Patents

Literature

96results about "Gasification catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

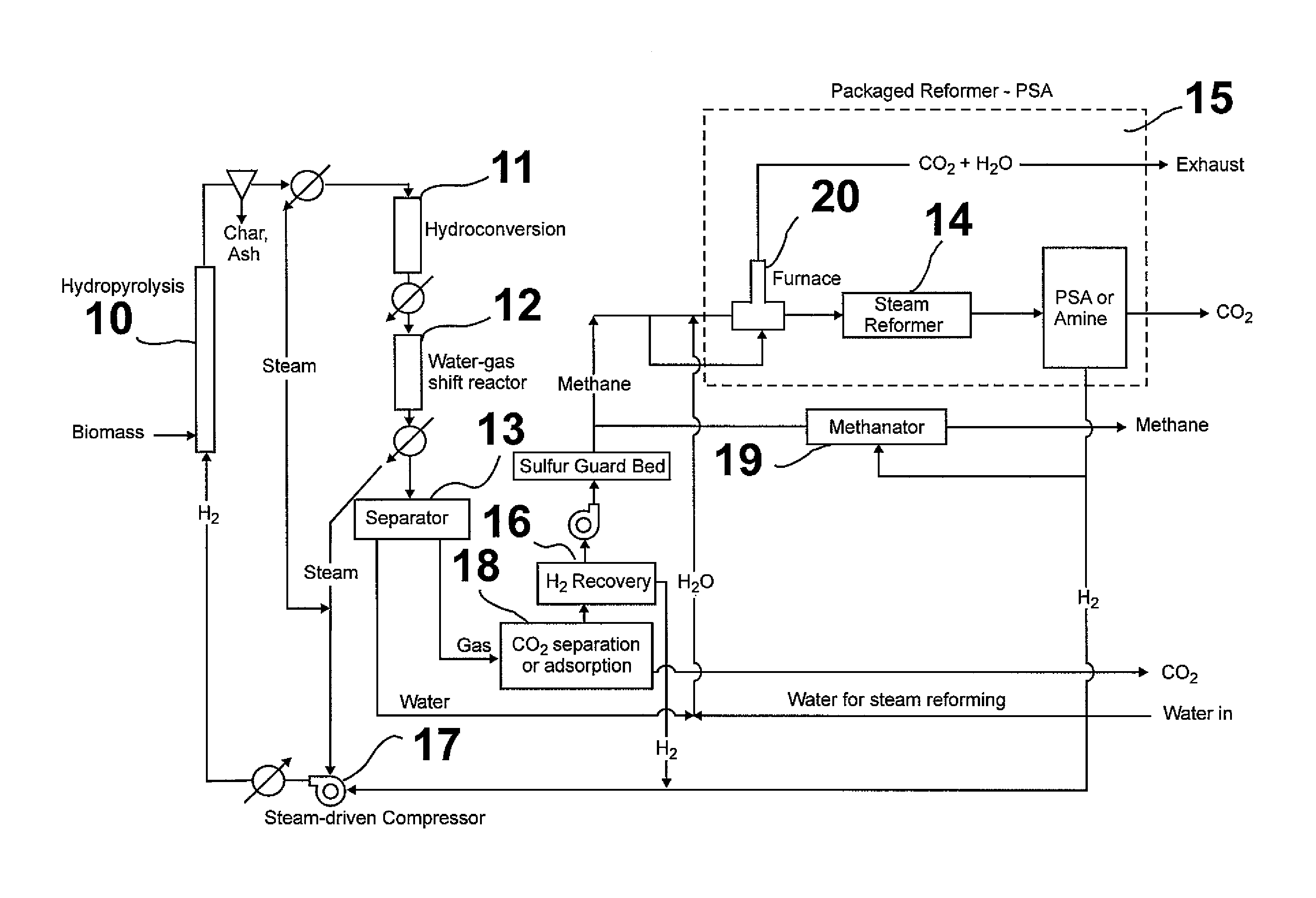

Method for producing methane from biomass

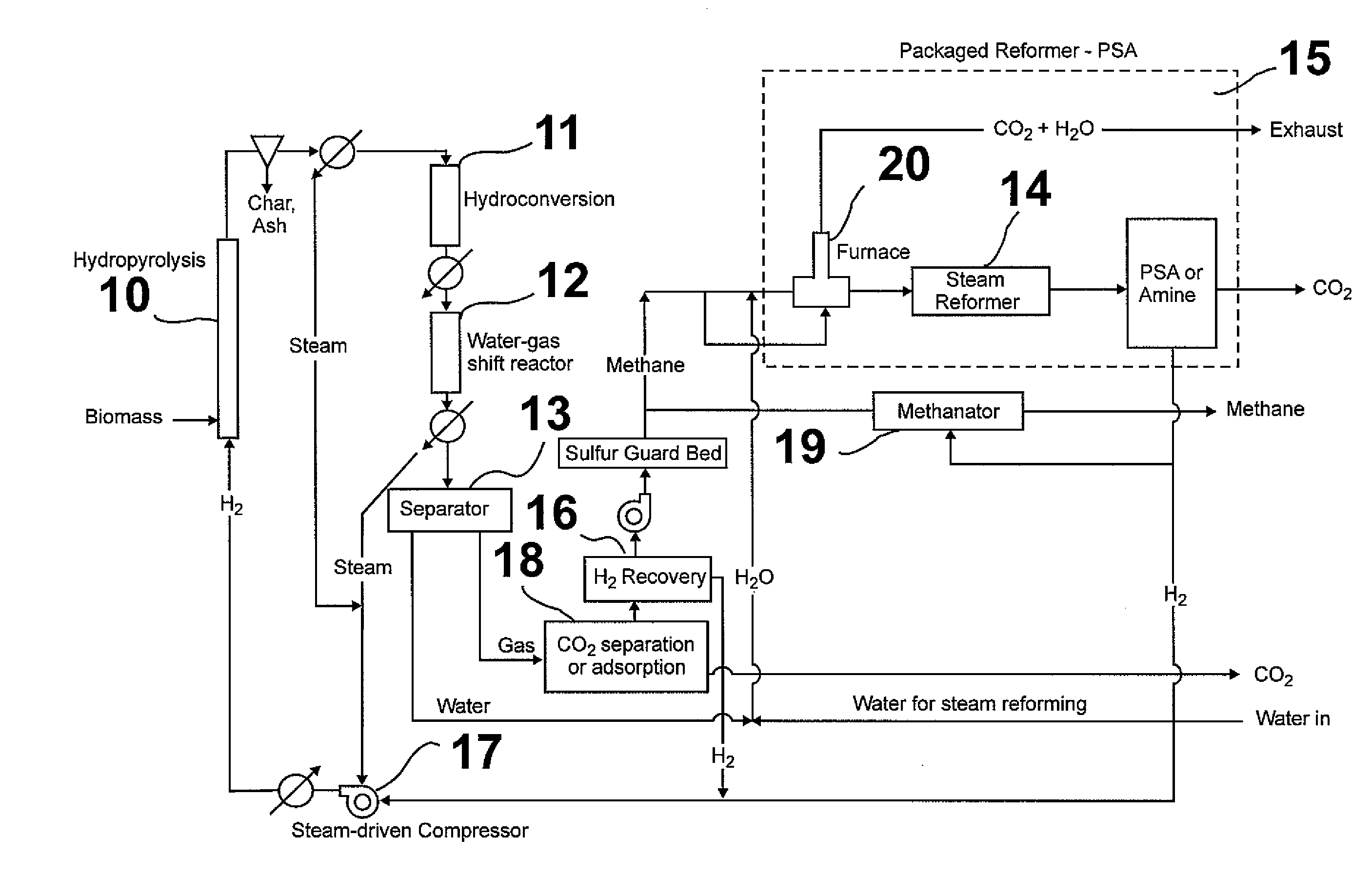

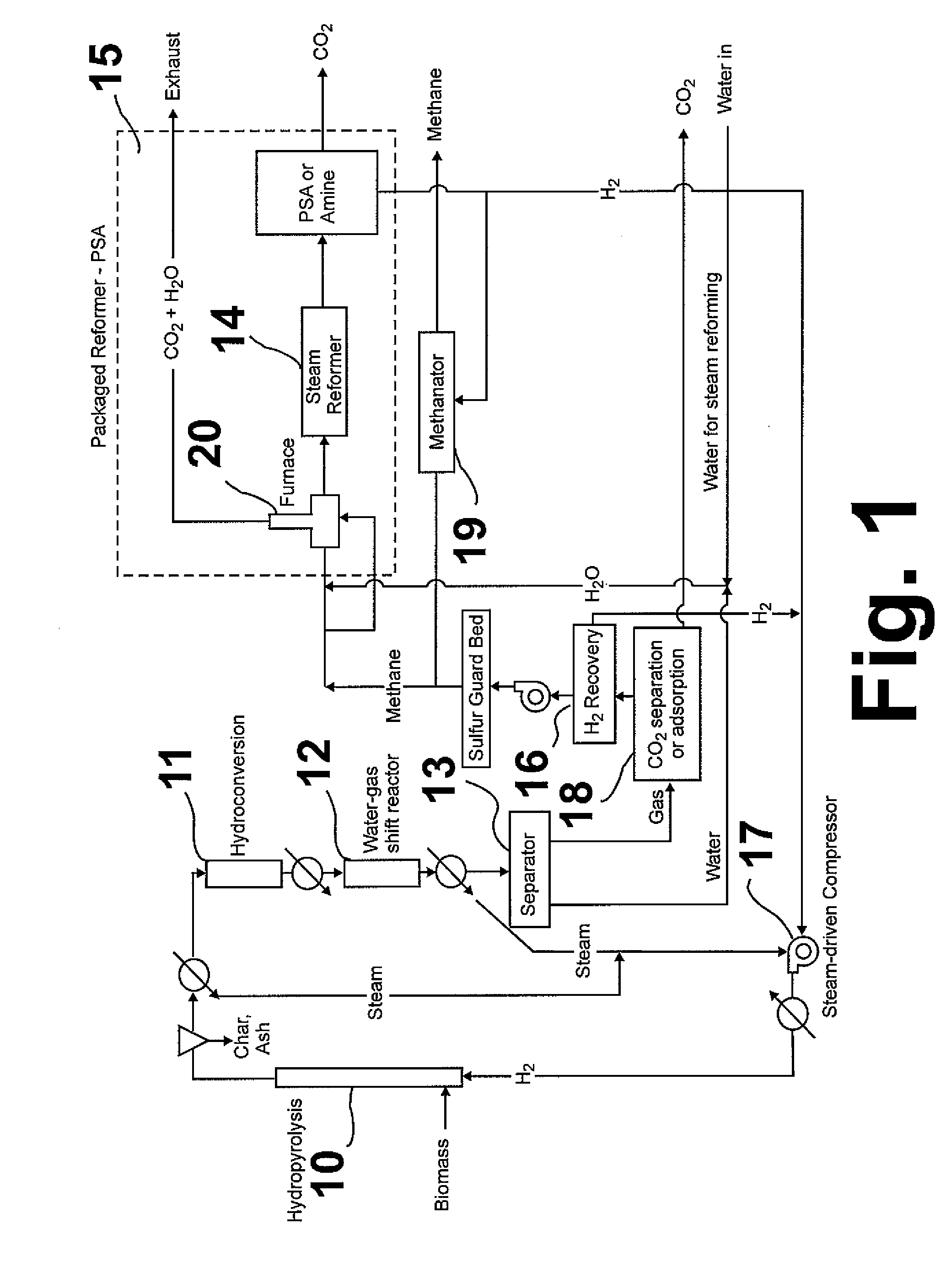

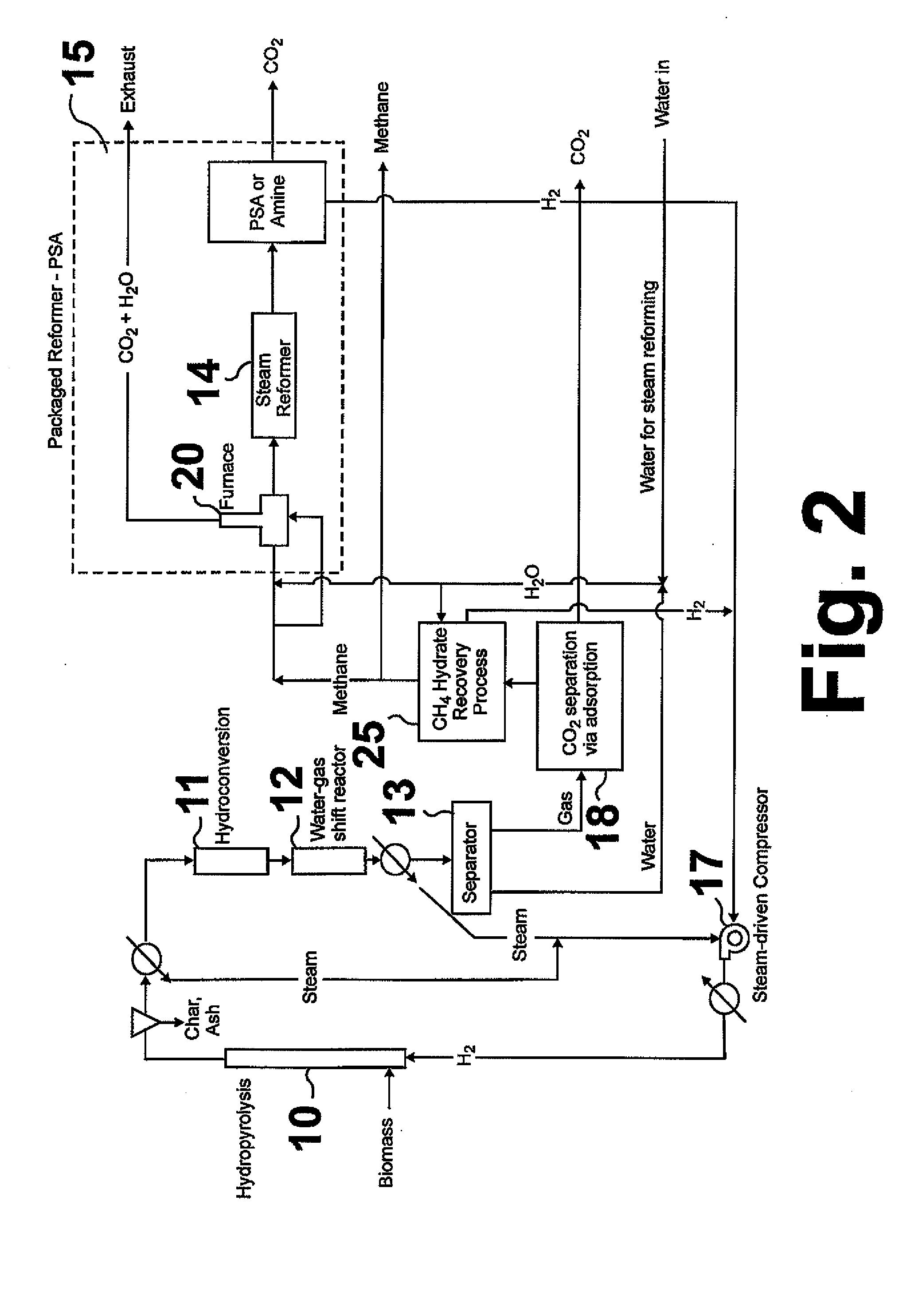

ActiveUS20100251615A1Superior methane yieldFast pyrolysisGasification catalystsDirect heating destructive distillationHydrogenProduct gas

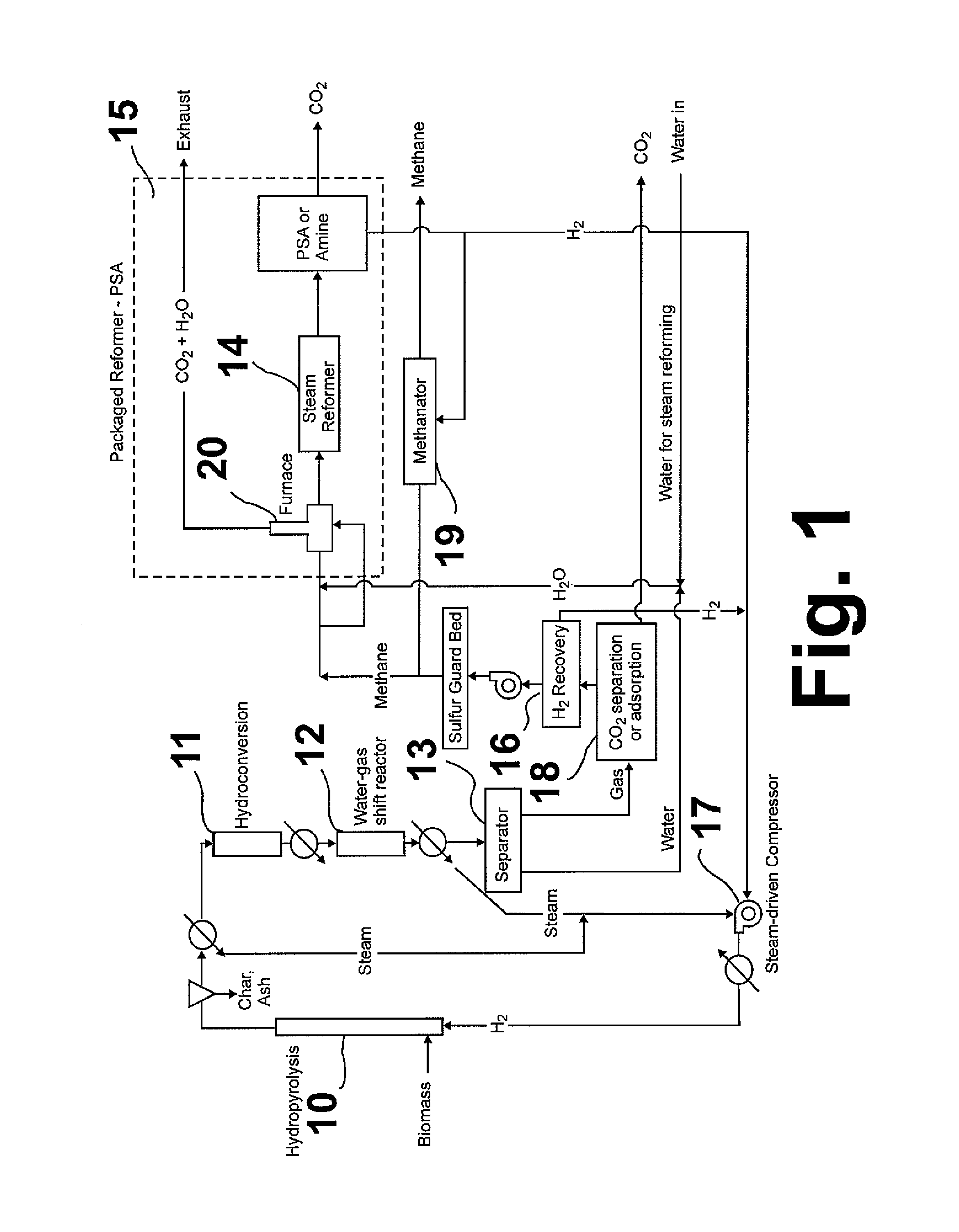

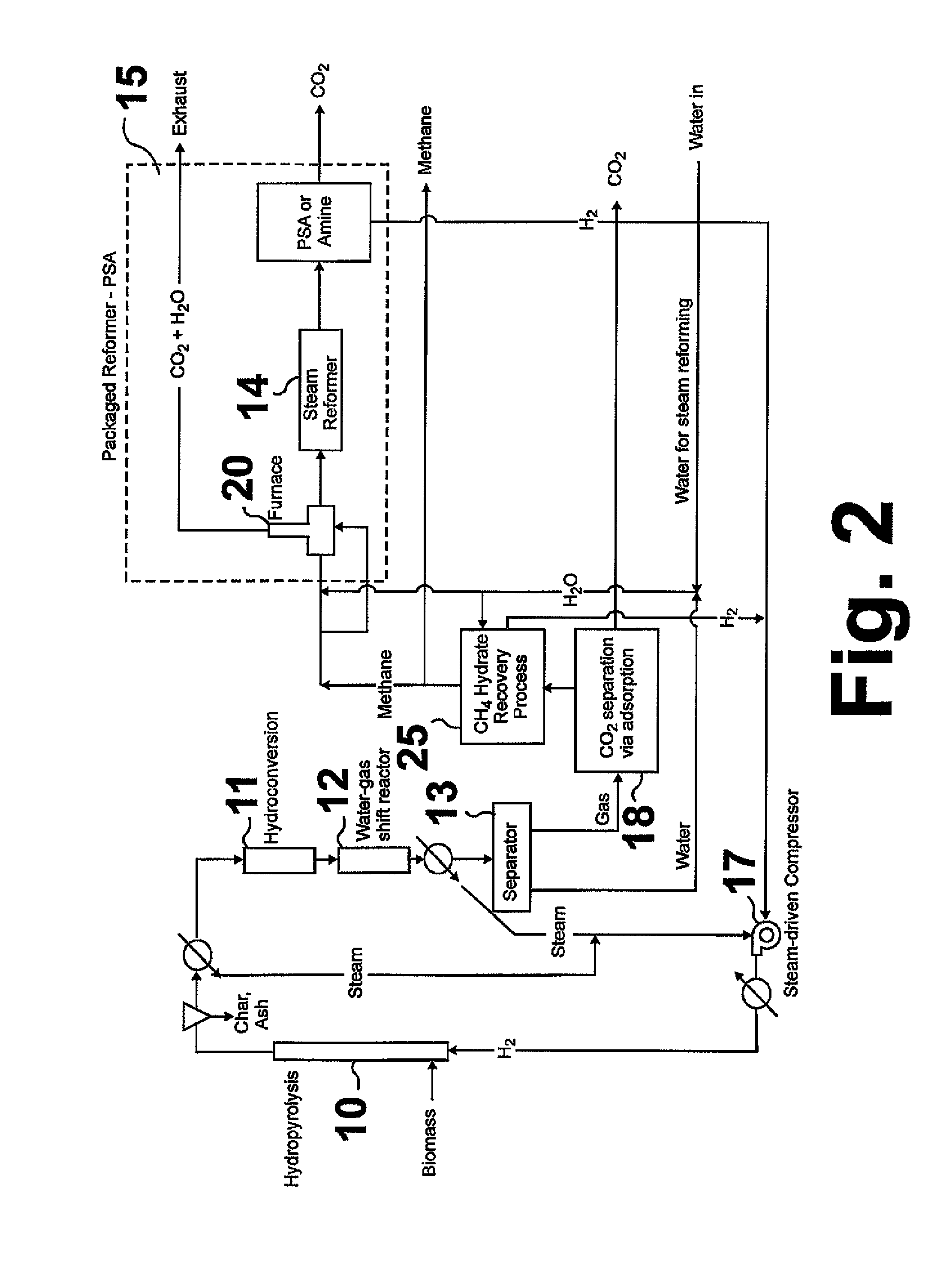

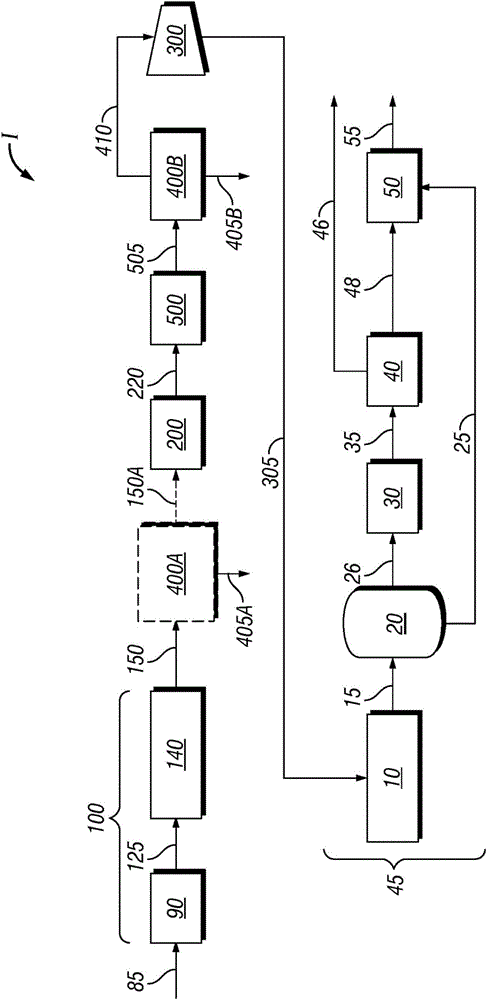

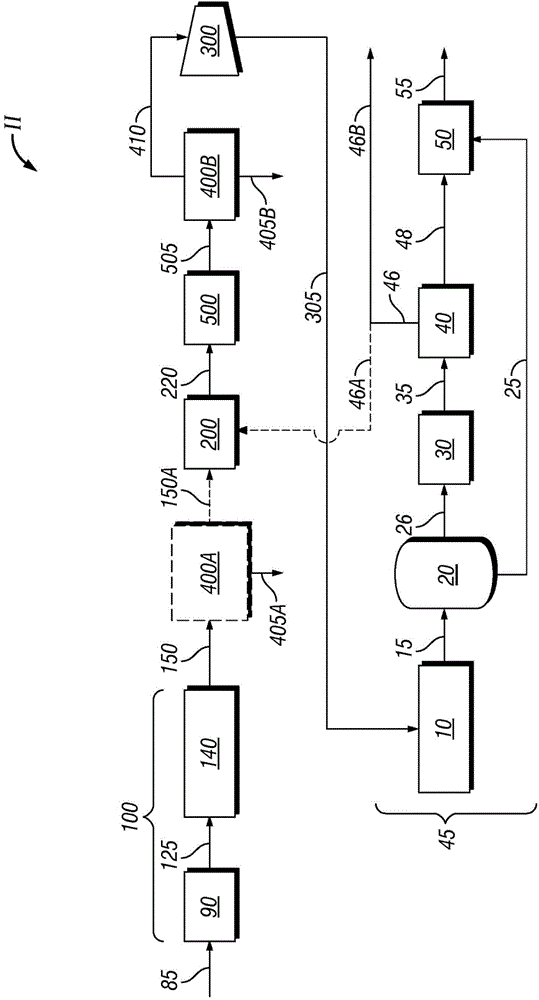

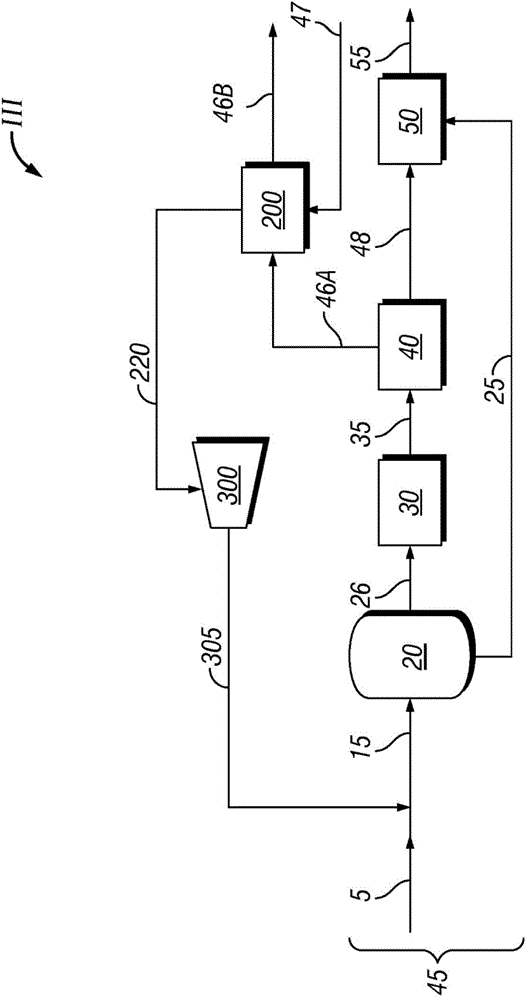

A multi-stage method and apparatus for producing methane from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, the output of which is hydrogenated using a hydroconversion catalyst. The output from the hydroconversion step is provided to a water-gas-shift process providing a mixture of H2O and product gases including CO2, H2, and methane. The mixture components are separated, resulting in a product stream comprising substantially only methane.

