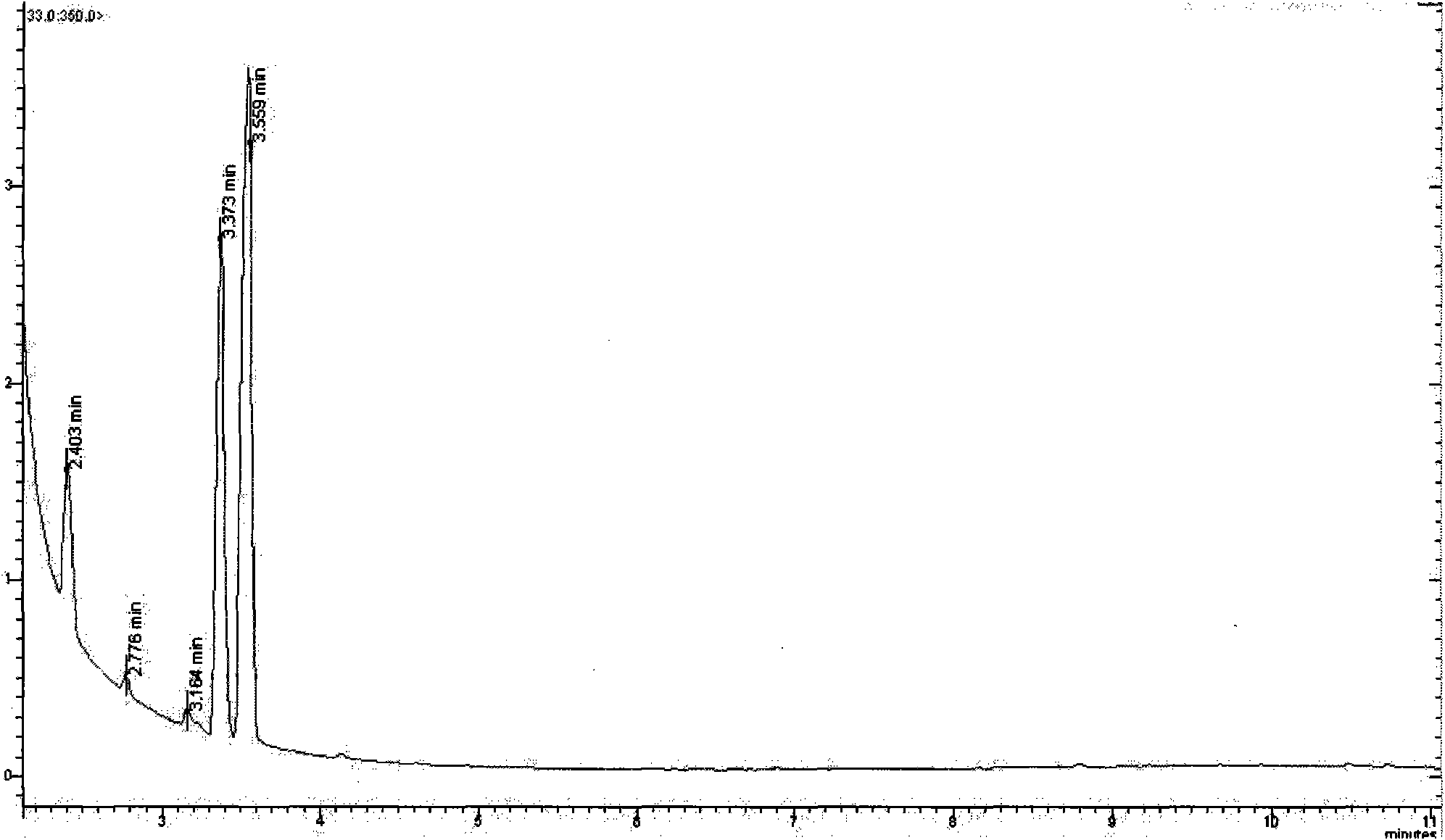

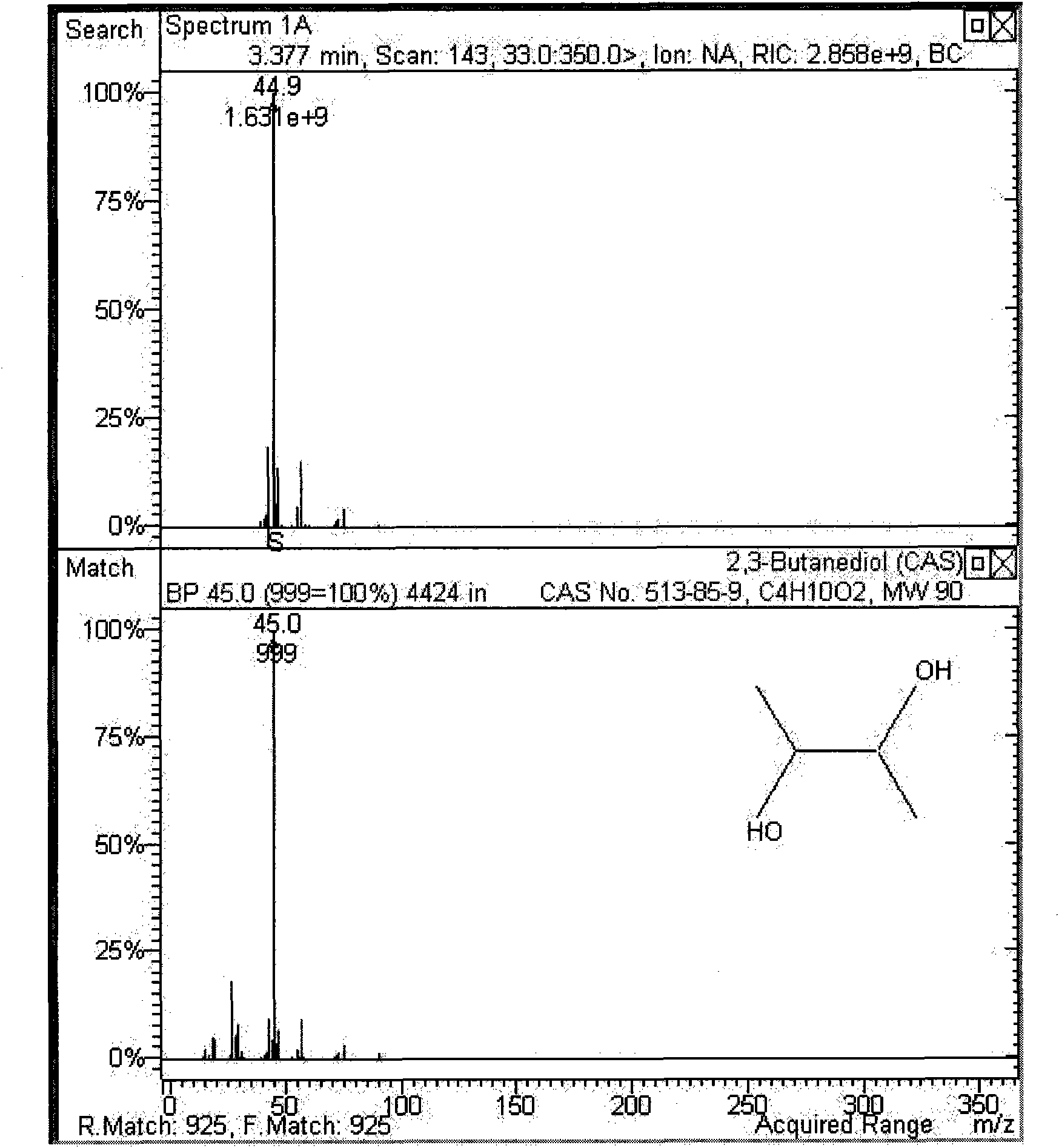

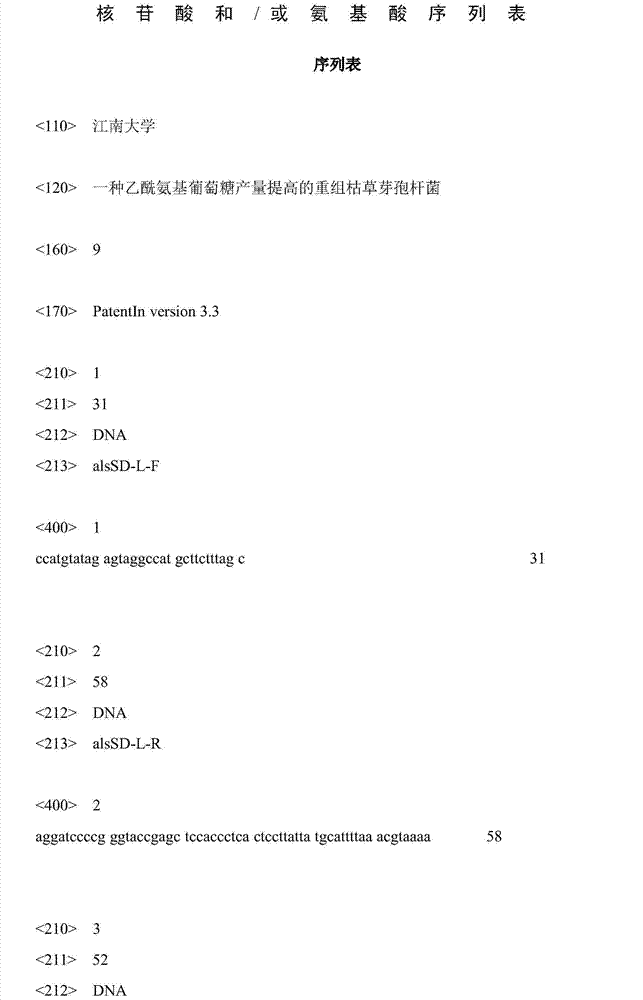

Recombinant bacillus subtilis increased in yield of acetylglucosamine

ActiveCN104498394AEasy to buildEasy to useBacteriaMicroorganism based processes2,3-ButanediolAcetolactate Synthetase

The invention discloses a recombinant bacillus subtilis increased in yield of acetylglucosamine and belongs to the field of genetic engineering. According to the recombinant bacillus subtilis increased in yield of acetylglucosamine, the recombinant bacillus subtilis BSGN6-PxylA-glmS is taken as an original strain, an alpha-acetolactate synthetase encoding gene and an alpha-acetolacetate decearboxylase encoding gene are knocked out by virtue of homologous recombination, and therefore, the approach by which acetoin and butanediol are generated from 2,3-pyroracemic acid in host bacteria is blocked. In the host bacteria from which the alsS and alsD are knocked out, the glucosamine acetylase encoding gene derived from saccharomyces cerevisiae is excessively expressed, and therefore, the route of synthesis of the acetylglucosamine is enhanced, the yield of the acetylglucosamine in the recombinant bacillus subtilis is increased to 38.46g / L, and a foundation is laid for producing the glucosamine by modifying the bacillus subtilis in the metabolic engineering.

Owner:JIANGNAN UNIV

Optimised fermentation media

InactiveUS20110300593A1Improve growth efficiencyMaintaining and increasing production rateBacteriaSulfur compoundsAlcohol2,3-Butanediol

The invention relates to improvements in the production of alcohols by microbial fermentation, particularly to production of alcohols by microbial fermentation of a substrate comprising CO. It more particularly relates to the provision of an inorganic organic sulfur source to a fermentation system such that one or more micro-organisms convert a substrate comprising CO to alcohols. In a particular embodiment, a microbial culture is provided with sodium polysulfide, wherein a substrate comprising CO is converted to products including ethanol and 2,3-butanediol.

