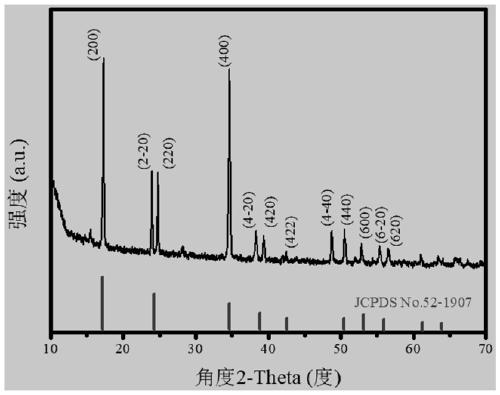

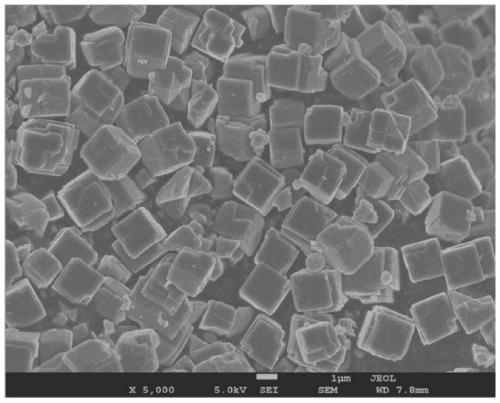

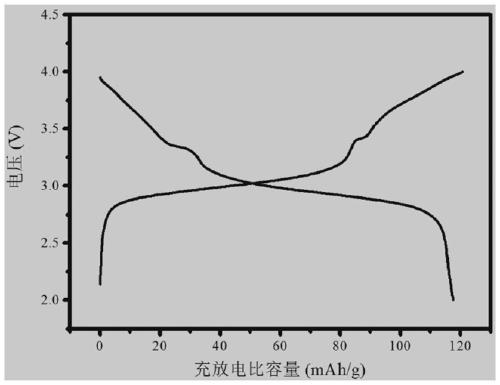

Prussian blue cathode material with high sodium content, preparation method and applications thereof, and sodium ion battery

A technology of Prussian blue and cathode materials, applied in the field of Prussian blue cathode materials with high sodium content and its preparation, and sodium ion batteries, can solve the problems of difficult control of reaction speed, influence on electrochemical performance, and difficulty in solid-liquid separation, and achieve easy industrial Large-scale production, excellent electrochemical performance, simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of Prussian blue cathode material:

[0046] (1) Nitrogen gas was blown into container A at 25°C, and 100ml of deionized water was added, followed by dissolving 0.1g of ascorbic acid, 6mmol of ferrous sulfate heptahydrate, 12mmol of citric acid, and 6mmol of sodium sulfate in container A, and adding ammonia water Adjust the pH of the solution in container A = 6.5. Nitrogen gas was passed into container B at 25°C, 100ml of deionized water was added, and then 0.1g of ascorbic acid, 4mmol of sodium ferrocyanide decahydrate, and 6mmol of sodium sulfate were dissolved in container B in turn, and the pH of the solution in container B = 6.5.

[0047] (2) Nitrogen gas is passed into container C at 25°C, and then the solutions in container A and container B are simultaneously added dropwise to container C at a speed of 2ml / min through a peristaltic pump, and the stirring speed in container C is 1000 Turn per hour, after all the solutions in container A and container...

Embodiment 2

[0052] Preparation of Prussian blue cathode material:

[0053] (1) At 25°C, blow nitrogen into container A, add 100ml of deionized water, then dissolve 0.1g of ascorbic acid, 6mmol of ferrous sulfate heptahydrate, 12mmol of citric acid, and 8mmol of sodium sulfate in container A, and add ammonia water Adjust the pH of the solution in container A = 6.5. Nitrogen gas was passed into container B at 25°C, 100ml of deionized water was added, and then 0.1g of ascorbic acid, 4mmol of sodium ferrocyanide decahydrate, and 8mmol of sodium sulfate were dissolved in container B in turn, and the pH of the solution in container B = 6.5.

[0054] (2) Nitrogen gas is passed into container C at 25°C, and then the solutions in container A and container B are simultaneously added dropwise to container C at a speed of 2ml / min through a peristaltic pump, and the stirring speed in container C is 1000 Turn per hour, after all the solutions in container A and container B are added to container C, c...

Embodiment 3

[0059] Preparation of Prussian blue cathode material:

[0060] (1) Nitrogen gas was passed into container A at 25°C, and 100ml of deionized water was added, followed by dissolving 0.1g of ascorbic acid, 4mmol of ferrous sulfate heptahydrate, 2mmol of manganese sulfate monohydrate, 12mmol of citric acid, and 10mmol of sodium sulfate in In container A, add ammonia water to adjust the pH of the solution in container A=6.5. Nitrogen gas was blown into container B at 25°C, 100ml of deionized water was added, and then 0.1g of ascorbic acid, 4mmol of sodium ferrocyanide decahydrate, and 10mmol of sodium sulfate were dissolved in container B in sequence, and the pH of the solution in container B = 6.5.

[0061] (3) Nitrogen gas is passed into container C at 25°C, and then the solutions in container A and container B are simultaneously dripped into container C at a speed of 2ml / min through a peristaltic pump, and the stirring speed in container C is 1000 Turn per hour, after all the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com