Owner:GAS TECH INST

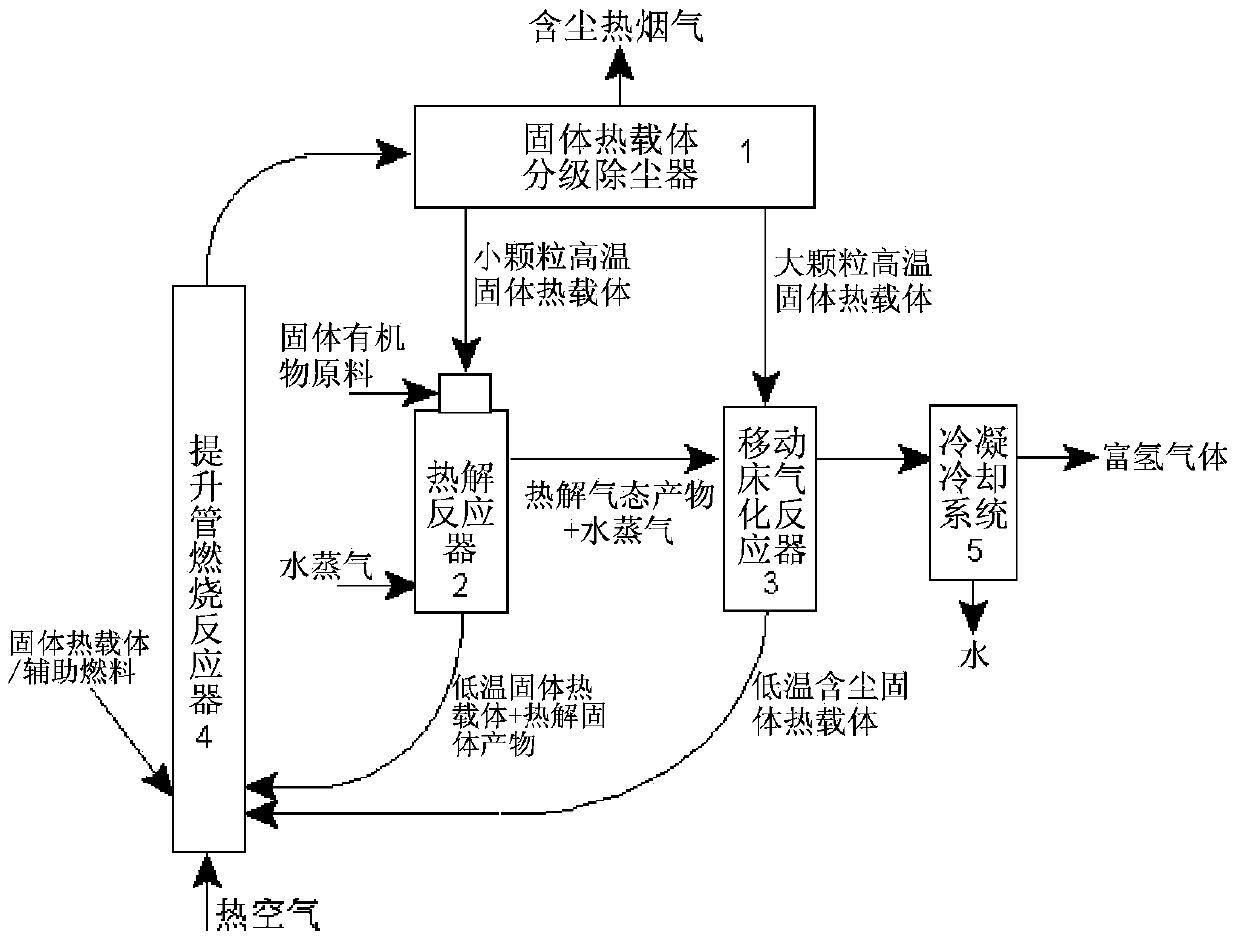

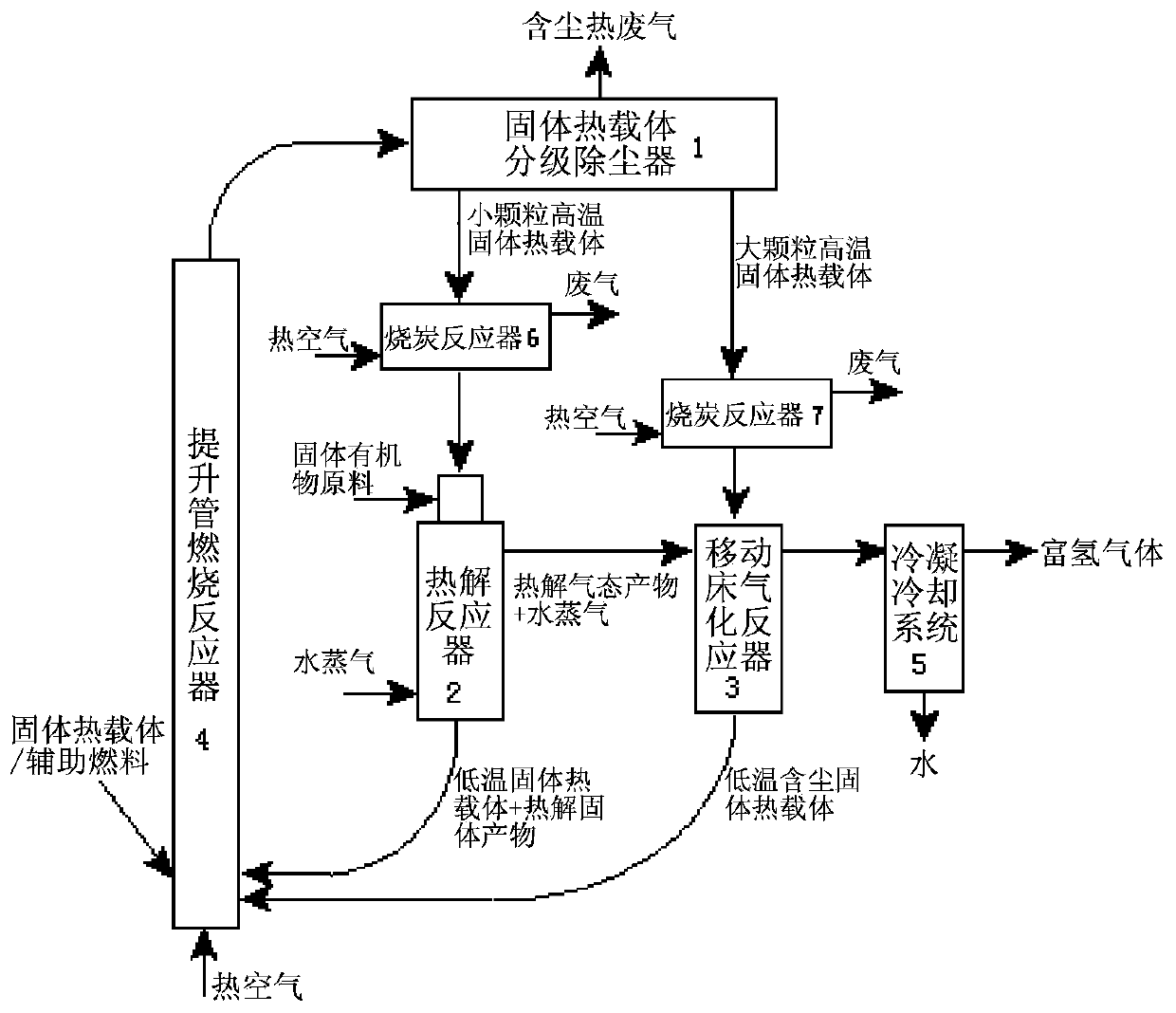

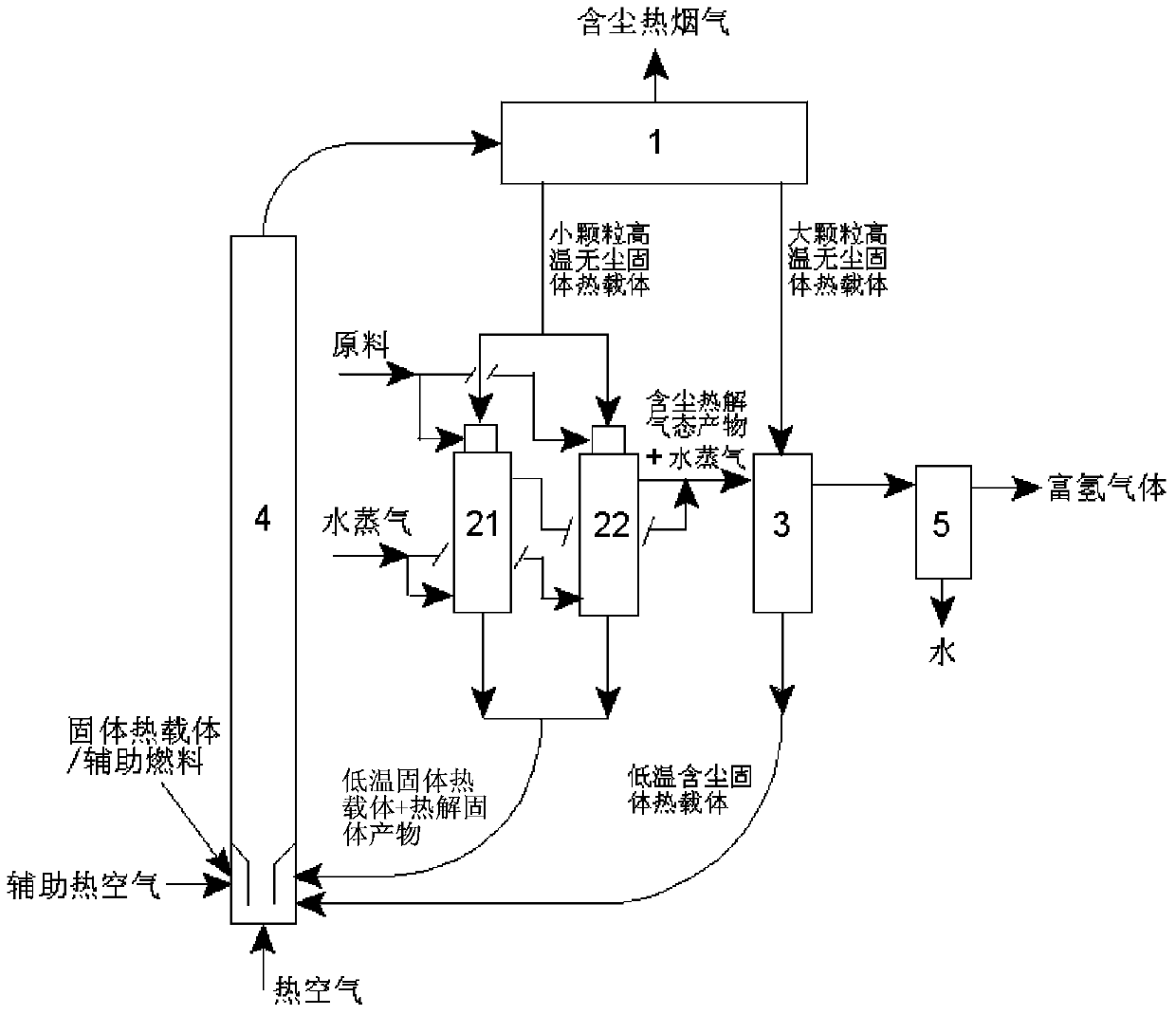

Preparation method for hydrogen-rich gas through steam gasification of solid organic matter

ActiveCN103468322AFast pyrolysisSimple processCombustible gas chemical modificationGasification catalystsWater vaporMoving bed

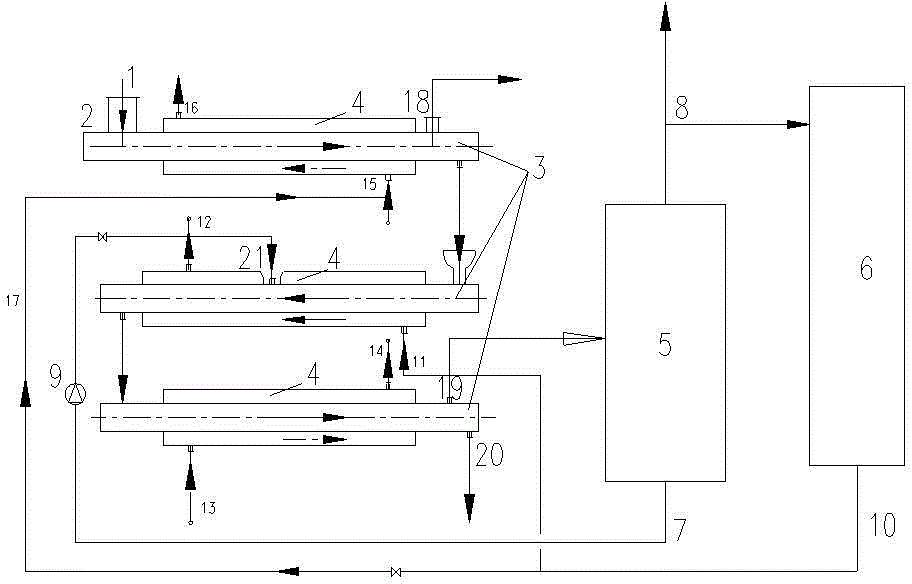

The invention provides a preparation method for hydrogen-rich gas through steam gasification of a solid organic matter. The method comprises the following steps: heating the raw material--the solid organic matter in a pyrolysis apparatus for pyrolysis; and subjecting a gaseous product produced after pyrolysis and steam to gasification in a moving bed gasification apparatus so as to produce the hydrogen-rich gas. The invention further provides a system for preparing the hydrogen-rich gas from the solid organic matter. The system comprises a solid thermal carrier gradient deduster, the pyrolysis apparatus, the moving bed gasification apparatus and a riser combustion reactor. The method provided by the invention is implemented at normal pressure, has simple process and is applicable to gasification and co-gasification of a variety of organic matters with high content of volatile components, including raw materials with high content of moisture, mineral matters and sulfur.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

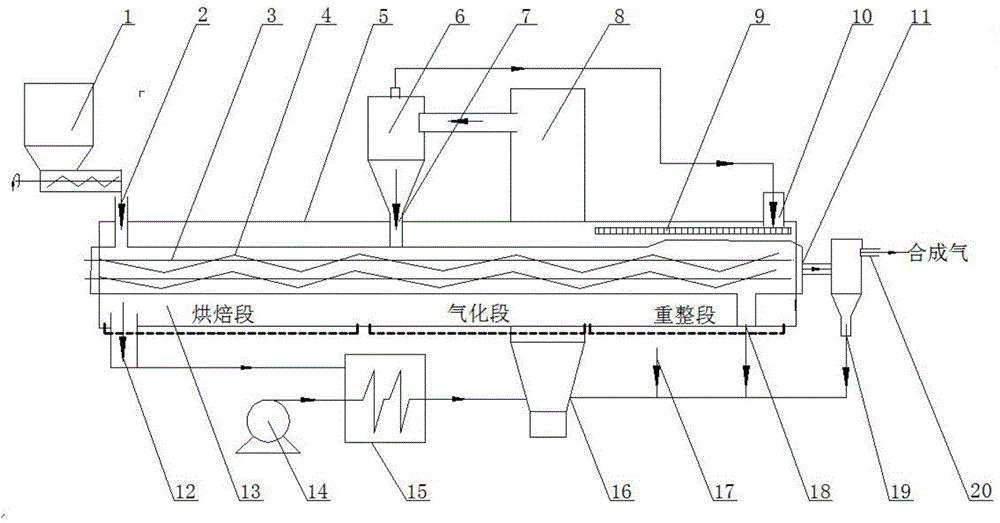

Method and device for preparing synthesis gas by biomass pyrolysis and gasification

InactiveCN104593090AImprove pore structureHigh activityHydrogenGasification catalystsProcess systemsRaw material

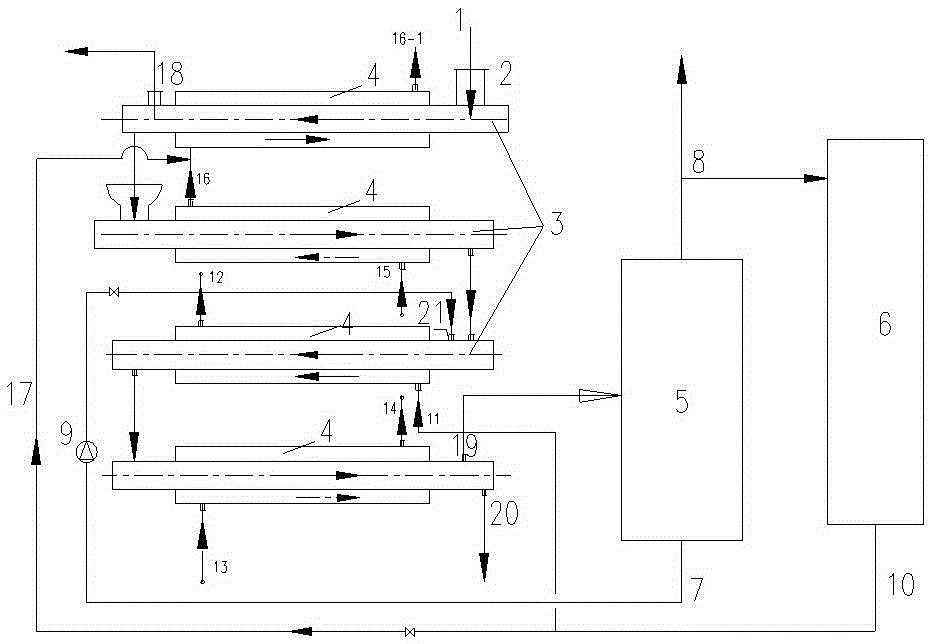

The invention provides a method and a device for preparing synthesis gas by biomass pyrolysis and gasification. The method comprises three stages of roasting at low temperature, catalytically gasifying at high temperature, and reforming through microwave; the three stages are respectively continuously performed in three relatively-independent spaces in a gasifying device, so as to obtain high-quality synthesis gas. The device comprises a double-shaft spiral pyrolysis reactor which is equipped with a roasting section at the front section, a gasifying section at the medium section, and a microwave assisting reforming section at the tail section; raw materials are fed into the double-shaft spiral pyrolysis reactor through a feeding device; the way of combining internal heat and external heat which are produced by smoke heat exchange, heat carried by a catalyst and microwave assisting heating is adopted to provide proper temperature of the three reaction stages to achieve staged pyrolysis and gasification; the produced gas is processed by a gas solid separator to obtain the synthesis gas; meanwhile, the deactivated catalyst and carbon coke and the like discharged by the reactor are fed into a combustion furnace to generate high-temperature smoke and regenerate the catalyst. With the adoption of the method and the device, the process system for preparing the synthesis gas can be simplified, the semi-coke and tar contents in pyrolysis and gasification can be decreased, and the gasifying efficiency of the system and the quality of the synthesis gas can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for producing methane from biomass

ActiveUS8915981B2High yieldFast pyrolysisGasification catalystsDirect heating destructive distillationHydrogenProduct gas

A multi-stage method and apparatus for producing methane from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, the output of which is hydrogenated using a hydroconversion catalyst. The output from the hydroconversion step is provided to a water-gas-shift process providing a mixture of H2O and product gases including CO2, H2, and methane. The mixture components are separated, resulting in a product stream comprising substantially only methane.