Owner:LANZATECH NZ INC

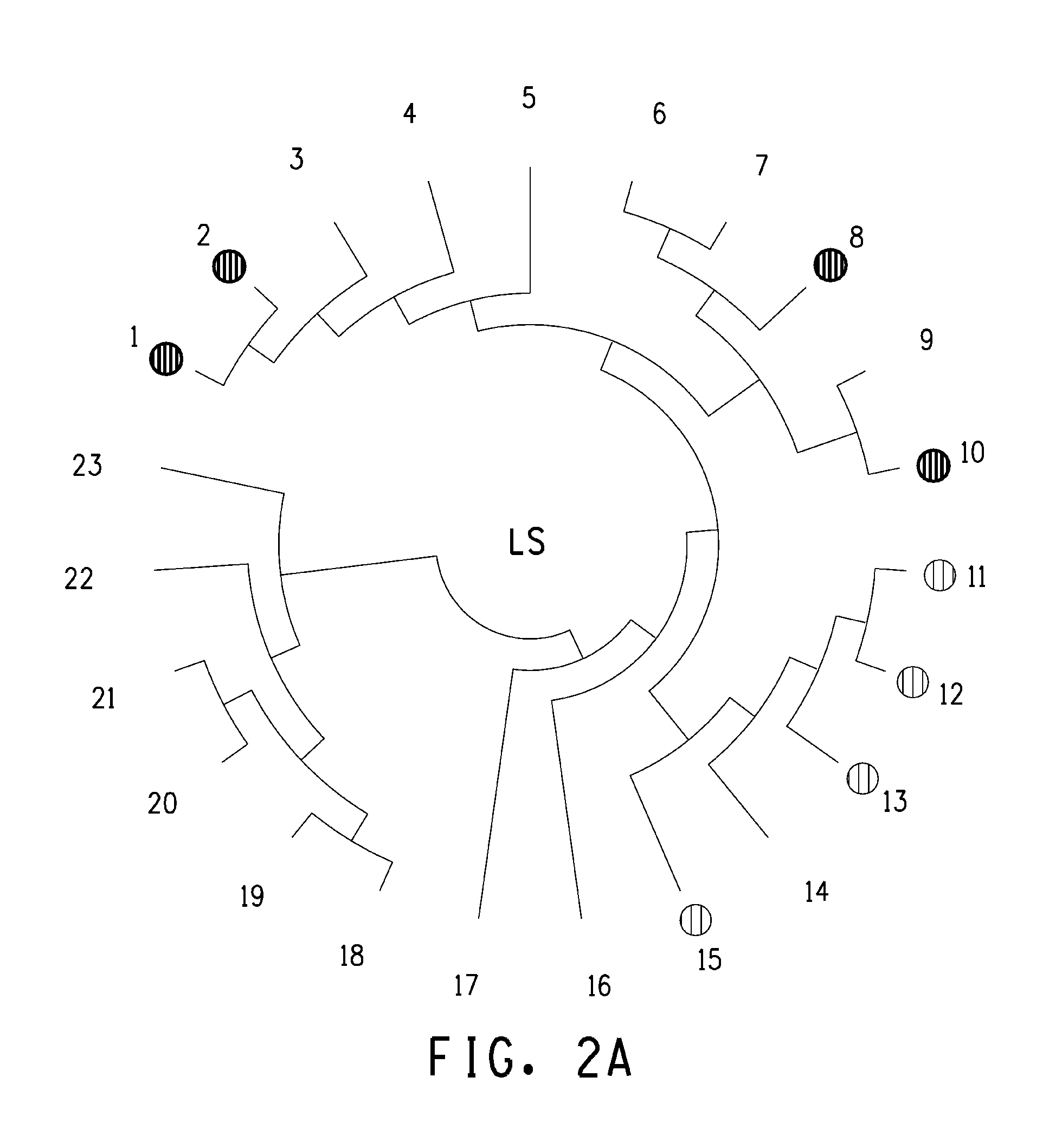

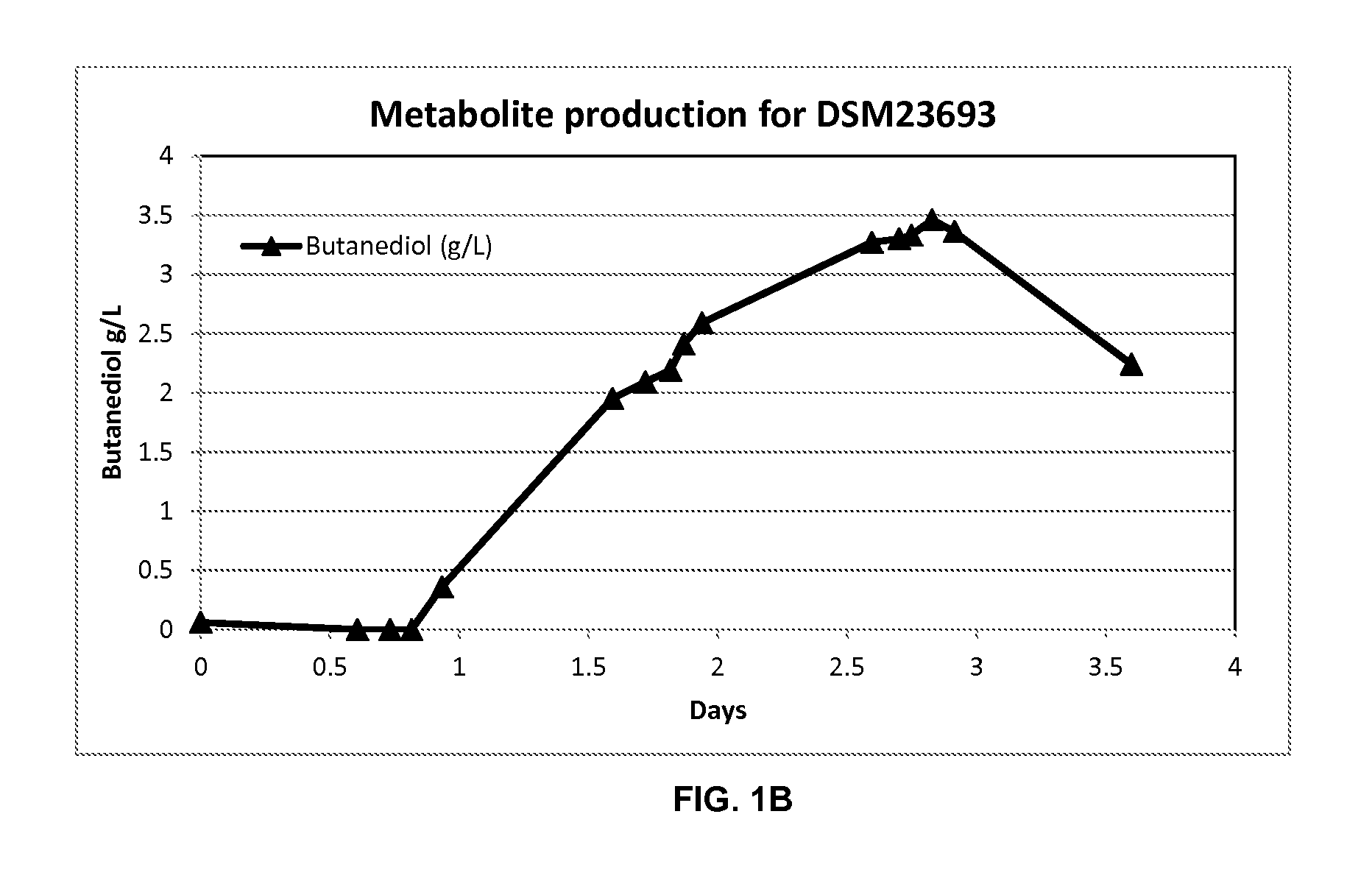

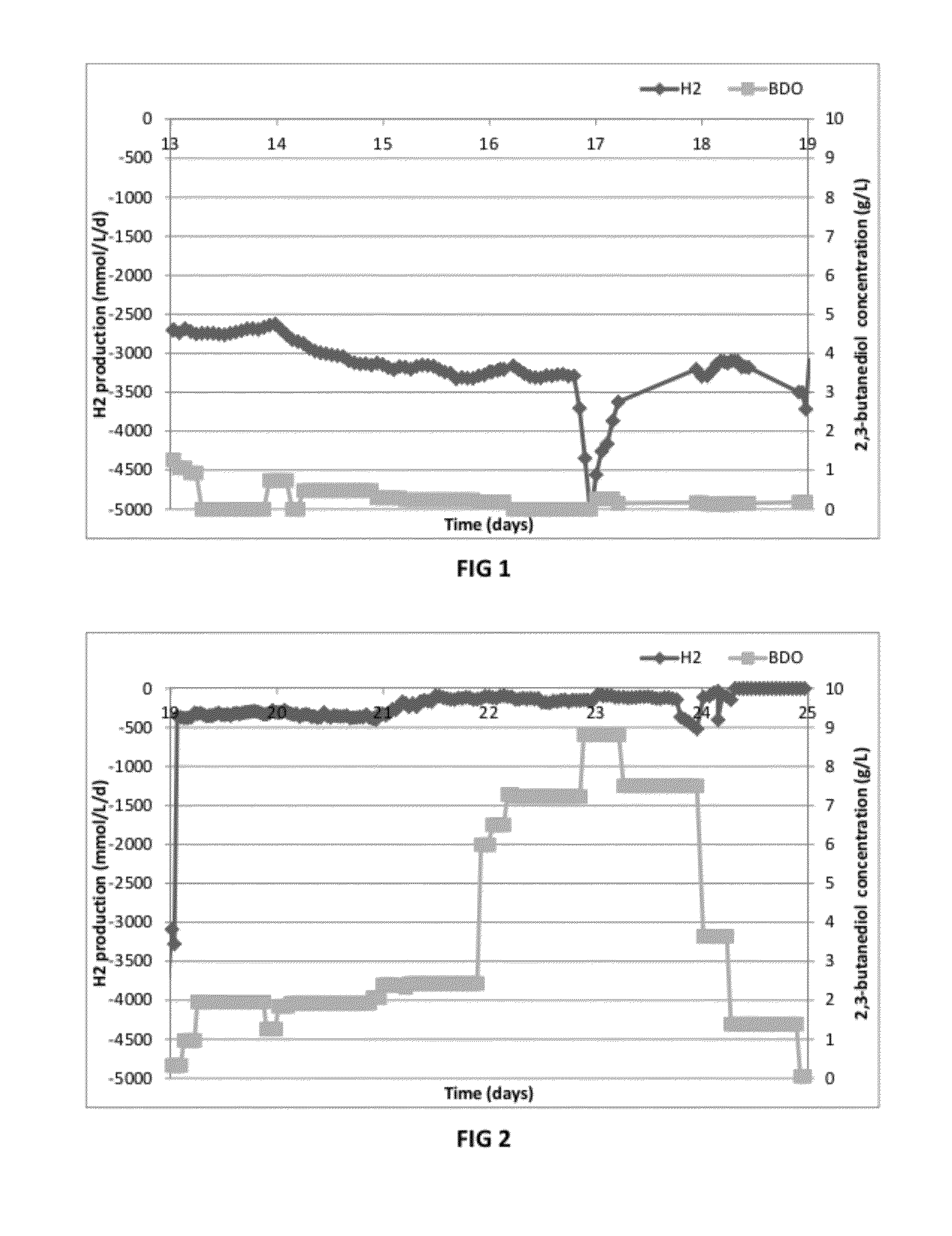

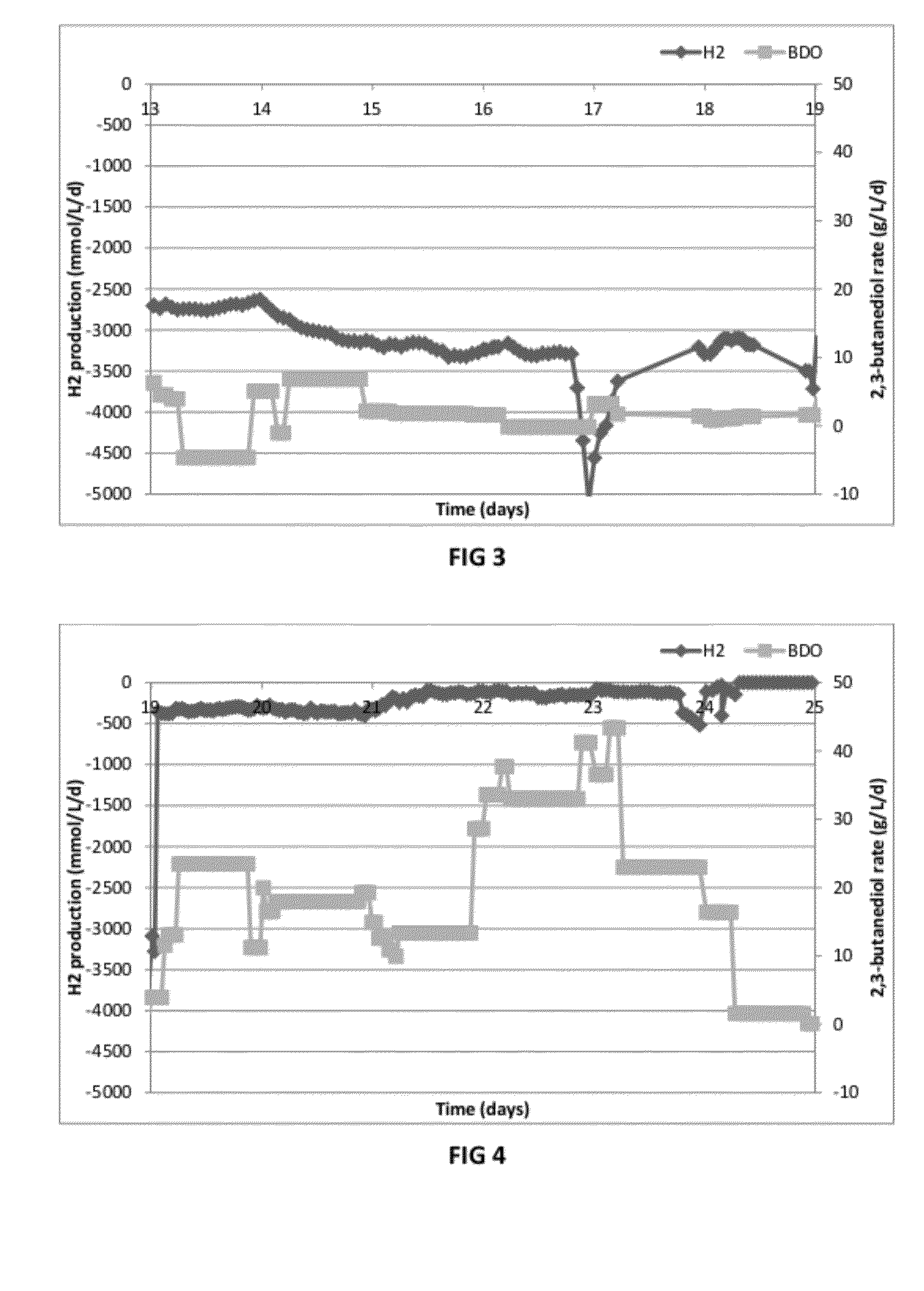

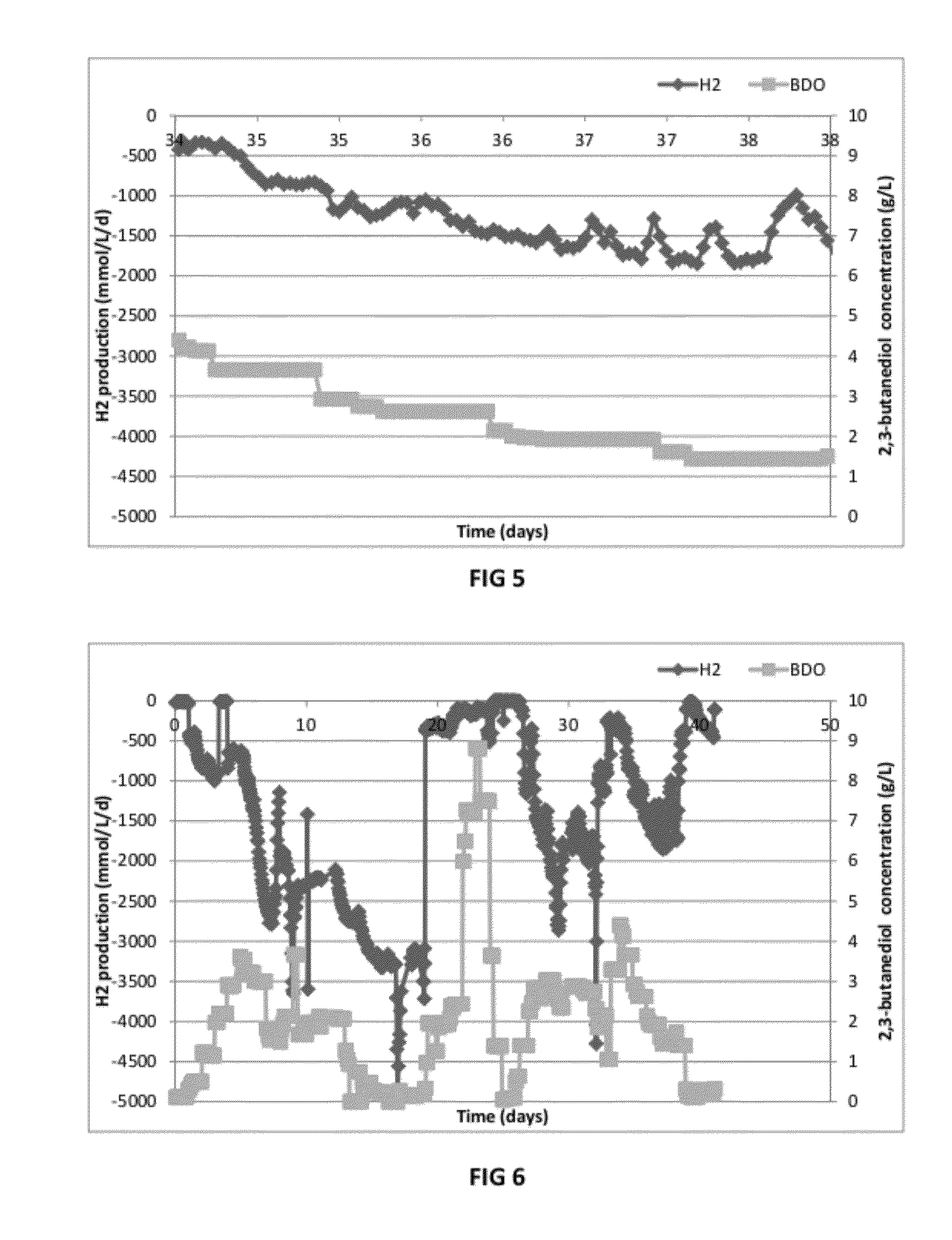

Fermentation Process For Controlling Butanediol Production

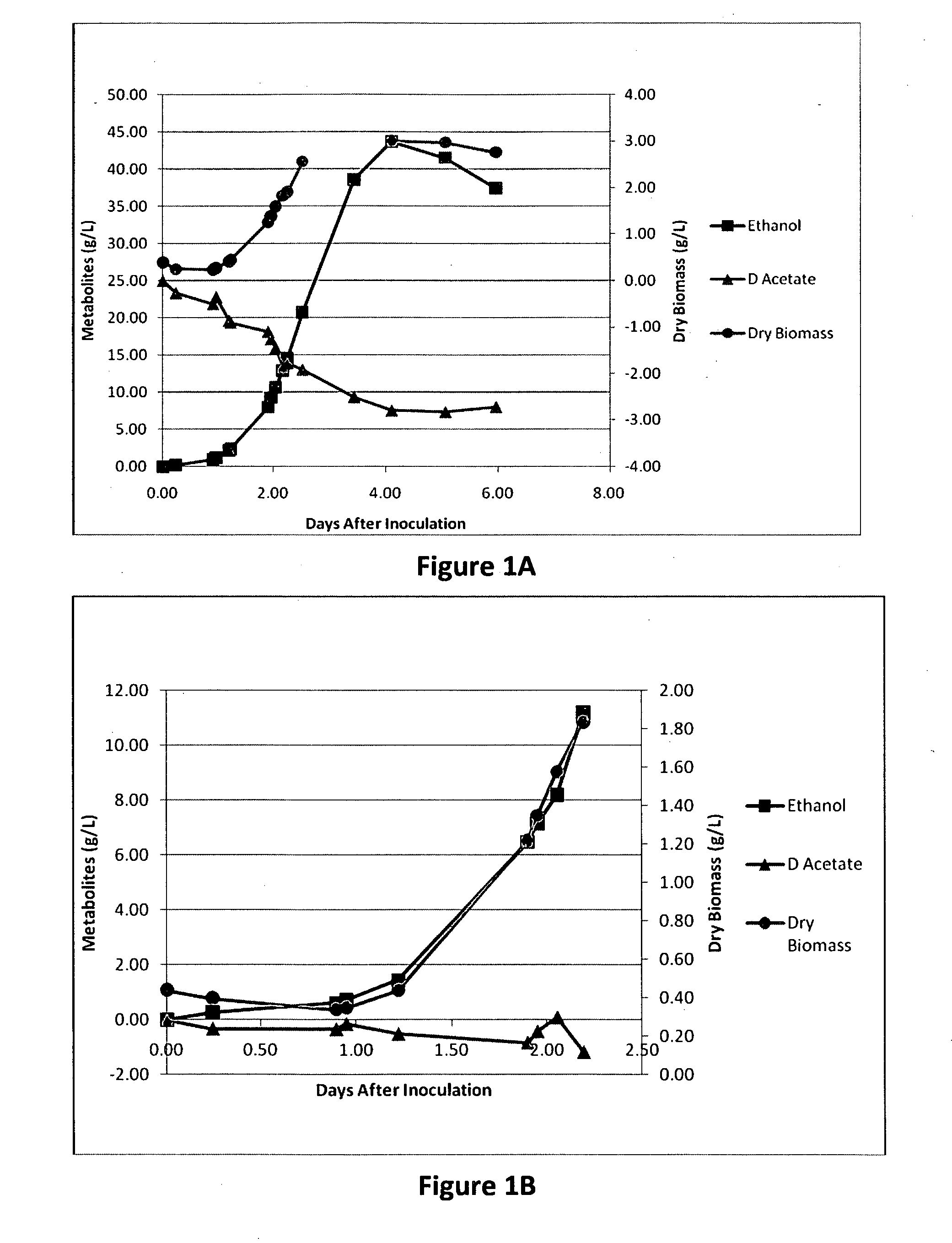

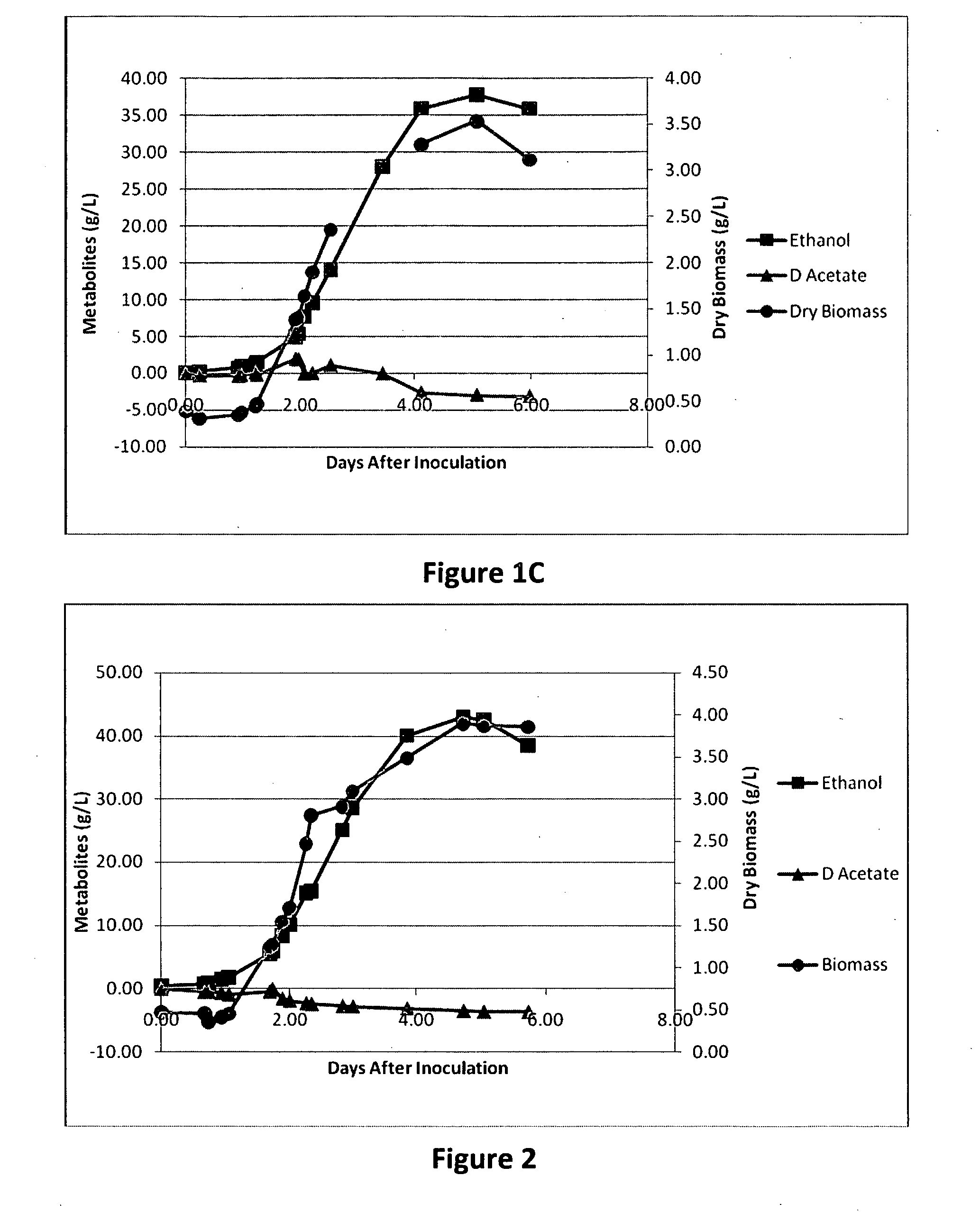

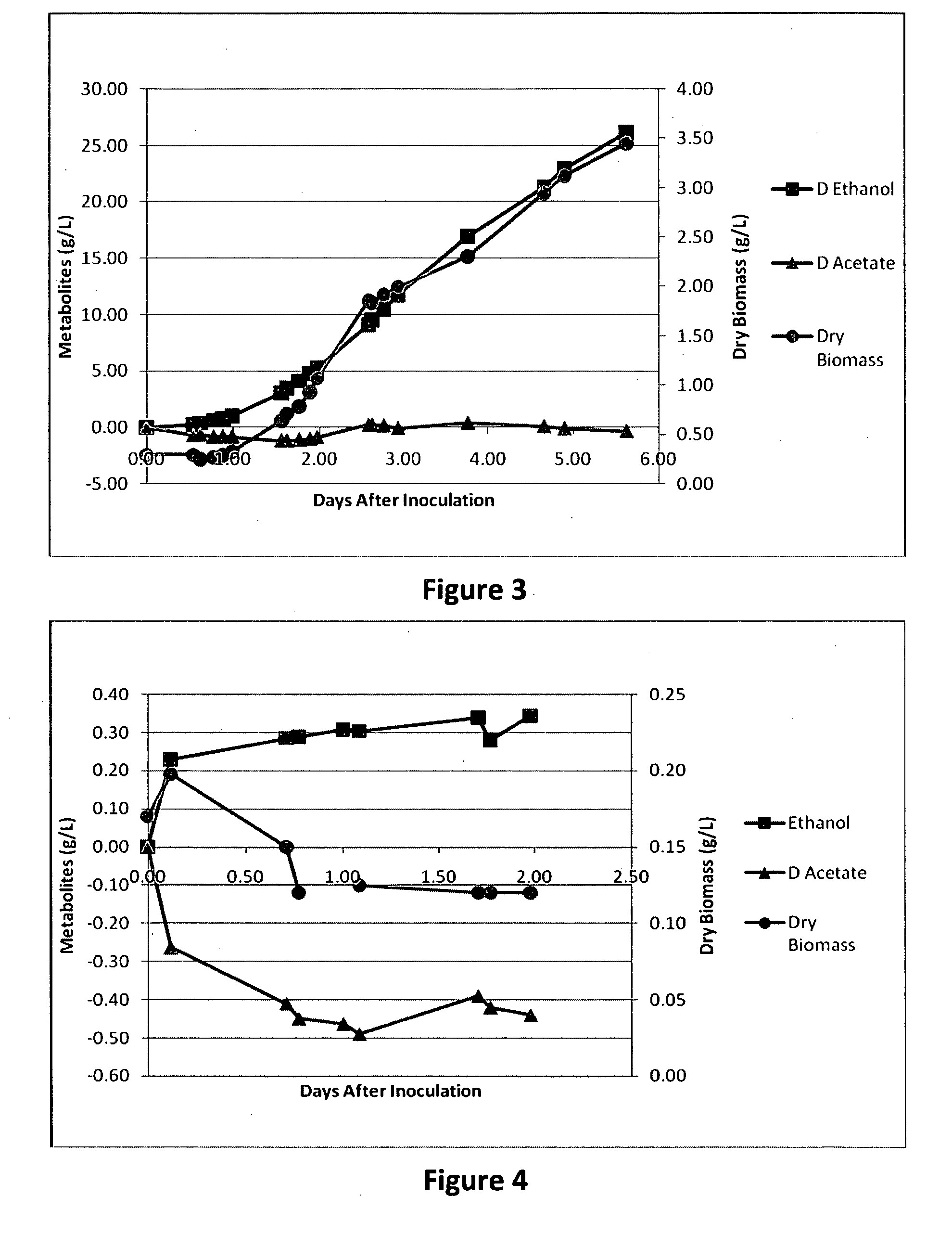

Methods for improving the efficiency of 2,3-butanediol fermentations are disclosed. More specifically methods of increasing the butanediol productivity from the anaerobic fermentation of a substrate comprising carbon monoxide or carbon monoxide and hydrogen by one or more caboxydotrophic acetogenic bacteria are disclosed. The method includes supplying a hydrogen depleted substrate to increase butanediol productivity. The method includes producing butanediol at a volumetric productivity rate of at least 15 g / L / day.

