Patents

Literature

488results about How to "Slow reaction speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of ZrO2 nanotube supported B2O3 catalyst

InactiveCN102125825AGood for performanceSimple preparation processPhysical/chemical process catalystsChemistryAnode oxidation

The invention discloses a preparation method of a ZrO2 nanotube supported B2O3 catalyst, which comprises the following steps of: preparing aqueous solution containing NH4F with the concentration of 0.5 to 1.0%, boride with the concentration of 0.1 to 6% and (NH4)2SO4 with the concentration of 5 to 12%, taking the aqueous solution as reaction medium, taking a zirconium plate as anode and a platinum plate as cathode with the spacing of 1.5cm therebetween, adopting 10-30V direct current for anode oxidation for 3 to 5 hours at room temperature, stopping reaction, drying and roasting the resultant oxide to obtain the catalyst, wherein all the concentration percents are mass percents. The B2O3 / ZrO2 catalyst prepared according to the method of the invention has large specific surface area and volume simultaneously, and when the specific surface area thereof is the same as that of nano powder, the volume is ten thousand times as much as that of nano powder, thus the contradiction between specific surface area and volume of powder carrier is settled, and the defects caused by the fact that powder ZrO2 supports the B2O3 catalyst can be overcome.

Owner:HEBEI UNIV OF TECH

Ultra-low resistance acid-type microemulsion plugging removal and stimulation technology for low permeability oil well

ActiveCN101691839AGood dispersionStrong solubilizationFluid removalDrilling compositionSolubilityLiquid surfaces

The invention relates to a plugging removal and stimulation method for a low permeability oil well. The ultra-low resistance acid-type microemulsion is prepared by the following components: 10%-25% of acid, 5%-20% of oil, 5%-25% of alcohol, 0.5%-5% of surfactant, 0.5%-3% of inorganic salt, 0.3-1.5% of corrosion inhibitor and the balance water. The method comprises the following steps: injecting the prepared microemulsion in the oil bearing reservoir of the oil well, closing the oil well to react for 4-10h, cleaning the oil well, flowing the reaction exhaust liquor back, and completing the oilwell to perform normal production. The ultra-low resistance acid-type microemulsion used by the invention has thermodynamic stability, is a high dispersive acid-type microemulsion with good solubilization capacity, has ultra-low surface and interfacial tensions and good solubilization capacity and can increase the dispersive capacity of crude in water and the emulsification and peeling function to oil film; the microemulsion also has good dissolubility in water or oil and good fluidity due to high carrying capability and low seepage resistances so that the oil yield of the oil well is increased and the water content is reduced; the liquid surface tension in oil reservoir is reduced and the flow resistance of the crude is lowered so that the mining rate of the crude is increased and the plugging removal and stimulation of the oil well can be realized.

Owner:陕西中孚石油信息技术有限公司 +1

Methanesulfonic acid-based matte pure tin electroplating solution and additive thereof

The invention relates to a methanesulfonic acid-based matte pure tin electroplating solution and an additive thereof. Each liter of an aqueous solution agent of the additive comprises the following components based on concentration: 1.5g / L-3g / L of grain refiner, 100g / L-200g / L of non-ionic surfactant, 10g / L-30g / L of antioxidant and 100g / L-150g / L of organic solvent, wherein the grain refiner is particularly heterocyclic compounds, amine compounds or a mixture of the two. The electroplating solution prepared by the additive in the invention has the advantages of good scatter performance, high flexibility and extensibility of the pure tin-based electroplating layer, and good weldability, and prevents the tin whisker from growing for a long time; and meanwhile, the electroplating solution contains no non-biodegradable substances or surfactant harmful to the environment and the like, thus facilitating the treatment of sewage and meeting the requirements for environmental protection. The invention is worthy of popularizing and applying.

Owner:济南德锡科技有限公司

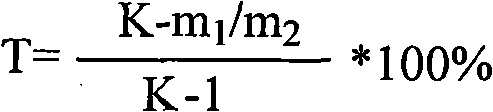

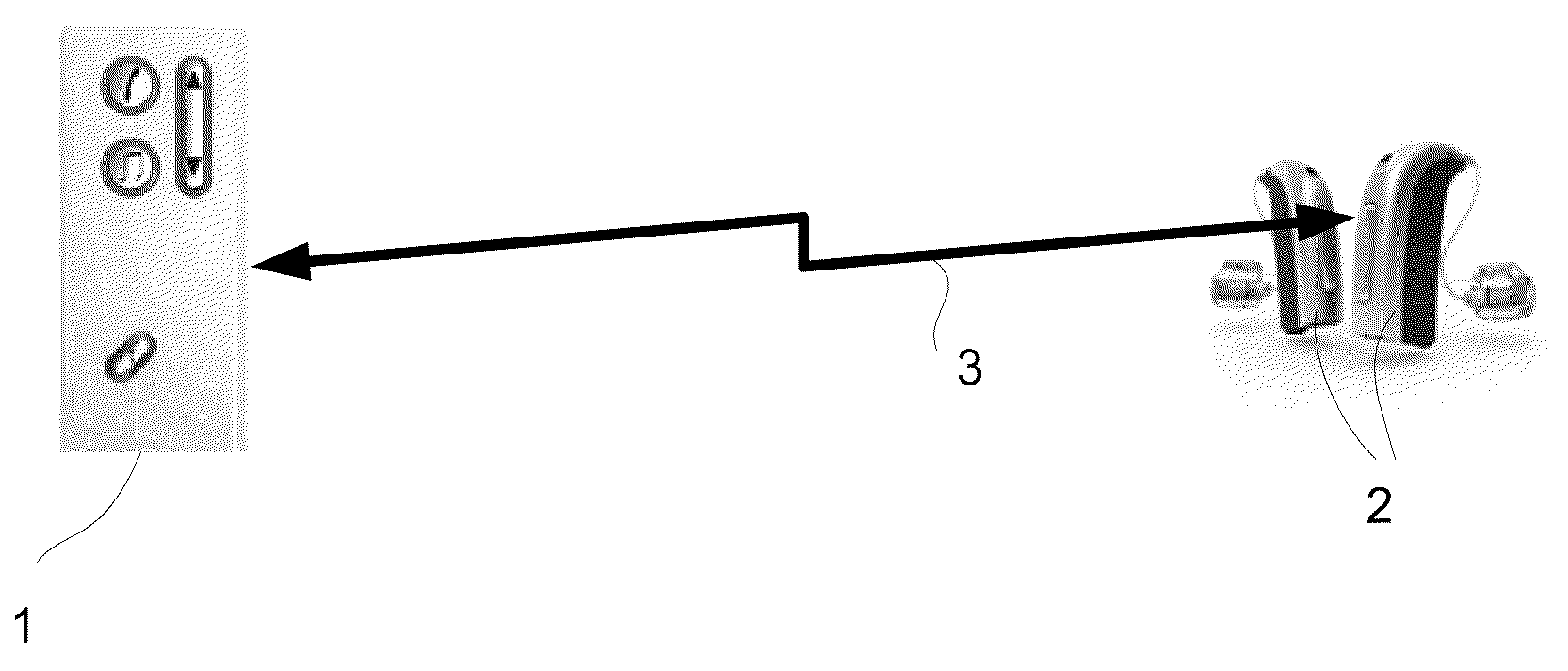

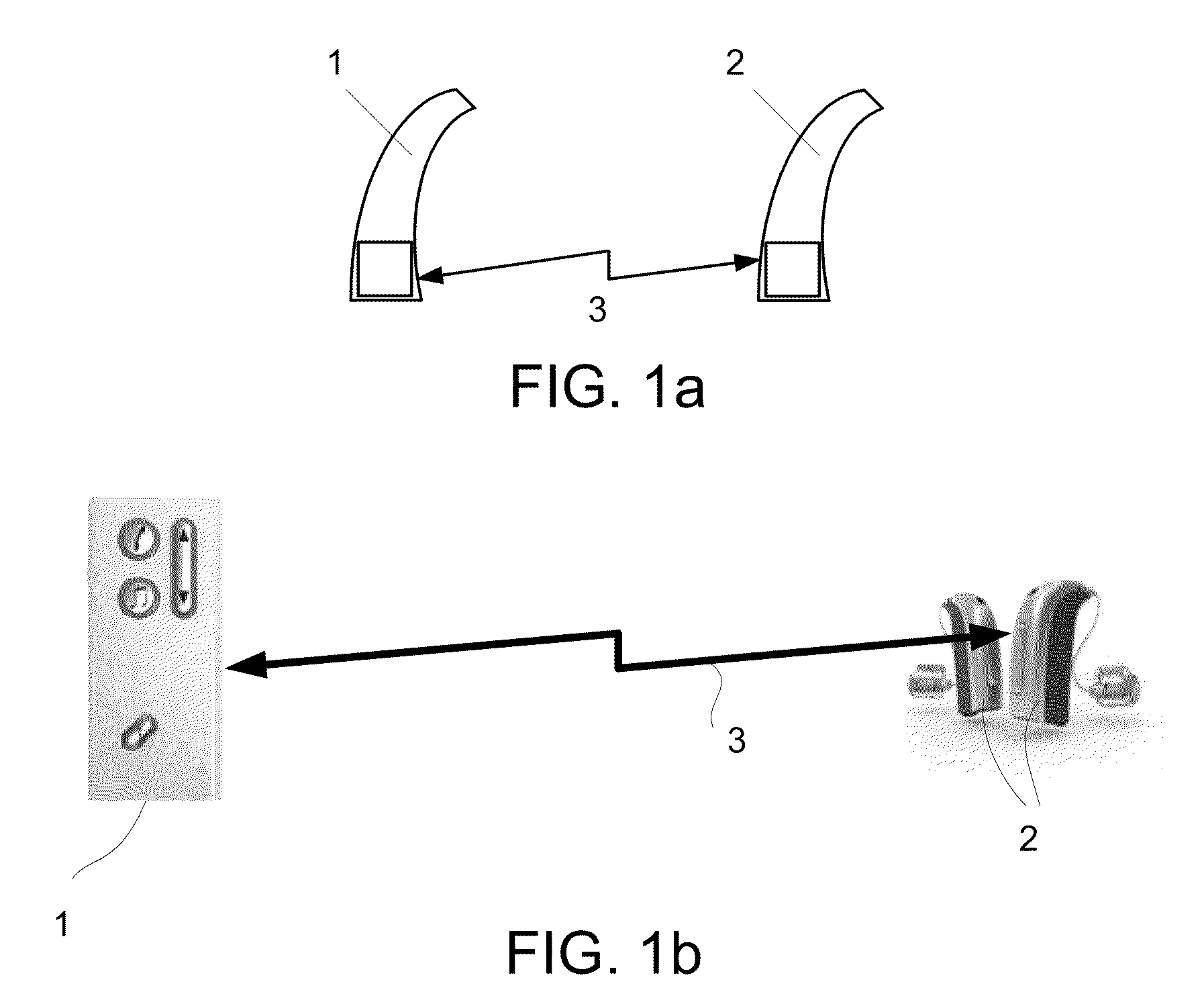

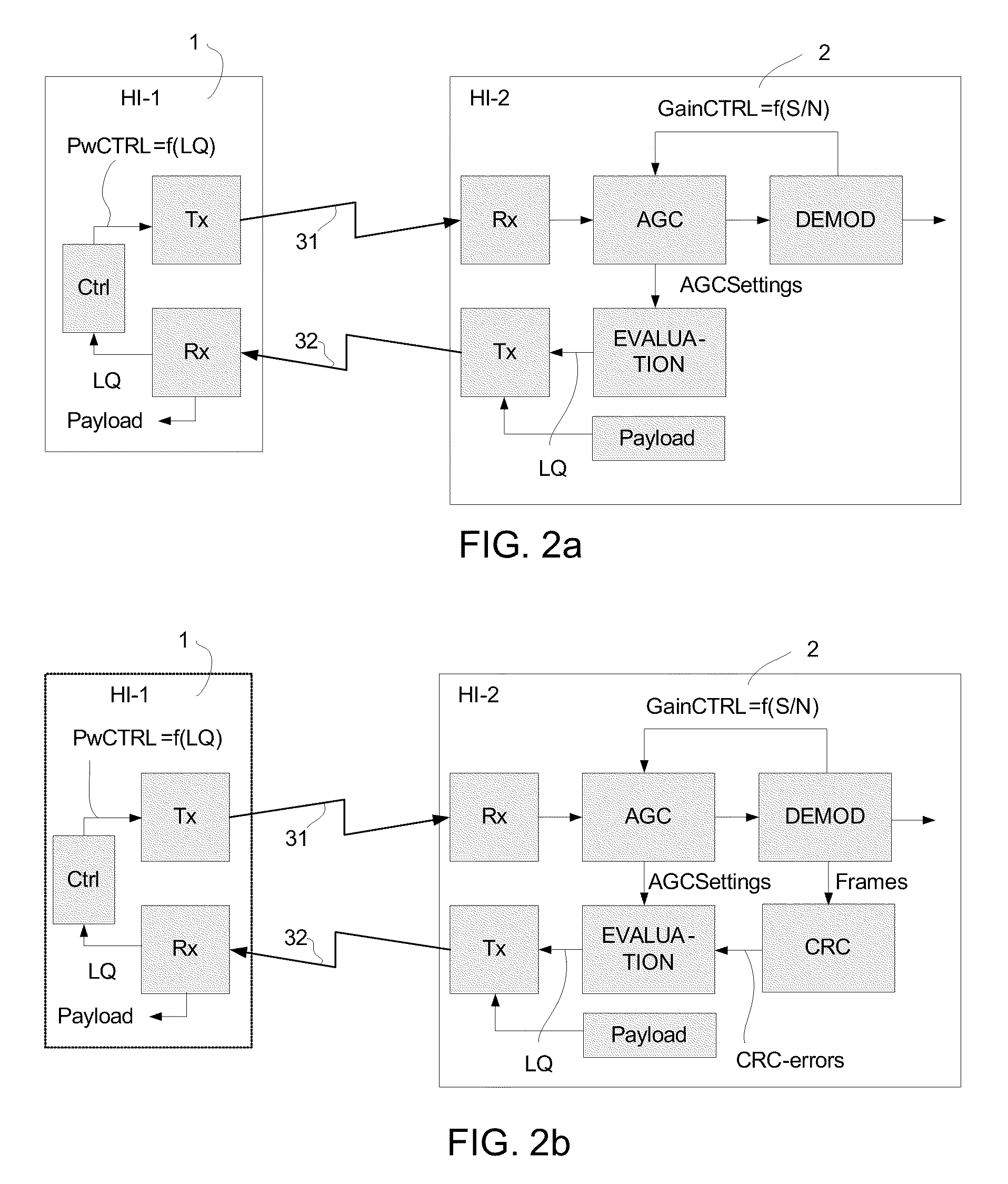

Power management in low power wireless link

ActiveUS20100184383A1Quick changeSignificant changePower managementNear-field transmissionData processing systemCommunications system

The invention relates to a communication system comprising a first and a second communication device, each comprising transmit and receive units for establishing a wireless link between the devices, wherein the first device is a portable listening device. The invention further relates to a method, a data processing system and a medium. The object of the present invention is to control power consumption in a short range wireless link. The problem is solved in that at least the first communication device comprises a control unit for dynamically adjusting the transmit power of its transmit unit based on a measure of the quality of the link, wherein the system is adapted to use the dynamic transmit power regulation to implement a partial power-down mode of the system, when the two communication devices are expected NOT to be in a normal use, wherein the partial power-down mode at least comprises a power-down of the components related to the wireless link. This has the advantage of enabling an adaptation of the power consumption to the current needs. The invention may e.g. be used for wireless communication between (portable) low power devices, e.g. between a pair of hearing instruments.

Owner:OTICON

Halogen-free cleaning-free rosin flux, and preparation and application thereof

ActiveCN102513732ALess corrosiveSlow growth rateWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention discloses a halogen-free cleaning-free rosin flux, and preparation and application thereof, and particularly relates to a flux suitable for surface mount lead-free welding paste, preparation of the flux and application of the flux. The flux comprises 20-50% (mass fraction, the same below) of rosin, 5-25% of film-forming agent, 30-50% of high boiling solvent, 3-8% of activator and 2-5% of thixotropic agent, and the flux does not contain any halogen. In order to control growth of interface IMC (intermediate compound) during welding, 0.3-1% of combined inhibitor is added. The welding paste prepared with the flux and lead-free tin-silver-copper powder has the advantages of excellent printing performance, fine weldability, less post-weld residue, thin and even welding spot interface IMC and excellent mechanical property, and is capable of meeting the requirement of high-end electronic products on packaging.

Owner:CENT SOUTH UNIV

High-performance epoxy bitumen mixture easy to construct and maintain and preparation method thereof

The invention discloses a high-performance epoxy bitumen mixture easy to construct and maintain, comprising four components of A, B, C and D. The high-performance epoxy bitumen mixture easy to construct and maintain is characterized in that the component A mainly comprises epoxy resin, a toughening agent, an accelerating agent and a diluent agent; the component B mainly comprises a curing agent, an accelerating agent, a compatilizer and a diluent agent; the component C comprises bitumen; the component D comprises aggregates and mineral powder, wherein the ratio of the component A to the component B is 100:50 to 100:100; the ratio of the sum of the component A and the component B to the component C is 100:100 to 100:160; and the ratio of the sum of the component A, the component B and the component C to the component D is 6:94 to 7:93. The high-performance epoxy bitumen mixture easy to construct and maintain has the characteristics of excellent mechanical property, temperature resistance, water resistance, solvent corrosion resistance, fatigue durability, simple construction process and short maintenance time. The high-performance epoxy bitumen mixture easy to construct and maintain is suitable for paving and maintenance of road surfaces, such as steel bridge floors, cement concrete bridge floors, tunnels, expressways and the like. The invention also discloses a preparation method of the high-performance epoxy bitumen mixture easy to construct and maintain.