Owner:GAS TECH INST

Reactor control method

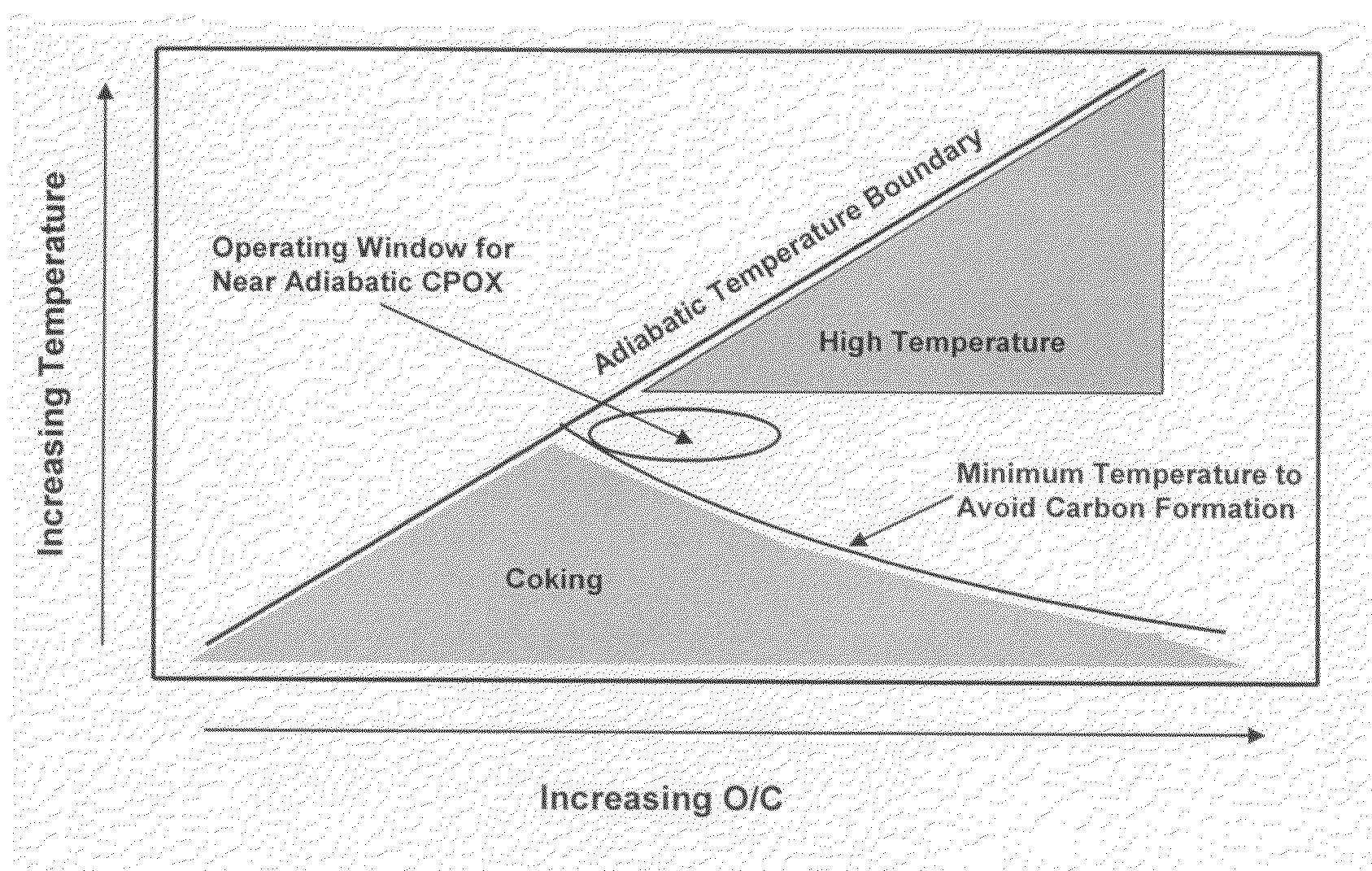

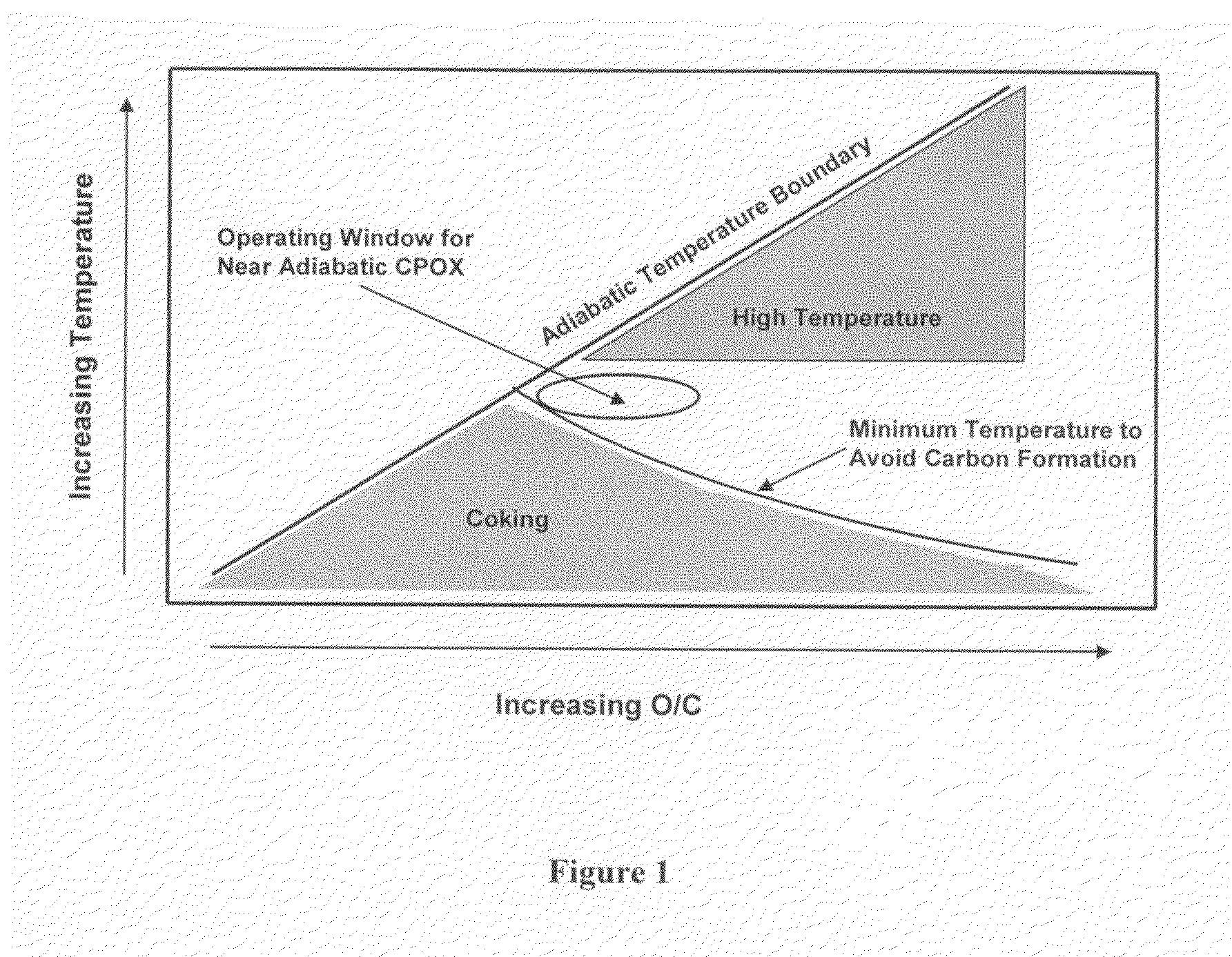

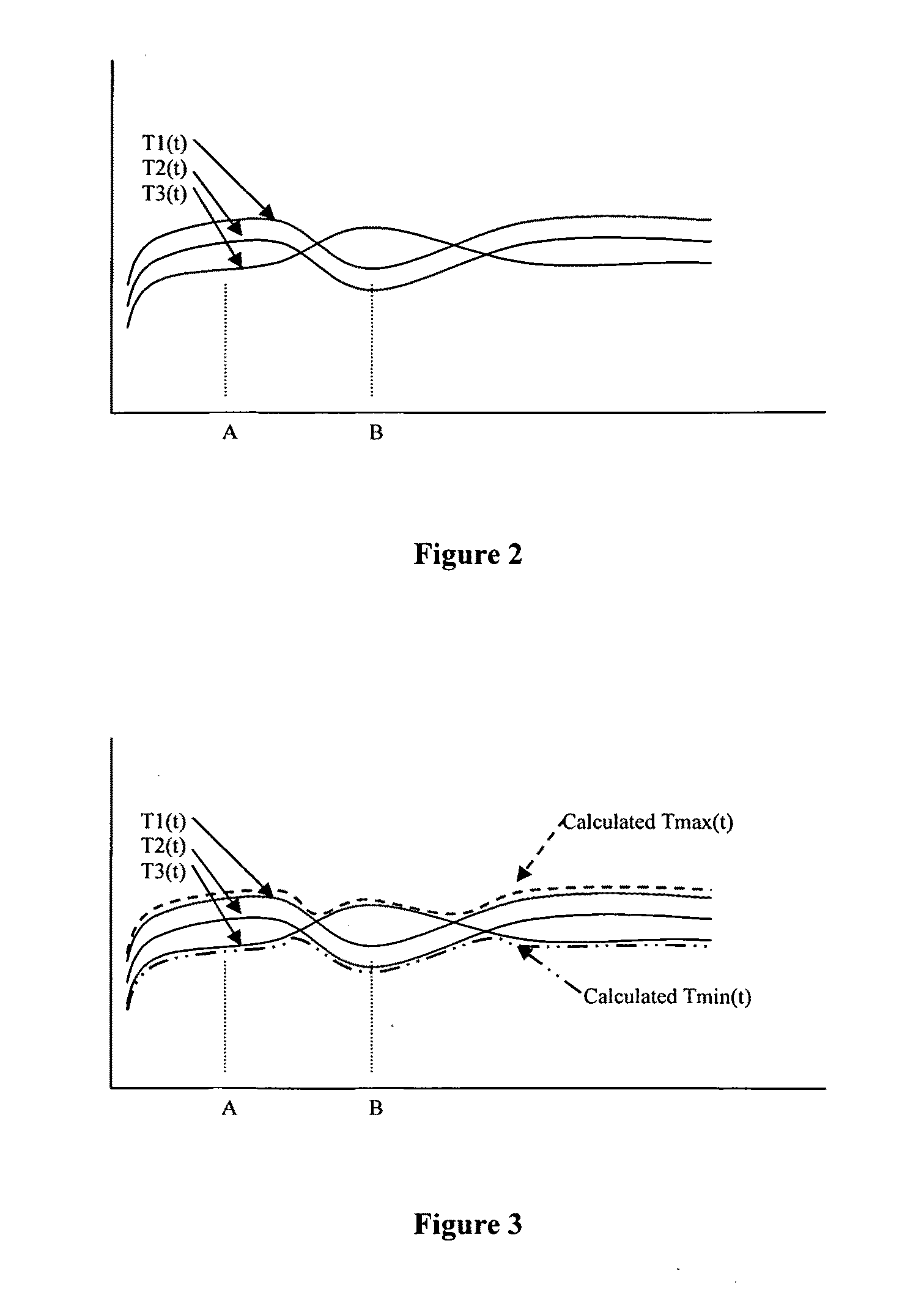

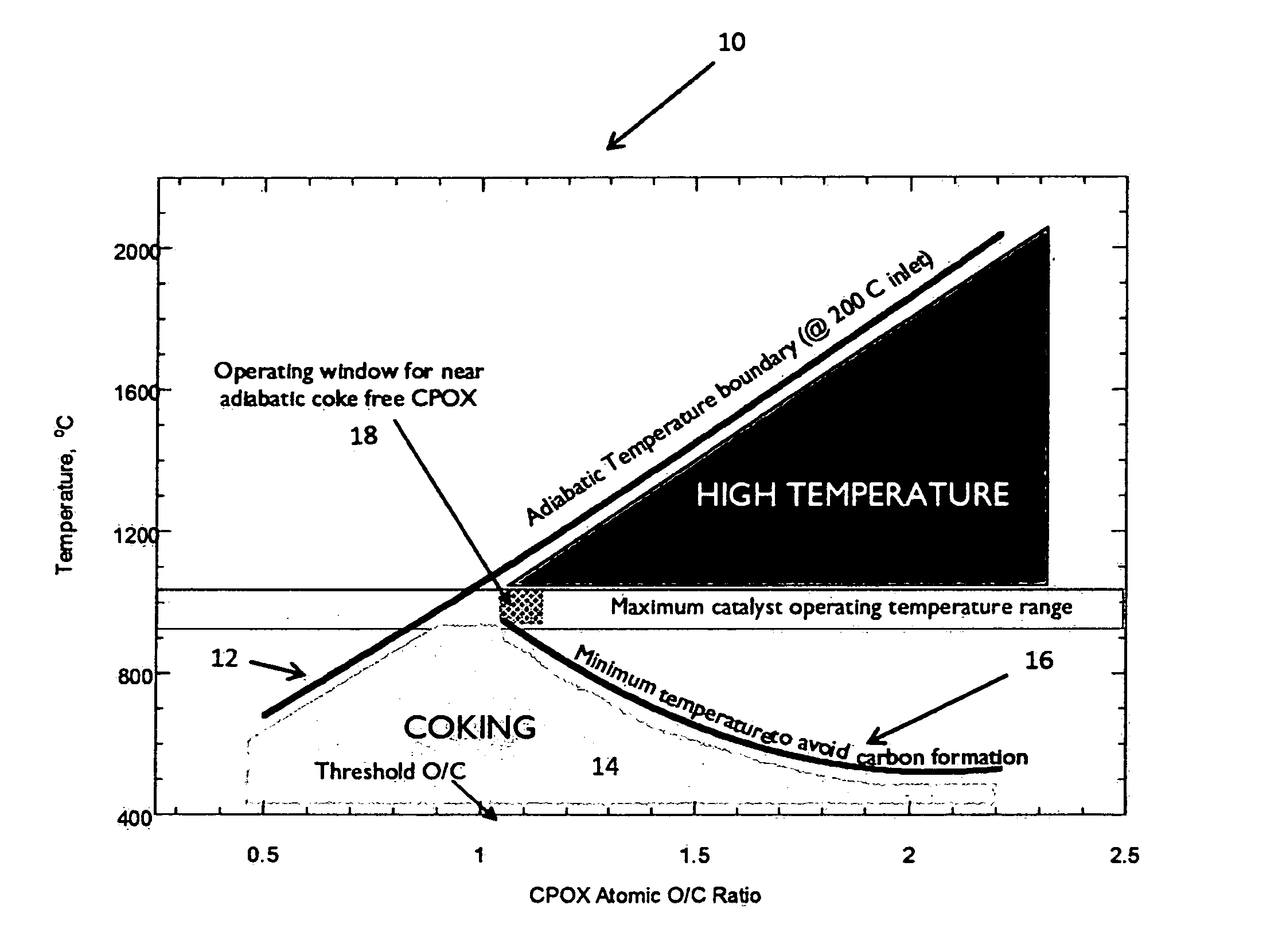

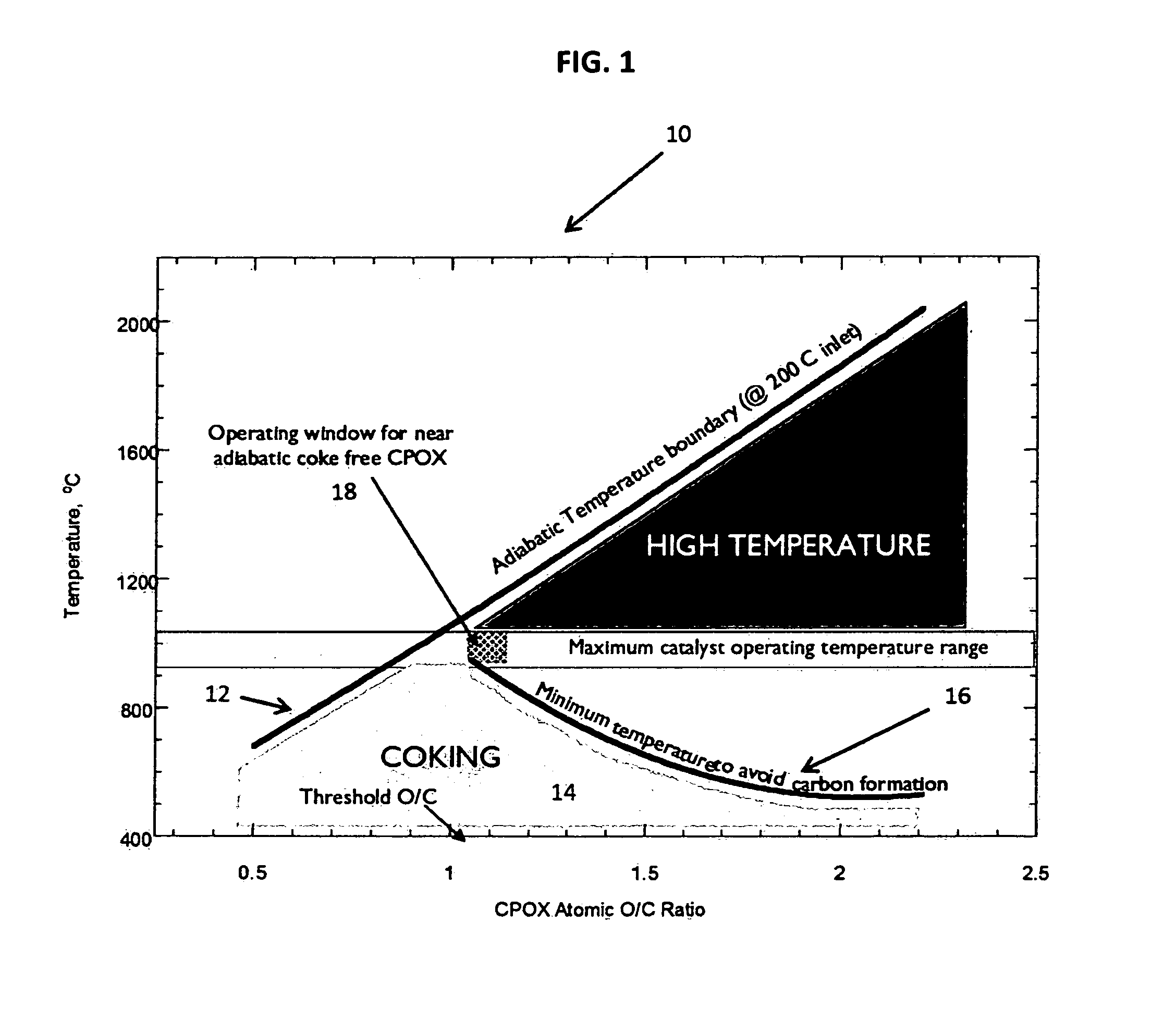

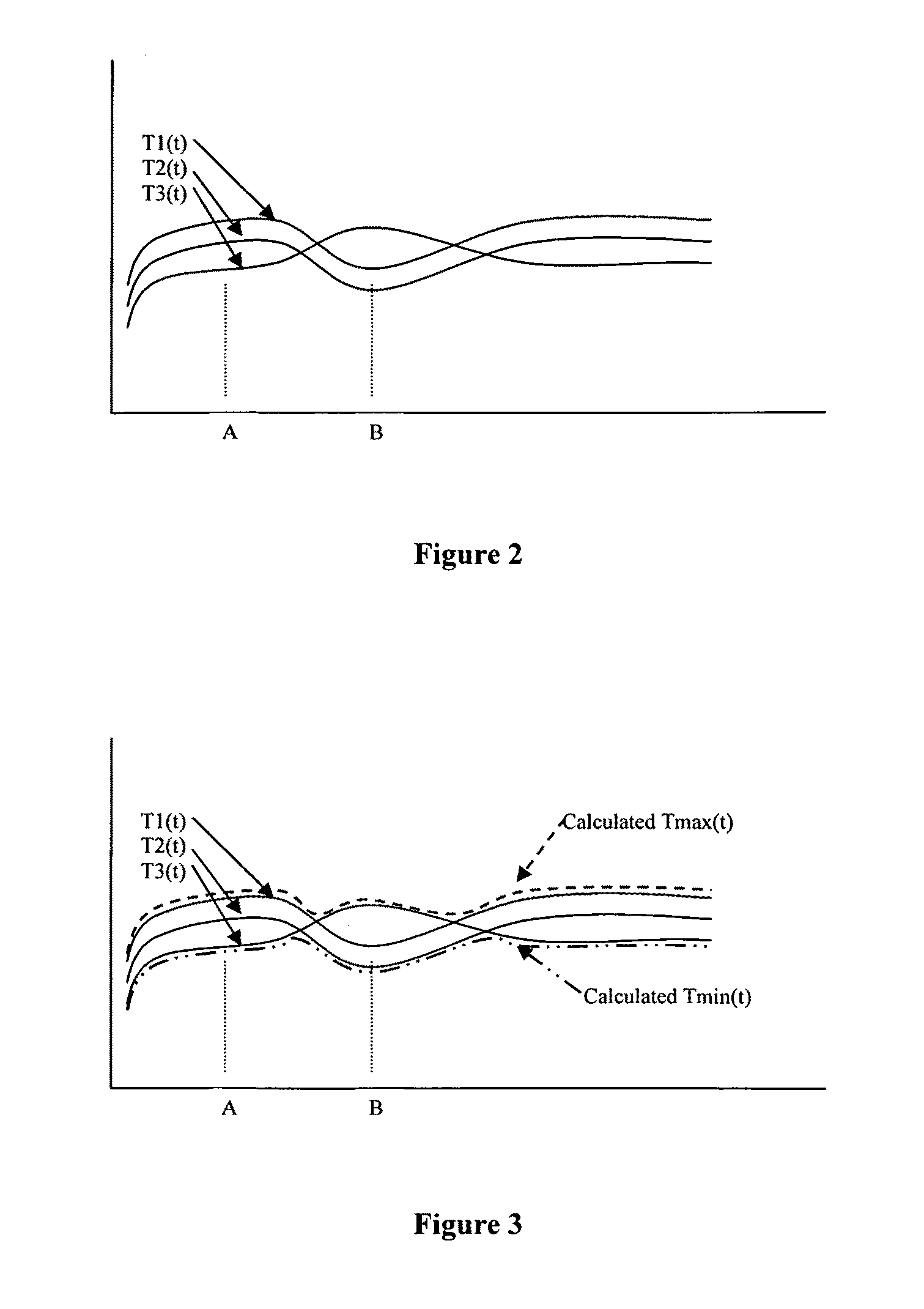

A method is provided for controlling the operating temperature of a catalytic reactor using a closed-loop system that provides for varying the reactor input and other operating parameters in order to maintain the operating temperature of the reactor at or near the initial setpoint temperature for operation of the reactor. In one example, maximum and minimum operating temperatures with a catalytic partial oxidation reactor are controlled, as well as maintaining control over the corresponding minimum required ratio of oxygen atoms to carbon atoms, such that the operating temperature within the reactor is maintained below the material limits but above threshold temperatures for coking.

Owner:PRECISION COMBUSTION

Reactor control method

A method is provided for controlling the operating temperature of a catalytic reactor using a closed-loop system that provides for varying the reactor input and other operating parameters in order to maintain the operating temperature of the reactor at or near the initial setpoint temperature for operation of the reactor. In one example, maximum and minimum operating temperatures with a catalytic partial oxidation reactor are controlled, as well as maintaining control over the corresponding minimum required ratio of oxygen atoms to carbon atoms, such that the operating temperature within the reactor is maintained below the material limits but above threshold temperatures for coking.

Owner:PRECISION COMBUSTION

Catalytic gasification device, system and method

ActiveCN107177384AEnsure safetyHigh methane contentGasification catalystsGasification processes detailsHydrogenWater vapor

The invention relates to the technical field of catalytic gasification, in particular to a catalytic gasification device, system and method, solves the problems that energy consumption is higher and industry expanding is difficult due to the fact that high-temperature overheating gasifying agents are required to be provided when carbon monoxide and hydrogen are returned to a furnace for preparation of methane in an oxygen-free gasification process in the prior art, and overcomes the defects of low methane content, poor safety and high oxygen consumption in an oxygen introducing process. The catalytic gasification device comprises a gasification furnace, wherein the gasification furnace comprises a gas distributing plate and at least one gas incident pipe, a fluidized bed reaction zone is arranged above the gas distributing plate, and the gas distributing plate is used for introducing steam and oxygen into the area, close to the gas distributing plate, of the fluidized bed reaction zone; each gas incident pipe is communicated with the area, far away from the gas distributing plate, of the fluidized bed reaction zone and is used for introducing carbon monoxide and hydrogen into the area, away from the gas distributing plate, of the fluidized bed reaction zone. The catalytic gasification device is used for preparing methane through catalytic gasification.

Owner:ENN SCI & TECH DEV

Method for producing catalytically-active materials

InactiveUS20050255995A1Reducing and eliminating tarOther chemical processesGasification catalystsMolten stateActive component

A method for producing a catalytically-active material having at least one base component and at least one catalytically-active component in which the at least one base component is heated to a softening or melting temperature to form a softened or molten base component. While the base component is in the softened or molten state, at least one catalytically-active component is incorporated into or onto the base component, forming the catalytically-active material. In accordance with one embodiment, a catalyst precursor is introduced into the base component and subsequently transformed to a catalytically-active component.

Owner:GAS TECH INST

Internal combustion type biomass gasifier

ActiveCN105602622AReduce tar contentReduce oxygen contentGasification catalystsGasification processes detailsWater vaporBiomass gasifier

Provided is an internal combustion type biomass gasifier. A sealing cover is arranged on the upper portion of a gasifier body, the sealing cover is connected with a screw feeder, and materials enter the screw feeder through a hopper. A stirring connector which is in transmission with a perforation lifting device via a gear and is driven by a lifting thread suspension shaft is arranged in the middle of the upper portion of the sealing cover and is located in a hearth, and the stirring connector can rotate and also can move vertically. Lateral gas discharge is adopted based on the down-draft type gasification principle, the staying time of gas in the gasifier is prolonged, the temperature of the gas discharged out of the gasifier is lowered, and the loss of heat is reduced. A tooth-type water cooling ash falling device can make water in a hollow water cooling tooth shaft generate vapor with high-temperature charcoal ash and also can reduce the influence of ash falling on the ash content in combustible gas, and the tar content in the generated combustible gas is relatively low; meanwhile, the oxygen content in the material gasification process is reduced, the N2 content in the combustible gas is reduced, material waste caused by direct combustion is reduced, the gas yield is increased, and the fuel gas quality is improved.

