Patents

Literature

194 results about "Integrated gasification combined cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

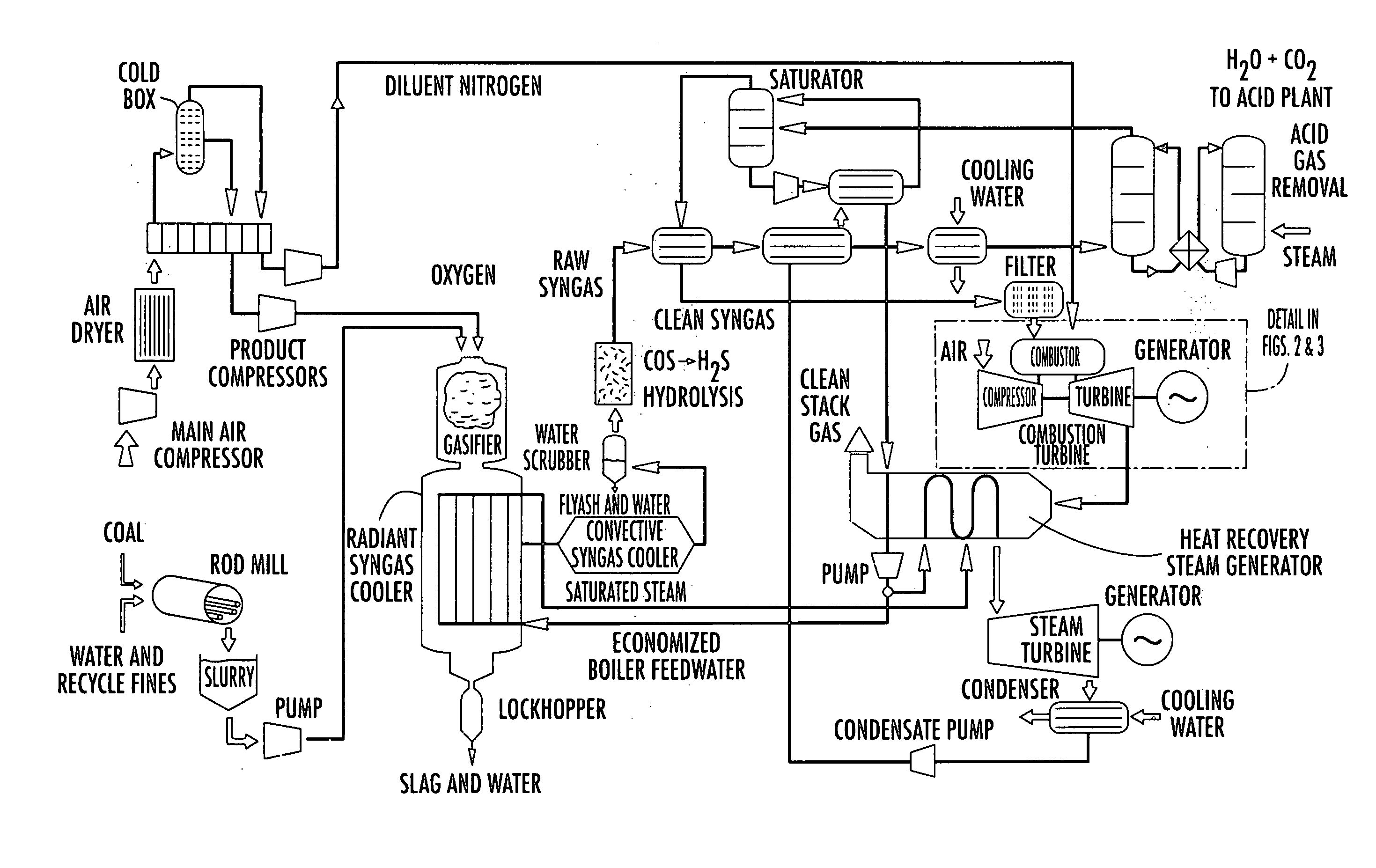

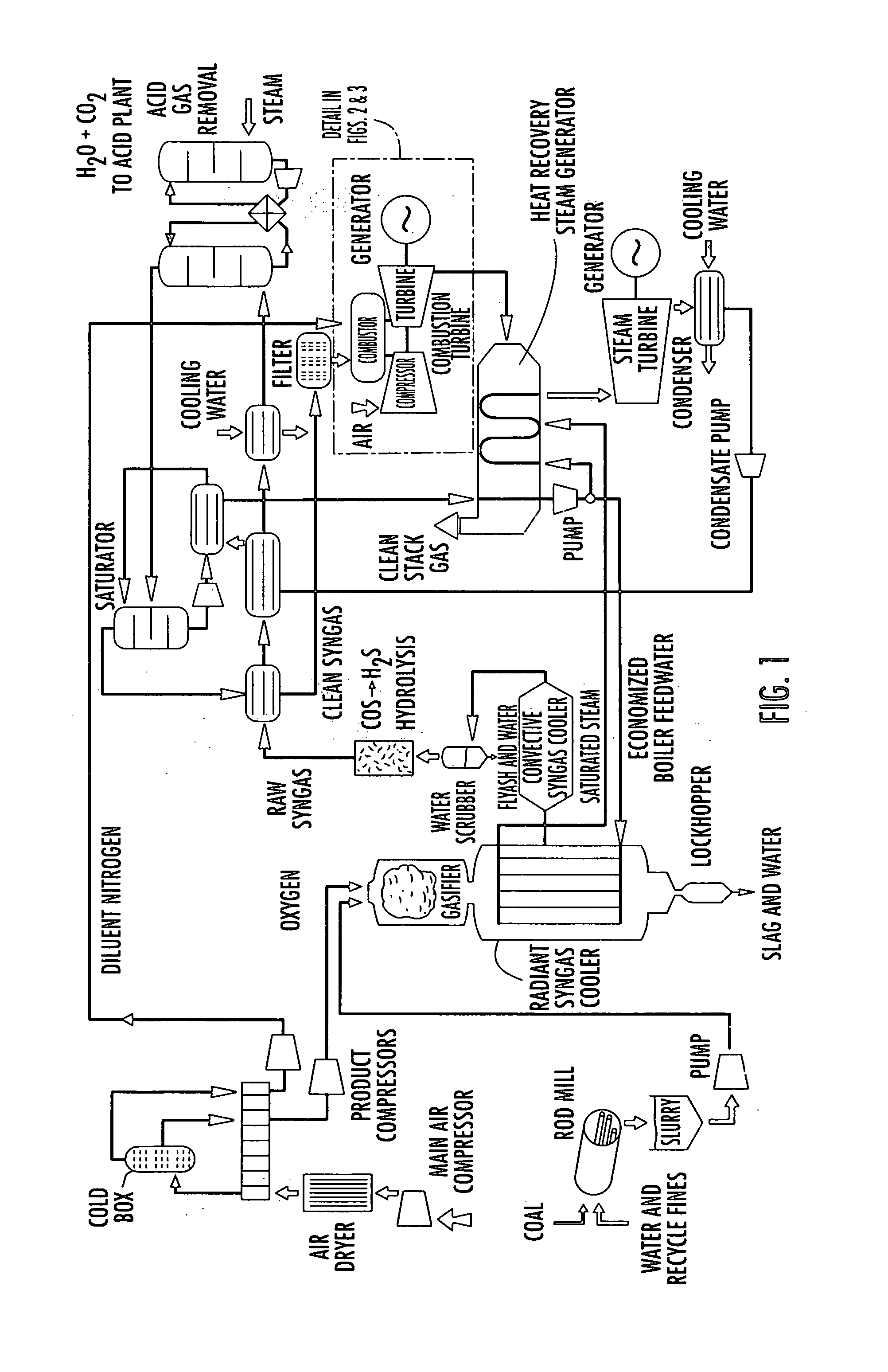

An integrated gasification combined cycle (IGCC) is a technology that uses a high pressure gasifier to turn coal and other carbon based fuels into pressurized gas—synthesis gas (syngas). It can then remove impurities from the syngas prior to the power generation cycle. Some of these pollutants, such as sulfur, can be turned into re-usable byproducts through the Claus process. This results in lower emissions of sulfur dioxide, particulates, mercury, and in some cases carbon dioxide. With additional process equipment, a water-gas shift reaction can increase gasification efficiency and reduce carbon monoxide emissions by converting it to carbon dioxide. The resulting carbon dioxide from the shift reaction can be separated, compressed, and stored through sequestration. Excess heat from the primary combustion and syngas fired generation is then passed to a steam cycle, similar to a combined cycle gas turbine. This process results in improved thermodynamic efficiency compared to conventional pulverized coal combustion.

System and method for oxygen separation in an integrated gasification combined cycle system

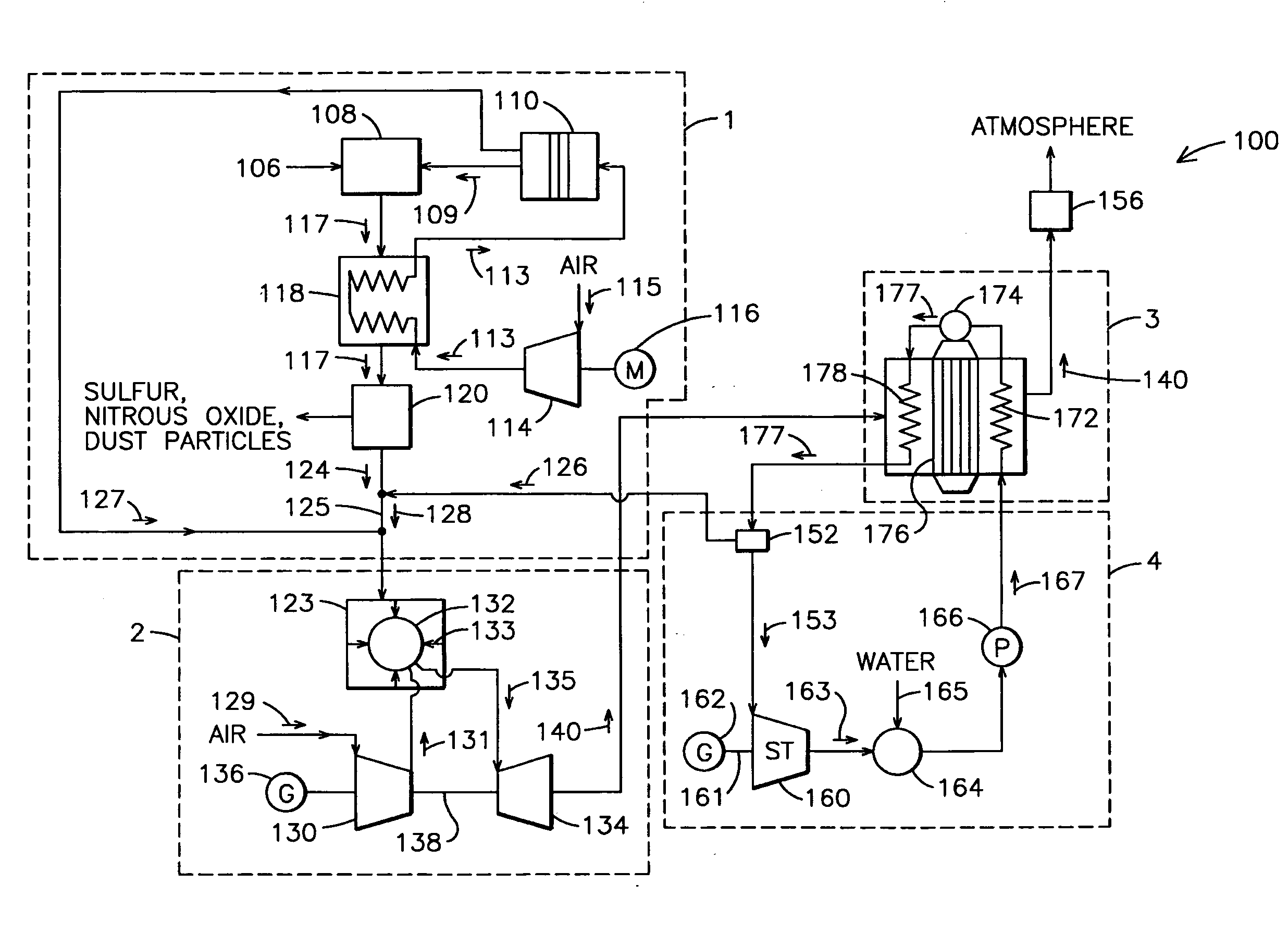

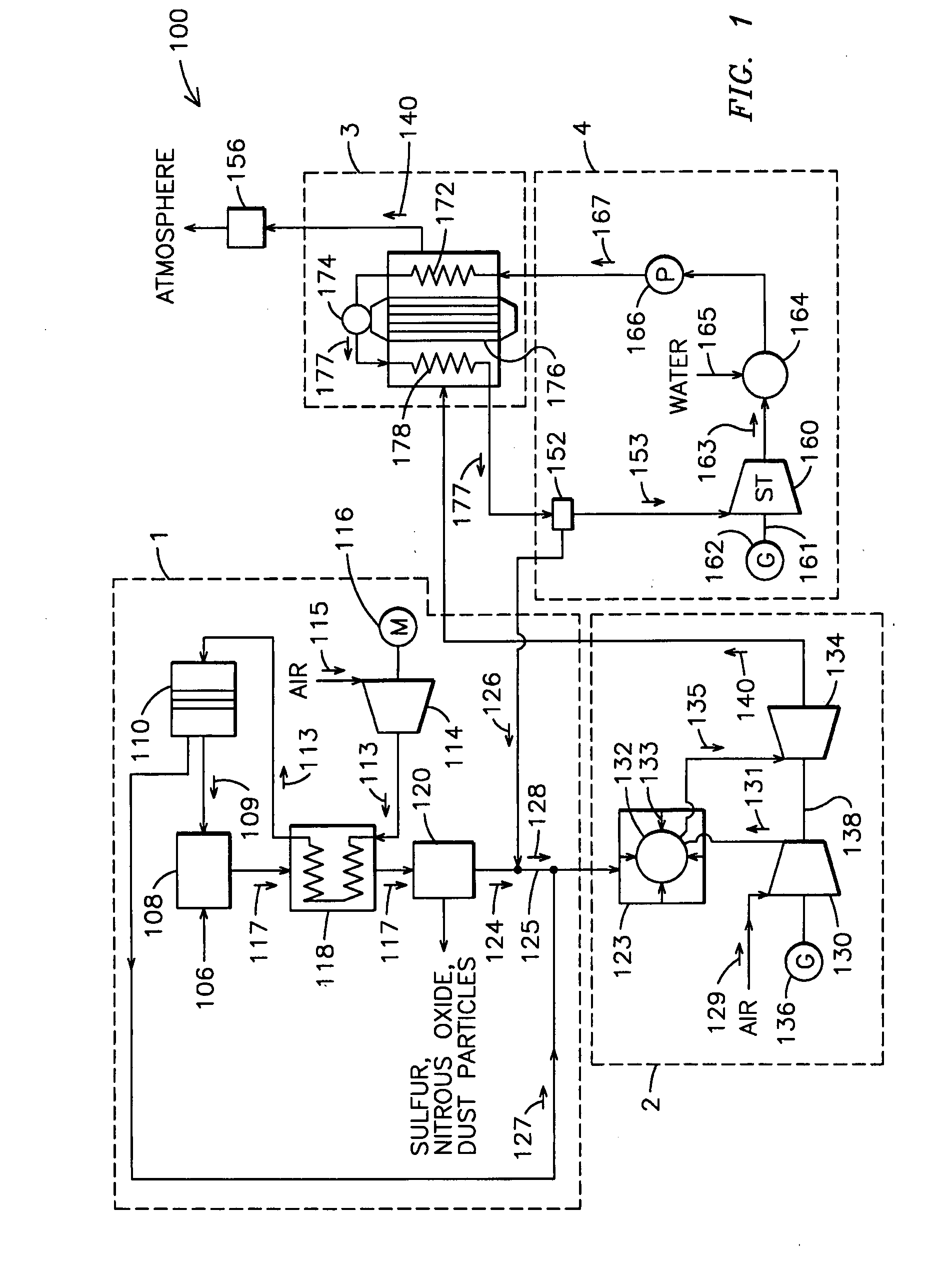

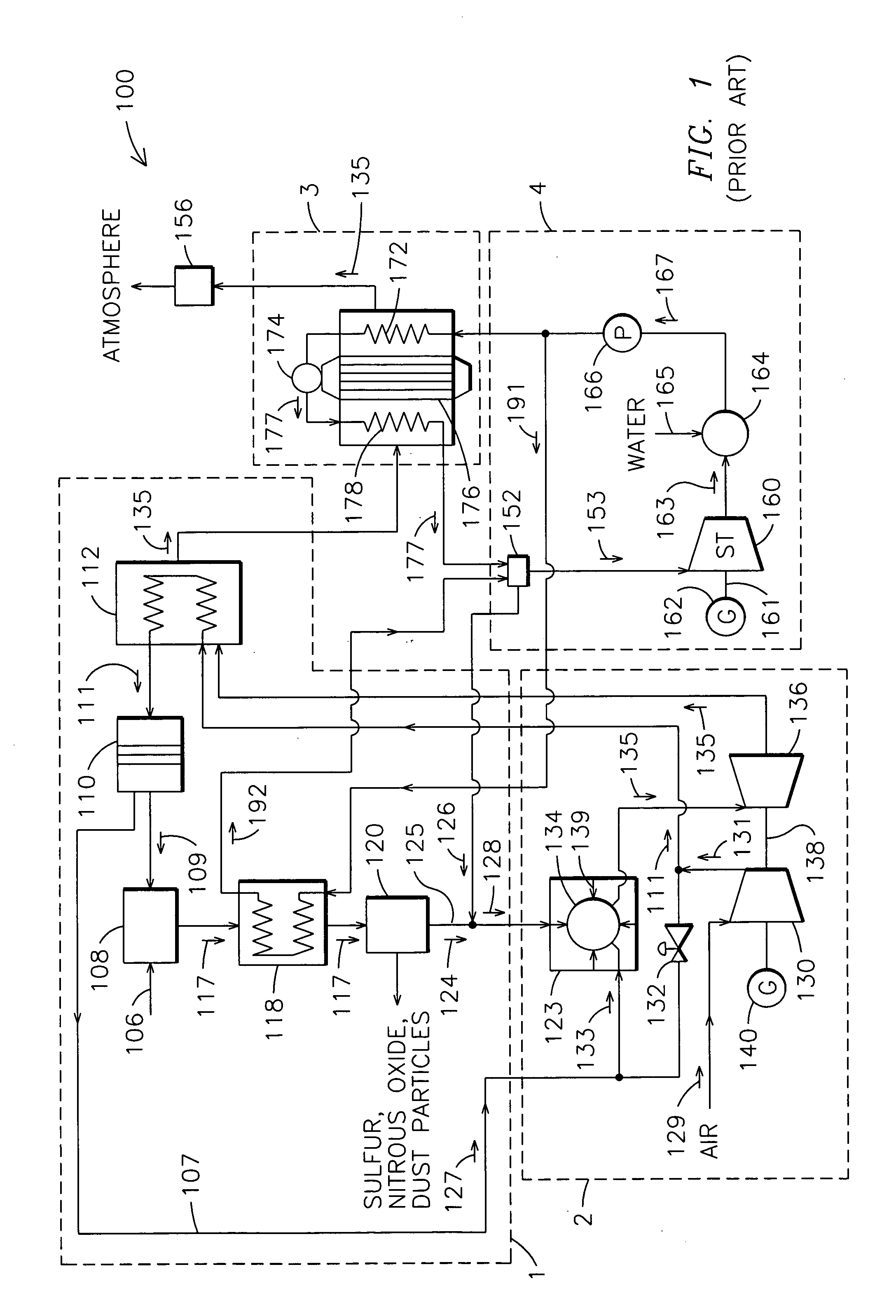

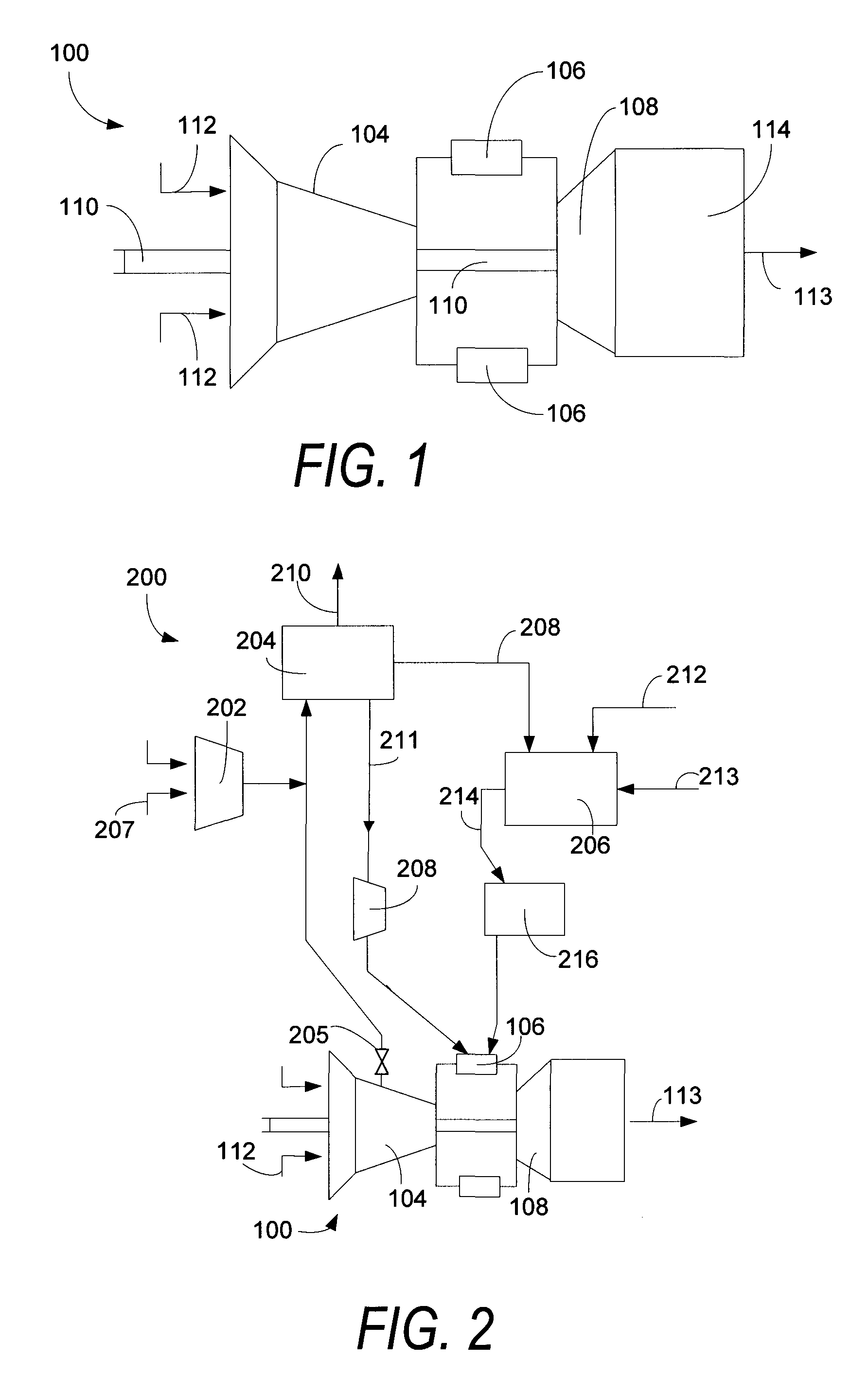

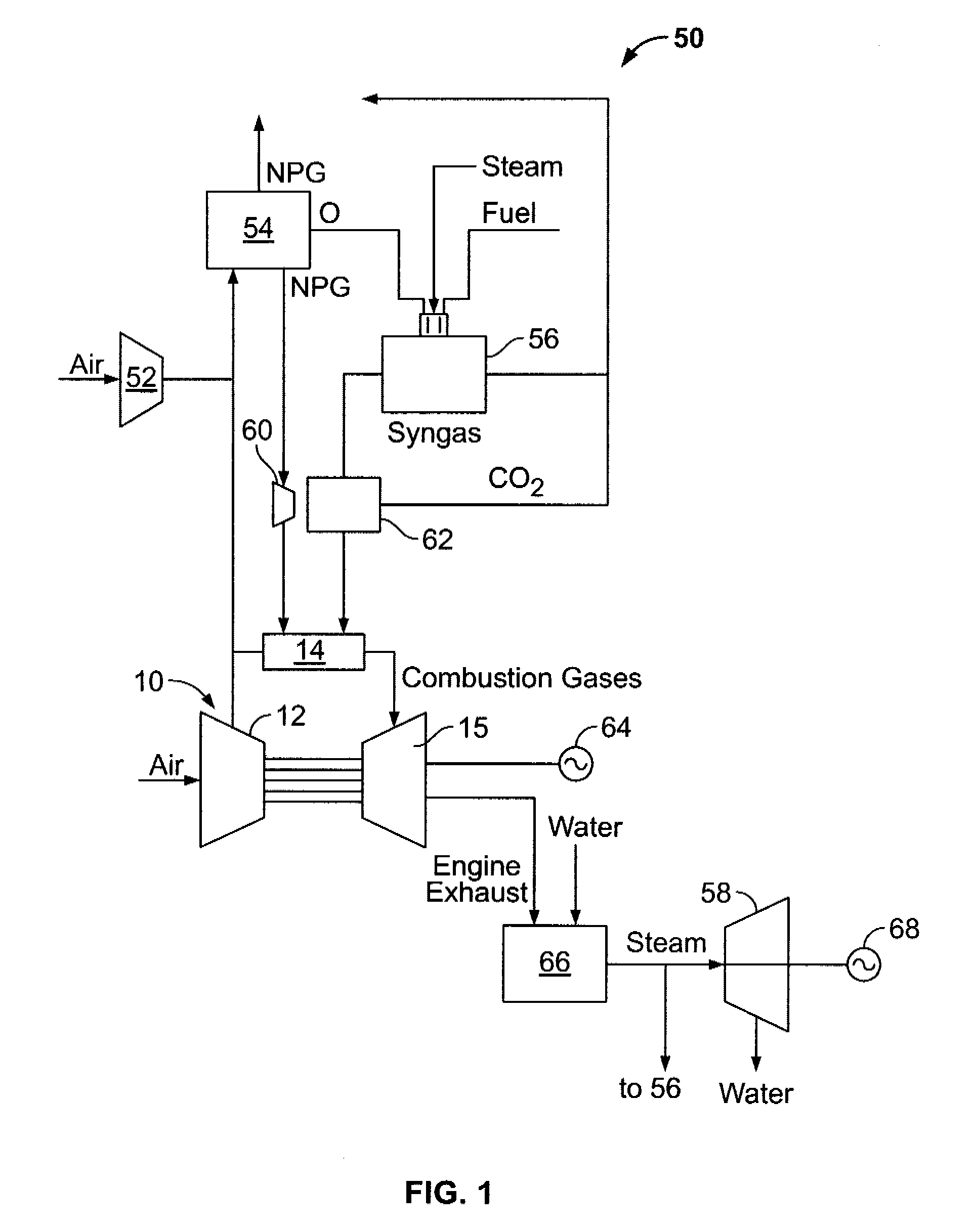

An integrated gasification combined cycle power generation system (100). In one embodiment, shown in FIG. 1, a gasifier (108) is configured to generate synthetic gas (117) from a carbonaceous material (106) and an oxygen supply (109) with a cleaning stage (120) positioned to receive synthetic gas (117) from the gasifier (108) and remove impurities therefrom. A gas turbine combustion system (2) including a turbine (123) is configured to receive fuel (128) from the gasifier (108) and a first air supply (131) from a first air compressor (130). A steam turbine system (4) is configured to generate power with heat recovered from exhaust (140) generated by the gas turbine system (2) and an ion transport membrane air separation unit (110) includes a second air compressor (114) for generating a second air supply (113). A first heat exchanger (118) is configured to cool the synthetic gas (117) prior to removal of impurities in the cleaning stage (120) by flowing the second air supply (113) through the first heat exchanger (118) so that the second air supply (113) receives heat from the synthetic gas (117).