Owner:NANJING UNIV

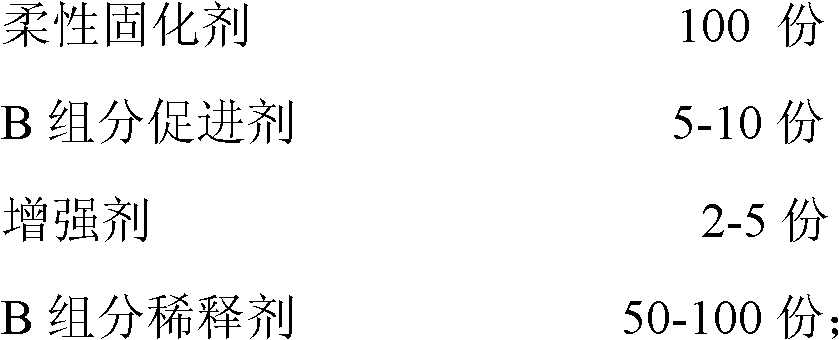

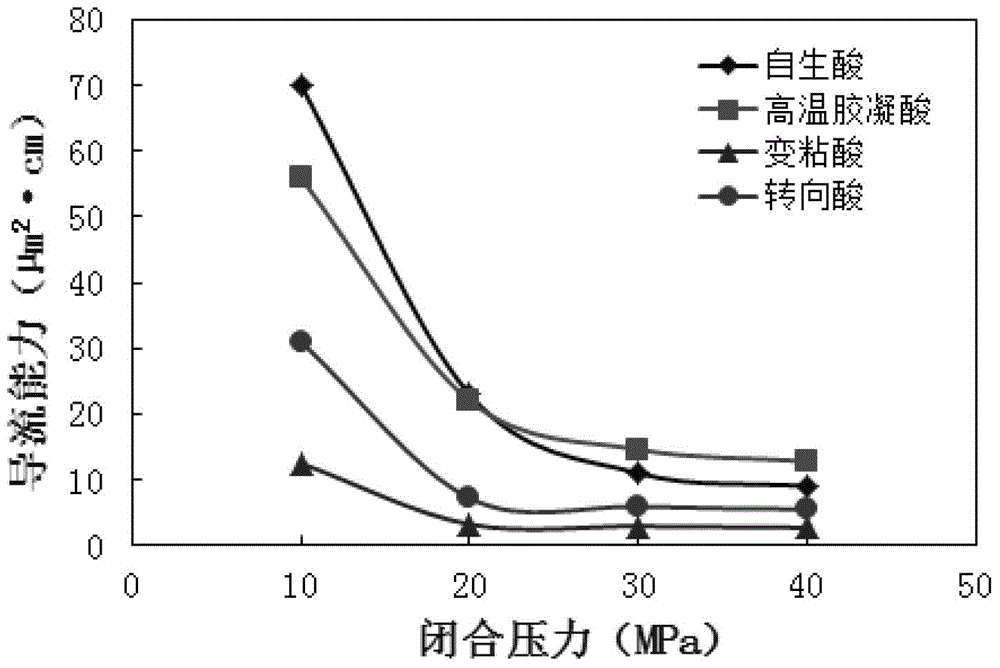

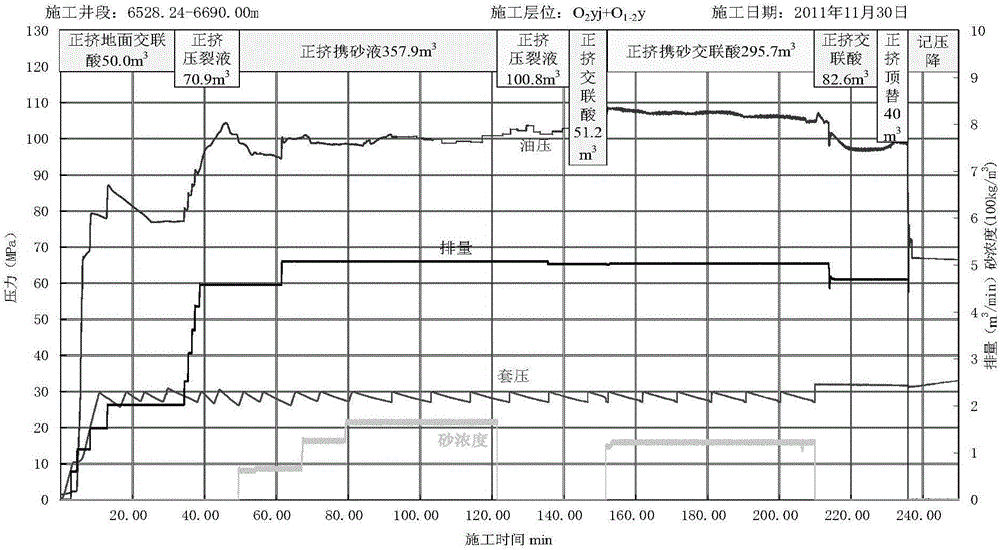

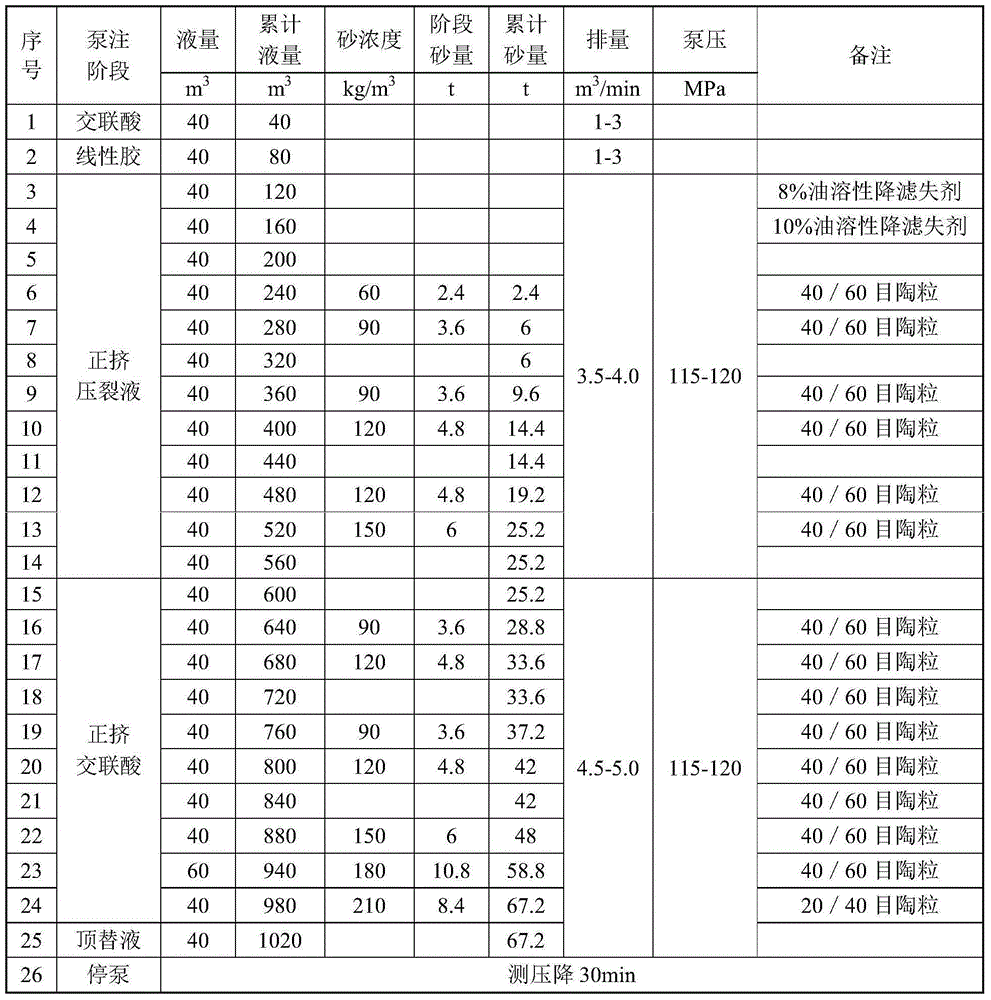

Self-born acid composite acid fracturing process for high-temperature deep well carbonate rock reservoir

ActiveCN104975840AImprove diversion capacityReduce corrosion rateFluid removalAcid fracturingHot Temperature

The invention relates to a self-born acid composite acid fracturing process for a high-temperature deep well carbonate rock reservoir. The process comprises the following work procedures of: (1) injecting slick water into a stratum through an oil pipe; (2) injecting non-crosslinked fracturing liquid into the stratum through the oil pipe; (3) injecting a self-born acid system into the stratum through the oil pipe; (4) injecting a gelled acid system into the stratum through the oil pipe in a low-displacement mode; and (5) injecting the slick water into the stratum through the oil pipe, wherein the volume proportions of liquid, accounting for the total liquid injected into the stratum, injected in the first to fifth work procedures are shown as follows: the slick water in the first work procedure accounts for 3 to 10 percent; the non-crosslinked fracturing liquid in the second work procedure accounts for 40 to 60 percent; the self-born acid system in the third work procedure accounts for 30 to 50 percent; the gelled acid system in the fourth procedure accounts for 3 to 10 percent; the volume proportion of the slick water in the fifth work procedure is 3 to 15 percent; and the volume unit is m<3>. Through the self-born acid composite acid fracturing process, the flow guide capability is improved by more than 140md.m, and the deep penetration effect of the high-temperature deep well carbonate rock reservoir is obvious.

Owner:CHINA PETROLEUM & CHEM CORP

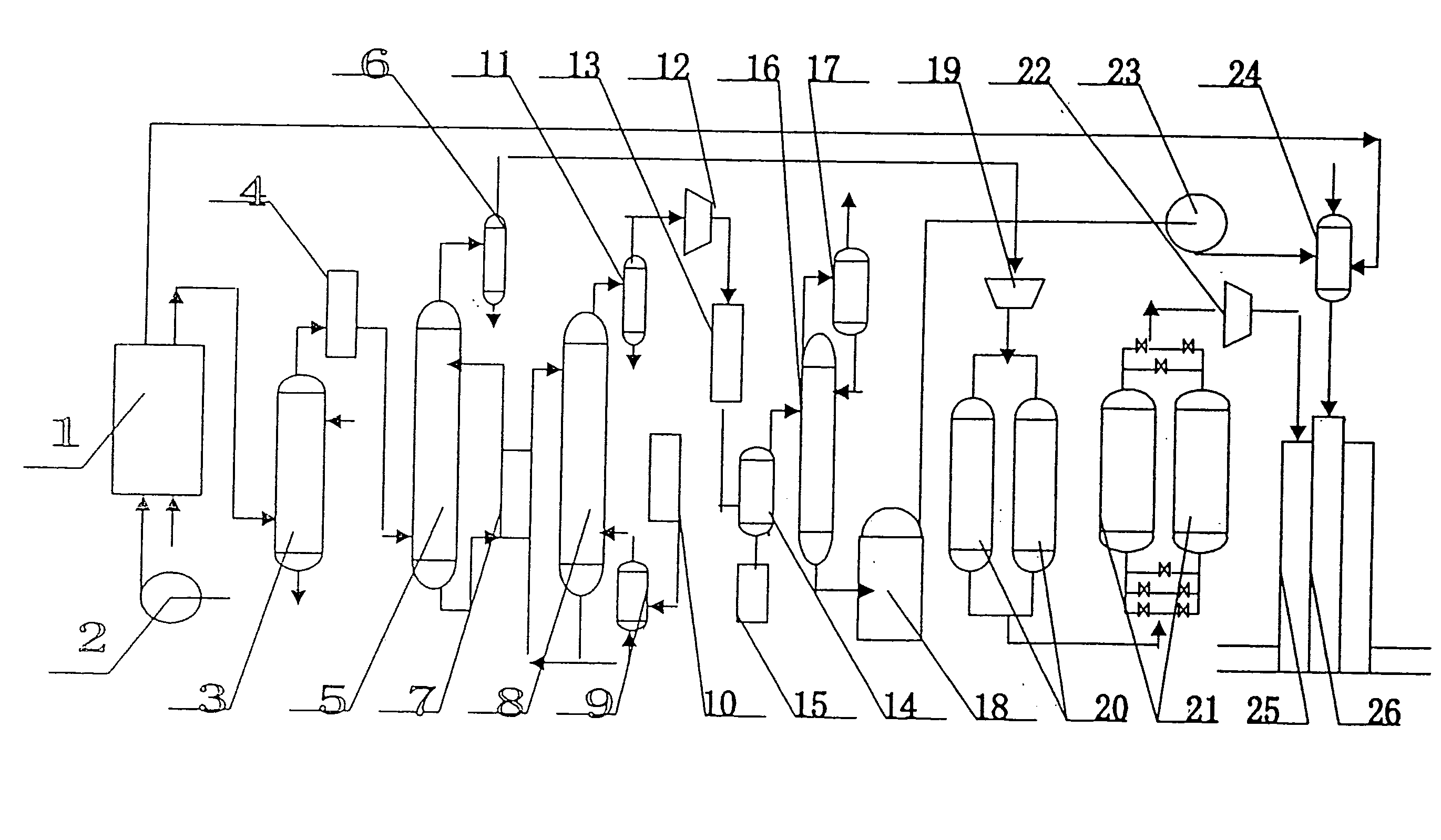

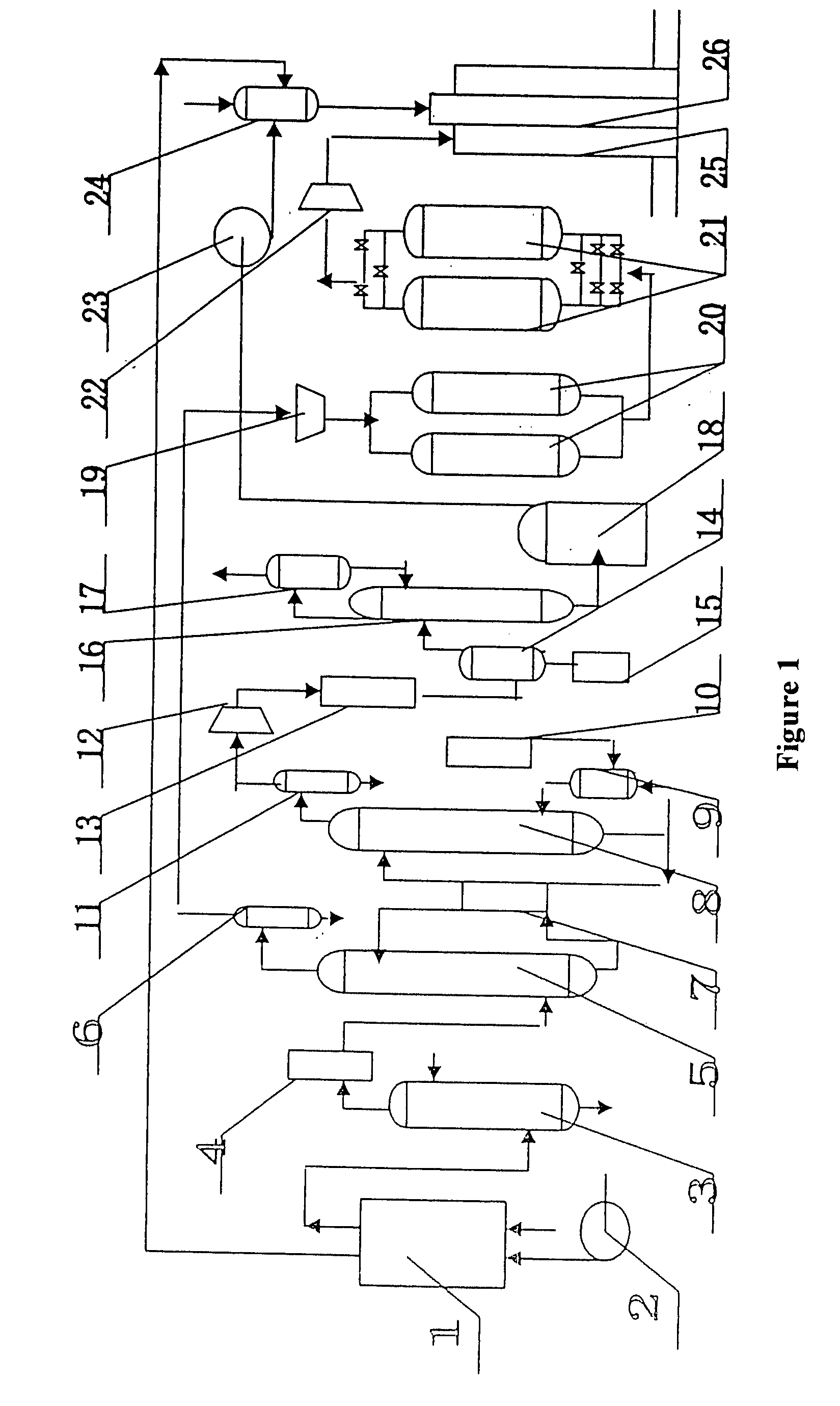

Method for reclaim of carbon dioxide and nitrogen from boiler flue gas

InactiveUS20090101868A1Low volatilization lossExcellent desorption capabilityCombination devicesGas treatmentCarbon dioxideSulfide

This invention discloses a method for the reclaim of carbon dioxide and nitrogen from boiler flue gas, which includes: the flue gas enters into the water-washing and desulfurizing tower from the inferior part and contacts the sulfide solution flowing backward for the cleaning and desulfurizing of the flue gas; the desulfurized flue gas is introduced to the inferior part of the chemical absorber, where the contained carbon dioxide contacts the carbon dioxide adsorption liquid (containing, by the total weight of the liquid, of, besides water, 20-60% water solution of compound amine, 5-10% polyxinolum, 1-5% antioxygen and 1-5% corrosion inhibitor) flowing backward;The adsorption liquid coming from the bottom of the absorber and having absorbed carbon dioxide, after heated when passing through heat exchangers, is sent to the top of the carbon dioxide regenerator and flows down through the packing layer; carbon dioxide is emitted out from the top of the regenerator;Nitrogen separated out from the top of the chemical absorber is freeze dried to reduce the content of saturated water to lower than 1.0%.This invention discloses a piece of equipment for the reclaim of carbon dioxide and nitrogen from boiler flue gas.