Owner:LANZATECH NZ INC

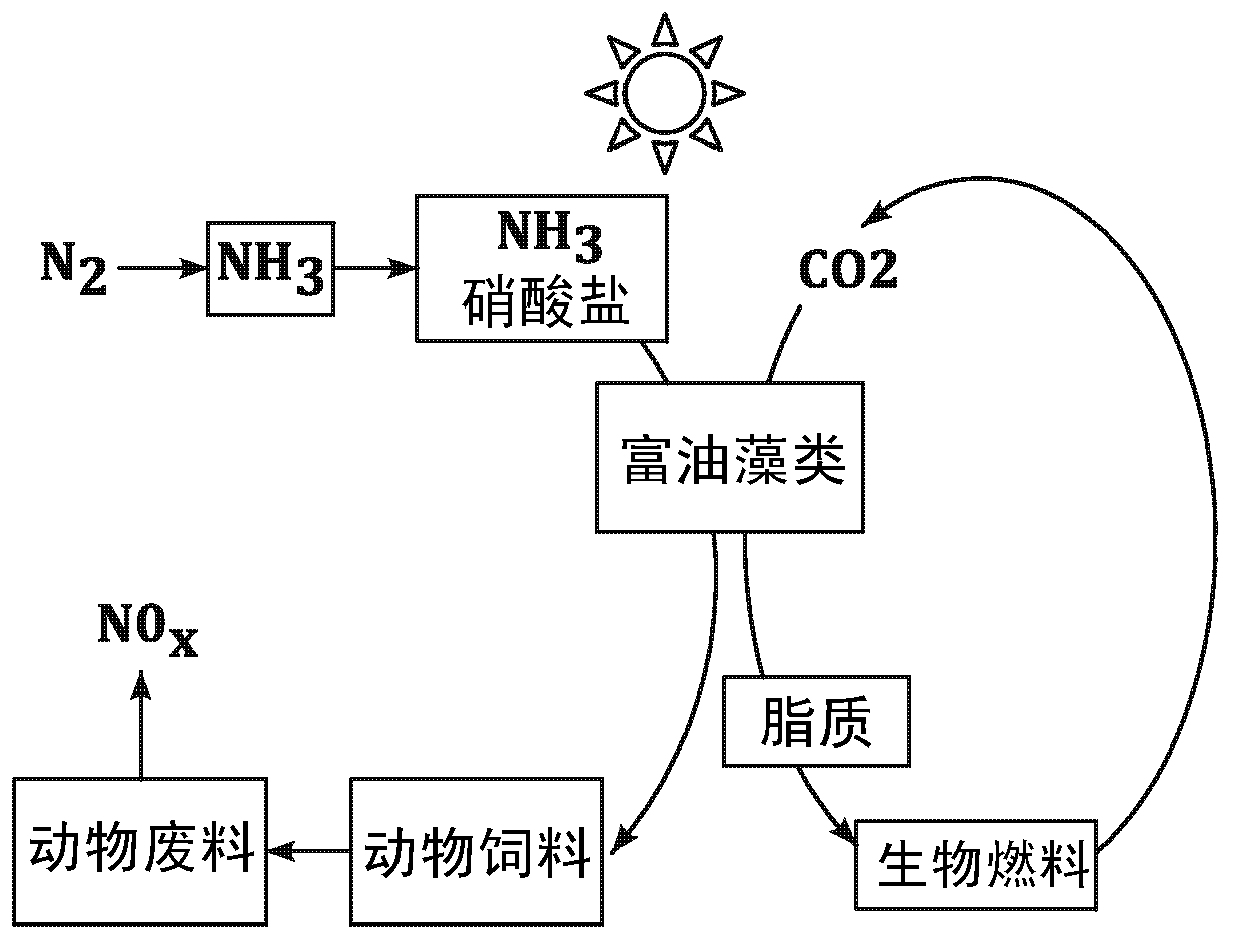

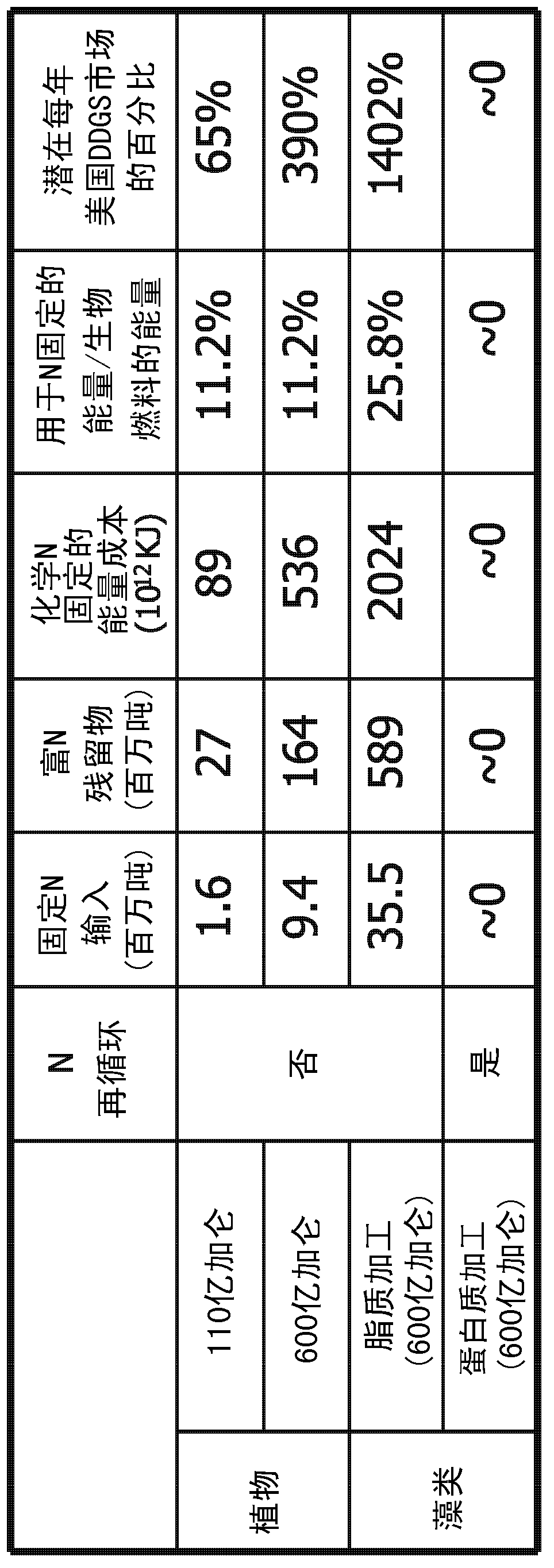

Biofuel and chemical production by recombinant microorganisms via fermentation of proteinacious biomass

Provided herein are metabolically modified microorganisms characterized by having an increased keto-acid flux when compared with the wild-type organism and comprising at least one polynucleotide encoding an enzyme, and causing the production of a greater quantity of a chemical product when compared with the wild-type organism. The recombinant microorganisms are useful for producing a large number of chemical compositions from various nitrogen containing biomass compositions and other carbon sources. More specifically, provided herein are methods of producing alcohols, acetaldehyde, acetate, isobutyraldehyde, isobutyric acid, n- butyraldehyde, n-butyric acid, 2-methyl-l-butyraldehyde, 2-methyl-l -butyric acid, 3- methyl-l-butyraldehyde, 3 -methyl- 1 -butyric acid, ammonia, ammonium, amino acids, 2,3-butanediol, 1,4-butanediol, 2-methyl-l, 4-butanediol, 2-methyl- 1,4-butanediamine, isobutene, itaconate, acetoin, acetone, isobutene, 1,5-diaminopentane, L-lactic acid, D- lactic acid, shikimic acid, mevalonate, polyhydroxybutyrate (PHB), isoprenoids, fatty acids, homoalanine, 4-aminobutyric acid (GABA), succinic acid, malic acid, citric acid, adipic acid, p-hydroxy-cinnamic acid, tetrahydrofuran, 3-methyl-tetrahydrofuran, gamma-butyrolactone, pyrrolidinone, n-methylpyrrolidone, aspartic acid, lysine, cadeverine, 2-ketoadipic acid, and / or S-adenosyl-methionine (SAM), from a suitable nitrogen rich biomass.

Owner:RGT UNIV OF CALIFORNIA

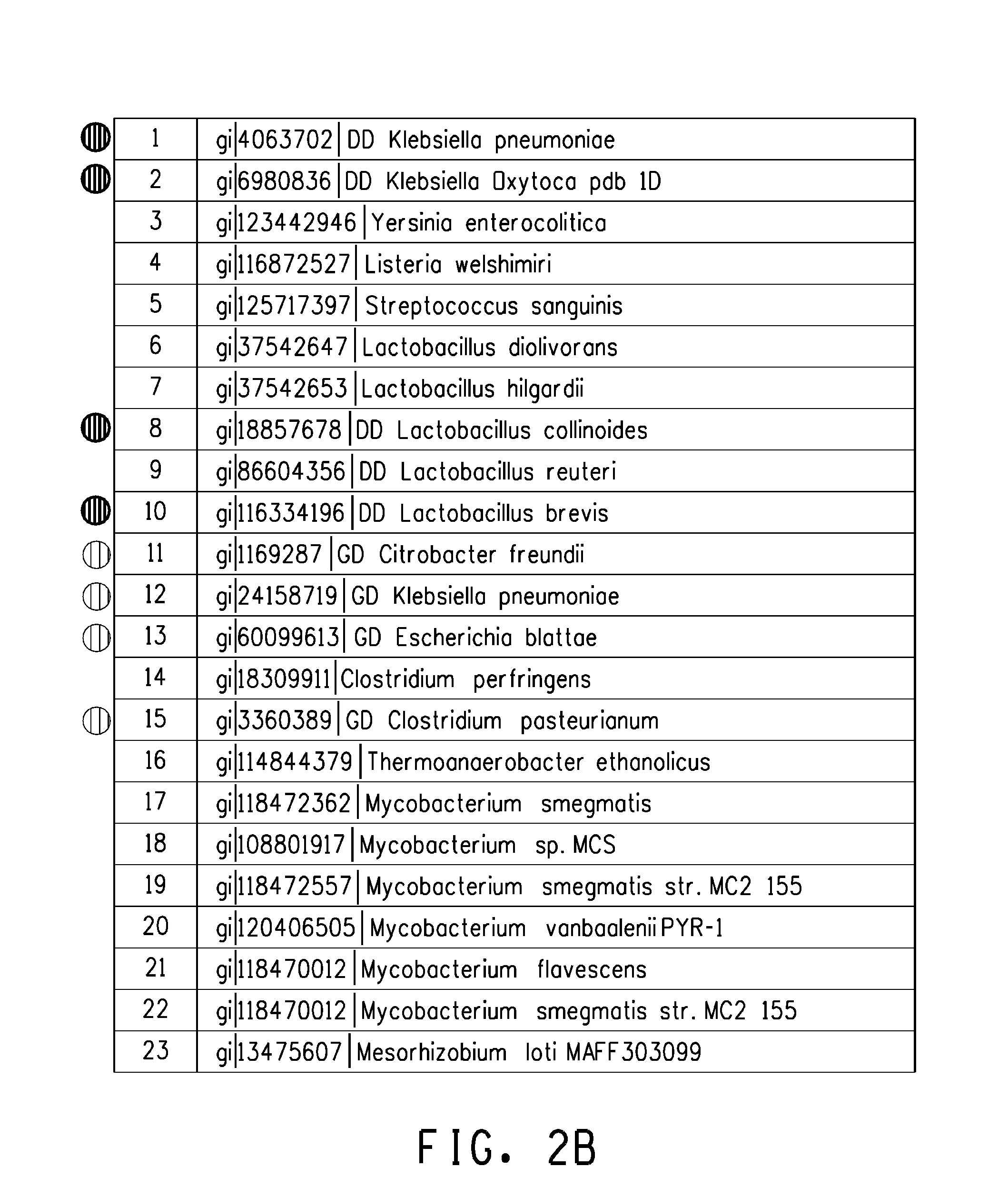

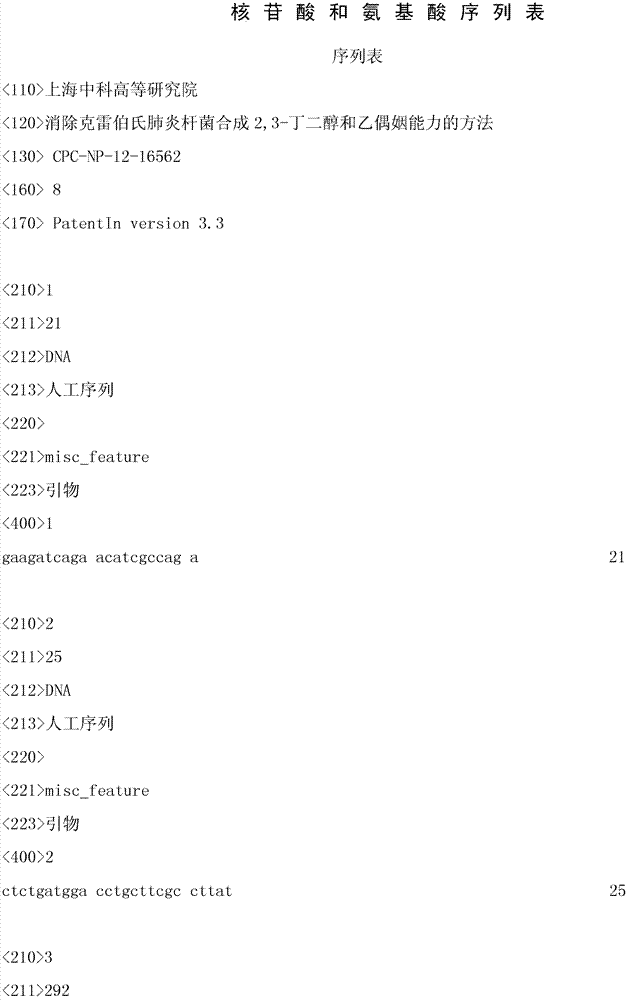

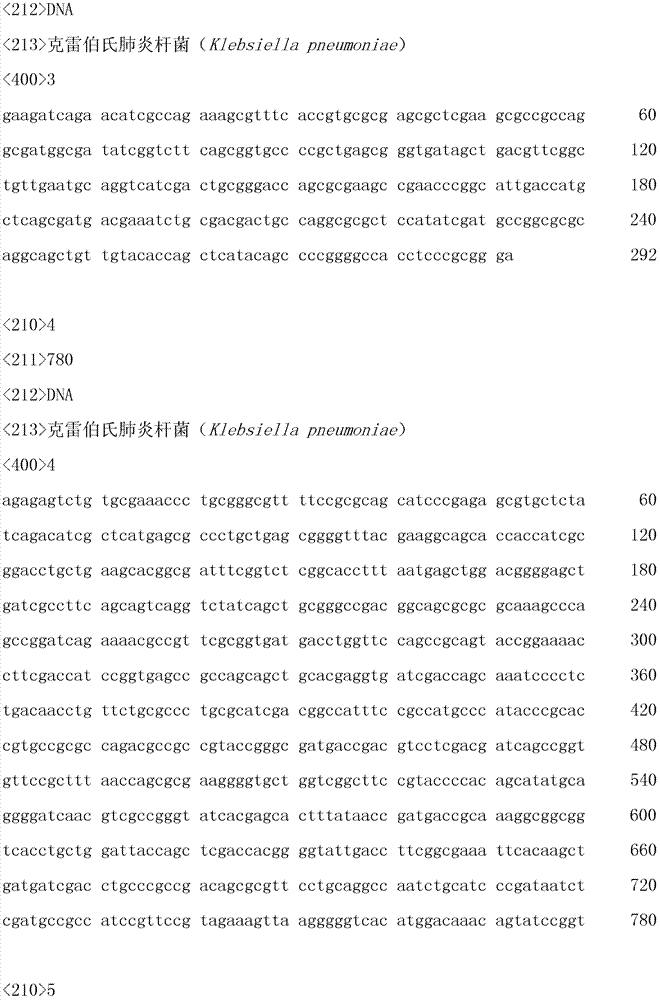

Method for eliminating capability of klebsiella pneumoniae in synthesizing 2,3-butanediol and acetoin

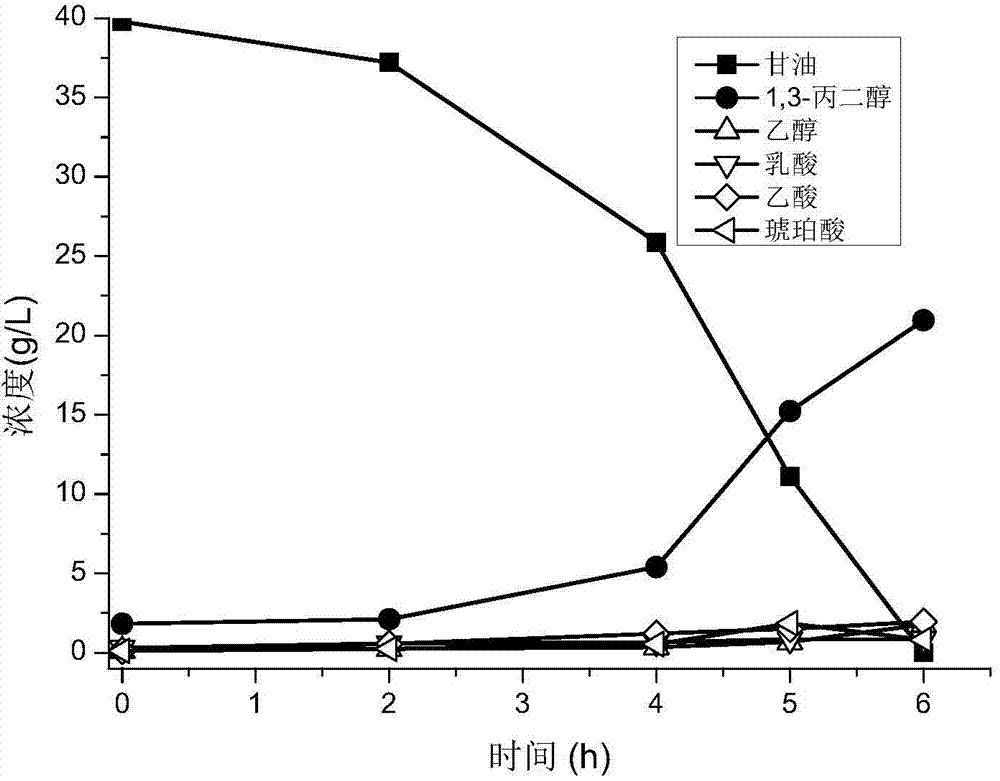

ActiveCN102952826AEliminate generationReduce separation and extraction stepsBacteriaStable introduction of DNA2,3-ButanediolGlycerol

The invention discloses a method for eliminating capability of klebsiella pneumoniae in synthesizing 2,3-butanediol and acetoin, comprising the following step of inactivating acetolacetate decearboxylase gene in a synthesis route of 2,3-butanediol by lebsiella pneumoniae to cut off the catalytic reaction that acetolactic acid is converted into acetoin. According to the method, when 1,3-propylene glycol is synthesized from glycerol by the klebsiella pneumoniae, the synthesis of byproducts, i.e. 2,3-butanediol and acetoin, can be eliminated, and the conversation rate of glycerol to 1,3-propylene glycol can be improved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method for synthetizing 2,3-butanediol

ActiveCN103193596AHigh selectivityShorten the production cyclePreparation by oxidation reactionsAlcohol2,3-Butanediol

The invention discloses a method for synthetizing 2,3-butanediol. Alcohol, mixed C4 hydrocarbon and hydrogen peroxide are loaded in a reactor with a catalyst, the mixed C4 hydrocarbon and the hydrogen peroxide react so as to generate the 2,3-butanediol. The method is simple and has short cycle, the percent conversion of the hydrogen peroxide is high, and the selectivity of the 2,3-butanediol is high; and the whole process is easy to realize, the cost is low, and the industrialization application prospect is wide.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

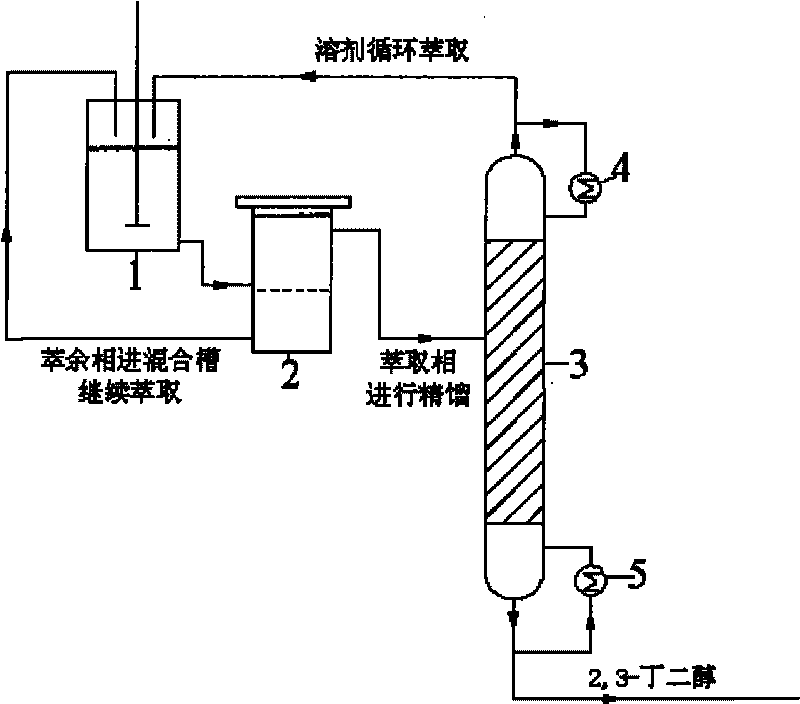

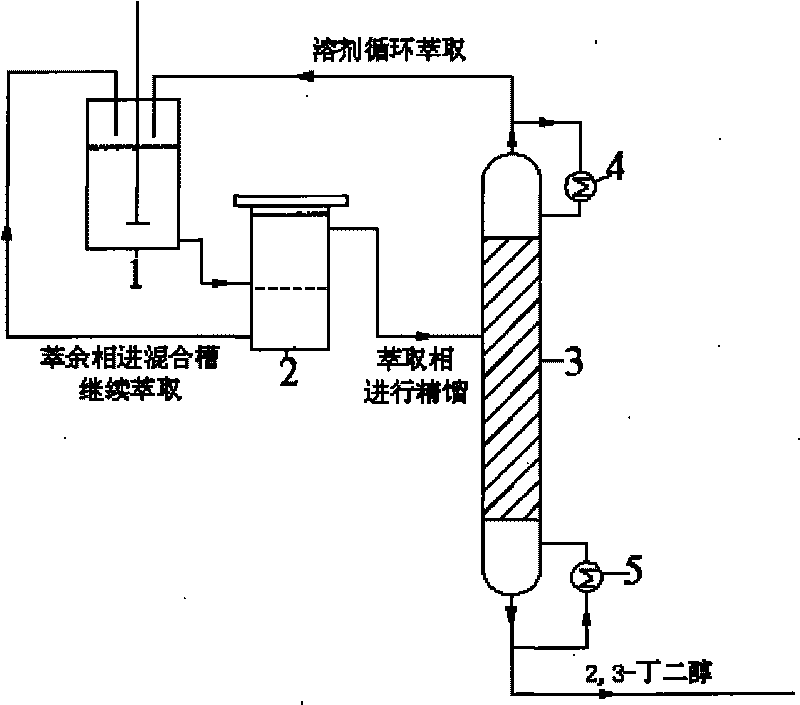

Method for separating and extracting 2,3-butanediol

InactiveCN101735012AReduce lossesSolve problemsHydroxy compound separation/purificationFlocculationFiltration

The invention discloses a method for separating and extracting 2,3-butanediol. The method comprises the steps of: taking solution obtained by performing preliminary separation such as flocculation, filtration, membrane separation and the like on an 2,3-butanediol fermentation liquid as a raw material, taking normal butanol as an extraction solvent, and adopting an extraction and rectification coupling method to separate and purify the 2,3-butanediol. Through the extraction-rectification coupling process, the purity of the 2,3-butanediol in a product can reach over 98 percent, the single extraction rate can reach over 74 percent, and a raffinate can return to the membrane separation process of the fermentation liquid and is used for recovering the residual 2,3-butanediol. The method has the advantages that: the method adopts the extraction and rectification coupling method, realizes the characteristics of basically unchanged phase ratio and cycling extraction of the solvent so as to successfully solve the difficulties during the extraction of the 2,3-butanediol, realizes the separation process of extracting the 2,3-butanediol from a fermentation filtrate, and achieves the aims of reducing energy consumption and improving efficiency; and the process is simple and practical, has high recovery rate and good economy, and is suitable for industrialized production.

