Patents

Literature

79 results about "N-Butyric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrostatic charge image developing toner, producing method therefor, image forming method and image forming apparatus utilizing the toner, construct and method for making the construct

InactiveUS7153622B2Uniform designExcellent in charge uniformityDiffusion transfer processesImpression caps3-Hydroxypropionic acidN-Butyric acid

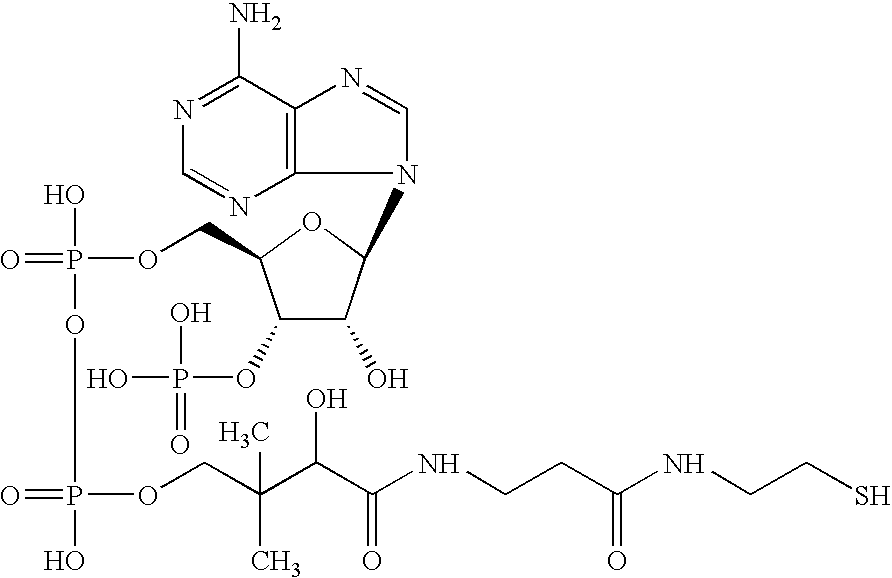

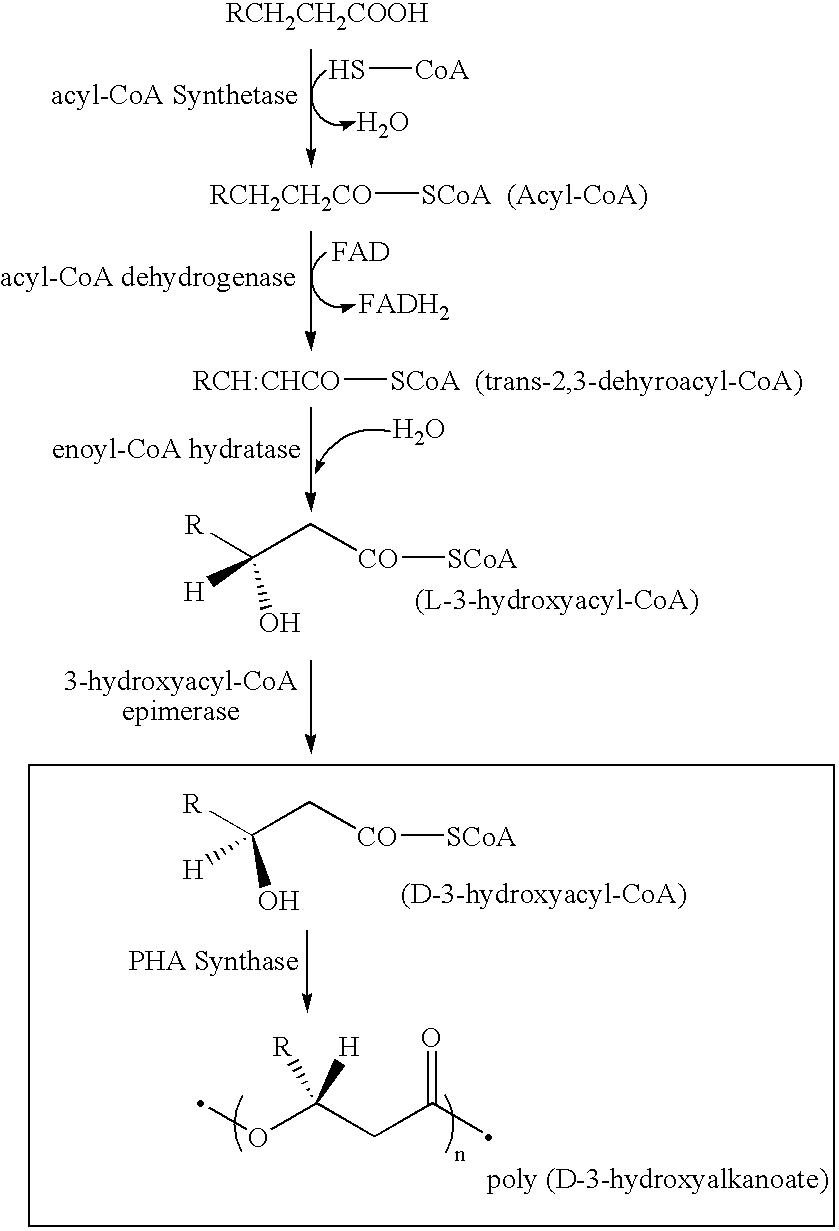

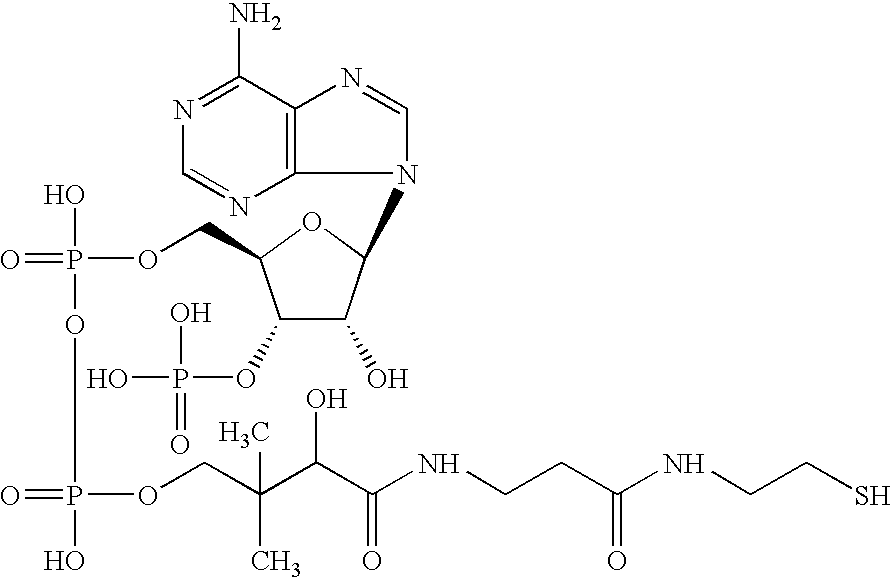

A construct that comprises a base material and a polyhydroxyalkanoate, wherein at least a part of the base material is coated with the polyhydroxyalkanoate, and the polyhydroxyalkanoate comprises a 3-hydroxyalkanoic acid unit other than 3-hydroxypropionic acid unit, 3-hydroxy-n-butyric acid unit, and 3-hydroxy-n-valeric acid unit.In addition, an electrostatic charge image developing toner allows to design the toner characteristics such as chargeability, flowability, stability in time and environmental stability uniform among the toners of different colors. The toner has a small particle size enough for enabling uniform dispersion and being excellent in color saturation and transparency. The toner also shows higher contribution to the environmental security. The toner includes a coloring agent of which at least a part of the surface is covered with polyhydroxyalkanoate (PHA). The toner is produced by dispersing the coloring agent in aqueous medium, then fixing PHA synthesizing enzyme to the coloring agent dispersed in the aqueous medium, then adding 3-hydroxyacyl CoA, and executing a PHA synthesizing reaction to cover at least a part of the surface of the coloring agent with PHA. The toner thus obtained is used for an image forming method.