Owner:CNPC GREAT WALL DRILLING COMPANY GWDC +1

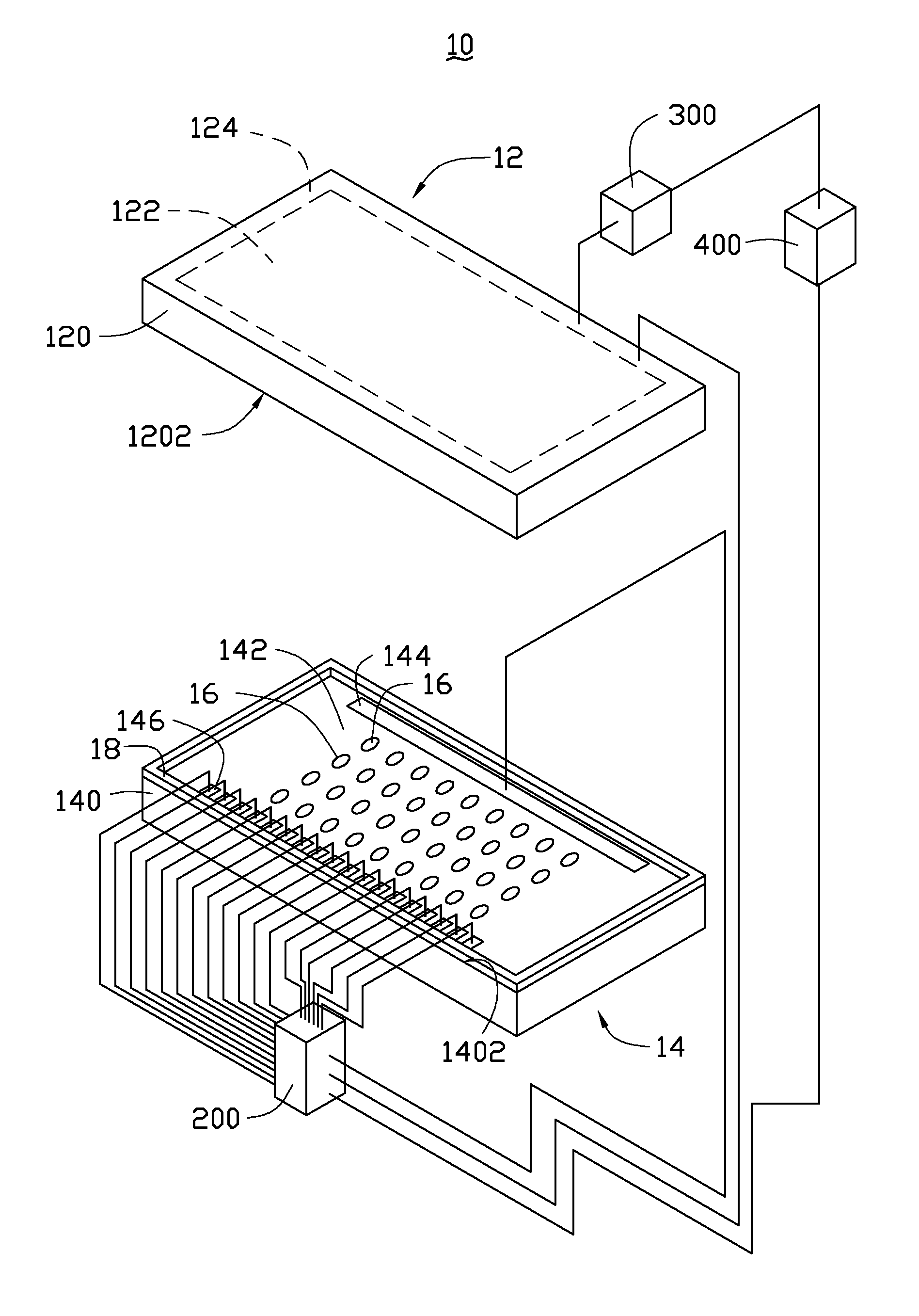

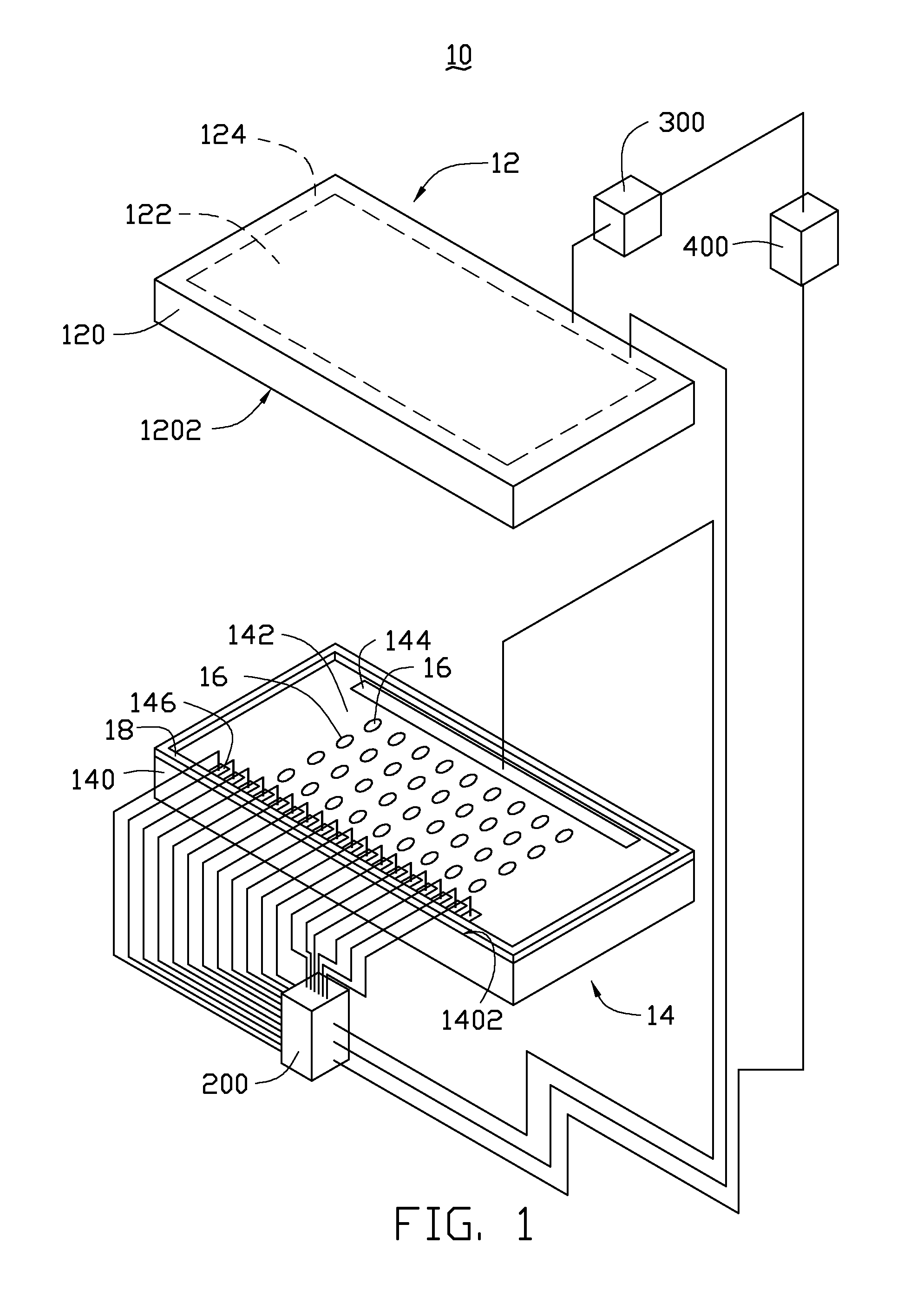

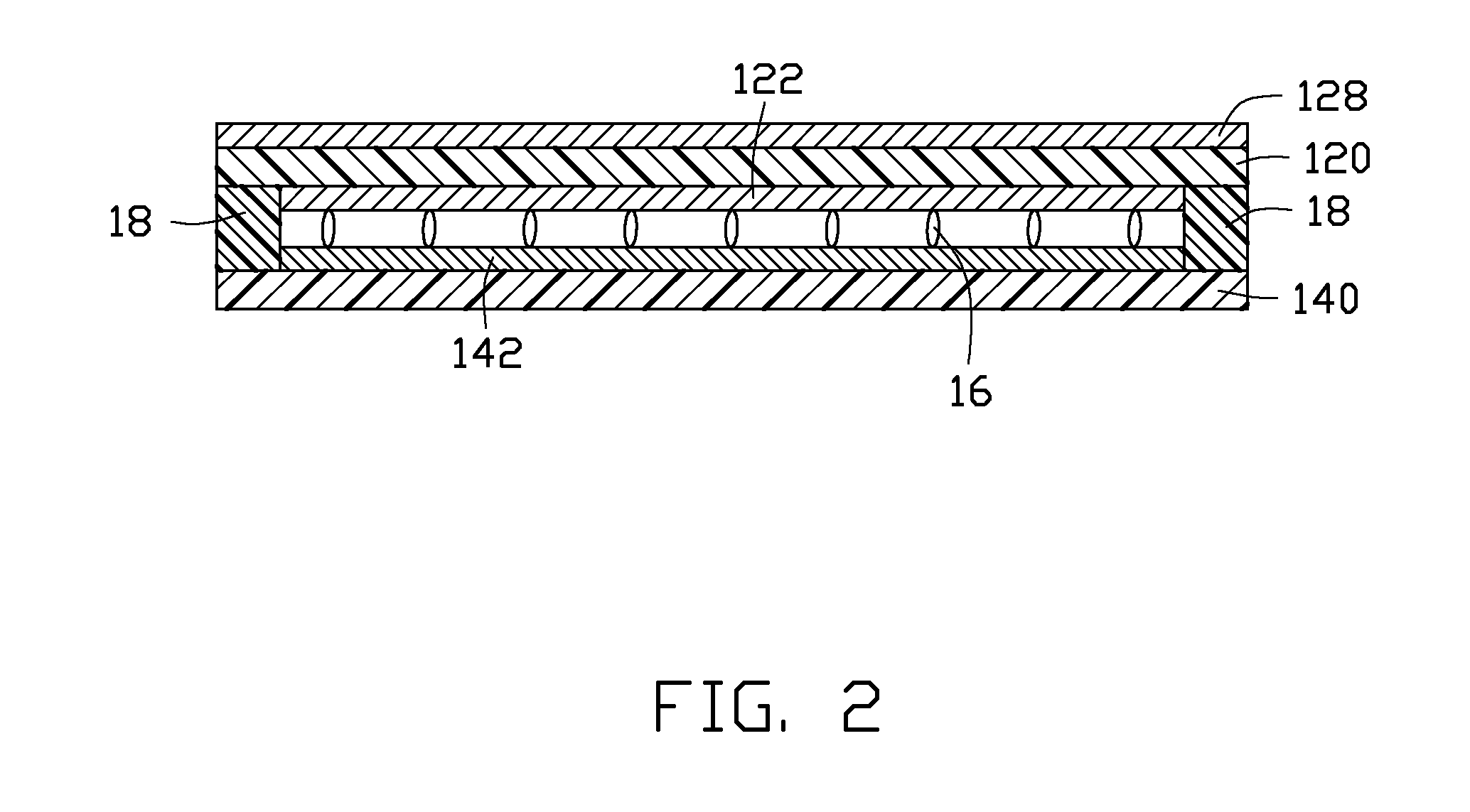

Touch panel

ActiveUS20110304579A1High definitionLong lastingTransmission systemsNanotechnologyOptoelectronicsTouch panel

A touch panel includes a first electrode plate, a second electrode plate, and a capacitive detector. The first electrode plate includes a first transparent conductive layer. The second electrode plate includes a second transparent conductive layer opposite to and spaced from the first transparent conductive layer. The second transparent conductive layer is a conductive film having different resistance along different directions. The capacitive detector is electrically connected with the first electrode plate.

Owner:BEIJING FUNATE INNOVATION TECH

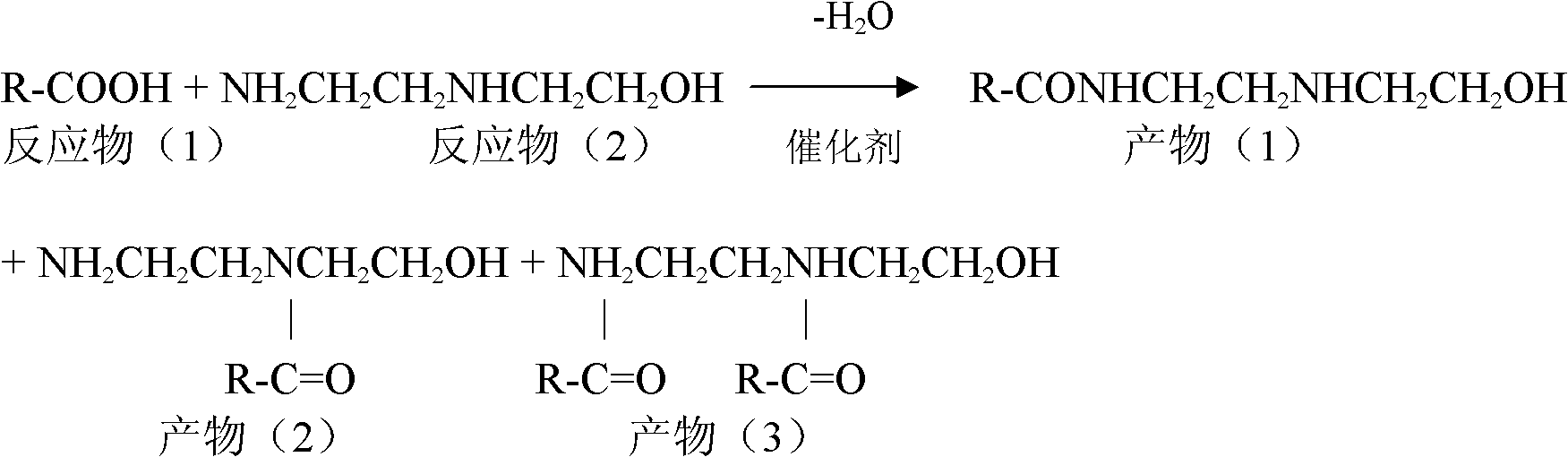

Synthesis method of imidazoline compound

ActiveCN102093296AReasonably determine the ratioReasonably determine the dosageOrganic chemistryTransportation and packagingEthylenediamineSynthesis methods

The invention discloses a synthesis method of an imidazoline compound. The method comprises the following steps of: heating fatty acid and hydroxyethyl ethylenediamine which are used as raw materials to 80-150 DEG C in the presence of a catalyst in a nitrogen atmosphere, and then rising the temperature to 190-220 DEG C in a gradient mode for carrying out a nitrogen acylation reaction to form alkyl amide; and carrying out gradient pressure reduction, dewatering and cyclization on the formed alkyl amide to prepare the imidazoline compound. The synthesis method has simple process and low requirement on production equipment; by adopting the method of the invention, the generation quantity of bi-amide which is a side product can be reduced, and the content of the bi-amide in the prepared imidazoline compound can be reduced to be below 0.5 percent by mass; and meanwhile, the prepared imidazoline compound has stable quality and can be placed for a long time without turbid phenomena.

Owner:广州星业科技股份有限公司

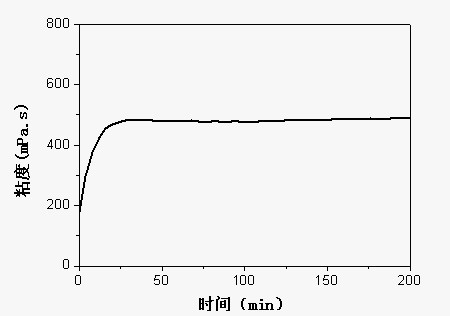

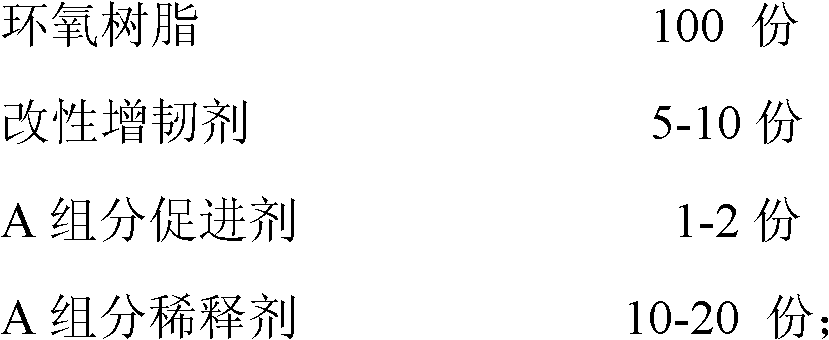

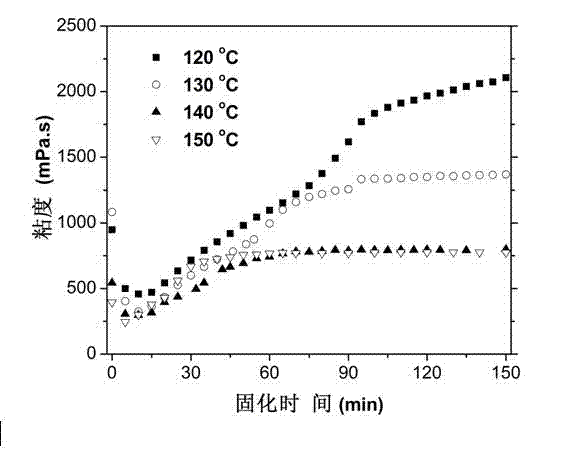

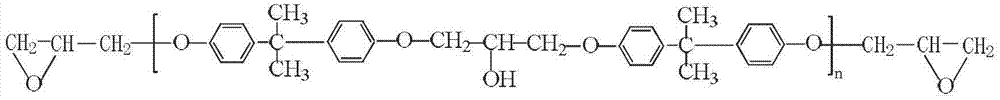

High-performance epoxy resin asphalt warm mixing agent and preparation method thereof

InactiveCN103113752ALow viscositySlow reaction speedClimate change adaptationBuilding insulationsDuctilityDefoaming Agents

The invention discloses a high-performance epoxy resin asphalt warm mixing agent comprising a component A and a component B, wherein the component A is composed of epoxy resin, a reinforcing agent and a coupling agent; the component B mainly comprises a flexible curing agent, an accelerant, a reinforcing agent, a toughening agent and a defoaming agent; and the mass proportion of the component A to the component B is equal to (100:250)-(100:300). High-performance warm mixing epoxy resin asphalt prepared by using the high-performance epoxy resin asphalt warm mixing agent provided by the invention has the characteristics of lower mixing temperature, high strength, better high-temperature ductility resistance and low-temperature fracture resistance, longer construction time, simple construction process, low-carbon and environment friendliness and the like and is suitable for paving pavements of roads, bridges, tunnels, airfield runways and the like. The invention discloses a preparation method of the high-performance epoxy resin asphalt warm mixing agent.