Owner:SIEMENS ENERGY INC

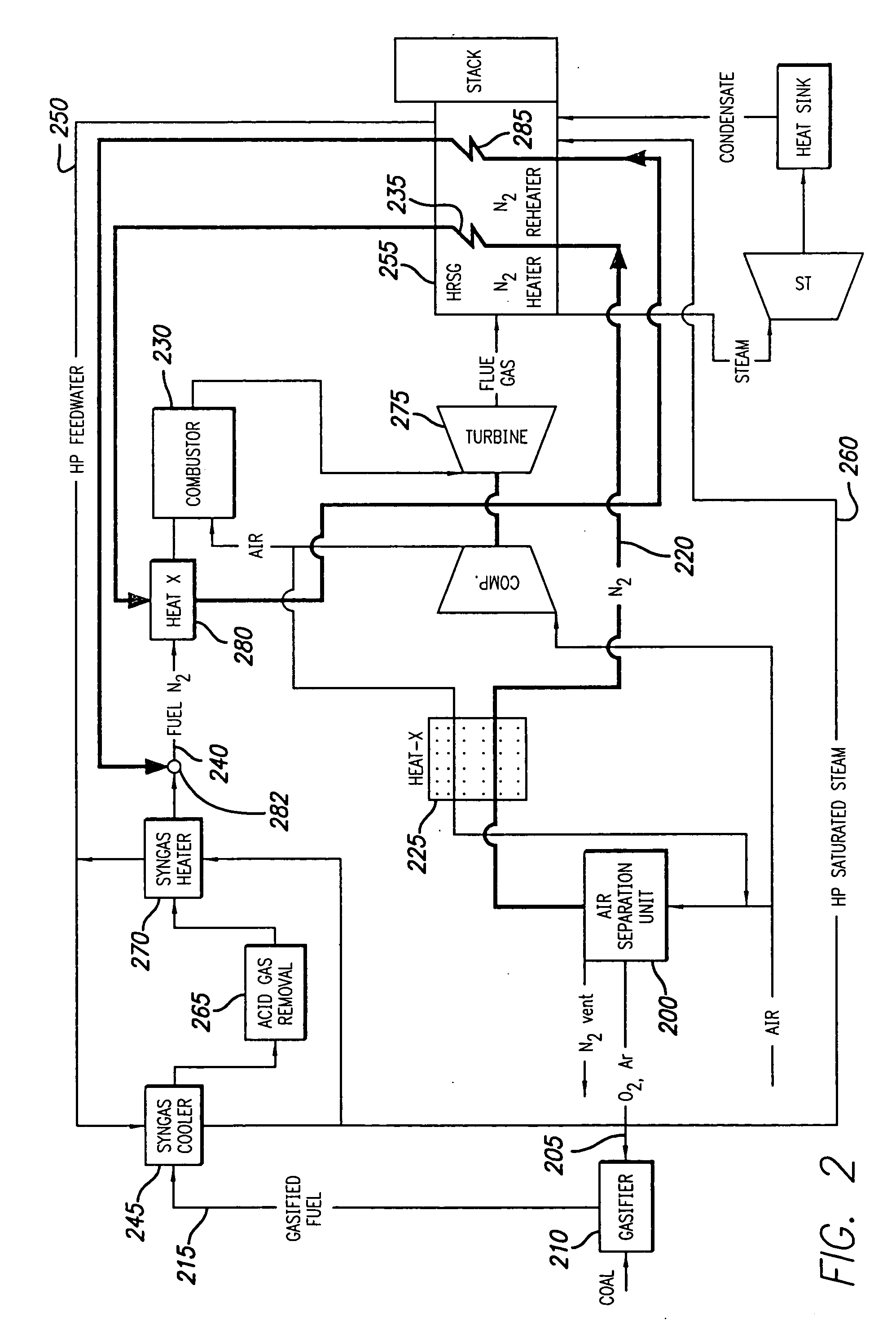

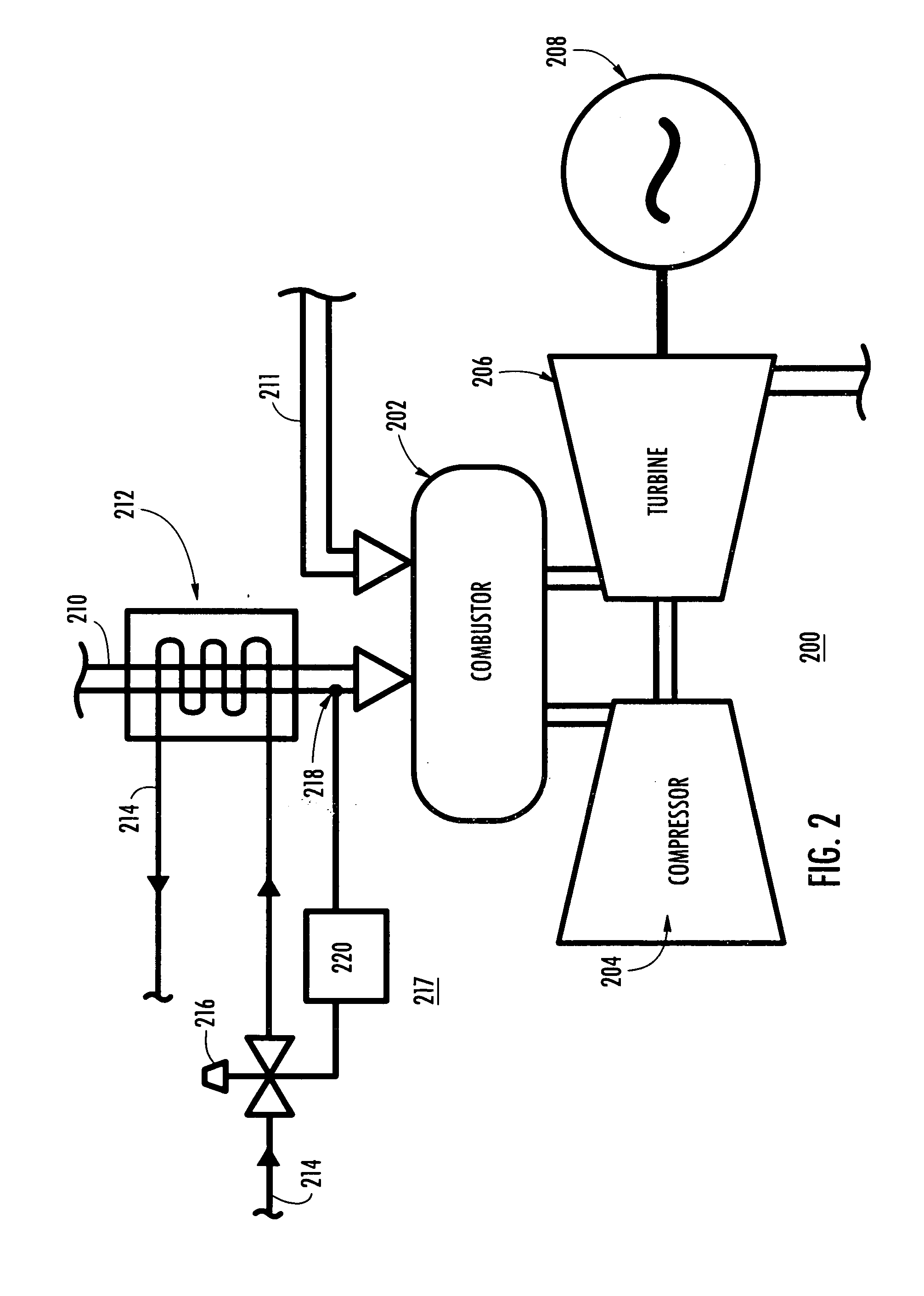

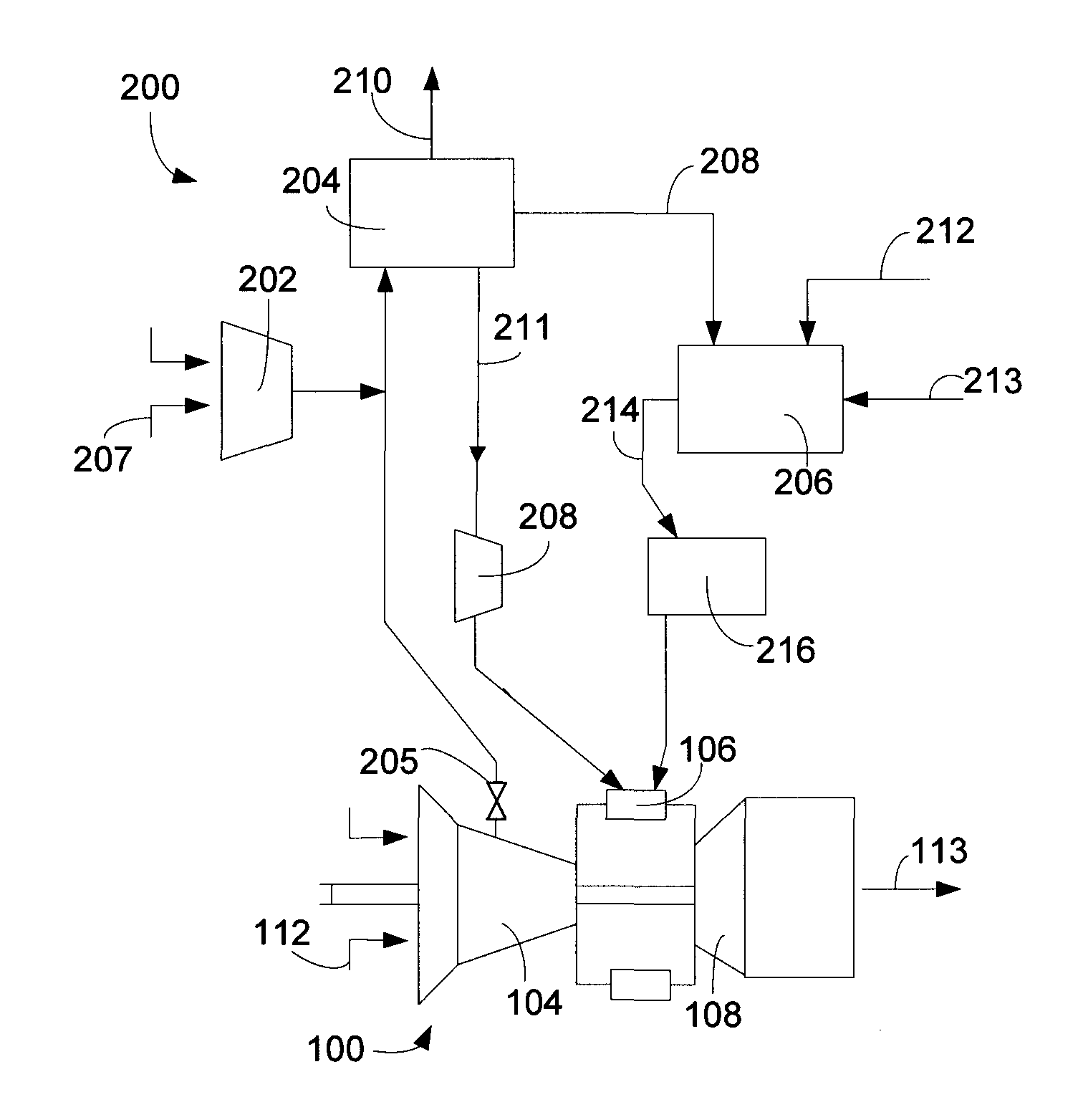

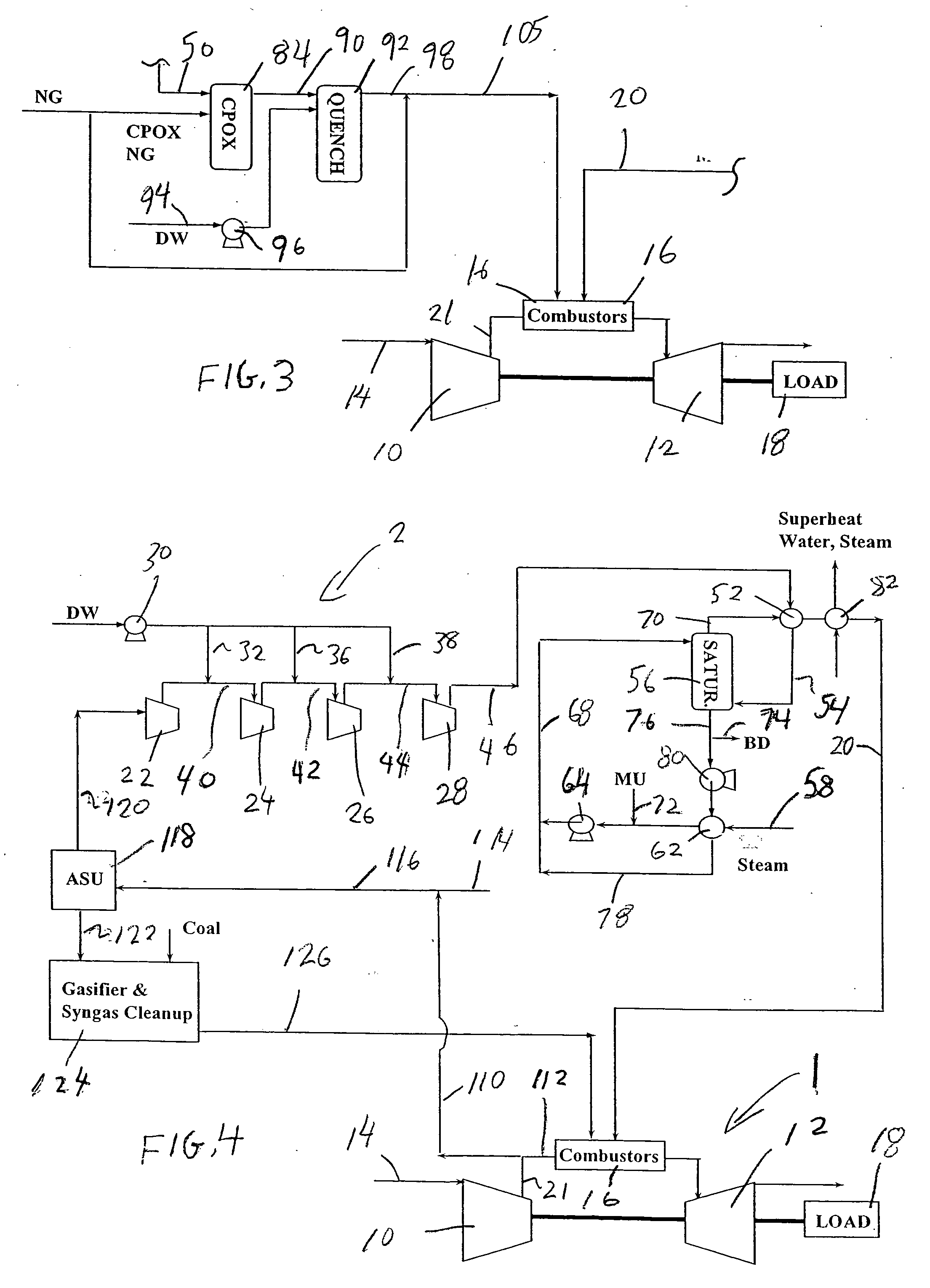

System and method for generation of high pressure air in an integrated gasification combined cycle system

InactiveUS20080115478A1Reduces capital equipment cost and operational costEasy temperature controlMuffle furnacesCombustion enginesAir separationProcess engineering

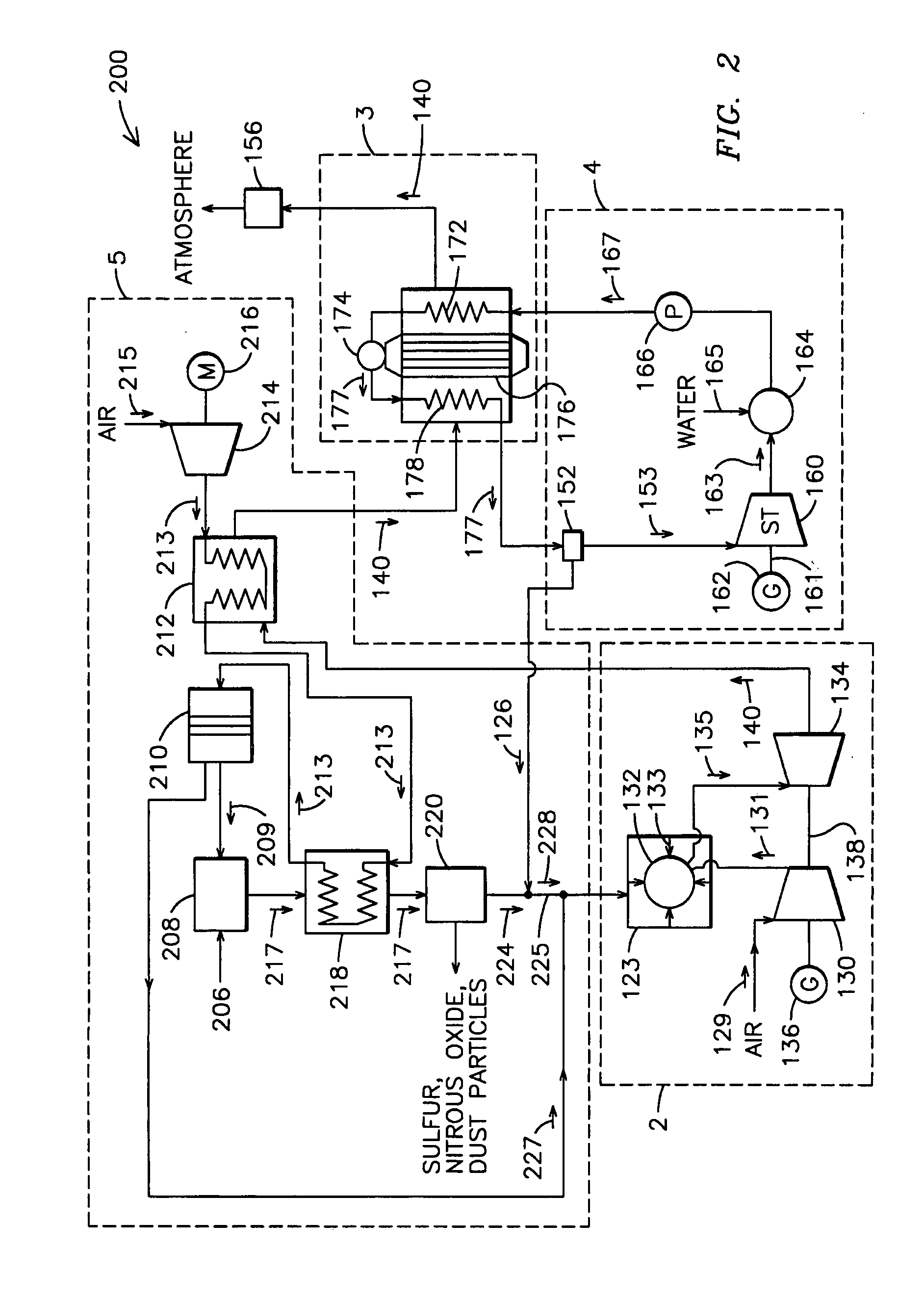

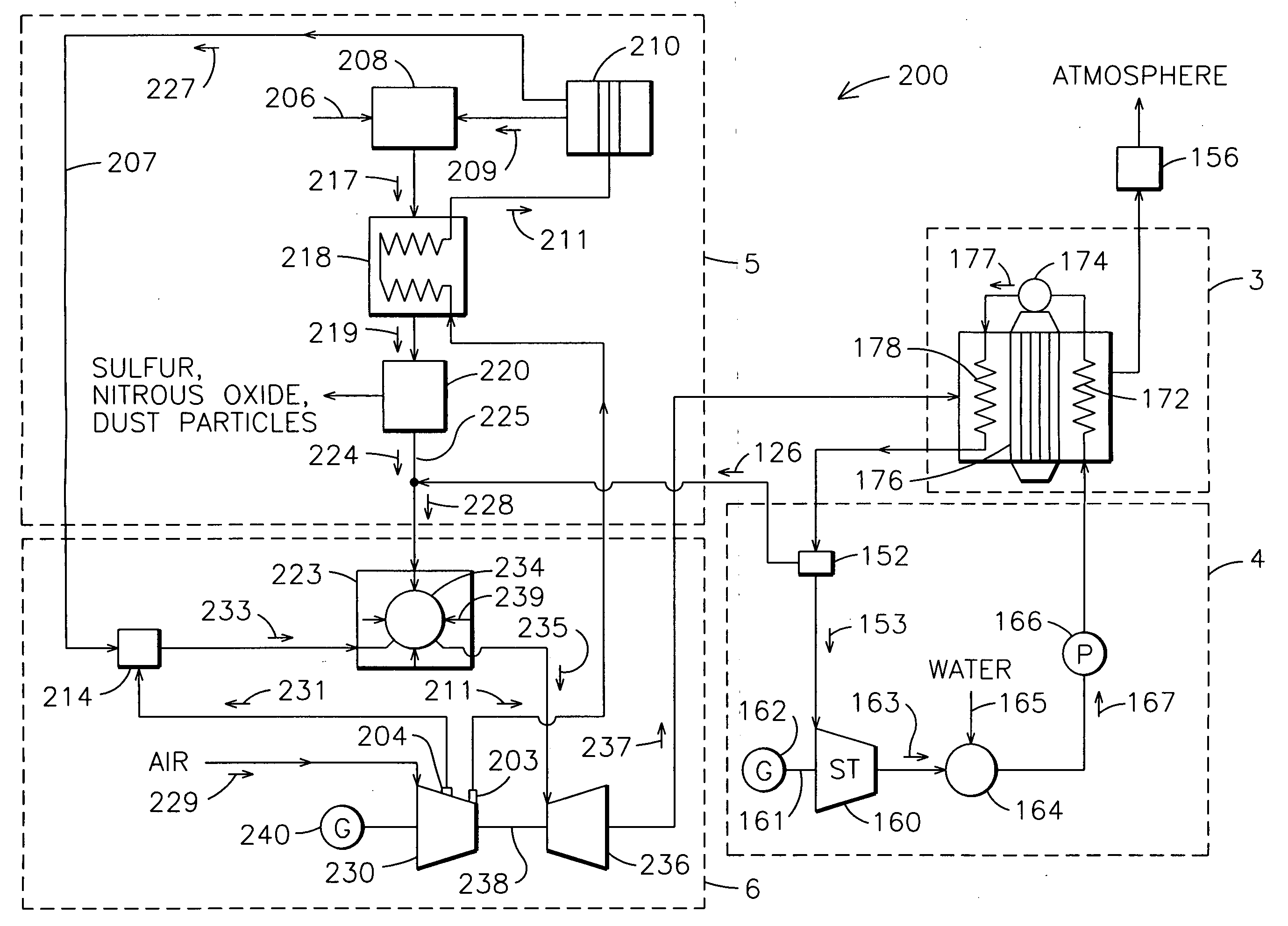

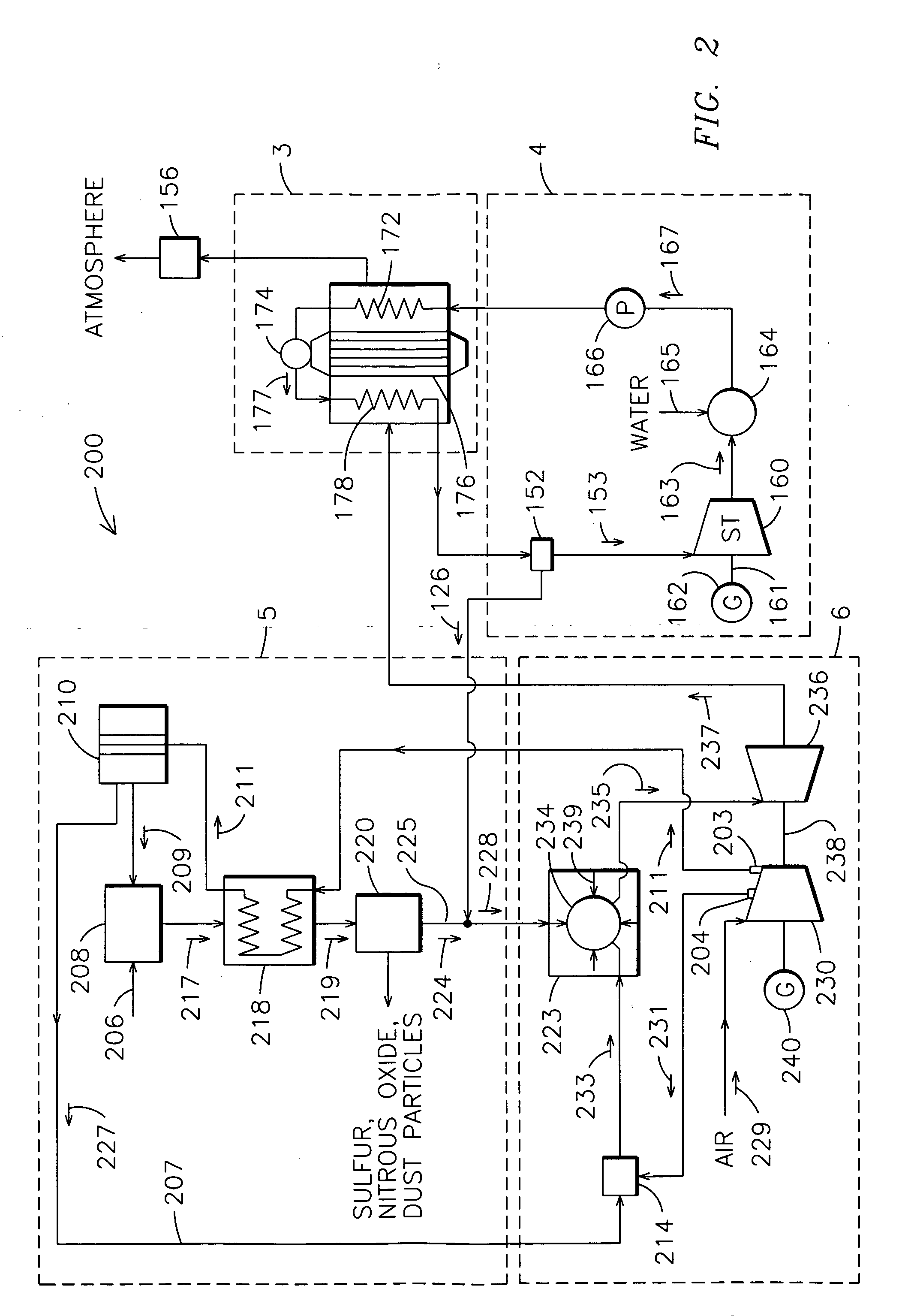

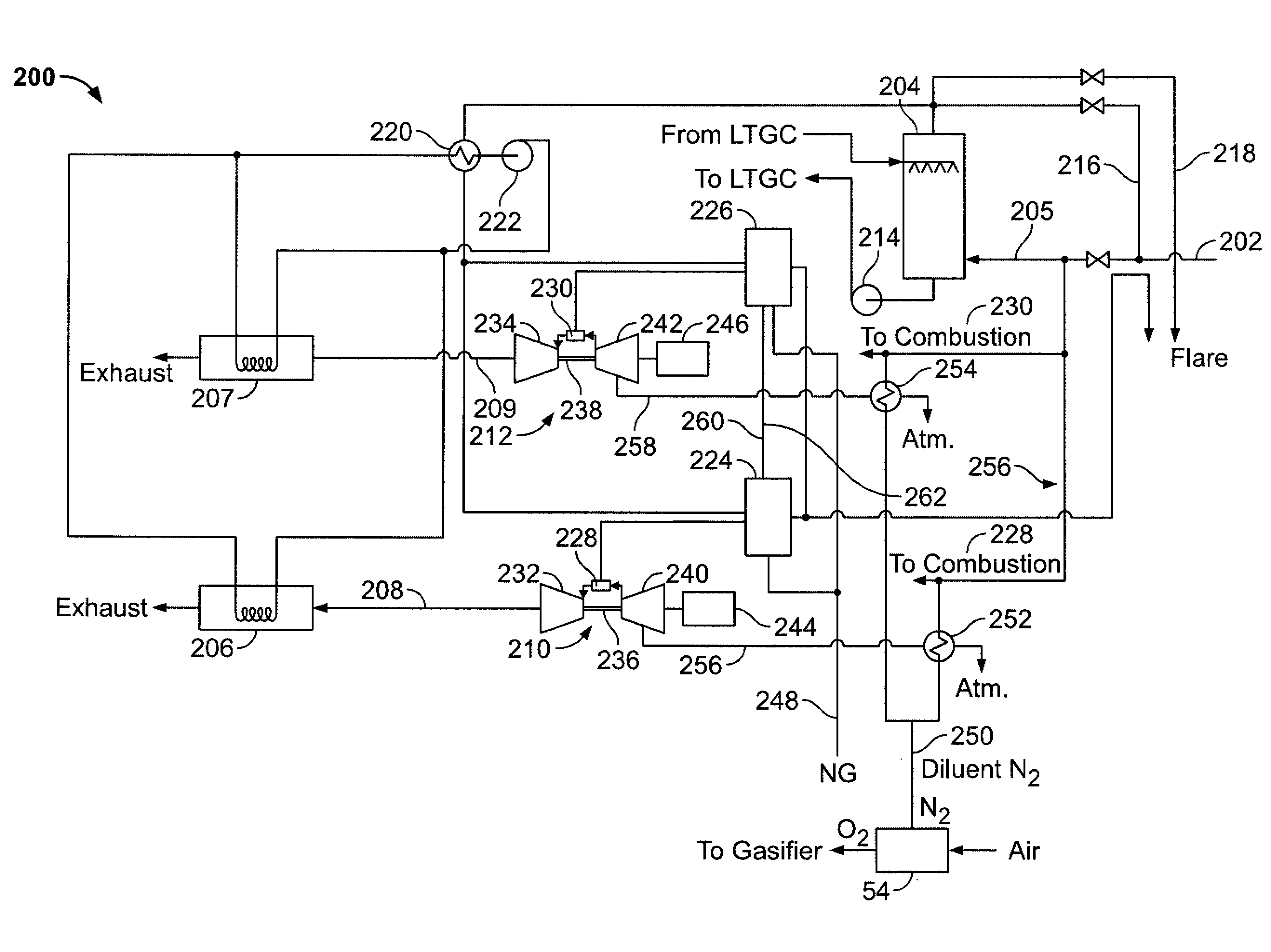

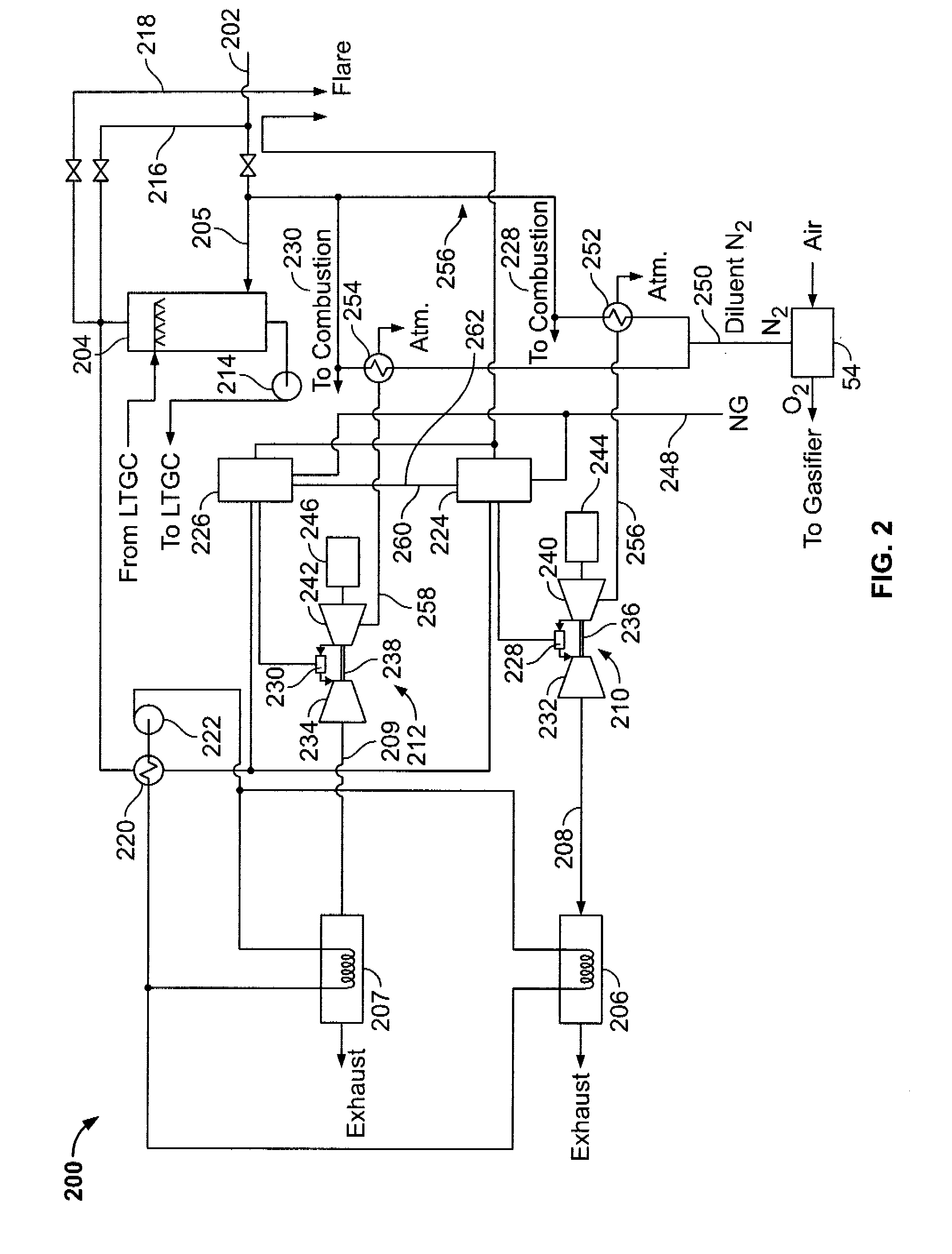

An integrated gasification combined cycle system. In one embodiment (FIG. 2) a system (200) includes an ion transport membrane air separation unit (210) for producing oxygen-enriched gas (209) and oxygen-depleted air (227), a gasification system (5) for generating syngas with the oxygen-enriched gas (209), a gas combustor (234) for reacting the syngas (224), and a subsystem configured to provide a first stream of air to the combustor (234) at a first pressure and to provide a second stream of air to the air separation unit (210) at a second pressure greater than the first pressure. The subsystem includes a compressor (230) having multi-pressure outlets (203, 204).