Owner:EAST CHINA UNIV OF SCI & TECH

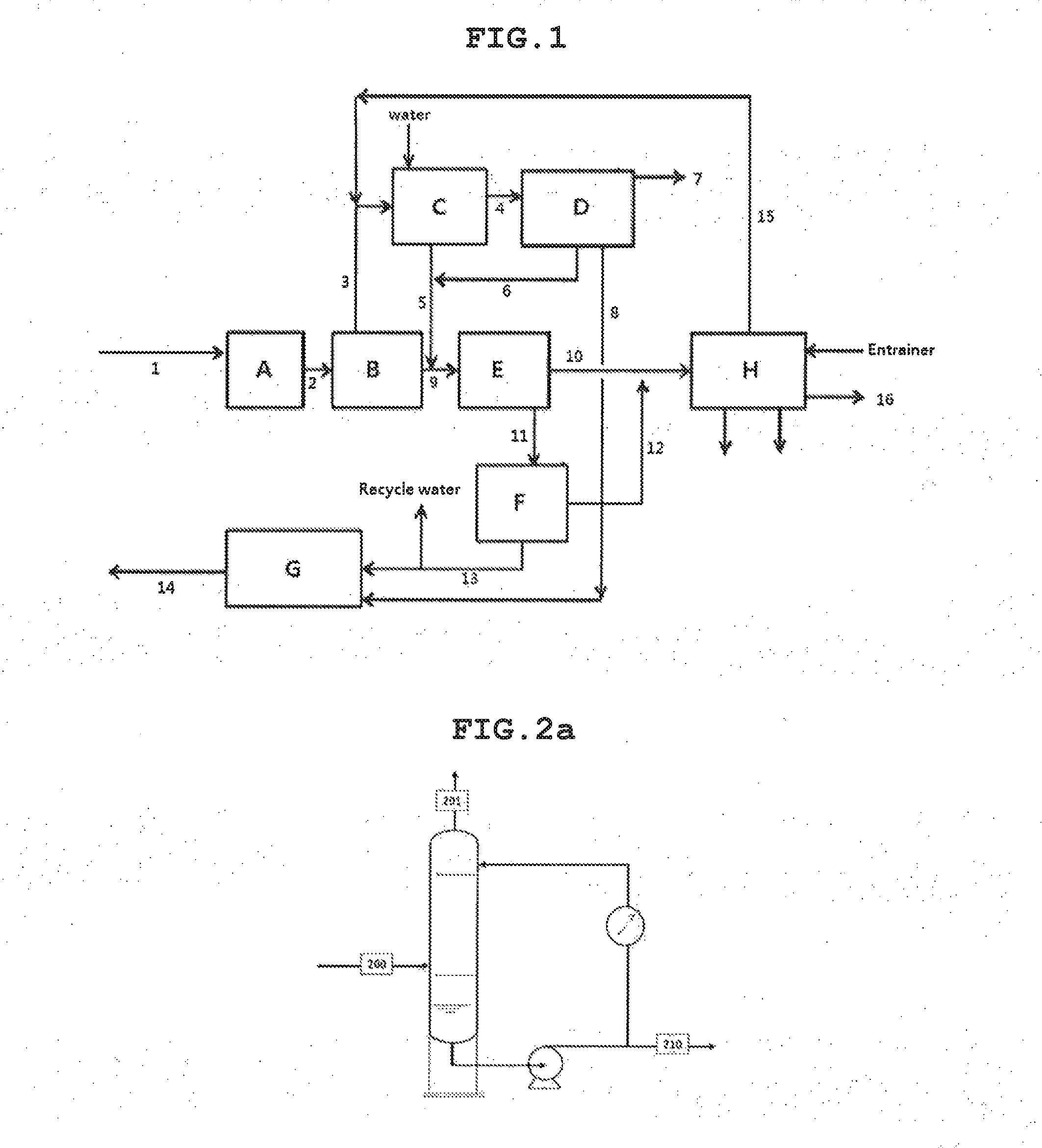

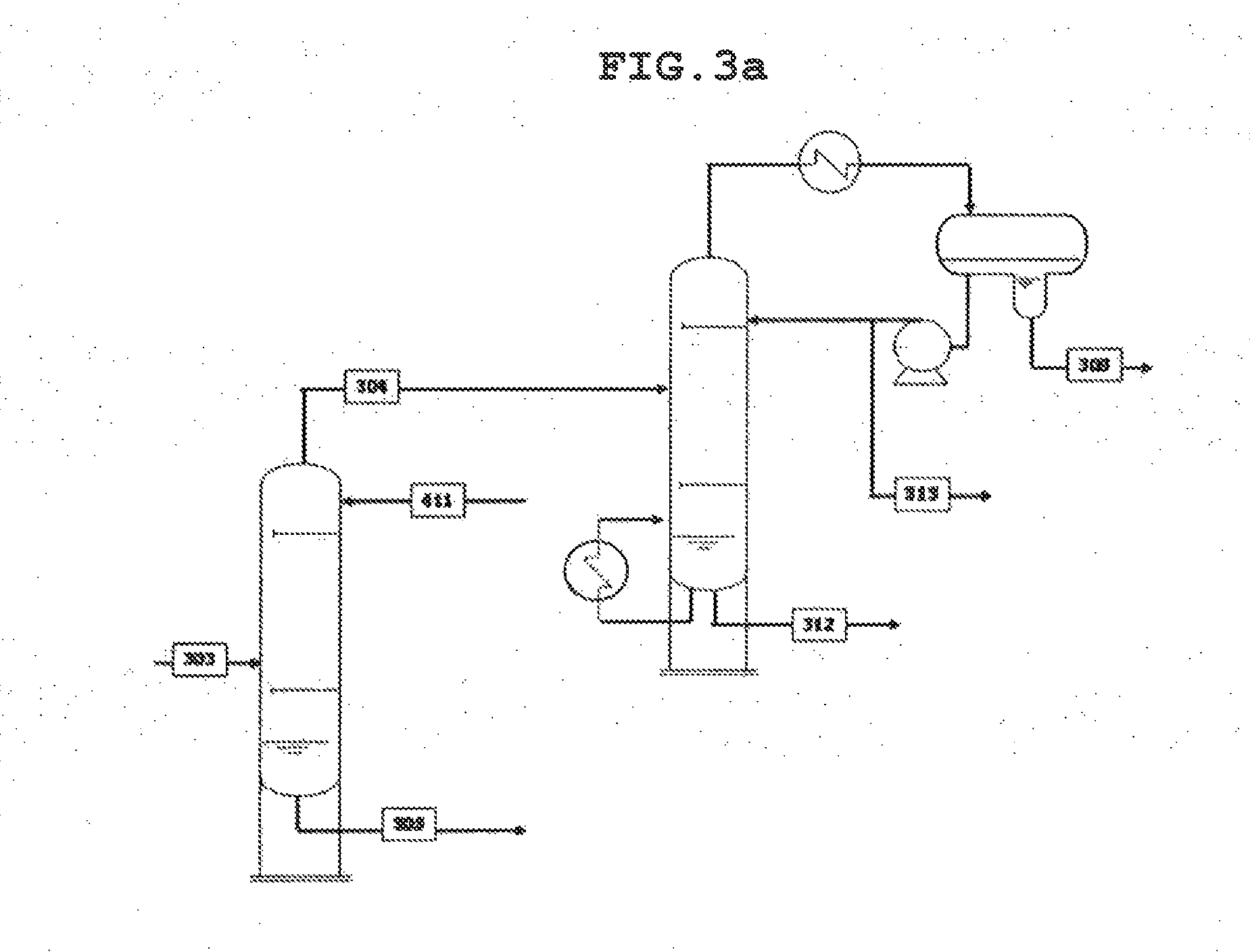

Method of recovering 1,3-butadiene and methylethylketone from dehydration products of 2,3-butanediol

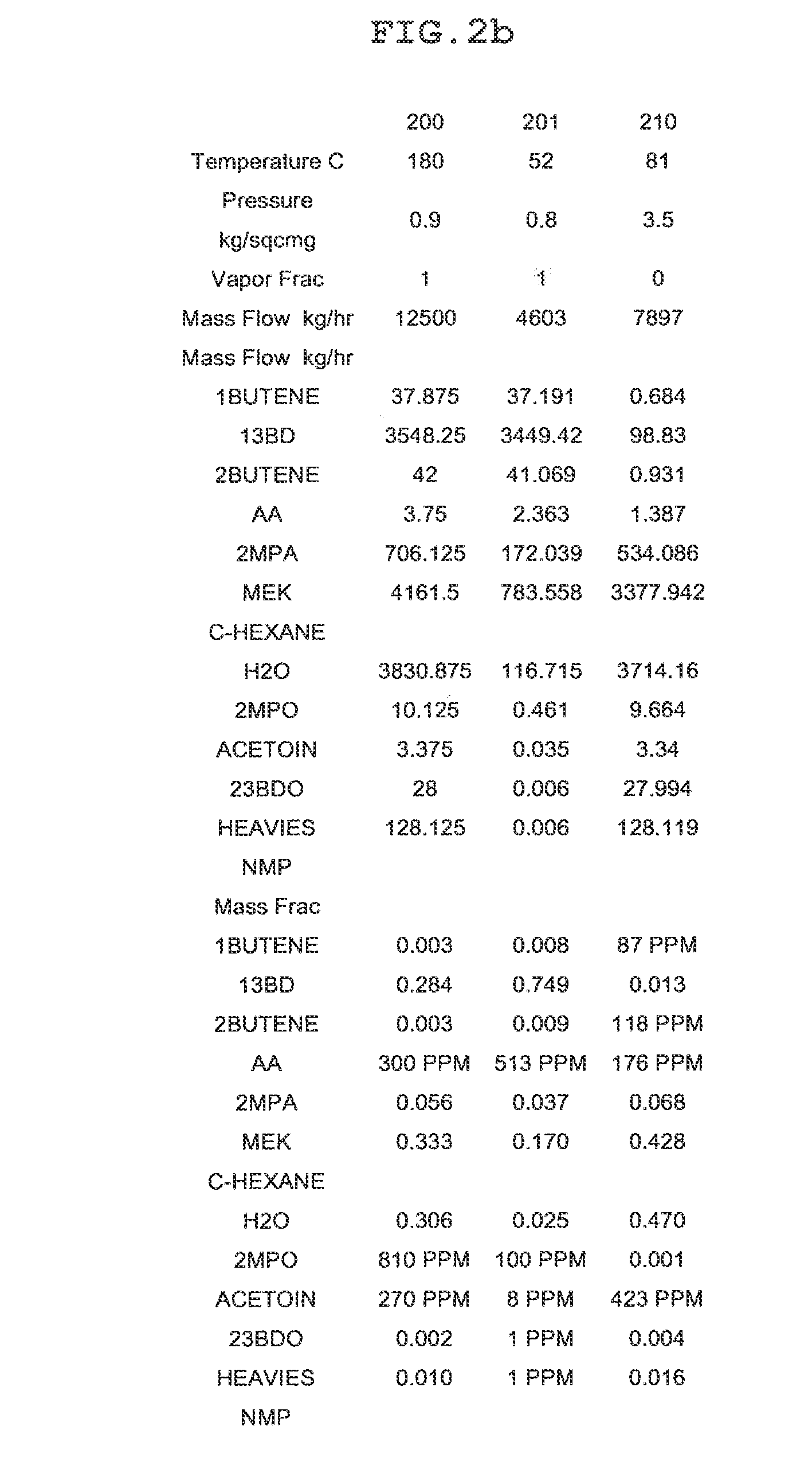

ActiveUS20160251281A1Efficiently recovering highly pureOvercome limitationsFermented solutions distillation/rectificationGas treatment2,3-ButanediolButanediol

Disclosed is a method of efficiently separating 1,3-butadiene and methylethylketone, which are compounds of interest, from byproducts or impurities in the dehydration products of 2,3-butanediol so as to recover the compounds of interest at high purity.

Owner:SK INNOVATION CO LTD +1

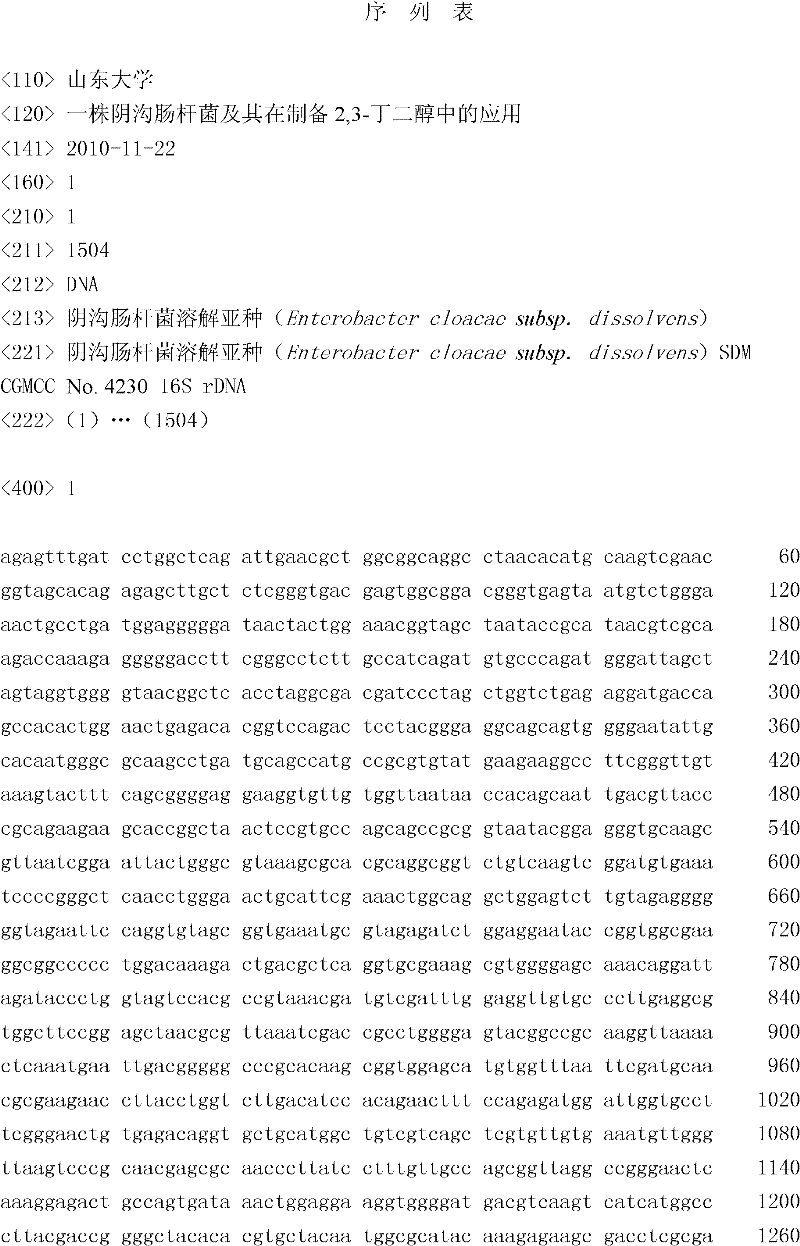

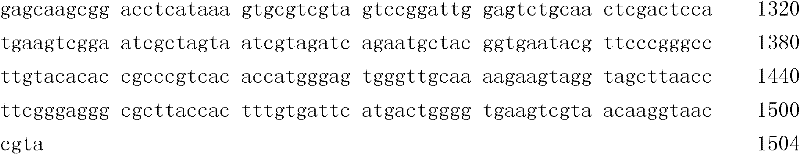

Strain of Enterobacter cloacae and its application in the preparation of 2,3-butylene glycol

ActiveCN102226159AIncrease concentrationImprove conversion rateBacteriaMicroorganism based processesProduction rateCellulose

The invention discloses a strain of Enterobacter cloacae subsp. dissolvens SDM and its application in the preparation of 2,3-butylene glycol. The preservation number of the Enterobacter cloacae subsp. dissolvens SDM is CGMCC No.4230. Pentose, hexose, molasses, starch raw material hydrolysate, lignocellulose raw material hydrolysate are utilized in the strain provided by the invention with high transformation rate, high product concentration and wide substrate spectrum. According to the invention, the application of the strain of Enterobacter cloacae in the preparation of 2,3-butylene glycol has advantages of simple operation method, low cost and high efficiency; the output of 2,3-butylene glycol by the fermentation cylinder fed batch fermentation can reach 125-162 g / L; the transformation rate accounts for 90-95% of the theoretical transformation rate; the maximum productivity of 2,3-butylene glycol is 4.1 g / (L<.>h). Thus, the invention has a great prospect for industrial popularization and application.

