Patents

Literature

235 results about "High sodium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High sodium levels in the blood indicate a condition called hypernatremia, which is caused by dehydration, medications, endocrine diseases, excessive consumption of salt and hyperventilation, according to Chemocare.

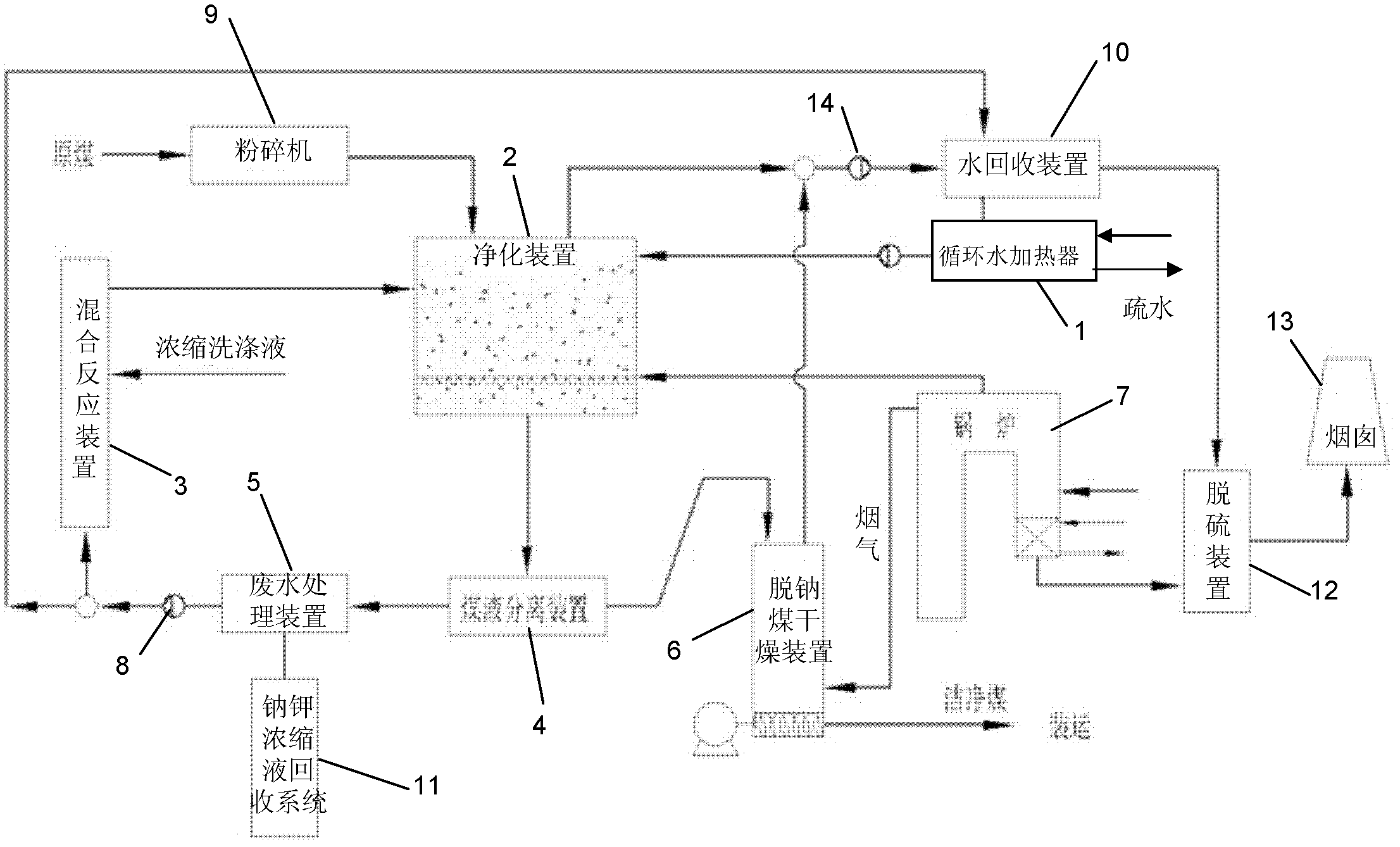

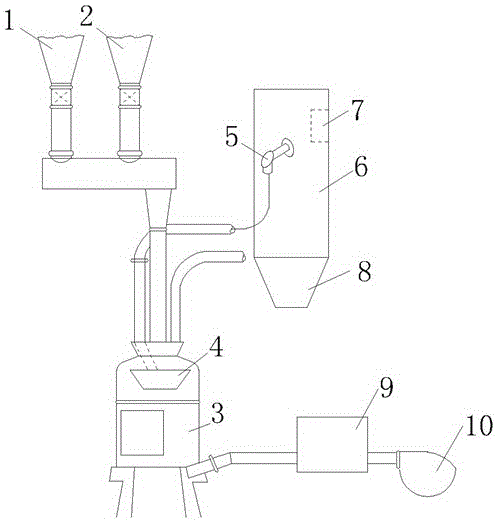

Sodium-removing purification cyclic system of high-sodium coal

InactiveCN102533383AReduce alkali metal contentSimple processSolid fuelsHigh sodiumWater circulation

The invention discloses a sodium-removing purification cyclic system of high-sodium coal. The system comprises a circulating water heater, a raw coal purification device, a mixing reaction device, a coal liquid separation device, a wastewater treatment device, a sodium-removing coal drying device and a steam heating source. The cyclic system heats water by utilizing a power plant heat source, andpurification and sodium removal are carried out on the raw coal through water circulation, thus good coal quality is reached, and the effects of saving water and the like are reached.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

High-sodium low-fluorine continuous casting mould fluxes and preparation method thereof

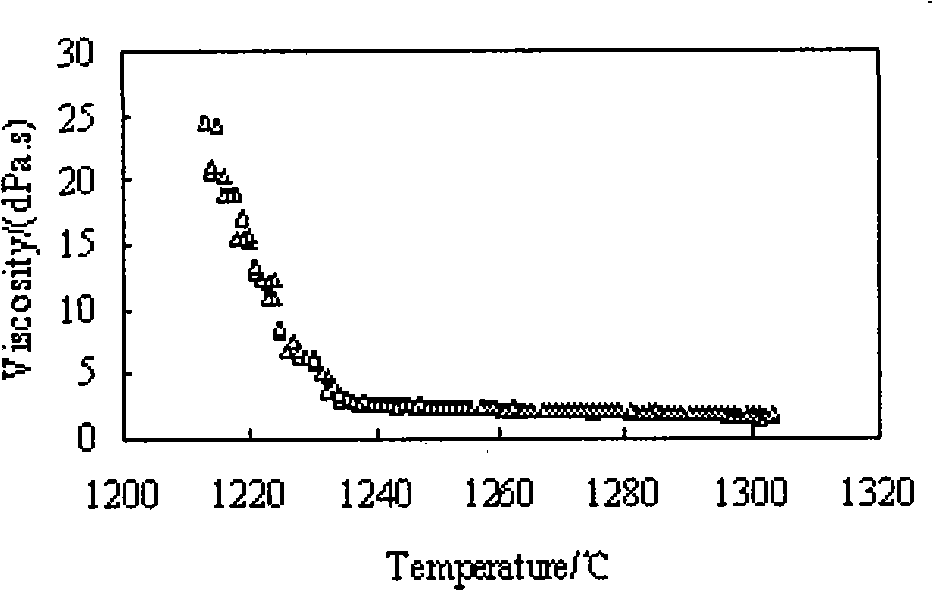

The invention relates to high-sodium low-fluorine covering slag, which is prepared from raw materials of wollastonite, limestone, quartz sand, fluorite, bauxite, manganese carbonate, magnesia, hydrous borax, industrial soda, lithium carbonate, and carbonaceous materials, and the chemical components of the covering slag meets the following weight percentage: more than 30 and less than 34 percent of CaO, more than 30 and less than 38 percent of SiO2, more than 12 and less than 25 percent of Na2O, less than 4 percent of MgO, less than 8 percent of MnO, less than 4 percent of B2O3, less than 1.5 percent of Li2O, less than 4 percent of Al2O3, less than 2 percent of F, more than 4 percent and less than 10 percent of C, and the balance being impurities. In the covering slag, the ratio of sigma CaO to the SiO2 is controlled to between 0.8 and 1.15 to ensure that the fused mass of the covering slag does not separate out crystals at high temperature and liquid slag in a slag film can lubricate a casting blank. Aiming at that the content of fluorine has adverse influence on environment and equipment, the invention adopts high-sodium low-fluorine continuous casting covering slag which not only can meet the requirement of coordinated control of heat transfer and lubrification of a continuous casting covering slag for crack sensitive steel to cast casting blank with good surface quality, but also can reduce the fluorine content in air and secondary cooling water, thus the air pollution is reduced and the corrosion of fluorine-contained water to equipment is reduced.

Owner:CHONGQING UNIV

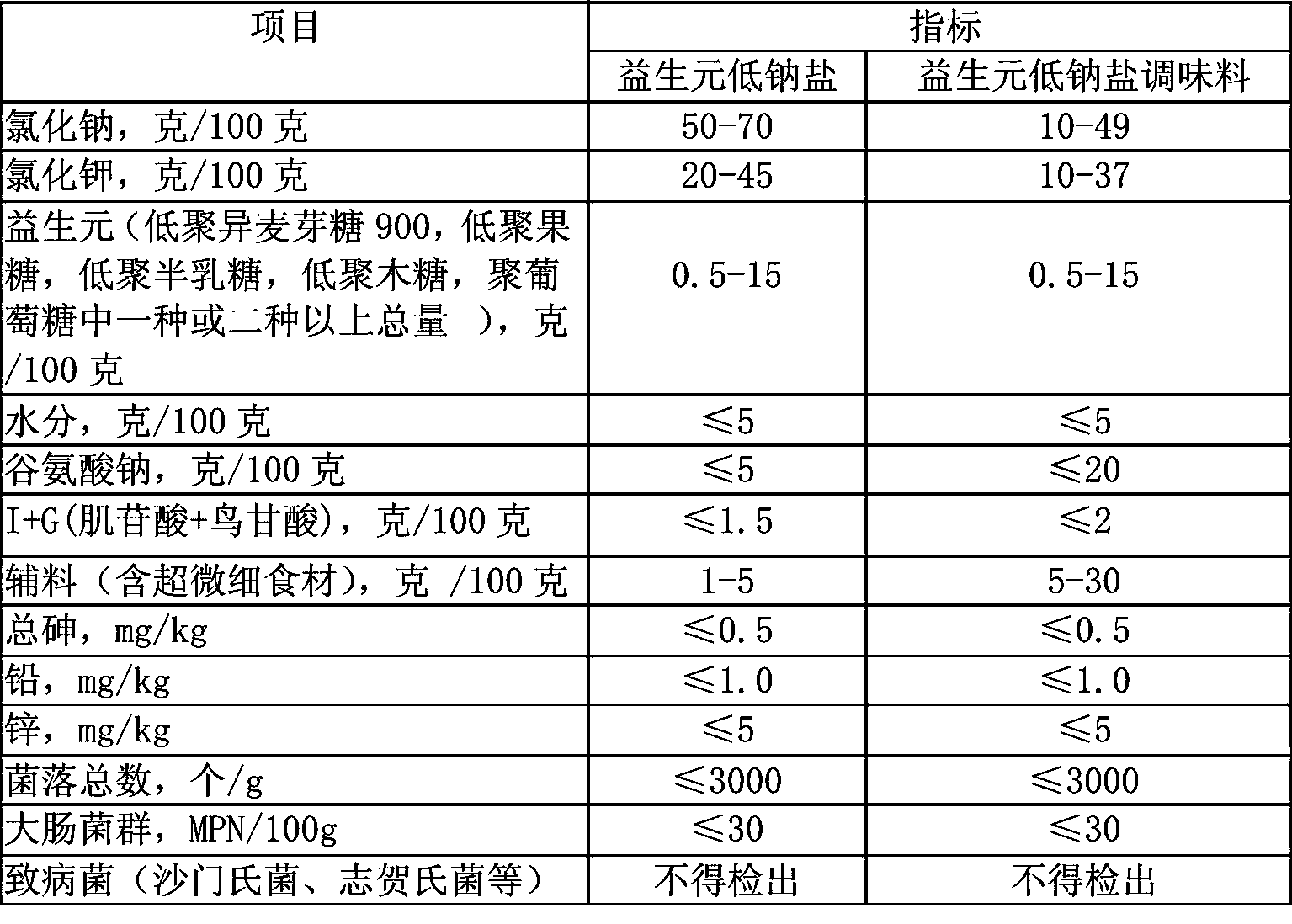

Prebiotic low-sodium salt and prebiotic low-sodium salt composite seasoning, and preparation method thereof

InactiveCN103876104APromote growth and reproductionPrevent sub-health diseasesSugar food ingredientsFood ingredient functionsBiotechnologyHigh sodium

The invention relates to a health-care seasoning, particularly a prebiotic low-sodium salt and a prebiotic low-sodium salt composite seasoning, and a preparation method thereof. The prebiotic low-sodium salt comprises 50-70% of sodium chloride, 20-45% of potassium chloride, 0.5-15% of prebiotic and 1-5% of ultrafine food powder and other auxiliary materials. Unless otherwise specified, the percents in the invention are mass percents. The prebiotic low-sodium salt seasoning comprises 10-49% of sodium chloride, 10-37% of potassium chloride, 0.5-15% of prebiotic and 5-30% of ultrafine food powder and other auxiliary materials. The prebiotic low-sodium salt and prebiotic low-sodium salt seasoning overcome the defects of high sodium chloride content, unbalanced sodium and potassium ions and high tendency to causing hypertension and kidney diseases of the human body; the water-soluble dietary fiber-oligosaccharide prebiotic, which is beneficial to the human health, is added to well promote growth and reproduction of the probiotic in the intestinal tract, thereby preventing constipation and subhealth diseases caused by accumulation of toxins in the intestinal tract.