Owner:NANJING UNIV

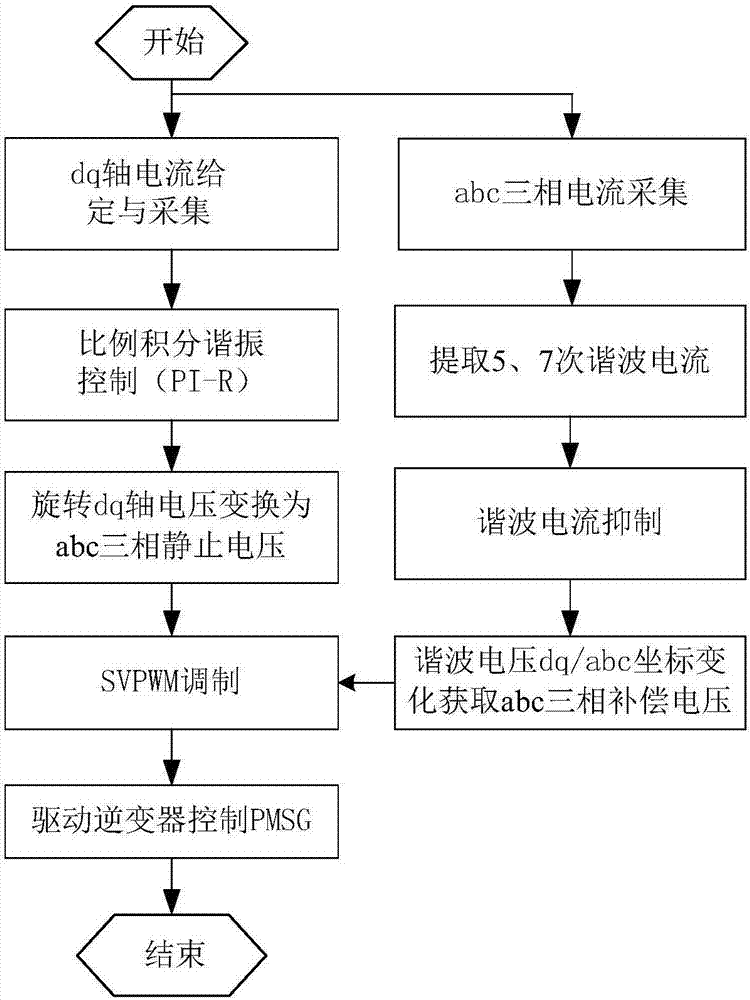

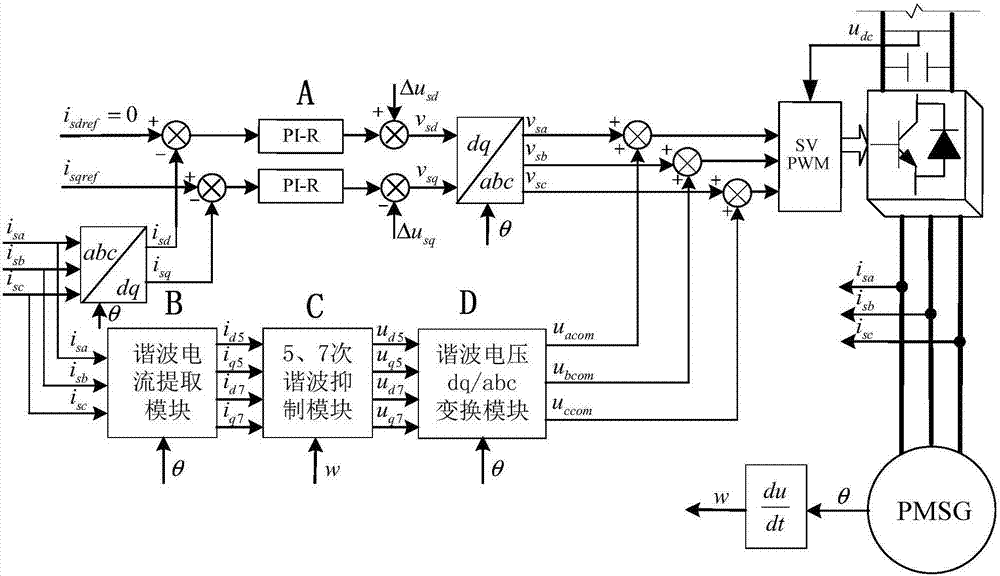

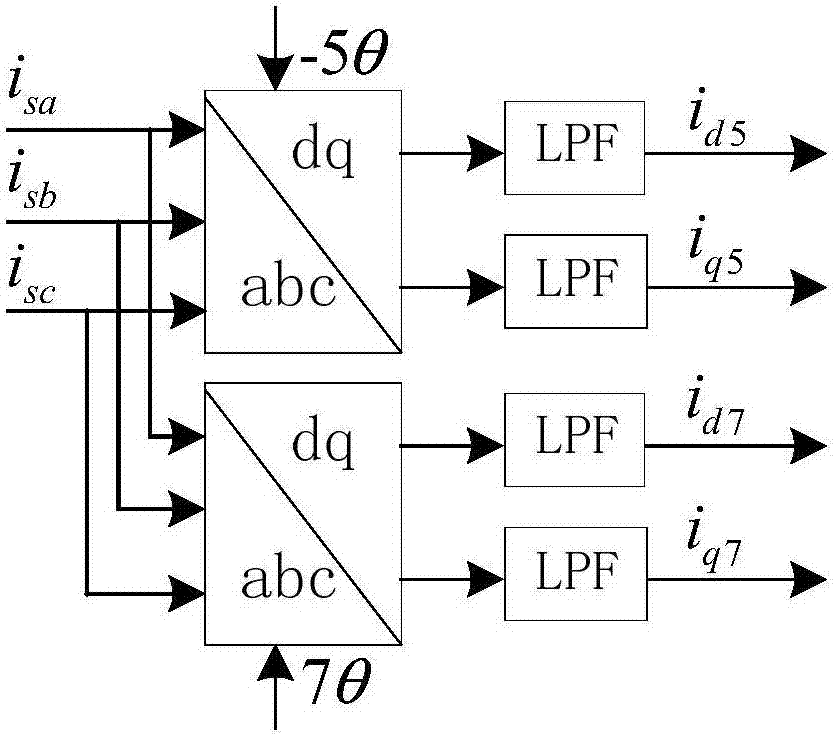

Direct-drive permanent magnet fan harmonic wave suppression optimizing method in asymmetric fault of power grid voltage

InactiveCN107453363AEliminate DC bus voltage fluctuationsSlow reaction speedElectronic commutation motor controlVector control systemsControl signalWave shape

The invention discloses direct-drive permanent magnet fan harmonic wave suppression optimizing method in an asymmetric fault of power grid voltage. The method comprises the steps of acquiring abc three-phase static voltage according to abc three-phase current at the motor side; extracting harmonic current by 5-7 times according to the abc three-phase current at the motor side, performing harmonic current suppression, and acquiring abc three-phase compensation voltage; adding the abc three-phase static voltage and the abc three-phase compensation voltage for obtaining a control signal; performing SVPWM modulation on the control signal for obtaining a PWM wave, and controlling an inverter switch of the direct-driven permanent magnet fan through the PWM wave, thereby driving a permanent magnet synchronous generator (PMSG) of the drive-drive permanent magnet fan. According to the method of the invention, through acquiring the abc three-phase compensation voltage after extracting the harmonic current by 5-7 times and performing harmonic current suppression, the abc three-phase static voltage is compensated for generating a control signal, and a harmonic wave component in the motor current on the condition of asymmetric fault can be compensated, thereby greatly reducing influence of DC bus voltage to a motor-side current transformer, improving waveform of the motor current and performing a relatively high harmonic wave suppression effect.

Owner:HUNAN UNIV

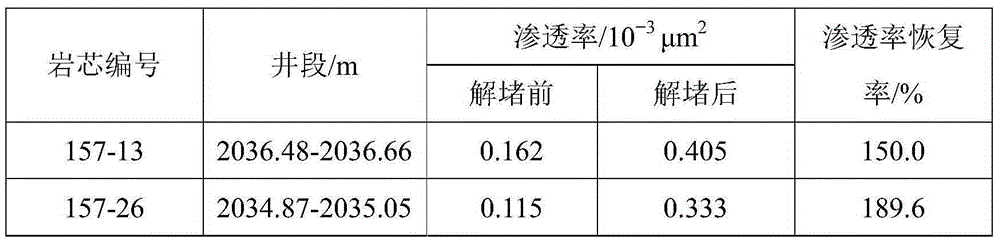

Slow blockage removing agent for oil well and blockage removing method

ActiveCN105255466AUnblock pollutionFree from secondary injuryDrilling compositionClay mineralsFluoboric acid

The invention discloses a slow blockage removing agent for an oil well and a blockage removing method, and belongs to the technical field of oil field exploitation. The slow blockage removing agent is prepared from prepad fluid, main fluid and post-pad fluid, the prepad fluid and the post-pad fluid both take hydrochloric acid as the main component of acid fluid for removing inorganic scale precipitation and dissolving reaction residues, and the main fluid takes glacial acetic acid and fluoboric acid as the main components of acid fluid for stabilizing clay mineral of a reservoir stratum, decreasomg the acid rock reaction speed, enlarging the blockage removing radius and increasing the blockage removing depth. For a fracturing production horizontal well, the treatment fluid is injected into the reservoir stratum in the former stage, the intermediate stage and the later stage, and liquid nitrogen is simultaneously injected, so that residual reaction fluid can be quickly drained after blockage removing construction is performed; pollution blockage near a well bore of the oil well can be effectively removed, the effective permeability near the well bore is increased, the individual-well producing rate is increased, damage caused by excessive acid corrosion to the rock framework of the reservoir stratum can be avoided, and therefore the reservoir stratum can be prevented from being subjected to secondary damage.

Owner:CHINA PETROLEUM & CHEM CORP +1

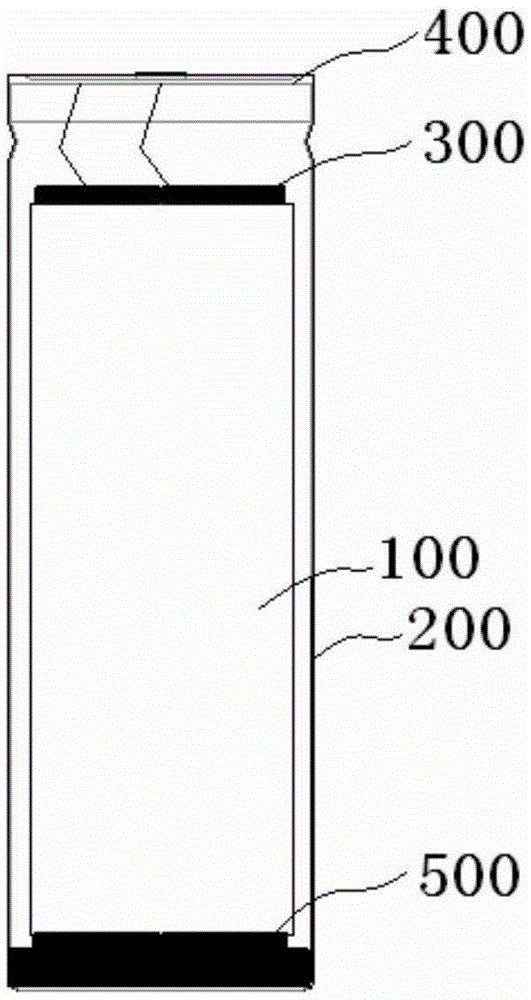

Super-wide-temperature-range nickel-hydrogen battery and manufacturing method therefor

ActiveCN105390755AImprove conductivityLower ohmic resistanceCell seperators/membranes/diaphragms/spacersFinal product manufacturePotassiumNickel electrode

The invention discloses a super-wide-temperature-range nickel-hydrogen battery. The battery comprises an iron shell as well as a nickel electrode, a hydrogen electrode, a diaphragm and an electrolyte solution mounted in the iron shell, wherein the nickel electrode takes foam nickel as a substrate material; the space in foam nickel is filled with a positive electrode active substance Ni(OH)2, a conductive agent, an additive and a binder; the hydrogen electrode takes a porous nickel-plated steel belt, a copper net or foam nickel as a substrate material; the porous nickel-plated steel belt, the copper net or foam nickel is coated with a negative electrode active substance, namely, hydrogen storage alloy powder, the conductive agent, the additive or the binder; and the electrolyte solution is a mixture of a potassium-rich alkaline aqueous solution and sodium tungstate or tungstic acid crystals. The invention furthermore discloses a manufacturing method for the super-wide-temperature-range nickel-hydrogen battery. According to the super-wide-temperature-range nickel-hydrogen battery disclosed by the invention, the ratio of 0.2C discharge capacity to normal-temperature capacity maximally can reach 70-80% in an environment with the temperature of -45 DEG C; and the ratio of 0.2C discharge capacity to normal-temperature capacity of the nickel hydrogen battery maximally can reach 85-95% in an environment with the temperature of 70 DEG C. Moreover, the manufacturing method is simple and suitable for large-scale production.