Owner:上海肆芃科技有限公司

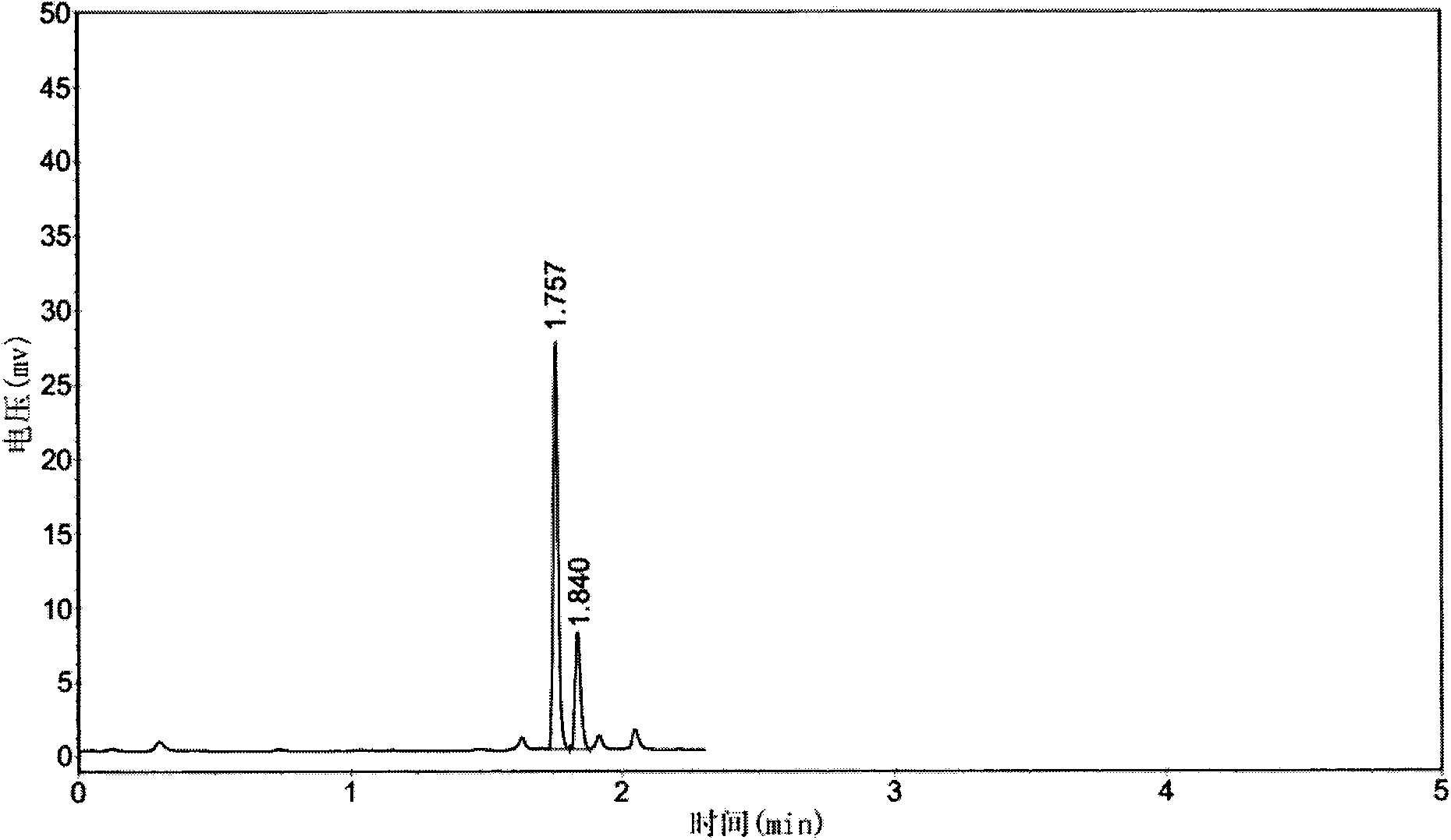

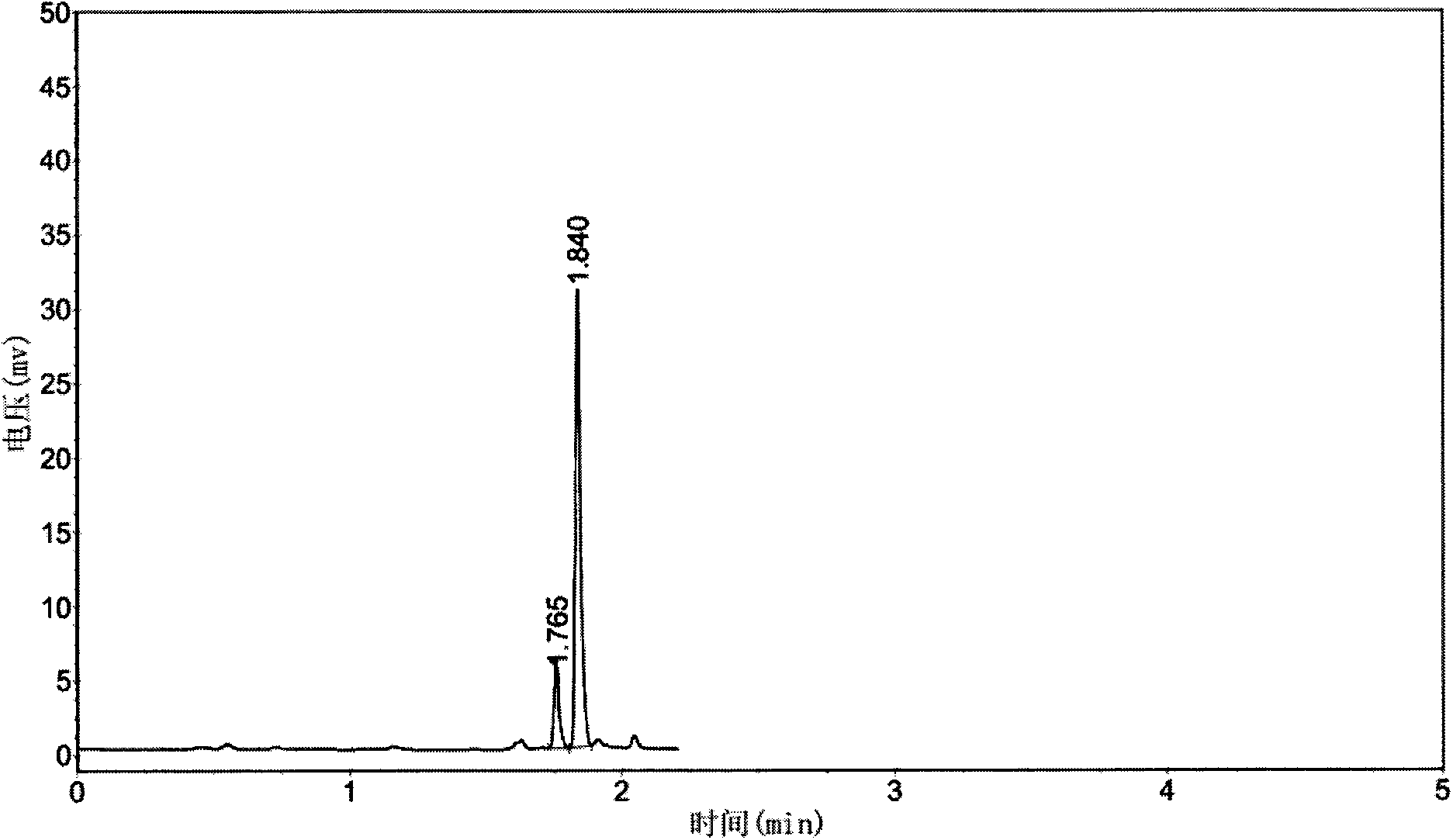

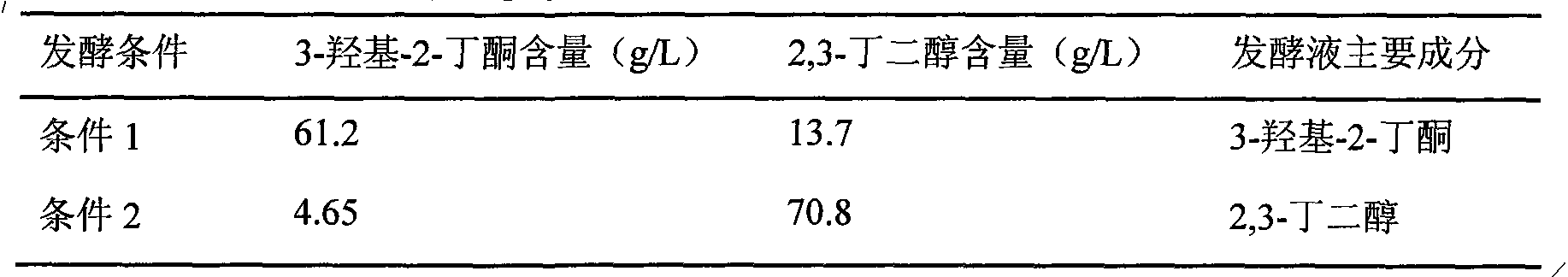

Method for selectively producing 3-hydroxyl-2-butanone and 2, 3-butanediol through microbial fermentation

ActiveCN103525877ALow costMeet the requirements of safe productionMicroorganism based processesFermentation2,3-ButanediolBacterial strain

The invention discloses a method for selectively producing 3-hydroxyl-2-butanone and 2, 3-butanediol by using an environmental safety bacterial strain Bacillus amyloliquefaciens with the CCTCC NO. M2012349 and changing the content of corn steep liquor in a medium, the stirring speed and the ventilation capacity, and belongs to the field of a fermentation technology in biological engineering. The method is characterized in that when the 3-hydroxyl-2-butanone is mainly synthesized, the concentration of the corn steep liquor in the fermentation medium can be reduced to be more than or equal to 5g / L, and the relatively high dissolved oxygen level (the air mass flow is 240m<3> / h.m<3> medium, and the stirring rotating speed is 450r / min) is maintained in a fermentation process; and when the 2, 3-butanediol is synthesized, the concentration of the corn steep liquor in the fermentation medium can be increased to be more than or equal to 40g / l, the relatively low dissolved oxygen level (the air mass flow is 120m<3> / h.m<3> medium, and the stirring rotating speed is 350r / min) is maintained in a fermentation process.

Owner:JIANGNAN UNIV

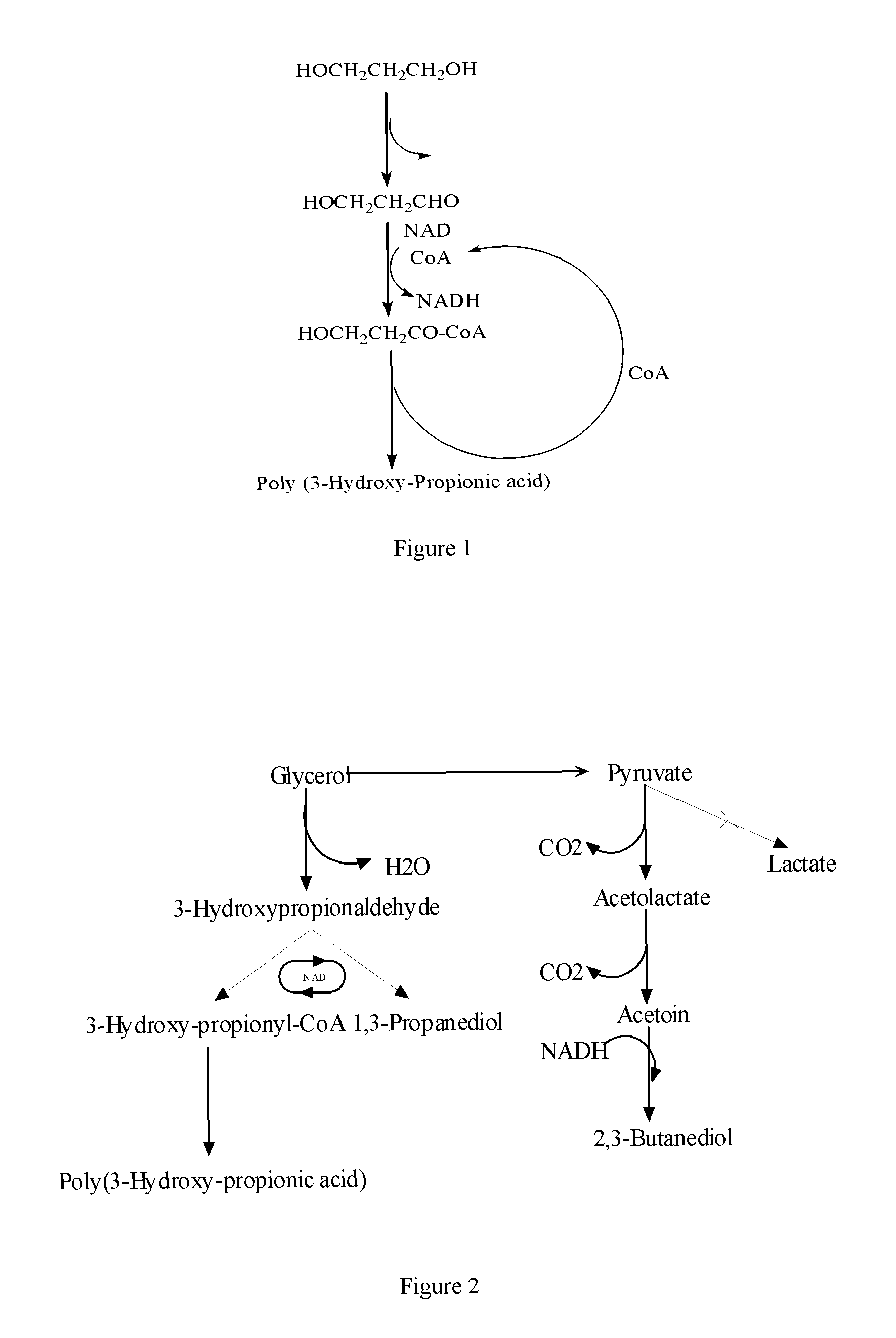

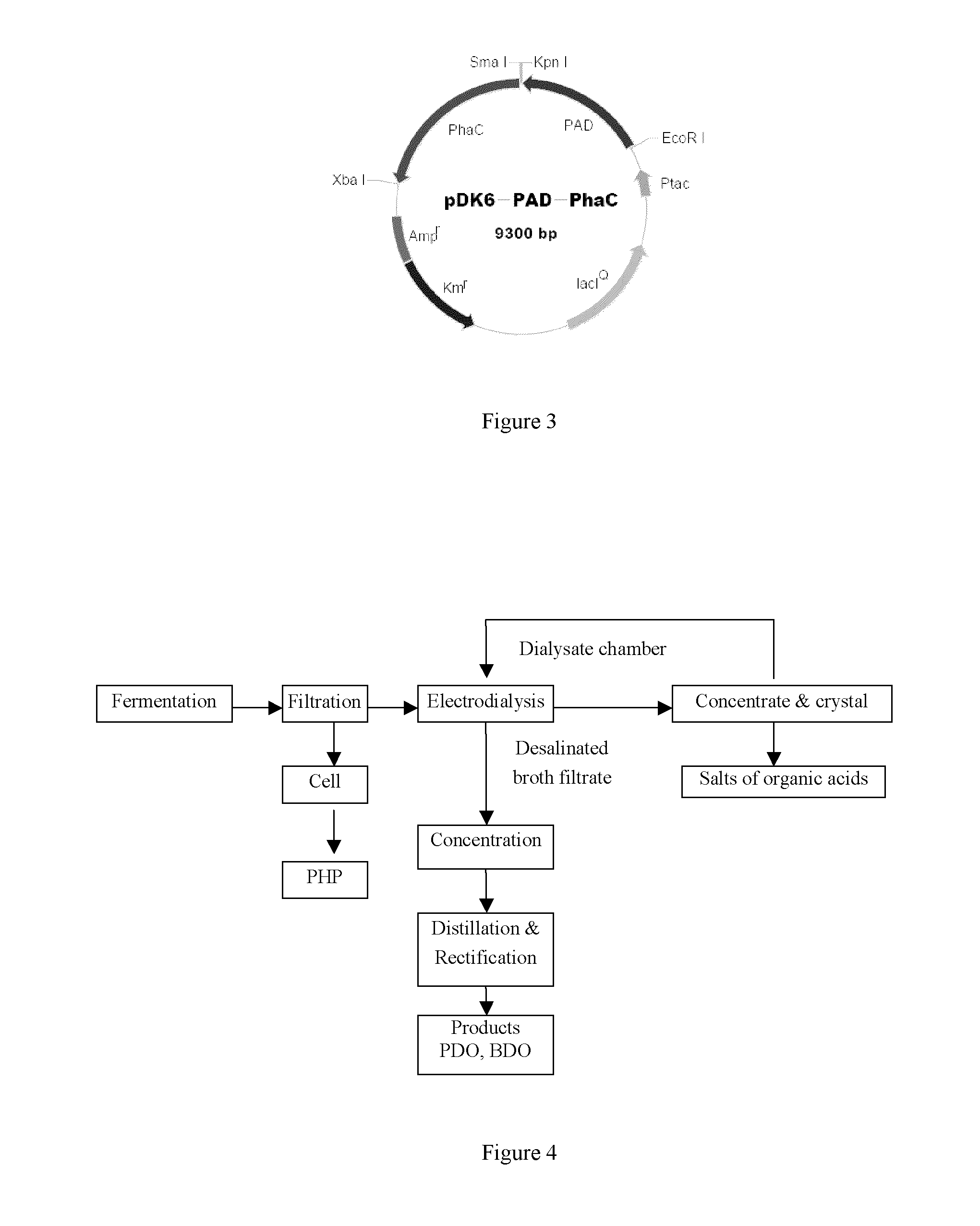

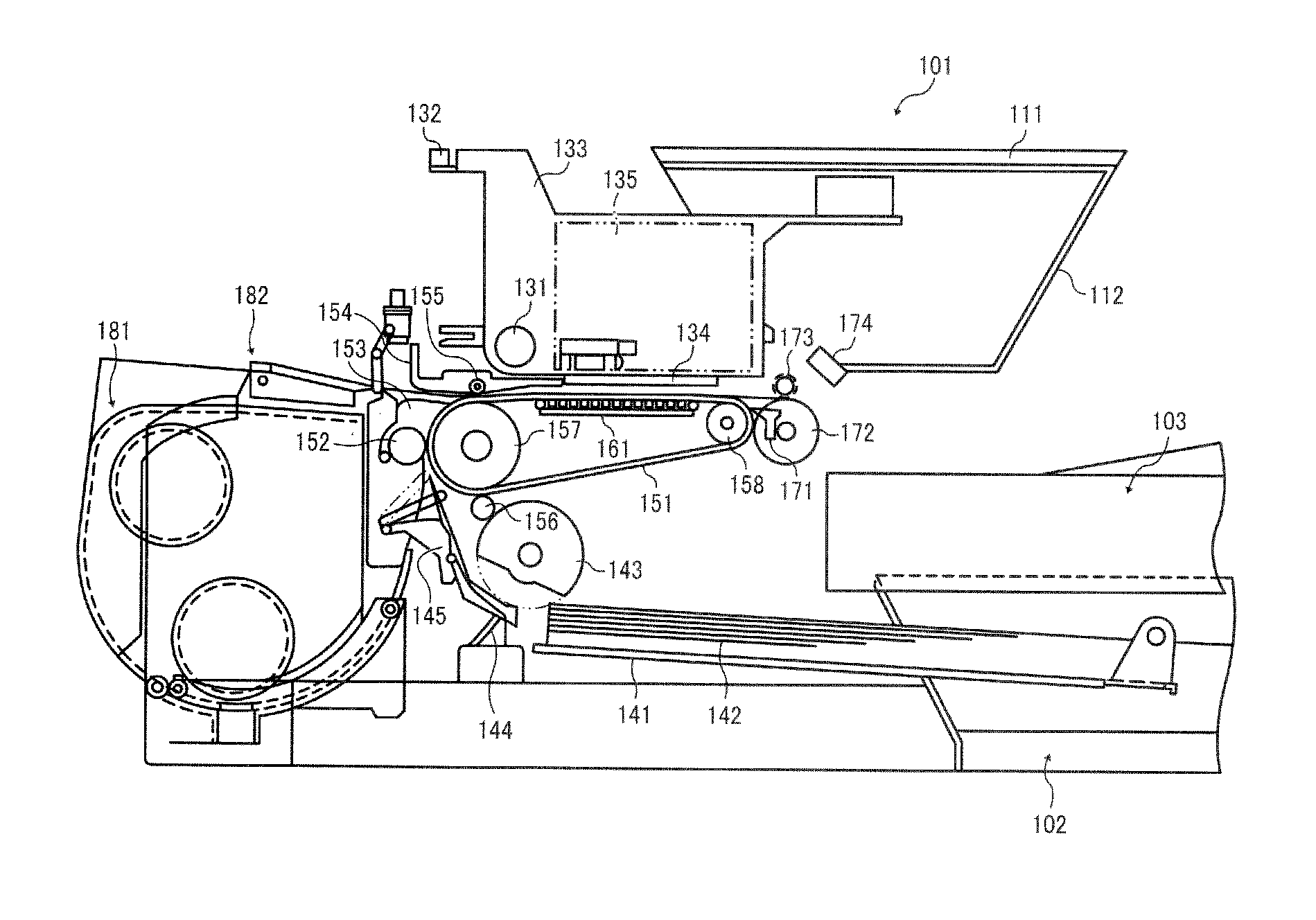

Methods and genetically engineered micro-organisms for the combined production of PDO, BDO and PHP by fermentation

The present invention relates to genetically engineered micro-organisms for the combined production of 1,3-propanediol (PDO), 2,3-butanediol (BDO), and polyhydroxypropionic acid (PHP) by fermentation. In particular, the invention relates to a genetically engineered micro-organism suitable for combined production of PDO, BDO and PHP by fermentation, characterized in that: compared with corresponding wild-type starting micro-organism, the D-lactate dehydrogenase gene in the genetically engineered micro-organism is deleted or functionally inactivated, and the genetically engineered micro-organism comprises a heterogenous polynucleotide encoding the Coenzyme A-dependent Aldehyde dehydrogenase and a heterogenous polynucleotide encoding the Polyhydroxyalkanoate synthase. Methods for the construction of such micro-organisms, and methods for combined production of PDO, BDO and PHP by fermentation of a genetically engineered bacterium are also taught.

