Method for producing 2, 3-butanediol and special bacillus licheniformis thereof

A technology of bacillus licheniformis and butanediol, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of unseen bacillus licheniformis production, achieve high production intensity, reduce energy consumption, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

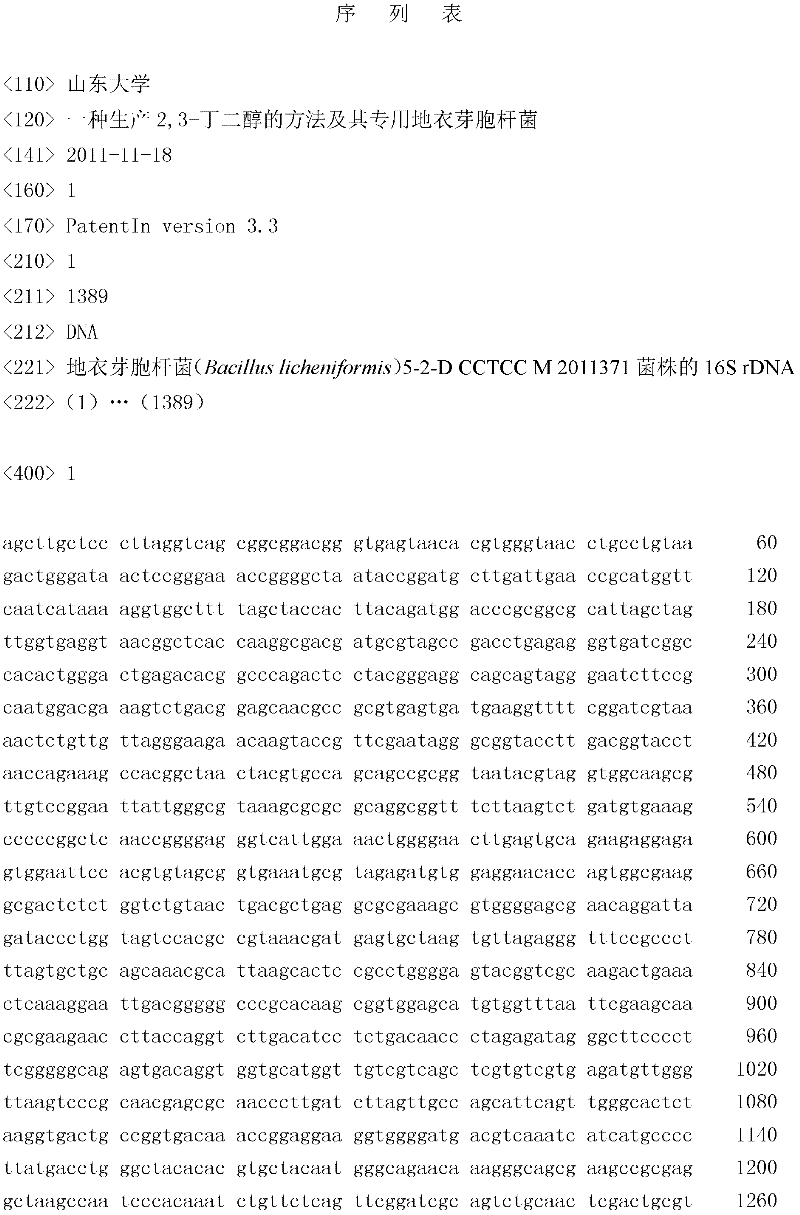

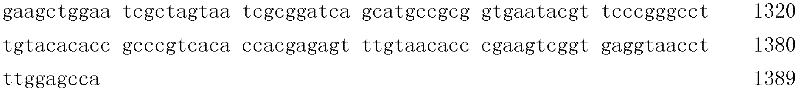

Image

Examples

Embodiment 1

[0029] Example 1: Screening of high sugar tolerance and capable of producing 2,3-butanediol strains

[0030] Soil samples were obtained from orchards and other places, soaked in screening medium for 2 hours, filled with 50 mL of soaking solution in a 500 mL Erlenmeyer flask, and cultured on a shaker at 180 r / min for 24 hours at 50 °C. Dilute the culture medium with 10 -2 、10 -3 、10 -4 、10 -5 、10 -6 Five dilutions were spread on petri dishes of solid screening medium, and cultured at 50°C for 12h. Pick a single colony, expand the culture, and conduct a preliminary screening through the VP reaction. Positive strains were screened out based on reaction time and color change. The screening principle is that 2,3-butanediol is oxidized to diacetyl under alkaline conditions, and the red substance is synthesized with creatine or guanidine derivatives. Adding α-naphthol and creatine can promote the reaction. Then measure the 2,3-butanediol production of the positive bacteria scr...

Embodiment 2

[0034] Embodiment 2: prepare the cell liquid culture of Bacillus licheniformis CCTCC M 2011371 bacterial strain

[0035]Pick a loop of Bacillus licheniformis CCTCC M 2011371 strain cultured on the slant of solid high-sugar LB medium, inoculate it in a 500mL Erlenmeyer flask containing 100mL of sterilized high-sugar LB medium, and place it in a shaker at 55°C. Cultivate on the bed at a rotational speed of 180 r / min for 24 hours to obtain a cell liquid culture of Bacillus licheniformis CCTCC M 2011371 strain.

[0036] The formula of the above-mentioned high-glucose LB medium is as follows: 1L of distilled water contains: 150g of glucose, 10g of peptone, 5g of yeast powder, 10g of NaCl, and sterilized at 115°C for 15min. The solid high-glucose LB medium is based on the above formula by adding 20g / L agar powder.

Embodiment 3

[0037] Embodiment 3: Utilize bacillus licheniformis CCTCC M 2011371 strain to ferment and produce 2,3-butanediol with fermentation medium 1 in Erlenmeyer flask

[0038] The liquid cell culture of the Bacillus licheniformis CCTCC M 2011371 bacterial strain obtained by Example 2 was inoculated in a 500mL Erlenmeyer flask containing sterilized 100mL fermentation medium with an inoculum size of 50mL / L, at 50°C, Place on a shaker and cultivate at a rotational speed of 180r / min. Samples are taken at intervals of 4 hours and the content of 2,3-butanediol is detected. At 34 hours, the concentration of 2,3-butanediol reaches 56.0g / L. At 60h, the Erlenmeyer flask was removed from the shaker to stop the fermentation.

[0039] Above-mentioned fermentation medium 1 formula is as follows:

[0040] Glucose 120 g / L, yeast powder 10 g / L, corn steep liquor 5 g / L, potassium dihydrogen phosphate 4 g / L, sodium acetate 1 g / L, potassium chloride 2 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com