Owner:SIEMENS ENERGY INC

Advanced ASU and HRSG integration for improved integrated gasification combined cycle efficiency

InactiveUS20070180768A1Improve efficiencyIncrease powerSolidificationHydrogenCombustionProcess engineering

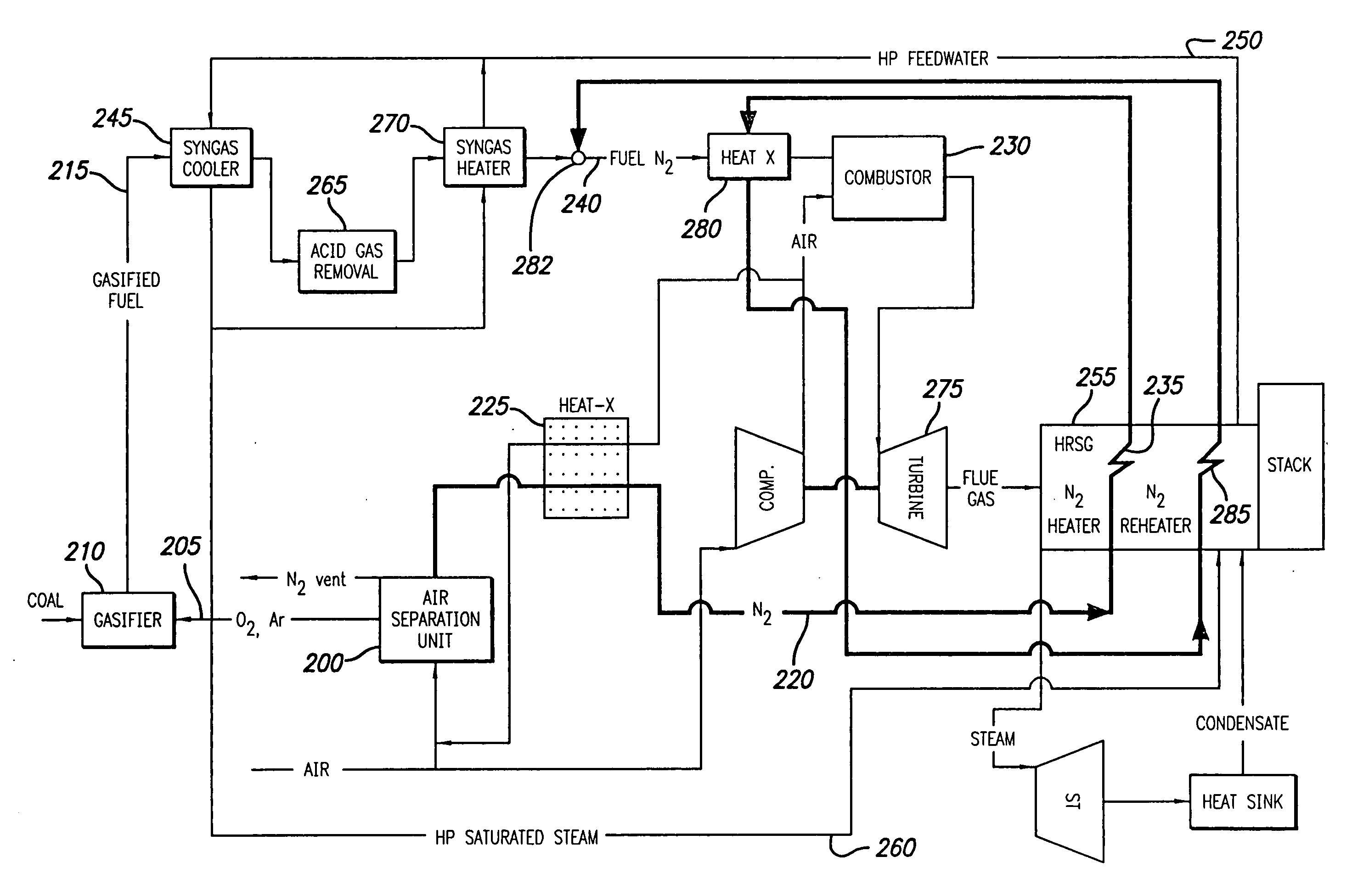

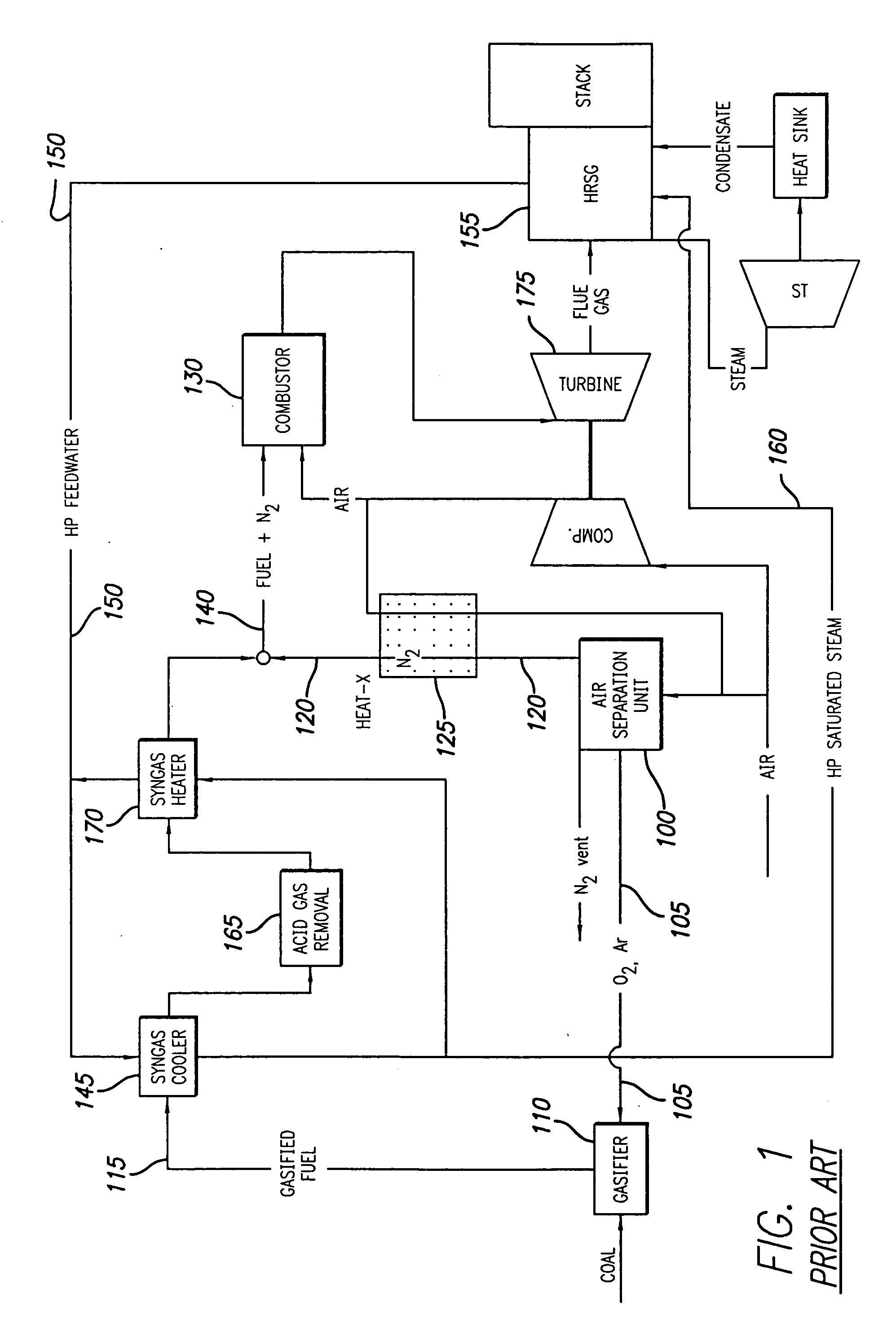

A system and method for increasing the efficiency and / or power produced by an integrated gasification combined cycle system by increasing the integration between the air separation unit island, the heat recovery steam generator and the remainder of the system. By integrating heat produced by the heat recovery steam generator in the remainder of the integrated gasification combined cycle system, heat may be utilized that may have otherwise been lost or used further downstream in the system. The integration helps to increase the efficiency of the combustion reaction and / or the gasification reaction used to produce the syngas utilized in the integrated gasification combined cycle system.

Owner:SIEMENS ENERGY INC

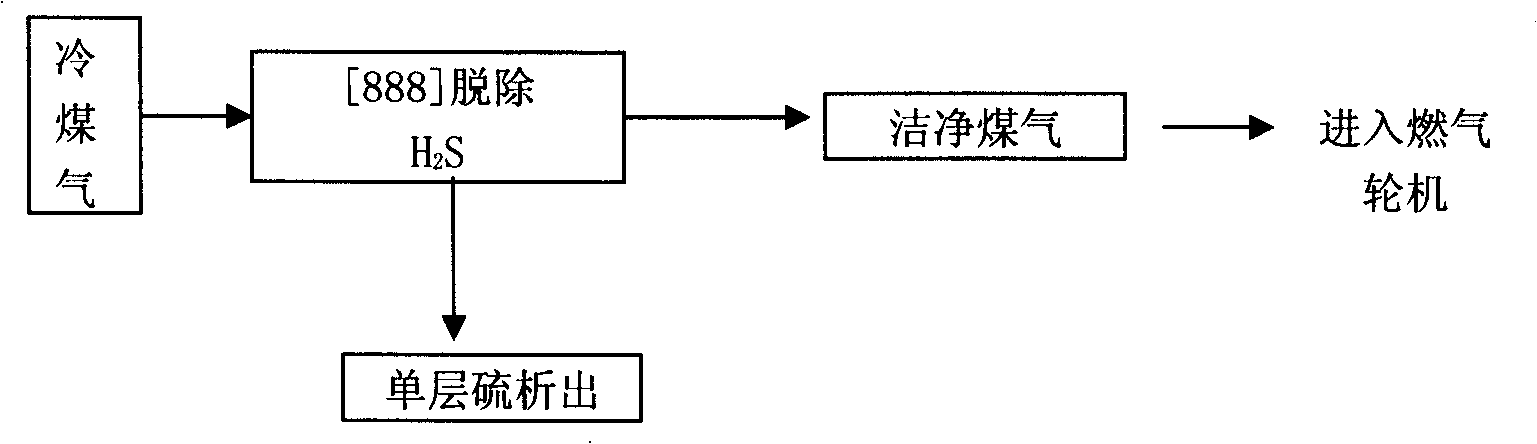

High-temperature gas composite oxide desulfurizer and production thereof

InactiveCN1712500AHigh mechanical strengthHigh wear resistanceGas purification by catalytic conversionActive componentFluidized bed

A high-temperature gas composite oxide desulfurizer and its production are disclosed. The desulfurizer consists of active component zinc oxide 33í½50% and multiple additives 31í½51% which comprises titanium dioxide, active stabilizer, surface modifier, strength reinforcer, regenerative improver and composite binder. The process is carried out by mixing active component with additives, grinding, kneading, forming, laying aside, drying, particle rectifying, calcining at 850í½1060íÒC in high-temperature furnace, and obtaining desulfurizer. It achieves better reactivity and efficiency, good abrasion resistance and regeneration. It can be used for fixed bed, fluidized bed and desulfurizing reactor of flowing bed.

Owner:CHINA COAL RES INST

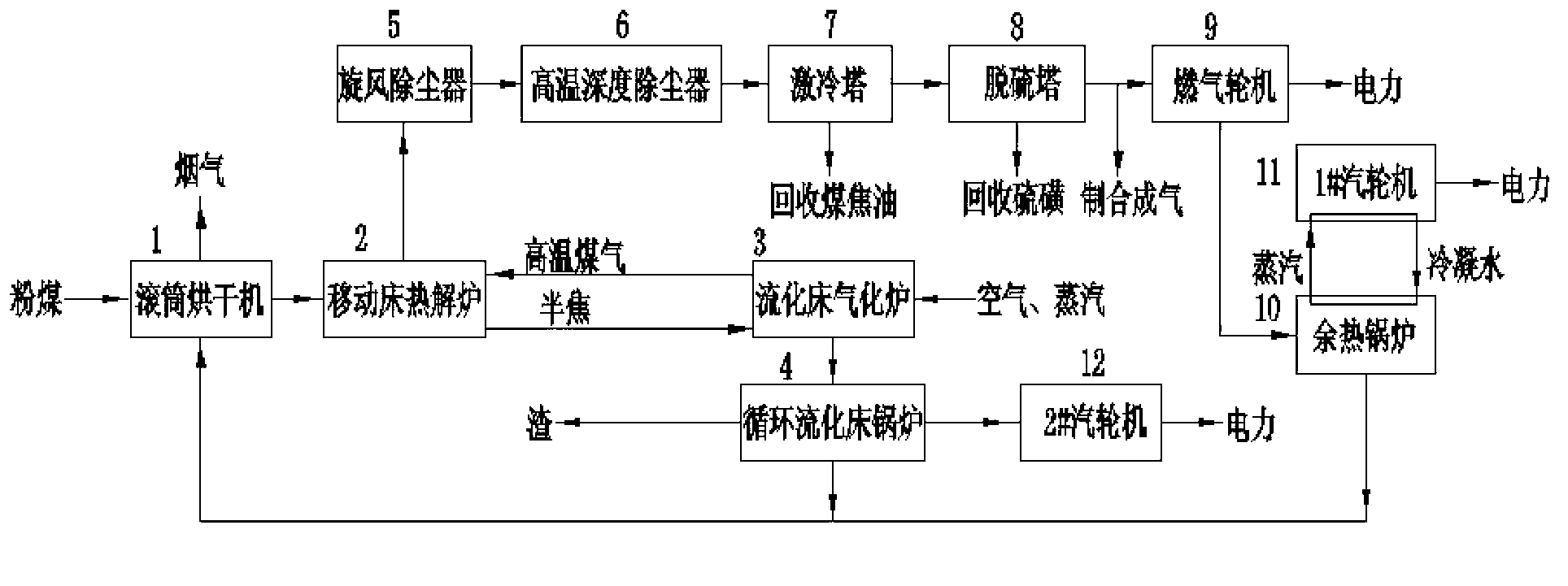

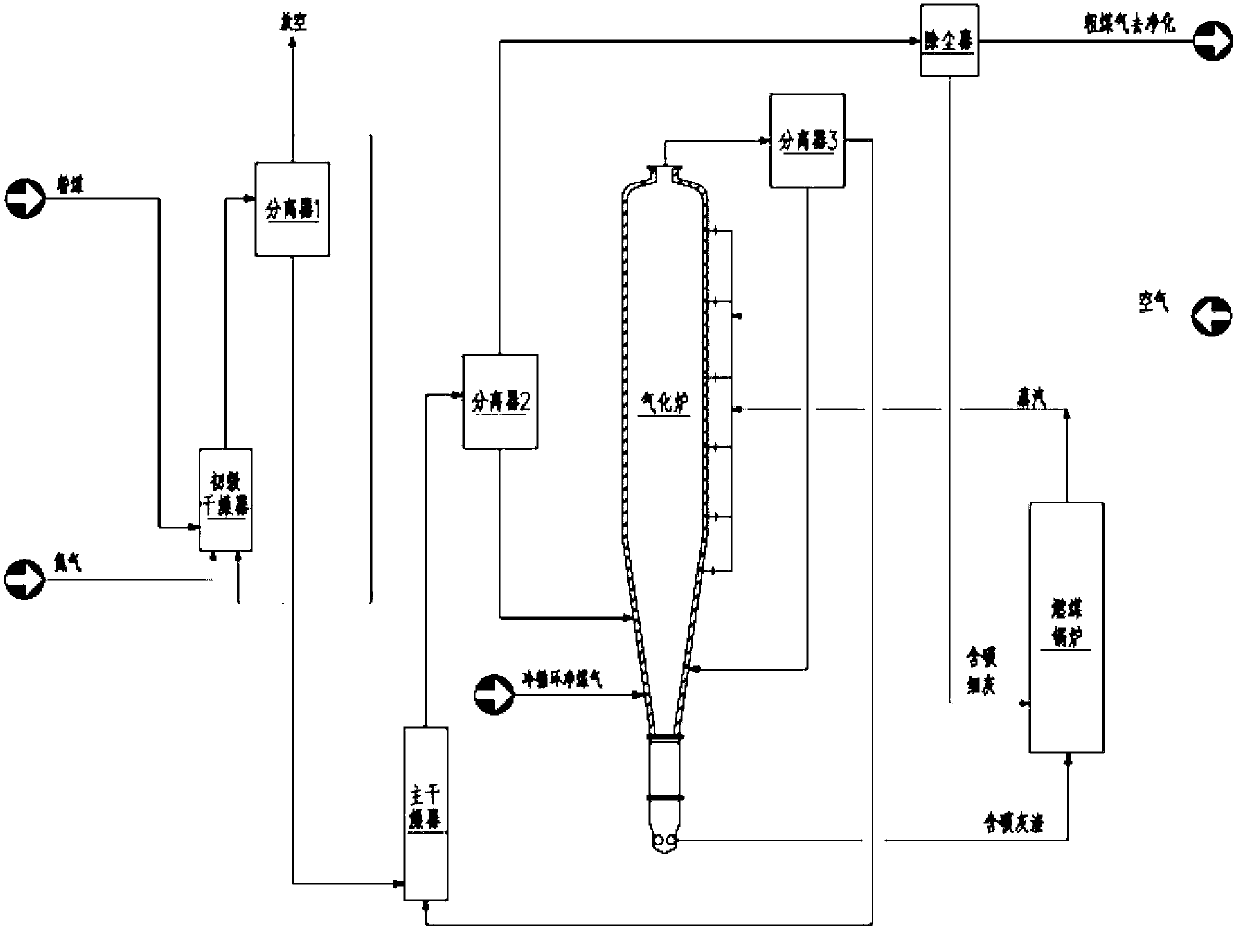

IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal

InactiveCN103013576ATake advantage ofAchieve integrationEnergy inputGas turbine plantsResource utilizationChemical products

The invention discloses an IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal. The device comprises a pyrolysis / gasification system, a coal gas purifying system, a circulating fluidized bed boiler and a gas turbine / steam turbine system. The method comprises the steps as follows: carrying out low temperature pyrolysis and partial air gasification on the low metamorphic powdered coal, grading and converting into coal gas, tar and semi-coke, and carrying out the IGCC poly-generation process by the semi-coke and the coal gas with high calorific value. According to the device and the method, the tar, sulphur and other chemical products can be produced while clean power is generated, the products obtained by grading and converting the low metamorphic powdered coal are fully utilized, the material conversion and energy conversion functions are integrated, the resource utilization rate is high, and the heat energy efficiency is high. The device and method are suitable for the low metamorphic powdered coal such as peat, brown coal, jet coal, non-sticking coal and the like, and the particle size of raw materials is 0-8 mm. The high-temperature coal gas generated in a fluidized bed gasification furnace contains a large amount of hydrogen, so that the powdered coal can be subjected to hydropyrolysis, and the tar recovery rate can reach more than 12%.

Owner:陕西华祥能源科技集团有限公司

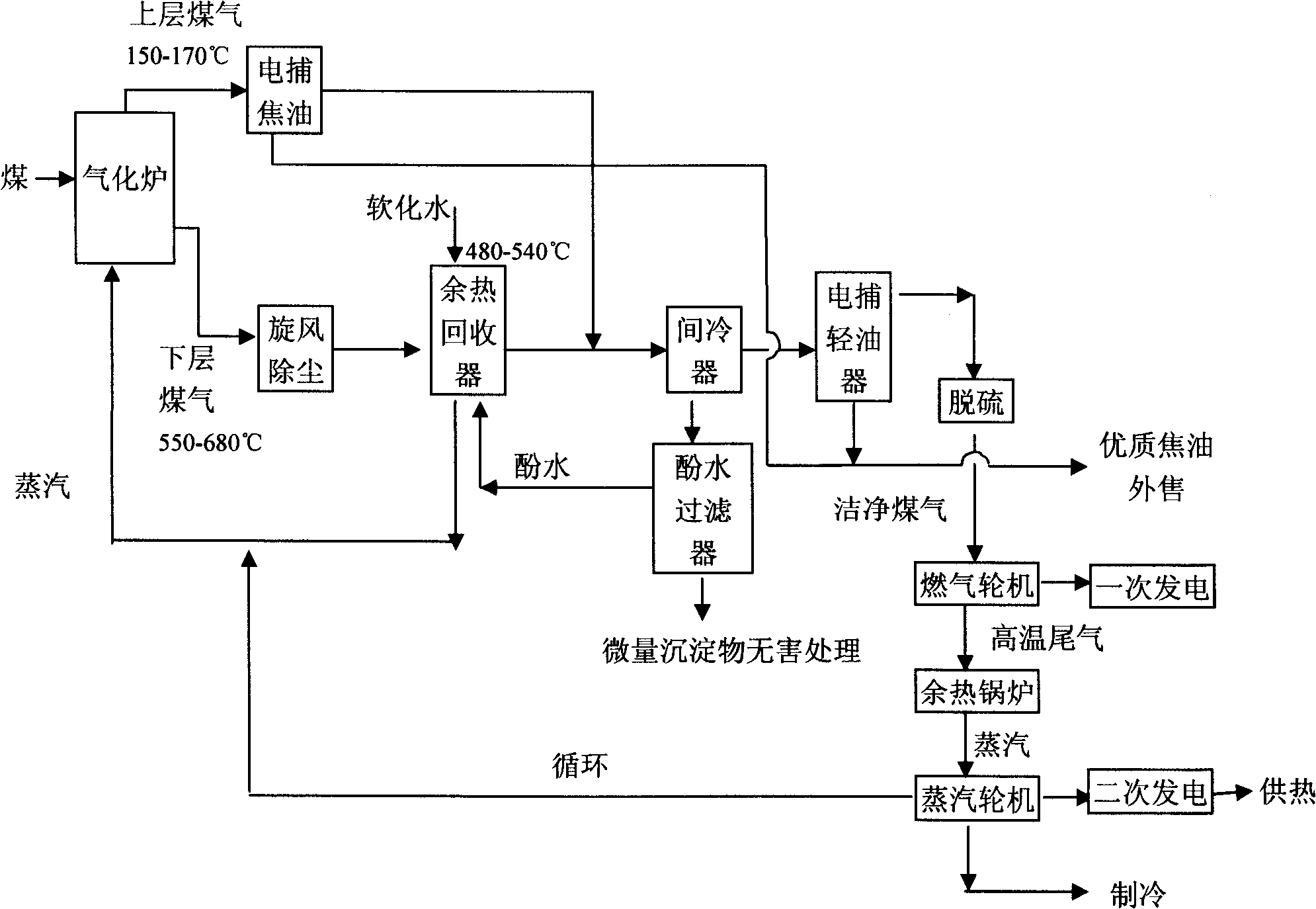

Integrated gasification combined cycle thermoelectric oil gas multi-production process for efficient clean region

InactiveCN101280223ATake advantage ofImprove economyEnergy inputGas turbine plantsHigh pressureIntegrated gasification combined cycle

The invention relates to a combined cycle thermoelectric oil gas multiple co-production process of high efficiency and clean regionally-integrated coal gasification, which includes the steps as follows: (1) the crushed coal is fed into the high pressure high efficiency gasifier for gasification when the air and steam are injected and the temperature and pressure are increased; (2) the coal gas generated through the gasification is divided into an upper layer and the lower layer; the coal gas in the lower layer is processed with dust collection and desulphurization; the coal gas in the upper layer is processed with electrical tar precipitation and desulphurization; (3) clean coal gas and the air are compressed to be fed into a gas turbine; the coal gas and the air are combusted to have expansion to drive the generator to generate electricity for once; (4) the high temperature tail gas is fed into a waste heat boiler to generate steam; the steam enters a steam turbine to drive the steam turbine to generate electricity for the second time; the steam is then used for heat supply or cool supply. The combined cycle thermoelectric oil gas multiple co-production process makes full use of the coal resources and integrates the coal compressed gasification, waste heat boiler supplemental combustion, coal gasification, the tar pyrolysis and the level two to level three pressure technique of the waste heat boiler into a whole to form the multiple co-production process which is applicable to the characteristics of the northern region of China.

Owner:山东联合能源技术有限公司

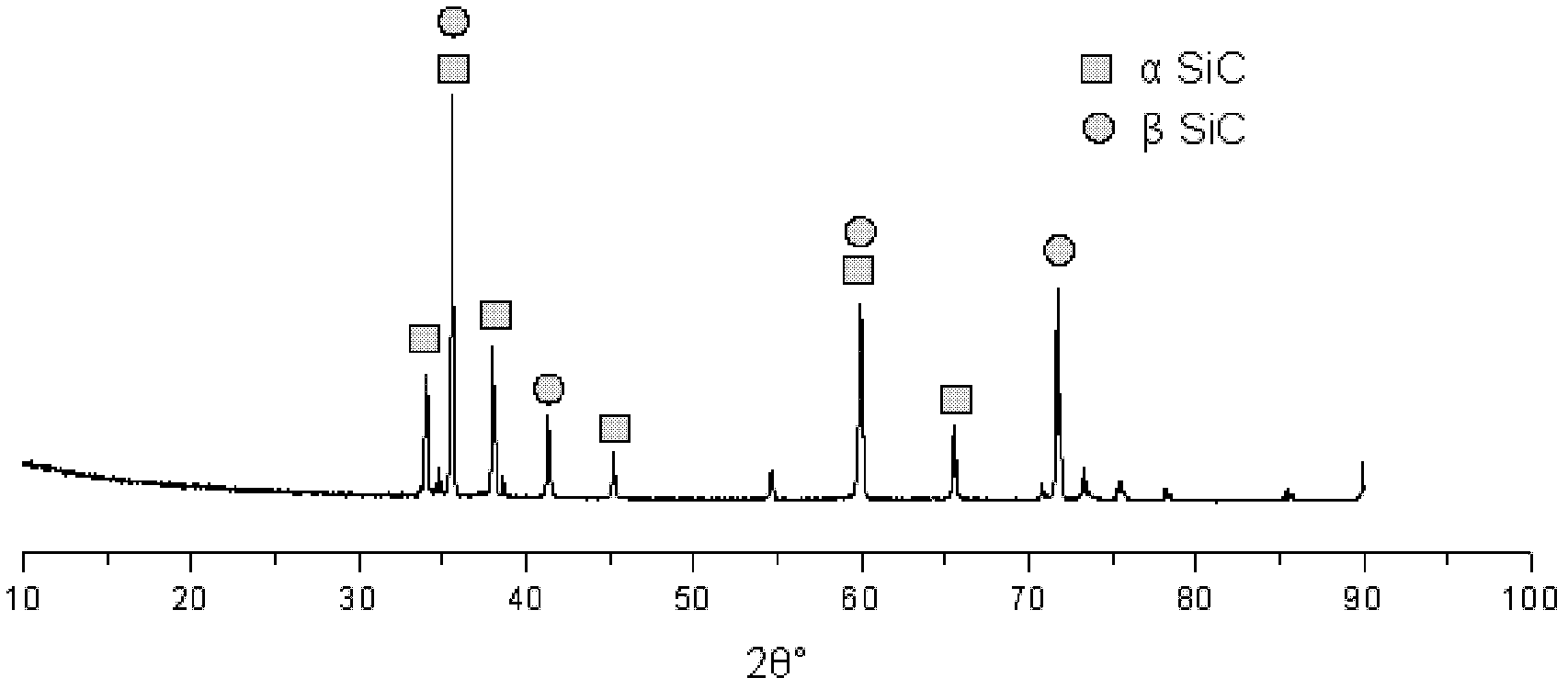

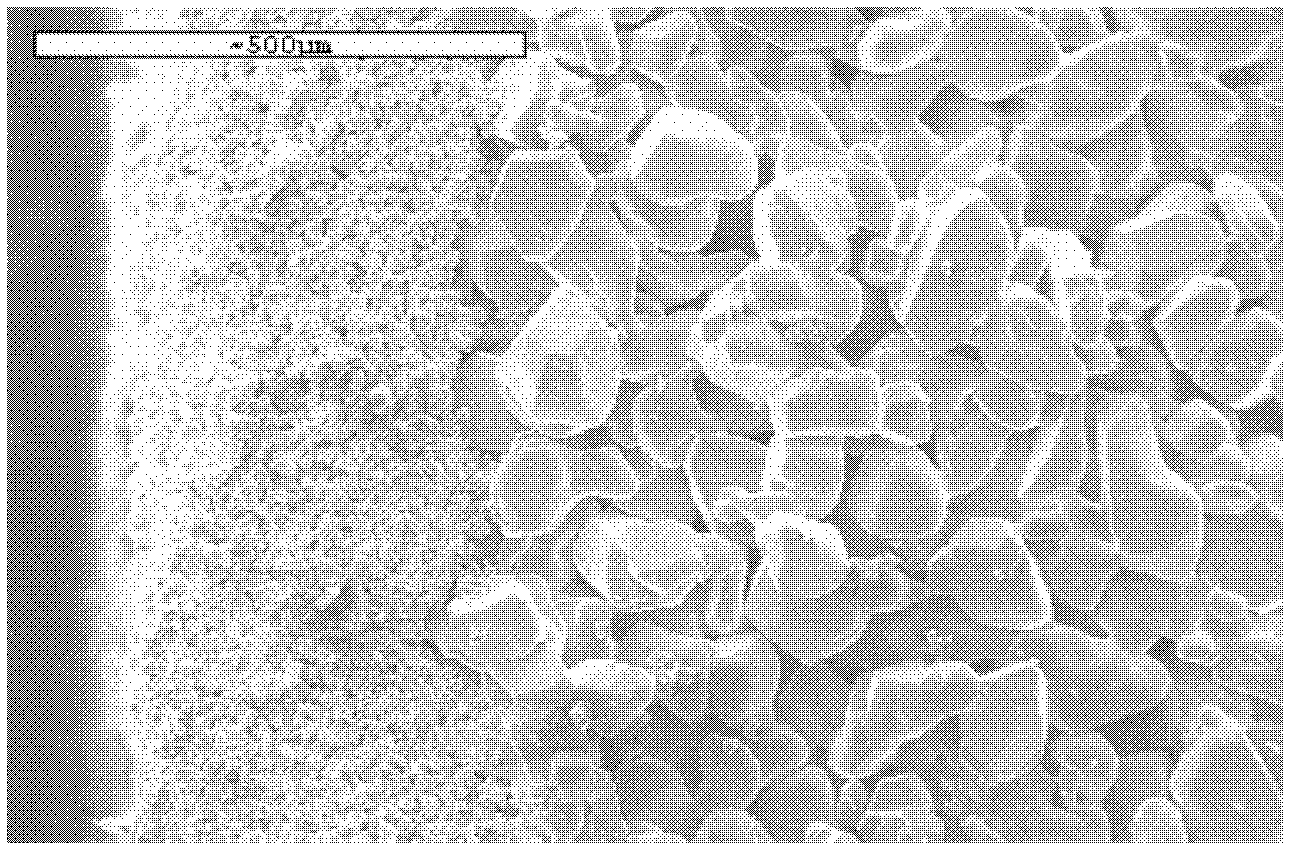

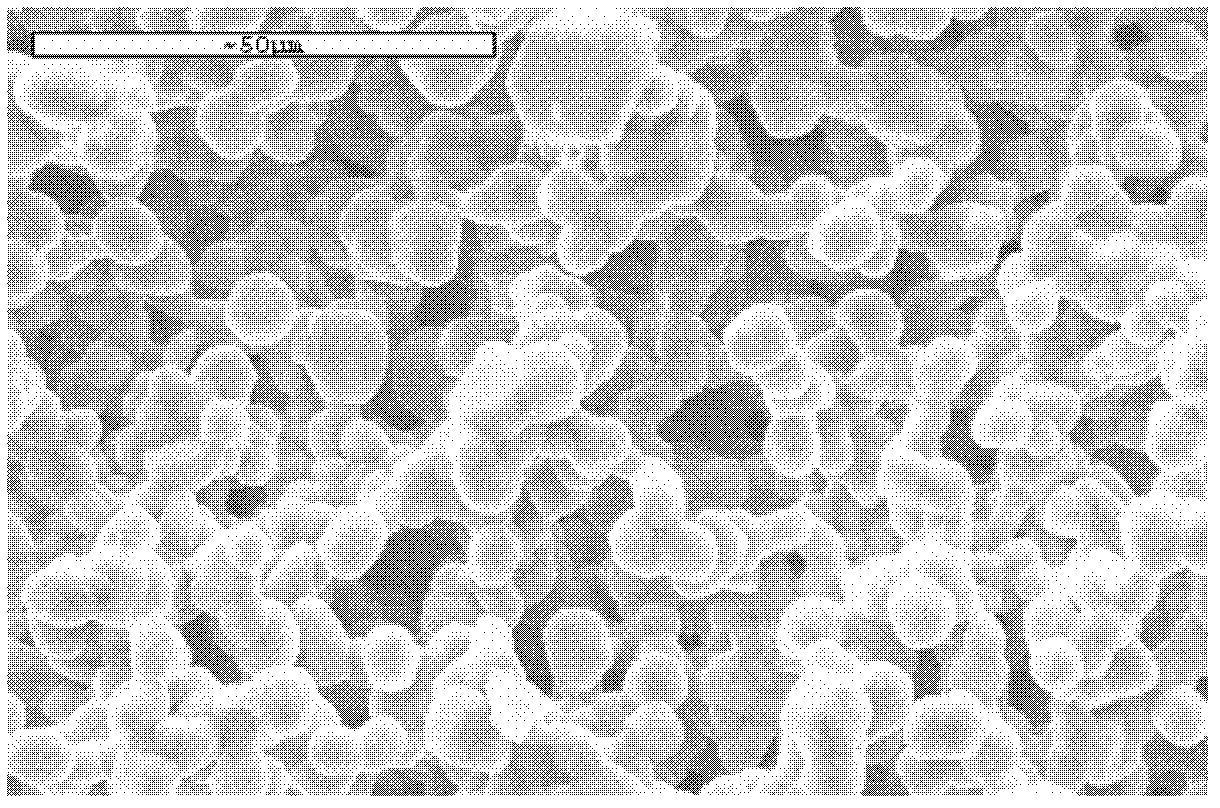

Pure silicon carbide filtering membrane and preparation method thereof

ActiveCN102659447AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareStrong acidsThermal shock

The invention belongs to the technical field of porous ceramic materials and their preparation and especially discloses a pure silicon carbide filtering membrane and a preparation method thereof. The pure silicon carbide filtering membrane has a high porosity, a low pressure drop, high strength, good thermal shock resistance and a high use temperature. The preparation method can be realized easily and can guarantee product performances. The pure silicon carbide filtering membrane comprises pure SiC, is a surface membrane layer obtained by pile-up and binding of fine SiC particles and has aperture sizes of 0.1 to 20 microns and membrane porosity of 25 to 50%. Fine SiC particles, silicon powder, a pore-forming additive and one or more organic resins as raw materials are prepared into a surface membrane layer by spraying or dipping and the surface membrane layer is dried and sintered to form the pure silicon carbide filtering membrane. The pure silicon carbide filtering membrane can be used in an oxidation atmosphere and in a reducing atmosphere, has strong acid corrosion and alkaline corrosion resistance, and can be used for various high / low temperature fluid filtering purification fields such as coal gasification chemical engineering, integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) coal gasification power generation, and high temperature flue gas, automobile exhaust and water purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