Owner:BEIJING UNIV OF TECH

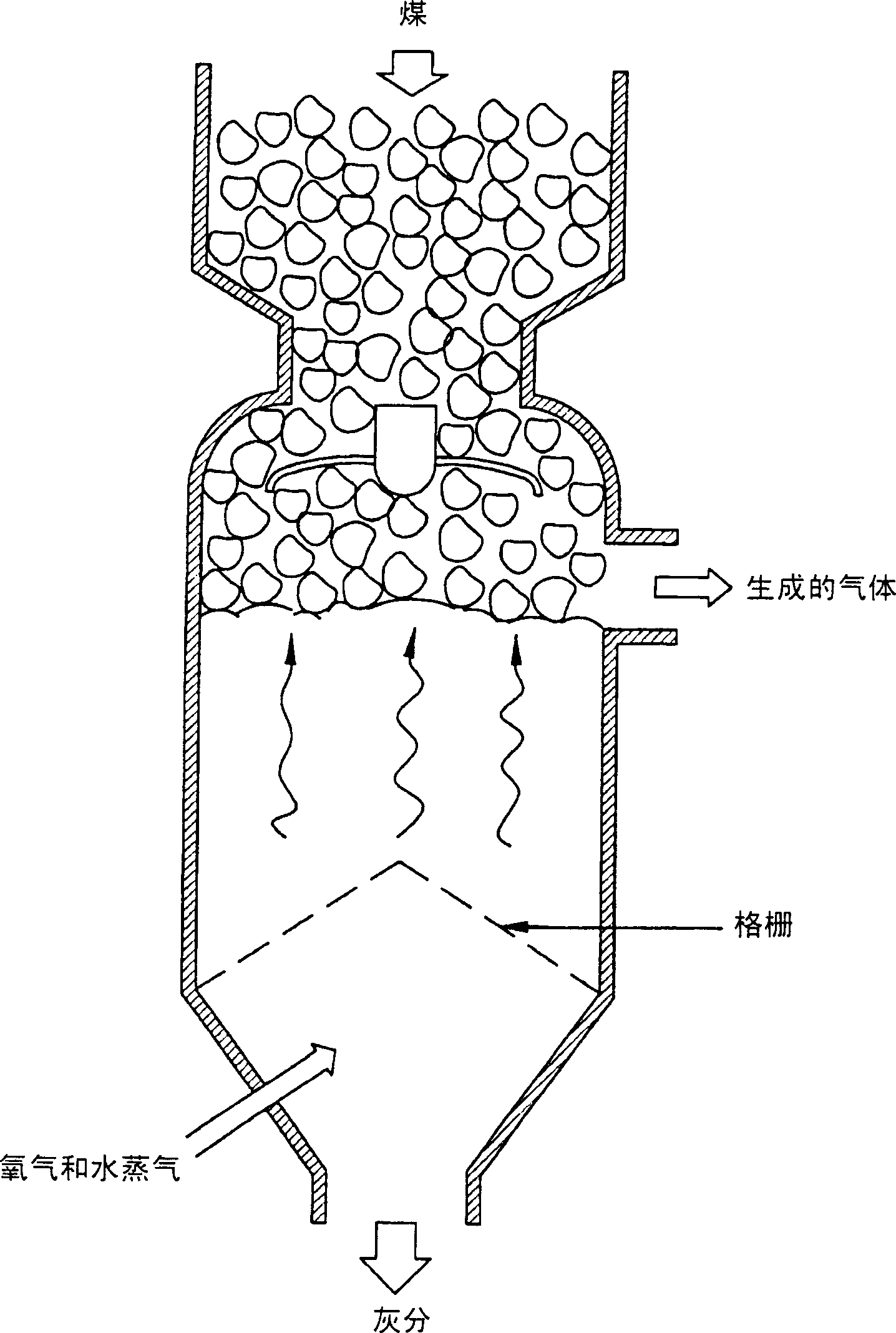

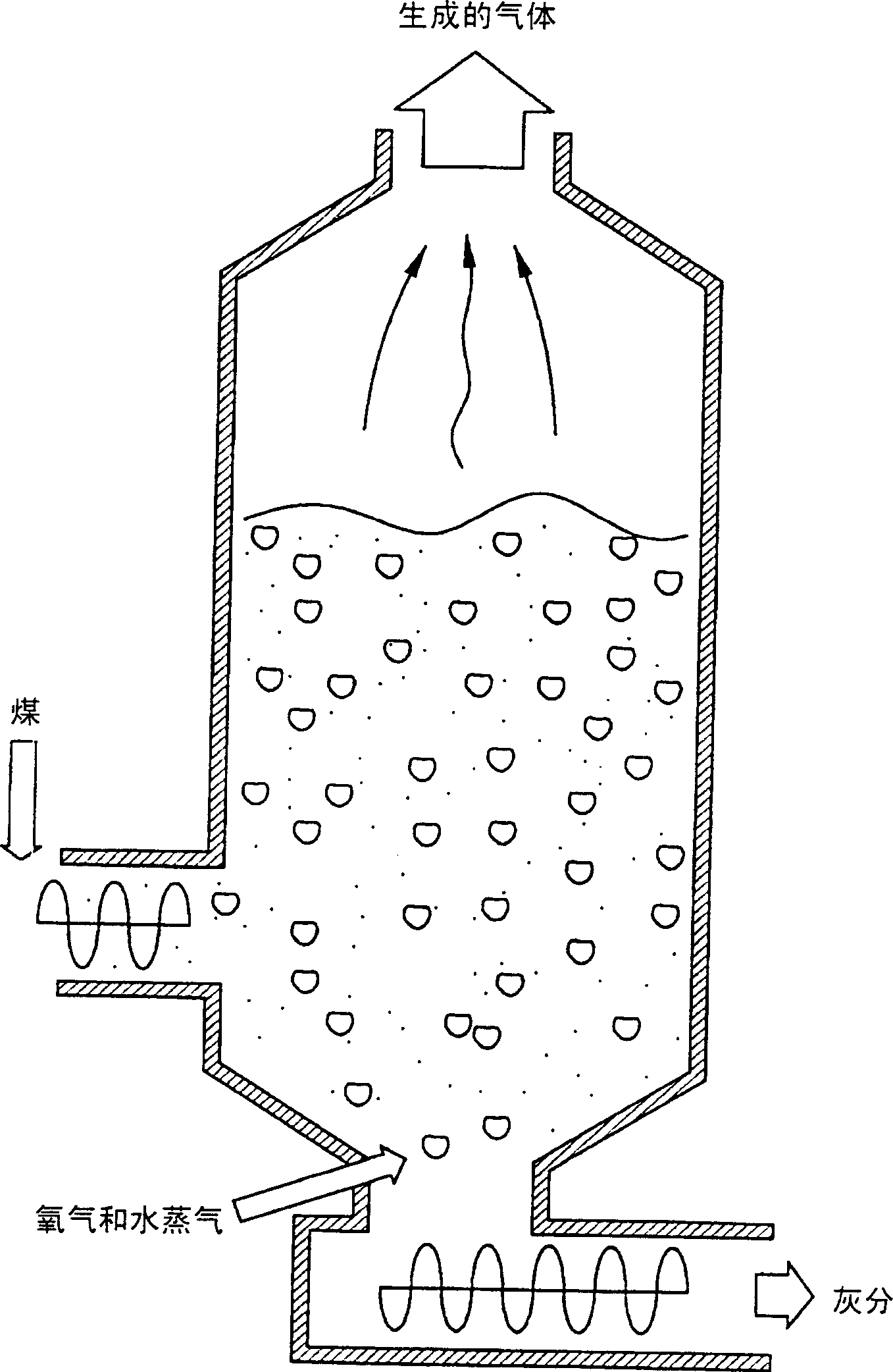

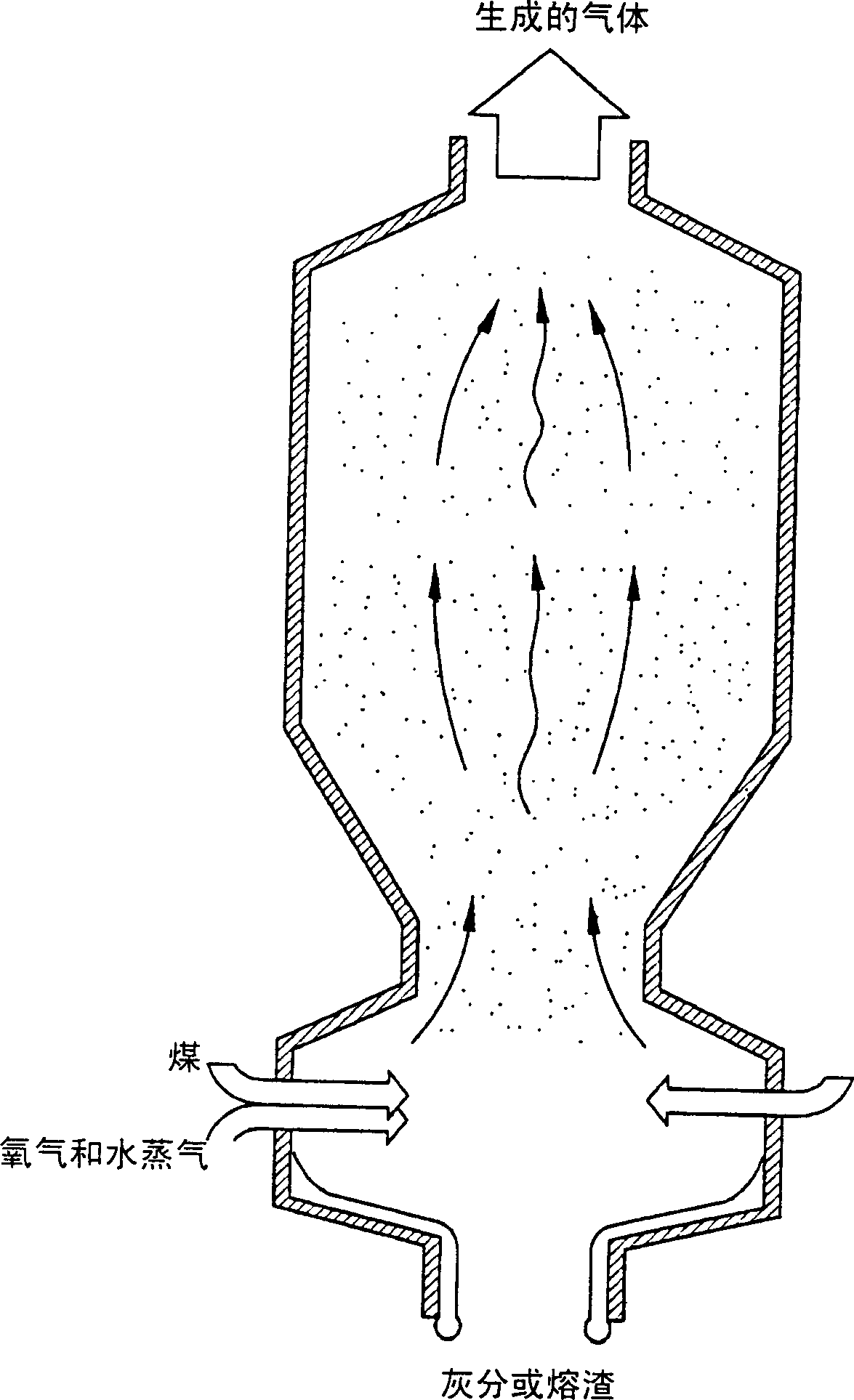

Method of gasifying carbonaceous material and apparatus therefor

InactiveCN1400998AQuality improvementIncrease concentrationGasification catalystsSolid waste disposalHydrogenProduct gas

A method of gasifying organic materials (carbonaceous compounds) such as coal, shredded waste tire or waste oil into gaseous fuel, carbon monoxide and hydrogen, and an apparatus therefore are provided. The method comprises the steps of supplying initial fuel gas and oxygen into a gasification reactor to produce water and carbon dioxide, supplying the organic materials into the reactor and reacting them with the water and carbon dioxide to produce carbon monoxide and hydrogen gas, discharging the carbon monoxide and hydrogen gas from the reactor, recycling a part of the carbon monoxide and hydrogen gas discharged from the reactor into the reactor, and reacting the carbon monoxide and hydrogen gas supplied into the reactor with oxygen to produce water and carbon dioxide. The method facilitates the control of temperature in the gasification reactor as well as produces fuel gas of high quality by increasing the concentration of hydrogen.

Owner:金显泳

Method for improving yield of coal microwave pyrolysis tar by using methane and carbon dioxide as reactant gases

InactiveCN105925317AHigh activityHigh yieldGasification catalystsGasification processes detailsMicrowave pyrolysisHydrogen

The invention discloses a method for improving the yield of coal microwave pyrolysis tar by using methane and carbon dioxide as reactant gases. The method is characterized in that: methane of which the volume ratio is 50-90% and carbon dioxide of which the volume ratio is 10-50% are used as reactant gases, methane and carbon dioxide are mixed together, then the mixed gas is introduced into a pyrolysis reactor and is subjected to co-pyrolysis with a mixture containing coal of which the mass percent is 30-90% and semi-coke of which the mass percent is 10-70% under the condition that the microwave heating temperature is 400-700 DEG C for a constant temperature time of 10-40min, volatile products after pyrolysis leave the reactor and then enter a condensing system for gas-liquid separation, and then a tar product is collected. The method disclosed by the invention has the advantages that the semi-coke is used as a catalyst, and methane and carbon dioxide replace hydrogen and serve as hydro-pyrolysis reactant gases, so that the yield of the pyrolysis tar can be obviously improved, and the hydro-pyrolysis cost is reduced; and the semi-coke is used as a catalyst for activating methane and carbon dioxide, the catalyst does not need to be recovered and separated from the product, the semi-coke is generated continuously during pyrolysis, and the problem of catalyst deactivation is avoided.

Owner:HENAN POLYTECHNIC UNIV

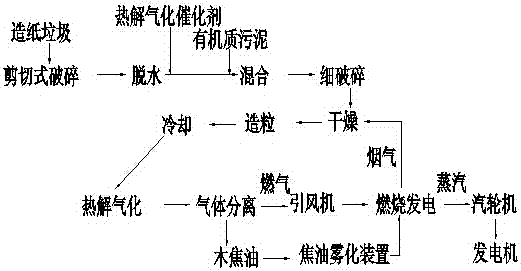

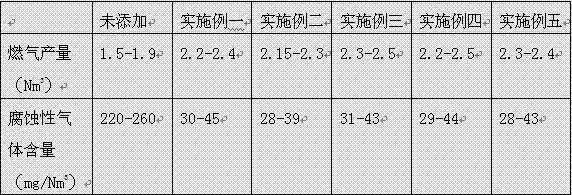

Pyrolysis gasification catalyst and papermaking waste treatment process using pyrolysis gasification catalyst

ActiveCN107497467AGood hygroscopicityImprove pyrolysis gasification efficiencyGasification catalystsOrganic-compounds/hydrides/coordination-complexes catalystsSodium bicarbonateEquivalence ratio

The invention discloses a pyrolysis gasification catalyst which comprises the following components: 35 to 50% of calcium oxide, 10 to 20% of zirconium oxide, 15 to 25% of titanium dioxide, 15 to 25% of sodium bicarbonate and 10 to 20 % of citric acid. The components are crushed to form a mixture; the present invention also discloses a papermaking waste treatment process comprising 1) crushing: crushing papermaking waste into flocculent; 2) dehydration: reducing the water of the papermaking waste to 20-40% ; 3) adding: adding the pyrolysis gasification catalyst accounting for 3-5% of the mass of the papermaking waste; 4) mixing: uniformly mixing the papermaking waste and the catalyst; 5) drying: controlling the water of the mixed material to 15-25%; 6) pelletizing: obtaining organic-matter-derived fuel particles; 7) cooling: cooling the particles to room temperature; 8) pyrolyzing and gasifying: pyrolyzing and gasifying the particles at 600-800 DEG C under micro-oxygen conditions of the air equivalence ratio of 0.1-0.28; and 9) gas separation: removing wood tar from mixed fuel gas through purification; and the pyrolysis gasification catalyst can effectively improve the gasification efficiency of the fuel particles and fuel gas production, can neutralize corrosive gases, greatly improves sludge utilization rate, and effectively protects the environment.

Owner:四川雷鸣环保装备有限公司

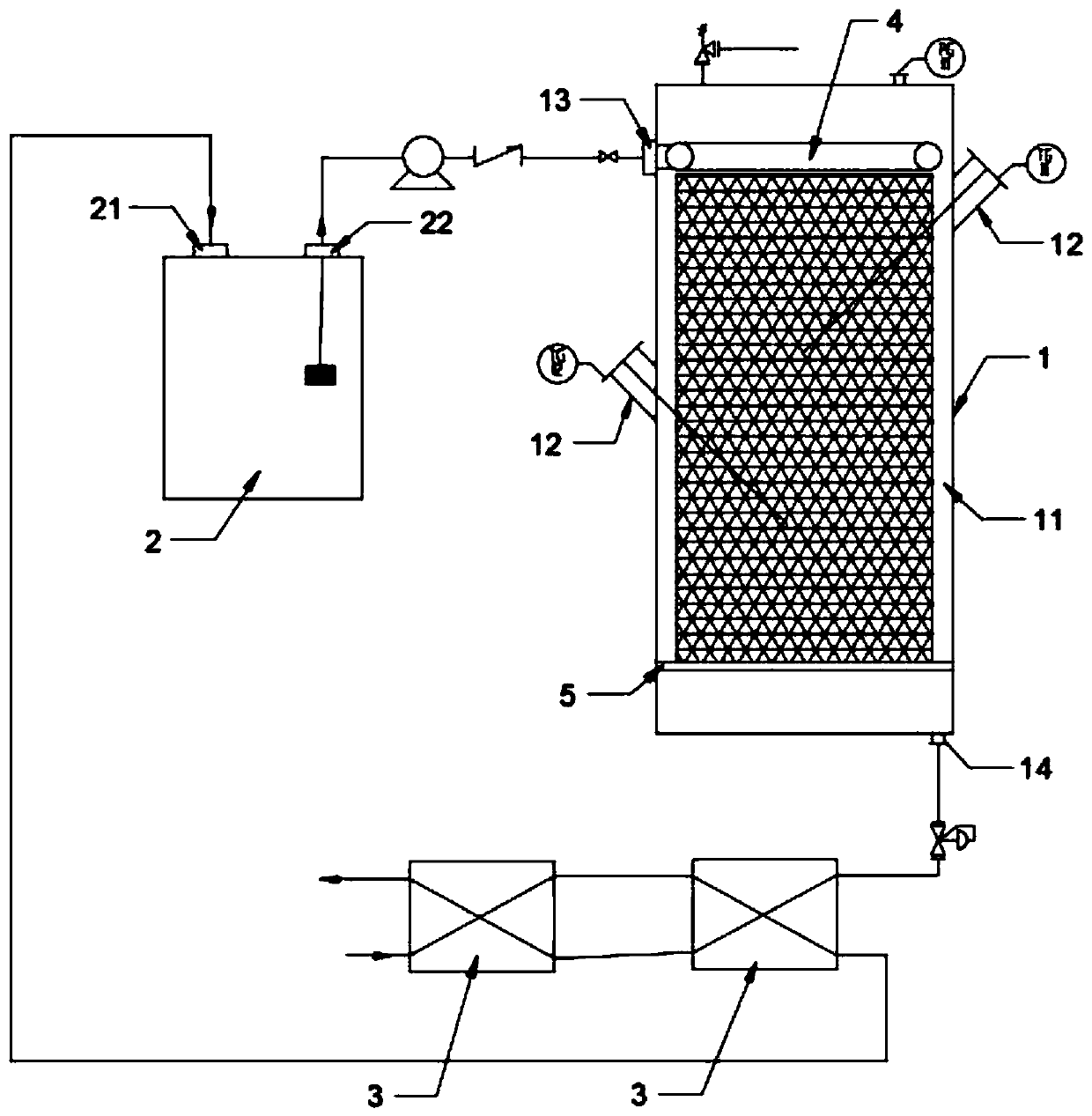

Device for treating high-concentration organic wastewater by catalyzing hydrothermal gasification

ActiveCN111362336ADealing with energy saving and environmental protectionReduce energy consumptionGasification catalystsWater contaminantsPtru catalystWastewater

The invention discloses a device for treating high-concentration organic wastewater through catalytic hydrothermal gasification. The device mainly comprises a CHG reactor, a wastewater temporary storage tank and a condensation heat exchanger, wherein the CHG reactor mainly comprises a shell, a thermocouple, a water distribution device and a filler bracket, the shell is provided with a feed port and a gas outlet, the filler bracket is used for supporting a catalyst filler and is arranged in the shell, the water distribution device is arranged in the shell above the catalyst filler, and the thermocouple is inserted into the side wall of the shell and extends into the catalyst filler. The condensation heat exchanger is communicated with the air outlet through a back pressure valve and a pipeline, the liquid inlet of the wastewater temporary storage tank is connected with the condensation heat exchanger through a high-pressure feeding pump and a pipeline, and the liquid outlet of the wastewater temporary storage tank is connected with the feeding port through the high-pressure feeding pump and a pipeline. The device can quickly convert high-concentration organic wastewater into clean energy or harmless gas at a low temperature under the action of a catalyst, greatly reduces the energy consumption in the treatment process, improves the treatment efficiency, and has potential application prospects.