Owner:CANON KK

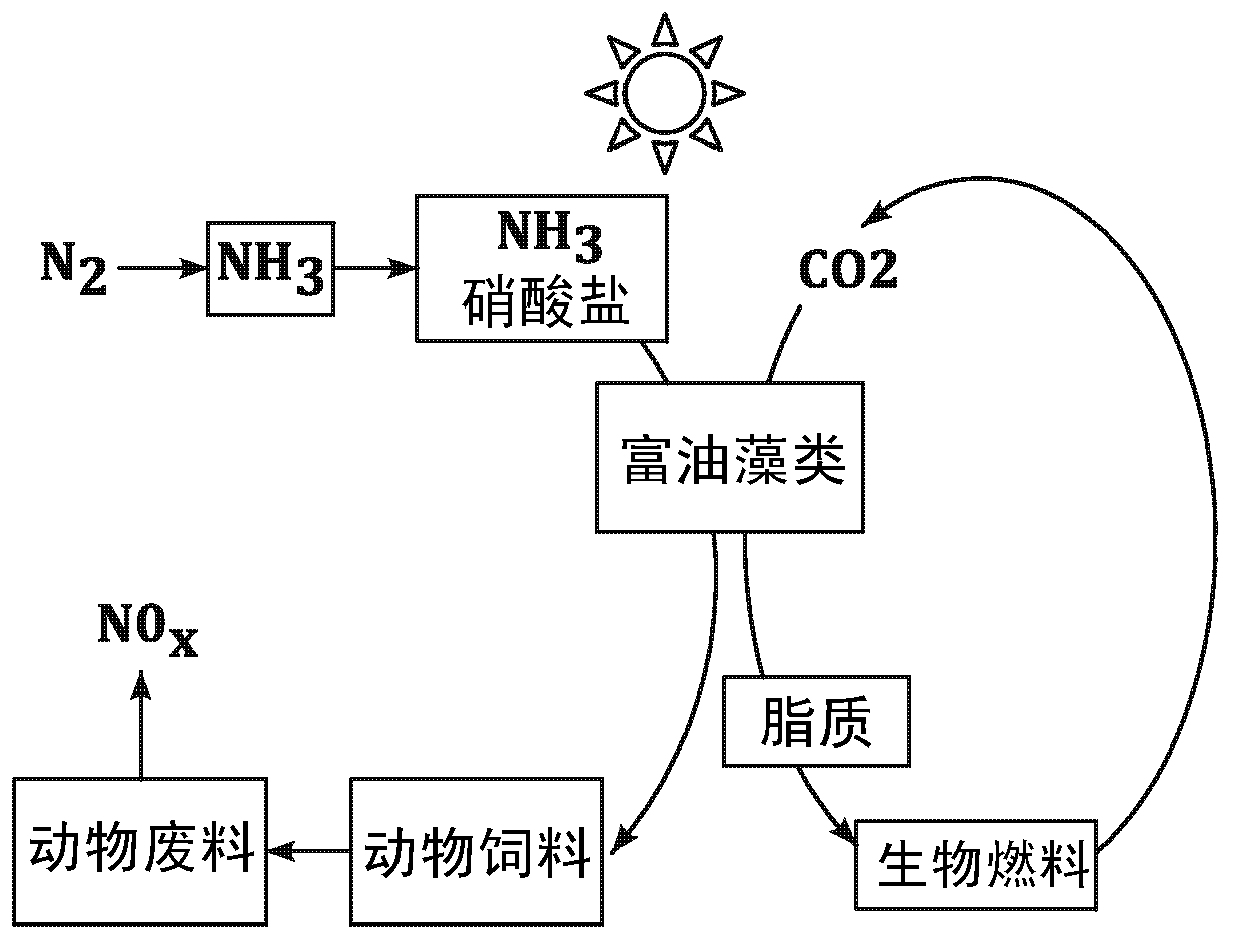

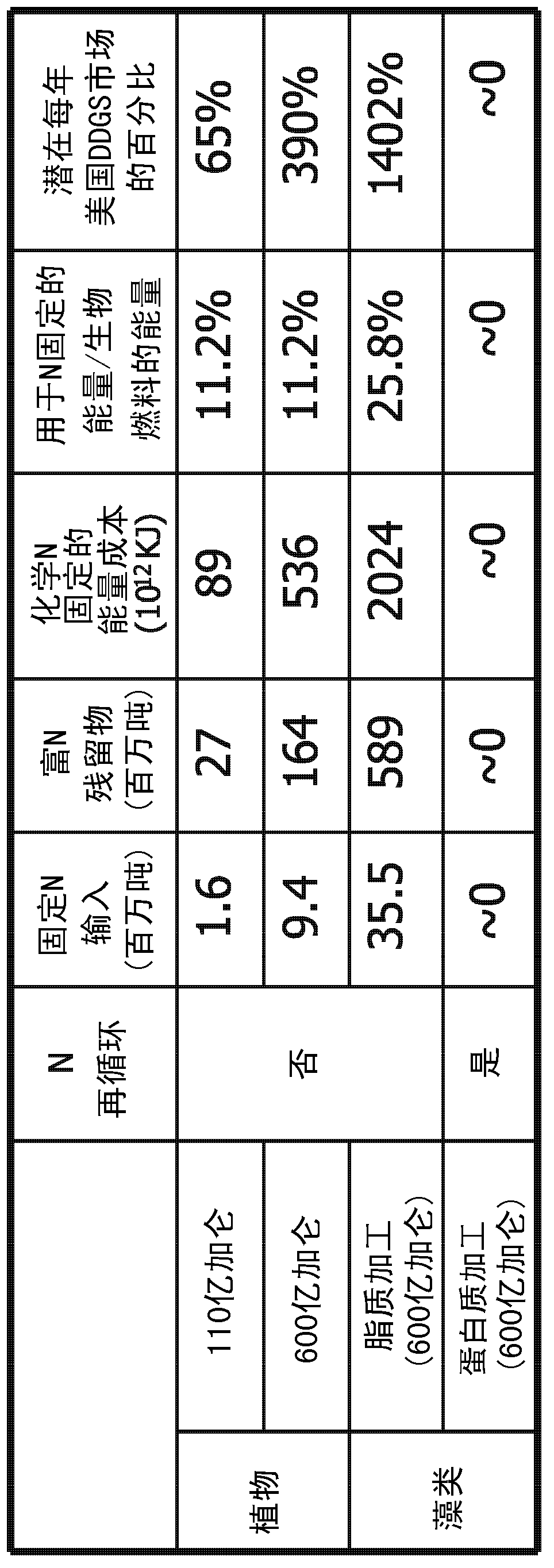

Biofuel and chemical production by recombinant microorganisms via fermentation of proteinacious biomass

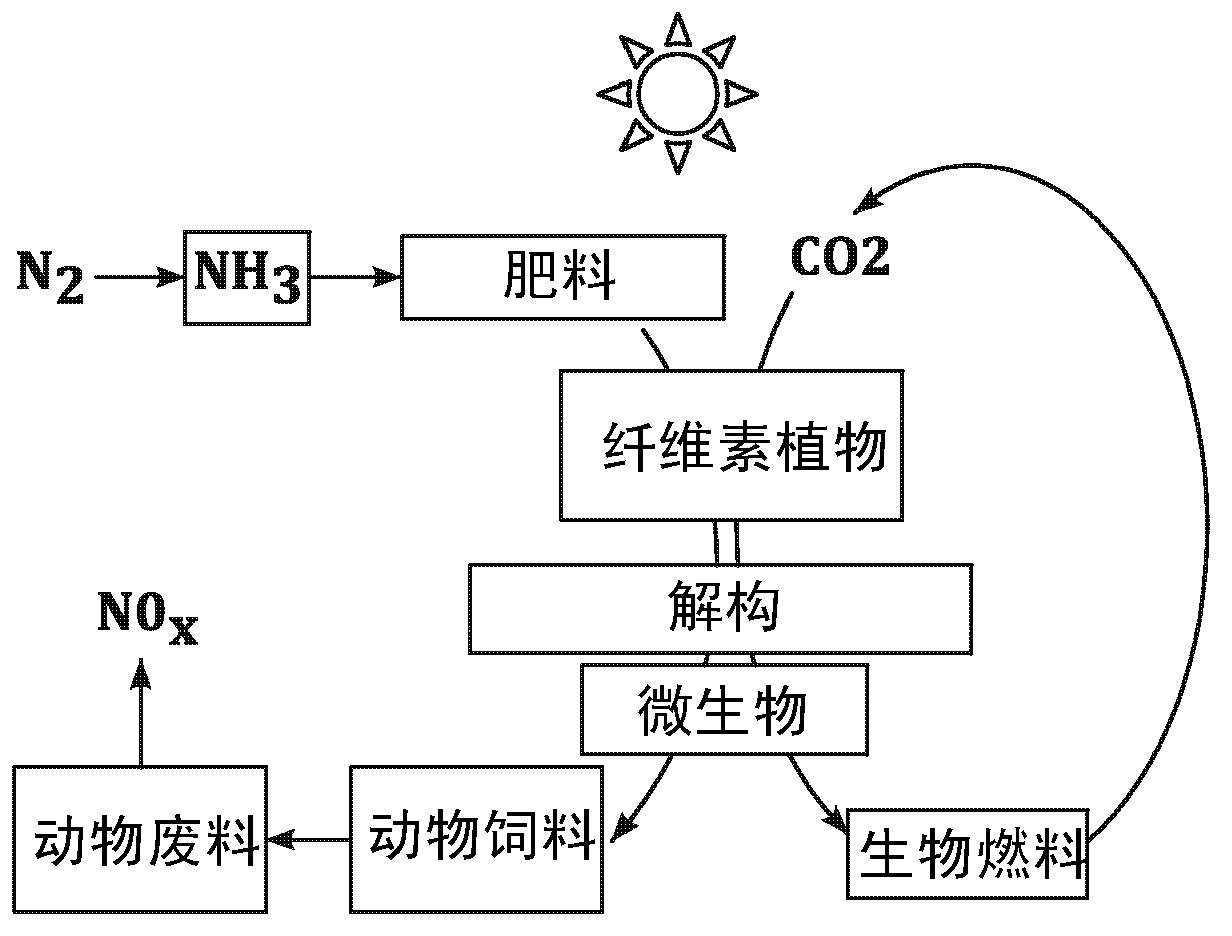

Provided herein are metabolically modified microorganisms characterized by having an increased keto-acid flux when compared with the wild-type organism and comprising at least one polynucleotide encoding an enzyme, and causing the production of a greater quantity of a chemical product when compared with the wild-type organism. The recombinant microorganisms are useful for producing a large number of chemical compositions from various nitrogen containing biomass compositions and other carbon sources. More specifically, provided herein are methods of producing alcohols, acetaldehyde, acetate, isobutyraldehyde, isobutyric acid, n- butyraldehyde, n-butyric acid, 2-methyl-l-butyraldehyde, 2-methyl-l -butyric acid, 3- methyl-l-butyraldehyde, 3 -methyl- 1 -butyric acid, ammonia, ammonium, amino acids, 2,3-butanediol, 1,4-butanediol, 2-methyl-l, 4-butanediol, 2-methyl- 1,4-butanediamine, isobutene, itaconate, acetoin, acetone, isobutene, 1,5-diaminopentane, L-lactic acid, D- lactic acid, shikimic acid, mevalonate, polyhydroxybutyrate (PHB), isoprenoids, fatty acids, homoalanine, 4-aminobutyric acid (GABA), succinic acid, malic acid, citric acid, adipic acid, p-hydroxy-cinnamic acid, tetrahydrofuran, 3-methyl-tetrahydrofuran, gamma-butyrolactone, pyrrolidinone, n-methylpyrrolidone, aspartic acid, lysine, cadeverine, 2-ketoadipic acid, and / or S-adenosyl-methionine (SAM), from a suitable nitrogen rich biomass.

Owner:RGT UNIV OF CALIFORNIA

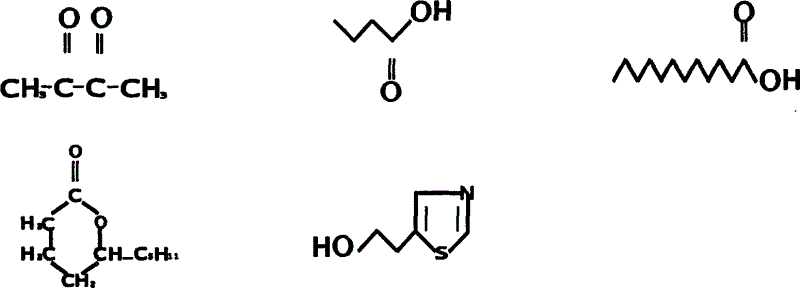

Perfume compositions

The invention relates to a perfume composition comprising the constituents (by weight proportion) of the following raw materials, delta-dodecalactone 1, enhancing compounds 0.005-10, which is selected from one or combination of more than one of butanedione, n-Butyric acid, dodecanic acid, delta-docalactone, 4-methyl-5(bata- ethoxyl) thiazole. The raw materials can be added by carrier based on requirement, wherein the carrier is one or combination of more than one of glucose, starch, maltodextrin, 95% ethanol, distilled water and propylene glycol.

Owner:周静龙

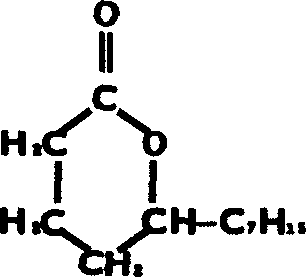

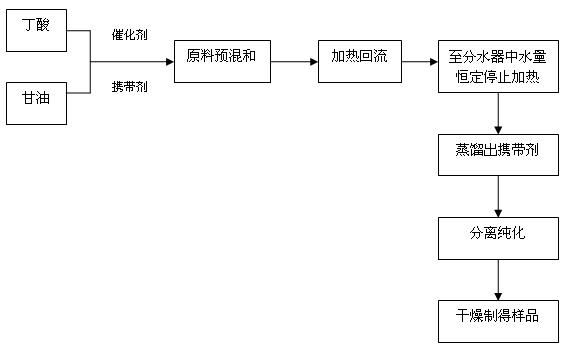

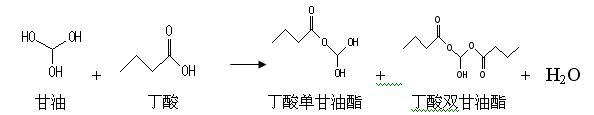

Synthesis method of functional feed additive butyric acid mono-and di-glyceride

InactiveCN102090517AConvenient sourceThe preparation method is simple and easy to controlOrganic compound preparationCarboxylic acid esters preparationN-Butyric acidSynthesis methods

The invention discloses a synthesis method of functional feed additive butyric acid mono-and di-glyceride, comprising the following steps: heating and reflowing glycerol and n-butyric acid in the presence of phosphoric acid serving as a catalyst and carbon tetrachloride serving as a water-carrying agent; stopping reacting until the amount of the water in a water knockout drum is almost constant; distilling out the carbon tetrachloride to prepare a crude product; rinsing the obtained crude product by utilizing a saturated salt solution with the pH of 10 for many times so as to remove the reactant and catalyst which do no react; and separating and purifying until the low-layer aqueous phase is alkaline, thus obtaining the butyric acid mono-and di-glyceride. The method is simple and easy to control, and has the advantages that the reaction condition is safe and moderate, separation and purification can be carried out easily, and the steps are less.

