Method for increasing yield of paenibacillus polymyxa 2,3-butanediol by using vitamin C

A technology of spore-like polymyxa and vitamins, which is applied in the field of fermentation engineering, can solve problems such as impact, and achieve the effect of reducing accumulation obstruction and promoting glucose consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for increasing the production of Bacillus polymyxa 2,3-butanediol by using vitamin C, comprising the following steps:

[0019] (1) Preparation of culture medium

[0020] The composition of the solid slant medium is calculated in g / L: starch 20, glucose 5, peptone 2, MgSO 4 .7H 2 O0.5, NaCl0.5, corn steep liquor 2, agar 20, steam sterilization at 121°C for 20 min;

[0021] The composition of the seed medium is calculated in g / L: starch 30, glucose 5, yeast extract 2, peptone 4, MgSO 4 .7H 2 O0.5, NaCl0.5, K 2 HPO 4 1.5, 121℃ steam sterilization for 20min;

[0022] Fermentation medium components in g / L: glucose 55, yeast extract powder 10, NaCl5, K 2 HPO 4 4. KH 2 PO 4 2, (NH4) 2 SO 4 2, Sodium Citrate 2, MgSO 4 ·7H 2 O0.7, KCl0.5, CaCl 2 0.05, ZnSO 4 ·7H 2 O0.005, FeSO 4 ·7H 2 O0.005, MnSO 4 ·H 2 O0.005, pH 7.0, steam sterilization at 121°C for 20min;

[0023] (2) Shake flask culture

[0024] Cultivation of primary seeds

[0025] Connect CJX-518 from the solid slant culture...

Embodiment 2

[0032] Control group: fermentation without vitamin C

[0033] (1)~(2) Same as steps (1)~(2) of Example 1;