Owner:SICHUAN YISHENGYUAN TECH CO LTD

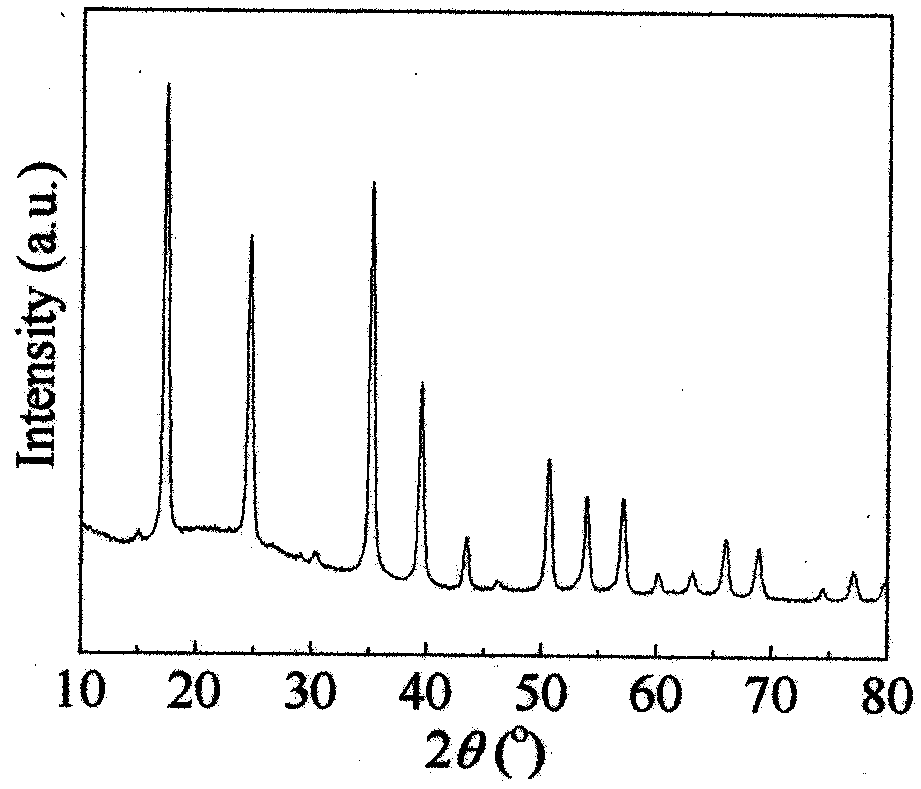

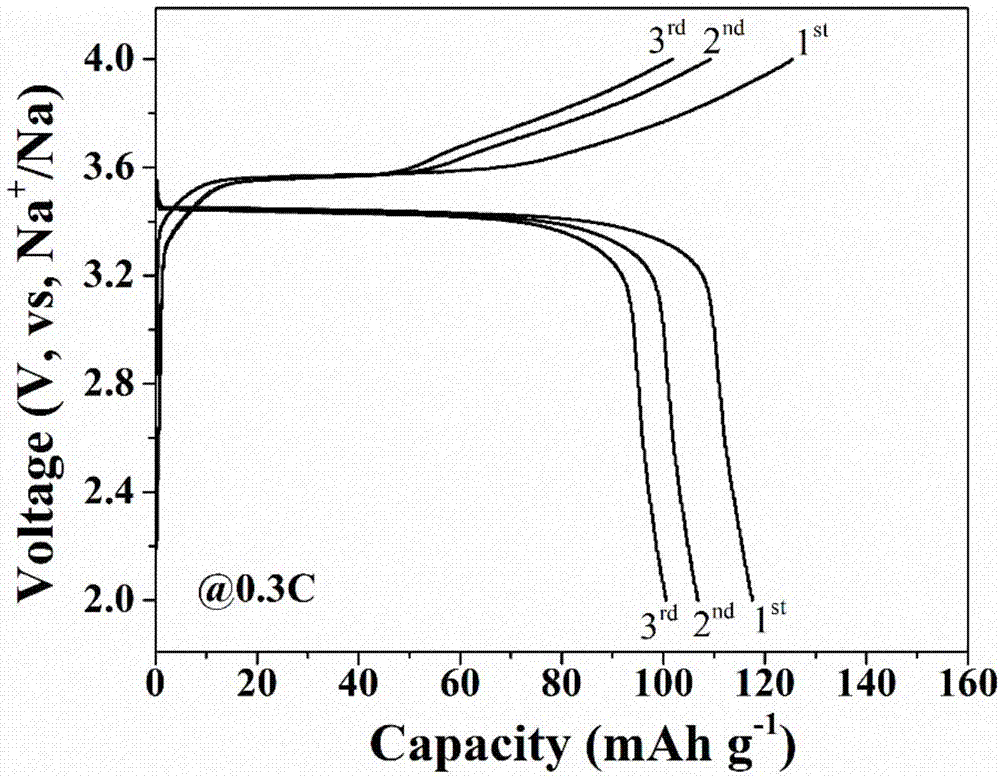

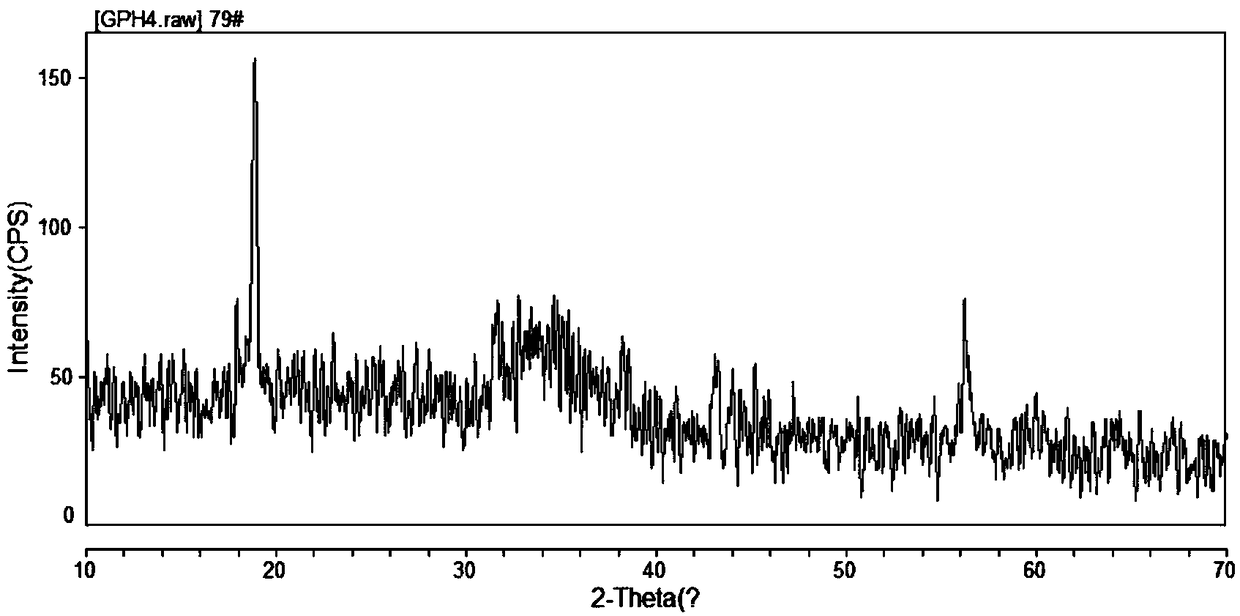

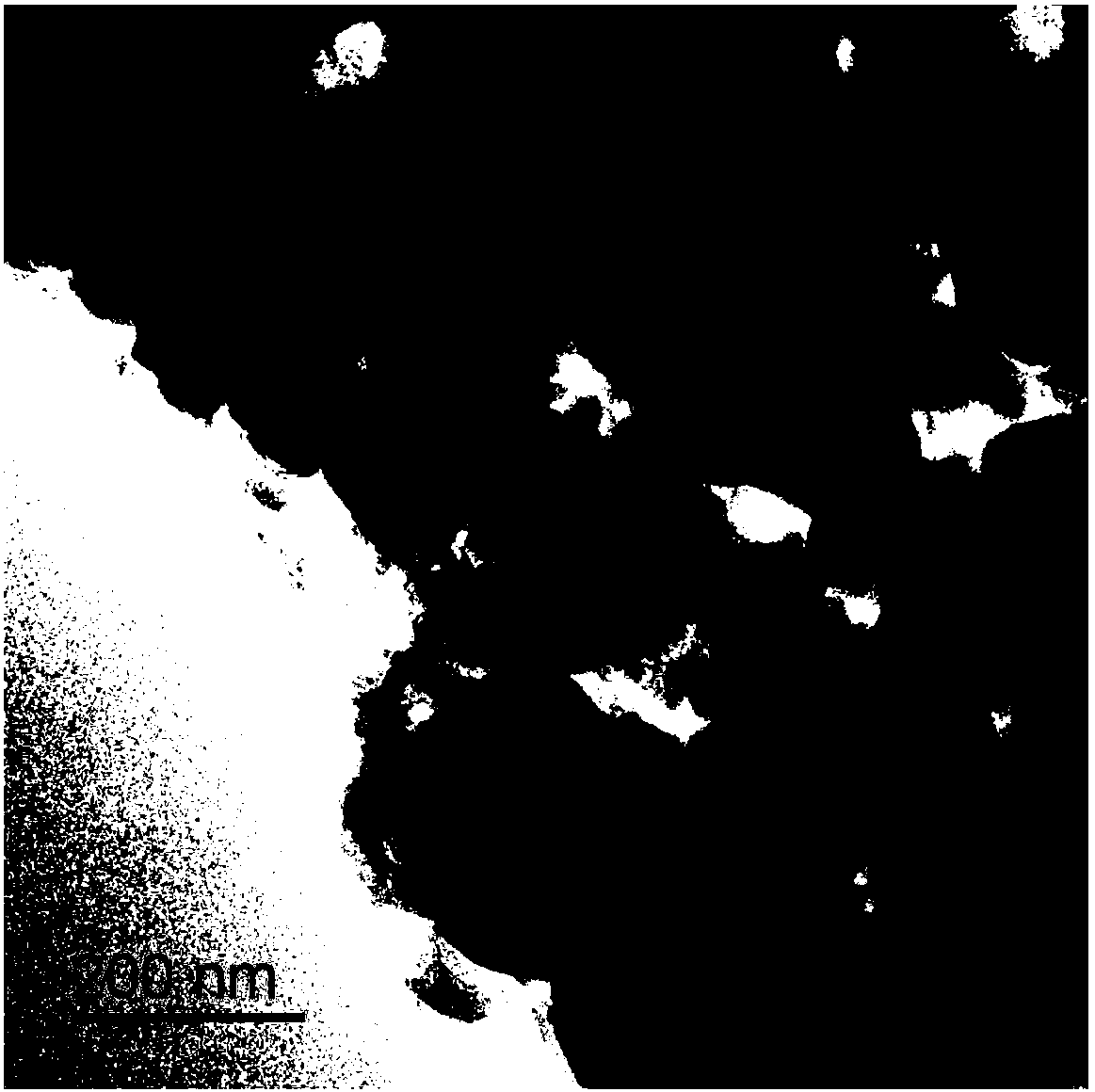

Method for synthesizing high-sodium iron-based Prussian blue electrode material

InactiveCN104282908AImprove electrochemical performanceLow costCell electrodesSecondary cellsHigh sodiumSodium-ion battery

The invention provides a method for synthesizing a high-sodium iron-based Prussian blue electrode material. The high-sodium iron-based Prussian blue electrode material comprises the following raw materials in percentage by mole: 25-43 percent of iron ion-containing metal salt, 25-43 percent of ferricyanide ion-containing metal salt and 14-50 percent of a complexing agent. The method comprises the following steps: 1, adding the iron ion-containing metal salt and the complexing agent into a container according to the ratio of the raw materials, adding a solvent, mixing, thereby obtaining a solution A; 2, adding the ferricyanide ion-containing metal salt into the container according to the ratio of the raw materials, adding the solvent, mixing, thereby obtaining a solution B; 3, mixing the solution A and the solution B, and reacting for 2-24 hours; and 4, respectively washing the obtained materials for several times by using water and ethanol, removing the impurities, drying, thereby obtaining the high-sodium iron-based Prussian blue electrode material. The obtained material serves as a sodium ion battery cathode material and has excellent electrochemical performance. The method is low in cost, readily available in raw materials, simple in process and easy for industrial production.

Owner:张五星

Sodium-ion battery and preparation method thereof

An embodiment of the invention provides a sodium-ion battery. The sodium-ion battery comprises a positive electrode, a negative electrode, a non-aqueous organic electrolyte and a diaphragm. The positive electrode comprises a positive electrode active material and a current collector, wherein the positive active material is NaXCoO2, NaXMnO2, NaXTiS2, NaXNbS2Cl2, NaXWO3-X, NaXV0.5Cr0.5S, amorphous NaXMoS3, NaXTaS2, NaXNi0.5Mn0.5O2, NaVPO4F or Na2FePO4F. The negative electrode comprises a negative electrode active material and a current collector, wherein the negative electrode active material is MoS2. The sodium-ion battery overcomes the defects that a conventional sodium-ion battery is difficult to balance high sodium embedded capacity and good dynamic characteristics. The sodium-ion battery has good cycling stability and good safety performance while keeping high capacity. The preparation method of the sodium-ion battery is simple and practicable; raw materials are abundant and cost is low.

Owner:徐州本色电力设备科技有限公司

Method for preparing Prussian blue positive electrode material, and sodium ion battery

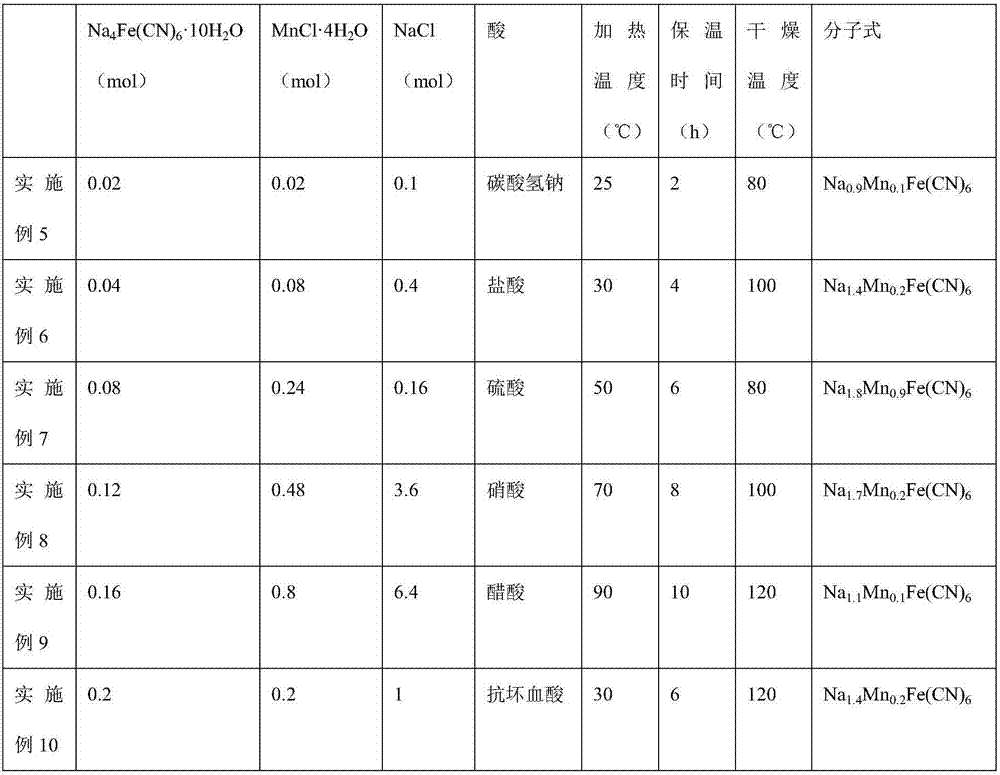

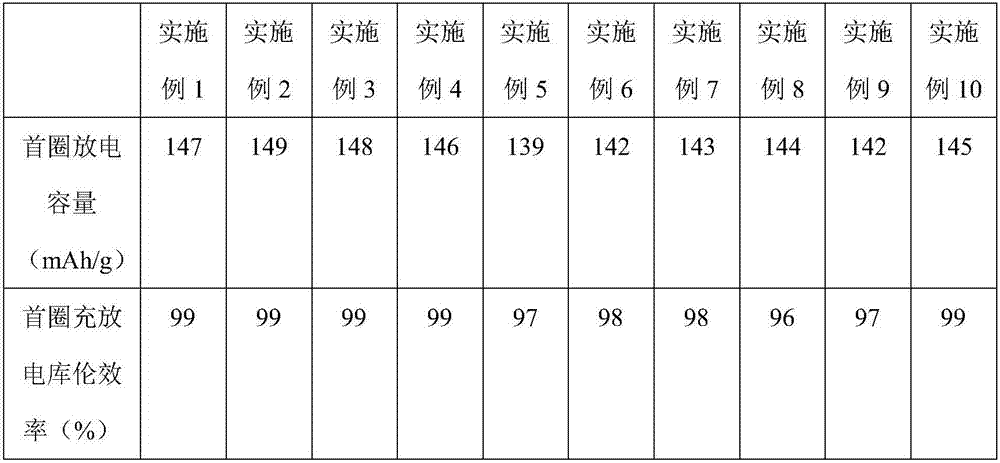

InactiveCN107364875AAvoid hydrolysisHigh specific capacityIron cyanidesCell electrodesHigh sodiumSodium-ion battery

The invention discloses a method for preparing a Prussian blue positive electrode material, and a sodium ion battery, wherein the molecular formula of the Prussian blue positive electrode material is Na2-xMyFe(CN)6, x is more than o 0 and is less than 2, y is more than 0 and is less than 1, and M is a transition metal. The preparation method comprises: adding a Na4Fe(CN)6 solution into a solution 2 containing the salt solution of M, a sodium salt and a pH value adjusting agent in a dropwise manner, maintain the pH value of the mixed solution at 6-7, and heating for a certain time in a protection atmosphere to obtain the Prussian blue positive electrode material. According to the present invention, the method has characteristics of simple process, easy control and continuous and scale production, and can be used for preparing the high sodium content Prussian blue positive electrode material; and the prepared Prussian blue positive electrode material as the sodium ion battery positive electrode material can improve the specific capacity of the battery, can reduce the polarization in the battery charging and discharging process, and has wide application prospects in the field of electric energy storage in the power grid.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

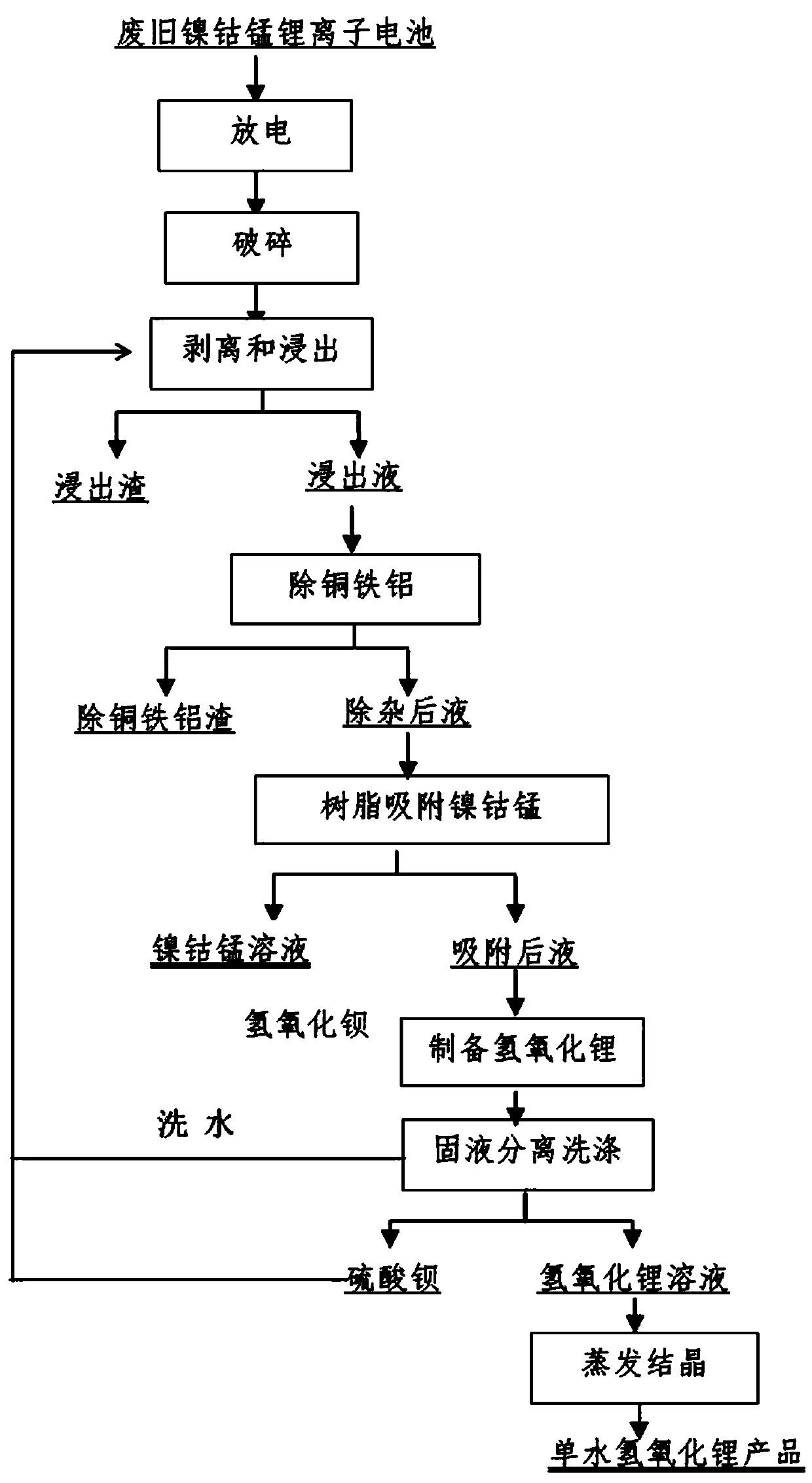

Method for recovering valuable metals in waste nickel-cobalt-manganese lithium ion battery by ion exchange method