Owner:NANCHANG UNIV

Cutting seedling rooting agent

InactiveCN107347935AEnhance immune functionImprove survival rateBiocidePlant growth regulatorsVitamin CN-Butyric acid

The invention discloses a cutting seedling rooting agent. The cutting seedling rooting agent is prepared from, by weight, 1 to 2 parts of ABT rooting powder, 0.2 to 0.5 part of heteroauxin, 0.1 to 0.5 part of naphthylacetic acid, 10 to 30 parts of ethanol, 0.5 to 1 part of vitamin C, 0.1 to 0.5 part of vitamin B, 0.1 to 0.5 part of an amino acid chelated selenium, 0.1 to 0.5 part of amino acid chelated zinc, 20 to 50 parts of water, 1 to 3 parts of sodium hydroxide, 1 to 2 parts of sodium chloride, 0.5 to 2 parts of a n-butyric acid salt, 0.5 to 2 parts of chitosan, and 1 to 5 parts of a plant extracted solution. According to a preparation method of the cutting seedling rooting agent, amino acid chelated selenium and amino acid chelated zinc which can be absorbed by cutting seedlings easily and are capable of improving the immunity of cutting seedlings are added, so that bacteria infection of the cutting seedlings is reduced, synergistic effect with the ABT rooting powder, heteroauxin, and naphthylacetic acid is achieved, and rapid rooting of the cutting seedlings is promoted.

Owner:广西鑫雅皇庭园林工程有限责任公司

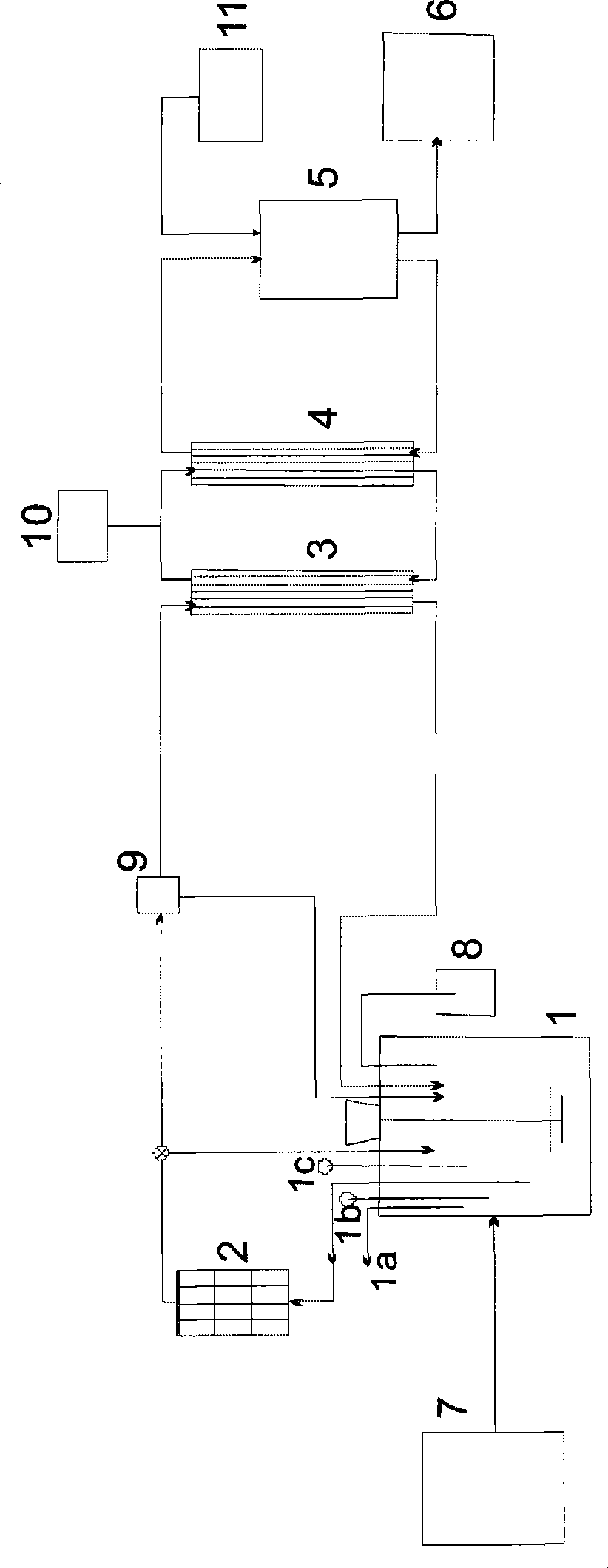

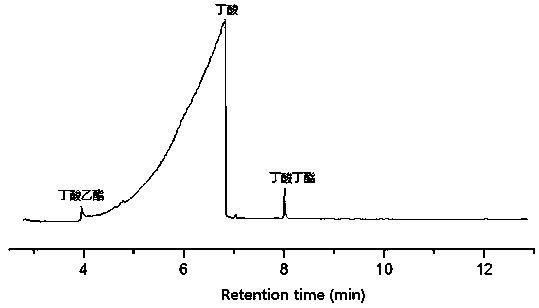

Method and device for producing n-butyric acid by microbial catalysis

ActiveCN101487029ASeparation in timeBreak or alleviate inhibitory effectsBioreactor/fermenter combinationsBiological substance pretreatmentsAcetic acidMicroorganism

The invention discloses a method for producing ethyl acetic acid catalytically by microorganism and a device thereof. The method comprises the steps: preparation of a microbial suspension, immobilization of microbial cells, immobilized clostridium catalytic production of ethyl acetic acid, online separation of ethyl acetic acid and extraction. The device for producing the ethyl acetic acid by the microorganism comprises a fermentation flask, an immobilization reactor, an extracting device and a back-extracting device. The method and the device effectively relieve the inhibitive effect of final products, improve online extraction efficiency, lower the microbial toxicity of extracting agents, realize continuous production of the ethyl acetic acid and lead catalytic production of ethyl acetic acid by the microorganism to be developed towards industrialized direction.

Owner:GUANGDONG INST OF MICROORGANISM

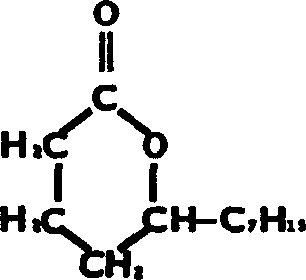

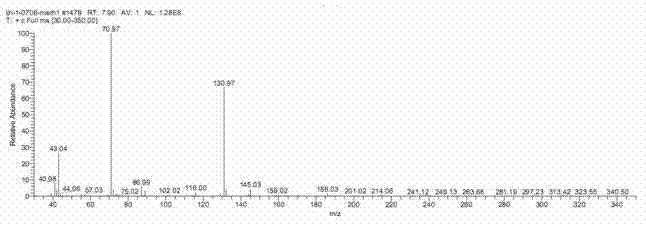

Catalytic synthesis method for functional animal nutrition additive butyrin

InactiveCN102850215AEasy to separateOrganic compound preparationCarboxylic acid esters preparationN-Butyric acidFiltration

The invention discloses a catalytic synthesis method for a functional animal nutrition additive butyrin. According to the method, n-butyric acid and glycerin undergo a heating reflux reaction under the conditions that a solid acid is used as a catalyst and toluene is used as a water-carrying agent; when water in a water separator reaches theoretical yield, the reaction is stopped, the solid acid catalyst is separated through filtration, an obtained filtrate is subjected to underpressure distillation so as to separate the water-carrying agent, and rinsing is carried out so as to obtain butyrin; the solid acid is a sulfonic acid type strong-acid ion exchange resin or a carbon-based solid acid, the usage amount of the solid acid is 1 to 5% of the mass of n-butyric acid, and a system temperature of the heating reflux reaction is 110 to 120 DEG C. Since the catalytic synthesis method for the functional animal nutrition additive butyrin uses the solid acid catalyst in the reaction, a target product can be prepared through simple filtration of the catalyst and underpressure distillation of the water-carrying agent after the reaction is finished; thus, separation is simple, and the separated catalyst obtained after filtration and the separated water carrying agent can be cyclically used.

Owner:SHENZHEN PREMIXINVE NUTRITION CO LTD +1

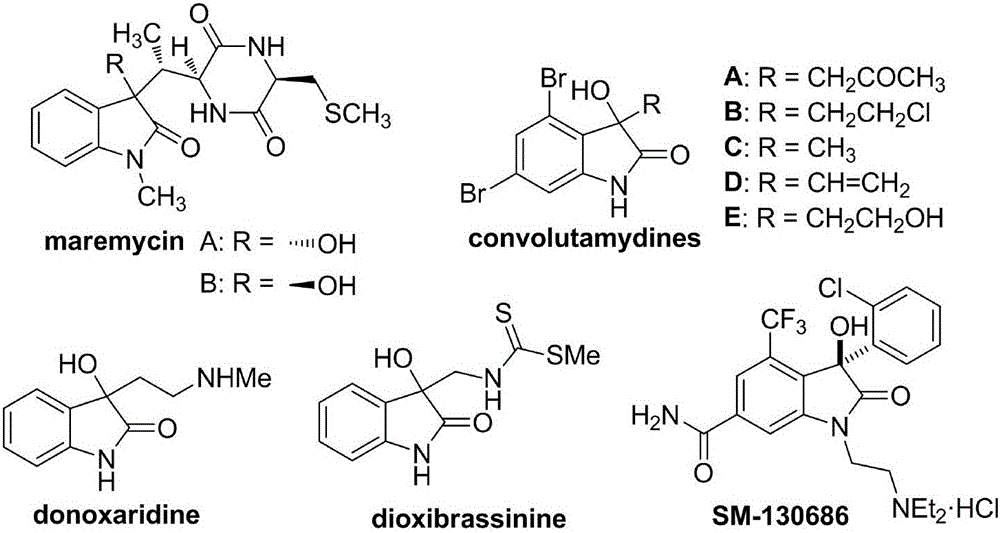

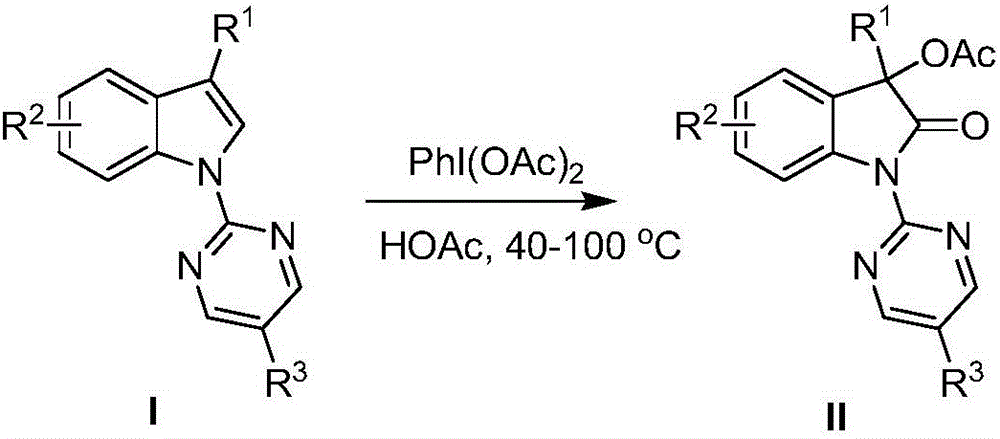

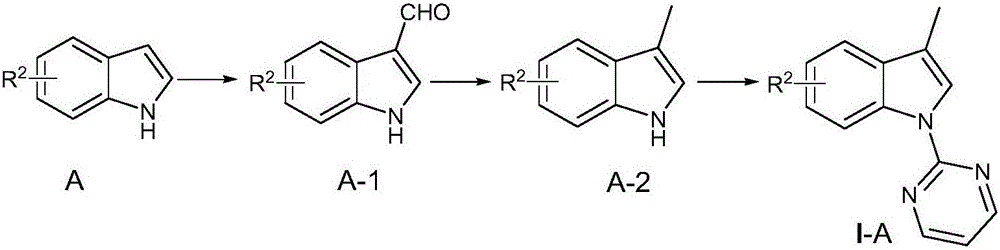

Method for synthesizing 3-hydroxyl oxoindole derivative

The invention discloses a method for synthesizing a 3-hydroxyl oxoindole derivative. The synthetic route is as shown in the specification, wherein R1 is methyl, ethyl, propyl, butyl, isopropyl, cyclohexyl, allyl, benzyloxyethyl or n-butyric acid methyl ester; a substituent R2 is methyl, methoxy, benzyloxy, fluorine, chlorine or bromine; and a substituent R3 is methyl, bromine or phenyl. The synthetic process comprises the following steps: dissolving a compound I and iodobenzene diacetate in acetic acid and reacting completely at 40-100 DEG C, and postprocessing and purifying to obtain a product II. The raw materials used in the method are easy to prepare, and iodobenzene diacetate can be sold in the market; there is no need to use a catalyst such as a metal catalyst or an organic catalyst, and cost is reduced and the method is environment-friendly.

