Environmentally-friendly breeding of bacillus subtilis for producing 2,3-butanediol by fermentation with glucose substrate

A Bacillus subtilis, environmentally safe technology, applied in the direction of bacteria, microorganisms, and methods based on microorganisms, can solve the problems of restricting industrial applications, difficult industrial production, and difficult operation, etc., and achieve high raw material utilization rate, easy control, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the screening of bacterial strain:

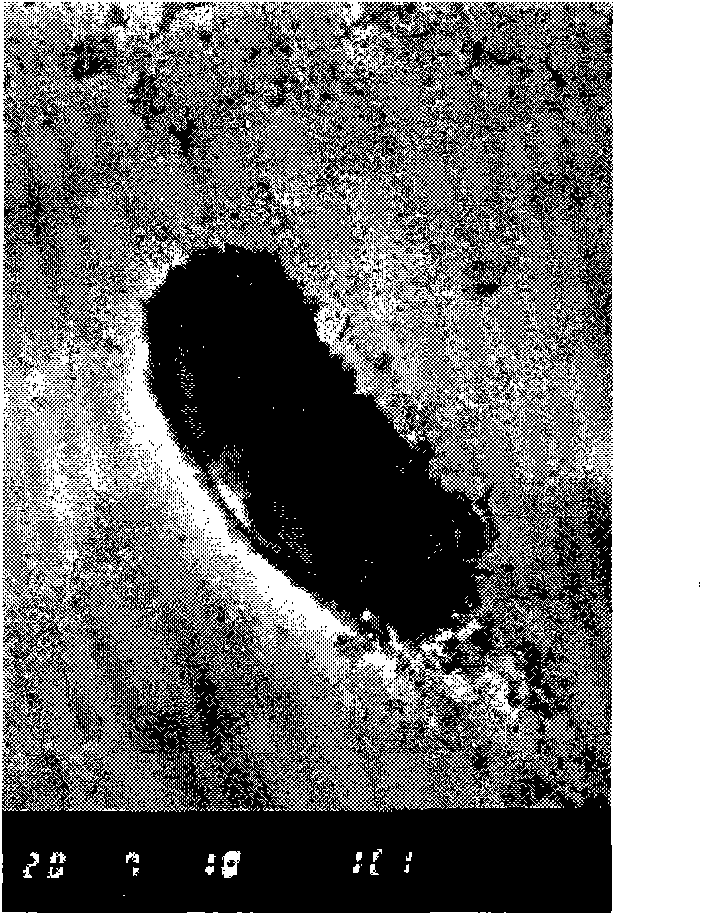

[0029] Screening of target strains: Enrich the collected samples in seed medium (glucose 20g / L, yeast extract 5g / L, peptone 10g / L, sodium chloride 10g / L pH 7.0), shake at 37°C 150r / min Bed for 10h, take different dilutions to spread and culture. Pick a single colony on the plate separation medium (yeast extract 5g / L, peptone 10g / L, sodium chloride 10g / L, agar powder 18g / LpH 7.0) for streak separation, culture at 37°C for 1d-2d, microscopic examination, The strains to be tested were preserved in the slant preservation medium for primary screening.

[0030] The seeds cultivated to the logarithmic phase with the seed medium were added to the fermentation medium containing 15% glucose according to the inoculum amount of 5%, and then placed at 37°C and 150r / min for shaking culture for 72h. The fermentation broth was collected, centrifuged, and the supernatant was taken for detection.

Embodiment 2

[0031] Embodiment 2: 2,3-BDO qualitative detection:

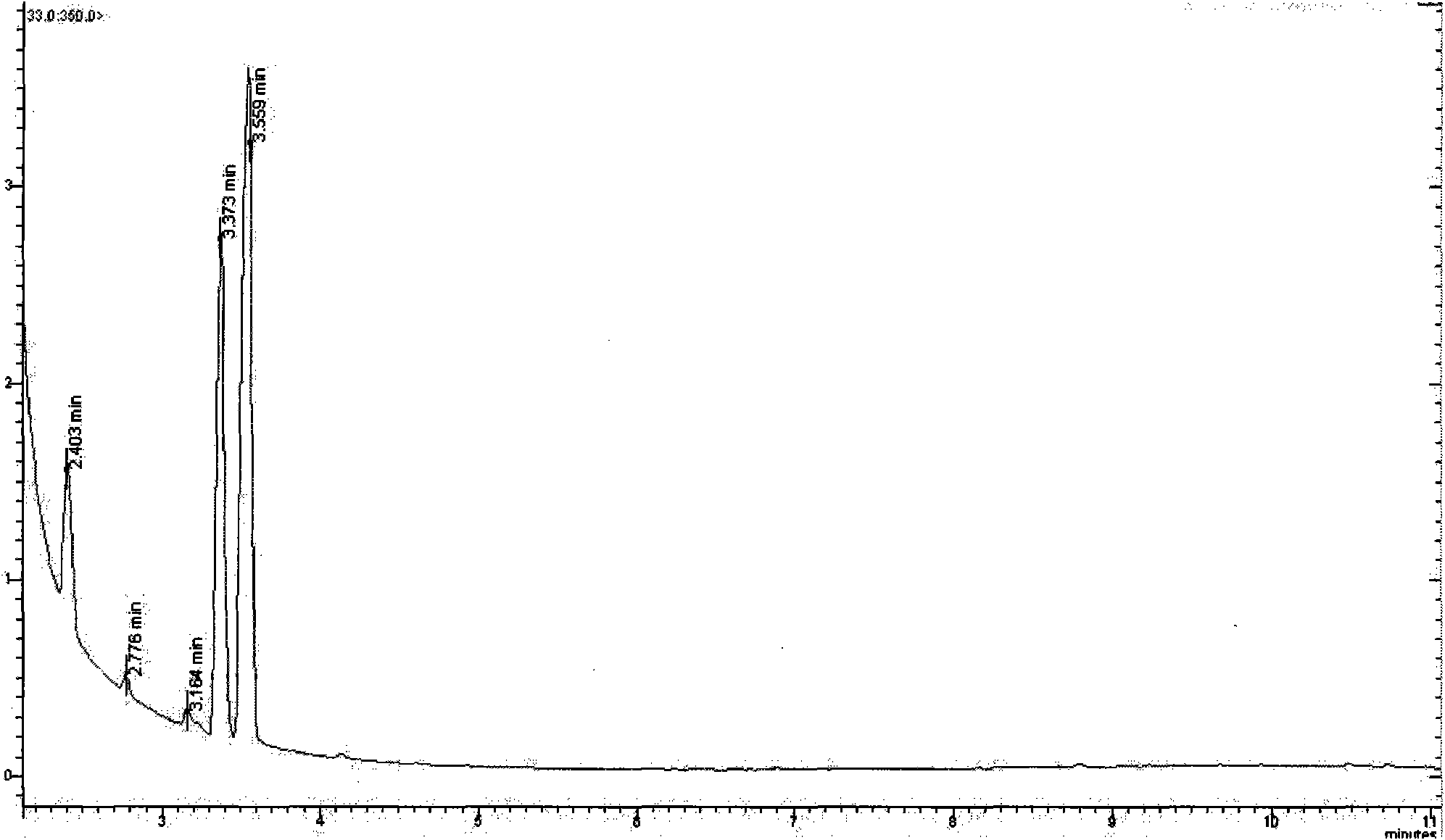

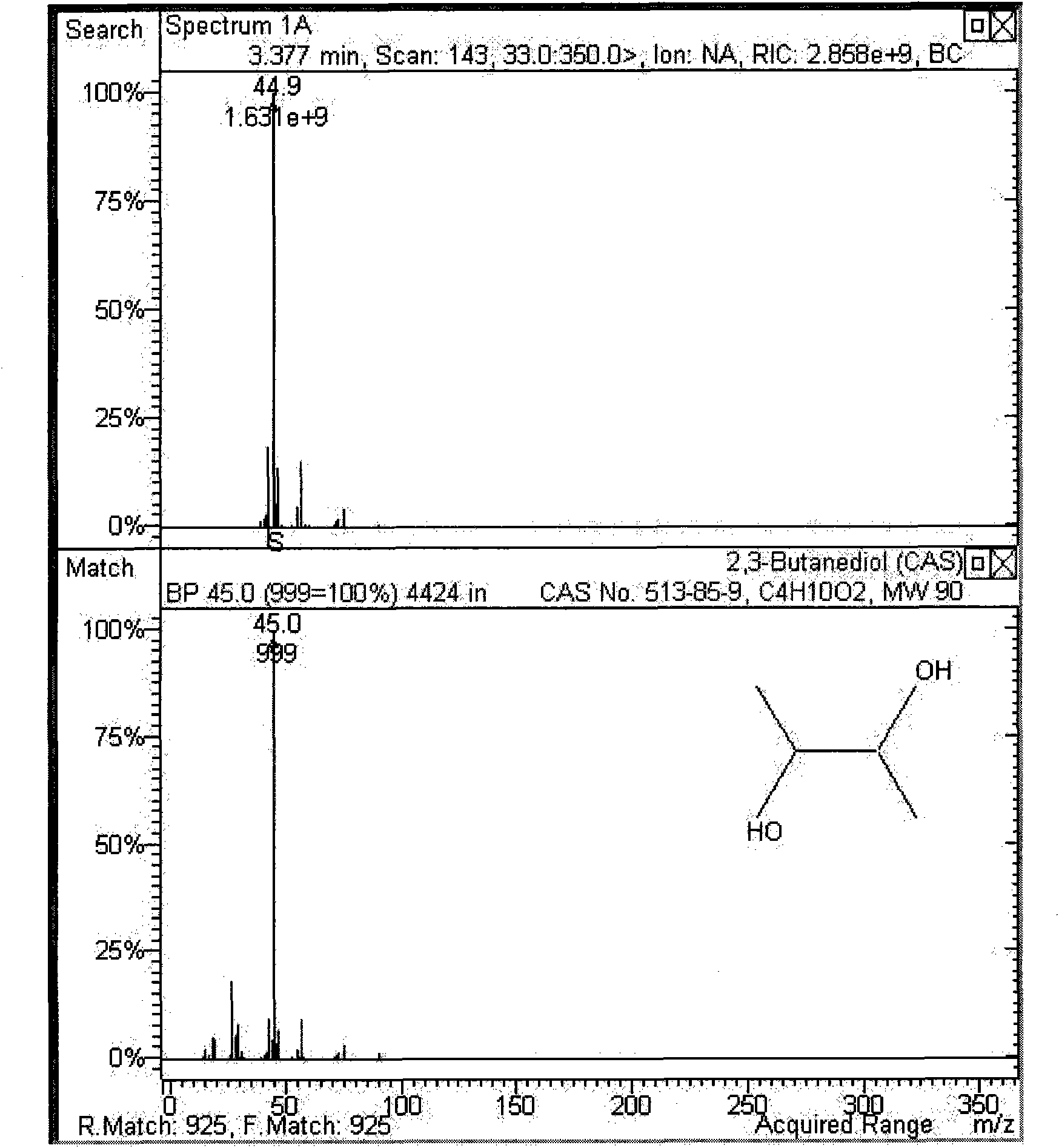

[0032] Take 2ml of the supernatant, extract with 2ml of ethyl acetate, and then use gas chromatography-mass spectrometry (GC-MS) to identify whether the extract contains 2,3-BDO. GC-MS detection conditions: The temperature control program of the chromatographic column is as follows: first, keep warm at 60°C for 1min, then raise the temperature to 90°C at a rate of 6°C / min and keep it for 2min, and finally increase the temperature at a rate of 30°C / min. To 180 ℃, constant temperature 2min. The temperature of the injection port is 250°C, the injection volume is 1 μL, the carrier gas is high-purity helium, the flow rate of the carrier gas is 1.2mL / min, and the detector temperature is 240°C;

[0033] TraceMS mass spectrometry conditions: EI+ bombardment source, full scan mode, scan mass range of 30-500amu, emission current of 200μA, electron energy of 70eV, mass spectrometry detection spectrum library is NIRT98 spectrum librar...

Embodiment 3

[0035] Embodiment 3: Detection of the ability to synthesize 2,3-butanediol of bacterial strains:

[0036]The 2,3-butanediol content in the fermented liquid obtained in Example 1 was determined by liquid chromatography. Waters liquid chromatography, sugar column Sugarpakl (6.5mmid × 300mm)); column temperature: 85 ° C; mobile phase: pure water, flow rate 0.4ml / min; injection volume is 10 μ L; detector: differential refractive index detector. The retention times of different configurations of 2,3-BDO were 19.3min and 22.5min, respectively.

[0037] 2,3-BDO standard HPLC diagram Figure 6 As shown, 6-7 uses glucose as the substrate 72h fermentation broth HPLC spectrum as shown in Figure 12;

[0038] After 72 hours of fermentation of a selected strain of Bacillus subtilis, the residual glucose in the fermentation liquid was about 1.5g / L, and the content of 2,3-butanediol was about 50g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com