InactiveCN110527836AAvoid introducingEliminate the evaporation crystallization processIon-exchange process apparatusIon-exchanger regenerationHigh sodiumIon content

The invention relates to a method for recovering the valuable metals in a waste nickel-cobalt-manganese-lithium ion battery by an ion exchange method, which comprises the following steps of disassembling, discharging and crushing the waste nickel-cobalt-manganese-lithium ion battery, leaching, replacing the leachate with nickel powder or cobalt powder to remove the copper, and hydrolyzing with a valuable metal alkali solution as a neutralizer to remove the iron and aluminum; regenerating the chelating resin with a lithium hydroxide solution, adsorbing the nickel, cobalt and manganese in the impurity-removed solution, and backwashing with sulfuric acid to obtain a nickel-cobalt-manganese mixed solution; and recovering the lithium in the liquid after resin adsorption in the form of lithium hydroxide. According to the method, the stripping and leaching of the waste nickel cobalt lithium manganate ion battery are completed in one step, the impurity elements are not introduced during the leachate impurity removal and valuable metal separation and extraction process, the lithium hydroxide used for ion exchange resin is regenerated via the lithium hydroxide, at the same time, the nickel-cobalt-manganese is absorbed, so that the lithium is prevented from being adsorbed and entering a nickel, cobalt and manganese solution to be lost, and the lithium recovery is prevented from being influenced due to the high sodium ion content in the solution with the sodium hydroxide. According to the present invention, the recovery rate of nickel, cobalt and manganese reaches 98% or above, the recovery rate of lithium reaches 90% or above, the technological process is short, the equipment is few, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

Novel decoking agent for fire coal

InactiveCN103627468AReduce stickinessMitigate the hazard of slaggingSolid fuelsHigh sodiumCombustion

The invention discloses a novel decoking agent for fire coal. According to the invention, an aluminum-system compound is used as a main agent, and a silicon-system compound is used as an auxiliary agent; in terms of oxides, the decoking agent comprises, by weight, 35 to 70 parts of alumina and 15 to 50 parts of silicon oxide, the sum of the weight parts of alumina and silicon oxide is no less than 60, and a ratio of the weight parts of alumina and silicon oxide is no less than 0.40. The novel decoking agent provided by the invention can directly increase the melting point of high-sodium coal ash during boiler combustion, substantially lowers down the degree to which a hearth and a heating surface are contaminated by sticky fusion products and the degrees of slag-bonding and coking during high temperature combustion, and has a decoking rate of 50 to 80%.

Owner:陈方

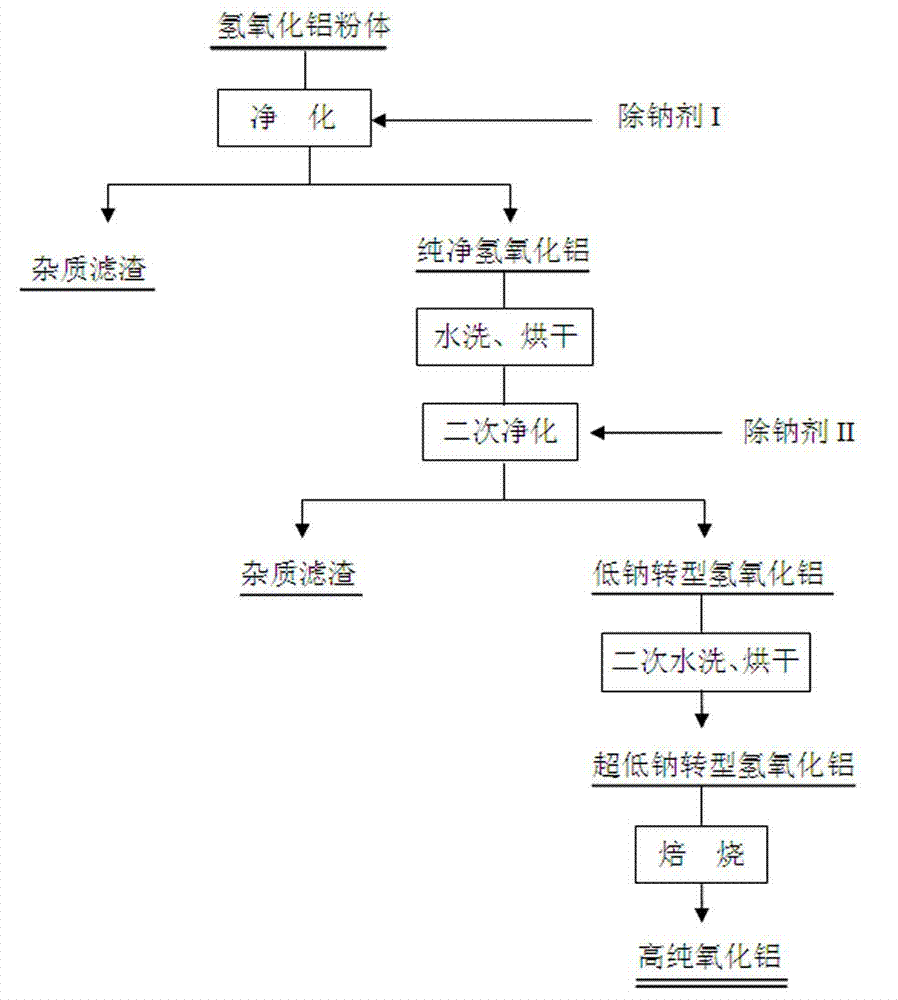

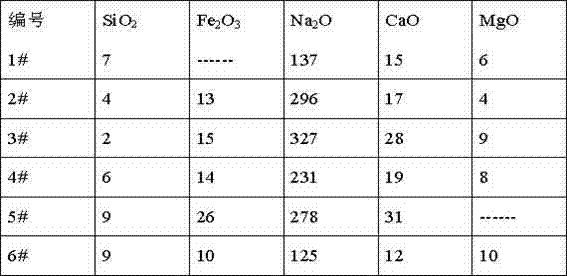

Method for removing sodium in preparation of high-purity alumina

ActiveCN103204530ATo achieve the purpose of removing sodiumSodium removal effect is obviousAluminates/aluminium-oxide/aluminium-hydroxide purificationWater bathsHigh sodium

The invention discloses a method for removing sodium in a preparation of high-purity alumina. The method comprises the steps of purifying, secondary purifying, washing, drying, secondary washing and drying again. The method specifically comprises the following steps of: grinding aluminium hydroxide with high sodium content to be less than or equal to 500mu m, stirring and washing for 2-3 times in thermostatic water bath with temperature being 50-55 DEG C by utilizing a sodium removing agent I to obtain pure aluminium hydroxide; washing the purified pure aluminium hydroxide with water till pH value is 7.0-7.5, drying and dehydrating; adding a sodium removing agent II to the washed and dried aluminium hydroxide, and stirring and washing for 2-3 times in the thermostatic water bath with temperature being 30-50 DEG C; and washing the aluminium hydroxide which is purified for the second time by utilizing pure water with temperature being 30-50 DEG C, drying, dehydrating and transforming the washed aluminium hydroxide to fluffy ultralow sodium aluminium hydroxide. The method has the advantages of convenience, conciseness, no pollution and good sodium-removing effect.

Owner:KUNMING METALLURGY INST

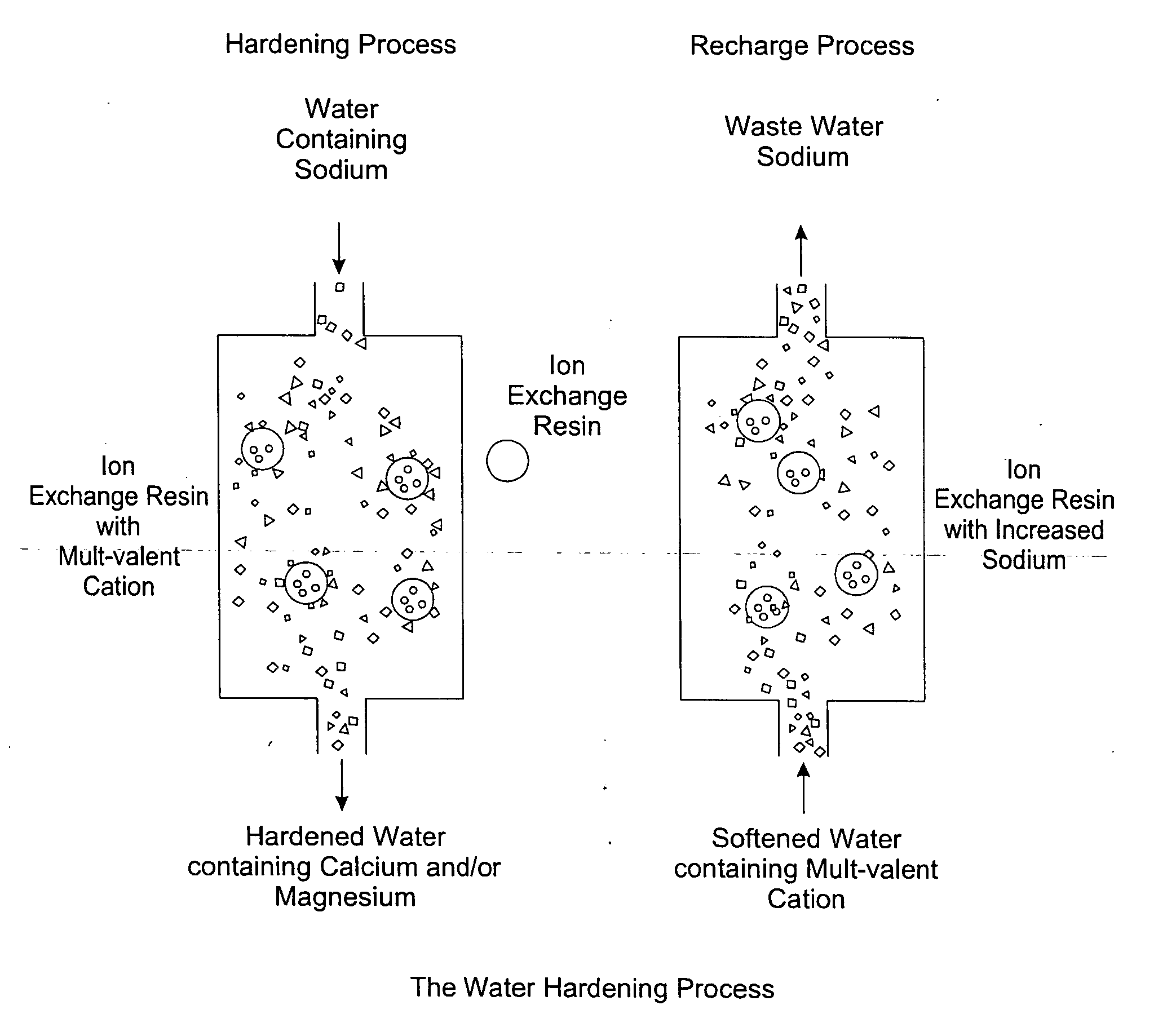

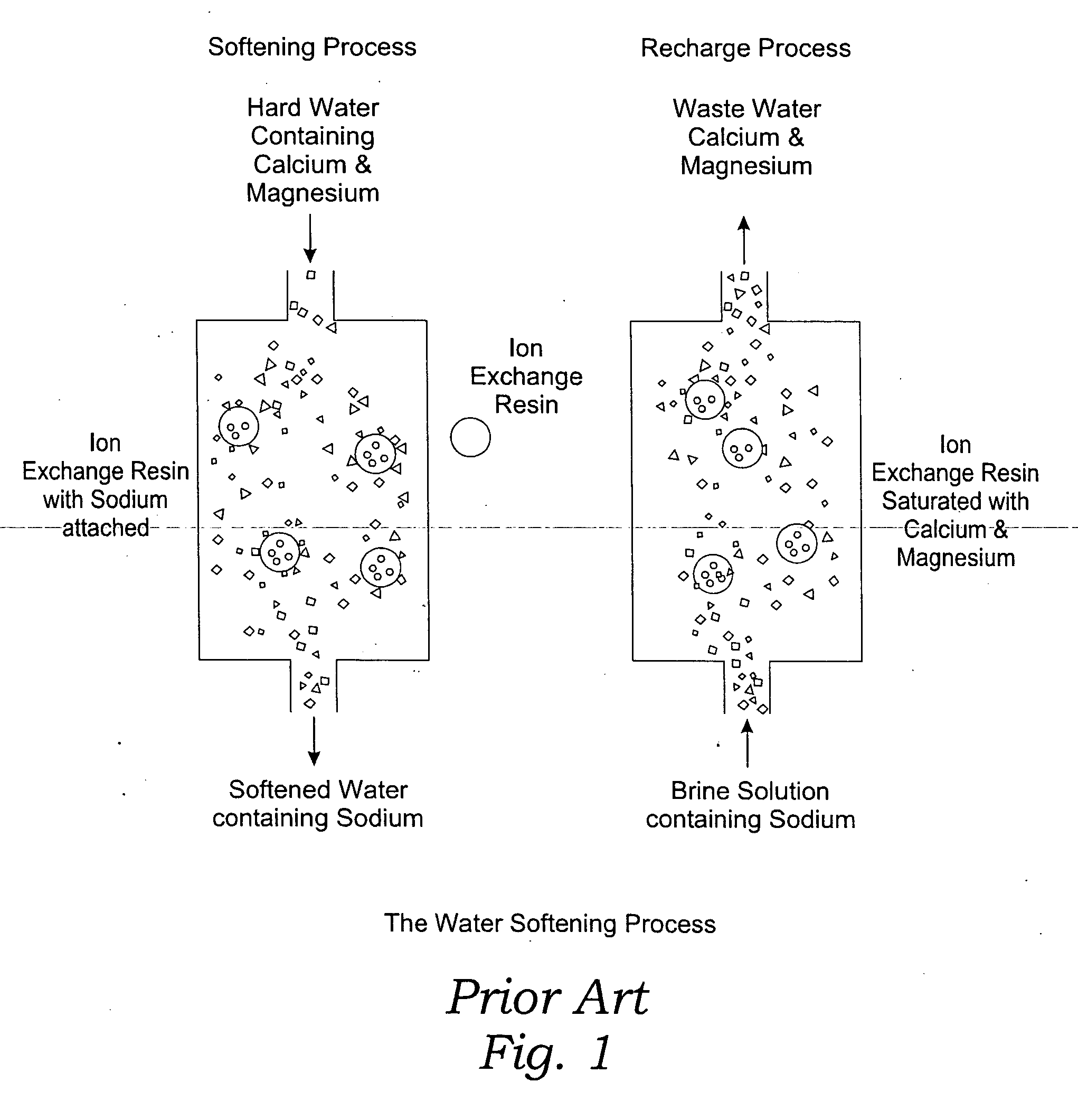

Methods of utilizing waste waters produced by water purification processing

InactiveUS20050210745A1Economically and efficiently processingLow sodium contentSpecific water treatment objectivesScale removal and water softeningDecreased sodiumHigh sodium