Owner:JIANGHAN UNIVERSITY

Composition for measuring glucose having improved substrate specificity

InactiveCN1912132AHigh precisionMicrobiological testing/measurementN-Butyric acid2-ketoglutaric acid

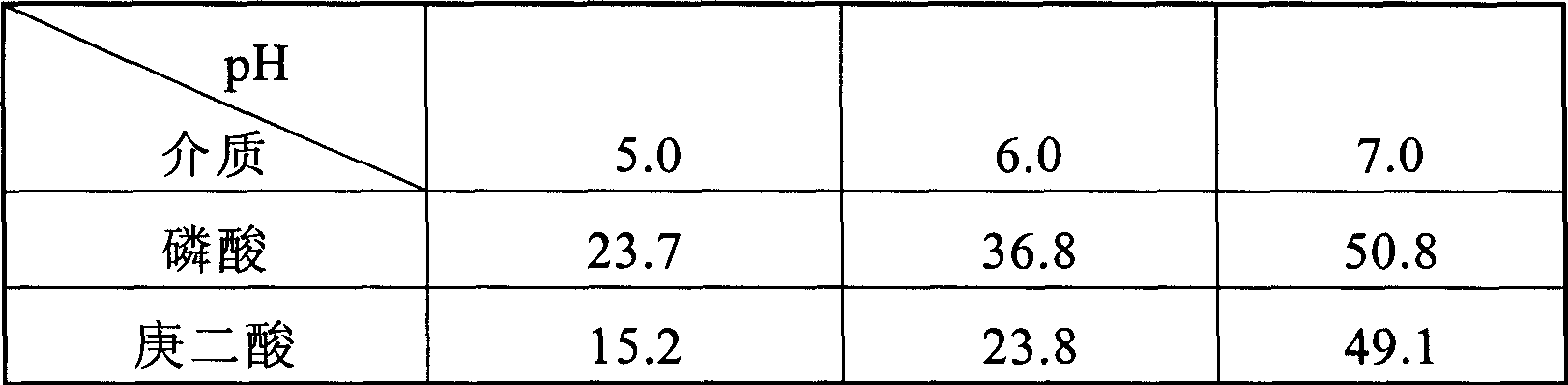

The present invention relates to a method for lowering activity with respect to maltose in glucose measurement comprising a step of reacting modified pyrroloquinoline quinone dependent glucose dehydrogenase subjected to amino acid sequence modification, wherein pyrroloquinoline quinone dependent glucose dehydrogenase is reacted in the presence of at least one type of substance selected from the group comprising succinic acid, malonic acid, glutaric acid, malic acid, phthalic acid, 2-ketoglutaric acid, 3,3-dimethylglutaric acid, pimeric acid, suberic acid, adipic acid, maleic acid, potassium chloride, ammonium chloride, diammonium hydrogen citrate, L-lysine, taurine, calcium glycerate, amino-n-butyric acid, sodium glycolate, sodium alpha-ketoglutarate, fumaric acid, glycine, glutamic acid, serine and citric acid.

Owner:TOYO TOYOBO CO LTD

Acetic bacterial cell-containing food composition and method of producing the same

ActiveUS20200268032A1Expand the marketIncrease consumers' appetiteFood scienceBiotechnologyN-Butyric acid

[Problem] Provided is a food composition containing acetic bacterial cells which has a good aroma, and a method of producing the food composition.[Solution] The food composition containing acetic bacterial cells of the present invention contains acetic acid and n-butyric acid, the peak area ratio between which is 40:1 to 1:20, as measured by solid phase micro extraction gas chromatography-mass spectrometry for odor components in the food composition. Surprisingly, such a food composition has a fermentative aroma like rice bran which can stimulate consumers' appetite.

Owner:Q P CORP

Efficient preparation process of gamma-amino-n-butyric acid

The invention discloses an efficient preparation process of gamma-amino-n-butyric acid. The process comprises the following steps: Lactobacillushilgardii and the improved and optimized MRS medium are utilized to perform step expansive culture, the bacterium solution is centrifuged and concentrated, the obtained solution is then mixed with the suspension of sodium glutamate, the cell transforming method is adopted to obtain gamma-amino-n-butyric acid solution of which the content of gamma-amino-n-butyric acid is 10-25%, the solution is purified to obtain a gamma-amino-n-butyric acid product which is white powder and of which purity is more than 98%, and dextrin is utilized to prepare the 20% finished product which can be directly used in the raw materials of food and health food. By adjusting the process conditions and optimizing and improving the fermentation culture medium, the preparation cost of gamma-amino-n-butyric acid can be reduced by 20-30% and the production cycle can be shortened by 30%.

Owner:王剑

Film coating agent for salted egg or preserved egg

InactiveCN101496614ALow costStable preservation effectEggs preservation by coatingFood preparationN-Butyric acidSolvent

The invention discloses preparation technology for a salted egg or preserved egg film coating agent. The salted egg or preserved egg film coating agent consists of food grade chitosan as a film forming agent and a water soluble organic acid solution as a solvent of the film forming agent; organic acids comprise the water soluble organic acids of an acetic acid, a lactic acid, a malic acid, an n-butyric acid, and the like; and a proper amount of food colorants can be added into the recipe. The salted egg or preserved egg film coating agent takes the chitosan as the main raw material and is assisted by the water soluble organic acids. When the salted egg or preserved egg film coating agent is coated on the salted eggs or preserved eggs, the salted egg or preserved egg film coating agent has better preservation effect. Simultaneously, as the chitosan is an innocuous and harmless edible natural polysaccharide, the salted egg or preserved egg film coating agent has great advantages on the green and environmental protection performance, and represents the development trend of the future preservation method.

Owner:方忠志

Preparation method of feed additive sodium butyrate

InactiveCN103601631AStable pHImprove qualityCarboxylic acid salt preparationSodium bicarbonateN-Butyric acid

The invention discloses a preparation method of feed additive sodium butyrate, which comprises the following steps: after dissolving n-butyric acid in water, heating to 50 DEG C, adding sodium carbonate or sodium hydroxide, keeping the temperature at 80 DEG C for 1-1.5 hours, adding sodium bicarbonate, stirring, controlling the pH value of the reaction end point at 8.0-10.0, distilling under reduced pressure and drying to obtain the sodium butyrate. The sodium bicarbonate is added in the reaction process to regulate the pH value of the neutralization reaction between the butyric acid and the sodium carbonate or sodium hydroxide, so that the pH value is stable in the reaction process, thereby enhancing the product quality.

Owner:HUBEI SHENZHOU CHEM

Process for the production of an n-butyric acid compound in micro encapsulated form, for animal or human consumption

ActiveUS20110287104A1Low production costBiocideLiquid surface applicatorsLipid formationN-Butyric acid

A process for the production of an n-butyric acid compound in microencapsulated form comprises the stages of:—providing a granular material based on the n-butyric acid compound, —mixing the granular material with a matrix having a content of long-chain C14-C22 saturated fatty acids of from 40% to 95%, and an amount of between 1% and 20% of a mineral agent in which an effective amount of calcium sulphate dihydrate is present, heating the mixture to a temperature higher than the melting temperature of the lipid component of the matrix, -—spraying the mixture into a cooling chamber having a temperature lower than the melting temperature of the lipid component of the matrix, so that the latter solidifies around the granular material, forming a covering thereof.

Owner:SILA

Method for extracting n-butyric acid, valeric acid and hexoic acid from lyechange as by-product of cyclohexanone production

InactiveCN101774903ANo emissionsSimple processFatty acid chemical modificationOrganic compound preparationCyclohexanoneN-Butyric acid

The invention relates to a method for extracting n-butyric acid, valeric acid and hexoic acid from lyechange as a by-product of cyclohexanone production. The method comprises the following steps: carrying out preprocessing on a sodium sulfate aqueous solution; preprocessing the evaporated mother liquor; conveying slurry in a concentration jar for concentration; washing the concentrated salt with a small amount of water; discharging the water for washing and the crystallization water into a delamination jar of the sodium sulfate aqueous solution through an outlet of the concentration jar; discharging the concentrated salt into a centrifugal machine for centrifugal dehydration from the concentration jar; self-flowing water dehydrated from the centrifugal machine into the delamination jar of the sodium sulfate aqueous solution through high order difference; re-separating organic matters in the crystallization water and the water dehydrated from the centrifugal machine; carrying out warming and reduced pressure distillation on saponifiedoil by using an enamelstill, a stainless steel kettle or a film evaporator; adding a reasonable amount of lower alcohol into the tail oil obtained by distilling monobasic acid; and carrying out esterification reaction on the tail oil and conversing the remained organic acid into esters.