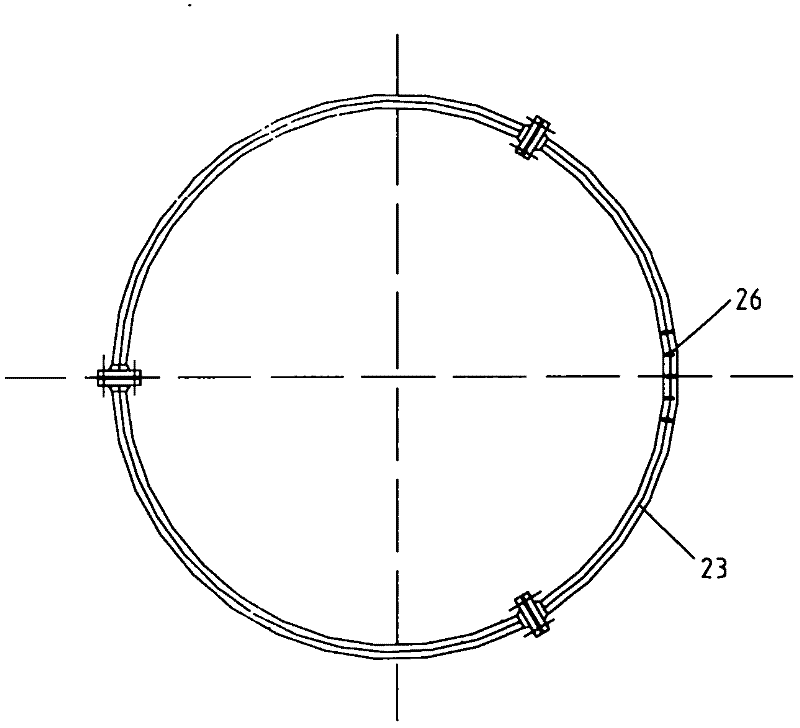

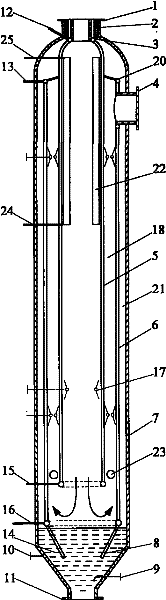

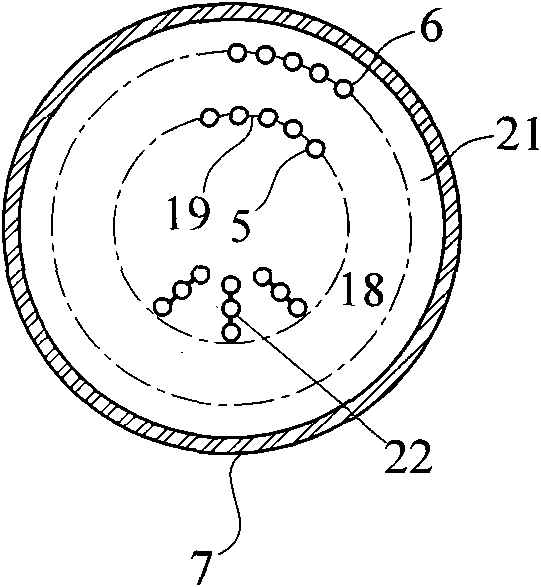

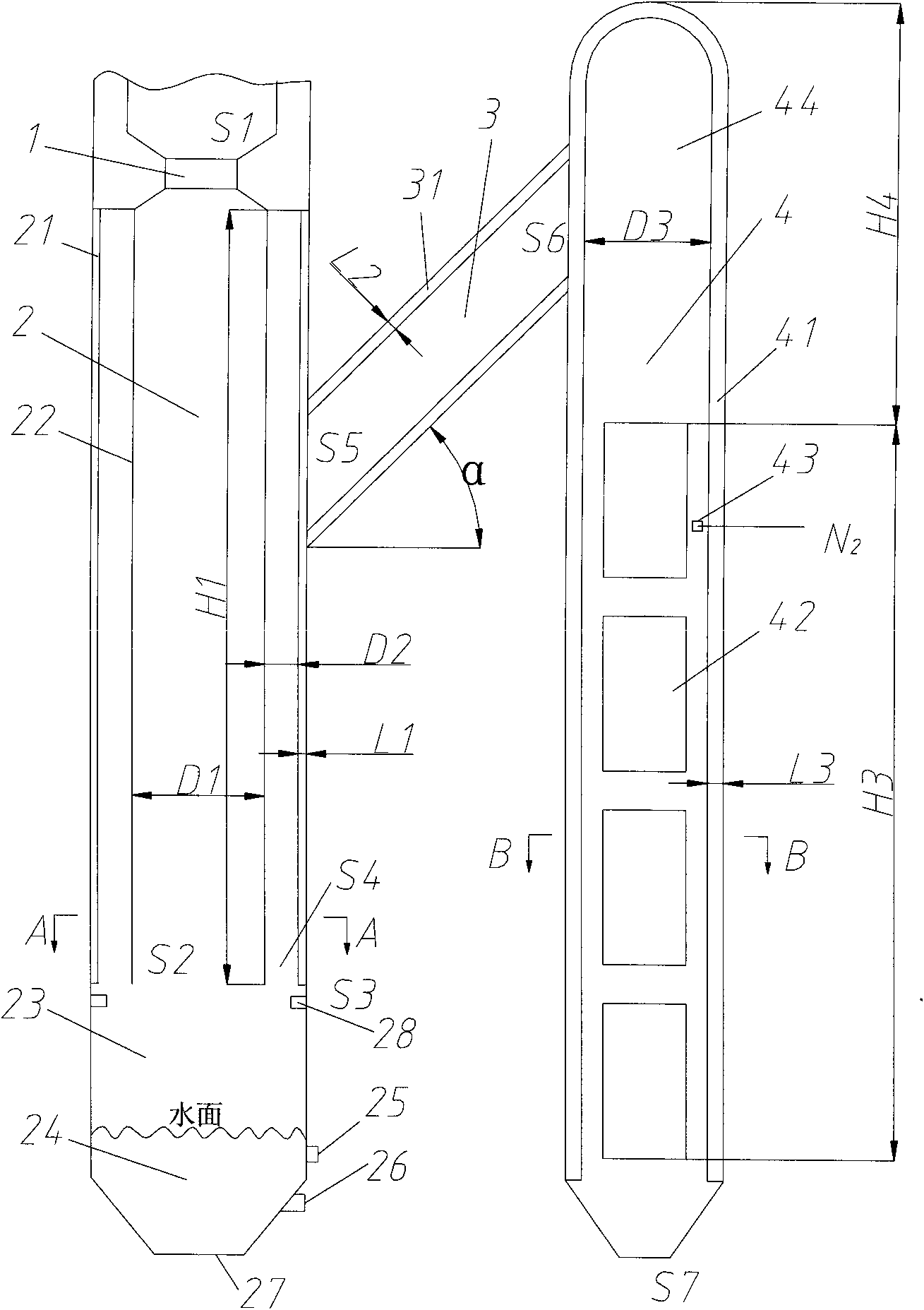

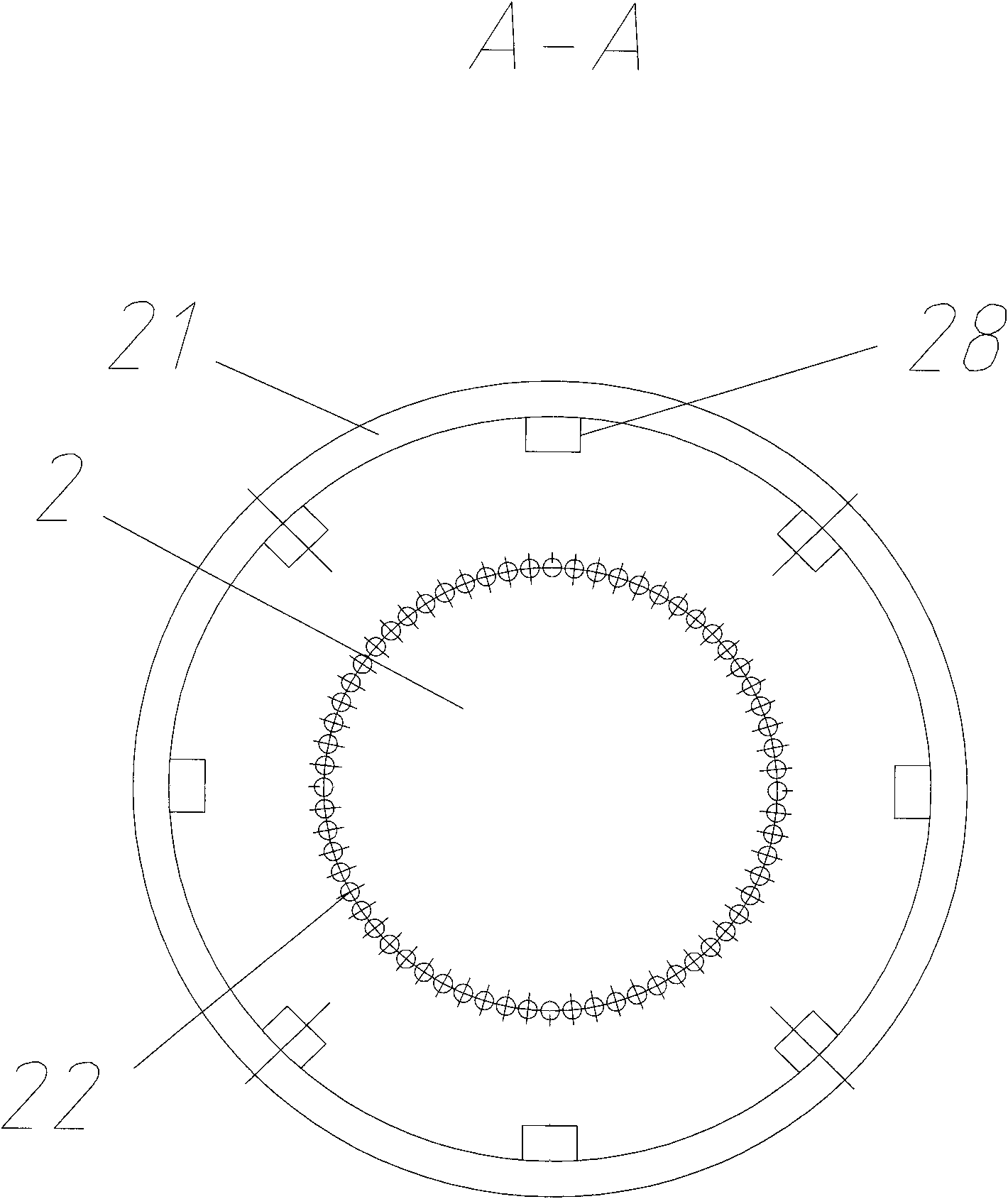

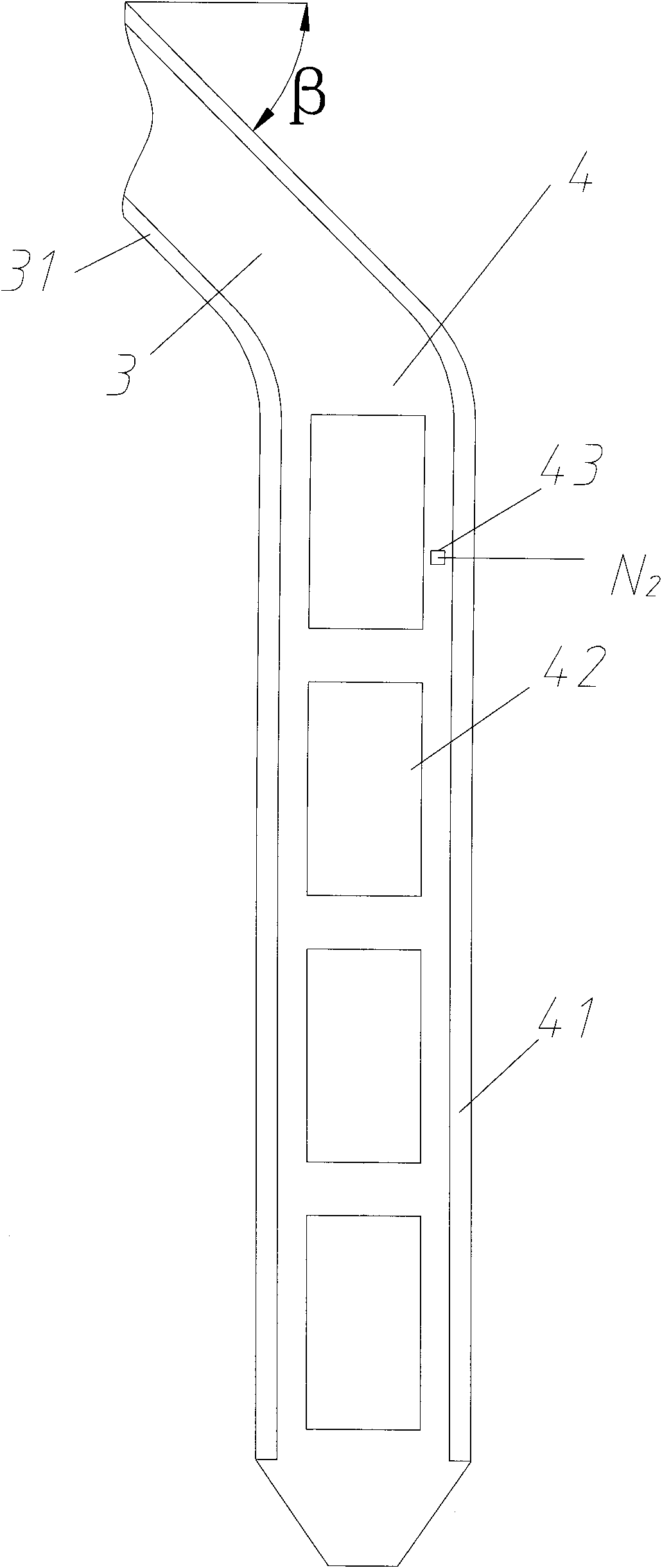

Double-barrel water cooled wall type radiation waste boiler with adjusting function and industrial application thereof

InactiveCN102213409AImprove utilization efficiencySmall sizeSteam boilersSteam boilers componentsSlagHigh pressure water

The invention discloses a recycling technology for sensible heat of high-temperature and high-pressure gasified products which are coal-gasified by an entrained flow bed, is particularly applicable for a waste boiler flow gasification furnace or a half waste boiler flower gasification furnace of a gasification island of an integrated gasification combined cycle (IGCC) power generation system, and provides a double-barrel water cooled wall type radiation waste boiler with an adjusting function. The double-barrel water cooled wall type radiation waste boiler consists of a flange connected with the gasification furnace, a shell for bearing high temperature and high pressure, an inner-layer water cooled wall, an outer-layer water cooled wall, a screen type water cooled wall, a soot blower and a slag pool positioned at the bottom, and comprises a water-spraying temperature reduction device with the adjusting function. Dust and slag which are carried by most air flows are caught and collected by the slag pool, and synthesized gas flows out from the single side of the radiation waste boiler. High-pressure water entering the radiation waste boiler recycles the sensible heat of the high-temperature and high-pressure gasified products and is converted into saturated high-pressure steam discharged from the outlet of the water cooled wall. By the double-barrel water cooled wall type radiation waste boiler, the high-position sensible heat of the gasified products can be recycled effectively, so the whole energy utilization efficiency can be improved; the double-barrel water cooled wall type radiation waste boiler has the characteristics of safe running, reliability and controllability, and is a clean and efficient energy recycling technology.

Owner:EAST CHINA UNIV OF SCI & TECH

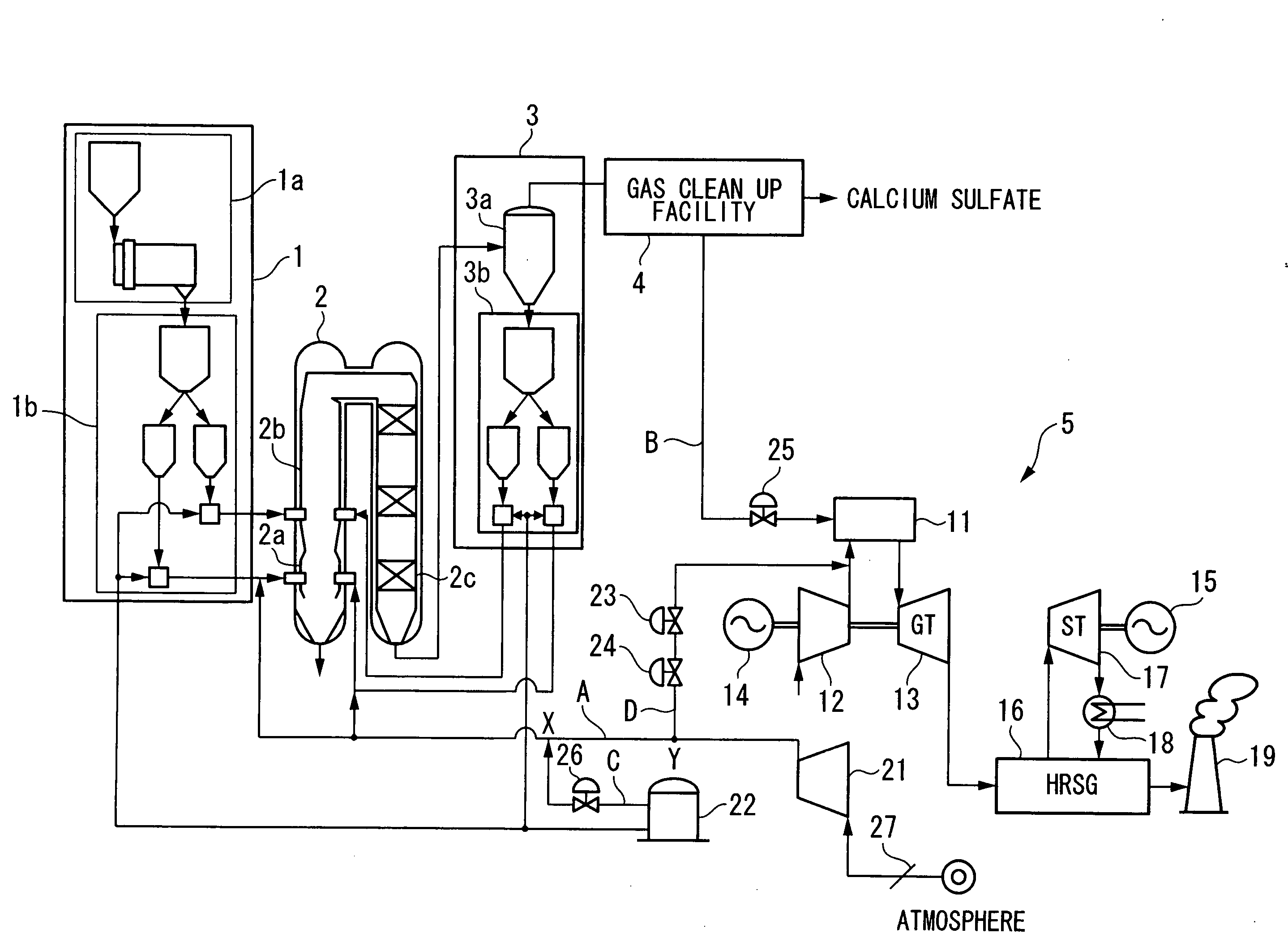

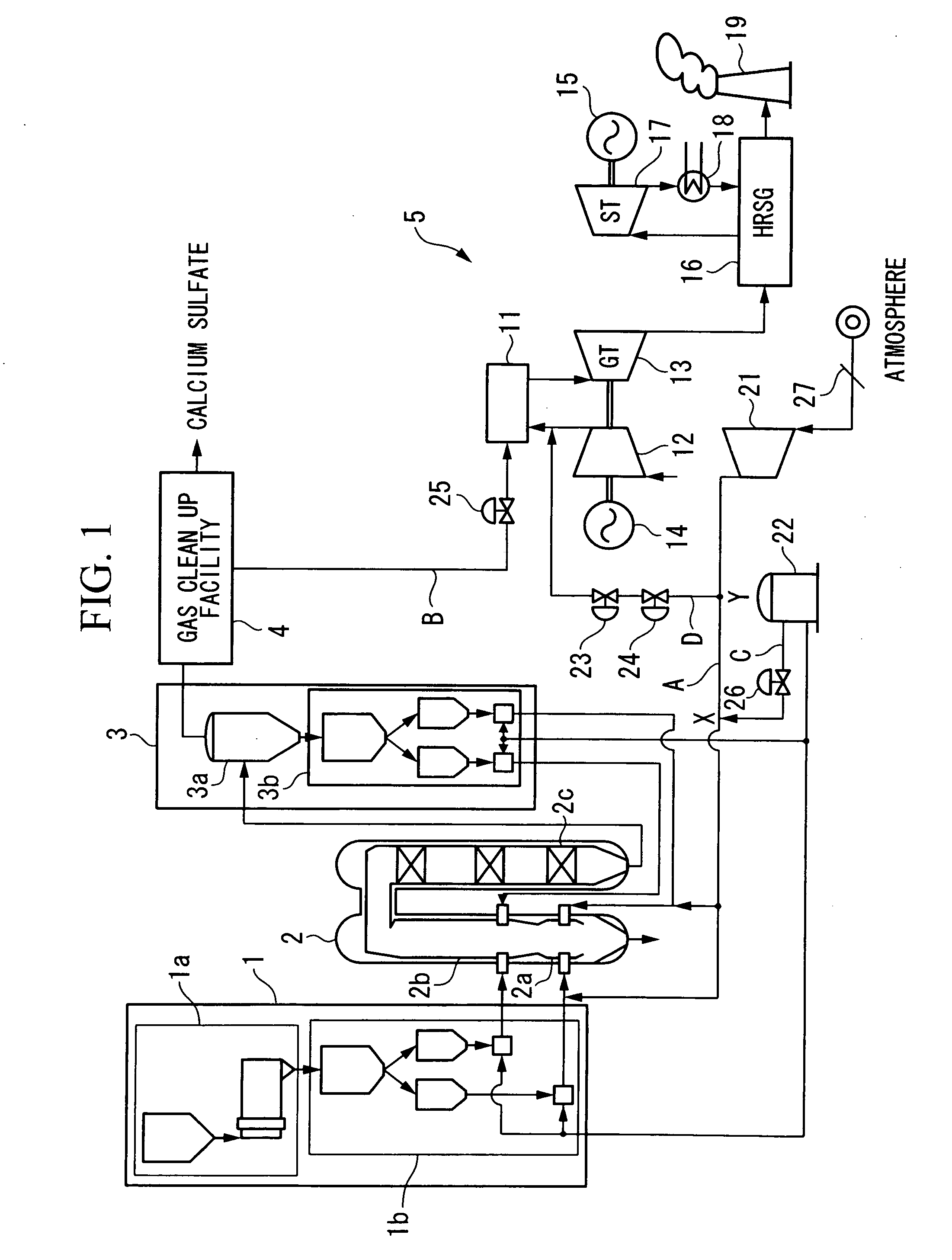

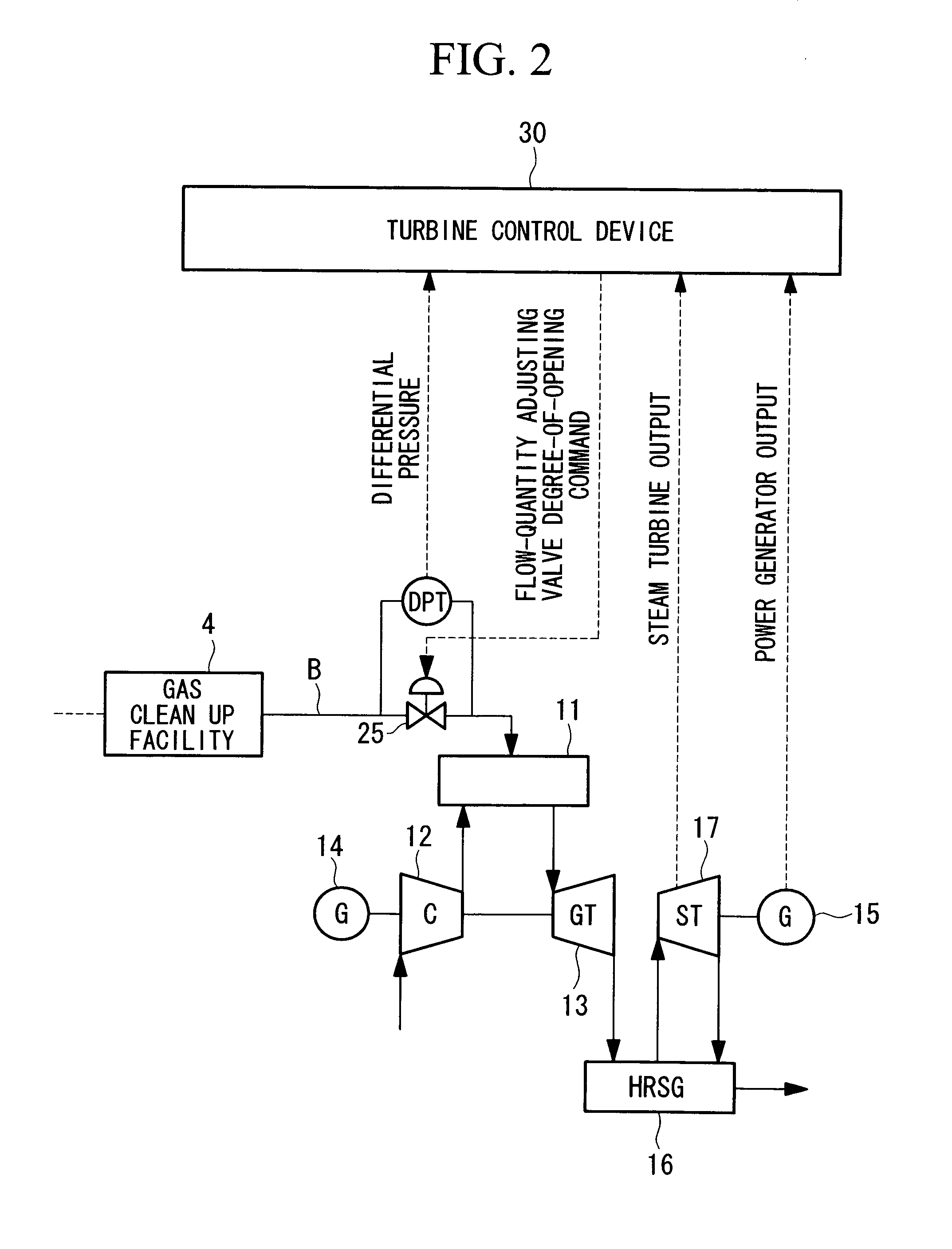

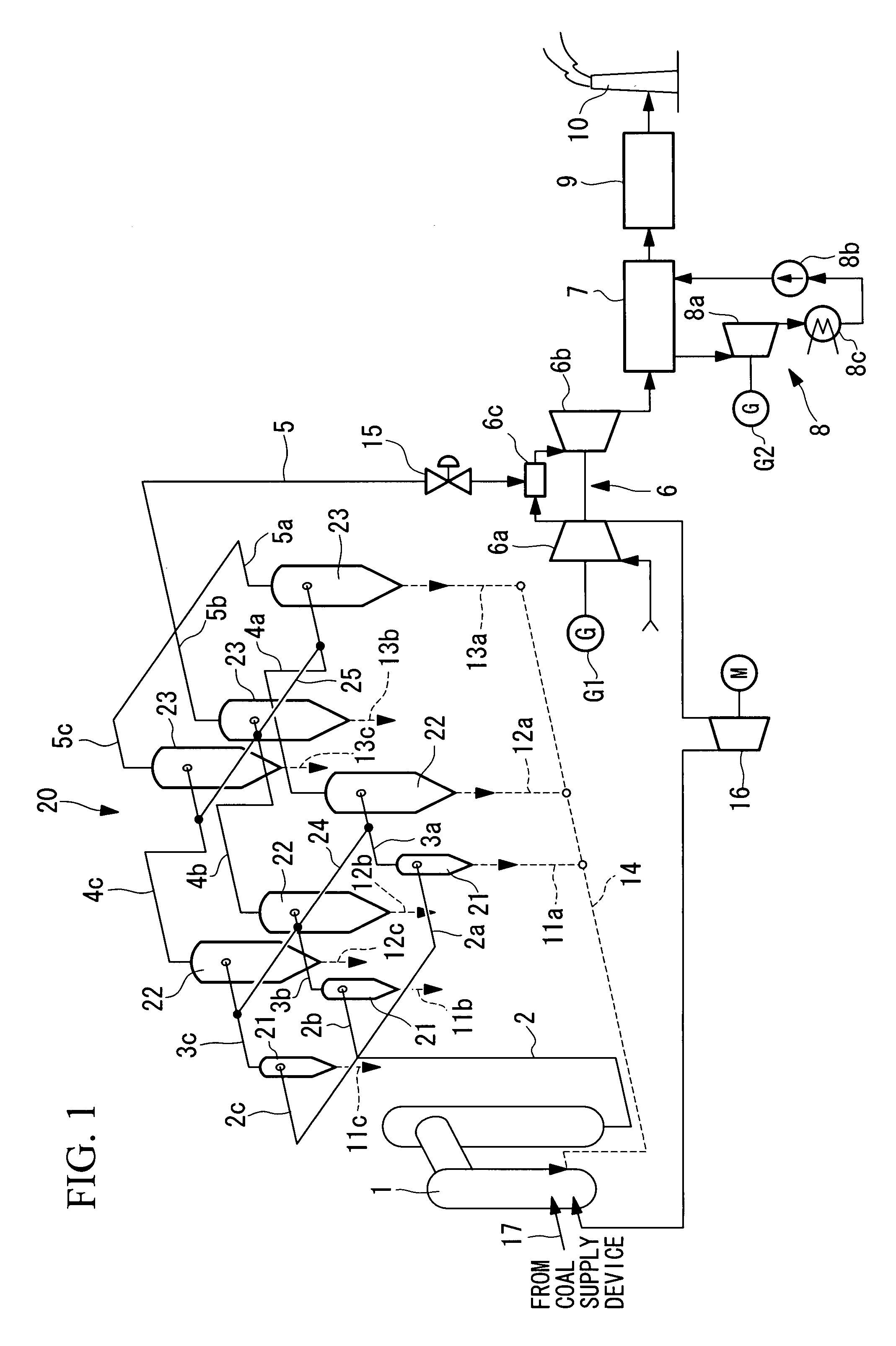

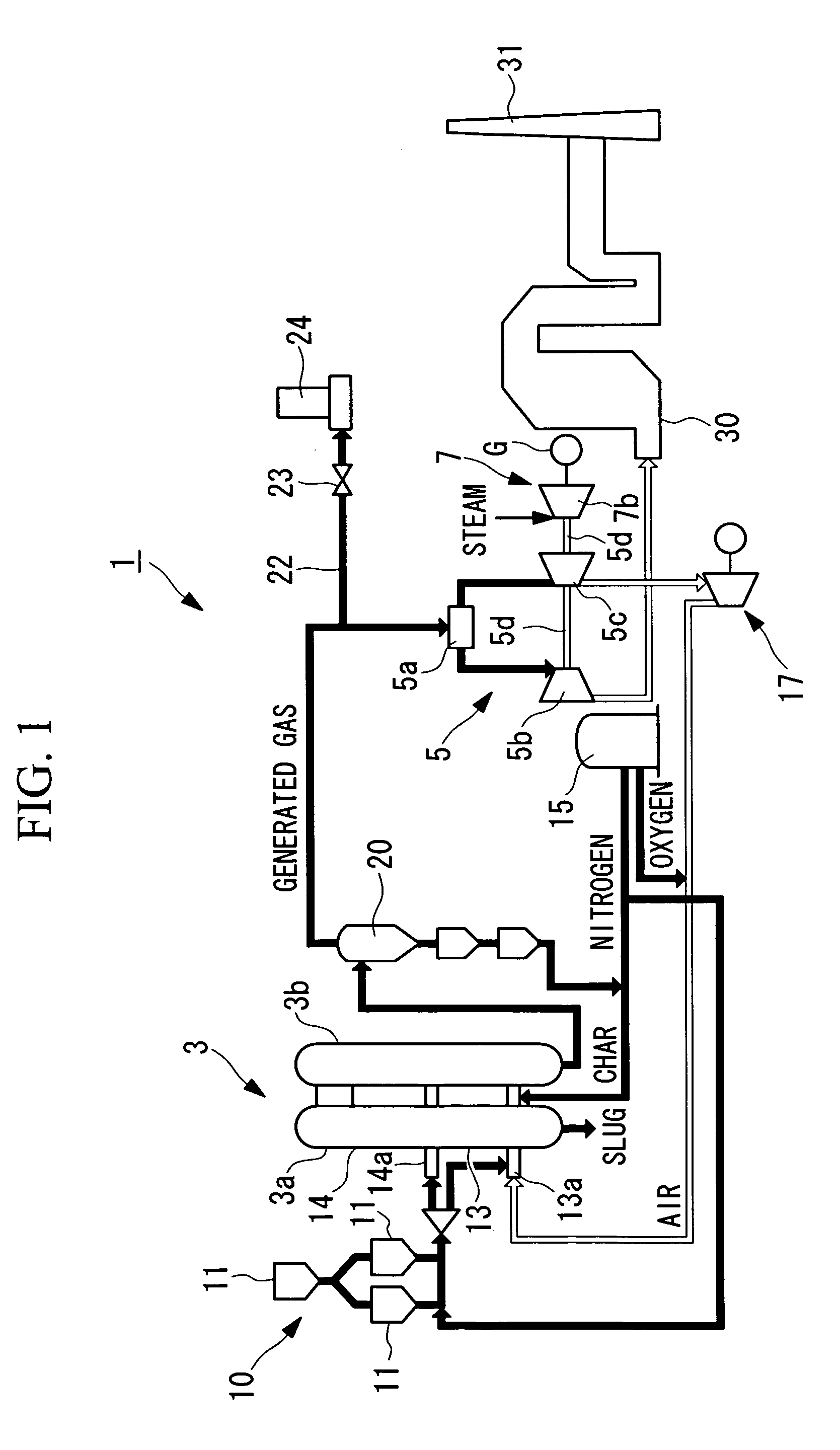

Integrated gasification combined cycle power generation plant

InactiveUS20080295480A1Boost overall plant efficiencyRelieve supply pressureCombustion enginesGas turbine plantsPower stationControl valves

A gasifying agent supply path A from an axial flow compressor 21 which boosts pressure of a gasifying agent to a gasifying furnace 2 is branched, and a gasifying agent bypass path D having an escaping pressure adjusting valve 23 is provided. The flow quantity or pressure of the gasifying agent supplied to the gasifying furnace 2 from the gasifying agent supply path A can be adjusted according to the degree of opening of the adjusting valve 23 disposed in the gasifying agent bypass path D, whereby providing a control valve in the gasifying agent supply path A is no longer necessary. Thus, pressure loss at the gasifying agent supply path A can be suppressed, and the discharge pressure of the axial flow compressor 21 can be greatly reduced.