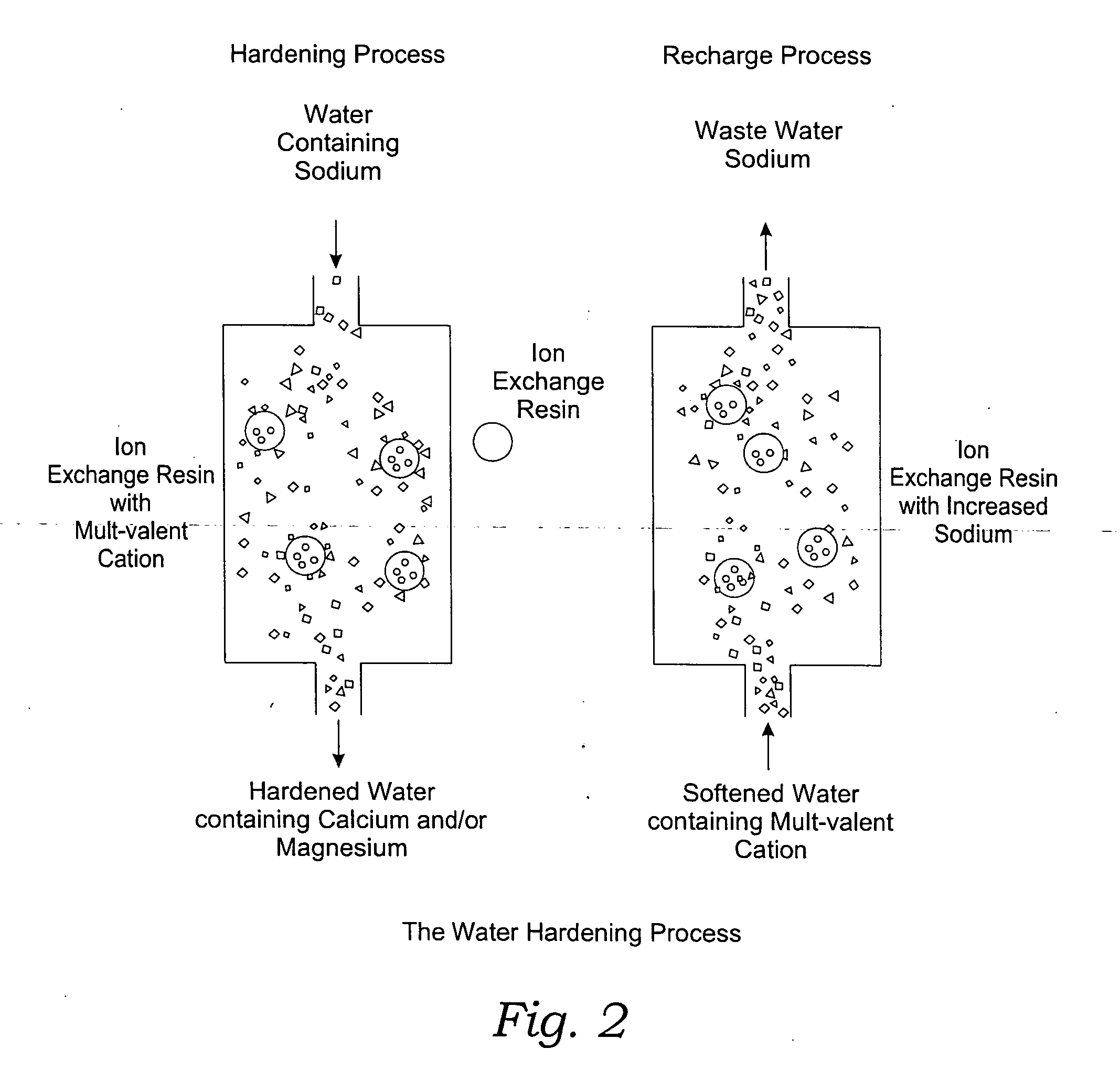

The invention relates to a process for treating unwanted moderately saline waters for producing waters acceptable for treating soil, such as for irrigation. The treated water is also suitable for human and livestock consumption. The process includes passing moderately saline waters having 0.05% or more by weight and less than 1.00% by weight of the salts of Na, K, Ca, Mg, Fe, Cl, SO4, or CO3 or combinations thereof through an ion exchange resin. The ion exchange resin is pre-treated to be saturated with multivalent cations. Preferred multivalent cations include calcium (Ca2+) or magnesium (Mg2+) ions, or combinations thereof. After passing through the ion exchange resin, the effluent has decreased sodium cations and increased calcium and / or magnesium cations compared to the pre-treated moderately saline water. As the moderately saline waters passes through the ion exchange resin, the sodium content of the resin rises as the multivalent cation content lowers until the resin is unacceptable for further water treatment in accordance with the present invention. To regenerate the ion exchange resin, the resin is flushed with a brine solution having more than 1.00% by weight of the salts of Na, K, Ca, Mg, Fe, Cl, SO4, or CO3. Preferably, the brine is particularly high in calcium and / or magnesium content and low in sodium. The brine solution is flushed through the ion exchange resin until the ion exchange resin is sufficiently saturated with multivalent cations to again process moderately saline water having high sodium content.

Owner:GROTT GERALD J

Drip-irrigation tree cultivation method on severe alkaline land

InactiveCN101507402AGuaranteed normal growthImprove the growing environmentFertilising methodsCultivating equipmentsWater useTree root

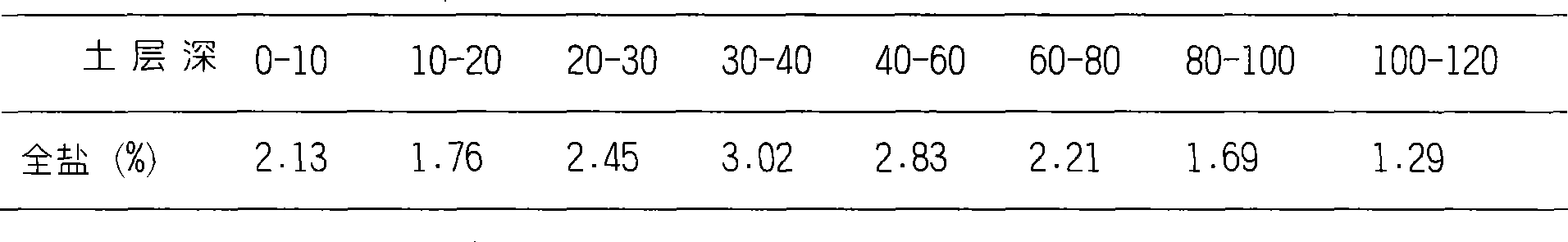

The invention provides a method for cultivating trees in heavy degree saline and alkaline land through dripping irrigation, which comprises ridging, planting and irrigation management. The method comprises: A, a step of manual ridging, in which the ridge height is 60 centimeters, the width of ridge top is 60 centimeters, and the ridge spacing is 300 centimeters, and the plant spacing is 200 centimeters; B, a step of planting, in which holes with a diameter of between 30 and 50 centimeters and a depth of between 30 and 50 centimeters are dug in the planting process, non-saline and alkaline soil dressing is filled in the holes after saplings are planted and fixed in the holes, and films are covered on the land; C, a step of drip irrigation zone setting, in which the center of each ridge is provided with a single-ridge single-strip drip irrigation zone and the drop spacing is 10 to 50 centimeters; and D, a step of drip irrigation, in which the land is irrigated initially on the same day of planting, the amount of water used for irrigation is four times of that of water used for daily irrigation, after that the land is irrigated one every other 1 to 2 days, with 4 to 5 millimeters of water each time. The method adopts ground irrigation and tree root soil replacement, and forms desalting areas at the root parts of the trees and ensures the normal growth of the trees. The method solves the problem that the soil structure of the saline and alkaline soil with a high sodium ion content is damaged after leaching, keeps the good soil structure of soil dressing during salt leaching and provides a good growing environment for the trees.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS +1

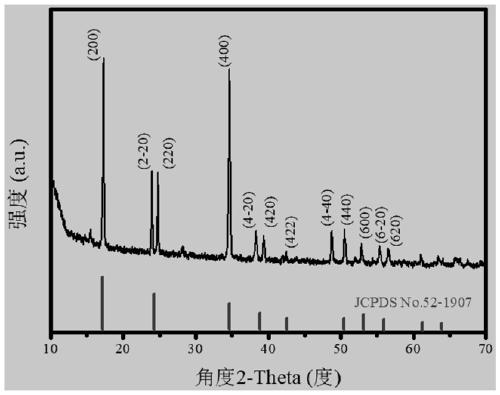

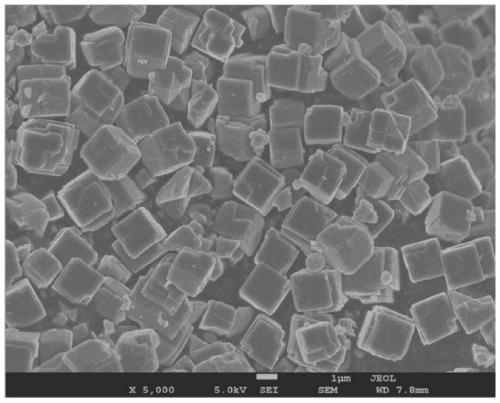

Prussian blue cathode material with high sodium content, preparation method and applications thereof, and sodium ion battery

ActiveCN110235292AGood effectRaise the sodium contentIron cyanidesSecondary cellsHigh sodiumPrussian blue

The invention belongs to the technical field of novel energy storage materials, and relates to a Prussian blue cathode material with a high sodium content, a preparation method and applications thereof, and a sodium ion battery. The molecular formula of the Prussian blue cathode material is Na<x>MNFe(CN)<6>; wherein M and N represent a same transition metal or different transition metals andcan be Fe, Co, Mn, Ni, Cu, Zn, Cr, V, Zr, or Ti; 1.8<x<2; 0<a<1; 0<b<1; and a+b=1. The cathode material has millimeter cubic morphology and excellent electrochemical properties. The preparation method has the advantages that the crystallization is slow, the sodium content of the cathode material is high, the preparation method is simple and easy to perform, the production efficiency and the yieldare high, the raw materials are cheap, and industrial production and enlarged production are easy to realize.