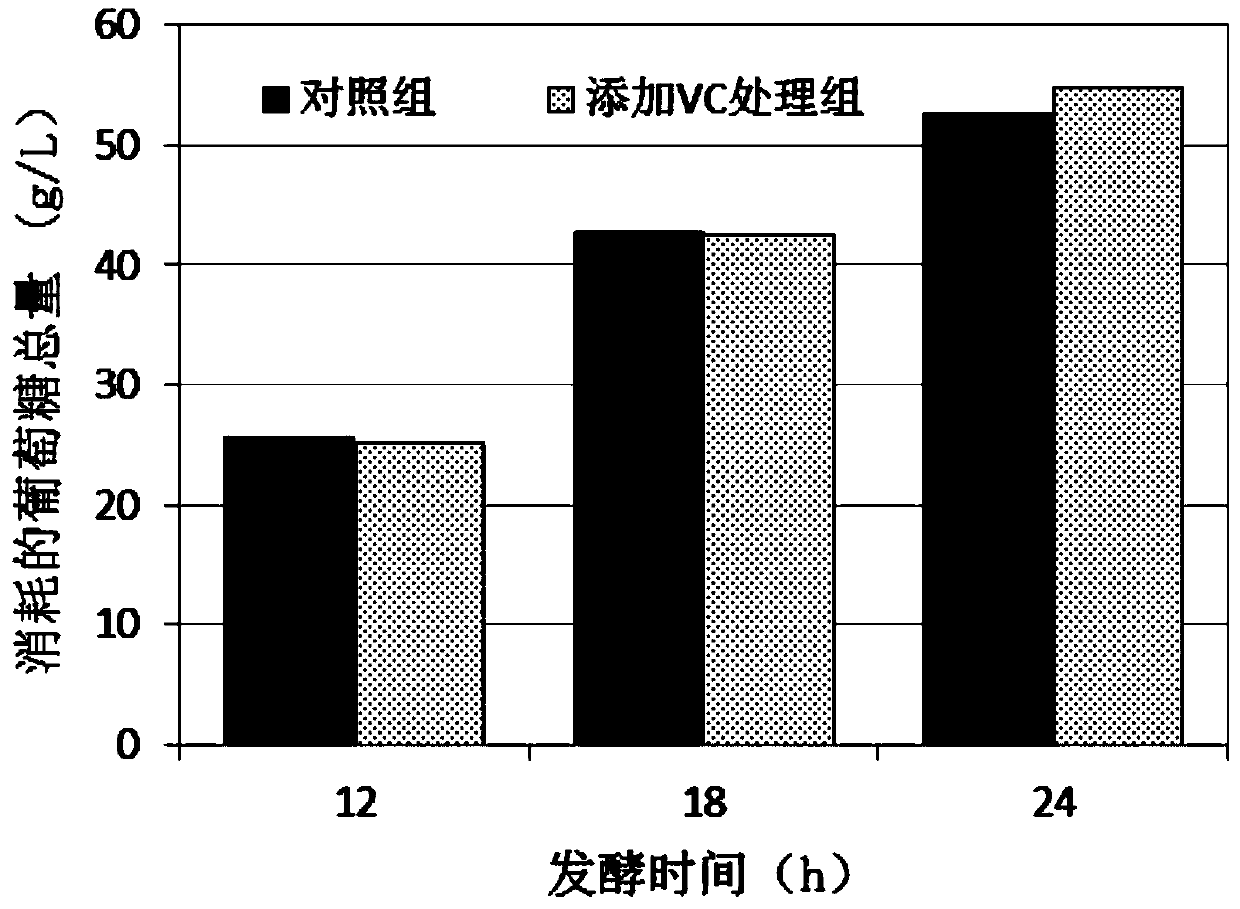

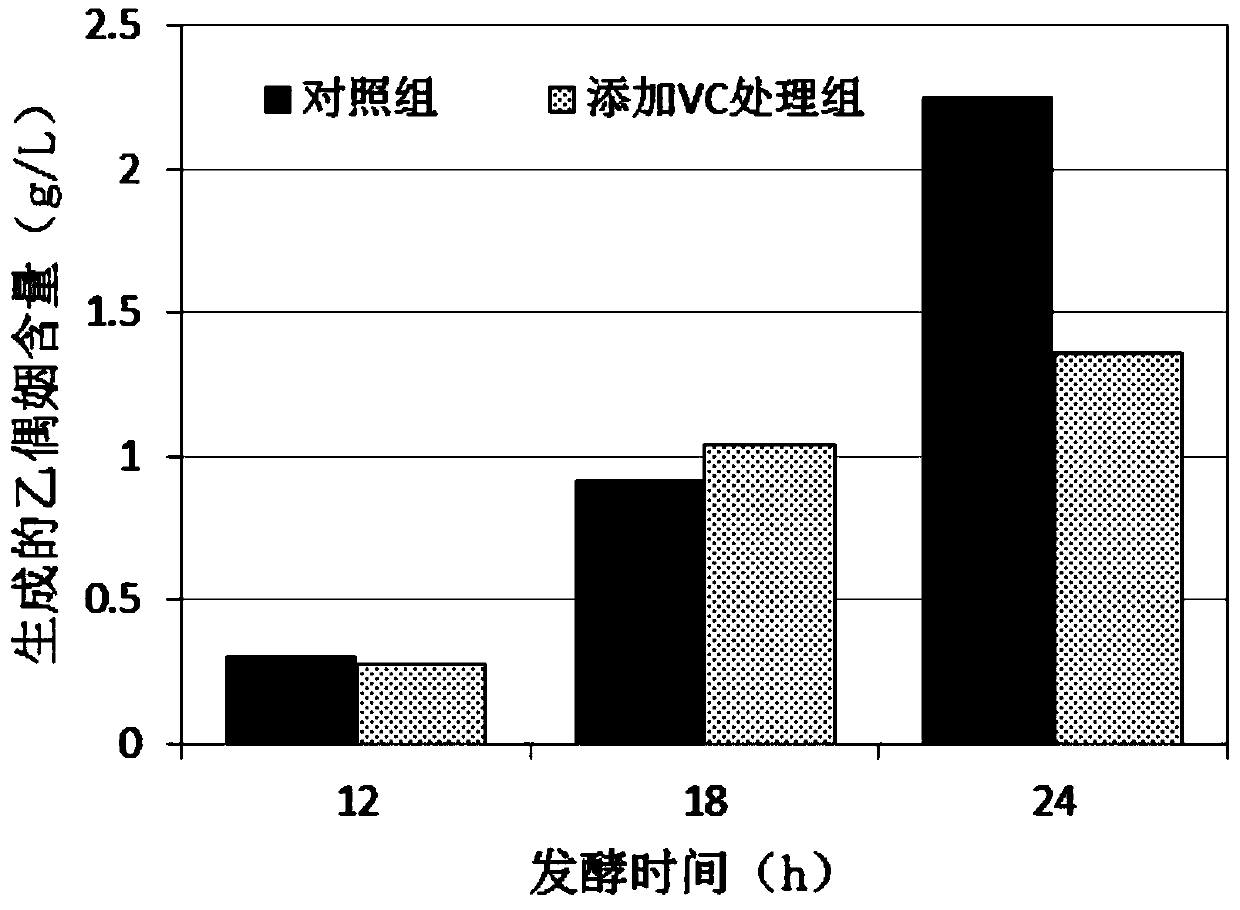

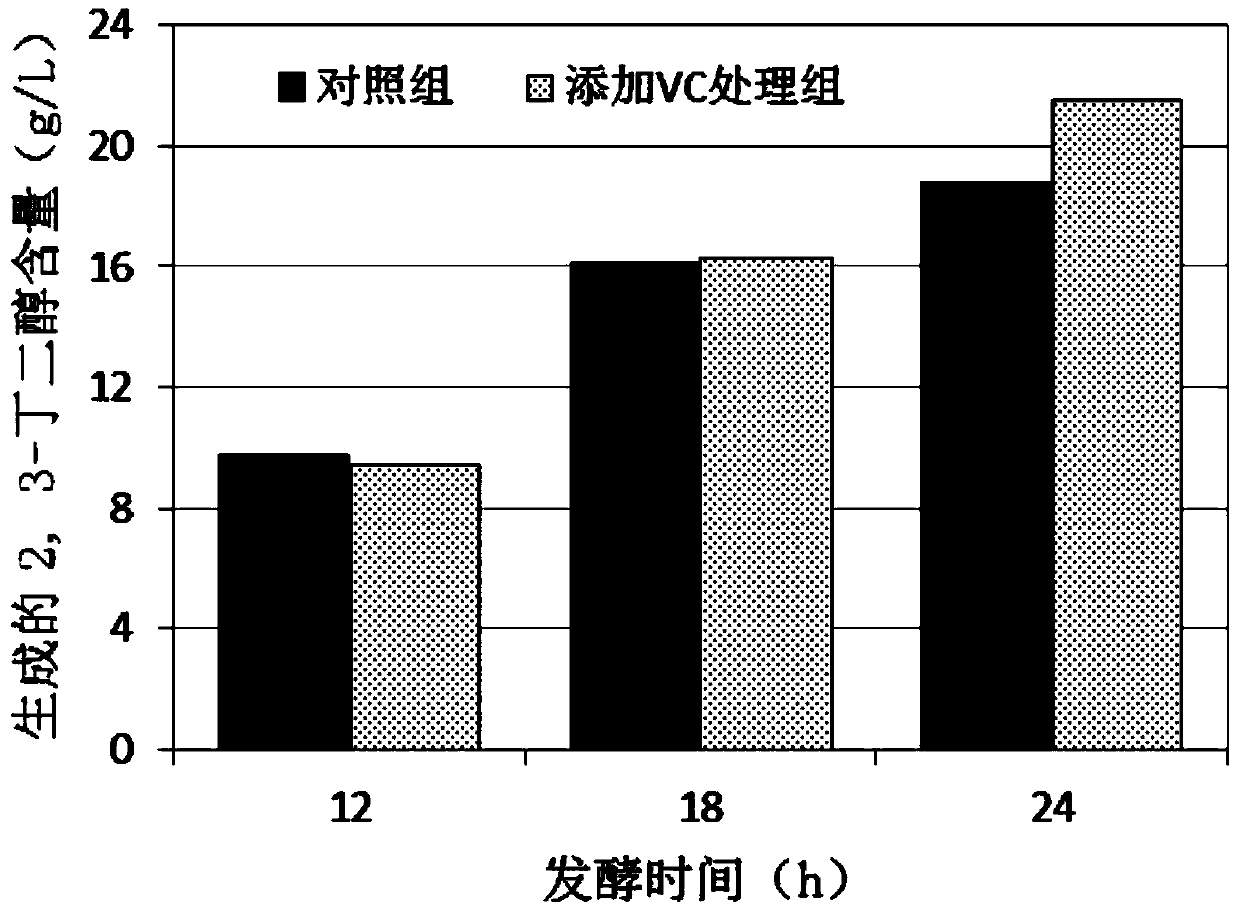

[0034] (3) Connect the secondary seed culture solution to a 5L fermentor equipped with 3L fermentation medium according to the volume percentage of 10% inoculation density, and ferment under the condition of aeration of 0.2vvm, stirring speed of 300rpm and temperature of 37℃ After 24h, take the fermentation broth at 12h, 18h, 24h, centrifuge at 12000rpm for 10min, take the supernatant, dilute with ultrapure water 10 times, filter with 0.22μm filter, high performance liquid chromatography to detect the content of fermentation product, the consumption detected in each time period The total amount of glucose such as figure 1 As shown in the control group, the concentration of acetoin produced is as figure 2 As shown in the control group, the concentration of (R,R)-2,3-butanediol produced is as follows image 3 Shown in the control group.

Embodiment 3

[0036] A method for increasing the production of Bacillus polymyxa 2,3-butanediol by using vitamin C, comprising the following steps:

[0037] (1) Seed cultivation: CJX-518 is cultivated in seed culture medium to obtain first-level seeds; first-level seeds are cultivated in seed culture medium to obtain second-level seeds; the preparation of seed culture medium is the same as in Example 1;

[0038] (2) Fermentation culture

[0039] Connect the secondary seeds to the fermentation medium at an inoculum density of 5% by volume. When the aeration rate is 0.8vvm, the stirring speed is 500rpm, the temperature is 42℃, and the fermentation time is 12h, when the glucose in the fermentation medium is detected When the concentration is reduced to 2g / L, add an aqueous solution of vitamin C with a concentration of 80g / L. The ratio of the amount of vitamin C to the volume of the fermentation medium is 160mg:1L each time, and vitamin C is added once every 1h until the end of the fermentation. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com