Owner:MITSUBISHI HEAVY IND LTD

IGCC design and operation for maximum plant output and minimum heat rate

InactiveUS20080087022A1Low efficiencyIncrease productionGas turbine plantsTurbine/propulsion fuel controlThermal energyAutomatic control

A system and method for operating an integrated gasification combined cycle (IGCC) gas turbine system that utilizes the fuel stream as a means of controlling the operation of the IGCC to achieve a target output and efficiency. The methods and systems enable the IGCC to be operated at reduced output, but without a corresponding drop in efficiency as compared to prior art gas turbine systems. Conversely, the IGCC may be operated at higher outputs. The methods and systems achieve the target output and efficiency by adjusting the chemical potential energy, sensible energy, or both of a fuel stream entering the combustion turbine. The chemical potential energy and sensible energy may be manually or automatically controlled.

Owner:SIEMENS ENERGY INC

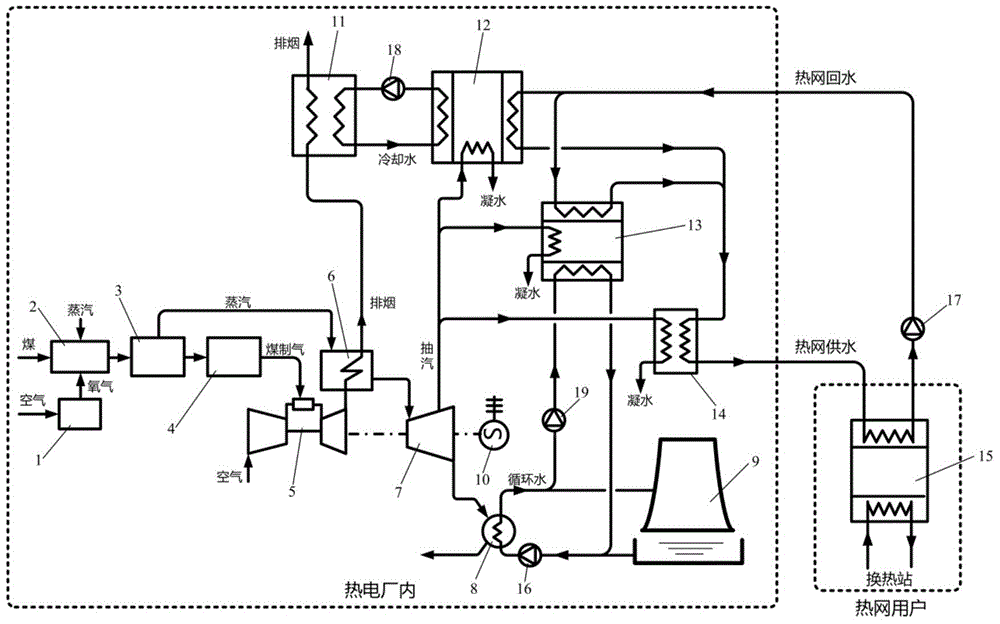

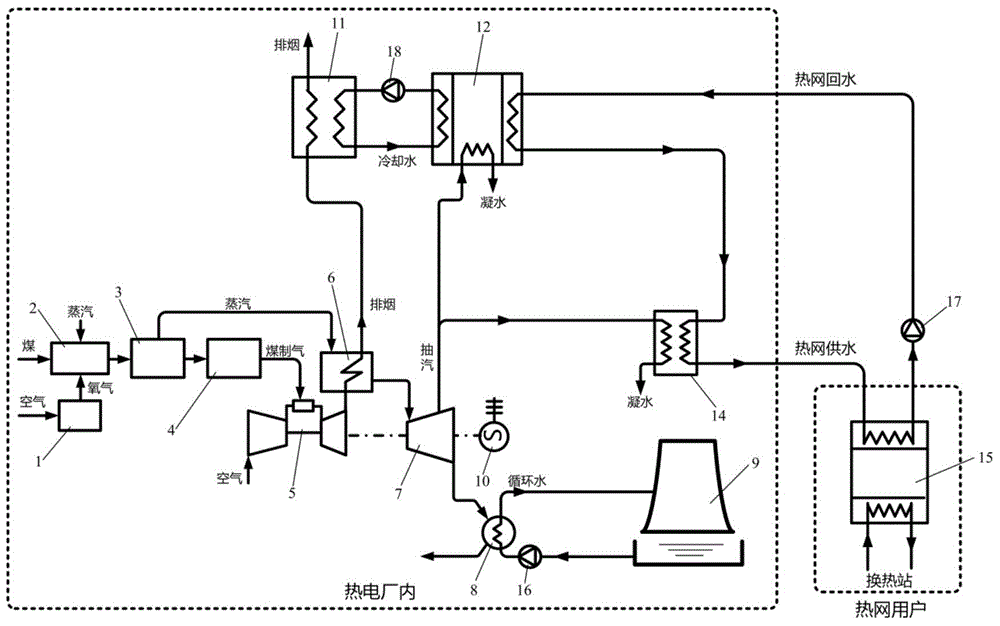

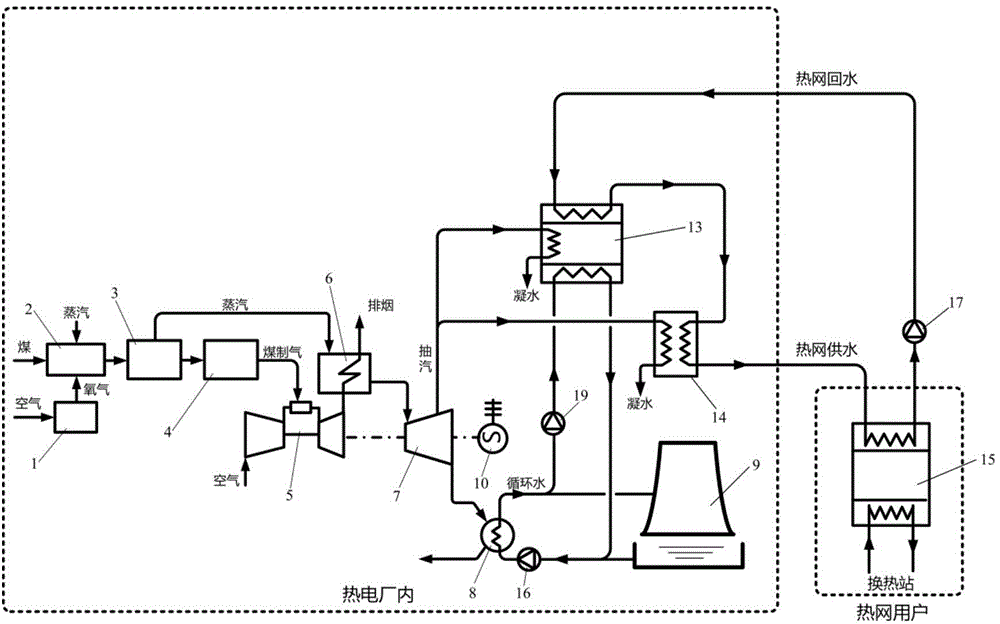

Waste heat recovery IGCC (integrated gasification combined cycle) combined heat and power generation central heating system and method

ActiveCN104533551AImprove economyGuaranteed annual power generation hoursLighting and heating apparatusSteam useCooling towerMature technology

The invention discloses a waste heat recovery IGCC (integrated gasification combined cycle) combined heat and power generation central heating system and method. The system comprises an air separation unit, a gasification furnace, a gas cooler, a purification plant, a gas turbine, a waste heat boiler, an absorption heat pump and a heat exchanger, which are connected successively. An exhaust smoke outlet of the waste heat boiler is emptied or is connected with a smoke inlet of a smoke condensation heat exchanger; a steam outlet of the waste heat boiler is connected with an inlet of a steam turbine; an exhaust steam outlet of the steam turbine is connected with a steam inlet of a condenser; a circulating water outlet of the condenser is connected with a cooling tower; a low-pressure extracted steam outlet of the steam turbine is divided into three paths, two paths or one path of temperature drop, and heat supply network return water is conveyed to a heat supply network for use after being heated. The invention also provides a central heating method. Clean and efficient IGCC is combined with extracted steam heat supply of the steam turbine, the extracted steam of the steam turbine is used for driving the absorption heat pump, the exhaust steam waste heat of the steam turbine and the smoke waste heat are recycled, and the extracted steam heat of the steam turbine and the recycled waste heat are utilized for central heating. The recovery waste heat IGCC combined heat and power generation central heating system and method have the characteristics of cleanliness, high efficiency, mature technology, high recycled waste heat amount, and capability of recycling smoke condensate water.

Owner:HUANENG CLEAN ENERGY RES INST +1

High-temperature synthesis gas sensible heat recovery device

ActiveCN101781586AIncreased thermal efficiency of gasificationGuaranteed uptimeChemical industryCombined combustion mitigationHigh pressureIntegrated gasification combined cycle

The invention relates to a high-temperature synthesis gas sensible heat recovery device which is characterized by comprising a radiation boiler, wherein the radiation boiler is connected with a convection boiler by a synthesis gas pipe. The invention recovers the sensible heat of the high-temperature synthesis gas from an entrained flow gasifier by using a radiation type steam generator, a gas quenching step and a convection type steam generator to generate medium-pressure or high-pressure steam, thereby increasing the thermal efficiency for the gasification of the entrained flow by more than10-15%. The device is concise and compact, has reliable operation and low investment, is a high-efficiency and energy-saving device, and can be widely used in the fields of integral gasification combination cycle power generation (IGCC), methanol and alkene production, coal-to-liquid, spongy iron production by the synthesis gas direct reduction iron-making method and the like.

Owner:SHANGHAI BOILER WORKS +2

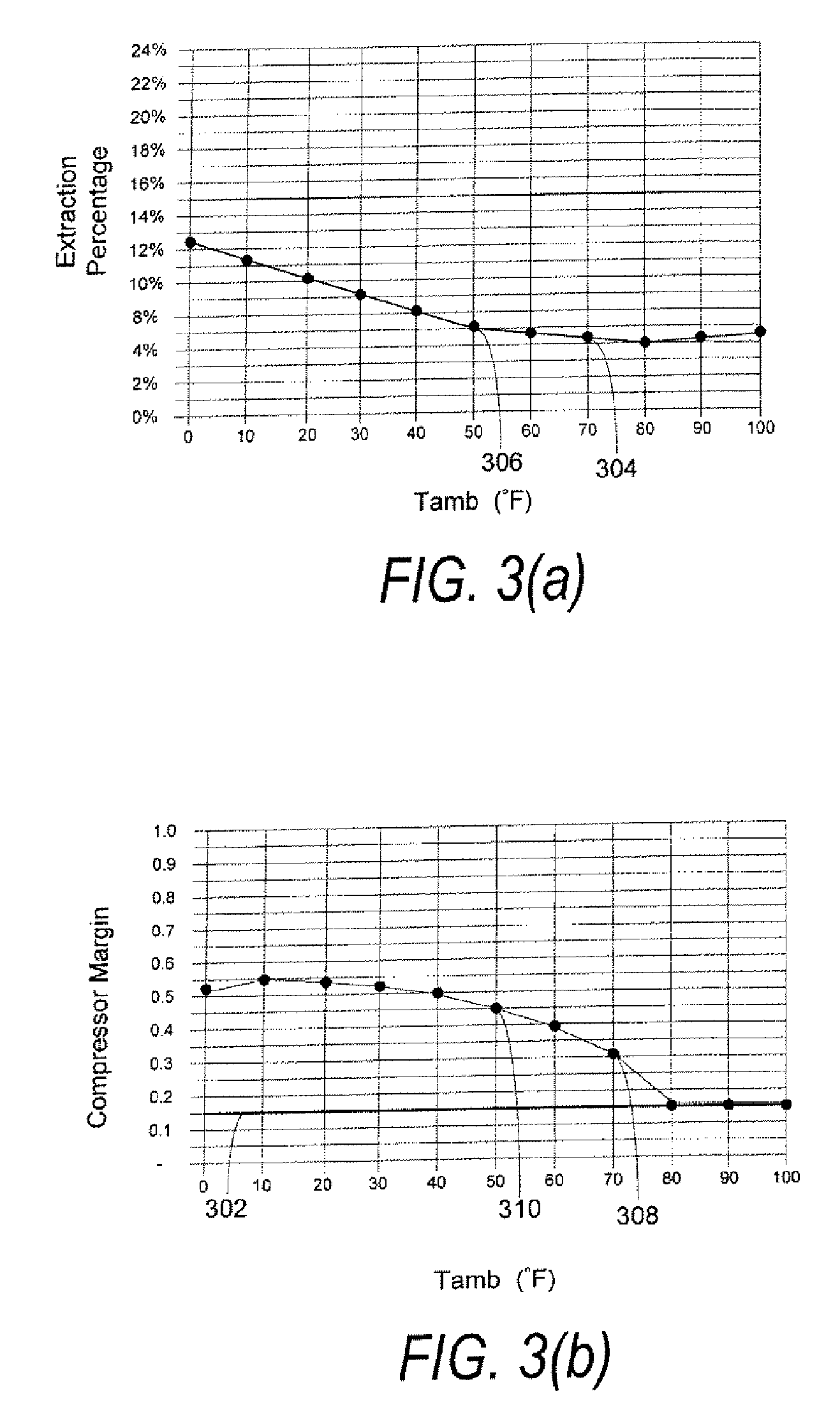

Methods and systems of variable extraction for gas turbine control

A method of controlling a load of a gas turbine engine that is part of an integrated gasification combined-cycle power generation system, which includes an air separation unit, that includes the steps of: (1) extracting an amount of compressed air that is compressed by a turbine compressor; (2) supplying the extracted amount of compressed air to the air separation unit; and (3) varying the amount of compressed air extracted from the turbine compressor based upon a desired load for the gas turbine engine.

Owner:GENERAL ELECTRIC CO

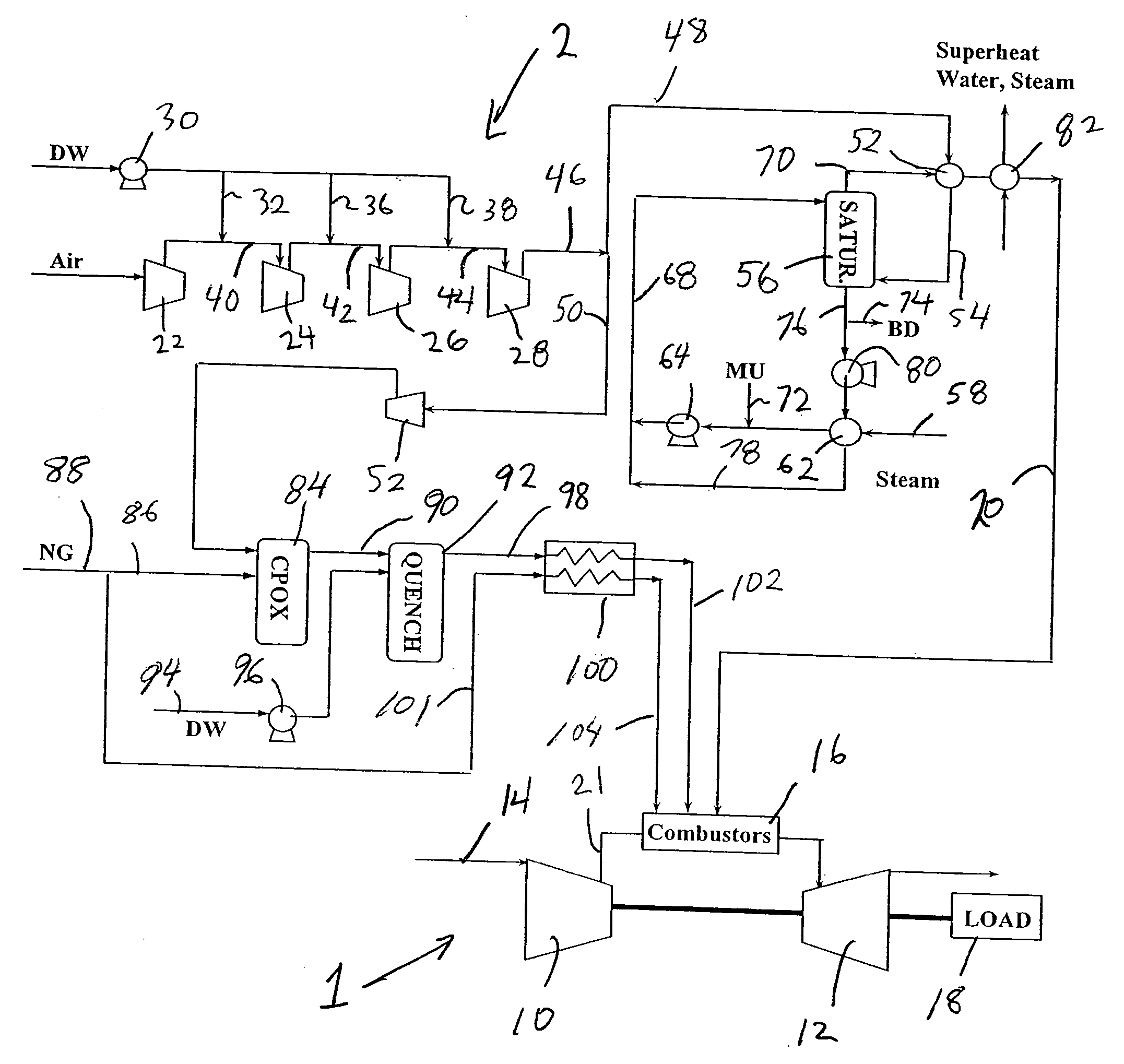

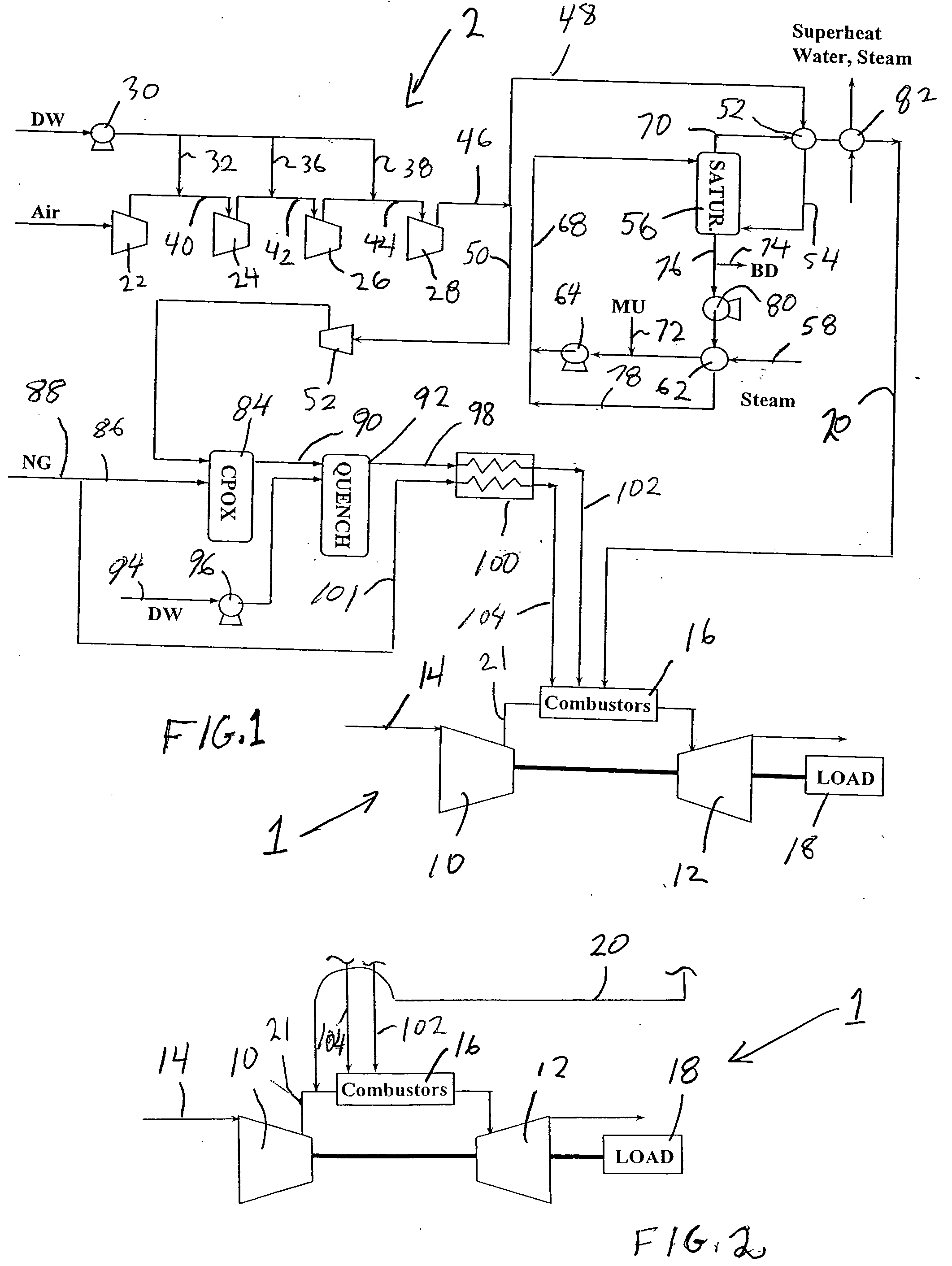

Gas turbine power augmentation method

A power augmentation method for a gas turbine in which water is injected into one or more stages of an auxiliary compressor to produce a vapor containing gas stream. The vapor containing gas stream is at least in part introduced into combustors of the gas turbine for power augmentation. Part of the vapor containing compressed gas stream can be introduced into a reactor to generate a hydrogen containing synthesis gas to support lower flame temperatures occurring within the combustors of the gas turbine due to the introduction of the vapor containing gas stream. In such manner, NOx emissions of the gas turbine can be reduced. Furthermore, the power augmentation method can be conducted in conjunction with an integrated gasification combined cycle.

Owner:PRAXAIR TECH INC

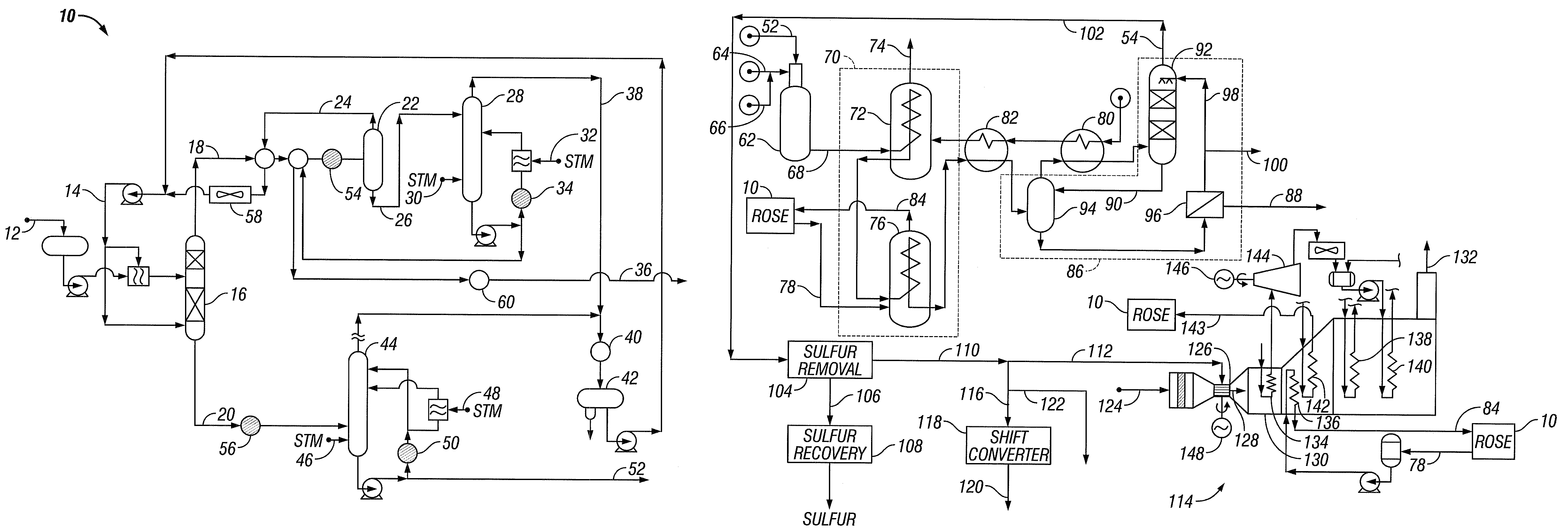

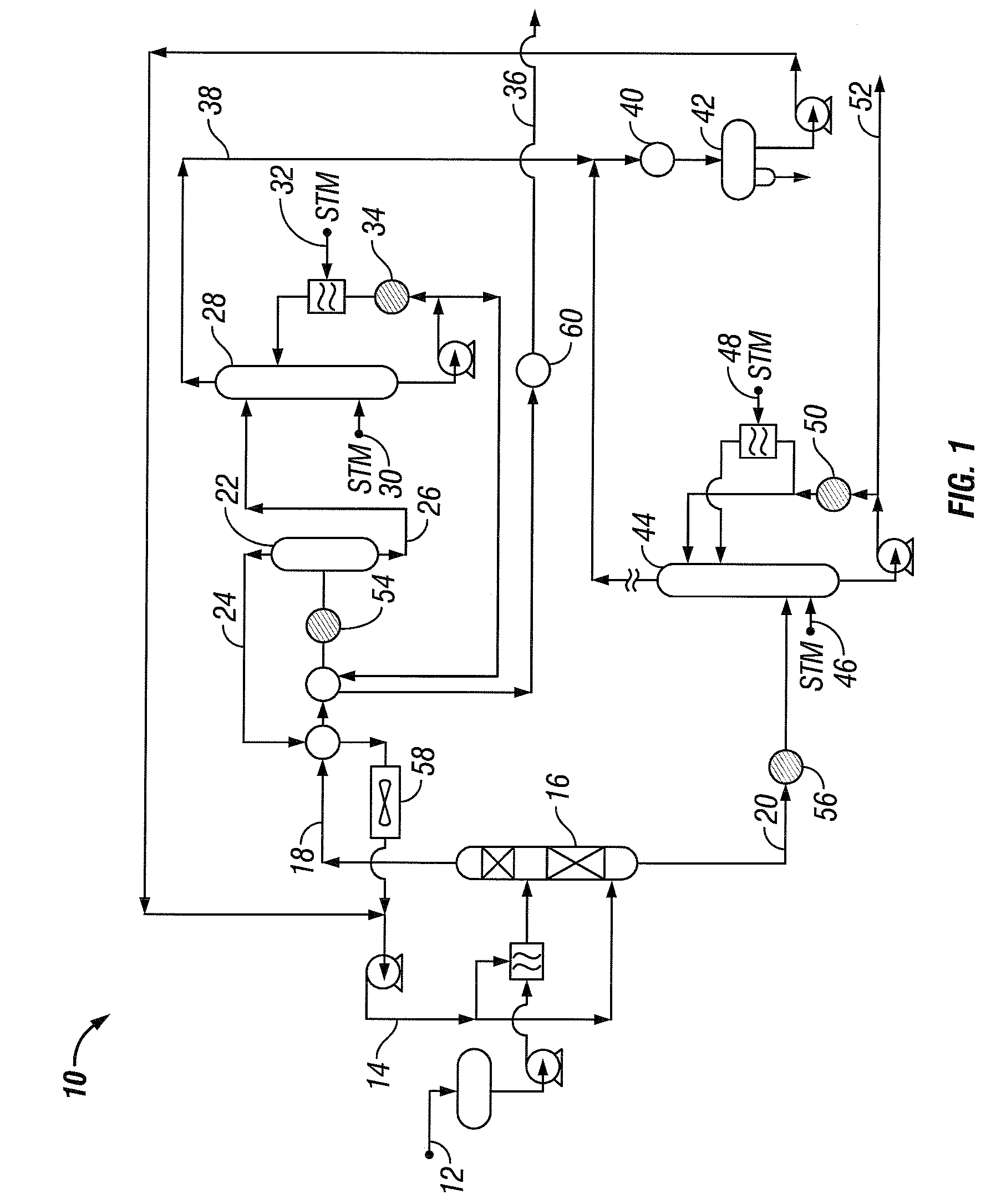

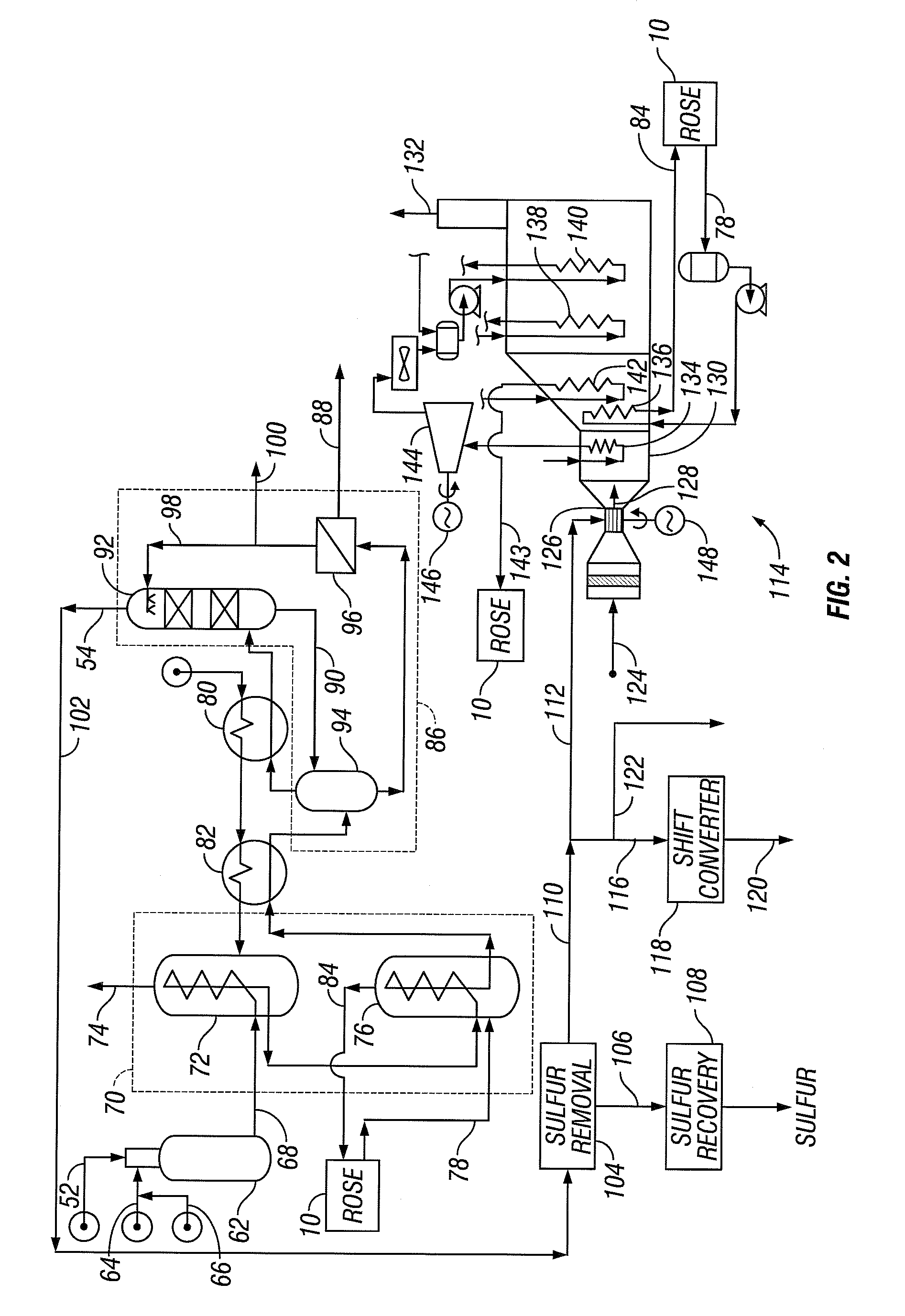

Processing of residual oil by residual oil supercritical extraction integrated with gasification combined cycle

ActiveUS7347051B2Reduce and eliminate export and disposalMaximize recoveryTreatment with plural serial stages onlyGas turbine plantsProcess engineeringResidual oil

Residual oil supercritical extraction (ROSE) 10 and integrated gasification combined-cycle (IGCC) power systems 70, 114 are cooperatively integrated. High-level heat from the IGCC is used via a heat transfer fluid 84 for high level process heating requirements in the ROSE unit. This can eliminate the fired heater normally required in the ROSE unit, and reduces the size of the gasifier 62 waste heat boiler 72 and / or the high-pressure steam coil 134 and steam turbine generator 144 in the IGCC.