Owner:陈庸彪

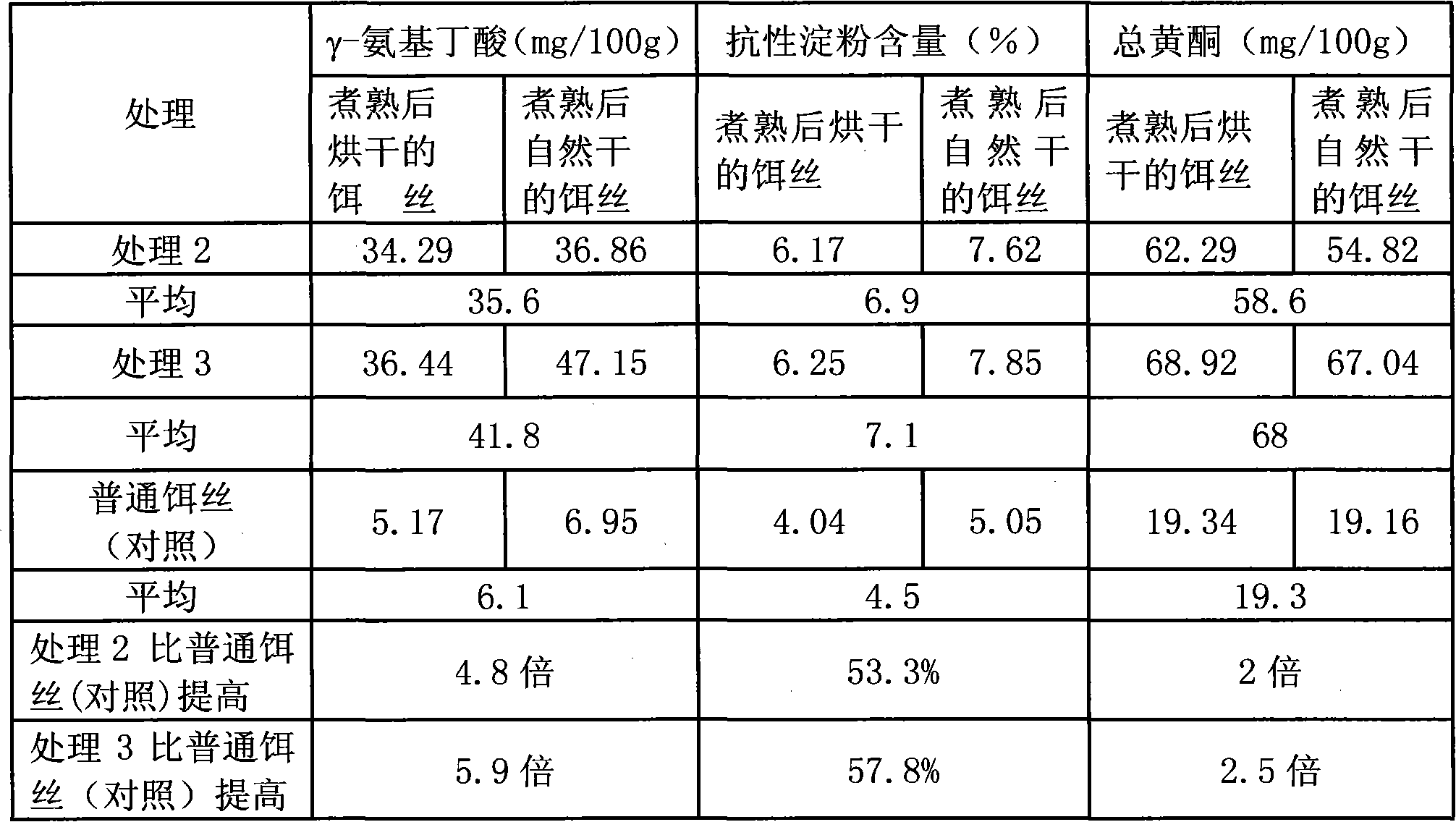

Functional barley rice noodle and making method thereof

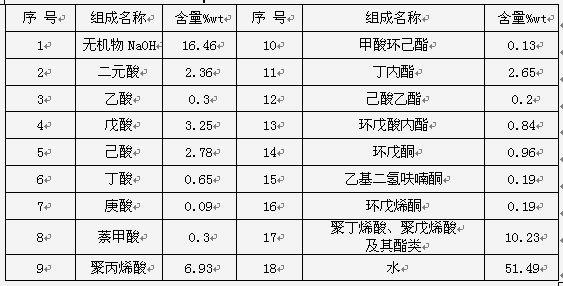

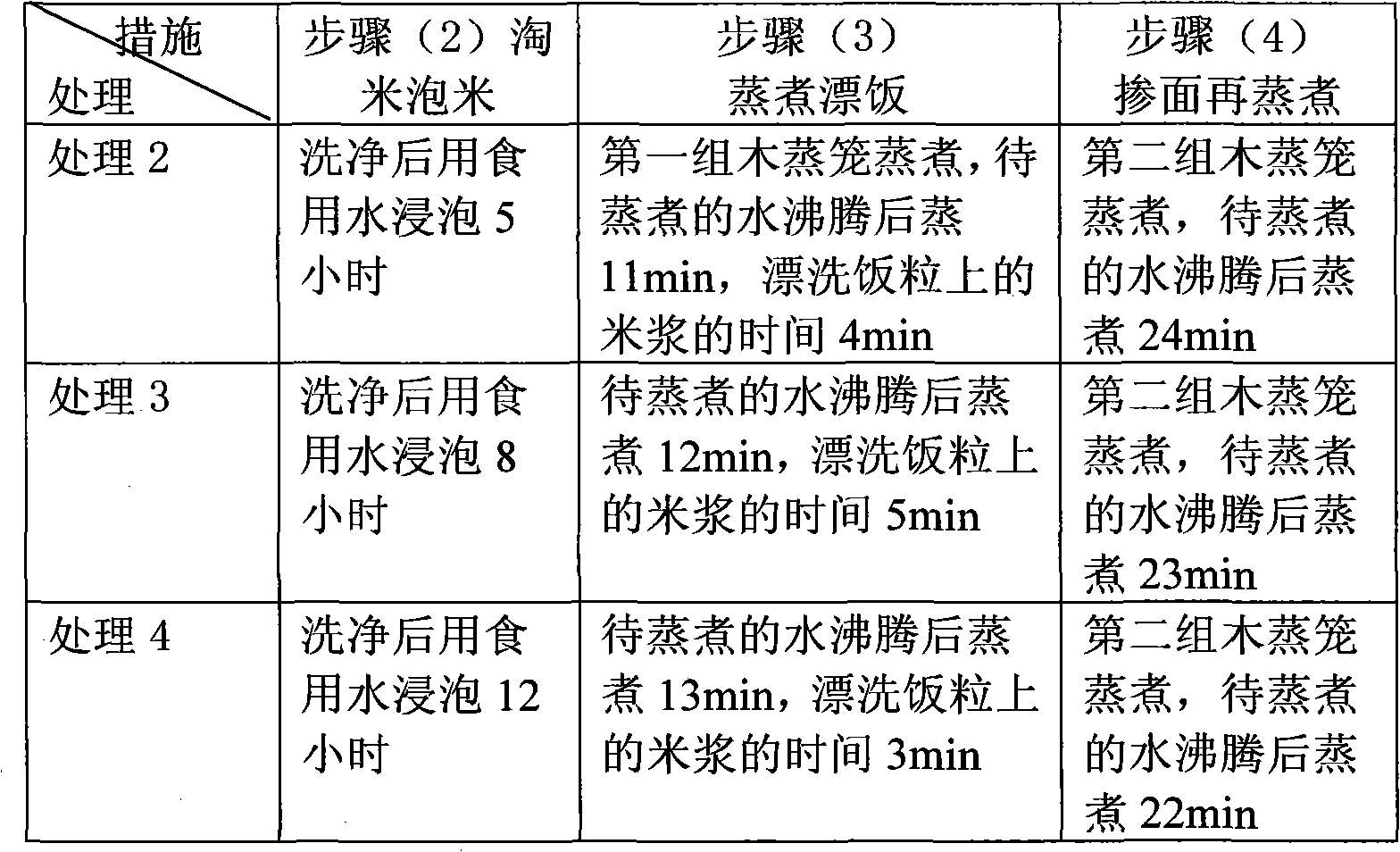

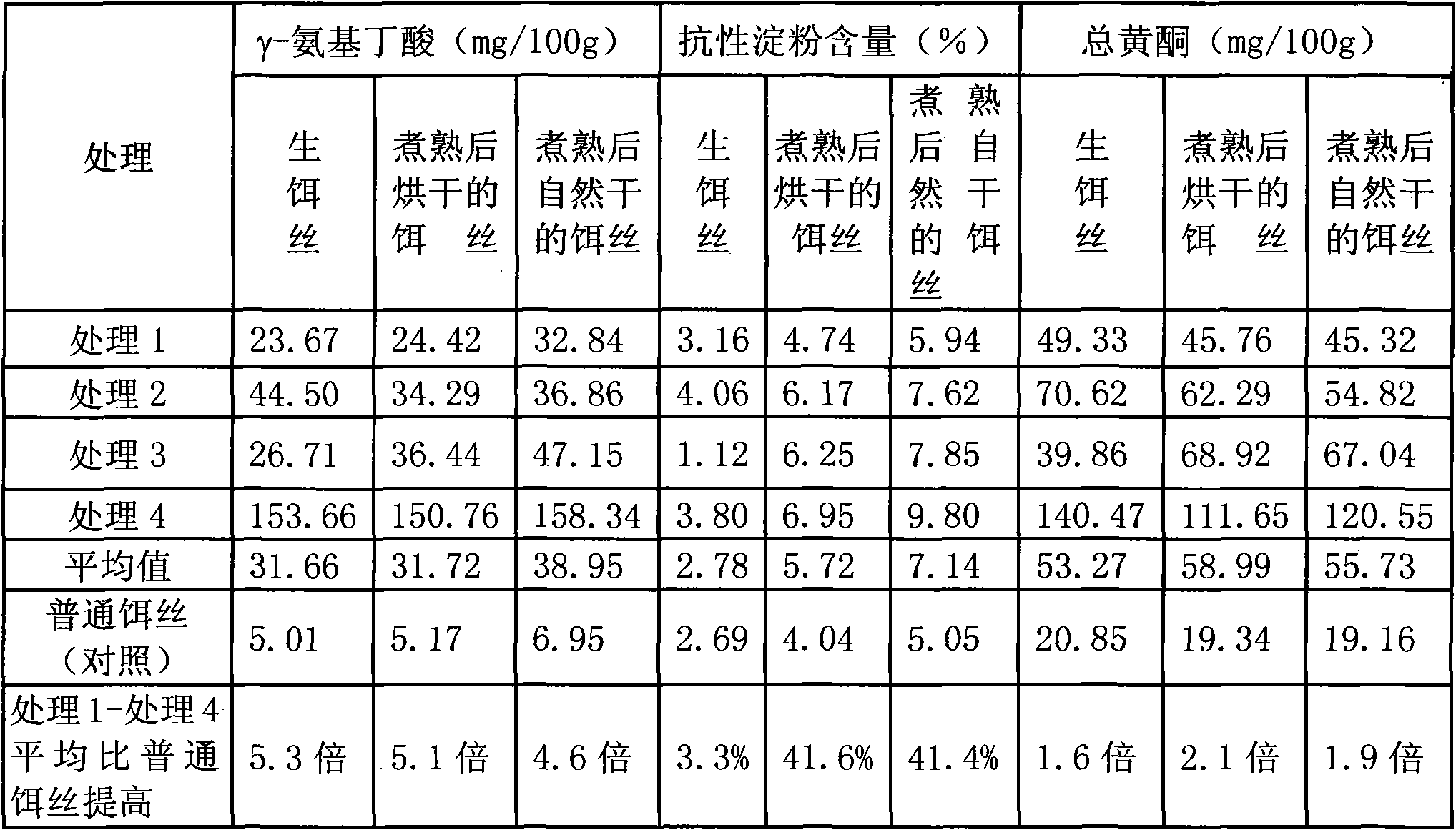

InactiveCN102067965AResistant starch increasesGamma-aminobutyric acid boostsFood preparationN-Butyric acidRice dishes

The invention relates to a functional barley rice noodle and a making method thereof. The materials of the functional barley rice noodle are rice noodle rice and functional barley flour, and the usage of the functional barley flour is 20 to 50 percent of the usage of the rice noodle rice. In the making method, the rice noodle rice is polished rice milled from rice noodle-dedicated paddy, the functional barley flour is made of barley grains processed by the flour-processing method, the rice noodle rice is cleaned, socked for 2 to 12 hours and put into a bamboo steamer, the rice noodle rice is steamed for 10 to 13 minutes after water is boiled, the rice milk upon the steamed rice is then washed off, moisture is filtered, the functional barley flour and the washed steamed rice are uniformly mixed according to the proportion, then put into the bamboo steamer, steamed for 22 to 25 minutes after water is boiled, then uniformly mixed and tableted, and the produced rice noodle tablet is cooled to the ambient temperature, and is then shred. The contents of resistant starch, Gamma-amino-n-butyric acid and total flavone in the cooked functional barley rice noodle are respectively increased by 41.5 percent, 4.9 times and 2 times compared with the contents of resistant starch, Gamma-amino-n-butyric acid and total flavone in the ordinary rice noodle, and the functional barley rice noodle has a health-care function, is added with the flavor of barley as well, and also solves the problem that the taste of barley is bad.