Owner:LIAONING STARRY SKY SODIUM BATTERY CO LTD

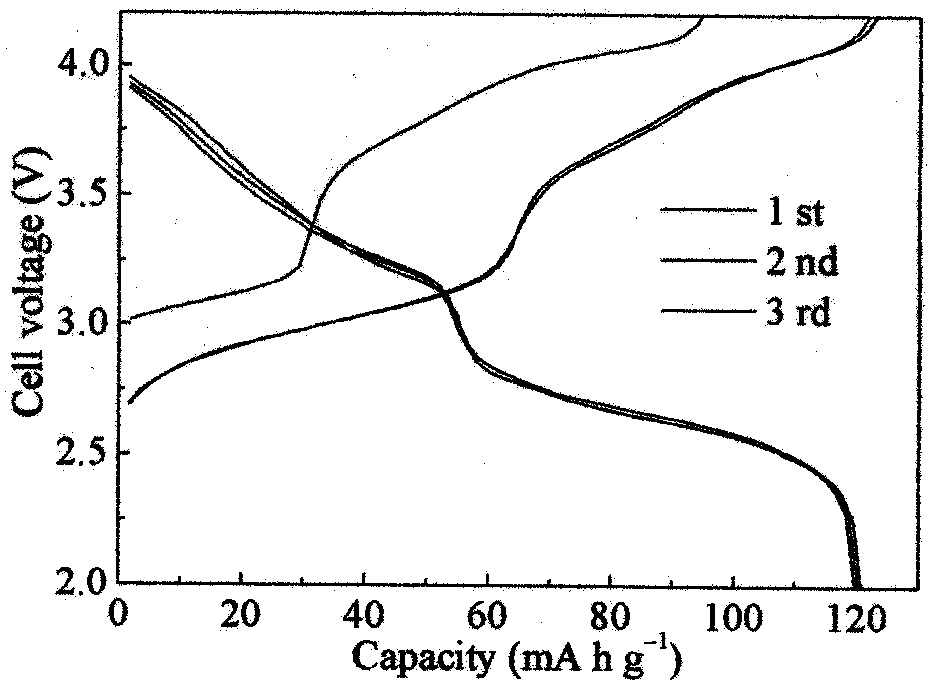

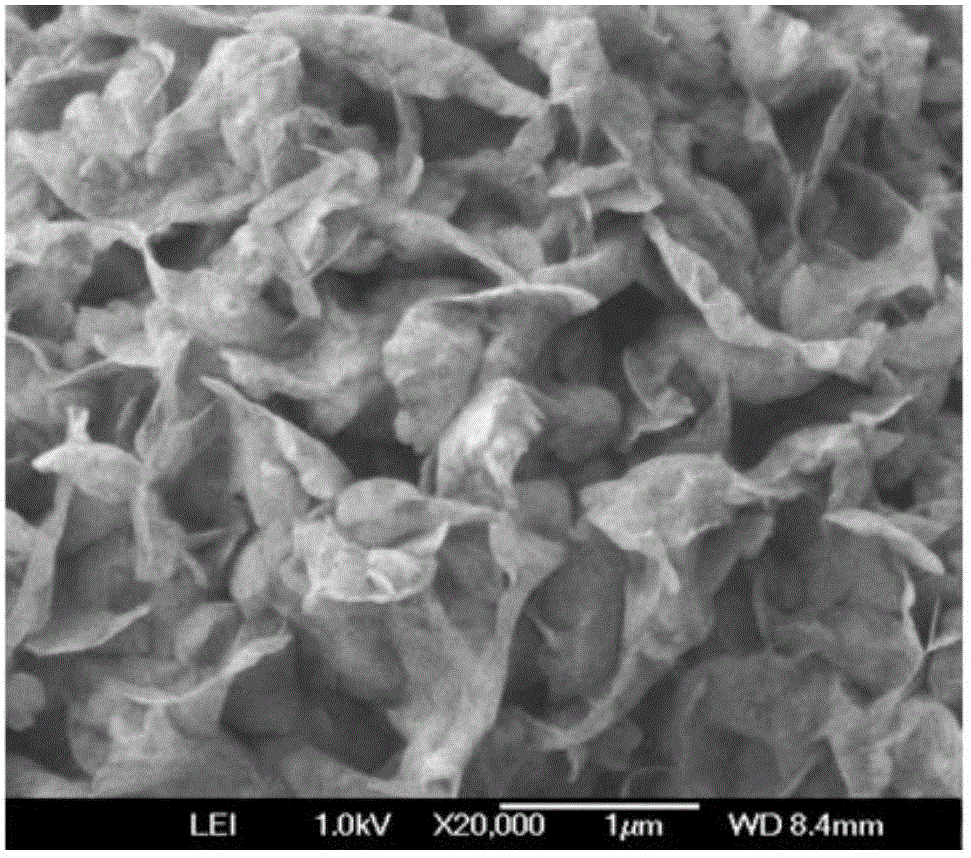

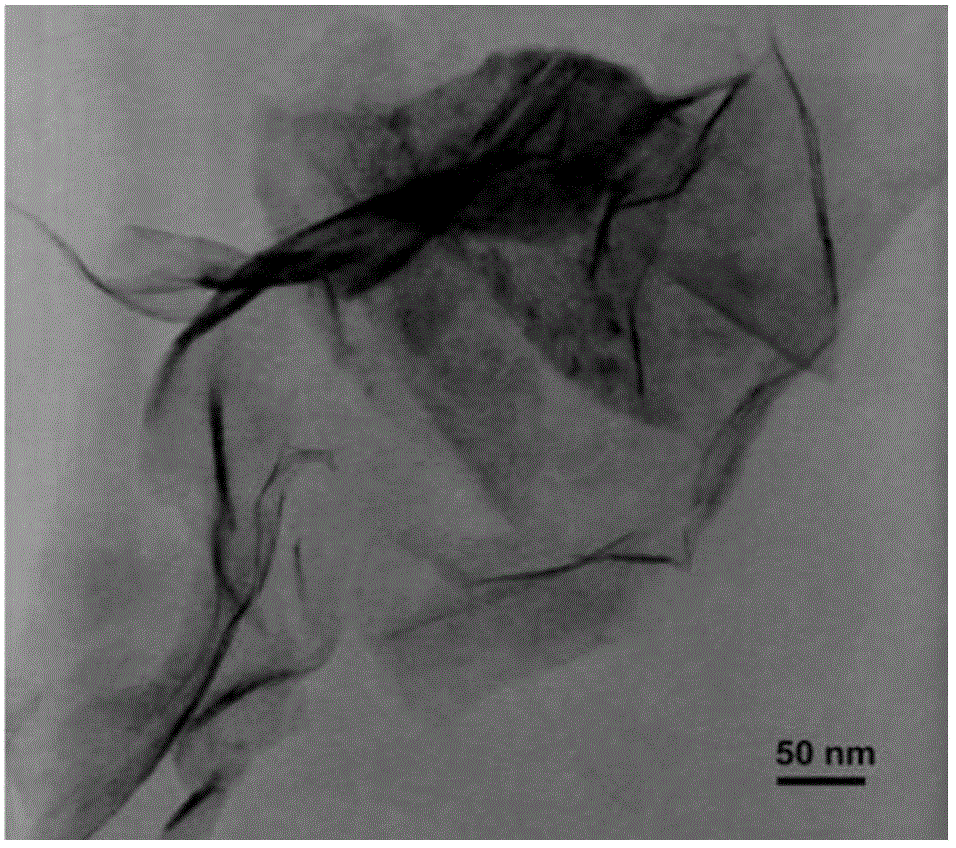

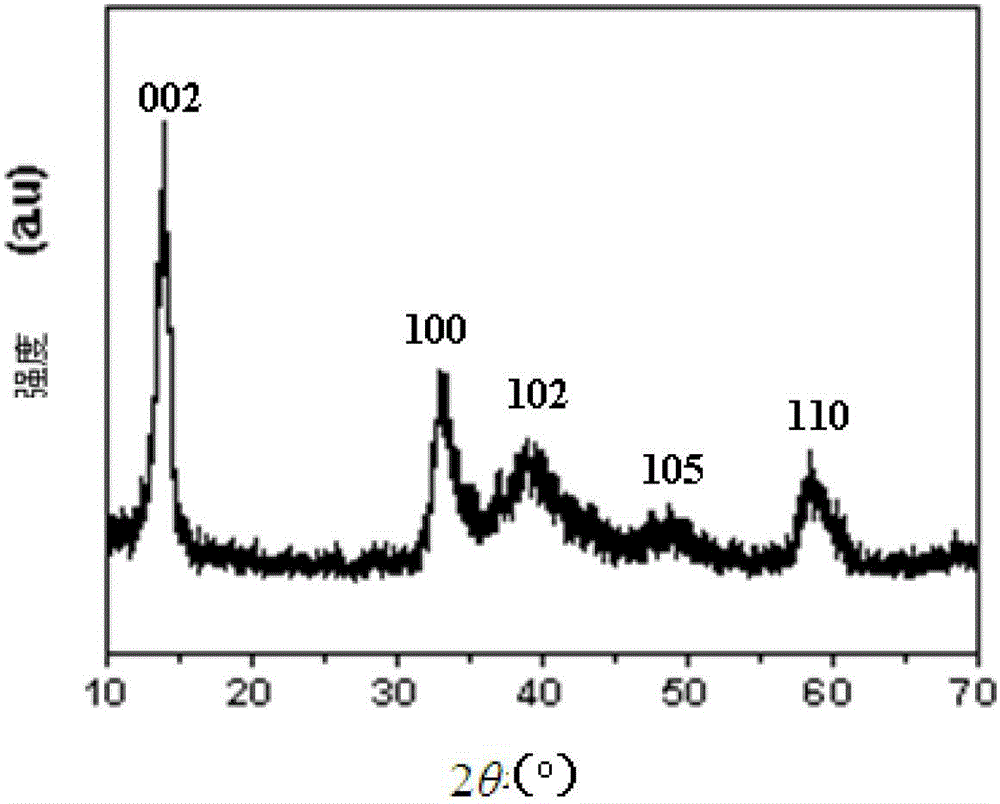

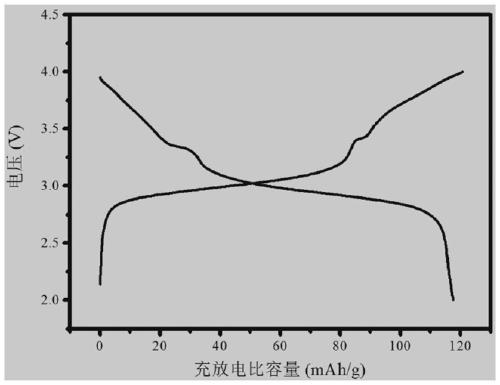

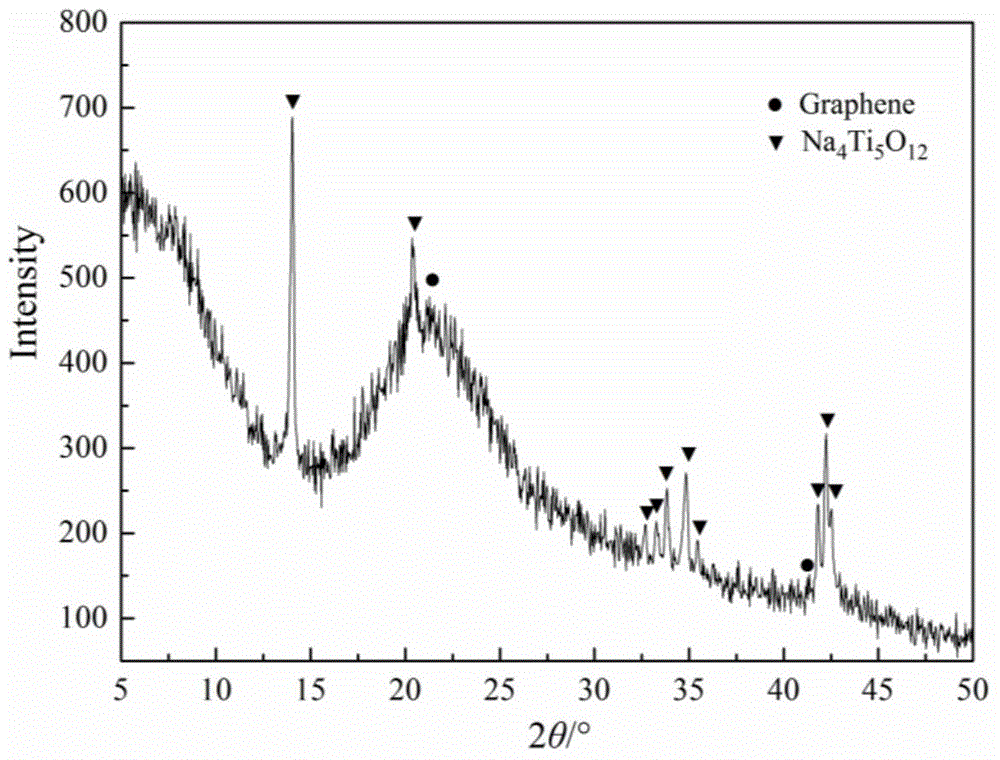

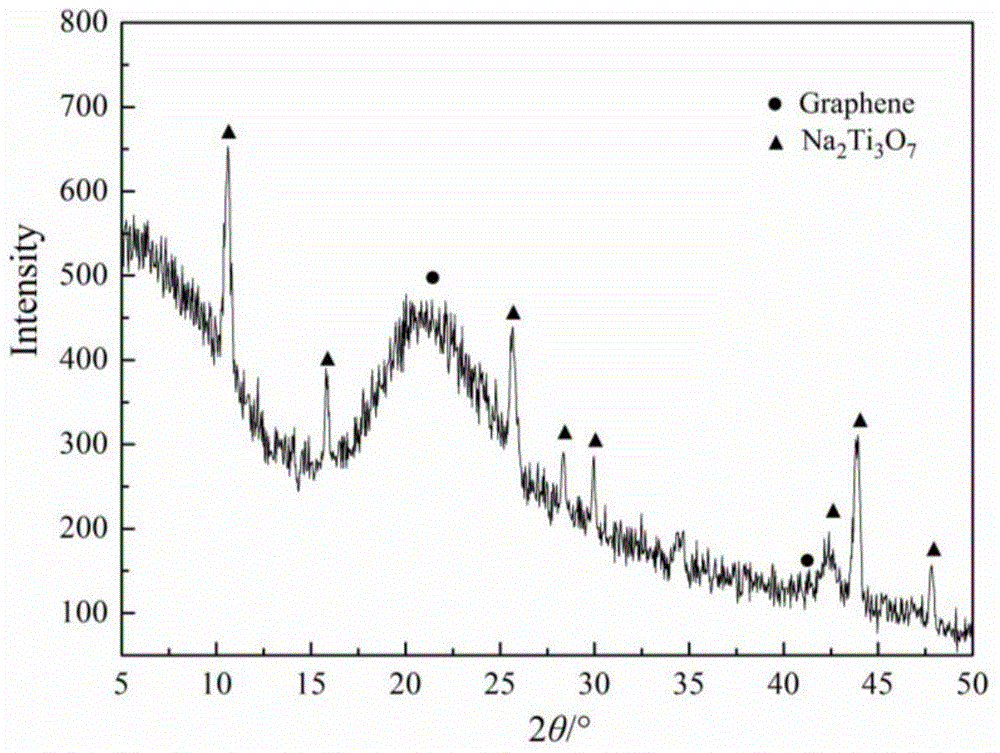

Preparation method of sodium titanate/graphene composite cathode material of sodium ion battery

ActiveCN104600271AEasy to storeFacilitated DiffusionCell electrodesSecondary cellsStrontium titanateHigh sodium

The invention provides a preparation method of a sodium titanate / graphene composite cathode material of a sodium ion battery, which is used for solving the problems in the prior art that no sodium ion battery cathode material with excellent comprehensive performance is provided, and belongs to the field of sodium ion secondary batteries. The method comprises the steps of dispersing graphene oxide to obtain a graphene oxide solution, mixing the graphene oxide solution, a sodium-containing compound and a titanium-containing compound, carrying out reaction to obtain a composite precursor, mixing the composite precursor with a binder, carrying out atomizing drying and granulating to obtain a spherical composite precursor, and finally burning the spherical composite precursor in an inert atmosphere to obtain a micro-scale spherical sodium titanate / graphene composite cathode material. The composite cathode material has the advantages of high sodium storage capacity, long cycle life, good large-current discharge property, high compaction density and the like, and the requirement of the high-performance sodium ion battery for the comprehensive performance of the cathode material can be met.

Owner:LIAONING TECHNICAL UNIVERSITY

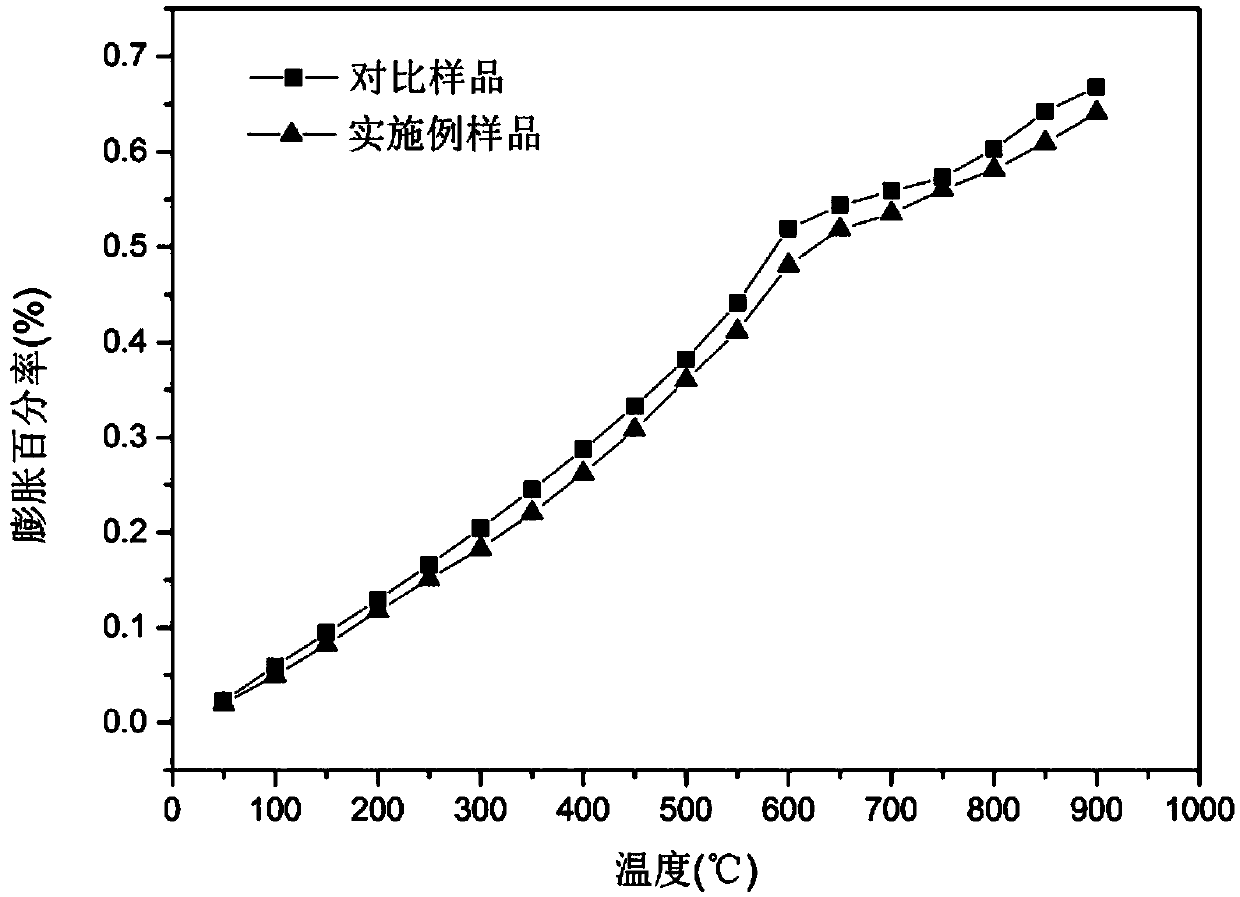

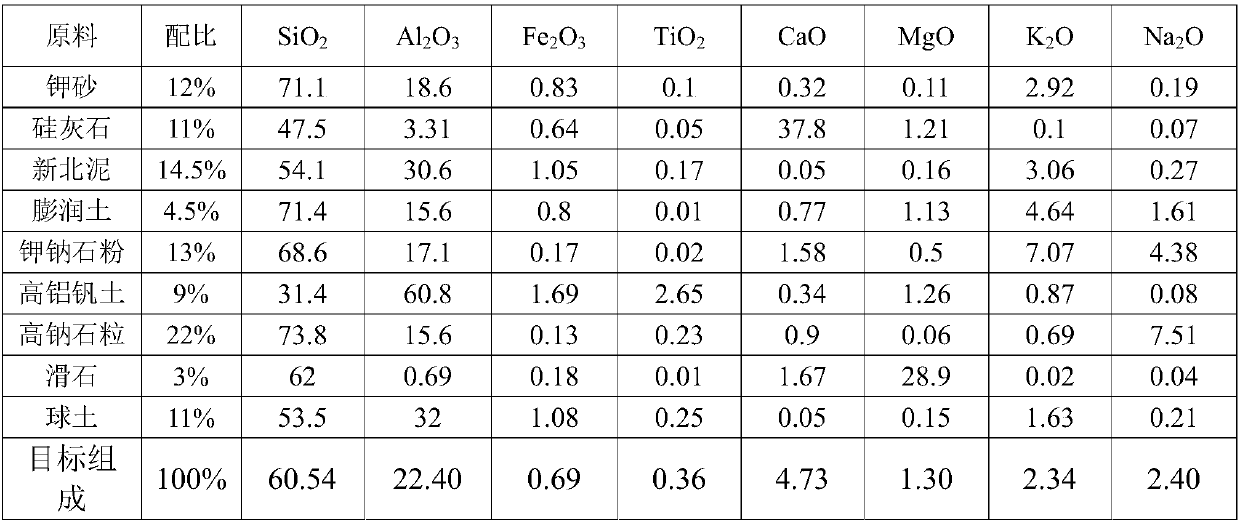

Large-size porcelain thin plate and production method thereof

The invention discloses a large-size porcelain thin plate and a production method thereof, wherein the large-size porcelain thin plate has an upper surface area of 1.62-2.88 m<2> and a thickness of 3.5-5.5 mm, and comprises the following raw materials by weight: 10-12% of potassium sand, 10-11% of wollastonite, 14.5-17.5% of Xinbei mud, 4-4.5% of bentonite, 12-13% of potassium sodium stone powder,7-9% of high bauxite, 21-22% of high sodium stone particles, 3-4% of talc, and 11-13% of ball clay. According to the present invention, by reducing the SiO2 content, the residual stress caused by thevolume change due to the quartz crystal form transformation during the firing cooling stage is reduced, and the content of the SiO2 glass phase is reduced, such that the product structure stability is good, the residual stress is low, no corner-chipping is generated during the machining, and the processing performance is significantly improved.

Owner:佛山市高明贝斯特陶瓷有限公司 +3

Coke slag tempering type decoking agent suitable for high-sodium coal and preparation method thereof and application thereof

ActiveCN105419903AHigh melting pointEffective destructionSolid fuelsFuel additivesHigh sodiumSodium Bentonite

The present invention relates to a coke slag tempering type decoking agent suitable for high-sodium coal and a preparation method thereof and an application thereof. The decoking agent comprises the following components in parts by weight: 1% to 90% of a magnesium compound, 1% to 85% of kaolin clay, 0% to 92% of bentonite, 0.5% to 20% of a copper compound, 0.1% to 20% of an oxidant, 0.1% to 10% of a catalyst, and 0.5% to 3% of a dispersant. According to the composition ratio of various substances including the magnesium compound, the kaolin clay, the bentonite, the copper compound, the oxidant, the catalyst and the dispersant, slag can be driven to fall in a combustion process of the high-sodium coal, formation of a low temperature eutectic mixture and coking can be avoided, release of alkali metals can be inhibited effectively in the combustion process of the high-sodium coal, coke slag chemical compositions and physical structures are changed by combustion, and contamination and coking of a boiler heated surface are prevented or relieved.