Owner:NANJING UNIV +1

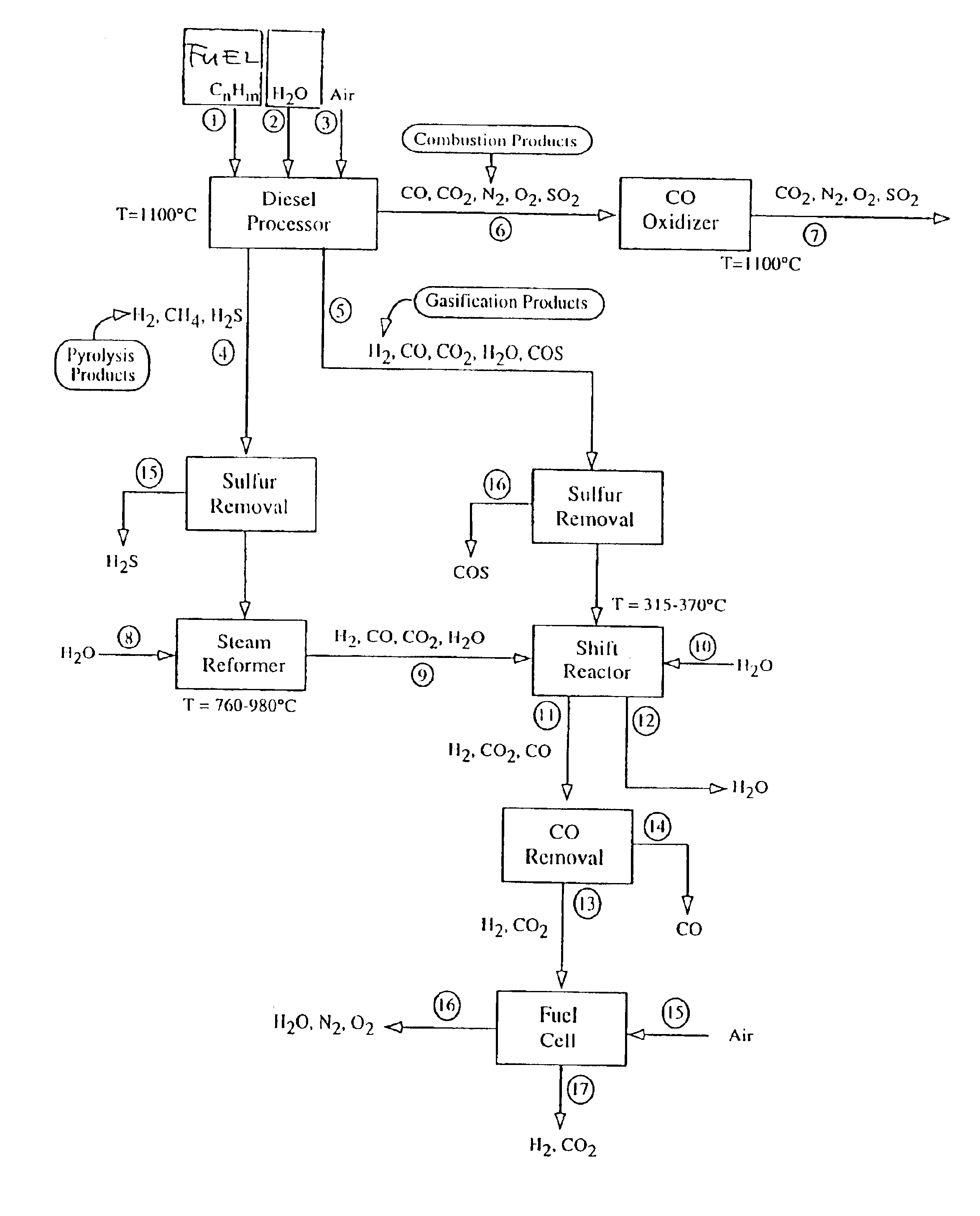

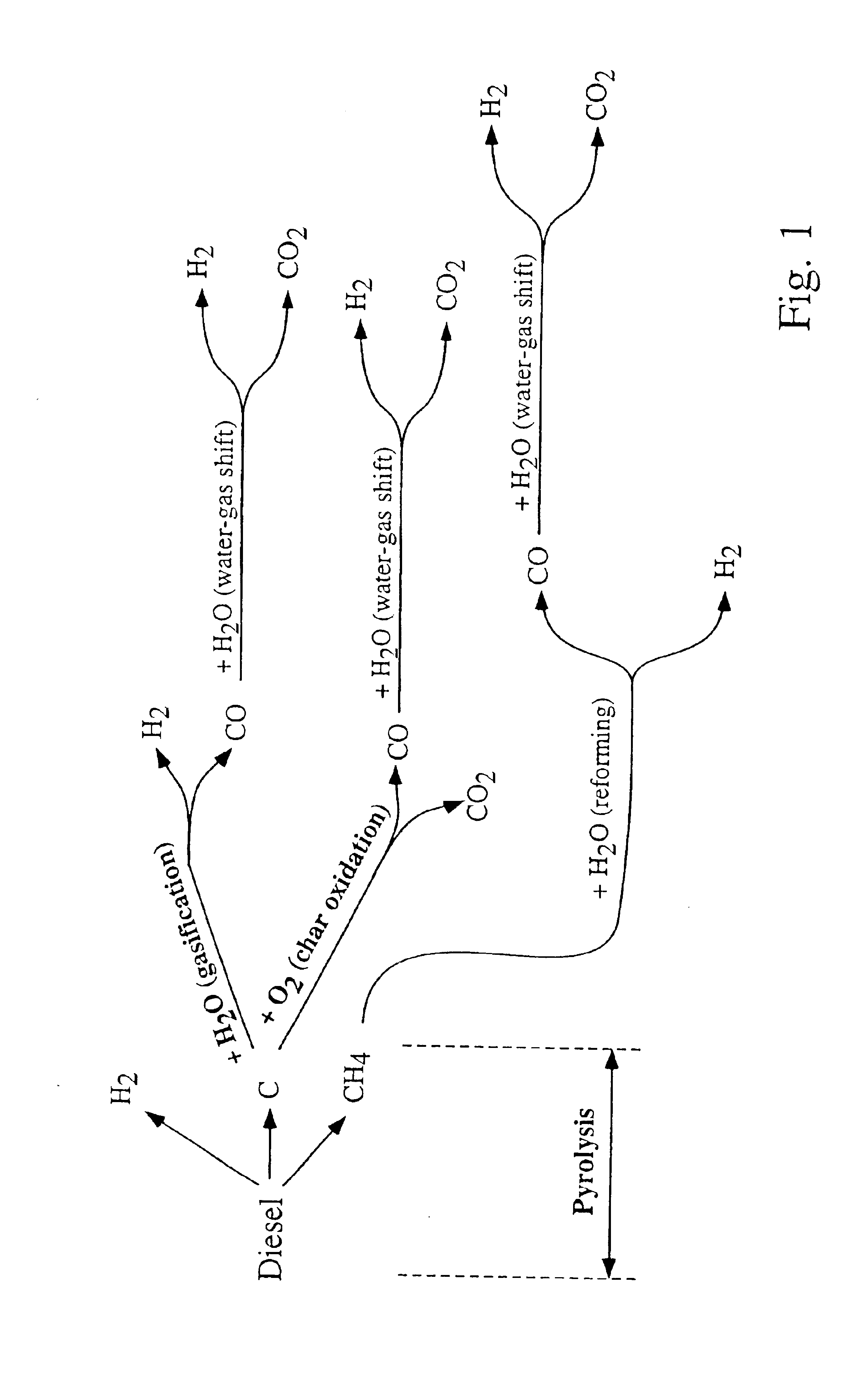

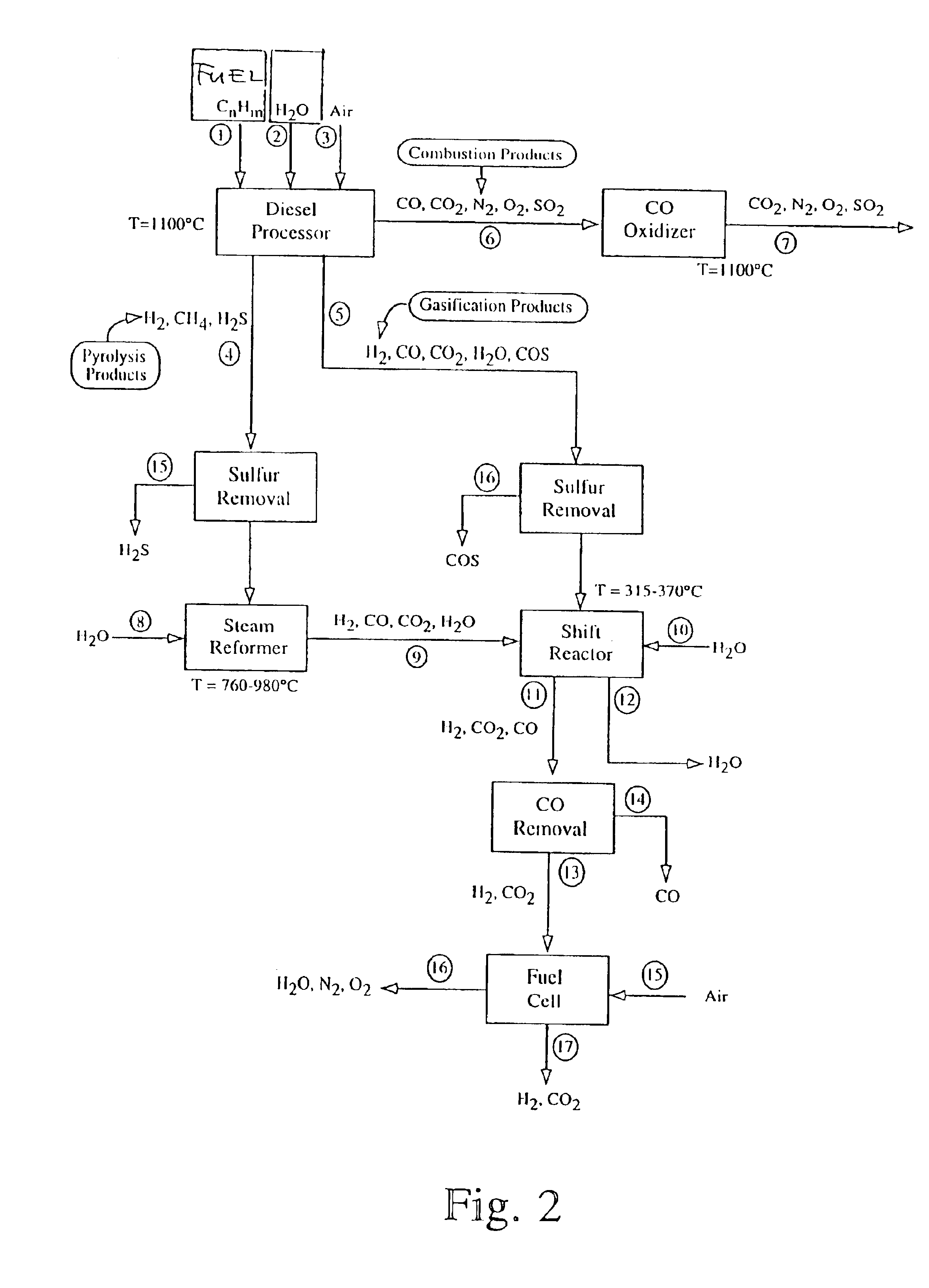

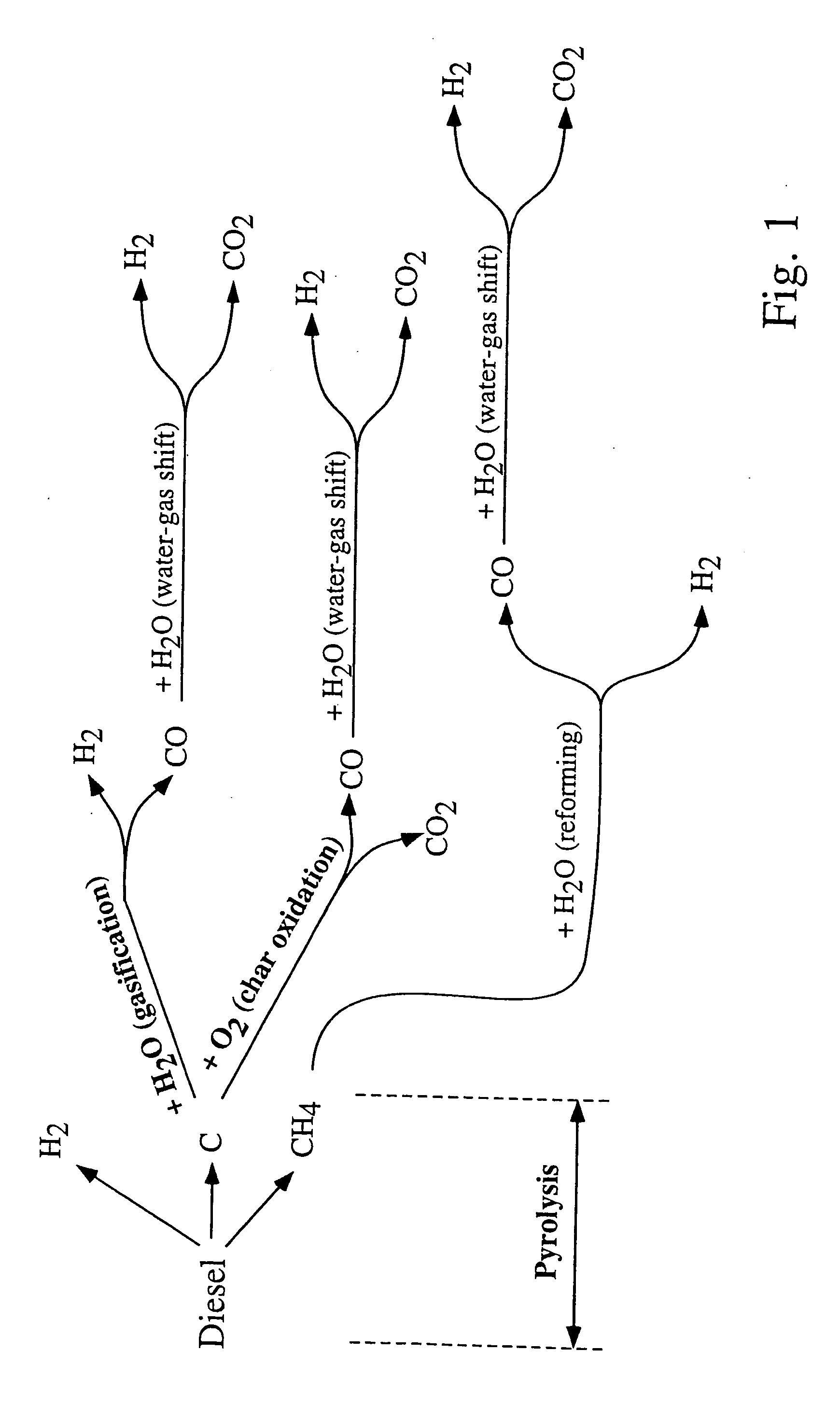

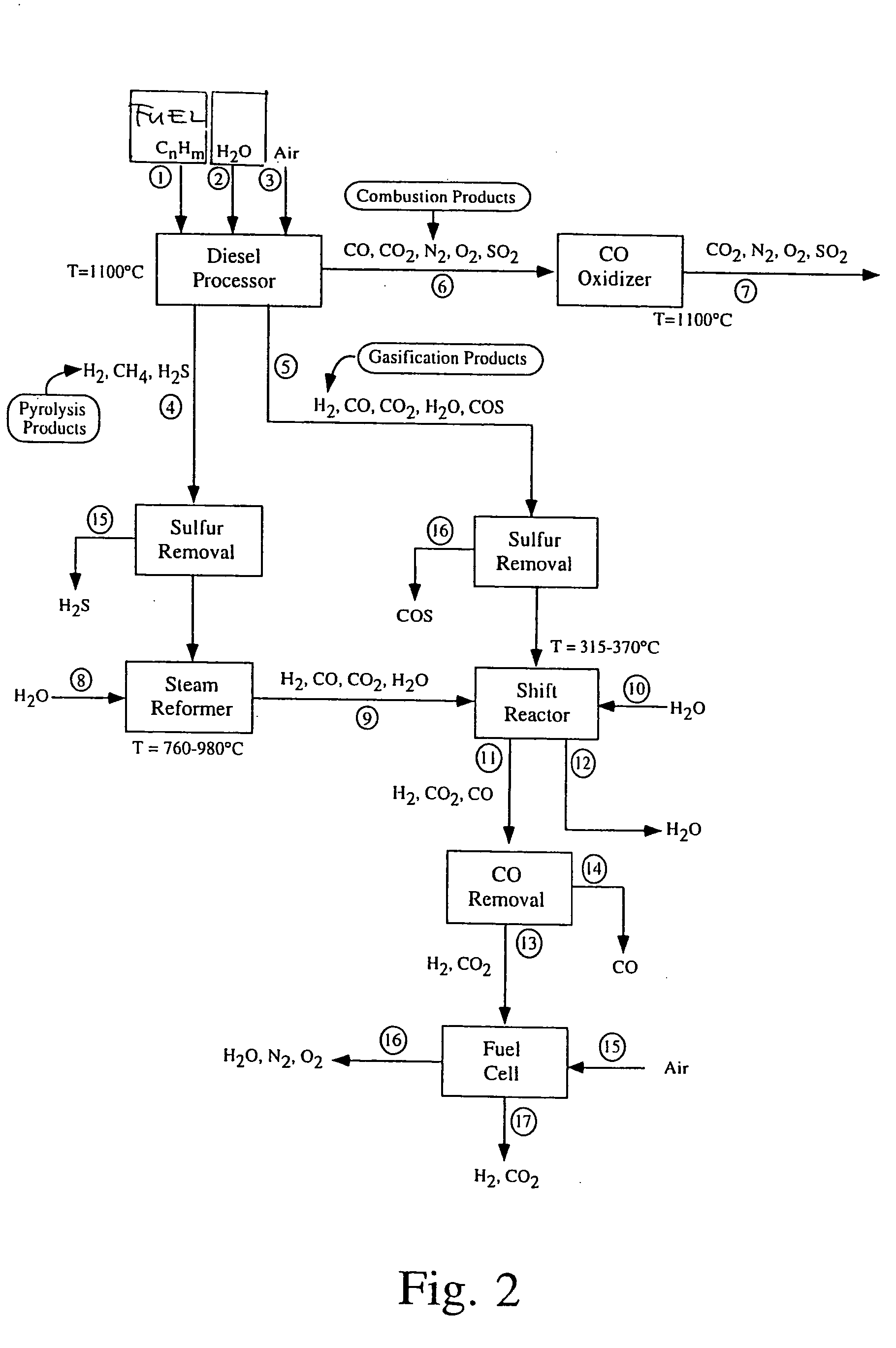

Pyrolysis-based fuel processing method and apparatus

InactiveUS6869580B2Sufficient supplyGasification catalystsFuel cell auxillariesSteam reformingWater-gas shift reaction

The method for generating a hydrogen-rich stream from hydrocarbon fuels, ultimately to produce hydrogen gas, involves the following two steps performed in a cyclic fashion: (1) pyrolysis of the hydrocarbon fuel to obtain a carbon-rich fraction and a hydrogen-rich fraction; and (2) oxidation of the carbon-rich fraction, or a portion of it, for heat generation. The method involves the following optional steps: (3) steam gasification of part of the carbon-rich fraction to produce additional amounts of hydrogen and carbon monoxide; (4) water-gas shift reaction to convert carbon monoxide to carbon dioxide with the simultaneous formation of additional amounts of hydrogen; and (5) steam reforming of light hydrocarbons that may be produced in step (1) to produce more hydrogen and carbon monoxide.

Owner:ADVANCED FUEL RES INC

Method and apparatus for gasifying raw material and gaseous product

ActiveUS20170313951A1Reduce nitrogen contentHigh calorific valueGasification catalystsGasification processes detailsCatalytic oxidationFixed bed

A method and apparatus for gasifying raw material. The method includes feeding the raw material into an upper part of a fixed-bed gasifier, introducing the raw material from the upper part of the gasifier to a pyrolysis zone of the gasifier to form the fixed-bed and pyrolyzing the raw material in the presence of pyrolysis air to form a pyrolysis product. Introducing the pyrolysis product from the pyrolysis zone to a lower part of the gasifier, introducing primary air countercurrently to the lower part, carrying out a final gasification in a lower part of the gasifier in order to form a gasified gas. Introducing the gasified gas to a catalytic oxidation part and through a catalyst layer of the catalytic oxidation part, and reforming the gasified gas by way of the catalytic oxidation in the presence of reforming air in the catalytic oxidation part, forming a gaseous product.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

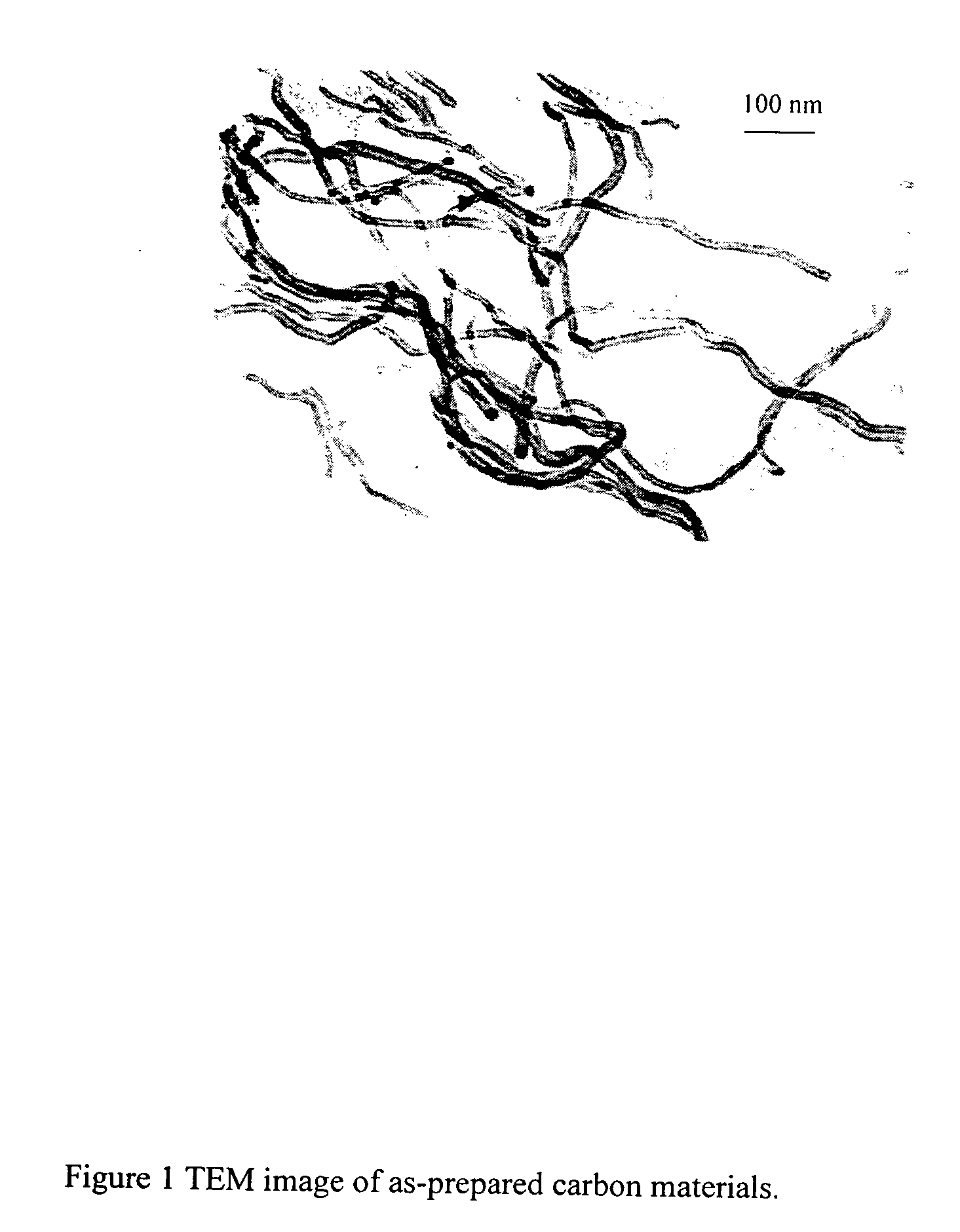

Method for hydrogen production

InactiveUS20040033193A1Material nanotechnologyGasification catalystsCatalytic decompositionCarbon nanotube

The present work provides a new route for production of hydrogen via water and preformed carbon materials at a relatively low temperature. The preformed carbon materials comprise carbon nanotubes or nanofibers bonded to a transition metal and are obtained by the catalytic decomposition of hydrocarbons in a reductive atmosphere in the presence of the transition metal catalyst. Experimental results demonstrate that the transition metal bonded to the carbon nanotubes or nanofibers has a high activity for the production of hydrogen at temperatures around 450° C.