Owner:云南省农业科学院生物技术与种质资源研究所 +4

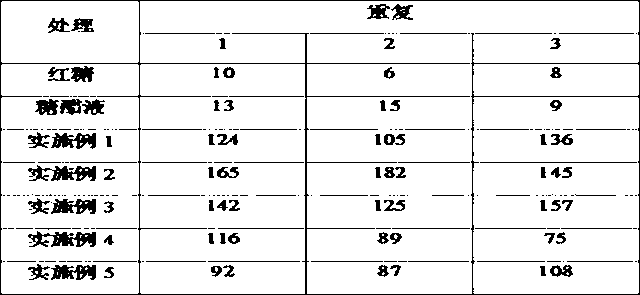

Housefly attractant

The invention relates to the technical field of attractants and particularly relates to a housefly attractant. The housefly attractant disclosed by the invention consists of the following components in percentage by weight: 0.001-1% of trans-9-tricosadienoic acid, 0.0001-1% of benzaldehyde, 0.0001-1% of 2-hexenal, 0.001-1% of n-butyric acid, 0.001-1% of 1-matsutake alcohol, 1-70% of brown sugar, 1-30% of glutinous rice flour, 1-20% of wheat bran, 1-10% of sodium dodecyl benzene sulfonate and the balance of water. The housefly attractant disclosed by the invention has the advantages that the attractive force to houseflies is strong, the environment pollution and the odor are avoided, and the use is simple and convenient; and the housefly attractant is nontoxic to human and livestock and is a safe, environment-friendly, efficient, simple and convenient housefly prevention and treatment product.

Owner:德清科中杰生物科技有限公司

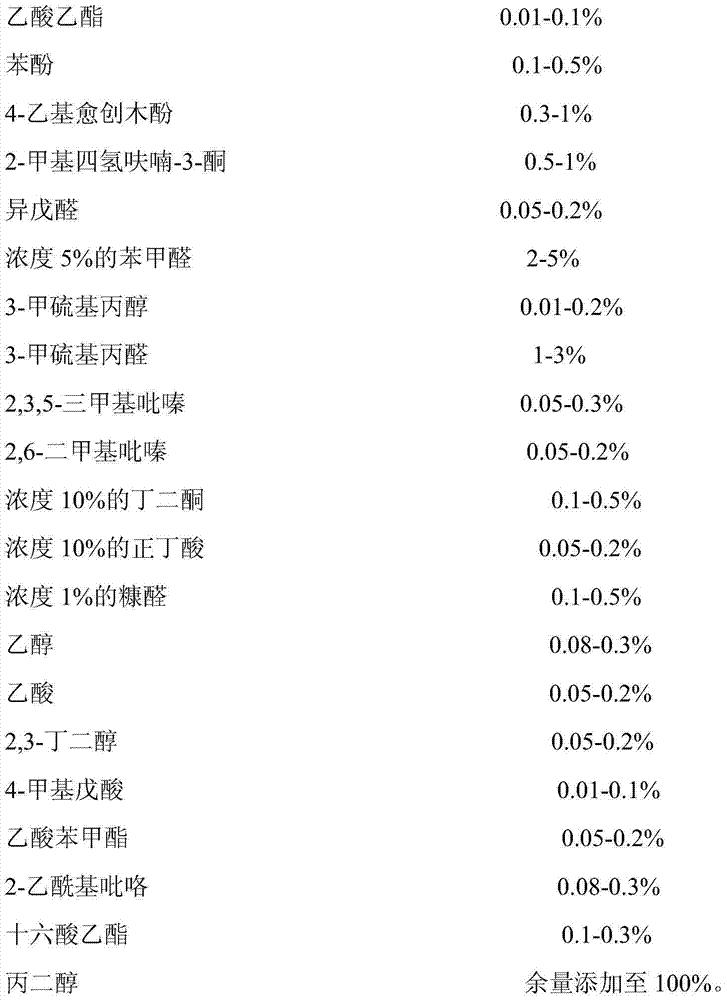

Soy sauce essence and preparation method thereof

Owner:TIANJIN CHUNFA BIO TECH GRP

Method for preparing n-butyric acid from poly 3-hydroxybutyrate

InactiveCN109265335AHigh purityOrganic compound preparationPreparation from carboxylic acid esters/lactonesPoly-3-hydroxybutyrateLiquid product

The invention relates to a method for preparing n-butyric acid from poly 3-hydroxybutyrate. The method comprises the following steps that poly 3-hydroxybutyrate is put into a sealed device; hydrogen gas is introduced for eliminating air; after the pressure of initial hydrogen gas is 2 to 6 MPa, stirring reaction is performed for 6 to 36h at 190 to 240 DEG C; the n-butyric acid is obtained. The preparation method provided by the invention has the advantages that catalysts and reaction catalysts are not needed; under the hydrogen gas atmosphere condition, the poly 3-hydroxybutyrate is convertedinto the n-butyric acid through one-step reaction; the conversion rate of the 3-hydroxybutyrate is 100 percent; the yield of the n-butyric acid reaches up to 97 percent; the purity of the n-butyric acid in the obtained liquid product reaches up to 98 percent; the additional continuous separation process of the obtained n-butyric acid product is not needed.

Owner:DONGGUAN UNIV OF TECH

Microbial preparation for treating excrement, preparation method thereof and application

InactiveCN106978377ASolve the technical problems of heavy pollution controlFungiBacteriaN-Butyric acidPropanoic acid

The invention discloses a microbial preparation for treating excrement, a preparation method thereof and an application. The microbial preparation is acquired through adding organic acid and excrement compound in a culture medium and then performing microbial gathering and domestication; the viable bacterial colony number in the microbial preparation is 5x108-2x109 CFU / g. The added organic acid includes acetic acid, propionic acid, n-butyric acid, isobutyric acid, n-pentanoic acid and isovaleric acid; the excrement compound comprises benzpyrole and skatole. The microbial preparation prepared by the invention can be applied to the in-situ harmless treatment of fecaluria at cow breeding bed; through degrading cellulose, hemicellulose, organic amino nitrogen and phosphorus, organic acid, and other excrement components, the microbial preparation reaches the technical effects of achieving zero emission and pollution cleaning, inhibiting harmful bacterium multiplication, and improving the cow feeding environment, and others.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Regulation and control method for fruit and vegetable waste high-load stable anaerobic digestion

InactiveCN105861760AGuaranteed uptimeAvoid instabilityMicrobiological testing/measurementWaste based fuelN-Butyric acidGas phase

The invention discloses a regulation and control method for fruit and vegetable waste high-load stable anaerobic digestion. Early warning is achieved by monitoring the concentrations of CH4 and CO2 in a gas phase and the alkalinity of bicarbonate and the concentration of n-butyric acid in a liquid phase in an anaerobic fermentation system, and the anaerobic fermentation system is regulated and controlled by means of at least one mode of reducing the feed load rate, backwards flowing biogas slurry or adding ammonium bicarbonate. The anaerobic fermentation system can stably run under the condition of high organic load rate, and the high volume gas productivity is achieved; early warning is achieved by monitoring the concentrations of CH4 and CO2 in the gas phase and the alkalinity of bicarbonate and the concentration of n-butyric acid in the liquid phase in the anaerobic fermentation system; by means of three instability early warning regulation and control methods, timely early warning is conducted for system acidification likely to appear, further instability of the biogas fermentation system is prevented by means of corresponding means, and the biogas fermentation system at an instable state is regulated back to the normal state.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

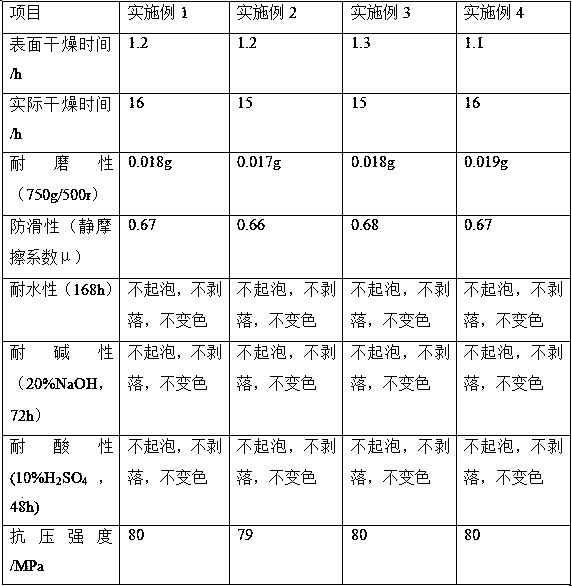

Solvent-free wear-resistant pattern coating

InactiveCN107916044AAdjust viscosityAdjust ThixotropyDuplicating/marking methodsEpoxy resin coatingsEnvironmental resistanceN-Butyric acid

The invention belongs to the technical field of coatings and in particular relates to a solvent-free wear-resistant pattern coating. The solvent-free wear-resistant pattern coating is composed of a component A and a component B, wherein the component A comprises the following raw materials: bisphenol A epoxy resin, bisphenol F epoxy resin, ethylene glycol diglycidyl ether, glycerol epoxy resin, talcum powder, silica powder, a wetting dispersant, a flatting agent, an antifoaming agent and color paste; and the component B comprises the following raw materials: modified alicyclic amine, ethidenediamine, n-butyric acid, a flatting agent BYK-354, an antifoaming agent BYK-054 and a wetting dispersant BYK-310. The coating prepared by blending the dual-component raw materials is fast in drying, excellent in heat resistance and excellent in corrosion resistance, and is excellent in wear resistance, high in durability, environment-friendly, applicable to high-end places, hotels, exhibition halls and the like, simple and convenient in construction and easy to maintain.

Owner:FUZHOU ROYAL FLOOR

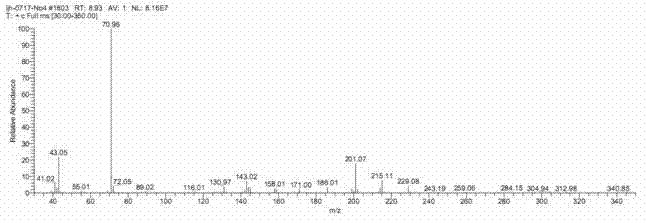

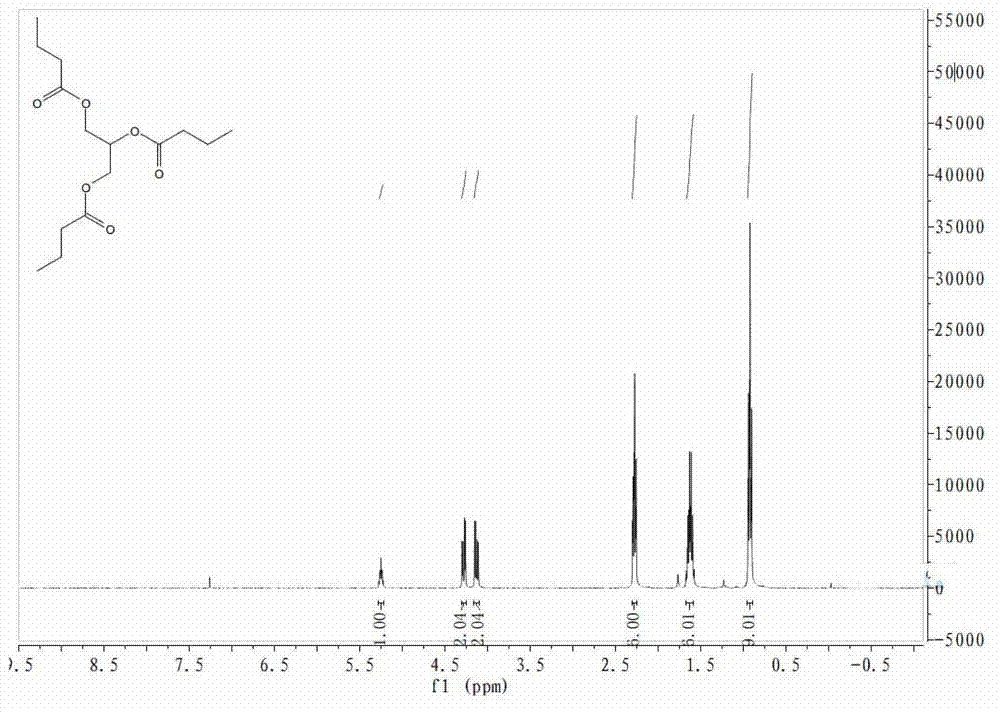

The preparation method of monoglyceride butyrate

ActiveCN104086422BPromote generationImprove responseMolecular sieve catalystsOrganic compound preparationMonoglycerideN-Butyric acid