Owner:HENGYANG BST POWER

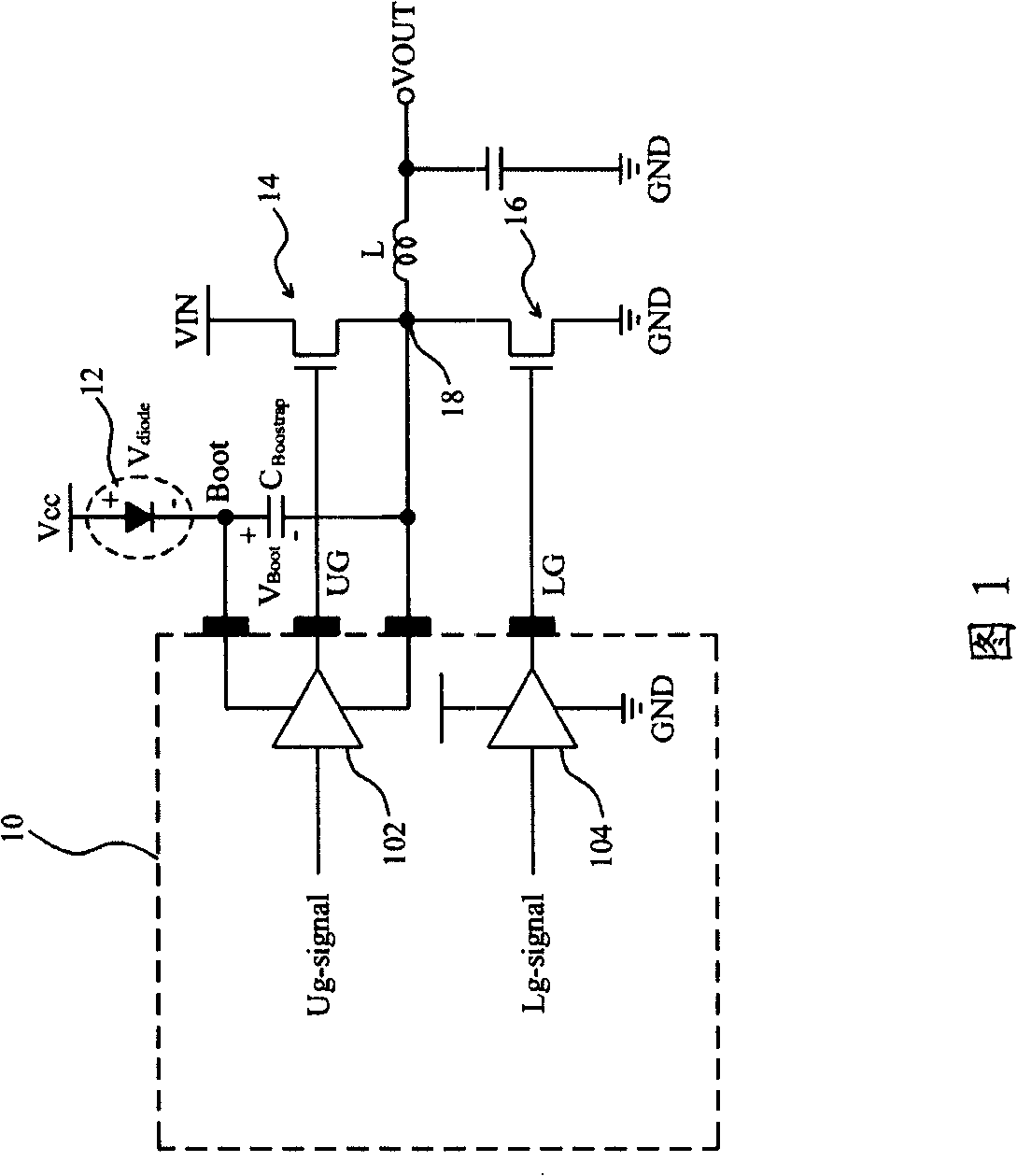

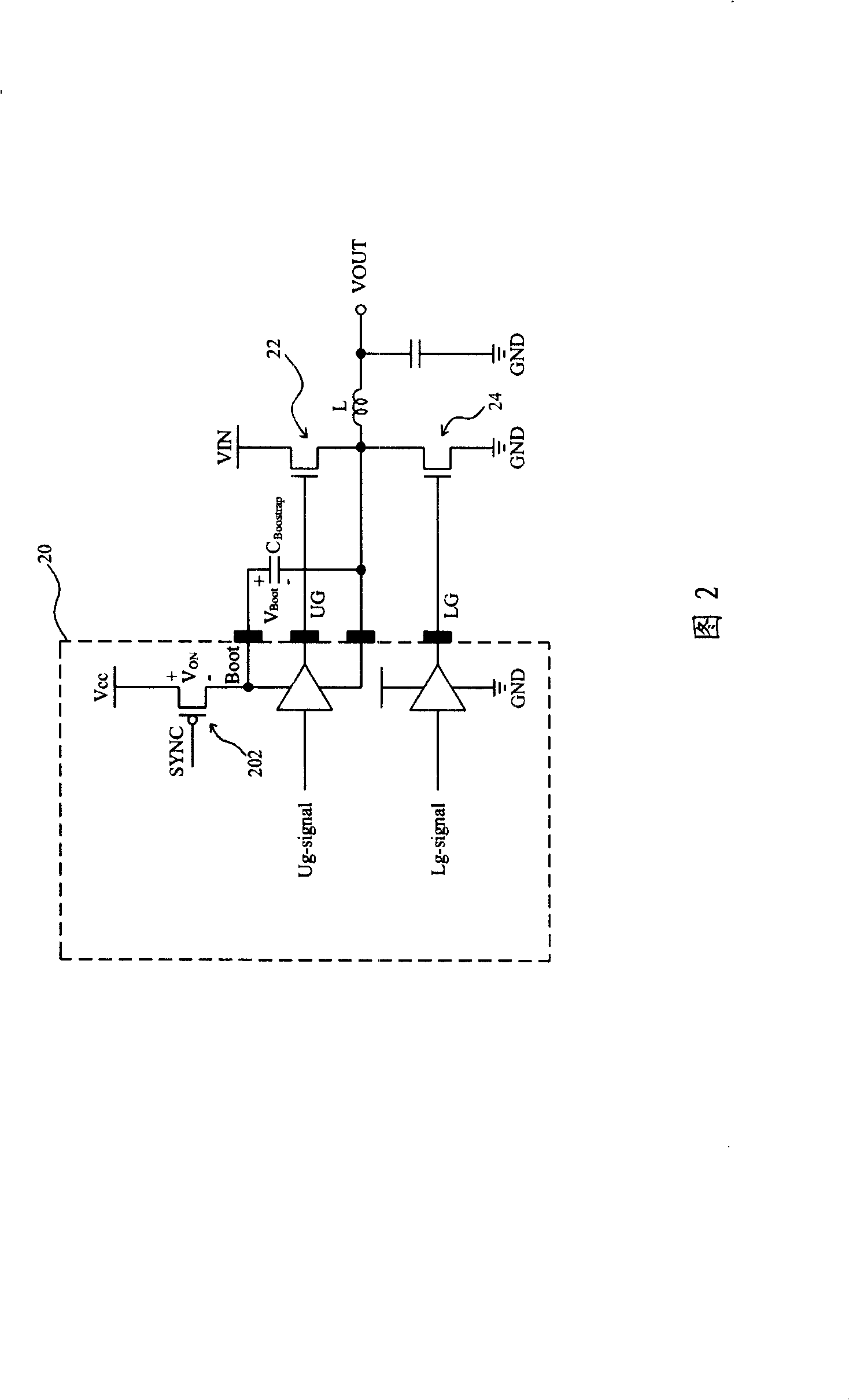

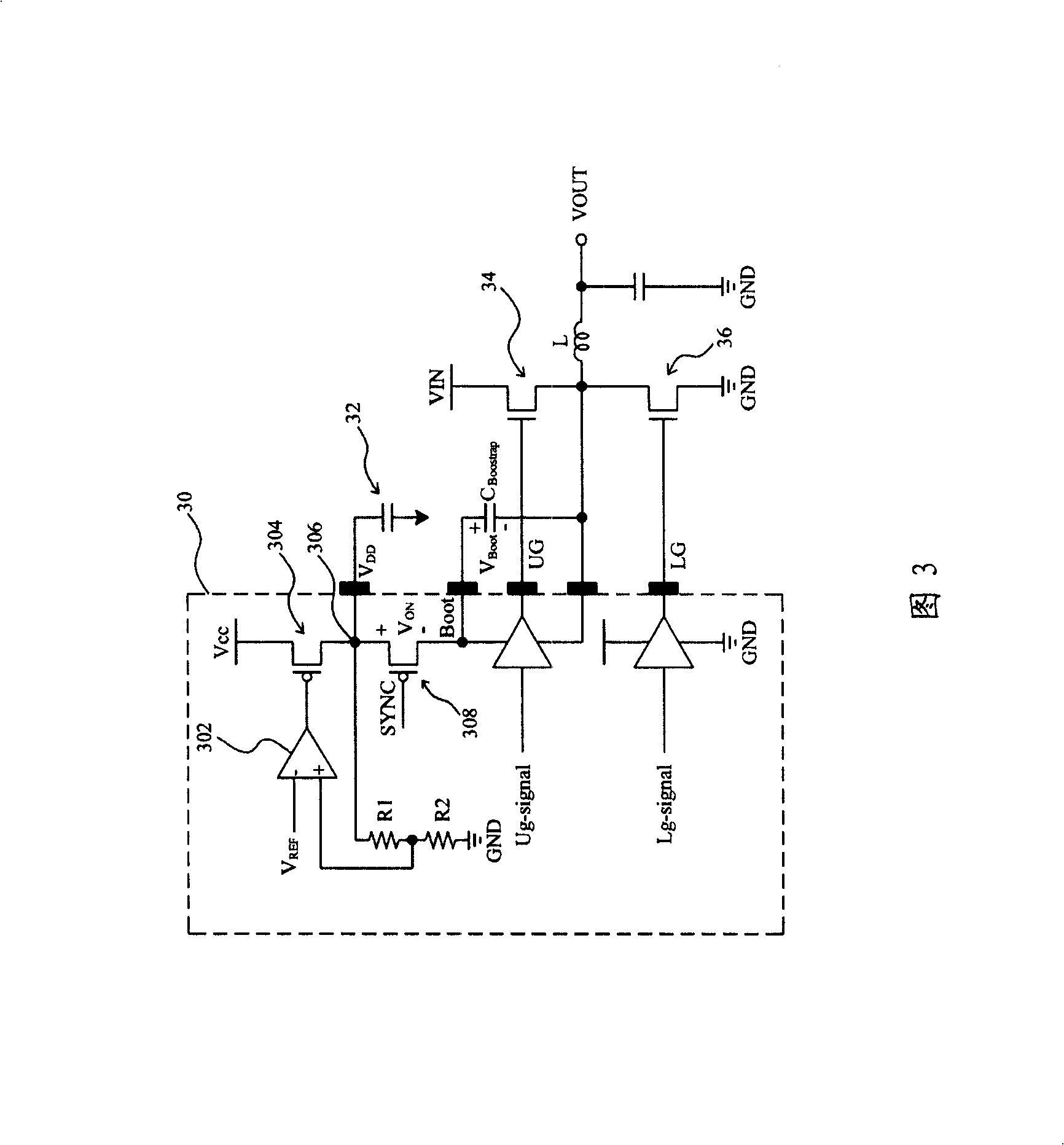

Circuit for charging bootstrap capacitor of voltage converter

ActiveCN101247080ASlow reaction speedSave bandwidthDc-dc conversionElectric variable regulationVoltage converterCapacitance

The present invention relates to a circuit for charging the bootstrap capacitor of the voltage converter, wherein, the voltage converter comprises a upper bridge transistor and a lower bridge transistor. The bootstrap capacitor is connected between the source of the upper bridge transistor and a driving electric source of the upper bridge driver. The circuit comprises a first transistor for connecting a power supply voltage and a feedback node, and a second transistor for connecting the feedback node and the bootstrap capacitor. The second transistor and the lower bridge transistor of the voltage converter are synchronously conducting and closing, a comparator obtains a feedback voltage from the feedback node and the first transistor is conducting when the feedback voltage is lower than a reference voltage, and the electric power voltage is provided to the second transistor thereby charging the bootstrap capacitor.

Owner:RICHTEK TECH

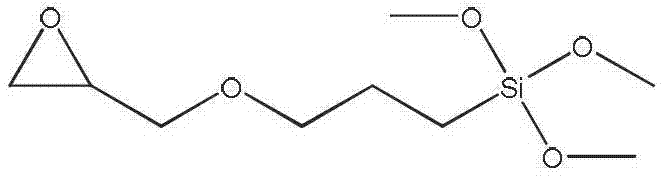

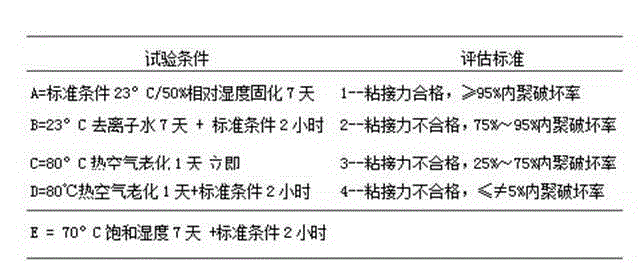

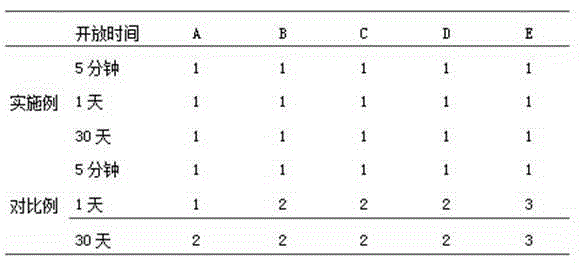

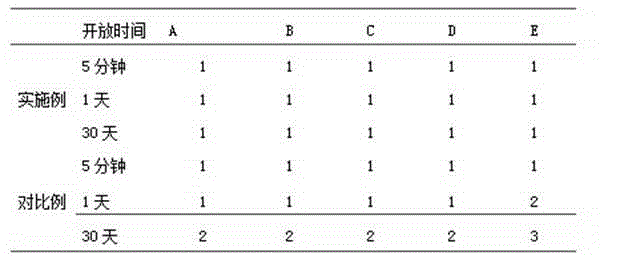

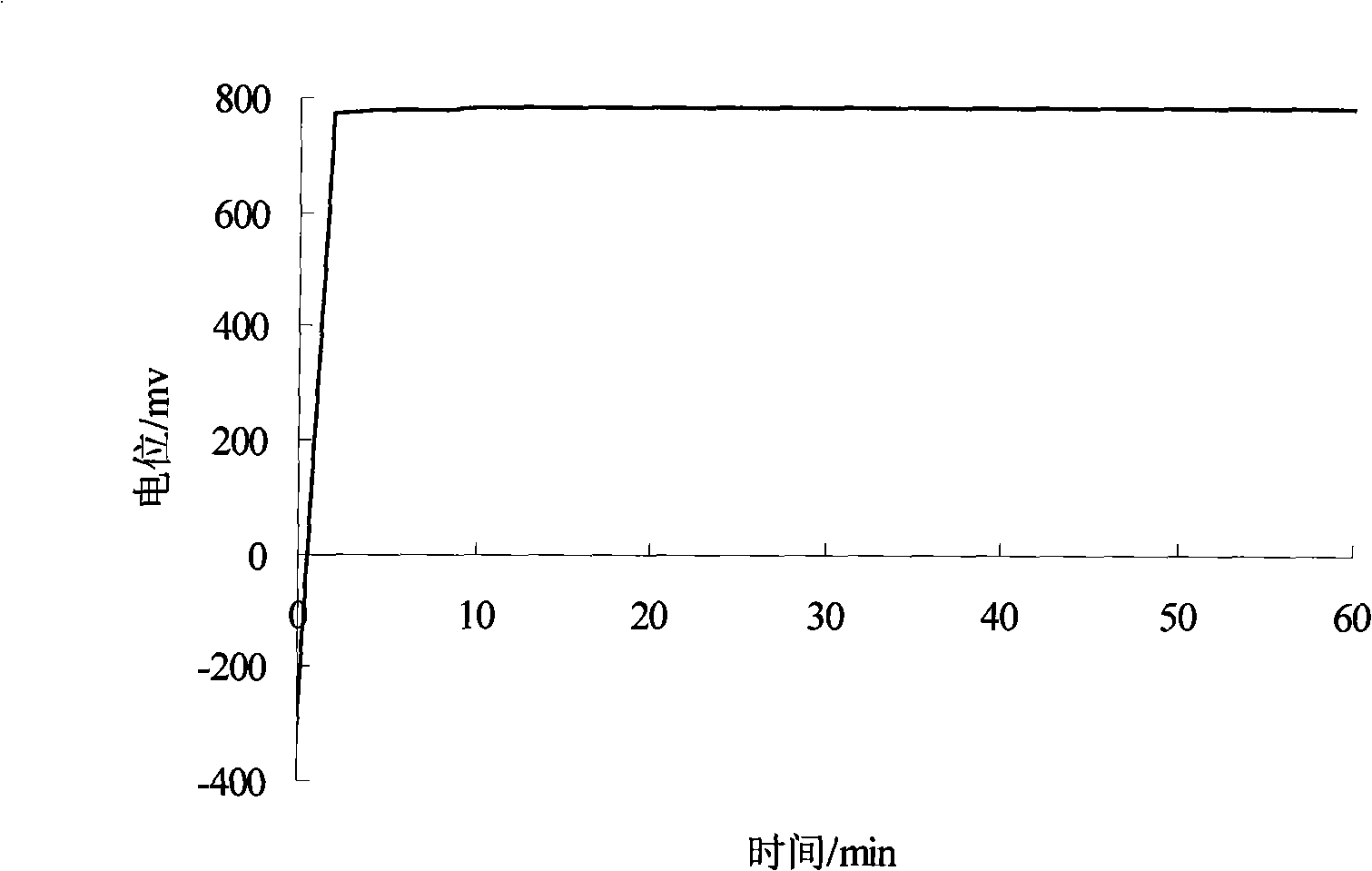

Long-opening-time primer and preparation method thereof

InactiveCN104673170ASlow reaction speedExtended opening hoursNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanatePolyurethane adhesive

The invention relates to a long-opening-time primer and a preparation method thereof. The primer is matched with a single-component moisture-curing polyurethane sealant. The primer comprises the following components in percentage by mass: 15-35% of silane terminated polymer, 2-10% of bonding accelerator, 0.1-2% of stabilizing agent, 1-10% of plasticizer, 3-15% of colorant, 0.3-1.5% of dispersing agent, 0.1-2.5% of antioxidant, 0.1-2.5% of ultraviolet absorbent, 0.1-2.5% of light stabilizer and 30-70% of solvent. The primer can be used for enhancing the bonding stability of the single-component polyurethane adhesive when being used for glass assembly and elastic bonding. The system is free of isocyanate, lowers the reaction speed, prolongs the opening time of the primer, has favorable adhesion with ink glass, common primers and finish coats, and enhances the medium resistance and bonding performance of the silane terminated polymer.

Owner:TONSAN ADHESIVES INC

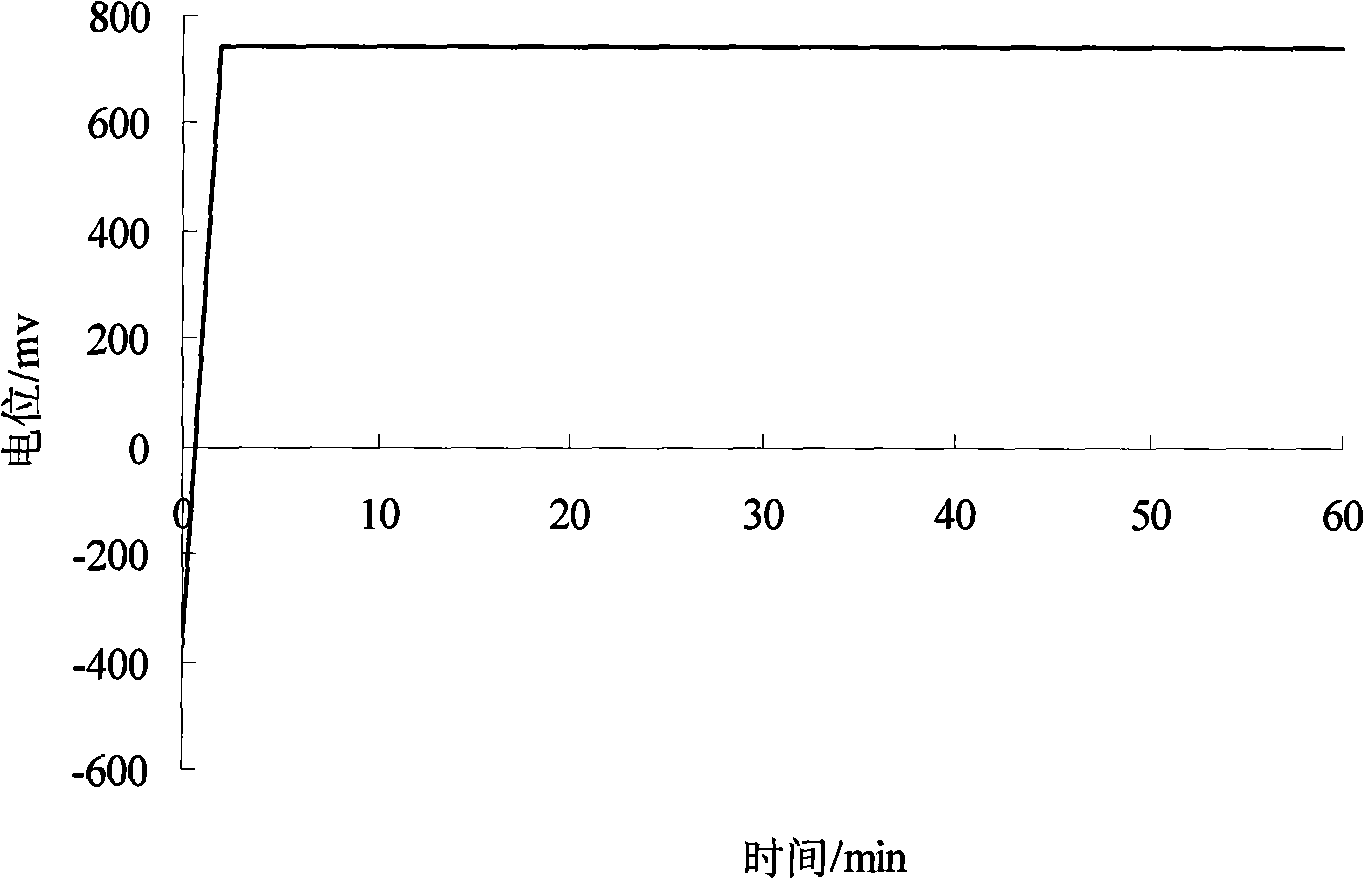

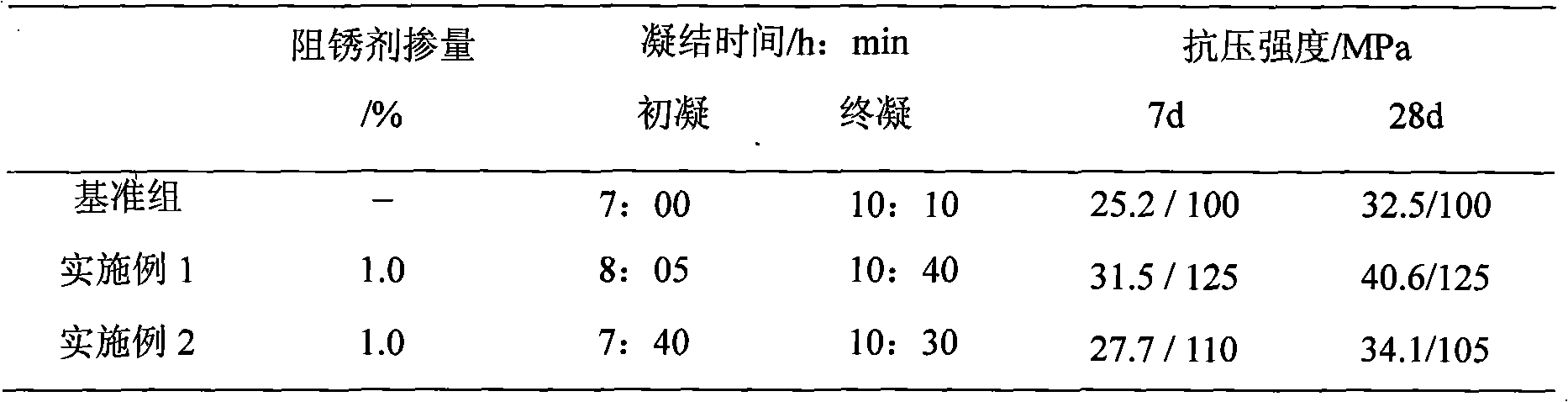

Alkali-free non-nitrite concrete reinforcement antirust

The invention discloses an alkali-free non-nitrite rust retardant agent for concrete steel bars, which consists of the components (according to weight percentage) as follows: 3-10 percent of zinc gluconate, 20-40 percent of lithium metasilicate, 10-20 percent of ammonium benzoate, 15-25 percent of low molecular weight (alcohol) amine and 20-40 percent of water. The rust retardant agent can obviously relieve damage to the steel bar passive films of chloride ions, has the advantages of environmental protection, alkali free, low usage, good suitability with cement and being capable of improving concrete property properly and the like, is a high-effictive rust retardant agent for concrete steel bars, and can be applied to steel bar concrete structures of water conservancy, railway, civil construction and the like.