Owner:山东默锐环境产业股份有限公司 +1

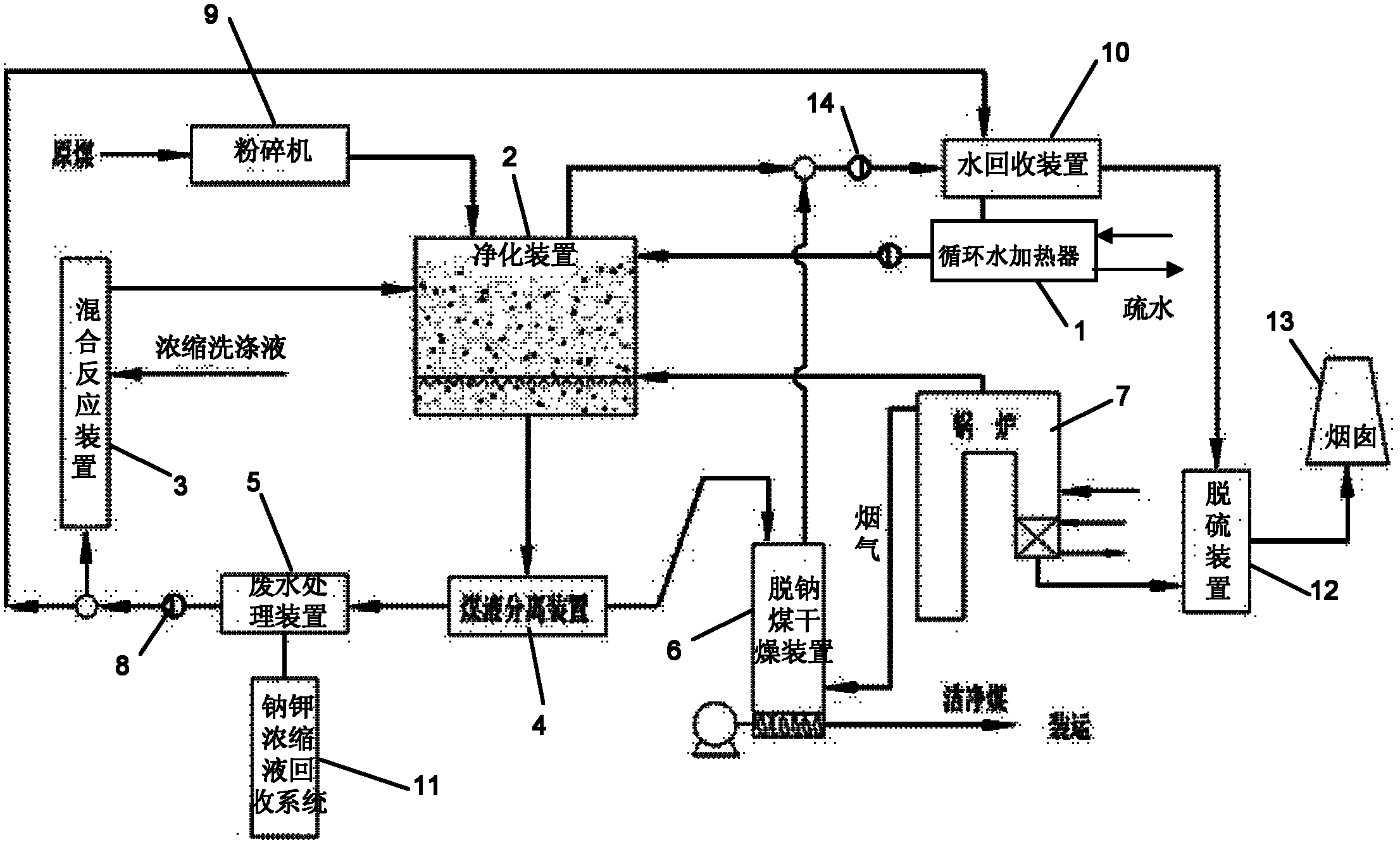

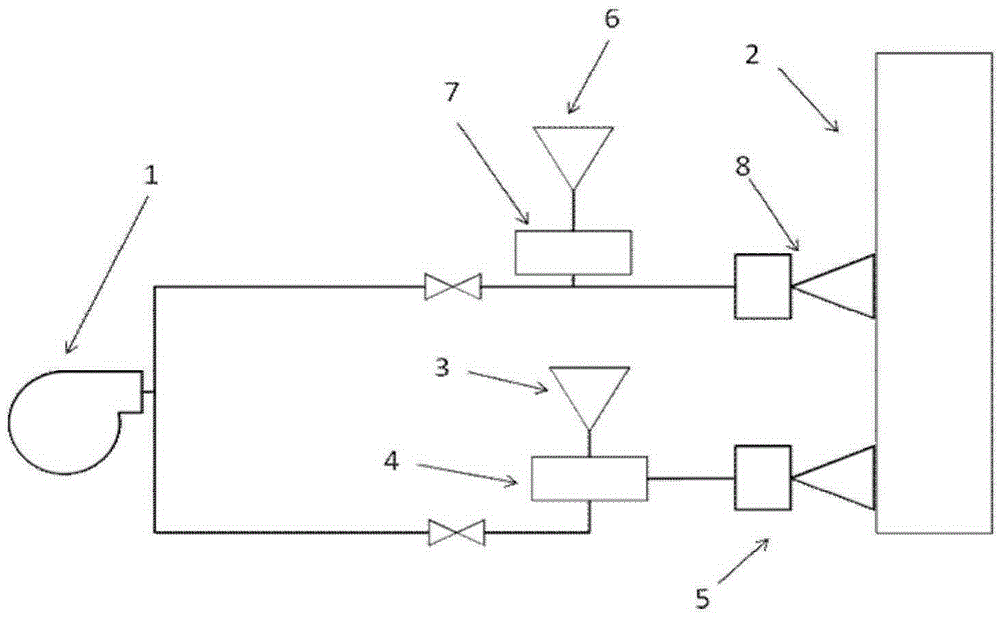

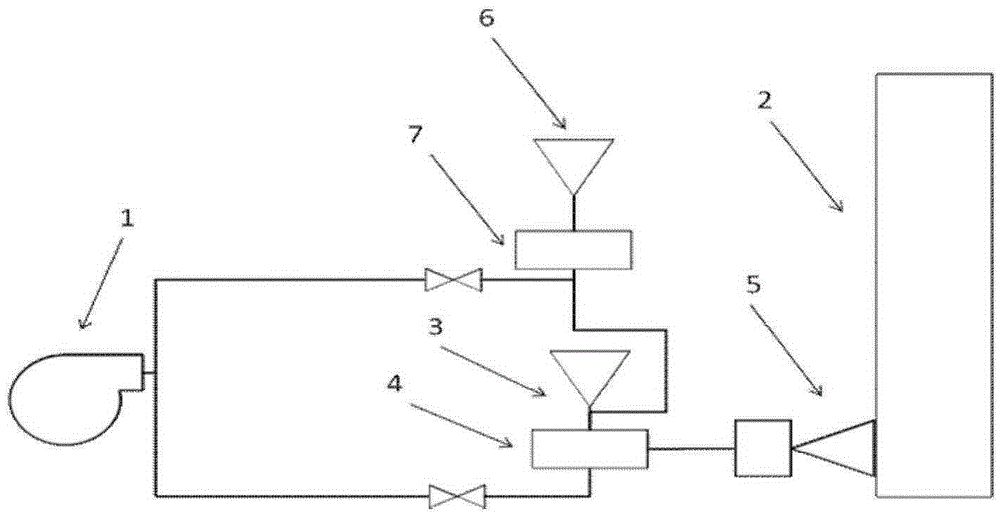

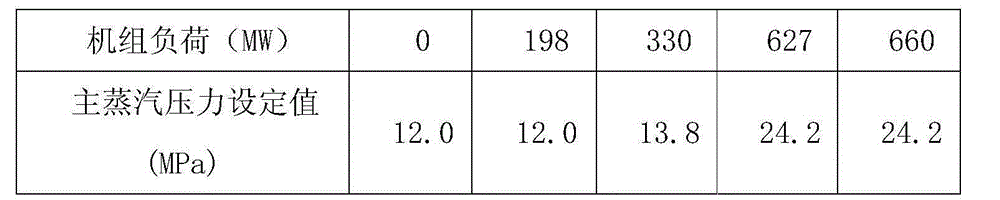

High-sodium coal sodium removal, quality improvement fan mill pulverization and water recovery combined cycle power generation system

InactiveCN103148495AReduce sodium, ashReduce mercury, sulfurSteam useEnergy industryHigh sodiumEngineering

The invention relates to a high-sodium coal sodium removal, quality improvement fan mill pulverization and water recovery combined cycle power generation system, which at least comprises a drying pipe, a coal mill, a pulverized coal separator, a pulverized collector, a pulverized coal bunker, an air and pulverized coal mixer and a boiler which are sequentially and serially connected. The system additionally comprises a mixing chamber, a steam turbine, and a steam exhaust waste heat recovery device, a steam exhaust condensation and recovery device, a raw coal sodium removal device, a separation device and a water treatment unit which are sequentially connected. The system has the advantages that the content of alkali metals in raw coal is reduced, the problems of furnace coking, heating surface contamination and corrosion and the like caused to a high-sodium-coal-fired power generator set are greatly improved or fundamentally solved, the system is effective and applicable to quality improvement treatment of East Junggar coal and other high-sodium, high-water-content and poor-quality coal, the process is simple, the operation safety is high, the investment is small, the energy is saved, the environment is protected, the goal of circular economy is realized, and the system not only can be used for supplying high-quality clean coal, but also can be used for high-sodium-coal-fired pithead power generator sets to realize coal and electricity co-production.

Owner:上海机易电站设备有限公司

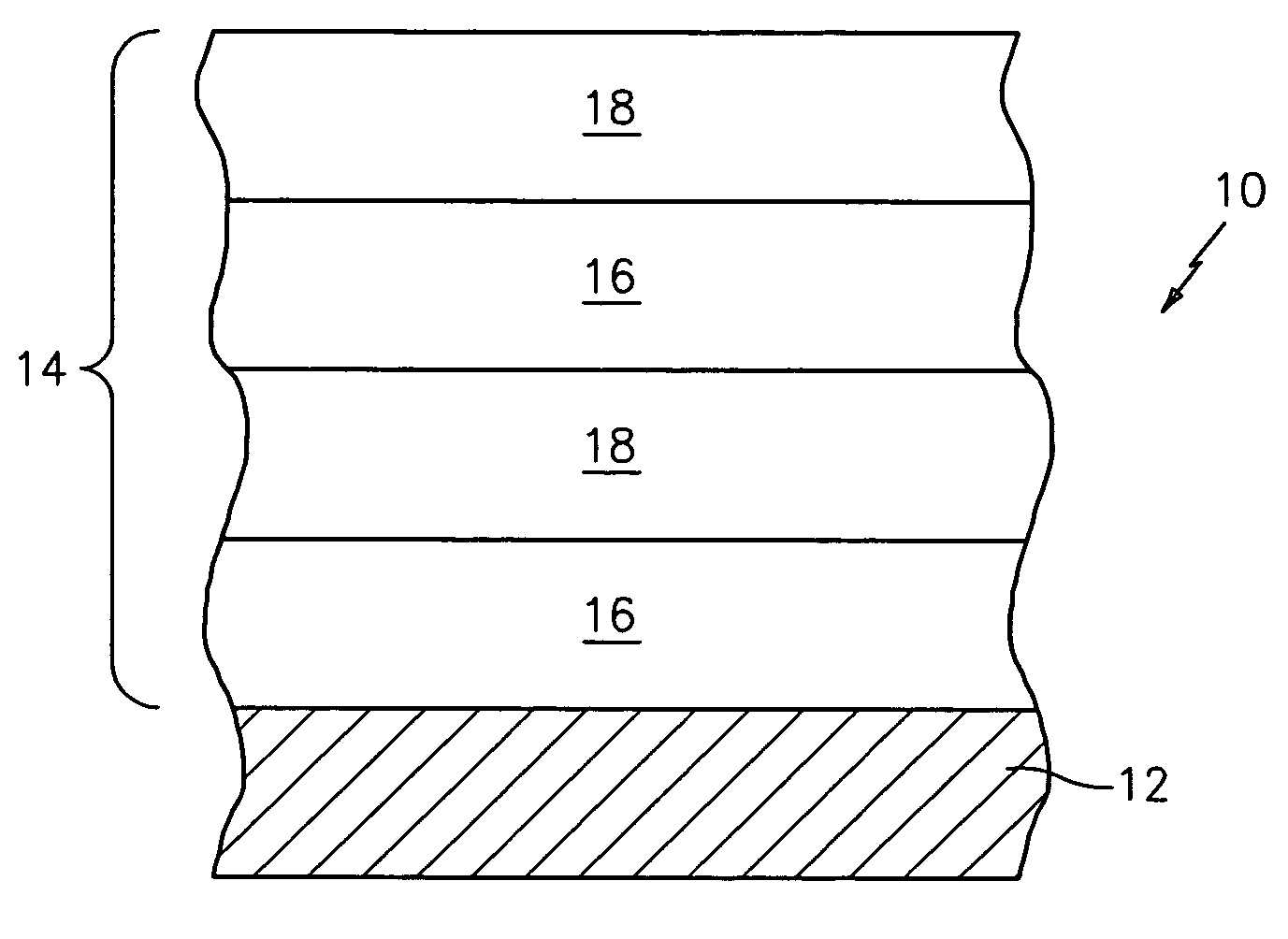

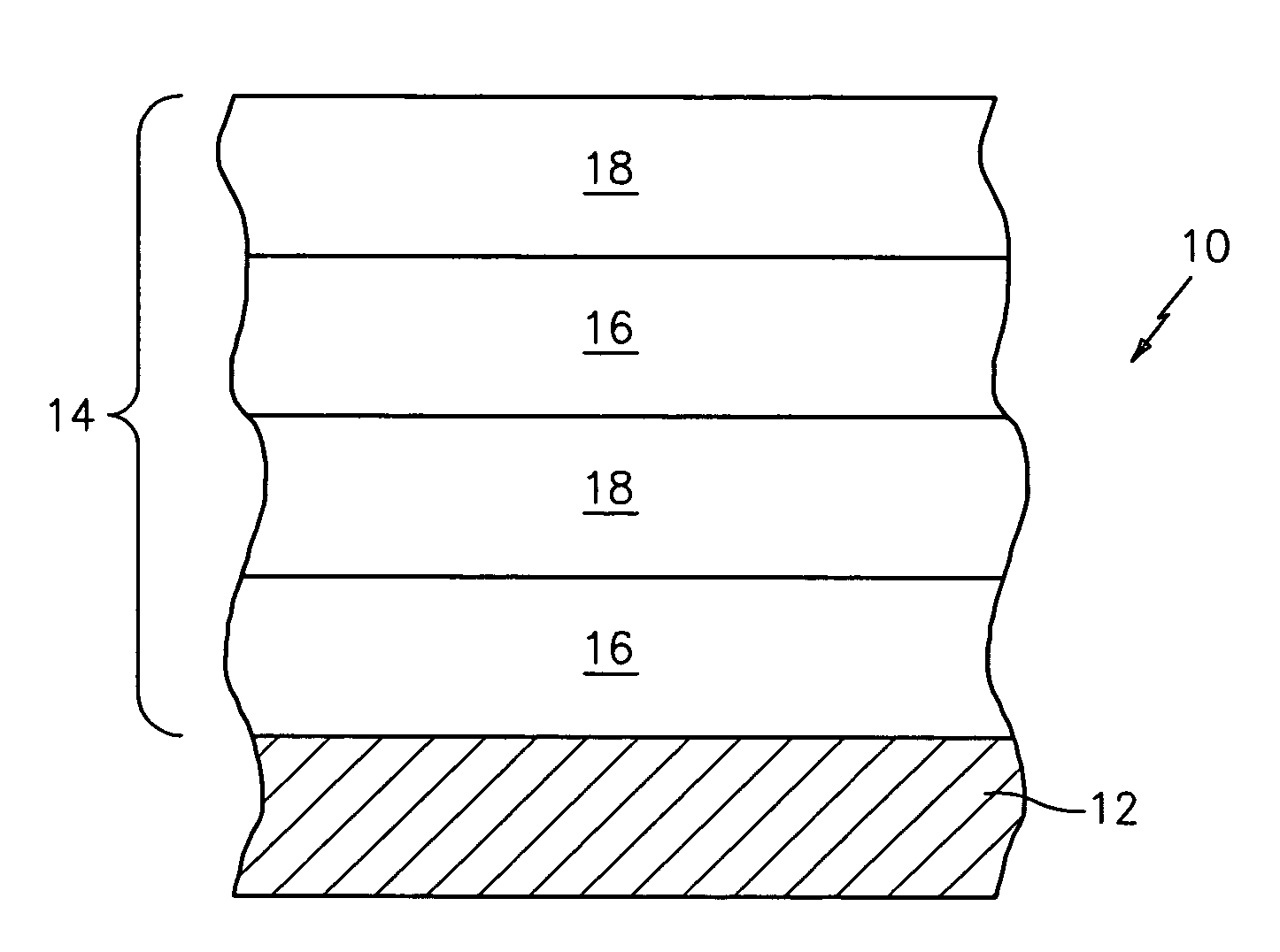

High sodium containing thermal barrier coating

ActiveUS20080044686A1Natural mineral layered productsSuperimposed coating processHigh sodiumSodium silicate

A turbine engine component has a substrate and a thermal barrier coating deposited onto the substrate. The thermal barrier coating comprises a ceramic material having a sodium containing compound incorporated therein. The sodium containing compound is present in a concentration so that when molten sand reacts with the coating, sodium silicate is formed as the by product.

Owner:RAYTHEON TECH CORP

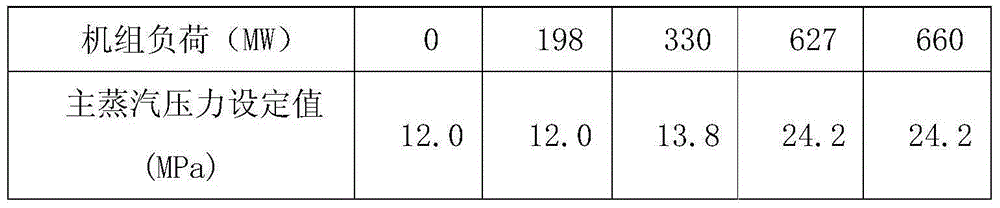

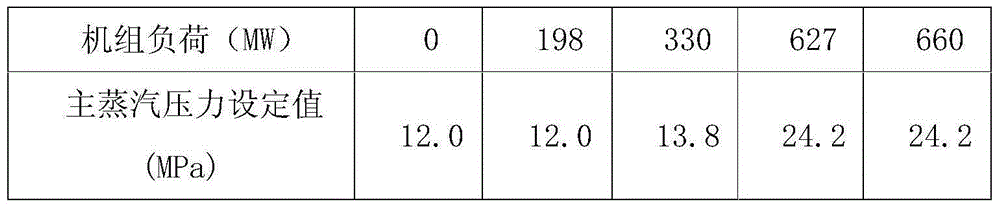

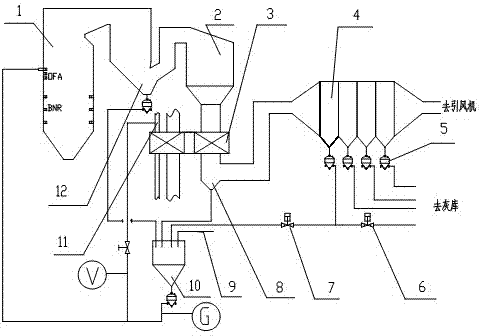

Induced draft fan RB control method of high-sodium lignite tower boiler unit

InactiveCN105135405AResolve downtimeImprove stabilityFuel supply regulationBoiler controlHigh sodiumControl mode

The invention discloses an induced draft fan RB control method of a high-sodium lignite tower boiler unit. After induced draft fan RB happens, a DCS is controlled in following manners that a) a unit control manner is switched to a TF manner, wherein master control of a boiler is switched into a manual manner; b) a main steam pressure set value firstly tracks actual main steam pressure, and then the RB sliding and pressing rate is changed into a target pressure value; c) air feeders on the same side are tripped, and the adjustable vane opening degrees of induced draft fans and air feeders which are not tripped on the opposite side are each increased at a certain rate on the basis of an original opening degree till a target value is achieved; d) upper layer coal mills are sequentially tripped, and finally four coal mills are reserved to operate; and a lower layer plasma burner is started to operate, and an upper layer plasma burner is started to operate after time is delayed by t2; and e) when a load reaches a target load, induced draft fan RB control automatically ends, or after unit main parameters are stable, an operating person manually confirms that induced draft fan RB control ends. The induced draft fan RB control method can improve RB control stability and safety.