The invention discloses a preparation method for glyceryl tributyrate. The preparation method comprises: taking glycerin and n-butyric acid as raw materials, adding a catalyst and heating to 100-110 DEG C with stirring, performing heating reflux as well as dropwise adding butyric anhydride, stopping reaction until no water is generated in the reaction solution during dropwise adding, cooling to room temperature, and filtering, so as to obtain glyceryl tributyrate. The catalyst is a mixture of sulfonic-acid mesoporous molecular sieve and ZSM-5 acidic zeolite, and the usage amount of the catalyst is 2-10% by weight of the sum of glycerin and n-butyric acid. By taking sulfonic-acid mesoporous molecular sieve and ZSM-5 acidic zeolite as the catalyst, the selectivity is high, the reaction time is shortened, the generation of by-products is reduced and the catalyst is reusable. By employing the method, the reaction system does not need a water-carrying agent, so that the reaction cost and safe hidden trouble are reduced, the purification step of the product is simplified, the post-processing process is simple, environment is protected and energy is saved. The obtained glyceryl tributyrate is high in purity and high in yield, the reaction speed is fast, and industrial production is easy to realize.

Owner:HUBEI XINZHOU CHEM

Strawberry essence

The invention relates to a strawberry essence which is prepared by the following formula: by weight, 10 parts of ethyl acetate, 20 parts of cis-3-hexenol, 11 parts of ethyl butyrate, 4 parts of gamma-undecalactone, 9 parts of ethyl isovalerate, 10 parts of ethyl acetoacetate, 1 part of ethyl propanoate, 2 parts of benzaldehyde (10% propylene glycol), 10 parts of isoamyl alcohol, 7 parts of maltol, 10 parts of n-butyric acid, 2 parts of vanillin and 4 parts of isovaleric acid. The essence having rich natural strawberry fragrance is prepared in the invention.

Owner:WUJIANG CITY LI DA LUSTRE FINISHED PROD

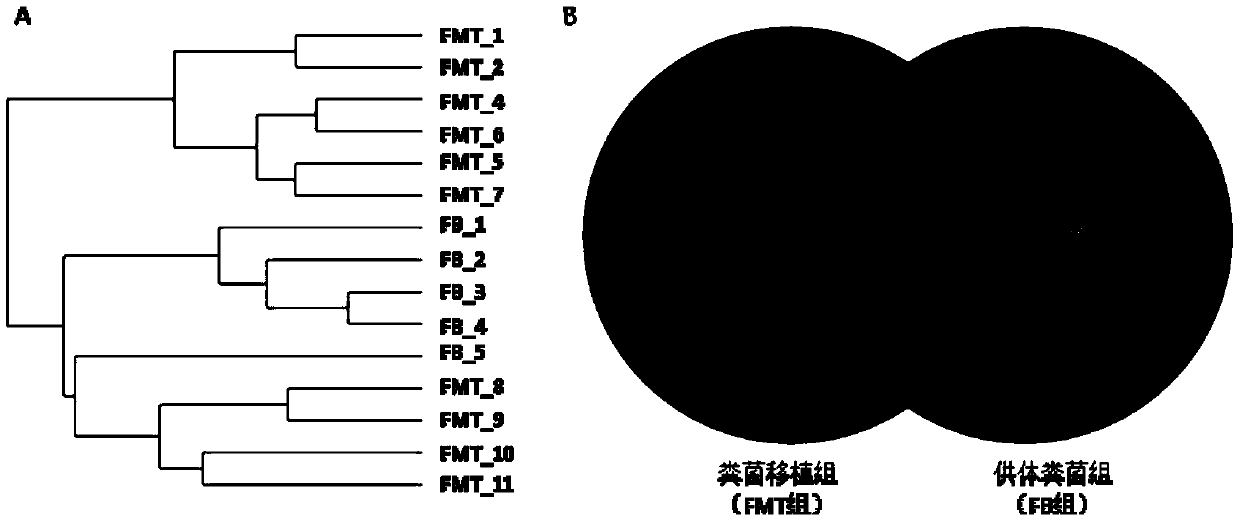

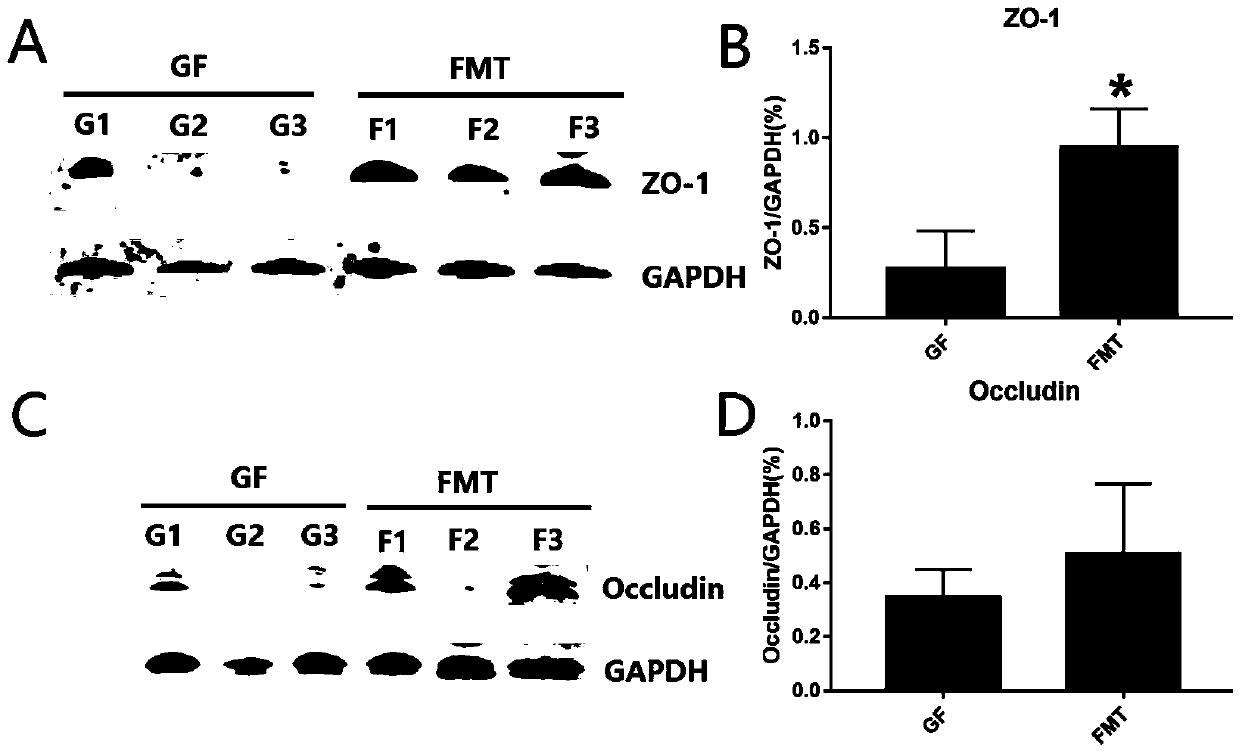

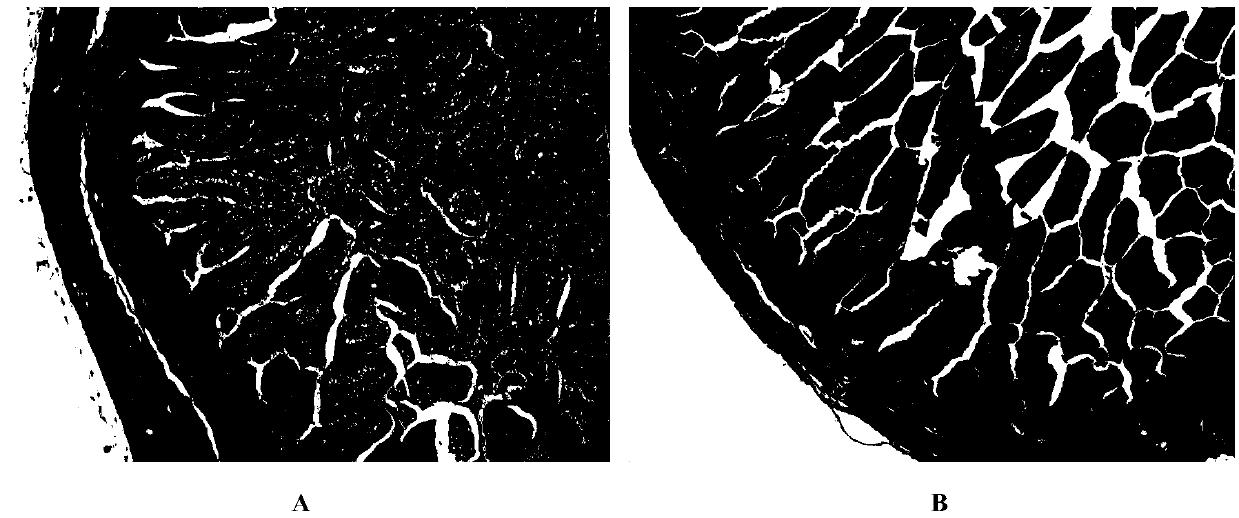

Construction method of feces transplantation experiment piglet model

InactiveCN109090033AModel results are reliableReliable resultsAnimal husbandryIntestinal structureN-Butyric acid

The invention belongs to the technical field of medical preparations of inorganic compounds containing ammonia, in particular to a construction method of a feces transplantation experiment piglet model, and the method is obtained by performing feces bacteria transplantation on a sterile newborn piglet. The method of the invention avoids the treatment of antibiotics or other sterilization drugs, the constructed fecal bacteria transplantation pig model has good effect with no drug residue, and the function of donor flora can be reflected more truly and reliably; the expression level of tight junction protein ZO-1 and Occludin in the empty intestine of the piglet can be improved; the development of muscular layer and gland of the intestinal wall of the piglet can be promoted; and the contentof various volatile short-chain fatty acids such as acetic acid, n-propionic acid, isobutyric acid, n-butyric acid, isovaleric acid, n-valeric acid and the like in intestinal tracts of the piglet is improved.

Owner:CHONGQING ACAD OF ANIMAL SCI

Chemical synthetic method for n-butyryl chloride

InactiveCN102199083AAdvanced process routeReasonable process conditionsOrganic compound preparationCarboxylic compound preparationChemical synthesisOrganic solvent

The invention relates to a green chemical synthetic method for n-butyryl chloride, in particular to a chemical synthetic method for preparing n-butyryl chloride by utilizing the reaction between bis (trichloromethyl) carbonate and n-butyric acid. The method comprises the steps of: with n-butyric acid and bis (trichloromethyl) carbonate as the raw materials, reacting in organic solvent at the temperature of 50 DEG C to 100 DEG C for 1 to 10 hours under the action of an organic amine catalyst, and then distilling to obtain the n-butyryl chloride. The method provided by the invention has the advantages of advanced process route, reasonable process conditions, simplicity and safety in operation, high reaction yield rate, low production cost, and less 'three wastes' (waste gas, waste water and waste residues); and the method has greater implementation value and social and economical benefits.