Owner:CHEN PING

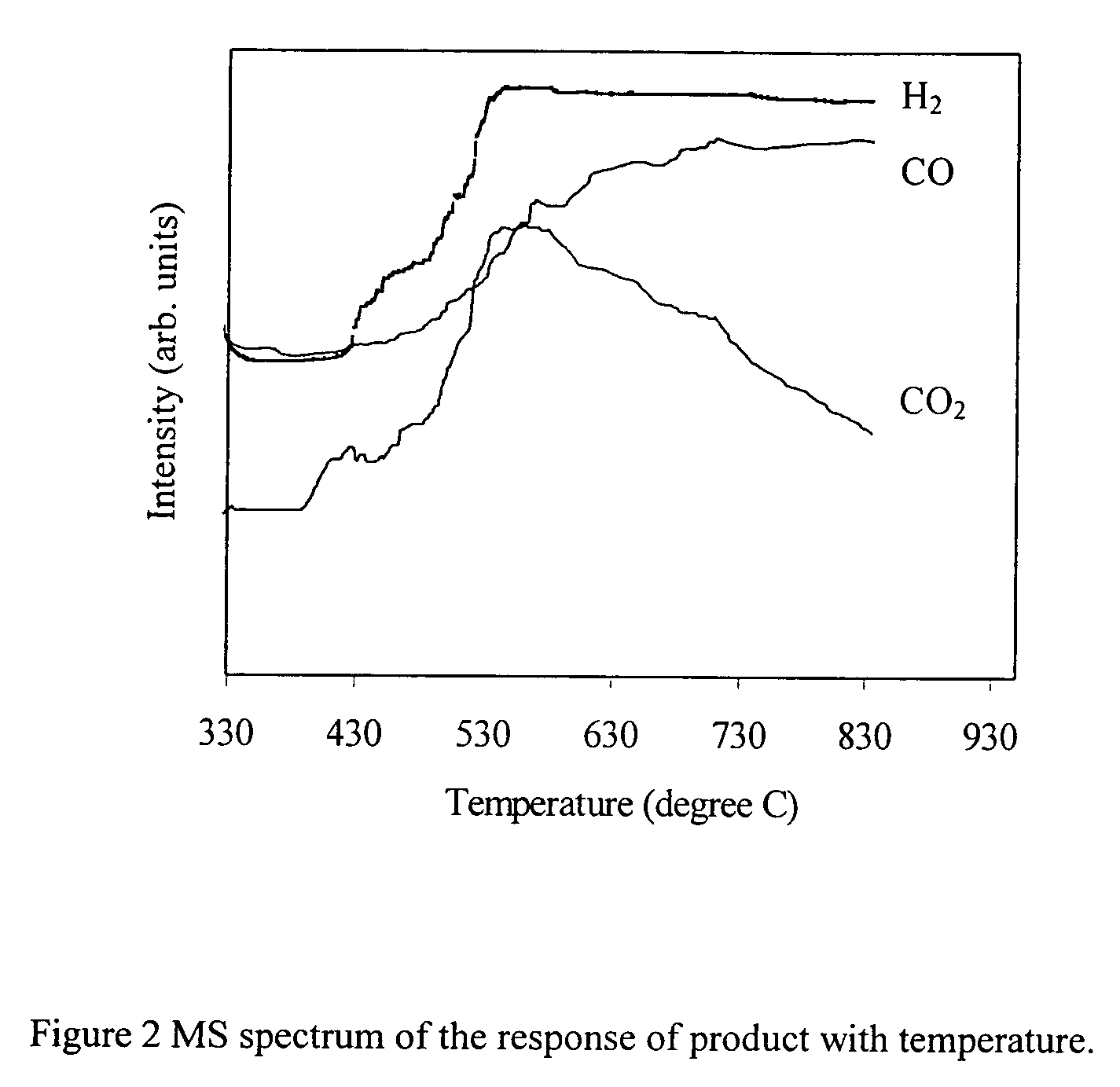

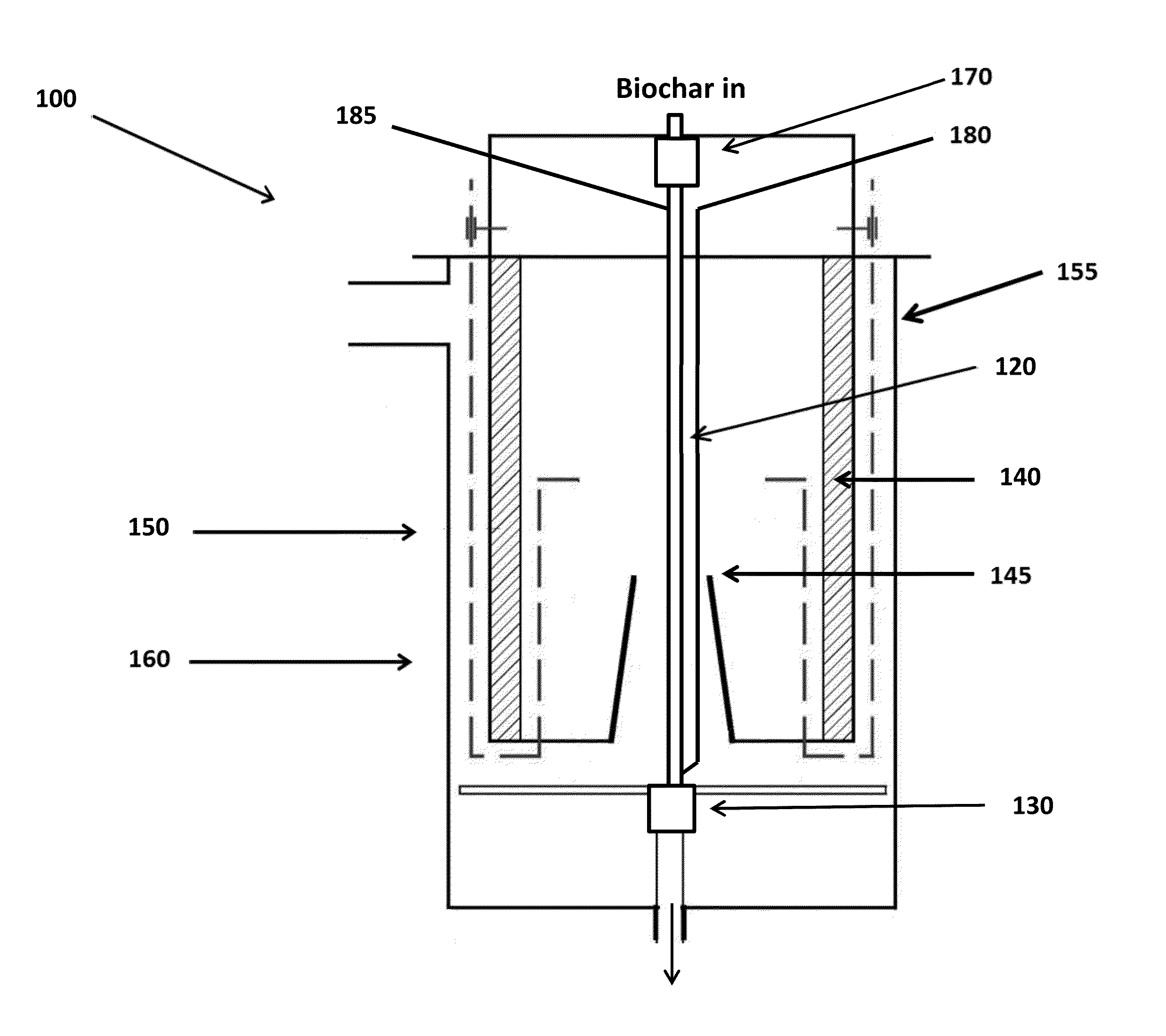

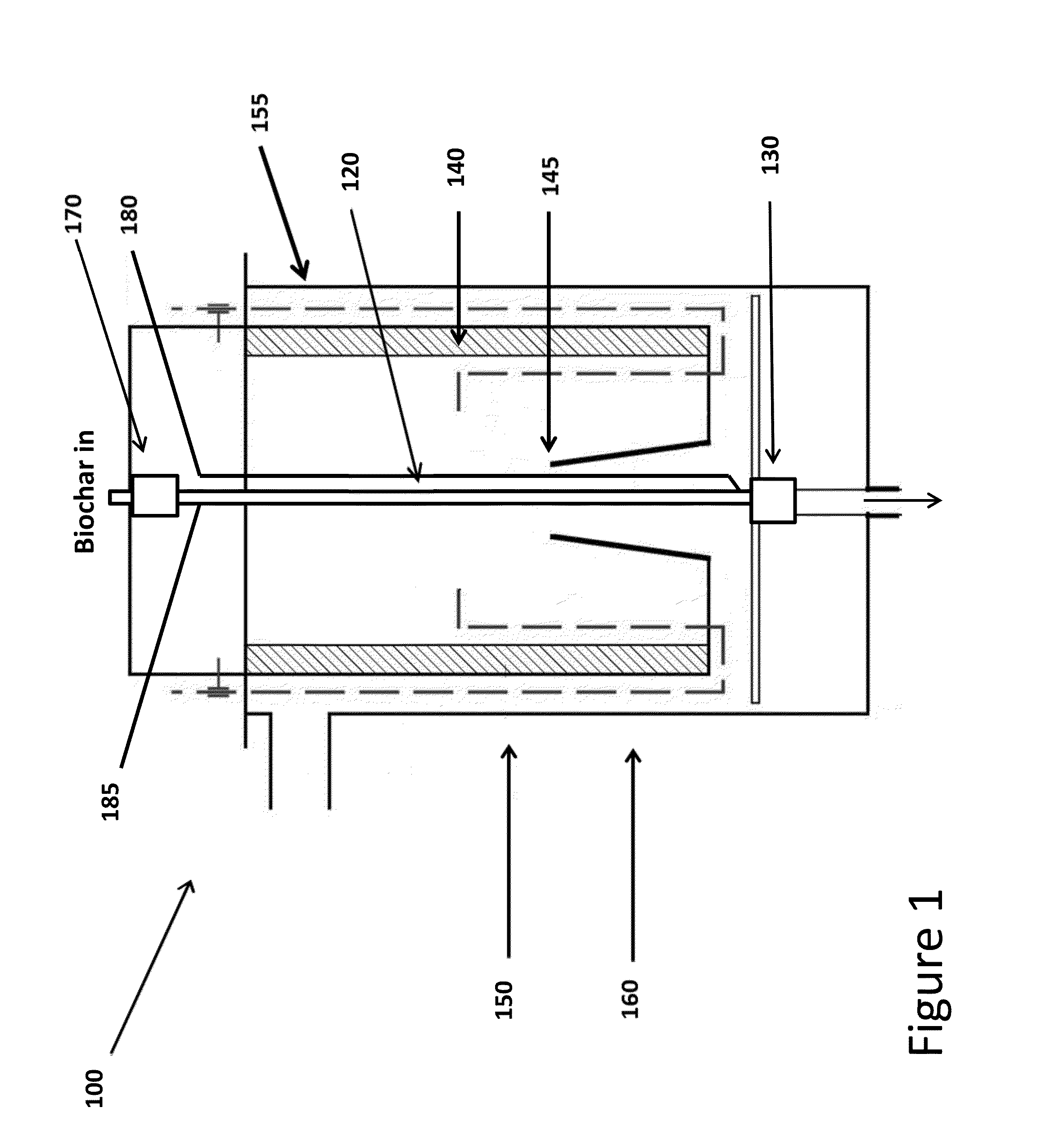

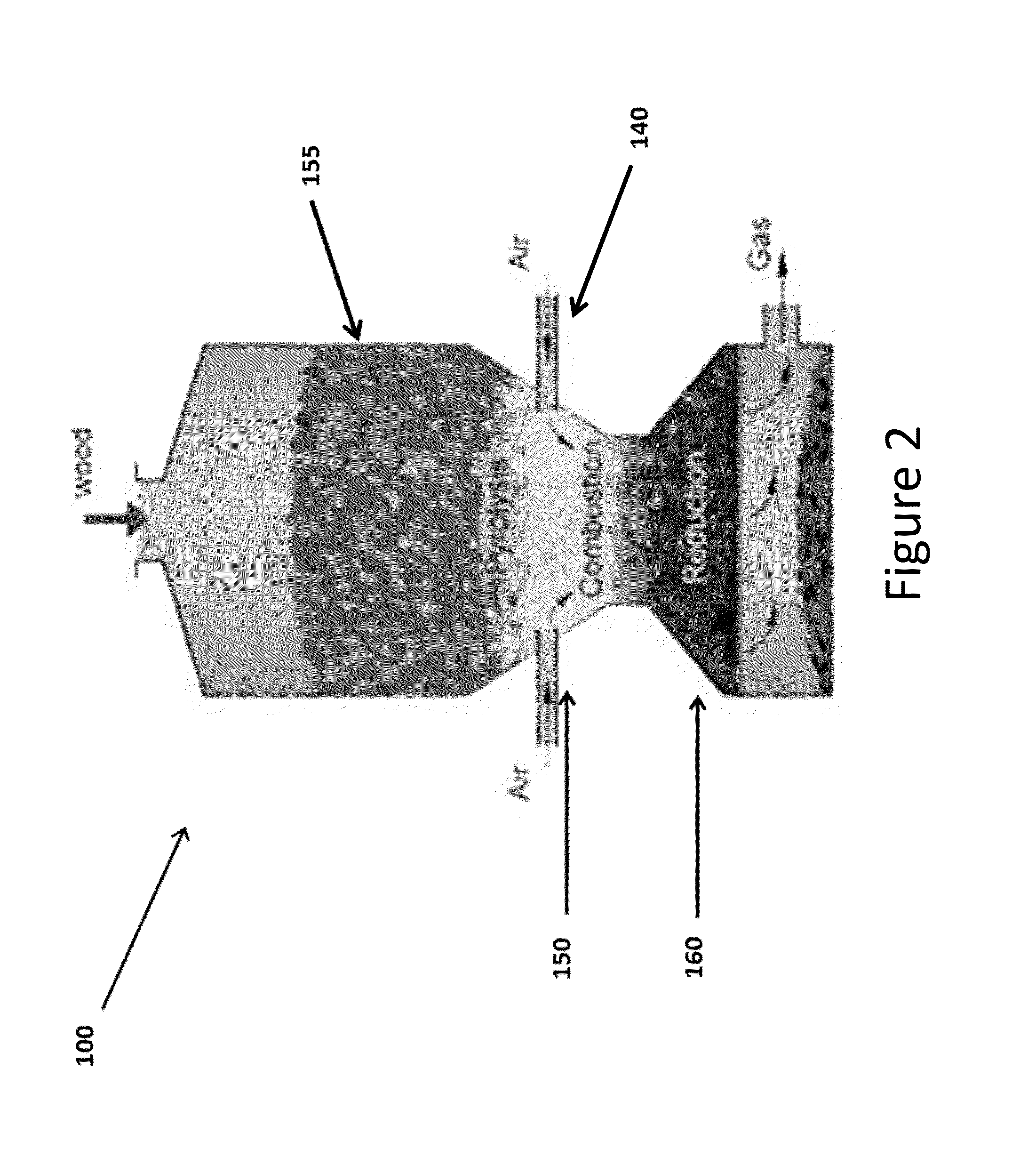

Coaxial gasifier for enhanced hydrogen production

Embodiments of the invention are directed toward a coaxial gasifier for enhanced hydrogen production, comprising: downdraft gasifier comprising a hot zone for converting biomass to synthesis gas; and a coaxial gas converter disposed within the downdraft gasifier, the coaxial gas converter comprising a biochar inlet valve, a coaxial char tube, and a biochar and ash outlet valve.

Owner:V GRID ENERGY SYST INC

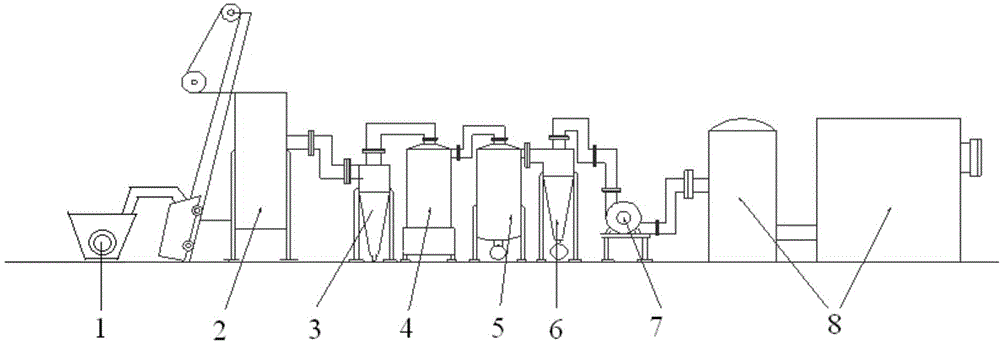

System for transforming waste combustible material recovered from building rubbish into clean gas

ActiveCN104531183ANo smellNo pollution in the processGasification catalystsGasification processes detailsTemperature controlHazardous substance

The invention relates to a system for transforming a waste combustible material recovered from building rubbish into clean gas. The system is characterized in that the waste combustible material recovered from the building rubbish is subjected to pyrolysis gasification in a temperature-controlled pyrolysis furnace, then subjected to primary purification and secondary purification and then subjected to primary separation and secondary separation; after the secondary separation, a tail gas is led out by using an air blower to be subjected to tertiary purification. The invention also discloses a process for gasifying the combustible material from the building rubbish. The system and process which are disclosed by the invention have the advantages of very high pertinence on the combustible material from the building rubbish, low tar content and low content of harmful substances contained in the tail gas.

Owner:北京国佳新创科技发展有限公司

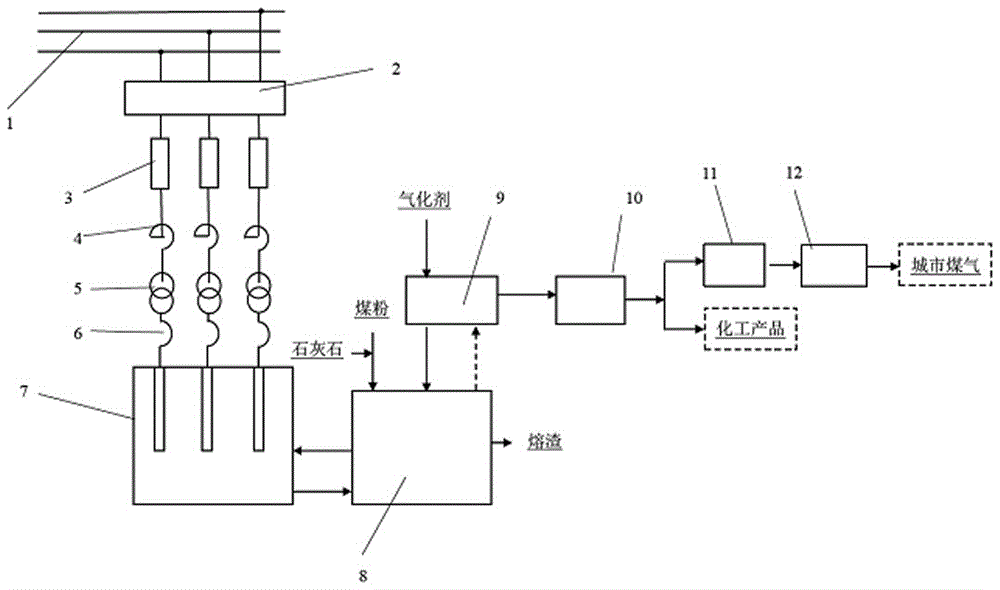

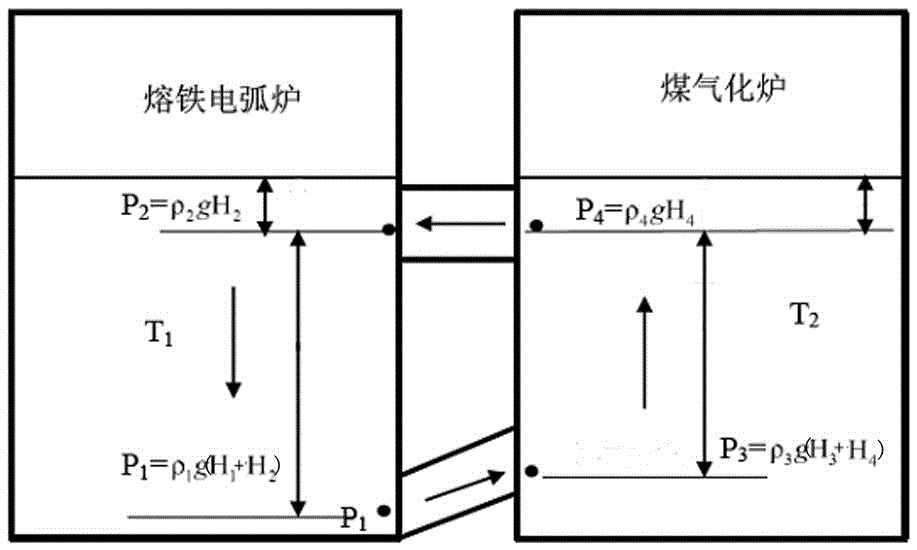

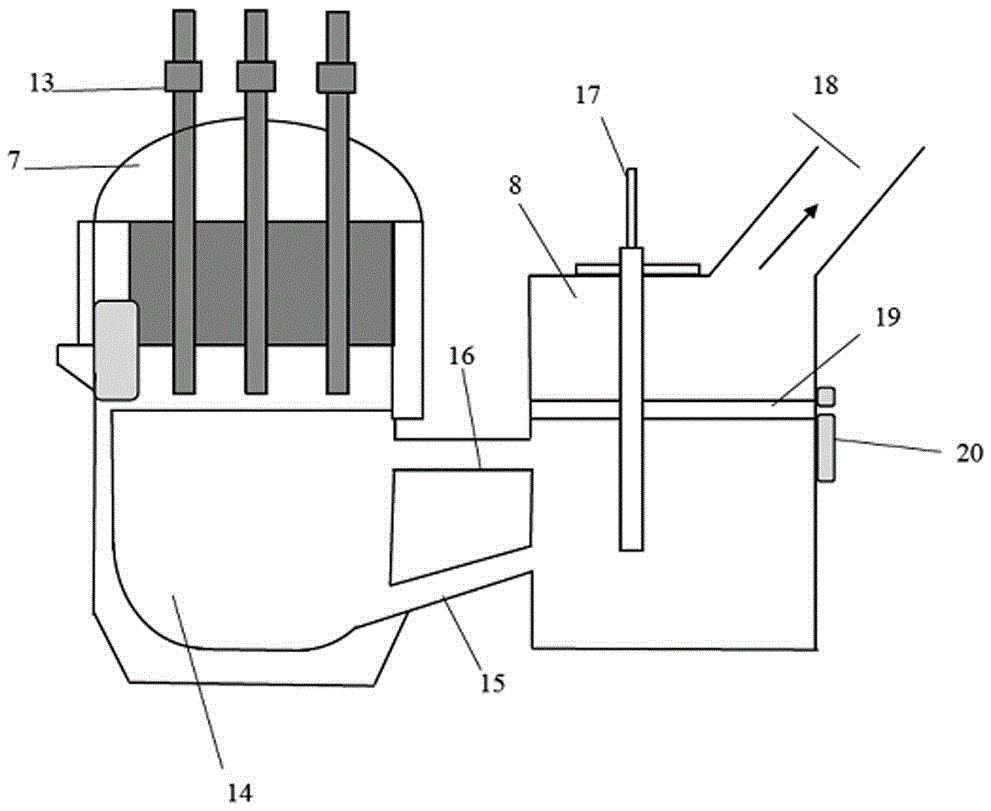

Power grid peak load regulation system and power grid peak load regulation method employing double-chamber iron bath coal gasification of electric arc furnace

ActiveCN106753573AImprove conversion efficiencySolve the peak shaving problemGasification catalystsChemical industryElectric arc furnacePower grid

The invention provides a power grid peak load regulation system and method employing double-chamber iron bath coal gasification of an electric arc furnace. The system comprises a power supply device, a melting electric arc furnace and a coal gasification furnace, wherein the power supply device is connected to the melting electric arc furnace; the melting electric arc furnace is connected with the coal gasification furnace through an upper connection pipe and a lower connection pipe and the pipe orifice distance H1 between the upper connection pipe and the lower connection pipe in the melting electric arc furnace and the pipe orifice distance H3 between the upper connection pipe and the lower connection pipe in the coal gasification furnace meet the following relationship: H3 is smaller than 0.953H1; the power supply device is connected with a power grid. The method comprises the steps of firstly heating molten iron in the melting electric arc furnace and the coal gasification furnace by adopting the system and making the temperature reach 1500-1600 DEG C; spraying pulverized coal and calcium carbonate mixed powder carried in a preheating gasifier into the coal gasification furnace for coal gasification reaction and absorbing heat of the molten iron in the coal gasification furnace and the melting electric arc furnace; and finally preparing a city gas or chemical product from a high-temperature coal gas.

Owner:NORTHEASTERN UNIV LIAONING

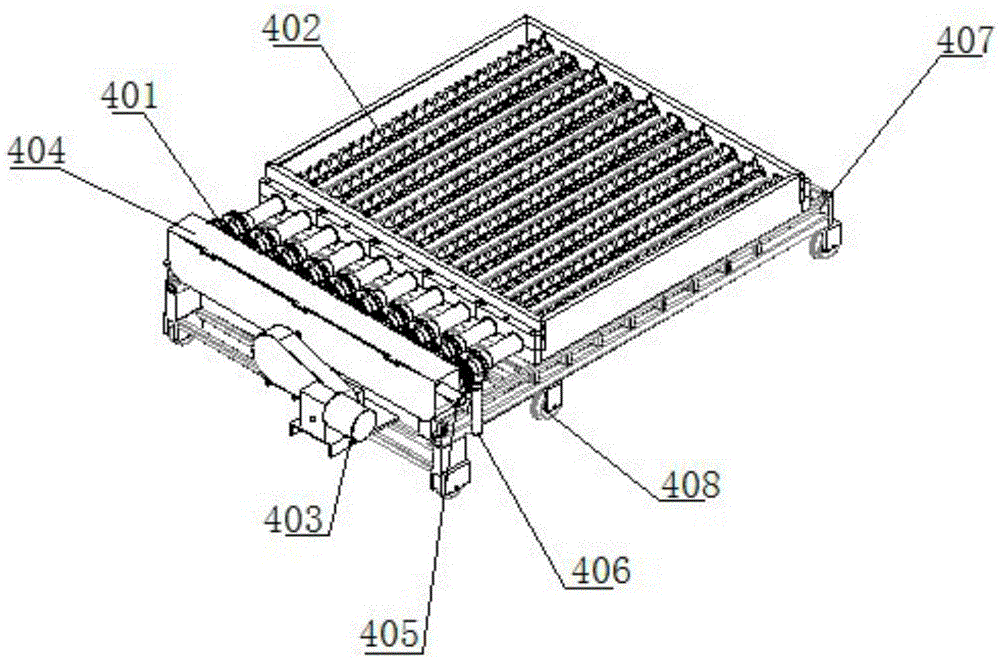

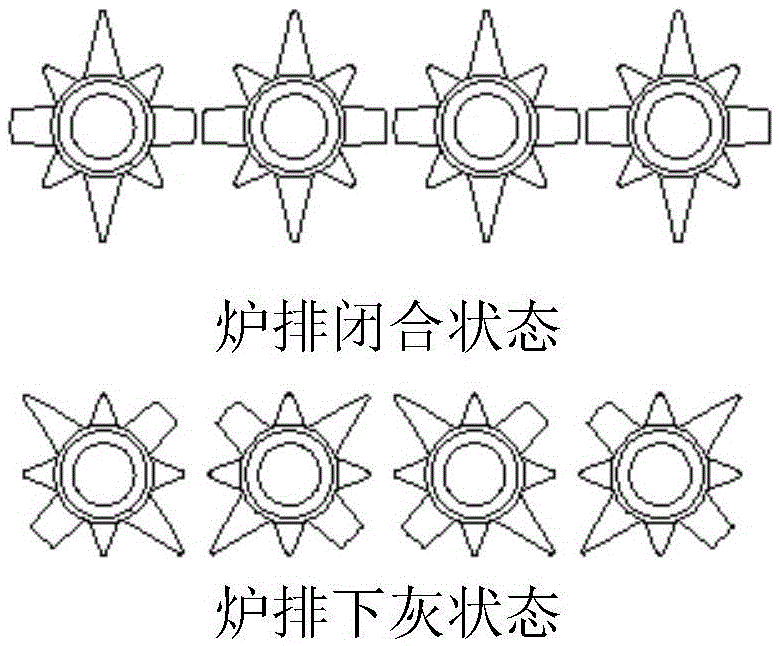

Charing and gasification composite furnace

ActiveCN106256877AEasy to controlEasy to shareGasifier feeding meansGasification catalystsSludgeFlue gas

The invention relates to a charing and gasification composite furnace, which can realize charing and gasification of to-be-processed materials such as garbage, sludge, sawdust, ground bark, rice husk, rice straw, peanut shell, peanut vine, coconut shell, palm shell, hemp xyloid stem, cotton stalk and straw, and two products of combustible gas and charcoal with calorific value of greater than 10-12 MJ / Nm<3> can be obtained. The charing and gasification composite furnace comprises a multistage pyrolysis channel, a flue gas channel, an oil and gas separator and a combustion gas combustion furnace. The multistage pyrolysis channel comprises a feed inlet of a to-be-processed material, a discharge port, an oil returning port, a volatile matter guiding outlet, a charcoal discharge port, and can form a segmentation sleeve with the flue gas channel; the discharge port is positioned at the pyrolysis channel with the feed inlet, the oil returning port is positioned at a middle and rear part of the pyrolysis channel; the volatile matter guiding outlet and an inlet of the oil and gas separator are connected; an oil chamber at the upper part of the oil and gas separator is connected with the oil returning port on the multistage charing pipe through an oil pump; and a gas chamber at the upper part of the oil and gas separator is simultaneously connected with a contact tube and a combustion gas combustion furnace. A connection pipe is arranged on a flue gas channel on outside of the pyrolysis channel with the oil returning port, and is connected with the combustion gas combustion furnace, and the flue gas departs from the channel, then passes through the high and low temperature material channels.