Owner:NANJING RUIDI HIGH TECH

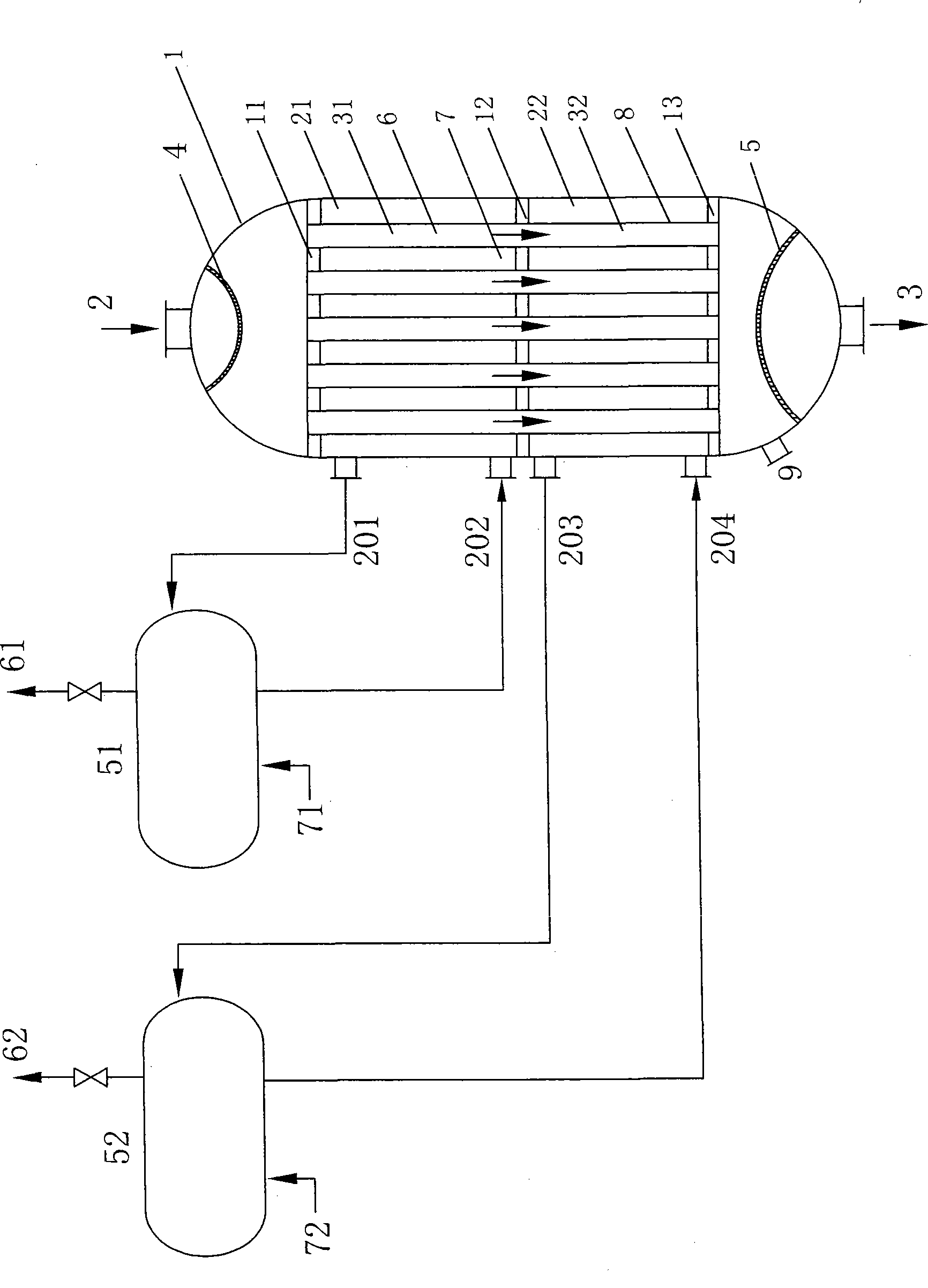

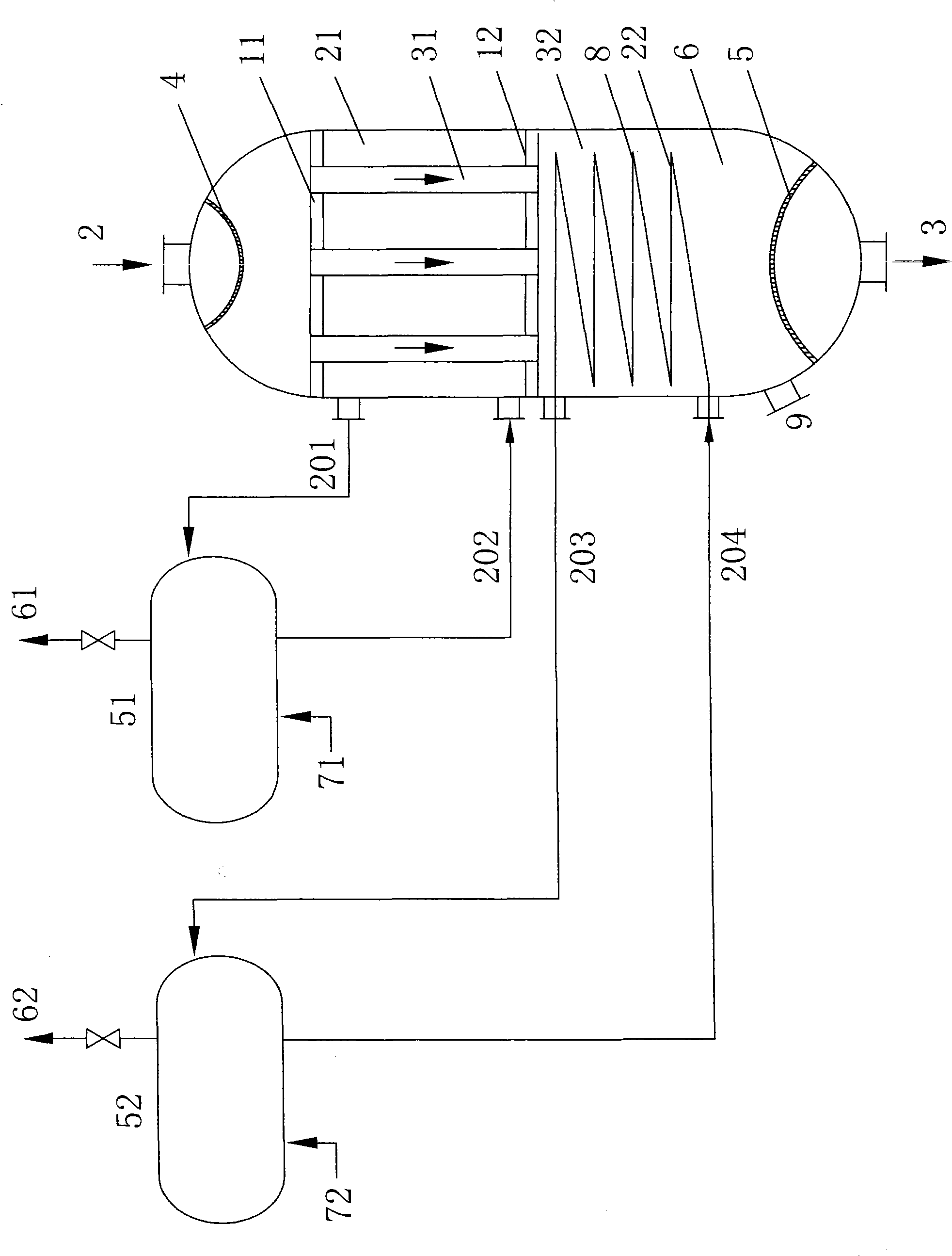

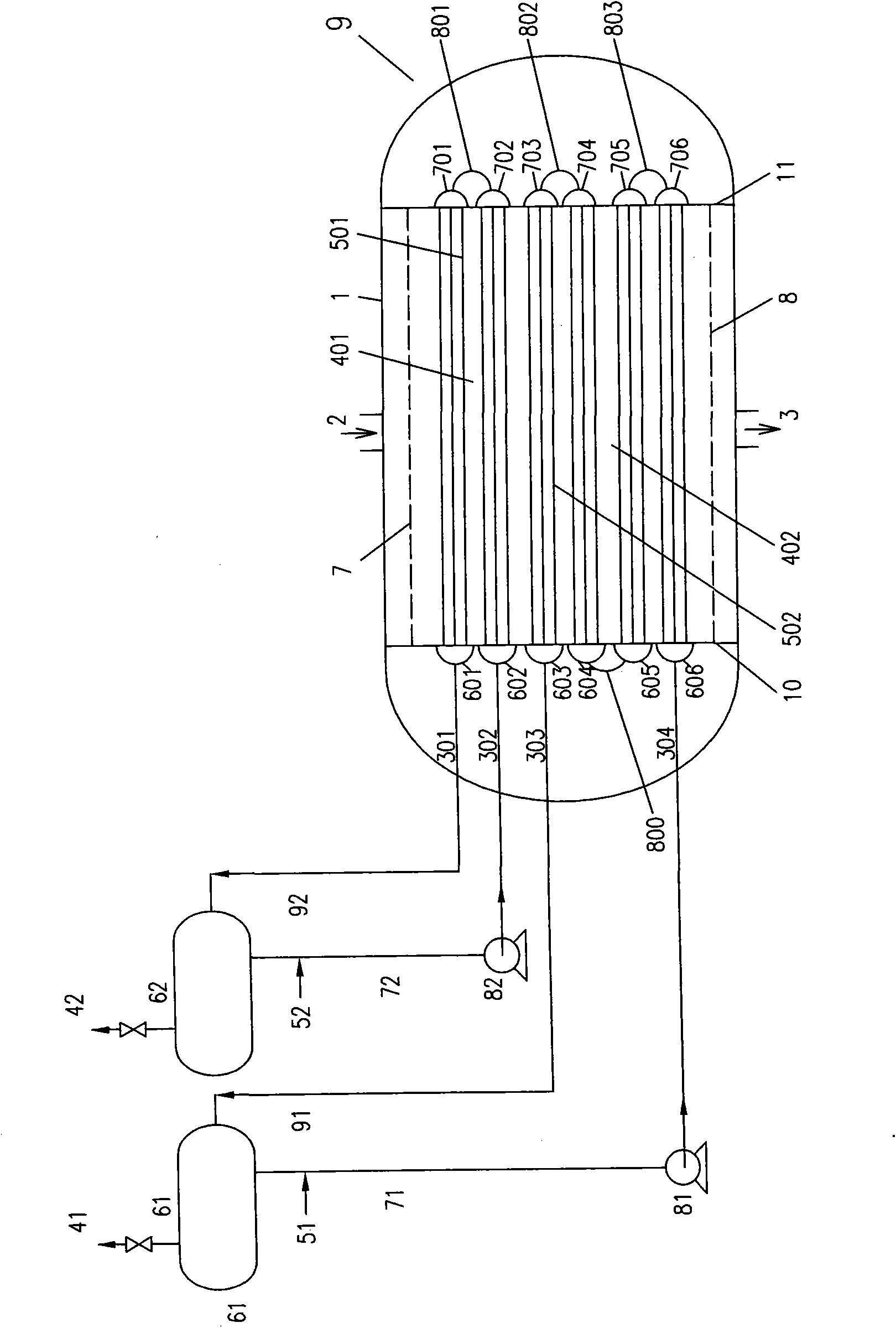

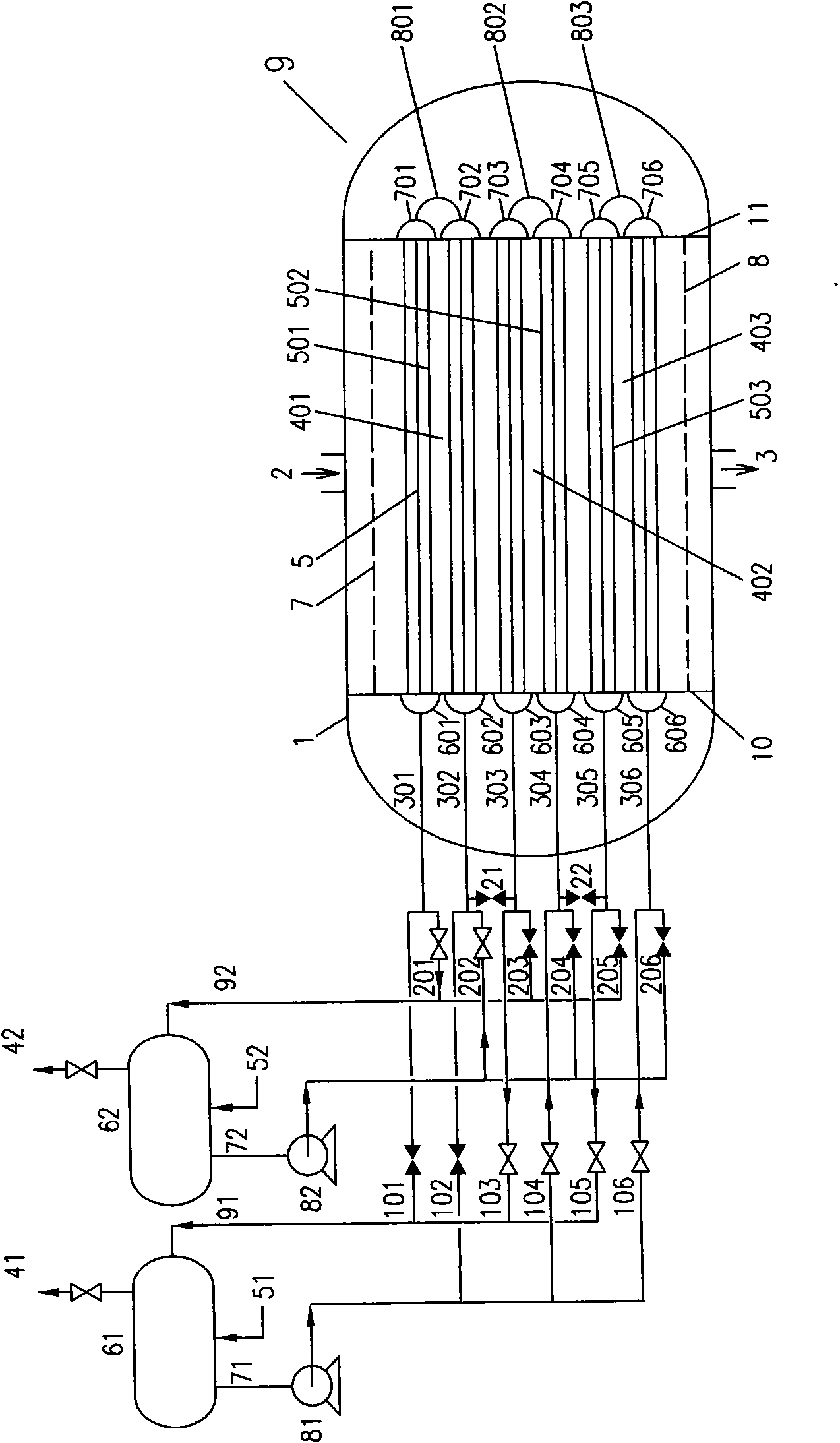

Fixed bed composite reaction equipment

ActiveCN101480592AQuick responseRelease more heat of reactionChemical/physical processesMethanationFixed bed

The invention relates to fixed bed combined reaction equipment which mainly comprises a cylindrical shell with an end enclosure, a reaction gas inlet and a reaction gas outlet on the shell, a porous gas distributor, a porous gas collection plate, a catalyst layer and a heat exchange pipe for cooling media to transfer heat; steam headers provided with stream pressure adjusting valves form a cooling medium circular loop of which catalysts in at least one heat exchange reaction area are filled in the pipe. The fixed bed combined reaction equipment ensures that heat transfer is designed according to the requirement on the amount of the reaction heat transfer in the reaction, is used for the synthesis of methanol and dimethyl ether, methanation, F-T reaction, the preparation of phthalic anhydride by ortho-xylene oxidation and other strong-effect reaction processes, reduces the temperature difference, improves the reaction efficiency and the yield, saves energy, reduces consumption and achieves the large-sized aim.

Owner:杭州林达化工技术工程有限公司

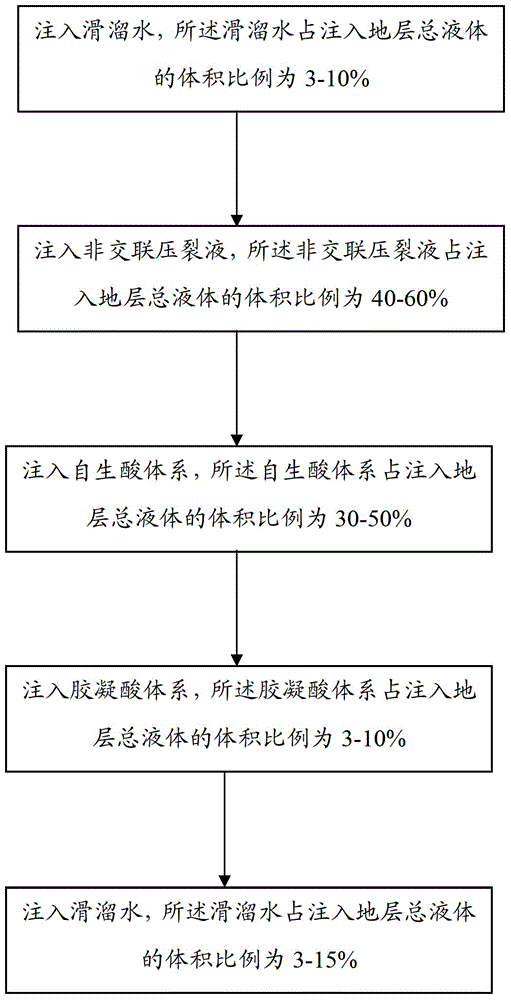

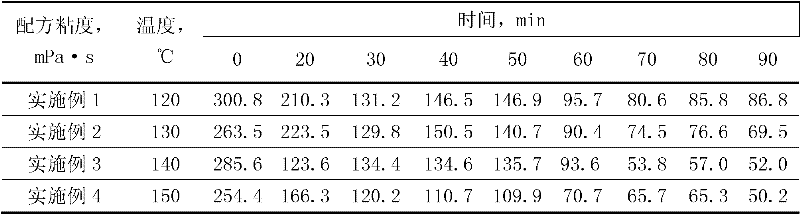

Preparation method of multi-component organic cross-linked acid liquid

The invention relates to a preparation method of multi-component organic cross-linked acid liquid, which comprises base liquid and a cross-linking agent, wherein the weight ratio of the base liquid and the cross-linking agent is 100:0.6-0.8; the base liquid comprises the following components in percentage by weight: 3.6-9 percent of formic acid, 4.8-12 percent of acetic acid, 5.5-13.75 percent ofhydrochloric acid, 0.6-0.8 percent of thickening agent, 4.0-5.0 percent of high-temperature corrosion inhibitors, 0.5-1.0 percent of long-term clay stabilizer, 1.0-1.5 percent of ferric ion stabilizers, 0.5-1.0 percent of broken emulsion discharge aiding agent and the balance is water; and the sum of the mass percentages of all the components is 100%. The method has the beneficial effects that the acid liquid system can be cross-linked under the conditions of high temperature and strong acid and is good in temperature resistance and shear resistance, less in filtration and complete in gelout;after the acid liquid is cross-linked, an acid rock is remarkably lower than ordinary gelled acid in reaction speed and is good in speed retarding performance; and the multi-component organic cross-linked acid liquid can be used for realizing the modification of depth acid pressure in a high-temperature deep well of a carbonate rock.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

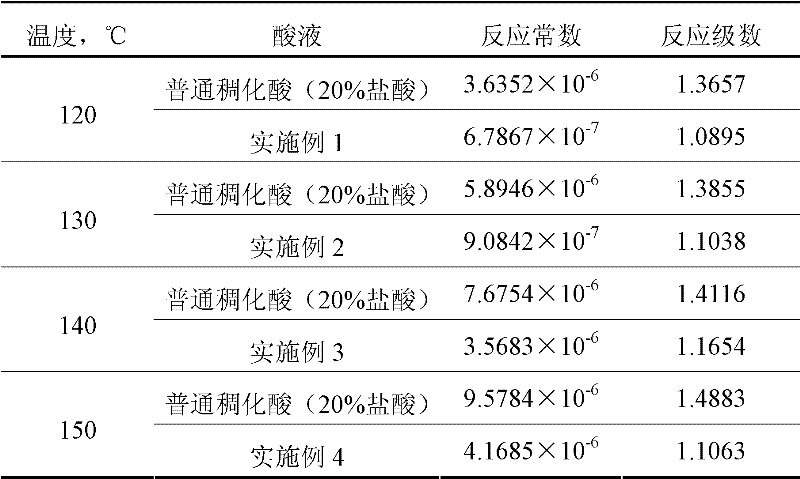

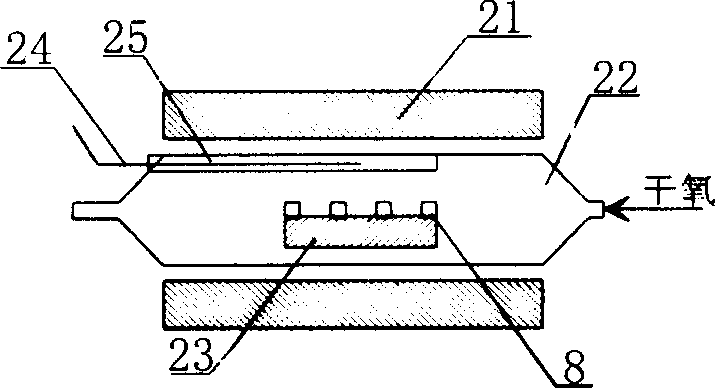

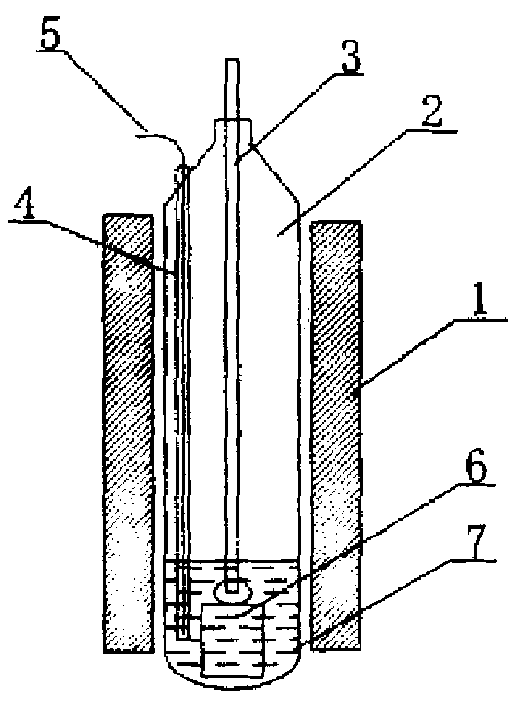

Proton exchange method and equipment for producing lithium niobate light waveguide

The present invention is proton exchange method and equipment for producing lithium niobate light waveguide. The production process includes cleaning substrate, preparing mask, photoetching to form waveguide pattern, proton exchnage, annealing, end polishing, regulating waveguide and inspection. The present invention uses lithium benzoate doluted benzoic acid solution as proteon source, and has high lithium ion density and low hydrogen ion density and thus low reeaction speed, low lithium ion exchanging amount, and refraction index difference between the waveguide and the substrate. The annealing results in refraction index distribution ever suitable for coupling with fiber, less corrosion of benzoic acid, less faults in waveguide and low waveguide loss.