Owner:KELLOGG BROWN & ROOT LLC

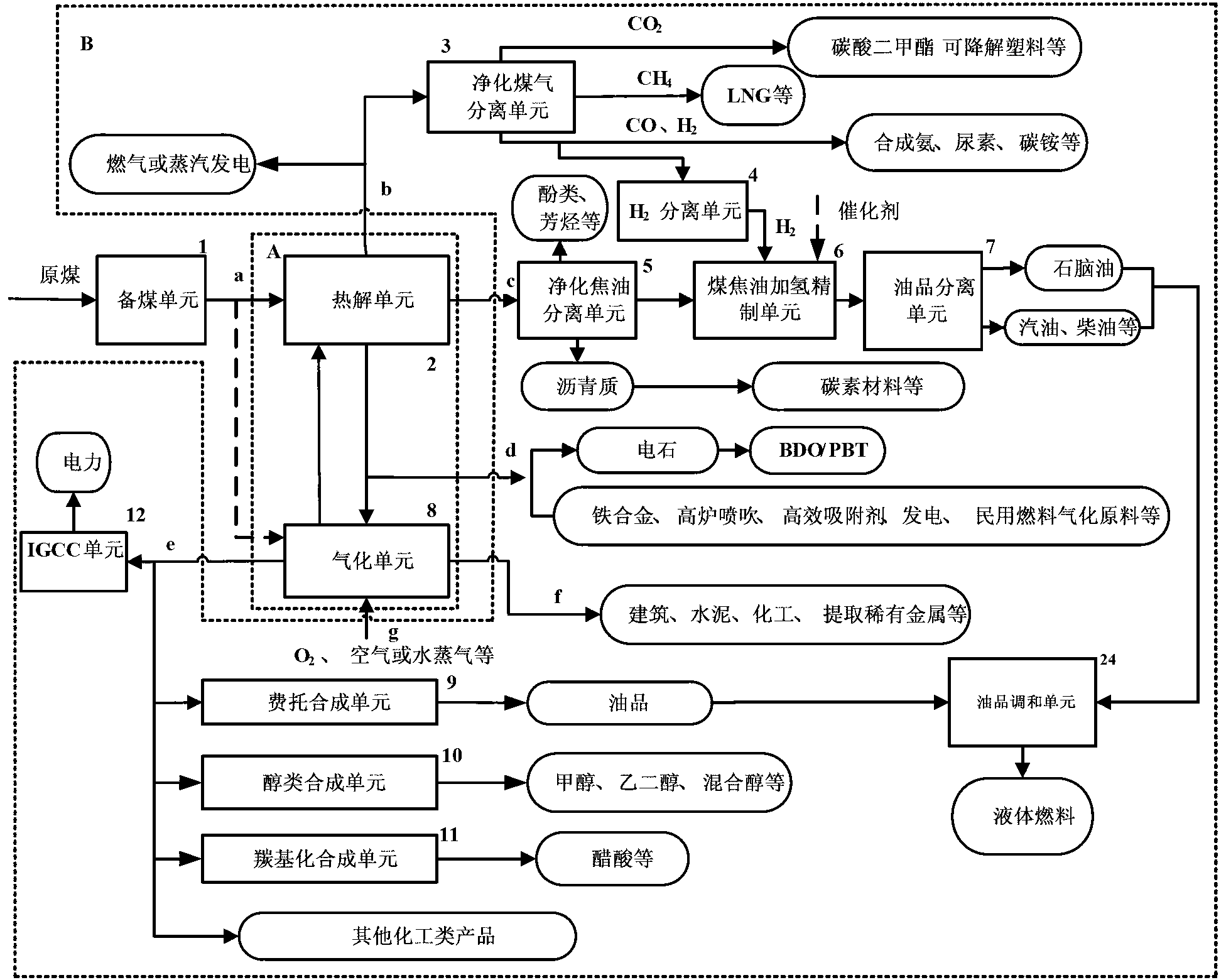

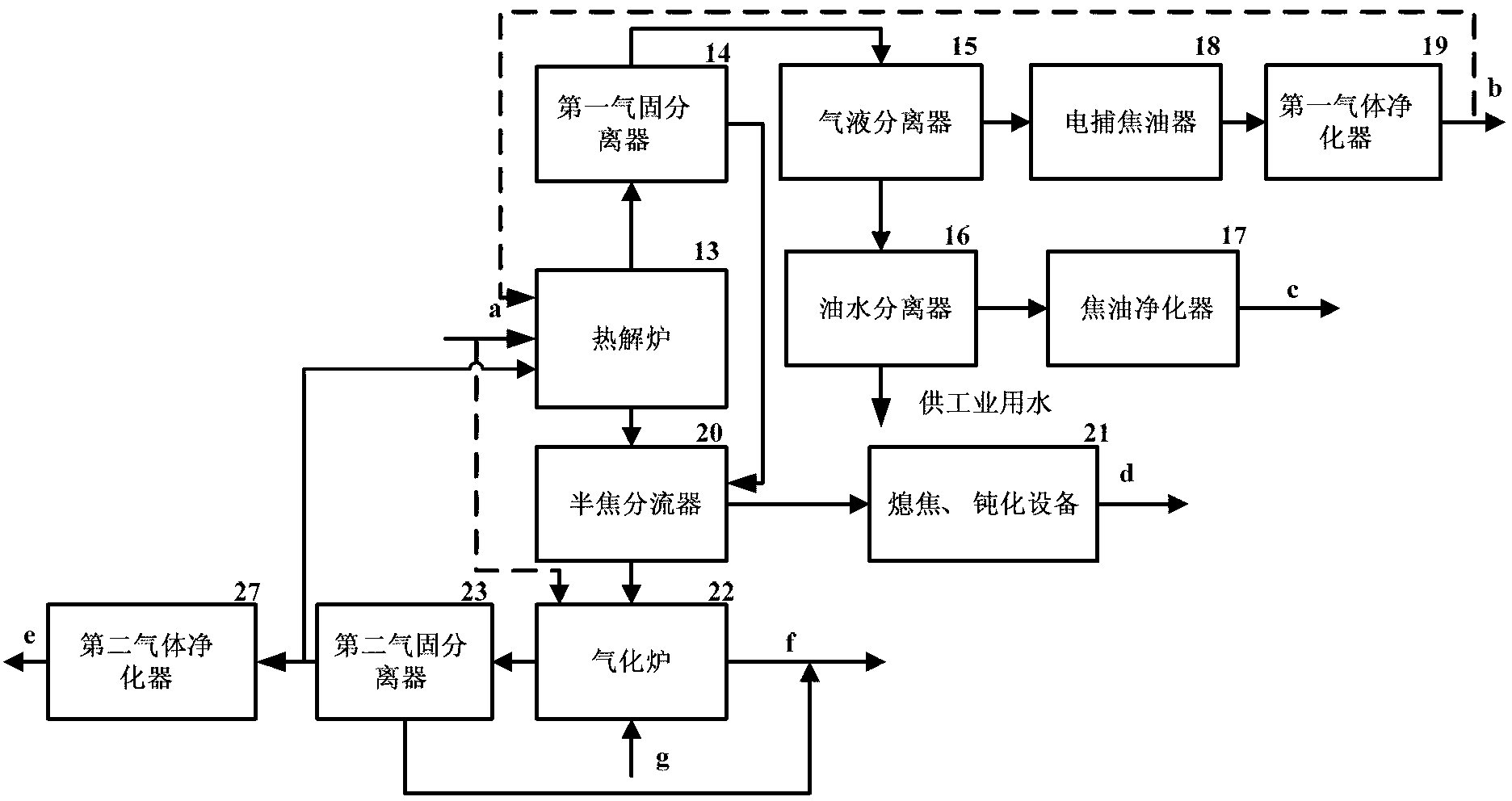

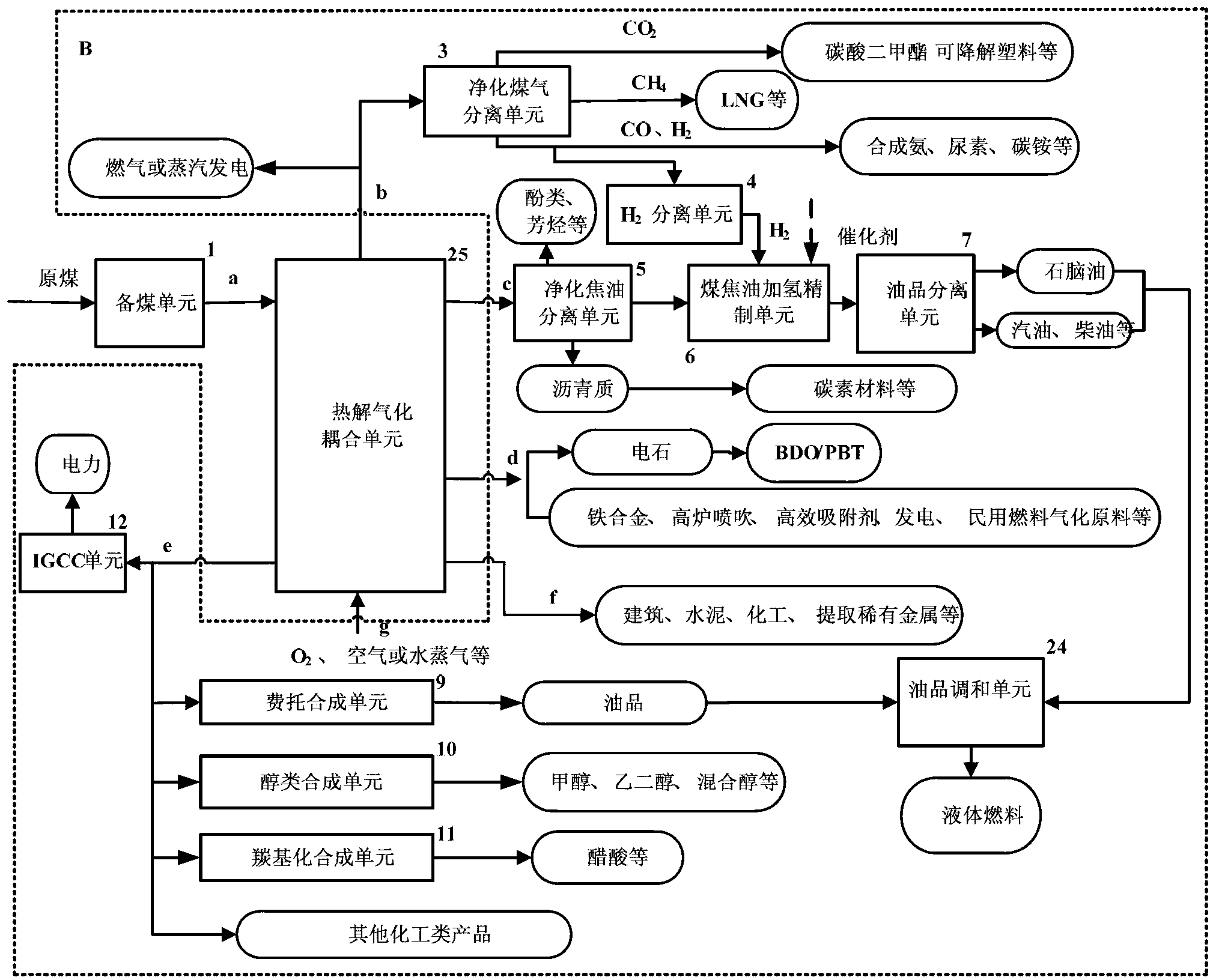

Pyrolysis gasification coupling integrated poly-generation system and process for coal chemical industry

ActiveCN103160296AImprove utilization efficiencyMaximize Utilization EfficiencyUrea derivatives preparationCarbon compoundsElectricityEngineering

The invention provides a pyrolysis gasification coupling integrated poly-generation system and process for the coal chemical industry. The system comprises a coal preparation unit, a pyrolysis-gasification coupling system A and a poly-generation system B, wherein the poly-generation system B comprises a purified gas separation unit connected with the purified gas outlet of the pyrolysis unit, a purified tar separation unit connected with the purified tar outlet of the pyrolysis unit, and a chemical product synthesis unit and an IGCC (Integrated Gasification Combined Cycle) unit which are respectively connected with purified gasification gas outlet of the gasification unit; and the purified tar separation unit is sequentially connected with a coal tar hydrofining unit and an oil product separation unit. The pyrolysis gasification coupling integrated poly-generation system and process can be used for organically combining coal pyrolysis gasification and the production process of oil, gas, chemicals, electricity and heat to realize integration of material conversion and energy conversion, maximize classified utilization, value promotion, utilization efficiency and economical benefit of coal resources, and improve the energy utilization efficiency.

Owner:SHAANXI COAL & CHEM TECH INST

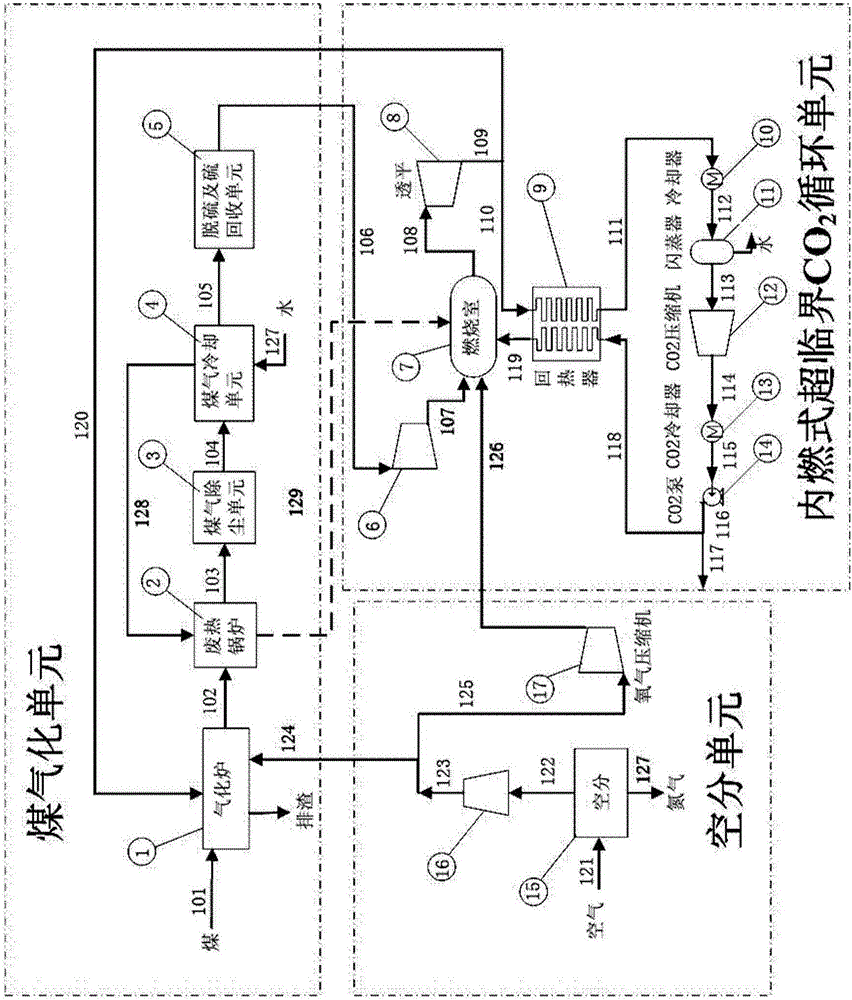

Gasification supercritical CO2 cycle power generation system

ActiveCN105820842AReduce oxygen consumptionReduce air separation power consumptionGas turbine plantsGasification processes detailsThermal energyCombustion chamber

A gasification supercritical CO2 cycle power generation system comprises a gasification unit, an air distribution unit and an internal combustion type supercritical CO2 circulation unit, wherein air is input into the air distribution unit, oxygen is generated and output in two paths, one path of oxygen is input into a gasification furnace, and the other path of oxygen is input into a combustion chamber of the internal combustion type supercritical CO2 circulation unit .The internal combustion type supercritical CO2 circulation unit further comprises a turbine for converting heat energy into mechanical energy and a heat regeneration unit used for heat exchanging, and a part of gas is extracted from the portion between turbine stages, or a turbine outlet or a cold side hot end outlet of the heat regeneration unit to serve as a gasification agent to be input into the gasification furnace in the gasification unit .While zero CO2 emission of the gasification supercritical CO2 cycle power generation system is achieved, high system efficiency is obtained, and the net efficiency is higher than that of an integrated gasification combined cycle power generation system based on pre-combustion trapping by 8-14%.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

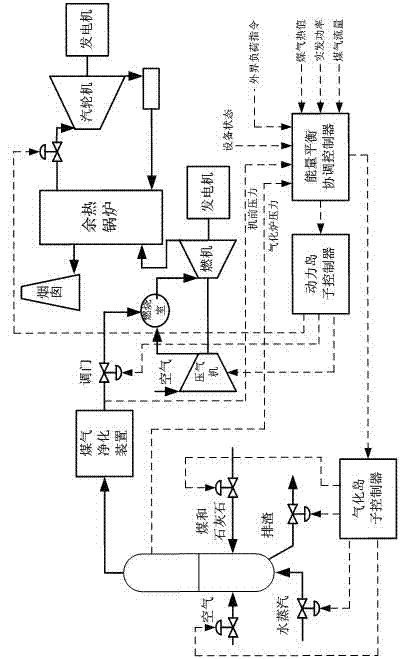

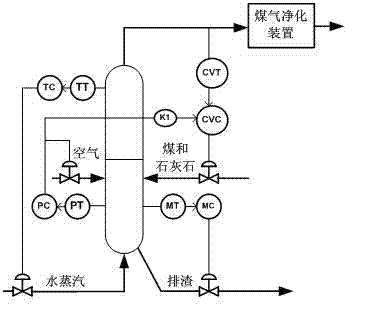

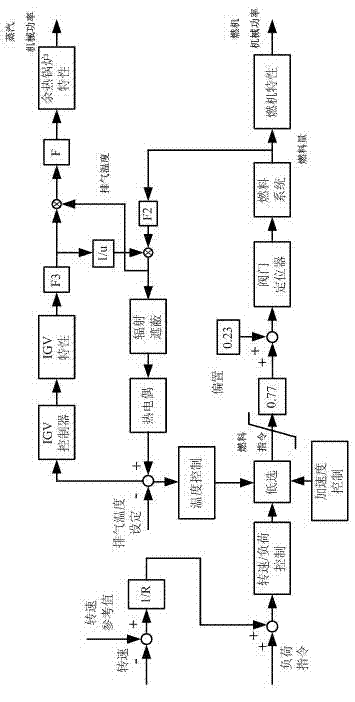

Energy-balance-based coordination control method of integrated gasification combined cycle power station

ActiveCN102778880ARealize decoupling controlIncrease the automatic input rateTotal factory controlProgramme total factory controlPower stationEnergy balanced

The invention provides a coordination control method of an integrated gasification combined cycle power station and particularly provides an energy-balance based coordination control method, aiming at the characteristic that time constant difference among all equipment of a controlled object of the integrated gasification combined cycle power station is large. According to the method, field signals are acquired, a gasification furnace and a gas turbine are regulated in the way of calculating the gasification furnace heat signal and the gas turbine heat signal, so the decoupling control on a power island and a gasification island is realized, gas turbine power and gas pressure before valve regulation are synchronously controlled, so that the heat signal tracks the energy signal, and thus the coordination control of the integrated gasification combined cycle power station is realized. Through control system architecture design and parameter regulation, in use, the method can effectively coordinate the operation of all the equipment of the gasification furnace and the power island of the power station, the load of the power station can be quickly and automatically regulated, and the operation stability of the power station can be ensured; and the method is a coordination control of a gas-steam combined cycle power station and has good stability and varying load performance.

Owner:NANJING GUODIAN NANZI WEIMEIDE AUTOMATION CO LTD

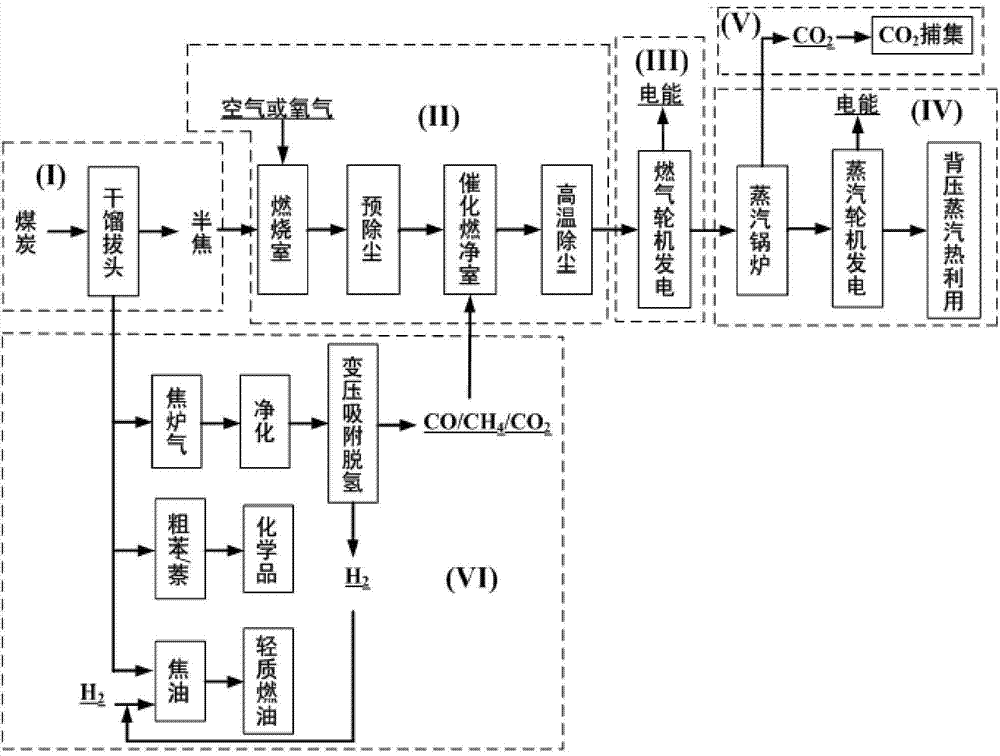

Efficient and clean utilization technology for highly volatile young coal

ActiveCN102965131AEfficient use ofHigh value-added utilizationHydrogen separationEnergy inputTrappingFuel oil

The invention relates to an efficient and clean utilization technology for highly volatile young coal. By means of integrated innovation of the following six technological modules: ''a young coal dry distillation topping process, a system for preparation of a high temperature gas turbine working medium by semi-coke oxygen-enriched direct combustion, gas-fired power generation, supercritical / ultra supercritical power generation, CO2 trapping, and a dry distillation topping gaseous product high-value utilization technique'', especially the method for preparation of high-temperature and high-pressure fuel gas meeting the gas turbine working medium purity requirement directly by semi-coke oxygen-enriched direct combustion without lowering temperature to remove dust and impurities, thermodynamic-chemical full-value clean utilization of coal can be realized. The power generation efficiency can reach over 60%. Compared with the IGCC (integrated gasification combined cycle) technology, the invention substitutes semi-coke oxygen-enriched direct combustion for a coal gasification process needing large investment, develops a high temperature dust removal technology, and makes full use of the useful work of high temperature fuel gas. The invention has the characteristics of less investment, simple process, and high power generation efficiency, etc., and also generates benzene, naphthalene, fuel oil and other high value-added chemicals as byproducts.

Owner:金涌

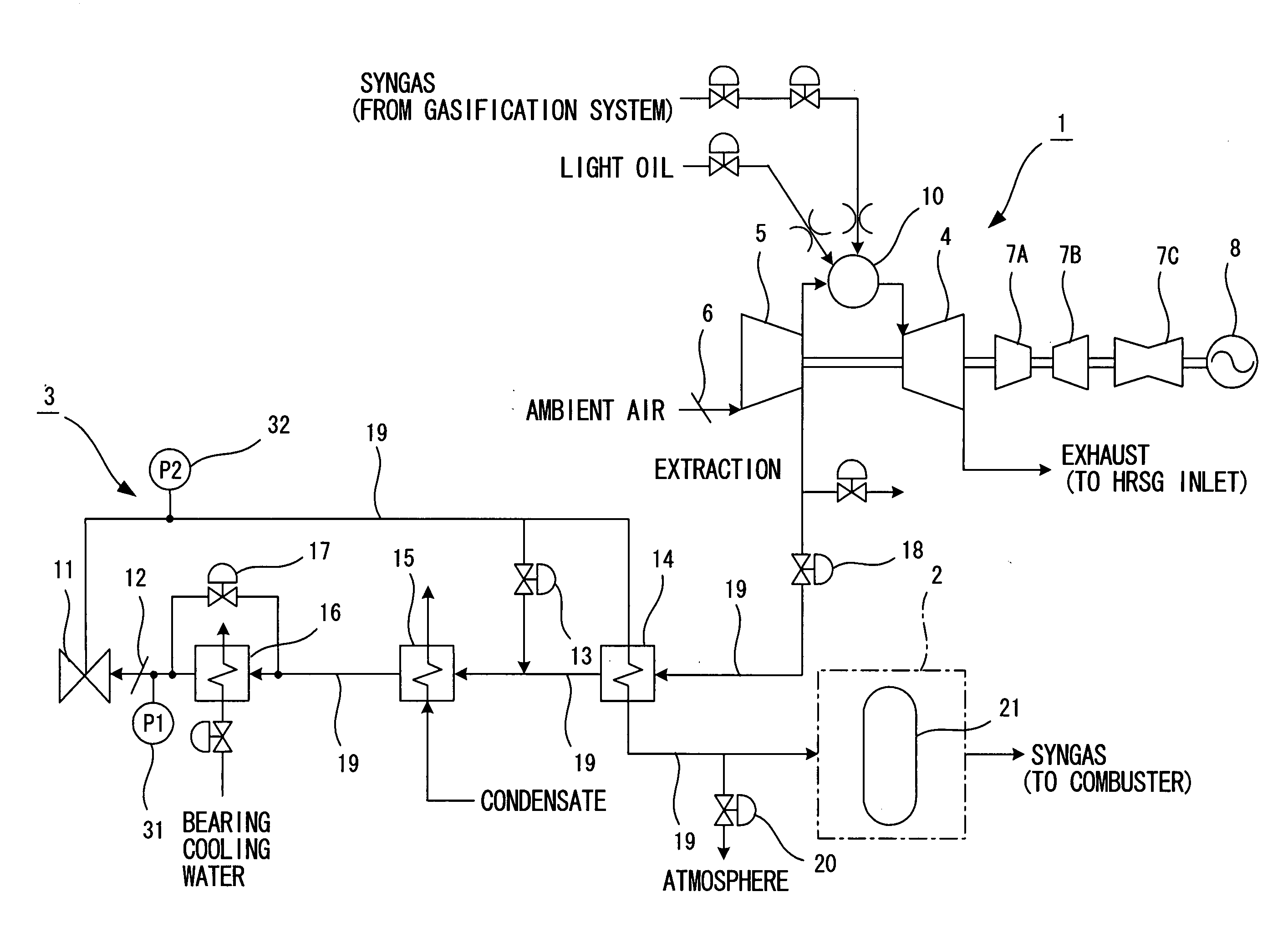

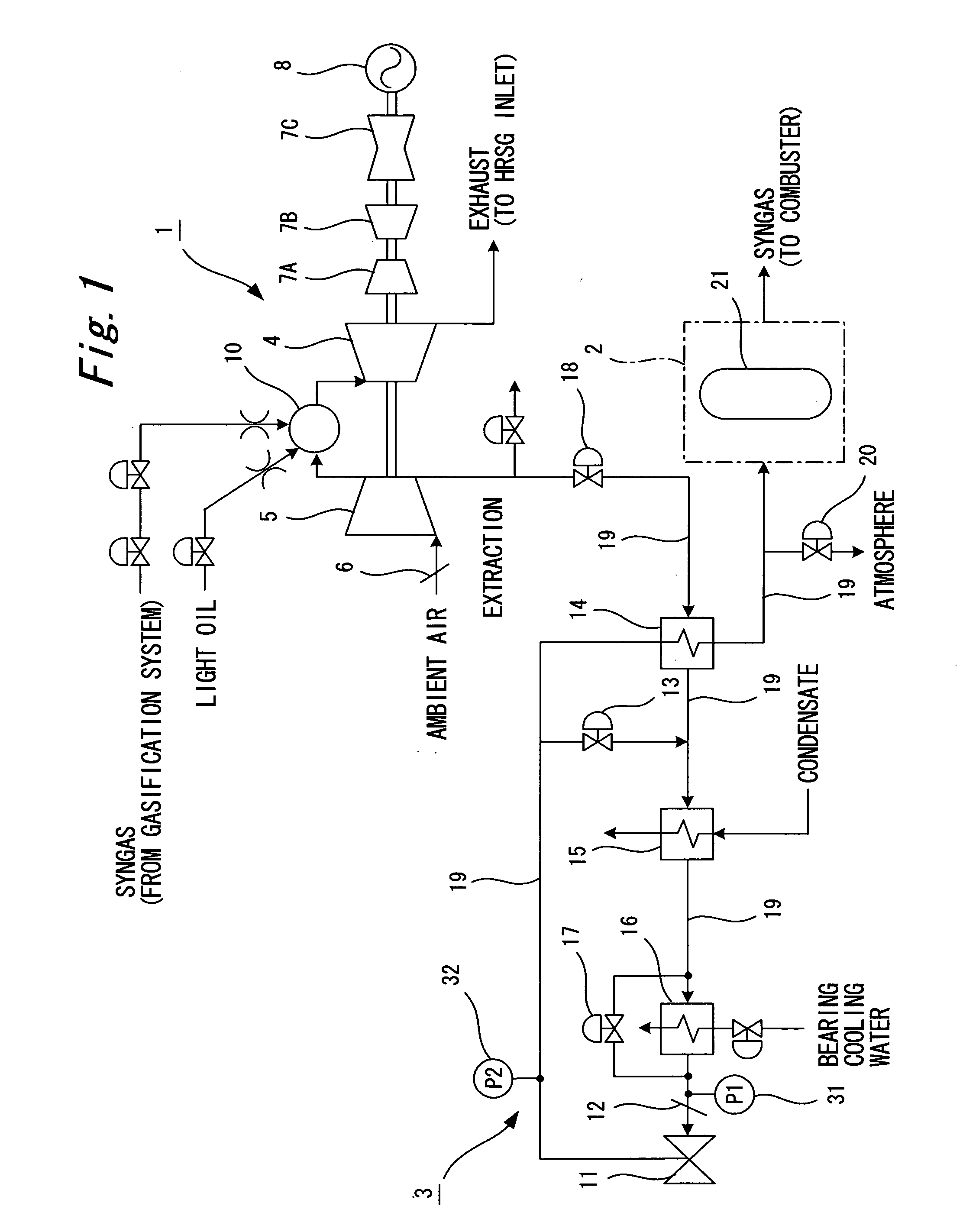

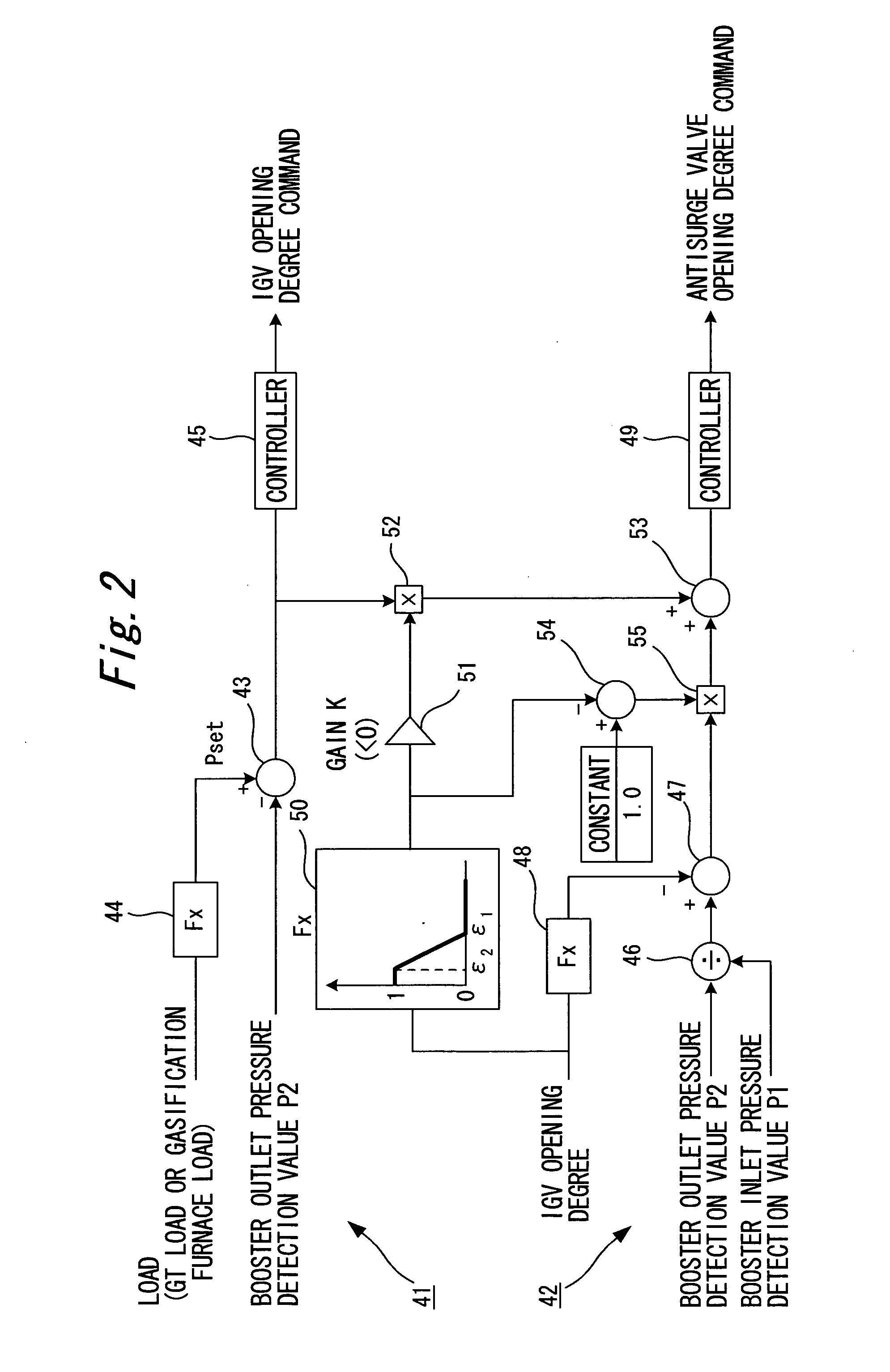

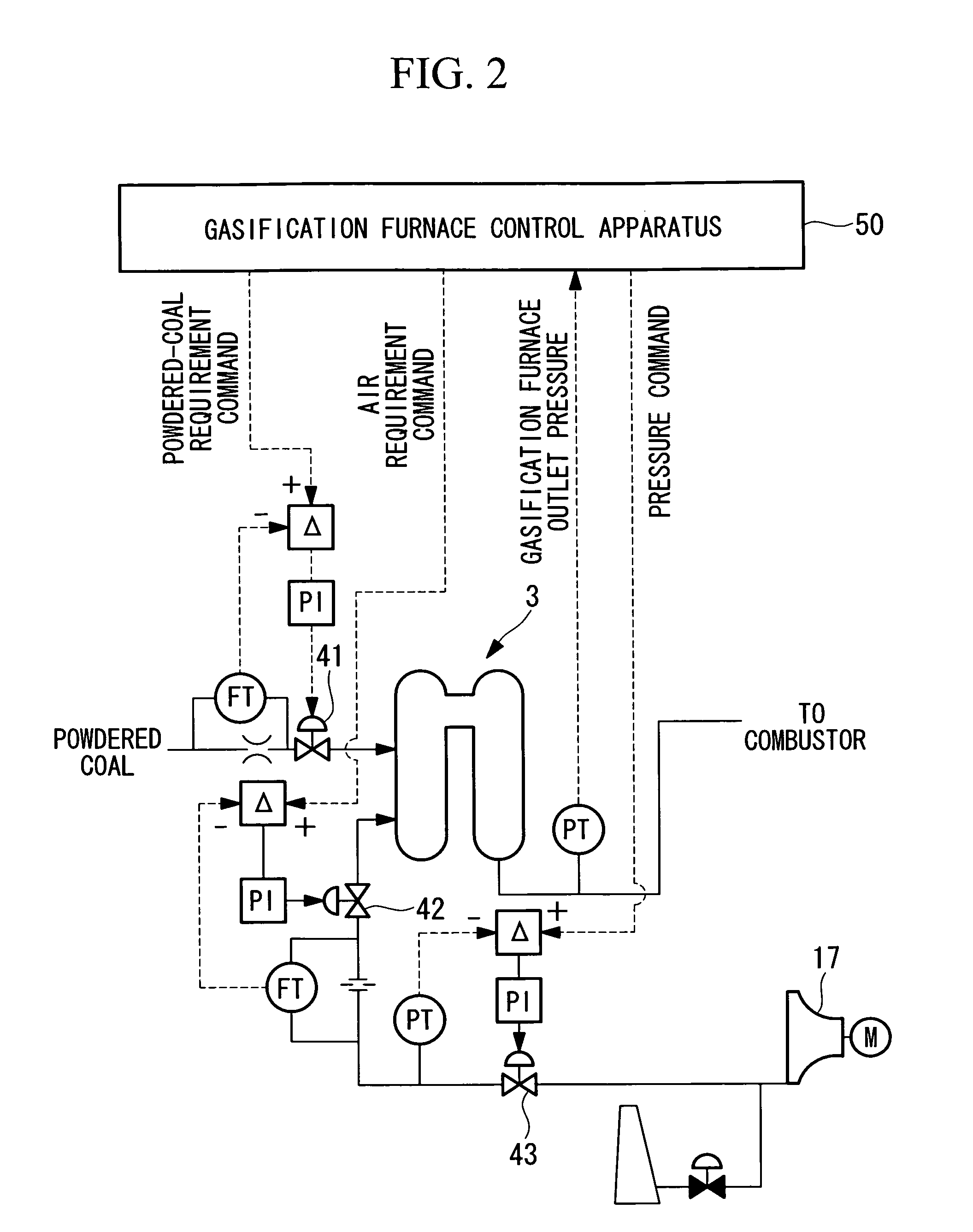

Control apparatus of extracted air booster system of integrated gasification combined cycle power plant

