Process for removing sodium in high-sodium coal and system thereof

A high-sodium coal and sodium system technology, which is applied to the high-sodium coal removal process and its system field, can solve the problems that are not described, and achieve the effects of improving quality, good sodium removal effect, and shortening production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The main indicators of raw coal are as follows:

[0036] Total water content 31.9 wt%, dry basis ash content 8.92 wt%, Na 2 The content of O is as high as 12.78wt%.

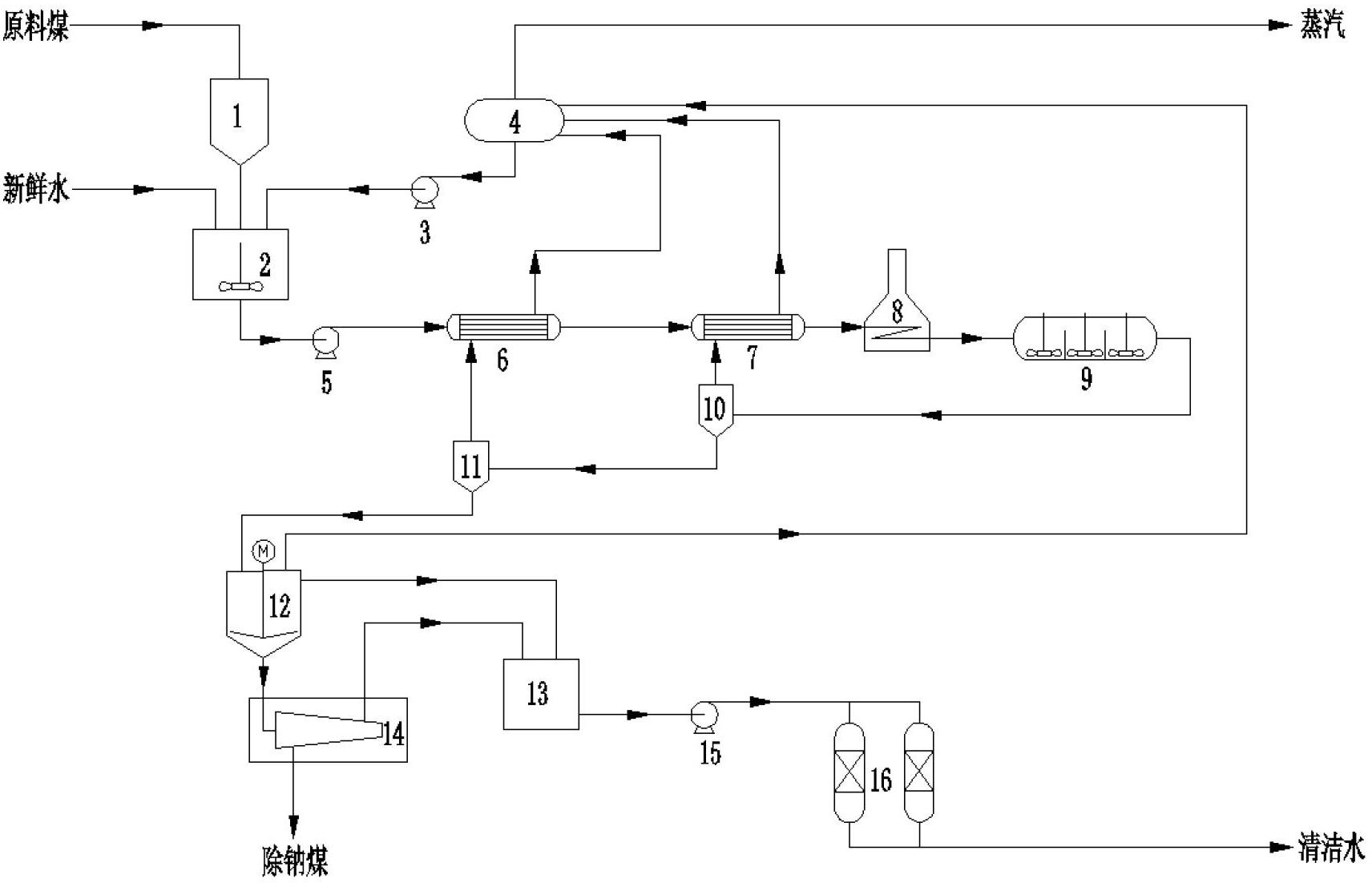

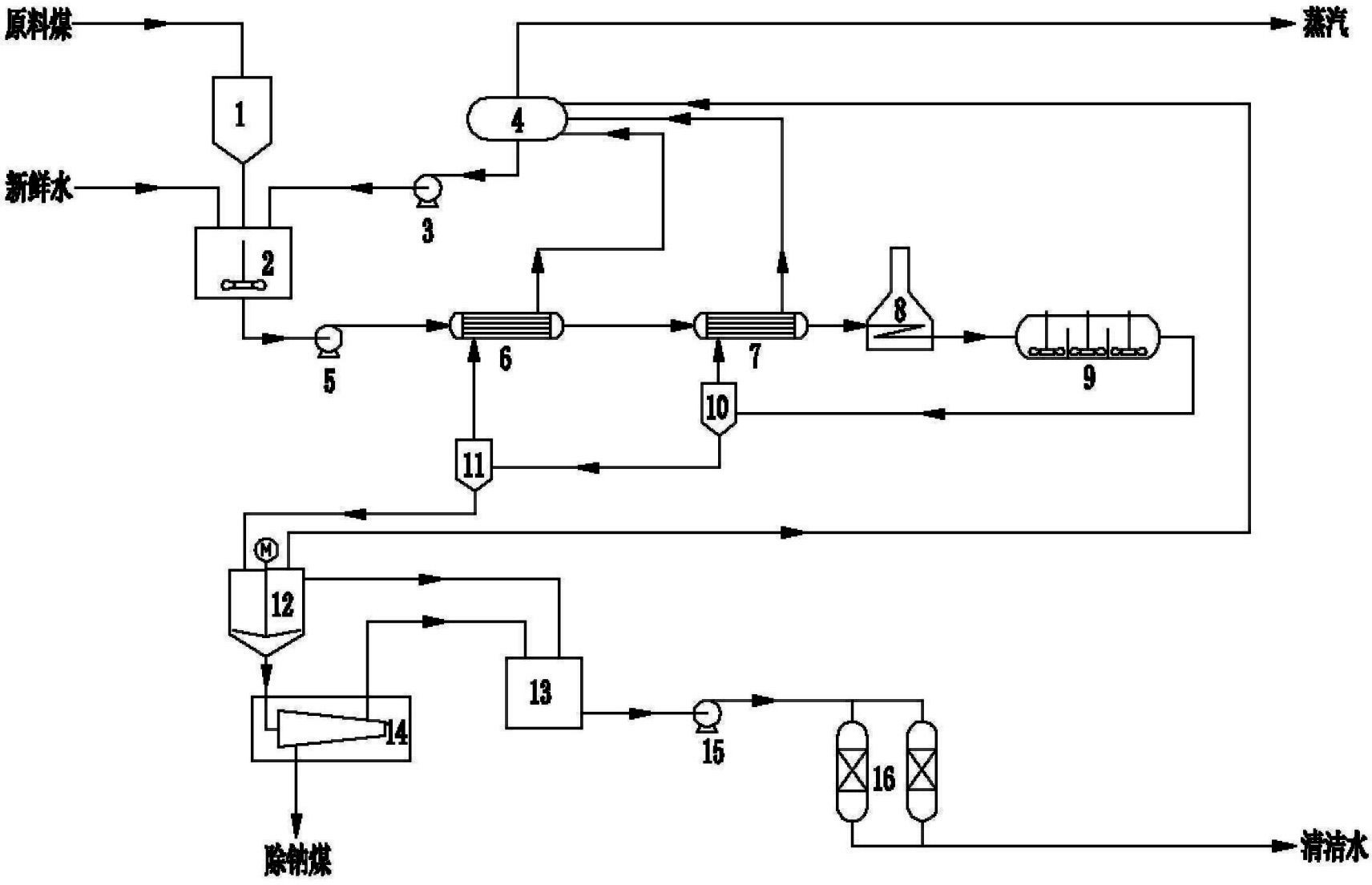

[0037] (1) High-sodium coal is sent to the mixing tank 2 through the lock hopper 1, and water (including fresh water and condensate from the steam drum circulation) is added to stir to make water-coal slurry. The weight ratio of water to coal is 2.5:1~1: 3. The stirring speed is 500-1500 rpm;

[0038] (2) The coal-water slurry obtained in step (1) passes through the high-pressure pump 5, the tube side of the primary heat exchanger 6 and the secondary heat exchanger 7, and the flash water from the low-pressure flash tank 11 and the high-pressure flash tank 12 After the steam is preheated to 130-170°C, it is sent to the heating furnace 8 to be heated to 200-270°C, and then sent to the autoclave 9 to pressurize to 80-160 barg;

[0039] (3) Send the coal-water slurry obtained in step (2) into the high-press...

Embodiment 2

[0044] The main indicators of raw coal are as follows:

[0045] Total water content 25.4 wt%, dry basis ash content 7.35 wt%, Na 2 The content of O is 6.53 wt%.

[0046] Except that the heating temperature of the coal-water slurry in step (2) is changed to 320-380° C., and the pressure is changed to 220-280 barg, the rest is the same as that of Example 1.

[0047] The water content in the sodium-removed coal obtained by the above-mentioned sodium-removal process method is about 2.8 wt%, the dry basis ash content is 2.8 wt%, and the Na 2 The content of O is 0.2 wt%.

[0048] The resulting clean water has a water content ≥ 99.9 wt%, ash content ≤ 20 ppm, Na 2 O content ≤ 2.5 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com