Owner:STATE GRID CORP OF CHINA +2

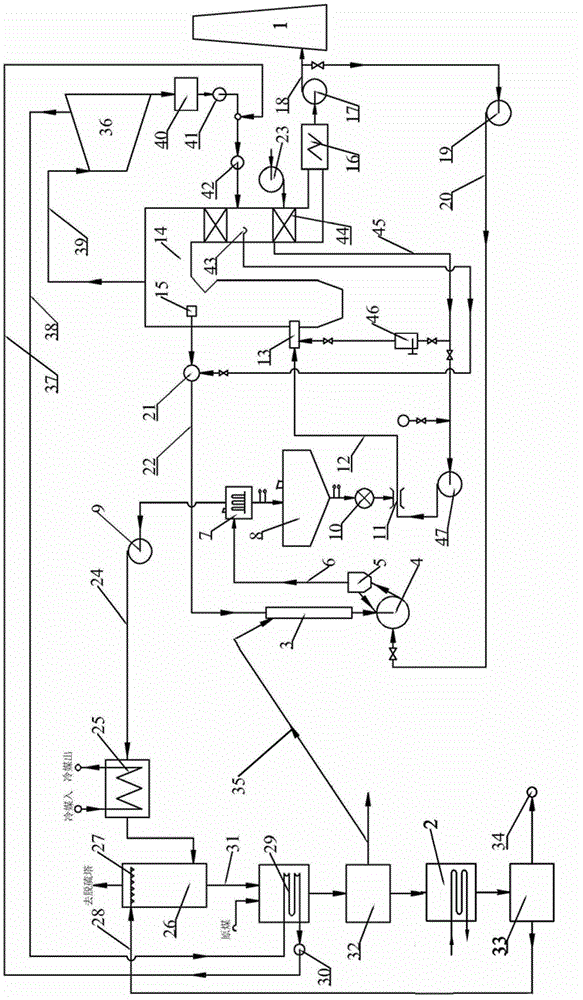

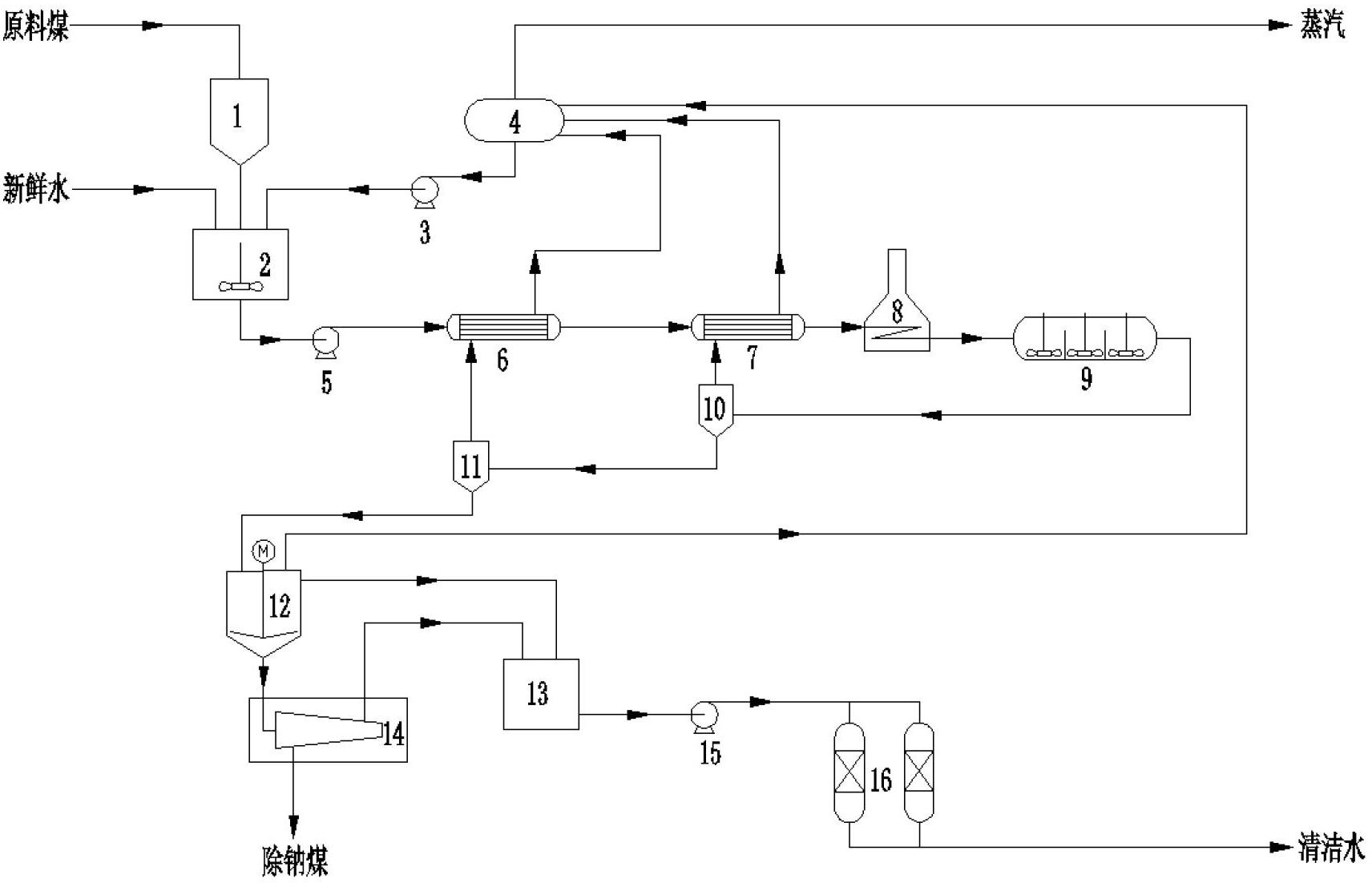

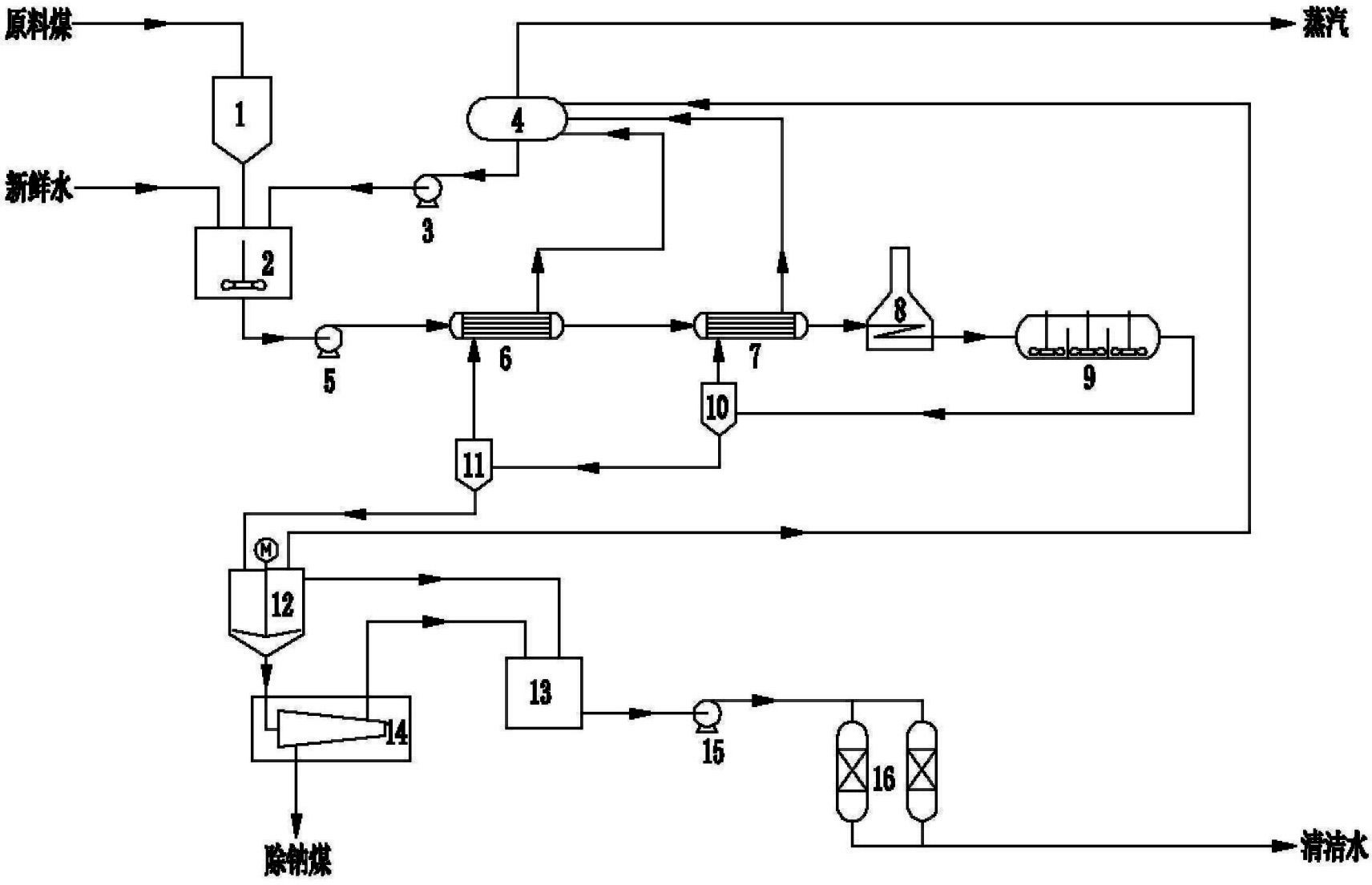

Process for removing sodium in high-sodium coal and system thereof

The invention relates to a process technology for removing sodium in high-sodium coal, which can solve the problems that a special removal process for the high-sodium coal is absent in the prior art, and follow-up processes and equipment are seriously affected. According to the process disclosed by the invention, sodium element in the coal can be removed by utilizing the principle of dissolving asodium compound at high temperature and high pressure and performing clarification and centrifugal separation through a black water treatment system to separate the sodium element from coal solid particles, the coal particles after sodium removal and ash removal and clean water can be simultaneously obtained, and the process is environment-friendly and has the advantages of simple process, high sodium removal efficiency, energy conservation and consumption reduction, and is suitable for purification, development and utilization of the sodium-containing coal and particularly suitable for coal gasification, IGCC (integrated gasification combined cycle) power generation and other technologies of the high-sodium coal after the sodium removal.

Owner:WUHUAN ENG

Stabilized flash calcined gibbsite as a catalyst support

InactiveUS20070098611A1Improve thermal stabilityLow costNitrogen compoundsInternal combustion piston enginesHigh sodiumChemical reaction

A low cost support useful in chemical reactions and automotive arts is formed by rehydrating a flash calcined gibbsite in an aqueous acidic solution. The rehydrated support can be subsequently stabilized by doping with a stabilizing metal such as lanthanum. The alumina support has excellent thermal stability, high sodium tolerance, high activity with low precious metal loading, and high pore volume and surface area.

Owner:ENGELHARD CORP

Method and system for preventing boiler heating surface from being contaminated through circulation of wearable materials

ActiveCN103615714AAvoid heavily soiled stateGuaranteed uptimeSolid removalCombustion apparatusHigh sodiumProcess engineering

The invention discloses a method and a system for preventing a boiler heating surface from being contaminated through circulation of wearable materials and belongs to the field of boilers. The method comprises the following steps of sending mixtures of the wearable materials and granular fly ash into burning wind region of a boiler, mixing the mixtures with exhaust gas of the boiler, and circularly recycling the wearable materials and the granular fly ash. The system comprises a circulated material caching tank, wherein a material outlet of the circulated material caching tank is communicated with the burning wind region of the boiler, a material inlet of the circulated material caching tank is communicated with a coal economizer ash bucket, a denitration inlet-outlet ash bucket, an air pre-heater ash bucket in the boiler as well as one or multiple parts in a first electric field of a dust remover, the circulated material caching tank is provided with a material feeding hole, and a pipeline for communicating the material outlet of the circulated material caching tank with the burning wind region of the boiler is further communicated with a primary hot wind branch pipe. by utilizing the method and the system, the convection heating surface of a high-sodium coal burning boiler can be prevented from being contaminated, the heating surface can be prevented from being seriously contaminated with low initial investment and operation costs on the basis that the structure of the boiler is basically unchanged, and the Zhundong (a region in a Uygur Autonomous Region) high-sodium coal can be completely burnt by the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Process for preparing sodium percarbonate

InactiveCN1463913AReduce heat loadReduce the amount neededOrganic compound preparationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh sodiumReaction rate

The present invention belongs to the field of oxygen-containing bleaching agent preparing technology. Sodium carbonate solution is emulsified and hydrated to prepare hydrated sodium carbonate suspension, and hydrated sodium carbonate suspension is reacted with 25-70 % concentration hydrogen peroxide solution to obtain crystal while adding sodium chloride or sodium sulfate as sallification agent,sodium silicate, organic phosphonic acid, EDTA or its sodium salt as crystallization assistant. The said preparation process has fast reaction rate and lowered sodium carbonate content in mother liquid, high sodium percarbonate yield and low material consumption, and the sodium percarbonate product has high active oxygen content, large grain size, high humid and heat stability.

Owner:ZHEJIANG JINKE CHEM

Preparation method of nitrogen-doped carbon composite transition metal carbodiimide

ActiveCN108390032AReduce manufacturing costLow priceCell electrodesSecondary cellsHigh sodiumCarbon composites

Disclosed is a preparation method of a nitrogen-doped carbon composite transition metal carbodiimide material. The method comprises the steps of: grinding an inorganic transition metal salt and a carbon and nitrogen containing organic compound to obtain a mixture, the mass ratio of the inorganic transition metal salt to the carbon and nitrogen containing organic compound in the mixture being 4:1-1:7; holding the mixture in an argon atmosphere at 140-200 DEG C for 10-50 min, and then holding at 300-700 DEG C for 30 min to 4h to obtain the nitrogen-doped carbon composite transition metal carbodiimide material. By compounding the prepared transition metal material structure with a nitrogen-doped carbon material, the conductivity and structural stability of the material during charge and discharge can be significantly improved. The nitrogen-doped carbon composite transition metal carbodiimide material prepared by the method has extremely high sodium ion storage performance, high charge anddischarge capacity and excellent rate performance.