Owner:TONGJI UNIV

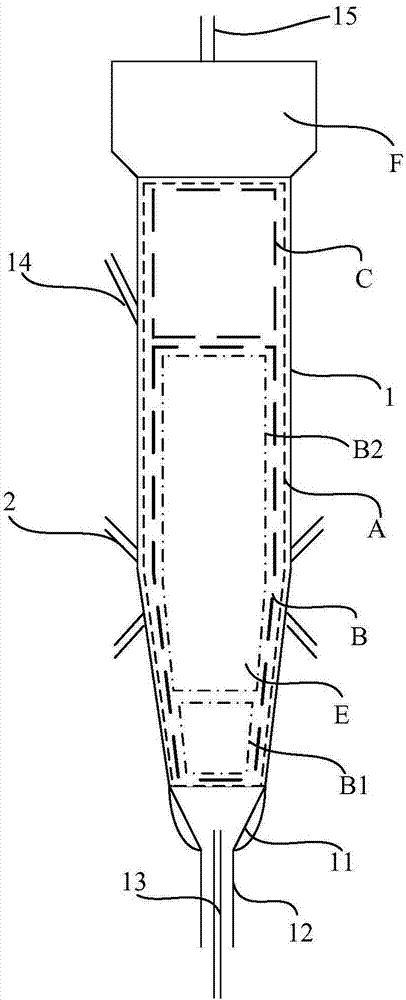

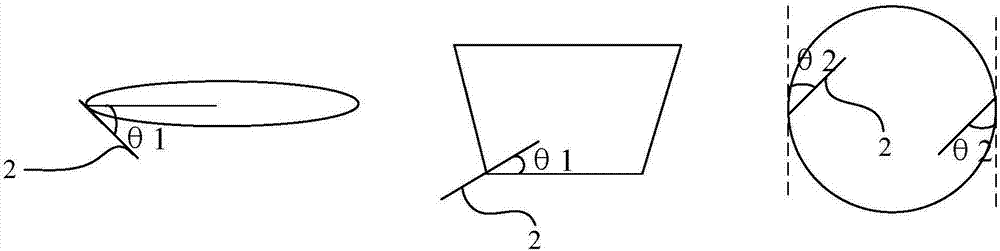

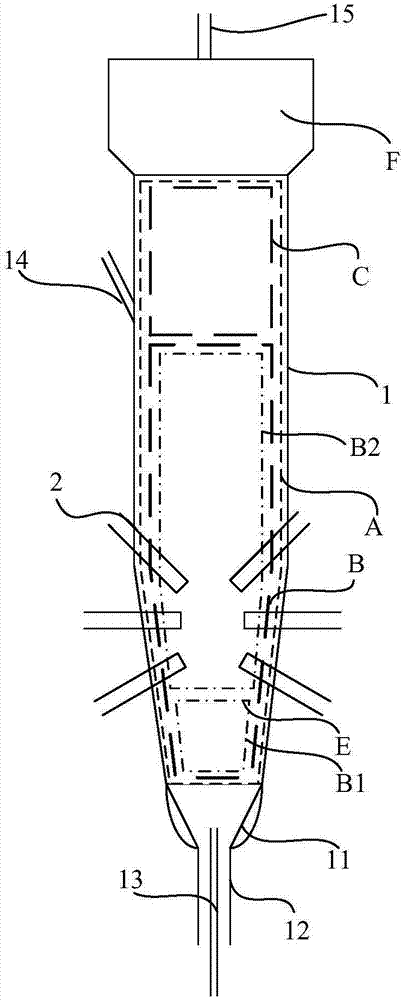

U-shaped fixed bed gasification-catalytic reaction device with tar degradation function

ActiveCN104774650AExtended stayAvoid stickingGasification catalystsGasification processes detailsParticulatesInsulation layer

The invention discloses a U-shaped fixed bed gasification-catalytic reaction device with a tar degradation function. The device mainly comprises a downdraft fixed bed gasification reactor, an updraft catalytic cracking reactor and a cyclone separator. The downdraft fixed bed gasification reactor has a feeding apparatus and an air distribution system. Flue gas moves in the shape of U in a furnace, and the whole U-shaped reactor is in a high temperature heating area and is protected by a heat insulation layer to ensure that gasified tar components do not cool and condense in the pipeline along the way, so that the tar components can enter the catalytic cracking reactor in a gaseous form and are fully decomposed in the catalytic reactor. The U-shaped fixed bed gasification-catalytic reaction device provided by the invention solves the problems of product gas purification cost increase and the like caused by excessive content of tar and particulate matters in the product gas after waste gasification.

Owner:ZHEJIANG UNIV

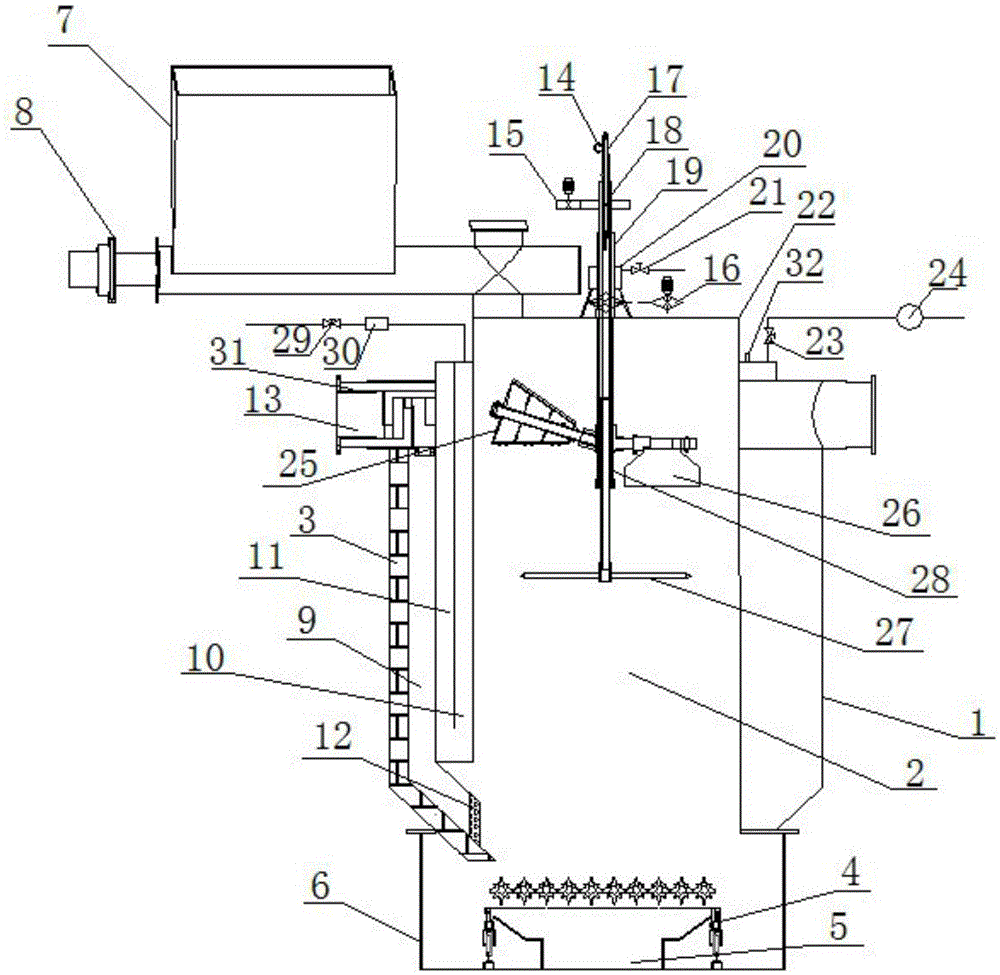

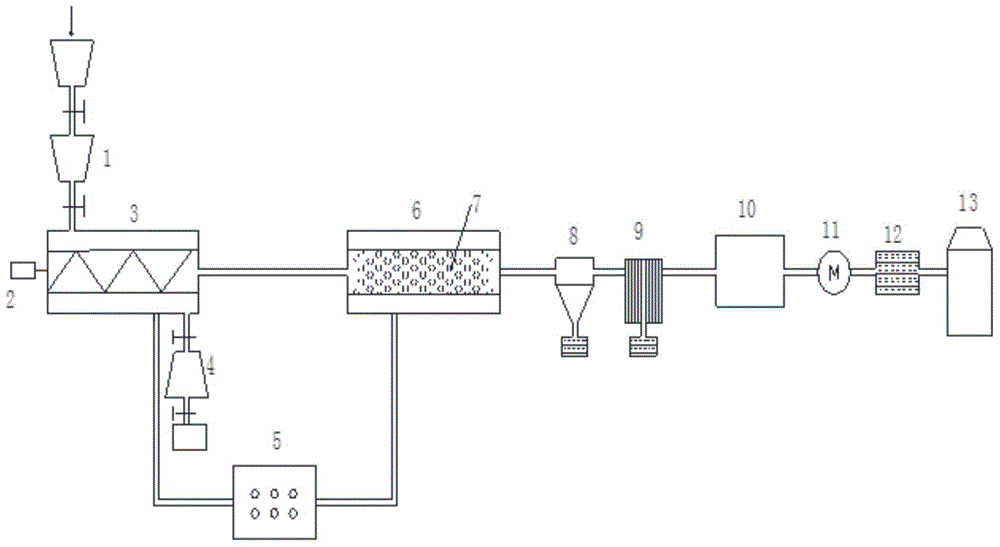

Device and method for producing synthetic gas by continuous two-stage catalytic pyrolysis

InactiveCN104388105AMeet the continuityFulfil requirementsHydrogenGasification catalystsCatalytic pyrolysisCatalytic reforming

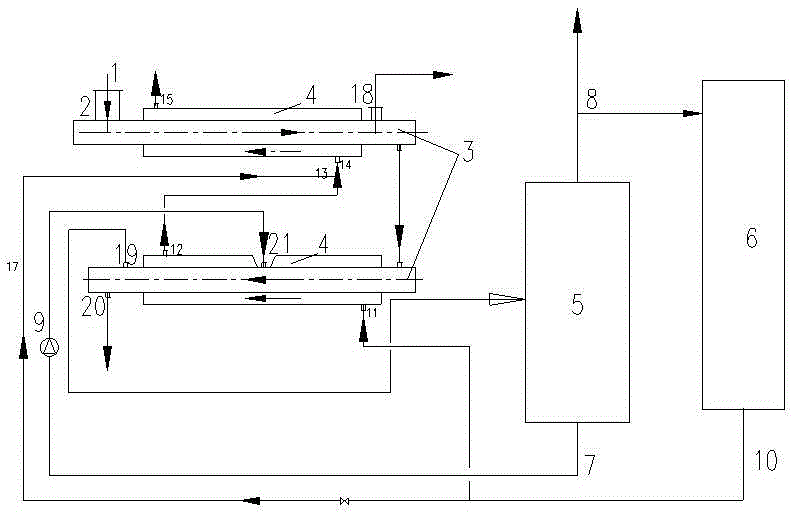

The invention belongs to the technical field of energy utilization of reaction raw materials containing organic matters and particularly relates to a device and method for producing synthetic gas by continuous two-stage catalytic pyrolysis. The device comprises a double-valve airtight feeding device, a first-stage screw conveying motor, a first-section medium temperature pyrolysis furnace, a double-valve discharging device, a second-stage screw conveying motor, a second-section high temperature catalytic pyrolysis furnace, a catalyst module, a gas-liquid separator, a water condenser, a water scrubber, an induced draft fan, a purifier and a gas storage box. According to the method disclosed by the invention, the reaction raw materials containing the organic matters are converted into charcoal and crude fuel gas through medium temperature pyrolysis; then, the crude fuel gas is converted into the synthetic gas through high temperature catalytic reforming; therefore, the utilization and damage problems of pyrolysis liquid are solved and fuel gas purification investment and secondary pollution are reduced. Particularly, reforming reaction is generated among water, CO2 and organic matters generated during the pyrolysis of the reaction raw materials containing the organic matters to generate the synthetic gas, thereby solving the energy utilization and damage problems of pyrolysis liquid and reducing fuel gas purification investment and secondary pollution.

Owner:TSINGHUA UNIV

Pyrolysis-based fuel processing method and apparatus

InactiveUS20050191531A1Gasification catalystsRegenerative fuel cellsSteam reformingWater-gas shift reaction

The method for generating a hydrogen-rich stream from hydrocarbon fuels, ultimately to produce hydrogen gas, involves the following two steps performed in a cyclic fashion: (1) pyrolysis of the hydrocarbon fuel to obtain a carbon-rich fraction and a hydrogen-rich fraction; and (2) oxidation of the carbon-rich fraction, or a portion of it, for heat generation. The method involves the following optional steps: (3) steam gasification of part of the carbon-rich fraction to produce additional amounts of hydrogen and carbon monoxide; (4) water-gas shift reaction to convert carbon monoxide to carbon dioxide with the simultaneous formation of additional amounts of hydrogen; and (5) steam reforming of light hydrocarbons that may be produced in step (1) to produce more hydrogen and carbon monoxide.

Owner:WOJTOWICZ MAREK A +3

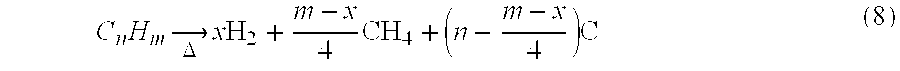

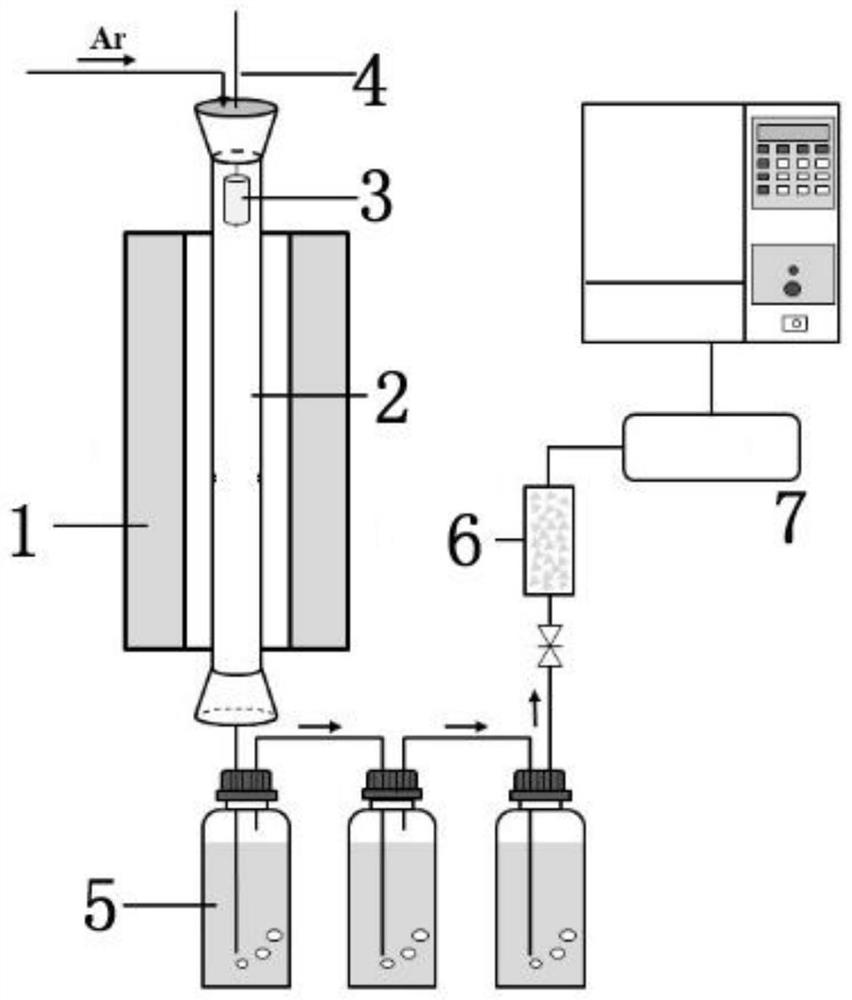

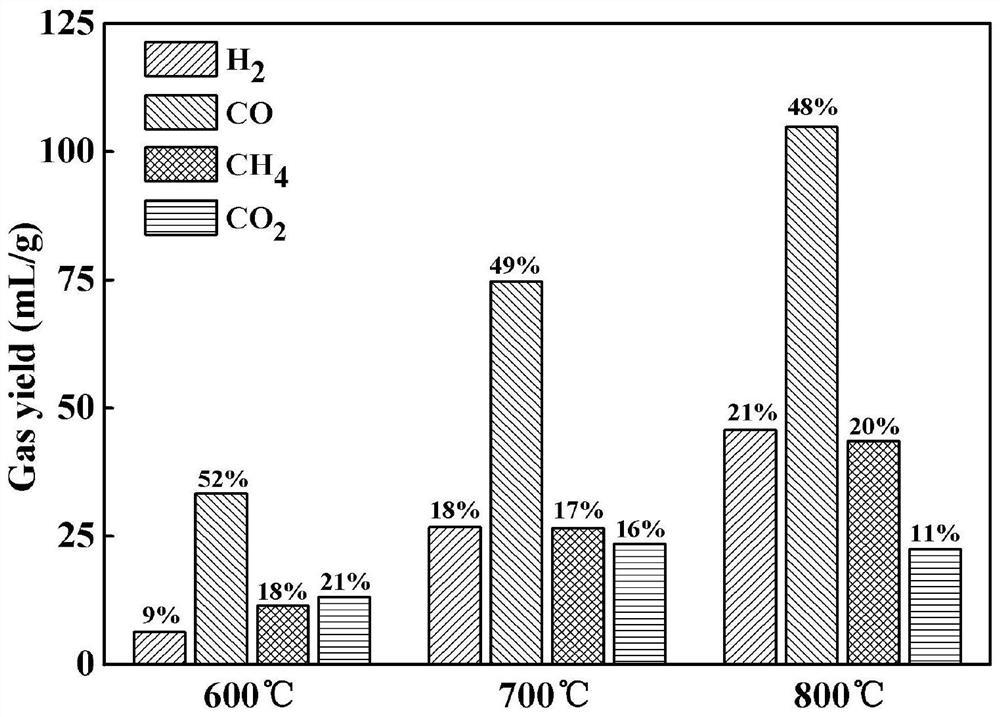

Method for preparing hydrogen-rich fuel gas through rapid co-pyrolysis of dewatered Fenton sludge and biomass

InactiveCN112961693AHigh yieldWay to increaseGasification catalystsSolid waste disposalPtru catalystCombustible gas

The invention discloses a method for preparing hydrogen-rich fuel gas through rapid co-pyrolysis of dewatered Fenton sludge and biomass. The method comprises the following steps: mixing dewatered Fenton sludge powder and biomass waste powder to prepare a pyrolysis precursor raw material; and then taking a proper amount of pyrolysis precursor raw material, pyrolyzing at 600-800 DEG C under the protection of Ar atmosphere, and collecting a gas-phase product through a gas collecting device. Based on the characteristic that the dewatered Fenton sludge contains iron and calcium elements, the dewatered Fenton sludge is used as a biomass pyrolysis catalyst. According to the dewatered Fenton sludge, the content of hydrogen in a biomass pyrolysis gas product can be remarkably increased, and especially at the pyrolysis temperature of 800 DEG C, the volume percent of hydrogen in combustible gas is remarkably increased. The hydrogen-rich fuel gas is prepared by co-pyrolysis of the dehydrated Fenton sludge and the biomass, the method is a good measure of turning waste into wealth and treating waste with waste, and an effective way is provided for proper treatment of waste and acquisition of hydrogen energy.

Owner:ZHEJIANG UNIV OF TECH

Method for producing catalytically-active materials

InactiveUS7449424B2Reducing and eliminating tarOther chemical processesGasification catalystsMolten stateMetallurgy

A method for producing a catalytically-active material having at least one base component and at least one catalytically-active component in which the at least one base component is heated to a softening or melting temperature to form a softened or molten base component. While the base component is in the softened or molten state, at least one catalytically-active component is incorporated into or onto the base component, forming the catalytically-active material. In accordance with one embodiment, a catalyst precursor is introduced into the base component and subsequently transformed to a catalytically-active component.

Owner:GAS TECH INST

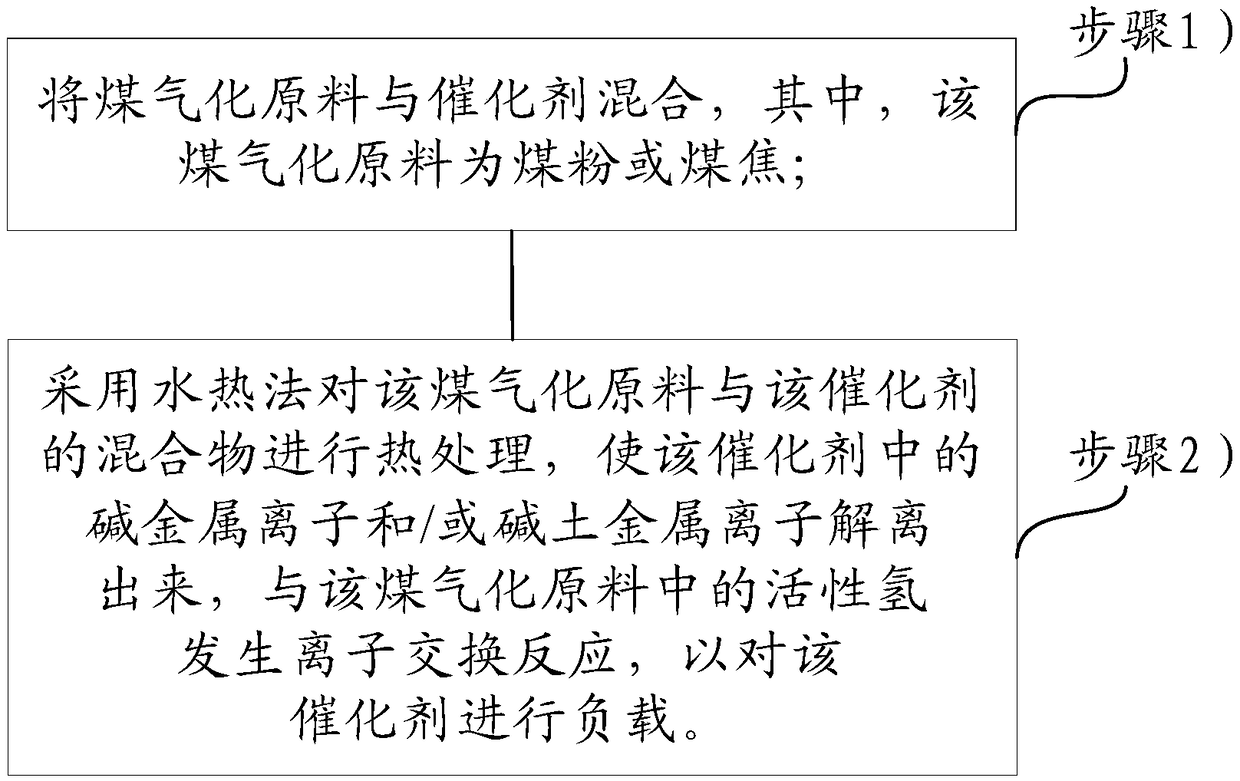

Loading method of catalyst as well as coal catalytic gasification method

ActiveCN108753359AIncrease payload capacityImprove catalytic performanceGasification catalystsCombustible gas productionAlkaline earth metalHydrogen

The invention relates to the technical field of coal catalytic gasification, in particular to a loading method of a catalyst as well as a coal catalytic gasification method. The effective loading quantity of the catalyst can be improved and the catalytic effect of the catalyst can be improved, so that the coal gasification conversion efficiency can be improved. The embodiment of the invention provides the loading method of the catalyst. The loading method comprises the following steps: mixing a coal gasification raw material with the catalyst, wherein the coal gasification raw material is coalpowder or coke; performing heat treatment on a mixture of the coal gasification raw material and the catalyst, to dissociate alkali metal ions and / or alkaline earth metal ions out of the catalyst, and carry out an ion exchange reaction with active hydrogen in the coal gasification raw material, so that the catalyst is loaded. The embodiment of the invention is applied to preparation of methane through coal gasification.

