Strain of Enterobacter cloacae and its application in the preparation of 2,3-butylene glycol

A technology of Enterobacter cloacae and butanediol is applied in the field of bioengineering, which can solve the problems that have not been seen before, and achieve the effects of high conversion rate, wide substrate spectrum and high product concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

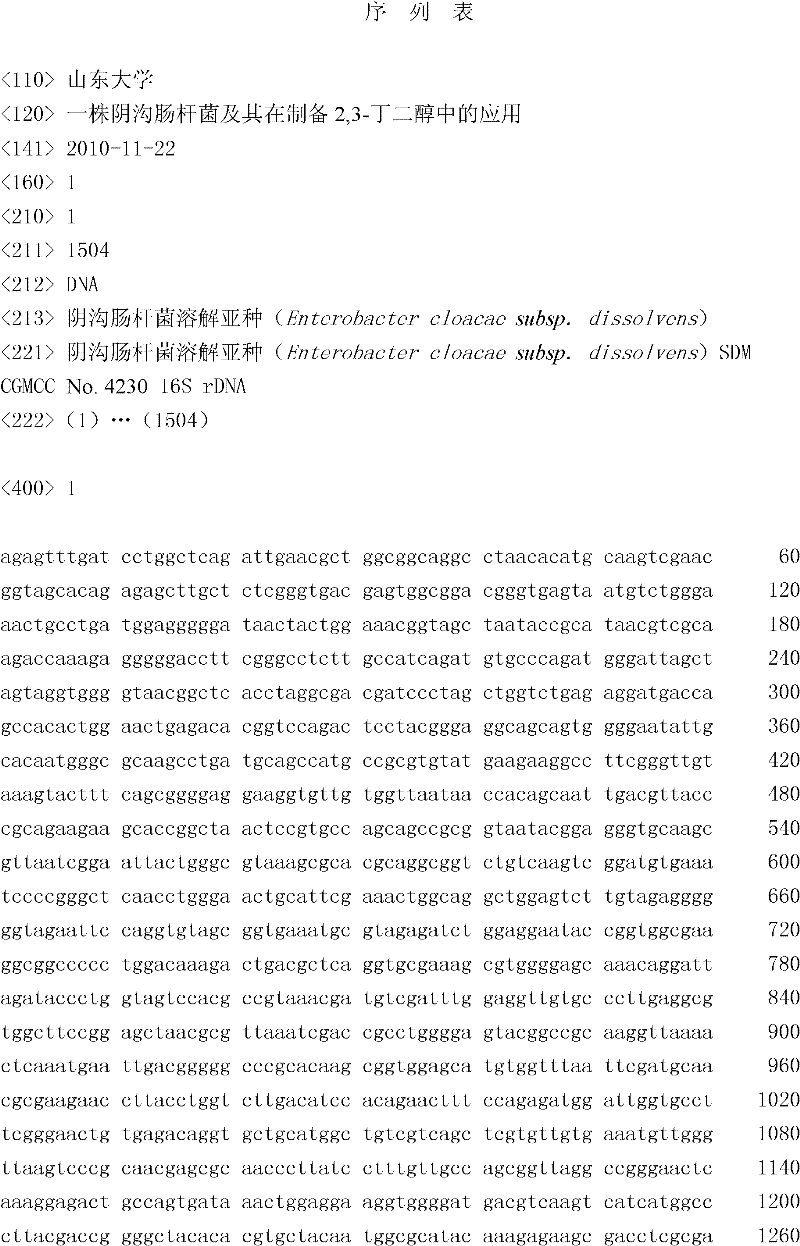

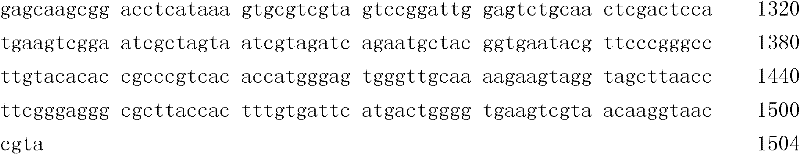

Image

Examples

preparation example Construction

[0041] Preparation of lignocellulosic raw material hydrolyzate: take the pulverized lignocellulosic raw material with a diameter of 0.45-0.9 mm, in terms of mass volume ratio, according to lignocellulose raw material: mass fraction is 1% sulfuric acid=1:10-1:3 Sulfuric acid was added in an amount of sulfuric acid, treated at 120° C. for 1 hour, centrifuged conventionally, and the supernatant was lignocellulosic raw material hydrolyzate with a sugar concentration of 15% to 35% in terms of mass volume ratio.

[0042] The above lignocellulosic raw materials are preferably wood, corncobs or straws.

[0043] The sugar concentration in the starch raw material hydrolyzate is preferably 25% to 35% by mass volume ratio; the sugar concentration in the lignocellulosic raw material hydrolyzate is preferably 25% to 30% by mass volume ratio.

[0044] The composition of lignocellulosic raw material hydrolyzate and the analysis method of total sugar refer to (Wang AL, et al. Appl Microbiol Bi...

Embodiment 1

[0049] Example 1: Isolation, screening and identification of Enterobacter cloacae subsp.dissolvens SDM CGMCC No.4230

[0050] The composition of the medium used in this embodiment is as follows:

[0051] Liquid screening medium: glucose 50g / L, sodium acetate 5g / L, potassium chloride 0.5g / L, magnesium sulfate 0.15g / L, ferrous sulfate heptahydrate 0.05g / l, manganese sulfate heptahydrate 0.03g / l, The pH is 7.

[0052] Solid screening medium: liquid screening medium, agar powder 18g / l, pH 7.

[0053] Fermentation medium: glucose 100g / L, yeast powder 10g / L, peptone 10g / L, sodium acetate 5g / L, pH 7.

[0054] Nutrient broth medium: glucose 50g / L, yeast powder 10g / L, peptone 10g / L, sodium chloride 5g / L, pH 7.

[0055] The specific operation process of this embodiment is as follows:

[0056] 1. Separation and screening

[0057] The soil was obtained from the farmland, 1 g was added to a 300 mL Erlenmeyer flask containing 50 mL of sterilized liquid screening medium, and cultured on...

Embodiment 2

[0061] Example 2, using Enterobacter cloacae subsp.dissolvens SDMCGMCC No.4230 to ferment 2,3-butanediol with glucose as carbon source

[0062] The sequence of steps involved in applying the method is as follows:

[0063] (1) Strain selection: select Enterobacter cloacae subsp.dissolvens SDM CGMCC No.4230;

[0064] (2) Slant culture: inoculate the strains on the slant medium, and culture at 37°C for 12 hours;

[0065] (3) Seed cultivation:

[0066] First-level seed culture: the bacterial strain cultivated in step (2) was placed in a 500mL Erlenmeyer flask with 100mL liquid seed medium with an inoculation loop under sterile conditions, placed on a shaking table with a rotation speed of 150rpm, and cultivated at 37°C for 12 hour, obtain the primary seed culture solution;

[0067] Expansion cultivation: the above-mentioned first-class seeds cultivated are inoculated in 5 liters of Erlenmeyer flasks of 1 liter of liquid seed medium with an inoculum size of 10% (volume ratio) un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com