Owner:HUAWEI TECH CO LTD

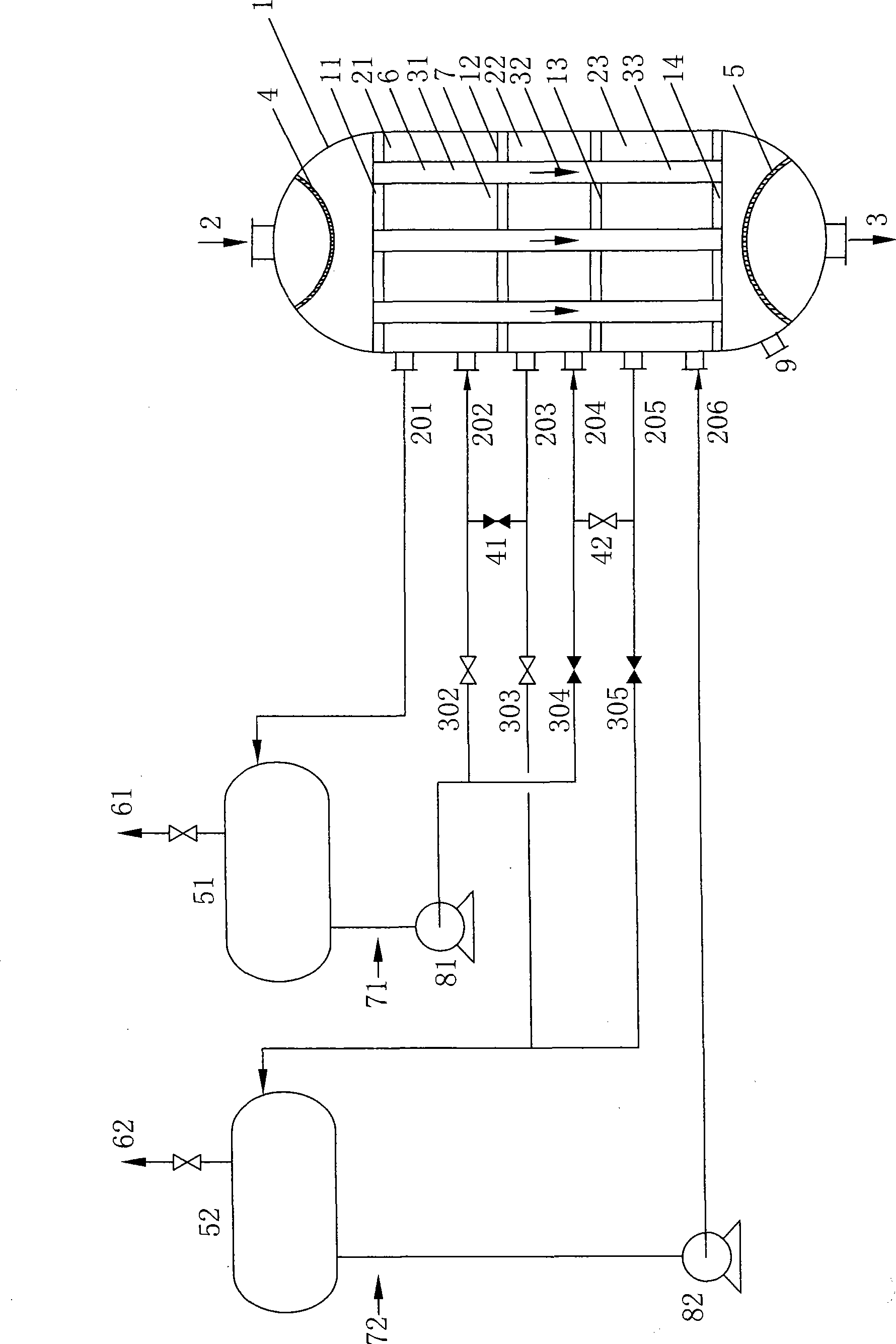

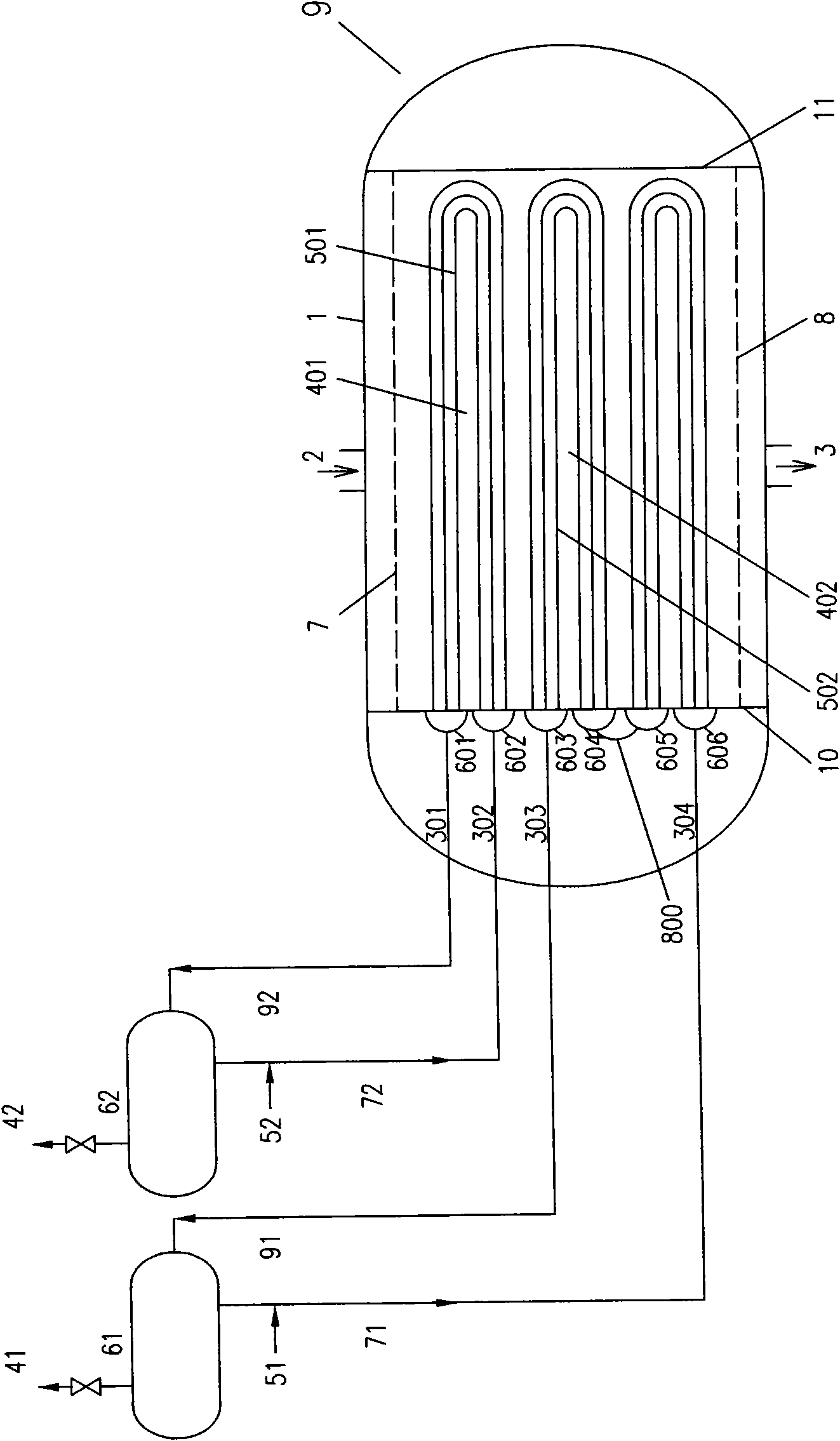

Combined reaction device

InactiveCN101773808AQuick responseRelease more heat of reactionChemical/physical processesExothermic reactionProcess engineering

A composite reaction device is characterized in that the reaction device 9 mainly comprises a cylindrical housing 1 with an end socket, a reaction gas inlet 2 and a reaction gas outlet 3 on the housing 1, a catalyst layer 4, a porous gas distributor 7, a porous gas gathering board 8 and a heat exchange tube 5 for exchanging heat of a cooling medium in the catalyst layer 4, is provided with steam drums 61, 62 of vapor pressure adjusting valve 41, 42 so that the amount of the heat exchanged in the reaction is designed according to the size requirement of reaction heat discharging, and is used for strong heat producing reaction processes such as synthesizing methyl alcohol, dimethyl ether, methanation, F-T reaction and H2S oxidation and the like, thereby decreasing the temperature difference, improving the reaction efficiency and the yield, saving the energy, reducing the consumption and realizing large scale purpose.

Owner:杭州林达化工技术工程有限公司

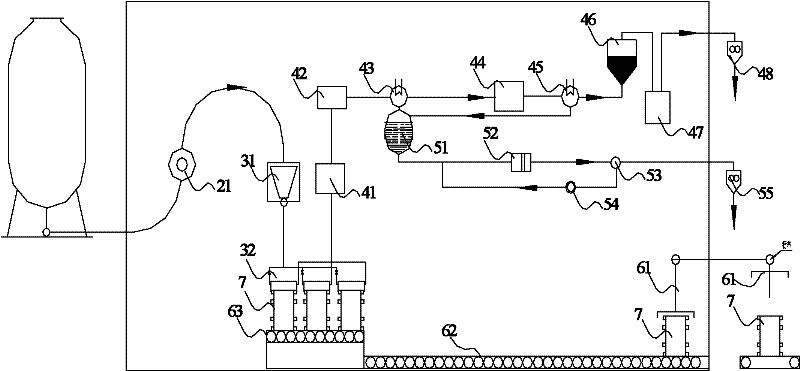

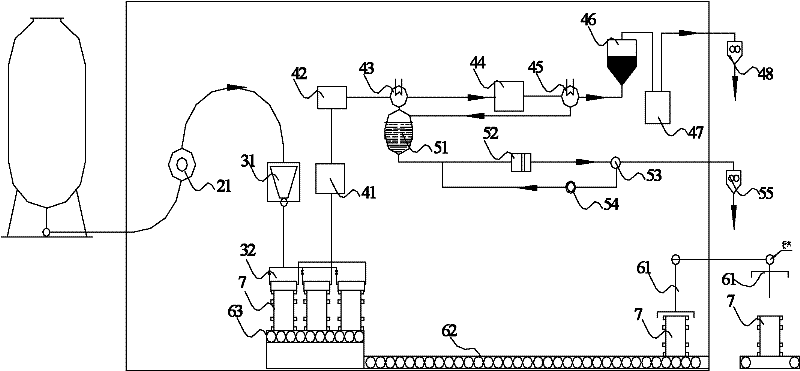

Radioactive liquid waste treatment device

The invention relates to a radioactive liquid waste treatment device comprising a feeding device, a volume reducer of radioactive wastes, a tail gas and residual liquid treatment device and a conveyer. The feeding device, the tail gas and residual liquid treatment device and the conveyer are respectively connected with the volume reducer; the feeding device, the tail gas and residual liquid treatment device, the conveyer and the volume reducer are integrally arranged under a vacuum environment; the volume reducer comprises a macroscopic dehydration volume-reduction unit for macroscopically dehydrating and reducing volume of the radioactive liquid wastes and a heating-drying volume-reduction unit, and the heating-drying volume-reduction unit and the macroscopic dehydration volume-reductionunit for breaking the organization structure of the radioactive wastes are connected by a pipeline to form a seal system. A movable radioactive liquid waste treatment device disclosed by the invention has the advantages of little environment pollution, safe and reliable treatment process and reduced storage space, and reaches the state standard of effluent discharge.

Owner:HUANCHUANG XIAMEN TECH

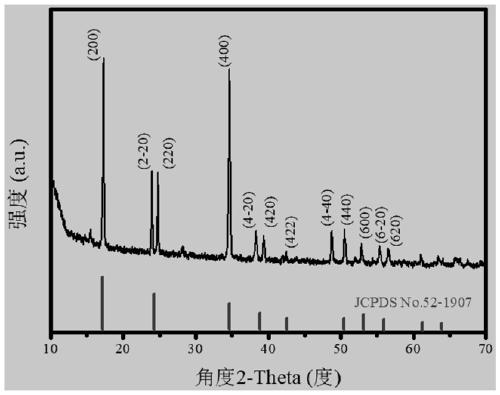

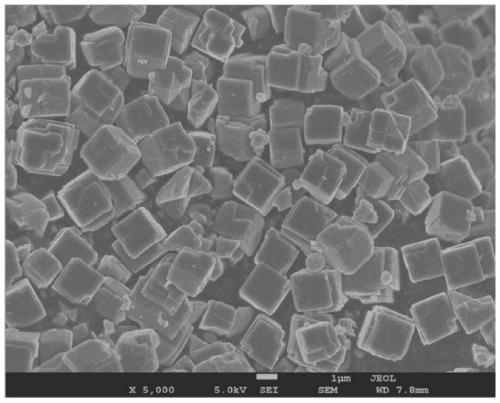

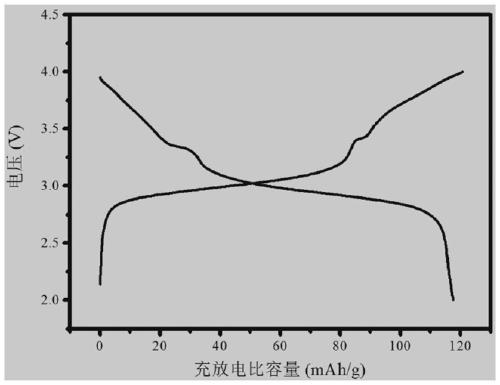

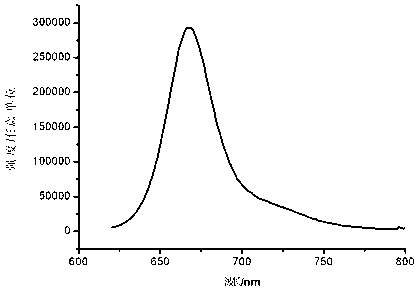

Prussian blue cathode material with high sodium content, preparation method and applications thereof, and sodium ion battery

ActiveCN110235292AGood effectRaise the sodium contentIron cyanidesSecondary cellsHigh sodiumPrussian blue

The invention belongs to the technical field of novel energy storage materials, and relates to a Prussian blue cathode material with a high sodium content, a preparation method and applications thereof, and a sodium ion battery. The molecular formula of the Prussian blue cathode material is Na<x>MNFe(CN)<6>; wherein M and N represent a same transition metal or different transition metals andcan be Fe, Co, Mn, Ni, Cu, Zn, Cr, V, Zr, or Ti; 1.8<x<2; 0<a<1; 0<b<1; and a+b=1. The cathode material has millimeter cubic morphology and excellent electrochemical properties. The preparation method has the advantages that the crystallization is slow, the sodium content of the cathode material is high, the preparation method is simple and easy to perform, the production efficiency and the yieldare high, the raw materials are cheap, and industrial production and enlarged production are easy to realize.

Owner:LIAONING STARRY SKY SODIUM BATTERY CO LTD

Proppant-carrying acid fracturing method for high-temperature ultra-deep carbonate reservoir

InactiveCN106321044ASimple processEasy to operateFluid removalDrilling compositionAcid fracturingFracturing fluid

The invention provides a proppant-carrying acid fracturing method for a high-temperature ultra-deep carbonate reservoir. The proppant-carrying acid fracturing method for the high-temperature ultra-deep carbonate reservoir comprises the following steps that (1) fracture forming is conducted through fracturing fluid; (2) ground crosslinked acid is adopted and is made to react with rock, so that an acid-etched fracture is generated in a formed fracture, and a proppant is carried with the ground crosslinked acid for supporting the acid-etched fracture; and (3) linear glue is used for replacement, and thus acid fracturing is completed. According to the proppant-carrying acid fracturing method for the high-temperature ultra-deep carbonate reservoir, the technique is simple, operation is convenient, and the construction effect is remarkable; and the proppant-carrying acid fracturing method is suitable for transforming construction of deep well carbonatite at the high temperature of 150-170 DEG C, a supporting fracture which has deep penetration and longer flow conductivity can be formed in a stratum, the productivity is increased and the production time is prolonged after acid fracturing and well fracturing, and the length of the formed fracture is larger than 120 m.