Owner:HUNAN RIVERS BIOTECH +1

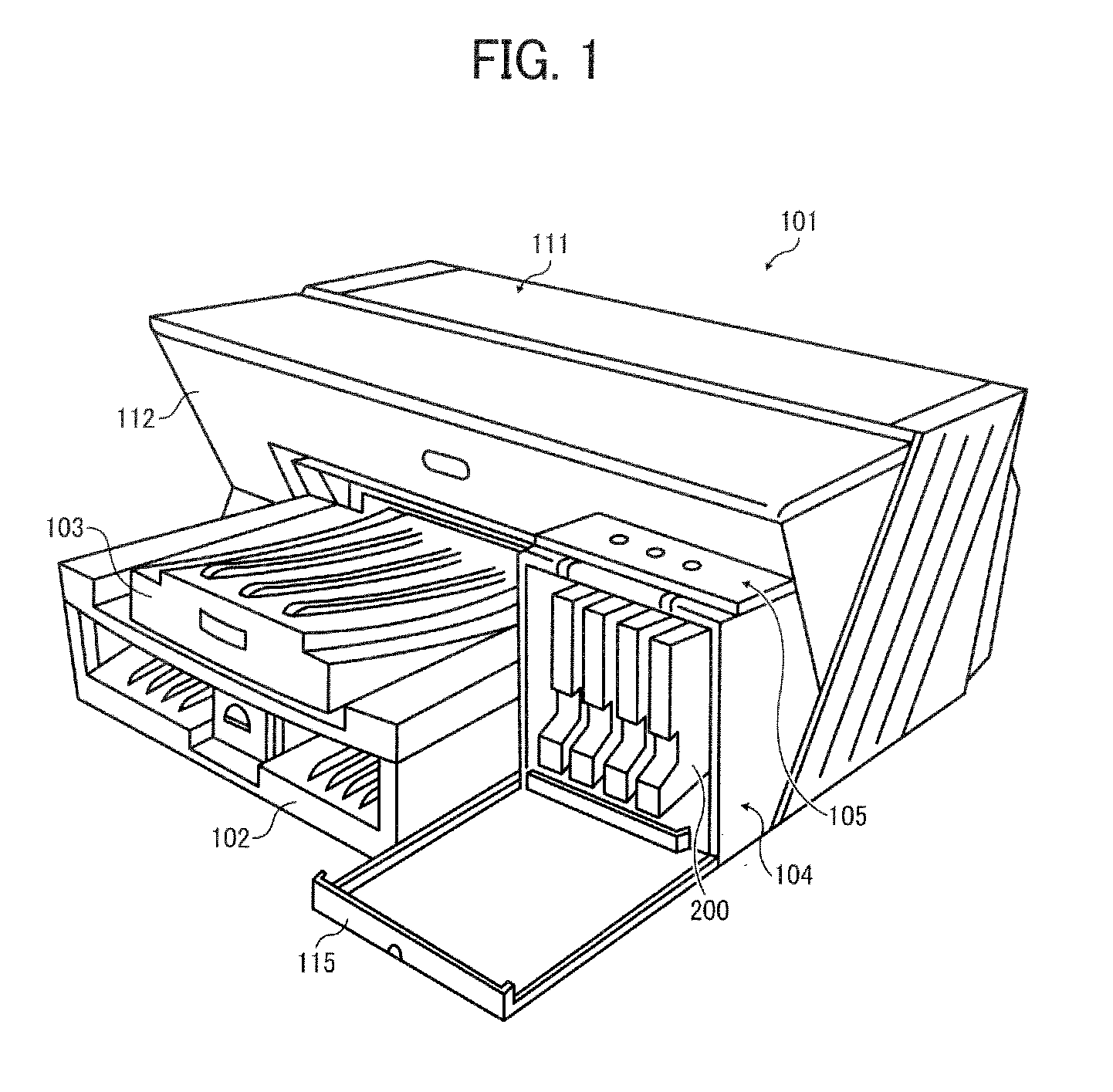

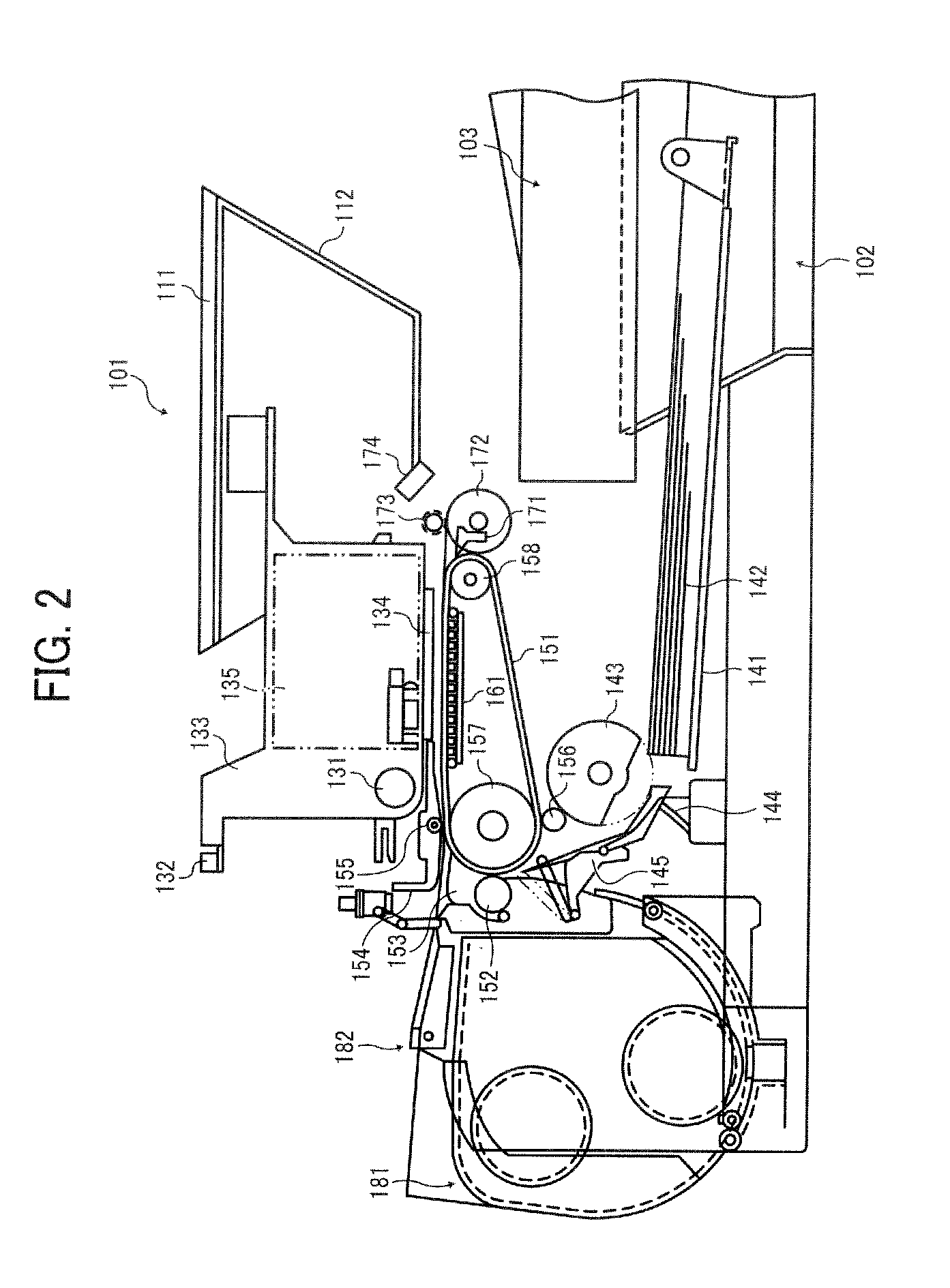

Aqueous ink for inkjet, inkjet recorder and inkjet recording method

ActiveUS20150116433A1Improve discharge performanceHigh glossInksPolyurea/polyurethane coatingsParticulatesOrganic solvent

An aqueous ink for inkjet includes water; a hydrosoluble organic solvent; a pigment; and a particulate resin. The hydrosoluble organic solvent includes 2,3-butanediol and 1,2-propanediol at a weight ratio (2,3-butanediol / 1,2-propanediol) of from 98 / 2 to 60 / 40.

Owner:RICOH KK

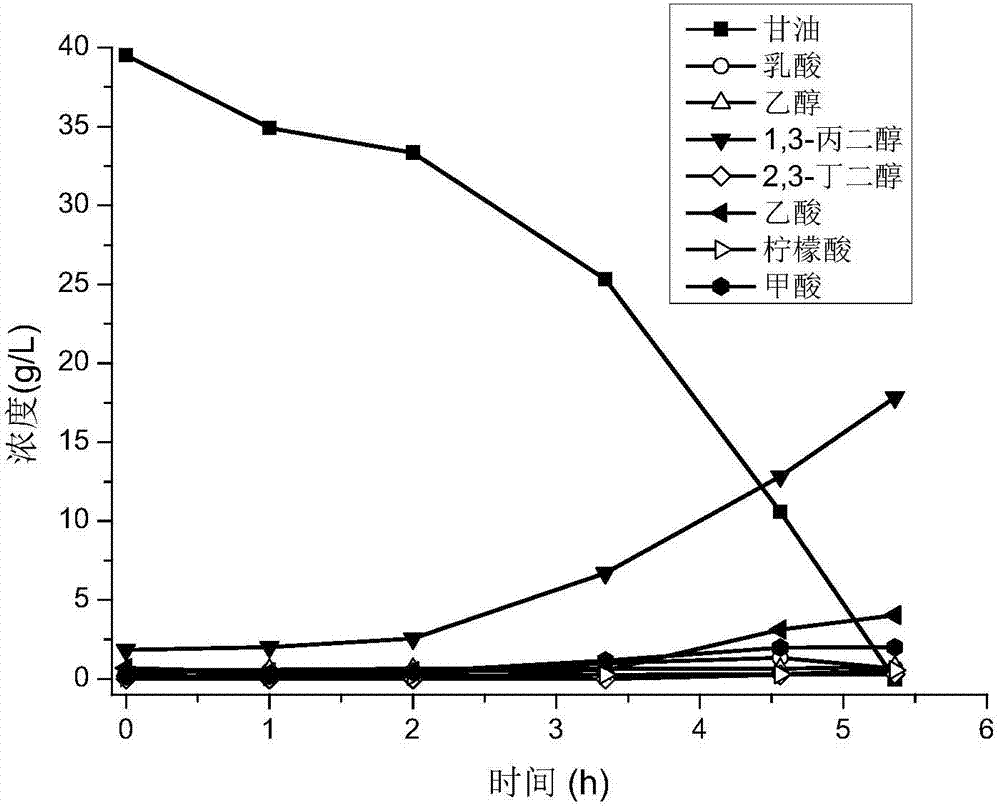

Method for producing 1,3-propanediol through mixed bacterium fermentation glycerinum

ActiveCN104774879ASame growing conditionsSimple and fast operationMicroorganism based processesFermentationMicroorganism2,3-Butanediol

The invention provides a method for producing 1,3-propanediol through mixed bacterium fermentation glycerinum. According to the method, Klebsiella pneumoniae W3, Klebsiella pneumoniae Y1 and Klebsiella pneumoniae Y5 with the preservation numbers being CGMCC NO.10440, CGMCC NO.10439 and CGMCC NO.10438 are in mixed fermentation in a fermentation medium with the glycerinum as a substrate to produce the 1,3-propanediol. Mixed bacteria are good in substrate tolerance, by-products of fermentation products are fewer, especially 2,3-butanediol is not generated, and the 1,3-propanediol as the main product can be separated. By the adoption of the method, the defect that a single bacterial strain is poor in substrate tolerance is overcome, production efficiency is improved, the products do not contain the 2,3-butanediol, the problem generated in following separation is avoided, the mixed bacteria can tolerate the concentration of the glycerinum of 200 g / L, and the yield of the 1,3-propanediol reaches 81.40 g / L. The method can hopefully provide a simple and economic fermentation process for industrialization of production of the 1,3-propanediol in a microbiological fermentation method.