ActiveUS20070125064A1Sufficient pressure control functionAppropriate performanceCombustion enginesGas turbine plantsPressure controlled ventilationIntegrated gasification combined cycle

Provided is a control apparatus of an extracted air booster system of an integrated gasification combined cycle power plant, which control apparatus can additionally serve a sufficient pressure control function and a sufficient antisurge control function. For example, when an inlet guide vane is fully closed or has a small opening degree equal to or smaller than a predetermined opening degree, a second control section of the control apparatus of an extracted air booster system performs pressure control based on a pressure deviation, instead of or as well as antisurge control. In the pressure control, the degree of opening of an antisurge valve is controlled so that a booster outlet pressure detection value can become equal to a set pressure value. In a case where a pressure ratio is larger than a set pressure ratio value, it is also effective that the second control section performs the antisurge control even when the inlet guide vane is fully closed.

Owner:MITSUBISHI POWER LTD

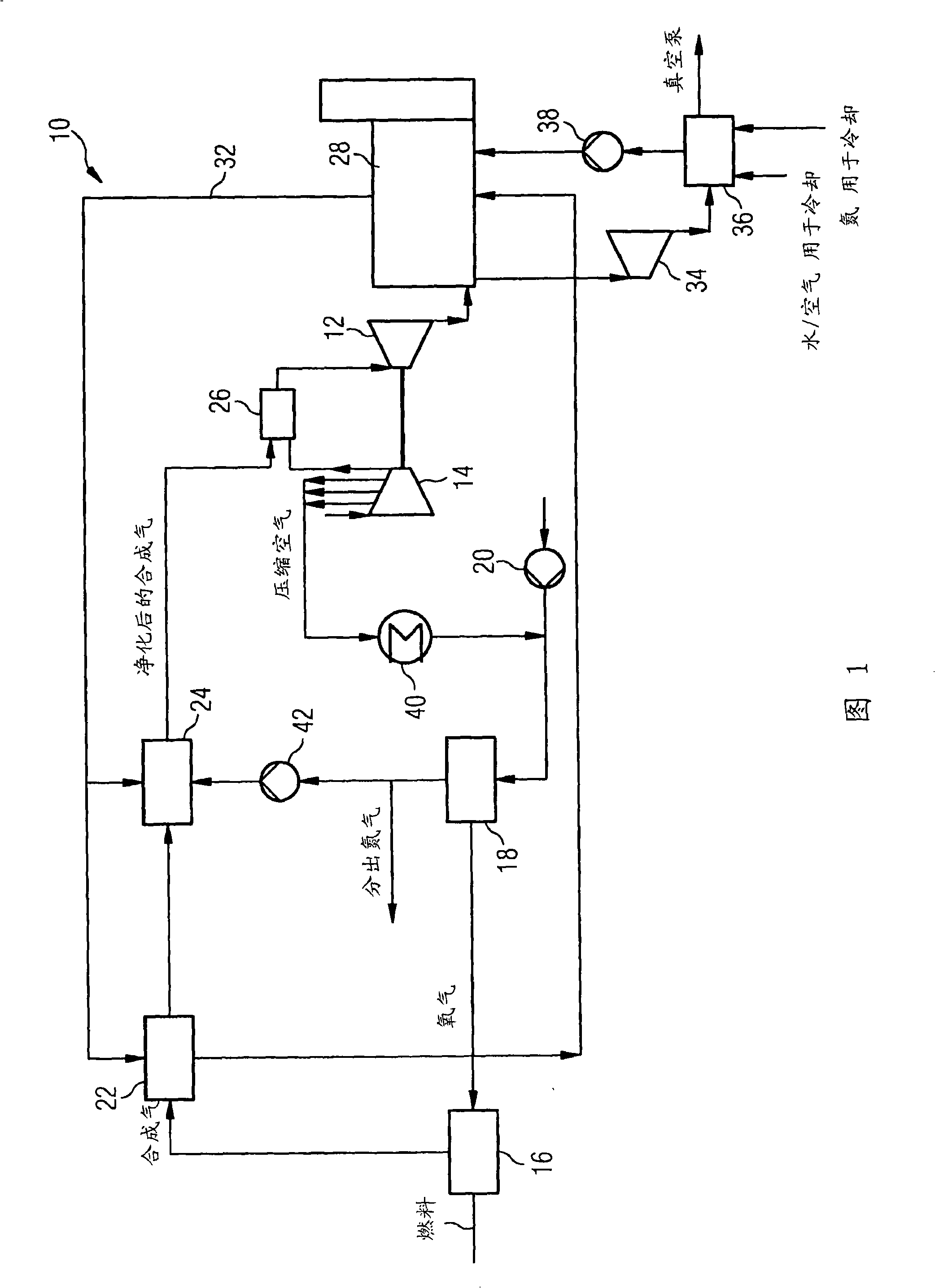

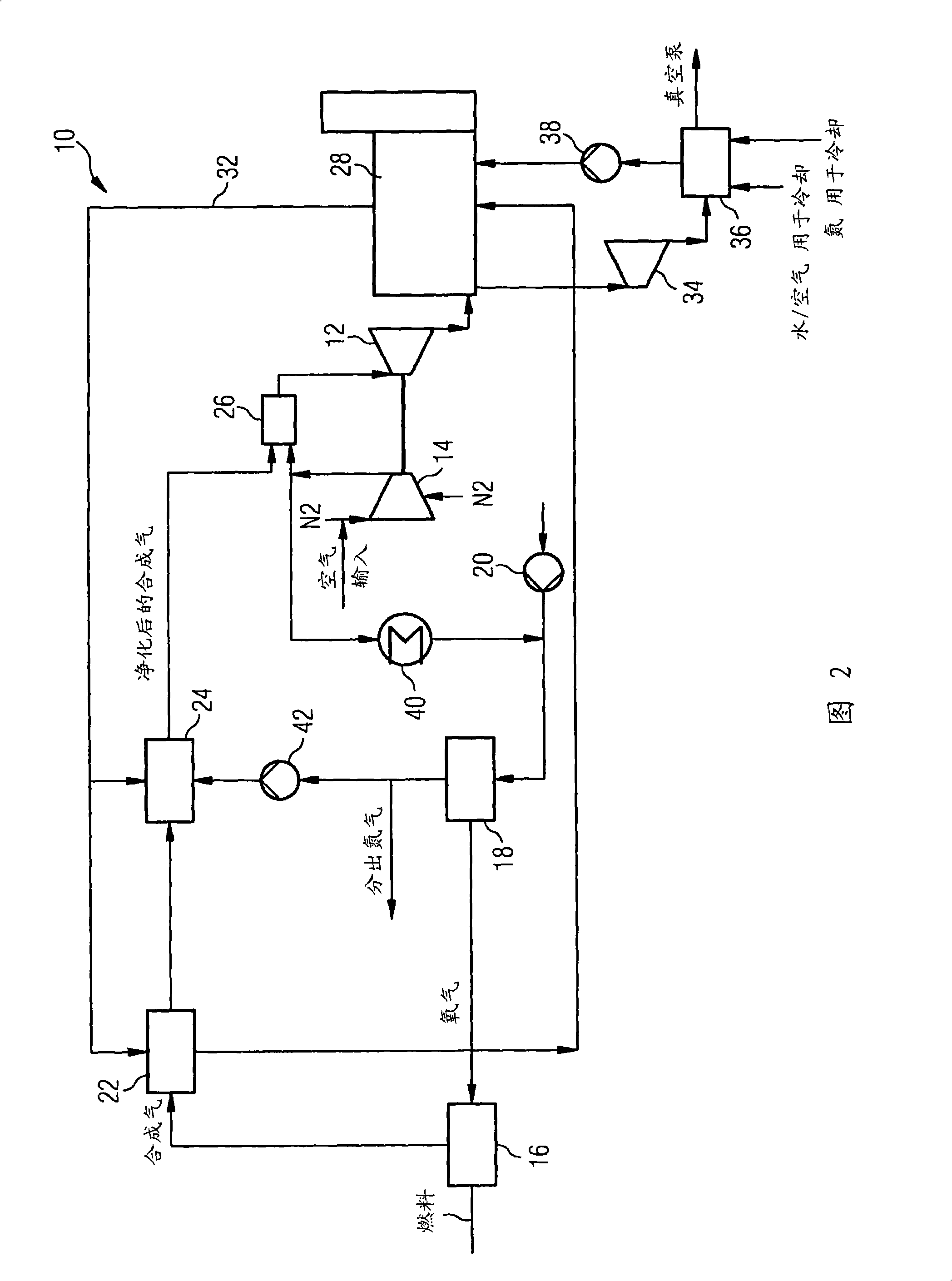

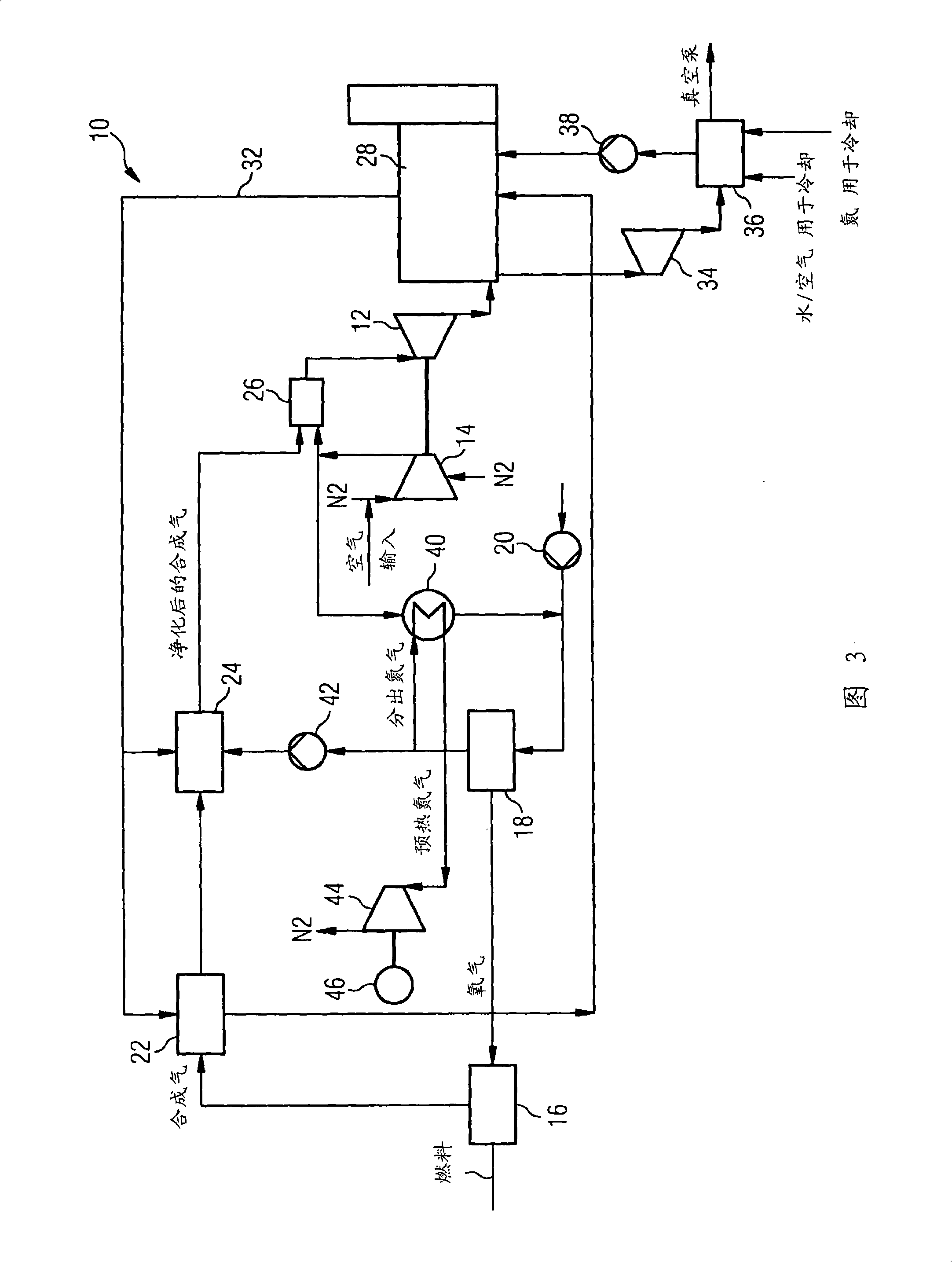

Method for increasing the efficiency of a combined gas/steam power station with integrated gasification combined cycle

InactiveCN101287893AReduce power lossReduce efficiency lossSolidificationLiquefactionEngineeringNitrogen gas

The present invention relates to a method for increasing the efficiency of a combined gas / steam power station (10) with integrated gasification combined cycle. Said power station comprises a gas turbine compressor (14) and an air-separation unit (18) having a defined working pressure. Compressed air is removed from the gas turbine compressor (14) at a pressure level that is adapted to the working pressure of the air-separation unit (18). The removed air is then supplied to the air-separation unit (18) where the air is broken down into its individual constituents, especially oxygen and nitrogen. The nitrogen produced in the air-separation unit (18) is removed from the air-separation unit and at least a part of the removed nitrogen quantity is used as a coolant in the gas / steam power station in order to improve its efficiency.