Owner:CHINA PETROLEUM & CHEM CORP +1

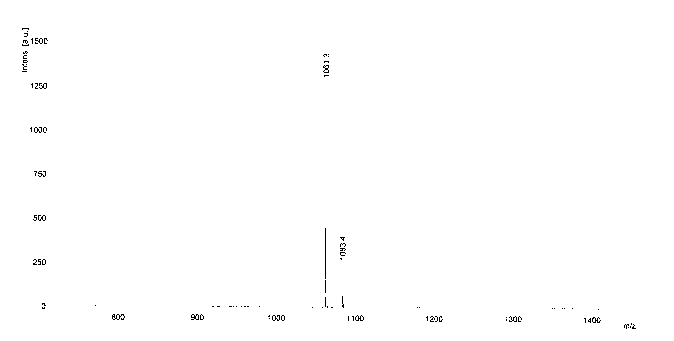

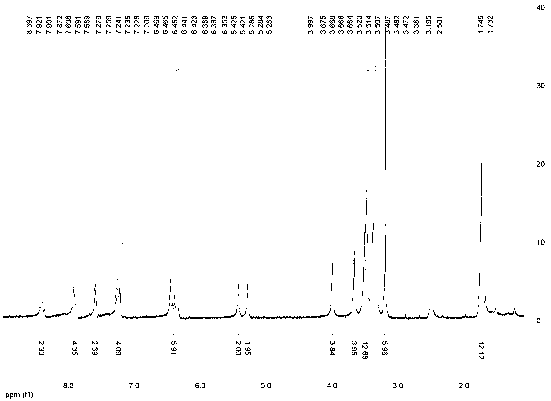

Water-soluble asymmetric indocyanine fluorescent dye and preparation method thereof

InactiveCN103073909AEasy to separateGood water solubilityMethine/polymethine dyesLuminescent compositionsAcetic anhydrideFiltration

The invention discloses a water-soluble asymmetric indocyanine fluorescent dye. A general formula of the dye is as shown in the specification, wherein n is equal to 1, 2 or 3. A preparation method comprises the steps that (1), N-(3,5-2(2-(2-methoxyethoxy) oxethyl) oxethyl) benzyl-2,3,3-trimethyl-5-sulfonic group-3H-indole is synthesized; 2,3,3-trimethyl-5-sulfonic group-3H-indole, organic sylvine, and 3,5-2(2-(2-methoxyethoxy) oxethyl) oxethyl) oxethyl benzylbromide are added to an alcohol solvent in sequence, and conduct backflow reaction for 20-40h under inert gas shielding; the solvent is distilled off after the reaction; column separation is conducted; a red solid product is obtained; and (2), N-carboxyl benzyl-2,3,3-trimethyl-5-sulfonic group-3H-indole, the product and a condensing agent are dissolved in an acetic acid / acetic anhydride mixed solvent; pyridine or pyrimidine is added, and reacts at 60-100 DEG C for 1-6h under the inert gas shielding; ethyl acetate is added after the reaction for dissolving out a precipitate; suction filtration is conducted; the product is separated by taking a methanol / acetonitrile mixed solvent as an eluent, and using a reverse phase silica gel filling separation column; three color strips are obtained; the second color strip is accepted; and the water-soluble asymmetric indocyanine fluorescent dye is obtained.

Owner:HENAN UNIVERSITY

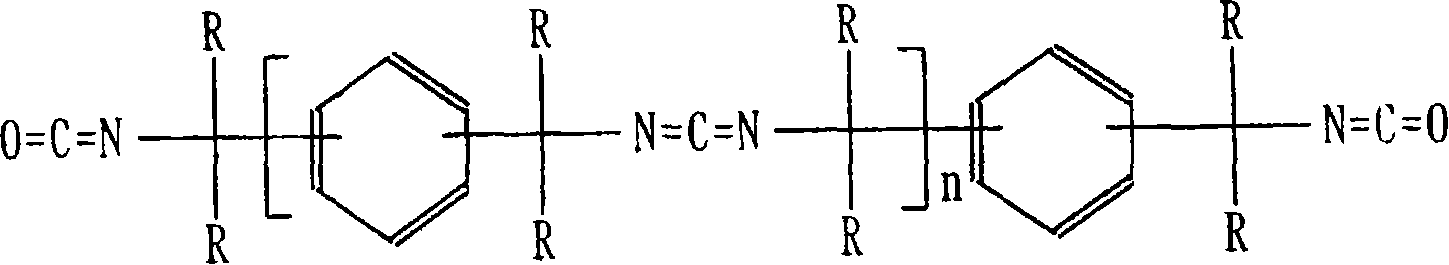

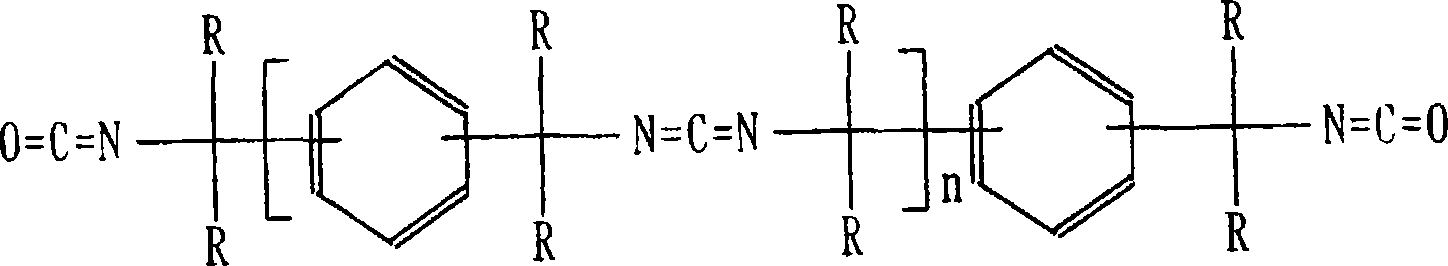

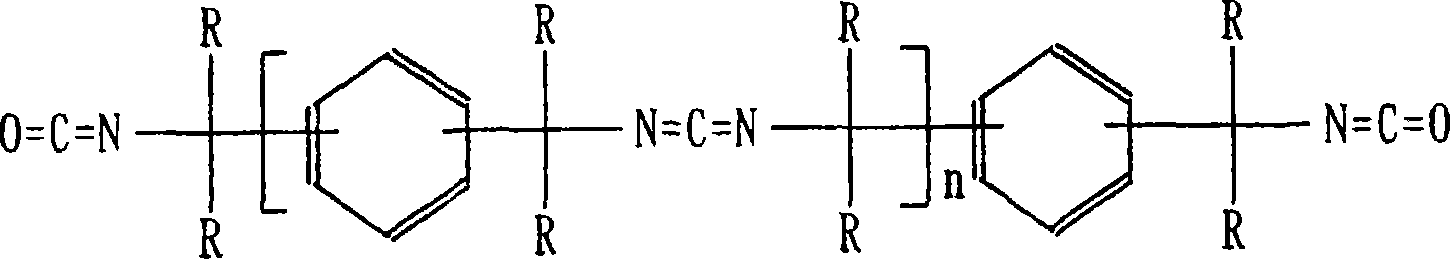

Polyester elastomer composition

The invention relates to a polyester elastomer composition which comprises (A) 100 parts by weight of a polyester elastomer, (B) 0.01 to 10 parts by weight of an epoxy compound having one or more epoxy groups per molecule, and (C) 0.01 to 10 parts by weight of a polycarbodiimide compound which has two or more carbodiimide groups per molecule and in which the two carbon atoms adjacently bonded respectively to both sides of one of the carbodiimide groups each has at least one C1-4 alkyl or at least one substituent having the effect of electronically reducing reaction rate. The composition is excellent in hydrolytic resistance, heat resistance, oil resistance, wearing resistance, and impact resistance.

Owner:DAICEL CHEM IND LTD

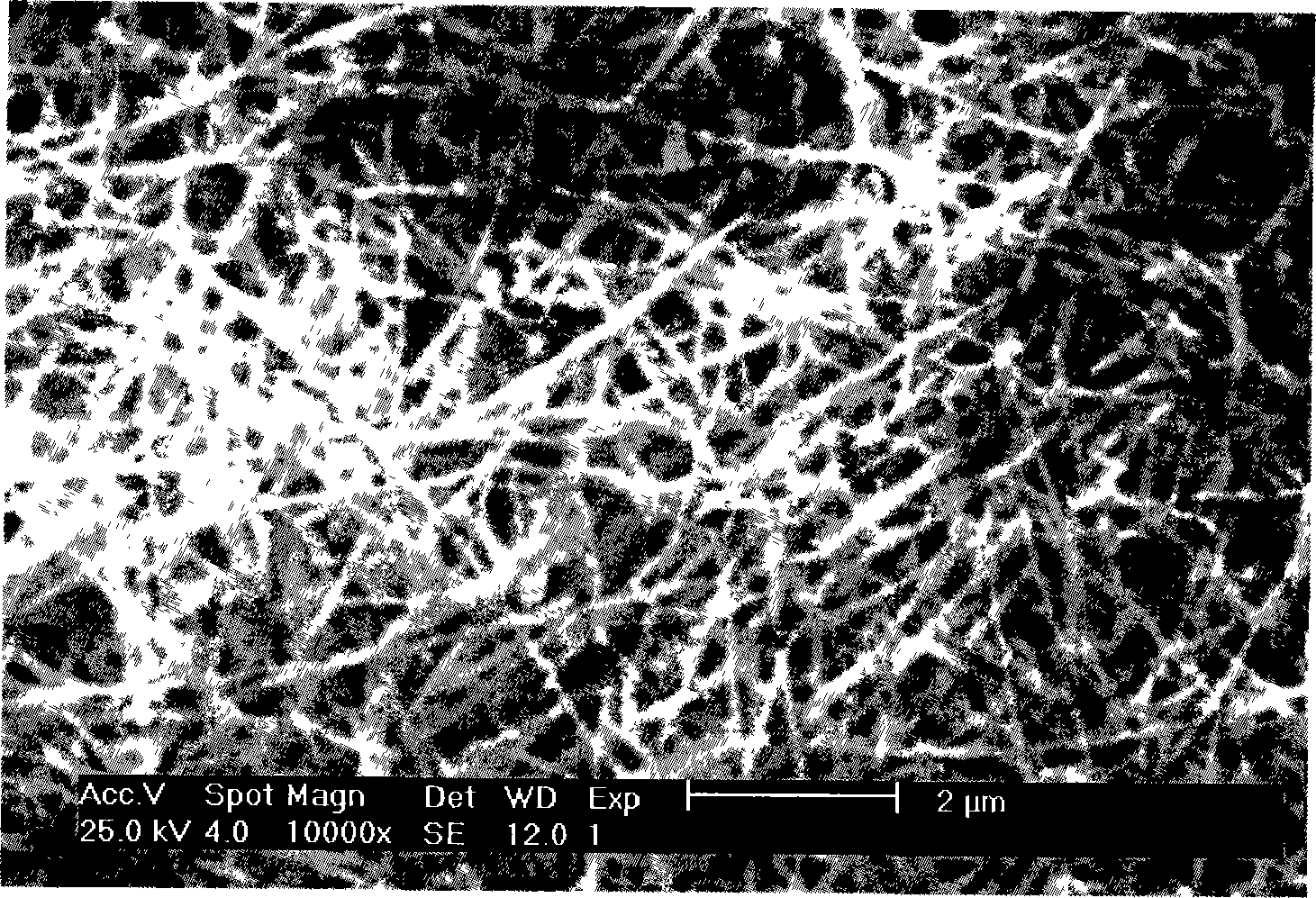

Method for preparing Nano tube of zirconium dioxide

InactiveCN101049964ASimple processEasy to operateNanostructure manufactureZirconium oxidesSolventZirconium dioxide

This invention relates to a method for preparing ZrO2 nanotubes by anodic oxidation. The method comprises: mixing formamide and alcohol solvent at a volume ratio of (1-3):1 to obtain a mixed solvent, preparing 0.5-1.5 wt.% fluoride solution, introducing the fluoride solution into a reactor with Zr plate as the anode and Pt plate or graphite plate as the cathode, performing anodic oxidation under 10-90 V DC at room temperature to generate ZrO2 nanotubes on the Zr plate, falling off during the reaction, separating precipitated to the bottom of the reactor, washing with water, and drying at 105 deg.C to obtain ZrO2 nanotubes. The distance between the anode and the cathode is 1.5 cm. The method has such advantages as simple process, low cost, no pollution and uniform wall thickness of ZrO2 nanotubes.

Owner:HEBEI UNIV OF TECH

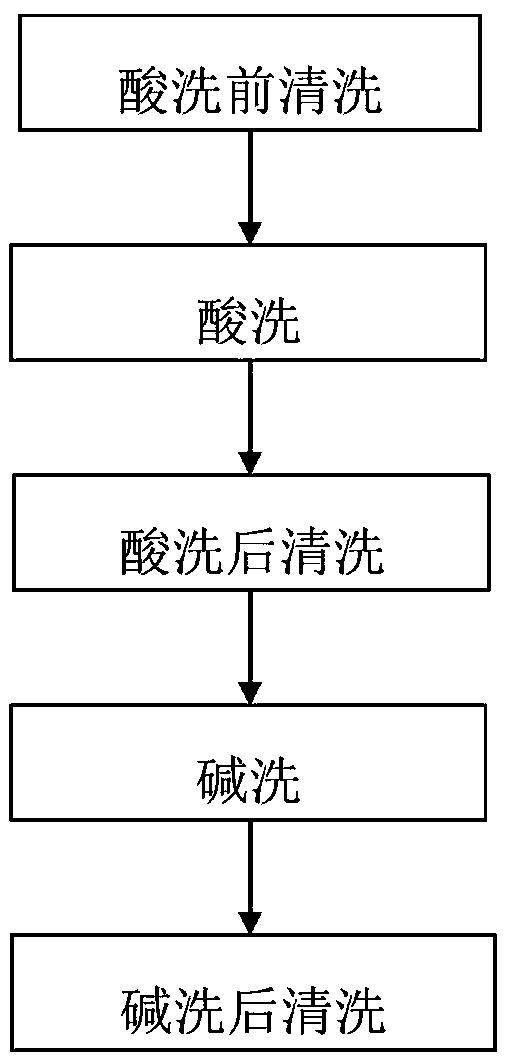

Chemical cleaning method for nanofiltration or reverse osmosis membranes

InactiveCN109224870AExtended service lifeImprove clear liquid handling capacitySemi-permeable membranesReverse osmosisNanofiltration

The invention discloses a chemical cleaning method for nanofiltration or reverse osmosis membranes. The chemical cleaning method includes the following steps: (1) pickling the nanofiltration or reverse osmosis membranes by acidic solutions; (2) cleaning the nanofiltration or reverse osmosis membranes by product water after pickling; (3) performing alkali washing on the nanofiltration or reverse osmosis membranes by alkaline cleaning solutions; (4) cleaning the nanofiltration or reverse osmosis membranes by the product water after alkali washing to complete cleaning of the nanofiltration or reverse osmosis membranes. The chemical cleaning method has the advantages that various pollutants on the nanofiltration or reverse osmosis membranes can be efficiently removed, the operating pressure ofthe nanofiltration or reverse osmosis membranes can be reduced, the yield of clear liquid of the nanofiltration or reverse osmosis membranes can be increased, the service life of the nanofiltration or reverse osmosis membranes can be prolonged, the power consumption of the clear liquid can be lowered, and stable operation of landfill leachate treatment plants can be guaranteed; the chemical cleaning method has the advantages of simple process, convenience in operation, low cleaning cost, high cleaning efficiency, good cleaning effect, high application value, good application prospect and thelike.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Anti-scaling multi-hydrogen retarded acid for highly argillaceous sandstone reservoir

The invention provides an anti-scaling multi-hydrogen retarded acid for a highly argillaceous sandstone reservoir. The retarded acid is prepared from the following raw materials by weight: 3 to 5 parts of hydrochloric acid, 3 to 5 parts of amino trimethylene phosphonic acid, 3.5 to 6 parts of ammonium bifluoride, 1 to 2.2 parts of a corrosion inhibitor, 0.5 to 1 part of a ferric ion stabilizing agent, 0.2 to 1 part of a clay stabilizing agent, 0.3 to 1 part of a de-emulsifier, 0.2 to 1 part of a mutual solvent and 78 to 87 parts of water. The anti-scaling multi-hydrogen retarded acid is used in the petroleum industry to control a reaction speed of hydrofluoric acid and clay so as to realize deep acidization of the highly argillaceous reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

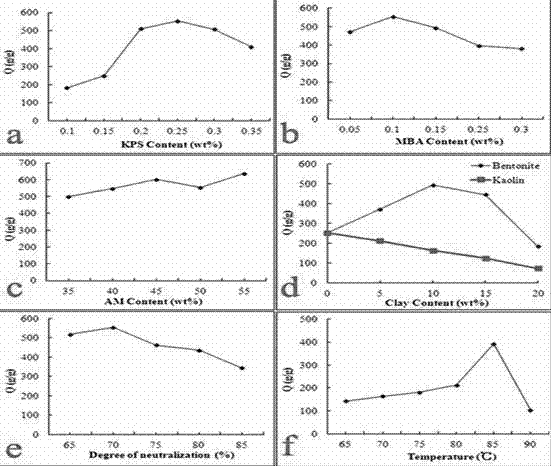

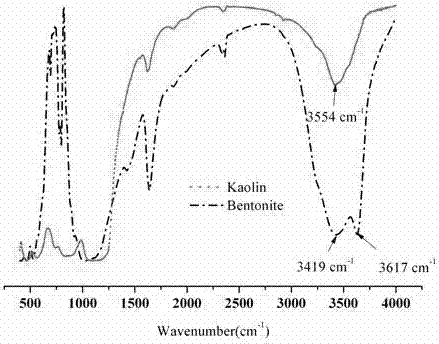

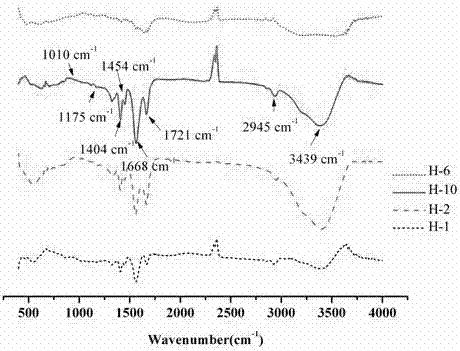

Preparation method for fire preventing and extinguishing colloid material for coal mines

The invention relates to a preparation method for a fire preventing and extinguishing colloid material for coal mines. According to the method, crylic acid and acrylamide serve as water absorption monomers, bentonite and kaolin serve as a filling agent or an enhancer, N,N'-methylene bisacrylamide serves as a cross-linking agent, and potassium peroxodisulfate serves as an initiator; an aqueous solution polymerization method is adopted for preparing bentonite / kaolin / crylic acid-acrylamide plural gel. The bentonite / kaolin / crylic acid-acrylamide plural gel prepared through the method is low in cost, resistant to high temperature and resistant to salt and alkali, and the fire preventing and extinguishing efficiency of the colloid material is greatly improved; the colloid material, loess, coal ash, water and the like are mixed and stirred to prepare coal mine fire preventing and extinguishing slurry; and the slurry material is high in water absorption capability, good in fire extinguishing effect and particularly suitable for fire preventing and extinguishing of the coal mines.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com