The preparation method of monoglyceride butyrate

A technology of butyric acid monoglyceride and glycerol is applied in the field of preparation of butyric acid monoglyceride, can solve the problems of low yield of butyric acid monoglyceride, poor quality of butyric acid glyceride, difficult industrialized production, etc. The effect of reaction time, avoiding poor quality, and reducing the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

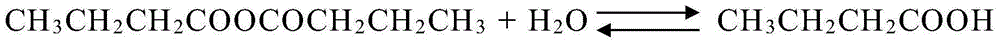

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of monoglyceride butyrate comprises the following steps:

[0017] 1) Preparation of sulfonic acid mesoporous molecular sieve: Dissolve 4g of template agent P123 in 130mL of 2mol / L hydrochloric acid solution at 35°C, stir to mix evenly, then add 8.4g of tetraethyl orthosilicate, 10g For p-toluenesulfonic acid, continue to stir for 24h, crystallize at 130°C for 24h, filter, wash and dry, and finally calcinate at 500°C for 6h to remove the template agent, then filter, wash and dry to obtain mesoporous molecular sieve SBA-15- SO 3 H.

[0018] 2) Mix 18.4 grams (200 mmol) of glycerin and 17.8 grams (200 mmol) of n-butyric acid, add a total of 1.78 grams of a mixed catalyst of sulfonic acid mesoporous molecular sieve and ZSM-5 acidic zeolite, heat and stir to 100 ° C, the sulfonic acid mesoporous The weight ratio of pore molecular sieve to ZSM-5 acidic zeolite is 3:1, heat to reflux, and use liquid chromatography for central control detection from the...

Embodiment 2

[0020] The preparation method of monoglyceride butyrate comprises the following steps:

[0021] 1) Preparation of sulfonic acid mesoporous molecular sieve: Dissolve 4g of template agent P123 in 130mL of 2mol / L hydrochloric acid solution at 40°C, stir to mix evenly, then add 8.4g of tetraethyl orthosilicate, 10g For p-toluenesulfonic acid, continue to stir for 28h, crystallize at 130°C for 36h, filter, wash and dry, and finally calcinate at 500°C for 8h to remove the template agent, then filter, wash and dry to obtain mesoporous molecular sieve SBA-15- SO 3 H.

[0022] 2) Mix 18.4 grams (200 mmol) of glycerin and 17.8 grams (200 mmol) of n-butyric acid, add a total of 1.07 grams of a mixed catalyst of sulfonic acid mesoporous molecular sieve and ZSM-5 acidic zeolite, heat and stir to 110 ° C, and the sulfonic acid media The weight ratio of pore molecular sieve to ZSM-5 acidic zeolite is 3:1, heat to reflux, and use liquid chromatography for central control detection from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com