Owner:DALIAN UNIV OF TECH

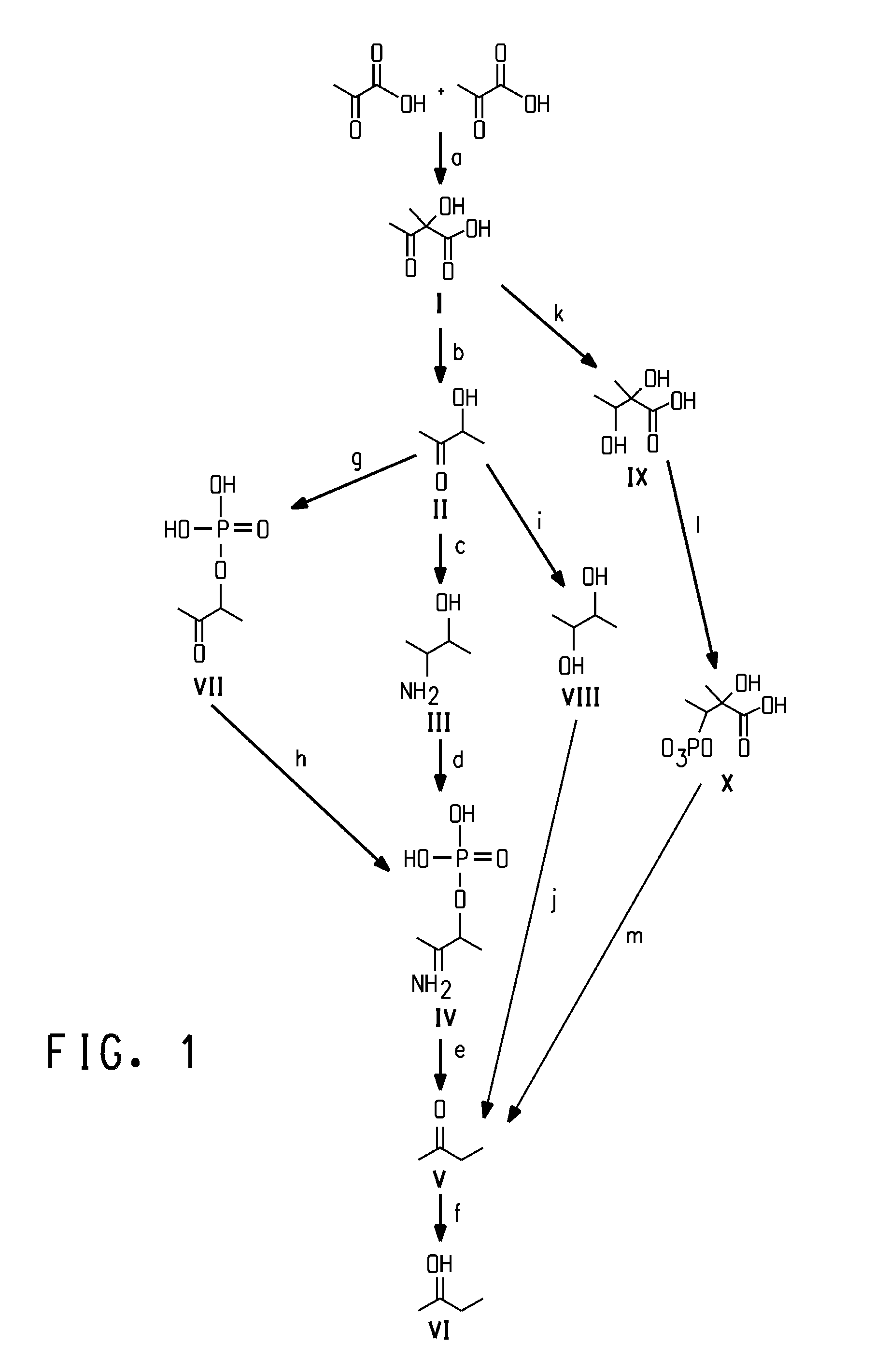

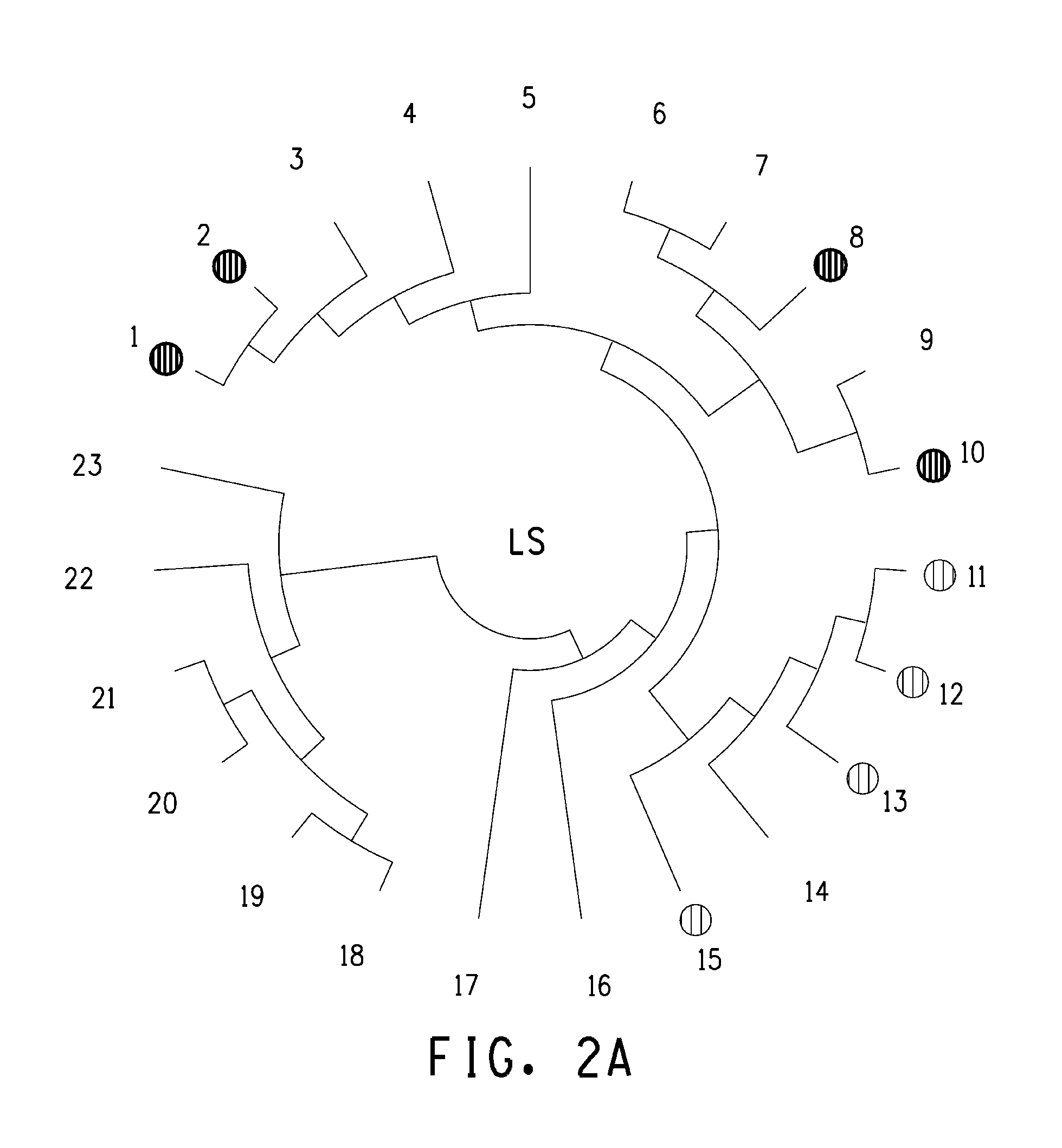

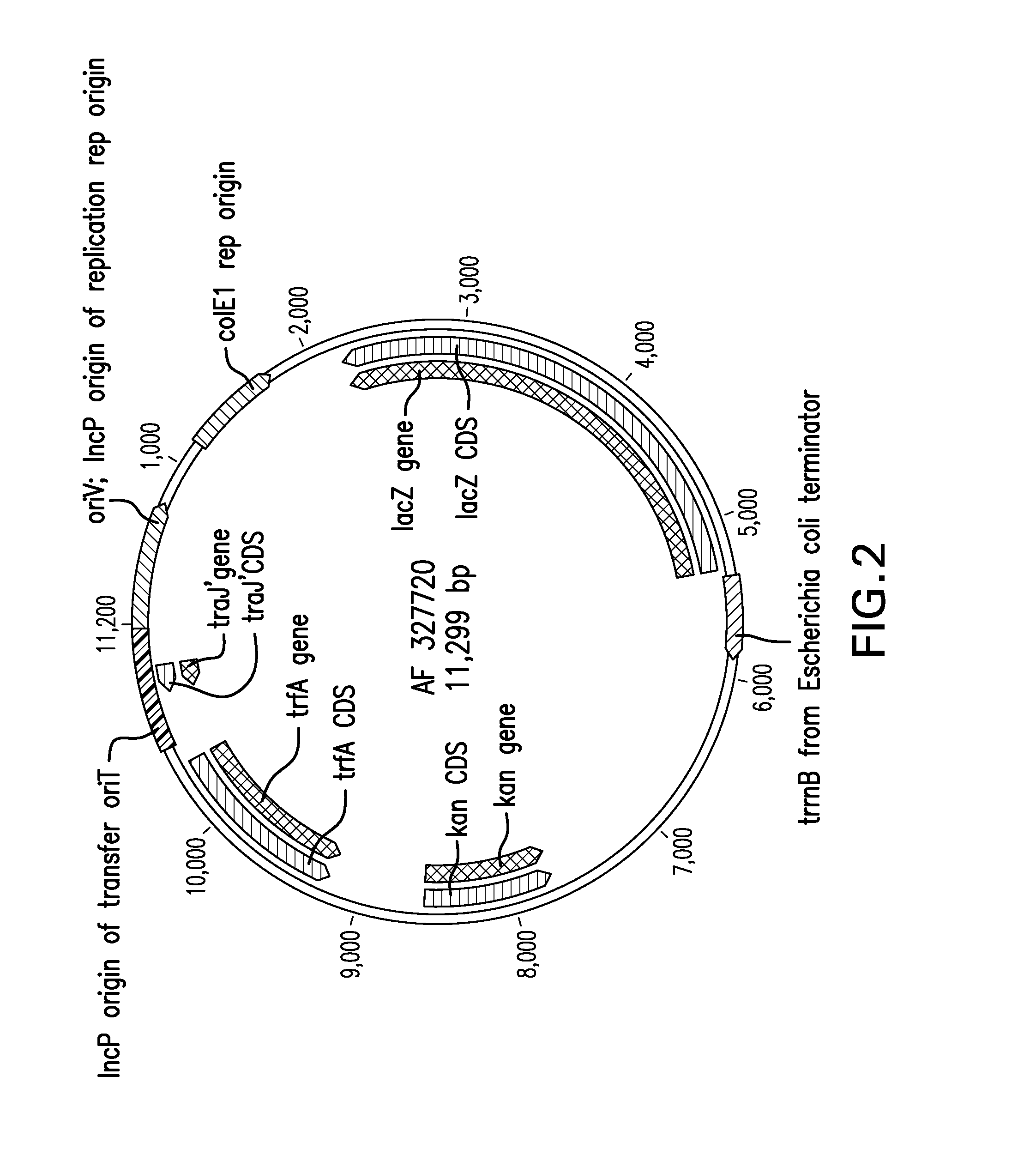

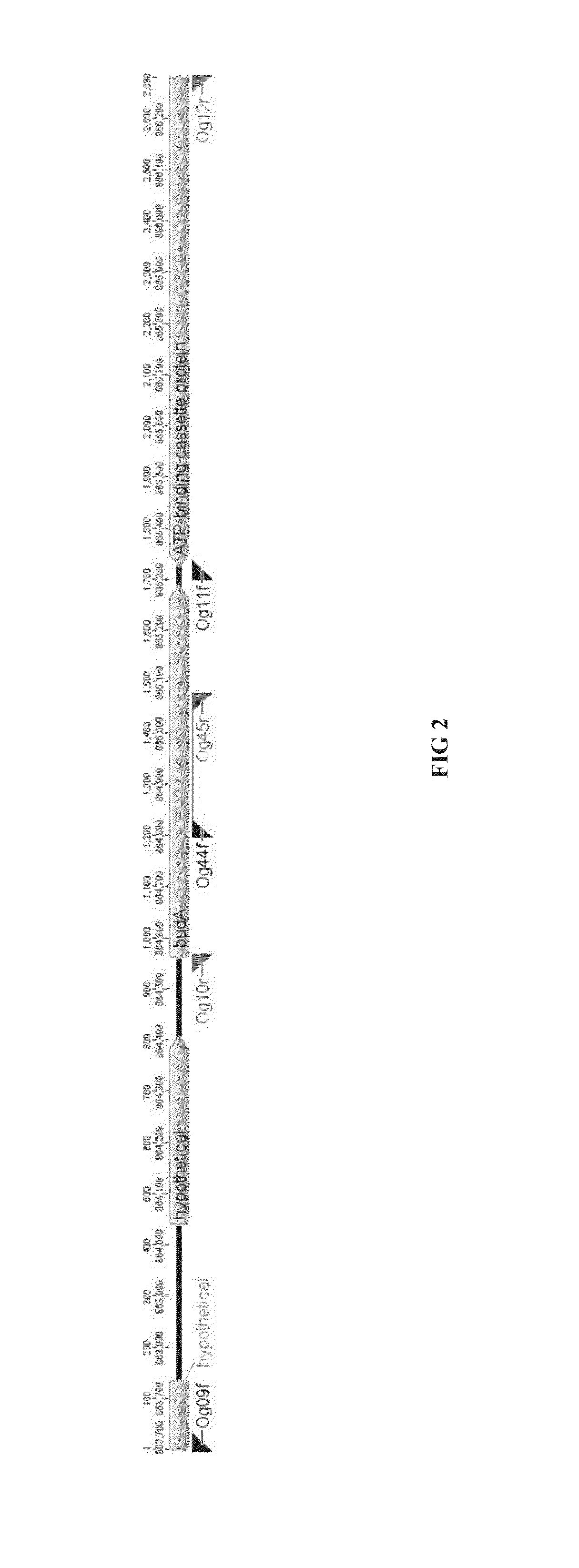

Recombinant microorganisms and methods of use thereof

ActiveUS20140206901A1Improve efficiencyIncrease productionBacteriaOrganic compound preparationMicroorganismChemical compound

The invention relates to methods for the production of chemical compounds, particularly but not exclusively ethanol, by microbial fermentation. Also described are genetically modified micro-organisms capable of using carbon monoxide to produce one or more products, particularly but not exclusively ethanol as a main product, and producing a reduced amount or substantially no 2,3-butanediol and / or a precursor thereof.

Owner:LANZATECH NZ INC

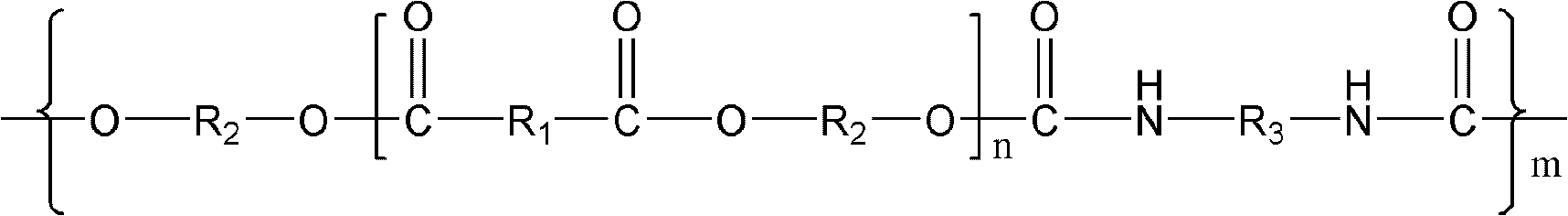

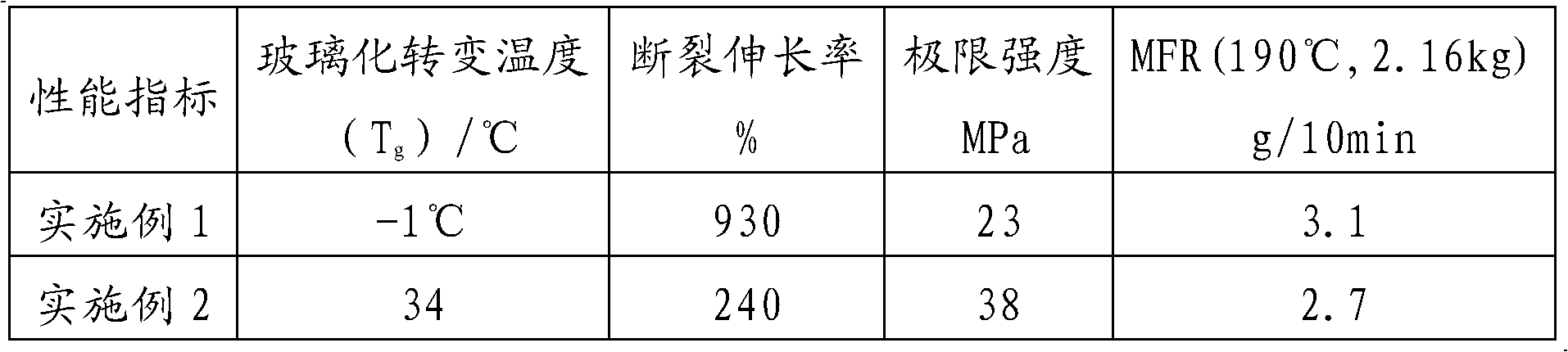

High-molecular-weight polyester plastic based on 2,3-butanediol and preparation method for same

The invention discloses a high-molecular-weight polyester plastic based on 2,3-butanediol. The polyester plastic has a repetition structure unit shown in the formula, wherein R1 is defined in the specification, p is 0-11, R2 is defined in the specification, R3 is defined in the specification, n is 1-1000, and m is 1-1000. The invention further discloses a preparation method for the high-molecular-weight polyester plastic based on 2,3-butanediol. The polyester plastic is a transparent polyester plastic due to the existence of the side-chain methyl of 2,3-butanediol, as well as is high in molecular weight, excellent in mechanical property, and wide in application prospect in the aspects of injection-moulded parts, optical devices, thin films, laminated materials and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

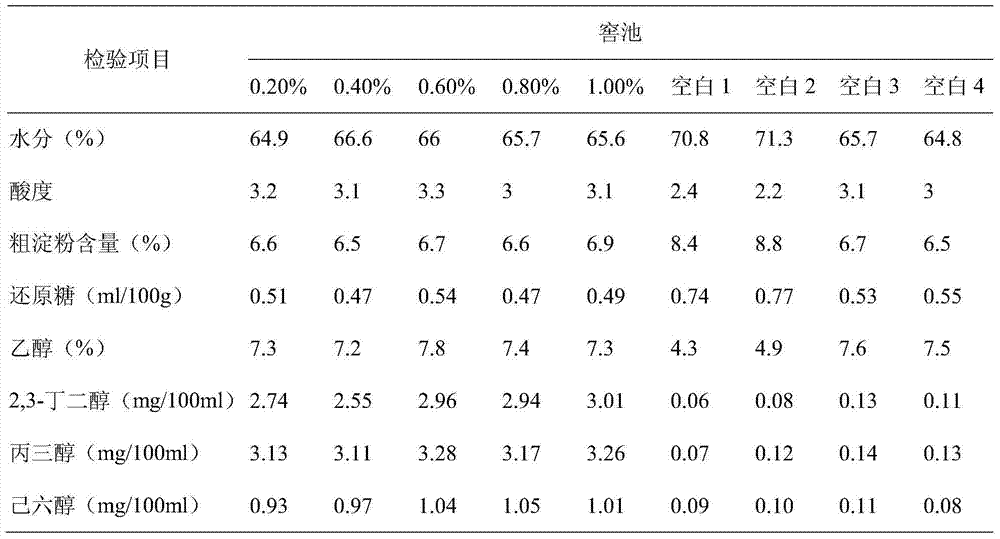

Bacillus subtilis and application of bacillus subtilis in simple and elegant liquor

ActiveCN104745503AEnhance typical flavorShorten the fermentation cycleBacteriaMicroorganism based processesYeast2,3-Butanediol

The invention discloses bacillus subtilis and an application of the bacillus subtilis in simple and elegant liquor. The inventor screens out a high-temperature-resistant bacillus subtilis strain CYC18 from yeast, and the preservation number of the high-temperature-resistant bacillus subtilis strain CYC18 is CCTCC NO.M2015037. The high-temperature-resistant bacillus subtilis strain CYC18 is added into wine making yeast in ratio of 0.1-1% (w / w), a fermentation period for producing the simple and elegant liquor can be obviously shortened, content of polyalcohol is increased, and the high-temperature-resistant bacillus subtilis strain CYC18 product has the characteristics of sweetness, tastiness and freshness due to generation of a large number of polyalcohols such as 2,3-butanediol, glycerol and hexanehexol.

Owner:湖北楚园春酒业有限公司

Screening and fermentation method for producing 2,3-butanediol strains by using straws

The invention belongs to separation and screening of strains and high-value utilization field of straw resources, and particularly relates to a screening method for producing 2,3-butanediol and cellulase strains at the same time and a method for producing 2,3-butanediol by direct fermentation by using straws as a raw material. The invention first provides the method for screening strains capable of producing the 2,3-butanediol and secreting cellulase at the same time from active sludge, the strains YB-4 capable of producing the 2,3-butanediol and secreting the cellulase at the same time are obtained by screening, the strains YB-4 are preserved in CGMCC on July 14th, 2010, and the preservation number is CGMCC No. 4005. Meanwhile, the invention provides the method for producing the 2,3-butanediol by using the fermentation straws of the strains, wherein the strains take the steam explosion straws as a carbon source, a nitrogen source is cultured for 4 to 7 days in a fermentation medium to obtain yeast extract, and the yield of the 2,3-butanediol is 8 to 12 percent of the dry weight of the straws (2,3-butanediol / straw dry weight, W / W). The method for producing the 2,3-butanediol by using the straws as the raw material does not need adding cellulase so as to greatly reduce the production cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method of preparing 2,3-butanediol by simultaneous saccharification and fermentation of corncob residues

ActiveCN102643869ARealize high value utilizationReduce pollutionMicroorganism based processesFermentationDry weightKlebsiella oxytoca

The invention discloses a method of preparing 2,3-butanediol by simultaneous saccharification and fermentation of corncob residues with xylose extracted from corncobs and belongs to the technical field of biochemical engineering. The method includes the steps of using the corncob residues as a carbon source and carbamide as a nitrogen source, using klebsiella pneumoniae CICC 10011, klebsiella oxytoca CICC 21518, bacillus polymyxa CICC 10010, bacillus cloacae CICC 10014 and a mixed bacterium solution to perform the simultaneous saccharification and fermentation, and enabling the weight of the 2,3-butanediol and acetoin to reach 19.59%-36.13% of the dry weight of the corncob residues. According to the method of preparing 2,3-butanediol by the simultaneous saccharification and fermentation of the corncob residues, the corncob residues are used as the carbon source, so that production cost is effectively reduced, high value utilization of resources is achieved, and huge economic benefits and social benefits are achieved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

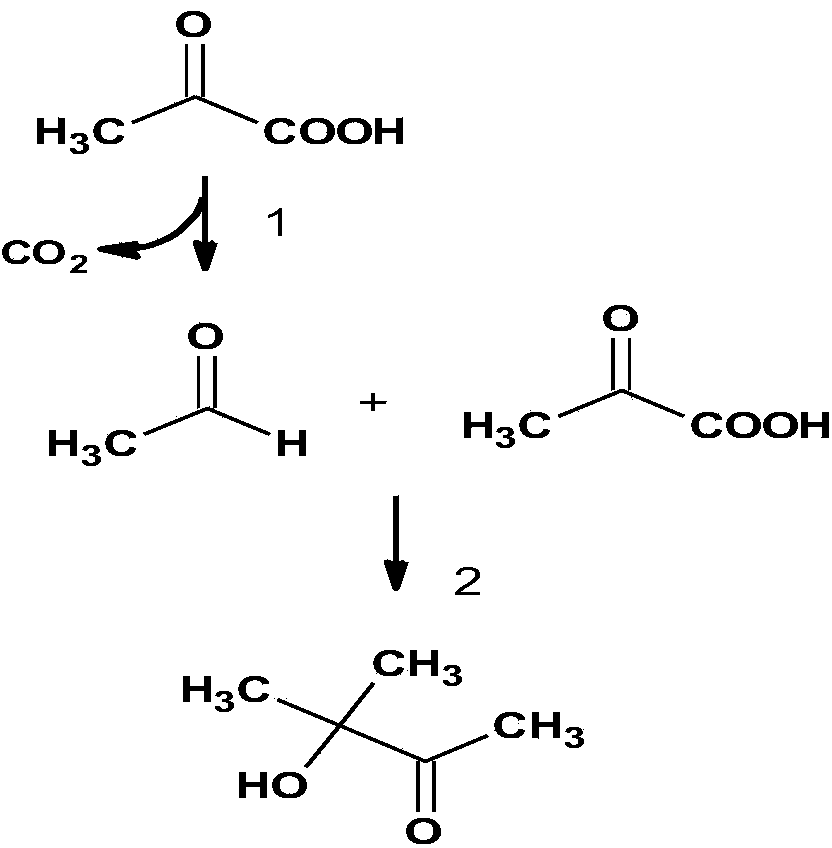

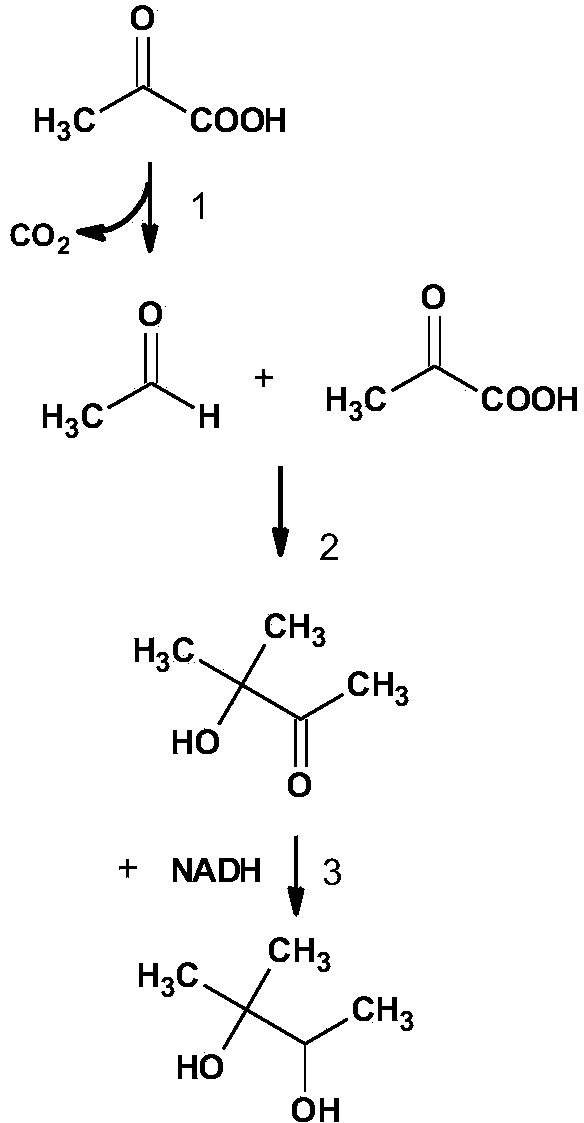

Method for synthesizing acetoin and derivative thereof through biological method

ActiveCN103725718AAddresses depletion affecting acetoinSolve productivityFermentationVector-based foreign material introductionEmulsion2,3-Butanediol

The invention discloses a method for synthesizing acetoin and a derivative thereof through a biological method, which belongs to the technical field of the molecular biology. The method comprises the steps of introducing pyruvate decarboxylase genes and genes with acetoin enzyme activity into host bacteria to obtain recombination bacteria, producing the acetoin by fermenting the recombination bacteria, and further producing 2,3-butanediol on the basis of the acetoin. By adopting the method, the acetoin and the 2,3-butanediol are successfully generated by fermenting the recombined bacteria strain, and the problem that the yield of the acetoin and the 2,3-butanediol is influenced by the consumption of an intermediate product acetyl emulsion in the natural production process can be solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

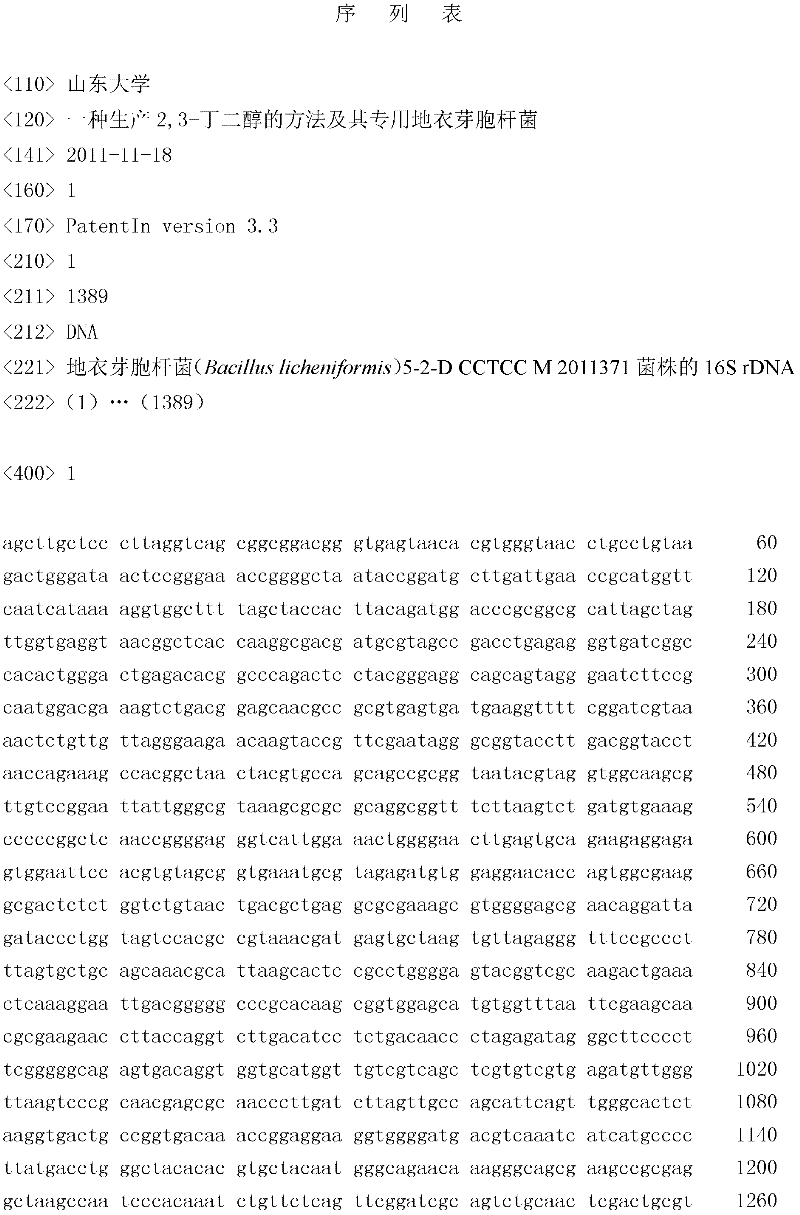

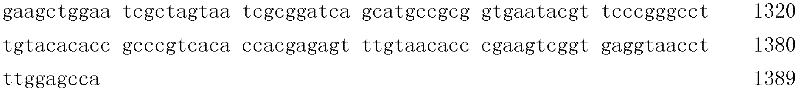

Method for producing 2, 3-butanediol and special bacillus licheniformis thereof

ActiveCN102391970AReduce consumptionReduce lossesBacteriaMicroorganism based processesHigh concentrationBiotechnology

The invention discloses bacillus licheniformis 5-2-D and a method for producing 2, 3-butanediol by using the same on the premise of taking the temperature of 42-55 DEG C and the culture stirring time of 20-60 hours as fermentation conditions and taking glucose as a substrate. In the method for producing the 2, 3-butanediol, which is provided by the invention, the advantages of high-temperature fermentation process are fully utilized, the probability of mixed fungi pollution is small, the sterilization is not performed on a fermentation culture medium, and the energy consumption and the loss of nutrient substances are reduced; simultaneously, the highest concentration of the obtained 2, 3-butanediol can achieve 92g / L and the production strength can achieve 2.56g / L / hour.