Owner:SIEMENS AG

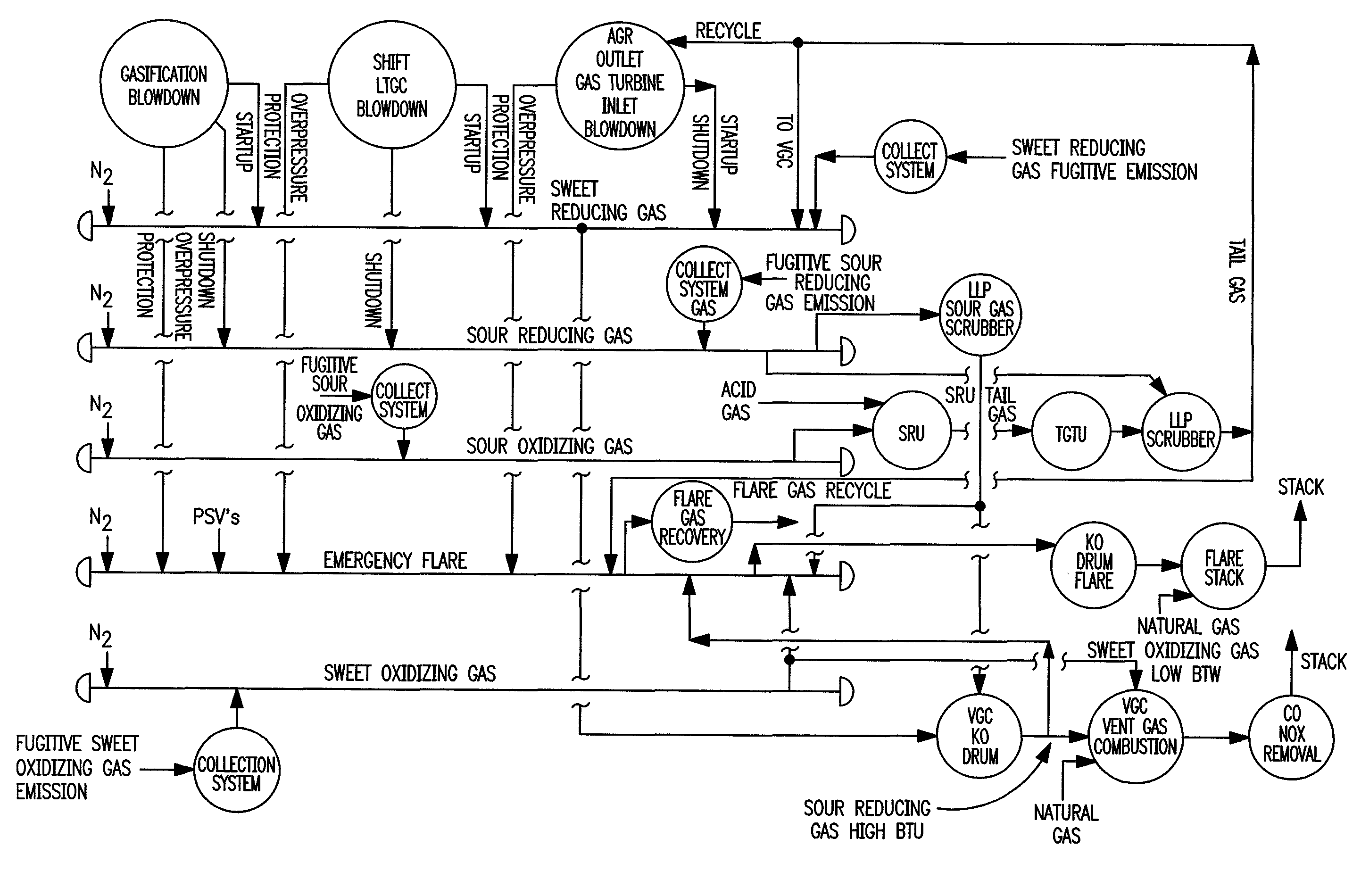

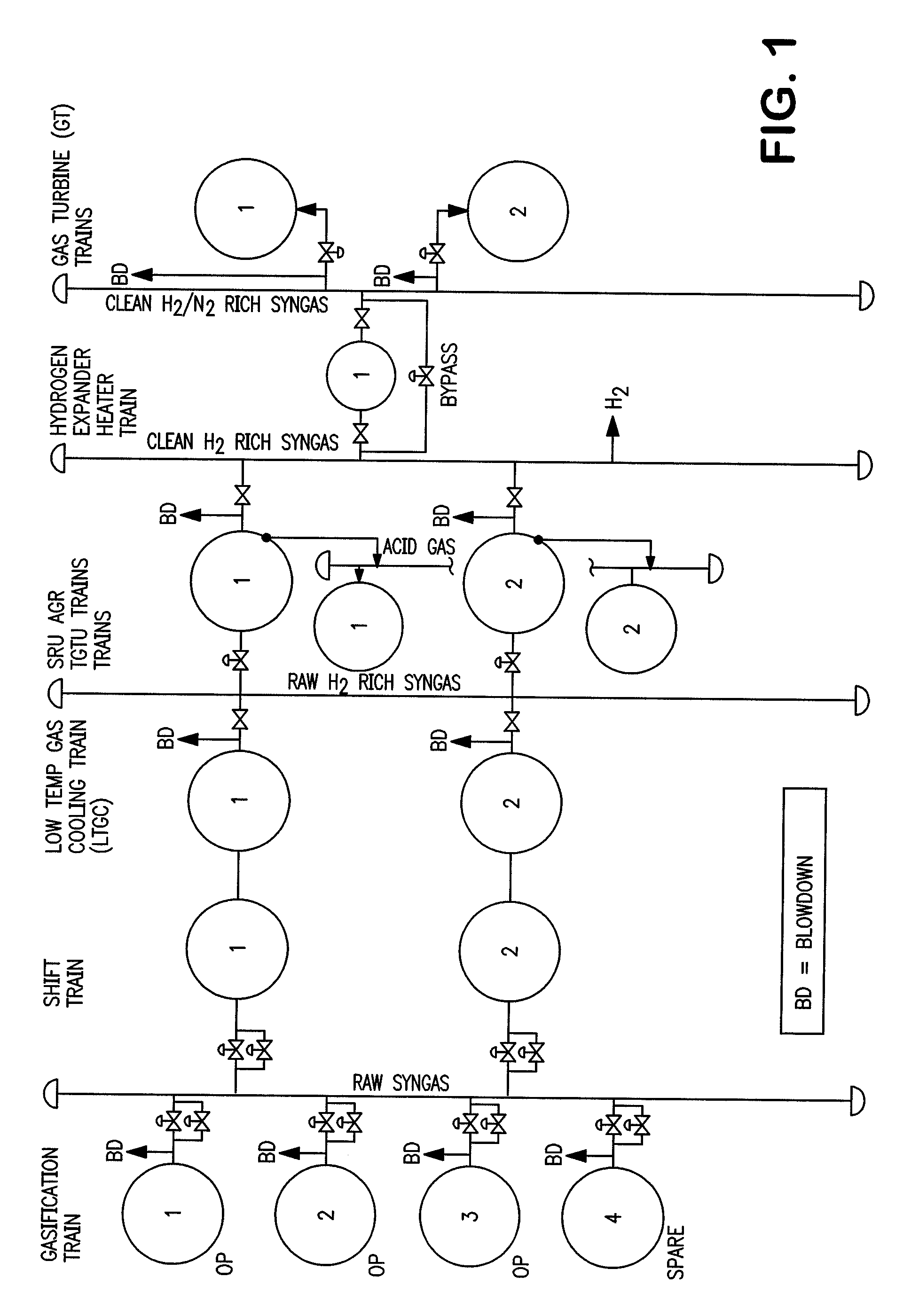

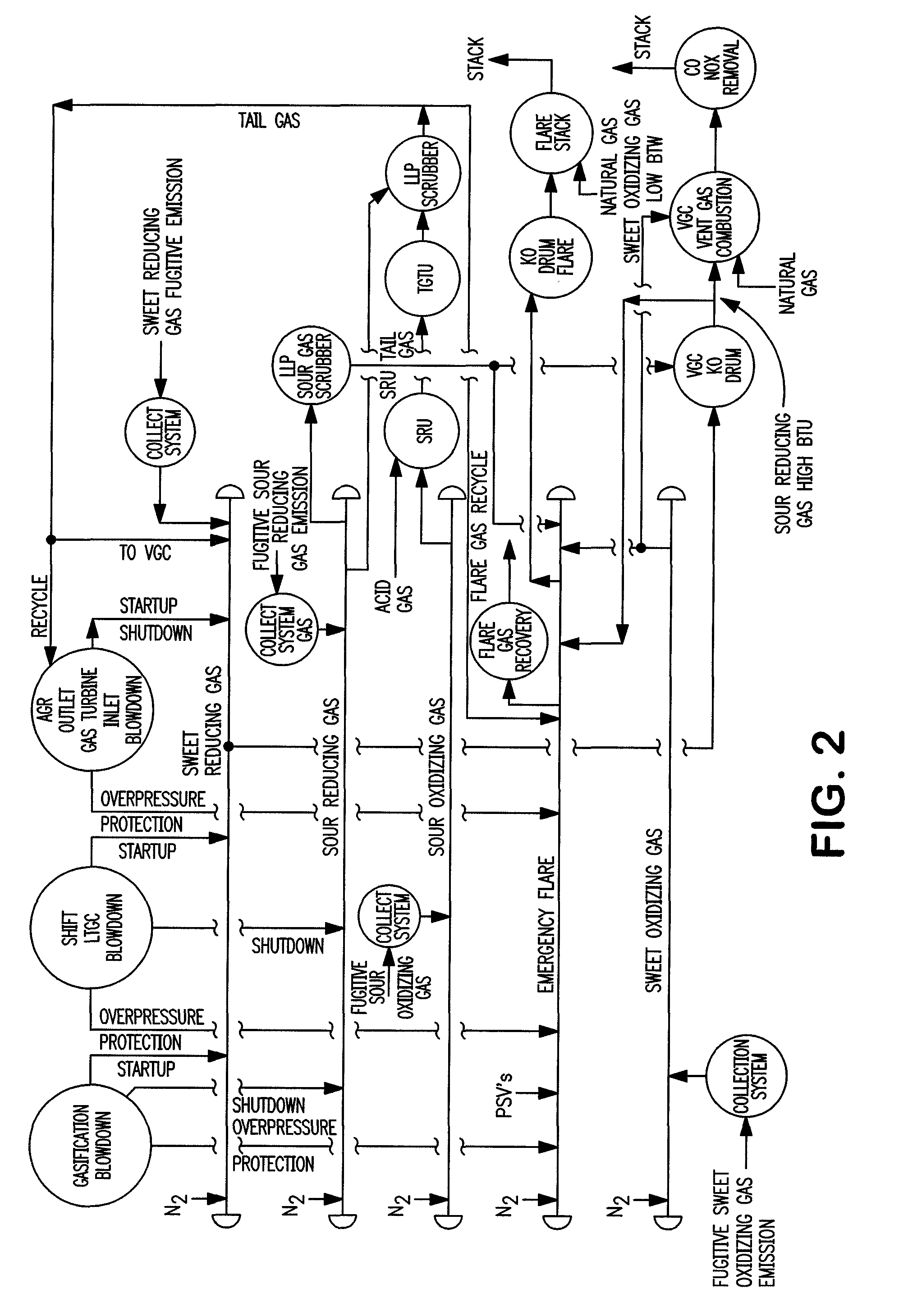

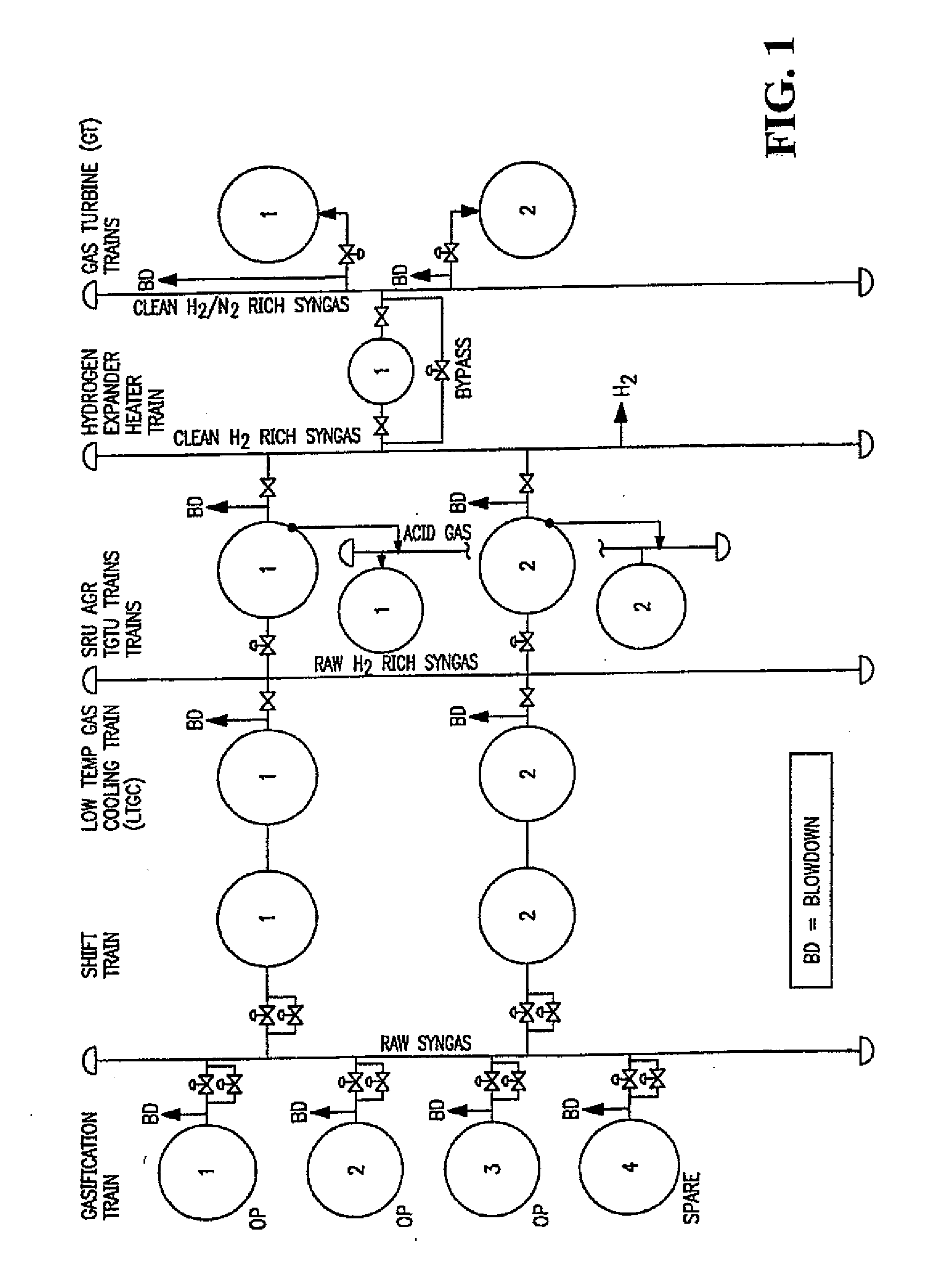

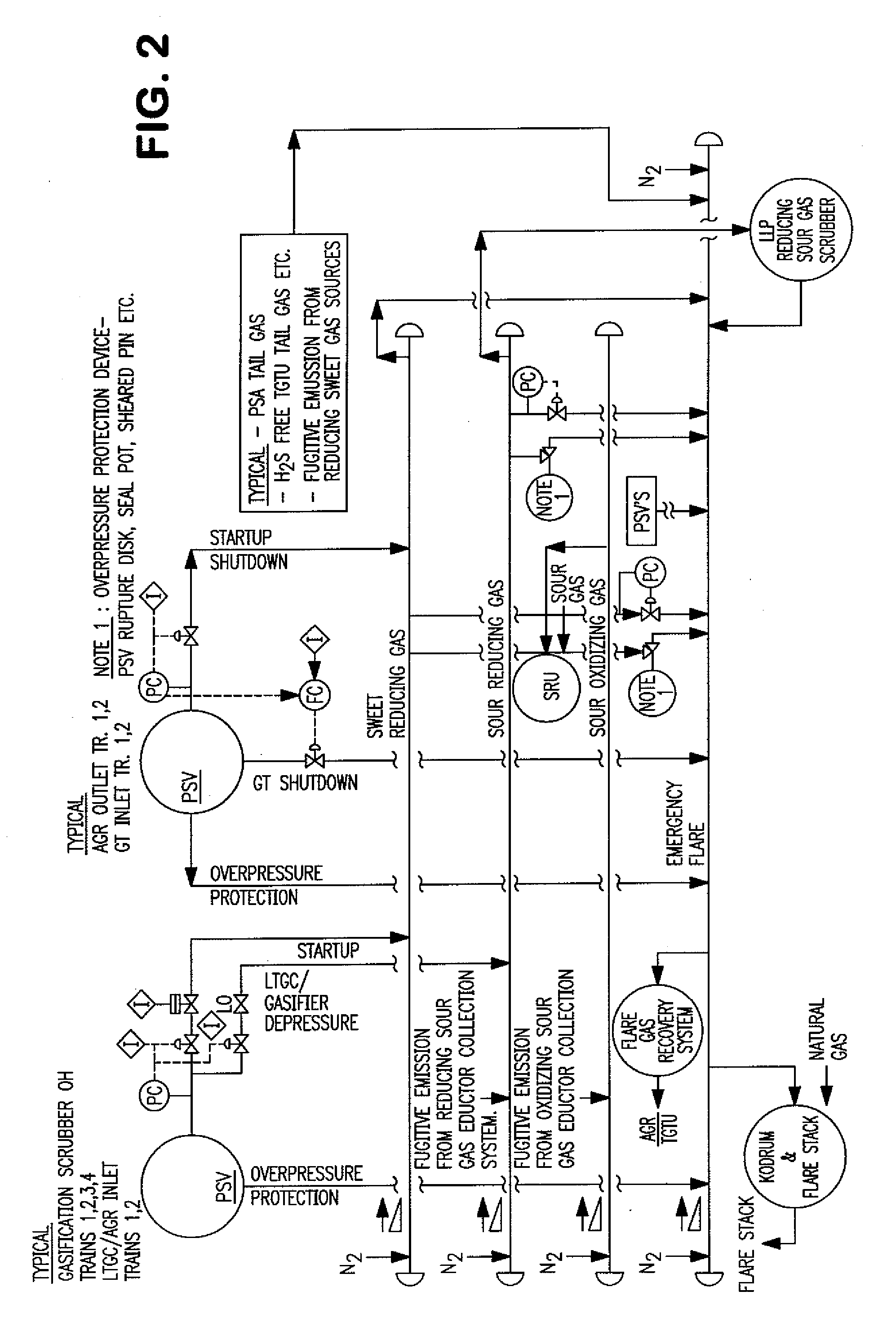

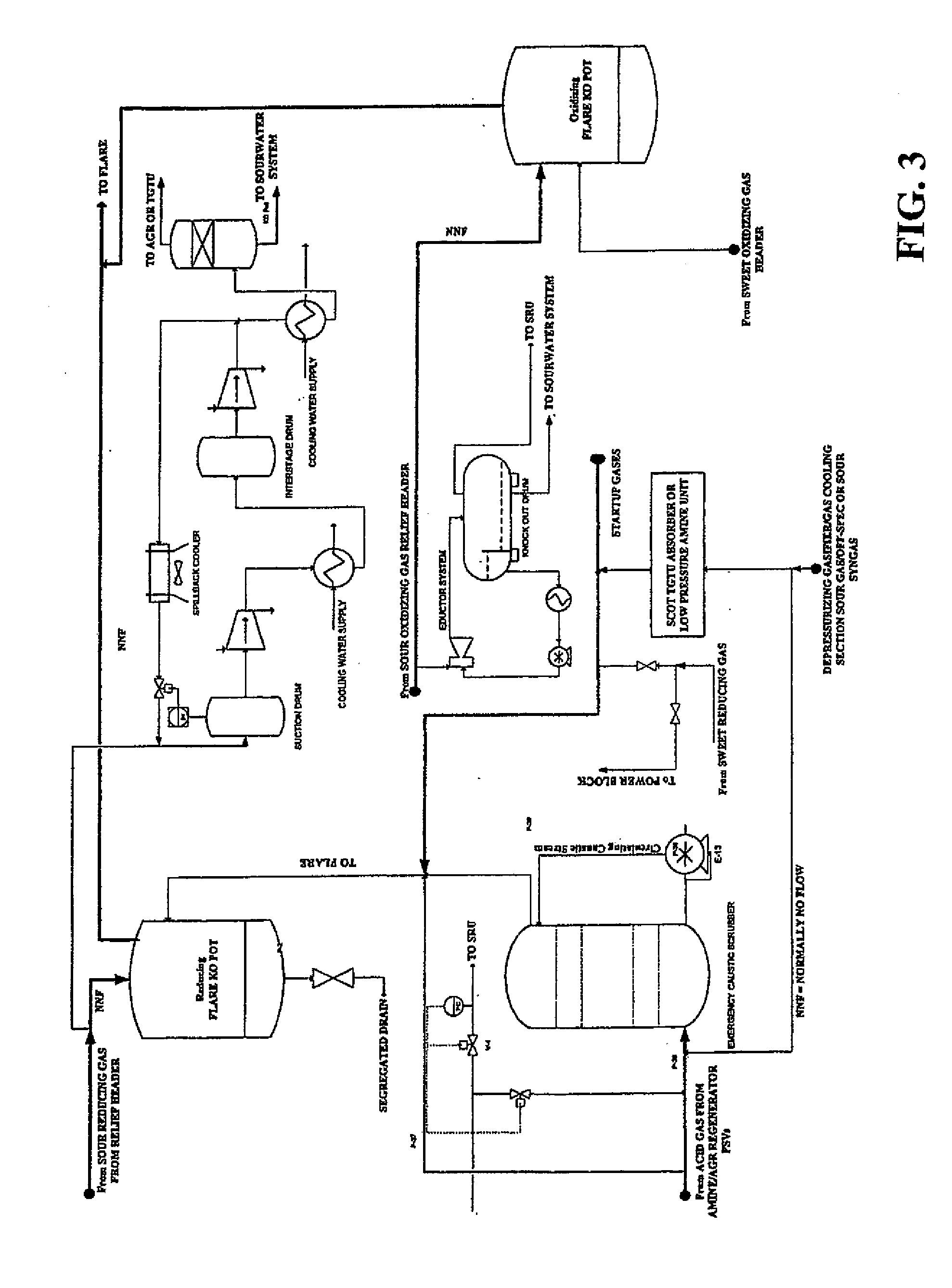

Emission free integrated gasification combined cycle

InactiveUS20100077767A1Improve efficiencyEmission reductionHydrogen separation using liquid contactGaseous fuelsBack burnsAtmospheric air

Disclosed is a process to start-up, operate, and shut down a gasifier and an integrated gasification combined cycle complex without flaring while additionally reducing the release of contaminants such as carbon monoxide, hydrogen sulfide, and nitrogen oxides. The process is accomplished by scrubbing ventable sour gases and passing scrubbed sour gases and ventable sweet gases to a vent gas combustor for controlled combustion prior to release of any such gases to the atmosphere. Additionally, the gases are subjected to a CO oxidation treatment and selective catalytic reduction treatment prior to release to the atmosphere.

Owner:HYDROGEN ENERGY INT

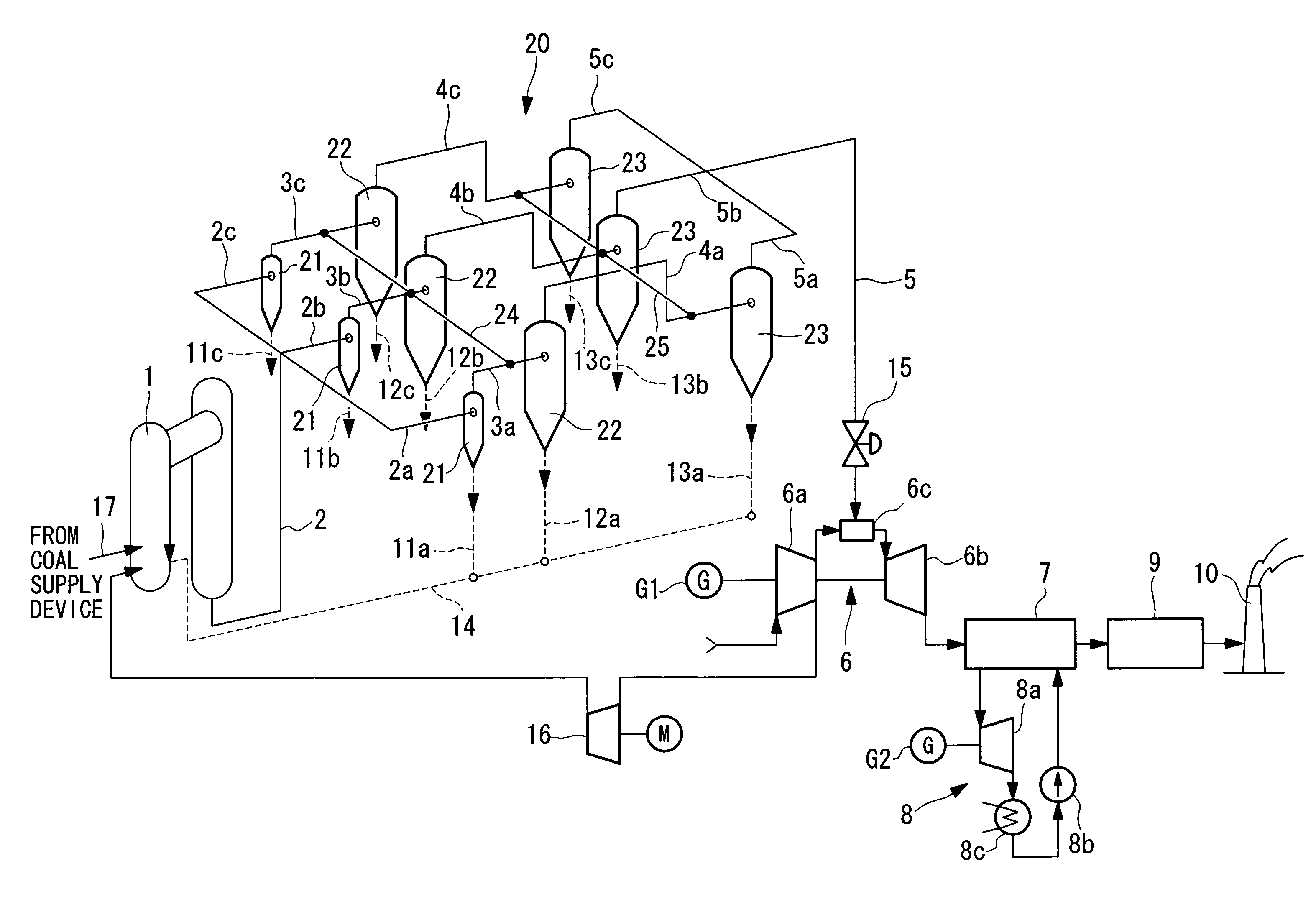

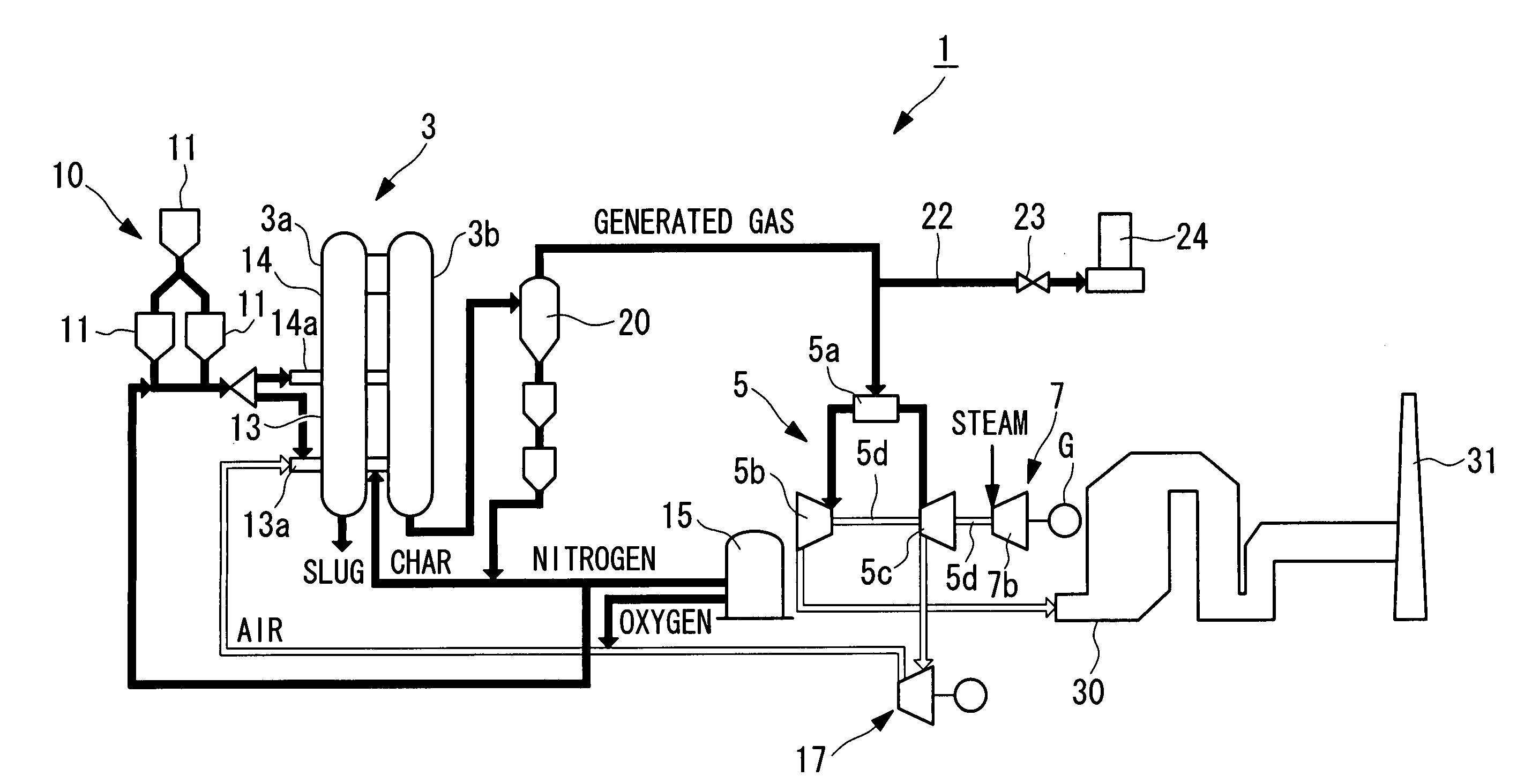

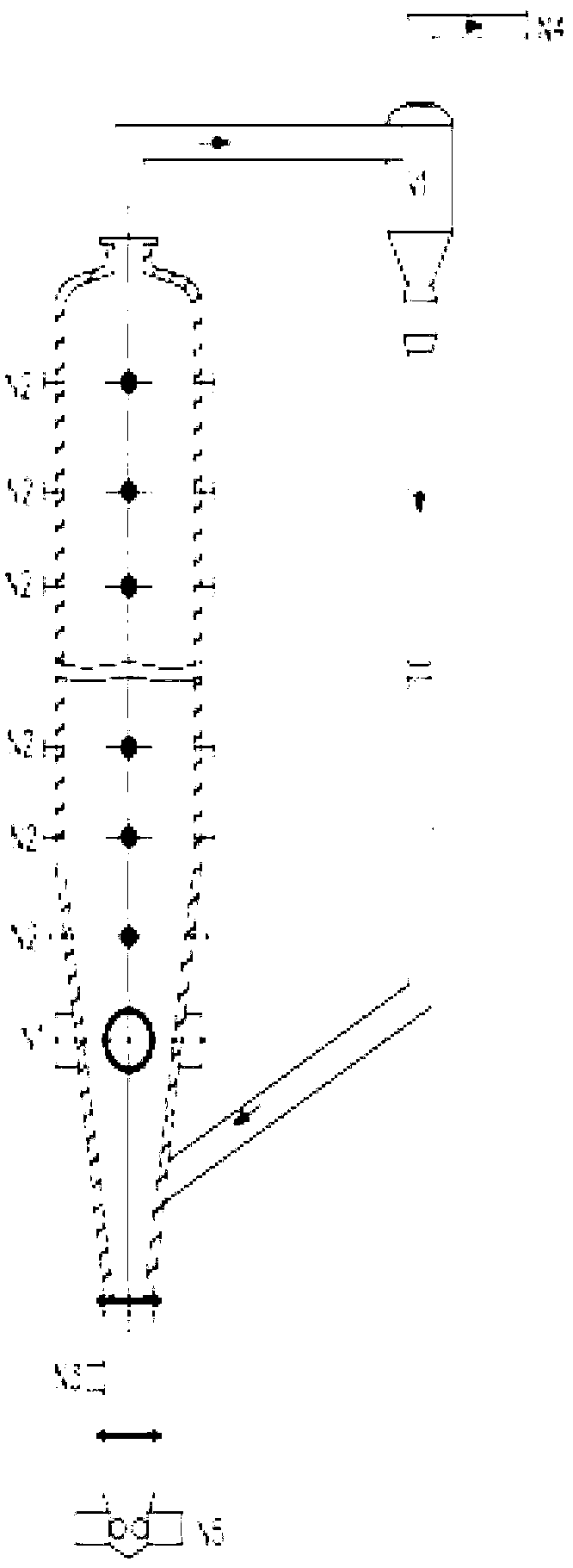

Integrated coal gasification combined cycle plant

InactiveUS20070137169A1High operating requirementsAvoid it happening againCombustion enginesGas turbine plantsCycloneIntegrated gasification combined cycle

A highly efficient integrated coal gasification combined cycle plant is provided having a dust removing system which can reliably exhibit a desired dust removing performance and which can maintain high operational reliability such that the occurrence of dust leaks is prevented. The integrated coal gasification combined cycle plant has a coal gasification furnace configured to yield a coal gas by gasification of coal, a gas turbine generator driven with a gas turbine which is operated using the coal gas as fuel and which discharges a high-temperature combustion exhaust gas, an exhaust heat recovery boiler configured to recover heat from the high-temperature combustion exhaust gas and to produce steam, and a steam turbine generator driven with a steam turbine operated using the steam produced by the exhaust heat recovery boiler. In the above plant, a flue gas desulfurization device configured to desulfurize the coal gas is provided downstream of the gas turbine and the exhaust heat recovery boiler, and the dust removing system which is configured to recover char and to remove dust from the coal gas has at least one line containing a cyclone, a front-stage filter, and a rear-stage filter.

Owner:MITSUBISHI HEAVY IND LTD

Preparation of high temperature gas desulfurizer

InactiveCN101475844AHigh sulfur capacityStable deliveryCombustible gas purificationPore distributionFuel cells

The invention discloses a method for preparing a high-temperature coal gas desulfurizer, which belongs to the field of preparation of desulfurizer. The method comprises the following steps that: four pore-forming agents with different pore-forming characteristics are prepared, mixed with red mud and burnt earth, ball ground to be below 200 meshes, kneaded by adding water, subjected to extruded molding, and then dried and roasted at high temperature. The specific surface area of the prepared desulfurizer is between 8 and 10m / g, the pore volume is between 0.3 and 0.5cm / g, and pores with dimensions more than 120nm account for 50 percent in the pore distribution. The desulfurizer consists of 80 to 90 weight percent of red mud, 5 to 15 weight percent of adhesive, and 5 to 10 weight percent of pore-forming agent. The desulfurizer prepared by the method has the characteristics of low cost, high sulfur capacity and good stability. The method can be used in the field of high-temperature coal gas purification-key technology of integrated gasification combined cycle power generation and fuel-cell power generation technologies, and the field of desulfurization purification of chemical raw material gas prepared by taking coal, petroleum and natural gas as raw materials.

Owner:TAIYUAN UNIV OF TECH

Minimal sour gas emission for an integrated gasification combined cycle complex

Disclosed is a process to start-up, operate, and shut down a gasifier and an integrated gasification combined cycle complex with minimal sour gas emissions while additionally reducing the release of contaminants such as carbon monoxide, hydrogen sulfide, and nitrogen oxides. The process is accomplished by starting up with a sulfur free feedstock and by scrubbing any ventable sour gases free of sulfur contaminants prior to release of any such gases to the atmosphere.

Owner:HYDROGEN ENERGY INT

Methods and systems for gas turbine syngas warm-up with low emissions

ActiveUS20100115962A1Turbine/propulsion fuel heatingGas turbine plantsProcess engineeringLow emission

Methods and systems of operating an integrated gasification combined cycle system are provided. The method includes coupling a non-fuel fluid conduit to a fuel conduit, warming a flow of non-fuel fluid, and channeling the warmed non-fuel fluid through the fuel conduit such that heat from the warmed non-fuel fluid heats the fuel conduit to a predetermined temperature.

Owner:AIR PROD & CHEM INC

Integrated Gasification Combined Cycle and Operation Control Method Thereof

ActiveUS20090151315A1Increase pressureReduce the amount requiredGas turbine plantsGasification processes detailsProduct gasIntegrated gasification combined cycle

An integrated gasification combined cycle that can adjust the balance of pressure / temperature in an overall plant and can stabilize the output of a gas turbine at an early stage during load variation, and an operation control method of the integrated gasification combined cycle are provided. When a calorific abnormality of fuel gas is detected during load variation of a gas turbine (5b), a load change command value of the gas turbine (5b) is set to zero or is decreased, and based on this load change command value, a power generation output command of the gas turbine (5b) is generated.

Owner:MITSUBISHI POWER LTD

Novel brown coal gasification process

InactiveCN103131477ANo emissionsImprove energy utilizationEnergy inputCombined combustion mitigationBrown coalPollutant emissions

The invention discloses a novel brown coal gasification process which adopts the brown coals as materials. The novel brown coal gasification process comprises the following steps of: primarily drying the brown coals; mainly drying the brown coals; and enabling the dried brown coals to react with gasifying agent under high temperature for being combusted. The fresh coal powder is dried and pre-heated by utilizing high-temperature coal gas generated by a gasifying furnace; vapor and air are sprayed to the gasifying furnace from a plurality of different layers at different heights, and are uniformly dispersed in the whole space. Carbon-containing ashes which are discharged from the bottom of the gasifying furnace and carbon-containing fine ashes generated in the whole process are fed to a coal-fired boiler for being further combusted, so that the carbon conversion efficiency is 95%-99%. The novel brown coal gasification process disclosed by the invention can be used for producing and generating furnace coal gas, water coal gas and synthesis gas or can be applied to the fields such as city gas and carbinol synthesis, synthesis ammonia and IGCC (Integrated Gasification Combined Cycle) power generation and the like. According to the novel brown coal gasification process disclosed by the invention, the coal powder is sufficiently combusted and converted during the whole process flow, the high-temperature coal gas and the vapor are circulated for use, so that the energy utilization rate is high. Besides, the novel brown coal gasification process is environment-friendly and free of pollutant emission.

Owner:CHINA TIANCHEN ENG +1

Ceramic based composite material filtering tube used for cleaning high-temp. gas smoke, and its prodn. method

InactiveCN1792412AHigh strengthImprove toughnessDispersed particle filtrationFiltration separationComposite ceramicAluminum silicate

A composite ceramic-based filtering pipe for cleaning high-temp gas or fume has 30-50% for porosity, one blind end and one open end and is formed by continuous aluminum silicate fiber reinforced silicon carbide ceramic. Its preparing process includes such steps as braiding aluminum silicate fibers on plastic core mould to obtain a prefabricated body, dipping in phenol solution, drying in the air, solidifying, heating to fuse plastic core mould for demoulding, continuous heating to 900-1000 deg.C for thermo-decomposing phenol to obtain thermo-decomposed carbon, chemical vapor osmosis to obtain silicon carbide base and filtering pipe blank, and grinding its open end.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

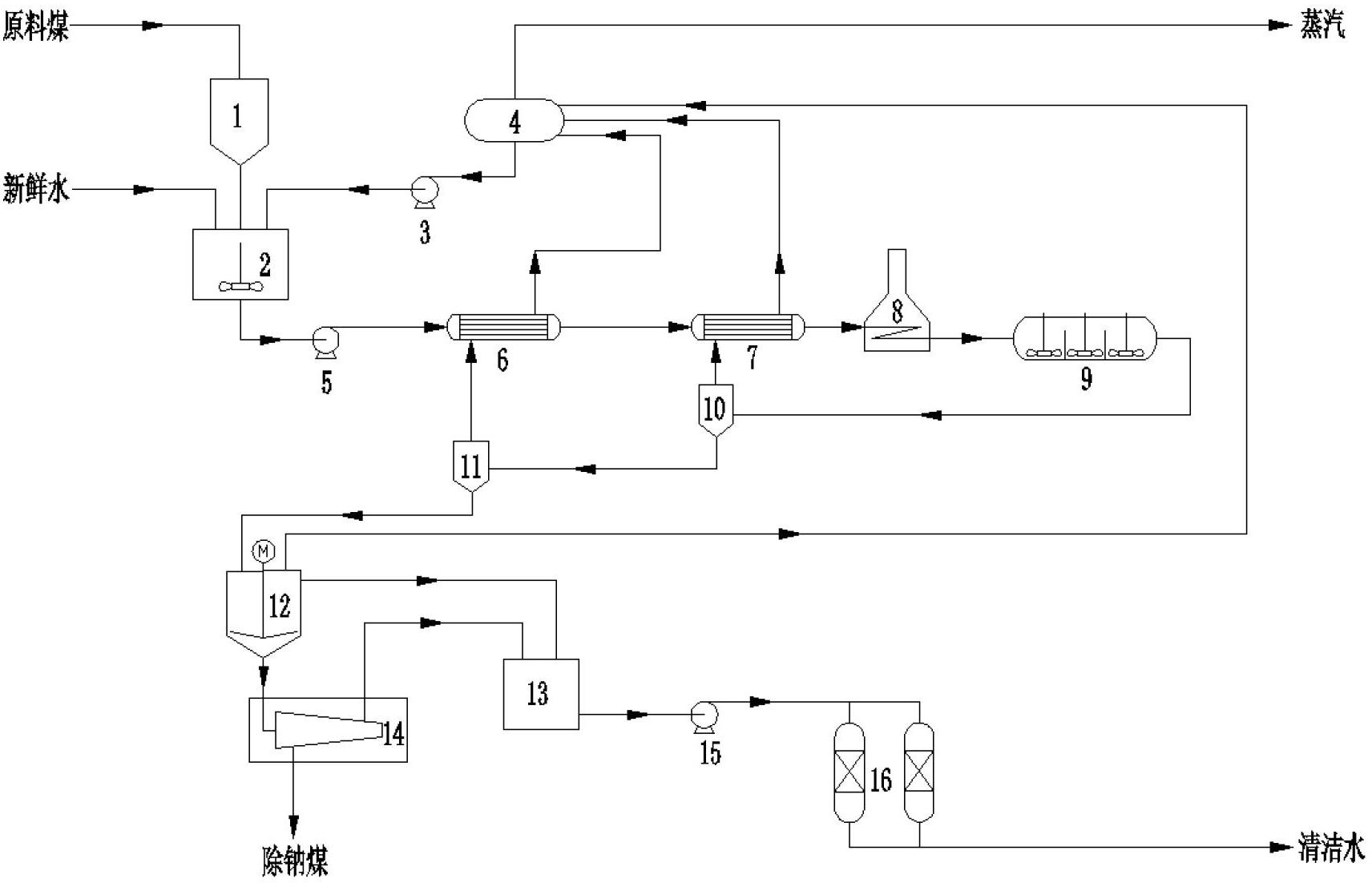

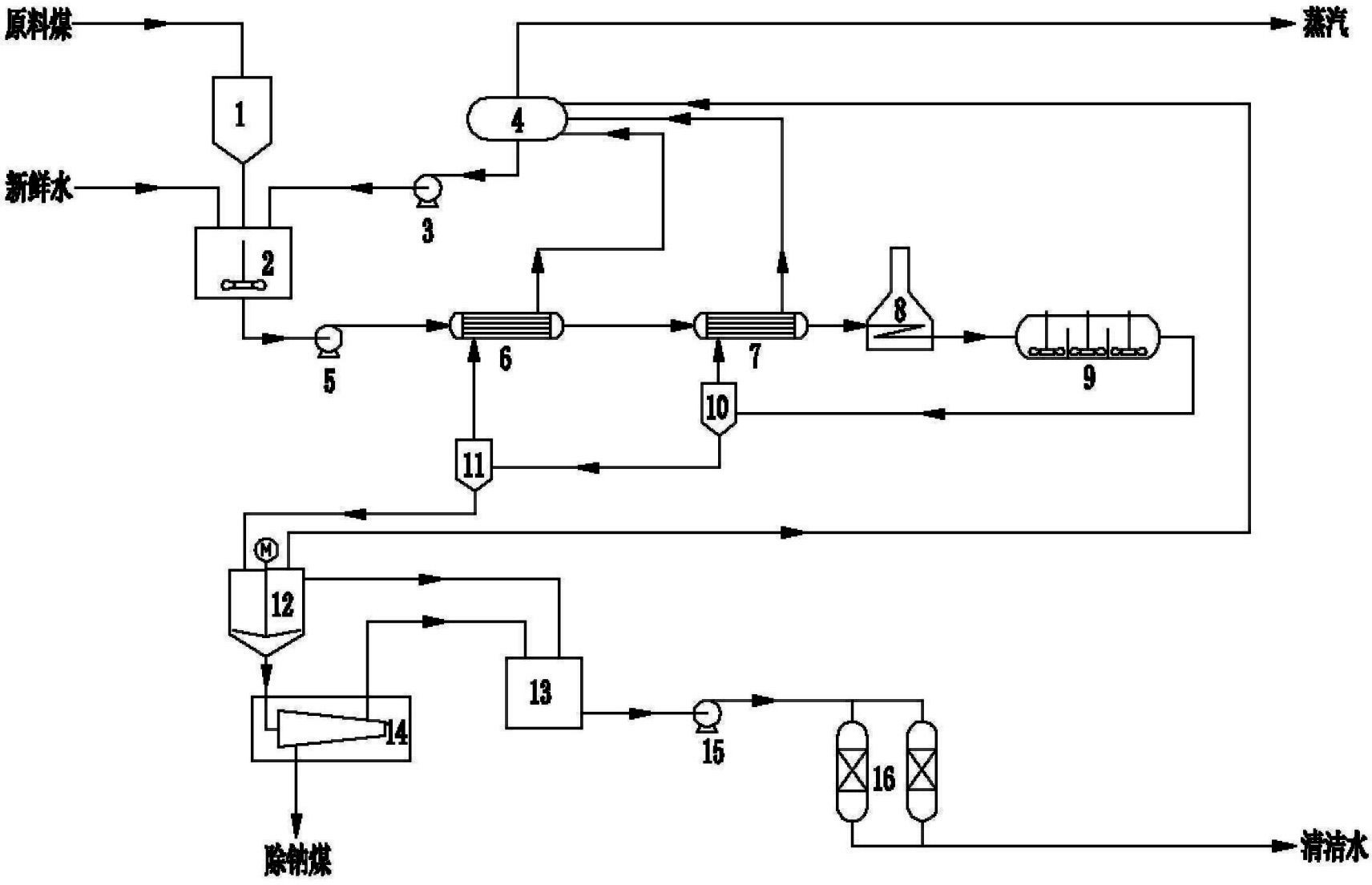

Process for removing sodium in high-sodium coal and system thereof

The invention relates to a process technology for removing sodium in high-sodium coal, which can solve the problems that a special removal process for the high-sodium coal is absent in the prior art, and follow-up processes and equipment are seriously affected. According to the process disclosed by the invention, sodium element in the coal can be removed by utilizing the principle of dissolving asodium compound at high temperature and high pressure and performing clarification and centrifugal separation through a black water treatment system to separate the sodium element from coal solid particles, the coal particles after sodium removal and ash removal and clean water can be simultaneously obtained, and the process is environment-friendly and has the advantages of simple process, high sodium removal efficiency, energy conservation and consumption reduction, and is suitable for purification, development and utilization of the sodium-containing coal and particularly suitable for coal gasification, IGCC (integrated gasification combined cycle) power generation and other technologies of the high-sodium coal after the sodium removal.

Owner:WUHUAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com