Gasification supercritical CO2 cycle power generation system

A cycle power generation and supercritical technology, which is applied in gasification process, machine/engine, and combustible gas production, can solve the problems of low steam flow rate, small turbine inlet and outlet temperature ratio, and difficult efficiency, so as to reduce oxygen consumption and The effect of air separation power consumption, increasing the total heat transfer on the hot side, and increasing the flow rate of the working fluid on the hot side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

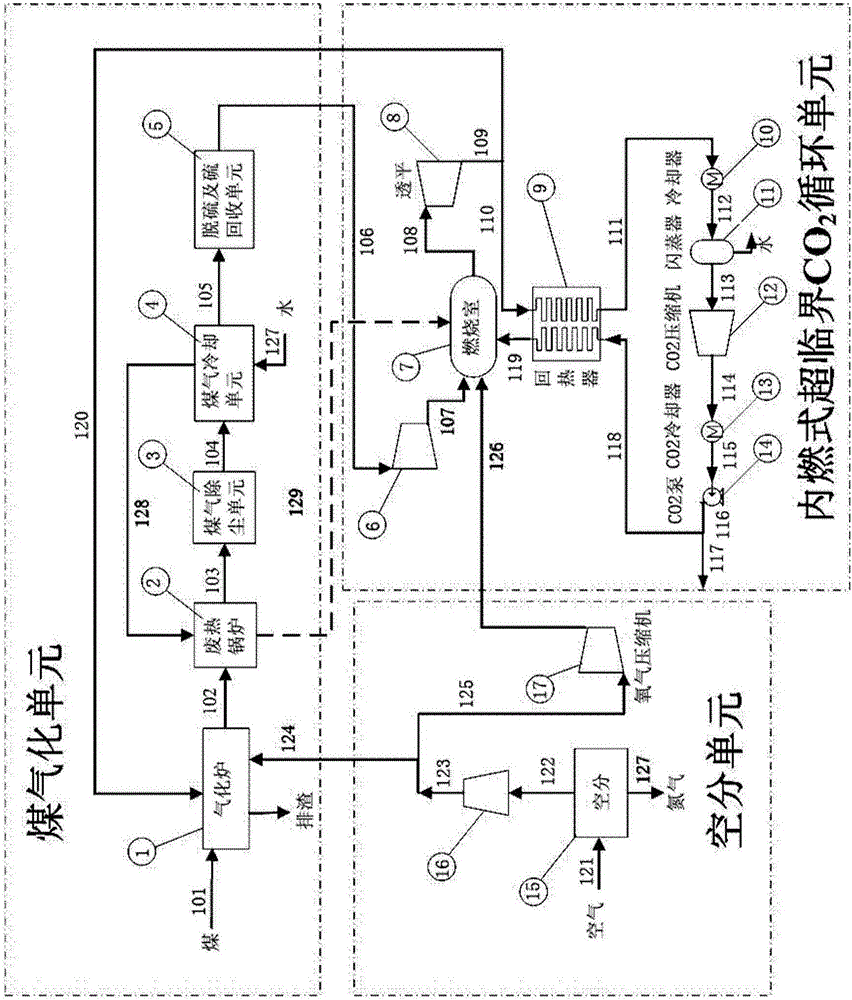

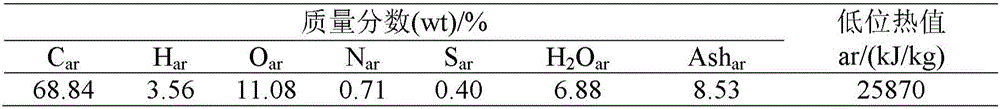

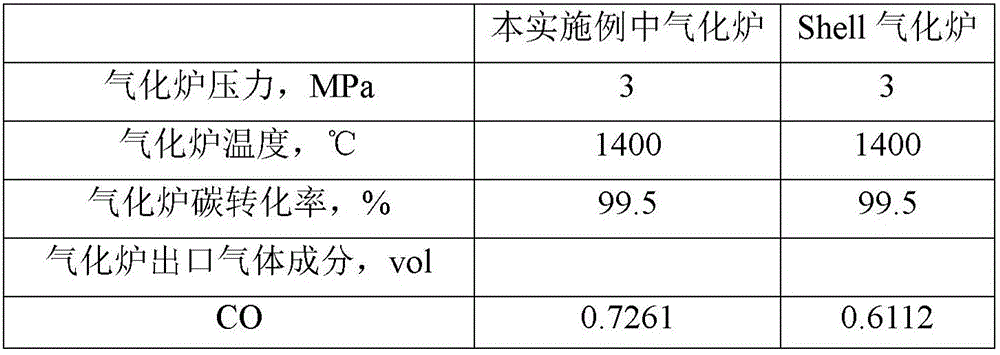

[0032] see figure 1 , a coal gasification supercritical CO proposed by the present invention 2 Circulation power generation system, coal 101 enters gasifier 1 at high temperature rich in CO 2 Under the action of working fluid 120 and oxygen 124, the reaction generates high-temperature crude synthesis gas 102, which is cooled to about 350°C by waste heat boiler 2 to become medium-temperature crude synthesis gas 103, and then enters dust removal unit 3 to remove most of the solid impurities. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com