Owner:ENN SCI & TECH DEV

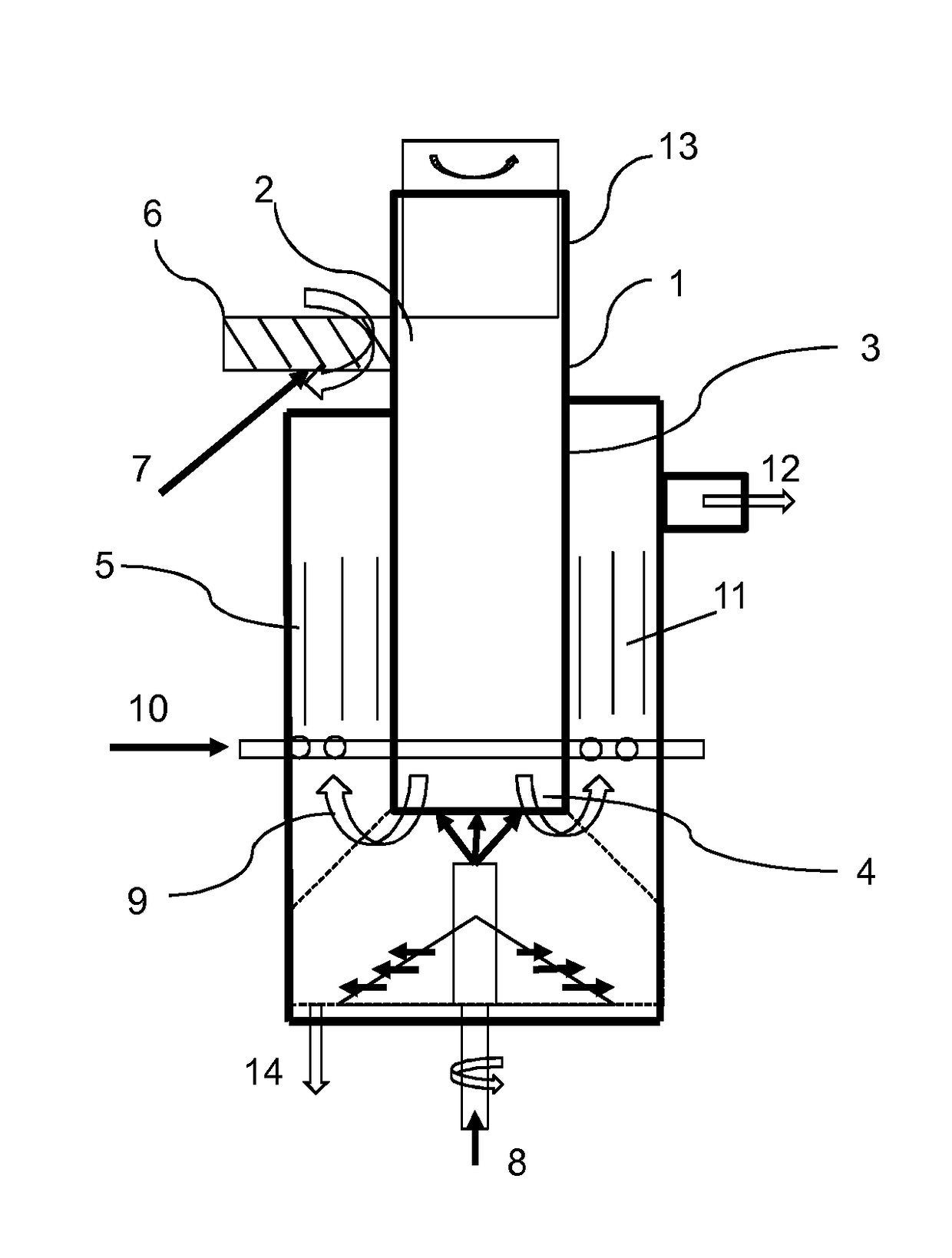

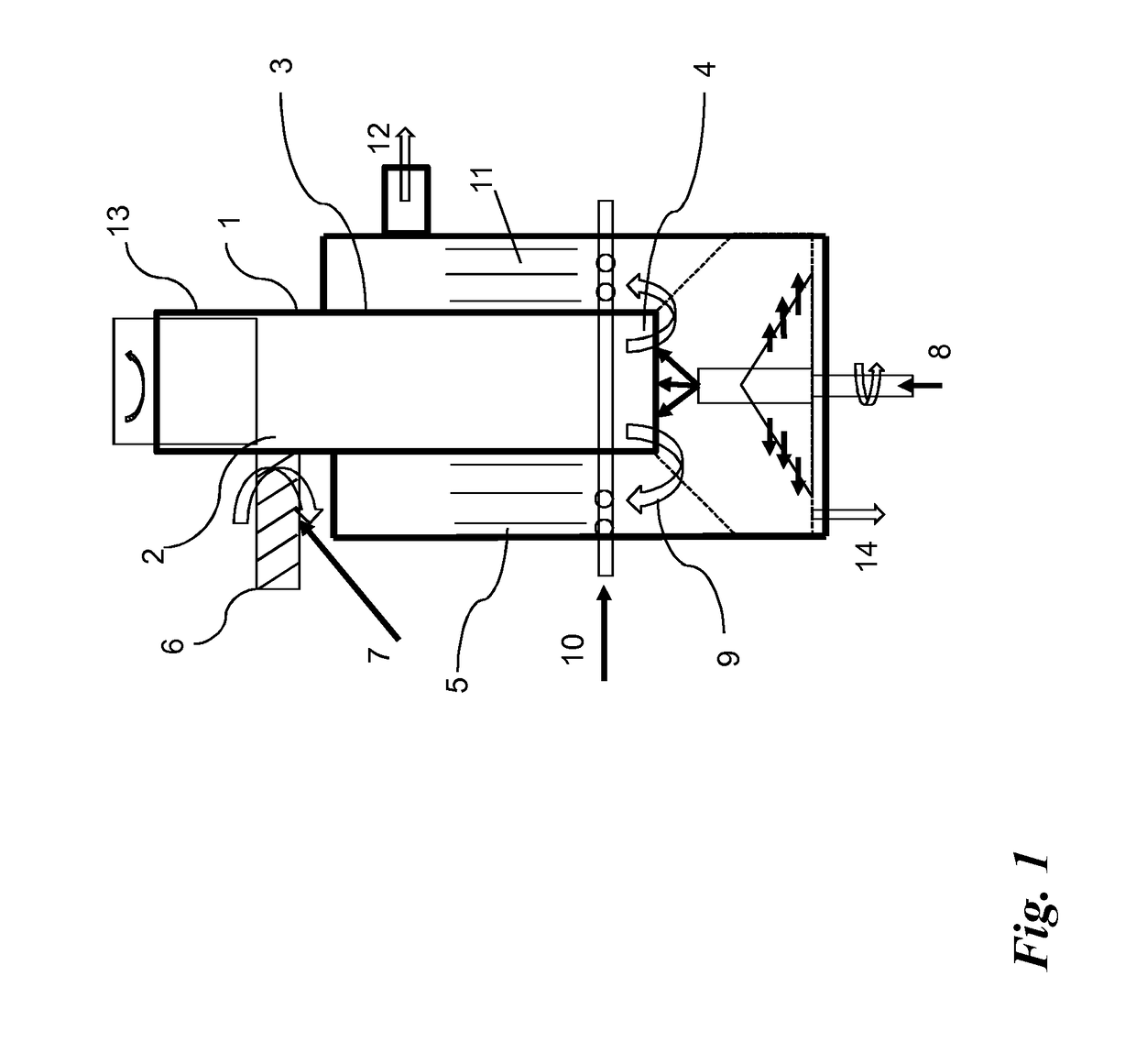

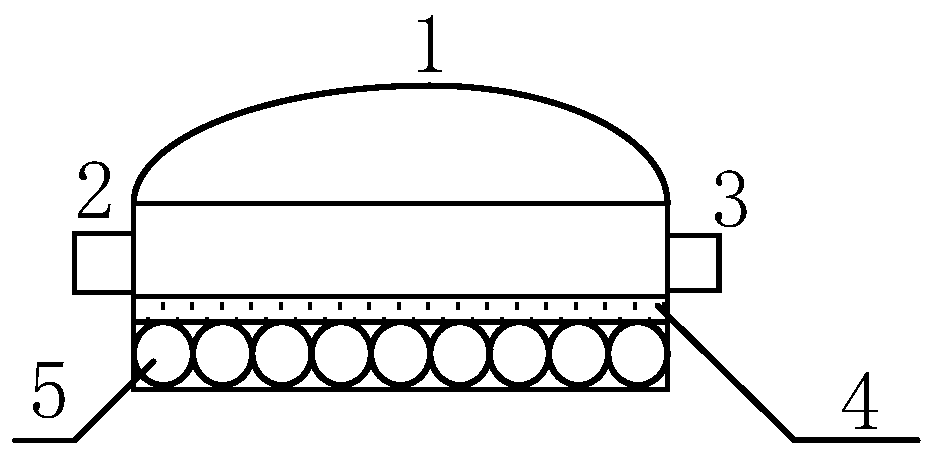

Device and method for reforming biomass tar to produce syngas

InactiveCN110016365AImprove gasification efficiencyReduce consumptionGasification catalystsGasification processes detailsSyngasResource utilization

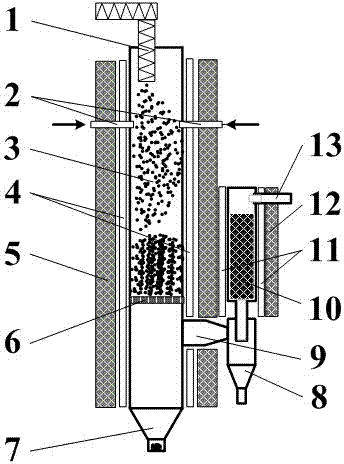

The invention discloses a device for reforming biomass tar to produce syngas. A solar transmission window (1) of the device is arranged at the upper part of the device, and has an arch-shaped structure; a catalyst loading plate (4) is arranged below the solar transmission window (1), a material inlet (2) and a material outlet (3) are respectively located in two ends of a space located between thesolar transmission window (1) and the catalyst loading plate (4), the upper surface of the catalyst loading plate (4) is filled with catalyst particles, and the lower surface of the catalyst loading plate (4) is provided with heating tubes (5); and a heating medium is introduced into the heating tube (5). The biomass tar reforming process is characterized in that under solar radiation, a compositecatalyst having photocatalytic properties and thermal catalytic properties is utilized to prepare the syngas through CO2 reforming of the biomass tar, so that conversion efficiency of preparing the syngas from the biomass tar can be improved, resource utilization of greenhouse gas CO2 can be realized, and consumption of non-renewable resources in the tar conversion process can be significantly reduced.

Owner:SOUTHEAST UNIV

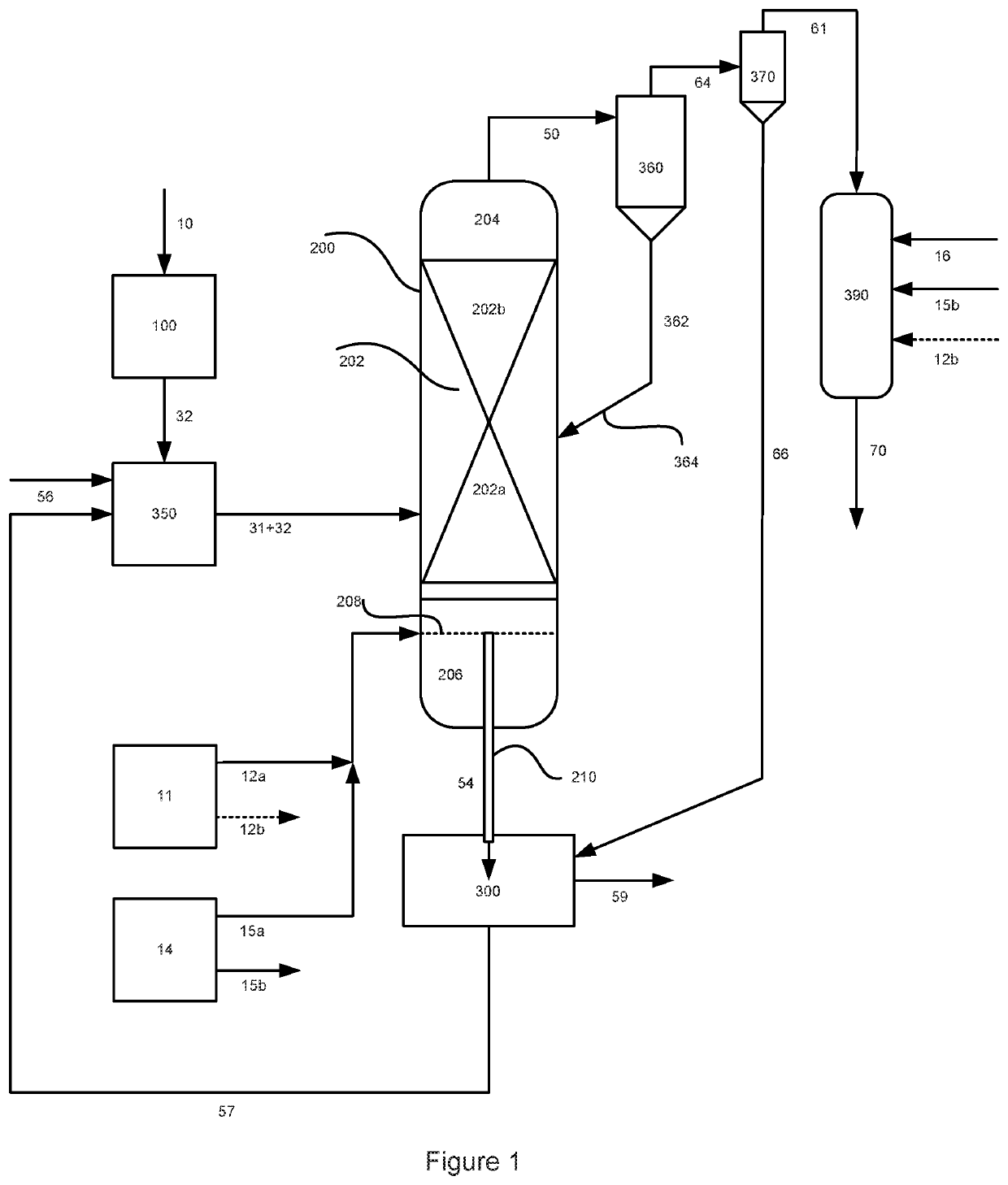

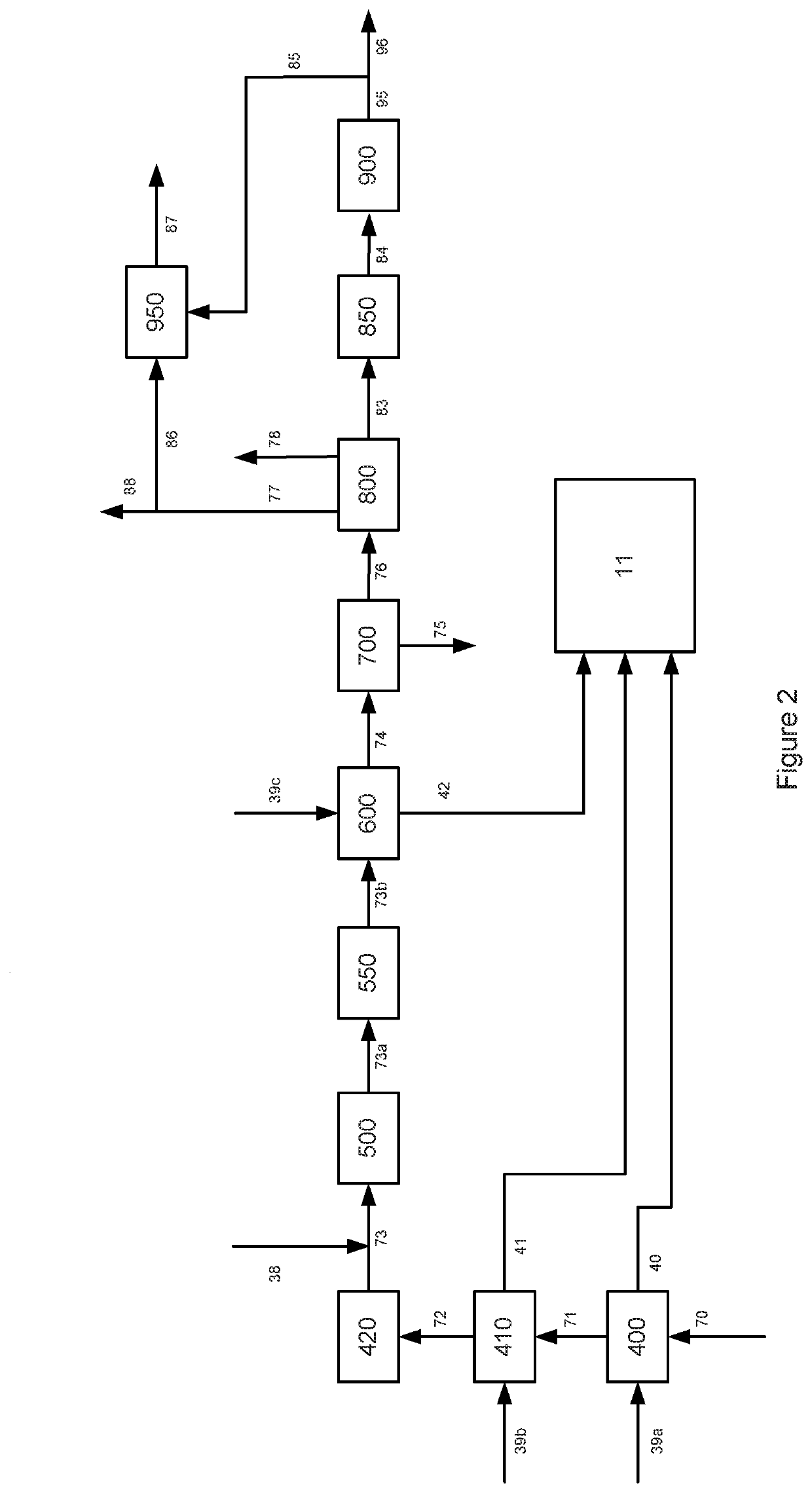

Integration of syngas generation technology with fischer-tropsch production via catalytic gas conversion

A system for the production of synthetic fuel, the system including a catalytic dual fluidized bed (DFB) configured to produce, from a DFB feedgas, a DFB product containing synthesis gas; and a Fischer-Tropsch (FT) synthesis apparatus fluidly connected with the catalytic DFB, wherein the FT synthesis apparatus includes an FT synthesis reactor configured to produce, from an FT feedgas, an FT overhead and a liquid FT product containing FT wax, wherein the FT feedgas contains at least a portion of the DFB product; and a product separator downstream of and fluidly connected with the FT synthesis reactor, wherein the product separator is configured to separate, from the FT overhead, an FT tailgas and an LFTL product containing LFTL. A method of producing synthetic fuel is also provided.

Owner:RES USA LLC

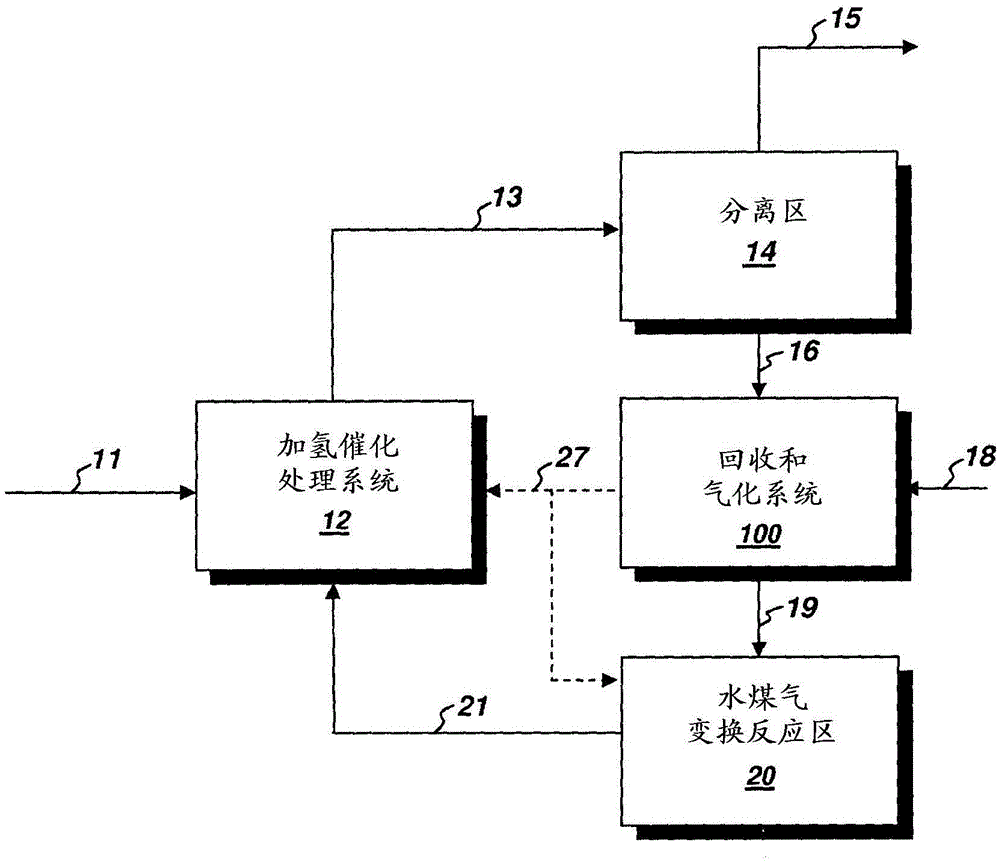

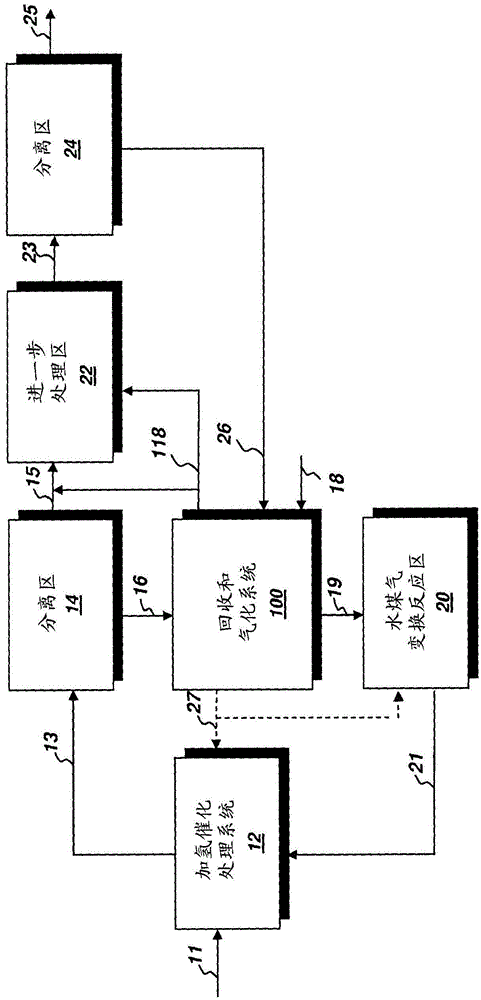

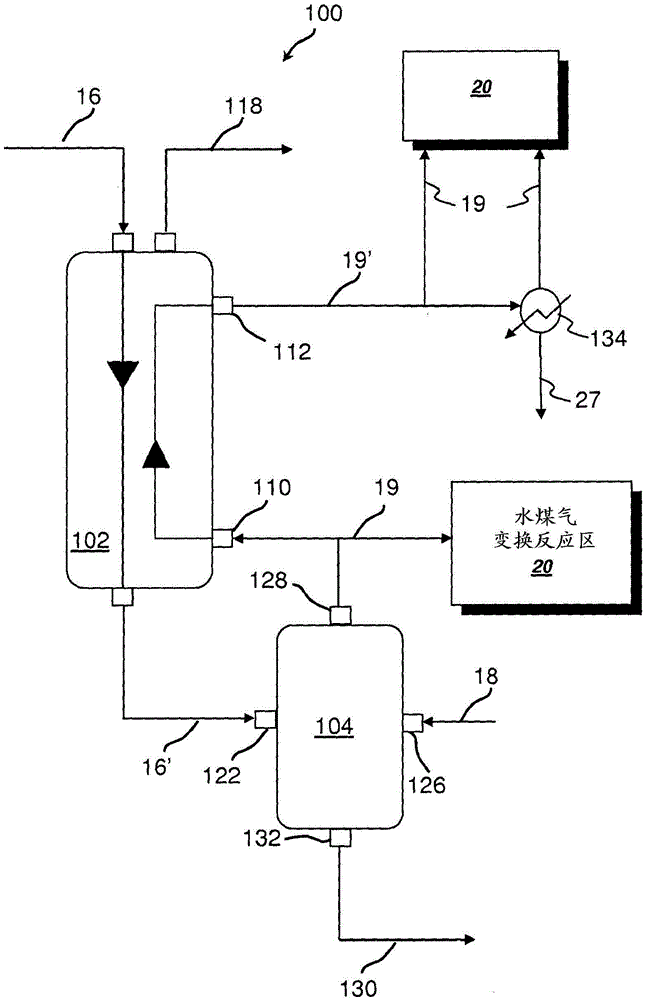

Methods and systems for supplying hydrogen to a hydrocatalytic reaction

InactiveCN105579556AGasification catalystsCombustible gas catalytic treatmentHydrogenVolatile organic compound

A bottom fraction of a product of a hydrocatalytic reaction is gasified to generate hydrogen for use in further hydrocatalytic reactions. In one embodiment, one or more volatile organic compounds is also vaporized using heat generated in the gasification process. In one embodiment, an overhead fraction of the hydrocatalytic reaction is further processed to generate higher molecular weight compounds. In another embodiment, a product of the further processing is separated into a bottom fraction and an overhead fraction, where the bottom fraction is also gasified to generate hydrogen for use in further hydrocatalytic reactions.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Catalytic gasification to produce ammonia and urea

ActiveUS10618818B1Reduce formationReduce oxygen consumptionUrea derivatives preparationGasification catalystsEnvironmental engineeringAmmonia

The present invention provides a process for preparing higher-value products from carbonaceous feedstocks. The process includes converting carbonaceous feedstock in a hydromethanation reactor to a methane-enriched raw product stream, converting the methane-enriched raw product stream to an ammonia synthesis feed gas, then converting the ammonia synthesis feed gas to higher-value products such as ammonia and urea.

Owner:SURE CHAMPION INVESTMENT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com