Owner:湖州沙龙化工有限公司

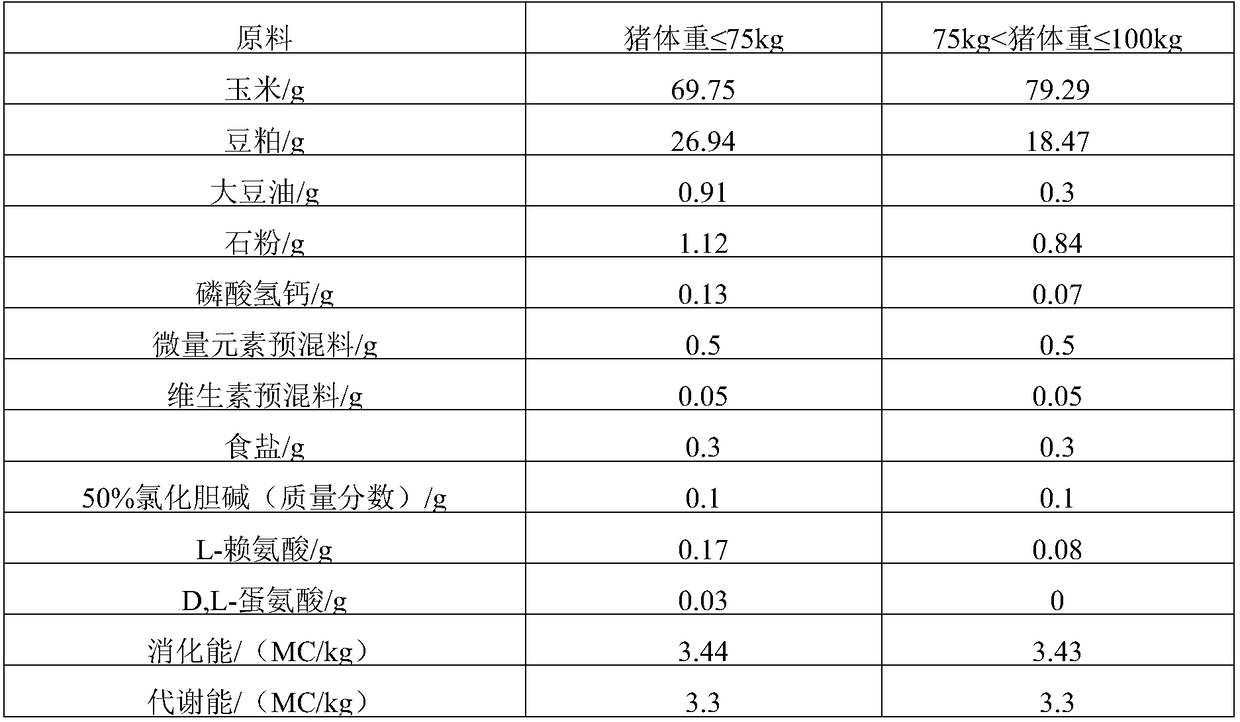

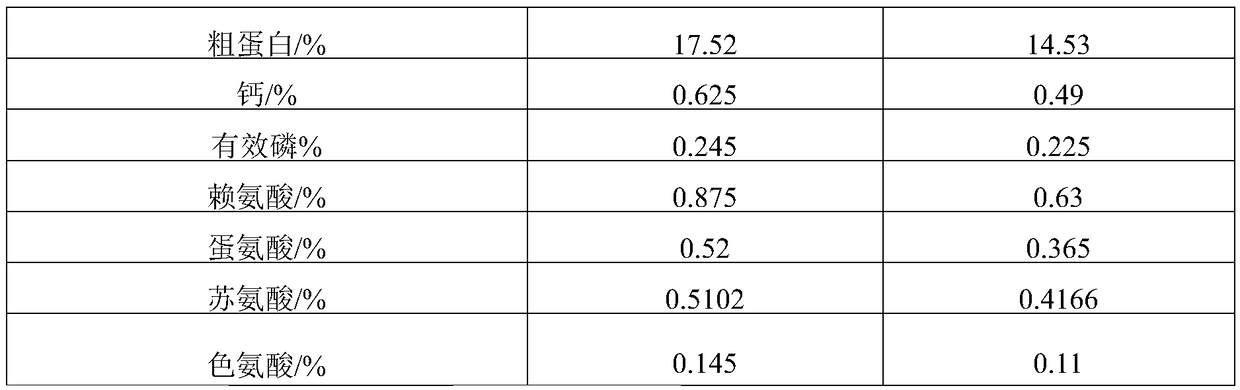

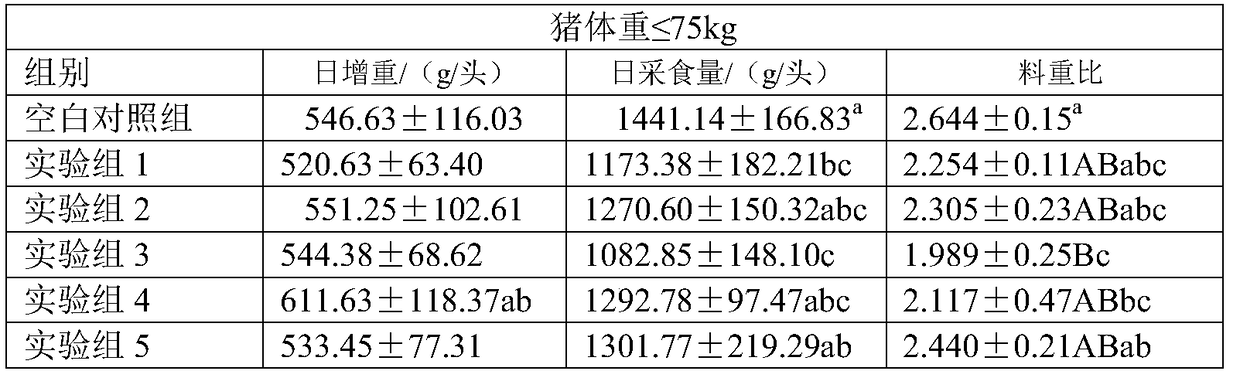

Feed additive for reducing discharge of stink compound in pig excrement

InactiveCN109221752AImprove material to weight ratioIncrease daily weight gainAnimal feeding stuffAccessory food factorsWeight gainingPropanoic acid

The invention belongs to the technical field of animal feeds specially applied to specific animals, and particularly relates to a feed additive for reducing the discharge of stink compound in pig excrement. Two of earthworms, yucca schidigera extract and bacillus subtilis are combined to form the feed additive. The feed additive can remarkably improve the feed to gain ratio and daily weight gain of pigs and increase reproductive capacity; the digestibility of nutrient substances for growing pigs can be increased, and the content of nitrogen and phosphorus in fecal and urine can be reduced; thecontent of undigested nutrients in excrement is reduced, and the content of stink substances (such as p-cresol, indole, n-propionic acid, n-butyric acid and n-pentanoic acid) in fecal and urine mixture is reduced; the discharge of stink substances (such as p-cresol, indole, n-propionic acid, n-butyric acid and n-pentanoic acid) produced after pig fecal and urine fermentation can be remarkably reduced, and environmental pollution caused by breeding waste gas is reduced; and the materials have a synergistic effect.

Owner:CHONGQING ACAD OF ANIMAL SCI

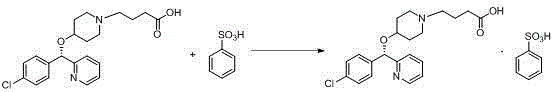

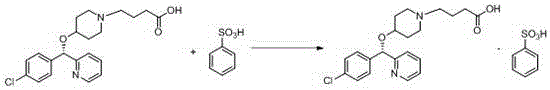

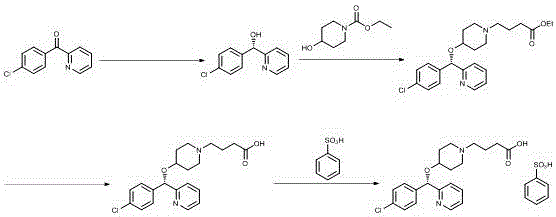

Salt-forming method of bepotastine besilate

ActiveCN106045974AIncrease productivityShort crystallization timeOrganic chemistryN-Butyric acidAlcohol

The invention discloses a salt-forming method of bepotastine besilate, wherein the method includes the steps of: 1) adding benzenesulfonic acid monohydrate to organic alcohol, stirring the solution until the benzenesulfonic acid is completely dissolved for later use; 2) dissolving (+)-(S)-4-{4-[(4-chlorophenyl)(2-pyridyl)methoxyl]piperidyl}n-butyric acid in organic alcohol, controlling the temperature at -20 - 20 DEG C and stirring speed at 50-200 rpm, adding a less amount of bepotastine besilate crystal seeds, dropwisely adding the benzenesulfonic acid organic alcohol solution, and then continuously stirring the solution with temperature maintained; and 3) performing crystallization for 1-5 h and filtering the solution, pour-washing a filter cake with the organic alcohol, and performing pressure reduced drying to obtain the bepotastine besilate. The method can form uniform granules in the product, is high in yield, has good impurity removal effect and excellent operability, is low in production cost and high in efficiency, and is suitable for industrial production.

Owner:HANGZHOU HEZE PHARMA TECH

Method for synthesizing 2-chlorobutyric acid

InactiveCN102241583AReduce dosageIncrease profitPreparation from carboxylic acid anhydridesChemical recyclingN-Butyric acidHydrogen

The invention discloses a method for synthesizing 2-chlorobutyric acid, which comprises the following steps that: n-butyric acid and liquid chlorine are reacted in the presence of butyric anhydride serving as a catalyst at 50 to 150 DEG C for 5 to 15 hours, namely chloride ions substitute hydrogen ions at position-2 of the molecules of butyric anhydride to form 2-chlorobutyric anhydride and then the 2-chlorobutyric anhydride reacts with n-butyric acid to form butyric anhydride and 2-chlorobutyric acid; and after reaction, the 2-chlorobutyric acid with a purity of over 99 percent can be obtained by rectification. In the invention, butyric anhydride is used as a catalyst, and by controlling the reaction temperature and chlorine content, the conversion rate can be kept between 85 and 95 percent, the by-products generated can be reduced, and excessive chlorination can be prevented; and after being hydrolyzed, the catalyst can be recycled, and unreacted n-butyric acid can be reclaimed by rectification and can be reused in subsequent production. In the invention, the used amount of chlorine is small, fewer byproducts are produced, the utilization rate of n-butyric acid is high, and the environment-protection effect is improved considerably.

Owner:JIAXING BOYUAN BIO CHEM TECH

Process for the production of an n-butyric acid compound in micro encapsulated form, for animal or human consumption

A process for the production of an n-butyric acid compound in microencapsulated form comprises the stages of:—providing a granular material based on the n-butyric acid compound, —mixing the granular material with a matrix having a content of long-chain C14-C22 saturated fatty acids of from 40% to 95%, and an amount of between 1% and 20% of a mineral agent in which an effective amount of calcium sulphate dihydrate is present, heating the mixture to a temperature higher than the melting temperature of the lipid component of the matrix, —spraying the mixture into a cooling chamber having a temperature lower than the melting temperature of the lipid component of the matrix, so that the latter solidifies around the granular material, forming a covering thereof.

Owner:SILA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com