Owner:上海肆芃科技有限公司

Biological production of multi-carbon compounds from methane

Owner:PRECIGEN INC

Method for producing 2-keto-D-gluconic acid by using fermentation method

InactiveCN102925499AImprove conversion rateEasy to controlMicroorganism based processesRecombinant DNA-technology2,3-ButanediolGluconic acid

The invention discloses a method for producing 2-keto-D-gluconic acid by using a fermentation method, which is used for producing the 2-keto-D-gluconic acid by using Lebsiella pneumoniae with a lost 2,3-butanediol synthetic route as a production strain and glucose as the raw material through controlling a fermentation liquor to be acidic under an aerobic fermentation condition. The method has the following characteristics of relatively high transformation rate, easily-controlled fermentation process and relatively low temperature reducing energy consumption in a fermentation process.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

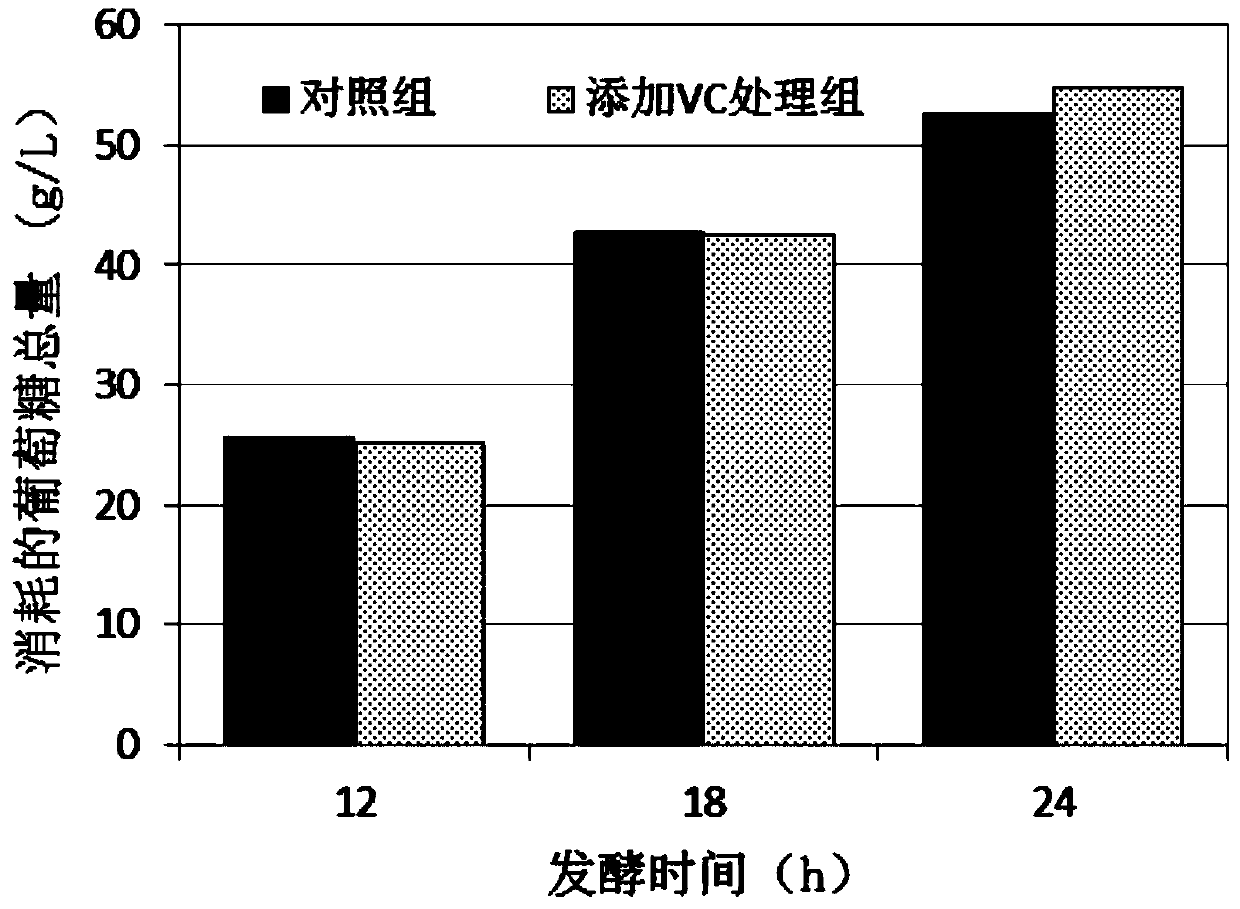

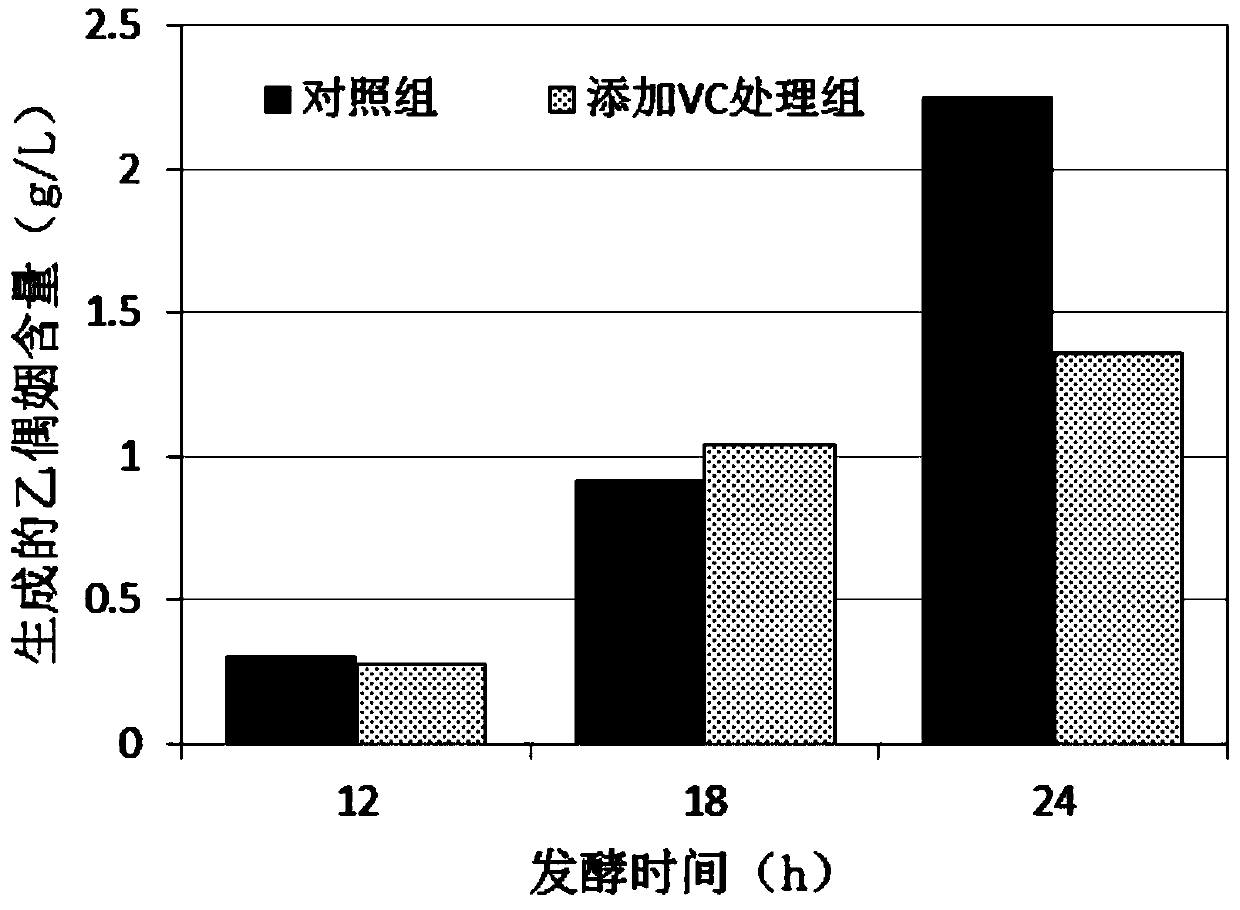

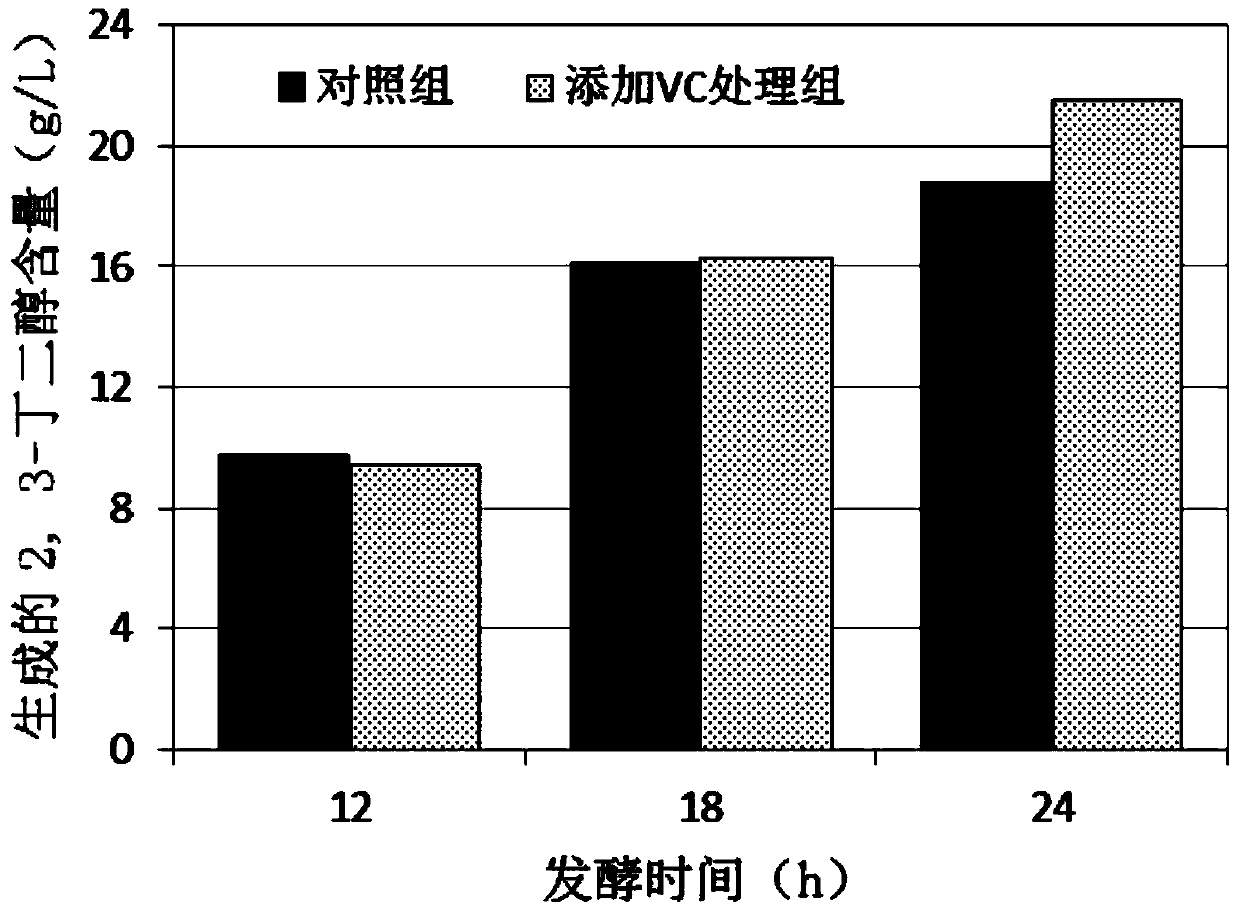

Method for increasing yield of paenibacillus polymyxa 2,3-butanediol by using vitamin C

InactiveCN103695477AReduce the impact of hindered accumulationIncrease consumptionMicroorganism based processesFermentationVitamin CConcentrations glucose

The invention discloses a method for increasing the yield of paenibacillus polymyxa 2,3-butanediol by using vitamin C. The method comprises the following steps: (1) seed culture; (2) fermentation culture: inoculating secondary seeds into a fermentation culture medium, performing fermentation under the conditions that the ventilatory capacity is 0.1-0.8vvm, the stirring rotating speed is 300-500rpm and the temperature is 32-42 DEG C for 12-24 hours, and adding 80-160g / L vitamin C solution when the concentration of glucose in the fermentation culture medium is reduced to 2-10g / L. By the adoption of a method for continuously adding a reducing agent, the method disclosed by the invention is favorable for maintenance of a redox situation of an external environment in which bionts exist in the whole fermentation process, so that consumption of the glucose in fermentation liquid and conversion of acetoin are finally promoted, and the accumulation of (R,R)-2,2- butanediol is improved.

Owner:TIANJIN UNIV

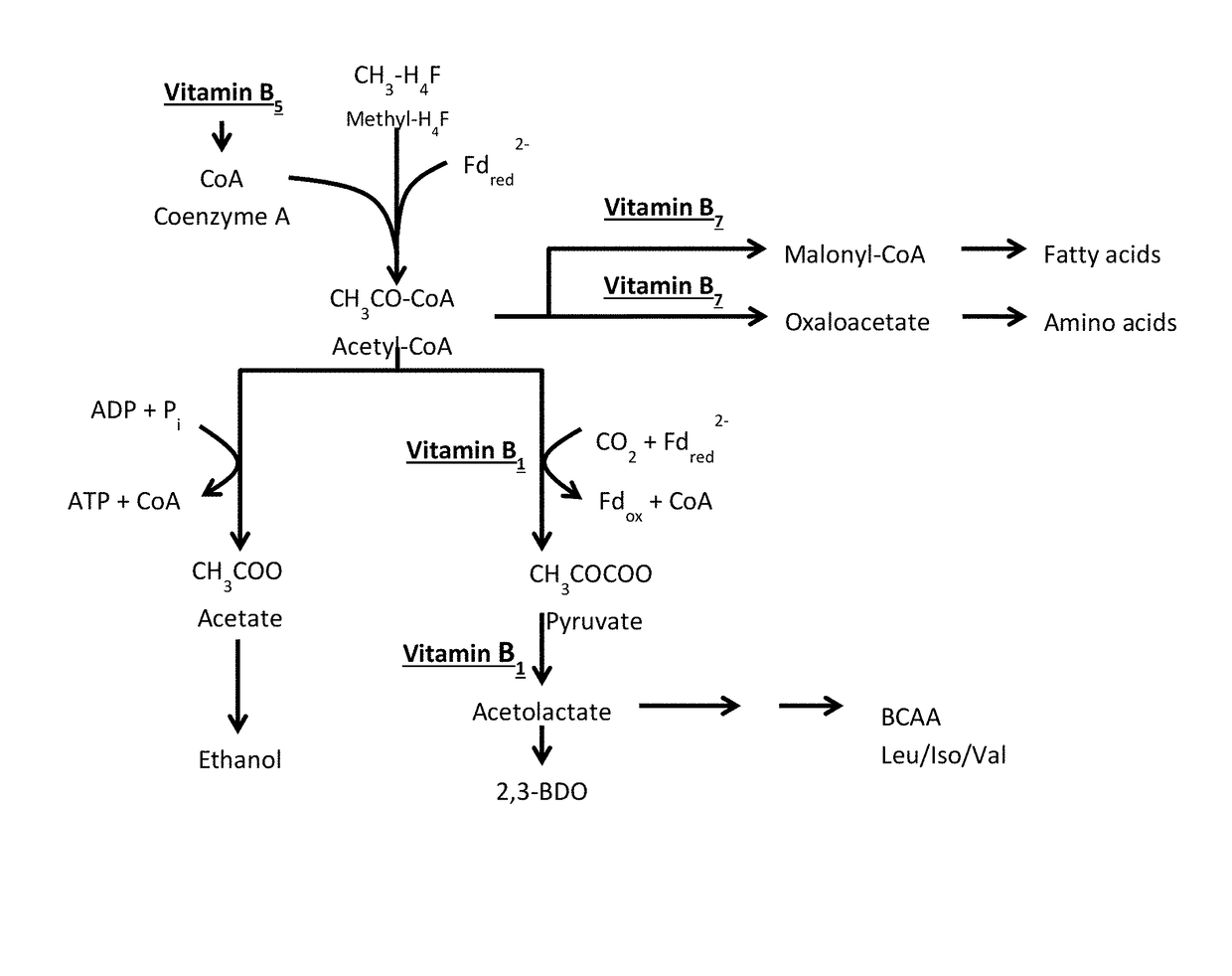

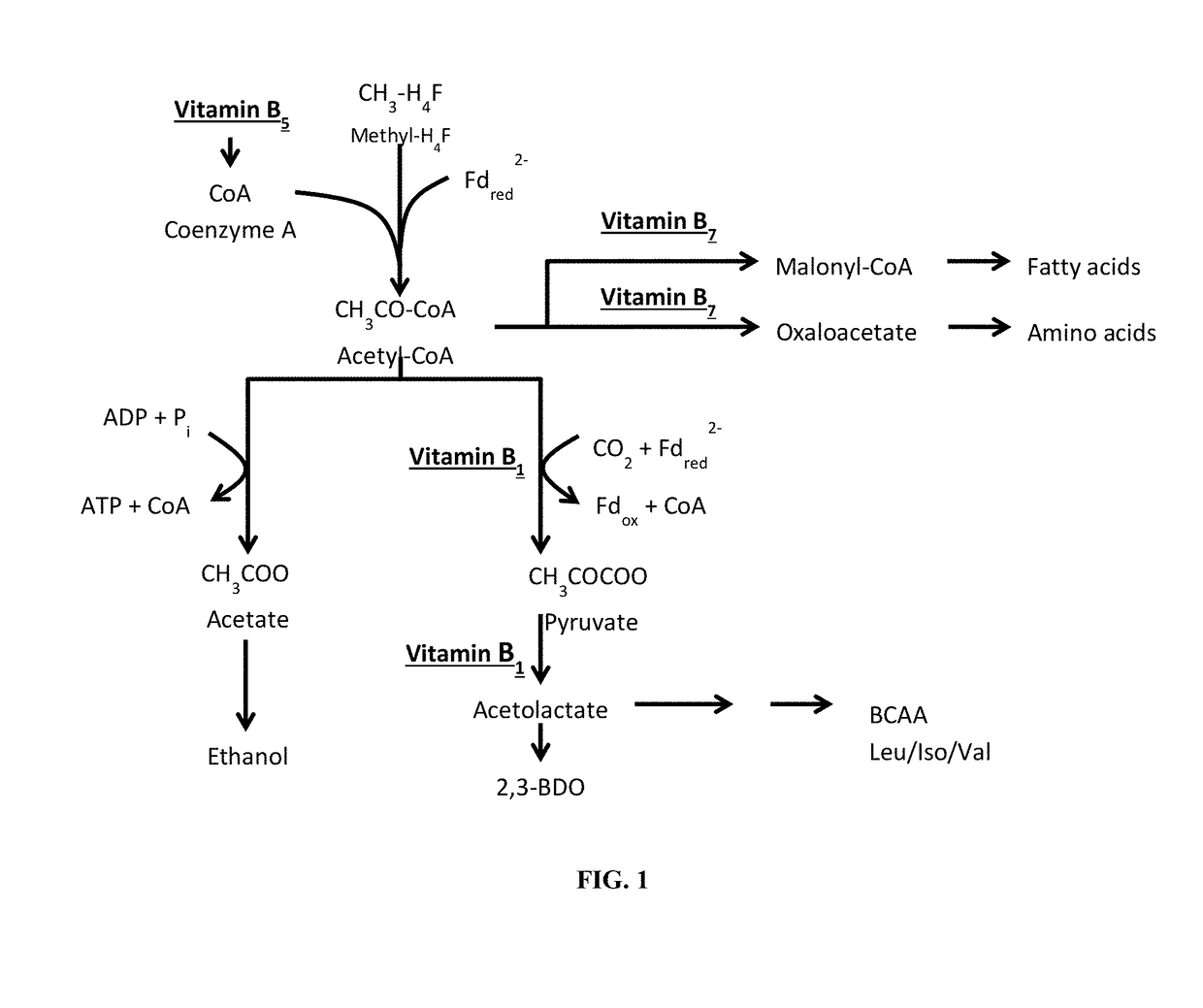

Fermentation process for the production and control of pyruvate-derived products

A process for producing and controlling pyruvate derived products during the fermentation of a CO containing substrate by an acetogenic carboxydotrophic microorganism has been developed. The process involves increasing the concentration of at least one nutrient selected from the group consisting of vitamin B1, vitamin B5, vitamin B7 and mixtures thereof above the cellular requirement of the microorganism. When the concentration is increased, the production of 2,3-butanediol (2,3-BDO) increases whereas the production of the other metabolites is virtually unchanged. The effect is reversible so that when the concentration is decreased, the production of 2,3-BDO is also decreased. This allows one to control the ratio of ethanol:2,3-BDO to a desired value which can vary from about 4:1 to about 1:2.

Owner:LANZATECH NZ INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com