Owner:SHAANXI UNIV OF SCI & TECH

A carbon nanomaterial and its application in sodium ion battery

InactiveCN108987750AImprove electrochemical performanceHigh specific capacityMaterial nanotechnologyHybrid capacitor electrodesHigh sodiumAlkyne

The invention discloses a preparation method of graphite alkyne carbon nano electrode material applied in sodium ion energy storage device, which improves capacity storage, large current charging anddischarging and long cycle performance of sodium ion battery by introducing an alkyne bond connected by a benzene ring and a nano pore structure into the carbon nano material. Graphene nanostructureswith special nanowires, nano-walls, nanoclusters or nanospheres were synthesized by optimizing the morphology and material quality of the matrix in the mixed solvent containing nitrogen ligands. The nanometer graphite alkyne prepared by the method has the characteristics of simple and controllable preparation process, stable material structure, and the like, can be directly applied to sodium ion energy storage devices, has high sodium storage specific capacity and good cycle life, and has broad application prospects in the field of sodium ion energy storage batteries.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

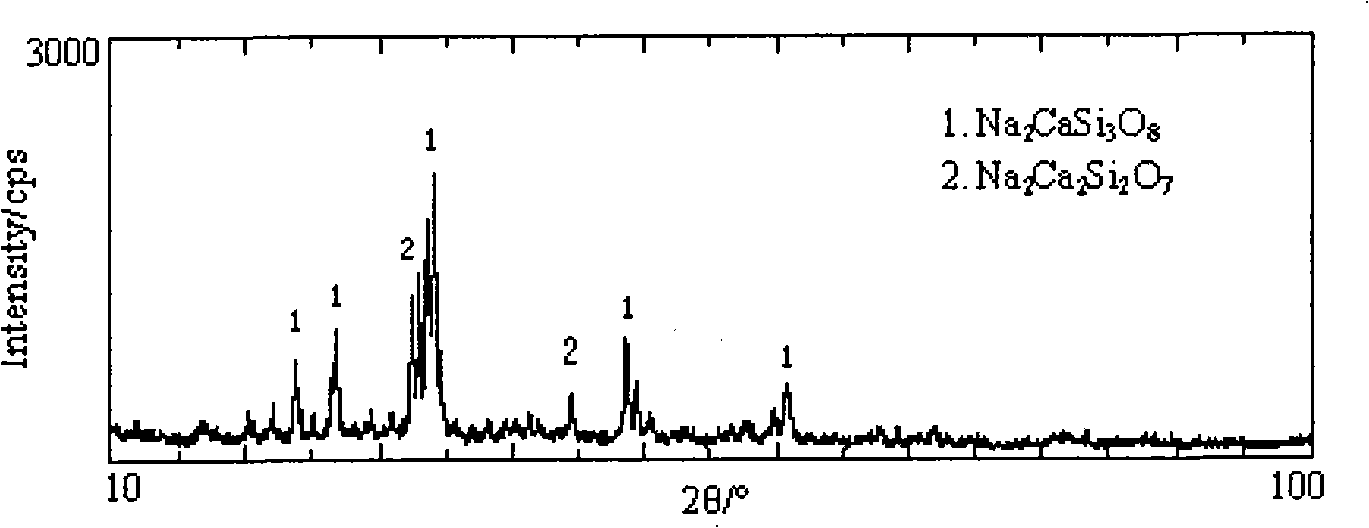

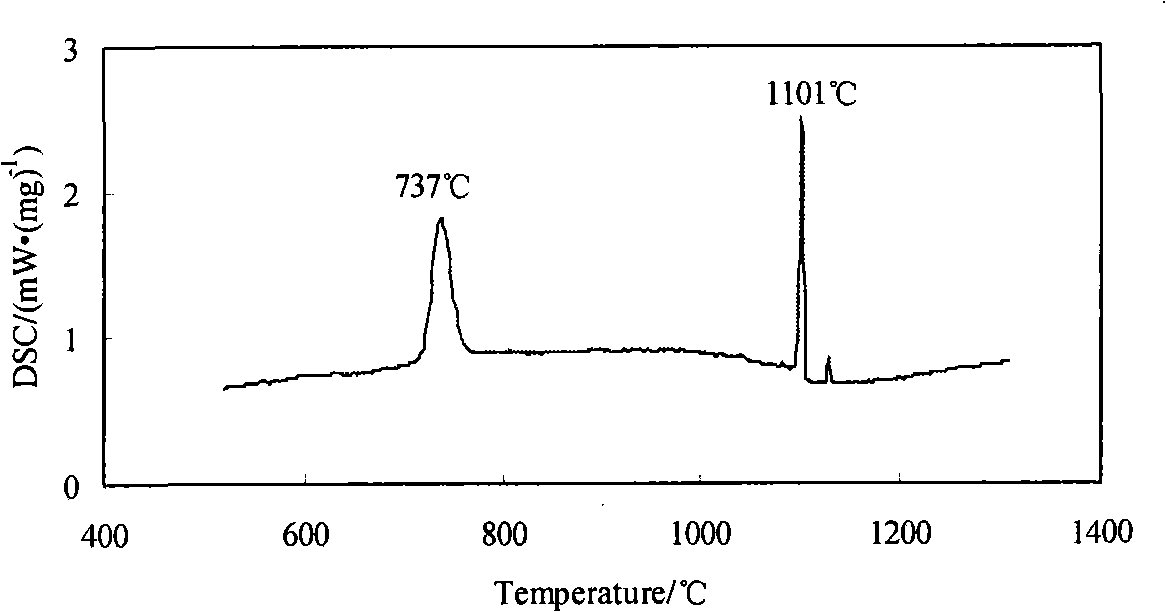

Eastern Junggar coal slagging and contamination improvement additive and application method thereof

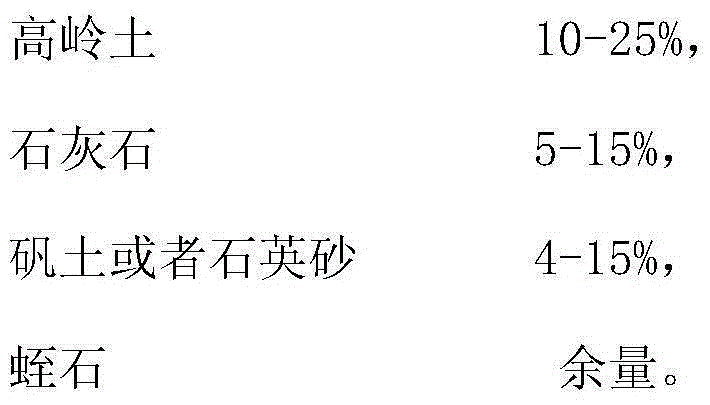

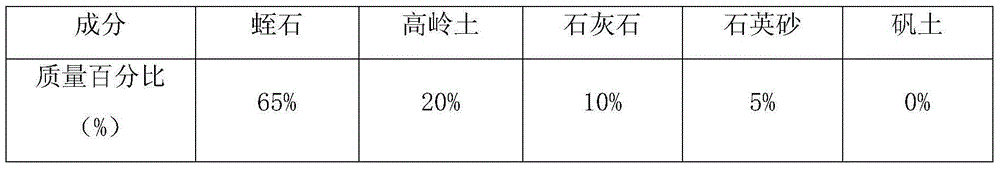

InactiveCN105132075AImproved ash fusion propertiesImprove melting propertiesSolid fuelsHigh sodiumSlag

The present invention discloses an eastern Junggar coal slagging and contamination improvement additive comprising the following components by mass: 10-25% of kaolin, 5-15% of limestone, 4-15% of alumina or quartz sand and the balance of vermiculite. The present invention also provides a method using the eastern Junggar coal slagging and contamination improvement additive to inhibit alkali metal release in eastern Junggar coal combustion, the additive is added into eastern Junggar high sodium coal, the mass ratio of the additive and eastern Junggar coal is 0.02 to 0.1 :1, after mixing, the additive and the eastern Junggar are sent into a coal mill for achieving the crushing and thorough mixing of the raw coal and the additive, and the pulverized coal and additive mixture is sequentially passed through a centrifugal separator, a pulverized coal exhauster and a pulverized coal combustor and sent into the hearth of a boiler for combustion. By adding of the eastern Junggar coal slagging and contamination improvement additive, the alkali metal release can be effectively suppressed by more than 50% of the alkali metal release, the eastern Junggar coal slagging and contamination improvement additive has some role in sulfur fixation, the coal ash melting characteristics can be significantly improved, a dense slag layer structure near a water cooling wall can be destroyed, and slag substance aggregation can be prevented.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

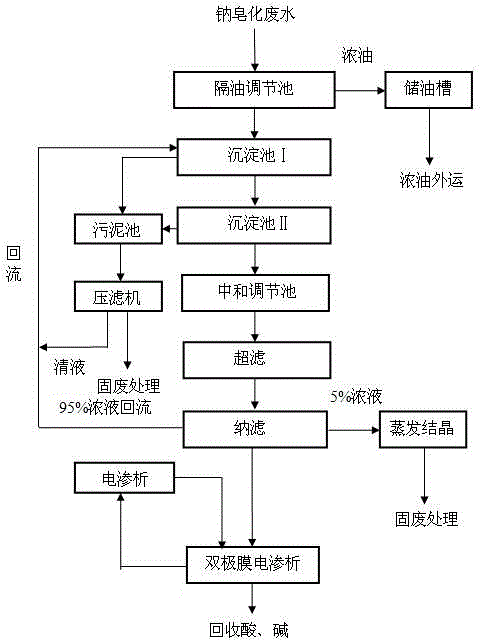

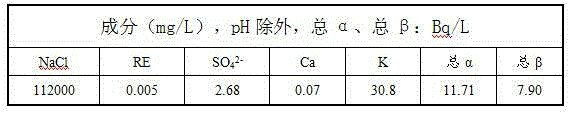

Acid and alkali resource recovery process technology from sodium saponification waste water

InactiveCN104591459AAchieving zero emissionsRealize high-content sodium chloride acid-base resourceFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processHigh sodiumResource recovery

The invention relates to an acid and alkali resource recovery process technology from sodium saponification waste water discharged in a rare earth separating and manufacturing process. The acid and alkali resource recovery process technology of the invention mainly comprises three steps, including pre-treating of the waste water, treating by a membrane process and recycling of acids and alkalis. According to the process of the invention, acids and alkalis needed in the rare earth separating process can be produced from the sodium saponification waste water with high sodium chloride content, so as to effectively realize the purpose of zero release and acid and alkali resource recovery after treatment of the waste water.

Owner:蓝星工程有限公司

Method for preparing viscose fiber

InactiveCN101104959AEasy to getImprove filtering effectMonocomponent cellulose artificial filamentWet spinning methodsHigh sodiumSulfate

The invention discloses a preparation method of viscose fibers, which is characterized in that the cellulose pulp is used in the viscous glue preparation procedure; the cellulose pulp together with an additional modifier are processed to cellulose xanthate with high esterification degree and ripeness degree; the spinning procedure is performed under such conditions as low coagulation bath temperature, low acidity and high sodium sulfate concentration, without using zinc sulfate which results in serious environmental pollution; the thickness of fiber skin is increased by drafting; and the produced viscose fiber has high strength and high wet modulus. The invention solves the problem of zinc pollution in the prior art, produces viscose fibers with high strength, high wet modulus, and good tension, and overcomes the disadvantages that the fabric is easy to deform, instable in size and nonresistant against base when the viscose fiber is in wet state. Compared with the prior viscose staple fibers, the fabric made of the inventive fibers is superior in high strength and good resistance against deformation and alkali.

Owner:CHTC HELON

Modified bamboo pulp fiber wallpaper preparation method

InactiveCN105544310AImprove antibacterial propertiesSound-absorbing and heat-insulatingBiochemical fibre treatmentVegetal fibresHigh sodiumFiber

The invention discloses a modified bamboo pulp fiber wallpaper preparation method, and belongs to the wallpaper technical field; the method comprises the following steps: using bamboo pulp fiber as raw material; using high sodium iodate solution to soak and oxidize the bamboo pulp fiber so as to obtain oxidation bamboo pulp fiber; combing the bamboo pulp fiber with sericin for graft modification under high temperature; drying the material, and carrying out ultrasonic vibration reaction with chitosan degraded liquid; filtering the material so as to obtain filter residue; using cuprammonium solution to soak and wash the filter residue so as to obtain the modified bamboo pulp fiber; using paper pulp mold equipment to process the modified bamboo pulp fiber through cold press and hot pressing procedures, thus obtaining the modified bamboo pulp fiber wallpaper. Embodiment shows, the bamboo pulp fiber wallpaper is more obvious in antibiosis capability, and bacteriostasis rate can reach above 65%; the novel wallpaper is sound-absorbing, good in heat insulation, waterproof moistureproof, and can prolong the life for 2-3 years when compared with a normal wallpaper.

Owner:ZHEJIANG FANGWEI DECORATION MATERIALS CO LTD

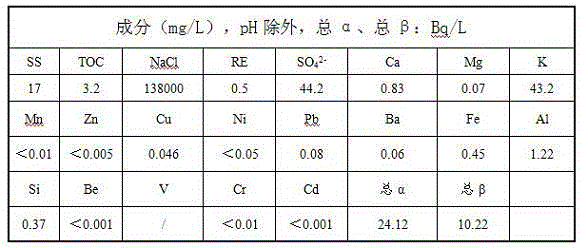

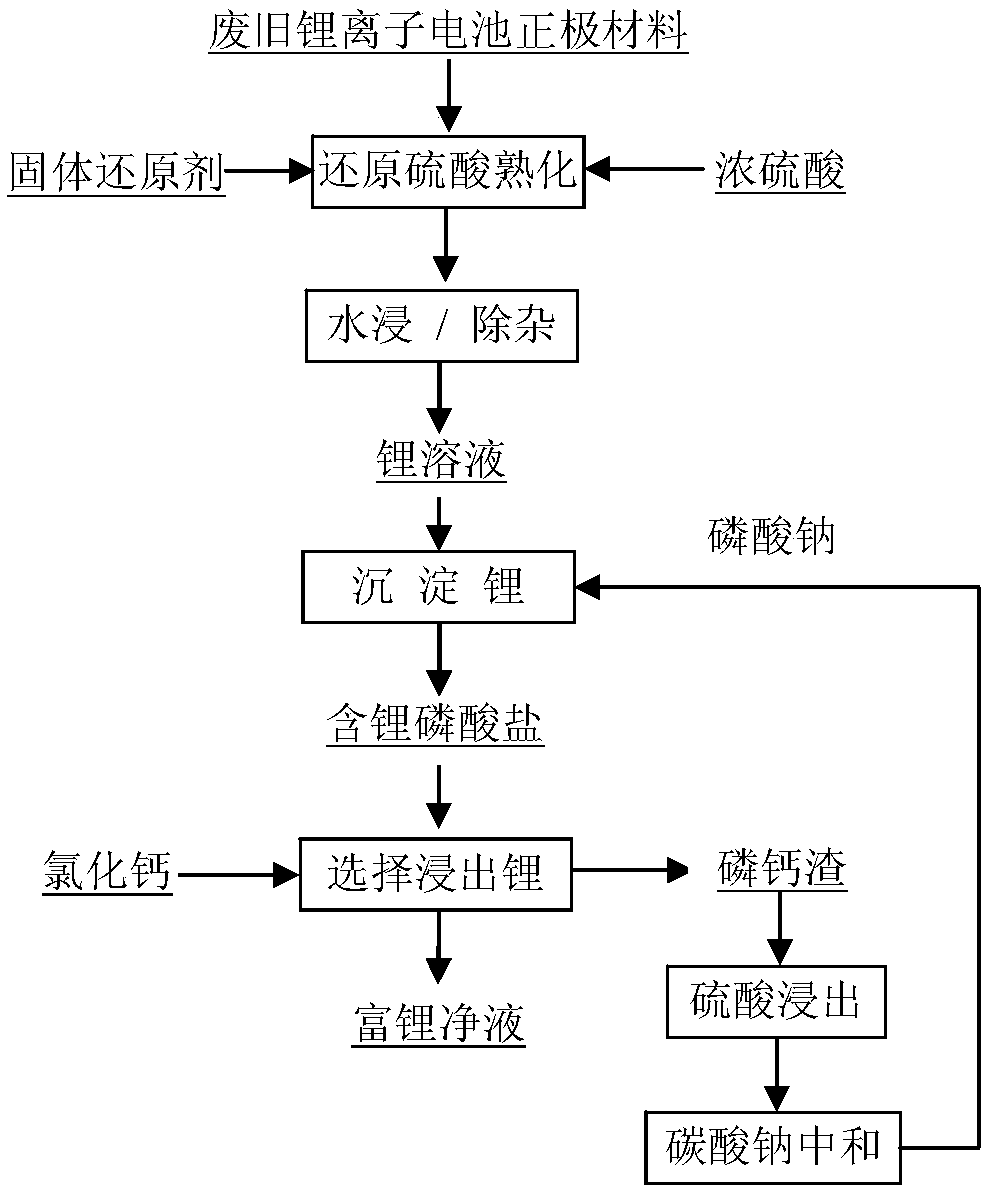

Method for producing lithium-rich pure solution from waste lithium ion battery positive electrode active material

ActiveCN108767353AHigh recovery rateAvoid pre-concentrationWaste accumulators reclaimingBattery recyclingHigh sodiumLithium chloride

The invention discloses a method for producing a lithium-rich pure solution from a waste lithium ion battery positive electrode active material, belongs to the technical field of waste lithium ion battery material recycling, and particularly provides a method for producing a lithium-rich pure solution from a reduced sulfuric acid leaching solution of a positive electrode active material. A high-sodium and low-lithium lithium sulfate solution obtained after the positive electrode active material is subjected to reduction leaching and leaching solution purification is subjected to lithium deposition with phosphoric acid or phosphate to obtain lithium-containing phosphate enrichment; lithium is selectively leached out from the lithium-containing phosphate enrichment by using less than a theoretically required amount of a calcium chloride solution to obtain the lithium-rich pure solution and lithium-containing phosphorus-calcium residues; and the lithium-containing pure solution is used for producing a product such as battery-grade lithium carbonate or lithium chloride through a conventional method such as deposition or crystallization, and a solution obtained after the lithium-containing phosphorus-calcium residues are subjected to sulfuric acid leaching and neutralization returns to the lithium deposition step for cyclic use. According to the method, the lithium-rich pure solution can be directly produced from the high-sodium and low-lithium solution without pre-concentration, the energy consumption and the cost are low, and the lithium recycling rate is high.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Treatment method for high-sodium-content fluoride-containing waste water

InactiveCN104803522AReduce consumptionLess distractionMultistage water/sewage treatmentCalcium hydroxideHigh sodium

The invention discloses a treatment method for high-sodium-content fluoride-containing waste water. The treatment method comprises the following steps of firstly, preparing fluosilicic acid: adding powdered silica in waste water, and filtering after the reaction is ended, wherein filtrate is fluosilicic acid pretreatment fluid; secondly, flocculating lime: adding calcium hydroxide powder in the fluosilicic acid pretreatment fluid, and controlling the pH value of an end point to be 6 to 9; adding a polyacrylamide flocculant, performing a stirring reaction, then standing and precipitating, and taking out supernate, namely primary effluent; thirdly, performing advanced treatment: adding a deep fluoride removing absorbent, performing a stirring reaction, and then standing and precipitating, wherein the precipitated bottom sludge can be recycled, supernate is secondary effluent, and the concentration of the supernate can reach over 5mg / L. According to the treatment method disclosed by the invention, the problems that lime mud in the high-sodium-content fluoride-containing waste water is difficultly precipitate and the effluent difficultly reaches the standard are solved; the consumption of lime is less, the discharge amount of solid wastes is small, effluent fluoride can be stably reduced to below 5mg / L, and the effluent is discharged after the standard is reached.

Owner:湖南有色金属投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com