Method for selectively producing 3-hydroxyl-2-butanone and 2, 3-butanediol through microbial fermentation

A selective, butanediol technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as non-compliance with industrial safety production, achieve high industrial application value, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) B.amyloliquefaciens CCTCC M2012349 seed culture

[0024] Pick a single colony from the activated plate and inoculate it in the seed medium for seed culture. The culture temperature is 37°C, the shaker speed is 160r / min, and the culture time is about 12h. The composition of the seed medium: yeast extract 5g / L, tryptone 10g / L, NaCl10g / L;

[0025] (2) B.amyloliquefaciens CCTCC M2012349 fermentation culture

[0026] The initial fermentation culture volume is 2.5L, and the components of the fermentation medium used are as follows:

[0027] 3-Hydroxy-2-butanone fermentation medium composition: glucose 160g / L, corn steep liquor 5g / L, urea 3g / L, sodium citrate 6g / L, K 2 HPO 4 4g / L, MgSO 4 0.2g / L; adjust the pH of the above fermentation medium to 6.5 with 5mol / L NaOH, and sterilize at 121°C for 30min.

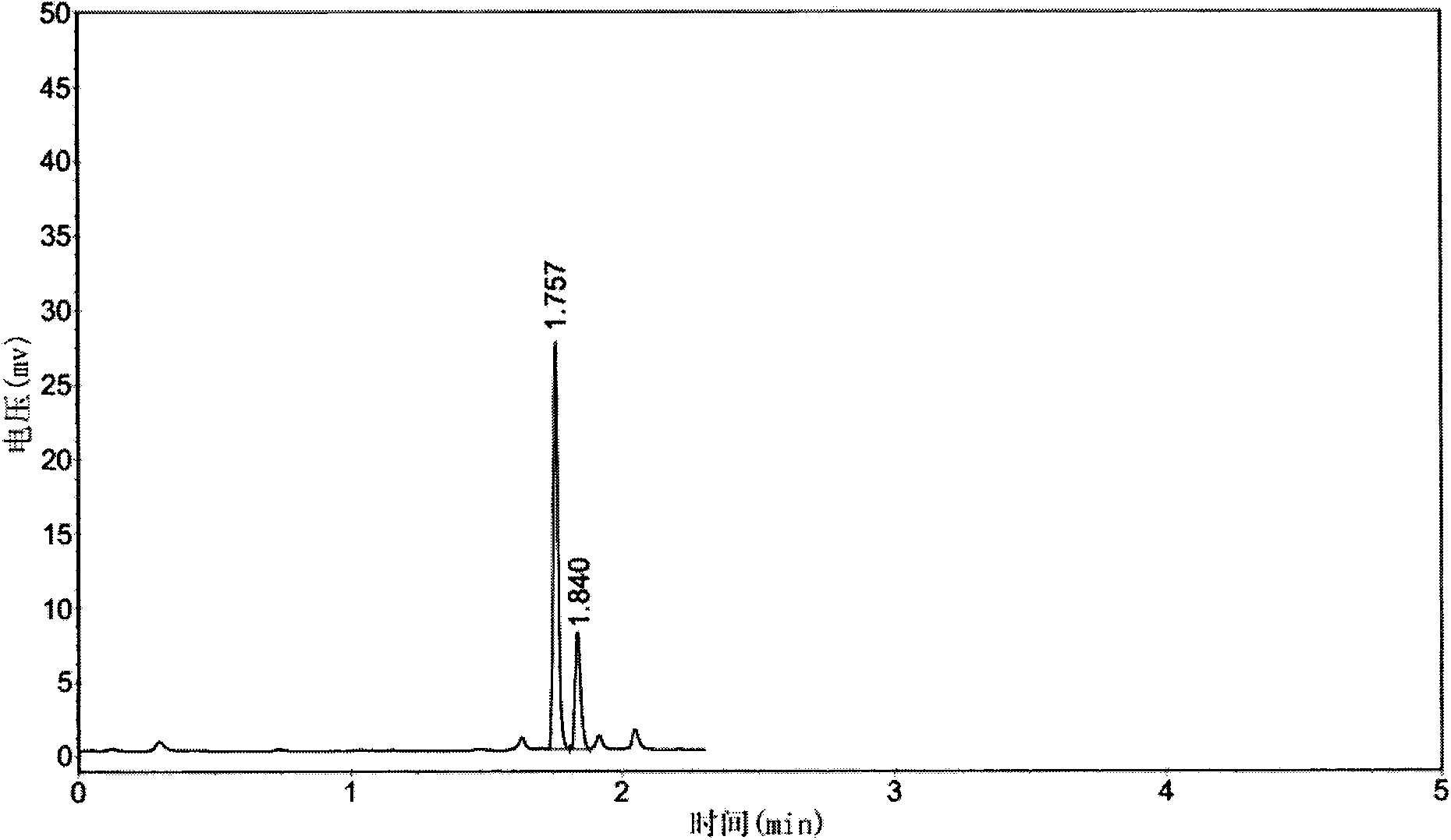

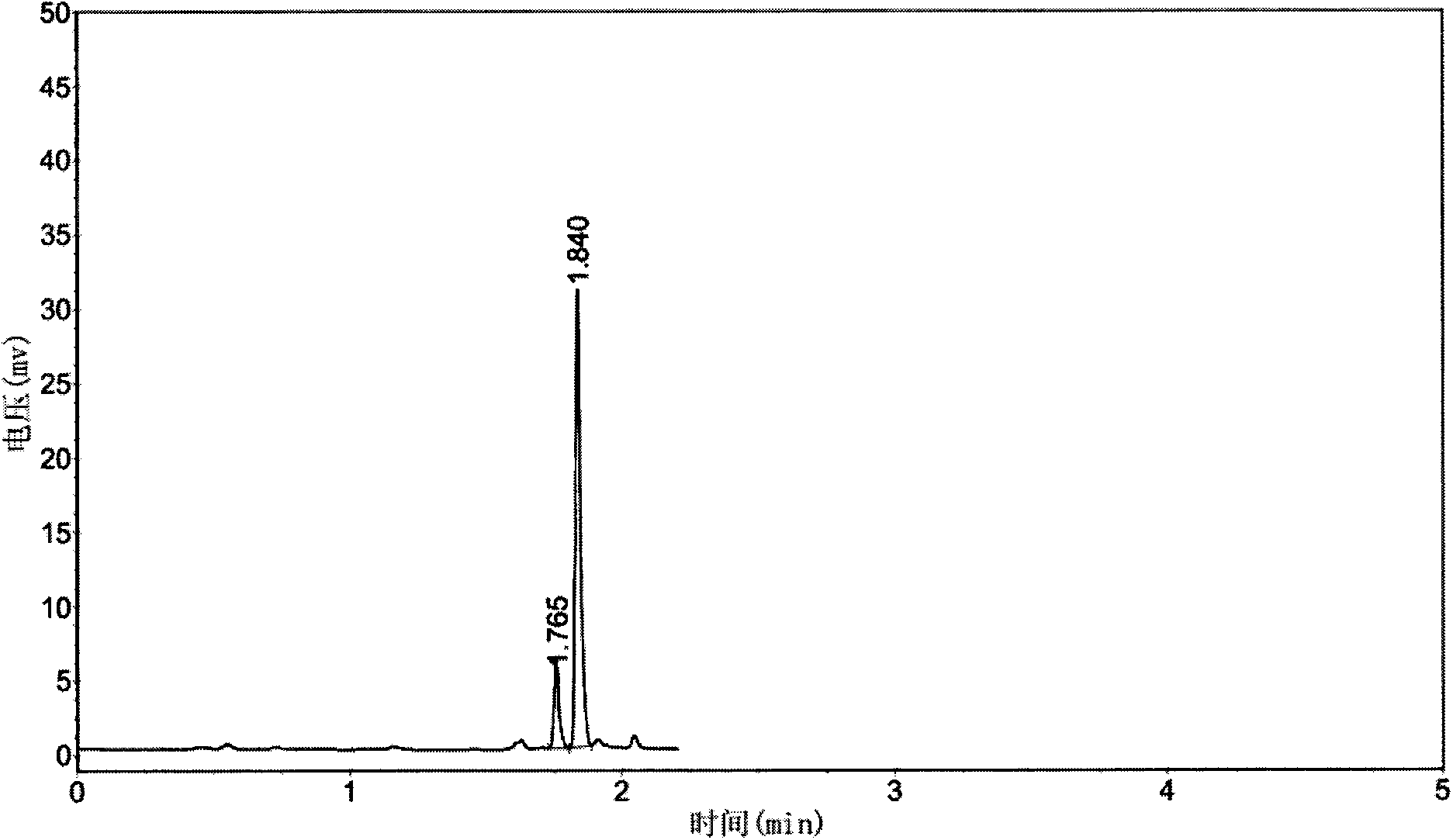

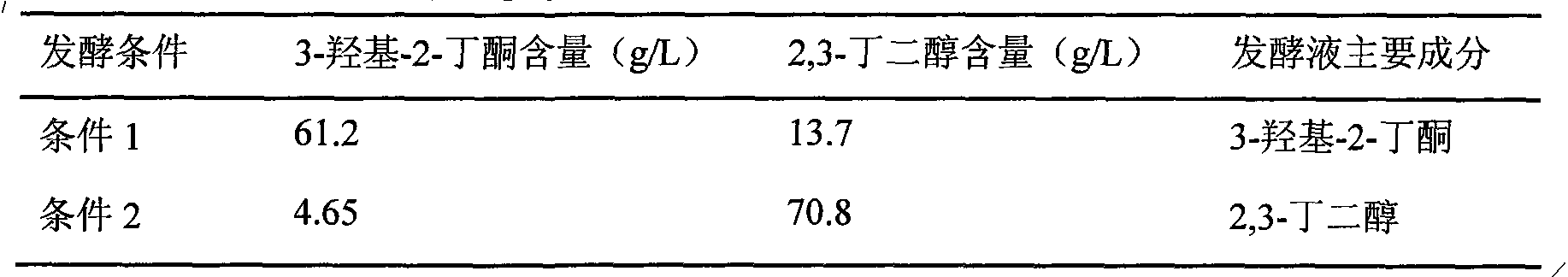

[0028] 3-Hydroxy-2-butanone fermentation Fermentation conditions: Inoculate the above-mentioned cultured seed liquid into the fermentation medium with a 4% inoculation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com